Page 1

SERVICE MANUAL

MODEL

.............. ......... ....................

DEST. CHASSIS NO. MODEL DEST. CHASSIS NO.

PFM-32C1 WORLD

PFM-32C1E WORLD

.............. ......... ....................

RM-971 WORLD

FLAT PANEL DISPLAY

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

WARNING!!

AN INSULATED TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECEIVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY A

DIAGRAMS, EXPLODED VIEWS AND IN THE PARTS LIST ARE

CRITICAL TO SAFE OPERATION. REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE PART NUMBERS APPEAR

AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

!!

! MARK ON THE SCHEMA TIC

!!

ATTENTION!!

AFIN D’ÉVITER TOUT RISQUE D’ÉLECTROCUTION

PROVENANT D’UN CHÂSSIS SOUS TENSION, UN

TRANSFORMA TEUR D’ISOLEMENT DOIT ETRE UTILISÉ LORS

DE TOUT DÉPANNA GE.

LE CHÂSSIS DE CE RÉCEPTEUR EST DIRECTEMENT

RACCORDÉ Á L’ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS Á LA

SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE MAPQUE

LES SCHÉMAS DE PRINCIPE, LES VUES EXPLOSÉES ET LES

LISTES DE PIECES SONT D’UNE IMPORTANCE CRITIQUE

POUR LA SÉCURITÉ DU FONCTIONNEMENT. NE LES

REMPLACER QUE PAR DES COMPOSANTS SONY DONT LE

NUMÉRO DE PIÈCE EST INDIQUÉ DANS LE PRÉSENT MANUEL

OU DANS DES SUPPLÉMENTS PUBLIÉS PAR SONY.

!!

! SUR

!!

PFM-32C1/32C1E

Page 3

CAUTION

ADVARSEL

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer’s instructions.

Vorsicht!

Explosionsgefahr bei unsachgemäßem Austausch

der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ. Entsorgung

gebrauchter Batterien nach Angaben des

Herstellers.

ATTENTION

Il y a danger d’explosion s’il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du même

type ou d’un type équivalent recommandé par le

constructeur.

Mettre au rebut les batteries usagées conformément

aux instructions du fabricant.

Lithiumbatteri - Eksplosjonsfare.

Ved utskifting benyttes kun batteri som

anbefalt av apparatfabrikanten.

Brukt batteri returneres

apparatleverandøren.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ

som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande

föreskrifter.

VAROITUS

Paristo voi räjähtää jos se on virheellisesti

asennettu.

Vaihda paristo ainoastaan laitevalmistajan

suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

PFM-32C1/32C1E

1 (P)

Page 4

For the customers in the Netherlands

Voor de klanten in Nederland

Hoe u de batterijen moet verwijderen, leest u in de tekst

van deze handleiding.

Gooi de batterij niet weg maar lever deze in als klein

chemisch afval (KCA).

Für Kunden in Deutschland

Entsorgungshinweis: Bitte werfen Sie nur entladene

Batterien in die Sammelboxen beim Handel oder den

Kommunen. Entladen sind Batterien in der Regel dann,

wenn das Gerät abschaltet und signalisiert “Batterie

leer” oder nach längerer Gebrauchsdauer der Batterien

“nicht mehr einwandfrei funktioniert”. Um

sicherzugehen, kleben Sie die Batteriepole z.B. mit

einem Klebestreifen ab oder geben Sie die Batterien

einzeln in einen Plastikbeutel.

For the customers in the U.S.A. and Canada

RECYCLING LITHIUM-ION BATTERIES

Lithium-Ion batteries are recyclable.

You can help preserve our environment

by returning your used rechargeable

batteries to the collection and recycling

location nearest you.

For more information regarding recycling of rechargeable batteries, call toll free

1-800-822-8837, or visit http://www.rbrc.org/

Caution: Do not handle damaged or leaking Lithium-Ion

batteries.

2 (P)

PFM-32C1/32C1E

Page 5

Table of Contents

1. Service Information

1-1. Board Layout............................................................................................... 1-1

1-2. Disassembly ................................................................................................1-2

1-2-1. QA Board Removal....................................................................1-2

1-2-2. Rear Cover Removal ..................................................................1-3

1-2-3. Bezel Assy Removal ..................................................................1-4

1-2-4. DC Fan (1) Removal .................................................................. 1-4

1-2-5. DC Fan (2) Removal .................................................................. 1-5

1-2-6. Switching Regulator Removal ...................................................1-5

1-2-7. Q Block Assy Removal (Q Board).............................................1-6

1-2-8. B Board Removal (Lithium Battery).......................................... 1-7

1-2-9. B Block Assy Removal .............................................................. 1-8

1-2-10. Power Cord.................................................................................1-8

1-2-11. Plasma Display Panel Unit Packing

When Sending it to FUJITSU (FHP) .........................................1-9

2. Electrical Adjustments

2-1. Equipment Required....................................................................................2-1

2-2. Electrical Adjustments Using the Service Mode ........................................2-1

2-3. White Balance Adjustment .......................................................................2-20

2-4. AD Calibration Adjustment ......................................................................2-20

2-5. Sub Color and Sub Hue Adjustments........................................................2-21

2-6. Video Decoder Adjustment.......................................................................2-21

2-7. Watch Error Adjustment ...........................................................................2-22

3. Troubleshooting

3-1. Judging Method When Image Does Not Appear ........................................ 3-1

3-2. Self Diagnosis Function ..............................................................................3-2

3-2-1. Overview ....................................................................................3-2

3-2-2. Abnormality Judgment Criterion ...............................................3-2

4. Semiconductors................................................................................. 4-1

5. Spare Parts

PFM-32C1/32C1E

5-1. Notes on Repair Parts..................................................................................5-1

5-2. Exploded Views .......................................................................................... 5-2

5-3. Electrical Parts List ..................................................................................... 5-8

1

Page 6

6. Block Diagrams.................................................................................. 6-1

B (1/3), Q (1/2), QA ............................................................................................... 6-1

B (2/3).....................................................................................................................6-2

B (3/3), Q (2/2), H1, H2, S .....................................................................................6-3

7. Diagrams

7-1. Frame Schematic Diagrams ........................................................................7-2

Frame (1/2) ............................................................................................... 7-2

Frame (2/2) ............................................................................................... 7-3

7-2. Schematic Diagrams and Printed Wiring Boards........................................7-4

Schematic Diagrams

QA.............................................................................................................7-4

Q (1/3) ....................................................................................................... 7-8

Q (2/3) ....................................................................................................... 7-9

Q (3/3) ..................................................................................................... 7-10

B (1/7) .....................................................................................................7-14

B (2/7) .....................................................................................................7-15

B (3/7) .....................................................................................................7-16

B (4/7) .....................................................................................................7-17

B (5/7) .....................................................................................................7-18

B (6/7) .....................................................................................................7-19

B (7/7) .....................................................................................................7-20

H1............................................................................................................ 7-25

H2............................................................................................................ 7-25

S ..............................................................................................................7-25

SP ............................................................................................................7-25

Printed Wiring Boards

QA.............................................................................................................7-5

Q................................................................................................................ 7-6

B .............................................................................................................. 7-12

H1............................................................................................................ 7-24

H2............................................................................................................ 7-24

S ..............................................................................................................7-24

SP ............................................................................................................7-24

2

PFM-32C1/32C1E

Page 7

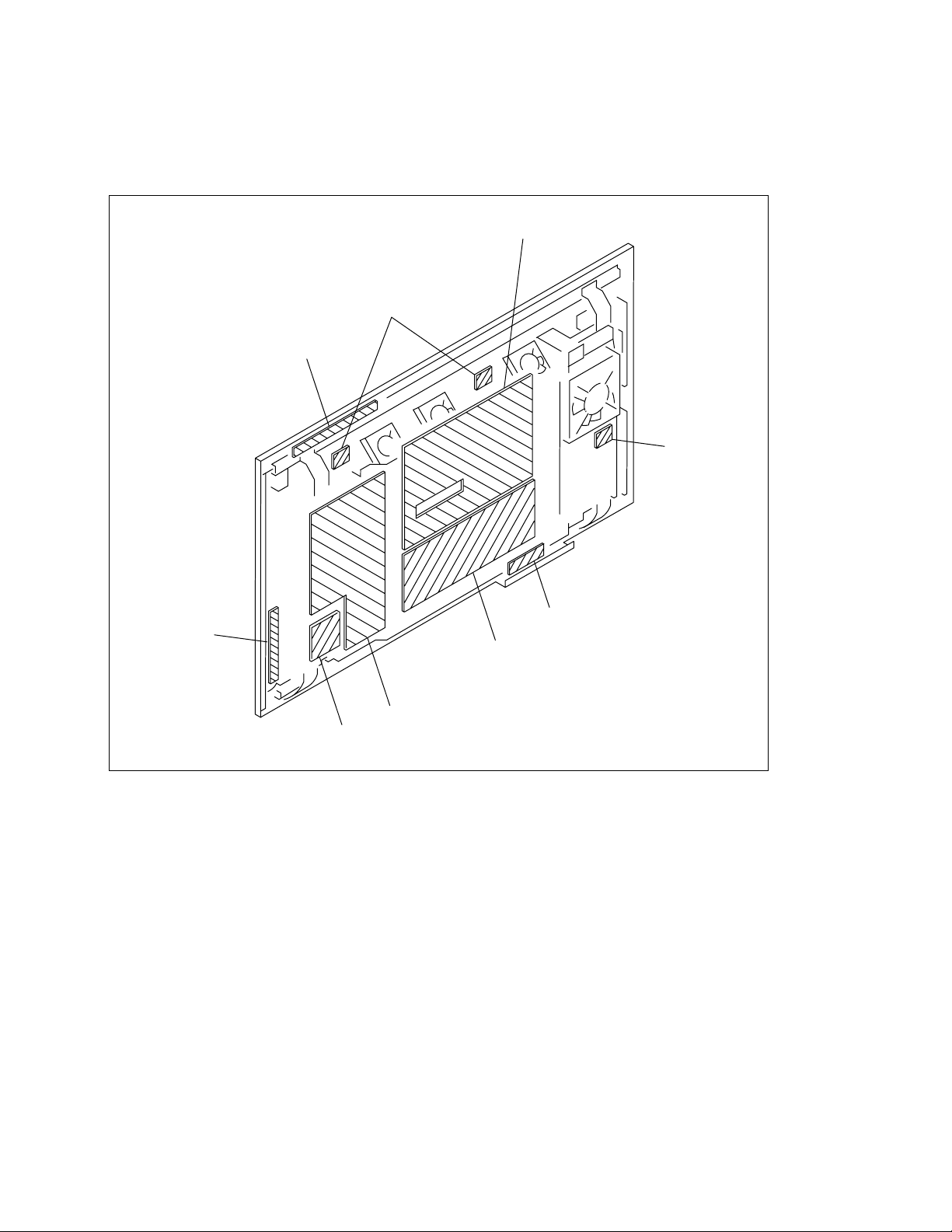

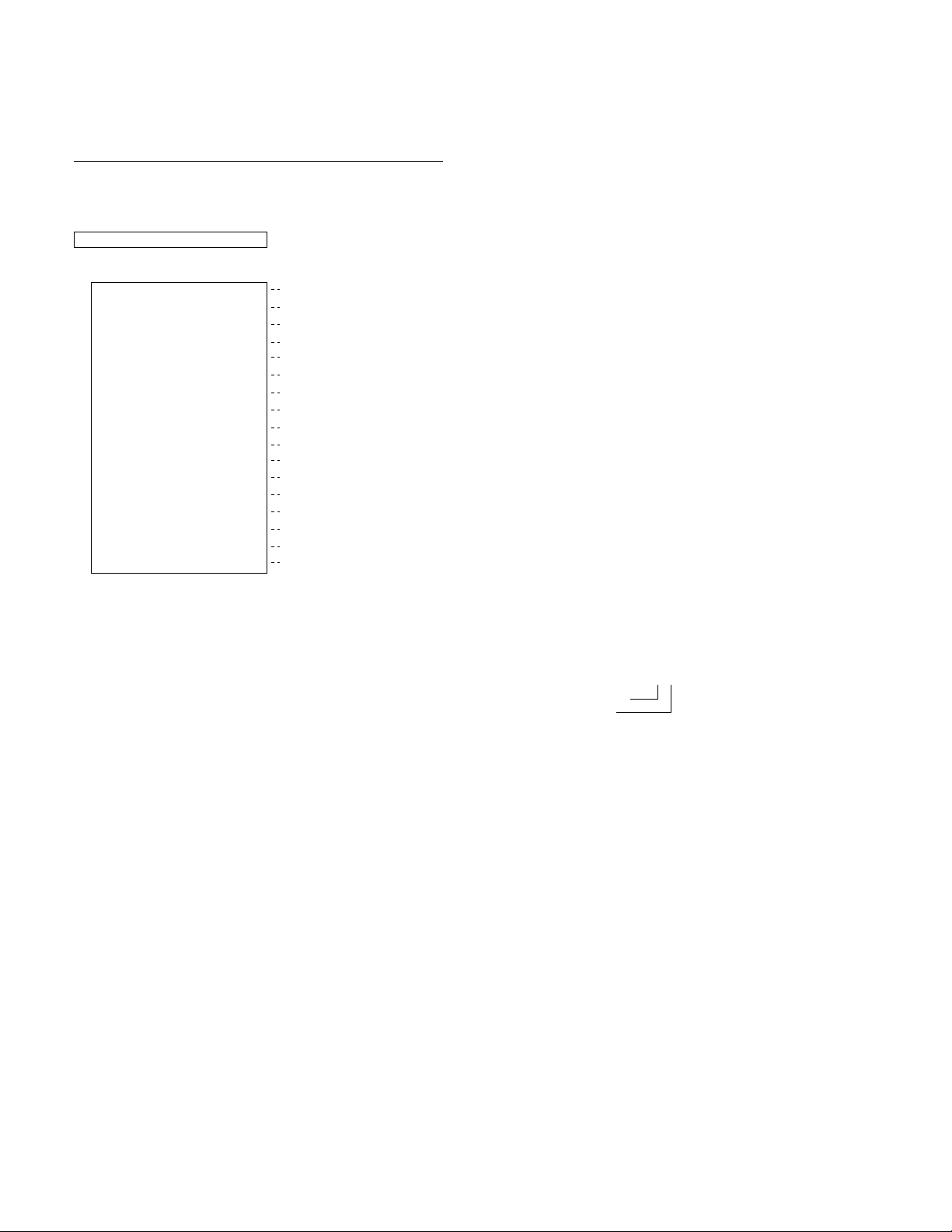

1-1. Board Layout

Section 1

Service Information

SWITCHING REGULATOR

S

H2

S

H1

SP

B

Q

QA (PFM-32C1)

PFM-32C1/32C1E

1-1

Page 8

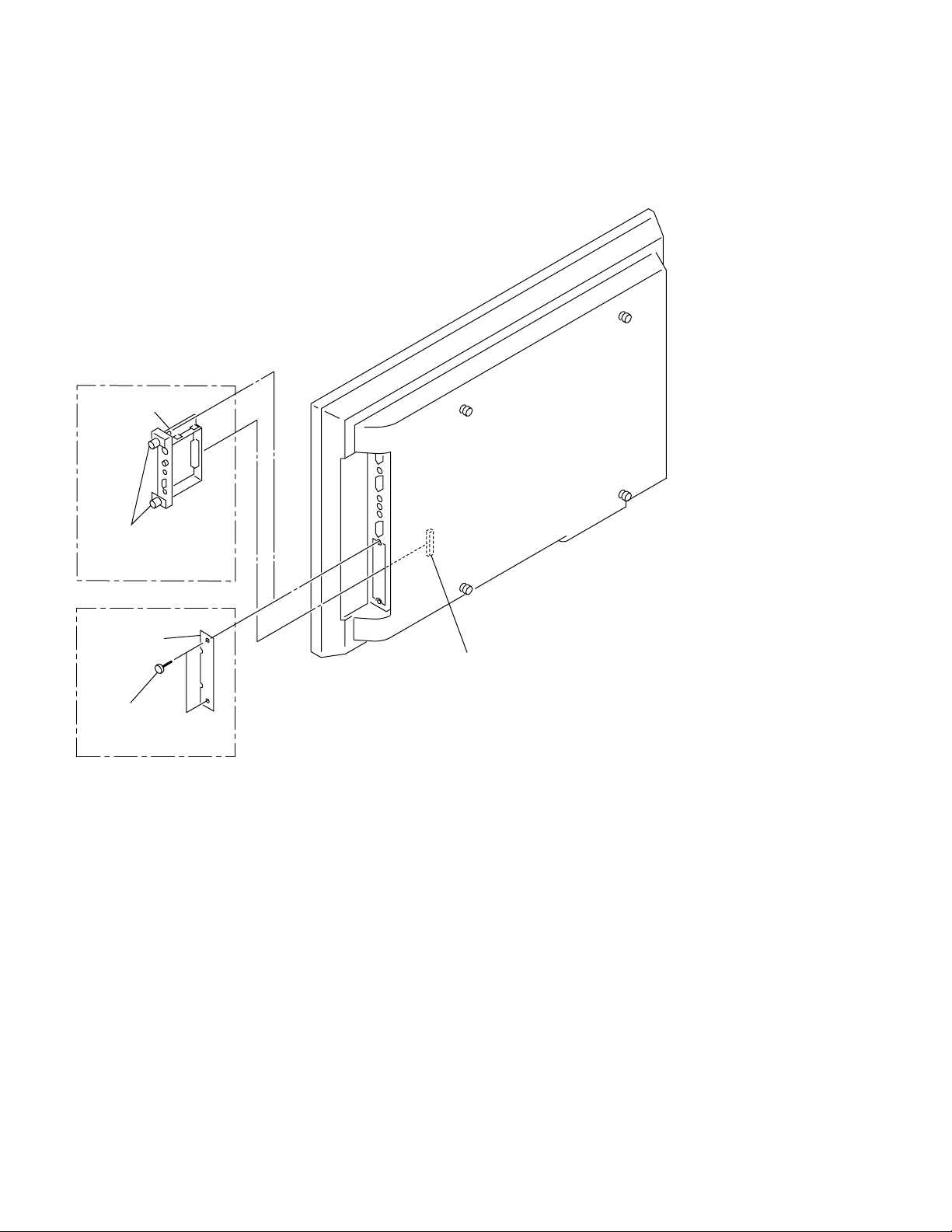

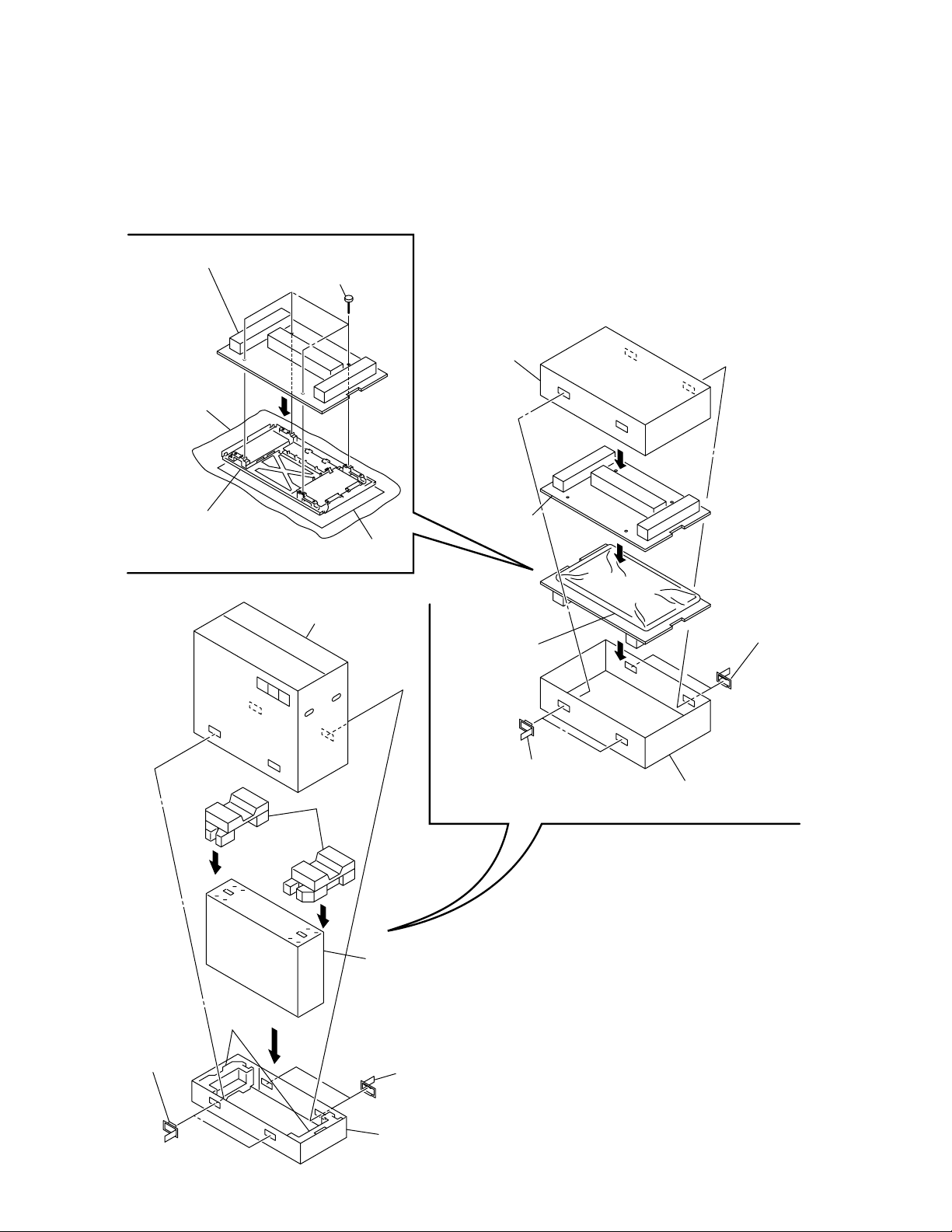

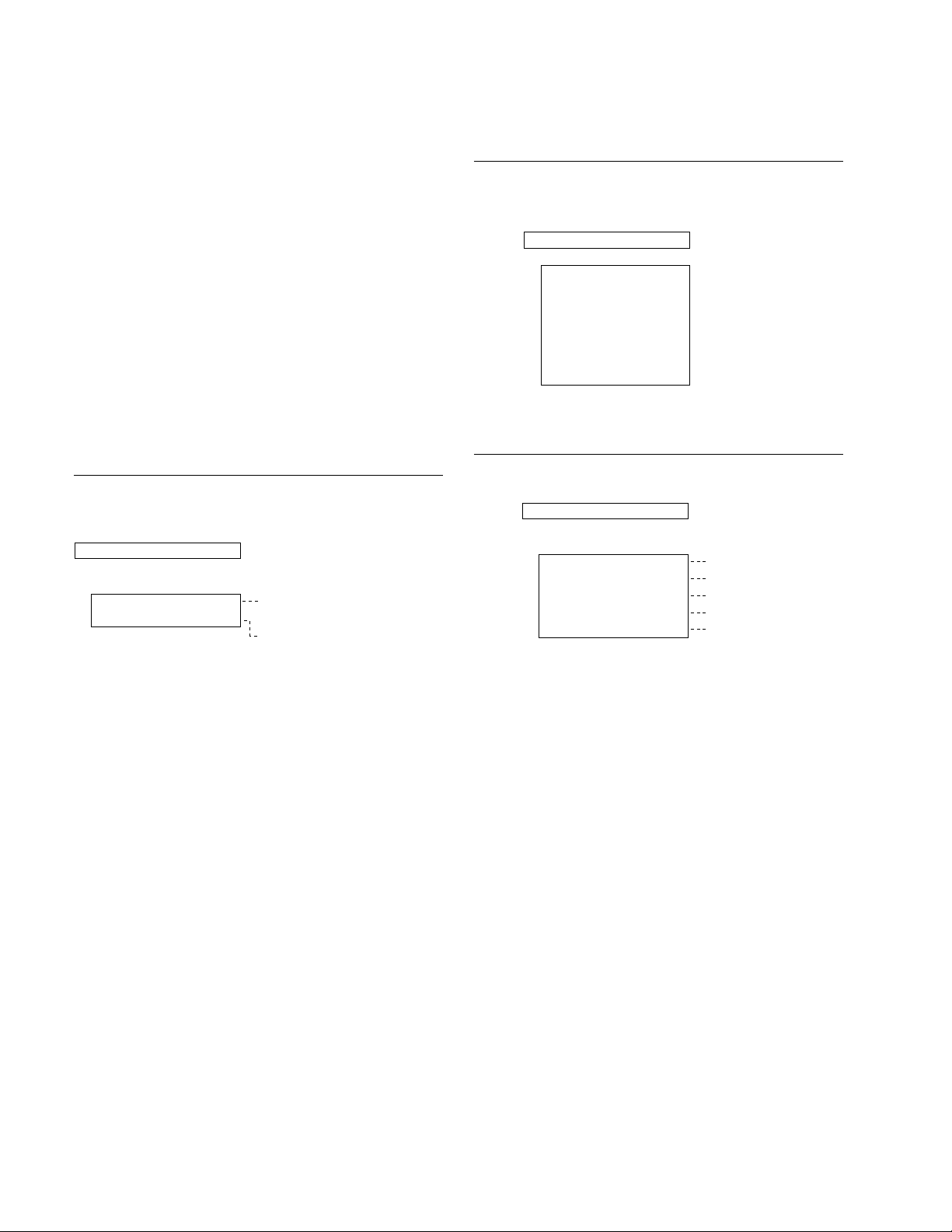

1-2. Disassembly

1-2-1. QA Board Removal

PFM-32C1

QA board

Remove blank panel

[Loosen two panel

stopper screws.]

PFM-32C1E

Blank panel

Two screws

(+PS 3 x 6)

CN3009

1-2

PFM-32C1/32C1E

Page 9

1-2-2. Rear Cover Removal

2 Four knobs

3 Seven screws

(+BVTP 4 x 12)

CN860

1 Four screws

(+PSW 5 x 20)

4 Seven screws

(+BVTP 4 x 12)

5 EG-GRIP screws

(+PWH 3 x 12)

6 Rear cover

7 Two screws

(+BVTP 3 x 12)

8 Control panel assy

0 Eight screws

(+BVTP 4 x 12)

9 Ten screws

(+PWH 3 x 6)

!- Eight screws

(+BVTP 4 x 12)

!= EMI shield assy

Cushion

Main chassis

PFM-32C1/32C1E

1-3

Page 10

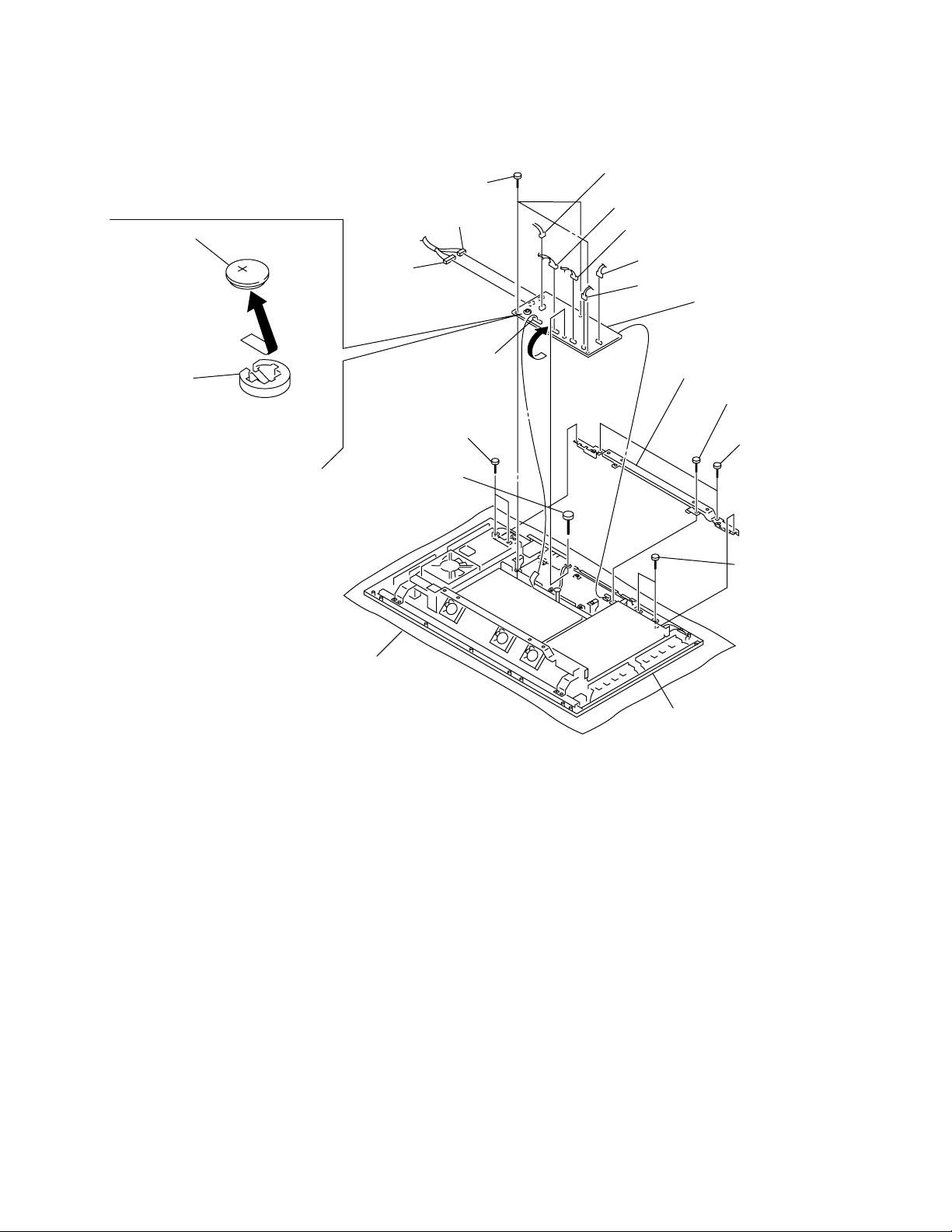

1-2-3. Bezel Assy Removal

1 Four screws

(+BVTP 4 x 12)

Wire (for reference)

Note: If two wires attached on the glass surface

of plasma display panel, be careful not to

cut them.

Q board

CN3003

2 Main chassis

1-2-4. DC Fan (1) Removal

2

Four

screws

(+PWH 3 x 6)

3 DC fan,

Fan bracket (B)

CN1501

Cushion

3 Bezel complete assy

S board

Mini clamper

1 Connector (3pins)

1-4

Cushion

Main chassis

PFM-32C1/32C1E

Page 11

1-2-5. DC Fan (2) Removal

6 Two screws

(+PWH 3 x 6)

8 DC fan,

Fan bracket

7 Screw

(+PSW 4 x 8)

1 Two screws

(+PWH 3 x 6)

3 Two screws

(+PSW 5 x 10)

5 Hook bracket

4 Screw

(+PWH 3 x 6)

1-2-6. Switching Regulator Removal

n

To remove the switching regulator, remove the DC fan (2) beforehand.

CN6CN1CN3005

CN2

1 Six screws

(+PWH 3 x 6)

CN42

CN52

CN7

2 Two screws

(+PWH 3 x 6)

Cushion

Main chassis

2 Switching regulator

PFM-32C1/32C1E

CN23

CN33

Cushion

Main chassis

1-5

Page 12

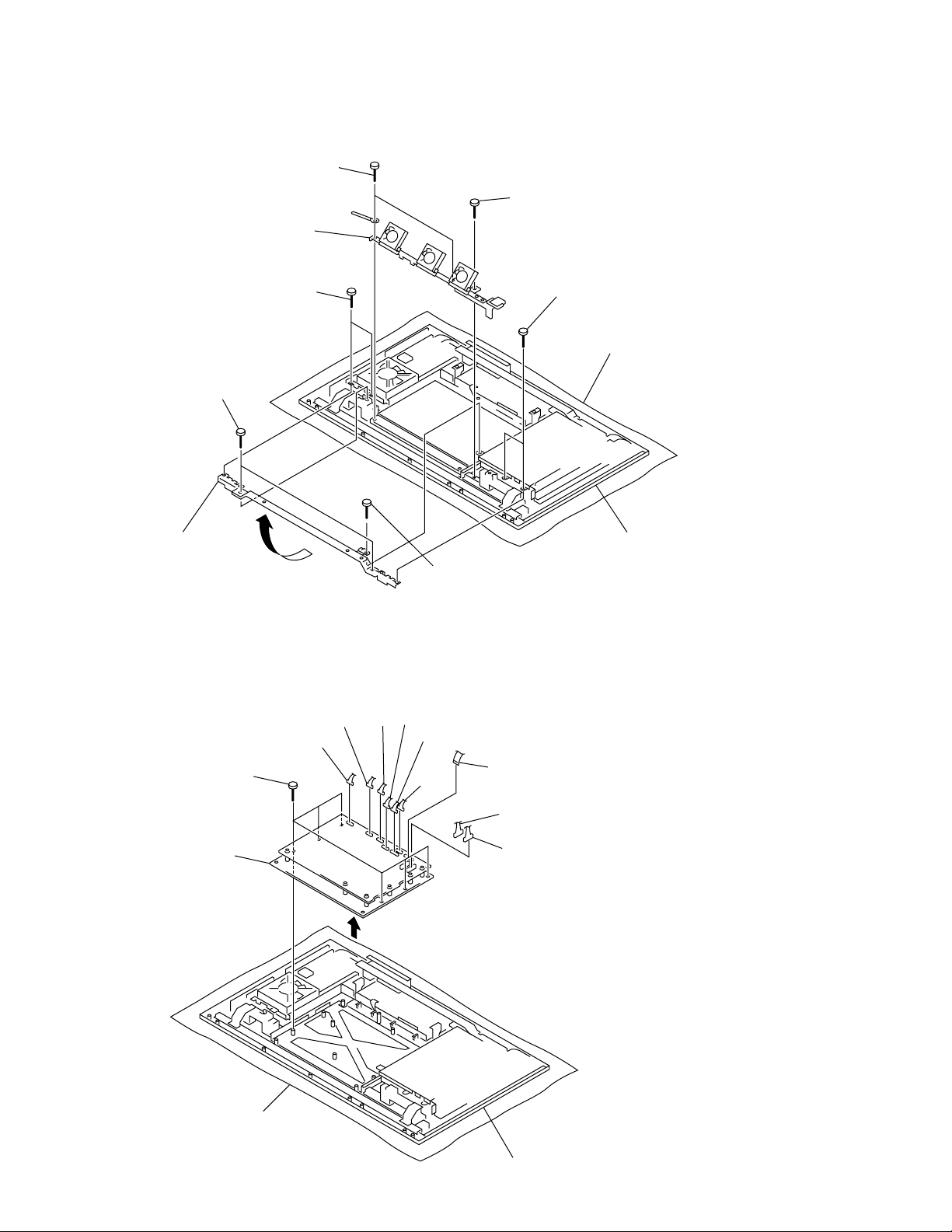

1-2-7. Q Block Assy Removal (Q Board)

CN3007

1 Two lock hinges

Cushion

CN3002

CN3011

CN3012

CN3008

CN3005

4 Q block assy

Main chassis

CN3001

CN3006

3 Four screws

(+P3 x 8) (EXT TOOTH)

CN3003

CN3003

2 MINIATURE Clamp

Q board removal

9 Q board

7 Q panel

8 Seven screws

(+PWH 3 x 6)

6 Three screws

(+PS 3 x 6)

5 Six hexagon screws

1-6

PFM-32C1/32C1E

Page 13

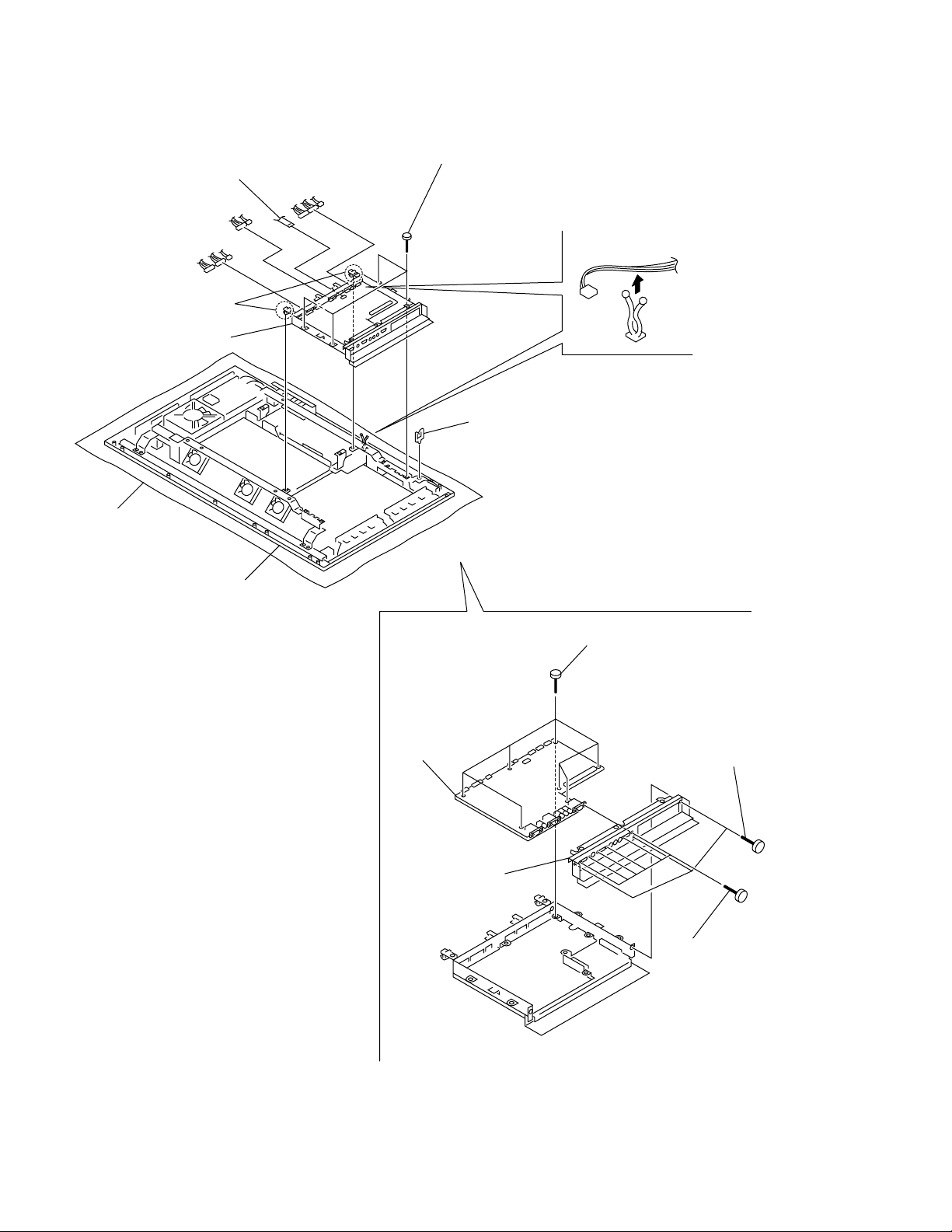

1-2-8. B Board Removal (Lithium Battery)

Lithium battery removal

Lithium battery

(CR-1220)

Battery holder

Remove the lithium battery

in the direction of arrow.

6 Three screws

(+PWH 3 x 6)

CN1204

CN1203

3 Two screws

(+PWH 3 x 6)

7 Screw

(+PWH 3 x 6)

CN1001

CN1005

CN101

CN401

CN102

CN1004

8 B board

5 Hook bracket

1 Screw

(+PWH 3 x 6)

4 Two screws

(+PSW 5 x 10)

2 Two screws

(+PWH 3 x 6)

Cushion

Main chassis

PFM-32C1/32C1E

1-7

Page 14

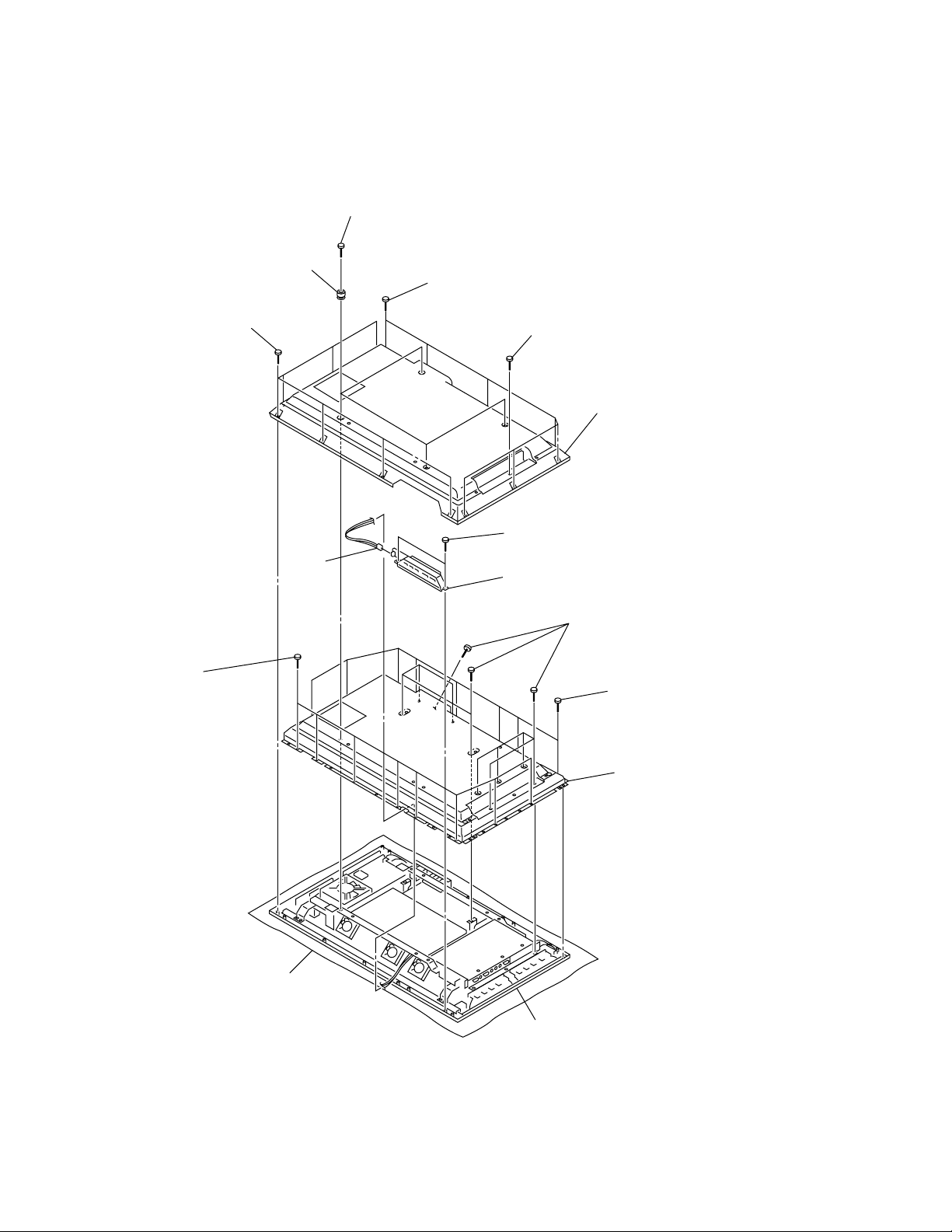

1-2-9. B Block Assy Removal

n

To remove the “B” block assy, remove the Q block and the B board (hook bracket) beforehand referring

to “B Board Removal”.

CN101

CN1005

CN1

CN2

CN9001

SP board

Cushion

CN102

2 Two screws

(+BVTP 4 x 12)

3 B block assy

1 Screw

(+PWH 3 x 6)

Main chassis

1-2-10.Power Cord

Use the proper power cord for your local power supply.

United States, Continental United Kingdom, Ireland, Japan

Canada Europe Australia, New Zealand

Plug type VM0233 COX-07 636 _a) VM1296

Female end VM0089 COX-02 VM0310B VM0303B VM1313

Cord type SVT H05VV-F CEE (13) 53rd (O.C) HVCTF

Minimum cord set rating 10A/125V 10A/250V 10A/250V 10A/125V

Safety approval UL/CSA VDE VDE DENAN-HO

a) Note : Use an appropriate rating plug which is applied to local regulations.

1-8

PFM-32C1/32C1E

Page 15

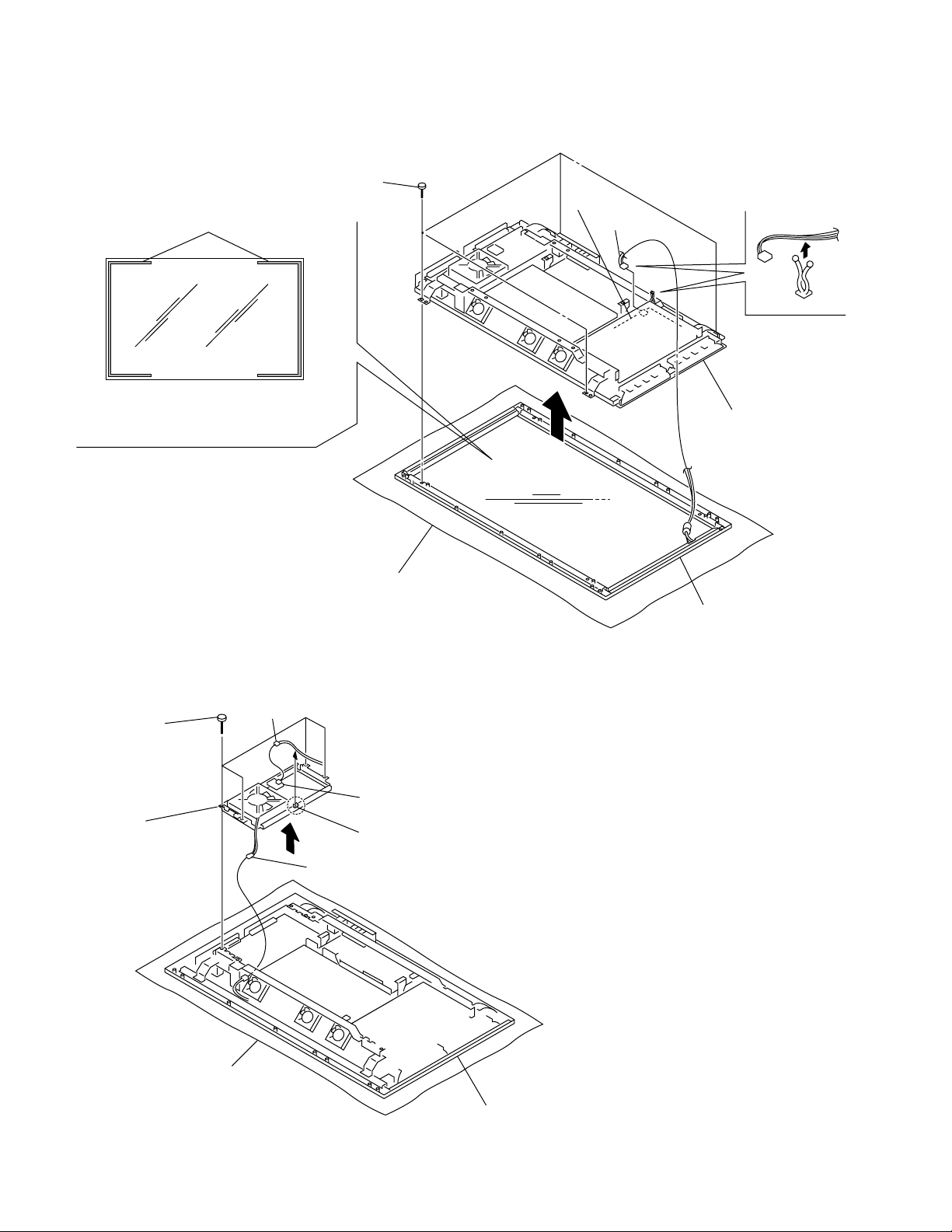

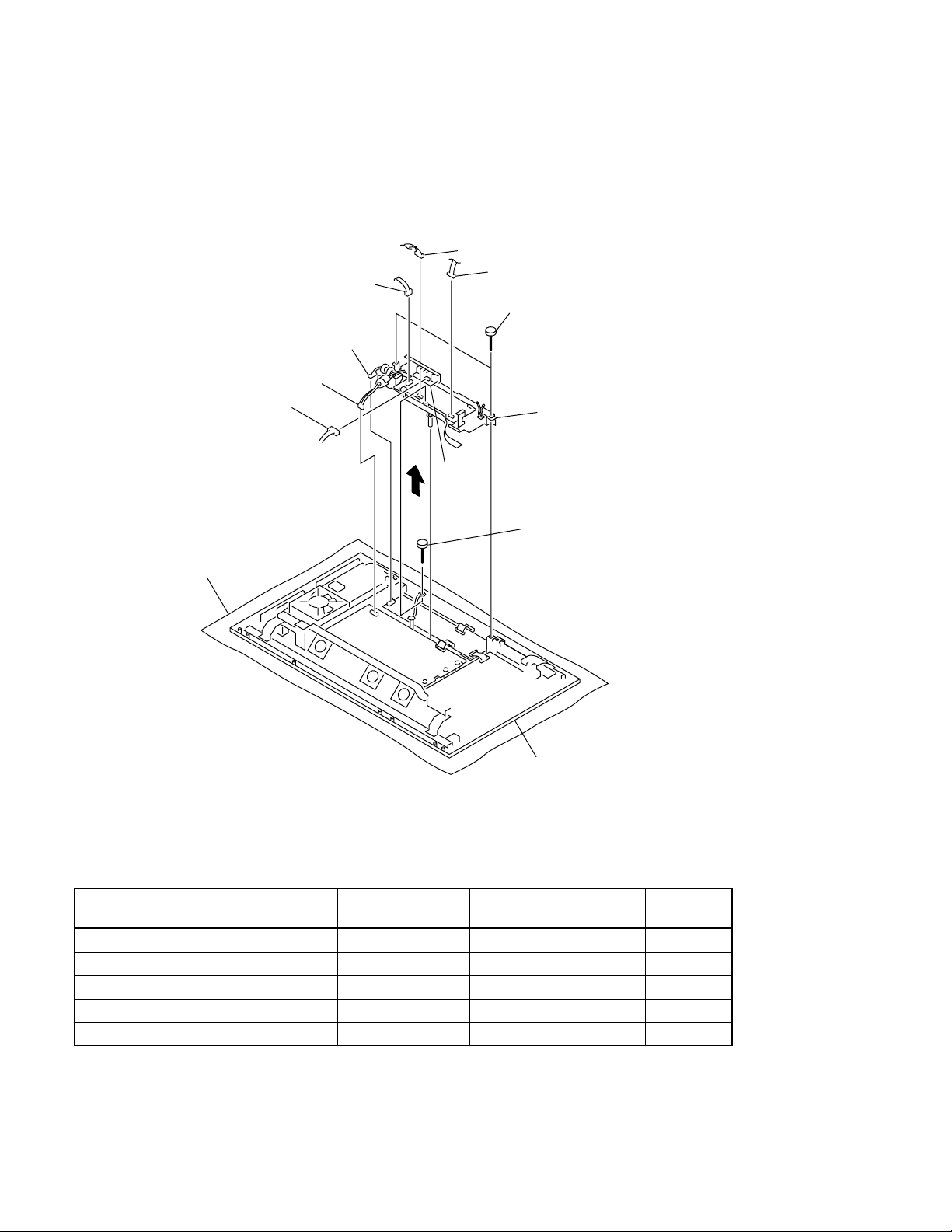

1-2-11. Plasma Display Panel Unit Packing When Sending it to FUJITSU (FHP)

n

Before sending the panel to FHP, remove the boards (B, H1, H2, Q, QA, S, SP) and switching regulator

producted by SONY.

3 Lower retainer

(Attached to cushion of plywood)

4 Four fixing screws

8 Inner box (Lid)

2 Wrapping by

polyethylene

1 Plasma display panel unit

*Glass face is lower side.

mirror mat

!\ Bottom box (Lid)

!] Two upper parts

7 Upper retainer

6 Plasma display

panel unit

* Glass face is

upper side.

Page 17

Section 2

Electrical Adjustments

2-1. Equipment Required

. Oscilloscope

Tektronix 2465 or equivalent

(band width : 350 MHz or more)

. VG (Programmable video signal generator)

VG814 or equivalent

. Frequency counter

Advantest TR5821AK or equivalent

. Digital voltmeter

Advantest TR6845 or equivalent

. Potential transformer

. Regulated DC power supply

. Remote commander (RM-971)

n

Perform the following adjustments at least 5 minutes after

turning on the power.

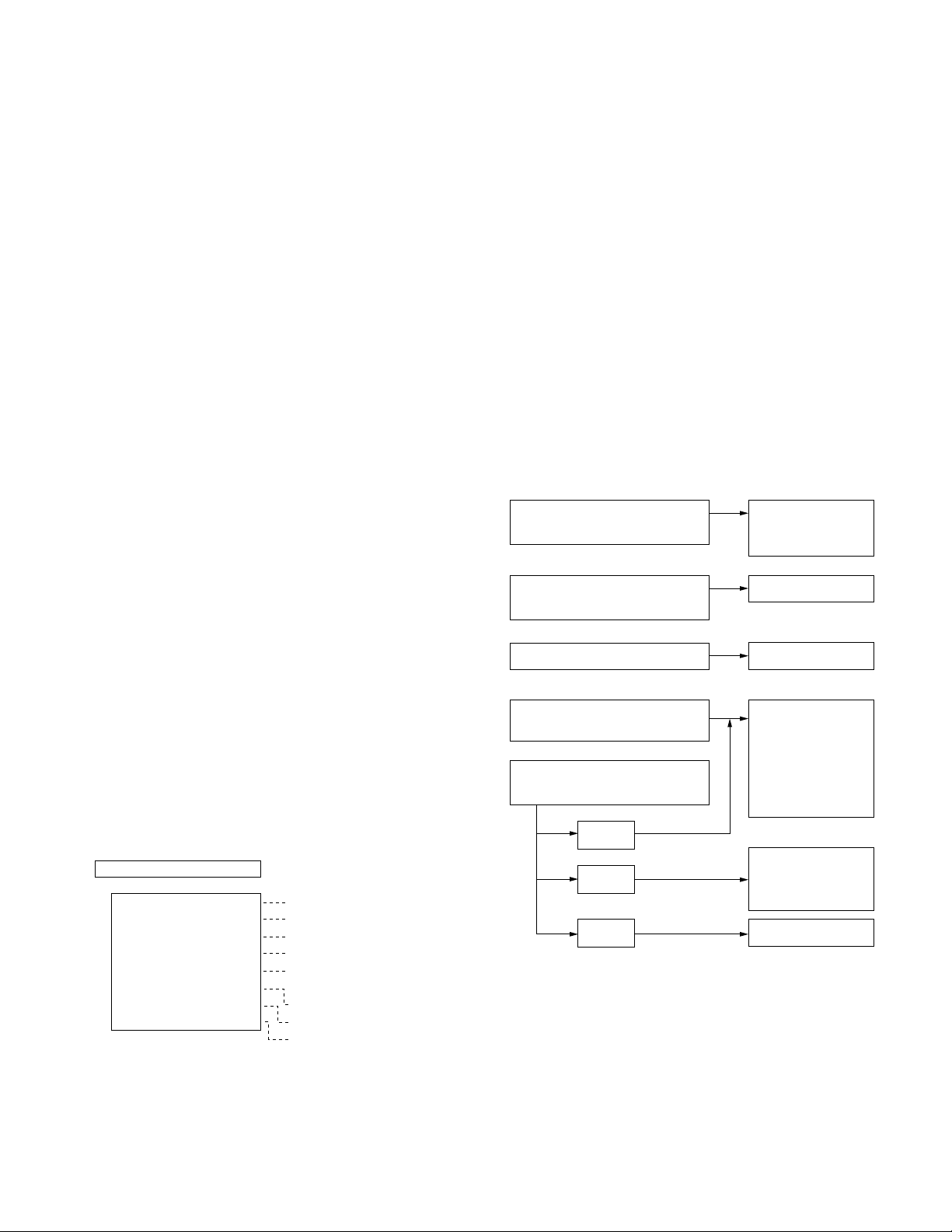

2-2. Electrical Adjustments Using the

Service Mode

Press the [STBY] key once and back on to enter the STANDBY state or turn off the main power to exit the Service Mode.

..

. Operation of remote commander in the Service

..

Mode

The six keys of MENU, ENTER, ←, →, ↑ and ↓ are the

basic operation keys in the same manner as in the user

adjustment. The other keys can be operated in the same

manner as in the user adjustment.

..

. The electrical adjustments using the Service

..

Mode become necessary in the following cases.

When either one of the following adjustment is made,

adjustment using the service mode becomes necessary.

When any repair related to picture

quality is executed.

When IC403/B board and its

peripheral part is replaced.

Chroma Decoder

AD Converter

White Balance

AD Converter

The electrical adjustments can be performed using the remote

commander RM-42B supplied with the PFM-32C1/32C1E. The

remote commander has the Service Mode. Select the Service

Mode to perform the electrical adjustments as listed below.

..

. Service Mode

..

When the machine enters the service menu, the “Service

Mode” submenu is displayed in addition to the ordinary

user menu. The electrical adjustment is executed using the

“Service Mode” submenu.

Service Mode

EEP ROM Initialize Initializes the EEP ROM

Chroma Decoder Chroma decoder adjustment

AD Converte A/D converter adjustment

White Balance White balance adjustment

General Other adjustments and the

Manual Control functions required for confirmation

Preset Edit Factory check menu (Not used in service)

Service Status Editing the preset signal

Internal status confirmation

How to enter the Service Mode using the RM-971 :

In the STAND-BY state, press the keys in the following

order.

[DISPLAY] → [5] → [VOL+] → [

POWER|ON

]

When PDP is replaced.

When memory (IC1007) on the

B board is replaced.

When any of the circuit boards

below is replaced.

B board

Q board

S board

White Balance

EEP ROM Initialize

Chroma Decoder

AD Converter

White Balance

General

Service Status

Chroma Decoder

AD Converter

Service Status

Service Status

Operation confirmation only

PFM-32C1/32C1E

2-1

Page 18

Service Mode

1. EEPROM Initialize

EEPROM Configuration

Table 1 shows the configuration of EEPROM. The entire

area or the respective areas of the EEPROM can be

separately initialized.

Menu Structure

Select the desired area of EEPROM to be initialized using

the following menu.

Service Mode

EEP ROM Initialize

Whole Area

Common

White Balance

Prog. Gamma

Tuner

Prog. Preset

Last Memory

User Memory

Factory

To initialize the desired area, firstly select the desired item

from the EEPROM RESET menu. Change the selected

item from “CANCEL” to “OK”. Then press “ENTER”.

a) Whole Area

It initializes whole area of EEP ROM.

This command is identical to executing the all items of

“Common”, “White Balance”, “Prog. Gamma”,

“Tuner”, “Prog. Preset”, “Last Memory”, “User

Memory” and “Factory”.

Execute this command only when the memory

(IC1007) on the B board is replaced.

b) Common

It initializes “Common (1)”, “Common (2)” and

“Common (3)” of the “COMMON DATA AREA”

shown in Table 1.

It initializes the data unique to the particular machine

and the shared data (various setup values of the user

menu”.

Because it initializes the serial number and accumulative operation hours, do not execute this command.

c) White Balance

It initializes “Color Temp (1)” and “ Color Temp (2)”

of the “COMMON DATA AREA” shown in Table 1.

It initializes the color temperature “High”, “Mid” and

“Low”, and all data of user setup 1 to 3 to all 0.

It also initializes the user name to “User1”, “User2”

and “User3”.

d) Prog. Gamma

This command is not used in this machine.

e) Tuner

This command is not used in this machine.

f) Prog. Preset

It initializes the “PRESET DATA AREA” shown in

Table 1.

It resets the backup preset area.

g) Last Memory

It initializes “LAST MEMORY AREA” shown in

Table 1.

It initializes the last memory data that user has adjusted for each signal.

h) User Memory

It initializes “USER MEMORY AREA” shown in

Table 1.

It resets all of the 20 types of the adjustment data that are

saved in the “User Memory” function of the user menu.

i) Factory

It resets the EEP ROM to the factory default status.

All of the EEP ROM areas except the following are

initialized by this command.

Items that are not initialized by the “FACTORY”

RESET function.

In the COMMON DATA AREA

1 Index Number stored in the Common (1) [General]

2 Watch Error and Serial Number data stored in the

Common (2) [General]

3 Service (1) [AD Converter] Adjustment data of 2-4.

AD Calibration Adjustment.

4 Service (2) [Chroma Decoder] Adjustment data of 2-5.

Sub Color, Sub Hue Adjustment and 2-6. Video

Decoder Adjustment.

5 Adjustment data in Color Temp (1) [Data & Name] at

the factory except user adjustment value. (Adjustment

data of 2-3. White Balance Adjustment)

2-2

PFM-32C1/32C1E

Page 19

2. Chroma Decoder

Menu structure

Hue and color of the video signal are adjusted.

Service Mode

Chroma Decoder

Hue

Sub Contrast : 8

Sub Color

Sharp Gain : 8

Sharp f0 : 3

Y Out Level : 18

C Out Level : 10

Y Delay

Cb Offset : 8

Cr Offset : 8

By Adj (SECAM) : 8

Ry Adj (SECAM) : 8

a) Hue

To adjust NTSC signal hue, adjust “Hue (NTSC)” in

the lower layer below this sub menu.

To adjust NTSC4.43 signal hue, adjust “Hue (NT443)”

in the lower layer below this sub menu.

Adjustment range is from 0 to 63.

b) Sub Contrast

Adjustment range is from 0 to 63.

Fixed value : 8

c) Sub Color

Adjust “Col (NTSC)”, “Col (PAL)” and “Col (SECAM)” for the respective signals of NTSC, PAL and

SECAM.

Adjustment range is from 0 to 15.

Fixed value for Col (NTSC) only : 6

d) Sharp Gain

Adjustment range is from 0 to 15.

Fixed value : 8

e) Sharp f0

Adjustment range is from 0 to 3.

Fixed value : 3

f) Y Out Level

Adjustment range is from 0 to 63.

Fixed value : 18

g) C Out Level

Receive the NTSC signal and adjust color. The color

adjustment of PAL and SECAM signals are performed

upon completion of the NTSC signal adjustment, and

use step c) Sub Color.

Adjustment range is from 0 to 63.

h) Y Delay

Y delay for the respective signals can be adjusted by

“YDL (NTSC)”, “YDL (PAL)”, “YDL (SECAM),

“YDL (NT443)”, “YDL (PALM)” and “YDL

(PALN)” respectively.

Adjustment range is from 0 to 15.

Fixed value : 5

i) Cb Offset

Adjustment range is from 0 to 15.

Fixed value : 8

j) Cr Offset

Adjustment range is from 0 to 15.

Fixed value : 8

k) By Adj (SECAM)

The blue offset when receiving the SECAM signal is

adjusted.

Adjustment range is from 0 to 15.

l) Ry Adj (SECAM)

The red offset when receiving the SECAM signal is

adjusted.

Adjustment range is from 0 to 15.

Sub Color and Sub Hue Adjustments

Refer to section “2-5. Sub Color and Sub Hue Adjustment”.

Video Decoder Adjustment

Refer to section “2-6. Video Decoder Adjustment”.

PFM-32C1/32C1E

2-3

Page 20

3. AD Converter

4. White Balance

Menu structure

This adjustment corrects non-uniformity between RGB (or

YCbCr) channels of AD converter (IC403).

Service Mode

AD Converter

Cal Mode : off

RGB Calibration

YUV Calibration

Video Calibration

a) Cal Mode

Set to “On” to enter the calibration mode.

Off : Normal operation

On : Calibration mode

b) RGB Calibration

The RGB signals are calibrated.

The RGB signals are calibrated by “Sub Cont RGB”,

“Red Gain”, “Green Gain”, “Blue Gain”, “Red Bias”,

“Green Bias” and “Blue Bias” that are located in the

lower layer below this sub menu.

Adjustment range is from 0 to 255 in each adjustment

item.

c) YUV Calibration

The component video signal is calibrated.

The component video signal is calibrated by “Sub

Cont YUV”, “Sub Brt YUV”, “Cb Offset YUV” and

“Cr Offset YUV”.

Adjustment range is from 0 to 255 for “Sub Cont

YUV” and “Sub Brt YUV”, and from 0 to 63 for “Cb

Offset YUV” and “Cr Offset YUV”.

d) Video Calibration

The composite video signal is calibrated.

The composite video signal is calibrated by “Sub Cont

Video”, “Sub Brt Video”, “Cb Offset Video” and “Cr

Offset Video”.

Adjustment range is from 0 to 255 for “Sub Cont

Video” and “Sub Brt Video”, and from 0 to 63 for “Cb

Offset Video” and “Cr Offset Video”.

Menu structure

White balance of PDP panel is adjusted.

Service Mode

White Balance

Window : Off

Color T emp . : High

Red Gain llllllllll

Green Gain llllllllll

Blue Gain llllllllll

a) Window

This machine has the built-in window signal for white

balanced adjustment. Select either small or large

window for suitable adjustment.

Off : Window is not displayed.

Small : Small window is displayed.

Large : Large window is displayed.

b) Color Temp.

Select the desired color temperature that you want to

adjust located in the lower layer below this sub menu.

Select the desired color temperature from “High”,

“Mid”, “Low”, “User 1”, “User 2” and “User 3”.

n

Because “User 1”, “User 2” and “User 3” can be

adjusted from the user menu, they are not adjusted

here.

c) Red Gain

Red gain of the selected “Color Temp.” is adjusted.

Adjustment range is from

__

_127 to +128.

__

d) Green Gain

Green gain of the selected “Color Temp.” is adjusted.

Adjustment range is from

__

_127 to +128.

__

e) Blue Gain

Blue gain of the selected “Color Temp.” is adjusted.

Adjustment range is from

__

_127 to +128.

__

White Balance Adjustment

AD Calibration Adjustment

Refer to section “2-4. AD Calibration Adjustment”.

2-4

Refer to section “2-3. White Balance Adjustment ”.

PFM-32C1/32C1E

Page 21

5. General

g) Fan Status

Menu structure

The data that are unique to the particular machine and the

fan control are checked.

Service Mode

General

Blue Only : 0

AGC Wide : 14

AGC Narrow : 13

32k Clock Out: Off

Watch Error : 32.76800

Serial Number: 2000001

Fan Status

Vs/Va Setting

a) Blue Only

When “1” is set, all colors of RGB channels on the

PDP become blue data only.

b) AGC Wide

This command is not used in this machine.

c) AGC Narrow

This command is not used in this machine.

d) 32k Clock Out

The clock signal that is used for the Watch Error

adjustment is output.

Off : Not output.

On : Output

e) Watch Error

It corrects error of the built-in watch.

Set the measurement value of the frequency counter

connected.

Adjustment range is from 32.76180 to 32.77420 kHz.

f) Serial Number

It sets serial number.

Menu structure

Service Mode

General

Fan Status

Fan Control : Auto

Ref Voltage : 8.5[V]

F/B Voltage : 8.5[V]

Drive Data 2B5F

P/S T emp : 43[dC]

Center T emp : 43[dC]

I/O Block Temp : 43[dC]

Left T emp : 43[dC]

Fan Control : You can select [Auto] or [Manual]. If

you select [Manual], you can set the any

desired voltage to the fan drive voltage

using [Ref Voltage]. Use this command

for checking operation of the fan drive

circuit. Select [Auto] during normal

operation.

Ref Voltage : You can set the any desired voltage to the

fan drive voltage when you have selected

[Manual] in the “Fan Control”. Range of

setting is from 0.0 V to 13.0 V. The fan

drive voltage returns to the default value

when the POWER is turn off and back on

again.

F/B Voltage : It indicates the fan drive voltage. The

voltage that is actually driving the fan is

displayed as the setting voltage is being

supplied.

Drive Data : It indicates the fan drive data.

P/S Temp : It indicates the temperature that is

measured by the temperature sensor built

in the power board.

Center Temp : It indicates the temperature that is

measured by the temperature sensor

attached on top of the power board.

I/O Block Temp :It indicates the temperature that is

measured by the temperature sensor

attached on top of the Q block assy.

Left Temp : It indicates the temperature that is

measured by the temperature sensor

attached near the fan (large).

PFM-32C1/32C1E

2-5

Page 22

h) Vs/Va Setting

6. Manual Control

Menu structure

Service Mode

General

Vs/Va Setting

Uvrs : 72

Uvra : 106

Set

Reset

Uvrs : You can establish the setup regarding the panel

power supply Vs. Calculate the setup value Uvrs

from equations (1) and (2) below.

Vs = 70 + 10 x Vrs........... equation (1)

where

Vrs = 2.99 x Uvrs/255 ...... equation (2)

Uvra : You can establish the setup regarding the panel

power supply Va. Calculate the setup value Uvra

from equations (3) and (4) below.

Va = 30 + 20 x Vra .......... equation (3)

where

Vra = 2.99 x Uvra/255 ..... equation (4)

Set : You can make the entered Uvrs and Uvra valid.

Change the menu item from [Cancel] to [OK] and

press [ENTER].

n

Perform this setup only when the logic board

located in the bottom center on the rear of the PDP

panel, is replaced. Take reading of the Vs voltage

value and the Va voltage value that is written on

the label on the rear of the PDP panel, and enter the

Vs and Va values in the equations (1) and (3).

These submenu items are used in factory for operation

checks.

Do not operate this function.

Reset :You can return the Uvrs and Uvra to their default

value. Change the menu item from [Cancel] to

[OK] and press [ENTER].

2-6

PFM-32C1/32C1E

Page 23

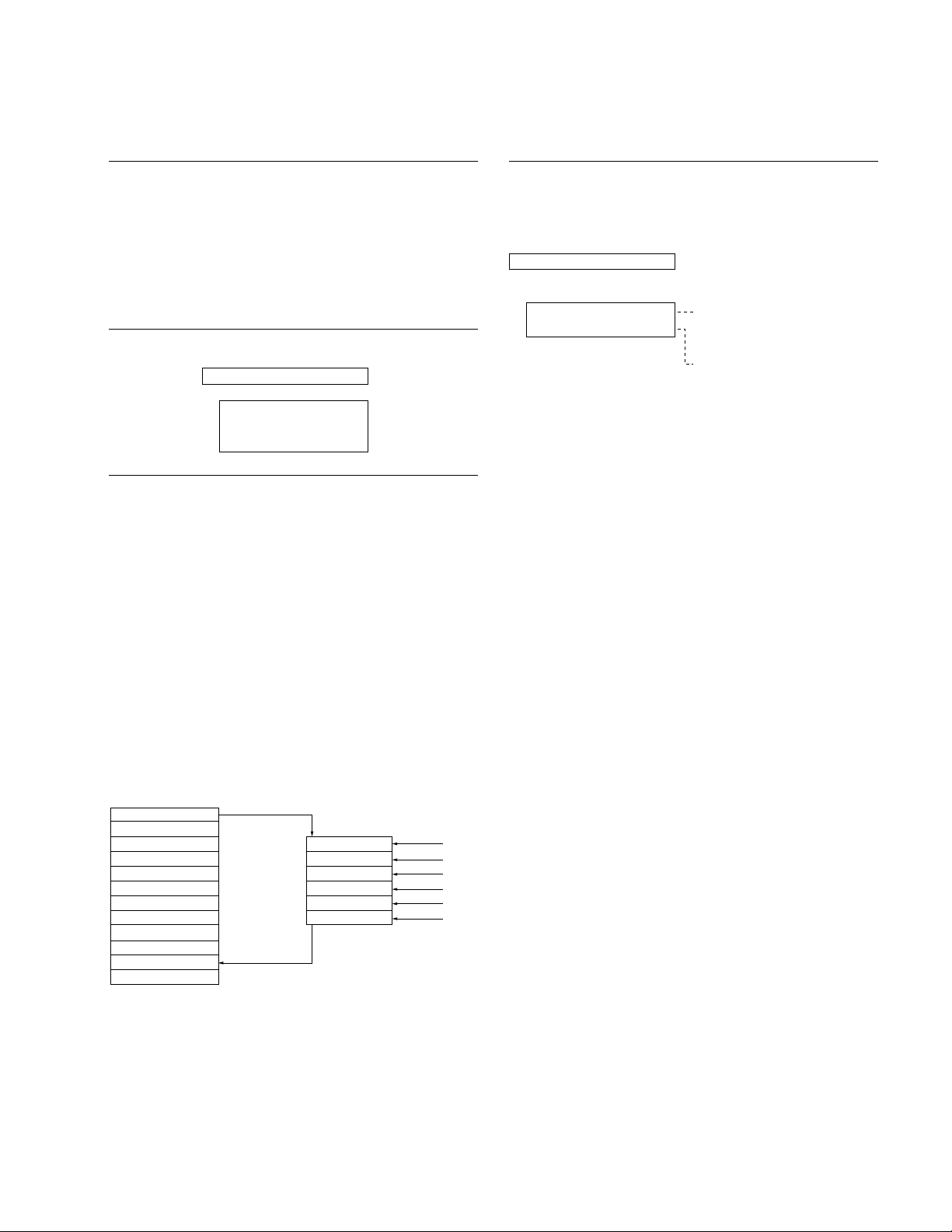

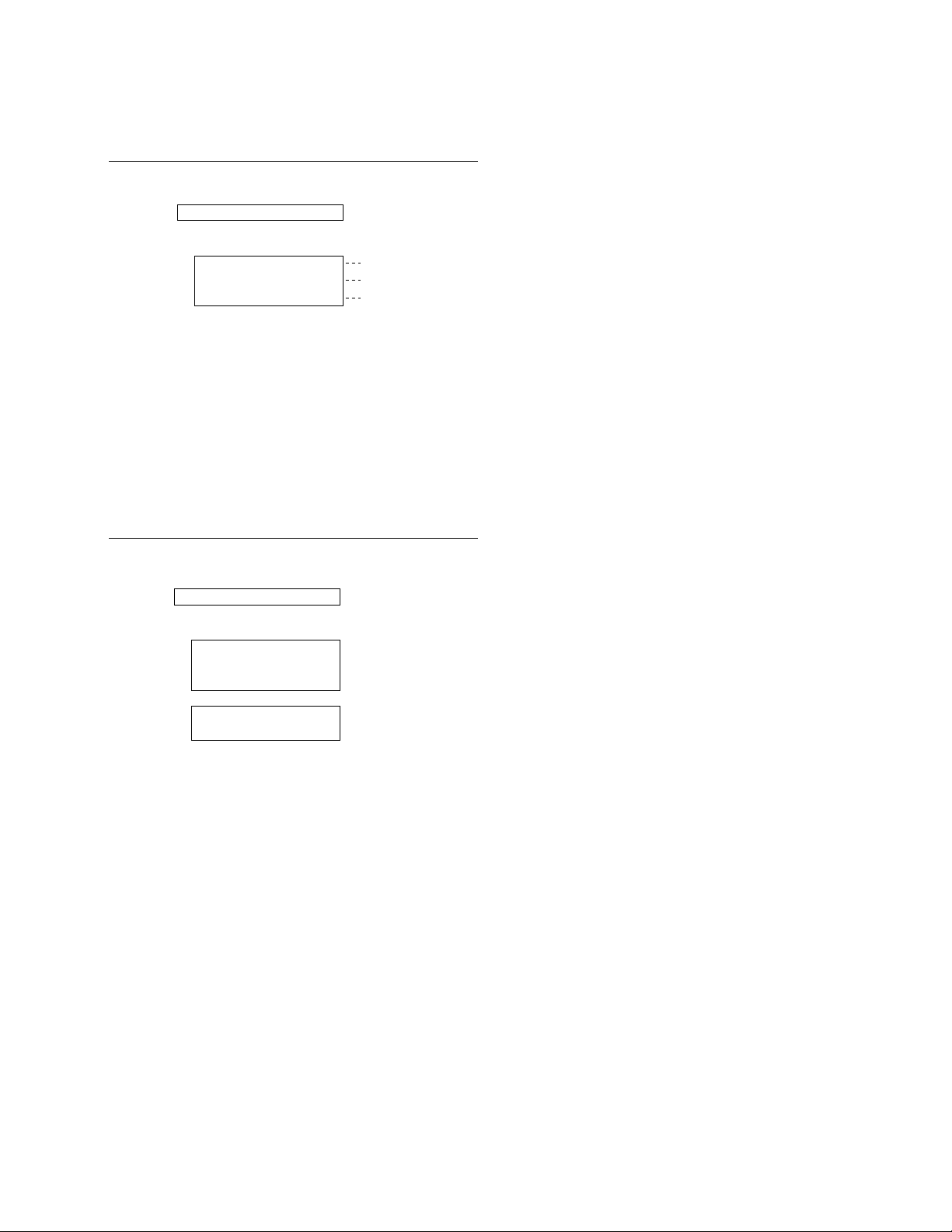

7. Preset Edit

a) Original Data Select

Preset data structure

You can add the preset signals in addition to the default

preset data.

The additional preset data are stored in [PROGRAM1] to

[PROGRAM12] of [PRESET DATA AREA]. [PROGRAM13] to [PROGRAM30] are not used.

Menu structure

Service Mode

Preset Edit

Original Data Select

Data Edit

Save Area Select

Editing procedure

An independent memory area (editing RAM) is assigned

for data editing inside the system controller as shown.

First, copy the source data for editing to the editing RAM.

Then modify the data on the editing RAM and save the

editing contents to the specified preset area of EEP ROM.

In addition to the default preset data that has been set

already when shipped from the factory, you can edit the

various data from the already saved data in EEP ROM or

the signal data that is being input at this moment.

(An example shows the case the data stored in the EEP

ROM preset area No.2 is used for editing and the edited

data is stored in the area No.11.)

EEP ROM

preset data area

PROGRAM1

PROGRAM2

PROGRAM3

PROGRAM4

PROGRAM5

PROGRAM6

PROGRAM7

PROGRAM8

PROGRAM9

PROGRAM10

PROGRAM11

PROGRAM12

System controller

Editing RAM

Editing

Menu structure

You can select the original data that is used for editing and

copy the selected original data to the editing RAM.

Service Mode

Preset Edit

Original Data Select

Current Data Select (1) The signal data that is being

Table input at this moment, is used

as the original data for editing.

(2) The data stored in the preset

area is used for editing.

(1) Current Data Select

When you select the signal data that is being input at

this moment for editing, move the cursor to this item

and press ENTER.

The selected data is copied to the editing RAM.

This mode is prepared for the case that the signal

specification is unknown, and you can make editing by

confirming the specification on screen.

Select the respective adjustment items and change the

data as desired using the ↑/↓ key or the ←/→ key. The

changed data are reflected on screen.

(If you press the ENTER key again, the screen returns

to the previous menu.)

Among the adjustment items, the three types of

adjustment [H Freq], [V Freq] and [Sync Pol] cannot

be modified.

(2) Table

When you select the data stored in the preset area,

move the cursor to this item and press ENTER. Select

the desired data using the ↑/↓ key. The selected data is

copied to the editing RAM.

This mode is prepared for the case that the signal

specification is already known. You can make adjustment and edit data of all items but the modified data

are not reflected to the actual picture images.

PFM-32C1/32C1E

2-7

Page 24

b) Data Edit

Menu structure

You can edit the data contents of the editing RAM.

Service Mode

Preset Edit

Data Edit

H Freq : 031.469[kHz] (1) Horizontal frequency

V Freq : 059.94[Hz] (2) Vertical frequency

Sync Pol : N/N (3) Sync signal polarity

H. Total Pixel : 800 (4) Total number of dots within horizontal

H. Active Pixel : 640 (5) Horizontal resolution power

H. Sync Pixel : 96 (6) Number of dots of horizontal sync signal

H. BP Pixel : 48 (7) Number of dots during the horizontal back porch

V. total Line : 525 (8) Total number of vertical lines

V. Active Line : 480 (9) Vertical resolution power (number of lines)

V. Sync Line : 2 (10) Total number of lines of vertical sync signal

V. BP Line : 33 (11) Number of lines during the vertical back porch

Clamp Posi : 60 (12) Clamp pulse position

Clamp Width : 8 (13) Clamp pulse width (number of dots)

Format Flag (14) Format flag

Picture Mode : Standard (15) Picture quality mode

Color Matrix : 12 (16) Color difference matrix

Zoom Mode : 4/3 (17) Wide selection

(1) H Freq

It sets the horizontal frequency.

n

When “Current Data Select” is selected in the Original

Data Select, this item cannot be modified because the

presently entered signal is selected for editing.

(2) V Freq

It sets the vertical frequency.

n

When “Current Data Select” is selected in the Original

Data Select, this item cannot be modified because the

presently entered signal is selected for editing.

(3) Sync Pol

It sets the sync signal polarity. Sync polarities are

displayed in the order of “Horizontal/Vertical”.

Sync Pol : N/N

Horizontal sync polarity

Vertical sync polarity

When you set the sync signal polarity, set it as shown

below.

Nagative polarity : N

Positive polarity : P

SOG : SOG

n

When “Current Data Select” is selected in the Original

Data Select, this item cannot be modified because the

presently entered signal is selected for editing.

(4) H. Total Pixel

It sets the total number of dots within a single horizontal cycle.

This setup value becomes the default value of the user

menu “Total H Pixel”.

n

You should set in a way that number of H. Total Pixels

is equal or more than sum of (H. Active Pixel +H.

Sync Pixel +H. BP Pixel).

2-8

PFM-32C1/32C1E

Page 25

(5) H. Active Pixel

It sets the horizontal resolution power.

(6) H. Sync Pixel

It sets the number of dots of horizontal sync signal.

(7) H. BP Pixel

It sets the number of dots during the horizontal back

porch.

(8) V. total Line

It sets the total number of vertical lines.

n

You should set in a way that number of V. Total Line

is equal or more than sum of (V. Active Line + V.

Sync Line + V. BP Line).

(9) V. Active Pixel

It sets the vertical resolution power.

(10)V. Sync Line

It sets the total number of lines of vertical sync signal.

(11)V. BP Pixel

It sets the number of lines during the vertical back

porch.

(12)Clamp Posi

It sets clamp pulse position.

The clamp pulse position is set starting (when data is

0) from the trailing edge of the horizontal sync signal.

When this data is increased, picture moves toward the

picture area.

The clamp pulse generation position Tcp is given by

the equation below starting from the trailing edge of

sync signal.

Tcp = Clamp Posi/(Horizontal sync frequency x H.

Total Pixel) [seconds]

(13)Clamp Width

It sets the clamp pulse width.

The clamp pulse width increases starting from the

position that is set by the Clamp Posi. When this value

is increased, the clamp pulse width is widened in the

direction toward picture area.

The clamp pulse width Wcp is given by the equation

below.

Wcp = Clamp Width/(Horizontal sync frequency x H.

Total Pixel) [seconds]

(14)Format Flag

It sets ON/OFF of the following respective items in

units of bit.

00000000 1 : ON

1234 0 : OFF

Upper 4 bits are not used.

1 Setting the IP converter

Set to OFF during normal operation.

2 Setting interlace

It sets the interlace input.

ON : When the input signal is the interlaced signal.

OFF : When the input signal is the progressive signal.

3 Setting to enable the “dot adjustment”

It enables or disables the “dot adjustment” in the user

menu.

ON : The “dot adjustment” is enabled in the user

menu.

OFF : The “dot adjustment” is disabled in the user

menu.

If the actual input signal specification is different from

the setups of “H. Total Pixel” and “H. Active Pixel”

due to fetching the interlace, set this item to OFF.

4 Frame synchronization setting

It sets synchronization setting of the picture input to

scan converter.

ON : Vertical sync of PDP panel synchronizes with

the input signal.

OFF : The PDP panel display signal is no more

synchronized with the input signal. When the

motion picture is going to be displayed, set this

item to ON.

n

This item can be set to ON only when the vertical

frequency of input signal is in the range from 50 to 60

Hz.

(15)Picture Mode

It sets the picture quality mode. Select the desired

mode from “Standard”, “Vivid”, “Use1”, “User2” or

“User3”.

This setting becomes the default value of the “Picture

Mode” of user menu.

PFM-32C1/32C1E

2-9

Page 26

(16)Color Matrix

It sets the color difference matrix when the color

difference component signal is input.

Either “12” or “13” can be set.

12 : In the case when the signal conforms to

SMPTE293M.

13 : In the case when the signal conforms to

SMPTE294M.

(17)Zoom Mode

It sets the wide selection. Select the desired mode from

“Expd. 4/3”, “Letterbx”, “Restore”, “Subtitle” or “4/

3”.

This setting becomes the default value of the “Picture

Quality Mode” of user menu.

c) Save Area Select

Menu structure

It saves the data of the editing RAM to the preset area.

Service Mode

Preset Edit

Save Area Select

Save Are : 1 (1) Select the preset data area

Data Save that stores the data.

(2) Executes saving of the data.

8. Service Status

Menu structure

You can confirm internal status of the PDP panel.

Service Mode

Service Status

Signal/Sync

Power Supply

Fan & Temp Status

Warning Status

Operation Time :

Software Version : 1.00

PLD Version : 000

00001H

a) Signal/Sync

Menu structure

Service Mode

Service Status

Signal/Sync

Format : 640 x 480/60 Signal specification

H Freq :

V Freq : 059.94[Hz] Vertical frequency

Sync Pol : N/N Sync signal polarity

Condition : Stable Sync signal status

031.469[kHz]

Horizontal frequency

(1) Save Area

It selects the preset data area that saves contents of the

editing RAM.

Select the desired area from “PROGRAM1” to

“PROGRAM12”.

(2) Data Save

It executes saving of the data into the area that is

selected by the Save Area.

Change the menu item from [Cancel] to [OK] and

press [ENTER].

n

You can judge coincidence of the preset data with the input

signal using the sync signal polarity of horizontal/vertical

frequencies.

If the same sync signal data exists within a preset area, the

specification that has the smaller preset number has

priority.

The sync signal status of the input signal is displayed.

Format : The preset signal name for the input signal is

displayed.

H Freq : Horizontal frequency of the input is displayed

in 6 digits.

V Freq : Vertical frequency of the input is displayed in

5 digits.

Sync Pol : Sync signal polarity is displayed.

Conditions : Sync signal status is displayed.

Stable : Stable

Insecure : Unstable

No Sync : Sync signal does not exist.

2-10

PFM-32C1/32C1E

Page 27

b) Power Supply

Menu structure

Service Mode

Service Status

Power Supply

Digital 5V : 5.0[V] 5 V for digital circuit

Digital 3V : 3.3[V] 3 V for digital circuit

Analog 6V : 6.0[V] 6 V for analog circuit

Main DC voltages of this model are displayed.

Digital 5 V : Internal 5 V power supply voltage is dis-

played.

Digital 3 V : Internal 3.3 V power supply voltage is

displayed.

Analog 6 V : Internal 6 V power supply voltage is dis-

played.

c) Fan & Temp Status

Menu structure

When the value that is displayed on the PDP panel, is

converted to the binary number, the each bit has the

following meaning.

Bit 0 : Audio Processor Each bit 0 : OK, 1 : NG

Bit 1 : Audio Switch

Bit 2 : AV Switch

Bit 3 : Closed Caption Decoder

Bit 4 : 3D Comb filter

Bit 5 : Chroma Decoder

Bit 6 : PDP

Bit 7 : Tuner (No Use for PFM)

Bit 8 : Auto Wide Decoder

Bit 9 : AD Converter

Bit 10 : EEP ROM

Bit 11 : IP Converter (System IC)

Bit 12 : OSD (No Use for PFM)

Bit 13 : PLD (No Use for PFM)

Bit 14 : RTC (No Use for PFM)

Bit 15 : Scan Converter (No Use for PFM)

n

Because this type of PDP panel is not equipped with the

AV switch, bit 2 always goes to 1.

Service Mode

Service Status

Fan&Temp Status

Fan Drive : OK

Fan : OK

P/S T emp : OK

P/S T emp : 44[dC]

NO ACK DEV : 0004

The internal temperature of the machine and the fan

operating status are displayed.

Fan Drive : Operating status of the fan drive circuit is

displayed. [OK] appears when it operates

normally. [NG] appears when it does not

operate normally.

Fan : Operating status of the fan is displayed.

[OK] appears when all fans operate

normally. [NG] appears when any one of

the fans does not operate normally.

P/S Temp : Temperature status inside the power

supply block is displayed. [OK] appears

when temperature is normal. [NG]

appears when temperature is abnormal.

P/S Temp : Temperature inside the power supply

block is displayed.

NO ACK DEV :

Status whether the communication with the

respective devices that are controlled by the

2

I

C bus, is established or not is displayed.

PFM-32C1/32C1E

2-11

Page 28

d) Warning Status

Menu structure

Service Mode

Service Status

Warning Status

EEP ID : OK

EEP Save : OK

EEP Load : OK

RTC Init : OK

RTC VDET : OK

RTC XSTOP : OK

PDP Init : OK

DEC Init : OK

DC Init : OK

Power Off : OK

The warning information is displayed.

EEP ID : ID CODE error

EEP Save : Data write error

EEP Load : Data read error

RTC Init : Watch initialization error

RTC VDET : Watch power voltage error (1.8 V or less)

RTC XSTOP : Watch oscillator error

PDP Init : PDP initialization error

DEC Init : Chroma decoder initialization error

DC Init : Power voltage (digital system 5 V, digital

system 3.3 V, analog system 6 V) error

Power Off : Power-off sequence error

e) Operation Time

Accumulative operating hours are indicated. (In units

of hour)

f) Software Version

Software version is indicated.

g) PLD Version

PLD version is indicated.

2-12

PFM-32C1/32C1E

Page 29

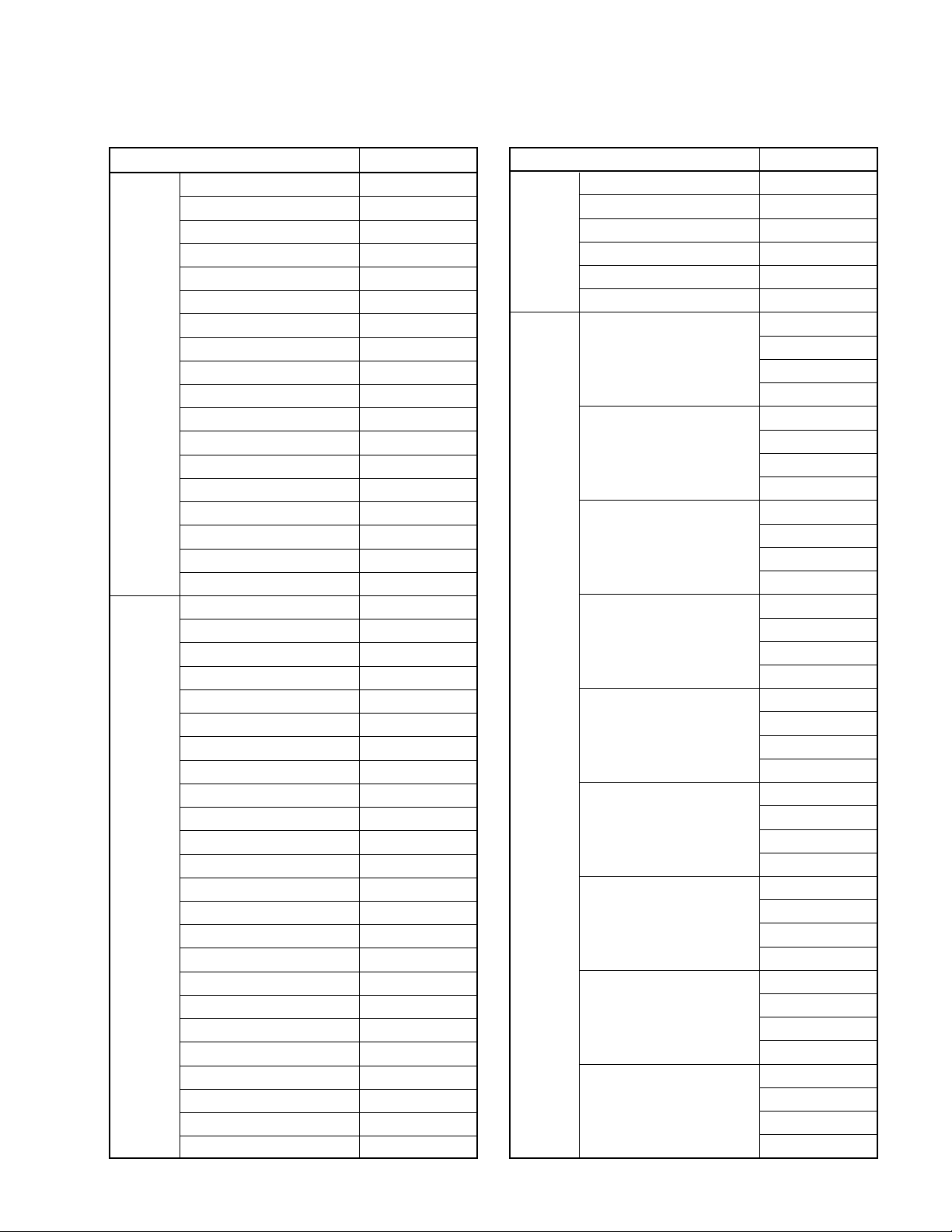

Table 1. EEP ROM memory map

Name Address

COMMON Common (1) [General] 0x0000 to 0x001F

DATA Common (2) [General] 0x0020 to 0x003F

AREA Common (3) [Parental Control] 0x0040 to 0x005F

System 0x0060 to 0x007F

Service (1) [AD Converter] 0x0080 to 0x009F

Service (2) [Chroma Decoder] 0x00A0 to 0x00BF

Service (3) [IP Converter] 0x00C0 to 0x00DF

reserved 0x00E0 to 0x00FF

reserved 0x0100 to 0x011F

Color Temp (1) [Data & Name] 0x0120 to 0x013F

Color Temp (2) [Name] 0x0140 to 0x015F

Programmable Gamma 0x0160 to 0x017F

Tv Tuner (1) [Common] 0x0180 to 0x019F

Tv Tuner (2) [Channel Number] 0x01A0 to 0x01BF

Tv Tuner (3) [Mode Flag1] 0x01C0 to 0x01DF

Tv Tuner (4) [Mode Flag2] 0x01E0 to 0x01FF

Tv Tuner (5) [Mode Flag3] 0x0200 to 0x021F

Tv Tuner (6) [Mode Flag4] 0x0220 to 0x023F

PRESET PROGRAM1 0x0240 to 0x025F

DATA PROGRAM2 0x0260 to 0x027F

AREA PROGRAM3 0x0280 to 0x029F

PROGRAM4 0x02A0 to 0x02BF

PROGRAM5 0x02C0 to 0x02DF

PROGRAM6 0x02E0 to 0x02FF

PROGRAM7 0x0300 to 0x031F

PROGRAM8 0x0320 to 0x033F

PROGRAM9 0x0340 to 0x035F

PROGRAM10 0x0360 to 0x037F

PROGRAM11 0x0380 to 0x039F

PROGRAM12 0x03A0 to 0x03BF

PROGRAM13 0x03C0 to 0x03DF

PROGRAM14 0x03E0 to 0x03FF

PROGRAM15 0x0400 to 0x041F

PROGRAM16 0x0420 to 0x043F

PROGRAM17 0x0440 to 0x045F

PROGRAM18 0x0460 to 0x047F

PROGRAM19 0x0480 to 0x049F

PROGRAM20 0x04A0 to 0x04BF

PROGRAM21 0x04C0 to 0x04DF

PROGRAM22 0x04E0 to 0x04FF

PROGRAM23 0x0500 to 0x051F

PROGRAM24 0x0520 to 0x053F

Name Address

PRESET PROGRAM25 0x0540 to 0x055F

DATA PROGRAM26 0x0560 to 0x057F

AREA PROGRAM27 0x0580 to 0x059F

PROGRAM28 0x05A0 to 0x05BF

PROGRAM29 0x05C0 to 0x05DF

PROGRAM30 0x05E0 to 0x05FF

LAST Area 1 0x0600 to 0x061F

MEMORY 0x0620 to 0x063F

AREA 0x0640 to 0x065F

0x0660 to 0x067F

Area 2 0x0680 to 0x069F

0x06A0 to 0x06BF

0x06C0 to 0x06DF

0x06E0 to 0x06FF

Area 3 0x0700 to 0x071F

0x0720 to 0x073F

0x0740 to 0x075F

0x0760 to 0x077F

Area 4 0x0780 to 0x079F

0x07A0 to 0x07BF

0x07C0 to 0x07DF

0x07E0 to 0x07FF

Area 5 0x0800 to 0x081F

0x0820 to 0x083F

0x0840 to 0x085F

0x0860 to 0x087F

Area 6 0x0880 to 0x089F

0x08A0 to 0x08BF

0x08C0 to 0x08DF

0x08E0 to 0x08FF

Area 7 0x0900 to 0x091F

0x0920 to 0x093F

0x0940 to 0x095F

0x0960 to 0x097F

Area 8 0x0980 to 0x099F

0x09A0 to 0x09BF

0x09C0 to 0x09DF

0x09E0 to 0x09FF

Area 9 0x0A00 to 0x0A1F

0x0A20 to 0x0A3F

0x0A40 to 0x0A5F

0x0A60 to 0x0A7F

PFM-32C1/32C1E

2-13

Page 30

Name Address

LAST Area 10 0x0A80 to 0x0A9F

MEMORY 0x0AA0 to 0x0ABF

AREA 0x0AC0 to 0x0ADF

0x0AE0 to 0x0AFF

Area 11 0x0B00 to 0x0B1F

0x0B20 to 0x0B3F

0x0B40 to 0x0B5F

0x0B60 to 0x0B7F

Area 12 0x0B80 to 0x0B9F

0x0BA0 to 0x0BBF

0x0BC0 to 0x0BDF

0x0BE0 to 0x0BFF

Area 13 0x0C00 to 0x0C1F

0x0C20 to 0x0C3F

0x0C40 to 0x0C5F

0x0C60 to 0x0C7F

Area 14 0x0C80 to 0x0C9F

0x0CA0 to 0x0CBF

0x0CC0 to 0x0CDF

0x0CE0 to 0x0CFF

Area 15 0x0D00 to 0x0D1F

0x0D20 to 0x0D3F

0x0D40 to 0x0D5F

0x0D60 to 0x0D7F

Area 16 0x0D80 to 0x0D9F

0x0DA0 to 0x0DBF

0x0DC0 to 0x0DDF

0x0DE0 to 0x0DFF

Area 17 0x0E00 to 0x0E1F

0x0E20 to 0x0E3F

0x0E40 to 0x0E5F

0x0E60 to 0x0E7F

Area 18 0x0E80 to 0x0E9F

0x0EA0 to 0x0EBF

0x0EC0 to 0x0EDF

0x0EE0 to 0x0EFF

Area 19 0x0F00 to 0x0F1F

0x0F20 to 0x0F3F

0x0F40 to 0x0F5F

0x0F60 to 0x0F7F

Area 20 0x0F80 to 0x0F9F

0x0FA0 to 0x0FBF

0x0FC0 to 0x0FDF

0x0FE0 to 0x0FFF

2-14

Name Address

LAST Area 21 0x1000 to 0x101F

MEMORY 0x1020 to 0x103F

AREA 0x1040 to 0x105F

0x1060 to 0x107F

Area 22 0x1080 to 0x109F

0x10A0 to 0x10BF

0x10C0 to 0x10DF

0x10E0 to 0x10FF

Area 23 0x1100 to 0x111F

0x1120 to 0x113F

0x1140 to 0x115F

0x1160 to 0x117F

Area 24 0x1180 to 0x119F

0x11A0 to 0x11BF

0x11C0 to 0x11DF

0x11E0 to 0x11FF

Area 25 0x1200 to 0x121F

0x1220 to 0x123F

0x1240 to 0x125F

0x1260 to 0x127F

Area 26 0x1280 to 0x129F

0x12A0 to 0x12BF

0x12C0 to 0x12DF

0x12E0 to 0x12FF

Area 27 0x1300 to 0x131F

0x1320 to 0x133F

0x1340 to 0x135F

0x1360 to 0x137F

Area 28 0x1380 to 0x139F

0x13A0 to 0x13BF

0x13C0 to 0x13DF

0x13E0 to 0x13FF

Area 29 0x1400 to 0x141F

0x1420 to 0x143F

0x1440 to 0x145F

0x1460 to 0x147F

Area 30 0x1480 to 0x149F

0x14A0 to 0x14BF

0x14C0 to 0x14DF

0x14E0 to 0x14FF

Area 31 0x1500 to 0x151F

0x1520 to 0x153F

0x1540 to 0x155F

0x1560 to 0x157F

PFM-32C1/32C1E

Page 31

Name Address

LAST Area 32 0x1580 to 0x159F

MEMORY 0x15A0 to 0x15BF

AREA 0x15C0 to 0x15DF

0x15E0 to 0x15FF

USER Area 1 0x1600 to 0x161F

MEMORY 0x1620 to 0x163F

AREA 0x1640 to 0x165F

0x1660 to 0x167F

Area 2 0x1680 to 0x169F

0x16A0 to 0x16BF

0x16C0 to 0x16DF

0x16E0 to 0x16FF

Area 3 0x1700 to 0x171F

0x1720 to 0x173F

0x1740 to 0x175F

0x1760 to 0x177F

Area 4 0x1780 to 0x179F

0x17A0 to 0x17BF

0x17C0 to 0x17DF

0x17E0 to 0x17FF

Area 5 0x1800 to 0x181F

0x1820 to 0x183F

0x1840 to 0x185F

0x1860 to 0x187F

Area 6 0x1880 to 0x189F

0x18A0 to 0x18BF

0x18C0 to 0x18DF

0x18E0 to 0x18FF

Area 7 0x1900 to 0x191F

0x1920 to 0x193F

0x1940 to 0x195F

0x1960 to 0x197F

Area 8 0x1980 to 0x199F

0x19A0 to 0x19BF

0x19C0 to 0x19DF

0x19E0 to 0x19FF

Area 9 0x1A00 to 0x1A1F

0x1A20 to 0x1A3F

0x1A40 to 0x1A5F

0x1A60 to 0x1A7F

Area 10 0x1A80 to 0x1A9F

0x1AA0 to 0x1ABF

0x1AC0 to 0x1ADF

0x1AE0 to 0x1AFF

PFM-32C1/32C1E

Name Address

Area 11 0x1B00 to 0x1B1F

0x1B20 to 0x1B3F

0x1B40 to 0x1B5F

0x1B60 to 0x1B7F

Area 12 0x1B80 to 0x1B9F

0x1BA0 to 0x1BBF

0x1BC0 to 0x1BDF

0x1BE0 to 0x1BFF

Area 13 0x1C00 to 0x1C1F

0x1C20 to 0x1C3F

0x1C40 to 0x1C5F

0x1C60 to 0x1C7F

Area 14 0x1C80 to 0x1C9F

0x1CA0 to 0x1CBF

0x1CC0 to 0x1CDF

0x1CE0 to 0x1CFF

Area 15 0x1D00 to 0x1D1F

0x1D20 to 0x1D3F

0x1D40 to 0x1D5F

0x1D60 to 0x1D7F

Area 16 0x1D80 to 0x1D9F

0x1DA0 to 0x1DBF

0x1DC0 to 0x1DDF

0x1DE0 to 0x1DFF

Area 17 0x1E00 to 0x1E1F

0x1E20 to 0x1E3F

0x1E40 to 0x1E5F

0x1E60 to 0x1E7F

Area 18 0x1E80 to 0x1E9F

0x1EA0 to 0x1EBF

0x1EC0 to 0x1EDF

0x1EE0 to 0x1EFF

Area 19 0x1F00 to 0x1F1F

0x1F20 to 0x1F3F

0x1F40 to 0x1F5F

0x1F60 to 0x1F7F

Area 20 0x1F80 to 0x1F9F

0x1FA0 to 0x1FBF

0x1FC0 to 0x1FDF

0x1FE0 to 0x1FFF

2-15

Page 32

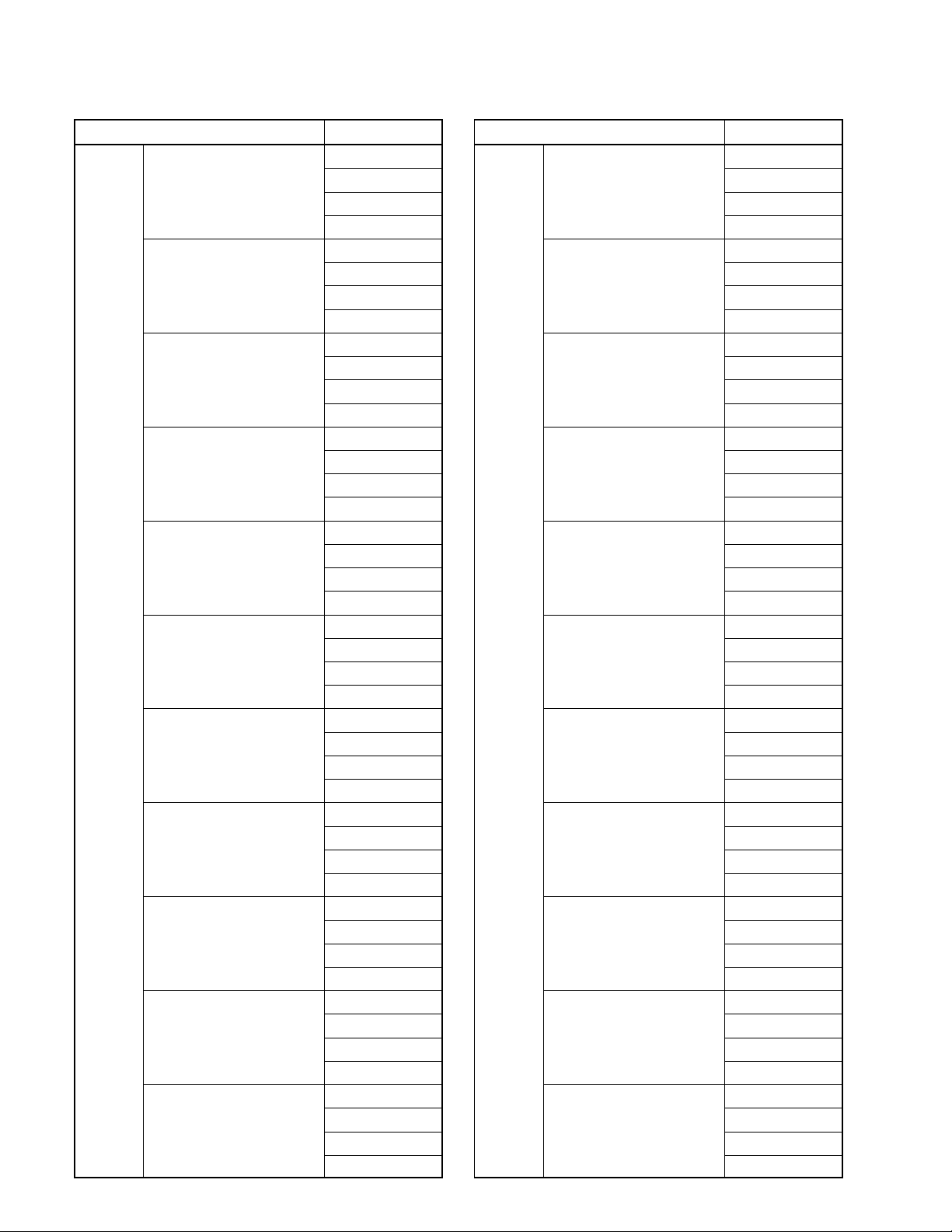

Table 2. Factory Preset Data

Format Name Resolution fh fv H/V Signal Scanning Pixel Clock Horizontal (dot)

x x

H(dot)

x V(line) [kHz] [Hz] Sync Type Format [MHz] Total Act Sync FP BP

x x

Polarity

1 VGA 640x350@70Hz 640 x 350 31.469 70.086 P/N RGB Progressive 25.175 800 640 96 16 48

2 VESA 640x350@85Hz 37.861 85.08 P/N RGB Progressive 31.5 832 640 64 32 96

3 VESA 640x400@85Hz 640 x 400 37.861 85.08 N/P RGB Progressive 31.5 832 640 64 32 96

4 VESA 640x480@60Hz 640 x 480 31.469 59.94 N/N RGB Progressive 25.175 800 640 96 16 48

5 MAC 13inch 35 66.667 N/N RGB Progressive 30.24 864 640 64 64 96

6 VESA 640x480@72Hz 37.861 72.809 N/N RGB Progressive 31.5 832 640 40 24 128

7 VESA 640x480@75Hz 37.5 75 N/N RGB Progressive 31.5 840 640 64 16 120

8 VESA 640x480@85Hz 43.269 85.008 N/N RGB Progressive 36 832 640 56 56 80

9 VGA 720x400@70Hz 720 x 400 31.469 70.087 N/P RGB Progressive 28.332 900 720 108 18 54

10 VESA 720x400@85Hz 37.927 85.039 N/P RGB Progressive 35.5 936 720 72 36 108

11 IO_DATA 852x480@60Hz 852 x 480 32 60 _ RGB Progressive 34.304 1072 852 128 28 64

12 MATROX_S1 856x480@60Hz 856 x 480 30.24 60 N/N RGB Progressive 33.627 1112 856 104 48 104

13 MATROX_S2 856x480@60Hz 30.057 59.637 N/N RGB Progressive 31.5 1048 856 64 32 96

14 MATROX_S3 856x480@60Hz 30.057 60.115 N/N RGB Progressive 31.5 1048 856 64 32 96

15 VESA 800x600@56Hz 800 x 600 35.156 56.25 P/P RGB Progressive 36 1024 800 72 24 128

16 VESA 800x600@60Hz 37.879 60.317 P/P RGB Progressive 40 1056 800 128 40 88

17 VESA 800x600@72Hz 48.077 72.188 P/P RGB Progressive 50 1040 800 120 56 64

18 VESA 800x600@75Hz 46.875 75 P/P RGB Progressive 49.5 1056 800 80 16 160

19 VESA 800x600@85Hz 53.674 85.061 P/P RGB Progressive 56.25 1048 800 64 32 152

20 MAC 16inch 832 x 624 49.724 74.55 N/N RGB Progressive 57.285 1152 832 64 32 224

21 SPECIAL 1024x576@60Hz 1024 x 576 36.427 60.21 _ RGB Progressive 48.375 1328 1024 128 48 128

22 VESA 1024x768@60Hz 1024 x 768 48.363 60.004 N/N RGB Progressive 65 1344 1024 136 24 160

23 VESA 1024x768@70Hz 56.476 70.069 N/N RGB Progressive 75 1328 1024 136 24 144

24 VESA 1024x768@75Hz 60.023 75.029 P/P RGB Progressive 78.75 1312 1024 96 16 176

25 VESA 1024x768@85Hz 68.677 84.997 P/P RGB Progressive 94.5 1376 1024 96 48 208

26 VESA 1152x864@75Hz 1152 x 864 67.5 75 P/P RGB Progressive 108 1600 1152 128 64 256

27 MAC 21inch 1152 x 870 68.681 75.061 N/N RGB Progressive 100 1456 1152 128 32 144

28 VESA 1280x960@60Hz 1280 x 960 60 60 P/P RGB Progressive 108 1800 1280 112 96 312

29 VESA 1280x960@85Hz 85.938 85.002 P/P RGB Progressive 148.5 1728 1280 160 64 224

30 VESA

31 SUN

32 VESA

33 SUN

34 VESA

35 VESA

36 PFM 852x480@60 852 x 480 31.469 60 P/N RGB Progressive 33.74 1072 852 124 32 64

37 PFM 1024x1024@60 1024 x 1024 67.5 60 P/N RGB Progressive 85.05 1260 1024 60 40 136

38 PFM 1280x768@56 1280 x 768 45 56 P/N RGB Progressive 77.04 1712 1280 92 80 260

39 VIDEO 525_60 720 x 483 15.734 60 SOG YUV Interlace 28.322 968 750 32 135 51

40 VIDEO 625_50 720 x 575 15.625 50 SOG YUV Interlace 28.125 1000 750 32 113 105

1280x1024@60Hz

1280x1024@67Hz

1280x1024@75Hz

1280x1024@76Hz

1280x1024@85Hz

1600x1200@60Hz

1280 x 1024 63.981 60.02 P/P RGB Progressive 108.5 1688 1280 112 48 248

71.691 67.189 N/N RGB Progressive 117 1632 1280 112 16 224

79.976 75.025 P/P RGB Progressive 135 1688 1280 144 16 248

81.13 76.107 N/N RGB Progressive 135 1664 1280 64 32 288

91.146 85.024 P/P RGB Progressive 157.5 1728 1280 160 64 224

1600 x 1200 75 60 P/P RGB Progressive 162 2160 1600 192 64 304

2-16

PFM-32C1/32C1E

Page 33

Vertical (line) Clamp Format Flag Default Data

Total Act Sync FP BP Position Width Frame PLL IP ZOOM

Lock Enable Interlace Convert Pic Mode MATRIX MODE

4491 350 2 37 60 62 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

445 350 3 32 60 36 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

445 400 3 1 41 36 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

525 480 2 10 33 60 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

525 480 3 3 39 39 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

520 480 3 9 28 29 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

500 480 3 1 16 41 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

509 480 3 1 25 24 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

449 400 2 12 35 61 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

446 400 3 1 42 37 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

529 480 3 12 34 60 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

504 480 3 1 20 56 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

504 480 3 1 20 37 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

500 480 8 1 11 37 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

625 600 2 1 22 39 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

628 600 4 1 23 53 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

666 600 6 37 23 35 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

625 600 3 1 21 32 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

631 600 3 1 27 21 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

667 624 3 3 37 27 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

605 576 3 1 25 47 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

806 768 6 3 29 36 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

806 768 6 3 29 29 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

800 768 3 1 28 20 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

808 768 3 1 36 17 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

900 864 3 1 32 21 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

915 870 3 3 39 17 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

1000 960 3 1 36 21 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

1011 960 3 1 47 15 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

1066 1024 3 1 38 19 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

1067 1024 8 2 33 15 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

1066 1024 3 1 38 16 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

1066 1024 8 2 32 7 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

1072 1024 3 1 44 13 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

1250 1200 3 1 46 18 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

525 480 2 10 33 59 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M FULL

1125 1024 5 48 48 8 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M FULL

804 768 7 3 26 26 8 OFF ON OFF OFF STANDARD MFID_IPC_MATRIX_293M FULL

525 454 2 22 47 96 39 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

625 534 2 27 62 96 39 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

PFM-32C1/32C1E

2-17

Page 34

Table 2. Factory Preset Data

Format Name Resolution fh fv H/V Signal Scanning Pixel Clock Horizontal (dot)

x x

H(dot)

x V(line) [kHz] [Hz] Sync Type Format [MHz] Total Act Sync FP BP

x x

Polarity

41 DTV 575/50p 720 x 575 31.25 50 SOG

42 DTV 480/60p 720 x 483 31.469 60 SOG

43 DTV 1080/24psf 1920 x 1080 27 48 SOG

44 DTV 1080/50i 1920 x 1080 28.125 50 SOG

15 DTV 1080/60i 1920 x 1080 33.75 60 SOG

46 DTV 1035/60i 1920 x 1035 33.75 60 SOG

47 DTV 720/60p 1280 x 720 45 60 SOG

48 SDTV NTSC_TV 720 x 483 15.734 59.94 SOG YUV Interlace 28.322 968 750 32 132 54

49 SDTV

50 SDTV

51 SDTV

52 SDTV

53 SDTV

54 SDTV

55 SDTV

56 SDTV

57 SDTV NTSC_YC 720 x 483 15.734 59.94 SOG YUV Interlace 28.322 968 750 32 132 54

58 SDTV PAL_YC 720 x 575 15.625 50 SOG YUV Interlace 28.125 1000 750 32 113 105

59 SDTV SECAM_YC 720 x 575 15.625 50 SOG YUV Interlace 28.125 1000 750 32 113 105

60 SDTV 443NT_YC 720 x 483 15.734 60 SOG YUV Interlace 28.322 968 750 32 132 54

61 SDTV PAL-M_YC 720 x 575 15.734 60 SOG YUV Interlace 28.125 968 750 32 132 54

62 SDTV PAL-N_YC 720 x 575 15.625 50 SOG YUV Interlace 28.125 1000 750 32 113 105

63 SDTV BW_YC60 720 x 483 15.734 60 SOG YUV Interlace 28.322 968 750 32 132 54

64 SDTV BW_YC50 720 x 483 15.625 50 SOG YUV Interlace 28.322 1000 750 32 113 105

65 SDTV PAL60 720 x 483 15.734 59.94 SOG YUV Interlace 28.322 968 750 32 132 54

66 OTHERS 640 x 480 31.469 59.94 N/N RGB Progressive 25.175 800 640 96 16 48

67 NO_SYNC 640 x 480 31.469 59.94 N/N RGB Progressive 25.175 800 640 96 16 48

NTSC_COMPOSITE

PAL_COMPOSITE

SECAM_COMPOSITE

443NT_COMPOSITE

PAL-M_COMPOSITE

PAL-N_COMPOSITE

BW_COMPOSITE60

BW_COMPOSITE50

720 x 483 15.734 59.94 SOG YUV Interlace 28.322 968 750 32 132 54

720 x 575 15.625 50 SOG YUV Interlace 28.125 1000 750 32 113 105

720 x 575 15.625 50 SOG YUV Interlace 28.125 1000 750 32 113 105

720 x 483 15.734 60 SOG YUV Interlace 28.322 968 750 32 132 54

720 x 575 15.734 60 SOG YUV Interlace 28.125 968 750 32 132 54

720 x 575 15.625 50 SOG YUV Interlace 28.125 1000 750 32 113 105

720 x 483 15.734 60 SOG YUV Interlace 28.322 968 750 32 132 54

720 x 483 15.625 50 SOG YUV Interlace 28.322 1000 750 32 113 105

YUV/RGB

YUV/RGB

YUV/RGB

YUV/RGB

YUV/RGB

YUV/RGB

YUV/RGB

Progressive 27 1000 750 60 54 136

Progressive 27 968 750 63 55 100

Interlace 74.25 2750 1820 44 662 224

Interlace 74.25 2640 1820 44 552 224

Interlace 74.25 2200 1820 44 112 224

Interlace 74.25 2200 1900 44 66 190

Progressive 74.25 1650 1216 40 117 277

2-18

PFM-32C1/32C1E

Page 35

Vertical (line) Clamp Format Flag Default Data

Total Act Sync FP BP Position Width Frame PLL IP ZOOM

Lock Enable Interlace Convert Pic Mode MATRIX MODE

625 534 3 26 62 42 12 ON OFF OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

525 454 6 22 43 38 12 ON OFF OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

1125 1024 10 34 57 19 12 ON OFF ON OFF STANDARD MFID_IPC_MATRIX_274M FULL

1125 1024 10 34 57 19 12 ON OFF ON OFF STANDARD MFID_IPC_MATRIX_274M FULL

1125 1024 10 34 57 19 12 ON OFF ON OFF STANDARD MFID_IPC_MATRIX_274M FULL

1125 1024 10 14 77 18 12 ON OFF ON OFF STANDARD MFID_IPC_MATRIX_274M FULL

750 684 5 23 38 22 12 ON OFF OFF OFF STANDARD MFID_IPC_MATRIX_274M FULL

525 454 2 24 45 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

525 454 2 24 45 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

625 534 2 27 62 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

625 534 2 27 62 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

525 454 2 24 45 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

525 454 2 24 45 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

625 534 2 27 62 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

525 454 2 24 45 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

625 534 2 27 62 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

525 454 2 24 45 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

625 534 2 27 62 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

625 534 2 27 62 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

525 454 2 24 45 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

525 454 2 24 45 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

625 534 2 27 62 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

525 454 2 24 45 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

625 534 2 27 62 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

525 454 2 24 45 30 58 ON OFF ON ON STANDARD MFID_IPC_MATRIX_293M NORMAL

525 480 2 10 33 30 58 OFF OFF OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

525 480 2 10 33 64 16 OFF OFF OFF OFF STANDARD MFID_IPC_MATRIX_293M NORMAL

PFM-32C1/32C1E

2-19

Page 36

2-3. White Balance Adjustment

1. Enter the Service Mode as follows. Generate the builtin adjustment signal.

Select [Service Mode] → [White Balance] → [Window], and select either [Small] or [Large].

2. Set the color temperature to [High] as follows.

Select [Color Temp.] → [High].

3. Adjust white balance using the R, G and B gain

adjustments as follows.

Adjust white balance by adjusting [Red Gain], [Green

Gain] and [Blue Gain] until color temperature satisfies

the specification of 9300 K. During this adjustment,

set [Green Gain] to 00 normally.

4. Set the color temperature to [Mid] as follows.

Select [Color Temp.] → [Mid].

5. Adjust white balance using the R, G and B gain

adjustments as follows.

Adjust white balance by adjusting [Red Gain], [Green

Gain] and [Blue Gain] until color temperature satisfies

the specification of 6500 K. During this adjustment,

set [Green Gain] to 00 normally.

6. Set the color temperature to [Low] as follows.

Select [Color Temp.] → [Low].

7. Adjust white balance using the R, G and B gain

adjustments as follows.

Adjust white balance by adjusting [Red Gain], [Green

Gain] and [Blue Gain] until color temperature satisfies

the specification of 3200 K. During this adjustment,

set [Green Gain] to 00 normally. However, if the white

balance adjustment cannot be performed by all means,

decrease the [Green Gain] until the specification is

satisfied.

2) Obtain the RGB balance by adjusting [Red Gain] and

[Blue Gain] of [RGB Calibration] until the R detection

value and the B detection value come very close to the

G detection value.

3) Adjust [Sub Cont RGB] until the R, B and G detection

values become the setup value. (Setup value = 230 ±3)

4) Set the RGB signal to the VGA (640 x 480 /60) all

gray 20 IRE.

5) Adjust [Red Bias], [Green Bias] and [Blue Bias] until

the R, B and G detection values become the setup

value. (Setup value = 51 ±3)

6) Repeat the above steps 1) to 5) until all the adjustment

values are satisfied at the same time.

3. AD Adjustment of Component Input

1) Set INPUT1 to the Component input.

2) Connect the component signal 1080/60i all white 90

IRE to INPUT1.

3) Adjust [Sub Cont YUV] of [YUV Calibration] until

the G detection value becomes the setup value. (Setup

value = 230 ±3)

4) Set the component signal to the 1080/60i all gray 20

IRE.

5) Adjust [Sub Brt YUV] until the G detection value

becomes the setup value. (Setup value = 51 ±3)

6) Adjust [Cb Offset YUV] until the B detection value

agrees with the G detection value.

7) Adjust [Cr Offset YUV] until the R detection value

agrees with the G detection value.

8) Repeat the above steps 5) to 7) until all adjustment

values are set to the setup value of step 5).

9) Repeat the above steps 2) to 8) until all adjustment

values are set to the setup values of steps 3) and 5).

2-4. AD Calibration Adjustment

1. Adjustment Preparation

1) Set the [RGB Mode] of the Custom Setup menu to

[PC].

2) Set [Cal Mode] of [AD Converter] of the Service

Setup menu to [On].

2. AD Adjustment of RGB Input

1) Connect the RGB signal VGA (640 x 480 /60) all

white 90 IRE to INPUT1.

2-20

4. AD Adjustment of Video Input (When the

Video Input connector is installed)

1) Set the INPUT to the Video input.

2) Connect the NTSC all white 90 IRE video signal to

INPUT.

3) Adjust [Sub Cont Video] of [Video Calibration] until

the G detection value becomes the setup value. (Setup

value = 230 ±3)

4) Set the video signal to the NTSC all gray 20 IRE.

5) Adjust [Sub Brt Video] until the G detection value

becomes the setup value. (Setup value = 51 ±3)

PFM-32C1/32C1E

Page 37

6) Adjust [Cb Offset Video] until the B detection value

agrees with the G detection value.

7) Adjust [Cr Offset Video] until the R detection value

agrees with the G detection value.

8) Repeat the above steps 5) to 7) until all adjustment

values are set to the setup value of step 5).

9) Repeat the above steps 2) to 8) until all adjustment

values are set to the setup values of steps 3) and 5).

5. Set [Cal Mode] to [Off].

n

The above described adjustment items 2, 3 and 4 must be

performed while the picture quality mode User1 is in the

standard condition.

2-5. Sub Color and Sub Hue

Adjustments

1. Connect the NTSC SMPTE color bar signal to Video

Input.

(1) (2) (3) (4)

(A) (B) (C) (D)

4. While observing the screen display, adjust the NTSC

Sub Color and Sub Hue as follows.

Select [Service Mode] → [Chroma Decoder] → [Sub

Color], and set [Col (NTSC)] to [6].

Adjust [C Out Level] of [Chroma Decoder] until (1)

has the same brightness as (A), and (4) has the same

brightness as (D).

Select [Hue] of [Chroma Decoder] and adjust [Hue

(NTSC)] until (2) has the same brightness as (B), and

(3) has the same brightness as (C).

Repeat the above described adjustments until all the

adjustment values are satisfied at the same time.

(Tracking)

5. Connect the PAL SMPTE color signal to Video Input.

6. While observing the screen display, adjust the PAL

Sub Color as follows.

Select [Service Mode] → [Chroma Decoder] → [Sub

Color].

Adjust [Col (PAL)] of [Chroma Decoder] until (1) has

the same brightness as (A), and (4) has the same

brightness as (D).

7. Connect the SECAM SMPTE color signal to Video

Input.

8. While observing the screen display, adjust the SECAM

Sub Color as follows.

Select [Service Mode] → [Chroma Decoder] → [Sub

Color].

Adjust [Col (SECAM)] of [Chroma Decoder] until (1)

has the same brightness as (A), and (4) has the same

brightness as (D).

SMPTE color bars

2. Set the picture quality setting User1 in the standard

condition as follows.

Select [Picture Mode] → [User1]. Then set [Reset] of

[Adjust Picture] to [OK].

3. Enter the Service Mode and then select the Blue Only

mode as follows.

Select [Service Mode] → [General] → [Blue Only],

and set [1].

PFM-32C1/32C1E

2-6. Video Decoder Adjustment

1. Connect the SECAM all gray 30 IRE signal to Video

Input.

2. Set [Cal Mode] of [AD Converter] of the Service

Mode menu to [On].

3. Adjust [By Adj (SECAM)] of [Chroma Decoder] of

the Service Mode menu until the Blue detection value

has the same value as the Green value.

4. Adjust [Ry Adj (SECAM)] of [Chroma Decoder] of

the Service Mode menu until the Red detection value

has the same value as the Green value.

5. Repeat steps 3 and 4 until the detection values of R, G

and B are within the range (±5 %) of tolerance error.

6. Set [Cal Mode] of [AD Converter] of the Service

Mode menu to [Off].

2-21

Page 38

2-7. Watch Error Adjustment

1. Select [32k Clock Out] in [General] of the Service

Mode and set it to [On].

2. Connect a frequency counter as shown below and

measure the frequency.

CN1003

VCC

CLOCK

GND

Make the cable as short as possible.

1

2

3

10kΩ

Frequency counter

3. Select [Watch Error] in [General] of the Service Mode

and enter the measurement result.

4. Select [32k Clock Out] in [General] of the Service

Mode and set it to [Off].

2-22

PFM-32C1/32C1E

Page 39

Section 3

Troubleshooting

3-1. Judging Method When Image Does

Not Appear

1. Flow chart

Picture does not appear

Check the indication on the indicator

in the lower right of the front panel. (STAND BY)

STBY LED flashes

12 123

0.3 0.3

0.3 0.3

2 times

3 times

6

4 times

3

5 times

6 times

When error code is detected from panel.

When temperature increases.

When 5 V digital system power voltage decreases (2.5 V or less)

or becomes excess voltage (6 V or more)

When 3.3 V digital system power voltage decreases (1.6 V or less)

or becomes excess voltage (4 V or more)

When 6 V analog system power voltage decreases (3 V or less)

or becomes excess voltage (7.2 V or more)

When the STBY LED does not flash, the power supply circuit is defective.

2. How to find PDP unit trouble

2) The input signal is supplied to the PDP panel correctly.

The LVDS signal is supplied to CN1 of the circuit board

1) The power voltage for the PDP is supplied correctly.

The power voltages are supplied from the switching

regulator board CN6, CN23, CN33, CN42 and CN52

in the bottom of the PDP panel.

(CN1 pin-1, pin-3, pin-5, pin-7, pin-9, pin-11, pin-13,

pin-15, pin-17 and pin-19)

to the PDP panel. The four types of power voltage that

are 3.3 V, 5 V, 55 V and 80 V are supplied.

If no images appears through the above conditions are

satisfied, the PDP unit will be defective.

PFM-32C1/32C1E

3-1

Page 40

3-2. Self Diagnosis Function

3-2-2. Abnormality Judgment Criterion

3-2-1. Overview