Sony NTM-30 Service manual

NTM-30

SERVICE MANUAL

Ver 1.0 1999. 03

Receiver

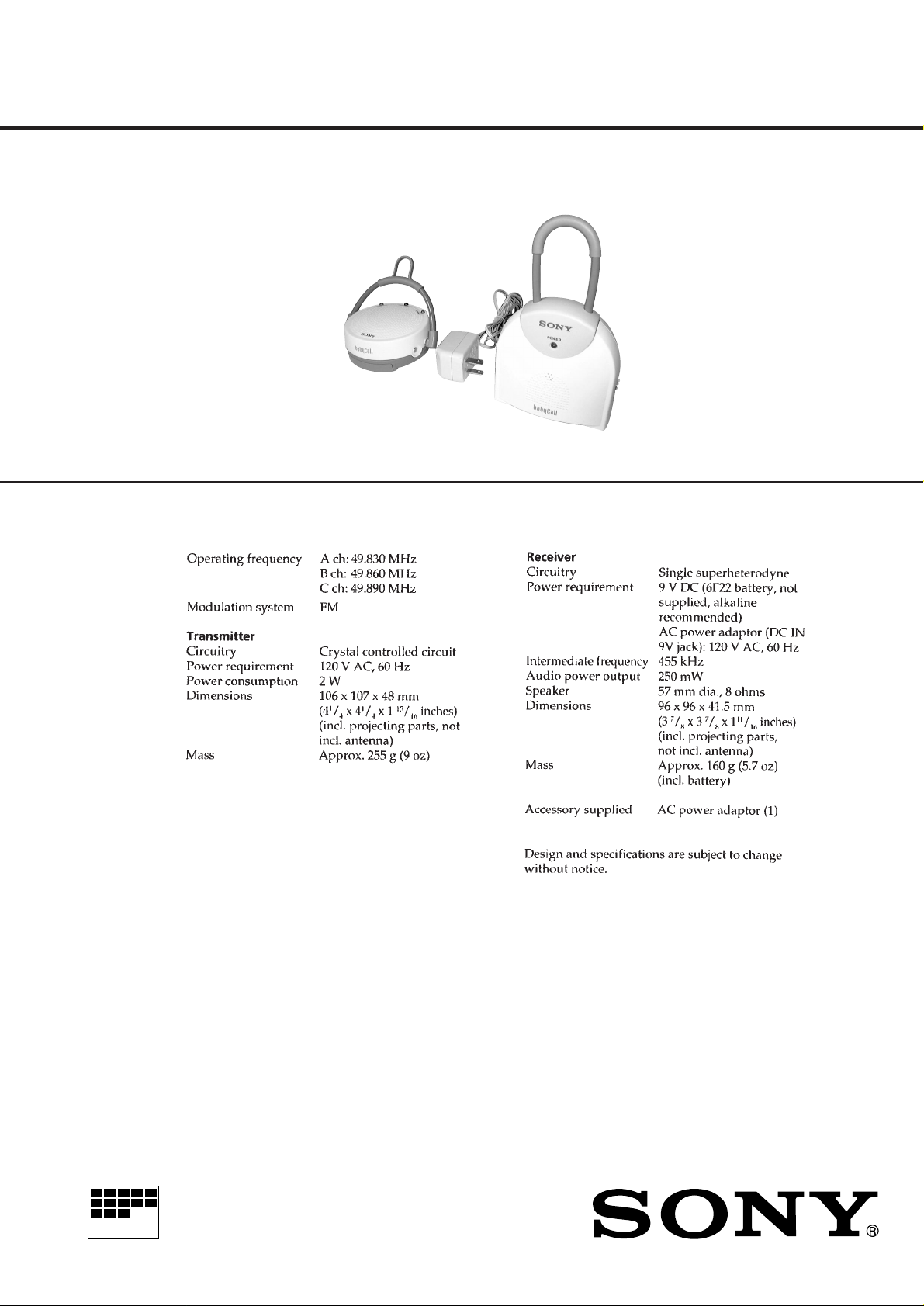

SPECIFICATIONS

US Model

E Model

Transmitter

MICROFILM

SOUND-SENSOR NURSERY MONITOR

TABLE OF CONTENTS

1. GENERAL ................................................................... 3

2. DISASSEMBLY ......................................................... 4

3. ELECTRICAL ADJUSTMENTS......................... 6

4. DIAGRAMS

4-1. Block Diagram ................................................................ 9

4-2. Schematic Diagram – TX/MIC Boards – ....................... 11

4-3. Printed Wiring Board – TX/MIC Boards – ................... 13

4-4. Printed Wiring Board – RX Board – ............................. 14

4-5. Schematic Diagram – RX Board – ................................ 15

5. EXPLODED VIEWS ................................................ 17

6. ELECTRICAL PARTS LIST ............................... 19

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

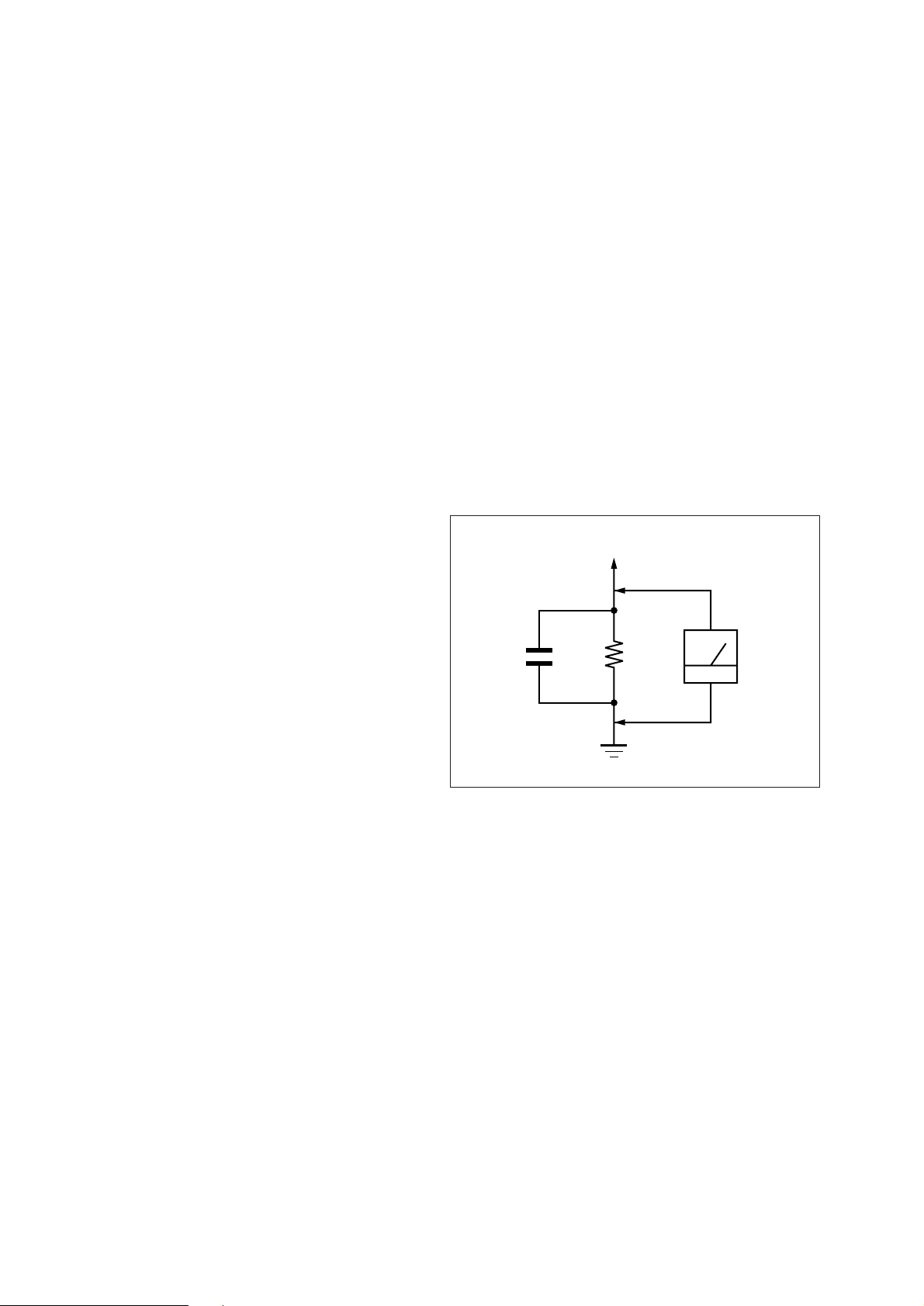

LEAKAGE TEST

The A C leaka ge from an y e xposed metal part to earth gr ound and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63T rd are e xamples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

Ω

Earth Ground

AC

voltmeter

(0.75 V)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

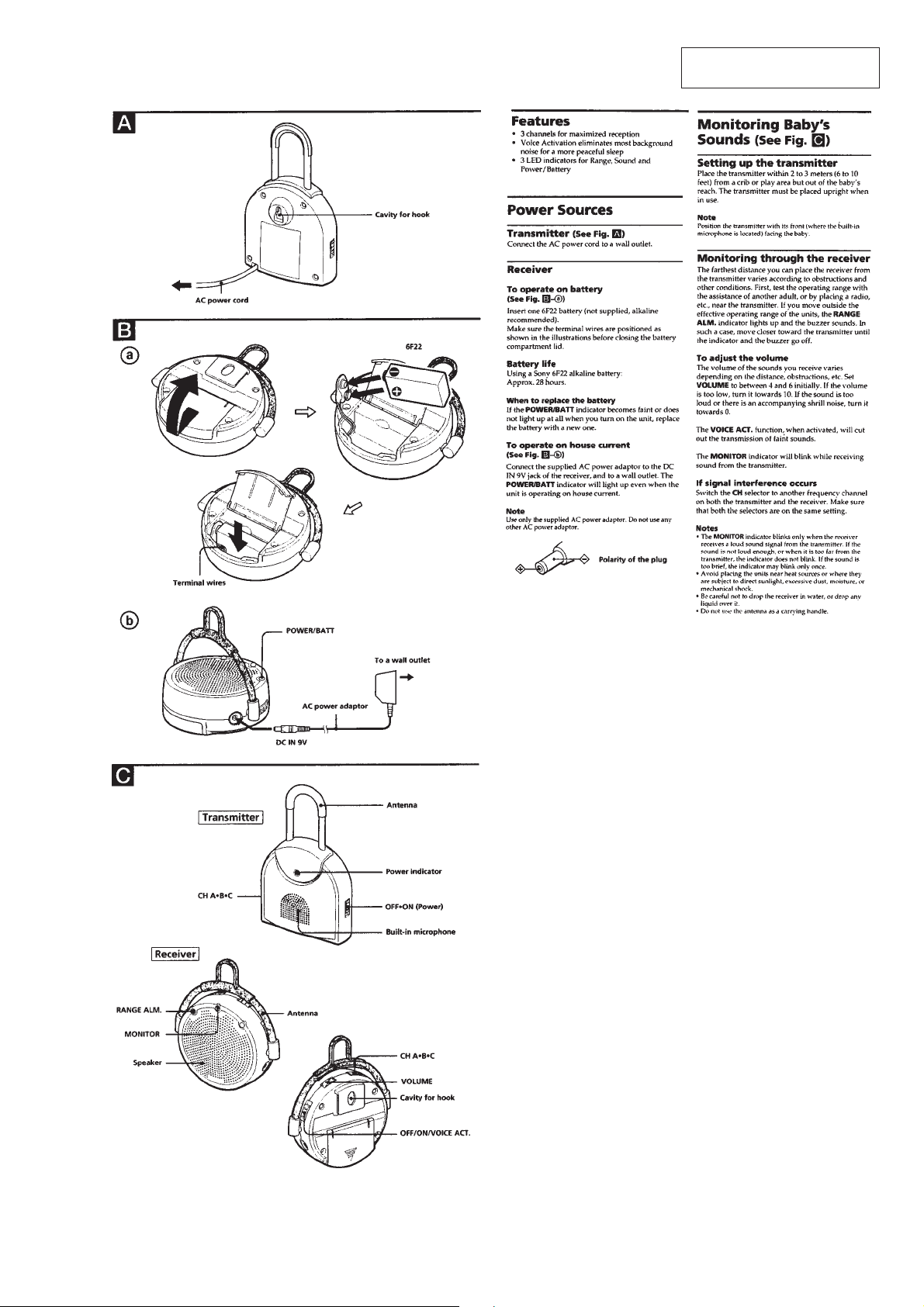

SECTION 1

GENERAL

This section is extracted from

instruction manual.

– 3 –

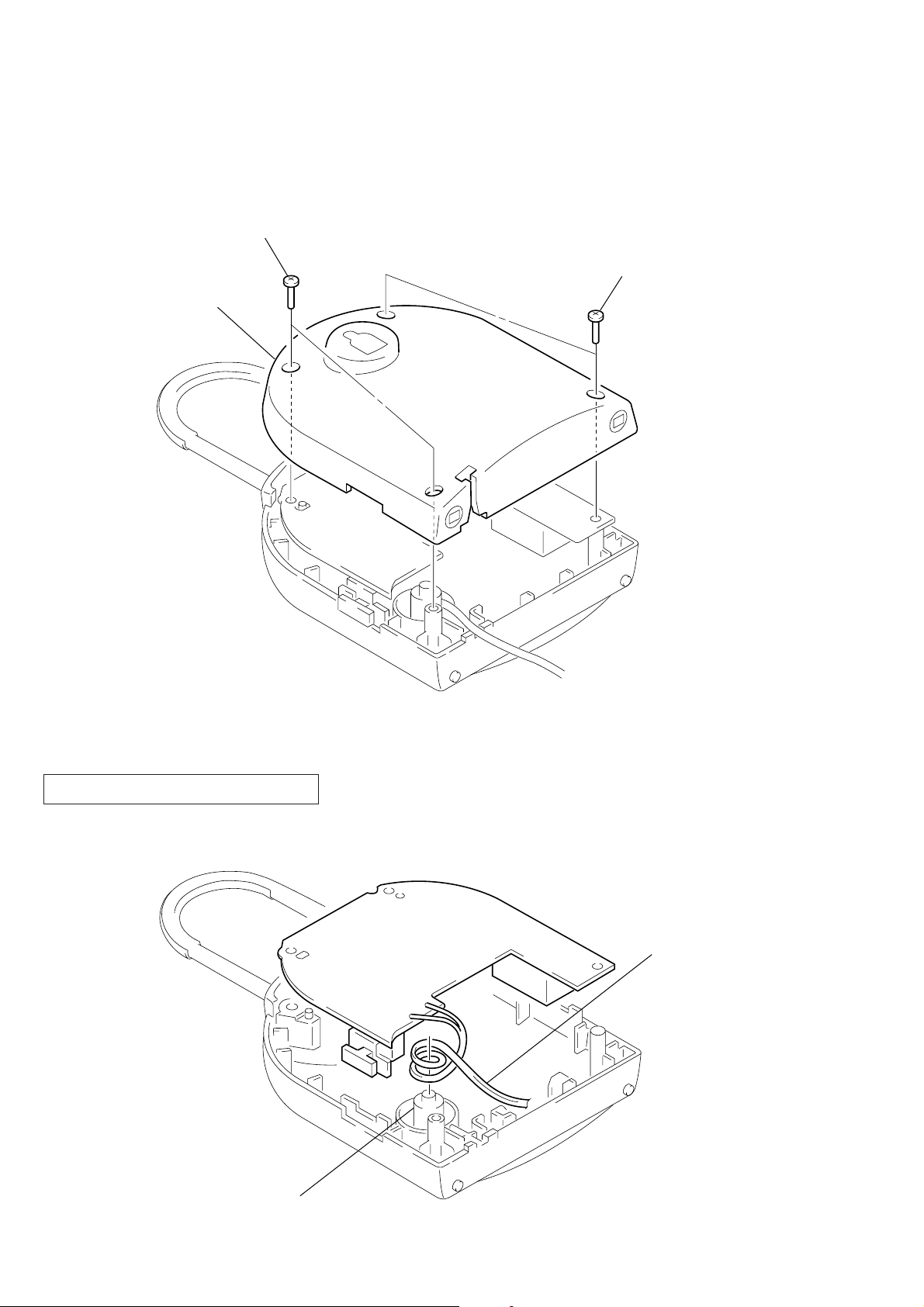

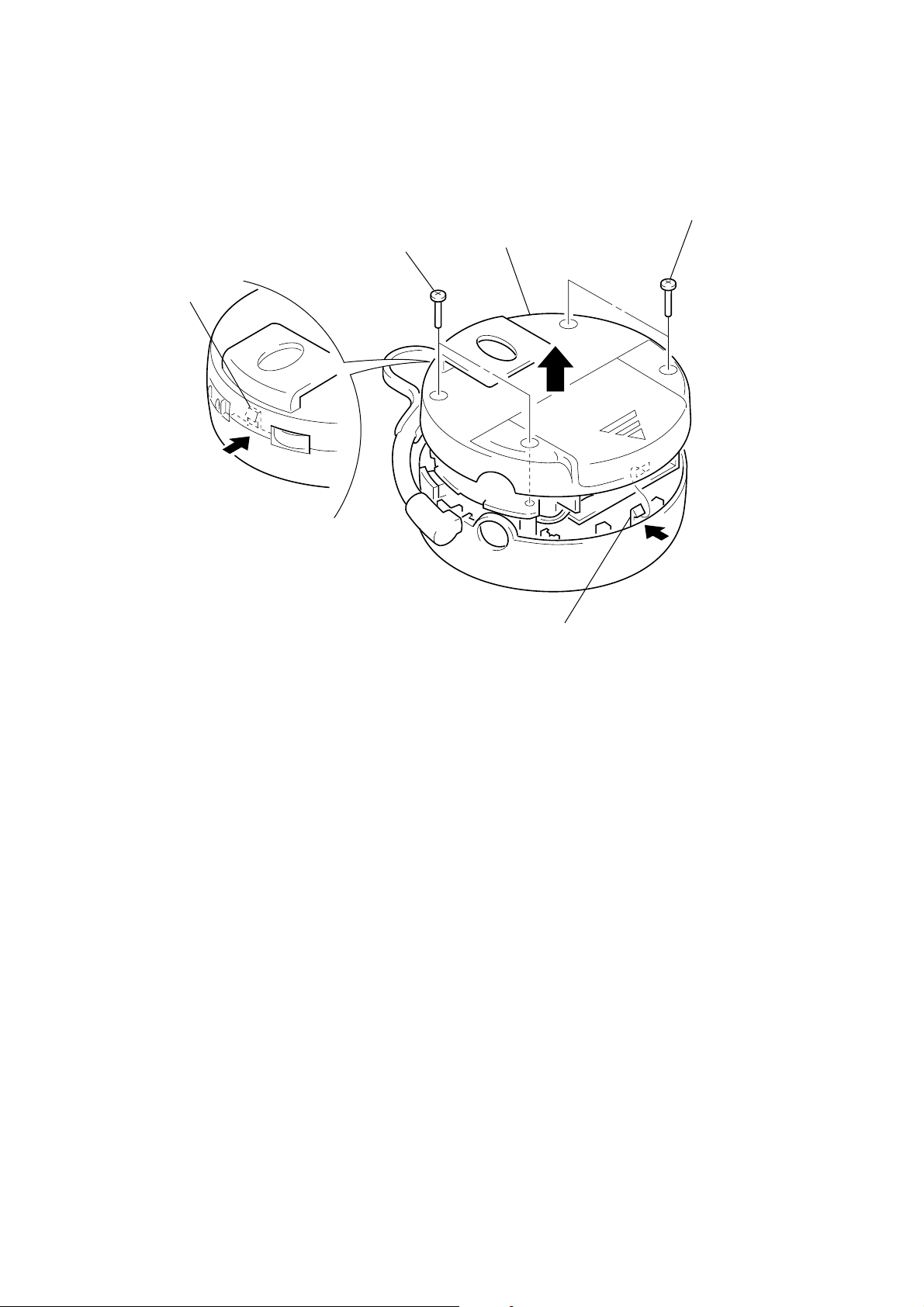

SECTION 2

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

• TRANSMITTER SECTION

REAR CABINET

1

two screws

(P2.6

×

12)

2

rear cabinet

1

two screws

(P2.6

×

12)

AC ADAPTER CORD SETTING

Wind the AC adaptor cord to boss 2 time.

boss

AC adaptor cord

– 4 –

• RECEIVER SECTION

LOWER CABINET

2

claw

1

two screws

(P2.6 × 12)

3

lower cabinet

1

two screws

(P2.6 × 12)

2

claw

– 5 –

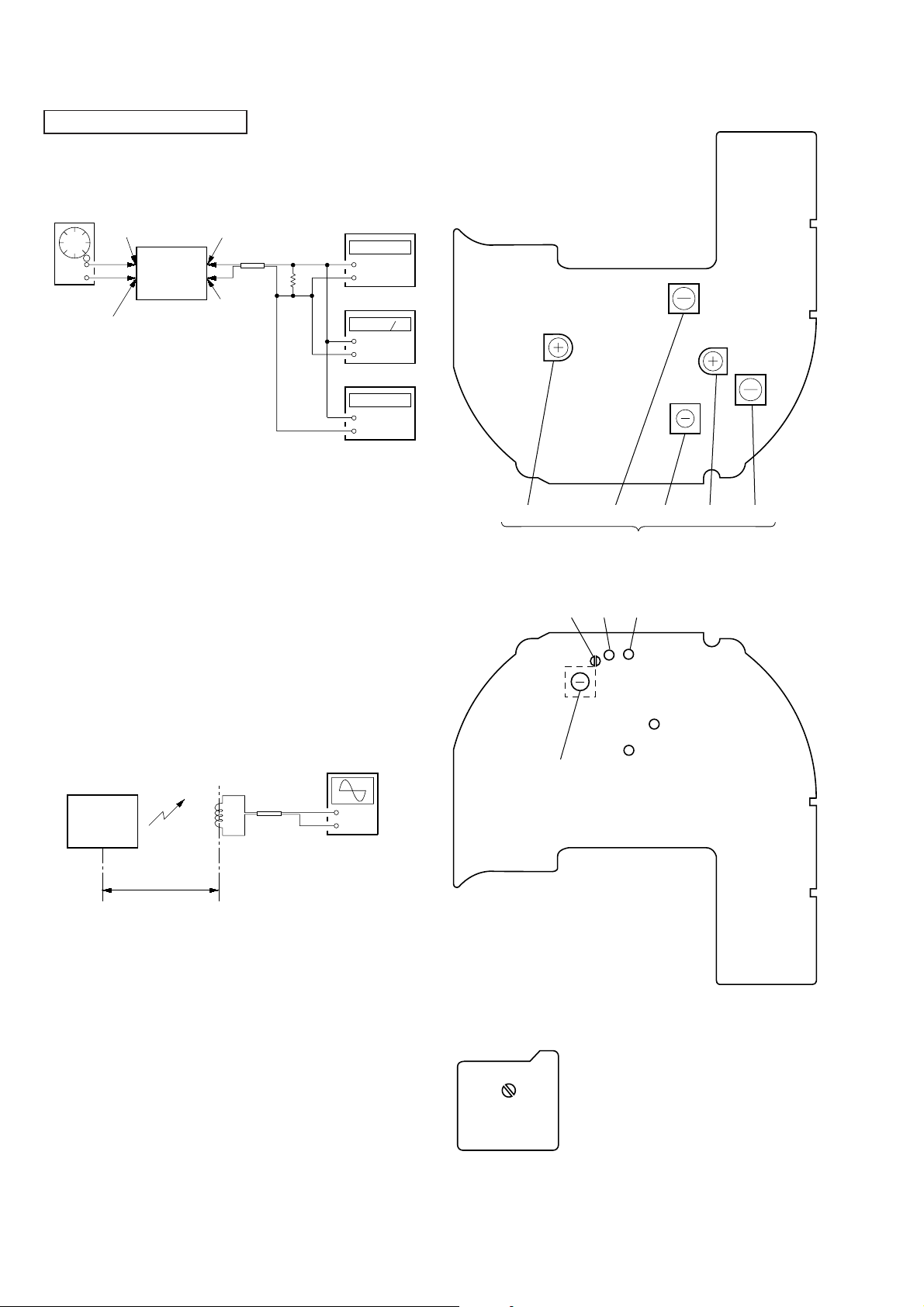

SECTION 3

r

e

ELECTRICAL ADJUSTMENTS

TRANSMITTER SECTION

Transmitter Output Adjustment

Setting:

CH switch (S101): B

AF OSC

Signal level:

–57 dB/1kHz

Procedure:

1. Take out solder for BP1 on the TX board, and take out solder

2. Connect the frequency counter, RF-VTVM and modulation

3. Adjust L105 for 49.860 MHz reading on the frequency counter.

4. Adjust T101and T102 for maximum reading on the RF-VTVM.

5. Adjust RV101 for 0.075 to 0.085 Vrms reading on the RF-

6. Connect the AF OSC with TP3 and TP4, and input the signal.

7. Adjust RV102 for 2.5 kHz deviation reading on the modula-

8. After adjustment take solder on BP1 and BP2

TX board

+

–

TX board

TP3

(transmitter)

TP4

TX board

Set

for BP2 on the MIC board.

meter with TP1 and TP2.

VTVM.

tion meter.

TP1

TX board

TP2

50

frequency counte

Ω

modulation meter

+

–

RF-VTVM

+

–

+

–

Adjustment Location:

– TX BOARD (Component Side) –

RV102 L105

Transmitter Output Adjustment

T101 RV101 T102

– TX BOARD (Conductor Side) –

TP2

TP1BP1

Transmitter Loading Coil Adjustment

Setting:

CH switch (S101): B

oscilloscop

Set

(transmitter)

about 300 mm

10 µH

+

–

Procedure:

Adjust L101 for maximum waveform on the oscilloscope.

TP4

TP3

Transmitter Loading Coil

– MIC BOARD –

(Conductor Side)

BP2

L101

Adjustment

– 6 –

Loading...

Loading...