Sony MCESV-7 Service manual

MCE-SV7

SERVICE MANUAL

Ver 1.0 2001.06

MCE-SV7 is the Video CD/CD play er

section in MHC-SV7AV.

E Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM63B

Base Unit Name BU-30BD61A

Optical Pick-up Name OP Assy (A-MAX.3)

SPECIFICATIONS

VIDEO CD/CD player section

System Compact disc and digital

Laser Semiconductor laser

Frequency response 2 Hz – 20 kHz (±0.5 dB)

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

Video color system format

OPTICAL OUT

(Square optical connector jack, rear panel)

General

Dimensions (w/h/d)

Mass Approx. 2.8 kg

Design and specifications are subject to change

without notice.

audio system

(λ=795 nm)

Emission duration:

continuous

NTSC, PAL

Approx. 280 x 108 x 330 mm

9-873-155-01 Sony Corporation

2001F0500-1 Home Audio Company

C 2001.6 Shinagawa Tec Service Manual Production Group

VIDEO CD/CD PLAYER

MCE-SV7

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and

check that the S curve waveforms is output three times.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board. (within 3 times)

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 4

2. GENERAL ................................................................... 5

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 6

3-2. Cover ............................................................................... 7

3-3. CD Mechanism Deck (CDM63B) .................................. 7

3-4. MAIN Board ................................................................... 8

3-5. Front Panel Section......................................................... 8

3-6. PANEL Board, SUB PANEL Board ............................... 9

3-7. Lid (CD) .......................................................................... 9

4. TEST MODE.............................................................. 10

5. ELECTRICAL ADJUSTMENTS

CD Section ...................................................................... 11

VIDEO Section ............................................................... 11

6. DIAGRAMS

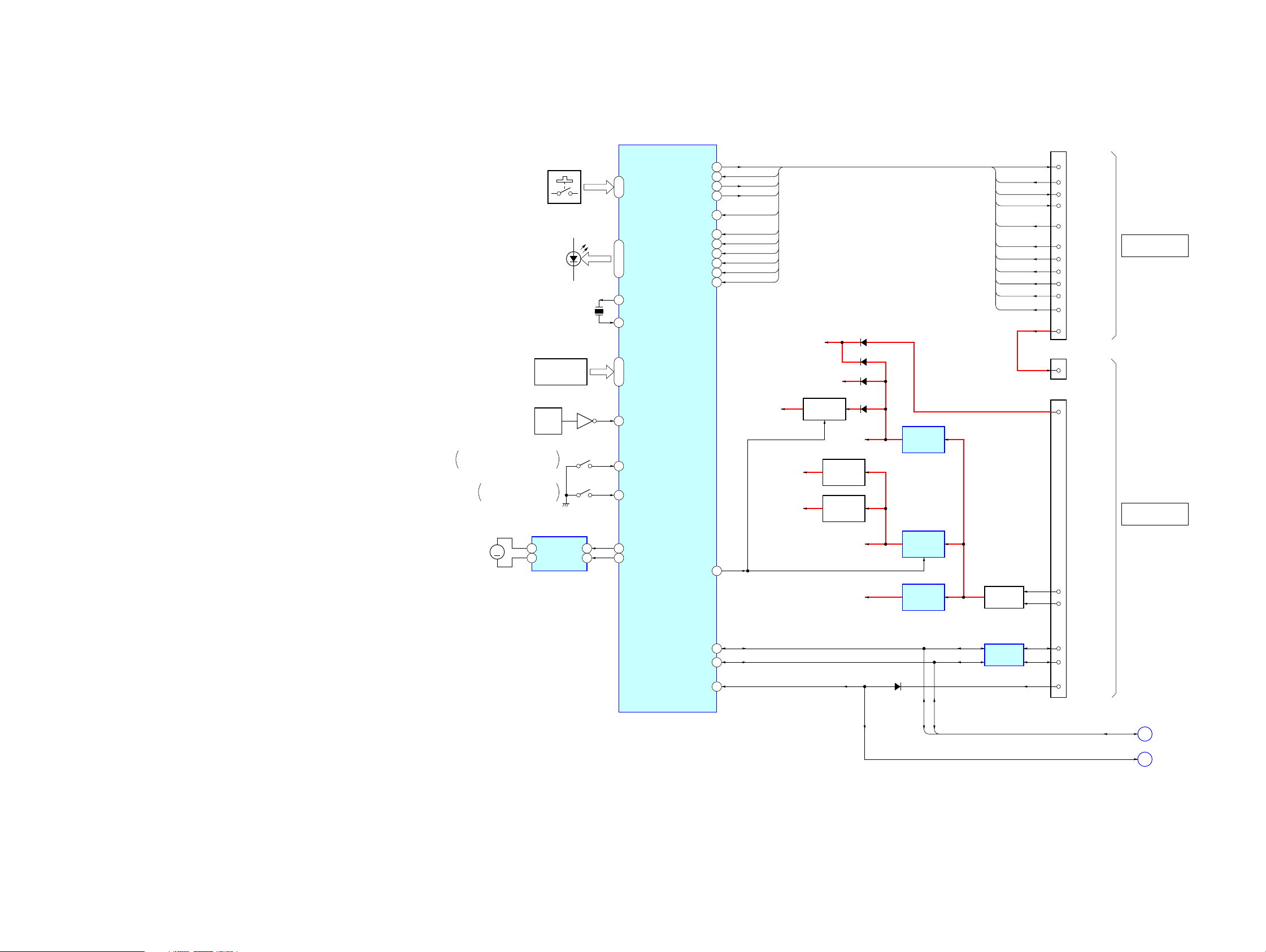

6-1. Block Diagram – CD SERVO Section – ....................... 12

6-2. Block Diagram – AUDIO/VIDEO Section – ................ 13

6-3. Block Diagram – MAIN Section – ................................ 14

6-4. Note For Printed Wiring Boards

and Schematic Diagrams ................................................ 15

6-5. Printed Wiring Board – BD Section – ........................... 16

6-6. Schematic Diagram – BD Section – .............................. 17

6-7. Printed Wiring Boards

– CD CHANGER Section –............................................ 18

6-8. Schematic Diagram – CD CHANGER Section – ......... 19

6-9. Printed Wiring Boards – AUDIO/VIDEO Section – ..... 20

6-10. Schematic Diagram

– AUDIO/VIDEO Section (1/3) – .................................. 21

6-11. Schematic Diagram

– AUDIO/VIDEO Section (2/3) – .................................. 22

6-12. Schematic Diagram

– AUDIO/VIDEO Section (3/3) – .................................. 23

6-13. Printed Wiring Boards – MAIN Section – .................... 24

6-14. Schematic Diagram – MAIN Section –......................... 25

6-15. Printed Wiring Boards – PANEL Section – .................. 26

6-16. Schematic Diagram – PANEL Section – ....................... 27

6-17. IC Pin Function Description ........................................... 32

MCE-SV7

7. EXPLODED VIEWS

7-1. Cover, Front Panel Section ............................................. 41

7-2. Chassis Section ............................................................... 42

7-3. CD Mechanism Deck Section-1 (CDM63B).................. 43

7-4. CD Mechanism Deck Section-2 (CDM63B).................. 44

7-5. Base Unit Section (BU-30BD61A) ................................ 45

8. ELECTRICAL PARTS LIST ............................... 46

3

MCE-SV7

SECTION 1

SERVICING NOTES

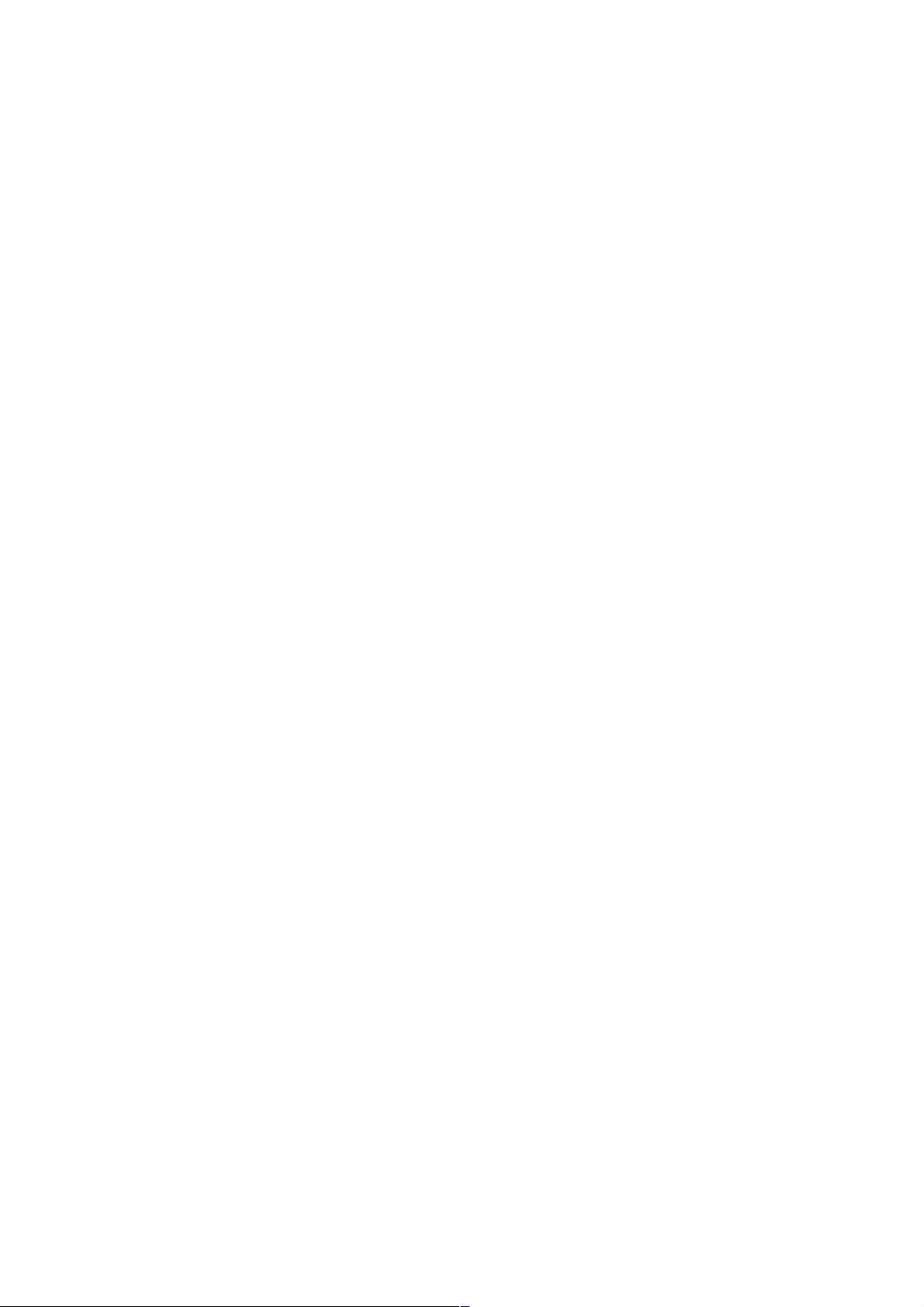

This set is a component of the MHC-SV7AV.

The MHC-SV7AV system configuration is as shown below, and

therefore it does not operate normally unless all four components

are connected.

In performing the repair, connect all components with the system

cables.

Note: The precaution to the users is described on the label stuck

on the back panel (Video CD player) and in the troubleshooting

section in the Operation Manual.

System Configuration:

AC IN

TA

POWER SUPPLY

ST

MASTER & GRAPHIC µcon

DISPLAY

MCE

HTC & VMP µcon

TC

TC µcon

CD-TEXT TEST DISC

This unit is able to display the test data (character information)

written in the CD on its fluorescent indicator tube.

The CD-TEXT TEST DISC (TGCS-313:4-989-366-01) is used

for checking the display.

To check, perform the following procedure.

Checking Method:

1. Press the I/1 button to turn the power on, set the disc to the

disc table with the “test disc” label facing up, and chuck the

disc.

2. Press the [CD] button to set CD function, and press the

N button to playback the disc.

3. The following will be displayed on the liquid crystal display.

Display : 1KHZ/0DB/L R

4. Pressing the [-- ] or [ +] button, select the track. The text

data of each track will be displayed.

For details of the displayed contents for each track, refer to “Table

1 : CD-TEXT TEST DISC TEXT Data Contents”.

Restrictions in CD-TEXT Display

In this unit, some special characters will not be displayed properly. These will be displayed as a space or a character resembling

it.

Table 1 : CD-TEXT TEST DISC TEXT Data Contents

(TRACKS No. 1 to 20:Normal Characters)

TRACK

No.

1 1kHz/0dB/L&R

2 20Hz/0dB/L&R

3 40Hz/0dB/L&R

4 100Hz/0dB/L&R

5 200Hz/0dB/L&R

6 500Hz/0dB/L&R

7 1kHz/0dB/L&R

8 5kHz/0dB/L&R

9 7kHz/0dB/L&R

10 10kHz/0dB/L&R

11 16kHz/0dB/L&R

12 18kHz/0dB/L&R

13 20kHz/0dB/L&R

14 1kHz/0dB/L&R

15 1kHz/–1dB/L&R

16 1kHz/–3dB/L&R

17 1kHz/–6dB/L&R

18 1kHz/–10dB/L&R

19 1kHz/–20dB/L&R

20 1kHz/–60dB/L&R

Note: Track No. 21 to 99 are not displayed.

.>

Displayed Contents

4

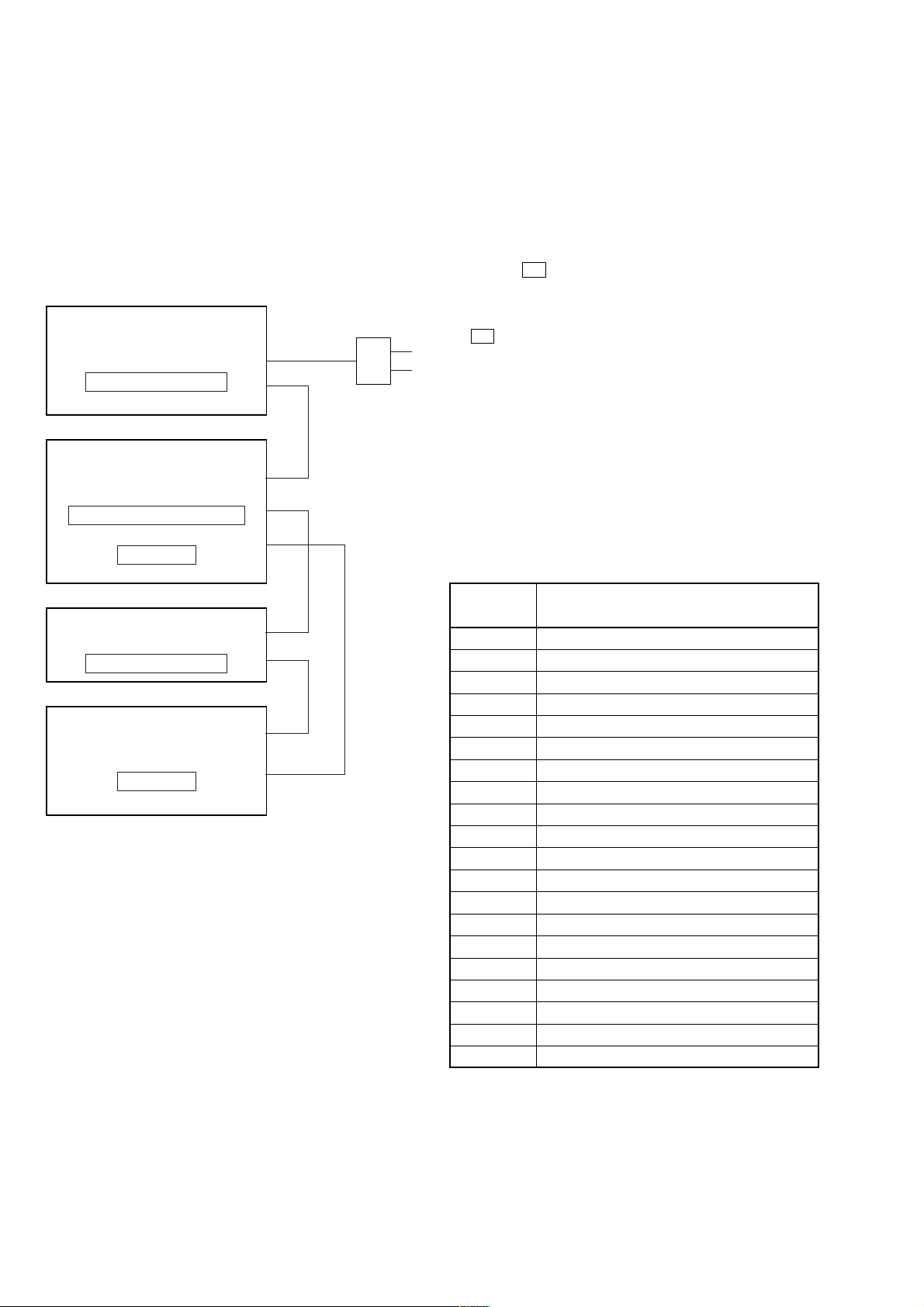

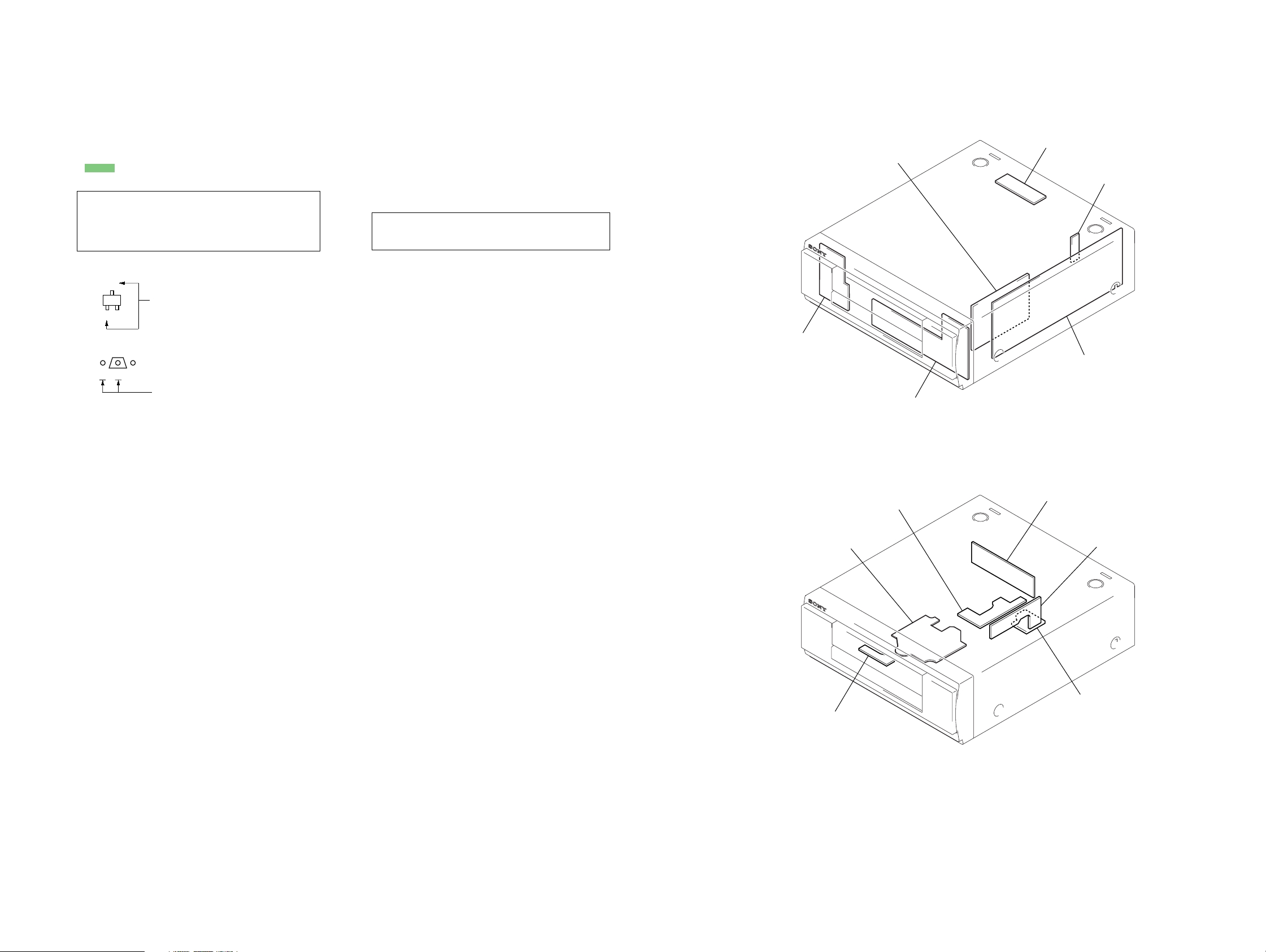

Parts Identification

The items are arranged in alphabetical order.

Refer to the pages indicated in parentheses ( ) for details.

SECTION 2

GENERAL

MCE-SV7

This section is extracted from

instruction manual.

Main unit

VIDEO CD/CD player

wk wle; ea

1 2 3

rs

DISC 1–3 rs (14, 16, 17, 25)

DISC 1–3 indicators ra

DISC 1–3 Z (eject) e; (14–16)

NEXT ek (14, 15)

PLAY MODE wk (14, 16, 17, 25)

PREV r; (14, 15)

REPEAT wl (15, 16)

RETURN O eh (15)

N SELECT (play) el (14–17,

19, 21, 34)

X (pause) ej (14, 16)

x (stop) eg (14–16, 19, 21, 24,

34)

. (go back) ef (14–17, 21,

25)

> (go forward) ed (14–17, 21,

25)

m (rewind) ea (14, 16)

M (fast forward) es (14, 16)

es

mM

.

>

HS x

ehekr;

Remote Control

1234 5

rg

rf

rd

ed

ef

rs

r;

ra

el

ek

ej

eh

egejelra

ef

es

e;

wk

eg

ed

ea

wl

wj

O

nNnN

Mm>.

wh

V

wg

Bb

v

6

7

8

9

q;

qa

qs

qd

qf

x

X

qh

qk

qg

qj

ql

w;

wa

ws

wd

wf

CHECK qd (17)

CLEAR qs (17, 19)

CLOCK/TIMER SELECT 3

(26, 35)

CLOCK/TIMER SET 2 (13, 25,

34)

DBFB ej (27)

DIGITAL r; (36, 40)

DISPLAY rd (13, 18, 33, 40)

D.SKIP 9 (14, 16, 20, 21)

ENTER wf (11, 13, 15, 17, 21,

22, 25, 26, 30–33, 35)

EQ wh (31)

EQ ON/OFF wa (32)

FILE SELECT +/– wd (27, 28,

32)

FUNCTION el (10, 14–17, 24,

25, 34, 36)

GROOVE ek (27)

KARAOKE PON qk (33)

KEY CONTROL / ql (33)

MD rs (36)

Numeric buttons 8 (15, 16, 19,

20, 21)

ON SCREEN wk (18)

PICTURE EFFECT wl (21)

PRESET –/+, PREV/NEXT ea

(14, 15, 20, 22)

REPEAT q; (15, 16)

RETURN O eg (15)

PLAY MODE qa (14, 16, 17, 25)

SELECT CD N es (14–17, 19,

21)

SET UP w; (11, 13, 30, 32, 33)

SLEEP 1 (34)

SPECIAL MENU e; (19, 20, 21)

SPECTRUM ANALYZER rf

(33)

SUR wj (30)

TAPE A nN ef (23)

TAPE B nN qf (23, 24)

TUNER/BAND ed (22)

TUNING –/+ qh (22)

TV CH +/– 7 (10)

TV VOL +/– 6 (10)

TV @/1 4 (10)

TV/VIDEO rg (10)

VIDEO ra (36)

VOL +/– ws

BUTTON DESCRIPTIONS

@/1 (power) 5

X (pause) qj

x (stop) qg

./> (go back/go forward)

ea

m/M (rewind/fast forward)

qh

O/o/P/p wg

>10 eh

5

MCE-SV7

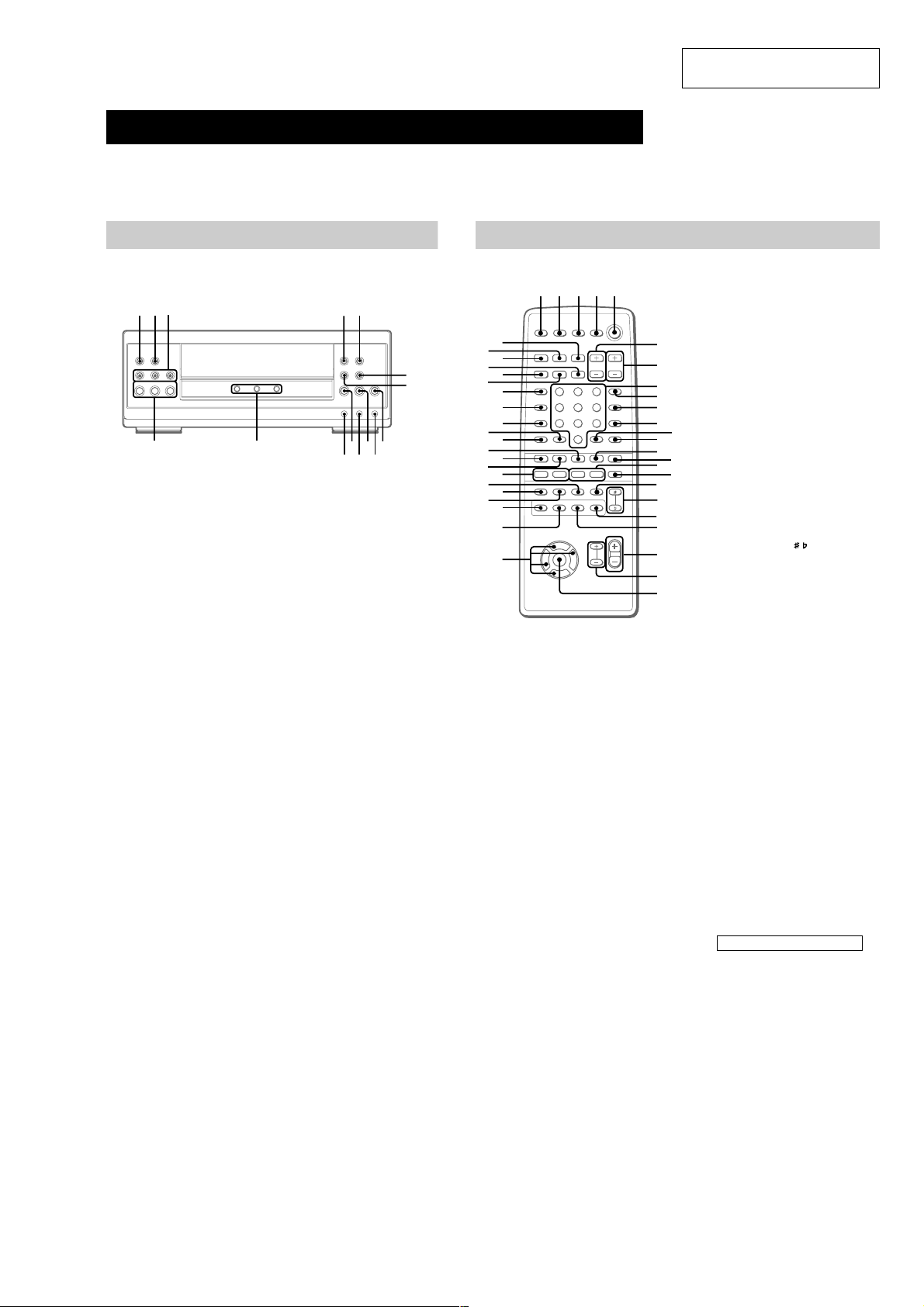

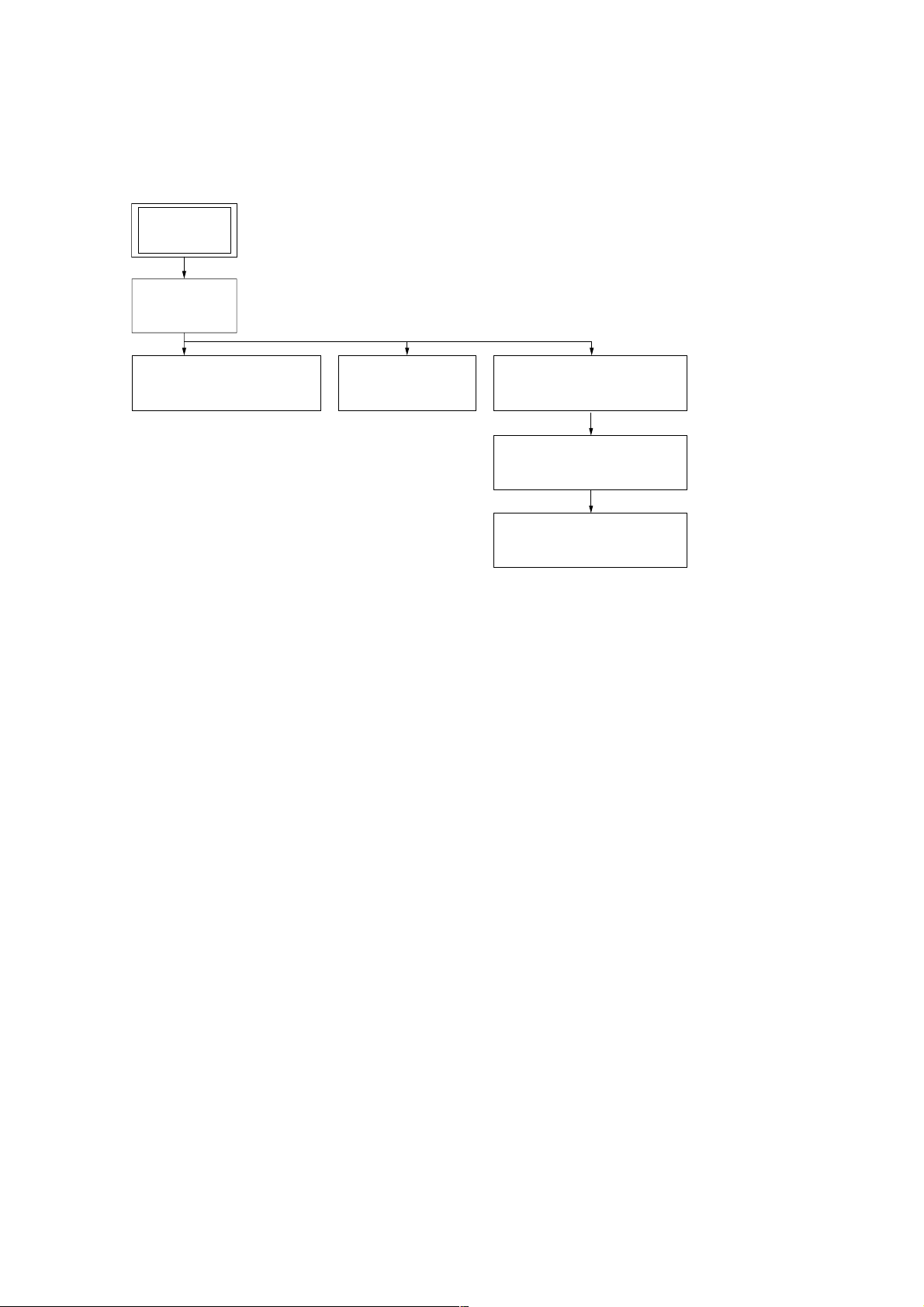

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. COVER

(Page 7)

SECTION 3

DISASSEMBLY

3-3. CD MECHANISM DECK

(CDM63B)

(Page 7)

3-4. MAIN BOARD

(Page 8)

3-5. FRONT PANEL SECTION

(Page 8)

3-6. PANEL BOARD,

SUB PANEL BOARD

(Page 9)

3-7. LID (CD)

(Page 9)

6

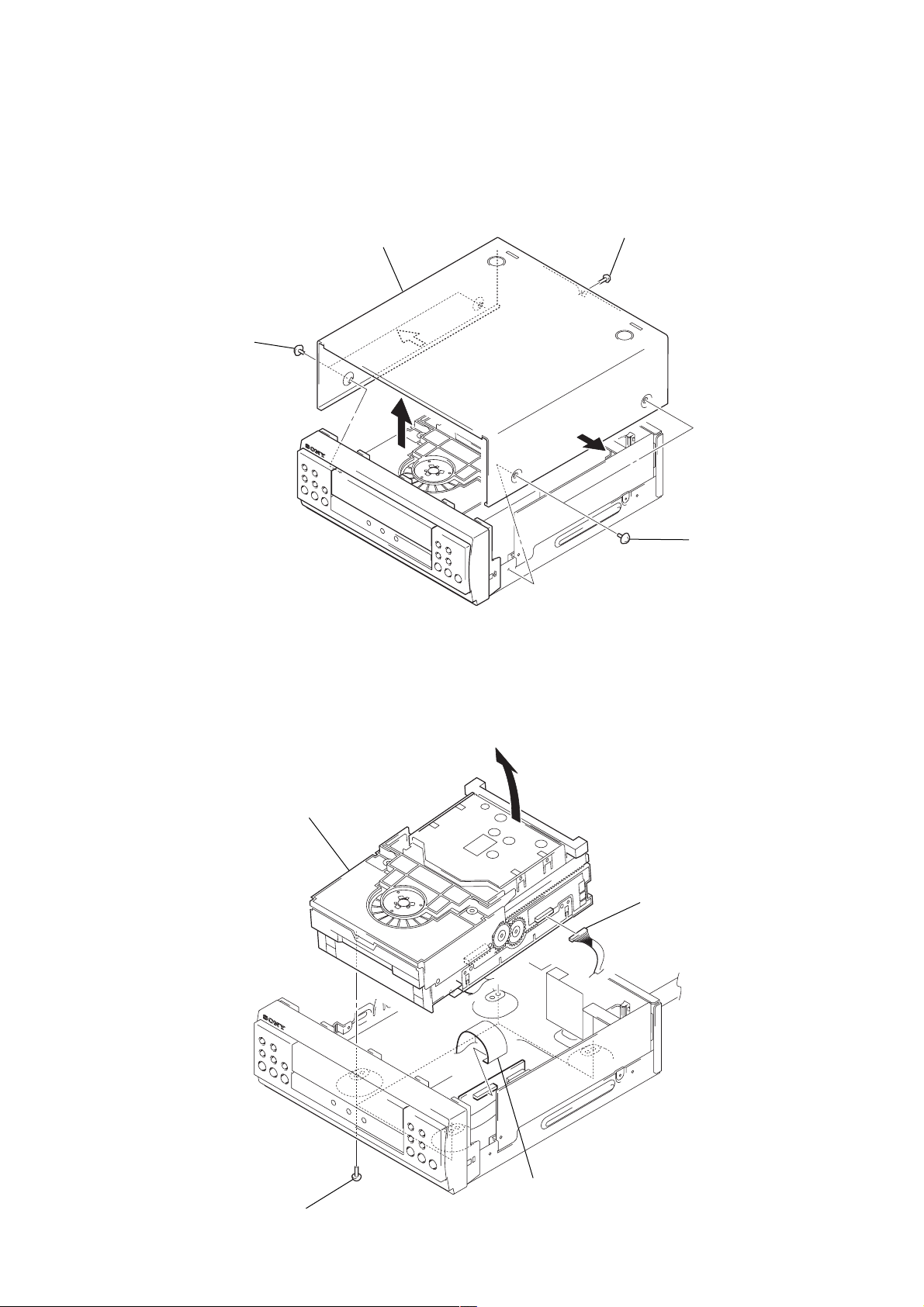

Note: Follow the disassembly procedure in the numerical order given.

)

r

3-2. COVER

3

cover

1

two screws

(case 3 TP2)

2

screw

(BVTT3 × 6)

MCE-SV7

3-3. CD MECHANISM DECK (CDM63B)

4

CD mechanism deck (CDM63B)

1

two screws

(case 3 TP2

2

connecto

(CN701)

3

four screws

(BVTP3

1

wire (flat type) (25 core)

(CN501)

×

8)

7

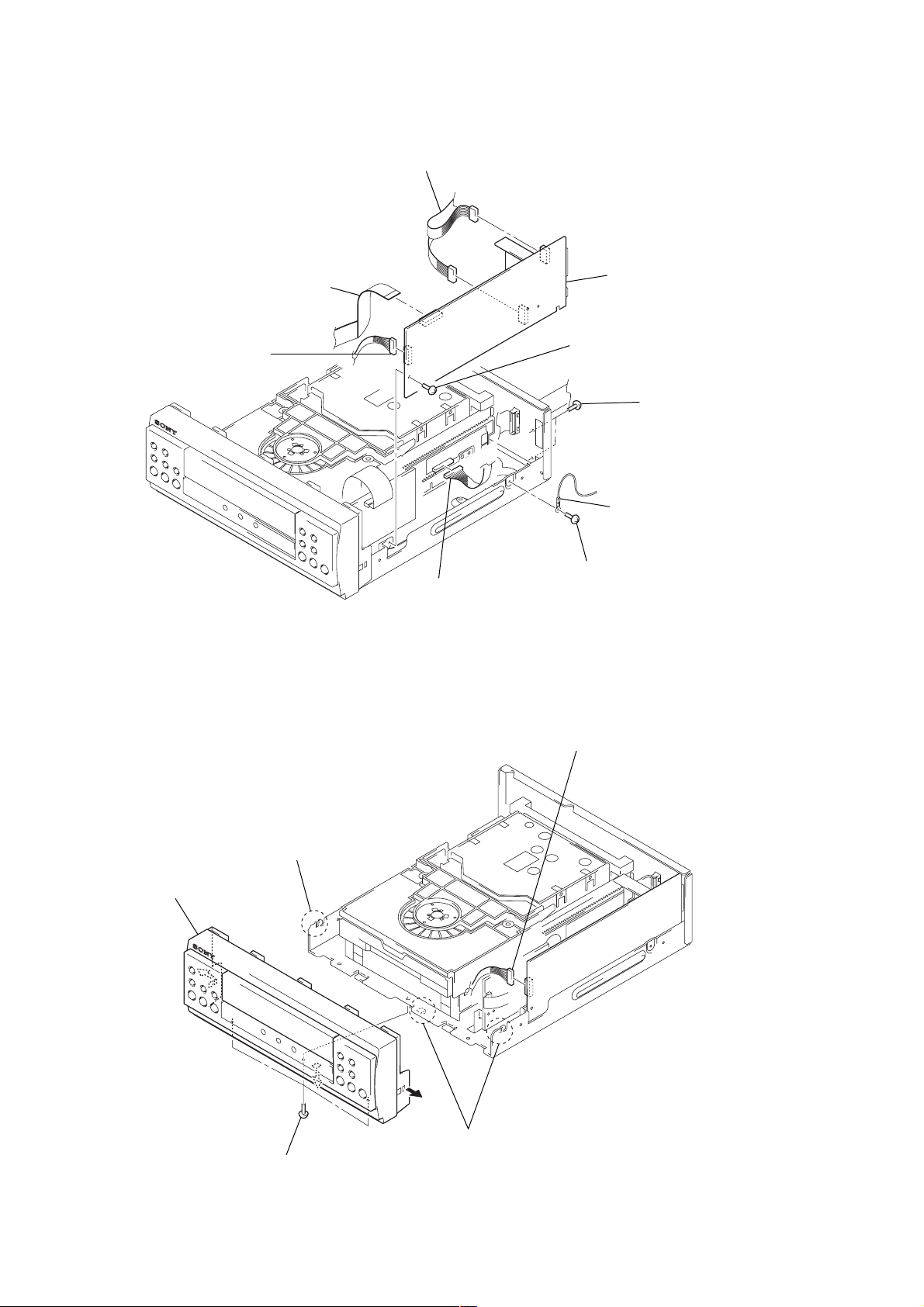

MCE-SV7

)

3-4. MAIN BOARD

1

wire (flat type) (13 core)

(CN301)

2

connector

(CN401)

2

two connectors

(CN101, 102)

5

3

screw

(BVTP3 × 8)

MAIN board

3

two screws

(BVTP3 × 8

3-5. FRONT PANEL SECTION

3

4

front panel section

claw

2

connector

(CN701)

3

1

connector

(CN401)

4

lug

screw

(BVTP3 × 8)

3

two claws

2

three screws

(BVTP3

×

8)

8

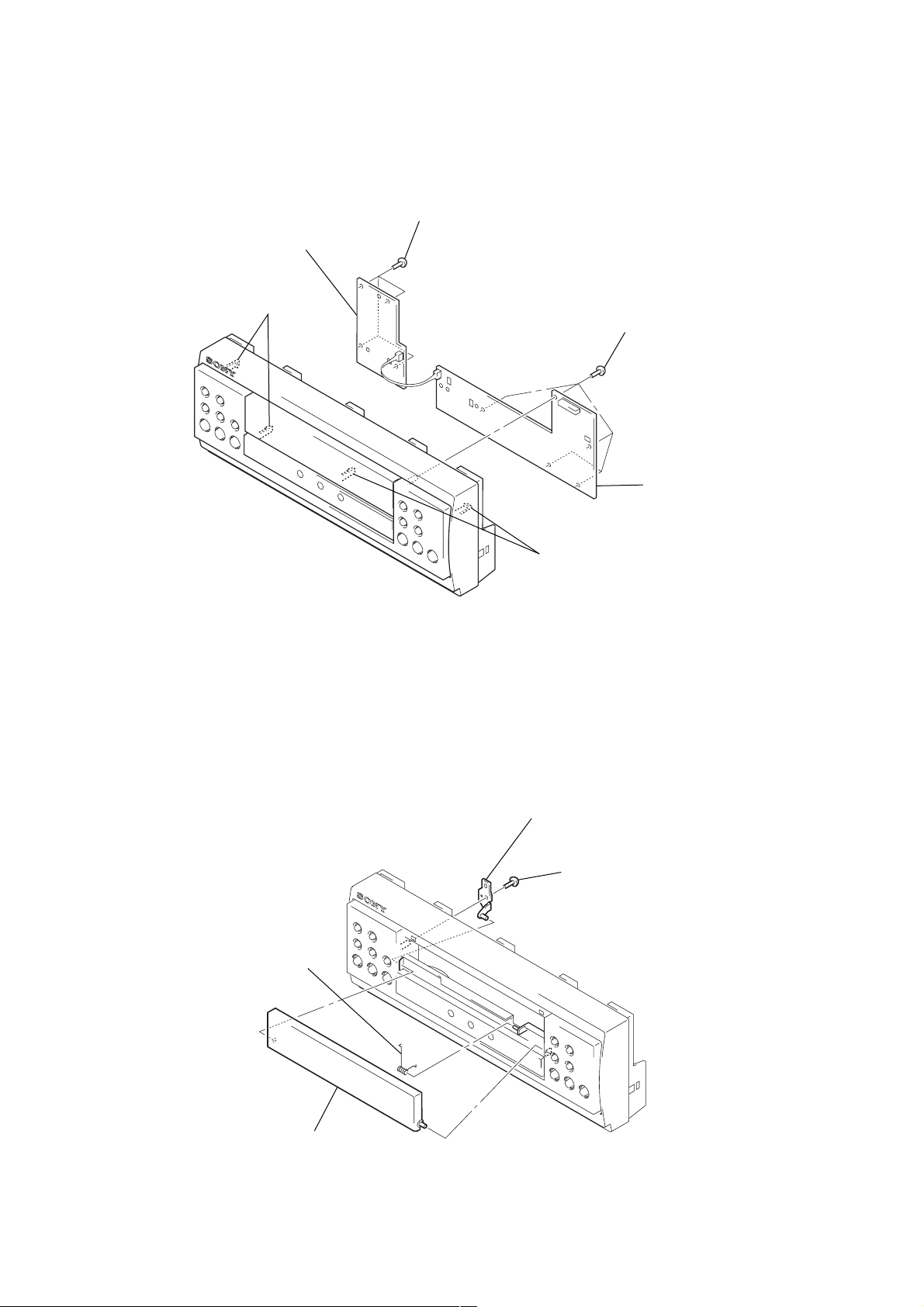

3-6. PANEL BOARD, SUB PANEL BOARD

d

)

4

6

SUB PANEL board

5

two claws

four screws

(BVTP2.6

MCE-SV7

×

8)

1

five screws

(BVTP2.6

3

×

8)

PANEL boar

3-7. LID (CD)

4

spring (CD)

2

two claws

2

bracket (LID) assy

1

screw

(BVTP2.6 × 8

3

lid (CD)

9

MCE-SV7

SECTION 4

TEST MODE

Note: Use following buttons in the test mode.

no mark: Button of video CD unit (MCE-SV7)

*1 : Button of amplifier unit (TA-SV7AV)

*2 : Button of tuner unit (ST-SV7)

[CD Delivery Mode]

• This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the I/1 *1 button to turn the power on.

2. Turn the [FILE SELECT] *1 knob to set the CD function.

3. While pressing the [EQ ON/OFF] *1 button, press the I/1 *

button.

4. The message “LOCK” is displayed on the fluorescent indica-

tor tube of tuner unit and turn the power off automatically , and

the CD delivery mode is set.

[GC Test Mode]

Enter the GC Test Mode

Procedure 1:

1. Press the I/1 *1 button to turn the power on.

2. While pressing the both [PLAY MODE] and [ ] buttons, press

Z

the [ ] (DISC 1) button.

x

3. LEDs and fluorescent indicator tube are all turned on of all

units.

Procedure 2:

1. Press the I/1 *1 button to turn the power on.

2. While pressing the both [STEREO/MONO] *2 and

[CINEMA STUDIO C] *

1

buttons, press the [CLOCK/TIMER]

*2 button.

3. LEDs and fluorescent indicator tube are all turned on of all

units.

[CD Service Mode]

• This mode can run the CD sled motor optionally. Use this mode,

for instance, when cleaning the optical pick-up.

Procedure:

1. Press the I/1 *1 button to turn the power on.

2. Turn the [FILE SELECT] *1 knob to set the CD function.

3. While pressing the both [PLAY MODE] and [ ] buttons, press

.

the [ ] button.

x

4. Set to the CD service mode.

5. With the CD in stop status, press the [ ] button to move the

M

optical pick-up to outside track, or press the [ ] button to

1

inside track.

6. To release from this mode, perform as follows.

1) Move the optical pick-up to the most inside track.

2) Disconnect the power cord.

Notes: • Always move the optical pick-up to most inside track when

releasing from this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear can

be chipped.

[CD Cancellation Mode of Repeat Limitation]

• This mode can cancel the CD repeat limitation (5 times).

Procedure:

1. Press the I/1 *1 button to turn the power on.

2. Turn the [FILE SELECT] *1 knob to set the CD function.

3. While pressing the both [PLAY MODE] and [ ] buttons, press

x

the [REPEAT] button.

4. CD repeat limitation is canceled.

5. To release this mode, disconnect the power cord.

m

Version Display Mode

Procedure:

1. Enter the GC test mode.

2. Each time the

[DISC 1] or [TUNER MEMORY] *

2

button is

pressed, microcomputer or mechanism deck version is displayed of each unit.

3. Press the [DISC 3] or [TUNING +] *2 button to detail is displayed the version.

Key Check Mode

Procedure:

1. Enter the GC test mode.

2. Press the [DISC 2] or [TUNING --] *2 button to set the key

check mode, and displays “K 0 J 0 V 0” on the fluorescent

indicator tube of tuner unit.

3. All buttons are pressed of video CD unit, all LEDs are blinking of video CD unit. (not change the display of fluorescent

indicator tube)

Releasing the GC Test Mode

T o release from this mode, press three buttons in the same manner

as entering this mode or disconnect the power cord.

10

SECTION 5

r

)

TP (DVC)

TP (FEO)

TP (XPCK)

TP (TEO)

TP (RFDC)

TP (VC)

TP

(RFAC)

IC103

IC101

TP (FEI)

R120

r

ELECTRICAL ADJUSTMENTS

MCE-SV7

CD SECTION

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated .

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

S-Curve Check

Oscilloscope

BD board

TP(FEO)

TP(DVC)

Procedure :

1. Connect an oscilloscope to TP (FEO) and TP (DVC).

2. Connect between TP (FEI) and TP (VC) by lead wire.

3. Turn Power switch on.

4. Load the disc (YEDS-18) and actuate the focus search. (In

consequence of open and close the disc tray, actuate the focus

search)

5. Confirm that the oscilloscope waveform (S-curve) is

symmetrical between A and B. And confirm peak to peak level

within 4 ±1 Vp-p.

S-curve waveform

symmetry

Note: Clear RF signal wav eform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500ns

level : 1.1 ± 0.3Vp-p

E-F Balance (1 Track jump) Check

oscilloscope

BD board

TP (TEO)

TP (DVC)

+

–

Procedure:

1. Connect an oscilloscope to TP (TEO) and TP (DVC).

2. Turn Power switch on.

3. Load the disc (YEDS-18) and playback the number five track.

4. Press the X button. (Becomes the 1track jump mode.)

5. Confirm that the level B and A (DC v oltage) on the oscilloscope

waveform.

1 track jump waveform

Center of

waveform

Checking Location :

[ BD BOARD ] — SIDE B —

VIDEO SECTION

Video Frequency Adjustment

Connection:

frequency counte

VMP board

TP (27MHz)

TP (GND)

Procedure:

1. Connect a frequency counter to TP (27MHz) and TP (GND).

2. Turn power switch on.

3. Turn the [FUNCTION] knob of amplifier unit (TA-SV7AV) to

set the CD function.

4. Adjust CT503 on the VMP board so that the frequency counter

reading 27.0 MHz ± 80 Hz at stop status.

Adjustment Location:

[VMP BOARD] (SIDE A)

J301

IC507

A

within 4 ±1Vp-p

B

7. After check, remove the lead wire connected in step 2.

Note : • Try to measure several times to make sure than the ratio

of A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

RF Level Check

oscilloscope

BD board

TP (RFAC) or TP(RFDC)

TP(DVC)

Procedure :

1. Connect an oscilloscope to TP (RFAC) and TP (DVC).

2. Turn Power switch on.

3. Load the disc (YEDS-18) and playback.

4. Confirm that the oscilloscope waveform is clear and check RF

5. Measure the RFDC in the same way.

signal level is correct or not.

B

0V

level=1.3 ±0.6Vp-p

Specification level: x 100=less than ±22%

A

B

Symmetry

A (DC voltage

6. After check, remove the lead wire connected in step 1.

RF PLL Free-run Frequency Check

Procedure :

1. Connect a frequency counter to TP (XPCK) and GND.

BD board

TP (XPCK)

frequency counte

+

–

2. Turn Power switch on.

3. Load the disc (YEDS-18) and playback the number five track.

4. Confirm that the reading on frequency counter is 4.3218MHz.

CN501

CN502

TP (27MHz)

TP (GND)

CT503

Video

Frequency

Adjustment

1111

MCE-SV7

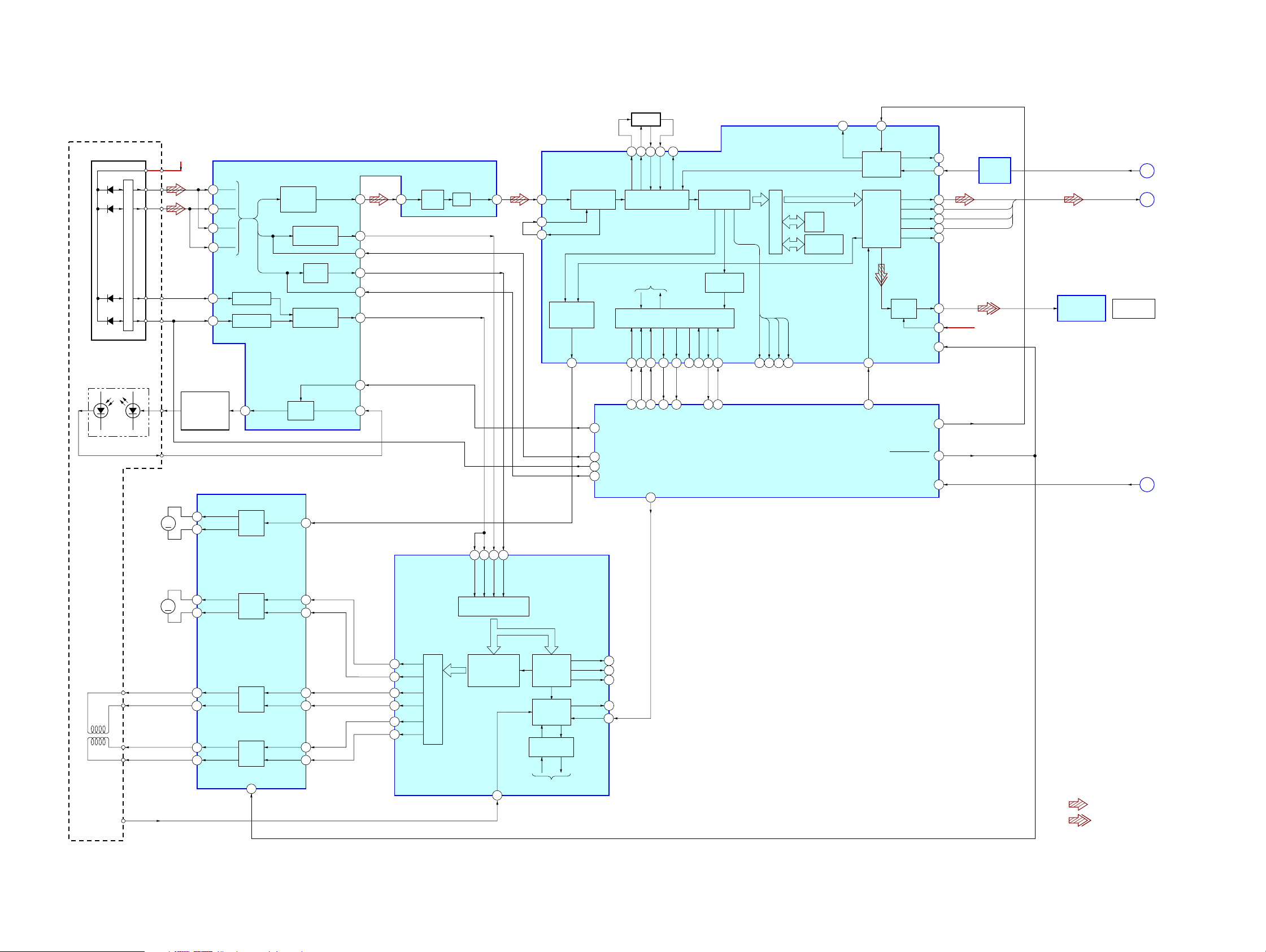

6-1. BLOCK DIAGRAM – CD SERVO Section –

SECTION 6

DIAGRAMS

DETECTOR

A

B

F

E

OPTICAL PICK-UP

BLOCK

(A-MAX. 3)

LASER DIODE

PD

I-V AMP

LD

M101

(SPINDLE)

M

CD +5V

A

6

B

7

C

8

D

9

F

11

F I-V AMP

E

10

E I-V AMP

AUTOMATIC

POWER

CONTROL

Q101

FOCUS/TRACKING COIL DRIVE,

VO4+

5

VO4–

10

1

SPINDLE/SLED MOTOR DRIVE

IC102

MOTOR

DRIVE

FILTER

RF AMP,

FOCUS/TRACKING ERROR AMP

RF

SUMMING

AMP

FOCUS

ERROR AMP

RF DC

AMP

TRACKING

ERROR AMP

LD

IN4R

APC LD

AMP

24

AC

SUM

RFDCO

RFDCI

SW

IC103

EQ

IN

4

FE

16

FEI

17

28

29

TE

18

12

PD

2

RFAC

3

VCA

RFAC

EQ

15

DIGITAL SIGNAL PROCESSOR

IC101 (1/2)

RFAC

50

49

48

ASYMMETRY

CORRECTOR

ASYI

ASYO

DIGITAL

CLV

PROCESSOR

MDP

25 76 77

LD ON

82

PWM1

28

PWM2

26

PWM3

24

53 55

FILO

TO SERVO AUTO

SEQUENCER

DATA

95 5 97 1 18 84 83 10

DSP DATA

FILI

PCO

CLTV

DIGITAL PLL

CPU INTERFACE

SENS

CLOK

XLAT

DSP CLK

DSP LATCH

SENSE CLK

2

125254

XPCK

EFM

DEMODULATOR

INTERNAL BUS

SUBCODE

PROCESSOR

SQCK

SQSO

EXCK

SCOR

SBSO

79 801574 6 5 10 111368 3

SCOR

SENSE

SUBQ CLK

SUBQ DATA

WFCK

XUGF

GFS

EMPH

VIDEO CD CONTROLLER

IC502 (1/2)

32K

RAM

ERROR

CORRECTOR

16 69

C4M

CLOCK

GENERATOR

DIGITAL

INTERFACE

MUTING

DSP MUTING

XTSL

D/A

DIGITAL

DEVICE RESET

OUT

XTAO

XTAI

PCMD

BCK

LRCK

C2PO

WDCK

DOUT

MD2

XRST

CTRL1

XRESET

72

71

66

67

65

14

17

64

63

2

11

77

12

OSC

BUFFER

IC106

DATA

BCK

LRCK

C2PO

CD +3.3V

OPTICAL

TRANSCEIVER

IC102

MCLK

33.8MHz

DATA, BCK,

LRCK, C2PO

OPTICAL OUT

TO ST-SV7

M-RESET

A

B

C

(Page 13)

(Page 13)

(Page 14)

2-AXIS

DEVICE

(TRACKING)

(FOCUS)

LIMIT

SWITCH

M102

(SLED)

40 41 39 43

DIGITAL SERVO

PROCESSOR

IC101 (2/2)

VO3+

1

M

2

55

56

47

52

VO3–

VO2+

VO2–

VO1+

VO1–

MOTOR

DRIVE

COIL

DRIVE

COIL

DRIVE

STBY

8

IN3+

IN3–

IN2+

IN2–

IN1+

IN1–

27

26

SFDR

29

SRDR

30

32

31

35

34

TFDR

31

TRDR

32

FFDR

33

FRDR

34

PWM GENERATOR

FOCUS/TRACKING/SLED

FE

TE

SE

RFDC

A/D

CONVERTER

FOCUS/

TRACKING/SLED

SERVO DSP

SSTP

26

MIRR,

DFCT, FOK

DETECTOR

SERVO

INTERFACE

SERVO AUTO

SEQUENCER

TO CPU INTERFACE

FOK

MIRR

DFCT

COUT

SCLK

22

20

21

19

8

• SIGNAL PATH

: CD PLAY (ANALOG OUT)

: CD PLAY (DIGITAL OUT)

1212

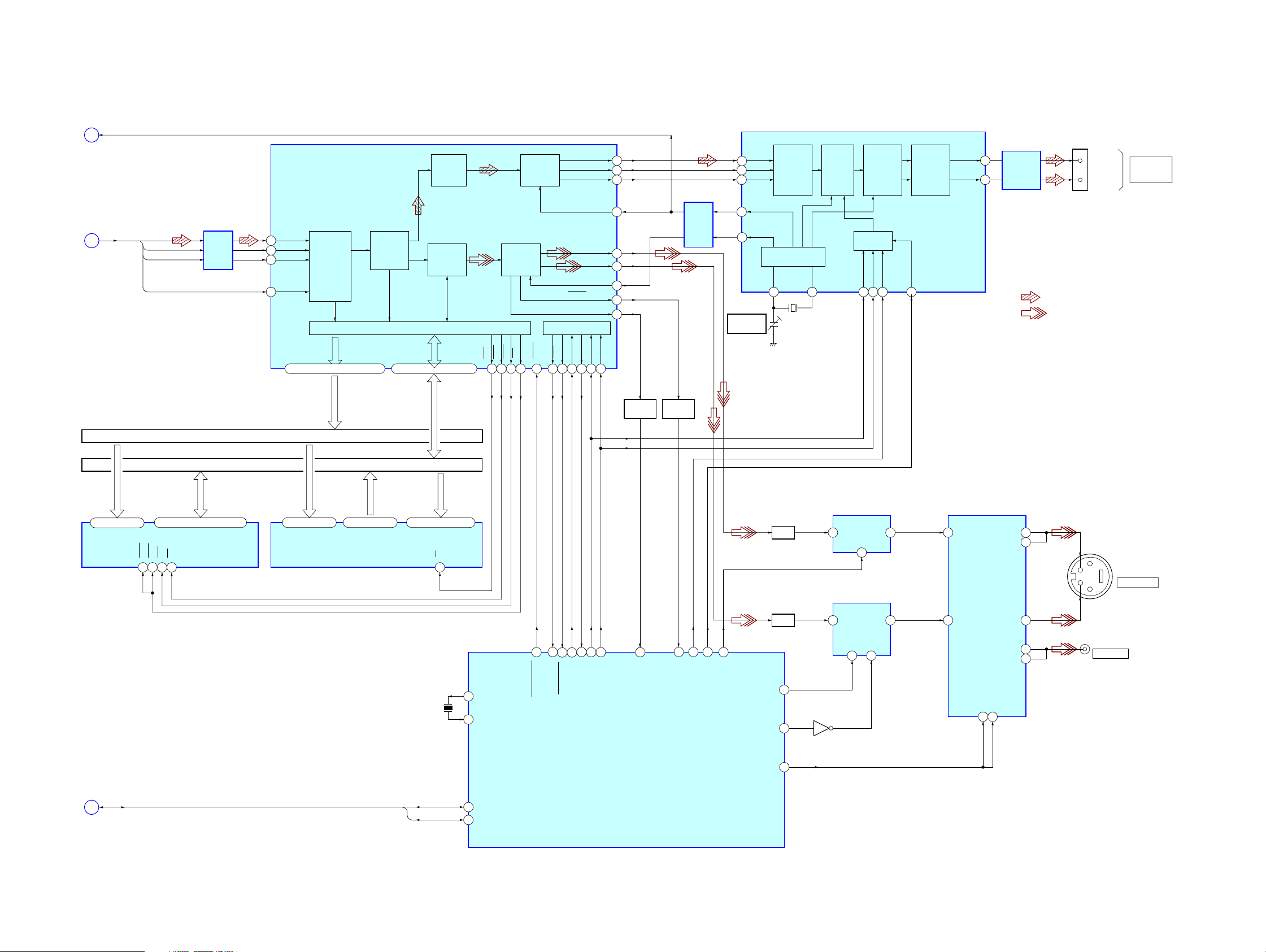

6-2. BLOCK DIAGRAM – AUDIO/VIDEO Section –

MCLK 33.8MHz

A

(Page 12)

MPEG VIDEO/AUDIO DECODER,

VIDEO SIGNAL PROCESSOR

IC505

MPEG

AUDIO

DECODER

AUDIO

INTERFACE

CIRCUIT

DA-DATA

DA-BCK

DA-LRCK

MCE-SV7

DIGITAL FILTER,

D/A CONVERTER

IC509

CN102 (1/2)

110

111

108

DATA

18

17

19

BCK

LRCK

INPUT

INTERFACE

CIRCUIT

DIGITAL

FILTER,

NOISE

SHAPER

CIRCUIT

D/A

CONVERTER

LOW-PASS

FILER

VOUTL

VOUTR

14

LOW-PASS

FILER

IC101

11

1

3

VCD L-IN

VCD R-IN

SYSTEM

CONTROL 3

TO ST-SV7

B

(Page 12)

16 – 19, 22 – 26

D-RAM

IC507

DATA, BCK,

LRCK, C2PO

A0 – A8

A0 – A8

UCAS

DATA

BCK

LRCK

C2PO

LCAS

DA-XCLK

86

CD-DATA

LEVEL

SHIFT

IC501

D0 – D15

DQ1 – DQ16

RAS

WE

14 132928

4

CD-BCK

3

CD-LRCK

5

CD-C2PO

6

MA0 – MA10

ADDRESS BUS

DATA BUS

12 – 5, 27, 26, 23

PROGRAM ROM

CD-ROM

INTERFACE

CIRCUIT

58 – 56, 54, 52 – 50, 48, 46 – 44 10 – 15, 17, 19, 21, 23 – 29

A0 – A10

A0 – A10

A0 – A10

IC510

13 – 15, 17 – 212 – 5, 7 – 10, 31 – 34, 36 – 39

MPEG

SYSTEM

DECODER

D-RAM/ROM INTERFACE

MD0 – MD15

D0 – D7

O0 – O7

MPEG

VIDEO

DECODER

D0 – D15

D8 – D14

25, 4, 28, 29, 3, 2, 30

A11 – A17

CE

22

PROCESS

CIRCUIT

RAS0

MWE

MCE

37

38 42 40 60

VIDEO

CAS

CPU INTERFACE

HRDY

HINT

RESET

113

114 121

Y-OUT

C-OUT

VCK-IN

VSYNC/CSYNC

HSYNC

HSEL

HD-OUT

HD-IN

112

119

117

HCK

DATA

CLK

69

75

106

93

101

BUFFER

Q501

BUFFER

Q502

OSC

BUFFER

IC504

384FSO

20

MCKO

4

CT503

VIDEO

FREQUENCY

TIMING CONTROL/

CLOCK GENERATOR

XT2

B.P.F.

X503

27MHz

XT1

MODE

CONTROL

ML

MC

MD

9 724 1

8

RSTB

10

• SIGNAL PATH

: CD PLAY (AUDIO)

: CD PLAY (VIDEO)

2

Y IN

Y/C DECODER

IC304

Y OUT1

Y OUT2

15

14

2

4

3

1

J801

S VIDEO OUT

Y AMP

IC303

10

VIN

CONT

C AMP

IC302

1

VOUT

5

D

(Page 14)

IIC-DATA,

IIC-CLK

X501

10MHz

IIC-DATA

IIC-CLK

13

15

30

29

XOUT

XIN

I2C_DATA

I2C_CLK

85

86

CL680 HINT

CL680 HRDY

CL680 RESET

VIDEO CD CONTROLLER

36

8720

DATAI

CL680 SEL

IC502 (2/2)

3735

CLK1

DATAO

21

H. SYNC IN

45

VSYNC

1313

88

DF LATCH

66

DAC RESET

3

RESOLUTION

V. MUTING

CHOMA

LEVEL

BGP

B.P.F.

22

65

1

VIN

TINT5BGP

8

4

Q301

VOUT

6

7

C IN

MIX OUT1

MIX OUT2

MUTE A8MUTE B

1

C OUT

9

12

11

J802

VIDEO OUT

MCE-SV7

6-3. BLOCK DIAGRAM – MAIN Section –

SYSTEM CONTROLLER

IC401

S701 – 708,

D701 – 705

SUB TRAY1 – 3

HEIGHT SENSOR

DISC IN

DETECT

IC751

ON: WHEN SUB TRAY SLIDES OUT

OF THE CHUCKING POSITION

ON: WHEN SUB TRAY IS

CHUCKING POSITION

LOADING MOTOR DRIVE

OUT1

M721

(LOADING)

MM

4

2

OUT2

S711 – 720

IC731 – 733

IC701

X401

16MHz

S741

S742

(OUT)

FIN

RIN

Q701

(IN)

97, 95

KEY0, KEY1T-SENS1 – TSENS3

LED_DISC1

LED_DISC2

LED_DISC3

LED_PLAY

65 – 83, 88

LED_PAUSE

13

X-OUT

15

X-IN

48 – 50

52

DISC-SENS

47

CLOSE

46

OPEN

45

7

9

44

LOAD-OUT

LOAD-IN

EXP-OUT DATA

EXP-IN DATA

EXP-CLK

EXP-LAT

KEY2 (TC)

A-TRIG

B-TRIG

R/PB/PASS

A-SHUT

B-SHUT

B-HALF

CD POWER

CN103

DATA-OUT

85

84

87

86

94

55

53

59

89

90

91

38

DATA-IN

CLK

LAT

KEY2

ATRIG

BTRIG

REC/PB/PAS

ASHUT

BSHUT

BHALF

A+5V (SW)

VIDEO +3.3V

CD +3.3V

EVER+5V

B+ SWITCH

Q501, 502

D+5V

OPT B+

+3.3V

REGULATOR

Q531

+3.3V

REGULATOR

Q301

D+5V (SW)

M+7V

D512

D513

D514

D511

+5.7V

REGULATOR

IC502

+5V

REGULATOR

IC501

+7V

REGULATOR

IC503

DATA-OUT

DATA-IN

CLK

LAT

KEY2

ATRIG

BTRIG

REC/PB/PAS

ASHUT

BSHUT

BHALF

RECT

D501 – 504

10

9

8

7

6

4

5

11

12

13

14

3

CN102 (2/2)

7

CN101

5

8

9

DATA-OUT

DATA-IN

CLK

LAT

KEY2

ATRIG

BTRIG

REC/PB/PAS

ASHUT

BSHUT

BHALF

UNREG

UNREG (TC)

EVER +5V

AC

AC

SYSTEM CONTROL 5

FROM TC-S3

SYSTEM CONTROL 3

TO ST-SV7

IIC-DATA

IIC-CLK

RESET

30

29

12

D105

IIC-DATA

IIC-CLK

BUFFER

IC504

2

1

4

MRESET

IIC-DATA,

IIC-CLK

M-RESET

D

C

(Page 13)

(Page 12)

1414

MCE-SV7

d

6-4. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

f

•

•

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

• Indication of transistor.

: internal component.

: Pattern from the side which enables seeing.

C

B

B

Q

E

Q

CE

These are omitted.

These are omitted.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• C : panel designation.

Note: The components identified by mark 0 or dotted line

• A : B+ Line.

• H : adjustment for repair.

• Voltages are taken with a V OM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.

with mark 0 are critical for safety.

Replace only with part number specified.

Voltage var iations may be noted due to normal production tolerances.

Voltage var iations may be noted due to normal production tolerances.

J : CD PLAY (ANALOG)

c : CD PLAY (DIGITAL)

g : VIDEO

4

• Circuit Boards Location

VIDEO board

VMP board

W or less unless otherwise

REG board

SUB PANEL board

MAIN board

PANEL board

IN OUT SW board

TRAY SENSOR board

BD board

DRIVER boar

MOTOR board

DISC SENSOR board

1515

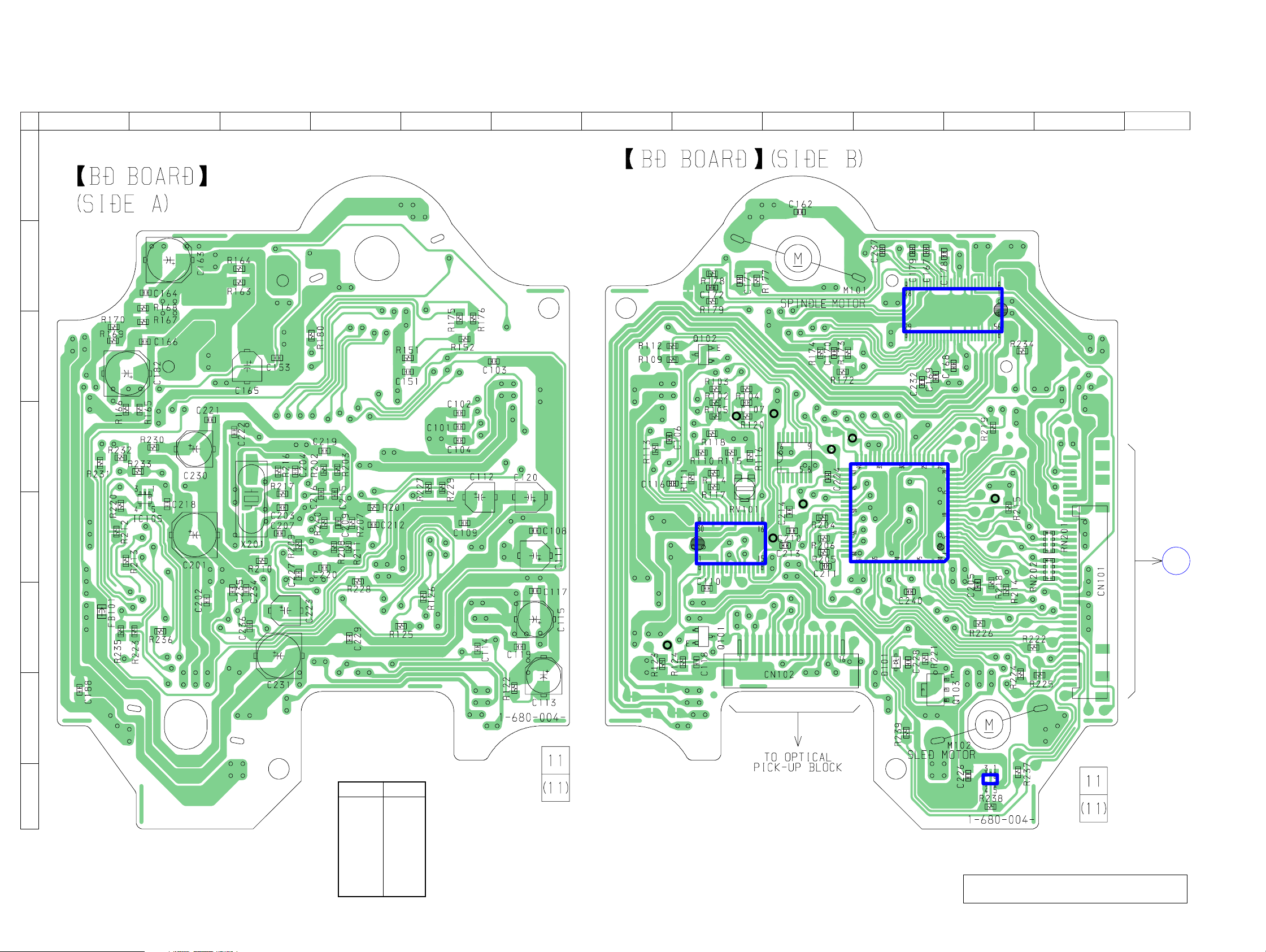

MCE-SV7

6-5. PRINTED WIRING BOARD – BD Section – • See page 15 for Circuit Boards Location.

1 2 3 4 5 6 7 8 9 10 11 12 13

A

B

IC102

C

D

E

TP (DVC)

TP (FEI)

IC103

IC104

TP (RFAC)

TP (TEO)

TP (RFDC)

TP (FEO)

IC101

TP (XPCK)

A

VMP

BOARD

CN501

(Page 20)

F

TP

(VC)

25

G

H

• Semiconductor

Location

Ref. No. Location

D101 F-10

IC101 E-10

IC102 B-11

IC103 E-8

IC106 H-11

Q101 F-8

Q103 G-10

IC106

(A-MAX.3)

There are a few cases that the part printed on

this diagram isn’t mounted in this model.

1616

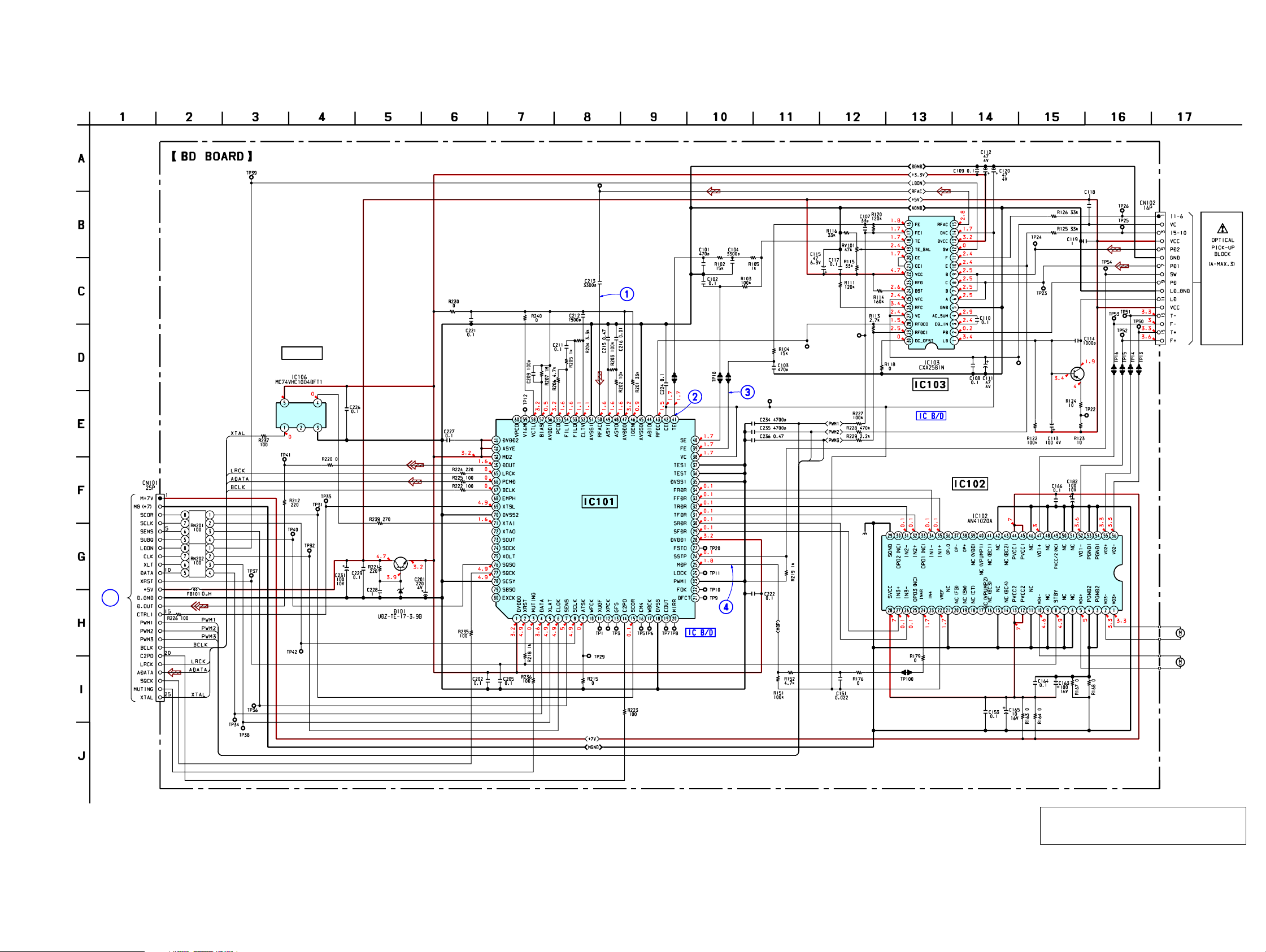

6-6. SCHEMATIC DIAGRAM – BD Section – • See page 28 for Waveforms. • See page 29 for IC Block Diagrams.

TP (RFAC)

IC 106

OSC BUFFER

3.2

(TEO)

MCE-SV7

TP

(FEI)

TP (RFDC)

Q101

AUTOMATIC

POWER CONTROL

TP

(VC)

TP

(FEO)

TP

TP (DVC)

RF AMP,

FOCUS/TRACKING ERROR AMP

Q101

2SB710A

A

VMP

BOARD (1/3)

CN501

(Page 21)

Q103

2SD1664

+3.3V

REGULATOR

DIGITAL SIGNAL PROCESSOR,

DIGITAL SERVO PROCESSOR

IC101

CXD3068Q

TP

(XPCK)

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

M102

(SLED)

M101

(SPINDLE)

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

1717

Loading...

Loading...