Sony TA SB500WR2 Service Manual

TA-SB500WR2

SERVICE MANUAL

Ver. 1.0 2007.03

• TA-SB500WR2 is the surround amplifier

section in DAV -HDX267W/HDX501W.

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC

DISTORTION:

With 3 ohms loads, both

channels dr iv en, from

120 Hz - 20,000 Hz; rated

60 watts per channel

minimum RMS power,

with no more than 0.7 %

total harmonic distortion

from 250 milli watts to

rated output.

Amplifier section

Surround mode (reference ) RMS output power

SL/SR* : 100 W

(per chan nel at 3 ohms, 1

kHz, 10 % THD)

*Depending on the sound field setting and the source,

there may be no sound output.

Power requireme nts:

Power consumption On: 40 W

Dimensions (approx.) 65 × 89 × 253 mm

Mass (approx.) 1.3 kg (2 lb 14 oz)

Design and specifications are subject to change

without notice.

120 V AC, 60 Hz

5

/8 × 3 5/8 × 10 inches)

(2

(w/h/d)

65 × 89 × 345 mm

5

(2

/8 3 × 5/8 × 13 5/8 inches)

(w/h/d) incl. speaker cord

cover

1.4 kg (3 lb 2 oz) incl.

speaker cord cover

US Model

9-887-591-01

2007C05-1

© 2007.03

SURROUND AMPLIFIER

Sony Corporation

Home Audio Division

Published by Sony Techno Create Corporation

TA-SB500WR2

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

TABLE OF CONTENTS

1. GENERAL ................................................................... 3

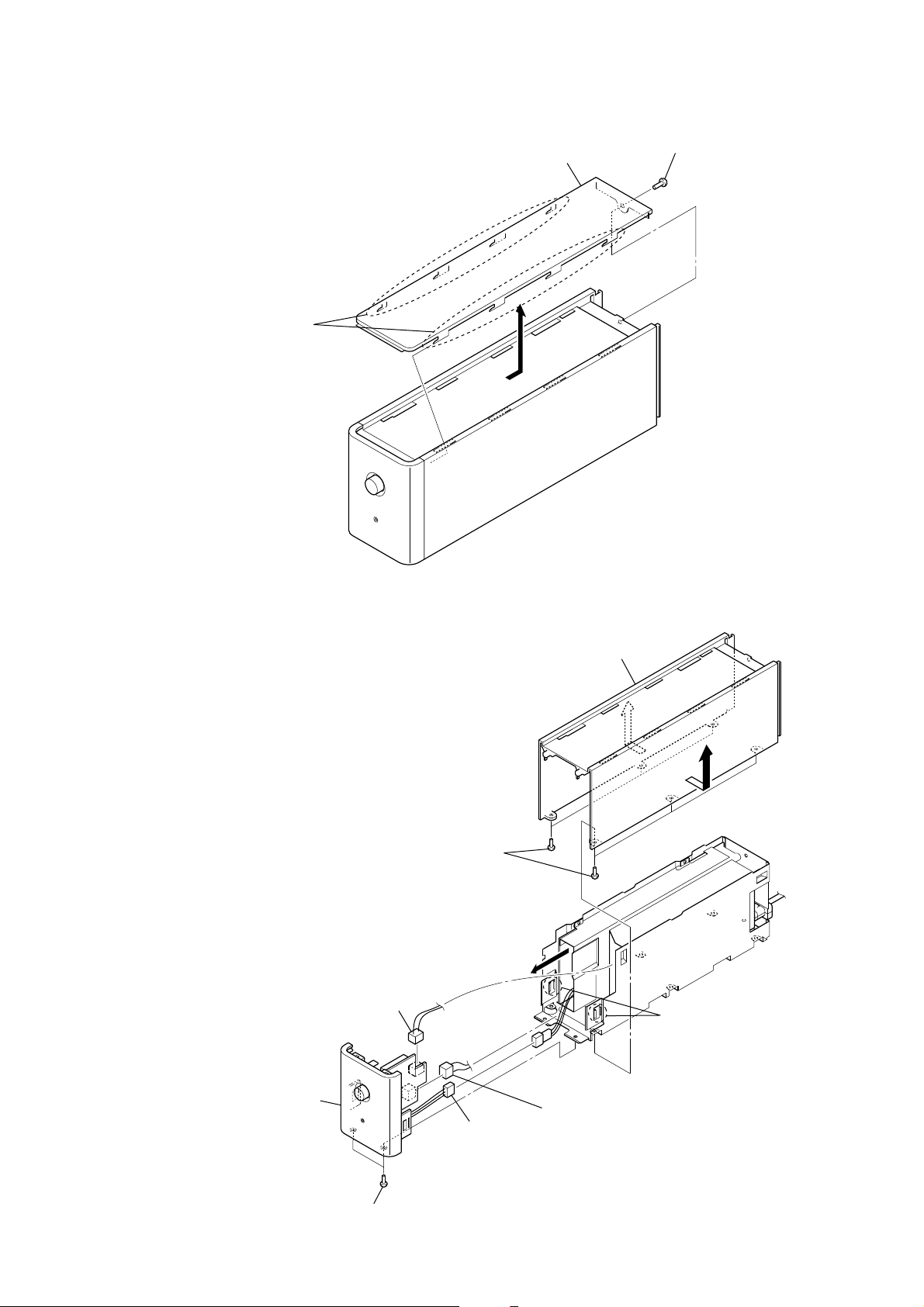

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 4

2-2. Wire Cover ...................................................................... 4

2-3. Top Panel ......................................................................... 5

2-4. Side Panel, Front Panel Block ......................................... 5

2-5. DIAT POWER Board ...................................................... 6

2-6. DIAT AMP Board............................................................ 6

3. DIAGRAMS

3-1. Block Diagram ................................................................ 7

3-2. Printed Wiring Board – DIAT AMP Section (1/2) – ....... 9

3-3. Printed Wiring Boards – DIAT AMP Section (2/2) –...... 10

3-4. Schematic Diagram – DIAT AMP Section (1/4) – .......... 11

3-5. Schematic Diagram – DIAT AMP Section (2/4) – .......... 12

3-6. Schematic Diagram – DIAT AMP Section (3/4) – .......... 13

3-7. Schematic Diagram – DIAT AMP Section (4/4) – .......... 14

3-8. Printed Wiring Boards – POWER SUPPLY Section –.... 15

3-9. Schematic Diagram – POWER SUPPLY Section – ........ 16

4. EXPLODED VIEWS

4-1. Panel Section ................................................................... 23

4-2. DIAT AMP/DIAT POWER Boards Section .................... 24

5. ELECTRICAL PARTS LIST................................ 25

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

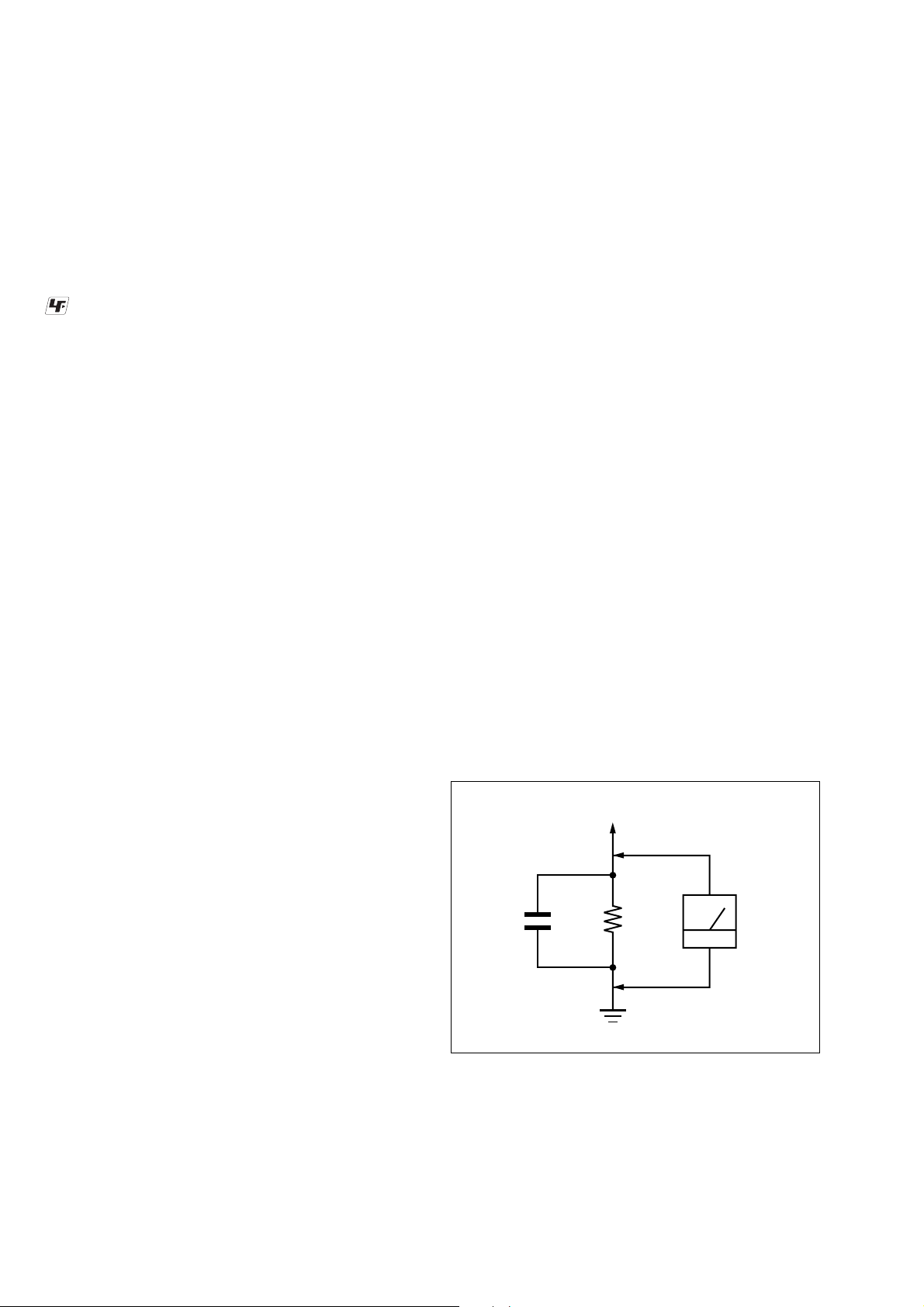

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the manufactur ers’ instructions to use these

instruments.

2. A battery-operated A C milliammeter . The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC v oltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-v oltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V A C range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

AC

0.15 µF

1.5 k

Ω

Earth Ground

voltmeter

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PAR TS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANU AL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

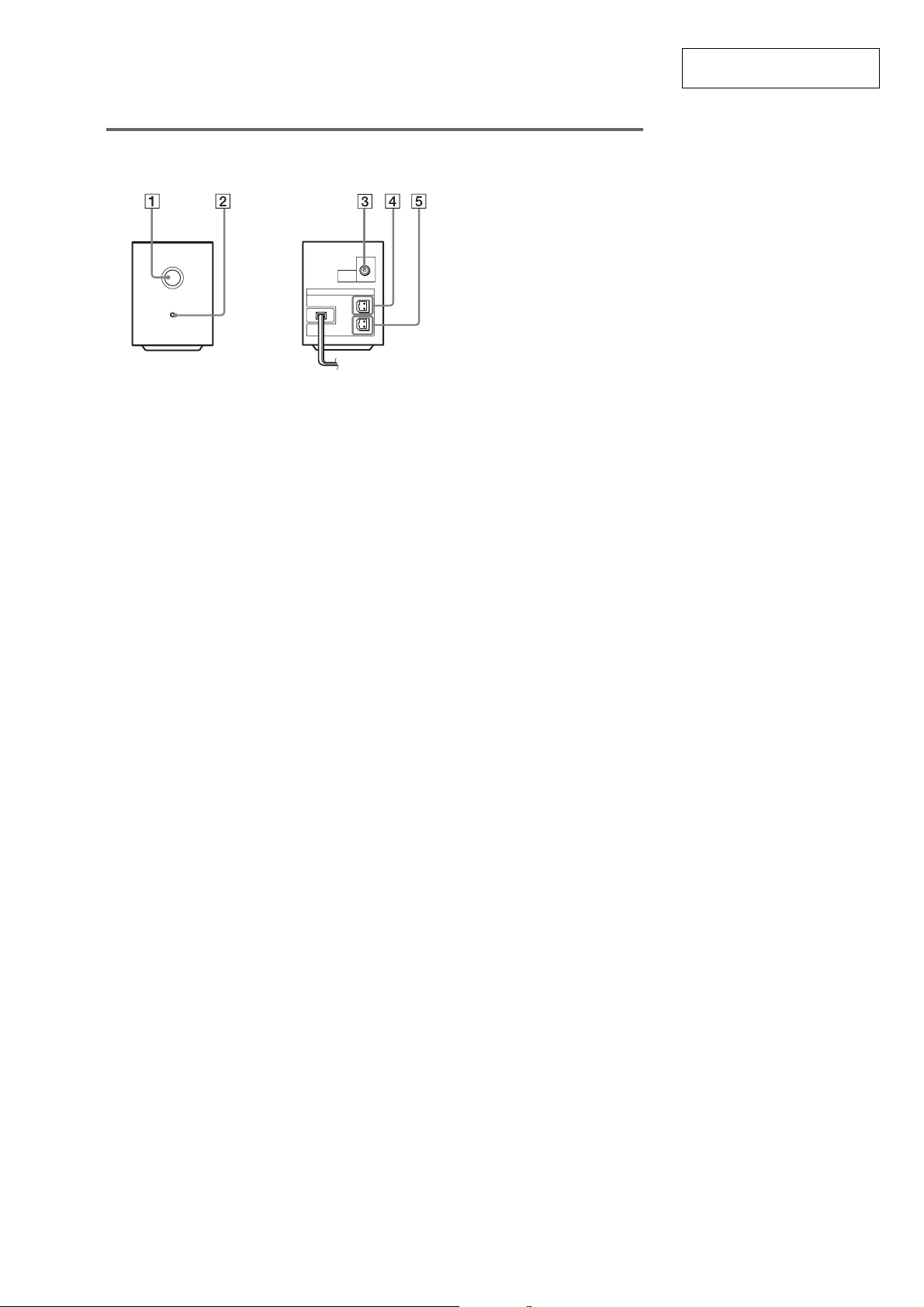

LOCATION OF CONTROLS

Surround amplifier

SECTION 1

GENERAL

TA-SB500WR2

This section is extracted from

instruction manual.

Front panel

POWER

POWER ON-LINE

A POWER (ON/OFF)

B POWER/ON LINE indicator

C DIR-R1 jack

D SURROUND L SPEAKER jack

E SURROUND R SPEAKER jack

Rear panel

DIR-R1

SPEAKER

SURROUND L

SURROUND R

3

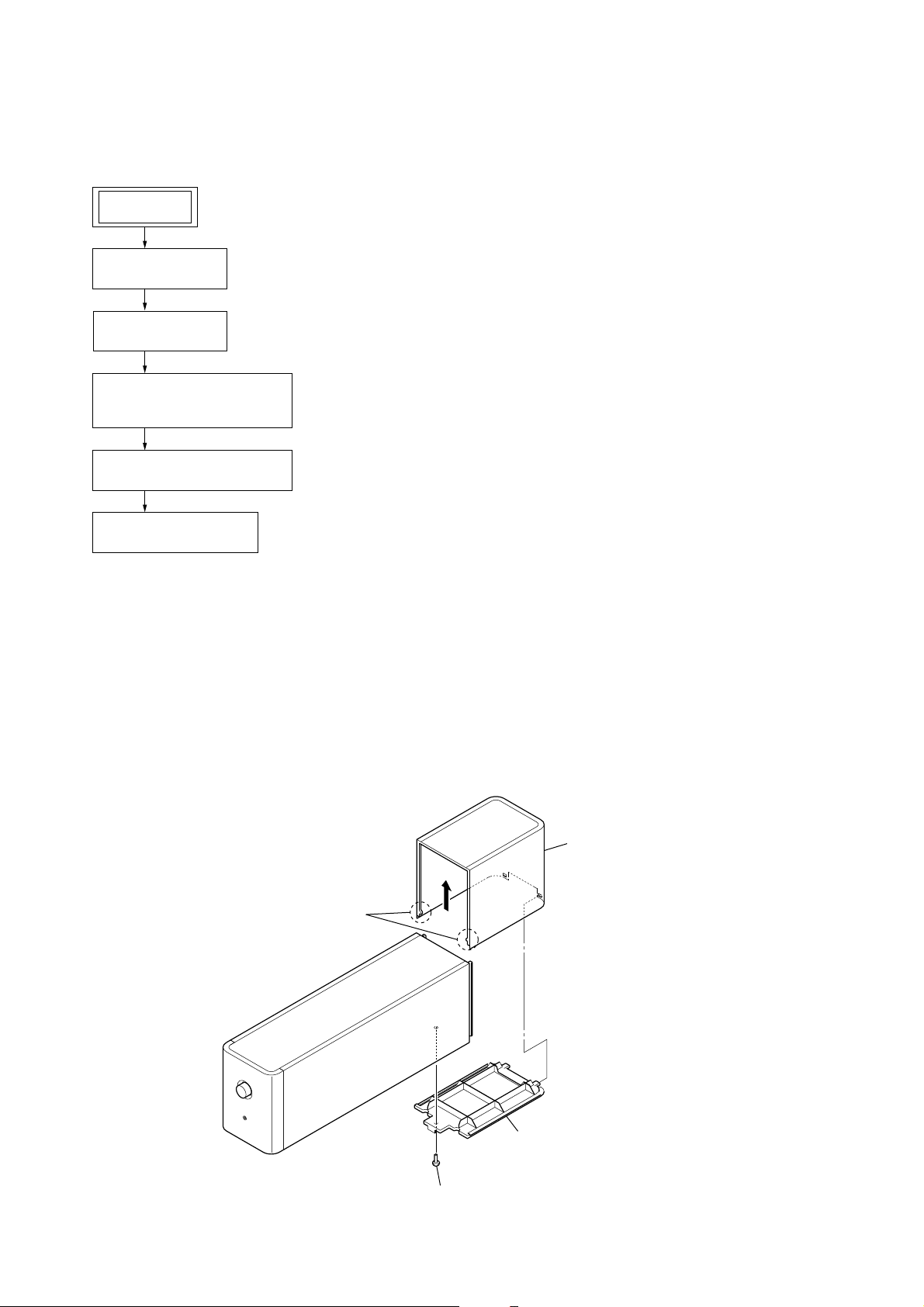

TA-SB500WR2

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

SET

2-2. WIRE COVER

(Page 4)

2-3. TOP PANEL

(Page 5)

2-4. SIDE PANEL,

FRONT PANEL BLOCK

(Page 5)

2-5. DIAT POWER BOARD

(Page 6)

SECTION 2

DISASSEMBLY

2-6. DIAT AMP BOARD

(Page 6)

Note: Follow the disassembly procedure in the numerical order given.

2-2. WIRE COVER

3

two claws

4

wire cover

2

wire (A) holder

1

screw (B3 × 8)

4

2-3. TOP PANEL

)

3

eight claws

4

top panel

2

1

screw

(BVTP3

TA-SB500WR2

×

10

2-4. SIDE PANEL, FRONT PANEL BLOCK

7

connector

(CN902)

1

six screws

(2.6

3

side panel

2

2

×

6)

6

5

two claws

8

front panel block

4

two screws

(2.6

7

connector

7

connector

×

6)

(CN901)

5

TA-SB500WR2

s

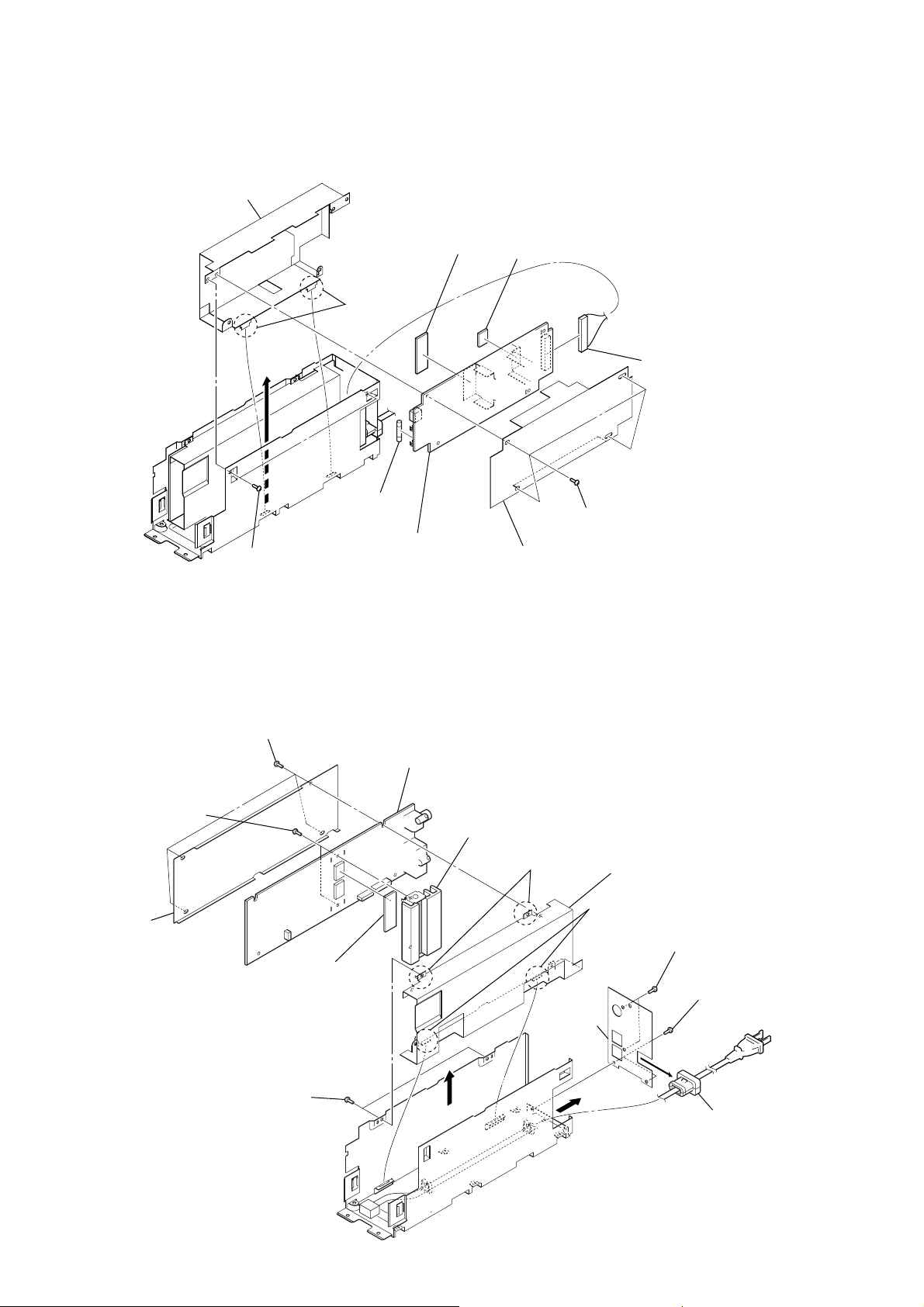

2-5. DIAT POWER BOARD

7

power shield

3

2

two claws

8

radiation sheet

(DMB)

8

radiation sheet

4

two connector

(CN904)

2-6. DIAT AMP BOARD

qd

two screws

qa

sheet AMP

(BVTP3

×

6)

1

0

four screws

(2.6

two screws

(2.6

×

6)

×

6)

qg

radiation sheet

9

fuse (F901)

0

DIAT POWER board

qh

DIAT AMP board

qf

6

A sheet power

heat sink block

7

two claws

5

back

panel

5

four screws

(2.6

qs

8

two claws

×

6)

AMP shield

1

two screws

(BVTP3

2

two screws

(BVTP3

×

8)

×

8)

6

two screws

(2.6

×

6)

9

3

4

cord bushing

6

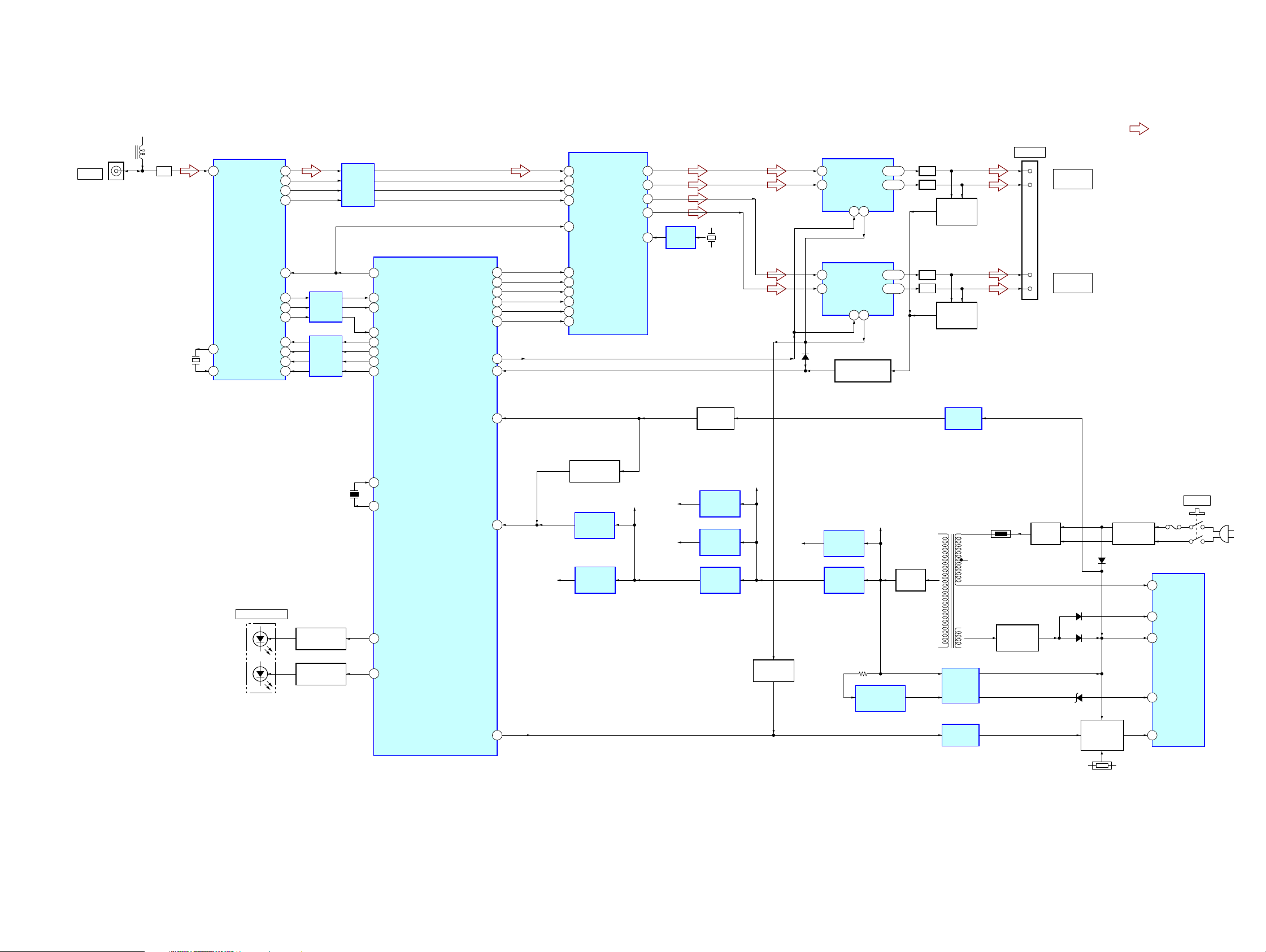

3-1. BLOCK DIAGRAM

VCC2

J301

DIR-R1

LPF

X101

12.288MHz

RF DEMODULATOR,

A/D CONVERTER

10

ADVIN

OSCO

4043OSCI

IC102

DAOUT

BCK

LRCK

APX

/XRST

CSOD

DTVALID

SRDT

SWDT

SCLK

/XSCEN

SCMODE

TA-SB500WR2

SECTION 3

DIAGRAMS

• SIGNAL PATH

IC301

STREAM PROCESSOR

60

54

59

31

13

33

61

34

35

37

36

38

IC106

LEVEL

SHIFT

IC103

LEVEL

SHIFT

IC109

LEVEL

SHIFT

SURROUND AMP CONTROLLER

26 XRST_INIT

15 CSOD

14 DTVALID

53 DIAT_SRDT

52 DIAT_SWDT

51 DIAT_SCLK

50 XSCEN

48 SCMODE

IC107

DAMP_SCDT

DAMP_SHIFT

DAMP_LATCH

DAMP_NSPMUTE

DAMP_SOFTMUTE

DAMP_PGMUTE

DRIVER_RST

DRIVER_OCP

61

60

59

35

34

33

37

38

31

DATA

30

BCK

29

LRCK

36

XFSIIN

27

INIT

21

SCDT

22

SCSHIFT

23

SCLATCH

18

NSPMUTE

19

SOFTMUTE

20

PGMUTE

OUTL1

OUTL2

OUTR1

OUTR2

XFSOIN

11

9

6

4

IC114

48

OSC

X103

49.152MHz

D300

POWER DRIVER

2

PWM_BP

17

PWM_AP

POWER DRIVER

2

PWM_BP

17

PWM_AP

PROTECT DETECT

IC110

/RST

4 13

IC112

/RST

4 13

Q107

OUT_B

OUT_A

/SD

OUT_B

OUT_A

/SD

29, 30

25, 26

29, 30

25, 26

LPF

LPF

LPF

LPF

Q108, 109

OVER LOAD

DETECT

Q105, 106

OVER LOAD

DETECT

TB301

SPEAKER

(+)

(–)

(+)

(–)

SURROUND

L

SURROUND

R

: AUDIO

D400

POWER/ON-LINE

LED DRIVE

Q104, 112

LED DRIVE

Q103, 111

X102

8MHz

22

X0

X1

23

41

LED_GREEN

42

LED_RED

AC CUT

/RESET

MAIN_OFF

17

RESET SWITCH

Q102

+3.3V

+1.5V

19

+1.8V

57

VOLTAGE

DETECT

IC105

+1.8V

REGULATOR

IC113

+2.5V

AC CUT

Q110

+1.5V

REGULATOR

IC101

+2.5V

REGULATOR

IC104

+3.3V

REGULATOR

IC108

VCC2

PROTECTOR

Q300

+12V

+12V

REGULATOR

IC903

DC/DC

CONVERTER

IC904

+27.5V

SHUNT

REGULATOR

IC905

RECT

D921

ISOLATOR

PC902

POWER

TRANSFORMER

T901

ISOLATOR

PC901

ISOLATOR

PC903

TH901

REGULATOR

Q901

RECT

D901

D907, 909

D908

D910

D911

OVER LOAD

PROTECT

Q902, 903

TH902

LINE FILTER

POWER

F901

1

D

7

OCP/BD

4

VCC

6

FB

5

OLP/SS

POWER CONTROL

IC901

S901

(AC IN)

TA-SB500WR2

77

TA-SB500WR2

20.3 ns

3.4 Vp-p

125 ns

3.4 Vp-p

325 ns

3.2 Vp-p

82 ns

2.9 Vp-p

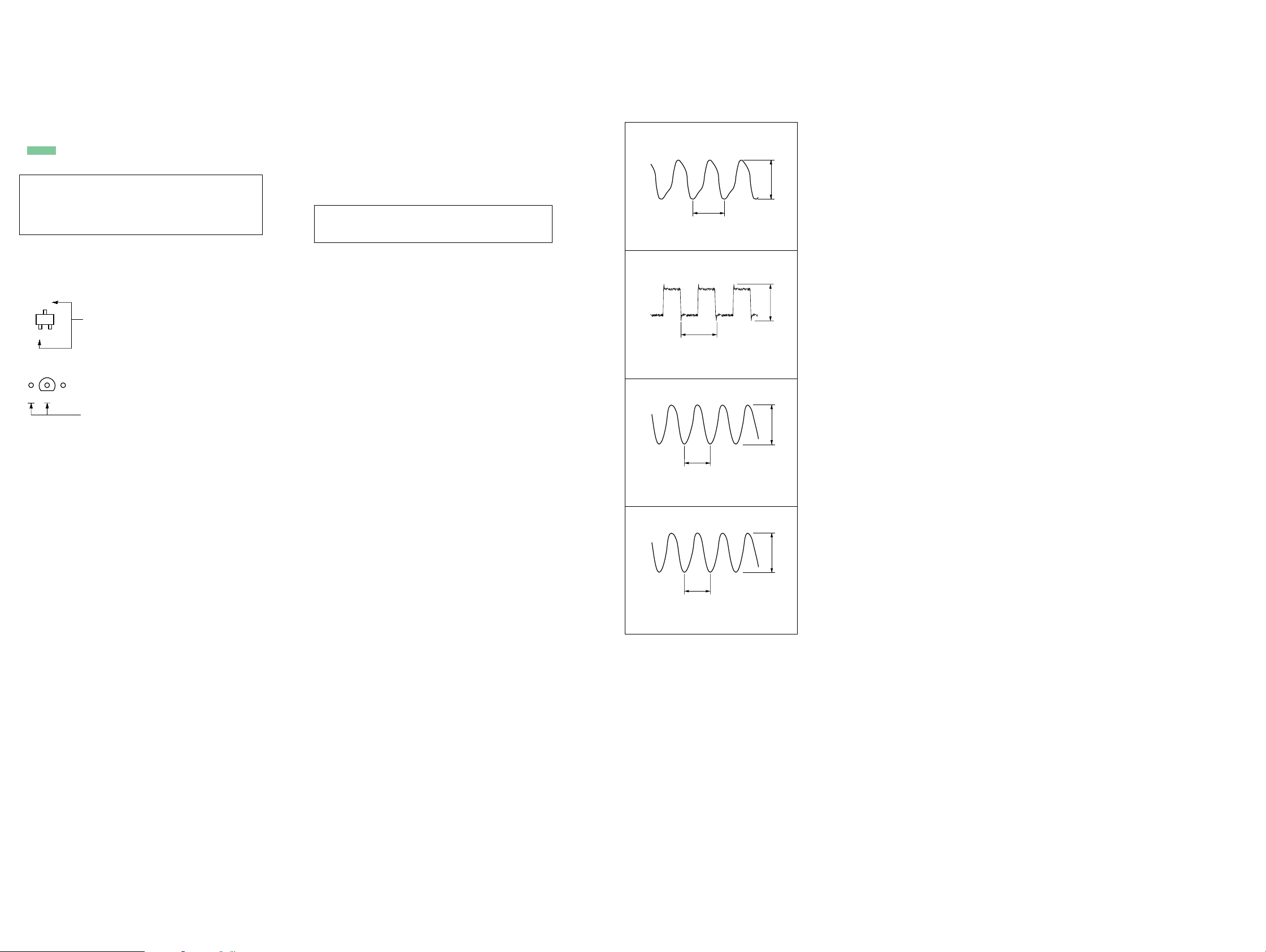

• Note for Printed Wiring Boards and Schematic Diagrams

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

f

•

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

• DIAT AMP board is multi-layer printed board.

• Indication of transistor.

: internal component.

However, the patter ns of intermediate layers have not been

included in diagrams.

C

B

Q

B

E

Q

CE

These are omitted.

These are omitted.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and

specified.

•

f : internal component.

• 2 : nonflammable resistor.

• C : panel designation.

Note: The components identified by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specified.

• A : B+ Line.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

Note: When mesurering voltages and waveforms, con-

nect with HCD-SB500W (HCD-SB500W states:

DVD play).

no mark : DVD PLAY

∗ : Impossible to measure

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

1

4

/

W or less unless otherwise

• Waveforms

– DIAT AMP Board –

IC102 rd (OSCO)

1

1 V/DIV, 50 ns/DIV

IC102 tf (BCK)

2

1 V/DIV, 200 ns/DIV

IC107 wd (X1)

3

4

1 V/DIV, 50 ns/DIV

IC114 4

2 V/DIV, 10 ns/DIV

TA-SB500WR2

88

TA-SB500WR2

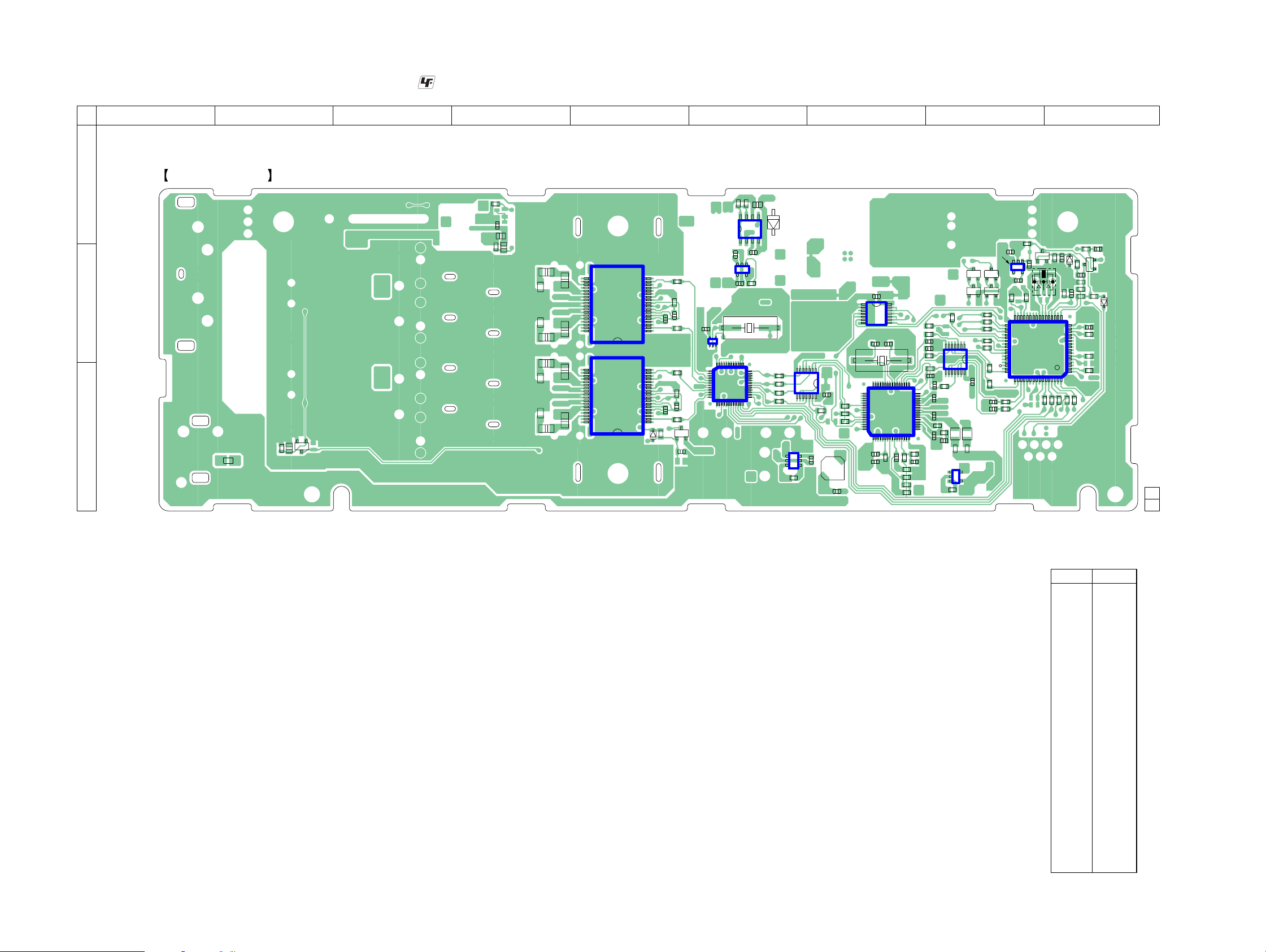

3-2. PRINTED WIRING BOARD – DIAT AMP Section (1/2) –

1 2 3 4 5 6 7 8 9

DIAT AMP BOARD

(COMPONENT SIDE)

A

B

C

R155

FB109

C166

Q107

E

B

C

: Uses unleaded solder.

R950

C938

C937

R952

C954

C222

R198

R189

C208

C191

R180

R167

C181

C221

C207

C190

C180

R940

14

1

3

54

R199

C223

X103

3748

36

25

24

C951

58

C940

IC113

R162

R163

R161

R160

D922

IC109

7

8

IC104

3

1

R117

R168

4

6

1

14

C142

IC106

C167

R119

R118

R120

L101

C105

1

7

49

64

C131

C132

C129

X101

C149

IC102

1

C120

R116

C124

R111

R111

R111

R264

R265

R140

R124

X102

R131

17

64

R137

C147

R134

D102

C266

16

1

R138

R259

R123

C

R130

E

B

C143

C143

C143

R171

R171

R171

R152

R152

R152

R133

R129

C253

Q110

D103

C156

R283

R258

R127

1-872-329-

11

(11)

Q102

C

EBE

C

EBE

R149

R151

L103

Q103

Q103

Q103

C

C

R141

R122

C145

R252

33

48

R145

IC105

Q112 Q111

B

B

14

8

R261

R115

C123

C126

R114

R112

C122

3348

C125

32

C108

17

C111

16

R110

R109

C116

R266

R262

IC103

7

8

R113

C113

R104

L102

R102

C110

FB101

135

R101

Q104

R146

R147

R148

R150

1

C133

14

C159

FB102

IC101

4

C158

C146

13

54

R253

32

IC107

49

R144

C148

C

E

B

R941

IC904

C234

R183

D300

18

1

18

1

C244

C243

R300

R196

C211

R181

IC114

R175

R178

C186

R173

C

BE

Q300

C300

C233

5

1

12

4

13

13

IC301

19

IC112

36

19

IC110

36

• Semiconductor

Location

Ref. No. Location

D102 B-9

D103 B-9

D300 C-5

D922 A-6

IC101 C-8

IC102 C-7

IC103 B-8

IC104 C-6

IC105 B-8

IC106 B-7

IC107 B-8

IC109 C-6

IC110 C-5

IC112 B-5

IC113 B-6

IC114 B-6

IC301 C-6

IC904 A-6

Q102 A-8

Q103 B-8

Q104 B-8

Q107 C-2

Q110 B-9

Q111 B-8

Q112 B-8

Q300 C-5

TA-SB500WR2

99

Loading...

Loading...