Sony SLV-L45AR, SLV-L65HFAR, SLV-L75HFAR Service Manual

SLV-L45AR/L65HFAR/L75HFAR

RMT-V241/V242V

SERVICE

MANUAL

Ver 1.0 1998.07

Sistema

Formato

VHS PAL-N/NTSC estándar

Cobertura de canales

VHF 2 a 13

UHF 14 a 69

CATV A-8 a A-1, A a W,

W+1 a W+84

Antena

Terminal de antena de 75 ohmios para VHF/UHF

Entradas/salidas

LINE IN (SLV-L65HFAR)

LINE IN y LINE IN 2 (SLV-L45AR/L75HFAR)

VIDEO IN

Toma fonográfica (1) (SLV-L65HFAR)

Tomas fonográficas (1 por cada) (SLV-L45AR/L75HFAR)

Señal de entrada : 1 Vp-p, 75 ohmios,

desequilibrada, sincronización negativa

AUDIO IN

Tomas fonográficas (2, L/R) (SLV-L65HFAR)

Tomas fonográficas (1 por cada) (SLV-L45AR)

Tomas fonográficas (2 por cada, L/R) (SLV-L75HFAR)

Nivel de entrada : 327 m Vrms,

Impedancia de entrada : superior a

47 kiloohmios

LINE OUT

VIDEO OUT

Toma fonográfica (1)

Señal de Salida : 1 Vp-p, 75 ohmios,

desequilibrada, sincronización negativa

AUDIO OUT

Tomas fonográficas (2, L/R) (SLV-L65HFAR/L75HFAR)

Toma fonográfica (1) (SLV-L45AR)

Salida estándar : 327 m Vrms,

Impedancia de carga : 47 kiloohmios

Impedancia de salida : inferior a

10 kiloohmios

Photo : SLV-L75HFAR

SPECIFICATIONS

General

Accesorios suministrados

Diseño y especificaciones sujetos a modificaciones sin previo aviso.

J VIDEO CASSETTE RECORDER

N-PAL NTSC

Argentina Model

Requisitos de alimentación

220 a 240 V CA, 50Hz

Consumo de energía

18 W

Temperatura de funcionamiento

5˚C a 40˚C

Temperatura de almacenamiento

-20˚C a 60˚C

Dimensiones

Aprox. 360 x 97 x 298 mm (an /al / fn)

incluidas las piezas y controles

sobresalientes

Masa

Aprox. 3,7 kg

Control remoto (1)

Pilas tipo R6 (tamaño AA) (2)

Cable de antena (1)

Cable de audio / video (1)

(sólo el modelo SLV-L65HFAR/L75HFAR)

Cable de alimentación de CA (1)

MICROFILM

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer :

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIA GRAMS AND

IN THE P ARTS LIST ARE CRITICAL T O SAFE OPERA TION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÈCURITÉ!

4. Look for parts which, though functioning, show obvious

signs of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTEDES

PIÉCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT.

NE REMPLACER CES COMPOSANTS QUE PAR DES

PIÉCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OUDANS

LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

TABLE OF CONTENTS

Section Title Page

______ ____ ____

Section Title Page

______ ____ ____

1. GENERAL

Paso 1 Conexiones........................................................1-1

Paso 2 Configuración de la videograbadora..................1-2

Paso 3 Ajuste del reloj...................................................1-3

Selección del idioma.....................................................1-3

Instrucciones adicionales de sintonización...................1-3

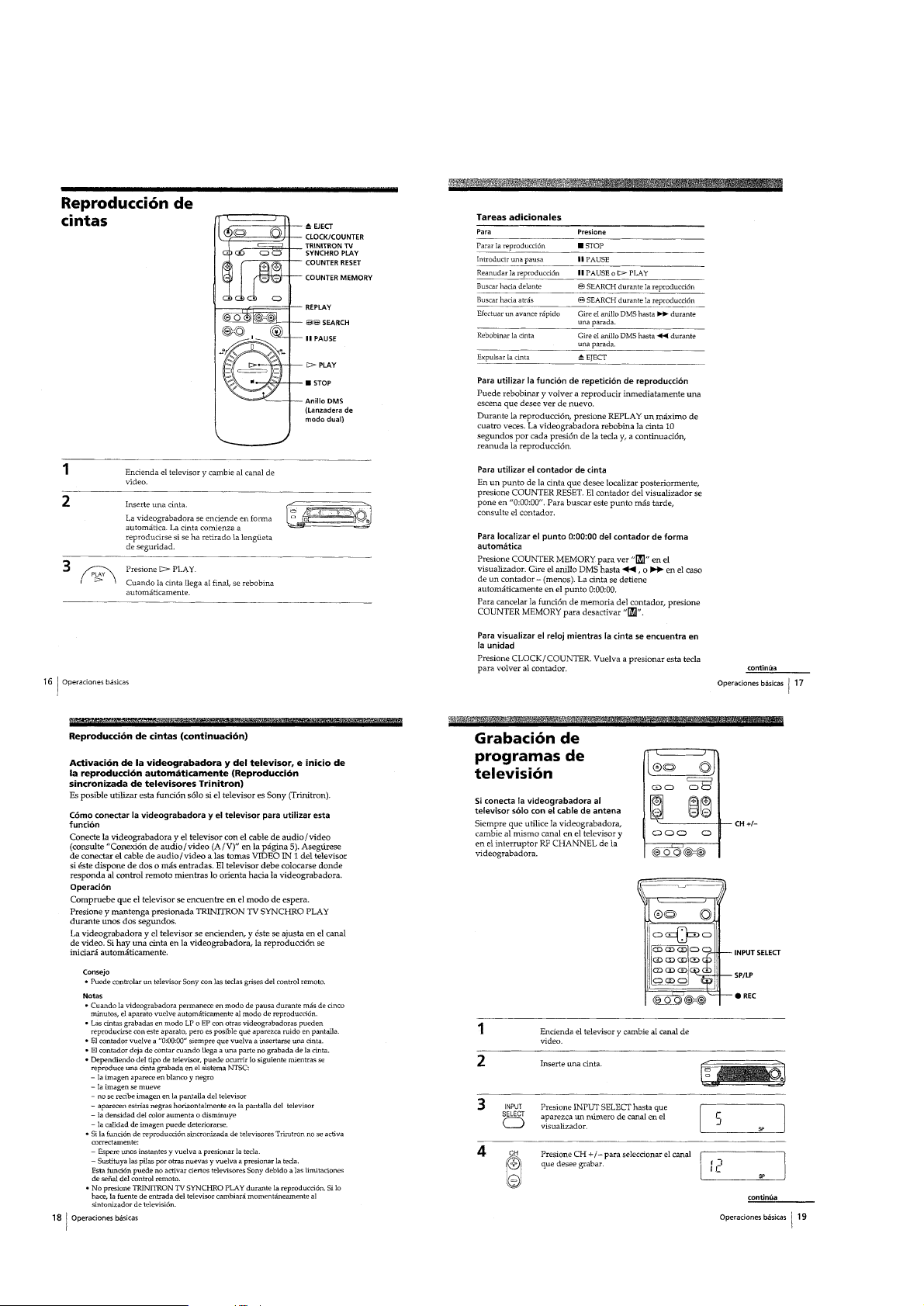

Reproducción de cintas.................................................1-4

Grabación de programas de televisión..........................1-4

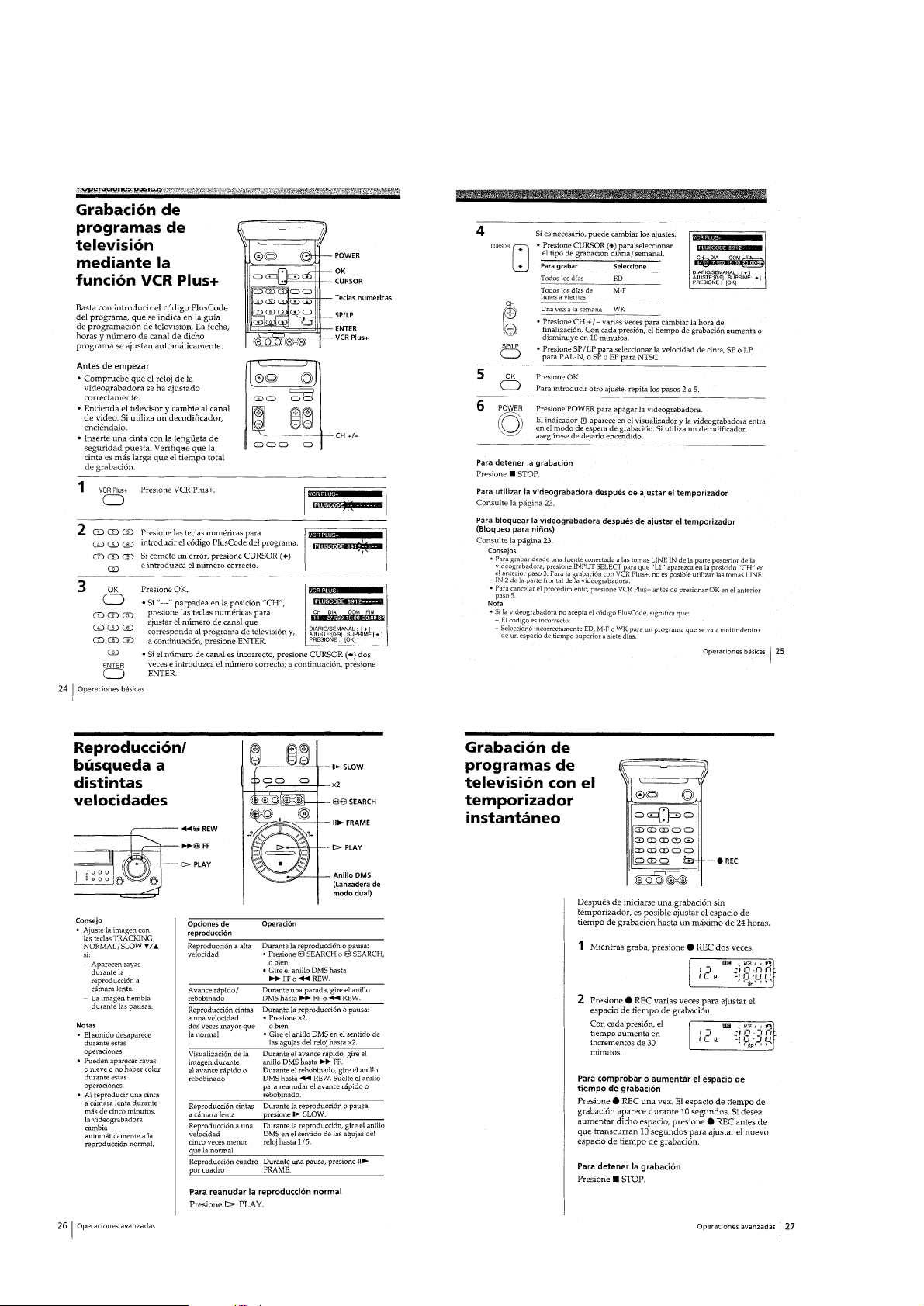

Grabación de programas de televisión con

temporizador.................................................................1-5

Grabación de programas de televisión mediante la

función VCR Plus +......................................................1-6

Reproducción/búsqueda a distintas velocidades...........1-6

Grabación de programas de televisión con el

temporizador instantáneo..............................................1-6

Comprobación/cancelación de ajustes del

temporizador.................................................................1-7

Búsquedas con la función de índice..............................1-7

Grabación de programas estéreo y bilingües................1-7

Edición con otra videograbadora..................................1-7

Ajuste de la imagen.......................................................1-8E

Indice visual..................................................................1-8E

2. DISASSEMBLY

1-1. Removal of Cabinet, Mechanism Unit and Main

Board.....................................................................2-1

Removing the Cabinet Parts..................................2-1

Removing the Mechanism Main Unit and the

CP-1 PWB Assembly.............................................2-1

l-2. Temporarily Setting Up and Connecting

CP-1 PWB Assembly.............................................2-3E

1-3. Installation of the Front Panel................................2-3E

3. DIAGRAMS

Circuit Boards Location................................................3-1

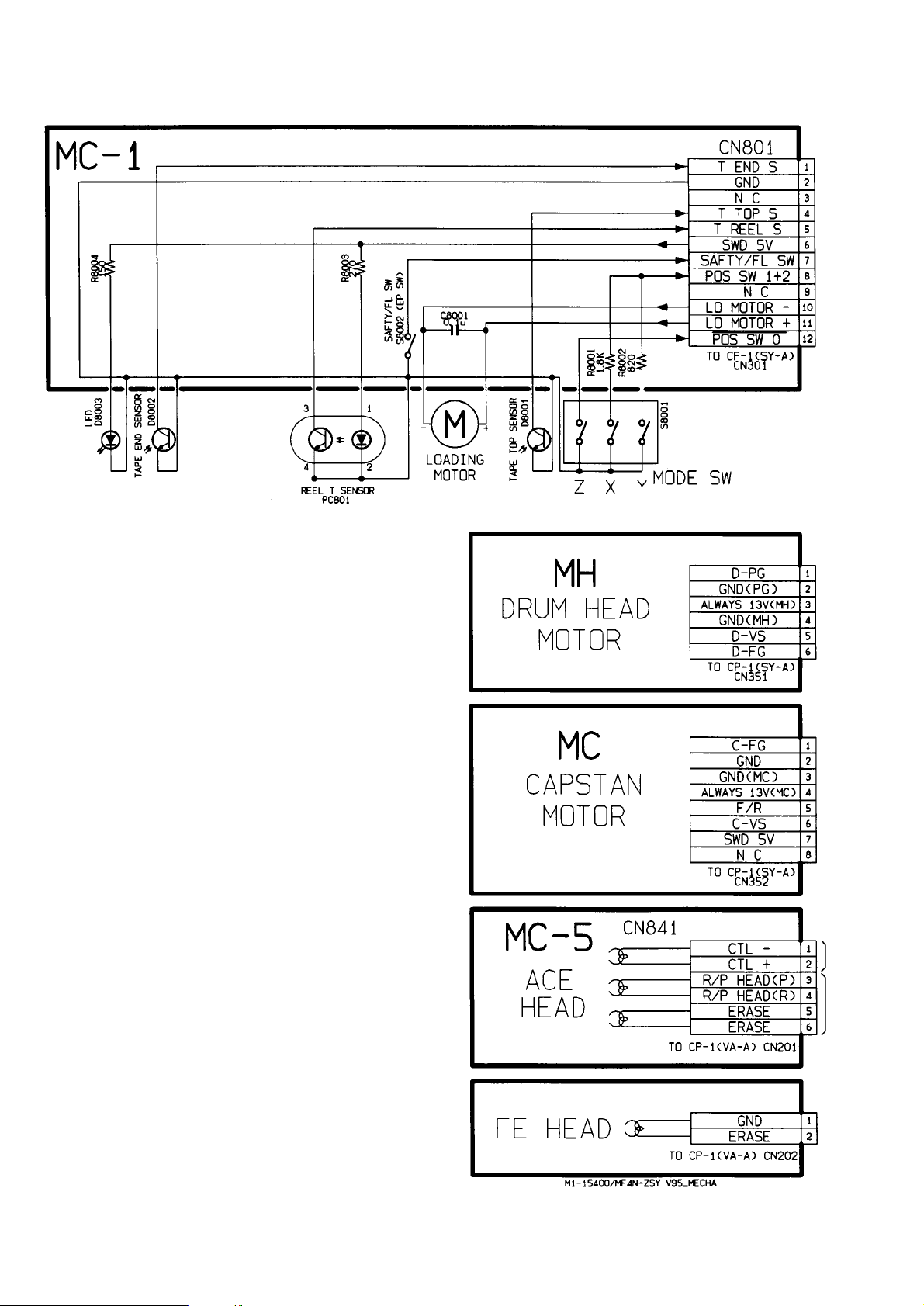

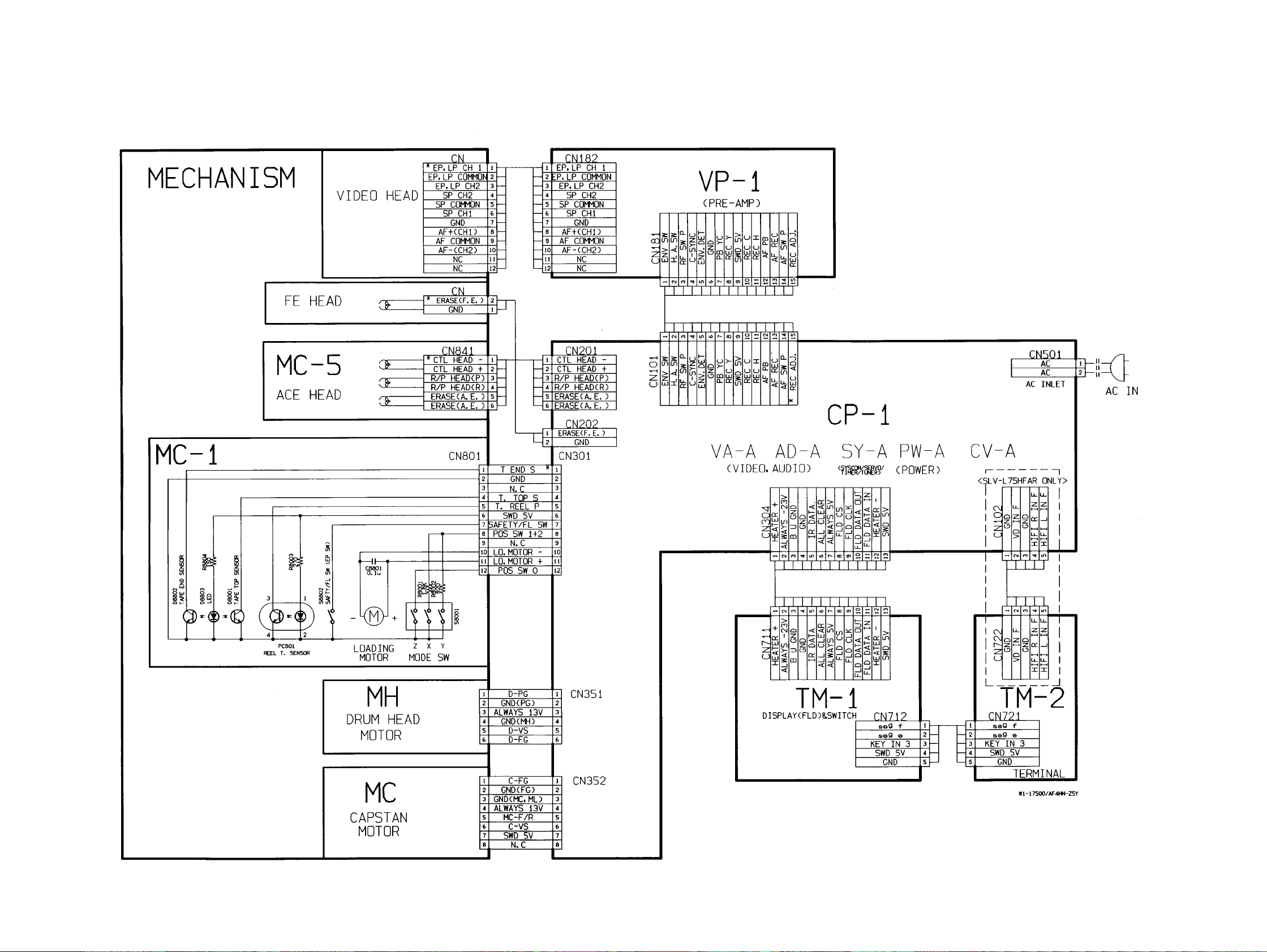

Mechanism Connection Diagram..................................3-2

Overall wiring Diagram (SLV-L45AR).........................3-3

Overall wiring Diagram (SLV-L65HFAR/L75HFAR)...3-5

System Control & Servo Circuit Diagram

(SLV-L45AR)................................................................3-7

System Control & Servo Circuit Diagram

(SLV-L65HFAR/L75HFAR).........................................3-9

Audio & Video Circuit Diagram (SLV-L45AR)...........3-11

Video & Audio Circuit Diagram

(SLV-L65HFAR/L75HFAR).........................................3-13

4. SCHEMATIC DIAGRAMS AND PRINTED

WIRING BOARDS

CP-1 Board (PW-A) Power Supply Circuit Diagram...4-1

CP-1 Board (VA-A) Video, Audio & Tuner

Circuit Diagram (SLV-L45AR).....................................4-3

CP-1 Board (VA-A) Video, Audio & Tuner

Circuit Diagram (SLV-L65HFAR/L75HFAR)..............4-5

Video Circuit Waveforms..............................................4-7

VP-1 Board Video Pre-Amp circuit Diagram

(SLV-L45AR)................................................................4-8

VP-1 Board Video Pre-Amp circuit Diagram

(SLV-L65HFAR/L75HFAR).........................................4-9

A7101 Display (FLD) Grid/Anode Assignment

Drawing & Table...........................................................4-11

TM-1, 2 Boards Operation Key, Display & Timer

Circuit Diagram (SLV-L45AR).....................................4-11

TM-1, 2 Boards Operation Key, Display & Timer

Circuit Diagram (SLV-L65HFAR/L75HFAR)..............4-13

Servo Circuit Waveforms..............................................4-15

IC 301 System Control & Tuning Control MPU Pin

Functions Table.............................................................4-16

CP-1 Board (SY-A) System Control & Servo

Circuit Diagram (SLV-L45AR).....................................4-17

CP-1 Board (SY-A) System Control & Servo

Circuit Diagram (SLV-L65HFAR/L75HFAR)..............4-19

5. ADJUSTMENTS

1. Maintaining and Checking the Mechanism...............5-1

l -1. Regular Checks and Maintenance Items...............5-1

1-1-1. Regular Checks................................................5-1

1-1-2. Cleaning............................................................5-1

1-2 Service Tools...........................................................5-2

1-2-1. Service Tools...................................................5-2

1-2-2. Using the Relay Cable (J-6090-057-A)............5-3

2. An Overview of the Mechanism................................5-3

2-1. Names of the Main Parts........................................5-3

2-1-1. Cassette Mechanism Assembly........................5-3

2-1-2. Top View..........................................................5-4

2-1-3. Under Side........................................................5-4

2-2. An Overview of the Mechanism Modes................5-5

2-2-1. Mechanism Mode Switching Table..................5-5

2-2-2. Movement Check List for the Main Parts of the

Mechanism........................................................5-6

2-2-3. How to Check the Mechanism

Mode Position...................................................5-6

2-2-4. Self-Diagnosis Display.....................................5-6

3. Disassembling the Main Parts of the Mechanism.....5-7

3-1. How to Make the Mechanism Move......................5-7

3-1-1. How to Operate the Loading Motor Using

A DC Voltage Supply.......................................5-7

3-1-2. Operating the Loading Motor

by the Manual Method......................................5-7

3-1-3. Making the Mechanism Move

Using the Manual Method................................5-7

3-2. Mechanism Unit.....................................................5-8

3-3. Cassette Drive Mechanism....................................5-8

3-3-1. Cassette Mechanism Assembly........................5-8

3-3-2. Cassette Drive Gear..........................................5-9

3-3-3. Door opener, Under Frame and Stand L...........5-9

3-3-4. Start Rack Gear and Front Rack Gear..............5-10

3-4. Cleaner Roller Assembly.......................................5-10

3-5. Cylinder (DRUM)..................................................5-11

3-5-1. Cylinder Motor (ROTOR and STATOR).........5-11

3-5-2. Cylinder Assembly...........................................5-11

3-6. FE Head and ACE Head........................................5-12

3-6-1. Audio R/P Head Assembly (ACE HEAD).......5-12

3-6-2. Full Erase Head................................................5-12

3-7. Capstan Motor........................................................5-13

3-7-1. Capstan Motor..................................................5-13

3-7-2. Capstan Brake Assembly..................................5-13

3-8. Loading Motor Assembly and

Worm Gear Assembly............................................5-14

3-9. Pinch Roller Pressure Mechanism.........................5-14

3-9-1. Pinch Roller Lever Assembly...........................5-14

3-9-2. Pinch Lift Cam and Pinch Cam Gear...............5-15

3-10. L Guide Lever Assembly and

Load Lever Assembly..........................................5-16

3-11. BT Lever Assembly.............................................5-16

3-12. Reel Drive Mechanism........................................5-17

3-12-1. Reel Belt, Reel Pulley, Friction Gear

Assembly and Clutch Change Lever..............5-17

3-12-2. Clutch Mounting Assembly............................5-17

– 3 –

Section Title Page

______ ____ ____

Section Title Page

______ ____ ____

3-12-3. S Soft Lever, Supply Reel Assembly

and S Reel Gear .............................................. 5-17

3-12-4. T Soft Brake Assembly, Take Up Reel

Assembly, T Reel Gear ................................... 5-18

3-13. Brakes .................................................................. 5-18

3-13-1. S Brake Assembly, T Brake

Assembly, T Brake ACT Slide........................ 5-18

3-13-2. Brake Control Lever and Brake ACT Lever

Assembly ........................................................ 5-19

3-13-3. S Brake ACT Slide and BT Spring Lever

Assembly ........................................................ 5-19

3-14. Guides .................................................................. 5-20

3-14-1. Guide Roller Assembly................................... 5-20

3-14-2. S and T Incline Mounting Assemblies............ 5-20

3-15. Wheel Gear 2, Main Cam and Mode Switch ....... 5-21

3-16. Crescent Slide ...................................................... 5-22

3-17. S Load Gear, T Load Gear, S Load Lever

Assembly and T Load Lever Assembly............... 5-23

3-18. Tape Sensors, Reel Sensor and EP SW Lever ..... 5-24

3-18-1. Tape Top Sensor and Tape End Sensor........... 5-24

3-18-2. Reel Sensor ..................................................... 5-24

3-18-3. EP Switch Lever ............................................. 5-24

4. Mechanism Checks and Adjustments........................ 5-25

4-1. Reel Table Torque Check ....................................... 5-25

4-2. Adjusting the BT Lever Assembly Position and

Checking the Back Tension Torque in Play Mode.....

4-2-1. BT Lever Pole Position Adjustment................. 5-25

4-2-2. Checking the Back Tension Torque

Play Mode......................................................... 5-25

4-3. T ape Path Adjustment ............................................ 5-26

4-3-1. Adjustment Procedure ...................................... 5-26

4-3-2. Load Lever Assembly Height Adjustment ....... 5-26

4-3-3. Guide Roller Height Adjustment...................... 5-27

4-3-4. Audio R/P Head (ACE HEAD) Height

Adjustment, Azimuth Adjustment and

Horizontal Position Adjustment........................ 5-28

4-3-5. Checking After Adjustment .............................. 5-29E

5-25

2-4-3. RF AGC Adjustment........................................ 6-10E

3. Test Points for Tape Path Adjustment ....................... 6-10E

7. EXPLODED VIEWS

7-1. Cabinet & Chassis Parts......................................... 7-1

7-2. Mechanism Parts-1 ................................................ 7-2

7-3. Mechanism Parts-2 ................................................ 7-4E

8. ELECTRICAL PARTS LIST ................................. 8-1

Hardware List................................................................ 8-9E

6. ELECTRICAL ADJUSTMENTS

Circuit Boards Location ................................................ 6-1

Self -Diagnosis Display................................................. 6-2

1. Self-Diagnosis Contents and Mechanism Mode

Display ...................................................................... 6-2

2. Electrical Adjustment ................................................ 6-4

2-1. Servo Circuit Adjustment....................................... 6-4

2-1-1. Test Equipment and Standards Required .......... 6-4

2-1-2. Location of Adjustment Points ......................... 6-4

2-1-3. Switching Position Adjustment ........................ 6-5

2-1-4. SP STIL V-LOCK Adjustment ......................... 6-5

2-2. Video Circuit Relay Jig .......................................... 6-6

2-2-1. Test Equipment and Standards Required .......... 6-6

2-3. MTS Decoder Circuit Adjustment

(SLV-L65HFAR/L75HFAR only).......................... 6-7

2-3-1. Test Equipment and Standards Required .......... 6-7

2-3-2. Location of Adjustment Points ......................... 6-7

2-3-3. Stereo/SAP Filter Adjustment .......................... 6-8

2-3-4. Stereo VCO Adjustment ................................... 6-8

2-3-5. Input Level Adjustment .................................... 6-8

2-3-6. Separation Adjustment...................................... 6-8

2-3-7.

Audio Output Mode and Output Signal Check

2-4. IF Circuit Adjustment ............................................ 6-10E

2-4-1. Test Equipment and Standard Required ........... 6-10E

2-4-2. Location of Adjustment Point........................... 6-10E

... 6-9

– 4 –

SECTION 1

GENERAL

SLV-L45AR/L65HFAR/L75HFAR

This section is extracted from SLVL75HFAR instruction manual.

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

E

SLV-L45AR/L65HFAR/L75HFAR

SECTION 2

DISASSEMBLY

1-1. REMOVAL OF CABINET, MECHANISM UNIT AND MAIN BOARD

REMOVING THE CABINET PARTS (Fig. 1-1-1 )

1. Remove the cabinet and bottom cover by removing the

four screws 1 and four screws 2 .

2. Remove the front panel by removing the locks of the

clamps (A) using a screwdriver, etc. and slightly rotating

the bottom part in the direction of the arrow.

Notes:• Electrical adjustments for the this model can be

performed with only the cabinet removed.

• When replacing the bottom cover, do not tighten

the screws 2 too much. Excess tightness may

damage the screws taps on the chassis.

REMOVING THE MECHANISM MAIN UNIT AND

THE CP-1 PWB ASSEMBLY (Fig.1-1-2 and 1-1-3)

After removing the cabinet parts, remove the mechanism

unit and the CP-1 PWB assembly connected as follows.

1

1

1. Spread out the lock clamps (C) in the arrow direction

slightly and remove the TM-1 PWB as shown in Fig. 1-1-2.

2. Remove the screw 4 at the chassis.

3. Remove the red screw 5 in the chassis, the red screw

6, and remove the holder in this order. (SLV-L45AR)

Remove the screw 5 in the chassis, the screw 6, and

the holder in this order. (SLV-L65HFAR/L75HFAR)

4. Remove the two screws 7 and two screws 8 of the

mechanism unit. The two screws 8 of the cassette tray

can be removed easily by pushing the tray lock lever in

the arrow direction to remove the lock as shown in the

enlarge view A and by pushing the lid opener lever in

the arrow direction to remove the lock as shown in the

enlarge view B.

5. Lift up the whole mechanism unit and main board (CP-1

PWB assembly), and as shown in Fig. 1-1-3, push the

two lock clamps (D) of the chassis in the arrow direction

so that they can be removed from the chassis.

Cabinet

Front Panel

Clamps(A

1

)

2

2

2

1

Main Unit

Bottom Cover

2

Fig. 1-1-1

2-1

Tray Lock Lever

TM-2 PWB

TM-2 PWB

A

3

SLV-L75HFAR

TM-2 PWB

(B)

Terminal Board

8

(C)

(B)

(C)

(C)

(C)

5

7

(C)

Cassette Tray

(C)

8

4

7

Chassis

Holder

6

Lid Opener Lever

B

SLV-L65HFAR

SLV-L45AR

SLV-L45AR

Mechanism Main Unit

TM-2 PWB

SLV-L75HFAR

TM-1 PWB

Clamps(D)

TM-1 PWB

Fig. 1-1-2

VP-1 PWB Assembly

CP-1 PWB Assembly

SLV-L65HFAR

Chassis

Fig. 1-1-3

2-2

1-2. TEMPORARILY SETTING UP AND CONNECTING CP-1 PWB ASSEMBLY

The following is an example of how to place and connect the main board without a jig, when repairing the CP-1 PWB

assembly.

1. Place the mechanism unit and main board up side down

as a whole on a flat surface with foil side of the main

board facing up.

CP-1 PWB Assembly (Foil side

Screws

9

Mechanism Main Unit

TM-1 PWB

Cassette Compartment

2. Operate the unit using the buttons on TM-1 PWB or the

remote control.

)

Terminal Boord

TM-2 PWB

1-3. INSTALLATION OF THE FRONT PANEL

When installing the front panel to the chassis after repaires and adjustments.

1. Pressing down the door opener lever of the mechanism

main unit.

2. Set the cassette door to half-opened state as shown in

Fig. 1-1-5, and install the front panel to the chassis.

Jutted part of

Cassette Holder

Front Panel

Note: Opened cassette door position does not install the

front panel to the chassis.

Door Opener Lever

Fig. 1-1-4

Cassette Door

(Position A)

Cassette Door

(Position B)

2-3

E

Fig. 1-1-5

CIRCUIT BOARDS LOCATION

CP-1 PWB Assembly

TM-1 PWB

TM-2 PWB

VP-1 PWB Assembly

3 in 1 Tuner

(

Tuner/IF/RF Conv.

)

SLV-L45AR/L65HFAR/L75HFAR

SECTION 3

DIAGRAMS

3-1

MECHANISM CONNECTION DIAGRAM

3-2

OVERALL WIRING DIAGRAM (SLV-L45AR)

SLV-L45AR/L65HFAR/L75HFAR

3-3

3-4

SLV-L45AR/L65HFAR/L75HFAR

OVERALL WIRING DIAGRAM (SLV-L65HFAR/L75HFAR)

3-5

3-6

SYSTEM CONTROL & SERVO CIRCUIT DIAGRAM (SLV-L45AR)

SLV-L45AR/L65HFAR/L75HFAR

3-7

3-8

SLV-L45AR/L65HFAR/L75HFAR

SYSTEM CONTROL & SERVO CIRCUIT DIAGRAM (SLV-L65HFAR/L75HFAR)

3-9

3-10

AUDIO CIRCUIT DIAGRAM (SLV-L45AR)

SLV-L45AR/L65HFAR/L75HFAR

VIDEO CIRCUIT DIAGRAM (SLV-L45AR)

3-11

3-12

SLV-L45AR/L65HFAR/L75HFAR

VIDEO CIRCUIT DIAGRAM (SLV-L65HFAR/L75HFAR)

AUDIO CIRCUIT DIAGRAM (SLV-L65HFAR/L75HFAR)

3-13

3-14E

SECTION 4

SCHEMATIC DIAGRAMS AND PRINTED WIRING BOARDS

CP-1 BOARD (PW-A) POWER SUPPLY CIRCUIT DIAGRAM

SLV-L45AR/L65HFAR/L75HFAR

4-1

4-2

SLV-L45AR/L65HFAR/L75HFAR

CP-1 BOARD (VA-A) VIDEO, AUDIO & TUNER CIRCUIT DIAGRAM (SLV-L45AR)

4-3

4-4

CP-1 BOARD (VA-A) VIDEO, AUDIO & TUNER CIRCUIT DIAGRAM (SLV-L65HFAR/L75HFAR)

SLV-L45AR/L65HFAR/L75HFAR

4-5

4-6

SLV-L45AR/L65HFAR/L75HFAR

VIDEO CIRCUIT WAVEFORMS

VP-1 BOARD VIDEO PRE-AMP CIRCUIT DIAGRAM (SLV-L45AR)

4-7

4-8

Loading...

Loading...