Page 1

i:I

H MECHANISM

OPERATION MANUAL

S

Page 2

Contents

1. Main parts layout diagram .......................................................................................... 3

2. Tape path .................................................................................................................... 4

3. Cassette IN --_ Loading --_ Stop ................................................................................. 5

4. Stop --_ Playback ...................................................................................................... 11

5. Stop --_ Power OFF .................................................................................................. 13

6. Playback --_ CUE ..................................................................................................... 15

7. Playback --_ REV ..................................................................................................... 17

8. Stop --_ Fast forward (FF) ........................................................................................ 19

9. Stop --_ Rewind (REW) ............................................................................................ 23

10. Stop --_ Unloading --_ Eject ...................................................................................... 27

1-16

Page 3

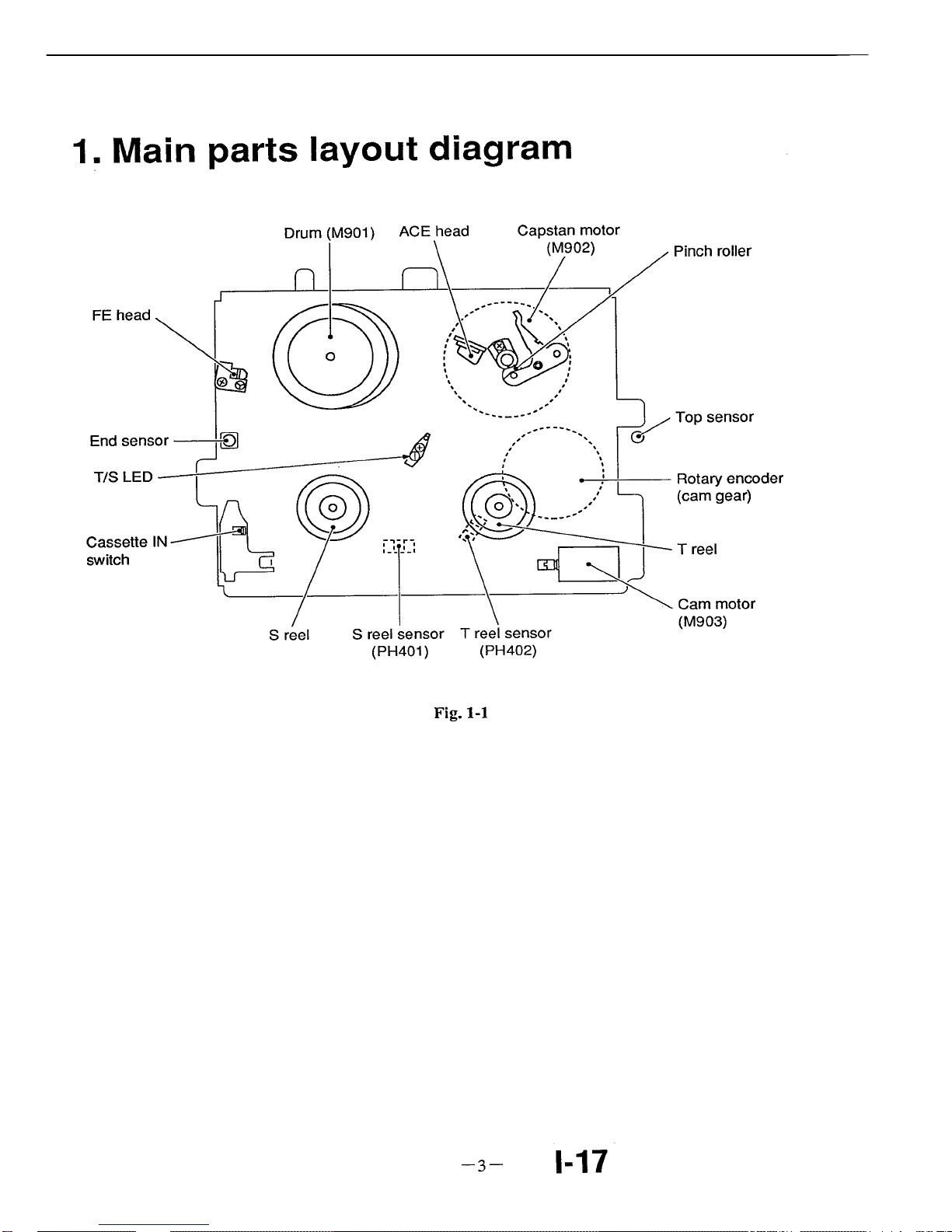

1. Main parts layout diagram

FE head

End sensor--

T/S LED -_

Cassette IN

switch _ /

S reel

Pinch roller

T

S reel sensor

(PH401)

Top sensor

Rotary

encoder

ot.._.Q____.__.........,I,_ L__ (cam gear>

_ [_ _ I_ "_" T reel

\ _ Cam motor

', (M903)

T reel sensor

(PH402)

Fig. 1-1

3 1-17

Page 4

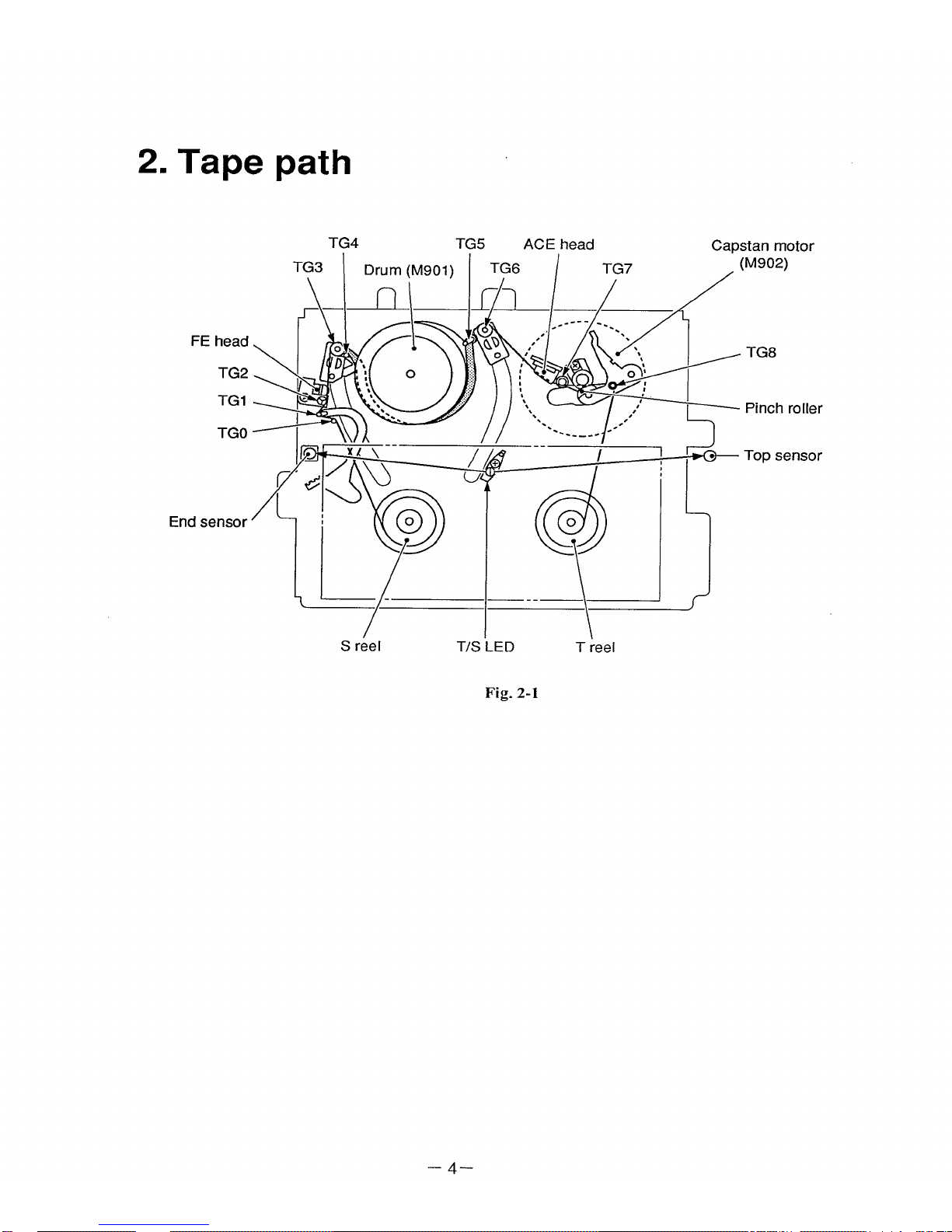

2. Tape path

TG4 TG5 ACE head Capstan motor

S reel T/S LED T reel

Fig. 2-1

4

Page 5

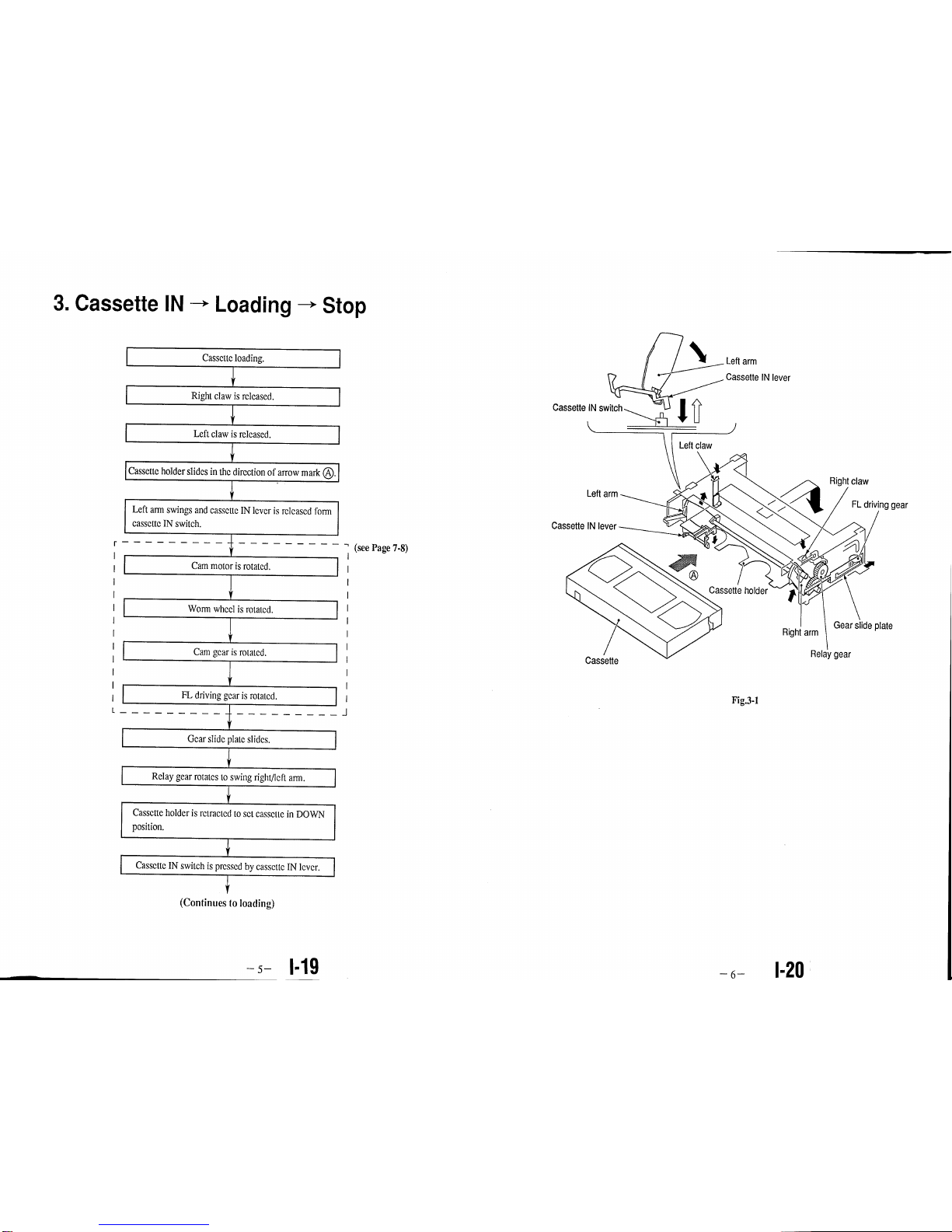

3. Cassette IN -- Loading--- Stop

Cassette loading.

Right claw is released.

Left claw is released.

I

I

5

ICassottchol_e,s,_cs,nthe_,rcc,ono_a_owma_k0.r

Left arm swings and cassette IN lever is released form I

|

cassette IN switch.

I

I Cam motor is rotated. [

1

[ Worm wheel is rotated. [

[ Cam gear is rotated. [

I FL driving gear is rotated. [

i Gear slide plate slides.

I Relay gear rotates to swing right/left arm.

t

Cassette holder is retracted to set cassette in DOWN

position.

Cassette IN switch is pressed by cassette IN lever.

(Continues to loading)

(see Page 7-8)

Cassette

Cassette IN switch

Leftclaw

IN lever

Leftarm

Cassette IN levi

Cassette holder

Cassette

Fig.3-1

Right claw

FLdriving gear

Right arm

Gear slide plate

Relay gear

1-20

-_- 1-19 6

Page 6

€

FL driving

gearisrotated.

ICassetteiNoperation,i

(seePages 5, 6)

TGI armloading.

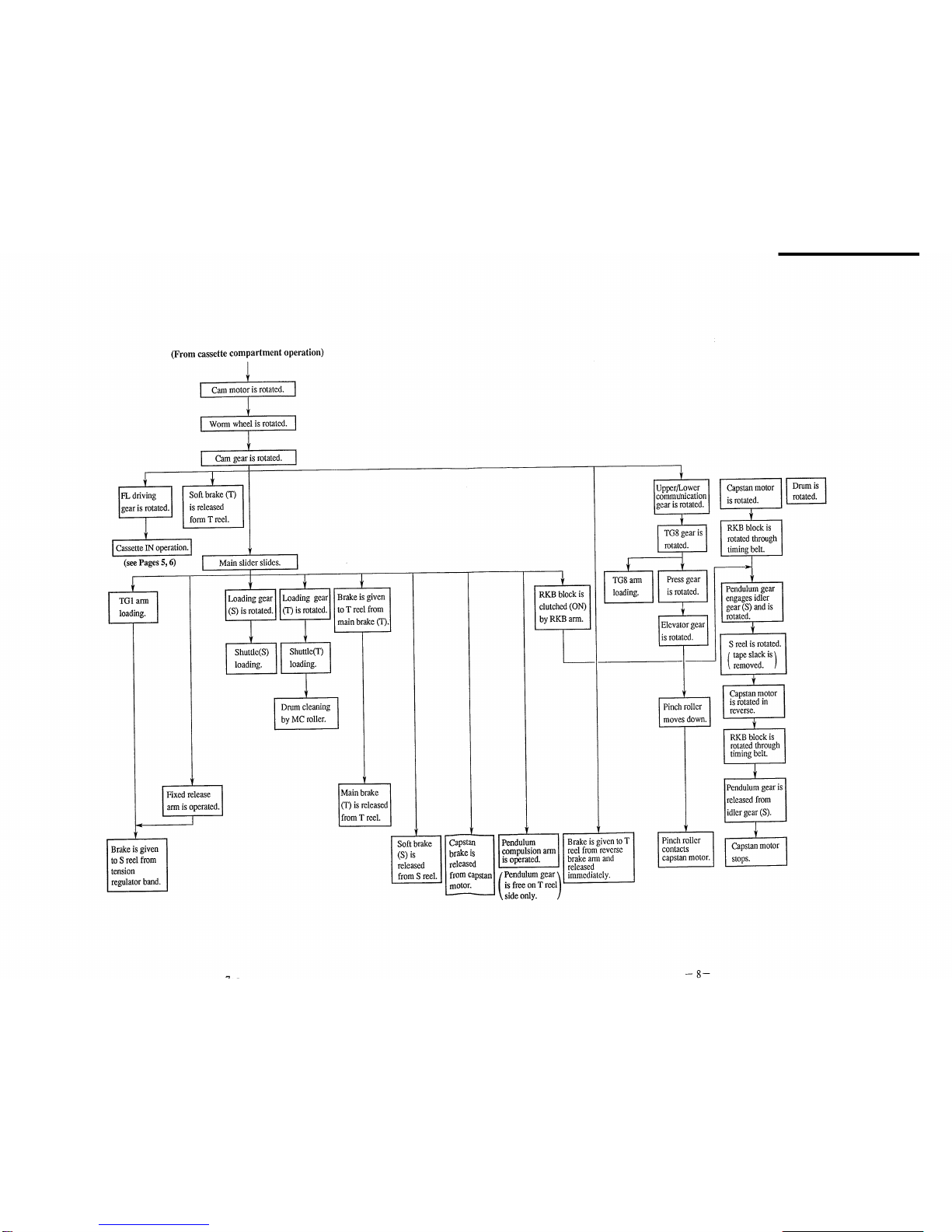

(From cassette compartment operation)

I Cammotor is rotated. I

[ Wormwheel is rotated. I

[ Cam gearis rotated. [

Softbrake (T) i

is released I

form T reel. [

I

Main slider slides.

ILoading gear

(S) isrotated.

I

(T) is rotated.[I to T reel from I

1 [ main brake(T).[

I ixed releasearm isoperated.

I

Brakeisgiven

to S reel from

tension

regulatorband.

Shuttle(S)loading.

I Shuttle(T)

loading.

I Dmm cleaningby MC roller.

Main brake

(T) is released

fromTreel.

Soft brake

(S)is

released

from S reel.

€

RKB block is

clutched(ON)

by RKB arm.

f !

["Capstan I [Pendulum

[brakeis I compulsionarm

Ireleased I isoperated.

[fromcapstanI[Pendulumgear'_

| is free on T reelI

\ side only.

€

TG8arm

loading.

Upper/Lower

commu'nication

gear is rotated.

t

i

TG8gear is I

I

rotated.

] :°22

Elevator gear

is rotated.

L

Pinchroller ]

moves down.

Brake is given toT

reel fromreverse

brake arm and

released

immediately.

Pinch roller

contacts

capstanmotor.

I II

RKB block is [

1

rotatedthrough

I

timingbelt.

Pendulumgear

engages idler

gear(S) and is

rotated.

S reel is rotated.

tape slack is /

removed. !

Capstan motor

is rotated in

reverse.

I RKBblockis ]

rotated through

timingbelt.

Pendulumgear is l

releasedfrom

idler gear(S).

l apstan motor

stops.

Drum is

rotated.

I

Page 7

Pinch roller moves Capstan shaft _ Pinch arm moves in the direction of

down in the direction _ _ / arrow mark_ and contacts capstan

ofarrowmarkt_..._7/_'_...._ L shaft. /

H _C_, _ "_ 9!,_7_--_ Capstan shaft

t_,/L I "_ /1 _ _ h'_'_ "-pinch r°ller

"" _r--_ll ,Jill _ _ _'_,_11 An opening(_ is

un n given between

Elevator gear ,-----F.L_._'\" f' _,./_ _,/,_'\ "_ '-_ pinch rollor and

_" _ \Press ear _Y_/_ \Pressgear pinch block by

" g ""_ / ..... _- press gearcam.

O Press.gea! andele.vato[ gear // _ Pinch'rolleris pressed in the direction

are ro_a_eei_tne direction or // ofarrow marki} by the tension of spring.

arrow mark U. ,/ -

Pinch block moves in the direction of

arrow mark _)through press gear cam.

Fig,3-2

Main slider moves in the direction of arrow mark O,

and RKB arm pushed up by step (_)moves in the

direction ofarrow mark I_).

_ Mainslider

?

arm

brock

,Timing belt

Pendulum g

Pendulum gear

RKB brock

I

!_ RKB arm moves in the direction of

arrow mark e, then RKB block moves

in the direction of arrow mark _) to

change the mesh of pendulum gear.

Timing belt

Fig.3-3

Shuttle (T)

Drum (M901)

TG1 arm

Shuttle (S)

Tension regulator

band

Fixed release arm

Soft brake (S)

Pendulum Capstan motor(M902)

compulsion (Capstan shaft)

arm

TG8 arm Pinch roller

MC roller MC arm

Upper/Lower

communication

gear

FLdriving gear

Cam gear

Cam

(M903)

S reel T reel

Pendulum gear

Idler gear (S) Neutrality arm

Capstan motor

(M902)

/

Loading gear (T)

Capstan brake

Idler gear (S)

Worm wheel

Drum (M901)

_r!__,

S reel

gear

Pinch arm

Fig.3-4

gear

gear

driving gear

Upper/Lower

communication

gear

RVS brake arm

Soft brake (T)

Main brake (T)

Cam motor

(M903)

Loadinggear (S)

Main slider

Timing belt

_____ Fixed

release arm

- - J4

Page 8

4. Stop --* Playback

ID'_m'sr°t_'_n_"I l

Press PLAY button. [

Capstan motor is rotated.

RKB block is rotated through I

timing belt (clutch ON).

Pendulum gear is meshed with

idler gear (T) and rotated.

T reel is rotated.

I

f

--11--

,: Drum

M901)

Capstan motor (M902) , 1

(Capstanshaft)

J

RKBbrock

T reel

Idlergear (T)

.._...j Pinchroller

Pendulum

compulsionarm

Capstan motor

RKBbrock

T re/_el

(M_02)

/

Idlergear (T)

Pendulumgear

Idler gear (S)

Tensionwheel

Timing belt

Fig. 4-1

Page 9

5. Stop --+Power OFF

I Soft brake(T)

is operated,

' Presspower button.

I Cam motor is rotated. }

[ Wormwheelisrotated[

[ Camgear is rotated. [

Upper/Lower

communicationgearis

rotated.

+

[ TG8gear is rotated, ]

I Pressgearisr°'ate_,i

Elevatorgear is rotated.

'_ If power is ON, it turns OFF

automatically about 5 minutes later.

I _ai_s,i_er_._o_-I

ainbrake s 'IIRKOp e,,e isI en°u,um

is operated. I compulsionarm

[is operated,

_ .....

Neutralityarm

is operated.

Fixedreleasearm is

operated,

+

Tensionregulatorband I

i

iensionbecomesweakto

ImakeS reelbrake weak.

Pinch-block [

movesinthe

directionof

arrowmark

andpinch

mileris

releasedfrom

capstanshaft.

1

Brakeis given [RKBblock ]

toS/I" reel. movesdown.

t

[

RKBblock becomesfree. I

Pendulumgearis releasedfrom Treel. ]

Capstan shaft

• Pinch block is operated and pinch roller

moves in the direction ofarrow mark O

until it is released from capstan shaft. ,,_ \

Pinch brock pin J_

./

Press gear cam/

j Pinch block

O Press gear is rotated in the direction of arrow mark O

and pinch block pin pushed to pressgear cam is

released from cam while pinch block moves in the

direction of arrow mark !_.

Fig. 5-2

Tension regulator

band

Fixed release arm

S reel

Capstan motor (M902) Elevator gear

Drum !M901) (Capsta_n shaft) Pinch roller/., Pinch arm

Main brake (S) RKI3brock Mainbrake (T)

Pendulum compulsion Neutralityarm

arm

_'ig.s-1

Capstan motor _

Upper/Lower

commt

gear

Cam

Cam motor

(M903)

Capstan brake Drum (M901)

R

Worm wheel Pendulum gear

Idler gear (T) RKB arm

Main slider

Fixed release

arm

J7 -13- -14- J8

Page 10

6. Playback CUE

Drum is rotating. I

I

Capstan motor is rotated at I

high speed.

I

,1

RKB block is rotated

through timing belt.

(clutch ON)

Pendulum gear and idler gear I

!

I

(T) are rotated at high speed. I

IT reel is rotated at high speed. I / Pinch roller is rotated

I i

L

at high speed.

•_ Difference from (Stop -" Playback)

(!) Capstan motor is rotating at high speed.

(g) Pendulum gear is meshed with

idler gear (T) from the beginning.

1

RKBbrock

RKBbrock

T reel

Drum(M901) Capstan motor (M902)

(Capstan shaft)

Pinch roller

Pendulumgear Treel

Idlergear (S) Idlergear (T)

Capstan motor

(Mi02)

Idlergear (T) Pendulum gear

Tension

/ wheel

___ Timing belt

Fig. 6-1

Page 11

7. Playback ---,REW

Cam motor is rotated. [

[ Worm wheel is rotated. ]

[ Cam gear is rotated. ]

I

reverse brake arm.

l Fixed release

arm is operated.

Brake is given to T reel by [

TG1 tension )

becomes weak.

Brake is given

to S reel by

soft brake (S).

Main slider slides.

Pendulum I

compulsion [

arm is operated. [

Pendulum

gear is free on

S reel only.

Drum is rotating.

I

Brake is given to

capstan motor by

capstan brake.

I

S winding arm is

operated to slightly

rotate S reel.

Capstan motor is rotated

in reverse at high speed.

S winding\

arm

Mainsliderj

S reel

When main slider moves in the direction of

arrow mark ®, S winding arm pressed by

main slider cam moves inthe direction of

arrow mark _ andS reel is rotateda little

in the direction of arrow mark.

RKB block is rotated

through timing belt.

(clutch ON)

"i

Pendulum gear is

meshed with idler gear

(S) and rotated.

S reel is rotated in

reverse at high speed.

_r

Pinch roller is

rotated in

reverse at high

speed.

Fig. 7-1

Drum

Fixed

arm

RKB

Pendulum

compulsion arm

Capstan motor (M902)

(Capstan shaft)

TG1 arm

S reel Pendulum gear Treel

Soft brake (S) Idler gear (S) RKB brock

Capstan brake

/ Tension wheel

Capstan motor (M902)

Cam motor

(M903)

Pendulumgear

Idler g_ear(S)

S reel

Fig. 7-2

roller

Elevator gear

gear

TG8 gear

Upper/Lower

communication

gear

RVS brake arm

-- Cam motor

(M903)

Main slider

_gbelt

release

arm

Jll J12

Page 12

8. Stop --, Fastfoward (FF)

•_ When this operation is mode

beforecassette tape is loaded for

playback, CUE mode is started

to readtape signaland then tape

is set in fast forwardmode.

Brakeis given to

T reel by soft

brake (T).

Upper/Lower

communication

gear is rotated.

TG8 gear is

rotated.

Pressgear is

rotated.

Pinch roller is

released from

capstan shaft.

I Cam motor is rotated. [

I Worm wheel is rotated. I

I Cam gear is rotated. I

I Main slider slides. [

Fixed release

arm is operated

to make TG1

arm tension

weak.

Brake is given

to capstan motor

by capstan

brake.

v

Capstan brake is

released from

capstan motor.

Brake is given [

to S reel by ]

main brake (S).]

Main brake (S)

is released

from S reel.

Brakeis given I

to T reel by [

main brake if).]

Main brake (T)

isreleased

form T reel.

Drumis rotating. ]

r

Pendulum

compulsionarm

is operated.

Neutrality arm ]

is operated.

,f

I r e everlslides.

I

Pendulumgear is locked )

inthe center between

S reel and T reel.

Neutrality arm is ]

operated again.

I

Pendulum

compulsion arm

is operated.

Pendulumgear is free on

S reel or T reel. )

I

RKBblock is

set in clutch

OFFby RKB

arm.

ICapstan motor is rotatedat [

high speed.

RKB block is rotated

through timing belt.

Pendulum gearis meshed

with idler gear (T) and

rotated.

T reelis rotated at high

speed.

Page 13

Pendulum

compulsion

arm

Drum (M901)

\

Capstan motor (M902)

TG8 gear (Capstan shaft) Pinch roller

Mainbrake (S)

Fixed release

arm

S

Pendulum gear T reel

RKB brock Idler (T)

Upper/Lower

communication

gear

Cam gear

RKB brock

Cam motor

(M903)

Capstan motor

(M902)

Worm wheel

T reel

Capstan brake Drum (M901)

Tension wheel

Trigger lever RKB arm

Pendulum gear Idler(

Fig. 8-1

gear

Pinch block

Press gear

Upper/Lower

_mmunication

gear

Neutrality arm

Mainbrake (T)

brake (T)

Cam motor

(M903)

Main slider

Timing belt

Main brake (S)

Fixed release

arm

J15 J16

Page 14

I

9. Stop -_ Rewind(REW)

T reelby soft II

brake (T). 11

I

•_ When this operation is mode l

before cassette tape is loaded for

I

playback, REV mode is started

to read tape signal and then tape

I

is set in rewind mode. I

I

Upper/Lower

communication

gear is rotated.

TG8 gear is

rotated.

Press gear is

rotated.

Fixed release

arm is operated

to make TG1

arm tension

weak.

Pinch roller is

released from

capstan shaft.

I

Brake is given

to capstan motor

by capstan

brake.

Cammotor is rotated.

Worm wheel is rotated.

1

Cam gear is rotated.

Main slider slides.

I

I

I

I

I

Brakeis given

to S reel by

main brake (S).

Capstan brake is [

released from [

capstan motor. [

,f

Main brake (S)

is released

from S reel.

I

Brake is given

toT reel by

main brake (T).

I

Main brake (T) [

1

is released

form T reel.

Drum is rotating.

Triggerlever

slides.

I

I

I

Neutralityarm

is operated.

r

Neutrality arm is

operated again.

I

_f

IPendulum [

compulsion ann

is operated.

Pendulumgear is locked \

)

in the center between

S reel and T reel.

Pendulum [

compulsion ann

is operated.

Pendulum gearis free on )S reelor T reel.

RKBblock is

setin clutch

OFF by RKB

alT0.

I

Capstan Motor is rotated

in reverse at high speed.

RKB block is rotated

throughtiming belt.

Pendulum gearis meshed

with idler gear (S) and

rotated.

S reel is rotated inreverse at high speed.

!

I

q

q

q

Page 15

Pendulum

compulsion

arm

Drum (M901)

\

Main brake (S)

Fixed release.

arm

S reel

Idler gear (S)

Capstan motor

(M902)

Upper/Lower

communication

gear

Cam,

RKB brock

Cam motor

(M903)

Worm wheel

Idler gear (T)

Capstan motor (M902)

(Capstan shaft)

TG8 gear Pinch roller

RKBbrock T reel

Pendulum gear

Capstan brake Drum (M901)

Tension wheel

Pendulum gear RKBarm

Idler _ear (S) S reel

Fig. 9-1

gear

Pinch block

Press gear

Upper/Lower

)mmunication

gear

LJtralityarm

Main brake (T)

Soft brake (T)

Cam motor

(M903)

slider

Timing belt

Trigger lever

Main brake (S)

Fixed release

arm

Page 16

!l'!_ip,

10. Stop -* Unloading Eject

Brakeis given

to capstan

motor by

capstanbrake.

S winding arm is

operated to rotate

S reel a little.

I am motor is rotated. [

I wormwheelisrotated.[

I am ea s otat I

[ Main slider slides. [

I

Brake is given[ Fiaxed

to S reelby [ release arm

softbrake (S). ! is operated.

TG1 arm [

unloading.

Tension regulator

band releases the

IBrakeis given

to T reel by

main brake (T).

brake from S reel.

Drum is rotating. I

Main brake (T)

]is released from

IT reel.

I Loading gear

(T)is rotated.

1

,I

Loading gear I

(S) is rotated.I

__3

Shuttle(S)

unloading.

Shuttle (T)

unloading.

k rum

cleaning by

MC roller.

Pendulum [Reverse brake

compulsion [arm gives

arm _s operated, ibrake to T reel

Pendulum gear \ /andis released

is free on S reel | [immediately.

only. /

RKBblock is

set in clutch

OFF by RKB

arm.

Upper/Lower [

communication gear is [

rotated. I

I

[Press gear is rotated. I

I

Pinch rolleris [Elevator gear is

released from Irotated.1

capstan motor.

IPinch roller moves up. I

r

I C_pa_e7mOtOris .I

RKBblock is

rotated through

timing belt.

(clutch ON)

Pendulum gear is

meshedwith idler

gear (S) and rotated.

( Tape is wound )

into cassette.

,l

[Capstan motor stops. I

IFL driving[ / Brakeis [

gearis givento [

rotated. T reelby [

softbrake[

(T). [

I oC;ratiUoenOUT1

(seePage 31, 32)

II

Page 17

Shuttle (S)

TG1 arm

Pendulum

compulsion Capstan motor (M902)

arm MC arm (Capstan shaft)

Shuttle (T) TG8 arm Pinch roller

Elevator gear

Pinch arm

Press gear

Tension regulator

band

Fixed releas,

arm

S reel Pendulum arm T reel

Soft brake (S) Idlergear (S) RKB brock

gear

Upper/Lower

communication

gear

FL driving gear

RVS brake arm

Soft brake (T)

Main brake (T)

Cam motor

(M903)

Upper/Lower

communication

gear

C

FL driving gear

Cam gear -_

J

Cam motor

(M903)

Capstan motor Shuttle (T)

(M902)

\

Capstan brake Drum (M901)

/

Worm wheel RKB arm

Shuttle (S)

i

Main slider

Idler gear (S)

\

Fixed release

arm

S reel

Fig. 10-1

0 Mainslider moves in the direction

of arrow mark 0 and RKB arm is

pushed up in the direction of

arrow mark • by step@.

Main slider

,O RKBarm

RKB brock

Pendulumgear

belt

When RKB arm moves inthe direction of

Pendulumgear RKB brock j arrow mark 0, RKB block moves inthe

![1_---" / _ direction of arrow mark _ to change

I , ,r

I I i_ /,l._) the mesh of pendulum gear.

o=. /

! ',

i

Fig. 10-2

• Pinch roller moves up in the

direction of arrow mark O.

Capstan shaft

O Pinch arm moves in the direction of

arrow mark _) and pinch roller is

released from capstan shaft.

shaft

ear

Pinch

Elevator gear

l[])Press gear and elevator gear

are rotated in the direction of

arrow mark O.

Pinch roller

I Press gear

Pinch block pushed by

press gear cam moves

in the direction of

arrow mark O.

Fig. 10-3

Page 18

IDoor is opened

by

I

door lever. I

I

(From unloading)

Gear slidc plate slidcs. ]

I elay gear is rotated to swing iright/left arm,

form cassette 1N switch.

Cassette IN switch is pressed by

cassette IN lever.

l Cam motor stops, I

I

[

Cassette holder slides.

,1

Cassette is ejected. I

Left arm

Door

Cassette IN lever

Cassette holder

FL driving gear

Right arm Gear slide plate

Cassette

Relay gear

Fig. 10-4

Loading...

Loading...