Sony SPP-N1001, SPP-N1003 Service manual

SPP-N1001/N1003

SERVICE MANUAL

Ver 1.1 2001.05

with SUPPLEMENT-1

(9-927-979-81)

Photo : SPP-N1003

SPECIFICATIONS

General

Operating frequency 902-928 MHz (0.3mW)

Frequency control Crystal-controlled PLL

Operation mode FM, duplex

Operation channel 30 channels

Supplied accessories AC power adaptor AC-T127

Telephone line cord

Headset TL-HD10, for the use of the left ear only (SPP-N1003)

Rechargeable battery pack BP-T50G

Directories (2 sheets)

Handset

Power source Rechargeable battery pack BP-T50

Battery life Standby: Approx. 30 days

Talk: Approx. 10 hours

Dimensions Approx. 2 1/4 x 7 1/8 x 1 15/16 inches (w/h/d), antenna excluded

(approx. 55 x 180 x 48 mm)

Antenna: Approx. 1 1/8 inches (approx. 27 mm) (SPP-N1001)

Antenna: Approx. 1 15/16 inches (approx. 48 mm) (SPP-N1003)

Mass Approx. 5.5 oz (approx. 155 g), battery included

Base unit

Power source DC 9V from AC power adaptor

Battery charging time Approx. 12 hours

Dimensions Approx. 3 7/8 x 2 1/8 x 8 3/8 inches (w/h/d)

(approx. 97 x 52 x 212 mm) (SPP-N1001)

Approx. 4 1/4 x 2 1/8 x 8 3/8 inches (w/h/d), antenna excluded

(approx. 107 x 52 x 212 mm) (SPP-N1003)

Antenna: Approx. 4 5/8 inches (approx. 115 mm) (SPP-N1003)

Mass Approx. 7.6 oz (approx. 215 g)

US Model

SPP-N1003

Canadian Model

SPP-N1001/N1003

E Model

SPP-N1001

9-927-979-12

2001E0200-1

© 2001.5

Head set (TL-HD10, for the use of the left ear only) (SPP-N1003)

Cord length Approx. 47 1/4 inches (approx. 1.2 m)

Mass Approx. 2 oz (approx. 55 g)

Design and specifications are subjec to change without notice.

CORDLESS TELEPHONE

Sony Corporation

Personal Audio Company

Shinagawa Tec Service Manual Production Group

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. GENERAL

Setting up the phone .......................................................... 3

Making and Receiving calls............................................... 4

Speed dialing...................................................................... 4

Paging ................................................................................ 4

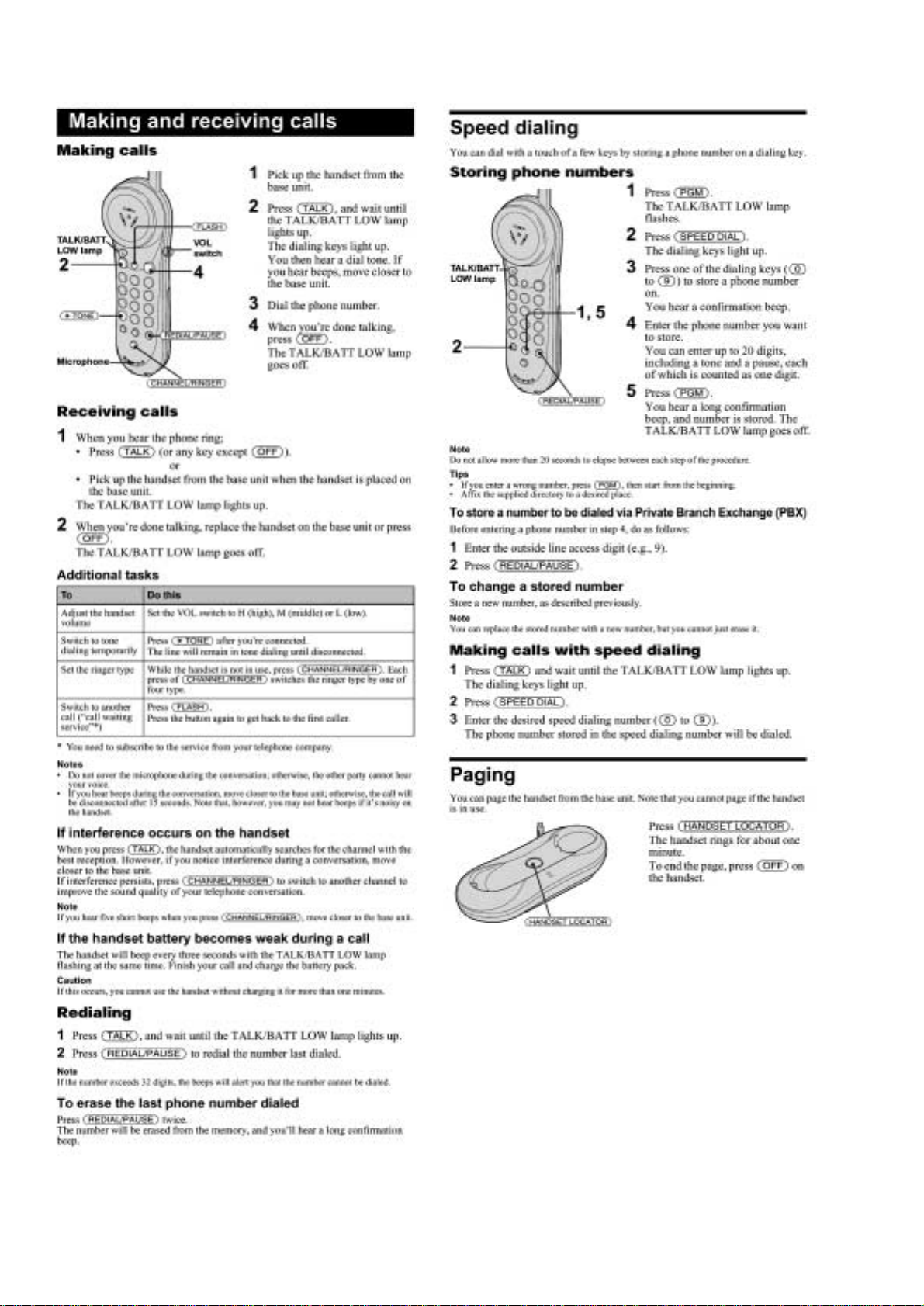

Making and Receiving calls using the

head set (SPP-N1003) ........................................................ 5

Mounting the base unit on a wall ....................................... 5

Resetting the digital security code ..................................... 5

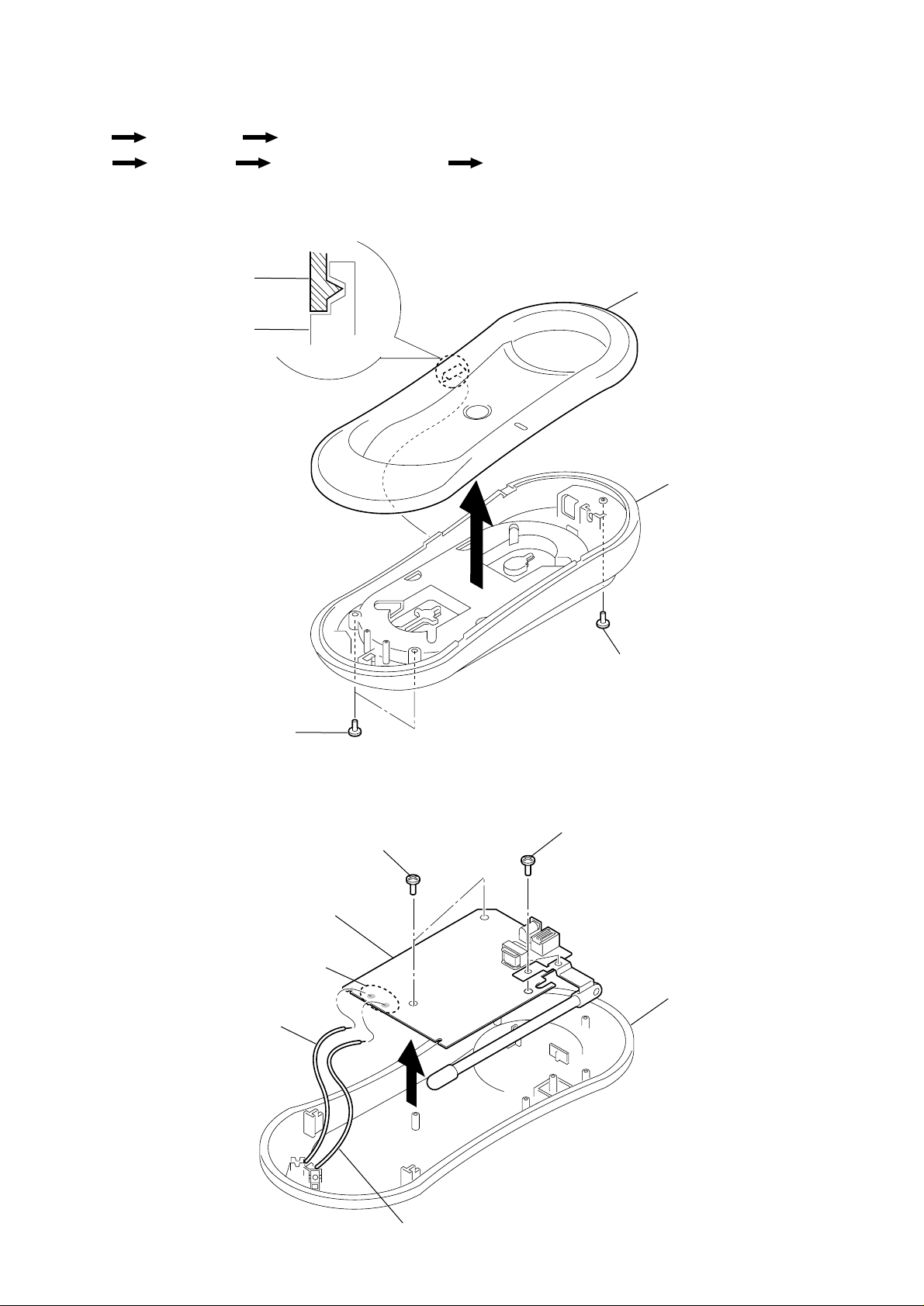

2. DISASSEMBLY

2-1. Cabinet (Upper) .......................................................... 6

2-2. Base Main Board ........................................................ 6

2-3. Cabinet (Rear)............................................................. 7

2-4. Jack Board (SPP-N1003 Only)................................... 7

2-5. Hand Main Board ....................................................... 8

3. TEST MODE................................................................... 9

4. ELECTRICAL ADJUSTMENTS

Base Unit Section..............................................................11

Handset section ................................................................ 13

5. DIAGRAMS

5-1. Explanation of IC Terminals..................................... 15

5-2. Block Diagrams (Base Unit Section)........................ 17

5-3. Block Diagrams (Handset Section) .......................... 19

5-4. Printed Wiring Boards (Base Unit Section).............. 21

5-5. Schematic Diagram (Base Unit Section) .................. 23

5-6. Printed Wiring Boards (Handset Section) ................ 25

5-7. Schematic Diagram (Handset Section)..................... 27

5-8. Printed Wiring Boards (Jack Section)

(SPP-N1003 Only) ................................................... 29

5-7. Schematic Diagram (Jack Section)

(SPP-N1003 Only) ................................................... 30

6. EXPLODED VIEWS

6-1. Base Unit Section ..................................................... 31

6-2. Handset Section ........................................................ 32

6-3. Head set Section (SPP-N1003 Only)........................ 33

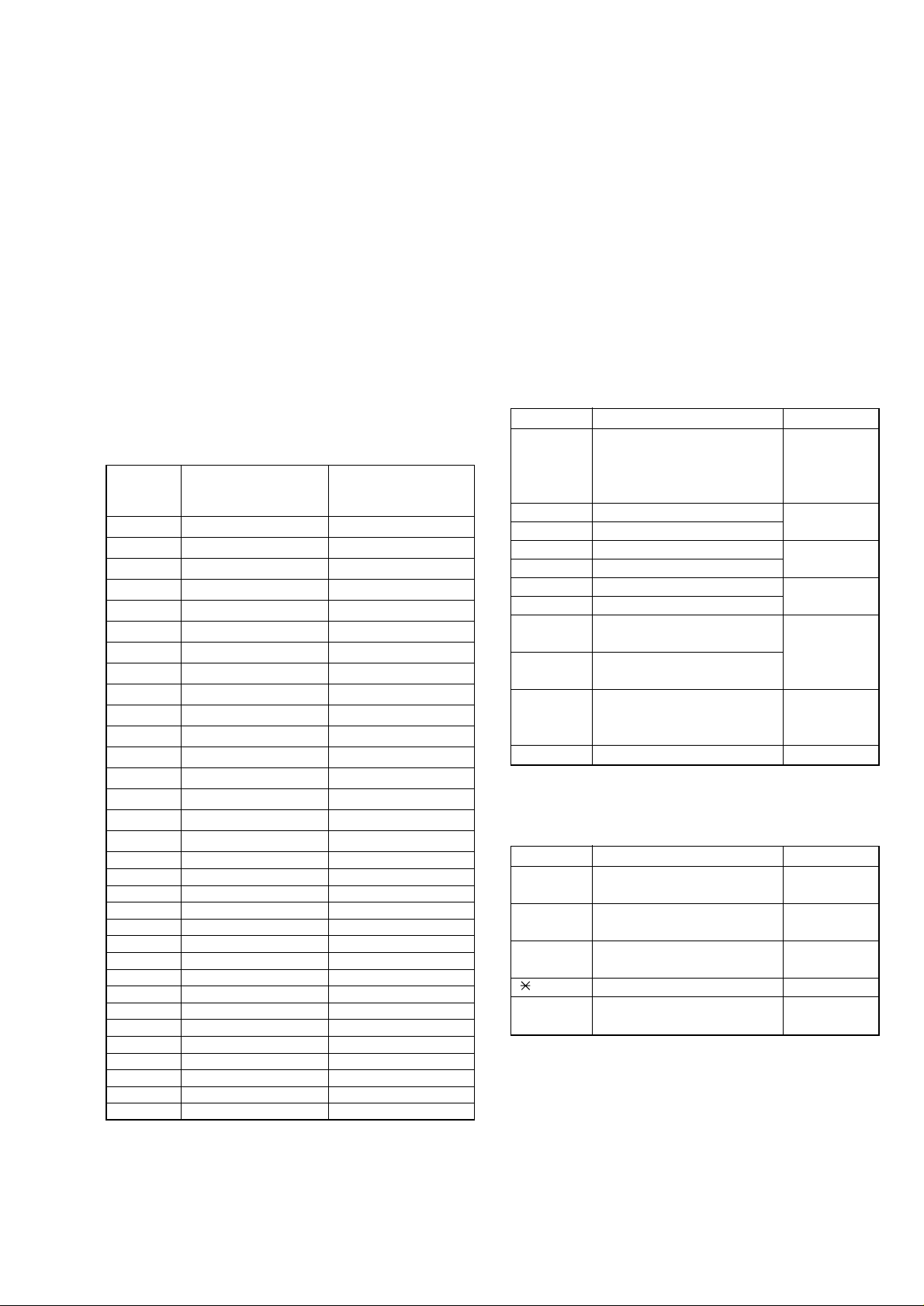

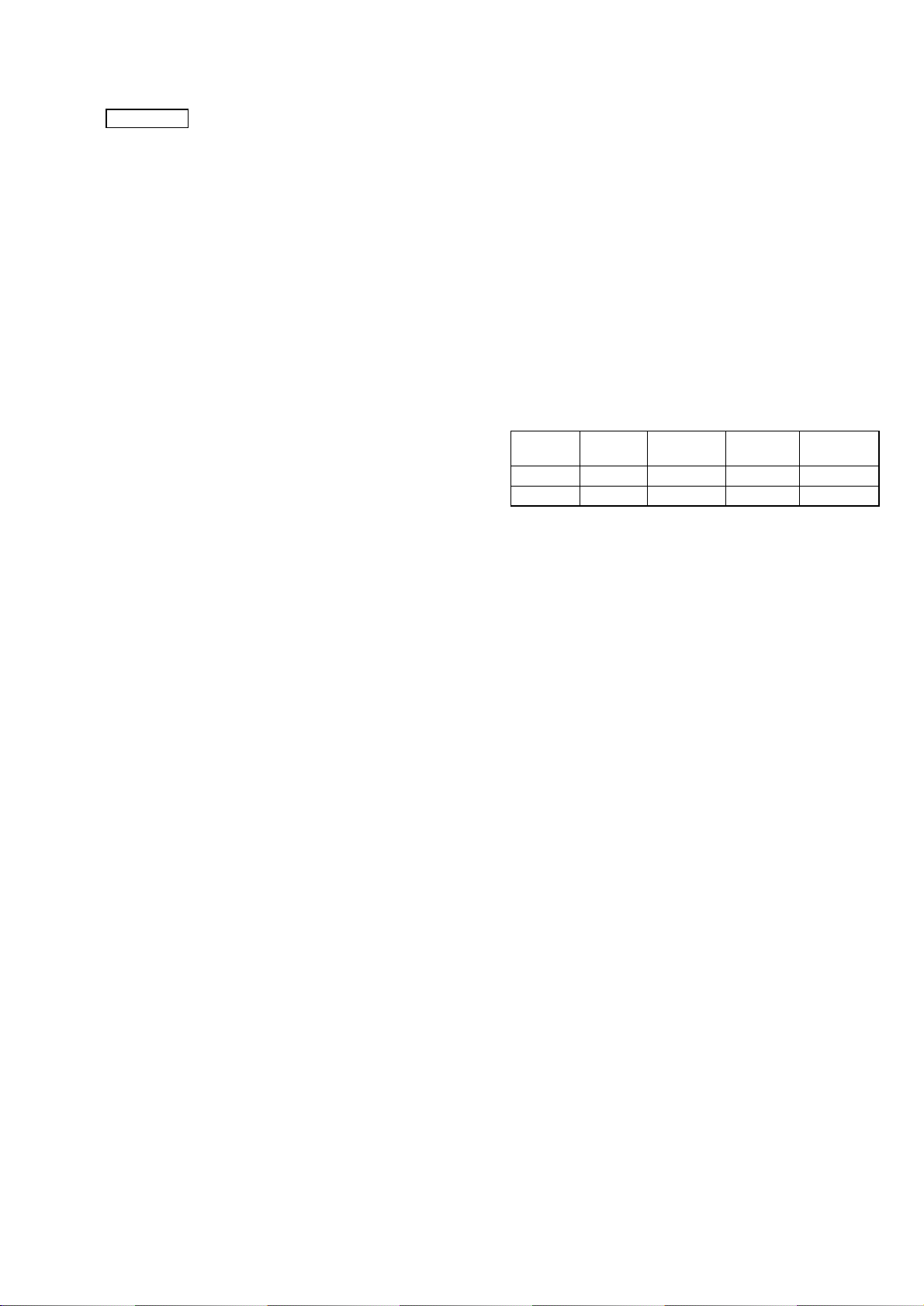

NOTE ON BASE MAIN BOARD AND HAND MAIN

BOARD REPAIR

As for base main board and hand main board, there are two type

of “A type” and “B type” by difference of diodes (D401 and

D402) used.

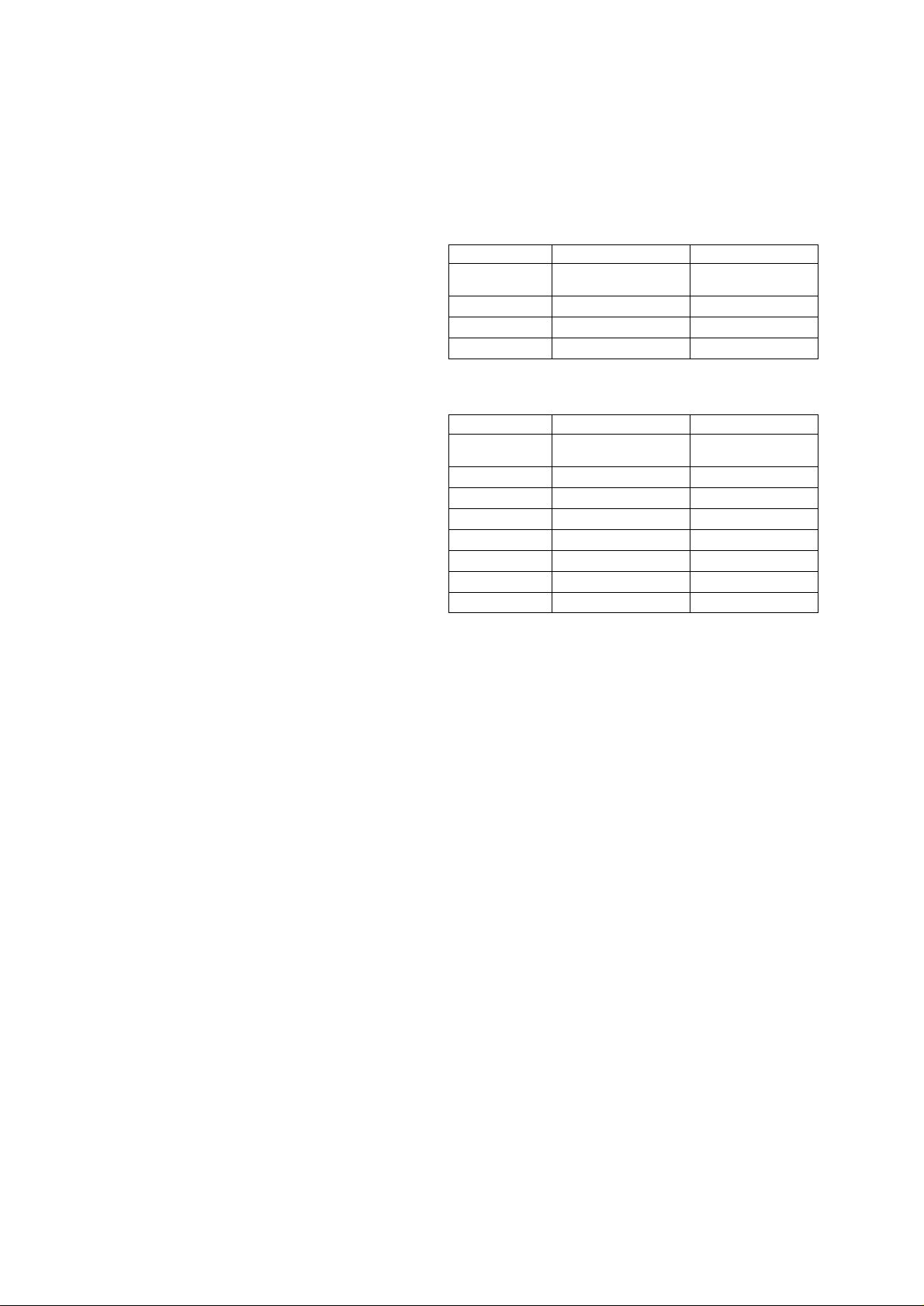

Difference parts list

Base main board

A type B type

D401, D402

BB145B-115 or

HVU-355BTRF

1SV314 (TPH3)

C451 10PF 12PF

C453 4PF 6PF

C454 8PF 7PF

• D401 and D402 using same thing.

Hand main board

A type B type

D401, D402

BB145B-115 or

HVU-355BTRF

1SV314 (TPH3)

C428 10PF 7PF

C450 10PF 12PF

C454 10PF 7PF

L405 15nH 18nH

L409 15nH 18nH

R418 10K 15K

R428 180 220

• D401 and D402 using same thing.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

7. ELECTRICAL PARTS LIST.................................... 34

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK !ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

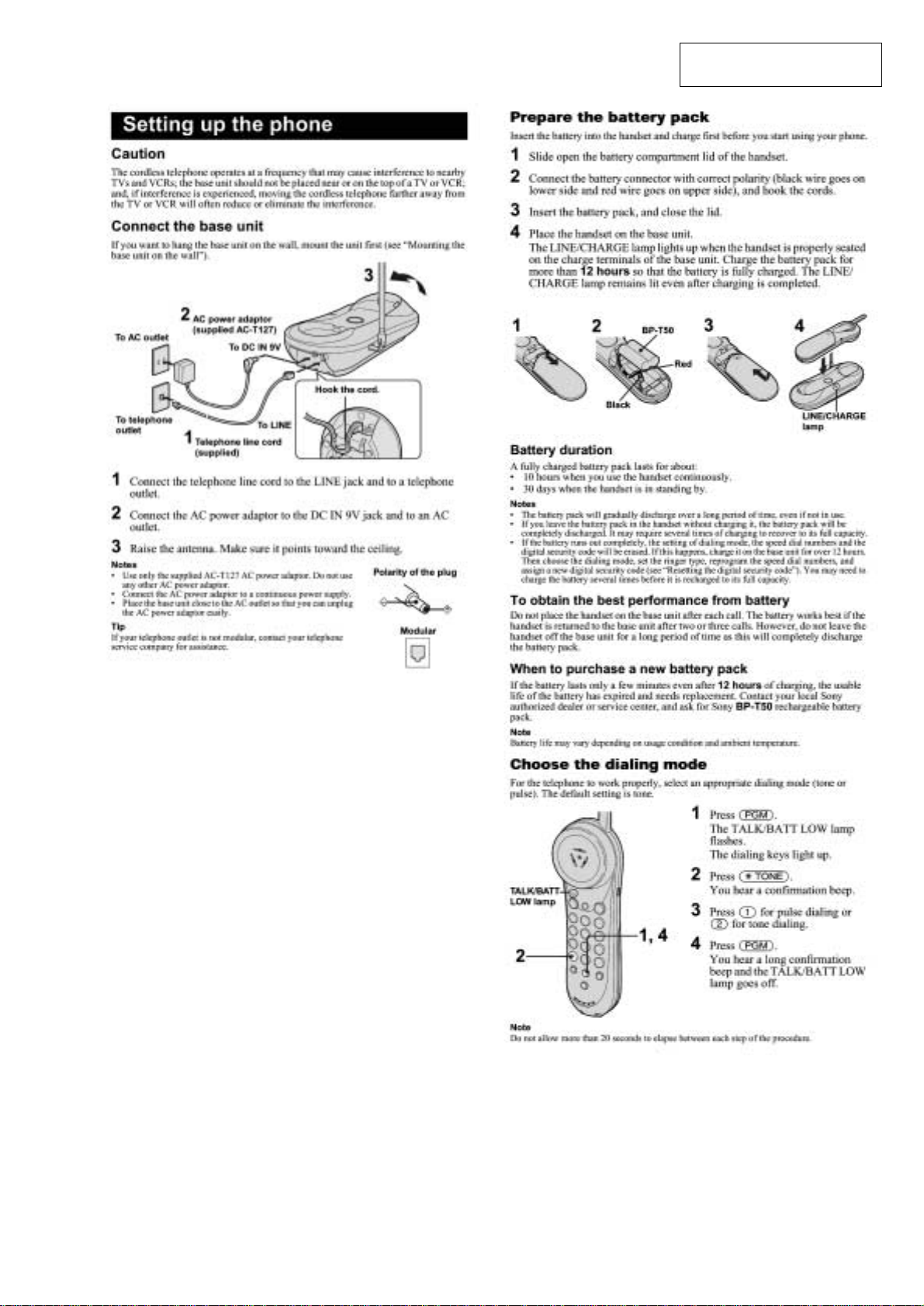

SECTION 1

GENERAL

This section is extracted from

instruction manual.

– 3 –

– 4 –

(SPP-N1003)

– 5 –

SECTION 2

)

DISASSEMBLY

r

The equipment can be removed using the following procedure.

Cabinet (upper)Base unit Base main board

Cabinet (rear)Handset Jack board (SPP-N1003 only) Hand main board

Note : Follow the disassembly procedure in the numerical order given.

2-1. CABINET (UPPER)

Cabinet (upper)

Cabinet (lower)

2

Claw

3

Cabinet (upper)

Cabinet (lower

1

Screw (+P 3x8)

1

Screws (+P 3x8)

2-2. BASE MAIN BOARD

2

Screws (+BTP 2.6x8)

Base main board

3

Remove solder

White

4

1

Screws (+BTP 2.6x8)

Cabinet (lower)

Red

– 6 –

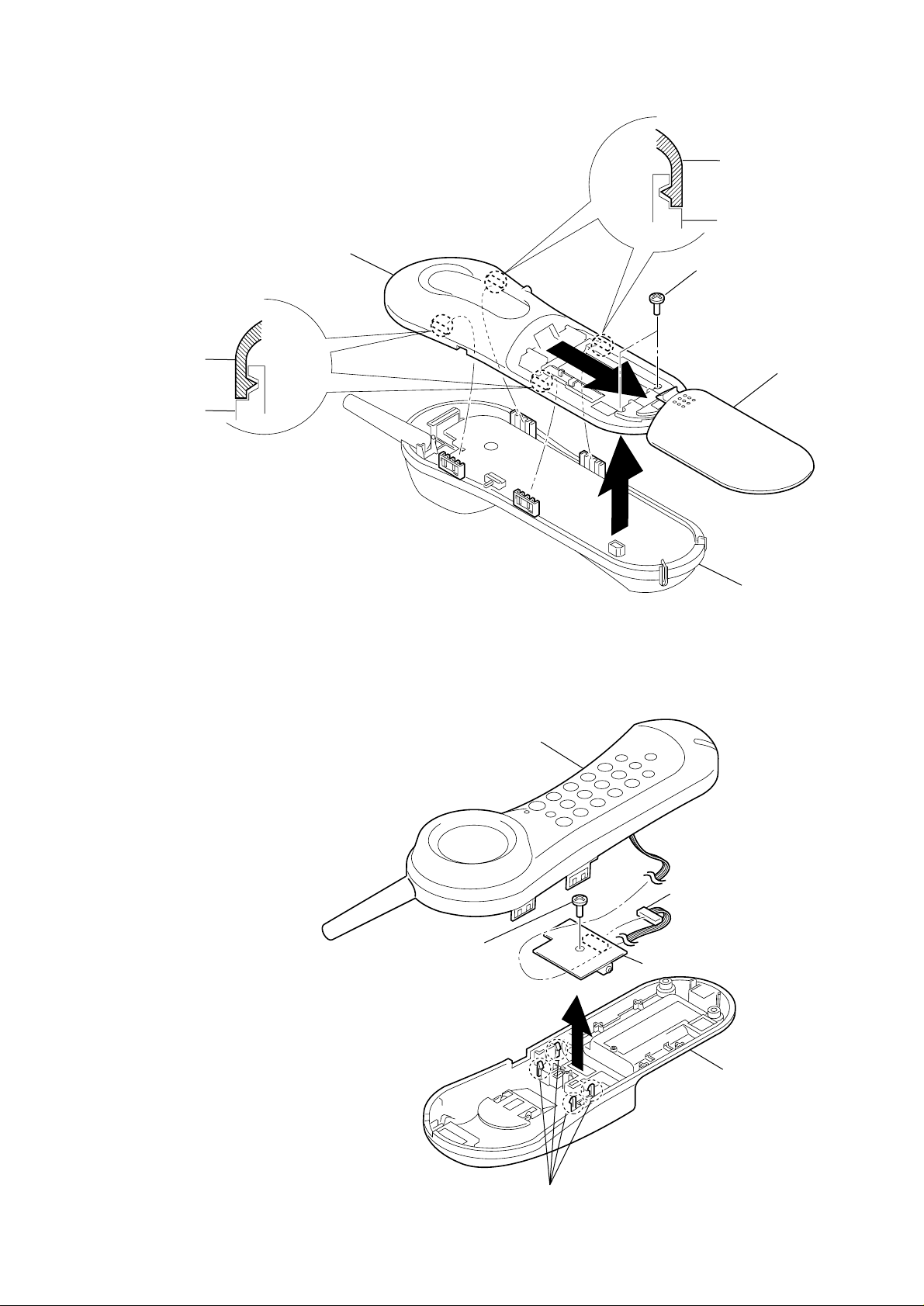

2-3. CABINET (REAR)

e

Cabinet (rear)

Cabinet (front)

Cabinet (rear)

Claws

3

1

3

Claws

4

Cabinet (rear)

Cabinet (front)

2

Screws (+BTP 2.6x12)

Lid, battery cas

Cabinet (front)

2-4. JACK BOARD (SPP-N1003 ONLY)

Cabinet (front)

1

Screws

(+BTP 2.6x8)

3

CN801

Jack board

Cabinet (rear)

– 7 –

2

Claws

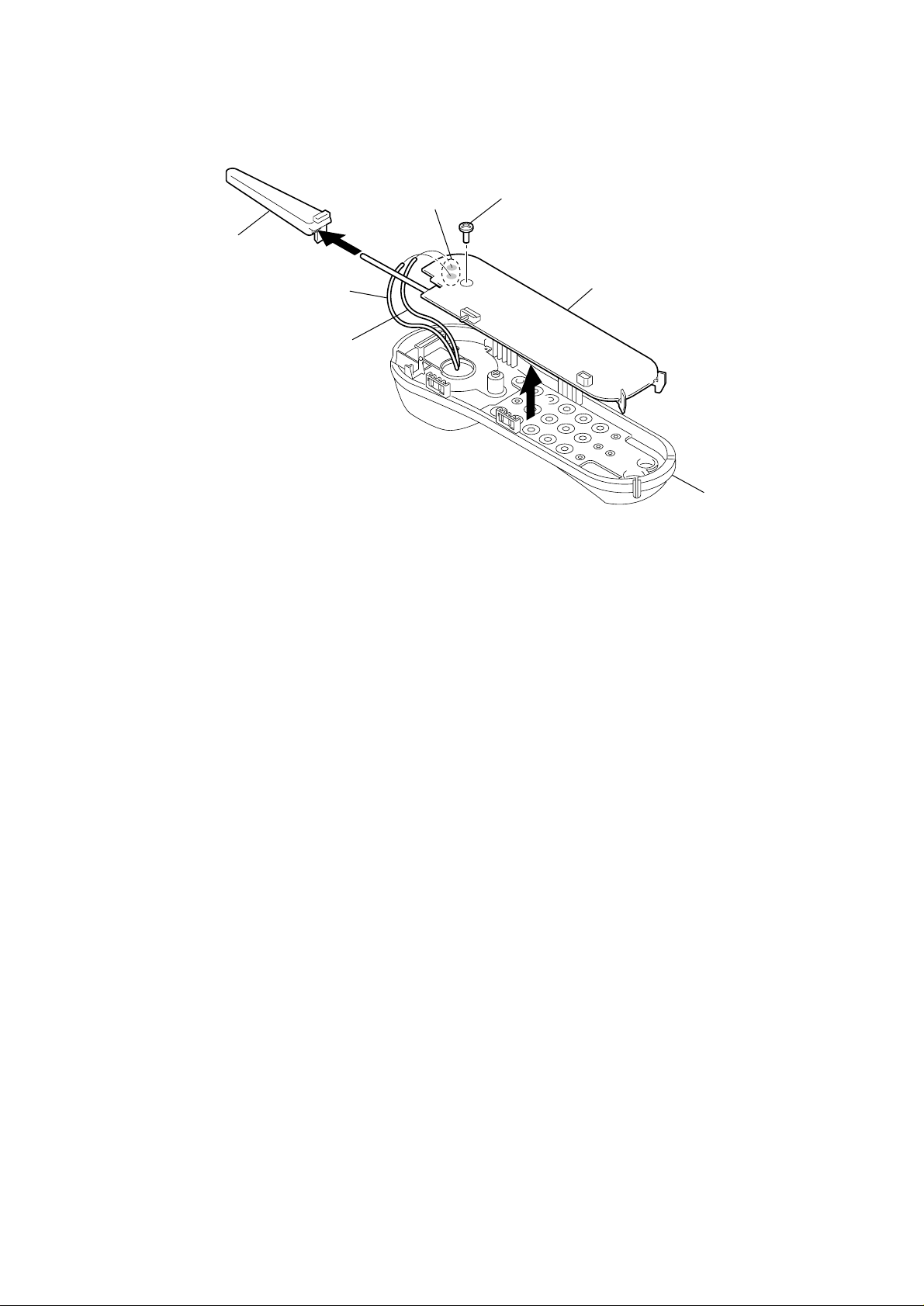

2-5. HAND MAIN BOARD

Cover (antenna)

1

Remove solder

4

Red

Black

2

Screws (+BTP 2.6x10)

Hand main board

3

Cabinet (front)

– 8 –

SECTION 3

TEST MODE

BASE UNIT MANUAL TEST MODE

1 Base Unit Manual Test Mode Startup Procedure

1. Turn on the power while holding down the HANDSET LOCATOR key, then perform the following steps within 10 seconds.

2. Set Charge ON (Place the handset on the base unit).

3. Set Charge OFF (Remove the handset).

4. Set Charge ON.

5. Set Charge OFF.

6. Release the HANDSET LOCATOR key.

7. Press the HANDSET LOCATOR key twice. (Transmit power

turns on. Default Channel = 1)

2 Changing Channels

The current channel number increases by 1 each time the HANDSET LOCATOR key is pressed after shifting to test mode. Channel 1 is the default channel.

After being in CH32, pressing the HANDSET LOCATOR key

returns to CH1.

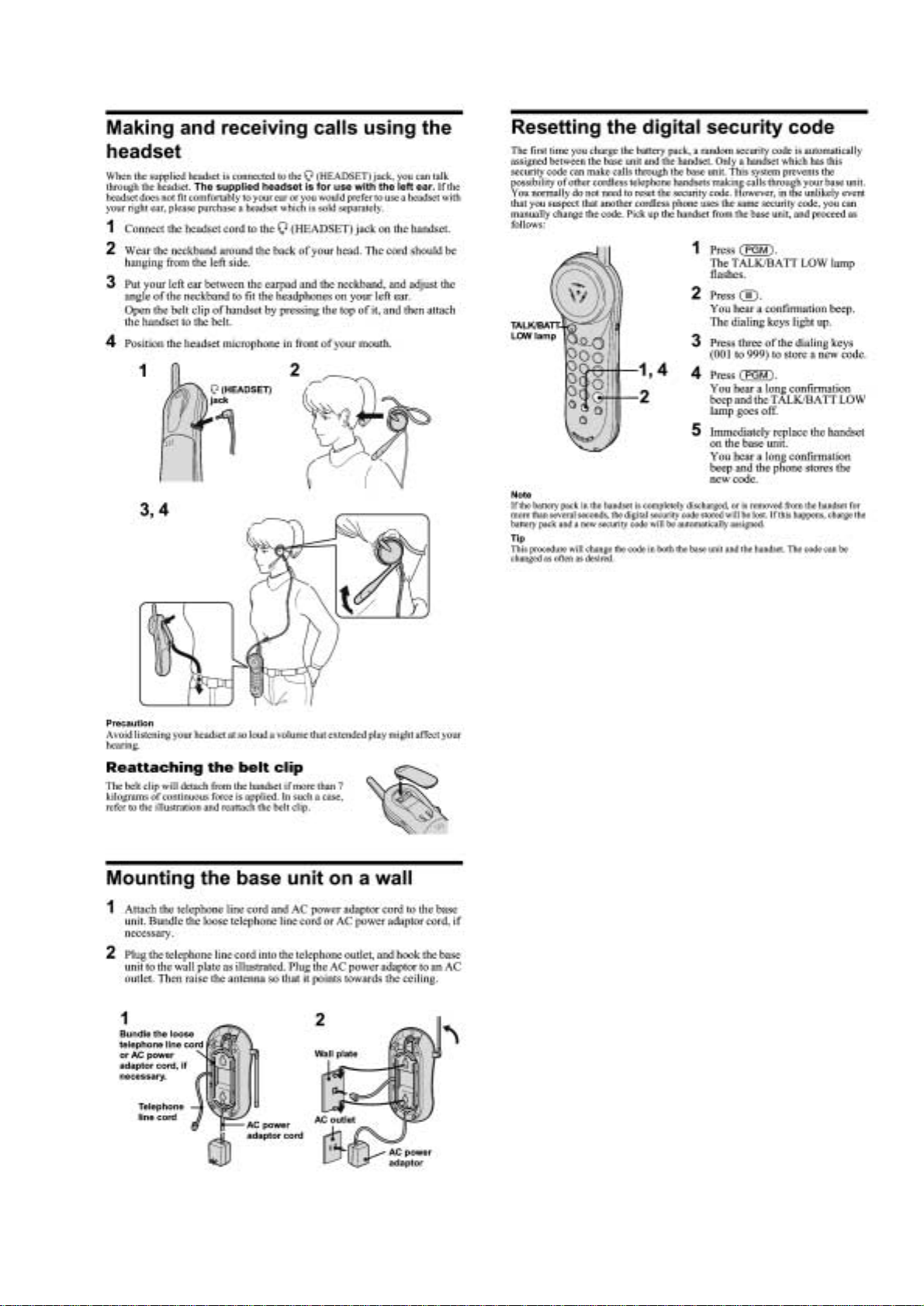

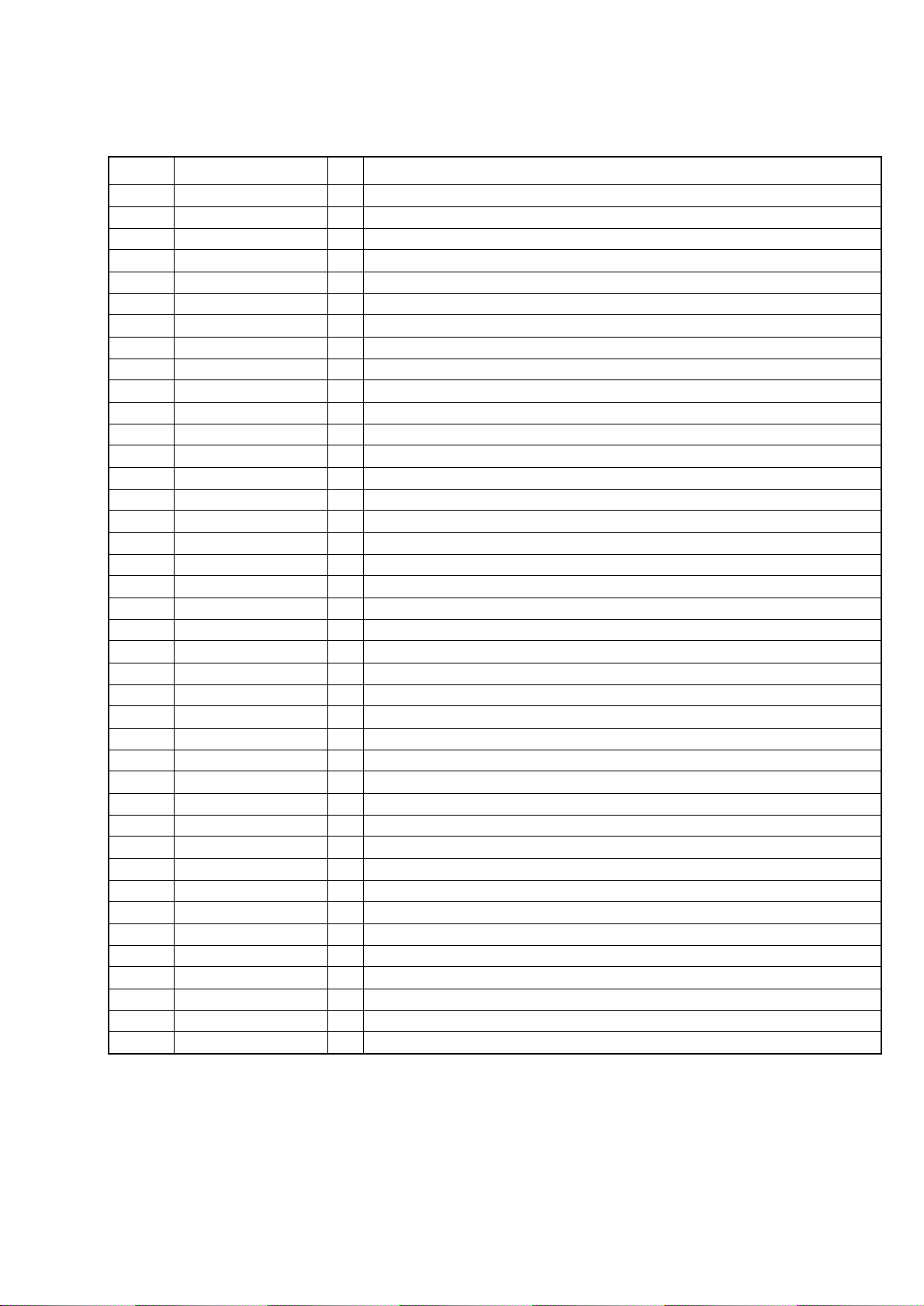

CHANNEL MAP

Handset TX Handset RX

CH Base RX Base RX

(MHz) (MHz)

1 902,200 924,900

2 902,300 925,000

3 902,400 925,100

4 902,500 925,200

5 902,600 925,300

6 902,700 925,400

7 902,800 925,500

8 902,900 925,600

9 903,000 925,700

10 903,100 925,800

11 903,200 925,900

12 903,300 926,000

13 903,400 926,100

14 903,500 926,200

15 903,600 926,300

16 903,700 926,400

17 903,800 926,500

18 903,900 926,600

19 904,000 926,700

20 904,100 926,800

21 904,200 926,900

22 904,300 927,000

23 904,400 927,100

24 904,500 927,200

25 904,600 927,300

26 904,700 927,400

27 904,800 927,500

28 904,900 927,600

29 905,000 927,700

30 905,100 927,800

31 902,000 924,700

32 905,300 928,000

HANDSET MANUAL TEST MODE

1 Handset Manual Test Mode Startup Procedure

1. Hold down the T ALK key for at least 2 seconds while pressing

the 0 and 1 keys in idle.

2. The call bell rings for half a second (500 msec) as test mode

starts up.

(Status after startup is called Test Idle mode).

2 Detecting Electromagnetic Intensity (RSSI)

After test mode starts up, electromagnetic intensity (RSSI) is measured. The TALK led lights up if the electromagnetic intensity

exceeds a certain level (Level indicating RF during normal receive scanning).

3 Key operation in Test Idle Mode

The following keys function as shown during test idle mode.

KEY DESCRIPTION REMARKS

CHANNEL Increments channel by +1 each

timepressed. Pressing

CHANNEL after being in CH32

returns to CH1.

1 Transmit power on Default TX

4 Transmit power off = off

2 Receive mute off Default RX

5 Receive mute on mute = off

3 RSSI sensitivity setting HIGH Default level

6 RSSI sensitivity setting HIGH = High

SPEED

DIAL Default

REDIAL/

PAUSE

FLASH selector (HIGH t MID t

OFF Quit test mode

Using the following keys in test idle mode shifts operation to a

specific mode. Shifting to these modes disables the key operations

in the above table. Pressing the OFF key returns to test idle mode.

KEY DESCRIPTION REMARKS

7

8

9

(STAR) Shifts to destination check mode

# (POUND)

Half-mute off

Half-mute on

Telephone receiver volume

NORMAL t HIGH)

Power saving measurement

mode 1 (in call status)

Power saving measurement

mode 2 (in call receive)

Power saving measurement

mode 3 (in standby)

Shifts to battery voltage test

mode

Default CH=1

HMUTE = off

Default volume

= High

– 9 –

4 Power Saving Measurement Mode

To enter power saving measurement mode, press one of the 7, 8,

9 keys while in test idle mode. Pressing the OFF key after entering power saving measurement mode returns the operation to test

idle mode.

KEY DESCRIPTION

7 Shifts to same status as during a call ON ON

Shifts to same status as in call

8

receive. (transmit off)

Shifts to same status as during

9

standby. (transmit/receive off)

5 Destination Check

To enter destination check mode, press the (star) key in test

idle mode. Pressing the OFF key after entering destination check

mode returns the operation to test idle mode.

Mexican model ON ON

Cenreal & South American model OFF OFF

US, Canadian model BLINK OFF

6 Battery Voltage Test Mode

To enter battery voltage test mode, press the # (pound) key in test

idle mode. In this mode, the T ALK LED lights up when the battery

is low.

Pressing the OFF key after entering battery voltage test mode returns the operation to test idle mode.

Battery low TALK LED on

Battery OK TALK LED off

TALK Lighted

LED Key

OFF OFF

OFF OFF

Battery Lighted Key

7 Data Reset

Recharging the handset while in test idle mode, resets the security code (handset ID), quick-dial & redial information, and different settings.

– 10 –

SECTION 4

ELECTRICAL ADJUSTMENTS

BASE UNIT

BASE UNIT TX ADJUSTMENT

1. Transmit Mode Setting Procedure

1. Start up the test mode according to the “Manual Test Mode

Startup Procedure”. (See page 9)

2. Press the PAGE key (HANDSET LOCATOR) and make the

channel settings. (Default CH=1)

3. Ground TP201 (RING DET).

2. TX Frequency Adjustment

Connect the frequency counter to TP406 (ANT), and adjust the

TX frequency by turning CT501.

Standard value : Transmit frequency ± 1kHz

BASE UNIT RX ADJUSTMENT

1. Transmit Mode Setting Procedure

1. Start up the test mode according to the Manual Test Mode

Startup Procedure. (See page 9)

2. Press the PAGE key (HANDSET LOCATOR) and make the

channel settings. (Default CH=1)

2. RX Carrier Adjustment

1. Start up the test mode according to the Manual Test Mode.

2. Set the signal generator to Setting1 and the audio analyzer to

DIST. mode. Turn T401 and adjust so that the output level is

near maximum and the DC voltage of TP404 is 1.1 volts.

Check that the output level on the audio analyzer is within the

standard value.

Standard value: 210 to 410 mV.

Also check on an oscilloscope that there is no waveform distortion on the demodulated signal.

3. RSSI (H) Sensitivity Adjustment

Set the signal generator to Setting 2 and adjust R V401 so that the

RSSI output voltage is 220 mV.

SIGNAL GENERATOR SETTINGS

Setting Frequency RF Output Modulation Modulation

No. (MHz) (dBµ VEMF) (kHzINT) Factor

Setting 1 60 1 20kHz

Setting 2 no signal - -

– 11 –

t

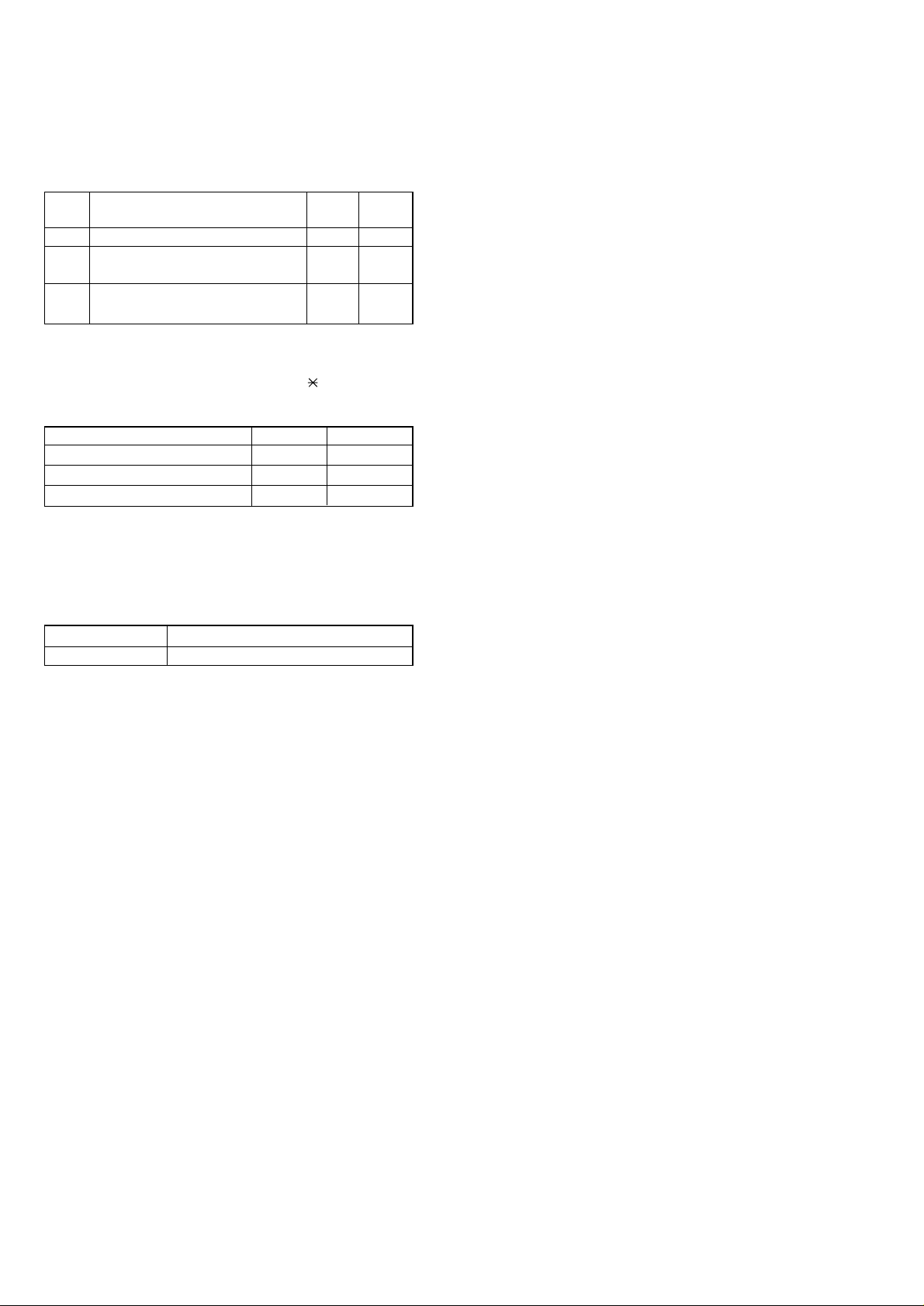

Connection and adjustment location :

FM RF signal

generator

TP406

(ANT)

TP407

(RF GND)

TP407

oscilloscope

(RF GND)

TP406

(ANT)

BASE MAIN BOARD (SIDE B)

TP101

(VDD)

TP406

(ANT)

TP102

(GND)

frequency counter

digital

voltmeter

TP407

(RF GND)

TP406

(ANT)

TP407

(RF GND)

TP404

(AF OUT)

TP404

(AF OUT)

BASE MAIN BOARD (SIDE A)

TP401

(RSSI)

digital

voltmeter

TP401

(RSSI)

CT501: TX Frequency adjustmernt

– 12 –

IC401

audio analyzer

IC401

t;

IC401

rl

T401 : RX Carrier adjustment

RV401 :

RSSI (H) Sensitivity adjustmen

HANDSET

HANDSET TX ADJUSTMENT

1 Initial Settings

1. Start up test mode according to the “Manual Test Mode Startup

Procedure”. (See page 9)

2. Press the CHANNEL key and make the channel settings. (Default CH=1)

3. Press the 1 key and set TX to ON.

2. TX Frequency Adjustment

Connect the frequency counter to TP401 (ANT), and adjust the

TX frequency by turning CT501.

Standard value: Transmit frequency ±1 kHz

HANDSET RX CHECK

1 Initial Settings

1. Start up test mode according to the “Manual T est Mode Startup

Procedure”. (See page 9)

2. Press the CHANNEL key and make the channel settings. (Default CH=1)

2. RX Carrier Adjustment

Set the signal generator to Setting1 and set the audio analyzer to

AC LEVEL mode. Turn T401 and adjust so that the output level

is near maximum and so the DC voltage of adjust TP403 (AF

OUT) is 1.1 V.

Check that the output level on the audio analyzer is within the

standard value.

Standard value: 190 to 320 mV.

Also check on an oscilloscope that there is no waveform distortion on the demodulated signal.

SIGNAL GENERATOR SETTINGS

Setting Frequency RF Output Modulation Modulation

No. (MHz) (dBµ VEMF) (kHzINT) Factor

Setting 1 60 1 20kHz

Setting 2 no signal - -

– 13 –

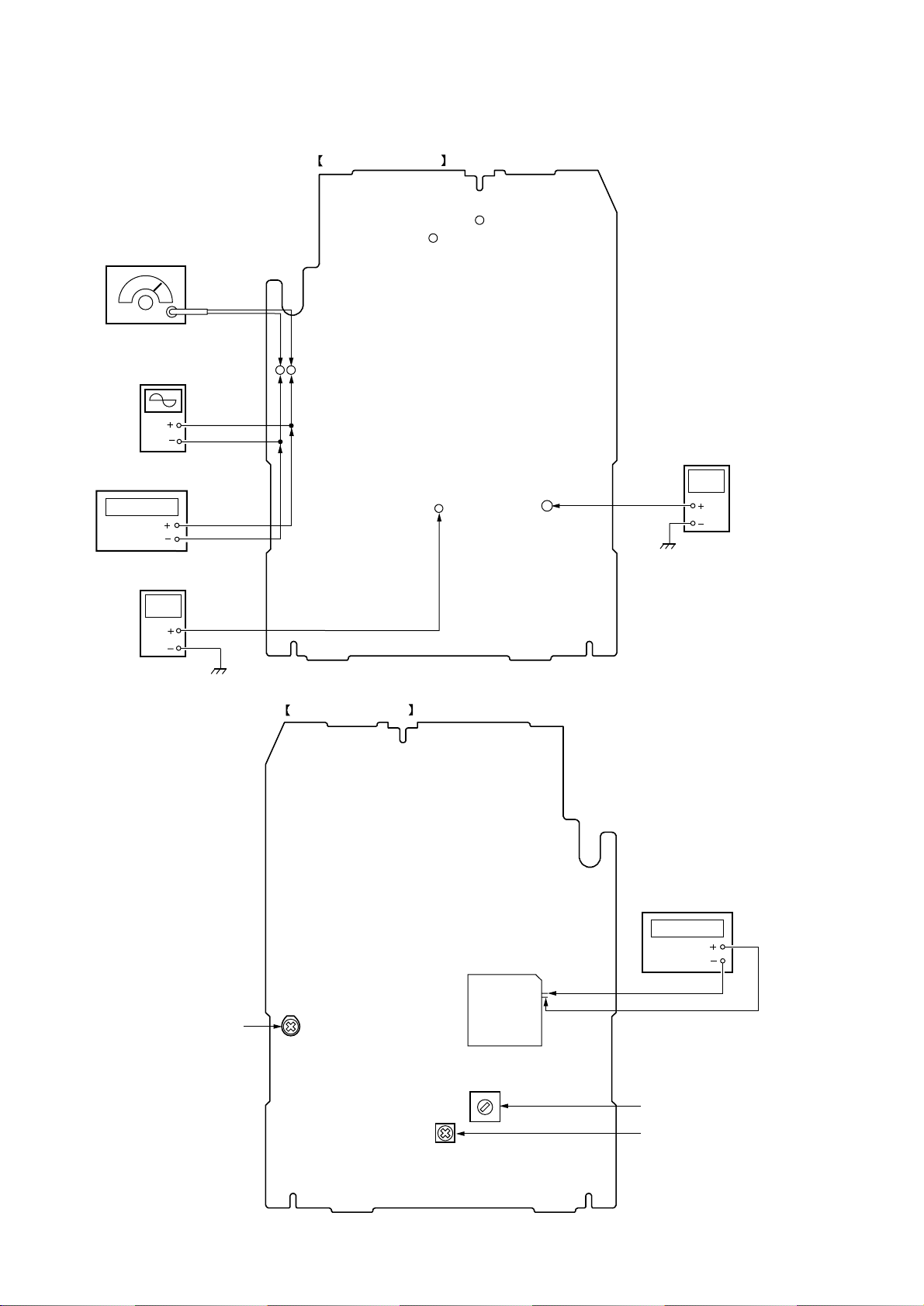

r

Connection and adjustment location :

FM RF signal

generator

oscilloscope

TP401 (ANT)

TP402 (RF GND)

HAND MAIN BOARD (SIDE B)

HAND MAIN BOARD (SIDE A)

audio analyzer

TP402

150

TP401

(ANT)

TP409

(SPB)

Ω

TP403

(AF OUT)

TP408

(SPR)

(RF GND)

TP403

TP408 (SPR)

(AF OUT)

TP409 (SPB)

CT501: TX Frequency adjustmernt

TP401

(ANT)

TP402

(RF GND)

digital

voltmeter

frequency counte

T401 :

RX Carrier adjustment

RV401 :

RSSI (H) Sensitivity adjustment

– 14 –

SECTION 5

DIAGRAMS

5-1. EXPLANATION OF IC TERMINALS

IC501 TMP87CH847U-1K06 (BASE UNIT SYSTEM CONTROL)

Pin No. Pin name I/O Description

1 RF CLK O Serial clock output.

2 DTMF LA O Latch output for DTMF IC.

3 QUICK CHG O Quick charge control output.

4 RX DATA I RX data input.

5 –––––––––– — Not used (OPEN).

6 MBR I Pulse Make/Break select input.

7 LINE LED O LED drive output.

8 – 12 DTMF 0 – 4 O Soft DTMF output 0-4.

13 –––––––––– — Not used (OPEN).

14 RESET I Reset input.

15 X IN I System clock input (8MHz).

16 X OUT O System clock output (8MHz).

17 VSS (VASS) — Ground terminal.

18 VAREF — A/D converter reference voltage.

19 –––––––––– — Not used (OPEN).

20 DTMF CD O Disable output for DTMF IC.

21 –––––––––– — Not used (OPEN).

22 DP O Pulse dial output.

23 BATT V I Power voltage input.

24 RSSI I RSSI volatile detection input.

25 PAGE KEY I Key input.

26 TX POWER O TX power control output.

27 –––––––––– — Not used (OPEN).

28 TX VCO O TX VCO power supply control output.

29 –––––––––– — Not used (OPEN).

30 RING DET I Ringer detection input.

31 CHG IN I Battery charge detection input.

32 TX DATA PU O TX data terminal pull-up output.

33 TX DATA O TX data output.

34 TEST IN2 I Test mode input.

35 TEST IN1 I Test mode terminal. “H”: T est mode. “L”: Normal mode

36 TEST OUT O Test mode output.

37 POWER DET I Power failure detection input.

38 –––––––––– — Not used (OPEN).

39 H MUTE O Half mute control output.

40 VDD — power supply terminal.

41 DTMF DATA O DTMF IC control output.

42 DTMF CLK O Clock output for DTMF IC.

43 RF DATA O RF IC control output.

44 RF STB O Strobe output for RF IC control.

– 15 –

Loading...

Loading...