Sony PFM-50C1,PFM-50C1E Service Manual

.............. ......... ....................

SERVICE MANUAL

.............. ......... ....................

MODEL

DEST. CHASSIS NO. MODEL DEST. CHASSIS NO.

PFM-50C1 WORLD

PFM-50C1E WORLD

FLAT PANEL DISPLAY

SU-P50C WORLD

RM-971 WORLD

PFM-50C1/50C1E FLAT PANEL DISPLAY

SU-P50C FLAT PANEL DISPLAY STAND

RM-971 REMOTE COMMANDER

PFM-50C1/50C1E

! W ARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

PFM-50C1/50C1E

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer’s instructions.

Vorsicht!

Explosionsgefahr bei unsachgemäßem Austausch

der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ. Entsorgung

gebrauchter Batterien nach Angaben des

Herstellers.

ATTENTION

Il y a danger d’explosion s’il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du même

type ou d’un type équivalent recommandé par le

constructeur.

Mettre au rebut les batteries usagées conformément

aux instructions du fabricant.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Lithiumbatteri - Eksplosjonsfare.

Ved utskifting benyttes kun batteri som

anbefalt av apparatfabrikanten.

Brukt batteri returneres

apparatleverandøren.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ

som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande

föreskrifter.

VAROITUS

Paristo voi räjähtää jos se on virheellisesti

asennettu.

Vaihda paristo ainoastaan laitevalmistajan

suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

1 (P)

PFM-50C1/50C1E

2 (P)

For the customers in the Netherlands

Voor de klanten in Nederland

Hoe u de batterijen moet verwijderen, leest u in de tekst

van deze handleiding.

Gooi de batterij niet weg maar lever deze in als klein

chemisch afval (KCA).

Für Kunden in Deutschland

Entsorgungshinweis: Bitte werfen Sie nur entladene

Batterien in die Sammelboxen beim Handel oder den

Kommunen. Entladen sind Batterien in der Regel dann,

wenn das Gerät abschaltet und signalisiert “Batterie

leer” oder nach längerer Gebrauchsdauer der Batterien

“nicht mehr einwandfrei funktioniert”. Um

sicherzugehen, kleben Sie die Batteriepole z.B. mit

einem Klebestreifen ab oder geben Sie die Batterien

einzeln in einen Plastikbeutel.

For the customers in the U.S.A. and Canada

RECYCLING LITHIUM-ION BATTERIES

Lithium-Ion batteries are recyclable.

You can help preserve our environment

by returning your used rechargeable

batteries to the collection and recycling

location nearest you.

For more information regarding recycling of rechargeable batteries, call toll free

1-800-822-8837, or visit http://www.rbrc.org/

Caution: Do not handle damaged or leaking Lithium-Ion

batteries.

1

PFM-50C1/50C1E

Table of Contents

1. Service Information

1-1. Board Layout............................................................................................... 1-1

1-2. Disassembly ................................................................................................1-2

1-2-1. QA Board Removal....................................................................1-2

1-2-2. Rear Cover Removal ..................................................................1-3

1-2-3. Q Board Removal.......................................................................1-4

1-2-4. B Board Removal .......................................................................1-5

1-2-5. DC Fan (R) Assy Removal ........................................................ 1-6

1-2-6. AC Inlet Block Assy and SP Board Removal ............................1-7

1-2-7. P Block Assy, S Board, Switching Regulator and DC Fan (B)

Removal .....................................................................................1-8

1-2-8. Bezel Complete Assy Removal..................................................1-9

1-2-9. H1 Board Removal...................................................................1-10

1-2-10. B Block Assy and Panel Assy Removal ..................................1-11

1-2-11. Q/B Bracket Assy Removal ..................................................... 1-12

1-2-12. Plasma Display Panel Removal ...............................................1-13

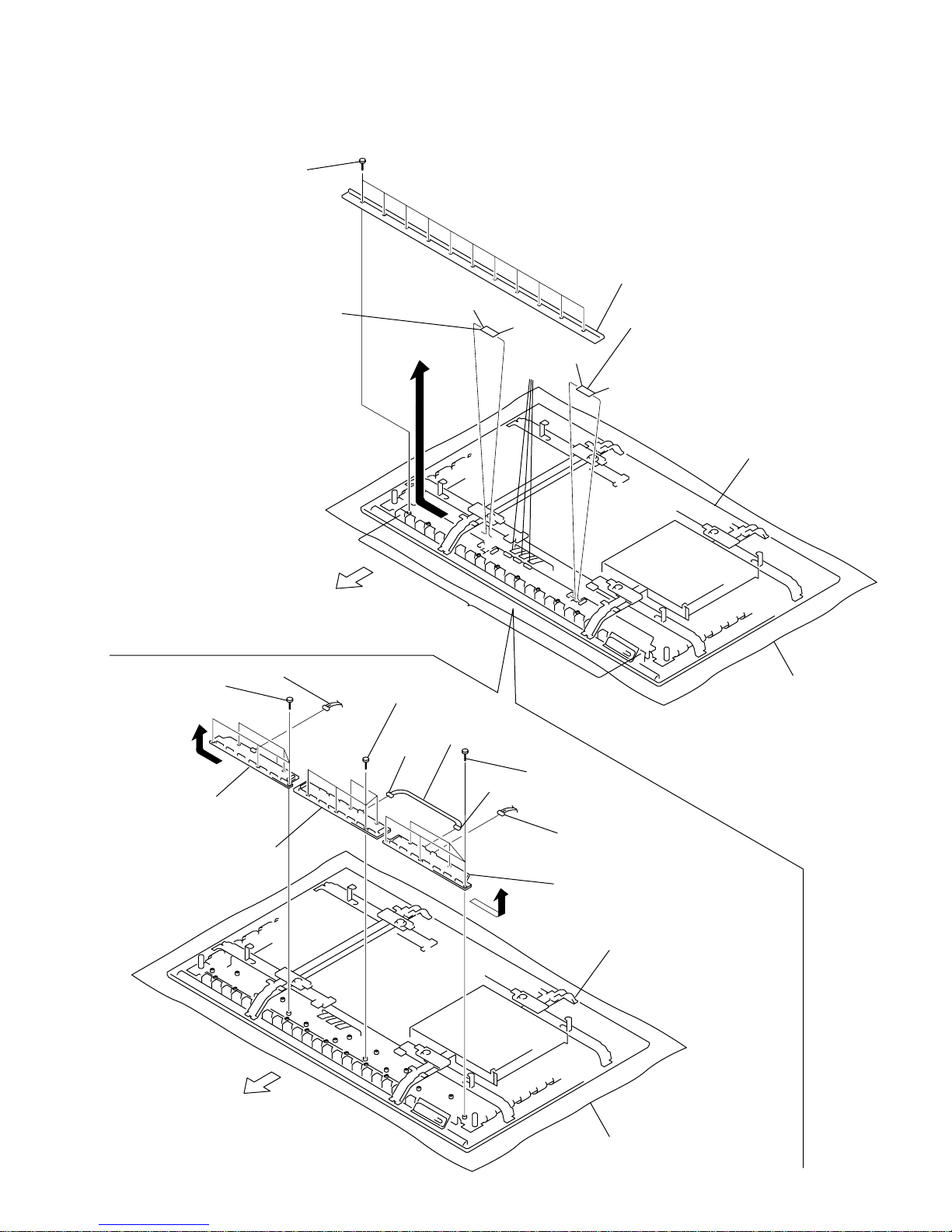

1-2-13. Common PKG Board Removal................................................ 1-14

1-2-14. Digital PKG Board Removal ...................................................1-15

1-2-15. Collection Joint PKG Board Removal .....................................1-16

1-2-16. Scan PKG Board Removal.......................................................1-17

1-2-17. Scan Joint PKG (A) and (B) Boards Removal.........................1-18

1-2-18. Signal Joint PKG (RU), (MU), (LU) Board Removal .............1-19

1-2-19. Signal Joint PKG (RL), (ML), (LL) Board Removal...............1-20

1-3. Service Position......................................................................................... 1-21

1-3-1. Service Position of Q Board.....................................................1-21

1-3-2. Service Position of B Board .....................................................1-22

1-4. Packaging of the Plasma Display Panel When It Is Shipped to NEC

Corporation ...............................................................................................1-23

1-5. Warning on Power Connection .................................................................1-24

2. Electrical Adjustments

2-1. Equipment Required....................................................................................2-1

2-2. Electrical Adjustments Using the Service Mode ........................................2-1

2-3. White Balance Adjustment .......................................................................2-20

2-4. AD Calibration Adjustment ......................................................................2-20

2-5. Sub Color and Sub Hue Adjustments........................................................2-21

2-6. Video Decoder Adjustment.......................................................................2-21

2-7. Watch Error Adjustment ...........................................................................2-22

2-8. Power Supply Block Adjustment ..............................................................2-22

2

PFM-50C1/50C1E

3. Troubleshooting

3-1. Judging Method When Image Does Not Appear ........................................ 3-1

3-2. Self Diagnosis Function ..............................................................................3-2

3-2-1. Overview ....................................................................................3-2

3-2-2. Abnormality Judgment Criterion ...............................................3-2

4 Semiconductors................................................................................. 4-1

5. Spare Parts

5-1. Notes on Repair Parts..................................................................................5-1

5-2. Exploded Views .......................................................................................... 5-2

5-3. Electrical Parts List ................................................................................... 5-13

6. Block Diagrams

B (1/3), Q (1/2), SP.................................................................................................6-1

B (2/3).....................................................................................................................6-2

B (3/3), Q (2/2), H1, H2, S .....................................................................................6-3

APS-184 (1/2).........................................................................................................6-4

APS-184 (2/2).........................................................................................................6-5

7. Diagrams

7-1. Frame Schematic Diagrams ........................................................................7-2

Frame ........................................................................................................7-2

7-2. Schematic Diagrams and Printed Wiring Boards........................................7-3

Schematic Diagrams

QA.............................................................................................................7-3

Q (1/3) ....................................................................................................... 7-5

Q (2/3) ....................................................................................................... 7-6

Q (3/3) ....................................................................................................... 7-7

B (1/8) .....................................................................................................7-12

B (2/8) .....................................................................................................7-13

B (3/8) .....................................................................................................7-14

B (4/8) .....................................................................................................7-15

B (5/8) .....................................................................................................7-16

B (6/8) .....................................................................................................7-17

B (7/8) .....................................................................................................7-18

B (8/8) .....................................................................................................7-19

H1............................................................................................................ 7-23

3

PFM-50C1/50C1E

H2............................................................................................................ 7-23

S ..............................................................................................................7-24

SP ............................................................................................................7-24

APS-184 (1/4) .........................................................................................7-28

APS-184 (2/4) .........................................................................................7-29

APS-184 (3/4) .........................................................................................7-30

APS-184 (4/4) .........................................................................................7-31

Printed Wiring Boards

QA.............................................................................................................7-3

Q................................................................................................................ 7-8

B .............................................................................................................. 7-10

H1............................................................................................................ 7-23

H2............................................................................................................ 7-23

S ..............................................................................................................7-24

SP ............................................................................................................7-24

APS-184 .................................................................................................. 7-26

1-1

PFM-50C1/50C1E

Section 1

Service Information

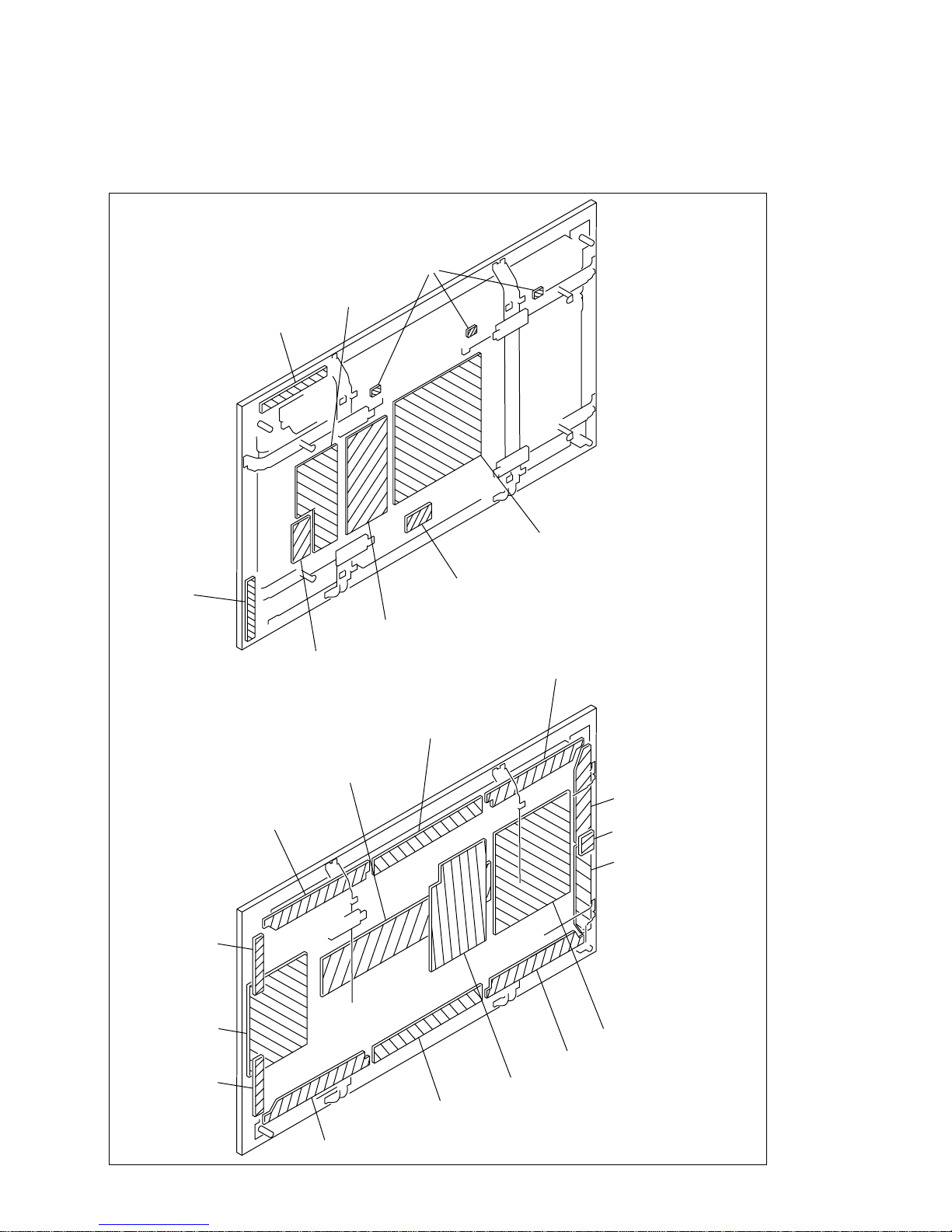

1-1. Board Layout

H2

SWITCHING REGULATOR (APS-184)

SP

SCAN JOINT-JOINT PKG

SCAN JOINT PKG (A)

COMMON JOINT

PKG (U)

COMMON JOINT

PKG (L)

SCAN JOINT PKG (B)

SCAN PKG

DIGITAL PKG

COMMON PKG

SIGNAL JOINT PKG (LU)

SIGNAL JOINT PKG (MU)

COLLECTION JOINT PKG

SIGNAL JOINT PKG (RU)

SIGNAL JOINT PKG (ML)

SIGNAL JOINT PKG (LL)

SIGNAL JOINT PKG (RL)

Q

B

S

H1

QA (PFM-50C1)

1-2

PFM-50C1/50C1E

1-2. Disassembly

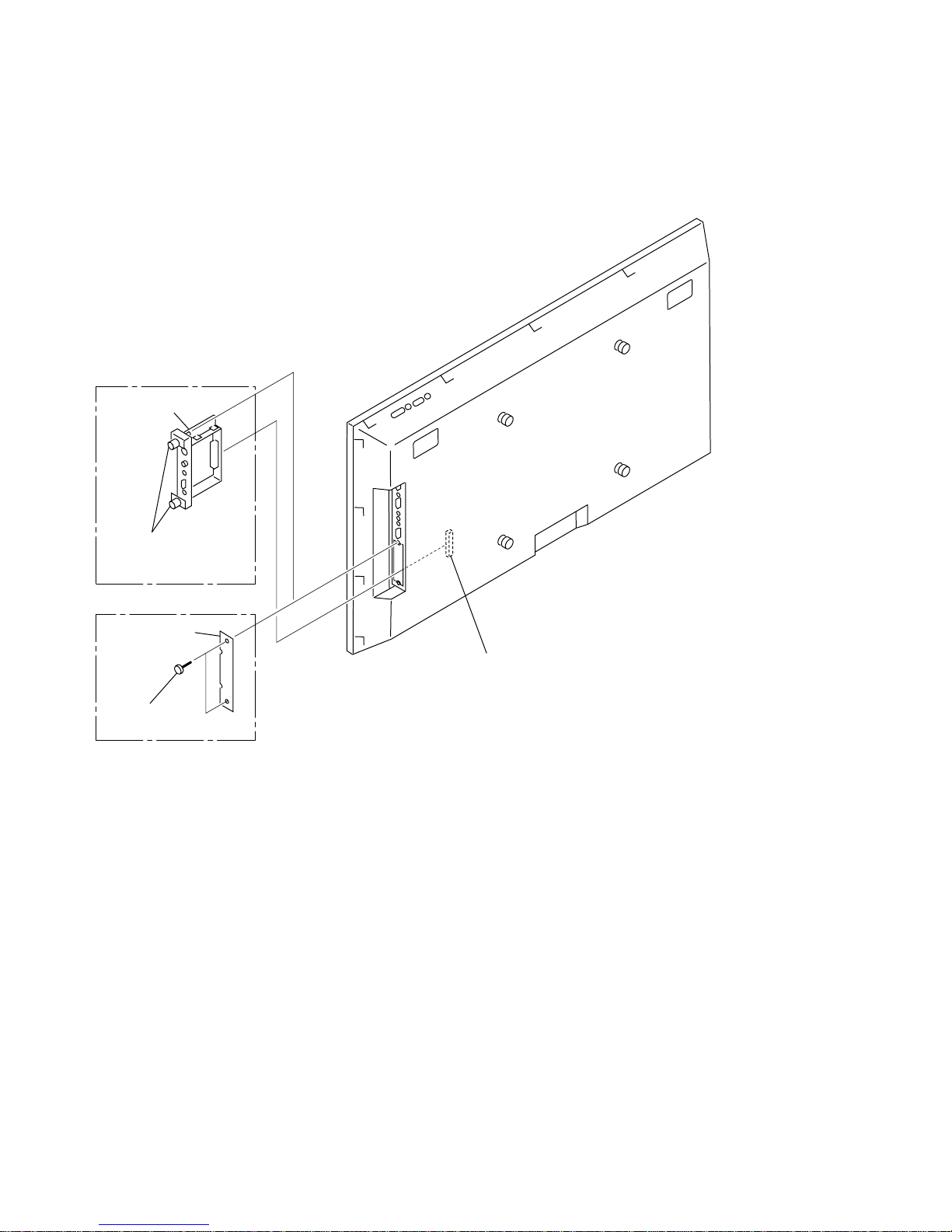

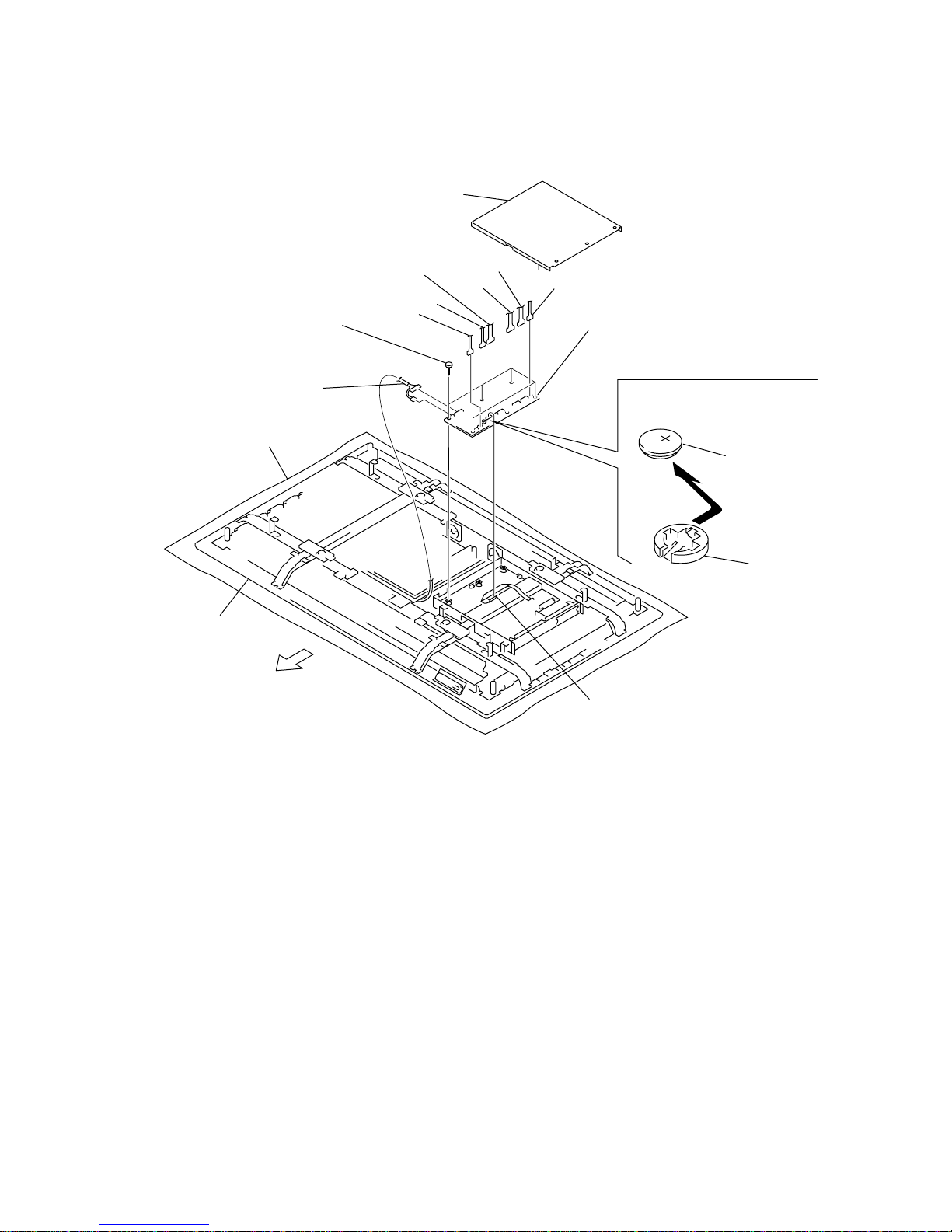

1-2-1. QA Board Removal

CN3009

PFM-50C1E

PFM-50C1

QA board

Blank panel

Two screws

(+PS 3 x 6)

Remove blank panel

[Loosen two panel

stopper screws.]

1-3

PFM-50C1/50C1E

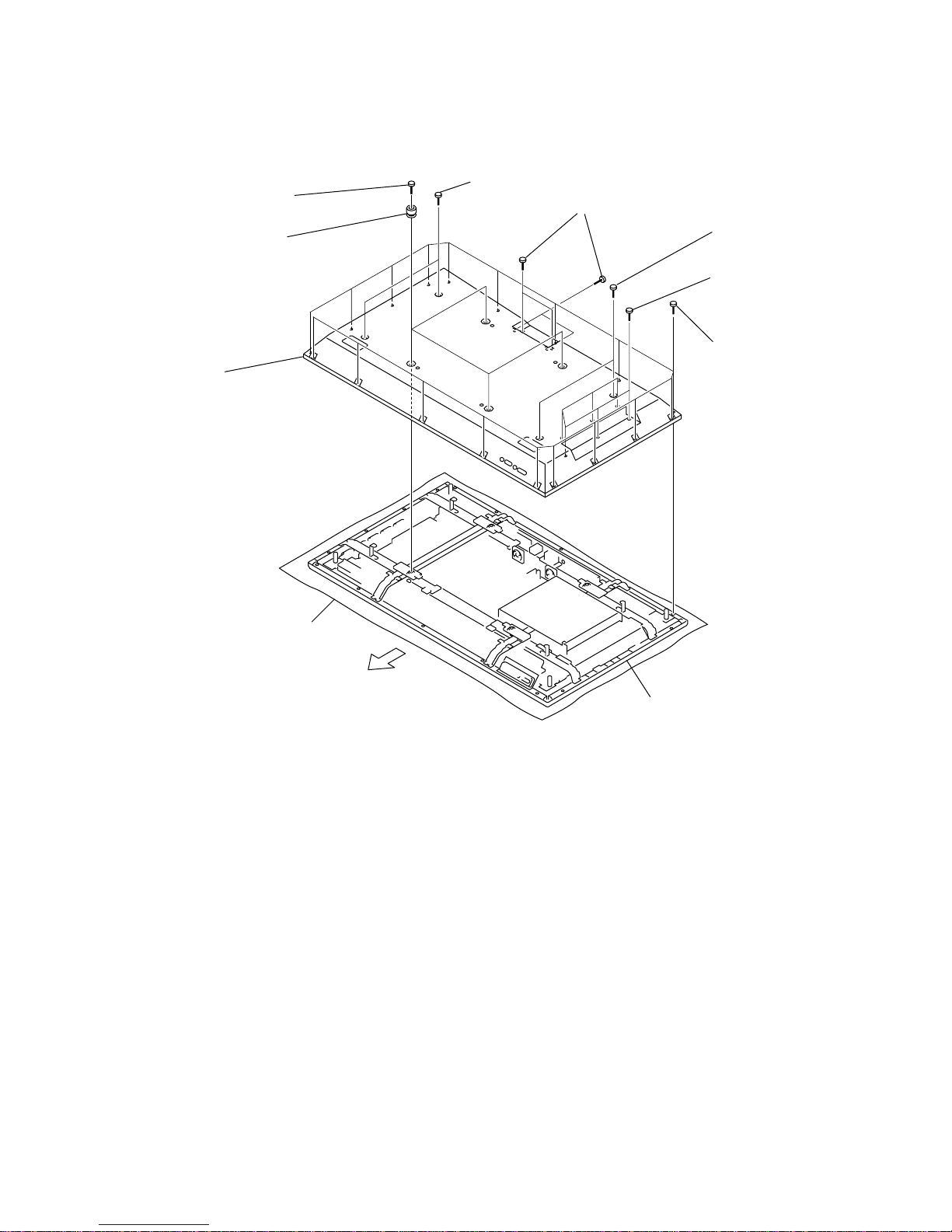

1-2-2. Rear Cover Removal

7

Eighteen

screws

(+BVTP

4 x 16)

8 Rear cover

Conductive cushion

Main chassis

1

Four screws

(+PSW 6 x 20)

6

Four screws

(+PS 3 x 8)

5 Six

screws

(+PS 3 x 8)

3 Two

screws

(+PSW 4 x 8)

4 Two

screws

(+PSW 4 x 8)

2

Four knobs

Top side

1-4

PFM-50C1/50C1E

1 Q/B shield cover

CN3003

CN3011

CN3012

CN3005

CN3007

CN3008

CN3006

CN3001

2 Seven screws

(+PSW 3 x 8)

3 Six hexagon screws

CN3002

4 Q board

Conductive cushion

Main chassis

Top side

1-2-3. Q Board Removal

1-5

PFM-50C1/50C1E

CN708

CN1001

CN1005

CN1006

CN101

CN401

CN102

CN1004

2

Six

screws

(+PSW 3 x 8)

3 B board

Conductive cushion

Main chassis

Remove the lithium battery in the

direction of arrow.

Lithium battery

(CR-1220)

Battery holder

Lithium battery removal

1 Q/B shield cover

Top side

1-2-4. B Board Removal

1-6

PFM-50C1/50C1E

3 Four screws

(+BVTP 3 x 10)

5 Fan bracket (R)

4

Purse lock

1

Four

screws

(+PSW 4 x 8)

2 DC fan

Conductive cushion

Main chassis

From Q board

Top side

1-2-5. DC Fan (R) Assy Removal

1-7

PFM-50C1/50C1E

5 SP board

0 Purse lock

!- Bottom bracket

9

AC inlet

8 Ferrite core

CN9001

CN9001

1

Two

screws

(+PSW 4 x 8)

6

Two

screws

(+PSW 3 x 12)

4

Two

screws

(+BVTP 3 x 10)

7

Plug holder (A

)

3

AC inlet block assy

2 Screw

(+PSW 4 x 8)

Conductive cushion

Main chassis

Top side

1-2-6. AC Inlet Block Assy and SP Board Removal

1-8

PFM-50C1/50C1E

4

Three

screws

(+BVTP 3 x 10)

3

P block assy

5

Three

S boards

CN9003

CN9002

CN1501

CN1501

CN1501

!]

Power bracket

7 Switching regulator

!= Three purse locks

1-9

PFM-50C1/50C1E

Main chassis

Note : When removing the main chassis, be sure that

the two persons or more must work together for removal.

Before starting removal, be sure to remove the operation button assy

from the bezel complete assy. Be very careful not to damage the flexible wires

in the top, bottom, right and left. Place the removed panel on the conductive cushion.

Bezel complete assy

2 Control button

assy

Connector

5 Bezel complete assy

Conductive cushion

Main chassis

Conductive cushion

1

Two screws

(+PSW 4 x 8)

4

Four screws

(+PSW 4 x 8)

3 S

ixteen screws

(+PSW 4 x 8)

6 Two screws

(+PSW 3 x 8)

8 Thrre screws

(+BVTP 2 x 5)

0

H2 board

7 Control button

bracket

9 Control button

CN8651

Top side

1-2-8. Bezel Complete Assy Removal

1-10

PFM-50C1/50C1E

1 Six screws

(+BVTP 4 x 16)

Bezel complete assy

Conductive cushion

2 Filter (V)

holder assy

3 Two screws

(+BVTP 3 x 10)

4 Earth plate

5 H1 board

Top side

1-2-9. H1 Board Removal

1-11

PFM-50C1/50C1E

Two SP boards

Conductive cushion

Main chassis

2

Two

screws

(+PSW 4 x 16)

1

Two

screws

(+PSW 4 x 16)

4 B block assy, Panel assy

3

Two

screws

(+PSW 3 x 16)

CN1501

CN708

Top side

Note : To remove the B block assy and panel assy, remove it after the bezel assembly

has already removed earlier. If not, it can result in distortion of bezel assembly

and damage of optical filter. Before starting removal, be sure to remove the operation button assy

from the bezel complete assy. Be v ery careful not to damage the flexible wires in the top,

bottom, right and left. Place the removed panel on the conductive cushion.

1-2-10.B Block Assy and Panel Assy Removal

n

To remove the B Block Assy and Panel Assy , remove the Bezel block assy, AC inlet block assy beforehand.

1-12

PFM-50C1/50C1E

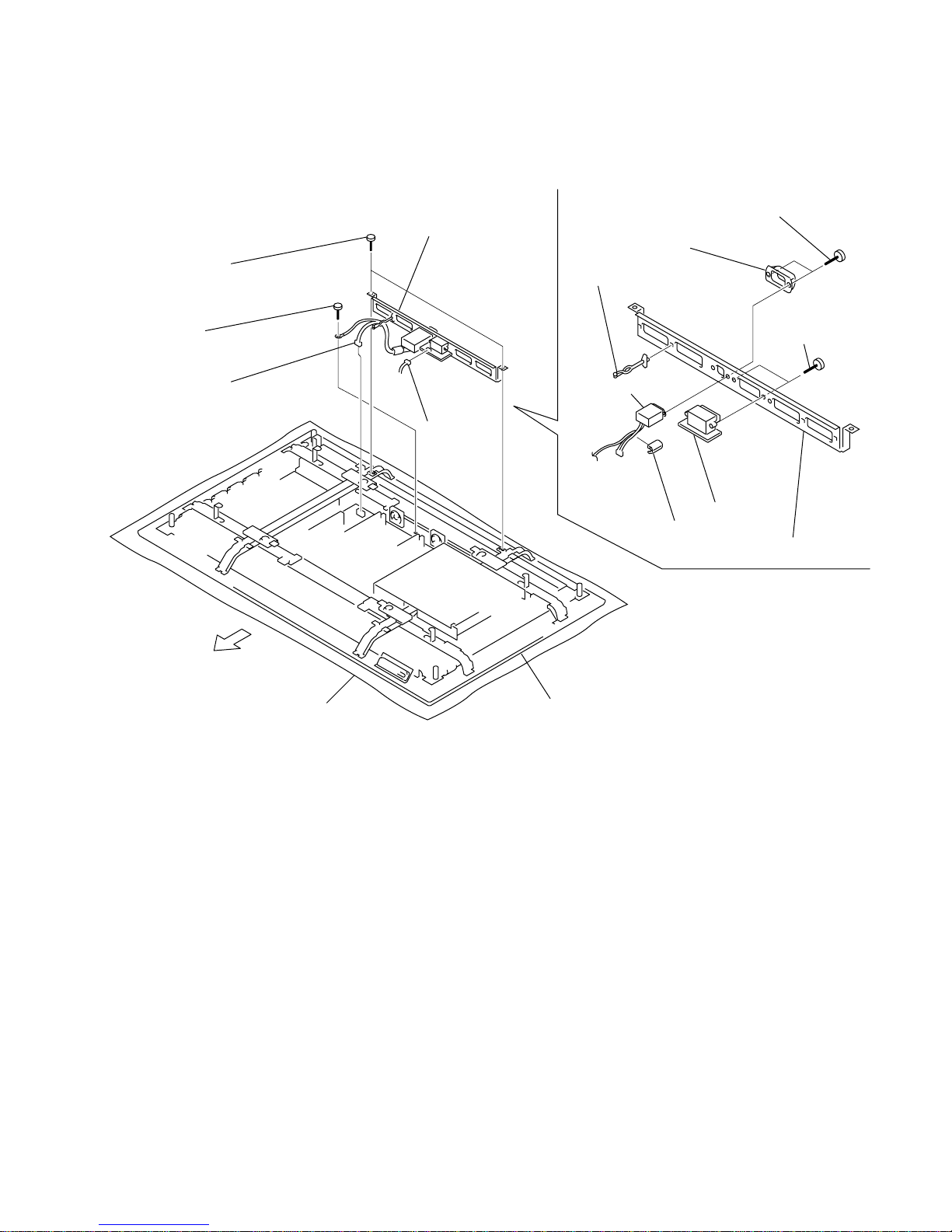

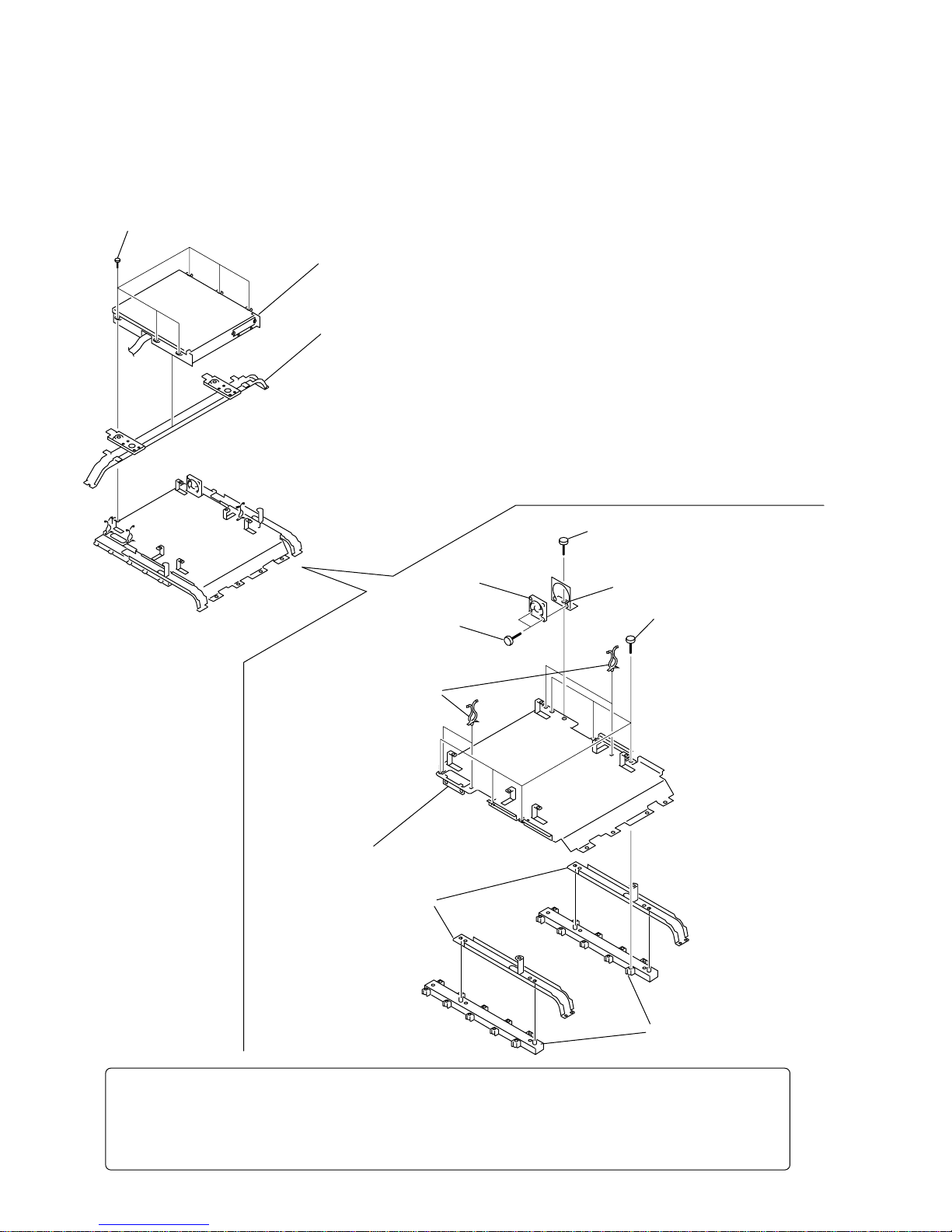

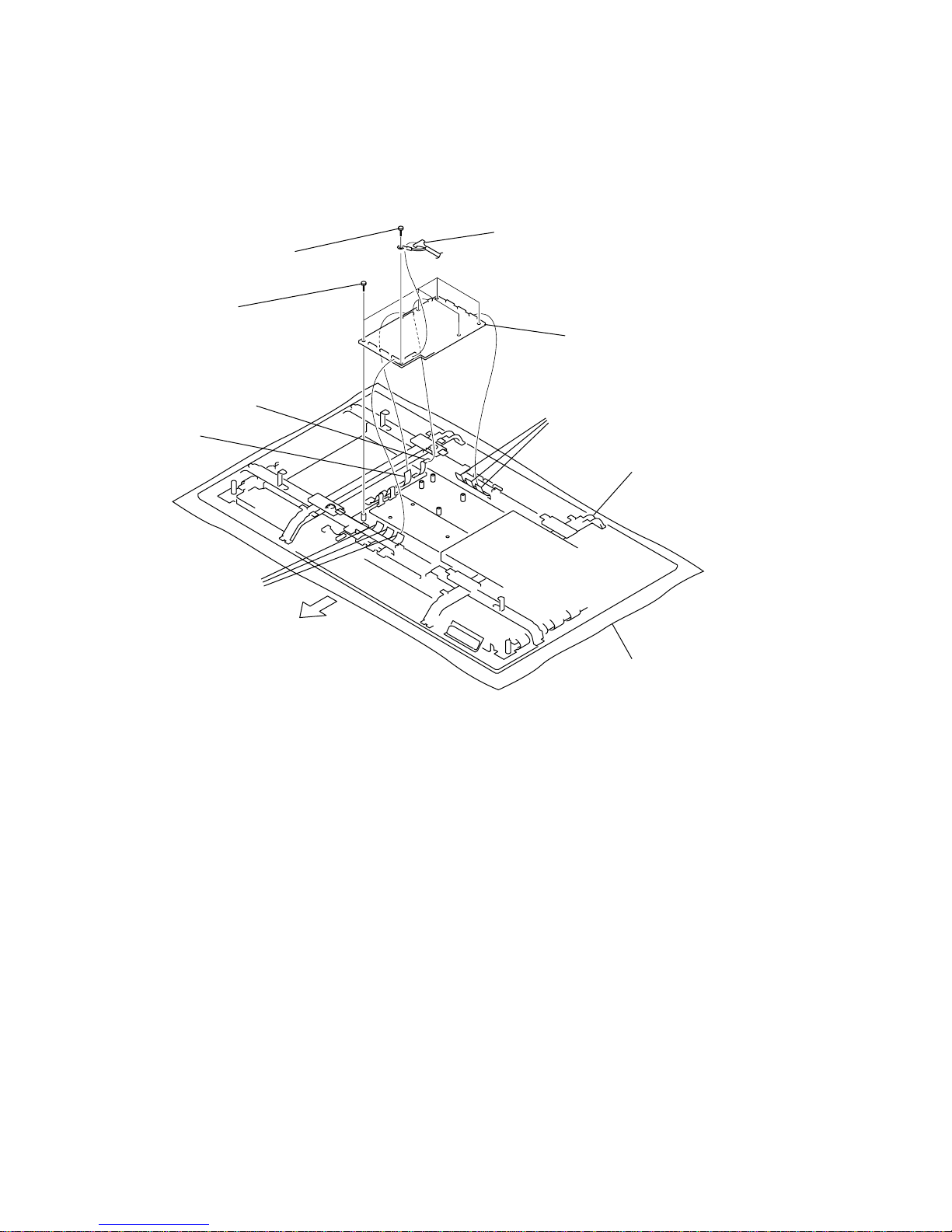

1-2-11.Q/B Bracket Assy Removal

n

To remove the Q/B bracket assy, remove the Bezel block assy, AC inlet block assy, B block assy beforehand.

3 Main frame, Two suspensions

2 B

block assy

6 Two sub frames

!= Q/B

bracket assy

9 DC

fan

0

Fan bracket

(P)

!-

Four purse locks

5

Two

positioning plates

7 Screw

(+PS 3 x 8)

8

Two

screws

(+PSW 3 x 16)

4

Six

screws

(+BVTP 3 x 10)

1

Six

screws

(+PSW 3 x 8)

Note : To remove the Q/B bracket, remove it after the bezel assembly has already removed earlier.

If not, it can result in distortion of bezel assembly and damage of optical filter.

Before starting removal, be sure to remove the operation button assy

from the bezel complete assy. Be very careful not to damage the flexible wires in the top,

bottom, right and left. Place the removed panel on the conductive cushion.

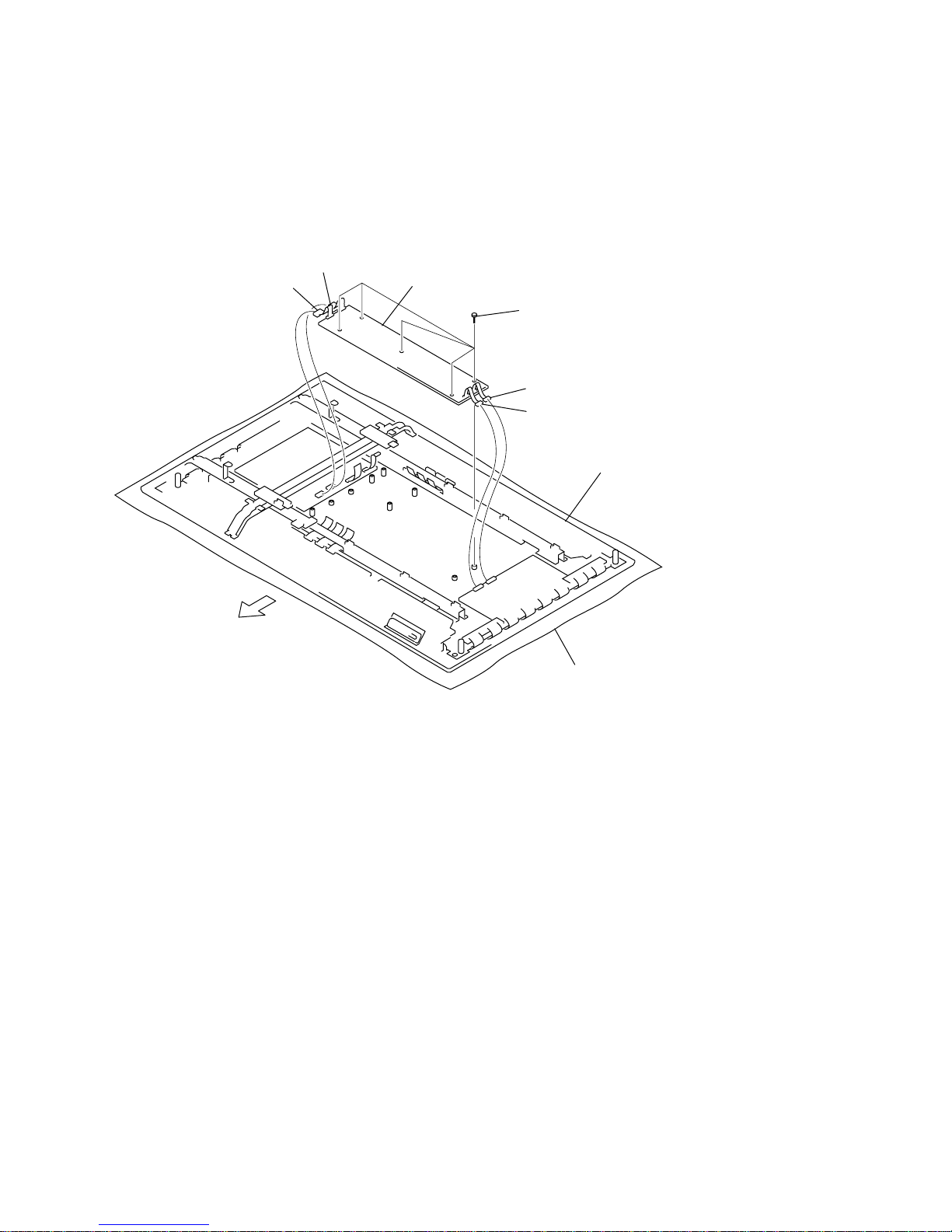

1-13

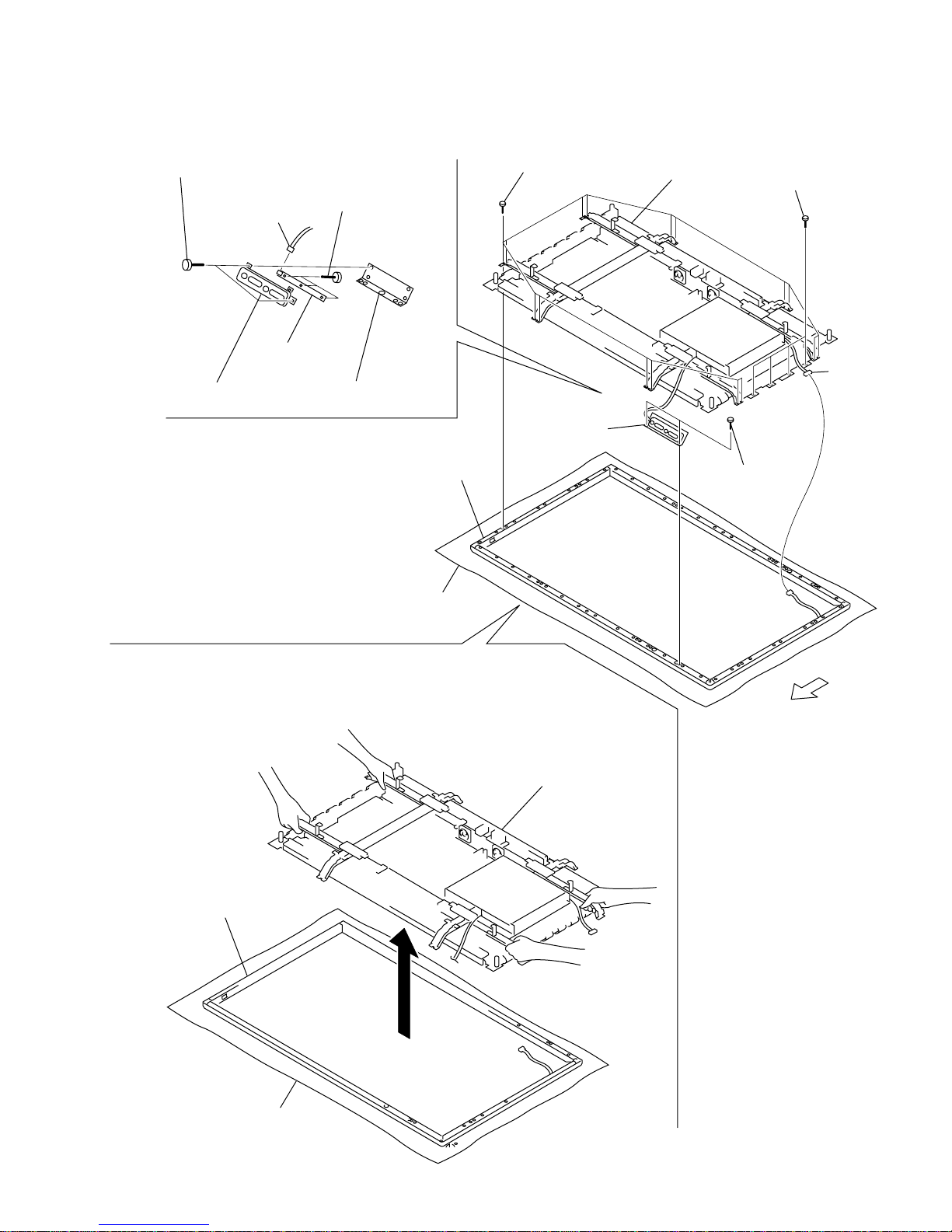

PFM-50C1/50C1E

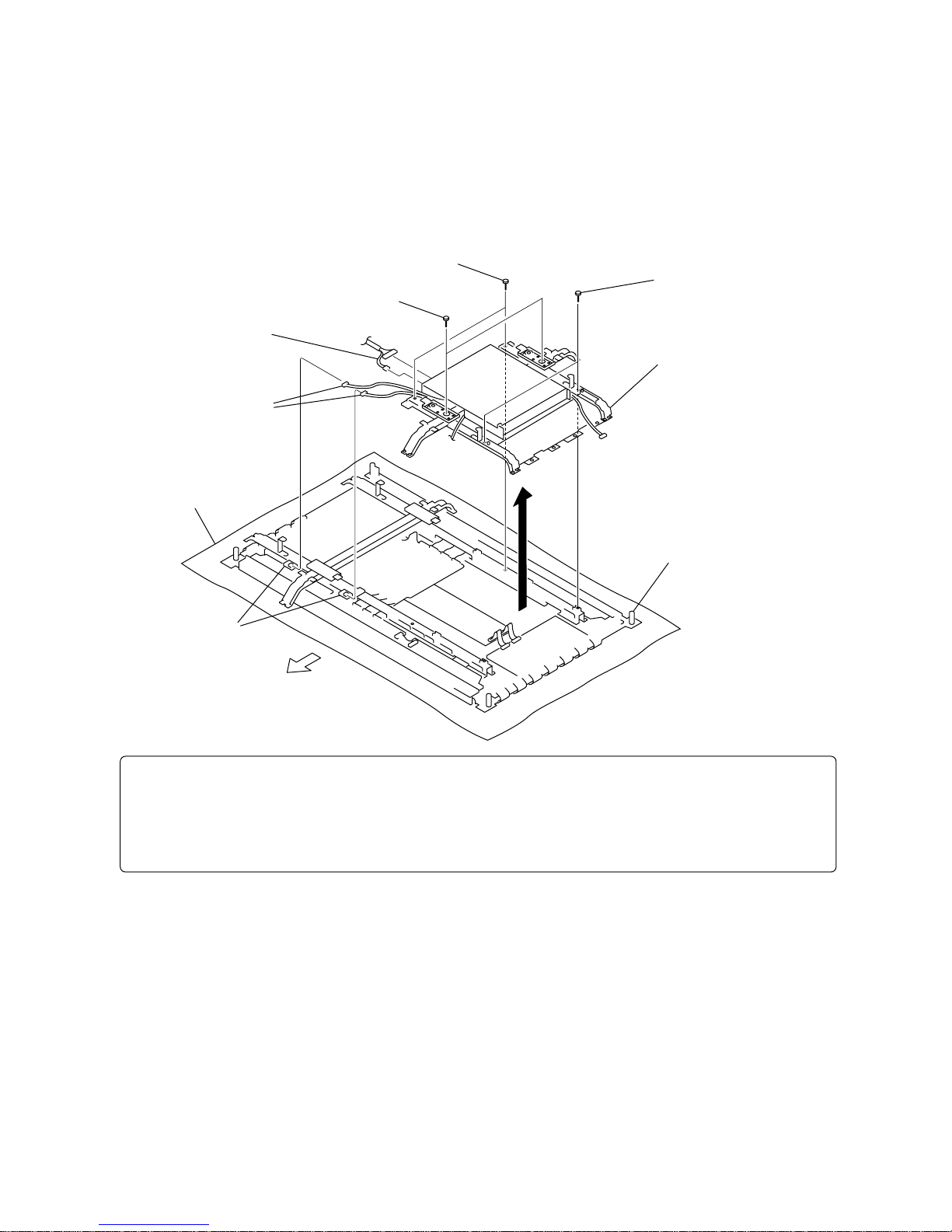

Plasma display panel

2

P block assy

1

AC inlet block assy

3 B block assy, Panel assy

Note : When installing the

B block assy and panel assy, install the position setting plate

referring to the “Q/B bracket removal” and determine position

of the Q/B block. After that, install the Q/B block.

Conductive cushion

Conductive cushion

Main chassis

Top side

Note :To remove the plasma display panel, remove it after the bezel assembly has already

removed earlier. If not, it can result in distortion of bezel assembly and

damage of optical filter. Before starting removal, be sure to remove the operation button assy

from the bezel complete assy. Be v ery careful not to damage the flexible wires in the top,

bottom, right and left. Place the removed panel on the conductive cushion.

1-2-12. Plasma Display Panel Removal

m

. When removing the plasma display panel, remove the bezel assembly, AC inlet block assembly, P block assembly, B

block assy and panel assy. Then remove the respective circuit boards that are attached to the panel.

. When removing the main chassis, be sure that the two persons or more must work together for removal.

1-14

PFM-50C1/50C1E

CN1 to CN4

CN7301

CN7303

6 Common PKG board

2 Common joint PKG (U) board

4 Common joint PKG (L) board

CN104

CN12

CN11

3

Two

screws

(+PSW 3 x 8)

1

Two

screws

(+PSW 3 x 8)

5

Four

screws

(+PSW 3 x 8)

CN7

CN8CN6

CN7304

CN7302

Conductive cushion

Main chassis

Top side

1-2-13.Common PKG Board Removal

n

To remove the Common PKG board, remove the AC inlet block assy, B block assy and panel assy

beforehand.

1-15

PFM-50C1/50C1E

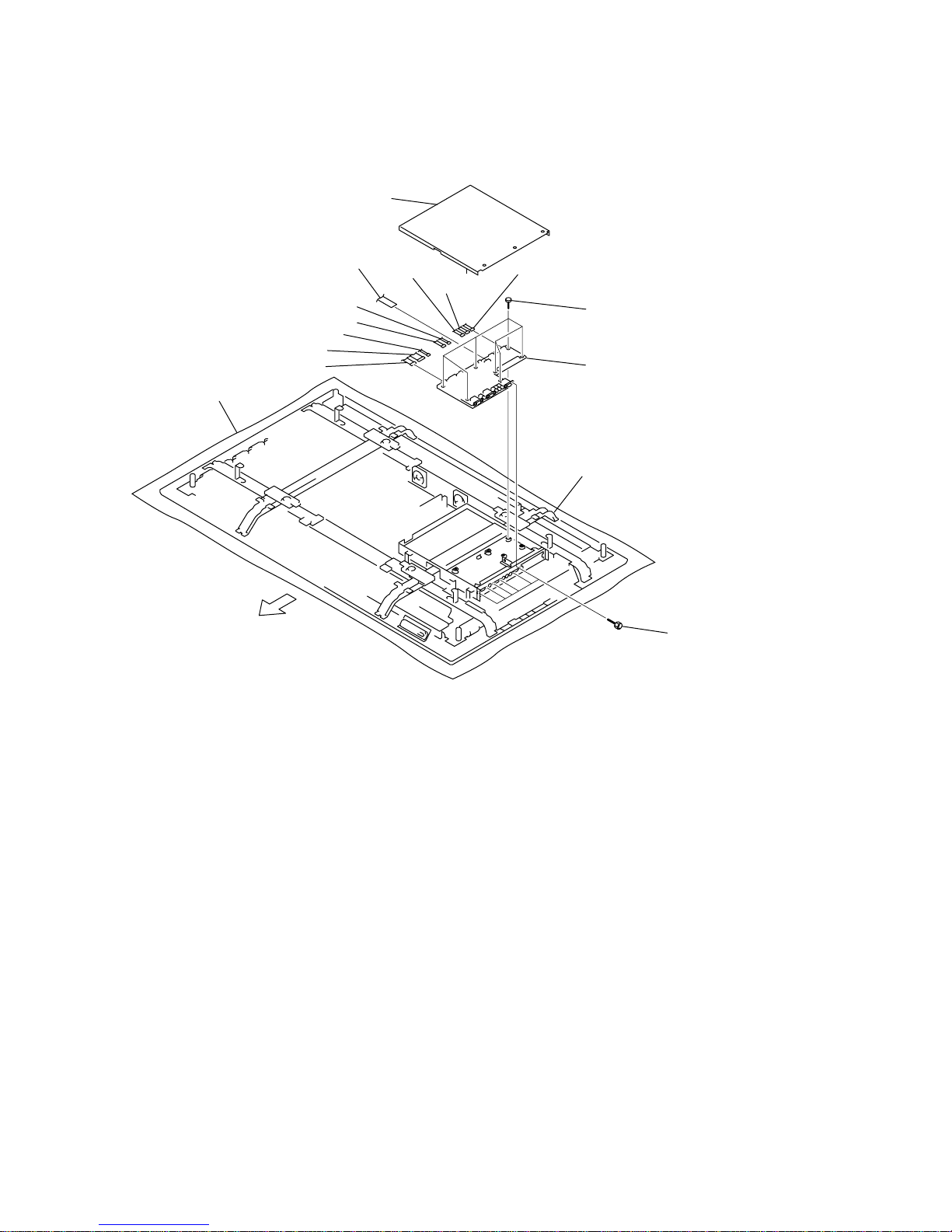

3 Digital PKG board

2 Five screws

(+PSW 3 x 8)

1 Screw (+PSW 3 x 8)

CN904 to CN906

CN901 to CN903

CN751

CN801

CN101

Conductive cushion

Main chassis

Top side

1-2-14.Digital PKG Board Removal

n

To remove the Digital PKG board, remove the P block assy beforehand.

1-16

PFM-50C1/50C1E

2 Collection joint PKG board

1 Five screws

(+PSW 3 x 8)

CN8

CN10

CN9

CN6

Conductive cushion

Main chassis

Top side

1-2-15.Collection Joint PKG Board Removal

n

To remove the collection joint PKG board, remove the AC inlet block assy, B block assy, panel assy,

P block and Digital PKG board beforehand.

1-17

PFM-50C1/50C1E

2 Remove the scan PKG board

in the direction of the arrow.

1

Ten

screws

(+PSW 3 x 8)

CN5

CN7

CN1

CN10

CN9

CN12

CN11

CN6

CN105

Conductive cushion

Main chassis

Top side

1-2-16.Scan PKG Board Removal

n

To remove the scan PKG board, remove the DC fan (R) assy beforehand.

1-18

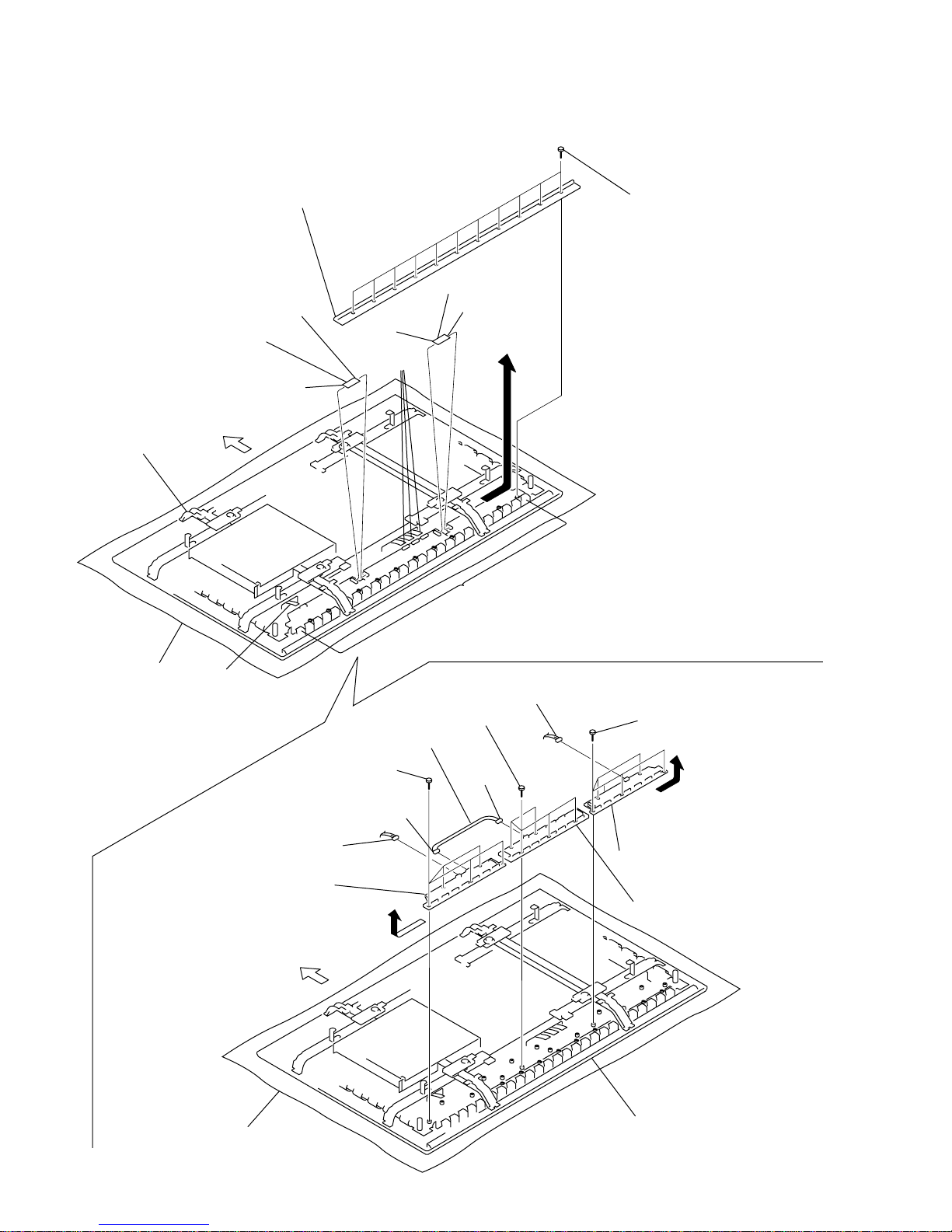

PFM-50C1/50C1E

5 Two sub frames

6 Two positioning plates

1

Two

screws

(+PSW 4 x 16)

2

Two

screws

(+PSW 4 x 16)

!= Scan joint PKG

(B) board

8 Scan joint- joint PKG board

0 Scan joint PKG

(A) board

7

Four

screws

(+PSW 3 x 8)

CN202 to CN209

9

Three

screws

(+PSW 3 x 8)

!-

Three

screws

(+PSW 3 x 8)

Conductive cushion

Main chassis

4 Main frame, Two suspensions

CN210

CN201

3

Two

screws

(+PSW 3 x 16)

Top side

Top side

Note : To remove the scan joint PKG (A) and (B) boards, remove it after the bezel assembly has

already removed earlier. If not, it can result in distortion of bezel assembly and damage of

optical filter. Before starting removal, be sure to remove the operation button assy

from the bezel complete assy. Be very careful not to damage the flexible wires in the top,

bottom, right and left. Place the removed panel on the conductive cushion.

1-2-17.Scan Joint PKG (A) and (B) Boards Removal

n

To remove the scan joint PKG (A) and (B) board, remove the bezel assy and the DC fan (R) assy beforehand.

1-19

PFM-50C1/50C1E

1 Eleven screws

(+PSW 3 x 8)

2 Remove the flexible board retaining

bracket in the direction of the arrow A.

3 FFC50C2-01

4 FFC50C2-01

CN1 to CN3

CN8

CN5

CN1

CN4

CN1 to CN22

6 Five screws

(+PSW 3 x 8)

8 Five screws

(+PSW 3 x 8)

0 Five screws

(+PSW 3 x 8)

7 Remove the signal joint PKG (LU)

board in the direction of the arrow B.

CN2

CN10

!- Remove the signal joint PKG

(RU) board in the direction

of the arrow C.

9 Signal joint PKG (MU) board

CN3

CN6

Conductive cushion

Main chassis

Conductive cushion

Main chassis

5 CBL50C2-04

Top side

Top side

A

B

C

1-2-18.Signal Joint PKG (RU), (MU), (LU) Board Removal

1-20

PFM-50C1/50C1E

CN8

CN9

3 FFC50C2-01

4 FFC50C2-01

CN1

to

CN3

CN4

CN5

CN1

6 Five screws

(+PSW 3 x 8)

8 Five screws

(+PSW 3 x 8)

0 Five screws

(+PSW 3 x 8)

7 Remove the signal joint PKG (LL)

board in the direction of the arrow B.

CN2

CN6

CN11

CN10

9 Signal joint PKG (ML) board

2 Remove the flexible board retaining

bracket in the direction of the arrow A.

1 Eleven screws

(+PSW 3 x 8)

Conductive cushion

Main chassis

Conductive cushion

Main chassis

CN1

to

CN22

!- Remove the signal joint PKG (RL)

board in the direction of the arrow C.

5 CBL50C2-04

Top side

Top side

A

B

C

1-2-19.Signal Joint PKG (RL), (ML), (LL) Board Removal

1-21

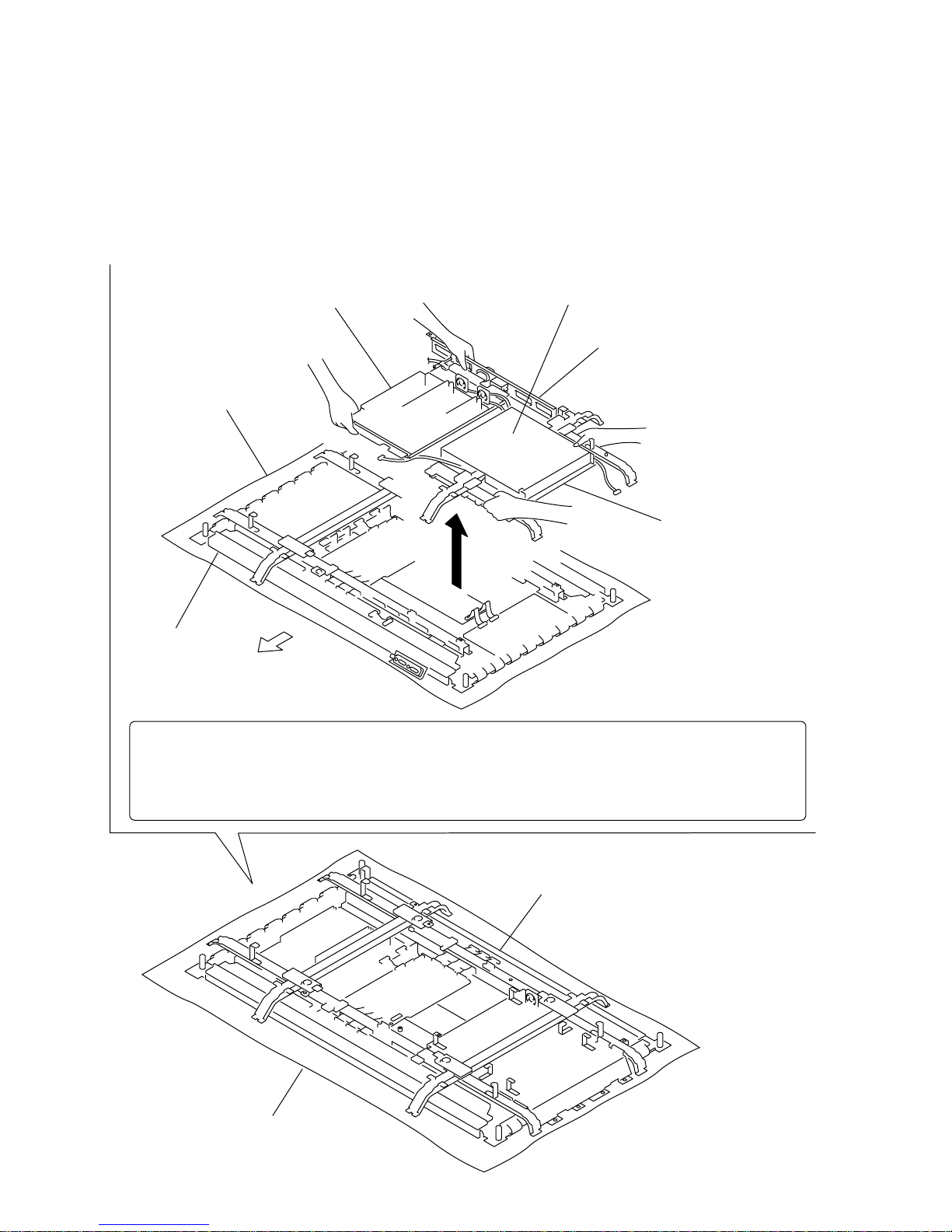

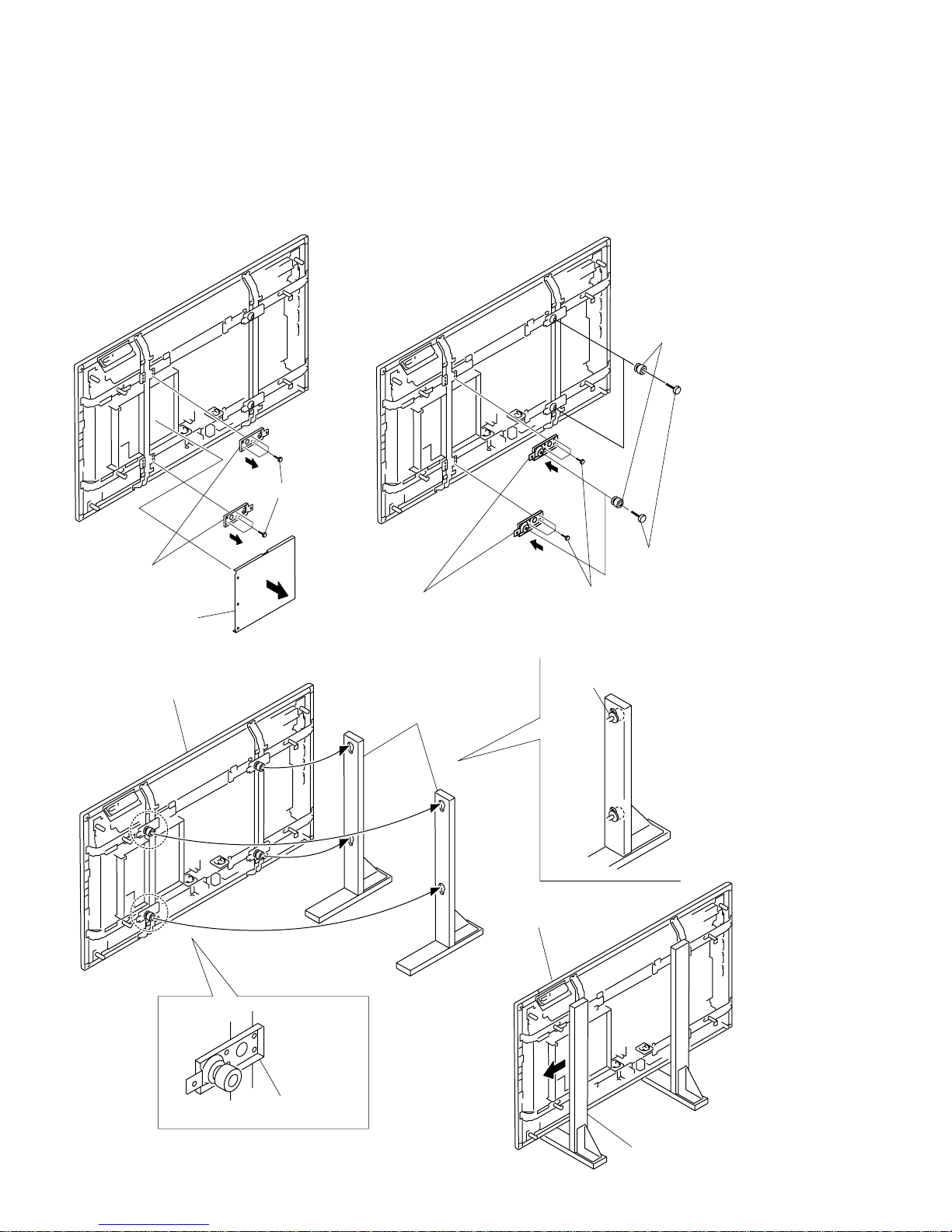

PFM-50C1/50C1E

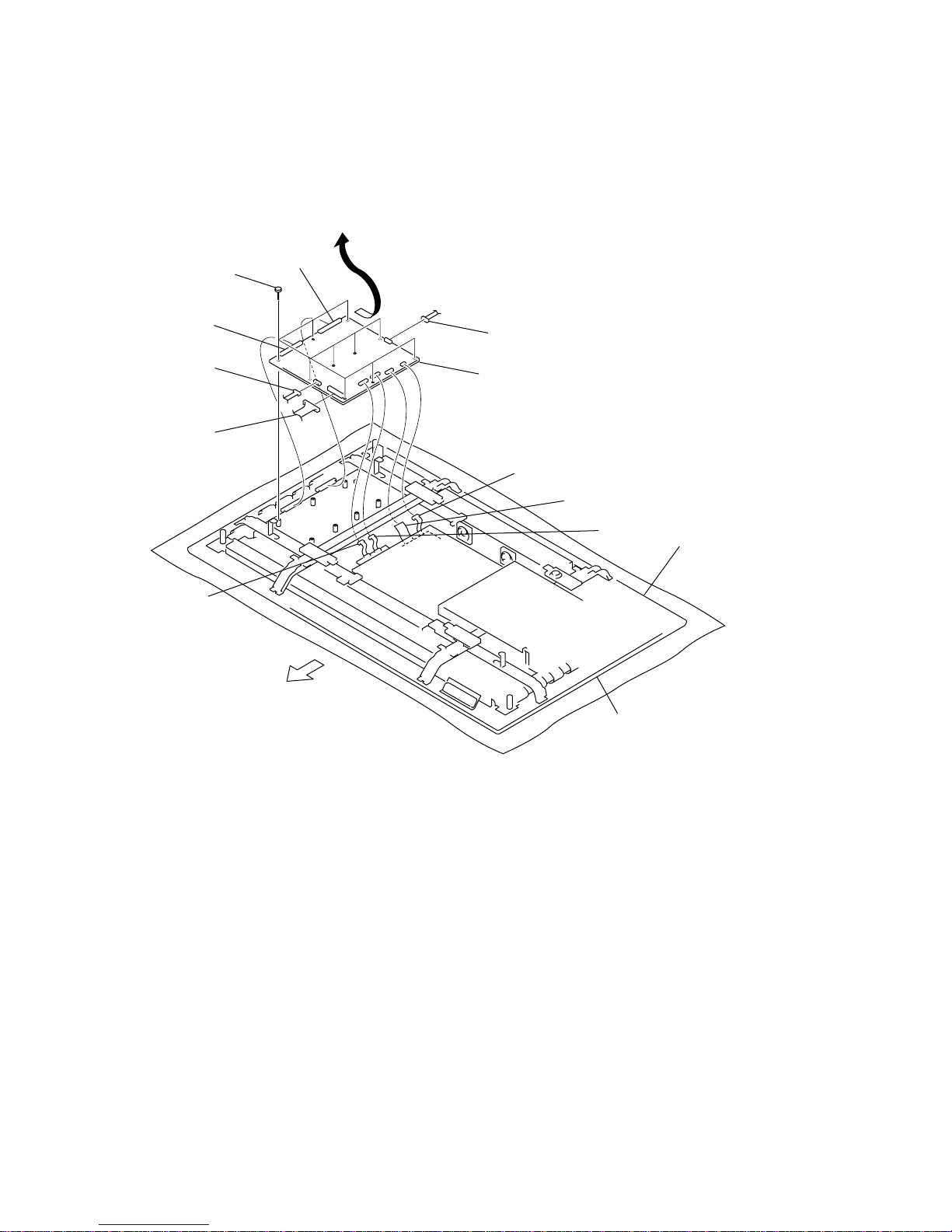

3 Four knobs

1 Q/B shield cover

2 Four screws

(+PSW 6 x 20)

4 Main chassis

Main chassis

5

Two

stands

7 The stand is attached

inside the PDP panel.

Direction of

the two suspensions.

6 Insert the four knobs

into the holes of the stand.

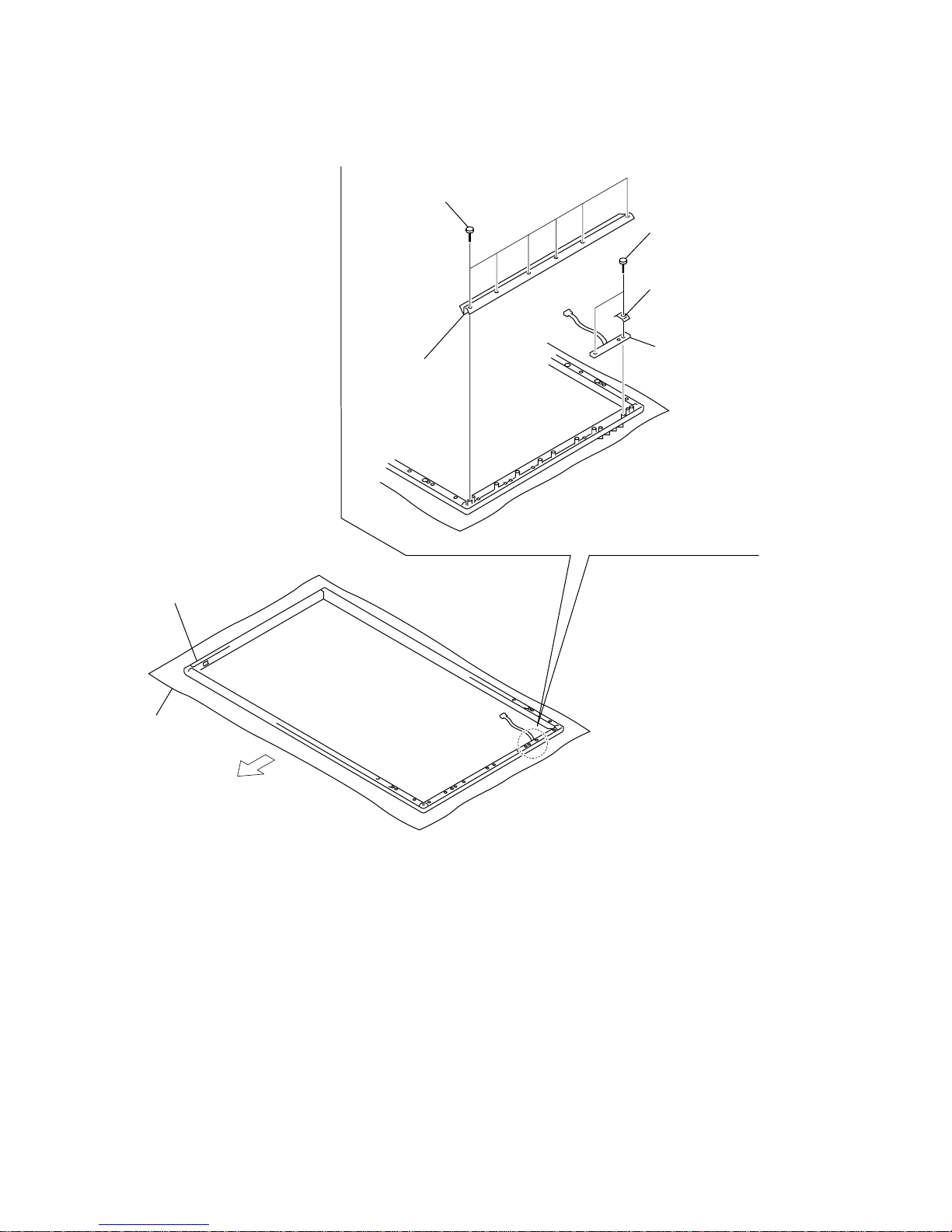

1-3. Service Position

1-3-1. Service Position of Q Board

n

When you are going to set up the PDP panel in the service position, remove the rear cover first, and then

set up the PDP panel in the service position.

1-22

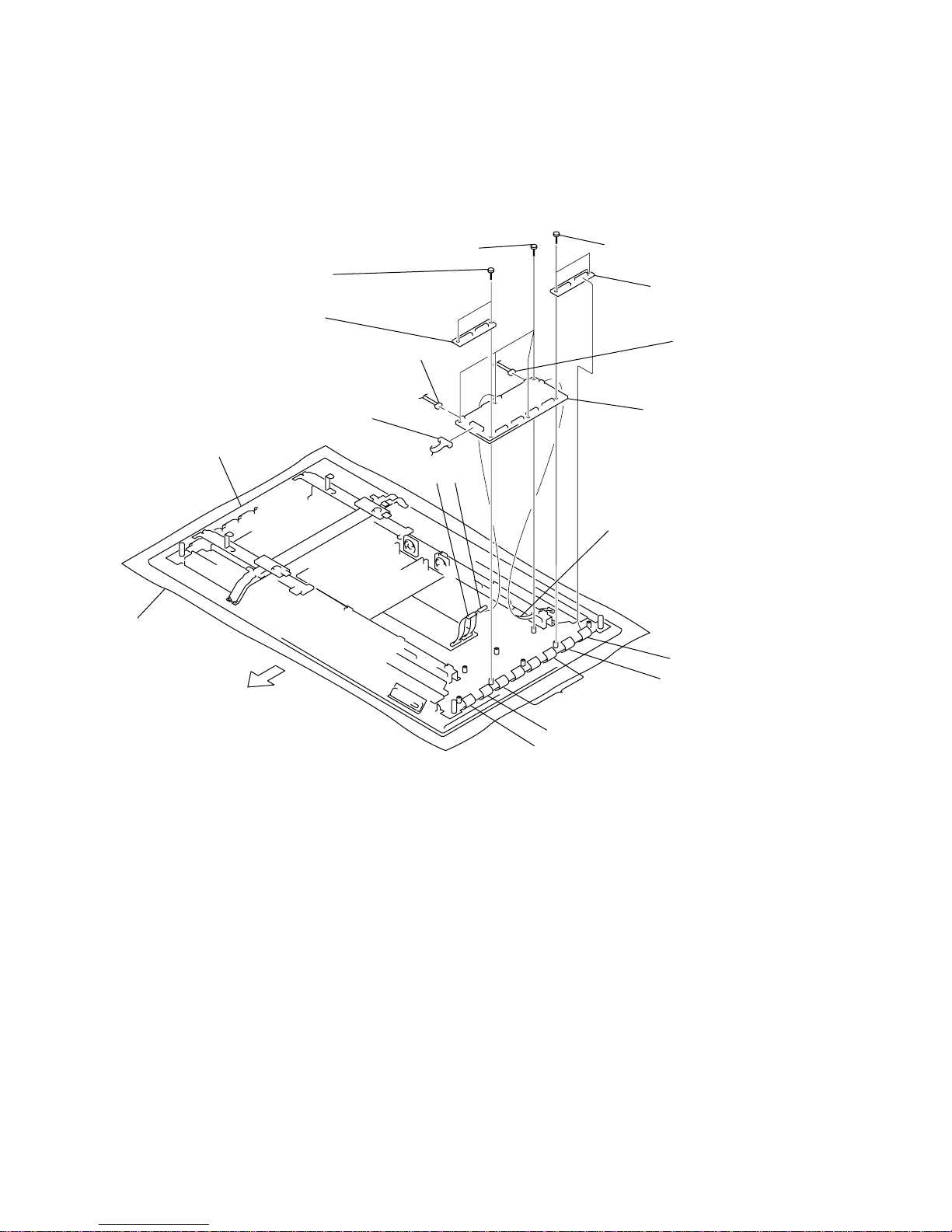

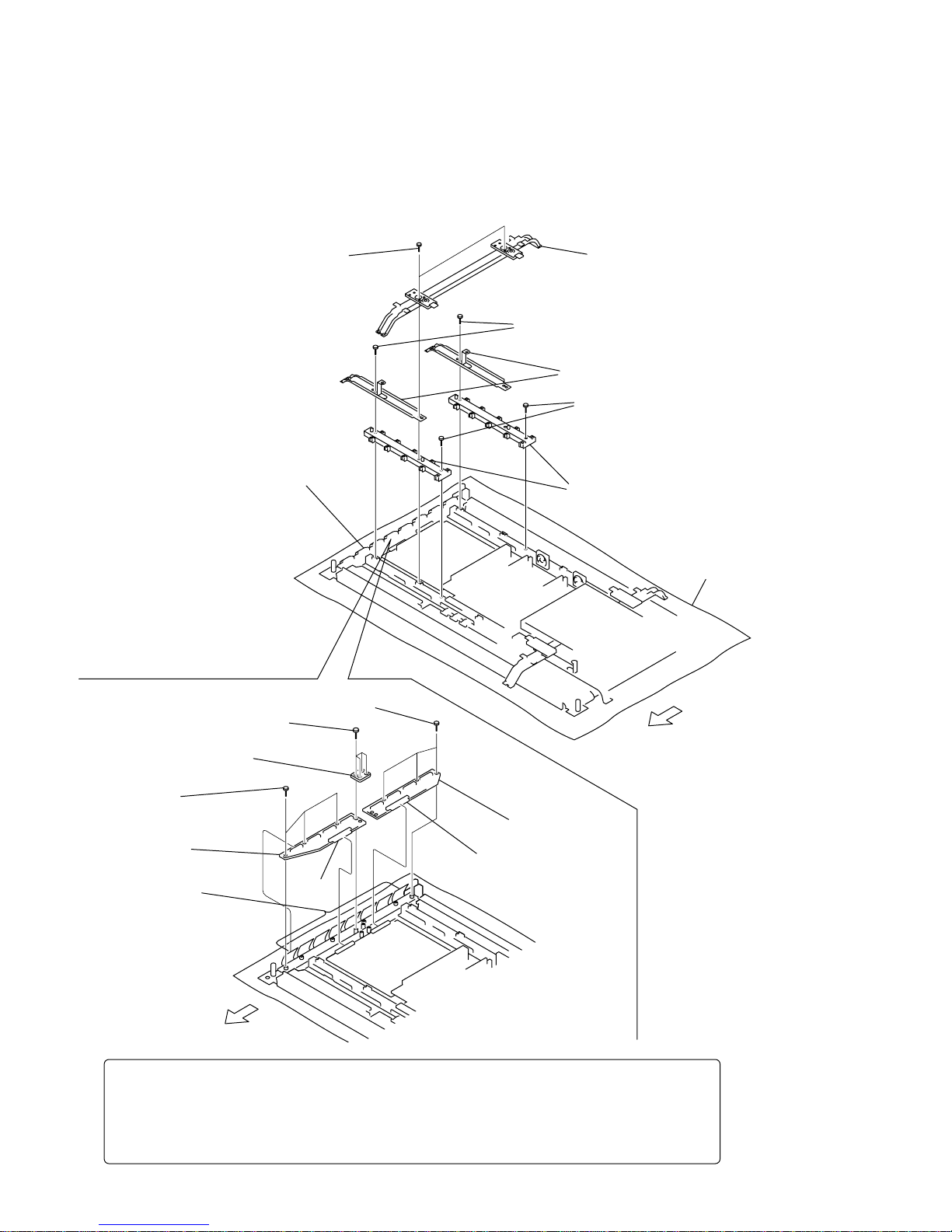

PFM-50C1/50C1E

1 Q/B shield cover

2 Six screws

(+PSW 4 x 8)

3 T wo suspensions

8 Main chassis

Main chassis

9 T wo suspensions

!- The stand is attached

outside the PDP panel.

Direction of installation

of the two suspensions.

!/Insert the four knobs

into the holes of the stand.

5 Six screws

(+PSW 4 x 8)

4 T wo suspensions

6 Four knobs

7 Four screws

(+PSW 6 x 20)

1-3-2. Service Position of B Board

n

When you are going to set up the PDP panel in the service position, remove the rear cover first, and then

set up the PDP panel in the service position.

Loading...

Loading...