Page 1

REVISION HISTORY

BX1L

CHASSIS

MODEL

KV-SA28M36

NO. SUFFIX DATE SUPPL. / CORR DESCRIPTION

1 -01 2004/10 -- 1st. Issue

PA RT NO. : 9-872-483-01

Page 2

SERVICE MANUAL

BX1L

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-SA28M36

RM-W107 Oceania SCC-V03N-A

MODEL COMMANDER DEST. CHASSIS NO.

RM-W107

TRINITRON

®

COLOR TV

Page 3

KV-SA28M36

RM-W107

TABLE OF CONTENTS

Section Title Page

SELF DIAGNOSTIC FUNCTION.............................. 3

1. DISASSEMBLY

1-1. Rear Cover Removal ................................................. 6

1-2. Speaker Removal ...................................................... 6

1-3. Chassis Assy Removal .............................................. 6

1-4. Service Position ........................................................ 6

1-5. Terminal Bracket and J3 Board Removal ................ 6

1-6. F Board Removal ...................................................... 6

1-7. BC Board Removal ................................................... 7

1-8. DL Board Removal ................................................... 7

1-9. WD Board Removal .................................................. 7

1-10.H4 and H6 Boards Removal ..................................... 7

1-11.A and B Boards Removal ......................................... 7

1-12.Picture Tube Removal ............................................... 8

2. SET-UP ADJUSTMENTS

2-1. Beam Landing ........................................................... 9

2-2. Convergence ............................................................ 10

2-3. Focus Adjustment .................................................... 12

2-4. G2 (SCREEN) Adjustments ................................... 12

2-5. White Balance Adjustment ..................................... 12

2-6. Sub Bright Adjustment ........................................... 12

3. CIRCUIT ADJUSTMENTS

3-1. Adjustment With Commander ................................ 13

3-2. Adjustment Method ................................................ 14

3-3. Picture Quality Adjustment .................................... 32

3-4. Deflection Adjustment ............................................ 33

3-5. Picture Distortion Adjustment ................................ 34

Section Title Page

4. DIAGRAMS

4-1. Block Diagram ........................................................ 36

4-2. Circuit Boards Location .......................................... 37

4-3. Schematic Diagram Information ............................ 37

4-3-1. A Board — Processor, Audio, Tuner, Jack

(Block 001) ................................................. 38

4-3-2. A Board — Power Supply, Deflection

(Block 002) ................................................ 40

4-3-3. A Board — Heat Sink (Block 003)............ 42

4-3-4. B Board Schematic Diagram ..................... 43

4-3-5. BC Board Schematic Diagram ................... 45

4-3-6. C Board Schematic Diagram ..................... 47

4-3-7. DL Board Schematic Diagram ................... 49

4-3-8. F and H4 Boards Schematic Diagram ....... 51

4-3-9. H6 Board Schematic Diagram ................... 52

4-3-10. J3 Board Schematic Diagram ..................... 54

4-3-11. VM Board Schematic Diagram .................. 55

4-3-12. WD Board Schematic Diagram ................. 57

4-4. Voltage Measurement and Waveforms ................... 58

4-5. Printed Wiring Boards ............................................ 65

4-6. Semiconductors ....................................................... 75

5. EXPLODED VIEWS

5-1. Picture Tube and Speaker Bracket.......................... 77

5-2. Chassis ..................................................................... 78

6. ELECTRICAL PARTS LIST .................................... 79

OPERATING INSTRUCTIONS

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND

THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD,

OR CARBON PAINTED ON THE CRT, AFTER REMOVING THE

ANODE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

Page 4

KV-SA28M36

SELF DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER lamp will automatically

begin to flash.

The number of times the lamp flashes translates to a probable source of the problem. If an error symptom cannot be

reproduced, the remote commander can be used to review the failure occurrence data stored in memory to reveal past

problems and how often these problems occur.

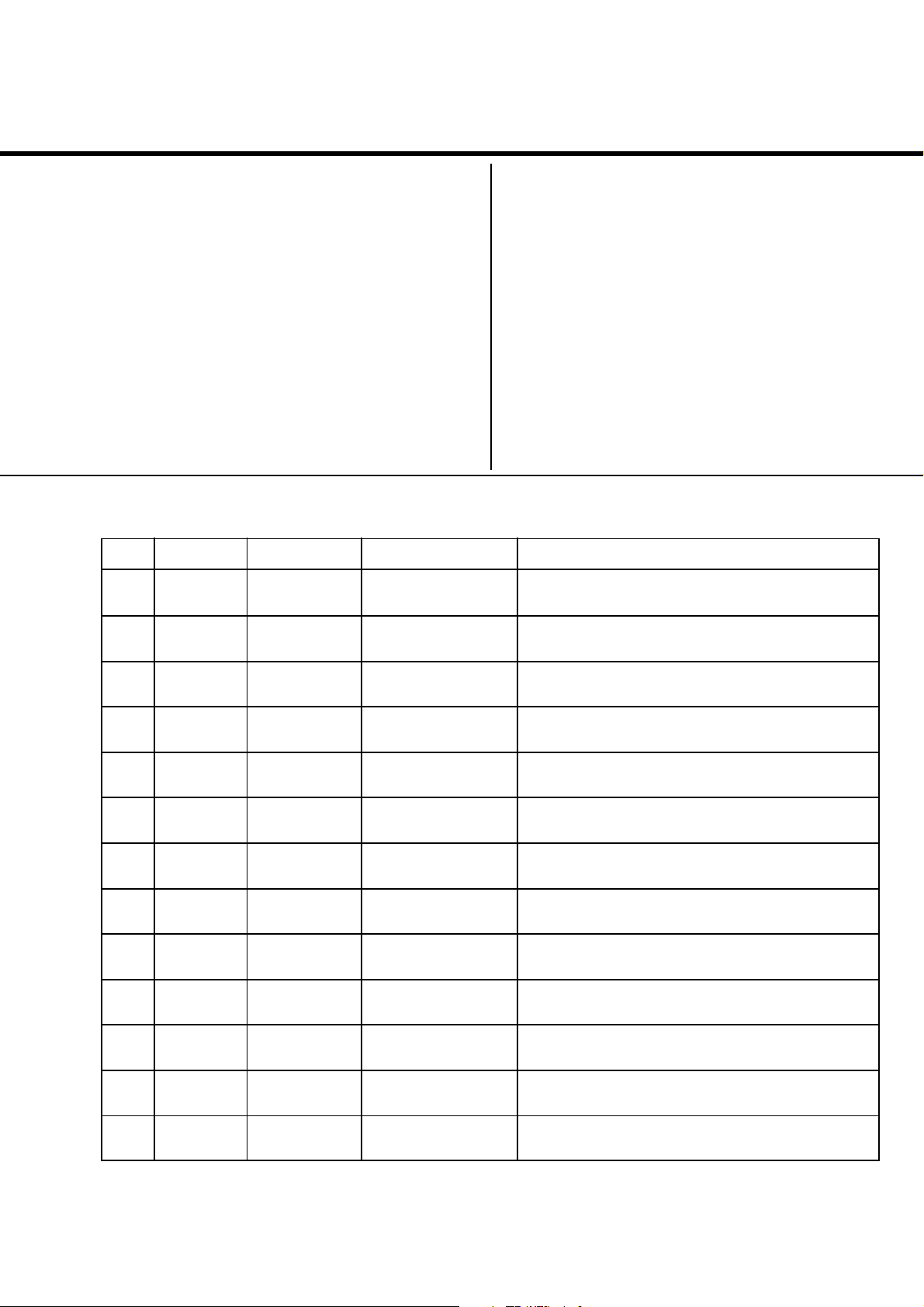

1. DIAGNOSTIC TEST INDICATORS

When an error occurs, the STANDBY/TIMER lamp will flash a number of times to indicate the possible cause of the

problem. If there is more than one error, the lamp will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen. No error has occured if the screen displays a “0”.

RM-W107

Diagnosis

Item

Description

• Power does not

turn on

• +B overcurrent

(OCP)*

• Vertical NG.

• IK (AKB)

No. of times

STANDBY lamp

flashes

Does not light

2 times

4 times

5 times

Self-diagnostic

display/Diagnosis

result

—

2:0

2:1 ~ 255

4:0

4:1 ~ 255

5:0

5:1 ~ 255

Probable

Cause

Location

• Power cord is not plugged

in.

• Fuse is burned out (F4601)

(F Board)

• H.OUT (Q511) is shorted.

(A board)

• IC751 is shorted.

(C/CV Board)

• +13V is not supplied.

(A Board)

• IC503 voltage list is faulty.

(A Board)

• Video OUT (IC751) is faulty.

(C Board)

• IC001 is faulty. (A Board)

• Screen (G2) is improperly

adjusted.

Detected

Symptoms

• Power does not come on.

• No power is supplied to the

TV.

• AC power supply is faulty.

• Power does not come on.

• Load on power line is

shorted.

• Has entered standby state

after horizontal raster.

• Vertical deflection pulse is

stopped.

• Power line is shorted or

power supply is stopped.

• No raster is generated.

• CRT cathode current

detection reference pulse

output is small.

• Supply Voltage

Protection

Note*: If a + B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously.

The symptom that is diagnosed first by the microcontroller is displayed on the screen.

8 times

8:0

8:1 ~ 255

• IC604 faulty.

• IC607 faulty.

• No power supply to CRT

ANODE.

• No RASTER is generated.

– 3 –

Page 5

KV-SA28M36

RM-W107

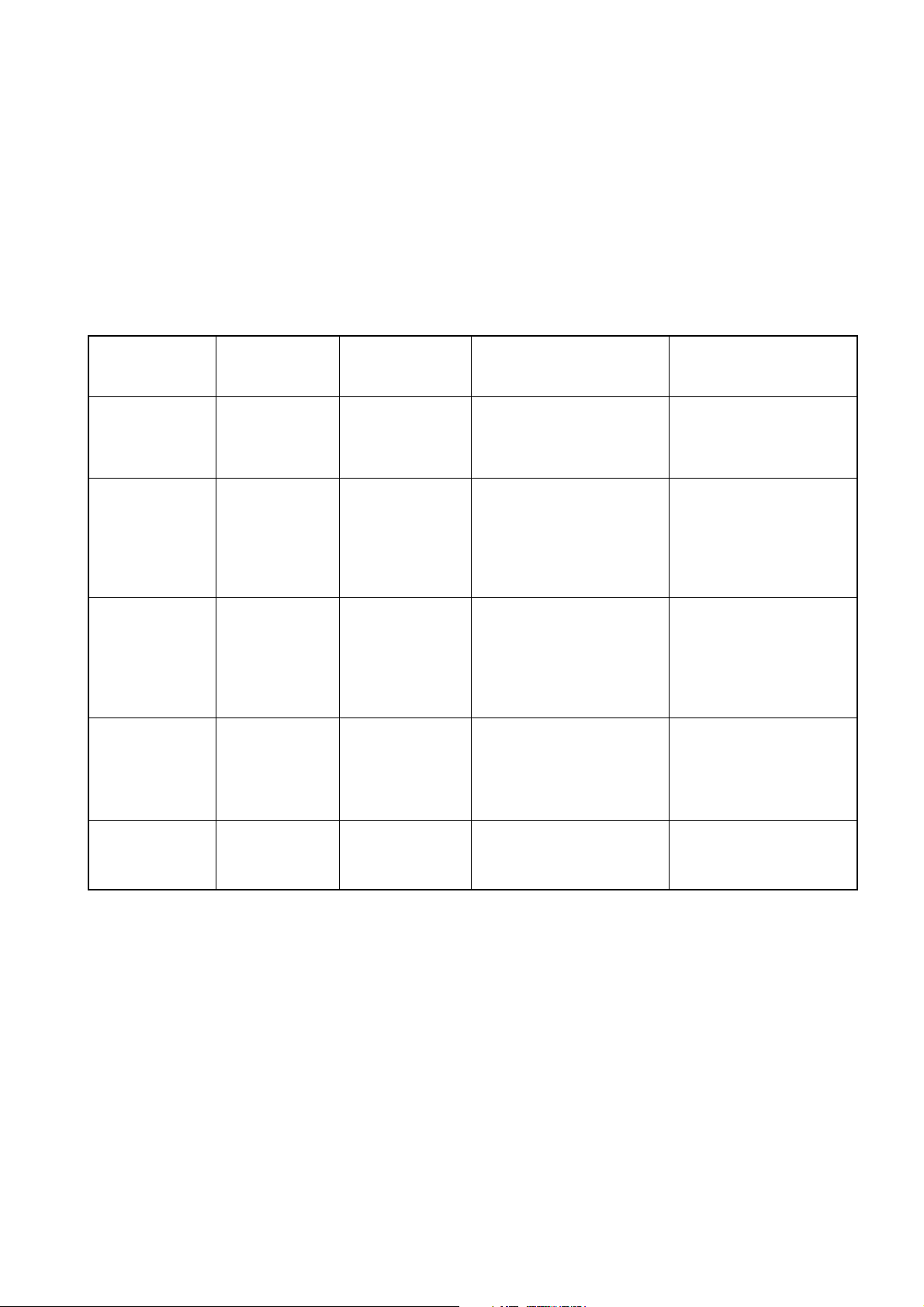

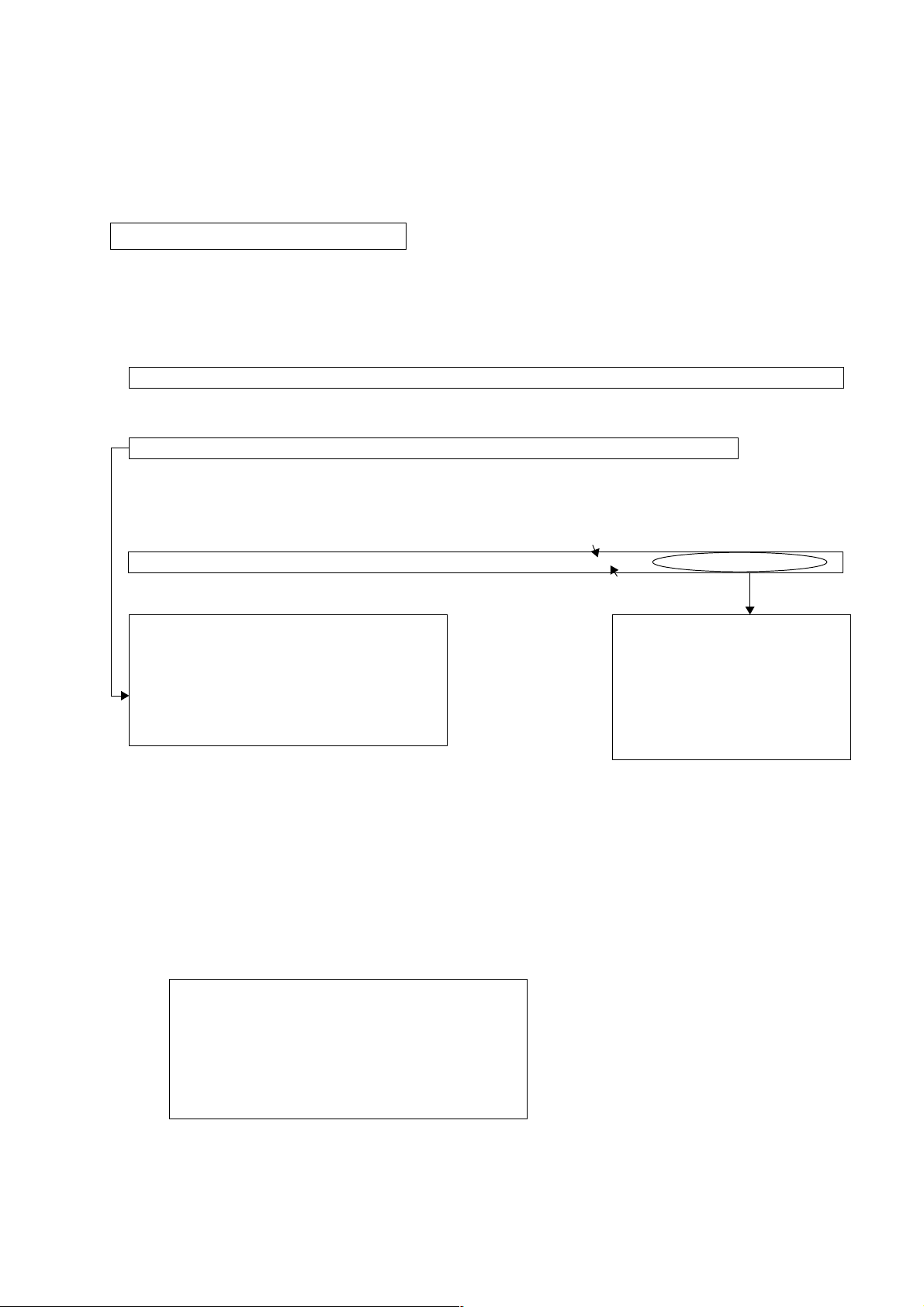

2. DISPLAY OF STANDBY (1) indicator FLASH

COUNT

Lamp ON 300ms

Lamp OFF 300ms

Lamp OFF 3 sec

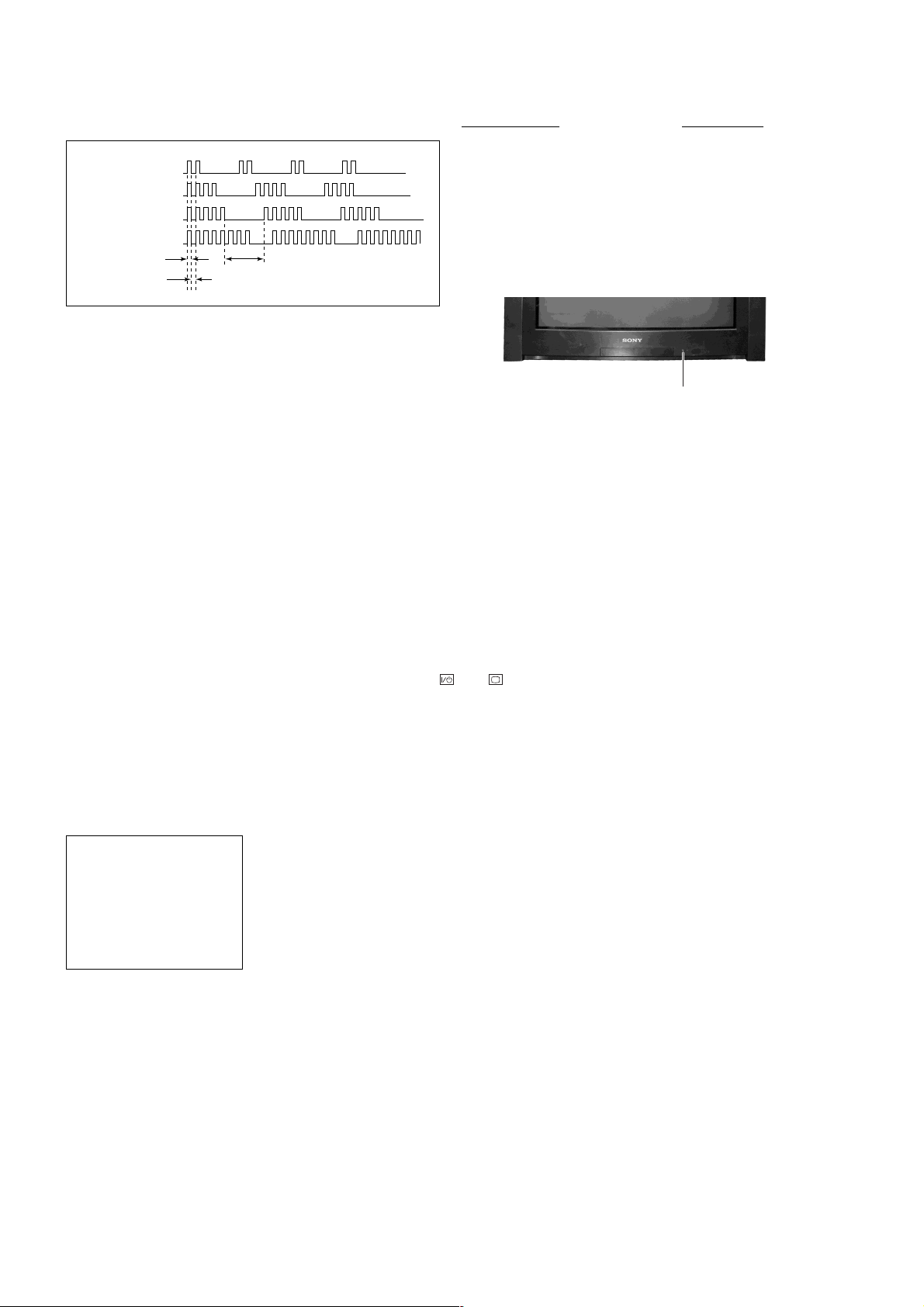

3. STOPPING THE STANDBY (1) indicator FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY (1) lamp

from flashing.

Diagnostic Item Flash Count*

+B overcurrent 2 times

Vertical NG. 4 times

IK (AKB) 5 times

Supply Voltage Protection 8 times

* One flash count is not used for self-diagnosis.

FLASH RED n Please refer diagnosis item.

FLASH GREEN n OK

STANDBY (1) indicator

4. SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as "power sometimes shuts off" or "screen sometimes goes out" that cannot be confirmed,

it is possible to bring up past occurrence of failure on the screen for confirmation.

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

[display] / channel [5] / volume [-] / Power

/ TV

˘

Note that this differs from entering the service mode (volume [+]).

Self-Diagnostic screen display

SELF DIAGNOSTIC

2 : 0

3 : N/A

4 : 0

5 : 1

8 : 0

101 : N/A

Numeral "0" means that no fault was detected.

Numeral "1" means the number of a fault occurrence (1~255).

– 4 –

Page 6

KV-SA28M36

5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

Since the diagnosis results displayed on the screen are not automatically cleared, always check the self-diagnostic screen

during repairs. When you have completed the repairs, clear the result display to "0".

Unless the result display is cleared to "0", the self-diagnosis function will not be able to detect subsequent faults after

completion of the repairs.

[Clearing the result display]

To clear the result display to "0", press buttons on the remote commander sequentially when the self-diagnostic screen is

displayed, as shown below:

Channel [8] / "0"

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

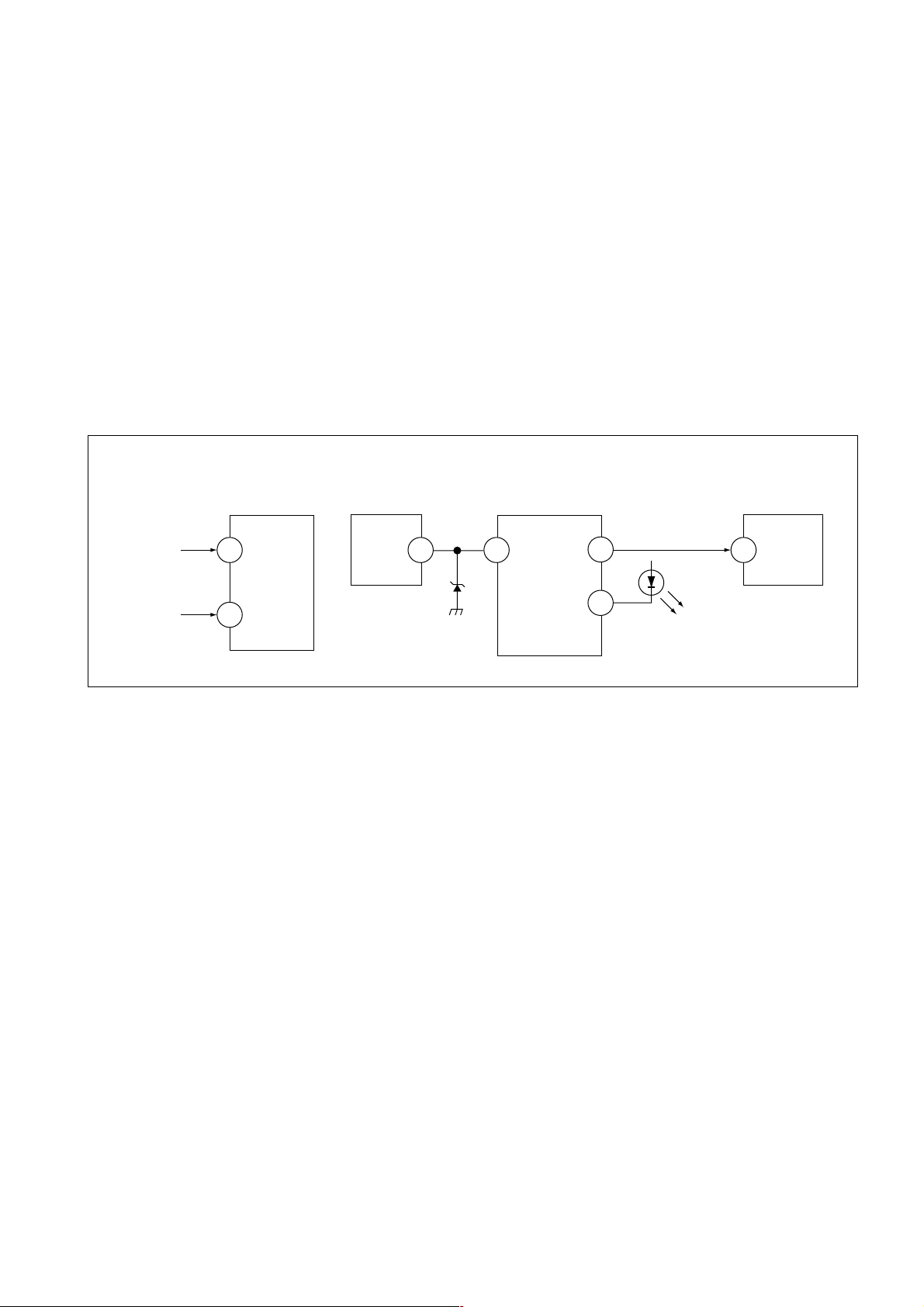

6. SELF-DIAGNOSTIC CIRCUIT

RM-W107

FROM

C BOARD

IC751 PIN 5

A BOARD

FROM

Q511

COLLECTOR

A BOARD

IC001

Y/CHROMA JUNGLE

IK

97

EHTO

A BOARD

IC503

V.OUT

F.B-PLS

A BOARD

IC001

SYSTEM

SDA1

3 11645

V.GUARD

RED LED

30

7

DISPLAY

A BOARD

IC003

MEMORY

5

SDA

[+B overcurrent OCP ] Occurs when an overcurrent on the +B (135V) line is detected by pin 97 of IC001

(A Board). If the voltage of pin 97 of IC001 (A Board) is less than 3.9V, the unit will

automatically go to standby.

[Vertical NG.] Occurs when an absence of the vertical deflection pulse is detected by pin 116 of

IC001 (A Board).

[IK $AKB%] If the RGB levels* do not balance within 15 sec after the power is turned on, this error

will be detected by IC001 (A Board). TV will stay on, and indicator will start to Blink 5

times.

[Supply Voltage Protection] Occurs when IC001 internal Supply Voltage Protection detects less than 4.2V due to

unproper power supply to IC001. TV cuts off high voltage power of anode CRT. No

picture will be detected eg IC607, IC604 go faulty.

* (Refers to the RGB levels of the AKB detection Ref pulse that detects 1K)

– 5 –

Page 7

KV-SA28M36

RM-W107

SECTION 1

DISASSEMBLY

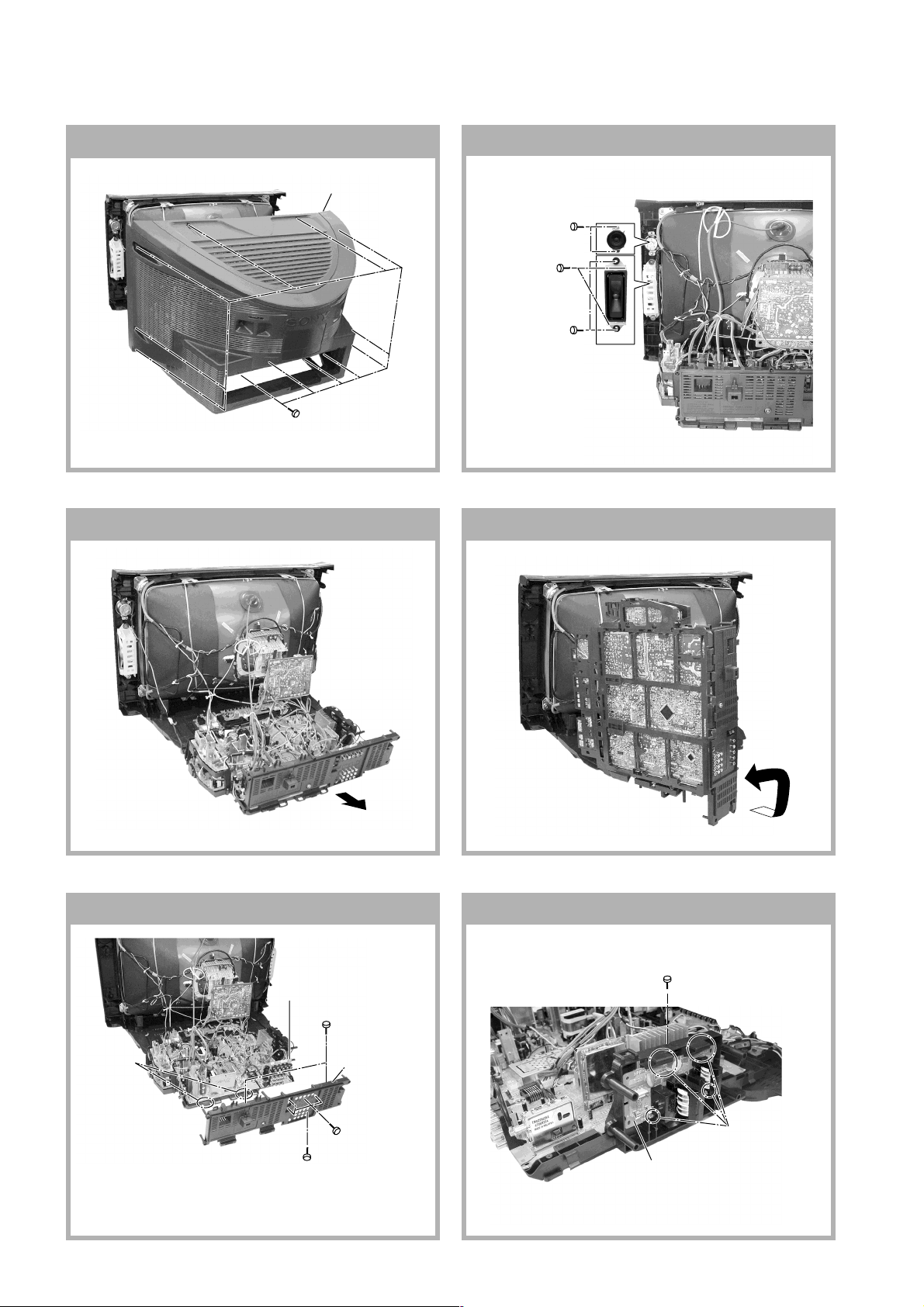

1-1. REAR COVER REMOVAL

2 Rear cover

1 Twelve screws

(+BVTP 4 × 16

Type2 IT-3)

1-2. SPEAKER REMOVAL

1 Two screws

(+BVTP 4 × 16

Type2 IT-3)

3 Two screws

(+BVTP 4 × 16

Type2 IT-3)

2 Two screws

(Washer Head)

(+P4x16)

1-3. CHASSIS ASSY REMOVAL 1-4. SERVICE POSITION

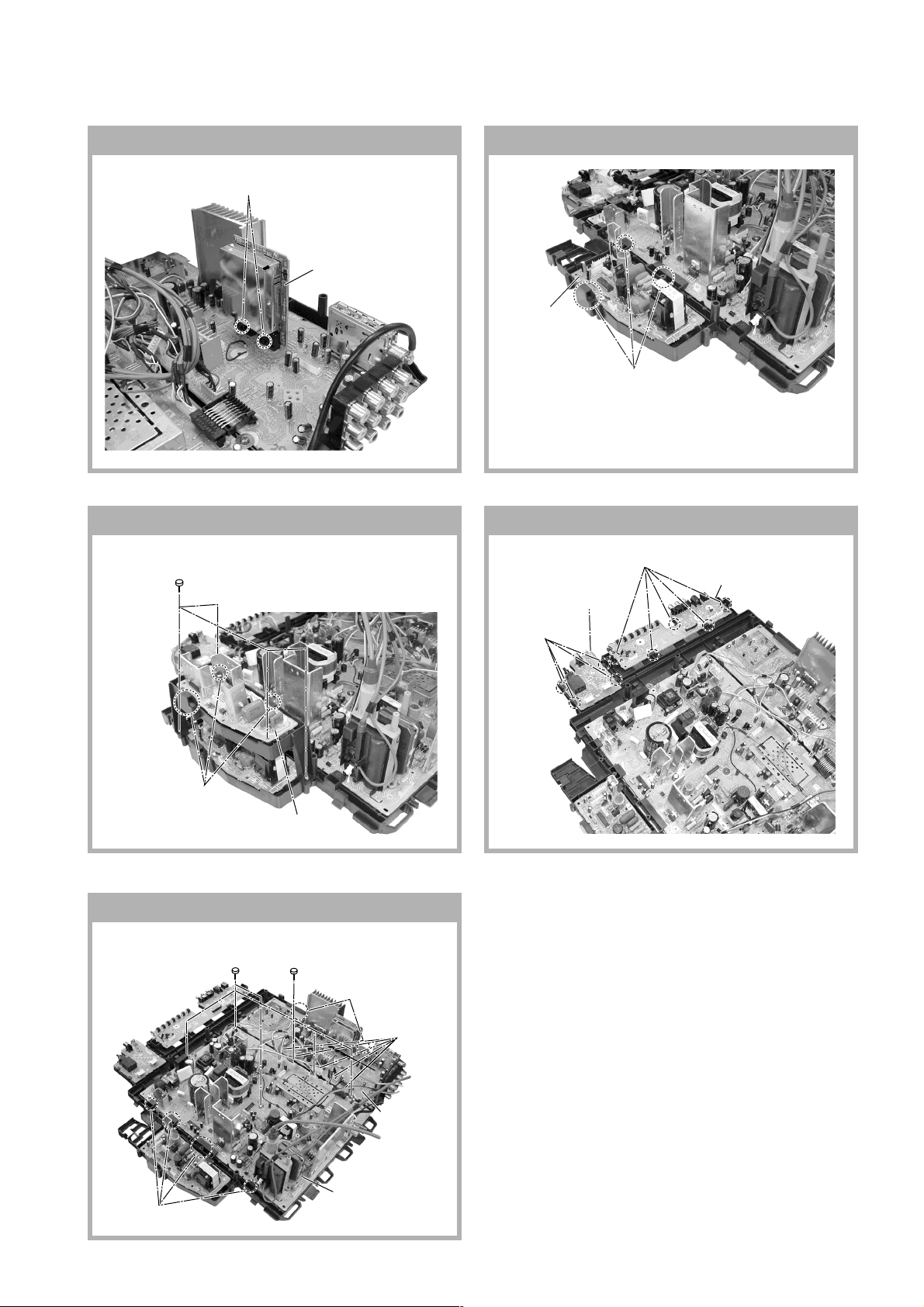

1-5.

TERMINAL BRACKET AND J3 BOARD REMOVAL

6 J3 Board

3 Two screws

(+BVTP 3 × 12

4 Two

hooks

1 One screw

(+BVTP 4 × 16

Type2 IT-3)

Type2 IT-3)

2 Four screws

(+BVTP 3 × 12

Type2 IT-3)

1-6. F BOARD REMOVAL

3 One screw

(+BVTP 3 × 12

Type2 IT-3)

5 Terminal

Bracket

1 Four hooks

2 F Board

– 6 –

Page 8

KV-SA28M36

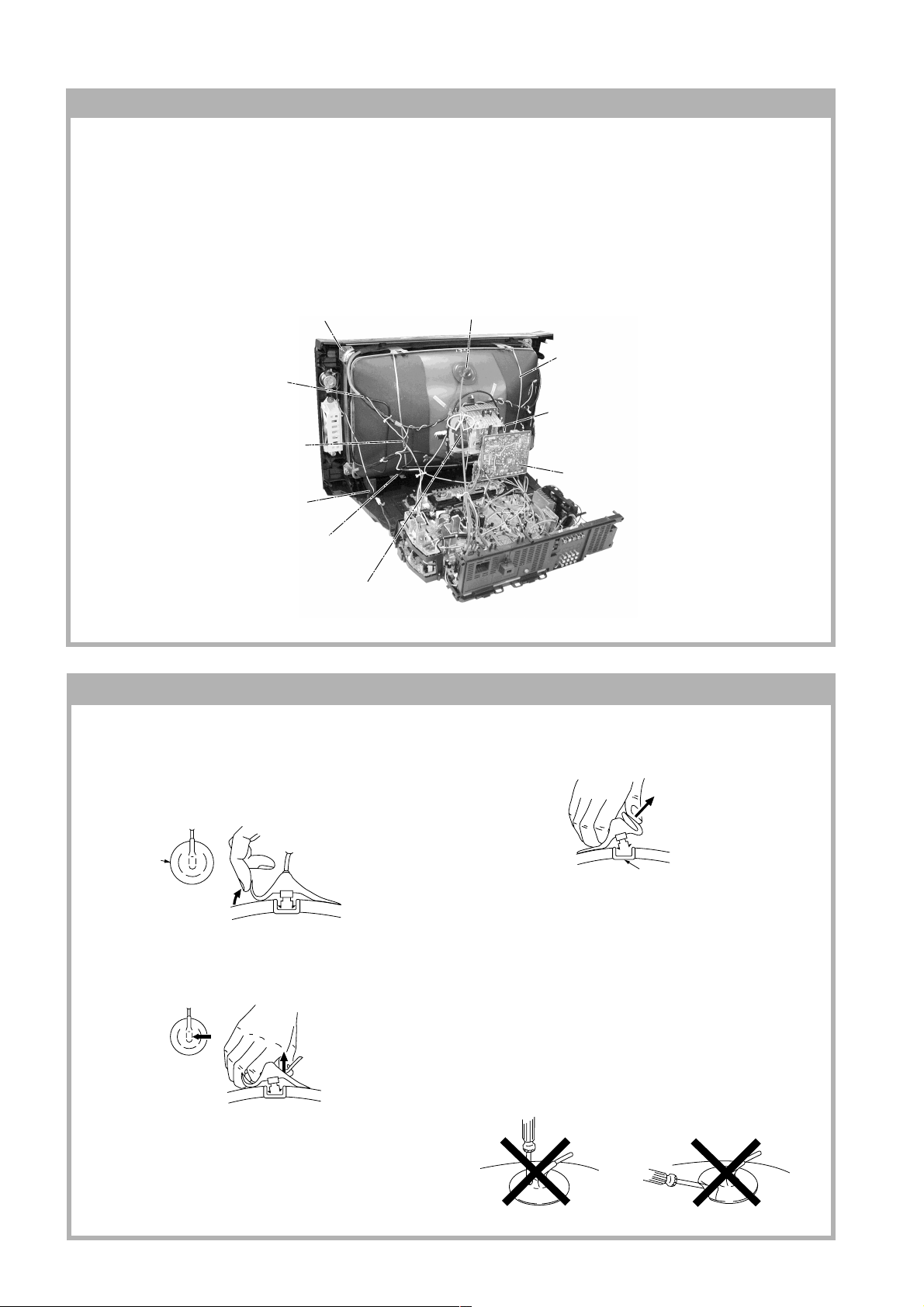

3 Four

hooks

1 Five hooks

2 H6 Board

4 H4 Board

RM-W107

1-7. BC BOARD REMOVAL

1 Two clips

1-9. WD BOARD REMOVAL

3 Four screws

(+BVTP 3 × 12 Type2 IT-3)

1-8. DL BOARD REMOVAL

2 BC Board

2 DL Board

1 Three hooks

1-10. H4 AND H6 BOARDS REMOVAL

1 Three hooks

2 WD Board

1-11. A AND B BOARDS REMOVAL

5 One screw

(Washer Head)

(+P 3 × 12)

6 Four hooks

2 Five screws

(3 × 12)(+) BVTAP

3 Two hooks

1 Five

connectors

7 B Board

4 A Board

– 7 –

Page 9

KV-SA28M36

RM-W107

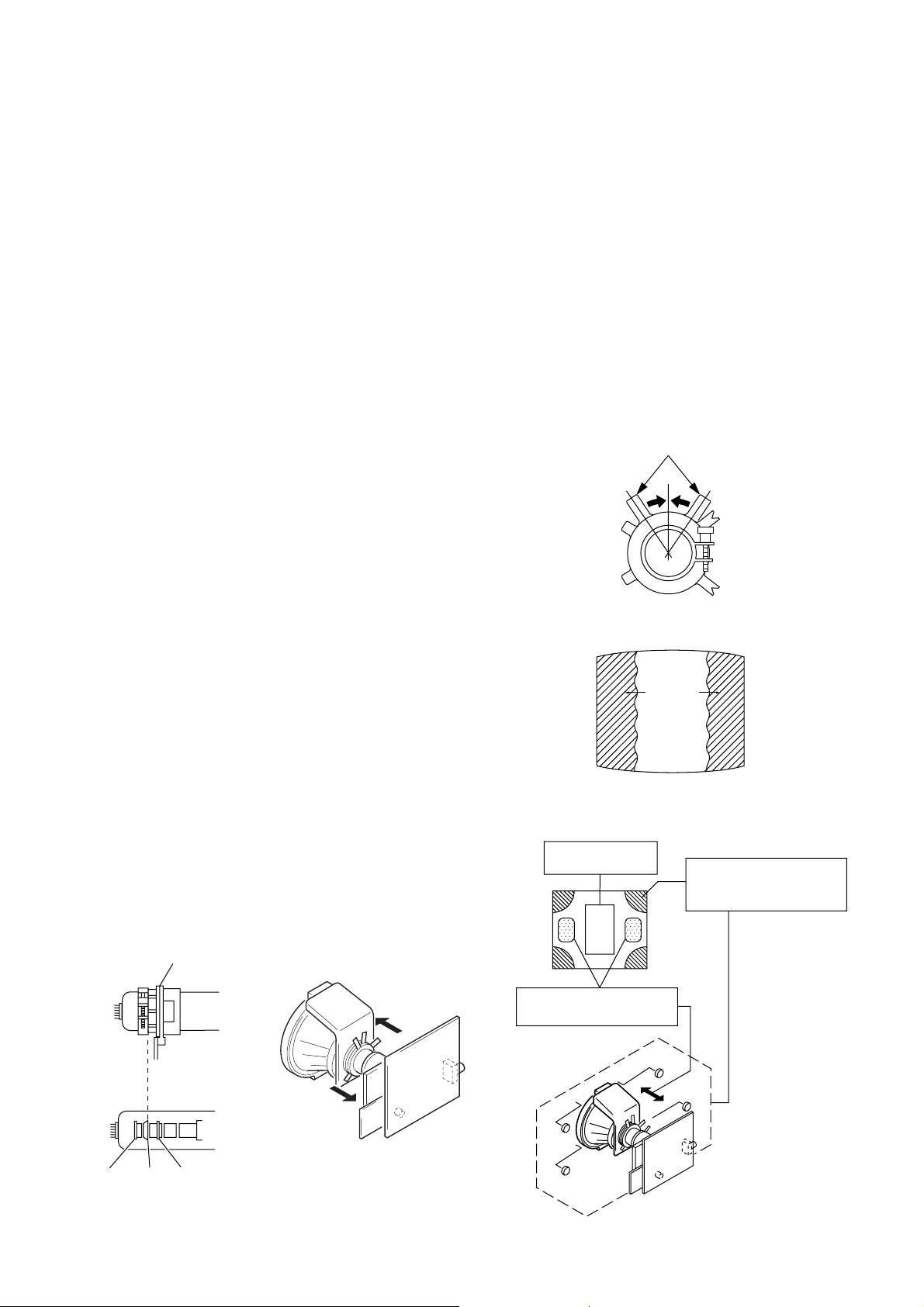

1-12. PICTURE TUBE REMOVAL

Note:

• The Picture tube is upside-down for this model and the position for the anode cap and tension springs are changed

accordingly.

• Please make sure the TV set is not in standing position before removing necessary CRT support located on bottom

right and left.

1) Remove the rear cover.

2) Unplug all interconnecting leads from the Deflection yoke, Neck assy, Degaussing Coil and CRT grounding strap.

Remove Chassis Assy.

3) Place the TV set with the CRT face down on a cushion jig

qd Screw, Tapping 7 +

Crown Washer

6 Degaussing Coil

5 Holder, DGC(2) Removal

qs Supports, CRT(2) Removal

7 Spring Tension(2)

Removal

qa Loosen the Deflection Yoke

fixing screw and remove

4 Anode Cap Removal

8 Earth Coating Assy Removal

q; Loosen the Neck Assembly

fixing screw and remove

Neck Assy & VM Board

9 C Board Removal

• REMOVAL OF ANODE-CAP

Note:

• After removing the anode, short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT

shield or carbon paint on the CRT.

• REMOVING PROCEDURES

a

a

1 Turn up one side of the rubber cap in the direction

indicated by the arrow a.

b

b

2 Using a thumb pull up the rubber cap firmly in the direc-

tion indicated by the arrow b.

c

Anode Button

3 When one side of the rubber cap is separated from the

anode button, the anode-cap can be removed by

turning up the rubber cap and pulling it up in the

direction of the arrow c.

• HOW TO HANDLE AN ANODE-CAP

1 Do not damage the surface of anode-caps with

sharp shaped objects.

2 Do not press the rubber too hard so as not to

damage the inside of anode-cap.

A metal fitting called the shatter-hook terminal is

built into the rubber.

3 Do not turn the foot of rubber over too hard.

The shatter-hook terminal will stick out or damage

the rubber.

– 8 –

Page 10

SECTION 2

SET-UP ADJUSTMENTS

KV-SA28M36

RM-W107

The following adjustments should be made when a

complete realignment is required or a new picture tube is

installed.

Perform the adjustments in the following order :

1. Beam Landing

2. Convergence

3. Focus

Set the controls as follows unless otherwise noted:

VIDEO MODE: .................................................... Standard

4. Screen(G2)

5. White Balance

PICTURE CONTROL:......................................... Normal

BRIGHTNESS CONTROL: ................................. Normal

Note : Test Equipment Required.

1. Pattern Generator

2. Degausser

3. DC Power Supply

4. Digital Multimeter

5. Oscilloscope

......................................................................................................................................................................................................................

Preparation :

• In order to reduce the influence of geomagnetism on

the set's picture tube, face it east or west.

Purity control

• Switch on the set's power and degauss with the

degausser.

2-1. BEAM LANDING

PICTURE MODE: DYNAMIC

1. Input a white signal with the pattern generator.

Contrast

Brightness

2. Position neck assy as shown in Fig 2-1.

}

normal

Fig. 2-3

3. Set the pattern generator raster signal to a green

raster.

4. Move the deflection yoke to the rear and adjust with

purity control so that the green is at the center and the

Blue

Red

blue and the red take up equally sized areas on each

side. (Figures 2-2 through 2-4.)

Green

5. Move the deflection yoke forward and adjust so that the

entire screen is green. (Figure 2-2.)

6. Switch the raster signal to blue, then to red and verify

the condition.

Fig. 2-4

7. When the position of the deflection yoke have been

decided, fasten the deflection yoke with the screws and

DY spacers.

8. If the beam does not land correctly in all the corners,

use a magnet to adjust it.

(Figure 2-5.)

Purity control

corrects this area.

b

a

Disk magnets or rotatable

disk magnets correct these

areas (a-d).

Neck assy

Align the edge of

the neck assy with

the edge of the G2 grid.

G2G1 G3

Fig. 2-1 Fig. 2-2

– 9 –

c

Deflection yoke positioning

corrects these areas.

a

d

d

Fig. 2-5

b

c

Page 11

KV-SA28M36

RM-W107

2-2. CONVERGENCE

• Before starting this adjustment, adjust the focus,

horizontal size and vertical size.

• Receive dot/hatch signal

• Pic mode: Soft

Center dot

R G B

H. STAT VR

R

G

B

V. STAT

Magnet

RV705

H. STAT

RV1800

SCREEN (G2)

C Board

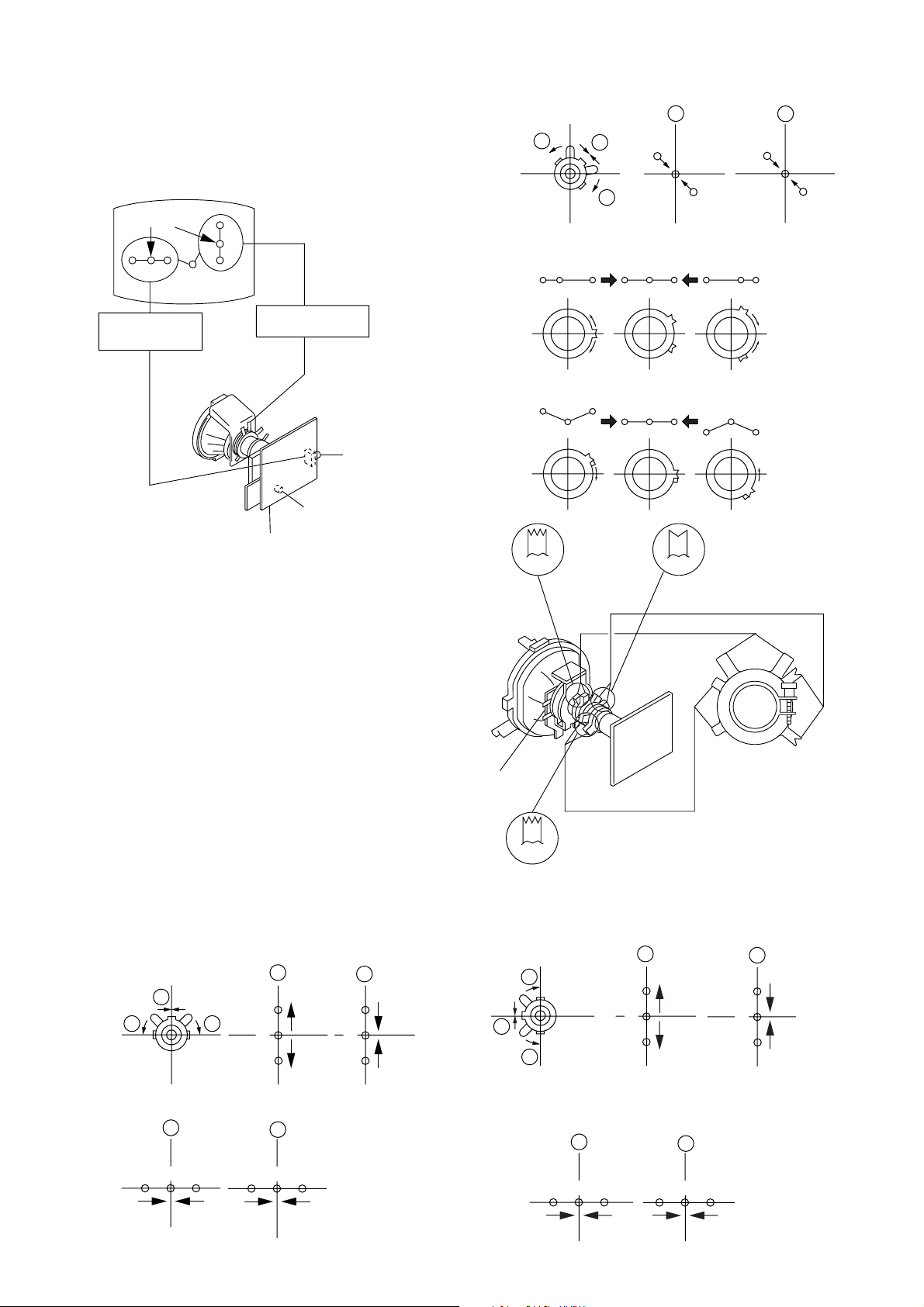

(1) Horizontal and Vertical Static Convergence

1. (Moving vertically), adjust the V.STAT magnet so that

the red, green and blue dots are on top of each other at

the centre of the screen.

2. (Moving horizontally), adjust the H.STAT VR control so

that the red, green and blue dots are on top of each

other at the center of the screen.

3. If the H.STAT variable resistor cannot bring the red,

green and blue dots together at the center of the

screen, adjust the horizontal convergence with the

H.STAT variable resistor and the V.STAT magnet in the

manner given below.

(In this case,the H.STAT variable resistor and the

V.STAT magnet influence each other so be sure to

perform adjustments while tracking).

4. BMC (Hexapole) Magnet.

If the red, green and blue dots are not balanced or

aligned, then use the BMC magnet to adjust in the

manner described below.

3 H. STAT

a

b

a

R

b

G

B

B

G

4 BMC (Hexapole) Magnet

RG B R G B R GB

RB

G

Purity

DY pocket

V.STAT

5. Operation of V.STAT magnet

If the V.STAT magnet is moved in the "a" and "b" arrows,

the red, green and blue dots moves as shown below.

RG

V.STAT

GB

RB

BMC

BMC (Hexapole)

Purity

b

R

1 V. STAT

a

b b

2 H. STAT VR

a

RGGBB

a

a

B

G

R

b

B

G

R

b

B

a

b

G

R

b

B

G

R

6. Moved RV705 H.STAT.

the red, green an blue dots move as shown below.

b

R

a

RGGBB

b

R

– 10 –

Page 12

KV-SA28M36

RM-W107

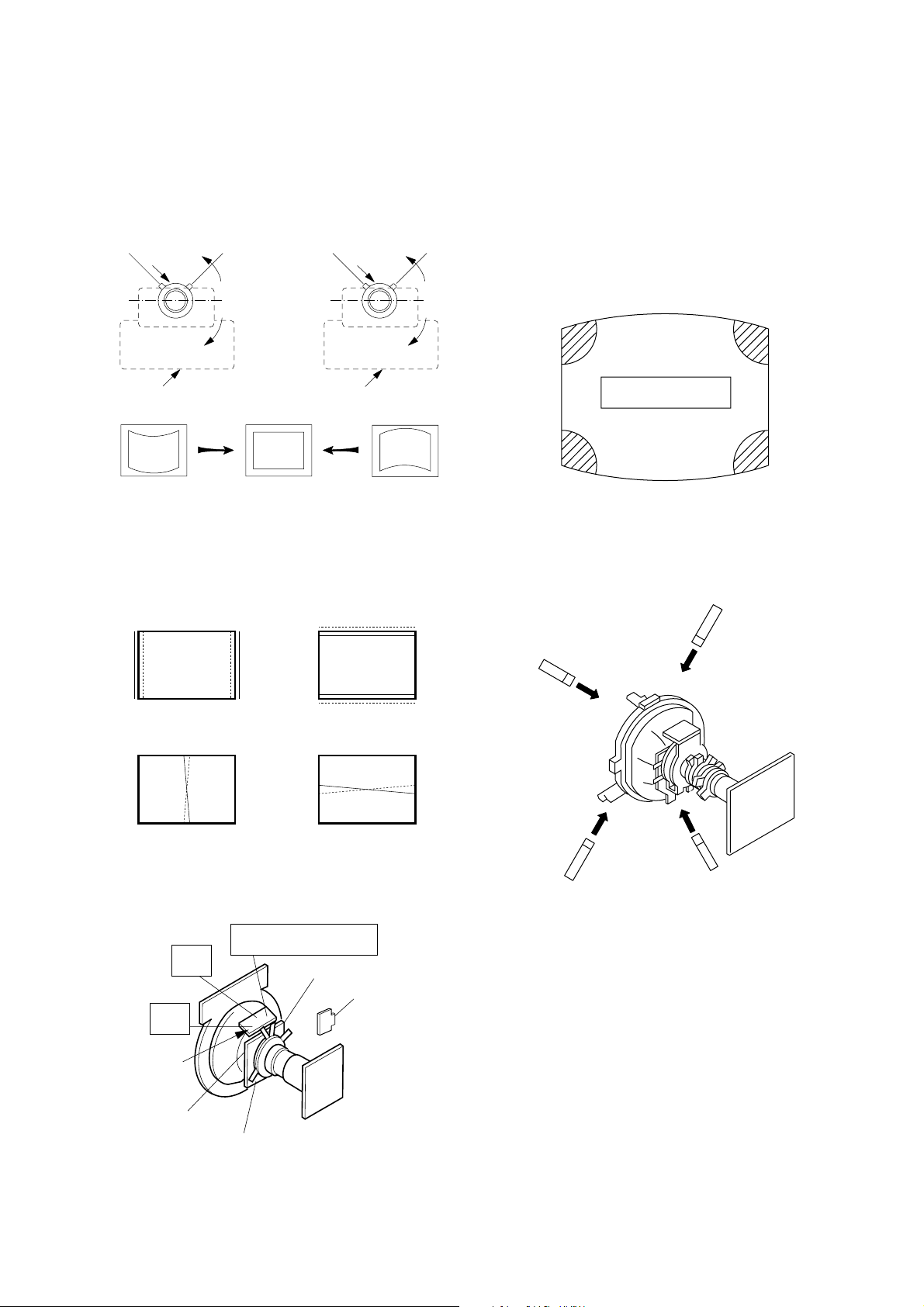

7. Y separation axis correction magnet adjustment.

1. Receive the cross-hatch signal and adjust

[PICTURE] to [MIN] and [BRIGHTNESS] to

[STANDARD] .

2. Adjust the Y separation axis correction magnet on

the neck assembly so that the horizontal lines at

the top and bottom of the screen are straight.

Neck assy Neck assy

VM board VM board

RedBlue

RedBlue

(2) Dynamic Convergence Adjustment

Preparation:

Before starting this adjustment, adjust the horizontal and

the vertical static convergence

RB

B

R

TLV Rotate TLV-2 VOL (29", 34") on DY

XCV Rotate XCV Adj core on DY

YCH Rotate YCH VOL on DY

TLH Insert TLH Correction Plate to DY Pocket

(Left or Right)

(3) Screen-corner Convergence

If you are unable to adjust the corner convergence

properly, this can be corrected with the use Permaloy

Assy Correction.

ba

a-d : screen-corner

misconvergence

cd

1. Affix the Permaloy Assy Correction corresponding to the

misconverged areas.

Fix a Permaloy Assy Correction

to the misconverged areas

a

b

ON DY:

TLH TLV

RB

YCH XCV

(VR1)

(VR2)

YCH

(VR3)

TLV2

(XCV)

DY pocket

TLV1 (no need to adjust)

DY pocket

(XCV)

R

B

d

c

a to d : Permaloy Assy Correction

TLH Plate

– 11 –

Page 13

KV-SA28M36

RM-W107

2-3. FOCUS ADJUSTMENT

FOCUS adjustment should be completed before W/B

adjustment.

1. Receive digital monoscope pattern.

2. Set "Picture Mode" to "DYNAMIC". (Multi), Set "Picture

Mode to VIVID (NTSC).

3. a) Adjust focus VR so that the center of screen

becomes just focus(28", 29", 32", 34").

b) Adjust focus VR so that the lion teeth

becomes just focus(25" ONLY).

4. Change the receiving signal to white pattern and blue

back.

5. Confirm Magenta ring is not noticeable. In case

magenta ring is obvious, adjust FOCUS VR to balance

between MAGENTA RING and FOCUS.

2-5. WHITE BALANCE ADJUSTMENT

1. Set to Service Mode (Refer Section 3-1:

ADJUSTMENTS WITH COMMANDER).

2. Input white raster signal.

3. Set Picture to DYNAMIC.

i. Set PICT 006 WTS to 00h (all models except SA and

SR series).

ii. For SA and SR series, set OPTB 006 : OPB6 to 00.

4. Select WHBL 002"RDRV" and adjust the value to 37.

5. Select WHBL 003"GDRV" and 004 "BDRV"and adjust

the data for the best white balance in highlight condition.

6. Adjust WHBL 000 "BKOR" and 001 "BKOG"and adjust

the data for best white balance cut-off condition.

7. Write into the memory by pressing [MUTING] then

-.

8. Write offset data for other mode.

After adjustment, please reset:

i. OPTM 006 – OPB6 to original data (SA and SR

series).

ii. PICT 006 – WTS to original data (All models except

SA and SR series)

Adjust Offset Offset

18000 t 12363 t 9300

BKOR –2 –3

BKOG +1 +2

RDRV 0 0

GDRV –3 –8

BDRV –8 –18

Focus

Screen

FLYBACK TRANSFORMER (T506)

2-4. G2 (SCREEN) ADJUSTMENTS

1. Set the PICTURE to Normal.

2. Go to Service mode. Change RGBB from 00 to 01.

3. Connect R,G,B of the C board cathode to the

oscilloscope.

4. Adjust cathode voltage to the value below.

5. Adjust G2 (screen) on the FBT until picture shows the

point before cut off.

Cathode setting voltage:

170 V ± 2 (VDC)

2-6. SUB BRIGHT ADJUSTMENT

1. Set to service mode.

2. Brightness set to 50%, Picture: Minimum.

3. Select WHBL 010 "SBRT" with

1 and 4, and adjust

'SBRT' data with 3 and 6 so that the third stripe from

right dimly lit.

4. Write into the memory by pressing [MUTING] then -.

5. Models cut-off: 10 IRE

Slightly Glimmer: 20 IRE

– 12 –

Page 14

SECTION 3

CIRCUIT ADJUSTMENTS

3-1. ADJUSTMENT WITH COMMANDER

Service adjustments to this model can be performed using the supplied remote commander RM-W107.

a. ENTERING SERVICE MODE

With the unit on standby

t [DISPLAY] t 5 t [VOL $+% ] t [POWER]

This operation sequence puts the unit into service mode.

This screen display is:

KV-SA28M36

RM-W107

Category in decimal Item name in decimal NG Command Frequency Video Input Name

GEOM 006 EWPW 031 x SERVICE 60 S VIDEO 1

Release ID Version in binary for factory Color System (decimal)

SUS01 3.50M 0001 1111 FF FF NTSC3 65553

Status SID,

Lock, SL

:not locked

(no signal) Status Status BC, Status Status S/N Status Status Display

:locked VW, IVWF HBC BCF LEVEL (0-7) GL Area

111 11 11 1 7 11 ZZ xy 1 1 000000 000000

S : for Sony

A : for AIWA

L : BX1L Full

B : BX1L Basic

D : DVD Combo

U S : Taiwan/Korea/Philippines

G A : General Area

01 : Serial no. of the M / P release for each destination

Item no. Service data NVM Service Field Channel no./

Software Service data Reserved Power On Time

Status

PTW

ZZ : DCXO Flash Value

xy : Value of x : Value of y

0 - unknown 0 - Mono

1 - BTSC 1 - Stereo

2 - A2 2 - Bilingual

3 - NICAM 4 - SAP/Single

4 - KOREAN

5 - Japan

6 - AV Stereo

b. METHOD OF CANCELLATION FROM SERVICE MODE

Set the standby condition (Press [POWER] button on the commander), then press [POWER] button again, hereupon it

becomes TV mode.

c. METHOD OF WRITE INTO MEMORY

1. Set to Service Mode.

2. Press 1 (UP) and 4 (DOWN), to select the adjustment item.

3. Change item by pressing

3, 6.

4. Press [MUTING] button to indicate WRITE on the screen.

5. Press

- button to write into memory.

1, 4 Select the adjustment item.

r

3, 6 Raise/lower the data value.

r

[MUTING] Writes.

r

- Executes the writing.

d. MEMORY WRITE CONFIRMATION METHOD

1. After adjustment, pull out the plug from AC outlet, and then plug into AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confirm adjustments were made.

– 13 –

Page 15

KV-SA28M36

RM-W107

e. OTHER FUNCTION VIA REMOTE COMMANDER

7, - All the data becomes the values in memory.

8, - All user control goes to the standard state.

[Display], - Service data initialization (Be sure not to use usually.)

2, 5 Select Device or Category (Up, Down)

3-2. ADJUSTMENT METHOD

Item Number 000 HPOS

This explanation uses H POSITION as an example.

1. Select "000 HPOS" with the

2. Raise/lower the data with the

3. Select the optimum state. (The standard is IF for PAL reception.)

4. Write with the [MUTING] button. (The display changes to WRITE.)

5. Execute the writing with the

SERVICE.)

Example on screen display :-

1 and 4 buttons, or 2 and 5.

3 and 6 buttons.

- button. (The WRITE display will be changed to red color while excuting, and back to

GEOM

SUS01

GEOM

SUS01

GEOM

SUS01

Use the same method for all Items. Use

[MUTING], then execute the write with

000

3.50M

000

3.50M

000

3.50M

HPOS

0001

HPOS

0001

HPOS

0001

-.

031

SERVICE

1111

1111

1111

1 and 4 to select the adjustment item, use 3 and 6 to adjust, write with

FF FF

031

WRITE

FF FF

Write with [MUTING]

031

WRITE

FF FF

Write executed with

50

NTSC3 65553

50

NTSC3 65553

50

NTSC3 65553

GREEN

Adjusted with 3

and 6 buttons.

GREEN

RED

The WRITE display

then the display

returns to green

SERVICE.

Note : 1. In [WRITE], the data for all items are written into memory together.

2. For adjustment items that have different standard data between 50Hz or 60Hz, be sure to use the respective

input signal after adjustment.

– 14 –

Page 16

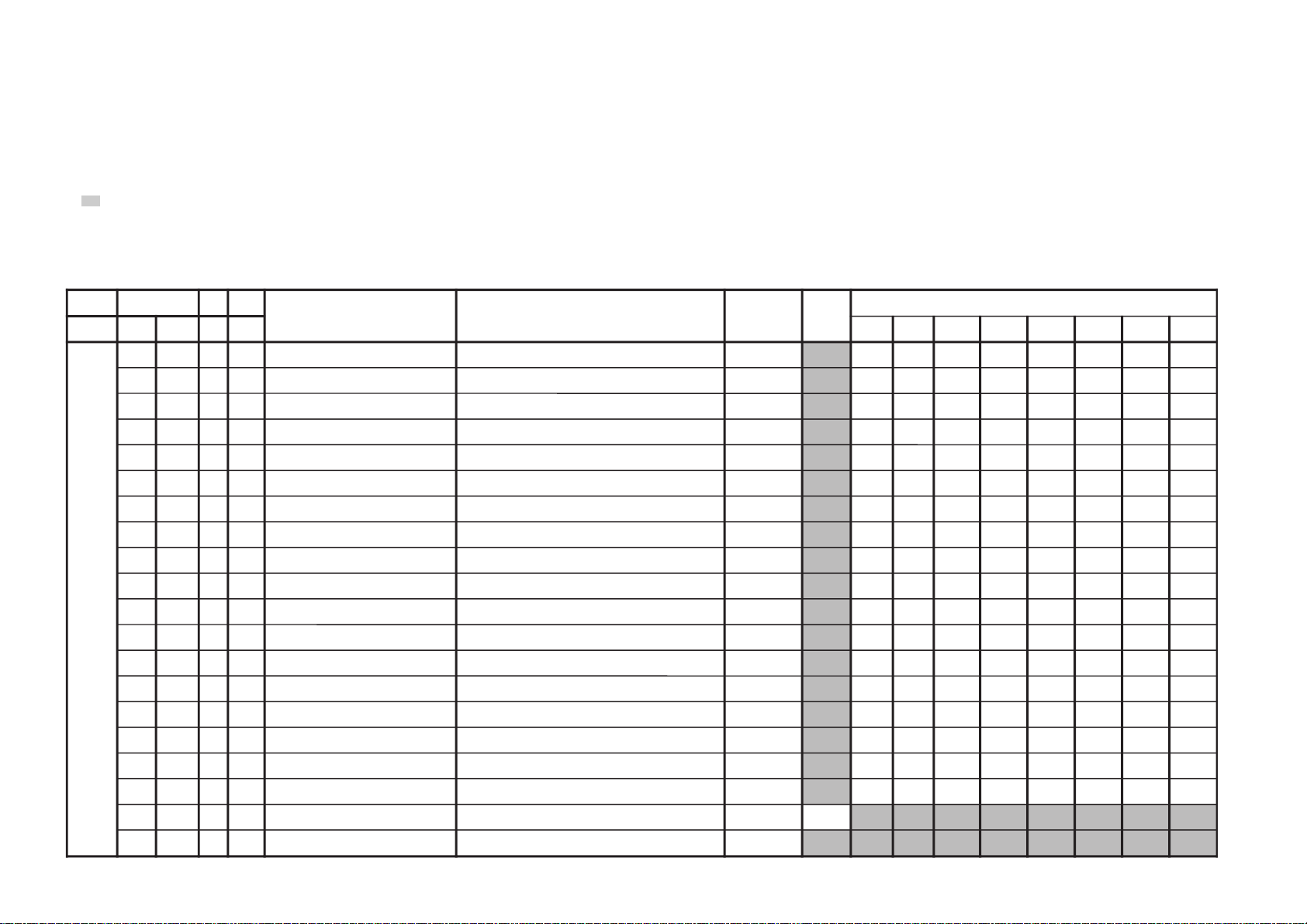

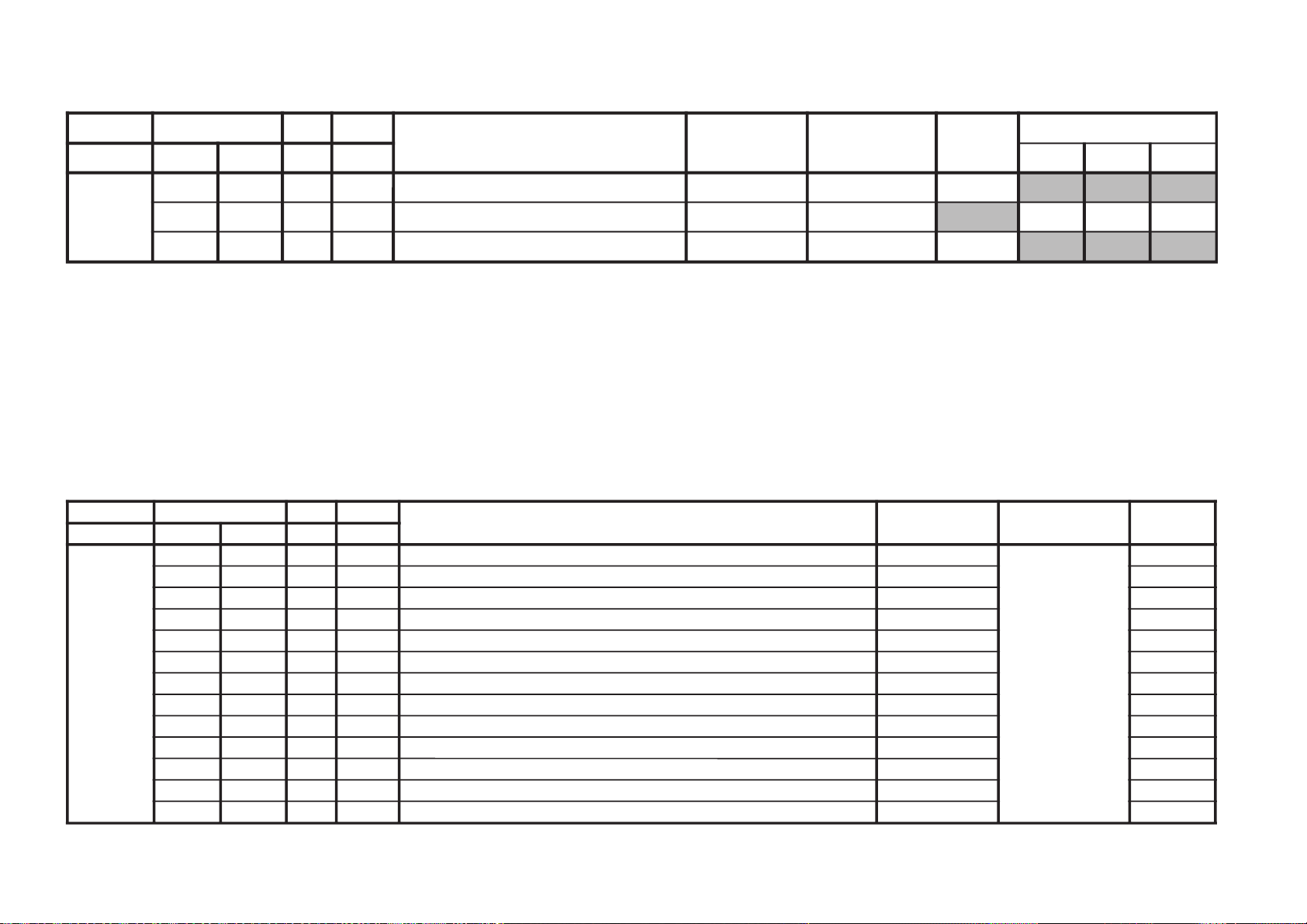

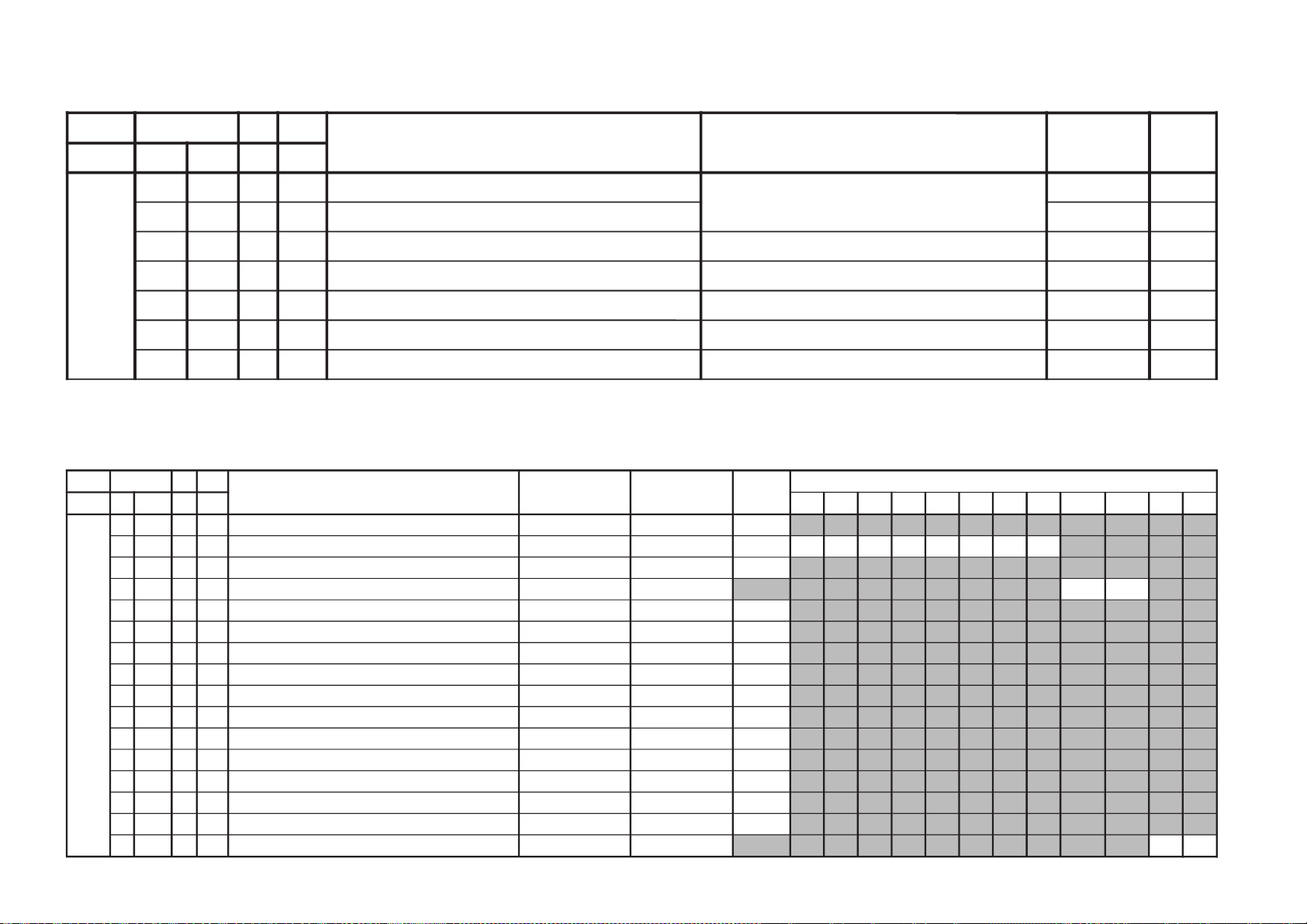

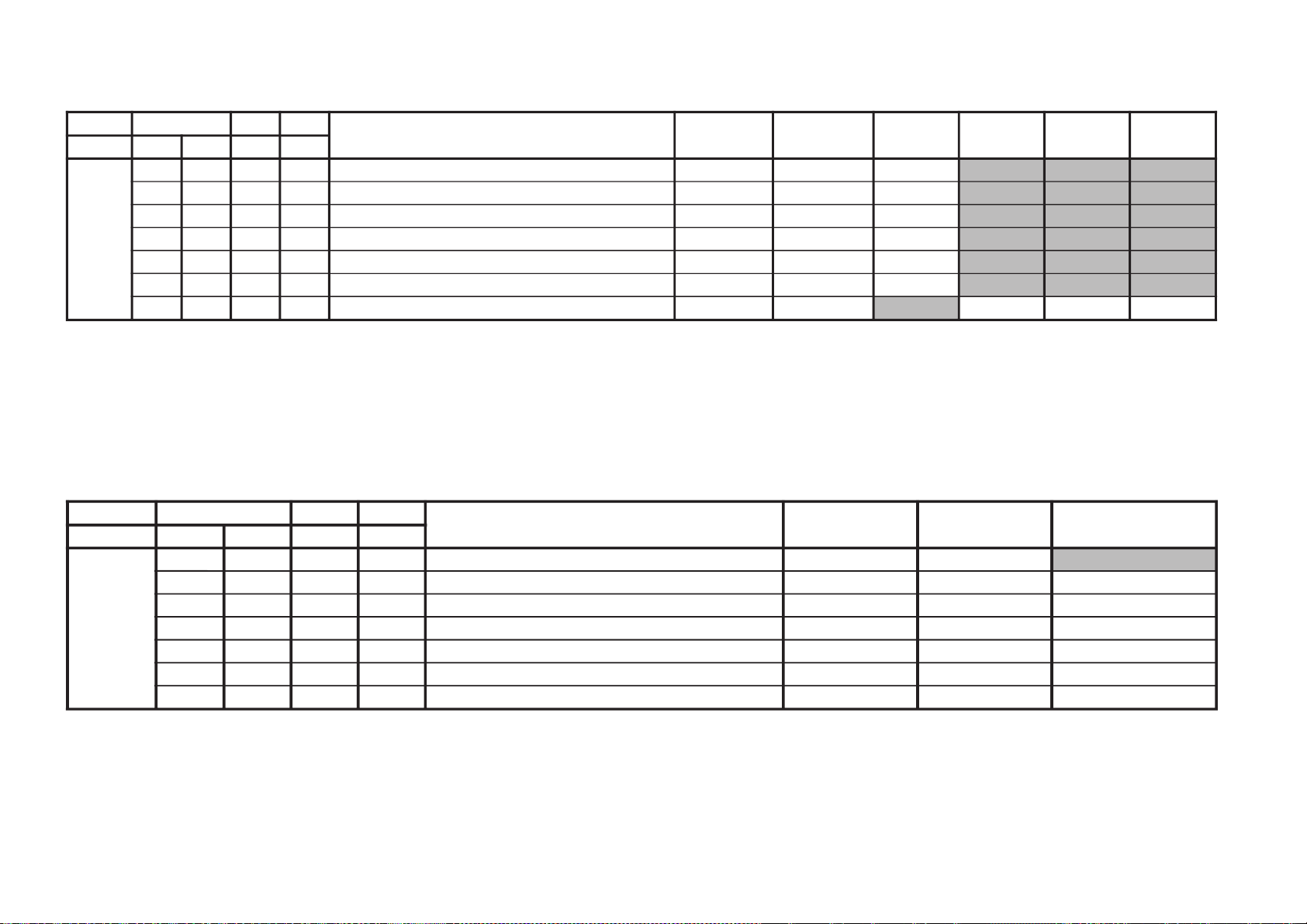

Adjustment Item Table

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD ZW05ZW06N05N06F05F06Z05Z06

MOEG000SOPH130360)SH(tfihSlatnoziroH >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4< rossecorP-VT

1313131313131313

100RAPH130360margolellaraPlatnoziroH >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

1313131313131313

200WOBH130360woBlatnoziroH >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

1313131313131313

300NILV130360ytiraeniLlacitreV >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

1313131313131313

400RCSV130360llorcSlacitreV >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

1313131313131313

500ZISH130360)WE(htdiWWE >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

5555020264646464

600WPWE130360)WP(htdiW/alobaraPWE >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

3333434313131313

700POCU710360alobaraPrenroCreppUWE >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

5353535353535353

800POCL710360alobaraPrenroCrewoLWE >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

0404040404040404

900ZTWE130360muizeparTWE >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

2222222222222222

010PLSV130360)SV(epolSlacitreV >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

1313131313131313

110ZISV510360edutilpmAlacitreV >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

0404040404040404

210ROCS410360)CS(noitcerroC-S >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

2222222222222222

310SOPV130360)HSV(tfihSlacitreV >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

8383838383838383

410MOOZV130360)ZV(mooZlacitreV >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

6262121291914444

510LBH000100edoMgniknalBBGR >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

10101010 1111

610FBW700510)FBW(gniknalBediWfognimiT >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

01505101015 015

710RBW700510)RBW(gniknalBediWfognimiT >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

3131515131313131

810LBS000100gniknalBecivreS enon00

910YPOC000100aeraMVNzH06/05llaotatadOEGehtypoC enon

NOTE

a) In the initial value (detailed) colomn, the data after the slash mark ("/") refers to NTSC model data.

No ("/") means data is common for Multi and NTSC model.

b) Item remarked "*" and "**", please refer page 28 for the data.

c)

shaded items are no data.

d) Standard data listed on the Adjustment Item Table are reference values, therefore it may be different for each model and for each mode.

e) Note for the Different Data those are the standard data values written on the microprocessor. Therefore, the data values of the models are stored respectively in the memory.

In the case of a device replacement, adjustment by rewriting the data value is necessary for some items.

f) Multi ver5.60, NTSC ver5.30

– 15 –

KV-SA28M36

RM-W107

Page 17

KV-SA28M36

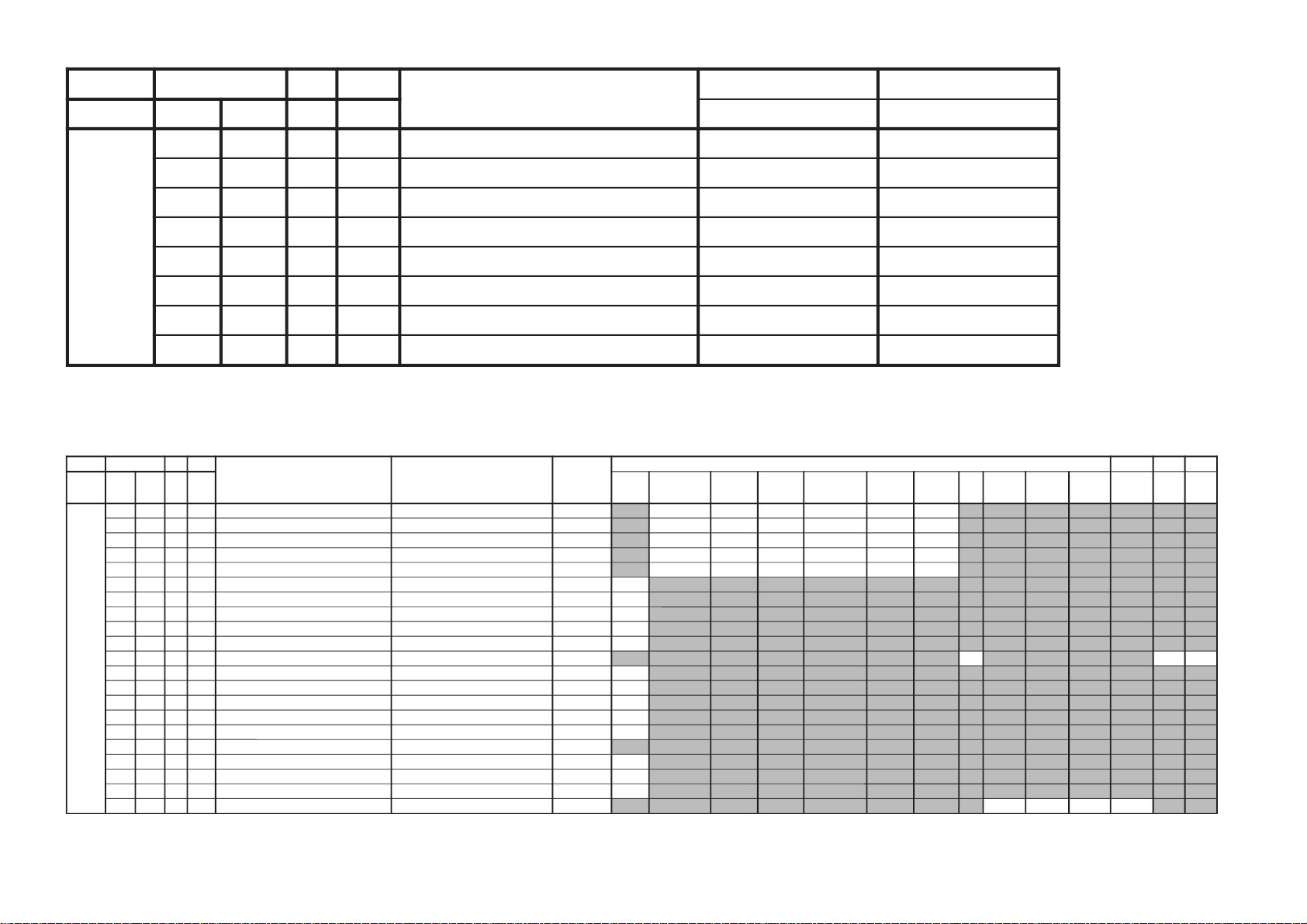

JVTytilanoitcnuF

.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

nommoCpmeTloC

)rehtohgiH(

pmeTloC

)rehtowol(

pmeTloC

)rehtomron(

HGIH(pmeTloC

)VUY

pmeTloC

)BGRWOL(

pmeTloC

LAMRON(

)VUY

VUY0edomciP

cimanyD

1edomciP

dradnatS

2edomciP

tfoS

2edomciP

lanosreP

VTOEDIV

LBHW

000ROKB

130360)10=BFO(BtesffO,)00=BFO(RtesffOleveLkcalB

)srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

rossecorP-VT

131313131313

100GOKB

130360GtesffOleveLkcalB

)srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

020202020202

200VRDR

730360RtnioPetihW

)srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

rossecorP-VT

737373737373

300VRDG

730360GtnioPetihW

)srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

542473542473

400VRDB

730360BtnioPetihW

)srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

840403840403

500GPL

000100teserPniaGBGR

enon

00

600RGP

130721)RGP(RniaGteserP

enon

05

700GGP

130721)GGP(GniaGteserP

enon

05

800BGP

130721)BGP(BniaGteserP

enon

05

900FONG

000510tesffOniaGteserP

enon

poolCCC01

010TRBS

130360ssenthgirB-buS

VUY/BGR/srehtO

83

8383

110ORBS

000300)ciPtnegilletnI(tesffOssenthgirB-buS

enon

00

210LGE

000100metsySCCCnipooLniaGelbanE

enon

00

310LGS

000300metsySCCCnitnerruChgiHfonoitceleS

enon

00

410BKA

000100noitazilibatStnerruCkcalB

enon

00

510SBC

000100gnitimiLtnerruCmaeBfoecneuqeSlortnoC

enon

00

610BBGR

000300gniknalBBGR

enon

710GBLB

000100tuptuOneerG&eulBfogniknalB

enon

00

810BFO

000100eulBtesffOleveLkcalB

enon

10

910RBSN

000510tesffOssenthgirBdradnatSnoN

enon

00

020PBW000300)woL:3,2,lamroN:1,hgiH:0(gnitteSpmeTroloC edoMerutciP

00102010

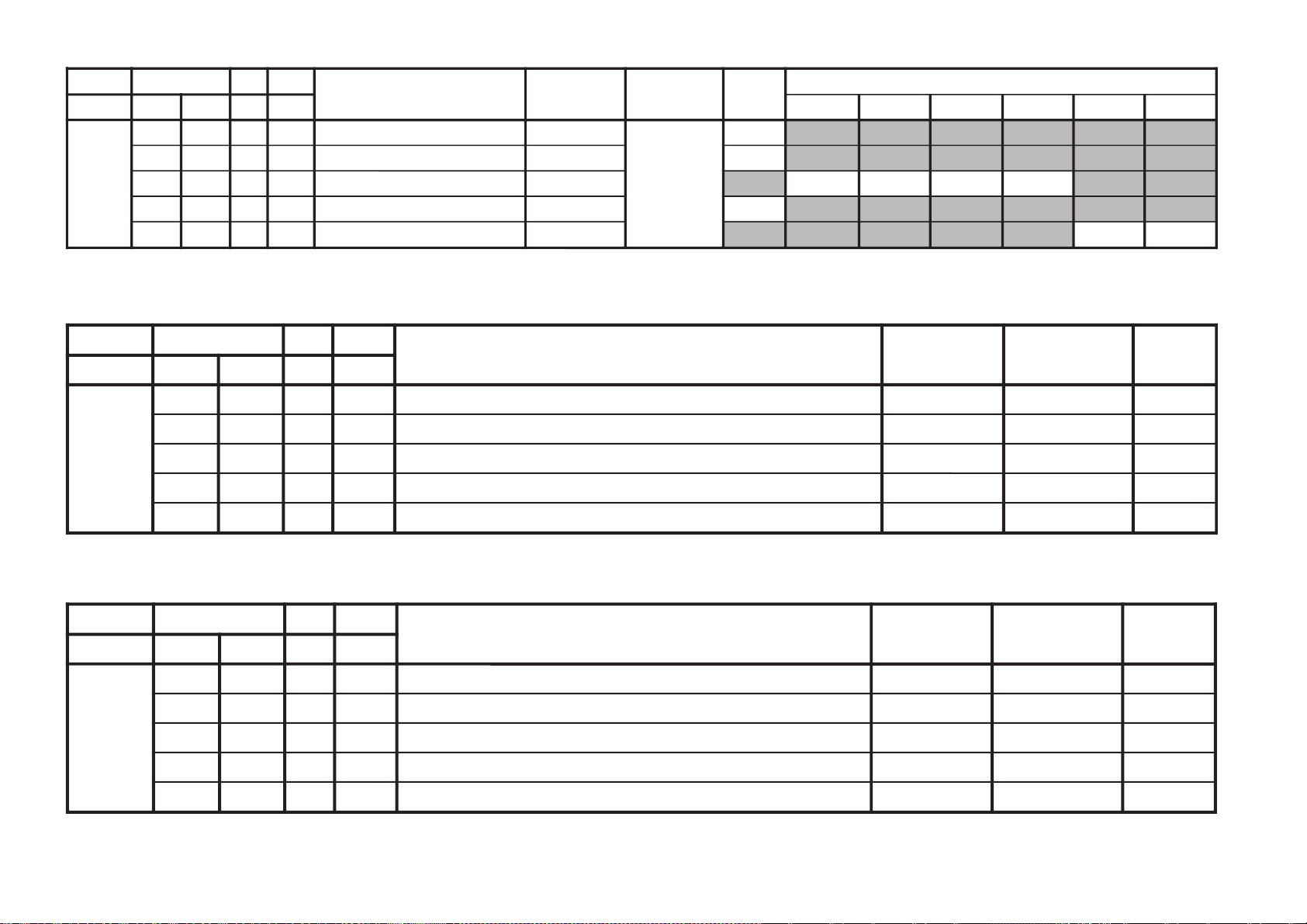

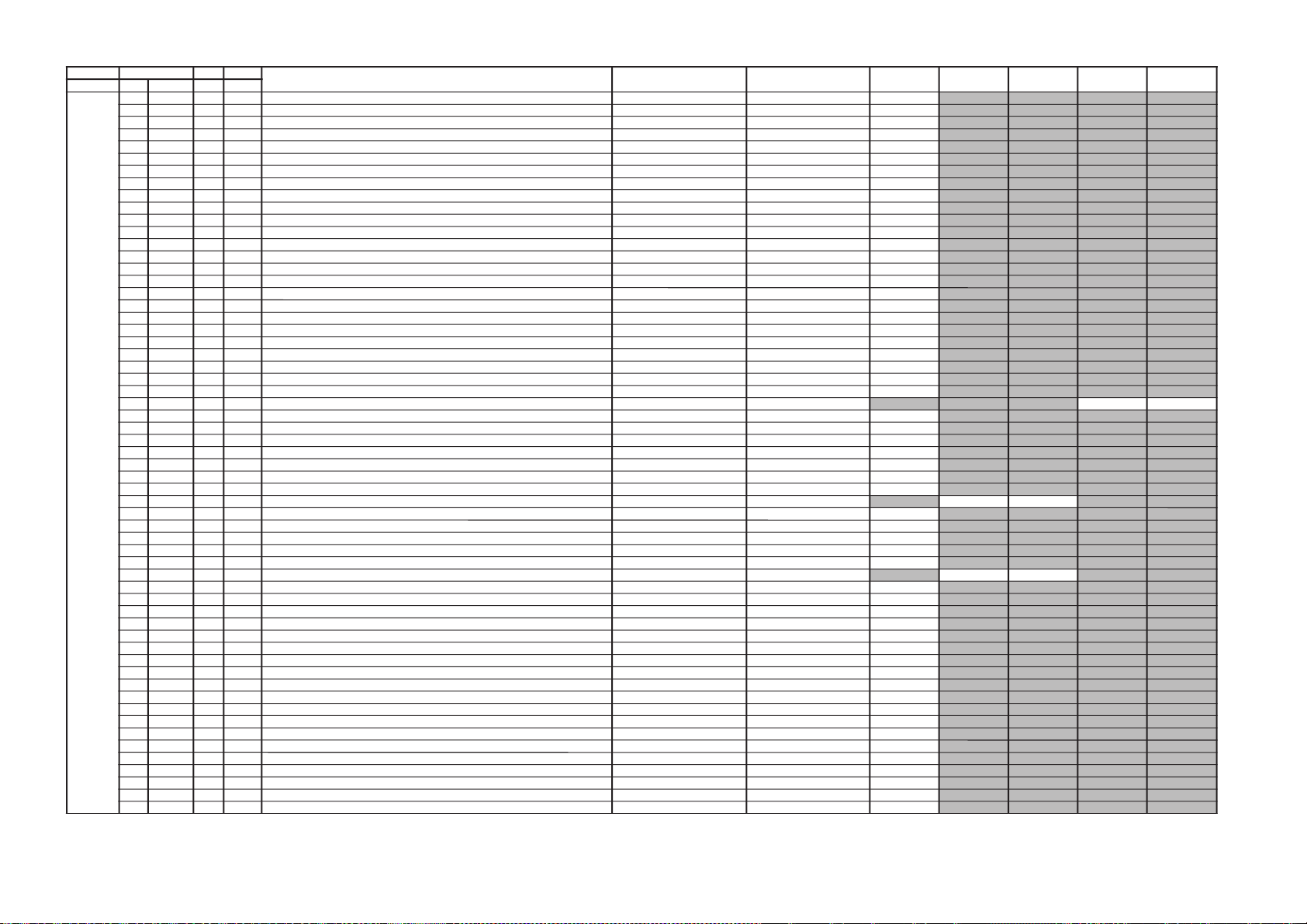

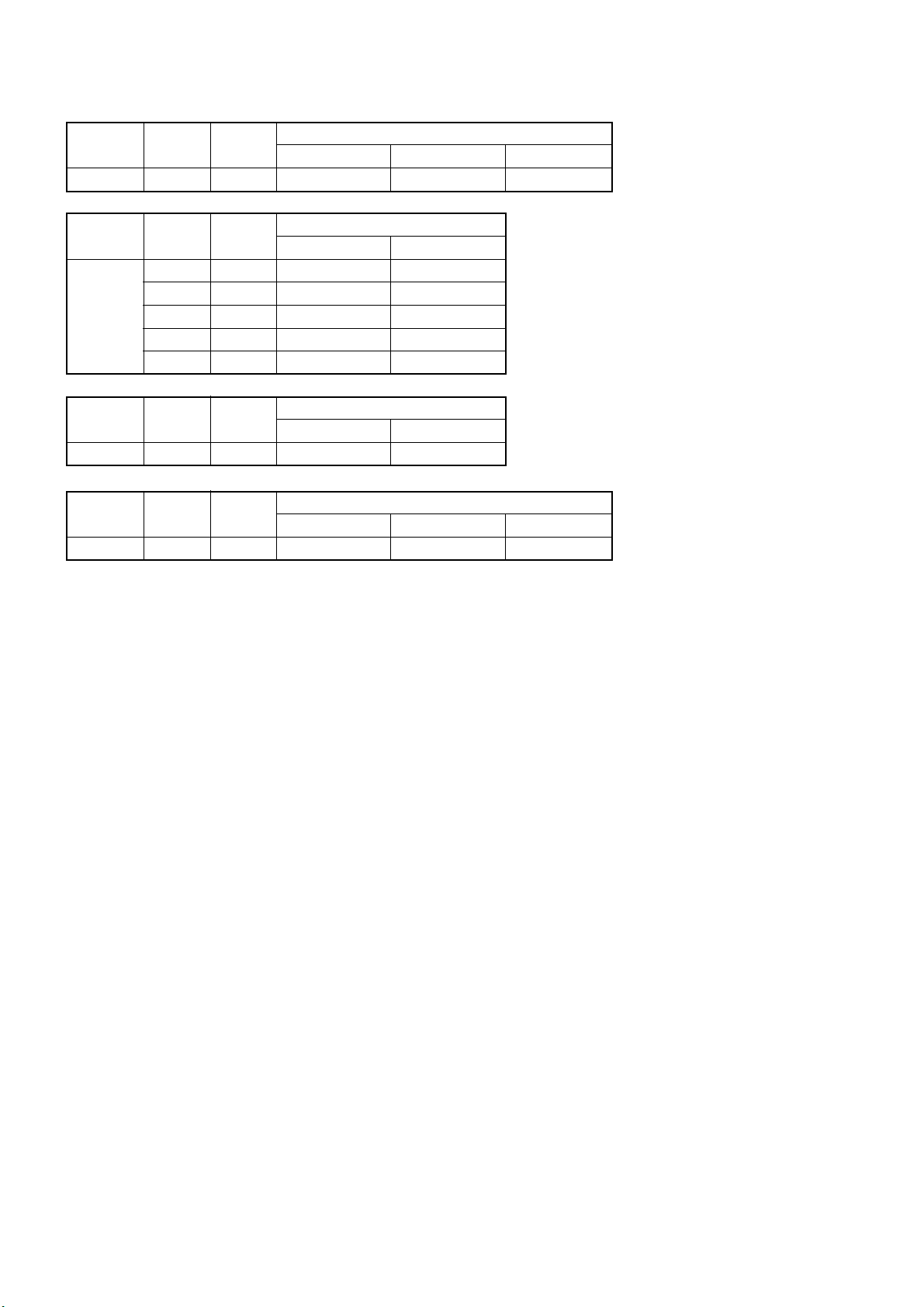

GVTytilanoitcnuF.tinIegnaRnoitcnuFemaNeciveD)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD)sserddAevalS(nommoC

DNAL000TDL360552ataDtnemtsujdACCLtfeLCAD721

100TDR360552ataDtnemtsujdACCLthgiR)hE4(721

200CLSN000360niaGnoitcerroChtuoS/htroNCCL 00

300NGWE000360niaGnoitcerroCtseW/tsaECCL 04

400XMCL000721timiLataDtnemtsujdA 46

500XMTR000510timiLnoitatoRerutciP 01

600XMPV000700timiLnoitisoP-VerutciP 5

700ETUM000100etuMtuptuO 0

RM-W107

– 16 –

Page 18

– 17 –

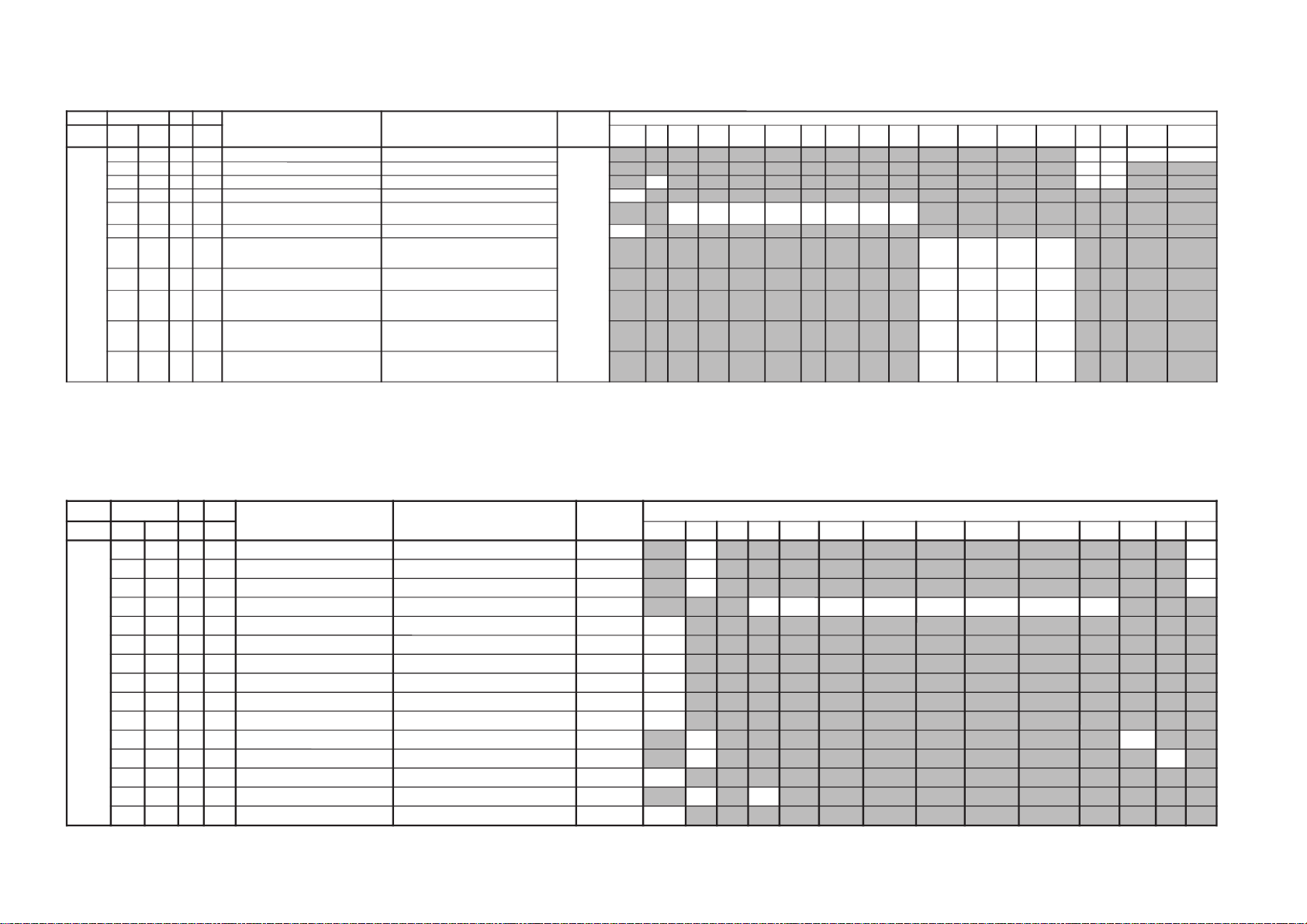

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

nommoCVUYlap05

)VT(

lap05

)oediV(

maces05

)VT(

maces05

)oediV(

VT06oediV06VUY05VUY06edomciP

0

edomciP

1

edomciP

2

edomciP

3

VToediVediWVTediWoediV

JDAS000XAMP360360mumixaMerutciP >ediW/lamroN</)ediW/lamroN(*)oediV/VT(rossecorP-VT

64640404

100EUHS700510euH-buS oediV/VT

2090

200PHSS510360ssenprahS-buS VUY/oediV/VT

03

3233

300OHSS000700)ciPtnegilletnI(tesffOssenprahS-buS enon40

400LOCS130360roloC-buS /)oediv(maces05/)vt(maces05/)oediv(lap05/)vt(lap05

BGR06/BGR05/VUY06/VUY05/oediv06/VT06

9292929203039203

500OOCS000300)ciPtnegilletnI(tesffOroloC-buS enon10

600CIP130721;)dilav(001~0:AG[lortnoCerutciP

tiberongi;)dilav(36~0:srehtO,)dilavni(001>

])dilavni(6

)ataDteseRresU=lanosreP:AG(ledoMerutciP

0010957001

700LOC130721,)dilavni(001>;)dilav(001~0:AG[lortnoCroloC

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

75055405

800TRB130721;)dilav(001~0:AG[lortnoCssenthgirB

tiberongi;)dilav(36~0:srehtO,)dilavni(001>

])dilavni(6

)ataDteseRresU=lanosreP:AG(ledoMerutciP

84050505

900EUH130721,)dilavni(001>;)dilav(001~0:AG[lortnoCeuH

dneS*(])dilavni(6tiberongi;)dilav(36~0:srehtO

)ledomSUhtiw)0-5(hE1#TNITot

)ataDteseRresU=lanosreP:AG(ledoMerutciP

05050505

010PHS130721;)dilav(001~0:AG[lortnoCssenprahS

tiberongi;)dilav(36~0:srehtO,)dilavni(001>

])dilavni(6

)ataDteseRresU=lanosreP:AG(ledoMerutciP

85055405

JVTytilanoitcnuF

.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD nommoCsrehtOBGRVUY)VT(LAP)VT(CSTN)VT(MACES)oediV(LAP)oediV(CSTN)oediV(MACESTUPNI-SMACESCSTNVT

CY000QRFP000300yaleDdnaycneuqerFretneCgnikaeP rehto/VTrossecorP-VT

00

00

100APR100300toohSrevO&erPoitaR rehto/VT

20

00

200OPR200300skaePevitageN&evitisoPfooitaR rehto/VT

20

20

300YLDY210510yaleD-Y TUPNI-S/VUY+)OEDIV/VT(*)MACES/CSTN/LAP(

0111606001116001

400TAMC000300xirtaM)ASU/napaJ(CSTNroMACES-LAP 00

500LCA100100gnitimiLroloCcitamotuA 10

600BC000100ycneuqerFretneCssapdnaBamorhC )xif0:oediV*(VThtiwylnodilav00

700OBS100300tesffOkcalBMACES 10

800ESHC100300ytivitisneStnedICSTN/LAP 30

900OLC000100retliF)lleB(ehcolCfoycneuqerFretneC 00

010PRTC000100edoMparTamorhC srehto/MACES

00

10

110SPB000100eniLyaleDdnab-esaBamorhCfossapyB srehto/CSTN

00

10

210OCF000100nOroloCdecroF 00

310TNIT130360lortnoCtniTdnaB-esaB srehto/VUY

23

23

410VUT000100slangiSVUnolortnoCtniT 00

KV-SA28M36

RM-W107

Page 19

KV-SA28M36

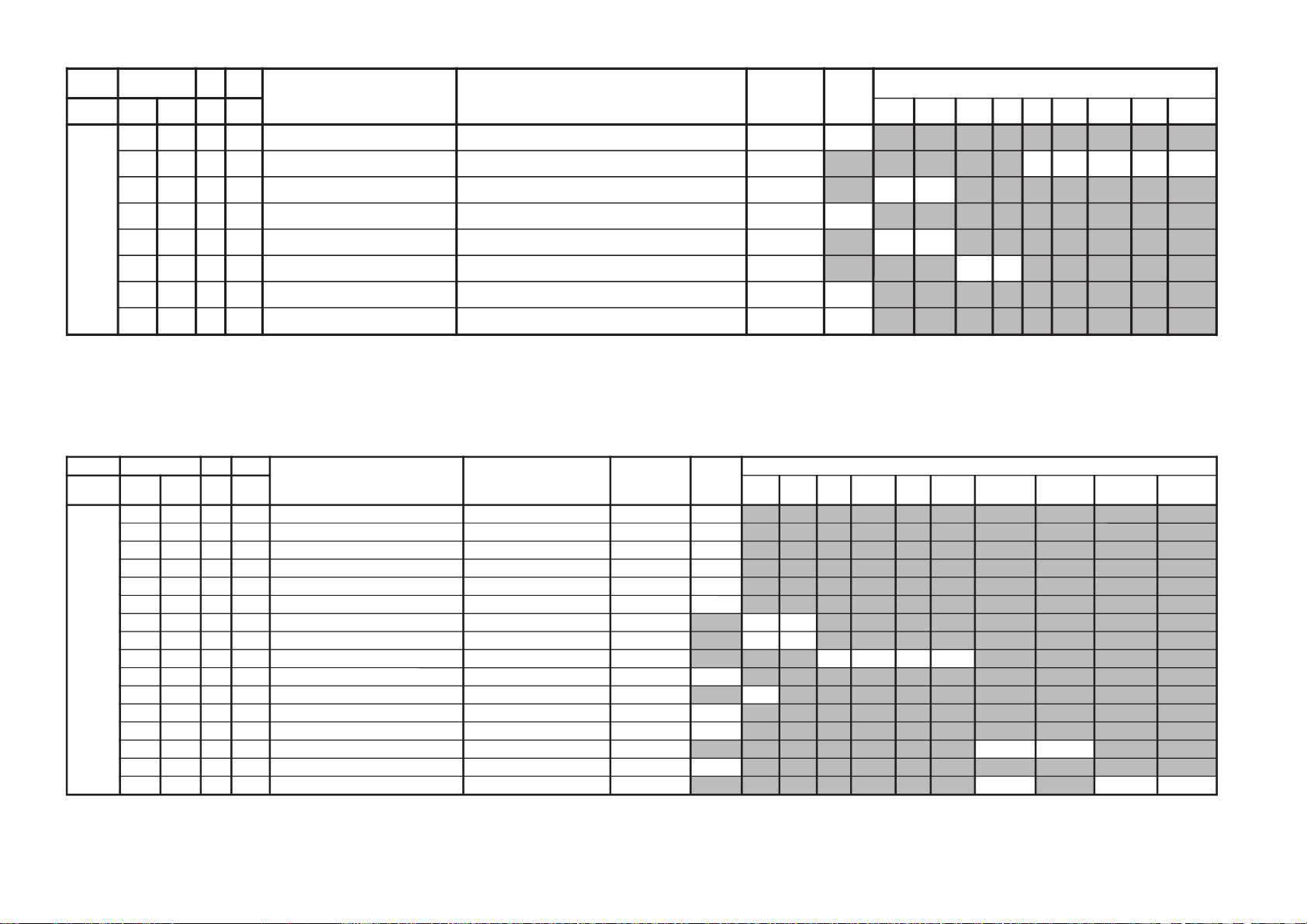

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

srehtOeviLVT

)nyD(

VT

)srehtO(

oediV

)nyD(

oediV

)srehtO(

pmeTroloC

)HGIH(

pmeTroloC

)srehtO(

roloC

)WOL(pmeT

pmeTroloC

)LAMRON(

TCIP000LDAC700510leveLevirDedohtaC 50

100AFC000300edoMretliFbmoC 00

200COS200300leveLgnippilCtfoS 20

300LWP100100hctiwSgnitimiLetihWkaeP 10

400LTHW600510gnitimiLetihWkaeP 00

500MAG100100ammaG 10

600STW100300hctertSetihWdnalortnoCammaGsrehtO/eviL

1010

700RFT000100langiSecnanimuLfooitaRrefsnarTCDsrehtO/eviL

1010

800ROC300300gniroC )srehto/anyD(*)oediV/VT(

10200010

900OROC000300)ciPtnegilletnI(tesffOgniroC 10

010SKB300300hctertSkcalBsrehto/BGR

20

110SAA100100hctertSkcalBehtffohctiwSotaerAkcalB 10

210KSD000100lortnoCnikScimanyD 00

310SLB000100hctertSeulB )SREHTO/HGIH(pmetloc

0000

410SLBN000100tiucriChctertSeulBnoitarepO 00

510RRN000100noitcudeRdeRnoN )LAMRON/WOL/HGIH(pmetloc

10

1010

JVTytilanoitcnuF

.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD 0506srehtOVUYVToediVtxeteleTpi-VTlangiSoN

CNYS000SYS000100tupnICNYSYnonoitazinorhcnyS 00

100OF000300tnatsnoCemiT1esahP )FR(langisoNrogninuTotuA/txeteleT/oediV/FFOPIVT/NOPIVT

3030100000

200DIV000100edoMtnedIoediV 06/05

0000

300LSF000100cnySlacitreVrofleveLgnicilSdecroF 00

400LSS000100rotarapeScnySleveLgnicilS 06/05

0000

500DIVS100700noitacifitnedIoediVrofnoitceleSecruoS srehtO/VUY

0000

600FROF000300ycneuqerFdleiFdecroF 30

700KVM000100gniyeKnoisiVorcaM 10

RM-W107

– 18 –

Page 20

– 19 –

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD VUYVToediV

WS0002VC000100noitceleSlangiStupnI2SBVC 00

100OVS10030084@niPISBVC/OVS/OVFIfonoitcnuFVUY/oediV/VT

301030

200LFD000100noitcetorPhsalF 10

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

FIV000DFIO630360rotaludomeDFItesffO rossecorP-VT63

100TCGA130360revo-ekaTCGA 42

200MTS000100edoMgninuThcraeS 10

300DG000100langiS1SBVCnoyaleDpuorG 00

400SCGA100300deepSCGAFI 10

500IFF000100LLPFIretliFtsaF 00

600IANL000100eulavlaitinitibANLpmAFR 00

700TANL591522leveLdlohserhTpmAFR 591

800NSNL400700dlohserhTleveLNSpmAFR 40

900DSNL200700dlohserhTporDleveLNSpmAFR 10

010XENL610360gnimiTporDNSkcehcpmAFR 03

110RTHC840721edoMresUpmAFRtesotgrPotuAretfadlohserhTlennahC 52

210OSUT000100desUrenuTYNOS 00

KV-SA28M36

RM-W107

Page 21

KV-SA28M36

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

MEDS000SWMF000300rotaludomeDMFrofnoitceleSwodniW rossecorP-VT20

100SSQ100100 )metsysMitlumAGrofA/N(edoMreifilpmA)SSQ(dnuoStilpSisauQ *

200BPB000100retliFssapdnaBdnuoSfossapyB 00

300OLMA000100dnuoSMAroflangiStuptuOoiduA 00

400CVPH000100lortnoCemuloVenohPdaeH 00

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

TXT000VXT930360spilihProfnoitisoPlacitreVtxeteleT redoceDtxeT93

100DHT010721tfihSegdEevitcAcnys-HtxeteleT 01

200RBT510130ssenthgirBBGRtxeteleT 22

300BCL000100)XETSAFrofgnittes(elbane:1elbasid:0BCLtxeteleT 00

400MCDP100100ossaciPotCDArofleveLCDteS rossecorPtxeT10

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD 0edomciP1edomciP2edomviP3edomciPrehtOMACES

MV000DBGR300700tuptuOMVottuptuOBGRfoyaleDenonrossecorP-VT30

100AMV300300tuptuOMVfoedutilpmAenon30

200PAMV200300)FFO:3,2,woL:1,hgiH:0(gnittesMVedoMerutciP

00001000

300OMMV300300edoMMV 30

400AMVF400400)erawtfoslluF(tuptuoMVfoedutilpmAsrehtO/MACES

3020

RM-W107

– 20 –

Page 22

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD VToediVffOWOW/SRSdnuorrusurToeretsIonomIretneC

rekaepS

buSFRoediV

buS

PSDS000MVA200700edoMLVA DSS20

100VVA500510leveLecnerefeRLVA 90

200LBB000510ruotnoCEBB 20

300HBB000510ssecorPEBB 60

400WLBB000510tesffOruotnoCEBB 60

500FOVS000510tesffOemuloVedoMtceffE/dnuorruS onomI/oeretsI/dnuorrusurT/)WOW/SRS(ffO

4011406040

600FOVI000700tesffOevitisoPemuloVretsaM 60

700FOVE000700tesffOevitageNemuloVretsaM 60

800DAL000130tsujdAleveLredoceD 50

900MAL000130tsujdAleveLonoM 50

010NAL000130tsujdAleveLmaciN 22

110SAL000130tsujdAleveLPAS 80

210AAL000130tsujdAleveLCDA buSoediV/buSFR/KPSretneC/oediV/FR

0000

000000

310FES300700tceffEoeretS/onoMelbidercnI onomI/oeretsI

5030

410L1A000552tfeLemuloV1XUA 00

510R1A000552thgiRemuloV1XUA 00

610SAB000510tesffOssaBniaM 12

710ERT000510tesffOelberTniaM 32

8101QE000510tesffO)zH001(dnaBlennahCniaMrezilauqE 20

9102QE000510tesffO)zH003(dnaBlennahCniaMrezilauqE 91

0203QE000510tesffO)zH0001(dnaBlennahCniaMrezilauqE 10

1204QE000510tesffO)zH0003(dnaBlennahCniaMrezilauqE 71

2205QE000510tesffO)zH0008(dnaBlennahCniaMrezilauqE 10

320TCFB500700lortnoCEBBdnaBUD,EBD 50

420NECS100510lortnoCretneCD3SRS 40

520APSS000510lortnoCecapSD3SRS 10

620WHBB000510edomWOWnitesffossecorpEBB 00

720ERTS200700edomdnuorrusroftesffOelberT 10

820THBB000510edomVTnitesffOEBB 00

920AWD000000???AWD 00

030ERTT200700edoMVTnitesffOelberT 30

130FOVK600120tesffOemuloVretsaMekoaraK 11

2301QEC800510H001(ataDdnaBreezilauqEnI-ertneC

2

) 60

3302QEC800510H003(ataDdnaBrezilauqEnI-ertneC

2

) 90

4303QEC400510H0001(ataDdnaBrezilauqEnI-ertneC

2

) 01

5304QWC800510H0003(ataDdnaBrezilauqEnI-retneC

2

) 01

6305QEC800510H0008(ataDdnaBrezilauqEnI-retneC

2

) 70

– 21 –

KV-SA28M36

RM-W107

Page 23

JVTytilanoitcnuF.tinIegnaRnoitcnuF etoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

CEDS000UTPM300510)CSTB(noitcetedtolipXPMrofdlohserhTreppU DSS20

100LTPM900510)CSTB(noitcetedtolipXPMrofdlohserhTrewoL 50

200UTPS300510noitcetedreirracPASrofdlohserhTreppU 80

300LTPS600510noitcetedreirracPASrofdlohserhTrewoL 51

400HT1C0001301CSfonoitcetedrofdlohserhTlamroN 00

500PA1C0001301CSfonoitcetedrofdlohserhTmargorPotuA 00

600HTPS000130PASfoetumotuarofdlohserhTesioN 00

700YHPS400510PASfoetumotuarofezissiseretsyH 30

800HTMF000130dradnats2AMFni2CSfoetumotuarofdlohserhTesioN 81

900YHMF400510dradnats2AMFni2CSfoetumotuarofezissiseretsyH 70

010HTTB000130reirracoeretsCSTBfoetumotuarofdlohserhTesioN 00

110YHTB400510oeretsCSTBfoetumotuarofezissiseretsyH 30

210HTJE000130reirracbusMFJAIEfoetumotuarofdlohserhTesioN 00

310YHJE400510reirracbusMFJAIEfoetumotuarofezissiseretsyH 40

410YLNO000100tuptuoCEDnoMACINdetalerylnoecudorpeR 00

510MAXE000100)PEDD(LdradnatsnietumotuafoesacniecruoskcabllaF 00

610TMIN000100)PEDD(etarrorretibnodnepednoitcnufetumotuaMACIN 00

710ELIN001552)PEDD(timilrorrerewolMACIN 05

810EUIN002552)PEDD(timilrorrereppuMACIN 002

910DMPE100300)PEDD(gnimmargorPysaECEDMED

1=1tiB3POdna0=SDTSdna0=DMPEfI

.revoekatlliwyrogetacCKDSdnaelbasiDsiyrogetacCEDS

*

020SDTS910130sedomSSSdnaDSArofdexelpitlumstiB *

120AMVO100100noitpadanoitaludomrevoMF 00

220WBLF000300htdiwdnabretlifrotaludomedMA/MF 30

320DMDI000300edomSSSnideepstnediMF 00

420LAPF000100gnidocedCSTBrofycneuqefeniL 00

520TMVO100200lanimonotevitalerdlohserhtlevelnoitaludomrevO 30

620IXCD000100retrevnIlortnoCgnilacSOXCDMACIN *

720GXCD000700niaGlortnoCgnilacSOXCDMACIN *

820LLCD110510)L(timiLlortnoCgnilacSOXCDMACIN 00

920HLCD000130)H(timiLlortnoCgnilacSOXCDMACIN *

030UEDI100300DTS2AnaeporuErofgnittesDOMDI 00

130RKDI100300DTSMnaeroKrofgnittesDOMDI 00

230PJDI100300DTSJAIErofgnittesDOMDI 00

– 22 –

KV-SA28M36

RM-W107

Page 24

JVTytilanoitcnuF.tinIegnaRnoitcnuF etoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

CKDS000LLNK000552etyBrewoLdlohserhTrewoLteDesioNnaeroK

1=1tiB3POdna0=SDTSdna0=DMPEfI

.revoekatlliwyrogetacCKDSdnaelbasiDsiyrogetacCEDS

100HLNK210552etyBrehgiHdlohserhTrewoLteDesioNnaeroK

200LHNK000552etyBrewoLdlohserhTreppUteDesioNnaeroK

300HHNK020552etyBrehgiHdlohserhTreppUteDesioNnaeroK

400CILK060552tnuoCgniniatniaMDItoliPtsoLnaeroK

500MILK100721reilpitluMtnuoCgniniatniaMDItoliPtsoLnaeroK

600CDSK600552tnuoCtceteDoeretSnaeroK

JVTytilanoitcnuF

.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaN

ceDceD ZW05ZW06N05N06F05F06Z05Z06zH05buSzH06buSVToediV

PIP

000SPH

150552noitisoPerutciPlatnoziroH X8829ADS54

100SPV

720552noitisoPerutciPlacitreV 038323030303036574

200PFV

800510noitisoPeniFlacitreV 00

300PFH

510510noitisoPeniFlatnoziroH

)ciPbuS(zH06/05

0040

400PSV

000100noitcudeResioNesluPcnySlacitreV 10

500LDV

000130yaleDesluPcnySlacitreV 00

600HRF

500700latnoziroHhtdiWemarF 50

700VWF

200300lacitreVhtdiWemarF 20

800YLD

100510yaleDtceleS 10

900DLC

610130yaleDgnipmalC 00

010MRA

300700edomGCA&teseRlortnoCniaGcitamotuA 30

110VGA

110510eulaVlortnoCniaGcitamotuA 80

210DPC

000300noitaruDgnipmalC 30

310OCB

000300tesffOnoitcerroCgnipmalC&siseretsyHeulavknalB 00

410MUL000300tesffOecnanimuL 00

510LLP

000300tnatsnoCemitLLPtresnI

oediV/VT

0000

(Not use for this model)

– 23 –

KV-SA28M36

RM-W107

Page 25

KV-SA28M36

JVTytilanoitcnuF

.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoCVToediV0506

yrogetaC.oNemaN

ceDceD

PIP

610FLB100100gniretliFeulavknalB 00

710DCY210510yaleDC/Y 40

810LIK000300dlohserhTrelliKroloC 00

910PGB000100noitisoPetaGtsruB 10

020MED100300noitceleSesahpmeeD 10

120CAD000100lortnoCamorhCcitamotuAelbasiD 00

220AMC100300htiwdnaBamorhC 00

320CFI200300retliFnoitasnepmoCFI 20

420EUH230360lortnoCEUH 20

520ACS600130tnemtsujdAreirracbuSroloC 60

620NOC000510tnemtsujdAtsartnoC 00

720RLB000510deRleveLgniknalB 00

820TRB000510tnemtsujdAssenthgirB 10

920GLB000510neerGleveLgniknalB 00

030BLB000510eulBleveLgniknalB 00

130RKP331552deRleveLkaeP 552

230GKP331552neerGleveLkaeP 061

330BKP331552eulBleveLkaeP 552

430YRF510510YroloCemarF 70

530TAS700510tnemtsujdAnoitarutaSroloC 01

630KPY300700tnemtsujdAgnikaePY 50

730OCY100100elbanEgniroCY 10

83012P0007001LDILAPdna2LDILAP 50

930LAP000100leveLDILaP 10

040VOP000700lacitreVtesffOnoitisoP 00

140HOP610130latnoziroHtesffOnoitisoP

2222

240OBP000100tsooBgnikaeP 10

340LPC100300htgneLesluPgnipmalC 30

440LRS000300leveLnoitcejeRmaceS 30

540LIS700700leveLnoitacifitnedImaceS 50

640DES100100rediviDmaceS 00

740AFB100100tnemtsujdAretliflleB 10

84021P0003002dna1tnemercnILAP 00

940SOL100300deepSgnikcoL oediV/VT

3030

050LAS000700leveLecnatpeccAmaceS 30

150AES000100ecnatpeccAmaceS 10

250SDA300300noitceleS&noitceted-kcoLlanoitiddA 30

350CLA100100rellik-roloCnoitceted-kcoLlanoitiddA 10

450DAN700700tnemtsujdAhctoN 30

550RSN000700LLPlatnoziroHroFnoitcudeResioN oediV/VT

6060

650HLS000300HdlohserhTleveLgnicilS 00

750JAI000300LLPlatnoziroHroFtnemtsujda-I 30

850LNE000100retimiLelbanE 10

95065D100100slangiszH06dnazH05fOnoitceteD 10

06005V000721zH05gninepOnoisserppuSesioNwodniWlacitreV 51

160OCB000100ffOgniroClevelknalB 00

26006V230721zH06gninepOnoisserppuSesioNwodniWlacitreV 04

360SNV000510zH06gnisolCnoisserppuSesioNwodniWlacitreV 90

460CSV000510zH05gnisolCnoisserppuSesioNwodniWlacitreV 01

560TSC100100ygetartSgnipmalC 00

660TVS510510VTLS&ytiraloPVdlohserhTleveLgnicilS 51

760MFV000300edoMleehwylFlacitreV 10

860WFV000100leehwylFlacitreV 10

960YCC000300SBVC/YcitsiretcarahCgnipmalC 00

070ISV300300tnatsnoCemiTnoitargretnI&epolSnoitceteDlacitreV 30

170SVL000300noitarapes-cnySlacitreVrofssapwoL 20

270ALC300300ycnetaLgnipmalC 30

370AYB100100CDASBVC/YrofretliFtsruB 10

470PCS400130esluPgnipmalCfotratS 62

RM-W107

– 24 –

Page 26

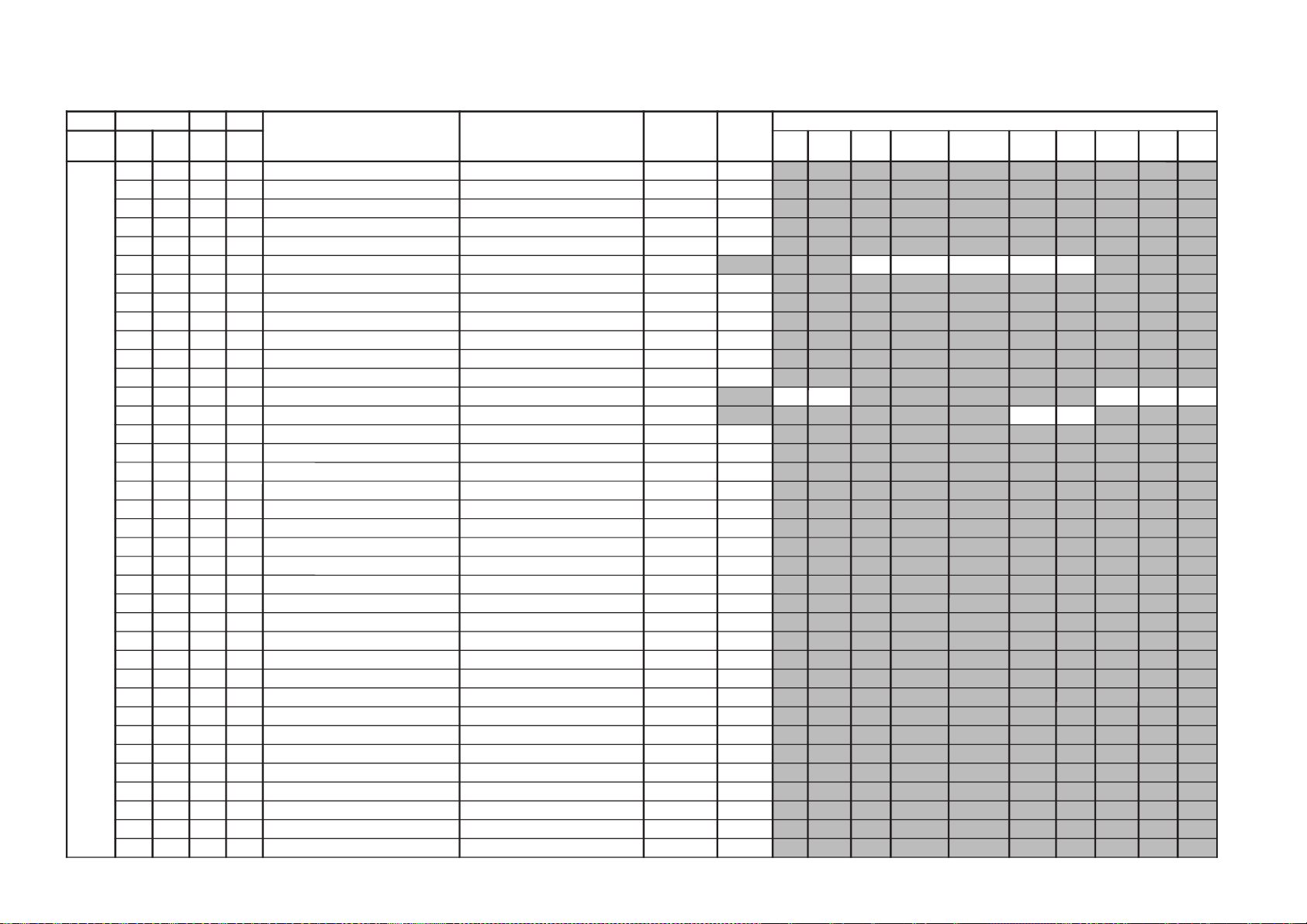

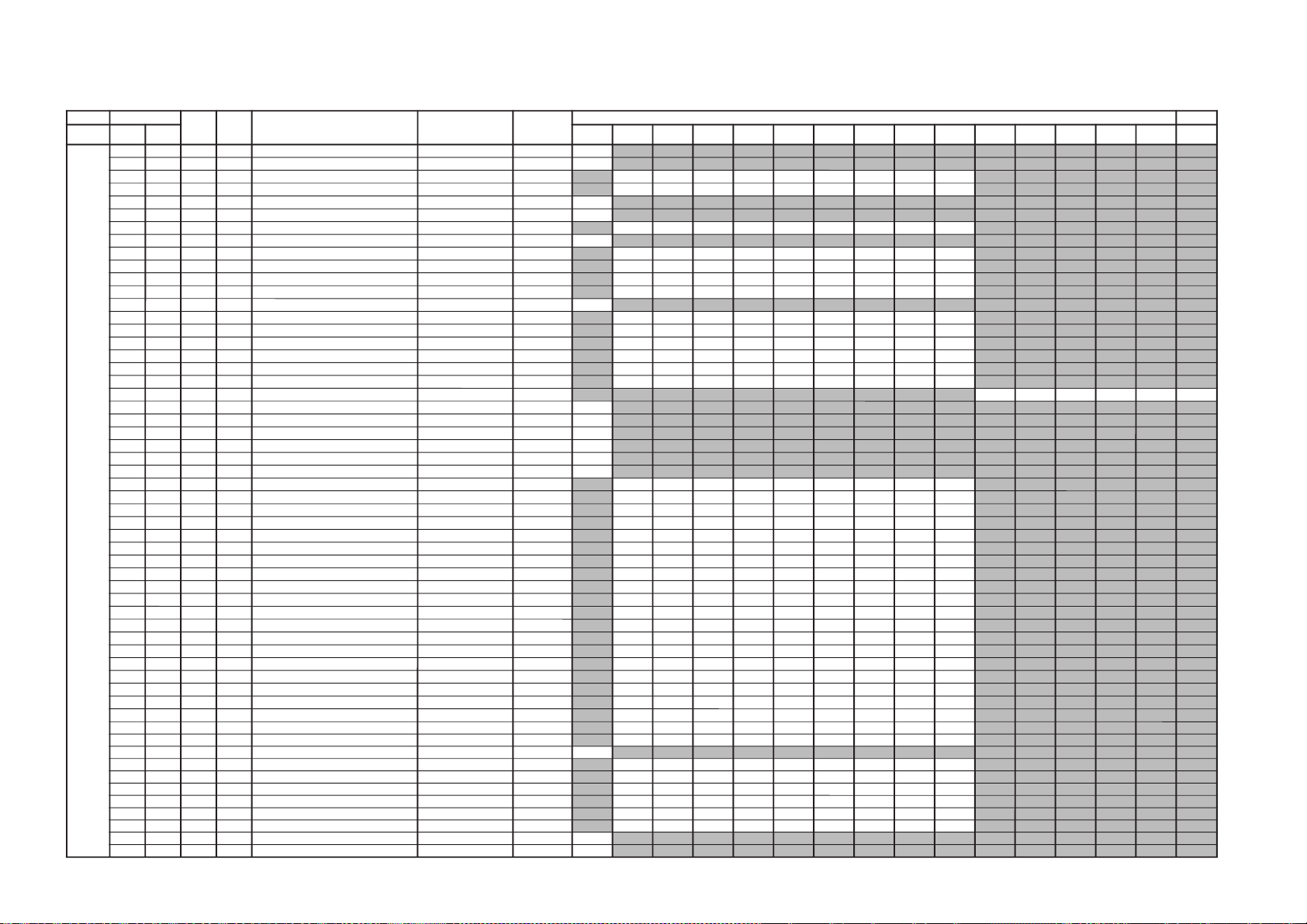

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoCORN1RN2RN3RN4RN0CSTN1CSTN1RN-FR

FR

1CSTN

LAP-VT

VT

CSTN

OEDIV

LAP

OEDIV

CSTN

LAP-SCSTN-S

RN3000SCY000300edoMSCY BMOCD300

100CER000100ceD-C:ceR 10

200TED3000700teDD3

7070707071070707070

300ROC3000100rroCRND3

100000000010000010

400FOB000100nOtsruB 10

500NYS000100nOCNYS 00

600CFA000300niaGCFA

303030303030303030

700GEH000300niaGahnEH 00

800RNC2000510miLRNCD2dnaKRNC-D2

004050909000004000

900CNY000700miLCN-Y;rellecnaCesioNY

003040405010104030

010RNY2000510niaGRNYD2;KRNY-D2

004020103010102000

110LNY2000300miLRNYD2

002030103020203030

210KLB000300pxEKLB 00

310RNC3000700miLRNCD3

000030707000000000

410KNC3000300KRNCD3

000000000000000000

510GNC3000700niaGRNCD3

002020707000004000

610RNY3000700miLRNYD3

003030607000001000

710KNY3000300KRNYD3

001020000000001030

810GNY3000700niaGRNYD3

002050607000001000

910YLDY000821yaleDtuptuOY

307060505151

020ACI000100otuApmalCTNI 10

120MCI000100launaMpmalCTNI 00

220HNEC000100ahnEC 10

320KCI000100yeKpmalCtupnI 10

420KGB000100yeKetaGtsruB 10

520LSS000100FPLpeSCNYS 00

620RCEV000300eroCahnEY

001010000000101010

720GEV000300niaGahnEY

001020100000102010

820NEV000300LNahnEV

001020100000102010

9201PMA0007001pmADH

606060606060606060

030VGDH000130VniaGDH

818181818181818181

1302PMA0007002pmADH

606060606060606060

2301GDH0001301niaGDH

313131313131313131

3303PMA0007003pmADH

505050505010105010

4302GDH0001302niaGDH

404040404010104010

530PLSC000510plsscAplsmcA

514101515101010101

630PLSY000510plssyAplsmyA

515101018041414141

730SMCA000510tesfmcAtesemcA

510101515151510151

830SSCA000510tesfscAtesescA

510101515101010101

930SMYA000510tesfmyAtesemyA

511101510151511151

040SSYA000510tesfsyAtesesyA

511141010101014101

140LSCB000510plsscBplsmcB

510101515151510151

240LSYB000510plssyBplsmyB

510101515131310131

340SMCB000510tesfmcBtesemcB

510101515101010101

440SSCB000510tesfscBtesescB

510101515101010101

540SMYB000510tesfmyBtesemyB

515101515151515151

640SSYB000510tesfsyBtesesyB

515101515101015101

740UMCB000100PUMCB 10

840MCEC000700PMCEC

704070404040407040

940MCSC000510PMCSC

510151000000005100

050VH1F000510reV1FdnaREH1F

508050505050508050

150FERM000510FERM

207040606010607010

250YEDC000300EYEDC

203020202020203020

350YEDY000300EYEDY

203020202020203030

450SAMH000700tuOksaM-H 00

550SAMV000130tuOksaM-V 00

– 25 –

KV-SA28M36

RM-W107

Page 27

– 26 –

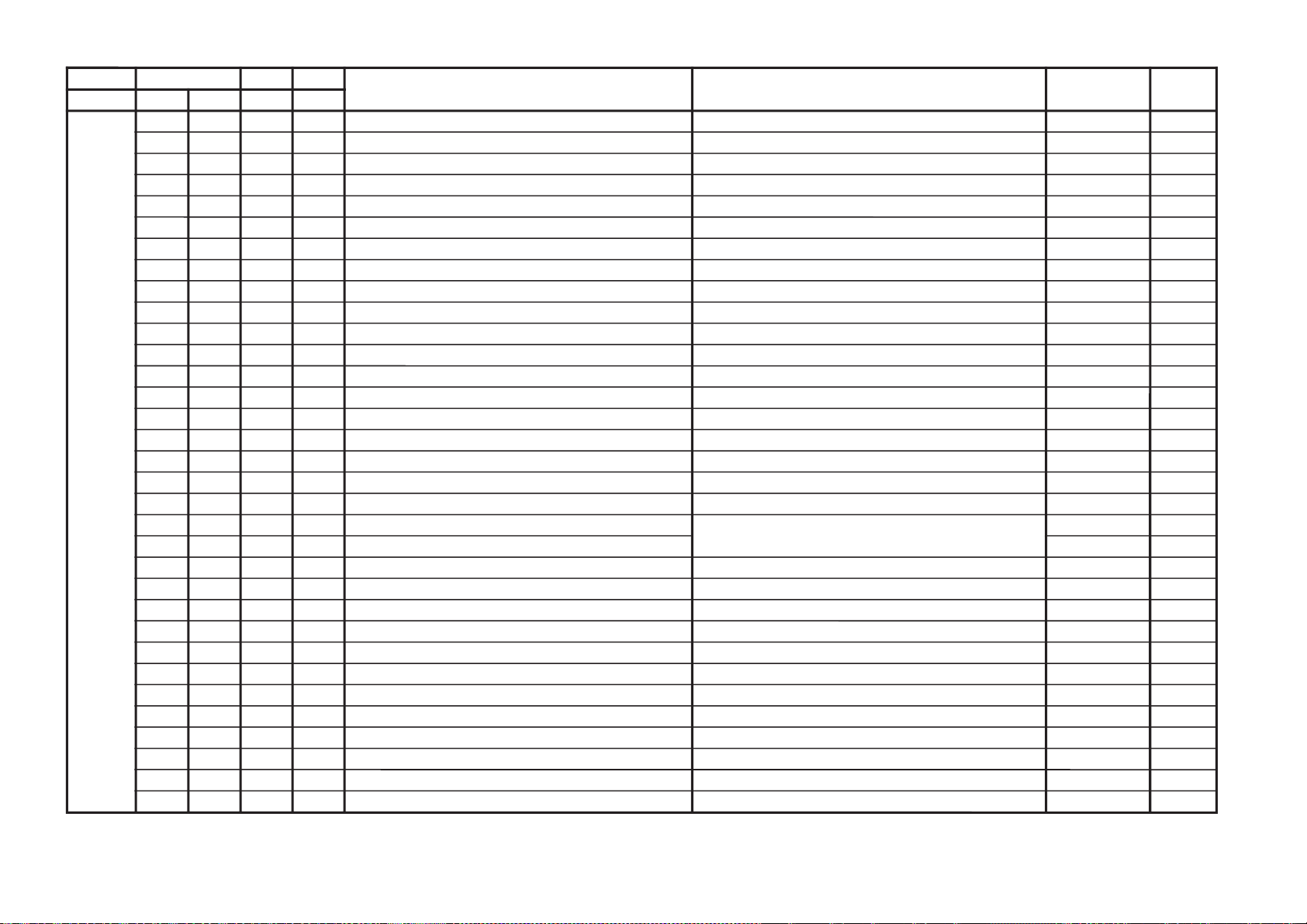

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

VTH100XAMV000360)XAMV+53=XAM(leveLemuloVmumixaM leveLemuloV00

200INIV520130norewoPtaleveLemuloVlaitinI leveLemuloV00

300YBTS000100 )YBTSsyawla=1,sutatsrewoptsalehtwollof=0(sutatSrewoPtsaL rewoPtsaL00

400GRPI100721)sledoMitluMrofylno(norewoPtarebmuNmargorPlaitinI rebmuNmargorP00

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD ZW05ZW06N05N06F05F06Z05Z06

MTPO000THSA600700)nim5*atad(remitffotuhsotuA 00

100BDSO000510ssenthgirbDSO h06orciM/RMM52

200HDSO800510noitisoPlatnoziroHDSO h06orciM/ATADX80

300VDSO730360noitisoPlacitreVDSO

)06/05(9:61<II>06/053:4<

>)lluFlamroN()mooZediW()ediW(

h06orciM/RMM

1533163316334484

400ETUM000100)delbane=1(hctiwSetuMlangiSoN 00

500LUFR510510)hf0nehwelbasiD(dekcolnUretfaretnuoCegnahClangiSFR 40

600KLFR510510)hf0nehwelbasiD(dekcoLretfaretnuoCegnahClangiSFR 00

700GNAL000300noitidnocgnippihsegaugnalDSO *

800TXTH000100wsrotarapescnyS rossecorP-VT00

900SSMC000100wscnyS rossecorP-VT10

010OXCD060592eulaVOXCD PSD/06orciM/RFS35

110LBXE000510esioNetihWetanimilEotremiTgniknalBdednetxE 80

210SYST000300 )ledoMAG(]M:3,K/D:2,I:1,G/B:0[teseRtseTtaMVNnisySVTeziromeM *

310WSNL100100)ffO:0,otuA:1(noitidnocteseRtseT/gnippihSretsooBlangiS 10

410LBL100100noitidnoclangiSoNtAnoitcudeRssenthgirB 10

510ORPH100100noitatoRerutciProftesffOarapH 30

610LUVA510510)hFOnehwelbasiD(dekcolnUretfaretnuoCegnahClangiSVA 40

710KLVA510510)hFOnehwelbasiD(dekcoLretfaretnuoCegnahClangiSVA 00

810SWFR000100edomFRnonoitcetedSSWelbanE 00

910RGFP130130tneidarGesahPFD 42

020RGQP130130tneidarGesahPPQD 02

120FNIY130130tcesretni-YFD 701

220QNIY130130tcesretni-YPQD 901

KV-SA28M36

RM-W107

Page 28

– 27 –

JVTytilanoitcnuF

.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoCsrehtOMACESCSTN

yrogetaC.oNemaN

ceDceD

PVPO

000SBPB

000100

)SBPB(edomoeretStaretliFssapdnaBdnuoSfossapyB

rossecorP-VT00

100CYWB

000100

)CYMB(metsysroloczHM85.3rofedoMCYtahtdiwdnaB

00

200BSO

000100

)BSO(rotaludomeDamorhCfoesluPyektsruBlanretnIfohtdiW

00

300VUYT

000100

)VUYTXT(noitceleStuptuOCC/TXT

00

400VLT

000300

)1VLTXT,0VLTXT(edutilpmAtxeteleTnomevacS

00

500DCL

000100

)DCL(edoMDCL

00

600CUB

000100

)DCL(edoMDCL

001000

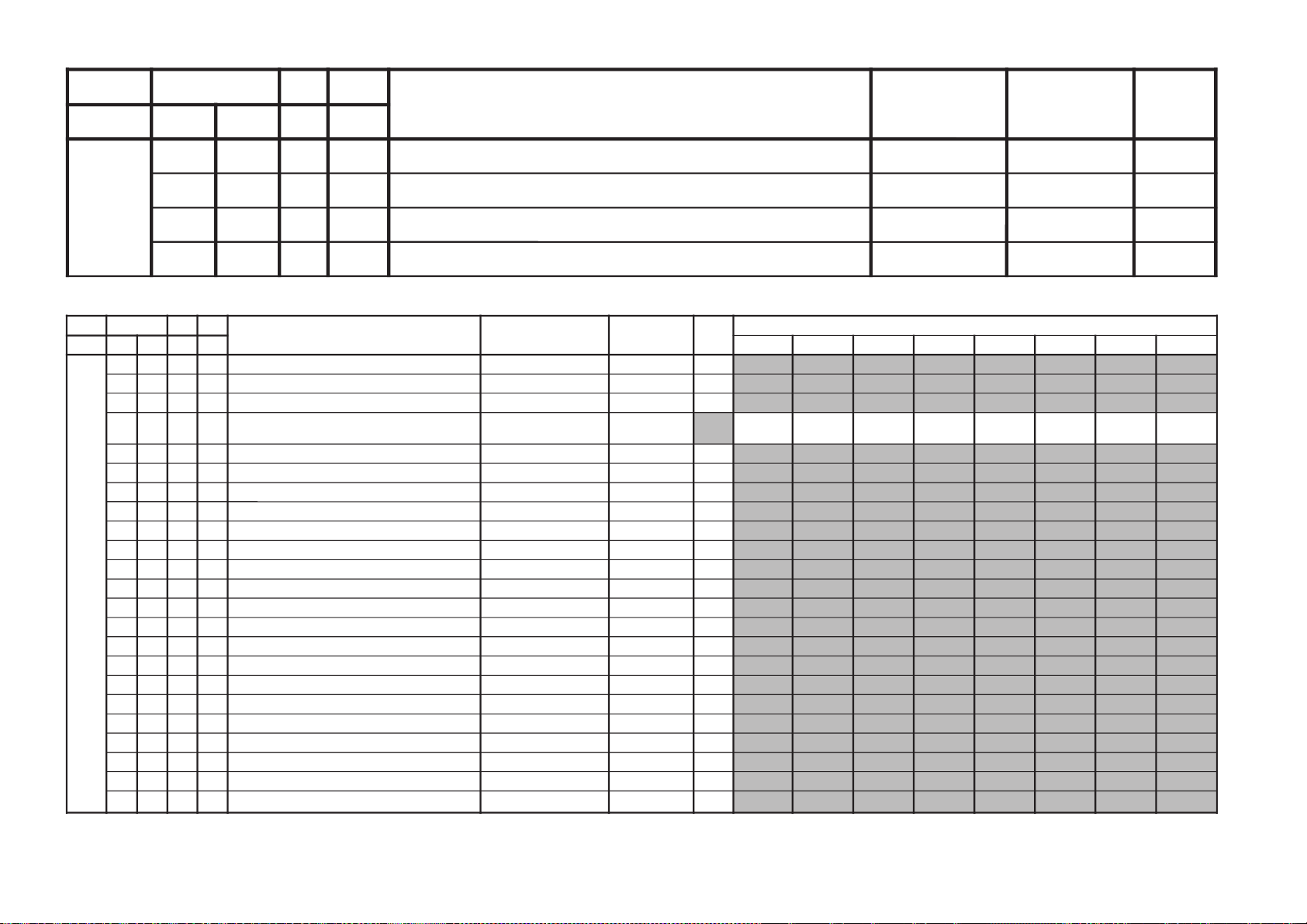

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

BTPO000LLAI000100)MVNnideziromemton(hctiwSetirWdradnatS

1001BPO000552)detalermetsyS(1noitpO noitpOreferesaelP

2002BPO000552)detalerlangiSoediV(2noitpO 92egaptatiB

3003BPO000552)detalergnidoceDoeretS(3noitpO

4004BPO000552)suoenallecsiM(4noitpO

5005BPO000552)suoenallecsiM(5noitpO

6006BPO000552)detaleregaugnaLDSO(6noitpO

KV-SA28M36

RM-W107

Page 29

KV-SA28M36

RM-W107

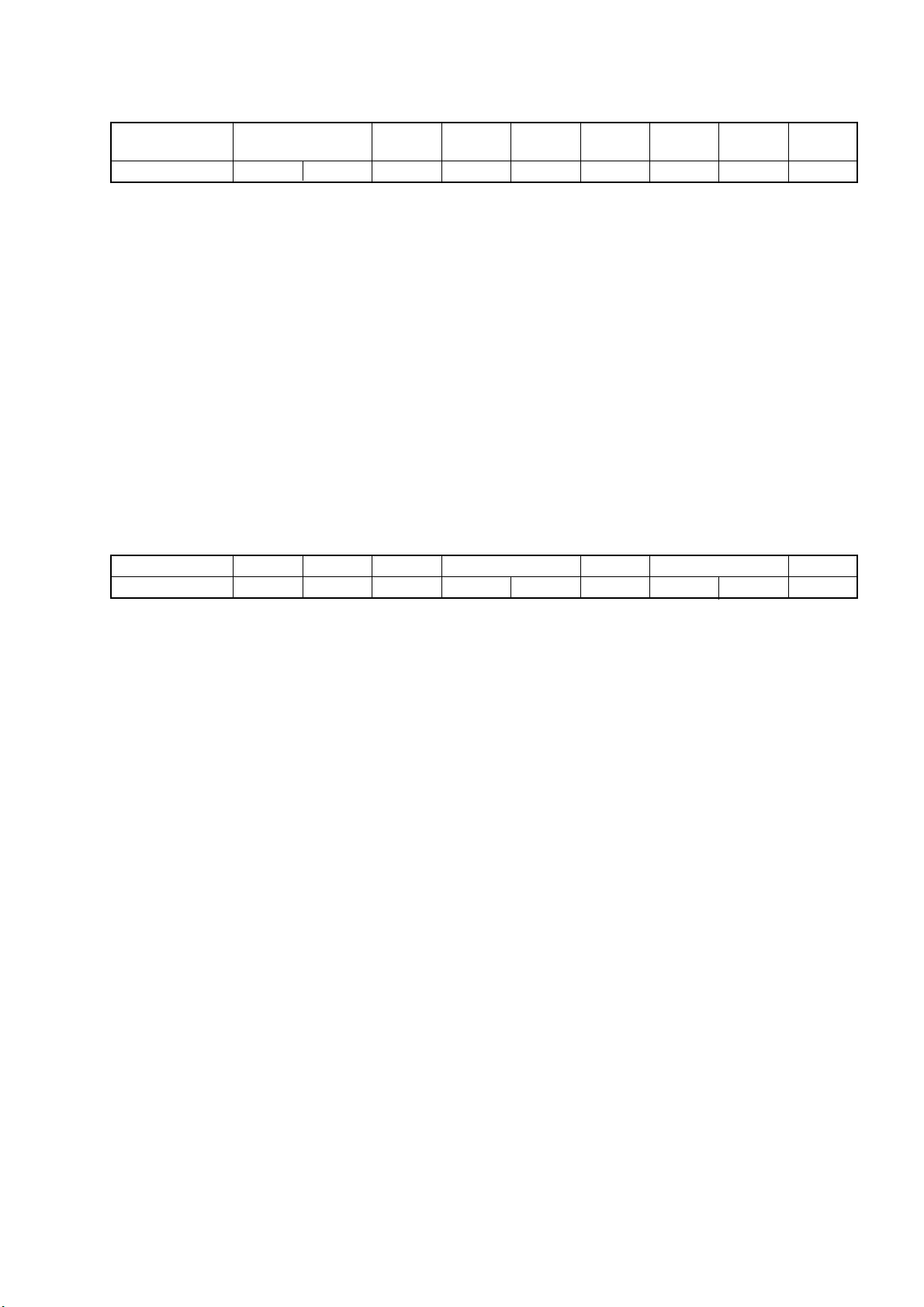

Data Variant depend on models

Category No Name Table

SDEM 001 QSS 01 01 00

Category No Name Table

SDEC 019 EPMD 02 01

Category No Name Table

OPTM 007 LANG 00 01

Stereo India/China AV Stereo

Stereo AV Stereo

020 STDS 31 13

026 DCXI 00 00

027 DCXG 03 00

029 DCLH 06 00

Others Russia

Category No Name Table

Hong Kong China Other

OPTM 012 TSYS 01 02 00

– 28 –

Page 30

ITEM INFORMATION

No. OPB1

Item

KV-SA28M36

SPEED SEARCH (Time of speed search) 00 = disabled (original cycle speed)

TV System Selection 0 = disabled, 1 = enabled

Home Theatre 1 = Home Theatre mode available

Wide Screen 1 = Wide Screen model

Speed Search

10

Home

Theatre

1

Wide

Screen

1

M (GA)

1

B/G

1

01 = 4 time speed from the original

10 = 6 time speed from the original

11 = 8 time speed from the original

I

1

D/K

1

KV-SA28M36

RM-W107

DEC

127

No. OPB2

Item

KV-SA28M36

SECAM

1

0

Component

1

1100

01 = 1 composite terminal 01 = 2 composite terminals

10 = 2 composite terminals 10 = 3 composite terminals

11 = 3 composite terminals 11 = 4 composite terminals

01 = NTSC (3.58MHz)

10 = PAL/NTSC (4.43MHz)

11 = PAL/NTSC (Tri-Norma)

Party Mode

Party Mode (karaoke function) 0 = not available, 1 = available

PAM Portable Audio Mode - GA 0 = not available, 1 = available

Component (Component [YCbCr] Terminals) 0 = not available, 1 = available

Composite (No. of Composite Terminals)

SECAM (SECAM Color System) 0 = disabled, 1 = enabled

Color decoding (Color Crystal Selection) 00 = PAL/NTSC (Multi)

PAM(GA)

0

BX1S/BX1L-Basic 00 = no composite terminal BX1L-Full 00 = no composite terminal

Color DecordingComposite (SCART)

DEC

60

– 29 –

Page 31

KV-SA28M36

RM-W107

No. OPB3

Item

KV-SA28M36

HDEV

0

HDEV (High Deviation Mode) 0 = disabled, 1 = enabled

NICAM ST (NICAM Stereo) 0 = disabled, 1 = enabled

NICAM BI (NICAM Bilingual) 0 = disabled, 1 = enabled

A2 ST/BI (A2 [West German]

Thai Bilingual (A2 [Thai] Bilingual)

US ST (US Stereo) 0 = disabled, 1 = enabled

Korean ST (Korean Stereo) 0 = disabled, 1 = enabled

MONO (Monaural Model) 0 = Stereo (SSD) Model

NICAM

ST

NICAM BI

1

Stereo/Bilingual) 0 = disabled, 1 = enabled

or Force SAP if US ST is active 0 = disabled, 1 = enabled

1

A2 ST

1

Thai

Bilingual

0

US ST

0

1 = Monaural Model

Korean

ST

0

MONO

0

DEC

112

No. OPB4

Item

KV-SA28M36

SMAT

1

SMAT Surround Matrix 0 = Active, 1 = Passive

1 spk Models 1 Speaker Models 0 = 2 or 3 Speaker Models,

VM (Velocity Modulation) 0 = disabled, 1 = enabled

Equalizer (5-band Equalizer Model) 0 = Bass/Treble Model, 1 = Equalizer Model

Surround (Surround Selection) 00 = Off/Simulated/Surround

TOP (Forced TOP) 0 = Auto Mode (TOP/FLOF), 1 = Forced TOP

TEXT (Teletext Model) 0 = Non-Teletext Model, 1 = Teletext Model

1 spk

Models

0

VM

1

1

SurroundEqualizer

10

1 = 1 speaker Models

01 = Off/Simulated/SRS (3D) Surround

10 = Off/Simulated/WOW/TruSurround

11 = Off/Simulated/WOW/TruSurround/Virtual

Bolby (not working now)

To p

1

Text

1

DEC

187

– 30 –

Page 32

No. OPB5

KV-SA28M36

RM-W107

Item

KV-SA28M36

Full

Surround

0

Full Surround (Full Surround option-no for 0 = Normal Surround Model

No Surround (No Surround Model) 0 = Surround Model, 1 = Non-Surround Model

COSMIC ASD Automatic Standard Detection 0 = disabled, 1 = enabled

ASD (Automatic Standard Detection) 0 = disabled, 1 = enabled

Tilt (Tilt Correction/PIC Rotation) 0 = disabled, 1 = enabled

IP Plus (Intelligent Picture Plus) 0 = disabled, 1 = enabled

IP (Intelligent Picture) 0 = disabled, 1 = enabled

Wide (Wide Mode/V-Compressed) 0 = disabled, 1 = enabled

No

Surround

COSMIC

ASD

0

EURO model) 1 = Full Surround Model

Using COSMIC (Non-Stereo)

0

ASD

1

Tilt

1

IP Plus

1

(Off/simulated/surround/

SRS/WOW/TruSurround)

IP

1

Wide

0

DEC

30

No. OPB6

Item

KV-SA28M36

GA US

0

GA US (US Model Destination) 0 = US/CANADA/Latin

3D OSD (BX1L Full version GA Multi 0 = Normal with 3D Intelligent picture OSD

Feature 2 (Temporary for BX1L) 0 = Comb Not available

Feature 1 (Temporary for BX1L) 0 = PiP Not Available

OSD Language Selection

3D OSD

Feature 2

0

Destination ONLY) 1 = Disable 3D Intelligent picture OSD

Feature 1

1

1

US (GA NTSC) 1x1x = Complicated Chinese

GA 1xxx = Simplified Chinese

OSD Language Selection

0001

1 = Taiwan/Korea/Philippine

(Wake-up timer enable)

(GA Surround Spec:OFF,

SIMULATED, SRS)

1 = Comb available

1 = PiP available

1xx1 = Korean (note: for BX1L, combination

of C.Chinese & Korean not available)

x1xx = Arabic

xx1x = Thai

xxx1 = Vietnamese

DEC

56

– 31 –

Page 33

KV-SA28M36

VB1

VB2

VB3

VB4

VB1 = VB2 = VB3 = VB4

80mV

VB1

VB2

VB3

VB4

VB1 = VB2 = VB3 = VB4

80mV

RM-W107

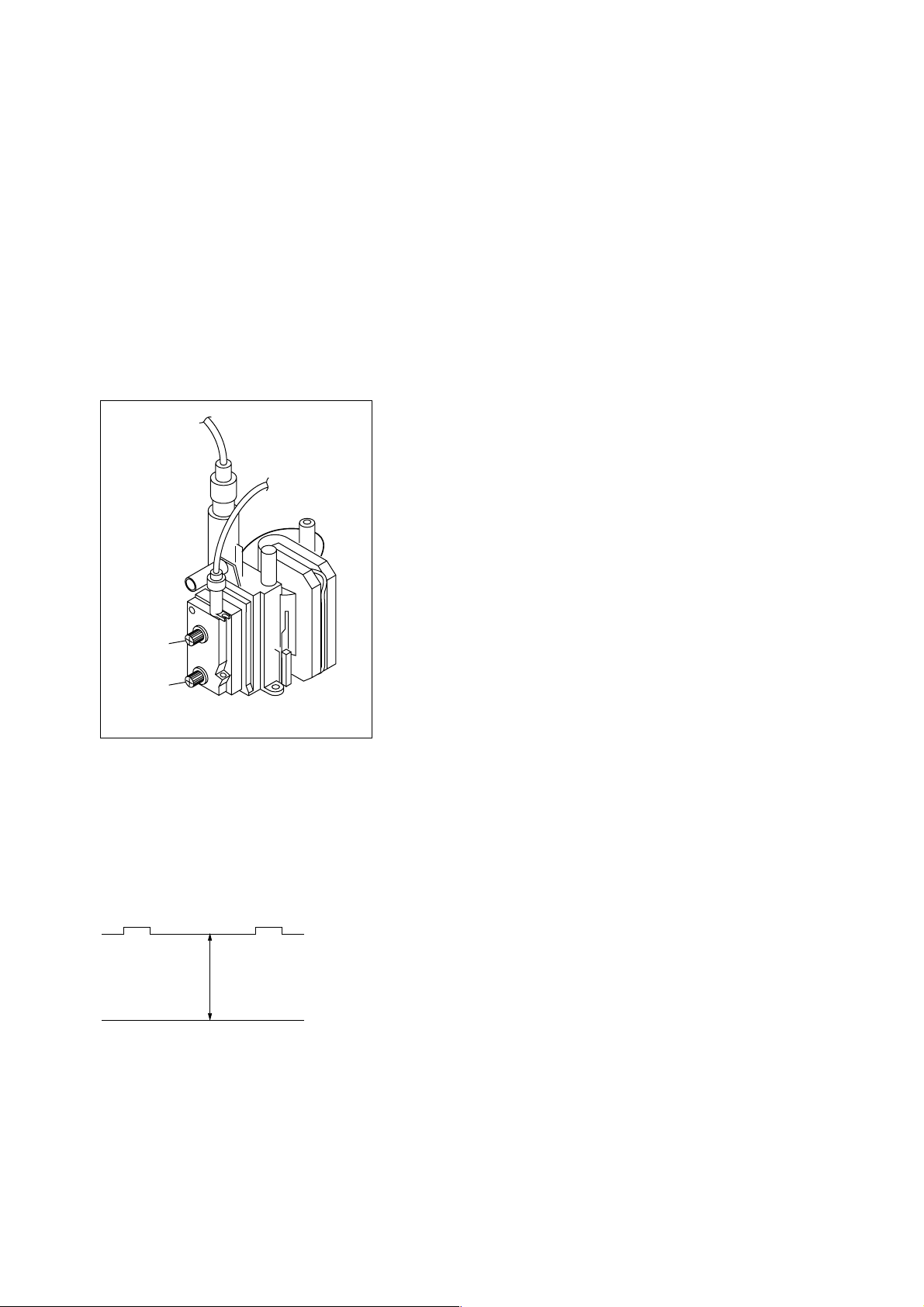

3-3. PICTURE QUALITY ADJUSTMENT

SUB COLOR ADJUSTMENT

1. Select Video.

2. Input PAL 100% Color Bar.

3. Set to following condition:

PICTURE 100%,COLOR 50%, BRIGHTNESS 50%,

HUE Center, SHP 50%.

4. Set the PICT 006 WTS to 00h.

5. Connect an oscilloscope to pin 2 (B OUTPUT) of

CN004 A Board.

6. Set the service mode and select SADJ 004 "SCOL"

1 and 4 of the commander then adjust to

with

VB2=VB3=VB4 with 3 and 6 (For PAL), write the

data as below :

VIDEO MODE RF MODE DVD MODE

SIZE

PAL SECAM PAL SECAM 50 Hz

28"

X+2 X+2 X+2 X+2 X+7

7. Input NTSC 75% Color Bar to TV set and repeat item no.

3 to 5.

8. Set the service mode and select SADJ 004 "SCOL"

1 and 4 of the commander then adjust to

with

VB1 = VB4. Write the data as below :

The highest level of VB1, VB2, VB3, VB4 must be

aligned at the same time.

The ideal difference between VB2 and VB3 is within ±

80mV.

Sub Hue Adjustment For YUV input

(not use for this model)

1. Select YUV input.

2. Input NTSC 3.58 Color Bar Into YUV mode.

Connect an oscilloscope to pin 1 (B output) of CN004.

3.

Set the service mode and select YC 013 "TINT" with

1 and 4 of the commander then adjust to

VB1=VB2=VB3=VB4 with 3 and 6.

5. Then press [MUTING] t - to write the data.

VIDEO MODE RF MODE DVD MODE

SIZE

28"

NTSC NTSC 60 Hz

Y+3 Y+3 Y+5

9. Set WTS back to original data.

VB1

VB2 VB3

VB4

VB2 = VB3 = VB4(For PAL sub color adjustment)

VB1 = VB4(For NTSC sub color adjustment)

(Difference is within 70mV)

SUB HUE ADJUSTMENT

1. Select Video.

2. Input NTSC 3.58 Color Bar to TV set.

3. Set to following condition:

PICTURE 100%,COLOR 50%, BRIGHTNESS 50%,

HUE Center, SHP 50%.

Connect an oscilloscope to pin 2 (B output) of CN004.

4.

5. Set the service mode and select YC 013 "TINT" with

1 and 4 of the commander then adjust to

VB1=VB2=VB3=VB4 with

6. Then press [MUTING] t - to write the data.

7.

Select TV channel with NTSC 3.58 and repeat item no.

3 to 6.

3 and 6.

The highest level of VB1, VB2, VB3, VB4 must be

aligned at the same time.

The ideal difference between VB2 and VB3 is within ±

80mV.

PMAX/CONTRAST ADJUSTMENT

Picture Mode : Personal

Wide Mode : Full (For SA28/SA32)

1. Select Video mode.

2. i)Input PAL Color Bar toTV set. (Other)

ii)Input NTSC 75% Color Bar (NTSC model).

3. Set the following condition:

PICTURE 100%, COLOR 0%,BRIGHTNESS 50%

4. Connect oscilloscope to pin 4 (R Output) of CN004,

5. Set to Service Mode PWL PICT 003 to 00h and

WHBL 017 BLBG to 01h.

Select SADJ 000 "PMAX" with 1 and 4 of the

6.

commander then adjust VR within spec with 3 and 6.

VR

Black

PA L

2.15±

0.03Vpp

2.15±

0.03Vpp

VR

32"

28"

– 32 –

Page 34

KV-SA28M36

RM-W107

7. Copy PMAX data to TV models.

8.

Select "WIDE" mode for TV & Video mode, Write the

data as below:

ADJUSTED PMAX VALUE : X

INCH

SA28

SA32

VIDEO MODE TV MODE

FULL NORMAL FULL NORMAL

X X-6 X X-6

9. Set the PWL & BLBG back to (PWL: 01h and

BLBG: 00h)

YOUTPUT LEVEL ADJUSTMENT

1. Input a color with bar with 100IRE white signal to pin

1 (CVBS) of CN2001 BC board.

2. Set to service mode and select 3D NR Bus data with

1 and 4 of the commander.

3. Press [MUTING] t

- to write the data to TC90A88F.

PICTURE CONFIRMATION

1. Input a color bar with 100IRE white signal to pin 1

(CVBS) of CN2001 BC board.

2. Confirm no dot structure can been seen and the

picture is normal on the screen.

3. Input signal RAMP to pin 1 (CVBS) of CN2001 BC

board.

4. Confirm no vertical stripes, no noise can be seen and

the picture is normal on the screen.

5. Adjust RV2001 (BC board) so that the output level of

CN2001 (BC board) pin 3 (YOUT) is within spec.

1.4 ± 0.05 Vpp

3. Using the 1 and 4 buttons select, category GEOM

(service mode) Raise/lower data using the 3 and 6

buttons to adjust the following items:Service Item

GEOM: 000 HPOS HORIZONTAL SHIFT (HS)

001 HPAR HORIZONTAL

PARALLELOGRAM

002 HBOW HORIZONTAL BOW

003 VLIN VERTICAL LINEARITY

005 HSIZ EW WIDTH (EW)

006 EWPW EW PARABOLA/WIDTH

(PW)

007 UCOP EW UPPER CORNER

PARABOLA

008 LCOP EW LOWER CORNER

PARABOLA

009 EWTZ EW TRAPEZIUM

010 VSLP VERTICAL SLOPE (VS)

011 VSIZ VERTICAL AMPLITUDE

012 SCOR S-CORRECTION (SC)

013 VPOS VERTICAL SHIFT (VSH)

4. For Korea models only:

a) For GEOM items, copy adjusted 60Hz to 50Hz

b) Add 6 steps to 50Hz "HPOS" item and save data.

c) Add 3 steps to 50Hz "HSIZ" item and save data.

WIDE MODE (50Hz)

(V-Compression Adjustment)

1. Input SPCB signal(For NTSC models select Video

mode)

2. Adjust condition to WIDE MODE : ON.

3. Copy (item from NORMAL MODE (50Hz) adjusted

data for the following items:

Service Item

3-4. DEFLECTION ADJUSTMENT

TILT CORRECTION ADJUSTMENT

(Picture Rotation Models Only)

1. Press [MENU] button on the remote commander.

2. Select [SETUP] and [PIC ROTATION].

3. Picture will rotate while pressing [f+,F-]. Make top

and bottom horizontal line parallel to edge of screen.

4. Press [TEST] + [NORMAL] button to set center

position.

H-TRAPEZOID ADJUSTMENT

1. Receive cross hatch/dot signal

2. Adjust RV750 on C-Board to make H-Trapezoid

distortion best.

NORMAL MODE (50Hz)

1. Set to Service Mode.

2. Input SPCB Signal (For NTSC models select Video

mode)

GEOM: 003 VLIN VERTICAL LINEARITY

005 HSIZ EW WIDTH (EW)

011 VSIZ VERTICAL AMPLITUDE

012 SCOR S-CORRECTION (SC)

4. Raise/lower data using the

3 and 6 buttons, select

and adjust the following item to obtain optimum image.

Service Item

GEOM: 000 HPOS HORIZONTAL SHIFT (HS)

001 HPAR HORIZONTAL

PARALLELOGRAM

002 HBOW HORIZONTAL BOW

005 HSIZ EW WIDTH (EW)

006 EWPW

EW PARABOLA/WIDTH (PW)

007 UCOP EW UPPER CORNER

PARABOLA

008 LCOP EW LOWER CORNER

PARABOLA

009 EWTZ EW TRAPEZIUM

013 VPOS VERTICAL SHIFT (VSH)

5. For Korea models only:

a) Copy adjusted 60Hz data to 50Hz

b) Add 6 steps to 50Hz "HPOS" item and save data.

– 33 –

Page 35

KV-SA28M36

()

()

RM-W107

NORMAL MODE (60Hz)

1. Input 525/60Hz signal.

2. Using the 1 and 4 buttons select category GEOM

(Service Mode.)

3. Raise/ lower data using the

3 and 6 buttons to

obtain optimum image.

Service Item

GEOM: 000 HPOS HORIZONTAL SHIFT (HS)

001 HPAR HORIZONTAL

PARALLELOGRAM

002 HBOW HORIZONTAL BOW

003 VLIN VERTICAL LINEARITY

005 HSIZ EW WIDTH (EW)

006 EWPW

EW PARABOLA/WIDTH

(PW)

007 UCOP EW UPPER CORNER

PARABOLA

008 LCOP EW LOWER CORNER

PARABOLA

009 EWTZ EW TRAPEZIUM

010 VSLP VERTICAL SLOPE (VS)

011 VSIZ VERTICAL AMPLITUDE

012 SCOR S-CORRECTION (SC)

013 VPOS VERTICAL SHIFT (VSH)

3-5. PICTURE DISTORTION ADJUSTMENT

H. CENTER ADJUSTMENT (HPOS)

1. Input Monoscope signal.

2. Activate the Service Mode.

3. Select the HPOS item with 1 and 4.

4. Adjust the value of HPOS with 3 and 6 for the best

horizontal center.

5. Press [MUTING] then - to save into the memory.

H. SIZE ADJUSTMENT (HSIZ)

1. Input Monoscope signal.

2. Activate the Service Mode.

3. Select HSIZ with

4. Adjust with 3 and 6 for the best horizontal size.

5. Press [MUTING] then - to save into the memory.

1 and 4.

WIDE MODE (60Hz)

(V-Compression Adjustment)

1. Input Monoscope signal

2. Adjust condition to WIDE MODE : ON.

3. Copy (item from NORMAL MODE 60Hz) adjusted

data for the following items:

Service Item

GEOM: 003 VLIN VERTICAL LINEARITY

010 VSLP VERTIVAL SLOPE (VS)

011 VSIZ VERTICAL AMPLITUDE

012 SCOR S-CORRECTION (SC)

4. Raise/lower data using

3 and 6 buttons, select and

adjust the following item to obtain optimum image.

Service Item

GEOM: 000 HPOS HORIZONTAL SHIFT (HS)

001 HPAR HORIZONTAL

PARALLELOGRAM

002 HBOW HORIZONTAL BOW

005 HSIZ EW WIDTH (EW)

006 EWPW EW PARABOLA/

WIDTH (PW)

007 UCOP EW UPPER CORNER

PARABOLA

008 LCOP EW LOWER CORNER

PARABOLA

009 EWTZ EW TRAPAZIUM

013 VPOS VERTICAL SHIFT (VSH)

– 34 –

Page 36

KV-SA28M36

RM-W107

V. SIZE ADJUSTMENT (VSIZ)

1. Input Monoscope signal.

2. Activate the Service Mode.

3. Select theVSIZ item with

1 and 4.

4. Adjust value of VSIZ with 3 and 6 for the best

vertical size.

5. Press [MUTING] then - to save into the memory.

V. CENTER ADJUSTMENT (VPOS)

1. Input Monoscope signal.

2. Activate the Service Mode.

3. Select VPOS item with

4. Adjust value of VPOS with

1 and 4.

3 and 6 for the best

vertical size.

5. Press [MUTING] then - to save into the memory.

HORIZONTOL PARALLELOGRAM (HPAR), H BOW

(HBOW), UPPER PIN (UCOP) AND LOW PIN (LCOP)

ADJUSTMENTS

1. Input Monoscope signal.

2. Activate the Service Mode.

3. Select the HPAR, HBOW, UCOP, and LCOP with

1

and 4.

4. Adjust with

3 and 6 for the best picture.

5. Press [MUTING] then - to save into the memory.

HORIZONTOLPARALLELOGRAM (HPAR)

HORIZONTOL BOW (HBOW)

EW UPPER CORNER PARABOLA (UCOP)

EW LOWER CORNER PARABOLA (LCOP)

V. LINEARITY (VLIN), S CORRECTION (SCOR), EW

PARABOLA/WIDTH (EWPW), AND EW TRAPEZIUM

(EWTZ) ADJUSTMENTS

1. Input Monoscope signal.

2. Activate the Service Mode.

3. Select VLIN, SCOR, EWPW, and EWTZ with

4.

1 and

4. Adjust with 3 and 6 for the best picture.

5. Press [MUTING] then - to save into the memory.

VERTICAL LINEARITY (VLIN)

S CORRECTION (SCOR)

EW PARABOLA/WIDTH (EWPW)

EW TRAPEZIUM (EWTZ)

– 35 –

Page 37

KV-SA28M36

VIF

SAW

SIF

SAW

MAIN

Power

Supply

Stdby

Power

FSS TUNER

AV

Switch

3D

COMB/NR

SUB

FSS

TUVIF

G/Y

B/PB

R/PR

L

R

24.576MHz

DVD in

Rear AV in

Front AV in

Mon out

Main CV

L,R in

Mon

out

AV

1,2

in

AV

1

in

RGB/

DVD

in

AC in ~

110-220V

RGB out 42-44

VM 64

VD + 107

VD – 104

EWD 108

LSL 69

LSR 68

118 XTAL OUT

119 XTAL IN

40 C1

71 CVBS / Y1

L, R

CISPR/

PFC

Relay

LOW B

Stdy 3.3

AUDIO VCC

FBT

L

2ch

10W

Tweeter

10W

Tweeter

Audio Amp

AT T

NVM

Pin out

H-drive

H-out

V-out

DF/DQP

VM

RGB Amp

Rot Amp

LCC Amp

feedback

R

L,R

H

P

EW, Hd

V+, V-

PWM

RGB

SIRCS

Key

buttons

PLL

YC out

Center in

SUB

Picture

CV/Y

UV in

PIP

I/O Port

I/O Port

VIF & SIF

POWER

Color

Decoder

YUV

Processor

Jungle

RGB

A

D

C

D

A

C

Stereo,

DSP

Micro

Te xt

CC & V-chip

L

E

D

+B

ID

Centre

in

VIFIN1 105

VIFIN2 104

32 SIRCS

10 KEY

6 Green Led

7 Red Led

21 SCLO

22 SDAO

– 36 –

4-1. BLOCK DIAGRAM

DIAGRAMS

RM-W107

SECTION 4

Page 38

4-2. CIRCUIT BOARDS LOCATION

WD Board

DL Board

A Board

C Board

H4 Board

B Board

J3 Board

KV-SA28M36

RM-W107

VM Board

H6 Board

F Board

BC Board

4-3. SCHEMATIC DIAGRAM INFORMATION

Note:

• All capacitors are in µF unless otherwise noted.

• All electrolytic capacitors are rated at 50V unless otherwise

noted.

• All resistors are in ohms.

kΩ = 1000Ω, MΩ = 1000kΩ

• Indication of resistance which does not have rating electrical

power is as follows.

Pitch: 5 mm

Rating electrical power 1/4W (CHIP: 1/10W)

• : nonflammable resistor.

• : fusible resistor.

• ¢ : internal component.

• : panel designation or adjustment for repair.

• All variable and adjustable resistors have characteristic curve

B unless otherwise noted.

• Readings are taken with a color-bar signal input.

no mark : Common

(): PAL

[ ] : NTSC 3.58

• Readings are taken with a 10MΩ digital multimeter.

• Voltage are dc with respect to ground unless otherwise

noted.

• Voltage variations may be noted due to normal production

tolerances.

• All voltage are in Volt.

• ✽ : Cannot be measured.

• Circled numbers are waveform references.

• : B +bus.

• : B –bus.

• k : signal path.

Note: The reference number which starts with Wxxx

(eg: W003) indicates a wire to wire connection.

Note: Components marked as XX are not fitted on this

model.

Reference information

RESISTOR : RN METAL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: RW NONFLAMMABLE WIREWOUND

: ✽ ADJUSTMENT RESISTOR

COIL : LF-8L MICRO INDUCTOR

CAPACITOR : TA TANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

Note: The component identified by shading and

mark ! are critical for safety. Replace only

with part number specified.

Note: "A" board schematic diagram is divided into 3

blocks. Each block is named by its function and

block "number". eg: Processor/Audio/Tuner/Jack

(Block 001).

Joint connection between boards can be identified

using the block number followed by the grid's guide.

eg:-<+B

002:16F

Meaning: Block 001 joint "+B" is connected to Block

002 joint "+B" located at grid 16F.

– 37 –

Page 39

4-3-1. A Board — Processor, Audio, Tuner, Jack (Block 001)

10

A

B

C

D

E

F

G

H

I

J

K

1.8V_AUDIO

DGC-RELAY

ROT_CTRL

1.8V_MAIN

B CLK

B DAT

B INT

GND

CN903

4P

BUS CONNECTOR

B CLK

B DAT

B INT

GND

AGC

CN904

XX

BUS CONNECTOR

002:16D

002:2D

3.3V

GND

LED G

LED R

SIRCS

GND

KEY

CN014

TO H6 BOARD

CN3905

3.3V

GND

LED G

LED R

SIRCS

GND

KEY

9V

CN016

XX

TO H5 BOARD

CN3911

3.3V

GND

LED G

LED R

SIRCS

GND

KEY

9V

MUTE

CN017

XX

STBY_SW

002:16C

ROT_SW

002:16G

002:16G

002:16D

LSL OUT

GND

LSR OUT

MUTE