Page 1

FLAT PANEL DISPLAY

PFM-42X1

PFM-42X1N

COMPONENT/RGB ACTIVE THROUGH ADAPTOR

BKM-V12

SPEAKER SYSTEM

SS-SP20B

SS-SP20S

REMOTE COMMANDER

RM-971

SERVICE MANUAL

1st Edition

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

PFM-42X1/42X1N

Page 3

CAUTION

ADVARSEL

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer’s instructions.

Vorsicht!

Explosionsgefahr bei unsachgemäßem Austausch

der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ. Entsorgung

gebrauchter Batterien nach Angaben des

Herstellers.

ATTENTION

Il y a danger d’explosion s’il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du même

type ou d’un type équivalent recommandé par le

constructeur.

Mettre au rebut les batteries usagées conformément

aux instructions du fabricant.

Lithiumbatteri - Eksplosjonsfare.

Ved utskifting benyttes kun batteri som

anbefalt av apparatfabrikanten.

Brukt batteri returneres

apparatleverandøren.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ

som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande

föreskrifter.

VAROITUS

Paristo voi räjähtää jos se on virheellisesti

asennettu.

Vaihda paristo ainoastaan laitevalmistajan

suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

Lithiumbatteri-Eksplosionsfare ved fejlagtig

Levér det brugte batteri tilbage til leverandøren.

PFM-42X1/42X1N

ADVARSEL!

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

1 (P)

Page 4

For the customers in the Netherlands

Voor de klanten in Nederland

Hoe u de batterijen moet verwijderen, leest u in de tekst

van deze handleiding.

Gooi de batterij niet weg maar lever deze in als klein

chemisch afval (KCA).

Für Kunden in Deutschland

Entsorgungshinweis: Bitte werfen Sie nur entladene

Batterien in die Sammelboxen beim Handel oder den

Kommunen. Entladen sind Batterien in der Regel dann,

wenn das Gerät abschaltet und signalisiert “Batterie

leer” oder nach längerer Gebrauchsdauer der Batterien

“nicht mehr einwandfrei funktioniert”. Um

sicherzugehen, kleben Sie die Batteriepole z.B. mit

einem Klebestreifen ab oder geben Sie die Batterien

einzeln in einen Plastikbeutel.

2 (P)

PFM-42X1/42X1N

Page 5

Table of Contents

1. Service Overview

1-1. Appearance Figure ...................................................................................... 1-1

1-2. Board Locations .......................................................................................... 1-1

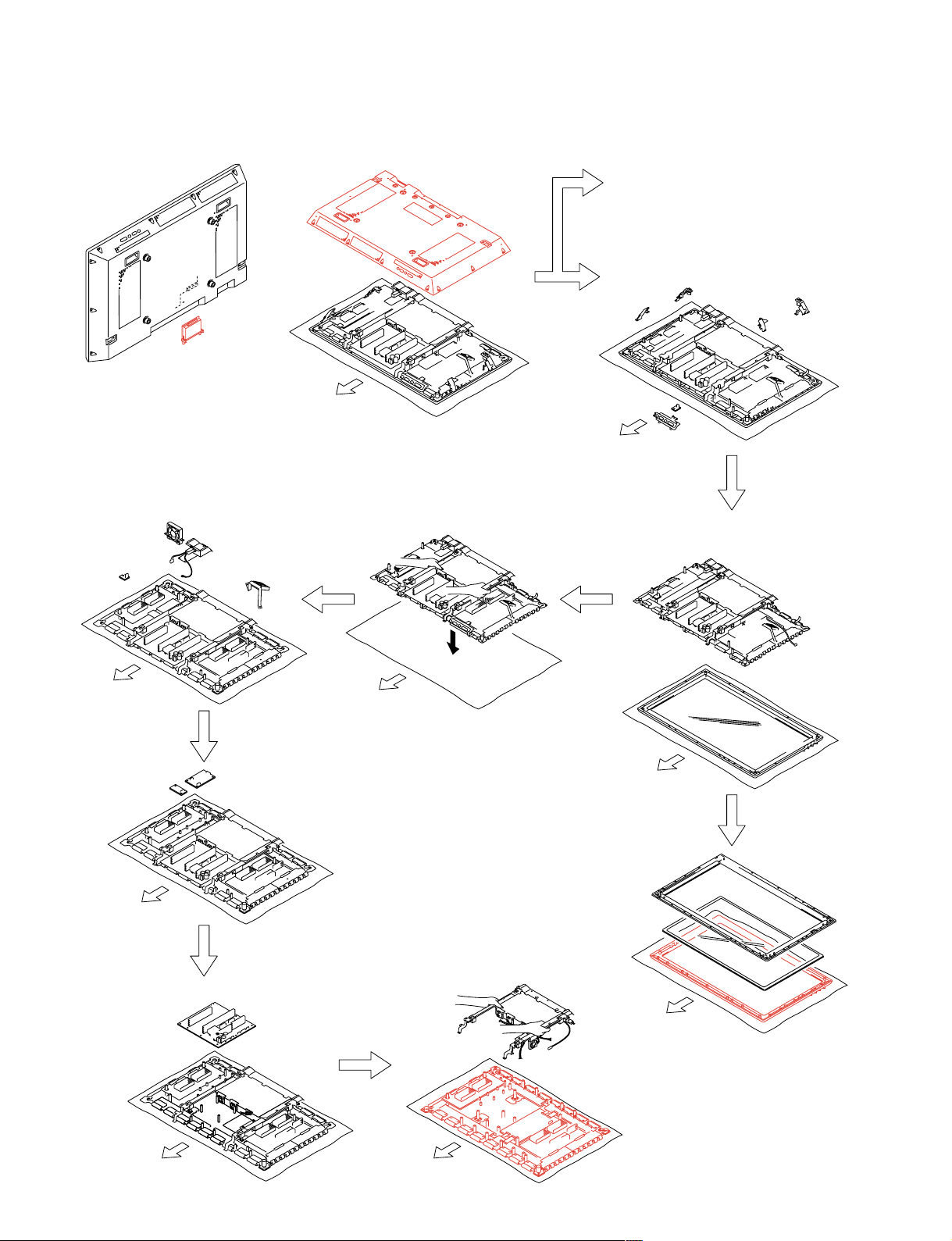

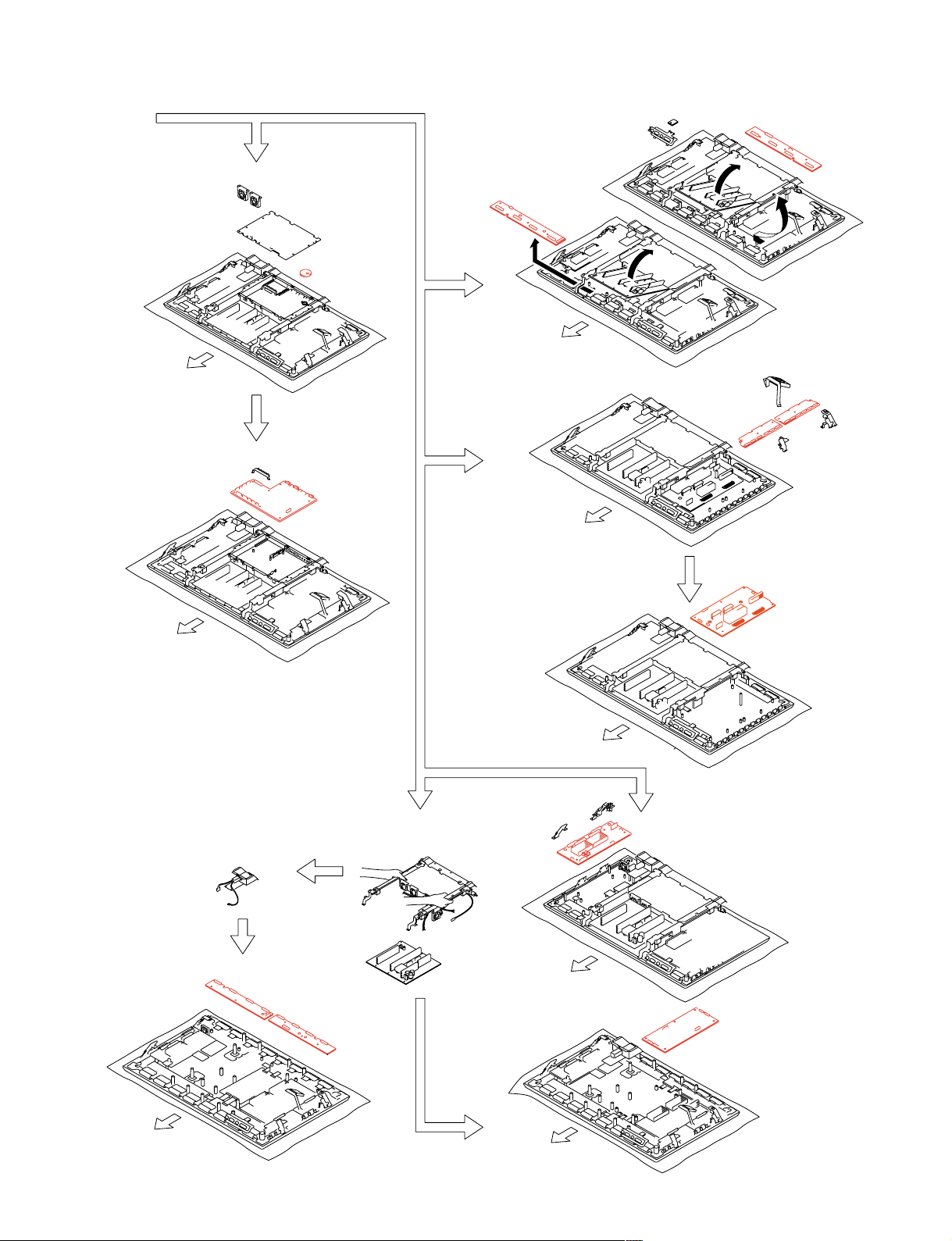

1-3. Disassembly ................................................................................................ 1-2

1-3-1. BKM-V10 .................................................................................. 1-4

1-3-2. Rear Cover Assembly ................................................................ 1-4

1-3-3. Bezel Assembly 1 ....................................................................... 1-5

1-3-4. Bezel Assembly 2 ....................................................................... 1-6

1-3-5. Plasma Display Panel 1 ..............................................................1-7

1-3-6. Plasma Display Panel 2 ..............................................................1-8

1-3-7. Litium Battery ............................................................................ 1-9

1-3-8. A Board ...................................................................................... 1-9

1-3-9. CTRL Board ............................................................................. 1-10

1-3-10. XRB Board and XLB Board .................................................... 1-10

1-3-11. XRT Board and XLT Board ..................................................... 1-11

1-3-12. YDB Board and YDT Board .................................................... 1-12

1-3-13. Z-SUS Board ............................................................................1-12

1-3-14. Y-SUS Board ........................................................................... 1-13

1-4. Warning on Power Connection ................................................................. 1-13

2. Electrical Adjustment

2-1. Setup Adjustment ........................................................................................2-1

2-2. White Balance Adjustment ......................................................................... 2-1

2-2-1. Initialization ............................................................................... 2-1

2-2-2. AD Calibration ........................................................................... 2-1

2-2-3. White Balance Adjustment ........................................................ 2-2

2-2-4. Shipment Condition Setting ....................................................... 2-2

2-3. Panel Adjustment ........................................................................................ 2-3

2-3-1. Application Object ..................................................................... 2-3

2-3-2. Notes .......................................................................................... 2-3

2-3-3. Adjustment Items ....................................................................... 2-3

2-3-4. Adjusting the Board Group (Applying the Tools) ..................... 2-3

2-3-5. Adjustment after Assembling (PDP Module Adjustment) ......... 2-4

2-4. Troubleshooting .......................................................................................... 2-7

2-4-1. Checking for No Picture ............................................................. 2-7

2-4-2. Hitch Diagnosis Based on the Display Condition ......................2-9

2-4-3. Checking for Component Damage ...........................................2-12

PFM-42X1/42X1N

1

Page 6

3. Troubleshooting Guide

3-1. Out of Order on Power ................................................................................3-1

3-2. No Raster State ............................................................................................ 3-3

3-3. Sound Troubleshooting ............................................................................... 3-7

4. Spare Parts

4-1. Notes on Repair Parts .................................................................................. 4-1

4-2. Exploded Views .......................................................................................... 4-2

2

PFM-42X1/42X1N

Page 7

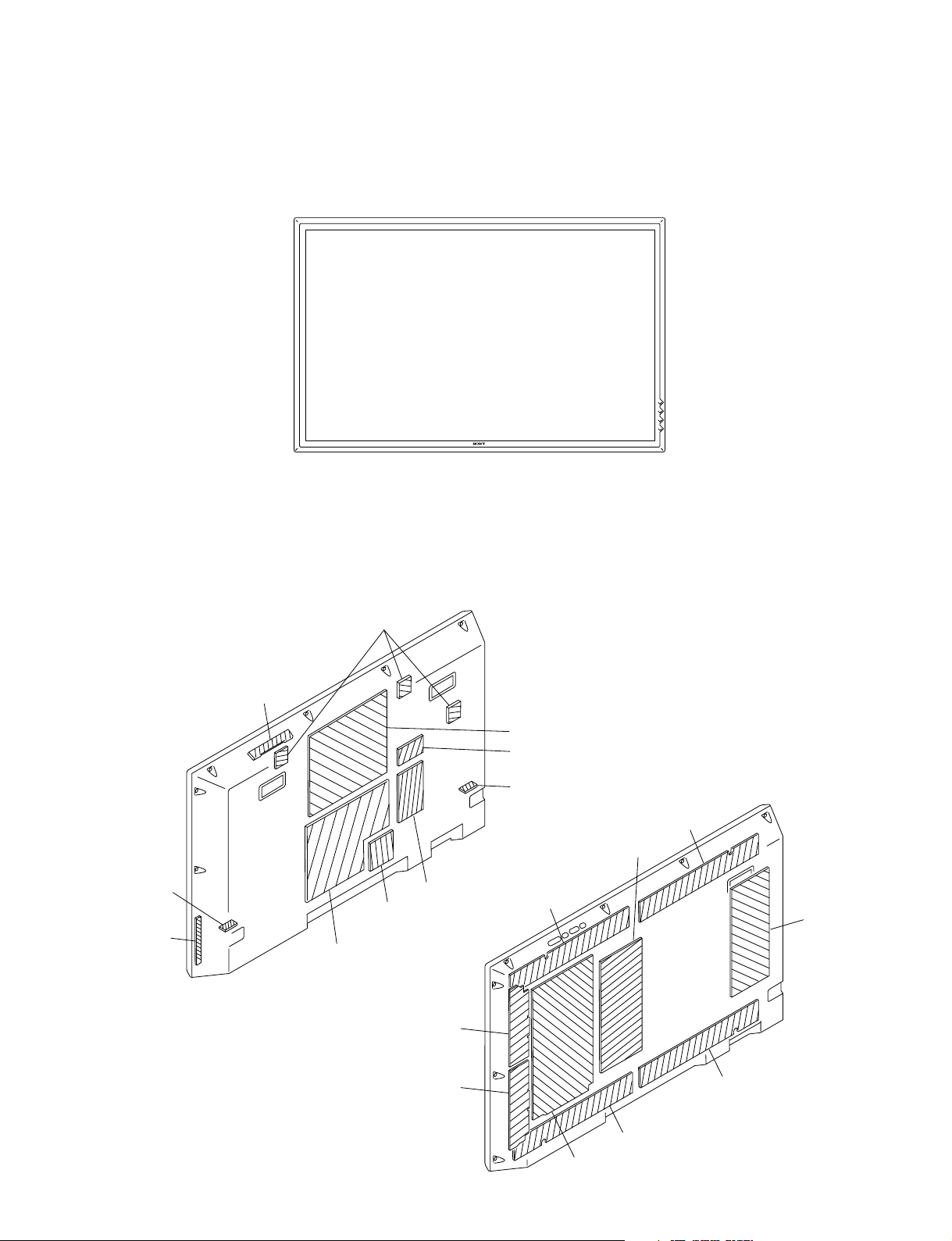

1-1. Appearance Figure

Section 1

Service Overview

1-2. Board Locations

H2 (User control)

T (L) (SP)

H1 (SW)

TEMP

A (Main)

BKM-V10

L (Audio)

YDT

G (Power)

DDC CI

T (R) (SP)

XRT

CTRL

XLT

Z-SUS

PFM-42X1/42X1N

YDB

XRB

XLB

Y-SUS

1-1

Page 8

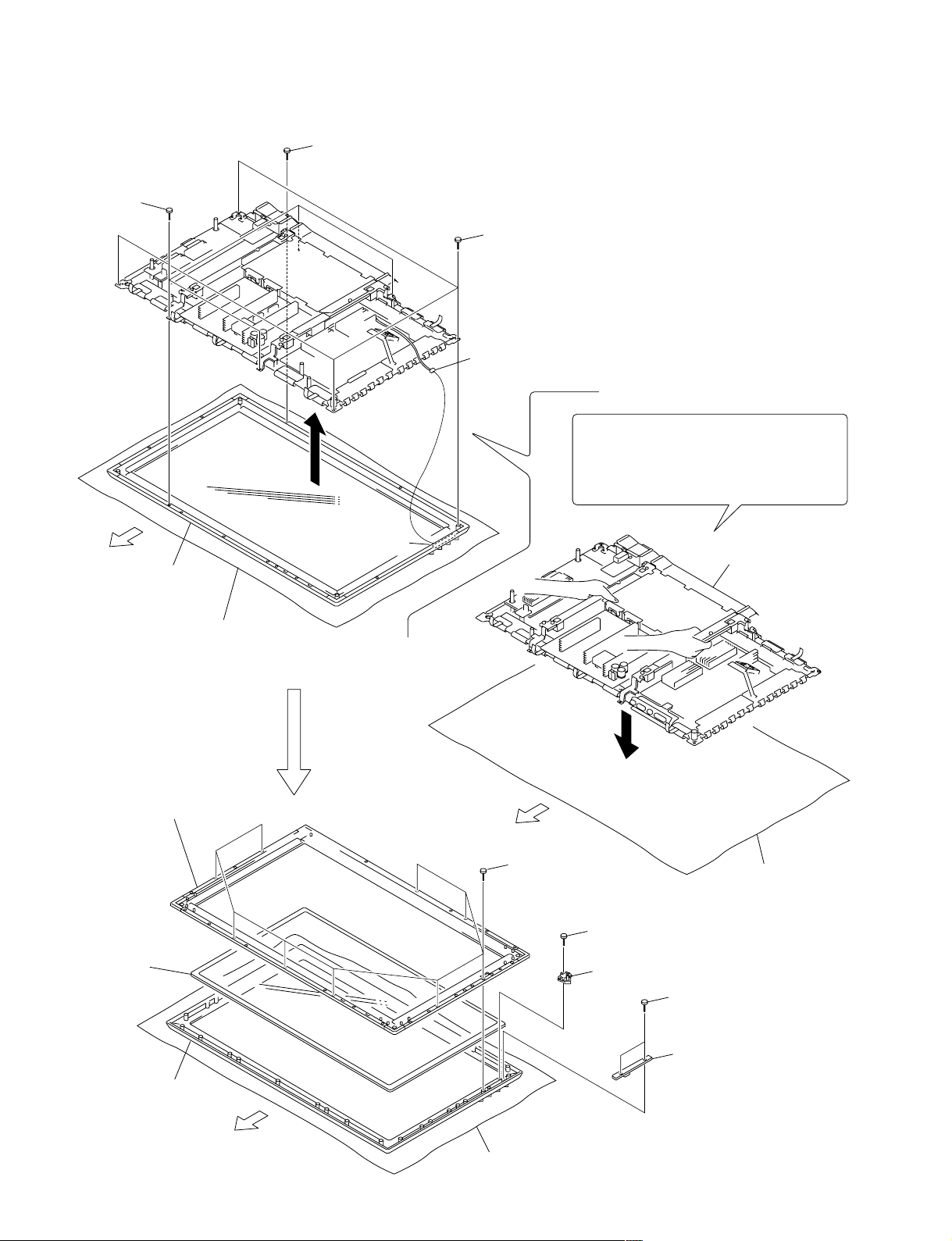

1-3. Disassembly

1-3-1. BKM-V10

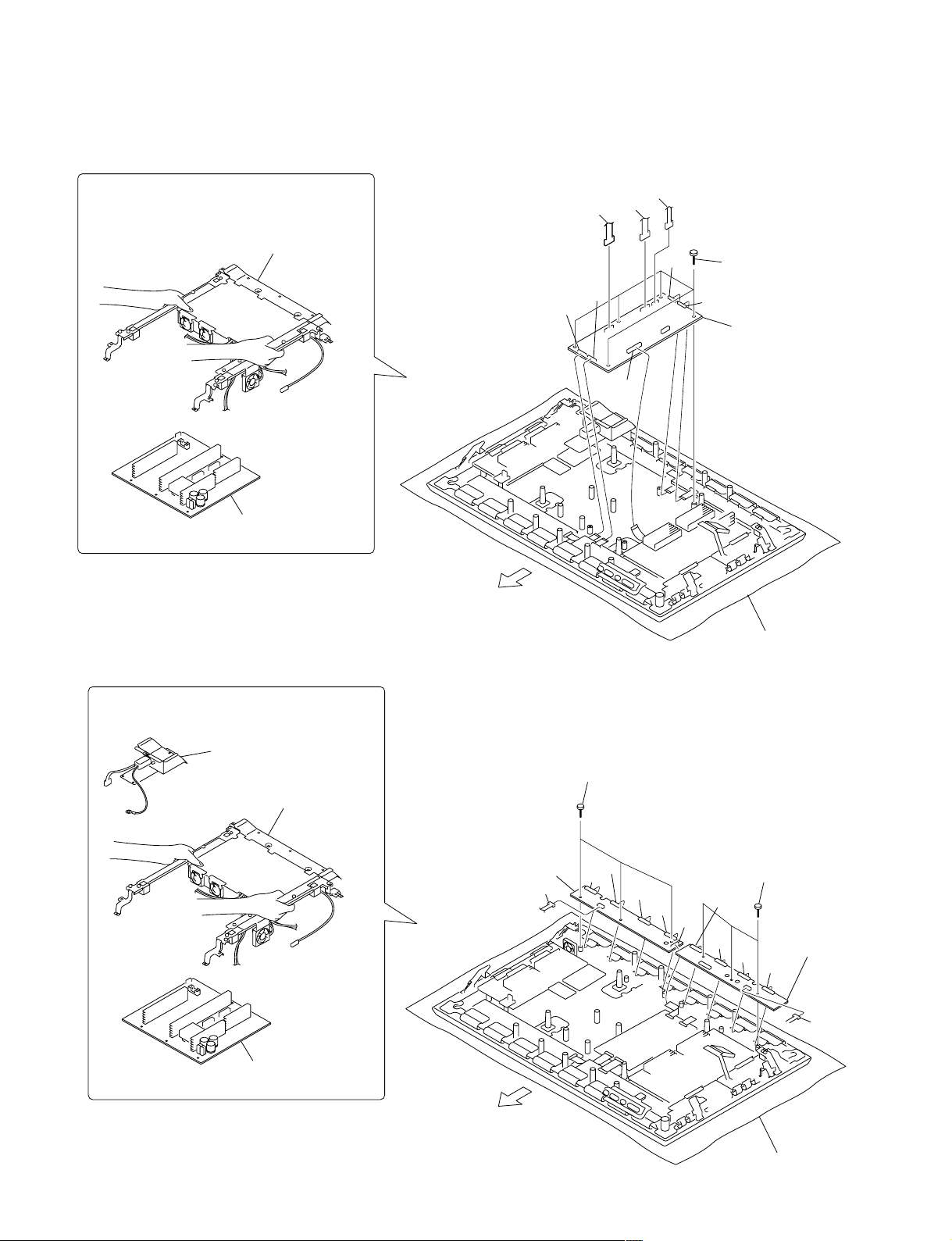

1-3-5. Plasma Display Panel 1

1-3-2. Rear Cover Assembly

A

1-3-3. Bezel Assembly 1

Upper

Side

Upper

Side

1-3-4. Bezel Assembly 2

Upper

Side

Upper

Side

1-3-6. Plasma Display Panel 2

Upper

Side

Upper

Side

Upper

Side

1-2

Upper

Side

Upper

Side

PFM-42X1/42X1N

Page 9

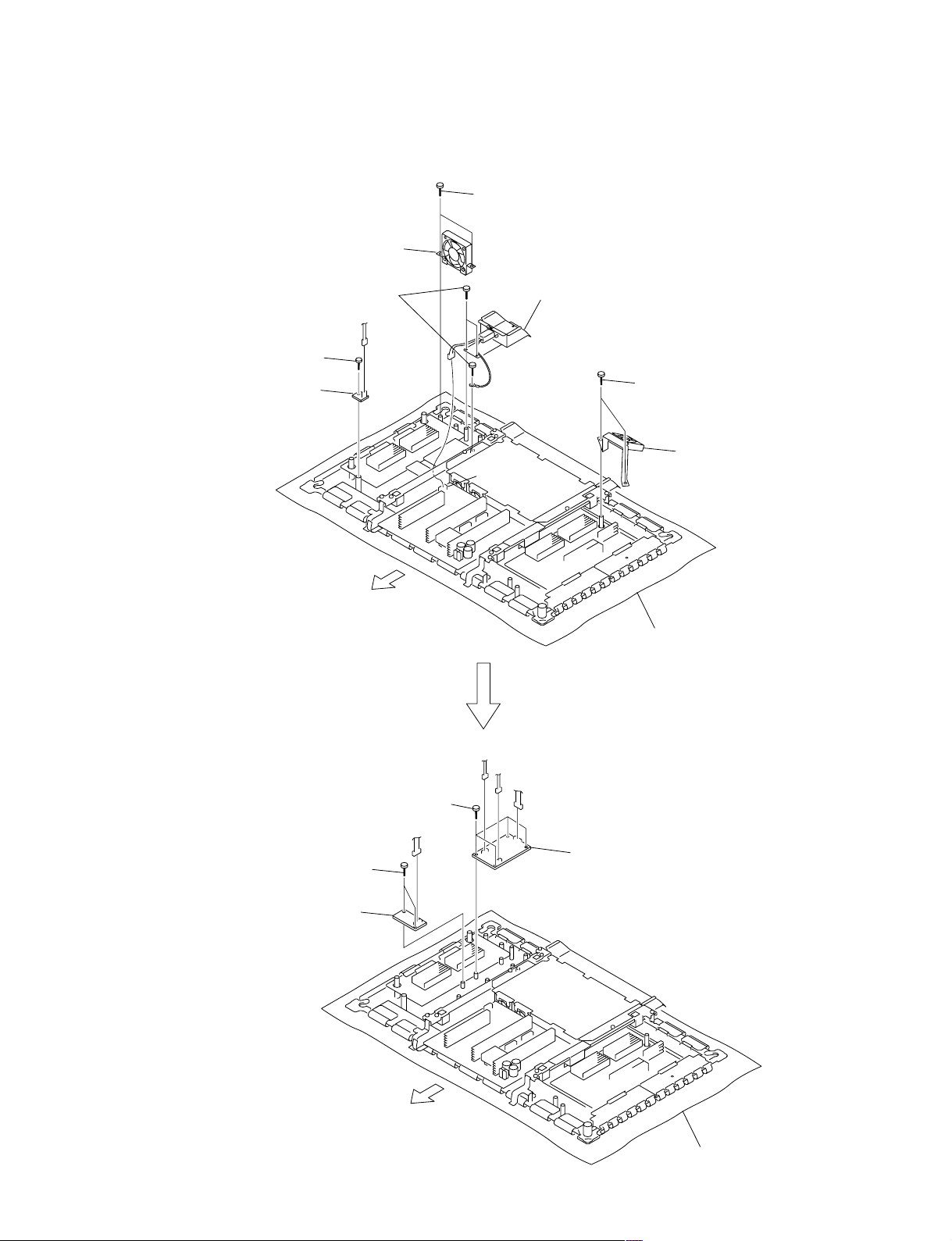

A

1-3-11. XRT Board and XLT Board

1-3-7. Lithium Battery

Upper

Side

Upper

Side

1-3-12. YDB Board and YDT Board

1-3-8. A Board

Upper

Side

Upper

Side

For removal procedure, refer to

"Plasma Display Panel 1.2".

1-3-10. XRB Board and XLB Board

For removal procedure, refer to

"Plasma Display Panel 2".

1-3-14. Y-SUS Board

Upper

Side

1-3-13. Z -SUS Board

Upper

Side

1-3-9. CTRL Board

Upper

Side

PFM-42X1/42X1N

Upper

Side

1-3

Page 10

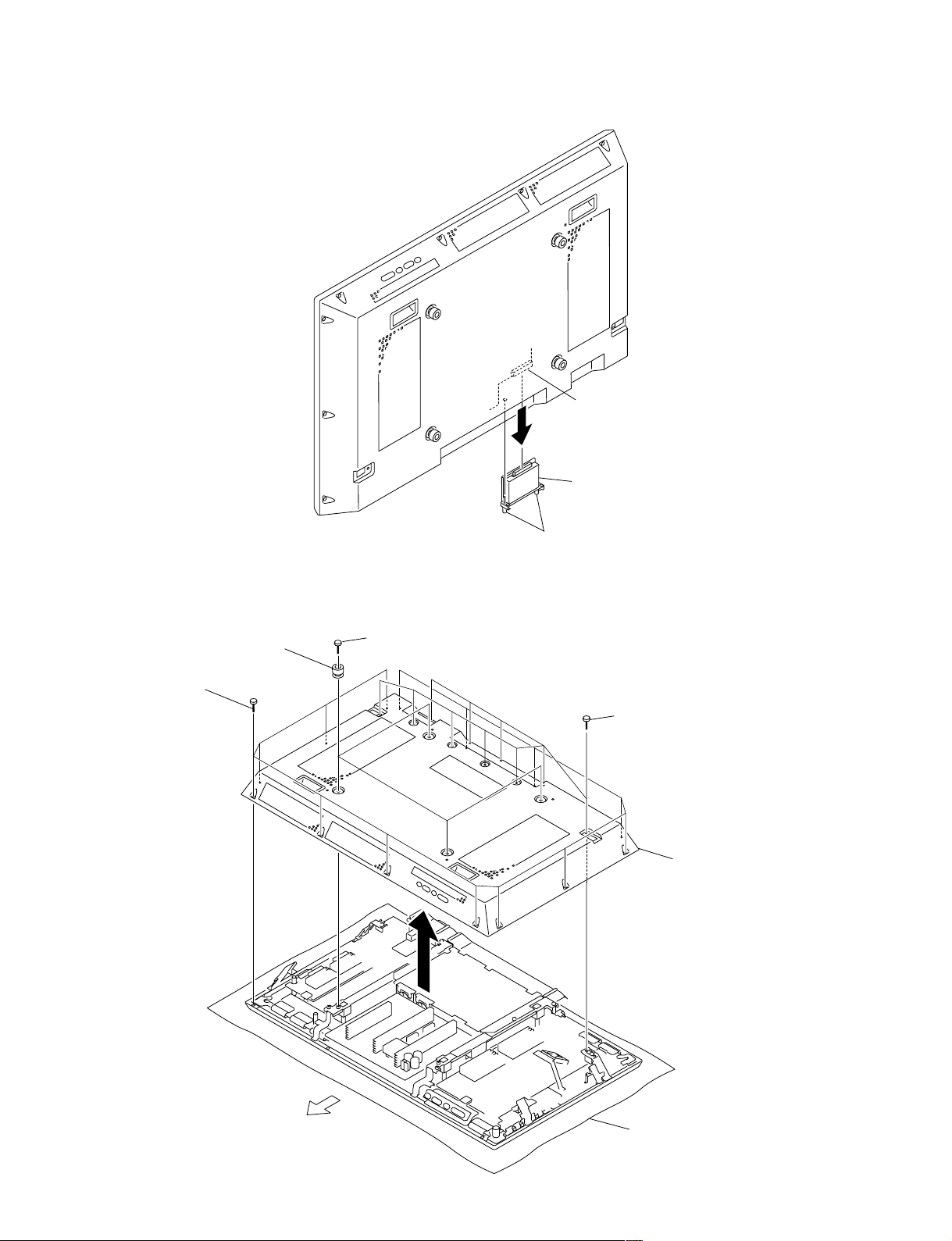

1-3-1. BKM-V10

CN7

A (Main) board

2 BKM-V10

1

Loosen the two screws.

1-3-2. Rear Cover Assembly

2 Four hooks

4 Fourteen screws

1 Four screws

3 Ten screws

5

Rear cover assembly

1-4

Upper

Side

Conductive cushion

PFM-42X1/42X1N

Page 11

1-3-3. Bezel Assembly 1

Upper

Side

1

Peel off the four tapes.

2

Peel off the four tapes.

Conductive cushion

Two brackets

8

9

Two s

crews

CN1101

!-

Multi button,

H2 board, Bracket

5 Three screws

P501

0

Temp board

CN1302

Upper

Side

6 T board (R),

Two brackets

Four screws

7

CN1304

3

Two screws

T board (L),

4

Two brackets

Conductive cushion

PFM-42X1/42X1N

1-5

Page 12

1-3-4. Bezel Assembly 2

1

Four

screws

2

Screw

3

4

Connector

Four screws

Note : When removing the main chassis,

be sure that the two persons or

more must work together for removal.

Place the removed main chassis on the

conductive cushion.

Upper

Side

Bezel assembly, etc.

7

Frame front assembly

!= Filter glass

Conductive cushion

H1 board

CN201

Upper

Side

Nine screws

6

0

Screw

!- Power button

5

Main chassis

Conductive cushion

8

Two screws

1-6

Bezel assembly

1-3-5. Plasma Display Panel 1

8

D.C. fan,

5 Three screws

Screw

3

Temp board

4

Upper

Side

Bracket

P501

7 Two screws

6

CN800

AC inlet, AC socket cover

Two screws

1

2

D.C. fan,

Bracket

9 Two screws

DDC CI board

0

Four screws

!-

CN901

Upper

Side

CN302

CN303

CN301

!=

L (Audio)

board

Conductive cushion

PFM-42X1/42X1N

Conductive cushion

1-7

Page 14

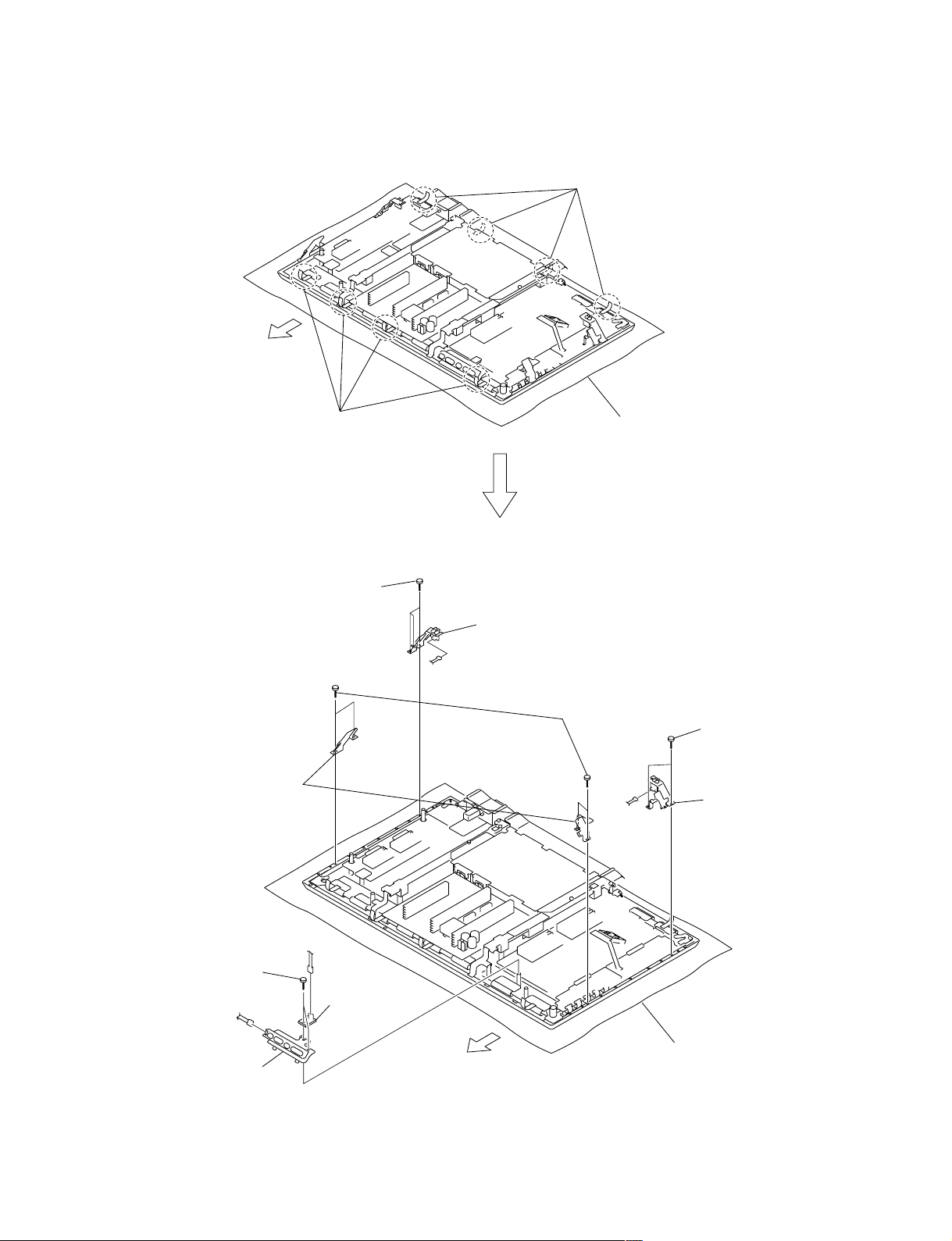

1-3-6. Plasma Display Panel 2

Holder

2

Upper

Side

CN806

CN807

CN802

CN808

CN801

CN803

1

Eight screws

3 G board

5 Four screws

4 Two screws

P9

Conductive cushion

Four screws

6

7 A board, Two frame module

metal assemblies, etc.

8 Plasma display panel

1-8

Upper

Side

Conductive cushion

PFM-42X1/42X1N

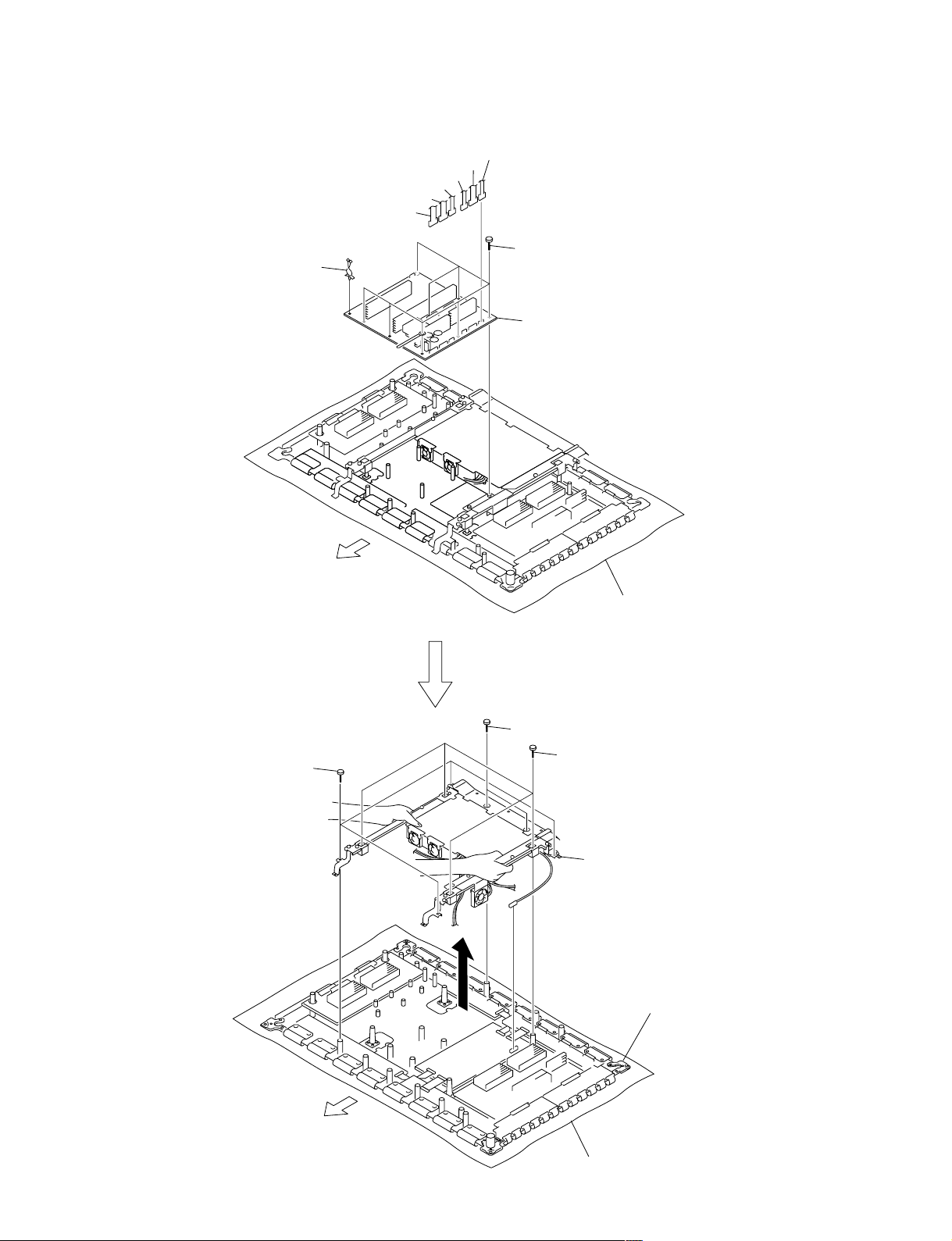

Page 15

1-3-7. Litium Battery

2 Two fans and brackets

1

Four

4

Upper

Side

screws

Shield

3

Four

screws

Lithium battery

5

Conductive cushion

Lithium battery removal

Lithium battery

(CR2032)

Battery holder

Remove the lithium battery in the

direction of arrow.

1-3-8. A Board

Seven screws

1

3 A board

Upper

Side

CN9

CN5

CN2

CN1

CN8

CN23

CN19

CN3

CN22

3

Shield

CN501

2

Six hexagon

screws

PFM-42X1/42X1N

Conductive cushion

1-9

Page 16

1-3-9. CTRL Board

For removal procedure, refer to

"Plasma Display Panel 2".

2 A board, Two frame module

metal assemblies, etc.

1

G board

Upper

Side

P103

P300

P102

P201

P200

P2

P106

3 Five screws

P105

4 CTRL board

1-3-10. XRB Board and XLB Board

For removal procedure, refer to

"Plasma Display Panel 1.2".

1 AC inlet, AC socket cover

3 A board, Two frame module

metal assemblies, etc.

2

G board

5 XRB board

Upper

Side

4 Three screws

P720

P750

P710

P730

P740

P510

P700

P520

Conductive cushion

6 Three screws

7

P530

XLB board

P540

P550

1-10

Conductive cushion

PFM-42X1/42X1N

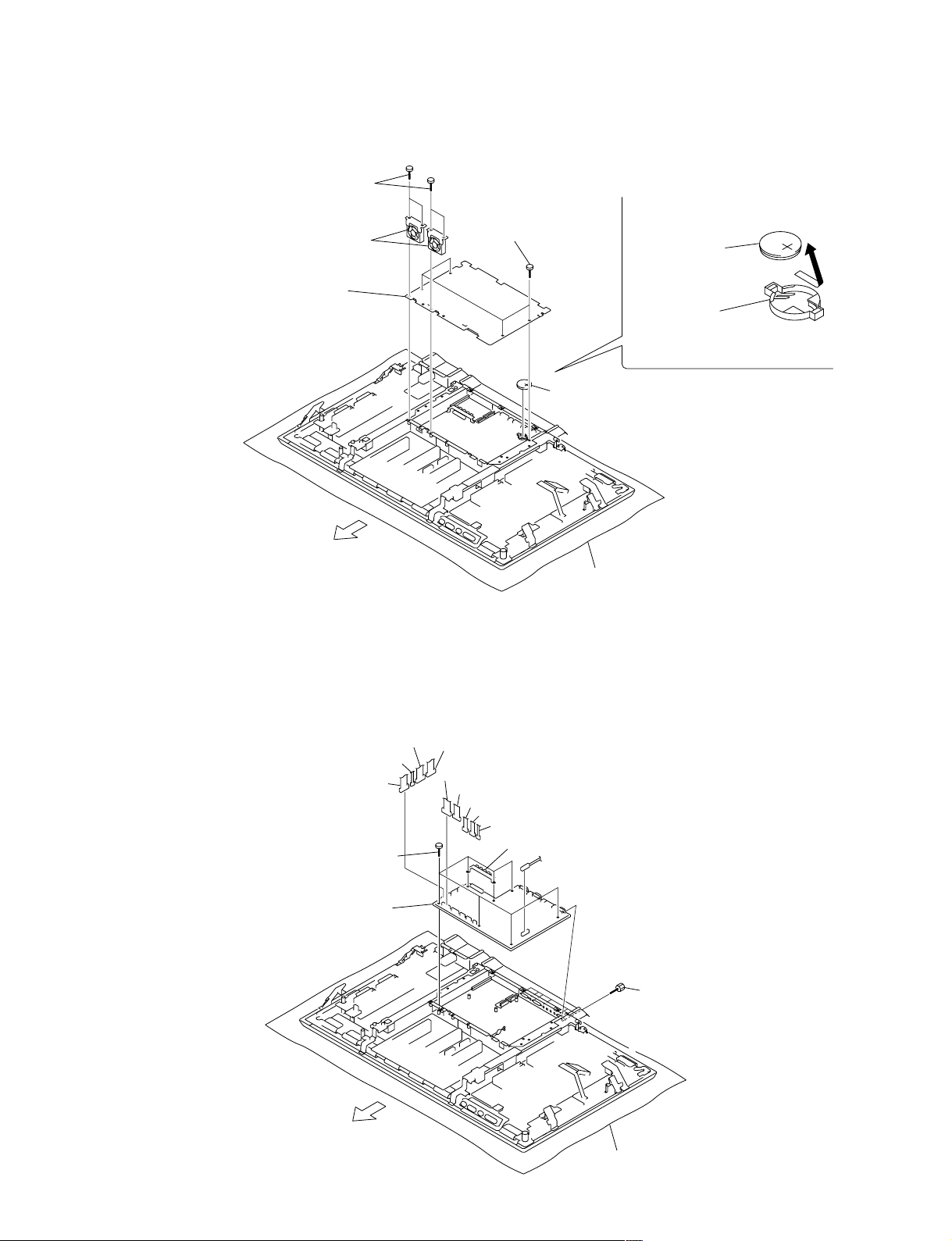

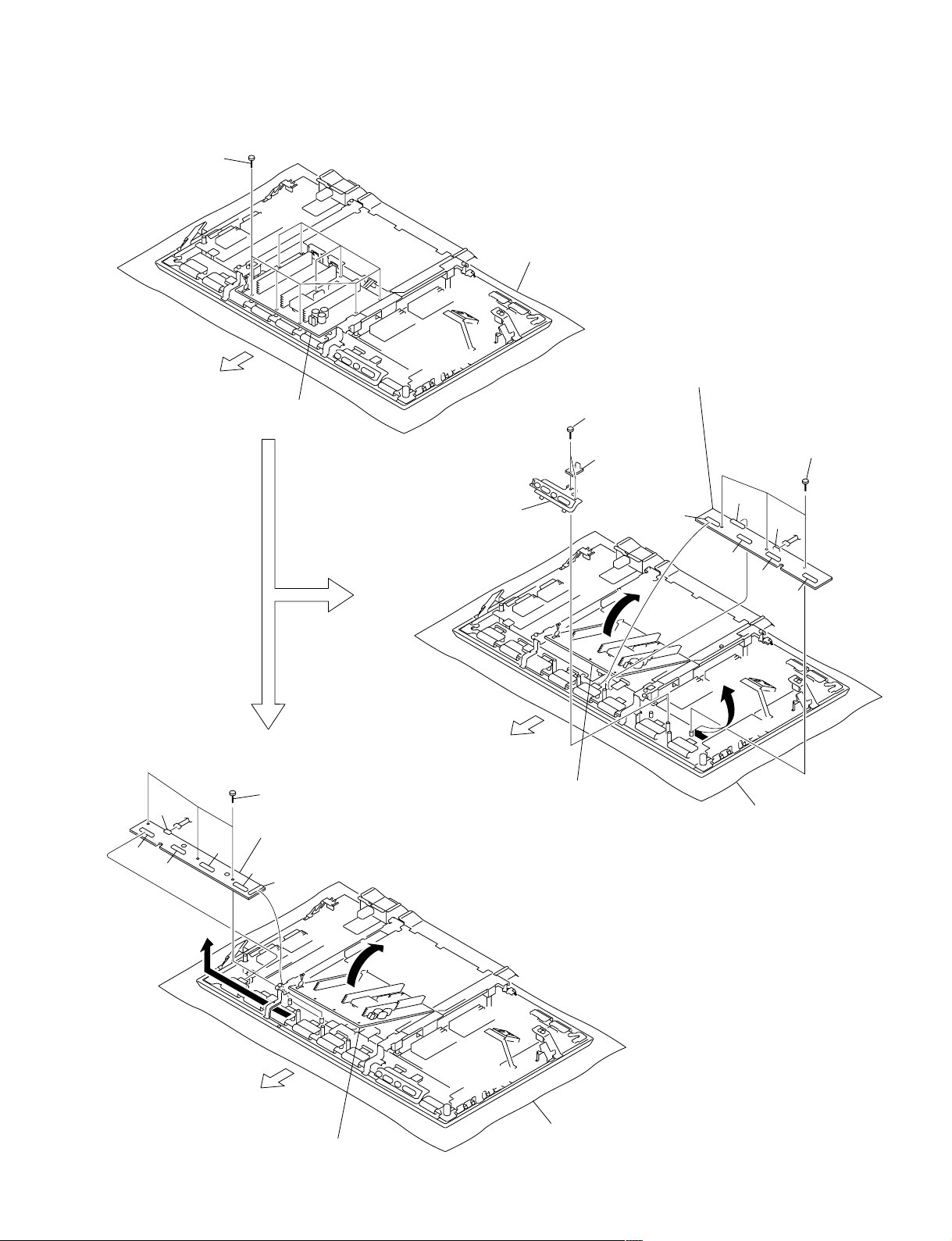

Page 17

1 Nine screws

3 Three screws

4

Remove the XRT board

in the direction of the arrow B.

0 Remove the XLT board

in the direction of the arrow B.

2

Open the G board in the

direction of the arrow A.

Conductive cushion

P340

P330

P320

P350

P310

P300

P110

P120

P130

P140

P100

P150

A

B

G board

8 Open the G board in the

direction of the arrow A.

Conductive cushion

A

B

9 Three screws

Conductive cushion

XRT Board

XLT Board

5

Two s

crews

6

Temp board

7

Multi button,

H2 board, Bracket

Upper

Side

Upper

Side

Upper

Side

1-3-11. XRT Board and XLT Board

PFM-42X1/42X1N

1-11

Page 18

1-3-12. YDB Board and YDT Board

Two screws

9

3

Two screws

4 D.C. fan,

Fan Bracket

A

5 Screw

Remove the YDB board

6

in the direction of the arrow A.

Conductive cushion

1-3-13. Z-SUS Board

1

Remove the YDT board

0

in the direction of the arrow B.

Upper

Side

3 Three screws

Two screws

P18

5

B

P19

P22

P20

P4

4 T board (R),

Two brackets

Five screws

P21

P5

P15

P24

P23

P25

P26

P27

P28

7 Two screws

Bracket

8

Two screws

1

2

T board (L),

Two brackets

1-12

2

Z-SUS board

6

Bracket

P6

P5

Upper

Side

P1

P4

P3

P2

Conductive cushion

PFM-42X1/42X1N

Page 19

1-3-14. Y-SUS Board

Conductive cushion

Upper

Side

P2

P5

P3

P1

1 Five screws

2

Y-SUS board

1-4. Warning on Power Connection

Use the proper power cord for your local power supply.

PFM-42X1 series

United State, Canada Continental Europe United Kingdom, Ireland, Austria, Japan

New Zealand

Plug type VM0233 COX-07 636 _

Female end VM0089 COX-02 VM0310B VM0303B VM1313

Cord type SVT H05VV-F CEE (13) 53rd (O, C) HVCTF

Minimum cord set rating 10A/125V 10A/250V 10A/250V 10A/125V

Safety approval UL/CSA VDE VDE

a) Note : Use an appropriate rating plug which complies with local regulations.

a)

VM1296

DENAN-HO

PFM-42X1/42X1N

1-13

Page 20

Page 21

Section 2

Electrical Adjustment

2-1. Setup Adjustment

. Required equipments

Remote commander (RM-971)

Digital voltmeter

Luminance meter :Minolta CA-110 or equivalent

If Minolta CA-110 or equivalent is

not available, make adjustment by

comparing the monitor with the

reference LCD monitor that has

already been calibrated correctly.

Signal generator : VG-854 or equivalent

. Preparation of the luminance meter

Place the light receptor block of the luminance meter

about 50 cm away from the monitor screen as shown.

1. How to enter the service mode

Luminance meter

about 50 cm

Monitor

3) Place the luminance meter (e.g. CA-110) 50 cm away

from the monitor. Align it with the vertical center of

the display, and adjust the focus to the optimum level

by using an eyepiece.

4) Place the monitor and the luminance meter (e.g. CA-

110) in a light-shielded room for adjustment.

5) Set up [SERVICE MODE] of the monitor.

3. Operation

For quick setup, set the data manually. Set Brightness,

Contrast, and Backlight to 50, 70, and 100 respectively.

Then, set the color temperature by adjusting its default

value.

4. Warm up time

Warm up for 30 minutes or more before performing any

adjustment.

2-2. White Balance Adjustment

2-2-1. Initialization

1) Turn on the power.

2) Input Enter → 1 → 8 → 2 from the remote controller

in this order to display SERVICE MODE OSD.

3) Select INITIALIZATION menu, and execute FILL

0xFF.

(When the initialization is completed, the power turns

off and restarts automatically.)

n

W/B readjustment is required after the panel, board or

microprocessor is replaced. However, before W/B adjustment, be sure to perform aging for more than 30 minutes

after RGB reset.

2. Setup

1) Set the timing and pattern data for the signal generator

according to the Sony timing specifications.

2) Connect the monitor video cable to the signal generator.

1) Input Enter → 1 → 8 → 2 from the remote controller

in this order to display SERVICE MODE OSD.

2) Select INITIALIZATION menu and, execute FILL

0xFF. (When the initialization is completed, the power

turns off and restarts automatically.)

2-2-2. AD Calibration

Execute Auto Calibration as follows by using a PC (1024

x 768 60 Hz) signal.

1. PC signal

1) Display SERVICE MODE OSD and select the AD

CALIBRATION menu.

2) Input Full Black (no video) pattern.

3) Execute PC. CUTOFF.

4) Input Full White pattern.

5) Execute PC.GAIN.

PFM-42X1/42X1N

2-1

Page 22

2-2-3. White Balance Adjustment

After aging the unit about 30 minutes, adjust the color

matrix of each one of the color temperatures of 11000 K,

9300 K, and 6500 K as follows.

1. Preparation of adjustment

1) Equipment : Signal generator (e.g. : VG-854), luminance meter (e.g. : CA-110)

2) Signals type : If a detailed timing is needed, refer to

Sony Timing Specifications.

PC XGA (1024 x 768 60 Hz)

1080I (Y/Pb/Pr)

480P (Y/Pb/Pr)

NTSC Composite

PAL Composite

480I (NTSC Composite)

575I (PAL Composite)

3) Signal level : 700 mVpp

4) Signal pattern : Full White, 16-step gray pattern

2. Color matrix adjustment

Execute the following programs in the following sequence

: PC → 1080i → 480p → 480i → 575i → NTSC Composite → PAL Composite.

1) After inputting each signal, adjust Sub-Offset.

. Input 16-step gray pattern.

. Display SERVICE MODE OSD and select the

WHITE BALANCE menu.

. Change Sub-Offset, and adjust the brightness of the

second step of the 16 steps of gray to be 0.5 cm/m

or less.

(Sub-Offset : ± 0.1)

2) Input Full White pattern.

3) Set the values of R-GAIN and R/G/B-OFFSET in the

WHITE BALANCE menu as shown in the following

figure.

2

4) Adjust the color matrix by changing the values of GGAIN and B-GAIN. (Refer to SONY Color Matrix

Specifications)

11000 K : x=276 (±15), y=282 (± 15)

9300 K : x=283 (±15), y=298 (± 15)

6500 K : x=313 (±15), y=329 (± 15)

5) Adjust each of the color temperatures of 11000 K,

9300 K, and 6500 K by repeating steps 3) and 4).

2-2-4. Shipment Condition Setting

Set the shipment condition (Refer to SONY Color Matrix

Specifications.).

1) Display the SERVICE MODE OSD menu.

2) Select the FOR TEST menu, and execute INIT

GOODS.

(When INIT GOODS is completed, the power turns

off and restarts automatically.)

PC 1080I 480P 480I 575I NTSC PAL

R-GAIN 33 34 34 34 34 34 34

R-OFFSET 61 51 51 52 51 57 53

G-OFFSET 60 53 52 52 52 62 57

B-OFFSET 63 52 51 52 51 60 55

2-2

PFM-42X1/42X1N

Page 23

2-3. Panel Adjustment

2-3-3. Adjustment Items

2-3-1. Application Object

This standard is applied to the PDP42X1##7# PDP

Module, which is manufactured by the manufacturing team

of PDP promotion department or elsewhere.

2-3-2. Notes

1) Without any special indication, the module should be

at the preliminary condition more than 10 minutes

before adjustment.

. Service signal : 100% Full White signal

.

Service DC voltage : Vcc : 5 V, Va : 65 V, Vs : 190 V

. DC/DC Pack voltage : V1st : 115 V, Vscw : 110 V,

_Vy : _175 V, Vzb=105 V

. Preliminary environment : Temperature (25 ±5dC),

relative humidity (65 ± 10%)

2)

After assembling the module, perform aging under the

following conditions for stabilizing its operation before

starting the adjustment.

. Service signal : 100% Full White, Red, Green, Blue

pattern signals (Service time of each pattern : within

5 minutes/cycle)

. Service DC voltage : Match the voltage with the

setup voltage at the first adjustment.

. Aging period : 4 hours or more

. Aging environment : Temperature (60 ±2dC),

relative humidity 75% or less

3) Module adjustment should be performed in the

following sequence.

. Set the initial voltage and adjust the voltage wave-

form of Vsetup.

. Measure the margin of the Vs voltage and determine

the voltage.

. Adjust and check the voltage of DC/DC pack (V1st,

Vsc, _Vy, _Vzb).

. Adjust the voltage waveform of Vset-down.

. Measure the margin of the Vset-up voltage and

determine the voltage.

. Adjust the waveform of the final voltage. The

adjustment value above may vary depending on

individual units.

4) Without any special indication, adjust the module

under the ambient temperature of 25 ± 5dC and the

relative humidity of 65 ± 10%.

c

If you leave the still image displayed for more than 10

minutes (especially the digital pattern or cross hatch

pattern, which has a clear gradation), afterimage may

remain in the black level part of screen.

1. Adjusting the board group

1) Adjusting the voltage waveform of Vset-up

2) Adjusting the voltage waveform of Vset-down

3) Adjusting the voltage waveform of Vzb

2. Adjustment after assembling (PDP module

adjustment)

1) Set the initial voltage and adjust the voltage waveform

of Vsetup.

2) Measure the margin of Vs voltage and determine the

voltage.

3) Adjust and check the voltage of DC/DC pack (V1st,

Vsc, _Vy, _Vzb).

4) Adjust the voltage waveform of Vset-down.

5) Measure the margin of the Vset-up voltage and

determine the voltage.

6) Adjust the waveform of the final voltage.

2-3-4. Adjusting the Board Group (Applying

the Tools)

1. Required tools

1) Digital oscilloscope : 200 MHz or more

2) DVM (Digital Multimeter) : Fluke 87 or equivalent

3) Signal generator : VG-854 or equivalent

4) DC power supply

. DC power supply for Vs (1) : Should be changeable

more than 0-200 V/ more than 10 A.

. DC power supply for Va (1) : Should be changeable

more than 0-100 V/ more than 5 A.

. DC power supply for 5 V (1) : Should be changeable

more than 0-10 V/ more than 10 A.

. DC-DC converter tool (1) : The tool that can output

the voltage equivalent to that of the PDF42x1##7#

module by using the Vs, Va, or 5 V voltage.

. Voltage stability of the power supply : Within ±1%

for Vs/Va, within ± 3% for 5 V

2. Connection diagram of the measuring

instrument and setting up the initial voltage

1) Connection diagram of measuring instrument

Refer to Fig. 1 (Connection diagram of measuring

instrument that adjusts the voltage waveform).

2) Setting up the initial voltage

Initial-setup voltage : Vcc : 5 V, Va : 65 V, Vs : 190 V

Adjust, the initial-setup voltage within the setup range

according to the module’s characteristics.

PFM-42X1/42X1N

2-3

Page 24

3. How to adjust

1) Adjusting the voltage waveform of Vsetup

1 Connect the measuring instrument as shown in the

connection diagram Fig. 1.

2 Turn on the power of the measuring instrument as

described in c under Fig. 1.

3 Connect the oscilloscope probe to the P4 connect-

er (80-pin) of Y-SUS PCB and GND.

4 Turn the VR1 of Y-SUS PCB to adjust the

waveform “A” in the following figure to be 10 ±5

µs.

2) Adjusting the Vset-down voltage waveform

1 Turn the VR2 of Y-SUS PCB to adjust the

waveform “B” in the following figure to be 120

± 5 µs.

3) Adjusting the Vzb voltage waveform

1 Turn the VR2 of Z-SUS PCB to adjust the wave-

form “C” in the following figure to be 33 ± 5 µs.

A 10 ±5 us

2-3-5. Adjustment after Assembling (PDP

Module Adjustment)

1. Required Tools

1) Digital oscilloscope : 200 MHz or more

2) DVM (Digital multimeter) : Fluke 87 or equivalent

3) Signal generator : VG-854 or equivalent

4) DC power supply

. DC power supply for Vs (1) : Should be changeable

more than 0-200 V/ more than 10 A.

. DC power supply for Va (1) : Should be changeable

more than 0-100 V/ more than 5 A.

. DC power supply for 5 V (1) : Should be changeable

more than 0-10 V/ more than 10 A.

. DC-DC converter tool (1) : The tool that can output

the voltage equivalent to that of the PDF42x1##7#

module by using the Vs, Va, or 5 V voltage.

. Voltage stability of the power supply : Within ±1%

for Vs/Va, within ±3% for 5 V.

Vset-up = Vs

Vs

Vzb: 105 ±1 V

140 us

_Vy: 175 ±1 V

Y, Z set-up waveform

B 120 ±5 us

Z B/D waveform

C 33 ±5c us

VSC: 110 ±1 V

2. Connection diagram of the measuring

instrument and setting up the initial voltage

1) Refer to fig 1. (Connection diagram of measuring

instrument that adjusts the voltage waveform).

2)

Initial-setup Voltage : Vcc : 5 V, Va : 65 V, Vs : 190 V

Adjust the initial-setup voltage within the setup range

according to the module’s characteristics.

3. How to adjust

1) Adjusting the initial voltage waveform

Check the voltage waveform by following the steps in

2-3-4 (3. How to adjust), and readjust the waveform

when it is out of range.

2) Checking the DC/DC pack voltage

1 Switch the signal of the signal generator to the

100% Full White signal.

2 Connect the GND probe of DVM to the R16’s

right leg of the Y B/D, and connect the positive

probe to the left leg of R30 to check the V1st

voltage (115 ±1 V). When there is abnormality in

the voltage, turn the variable resistor PS1 of DC/

DC Pack (V1st) on Y B/D to adjust it.

3 Connect the GND probe of DVM to P4 of the Y

B/D, and connect the positive probe to the lower

leg of R37 (or R50) to check the Vsc voltage

± 1 V)

. When there is abnormality in the voltage,

turn the variable resistor (PS3) of DC/DC Pack

(Vsc) on Y B/D to adjust it.

(115

2-4

PFM-42X1/42X1N

Page 25

4 Connect the GND probe of DMV to the GND of

the Y B/D, and connect the positive probe to the

lower leg of R44 to check the _Vy voltage

± 1 V)

. When there is abnormality in the voltage,

(_175

turn the variable resistor (PS2) of DC/DC Pack

(_Vy) on Y B/D to adjust it.

5 Connect the GND probe of DVM to the GND of

the Z B/D, and connect the positive probe to the

upper leg of B34 to check the Vzb voltage (_105

± 1 V). When there is abnormality in the voltage

turn the variable resistor (A2) of DC/DC Pack

(_Vzb) on Z B/D to adjust it.

3) Measuring the Vs voltage margin and determining the

voltage

1 Switch the signal of the signal generator to the

100% Full Red signal.

2 Turn the voltage adjusting knob of the Vs DC

power supply in the voltage-down direction, and

turn off the cells of the screen.

3 Turn the voltage adjusting knob of the Vs DC

power supply in the voltage-up direction until the

cells of the screen turn on. The first voltage, which

turns on the cells of the entire screen, is named as

Vsmin1. Record the value of Vsmin.

4 Turn the voltage adjusting knob of the Vs DC

power supply in the voltage-up direction slowly

until the cells of the screen turn off or until overelectric discharge happens. The first voltage,

which turns off the cells of the screen or causes

over-electric discharge, is named as Vsmax1.

Record the value of Vsmax1. (Note that the Vs

voltage variable should exceed the maximum of

195 V.)

5 Switch the signal of the signal generator to the

100% Full Green signal.

6 Repeat the previous adjustment step (2), and

record each voltage as Vsmin2/Vsmax2.

7 Switch the signal of the signal generator to 100%

Full Blue signal.

8 Repeat the previous adjustment step (2), and

record each voltage as Vsmin3/Vsmax3.

9 Switch the signal of the signal generator to 100%

Full White signal.

0 Repeat the previous adjustment step (2), and

record each voltage as Vsmin4/Vsmax4.

!- Switch the signal of the signal generator to 100%

Full Black signal.

!= Repeat the previous adjustment step (2), and

record each voltage as Vsmin5/Vsmax5.

![ At this time, the maximum voltage is set by

adding 6 V to the Vs voltage (Vsmin1 to Vsmin5).

Set the voltage within the setting range (180 V <

Vs < 195 V) while considering other characteristics as well.

!] Turn the voltage adjusting knob of the Vs DC

power supply, and determine the Vs voltage.

!\ Adjust the Vset-down waveform by setting the Vs

voltage as described in 2-3-4.

4) Adjusting the final voltage waveform

1 Check the voltage waveform as described in 2-3-4

(3. How to adjust), and readjust the waveform

when it is out of range.

5) DC-DC Pack voltage setup range

V1st : 100V to 160 V

Vsc : 100 V to 160 V

_Vy : _160 V to _200 V

_Vzb : 100 V to 160 V

PFM-42X1/42X1N

2-5

Page 26

Rigid right topRigid left top

Y SUS

5V, Va

Rigid left bot

5V, Va

5V

Vs

Va

Controller

5V

+5 V power supply (Vcc)

5V, Va

5V, Va, Vs

Z_SUS

5V, Va

Rigid right bot

Va power supply

Powe r

Signal generator (VG-854 )

External power supply (5V, Va, Vs)

Fig. 1 Connection diagram of the measuring instrument

Vs power supply

c

1) The power of the signal generator should be turned on before turning on the power of the DC power

supply.

2) The voltage of the DC power supply should be preset as below in the same way as the standard

module input voltage.

Vcc : 5 V, Va : 65 V, Vs : 190 V

3) The power supply must be turned on in the following sequence. Reverse the sequence when turning

off the power.

* Module on : 5 V → Va → Vs, Module off : Vs → Va → 5 V

4) Select the 1024 x 768 mode for the signal generator.

2-6

PFM-42X1/42X1N

Page 27

2-4. Troubleshooting

2-4-1. Checking for No Picture

Check the following points if the monitor shows the Full Black pattern or the power is off and no picture

appears on screen.

1) Check whether the CTRL B/D LED (D10, D11, D12, D13, D17) is turned on or not.

2) Check the power and signal cable of the CTRL B/D.

3) Check whether the X B/D, Y B/D, and Z B/D are plugged securely.

4) Check the connection of the X B/D, Y B/D and Z B/D to the CTRL B/D.

5) Measure the output wave of the X, Y, and Z B/D with the oscilloscope (200 MHz or more) and check

if there is any problem on the boards by comparing the output wave with the following figure.

. Measurement point for the Y B/D : TP (Bead B50)

. Measurement point for the Z B/D : TP (Bead B35)

. Measurement point for the X B/D : COF TP

6) Check the SCAN (Y side) IC.

7) Check the DATA (X side) COF IC.

8) Replace the CTRL B/D.

<A: Y B/D Output wave - 1 FRAME>

<B: Y B/D Output wave - 1 SF>

<A: Y B/D Output wave - 1 FRAME>

<B: Y B/D Output wave - 2,4 to 12 SF>

PFM-42X1/42X1N

2-7

Page 28

< A: Y B/D Output wave - 1 FRAME >

< B: Y B/D Output wave - 3 SF >

< A: Y B/D Output wave - 1 FRAME >

< B: Z B/D Output wave - 1 FRAME >

< C: Z B/D Output wave – 1 to 12 SF>

< X B/D Output wave - 1 FRAME >

< X B/D Output wave - 1 SF >

< X B/D Output wave - Enlarged >

2-8

PFM-42X1/42X1N

Page 29

2-4-2. Hitch Diagnosis Based on the Display

<Case 1>

<Case 2>

<Case 3>

<Case 4>

<Case 5>

An unusual screen that

corresponds to one IC

appears in one COF.

An unusual screen that

corresponds to two ICs

appears in one COF.

An unusual screen that

corresponds to four ICs

appears in one COF.

An unusual screen that

corresponds to one Data

COF IC unit appears in

an entire X B/D.

An unusual screen that

corresponds to one Data

COF IC unit appears in

the entire upper or lower

part of the screen.

Condition

1. 4/7 or 3/7 of the screen is not displayed

1) Check if the power connector of the X B/D that

corresponds to the screen portion with no picture is

securely connected.

2) Check whether the connector that connects the CTRL

B/D and the X B/D that correspond to the screen

portion with no picture is securely connected.

3) Replace the corresponding X B/D.

How to examine Data COF IC

2 Resistance

1 GND

Relationship between the screen and X B/D

Screen X B/D

Left 4/7 portion of the screen ↔ Right X B/D

Right 3/7 portion of the screen ↔ Left X B/D

Screen display forms

Left of the screen (4/7) Right of the screen (3/7)

Displayed

Not displayed

2. Data COF is not shown on screen (Including

the case where a part of Data COF is not

shown)

1) When Data COF is not shown, in many cases a

problem resides between Data COF and the X B/D.

2) Check if the Data COF and the X B/D that correspond

to the screen portion with no picture are securely

connected.

3) Check if the Data COF is not damaged, and replace the

X B/D.

Examples of the screen display form

(Any one of the 7 Data COF can be seen next to the below

pictures.)

. Change “1 GND” into ANODE, “2 Resistance” into

CATHODE, and then examine the diode in the forward

or backward direction.

. Measure the resistance value (10 Ω).

3. An unusual pattern corresponding to the Data

COF IC unit is shown

1) If an unusual pattern corresponding to the Data COF

IC unit is displayed as shown below, the input to the

Data COF IC has a problem.

2) In the case of <Case 1, 2, 3>

. Check the connection of the Data COF connector.

. Replace the corresponding X B/D.

3) In the case of <Case 4, 5>

. Check the connector that connects the CTRL to the

X B/D.

. Replace the corresponding XB/D or CTRL B/D.

Screen display forms

PFM-42X1/42X1N

: All

: Partial

: Not at all

2-9

Page 30

4. Regular stripes that correspond to the area of

one or more DATA COF ICs are displayed

1) If the stripes that correspond to the area of one Data

COF IC are displayed regularly, the output from the

output platform of the X B/D has a problem.

If the stripes that correspond to the area of two Data

COF ICs are displayed regularly, the data from the

CTRL B/D is not transmitted correctly.

2) Check if the connection connector of the X B/D that

corresponds to the unusual screen is connected

securely.

3) Replace the corresponding XB/D or CTRL B/D.

Relationship between the screen and X B/D

Screen X B/D

Left 4/7 portion of the screen ↔ Right X B/D

Right 3/7 portion of the screen ↔ Left X B/D

Screen display form

A stripe that corresponds to

one IC may split, or a group of

stripes may be bundled

together and displayed on

another part of the screen.

Checking method of SCAN IC

Change the Vpp pin into ANODE and GND pin into

CATHODE, and then test the diode in the forward or

backward direction.

6. The screen has vertical lines with a regular

gap. (A vertical stripe flashes in a specific

color)

1) The control B/D has a problem.

2) Replace the control B/D.

Screen display form

5. The scan FPC has a problem for screen

display.

1) There may be a problem between the Scan FPC and Y

B/D.

2) Check the connection between the Y B/D and Scan

FPC.

3) If the Scan IC has a failure, replace the Y DRV B/D.

Screen display forms

One eighth of screen

The screen display is very good

The screen display is poor

The screen shows vertical

lines with a regular gap

7. A data copy occurs in the vertical direction.

1) This is due to the incorrect marking of a scan wave.

2) Replace the Y DRV B/D or Y SUS B/D.

Screen display forms

Case 1 : Entire CopyDisplay Pattern

Case 2 : Top Copy Case 3 : Bottom Copy Case 4 : Entire Copy

2-10

PFM-42X1/42X1N

Page 31

8. The screen shows one or several vertical lines

1) This is not the problem of the controller B/D or XB/D.

2) It may be due to following reasons.

. The panel has a failure.

. The DATA COF FPC that is attached to the panel is

open or shorted.

. The DATA COF that is attached to the panel has a

failure.

3) Replace the module.

Screen display form

Several vertical lines appear

in the quarter or another

portion of the screen as the

case shown on the left.

9. The screen has one or several horizontal lines

1) This is not the problem of the controller B/D or XB/D.

2) It may be due to one of the following reasons.

. The panel has a failure.

. The SCAN FPC that is attached to the panel is open

or shorted.

. The SCAN IC that is attached to the panel has a

failure.

3) Replace the Y DRV B/D

Screen display form

Several horizontal lines may

appear as the case shown on

the left.

11. Another color may appear partially in the full

white screen, or a signal appears on the full

black screen

1) Check the inclination of the waveform at the Y B/D

setup, and reduce the waveform.

2) Check the inclination of the Z B/D ramp wave.

3) Measure each output waveform with the oscilloscope

(200 MHz or more) and compare the data with the data

shown in the following figure.

Adjust the Y B/D setup (Test-up : B/C[µs/µs]),

setdown (Test-down : D[µs]) and Z B/D ramp (Tramp

: F/G[µs/µs]) inclination by changing VR1/VR2/VR3.

. Measuring point of the Y B/D : B50 (SUS_UP)

. Measuring point of the Z B/D : B35 (SUS_OUT)

Vset-up = Vs

Vs

140 us

_Vy: 175 ±1 V

10 ±5 us

120 ±5 us

Vsc: 110 ±1 V

Vzb: 105 ±1 V

33 ±5 us

12. A center of the screen is darker than the

edges at full white pattern

1) The Z B/D has a failure.

2) Check the connection cable between the Z B/D and

CTRL B/D.

3) Replace the Z B/D.

Screen display form

10. The screen displays an input signal pattern

but the brightness is low

1) In this case, the Z B/D operation has a failure.

2) Check the power cable of the Z B/D.

3) Check the connector that connects the Z B/D and

controller B/D.

4) Replace the controller B/D or Z B/D.

PFM-42X1/42X1N

13. A specific color does not have a specific

brightness.

1) Check the connector of the CTRL B/D input signal.

2) Replace the CTRL B/D.

2-11

Page 32

2-4-3. Checking for Component Damage

1. Y IPM (IC100, 101) or Z IPM (IC4, 5) damage

1) When the internal Sustain_FET of Y IPM or ZIPM is

damaged, the screen is not displayed or electric

discharge occurs.

.

Test point : GND to B50 (Y B/D), GND to B35 (Z B/D).

. Waveform : B50 (Y B/D) or B35 (Z B/D) has no

wave output.

2) When the internal ER_FET of Y IPM or Z IPM is

damaged, Y IPM or Z IPM emission increases.

.

Test point : GND to B50 (Y B/D), GND to B35 (Z B/D).

. Waveform : As shown in Fig. 2.

2. FET ass’y (Y B/D : HS1) damage

1) When Set_Up FET is damaged, screen is not displayed.

. Test point : Enlarged after measuring GND through

B50 (YB/D).

. Waveform : As shown in Fig. 3.

Set-up wave does not occur.

Fig. 3 When the Set_Up FET is damaged

2) When Set_Down FET is damaged, electric discharge

occurs over the entire screen.

. Test point : Enlarged after measuring GND through

B50 (YB/D).

. Waveform : As shown in Fig. 4.

Crushed pulse ocurrance

Fig. 2 When the ER_FET is damaged

<IPM normal output wave>

. Measuring position : Sustain the enlarged picture after

measuring the B50 waveform of

the Y B/D and the B35 waveform

of the Z B/D (Full White pattern).

Set-down wave does

not occur.

Fig. 4 When the Set_Down FET is damaged

Set-up

Set-down

<FET Ass’y normal output wave>

2-12

. Measuring position : Enlarged wave of the reset section

of TP B50 (Y B/D) (Full White

pattern).

PFM-42X1/42X1N

Page 33

3. SCAN IC (Y drv B/D : IC1 to 12) damage

Enlarge the scan pulse

Decrease voltage of the

scan pulse

Widen the pulse width

SCAN section

SCAN PULSE

1) If the SCAN IC has a failure, one horizontal line may

not be display on the screen.

. Test point : ICT measurement of GND through Y

drive B/D output.

. Waveform : As shown in Fig. 5.

4) If the SCAN IC output is shorted by a dust or a foreign

substance, two horizontal lines may overlap on screen.

.

Test point : ICT measurement of GND through Y

drive B/D.

. Output waveform : As shown in Fig. 7.

SCAN pulse does not occur

2) The screen may not be displayed when the SCAN IC is

damaged due to the SCAN IC failure, external electricity or spark.

. Test point : ICT measurement of GND through Y

. Waveform : Output waveform is not output (The

3) The screen may fluctuate horizontally when the cable

on the top or bottom of the Y B/D is damaged.

. Test point : ICT measurement of GND through Y

. Waveform : As shown in Fig. 6.

When the internal output FET

of IC is damaged

Fig. 5 When SCAN IC is poor

drive B/D output.

damage can be seen in the SCAN IC on

the top or bottom of the Y drive B/D).

drive B/D output.

Normal scan pulse

Fig. 7 When SCAN ID output is shorted

Noise occurance at scan section

Fig. 6 When the Y drv B/D top or bottom cable is damaged

PFM-42X1/42X1N

<SCAN IC normal output wave>

. Measuring position : The enlarged SCAN section after

measuring the output ICT of the Y

drive B/D. (Full White pattern).

2-13

Page 34

Page 35

3-1. Out of Order on Power

NO POWER

Section 3

Troubleshooting Guide

Check 5V-ST

CN (Pin#3)

Pass

Check Ctrl signal

CN9 Pin#2

‘RLY’

Pass

Check Ctrl signal

CN9 Pin#1

‘ACD ’

Fail

Fail

Fail

Check

Connector or

5V-ST Output

On Power Board

Pass

Check

IC8 Pin #6

Pass

Check

IC2 Pin #3

Fail

Fail

Fail

Replace

the Power Board

Replace

the Power Board

Replace

the Power Board

PFM-42X1/42X1N

Pass

Check Ctrl signal

CN9 (Pin#5)

‘VS07’

Pass

Check the Power

Cable connection

Fail

Pass

Check

IC8 Pin #9

Fail

Replace

the Power Board

3-1

Page 36

NO RASTER ON DIGITAL

SIGNAL (DV1)

Repeat

‘A ’ Process

Pass

Check The

EDID Data

Fail

Rewrite EDID

Data

3-2

PFM-42X1/42X1N

Page 37

3-2. No Raster State

NO RASTER ON ANALOG

SIGNAL

‘ A ’ Process

Check LED

Status on

Display Head

Amber

Check

U12(AD9888)

.HSYNC-ADC

.VSYNC-ADC

.DCLK-ADC

.DATA

Pass

Green

Fail

Check

Power Line

IC21, IC45,

IC20, IC22,

IC23, IC24

Replace Device

IC21, IC30, IC4

3.3 V

2.5 V

Check

Ctrl signal

IC44 Pin#32

(LVDS583)

Pass

Check

Scaler (IC14)

Output

. PCLOCK

. PVSYNC

. PHSYNC

. PVALID

.DATA

Pass

Check

Control Signal

‘ DISPEN ’

CN501 Pin #27

Fail

Fail

Fail

Fail

Replace

the Main Board

Replace

the Power Board

Replace

the Main Board

Replace

the Main Board

. Check the D-sub Connection

- Y/Pb/Pr Jack check

. Check the other Device

- IC26, IC27 (SD RAM)

- IC44 (LVDS83) Pin#32

PFM-42X1/42X1N

Fail

Pass

Find a

Soldering Error

or check the

oscillator (X5)

Fail

Replace

the Main Board

3-3

Page 38

NO RASTER ON Y, Pb, Pr/Y,Cb Cr SIGNAL

Repeat

‘A ’ Process

Input Select

Input 1, Option

Replace Device

Q53, 54, 55, 50, 51, 52

Pass

Microvision Copy

Protection & Input Select

IC43(CXA2171)

PassPass

Power S/W off and on

after removing the Input

signal cable

480P

480i

Check

Pass

Analog Switch DTV

IC4(BA7657)

Pass

IC12(AD9888)

. In/Out H/V Sync

. Output Data

Pass

IC10(FLI2310)

. S2310-RESET

. In/Out H/V Sync

. Output Data

Pass

720P

1080i

Check

Check

Check

Fail

Fail

Replace

the Main Board

Replace

the Main Board

Fail

Replace

the Main Board

3-4

PFM-42X1/42X1N

Page 39

NO RASTER ON AV SIGNAL

(CVBS, S-VIDEO)

Repeat

‘A ’ Process

Pass

Check

Input Select for AV

IC41(CXA2069)

Pass

Check

3D Comb Filter

IC31(uPD64083)

Pass

Check

U601(VPC3230D)

. In/Out H/V Sync

. Output Data

. Input Signal

Pass

Check

U302(FLI2310)

. VPC-RESET

. In/Out H/V Sync

. Output Data

Fail

Fail

Fail

Fail

Replace

the Main Board

Replace

the Main Board

Replace

the Main Board

Replace

the Main Board

Pass

PFM-42X1/42X1N

Check the Input jack and cable

3-5

Page 40

No Raster On analog Signal

VS-Board

Input

VS-Board

Input

A Process

No Raster On Y, Pb, Pr/Y, Cb, Cr

Option #2

Input

Check

CN207(44Pin Wafer)

B12,B13,B14,B15,B16

Check

CN2

R/G/B/H/V

Pass

Option #2

Input

Fail

Replace

the Main Board

Fail

Connector Line

A Process

Check

CN207(44Pin Wafer)

B12,B13,B14

Check

CN2

Pb/Y/Pr

Pass

Fail

Connector Line

Fail

Connector Line

3-6

PFM-42X1/42X1N

Page 41

3-3. Sound Troubleshooting

NO SOUND OUTPUT

Replace

the Main board

Fail

Check Connector

Main Board:CN12, CN14

Video Board:CN103

Option Board:CN206

Pass

Check

Audio Input Select

IC41 (CXA2069)

Pass

Sound B,d Check

Pass

Check Connector

Sound Board:CN301

Pin#1,3

Pass

Check

Audio Process

IC301(TA1343N)

Pass

Check

Audio Amp.

IC351

(TPA3002D2)

n

Fail

Replace

the Audio board

Replace

the Audio board

n

Sound output device (IC351) has over lod protection circuit.

If speaker terminal is shorted in a moment.

Sound function is stopped until the power switch off and on.

PFM-42X1/42X1N

3-7

Page 42

Page 43

4-1. Notes on Repair Parts

1. Safety Related Components Warning

w

Components marked ! are critical to safe operation.

Therefore, specified parts should be used in the case of

replacement.

[WARNHINWEIS][WARNHINWEIS]

[WARNHINWEIS]

[WARNHINWEIS][WARNHINWEIS]

Les composants identifiés par la marque ! sont

critiques pour la sécurité.

Ne les remplacer que par une pièce portant le numéro

spécifié.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts commonality and improvement.

Parts List has the present standardized repair parts.

Section 4

Spare Parts

3. Stock of Parts

Parts marked with “o” at SP (Supply Code) column of

the Spare Parts list may not be stocked. Therefore, the

delivery date will be delayed.

Items with no part number and no description are not

stocked because they are seldom required for routine

service.

4. Units for Capacitors, Inductors and Resistors

The following units are assumed in Schematic Diagrams, Electrical Parts List and Exploded Views

unless otherwise specified.

Capacitors : µF

Inductors : µH

Resistors : Ω

PFM-42X1/42X1N

4-1

Page 44

Screw Kit

4-2. Exploded Views

18

22 22 2

6

4

2

2

2

6

1

7

7

11

13

6

12

12

6

6

13

4

2 252

6

12

6

6

6

9

7

10

a

b

5

6

4

13

6

6

6

3

13

4

8

2

6

11

12

6

6

7

11 7 5

2

6

6

2

2

2

2

125

19

14

14

14

14

15 15 15 15

14 14 14

1

14

14

14

14141414

4-2

PFM-42X1/42X1N

Page 45

Screw Kit

20

16

17

Note : The screws can be ordered in units of screw kit. (Sony part No. 20 to 22)

No. Part No. SP Description

18 X-2022-846-1 s SCREW KIT, INSIDE

INSIDE SCREW KIT

1

1SZZTMP007C

2

332-102C

3

339-006B

4

339-009C

5

1SZZTMP007A

6

339-008H

7

339-008K

8

339-008L

9

1SZZTMF012A

0

332-113E

!-

332-113D

!=

339-008F

![

1SZZTMB005B

a

1NHB0302118

b

1WZZTKK005A

No. Part No. SP Description

19 X-2022-848-1 s SCREW KIT, OUTSIDE

OUTSIDE SCREW KIT

!]

332-102R

!\

339-008K

•

The numbers encircled by round corresponds to numbers in illustrations.

No. Part No. SP Description

20 X-2022-847-1 s SCREW KIT, WALL MOUNT

WALL MOUNT SCREW KIT

!;

1WZZTKK004B

!'

1SZZTMH003B

PFM-42X1/42X1N

4-3

Page 46

Cover

102

121

111

110

113

122

108

117

106

105

119

104

123

124

118

107

114

115

4-4

103

UPPER

SIDE

101

112

116

120

109

PFM-42X1/42X1N

Page 47

No. Part No. SP Description

101 ! X-2022-844-1 s ASSY, BEZEL (BLACK)

! X-2022-849-1 s ASSY, BEZEL (SILVER)

102 ! X-2022-845-1 s ASSY, REAR COVER (BLACK)

! X-2022-852-1 s ASSY, REAR COVER (SILVER)

103 X-2024-229-1 s ASSY,FRONT FRAME

104 ! 1-576-300-12 s FUSE H.B.C. (8A/250V)

105 ! 1-417-398-11 s AC INLET

106 ! 1-761-969-11 s MOUNTED CIRCUIT BOARD, G

107 1-761-970-11 s MOUNTED CIRCUIT BOARD, A

1-761-982-11 s MOUNTED CIRCUIT BOARD, A (PFM-42X1N)

108 1-761-971-11 s MOUNTED CIRCUIT BOARD, L

109 1-761-972-11 s MOUNTED CIRCUIT BOARD, H1

110 1-761-973-11 s MOUNTED CIRCUIT BOARD, H2

111 1-761-974-11 s MOUNTED CIRCUIT BOARD, TEMP

112 1-761-975-11 s MOUNTED CIRCUIT BOARD, T (L)

113 1-761-976-11 s MOUNTED CIRCUIT BOARD, T (R)

114 ! 1-787-207-11 s FAN,DC

115 ! 1-787-254-11 s DC FAN

116 2-159-847-01 s GLASS, FILTER

117 2-318-610-01 s AC SOCKET COVER (BLACK)

2-318-610-11 s AC SOCKET COVER (SILVER)

118 2-318-611-01 s MAIN FLAME COVER (BLACK)

2-318-611-11 s MAIN FLAME COVER (SILVER)

2-318-611-21 s MAIN FLAME COVER (PFM-42X1N)

119 2-990-241-01 s HOLDER (A), PLUG

120 4-101-215-01 s BUTTON, POWER

Cover

121 4-101-217-01 s MULTI BUTTON (GRAY)

4-101-217-11 s MULTI BUTTON (BLACK)

122 1-789-070-11 s MOUNTED CIRCUIT BOARD DDC CI

123 ! 1-528-174-11 s BATTERY, LITHIUM (CR2032 TYPE)

124 1-761-816-11 s MOUNTED CIRCUIT BOARD, OP-1

PFM-42X1/42X1N

4-5

Page 48

Panel

210

206

211

202

207

205

211

209

208

201

204

203

4-6

UPPER

SIDE

PFM-42X1/42X1N

Page 49

No. Part No. SP Description

201 1-761-977-11 s MOUNTED CIRCUIT BOARD, Y-SUS

202 1-761-978-11 s MOUNTED CIRCUIT BOARD, Z-SUS

203 1-761-979-11 s MOUNTED CIRCUIT BOARD, YDT

204 1-761-980-11 s MOUNTED CIRCUIT BOARD, YDB

205 1-761-988-11 s MOUNTED CIRCUIT BOARD, XLT

206 1-761-989-11 s MOUNTED CIRCUIT BOARD, XRB

207 1-761-990-11 s MOUNTED CIRCUIT BOARD, XRT

208 1-761-991-11 s MOUNTED CIRCUIT BOARD, XLB

209 1-761-992-11 s MOUNTED CIRCUIT BOARD, CTRL

210 ! 1-805-659-11 s DISPLAY PANEL, PLASMA

211 ! 1-576-233-12 s FUSE (H.B.C.) 6.3A/250V

Panel

PFM-42X1/42X1N

4-7

Page 50

SS-SP20B/SP20S (Speaker)

303

301

302

PSW 4X10

No. Part No. SP Description

301 1-825-627-11 s LOUDSPEAKER L (BLACK)

1-825-628-11 s LOUDSPEAKER L (SILVER)

302 1-825-627-21 s LOUDSPEAKER R (BLACK)

1-825-628-21 s LOUDSPEAKER R (SILVER)

303 1-900-276-27 s CONNECTOR ASSY (SP)

Screws/Washers

7-682-962-09 s SCREW PSW 4X10

4-8

PFM-42X1/42X1N

Page 51

405

Packing

407

404

403

414

408

410

409

407

411

401

412

406

413

402

No. Part No. SP Description

401 1-477-278-12 s REMOTE COMMANDER (RM-971)

402 1-827-782-11 s CABLE, DVI

403 2-990-242—01 s HOLDER (B), PLUG

404 3-613-640-01 o HOLDER (C), PLUG

405 2-176-251-01 o INDIVIDUAL CARTON

PFM-42X1/42X1N

406 2-149-020-01 s MANUAL, INSTRUCTION

(JAPANESE,ENGLISH,FRENCH,GERMAN,

SPANISH,ITALIAN,SIMPLIFIED CHINESE)

407 4-101-220-01 o CUSHION, TOP& BOTTOM

408 4-101-222-01 o CARTON, INSIDE

409 4-101-224-01 o ACCESSORY BOX

410 4-101-223-01 o BAG, PROTECTION

411 4-101-219-01 o TRAY, BOTTOM

412 4-978-977-01 s LID, BATTERY (BLACK)

413 4-101-214-01 s HOLDER, CABLE

414 ! ------------ s CORD, SET POWER (See 1-4. Warning on

Power Connection.)

4-9

Page 52

Board Connections

XLB

board

CN201

T (L) SP

board

CN1304

H1 (SW) board

YDB board

P9

![

A (Main)

board

0

CN501

!]

7

P300

CN22

CN3

CN19

Y-SUS board

CTRL board

CN803

CN801

YDT board

P2

CN808

CN802

CN806

2345

1

!]

CN807

!-

XLT

board

TEMP

board

P501

CN1101

9

H2 (User control)

board

UPPER

SIDE

XRB

board

AC inlet

T (R) SP board

BKM-V10

CN1302

CN1

6

CN301

CN2

CN15

L (Audio)

board

CN302

CN9

CN303

!=

CN8

Z-SUS

board

CN808

8

CN901

DDC CI

board

G (Power) board

P1

TEMP

board

!]

P501

!]

TEMP

board

P501

XRT

board

4-10

PFM-42X1/42X1N

Page 53

No. Part No. SP Description

1

1-910-002-73 o CONNECTOR ASSY, Y SUS 9P

2

1-910-002-74 o CONNECTOR ASSY, X SUS 8P

3

1-910-002-75 o CONNECTOR ASSY, MAIN 4P

4

1-910-002-76 o CONNECTOR ASSY, MAIN 12P

5

1-910-002-77 o CONNECTOR ASSY, MAIN 7P

6

1-910-002-78 o CONNECTOR ASSY, AU 12P

7

1-910-002-79 o CONNECTOR ASSY, RMT 8P

8

1-910-002-80 o CONNECTOR ASSY, DDC CI 11P

9

1-910-002-81 o CONNECTOR ASSY, KEY 4P

0

1-910-002-82 o CONNECTOR ASSY, SPKL 4P

!-

1-910-002-83 o CONNECTOR ASSY, Z-SUS 8P

!=

1-910-002-84 o CONNECTOR ASSY, SPK R 4P

![

1-910-002-85 o CONNECTOR ASSY, LVDS

!]

1-910-002-86 o CONNECTOR ASSY, SENS 9P

.

The numbers encircled by round corresponds to those

of the left illustration.

Board Connections

PFM-42X1/42X1N

4-11

Page 54

Page 55

SAFETY CHECK-OUT

After correcting the original service problem,

perform the following safety checks before

releasing the set to the customer :

Check the metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC

leakage. Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to

earth ground and from all exposed metal parts to

any exposed metal part having a return to

chassis, must not exceed 0.5 mA. Leakage

current can be measured by any one of three

methods.

1. A commercial leakage tester, such as the

Simpson 229 or RCA WT-540A. Follow the

manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The

Data Precision 245 digital multimeter is

suitable for this job.

3. Measuring the voltage drop across a resistor

by means of a VOM or battery-operated AC

voltmeter. The “limit” indication is 0.75 V, so

analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa

SH-63Trd are examples of a passive VOM

that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range

are suitable. (See Fig. A)

PFM-42X1/42X1N

To Exposed Metal

Parts on Set

0.15 µF 1.5 k

Fig A. Using an AC voltmeter to check AC leakage.

Z

Earth Ground

AC

voltmeter

(0.75V)

Page 56

PFM-42X1 (SY)

PFM-42X1N (SY) E

9-968-071-01

Printed in Japan

Sony Corporation 2004. 8 16

B&P Company ©2004

Loading...

Loading...