Page 1

LCD VIDEO MONITOR

PVM-L1700

OPERATION MANUAL [English]

1st Edition (Revised 2)

Page 2

Before operating the unit, please read this manual

thoroughly and retain it for future reference.

Important Safety Instructions

WARNING

To reduce the risk of fire or electric shock, do not

expose this apparatus to rain or moisture.

• Read these instructions.

• Keep these instructions.

• Heed all warnings.

• Follow all instructions.

• Do not use this apparatus near water.

• Clean only with dry cloth.

• Do not block any ventilation openings.

Install in accordance with the manufacturer's

instructions.

• Do not install near any heat sources such as radiators,

heat registers, stoves, or other apparatus (including

amplifiers) that produce heat.

• Do not defeat the safety purpose of the polarized or

grounding-type plug. A polarized plug has two blades

with one wider than the other. A grounding-type plug

has two blades and a third grounding prong. The wide

blade or the third prong are provided for your safety. If

the provided plug does not fit into your outlet, consult an

electrician for replacement of the obsolete outlet.

• Protect the power cord from being walked on or pinched

particularly at plugs, convenience receptacles, and the

point where they exit from the apparatus.

• Only use attachments/accessories specified by the

manufacturer.

• Use only with the cart, stand, tripod, bracket, or table

specified by the manufacturer, or sold with the

apparatus. When a cart is used, use caution when

moving the cart/apparatus combination to avoid injury

from tip-over.

To avoid electrical shock, do not open the

cabinet. Refer servicing to qualified personnel

only.

THIS APPARATUS MUST BE EARTHED.

When installing the unit, incorporate a readily accessible

disconnect device in the fixed wiring, or connect the power

plug to an easily accessible socket-outlet near the unit. If a

fault should occur during operation of the unit, operate the

disconnect device to switch the power supply off, or

disconnect the power plug.

CAUTION

The apparatus shall not be exposed to dripping or

splashing. No objects filled with liquids, such as vases,

shall be placed on the apparatus.

CAUTION

The unit is not disconnected from the AC power source

(mains) as long as it is connected to the wall outlet, even if

the unit itself has been turned off.

• Unplug this apparatus during lightning storms or when

unused for long periods of time.

• Refer all servicing to qualified service personnel.

Servicing is required when the apparatus has been

damaged in any way, such as power-supply cord or plug

is damaged, liquid has been spilled or objects have fallen

into the apparatus, the apparatus has been exposed to

rain or moisture, does not operate normally, or has been

dropped.

2

This symbol is intended to alert the user to

the presence of uninsulated “dangerous

voltage” within the product’s enclosure that

may be of sufficient magnitude to constitute

a risk of electric shock to persons.

This symbol is intended to alert the user to

the presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the appliance.

For the customers in the U.S.A.

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when

the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications. Operation

Page 3

of this equipment in a residential area is likely to cause

harmful interference in which case the user will be

required to correct the interference at his own expense.

You are cautioned that any changes or modifications not

expressly approved in this manual could void your

authority to operate this equipment.

All interface cables used to connect peripherals must be

shielded in order to comply with the limits for a digital

device pursuant to Subpart B of Part 15 of FCC Rules.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2) this

device must accept any interference received, including

interference that may cause undesired operation.

WARNING

Using this unit at a voltage other than 120 V may require

the use of a different line cord or attachment plug, or both.

To reduce the risk of fire or electric shock, refer servicing

to qualified service personnel.

Lamp in this product contains mercury. Disposal of these

materials may be regulated due to environmental

considerations. For disposal or recycling information,

please contact your local authorities or the Electronic

Industries Alliance (www.eiae.org).

For the customers in Canada

This Class A digital apparatus complies with Canadian

ICES-003.

For the customers in Europe

This product with the CE marking complies with the EMC

Directive issued by the Commission of the European

Community.

Compliance with this directive implies conformity to the

following European standards:

• EN55103-1 : Electromagnetic Interference (Emission)

• EN55103-2 : Electromagnetic Susceptibility (Immunity)

This product is intended for use in the following

Electromagnetic Environment: E4 (controlled EMC

environment, ex. TV studio).

For the customers in Europe, Australia and New

Zealand

WARNING

This is a Class A product. In a domestic environment, this

product may cause radio interference in which case the

user may be required to take adequate measures.

Attention-when the product is installed in Rack:

1.Prevention against overloading of branch

circuit

When this product is installed in a rack and is supplied

power from an outlet on the rack, please make sure that the

rack does not overload the supply circuit.

2.Providing protective earth

When this product is installed in a rack and is supplied

power from an outlet on the rack, please confirm that the

outlet is provided with a suitable protective earth

connection.

3.Internal air ambient temperature of the rack

When this product is installed in a rack, please make sure

that the internal air ambient temperature of the rack is

within the specified limit of this product.

4.Prevention against achieving hazardous

condition due to uneven mechanical loading

When this product is installed in a rack, please make sure

that the rack does not achieve hazardous condition due to

uneven mechanical loading.

5.Install the equipment while taking the operating

temperature of the equipment into consideration

For the operating temperature of the equipment, refer to

the specifications of the Operation Manual.

6.When performing the installation, keep the

following space away from walls in order to

obtain proper exhaust and radiation of heat.

Lower, Upper: 4.4 cm (1

Right, Left: 1.0 cm (

Back: 20 cm (7

7

/8 inches) or more

3

/4 inches) or more

3

/8 inches) or more

For kundene i Norge

Dette utstyret kan kobles til et IT-strømfordelingssystem.

The manufacturer of this product is Sony Corporation, 17-1 Konan, Minato-ku, Tokyo, Japan.

The Authorized Representative for EMC and product

safety is Sony Deutschland GmbH, Hedelfinger Strasse

61, 70327 Stuttgart, Germany. For any service or

guarantee matters please refer to the addresses given in

separate service or guarantee documents.

This apparatus shall not be used in the residential area.

Apparatet må tilkoples jordet stikkontakt

Suomessa asuville asiakkaille

Laite on liitettävä suojamaadoituskoskettimilla

varustettuun pistorasiaan

För kunderna i Sverige

Apparaten skall anslutas till jordat uttag

3

Page 4

Table of Contents

Chapter 1 Overview

Precautions ........................................................................... 7

On Safety ....................................................................................7

On Installation ............................................................................ 7

Handling the LCD Screen ..........................................................7

With Protection Plate Installed................................................... 7

On Cleaning................................................................................7

On Repacking ............................................................................. 8

On Rack Mounting ..................................................................... 8

Functions Supported in Software Version 1.1 ................... 9

Features ............................................................................... 10

Options ................................................................................ 12

Input/Output Connector and Adaptor....................................... 13

Location and Function of Parts ......................................... 15

Front Panel................................................................................15

Rear Panel.................................................................................17

Chapter 2 Preparations

Environments of the Installation Location ....................... 19

Installing an Input Adaptor ................................................ 20

Removing the Protection Plate.......................................... 21

Mounting the Unit in a Rack............................................... 22

Connections ........................................................................ 22

Connecting the Controller (BKM-16R).................................... 23

Connecting the Multiple Units with the LAN ..........................23

Turning on the Power ......................................................... 25

Connecting to Power ................................................................25

Turning on the Monitor ............................................................ 25

Settings................................................................................ 26

Selecting the Area..................................................................... 26

Setting for the LAN to Connect the Multiple Units ................. 27

Selecting the Monitor (Designation of the Monitor or Group ID

Number)..................................................................... 28

Assigning the Input Signal to the Channel............................... 28

Setting the Display Mode of the Picture................................... 29

Adjusting ............................................................................. 29

Chroma/Phase Adjustment .......................................................29

4

Table of Contents

Page 5

Chapter 3 Menu

Color Temperature (White Balance) Adjustment.....................30

Brightness/Contrast Adjustment...............................................30

Basic Menu Operations.......................................................32

Menu Operation Buttons...........................................................32

Displaying the Menu.................................................................33

Setting or Adjusting in the Menu Operation.............................33

Entering the Channel Number ..................................................35

Aborting Menu Operation.........................................................35

Menu Structure ....................................................................36

Adjustment Menu.................................................................43

Overview...................................................................................43

Menu Function and Operation ..................................................43

Input Configuration Menu ...................................................49

Overview...................................................................................49

Menu Function and Operation ..................................................49

Display Setting Menu ..........................................................55

Overview...................................................................................55

Menu Function and Operation ..................................................55

Display Function Menu .......................................................57

Overview...................................................................................57

Menu Function and Operation ..................................................57

System Configuration Menu...............................................65

Overview...................................................................................65

Menu Function and Operation ..................................................65

File Management Menu .......................................................72

Overview...................................................................................72

Menu Function and Operation ..................................................72

Status Menu .........................................................................74

Overview...................................................................................74

Menu Function and Operation ..................................................74

Controller Menu ...................................................................76

Overview...................................................................................76

Menu Function and Operation ..................................................76

Key Protect Menu ................................................................80

Overview...................................................................................80

Menu Function and Operation ..................................................80

Chapter 4 Operations

Selecting Display Mode.......................................................81

Setting the Display of Native Scan Mode ..........................82

Table of Contents

5

Page 6

Selecting the Native Scan/Scan Mode .............................. 83

Displaying Two Signals on One Screen

(Picture&Picture).................................................... 84

Magnifying the Picture (Pixel Zoom)................................. 85

Displaying the Picture in Black Detail Mode .................... 86

Capturing the Picture of the HD Signal

(HD Frame Capture) ............................................... 87

Displaying the Area Marker or Aspect Marker ................. 88

Displaying the Audio Level Meter ..................................... 88

Displaying the Time Code .................................................. 89

Switching the Display of the 3D Video Signal.................. 90

Copying the Setting or Adjustment Value to Another

Monitor .................................................................... 91

Assigning the Function on the Function Button.............. 92

Upgrading the Monitor and Controller.............................. 92

Saving the Upgrade Data in a “Memory Stick PRO”............... 92

Upgrading the Monitor .............................................................93

Upgrading the Controller.......................................................... 93

Appendixes

Specifications...................................................................... 95

Input Signals and Adjustable/Setting Items ..................... 97

Available Signal Systems................................................... 99

Available Signal Formats ................................................. 101

Aperture Modification Frequency.................................... 107

Picture Display Size.......................................................... 108

Picture·Frame Display ...................................................... 111

Matrix/Gamma Setting Table............................................ 114

Scan Mode Image.............................................................. 121

Troubleshooting................................................................ 124

Dimensions........................................................................ 126

Connection Cable Specifications for Color Temperature

Probes ................................................................... 127

Inserting/Ejecting the “Memory Stick” ........................... 129

Notes on “Memory Stick” ...................................................... 129

Menu Index 131

6

Table of Contents

Page 7

Chapter 1 Overview

Overview

Precautions

On Safety

• Operate the unit only with a power source as specified

in the “Specifications” section.

• A nameplate indicating operating voltage, power

consumption, etc., is located on the rear panel.

• Should any solid object or liquid fall into the cabinet,

unplug the unit and have it checked by qualified

personnel before operating it any further.

• Do not drop or place heavy objects on the power cord.

If the power cord is damaged, turn off the power

immediately. It is dangerous to use the unit with a

damaged power cord.

• Unplug the unit from the wall outlet if it is not to be used

for several days or more.

• Disconnect the power cord from the AC outlet by

grasping the plug, not by pulling the cord.

• The socket-outlet shall be installed near the equipment

and shall be easily accessible.

Chapter

of pixels may be “stuck”, either always off (black),

always on (red, green, or blue), or flashing. In addition,

over a long period of use, because of the physical

characteristics of the liquid crystal display, such “stuck”

pixels may appear spontaneously. These problems are

not a malfunction.

• Do not leave the LCD screen facing the sun as it can

damage the LCD screen. Take care when you place the

unit by a window.

• Do not push or scratch the LCD monitor’s screen. Do

not place a heavy object on the LCD monitor’s screen.

This may cause the screen to lose uniformity.

• If the unit is used in a cold place, horizontal lines or a

residual image may appear on the screen. This is not a

malfunction. When the monitor becomes warm, the

screen returns to normal.

• If a fixed picture such as a frame of a divided picture or

time code, or a still picture is displayed for a long time,

an image may remain on the screen and be

superimposed as a ghosting image.

• The screen and the cabinet become warm during

operation. This is not a malfunction.

1

With Protection Plate Installed

On Installation

• Allow adequate air circulation to prevent internal heat

build-up.

Do not place the unit on surfaces (rugs, blankets, etc.) or

near materials (curtains, draperies) that may block the

ventilation holes.

• Do not install the unit in a location near heat sources

such as radiators or air ducts, or in a place subject to

direct sunlight, excessive dust, mechanical vibration or

shock.

Handling the LCD Screen

• The LCD panel fitted to this unit is manufactured with

high precision technology, giving a functioning pixel

ratio of at least 99.99%. Thus a very small proportion

The protection plate is installed on the monitor to protect

the LCD panel at the factory.

• When viewed from an oblique angle, the picture with

the protection plate installed may differ in color from

that without the protection plate.

• With the protection plate installed, there may be more

reflection of light than without.

• As the internal heat of the monitor increases when the

protection plate is installed, the fan starts to run earlier

than when the protection plate is not installed.

On Cleaning

Before cleaning

Be sure to disconnect the AC power cord from the AC

outlet.

Precautions

7

Page 8

On cleaning the monitor screen

The monitor screen surface is especially treated to reduce

reflection of light.

As incorrect maintenance may impair the performance of

the monitor, take care with respect to the following:

• Wipe the screen gently with a soft cloth such as a

Chapter 1 Overview

cleaning cloth or glass cleaning cloth.

If you wipe the screen using too much force, the screen

surface may lose uniformity or the LCD panel may

malfunction.

Never use tissue as it may scar the surface of the screen.

• Stubborn stains may be removed with a soft cloth such as

a cleaning cloth or glass cleaning cloth lightly dampened

with water.

• Never use solvent such as alcohol, benzene or thinner, or

acid, alkaline or abrasive detergent, or chemical cleaning

cloth, as they will damage the screen surface.

On cleaning the cabinet

• Clean the cabinet gently with a soft dry cloth. Stubborn

stains may be removed with a cloth lightly dampened

with mild detergent solution, followed by wiping with a

soft dry cloth.

• Use of alcohol, benzene, thinner or insecticide may

damage the finish of the cabinet or remove the

indications on the cabinet. Do not use these chemicals.

• If you rub on the cabinet with a stained cloth, the cabinet

may be scratched.

• If the cabinet is in contact with a rubber or vinyl resin

product for a long period of time, the finish of the cabinet

may deteriorate or the coating may come off.

On Repacking

Do not throw away the carton and packing materials. They

make an ideal container which to transport the unit.

On Rack Mounting

When the monitor is mounted on a rack, the temperature

around the monitor may rise due to heat generated from

other equipment and reduced air circulation, causing

damage to the monitor. To prevent this, keep the space

around the monitor (1U or more space above and below the

monitor), and install a ventilation fan or take other

effective countermeasures so that the temperature around

the monitor is within the specified range: operating

temperature range of 0 to 35 °C (32 to 95°F).

If you have any questions about this unit, please contact

your Sony service representative.

8

Precautions

Page 9

Functions Supported in Software Version 1.1

The following new functions are supported for Version 1.1 of the PVM-L1700.

Menu Supported function Reference page

• Checkerboard

•L/R Switch

(in the Function Switch menu of the Display

Function menu)

(in the Parallel Remote menu of the System

Configuration menu)

(in the Function Key menu of the Controller menu)

Simultaneous display or left/right switching display of

the left and right 3D video signals is available by

installing an optional BKM-250TG (with serial number

7100001 or higher).

64, 67, 79, 90

Chapter 1 Overview

Functions Supported in Software Version 1.1

9

Page 10

Features

The PVM-L1700 is 17-inch LCD Video Monitor. This is

Chapter 1 Overview

suitable for television stations or video production houses,

where precise image reproduction is required.

For setting the display, see “Selecting Display Mode” on

page 81.

Black frame insertion display mode

Motion blur caused by the holding-type display of the LCD

is decreased by inserting the black frame between the

picture frames in double frame rate (100/120Hz) operation

of the LCD panel.

The PVM-L1700 features flat panel and “TRIMASTER*”,

which is a new technology developed for three elements,

“accurate color reproduction”, “precision imaging” and

“quality picture consistency”, that are in demand for

professional use. “TRIMASTER” decreases the viewing

difference that occurs due to the individuality of each

panel. Also, the PVM-L1700 realizes the high picture

quality and high-trust by the color management system

with its wide color gamut device, high-resolution/precise

gradation display, animation improvement technology and

signal processing of high accuracy/calibration/feedback

system.

* TRIMASTER is a trademark of Sony Corporation.

17-inch LCD panel developed for the PVML1700

The 17-inch (16.52 inch) LCD panel was developed for the

PVM-L1700 and supports the full HD signal.

It offers a 10-bit driver, high-speed response, high

resolution and high color gradation.

12-bit precision display engine for professional

use

The panel is equipped with a unique signal process engine

developed for the professional use monitor. This engine

incorporates 12-bit output accuracy at each process, and

provides a high-quality I/P conversion algorithm, scaling

processing, panel driving and a highly accurate color

management system.

Multi color space

A color management system which uses the unique 3D

LUT (Look Up Table) reproduces the color space that

complies with the broadcast standard ITU-R BT.709, EBU

and SMPTE-C accurately.

High-quality I/P conversion processing

A high-quality picture near the original one, in which

jagged lines and conversion errors are decreased by

detecting the feature of the picture inside the subdivided

block and processing properly, is reproduced.

The signal delay is decreased by judging the animation or

still picture from the past video signal.

Interlace display mode

The interlace signal is displayed as the interlace picture by

inserting the black line without I/P conversion processing.

A picture faithful to the original signal and with the same

feel as a CRT is gained.

For setting the display, see “Selecting Display Mode” on

page 81.

Available to a multi signal format

The monitor supports various input signals such as 720 ×

576/50i to 1920 × 1080/50P, 60P and variable computer

signals up to 1920 × 1080. A DVI-D (HDCP

correspondence), HDMI* (HDCP correspondence) and

four option slots are equipped as the interface and the

monitor supports HD-SDI, Dual-link HD-SDI, 3G-SDI,

SD-SDI, RGB, YPbPr, Y/C and composite signal input.

* HDMI, the HDMI logo and High-Definition Multimedia

Interface are trademarks or registered trademarks of

HDMI Licensing LLC.

HD frame capture function

The frame of the 3G/HD-SDI input signal is captured and

saved as a picture file in the “Memory Stick”. This is used

to confirm the color tone and picture angle of the current

scene and recorded scene by using the multi display

(Picture&Picture) function.

* As the frame of the input signal is captured, the data and

marker set by the monitor is not reflected.

For the operation, see “Capturing the Picture of the HD

Signal (HD Frame Capture)” on page 87.

Multi display function

Two kinds of input signals are output on the monitor. Side

by Side mode is useful for adjusting the color or comparing

two pictures.

For the operation, see “Displaying Two Signals on One

Screen (Picture&Picture)” on page 84.

Pixel zoom function

As part of the picture is magnified up to 8 times without

scaling processing, this is convenient for confirming a

minute part of the signal.

For the operation, see “Magnifying the Picture (Pixel

Zoom)” on page 85.

Safe area marker and aspect marker functions

The monitor is equipped with two area markers and center

marker as the safe area marker and aspect marker for

confirming the picture angle.

10

Features

Page 11

For the operation, see “Displaying the Area Marker or

Aspect Marker” on page 88.

Scan selection/Native scan display function

You can select from under scan (–3%), normal scan (0%)

and over scan (mask of the 5% over scan portion in the

normal scan) for the picture display.

The monitor is equipped with a native scan display

function which maps the pixel of the signal to the panel in

one-to-one mode. You can select the mode from ×1, ×2 or

Aspect Correction to display a signal in native mode. An

SD signal of non-square pixels (the number of H pixels of

the signal system is 720 or 1440) or a 640 × 480 SD signal

of DVI video/HDMI video is displayed correctly by

scaling processing of doubling for the V direction and

correct aspect ratio for the H direction, and the picture is

also optimized and displayed by modifying the aperture

coefficient value, filter coefficient value, etc. in Aspect

Correction mode.

For the operation, see “Selecting the Native Scan/Scan

Mode” on page 83.

Black detail mode display function

You can reduce to dull black color by backlight leaking and

precisely assess any parts with low color gradation.

You can decrease the black level up to 40% of the normal

display (100 cd/m

2

at 100% signal). The parts with high

color gradation (higher than 75 IRE) are clipped by the

dynamic range of the circuit, but a zebra pattern

(selectable) is displayed in the clipped portions.

For the operation, see “Displaying the Picture in Black

Detail Mode” on page 86.

Aspect selectable function

A squeezed and recorded signal is displayed with the

correct angle. You can select from 4:3 and 16:9 aspect

modes.

Audio level meter/time code display function

Audio level of the embedded audio and time code signals

superimposed on the SDI signals are displayed by

installing the optional input adaptor (BKM-250TG).

3D signal analyzing function

Left (L) and right (R) 3D video signals can be displayed in

a checkerboard pattern on the same screen, or they can be

switched alternately by installing the optional input

adaptor (BKM-250TG with serial number 7100001 or

higher). For this function, two-dimensional (2D) view is

used. The signals are not displayed in stereoscopic view.

For the operation, see “Switching the Display of the 3D

Video Signal” on page 90.

Variable picture adjustment functions

Auto chroma, phase and matrix adjustment function are

equipped. The white balance is automatically adjusted by

using a commercially available probe (Konica Minolta

CA-210, DK-Technologies PM5639/06, X-Rite Eye-One

Pro).

Other features

• The color temperature is selectable from D65, D93 and

User.

• Built-in test pattern for 100% white signal, 20% gray

signal, 0% black signal, PLUGE (Picture Line Up

Generation Equipment) signal, color-bar signal, 5 step

gray scale signal and ramp signal.

• Chroma Up function that increases the chroma setting by

12 dB.

• Blue only function and RGB cut off function to monitor

signal noise.

• A parallel remote of the contact point control connector

is equipped.

Chapter 1 Overview

Remote control function (Ethernet control)

The controller controls up to 32 monitors by the Ethernet

(10BASE-T/100BASE-TX) connection. Up to four

controllers are connected to one monitor in single mode.

You can control individual monitors or monitor groups

simply by entering the monitor ID number or group ID

number. You can also execute the same operation on all

connected monitors, or put all connected monitors into the

same setup and adjustment state.

Closed caption display function

EIA/CEA-608 or EIA/CEA-708 standard closed caption

signals superimposed on the SDI signals are displayed by

installing the optional input adaptor (BKM-244CC).

Features

11

Page 12

Options

BKM-227W NTSC/PAL Input Adaptor

Includes a decoder for NTSC/PAL/PAL-M/SECAM

signals. Input/output connectors for each one composite

signal channel and Y/C signal channel are equipped.

For external control

Chapter 1 Overview

BKM-16R Monitor Control Unit

The BKM-16R is a controller of the PVM-L1700 and you

can control multiple monitors from one controller.

In this manual, the BKM-16R is referred to as the

controller.

For installation

BKM-39H Controller Attachment Stand

Used to join a BKM-16R and the PVM-L1700.

SMF-700 Monitor Interface Cable

Used to connect the PVM-L1700 to the BKM-16R.

Input adaptors

The input connector panel is composed by installing the

optional input adaptor into the input option slot on the rear

panel of the monitor. Up to four adaptors can be installed

to the monitor.

The input signal type for each connector of the adaptor is

set with the Input Configuration menu, in accordance with

the configuration of the connector panel.

BKM-229X Analog Component Input Adaptor

Includes a decoder for analog component signals and

analog RGB signals. Input connector for one channel is

equipped.

BKM-243HS HD/D1-SDI Input Adaptor

Includes a decoder for serial digital component signals.

Input/output connectors for two serial digital channels and

output connector for one monitor channel are equipped.

Note

The signal from the MONITOR OUT connector of the

BKM-243HS does not satisfy the ON-LINE signal

specifications.

BKM-244CC HD/SD-SDI Closed Caption

Adaptor

Includes a decoder for serial digital component signals.

EIA/CEA-608 or EIA/CEA-708 standard closed caption

signals superimposed on the SDI signals are decoded and

displayed. Input/output connectors for two serial digital

channels and output connector for one monitor channel are

equipped.

Note

Note

When installing the adaptor, be sure to perform the

necessary input signal setup with the Input Configuration

menu. If the setup is not performed, the adaptors may not

function correctly.

For information about the Input Configuration menu, see

page 49.

For details of each input adaptor, refer to the operating

instructions of each model.

BKM-220D SDI 4:2:2 Input Adaptor

Includes a decoder for serial digital signals (525/625

component). Input/output connectors for two serial digital

channels and output connector for one monitor channel are

equipped.

Note

The signal from the MONITOR OUT connector of the

BKM-220D does not satisfy the ON-LINE signal

specifications.

The signal from the MONITOR OUT connector of the

BKM-244CC does not satisfy the ON-LINE signal

specifications.

BKM-250TG 3G/HD/SD-SDI Input Adaptor

Includes a decoder for serial digital component signals.

Time code and audio level of the embedded audio signals

superimposed on the SDI signals are displayed. Input/

output connectors for two serial digital channels and output

connector for two monitor channels are equipped.

Note

The signal from the MONITOR OUT connector of the

BKM-250TG does not satisfy the ON-LINE signal

specifications.

Caution

When you install the following input adaptors to this

equipment, use those with the serial numbers given below.

• BKM-220D with serial number 2100001 or higher

• BKM-229X with serial number 2200001 or higher

• BKM-243HS with serial number 2108355 or higher

• BKM-250TG with serial number 7100001 or higher

BKM-220D: This equipment may not meet the

requirements of the electromagnetic interference standard

if designated input adaptors are not installed.

12

Options

Page 13

BKM-229X: This equipment may not work correctly or

you may not be satisfied with the performance if

designated input adaptors are not installed.

BKM-243HS: This equipment may not meet the

requirements of the electromagnetic interference standard

or work correctly, or you may not be satisfied with the

performance if designated input adaptors are not installed.

BKM-250TG: The 3D signal analyzing function does not

operate if designated input adaptors are not installed.

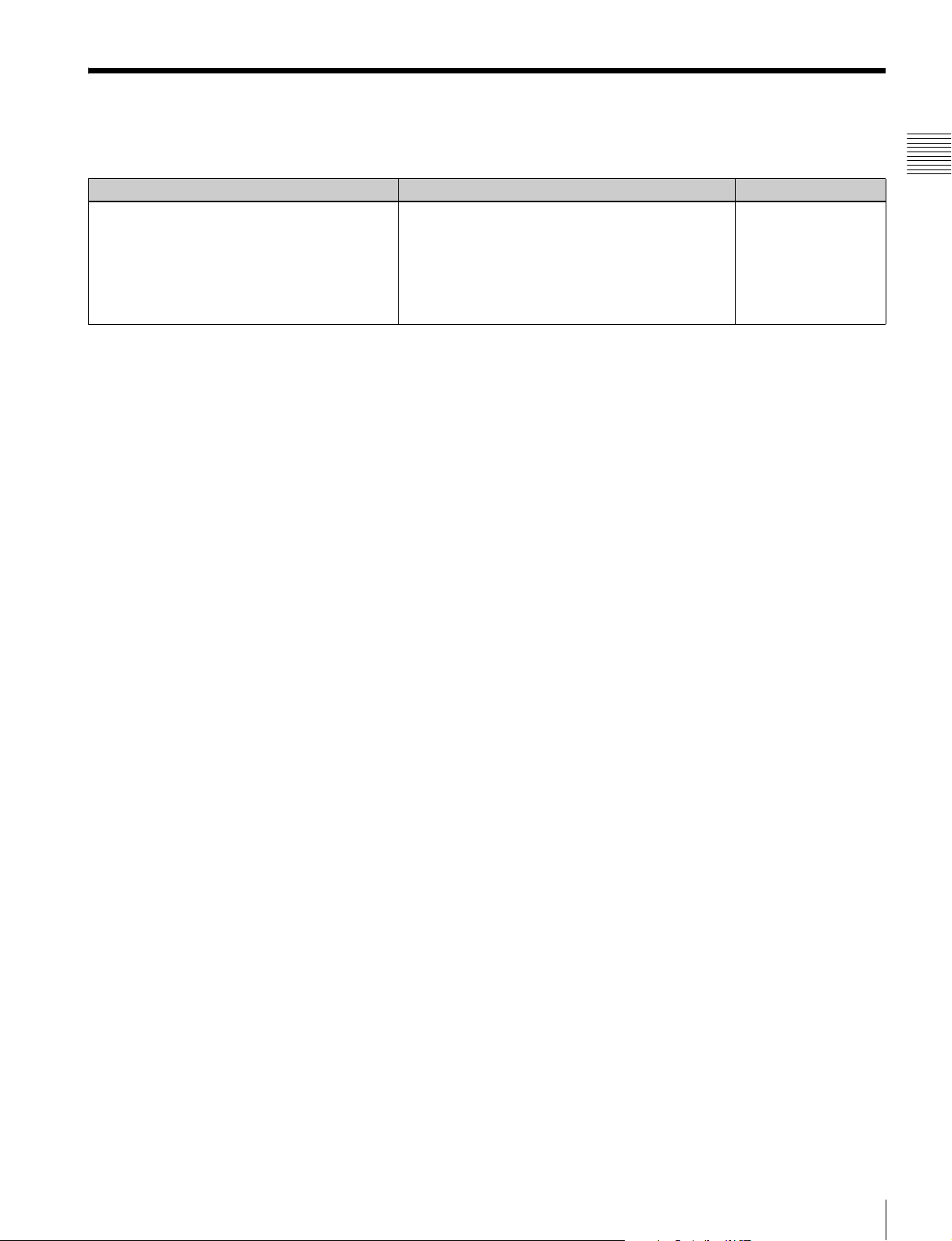

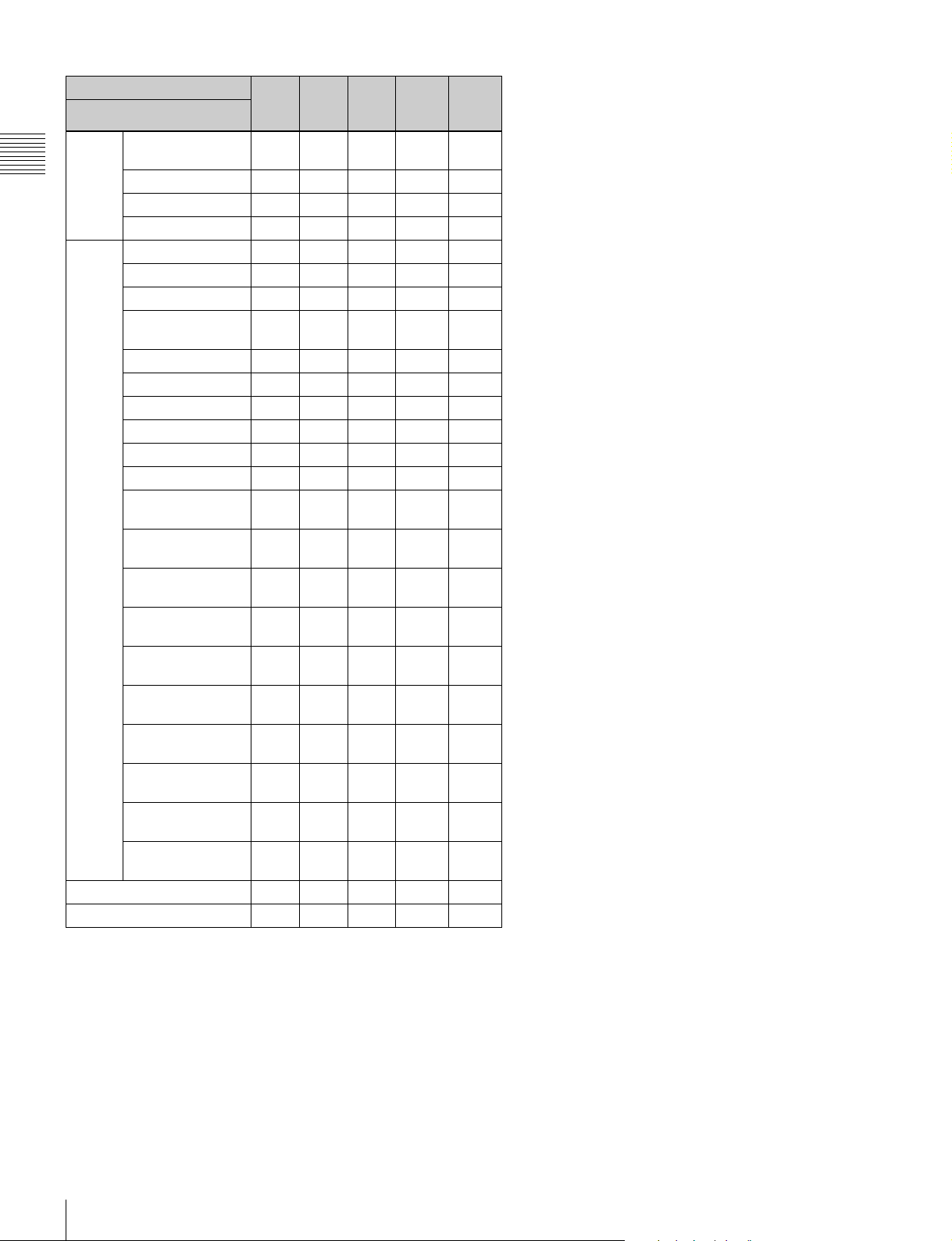

Input/Output Connector and Adaptor

By adding the optional input expansion adaptors, the input/

output connector panel can be assembled in a wide variety

of configurations. The signals that each of the adaptors’

connectors supports are given in the following table. The

type of signal to be applied to each input/output connector

is set with the Input Configuration menu.

For information about the Input Configuration menu, see

page 49.

Chapter 1 Overview

Options

13

Page 14

Input adaptor BKM-

Input signal

Component 525/

Chapter 1 Overview

Number of digital inputs 2 – – 2 2

Number of analog inputs – 1 1 – –

625

Single-link HD-SDI aa

input

Dual-link HD-SDI a(2) a

Serial digital

Single-link 3G-SDI a

Composite NTSC a

Composite PAL a

Composite PAL-M a

Composite

SECAM

Y/C NTSC a

Y/C PAL a

Y/C PAL-M a

Y/C SECAM a

YPbPr 525i/625i a

RGB 525i/625i a

YPbPr/RGB

1080/24PsF

YPbPr/RGB

1080/24P

YPbPr/RGB

Analog input

1080/50i (25PsF)

YPbPr/RGB

1080/25P

YPbPr/RGB

576/50P

YPbPr/RGB

480/60P

YPbPr/RGB

1080/60i (30PsF)

YPbPr/RGB

1080/30P

YPbPr/RGB

720/50P

YPbPr/RGB

720/60P

220D

BKM227W

a

BKM229X

a

a

a

a

a

a

a

a

a

a

a

BKM243HS/

244CC

BKM250TG

aa

a: Signal can be reproduced.

a(2): Two adaptors are used.

For details, see “Available Signal Formats” on page 101.

Options

14

Page 15

Location and Function of Parts

Front Panel

6 OPTION B

connector

5 OPTION A

connector

a Tally lamp

With factory settings, the tally lamp lights when pins No. 8

and No. 9 of the PARALLEL REMOTE connector on the

rear panel are shorted. By changing the setting in the

Parallel Remote menu, different pins on the PARALLEL

REMOTE connector can be used to control the tally lamp.

For information about the Parallel Remote menu, see

“Parallel Remote” (page 66) of the System Configuration

Menu.

Chapter 1 Overview

1 Tally lamp

2 OPERATE lamp

3 STATUS lamp

4 OVER RANGE lamp

Notes

• When the lamp is flashing in red, the monitor cannot be

put into operation mode. (Internal data initialization is

taking place.) Wait until the lamp is steadily lit.

• The lamp may show the error, warning or operation

mode.

For details, see “Error/warning/operation mode display

by the lamp” on page 16.

b OPERATE lamp

Lights in red when the monitor is in standby mode. The

monitor will be in standby mode under the following

conditions:

• Standby Mode is set to On in the Power menu of the

System Configuration menu and the ON/OFF (power)

switch (on the rear panel) is turned on. (The OPERATE

lamp will flash for initialization after the switch is turned

on, then will light.)

• The monitor is changed from operation mode to standby

mode by external control.

Lights in green when the monitor is put into operation

mode from standby mode by pressing the MONITOR I/1

switch of the controller.

For information about the Power menu, see “Power”

(page 68) of the System Configuration Menu.

c STATUS lamp

Lights in blue when the error is detected.

For details, see “Error/warning/operation mode display

by the lamp” on page 16.

d OVER RANGE lamp

Lights in orange when the picture is displayed in black

detail mode or when the dynamic range of the following

item is exceeded.

• Contrast (contrast)

Flashes when the luminance is decreased to protect the

monitor from a rise in temperature.

For details of the black detail mode display, see

“Displaying the Picture in Black Detail Mode” on page

86.

Location and Function of Parts

15

Page 16

Note

The lamp may show the error, warning or operation mode.

For details, see “Error/warning/operation mode display

Chapter 1 Overview

by the lamp” on page 16.

e OPTION A connector

Used to connect a probe for automatic adjustment.

f OPTION B connector

Used for future expansion.

The cover is attached at the factory.

Error/warning/operation mode display by

the lamp

The OVER RANGE lamp, STATUS lamp or OPERATE

lamp on the front panel may show an error, warning or

operation mode while the monitor is being operated.

Error display

If the error is shown, please contact your Sony

representative.

OVER

RANGE

lamp

Lights in

orange

–: Status except for error display.

STATUS

lamp

OPERATE

lamp

––

Symptoms

• The dynamic range is

exceeded when

contrast is adjusted.

g Reduce the contrast

setting.

However, when the

contrast of the

backlight does not

increase in the low

temperature, the

lamp may light.

• When the picture is

displayed in black detail

mode

OVER

RANGE

lamp

Lights in

orange

Flashes

in orange

Goes out

Goes out

Lights in

orange

Lights in

orange

Flashes

in orange

STATUS

lamp

Goes out

Goes out

Lights in

blue

Flashes in

blue

Lights in

blue

Goes out

Goes out

OPERATE

lamp

Flashes in

red

Flashes in

red

Flashes in

red

Flashes in

green

Flashes in

red

Flashes in

green

Flashes in

green

The power in the

backlight part is

overcurrent.

The power in the

backlight part is

overvoltage.

The temperature of the

backlight part is unusual.

The temperature sensor

is unusual.

The temperature of the

LCD panel is unusual.

The RGB sensor of the

backlight part is unusual.

Fan error.

Warning/operation mode display

OVER

RANGE

lamp

Flashes

in orange

STATUS

lamp

OPERATE

lamp

––

The luminance is reduced

to protect the circuit from

an increase of

temperature in the

backlight part.

g Please contact your

Sony representative.

Symptoms

Symptoms

Location and Function of Parts

16

Page 17

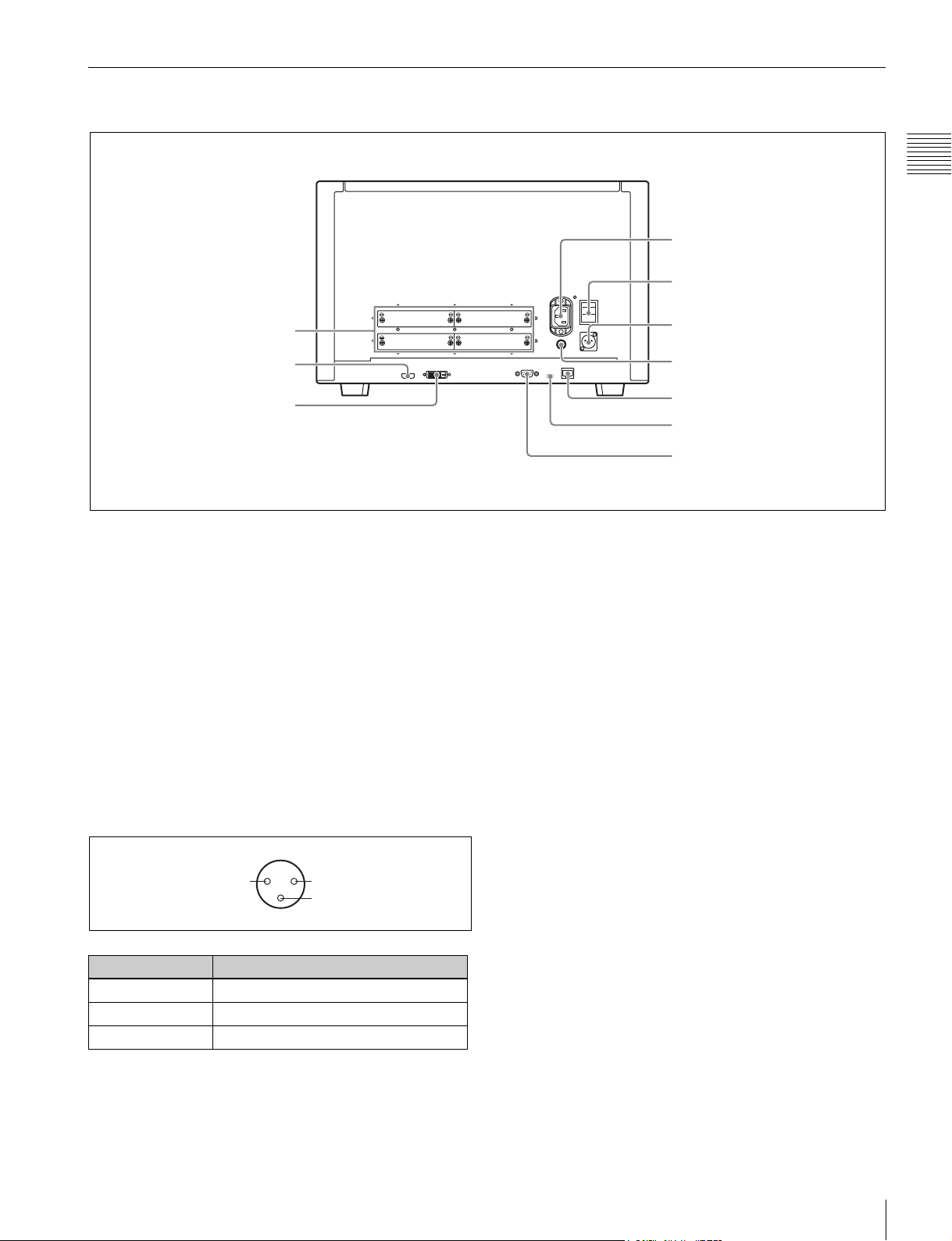

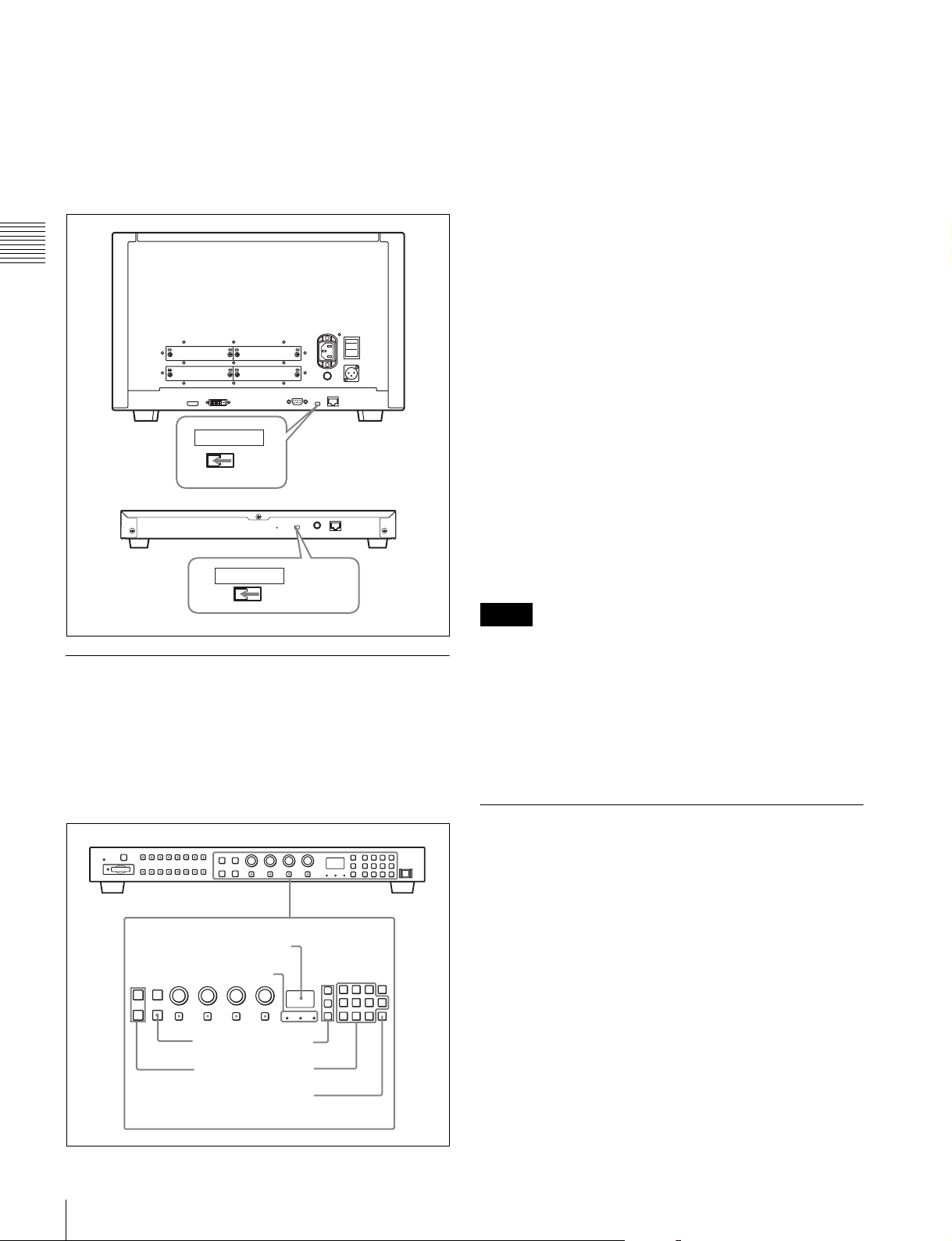

Rear Panel

Chapter 1 Overview

1 AC IN connector

2 ON/OFF switch

q; Input option slots

9 HDMI input connector

8 DVI-D input connector

a AC IN connector (3-pin)

Connects the monitor to an AC power source, via the

supplied AC power cord.

b ON/OFF (power) switch

When turned on (ON), the monitor enters operation mode.

By setting in Power menu of the System Configuration

menu, the monitor can also be set to enter standby mode

when the ON/OFF switch is turned on.

For information about the Power menu, see “Power”

(page 68) of the System Configuration Menu.

c DC IN 24 - 28V (DC power input) connector (XLR

3-pin, male)

Connect the 24 to 28 V DC power supply.

21

3

Pin number Function

1 – (GND)

2 + (24 to 28 V DC)

3NC

d DC 5V OUT connector (female)

Supplies the DC power to the controller.

3 DC IN 24 - 28V connector

4 DC 5V OUT connector

5 LAN (10/100) connector

6 NETWORK switch

7 PARALLEL REMOTE connector

Connect to the DC 5V/12V IN connector of the controller

with the SMF-700 or the cable supplied with the BKM39H.

e LAN (10/100) connector (10BASE-T/100BASE-TX)

Connect to the LAN (10/100) connector of the controller

by using the SMF-700 or the cable supplied with the BKM39H. Or connect to the network or the LAN (10/100)

connector of the controller by using a 10BASE-T/

100BASE-TX LAN cable (shielded-type, optional).

CAUTION

• For safety, do not connect the connector for peripheral

device wiring that might have excessive voltage to this

port. Follow the instructions for this port.

• When you connect the LAN cable of the unit to

peripheral device, use a shielded-type cable to prevent

malfunction due to radiation noise.

• To connect the monitor to the LAN (10/100) connector

of the controller in 1 to 1 connection (NETWORK switch

is set to PEER TO PEER), use a straight (shielded-type)

cable.

• The connection speed may be affected by the network

system.

f NETWORK switch

LAN: To connect to the network.

PEER TO PEER: To connect to the LAN (10/100)

connector of the controller in 1 to 1 connection.

Location and Function of Parts

17

Page 18

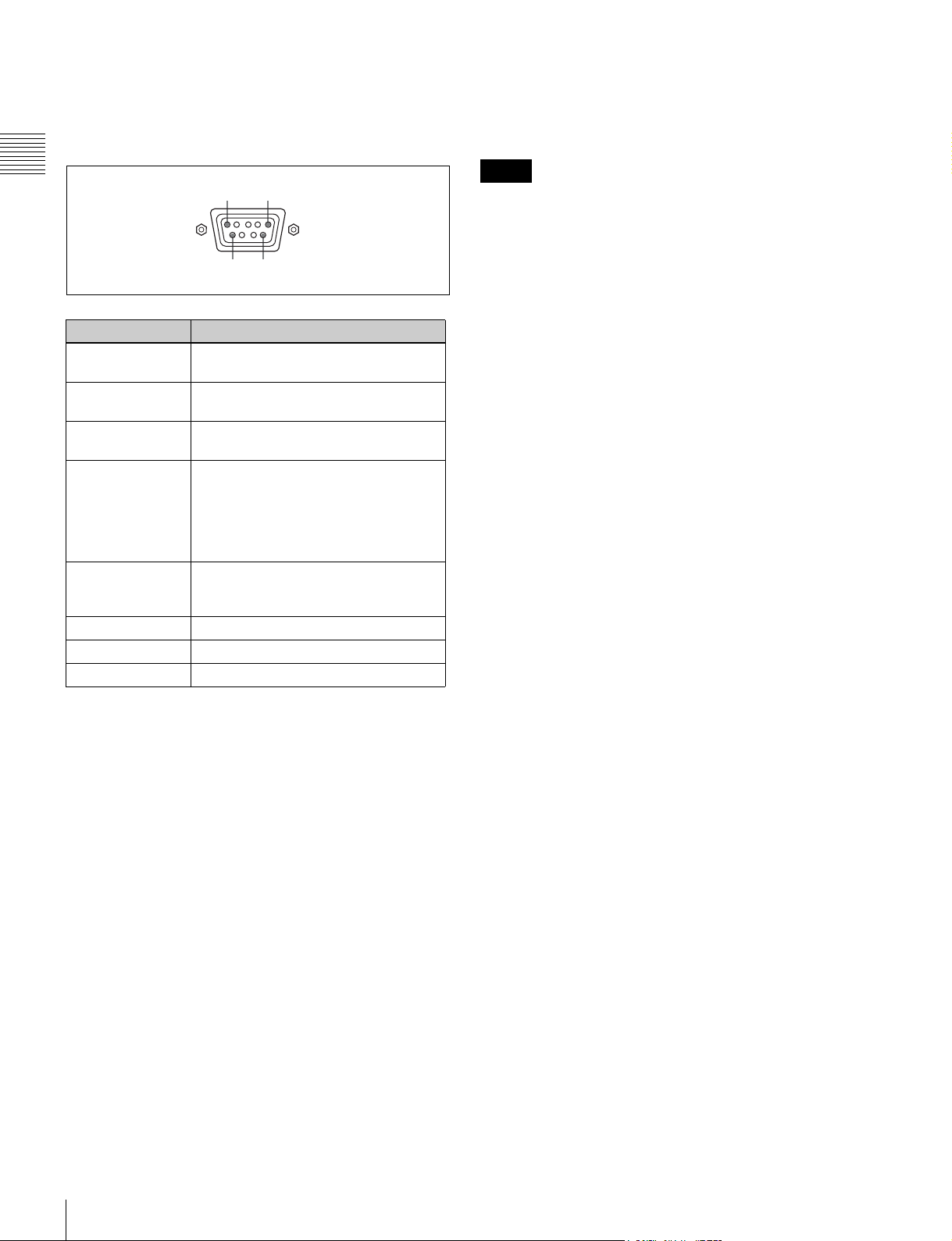

g PARALLEL REMOTE connector (D-sub 9-pin,

female)

Forms a parallel switch and controls the monitor

externally. The pin assignment and factory setting

function assigned to each pin are given below.

Chapter 1 Overview

15

digital picture. The HDMI specification supports HDCP

(High-bandwidth Digital Content Protection), a copy

protection technology that incorporates coding technology

for digital video signals.

Notes

• The HDMI audio signal is not available for this monitor.

• Use HDMI compliant cable (optional), Category 2 (High

Speed HDMI cable), with HDMI logo.

96

Pin number Function

1 Sets input signal channel 1 (numeric

keypad function).

2 Sets input signal channel 2 (numeric

keypad function).

3 Selects sync signal (SYNC button

function).

4 Selects whether monochrome image is

displayed or the monitor switches the

display mode automatically between

color image and monochrome image

depending on the input signal (MONO

button function).

5 Marker (set in the Marker Setting

menu) On/Off (MARKER button

function).

6, 7 Not connected

8 Tally lamp On/Off

9Ground

All pin function assignments can be changed with the

Parallel Remote menu.

j Input option slots

Used to install the optional input adaptors.

For installing the input adaptor, see page 20.

For the input signals, see “Input/Output Connector and

Adaptor” on page 13.

For information about the Parallel Remote menu, see

“Parallel Remote” (page 66) of the System Configuration

Menu.

To switch each function between On and Off or between

enable and disable, change pin connections in the

following way.

On or enabled: Short each pin and pin 9 together.

Off or disabled: Leave each pin open.

h DVI-D (digital DVI) input connector

Inputs DVI Rev.1.0 applicable Single-link digital RGB

signal.

To monitor the DVI signal of SXGA or higher resolution,

use the cable within 3 m (118

1

/8 inches) in length.

i HDMI input connector

Inputs the HDMI signal.

HDMI (High-Definition Multimedia Interface) is an

interface that supports both video and audio on a single

digital connection, allowing you to display high quality

Location and Function of Parts

18

Page 19

Preparations

Chapter

Environments of the Installation Location

2

Chapter 2 Preparations

Illumination environments

The apparent color reproduction on the monitor is greatly

affected by ambient light or glare.

The LCD device controls the brightness by moving LCD

molecules with the backlight always lit. For this reason,

in a dark place, an LCD monitor screen shows very dim

light leaks from the black image. We recommend that you

adjust the ambient light and use in an environment that

does not degrade the reproduction of black.

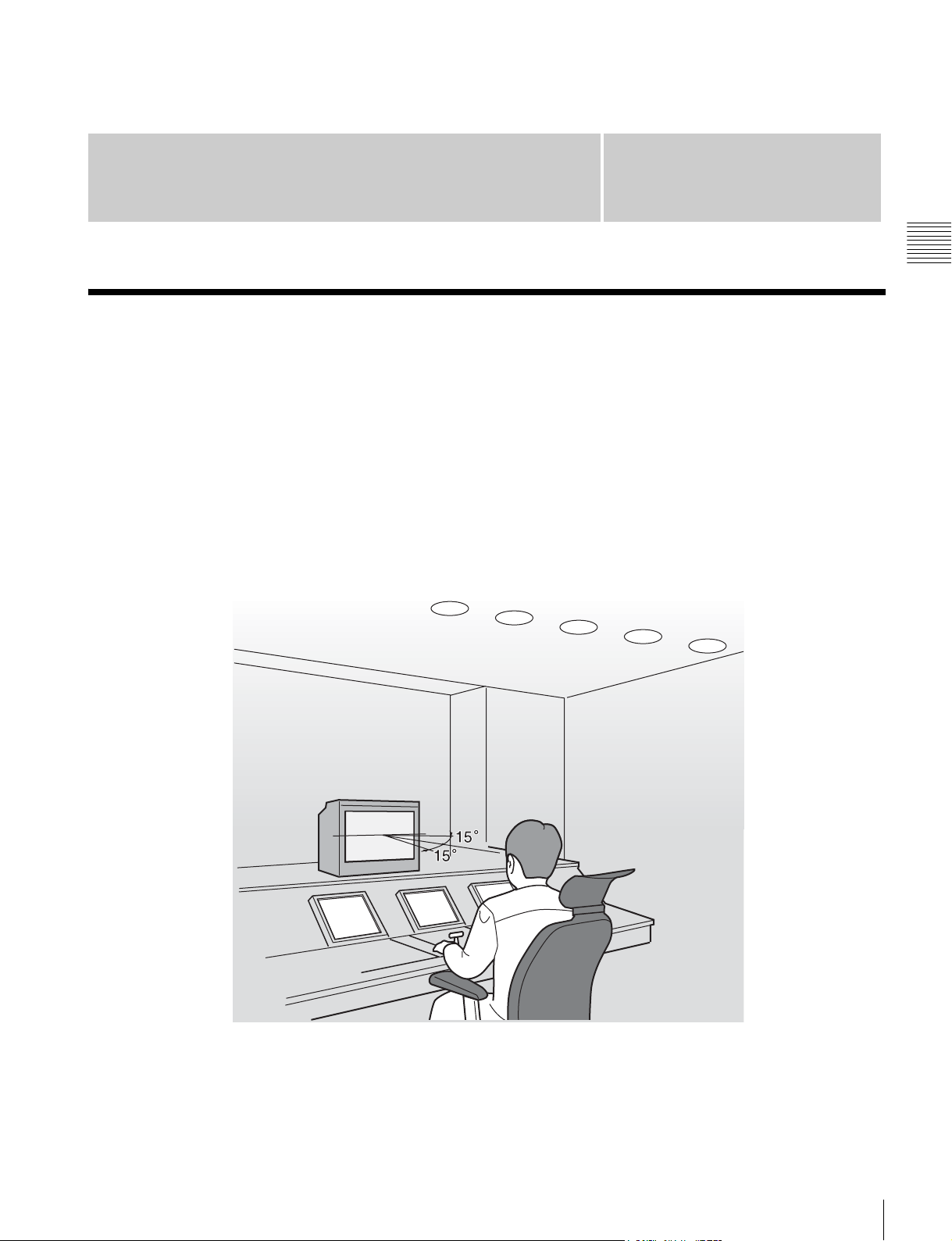

Viewing angle

The ideal viewing angle is within 5 degrees (up/down/left/

right) off the center of the monitor screen when the

operator views the entire monitor screen. Keep the

viewing angle within 15 degrees off the center of the

monitor screen.

Environments of the Installation Location

19

Page 20

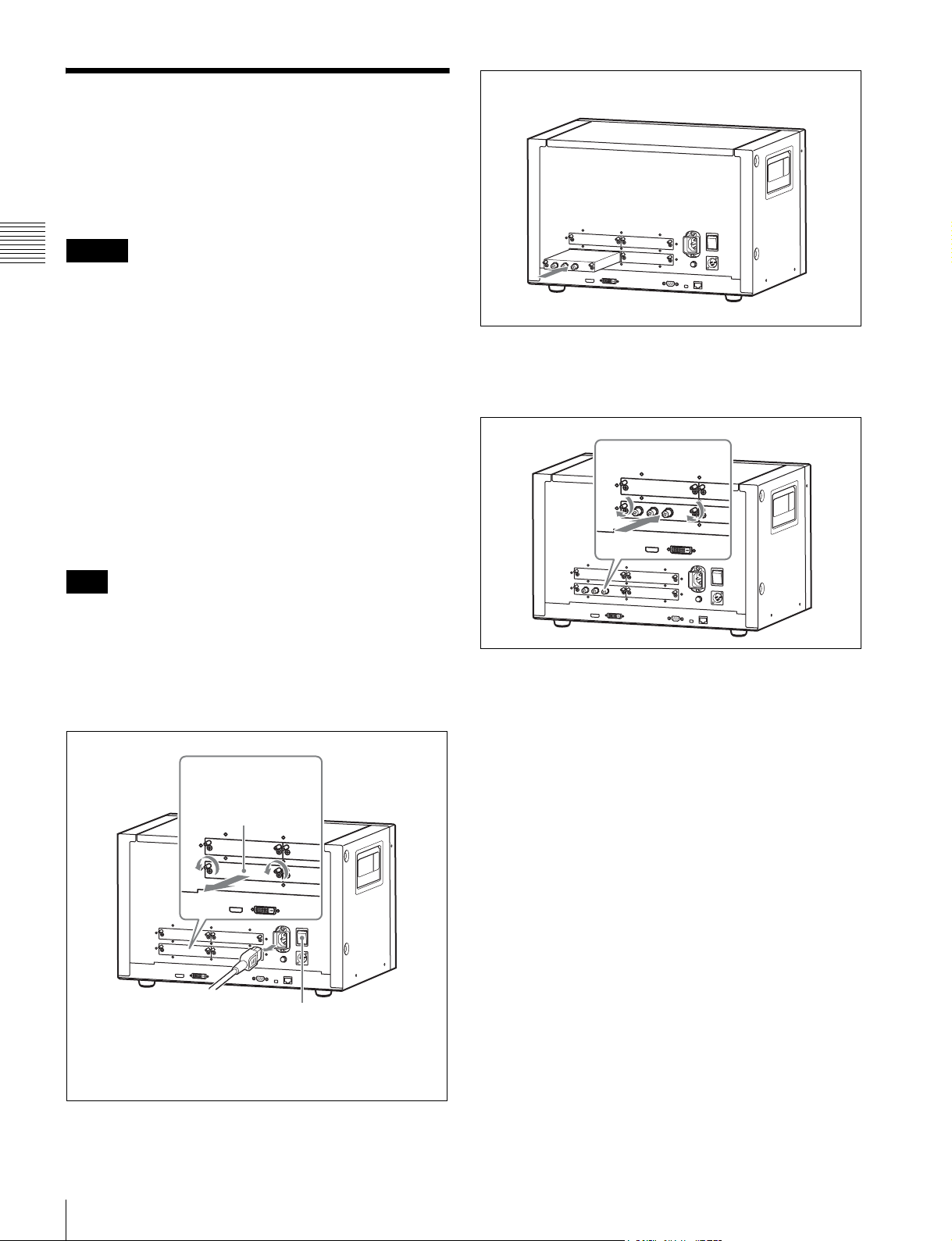

Installing an Input Adaptor

Each input adaptor can be installed in any input option slot

on the rear panel.

Caution

Chapter 2 Preparations

When you install the following input adaptors to this

equipment, use those with the serial numbers given below.

• BKM-220D with serial number 2100001 or higher

• BKM-229X with serial number 2200001 or higher

• BKM-243HS with serial number 2108355 or higher

BKM-220D: This equipment may not meet the

requirements of the electromagnetic interference standard

if designated input adaptors are not installed.

BKM-229X: This equipment may not work correctly or

you may not be satisfied with their performance if

designated input adaptors are not installed.

BKM-243HS: This equipment may not meet the

requirements of the electromagnetic interference standard

or work correctly, or you may not be satisfied with the

performance if designated input adaptors are not installed.

3

Push the adaptor in until it is firmly fit into the

connector inside the monitor, then tighten the two

screws to secure the adaptor.

Note

Turn off the ON/OFF (power) switch of the monitor (OFF)

and disconnect the AC power cord before installing or

removing adaptors.

1

Loosen two screws and remove the cover of an input

option slot on the rear panel of the monitor.

Cover of an input

option slot

O

N

OFF

Make sure the ON/OFF

switch is turned off, and

disconnect the AC power

cord.

For Dual-link operation

Two BKM-243HS or BKM-244CC input adaptors or one

BKM-250TG input adaptor is required. When the BKM243HS or BKM-244CC adaptors are used, install the input

adaptors in OPTION 1 and 2 option slots, or OPTION 3

and 4 option slots. The BKM-243HS or BKM-244CC

cannot be used with the BKM-250TG for Dual-link

operation.

To connect the cable

When the BKM-243HS or BKM-244CC adaptors are

used, install the Link A signal to OPTION 1 or 3, and the

Link B signal to OPTION 2 or 4.

Connect the cable to the same input number (both INPUT

1 or both INPUT 2) of the input adaptors installed in

OPTION 1 and 2 option slots, or OPTION 3 and 4 option

slots.

2

Insert the adaptor.

Installing an Input Adaptor

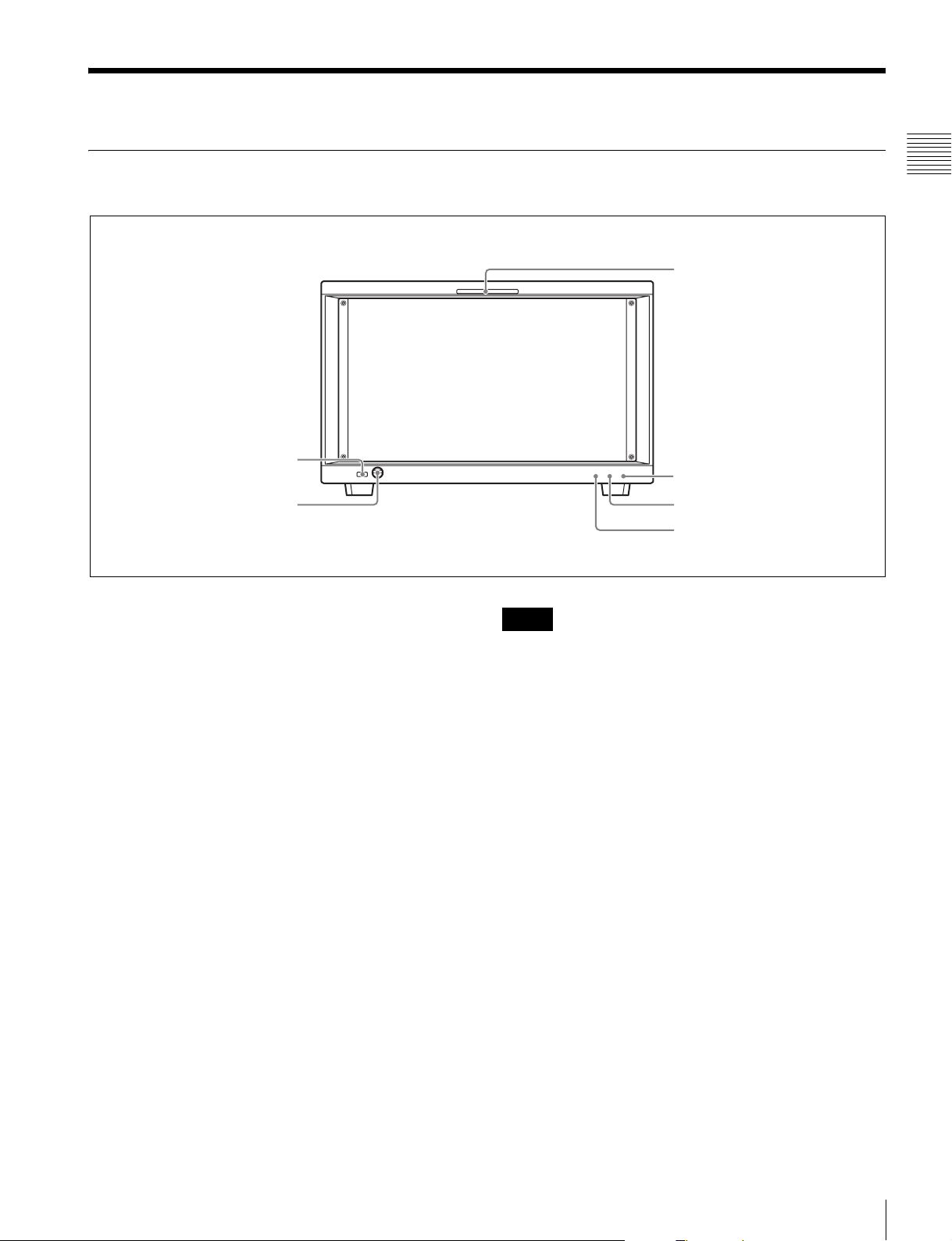

20

Page 21

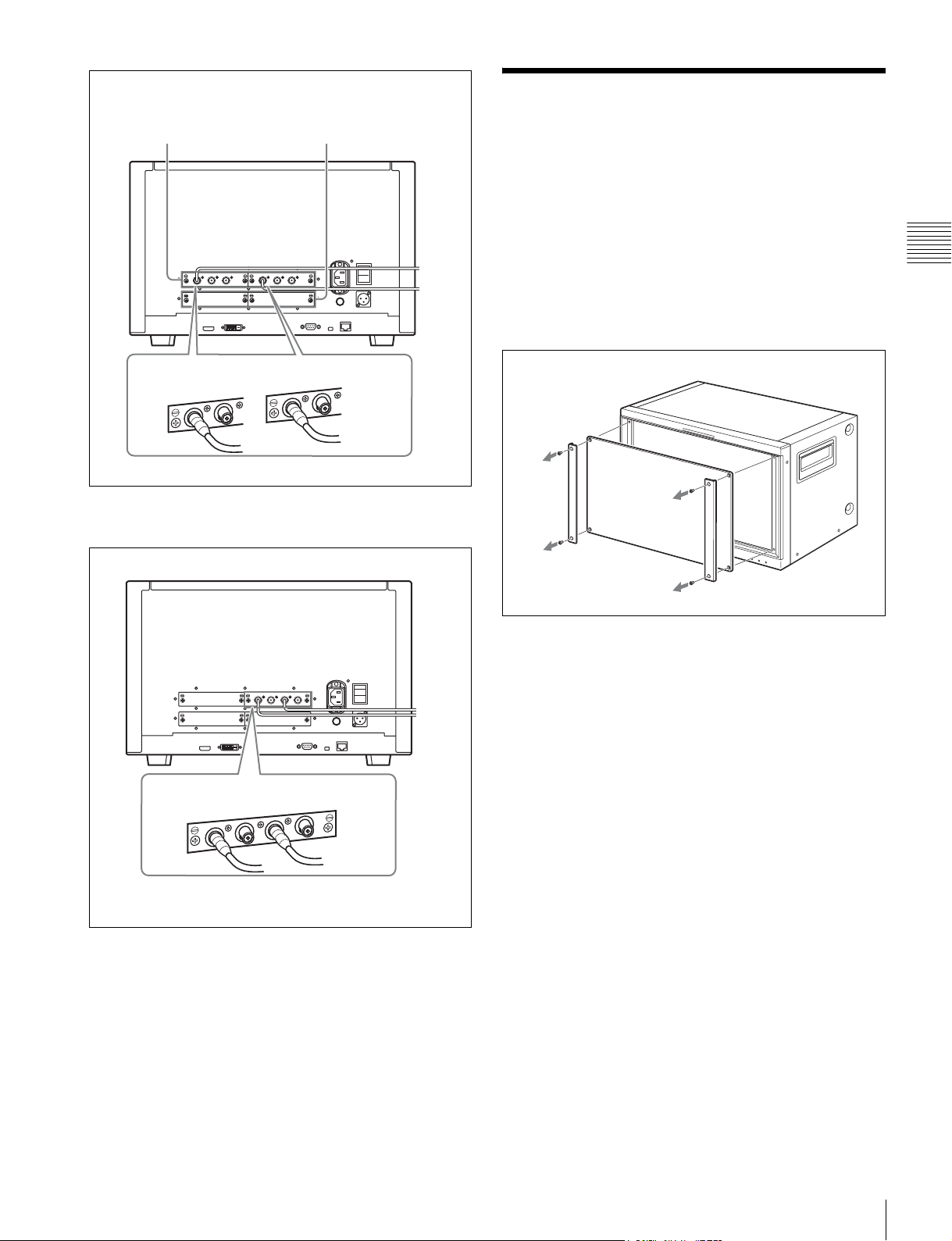

Example of Dual-link cable connection

Removing the Protection

OPTION 3 and 4

When the BKM-250TG is used, install the Link A signal

to INPUT 1, and the Link B signal to INPUT 2.

OPTION 1 and 2

INPUT 2INPUT 1INPUT 2INPUT 1

Plate

The protection plate is installed on the monitor to protect

the LCD panel at the factory.

You can remove the protection plate when the picture

differs in color from that without the protection plate and/

or when there is more reflection of light than without.

1

Remove the four screws and then remove the

protection plate.

Chapter 2 Preparations

INPUT 2INPUT 1

For 3D signal analyzing function

Use a 3D-compatible BKM-250TG (with serial number

7100001 or higher) and input the left 3D signal to INPUT 1

and the right signal to INPUT 2.

2

Reinstall the four screws in their original position on

the monitor.

Removing the Protection Plate

21

Page 22

Mounting the Unit in a Rack

To mount the unit in an EIA standard 19-inch rack, use the

supplied rack mount brackets and screws.

1

Chapter 2 Preparations

Remove the four feet from the bottom of the unit.

2

Attach the rack mount brackets to each side of the unit

with the rack mount attachment screws.

PVM-L1700

Rack mount bracket

Rack mount

attachment screws

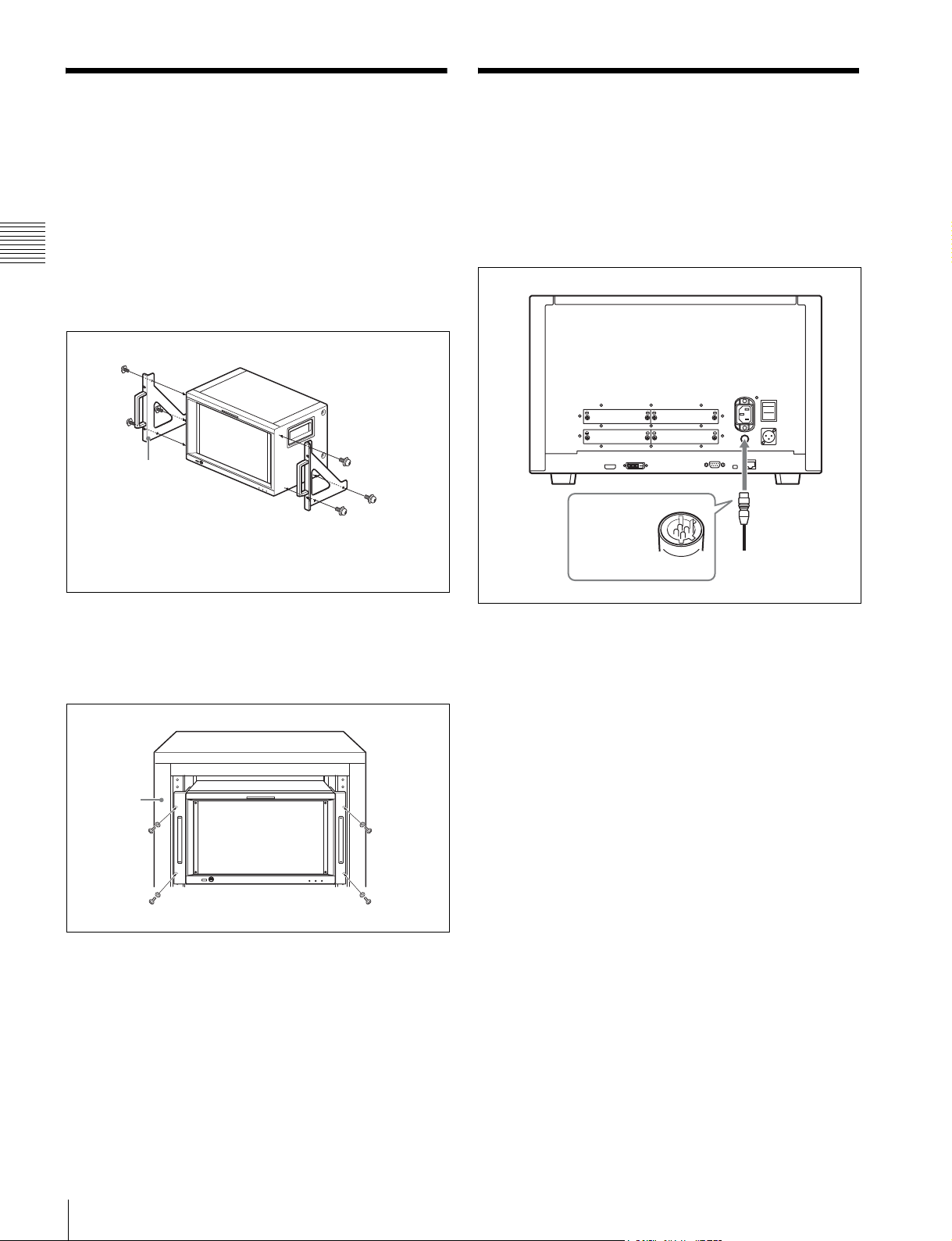

Connections

Note on connecting the cable to the DC 5V OUT

connector

Be sure to plug the male connector of the cable into the DC

5V OUT connector of the monitor.

Insert the connector so as to fit the shape of the DC 5V

OUT connector.

Plug the male

connector into

the monitor.

3

Screw the rack mount brackets to the rack to mount the

unit.

Use the commercially available screws that match the

size of the rack’s holes.

Rack

Mounting the Unit in a Rack / Connections

22

Page 23

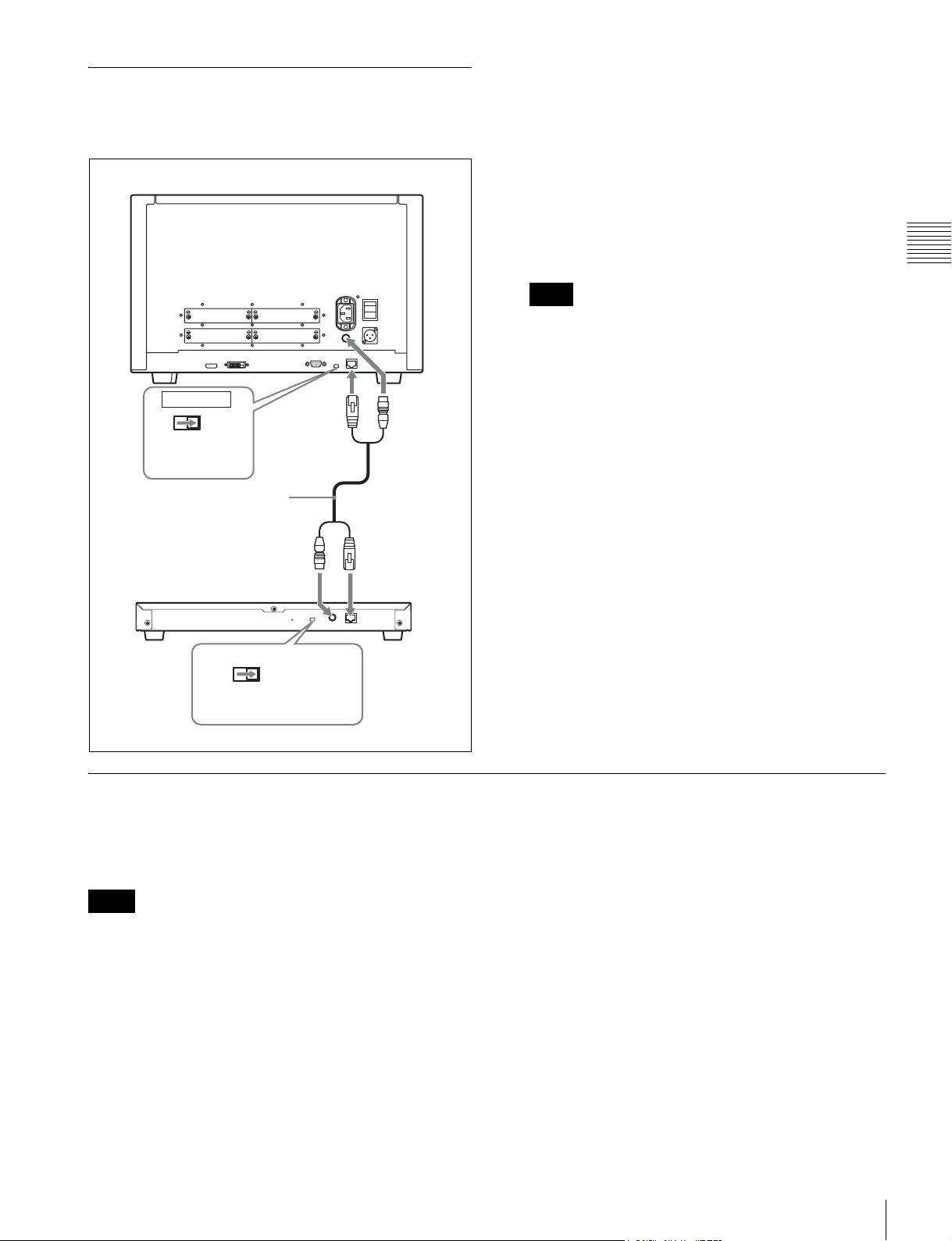

Connecting the Controller (BKM16R)

1

Turn off the ON/OFF (power) switch of the monitor

(OFF) before connecting the units.

2

Set the NETWORK switches of the monitor and the

controller to PEER TO PEER.

Monitor

LAN

Set to PEER TO

PEER.

Controller

(BKM-16R)

NETWORK

PEER TO

PEER

SMF-700, etc.

LAN (10/100)

connector

DC 5V/12V IN

connector

DC 5V OUT

connector

LAN (10/100)

connector

3

Connect the LAN (10/100) connector of the monitor

and the LAN (10/100) connector of the controller by

using the SMF-700 or the cable supplied with the

BKM-39H, or a 10BASE-T/100BASE-TX straight

LAN cable (shielded-type, optional).

Note

When an optional LAN cable is connected, use a

shielded-type cable to prevent a malfunction due to

noises.

4

Connect the DC 5V OUT connector of the monitor and

the DC 5V/12V IN connector of the controller by using

the SMF-700 or the cable supplied with the BKM-39H.

Or connect the output cable of the AC adaptor supplied

with the controller to the DC 5V/12V IN connector of

the controller.

Chapter 2 Preparations

NETWORK

LAN

Set to PEER TO PEER.

PEER TO PEER

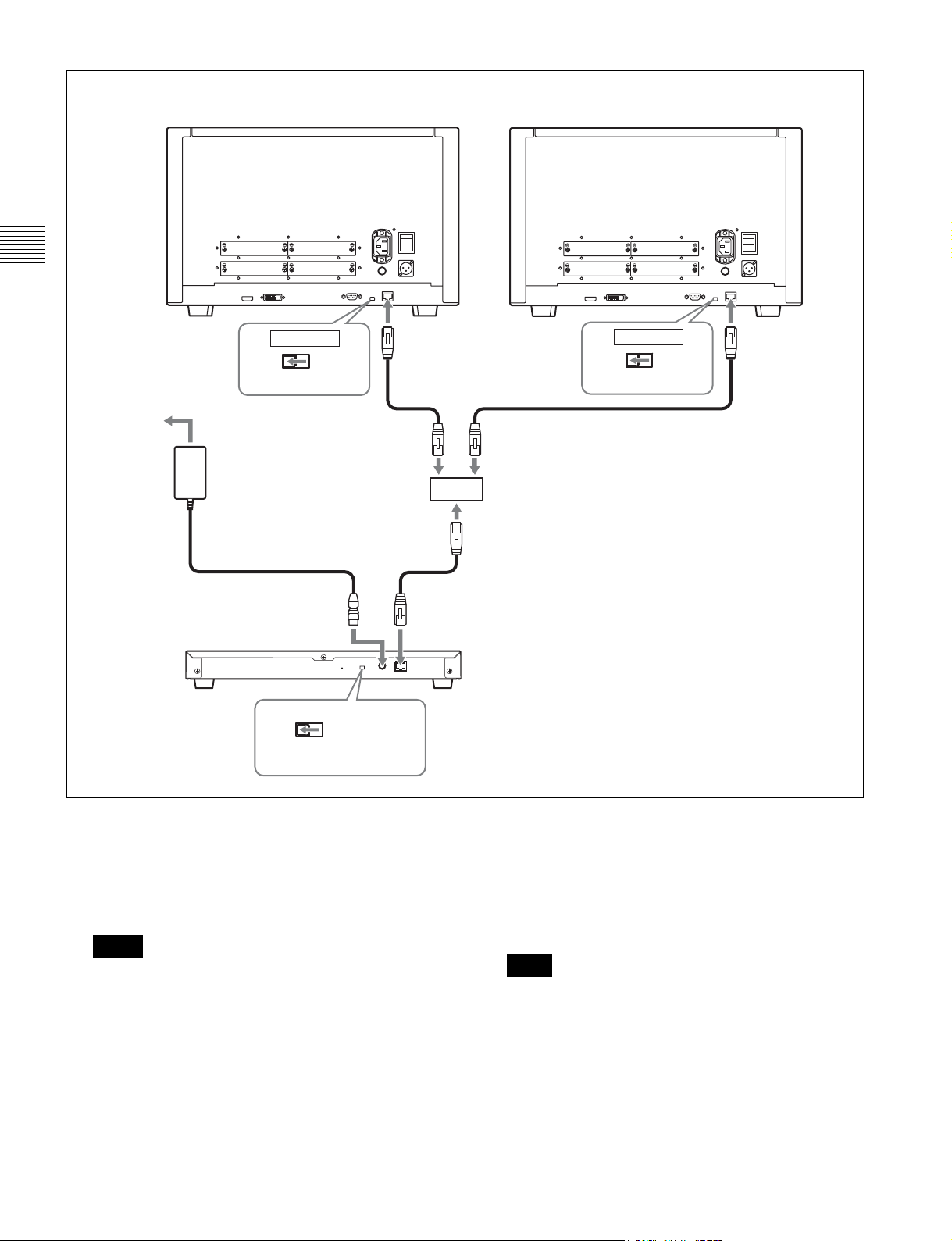

Connecting the Multiple Units with the LAN

The controller controls up to 32 monitors. Up to four

controllers are connected to one monitor in single mode.

Note

The controller cannot control monitors in another

subnetwork.

Connections

23

Page 24

Monitor

Chapter 2 Preparations

Monitor

AC adaptor (supplied

with the BKM-16R)

Controller (BKM-16R)

NETWORK

LAN

Set to LAN.

DC 5V/12V IN

connector

LAN

PEER TO

PEER

NETWORK

Set to LAN.

PEER TO PEER

LAN (10/100)

connector

LAN (10/100)

connector

Switching hub

(recommended: with

AUTO MDI/MDI-X

function)

NETWORK

LAN

Set to LAN.

PEER TO

PEER

LAN (10/100)

connector

24

1

Turn off the ON/OFF (power) switch of the monitor

(OFF) before connecting the units.

2

Connect to the network by using a 10BASE-T/

100BASE-TX cable (shielded-type, optional).

Notes

• When an optional LAN cable is connected, use a

shielded-type cable to prevent a malfunction due to

noises.

• We recommend to use an optional switching hub

with auto selection function (AUTO MDI/MDI-X)

of a straight/cross cable.

When the switching hub without auto selection

function is used, connect the monitor and switching

Connections

hub with the straight cable, and the controller and

switching hub with the cross cable.

3

Connect the output cable on the AC adaptor supplied

with controller to the DC 5V/12V IN connector of the

controller.

Note

When the multiple units are connected, set for the LAN

before setting the NETWORK switch to LAN (page

27).

4

Set the NETWORK switches of each monitor and the

controller to LAN.

Page 25

Turning on the Power

Connecting to Power

You can operate the monitor with AC or DC power supply.

Turning on the Monitor

Press the ON/OFF (power) switch on the rear panel (ON)

to turn on the power.

When you turn on the monitor for the first time after

purchasing it, the Select Area screen is displayed. Select

the area where you intend to use this monitor.

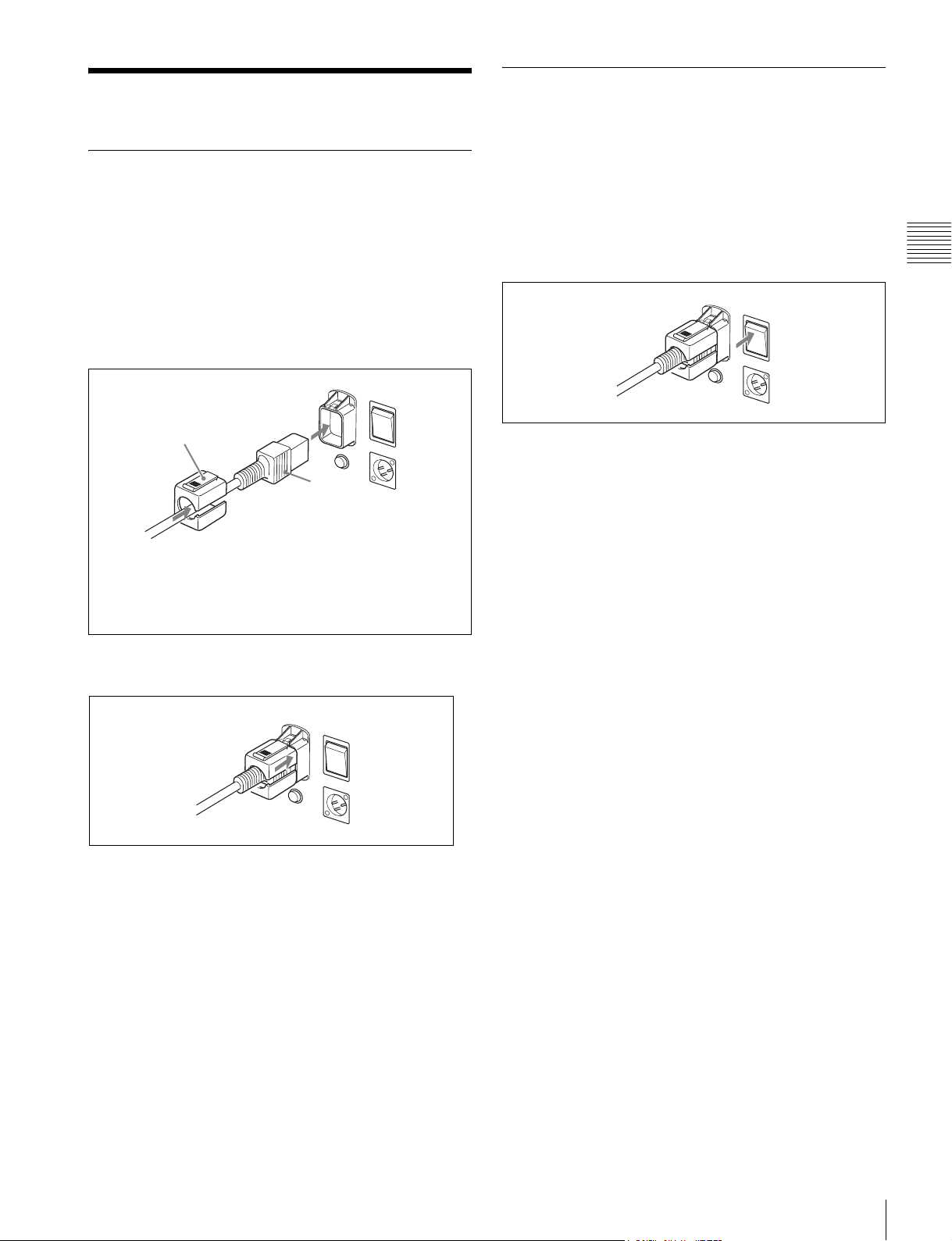

To connect the AC power cord

1

Plug the AC power cord into the AC IN connector on

the rear panel. Then, attach the AC plug holder

(supplied) to the AC power cord.

AC plug holder

(supplied)

AC power cord

(supplied)

Attach the AC plug holder to the AC power cord, and connect

the cord to the AC IN connector so that the cord does not come

loose.

2

Slide the AC plug holder over the cord until it locks.

For selecting the area, see page 26.

Chapter 2 Preparations

O

N

O

FF

O

N

O

F

F

The warm-up time is more than 30 minutes, approximately.

When the monitor is in standby mode

As the OPERATE lamp lights in red in standby mode,

press the MONITOR I/1 switch of the controller.

The OPERATE lamp lights in green and the monitor enters

operation mode.

O

N

O

FF

To disconnect the AC power cord

Pull out the AC plug holder while pressing the lock levers.

To connect the DC power supply

Connect the DC power supply to the DC IN 24 - 28V

connector.

When the AC power cord and DC power supply are

connected, the AC power supply is given preference to

over the DC power supply. To use the DC power supply,

disconnect the AC power cord.

Turning on the Power

25

Page 26

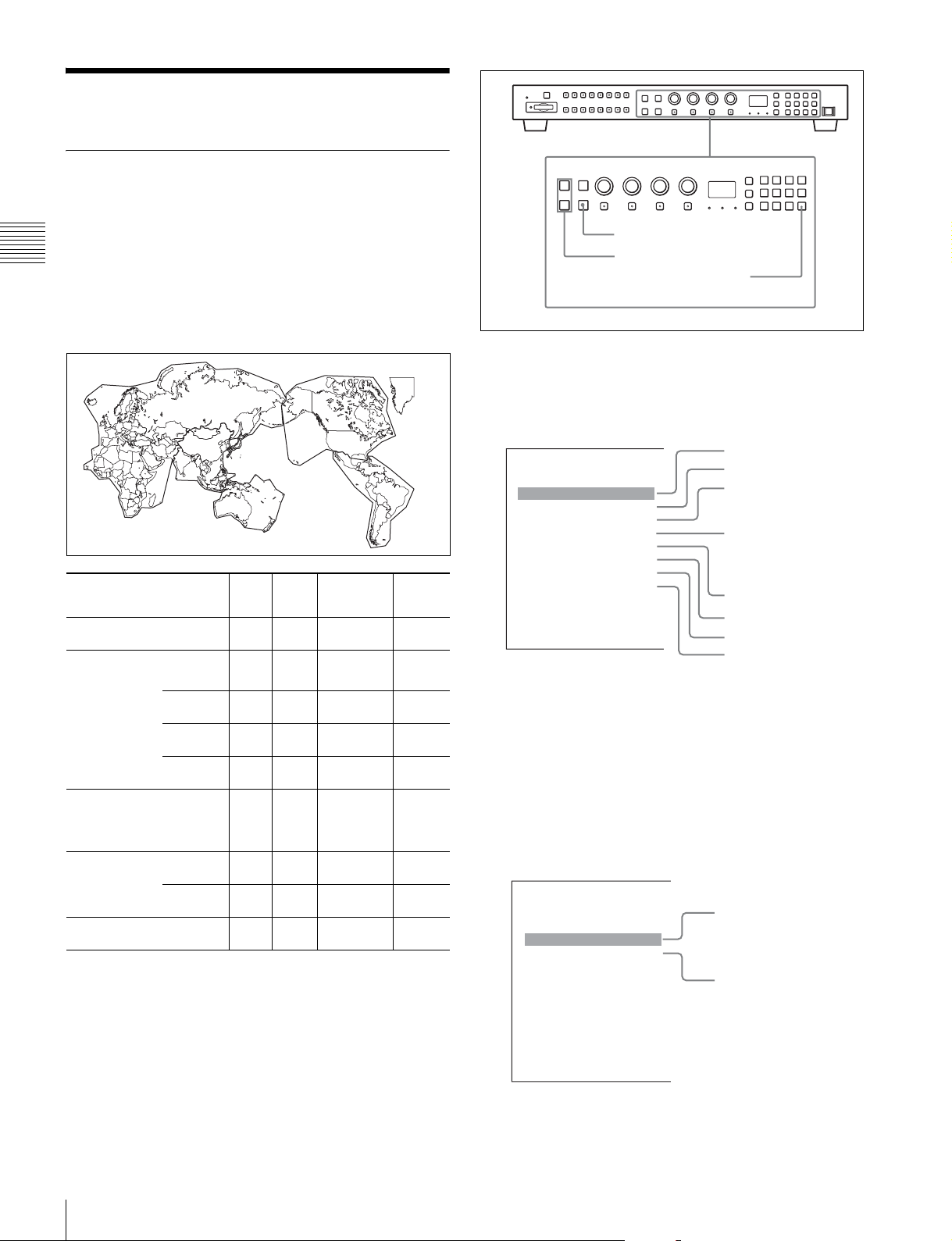

Settings

Selecting the Area

When you turn on the monitor for the first time after

purchasing it, select the area where you intend to use this

monitor from among the options.

Chapter 2 Preparations

When the area is selected, the menu item settings suitable

for the selected area are applied.

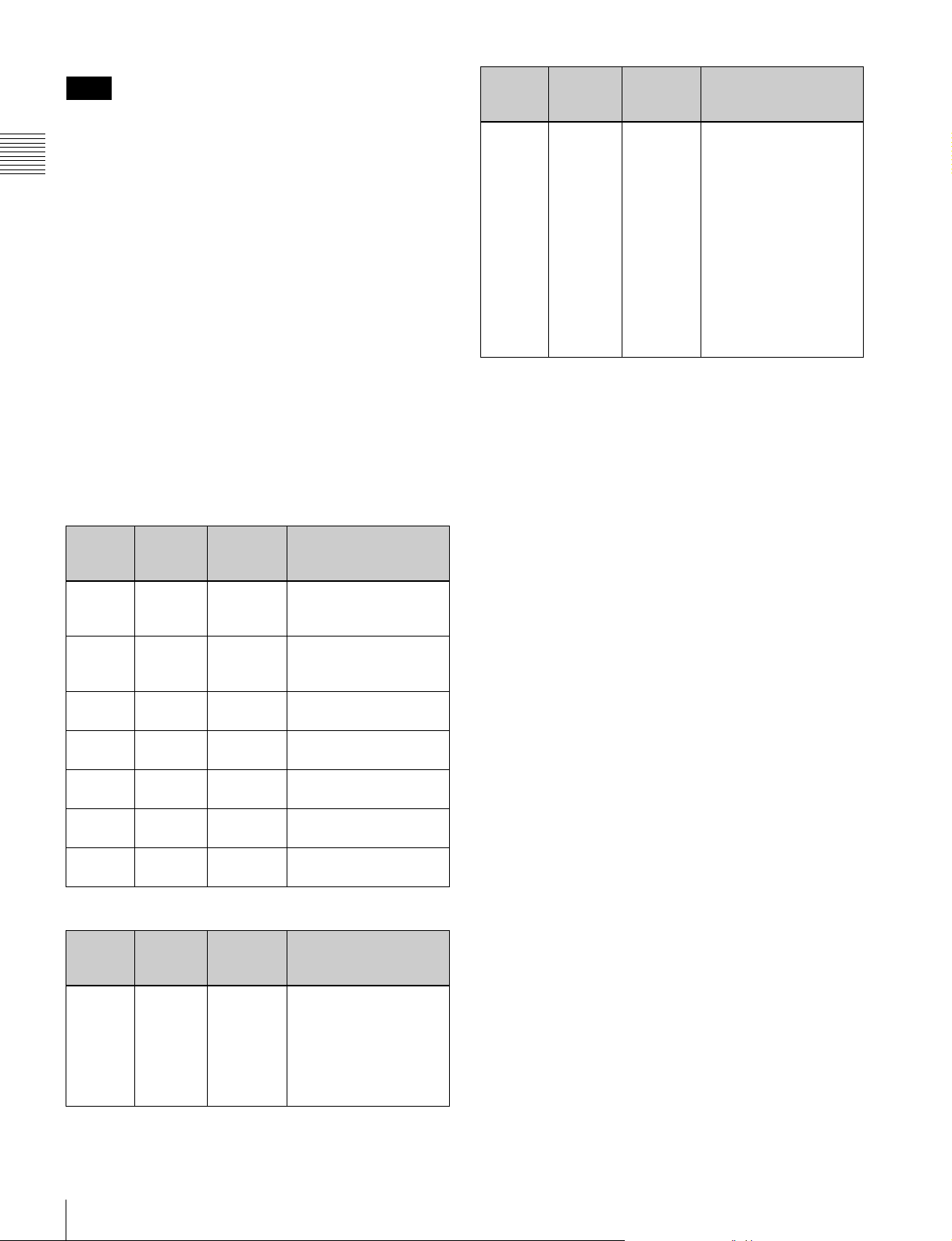

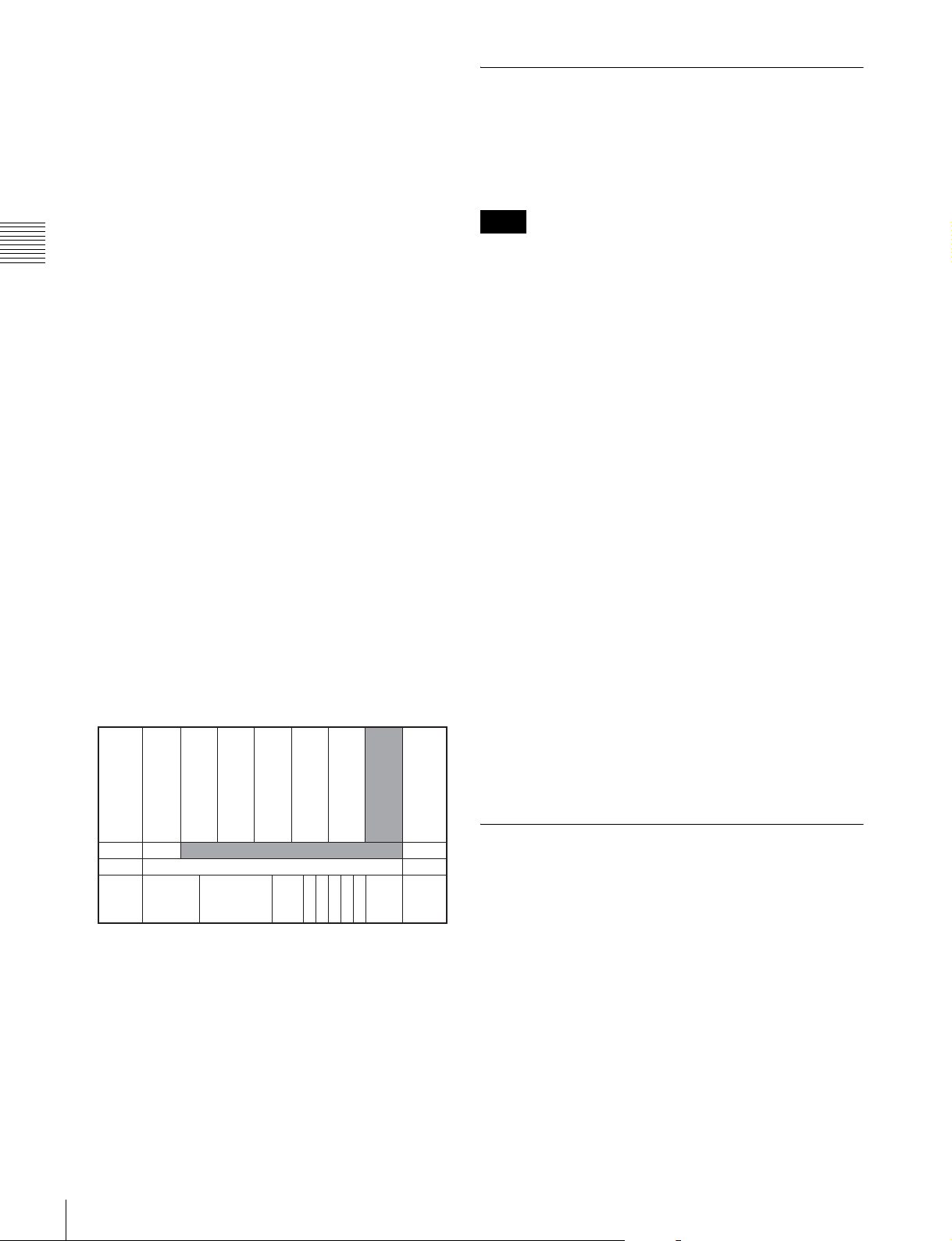

Default value for each area

1

5

4

3

1North America D65 7.5% Betacam

2Latin America

PAL& PAL-N

Area

NTSC&PALM Area

3Africa

Australasia

Europe

Middle-East

4Asia Except

Japan

5Japan D93 0%

Argentina D65 0%

Paraguay D65 0%

Uruguay D65 0%

Other Area D65 7.5% Betacam

NTSC Area D65 7.5% Betacam

PAL Area D65 0%

3

Color

Tem p

D65 0%

Setup

Level

2

Component

Level

SMPTE/

EBU-N10

SMPTE/

EBU-N10

SMPTE/

EBU-N10

SMPTE/

EBU-N10

SMPTE/

EBU-N10

SMPTE/

EBU-N10

3

Color

Gamut

Emulation

BVM

SMPTE-C

BVM EBU

BVM EBU

BVM EBU

BVM

SMPTE-C

BVM EBU

BVM

SMPTE-C

BVM EBU

BVM EBU

ENTER button

UP/DOWN buttons

Ent button

1

Turn on the monitor with the ON/OFF (power) switch

(ON).

The Select Area screen appears.

1 North America

Select Area

North America B

Latin America B

Africa B

Australasia B

Europe B

Middle-East B

Asia Except Japan B

Japan B

2

Press the UP or DOWN button of the controller to

2 Latin America

3 Africa

Australia/New Zealand

Europe/Russia

Middle East

4 Asia Except Japan

5 Japan

select the area where you intend to use the monitor and

press the ENTER (Ent) button.

If you select either Latin America or Asia Except

Japan, one of the following screens appears.

If 2 Latin America is selected:

Select Area

Latin America

PAL & PAL-N Area B

NTSC & PAL-M Area B

PAL&PAL-N area

26

NTSC&PAL-M area

Select PAL & PAL-N or NTSC & PAL-M and press

the ENTER (Ent) button.

Settings

Page 27

If 4 Asia Except Japan is selected:

Select Area

Asia Except Japan

NTSC Area B

PAL Area B

NTSC area

PAL area

Customers who will use this monitor in the shaded

areas shown in the map below should select NTSC

Area.

Other customers should select PAL Area.

Then press the ENTER (Ent) button.

After saving and reflecting the setting, you can change the

setting with the menu.

• Color Temp (color temperature) (page 51)

• Setup Level (NTSC Setup Level: page 53, Betacam

Setup Level: page 53)

• Component Level (page 53)

• Color Gamut Emulation (page 53)

Setting for the LAN to Connect the Multiple Units

You can control the multiple monitors using the controller

connected via each LAN (10/100) connector. You can also

control a specific monitor or monitor group.

Set an IP address to the monitors and the controller and a

monitor ID number and group ID number to each monitor.

1

Set the NETWORK switches of each monitor and the

controller to PEER TO PEER.

Chapter 2 Preparations

3

Confirm the settings.

Select Area

XXXXXXXXXX

Color Temp: xx

Setup Level: xx

Component Level: xx

Color Gamut Emulation:

Cancel

Confirm

xx

Cancel: Select to cancel the setting and return to the

Select Area screen.

Confirm: Select to save the setting and end selecting

the area.

See “Default value for each area” on page 26 on the

setting value.

NETWORK

NETWORK

LAN

PEER TO

PEER

PEER TO PEER

LAN

2

Set the different IP address to each monitor and the

controller.

Monitor: Set the IP address in the Network Setting

menu of the System Configuration menu (page 65).

Controller: Set the IP address in the Network Setting

menu of the Controller menu (page 76).

3

Set Monitor ID and Group ID in the Network menu of

the System Configuration menu (page 65).

Settings

27

Page 28

Set the different monitor ID number to each monitor

and if necessary, group ID number.

You can use the numbers 1 to 99 as a monitor ID

number or group ID number.

4

Set the NETWORK switches of the monitor and the

controller to LAN.

Chapter 2 Preparations

NETWORK

LAN

PEER TO

PEER

1

Press the corresponding button to select the connection

mode.

SINGLE button: Selects single connection mode.

The designated monitor is connected remotely.

The monitor ID number is displayed on all connected

monitors when the button is held pressed.

GROUP button: Selects group connection mode.

The monitor of the designated group is connected

remotely.

The group ID number is displayed on all connected

monitors when the button is held pressed.

ALL button: Selects all connection mode.

All monitors are connected remotely.

The lamp corresponding the pressed button flashes and

lights after recognizing the monitor.

2

Select the monitor ID number for the single connection

mode or group ID number for the group connection

mode by pressing the UP/DOWN or numeric button.

Up to 99 is entered as the monitor ID or group ID

number.

NETWORK

LAN

PEER TO PEER

Selecting the Monitor (Designation of the Monitor or Group ID Number)

When the multiple monitors are connected by the network

connections, you can remotely connect the monitors from

the controller by designating the set monitor ID number or

group ID number.

Display window

Lamp

3

Press the ENTER or Ent button to confirm the setting.

The monitor ID number, group ID number or ALL is

displayed in the display window.

Notes

• When the monitor with no assigned monitor ID number

or group ID number is selected, the setting is not changed

and the previous connection status is maintained.

• When there are monitors with the same ID number, the

monitor with the lower IP address is selected.

• Even if a different monitor ID number is set to the

monitors, when the same IP address is set to another

monitor, the monitor cannot be connected to the network.

Assigning the Input Signal to the Channel

When you assign the input signal to the channel, you can

select the channel and change the input signal by pressing

the numeric button. The input signal is assigned to one of

channels 1 to 30.

28

Settings

3

2

1

2

3

Page 29

Adjusting

Before adjusting

The monitor must be warmed up sufficiently.

To perform stable color reproduction, turn on the power of

the monitor, display the white signal and leave it in this

state for more than 30 minutes.

1

1

Select the channel (CH1 to CH30) to be assigned by

pressing the numeric button of the controller.

To assign to a channel number from 1 to 9, press the

appropriate one-digit channel number on the numeric

keypad.

To assign to a channel number from 10 to 30, press the

0 button, then press the appropriate two-digit channel

number.

2

Set the input signal for the selected channel in Input

Configuration menu (page 49).

The required setting is different due to the input signal

or picture quality to be displayed.

For details of the setting, see the Input Configuration

menu (page 49).

Setting the Display Mode of the Picture

Set the display mode condition of the input signal to

display on the screen. The setting items are following.

• Setting Matrix/Gamma (transmission matrix and

transmission gamma)

• Selecting the color gamut (color space and gamma)

About monitor adjustment

The monitor is used as a measuring instrument and is

required to faithfully reproduce the input signal. To

measure the signal accurately, the monitor must be

calibrated correctly using a reference signal.

To calibrate, adjust the following items in sequence.

1 Chroma/phase adjustment

You can save the adjustment value in Preset1 to

Preset5. The data of Preset1 to Preset5 is set to the

channel in the Picture Preset menu (page 51) of the

Input Configuration menu.

Adjust the picture automatically with the auto chroma/

phase/matrix function for every signal format and

signal system to display the composite signal or Y/C

signal from the BKM-227W, or analog component

signal or analog RGB signal from the BKM-229X. If

the picture is not adjusted, the picture may not be

displayed correctly.

2 Color Temperature (white balance) adjustment

You can adjust the data set to the channel in the Color

Temp menu (page 51) of the Input Configuration

menu.

You can adjust D93, D65 or User1 to User5.

3 Brightness/Contrast adjustment

You can save the adjustment value in Preset1 to

Preset5. The data of Preset1 to Preset5 is set to the

channel in the Picture Preset menu (page 51) of the

Input Configuration menu.

Chroma/Phase Adjustment

Chapter 2 Preparations

1

Set Matrix/Gamma in the Matrix/Gamma menu (page

52) of the Input Configuration menu.

2

Select the color gamut (color space and gamma) in the

Emulation menu (page 53) of the Color Gamut menu

of the Input Configuration menu.

Automatic adjustment (with auto chroma/phase/matrix

function) is required for each signal format, signal system

and matrix to display the composite or Y/C signal from the

BKM-227W, or the analog component or analog RGB

signal from the BKM-229X.

As you can automatically adjust the chroma, phase, matrix

and also 100% (white) and 0% (black) levels of the monitor

to the same as those of the reference signal by performing

the automatic adjustment, the automatic adjustment is also

effective for the RGB signal.

Perform the manual adjustment of chroma and phase to

adjust them further after automatic adjustment or the

digital signal from the BKM-220D, BKM-243HS, BKM244CC or BKM-250TG.

Adjusting

29

Page 30

Automatic adjustment (recommended)

1

Input the reference color-bar signal to the monitor.

2

Select Auto in the Picture Adj menu of the Adjustment

menu and perform the automatic adjustment of the

chroma, phase and matrix in Auto Adjust (page 43).

Color Temperature (White Balance) Adjustment

You can adjust manually or automatically with a specified

color temperature probe.

Manual adjustment

The following is the example of the method to perform the

manual adjustment of the chroma and phase.

Chapter 2 Preparations

1

Input the multi format color-bar signal or SMPTE

color-bar signal to the monitor.

2

Set the BLUE ONLY button to on.

Red and green signals are cut, and only the blue signal

is displayed as a monochrome picture.

The following is the example of the adjustment when the

multi format color-bar signal is used.

3

Select the Manual Adjust menu (page 44) in the Picture

Adj menu of the Adjustment menu and adjust the

levels with the CHROMA or PHASE knob of the

controller while tracking so that the brightness of bars

“a” (Blue part) and “b” (75% White part) (in the

following illustration) are the same.

For the composite and Y/C signals

Adjust the levels with the CHROMA and PHASE

knob.

For the component signal

Adjust the levels with the CHROMA knob.

Note

When the DVI Computer signal, or the computer signal of

HDMI is displayed, the color temperature cannot be

adjusted automatically.

Perform the manual adjustment of the color temperature.

Automatic adjustment

Use one of the following probes.

• Konica Minolta CA-210

• DK-Technologies PM5639/06

• X-Rite Eye-One Pro

1

Connect the color temperature probe.

For the cable to connect the color temperature probe,

see page 127.

2

Select Auto Adjust (page 46) in the Color Temp Adj

menu of the Adjustment menu and adjust the color

temperature.

Manual adjustment

1

Select Manual Adjust (page 45) in Manual of the Color

Temp Adj menu of the Adjustment menu.

2

Adjust the color as desired with the PHASE,

CHROMA or BRIGHT knob.

30

b (75% White)

4

Press the ENTER or Ent button.

The adjusted data is confirmed.

5

Set the BLUE ONLY button to off.

Adjusting

3

Press the ENTER or Ent button.

a (Blue)

The adjusted data is confirmed.

Brightness/Contrast Adjustment

As an image on a color video monitor is seen differently

according to the ambient light (environmental brightness),

adjust the brightness (black level) according to the ambient

light and the black level of the image to be reproduced and

adjust the contrast (white level) according to the ambient

light.

Adjust the brightness/contrast with an external reference

signal of a multi format color-bar signal or SMPTE colorbar signal.

1

Input the multi format color-bar signal or SMPTE

color-bar signal to the monitor.

Page 31

The following are explained as the example when the

SD

multi format color-bar signal is used for adjustment.

2

Select the Manual Adjust menu (page 44) in the Picture

Adj menu of the Adjustment menu.

3

Adjust the –2%, 0% and +2% ranges or the 0%, +2%

and +4% ranges of the PLUGE signal section of the

color-bar with the BRIGHT knob.

HD signal

Adjust so that the –2% and 0% ranges are seen as equal

and the +2% and 0% ranges are more distinctive.

SD signal

Adjust so that the 0% and +2% ranges are seen as equal

and the +2% and +4% ranges are more distinctive.

SD

SD

HD

+4%

0%

+2%-2%

0%

4

Adjust so that the luminance of the 100% white signal

of the color-bar is set to the desired value with the

CONTRAST knob.

Chapter 2 Preparations

We recommend adjusting the luminance to 100 [cd/

2

m

] when Preset1 to Preset5 is selected in the Picture

Preset menu of the Input Configuration menu.

5

As the brightness and contrast adjustments affect each

other, repeat the adjustments of step 3 and 4.

Note

When the contrast of this unit is adjusted, the luminance of

the backlight is adjusted for a picture of luminance 40 [cd/

2

m

] (20 [cd/m2] in interlace display mode) or higher, and

the contrast is adjusted by the signal level for a picture of

luminance lower than 40 [cd/m

2

] (20 [cd/m2] in interlace

display mode).

Adjusting

31

Page 32

Menu

Basic Menu Operations

Chapter 3 Menu

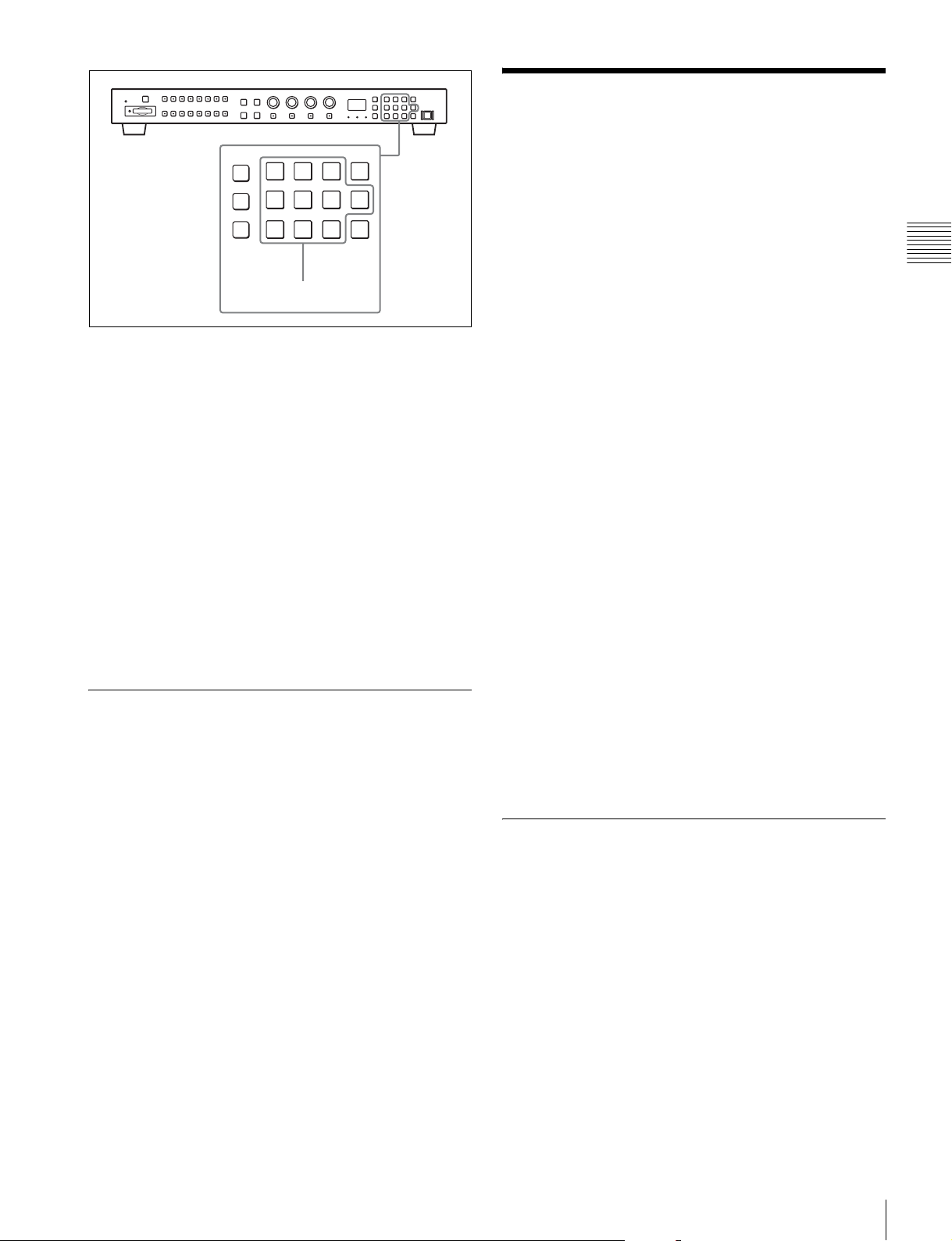

Menu Operation Buttons

The menu is operated using the menu operation buttons on

the controller (BKM-16R, optional).

Controller (BKM-16R)

1 UP/DOWN buttons

2 MENU button

3 ENTER button

4 PHASE knob

UP MENU

DOWN

PHASE

ENTER

MANUAL MANUAL MANUAL MANUAL

CHROMA

BRIGHT

CONTRAST

SINGLE

GROUP ALL

Chapter

REMOTE

SINGLE

GROUP

ALL

INPUT

1

2

4

5

7

8

3

3

Del

0

6

Ent

9

The functions of the menu operation buttons are described

below.

Button Function

1 UP button

1 DOWN button

2 MENU button

3 ENTER

button

Moves the cursor upward. In setting

mode, increases the setting or adjustment

value.

Moves the cursor downward. In setting

mode, decreases the setting or

adjustment value.

Displays the menu. Goes back to the

menu of the upper level. (On the main

menu, goes back to the normal picture.)

Changes the item. In setting mode,

confirms the adjustment or setting value.

5 Numeric buttons

6 Ent button

7 Del button

Button Function

4 PHASE knob

5 Numeric

buttons

6 Ent button

7 Del button

By turning this knob clockwise, the cursor

moves upward. In setting mode,

increases the setting or adjustment value

(has the same function as UP button).

By turning this knob counterclockwise, the

cursor moves downward. In setting mode,

decreases the setting or adjustment value

(has the same function as DOWN button).

Enters the numerical values.

Changes the item. In setting mode,

confirms the adjustment or setting value.

Deletes the values and characters

entered.

Basic Menu Operations

32

Page 33

Displaying the Menu

The current settings are displayed in place of the x

marks on the illustrations of the menu screen.

Press the MENU button.

The main menu is displayed on the screen.

MENU

Adjustment B

Input Configuration B

Display Setting B