Sony TCM-50-DV Service manual

TCM-50DV

MICROFILM

SERVICE MANUAL

Ver 1.1 2000. 08

With SUPPLEMENT-1

(9-926-919-81)

SPECIFICATIONS

US Model

Canadian Model

AEP Model

E Model

Tourist Model

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type MT-50-30

Recording system

2-track 1 channel monaural

Tape speed

4.8 cm/s or 2.4 cm/s

Frequency range

250 - 6,300 Hz using normal (TYPE I) cassette (with REC TIME switch

at “NORMAL”)

Speaker

Approx. 3.6 cm (1

Power output

250 mW (at 10% harmonic distortion)

Input

Microphone input jack (minijack) sensitivity 0.2 mV for 3 kilohms or

lower impedance microphone

Output

Earphone jack (minijack) for 8 - 300 ohms earphone

Variable range of the tape speed

From approx. +25% to –15% (with REC TIME switch at “NORMAL”)

Power requirements

3 V DC batteries AA (R6) × 2/External DC 3 V power sources

Battery life (Approx. hours) (EIAJ*)

Playback 9.5 1.5

Recording 10.5 2

* Measured value by the standard of EIAJ (Electronic Industries

Association of Japan). (Using a Sony HF series cassette tape)

7/16 in.) dia.

Sony alkaline LR6 (SG) Sony R6P (SR)

Dimensions (w/h/d) (inci. projecting parts and controls)

Approx. 88.7 × 115.3 × 37.2 mm (3

Mass

Approx. 250 g (8.9

Supplied accessories

Size AA (R6) batteries (2) (Tourist model only)

Earphone (1) (Tourist model only)

Design and specifications are subject to change without notice.

oz.)

1/2 × 4 5/8 × 1 1/2 in.)

CASSETTE-CORDER

– 1 –

TABLE OF CONTENTS

1. SERVICING NOTE ..................................................... 3

2. GENERAL

Operating the Unit ................................................................... 4

3. DISASSEMBLY

3-1. Cabinet, Cassette Lid Assy .................................................6

3-2. MAIN Board, Cassette Machanism .................................... 7

3-3. Belt ...................................................................................... 8

3-4. Head .................................................................................... 8

3-5. Motor, DC ........................................................................... 9

3-6. Note for Installation of Main Board.................................... 9

4. MECHANICAL ADJUSTMENTS............................ 10

5. ELECTRICAL ADJUSTMENTS .............................10

6. DIAGRAMS

6-1. Block Diagram .................................................................. 11

6-2. Printed Wiring Board –Main Section– .............................. 13

6-3. Schematic Diagram –Main Section–.................................15

6-4. Printed Wiring Board –Panel Section– ............................. 17

6-5. Schematic Diagram –Panel Section– ................................ 18

6-6. IC Pin Description............................................................. 20

7. EXPLODED VIEWS

7-1. Case Section ...................................................................... 21

7-2. Panel Section..................................................................... 22

7-3. Mechanism Deck Section-1 .............................................. 23

7-4. Mechanism Deck Section-2 .............................................. 24

8. ELECTRICAL PARTS LIST ....................................25

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

– 2 –

SECTION 1

SERVICING NOTE

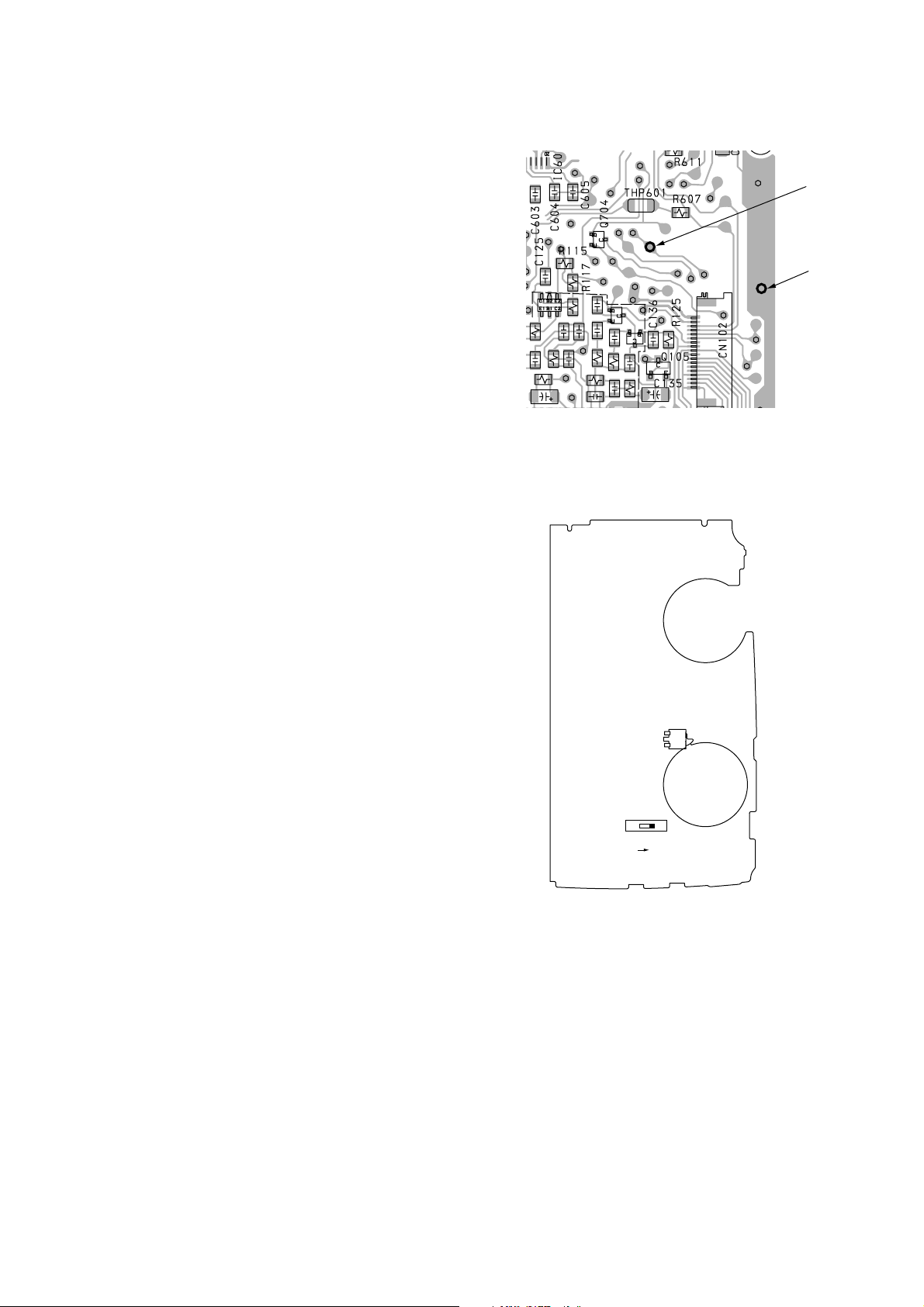

1-1. SERVICE MODE

Mode to allow the mechanical parts to operate with the main board

open.

This set uses the photo reflector PH701 to detect the rotation of the

idler gear. PH701 is on the main board and so remo val of the main

board does not allow the set to detect the rotation of the idler gear.

This makes motor control impossible which prevents normal

operation.

When repairing the set as energized with the main board removed,

proceed as follows:

1. Setting

1) Remove the cabinet (rear) (refer to the Disassembly) and open

the main board.

2) Apply a trapezoidal of 10 to 100 Hz (at 1.3 V) from oscillator to

TP20. (Connect the ground to TP30.)

3) Supply DC 3.0 V to the positive and negative terminals of the

battery with a stabilized power supply.

2. FF mode

1) Apply a trapezoidal to hall sensor TP20.

2) Press the FF key.

3) Turn on the S103 (POWER) switch.

3. REW mode

1) Apply a trapezoidal to hall sensor TP20.

2) Press the REW key.

3) Turn on the S103 (POWER) switch.

– main board (conductor side) –

TP20

– main board (component side) –

TP30

TP20

TP30

4. PLAY mode

1) Apply a trapezoidal to hall sensor TP20.

2) Press the PLAY key.

3) Change over the S101 (REC/PB) switch to PB side.

4) Turn on the S103 (POWER) switch.

5. REC mode

1) Apply a trapezoidal to hall sensor TP20.

2) Press the REC key.

3) Change over the S101 (REC/PB) switch to REC side.

4) Turn on the S103 (POWER) switch.

S103

(POWER)

S101

PB REC

– 3 –

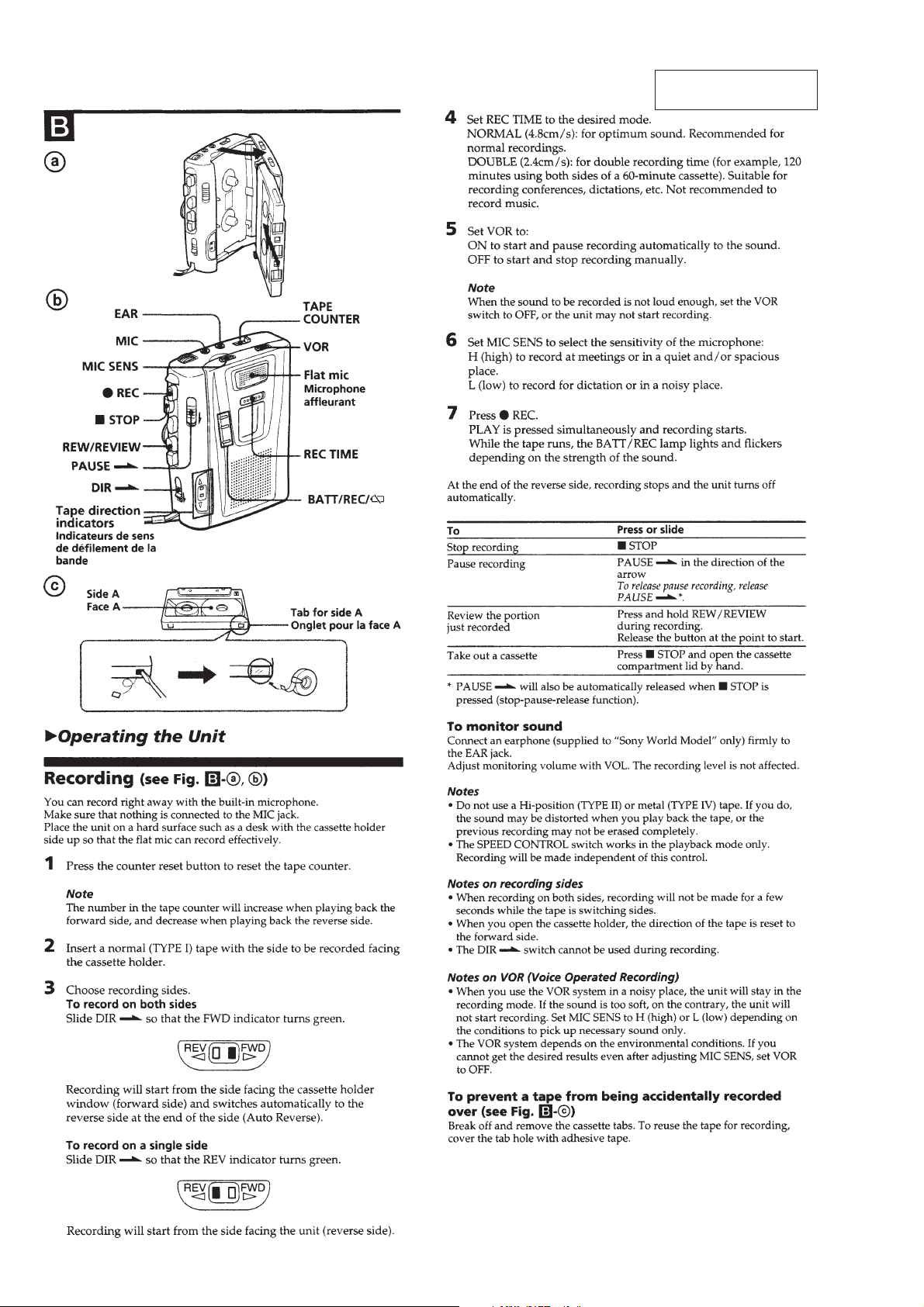

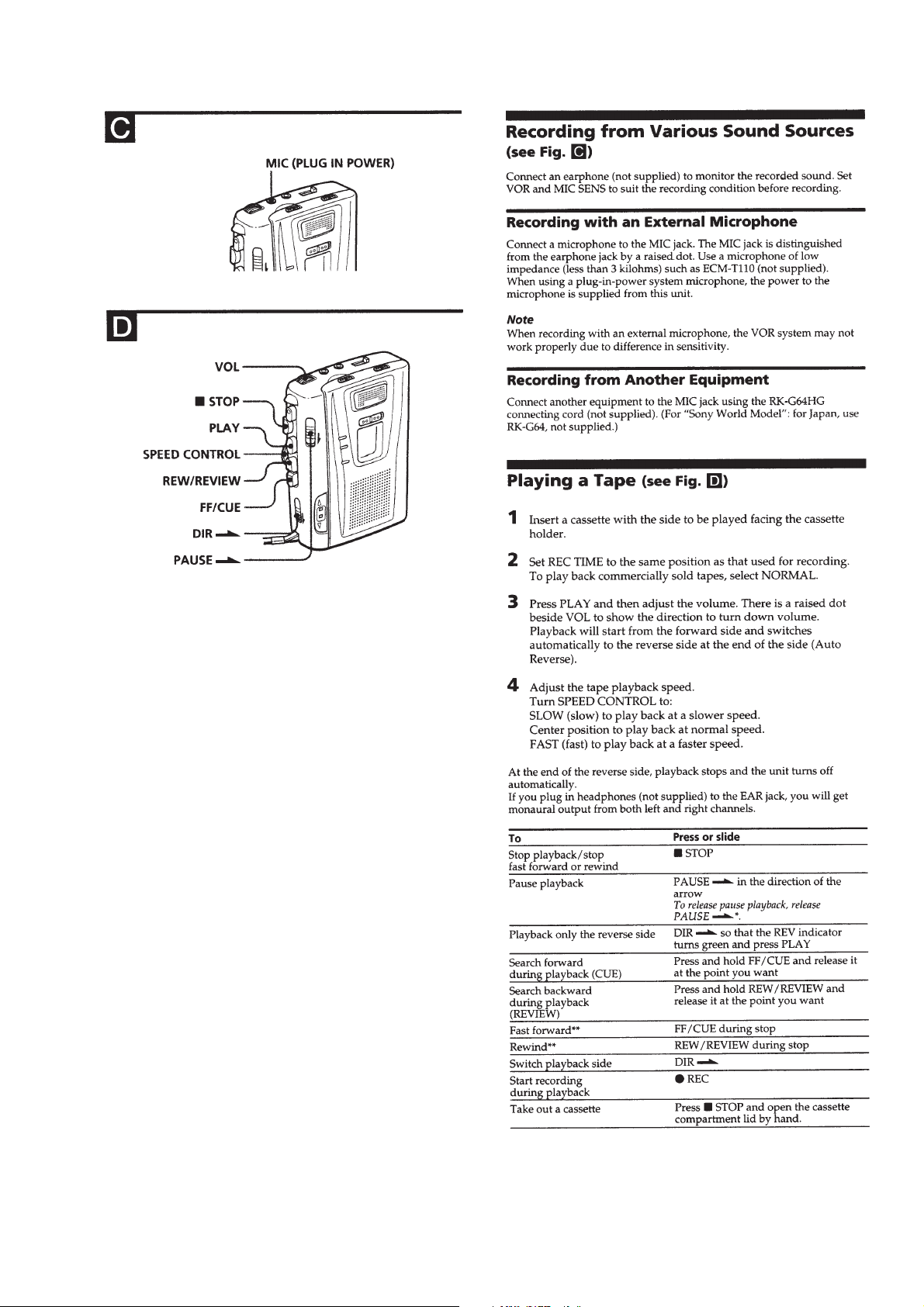

SECTION 2

GENERAL

This section is extracted

from instruction manual.

– 4 –

– 5 –

SECTION 3

d

DISASSEMBLY

• The equipment can be removed using the following procedure.

Cabinet (rear),

Cassette Lid Assy

Note : Follow the disassembly procedure in the numerical order given.

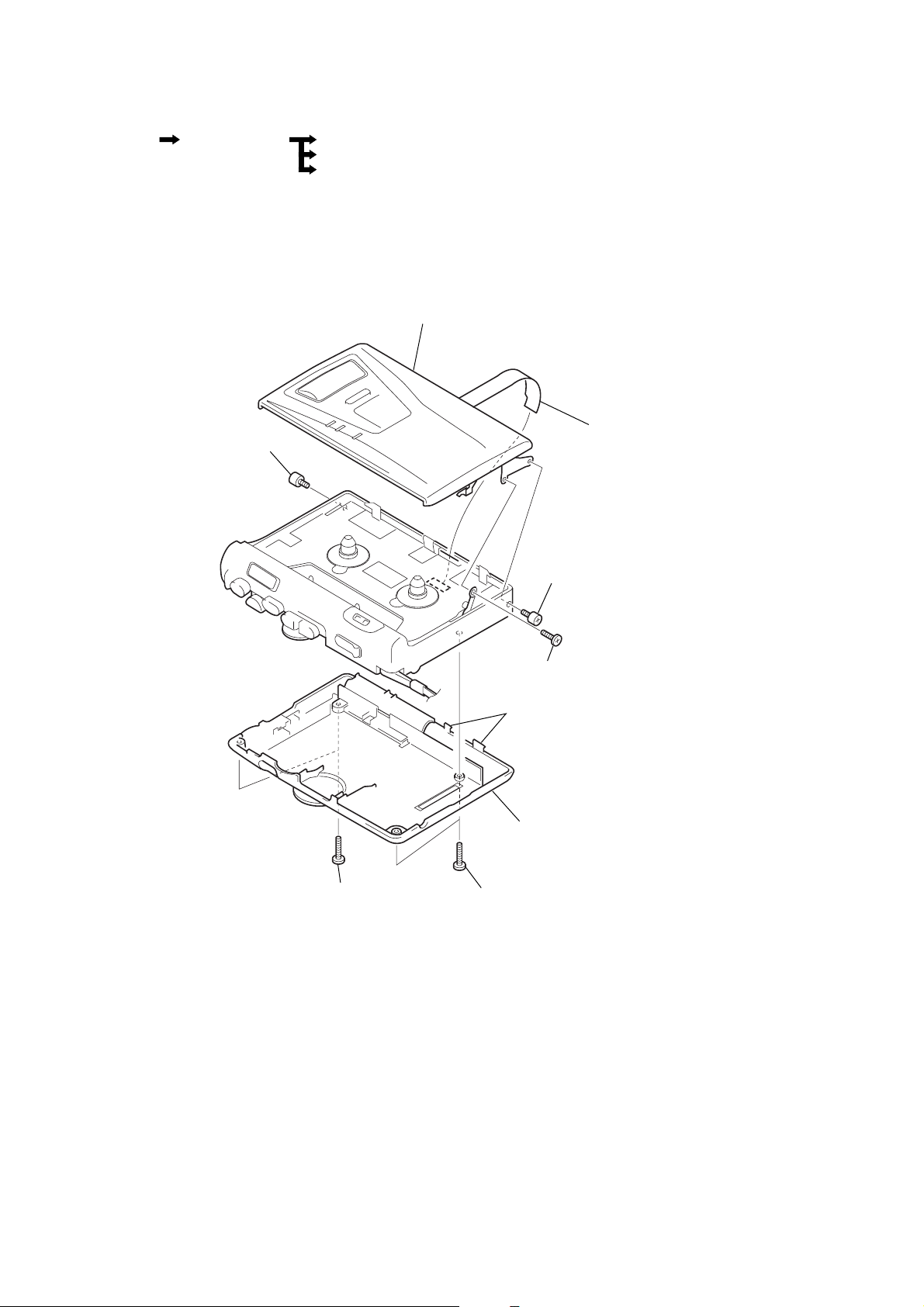

3-1. CABINET (REAR), CASSETTE LID ASSY

Mechanism Deck,

Main board

8

screw, ornamental

Belts

Head

Motor, DC

9

cassette lid assy

5

LED flexible boar

2

two screws

(screw (B1.7x9), tapping)

7

screw, ornamental

6

shaft (A), stopper

3

two claws

4

cabinet (rear)

1

two screws

(screw (B1.7x9), tapping)

– 6 –

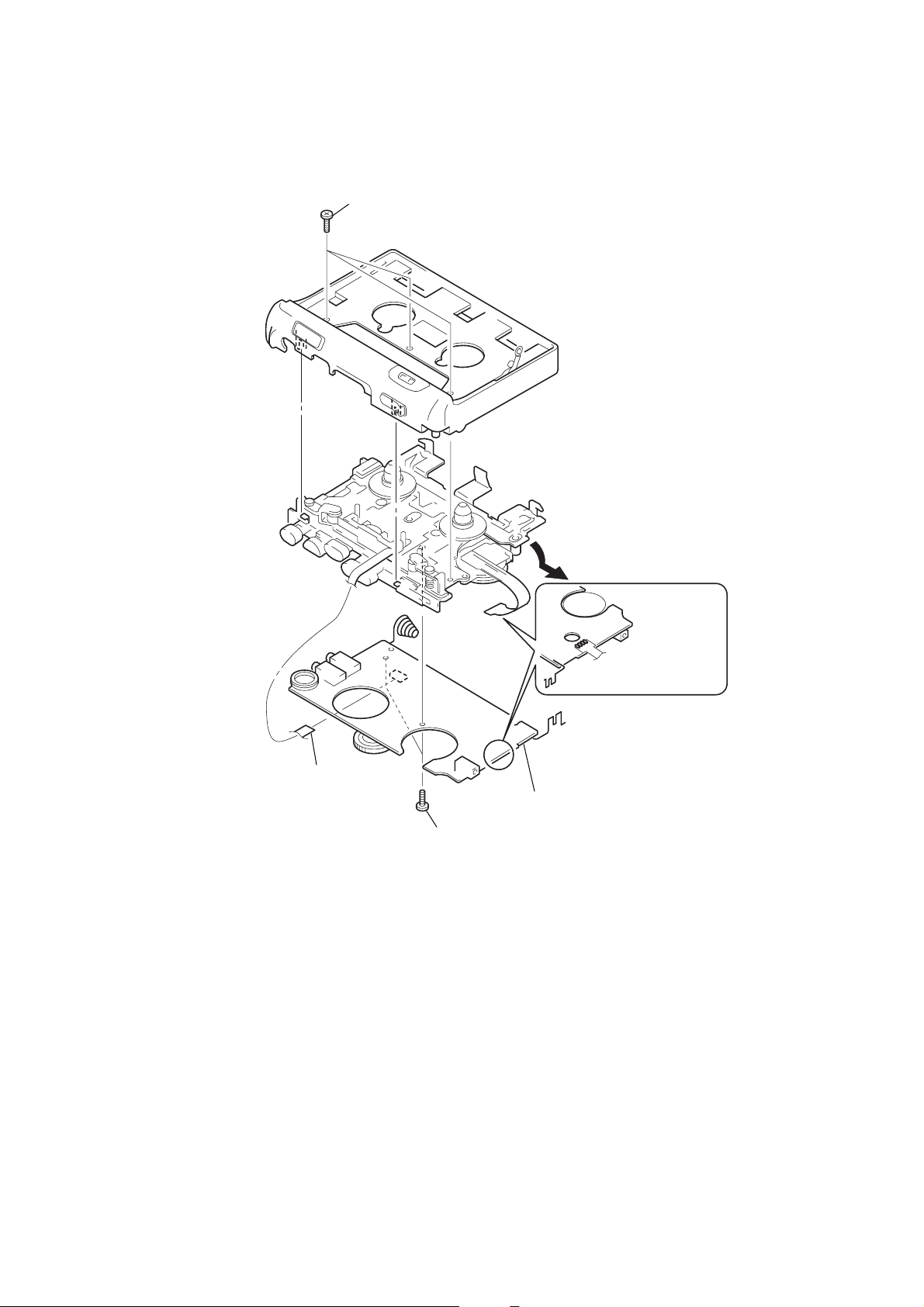

3-2. MACHANISM DECK, MAIN BOARD

1

three screws

(screw (IB lock))

2

mechanism deck,

MAIN board

4

head flexible board

6

MAIN board

5

two screws

(screw (M1.4), toothed lock)

3

Remove the four solders.

– 7 –

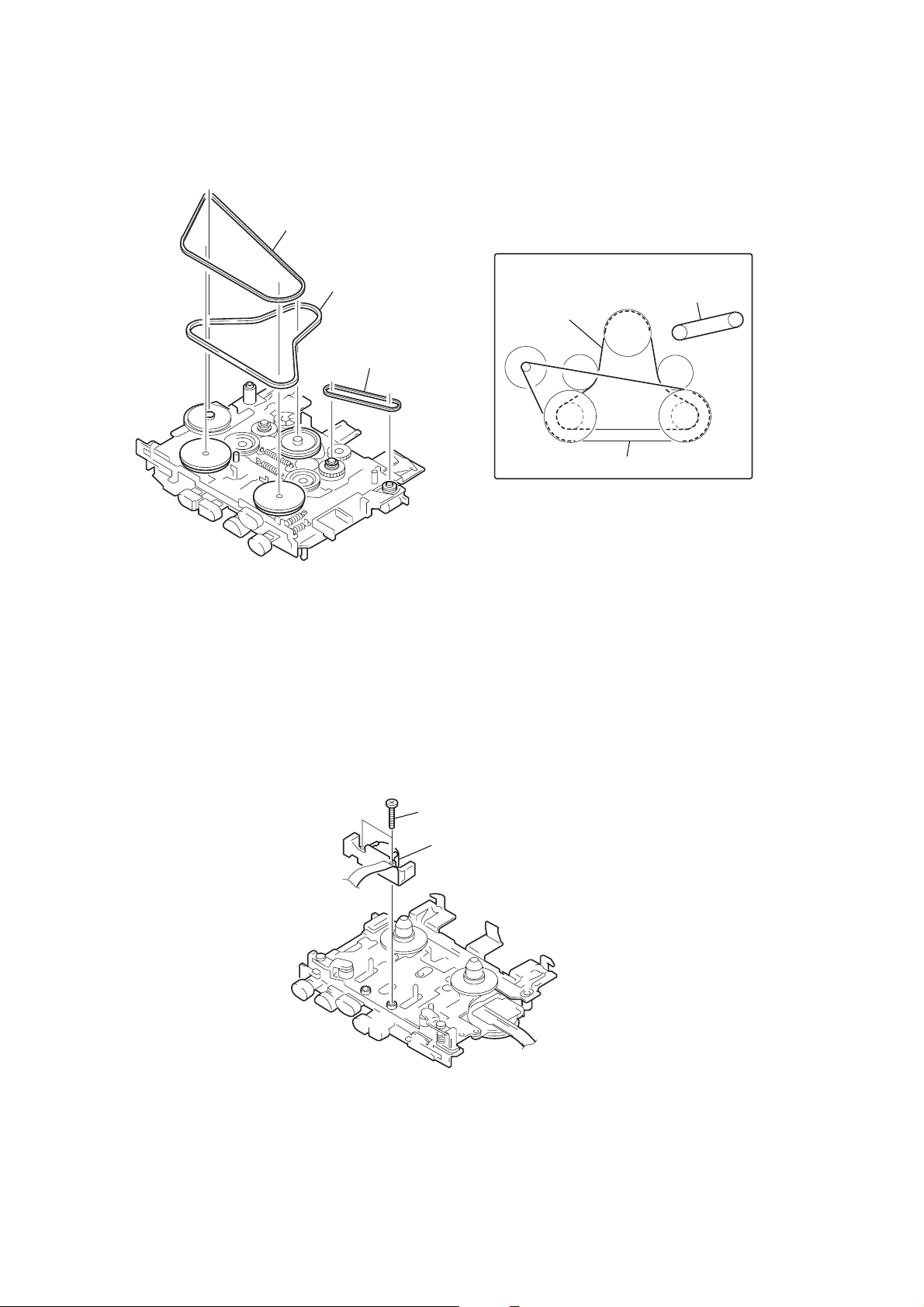

3-3. BELTS

1

belt (motor)

2

belt (flywheel)

3

belt (counter)

• How to apply the belts

belt (counter)

belt (flywheel)

belt (motor)

3-4. HEAD

1

two screws

2

head, magnetic

(REC/PB/ERASE)

– 8 –

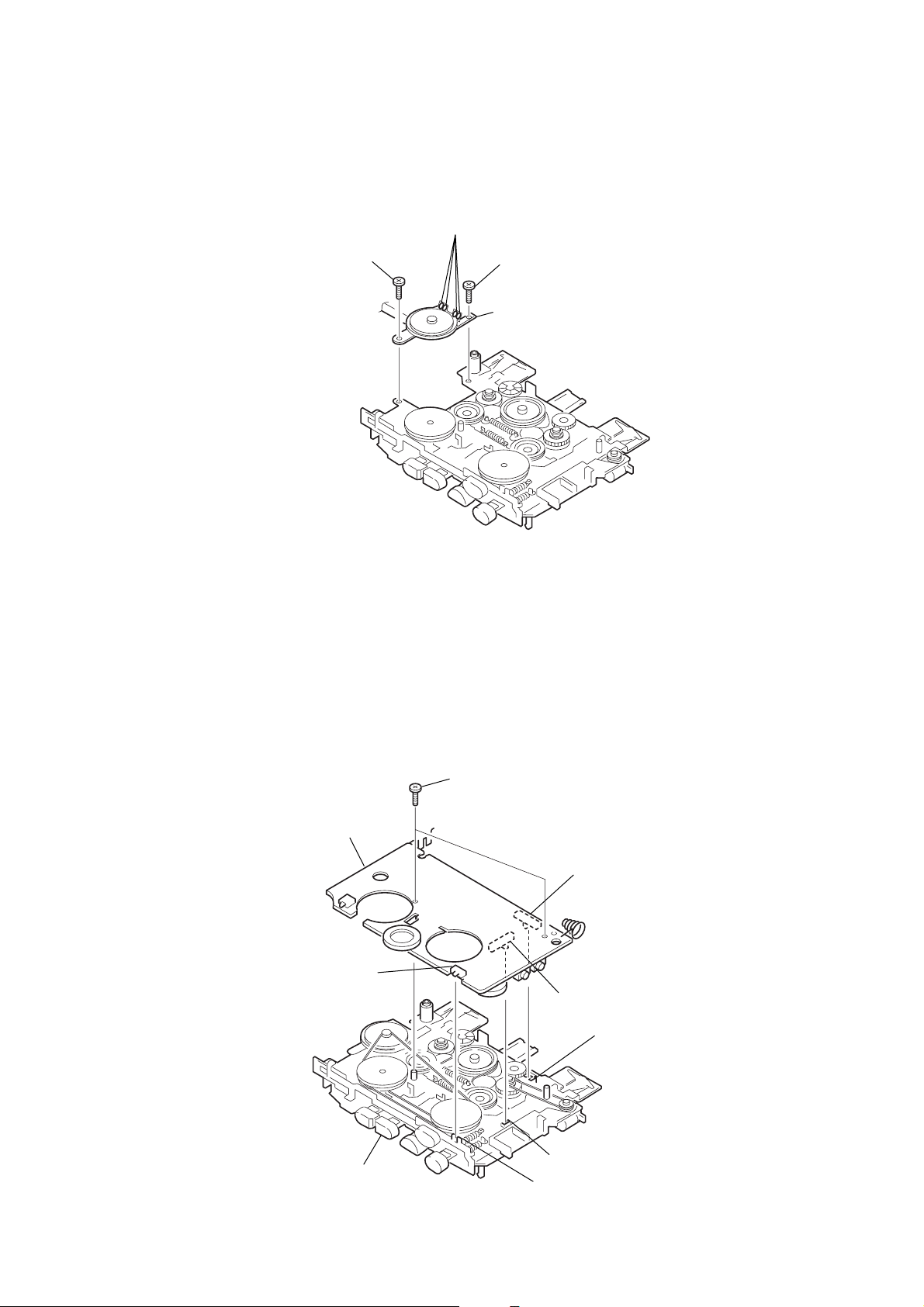

3-5. MOTOR, DC

2

screw (1.4)

3

Remove the four solders.

1

screw (1.4)

4

Motor, DC

3-6. NOTE FOR INSTALLATION OF MAIN BOARD

Align the knobs of S101, S103 and S701 on the main board with the

claws of the lever (REC) le ver (erase proof 2) and lever (REC) of the

mechanism deck respectively, and install the main board.

screws (M1.4), toothed lock

MAIN board

S701

S103

S101

lever (erase proof 2)

mechanism deck

lever (REC)

lever (PAUSE)

– 9 –

Loading...

Loading...