Page 1

Scale Unit

SH11 Series

Read all the instructions in the manual carefully before use and strictly follow them.

Keep the manual for future references.

Instruction Manual

Page 2

[For the customers in U. S. A.]

[ For EU and EFTA countries ]

WARNING

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful

interference when the equipment is operated in a

commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the

instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in

a residential area is likely to cause harmful

interference in which case the user will be required to

correct the interference at his own expense.

You are cautioned that any changes or modifications

not expressly approved in this manual could void your

authority to operate this equipment.

■ Precautions on use

When using Sony Manufacturing Systems Corporation

products, observe the following general precautions along

with those given specifically in this manual to ensure proper

use of the products.

• Before and during operations, be sure to check that our

products function properly.

• Provide adequate safety measures to prevent damages

in case our products should develop malfunctions.

• Use outside indicated specifications or purposes and

modification of our products will void any warranty of the

functions and performance as specified of our products.

• When using our products in combination with other

equipment, the functions and performances as noted in

this manual may not be attained, depending on operating

and environmental conditions.

• Absolutely do not disassemble parts other than those

specified, as this may cause malfunctions.

• Sony Manufacturing Systems Corporation reserves the

right to change specifications and functions without

notice.

CE Notice

Making by the symbol CE indicates compliance of the

EMC directive of the European Community. Such

marking is indicative meets of exceeds the following

technical standards.

EN 55 011 Group 1 Class A / 91 :

"Limits and methods of measurement of

electromagnetic disturbance characteristics of

industrial, scientific and medical (ISM) radio-frequency

equipment"

EN 50 082-2 / 95:

"Electromagnetic compatibility - Generic immunity

standard Part 2 : Industrial environment"

警告

本装置を機械指令(EN60204-1)の適合を受ける機器

にご使用の場合は、その規格に適合するように方策

を講じてから、ご使用ください。

Warning

When using this device with equipment governed by

Machine Directives EN 60 204-1, measures should be

taken to ensure conformance with those directives.

Warnung

Wenn dieses Gerät mit Ausrüstungsteilen verwendet

wird, die von den Maschinenrichtlinien EN 60 204-1

geregelt werden, müssen Maßnahmen ergriffen

werden, um eine Übereinstimmung mit diesen

Normen zu gewährleisten.

Page 3

Safety Precautions

Sony Manufacturing Systems Corporation products are designed in full consideration of

safety. However, improper handling during operation or installation is dangerous and may

lead to fire, electric shock or other accidents resulting in serious injury or death. In addition,

these actions may also worsen machine performance.

Therefore, be sure to observe the following safety precautions in order to prevent these types

of accidents, and to read these “Safety Precautions” before operating, installing, maintaining,

inspecting, repairing or otherwise working on this unit.

Warning indication meanings

The following indications are used throughout this manual, and their contents should be

understood before reading the text.

Warning

Failure to observe these precautions may lead to fire, electric shock or other accidents

resulting in serious injury or death.

Caution

Failure to observe these precautions may lead to electric shock or other accidents resulting in

injury or damage to surrounding objects.

Note

This indicates precautions which should be observed to ensure proper handling of the equipment.

Warning

• Do not use this unit with voltages other than the specified supply voltage as this may result

in fire or electric shock.

• Do not perform installation work with wet hands as this may result in electric shock.

• Do not disassemble or modify the unit as this may result in injury or damage the internal

circuits.

Caution

• Be sure to check the machine and device conditions to ensure work safety before working

on the machine.

• Be sure to cut off the power supply, air and other sources of drive power before working on

the machine. Failure to do so may result in fire or accidents.

• When turning on the power supply, etc. to operate the machine, take care not to catch your

fingers in peripheral machines and devices.

i

Page 4

Handling Precautions

Installation precautions

When installing this unit, care should be given to the following points to prevent noise and

electromagnetic wave interference from other equipment.

1. Do not pass lead and connection cables through the same ducts as power lines.

2. Be sure to install the unit at least 0.5 m or more away from high voltage or large current

sources or high-power relays.

3. Absolutely do not bring the unit near magnets or sources of electromagnetic waves.

Installation place precautions

1. The scale unit should be used within an ambient temperature range of 0 to 45°C (113°F).

Avoid use in places exposed to direct sunlight or hot winds or near heating equipment.

2. Avoid use in places subject to strong vibrations or impacts.

3. If there is the chance that the scale unit may come into contact with cut or measured

objects, tools or jigs, be sure to protect the unit with a sufficiently strong cover.

ii

Page 5

Contents

Introduction ............................................................................................................1

Introduction ....................................................................................................1

Checklist for Unpacking and Accessories .....................................................2

Chapter 1 Overview ......................................................................................... 1-1

1-1. Special Features .............................................................................. 1-1

1-2. Part Names ...................................................................................... 1-2

1-3. System Configuration ...................................................................... 1-3

Chapter 2 Design and Installation ................................................................. 2-1

2-1. External Dimensions ........................................................................ 2-1

2-2. Installation Design ........................................................................... 2-3

2-3. Installation Procedure ...................................................................... 2-6

2-3-1. Installing the Scale Unit.................................................... 2-6

2-3-2. Securing the Scanning Unit to the Mounting Bracket ...... 2-8

2-3-3. Removing the Slider Holders ........................................... 2-9

2-3-4. Cable Management ........................................................ 2-10

2-3-5. Precautions when the Scanning Unit is Connected

to a Movable Component ............................................... 2-11

2-3-6. Connection Example (Reference) .................................. 2-12

2-4. Managing the Operating Environment ........................................... 2-13

2-5. Air Purge ........................................................................................ 2-14

Chapter 3 Maintenance ................................................................................... 3-1

3-1. Start-up Inspection .......................................................................... 3-1

3-2. Regular Inspections ......................................................................... 3-1

Chapter 4 Specifications ................................................................................ 4-1

4-1. General Specifications and Performance Specifications ................ 4-1

4-2. Resolution and Response Speeds .................................................. 4-2

4-3. Electrical Characteristics ................................................................. 4-3

4-3. Cable Specifications ........................................................................ 4-4

Chapter 5 Appendix ........................................................................................ 5-1

5-1. Model Summary .............................................................................. 5-1

Page 6

Page 7

Introduction

Introduction

Thank you for purchasing this SH11 scale.

Please note that improper usage and handling may not only prevent this unit from

functioning to its fullest potential, but may also cause unexpected breakdowns or

shorten the life of the unit.

Be sure to read this instruction manual carefully and take the greatest care in handling

the unit.

The precautions listed below are important for the proper handling of this product.

Therefore, be sure to comply with the items and explanations in this instruction manual

that advise caution.

In this instruction manual, we have endeavored to state wherever possible, the

individual specifications and functions, and their interrelationships. Please assume that

aspects not covered in this manual are not permitted.

Every care has been taken to make this manual as comprehensive as possible, but if

you have any unanswered questions, do not hesitate to contact our sales center.

1

Page 8

Checklist for Unpacking and Accessories

After unpacking this product, confirm the following:

• Is the article the one you ordered?

• Has any damage occurred during transit?

Check to make sure the following accessories are included:

• Standard Accessories

Accessory name Dimensions Number Application

Certificate of inspection 1

Installation manual 1

Hexagonal socket head cap screw M4×22 4 For installing the scale

Cable clamp 2 For securing the head cable

Pan-head machine screw M4×10 2 For securing the head cable

Pan-head machine screw 3P M4×28 2 For securing the detector unit

Support bracket components (See table below)

• Support bracket components (The number of articles may differ depending on the

scale model.)

Scale model

SH-11-0072

to -0472

SH-11-0522

to -0923

SH-11-1023

to -1243

Support bracket

ABM3×6M4×18 Washers

—————

11211

22422

Hexagonal socket head cap screws, etc.

for securing

2

Page 9

Chapter 1 Overview

1-1. Special Features

The SH11 Series uses a high precision interpolation circuit to achieve an insertion error

of 0.1 µm or less within a scale engraving pitch of 16 µm.

The output signal is a 5 V line driver, so it can be connected directly to a numerical

controller to provide position feedback.

Installation is easy for this unit-type scale. For scales with a measuring length of

520 mm (20.47 in) or more, use standard accessory support bracket A or B to increase

the rigidity at the intermediate position.

Wide Variation

Twenty measuring lengths are available in the range of 70 to 1,240 mm (2.76 to 48.82

in).

Choose the optimum scale length to match the required stroke.

High Precision

The scale precision is as follows.

• Measuring length 70 to 620: ± 2 µm

• Measuring length 670 to 1240: ± 3 µm

Excellent Resistance to Working Environment

The detector component employs a large-area optical exchange device using Moiré

interference fringes. Employing our unique stable Moiré detection system, the effects of

dust can be minimized and reading errors reduced.

Durable Construction

The detector component employs sturdy, precision die-cast aluminum, making it

possible to obtain stable Moiré fringes. A bearing guide system enables maintenance

of ideal traveling conditions.

Minimum Wiring

Position detection signals are provided for only the following three pairs.

• Position signal.............. A phase, A phase, B phase, B phase

• Zero point signal .......... Z phase, Z phase

Each of these employs the noise-resistant line-driver method.

Simple Maintenance

The detector component is designed to be replaceable, so if a problem occurs, the

scanning unit can be speedily replaced and normal operation resumed.

1-1

Page 10

1-2. Part Names

Slider holder L

Detector unit

Scale unit

Support bracket A

Support bracket B

Dust lip

Scanning unit

Head cable

Air inlet plug

1-2

Connecting cable

(not supplied)

Slider holder R

Polarity switch

Page 11

1-3. System Configuration

Work

NC control device

Scale

Tool

Table

Servo motor

1-3

Page 12

Page 13

(

)

Chapter 2 Design and Installation

2-1. External Dimensions

External dimensions of scale unit

Overall scale length (L+105(4.13))

Scale mounting hole pitch (L+94(3.70))5.5(0.217) (5.5(0.217))

(n-1)×P1

ø6.5(0.256)

35(1.378)

18(0.71)

Suppor

bracket B

ø5(0.197)

2(0.079)

A

Scanning unit

Support

bracket A

A

12(0.472)

4.6(0.181)

20(0.787)

6(0.236)

12(0.472)

3(0.118)

(25(0.984))

3(0.118)

3(0.118) 74(2.91) 3(0.118)

56(2.20)

80(3.15)

Z1

5(0.197)

42(1.65)

2-M4 (P=0.7)×28L

74(2.91)

2-M4 (depth 10)

12(0.472)

33(1.30) (4.5(0.177))

4.5(0.177)

ø16(0.630)

Head cable length = 1000(39.37)

12(0.472)

Z2

Measuring length (L)

8(0.315)

76(2.99)

67(2.64)4.8(0.189)

3(0.118)

10(0.394)

10(0.394)

9(0.354)

(25(0.98))

(Z1)

(11.5(0.453))

(4.2(0.165))

ø14(0.551)

ø5(0.197)

2-ø6.5(0.256) hole

ø5(0.197)

FW (ø9(0.354))

M4×18

M4×22

M4×22

Air inlet plug (M5)

M3×6

21(0.827)

6(0.236)

7(0.276)

M4×18

6(0.236)

6(0.236)

26(1.02)

0.157

4

13(0.512)

5.5(0.217)

7.5(0.295)

13(0.512)

±0.3

2.5

±0.012

(0.098

43.5(1.71)

26.5(1.04)

15(0.591)

1. The installation side is marked ▼.

2. The screws shown in the drawing are included.

3. A support bracket or brackets are required for scales with

a measuring length of 520 mm (20.47 in) or more.

4. A type or B type support brackets can be selected.

5. The zero point signal is output when the on the scale

is approximately aligned with the on the scanning unit.

6. If the scale is moved beyond its measuring length, it will

)

be damaged. Therefore, take steps to ensure that the

stroke of the machine ends 10 mm (0.394 in) or more to

the inside of both ends of the measuring length.

Unit [mm(in)]

2-1

Page 14

Scale Unit Dimensions

Scale Model SH11- 007

2 012

2 017

2 022

2

Measuring length L [mm(in)] 70(2.76) 120(4.72) 170(6.69) 220(8.66)

Support bracket n (No.) ————

Support bracket A [mm(in)] ————

Mounting hole pitch P1 [mm(in)] ————

Zero point position

Z1 [mm(in)] 35(1.38) 35(1.38) 35(1.38) 35(1.38)

Z2 [mm(in)] — 50(1.97) 100(3.94) 150(5.91)

Scale Model SH11- 027

2 032

2 037

2 042

2

Measuring length L [mm(in)] 270(10.63) 320(12.60) 370(14.57) 420(16.54)

Support bracket n (No.) ————

Support bracket A [mm(in)] ————

Mounting hole pitch P1 [mm(in)] ————

Zero point position

Z1 [mm(in)] 35(1.38) 35(1.38) 35(1.38) 35(1.38)

Z2 [mm(in)] 200(7.87) 250(9.84) 300(11.81) 350(13.78)

Scale Model SH11- 047

2 052

2 057

2 062

2

Measuring length L [mm(in)] 470(18.50) 520(20.47) 570(22.44) 620(24.41)

Support bracket n (No.) — 111

Support bracket A [mm(in)] — 307(12.09) 332(13.07) 357(14.06)

Mounting hole pitch P1 [mm(in)] ————

Zero point position

Z1 [mm(in)] 35(1.38) 35(1.38) 35(1.38) 35(1.38)

Z2 [mm(in)] 400(15.75) 450(17.72) 500(19.69) 550(21.65)

Scale Model SH11- 067

3 072

3 077

3 082

3

Measuring length L [mm(in)] 670(26.38) 720(28.35) 770(30.31) 820(32.28)

Support bracket n (No.) 1 1 1 1

Support bracket A [mm(in)] 382(15.04) 407(16.02) 432(17.01) 457(17.99)

Mounting hole pitch P1 [mm(in)] ————

Zero point position

Z1 [mm(in)] 35(1.38) 35(1.38) 35(1.38) 35(1.38)

Z2 [mm(in)] 600(23.62) 650(25.59) 700(27.56) 750(29.53)

Scale Model SH11- 092

3 102

3 114

3 124

3

Measuring length L [mm(in)] 920(36.22) 1020(40.16) 1140(44.88) 1240(48.82)

Support bracket n (No.) 1 2 2 2

Support bracket A [mm(in)] 507(19.96) 380(14.96) 420(16.54) 450(17.72)

Mounting hole pitch P1 [mm(in)] — 354(13.94) 394(15.51) 434(17.09)

Zero point position

Z1 [mm(in)] 35(1.38) 35(1.38) 45(1.77) 45(1.77)

Z2 [mm(in)] 850(33.46) 950(37.40) 1050(41.34) 1150(45.28)

2-2

Page 15

2-2. Installation Design

Installing the product incorrectly may shorten its life or affect its performance.

Design the installation surface and mounting bracket in accordance with the

checkpoints given below.

Selecting the Mounting Location

To obtain full performance from the scale unit, select a mounting location that satisfies

the following criteria:

• Not subject to vibration or dust

• As close as possible to the machine’s cutting tool to guarantee machining accuracy

• A place that ensures ease of scale unit maintenance

• A place that enables smooth installation

Checking the Measuring Length

Select a scale with a measuring length that extends at least 10 mm (0.394 in) from both

ends of the machine’s maximum stroke. If there is a possibility that the machine might

exceed the scale measuring length, install mechanical stoppers or otherwise restrict

the machine’s range of movement.

Measuring length

Maximum stroke of machine

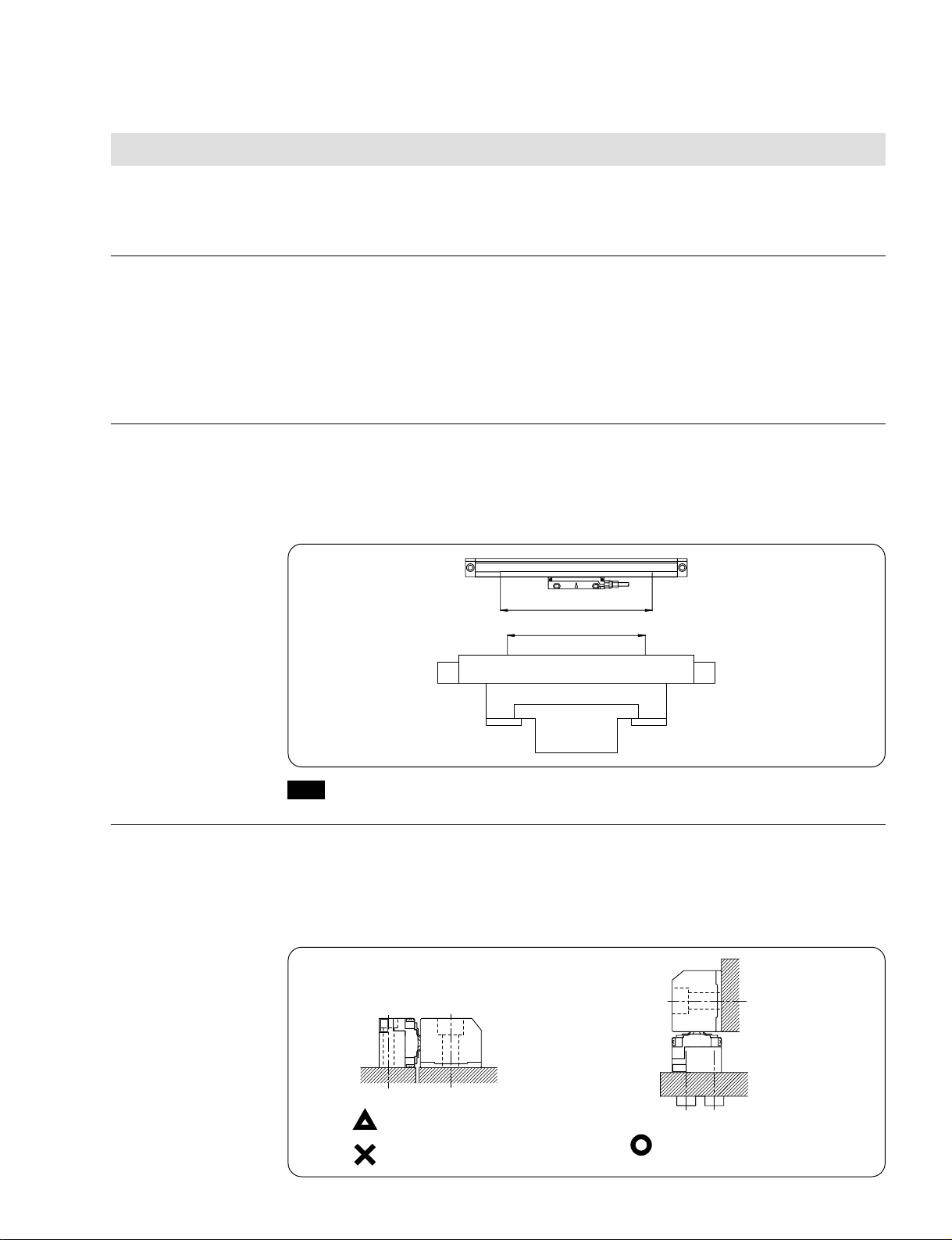

Installation Direction

Note

The scale will be damaged if it moves beyond the measuring length.

Although the traveling part of the scale unit is partially sealed, it is not completely

sealed off for structural reasons. When mounting the scale to the horizontal axis, install

it so that the opening points downwards. When mounting the scale to the vertical axis,

install it so that the opening points to the outside, away from the cutting tool.

Vertical installation

Horizontal installation

When it is impossible for debris to enter

Prohibited

When it is possible for debris to enter

Recommended installation direction

2-3

Page 16

Flatness and Parallelism of the Installation Surface

• The installation surface of the scale unit should be finished along its entire length to

finish symbol 6.3S or better and should be machined to a flatness of 0.05 mm

(0.002 in)/M (where M is the machine guide’s length).

If the scale overhangs the machine, it must be reinforced with a backplate made of

flat polished steel plate at least 12 mm (0.472 in) thick. Ensure that the installation

surface is free of gouges or flaws.

Flatness: 0.05 mm (0.002 in)/M

Overall scale length

• Design the installation surface so that the parallelism of the installation surface and

the scale in the vicinity of each scale mounting screw is 0.05 mm (0.002 in).

0.05

0.1

M

±0.3(0.012)

0

M: Machine guideway

50 mm (1.97 in)

0.1

0.05

M

21(0.827)

±0.3(0.012)

0.05

M

)

0.1

±0.5

±0.020

30.5

(1.20

Unit [mm(in)]

2-4

Parallelism: 0.05 mm (0.002 in)/M

50 mm (1.97 in)

Page 17

Designing the Scanning Unit Mounting Bracket

• The mounting bracket should be designed to have adequate rigidity relative to the

direction of travel.

Ensuring Sufficient Maintenance Space

• The scale unit must be removed when replacing the scanning or detector unit.

Therefore, ensure sufficient space for removing the scale unit.

Prohibited

Installation and removal space

Scanning unit

Detector unit

Installation and removal space

2-5

Page 18

2-3. Installation Procedure

The installation procedure for the scale unit is explained below. Note that the following

components must not be disassembled, as doing so may cause breakdowns.

[Do not Disassemble the Following]

• Mechanical and electrical components of the scanning unit

• Scale unit cable connectors

• Glass scale

The scale unit is composed of precision components, so applying undue force may

adversely affect the precision and life of the unit. Ensure that undue force is not exerted

on the scale unit during operation.

Support the main body of the scale unit and scanning unit during transport. Do not lift by

the cables or connectors.

2-3-1. Installing the Scale Unit

1. Checking the Flatness of the Scale Unit Installation Surface

• Check that the installation surface of the scale unit is finished along its entire length

to finish symbol 6.3S or better, and check that it has a flatness of 0.05 mm

(0.002 in)/M (where M is the machine guide’s length).

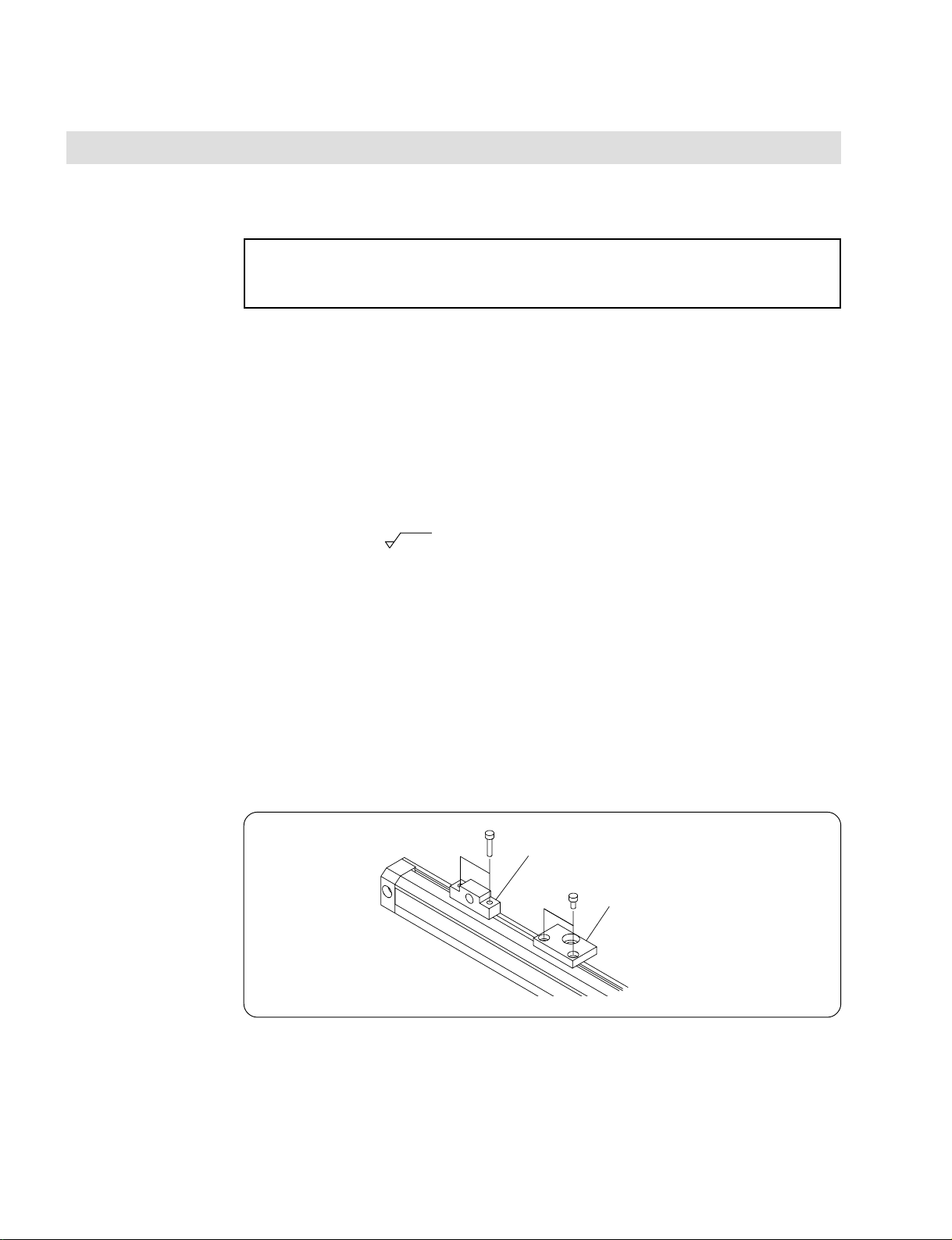

2. Installing the Support Bracket to the Scale

• A support bracket or brackets are supplied with scales which have a measuring

length of 520 mm (20.47 in) or more.

• Fixing nuts for the support brackets are inserted in the slit on the top face of the

scale. Install the support bracket or brackets using hexagonal socket head cap

screws (M3×6). Using a torque wrench, tighten to a torque of 1.5 N•m.

• Position the support bracket at the center of the scale. For scales with a measuring

length of 1020 mm (40.16 in) or more, position the support brackets so that the scale

is divided into equal parts.

• Either support bracket A or B can be selected.

2-6

Support bracket B

Support bracket A

3. Temporarily Securing the Scale Unit

• Move the movable machine part to roughly the center of the stroke and lightly secure

it with the supplied hexagonal socket head cap screws (M4×22).

4. Temporarily Securing the Support Bracket

• Temporarily secure the scale unit, then lightly secure the support bracket with the

supplied hexagonal socket head cap screws (M4×18).

Page 19

5. Checking the Parallelism of the Scale Unit

• Place a dial gauge on the top face of the scale unit and check its parallelism.

• The tolerance for the parallelism is 0.05 mm (0.002 in) in the vicinity of each scale

mounting screw. Adjust the scale unit so that the reading comes within this range.

50 mm (1.97 in)

Parallelism: 0.05 mm (0.002 in)/M

50 mm (1.97 in)

6. Securing the Scale Unit

• After checking the flatness and parallelism, tighten the hexagonal socket head cap

screws. Using a torque wrench, tighten to a torque of 2 N•m. Do not completely

tighten the hexagonal socket head cap screws one by one; rather, tighten all screws

evenly.

Hexagonal socket head cap screws M4×22

Support bracket

Hexagonal socket head cap screw M4×18

2-7

Page 20

2-3-2. Securing the Scanning Unit to the Mounting Bracket

When mounting the scanning unit into the mounting bracket, always make sure both

slider holders L and R are attached.

If slider holders L and R become detached, remount them.

When installing slider holders L and R for the first time, insert them into the scale

groove from the ends of the scale.

Inserting slider holders L and R into the scanning unit will determine the relative

positions of the scale and scanning unit.

Twisting the scanning unit while the slider holders are not in use may dislodge the

scanning unit dust seal from the dust seal guide groove. If the dust seal becomes

dislodged, it can be refitted without any problems. However, be careful not to dislodge

it during the installation work.

1. Checking Slider Holders L and R

• Check to make sure slider holders L and R are attached. If they have become

detached, remount them.

2-8

Slider holder L

Slider holder R

2. Checking for Installation Errors

• The mounting tolerance for the positions and height of the scale unit and scanning

unit is ±0.3 mm (0.012 in). If there is a gap between the scanning unit and the

mounting bracket, adjust with spacers or similar items. If the mounting bracket is too

high, switch to a lower mounting bracket.

Page 21

3. Securing the Scanning Unit

• With the scanning unit supported by slider holders L and R, slide it into the

installation position and secure it in place with the hexagonal socket head cap

screws (M4×22). Using a torque wrench, tighten to a torque of 2 N•m.

Mounting bracket

2-3-3. Removing the Slider Holders

1. Checking the Cap Screw Tightness

• Before removing the slider holders, double-check to make sure the scale and

scanning unit mounting cap screws are tightened.

2. Removing Slider Holders L and R

• Take out slider holders L and R from the ends of the scale.

• Trying to move the scale before removing the slider holders may damage the scale.

Pan-head machine

screw M3×5

Slider holder L

Slider holder R

2-9

Page 22

2-3-4. Cable Management

Managing Cables

• Manage cables so that they do not hinder machine operations or become entangled.

Handle cables carefully, as forceful pulling or repeated bending may damage them.

• The connector of the head cable has been waterproofed, but ensure that it is fitted in

a location where it is not exposed to chips or cutting fluid.

Minimum Cable Bending Radius

• Ensure that cables are arranged so that their bending radius tolerances are not

exceeded.

• The cable bending radii are as follows:

Head Cable

When the cable does not move during use ... Bending radius: 30 mm (1.18 in) or more

When the cable moves during use ................ Repeated bending not permitted

Connecting Cable

(Secure with a bending radius of 30 mm

(1.18 in) or more.)

When the cable does not move during use ... Bending radius: 50 mm (1.969 in) or more

When the cable moves during use ................ Bending radius: 100 mm (3.937 in) or more

Securing Cables

• Secure the head cable with cable clamps or similar items near the outlet. Also,

secure the connecting cable firmly so that it does not hinder machine operations or

become entangled.

Protecting the Connecting Cable Polarity Switch

• A polarity switch is attached to the connector that leads to the control unit. This

switch can be reversed to suit the reading direction of the scale.

Note

This switch can be operated during use, but doing so is very dangerous, as this reverses the

feedback signal.

Attach a protective cover to the polarity switch on the connector that leads to the control unit so

that it cannot be operated accidentally.

MR-20LS1

Polarity switch

FI-20-CV3

Polarity switch

2-10

39.3(1.55)

30(1.18)

Page 23

2-3-5. Precautions when the Scanning Unit is Connected to a Movable Component

Mounting the scale unit to a movable part and the scanning unit to a fixed part is ideal,

but if the reverse is necessary for structural reasons, the following points should be

noted:

Managing the Head Cable

• Secure the head cable and allow the connecting cable to bend.

• Secure the largest bending radius possible for the head cable.

• The allowable bending radius for the head cable is 30 mm (1.18 in) or more.

Managing the Connecting Cable

• Secure the connecting cable firmly so that it does not hinder machine operations or

become entangled. The cable getting caught on the operator or objects in the vicinity

presents a hazard. Furthermore, even if it does not appear so from the outside, the

internal core wire may be severed.

• The allowable bending radius of the connecting cable is 100 mm (3.937 in) or more.

The cable wires may be severed if subjected to repeated bending at radii smaller

than this.

Extending the Connecting Cable

• Do not extend the connecting cable to a length of more than 30 m (1181.10 in).

2-11

Page 24

2-3-6. Connection Example (Reference)

The drawing below shows an example of an interface.

When using a 26LS32, attach external resistance of 150 , since the IC does not have

an internally terminated resistor (Rt). The drawing below also shows the open circuit

alarm detection circuit.

Phase A

Phase B

Phase Tx

Scale side

26LS31

Tx

A

A

B

B

Tx

0.18 mm2 twisted

pair wire shield

Receiving side - example

5V

560Ω

560Ω

560Ω

560Ω

560Ω

560Ω

75115 or 26LS32

Rt

74LS86

5V

Rt

74LS86

5V

Rt

74LS86

Phase A

Phase B

Phase Tx

2-12

5V

GND

FG

Note

Use two core wires twisted together for each of the 5 V and GND power sources.

(Note)

Each power source

uses 2 lines.

Standard cable

5V

GND

FG

74LS86

CR time constant: about

10 µs is appropriate.

S

R

R

Open circuit alarm

Q

Reset

C

Page 25

2-4. Managing the Operating Environment

Installation Direction

• Although the traveling part of the scale unit is partially sealed, it is not completely

sealed off for structural reasons. When mounting the scale to the horizontal axis,

install it so that the opening points downwards. When mounting the scale to the

vertical axis, install it so that the opening points to the outside, away from the cutting

tool.

Horizontal installation

When it is impossible for debris to enter

Prohibited

When it is possible for debris to enter

Vertical installation

Recommended installation direction

Protective Cover

Scale unit cover

Sealed part

Scanning unit

Spattered

cutting fluid

• Attach a protective cover with the necessary strength if the scale is installed in a

location where the operator may place his elbows or legs.

• Preferably, choose a mounting location where the scale will not be exposed to chips

or cutting fluid. If that is impossible, attach an appropriate cover.

Scale

Scale unit cover

Table

Sealed part

Scanning unit

Spattered

cutting fluid

Scale

Table

Prohibited

2-13

Page 26

2-5. Air Purge

The scale bracket is fitted with standard M5 tap holes on both sides to allow air intake.

If the scale unit is to be used in the environments listed below, harmful effects can be

reduced by blowing clean air into the unit.

• Dusty locations

• Highly humid locations

• Locations where changes in temperature and humidity give rise to condensation

As the efficacy of introducing air depends on the service conditions, do so only after

verifying the effectiveness.

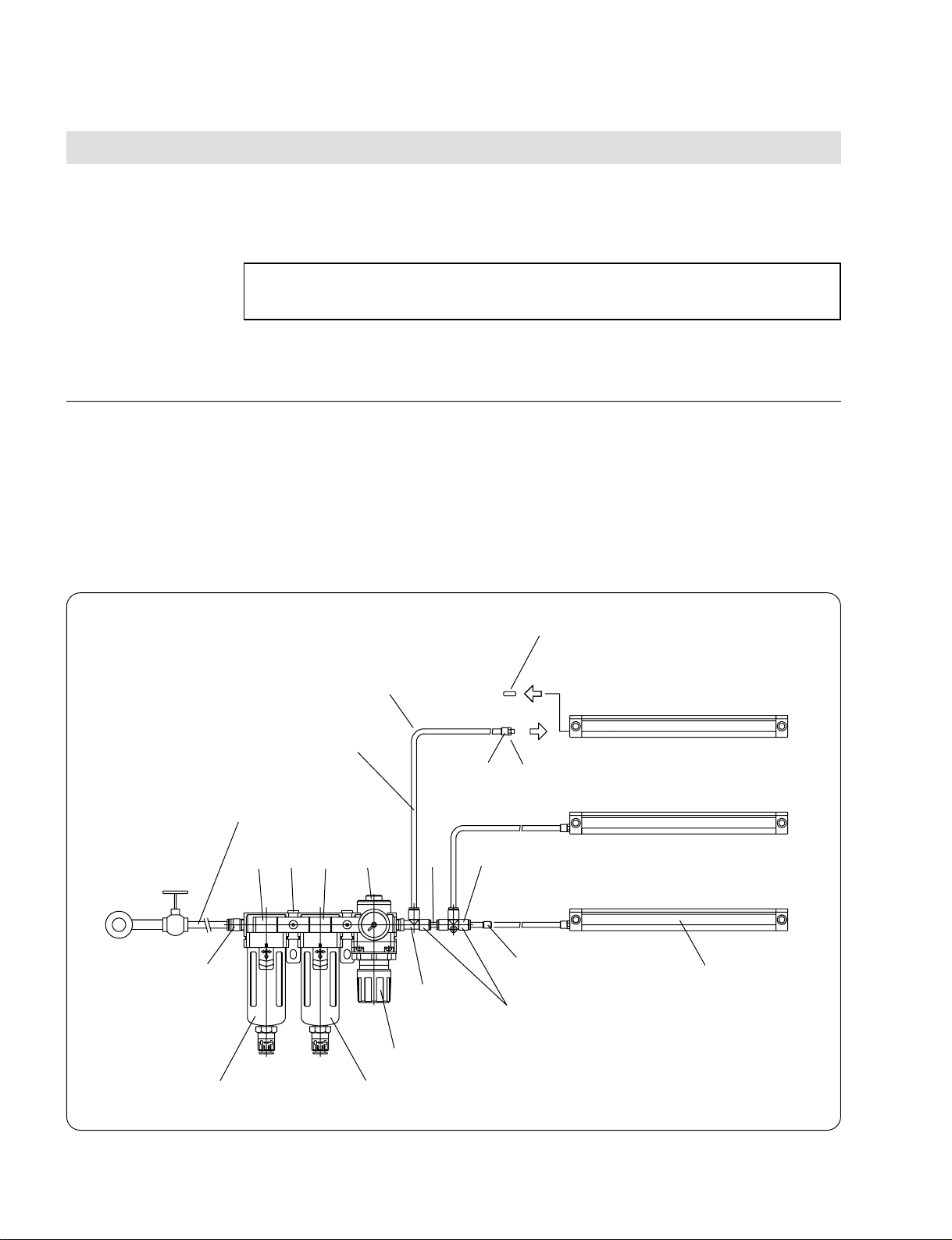

Air Tubing Route and Equipment Configuration

• Take into consideration the tubing route and other factors when choosing between

the left and right air intake ports.

Note that the air intake ports are capped with M5×5 hexagonal socket head locking

screws, which should be removed before use.

• Prepare the equipment and tubing as shown in the figure below to allow air to be

introduced into the scale unit.

Tube, bending radius 15 mm(0.59 in) or more

Polyurethane tube, outer diameter 6 mm(0.236 in)

inner diameter 4 mm(0.157 in)

Nylon tube, outer diameter 8 mm(0.315 in)

2

3

Air pressure source

1

4

5

M5×5 hexagonal socket head locking screws

Hose nipple

!º

8

7

9

6

Distributor

Pressure-reducing valve

Scale unit

2-14

Filter [nominal filtration rating

5 µm(0.000197 in)]

Mist separator [nominal filtration rating

0.3 µm(0.0000118 in)]

Page 27

• The air supply unit and fittings should be provided by the customer.

The tables below provide standard equipment specifications and component parts

(manufacturers) for reference.

Specifications

Item Specification

Proof pressure 1.5 MPa

Maximum service pressure 1020 kPa

Set pressure range 20 to 200 kPa

Service fluid Air

Ambient temperature and service fluid temperature –5 to +60°C (33 to 140°F)

(must not freeze)

Nominal filtration rating Air filter: 5 µm (0.000197 in)

Mist separator: 0.3 µm (0.0000118 in)

Pressure gauge connection diameter 2-Rc (PT) 1/8

Tubing connection diameter IN side: Outer diameter of tube 8 mm

(0.315 in) (one location)

OUT side: Outer diameter of tube

6 mm (0.236 in) (three locations)

Auto drain differential pressure 150 to 1020 kPa

Component Parts

Part No. Model No. Name Quantity Manufacturer

1 AF3000-02C Air filter 1 SMC

(nominal filtration rating: 5 µm (0.000197 in))

2 AFM3000-02C Mist separator 1 SMC

(nominal filtration rating: 0.3 µm (0.0000118 in))

3 AR3000-02G-1 Pressure-reducing valve 1 SMC

4 Y30L Spacer assembly with L-shaped bracket 2 SMC

5 KQH08-02S Half-union 1 SMC

6 KQY06-02S Service cheese union 1 SMC

7 KQT06-00 Cheese 1 SMC

8 KQN06-99 Nipple 1 SMC

9 KQP-06 Plug 3 SMC

10 M-5H6 Hose nipple 3 SMC

2-15

Page 28

Tubing

0

10

20

30

40

50

60

70

80

012345678910

Tube Installation

Ensure a tube bending radius of 15 mm (0.59 in) or more, and do not allow the tube to

bend sharply. Also, when installing tubes in parallel in electrical, hydraulic or other

ducts, make sure that the movement of the duct does not cause the tube to collapse.

Tube Length

To match the air intake pressure into each scale unit, always ensure that the tubes from

the air supply unit distributors to the intake ports are the same length.

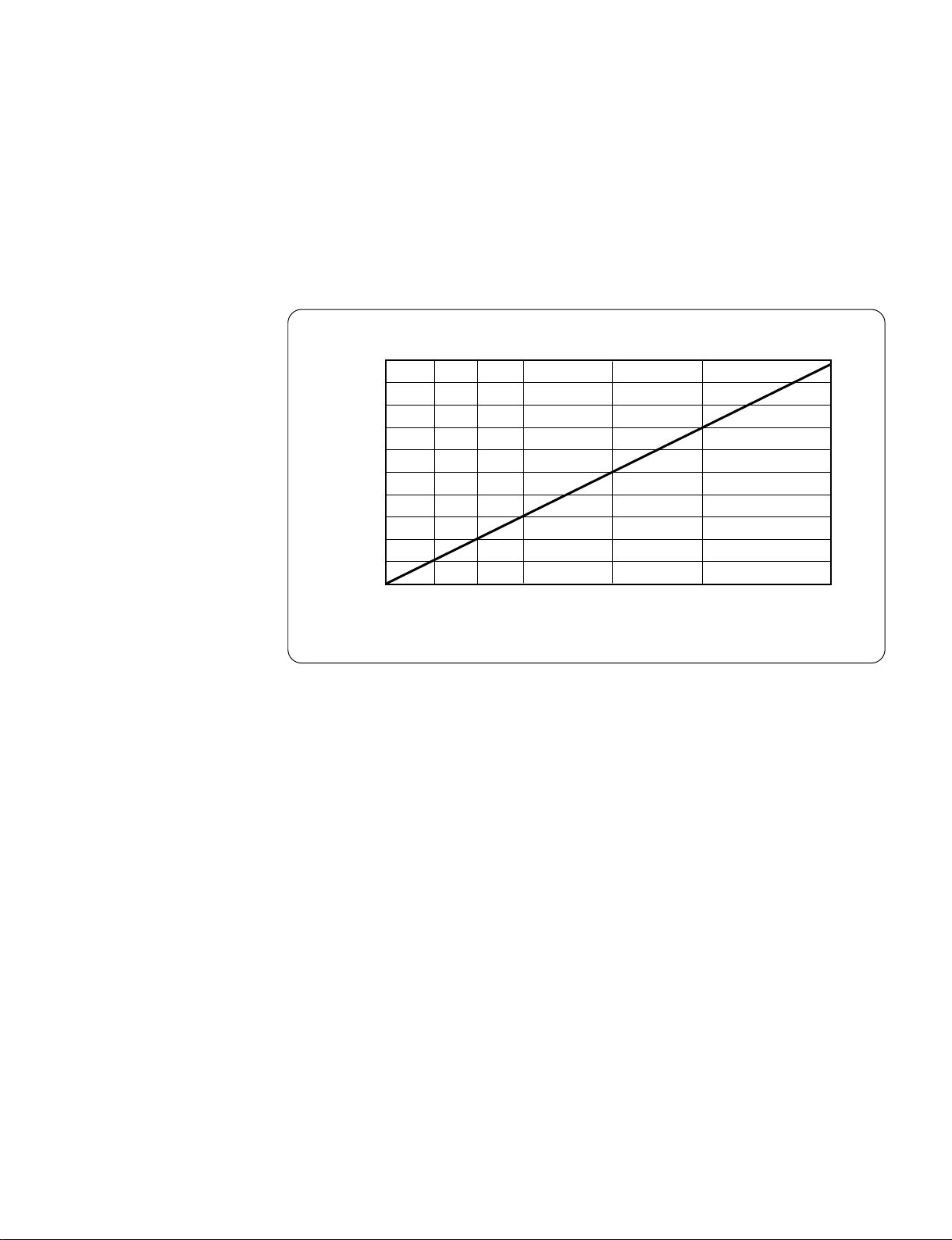

Pressure-Reducing Valve Set Pressure and Tube Length

If the intake air pressure into each scale unit is around 20±10 kPa, the humidity of the

air in the scale unit can be kept low. However, the length of the tube precludes the use

of the pressure-reducing valve to obtain an intake air pressure of 20±10 kPa.

Determine the set pressure for the pressure-reducing valve with reference to the

diagram below, “Pressure-Reducing Valve Set Pressure and Tube Length”.

Pressure-Reducing Valve Set Pressure

(kPa)

Polyurethane tubing length (outer dia. 6 mm (0.236 in), inner dia. 4 mm (0.157 in)

Pressure-Reducing Valve Set Pressure and Tube Length

This diagram shows the relationship between the set pressure for the pressurereducing valve and the tube length for an intake air pressure of 20 kPa.

Tube length here means the length from the distributor of the air supply unit to the

intake port of the scale unit.

When the intake air pressure is 20 kPa, the amount of air consumed for each unit is

2-16

approximately 30 Nr/min.

Flushing the Tubing

Using the air source, flush the air supply unit connection and the inlet portion leading

into the scale. This cleans the tubing, prevents debris from getting caught in the

machinery, and also serves as a check for the tubing.

Page 29

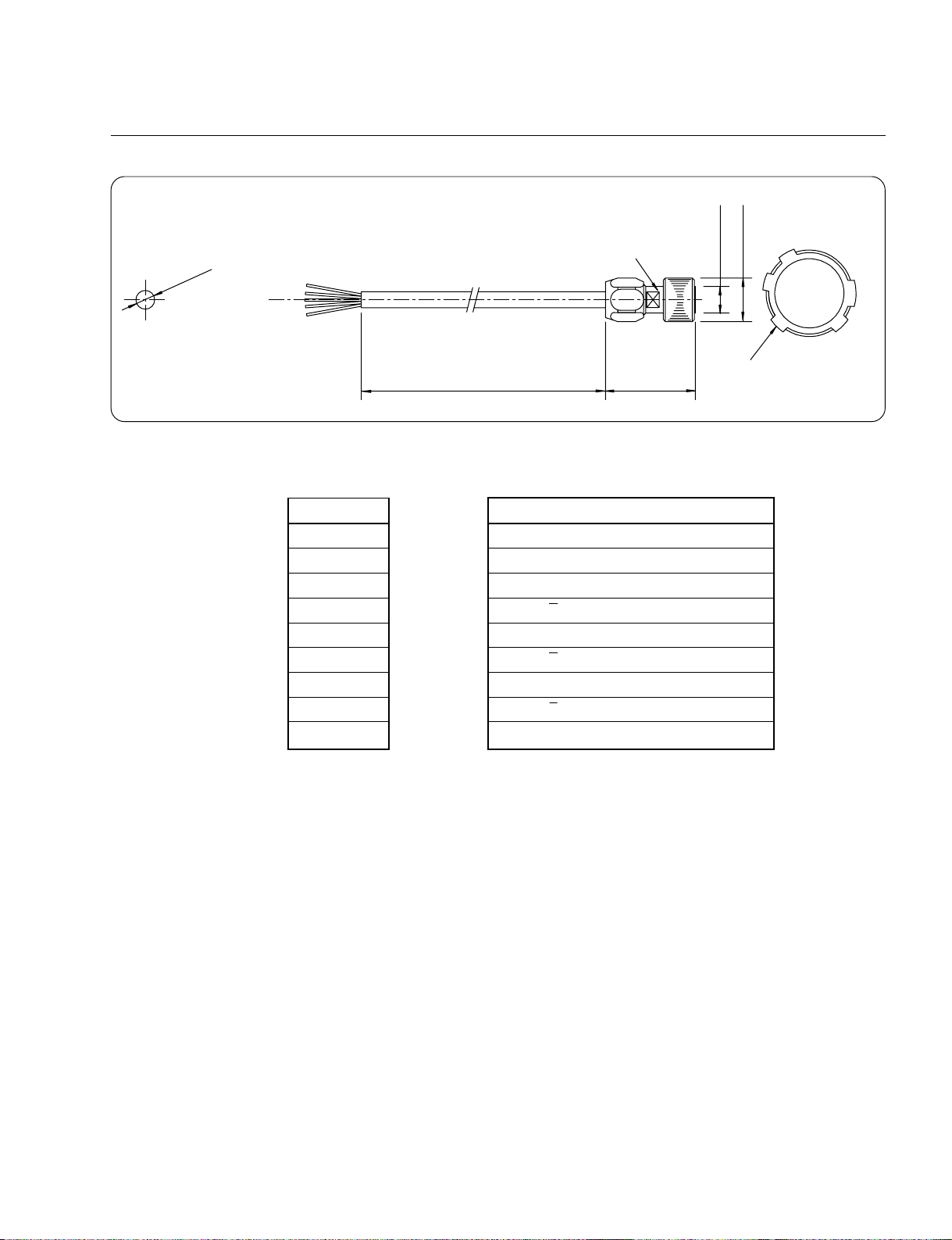

Air Pressure Source

When using a compressor as the air pressure source, select an appropriate

compressor in consideration of the volume of air to be consumed (approx. 30 Nr/min.

per unit). The following diagram, “Delivery Capacity and Rated Output”, may provide

some assistance in choosing the compressor, but note that specifications vary between

different models.

Delivery Capacity

(Nr/min.)

1000

800

600

400

200

0

0 1 2 3 5 7.5 10

Rated Output (PS)

Delivery Capacity and Rated Output

2-17

Page 30

Page 31

Chapter 3 Maintenance

3-1. Start-up Inspection

Checking for Open Circuits

The scanning unit is normally connected to the control unit by a connecting cable

through the cable (head cable) from the scanning unit. Both the head cable and

connecting cable must be checked if there is an open circuit. Shake the movable parts

of the head cable and connecting cable and confirm that the open circuit alarm is not

displayed on the control unit. If it is, the severed cable unit must be repaired. It is

extremely dangerous to continue operations without repairing the cable; immediately

stop the machine and contact your Sony Manufacturing Systems Corporation

distributor.

While checking the head cable, pay close attention to the connection with the scanning

unit and the junction connector. Also, when using a conduit connecting cable, check

very carefully as there may be open circuits caused by microscopic chips.

Checking for Dust Lip Wear

Look at the underside of the scale, and check to see if the edge of the dust lip is worn.

If it is, the scale glass and inside detector part must be cleaned and the dust lip

replaced. Contact your Sony Manufacturing Systems Corporation distributor.

Checking for Odd Noises

Slowly move the machine and listen to see if any odd noises occur. If so, the scale main

body and scanning unit may be in contact. Continuing operation in this condition may

lead to major breakdowns, so stop the machine immediately and contact your Sony

Manufacturing Systems Corporation distributor.

Strictly Enforce Cleaning

Ensure that chips are cleaned up before starting work and at the end of work each day

to prevent them from building up around the scale. Otherwise, chip buildup may prevent

the scale from sliding and cause breakdowns. Avoid using air guns or similar

devices for cleaning, because while the traveling part of the scale unit is sealed, it is

not completely sealed off for structural reasons. Use of an air gun may cause chips or

other debris to penetrate into the scale and cause breakdowns.

3-2. Regular Inspections

Presence of Condensation

If mist, condensation, dust or coolant (water-miscible cutting fluid) are present on the

dust lip of the scale unit, strengthen the cover and supply air to the unit.

3-1

Page 32

Page 33

Chapter 4 Specifications

4-1. General Specifications and Performance Specifications

General Specifications

Item Specification

Service temperature range 0°C to +45°C (32°F to 113°F)

Storage temperature range –10°C to +60°C (14°F to 141°F)

Service humidity range Relative humidity 30% to 90% (no condensation)

Rate of change of temperature, humidity A rate that does not cause condensation

Service environment No corrosive gas

Vibration resistance 68.6 m/s2 or less (30 to 1000 Hz for 30 min.)

Impact resistance 147 m/s2 or less (11 ms X, Y, Z directions, three times each)

Performance Specifications

Item Specification

Detection system Optical Moiré fringe detection system (transmission model)

Output system Two-phase signal (Phase A, Phase B), Line driver output

Light source and light-receiving device Infrared light-emitting diode, photodiode

Measuring length [mm(inch)] 20 lengths: 70(2.76), 120(4.72), 170(6.69), 220(8.66), 270(10.63),

320(12.60), 370(14.57), 420(16.54), 470(18.50), 520(20.47),

570(22.44), 620(24.41), 670(26.38), 720(28.35), 770(30.31),

820(32.28), 920(36.22), 1020(40.16), 1140(44.88), 1240(48.82)

Maximum response speed Resolution: 0.05 µm, t = 0.16 µs, 12 m/min.

t = 0.3 µs, 6 m/min.

Resolution: 0.1 µm, t = 0.16 µs, 24 m/min.

t = 0.3 µs, 12 m/min.

Zero point detection speed 0.05 µm 0.01 to 0.05 m/min

0.1 µm 0.01 to 0.2 m/min

Scale resolution 0.05 µm (0.00000195 in), 0.1 µm (0.0000039 in)

Glass grating pitch 16 µm (0.00063 in)

Scale zero point One point in the center for a measuring length of 70 mm (2.756 in),

otherwise, two points at the left and right ends inside the measuring

length.

Scale precision Measuring length

70(2.76) to 620(24.41) mm(in): ±2 µm

670(26.38) to 1240(48.82) mm(in): ±3 µm

Allowable mounting parallelism 0.05 mm (0.00197 in)

Precision proof temperature 20°C (68°F)

Glass thermal expansion coefficient (8.8 ± 1) ×10

Protection class IP53 (when used in accordance with the instruction manual)

Power supply and current consumption DC +5 V ±5%, 250 mA

-6

/°C

4-1

Page 34

4-2. Resolution and Response Speeds

Relationship between Resolution and Maximum Response Speed

Model Resolution Min. Phase Difference Grating Pitch Max. Response Speed

SH11-B1A 0.05 µm 0.16 µs 16 µm 12 m/min

SH11-B1B 0.05 µm 0.3 µs 16 µm 6 m/min

SH11-C1A 0.1 µm 0.16 µs 16 µm 24 m/min

SH11-C1B 0.1 µm 0.3 µs 16 µm 12 m/min

Relationship between Resolution and Zero Point Detection Speed

Model Resolution Min. Phase Difference Zero Point Detection Speed Range

SH11-B1A 0.05 µm 0.16 µs 0.01 to 0.05 m/min

SH11-B1B 0.05 µm 0.3 µs 0.01 to 0.05 m/min

SH11-C1A 0.1 µm 0.16 µs 0.01 to 0.2 m/min

SH11-C1B 0.1 µm 0.3 µs 0.01 to 0.2 m/min

Phase A

Phase B

tttt tttt

t = 10 to 15 µs

Time

Example of output waveform (Symbol: C1, t = 0.3 µs)

• Connect to a control unit able to read the

minimum phase difference (t).

• Set the minimum phase difference able to be read

by the control unit so that X < t when the (X) scale

minimum phase difference is set to (t).

• The A-phase and B-phase output signals are

output at intervals. The figure at left shows an

example when these signals are output at a fixed

speed exceeding the zero point detection speed.

4-2

Page 35

4-3. Electrical Characteristics

1. Output Waveform

Normal operation

Fault or

power on

(high impedance)

Phase A

Phase B

Zero point

A

A

Note

rr

•

r = P/4 (

B

rr

• The phase relationship between the zero

rr

r = scale resolution)

rr

point signal and phases A and B is not

B

specified.

• Perform zero point detection in a fixed

rr rr

P

direction.

• As shown in the figure at left, the output is

high impedance when the cable is severed

or a fault occurs in the scale. Therefore,

be sure to connect to a circuit that can

receive the signal at the control unit.

Z

Z

Te: 0.5 s Tf: 10 ms

Zero point position

Scale unit

2. Output Format

Scanning unit

AM26LS31 or equivalent

The above figure shows an output waveform when the scanning unit is

secured in place and the scale unit is moved from left to right.

A

A

B

B

IOH: –30 mA min

Z

Z

IOL: 30 mA max

VOH: +2.5 V min

OH

(at I

= –30 mA)

VOL: +0.5 V max

OL

(at I

= 30 mA)

4-3

Page 36

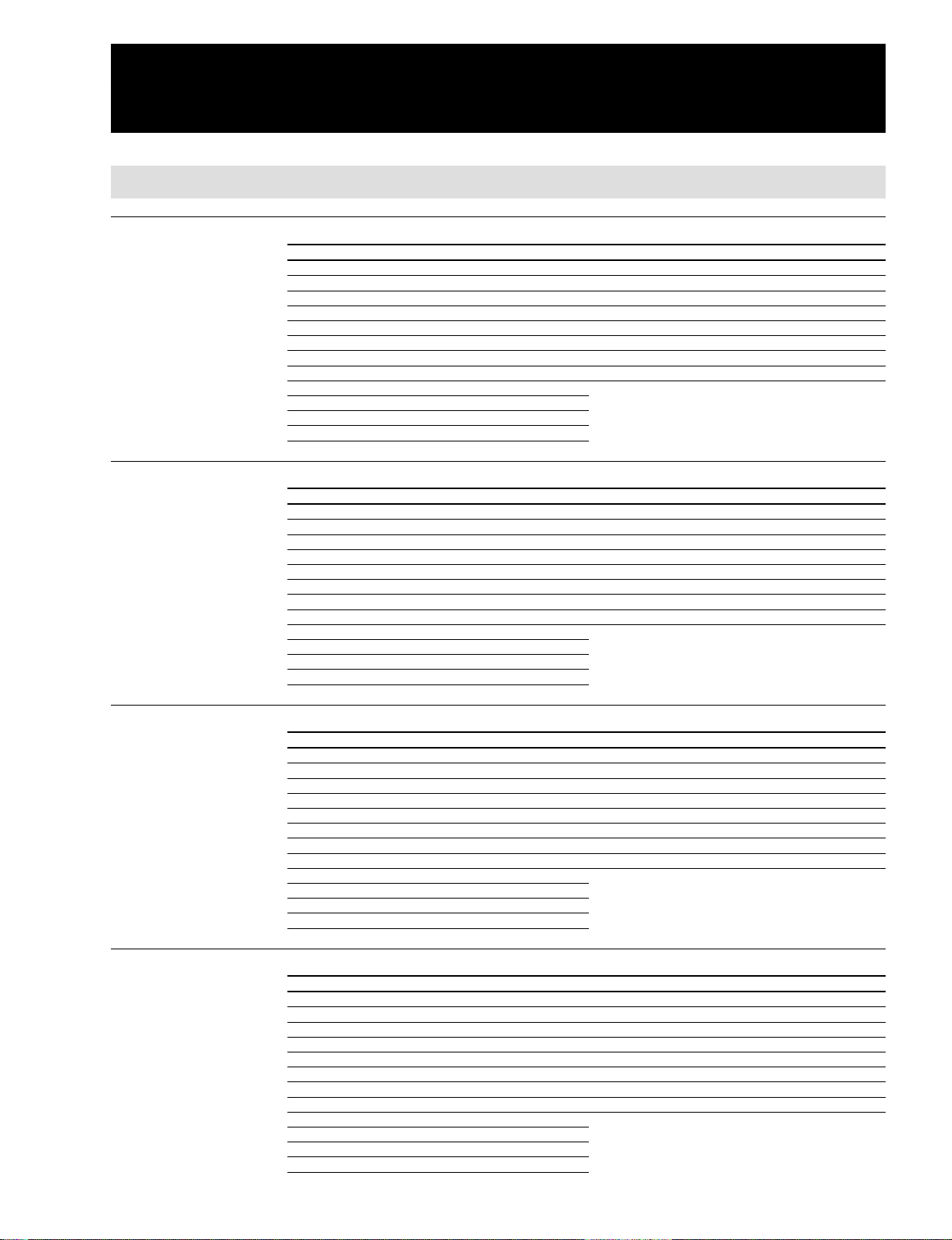

4-4. Cable Specifications

A connecting cable is used to join the scale unit and the control unit.

Whether or not to use a conduit connecting cable is specified by the shape of the

terminal that leads to the control unit.

When used in an environment where there is a concern that the cable segment might

be damaged, choose a conduit cable.

The connector has a dust-proof, drip-proof construction (except for the connector that

leads to the control unit).

The connector that leads to the control unit is fitted with a polarity switch, which can be

used to reverse the scale reading direction. This switch can be operated during use, but

doing so is extremely dangerous as it reverses the feedback signal. Attach a cover or

similar device to the polarity switch on the connector that leads to the control unit to

prevent against accidental operation.

Connecting Cable

Model

Cable length MR connector Mini Dsub connector Frayed tip

Conduit cable Conduit cable No conduit cable No conduit cable

2 m (78.7 in) CR1-02MC — CR1-02DC —

3 m (118.1 in) CR1-03MC — CR1-03DC —

5 m (196.9 in) CR1-05MC CR1-05DC — CR1-05NN

7 m (275.6 in) CR1-07MC CR1-07DC ——

10 m (393.7 in) CR1-10MC CR1-10DC — CR1-10NN

15 m (590.6 in) CR1-15MC CR1-15DC ——

20 m (787.4 in) CR1-20MC CR1-20DC — CR1-20NN

30 m (1181.1 in) CR1-30MC CR1-30DC — CR1-30NN

4-4

Page 37

Model CR1-

7

1

!£

8

@º

!¢

19.5(0.768)

MR-20F

MR-20LS1

39.3(1.55)

48(1.89)

ø10(0.394)

ø12(0.472)

ø19.6(0.772)

1

2

3

4

5

6

7

8

9

!º

!¡

!™

43.5(1.71)

Connector pin configuration

17(0.669)

Cable length

Polarity switch

Conduit cable

Connector: HR10WT 12P-12S

MC (MR connector, Conduit)

Wiring Chart

Wire Color MR-20F Pin No. Signal Name HR10WT Pin No.

Gray, purple 1, 2, 3 GND 6, 11

Shield 20 FG 7

Red 16 Phase A 2*

Orange 17 Phase A 8*

Yellow 18 Phase B 3

Green 19 Phase B 9

Black 14 Phase Z 4

Brown 15 Phase Z 10 (Zero point)

Blue, white 4, 5, 6 +5 V 5, 12

Unit [mm(in)]

*

This chart applies when the polarity switch on the connector is set to [I].

When the polarity switch is set to [II], phases A and A are substituted.

4-5

Page 38

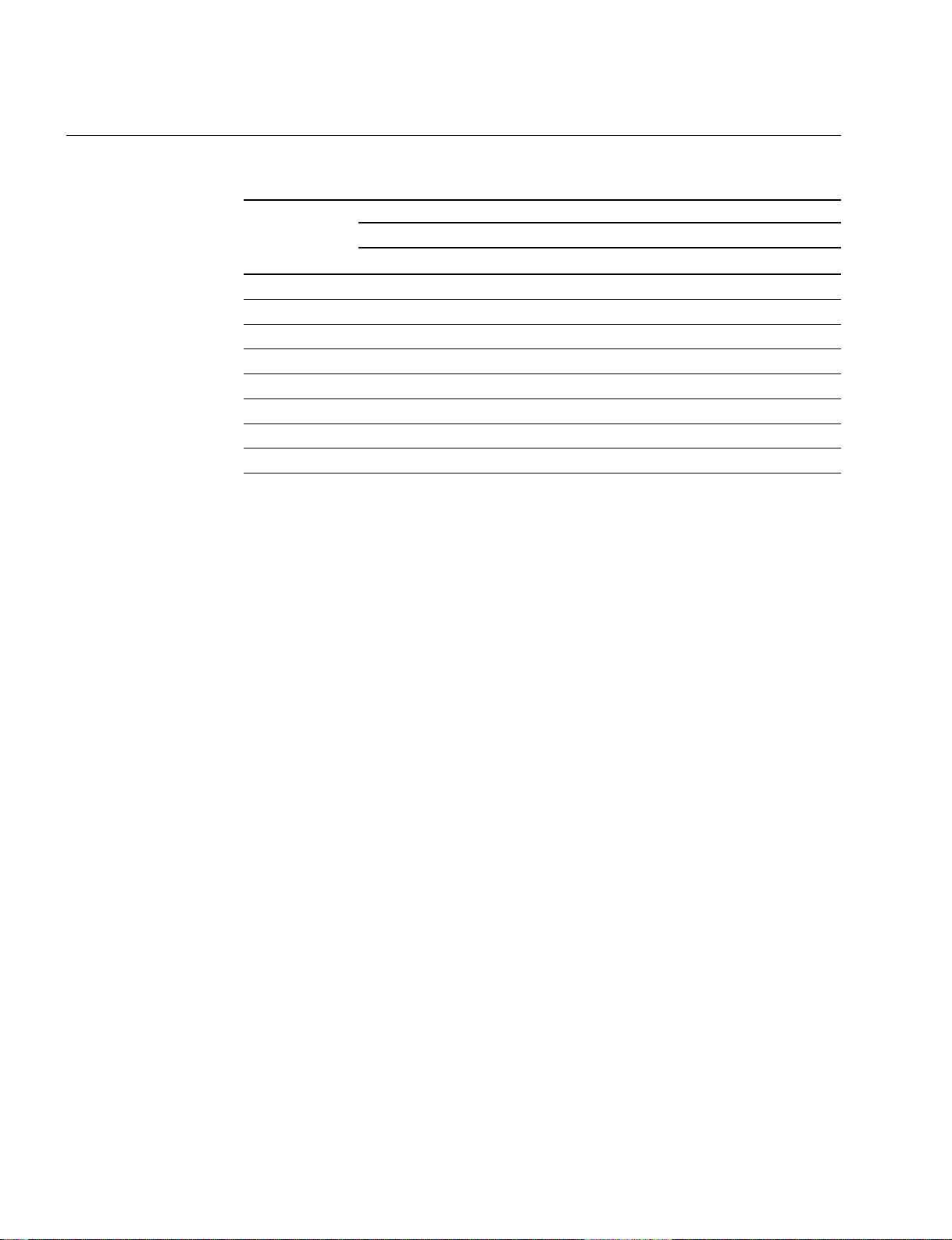

Model CR1-

DC (Mini Dsub connector, Conduit)

Crimped terminal ø6(0.236)

FI40-2015S

@º

!º

!•

!§

!¢

!™

1

12(0.472)

Model CR1-

FI40-2015S

@º

!º

!•

!§

!¢

!™

1

12(0.472)

FI-20-CV3

500(19.69)

Polarity switch

Earth wire

ø18

(0.709)

30(1.18)

42(1.65) 43.5(1.71)

DC (Mini Dsub connector, No conduit)

FI-20-CV3

Cable

length

seal

2000(78.74)

500(19.69)

Conduit securing nut

22(0.866)

Cable length

Polarity switch

Earth wire

30(1.18)

42(1.65)

Cable length

Connector: HR10WT 12P-12S

ø12

(0.472)

Connector pin configuration

Crimped terminal ø6(0.236)

Connector: HR10WT 12P-12S

ø12

43.5(1.71)

Connector pin configuration

ø19.6

(0.472)

ø19.6

(0.772)

(0.772)

7

8

6

!™

5

!º

1

!¡

4

2

3

Unit [mm(in)]

7

8

6

!™

5

!º

!¡

4

2

3

9

9

1

4-6

Wiring Chart

Wire Color FI140-2015S Pin No. Signal Name HR10WT Pin No.

Gray, purple 12, 14, 16 GND 6, 11

Shield — FG 7 (Earth wire)

Red 1 Phase A 2*

Orange 2 Phase A 8*

Yellow 3 Phase B 3

Green 4 Phase B 9

Black 5 Phase Z 4 (Zero point)

Brown 6 Phase Z 10

Blue, white 9, 18, 20 +5 V 5, 12

*

This chart applies when the polarity switch on the connector is set to [I].

When the polarity switch is set to [II], phases A and A are substituted.

Unit [mm(in)]

Page 39

Model CR1-

1

2

3

4

5

6

7

8

9

!º

!¡

!™

ø12(0.472)

ø19.6(0.772)

43.5(1.71)

Connector pin configuration

Cable length

Connector: HR10WT 12P-12S

ø7(0.276)

NN (Frayed tip, No conduit)

Wiring Chart

Wire Color Signal Name HR10WT Pin No.

Gray, purple GND 6, 11

Shield FG 7

Red Phase A 2

Orange Phase A 8

Yellow Phase B 3

Green Phase B 9

Black Phase Z 4 (Zero point)

Brown Phase Z 10

Blue, white +5 V 5, 12

......................

......................

......................

......................

......................

......................

......................

......................

......................

Unit [mm(in)]

4-7

Page 40

Precautions When Using the Connecting Cable

• Protecting the Connecting Cable Polarity Switch

A polarity switch is attached to the connector which leads to the control unit. This

switch can be reversed to suit the reading direction of the scale.

Note

This switch can be operated during use, but doing so is very dangerous, as this reverses the

feedback signal.

Attach a protective cover to the polarity switch on the connector that leads to the control unit so

that it cannot be operated accidentally.

• Minimum Connecting Cable Bending Radius

The connecting cable bending radii are as follows:

When the cable does not move during use ...... Bending radius: 50 mm (1.97 in) or more

When the cable moves during use .................. Bending radius: 100 mm (3.94 in) or more

• Extending the Connecting Cable

Do not extend the connecting cable to a length of more than 30 m (1181.1 in).

4-8

Page 41

Chapter 5 Appendix

5-1. Model Summary

Scale Unit (Resolution: 0.05 µm (0.00000195 in), minimum phase difference: 0.16 µs)

Measuring length Model Measuring length Model

70 (2.76) SH11-007B1A2 670 (26.38) SH11-067B1A3

120 (4.72) SH11-012B1A2 720 (28.35) SH11-072B1A3

170 (6.69) SH11-017B1A2 770 (30.31) SH11-077B1A3

220 (8.66) SH11-022B1A2 820 (32.28) SH11-082B1A3

270 (10.63) SH11-027B1A2 920 (36.22) SH11-092B1A3

320 (12.60) SH11-032B1A2 1020 (40.16) SH11-102B1A3

370 (14.57) SH11-037B1A2 1140 (44.88) SH11-114B1A3

420 (16.54) SH11-042B1A2 1240 (48.82) SH11-124B1A3

470 (18.50) SH11-047B1A2

520 (20.47) SH11-052B1A2

570 (22.44) SH11-057B1A2

620 (24.41) SH11-062B1A2

Scale Unit (Resolution: 0.05 µm (0.00000195 in), minimum phase difference: 0.3 µs)

Measuring length Model Measuring length Model

70 (2.76) SH11-007B1B2 670 (26.38) SH11-067B1B3

120 (4.72) SH11-012B1B2 720 (28.35) SH11-072B1B3

170 (6.69) SH11-017B1B2 770 (30.31) SH11-077B1B3

220 (8.66) SH11-022B1B2 820 (32.28) SH11-082B1B3

270 (10.63) SH11-027B1B2 920 (36.22) SH11-092B1B3

320 (12.60) SH11-032B1B2 1020 (40.16) SH11-102B1B3

370 (14.57) SH11-037B1B2 1140 (44.88) SH11-114B1B3

420 (16.54) SH11-042B1B2 1240 (48.82) SH11-124B1B3

470 (18.50) SH11-047B1B2

520 (20.47) SH11-052B1B2

570 (22.44) SH11-057B1B2

620 (24.41) SH11-062B1B2

Unit [mm (in)]

Unit [mm (in)]

Scale Unit (Resolution: 0.1 µm (0.0000039 in), minimum phase difference: 0.16 µs)

Measuring length Model Measuring length Model

70 (2.76) SH11-007C1A2 670 (26.38) SH11-067C1A3

120 (4.72) SH11-012C1A2 720 (28.35) SH11-072C1A3

170 (6.69) SH11-017C1A2 770 (30.31) SH11-077C1A3

220 (8.66) SH11-022C1A2 820 (32.28) SH11-082C1A3

270 (10.63) SH11-027C1A2 920 (36.22) SH11-092C1A3

320 (12.60) SH11-032C1A2 1020 (40.16) SH11-102C1A3

370 (14.57) SH11-037C1A2 1140 (44.88) SH11-114C1A3

420 (16.54) SH11-042C1A2 1240 (48.82) SH11-124C1A3

470 (18.50) SH11-047C1A2

520 (20.47) SH11-052C1A2

570 (22.44) SH11-057C1A2

620 (24.41) SH11-062C1A2

Scale Unit (Resolution: 0.1 µm (0.0000039 in), minimum phase difference: 0.3 µs)

Measuring length Model Measuring length Model

70 (2.76) SH11-007C1B2 670 (26.38) SH11-067C1B3

120 (4.72) SH11-012C1B2 720 (28.35) SH11-072C1B3

170 (6.69) SH11-017C1B2 770 (30.31) SH11-077C1B3

220 (8.66) SH11-022C1B2 820 (32.28) SH11-082C1B3

270 (10.63) SH11-027C1B2 920 (36.22) SH11-092C1B3

320 (12.60) SH11-032C1B2 1020 (40.16) SH11-102C1B3

370 (14.57) SH11-037C1B2 1140 (44.88) SH11-114C1B3

420 (16.54) SH11-042C1B2 1240 (48.82) SH11-124C1B3

470 (18.50) SH11-047C1B2

520 (20.47) SH11-052C1B2

570 (22.44) SH11-057C1B2

620 (24.41) SH11-062C1B2

Unit [mm (in)]

Unit [mm (in)]

5-1

Page 42

Connecting Cable (Connector, Conduit)

Cable length MR connector Mini Dsub connector Frayed tip

2 m (78.7 in) CR1-02MC — CR1-02DC —

3 m (118.1 in) CR1-03MC — CR1-03DC —

5 m (196.9 in) CR1-05MC CR1-05DC — CR1-05NN

7 m (275.6 in) CR1-07MC CR1-07DC ——

10 m (393.7 in) CR1-10MC CR1-10DC — CR1-10NN

15 m (590.6 in) CR1-15MC CR1-15DC ——

20 m (787.4 in) CR1-20MC CR1-20DC — CR1-20NN

30 m (1181.1 in) CR1-30MC CR1-30DC — CR1-30NN

Model

Conduit cable Conduit cable No conduit cable No conduit cable

5-2

Page 43

このマニュアルに記載されている事柄の著作権は当社にあ

り、説明内容は機器購入者の使用を目的としています。

したがって、当社の許可なしに無断で複写したり、説明内

容(操作、保守など)と異なる目的で本マニュアルを使用

することを禁止します。

The material contained in this manual consists of

information that is the property of Sony Manufacturing

Systems Corporation and is intended solely for use by

the purchasers of the equipment described in this

manual.

Sony Manufacturing Systems Corporation expressly

prohibits the duplication of any portion of this manual

or the use thereof for any purpose other than the

operation or maintenance of the equipment described

in this manual without the express written permission

of Sony Manufacturing Systems Corporation.

Le matériel contenu dans ce manuel consiste en

informations qui sont la propriété de Sony

Manufacturing Systems Corporation et sont destinées

exclusivement à l'usage des acquéreurs de

l'équipement décrit dans ce manuel.

Sony Manufacturing Systems Corporation interdit

formellement la copie de quelque partie que ce soit de

ce manuel ou son emploi pour tout autre but que des

opérations ou entretiens de l'équipement à moins

d'une permission écrite de Sony Manufacturing

Systems Corporation.

Die in dieser Anleitung enthaltenen Informationen

sind Eigentum von Sony Manufacturing Systems

Corporation und sind ausschließlich für den Gebrauch

durch den Käufer der in dieser Anleitung

beschriebenen Ausrüstung bestimmt.

Sony Manufacturing Systems Corporation untersagt

ausdrücklich die Vervielfältigung jeglicher Teile dieser

Anleitung oder den Gebrauch derselben für

irgendeinen anderen Zweck als die Bedienung oder

Wartung der in dieser Anleitung beschriebenen

Ausrüstung ohne ausdrückliche schriftliche Erlaubnis

von Sony Manufacturing Systems Corporation.

Page 44

Sony Manufacturing Systems Corporation

Isehara Plant

45 Suzukawa, Isehara-shi, Kanagawa 259-1146 Japan TEL: +81 (463) 92-7971 FAX: +81 (463) 92-7978

Sony Precision Technology America, Inc.

20381 Hermana Circle, Lake Forest, CA 92630, U.S.A. TEL: (949) 770-8400 FAX: (949) 770-8408

Sony Precision Technology Europe GmbH

Heinrich-Hertz-Strasse 1 , 70327 Stuttgart, Germany TEL: (0711) 5858-777 FAX: (0711) 580715

http://www.sonysms.co.jp/

Sony Manufacturing Systems Corporation

SH11 Series

3-861-878-14

1-10 Kiyoku-cho, Kuki-shi, Saitama 346-0035 Japan

2004.4

Printed in Japan

©1997 Sony Manufacturing Systems Corporation

Loading...

Loading...