Page 1

DCR-TRV890E/TRV900/TRV900E

RMT-811/812

US Model

SERVICE MANUAL

Canadian Model

DCR-TRV900

AEP Model

UK Model

DCR-TRV890E/TRV900E

E Model

Hong Kong Model

Tourist Model

DCR-TRV900/TRV900E

C MECHANISM

Difference table

Model

Color System

Remote Commander

Line recording

The POWER switch

position during playback

Base Band Input

DCR-TRV890E

Ver 1.0 1998.08

DCR-TRV900

PAL

RMT-812

—

PLAYER

—

NTSC

RMT-811

Photo: DCR-TRV900E

RMT-811

DCR-TRV900E

PAL

VTR

SPECIFICATIONS

Australian Model

Chinese Model

DCR-TRV900E

For MECHANISM ADJUSTMENTS, refer to the

“DV MECHANICAL ADJUSTMENT MANUAL

C MECHANISM ” (9-974-050-11)

MICROFILM

— Continued on next page —

DIGITAL VIDEO CAMERA RECORDER

Page 2

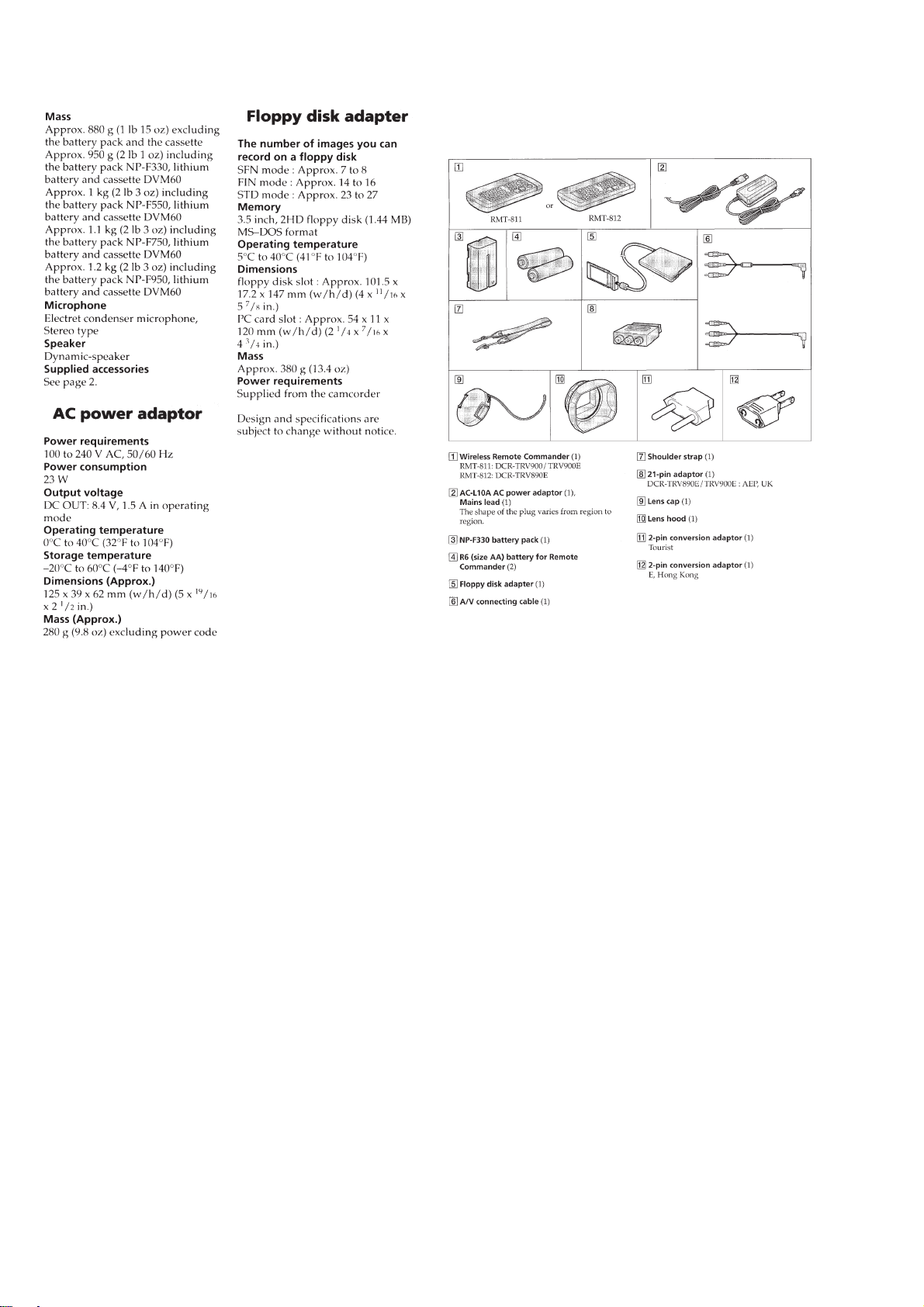

• SUPPLIED ACCESSORIES

Check that the following accessories are supplied with your

camcorder.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

ATTENTION AU COMPOSANT A YANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS P AR SONY.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

— 2 —

Page 3

T ABLE OF CONTENTS

SERVICE NOTE

1. Power Supply During Repairs ............................................6

2. How to Take a Cassette Out When the Main Power Cannot

Be Turned On ..................................................................... 6

SELF-DIAGNOSIS FUNCTION

1. Self-Diagnosis Function ..................................................... 7

2. Self-Diagnosis Display....................................................... 7

3. Service Mode Display ........................................................ 7

3-1. Display Method .................................................................. 7

3-2. Switching of Backup No. ................................................... 7

3-3. End of Display.................................................................... 7

4. Self-Diagnosis Code Table ................................................. 8

1. GENERAL

Before you begin

Using this manual ..................................................................1-1

Checking supplied accessories ..............................................1-1

Getting started

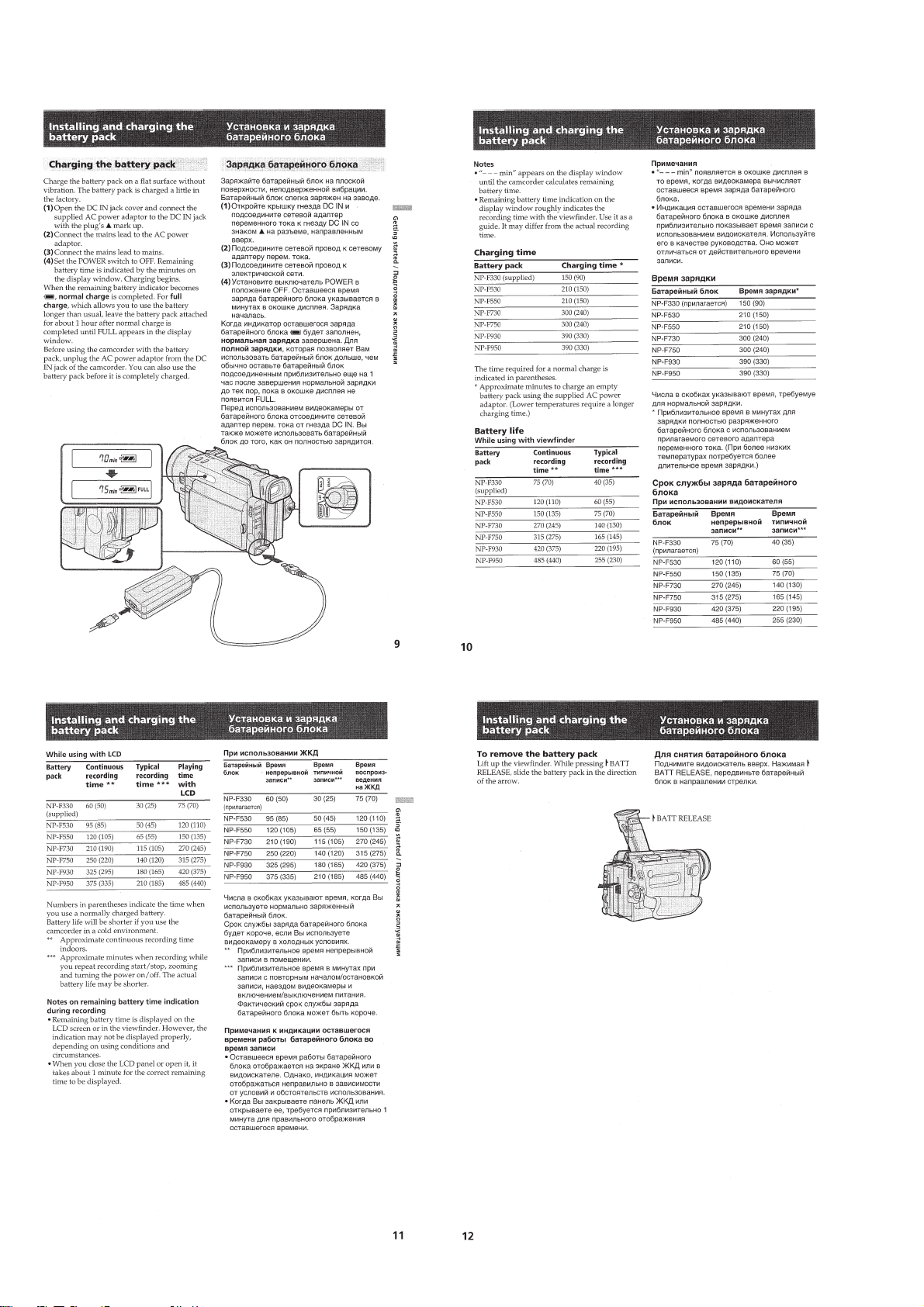

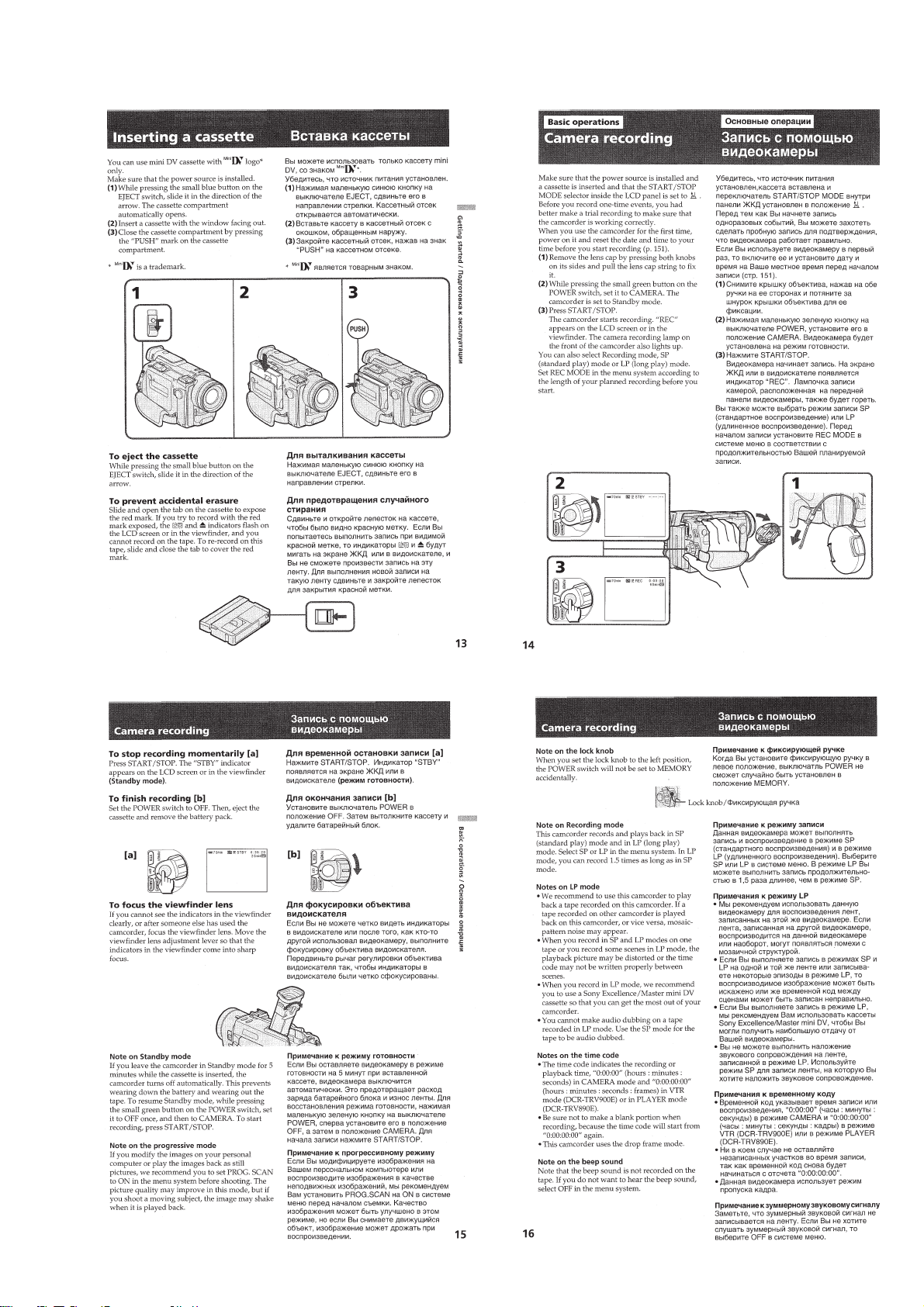

Installing and charging the battery pack ................................1-1

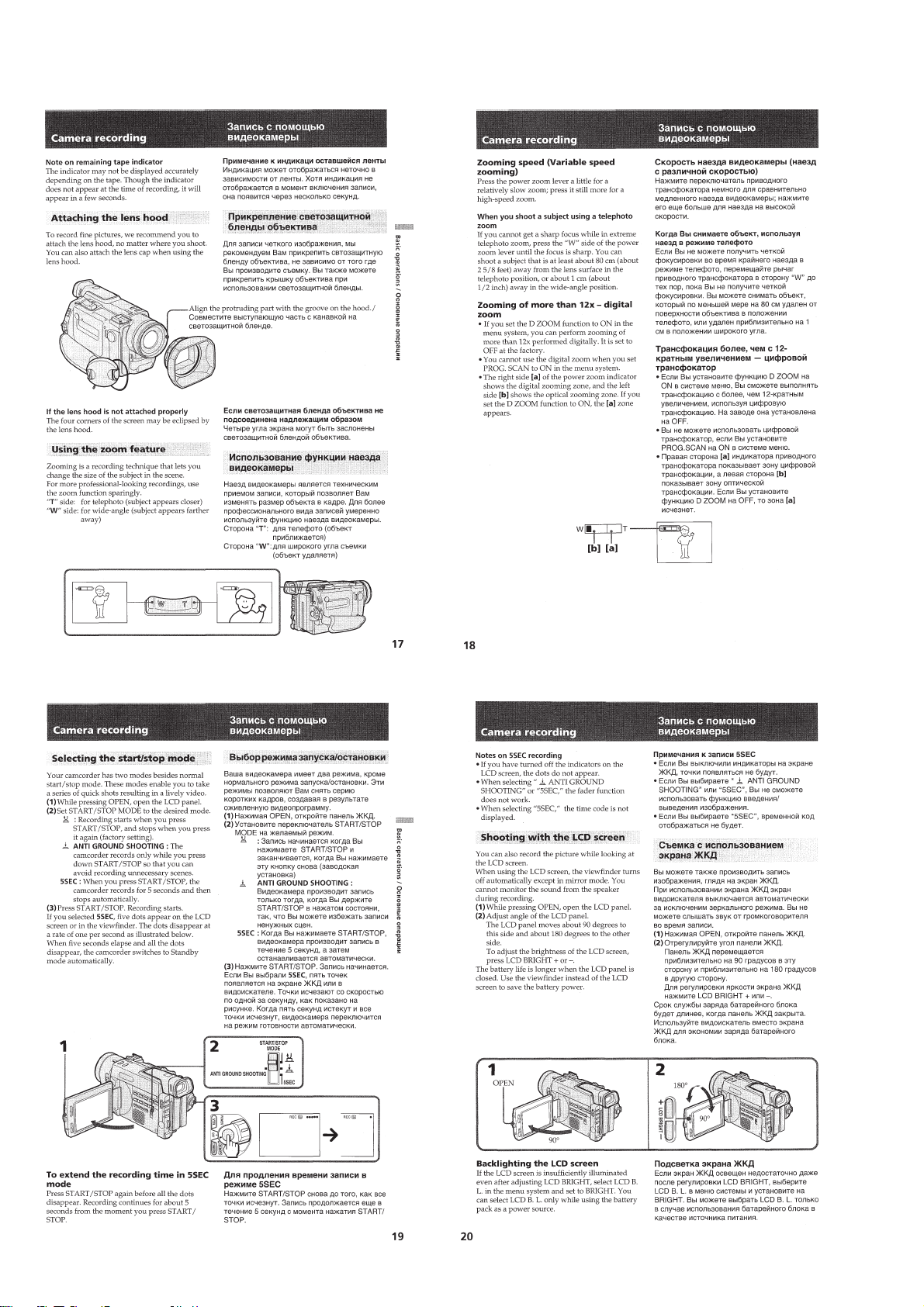

Inserting a cassette .................................................................1-3

Basic operations

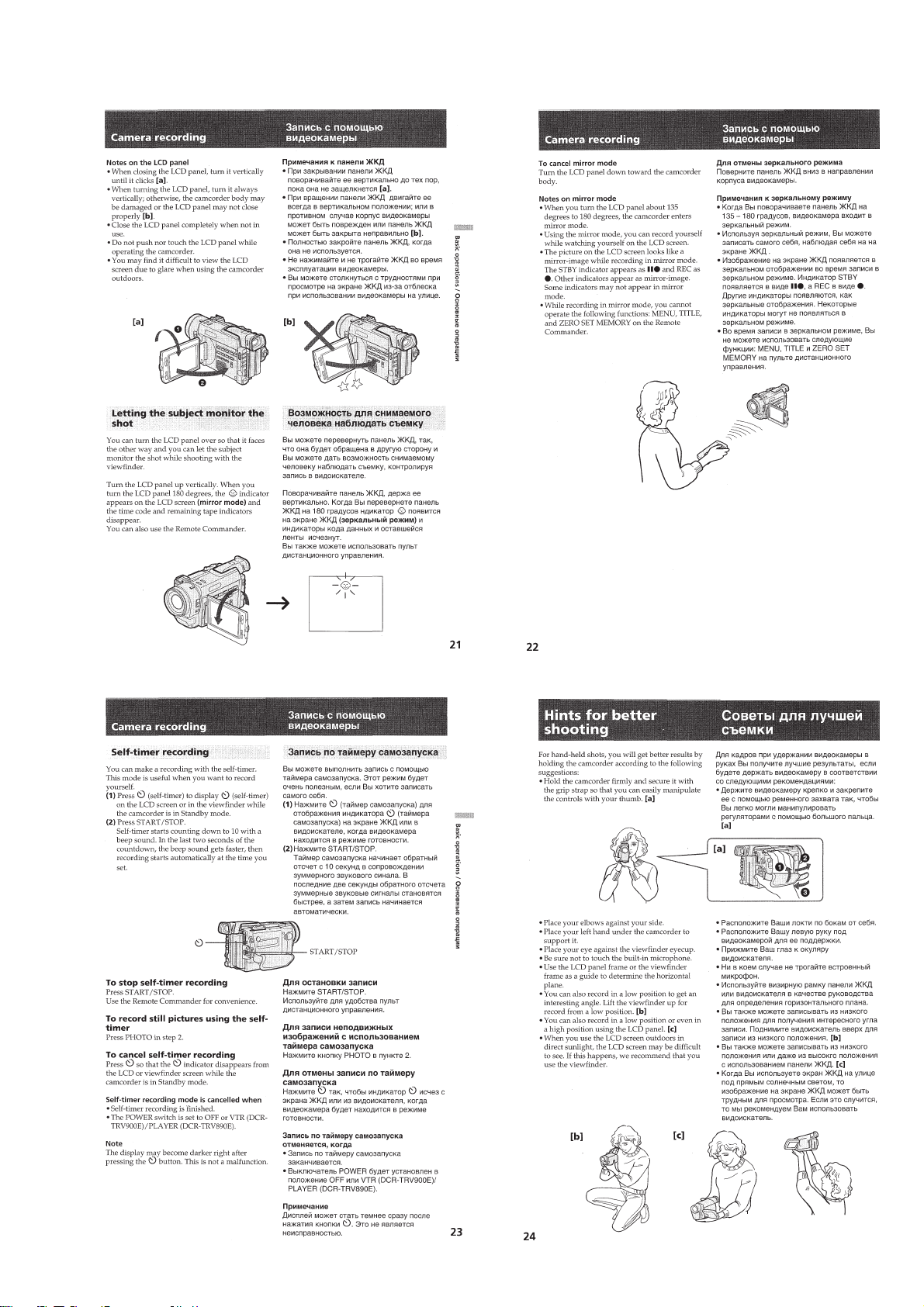

Camera recording...................................................................1-3

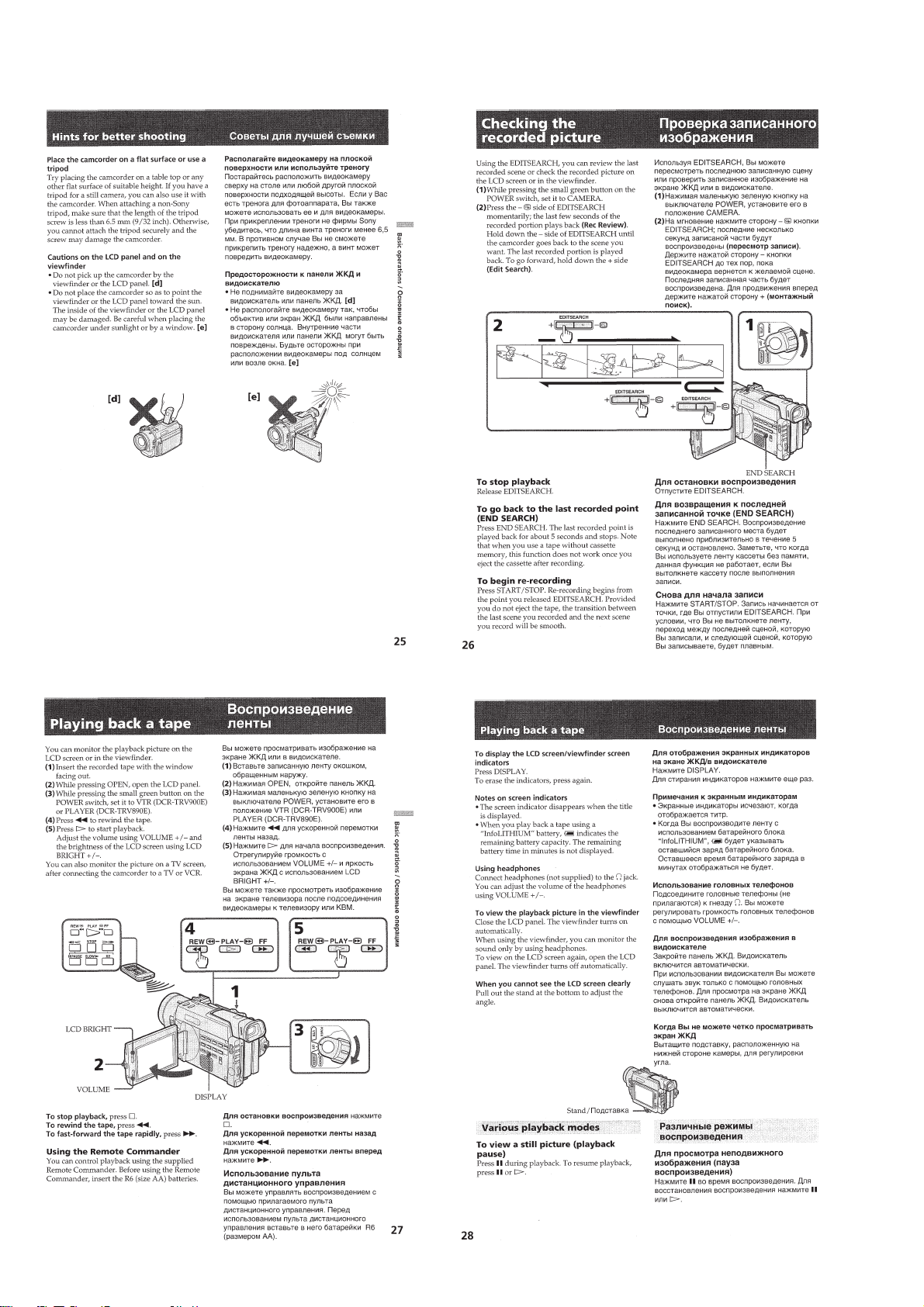

Hints for better shooting ........................................................1-5

Checking the recorded picture ...............................................1-6

Playing back a tape ................................................................1-6

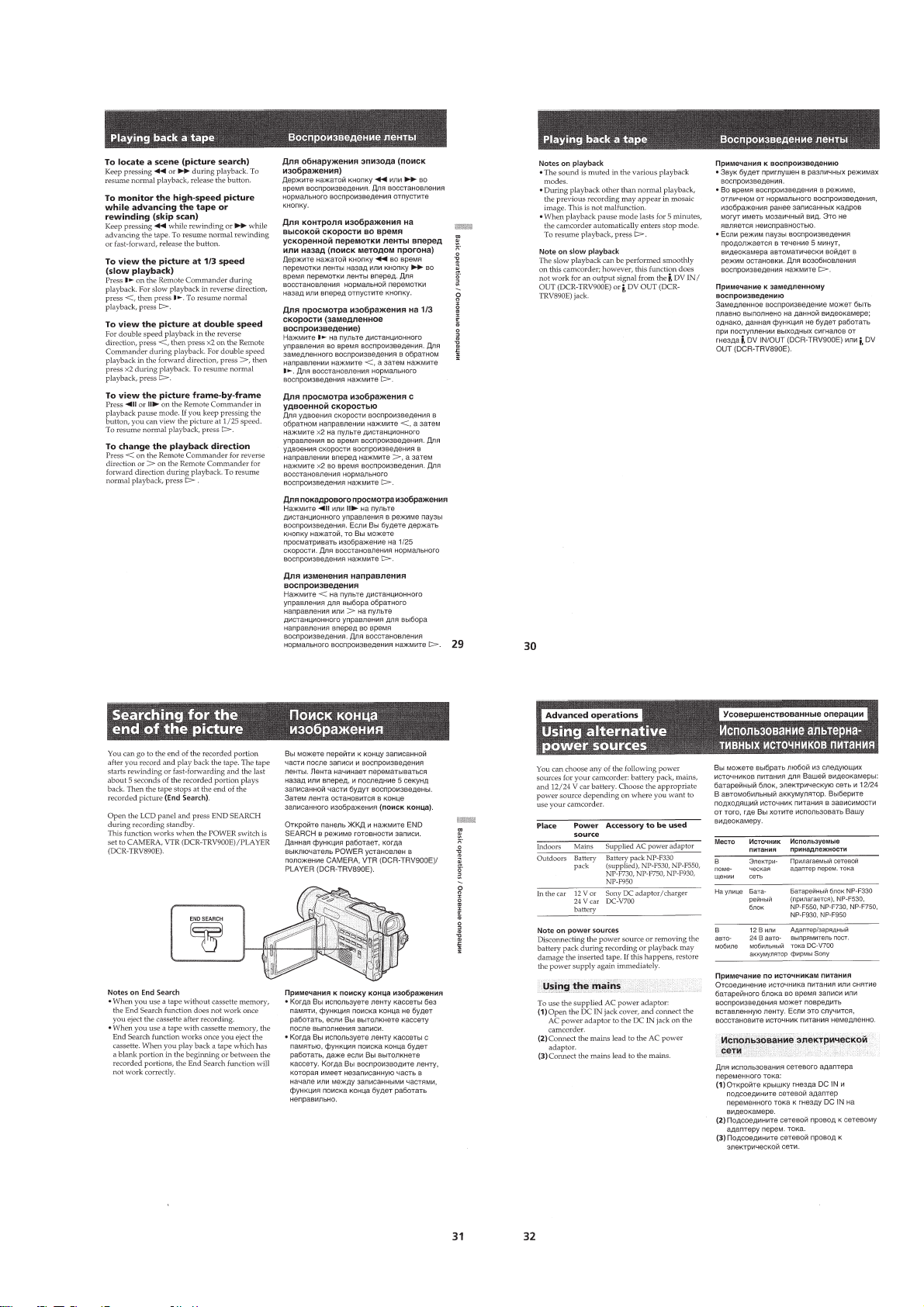

Searching for the end of the picture.......................................1-7

Advanced operations

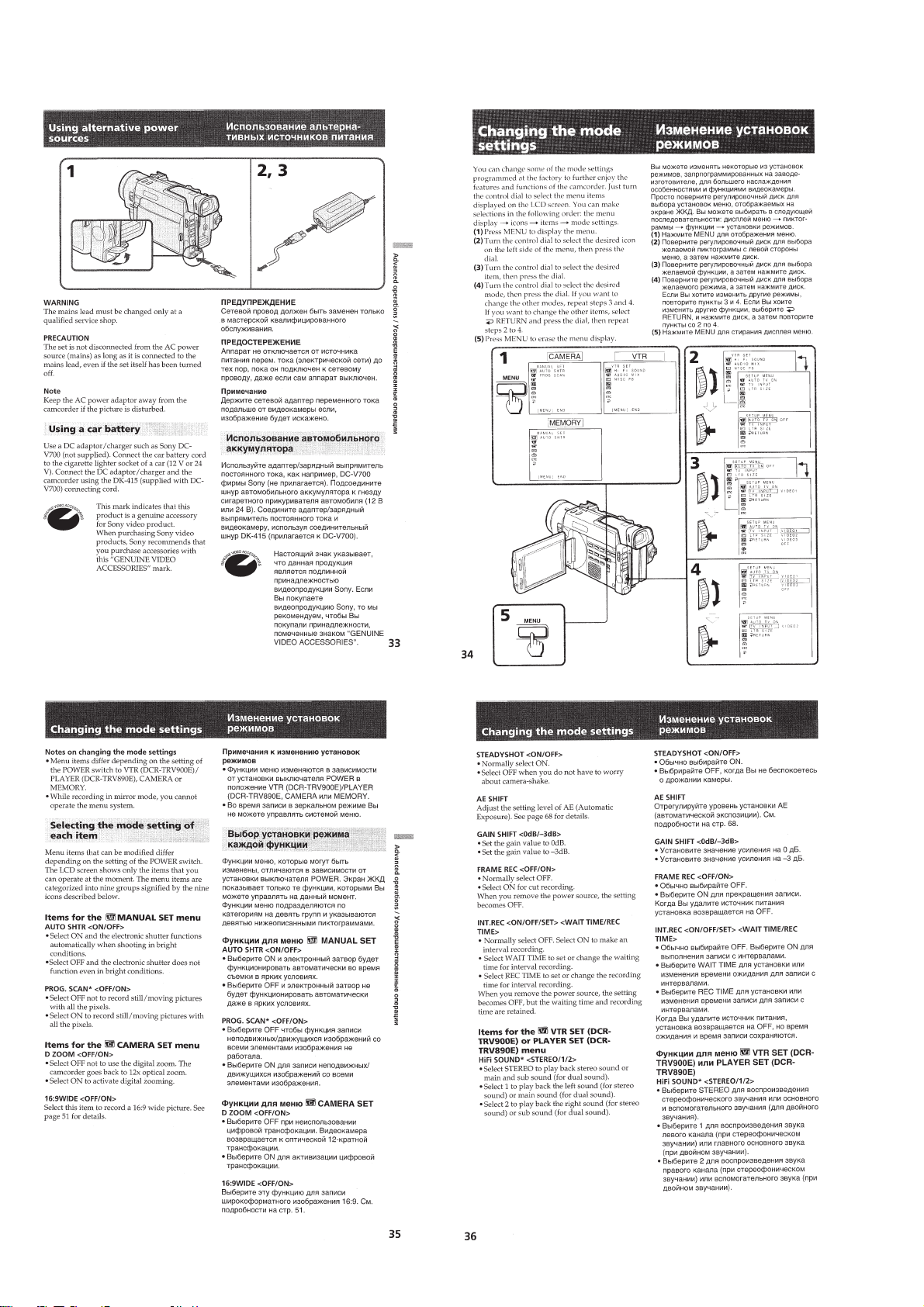

Using alternative power sources ............................................1-7

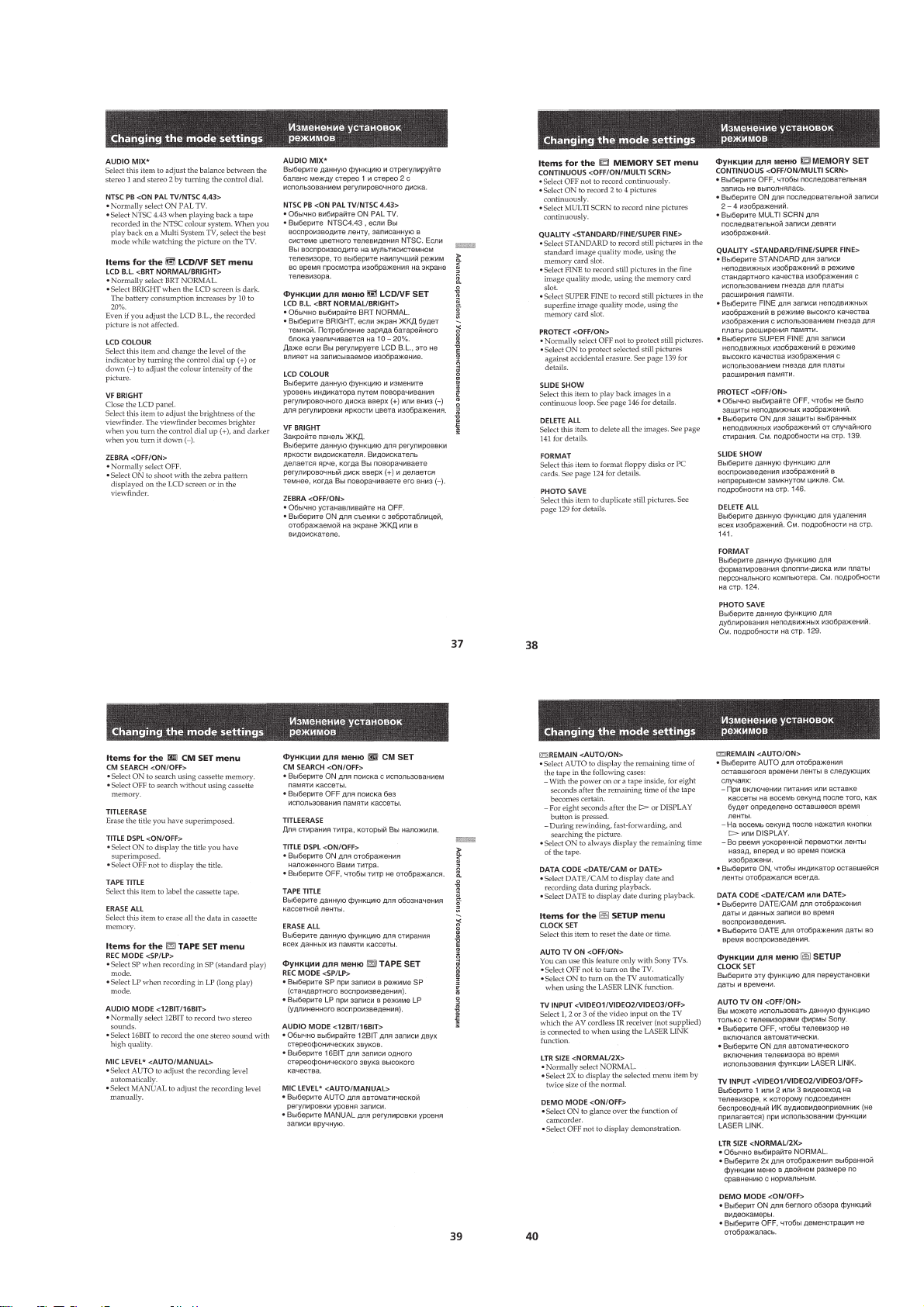

Changing the mode settings...................................................1-8

Photo recording....................................................................1-10

Shooting with all the pixels - PROG.SCAN........................1-11

Using the FADER function .................................................. 1-11

Shooting with backlighting..................................................1-12

Using the wide mode function .............................................1-12

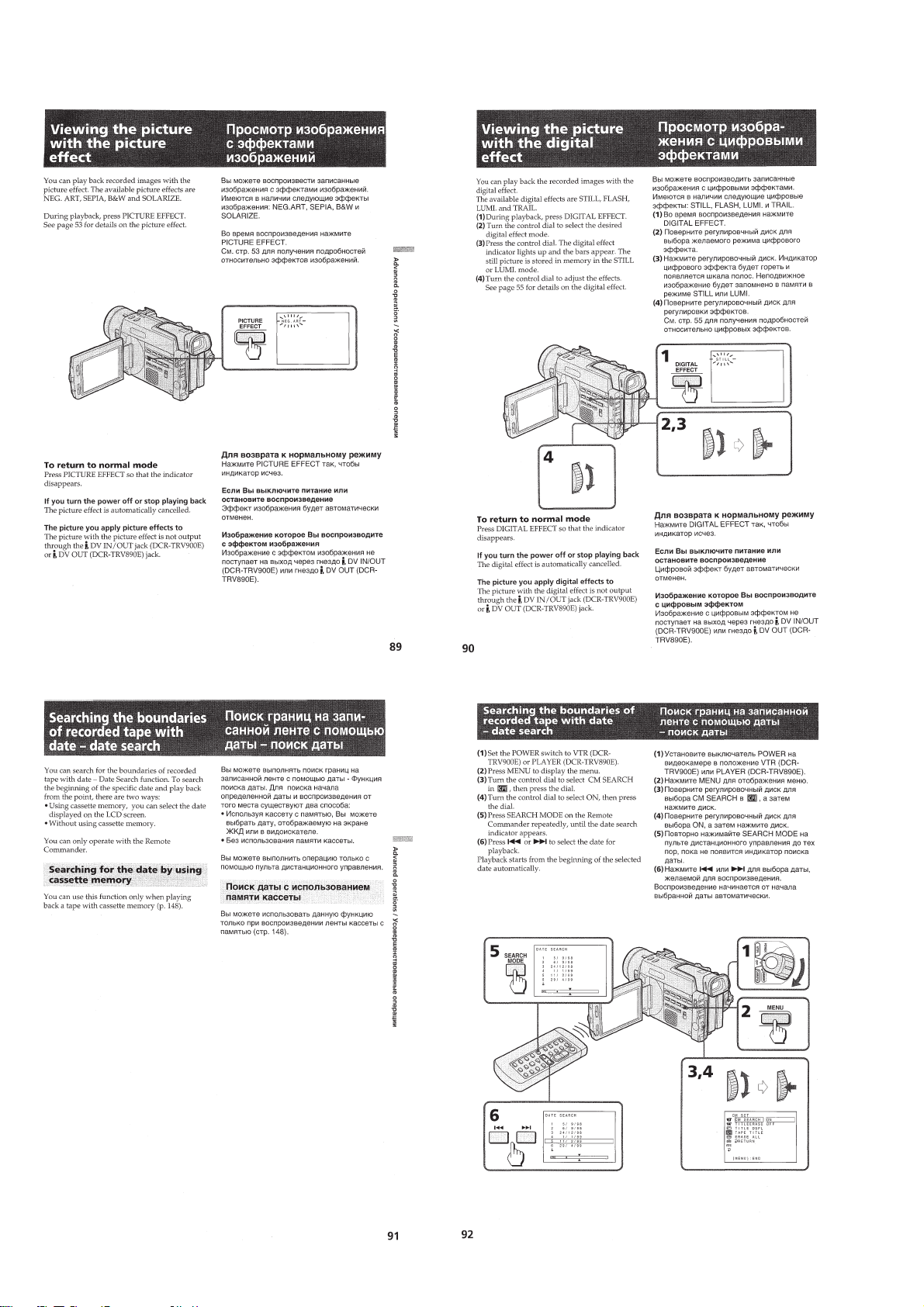

Enjoying picture effect.........................................................1-13

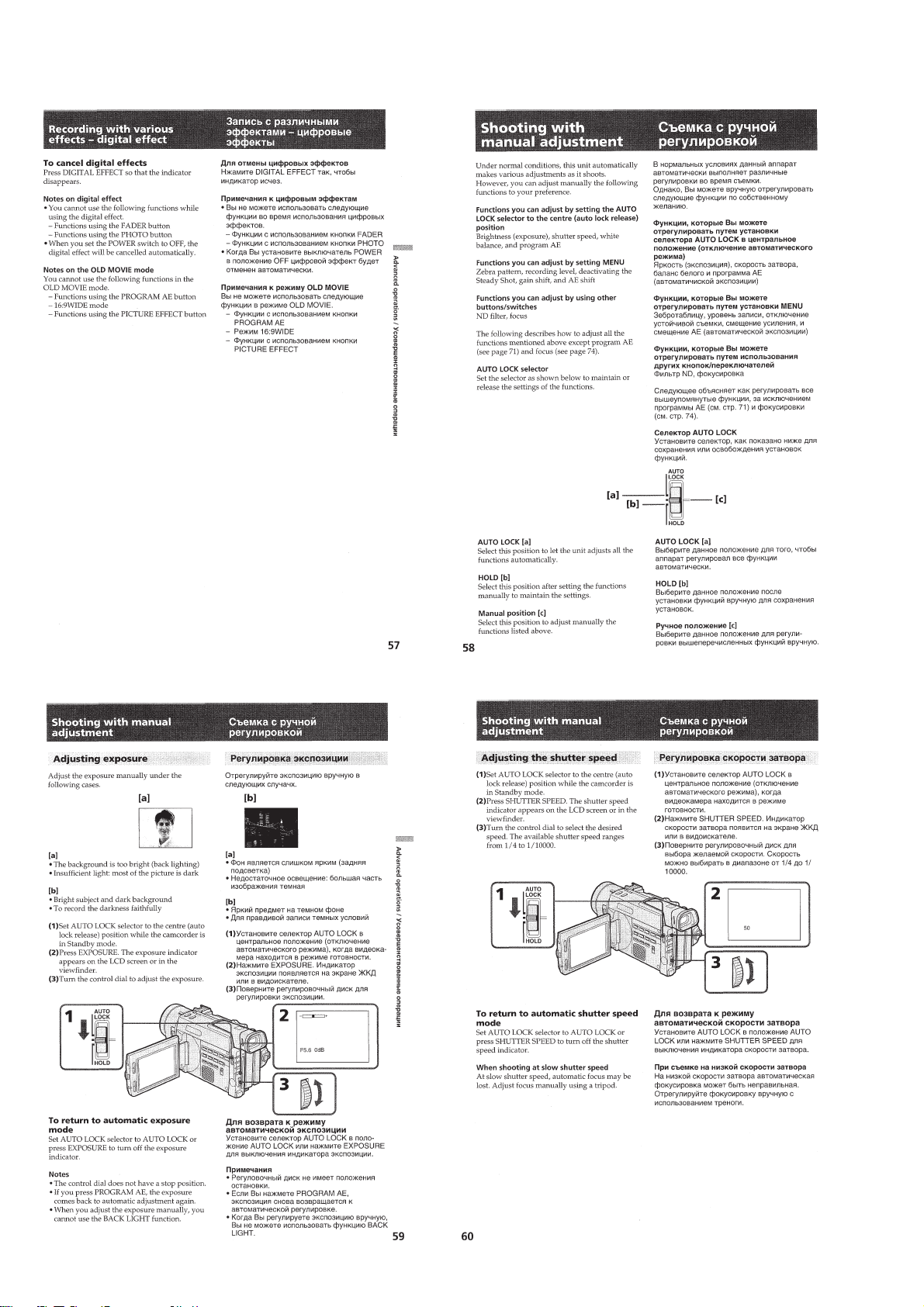

Recording with various effects - digital effect.....................1-13

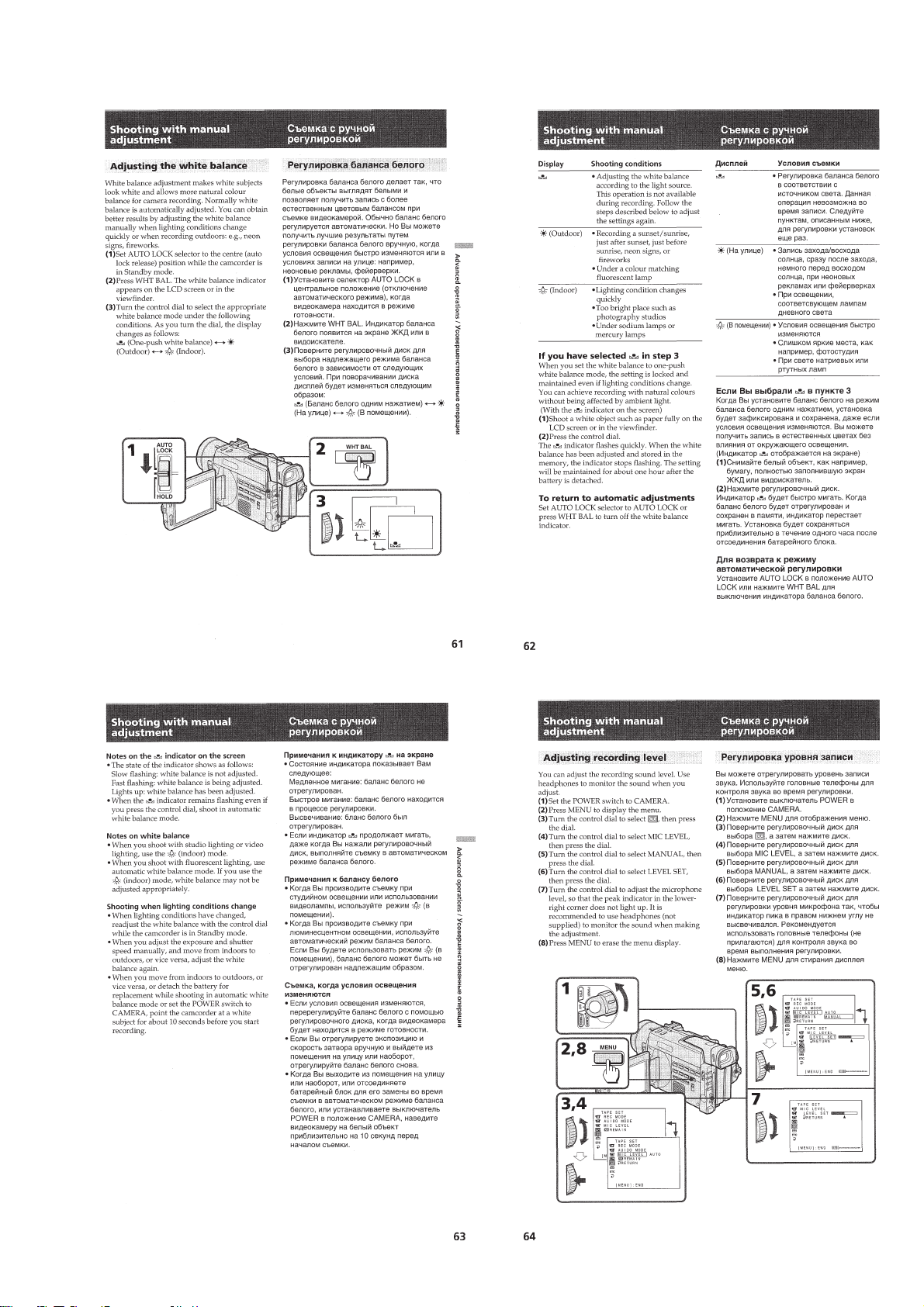

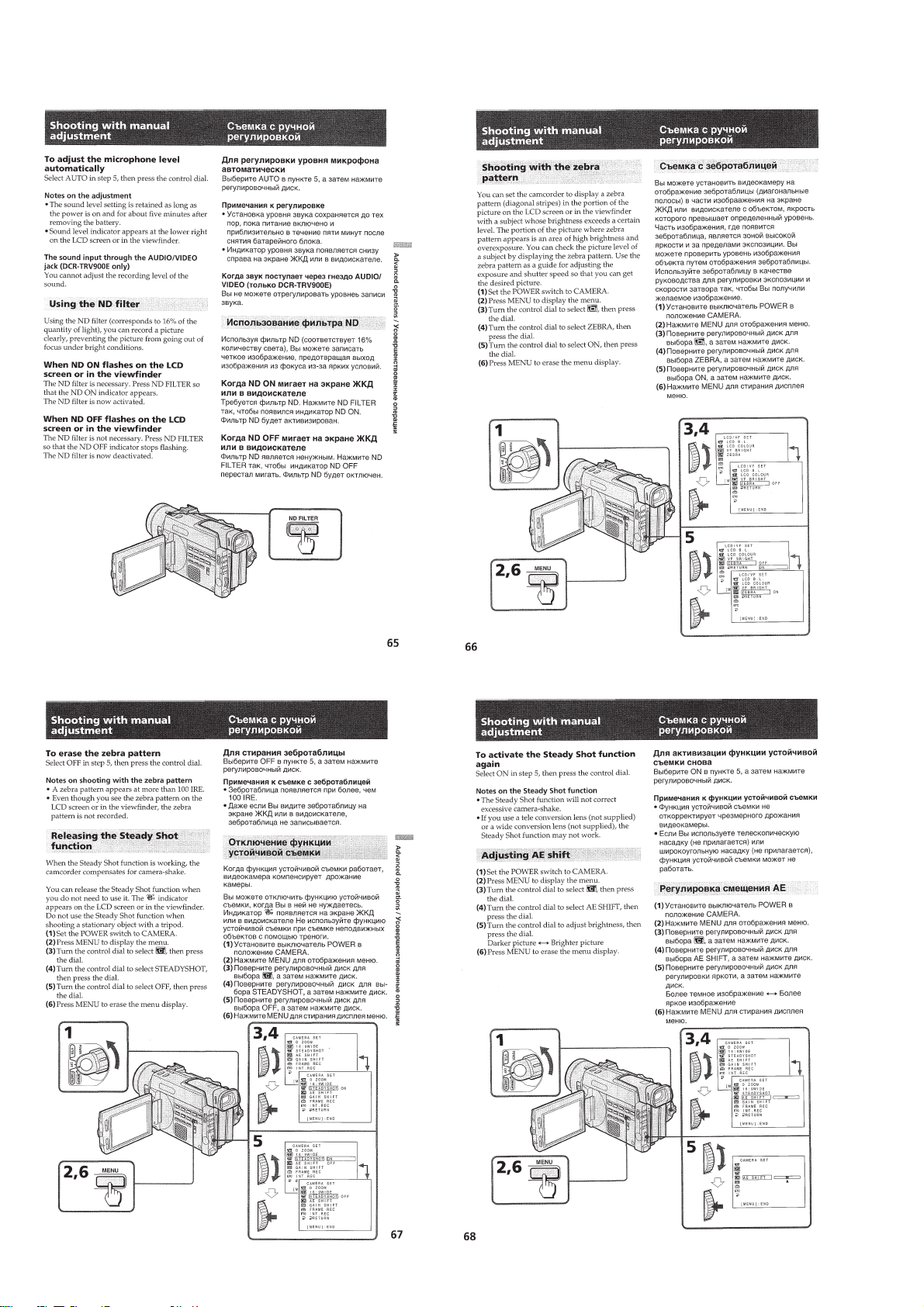

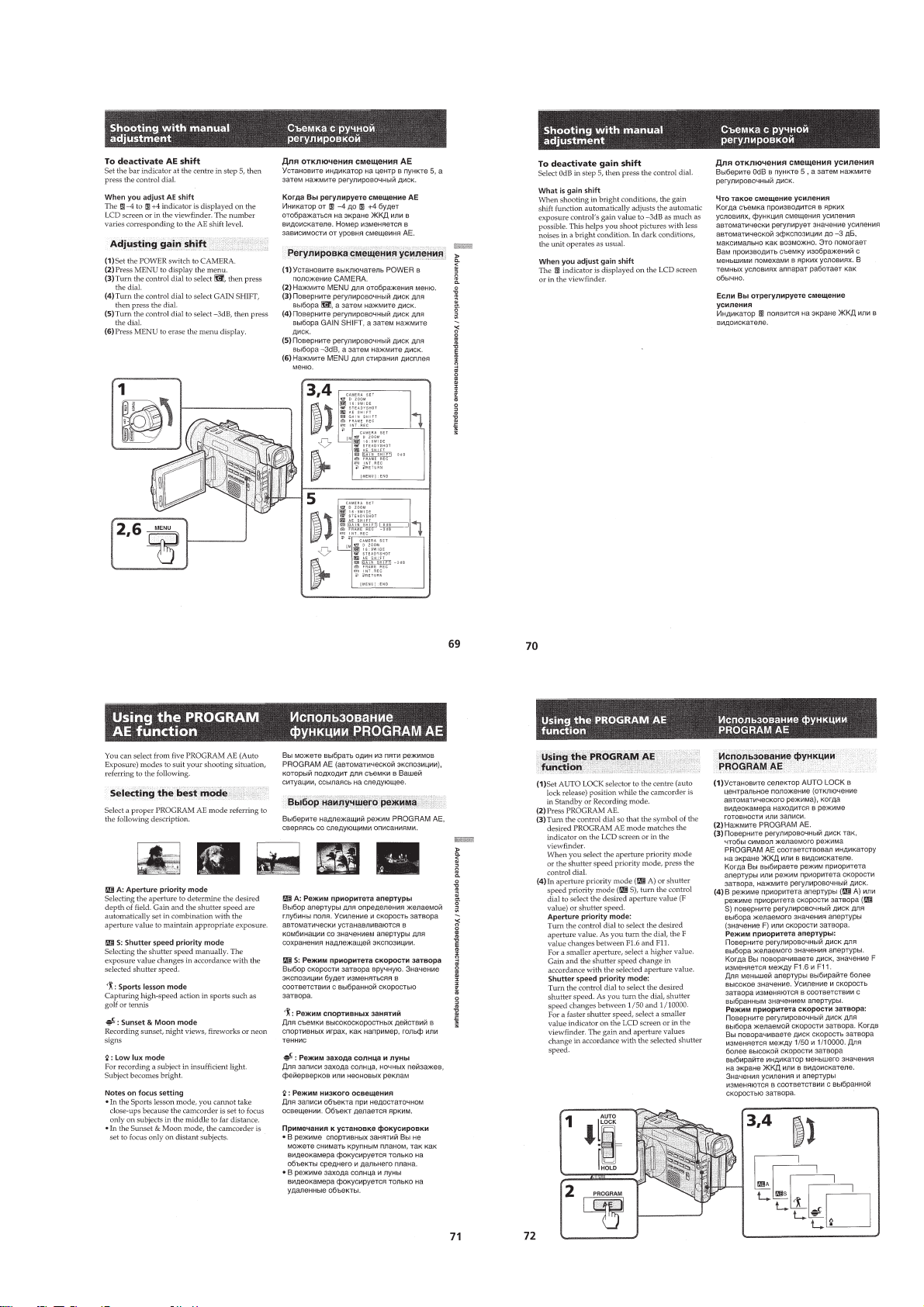

Shooting with manual adjustment ....................................... 1-14

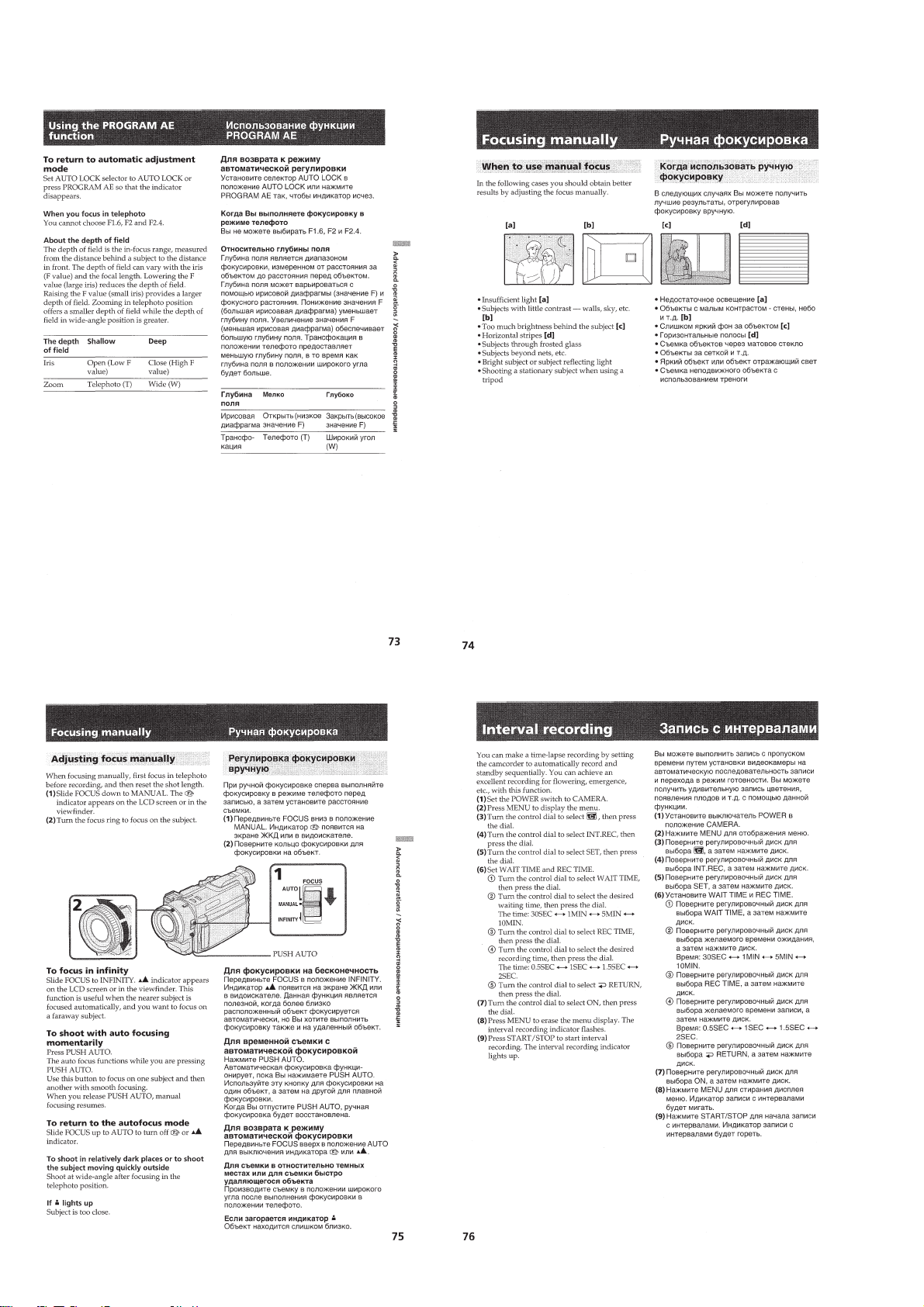

Using the PROGRAM AE function ..................................... 1-17

Focusing manually...............................................................1-18

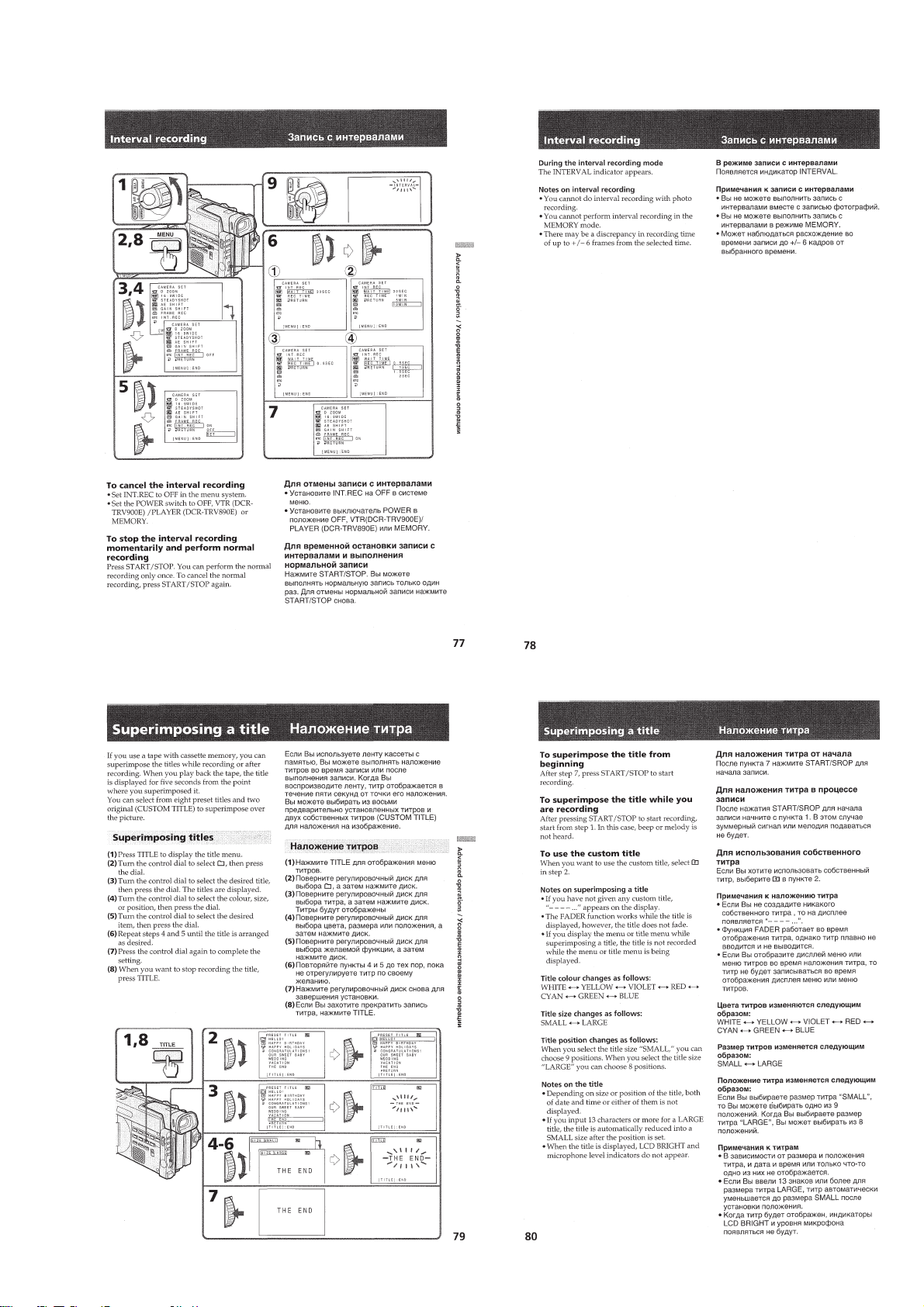

Interval recording.................................................................1-18

Superimposing a title ...........................................................1-19

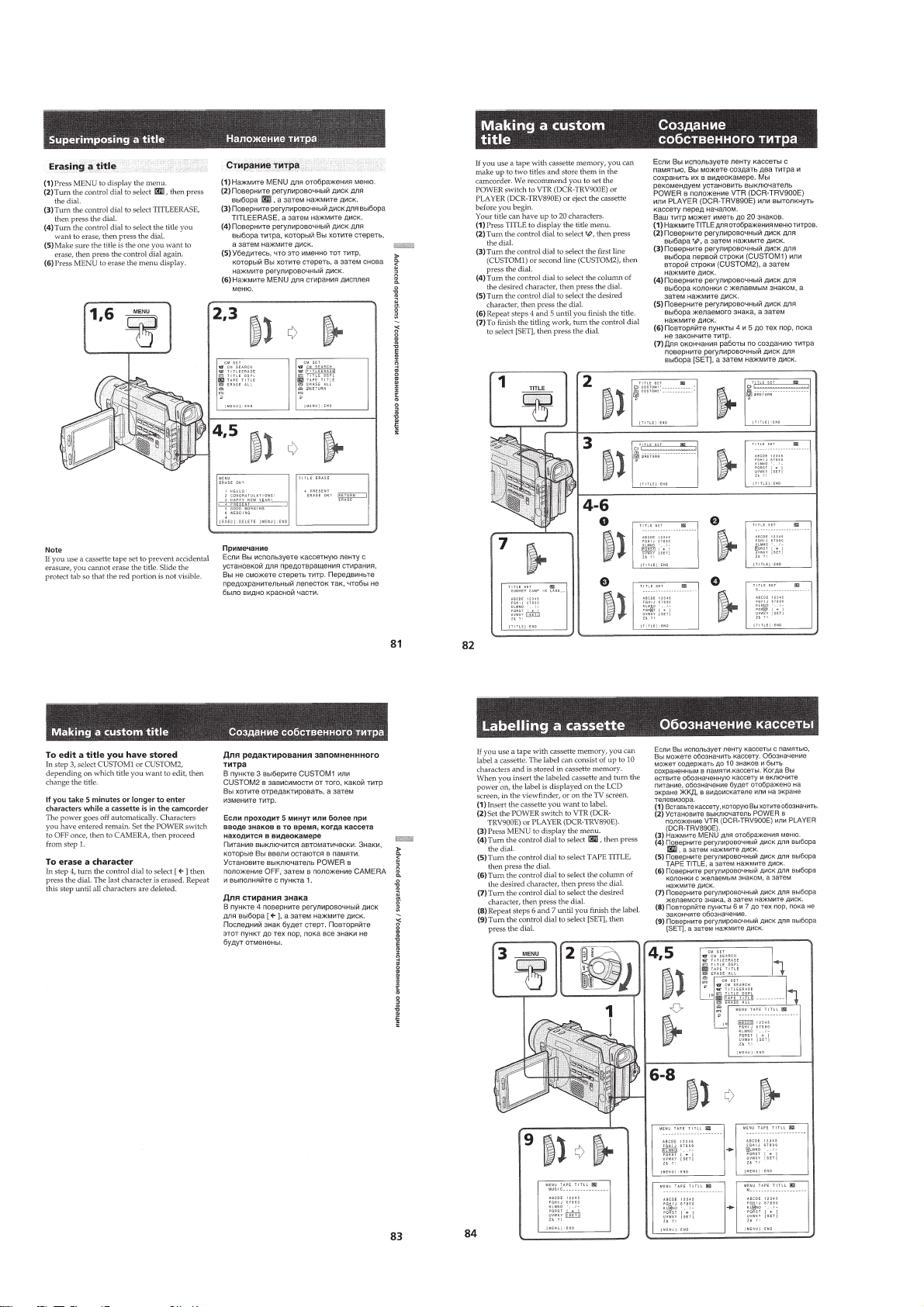

Making a custom title ..........................................................1-20

Labelling a cassette..............................................................1-20

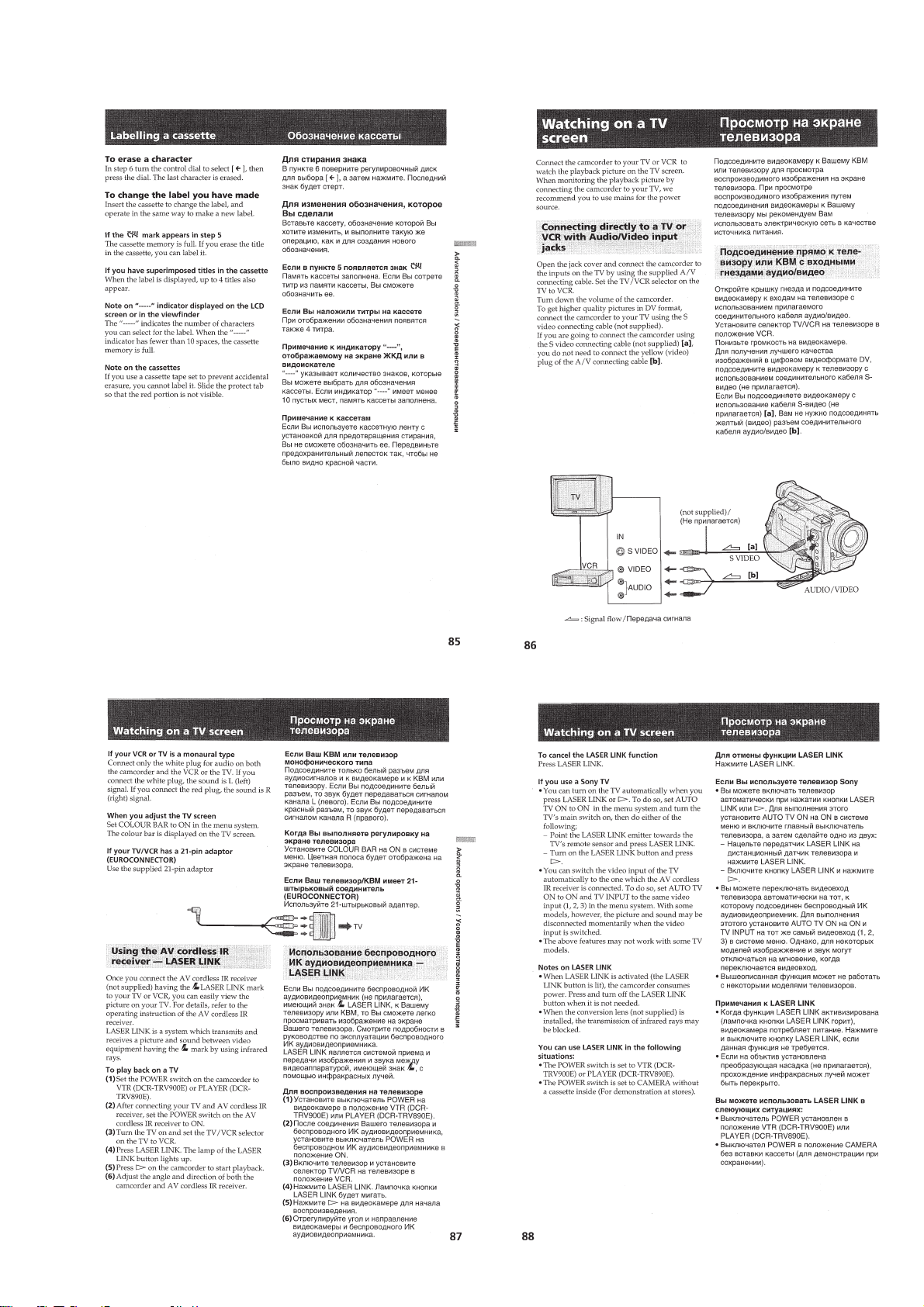

Watching on a TV screen ..................................................... 1-21

Viewing the picture with the picture effect ..........................1-22

Searching the boundaries of recorded tape with date - date

search ...................................................................................1-22

Searching the boundaries of recorded tape with title - title

search ...................................................................................1-23

Searching for a photo - photo search/photo scan.................1-24

Returning to a preregistered position...................................1-25

Display recording data - data code function ........................1-25

Editing onto another tape.....................................................1-25

Editing partially on a mini DV tape - DV synchro-editing .. 1-26

Recording from a VCR or TV (DCR-TRV900E only) ........ 1-26

Replacing recording on a tape - insert editing

(DCR-TRV900E only) .........................................................1-27

Audio dubbing (DCR-TRV900E only) ................................ 1-27

Memory card slot operations

Using the memory card slot - introduction .......................... 1-28

Recording an image from a mini DV tape as a still image ..1-31

Copying still images from a mini DV tape - photo save ......1-32

Recording still images on PC cards (not supplied) - memory

photo recording ....................................................................1-32

Viewing a still picture - memory photo playback ................ 1-33

Preventing accidental erasure - PROTECT..........................1-34

Deleting images ...................................................................1-35

Copying the image recorded with the memory card slot to

mini DV tapes (DCR-TRV900E only).................................1-35

Playing back images in a continuous loop - SLIDE SHOW ..1-36

Additional information

Usable cassettes and playback modes..................................1-36

Charging the vanadium-lithium battery in the camcorder ...1-37

Resetting the date and time..................................................1-37

Simple setting of clock by time difference .......................... 1-38

Tips for using the battery pack ............................................ 1-38

Maintenance information and precautions...........................1-40

Using your camcorder abroad..............................................1-41

Trouble check ......................................................................1-41

Self-diagnosis function ........................................................1-42

Identifying the parts .............................................................1-43

Warning indicators ...............................................................1-46

2. DISASSEMBLY

2-1. Cabinet (Upper) Assembly, Front Panel Assembly .........2-1

2-2. Battery Panel Assembly...................................................2-2

2-3. Cabinet (R) Assembly, Cabinet (L) Assembly ................2-2

2-4. Mechanism Deck, Lens Assembly, VC-208, VI-151,

SE-75 Boards...................................................................2-3

2-5. JK-163 Board ..................................................................2-3

2-6. CK-80 Board ...................................................................2-4

2-7. LCD Panel Assembly, Hinge Assembly ..........................2-4

2-8. PD-101 Board..................................................................2-5

2-9. BT Terminal Board, DC-IN Connector ...........................2-5

2-10. ED-48, VF-121 Boards ....................................................2-6

2-11. LB-55 Board....................................................................2-6

2-12. MA-333 Board ................................................................ 2-7

2-13. Service Position (Mainly for and voltag e measurement)...2-7

2-14. Circuit Boards Location ..................................................2-8

2-15. Flexible Boards Location ................................................2-9

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram ...................................................3-1

3-2. Power Block Diagram .....................................................3-5

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagram-1...........................................4-1

Frame Schematic Diagram-2...........................................4-5

4-2. Printed Wiring Boards and Schematic Diagrams............4-9

• CD-202 (CCD Imager) Schematic Diagram ...............4-11

• CD-202 (CCD Imager) Printed Wiring Board............4-13

• VC-208 (Sample Hold & AGC, Camera Processor, Base

Band Input, Motor Drive, VAP Driver, Card Control,

PWN Control, Honey, PCMCIA Control)

Printed Wiring Board ....................................4-17

• VC-208 (Sample Hold & AGC)(1/7)

Schematic Diagram ....................................... 4-24

• VC-208 (Camera Processor)(2/7)

Schematic Diagram ....................................... 4-27

• VC-208 (Base Band Input)(3/7)

Schematic Diagram ....................................... 4-32

• VC-208 (Motor Drive)(4/7)

Schematic Diagram ....................................... 4-35

• SE-75 (YAW/Pitch Sensor)

Printed Wiring Board ....................................4-39

• VC-208 (VAP Driver)(5/7)

Schematic Diagram ....................................... 4-40

• VC-208 (Card Control, PWM Control)(6/7)

Schematic Diagram ....................................... 4-43

• VC-208 (Honey, PCMCIA Control)(7/7)

Schematic Diagram ....................................... 4-47

— 3 —

Page 4

• VI-151 (REC/PB AMP)(1/10)

Schematic Diagram ....................................... 4-51

• VI-151 (Timing Generator)(2/10)

Schematic Diagram ....................................... 4-55

• VI-151 (Video Interface)(3/10)

Schematic Diagram ....................................... 4-57

• VI-151 (DCT/IDCT)(4/10)

Schematic Diagram ....................................... 4-62

• VI-151 (IR Transmitter)(5/10)

Schematic Diagram ....................................... 4-65

• VI-151 (Audio Processor)(6/10)

Schematic Diagram ....................................... 4-68

• VI-151 (HI Control)(7/10)

Schematic Diagram ....................................... 4-71

• VI-151 (Mechanism Control)(8/10)

Schematic Diagram ....................................... 4-77

• VI-151 (Drum/Capstan Motor Drive)(9/10)

Schematic Diagram ....................................... 4-79

• VI-151 (DC/DC Converter)(10/10)

Schematic Diagram ....................................... 4-83

• FP-594 (Loading Motor, ST Reel Sensor)

Printed Wiring Board ....................................4-87

• FK-4880 (User Control) Schematic Diagram .............4-88

• VI-151 (REC PB AMP, Timing Generator, Video

Interface, DCT/IDCT, IR Transmitter, Audio Processor,

HI Control, Mechanism Control, Drum/Capstan Motor

Drive, DC/DC Converter)

Printed Wiring Board ....................................4-91

• FP-21 (Focus SW) Flexible Board..............................4-96

• FP-22 (MIC Jack) Flexible Board...............................4-96

• MA-333 (Stereo MIC AMP)

Printed Wiring Board ....................................4-97

• RI-10 (Sircs Receiver)

Printed Wiring Board ....................................4-98

• MA-333 (Stereo MIC AMP)

Schematic Diagram ....................................... 4-99

• RI-10 (Sircs Receiver)

Schematic Diagram ..................................... 4-101

• FP-16 (Panel Switch) Flexible Board ......................4-103

• FP-18 (User Control) Flexible Board .......................4-103

• ED-48 (User Control) Schematic Diagram...............4-103

• CK-80 (User Control) Schematic Diagram ..............4-104

• CK-80 (User Control) Printed Wiring Board............4-107

• ED-48 (User Control) Printed Wiring Board............4-110

• FP-23 (S Video) Flexible Board................................4-111

• JK-163 (Audio/Video IN/OUT)

Printed Wiring Board and

Schematic Diagram ..................................... 4-112

• PD-101 (RGB Driver)(1/2)

Schematic Diagram ..................................... 4-115

• PD-101 (Timing Generator, Back-Light)(2/2)

Schematic Diagram ..................................... 4-119

• PD-101 (RGB Driver, Timing Generator, Back-Light)

Printed Wiring Board ..................................4-121

• FP-19 (User Control) Flexible Board .......................4-121

• VF-121 (Color EVF) Printed Wiring Board .............4-123

• VF-121 (Color EVF) Schematic Diagram ................4-125

• LB-55 (EVF Back-Light)

Printed Wiring Board and

Schematic Diagram ..................................... 4-128

5. ADJUSTMENTS

5-1. Camera Section Adjustment ............................................5-1

1-1. Preparations before Adjustment (Camera Section) .........5-1

1-1-1.List of Service Tools ........................................................ 5-1

1-1-2. Preparations ....................................................................5-2

1-1-3.Precaution ........................................................................5-4

1. Setting the Switch............................................................ 5-4

2. Order of Adjustments ......................................................5-4

3. Subjects ...........................................................................5-4

1-2. Initialization of F, E Page Data........................................5-5

1. Initializing the F, E Page Data .........................................5-5

2. Modification of F, E Page Data .......................................5-5

3. F Page Table ....................................................................5-5

4. E Page Table ....................................................................5-8

1-3. Camera System Adjustments.........................................5-10

1. 27MHz Origin Oscillation Adjustment

(VC-208 board) .............................................................5-10

2. IRIS & ND HALL Auto Adjustment.............................5-10

3. Offset Adjustment..........................................................5-11

4. Flange Back Adjustment ...............................................5-12

4-1. Flange Back Adjustment (1)..........................................5-12

4-2. Flange Back Adjustment (2)..........................................5-12

5. Flange Back Check........................................................ 5-13

6. Picture Frame Setting ....................................................5-13

7. Pre White Balance Data Input ....................................... 5-14

8. Auto White Balance Standard Data Input .....................5-14

9. MAX GAIN Adjustment ...............................................5-15

10. LV Standard Data Input .................................................5-15

11. White Balance ND Filter Compensation Adjustment ...5-16

12. Auto White Balance Adjustment ...................................5-16

13. Color Reproduction Adjustment (ND Filter OFF) ........ 5-17

14. Color Reproduction Adjustment (ND Filter ON)..........5-17

15. White Balance Check ....................................................5-18

16. PSD Sensor Gain Adjustment........................................5-19

16-1. PSD Sensor Gain Adjustment (1)..................................5-19

16-2. PSD Sensor Gain Adjustment (2)..................................5-20

17. Angular Velocity Sensor Sensitivity Adjustment ..........5-21

1-4. Color Electronic Viewfinder System Adjustment ..........5-22

1. VCO Adjustment (VF-121 board).................................5-22

2. Bright Adjustment (VF-121 board) ...............................5-23

3. Contrast Adjustment (VF-121 board)............................5-23

4. Backlight Consumption Current Adjustment

(VF-121 board)..............................................................5-24

5. White Balance Adjustment (VF-121 board)..................5-24

1-5. LCD SYSTEM ADJUSTMENT ...................................5-25

1. VCO Adjustment (PD-101 board).................................5-25

2. D range Adjustment (PD-101 board).............................5-26

3. Bright Adjustment (PD-101 board) ...............................5-26

4. Contrast Adjustment (PD-101 board)............................5-27

5. V-COM Level Adjustment (PD-101 board) ..................5-27

6. V-COM Adjustment (PD-101 board) ............................5-28

7. White Balance Adjustment (PD-101 board)..................5-28

5-2. Mechanism Section Adjustment.................................... 5-29

2-1. How to Enter Record Mode without Cassette ...............5-29

2-2. How to Enter Playback Mode without Cassette ............5-29

2-3. Tape Path Adjustment....................................................5-29

1. Preparations for Adjustment..........................................5-29

2. Procedure after Operations ............................................5-29

5-3. Video Section Adjustments ...........................................5-30

3-1. Preparations before Adjustments...................................5-30

3-1-1.Equipment Required ......................................................5-30

3-1-2.Precautions on Adjusting...............................................5-31

3-1-3.Adjusting Connectors ....................................................5-32

3-1-4.Connecting the Equipment ............................................5-32

3-1-5.Checking the Input Signals............................................5-32

3-1-6.Alignment Tapes............................................................5-33

3-1-7.Input/Output Level and Impedance ...............................5-33

3-2. Initialization of B, C, D Page Data................................5-34

1. Initializing the C Page Data...........................................5-34

2. Modification of C Page Data.........................................5-34

3. C Page Table .................................................................. 5-34

4. Initializing the D Page Data ..........................................5-36

5. Modification of D Page Data.........................................5-36

— 4 —

Page 5

6. D Page Table..................................................................5-36

7. Initializing the B Page Data...........................................5-38

8. Modification of B Page Data.........................................5-38

9. B Page Table .................................................................. 5-38

3-3. System Control System Adjustment..............................5-41

1. Battery End Adjustment (VI-151 Board) ......................5-41

3-4. Servo and RF System Adjustments ............................... 5-42

1. Cap FG Duty Adjustment (VI-151 Board)....................5-42

2. T Reel FG Duty Adjustment (VI-151 Board)................5-42

3. PLL f0 & LPF f0 Adjustment (VI-151 Board)...............5-42

4. Switching Position Adjustment (VI-151 Board) ........... 5-43

5. AGC Center Level Adjustment (VI-151 Board)............ 5-43

6. APC & AEQ Adjustment (VI-151 Board).....................5-44

7. PLL f0 & LPF f0 Final Adjustment (VI-151 Board)......5-44

3-5. Video System Adjustments............................................5-45

3-5-1.Base Band Block Adjustments ......................................5-45

1. Chroma BPF f0 Adjustment (VI-151 Board).................5-45

2. S Video Out Y Level Adjustment (VI-151 Board) ........5-45

3. S Video Out Chroma Level Adjustment

(VI-151 Board) ..............................................................5-46

4. AV Out Y, Chroma Le vel Adjustment (VI-151 Board) ....5-46

5. PLL Adjustment (VC-208 Board) .................................5-47

3-5-2.BIST Check ...................................................................5-48

1. Playback System Check ................................................ 5-48

1-1. Preparation for Playback ...............................................5-48

1-2. IC1814 (TRF) BIST (PB) Check...................................5-48

1-3. IC1601 (TFD) BIST (PB) Check .................................. 5-48

1-4. IC1800 (SFD) BIST (PB) Check...................................5-48

1-5. IC1501 (VFD) BIST (PB) Check ..................................5-49

2. Recording System Check .............................................. 5-51

2-1. Preparations for recording .............................................5-51

2-2. IC1501 (VFD) BIST (REC) Check ...............................5-51

2-3. IC1600 (SFD) BIST (REC) Check................................5-51

2-4. IC1601 (TFD) BIST (REC) Check ...............................5-51

2-5. IC1900 (TRX) BIST (REC) Check ...............................5-52

3-6. IR Transmitter Adjustments...........................................5-53

1. IR Video Carrier Frequency Adjustment

(VI-151 board)............................................................... 5-53

2. IR Video Deviation Adjustment (VI-151 board) ........... 5-53

3. IR Audio Deviation Adjustment (VI-151 board)...........5-54

3-7. Audio System Adjustments ...........................................5-55

1. Playback Level Check ................................................... 5-56

2. Overall Level Characteristics Check .............................5-56

3. Overall Distortion Check...............................................5-56

4. Overall Noise Level Check............................................5-56

5. Overall Separation Check.............................................. 5-56

5-4. Service Mode................................................................. 5-57

4-1. Adjustment Remote Commander ..................................5-57

1. Using the adjustment remote commander .....................5-57

2. Precautions upon using the

adjustment remote commander .....................................5-57

4-2. Data Process ..................................................................5-58

4-3. Service Mode................................................................. 5-59

1. Setting the Test Mode ....................................................5-59

2. Emergence Memory Address ........................................5-59

2-1. EMG Code (Emergency Code) ..................................... 5-59

2-2. MSW Code ....................................................................5-60

3. Bit value discrimination ................................................ 5-61

4. Switch check (1) ............................................................5-61

5. Switch check (2) ............................................................5-62

6. Record of Use check......................................................5-62

6-1-4.Cabinet (R) Section .........................................................6-4

6-1-5.LCD Panel Section ..........................................................6-5

6-1-6.Battery Panel Section ......................................................6-6

6-1-7.Cabinet (Upper) Section ..................................................6-7

6-1-8.EVF Section ....................................................................6-8

6-1-9.Front Panel Section .........................................................6-9

6-1-10. Lens Block Section .....................................................6-10

6-1-11. Cassette Compartment,

Drum and Reel Table Assembly ..................................6-11

6-1-12. Tape Guide, Pinch Slider Assembly

and Brake Slider Assembly .........................................6-12

6-1-13. Each Gears and Loading/Capstan Motor Assembly ...6-13

6-2. Electrical Parts List .......................................................6-14

* The optical axis frame and color reproduction frame is shown

on page 300 and 301.

6. REPAIR PARTS LIST

6-1. Exploded Vie ws...............................................................6-1

6-1-1.Overall Section ................................................................6-1

6-1-2.Mechanism Frame Section ..............................................6-2

6-1-3.Cabinet (L) Section .........................................................6-3

— 5 —

Page 6

DCR-TRV890E/TRV900/TRV900E

)

SERVICE NOTE

1. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied (8.4V) to the

battery terminal using the service power cord (J-6082-223-A), the

power is shut off so that the unit cannot operate.

This following two methods are av ailable to pre vent this. Take note

of which to use during repairs.

Method 1.

Connect the servicing remote commander RM-95 (J-6082-053-B)

to the LANC jack, and set the remote commander switch to the

“ADJ” side.

Method 2.

Press the battery switch of the battery terminal using adhesive tape,

etc.

Method 3.

Use the AC power adaptor.

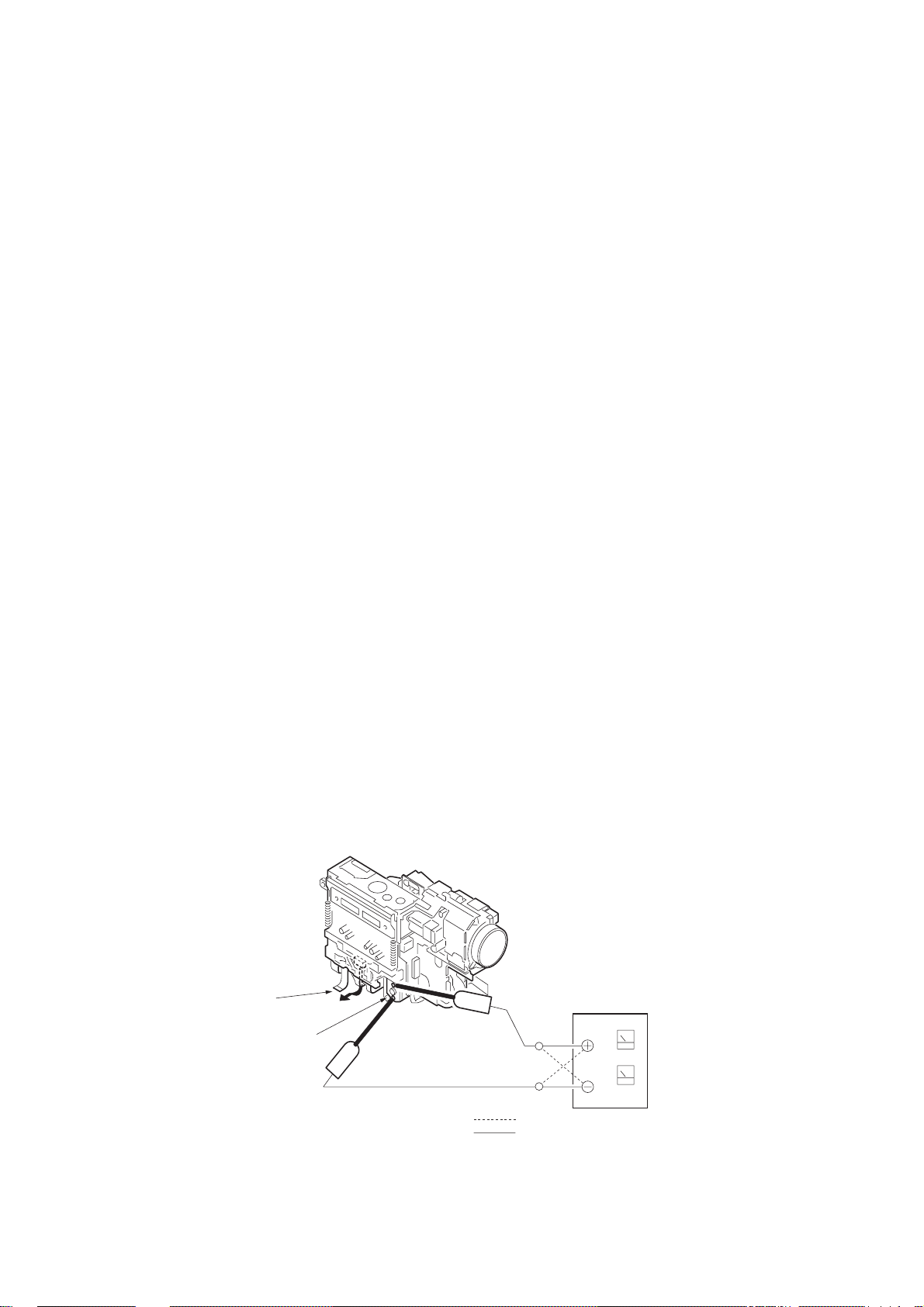

2. HOW TO TAKE A CASSETTE OUT

WHEN THE MAIN POWER CANNOT

BE TURNED ON

Note: To take a cassette out forcibly as follows when the main power

cannot be turned on, remove the cassette lid, cabinet (L) and cabinet

(R). Apply +4.5 V power from an external power supply to the

loading motor, as shown below. Refer to sections 2-1 and 2-2 for

the procedure to remove the cabinet (L) assembly.

Procedure:

1) Disconnect the CN2913 of VI-151 board.

2) Apply +4.5 V directly to the loading motor as shown to drive

the loading motor that ejects a cassette.

Disconnect CN2913

of VI-151 board.

DC power supply (+4.5V

Loading motor

: loading

: unloading

— 6 —

Page 7

DCR-TRV890E/TRV900/TRV900E

Control dial

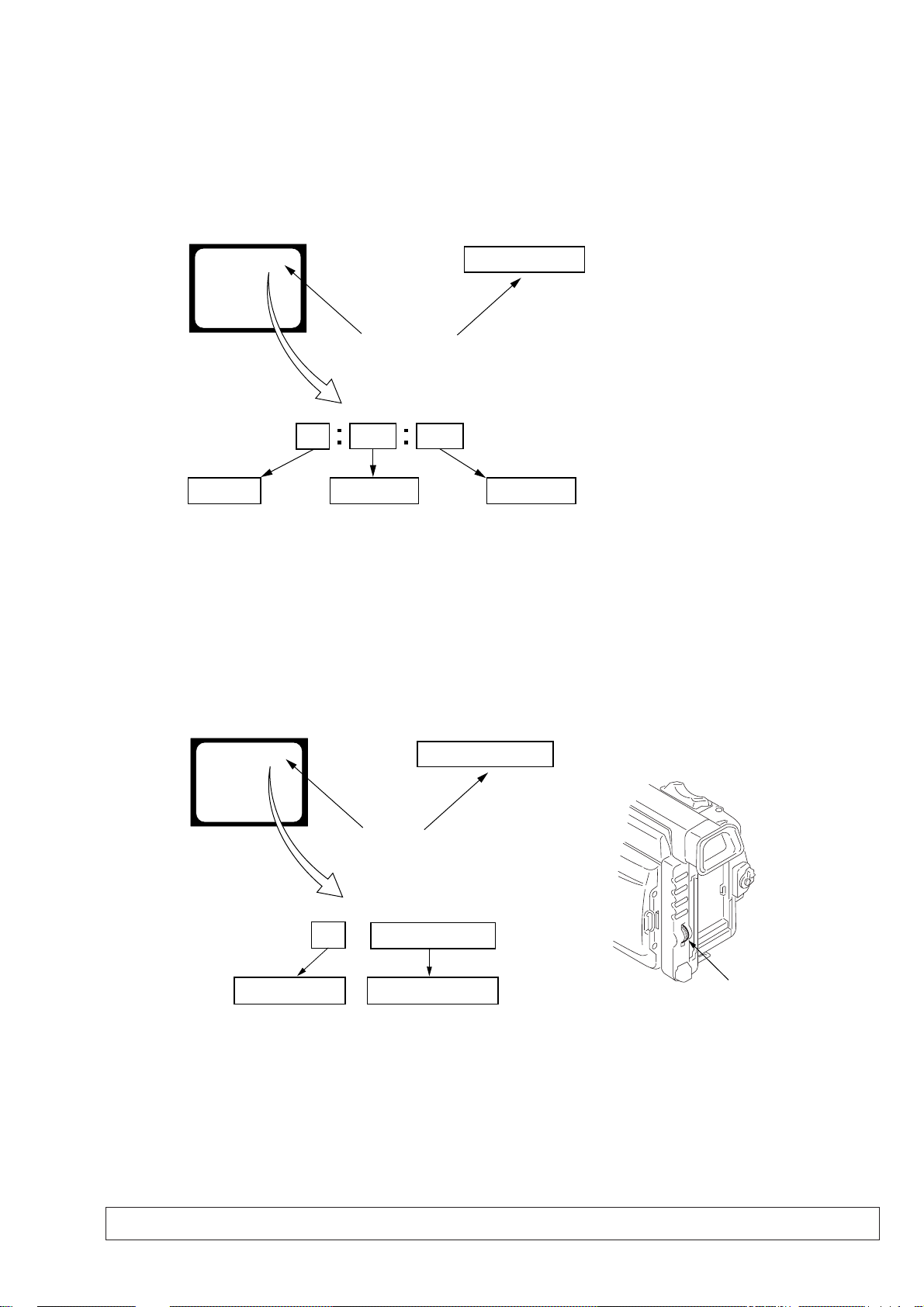

SELF-DIAGNOSIS FUNCTION

1. SELF-DIAGNOSIS FUNCTION

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewf inder, LCD screen

or LCD window what to do. This function consists of two display;

self-diagnosis display and service mode display.

Details of the self-diagnosis functions are provided in the Instruction

manual.

Viewfinder or LCD screen LCD window

C : 3 1 : 1 1

Blinks at 3.2Hz

1 1

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

C

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn on power again.

3 1

Block

2. SELF-DIAGNOSIS DISPLA Y

When problems occur while the unit is operating, the counter of the

viewfinder, LCD screen or LCD window consists of an alphabet

and 4-digit numbers, which blinks at 3.2 Hz. This 5-character display

indicates the “repaired by:”, “block” in which the problem occurred,

and “detailed code” of the problem.

C : 3 1 : 11

Detailed Code

Refer to page 8.

Self-diagnosis Code Table.

3. SERVICE MODE DISPLAY

The service mode display shows up to six self-diagnosis codes shown in the past.

3-1. Display Method

While pressing the “STOP” key, set the switch from OFF to “VTR or PLAYER”, and continue pressing the “STOP” key for 5 seconds

continuously. The service mode will be displayed, and the counter will show the backup No. and the 5-character self-diagnosis codes.

Viewfinder or LCD screen

[3] C : 3 1 : 1 1

Lights up

[3]

Backup No.

Order of previous errors

C : 3 1 : 1 1

Self-diagnosis Codes

3-2. Switching of Backup No.

By rotating the control dial, past self-diagnosis codes will be shown in order. The backup No. in the [] indicates the order in which the

problem occurred. (If the number of problems which occurred is less than 6, only the number of problems which occurred will be shown.)

[1] : Occurred first time [4] : Occurred fourth time

[2] : Occurred second time [5] : Occurred fifth time

[3] : Occurred third time [6] : Occurred the last time

LCD window

3 C : 3 1 : 11

3-3. End of Display

Turning OFF the power supply will end the service mode display.

Note: The “self-diagnosis display” data will be backed up by the coin-type lithium battery of CK-80 board BT7200. When this coin-type lithium battery

is removed, the “self-diagnosis display” data will be lost by initialization.

— 7 —

Page 8

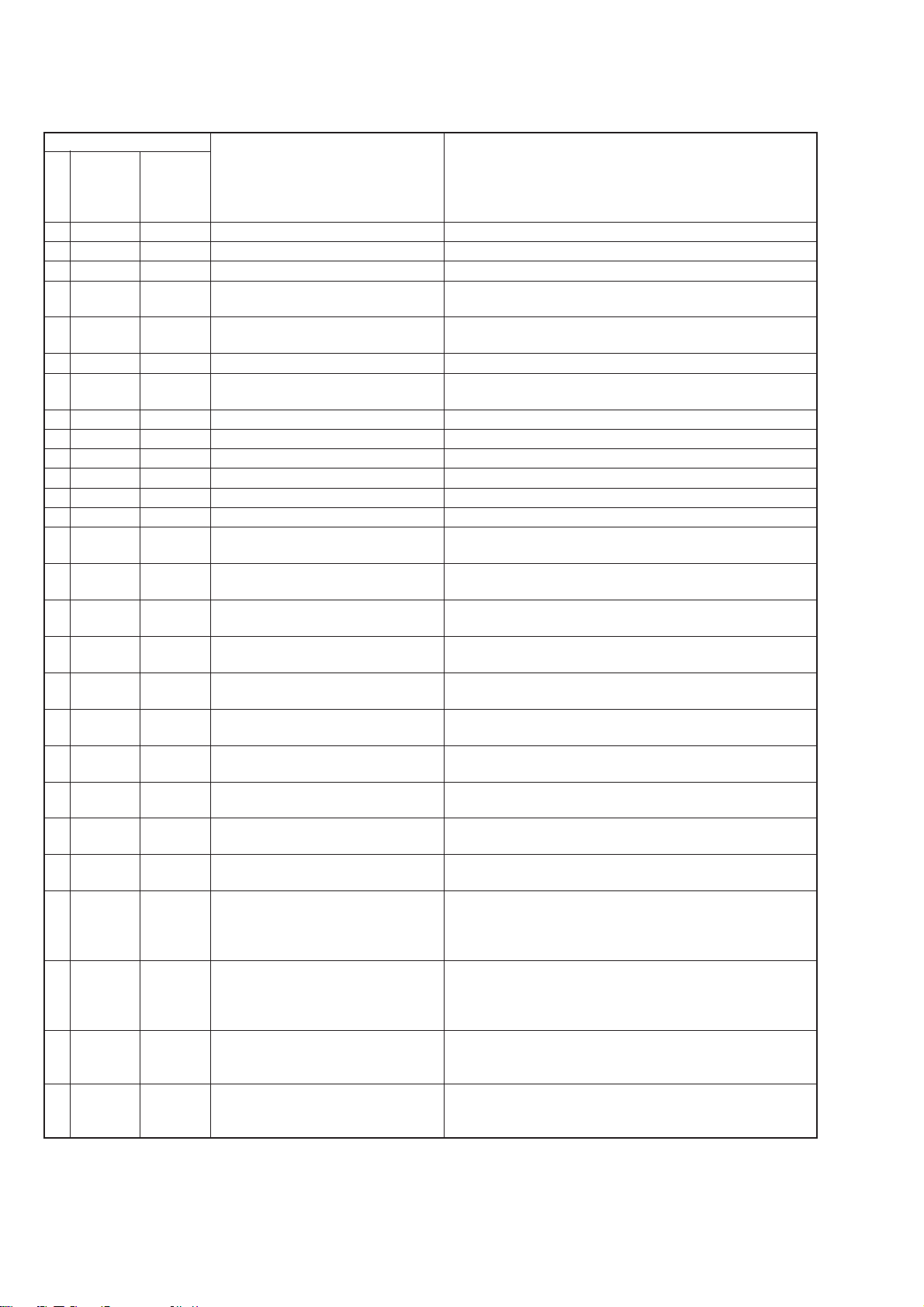

4. SELF-DIAGNOSIS CODE T ABLE

Self-diagnosis Code

Block

Function

Repaired by:

C

21

C

22

C

23

C

31

C

31

C

31

C

31

C

31

C

31

C

31

C

31

C

31

C

31

C

31

C

31

C

32

C

32

C

32

C

32

C

32

C

32

C

32

C

32

E

61

E

61

E

62

E

62

Detailed

Code

00

00

00

10

11

20

21

22

23

24

30

40

42

10

11

20

21

22

23

24

30

40

42

00

10

00

01

Symptom/State

Condensation.

Video head is dirty.

Non-standard battery is used.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum

FG fault during normal drum

operations

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

Steadyshot function does not work well.

(With pitch angular velocity sensor output

stopped.)

Steadyshot function does not work well.

(With yaw angular velocity sensor output

stopped.)

Correction

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Use the info LITHIUM battery.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Inspect the lens block focus reset sensor (Pin !º of CN500 of VC-

208 board) when focusing is performed when the control dial is

rotated in the focus manual mode, and the focus motor drive circuit

(IC500 of VC-208 board) when the focusing is not performed.

Inspect the lens block zoom reset sensor (Pin !™ of CN500 of VC208 board) when zooming is performed when the zoom lens is

operated and the zoom motor drive circuit (IC500 of VC-208 board)

when zooming is not performed.

Inspect pitch angular velocity sensor (SE451 of SE-75 board)

peripheral circuits.

Inspect yaw angular velocity sensor (SE450 of SE-75 board)

peripheral circuits.

— 8 —

Page 9

SECTION 1

GENERAL

DCR-TRV890E/TRV900/TRV900E

This section is extracted from instruction

manual. (DCR-TRV890E/TRV900E model)

1-1

Page 10

1-2

Page 11

1-3

Page 12

1-4

Page 13

1-5

Page 14

1-6

Page 15

1-7

Page 16

1-8

Page 17

1-9

Page 18

1-10

Page 19

1-11

Page 20

1-12

Page 21

1-13

Page 22

1-14

Page 23

1-15

Page 24

1-16

Page 25

1-17

Page 26

1-18

Page 27

1-19

Page 28

1-20

Page 29

1-21

Page 30

1-22

Page 31

1-23

Page 32

1-24

Page 33

1-25

Page 34

1-26

Page 35

1-27

Page 36

1-28

Page 37

1-29

Page 38

1-30

Page 39

1-31

Page 40

1-32

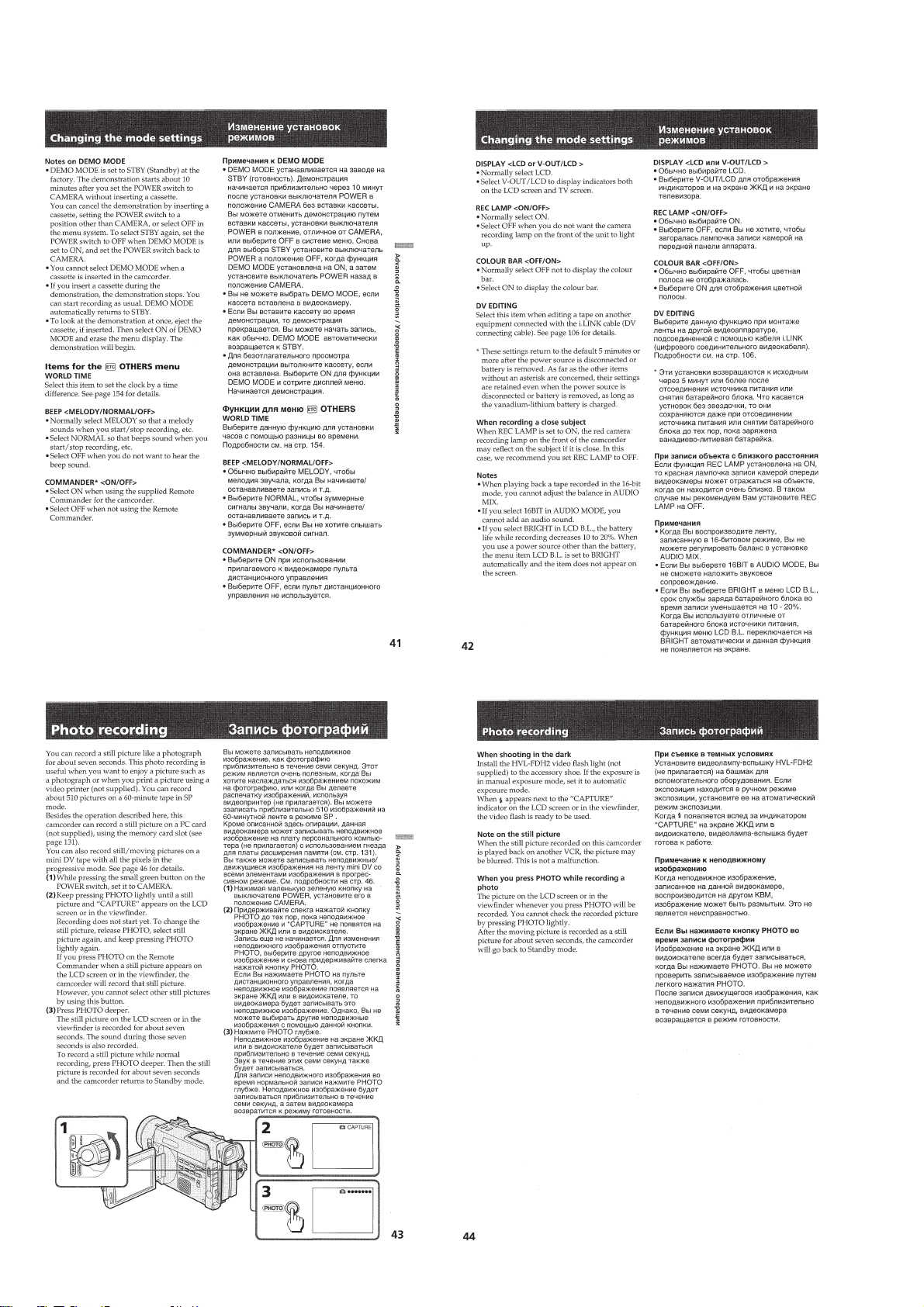

Page 41

1-33

Page 42

1-34

Page 43

1-35

Page 44

1-36

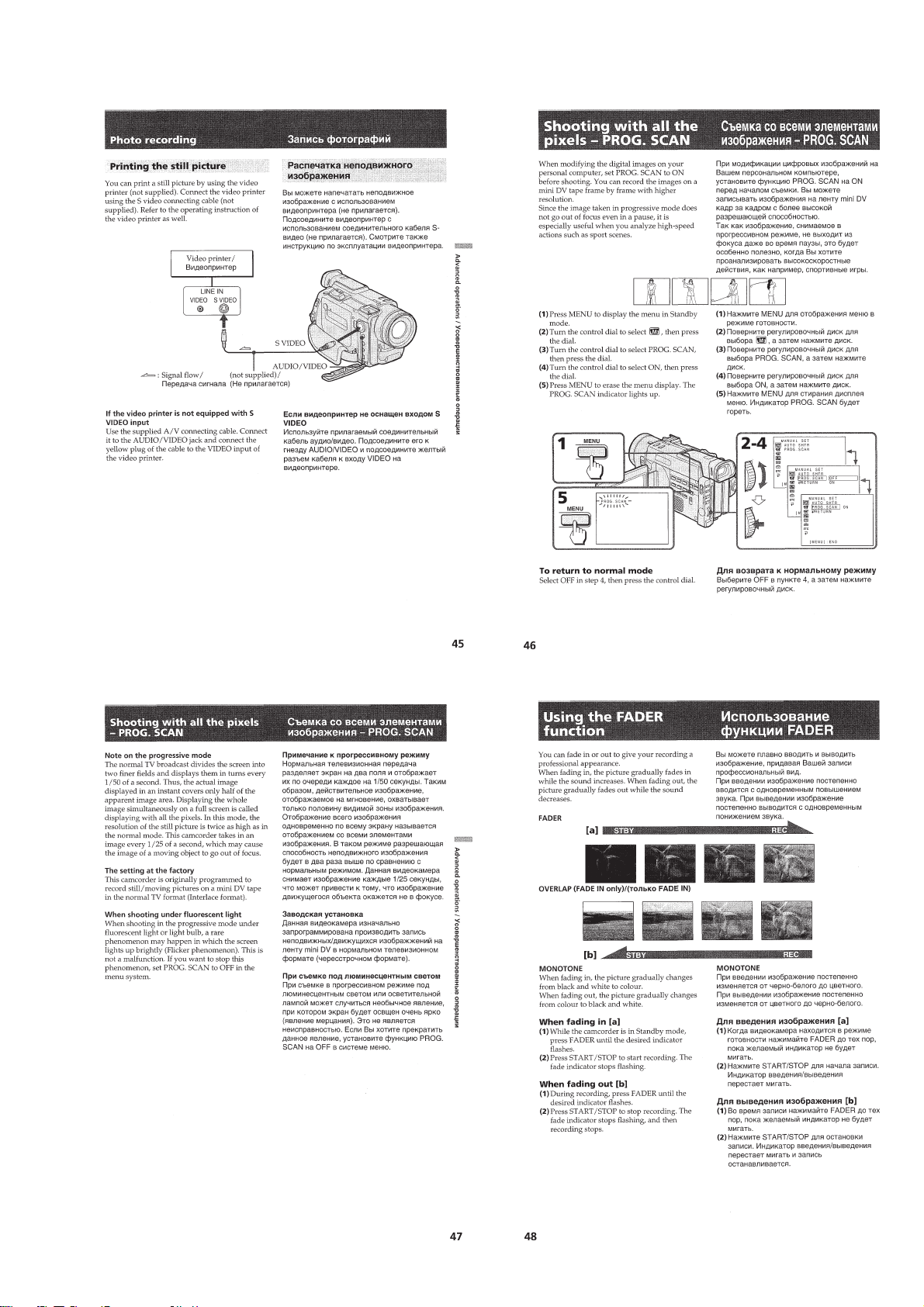

Page 45

1-37

Page 46

1-38

Page 47

1-39

Page 48

1-40

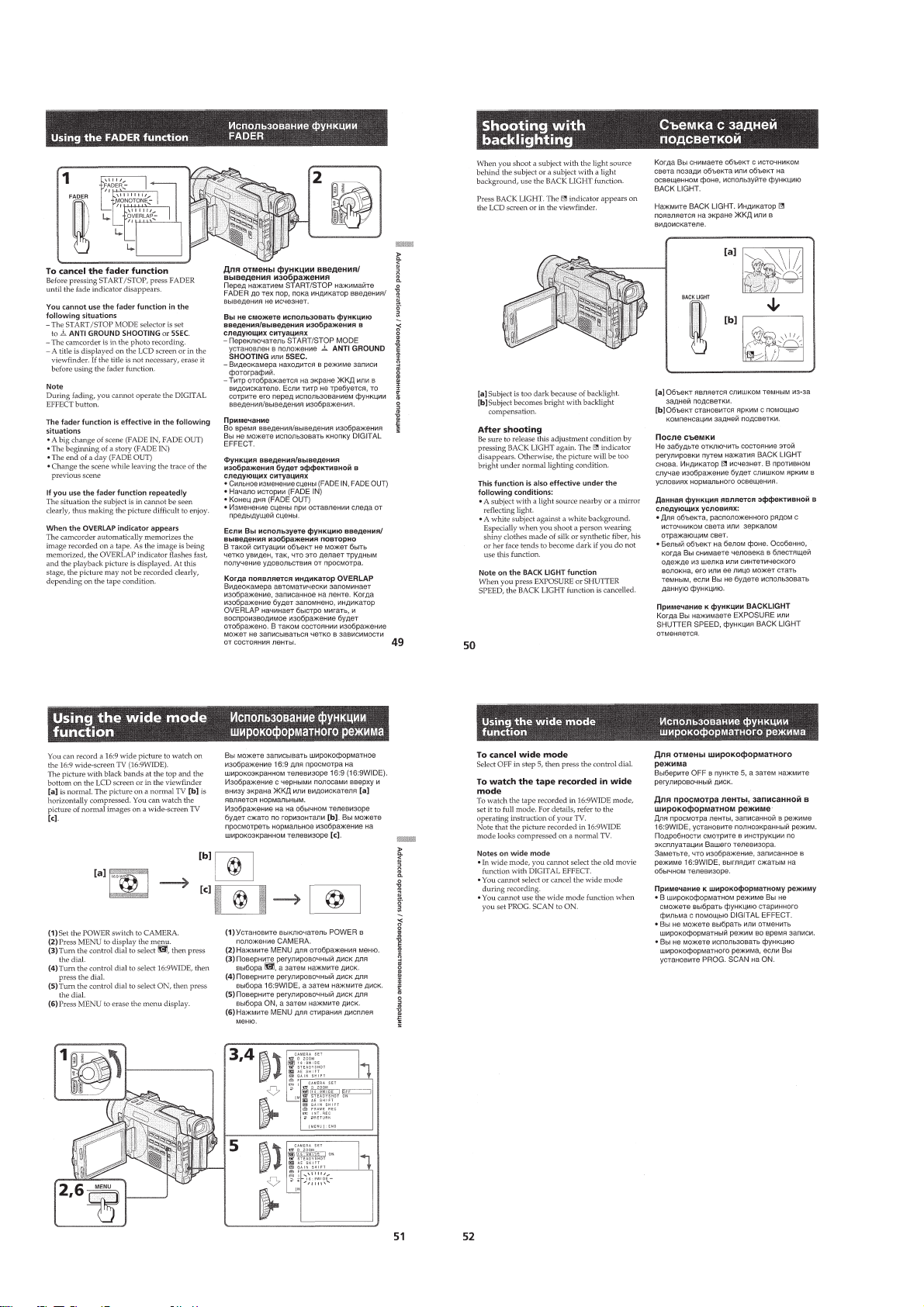

Page 49

1-41

Page 50

1-42

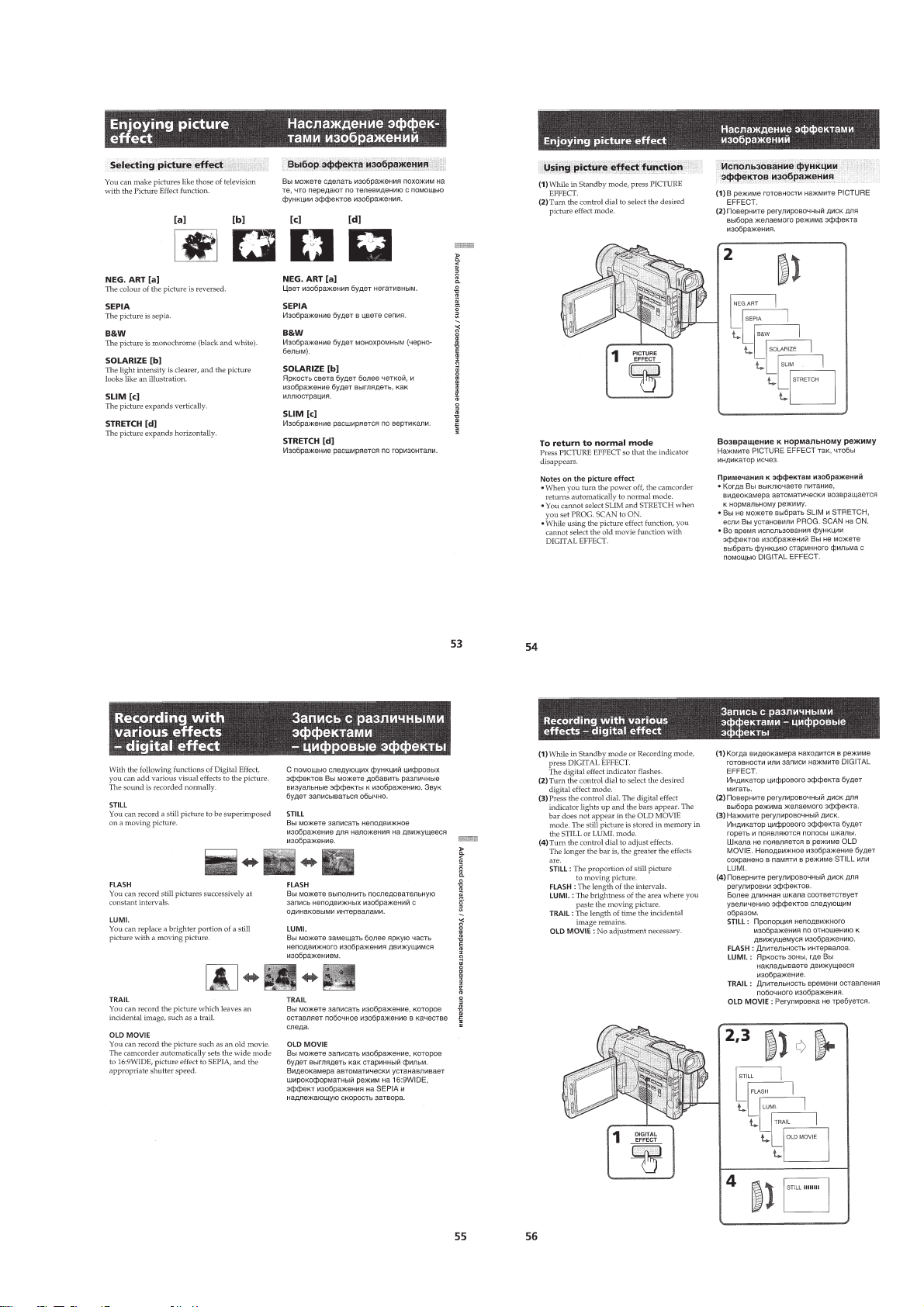

Page 51

1-43

Page 52

1-44

Page 53

1-45

Page 54

1-46E

Page 55

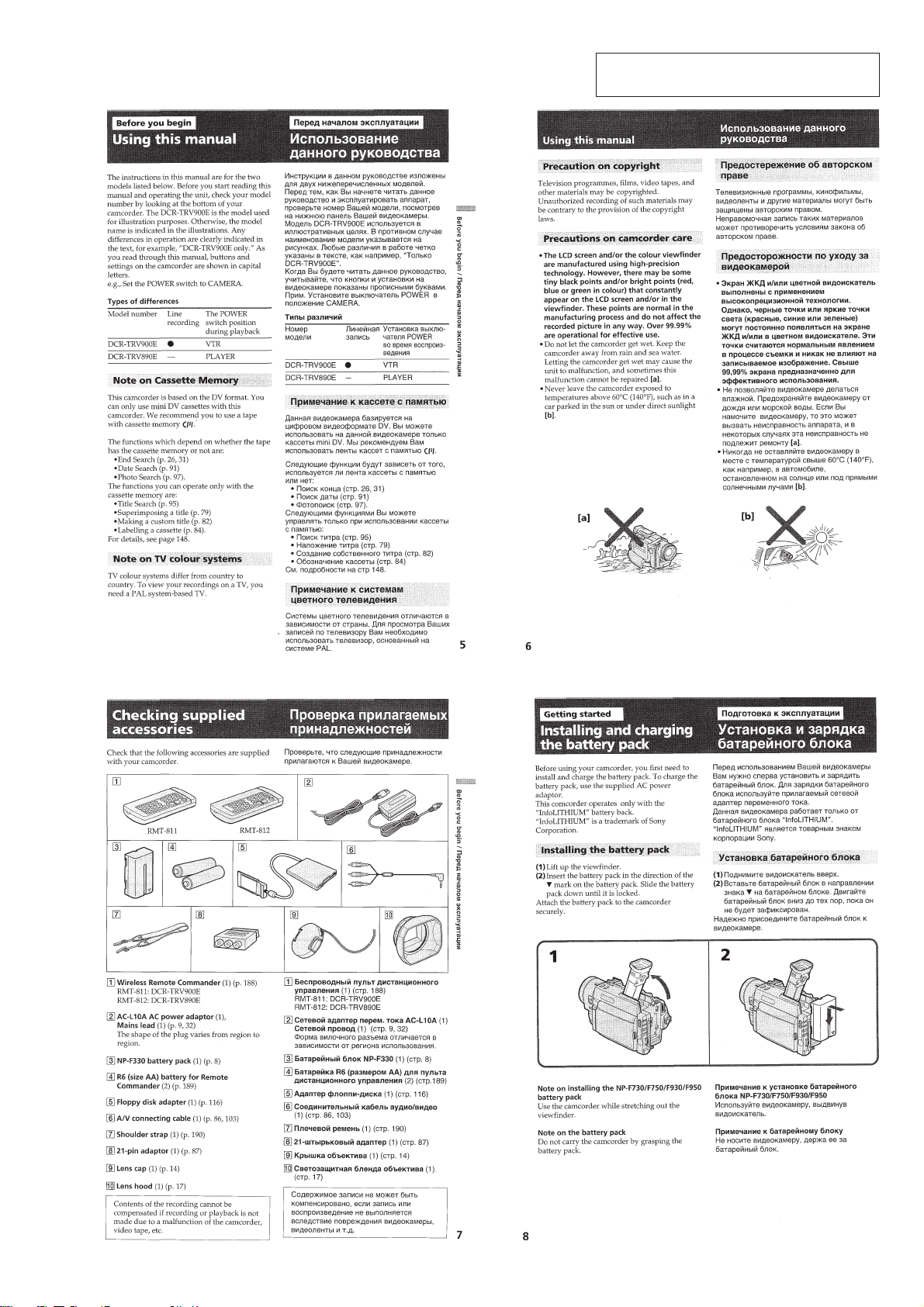

SECTION 2

DISASSEMBLY

NOTE: Follow the disassembly procedure as shown in the flow chart below.

DCR-TRV890E/TRV900/TRV900E

2-1. Cabinet (upper) assembly, Front panel assembly

2-2. Battery panel assembly

2-3. Cabinet (R) assembly, Cabinet (L) assembly

2-4.

SE-75 board

2-4.

Lens assembly

1-5

2-4.

VC-208 board

6-@º

2-4.

VI-151 board

!£-@º

2-4.

Mechanism deck

@¡-@£

@¢-@¶

2-5 JK-163 board

2-6. CK-80 board

2-7. Hinge assembly

2-8. PD-101 board

2-12. MA-333 board

DCR-TRV890E/TRV900/TRV900E

2-10.

ED-48 board

1-4

2-10.

VF-121 board

5-!£

2-11. LB-55 board

2-9. BT terminal board DC-IN connector

NOTE: Follow the disassembly procedure in the numerical order given.

2-1. CABINET (UPPER) ASSEMBLY, FRONT PANEL ASSEMBLY

4

Screw (M2 × 4)

6

Flexible board

CN7207 24P (CK-80 board)

5

FP-17 flexible board

CN7203 6P (CK-80 board)

8

Cabinet (upper) assembly

7

FP-10 flexible board

CN2905 20P (VI-151 board)

3

Screw (M2 × 4)

9

Open the jack cover and

remove the screw (M2 × 4).

!¡

Front panel assembly

(Remove it while being

careful of the claw a.)

a

a

!™

CN7304 26P (MA-333 board)

!º

Two screws (M2 × 4)

FP-12 flexible board

2-1

1

2

Screw (M2 × 4)

Screw (M2 × 4)

Page 56

2-2. BATTERY PANEL ASSEMBLY

9

Cable CN3200 4P (VI-151 board)

1

Screw (M2 × 4)

7

8

Cable 3P, CN3201 3P (VI-151 board)

2

Two screws (M2 × 4)

6

Battery panel assembly

Remove it by opening to a

side a little together with the

cabinet (R) assembly)

FP-18 flexible board CN7210 8P (CK-80 board)

3

Screw (M2 × 4)

4

CPC cover

Cabinet (R) assembly

5

Three screws (M2 × 4)

2-3. CABINET (R) ASSEMBLY, CABINET (L) ASSEMBLY

5

4

Two screws (M2(step))

!¡

Cabinet (L) assembly

Cassette lid

6

Screw

(M2

1-3

Cabinet (R) assembly

4-!¡

Cabinet (L) assembly

7

Screw (M2 × 4)

×

4)

9

Control switch block (FK-4880),

CN2907 18P (VI-151 board)

Mechanism deck, lens assembly

1

FP-9 flexible board

CN2906 60P (VI-151 board)

8

Screw

(M2

×

4)

!º

FP-12 flexible board

CN2902 27P (VI-151 board)

2

FP-13 flexible board

CN761 60P (VC-208 board)

2-2

3

Cabinet (R) assembly

Page 57

2-4. MECHANISM DECK, LENS ASSEMBLY, VC-208, VI-151, SE-75 BOARDS

)

1-5

Lens assembly

6-!º

VC-208 board

!¡-!•

VI-151 board

!ª-@¡

Mechanism deck

@™-@∞

SE-75 board

@¡

Mechanism deck

@§

MD frame assembly

@º

Two screws

(M2 step)

!ª

Screw

(M2 step)

!™

Screw (M2)

!£ a

flexible board (from capstan motor

CN2912 27P (VI-151 board)

!¢ b

flexible board (from loading motor,

S/T reel sensor)

CN2913 27P (VI-151 board)

!∞ c

flexible board (from drum motor)

CN2911 11P (VI-151 board)

!§ d

flexible board (from video head)

CN1810 10P (VI-151 board)

4

Flexible board

CN500 26P (VC-208 board)

3

Flexible board

@∞

SE-75 board

@¢

Two screws (M2 × 4)

@™

FP-14 flexible board

CN450 6P (ED-75 board)

@£

Screw (M2 × 4)

5

SE-75

BOARD

Lens block

2

Two screws

(M2

×

4)

!¶

FP-12 flexible board

VI-151

BOARD

c

d

!•

VI-151

board

!¡

Two

screws

(M2

×

4)

8

FP-8 flexible board

CN900 100P (VC-208 board)

9

FP-8 flexible board

CN2901 100P (VI-151 board)

b

a

VC-208

BOARD

CN351 8P (VC-208 board)

!º

VC-208 board

1

CD-202 board

CN200 40P

(VC-208 board)

7

Three screws (M2 × 3)

6

FP-14 flexible board

CN400 6P (VC-208 board)

CN2902 27P (VI-151 board)

2-5. JK-163 BOARD

1

FP-11 flexible assembly

2-6

JK-163 board

7-!£

Control switch block

(FK-4880)

!¢-@¡

FP-23 flexible board

external connector

(hot shoe)

e

9

Screw (M2 × 4)

!•

Remove the FP-23

flexible board.

!£

Control switch block (FK-4880) flexible board

Remove the

direction of

d

portion in the

b

and remove the

and e portions in the arrow direction

as shown without applying force to the

a

portion of the flexible board.

a

c

c

Shoe retainer

Craw

!¶

While raising the shoe

retainer in order to release

the claw, push the shoe

retainer in the direction of

e

to remove it.

@º

Shoe retainer

!ª

Four screws (M2 × 3)

6

JK-163 board

5

Screw (M2 × 3)

1

FP-11 flexible board

CN7102 39P (JK-163 board)

@¡

External

connector

(hot shoe)

!§

the S-terminal.

Remove

!¡

FK frame

JK-163

BOARD

2-3

b

d

!º

Two tapping

screws (B2

!∞

S-terminal metal plate

!™

Tapping screw (B2 × 4)

8

×

4)

!¢

Two tapping screws (B2 × 4)

4

J-K retaining metal plate

3

Four tapping screws (B2 × 4)

2

FP-23 flexible board CN7101 14P

(JK-163 board)

e

Strap metal plate

7

B2 × 4

Page 58

2-6. CK-80 BOARD

1-6

PM slider assembly

7-!¶

CK-80 board

!•-@¡

Speaker

1

Screw (M2 × 3)

2

PM cover

!™

FP-16 flexible board

CN7202 6P

(CK-80 board)

9

Two screws

(M1.7 × 3)

Insert the craw

into the slider

when re-assembling.

8

Two screws

(M1.7 × 3)

7

Two screws

(M1.7 × 3)

CK-80

BOARD

!¶

Card ejector

(Slide it in the direction

of the arrow.)

!º

CK-80

board

!∞

FP-9 flexible board CN7204 60P

(CK-80 board)

!•

Two screws (M2 × 3)

!ª

Speaker fixing plate

@º

Speaker

@¡

SP folder

!¢

FP-13 flexible board

CN7208 6P

(CK-80 board)

!£

Remove the harness

(CP-81, CP-82).

6

PM slider assembly

!¡

Remove the

harness.

(SP-156)

5

Two screws (M2 × 3)

3

Two screws (M2 × 4)

2-7. LCD PANEL ASSEMBLY, HINGE ASSEMBLY

1-8

9-!¶

!º

LCD hinge lid

9

Three screws

(M2 × 3)

!™

Three screws

(M2 × 3)

LCD panel block

Hinge assembly

!¡

Blind plate

!¶

Hinge cover

(front)

7

Two screws

(M2 × 3)

d

d

!£

Hinge assembly

(Remove it in the direction

of the arrow a.)

!§

Hinge cover (rear)

(Remove it while being

careful of the craw.)

!¢

Screw (M1.7 × 3)

a

5

Remove the

Craws

CP-81 harness.

6

Remove

the CP-82

harness.

4

Stand

PD-101

BOARD

LCD panel assembly

!§

Four screws (M2 × 7)

Rotate it by 90

direction of the arrow

b

2

Screw

(M2 × 4)

8

LCD panel block

°

in the

b.

Rotate it by 90

in the direction

of the arrow c.

C

3

Screw (M2 × 4)

°

Rotate it by 90 ° in the

direction of the arrow d.

!∞

Two screws

(M1.7 × 3)

4

P cabinet (C) assembly

2-4

1

Two screws (M2 × 4)

Page 59

2-8. PD-101 BOARD

1-5

PD-101 board

6-8

FP-19 flexible board

9-!™

LCD panel

9

Cold cathode fluorescent

tube with light-conduction plate

2

Flexible board

6

Panel frame

(Remove it while being

careful of the four craws.)

CN5701 10P

(PD-101 board)

!º

Light-conduction

plate insulation sheet

!¡

LCD module

Craws

!™

P cabinet (M) assembly

3

Flexible board (FP-55)

CN5601 24P

(PD-101 board)

Craws

PD-101

BOARD

4

1

Screw

(M2

×

3)

5

PD-101 board

FP-19 flexible board

CN5805 6P (PD-101 board)

2-9. BT TERMINAL BOARD, DC-IN CONNECTOR

1-3

BT terminal plate

4-6

DC-IN connector

7-!º

FP-18 flexible board

3

BT terminal board

7

Two screws (M2 × 3)

8

FP-19 flexible board

Battery panel assembly

1

6

DC-IN connector

Screw (M2 × 4)

2

Strap metal plate

7

Two tapping

screws (B2 × 5)

!º

9

AL knob

8

AL knob folder

2-5

4

Two tapping screws (B2 × 5)

FP-18 flexible board

5

DC fixing plate

Page 60

2-10.ED-48, VF-121 BOARDS

1-4

ED-48 board

5-8

EVF assembly

9-!£

VF-121 board

!¢-!¶

VF slide base

4

Edit button

3

ED-48

board

1

Four screws

×

3)

(M2

2

FP-17 flexible board

CN7000 6P (ED-48 board)

7

Two screws

×

(M2

4)

5

Four screws (M2 × 4)

6

Slider ground plate

8

EVF assembly

9

CN5001 21P (VF-121 board)

!§

VF click plate

!™

the craw.

FP-10 flexible board

!∞

Slide here.

Release

!¶

VF slide base

!¢

Peel off the cushion.

!£

VF-121 board

!¡

Release the two craws.

!º

FP-20 flexible board

CN5101 30P

(VF-121 board)

2-11.LB-55 BOARD

9

Flexible board

CN5202 16P (LB-55 board)

!£

BL diffusion plate

8

FP-20 flexible board

CN5201 27P

(LB-55 board)

!¢

!™

LCD cushion

3

Two tapping screws (M2 × 4)

!º

VF lens assembly

(Remove it in the direction

of the arrow a.)

!§

LCD cushion 1

!∞

LCD

LCD cushion

6

EVF cabinet (upper)

a

7

Eye cup assembly

4

EVF cabinet

(lower) assembly

1

Four tapping screws

(M1.7 × 5)

5

VF slider assembly

!¡

LB-55 board

2

Two tapping screws (M1.7 × 8)

2-6

Page 61

MA-333

BOARD

FP-21

!¶

Screw (M2 × 3)

1-7

MA-333 board

8-0

FP-22 flexible board (MIC jack)

!¡-!¶

FP-21 flexible board

!£

MF reinforcement plate

!•

FP-21 flexible board

2

FP-21 flexible board

CN7302 10P (MA-333 board)

3

FP-37 flexible board

CN7305 6P (MA-333 board)

6

Cable (MIC)

CN7300 2P (MA-333 board)

5

Cable (MIC)

CN7301 2P (MA-333 board)

1

Sound insulation sheet

!¢

MF retainer

assembly

!§

Tapping screw

(B2

×

5)

!∞

Screw (M2 × 3)

0

Jack retainer

9

Tapping screw

(B2

×

5)

4

Two tapping screws (B2 × 5)

8

MA-333 board

!¡

FP-22 flexible board

(MIC jack)

7

FP-22 flexible board

CN7303 5P (MA-333 board)

!™

Tapping screw

(B2

×

5)

2-12.MA-333 BOARD

2-13.SERVICE POSITION (Mainly for check and voltage measurement)

Firstly, remove the following parts referring to DISASSEMBLY (sections 2-1 to 2-6, 2-10 and 2-12), and connect parts as shown

below.

Control switch block

(FK-4880)

LCD panel

PD-101 board

VF-121

board

When the ED-48 board and LCD display panel are

not needed to connect during check and voltage

measurement, this connection is not necessary.

ED-48 board

a

b

Extension

cable

(J-6082 431-A)

CK-80

BOARD

FP-9

FP-10

LCD display panel

SE-75 board

FP-14

FP-13

a

b

VI-151

BOARD

Base 2

Lens block

VC-208

BOARD

FP-12

CD-202 board

Extension

cable

(J-6082 432-A)

MA-333

board

FP-73

RI-10 board

Base 1: Using a box or the like,

support the lens block,

CD-202 board and

VC-208 board as shown.

Base 2: Using a box or the like,

support the VI-151

board as shown.

Base 1

FP-23

JK-163 board

EVF (LB-55 board, LCD)

Battery case assembly

2-7

AC

adapter

AC IN

Extension cable

(J-6082-433-A)

Mechanism deck

Adjustment remote

commander (RM-95)

Page 62

)

2-14.CIRCUIT BOARDS LOCATION

ED-48

SE-75

(YAW/PITCH SENSOR)

JK-163

(AUDIO/VIDEO IN/OUT)

RI-10

(SIRCS RECEIVER)

(USER CONTROL)

MA-333

(STEREO MIC AMP)

LB-55

(EVF BACK-LIGHT)

VF-121

(COLOR EVF)

CK-80

USER CONTROL,

LCD DRIVE

CD-202

(CCD IMAGER)

PD-101

(RGB DRIVER, TIMING GENERATOR, BACK-LIGHT

VC-208

SAMPLE HOLD & AGC,

CAMERA PROCESSOR,

BASE BAND INPUT,

MOTOR DRIVE, VAP DRIVER,

CARD CONTROL,

PWM CONTROL,

HONEY/PCMCIA CONTROL

VI-151

REC/PB AMP, TIMING GENERATOR, VIDEO INTERFACE,

DCT/IDCT, IR TRANSMITTER, AUDIO PROCESSOR,

HI CONTROL, MECHANISM CONTROL,

DRUM/CAPSTAN MOTOR DRIVE, DC/DC CONVERTER

2-8

Page 63

)

2-15.FLEXIBLE BOARDS LOCATION

FK-4880

(USER CONTROL)

FP-17

FP-23

(S-Y/C IN/OUT)

FP-16

FP-11

FP-13

FP-8

FP-18

(USER CONTROL

For LED

LENS BLOCK

FP-21

(FOCUS)

FP-22

(MIC JACK)

FP-10

FP-19

(USER CONTROL)

FP-20

FP-9

(From CAPSTAN MOTOR)

From LOADING MOTOR,

S/T REEL SENSOR

(From DRUM MOTOR)

FP-12

FP-37

FP-14

(From VIDEO HEAD)

2-9E

Page 64

3-1. OVERALL BLOCK DIAGRAM

SECTION 3

DCR-TRV890E/TRV900/TR V900E

BLOCK DIAGRAMS

3-1 3-2 3-3 3-4

Page 65

DCR-TRV890E/TRV900/TR V900E

3-2. POWER BLOCK DIAGRAM

3-5 3-6 3-7 3-8E

Page 66

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMA TIC DIAGRAM-1

SECTION 4

DCR-TRV890E/TRV900/TR V900E

4-1 4-2 4-3 4-4

FRAME SCHEMA TIC DIAGRAM-1

Page 67

DCR-TRV890E/TRV900/TR V900E

FRAME SCHEMA TIC DIAGRAM-2

FRAME SCHEMA TIC DIAGRAM-2

4-5 4-6 4-7 4-8

Page 68

DCR-TRV890E/TRV900/TR V900E

4-2. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR WIRING BOARDS AND SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

DCR-TRV890E/TRV900/TR V900E

(For printed wiring boards)

• b: Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

• Through hole is omitted.

• Circled numbers refer to waveforms.

• There are few cases that the part printed on diagram

isn’t mounted in this model.

• Chip parts.

Transistor Diode

C

5

BE

64

2

13

5

46

2

31

45

2

31

12

4

53

3

21321321

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µµF.

50V or less are not indicated except for electrolytics and

tantalums.

• Chip resistors are 1/10W unless otherwise noted.

kΩ=1000Ω, MΩ=1000kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

Temperature characteristics

External dimensions (mm)

• Constants of resistors, capacitors, ICs and etc with XX indicate

that they are not used.

In such cases, the unused circuits may be indicated.

• Parts with ★ differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors have characteristic curve B,

unless otherwise noted.

• Signal name

XEDIT→ EDIT PB/XREC → PB/REC

• 2 : non flammable resistor

• 1 : fusible resistor

• C : panel designation

• A : B+ Line *

• B : B– Line *

• J : IN/OUT direction of (+,–) B LINE. *

• C : adjustment for repair. *

• Circled numbers refer to waveforms. *

*Indicated by the color red.

Note :

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Note :

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

(Measuring conditions voltage and waveform)

• Voltages and waveforms are measured between the measurement points and ground when camera shoots color bar chart of

pattern box. They are reference values and reference waveforms. *

(VOM of DC 10 MW input impedance is used.).

• Voltage values change depending upon input impedance of VOM

used.)

1. Connection

Pattern box

95 cm

Front side of the lens

2. Adjust the distance so that the output waveform of Fig. a and

the Fig. b can be obtain.

H

Yellow

Cyan

White

Magenta

Green

AABBA=B

Fig. a (Video output terminal output waveform)

Cyan

White

Green

Yellow

Magenta

Fig.b (Picture on monitor TV)

3. • The LINE REC waveform shows the waveform when the color

for signal (video signal) is input from a color bar pattern.

• The LINE OUT waveform shows the waveform when the

signals are connected to the S-VIDEO and VIDEO/AUDIO

jacks but not to other jacks.

When indicating parts by reference number, pleas include

the board name.

Red

Blue

Red

Blue

Electron beam

scanned frame

CRT picture frame

4-9

Page 69

DCR-TRV890E/TRV900/TRV900E

CD-202

CAMERA REC

IC100 1, 2

1

IC101 1, 2

IC102 1, 2

IC100 3, IC101 3

2

IC102 3

IC100 !£, !¢

3

IC101 !£, !¢

IC102 !£, !¢

13.5 MHz

IC100 !™, IC101 !™

4

IC102 !™

BOARD

H

V

8.4Vp-p

22Vp-p

3.0Vp-p

5

Q101 E

6

Q100 E

7

Q102 E

13.5 MHz

H

H

H

H

H

3.0Vp-p

0.6Vp-p

0.6Vp-p

0.5Vp-p

CCD IMAGER

CD-202

4-11 4-12

Page 70

DCR-TRV890E/TRV900/TR V900E

DCR-TRV890E/TRV900/TR V900E

CD-202 (CCD IMAGER) PRINTED WIRING BOARD

— Ref. No. CD-202 Board; 10,000 Series —

CD-202 BOARD

C100 C-5

C101 C-5

C102 F-5

C103 A-5

C104 D-5

C105 F-5

C106 A-5

C107 C-5

C108 C-5

C109 C-5

C110 C-6

C111 A-5

C112 A-6

C113 E-5

C114 A-6

C115 A-5

C116 A-5

C117 F-5

C118 F-5

C119 F-5

C120 E-5

CN100 B-1

IC100 F-7

IC101 C-7

IC102 A-7

L100 C-5

L101 A-5

L102 E-5

Q100 C-6

Q101 F-5

Q102 A-6

R100 C-5

R101 F-5

R102 A-5

R103 C-5

R104 F-5

R105 A-5

4-13 4-14

CCD IMAGER

CD-202

For printed wiring boards

• This board is six-layer print board. However, the patterns of layers two to five have not been included in

the diagram.

• Chip parts

Transistor

C

BE

There are few cases that the part printed on this

diagram isn’t mounted in this model.

CD-202

(CCD IMAGER)

VI-151

REC/PB AMP, TIMING GENERATOR, VIDEO INTERFACE,

DCT/IDCT, IR TRANSMITTER, AUDIO PROCESSOR,

HI CONTROL, MECHANISM CONTROL,

DRUM/CAPSTAN MOTOR DRIVE, DC/DC CONVERTER

VC-208

SAMPLE HOLD & AGC,

CAMERA PROCESSOR,

BASE BAND INPUT,

MOTOR DRIVE, VAP DRIVER,

CARD CONTROL,

PWM CONTROL,

HONEY/PCMCIA CONTROL

Page 71

DCR-TRV890E/TRV900/TR V900E

VC-208 BOARD (SIDE A)

C228 E-7

C234 E-6

C235 E-6

C236 D-7

C237 D-7

C238 E-6

C239 E-5

C252 E-7

C253 E-6

C254 E-5

C255 E-8

C256 E-7

C257 E-7

C258 E-6

C259 E-6

C260 E-6

C300 D-7

C301 C-8

C500 D-5

C501 C-5

C502 C-4

C503 C-4

C504 C-5

C505 C-5

C506 D-5

C507 D-5

C508 D-4

C509 C-5

C510 D-5

C511 C-5

C512 C-5

C514 D-5

C515 D-5

C516 C-4

C517 D-4

C518 C-4

C519 D-5

C520 D-5

C521 C-6

C522 C-6

C523 D-6

C524 D-6

C525 C-6

C526 D-6

C527 C-6

C528 C-6

C530 D-6

C531 D-5

C532 C-3

C533 C-5

C534 C-6

C701 A-1

C703 A-1

C704 A-1

C733 B-2

C734 A-2

C735 C-1

C736 A-1

C737 A-1

C738 B-1

C739 C-1

C740 B-3

C742 C-2

C743 C-3

C752 C-3

C753 C-3

C754 C-5

C760 A-5

C762 B-4

C763 C-5

C764 A-7

C765 A-8

C766 A-8

C767 B-7

C768 B-7

CN200 E-8

CN351 C-3

CN400 A-2

CN500 C-2

CN761 B-1

D500 C-5

D501 D-5

D721 B-2

D722 B-2

FB202 D-7

FB300 C-8

FB301 D-6

FB501 C-4

FB752 C-5

FB754 A-7

IC205 D-8

IC206 D-7

IC207 D-6

IC300 C-7

IC500 C-4

IC501 C-5

IC502 C-6

IC752 B-3

IC756 B-5

IC757 B-6

IC758 B-8

L201 E-6

L500 D-4

L501 C-4

L503 D-5

L721 B-2

L722 B-2

L723 B-1

L723 C-2

L724 B-1

L725 B-3

L726 C-1

L727 C-2

L751 C-4

L752 A-8

Q500 C-4

Q501 C-5

Q502 C-5

Q503 D-5

Q504 C-6

Q505 C-4

Q701 A-1

Q702 A-3

Q721 B-2

Q722 B-2

R201 D-7

R204 D-5

R205 D-6

R325 B-8

R326 B-8

R500 C-3

R501 C-4

R502 C-5

R503 C-3

R504 C-5

R505 C-5

R506 C-5

R507 C-5

R508 C-5

R509 C-5

R510 D-5

R511 C-5

R512 D-5

R513 D-5

R514 C-5

R515 D-5

R516 D-5

R517 D-5

R518 C-5

R519 C-5

R520 C-5

R521 C-5

R522 C-5

R523 D-5

R524 D-6

R525 C-6

R526 C-6

R528 C-6

R529 C-6

R530 D-6

R531 C-6

R532 D-6

R533 D-6

R534 C-6

R535 D-6

R536 D-6

R537 D-6

R538 C-6

R539 C-6

R540 C-6

R541 C-6

R542 C-6

R543 C-3

R544 D-5

R545 C-4

R701 A-1

R702 A-1

R703 A-1

R704 A-1

R734 B-2

R735 B-2

R765 B-9

R766 B-9

R767 B-9

R768 B-8

R769 B-8

R770 B-8

R771 B-8

R772 B-8

R773 A-8

R774 A-8

R775 A-8

R776 A-8

R777 A-8

R778 A-9

R779 A-9

R780 A-9

R788 B-6

R789 A-7

R790 A-7

R791 B-6

R792 A-6

R800 A-8

R801 B-8

R802 B-6

R803 B-6

R807 C-6

R808 C-4

R810 C-4

R811 C-4

R900 B-5

R901 B-5

R902 B-5

R903 B-5

R904 B-5

R905 B-5

R906 B-5

R907 B-5

R908 B-5

R909 B-5

R910 B-5

R919 B-6

VC-208 (SAMPLE HOLD & AGC, CAMERA PROCESSOR, BASE BAND INPUT, MOTOR DRIVE, VAP DRIVER, CARD CONTROL, PWM CONTROL, HONEY, PCMCIA CONTROL) PRINTED WIRING BOARD

— Ref. No. VC-208 Board; 10,000 Series —

For printed wiring boards

• This board is six-layer print board. However, the patterns of layers two to five have not been included in

the diagram.

• Chip parts

Transistor Diode

C

BE

5

64

2

13

3

21

There are few cases that the part printed on this

diagram isn’t mounted in this model.

CD-202

(CCD IMAGER)

VC-208

SAMPLE HOLD & AGC,

CAMERA PROCESSOR,

BASE BAND INPUT,

MOTOR DRIVE, VAP DRIVER,

CARD CONTROL,

PWM CONTROL,

HONEY/PCMCIA CONTROL

VI-151

REC/PB AMP, TIMING GENERATOR, VIDEO INTERFACE,

DCT/IDCT, IR TRANSMITTER, AUDIO PROCESSOR,

HI CONTROL, MECHANISM CONTROL,

DRUM/CAPSTAN MOTOR DRIVE, DC/DC CONVERTER

CAMERA PROCESS & CNT, S/H &AGC, BASE BAND INPUT, LENS DRIVER, VAP SENSOR, FLASH DD/CNT, VAP DRIVER

VC-208

4-17 4-18

Page 72

VC-208 (SAMPLE HOLD & AGC, CAMERA PROCESSOR, BASE BAND INPUT, MOTOR DRIVE, VAP DRIVER, CARD CONTROL, PWM CONTROL, HONEY, PCMCIA CONTROL) PRINTED WIRING BOARD

— Ref. No. VC-208 Board; 10,000 Series —

VC-208 BOARD (SIDE B)

C201 E-13

C202 E-13

C203 E-13

C204 E-12

C205 E-12

C206 E-12

C207 D-12

C208 D-12

C209 D-12

C211 D-13

C212 D-12

C213 D-12

C214 D-13

C215 D-12

C216 D-12

C216 E-11

C217 D-13

C218 D-13

C219 D-12

C220 D-12

C221 D-12

C222 D-14

C227 D-11

C229 E-11

C230 E-11

C231 E-11

C232 D-12

C233 D-12

C240 E-13

C241 E-12

C242 E-12

C243 D-12

C244 E-12

C245 D-12

C246 D-12

C247 E-11

C248 D-11

C249 D-11

C250 D-12

C261 D-11

C262 D-11

C302 C-11

C303 C-12

C305 A-10

C306 A-10

C307 A-10

C308 C-12

C309 D-12

C310 A-10

C311 C-18

C351 D-15

C353 D-15

C354 D-15

C355 D-15

C357 C-15

C358 C-14

C359 C-14

C360 D-14

C361 C-14

C362 C-14

C368 C-12

C370 D-13

C371 D-13

C372 D-13

C373 C-13

C374 C-13

C375 C-13

C376 C-14

C377 C-14

C379 D-14

C380 C-13

C381 D-14

C382 D-15

C383 D-15

C400 B-12

C401 B-13

C402 A-13

C403 B-12

C404 B-12

C405 B-12

C406 B-12

C407 B-12

C408 A-13

C409 A-12

C410 A-12

C411 A-12

C412 B-13

C413 B-12

C414 B-12

C415 B-12

C702 B-17

C705 A-18

C721 B-18

C722 B-17

C723 B-18

C724 B-18

C725 B-18

C726 B-17

C727 B-18

C728 B-18

C729 B-18

C730 B-18

C731 C-18

C732 C-17

C744 B-17

C751 B-13

C755 C-13

C756 B-14

C757 B-14

C758 C-14

C759 B-15

C761 A-13

C769 C-12

C770 C-12

C771 C-12

C772 A-14

C1200 B-16

C1201 B-16

C1202 B-16

C1203 B-17

C1204 A-16

C1205 B-16

C1206 A-15

C1207 B-16

C1208 B-16

C1209 A-16

C1210 B-16

C1211 A-16

C1212 B-14

C1213 A-15

C1214 A-15

C1215 B-16

C1216 A-15

C1217 A-15

C1218 A-15

C1219 A-16

C1220 A-16

C1221 A-15

C1222 A-15

C1223 A-16

C1224 B-16

C1225 B-15

C1226 B-16

C1227 B-16

C1228 B-16

C1229 A-16

C1230 B-16

C1231 B-15

C1232 B-14

C1233 B-15

C1234 B-15

C1235 C-15

CN900 C-17

D204 E-11

D723 C-18

D724 C-18

D1200 C-16

D1201 C-15

FB200 D-12

FB201 D-11

FB203 E-13

FB204 E-14

IC203 D-13

IC204 D-11

IC208 D-14

IC301 C-11

IC302 B-11

IC305 C-11

IC351 C-15

IC352 C-15

IC354 C-13

IC355 C-13

IC356 C-14

IC357 D-14

IC400 B-12

IC701 A-17

IC721 B-18

IC722 B-17

IC751 B-13

IC753 C-13

IC754 A-14

IC755 A-13

IC759 C-12

IC760 A-14

IC1200 B-15

L200 D-13

L300 C-11

L301 D-12

L351 C-15

L352 D-14

L400 C-12

L754 C-15

L1200 A-16

L1201 B-17

L1202 C-16

L1203 A-16

L1204 B-16

L1205 B-14

Q200 E-13

Q201 E-13

Q301 B-12

Q351 C-14

Q352 D-14

Q353 D-15

Q354 C-15

Q727 B-18

Q751 C-13

Q752 C-14

Q753 B-14

Q754 C-14

Q755 C-12

Q1200 A-16

Q1201 B-16

Q1202 B-16

Q1203 A-16

Q1204 A-16

Q1205 B-16

Q1206 B-16

Q1207 A-15

Q1208 C-17

Q1209 B-16

R200 D-11

R202 E-11

R203 D-11

R207 E-12

R208 E-12

R209 D-12

R210 E-12

R211 D-12

R212 D-12

R213 E-11

R214 D-11

R215 D-11

R216 D-12

R217 E-12

R218 D-12

R219 D-13

R220 D-13

R221 D-14

R222 D-12

R223 D-12

R224 D-12

R225 D-12

R226 D-12

R227 D-12

R235 E-12

R236 E-12

R237 E-13

R300 B-11

R301 B-12

R302 B-12

R303 C-11

R304 B-11

R305 B-11

R306 B-11

R307 B-11

R308 B-11

R309 C-11

R311 B-11

R314 A-10

R316 A-10

R317 A-10

R318 B-10

R319 B-12

R320 B-10

R327 A-11

R328 A-11

R329 A-11

R330 A-11

R331 B-10

R332 A-11

R333 A-11

R334 A-11

R335 A-11

R336 A-11

R350 C-13

R353 D-14

R354 D-14

R355 D-14

R356 D-14

R357 C-15

R358 D-15

R359 C-15

R360 D-15

R361 D-15

R362 C-15

R363 D-15

R364 C-15

R365 D-15

R366 D-15

R367 D-14

R368 D-14

R369 C-14

R370 C-14

R371 C-14

R372 C-14

R373 C-14

R374 C-13

R375 D-13

R376 D-14

R377 C-13

R378 D-13

R379 D-13

R380 C-13

R381 C-13

R382 C-13

R383 C-13

R384 D-13

R385 D-13

R386 D-13

R387 C-14

R388 C-14

R389 D-16

R390 C-16

R391 D-15

R392 D-15

R393 C-14

R394 C-14

R395 D-14

R396 D-13

R400 B-12

R401 B-13

R402 B-13

R403 B-12

R404 B-12

R405 B-12

R406 B-12

R407 B-13

R408 B-12

R409 B-12

R721 B-18

R722 B-18

R723 B-18

R724 B-17

R725 B-18

R726 C-18

R727 B-17

R728 B-18

R729 B-18

R730 B-18

R731 B-17

R732 B-17

R733 B-17

R740 C-18

R741 B-18

R742 C-18

R743 C-18

R744 C-18

R745 C-17

R751 C-13

R752 C-13

R754 C-13

R755 C-14

R756 B-14

R757 B-14

R758 B-14

R759 B-14

R760 A-14

R761 A-14

R762 A-13

R763 C-14

R764 B-14

R781 A-13

R782 A-13

R783 A-13

R784 A-13

R785 A-13

R786 A-13

R787 A-13

R793 A-13

R794 C-12

R795 C-12

R796 C-12

R797 C-12

R804 A-14

R805 A-14

R806 A-14

R809 C-12

R911 B-15

R912 C-15

R913 B-15

R914 C-15

R915 B-15

R916 C-15

R917 B-15

R918 C-15

R920 C-17

R921 C-17

R1202 B-16

R1203 B-16

R1204 B-17

R1205 A-15

R1206 A-16

R1207 B-16

R1208 B-16

R1209 B-16

R1210 A-16

R1211 A-16

R1212 B-16

R1213 B-16

R1214 A-15

R1216 B-16

R1217 A-15

R1218 B-16

R1219 A-15

R1266 B-15

R1267 B-16

R1268 B-16

R1269 B-16

R1270 B-15

R1271 C-15

X1200 C-16

X200 E-11

X300 C-11

X751 B-14

DCR-TRV890E/TRV900/TR V900E

DCR-TRV890E/TRV900/TR V900E

4-19 4-20

CAMERA PROCESS & CNT, S/H &AGC, BASE BAND INPUT, LENS DRIVER, VAP SENSOR, FLASH DD/CNT, VAP DRIVER

VC-208

Page 73

DCR-TRV890E/TRV900/TR V900E

DCR-TRV890E/TRV900/TRV900E

For schematic diagram

• Refer to page 4-17 for printed wiring board.

VC-208

1

CAMERA REC

2

CAMERA REC

3

CAMERA REC

4

CAMERA REC

BOARD (1/7)

IC203 @•, @ª

H

IC203 #¡, #™

H

IC203 #¢, #∞

H

IC203 5

6

0.6Vp-p

0.5Vp-p

0.6Vp-p

IC203 9

CAMERA REC

7

IC204 #¡

CAMERA REC

8

IC204 $¶

CAMERA REC/PB

9

IC205 1 – 5 , 8 – !™

IC206 1 – 5 , 8 – !™

IC207 1 – 5 , 8 – !™

CAMERA REC

H

27.0 MHz

13.5 MHz

0.34Vp-p

3.4Vp-p

3.0Vp-p

H

5

IC203 7

CAMERA REC

H

0.28Vp-p

0.34Vp-p

74 nsec

2.8Vp-p

SAMPLE HOLD & AGC

VC-208 (1/7)

4-24 4-25 4-26

Page 74

For schematic diagram

• Refer to page 4-17 for printed wiring board.

DCR-TRV890E/TRV900/TR V900E

DCR-TRV890E/TRV900/TR V900E

VC-208

!º

CAMERA REC/PB

!¡

CAMERA REC/PB

BOARD (2/7)

IC300 &¶

13.5MHz

IC302 $º

20.0MHz

3.0Vp-p

2.8Vp-p

4-27 4-28 4-29

CAMERA PROCESSOR

VC-208 (2/7)

Page 75

DCR-TRV890E/TRV900/TR V900E

DCR-TRV890E/TRV900/TRV900E

For schematic diagram

• Refer to page 4-17 for printed wiring board.

VC-208

!™

LINE REC

!™

CAMERA REC/PB

!£

LINE REC

!£

CAMERA REC/PB

BOARD (3/7)

IC1200 @∞

H

IC1200 @∞

H

IC1200 #£

H

IC1200 #£

0.44Vp-p

1.0Vp-p

0.5Vp-p

H

!¢

IC1200 #¢

LINE REC

!¢

IC1200 #¢

CAMERA REC/PB

IC1200 $¢

!∞

LINE REC

!§

IC1200 ^¡ – ^•

CAMERA REC/PB,

LINE REC

H

H

40.5MHz

1.5Vp-p

0.44Vp-p

2.0Vp-p

3.0Vp-p

4-31

74 nsec

2.8Vp-p

BASE BAND INPUT

VC-208 (3/7)

4-32 4-33 4-34

Page 76

For schematic diagram

• Refer to page 4-17 for printed wiring board.

DCR-TRV890E/TRV900/TR V900E

DCR-TRV890E/TRV900/TR V900E

4-35 4-36

MOTOR DRIVE

VC-208 (4/7)

Page 77

DCR-TRV890E/TRV900/TR V900E

)

SE-75 (Y AW/PITCH SENSOR) PRINTED WIRING BOARD

— Ref. No. SE-75 Board; 10,000 Series —

SE-75 BOARD

C450 B-2

C451 A-2

CN450 A-2

L450 B-1

SE450 B-2

SE451 C-1

For schematic diagram

• Refer to page 4-17 for printed wiring board of VC-208.

For printed wiring boards

• This board is six-layer print board. However, the patterns of layers two to five have not been included in

the diagram.

There are few cases that the part printed on this

diagram isn’t mounted in this model.

LB-55

(EVF BACK-LIGHT)

VF-121

(COLOR EVF)

ED-48

(USER CONTROL)

SE-75

(YAW/PITCH SENSOR)

JK-163

(AUDIO/VIDEO IN/OUT)

RI-10

(SIRCS RECEIVER)

MA-333

(STEREO MIC AMP)

CK-80

USER CONTROL,

LCD DRIVE

PD-101

(RGB DRIVER, TIMING GENERATOR, BACK-LIGHT

VAP DRIVER

VC-208 (5/7)

YAW/PITCH SENSOR

/

SE-75

4-39 4-40 4-41 4-42

Page 78

For schematic diagram

• Refer to page 4-17 for printed wiring board.

DCR-TRV890E/TRV900/TR V900E

VC-208 BOARD (6/7)

CAMERA REC/PB

!¶ IC722 !º

2.3µsec

0.8Vp-p

4-43 4-44 4-45 4-46

CARD CONTROL, PWM CONTROL

VC-208 (6/7)

Page 79

DCR-TRV890E/TRV900/TR V900E

For schematic diagram

• Refer to page 4-17 for printed wiring board.

HONEY, PCMCIA CONTROL

VC-208 (7/7)

4-47 4-48 4-49 4-50

VC-208

!•

CAMERA REC/PB

BOARD (7/7)

IC751 &¶

6.85MHz

3.8Vp-p

Page 80

For schematic diagram

• Refer to page 4-91 for printed wiring board.

DCR-TRV890E/TRV900/TR V900E

VI-151 BOARD (1/10)

1 IC1816 1, 2, 6, 7

CAMERA REC

6.8msec

3.5Vp-p

2 IC1816 !¡, !™

CAMERA REC

6.8msec

2.0Vp-p

3 IC1816 @¶ PB

0.35Vp-p

6.8msec

4 IC1816 $º

CAMERA REC/PB

41.7MHz

5 IC1816 $™

CAMERA REC

25nsec

6 IC1814 !£ PB

41.85MHz

7 IC1814 !∞ – @º PB

25nsec

2.3Vp-p

2.2Vp-p

2.0Vp-p

2.2Vp-p

8 IC1814 #¡

CAMERA REC/PB

6.8msec

4-51 4-52 4-53

2.6Vp-p

REC/PB AMP

VI-151 (1/10)

Page 81

DCR-TRV890E/TRV900/TR V900E

DCR-TRV890E/TRV900/TRV900E

For schematic diagram

• Refer to page 4-91 for printed wiring board.

VI-151

CAMERA REC

9

BOARD (2/10)

IC1900 $¡

13.5MHz

3.2Vp-p

TIMING GENERA TOR

VI-151 (2/10)

4-55 4-56

Page 82

For schematic diagram

• Refer to page 4-91 for printed wiring board.

DCR-TRV890E/TRV900/TR V900E

DCR-TRV890E/TRV900/TR V900E

VI-151

!º

CAMERA REC

!º

!¡

CAMERA REC

!¡

BOARD (3/10)

Q1500 E

H

Q1500 E LINE REC

Q1501 E

H

Q1501 E LINE REC

0.22Vp-p

0.3Vp-p

H

0.2Vp-p

H

!™

Q1502 E

CAMERA REC

H

!™

Q1502 E LINE REC

H

0.3Vp-p

0.34Vp-p

0.38Vp-p

4-57 4-58 4-59

VIDEO INTERFACE

VI-151 (3/10)

Page 83

DCR-TRV890E/TRV900/TR V900E

DCR-TRV890E/TRV900/TRV900E

For schematic diagram

• Refer to page 4-91 for printed wiring board.

VI-151 BOARD (4/10)

CAMERA REC/PB

!£ IC1600 !¢ (R1627)

24.58MHz

2.6Vp-p

DCT/IDCT

VI-151 (4/10)

4-62 4-63 4-64

Page 84

For schematic diagram

• Refer to page 4-91 for printed wiring board.

DCR-TRV890E/TRV900/TR V900E

DCR-TRV890E/TRV900/TR V900E

VI-151

!¢

LINE REC/PB (IR ON)

82nsec

!∞

!∞

!§

CAMERA REC/PB

BOARD (5/10)

IC1403 @™

IC1403 $¡ PB

H