SONY SCD XB940 Service Manual

SERVICE MANUAL

SUPPLEMENT-1

File this supplement with the service manual.

Subject:

1. Addition of Test Mode

2. Addition of Block Diagram and IC Pin

Function Description

SCD-XB940

AEP Model

UK Model

TABLE OF CONTENTS

1. TEST MODE.............................................................. 2

2. DIAGRAMS

2-1. Block Diagram – RF/SERVO Section –........................ 9

2-2. Block Diagram – MAIN Section (1/2) –....................... 10

2-3. Block Diagram – MAIN Section (2/2) –....................... 11

2-4. Block Diagram – AUDIO Section – .............................. 12

2-5. Block Diagram

– DISPLAY/POWER SUPPLY Section – ...................... 13

2-6. IC Pin Function Description ........................................... 14

1. TEST MODE

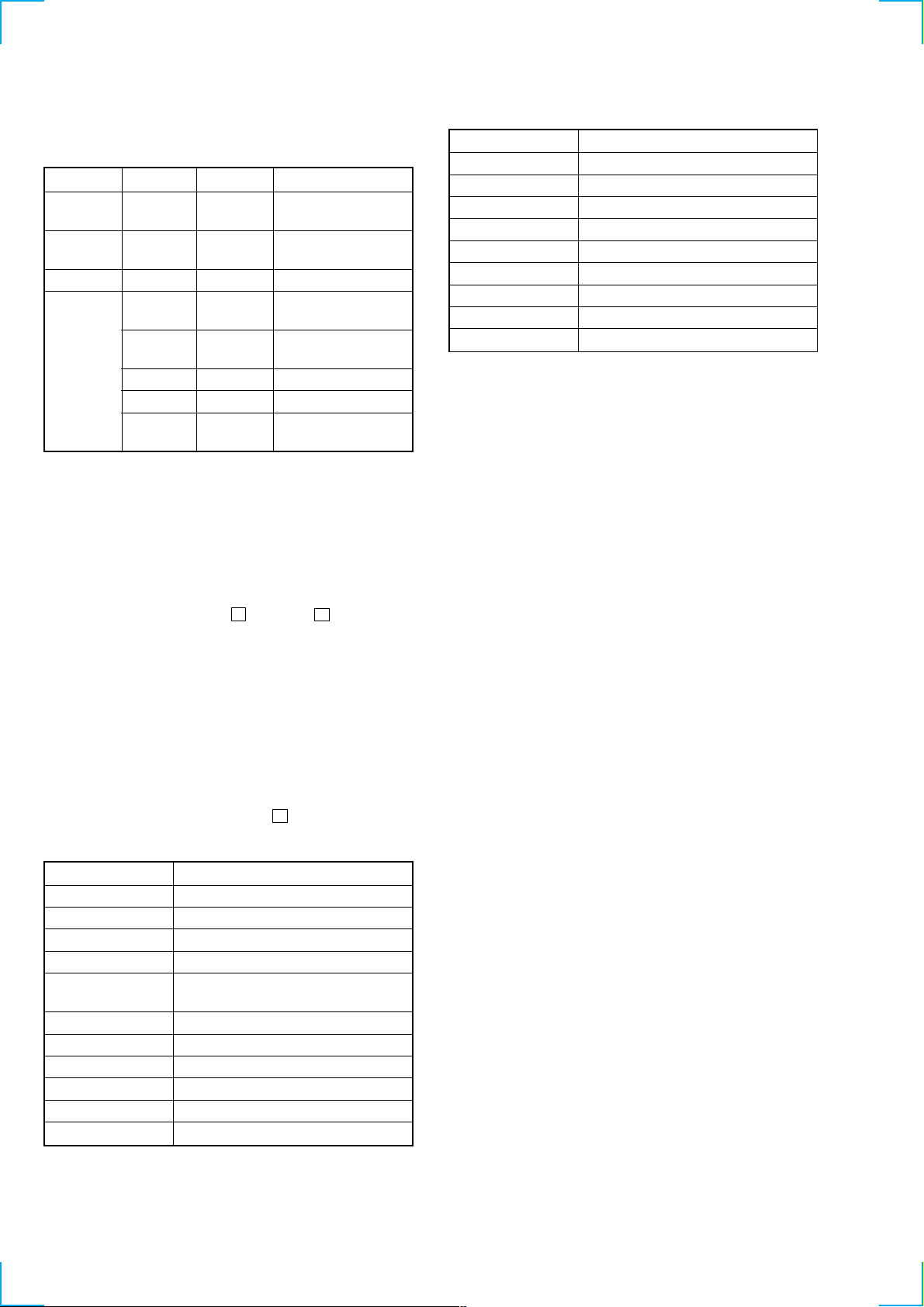

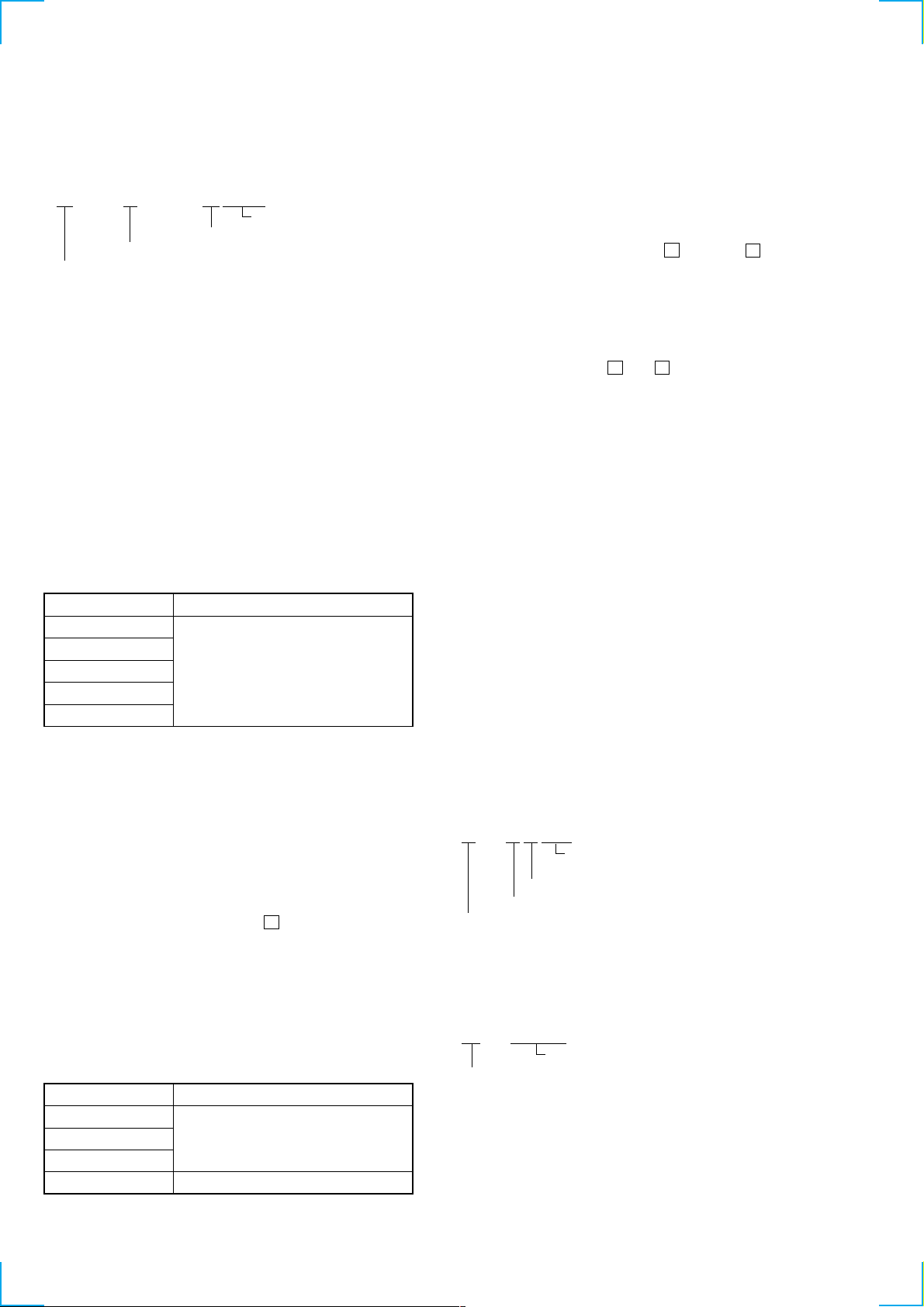

Jigs

• Disc

Model Type *1 Category Application

HLX-503/

HLX-504

HLX-501/

HLX-505

PATD-012 CD 12 cm adjustment and check

*2

*1 SL: Single Layer

DL: Dual Layer

*2 Normally do not use.

• Remote Commander

• Extension cable (MAIN board (CN601) ↔ DISPLAY board

(CN202)) (Part No. J-2501-195-A)

How to Enter the Test Mode

l L

With [ AMS ] controller pressed, turn the [POWER] switch

ON. Then, immediately press x button. If x button is not

pressed, the set will start in normal mode. When the Test mode is

activated, “Test Mode Menu” is displayed.

How to Exit the Test Mode

Turn the

Selection of Test Mode

To select “Test Mode Menu”, perform as follows.

(1) Rotating [ AMS ] controller, select the menu and press

l L

[ AMS ] controller to enter. (If the remote commander

is available, select and enter the number directly.)

(2) To return to the previous step, press X button.

Contents of “Test Mode Menu”

DISPLAY Contents of Menu

0. Syscon Diag Self diagnosis

1. Auto Adjust Servo adjustment (Auto)

2. Manual Opr Manual operation adjustment

3. Mecha Aging Mechanism aging

4. Emg History

5. Ver Info Version information display

6. RF Jit Disp RF jitter measured value display

7. PDM Mode Normally do not use

8. CDM Adjust Normally do not use

9. Set Up Init Initializing and restart

10. Sld Ship Pos Sled ship position

Execution of Test Mode Menu

0. Syscon Diag menu

From the “Test Mode Menu”, rotate

counterclockwise to select “0. Syscon Diag”. Press [ AMS ]

controller, and “SELF DIAG Menu” will be displayed. Rotating

SL 12 cm adjustment and check

DL 12 cm adjustment and check

HYBRID

-L1

HYBRID

-L0

SL 8 cm Check

CD 8 cm Check

HYBRID

-L1

12 cm adjustment and check

12 cm adjustment and check

8 cm Check

[POWER] switch OFF , and the Test mode is deactivated.

l L

Servo emergency history information

display

[ AMS ] controller

l L

l L

l L

[ AMS ] controller can select the following menu.

DISPLAY Contents of Menu

0. All (SELF) Self diagnosis of all items 1. – 7.

1. SRAM Self diagnosis of SRAM

2. EEPROM Self diagnosis of EEPROM

3. HGA Self diagnosis of HGA

4. Servo DSP Self diagnosis of servo DSP

5. ARP Self diagnosis of ARP

6. SACD Chip Self diagnosis of SACD chip

7. SD Bus Self diagnosis of SD Bus

8. Diag Hist Self diagnosis emergency history display

(1) 0. All (SELF)

From the “SELF DIAG Menu” display, rotate [ AMS ]

controller clockwise to select “0. All (SELF)”, and press

l L

[ AMS ] controller. Then, the self diagnosis of items 1. –7.

will be executed in the following order. At successful completion,

“All Success” is displayed and the set returns to the first step.

“0. All (SELF)” → “SRAM Check” → “ExSRAM Start” →

“ExRAM OK” → “EEPROM Check” → “EEPROM Start” →

“Check 00” → “Check 10” → “Check 20” → “Check 30” →

“Check 40” → “Check 50” → “Check 60” → “Check 70” →

“Check 80” → “Check 90” → “Check A0” → “Check B0” →

“Check C0” → “Check D0” → “Check E0” → “Check F0” →

“ EEPROM OK” → “HGA Check” → “HGA Start” → “HGA

OK” → “Servo DSP” → “SDSP Start” → “SDSP OK” → “ARP

Register” → “ARP Reg Start” → “ARP Reg OK” → “ARP Data”

→ “ ARP DBus Start” → “ARP DBus OK” → “ARP Address” →

“ ARP ABus Start” → “ARP ABus OK” → “ARP DRAM” →

“ ARP DRAM Start” → “Wait ...” → “ARP DRAM OK” → “DSD

Chp Bus” → “DSD Bus Start” → “DSD Bus OK” → “DSD Chp

DRAM” → “DSD DRAM Start” → “Wait ...” → “DSD DRAM

OK” → “SDBus Chec k” → “SDBus Start” → “W ait ...” → “SDBus

OK” → “All Success” → “ 0. All (SELF)”

In case of an error in the Self Diag mode, the diagnosis restarting

method can be selected in three ways, “QUIT”, “REPEAT” and

“CONTINUE”, which function as follows:

QUIT : Quit diagnosis and return to the menu.

REPEAT : Restart diagnosis from the address where an

error occurred.

CONTINUE : Restart diagnosis from the address next to the

one where an error occurred.

• The error codes are listed in Self diagnosis error code list. (see

page 8)

(2) 1. SRAM

From the “SELF DIAG Menu” display, rotate [ AMS ]

controller clockwise to select “1. SRAM” and press

l L

[ AMS ] controller.

Then, “ExSRAM Start” → “ExRAM OK” → “1. SRAM” will be

displayed and the check will finish.

(3) 2. EEPROM

From the “SELF DIAG Menu” display, rotate [ AMS ]

controller clockwise to select “2. EEPROM” and press

l L

[ AMS ] controller.

Then, the following will be displayed and the check will finish.

“EEPROM Start” → “Check 00” → “Check 10” → “Check 20”

→ “Check 30” → “Check 40” → “Check 50” → “Check 60” →

“Check 70” → “Check 80” → “Check 90” → “Check A0” →

“Check B0” → “Check C0” → “Check D0” → “Check E0” →

l L

l L

l L

2

“Check F0” → “EEPROM OK” → “2. EEPROM”

(4) 3. HGA

l L

From the “SELF DIAG Menu” display, rotate

controller clockwise to select “3. HGA” and press [ AMS ]

[ AMS ]

l L

controller.

Then, “HGA Start” → “HGA OK” → “3. HGA” will be displayed

and the check will finish.

(5) 4. Servo DSP

From the “SELF DIAG Menu” display, rotate [ AMS ]

l L

controller clockwise to select “4. Servo DSP” and press

[ AMS ] controller.

l L

Then, “SDSP Start” → “SDSP OK” → “4. Servo DSP” will be

displayed and the check will finish.

(6) 5. ARP Check

From the “SELF DIAG Menu” display, rotate [ AMS ]

l L

controller clockwise to select “5. ARP”.

• Checking items

DISPLAY Contents of Check

0. All Check Check of all items 1. – 4.

1. ARP Register ARP register check

2. ARP Data ARP data check

3. ARP Address ARP address check

4. ARP DRAM ARM DRAM check

1 1. ARP Register

From the “5. ARP” display, press [ AMS ] controller, and

l L

then “1. ARP Register” will be displayed.

l L

[ AMS ] controller once more, and then “ARP Reg

Press

Start” → “ARP Reg OK” will be displayed and the check will

finish.

2 2. ARP Data

From the “1. ARP Register” display, rotate [ AMS ] con-

l L

troller clockwise to select “2. ARP Data”.

l L

Press [ AMS ] controller, and then “ARP DBus Start” →

“ARP DBus OK” → “2. ARP Data” will be displayed and the

check will finish.

3 3. ARP Address

From the “1. ARP Register” display, rotate [ AMS ] con-

l L

troller clockwise to select “3. ARP Address”.

l L

Press [ AMS ] controller, and then “ARP ABus Start” →

“ ARP ABus OK” → “3. ARP Address” will be displayed and the

check will finish.

4 4. ARP DRAM

From the “1. ARP Register” display, rotate [ AMS ] con-

l L

troller clockwise to select “4. ARP DRAM”.

l L

Press [ AMS ] controller, and then “ARP DRAM Start” →

“Wait ...” → “ARP DRAM OK” → “4. ARP DRAM” will be displayed and the check will finish.

5 0. All Check

From the “1. ARP Register” display, rotate [ AMS ] con-

l L

troller counterclockwise to select “0. All Check”.

l L

Press [ AMS ] controller, and then the following will be

displayed and the check will finish.

“ARP Register” → “ARP Reg Start” → “ARP Reg OK” → “ARP

Data” → “ARP DBus Start” → “ARP DBus OK” → “ARP Ad-

dress” → “ARP ABus Start” → “ ARP ABus OK” → “ ARP DRAM”

→ “ARP DRAM Start” → “Wait ...” → “ARP DRAM OK” →

“Diag Success” → “0. All Check”

(7) 6. SACD Chip

From the “SELF DIAG Menu” display, rotate [ AMS ]

l L

controller clockwise to select “6. SACD Chip”.

• Checking items

DISPLAY Contents of Check

0. All Check Check of all items 1. and 2.

1. DSD Chp Bus

2. DSD Chp DRAM

Check presence of error in SACD DSD

Chp Bus

Check presence of error in SACD DSD

Chp DRAM

1 1. DSD Chp Bus

From the “6. SACD Chip” display, press

[ AMS ] controller,

l L

and then “1. DSD Chp Bus” will be displayed.

Press [ AMS ] controller once more, and then “DSD Bus

l L

Start” → “DSD Bus OK” → “1. DSD Chp Bus” will be displayed and the check will finish.

2 2. DSD Chp DRAM

From the “1. DSD Chp Bus” display, rotate [ AMS ] con-

l L

troller clockwise to select “2. DSD Chp DRAM”.

Press [ AMS ] controller, and then “DSD DRAM Start” →

l L

“Wait ...” → “DSD DRAM OK” → “DSD Chp DRAM” will be

displayed and the check will finish.

3 0. All Check

From the “1. DSD Chp Bus” display, rotate [ AMS ] con-

l L

troller counterclockwise to select “0. All Check”.

Press [ AMS ] controller, and then the following will be

l L

displayed and the check will finish.

“DSD Chp Bus” → “DSD Bus Start” → “DSD Bus OK” →

“DSD Chp DRAM” → “DSD DRAM Start” → “Wait ...” →

“DSD DRAM OK” → “Diag Success” → “0. All Check”

(8) 7. SDBus

From the “SELF DIAG Menu” display, rotate [ AMS ]

l L

controller clockwise to select “7. SDBus”.

Press [ AMS ] controller, and then “SDBus Start” →

l L

“Wait ...” → “SDBus OK” → “7. SDBus” will be displayed and

the check will finish.

(9) 8. Diag Hist

From the “SELF DIAG Menu” display, rotate [ AMS ]

l L

controller clockwise to select “8. Diag Hist”.

l L

Press [ AMS ] controller, and then “1.” will be displayed,

and as the [ AMS ] controller is rotated c lockwise, “2.” –

l L

“10.” will be displayed.

1. Auto Adjust Menu

From the “Test Mode Menu”, rotate [ AMS ] controller

l L

clockwise to select “1. Auto Adjust”.

l L

Press [ AMS ] controller, and then “Auto Adj Menu” will

be displayed, where you can select the following menu by rotating

l L

the [ AMS ] controller .

DISPLAY Contents of Adjustment

0. All (Adjust) Adjustment of all items 1. – 3.

1. SACD-SL SACD-SL adjustment

2. CD CD adjustment

3. SACD-DL SACD-DL adjustment

4. HYBRID HYBRID adjustment

5. All-Adj LFO

Adjustment of all items 1. – 3. with

LFO value

6. Memory Check Memory check

3

(1) 0. All (Adjust)

From the “Auto Adj Menu”, rotate [ AMS ] controller

clockwise to select “0. All (Adjust)”. Press [ AMS ] con-

l L

l L

troller, and then the servo setting data in the EEPROM will be

cleared and initialized. After that, set the disc following the message and press [ AMS ] controller, so that the adjustments

l L

1. – 3. are executed in order.

1 In setting a disc, the disc type and size necessary for adjust-

ment are displayed such as “Set SACD-SL 12”, and accordingly set the specified disc.

2 Each time the adjustment for one disc finished, the disc is

ejected. Replace it with the disc specified by the message.

3 In performing auto adjustment that requires the Loop Filter

Offset value to be adjusted, from the “Auto Adj Menu”, rotate

l L

[ AMS ] controller clockwise to select “5. All-Adj

LFO”. Set default value to the servo setting in the EEPROM,

and then perform the Loop Filter Offset adjustment.

For details of the adjustment, see (6) 5. All-Adj LFO.

(2) 1. SACD-SL (Single Layer Disc) Adjustment

From the “Auto Adj Menu”, rotate [ AMS ] controller to

select “1. SACD-SL”, and press [ AMS ] controller.

l L

l L

Following the message “Set SACD-SL 12”, insert the disc and

press [ AMS ] controller. Then, the adjustment will be exe-

l L

cuted in the adjustment values will be written to the EEPROM.

Upon completion, “Remove Disc” message is displayed and the

CD is ejected.

(3) 2. CD (CD Disc) Adjustment

From the “Auto Adj Menu”, rotate [ AMS ] controller to

select “2. CD”, and press [ AMS ] controller. Following

the message “Set CD 12”, insert the disc and press [ AMS ]

l L

l L

l L

controller. Then, the adjustment will be executed in theadjustment

values will be written to the EEPROM.

Upon completion, “Remove Disc” message is displayed and the

CD is ejected.

“L.F. OFFSET = 09”

Offset value

(00 ← 01 ← 02 ← 03 ← 04 ← 05 ← 06 ←

07 ← 08 ← 09 → 0A → 0B → 0C → 0D →

0E → 0F → 10 → 11 → 12 → 13 → 14 →

15 → 16 →17 → 18 → 19 → 1A → 1B →

1C → 1D .... → F8 → F9 → FA → FB → FC

→ FD → FE → FF)

Select L.F. OFFSET value and press [ AMS ] controller,

l L

and then the CD, SACD-SL and SACD-DL will be adjusted with

the L.F. OFFSET value specified here.

The subsequent operation is similar to that in (1) 0. All (Adjust).

(7) 6. Memory Check

The Memory Check displays the contents of servo setting stored

in the EEPROM.

From the “Auto Adj Menu”, rotate [ AMS ] controller

l L

clockwise to select “6. Memory Check”. “EEPROM Data” will be

displayed if [ AMS ] controller is pressed, or “CD” →

l L

“HYBR” → “SL” → “DL-L0” → “DL-L1” will be displayed if

l L

[ AMS ] controller is rotated clockwise.

At each mode display, press [ AMS ] controller and rotate

l L

[ AMS ] controller, and then the following will

l L

be displayed. (oo: HEX)

1 Contents of CD servo setting

CD FG = oo TG = oo

CD F0 = oo T0 = oo

CD L0 = oo EB = oo

CD JT = oo MT = oo

2 Contents of HYBR servo setting

H1 FG = oo TG = oo

H1 F0 = oo T0 = oo

H1 L0 = oo EB = oo

H1 JT = oo

(4) 3. SACD-DL (Dual Layer Disc) Adjustment

From the “Auto Adj Menu”, rotate [ AMS ] controller to

select “3. SACD-DL”, and press [ AMS ] controller. Fol-

l L

l L

lowing the message “Set SACD-DL 12”, insert the disc and press

[ AMS ] controller. Then, the adjustment will be executed

l L

in the following steps and the adjustment values will be written to

the EEPROM.

Upon completion, “Remove Disc” message is displayed and the

CD is ejected.

(5) 4. HYBRID (Hybrid Disc CD Layer) Adjustment

From the “Auto Adj Menu”, rotate [ AMS ] controller to

select “4. HYBRID”, and press [ AMS ] controller. Fol-

l L

l L

lowing the message “Set HYBRID 12”, insert the disc and press

[ AMS ] controller. Then, the adjustment will be executed

l L

in the following steps and the adjustment values will be written to

the EEPROM.

Howev er, if a hybr id disc (12 cm) is not availa ble, skip this adjustment. In this case, press the x button to quit the adjustment.

Upon completion, “Remove Disc” message is displayed and the

CD is ejected.

(6) 5. All-Adj LFO

From the “Auto Adj Menu”, rotate [ AMS ] controller

l L

clockwise to select “5. All-Adj LFO”.

Press [ AMS ] controller, and then “Press Enter” will be

l L

displayed, and press it once more, and then “EepDfltSet” → “L.F .

OFFSET=09” will be displayed. From the “L.F. OFFSET=09”

display, rotate [ AMS ] controller , and then the L.F.OFFSET

l L

value can be increased or decreased as shown below.

3 Contents of SL servo setting

SL FG = oo TG = oo

SL F0 = oo T0 = oo

SL L0 = oo EB = oo

SL JT = oo MT = oo

4 Contents of DL-L0 servo setting

D0 FG = oo TG = oo

D0 F0 = oo T0 = oo

D0 L0 = oo EB = oo

D0 JT = oo MT = oo

5 Contents of DL-L1 servo setting

D1 FG = oo TG = oo

D1 F0 = oo T0 = oo

D1 L0 = oo EB = oo

D1 JT = oo

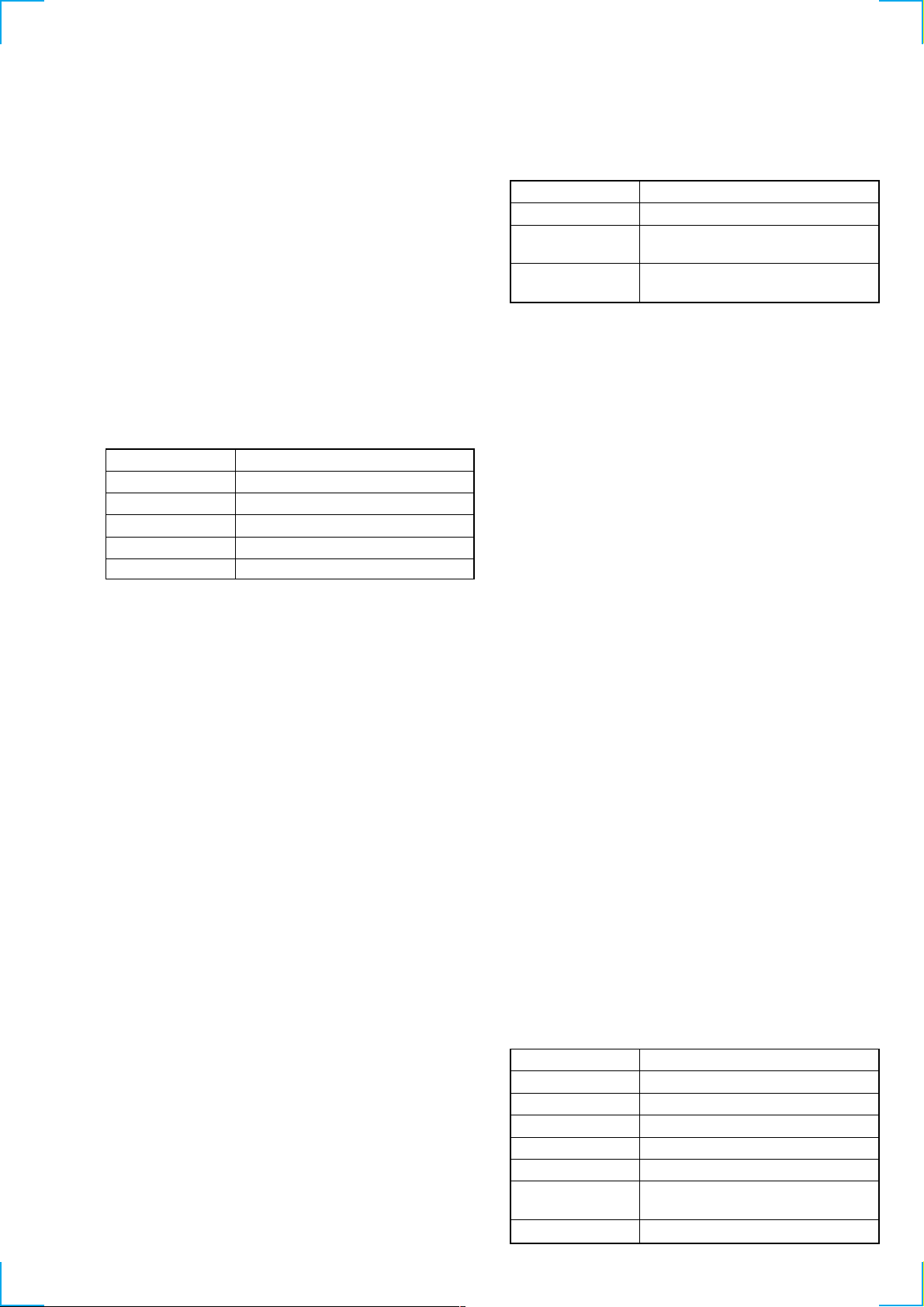

• How to See Error Code

If a fatal error occurred during adjustment and the adjustment could

not continue, the adjustment is interrupted and the error is displayed.

[Example]

Error 15 11 35

DSP error code

Mechanism error

Service command

This case shows “Focus ON command, DSP error, Sequence interrupted during Focus ON operation”.

4

Mechanism error code list (see page 7)

Service command list (see page 8)

DSP error code list (see page 8)

• Error Detection at the End of Adjustment

At the end of adjustment, whether the jitter is proper, and whether

the adjustment value is within allowable range are judged and displayed as a whole. If all parameters are within allowable range,

“Param Chk OK” will be displayed. If parameters out of the range

are detected, an error message such as “3 Errs occur” will be displayed (this case shows three errors occurred). Press [ AMS ]

l L

controller once to switch the display to the error list.

[Example]

1. SL TG High

Parameter type

Disc type

Error No.

This case shows “the track gain exceeds the upper limit in single

layer disc adjustment”. If you want to know more details, with the

above display, press again the [ AMS ] controller to display

l L

details.

Err: SL TG Prm

In this state, rotate again the [ AMS ] controller clockwise,

l L

and the following will be displayed.

M:7C E:3F U:27

Limit value (U: Upper limit, L:

Lower limit)

Value stored in EEPROM

Adjustment value

This case shows “adjustment value 7C exceeds the upper limit,

and EEPROM holds the last value 3F”.

l L

In this state, rotate again the

[ AMS ] controller clockwise,

and the judge result message will be displayed as follows:

“TG Too High”

To return to the previous step, or to exit from the error display,

press the X button.

2. Manual Opr Menu

From the “Test Mode Menu”, rotate [ AMS ] controller

clockwise to select “2. Manual Opr”. Press [ AMS ] con-

l L

l L

troller, and then “TiltSledReset” → “Manual Opr” will be displayed, where you can select the following menu by rotating the

l L

[ AMS ] controller clockwise.

DISPLAY Contents of Menu

1. Disc Type Disc type check

2. Srv Control Servo control

3. T/L Jump Tracking jump

4. Manual Adj Manual adjustment

5. Auto Adj Auto adjustment

6. Mem Check Servo memory check

0. Disc Chk Mem Disc check

(1) 1. Disc Type

From the “Manual Opr” menu, rotate [ AMS ] controller

clockwise to select “1. Disc Type”. Press [ AMS ] controller,

l L

l L

and then “Disc Type” will be displayed, where you can select the

following menu by rotating the [ AMS ] controller and

also can check each menu item by pressing the [ AMS ]

l L

l L

controller.

DISPLAY Contents of Menu

1. Type Auto Disc type is checked and the mode for

that disc is set.

2. SACD SL 12cm

3. SACD DL 12cm

4. CD 12cm

5. HYBR-L1 12cm

Disc type is set.

6. HYBR-L0 12cm

7. SACD SL 8cm

8. CD 8cm

9. HYBR-L1 8cm

0. RST Sld/Tlt Tilt/Sled are reset.

Note: For the hybrid disc, the HL1 (CD layer) mode is activated, and if

HD layer is to be played, use 6. HYBR-L0. However, for hybrid

disc (8 cm), only the CD layer can be played.

(2) 2. Srv Control

From the “Manual Opr” menu, rotate [ AMS ] controller

l L

clockwise to select “2. Srv Control”.

l L

Press [ AMS ] controller, and then “Srv Con” → “NO DISC”

→ “Srv Con 0000000” will be displayed, where you can select the

following menu by rotating the [ AMS ] controller clock-

l L

wise.

Note: Before “Servo Control”, “Disc Type Set” is needed.

DISPLAY Contents of Menu

1. LD

2. SD

3. Focus

(1: ON, 0: OFF)

4. TRK

5. SLED

6. CLVA

7. F-Sch Focus search

8. R S/T Tilt/Sled are reset.

FF/FR move up and down the Tilt respectively, while Prev/Next

Index move the Sled inward and outward respecti v ely. The operation stops when the x button is pressed. Until then, the commands

are issued successively, which could cause a trouble. Therefore,

normally do not use this menu.

• Checking method

Select each menu, and press the [ AMS ] controller, and

l L

then the following will be displayed for checking.

“1. LD” 1 0 0 0000

Focus Search ON

CLVA ON

Sled ON

Tracking ON

Focus ON

Spindle ON

LD ON

Execution command

The above case is that only the LD is turned on. Rotating

l L

[ AMS ] controller clockwise, turn on the servo in order of

1. – 6. to check the servo.

5

Also, with the servo of 1. – 6. turned on, press the [CHECK] button on the remote commander, so that you can check the disc type,

jitter, etc. To return to original display, press the [CHECK] button

again.

[Example]

SL 18 2A 020520

Sector address

CLV status

Jitter value

Disc type

CAUTION: In 7. F-Sch menu, the servo is not applied, thus causing opti-

cal system to be damaged if used together with other menu.

Never use it.

(3) 3. T/L Jump

This adjustment is not normally used.

(4) 4. Manual Adj

This adjustment is not normally used.

(5) 5. Auto Adj

This adjustment is not normally used.

(6) 6. Mem Check

From the “Manual Opr” menu, rotate [ AMS ] controller

clockwise to select “6. Mem Check”. Press [ AMS ]

l L

l L

controller, and then “EEPROM Data” will be displayed, where

you can select the following menu by rotating the [ AMS ]

l L

controller clockwise.

DISPLAY Contents of Menu

CD

HYBR

SL Servo setting check

DL-L0

DL-L1

1 Select each menu and press

l L

[ AMS ] controller, and

then the contents of servo setting stored in the EEPROM will

be displayed.

2 The contents of servo setting are same as those in (7) 6.

Memory Check of Auto Adjust menu. (See page 4)

3 In this menu, default value can be written to the EEPROM.

Press the [CLEAR] buttonon on the Remote commander,

“Deflt Set? Y/N” message will be displayed, and then press

[ AMS ] controller. When “EepDfltSet” message is dis-

l L

played, default value can be written to the EEPROM. To cancel default value setting, press the X button.

CAUTION: If you do “EepDfltSet”, after “EepDfltSet”, “Auto Adjust-

ment” is needed. (see page 3)

(7) 7. Disc Chk Mem

From the “Manual Opr” menu, rotate [ AMS ] controller

clockwise to select “0. Disc Chk Mem”. Press [ AMS ]

l L

l L

controller, and then “Disc Check” will be displayed, where you

can select the following menu by rotating the [ AMS ]

l L

controller clockwise.

DISPLAY Contents of Menu

1. SL Disc Chk

2. CD Disc Chk Disc Type Check

3. DL Disc Chk

0. Rst Sld/Tlt Tilt and Sled are reset.

• Select the menu 1. – 3. and press the [ AMS ] control-

l L

ler, and “New 3D” will be displayed, and then each display

corresponding to the selected menu 1. – 3. will return.

3. Mecha Aging Menu

This is the mechanism aging mode.

From the “Test Mode Menu”, rotate [ AMS ] controller

clockwise to select “3. Mecha Aging”. Press [ AMS ] con-

l L

l L

controller, and “Mecha Aging” → “Abort Stop Key” → “Press

Open Key” will be displayed. Press A button → G button in

this order, and the tray will be opened and closed repeatedly, and

its count will be displayed. Up to 2,147,483,647 times can be

counted. In such a case, the disc type is also checked.

[Example]

C: 2526

Number of counts

T o quit this operation, press x and X buttons. (Simultaneously,

the count is cleared.)

4. Emg History Menu

From the “Test Mode Menu”, rotate [ AMS ] controller

clockwise to select “4. Emg History”. Press [ AMS ] con-

l L

l L

troller, and “EMG History” message will be displayed. Rotating

l L

the [ AMS ] controller clockwise switches to the following

display where the servo emergency history (1. – 10.) and the laser

lighting hours are displayed.

1. 1F 06080000

2. 2F 06080000

3. 00 00000000

4. 00 00000000

5. 00 00000000

6. 00 00000000

7. 00 00000000

8. 00 00000000

9. 00 00000000

10. 00 00000000

LASR 0h

CD 0h

SACD 0h

Clear History?

1 How to see code

[Example]

11 06 04 C701

History buffer 2byte DSP error code

(see page 8)

History disc type (see page 8)

Mechanism mode (see page 8)

Mechanism error code (see page 7)

This case shows “DSP error, Spin up mode, SL 12cm, CLV unlock at Sled ON”.

Also, at this time, pressing [ AMS ] controller causes all

l L

emergency information (16 bytes) to be displayed every 4 bytes

for 4 items.

[Example]

1-1 00000000

Emergency information 1

Item No.: Varia ble each time the [ AMS ] controller is

l L

pressed

2 Laser lighting hours

[Example]

LASR 14h

CD 6h

SACD 8h

LASR displayed value is the total of CD and SACD laser lighting

hours. (The time less than minutes is omitted.)

6

3 History clear

• How to clear all history data

For the items with “Clear History?” message, press [ AMS ]

l L

controller, and all emergency history data and all laser lighting

hours are cleared to 0.

7. PDM Mode Menu

This mode is not normally used.

8. CDM Adj Menu

This mode is not normally used.

• How to clear individual data

1 Emergency history clear

Press

[DISPLAY MODE], [CLEAR] buttons on the remote com-

mander in this order.

2 Laser lighting hour clear

Press [SACD/CD], [CLEAR] buttons on the remote commander

in this order.

3 Setup clear

Press [REPEAT], [CLEAR] buttons on the remote commander in

this order.

Five backup data of [PLAY MODE], [CLEAR], [SACD/CD],

[TIME/TEXT], [DIGITAL FILTER] are cleared to the initial data.

5. Ver Info Menu

From the “Test Mode Menu”, rotate [ AMS ] controller

clockwise to select “5. Ver Info”. Press[ AMS ] controller, and “Version Info” message will be displayed. Rotating the

l L

[ AMS ] controller clockwise switches to the following dis-

play where the ROM version, date of creation, serv o DSP version,

and checksum are displayed.

[Example]

V1.00 00/02/14

SrvDSP 1.000

RomCsum 711C

6. RF Jit Disp

From the “Test Mode Menu”, rotate

clockwise to select “6. RF Jit Disp”. Press [ AMS ] controller, and then “Set Disc” message will be displayed. Set a disc and

l L

press [ AMS ] controller, and “Sinup...” will be displayed,

then the jitter will be measured and displayed. To exit from this

mode, press the X button.

<Jitter measurement and display example>

CD 22 2A 000000

Sector address

CLV status

Jitter value

Disc type (auto check)

SL : Single layer disc

HC: Hybrid layer disc, CD layer

HD: Hybrid layer disc, SACD layer

DL : Dual layer disc

CD: CD disc

1 The disc type is checked automatically.

2 For a hybrid disc, rotating the [ AMS ] controller can

switch the layer during jitter adjustment. Also, rotating the

[ AMS ] controller can jump to inner track, middle track,

l L

or outer track.However, the address is fixed. Music cannot be

searched. For a dual layer disc, a jump between layers is possible.

1. Play HD-HL0

2. Play CD-HL1

3. Jp Md1 Track

4. Jp Inn Track

5. Jp Out Track

6. Jp DL0 -> DL1

7. Jp DL1 -> DL0

3 Press A button to change the disc.

l L

l L

[ AMS ] controller

l L

l L

l L

9. Set Up Init Menu

From the “Test Mode Menu”, rotate [ AMS ] controller

clockwise to select “7. Set Up Init”. Press [ AMS ]

l L

l L

controller, and “Initialized” will be displayed, then “Reset? Y/N”

will be displayed. Press again [ AMS ] controller, and

l L

“Restart ...” will be displayed, and then the player will be reset

and restarted. (At the restart, the set exits from the Test mode.)

10. Sld Ship Pos Menu

Moving sled the fuctory set up position.

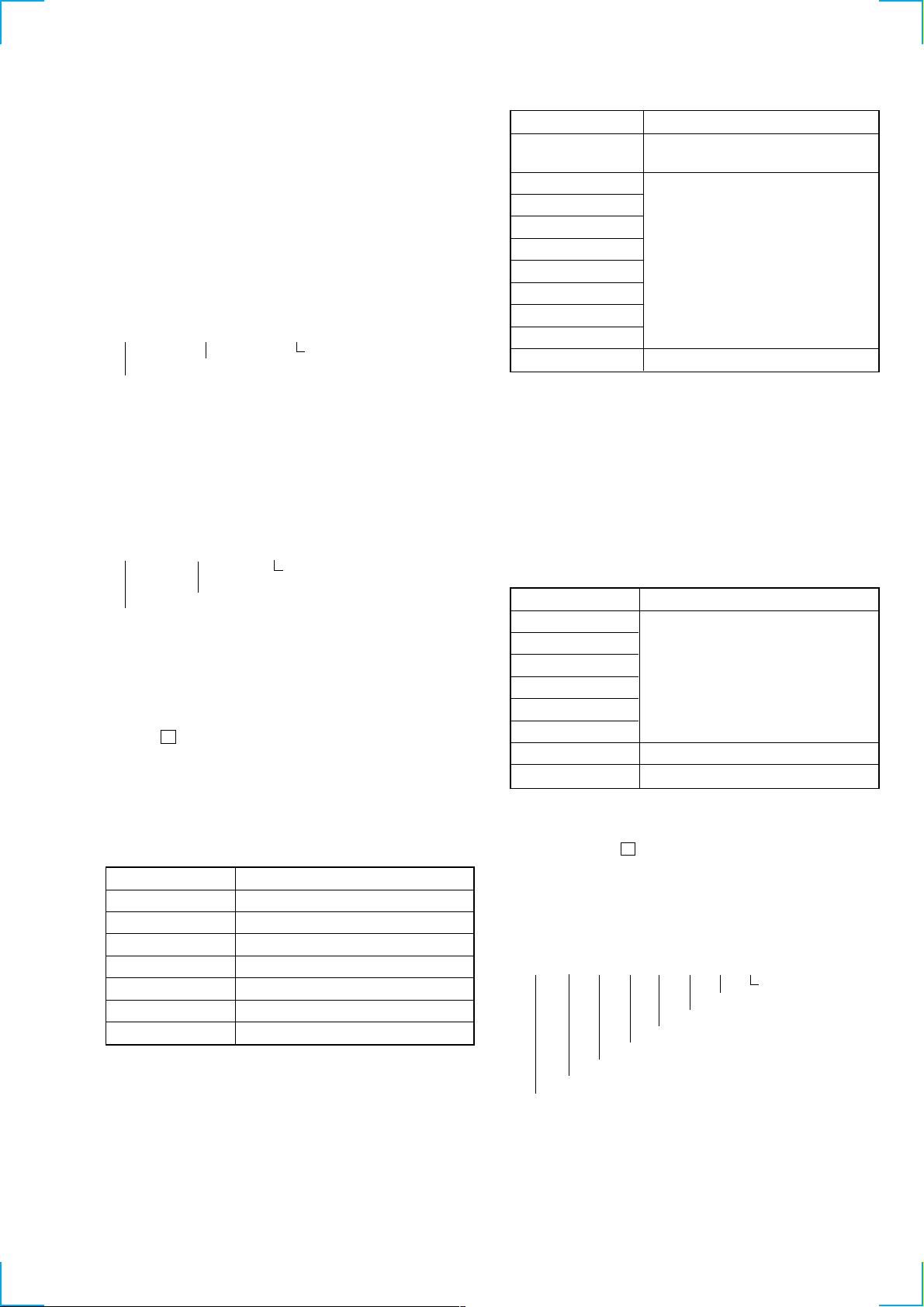

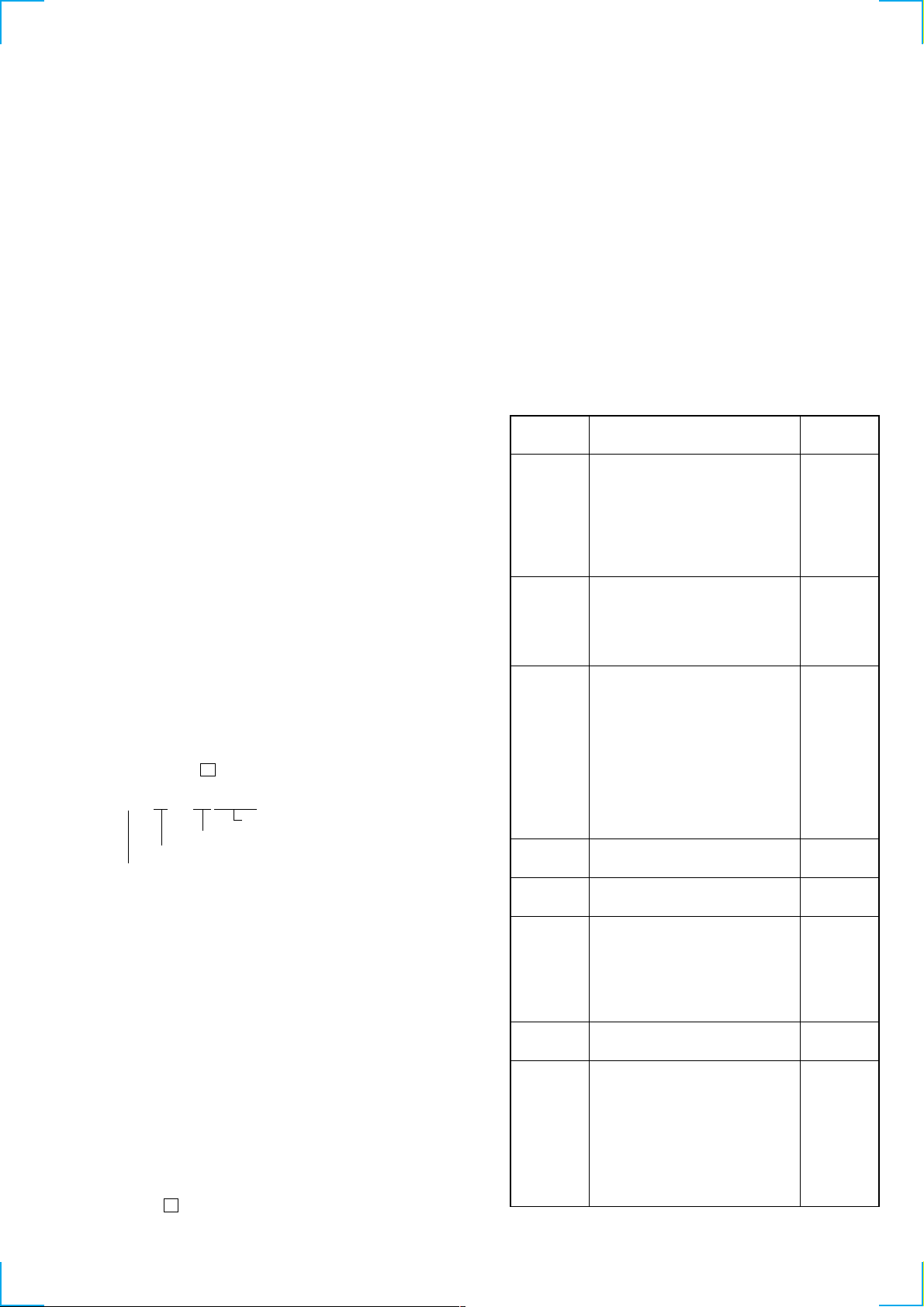

Mechanism error code

Category Emergancy Name

Emergency

Code

Electrical SSI ERR 10

DSP ERR 11

EEP ERR 12

EEP HOURS METER WRITE ERR 13

DSP BUSY TIME OUT 14

EEP CHECK SUM NG 15

DSP BUSY TIME OUT ESCAPE 16

Mechanism TILT SLED RESET NG 20

TILT MOVE NG 21

TILT REQ POSI NG 22

SLED MOVE NG 23

SLED REQ POSI NG 24

Adjustment ADJ TRK BAL NG 30

ADJ TRK GAIN 31

ADJ FCS BAL NG 32

ADJ FCS BIAS NG 33

ADJ FCS GAIN 34

ADJ TILT NG 35

ADJ EQ BOOST NG 36

ADJ GD NG 37

ADJ LAST JITTER NG 38

ADJ GAIN RANGE OVER 3F

Focus FOCUS NG F1

FOCUS JUMP COUNT OVER 41

Spindle CLV LOCK NG 1F

SPDL BRAKE COUNT OVER 51

Sheek SACD REQ ADR NG 60

CD REQ ADR NG 61

CD REQ INDEX NG 62

SACD SEEK COUNT OVER 63

CD SA SEARCH COUNT OVER 64

CD INDEX SEARCH COUNT OVER

65

Date SACD INFO NG 70

CD INFO TIME OUT 71

Other RECOVERY DISC CHECK NG DF

RECOVERY COUNT OVER 81

DISC CHECK ERR DF

DISC CHECK TIME OUT 83

INVALID CMD CODE 84

INVALID CMD 85

DUMMY JOB 86

NEXT MODE NONE 87

7

Loading...

Loading...