Sony TCM-500-DV Service manual

TCM-500DV

SERVICE MANUAL

Ver 1.2 2004. 04

SPECIFICATIONS

Recording system

Tape speed

Frequency range

TIME/PLAY MODE switch at “NORMAL”)

Speaker

Power output

Input

Output

Variable range of the tape speed

MODE switch at “NORMAL”)

Power requirements

Dimensions (w/h/d) (incl. projecting parts and controls)

Mass (main unit only)

2-track 1 channel monaural

4.8 cm/s or 2.4 cm/s

350 - 6 300 Hz using nomal (TYPE I) cassette (with REC

Approx. 3.6 cm (1

450 mW + 450 mW (at 10 % harmonic distortion)

Microphone input jack (minijack)

sensitivity 0.2 mV for 3kΩ or lower impedance microphone

Earphone jack (minijack) for 8 -300Ω earphone

From approx. +30% to –15% (with REC TIME/PLAY

• 3 V DC, batteries AA (R6) x 2

• External DC 3 V power sources

Approx. 87.6 x 113.0 x 37.1 mm

1

/2 x 4 1 /2 x 1 1 /2 in.)

(3

Approx. 215 g (7.6 oz.)

7

/16 in.) dia.

US Model

Canadian Model

AEP Model

E Model

Tourist Model

Model Name Using Similar Mechanism New

Tape Transport Mechanism Type MT-500-175

9-877-111-03

2004D02-1

© 2004.04

Design and specifications are subject to change without notice.

CASSETTE-CORDER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

TCM-500DV

E

TABLE OF CONTENTS

1. GENERAL ................................................................... 2

2. SERVICING NOTES ................................................ 2

3. DISASSEMBLY ......................................................... 3

3-1. Cabinet Rear Assy (500), Lid Assy (500),

Cassette .................................................................. 3

3-2. MAIN Board .......................................................... 4

3-3. Mechanism Deck ................................................... 4

3-4. Head, Magnetic (Rec/PB/Erase) (HRPE901),

Belt (AR), Capstan/Reel (M601) .......................... 5

3-5. LED Board ............................................................. 5

3-6. SP Board ................................................................ 6

4. MECHANICAL ADJUSTMENTS ....................... 7

5. ELECTRICAL ADJUSTMENTS ......................... 7

6. DIAGRAMS

6-1. Block Diagrams ...................................................... 8

6-2. Printed Wiring Board –MAIN Board (Side A) –... 9

6-3. Printed Wiring Board –MAIN Board (Side B) –... 10

6-4. Schematic Diagram –MAIN Board (1/2) – ........... 11

6-5. Schematic Diagram –MAIN Board (2/2) – ........... 12

6-6. Printed Wiring Board –LED, SP Board – .............. 13

6-7. IC BLOCK DIAGRAMS ....................................... 14

7. EXPLODED VIEWS ................................................ 15

7-1. Cabinet Section ...................................................... 15

7-2. Cassette Holder Section ........................................ 16

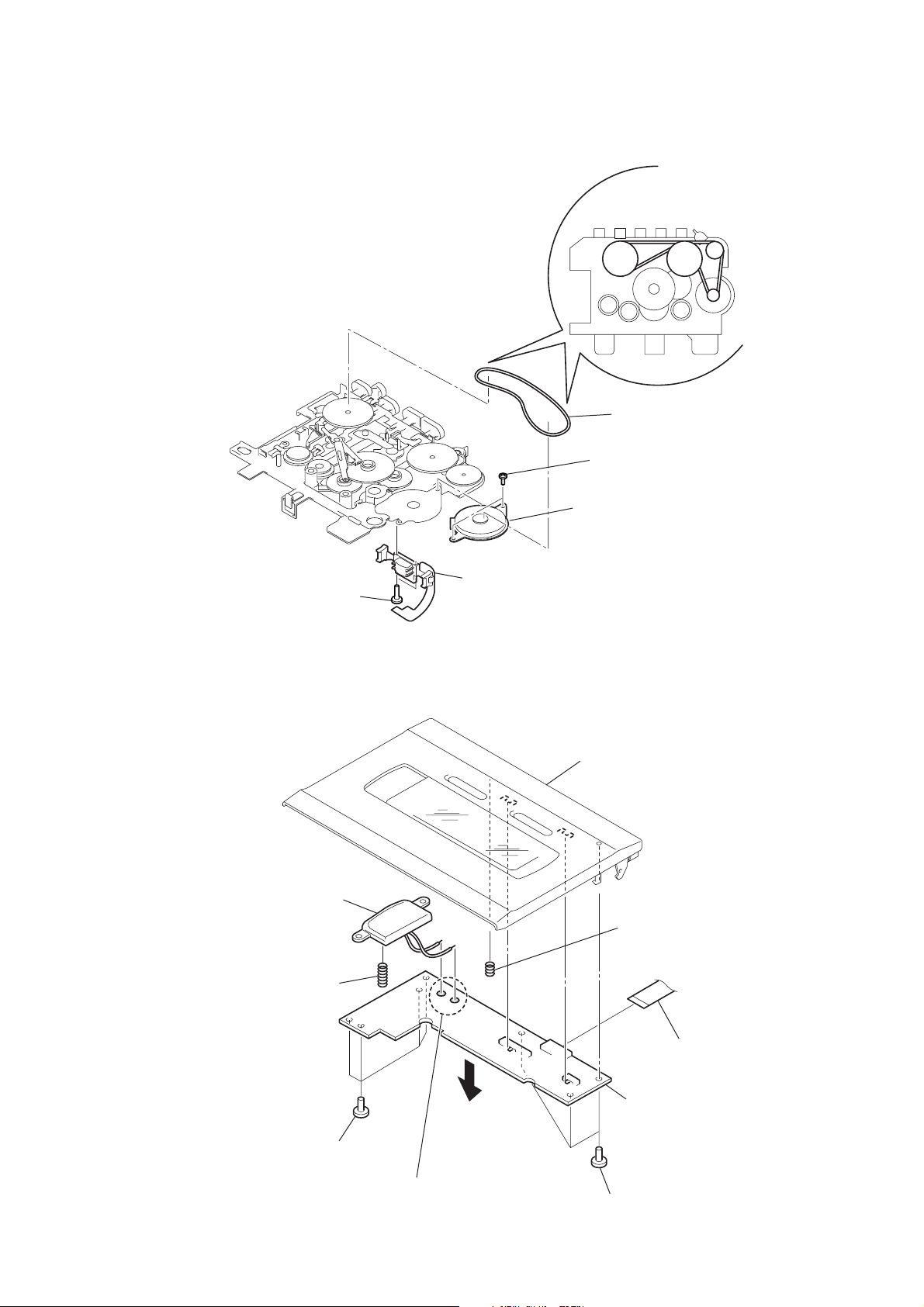

7-3. Mechanism Deck Section-1 (MT-500-175) .......... 17

7-4. Mechanism Deck Section-2 (MT-500-175) .......... 18

8. ELECTRICAL PARTS LIST ............................... 19

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

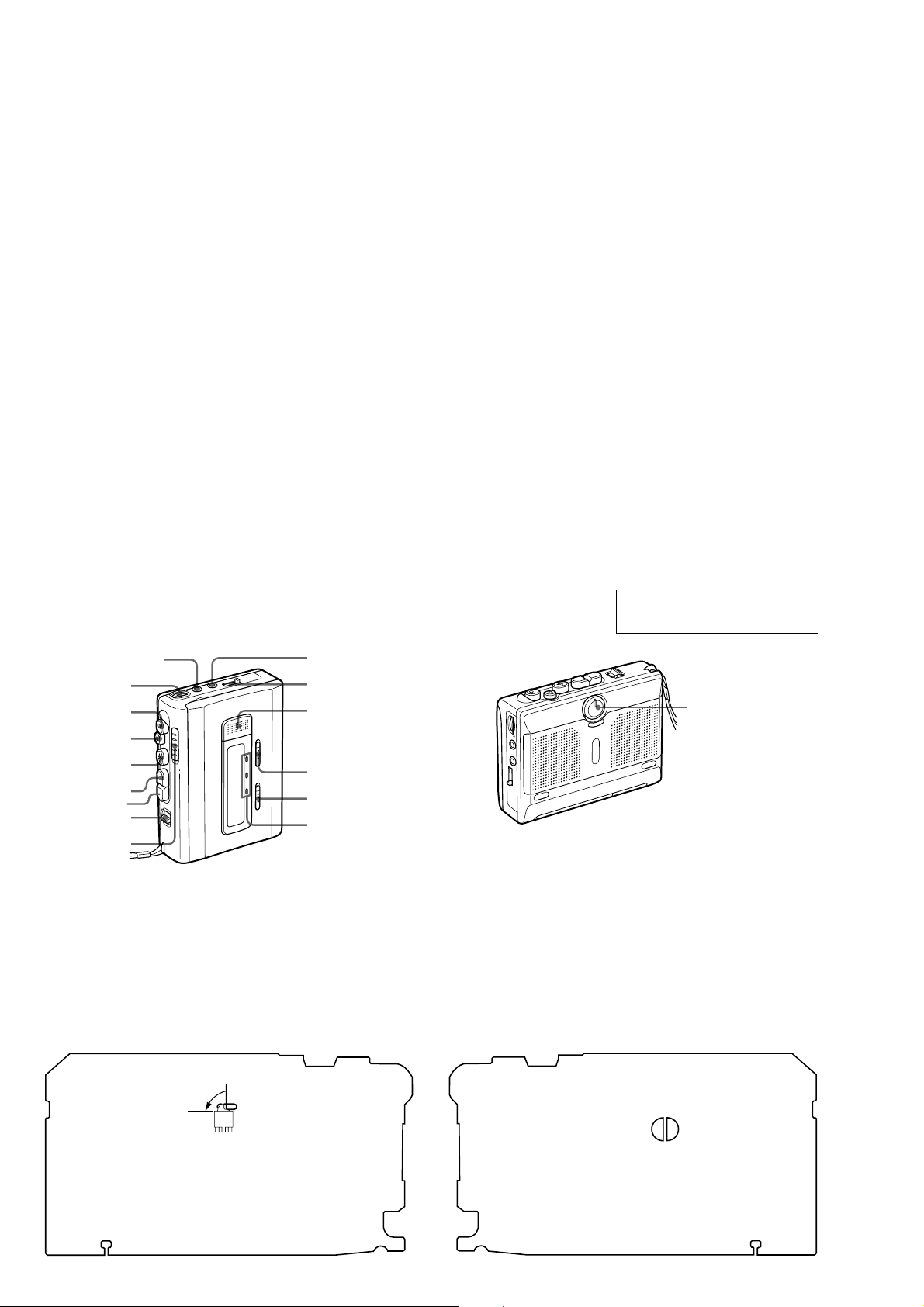

MIC (PLUG IN POWER)

VOL

z

REC

x

STOP

nN

PLAY

REW/REVIEW

FF/CUE

n

DIR

N

.

PAUSE

SECTION 1

GENERAL

EAR

TAPE COUNTER

Flat Mic

Microphone affleurant

REC TIME/PLAY MOD

VOR

REC, BATT, E lamps

Témoins REC, BATT,

E

This section is extracted from

instruction manual.

SPEED CONTROL

SECTION 2

SERVICING NOTES

In this set, the S102 (POWER) detects REC/PLAYBACK on.

It is mounted on the MAIN board, and therefore the REC/PLAYBACK on cannot be detected with the MAIN board removed.

When making an operation check and voltage check of mechnical deck with the MAIN board removed, fix the S102 at turn on.

Also, soldering the lands SL101 bridge makes S102 to turn on.

–MAIN BOARD (side A) – –MAIN BOARD (side B) –

*

ON

S102

2

SL101

• This set can be disassembled in the order shown below.

qa

5

qg

Lid assy (500), cassette

6

Flexible doard (CN201)

Cabinet (front) assy (500)

2

Screws (B1.7 x 9)

3

Screws (1.7 x 16)

4

Claws

8

Strap, hand

1

Foot (B)

7

Cabinet rear assy (500)

0

Screw (B1.7 x 3)

9

Flexible board (CN401)

Returning lever

Note on Assembling "Lid Assy (500),

Cassette"

On assembling the lid assy (500),

cassette, insert the one side of the l

id spring to the hole on the lid assy,

and fit the other side to the cabinet

(front) assy (500) as shown in the

figure.

qs

Remove the "lid assy (500),

cassette" while pushing the

pivot with a phillips-head

screwdriver or the like.

qd

Remove the returning lever from the

pivot of the "lid assy (500), cassette"

while inserting a screwdriver between

the "lid assy (500), cassette" and the

returning lever.

qf

Remove the "lid assy (500), cassette"

while pushing the pivot with a phillips head screwdriver or the like.

TCM-500DV

SECTION 3

DISASSEMBLY

Cabinet (Front) assy (500) MAIN board

Set

Note: Follow the disassembly procedure in the numerical order given.

Lid assy (500), Casette

Cabinet Rear assy (500)

LED board

SP board

Mechanism Deck

Head, Magnetic (Rec/Pb/Erase) (HRPE901), Belt (AR),

Capstan/Reel Motor (M601)

3-1.CABINET REAR ASSY (500), "LID ASSY (500), CASSETTE"

3

TCM-500DV

)

r

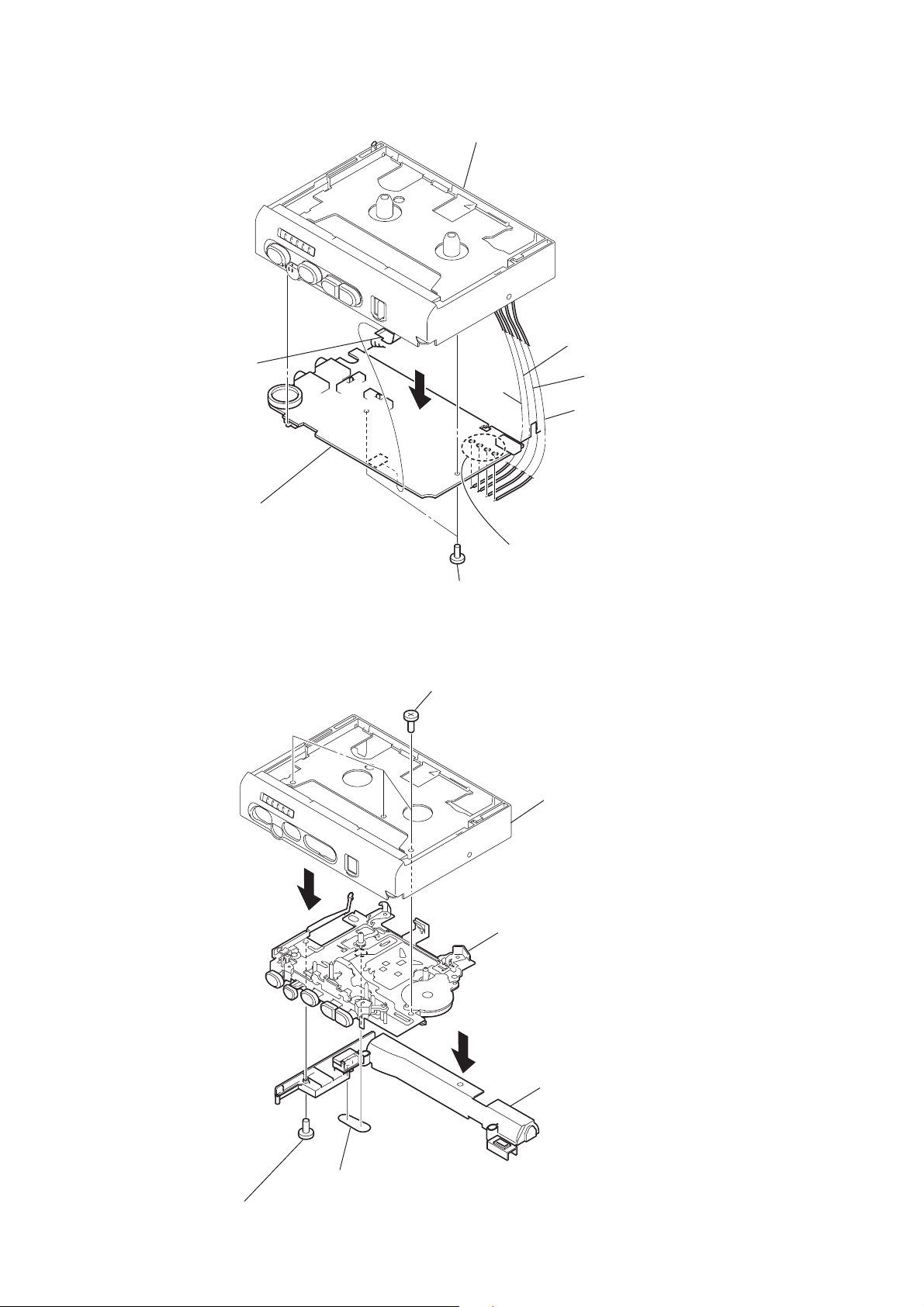

3-2. MAIN BOARD

2

Flexible board (CN101)

5

MAIN board

Cabinet (front) assy (500)

4

White

1

Remove four solders of capstan/reel moto

Orange

Black

Red

3-3. MECHANISM DECK

6

3

Screws (M1.4)

5

Screws (M1.4 x 2.5)

7

Cabinet (front) assy (500)

Mechanism deck (MT-500-175

3

4

Jack (600)

1

Belt (counter)

2

Screw (M1.4 x 2.5)

4

TCM-500DV

3-4.HEAD, MAGNETIC (REC/PB/ERASE) (HRPE901), BELT (AR), CAPSTAN/REEL MOTOR (M601)

How to attach a belt

3 Belt (AR)

4 Screw (M1.4)

3-5.LED BOARD

1 Screw (M1.4)

8

Mic 901

5 Capstan/reel motor (M601)

2 Head, magnetic (rec/pb/erase) (HRPE901)

Lid assy (500) cassette

5

Spring (earth)

7

Sprng (500), ground

1

Screws

6

Remove two solders of mic

3

4

Flexible board (CN402)

9

LED board

2

Screws

5

TCM-500DV

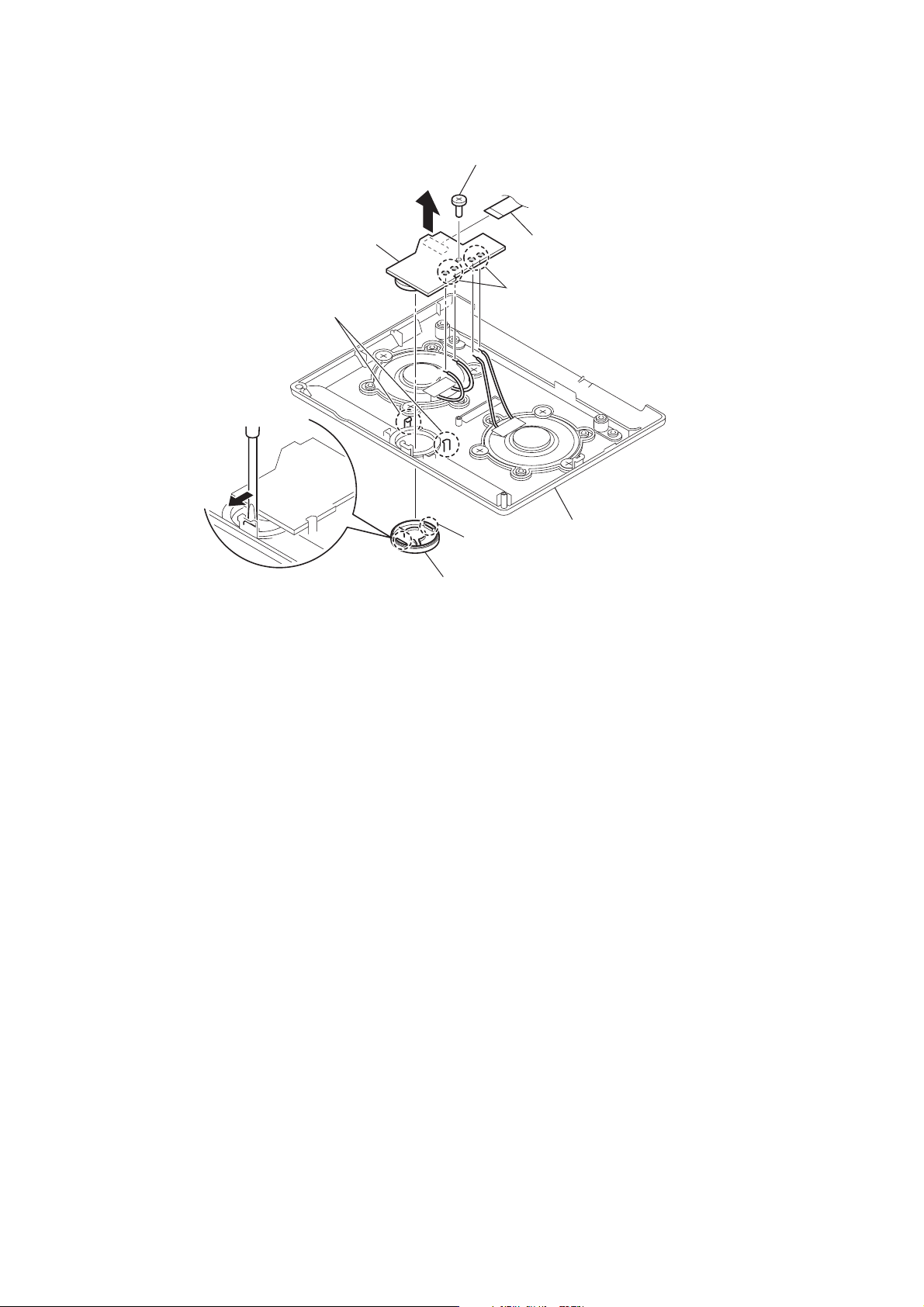

3-6. SP BOARD

1

Remove a claw of knob

(speed) (600) by a screwdriver

9

SP board

5

Claws

6

4

Screw

7

Flexible board (CN202)

8

Remove four solders of speaker leads

2

Claw

3

Knob (speed) (600)

Cabinet rear assy (500)

6

SECTION 4

t

MECHANICAL ADJUSTMENTS

SECTION 5

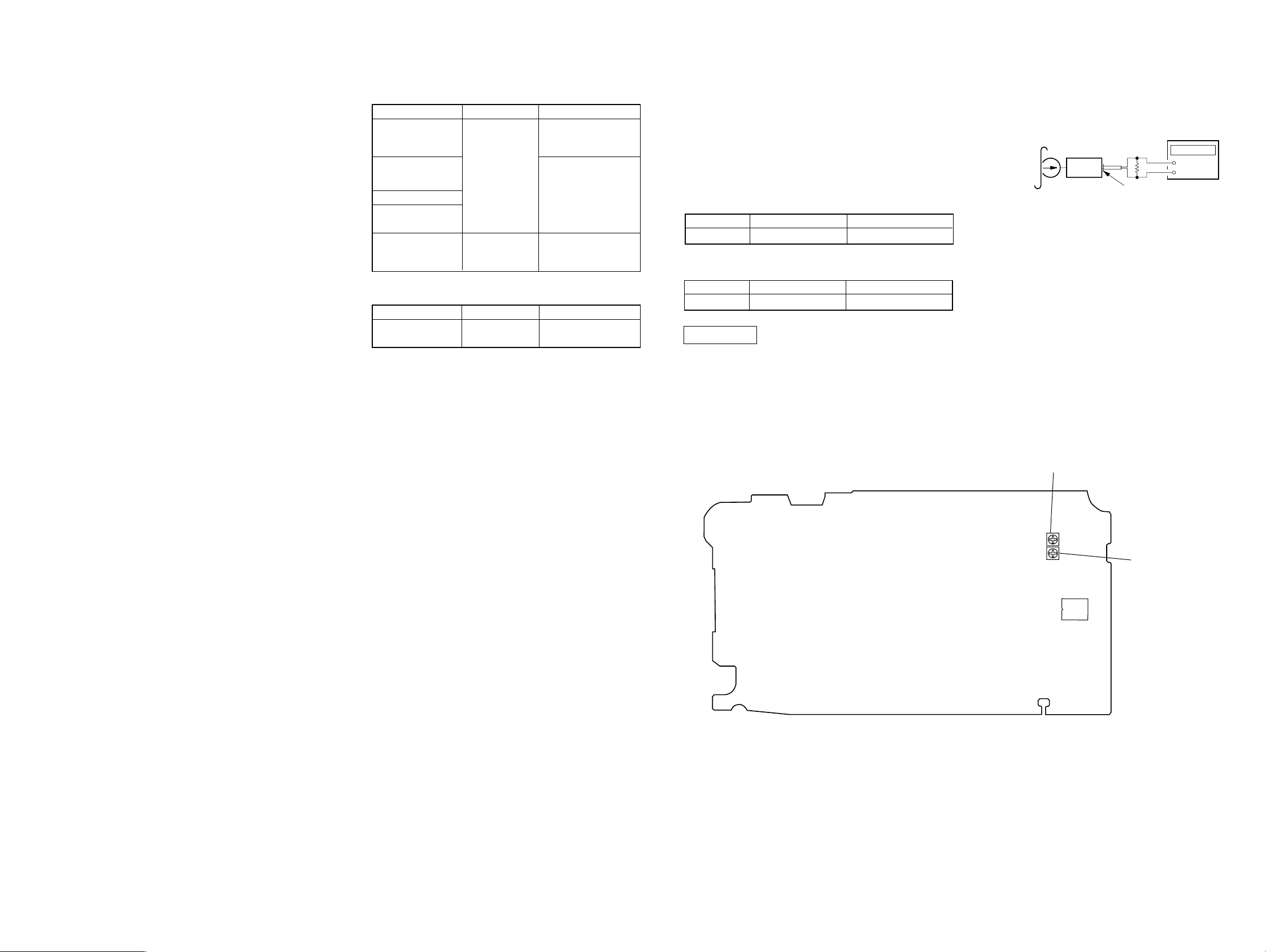

ELECTRICAL ADJUSTMENTS

TCM-500DV

Ver 1.2

1. Clean the following parts with a denatured-alcohol-moistened

swab:

record/playback/erase head pinch roller

capstan rubber belt

2. Demagnetize the record/playback/erase head with a head demag

netizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the rated power supply

voltage (3 V) unless otherwise noted.

Torque Measurement

Mode Torque Meter Meter Reading

FWD (20 – 40 g•cm)

CQ-102C

FWD

Back Tension

REV (0.5– 5 g•cm)

REV (0.007 – 0.069 oz•inch)

Back Tension

FF, REW CQ-201B

1.97 – 3.92mN•m

(0.28 – 0.55 oz•inch)

0.05 – 0.49 mN•m

more than 4.91 mN•m

(more than 50 g•cm)

(more than 0.69 oz•inch)

Tape Tension Measurement

Mode Tension Meter Meter Reading

FWD CQ-403A

more than 50 g

(more than 1.76 oz)

Setting:

• Supplied voltage: 3 V (DC)

• Switch and control position

VOL contorl (RV101) : mechanical center

REC SPEED switch (S401) : normal (4.8cm/s)

PAUSE switch (S601) : OFF

SPEED CONTROL (RV201) : center click

VOR switch (S402) : OFF

Regulation Level

input level Mic –60dBs

output level earphone 16Ω, –20dBs

Test T ape

Type Signal Used for

WS-48A 3 kHz, 0 dB tape speed adjustment

0 dB=0.775 V

Tape Speed Adjustment

Mode: playback

test tape

WS-48A

(3 kHz, 0 dB)

16 Ω

set

EAR jack (J102)

frequency

counter

+

–

Procedure:

1. Set [REC TIME] switch (S401) to NORMAL (4.8 cm/s) posi tion, and playback the tape (WS-48A) .

2. Adjust RV602 so that frequency counter reading becomes 3,010

Hz.

3. Set [REC TIME] switch (S401) to DOUBLE (2.4 cm/s) posi tion.

4.Playback the tape from the beginning for two minutes, then ad just R V601 so that frequency counter reading becomes 1,505 Hz.

Confirm that deflection of the frequency counter reading between

the beginning and the end of tape is within 2% (NORMAL: approx.

60 Hz, DOUBLE: approx. 30 Hz) .

Adjustment Location:

– MAIN BOARD (Conductor Side) –

RV601

Tape Speed Adjustment

(Double Speed)

11

20

IC601

10

1

RV602

Tape Speed Adjustmen

(Normal Speed)

77

Loading...

Loading...