Sony M-98-V Service manual

M-98V

SERVICE MANUAL

Ver 1.0 1999. 03

SPECIFICATIONS

US Model

Canadian Model

AEP Model

E Model

Tourist Model

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type MZ-98-100

Tape

y (normal position type)

Recording system

2-track 1 channel monaural

Frequency range

400 - 3,000 Hz (2.4 cm/s)

Speaker

Approx. 2.8 cm (1 1/8 in.) dia.

Power output

250 mW

Input

Microphone input jack (minijack/plug in power) sensitivity

0.37 mV for 3 kilohms or lower impedance microphone

Output

Earphone jack (minijack) for 8 - 300 ohms earphone

Power requirements

3 V DC batteries R03 (size AAA) × 2/External DC 3 V power

sources

Battery life (Approximate hours) (EIAJ*)

Battery Recording

Sony alkaline LR03 (SG) 9.5

Sony R03 (SB) 3.5

* Measured value by the standard of EIAJ (Electronic Industries

Association of Japan). (Using a Sony Microcassette tape)

For maximum performance, we recommend that you use

alkaline batteries.

Dimensions (w/h/d) (incl. projecting parts and controls)

Approx. 60.5 × 93.9 × 26.0 mm (2 1/2 × 3 3/4 × 1 11/16 in.)

Mass

Approx. 130 g (4.6 oz.)

Supplied accessories

Remote control microphone ECM-J805 (1)

Microcassette tape MC-30 (1)

Earphone MDR-E123 (1)

Carrying case (1)

Hand strap (1)

Batteries R03 (SB) (2) (Tourist model only)

Design and specifications are subject to change without notice.

MICROFILM

– 1 –

MICROCASSETTE

-CORDER

TM

TABLE OF CONTENTS

1. SERVICE NOTE..........................................................3

2. GENERAL ....................................................................4

3. DISASSEMBLY

3-1. Panel (Rear) Assy ................................................................5

3-2. Panel (Lid) Assy..................................................................5

3-3. MD Block Assy...................................................................6

3-4. Main board, complete ......................................................... 6

3-5. Frame .................................................................................. 7

3-6. Mode Motor Block.............................................................. 7

4. MECHANICAL ADJUSTMENTS..............................8

5. ELECTRICAL ADJUSTMENTS ...............................8

6. DIAGRAMS

6-1. IC Pin Description............................................................. 10

6-2. Block Diagram .................................................................. 12

6-3. Printed Wiring Board ........................................................ 14

6-4. Schematic Diagram ........................................................... 17

7. EXPLODED VIEWS

7-1. Panel (Lid) Section............................................................22

7-2. Main Board Section .......................................................... 23

7-3. Mechanism Section (1) ..................................................... 24

7-4. Mechanism Section (2) ..................................................... 25

8. ELECTRICAL PARTS LIST ....................................26

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

– 2 –

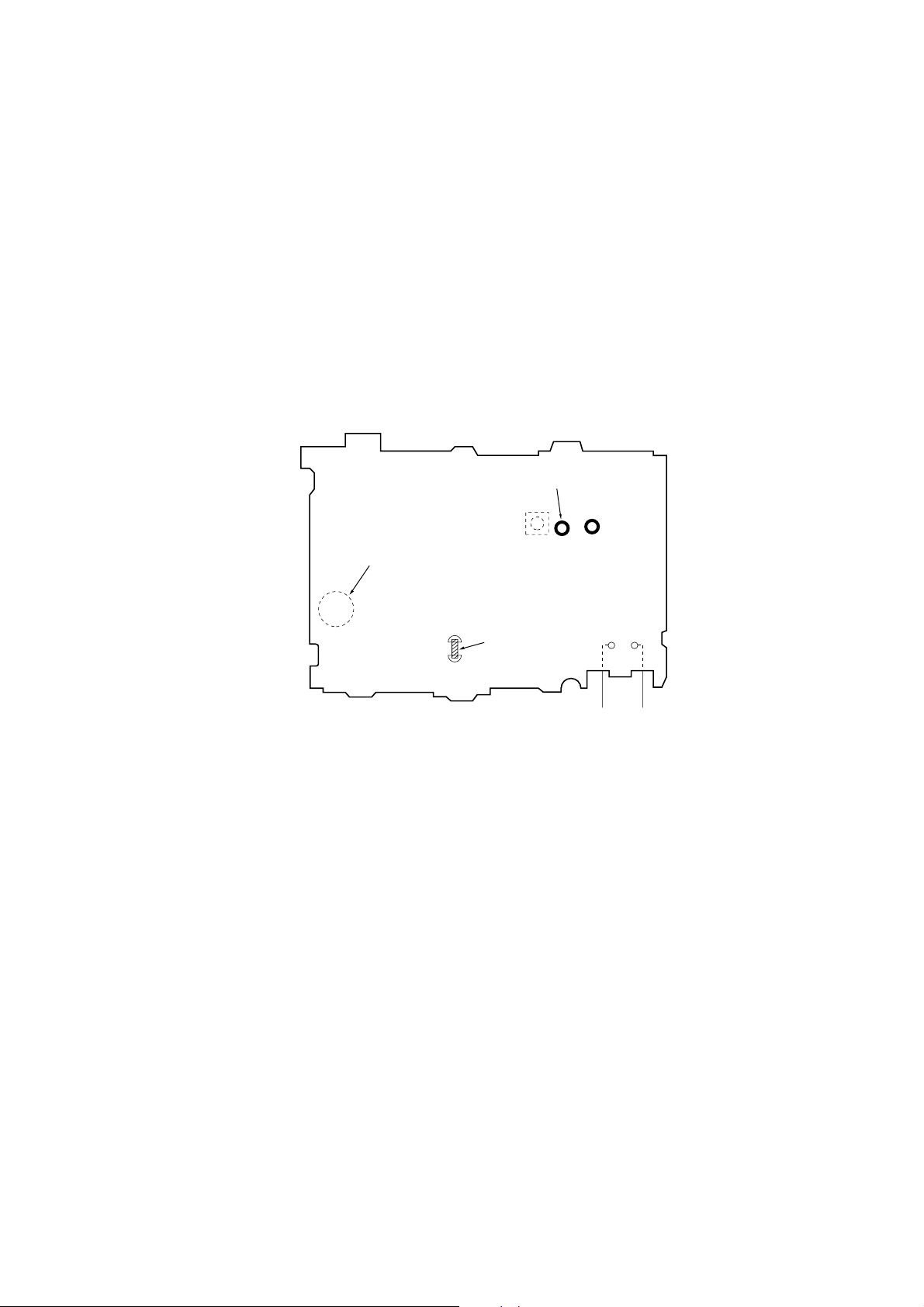

SECTION 1

SERVICE NOTE

This set uses the photo reflector PH701 to detect the rotation of the gear. PH701 is on the main board and so remo v al of the main board does

not allow the set to detect the rotation of the gear. This makes motor control impossible which prevents normal operation.

When repairing the set as energized with the main board removed, proceed as follows:

• Service the Main Board

1. Short the BP701 (SERVICE) on the main board. (see the Fig. 1.)

2. Refer to the “SECTION3 DISASSEMBLY” (page 5) and open the main board.

3. Put a tape in the set.

4. Fixed at S703 (TAPE DET) on mode or connect the jumper wire between TP38 and GND (TP66).

5. Supply 3 V DC to the battery terminals.

6. Rotate the S701 (MODE SELECT) one turn by hand (mode sensor).

7. Press the desired operating switch (9 (, FF, etc.).

8. Check the mode on the liquid crystal panel. Use item 6 repeatedly to switch modes.

9. When finished with the job, disconnect the power and open (remove the short) the BP701 (SERVICE).

– MAIN BOARD (SIDE B) –

TP38

S701

(MODE SELECT)

BP701

(SERVICE)

S703

(TAPE DET)

SHORT

Fig. 1.

TP66

‘

terminal

’

terminal

– 3 –

SECTION 2

GENERAL

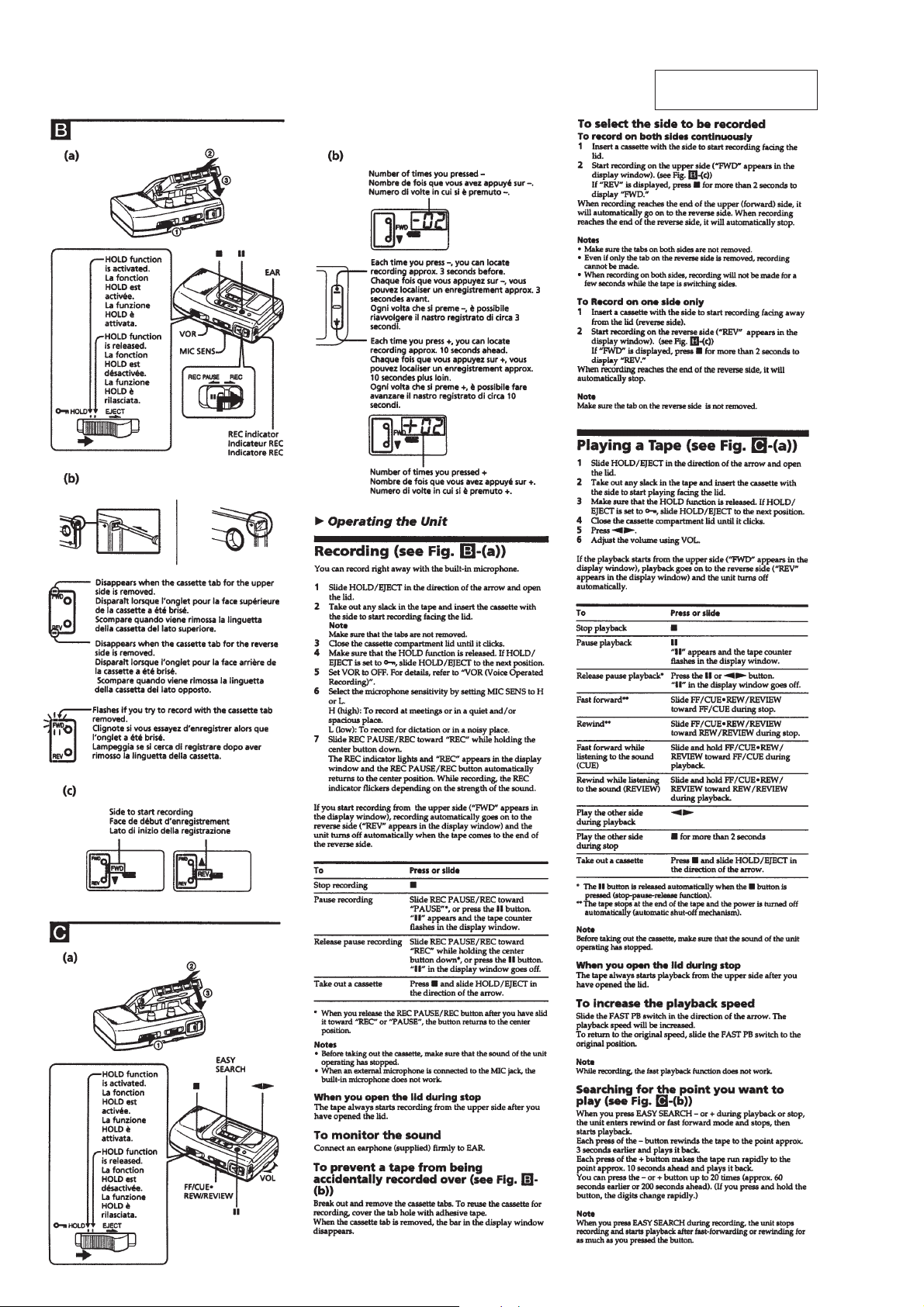

This section is extracted

from instruction manual.

– 4 –

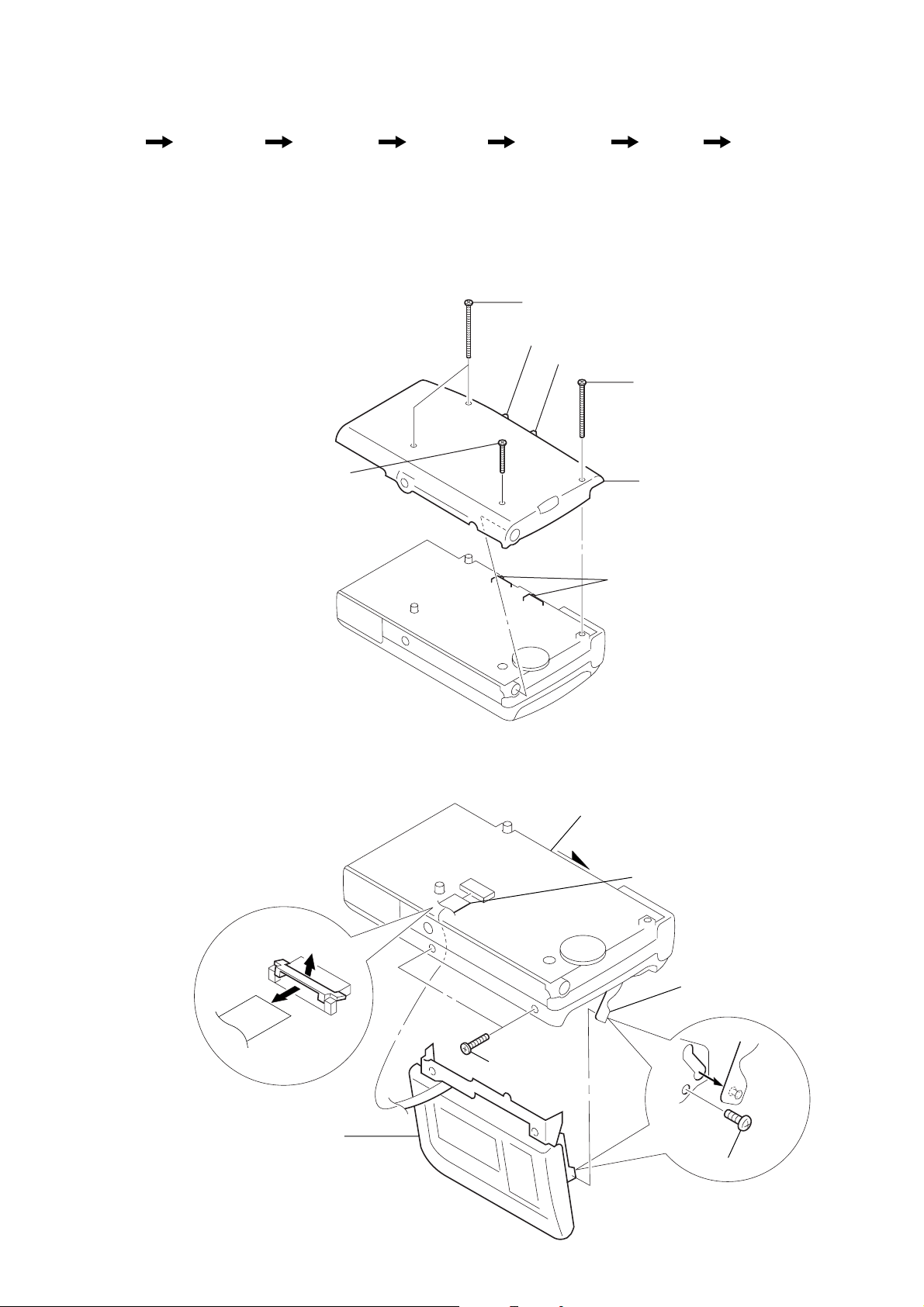

SECTION 3

DISASSEMBLY

Note : This set can be disassemble according to the following sequence.

Set Panel (rear)

assy

Note : Follow the disassembly procedure in the numerical order given.

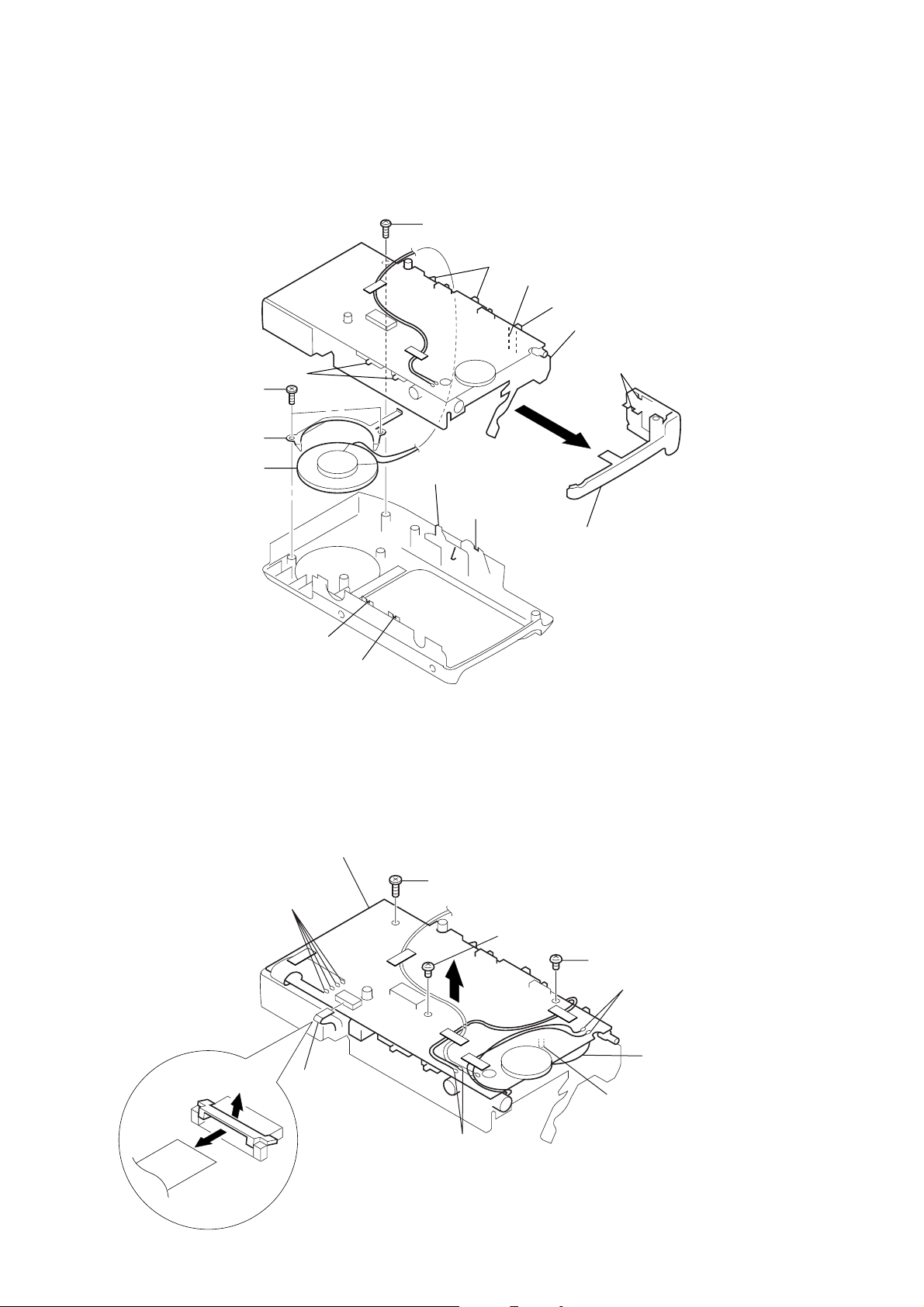

3-1. PANEL (REAR) ASSY

• When installing, position the knobs (V•O•R, MIC SENS) and the switches.

3

screw (M1.4x5.0), locking

Panel (lid)

assy

MD block

assy

Main board,

Frame Mode motor

complete

1

screws (B1.7x18) (G), tapping

knob (MIC SENS)

knob (V

•O •

R)

2

screw (B1.7x18) (G), tapping

4

panel (rear) assy

block

3-2. PANEL (LID) ASSY

b

a

switches

1

knob (EJECT)

2

CN102

5

lever (C holder) assy

6

panel (lid) assy

screws (M1.4),

3

toothed lock

– 5 –

4

screw

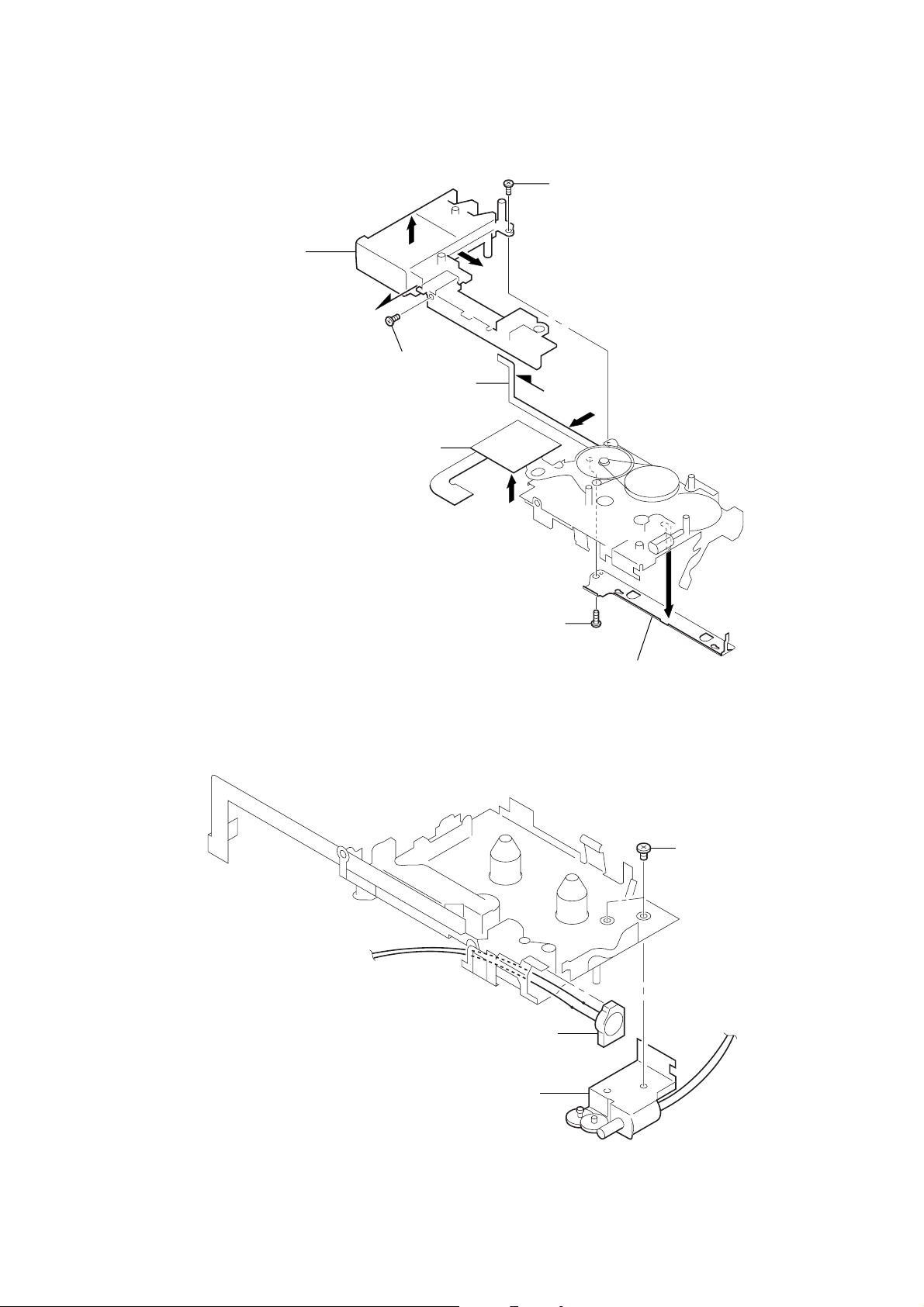

3-3. MD BLOCK ASSY

• When installing the MD block assy, position the knobs with the switches.

• When installing the microphone cabinet assy, align the knobs with the spring and switches.

1

screw (B1.7x4), tapping

switches

spring

4

screws (1.7x3), tapping

5

bracket (speaker)

6

speaker (2.8cm)

switches

knob

(HOLD EJECT)

knob

(FF/CUE•REW/REVIEW)

switch

2

MD block assy

knobs

(REC PAUSE/REC)

3

cabinet assy, microphone

knob (TAPE SPEED)

knob (FAST PB)

3-4. MAIN BOARD, COMPLETE

• When installing, position the cam gear with the switch.

8

3

unsolders

4

CN101

a

MAIN board, complete

7

screw (B1.7x4), tapping

6

screw, precision +P 1.4x1.6

5

screw, precision +P 1.4x1.6

1

switch

unsolders

gear, cam

b

– 6 –

2

unsolders

3-5. FRAME

• Be careful not to damage the flexible board.

• Remove from a to b to c.

7

frame

6

flexible board (head, magnetic)

5

absorbent, acoustic, reflection

a

b

3

screw

c

b

4

a

screw

c

3-6. MODE MOTOR BLOCK

1

screw (1.7x4), tapping (B)

3

microphone, electret condenser

2

cover (HD)

1

screws (M1.4)

2

mode motor block

– 7 –

SECTION 4

MECHANICAL ADJUSTMENTS

SECTION 5

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Before adjusting, clean the following parts with a piece of

cotton moistened with alcohol.

record/playback/erase head pinch roller

rubber belt capstan

2. Demagnetize the record/playback/erase head using a head

demagnetizer. (Do not bring the head demagnetizer close to the

erase head.)

3. Do not use a magnetized screwdriver for adjustments.

4. After adjusting, apply screw-locking compound to the adjusted

parts.

5. Unless specified otherwise, use a specified voltage (2.5 V DC)

to perform the adjustments.

Torque Measurement

TAPE SPEED switch : 2.4cm/s

Mode Torque Meter Meter Reading

FWD, REV

FF, REW CQ-201M

T ape Tension Measurement

TAPE SPEED switch : 2.4cm/s

Mode Torque Meter Meter Reading

FWD CQ-403M

CQ-103M

5 – 10 g • cm

(0.07 – 0.13 oz • inch)

more than 15 g • cm

(more than 0.209 oz • inch)

more than 15 g

(more than 0.53 oz)

Standard Input Level

Input terminal MIC (PLUG IN POWER) jack

Source impedance 300 Ω

Input level 0.77 mV (–60 dB)

Frequency 1 kHz

Standard Output Level

Output terminal EAR jack

Load impedance 10 kΩ

Output level 78 mV (–20 dB)

Test Tape

Type Signal User for

S-2-A030 3 kHz, –20 dB Azimuth Adjustment

WS-24 3 kHz, –10 dB Tape Speed Adjustment

0 dB = 0.775 V

PRECAUTION

• Switch and control position

VOL control : 5 (Mechanical center)

TAPE SPEED switch : 2.4cm/s

V•O•R switch : OFF

FAST PB switch : OFF

MIC SENS switch : H

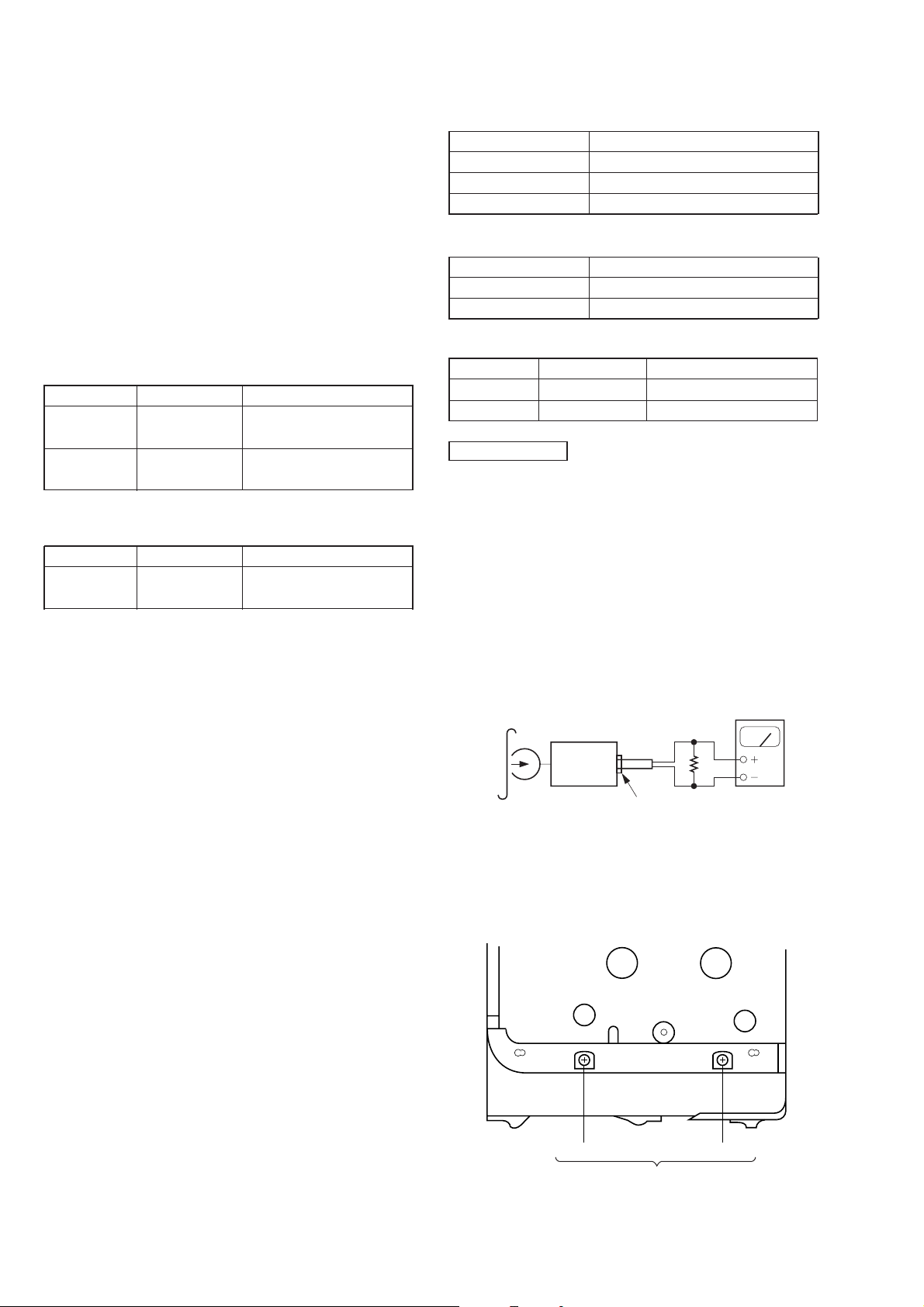

Record/Playback/Erase Head Azimuth Adjustment

Procedure :

– FWD/REV playback –

test tape

S-2-A030

(3 kHz, –20 dB)

set

• Rotate the screw to adjust level meter reading to the maximum.

Note : Adjust to the maximum peak though there may be two or

three peaks.

Adjustment Location :

10 k

EAR jack (J102)

level meter

Ω

– 8 –

REV side

adjustment screws

FWD side

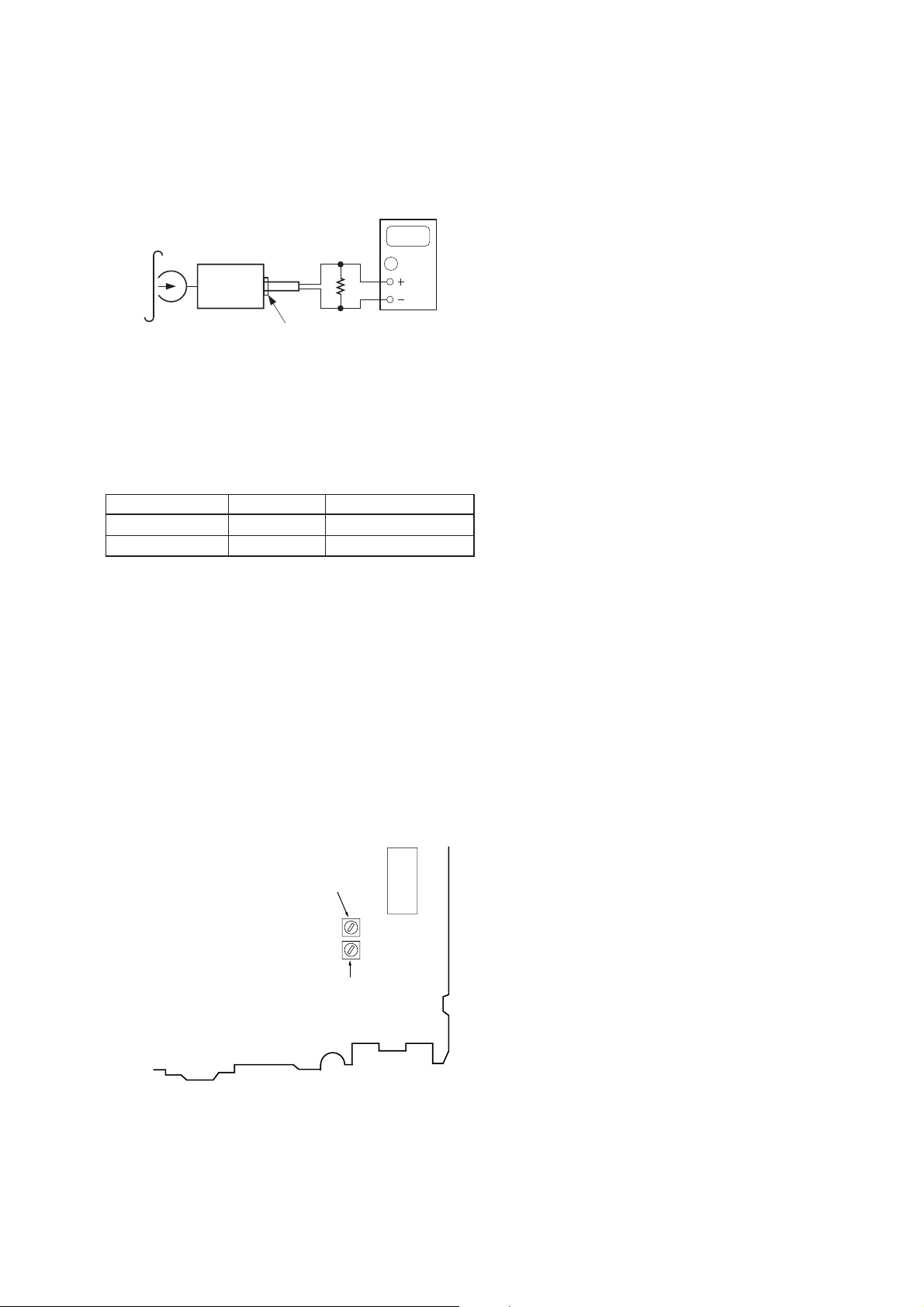

T ape Speed Adjustment

Procedure :

After adjusting the 2.4cm/s speed, adjust the 1.2cm/s speed.

– FWD/REV playback –

digital frequency

test tape

WS-24

(3 kHz, –10 dB)

10 k

set

EAR jack (J102)

counter

0000

Ω

1. Tape Speed : 2.4cm/s/FWD

Playback WS-24 (tape center part) and adjust RV601 so that

reading on the digital frequency counter becomes 3,000 Hz.

2. Tape Speed : 1.2cm/s/FWD

Playback WS-24 (tape center part) and adjust RV601 so that

reading on the digital frequency counter becomes 1,500 Hz.

Specification Value :

Adjustment part Tape speed Frequency counter

RV601 2.4cm/s 2,985 – 3,045 Hz

RV602 1.2cm/s 1,470 – 1,530 Hz

3. Tape Speed : 2.4cm/s/REV

Playback WS-24 (tape center part) in the REV state.

Check that digital frequency counter reading is within ± 2% of

reading of step 1.

4. Tape Speed : 1.2cm/s/REV

Playback WS-24 (tape center part) in the REV state.

Check that digital frequency counter reading is within ± 2% of

reading of step 2.

2.4cm/s : 60 Hz

1.2cm/s : 30 Hz

Adjustment Location : main board

– MAIN BOARD (SIDE B) –

IC601

RV602 1.2cm/s

RV601 2.4cm/s

– 9 –

Loading...

Loading...