Page 1

SPP-904

SERVICE MANUAL

SPECIFICATIONS

E Model

MICROFILM

CORDLESS TELEPHONE

Page 2

TABLE OF CONTENTS

1. GENERAL

Setting Up the Phone ...................................................... 3

Making and Receiving Calls........................................... 3

2. DISASSEMBLY ......................................................... 5

3. TEST MODE.............................................................. 7

4. ELECTRICAL ADJUSTMENTS

Base Unit ......................................................................... 10

Handset ............................................................................ 13

5. DIAGRAMS

5-1. Block Diagram – BASE UNIT Section –...................... 17

5-2. Block Diagram – HANDSET Section –........................ 18

5-3. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 19

5-4. Printed Wiring Board – BASE RF Section – ................ 20

5-5. Schematic Diagram – BASE RF Section – ................... 21

5-6. Printed Wiring Board – BASE MAIN Section –........... 22

5-7. Schematic Diagram – BASE MAIN Section – ............. 23

5-8. Printed Wiring Board – HAND RF Section –............... 24

5-9. Schematic Diagram – HAND RF Section – .................. 25

5-10. Printed Wiring Board – HAND MAIN Section – ........ 26

5-11. Schematic Diagram – HAND MAIN Section – ............ 27

5-12. IC Pin Function Description ........................................... 29

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

6. EXPLODED VIEWS ................................................ 31

7. ELECTRICAL PARTS LIST ............................... 33

2

Page 3

SECTION 1

GENERAL

This section is extracted from

instruction manual.

3

Page 4

4

Page 5

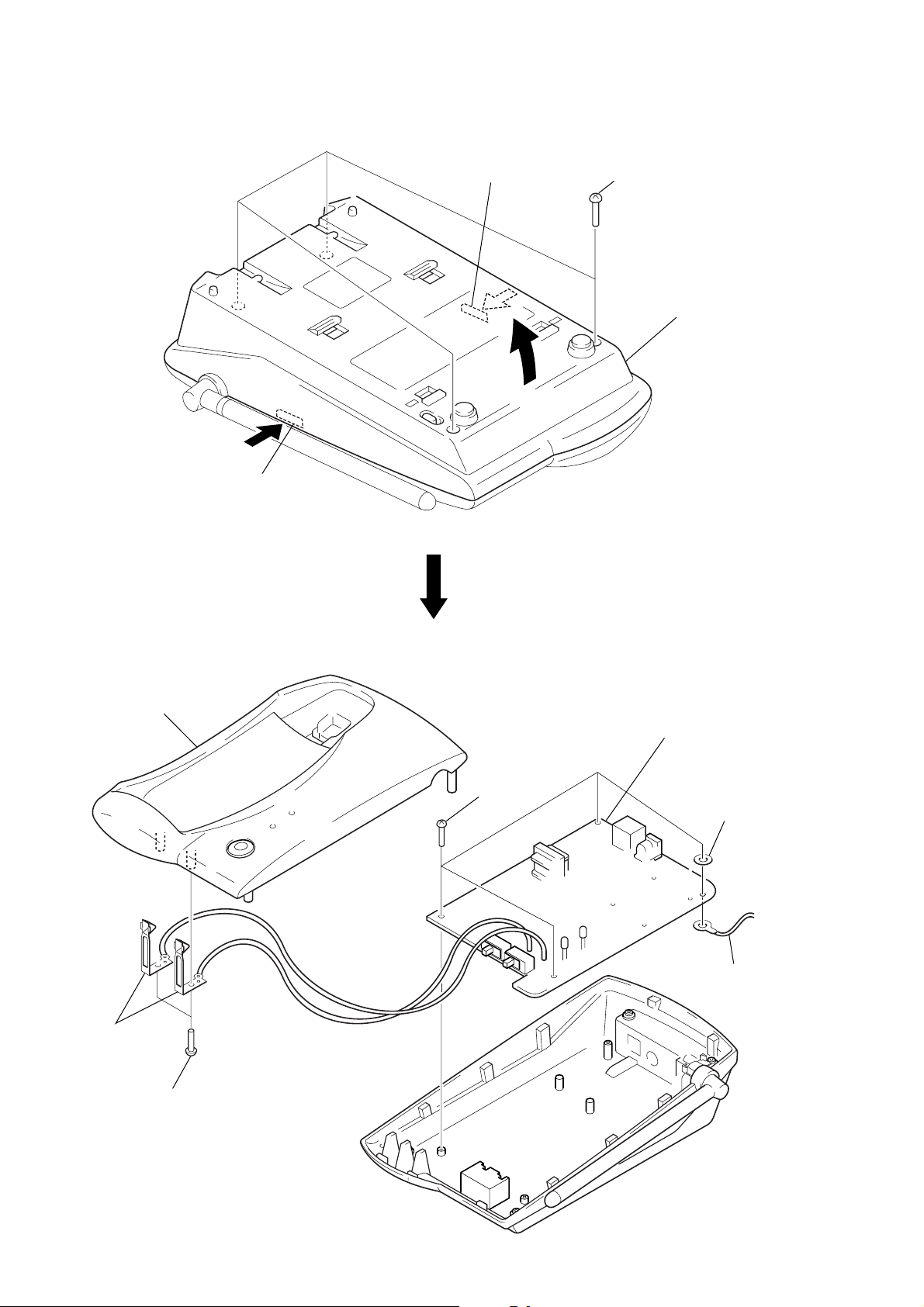

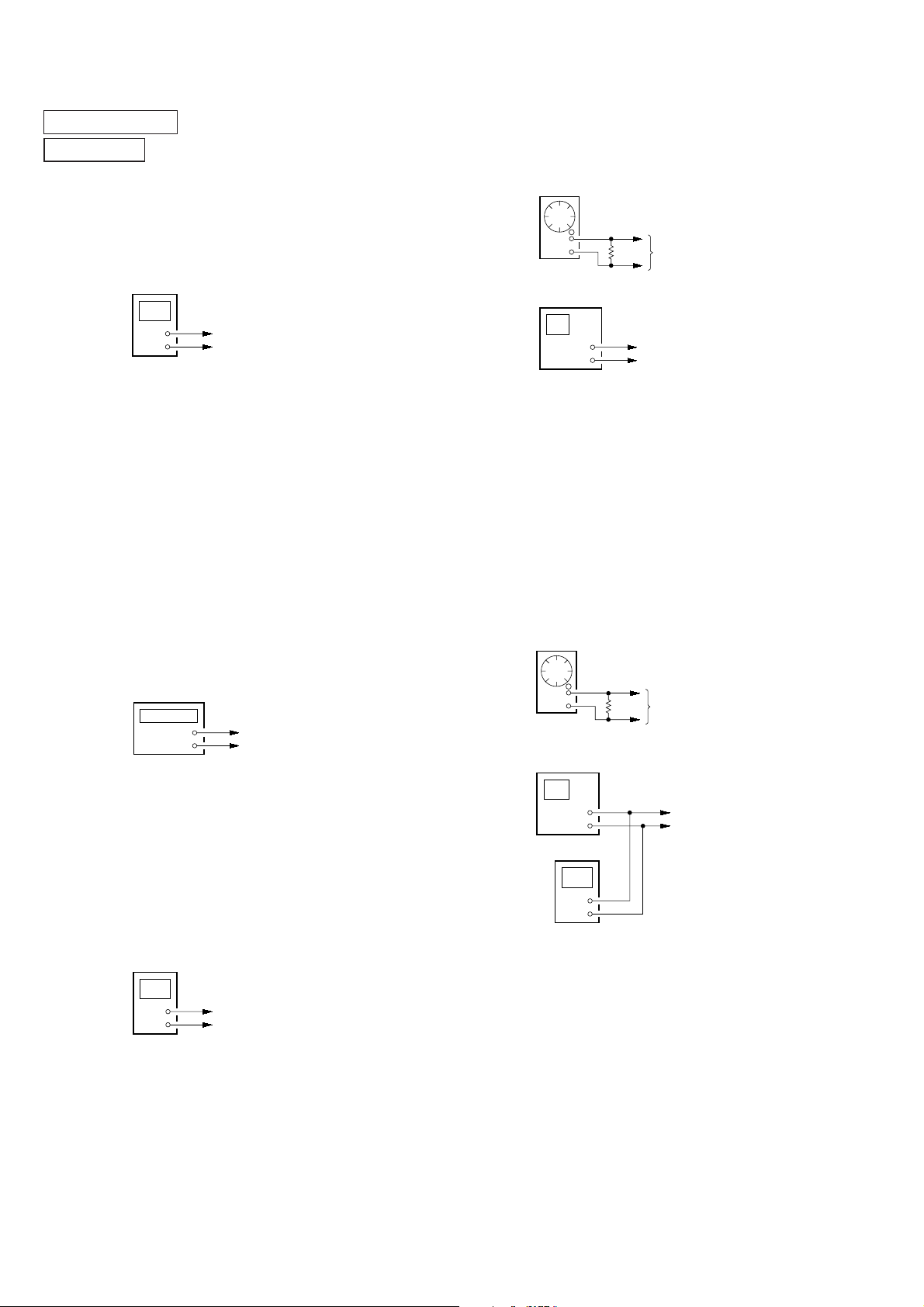

SECTION 2

d

)

DISASSEMBLY

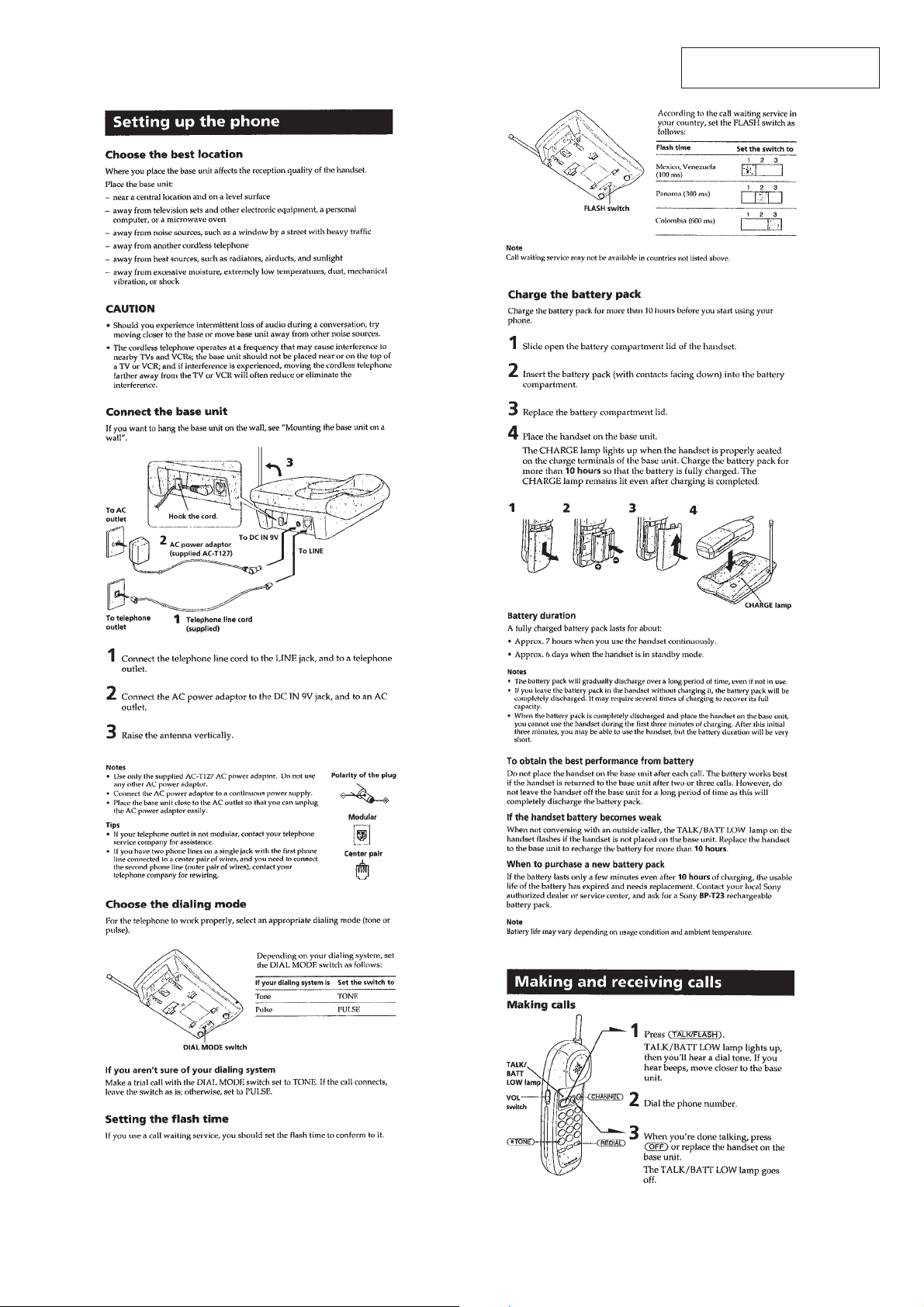

Note: Follow the disassembly procedure in the numerical order given.

HAND CABINET (REAR)

5

Remove the hand cabinet (rear)

to direction of the arrow B.

4

claw

3

two claws

B

3

two claws

2

two screws

(BTP2.6 × 12)

A

1

Remove the battery case li

to direction of the arrow A.

HAND MAIN BOARD

6

antenna cover

2

screw

(BTP2.6

×

8)

1

C

vol knob (U)

2

four screws

(BTP2.6

×

8)

5

Remove the hand main board

to direction of the arrow

3

two screws

(BTP2

4

two charge terminals (U

C

.

×

6)

5

Page 6

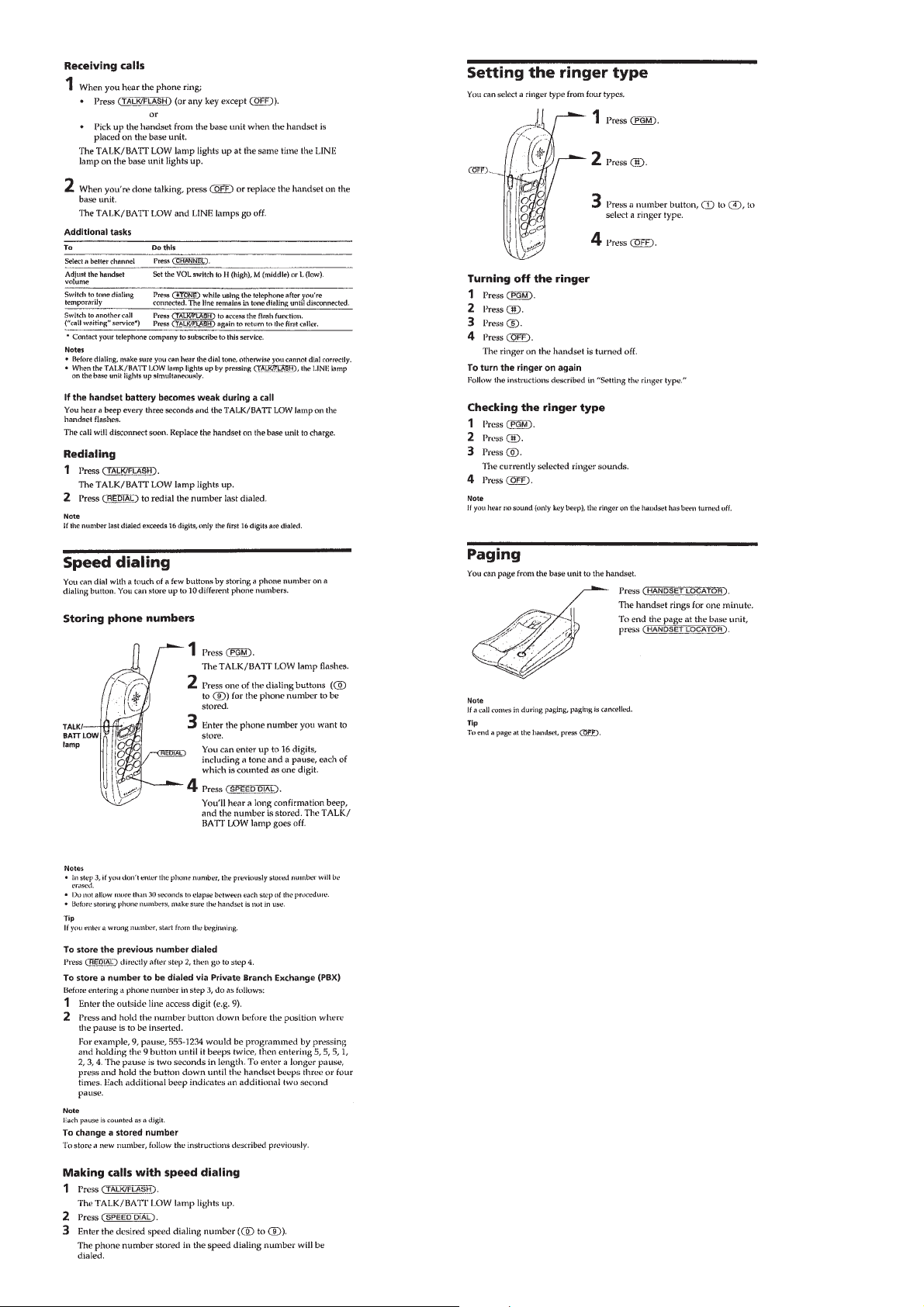

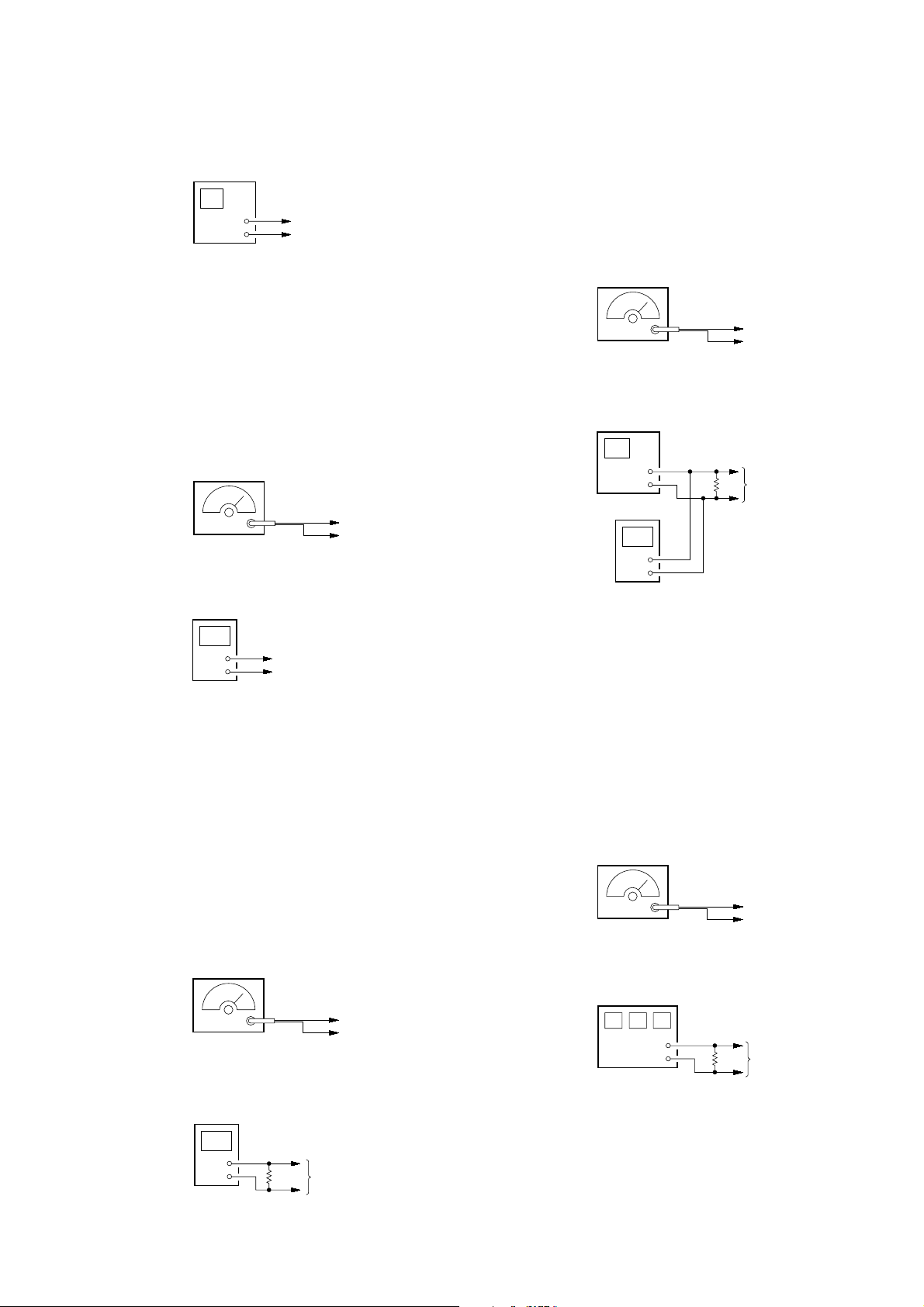

BASE CABINET

2

claw

2

claw

1

four screws

(BTP2.6

×

10)

3

cabinet (lower)

BASE MAIN BOARD

3

cabinet (upper)

2

two charge

springs (U)

1

two screws

(BTP2.6

6

base main board

4

four screws

(BTP2.6

×

8)

×

8)

5

washer (SP)

7

harness

6

Page 7

SECTION 3

TEST MODE

BASE UNIT

[Setting the Test Mode]

1. Power on with pressing the [HANDSET LOCATOR] key for two seconds.

2. CHARGE and LINE LEDs turn on for 50 msec, and the test mode is set.

* If setting the test mode with the status that [TONE] position is selected at [DIAL MODE] switch, the unit cold stars next time when the

power is turned on.

[Releasing the Test Mode]

To release the test mode, perform as follows:

• Turn the power off (disconnect the AC adapter plug).

• Set the handset to charge on the base unit (except Test Mode 9).

• Bell in.

[Changing the Test Mode Step]

1. Set the [DIAL MODE] switch to the [PULSE] position.

2. Press the [HANDSET LOCATOR] key.

3. A step is changed each time the key is pressed, and CHARGE and LINE LEDs turn on for 50 msec.

[Changing the Channel]

1. Set the [DIAL MODE] switch to the [TONE] position.

2. Press the [HANDSET LOCATOR] key.

3. A channel is changed each time the key is pressed, and CHARGE and LINE LEDs turn on for 50 msec.

* Channel will be back to initial channel (19CH), when the test mode step is changed.

• Channel Rotation

21CH 40CH 1CH 2CH 3CH 39CH 40CH20CH19CH

. . .

7

Page 8

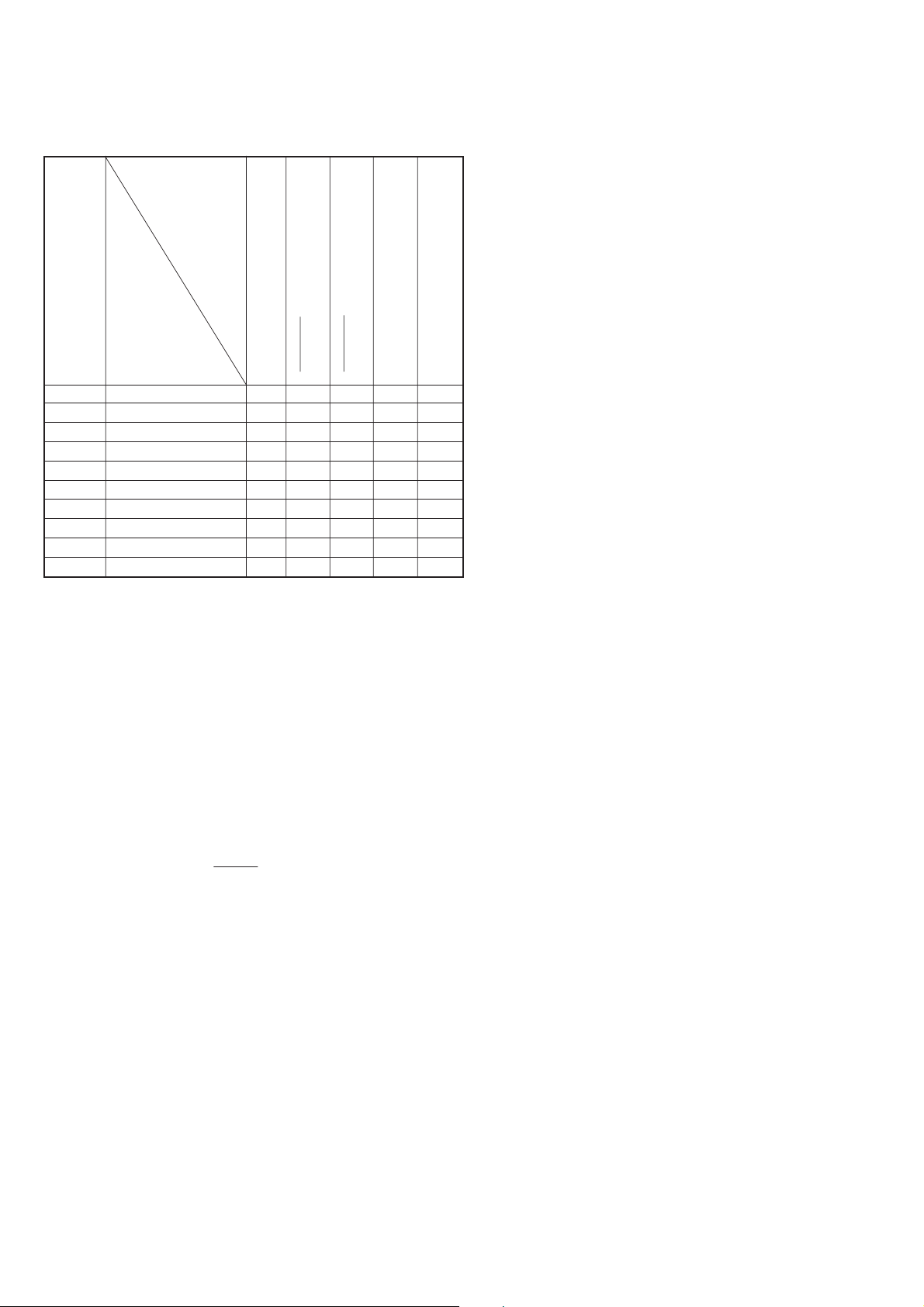

[Test Mode Execution]

Press the [HANDSET LOCATOR] key to execute any of the following tests:

Step

1 VCO/TX FREQ. ADJ L L L L

2 TX MOD CHECK L H L H

3 TX DATA L L L L *1

4 RX SENS H L H H

5 SQ SENS L L *A H

6 DTMF SINGLE TONE H L L H *2

7 DTMF DUAL TONE H L L H *3

8 DATA IN CHECK L L L L *4

9 CHARGE CHECK H L L L *5

10 DUPLEX L H H H

Test Mode

Name

Remarks

TALK (IC5 pin qd)

RX MUTE (IC5 pin eh)

TX MUTE (IC5 pin ej)

TX (IC5 pin rh)

* Initial Channel of each step: 19CH

*A. SQ on: H (CHARGE LED turns on)

SQ off: L (CHARGE LED turns off)

*1. Test Mode 3: Continue output TX data as “ 0000……”.

*2. Test Mode 6: Set the

[DIAL MODE] switch to the [TONE] position, and press the [HANDSET LOCATOR] key.

DTMF will be changed.

ROW 1 → ROW 2 → ROW 3 → ROW 4 → COL1 → COL2 → COL3 → ROW1 → …… .

*DTMF frequency

ROW 1: 696.95 Hz COL1: 1209.31 Hz

ROW 2: 770.13 Hz COL2: 1335.65 Hz

ROW 3: 852.27 Hz COL3: 1476.71 Hz

ROW 4: 940.99 Hz

*3. Test Mode 7: Set the [DIAL MODE] switch to the [TONE] position, and press the [HANDSET LOCATOR] key.

DTMF will be changed.

1 → 2 → 3 → 4 → 5 → 6 → 7 → 8 → 9 → 0 → → # → 1 → …… .

*

*4. Test Mode 8: When locked receiving data is “ 0000……”, CHARGE LED turns on.

*5. Test Mode 9: When CHGIN (IC5 pin eg) is “ L” (charge on), CHARGE LED turns on.

8

Page 9

HANDSET

[Setting the Test Mode]

1. Power on with press the [*] key and the [#] key simultaneously for one second.

2. It beeps confirm tone, and the test mode is set.

* If the [PGM] key is pressed, the unit cold starts next time when the power is turned on.

[Releasing the Test Mode]

To release the test mode, perform as follows:

• Press the [FLASH, TALK] key.

• Turn the power off (remove the battery pack).

• Set the handset to charge on the base unit (except Test Mode 9).

[Changing the Test Mode Step]

Press the each key of the test mode step number.

[Changing the Channel]

Press the [CHANNEL] key.

* The channel is back to initial channel (6CH), when test mode step is changed.

• Channel Rotation

19CH 40CH 1CH 2CH 3CH 39CH 40CH20CH21CH

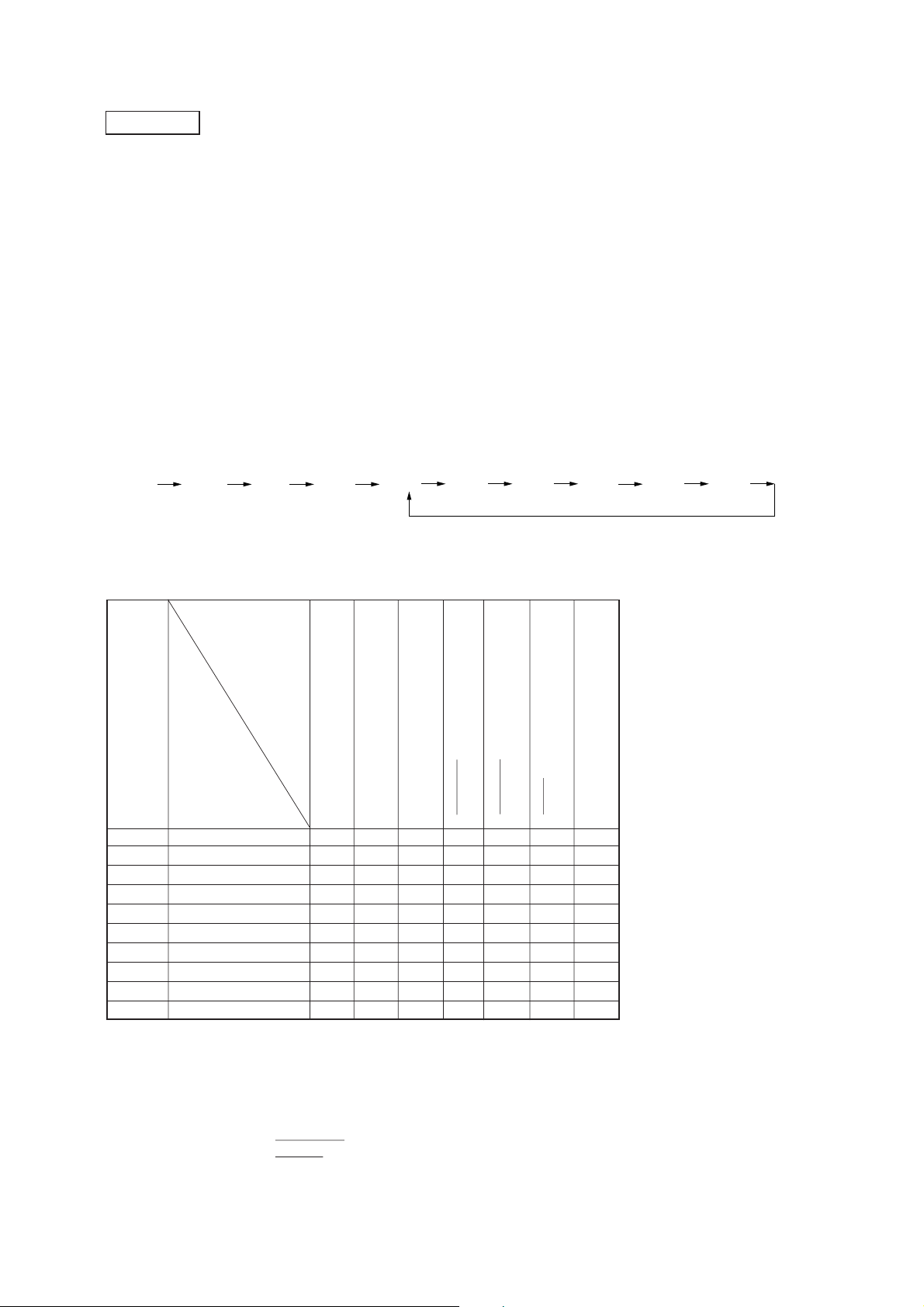

[Test Mode Execution]

Press the each key for the desired test mode step to execute any of the following tests:

No.

1 VCO/TX FREQ. ADJ 1 L H L L L

2 TX MOD CHECK 2 L H H L H

3 TX DATA 3 L H L L H *1

4 RX SENS 4 H H L H H *2

5 SQ SENS 5 L H L *A H

6 RECEIVE DATA CHECK 6 L H L L H *3

7 BELL CHECK 7 H L L L H

8 BAT. LOW CHECK 8 H L L L H *4

9 CHARGE CHECK 9 H L L L H *5

10 DUPLEX 0 L H H H L *2

Test Mode

Name

KEY

RX PWR (IC404 pin qd)

TX B (IC404 pin rs)

TX MUTE (IC404 pin qa)

CONV (IC404 pin ej)

RX MUTE (IC404 pin qs)

* Initial Channel of each step: 21CH

. . .

Remarks

*A. SQ on: H

SQ off: L

*1. Test Mode 3: Continue output TX data as “ 0000……”.

*2. Test Mode 4, 10: It is possible to change the speaker output level by [VOL] switch.

*3. Test Mode 6: When locked receiving data is “ 0000……”, it beeps confirm tone. (1 kHz)

*4. Test Mode 8: When BATT LOW (IC404 pin eg) is “ L” (battery low), it beeps confirm tone.

*5. Test Mode 9: When CHG IN (IC404 pin eh) is “ L” (charge on), it beeps confirm tone.

9

Page 10

SECTION 4

+

–

deviation meter

TP (ANT)

TP (GND)

ELECTRICAL ADJUSTMENTS

0 dBm = 0.775 V

BASE UNIT

• Make the set in test mode. (See page 7.)

– TX Adjustments and Checks –

1. TX VCO Check

Setting:

digital voltmeter

+

–

Procedure:

1. Connect a digital voltmeter to TP (TX VCO), TP (RX VCO)

and TP (GND) on the BASE RF board.

2. Check that both TP (TX VCO) and TP (RX VCO) voltage of

digital voltmeter are 0.8 V to 2.2 V.

3. Set the

[DIAL MODE] switch (S2) to the [TONE] position.

4. Press the [HANDSET LOCATOR] key (S1) three times to change

the channel to 40CH.

5. Check that both TP (TX VCO) and TP (RX VCO) voltage of

digital voltmeter are 0.8 V to 2.2 V.

6. Press the [HANDSET LOCATOR] key (S1) once to change

the channel to 1CH.

7. Check that both TP (TX VCO) and TP (RX VCO) voltage of

digital voltmeter are 0.8 V to 2.2 V.

TP (TX VCO), TP (RX VCO)

TP (GND)

7. Check that the value of power meter is –5.5 dBm ± 1.5 dBm.

4. Modulation Sensitivity Adjustment

Setting:

AF OSC

600

+

–

1 kHz, –20 dBm

Ω

LINE jack (J1)

Procedure:

1. Connect an AF OSC to the LINE jack (J1) on the B ASE MAIN

board.

2. Connect a de viation meter to TP (ANT) and TP (GND) on the

BASE MAIN board.

3. Set the [DIAL MODE] switch (S2) to the [PULSE] position.

4. Press the [HANDSET LOCATOR] key (S1) once to change

the test mode step to TX MOD CHECK.

5. Adjust RT3 on the BASE MAIN board so that the value of

deviation meter becomes 8 kHz ± 0.5 kHz.

5. Distortion and S/N Ratio Check

Setting:

2. TX Frequency Adjustment

Setting:

frequency counter

+

–

TP (ANT)

TP (GND)

Procedure:

1. Connect a frequency counter to TP (ANT) and TP (GND) on

the BASE MAIN board.

2. Restart the test mode to change the channel to 19CH.

3. Adjust CT1 on the BASE MAIN board so that the value of

frequency counter becomes 926.897468 MHz ± 600 Hz.

3. TX Power Adjustment

Setting:

power meter

+

–

TP (ANT)

TP (GND)

Procedure:

1. Connect a power meter to TP (ANT) and TP (GND) on the

BASE MAIN board.

2. Adjust R T301 on the B ASE RF board so that the value of pow er

meter becomes –5.5 dBm ± 1 dBm.

3. Set the

[DIAL MODE] switch (S2) to the [TONE] position.

4. Press the [HANDSET LOCATOR] key (S1) three times to change

the channel to 40CH.

5. Check that the value of power meter is –5.5 dBm ± 1.5 dBm.

6. Press the [HANDSET LOCATOR] key (S1) once to change

the channel to 1CH.

AF OSC

600

+

–

1 kHz, –20 dBm

distortion meter

noise meter

CCITT: on

Ω

LINE jack (J1)

+

–

+

–

TP (ANT)

TP (GND)

Procedure:

1. Connect a distortion meter and noise meter to TP (ANT) and

TP (GND) on the BASE MAIN board.

2. Check that the value of distortion meter is less than 4%.

3. Check that the value of noise meter, and record it.

4. Stop outputting the signal of AF OSC.

5. Check that the v alue of noise meter again. And check that difference of level between in step3 and in step5 is less than

30 dB.

10

Page 11

6. Code Deviation Check

600

Ω

+

–

SINAD meter

LINE jack (J1)

Setting:

deviation meter

+

–

TP (ANT)

TP (GND)

Procedure:

1. Connect a de viation meter to TP (ANT) and TP (GND) on the

BASE MAIN board.

2. Press the [HANDSET LOCATOR] key (S1) once to change

the test mode step to TX DATA.

3. Check that the value of deviation meter is 6 kHz to 10 kHz.

– RX Adjustments and Checks –

1. DISCRI Volta ge Adjustment

Setting:

SSG

TP (ANT)

Carrier frequency: 902.952467 MHz

Modulation: no modulation

Output level: – 47 dBm

digital voltmeter

TP (GND)

Procedure:

1. Change the modulation of SSG to 1 kHz, ± 8 kHz deviation.

2. Connect a noise meter to the LINE jack (J1) on the BASE

MAIN board.

3. Adjust RT2 on the BASE MAIN board so that the value of

noise meter becomes 265 mV ± 10 mV.

3. Distortion and S/N Ratio Check

Setting:

SSG

TP (ANT)

Carrier frequency: 902.952467 MHz

Modulation: 1 kHz,

Output level: – 47 dBm

distortion meter

±

8 kHz deviation

+

–

noise meter

+

–

CCITT: on

600

TP (GND)

Ω

LINE jack (J1)

+

–

TP (DISCRI)

TP (GND)

Procedure:

1. Connect a SSG to TP (ANT) and TP (GND) on the BASE

MAIN board.

2. Connect a digital v oltmeter to TP (DISCRI) and TP (GND) on

the BASE MAIN board.

3. Set the

[DIAL MODE] switch (S2) to the [PULSE] position.

4. Press the [HANDSET LOCATOR] key (S1) three times to change

the test mode step to RX SENS.

5. Adjust L3 on the B ASE MAIN board so tha t the value of digital voltmeter becomes 1 V ± 0.05 V.

2. TEL Out Level Adjustment

Setting:

SSG

TP (ANT)

Carrier frequency: 902.952467 MHz

Modulation: 1 kHz,

Output level: – 47 dBm

±

8 kHz deviation

TP (GND)

Procedure:

1. Connect a distortion meter to the LINE jack (J1) on the B ASE

MAIN board.

2. Set the CCITT of noise meter on.

3. Check that the value of distortion meter is less than 4%.

4. Check that the value of noise meter, and record it.

5. Change the modulation of SSG to no modulation.

6. Check that the v alue of noise meter again. And check that difference of level between in step3 and in step5 is more than

60 dB.

4. RX Sensitivity Check

Setting:

SSG

TP (ANT)

Carrier frequency: 902.952467 MHz

Modulation: 1 kHz,

Output level: –111 dBm

±

8 kHz deviation

TP (GND)

noise meter

+

–

600

Ω

LINE jack (J1)

Procedure:

1. Connect a SINAD meter to the LINE jack (J1) on the BASE

MAIN board.

2. Change the output level of SSG to –111 dBm, and change the

modulation to 1 kHz ± 8 kHz devition.

3. Check that the value of SINAD meter is more than 12 dB.

11

Page 12

5. SQ Sensitivity Adjustment

Setting:

6. DTMF Level Check

Setting:

SSG

Carrier frequency: 902.952467 MHz

Modulation: 1 kHz, ±8 kHz deviation

Output level: –113 dBm

TP (ANT)

TP (GND)

noise meter

+

–

600

Ω

LINE jack (J1)

Procedure:

1. Connect a noise meter to the LINE jack (J1) on the BASE

Procedure:

1. Change the output level of SSG to –113 dBm.

2. Press the [HANDSET LOCATOR] key (S1) once to change

the test mode step to SQ SENS.

MAIN board.

2. Press the [HANDSET LOCATOR] key (S1) twice to change

the test mode step to DTMF DUAL TONE.

3. Check that the value of noise meter is –5 dBm to 0 dBm.

3. Adjust RT1 so that the CHARGE LED (D6) becomes blinking.

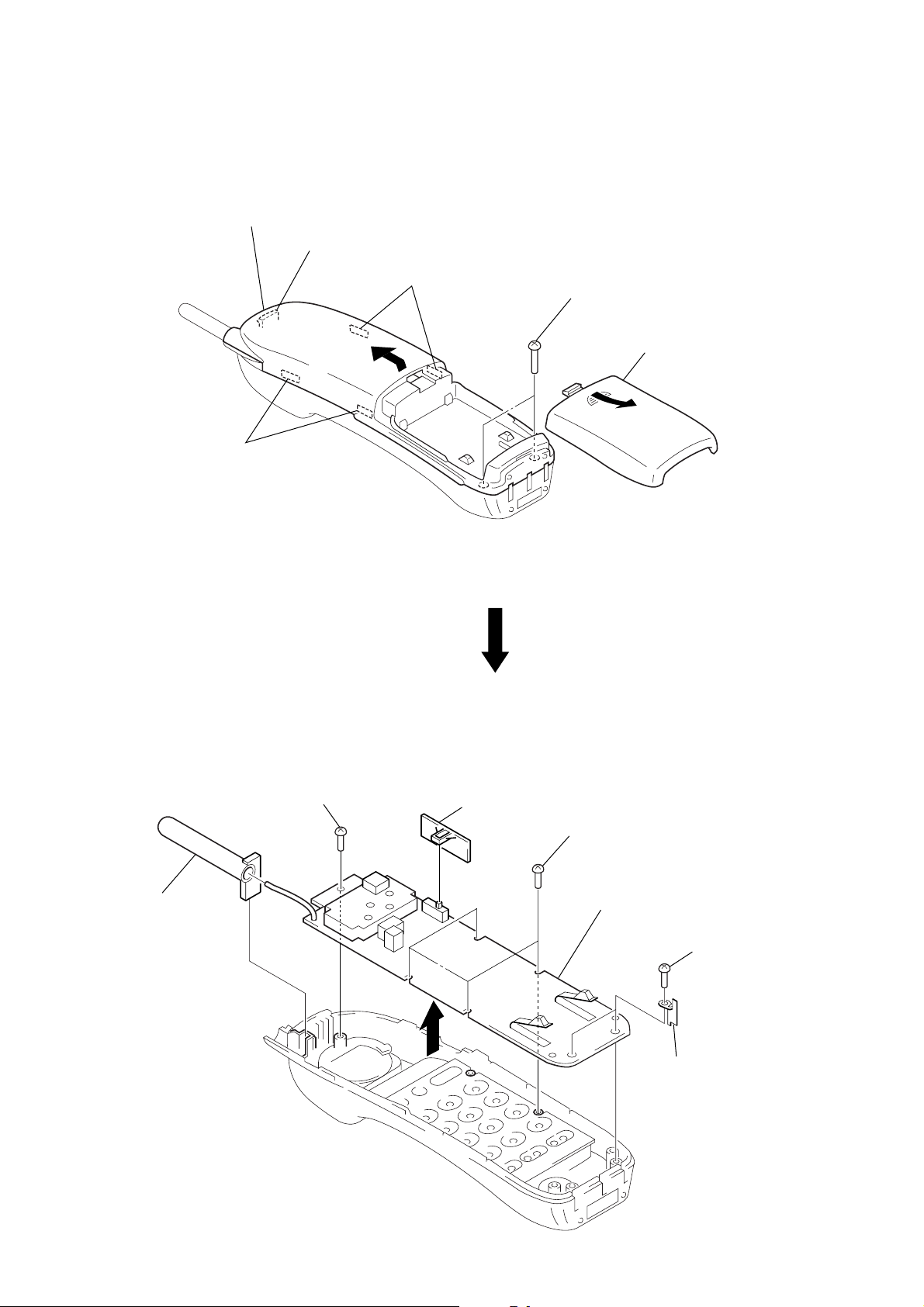

Adjustment Location:

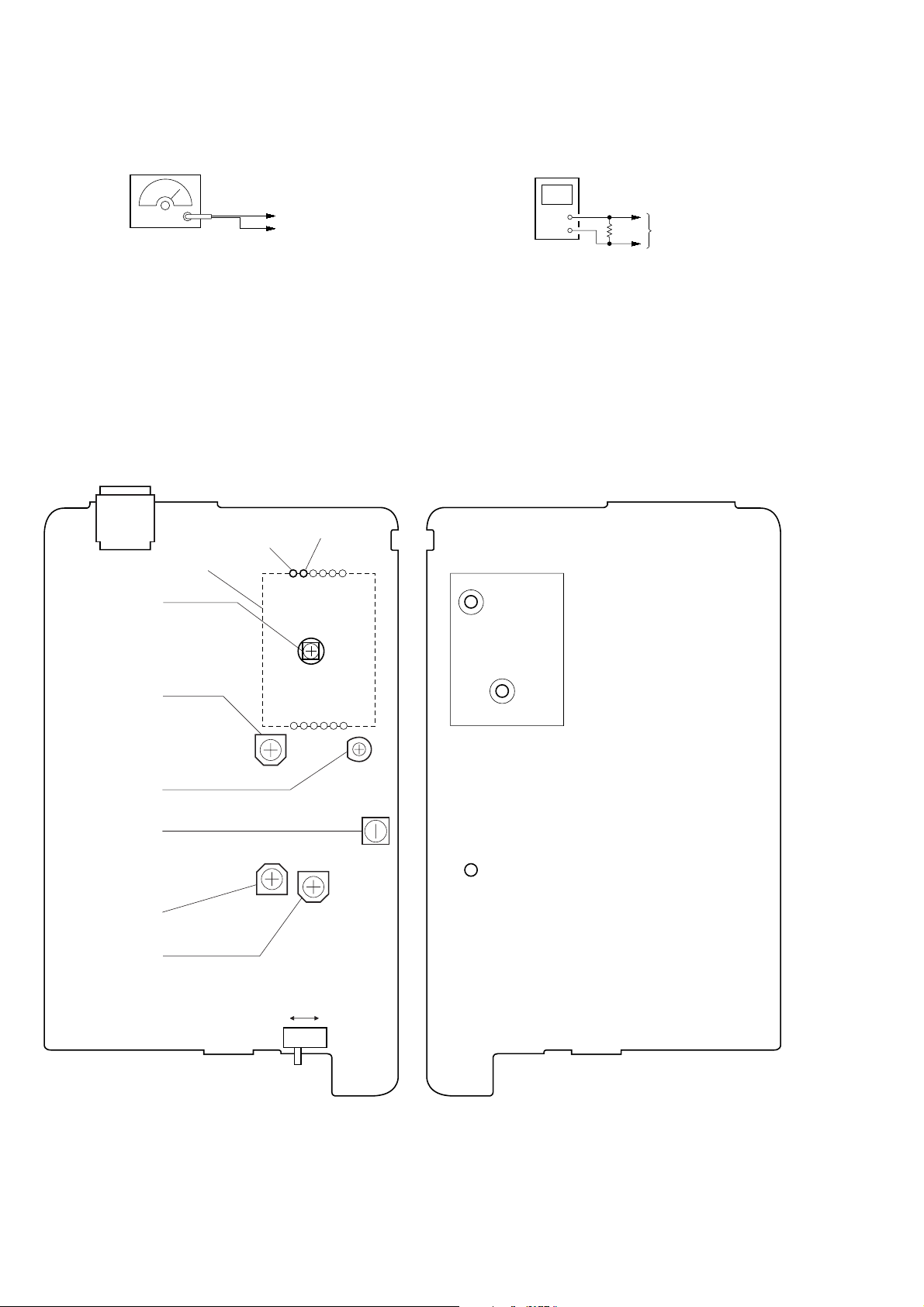

– BASE MAIN BOARD (Component Side) – – BASE MAIN BOARD (Conductor Side) –

J1

TP(ANT)

BASE RF Board BASE RF Board

RT301

TX Power Adjustment

TP(GND)

TP(RX VCO)

Modulation Sensitivity

RT3

Adjustment

CT1

TX Frequency Adjustment

L3

DISCRI Voltage Adjustment

RT2

TEL Out Level Adjustment

RT1

SQ Sensitivity Adjustment

TP(TX VCO)

TP(DISCRI)

TONE PULSE

S2

12

Page 13

HANDSET

TP (MIC+)

TP (MIC–)

AF OSC

1 kHz, 9 mV

+

–

• Make the set in test mode. (See page 9.)

– TX Adjustments and Checks –

4. Modulation Sensitivity Adjustment

Setting:

AF OSC

1. TX VCO Check

Setting:

digital voltmeter

+

–

TP (TX VCO), TP (RX VCO)

TP (GND)

Procedure:

1. Connect a digital voltmeter to TP (TX VCO), TP (RX VCO)

and TP (GND) on the HAND RF board.

2. Check that both TP (TX VCO) and TP (RX VCO) voltage of

digital voltmeter are 0.8 V to 2.2 V.

3. Press the [CHANNEL] key three times to change the channel

to 40CH.

4. Check that both TP (TX VCO) and TP (RX VCO) voltage of

digital voltmeter are 0.8 V to 2.2 V.

5. Press the [CHANNEL] key once to change the channel to 1CH.

6. Check that both TP (TX VCO) and TP (RX VCO) voltage of

digital voltmeter are 0.8 V to 2.2 V.

2. TX Frequency Adjustment

Setting:

frequency counter

+

–

TP (MIC+)

TP (MIC–)

TP (ANT)

TP (GND)

+

–

1 kHz, 9 mV

deviation meter

Procedure:

1. Disconnect the microphone (MC401).

2. Connect an AF OSC to TP (MIC+) and TP (MIC–) on the

HAND MAIN board.

3. Connect a de viation meter to TP (ANT) and TP (GND) on the

HAND MAIN board.

4. Press the [2] key to change the test mode step to TX MOD

CHECK.

5. Adjust RT403 on the HAND MAIN board so that the value of

deviation meter becomes 8 kHz ± 0.5 kHz.

5. Distortion and S/N Ratio Check

Setting:

+

–

TP (ANT)

TP (GND)

Procedure:

1. Connect a frequency counter to TP (ANT) and TP (GND) on

the HAND MAIN board.

2. Restart the test mode to change the channel to 21CH.

3. Adjust CT401 on the HAND MAIN board so that the v alue of

frequency counter becomes 903.052467 MHz ± 600 Hz.

3. TX Power Adjustment

Setting:

power meter

+

–

TP (ANT)

TP (GND)

Procedure:

1. Connect a power meter to TP (ANT) and TP (GND) on the

HAND MAIN board.

2. Adjust RT501 on the HAND RF board so that the value of

power meter becomes –7.5 dBm ± 1 dBm.

3. Press the [CHANNEL] key three times to change the channel

to 40CH.

4. Check that the value of power meter is –7.5 dBm ± 1.5 dBm.

5. Press the [CHANNEL] key once to change the channel to 1CH.

6. Check that the value of power meter is –7.5 dBm ± 1.5 dBm.

distortion meter

+

–

noise meter

+

–

CCITT: on

TP (ANT)

TP (GND)

Procedure:

1. Connect a distortion meter and noise meter to TP (ANT) and

TP (GND) on the HAND MAIN board.

2. Check that the value of distortion meter is less than 4%.

3. Check that the value of noise meter, and record it.

4. Stop outputting the signal of AF OSC.

5. Check that the v alue of noise meter again. And check that difference of level between in step3 and in step5 is less than

30 dB.

13

Page 14

6. Code Deviation Check

Setting:

deviation meter

+

–

TP (ANT)

TP (GND)

4. Set the [VOL] switch (S401) to [M] position.

5. Adjust RT402 on the HAND MAIN board so that the value of

noise meter becomes 115 mV ± 10 mV.

3. Distortion and S/N Ratio Check

Setting:

SSG

Procedure:

1. Connect a de viation meter to TP (ANT) and TP (GND) on the

HAND MAIN board.

2. Press the [3] key to change the test mode step to TX DATA.

3. Check that the value of deviation meter is 6 kHz to 10 kHz.

– RX Adjustments and Checks –

1. DISCRI V oltage Adjustment

Setting:

SSG

TP (ANT)

Carrier frequency: 926.997467 MHz

Modulation: no modulation

Output level: – 47 dBm

digital voltmeter

+

–

TP (DISCRI)

TP (GND)

TP (GND)

Procedure:

1. Connect a SSG to TP (ANT) and TP (GND) on the HAND

MAIN board.

2. Connect a digital v oltmeter to TP (DISCRI) and TP (GND) on

the HAND MAIN board.

3. Press the

[4] key to change the test mode step to RX SENS.

4. Adjust L402 on the HAND MAIN board so that the value of

digital voltmeter becomes 1 V ± 0.05 V.

2. Speaker Out Level Adjustment

Setting:

SSG

TP (ANT)

Ω

TP (GND)

TP (SP+)

TP (SP–)

Carrier frequency: 926.997467 MHz

Modulation: 1 kHz,

Output level: – 47 dBm

distortion meter

±

8 kHz deviation

+

–

noise meter

+

–

CCITT: on

150

Procedure:

1. Connect a distortion meter to TP (SP+) and TP (SP–) on the

HAND MAIN board.

2. Check that the value of distortion meter is less than 4%.

3. Check that the value of noise meter, and record it.

4. Change the modulation of SSG to no modulation.

5. Check that the v alue of noise meter again. And check that difference of level between in step3 and in step5 is more than

60 dB.

4. RX Sensitivity Check

Setting:

SSG

TP (ANT)

Carrier frequency: 926.997467 MHz

Modulation: 1 kHz,

Output level: –111 dBm

SINAD meter

±

8 kHz deviation

TP (GND)

TP (ANT)

Carrier frequency: 926.997467 MHz

Modulation: 1 kHz, ±8 kHz deviation

Output level: – 47 dBm

noise meter

150

+

–

Ω

TP (GND)

TP (SP+)

TP (SP–)

Procedure:

1. Change the modulation of SSG to 1 kHz, ± 8 kHz deviation.

2. Disconnect the speaker (SP801).

3. Connect a noise meter to TP (SP+) and TP (SP–) on the HAND

MAIN board.

14

150

+

–

Ω

TP (SP+)

TP (SP–)

Procedure:

1. Change the output level of SSG to –111 dBm.

2. Connect a SINAD meter to TP (SP+) and TP (SP–) on the

HAND MAIN board.

3. Check that the value of SINAD meter is more than 12 dB.

Page 15

5. SQ Sensitivity Adjustment

Setting:

SSG

TP (ANT)

Carrier frequency: 926.997467 MHz

Modulation: 1 kHz,

Output level: –113 dBm

±

8 kHz deviation

TP (GND)

Procedure:

1. Change the output level of SSG to –113 dBm.

2. Press the [5] key to change the test mode step to SQ SENS.

3. Adjust RT401 so that the TALK/BATT LOW LED (D408)

becomes blinking.

Adjustment Location:

RT501

TX Power

Adjustment

TP

(RX VCO)

CT401

TX Frequency

Adjustment

L402

DISCRI Voltage

Adjustment

RT402

Speaker Out Level

Adjustment

RT403

Modulation Sensitivity

Adjustment

– HAND MAIN BOARD –

(Component Side)

TP(SP–)

TP(SP+)

HAND RF Board

TP(TX VCO)

– HAND MAIN BOARD –

(Conductor Side)

TP(ANT)

TP(GND)

TP(DISCRI)

RT401

SQ Sensitivity

Adjustment

TP(MIC+)

TP(MIC–)

MC401

15

Page 16

16

Page 17

SECTION 5

DIAGRAMS

5-1. BLOCK DIAGRAM – BASE UNIT Section –

ANT1

(ANTENNA)

TX AMP

Q306, 307

2

RT301

TX

POWER

TX

OUT

RF AMP

Q301

B.P.F.

FT301

TX B+

SWITCH

Q302

2 DOUBLER

TX AMP

1st MIXER, VCO, PLL SYNTHESIZER

24

TX B+

14

MIX

IN

MIXER

LOCAL OSC

BUFFER

(RX SYSTEM)

LOCK

(TX SYSTEM)

IC302

1st

VCO

VCO

MIX

OUT

TXE

TXB

RXE

RXB

13

10.555MHz

20

21

5

4

FT1

RX VCO

Q312

TX

VCO

IF AMP

Q1

X2

10.1MHz

CT1

TX

FREQUENCY

L.P.F.

D303

LOCK

DETECTOR

L.P.F.

D302

2nd MIXER, LIMITER AMP, DET,

AF AMP, SQUELCH CONTROL

16

MIX

IN

18

7

2nd

MIXER

LOCAL

OSC

OSC

1 2

PD2

PD1

IC3

OSC

MIX

OUT

PHASE

DETECTOR

PHASE

DETECTOR

SPP-904

L3

DISCRI

VOLTAGE

FT2

455kHz

3

LIM

IN

5

PROGRAM-

MABLE

DIVIDER

LATCH

PROGRAM-

MABLE

DIVIDER

LATCH

LIMITER

AMP

SQUELCH

TRIGGER

WITH

HYSTERESIS

SCAN

CONTROL

13

QUAD COIL

MODULATOR

12

1/32, 1/33

PRESCALER

1/16, 1/17

PRESCALER

DE-

B+ (+3V)

EXPANDER, COMPRESSOR, LIMITER

8

AF

OUT

AF

9

FIL

INSQ IN

1011

RT3

MODULATION

SENSITIVITY

FIL

OUT

AMP

FILTER

AMP

RT2

TEL

OUT LEVEL

RT1

SQ

SENSITIVITY

47 48

39

SQ IN

DATA EN

DATA OUT

SYSTEM CONTROLLER

IC5

PREAMP

COMP

OUT

20

TX MUTE

RX MUTE

DATA IN

DTMF

DTMF

TALK

BELL IN

EXP

IN

Q2

LIMITER

37

36

38

1

34

13

21

3

LPF1

IN

1

MUTE

CMP MUTE

CONT

EXP MUTE

EXPANDER

VCA

L.P.F.

COMPRESSOR

CONT

1617

IC1

VCA

SUM

AMP

DATA

SHAPE

SUM

AMP

MUTE

DRIVE

TEL

OUT

FSK

OUT

PRE

AMP

6

10

PRE

IN

+

24

HOOK ON/OFF

RELAY DRIVE

Q10

RINGER DETECT

IC4

LPF2

IN

19

L.P.F.

AF AMP

Q4

LPF2

OUT

RL1

18

HYBRID

AMP

Q3

T1

LINE

TRANSFORMER

J1

LINE

• SIGNAL PATH

: RX

: TX

: BELL

05

1/2

SHIFT

XIN

9

XOUT

10

SI

16

CPS

15

17

RST

S1

PULSE

TONE

1

2

3

41

PLL DATA

40

PLL CLK

42

PLL EN

20

PAGE

22

TONE/PULSE

FLASH 100

24

23

FLASH 270

LED CHG1

LED CHG2

LED INUSE1

LED INUSE2

X0

5

BATT OFF

RESET

TX B

CHG OUT

CHG IN

X1

6

32

31

30

29

18

2

46

25

35

PROGRAM-

MABLE

DIVIDER

LATCH

OSC &

1/2 DIVIDER

REGISTER &

LATCH

PULSE

COUNTER

HANDSET

LOCATOR

S2

DIAL MODE

S3

FLASH

D6

CHARGE

D7

LINE

RESET SIGNAL

GENERATOR

Q9

B+ (+3V)

BATTERY

VOLTAGE DETECT

IC6

B+ (+3V)

TX B+ (+3V)

B+ SWITCH

(FOR TX SYSTEM)

Q12

REGULATOR

CHARGE CONTROL

Q8

CHARGE DETECT

Q6

+3V

Q11

B+ (+6V)

+6V

REGULATOR

Q7

J2

!

DC IN 9V

+

–

CHARGE

TERMINAL

X1

3.579545MHz

1717

Page 18

SPP-904

5-2. BLOCK DIAGRAM – HANDSET Section –

ANT2

(ANTENNA)

TX AMP

Q506, 507

RT501

TX

POWER

RF AMP

Q501

B.P.F.

FT501

SWITCH

1st MIXER, VCO, PLL SYNTHESIZER

24

TX B+

TX B+

Q502

14

MIX

IN

MIXER

LOCAL OSC

BUFFER

(RX SYSTEM)

LOCK

IC502

1st

VCO

MIX

OUT

RXE

RXB

13

10.555MHz

20

21

FT401

RX VCO

Q512

IF AMP

Q401

X401

10.1MHz

CT401

TX

FREQUENCY

L.P.F.

D503

LOCK

DETECTOR

2nd MIXER, LIMITER AMP, DET,

AF AMP, SQUELCH CONTROL

IC401

MIX

IN

16

18

2nd

MIXER

LOCAL

OSC

OSC

1 2

PD2

OSC

MIX

OUT

PHASE

DETECTOR

L402

DISCRI

VOLTAGE

FT402

455kHz

3

LIM

IN

5

PROGRAM-

MABLE

DIVIDER

LATCH

LIMITER

AMP

SQUELCH

TRIGGER

WITH

HYSTERESIS

SCAN

CONTROL

13

QUAD COIL

MODULATOR

12

1/32, 1/33

PRESCALER

DE-

B+ (+3V)

8

AF

OUT

FIL

OUT

AF

AMP

FILTER

AMP

9

FIL

INSQ IN

1011

RT403

MODULATION

SENSITIVITY

RT402

SPEAKER

OUT LEVEL

RT401

SQ

SENSITIVITY

44 45

41

SQ IN

DATA OUT

SYSTEM CONTROLLER

IC404

PREAMP

DATA EN

TX MUTE

RX MUTE

DATA IN

CONV

Q402

20

COMP

OUT

11

12

40

37

EXPANDER, COMPRESSOR, LIMITER

EXP

IN

3

LPF1

IN

1

LIMITER

EXPANDER

VCA

L.P.F.

MUTE

CMP MUTE

CONT

IC403

EXP MUTE

CONT

1617

SUM

AMP

DATA

SHAPE

COMPRESSOR

VCA

MUTE

DRIVE

SUM

AMP

INT

OUT

FSK

OUT

S401

VOL

H/M/L

VOLUME

5

CONTROL

S401

VREF B+

10

PRE

IN

PRE

AMP

24

LPF2

IN

19

VREF

14 13

L.P.F.

REG.

LPF2

OUT

VCC

ST.BY.

18

12

MIC AMP

Q404

B+ (+3V)

STANDBY

SWITCH

Q412

AF AMP

Q405, 406

SP801

(SPEAKER)

MC401

(MIC)

TX

OUT

2

2 DOUBLER

TX AMP

• SIGNAL PATH

: RX

: TX

: BELL

05

VCO

(TX SYSTEM)

TXE

TXB

D408

RINGER DRIVE

Q408

(KEY BACK LIGHT)

BATT B+

D421 – 424

B+ (+3V)

TX B+ (+3V)

PROGRAM-

5

4

TX

VCO

L.P.F.

D502

PD1

7

PHASE

DETECTOR

1/2

MABLE

DIVIDER

LATCH

PROGRAM-

MABLE

DIVIDER

LATCH

1/16, 1/17

PRESCALER

OSC &

1/2 DIVIDER

SHIFT

REGISTER &

LATCH

PULSE

COUNTER

XIN

XOUT

CPS

SI

RST

9

10

16

15

17

47

46

48

PLL DATA

PLL CLK

PLL EN

RING OUT

RING VOL

KEY LED

TALK LED

TALK LED

TX B

CHG IN

38

RINGER VOLUME

39

17

16

15

42

13

SC

36

SWITCH

Q409

LED DRIVE

Q421

TALK/BATT LOW

Y401

(BUZZER)

SYSTEM CONTROLLER (IC404) B+

B+ SWITCH

(FOR TX SYSTEM)

Q403

CHARGE

DETECT

Q410

D407

+3V

REGULATOR

IC405

D406

BATT B+

D405

D403D404

BT901

RECHARGEABLE

BATTERY PACK

(BP-T23)

+

CHARGE

TERMINAL

–

KEY MATRIX

(SHEET KEY)

S901 – S918

ROW1 – ROW4

34 – 30 25 – 22

COL1 – COL5

BATT LOW

X0

5

BATT OFF

RESET

X1

6

35

29

2

RESET SIGNAL

GENERATOR

Q411

VDET1

1

VDET2

5

BATTERY

VOLTAGE DETECT

IC406

COMPARATOR

COMPARATOR

VREF

VIN1

VIN2

2

4

BATT B+

X402

3.579545MHz

1818

Page 19

5-3. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• W : indicates side identified with part number.

f

•

: internal component.

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

• : carbon pattern

Caution:

Pattern face side: Parts on the pattern f ace side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the par ts face side seen from

(Component Side) the parts face are indicated.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

: internal component.

4

W or less unless otherwise

• 2 : nonflammable resistor.

• 4: printed coil.

• C : panel designation.

• U : B+ Line.

• H : adjustment for repair.

• Power voltages are dc 9 V and fed with regulated dc pow er

supply from external power voltage jac k (J2) on the BASE

MAIN board, dc 12 V and fed with regulated dc power

supply from modular jack (J1) on the BASE MAIN board

with 100 Ω in series, and dc 3.6 V and f ed with regulated

dc power supply from battery terminal on the HAND MAIN

board.

• Voltages and wav eforms are dc with respect to ground in

test mode.

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

N : RX

O : TX

P : BELL

19

Page 20

5-4. PRINTED WIRING BOARD – BASE RF Section –

1234 567

A

B

A

BASE MAIN

BOARD

(Page 22)

C

ANT

GND

VCC

LE

DATA

CLK

D

BASE RF BOARD

L310

C303

L303

C315

C301

L301

R302

C398

R304

C378

L351

(SHIELD CASE)

C337

+

C339

L307

C334

L352

BASE RF BOARD

(COMPONENT SIDE)

1

FT301

3

C304

C307

C306

R342

R361C309

Q312

C324

BCE

C323

C362

AK

D303

R309

TP

R307

(RX VCO)

R328

C338

(CONDUCTOR SIDE)

C336

6

4

E

C

L302

C320

R329

C314

C312

C302

Q301

C325

L351-357

C373

+

R333

L354

C351

C341

AK

D302

C360

R327

C358

(PRINTED COIL)

(SHIELD CASE)

R319

C353

+

C357

C350

R326

TP(TX VOC)

1-675-273-

L353

C367

11

(11)

MOD

TX

GND

LO

GND

IF

B

BASE MAIN

BOARD

(Page 22)

C375

B

C369

E

C364

C365

L355

C371

C372

R351

Q306

C376

L357

C366

C310

R352

BCE

L356

C368

R354

C374

Q307

BCE

C370

R353

C363

R348

Q302

BCE

R339

R330

C344

C333

R344

R321

R303

C390

R331

L304

R306

R340

E

R397

R398

R399

C335

F

G

CLK

DATA

LE

VCC

GND

ANT

L306

R305

R332

C380

C381

C321

C326

C327

R322

C308

C305

C319

PRINTED

(

C379

L350

COIL

C311

R341

C342

12

C397

R316

C340

C348

C346

C345

R317

1

C347

C383

R359

R320

C382

IF

GND

LO

GND

TX

MOD

13

IC302

24

C386

C343

RT301

(

H

• Semiconductor

Location

Ref. No. Location

D302 C-5

D303 C-3

IC302 F-4

Q301 B-3

Q302 C-4

Q306 A-4

Q307 B-4

Q312 C-3

20

C349

L309

1-657-273-

05

11

(11)

Page 21

5-5. SCHEMATIC DIAGRAM – BASE RF Section – • See page 28 for IC Block Diagram.

SPP-904

1

BASE MAIN

BOARD

(Page 23)

ANT

GND

BASE RF BOARD

L310

18nH

2.4

C306

0.5p

Q306

0.8

R354

18k

C371

0.01

3

1

FT301

2

L307

6.8nH

R302

L356

C368

47k

4p

TP301

TP302

C375

2p

C302

12p

L302

6.8nH

C304

33p

C376

4p

C315

2p

L303

5.6nH

2SC4095-R47

R351

100

C369

33p

C301

2p

C303

2p

L301

18nH

Q301

RF AMP

0.8

2.1

L355

2SC5065-Y

TX AMP

C374

8p

C372

100p

R304

220

4

6

B.P.F.

5

R342

150

IC302

1st MIXER, VCO,

PLL SYNTHESIZER

M64884FP-C60J

C373

6p

1.6

L357

R352

10

C364

C365

0.1

33p

C390

0.01

C308

2p

C305

7p

C307

33p

IC302

0.7

Q307

2SC5065-Y

TX AMP

C370

TX POWER

RT301

4.7K

5p

C325

33p

R303

C321

L350

C363

R353

0.001

C310

C366

33p

6.8

33p

1.7

7p

39k

B+

C326

0.01

C319

33p

24

IN

MIX

TX GND1

1

1.9

R348

0

R341

1k

C360

10

6.3V

R322

33

B+

3.2

23

MIX GND

TX OUT

2

2.9

C342

3p

C386

0.01

B+

Q312

2SC5065-Y

RX VCO

C320

0.001

B+

22

RX VCC

TX VCC

3

1.7

B+

R344

33

C343

82p

21

4

2.8

C327

3p

1.8

RXB

TXB

0.9

C345

15p

R317

390

20

5

R361

1.3

R329

390

RXE

TXE

C346

15p

33k

2

C324

5p

C323

5p

1.4

19

RX GND

TX GND2

6

1.1

C347

8p

L353

L309

39nH

18

7

C309

L306

12nH

3.2

PD2

PD1

3.2

C348

0.01

B+

5p

17

8

L354

L351

3.2

16

RST

VCC

2.9

B+

C350

15p

D302

1SV270

C349

4p

9

L352

SI

XIN

C340

33p

C334

5p

1SV314

0

15

10

C341

4p

C351

100p

D303

C335

C344

0.01

CPS

XOUT

3p

0

14

11

(TX VCO)

R326

10k

C367

0.01

3.2

LOCK

XBO

TP

13

12

R319

0

R359

1.5k

TP

(RX VCO)

R305

10k

C362

3p

C311

27p

R340

4.7k

MIX OUT

GND

R321

10k

C353

0.01

R309

10k

C336

C397

100p

0.0033

R333

1.2k

R320

100k

C358

0.01

R307

3.3k

C337

C338

0.0047

0.0022

R339

330k

Q302

2SA812(M)-M6A

TX B+

SWITCH

2.4

3.1

R316

0

R330

10

R327

1k

C357

6.8

10V

R328

4.7k

C339

0.22

35V

B+

3.2

R332

1k

B+

R331

27

L304

4.7µH

C312

0.01

R306

1k

C314

0.01

C333

33p

C383

100p

100p

C381

R398

100p

C380

C379

100p

C378

R399

1k

R397

1k

B+

33p

B+

1k

B+

C398

100p

B+

C382

100p

B+

TP303

TP304

TP305

TP306

TP312

TP311

TP310

TP309

TP308

TP307

VCC

LE

DATA

CLK

MOD

TX

GND

LO

GND

IF

(Page 23)

2

BASE MAIN

BOARD

3

BASE MAIN

BOARD

(Page 23)

B+

05

B+

B+

2121

Page 22

SPP-904

5-6. PRINTED WIRING BOARD – BASE MAIN Section –

• Semiconductor

Location

Ref. No. Location

D1 G-9

D3 A-5

D4 C-3

D6 G-10

D7 G-11

D9 D-4

D10 C-12

D11 D-6

D13 E-3

IC1 C-8

IC3 G-8

IC4 D-3

IC5 B-11

IC6 D-11

Q1 F-7

Q2 F-9

Q3 A-8

Q4 C-7

Q6 E-12

Q7 D-5

Q8 E-11

Q9 D-11

Q10 D-6

Q11 E-3

Q12 F-6

1

2

3

4

5

6 7 8 9 10 11 12 13

BASE MAIN BOARD

A

C23

C22

C81

B

C

J1

LINE

6

4

2

1

3

5

C80

R25

D4

R37

1

2

R24

J2

C55

+

Q11

IC4

43

D13

R59

R58

C45

C51

+

–

DC IN 9V

D

C50

E

R51

R50

R65

TP(ANT)

TP(GND)

ANT

GND

VCC

LE

DATA

CLK

R70

C72

F

G

ANT1

PRINTED

(

BP(ANT)

COIL

L6

L50

(

C73

C82

R49

MOUNTED ON THE CONDUCTOR

(

SIDE OF BASE MAIN BOARD

D3

D9

Q7

C56

+

BASE RF BOARD

(SHIELD CASE)

C39

R38

RL1

Q10

C49

R60

(

C52

MOD

TX

GND

LO

GND

IF

H

05

BCE

+

LINE

TRANSFORMER

R76

R75

C83

Q12

1

2

FT1

3

R81

T1

D11

BCE

CT1

RT3

R36

C54

R48

R69

C79

C62

C65

C99

C38

R33

ECB

C36

C24L2R28 C25

C68

R92

C66

C64

1

C77

4

R23

X2

FT2

Q4

+

R99

Q1

BCE

R26 C1

R61 C30

C67

5

C35

R47

R68

R40

C26

Q3

BCE

R90

R88

R18

R19

C19

R21

R22

R34

R17

C18

R20

+

C10

C71 R86

13

IC1

24

+

C32

C13

+

R91

R45

R30

C63

12

1

+

C42

R84

C74

C31

C44

C12

R15

C17C75

R13

R16

C41

R42

R46

+

C43

R11

R89

C20

+

C37

C61

R41

C14

C78

R87

+

C33

R97

R70

R53

C34R14

C46

R98

C59

+

2536

R72

C58

R74

R79

24

13

12

C60

R57

C48

R80

3

1

IC6

2

R56

R78

R64

R95

R96

R94

R93

D10

S3

FLASH

R66

37

IC5

48

1

R71

C47

R73

X1

C57

Q9

BCE

Q6

R52

1

8

R27

BCE

R62

R39

R67

R63

Q8

C11 R9

R54

Q2

R1

16

IC3

9

C27

R29

+

C28

BCE

R8

R10

R2

C2

+

R3

C3

R4

C4 C7

C5

R6

L3

C9

D1

TP(DISCRI)

RT2

BLK

R5

C8

C6

RT1

CHARGE

R43

R55

R77

R44

D7D6

LINE

RED

3

2

1

S2

DIAL MODE

TONE

PULSE

C53

S1

HANDSET

LOCATOR

1-675-272-

A

(Page 20)

BASE RF BOARD

BASE RF BOARD

B

(Page 20)

+

–

CHARGE TERMINAL

11

(11)

2222

Page 23

5-7. SCHEMATIC DIAGRAM – BASE MAIN Section – • See page 24 for Waveforms. • See page 28 for IC Block Diagrams.

SPP-904

BASE MAIN BOARD

1.9

2SC2714-Y

0.001

C68

47p

C62

39p

(Page 21)

3

BASE RF

BOARD

(Page 21)

1

BASE RF

BOARD

2

BASE RF

BOARD

(Page 21)

CHARGE

TERMINAL

J2

DC IN 9V

Q1

IF AMP

L2

3.9µH

R26

220k

C24

1

BPF

2

0.7

FT1

GND

GND

MOD

ANT1

ANT

GND

VCC

DATA

CLK

C25

0.01

IF

LO

TX

LE

05

3

R1

680

0

R28

0

TP

(MOD)

B+

B+

R54

1k

10.1MHz

C77

FREQUENCY

R92

2.2k

R81

0

B+

L6

3.9nH

(ANT)

C73

2p

TP

7p

C1

33p

R2

18k

R27

470

3.2

IN

MIX

GND

OSC1

3.2 3.22.7 2.6 3.2 2.8 2.8 2.8

1

B+

X2

C66

100p

C64

0.01

CT1

C67

10p

3.2

BP

C70

100p

C53

2SA812

C79

0.0022

B+

2.4

Q12

L50

C72

0.001

100p

B+

C82

4p

C50

0.047

TP

(GND)

C65

15p

RT3

20K

(ANT)

CT1

TX

3.2

0.022

D1

1N4148

C2

2.2

50V

3.1 0.5 0.7 0.7

141516 1112 91013

SQ

SCAN

CONT

MUTE

OSC2

MIX

OUT

VCC

LIMITINDEC2

3216587

4

B+

FT2

5

1

BPF

4

2

3

C99

R61

4.7k

R41

18k

C14

0.1

(FOR TX SYSTEM)

RT3

MODULATION

SENSITIVITY

B+

R51

4.7k

1k

R50

1k

R49

0

CHARGE

CONTROL

2SC1623-L6

0

R62

47k

R39

10

B+

B+

C49

C51

Q7

+6V REGULATOR

C4

C3

220p

0.1

R3

2.2k

R4

470k

IN

OUT

DEC1

C26

0.047

C27

0.047

B+

33p

B+

Q12

B+ SWITCH

R40

22k

R66

47k

Q8

2SD471-L

Q6

CHARGE

DETECT

0

9

R60

150

C5

220p

1

FLINFL

R29

10k

C28

4.7

50V

R52

1k

0.7

2SD471-L

6.8

C52

100

16V

D11

HZ7A3

RT1

SQ SENSITIVITY

RT1

200K

R5

3.3k

C6

R6

33p

10k

0.0039

IC3

AF

MC3361CDR2

OUT

QUAD

Q7

COIL

B+

1k

R67

3.2

C83

0.047

0.1

IC3

2nd MIXER,

LIMITER AMP, DET,

AF AMP, SQUELCH CONTROL

L3

DISCRI

VOLTAGE

C30

0.01

R53

1.5k

R63

R69

100k

6.16.1

B+

C54

R65

220

C55

100

16V

B+

C7

330p

R8

470k

C9

0.1

RT2

100K

C8

R42

1k

C34

0.1

0

1.6

3.1

0

3.2

3.2

0.2

27k

0.7

0

R70

100k

R68

100k

Q11

+3V REGULATOR

Q11

2SD471-L

3.9

B+

C56

D13

330

HZ4B1

6.3V

RT2

TEL OUT LEVEL

Q2

2SC1623-L6

PREAMP

0.8

R9

270

R46

100k

R97

10

0

TX MUTE

37

DATA IN

38

SQ IN

39

PLL CLK

40

PLL DATA

41

PLL LE

42

GND

42

44

NC

45

TX B

46

DATA OUT

47

DATA IN

48

DTMF

B+

B+

3.2

D10

1N4148

C46

0.0022

1.9

0

R10

2.2k

B+

C61

0.1

R45

1k

R30

1k

R98

47k

3.2

0

2.3

DTMF

CHG IN

MB89173PF-G-

MOD0

RESET

0

3.2

0.01

C47

C57

27p

C11

0.01

C10

47

10V

R14

39k

2.3

NC

LEDCHG2

LEDCHG1

IC5

SYSTEM

CONTROLLER

IC5

256-BND

2

X0

MOD1

X1

1.5

1.2

1k

R71

X1

3.579545MHz

C58

27p

C43

0.0056

R11

10k

C31

0.047

2.1

2.1

LEDINUSE1

LEDINUSE2

VCC

X0A

3.2

22

R72

16V

100

C59

C41

50V

1.6

R89

C44

100k

0.1

100k

1.7 1.6

R15

1

C12

0.047

R86

1.6 1.9 1.9 1.9

0

C42

0.47

50V

0.7

R13

22k

C17

0.0056

121110987654321

STBY

VCC

GND

VREF

FSK

TX

OUT

CHG

EXP

MUTE

DATA IN

CONT

CONT

CMP

INT

CONT

MUTE

CONT

V HOLD

LPF2

OUT

TEL

LPF2

OUT

IN

INT

CMP

OUT

OUT

EXP

CMP

VREC

V REC

IN

EXP

CMP NF

LPF1

13 14 15 16 17 18 19 20 21 22 23 24

B+

R91

100k

NC

X1A

B+

R73

1k

3.2

C60

1

NC

NCNCNC

C13

10

50V

2.7

252627282930313233343536

CHG OUTRX MUTE

NC

FLASH100

FLASH270

TONE

BELL IN

PAGE

BATT OFF

TALK

111098765433221

12

2SC1623-L6

RESET SIGNAL

GENERATOR

0

GND

470k

NCNC

NC

NC

NC

Q9

R74

100k

R79

R47

R44

220

R43

220

C63

C74

0.01

3.3k

0.1

24

3.2

23

3.2

22

3.2

21

3.2

20

19

3.2

18

0.0018

D6

MVR3338S

CHARGE

D7

MPG3371X

LINE

17

16

15

14

0

13

R56

10k

1k

R55

B+

IC6

BATTERY

VOLTAGE DETECT

3.2

1

C48

0.01

R57

47k

R80

2.2M

C33

C32

4.7

0.47

50V

50V

R84

18k

RL1

(1/2)

R75

1k

0

R76

2.2k

R77

47k

R78

O

G

47k

I

3.2

S1

IC6 RH5VL28CA

OUT

PRE NF

R87

3.9k

C36

2.2

50V

6.1

R16

22k

0.0039

IN

LPF1

IC1

LA8633V

PRE

IN

1.61.61.61.61.61.63.2 1.7 0.600

C78

0.01

B+

B+

B+

D9

1N4148

Q10

2SC1623-L6

S2

C75

EXPANDER, COMPRESSOR,

Q3

2SC1623-L6

HYBRID AMP

1.5

R90

C71

1k

1

R34

R99

68k

10M

0.0022

R48

1k

B+

R94

47k

R64

1k

R58

100k

C45

0.033

HOOK ON/OFF

RELAY DRIVE

B+

HANDSET LOCATOR

DIAL MODE

PULSE

R88

47k

C35

Q10

S1

S2

IC1

LIMITER

0.9

C37

100

10V

0.5

R93

47k

TONE

4.4

C19

R18

0.1

560

R19

1k

C18

R17

0.1

68

R33

220k

1.5

1.1

Q4

2SC1623-L6

AF AMP

R95

1k

R96

1k

R59

10k

B+

R22

68k

R21

8.2k

R20

8.2k

C38

0.1

S3

FLASH

C20

B+

R23

680

R36

100

B+

T1

LINE TRANSFORMER

RL1

(2/2)

R38

330

IC4

PS2501-1

0

4

3

IC4

RINGER DETECT

C22

0.001

R24

10k

R37

1k

0.001

500V

1

2

C39

0

0

C23

0.56

250V

D3

HZ33-2

C80

470p

1000V

C81

470p

1000V

D4

1N4148

R25

150

1W

J1

LINE

POWER SUPPLY

(12V)

100Ω

+

–

2323

Page 24

SPP-904

• Waveforms

– BASE MAIN Board –

1 IC3 1 (OSC1)

99 ns

2 IC5 5 (X0)

280 ns

1.6 Vp-p

2.5 Vp-p

– HAND MAIN Board –

1 IC401 1 (OSC1)

99 ns

2 IC404 5 (X0)

280 ns

1.4 Vp-p

2.5 Vp-p

5-8. PRINTED WIRING BOARD – HAND RF Section –

1

2

3

HAND RF BOARD (COMPONENT SIDE)

A

L502

C520

R529

C514

C512

C502

Q501

C525

C575

L566

C576

C571

C572

R551

C569

C564

C565

RT501

R503

C590

R531

L504

R506

L557

C566

C510

Q502

BCE

R539

R530

R540

C544

BE

E

B

C

C

HAND MAIN

BOARD

(Page 26)

ANT

GND

VCC

LE

DATA

CLK

C503

L503

C501

R502

C598

C578

C509

L551

L522

(SHIELD CASE)

C537

C539

R504

+

L507

C534

R509

R507

R528

L510L501

R561

R542

C524

1

3

C504

C507

C506

Q512

C562

(RX VCO)

FT501

BCE

AK

D503

TP

C538

6

4

C

C523

C536

D

HAND RF BOARD (CONDUCTOR SIDE)

4

Q506

C533

BCE

C568

R554

R552

L555

Q507

BCE

C570

R553

C563

R548

C574

R544

(PRINTED COIL)

C573

+

C560

R521

R527

R533

C558

L551-557

L554

C551

C541

AK

D502

C553

5

R519

+

C557

L553

C550

R526

(SHIELD CASE)

TP(TX VCO)

1-675-275-

C567

67

MOD

TX

GND

LO

GND

IF

11

(11)

D

HAND MAIN

BOARD

(Page 26)

R597

E

CLK

F

G

DATA

LE

VCC

GND

ANT

R598

R599

C535

L506

R505

C580

C581

R532

C508

C521

C526

C527

R522

C519

(PRINTED COIL)

C505

C579

L550

C511

13

IC502

24

C586

C543

R541

C542

5

R516C597

C540

C548

C546

C545

C547

C549

L509

R517

C583

R559

R520

C582

1

1-675-275-

IF

GND

LO

GND

TX

MOD

11

(11)

H

• Semiconductor

Location

Ref. No. Location

D502 B-5

D503 C-3

IC502 F-4

Q501 B-3

Q502 C-4

Q506 A-4

Q507 B-4

Q512 C-3

2424

Page 25

5-9. SCHEMATIC DIAGRAM – HAND RF Section – • See page 28 for IC Block Diagram.

R503

6.8

C521

33p

L550

1.7

C563

7p

R553

39k

C510

33p

24

1

B+

C526

0.01

C519

IN

MIX

R548

R541

C560

6.3V

33p

1.7

0

1k

10

R522

100

B+

B+

23

MIX GND

TX OUT

2

2.7

C542

3p

C586

0.01

3

22

RX VCC

3

B+

4

HAND MAIN

BOARD

(Page 27)

ANT

GND

HAND RF BOARD

L510

27nH

C506

0.5p

Q506

0.8

R554

C571

0.01

18k

3

1

FT501

2

L507

6.8nH

R502

L556

C568

47k

4p

B.P.F.

C573

6p

R552

10

C565

33p

TP501

TP502

C575

3p

L503

15nH

C502

12p

L502

6.8nH

C504

33p

C576

4p

C501

C503

2SC4095-R47

RF AMP

L555

R551

100

C569

33p

3p

3p

Q501

L501

22µH

0.8

2

2.4

2SC5065-Y

TX AMP

C574

2p

C572

100p

R504

220

4

6

5

C508

R542

150

C507

33p

IC502

1st MIXER, VCO,

PLL SYNTHESIZER

IC502

M64884FP-C60J

1.1

2SC5065-Y

L557

TX POWER

C564

0.1

C590

0.01

2p

C505

7p

0.8

Q507

TX AMP

C570

RT501

4.7K

5p

C525

33p

0.001

C566

Q512

2SC5065-Y

C520

0.001

C527

B+

21

RXB

TX VCC

TXB

4

1.7

R544

33

C545

15p

R517

C543

390

82p

2.6

1.2

3p

1.9

0.9

20

5

R561

R529

390

RXE

TXE

C546

15p

33k

1.9

C524

5p

C523

5p

2.4

19

RX GND

TX GND2

6

1.8

B+

C547

6p

L509

33nH

18

7

L553

C509

L506

12nH

PD2

PD1

2.9

5p

3

17

8

B+

L554

L551

3

RST

VCC

2.7

C548

0.01

C550

15p

D502

1SV270

C549

16

7p

9

L552

SI

XIN

C540

33p

C534

5p

D503

1SV314

0

15

10

C541

4p

C551

100p

C535

3p

C544

0.01

CPS

XOUT

0

14

LOCK

XBO

11

TP

(TX VCO)

R526

10k

C567

0.01

3

13

12

R519

0

R559

1.5k

TP

(RX VCO)

R505

10k

C562

1p

C511

27p

R540

4.7k

MIX OUT

GND

R521

10k

C553

0.01

R507

R509

10k

C536

0.0033

2SA812(M)-M6A

C597

100p

B+

R533

1.2k

R520

100k

C558

0.01

3.3k

C537

0.0047

TX B+

SWITCH

R516

R530

R539

330k

Q502

2.2

0

10

R527

C557

6.8

10V

C538

1k

R528

4.7k

C539

0.22

35V

0.0022

2.9

B+

SPP-904

(Page 27)

R599

C533

R506

L504

4.7µH

1k

B+

R531

27

C512

0.01

R532

B+

3

1k

C514

0.01

33p

C583

100p

100p

C581

R598

100p

C580

C579

100p

C578

R597

33p

B+

1k

1k

1k

B+

B+

C598

100p

C582

B+

100p

B+

TP503

TP504

TP505

TP506

TP512

TP511

TP510

TP509

TP508

TP507

VCC

LE

DATA

CLK

MOD

TX

GND

LO

GND

IF

5

HAND MAIN

BOARD

6

HAND MAIN

BOARD

(Page 27)

B+

05

B+

B+

2525

Page 26

SPP-904

5-10. PRINTED WIRING BOARD – HAND MAIN Section –

• Semiconductor

Location

Ref. No. Location

D401 B-7

D402 D-13

D403 C-13

D404 C-13

D405 C-12

D406 C-12

D407 D-10

D408 I-6

D421 H-8

D422 G-8

D423 H-10

D424 G-10

D431 I-2

D432 I-1

IC401 C-6

IC403 H-3

IC404 C-10

IC405 G-4

IC406 D-12

Q401 B-6

Q402 D-7

Q403 G-4

Q404 H-2

Q405 G-2

Q406 G-2

Q408 D-12

Q409 C-12

Q410 C-12

Q411 D-11

Q412 H-4

Q421 B-8

1

2

3

4

5

6 7 8 9 10 11 12 13 14

A

SP801

BLK

TP

(SP–)

TP

(SP+)

WHT

B

C

D

HAND MAIN BOARD (COMPONENT SIDE)

C435

HAND RF BOARD

(SHIELD CASE)

C469

R404

R401

C402

C424

R405

R406

+

C403

C422R402

L401

C421 C423

Q401

R403

BCE

C401

16 9

IC401

18

C431R412

C433

C410

D401

AK

C404C405

R407

R421

C408

BCE

Q402

R411

RT402

C407

C409

R408

R410

C406

RT401

R441

C454

R409

C453

R442

R443

R429

RT403

R428

R423

C461

C467

+

+

X402

Q421

R496

R492

R494

BCE

R493

R495

37

R444

R445

48

R450

R430

R448

36

1

C460 C459

R449

R465

R473

IC404

C464

C462

C474

R478

+

MC401

AK

D403 D404

Y401

AK

AK

C466 C465

1-675-274-

11

CHARGE

TERMINAL

25

24

R491

R472

13

12

D407

KAK

R464

C468

C463

Q411

R466

R474

R451 C471

BCE

R475

R471

IC406

54

13

R470

Q410

R468

CE

B

C472

R467

R469

R457

Q409

D405

AK

R456

BCE

Q408

D406

AK

R454

BCE

D402

(11)

E

(Page 24)

C

HAND RF

BOARD

F

G

H

ANT2

D432AKD431

R482

R452

CE

Q406

R420

AK

C451

B

C456

ANT

GND

VCCLFDATA

BP

(ANT)

L403

TP(ANT)

C449

C447

R437

R481

BCE

R434

R455

Q404

BCE

C457 R438

R436

C450

R439

R484

R435

R453

+

Q405

R419

+

+

C458

C438

R463 R460

C444

C445

C443

R480

+

R433

24 13

C446R432

IC403

112

C448

C419

R418

C416

R416

R478

+

C439

C417

R427

R462 R459

R458

R461

R417

C437

R440

Q403

CLK

BCE

R414

I

05

J

(Page 24)

MODTXGNDLOGND

HAND RF

D

BOARD

IF

HAND MAIN BOARD (CONDUCTOR SIDE)

13

C418

C470

IC405

4

R422

C441

C440

Q412

BCE

C414

5

C455

R452

C473

R490

C442

FT401

FT402

4

5

+

C491

C432

1

C434

X401

R431

31

C426

CT401

C427

C425

R483

D408

TALK/BATT LOW

HM L

L402

R477

RECHARGEABLE

S903 S906 S909 S912 S915 S918

CHANNEL

D421–424

(KEY BACK LIGHT)

S902

OFF 2 ABC

TP(DISCRI)

C430 C428

AK

S901

TALK

FLASH

S401

VOL

3 DEF

S905

S904

D422

AK

D421

AK

D424

AK

S908

5 JKL 8 TUV 0 OPER

S907

S911

S910

D423

AK

S714

S713

TONE7 PQRS4 GHI1

REDIAL9 WXYZ6 MNO

S917

SPEED DIAL

S916

PGM

1-675-274-

BATTERY PACK

(BP–T23)

DC3.6V 600mA

11

(11)

2626

Page 27

5-11. SCHEMATIC DIAGRAM – HAND MAIN Section – • See page 24 for Waveforms. • See page 28 for IC Block Diagrams.

C404

HAND MAIN BOARD

Q401

0.7

C424

C423

0.01

0.001

R401

220k

CT401

TX FREQUENCY

X401

10.1MHz

C425

3p

2

C422

39p

BPF

1

IF

GND

LO

GND

TX

TP

(MOD)

RT403

MODULATION

SENSITIVITY

ANT

GND

VCC

LE

CLK

+

–

1.9

R402

0

C426

0.01

CT401

10p

FT401

22K

(ANT)

BP

(ANT)

B+

B+

D403

3

RT403

TP

HZ6CT2

R403

680

C428

100p

C427

12p

2SC2714-Y

3.9µH

47p

C421

(Page 25)

6

HAND RF

BOARD

ANT2

(Page 25)

4

HAND RF

BOARD

5

HAND RF

BOARD

(Page 25)

CHARGE

TERMINAL

RECHARGEABLE

BATTERY PACK

(BP-T23)

DC3.6V 600mA

IF AMP

L401

MOD

DATA

R404

470

C452

3p

L403

5.6nH

TP

(GND)

R460

R459

R458

4.7k

Q410

CHARGE

DETECT

C466

0.0033

D405

RLS4148

D406

RLS4148

D404

HZ6CT2

D401

RLS4148

R405

18k

R477

4.7k

R483

2.2k

C453

0.001

C458

1.5p

2.2k

4.7k

C465

0.0033

B+

C401

33p

1

R467

33k

3

B+

3

IN

MIX

OSC1

2.5 2.7

C430

100p

B+

R461

10k

2SC1623-L6

B+

C467

100

6.3V

C403

0.1

R406

2.2k

C402

1

2.9 0.9 0.7 0.7

141516 1112 91013

GND

SCAN

CONT

MUTE

OSC2

MIX

OUT

VCC

321

3

2.6

B+

FT402

1

5

BPF

2

4

3

Q403

2SA812(M)-M6A

B+ SWITCH

(FOR TX SYSTEM)

R440

18k

C454

0.1

R441

56k

R442

B+

C459

R463

R462

3.3k

10k

3.6

Q410

0

R470

15k

R468

33k

B+

R469

47k

C468

0.01

220p

C405

220p

R407

470k

1

IN

FLINFL

SQ

OUT

LIMITINDEC2

DEC1

65874

3

2.6 2.6

R421

C431

0.047

C433

0.047

B+

B+

3

3

B+

82k

R443

X402

3.579545MHz

R464

C461

C460

33p

33p

B+

IC405

+3V REGULATOR

1.3

VREF

VOUT VIN

3

C469

B+

AF

QUAD

10k

B+

100k

22

100

6.3V

C470

0.022

10

6.3V

C432

2.2

(DISCRI)

OUT

COIL

4.7

6.3V

C462

C407

330p

RT401

220K

TP

IC401

R465

0.01

CONTGND

C434

0.01

C435

R423

4.7k

MC3361CDR2

L402

0.1

1k

C464

3.2

123

54

3.6

RT401

SQ SENSITIVITY

IC401

2nd MIXER,

LIMITER AMP, DET,

AF AMP, SQUELCH CONTROL

R408

3.3k

R409

C406

10k

33p

0.0033

L402

DICRI

VOLTAGE

C463

0.01

B+

1

HSM88WA

B+

R466

1k

3.2

B+

2SC1623-L6

IC405

TK11130SC

GENERATOR

C408

SPEAKER OUT

B+

D407

0

Q411

RESET

SIGNAL

RT402

100K

RT402

LEVEL

B+

3.2

1.2

1.5

3.2

0

0

BATT LOW

R475

100k

R474

560k

Q402

2SC1623-L6

R410

PREAMP

470k

1.7

0.8

0.2

C409

0.1

3

DTMF

1

RESET

23456

MOD0

MOD1

X0

2

X1

789

VCC

X0A

X1A

NC

10

TX MUTE

11

RX MUTE

12

3.2 0.2

D408

TALK/

R471

100k

C471

0.01

3.6 3.6

VDET2

VDET1 VSS

R412

2.2k

R411

270

B+

R444

100k

45

46

47

48

PLL EN

PLL CLK

DATA EN

PLL DATA

MB89174LPF-G

SCNCTALK LED

TALK LED

16

15

14

13

R472

470

D408

SML-310VT

45

VIN2

VIN1

321

3.63.6

B+

C410

0.01

R428

R422

1k

27k

R445

0.8

42

43

44

GND

TX B

DATA OUT

IC404

SYSTEM

CONTROLER

IC404

-257-BND

PAGENCGND

19

18

17

0.2

B+

IC403

EXPANDER,

COMPRESSOR,

LIMITER

R429

100k

R430

1k

R450

C440

0.15

1k

Q412

2SC1623-L6

STANDBY

SWITCH

000003

1.6

2.9

0.2

37

38

39

40

41

SQ IN

NC

20

DATA IN

RING VOL

NC

ROW4

22

21

000

9

8

CONV

CHG IN

RING OUT

BATT LOW

COL1

COL2

COL3

COL4

COL5

BATT OFF

WAKEUP

STPCNT

ROW1

ROW3

ROW2

24

23

7

IC406

BATTERY VOLTAGE

DETECT

IC406

XC612N3328MR

C473

C472

0.1

0.01

3.3k

R427

C414

0.1

0.6

0.01

C437

R414

15k

1.6 1.7 1.71.7000

121110987654321

FSK

OUT

CHG

GND

STBY

VCC

13 14 15 16 17 18 19 20 21 22 23 24

B+

C438

4.7

6.3V

1k

R431

0.6

S401

VOL

HML

0

3.6

363534333231302928272625

3.6

3.2

3.2

0

3.2

3.2

3.6

3.2

0

EXP

MUTE

TX

DATA IN

VREF

03 000000000

R432

2.2k

R480

100k

C439

4.7

6.3V

R490

C442

820

0.01

2.2k

1

2

3

4

5

6

R491

1k

R473

1k

R478

C418

CONT

CONT

CMP

R448

R449

1k

0

0.1

INT

MUTE

0.022

1k

CONT

CONT

C491

R452

4.7k

R417

100k

V HOLD

LPF2

OUT

R451

100k

R416

22k

B+

TEL

LPF2

C416

C417

0.47

OUT

IN

C441

0.1

C443

C455

0.0047

0.0056

0.1

IN

INT

EXP

EXP

OUT

VREC

CMP NF

CMP

V REC

CMP

OUT

0.47

C444

4.7

6.3V

D421-424

(KEY BACK LIGHT)

R492

330

R493

330

R494

330

R495

330

3.5

2.8

2SA812(M)-M6A

3.6

B+

C419

OUT

LPF1

LPF1

PRE

PRE NF

6.8k

R433

C445

0.47

Q404

MIC AMP

B+

D421

SML-310MT

D422

SML-310MT

D423

SML-310MT

SML-310MT

Q421

LED DRIVE

R418

22k

IN

IC403

LA8633V

IN

C447

0.22

C446

0.01

1.9

Q404

2SC1623-L6

0.4

R484

R453

2.2M

820

R476

150k

C474

10

6.3V

D424

C448

0.0039

R435

18k

R434

470k

SPP-904

B+

R420

R419

220

220

Q405, 406

AF AMP

3.6 3.6

Q405

2SC1623-L6

0

B+

1

R436

15k

R455

1k

6

7

8

9

C450

0.047

R481

C456

C457

0.0047

B+

R454

2.2k

R456

2.2k

1

15k

10

16V

2SD1048-X7

RINGER VOLUME

SWITCH

S904

1

S907

4 GHI

S910

7 PQRS

S913

TONE

C449

0.047

Q409

2

0

000

S905

2 ABC

S908

5 JKL

S911

8 TUV

S914

0 OPER

2SC1623-L6

R437

47

R457

82

Q406

0

R439

15k

R438

2.2k

Q408

2SD1048-X7

RINGER

DRIVE

3

S906

3 DEF

S909

6 MNO

S912

9 WXYZ

S915

C451

4.7

R482

25V

15k

3.6

4

CHANNEL

#

HZK6C

D402

RLS4148

S901

FLASH

TALK

S902

OFF

S903

D431

D432

HZK6C

5

S916

PGM

S917

SPEED DIAL

S918

REDIAL

SP801

MC401

B+

Y401

05

2727

Page 28

SPP-904

• IC Block Diagrams

IC1 LA8633VU-TLM (BASE MAIN Board)

IC403 LA8633VU-TLM (HAND MAIN Board)

VB

DATA

SHAPE