Page 1

TROUBLE SHOOTING GUIDE

MODEL

.............. ......... ....................

DEST. CHASSIS NO. MODEL DEST. CHASSIS NO.

PFM-500A1WU US/CND

PFM-500A1WE AEP

.............. ......... ....................

MB-514

RM-921

PFM-500A1WU/WE Flat Panel Monitor

MB-514 Mounting Bracket

RM-921 Remote Commander

FLAT PANEL MONITOR

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

PFM-500A1WU/500A1WE

Page 3

Table of Contents

1. Introduction

1-1. PDP Unit (FPF42C10660UD) Analysis Manual ........................................1-1

1-2. Test Equipment ...........................................................................................1-2

1-3. Burn-in Device ............................................................................................1-3

1-4. Measuring Device .......................................................................................1-3

1-5. Parts List and Their Outlined Description of the PDP Unit........................1-4

2. Repair Flow........................................................................................... 2-1

3. Data

3-1. Check Point (X-SUS) .................................................................................. 3-1

3-2. Check Point (Y-COM) ................................................................................3-2

3-3. Check Point (DC/DC) ................................................................................. 3-3

3-4. Check Point of Voltage (X-SUS, Y-SUS) ..................................................3-4

3-5. Glossary....................................................................................................... 3-5

3-6. Connection to Test Equipment....................................................................3-6

3-7. Test Equipment ...........................................................................................3-7

3-8. Photo (Burn-in Unit) ................................................................................... 3-8

3-9. Burn-in Unit Instruction Manual.................................................................3-9

3-10. Criteria Table ............................................................................................3-13

3-11. Voltage Setting Procedure.........................................................................3-19

3-12. Display Test Manual ................................................................................. 3-24

3-13. VG-826 Program Display Pattern .............................................................3-28

3-14. Fixed Display Exclusive-key Pattern ........................................................3-30

3-15. Decision Criteria Table ............................................................................. 3-31

3-16. PC Board Replacing Proceduce ................................................................ 3-32

3-17. Each PC Board Installation Screw Position/Connector Position ..............3-33

PFM-500A1WU/500A1WE

1

Page 4

Page 5

1. Introduction

1-1. PDP Unit (FPF42C10660UD) Analysis Manual

This manual explains the failure analysis procedure l for PDP unit and it is applied to analysis by

the test equipment below. To perform failure analysis, see the data, as follows :

. Repair flow

. Check point (X-SUS) ............................ 3-1.

. Check point (Y-COM) .......................... 3-2.

. Check point (DC/DC) ........................... 3-3.

. Voltage check........................................ 3-4.

. Glossary ................................................ 3-5.

. Connection to test equipment ................ 3-6.

. Test equipment....................................... 3-7.

. Photo (Burn-in unit) .............................. 3-8.

. Burn-in unit Instruction Manual ........... 3-9.

. Criteria table.......................................... 3-10.

. Voltage setting procedure ..................... 3-11.

. Display test Manual .............................. 3-12.

. PC board replacing procedure............... 3-16.

Always, allow the self electrical discharge about 30 seconds between shutting down the external power

supply and the operation of replacing each PC board or disconnecting connectors in the repair and

analysis process.

PFM-500A1WU/500A1WE

1-1

Page 6

1-2. Test Equipment (3-6, 7)

Display test is conducted with the facilities listed below and whether the test results can satisfy the criteria

is determined by the display special point standard in the 3-11.

<Facilities used>

1. Video signal generator : Astro design VG-826 (Refer to the 3-12)

2. External keyboard : Astro design RB-614C (Refer to the 3-12)

3. PDP function test switch (APC/DISP ENABLE/HQEN/luminance variable volume)

1 APC (monitoring power consumption/abnormal operation)

ON: NEW.APC mode [Stability hour (about 3 minutes)]

It can monitor the power consumption on the circuit to maintain the rating power.

In addition, it can monitor the X/YSUS operation and shut down the PDP circuit immediately

when any abnormal operation is detected. This prevents further damage to the circuit.

OFF: OLD.APC mode [Stability hour (about 10 seconds)]

In this mode, the internal power supply is activated forcibly to run the electricity

on the circuit, regardless of whether abnormal operation is detected.

Set this mode with care for failure analysis.

The use of APC switch in “OFF” mode may likely cause a secondary failure. Thus, handle this switch

with care. Do not power on the external power supplies at one time.

2 DISP ENABLE (screen display ON/OFF)

ON : Every operation of displaying data is disabled.

OFF : Every operation of displaying data is enabled.

3 HQEN ENABLE (false frame line deletion function)

ON : The difference of each step is lightened in gradation display

OFF : Each step in gradation is displayed as it is and false frame line can be seen.

4 Luminance variable volume (for changing the screen luminance)

Turn the volume to the right to increase the brightness or turn the volume to the left to decrease

the brightness.

4. External power supplies (See the 3-7)

1 Vcc 0 ~ 6 V 10 A

2 Va 0 ~ 110 V 2.0 A

3 Vs 0 ~ 250 V 15 A

* Observe the following sequence, as shown below when using external power supplies:

Power ON : Vcc → Va → Vs

Power OFF : Vs → Va → Vcc

5. Power supply for exclusive use (See the 3-6)

FPF10P-AC100/240 B Rev.B

1-2

PFM-500A1WU/500A1WE

Page 7

1-3. Burn-in Device (3-8) 1

(for the Handling Method, Refer to 3-9.)

1-4. Measuring Device

1 Oscilloscope...................... 1 (equivalent to 100 MHz)

2 Digital Multimeter ............ 1

3 Analog tester ..................... 1

PFM-500A1WU/500A1WE

1-3

Page 8

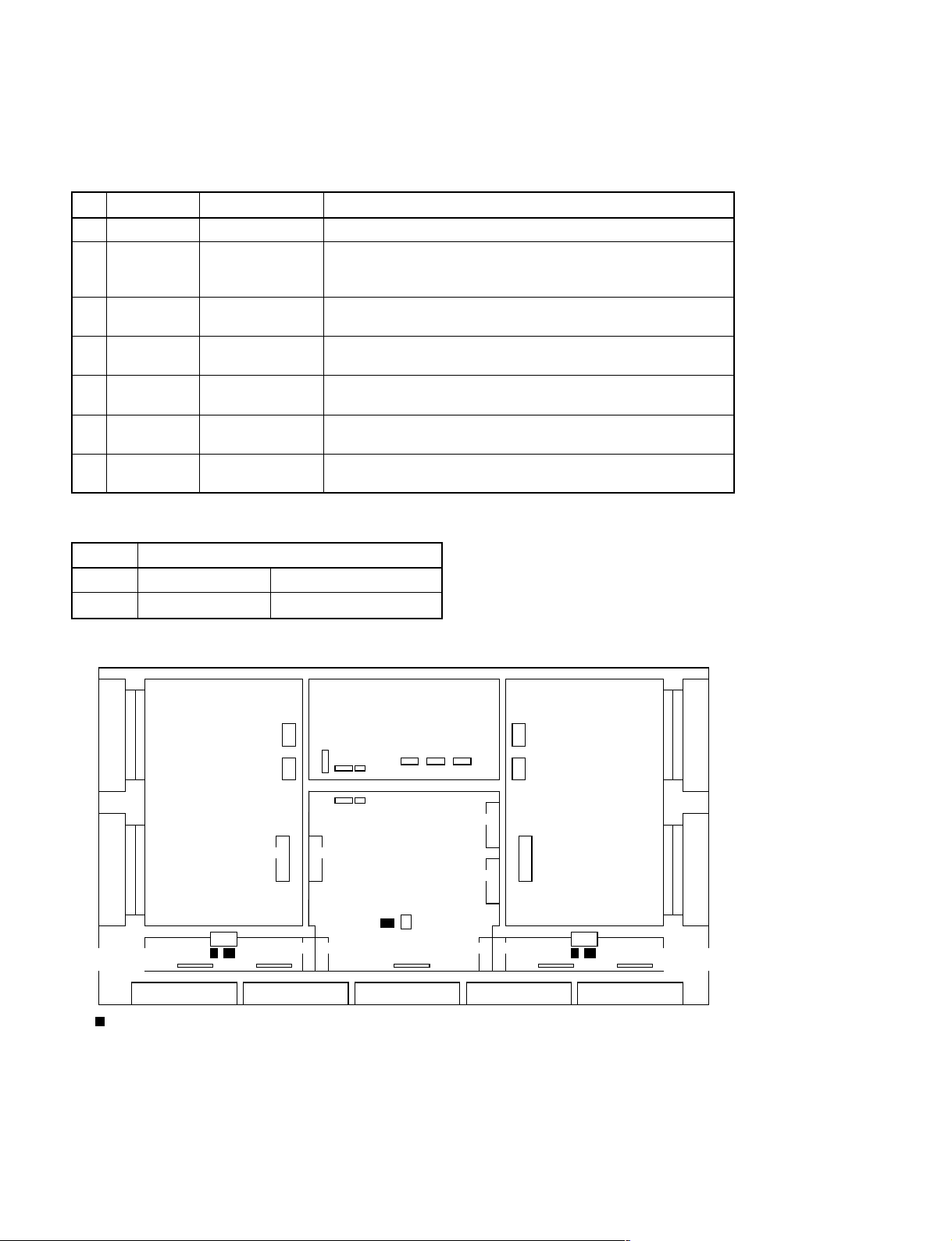

1-5. Parts List and Their Outlined Description of the PDP Unit

<Outlined description of each part>

No NAME Drawing number Basic operation outline

1 Panel FPF10R-UCPANEL Processes and displays data in image processing

2 Logic FPF10R-LOGIC12 Stores and processes data and monitors the power consumption and

PC board X/YSUS operation.

3 XSUS FPF10R-XSUS Controls reservation, deletion, and writing of display data.

PC board

4 YSUS FPF10R-YSUS13 Controls writing and reservation of display data.

PC board

5 RBUS FPF10R-ABUSR Controls output of screen data to ACOM1, 2.

PC board

6 LBUS FPF10R-ABUSL Controls output of screen data to ACOM4, 5.

PC board

7 DC/DC FPF10R-DC/DC Generates the secondary power supplies Ve. Vsc.

PC board Vw. and _Vy by the external power supply.

<EP ROM and YSUS Correspondence table>

Model UD01

ROM 197G 197L

YSUS NA21701-B192 NA21701-B241

Controls output of screen data to ACOM3.

<Mounting diagram each PC board (rear view)>

YCOM UP

CN

YCOM DOWN

CN

LBUS PC board

Fuse mounting position

46

47

CN43

CN44

ACOM5

YSUS PC board

CN18

CN13

CN41

CN42

CN40

CN17

CN12

ACOM4

CN30

CN20CN37

CN37

CN5CN4

CN3

CN18

DC/DC

CN49

CN25CN24CN23

CN2

Logic PC board

1 or 2

CN9

CN16

ACOM3 ACOM2 ACOM1

CN1

CN7

CN50

XSUS PC board

CN48

CN10

CN15

CN11

CN51

CN52

CN14

XBUS UP

CN

53

XBUS DOWN

CN

54

RBUS PC board

1-4

PFM-500A1WU/500A1WE

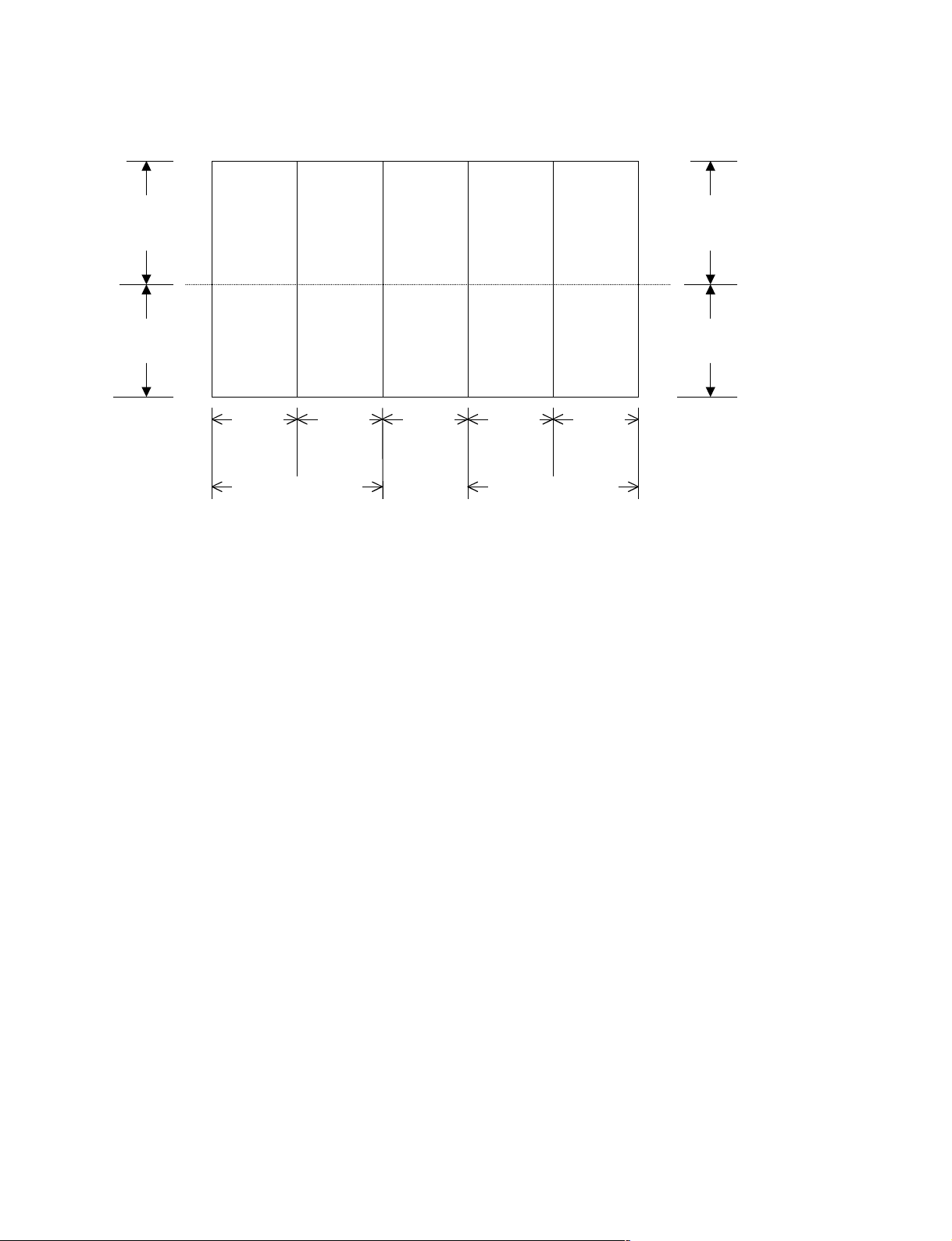

Page 9

<Control section of each display (front view)>

XBUS UP

Display control

section

XBUS DOWN

Display control

section

1/2 1/2

Panel

1/2

1/5

1/5 1/5 1/5 1/5

ACOM1 ACOM2 ACOM 3 ACOM4 ACOM5

Display control

section

FUSE2 FUSE1

RBUS control section LBUS control section

Display control

section

Display control

section

FUSE201

Logic control

Display control

section

FUSE2

Display control

section

FUSE1

section

1/2

YCOM UP

Display control

section

YCOM DOWN

Display control

section

PFM-500A1WU/500A1WE

1-5

Page 10

Page 11

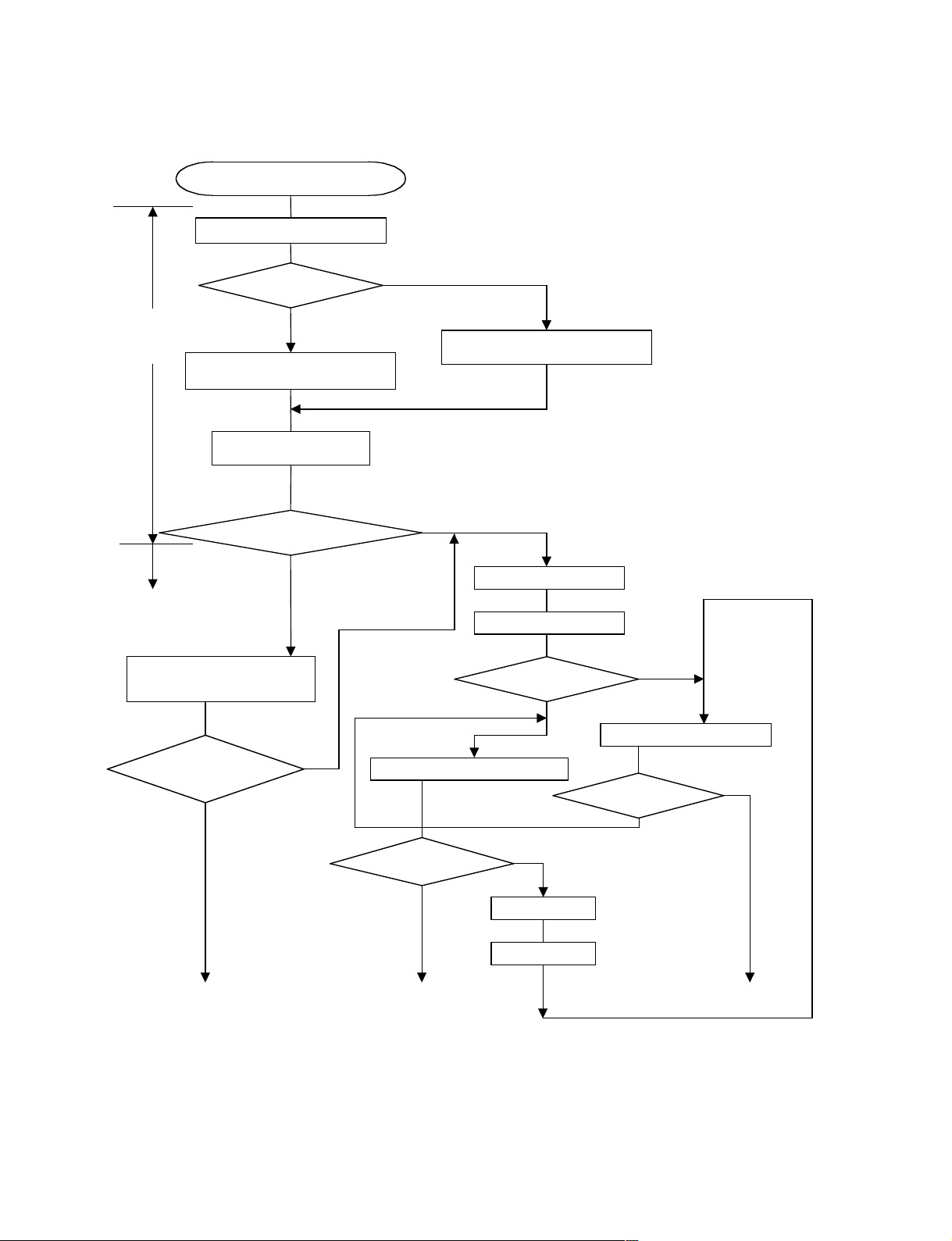

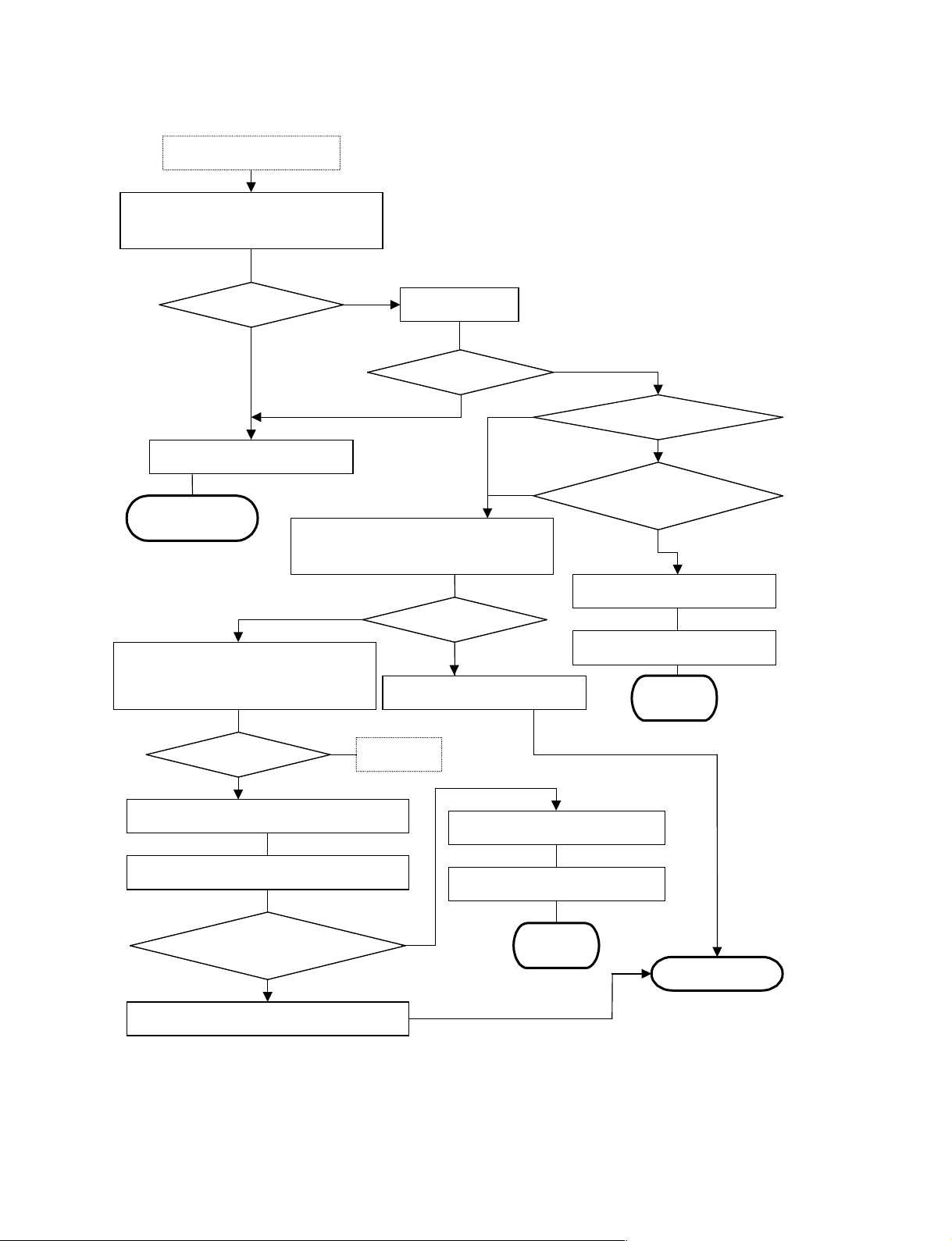

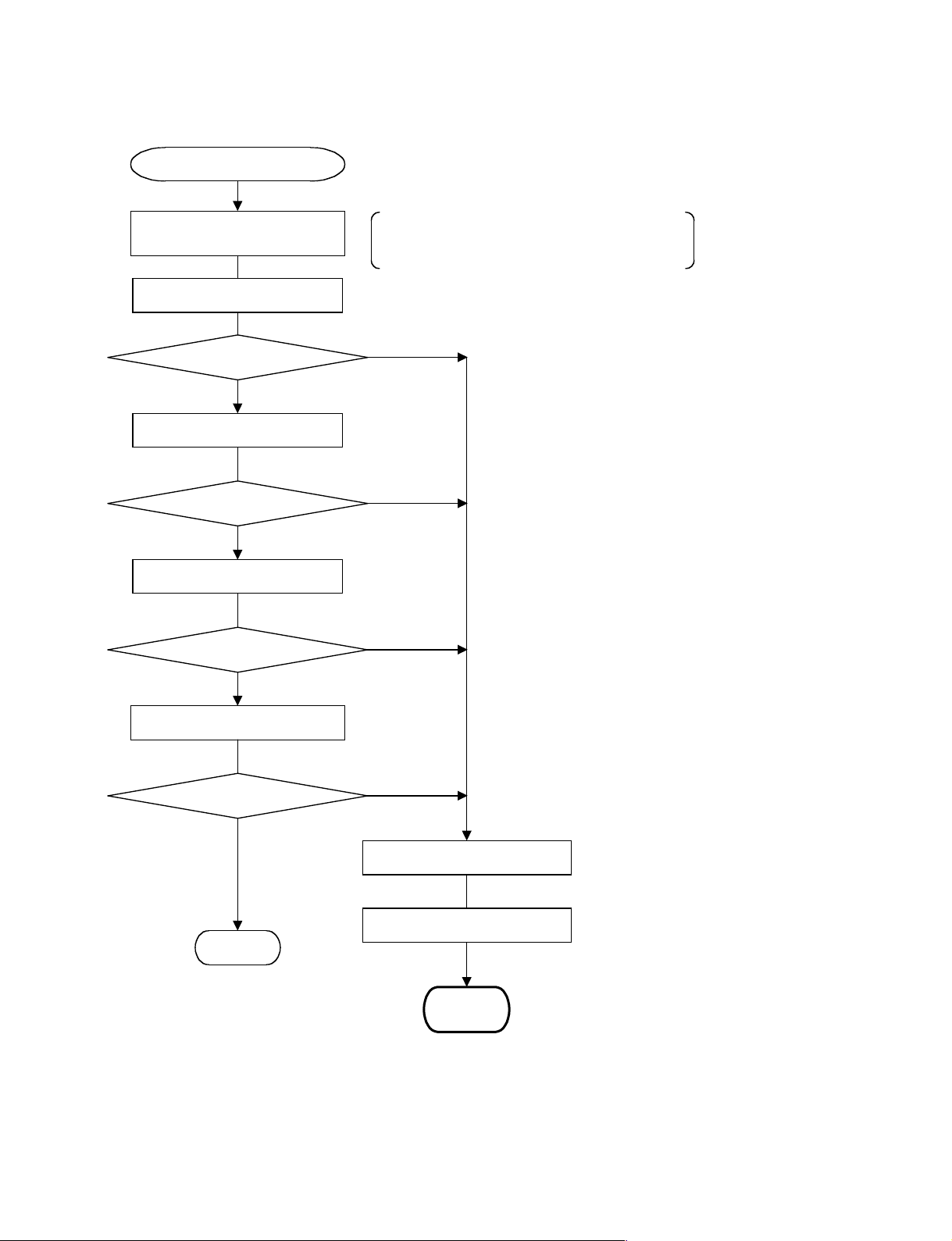

2. Repair Flow

Acceptance of returned unit

Check the contents of a fault

Before repair flow

Check the contents of a fault

according to IRIS CODE table.

Appearance inspection

Appearance defect?

Starts repair flow

Repair the defective position

Repair part describing clearly

Appearance

repair request?

Yes

IRIS CODE

Yes

Yes

No

No

Check the contents of a request

No

Connect to test device

Connect to test device

Fault occurs?

Check the contents of fault request

Yes

No

Non-recurrent analysis mode

Fault occurs?

Yes

No

Go to 6 (P2-2) Go to 1 (P2-2) Go to 3 (P2-2)

PFM-500A1WU/500A1WE

Appearance defect?

Yes

No

Failure analysis

Repair

2-1

Page 12

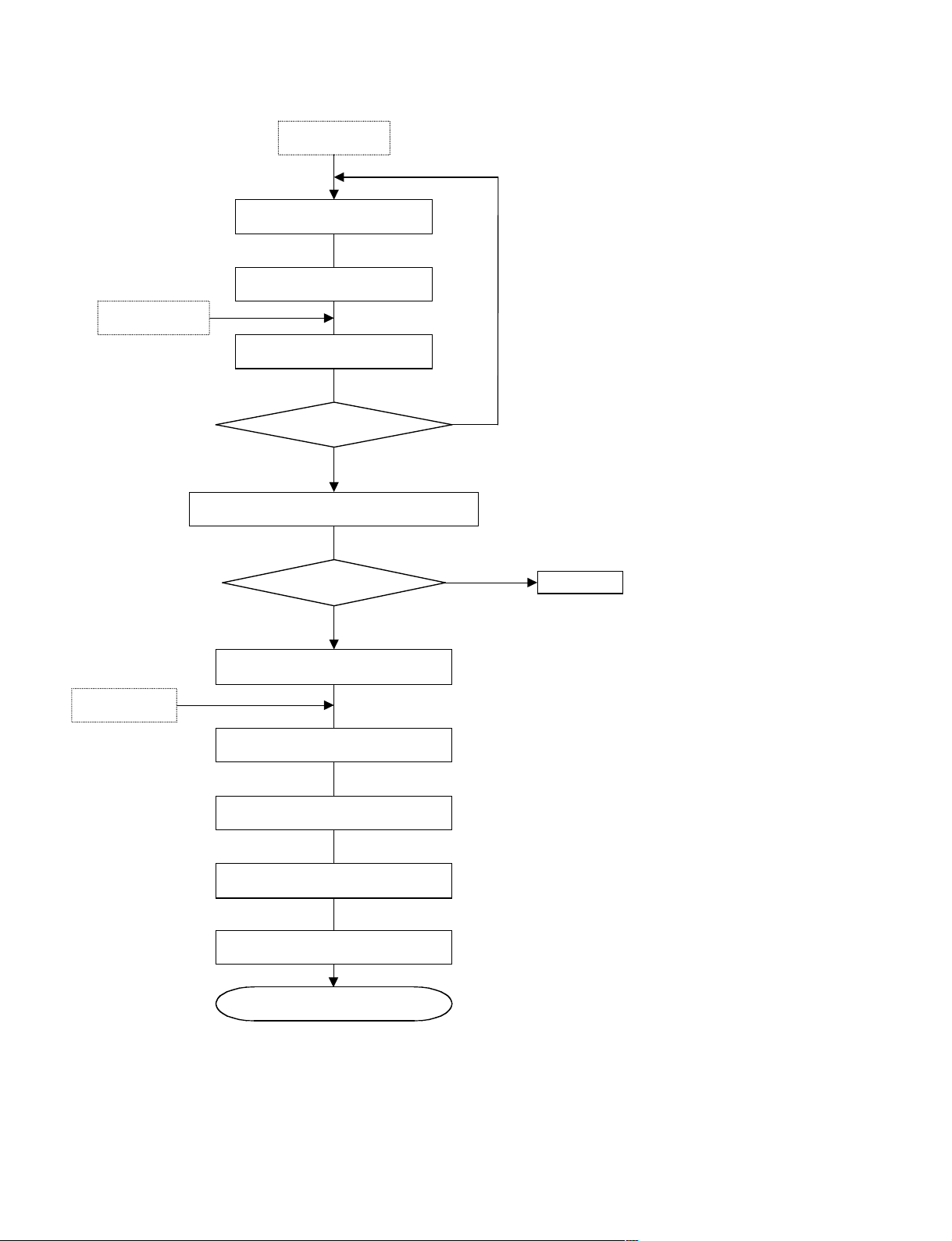

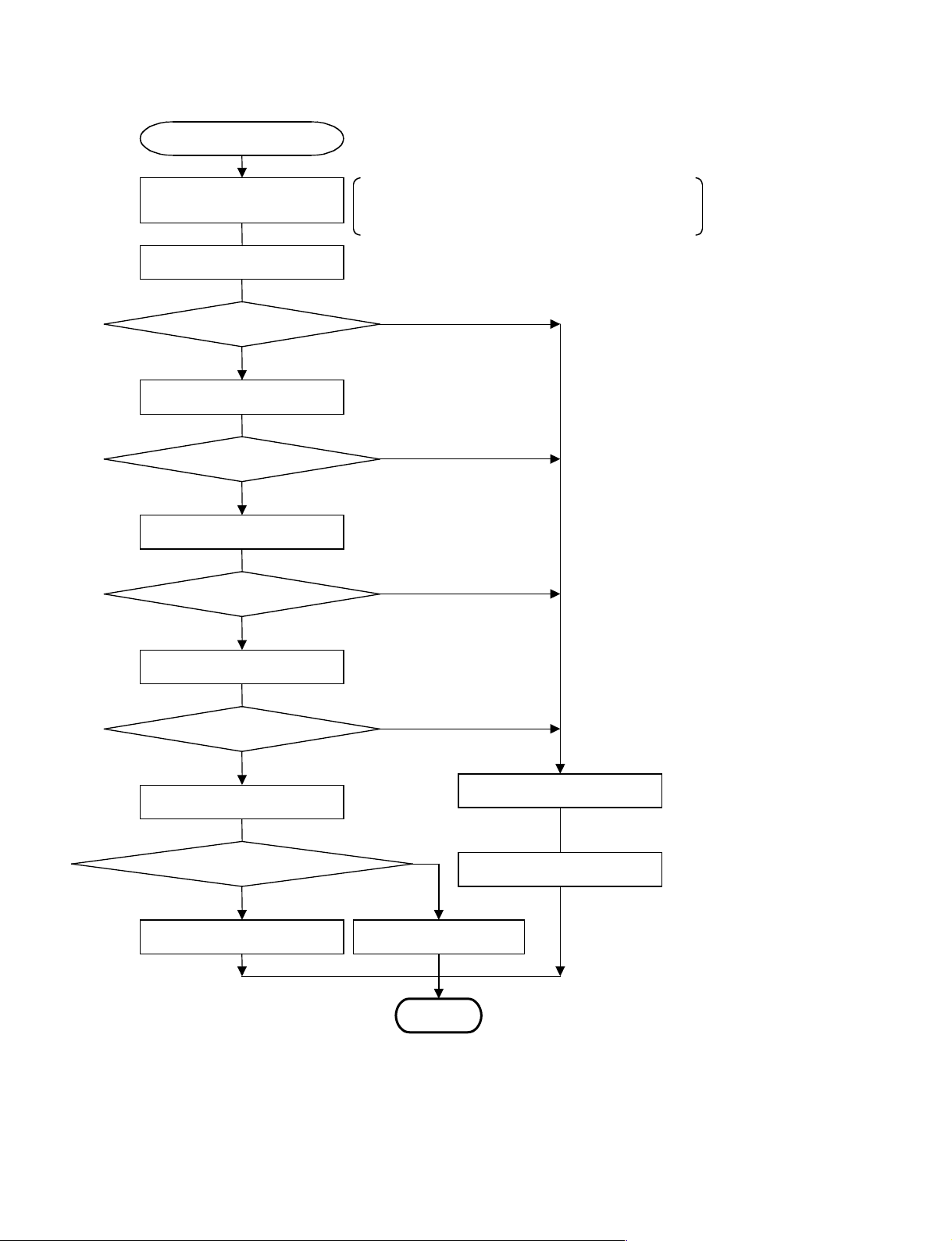

From 6 (P2-1)

From 1 (P2-1)

Failure analysis

Repair the defective position

Display test

From 3 (P2-1)

Repair complete?

Yes

Re-install the defective parts (except panel).

Fault recur?

Yes

Change the defective parts again.

Check the CPU/ROM revision No.

Conduct display function test.

No

No

Repair

Go to 4 (P2-1)

2-2

Assurance test (running)

Repair complete

END (Shipping)

PFM-500A1WU/500A1WE

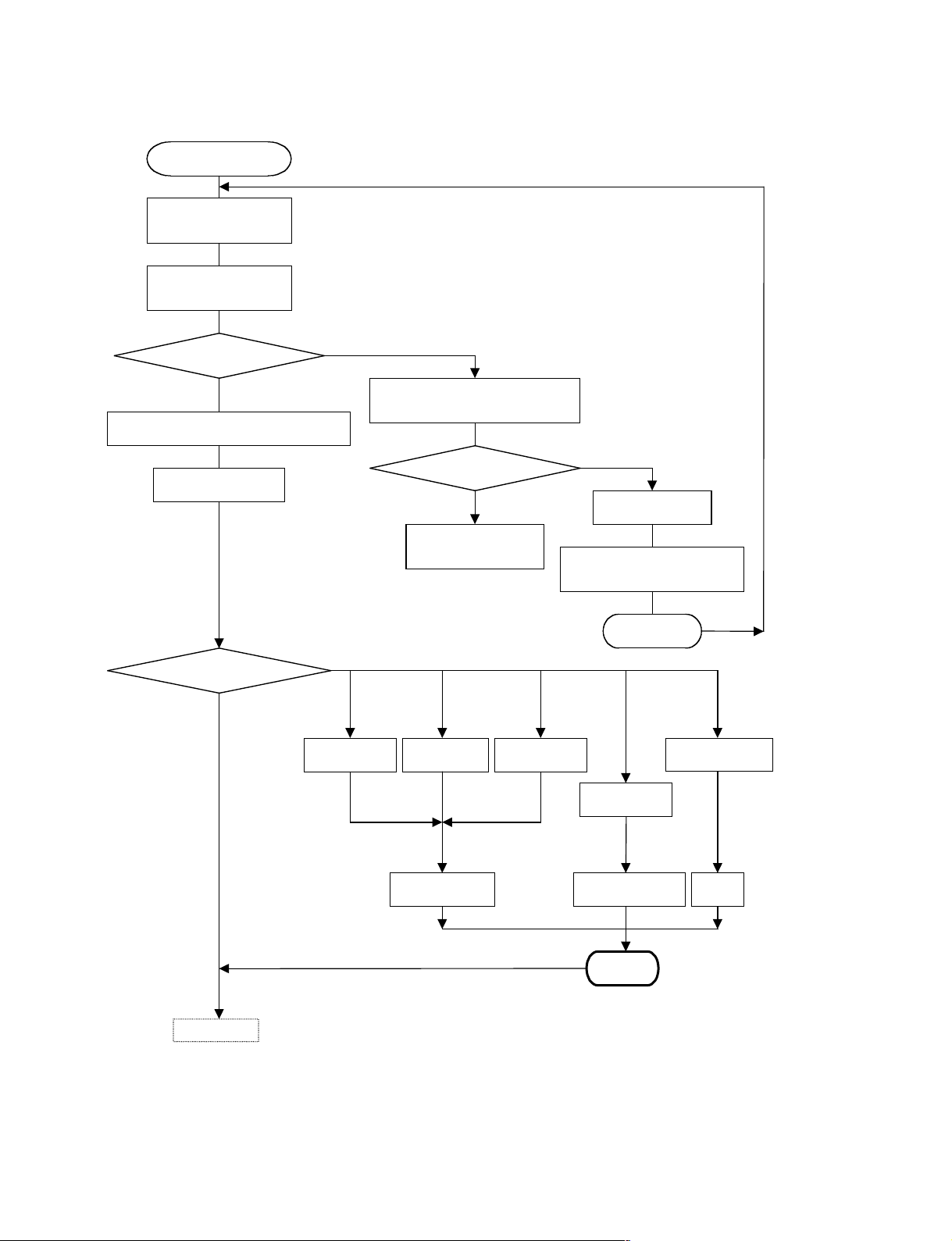

Page 13

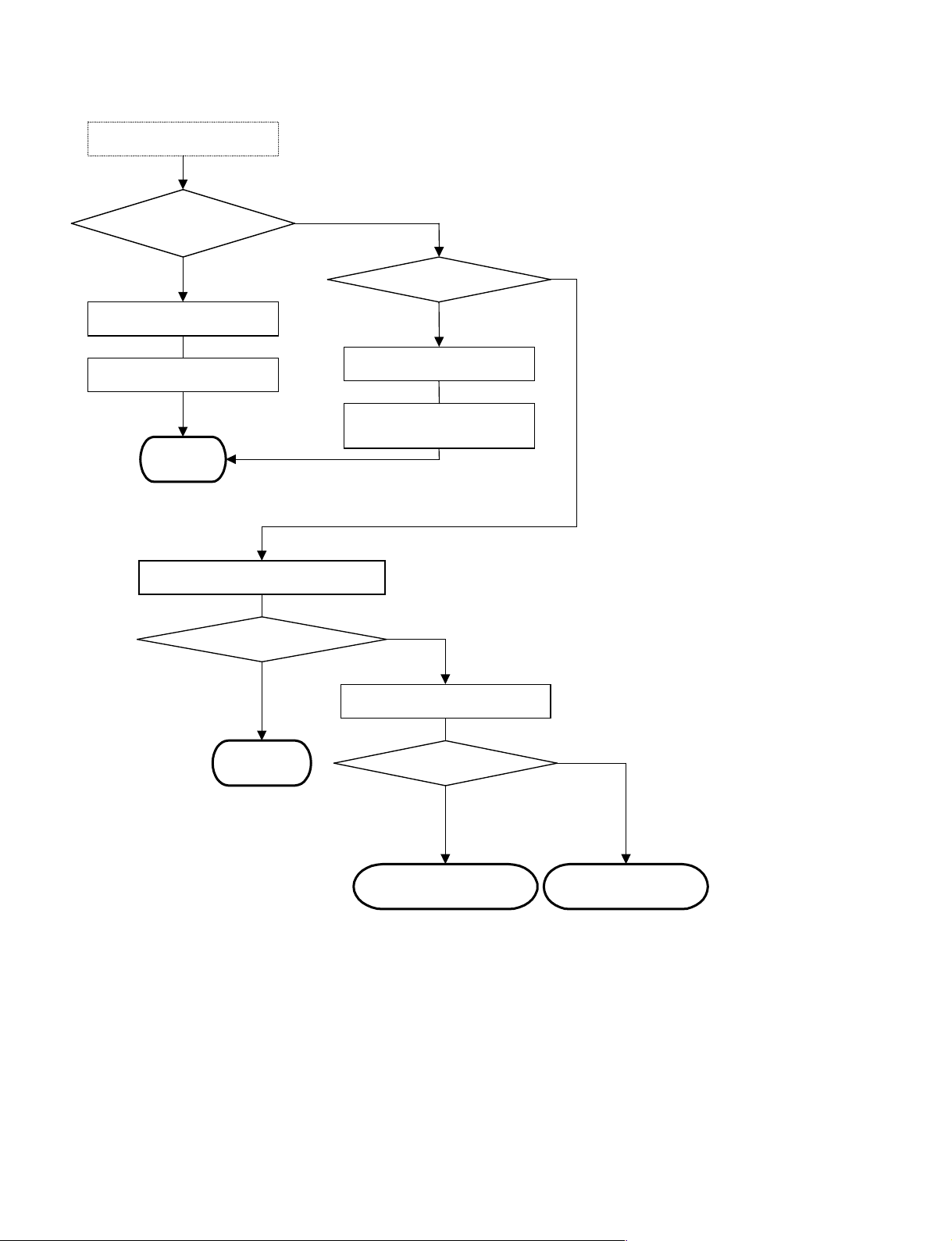

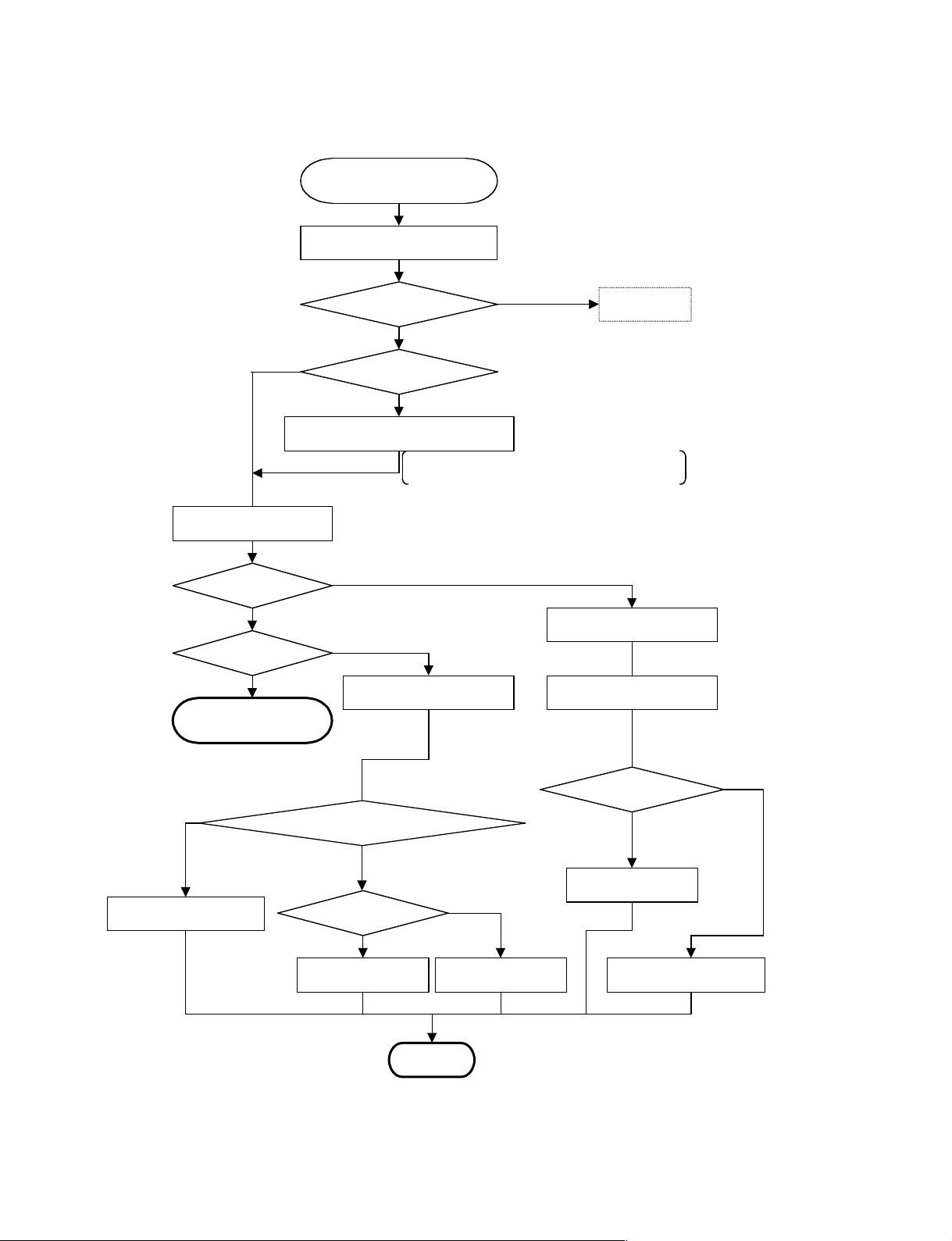

t

START

Test equipment

MAIN-SW ON

Signal generator

SW ON

* A-1 to A-4: See the 3-10 (P3-13)

A-1

Operation OK?

Check the contents of a fault

Appearance check

A-3

Appearance OK?

Yes

Yes

No

No

COM failure

Power supply AC100V measure

(MAIN-SW IN/OUT)

A-2

AC100V OK?

Yes

Fault of Test device

Repair request

Panel failure

Flexible cable

failure

No

MAIN-SW OFF

AC power supply correction

treatment execution

ART

ST

Other appearance

defect

Go to P2-4

PFM-500A1WU/500A1WE

Change panel

Lacking parts

Supply, change Repair

TEST

2-3

Page 14

From P2-3

Protect-cover installation

Fixes to the unit folder

Signal cable is connected with

Logic PC board (CN1)

Special power supply connection

APC function ON Program-key

PUSH “01”

Remote-control SW ON

Analysis A

Fixes to the unit folder

A-4

Screen lighting?

Yes

Evaluation analysis

Go to P2-11

No

Remote-control SW OFF

Separation of Special power supply

External power supply connection

APC function OFF

Program-key PUSH “01”

Go to P2-5

Signal cable is connected with

Logic PC board (CN1)

Analysis B

2-4

PFM-500A1WU/500A1WE

Page 15

From P2-4

Vcc ON

Vcc is gradually raised, and the voltage is set to 5V.

* B-1 to B-!- : See the 3-10 (P3-13)

B-1

Overcurrent?

No

Yes

External power supply OFF

Separation of SUS

Go to P2-7

Va is gradually raised, and the voltage is set to 65V.

No

APC function ON/Vs ON Vs is gradually raised,

and the voltage is set to 180V.

B-6

Overcurrent?

No

Vcc OFF→ON

B-2

Overcurrent?

Yes

Va ON

B-5

Overcurrent?

Yes

External power supply OFF

Go to P2-6

No

No

No

B-3

Vcc or Va checks?

Yes

B-4

Xsus or Ysus separated?

Yes

External power supply OFF

Separation SUS exchange

Analysis A

Go to P2-4

External power supply OFF

Check the separation of YCOM PC board

B-7

YCOM PC board separated?

Separation of YCOM PC board

PFM-500A1WU/500A1WE

Yes

Yes

No

External power supply OFF

Separation of YCOM PC board

Analysis A

Go to P2-4

Separation of SUS

Go to P2-7

2-5

Page 16

From P2-5

B-8

YCOM PC board

separated?

External power supply OFF

Change panel

Analysis A

Go to P2-4

B-0

Yes

Check display

Screen flicker OK?

No

B-9

SUS separated?

External power supply OFF

Change the separated

SUS PC board

No

No

Yes

Yes

Check flicker

Go to P2-9

All white color display check

B-!-

Any data display

Evaluation analysis No display analysis

Go to P2-11

No

Yes

Go to P2-19

2-6

PFM-500A1WU/500A1WE

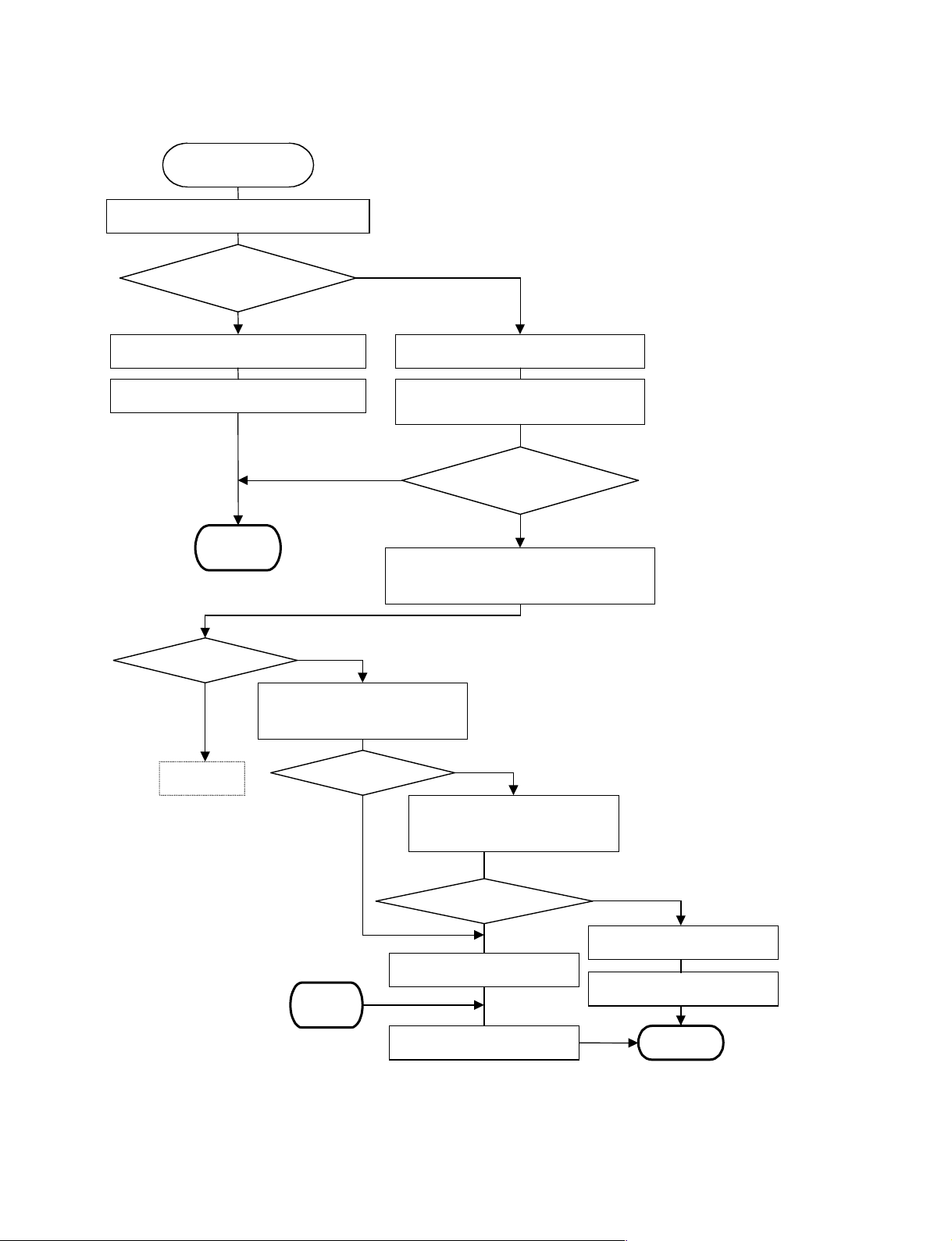

Page 17

* C-1 to C-8 : See the 3-10 (P3-14)

Separation of SUS

From P2-5

Check of connector for XSUS PC board

C-1

Separate the

XSUS PC board?

Yes

XSUS CN49/50 connection

YSUS CN41/42 separation

Analysis B

Go to P2-4

No

XSUS CN49/50 separation

YSUS PC board connector separation check

C-2

No

Separate theYSUS

PC board?

Yes

External power supply Vcc ON Vcc is gradually raised,

and the voltage is set to 5V.

C-3

Overcurrent?

Yes

Go to P2-8

No

Va ON

Va is gradually raised,

and the voltage is set to 65V.

C-4

Overcurrent?

Yes

and the voltage is set to 180V.

C-5

External power supply OFF

DC/DC

From P2-8

No

Vs O

N

Vs is gradually raised,

Overcurrent?

Yes

No

External power supply OFF

Change X / YSUS PC board

Change DC/DC Analysis A

Go to P2-4

PFM-500A1WU/500A1WE

2-7

Page 18

From P2-7

External power supply Vcc OFF

Separation of Logic PC board

External power supply Vcc ON

C-6

Overcurrent?

Yes

External power supply Vcc OFF

Separation of LBUS (CN11)

External power supply Vcc ON

C-7

Overcurrent?

Yes

External power supply Vcc OFF

Separation of LBUS (CN13)

External power supply Vcc ON

No

External power supply Vcc OFF

Change Logic PC board

Analysis A

Go to P2-4

No

External power supply Vcc OFF

Change LBUS

Analysis A

C-8

Overcurrent?

Yes

External power supply Vcc OFF

DC/DC

Go to P2-7

2-8

No

Go to P2-4

External power supply Vcc OFF

Change LBUS

Analysis A

Go to P2-4

PFM-500A1WU/500A1WE

Page 19

Check flicker

* D-1 to D-9 See the 3-10 (P3-14)

From P2-6

XSUS PC board operation test.

Pump output measurement.

Measurements at probe VH27

D-1

Measurement OK?

Measurement at probe VH28

D-2

Measurement OK?

Yes

Measurement at probe VH29

D-3

Measurement OK?

Measure the output at VH27 to VH30.

Voltages are within 1.3 V to 1.8 V on the oscilloscope.

See the 3-4 for the measuring points.

No

Yes

No

No

Measurement at probe VH30

D-4

Measurement OK?

Y test

Go to P2-10

Yes

No

Yes

External power supply OFF

Change XSUS PC board

Analysis A

Go to P2-4

PFM-500A1WU/500A1WE

2-9

Page 20

Y test

From P2-9

D-5

D-6

D-7

YSUS PC board operation test

Pump output measurement

Measurement at probe VH32

Measurement OK?

Yes

Measurement at probe VH33

Measurement OK?

Yes

Measurement at probe VH34

Measurement OK?

Yes

Measure the output at VH32 to VH35.

Voltages are within 1.3 V to 1.8 V on the oscilloscope.

See the 3-4 for the measuring points.

No

No

No

D-9

D-8

Measurement at probe VH35

Measurement OK?

Yes

External power supply OFF

DC/DC changed already?

Yes

Change logic PC board

No

External power supply OFF

No

Change YSUS PC board

Change DC/DC

Analysis A

Go to P2-4

2-10

PFM-500A1WU/500A1WE

Page 21

* E-1 to E-!-: See the 3-10 (P3-15)

E-3

E-4

Display test

APC OK?

Yes

Display OK?

Evaluation analysis

All white color display check

E-1

Display OK?

Yes

E-2

No

Measure and set the panel voltage

New panel?

Yes

For the panel voltage measuring procedure,

see the 3-11.

No

No

From P2-4, 2- 6

No

Go to P2-12

External power OFF

Shipping process

Go to P2-13

E-5

No

Change logic PC board

Yes

Logic PC board Changed?

E-6

New LBUS?

External power OFF

Yes

No

Yes

Analysis A

Go to P2-4

Logic PC board changed

E-7

Changed?

Yes

Change DC/DC

Change logic PC boardChange LBUSChange RBUS

No

PFM-500A1WU/500A1WE

2-11

Page 22

No

E-8

From P2-11

Lateral display error?

Yes

Monitor XSUS PC board

E-9

Waveform OK?

Yes

Monitor YSUS PC board

See the 3-2 for the measuring points of

DOXE/DOXO.

See figure 1 in the 3-1 for the

monitored waveform.

No

External power OFF

E-!-

See the 3-2 for the measuring

points of DOYSU/DOYSD/YCOMDV.

See figure 2,3 in the 3-1

for the monitored waveform.

E-0

Waveform OK?

Yes

Failure caused by panel error?

Yes

External power OFF

Change panel

Change XSUS PC board

Analysis A

Go to P2-4

No

SUS Check

Go to P2-18

No

Separation

Go to P2-15

2-12

Analysis A

Go to P2-4

PFM-500A1WU/500A1WE

Page 23

* F-1 to F-4: See the 3-10 (P3-15)

F-1

Shipping process

Non-recurrent product?

Yes

Non-recurrent product

analysis process

Go to P2-25

From P2-11

No

No

External power OFF

Re-install the faulty PC board

External power ON

Fault recurrent check test

F-2

Fault recur?

Yes

Non-recurrent product analysis process

Go to P2-25

External power OFF

Change into normal PC board

Go to P2-14

PFM-500A1WU/500A1WE

2-13

Page 24

From P2-13

External power ON

Ve readjustment VE=16V ±0.1V

ROM version No. Check

F-3

ROM version No. OK?

Yes

Install the PC board in the burn-in rack and conduct

the running test for 2 hours,

keeping the display solid white.

F-4

Display operation OK?

Yes

Shipping

Go to P2-26

No

ROM version up

No

Analysis B

Go to P2-4

2-14

PFM-500A1WU/500A1WE

Page 25

* G-1 to G-5: See the 3-10 (P3-16)

Lateral direction

External power OFF

Change panel

Separation

No display in whole screen

Fuse check

G-3

Fuse blown?

Change Fuse

Yes

From P2-12, P2-20

G-1

No

Change logic PC board

Vertical direction

ACOM PC board unit?

Yes

Retrieve COM

Go to P2-16

G-2

Single line missing?

No

No

Yes

Change panel

BUS board Change

Analysis A

Go to P2-5

G-4

External power OFF

G-5

No

Change logic PC board

BUS board changed?

Regularity?

Yes

Yes

No

Change panel

PFM-500A1WU/500A1WE

2-15

Page 26

* H-1 to H-7 See the 3-10 (P3-16)

COM connector check

H-1

Connector OK?

External power OFF

H-4

Retrieve COM

From P2-15

Yes

Fuse check

Fuse blown?

No

External power OFF

Insert CN again

Analysis B

Go to P2-4

No

Appearance

ACOM failure check.

Visual check on the chip section

H-2

Chip OK?

Yes

H-3

Fuse changed?

Yes

Change fuse Change panel

No

No

Yes

Appearance

Go to P2-17

Analysis A

Go to P2-4

2-16

PFM-500A1WU/500A1WE

Page 27

From P2-16

H-5

RBUS changed?

Change RBUS

Fault in RBUS

NoNo

Yes

Change Logic PC board

Change panel Change panel Change LBUS Change panel

Fault in Logic PC board

H-6

Logic changed?

Yes

No

Fault in LBUS

H-7

LBUS changed?

Yes

PFM-500A1WU/500A1WE

Analysis A

Go to P2-4

2-17

Page 28

SUS Check

From P2-12, P2-19

External power OFF

* K-1 to K-6: See the 3-10 (P3-16)

K-1

Both SUS?

Yes

Logic changed

K-3

Changed?

Yes

APC OFF

Separate S/YSUS PC board

External power ON

No

No

K-2

XSUS PC board changed

K-4

Changed?

X SUS?

Yes

Yes

Change YSUS PC board

No

No

YSUS PC board changed

K-5

Change logic PC board

Changed?

Yes

Change YSUS PC board

No

DC/DC output measurement

Mesurement point/

mesurement voltage,

K-6

Output OK?

External power OFF

Change X/YSUS PC board

see the 3-3

Yes

Change logic PC board

No

External power OFF

Change DC/DC

Analysis A

Go to P2-4

2-18

PFM-500A1WU/500A1WE

Page 29

No display analysis

From P2-6

Background light emission check

* L-1 to L-8 : See the 3-10 (P3-17)

L-1

Light emission from background?

YCOMDV output measurement.

See Figure 4 in 3-2

Go to P2-20

Yes

D check

Go to P2-22

L-3

No

Ve measurement

L-2

No

Output OK?

Yes

Measuring points For the DOYSU/DOYSD/DOXE/DOXO.

Measuring waveform, see Figures 1, 2, and 3 in 3-1, 2.

Waveform OK?

No

Yes

PFM-500A1WU/500A1WE

External power OFF

Change panel

Analysis A SUS check

Go to P2-4 Go to P2-18

2-19

Page 30

From P2-19

L-4

Output OK?

Yes

XSUS output measurement.

For the measuring point, see

Figure 1 in the 3-1.

L-5

Output OK?

Yes

External power OFF

XSUS PC board changed

L-7

Changed?

No

No

Yes

YCOMDV waveform

Waveform (A)

+Vs→

OV→

_Vy→

No

L-6

External power OFF

Waveform (B)

+Vs→

OV→

_Vy→

Waveform A?

Yes

Change panel

L-8

Vsc→

(No scanning wave)

No

External power OFF

YSUS PC board changed

Changed?

Yes

No

Re-mounting XSUS PC board

Separation

Go to P2-15

Change logic PC board

Change XSUS PC board

Re-mounting YSUS PC board

Change YSUS PC board

Change logic PC board

Analysis A

Go to P2-4

2-20

PFM-500A1WU/500A1WE

Page 31

XPUMP

From P2-22

External power OFF

External power separation

Special power connection

XSUS VPON measuring

Special power ON

* M-1 to M-5: See the 3-10 (P3-17)

XSUS and YSUS PC board operation check

Monitoring signal VPON

Connection of the probe to circuit No. M1 (LV244) 04 pin

Monitoring device: Oscilloscope

Measuring range: 2v/div, 1ms/div

Output the charge up signal VPON at around 4 v/ms from

the logic section about 2 seconds after the external power

and VS have been entered.

See the 3-4 for the measuring points.

M-1

Special power OFF

Special power ON

M-2

Input OK?

Yes

XPUMP check

YPUMP

Input OK?

Yes

No

Go to P2-23

From P2-23

External power OFF

No

Change logic PC board

Special power OFF

YPUMP check

Go to P2-24

PFM-500A1WU/500A1WE

Analysis A

Go to P2-4

2-21

Page 32

D check

From P2-19

External power OFF

VEGO/VWYGO measuring

External power ON

M-3

VEGO OK?

Yes

External power OFF

External power ON

M-4

VWYGO OK?

s

Ye

Monitoring device: Oscilloscope

Measuring range: 2v/div, 20 m/s

Measuring points: Logic section (CN4)

No

No

External power OFF

2-22

X PUMP

Go to P2-21

M-5

Always “0”?

Change Logic PC board

No

Yes

Change DC/DC

Analysis A

Go to P2-4

PFM-500A1WU/500A1WE

Page 33

XPUMP Check

From P2-21

* N-1 to N-8: See the 3-10 (P3-18)

XSUS PC board operation test

Pump output measurement

Connection to probe VH27

Special power ON

N-1

Output OK?

Yes

Special power OFF

Connection to probe VH28

Special power ON

N-2

Output OK?

Monitoring device: Oscilloscope

Measuring range: 1 v/div, 1 ms/div

Check that the voltage around 1.3V to 1.8V is output about 2

seconds later than entry of power. (Time: about 7ms)

Measuring points:VH27 to VH30: VH32 to VH35 (See the 3-4)

No

Special power OFF

No

Yes

Special power OFF

Connection to probe VH29

Special power ON

N-3

Output OK?

Yes

No

Connection to probe VH30

Special power ON

N-4

Output OK?

Yes

YPUMP

Go to P2-21 Go to P2-4

No

Special power OFF

Change XSUS PC board

Analysis A

PFM-500A1WU/500A1WE

2-23

Page 34

YPUMP check

From P2-21

YSUS PC board operation test.

Pump output measurement.

Connection to probe VH32

Special power ON

N-5

Output OK?

Special power OFF

Connection to probe VH33

Special power ON

N-6

Output OK?

Special power OFF

Connection to probe VH34

Yes

Yes

No

No

Special power OFF

Connection to probe VH35

Special power ON

N-8

Output OK?

Yes

Special power OFF

No

Special power OFF

N-7

2-24

Special power ON

Output OK?

Yes

Change YSUS PC board

Change logic PC board

No

Analysis A

Go to P2-4

PFM-500A1WU/500A1WE

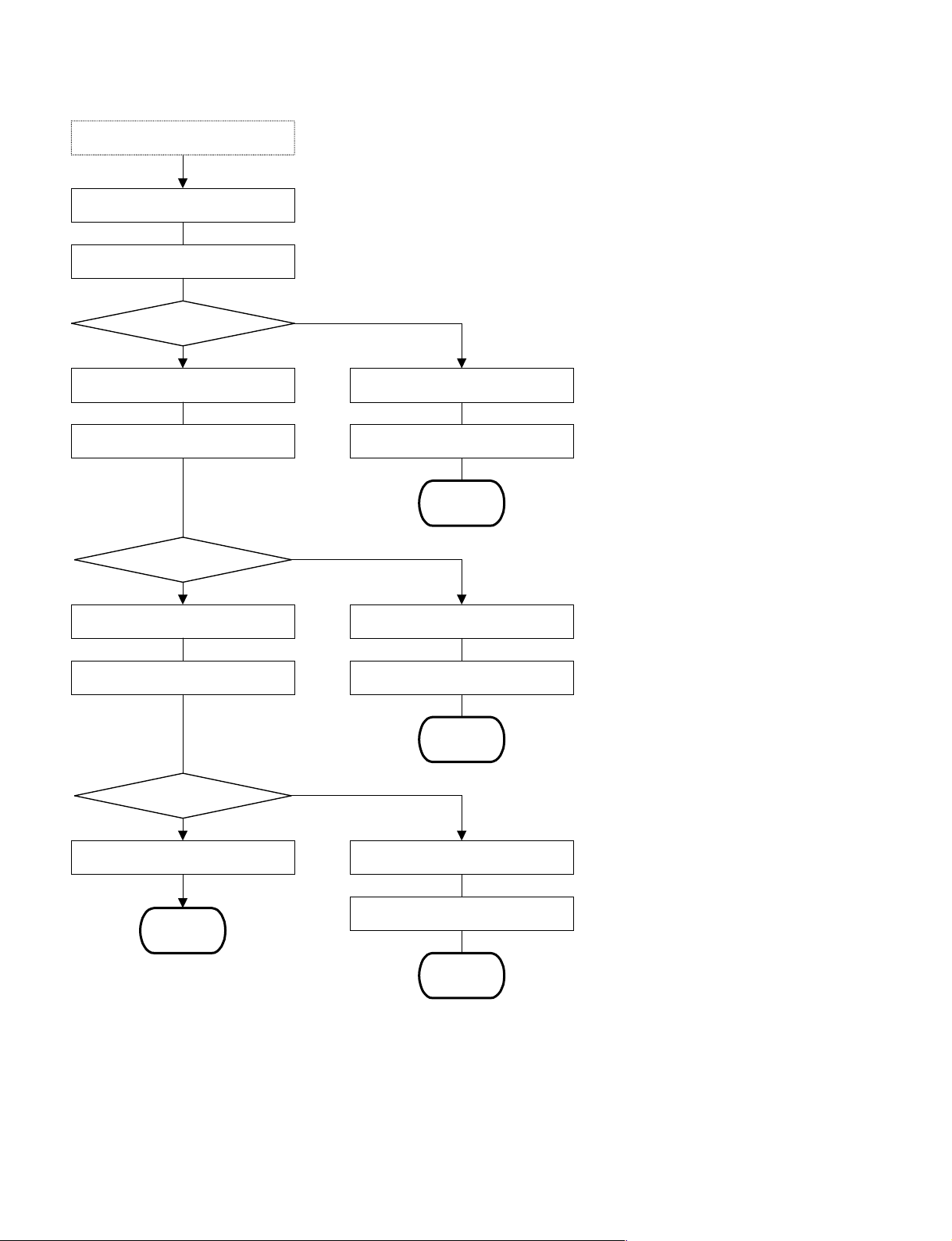

Page 35

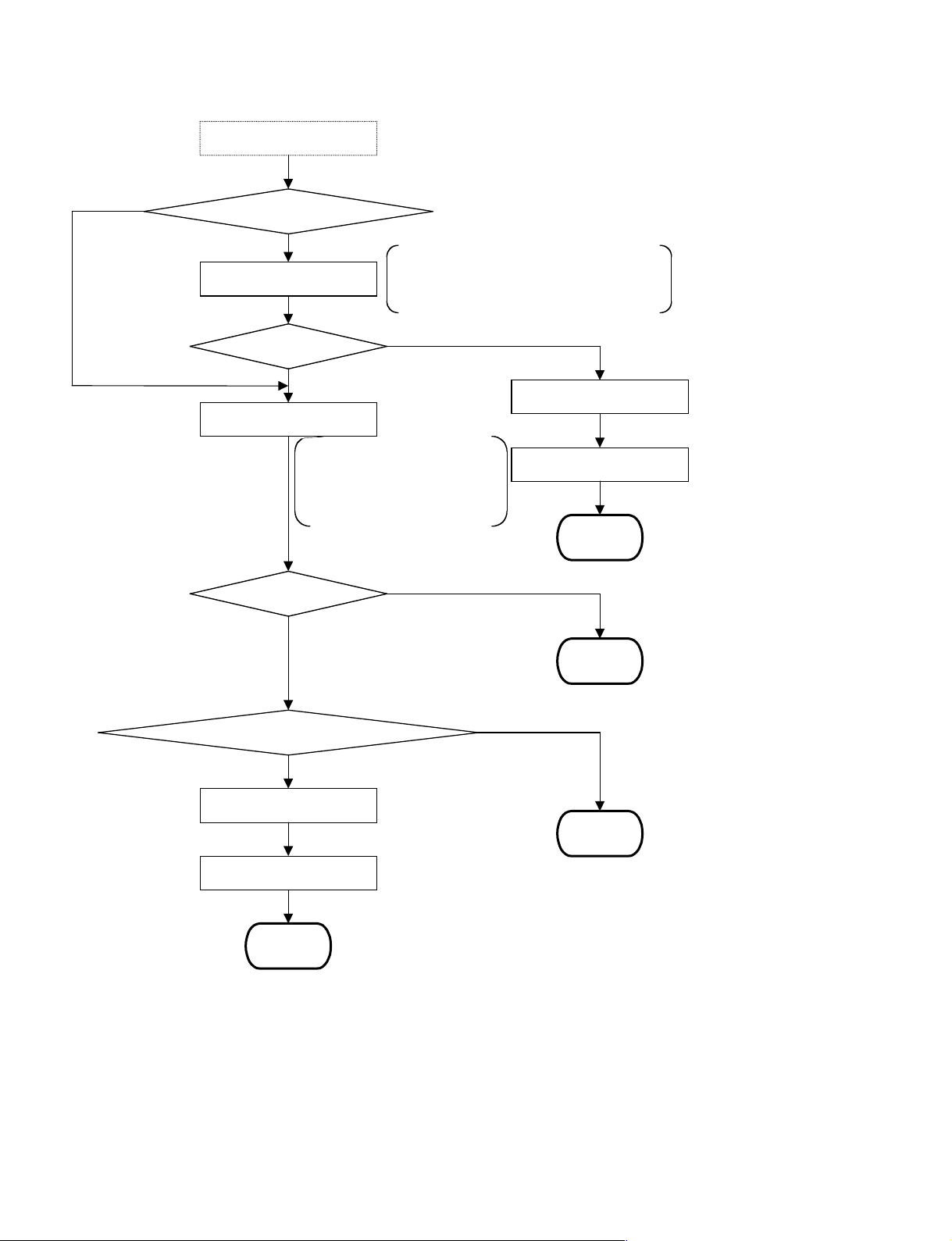

Non-recurrent analysis / Shipping mode

Non-recurrent analysis

From P2-13

Tapping on each PC board

* P-1 to P-5 : See the3-10 (P3-18)

P-1

Trouble reproduction?

External power OFF

Change the defective PC board

Analysis A

Go to P2-4

Yes

No

ROM version No. check

P-2

ROM version No. OK?

Yes

Ve readjustment

VE=16V ±0.1V

External power OFF / Separation

Leave the unit for 4 hours after

installing the running device.

No

ROM version up

PFM-500A1WU/500A1WE

P-3

Trouble reproduction? Go to P2-26

Yes

Analysis B

Go to P2-4

No

2-25

Page 36

From P2-25

Shipping

From P2-2, P2-14

P-5

Connections to power supply for exclusive use.

Install in test equipment.

APC function ON / Special power ON

Display test

P-4

OK?

Yes

Non-recurrent and returned unit?

Ye

No

s

Analysis B

Go to P2-4

No

2-26

Shipping substitute

Repair completed

(Shipping)

PFM-500A1WU/500A1WE

Page 37

3. Data

3-1. Check Point (X-SUS)

* V sync

X-SUS

1/8SF 2/8SF 3/8SF 6/8SF 7/8SF 8/8SF

Figure-1

DOYSD

Figure-2

DO YSU / F. VCC (=D OY SU+1 0V )

(DOXO)

Vs

0v

Vsc

EVEN ODD

+Va

0v (DOXE)

EVEN ODD

SUS

Vsw (350V)

PFM-500A1WU/500A1WE

Figure-3

_

Vs

0v

Vy

3-1

Page 38

3-2. Check Point (Y-COM)

Figure-4

GND

Vsc

_Vy

1 Frame

SUS (Vs)

240 240

EVEN LINE

1 Line selected signal (1/480)

Measurement point

ODD LINE

Y-COM

YCOMDV

Check-terminal

M1

M4

CN43CN46

YCN

YSUS PC board

FVCC

CN43 A1-A6

B1-B6

DOYSU

CN43 A13-A25

DOYSD

CN43 A28-A45

XSUS PC board

B13-B25

B28-B45

CN51

CN

CN53

X-BUS

XBUS

Measurement position

DOXO

A01-A21

CN53

B01-B21

DOXE

CN53

A25-A45

B25-B45

3-2

PFM-500A1WU/500A1WE

Page 39

3-3. Check Point (DC/DC)

Q31

T2

C41

C31

T1

C21

CN28

VW

CN33

C13

CN27

CN29

CN39

CN30

Voltage Circuit Adjustment point Set point Measurement point Measurement device

_Vy VR41 _Vy volume 160V ~ 180V ±1 % 3 digital multimeter

Ve VR61 Ve volume 16V ±0.1V 4 digital multimeter

Vrs VR54 Vrs volume 0 ~ 2V 5 digital multimeter

Vsc __ 100V ±0.1 % 1 digital multimeter

Vw __ 170V ±0.1 % 6 digital multimeter

C55

VSC

C75

G_4

IC81

CN37

1 Vsc Point

_

VY

2 GND Terminal

IC41

_VY

VR41

CN20

3 _Vy Point

C93

IC71

VR61

CN38

C54

VW

VR21

CN25

4 Ve Point 5 Vrs Point 6 Vw Point

VE

VRS

CN32

VR54

Vrs

CN24

CN31

C3

C1

C11

CN23

* Measurement point of Vsc : Vsc point and _Vy point.

PFM-500A1WU/500A1WE

3-3

Page 40

3-4. Check Point of Voltage (X-SUS, Y-SUS)

M6

M7

M16

M14

M8

M9

YSUS PC board

M10

M11

M12

M13

M3

M2

M1

CN41

CN42

M5

CN40

CN51

CN48

CN49

M13

M14

M4

M2

M1

M15

M16

XSUS PC board

M9

M11

M12

M5

M6M10

M17

M7

M8

18

19

20

10

M1

LV244

VH 32 VH 35

R13

R14

VH 33

2

1

M5

MB3615

R16

R15

VH 34

10

1

2

LV244

VH 27

VH 28

M1

20

19

18

R3 R6

R4 R5

C9

M4

MB3615

VH 30

VH 29

3-4

PFM-500A1WU/500A1WE

Page 41

3-5. Glossary

Oscilloscope : A device that allows the flow and strength of the running current to be visually

checked and measured.

Gradation : Shading of the display color.

External power ON : Running the external powers (Vcc. Va. Vs) on the designated voltage, unless

otherwise specified.

External power OFF : Making the external powers (Vcc. Va. Vs) to stop their operation completely,

unless otherwise specified.

White solid : A condition when the screen display is entirely white.

Tapping : Light impact.

Panel : The indication part of the plasma display panel (PDP).

Parts : Each PC board and parts mounted in the PC boards.

Panel voltage : The voltage required to operate the PDP normally.

Burn-in rack : Test equipment of the shelf test in which the PDP unit is left to stand in drive

condition.

Flexible cable : The cable for connecting the electric circuit to the panel.

Flicker : Continuous switching between bright and dark views by the PDP itself.

Protection cover : A cover made by aluminum to protect the PDP entirely during test.

Probe : A cable with contact finger that can transfer the status of the electric circuit to be

measured to an oscilloscope.

Remote control box : The device that can control the power on/off state of the power supply for

exclusive use (FPF10P-AC100/240B).

Unit of COM : The unit of circuits connected to the panel with flexible cable.

(YCOM UP/DOWN, XBUS UP/DOWN, address sections, the unit of PC boards

in ACOM1 to 5)

CPU : The unit for controlling the circuit operation.

DOYSU : Used in the drive voltage in the Y direction.

DOYSD : Used in the drive voltage in the Y direction.

DOXE : The control voltage for even-numbered lines in the X direction.

DOXO : The control voltage for odd-numbered lines in the X direction.

PUMP : The name of a circuit where the current from X/YSUS is returned.

PDP : Plasma display panel abbreviated.

ROM : Memory that stores the drive sequence and other data.

SUS : XSUS or YSUS.

Vcc : The power supply at 5 V, which is used to operate the logic section mainly.

Va : The power supply at 60 V, which is used to write data on the panel.

Vs : The power supply ranging from 127 V to 180 V, which is used to maintain

display data. In addition, this can serve as the primary side for the secondary

voltage (Vw, _Vy, Vsc).

XSUS: The name of the circuit that controls the panel operation in the X direction.

YCOMDV: The name of the panel drives voltage signal output from YCOM UP/DOWN

section.

YCOM: The circuit used to output a panel Y line selection signal and the voltage of a

display data keep signal.

YSUS: The name of the circuit that controls the panel operation in the Y direction.

PFM-500A1WU/500A1WE

3-5

Page 42

3-6. Connection to Test Equipment

PDP fixing jig

VG-826 remote control box

Function SW/RB-614C

Vcc/Va/Vs power supply

Power supply for exclusive use

Mount a protection cover on the PDP.

In case of an external power supply

Check that each power supply is turned off. Check that the remote control box switch is turned off.

Set the PDP on the PDP fixing tool of the test equipment and

connect a signal cable from the remote control box to CN1 on the logic PC board.

Connect the connector from the external

power supply to the DC/DC PC board

(CN23/CN24).

Each process Each process

In case of a power supply for exclusive use

Connect the connector from power supply to the

DC/DC PC board (CN23 to CN25).

Connection cable at 100VAC

3-6

PFM-500A1WU/500A1WE

Page 43

3-7. Test Equipment

6

5

7

4

3

1

2

4

5

6

Function

SW

VG-826

Remote control box

7

RB-614C

1 2

Vc Power supply Va Power supply

3

Vs Power supply

External power supply

PFM-500A1WU/500A1WE

3-7

Page 44

3-8. Photo (Burn-in Unit)

Burn-in equipment

3-8

Signal generator

PFM-500A1WU/500A1WE

Page 45

3-9. Burn-in Unit Instruction Manual

This manual explains the procedure of connecting the Burn-in unit and outlines the basic operations only

in the PDP signal generator.

Usage condition : AC input : 240 VAC

No. of running units : maximum of 2

I. Configuration

1. Power controller

1 AC power supply ON/OFF switch x 1 (breaker EG32F)

2 Individual power supply ON/OFF switch x 2 (FRONT, REAR)

2. Signal generator (1)

3. Individual power supply for exclusive use (2)

4. Cabinet (with PDP stand)

II. Names and Operations of Parts in Signal Generator

1. POWER switch

This switch can turn ON/OFF the external power supply.

2. Keyboard

This is used to set various functions.

3. Indicator

This is used to display the current operating status and data entered from the keyboard.

4. Output 1 to 4 ON/OFF switch (correspond to output 1 to 4)

This switch can turn ON/OFF the external output.

5. Output monitor LED (display the operating status. )

1 Output 1 to 4

2 R, G, B, (ON/OFF)

3 Reverse indication (ON/OFF)

4 DISP-ENB (Hi/Low)

5 Gradation status

16 steps 64 steps 256 steps

LED 1

LED 2

OFF

ON

6 Hi-QUALITY (Hi/Low)

7 TEST (Hi/Low)

III. Connection

1 Mount a protection cover on the PDP.

2 Check that the AC power supply switch and individual power switch in the burn-in unit are turned

off.

3 Connect AC cable from the burn-in unit to 240VAC.

4 Install the PDP on the stand of the unit and fix it.

5 Connect output cable from the power supply for exclusive use to DC/DC connector of PDP

(CN23 to 25).

6 Connect signal cable from the signal generator to CN1 in the logic section of PDP.

7 Turn on the AC power supply switch in the burn-in unit.

8 Turn on the power switch in the signal generator.

9 Turn on the power switch of the installed side -- FRONT or REAR.

Operation start

PFM-500A1WU/500A1WE

3-9

Page 46

IV. Changing and Selecting the Screen Display

The PDP unit enables the selection of 15 different patterns below. In addition, self test can be conducted

in any display pattern.

1. Available patterns and operations

Pattern No. Display pattern Pattern No. Display pattern

00 Automatic operation 09 Slant 8-color bar, vertical scroll

01 All solid 10 Cell plaid pattern

02 Vertical pattern 11 Most outer periphery frame + slant slash

03 Horizontal pattern 12 16 blocks

04 Plaid pattern 13 Vertical band

05 Vertical gradation 14 Lateral band

06 Horizontal gradation 15 Cross line

07 Vertical 8-color bar 16 Cross dot

08 Horizontal 8-color bar 17 _

2. Selecting the display pattern (for example, white solid pattern)

Key entry

Monitor indicator

Select

Pattern

0

1

Set

0 8 3 2 0 0 0 0

P T N 0 8

Operation mode indicator

P T N 0 0

P T N 0 1

0 8 3 2 0 0 0 0

Display pattern selection input field

(Select from the above table)

As the results of this operation, the PDP screen will be displayed in “white solid” pattern.

Any other pattern can be selected by entering the desired pattern No. (01 to 16) in the display Selection

field.

3-10

PFM-500A1WU/500A1WE

Page 47

3. Automatice display setting (used for running test)

Select

Display time

X

Set

(Automatic operation flow)

Select automatic display

Slant 8-color bar, vertical scroll display

XXXX second

White solid display

0 8 3 2 0 0 0 0

T I M 1 2 0 0

T I M X X X X

0 8 3 2 0 0 0 0

Current time (in sec)

Switching time input (0 to 3600 seconds)

Consecutive 75 hours

4. Palette setting

The gradation of all display colors can be checked with this setting.

0 8 3 2 0 0 0 0

P L A 0

OR 1

P L A 0 R 2 5 5

Indication and input area of current step No.(0 to 255)

Vary as instructed(R, B, and B)

P L A 0 R X X X

Input any value (0 to 255)

0 8 3 2 0 0 0 0

OR

Select

Pallet 0

R

OR

X

Set

G

B

PFM-500A1WU/500A1WE

3-11

Page 48

5. RGB ON/OFF

The indication of each color can be set to disable (used for checking a single color).

Select

3

R

G

OR

B

OR

Set

6. Function setting

Select

7

0 8 3 2 0 0 0 0

O N

R O N

Selected color

R O F F

0 8 3 2 0 0 0 0

0 8 3 2 0 0 0 0

D S E H I

/

O F F

Status of the display color (ON or OFF)

Vary as instructed

Current LED status

DISP ENB

HI LO

OR

4

OR

0

Set

H Q E L O

T S L O

D S E L O

Press

0 8 3 2 0 0 0 0

key to display HI and LO alternately

HI-QEN

HI LO

TEST

HI

HI

LO

DISP ENB

LO

3-12

PFM-500A1WU/500A1WE

Page 49

3-10. Criteria Table

(Scope : UD-01)

Item P2-3, 4 Judgment

No. Branch condition YES NO

A-1 Operation OK? The fan of the signal generator rotates, The fan of the signal generator does not

A-2 AC100V OK? Measured with Digital bottle-meter, AC100V isn’t input..

A-3 Appearance OK? The product is regarded to Product with defect in appearance

A-4 Screen lighting? Some data is displayed on the screen.

and the LED display is 001. rotate, and the LED display is not 001.

and AC100V is input..

operate normally because it does YCOM failure (hole)

not show any defect in Panel failure (fracture, crack of chip pipe)

appearance as mentioned above. Flexible cable failure

(break, peeling, and others)

In particular, check the panel to

see if there are any cracks in the

corner (gas leak)

Blur, flow, parts failure, missing

parts, disconnection of cable,

and other defects in appearance

may affect PDP operation.

(The background light emission is included.) No data is displayed on the screen.

Item P2-5, 6 Judgment

No. Branch condition YES NO

B-1 Overcurrent? Icc>2.5 Icc<2.5

B-2 Overcurrent? Icc>2.5 Icc<2.5

B-3 Vcc or Va checks? Abnormal check of VCC and Va. Checks other than Vcc and Va.

B-4 XSUS or YSUS XSUS or YSUS is separated. XSUS or YSUS is not separated.

Separated?

B-5 Overcurrent? Ia>0.2(A) Ia<0.2(A)

B-6 Overcurrent? Is>3.5(A) Is<3.5(A)

B-7 YCOM PC board Separated because CN46 and CN47 on Not separated because YCOM UP and

Separated? YCOM UP and DOWN sections are DOWN both or either section is connected

disconnected from CN43 and CN44 to CN43 or CN44 on YSUS.

on YSUS.

B-8 YCOM Separated because CN46 and CN47 on Not separated because YCOM UP and

separated? YCOM UP and DOWN sections are DOWN both or either section is connected

B-9 SUS separated? The power connectors CN49 and CN50 XSUS and YSUS are not separated from

B-!/ Screen flicker OK? PDP shows bright (turn on) and Abnormal condition, not showing the right

B-!- Any data display Some data is displayed on the screen. No data is displayed on the screen.

disconnected from CN43 and CN44 to CN43 or CN44 on YSUS.

on YSUS.

for XSUS or the power connectors CN41 DC/DC.

and CN42 for YSUS are disconnected from

DC/DC connector.

dark (turn off) views alternately condition

on the entire screen.

PFM-500A1WU/500A1WE

3-13

Page 50

(Scope : UD-01)

Item P2-7, 8 Judgment

No. Branch condition YES NO

C-1 Separate the XSUS The power connectors CN49 and CN50 for The power connectors CN49 and CN50 for

PC board? XSUS are disconnected from XSUS are not disconnected from

C-2 Separate the YSUS The power connectors CN41 and CN42 for The power connectors CN41 and CN42 for

PC board? YSUS are disconnected from YSUS are not disconnected from

C-3 Overcurrent? Icc>1.7(A) Icc<1.7(A)

C-4 Overcurrent? Ia>0.2(A) Ia<0.2(A)

C-5 Overcurrent? Is>0(A) Is=0

C-6 Overcurrent? Icc>1.7(A) Icc<1.7(A)

C-7 Overcurrent? Icc>1.7(A) Icc<1.7(A)

C-8 Overcurrent? Icc>1.7(A) Icc<1.7(A)

Item P2-9, 10 Judgment

No. Branch condition YES NO

D-1

Measurement OK?

D-2

Measurement OK?

D-3

Measurement OK?

D-4

Measurement OK?

D-5

Measurement OK?

D-6

Measurement OK?

D-7

Measurement OK?

D-8

Measurement OK?

D-9 DC/DC changed Changed DC/DC supply already. Not changed DC/DC supply.

already?

the DC/DC connector. the DC/DC connector.

the DC/DC connector. the DC/DC connector.

VH27<1.8 or VH27>1.3 VH27>1.8 or VH27<1.3

VH32<1.8 or VH32>1.3 VH32>1.8 or VH32<1.3

VH28<1.8 or VH28>1.3 VH28>1.8 or VH28<1.3

VH33<1.8 or VH33>1.3 VH33>1.8 or VH33<1.3

VH29<1.8 or VH29>1.3 VH29>1.8 or VH29<1.3

VH34<1.8 or VH34>1.3 VH34>1.8 or VH34<1.3

VH30<1.8 or VH30>1.3 VH30>1.8 or VH30<1.3

VH35<1.8 or VH35>1.3 VH35>1.8 or VH35<1.3

3-14

PFM-500A1WU/500A1WE

Page 51

(Scope : UD-01)

Item P2-11, 12 Judgment

No. Branch condition YES NO

E-1 Display OK? The screen is all white color display. Display omission in white color display.

E-2 New panel? Already changed due to a defective panel. Not changed.

E-3 APC OK? APC Operations normal. APC Operations is abnormal.

E-4 Display OK? A surplus, a defect, a step, A surplus, a defect, a step, and a tone

E-5 Logic PC board Changed Logic PC board already. Not Changed Logic PC board.

Changed?

E-6 New LBUS? Changed LBUS PC board already. Not changed LBUS PC board.

E-7 Changed? Changed Logic PC board already. Not changed Logic PC board.

E-8 Lateral display Found display error in the lateral direction No display error in the lateral direction.

error? on the screen.

E-9 Waveform OK? Upon monitoring the waveform output Upon monitoring the waveform output

E-!/ Waveform OK? YSUS waveform is normal. YSUS waveform is abnormal.

E-!- Failure caused by Panel failure caused by display cell Panel failure not caused by display cell

panel error? defect and brightness variation defect and brightness variation

and a tone operation are normal. operation are abnormal.

(For example, lack of indication or fringes

in the lateral direction.

from DOXE and DOXO for XSUS, from DOXE and DOXO for XSUS,

it was found that waveforms on EVEN an inclination (not level) was found on

and ODD at around 50(V) are even. EVEN and ODD at around 50(V).

In addition, other abnormal waveforms Alternatively, some abnormal waveforms

were not found. were found.

in the panel. in the panel.

Item P2-13, 14 Judgment

No. Branch condition YES NO

F-1 Non-recurrent The fault did not recur. The specified fault recurred.

product?

F-2 Faults recur? The fault does not recur upon The fault does not recur upon

re-installation of new parts. re-installation of new parts.

F-3 ROM version No. The ROM installed are listed in The ROM installed is not listed in

OK? the table below. the table to the left.

Model UD01

ROM 197 or 197G

F-4 Display operation Not found abnormality or failure in Found abnormality or failure in the display

OK? the display operation. operation.

PFM-500A1WU/500A1WE

3-15

Page 52

(Scope : UD-01)

tem P2-15 Judgment

No. Branch condition YES NO

G-1 ACOM Found abnormality in a single A-COM unit Not found abnormality such as vertical line,

PC board unit? (one-fifth of screen width) or more. vertical band, and vertical fringe in the

G-2 Single line missing Found abnormality in one line or band. Found abnormality in two or more lines or

G-3 Fuse blown? Fuse is blown (not conductive). Fuse is not blown (conductive).

The tester reads ∞ ohm in one range. The tester reads 0 ohm in one range.

G-4 Regularity? Found some regularity for display error in No regular recurrence of display errors in

vertical direction -- at a certain interval, the vertical direction.

and others.

G-5 BUS board Changed BUS board already Not changed BUS board

changed?

Item P2-16, 17 Judgment

No. Branch condition YES NO

H-1 Connector OK? The cards for A-COM1 to 5 are The cards for A-COM1 to 5 are discon-

connected to RBUS, LBUS, nected from RBUS, LBUS, or

and logic PC boards properly. logic PC board or not connected properly.

H-2 Chip OK? Found no ACOM chip failure in Found ACOM chip failure in visual

visual checking. checking.

H-3 Fuse changed? Changed fuse already. Not changed fuse.

H-4 Fuse blown? Fuse is blown (not conductive). Fuse is not blown (conductive).

The tester reads ∞ ohm in one range. The tester reads 0 ohm in one range.

H-5 RBUS changed? Changed RBUS PC board already. Not changed RBUS PC board.

H-6 Logic changed? Changed Logic PC board already. Not changed Logic PC board.

H-7 LBUS changed? Changed LBUS PC board already. Not changed LBUS PC board.

ACOM unit (one-fifth of screen width).

bands.

Item P2-18 Judgment

No. Branch condition YES NO

K-1 Both SUS? Likely failure in both XSUS and YSUS. Failure in either XSUS or YSUS.

K-2 XSUS? XSUS failure (waveform). YSUS failure (waveform).

K-3 Changed? Changed logic PC board already. Not changed Logic PC board.

K-4 Changed? Changed XSUS PC board already. Not changed XSUS PC board.

K-5 Changed? Changed YSUS PC board already. Not changed YSUS PC board.

K-6 Output OK? Ve 16 V ~ 18 V ±0.1 % ,Vsc 100 V ±0.1 % The voltage (Ve, Vsc., Vw, _Vy) do not

Vw 180 V ±0.1 % , _Vy 170 ~ 180 ±1.0 % indicate the values as

mentioned on the right.

3-16

PFM-500A1WU/500A1WE

Page 53

(Scope : UD-01)

Item P2-19, 20 Judgment

No. Branch condition YES NO

L-1 Light emission Found light emission from background. Not found light emission from background.

from background?

L-2 Output OK? Ve output is Ve>16 and Ve<18. Ve output is Ve<16 and Ve>18.

L-3 Waveform OK? An output waveform shown by figure 1,2 It isn’t an output waveform shown by figure

L-4 Output OK? YCOMDV output is normal. YCOMDV output is abnormal. (see the

L-5 Output OK? An output shown by figure 1 of appendix 1. It Isn’t an output shown by figure 1 of

L-6 Waveform A? An output waveform (A) shown by An output waveform (B) shown by flow

L-7 Changed? Changed XSUS PC board already. Not changed XSUS PC board.

L-8 Changed? Not changed YSUS PC board. Changed YSUS PC board already.

Item P2-21, 22 Judgment

No. Branch condition YES NO

M-1 Input OK? Found VPON entry (XSUS). Not found VPON entry (XSUS).

M-2 Input OK? Found VPON entry (YSUS). Not found VPON entry (YSUS).

M-3 VEGO OK? After YEGO outputs about 120ms Excluding the left

M-4 VWYGO OK? After VWYGO outputs about 120ms Excluding the left

M-5 Always “0”? A logical output is always “0” A logical output is not “0”

and 3 of appendix 1,2. 1,2 and 3 of appendix 1,2.

(see the figure 4 of appendix 2) figure 4 of appendix 2)

appendix 1.

flow chart. chart.

and about 5 V, YEGO becomes 0V.

and about 5 V, VWYGO becomes 0V.

PFM-500A1WU/500A1WE

3-17

Page 54

(Scope: UD-01)

Item P2-23, 24 Judgment

No. Branch condition YES NO

N-1 Output OK? VH27<1.8 or VH27>1.3 VH27>1.8 or VH27<1.3

N-2 Output OK? VH32<1.8 or VH32>1.3 VH32>1.8 or VH32<1.3

N-3 Output OK? VH28<1.8 or VH28>1.3 VH28>1.8 or VH28<1.3

N-4 Output OK? VH33<1.8 or VH33>1.3 VH33>1.8 or VH33<1.3

N-5 Output OK? VH29<1.8 or VH29>1.3 VH29>1.8 or VH29<1.3

N-6 Output OK? VH34<1.8 or VH34>1.3 VH34>1.8 or VH34<1.3

N-7 Output OK? VH30<1.8 or VH30>1.3 VH30>1.8 or VH30<1.3

N-8 Output OK? VH35<1.8 or VH35>1.3 VH35>1.8 or VH35<1.3

Item P2-25, 26 Judgment

No. Branch condition YES NO

P-1 Trouble The fault recurred. The specified fault does not recur.

reproduction?

P-2 ROM The ROM installed are listed The ROM installed is not listed

version No. OK? in the table below. in the table to the left.

Model UD01

ROM 197L or 197G

P-3 Trouble Some problem occurred or the fault Any fault including the specified fault does

reproduction? recurred during running test. not occur.

P-4 OK? The PDP function works perfectly normal. Some fault or problem occurred.

P-5 Non-recurrent The PDP unit, which was once returned Not returned due to the same fault in the

and due to a fault, has been inspected and same position as before.

returned unit? shipped following no recurrence of the fault.

Then, the unit was returned again with

the same fault. However, the faulty part

cannot be isolated because the fault

has not recurred yet.

3-18

PFM-500A1WU/500A1WE

Page 55

3-11. Voltage Setting Procedure

Vs and _Vy fluctuation, voltage margin is measured and a set voltage is decided. Use the external and

internal (DC/DC in 3-3) power supplies to generate +Vs and _Vy respectively.

Please see to Display Test Manual (3-12) for each display pattern.

1. Panel Voltage Measuring Procedure

Judgment of the minimum voltage : The level at which every point is turned on upon raising the voltage

slowly at each point (except the special points).

Special point : The point that is not turned on when every other point is turned on.

This point requires a higher voltage to be turned on.

Judgment of the maximum voltage : The level at which the surplus points are disappeared with a straight

change in voltage upon lowering the voltage slowly at each point.

Surplus point : The display point other than display data

(Except constant surplus point).

(Procedure) (Operation)

1 Preparation Install and turn on the test equipment in the white solid display in the

highest level for four minutes.

2 Vs(min) setting _Vy = _160 V (Temporary setting)

Setting : APC : ON, HQEN : OFF

Display : Gray-scale [R16 gradation : Left discernment-Right privily]

Cross-hatch + slash-pattern (G The highest gradation)

3 Vs Set value Decision [The set value of Vs is decided from Vs (min) in this paragraph.]

Vs (min)=Vs (min) +4 V

(1) For Vs (min)<180 V/Vs(Set value)=180 V

(2) At setting Vs = 180 V, Margin measurement in clause 4-7.

When abnormality is found in the display confirmation, VS is

assumed 170 V, and executes clause 4-7. But, it is assumed Vs

(min) <170 V.

4 _Vy Margin measurement [Set value as for Vs. _Vy margin is measured in this paragraph.]

Setting : APC : ON, HQEN : OFF

Display : _Vy (min) : Overall lighting

(W, R, G, B Each color highest gradation)

Cross-hatch +slash-pattern (G The highest

gradation)

_Vy (max) : Overall lighting (W The highest gradation)

Gray-scale

[R, G, B Each color 16 gradation :

Left discernment-Right privily]

Length color bar

[R=172, G=192, B=255 Each color specification

gradation (50 Hz)]

Cross-hatch + slash-pattern

(W The highest gradation)

Next page

PFM-500A1WU/500A1WE

3-19

Page 56

Before page

5 _Vy Set value Decision [The set value of _Vy from _Vy margin is decided in this paragraph.]

(1) _Vy (Set value) = _Vy _4 V

But, for a | _Vy (Set value) |<| _145 V|, _Vy(Set value) _145

(2) _Vy (Set value) _4V<_Vy (max)

6 Margin confirmation [The Vs margin is finally set by the result of the _Vy setting.]

Vs (min) is confirmed with Vs _3V.

Vs (max) is confirmed with Vs +4V.

Setting : APC : ON, HQEN : OFF

Display : _Vy (min) : Overall lighting (B The highest gradation)

Gray-scale

[R, G, B Each color 16 gradation :

Left discernment-Right privily]

Cross-hatch +slash-pattern

[W, R, G, B Each color highest gradation)

_Vy (max) : Overall lighting (W The highest gradation)

Gray-scale

[R, G, B each color 16 gradation :

Left discernment-Right privily]

Length color bar

[R = 172, G = 192, B = 255 Each color specification gradation (50 Hz)]

7 Display confirmation [The display confirmation of Vs and _Vy is done by the set value.]

Setting : APC : ON, HQEN : OFF

But, gradation plover pattern HQEN : ON

Display : Length belt pattern

[R : 134 & 136] AUTO program mode test (10 cycle)

[See the next page]

Gradation plover pattern [G : 62 & 64]

Length color bar

[R = 172, G = 192, B = 255 Each color specification gradation

(50 Hz)]

Gray-scale

[R, G, B Each color 16 gradation : Left discernment-Right

privily]

Length belt pattern and gradation plover pattern are numbers 0 of

blinking faults. But, the cell defect-blinking fault is excluded.

Length belt pattern and gray-scale are five pixel or less of blinking

faults.

But, the cell defect-blinking fault is excluded. (Self-erase judgment :

SE)

3-20

PFM-500A1WU/500A1WE

Page 57

AUTO Program Mode Test (Operation and Stop Procedure)

Purpose : Black point noise Evaluation pattern (No.22 . 23) is alternately displayed, and the presence of

Black point noise is confirmed.

Method : The undermentioned operation is executed from RB-614C keyboard.

FUNC Key PUSH

1

SET

SET

Program No.22

Black Point Pattern display

Program No.23

Black Point Pattern display

FUNC push?

Yes

Program No.22

Black Point Pattern display

Key PUSH

Key PUSH

Key PUSH

No

Keeps pushing for about 3 seconds.

0

SET

AUTO Program Mode STOP

Arbitrary key

PFM-500A1WU/500A1WE

Key PUSH

Key PUSH

3-21

Page 58

Marginal diagram (reference drawing for setting voltage when Vs=180V)

Vs (v)

185

180

175

170

-Vs min-4V

Vs Set value

-Vs min

-Vy Set value

Check point Vs max (Vs +4 V)

Check point -Vy (Set value = _4 V)

Check point Vs min(Vs _3 V)

Vs min

_160

_Vy max

_170_150 _152 _156

Area which can be set

DC/DC internal voltage setting (see the 3-3 for the measuring points for Vrs, _Vy voltages)

1 Connect the external power supply to CN23 to 25 on the DC/DC PC board.

2 Set a digital multimeter to the voltage of Vrs on the DC/DC PC board.

3 Turn on the external power supply.

_Vy (v)

4 Set to the voltage of Vrs on the DC/DC PC board. (Vs formula : Vs = 165 +10xVrs, Vrs = 0 to 2.0 V)

5 Set the marginal value to _Vy.

6 Complete setting after display test.

3-22

PFM-500A1WU/500A1WE

Page 59

2. Voltage Setting Procedure in Replacement of the DC/DC

Measure the voltage on the old DC/DC PC board and set the measurement on the new voltage.

Measuring points and setting voltage

1 Vrs voltage

2 _Vy setting voltage

Setting procedure when an invalid voltage exists

1 Set Vs to 180 V.

2 Set _Vy to 160 V and perform the display operation to check if the resulting value is valid with the

table as shown below. Obtain the setting voltage by fluctuating the value within the standard electric

potential and set this value.

PFM-500A1WU/500A1WE

3-23

Page 60

3-12. Display Test Manual

This manual explains the examination procedure and the operation method when 42-model PDP is

examined by using VG-826. The display pattern is recorded. The display function of PDP is confirmed.

1. Signal generator

VG-826 is used as a display signal generator. The display pattern is built into panel ROM by the program

form. The program No. is selected from the keyboard, and the display function is confirmed.

Signal generator

External keyboard (RB-614C)

Ten-key for program No. input

Exclusive pattern-key

FUNCTION-key

Panel ROM

2. Panel ROM and External keyboard

In ROM, there is a test pattern for a lot of displays. The selection of the test pattern inputs the figure of

two digits (01 ~ 36) by External keyboard.

This program is a display test pattern to examine the PDP-unit connected with VG-826. The display

pattern for this test is in program ROM.

Mount panel ROM so that VG-826 may operate by the program data.

1 Panel ROM

Memory of display data as program

Selection program ....... 36 pattern

2 RB-614C External keyboard function

Key name Number Key-function

Fixed display exclusive key 11 A fixed pattern is displayed.

Option-key 1 1 23 kinds of patterns can be displayed.

Option-key 2 1 23 kinds of patterns can be displayed.

FUNCTION 1 VG-826 Function selection key (Unused usually)

SET 1 Key which effectively does function selection (Unused usually)

INV 1 The screen display is reversed.

R,G,B (Each) 3 The display of each color is switched.(ON / OFF)

H-T 1 Unused

&

3-24

PFM-500A1WU/500A1WE

Page 61

t

3. Test equipment connection diagram

Check whether the connection of the test equipment is normal, before doing trouble analysis and the

display test of the PDP device. (See the undermentioned connection diagram)

68 p connector

Logic (go to CN1)

To DC/DC CN24

34 line flat cable

APC D.EN HQEN B.CONT

OFF OFF OFF

8P connector

CN 4 CN5

CN6

flat cable

DIGITAL OUT

VG-826

DIGITAL

VIDEO

GENERATOR

50P

flat cable

3

CN

Remote Control BOX

POWER

POWER/SW

50P

AC100V

CN1 CN2

POWER OFF 0

POWER ON 1

REMOTE

3P DC24 V

2

CN

MAIN SW BOX

OFF

(AC100V)

o

(AC240V)

INC DEC SET

RB-614C

PDP Special power

supply

To DC/DC CN25

To DC/DC CN26

To DC/DC CN25

To DC/DC CN26

9P connector

10P connector

9P connector

10Pconnector

ROM

LED display window

External power supply

Vcc Va Vs

(FPF10P-AC100/240B)

AC100 V

PFM-500A1WU/500A1WE

3-25

Page 62

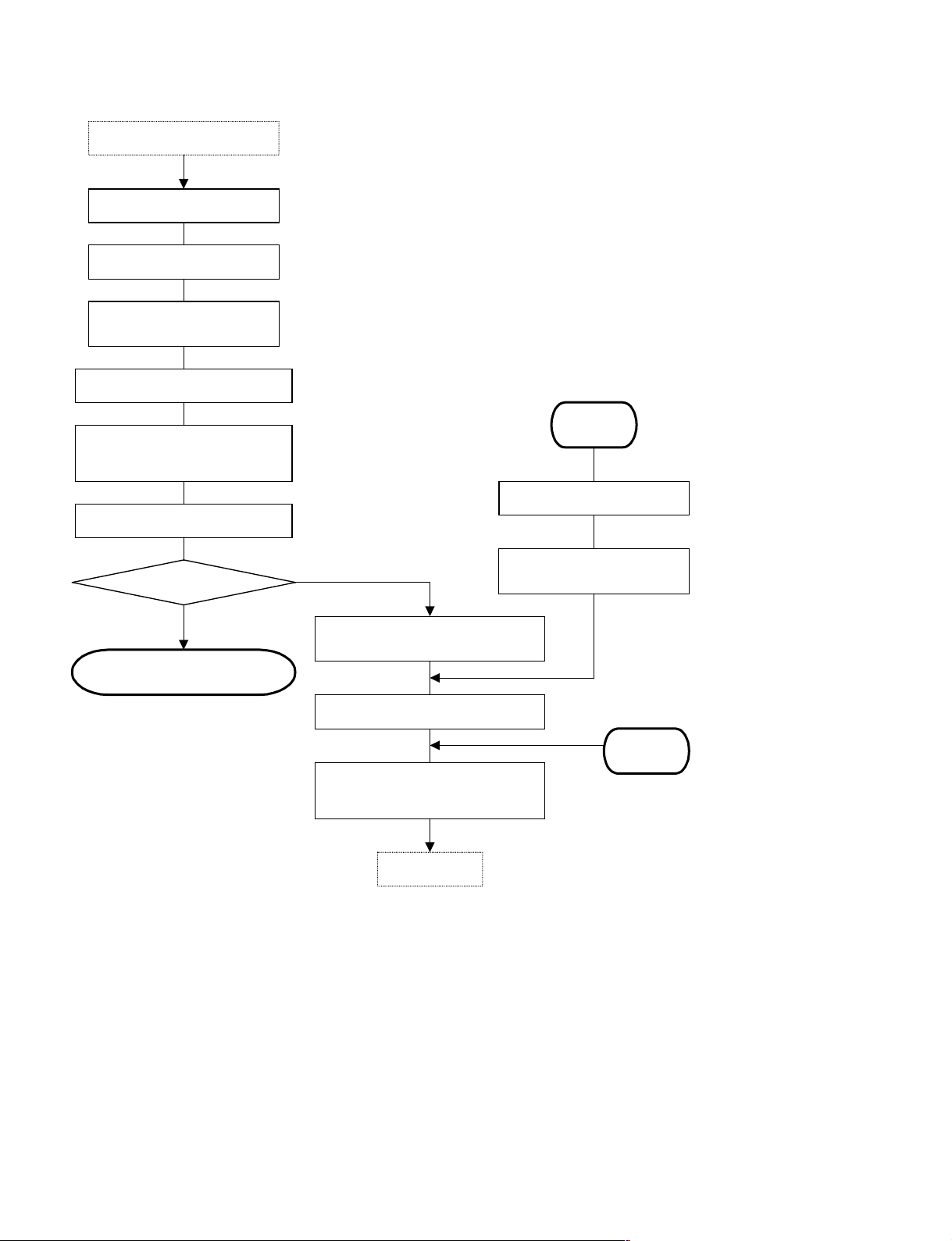

4. Test equipment Start procedure and Equipment connection

Each decision criteria is described to the attached paper. (See the 3-15)

Connection

Check MAIN SW OFF

A-1

MAIN SW OFF

Yes

Check VG-826 POWER SW OFF

A-2

POWER SW OFF

Yes

Test equipment power supply connection

Test equipment MAIN SW ON

VG-826 POWER SW ON

A-3

VG-826 Operation OK?

No

MAIN SW OFF

No

POWER SW OFF

No

Yes

68P connector is connected with

the logic part (CN1)

External power supply or Special power supply

cable is connected with DC/DC.

External power supply is connected individual SW

OFF is confirmed.

Equipment connection completion

3-26

VG-826 input check

A-4

AC input OK?

VG-826 Repair request

No

Yes

AC input improvement processing

Go to Connection

PFM-500A1WU/500A1WE

Page 63

5. Operation method and Display

1 Operation method

The signal generator enters command input standby by turning the POWER SW to ON.

RB-614C can select the display pattern by the input numerical value (01-36) of two digits from a numeric

key. (You can see the Display pattern on P3-28, 29.)

POWER ON

Command input standby

B-1

Input ?

Yes

Selection pattern display OK ?

Yes

No

No

PFM-500A1WU/500A1WE

3-27

Page 64

3-13. VG-826 Program Display Pattern

P-No. Color Display pattern P-No. Color Display pattern

01 W 16 W

02 R

03 G

04 B

One color on all screens display Discernment --- 256 gradation --- Privily

05 W 17 W

06 R 18 R

07 G 19 G

08 B 20 B

Lattice +Slash +Frame Window

09 W 21 W

Privily --- 256 gradation --- Discernment English

10 No display 22 R

11 W 23 R

12 R

13 G

14 B

Horizontal belt Length belt

15 W 24 G

The middle gradation display Gradation plover pattern

3-28

PFM-500A1WU/500A1WE

Page 65

P-No. Color Display pattern P-No. Color Display pattern

25 W 32 Mix

Length belt Color-bar

26 W 33 W

27 R 34 R

28 G 35 G

29 B 36 B

Frame +Slash Window

31 W

Half tone

PFM-500A1WU/500A1WE

3-29

Page 66

3-14. Fixed Display Exclusive-key Pattern

The thing to push an exclusive-key can display these screens.

CHARA CROSS DOT

CIRC COLOR GLAY

BRST

WINDOW

++

+

++

xx

x

xx

3-30

PFM-500A1WU/500A1WE

Page 67

3-15. Decision Criteria Table (Object Page : P3-26, 27)

YES NO

A-1 MAIN SW OFF MAIN SW ON

A-2 VG-826 POWER SW OFF VG-826 POWER SW ON

A-3 The fan of the signal generator (VG-826) rotates, The fan of the signal generator (VG-826) doesn’t

and the LED display is 001. rotate. /LED is not displayed.

A-4 AC100V is input. AC100V is not input.

B-1 Two-digit numerical value to 01-36 is input. Numerical values other than the left were input.

PFM-500A1WU/500A1WE

3-31

Page 68

3-16. PC Board Replacing Proceduce

Replacing-procedure of Print PC board is shown in the following. PC board replacing work after a

defective PC board separates works in reverse-procedure.

n

Please note insulating bushing position when you install PC-board.

Exchange PC board confirmation

Check each power supply OFF

XSUS PC board exchange

YSUS PC board exchange

CN48 to CN50

Separation

PC board fixation

screw detaching

screw (3 x12 mm) x10

Insulating bushing

UC-02 x9

Others x2

XSUS Separation of

connector

CN51-53/CN52-54

XSUS PC board

Separation

XSUS PC board

exchange

External power supply ?

Yes

Signal cable and power supply cables are separated.

PDP is moved to the work stand and the protecting cover is removed.

Defective PC board selection

DC/DC PC-board exchange

CN40 to CN42

Separation

PC board fixation

screw detaching

screw (3 x12mm) x10

Insulating bushing x10

UC-02 x10

Others x2

YSUS Separation of

connector

CN43-46/CN44-47

XSUS PC board

Separation

XSUS PC board

exchange

CN5, 9,11,13,37,41,42,49, 50

Each connector separation

PC board fixation

screw detaching

screw (3 x12mm) x 2

Thai lap cutting

(8 places)

DC/DC PC board

Separation

DC/DC PC

board exchange

No

Check Remote-Ctrl BOX SW OFF

Address PC board exchange

Logic PC board exchange

CN2 to 5, 16

Separation

Address PC board

Separation

PC board fixation

screw detaching

screw (3 x12mm) x2

Logic PC board

Separation

Logic PC board

exchange

L-BUS (CN13, 17,18)

Separation

R-BUS (CN11, 14,15)

Separation

Each ABUS PC board

PC board fixation

screw detaching

screw (3x20mm)x2

Connector separation

L-BUS (CN12-CN8)

separation

R-BUS (CN10-CN7)

separation

L or R-BUS PC board

Separation

Address PC board

exchange

3-32

PFM-500A1WU/500A1WE

Page 69

3-17. Each PC Board Installation Screw Position/Connector Position

UD-01

YCOM UP

CN

46

YCOM DOWN

CN

47

CN37

CN4 CN5

CN3

Logic PC board

CN18

DC/DC

CN25 CN24 CN23

9

CN

CN16

CN

CN

CN7

2

1

CN10

CN15

CN49

CN50

XSUS PC board

CN48

CN11

RBUS PC board

CN43

YSUS PC board

4

CN4

CN13

LBUS PC board

CN18

ACOM5 ACOM3ACOM4 ACOM2 ACOM1

CN41

CN42

CN40

PC board installation screw position

Insulating bushing (NA18100-X024) Installation screw position

With core (Cable with core)

CN26 CN37

CN12

CN17

CN51

CN52

CN14

XBUS UP

CN

53

XBUS DOWN

CN

54

PFM-500A1WU/500A1WE

3-33

Page 70

Page 71

The material contained in this manual consists of

information that is the property of Sony Corporation.

Sony Corporation expressly prohibits the duplication of

any portion of this manual or the use thereof for any

purpose other than the operation or maintenance of the

equipment described in this manual without the express

written permission of Sony Corporation.

Le matériel contenu dans ce manuel consiste en

informations qui sont la propriété de Sony Corporation.

Sony Corporation interdit formellement la copie de

quelque partie que ce soit de ce manuel ou son emploi

pour tout autre but que des opérations ou entretiens de

l’équipement à moins d’une permission écrite de Sony

Corporation.

Das in dieser Anleitung enthaltene Material besteht aus

Informationen, die Eigentum der Sony Corporation sind.

Die Sony Corporation untersagt ausdrücklich die

Vervielfältigung jeglicher Teile dieser Anleitung oder den

Gebrauch derselben für irgendeinen anderen Zweck als

die Bedienung oder Wartung der in dieser Anleitung

beschriebenen Ausrüstung ohne ausdrückliche

schriftliche Erlaubnis der Sony Corporation.

PFM-500A1WU/500A1WE

Page 72

Sony Corporation

B&P Company

©2001 FUJITSU HITACHI PLASMA DISPLAY LIMITED9-976-682-41

Printed in Japan

English

01HS16-1

©2001.8

Loading...

Loading...