Page 1

SCD-1/777ES

SERVICE MANUAL

For Technical service

TABLE OF CONTENTS

US Model

Canadian Model

AEP Model

3. SERVICING NOTES ............................................... 3

4. DISASSEMBLY-2 ..................................................... 5

5. TEST MODE.............................................................. 10

6. ELECTRICAL ADJUSTMENTS......................... 12

7. DIAGRAMS

7-1. Notes for Printed Wiring Board and

Schematic Diagram ......................................................... 17

7-2. Printed Wiring Boards – RF/SLD-FG/SLD-MOT

Boards –........................................................................... 18

7-3. Schematic Diagram – RF/SLD-FG/SLD-MOT

Boards –........................................................................... 19

7-4. Printed Wiring Boards – LOAD-CN/LOAD-MOT/

LOAD-SW/STB Boards – .............................................. 20

7-5. Schematic Diagram – LOAD-CN/LOAD-MOT/

LOAD-SW/STB Boards – .............................................. 21

7-6. Printed Wiring Board – MAIN Board

(component side) –.......................................................... 22

7-7. Printed Wiring Board – MAIN Board

(conductor side) – ........................................................... 23

7-8. Schematic Diagram – MAIN Board (1/7) – .................. 24

7-9. Schematic Diagram – MAIN Board (2/7) – .................. 25

7-10. Schematic Diagram – MAIN Board (3/7) – .................. 26

7-11. Schematic Diagram – MAIN Board (4/7) – .................. 27

7-12. Schematic Diagram – MAIN Board (5/7) – .................. 28

7-13. Schematic Diagram – MAIN Board (6/7) – .................. 29

7-14. Schematic Diagram – MAIN Board (7/7) – .................. 30

7-15. Printed Wiring Board – AUDIO Board – ...................... 31

7-16. Schematic Diagram – AUDIO Board (1/2) – ................ 32

7-17. Schematic Diagram – AUDIO Board (2/2) – ................ 33

7-18. Printed Wiring Boards – BAL(SCD-1)/COAX/

OPT/PIN/SW Boards – ................................................... 34

7-19. Schematic Diagram – BAL(SCD-1)/COAX/

OPT/PIN/SW Boards – ................................................... 35

7-20. Printed Wiring Boards – DISPLAY/SW-L/

SW-R Boards –................................................................ 36

7-21. Schematic Diagram – DISPLAY/SW-L/

SW-R Boards –................................................................ 37

7-22. Printed Wiring Boards – AC/POWER Boards – ........... 38

7-23. Schematic Diagram – AC/POWER Boards –................ 39

7-24. IC Pin Function Description ........................................... 43

8. EXPLODED VIEWS ................................................ 50

9. ELECTRICAL PARTS LIST ............................... 59

Page 2

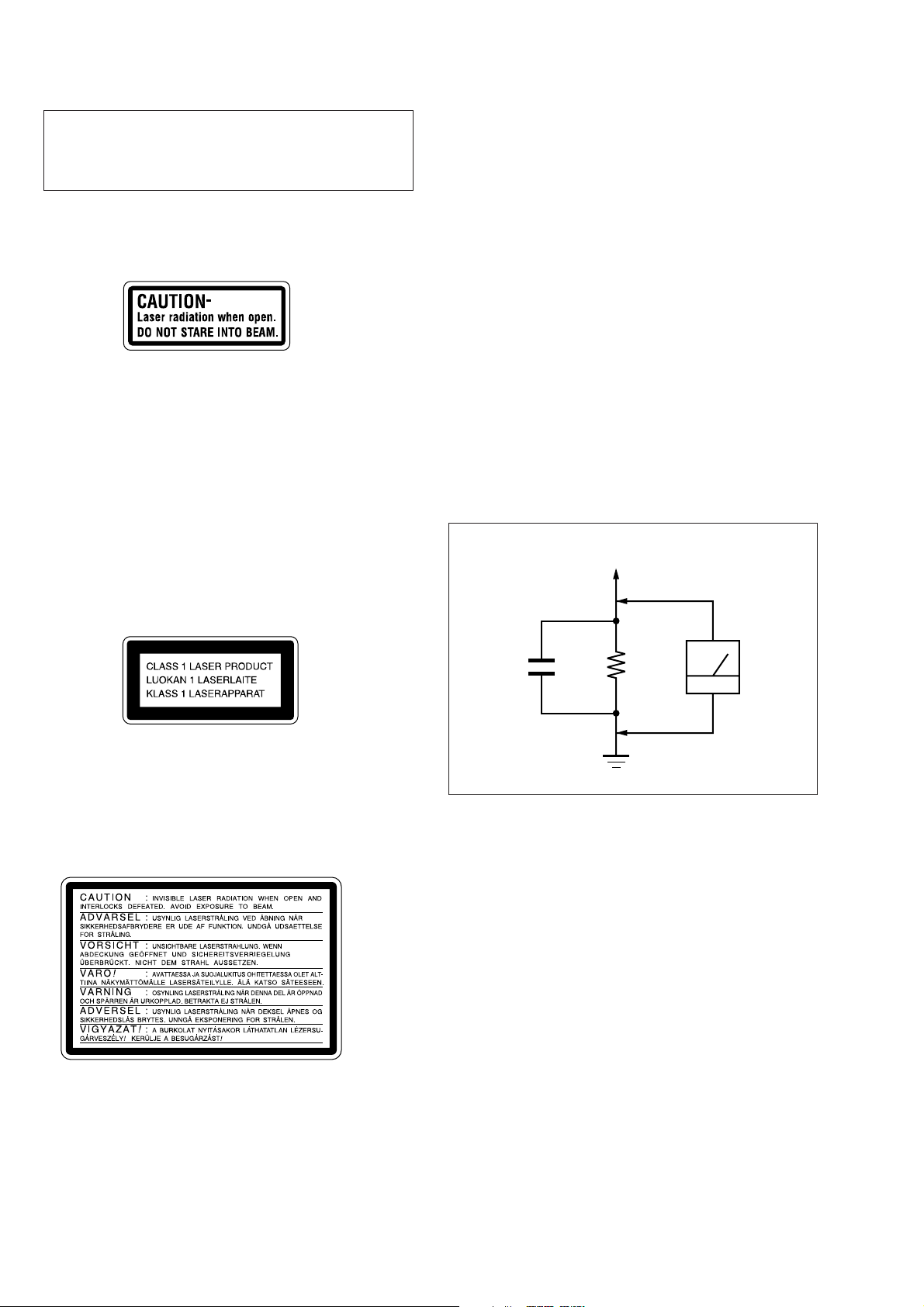

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

The following caution label is located

inside of the unit.

For the customers in Canada

CAUTION

TO PREVENT ELECTRIC SHOCK, DO

NOT USE THIS POLARIZED AC PLUG

WITH AN EXTENSION CORD,

RECEPTACLE OR OTHER OUTLET

UNLESS THE BLADES CAN BE FULLY

INSERTED TO PREVENT BLADE

EXPOSURE.

For the customers in Europe

This appliance is classified as a CLASS 1

LASER product.

The CLASS 1 LASER PRODUCT

MARKING is located on the rear exterior.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

AC

0.15 µF

1.5 k

Ω

voltmeter

(0.75 V)

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

2

Page 3

SECTION 3

t

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objecti ve lens.

MODEL IDENTIFICATION

– Back Panel –

CHECKING METHOD OF MICROCOMPUTER ROM

VERSION

1. Set the CD1/CD2 switch on the remote commander to CD1.

2. With the power turned on, press the [CHECK] button on the

remote commander while pressing the [TEXT] button on the

set.

3. 15-digit numeric value will be displayed, and the top 4 digits

(left side) of the numeric value imply the microcomputer ROM

version.

Example: If “200006100FFFF3C” is displayed, the ROM ver sion is 2.000.

4. To cancel the ROM version check mode, press the [CHECK]

button on the remote commander while pressing the [TEXT]

button on the set.

DISPLAY OF TOC ERROR

Display Contents

TOC ERROR

TOC ERROR

Illegal SACD disc (pirate edition)

****

Not SACD (DVD disc etc.)

*

Part No.

Model Part No.

SCD-1: US, Canadian 4-215-784-1

SCD-1: AEP 4-215-784-2

SCD-777ES: AEP 4-221-854-0

SCD-777ES: US, Canadian 4-221-854-1

s

s

s

s

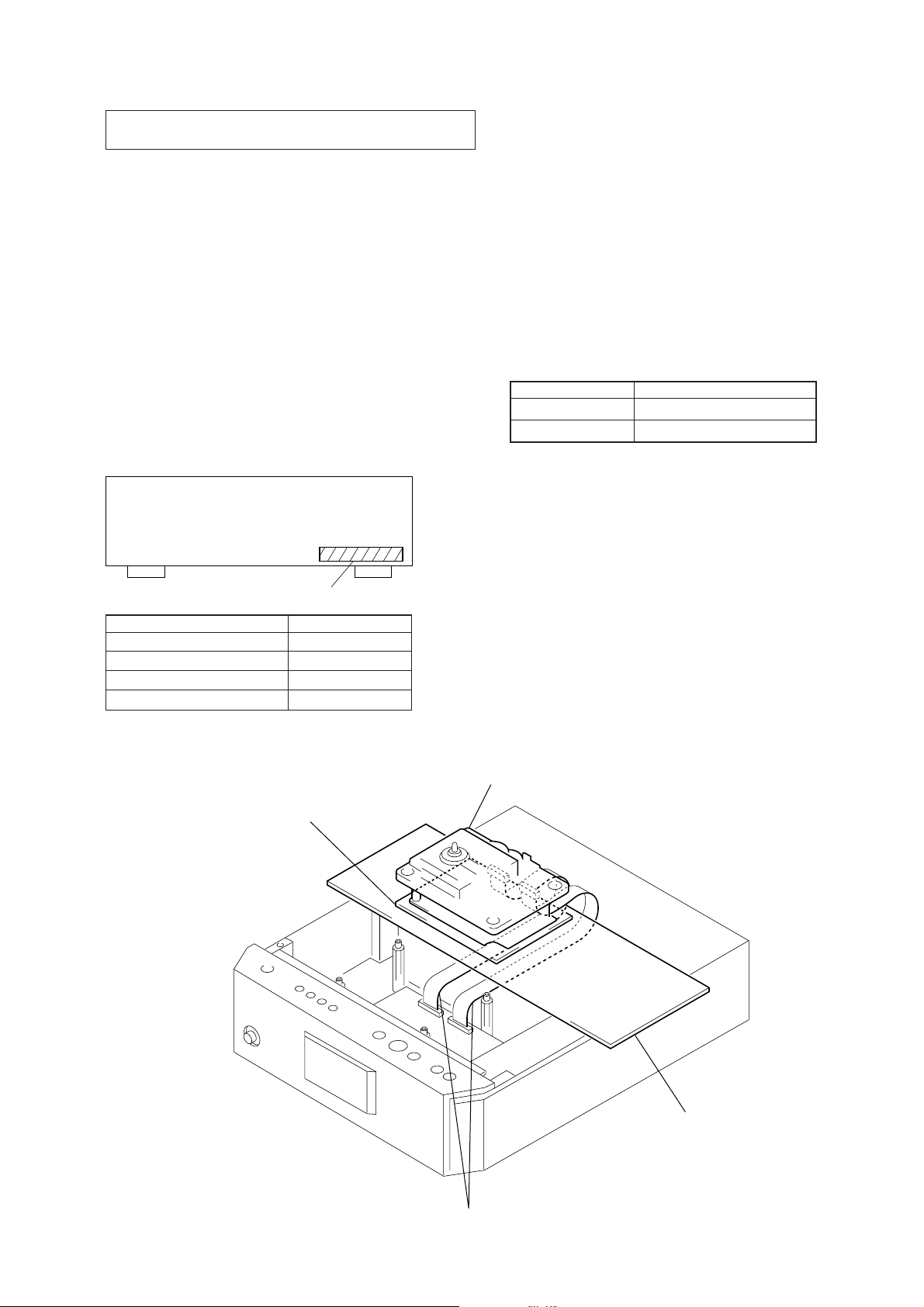

SERVICE POSITION

In checking the BU section, prepare two new jigs (extension cable J-2501-164-A: 1.00 mm 26 cores).

OP mechanism section (BU-23)

insulator

connect two jigs (extension cable J-2501-164-A) to the RF board

(CN001, 002) and Main board (CN501, 502).

Any board to pu

3

Page 4

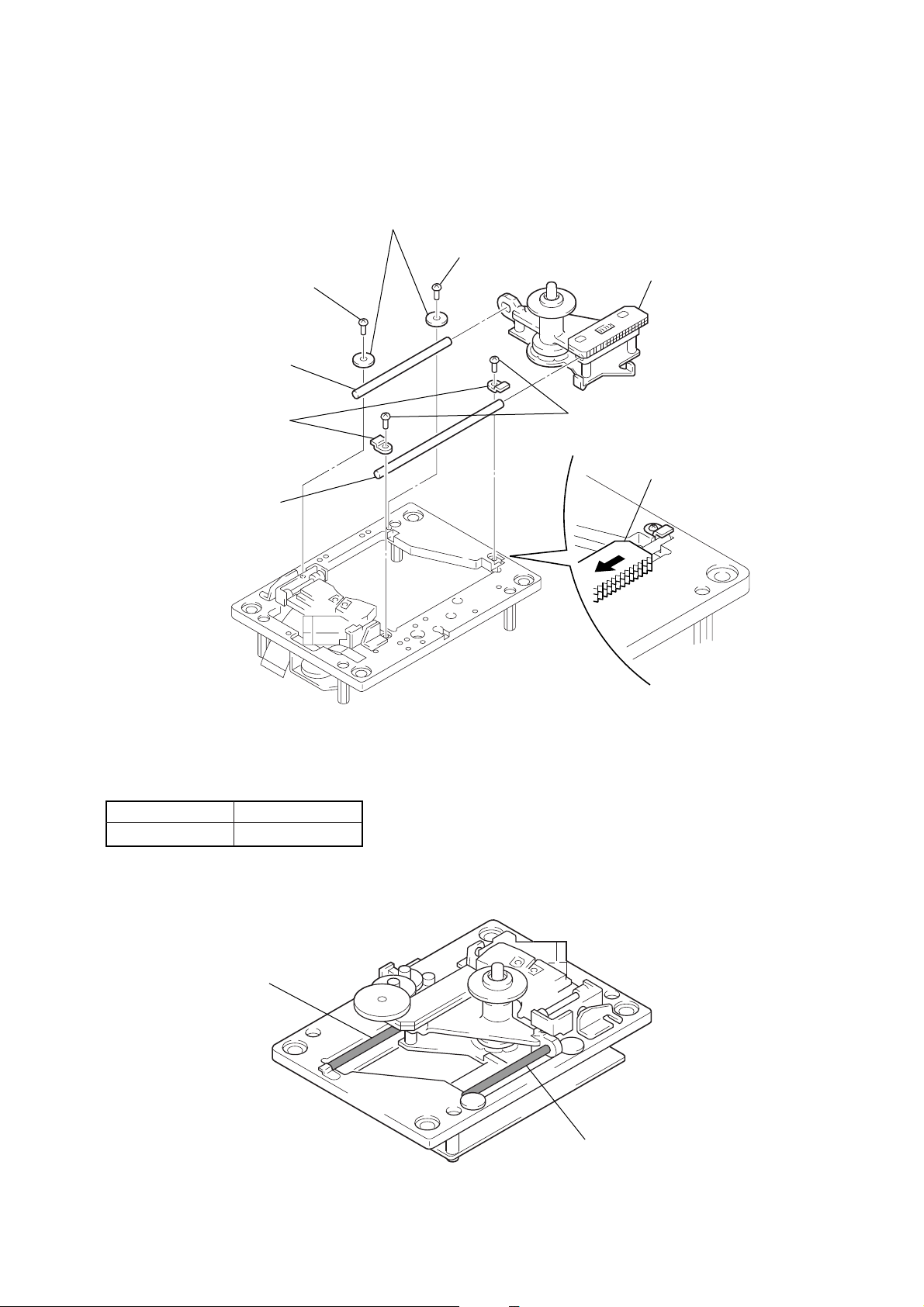

REPLACING OPTICAL PICK-UP

Handling

1) A red laser diode for Super Audio CD Player requires more

attention to static electricity than general infrared laser diodes

for CD.

Because its durability to static electricity is far weaker than

that of infrared laser diodes, always use an earth band when

handling the optical pick-up block as service parts.

2) As for the flexible board KHS-180A (RP) packed as service

parts, the short lands have been soldered to protect from static

electricity. Accordingly, remove solders when replacing optical pick-up. (See Fig. 1)

DVD short land

3) In handling the KHS-180A (RP), do not touch inhibited parts

shown in Fig. 2, but grip the slide base bearing and U-shaped

guide.

Slide base bearing

Skew sensor

Lens actuator

covers

Objective lenses

CD short land

Fig. 1 Flexible board

Laser holder

U-shaped guide

OEIC

Touch inhibited parts

• Objective lens

• Skew sensor

• Laser holder

• Laser coupler

• Flexible board

• OEIC

• Lens actuator covers

Flexible board

Connector

Laser coupler

Fig. 2 KHS-180A (RP)

4

Page 5

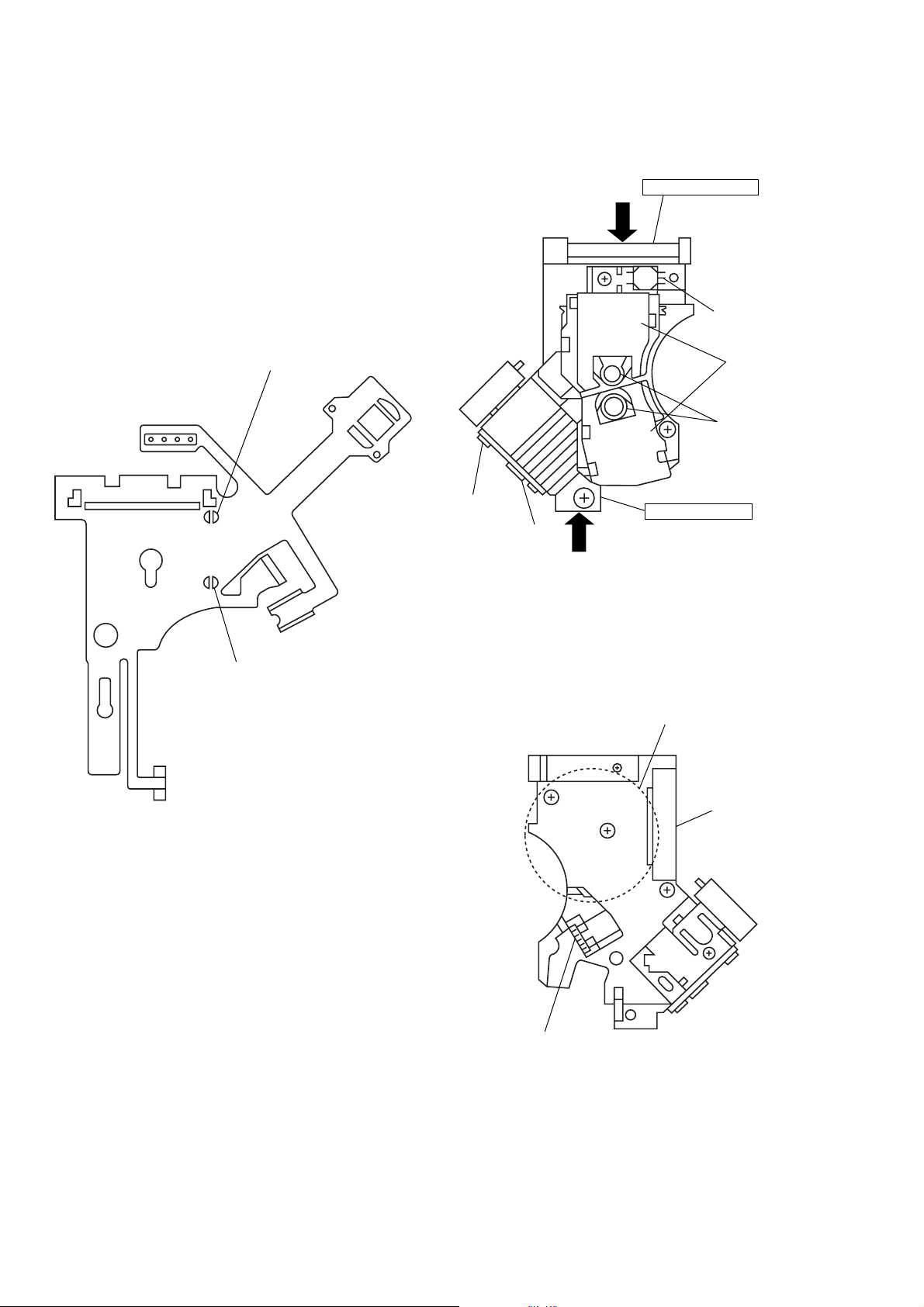

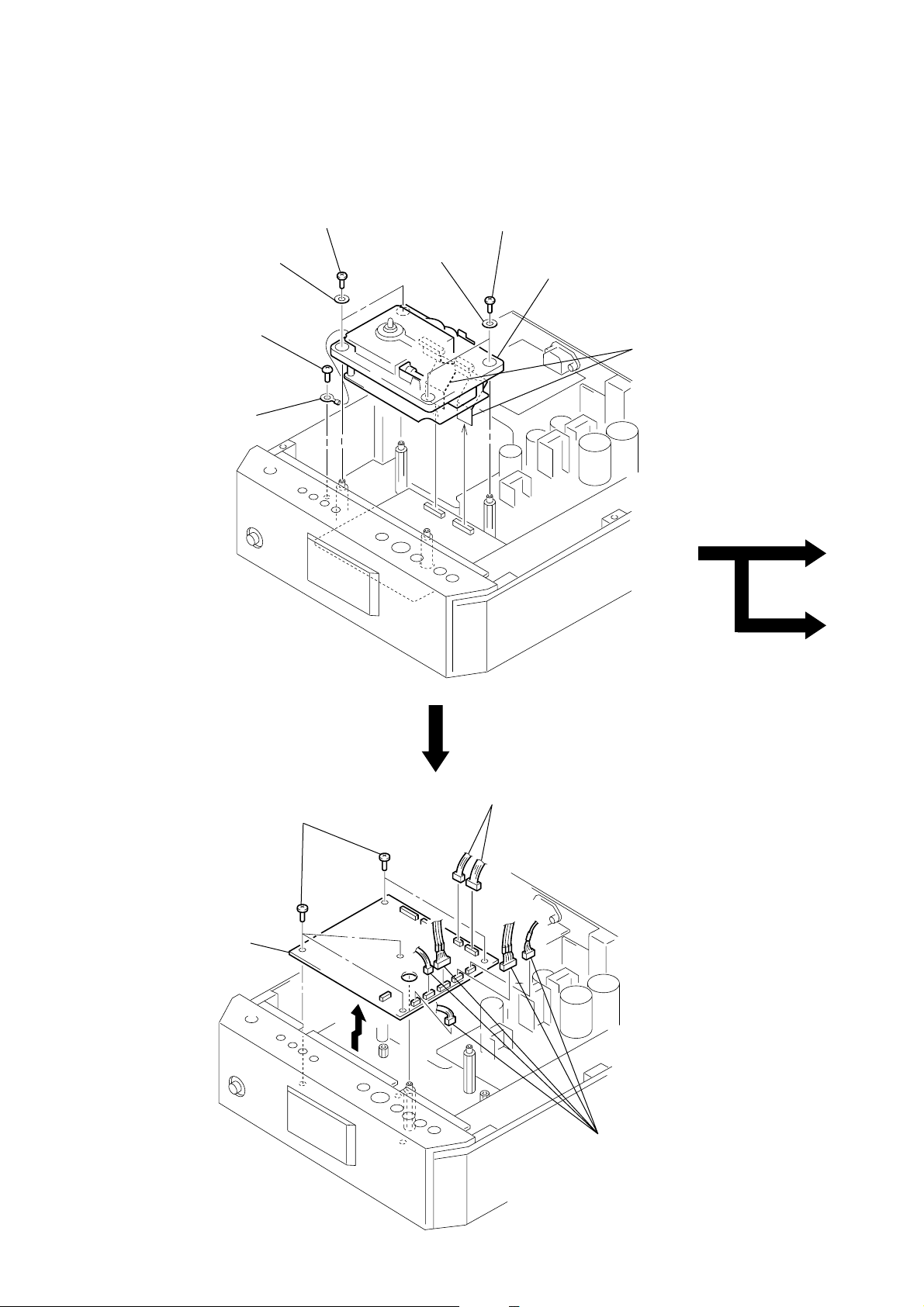

SECTION 4

OPTICAL PICK-UP

(KHS-180A/J1N) (Page 7)

RF BOARD (Page 7)

DISASSEMBLY-2

Note: Follow the disassembly procedure in the numerical order given.

OP MECHANISM SECTION (BU-23)

3

two screws

(B2.6

×

5)

4

4

1

screw (PS3 × 5)

two washers

2

lag

two washers

3

two screws

(B2.6

×

5)

5

Lift up OP mechanism section (BU-23).

6

two wires (flat type) (26 core)

(CN501, 502)

MAIN BOARD

3

MAIN board

2

five screws

(PS 3

1

two connectors

×

5)

(CN701, 708)

1

five connectors

(CN702-706)

5

Page 6

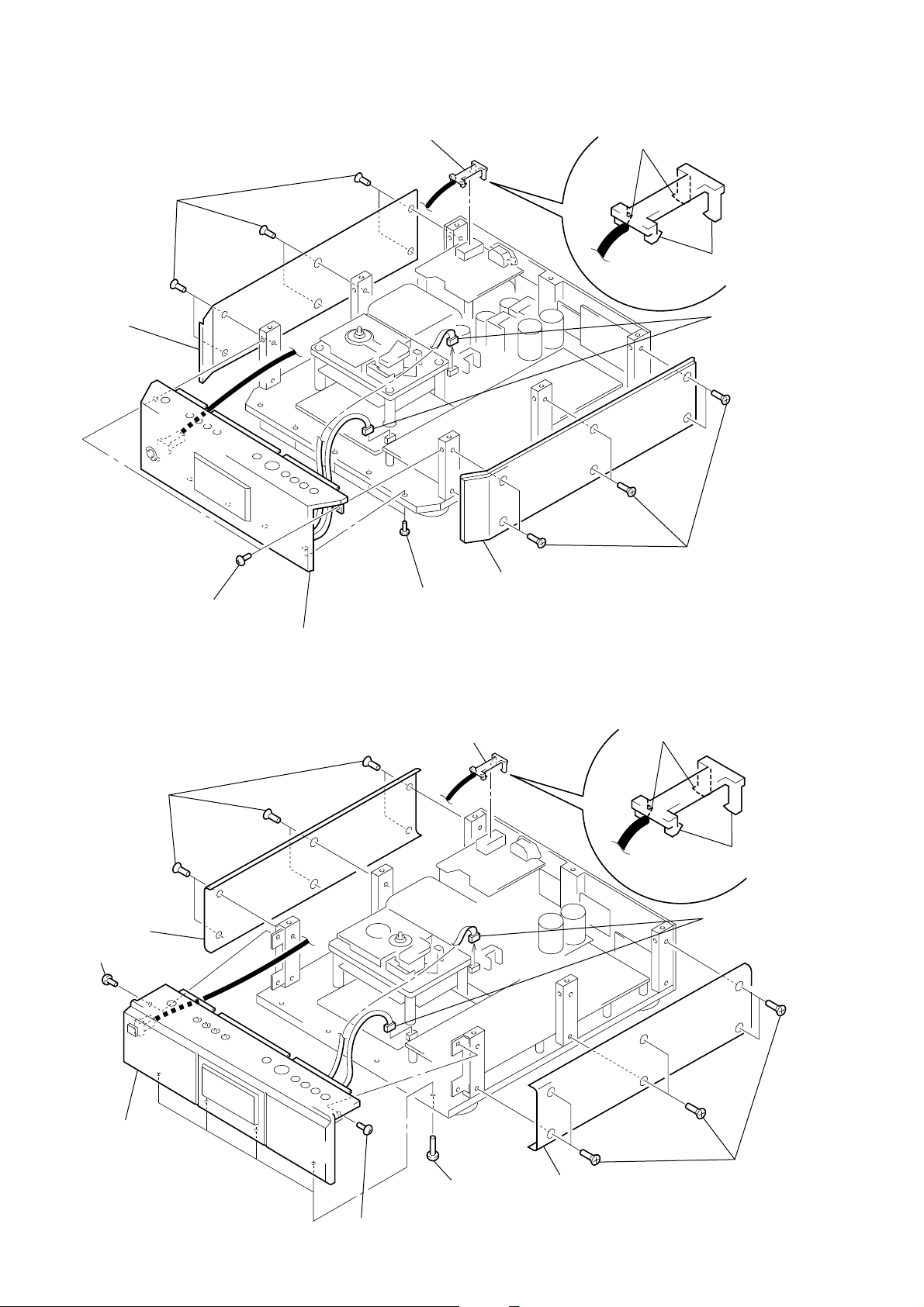

s

FRONT PANEL SECTION (SCD-1)

4

six screws

×

8)

(RK4

5

side plate (L)

7

two screws

×

(BVTT4

6)

3

push (control block) (wire) switch

8

front panel section

6

five screws

(BVTP3

×

5

10)

side plate (R)

2

two claws

2

1

4

six screws

(RK4

two claws

two connectors

(CN452, 702)

×

8)

FRONT PANEL SECTION (SCD-777ES)

4

six screws

(RK4

×

8)

5

side plate (R)

7

screw (BVTT3 × 6)

8

front panel section

3

push (control block) (wire) switch

2

two claws

2

two claws

1

two connectors

(CN452, 702)

4

six screw

(RK4 × 8)

7

screw (BVTT3 × 6)

6

four screws

(BVTP3

×

10)

5

side plate (L)

6

Page 7

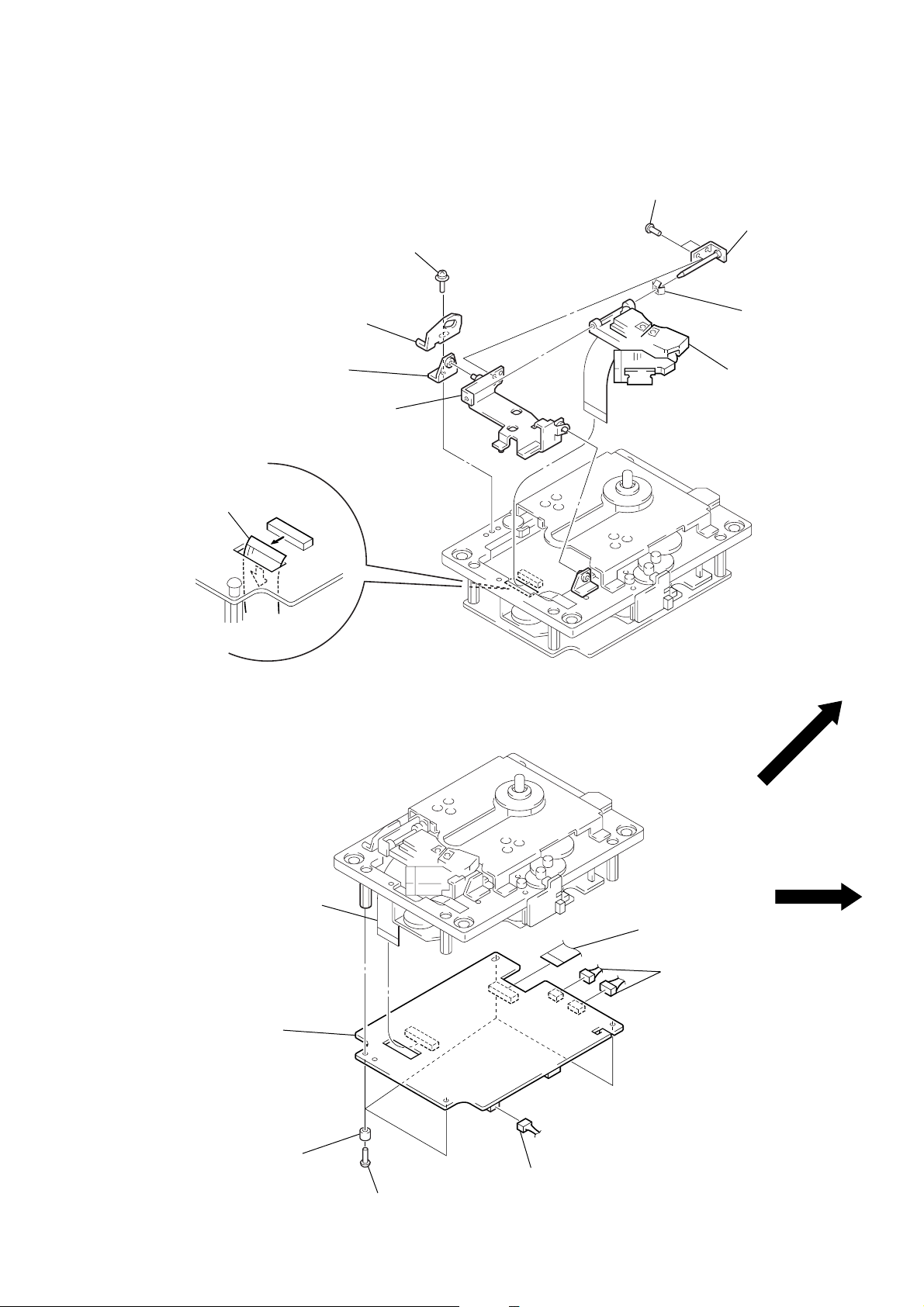

OPTICAL PICK-UP (KHS-180A/J1N)

y

)

2

3

holder (R2)

4

holder (R)

5

bracket (OP) ass'y

1

OP-15 flexible print board

(CN003)

screw

(PSW3

×

10)

6

two screws (B3 × 5)

9

7

retainer (OP) ass'

8

leaf spring (Y)

optical pick-up

(KHS-180A/J1N)

RF BOARD

1

OP-15 flexible print board

(CN003)

5

RF board

4

four spacers (3 × 5)

3

four screws

(B3

×

10)

2

connector

(CN005)

1

wire (flat type) (14 core

(CN007)

2

two connectors

(CN004, 006)

7

Page 8

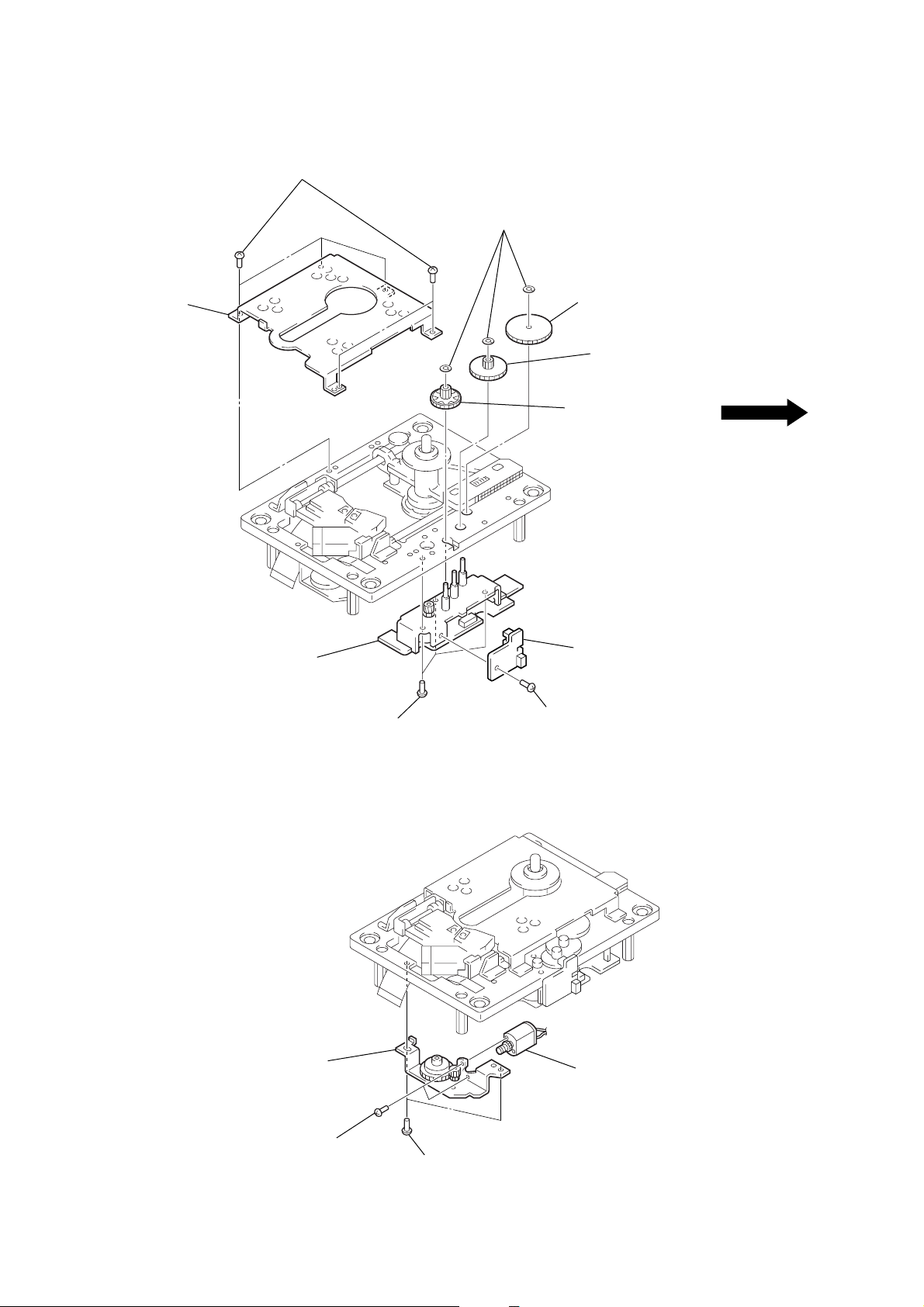

SLED MOTOR ASS'Y SECTION

d

1

2

cover (BU)

five screws

(B3 × 5)

3

three poly-slider washers

4

gear (D)

5

6

gear (B)

gear (C)

0

sled motor ass'y section

TILT MOTOR ASS'Y (M3)

2

bracket (tilt) ass'y

9

three screws

(B3 × 5)

7

8

SLD-MOT boar

screw

(B3 × 5)

4

tilt motor ass'y (M3)

3

two precision screws

(P2

×

2.5)

1

two screws

(B3

×

5)

8

Page 9

SPINDLE MOTOR BLOCK

2

screw

(B3

6

sled shaft (sub)

4

two shaft retainers (main)

7

sled shaft (main)

3

two shaft retainers (sub)

×

5)

2

screw

(B3

×

5)

2

two screws

(B3

5

spindle motor block

×

5)

1

slide the spindle motor block

toward the arrow.

APPLYING OIL AT REPLACEMENT OF MOTOR (SPINDLE) (M7)

When replacing the motor (spindle) (M7), apply a drop of oil to the

sled shaft (sub) and the sled shaft (main) respectively.

Part Name Part No

FLOIL (946P) 7-662-001-37

Notes:

• Do not attach oil to other than specified parts.

• Do not touch the lens and laser diode during work.

sled shaft (main)

sled shaft (sub)

9

Page 10

SECTION 5

TEST MODE

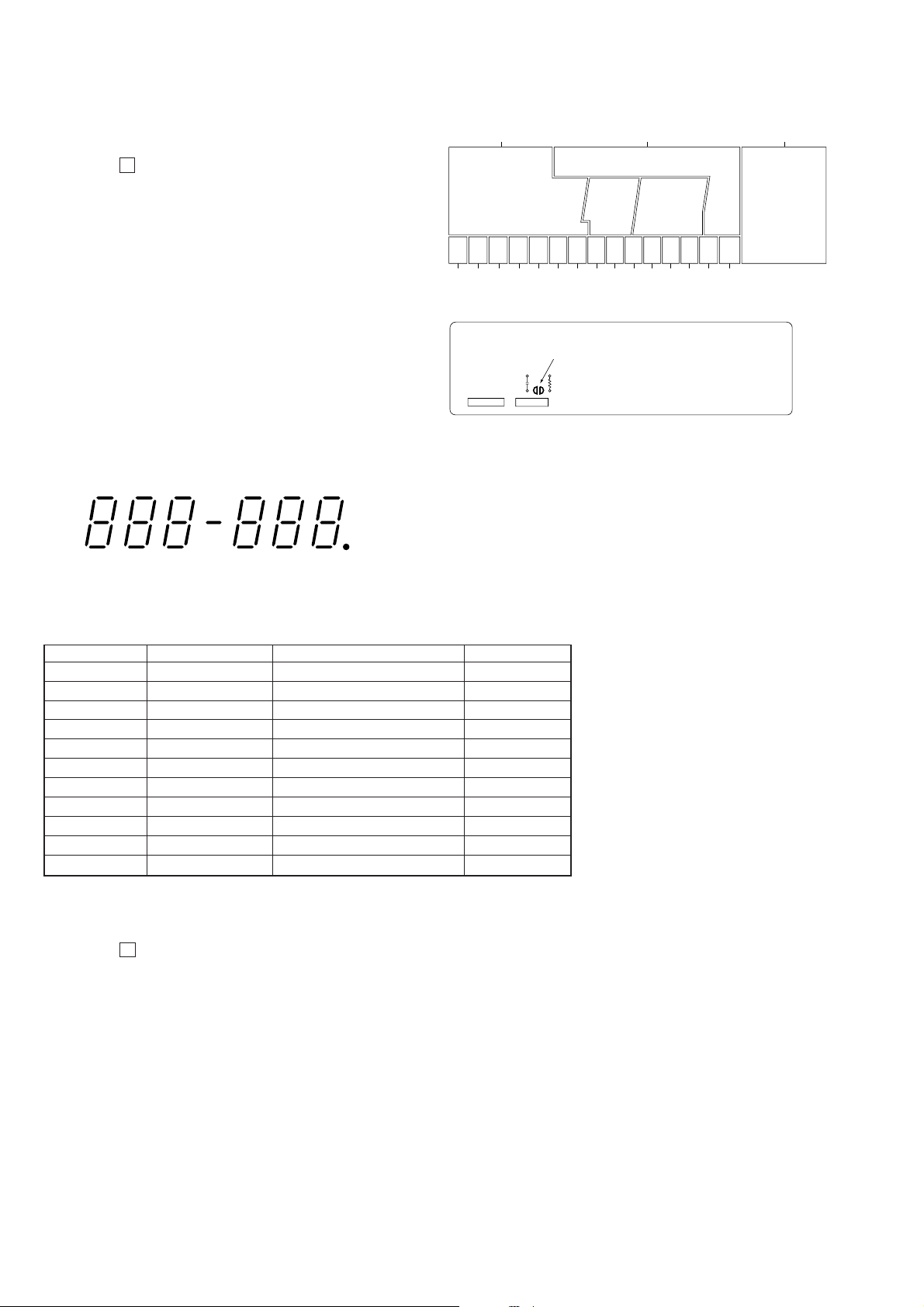

5-1. FLUORESCENT INDICATOR TUBE MODE

Note: Set the CD1/CD2 switch on the remote commander to CD1.

Procedure:

1. Press the ! button while shorting the BP (TEST MODE) on

the DISPLA Y board with tweezers, etc. and turn on the po wer,

so that the following operation will be executed automatically.

(1) All segments from 1G to 19G light up in order, starting from

1G.

(2) Vertical one line (total 7) of all grids from 1G to 15G lights up

in order, starting from the left.

(3) Horizontal one line (total 5) of all grids from 1G to 15G lights

up in order, starting from the top.

(4) Grids from 1G to 15G go off, and all segments from 16G to

19G light up.

2. With the set in the 1-(4) status, pressing any ke y on the remote

commander changes the display as shown below , and acti vates

the key check standby mode.

ARTIST

STEP

INDEX

CD1 CD2 CD3

MIN

Geid Assignment

16G 19G 20G

18G17G

1G 2G 3G 4G 5G 6G 7G 8G 9G 10G 11G 12G 13G 14G 15G

– DISPLAY Board (Conductor Side) –

BP (TEST MODE)

CN1002

CN1001

3. When a key on the front panel is pressed, the corresponding

segment and LED light up. (See table below)

key on set Key Attribute Lighting segment (in 19 grids) Lightning LED

A EJECT 20 bit –

TIME TIME 24 bit –

TEXT TEXT __|_____ (DIGITAL FILTER) –

DIGITAL OUT DIGITAL OUT DIGITAL OUTPUT –

FILTER FILTER __|_____ (DIGITAL OUTPUT) –

SACD/CD SACD/CD NORM –

H PLAY WIDE PLAY LED

X PAUSE STD1234 PAUSE LED

x STOP DIGITAL FILTER –

l AMS-BACK 16 bit CD LED

L AMS-FORWARD OFF SACD LED

4. If “!%%TEST-END!!%%” is displayed after the keys listed

above were all pressed, the key check terminated successfully .

Note: As this test does not check the LEDs, check them visually.

5. Press the ! button to turn the power off, and disconnect the

plug from the socket.

10

Page 11

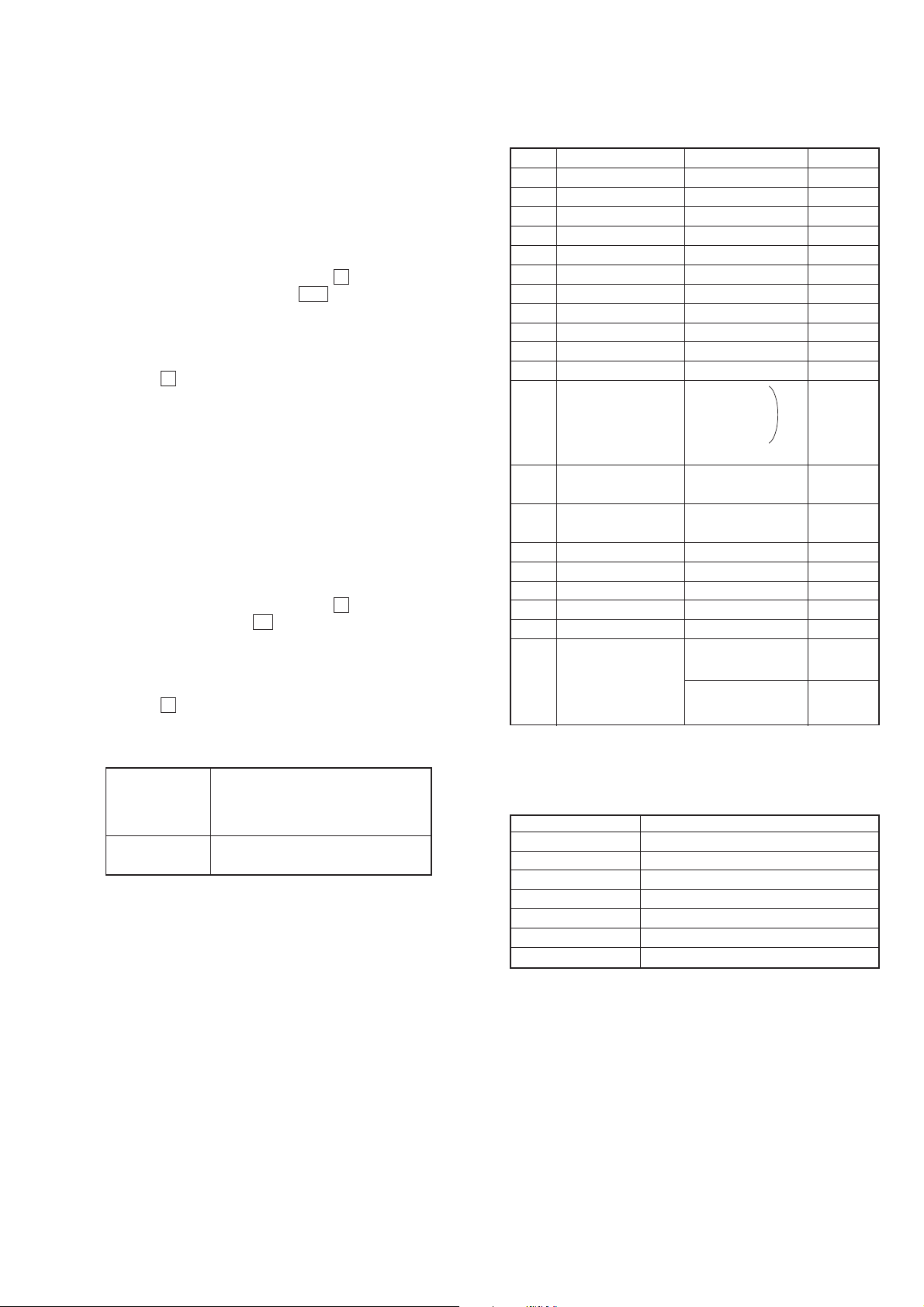

5-2. ADJUSTMENT-1 MODE

This mode is a special mode used to perform overall adjustment,

optical pick-up height adjustment, and service check.

Note:

1. Wrong setting method can cause a trouble.

2. Never operate the set with the loading panel mounted, which otherwise

causes a trouble.

Setting Method:

1. With the power turned of f, press the ! button while pressing

the [DIGITAL OUT] button and l button.

2. Display of “bbb” implies that the set is now in the Adjust-

ment-1 Mode.

Resetting Method:

Press the ! button to turn the power off, and disconnect the plug

from the socket.

5-3. ADJUSTMENT-2 MODE

This mode is a special mode used to perform CL V jitter check and

usually movement check.

Note:

1. Wrong setting method can cause a trouble.

2. Never operate the set with the loading panel mounted, which otherwise

causes a trouble.

Setting Method:

1. With the power turned of f, press the ! button while pressing

the [TIME] button and H button.

2. Display of “# OPEN #” implies that the set is now in the Ad-

justment-2 Mode.

Resetting Method:

Press the

! button to turn the power off, and disconnect the plug

from the socket.

Adjustment item

Traverse check, S curve check,

Adjustment-1 RF level check, optical pick-up

Mode height adjustment, and see contents of

Adjustment-1 Mode list.

Adjustment-2 CLV jitter check and usually

Mode movemant check

Adjustment-1 Mode List

Note: Set the CD1/CD2 switch on the remote commander to CD1.

Codes Contents Remarks Disc

01 LD ON/OFF CD, SL, DL

02 Spindle ON/OFF CD, SL, DL

03 Forcus Search CD, SL, DL

04 Forcus Servo ON/OFF CD, SL, DL

05 Track Servo ON/OFF CD, SL, DL

06 CLV ON CD, SL, DL

07 Sled Servo ON/OFF CD, SL, DL

22 Tilt Servo ON/OFF CD, SL, DL

23 Tilt Bias Up CD, SL, DL

24 Tilt Bias Down CD, SL, DL

30 Disc Check CD, SL, DL

5: Thresholds

check

60 Overall Adjustment 9: No thresholds CD, SL, DL

61 Result Display

62 Adj. V alue Clear

PLAY PLAY CD, SL, DL

PAUSE PAUSE CD, SL, DL

STOP STOP CD, SL, DL

NEXT NEXT CD, SL, DL

PREV PREV CD, SL, DL

FILTER Focus Search/PLAY

Note:

1. Selection of an adjustment item where no disc is present could damage

the optical pick-up.

2. Do not use other than above listed codes.

check

0: Cancel

1: Proceed

2: Return

9: Go

0: Cancel

SACD select

(SACD/CD key)

CD select

(SACD/CD key)

Go

CD, SL, DL

CD, SL, DL

SL

CD

*1: Disc check list

Display Result of Disc Check

Discchk DO SL No disc

Discchk D1 SL SL

Discchk D2 CD CD

Discchk D3 CD Hybrid CD layer

Discchk D3 HD Hybrid HD layer

Discchk D4 D0 DL L0 layer

Discchk D4 D1 DL L1 layer

*1

11

Page 12

SECTION 6

ELECTRICAL ADJUSTMENTS

Note on Adjustment

1. When the following parts were replaced, adjust and check the

items marked with a in the given order.

Parts

Adjustment & check pick-up MAIN board motor (M7)

1. Optical Pick-up

Height Adjustment

2. Overall Adjustment aa ×

3. Traverse Check a ××

4. S Curve Check a ××

5. RF Level Check a ××

6. CLV Jitter Check ×× a

Optical IC on RF or Spindle

a × a

2. Adjustment jigs

The following jigs are exclusively used for electrical adjustment and check of this set. Do not use them for other applications.

(1) Disc

Model Type*1 Category Applications

SATD-S1 SL 8cm disc Optical pic-kup H adj.

SATD-S2 SL Reference disc Overall adj. and check

SATD-S3 DL Reference disc Overall adj. and check

SATD-S4 SL Reference disc Audio characteristic check

TCD-784 CD Reference disc Overall adj. and check

*1 SL: Single Layer

DL: Dual Layer

(2) Remote commander: Assessory for set or RM-D950 (Part No.

1-473-944-1)

(3) Extension cable (Part No. J-2501-164-A) 2 pcs.

3. In making adjustment and check, set the CD1/CD2 switch on

the remote commander to CD1.

4. The impedance of oscilloscope should be more than 10M .

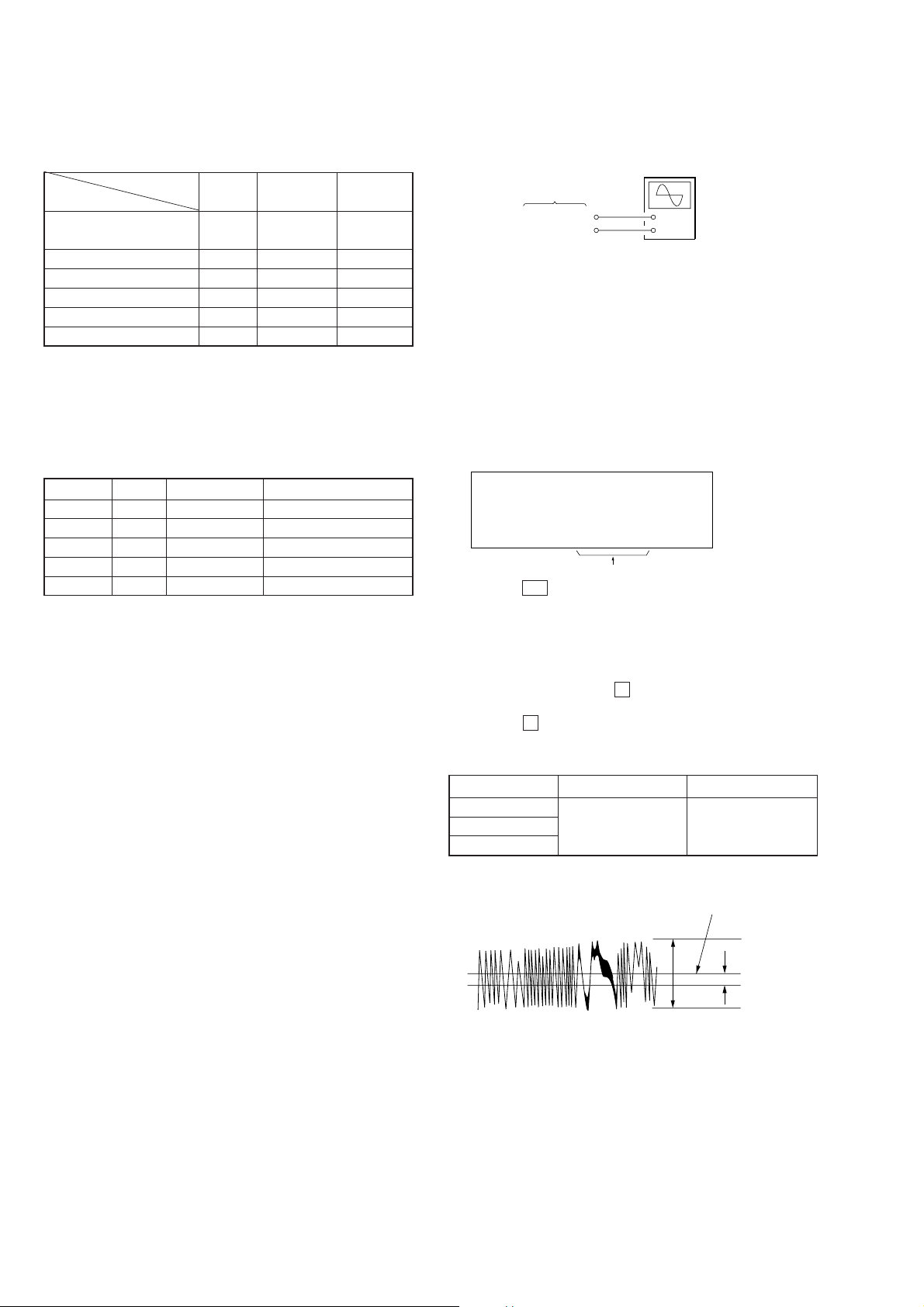

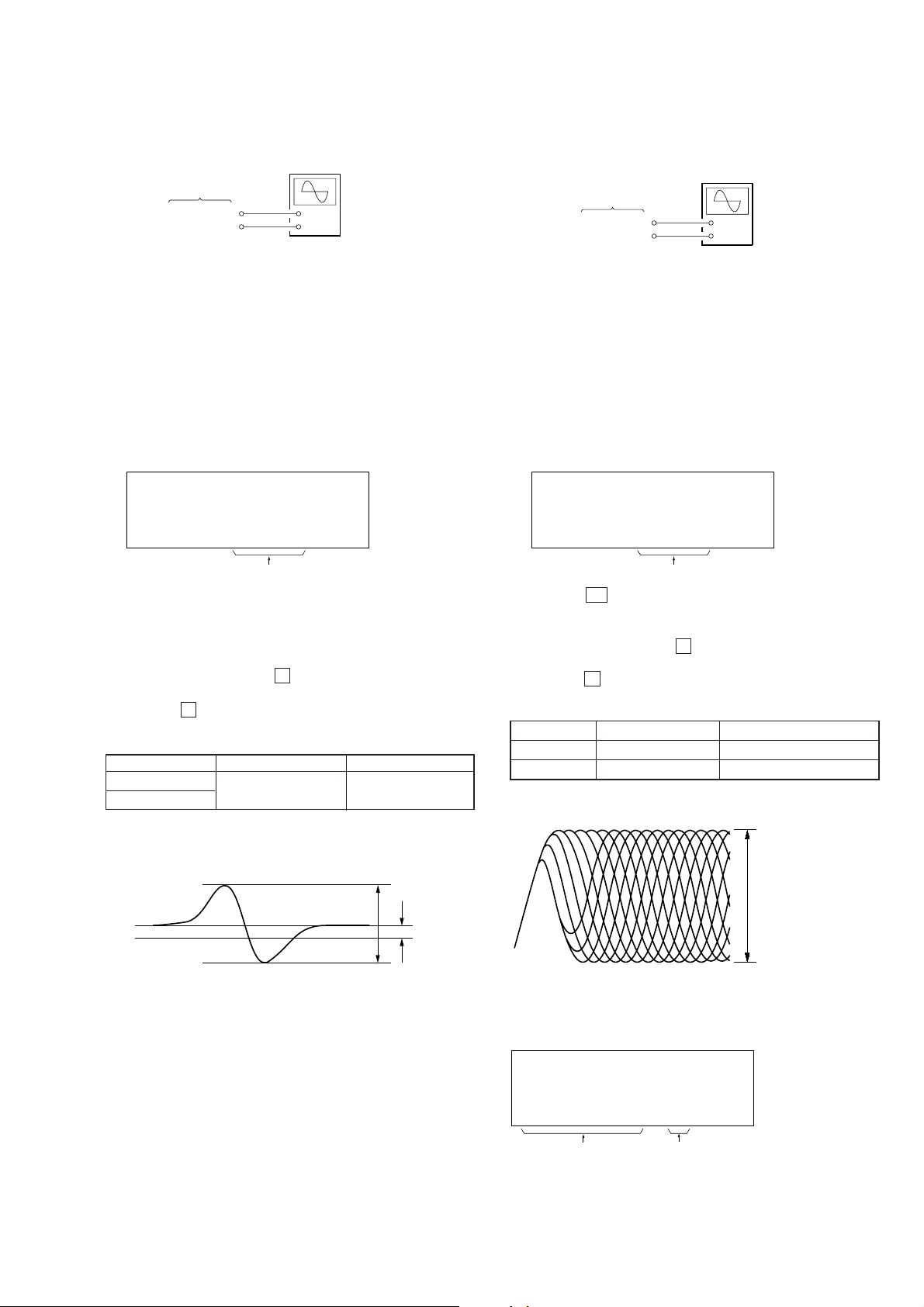

Traverse Check

Connection:

oscilloscope

(auto or normal mode)

MAIN board

TP516 (TE)

TP501 (VC)

+

–

Procedure:

1. Connect an oscilloscope to the TP516(TE) and TP501(VC) on

the MAIN board.

2. Set the Adjustment-1 Mode. (See 5-2. Adjustment-1 Mode in

SECTION 5 (page 11))

3. Set a disc (SATD-S2, SATD-S3, or TCD-784).

4. Press the 3 button and - button on the remote commander

to make the disc type checked.

Note: If the disc check was made in the Adjustment-1 Mode, pressing

another button immediately after pressing the 3 and - buttons

on the remote commander could cause the microcomputer to run

out of control, thus requiring extreme care.

5. Confirm that the disc was checked.

bbb

CD1

Discchk XX XX

Disc type (refer to Disc check list (page 11))

6. Press the H button.

7. Press the - button and 7 button, and the - button and 5

button on the remote commander successively to turn off the

tracking servo.

8. Check that the waveform on oscilloscope is within the level

A and B specifications.

9. After checking, press the x button.

10. Repeat steps 3 through 9 respective discs.

11. Press the ! button to turn the power off.

Specified Value:

Disc A

SATD-S2

SATD-S3 1.3 to 2.4 Vp-p - 0.1 to +0.1 V

TCD-784

B

12

Traverse waveform

VC

Adjustment Location : See page16.

Center fo the waveform

A

B

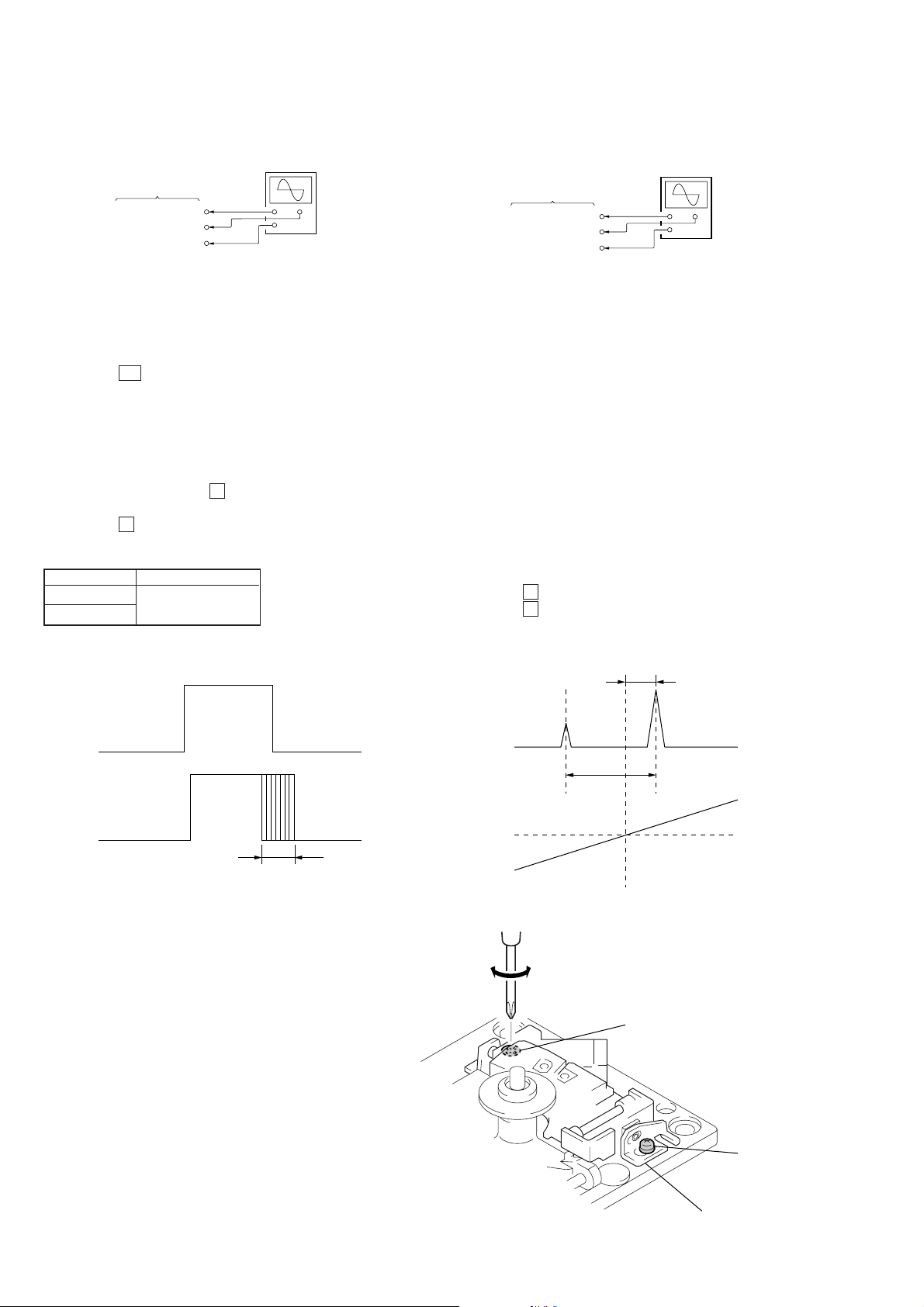

Page 13

S Curve Check

)

MAIN board

TP503 (RF)

TP501 (VC)

+

–

oscilloscope

(auto mode)

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

RF signal waveform

A

Connection:

MAIN board

TP524 (FE)

TP501 (VC)

RF Level Check

Connection:

oscilloscope

(normal mode

+

–

Procedure:

1. Connect an oscilloscope to the TP524(FE) and TP501(VC) on

the MAIN board.

2. Set the Adjustment-1 Mode. (See 5-2. Adjustment-1 Mode in

SECTION 5 (page 11))

3. Set a disc (SATD-S2 or TCD-784).

4. Press the 3 button and - button on the remote commander

to make the disc type checked.

Note: If the disc check was made in the Adjustment-1 Mode, pressing

another button immediately after pressing the 3 and - buttons

on the remote commander could cause the microcomputer to run

out of control, thus requiring extreme care.

5. Confirm that the disc was checked.

bbb

CD1

Discchk XX XX

Disc type (refer to Disc check list (page 11))

6. Press the - button and 1 button, the - button and 2 button, and the - button and 3 button on the remote commander

successively to execute the focus search.

7. Check that the waveform on oscilloscope is within the level

A and B specifications.

8. After checking, press the x button.

9. Repeat steps 3 through 8 for respective discs.

10. Press the ! button to turn the power off.

Specified V alue:

Disc

SA TD-S2

TCD-784

AB

1.5 to 2.3Vp-p - 0.1 to +0.1V

Procedure:

1. Connect an oscilloscope to the TP503(RF) and TP501(VC) on

the MAIN board.

2. Set the Adjustment-1 Mode. (See 5-2. Adjustment-1 Mode in

SECTION 5 (page 11))

3. Set a disc (SATD-S2 or TCD-784).

4. Press the 3 button and - button on the remote commander

to make the disc type checked.

Note: If the disc check was made in the Adjustment-1 Mode, pressing

another button immediately after pressing the 3 and - buttons

on the remote commander could cause the microcomputer to run

out of control, thus requiring extreme care.

5. Confirm that the disc was checked.

bbb

CD1

Discchk XX XX

Disc type (refer to Disc check list (page 11))

6. Press the H button.

7. Check that the waveform on oscilloscope is clear, and the le vel

and jitter of waveform satisfy the specifications.

8. After checking, press the x button.

9. Repeat steps 3 through 8 for respective discs.

10. Press the ! button to turn the power off.

Specified Value:

Disc A Jitter (displayed value)

SATD-S2 1.25 to 1.65 Vp-p 20 (Hex) or less

TCD-784 1.3 to 1.7 Vp-p 15 (Hex) or less

S curve waveform

A

VC

Note: For easier observation of this waveform, extend the sweep time

and raise the brightness.

B

Adjustment Location : See page16.

Note: Clear RF waveform refers to the waveform where ◊ shapes should

be distinctively observed in the center.

Display example:

bbb

CD1

+ 00 00 ~00 09

not fixed

Jitter value

(HEX)

Adjustment Location : See page16.

13

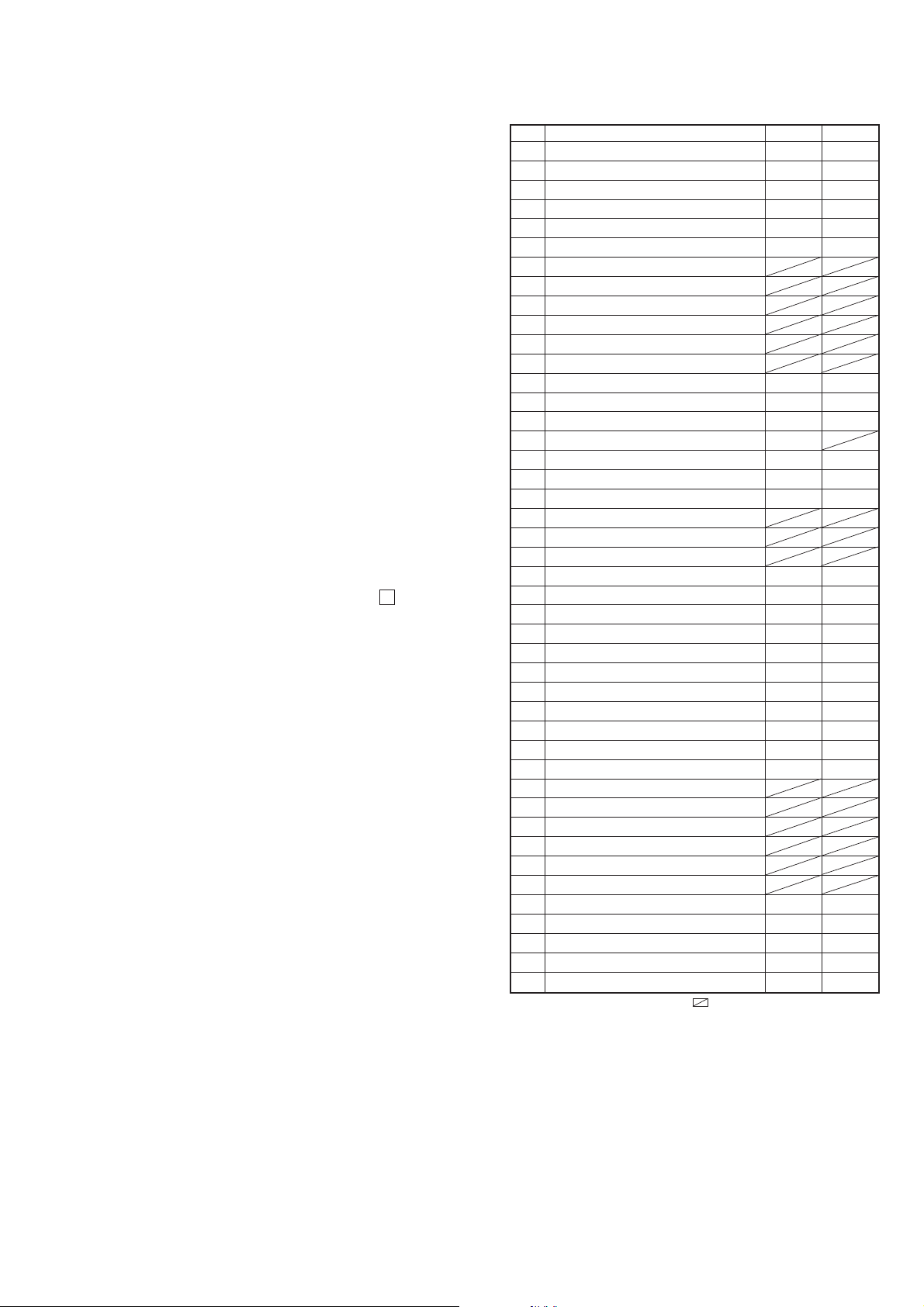

Page 14

)

CLV Jitter Check

w

Connection:

MAIN board

TP702 (MNT4)

TP703 (MNT5)

TP521 (GND)

(normal mode

(CH2)

(CH1)

oscilloscope

+ +

–

Optical Pick-up Height Adjustment

Connection:

TP511 (FOUT)

MAIN board

TP515 (PI)

TP501 (VC)

(CH1)

(CH2)

storage

oscilloscope

(normal mode)

+

+

–

Procedure:

1. Connect an oscilloscope to the TP702(MNT4)(CH1),

TP703(MNT5)(CH2) and TP521(GND) on the MAIN board.

2. Set the Adjustment-2 Mode. (See 5-3. Adjustment-2 Mode in

SECTION 5 (page 11))

3. Set a disc (SATD-S2 or TCD-784).

4. Press the H button.

5. Move the sled to the middle track.

• Sled middle track

SATD-S2:TN05

TCD-784:TN05

6. Check that the A value of waveform on oscilloscope satisf ies

the specification.

7. After checking, press the x button.

8. Repeat steps 3 through 7 for respective discs.

9. Press the ! button to turn the power off.

Specified Value:

Disc A

SATD-S2

TCD-784

CLV jitter waveform

55 µsec or less

Procedure:

1. Connect an oscilloscope to the TP515(PI)(CH1),

TP511(FOUT) (CH2) and TP501(VC) on the MAIN board.

2. Set the Adjustment-1 Mode. (See 5-2. Adjustment-1 Mode in

SECTION 5 (page 11))

3. Set a disc (SATD-S1).

4. Press the [FILTER] button to set the Focus Search mode.

5. Loosen the OP height adjusting screw 1, and while shifting

the Holder (R2), adjust the height so that the waveform on

oscilloscope satisfies the specified value.

6. Press the [FILTER] button to set the Play mode.

7. Adjust the TAN skew 2 so as to attain most preferable jitter

value on the display.

8. Press the [FILTER] button to set the Focus Search mode.

9. Check that the B value of waveform on oscilloscope satisf ies

the specification.

10. Repeat steps 5 through 9.

11. Lock the OP height adjusting screw 1 when adjustment finished.

12. Press the x button.

13. Press the ! button to turn the power off.

Specified Value: B is more than 0, and less than A/3

B

Adjustment Location : See page16.

A

VC

A

VC

PI

FOUT

*1: Normal-trigger the oscilloscope using FOUT on CH2.

2

TAN skew

1

OP height

adjusting scre

*1

14

Adjustment Location : See page16.

Holder (R2)

Page 15

Overall Adjustment

Procedure:

1. Set the Adjustment-1 Mode. (See 5-2. Adjustment-1 Mode in

SECTION 5 (page 11))

2. Press the 6 button and 2 button, then the 9 button on the

remote commander (to initialize data).

3. Set a disc (TCD-784).

4. Press the 6 button and - button, then the 5 button on the

remote commander. (Adjustment will take about 2 minutes.)

5. Remove the disc when "CD END" is displayed.

6. Set a disc (SATD-S2).

7. Press the 6 button and - button, then the 5 button on the

remote commander. (Adjustment will take about 1 minute 30

seconds.)

8. Remove the disc when "SL END" is displayed.

9. Set a disc (SATD-S3).

10. Press the 6 button and - button, then the 5 button on the

remote commander. (Adjustment will take about 1 minute.)

11. Remove the disc when "DL END" is displayed.

Note: If an error is displayed during the adjustment so far, press again the

6 button and - button on the remote commander to execute readjustment.

12. Press the 6 button and 1 button on the remote commander.

13. As the number and adjusted value are displayed, make sure

that it is within the threshold.

14. Press the 1 button on the remote commander to proceed to

the next item. (To return to the previous item, press the 2

button.)

15. Repeat steps 13 and 14.

16. After checking items up to No.43, press the ! button to turn

the power off.

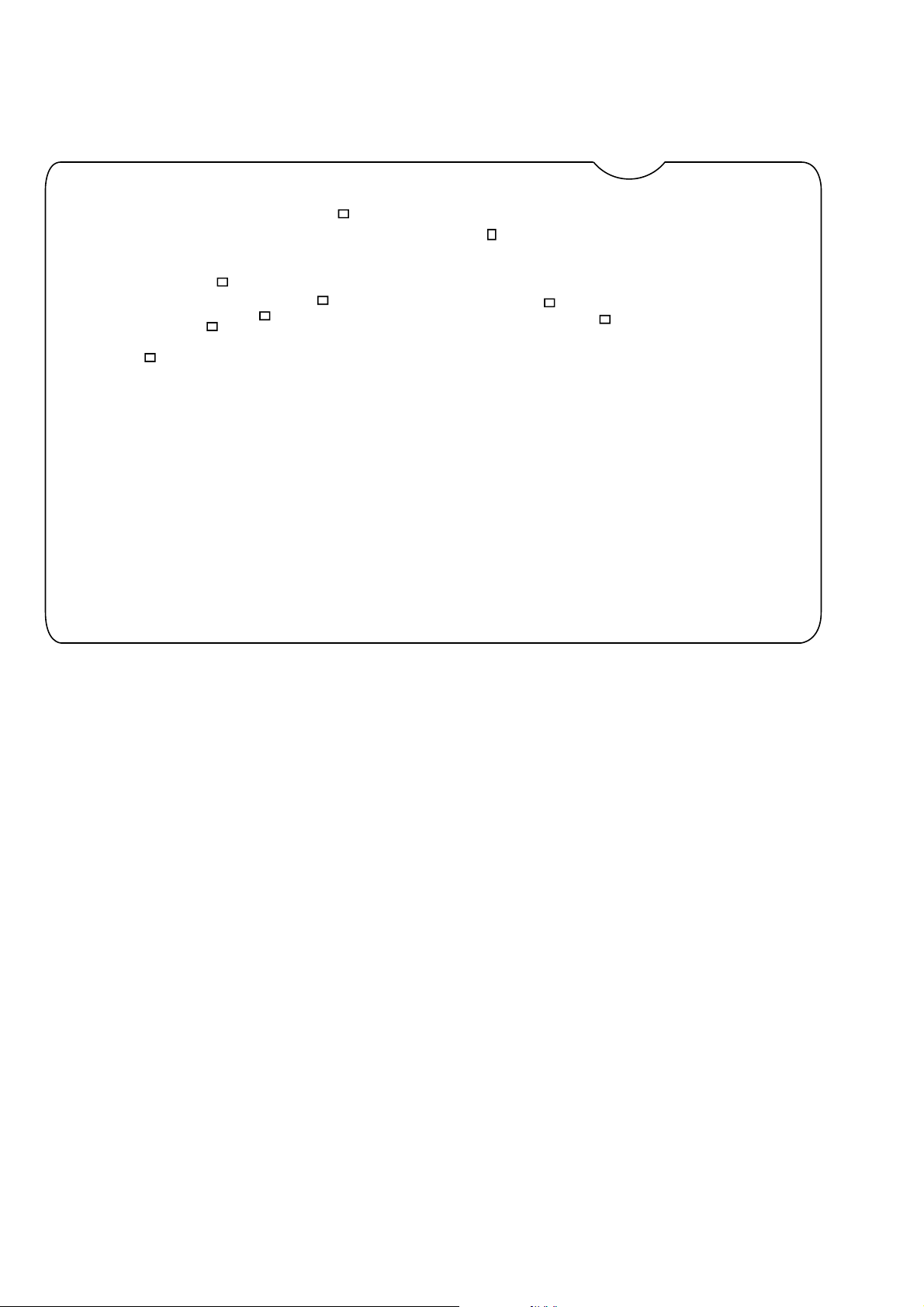

Thresholds for Overall Adjustment

No. Description U limit L limit

00 PI Level SL 0 4

01 PI Level DL 3 7

02 PI Offset CD 15D 2A3

03 PI Offset SL 15D 2A3

04 PI Offset DL 15D 2A3

05 PI Offset Disc Check 100 2FF

06 Traverse Offset CD

07 Traverse Offset SL

08 Traverse Offset DL

09 Traverse Gain CD

10 Traverse Gain SL

11 Traverse Gain DL

12 For PI Level Disc Check 0 2

13 PI Reflectance SL 2D28 7333

14 PI Reflectance DL 936 4083

15 Surface Reflect to CD Layer Distance 82

16 Surface Reflect to DSD Layer Distance 41 82

17 Low Push-pull for Disc Check 4FDF 9999

18 High T Bal for Disc Check 0000 47AE

19 FE Offset CD

20 FE Offset SL

21 FE Offset DL

22 Focus Bias CD E0 20

23 Focus Bias SL E0 20

24 Focus Bias DL0 E0 20

25 AGC Focus Gain CD 1500 3000

26 AGC Focus Gain DL 0851 1A00

27 AGC Focus Gain SL 0C28 2500

28 AGC Tracking Gain CD 1A00 3C00

29 AGC Tracking Gain SL 1100 2500

30 AGC Tracking Gain DL 1400 2700

31 RF Loop Filter Offset CD F6 0A

32 RF Loop Filter Offset DSD F6 0A

33 Tilt Disordered Point CD +side

34 Tilt Disordered Point CD -side

35 Tilt Disordered Point SL +side

36 Tilt Disordered Point SL -side

37 Tilt Disordered Point DL +side

38 Tilt Disordered Point DL -side/

39 Tilt Offset CD F0 10

40 Tilt Offset SL F0 10

41 Tilt Offset DL F0 10

42 Focus Balance SL

43 Focus Balance DL

Note: 1. No threshold specified for items.

2. All thresholds are displayed in Hex.

15

Page 16

Adjustment Location:

– MAIN Board (Component Side) –

TP524

(FE)

TP501

TP521

(GND)

(VC)

TP503

(RF)

TP703

(MNT5)

TP511

(FOUT)

TP515

(PI)

TP516

(TE)

TP702

(MNT4)

16

Page 17

SECTION 7

)

d

DIAGRAMS

7-1. NOTES FOR PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

a

•

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the par ts face side seen from

(Component Side) the parts face are indicated.

• Indication of transistor

: Through hole.

C

Q

B

E

These are omitted.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• % : indicates tolerance.

f

•

• 5 : fusible resistor.

• C : panel designation.

Note:

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specified.

• U : B+ Line.

• V : B– Line.

• Voltages and wav eforms are dc with respect to ground in

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.

adjustment mode.

no mark :STOP

( ) :SACD

〈〈 〉〉 :CD

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

J : SACD

c : CD

I : DIGITAL OUT

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro

spécifié.

• Circuit Boards Location

MAIN board

SW-L board

DISPLAY board

POWER board

STB board

AC board

SW-R board

COAX board

OPT board

SW board

BAL board (SCD-1

PIN board

LOAD-SW board

LOAD-MOT board

AUDIO board

LOAD-CN board

SLD-MOT board

SLD-FG boar

RF board

1717

Page 18

SCD-1/777ES

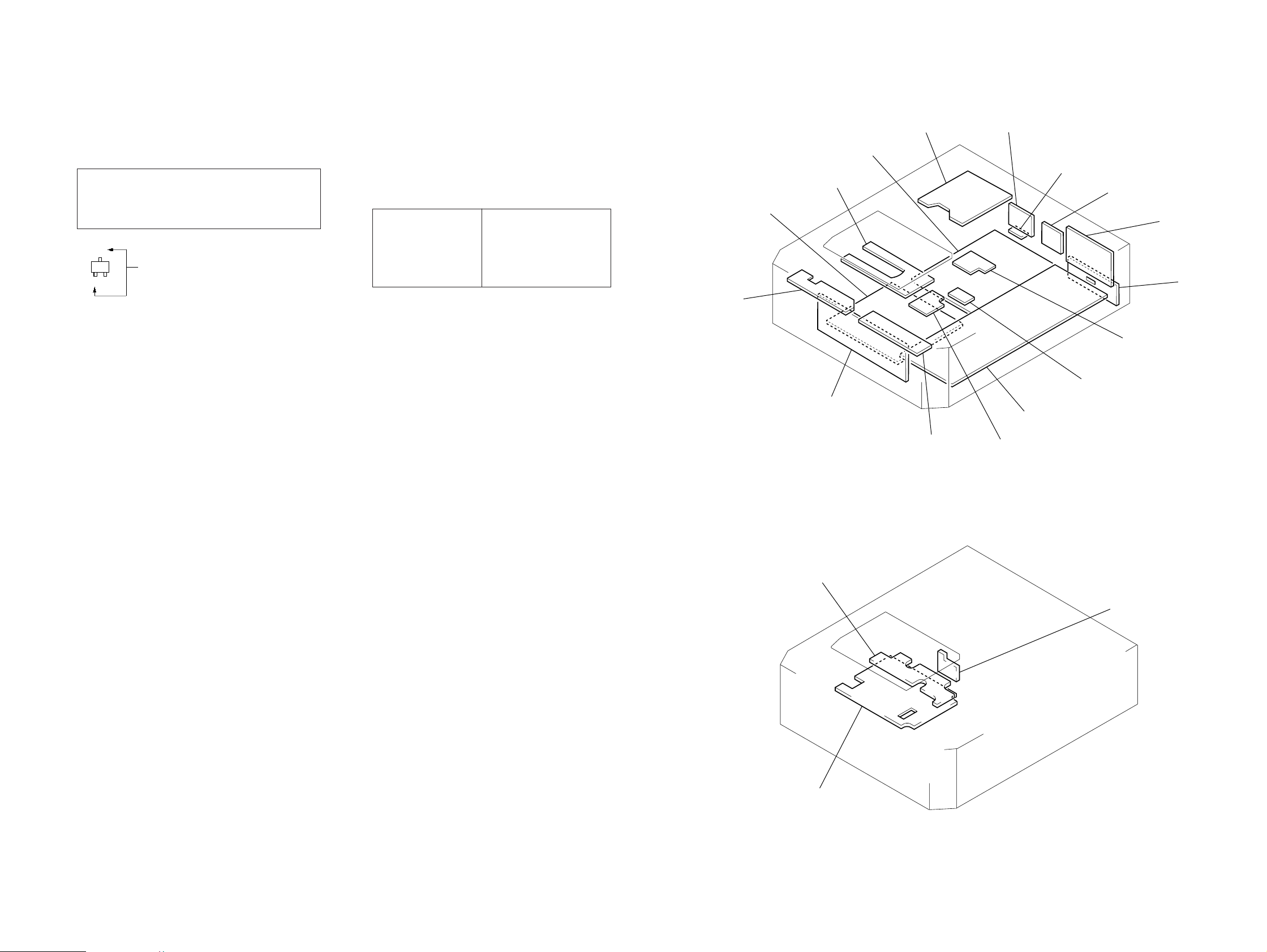

7-2. PRINTED WIRING BOARDS – RF/SLD-FG/SLD-MOT Boards – • See page 17 for Circuit Boards Location.

(Page 22)

(Page 22)

• Semiconductor Location

–RF Board–

Ref. No. LocationRef. No. Location

IC001 E-2

IC002 C-4

IC003 A-3

IC004 A-2

IC005 C-3

IC006 C-3

IC007 C-2

IC010 A-2

IC011 C-2

IC012 A-1

Q001 F-3

Q002 B-5

Q003 B-4

Ref. No. Location

Q004 B-4

Q006 A-3

Q007 D-5

Q008 B-5

Q009 B-5

1818

Page 19

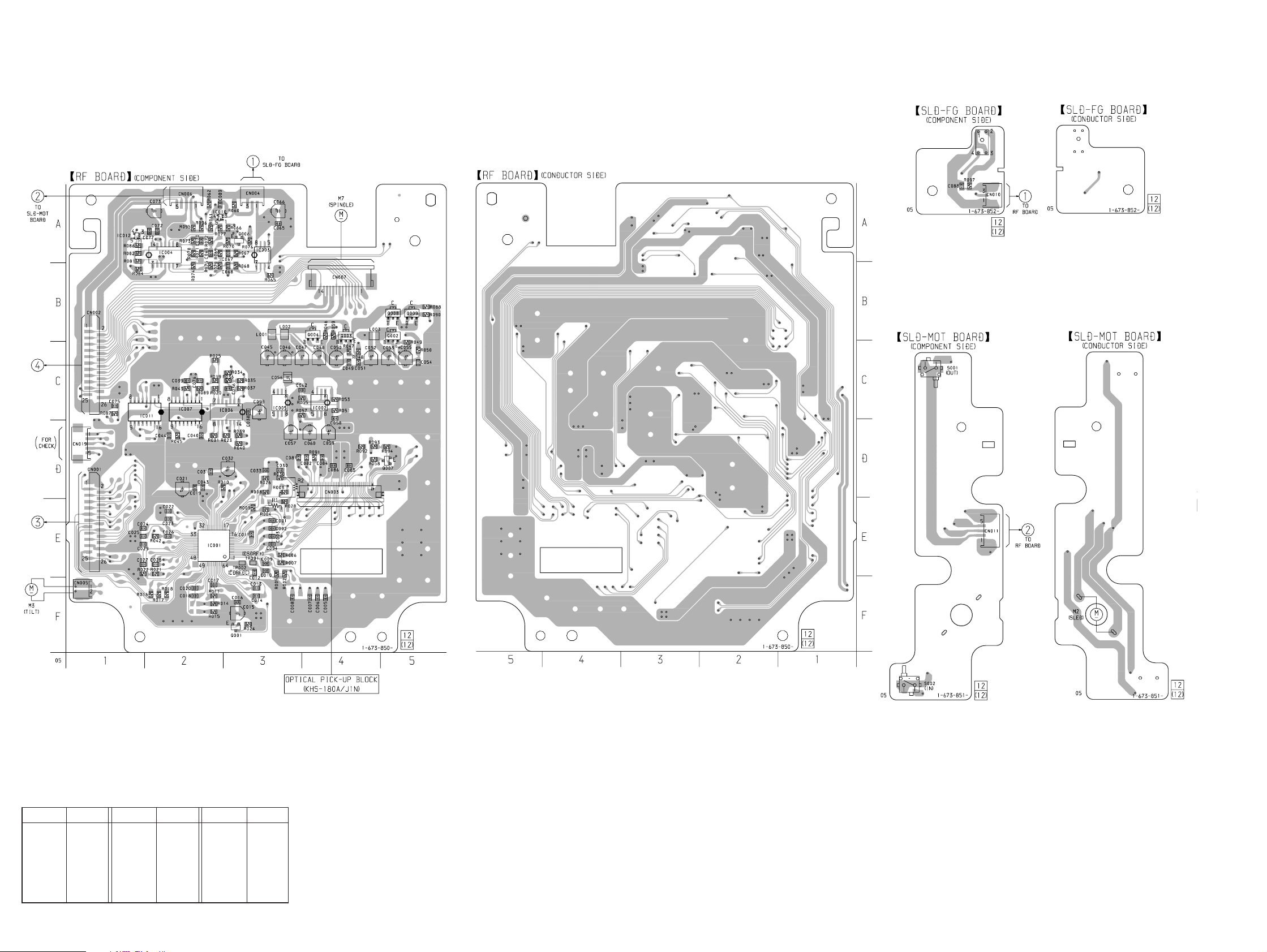

7-3. SCHEMATIC DIAGRAM – RF/SLD-FG/SLD-MOT Boards – • See page 40 for Waveforms.

SCD-1/777ES

(Page

29)

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

(Page

28)

Les composants identifiés par une marque 0 sont

critiques pour la sécurité. Ne les remplacer que

par une pièce portant le numéro spécifié.

1919

Page 20

SCD-1/777ES

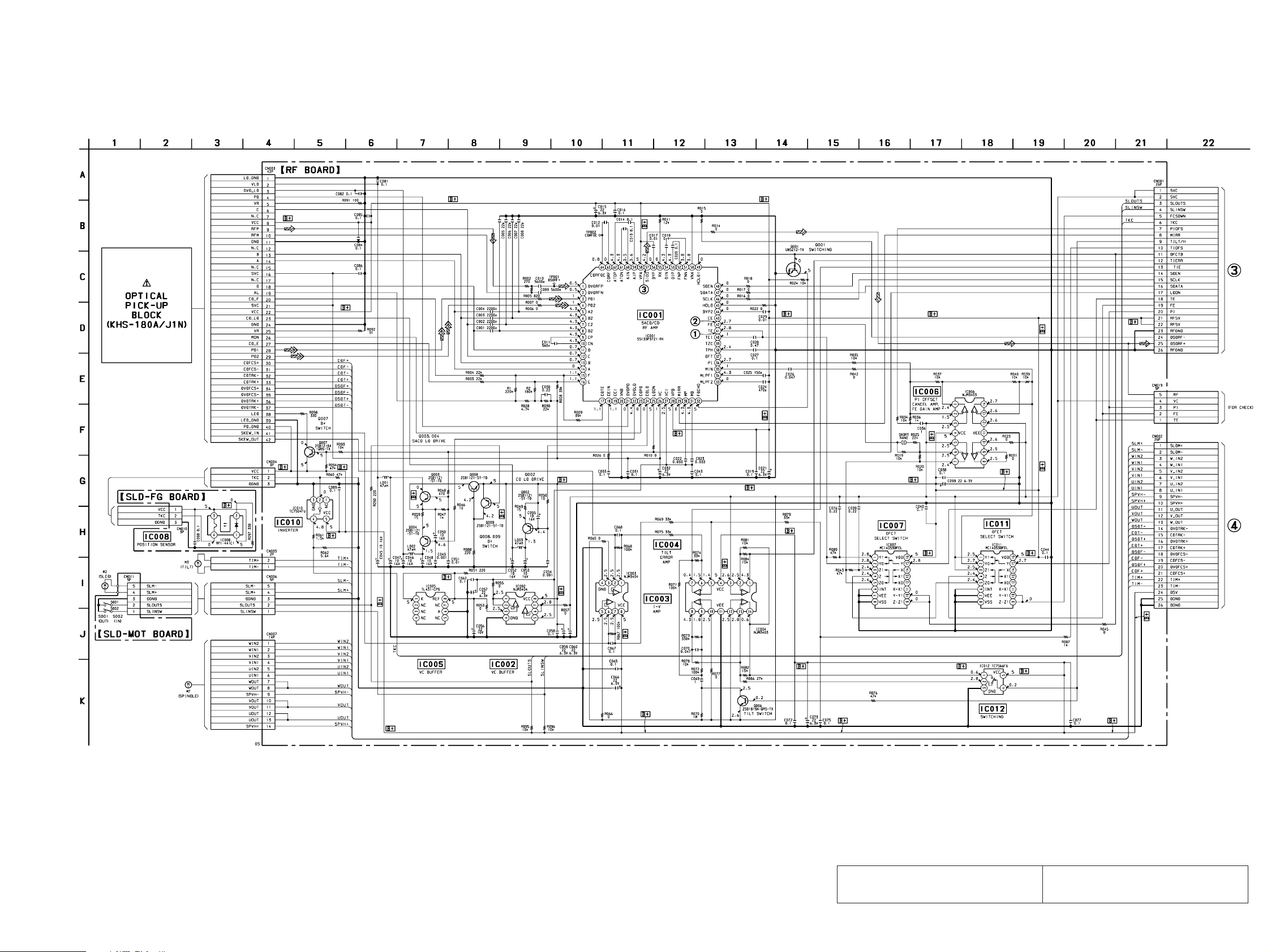

7-4. PRINTED WIRING BOARDS – LOAD-CN/LOAD-MOT/LOAD-SW/STB Boards – • See page 17 for Circuit Boards Location.

(Page 22)

2020

Page 21

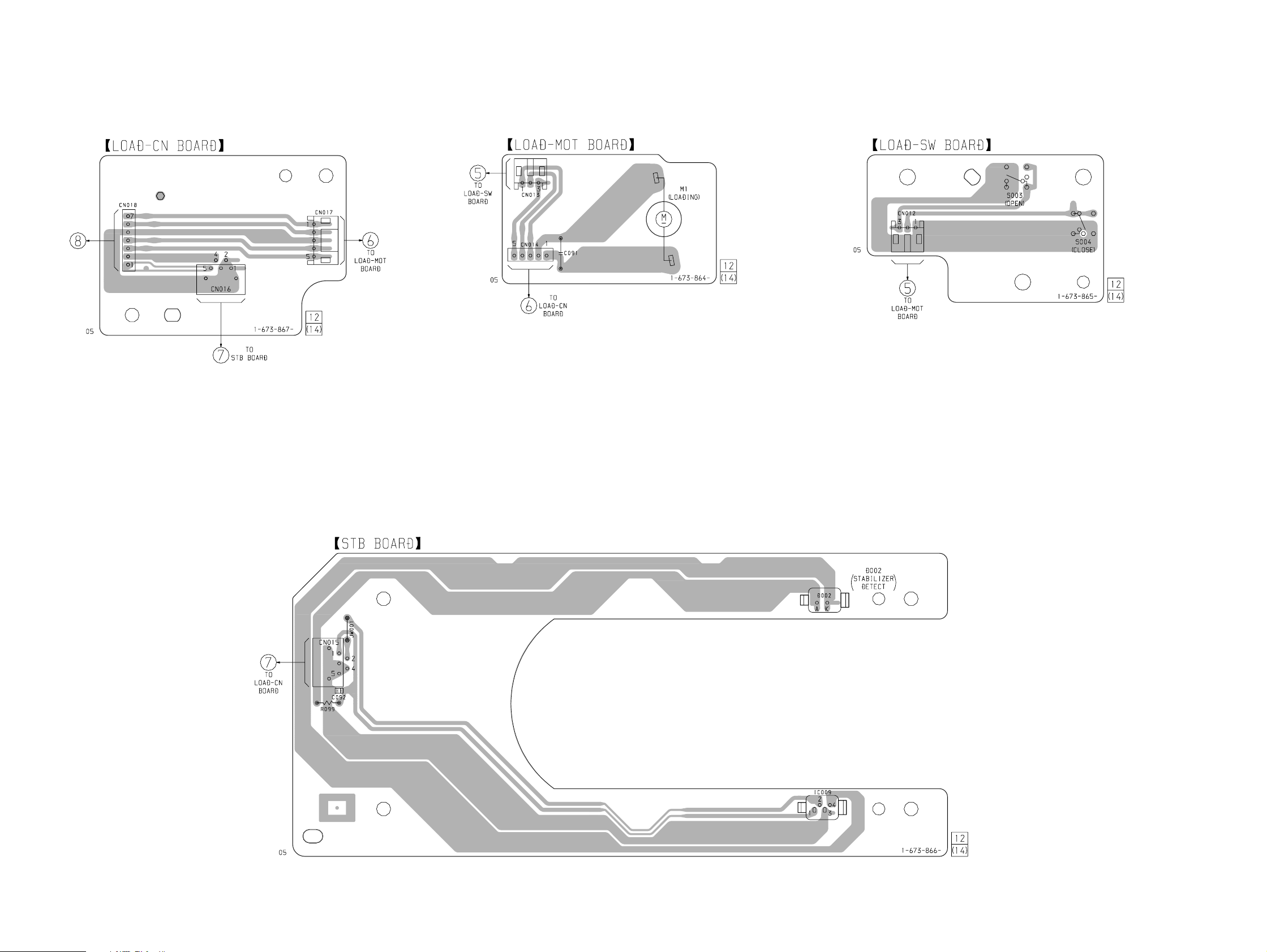

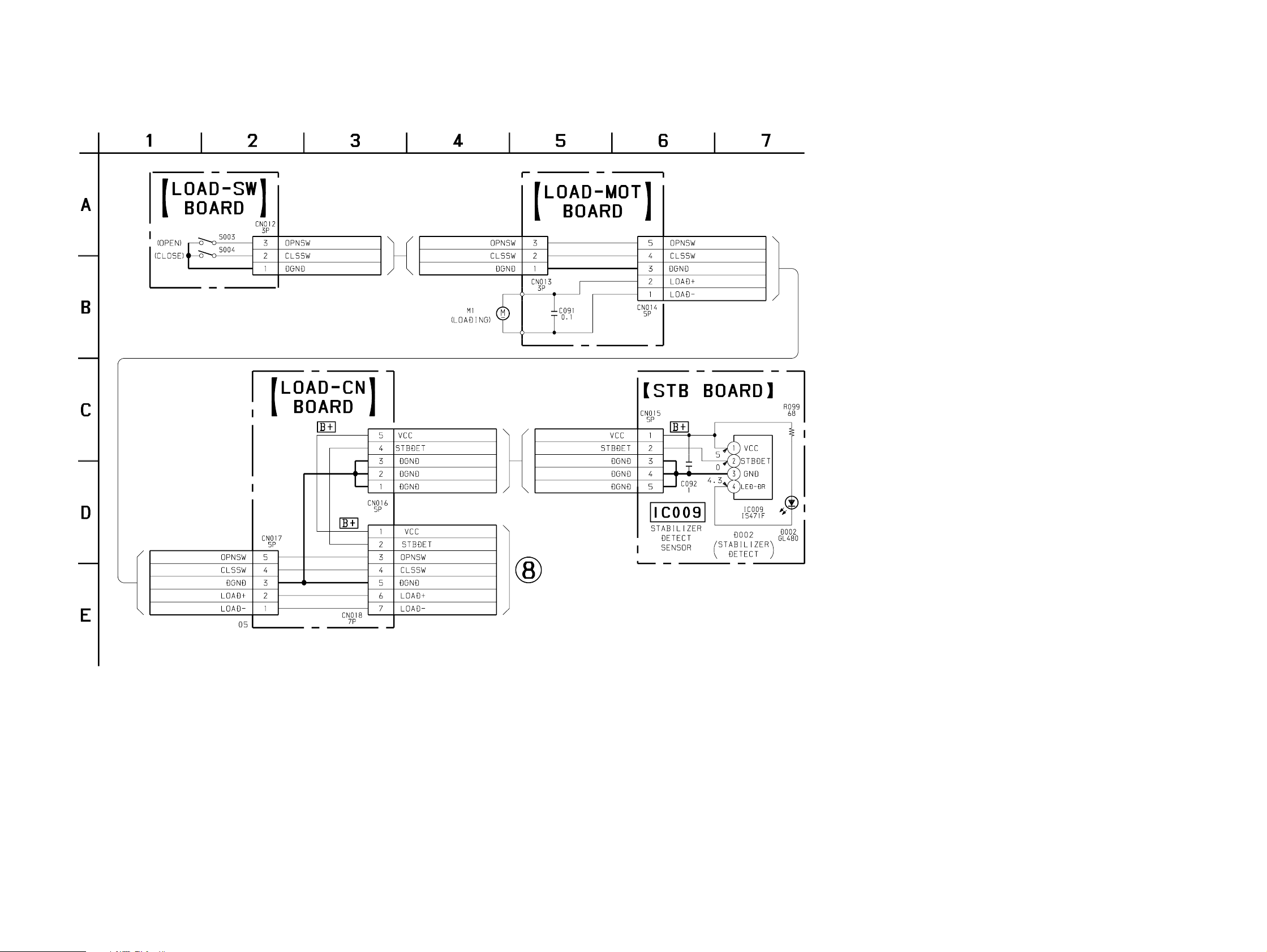

7-5. SCHEMATIC DIAGRAM – LOAD-CN/LOAD-MOT/LOAD-SW/STB Boards –

SCD-1/777ES

(Page 29)

2121

Page 22

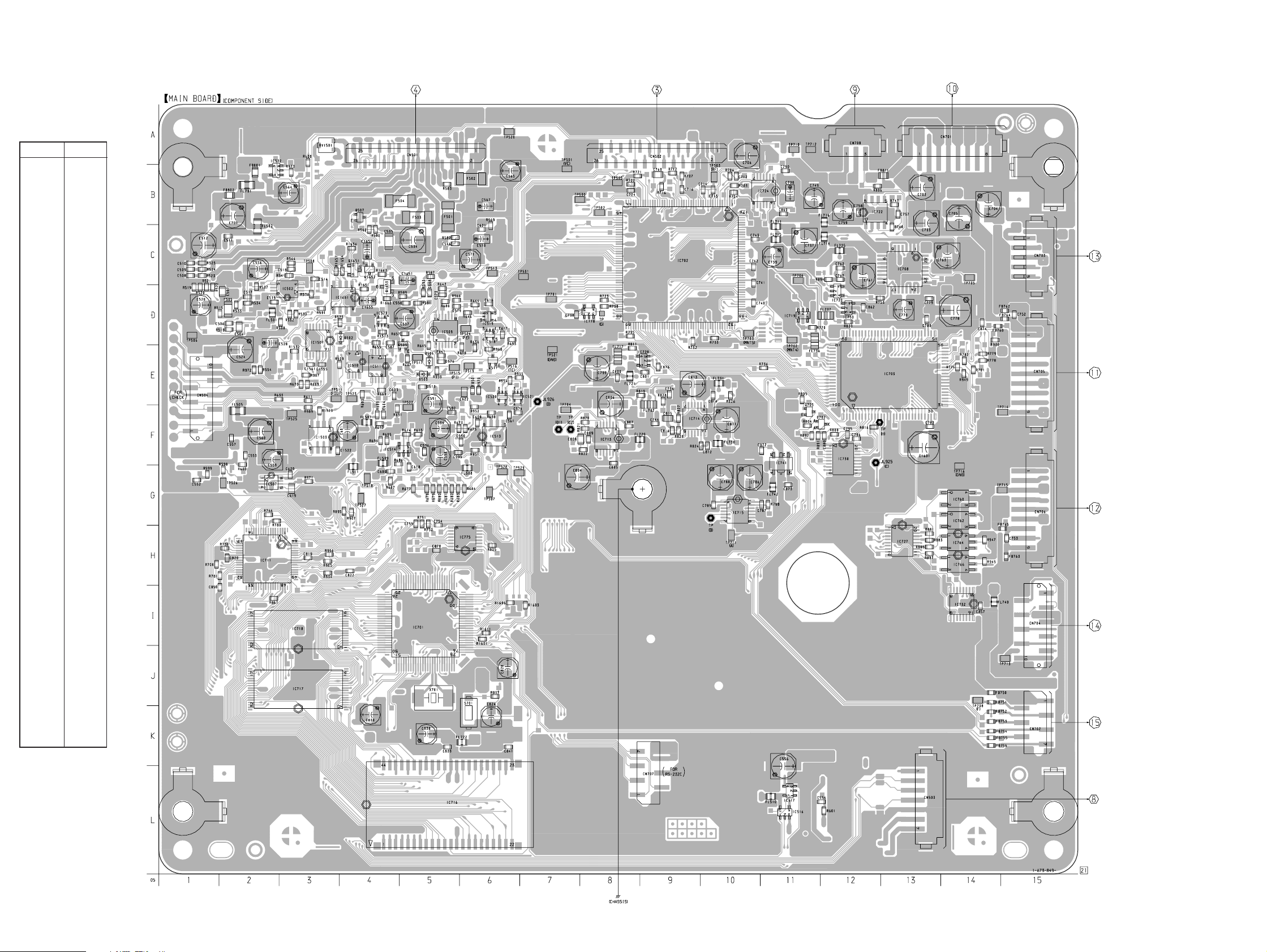

SCD-1/777ES

7-6. PRINTED WIRING BOARD – MAIN Board (component side) – • See page 17 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

D501 E-5

D502 D-4

D503 E-5

D702 F-12

IC502 D-3

IC507 G-2

IC509 D-5

IC510 E-4

IC511 E-4

IC513 F-6

IC514 F-5

IC516 L-11

IC517 L-11

IC519 D-6

IC520 E-6

IC521 E-6

IC522 B-2

IC523 D-4

IC701 I-5

IC702 C-9

IC703 E-13

IC708 C-13

IC711 H-2

IC713 F-8

IC714 F-9

IC715 G-10

IC716 L-5

IC717 J-3

IC718 I-3

IC719 D-11

IC720 D-12

IC722 B-12

IC724 B-11

IC727 H-13

IC728 E-9

IC730 F-12

IC732 I-14

IC741 F-11

IC750 D-12

IC760 G-14

IC762 G-14

IC764 H-14

IC766 H-14

IC775 H-6

IC778 D-8

IC1501 D-3

IC1503 F-3

IC1651 D-4

(Page 18) (Page 18)

(Page 38)

(Page 38)

(Page 34)

(Page 31)

(Page 31)

(Page 31)

Q507 B-4

Q509 E-5

Q511 E-6

Q705 F-11

Q1651 C-4

Q1652 C-4

Q1653 D-4

(Page 36)

(Page 20)

2222

Page 23

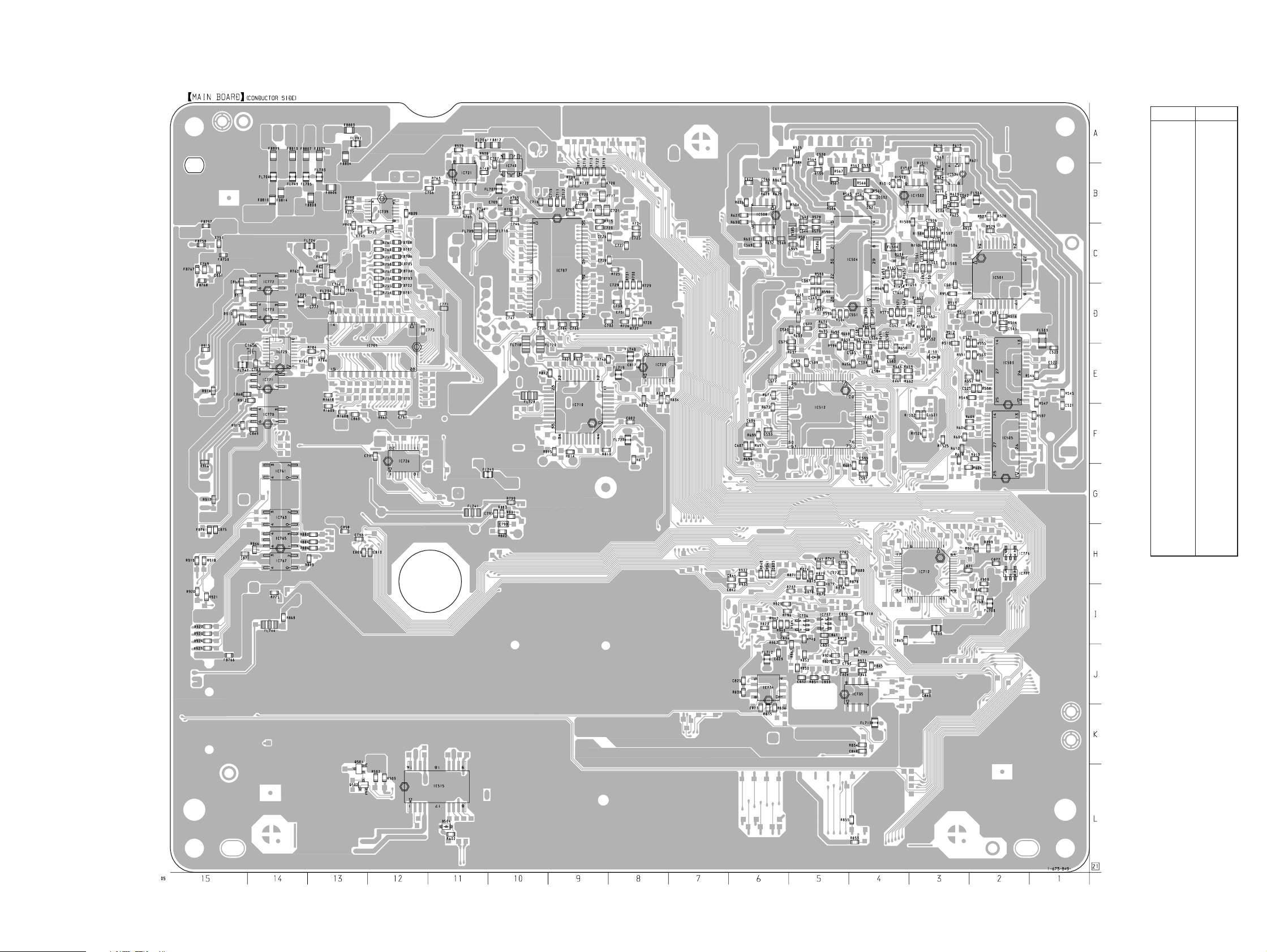

7-7. PRINTED WIRING BOARD – MAIN Board (conductor side) – • See page 17 for Circuit Boards Location.

SCD-1/777ES

• Semiconductor

Location

Ref. No. Location

D504 L-11

D701 C-13

D1501 E-3

IC501 C-2

IC503 E-2

IC504 C-4

IC505 F-2

IC506 B-3

IC508 B-6

IC512 F-5

IC515 L-11

IC707 C-9

IC709 E-12

IC710 F-9

IC712 H-3

IC721 B-11

IC725 E-14

IC726 F-12

IC729 E-8

IC734 J-6

IC735 J-4

IC736 I-5

IC737 I-5

IC739 B-12

IC740 B-10

IC761 G-14

IC763 G-14

IC765 H-14

IC767 H-14

IC770 F-14

IC771 E-14

IC772 C-14

IC773 D-14

IC776 H-2

IC777 H-2

IC1502 B-3

Q501 L-13

Q502 L-13

Q506 C-4

Q508 B-3

2323

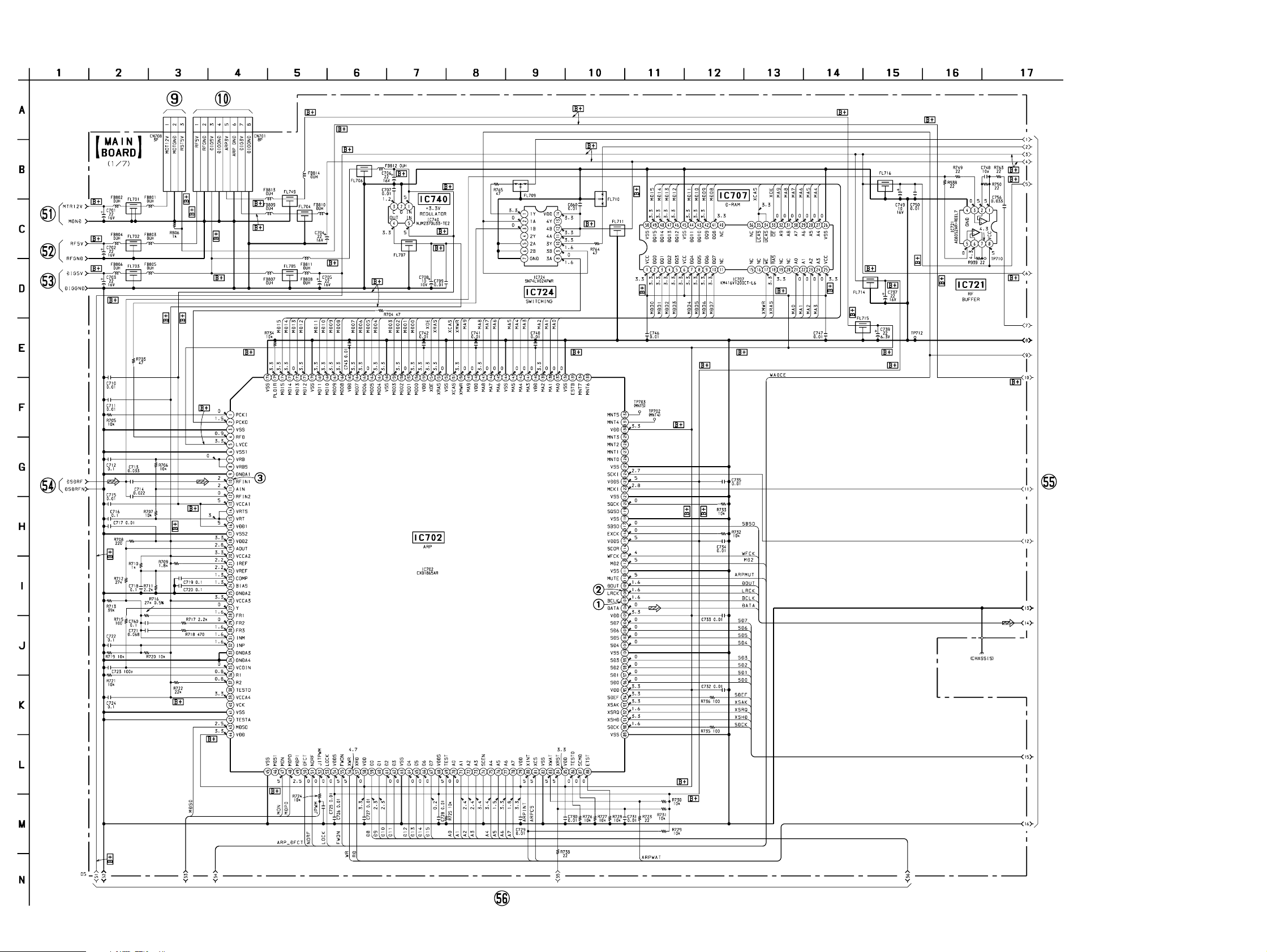

Page 24

SCD-1/777ES

7-8. SCHEMATIC DIAGRAM – MAIN Board (1/7) – • See page 40 for Waveforms.

(Page 28)

(Page 29)

(Page 28)

(Page 39)

(Page 39)

(Page 29)

(Page 25)

(Page 26)

2424

Page 25

7-9. SCHEMATIC DIAGRAM – MAIN Board (2/7) – • See page 40 for Waveforms. • See page 42 for IC Block Diagrams.

SCD-1/777ES

(Page

32)

(Page

32)

(Page

24)

(Page 27)

2525

Page 26

SCD-1/777ES

7-10. SCHEMATIC DIAGRAM – MAIN Board (3/7) – • See page 40 for Waveforms.

(Page 24)

(Page 29)

(Page 28)

(Page 30)

(Page 30)

(Page 30)

(Page 30)

(Page 28)

(Page 30)

(Page 29)

(Page 29)

(Page 25)

(Page 25)

(Page 27)

(Page 29)

(Page 29)

(Page 30)

(Page 29)

(Page 30)

(Page 29)

2626

Page 27

7-11. SCHEMATIC DIAGRAM – MAIN Board (4/7) –

SCD-1/777ES

(Page 25)

(Page

26)

(Page

35)

(Page

32)

(Page

37)

2727

Page 28

SCD-1/777ES

7-12. SCHEMATIC DIAGRAM – MAIN Board (5/7) – • See page 42 for IC Block Diagrams.

(Page 24)

(Page 26)

(Page 26)

(Page

19)

(Page 24)

(Page 29)

(Page 30)

2828

Page 29

7-13. SCHEMATIC DIAGRAM – MAIN Board (6/7) – • See page 42 for IC Block Diagrams.

(Page 24)

SCD-1/777ES

(Page 28)

(Page 26)

(Page 26)

(Page 26)

(Page 26)

(Page 24)

(Page

19)

(Page 30)

(Page 26)

(Page 26)

(Page 26)

(Page

21)

(Page 30)

2929

Page 30

SCD-1/777ES

7-14. SCHEMATIC DIAGRAM – MAIN Board (7/7) – • See page 40 for Waveforms.

(Page 28)

(Page 26)

(Page 26)

(Page 26)

(Page 26)

• Semiconductor

Location

(Conductor Side)

Ref. No. Location

D101 B-10

D102 B-7

D103 C-10

D201 D-10

D202 C-7

D203 C-10

D401 E-1

D402 A-1

D413 D-2

D414 B-2

(Page

29)

(Page 29)

(Page 26)

(Page 26)

(Page 26)

IC101 B-11

IC102 A-9

IC105 B-9

IC106 B-9

IC201 D-11

IC202 D-9

IC205 D-9

IC206 C-9

IC304 C-10

IC308 C-9

Q103 A-5

Q104 A-5

Q105 A-4

Q106 A-4

Q107 B-5

Q108 B-5

Q109 B-9

Q203 E-5

Q204 E-5

Q205 E-4

Q206 E-4

Q207 D-5

Q208 D-5

Q209 D-9

Q301 E-12

Q302 E-12

Q303 D-12

Q304 D-12

Q401 D-2

Q402 B-2

Q403 D-2

Q404 B-2

Q405 D-2

Q406 B-2

Q407 D-1

Q408 B-1

Q409 E-1

Q410 A-1

Q411 E-2

Q412 A-2

Q413 E-2

Q414 A-2

Q415 E-3

Q416 A-3

Q417 E-2

Q418 A-2

3030

Page 31

7-15. PRINTED WIRING BOARD – AUDIO Board – • See page 17 for Circuit Boards Location.

SCD-1/777ES

• Semiconductor

Location

(Component Side)

Ref. No. Location

IC103 B-8

IC104 B-6

IC107 B-9

IC108 B-7

IC109 B-7

IC203 D-8

IC204 D-6

IC207 D-9

IC208 D-7

IC209 D-7

IC301 C-13

IC302 C-12

IC305 A-13

IC306 A-12

IC307 B-12

IC309 C-8

PHD301 E-12

PHD302 D-12

PHD303 D-13

PHD304 B-13

(Page

38)

(Page 38)

(Page 38)

(Page 34)

(Page 34)

(Page 34)

Q101 A-4

Q102 A-5

Q201 E-4

Q202 E-5

(Page 38)

(Page 22)

(Page 38)

(Page 22)

(Page 38)

(Page 38)

(Page 34)

(Page 22)

(Page 34)

(Page 34)

3131

Page 32

SCD-1/777ES

7-16. SCHEMATIC DIAGRAM – AUDIO Board (1/2) – • See page 40 for Waveforms. • See page 41 for IC Block Diagrams.

(Page 39)

(Page

27)

(Page

25)

(Page

25)

(Page 39)

(Page 33)

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque 0 sont

critiques pour la sécurité. Ne les remplacer que

par une pièce portant le numéro spécifié.

3232

Page 33

7-17. SCHEMATIC DIAGRAM – AUDIO Board (2/2) – • See page 40 for Waveforms.

SCD-1/777ES

(Page 35)

(Page 35)

(Page 35)

(Page 39)

(Page

32)

(Page 39)

(Page 39)

(Page 39)

(Page 39)

(Page

35)

(Page

35)

(Page 35)

3333

Page 34

SCD-1/777ES

7-18. PRINTED WIRING BOARDS – BAL (SCD-1)/COAX/OPT/PIN/SW Boards – • See page 17 for Circuit Boards Location.

(Page 31)

(Page 31) (Page 31)

(Page 22)

(Page 31)

(Page 31)

(Page 31)

3434

Page 35

7-19. SCHEMATIC DIAGRAM – BAL (SCD-1)/COAX/OPT/PIN/SW Boards –

(Page 33)

SCD-1/777ES

(Page 33)

(Page 33)

(Page

27)

(Page 33)

(Page 33)

(Page 33)

3535

Page 36

SCD-1/777ES

7-20. PRINTED WIRING BOARDS – DISPLAY/SW-L/SW-R Boards – • See page 17 for Circuit Boards Location.

• Semiconductor

Location

–DISPLAY Board–

Ref. No. Location

D1005 C-2

IC1001 B-4

IC1002 C-9

IC1003 C-8

Q1001 B-8

Q1002 B-8

Q1003 B-7

Q1004 B-7

Q1005 B-7

Q1006 B-7

Q1007 B-6

Q1008 B-6

Q1009 A-5

Q1010 B-3

Q1011 B-2

Q1012 B-2

Q1021 B-2

Q1022 B-2

Q1023 B-3

Q1024 B-3

(Page 22) (Page 38)

3636

Page 37

7-21. SCHEMATIC DIAGRAM – DISPLAY/SW-L/SW-R Boards – • See page 40 for Waveforms.

SCD-1/777ES

(Page 27)

(Page 39)

3737

Page 38

SCD-1/777ES

7-22. PRINTED WIRING BOARDS – AC/POWER Boards – • See page 17 for Circuit Boards Location.

(Page 31)

(Page 22)

(Page 22)

(Page 36)

(Page 31) (Page 31)(Page 31) (Page 31) (Page 31)(Page 31)

• Semiconductor Location –POWER Board–

Ref. No. Location Ref. No. Location

D456 F-2

D457 E-3

D458 E-3

D459 E-4

IC401 B-1

IC402 B-2

D403 C-5

D404 C-6

D405 B-1

D406 B-2

D407 B-4

D408 C-1

D409 C-1

Ref. No. LocationRef. No. Location

D410 C-5

D411 C-6

D451 D-1

D452 D-1

D453 E-1

D454 F-6

D455 F-4

3838

IC403 B-3

IC451 D-6

IC452 D-4

IC453 D-2

Q451 D-1

Page 39

7-23. SCHEMATIC DIAGRAM – AC/POWER Boards –

(Page 32)

(Page 32)

SCD-1/777ES

(Page 33)

(Page

33)

(Page

33)

(Page

33)

(Page 33)

(Page 37)

(Page 24)

(Page 24)

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque 0 sont

critiques pour la sécurité. Ne les remplacer que

par une pièce portant le numéro spécifié.

3939

Page 40

• Waveforms

4.1 Vp-p

22.58 MHz

– RF Board –

– MAIN Board –

– AUDIO Board –

1 IC001 ra (TE) (SACD PLAY)

1 IC001 ra (TE) (CD PLAY)

2 IC001 rs (FE) (SACD PLAY)

Approx.

300 mVp-p

Approx.

400 mVp-p

3 IC001 tj (SIGO) (CD PLAY)

Approx.

1.5 Vp-p

1 IC702 <z/m> (BCLK)

354 ns

2 IC702 <z/,> (LRCK)

µ

s

22.7

3 IC702 q; (RFIN1) (SACD PLAY)

5.5 Vp-p

5.3 Vp-p

5 IC701 yh (EXTAL)

4 Vp-p

16 MHz

6 IC512 wf (TE) (SACD PLAY) 2 IC301 t; (LRCKI) 7 IC302 q; (XIN)

Approx.

300 mVp-p

6 IC512 wf (TE) (CD PLAY) 3 IC301 ta (SBCKI)

1 IC301 rl (BCKI) 6 IC302 eg (256FSO)

5.5 Vp-p

354 ns

5.3 Vp-p

22.7 µs

11.28 MHz

45 MHz

5.1 Vp-p

2.4 Vp-p

2 IC001 rs (FE) (CD PLAY)

3 IC001 tj (SIGO) (SACD PLAY)

Approx.

100 mVp-p

Approx.

200 mVp-p

Approx.

1.4 Vp-p

Approx.

1.4 Vp-p

3 IC702 q; (RFIN1) (CD PLAY)

Approx.

1.5 Vp-p

4 IC703 ql (LRCK) 7 IC512 wh (FE) (CD PLAY) 5 IC301 qd (XIN), IC302 ed LVCK01 2 IC1001 ea (EXTAL)

3.8 Vp-p

7 IC512 wh (FE) (SACD PLAY) 4 IC301 q; (64FSI), IC302 r; (64FSO)

Approx.

400 mVp-p

Approx.

100 mVp-p

Approx.

200 mVp-p

354 ns

2.8 MHz

5 Vp-p

– DISPLAY Board –

1 IC1002 yg (OSC0)

6.1 Vp-p

494 ns

2.3 Vp-p

4.3 Vp-p

22.7

µ

s

8 MHz

4040

Page 41

• IC Block Diagrams

– AUDIO Board –

IC101, 201 CXA8042AS

1

I01+

2

I02–

3

NC

4

I01–

5

I02+

6

NC

7

VCC2

8

C2

C1

9

10

VCC1

VREF

11

12

VCNT

13

GND1

RIREF

14

IC302 CXD8594Q

MUTE

51

50

REFERENCE

VOLTAGE

CIRCUIT

49

NSDIL3

NSDIL4

48

SWITCHING

CIRCUIT

CONSTANT

CURRENT

CIRCUIT

CONTROL

CIRCUIT

NSDIL1

NSDIL2

46

47

28

IN2–

27

IN2+

26

NC

25

IN1+

IN1–

24

NC

23

C4

22

C3

21

GND2

20

VEE2

19

18

VEE1

17

C6

C5

16

15

CIREF

45

CKSEL2

CKSEL3

44

DVDD43DVDD

42

41

64FSO

CKSEL1

40

NSDIR1

39

38

NSDIR3

NSDIR2

37

36

256FSO

NSDIR4

35

34

LVCKO1

CKVDD

33

SYNCNC52

IFSEL

NC

DVSS

VSS2

REGISTER

BUFFER

53

54

55

56SUB(D)

57SUB(C)

58VDD2

59VDD

60L1(-)

61VSS

62L1(+)

63VSS2

64

4

3

2

1

NC

VSS

L2(+)

L2(-)

MUTE

PLM-L1

PLM-L2

7

6

5

VDD

VDD2

VSUB(A)L

SYNC

NSDATA(L/Rch)

1024Fs CLOCK BUFFER

1098 11 12

XIN

XVSS

XOUT

XVDD

XVSS

CLOCK

GENERATOR

PLM-R1

PLM-R2

13

14

VSUB(A)R

15

VDD2

VDD

BUFFER

16

R2(-)

CLOCK

17

VSS

8

19

R2(+)

32 LVCKO2

31 DRPOL

30 NC

29 DVSS

28 SUB(D)

27 SUB(C)

26 VDD2

25 VDD

24 R1(-)

23 VSS

22 R1(+)

21 VSS2

20 VSS2

NC

41

Page 42

– MAIN Board –

IC503, 505 BA5912AFP-YE2

OP2-OUT

IN1

IN1’

25 24 23 22 21 20 19 18 17 16 15 14

–

+

OP2-IN+

OP2-IN–

BIAS

GND

OP1-IN+

OP1-IN–

OP1-OUT

IN2’

IN2

–

+

+

OUT2–

+

–

REF2

SWITCH

PRE VCC

POW VCC2

REF2

CH2

MUTE

MUTE2

+

–

1

MUTE

GND

CH1

2

MUTE1

REF1

SWITCH

LEVEL SHIFT

VREF2VREF1

+

–

345 6 7 8 910111213

REF1

POW VCC1

OUT1–

+

–

OUT1+

GND

LEVEL SHIFT

+

–

OUT2+

–

IC713, 714, 715 TLC2932IPW-E20 IC1501 MC14053BDTR2

LOGIC

VDD

1 2 3 4 5 6 7

SELECT

VCO

OUT

1/2 DIVIDER

VCO

FIN-A FIN-B

PFD

PFD

OUT

LOGIC

GND

C.COM

INH

VEE

VSS

1

B1

B0

2

3

C1

4

5

CO

6

7

8

OPEN

OPEN

OPEN

VDD

16

B.COM

15

14

A.COM

13

A1

A0

12

11

A

10

B

C

9

42

14 13 12 11 10 9 8

VCO

R BIAS VCOINVCO

VDD

GND

VCO

INHIBIT

PFD

INHIBIT

NC

Page 43

7-24. IC PIN FUNCTION DESCRIPTION

• MAIN BOARD IC701 HD6413002F16 (CPU)

Pin No. Pin Name I/O Description

1 VCC —

2 SSSD I/O

3 SSI CLK O

4 PWM O

5 JIG CTR I/O

6 DF LT O

7 DCMF LT O

8 DATA O

9 SHIFT O

10 X RES0 O

11 VSS —

12 SOUT0 O

13 SOUT1 O

14 SIN0 I

15 SIN1 I

16 SCK0 O

17 SCK1 O

18 D0 I/O

19 D1 I/O

20 D2 I/O

21 D3 I/O

22 VSS —

23 D4 I/O

24 D5 I/O

25 D6 I/O

26 D7 I/O

27 D8 I/O

28 D9 I/O

29 D10 I/O

30 D11 I/O

31 D12 I/O

32 D13 I/O

33 D14 I/O

34 D15 I/O

35 VCC —

36 A0 O

37 A1 O

38 A2 O

39 A3 O

40 A4 O

41 A5 O

42 A6 O

43 A7 O

44 VSS —

Power supply terminal (+5V)

Two-way data bus with the SACD/CD RF AMP (IC001)

Serial data transfer clock signal output to the SACD/CD RF AMP (IC001)

PWM signal output to the loading motor drive (IC515)

Two-way data bus with the RS-232C (for check)

Latch signal output to the digital filter (IC301)

Not used (open)

Serial data output to the digital filter (IC301)

SHIFT signal output to the digital filter (IC301)

Not used (open)

Ground terminal

Serial data output to the RS-232C (for check)

Serial data output to the DSD decoder (IC703)

Serial data input from the RS-232C (for check)

Serial data input from the DSD decoder (IC703)

Serial data output to the RS-232C (for check)

Serial data output to the DSD decoder (IC703)

Two-way data bus with the expander (IC712) , flash memory (IC716) and S-RAM (IC718)

Ground terminal

Two-way data bus with the expander (IC712) , flash memory (IC716) and S-RAM (IC718)

Two-way data bus with the expander (IC712) , flash memory (IC716) and S-RAM (IC718)

Two-way data bus with the servo digital signal processor (IC512), ARP (IC702), expander

(IC711), flash memory (IC716) and S-RAM (IC717)

Power supply terminal (+5V)

Address signal output to the ARP (IC702)

Address signal output to the servo digital signal processor (IC512), ARP (IC702), expander

(IC711, 712), flash memory (IC716) and S-RAM (IC717, 718)

Address signal output to the ARP (IC702), expander (IC711, 712), flash memory (IC716) and

S-RAM (IC717, 718)

Two-way data bus with the expander (IC712) , flash memory (IC716) and S-RAM (IC718)

Address signal output to the ARP (IC702), flash memory (IC716) and S-RAM (IC717, 718)

Ground terminal

43

Page 44

Pin No. Pin Name I/O Description

45 A8 O

46 A9 O

47 A10 O

48 A11 O

49 A12 O

50 A13 O

51 A14 O

52 A15 O

53 A16 O

54 A17 O

55 A18 O

56 A19 O

57 VSS —

58 WAIT I

59 EEP SIO I/O

60 EEP SCL O

61 CLK O

62 STBY I

63 RES I

64 NMI I

65 VSS —

66 EXTAL I

67 XTAL I

68 VCC —

69 AS O

70 RD O

71 HWR O

72 LWR O

73 MD0 I

74 MD1 I

75 MD2 I

76 AVCC —

77 VREF I

78 AN0 I

79 BUSY2 I

80 ADS RDY I

81 IFBSY I

82 PLIN I

83 AK0 I

84 AK1 O

85 AK2 O

86 AVSS —

Address signal output to the flash memory (IC716) and S-RAM (IC717, 718)

Address signal output to the flash memory (IC716)

Address signal output terminal Not used (open)

Ground terminal

Wait signal input from the ARP (IC702)

Two-way data bus with the EEPROM (IC735)

clock signal output to the EEPROM (IC735)

System clock output terminal Not used (open)

Hardware standby signal input terminal (fixed at “H”)

System reset signal input from the ARP (IC702) and reset signal generator (IC734) “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

NMI signal input terminal Not used (pull up)

Ground terminal

System clock input terminal (16 MHz)

System clock input terminal (16 MHz)

Power supply terminal (+5V)

Address strobe signal output terminal Not used (open)

Strobe signal output for data reading to the servo digital signal processor (IC512), ARP (IC702),

expander (IC711, 712), flash memory (IC716) and S-RAM (IC717, 718)

Strobe signal output for data writing to the servo digital signal processor (IC512), ARP (IC702),

expander (IC712), flash memory (IC716) and upper byte data writing strobe signal output to the

S-RAM (IC717)

Strobe signal output for data writing to the expander (IC711) and lower byte data writing strobe

signal output to the S-RAM (IC716)

Input terminal for setting microcomputer operation mode (fixed at “L”)

Input terminal for setting microcomputer operation mode (fixed at “L”)

Input terminal for setting microcomputer operation mode (fixed at “H”)

Power supply terminal (+5V)

Reference voltage input terminal (+5V)

Serial data input from the RS-232C (for check)

BUSY signal input from the servo digital signal processor (IC512)

Ready signal input terminal (fixed at “H”)

BUSY signal input from the FL controller (IC1001)

PL signal input from the servo digital signal processor (IC512)

Monitor signal input from the expander (IC711)

Two-way data bus with the expander (IC712) , flash memory (IC716) and S-RAM (IC718)

Monitor signal output terminal (fixed at “L”)

Two-way data bus with the expander (IC712) , flash memory (IC716) and S-RAM (IC718)

Two-way data bus with the expander (IC712) , flash memory (IC716) and S-RAM (IC718)

Ground terminal

44

Page 45

Pin No. Pin Name I/O Description

87 ARPINT I

88 SDSCS O

89 SDSACK I

90 CS1 O

91 CS0 O

92 VSS —

93 SHR RDY I

94 IFREQ O

95 RST OUT O

96 TKC I

97 HFG I

98 A22 O

99 A21 O

100 A20 O

Interrupt signal input from the ARP (IC702)

Chip enable signal output to the servo digital signal processor (IC512)

Chip enable signal input from the servo digital signal processor (IC512)

Chip enable signal output to the S-RAM (IC717, 718)

Chip enable signal output to the flash memory (IC716)

Ground terminal

Ready signal Input from the DSD decoder (IC703)

Request signal output to the FL controller (IC1001)

System reset signal output to the servo digital signal processor (IC512) and expander (IC711,712)

Sled FG signal input from the position sensor (IC008)

HFG signal input from the spindle motor drive (IC501)

Address signal output to the ARP (IC702) and expander (IC711,712)

45

Page 46

• MAIN BOARD IC711 CXD1095R (EXPANDER)

Pin No. Pin Name I/O Description

1 AK1 O

2 AK2 O

3 MON3 O

4 MON4 O

5 MON5 O

6 MON6 O

7 MON7 O

8 VSS —

9 WADCE O

10 TEST O

11 WMGC0 O

12 WMGC1 O

13 SHR RST O

14 SHR MUTE O

15 SHR LT O

16 — O

17 NC —

18 FWON O

19 MD2 O

20 MUTE O

21 ARP RST O

22 DFCT I

23 VSS —

24 VDD —

25 NORF I

26 LOCK I

27 FIL SET I

28 D0 I/O

29 D1 I/O

30 D2 I/O

31 NC —

32 NC —

33 D3 I/O

34 D4 I/O

35 D5 I/O

36 D6 I/O

37 D7 I/O

38 XCLR I

39 XDIS I

40 VSS —

41 XWR I

42 XRD I

43 XCS I

Monitor signal output terminal Not used (open)

Ground terminal

Watermark signal output to the RF AD (IC708)

Test signal output to the DSD decoder (IC703) “H”:active

RF gain control for watermark signal output to the RF AD (IC708)

RF gain control for watermark signal output to the RF AD (IC708)

Reset signal output to the DSD decoder (IC703)

Mute signal output to the DSD decoder (IC703)

Latch pulse signal output to the DSD decoder (IC703)

Not used (open)

Not used (open)

FWON signal output to the ARP (IC702)

CD-TX mute signal output to the ARP (IC702)

CD-DA mute signal output to the ARP (IC702)

Reset signal output to the ARP (IC702)

DFCT signal input from the ARP (IC702)

Ground terminal

Power supply terminal (+5V)

NORF signal input from the ARP (IC702)

Lock signal input from the ARP (IC702)

Filter select signal input from the STANDARD/CUSTOM switch (S173) “L”:CUSTOM “H”

:STANDARD

Two-way data bus with the CPU (IC701)

Not used (open)

Not used (open)

Two-way data bus with the CPU (IC701)

Clear signal input terminal (pull up)

Reset signal input from the ARP (IC702)

Ground terminal

Strobe signal input from the CPU (IC701)

Strobe signal input from the CPU (IC701)

Chip enable signal input from the CPU (IC701)

46

Page 47

Pin No. Pin Name I/O Description

44 A0 I

45 A1 I

46 A2 I

47 REM CODE O

48 — I

49 NC —

50 — I

51 — O

52 DF INIT O

53 MODE O

54 A FILE O

55 VSS —

56 VDD —

57 A MUTE O

58 XLR ON O

59 ADS LT O

60 DCMF INIT O

61 DOCTRL O

62 AK0 O

63 NC —

64 NC —

Address signal input from the CPU (IC701)

Remote category signal output terminal “L”:CD2 “H”:CD1

Not used (open)

Not used (open)

Not used (open)

Not used (open)

Initial signal output to the digital filter (IC301)

SACD/CD mode signal output to the digital filter (IC301)

Filter signal output terminal

Ground terminal

Power supply terminal (+5V)

Audio mute signal output terminal “L”:mute

Balance signal output terminal

Not used (open)

Not used (open)

Digital control signal output to the select switch (IC732)

Monitor signal output to the CPU (IC701)

Not used (open)

Not used (open)

47

Page 48

• MAIN BOARD IC712 CXD1095R (EXPANDER)

Pin No. Pin Name I/O Description

1 STBL DTC I

2—I

3—I

4 LD SW1 I

5 LD SW0 I

6 SLD SW1 I

7 SLD SW0 I

8 VSS —

9 LOAD O

10 UNLOAD O

11 STBL DRV O

12 SPCTL1 O

13 SPCTL0 O

14 SPGC2 O

15 SPGC1 O

16 PIHG O

17 NC —

18 SRVRST O

19 PISEL O

20 TEAGC0 O

21 TEAGC1 O

22 ERROR I

23 VSS —

24 VDD —

25 FON I

26 TIUNLK I

27 — I

28 D0 I/O

29 D1 I/O

30 D2 I/O

31 NC —

32 NC —

33 D3 I/O

34 D4 I/O

35 D5 I/O

36 D6 I/O

37 D7 I/O

38 XCLR I

39 XDIS I

40 VSS —

41 XWR I

42 XRD I

43 XCS I

44 A0 I

45 A1 I

46 A2 I

Stabilizer detect signal input from the stabilizer detect sensor (IC009)

Not used (open)

Not used (open)

Loading panel close signal input from the close switch (S004)

Loading panel open signal input from the open switch (S003)

Sled motor (out) signal input from the out switch (S001)

Sled motor (in) signal input from the in switch (S001)

Ground terminal

Load signal output to the loading motor drive (IC515)

Unload signal output to the loading motor drive (IC515)

Stabilizer drive signal output terminal

Spindle motor control signal output to spindle motor drive (IC501)

Spindle motor control signal output terminal Not used (open)

Spindle motor control signal output to spindle motor drive (IC501)

Spindle motor control signal output to spindle motor drive (IC501)

PIHG signal output terminal Not used (open)

Not used (open)

Servo reset signal output to the servo digital signal processor (IC512)

PI select signal output terminal

Tracking error signal output terminal

Tracking error signal output terminal

Error signal input from the servo digital signal processor (IC512)

Ground terminal

Power supply terminal (+5V)

FON signal input from the servo digital signal processor (IC512)

Tilt motor control signal input from the tilt motor drive (IC505)

Not used (open)

Two-way data bus with the CPU (IC701)

Not used (open)

Not used (open)

Two-way data bus with the CPU (IC701)

Clear signal input terminal (pull up)

Reset signal input from the ARP (IC702)

Ground terminal

Strobe signal input from the CPU (IC701)

Strobe signal input from the CPU (IC701)

Chip enable signal input from the CPU (IC701)

Address signal input from the CPU (IC701)

48

Page 49

Pin No. Pin Name I/O Description

47 — I

48 — I

49 NC —

50 FCSDWN I/O

51 SDPREK O

52 SACDLDON O

53 TILT OUT O

54 A ERR O

55 VSS —

56 VDD —

57 TILT/H O

58 SLDDLY O

59 SDEN O

60 SL MUTE O

61 LM MUTE O

62 CHUCK I

63 NC —

64 NC —

Not used (open)

Not used (open)

Not used (open)

Two-way data bus with the SACD/CD RF AMP (IC001)

SDPREK signal output to the sled motor drive (IC503)

Load signal output to the SACD/CD RF AMP (IC001)

Tilt out signal output to the tilt motor drive (IC505)

Not used (open)

Ground terminal

Power supply terminal (+5V)

Tilt error signal output to the tilt error AMP (IC004)

SLDDLY signal output to the sled motor drive (IC503)

SDEN signal output to the SACD/CD RF AMP (IC001)

Mute signal output to the sled motor drive (IC503)

Mute signal output terminal Not used (open)

Not used (open)

Not used (open)

Not used (open)

49

Page 50

SECTION 8

EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

(1) GENERAL (SCD-1)

6

5

4

#2

3

10

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• The mechanical parts with no reference number in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of the

electrical parts list.

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque 0 sont critiquens pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

6

loading ass'y section

2

#2

#2

1

not supplied

#1

front panel section

not

supplied

8

not

supplied

#2

7

#2

#1

not supplied

#2

9

8

Ref. No. Part No. Description Remark

1 4-215-794-01 PLATE (L), SIDE

2 X-4951-357-1 PANEL (LOADING) ASSY

3 4-218-606-01 CUSHION (LD)

4 4-216-860-01 EMBLEM (SACD)

5 4-216-431-01 BOLT (M5X10), HEXAGON SOCKET

50

Ref. No. Part No. Description Remark

6 4-216-429-01 BOLT (M4X8), HEXAGON SOCKET

7 4-215-795-01 PLATE (R), SIDE

* 8 2-127-516-01 TAPE (TV LOCK HANDLE)

9 4-968-977-11 SCREW (3X10), +BVTP

10 4-218-606-11 CUSHION (LD)

Page 51

(2) GENERAL (SCD-777ES)

55

(for GOLD)

#40 (for BLACK)

(for GOLD)

56

#41 (for BLACK)

(for GOLD)

56

#41 (for BLACK)

52

#2

57

54

#11

53

60

#2

not supplied

58

loading ass'y section

#2

not

supplied

not

supplied

#2

front panel section

#11

58

Ref. No. Part No. Description Remark

51 4-221-849-01 PLATE (L), SIDE (GOLD)

51 4-221-849-11 PLATE (L), SIDE (BLACK)

52 X-4951-857-1 PANEL (LOADING) ASSY (GOLD)

52 X-4951-858-1 PANEL (LOADING) ASSY (BLACK)

53 4-218-606-01 CUSHION (LD)

54 4-216-860-21 EMBLEM (SACD) (SCD-777ES: BLACK)

54 4-216-860-11 EMBLEM (SACD) (SCD-777ES: GOLD)

not

supplied

#2

#2

59

Ref. No. Part No. Description Remark

55 4-216-431-01 BOLT (M5X10), HEXAGON SOCKET (for GOLD)

56 4-216-429-01 BOLT (M4X8), HEXAGON SOCKET (for GOLD)

57 4-221-850-01 PLATE (R), SIDE (GOLD)

57 4-221-850-11 PLATE (R), SIDE (BLACK)

* 58 2-127-516-01 TAPE (TV LOCK HANDLE)

59 4-968-977-11 SCREW (3X10), +BVTP

60 4-218-606-11 CUSHION (LD)

51

51

Page 52

(3) LOADING ASSY SECTION

118

#3

137

134

117

not supplied

#3

114

116

not

supplied

112

113

#33

not

supplied

109

108

107

#6

136

#4

#5

135

110

#4

109

108

M1

#3

106

119

121

135

116

105

120

102

122

115

#3

123

134

#3

not

supplied

103

104

124

#6

125

134

not supplied

133

not supplied

#33

136

#7

132

126

122

131

#3

134

128

not supplied

not supplied

#9

127

122

128

134

129

#10

not supplied

#3

101

Ref. No. Part No. Description Remark

101 4-215-791-01 PLATE (B), ORNAMENTAL

102 4-215-767-01 PLATE (A), ORNAMENTAL

103 1-673-865-12 LOAD-SW BOARD

104 1-790-587-11 WIRE (FLAT TYPE) (5 CORE)

105 1-673-867-12 LOAD-CN BOARD

106 1-673-864-12 LOAD-MOT BOARD

107 4-218-604-01 DAMPER (MOTOR)

* 108 4-928-026-01 COLLAR (B)

* 109 4-888-798-00 BUSHING, RUBBER

* 110 3-694-225-01 CLAMP

112 3-011-999-01 RUBBER (B)

113 X-4945-209-1 PULLEY (FIRST) ASSY

114 4-968-905-01 BELT (CDM)

115 4-215-762-01 SHAFT (MAIN)

116 3-910-695-01 FELT

117 4-215-775-01 GEAR (SHUTTER)

118 X-4951-127-2 LEVER (STOPPER) ASSY

119 4-217-469-01 SPRING (STOPPER)

120 4-220-666-01 WASHER (SHUTTER)

121 4-215-771-01 SHUTTER, SLIDE

#8

130

#8

Ref. No. Part No. Description Remark

122 3-325-697-01 WASHER

123 4-968-898-01 GEAR (FIRST)

124 4-968-899-01 GEAR (MIDLE)

125 4-215-774-01 GEAR (SWING)

126 X-4950-850-3 ARM (SWING) ASSY

127 4-215-780-03 CASE (TOP PLATE) (SCD-1)

127 4-221-848-01 PLATE, TOP (SCD-777ES: GOLD)

127 4-221-848-11 PLATE, TOP (SCD-777ES: BLACK)

128 4-215-766-04 ROLLER (SLIDE)

129 4-215-769-01 RACK, J

130 1-673-866-12 STB BOARD

131 4-215-770-01 RACK, I

132 4-215-792-02 PLATE (C), ORNAMENTAL

133 3-701-445-11 WASHER, 7

134 3-363-191-01 WASHER (BA)

135 4-220-665-01 ROLLER (SHUTTER)

136 4-221-221-03 RAIL, GUIDE

137 4-949-302-51 WASHER

M1 A-4672-674-A MOTOR ASSY (LOADING)

52

Page 53

(4) FRONT PANEL SECTION (SCD-1)

not supplied

#6

160

153

154

152

151

not supplied

#11

159

158

161

#22

153

156

157

S901

not supplied

#12

165

#6

154

153

152

not supplied

#11

164

not supplied

163

not

supplied

166

#11

167

#11

not supplied

not supplied

162

#11

151

155

not supplied

Ref. No. Part No. Description Remark

151 4-947-420-01 RING (DIA. 2.53), RETAINING

152 4-215-806-01 GUIDE (OPEN/CLOSE)

153 4-216-427-02 CUSHION (BUTTON)

154 X-4950-852-1 BUTTON (O/C) ASSY

* 155 4-900-228-01 INDICATOR (MONITOR)

156 4-215-807-01 GUIDE (PLAY)

157 X-4950-853-1 BUTTON (PLAY) ASSY

158 4-211-455-01 BUTTON (LED)

159 4-215-789-02 GUIDE (GOMA KEY) (SCD-1)

151

Ref. No. Part No. Description Remark

160 4-215-810-01 PANEL, FRONT

161 X-4950-854-1 BUTTON ASSY, POWER

162 1-673-863-12 SW-R BOARD

163 4-216-430-04 PLATE, HALF MIRROR

164 4-218-605-01 SPACER (INDICATION PLATE)

165 4-215-803-01 PLATE, INDICATION

166 1-673-862-13 SW-L BOARD

167 A-4724-528-A DISPLAY BOARD, COMPLETE

S901 1-771-685-11 SWITCH, PUSH (CONTROL BLOCK)

53

Page 54

(5) FRONT PANEL SECTION (SCD-777ES)

218

not supplied

210

#6

220

219

#22

not supplied

211

#11

S901

#22

not supplied

#22

#22

215

#11

214

not supplied

213

#22

not supplied

#11

not

supplied

216

217

#11

not supplied

BLACK

204

203

202

209

207

203

208

201

Ref. No. Part No. Description Remark

201 4-947-420-01 RING (DIA. 2.53), RETAINING

202 4-215-806-01 GUIDE (OPEN/CLOSE)

203 4-216-427-02 CUSHION (BUTTON)

204 X-4951-861-1 BUTTON (O/C) ASSY (GOLD)

204 X-4951-862-1 BUTTON (O/C) ASSY (BLACK)

* 205 4-900-228-01 INDICATOR (MONITOR)

206 4-215-807-01 GUIDE (PLAY)

207 X-4951-863-1 BUTTON (PLAY) ASSY (GOLD)

207 X-4951-864-1 BUTTON (PLAY) ASSY (BLACK)

208 4-211-455-01 BUTTON (LED)

206

201

205

not supplied

218

not supplied

#22

204

not supplied

#6

not supplied

203

202

212

201

#11

Ref. No. Part No. Description Remark

211 X-4950-228-1 BUTTON ASSY, POWER (BLACK)

* 212 1-673-863-12 SW-R BOARD

213 4-221-842-02 PLATE, HALF MIRROR (for GOLD)

213 4-221-842-11 PLATE, HALF MIRROR (for BLACK)

214 4-221-843-01 SPACER (DISPLAY)

215 4-221-841-01 PLATE, INDICATION (for BLACK)

215 4-221-841-11 PLATE, INDICATION (for GOLD)

216 1-673-862-13 SW-L BOARD

217 A-4724-528-A DISPLAY BOARD, COMPLETE

218 4-221-840-01 PLATE (PANEL), SIDE (GOLD)

209 4-215-789-11 GUIDE (GOMA KEY) (GOLD)

209 4-215-789-21 GUIDE (GOMA KEY) (BLACK)

210 4-221-839-01 PANEL, FRONT (GOLD)

210 4-221-839-31 PANEL, FRONT (BLACK)

211 X-4950-227-1 BUTTON ASSY, POWER (GOLD)

54

218 4-221-840-11 PLATE (PANEL), SIDE (BLACK)

219 4-921-415-05 ESCUTCHEON, POWER KNOB (BLACK)

219 4-921-415-14 ESCUTCHEON, POWER KNOB (GOLD)

220 4-942-568-41 EMBLEM (NO. 5), SONY (for BLACK)

S901 1-771-685-11 SWITCH, PUSH (CONTROL BLOCK)

Page 55

(6) MAIN SECTION

253

BU-23

251

not

supplied

#32

256

#32

#22

255

257

253

254

#22

not

supplied

257

252

T451

not supplied

258

260

#14

#17

261

T401

259

not

supplied

SCD-777ES

#16

#15

not supplied

US, Canadian

SCD-1

not

supplied

US,

Canadian

not supplied

#16

#15

262

263

supplied with J150

#36

#1

#3

#18

US, Canadian

#3

#18

259

US, Canadian

#19

#14

#36

#3

268

supplied with J170, J270

#19

269

#14

#1

#3

268

264

not supplied

#3

#36

267

#21

#1

267

269

J250

J150

J170,

J270

#20

J250

J150

Ref. No. Part No. Description Remark

251 A-4724-951-A MAIN BOARD, COMPLETE

252 1-790-659-11 WIRE (FLAT TYPE) (26 CORE)

253 4-221-249-01 WASHER

254 1-673-854-14 AC BOARD

255 3-701-822-01 HOLDER, WIRE

256 1-771-685-21 SWITCH, PUSH (CONTROL BLOCK) (WIRE)

257 X-4908-910-1 SCREW ASSY (+ BVTT)

258 A-4724-529-A POWER BOARD, COMPLETE

* 259 4-931-964-01 SCREW (M4X6)

260 A-4724-524-A COAX BOARD, COMPLETE

* 261 4-913-152-01 ESCUTCHEON, D/O

262 1-673-858-14 OPT BOARD

263 1-673-859-14 SW BOARD

264 A-4724-931-A BAL BOARD, COMPLETE (SCD-1)

265 1-673-855-14 PIN BOARD

266 A-4724-518-A AUDIO BOARD, COMPLETE (SCD-1)

266 A-4724-953-A AUDIO BOARD, COMPLETE (SCD-777ES)

267 4-215-784-11 PANEL, BACK (SCD-1: US, Canadian)

267 4-215-784-21 PANEL, BACK (SCD-1: AEP)

267 4-221-854-01 PANEL, BACK (SCD-777ES: AEP)

267 4-221-854-11 PANEL, BACK (SCD-777ES: US, Canadian)

268 3-701-428-11 SCREW, +B 2.6 CLAW

269 4-221-222-11 BRACKET (FILTER) (SCD-777ES)

269 4-221-222-01 BRACKET (FILTER) (SCD-1)

J150 1-568-918-31 JACK, PIN 1P (LINE OUT (ANALOG) L)

(SCD-777ES)

Ref. No. Part No. Description Remark

J150 1-568-918-31 JACK, PIN 1P (LINE OUT (ANALOG)

J170 1-563-030-21 CONNECTOR (RECEPTACLE) 3P

J250 1-568-918-31 JACK, PIN 1P (LINE OUT (ANALOG)

J250 1-568-918-41 JACK, PIN 1P (LINE OUT (ANALOG) R)

J270 1-563-030-21 CONNECTOR (RECEPTACLE) 3P

! T401 1-435-108-11 TRANSFORMER, POWER (ANALOG)

! T401 1-435-110-11 TRANSFORMER, POWER (ANALOG)

! T401 1-435-114-11 TRANSFORMER, POWER (ANALOG)

! T401 1-435-116-11 TRANSFORMER, POWER (ANALOG)

! T451 1-435-109-11 TRANSFORMER, POWER (DIGITAL)

! T451 1-435-111-11 TRANSFORMER, POWER (DIGITAL)

! T451 1-435-115-11 TRANSFORMER, POWER (DIGITAL)

! T451 1-435-117-11 TRANSFORMER, POWER (DIGITAL)

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety .

Replace only with part number specified.

(LINE OUT (ANALOG) BALANCED L) (SCD-1)

(LINE OUT (ANALOG) BALANCED R) (SCD-1)

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

UNBALANCED L) (SCD-1)

UNBALANCED R) (SCD-1)

(SCD-777ES)

(SCD-777ES: AEP)

(SCD-777ES: US, Canadian)

(SCD-1: AEP)

(SCD-1: US, Canadian)

(SCD-777ES: AEP)

(SCD-777ES: US, Canadian)

(SCD-1: AEP)

(SCD-1: US, Canadian)

#13

255

257

266

257

supplied with J250

265

5555

Page 56

(7) CHASSIS SECTION (SCD-1) (8) CHASSIS SECTION (SCD-777ES)

307

306

not

supplied

#25

307

306

not

supplied

#34

#4

#4

#4

not

supplied

#25

#25

#25

307

306

#26

307

306

not supplied

#25

#4

#26

not supplied

#26

#4

307

307

306

307

306

306

355

354

#36

not

supplied

not

supplied

355

354

not

supplied

#38

#4

#4

#4

not

supplied

355

354

#26

355

354

not supplied

#4

#26

not supplied

#26

#4

#36

not supplied

355

355

354

355

354

354