SERVICE MANUAL

BG-1L

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-J25MF8J

RM-873 ME SCC-K57P-A

MODEL COMMANDER DEST. CHASSIS NO.

KV-J29MF8J

RM-873 ME SCC-K57N-A

TRINITRON

®

COLOR TV

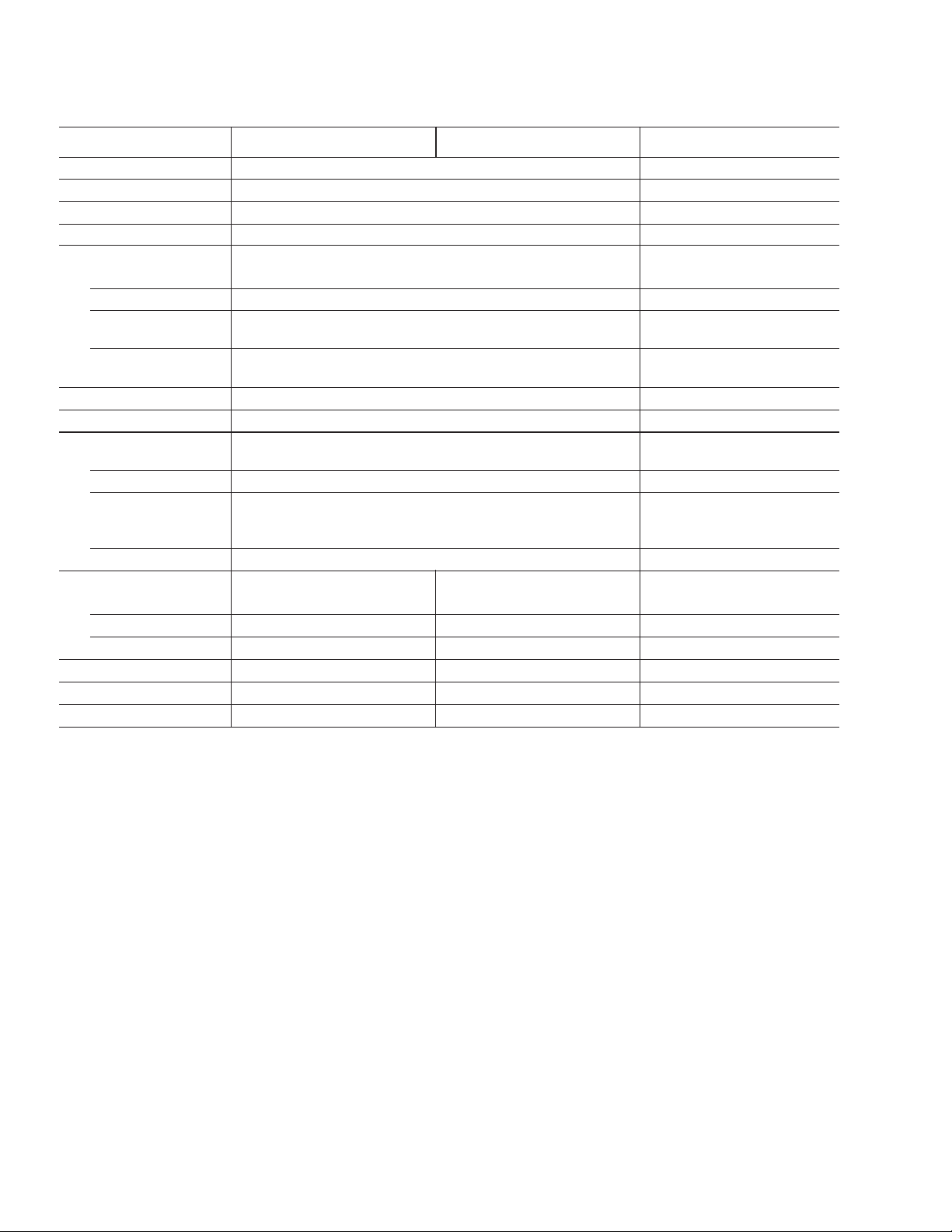

SPECIFICATIONS

KV-J25MF8J KV-J29MF8J

Note

Power requirements 110-240 V AC, 50/60 Hz

Power consumption (W) Indicated on the rear of the TV

Television system B/G, I, D/K, M

Color system PAL, PAL 60, SECAM, NTSC4.43, NTSC3.58

Channel coverage

B/G VHF: E2 to E12 / UHF: E21 to E69 / CATV: S01 to S03, S1 to S41

I UHF: B21 to B68 / CATV: S01 to S03, S1 to S41

D/K VHF: C1 to C12, R1 to R12 / UHF: C13 to C57, R21 to R60

CATV: Z1 to Z39, S01 to S03, S1 to S41

M VHF: A2 to A13 / UHF: A14 to A79 /

CATV: A-8 to A-2, A to W+4, W+6 to W+84

Antenna 75-ohm external terminal

Audio output (speaker) 6W + 6W

Number of terminal

Video Input: 3 Output:1 Phono jacks; 1 Vp-p, 75 ohms

Audio Input: 3 Output: 1 Phono jacks; 500 mVrms

S Video Input: 1 Y : 1 Vp-p, 75 ohms,

unbalanced, sync negative

C : 0.286 Vp-p, 75 ohms

Headphone Output: 1 Minijack

Picture tube Super Trinitron Super Trinitron Plus

(25 in.) (29 in.)

Tube size (cm) 64 72 Measured diagonally

Screen size (cm) 60 68 Measured diagonally

Dimension (w/h/d, mm) 712 × 521 × 520 780 × 577 × 542

Mass (kg) 33 43

Accessory (optional) TV stand (SU-25H) TV stand (SU-29H)

Design and specifications are subject to change without notice.

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE

AND THE ANODE CAP TO THE METAL CHASSIS, CRT

SHIELD, OR CARBON PAINTED ON THE CRT, AFTER

REMOVING THE ANODE.

SAFETY-RELATED COMPONENT W ARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK !

ON THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND

IN THE PARTS LIST ARE CRITICAL T O SAFE OPERA TION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

TABLE OF CONTENTS

Section Title Page

1. GENERAL ........................................................................ 4

2. DISASSEMBLY

2-1. Rear Cover Removal ................................................ 11

2-2. Speaker Removal ..................................................... 11

2-3. Chassis Assy Removal ............................................. 11

2-4. Service Position ....................................................... 12

2-5. S1 Board Removal ................................................... 12

2-6. A and D Boards Removal ........................................ 12

2-7. F1 and H3 Boards Removal..................................... 13

2-8. Picture Tube Removal.............................................. 13

3. SET-UP ADJUSTMENTS

3-1. Beam Landing .......................................................... 15

3-2. Convergence............................................................. 16

3-3. Focus Adjustment .................................................... 19

3-4. G2 (Screen) and White Balance Adjustments......... 20

4. SELF DIAGNOSIS FUNCTION................................ 21

5. CIRCUIT ADJUSTMENT

5-1. Adjustments with Commander ................................ 22

5-2. Adjustment Method ................................................. 23

5-3. Picture Quality Adjustment ..................................... 27

5-4. A Board Adjustment ................................................ 27

5-5. ABoard Adjustyment After IC003 (Memory)

Replacement............................................................. 28

5-6. Picture Distortion Adjustment................................. 28

Section Title Page

6. DIAGRAMS

6-1. Block Diagram ......................................................... 29

6-2. Frame Schematic Diagram ...................................... 31

6-3 Circuit Boards Location .......................................... 34

6-4. Schematic Diagrams and Printed Wiring Boards .... 34

(1) Schematic Diagrams of D, F1 and H3 Boards ........ 35

(2) Schematic Diagram of A Board ............................... 43

(3) Schematic Diagram of S1 Board ............................. 50

(4) Schematic Diagram of C2 Board ............................ 53

(5) Schematic Diagrams of VM Board ......................... 55

6-5. Semiconductors........................................................ 57

7. EXPLODED VIEWS

7-1. Picture Tube ............................................................. 59

7-2. Chassis ..................................................................... 60

8. ELECTRICAL PARTS LIST....................................... 61

– 3 –

– 4 –

SECTION 1

GENERAL

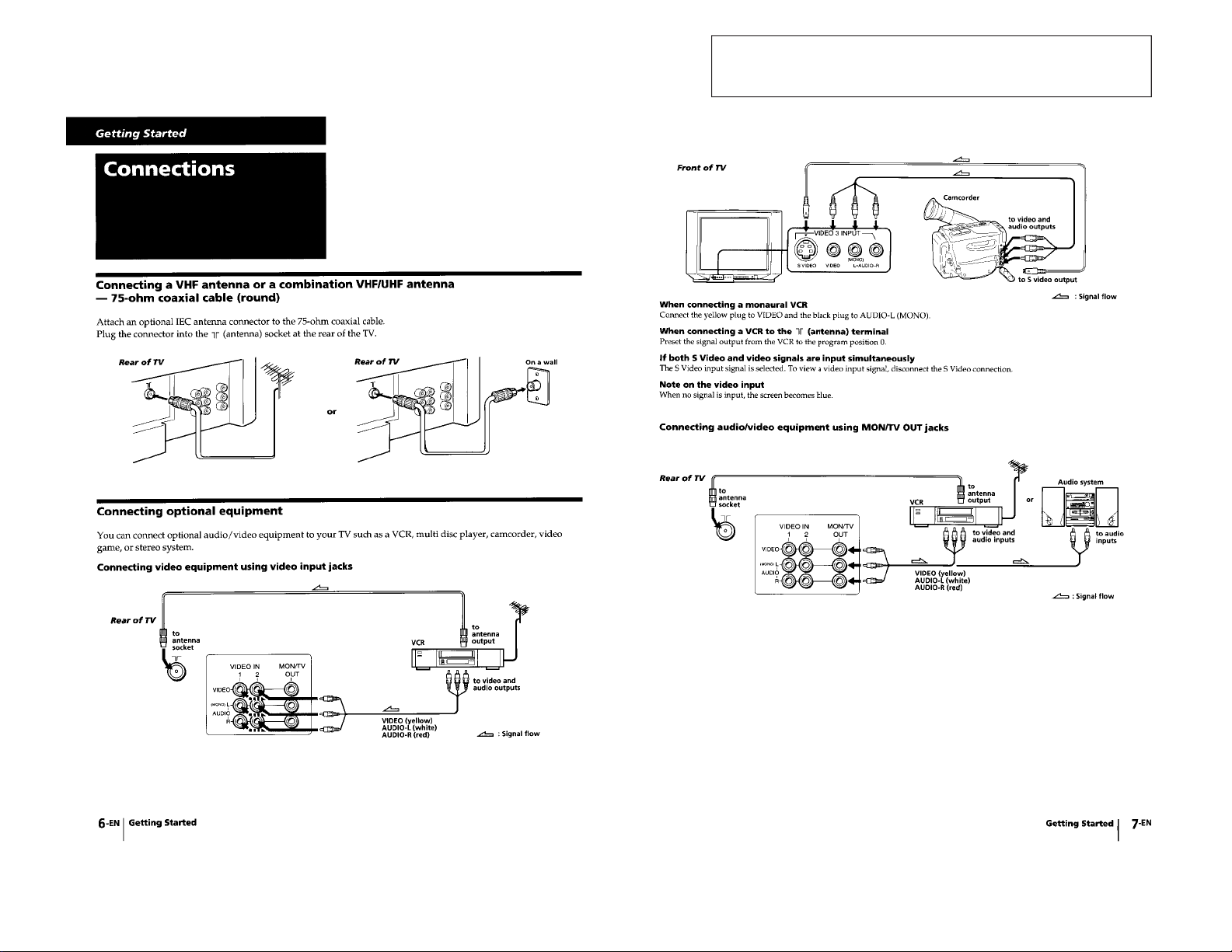

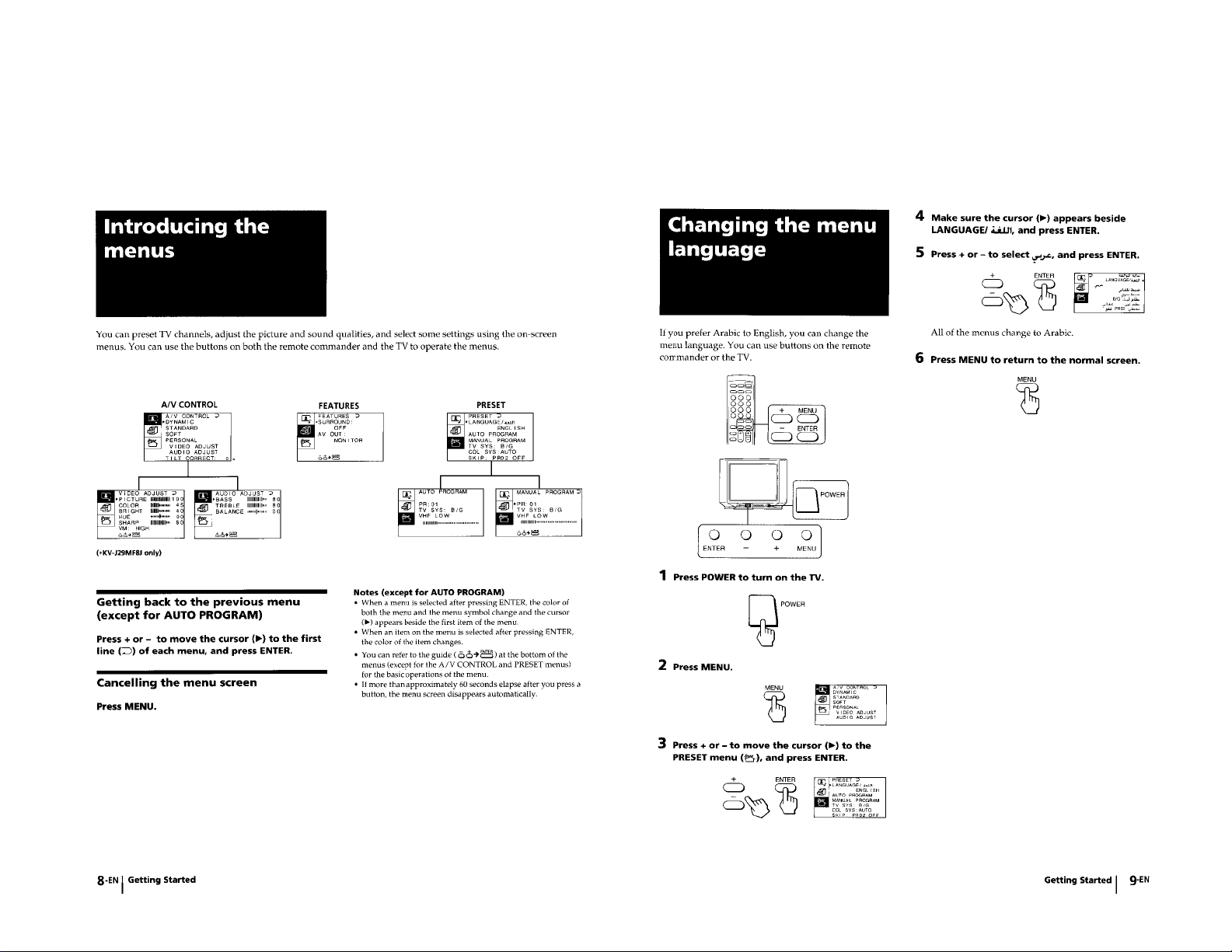

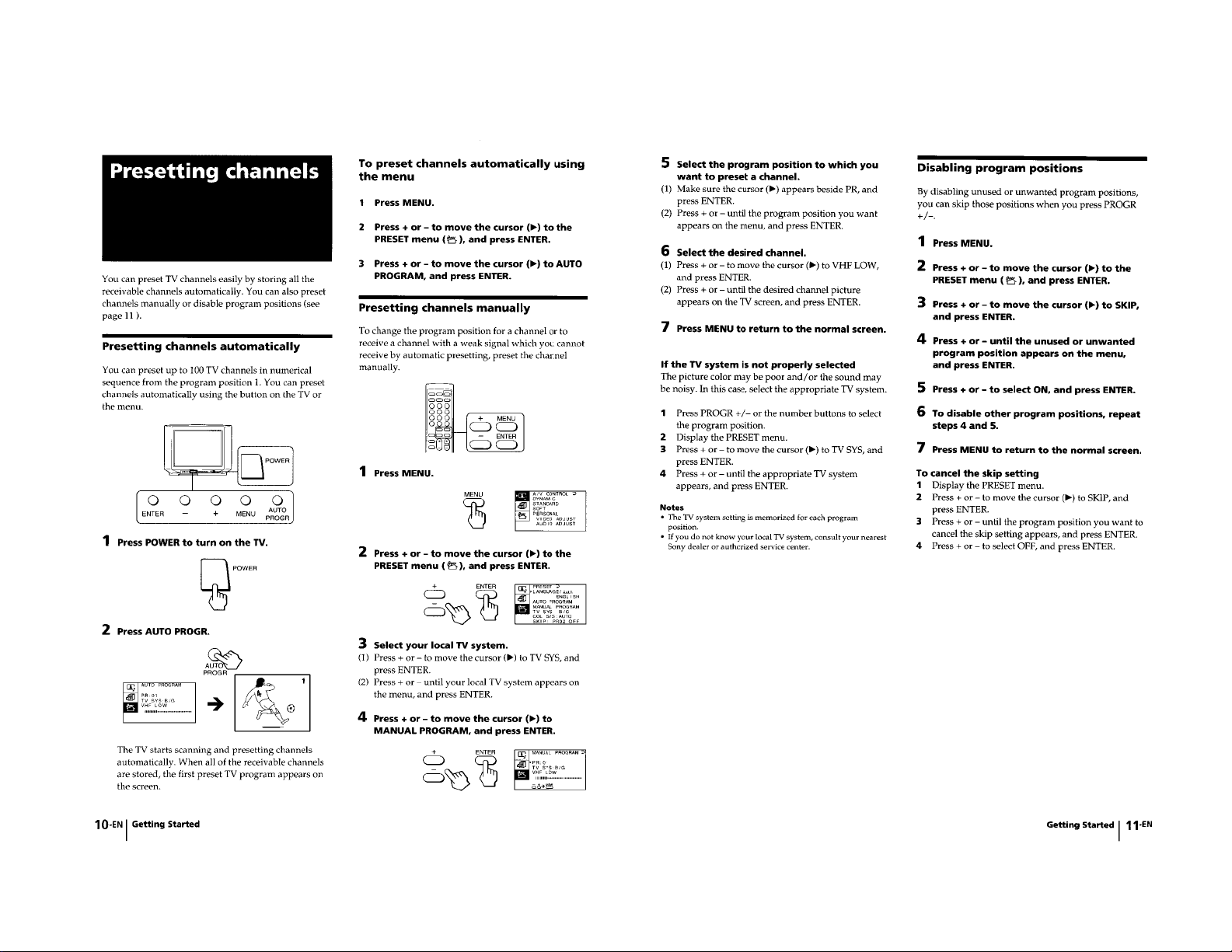

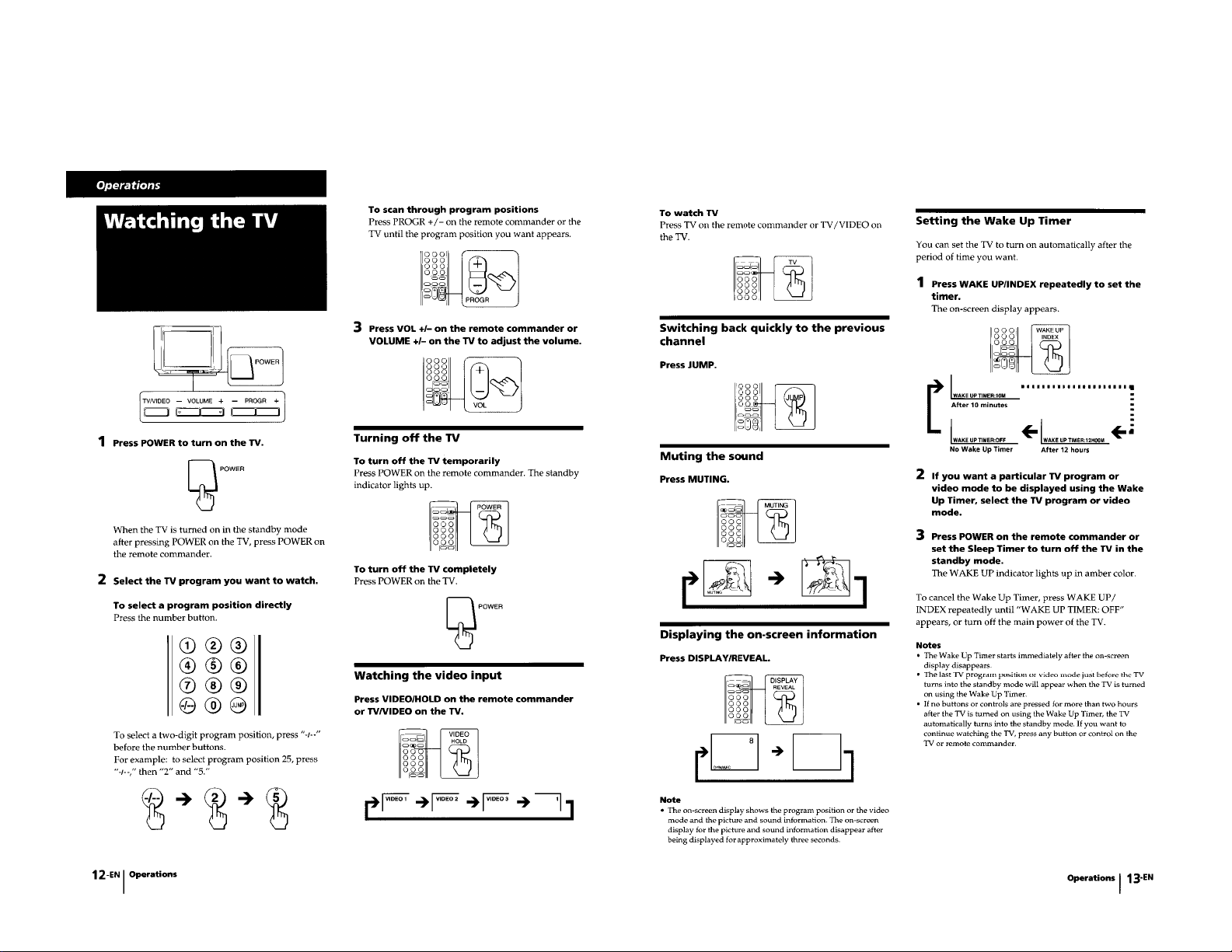

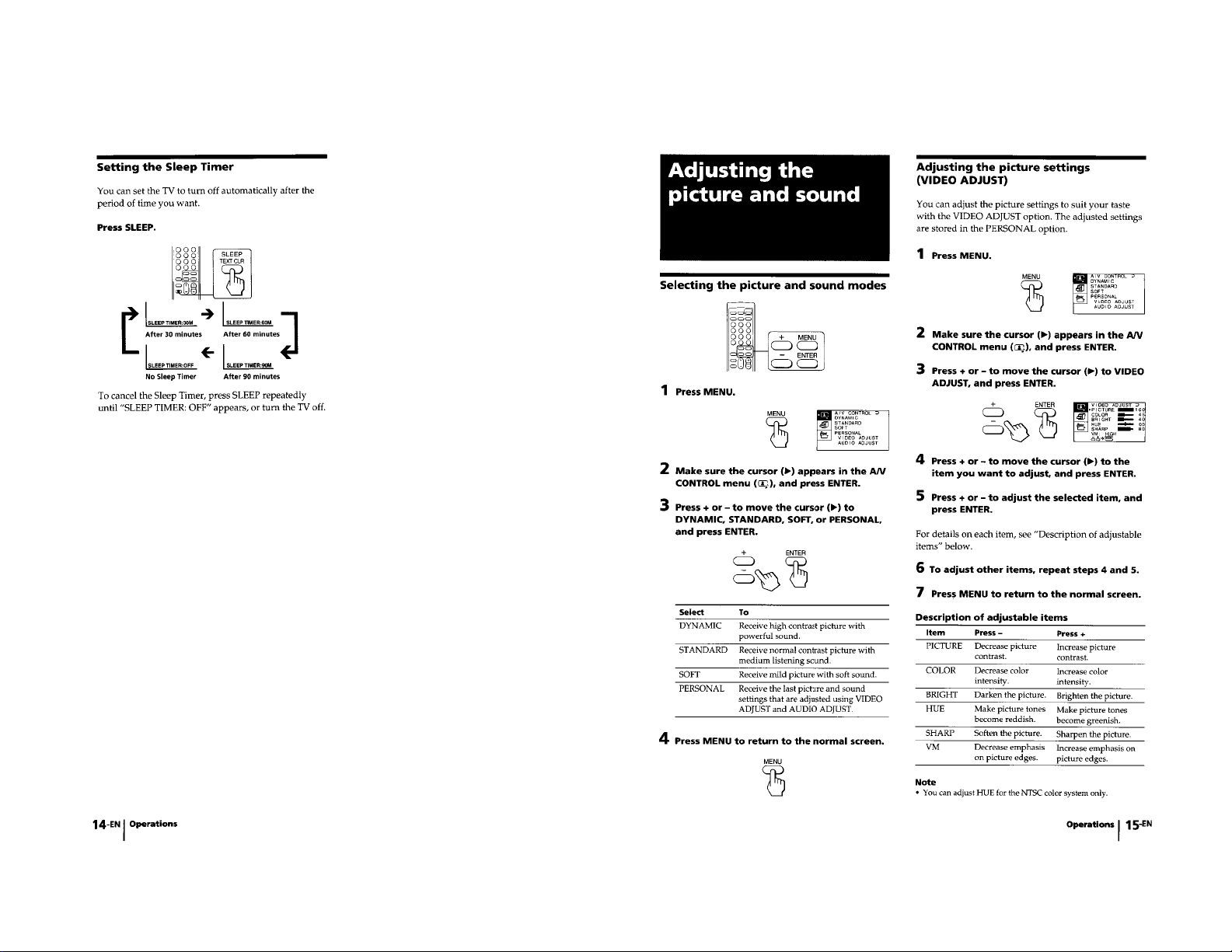

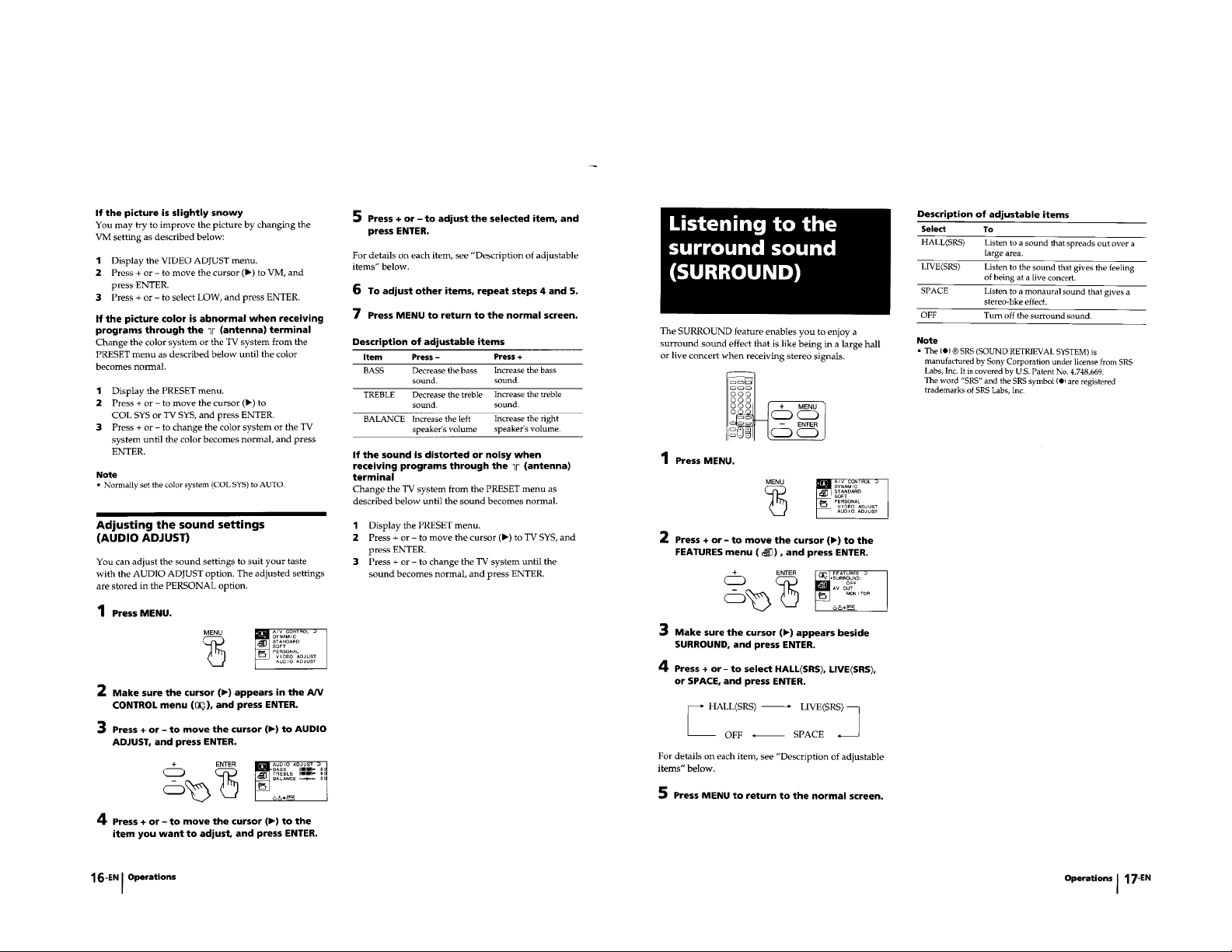

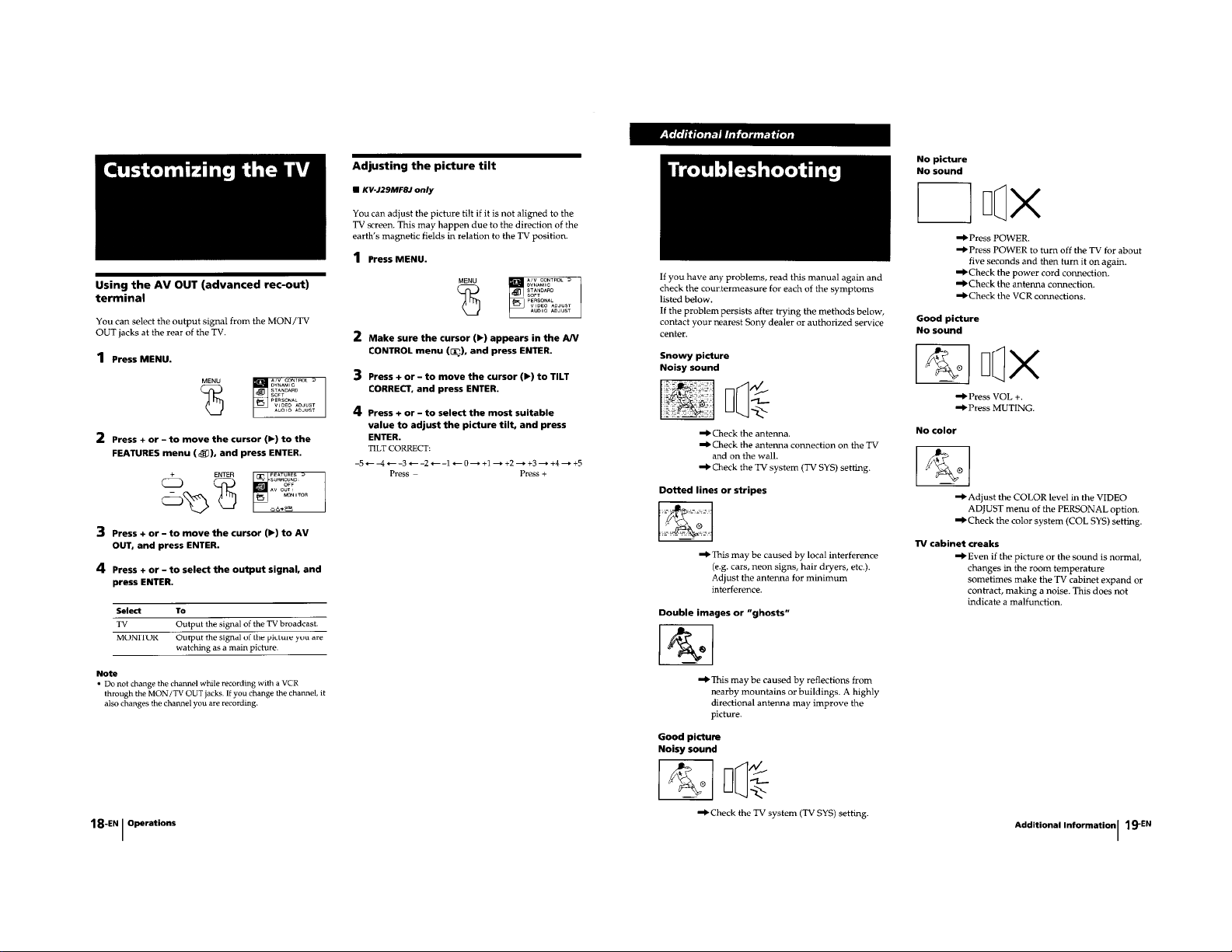

The operating instructions mentioned here are partial abstracts from

the Operating Instruction Manual. The page numbers of the

Operating Instruction Manual remain as in the manual.

– 5 –

– 6 –

– 7 –

– 8 –

– 9 –

– 10 –

SECTION 2

DISASSEMBLY

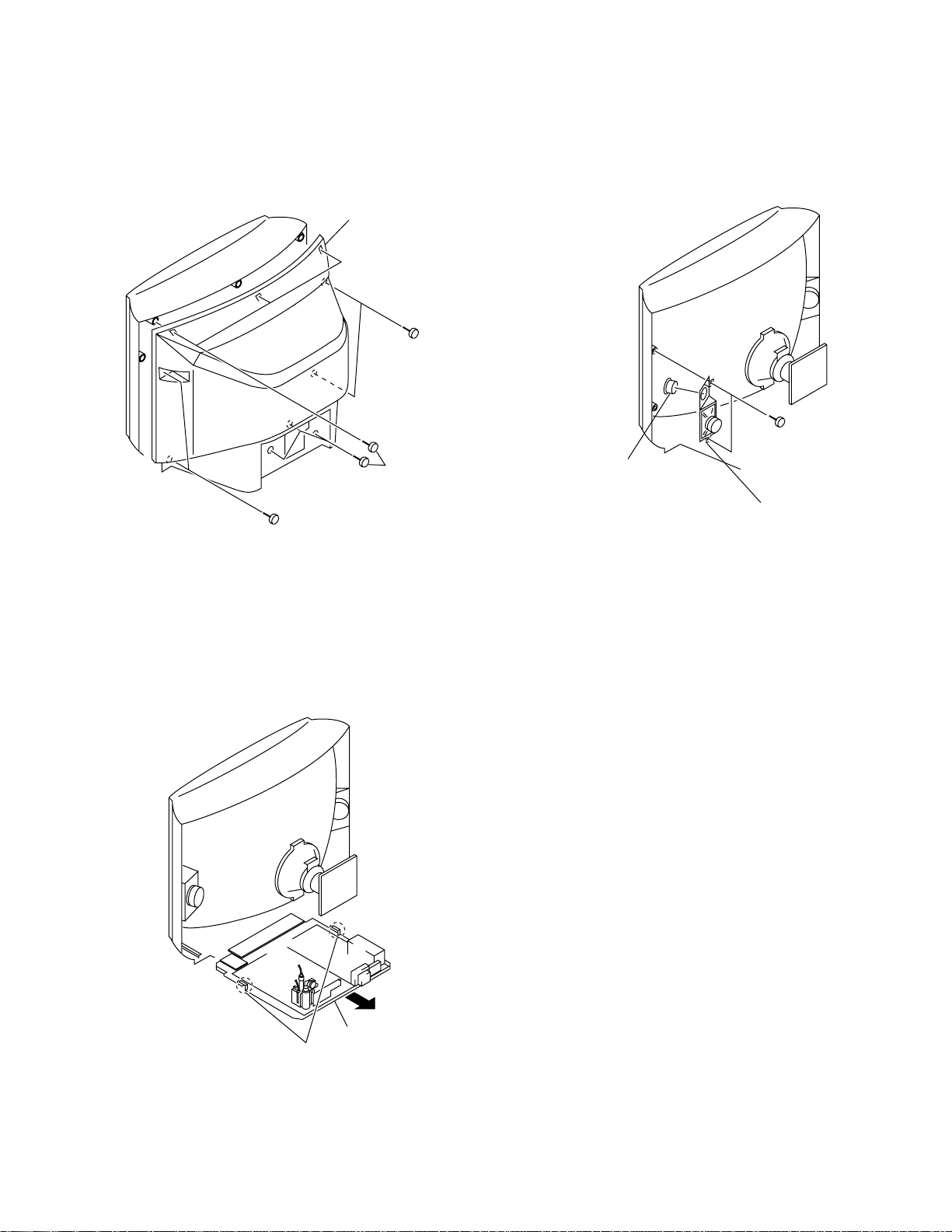

2-1. REAR COVER REMOVAL

1Two screws

(+BVTP4x16)

2 Rear cover

1Two screws

(+BVTP4x16)

1Six screws

(+BVTP4x16)

2-2. SPEAKER REMOVAL

3Speaker (5cm)

[KV-J29MF8J]

1Two screws

(+BVTP4 x16)

2Bracket (R) assy,sp

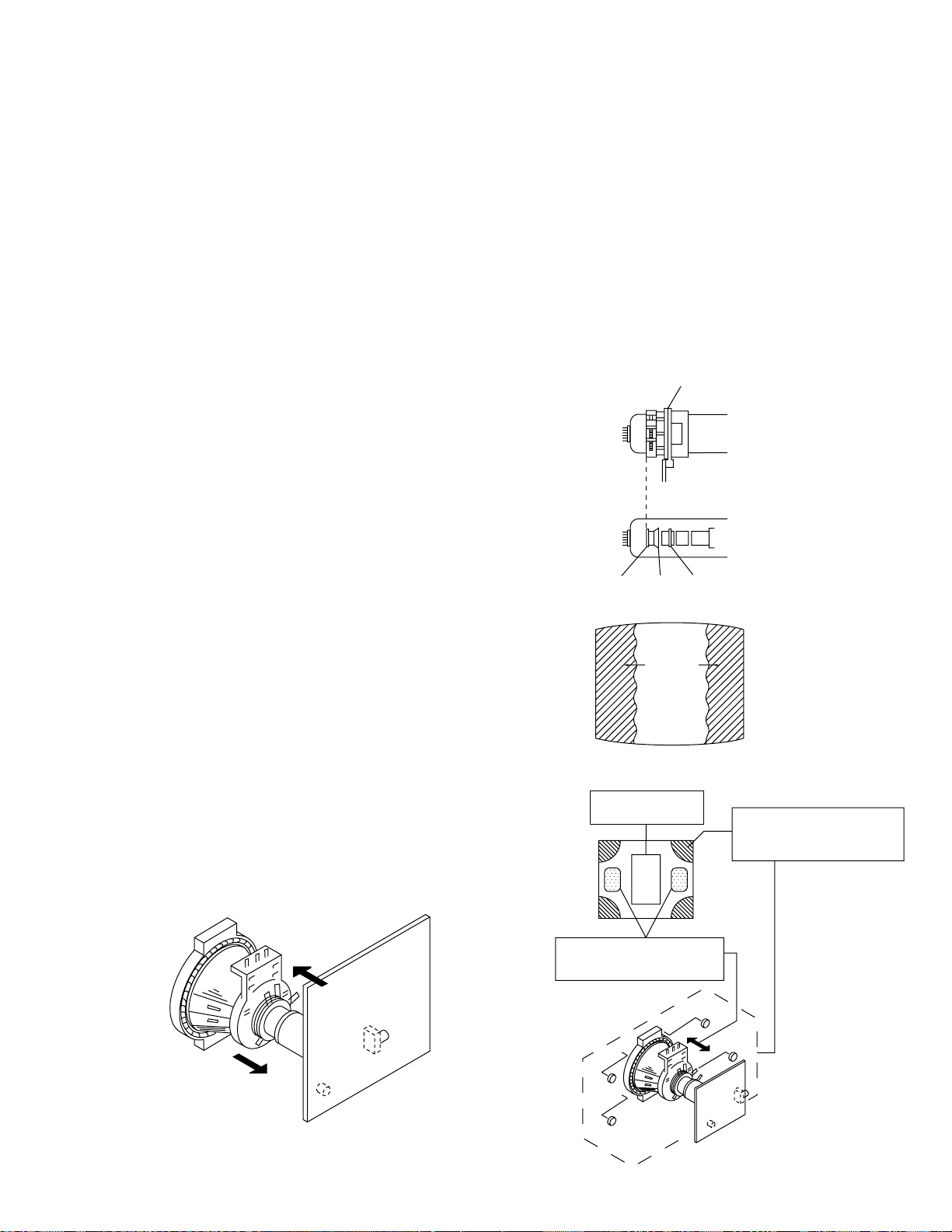

2-3. CHASSIS ASSY REMOVAL

1Two claws

2Chassis assy

– 11 –

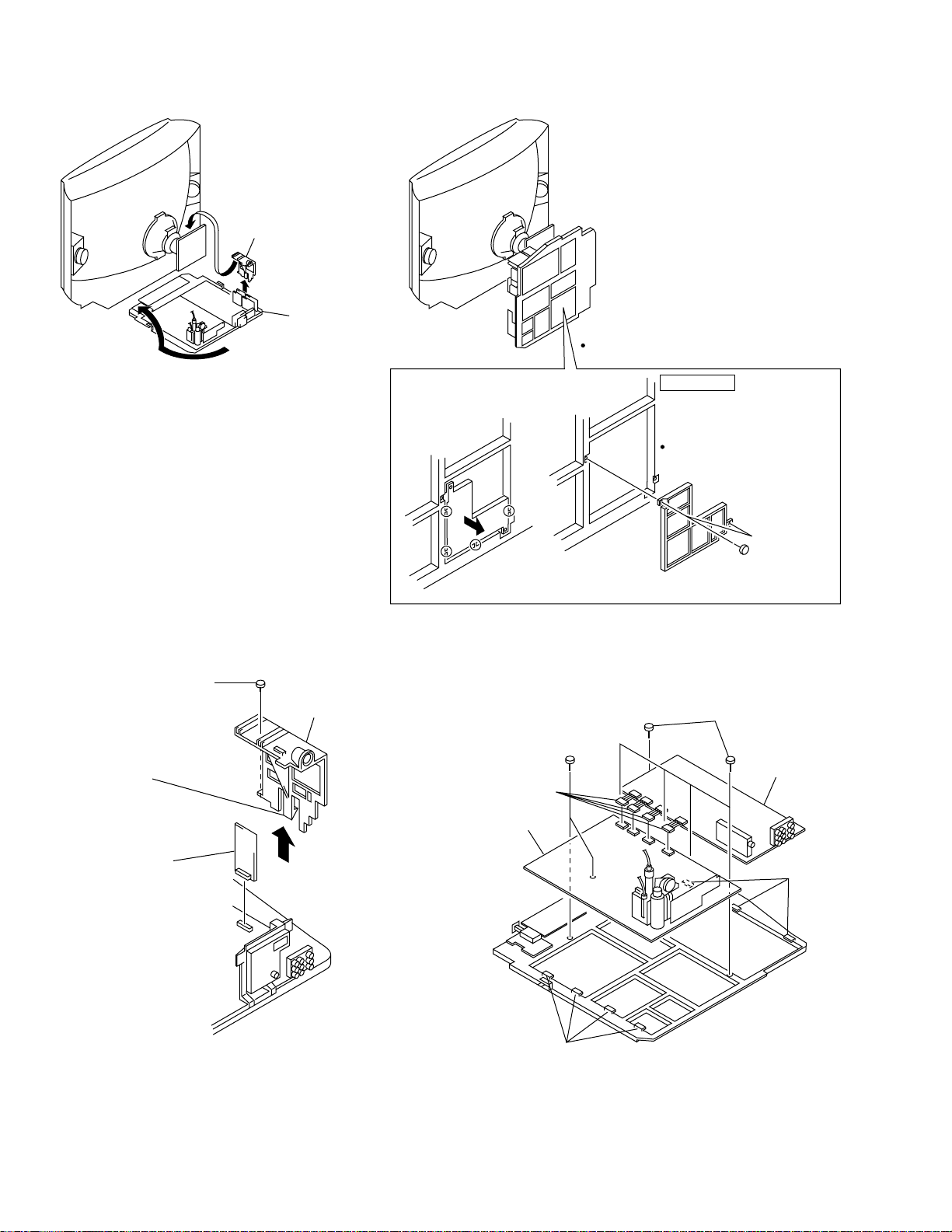

2-4. SERVICE POSITION

1PCB holder

2Chassis assy

Cut the four marked sections

1

with a nippers to remove a

part of bracket.

1

When measuring the power supply voltage,

just remove a part of bracket shown below.

ATTENTION

For safety reason this plate

2

must be remounted after

cutting and taking away.

SAFETY REQUIREMENT

2 Two screws

(+BVTP3 x 8)

(7-685-646-71)

2-5. S1 BOARD REMOVAL

1 Screw

(+BVTP3x12)

2 One claw

4 S1 Board

3 PCB holder

2-6. A AND D BOARDS REMOVAL

2 Five screws

(+BVTP3 x12)

5 Two screws

(+BVTP3 x12)

1 Four

connectors

7 D board

6 Four claws

4 A Board

3 Three

claws

– 12 –

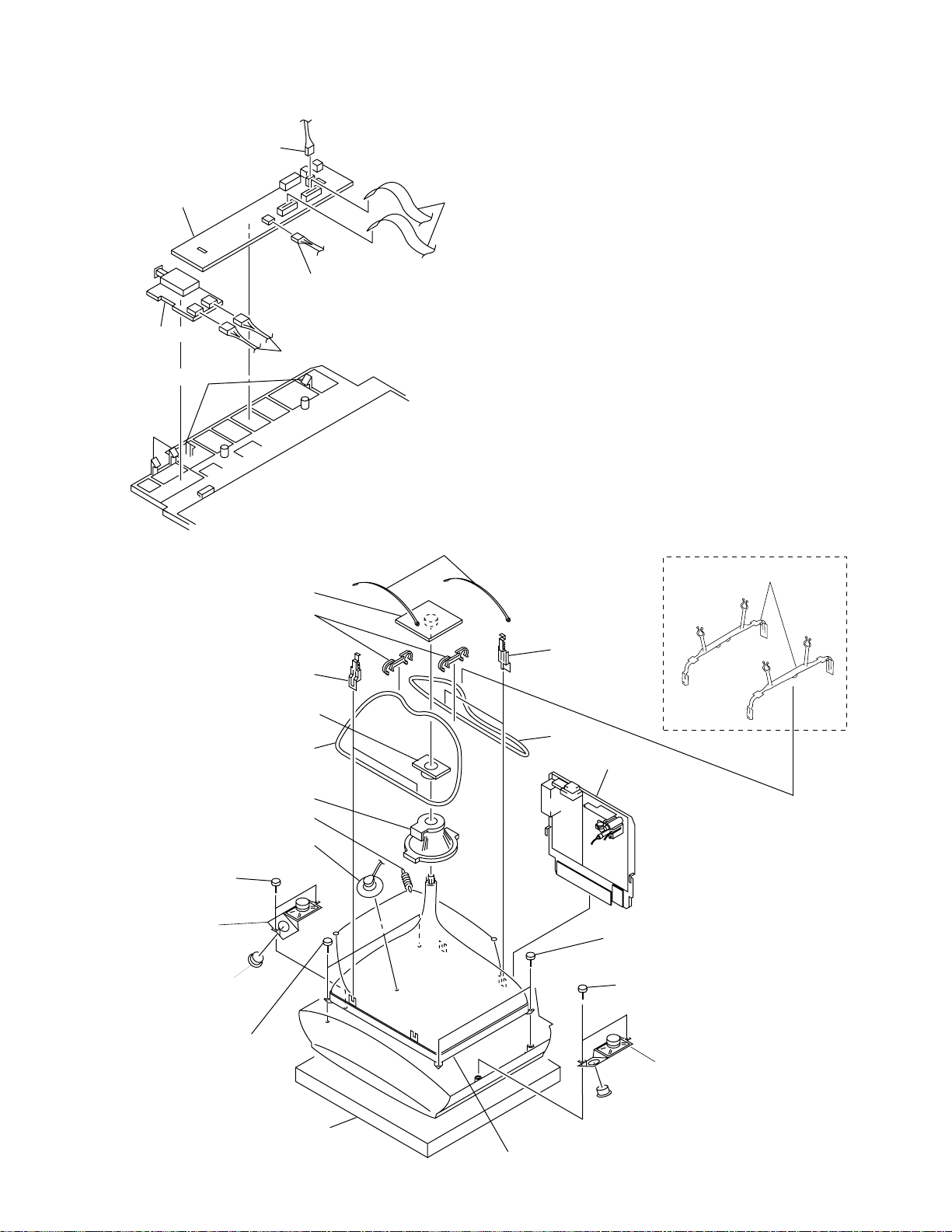

2-7. F1 AND H3 BOARDS REMOVAL

5 connector

8 H3 Board

6 connector

3 F1 Board

1 Two connector

7 Two claws

2 Two

claws

4 Two Flat

cables

2-8. PICTURE TUBE REOVAL

6 C2 Board

0 Two DGC holder

[KV-J29MF8J]

! DGC clip

7 Neck assy

@ DGC

8 Deflection yoke

# Tension spring

4 Anode cap

1 Two screws

(+BVTP4 x16)

2 Speaker

bracket(L)assy

3 Speaker (5cm)

[KV-J29MF8J ]

$ Two screws

(Tapping 7+Crown

Washer)

Cushion

9 Two DGC band

% Picture tube

[KV-J25MF8J]

0 Two DGC holder

! DGC clip

[KV-J29MF8J]

@ DGC

5 Chassis assy

$ Two screws

(Tapping 7+Crown

Washer)

1 Two screws

(+BVTP4 x16)

2 Speaker

bracket(R)assy

3 Speaker (5cm)

[KV-J29MF8J]

– 13 –

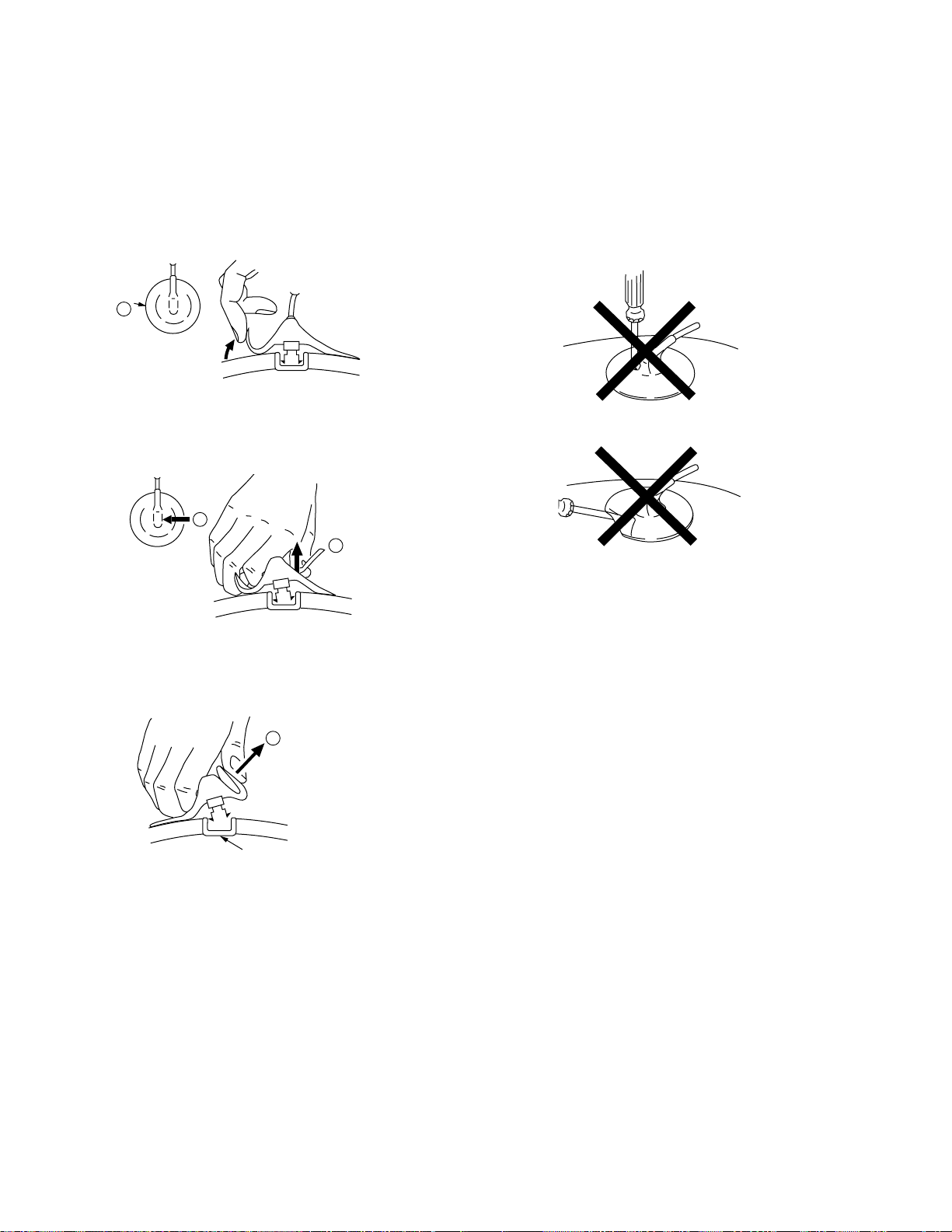

• REMOVAL OF ANODE-CAP

a

b

b

c

NOTE : Short circuit the anode of the picture tube and the anode cap

to the metal chassis, CRT shield or carbon paint on the CRT,

after removing the anode.

• REMOVING PROCEDURES

1 Turn up one side of the rubber cap in the direction

indicated by the arrow a.

• HOW TO HANDLE AN ANODE-CAP

1 Don't hurt the surface of anode-caps with sharp shaped

material!

2 Don't press the rubber hardly not to hurt inside of anode-

caps! A material fitting called as shatter-hook terminal

is built in the rubber.

3 Don't turn the foot of rubber over hardly! The shatter-

hook terminal will stick out or hurt the rubber.

2 Using a thumb pull up the rubber cap firmly in the direction

indicated by the arrow b.

Anode button

3 When one side of the rubber cap is separated from the

anode button, the anode-cap can be removed by turning

up the rubber cap and pulling up it in the direction of the

arrow c.

– 14 –

SECTION 3

SET-UP ADJUSTMENTS

• The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

• These adjustments should be performed with rated power

supply voltage unless otherwise noted.

Controls and switch should be set as follows unless otherwise noted:

PICTURE control.......................................................... RESET

BRIGHTNESS control............................................... CENTER

.................................................................................................................................................................................................................................

Preparations :

• In order to reduce the influence of geomagnetism on the set's

picture tube, face it east or west.

• Switch on the set's power and degauss with the degausser.

Perform the adjustments in order as follows :

1. Beam Landing

2. Convergence

3. Focus

4. White Balance

Note : Test Equipment Required.

1. Color-bar/Pattern Generator

2. Degausser

3. Oscilloscope

Neck assy

Behind the G1 edge

3-1. BEAM LANDING

1. Input a white signal with the pattern generator.

Contrast

Brightness

2. Position neck ass'y as shown in Fig3-2.

3. Set the pattern generator raster signal to a red raster.

4. Move the deflection yoke to the rear and adjust with the purity

control so that the red is at the center and the blue and the green

take up equally sized areas on each side.

(See Figures 3-1 through 3-3.)

5. Move the deflection yoke forward and adjust so that the entire

screen is red. (See Figure 3-1.)

6. Switch the raster signal to blue, then to green and verify the

condition.

7. When the position of the deflection yoke has been decided,

fasten the deflection yoke with the screws and DY spacers.

8. If the beam does not land correctly in all the corners, use a

magnet to adjust it.

(See Figure 3-4.)

}

normal

G2G1 G3

Blue

Green

Red

Purity control

corrects this area.

ab

Fig. 3-2

Fig. 3-3

Disk magnets or rotatable

disk magnets correct these

areas (a-b).

Fig. 3-1

– 15 –

c

Deflection yoke positioning

corrects these areas.

a

d

d

b

c

Fig. 3-4

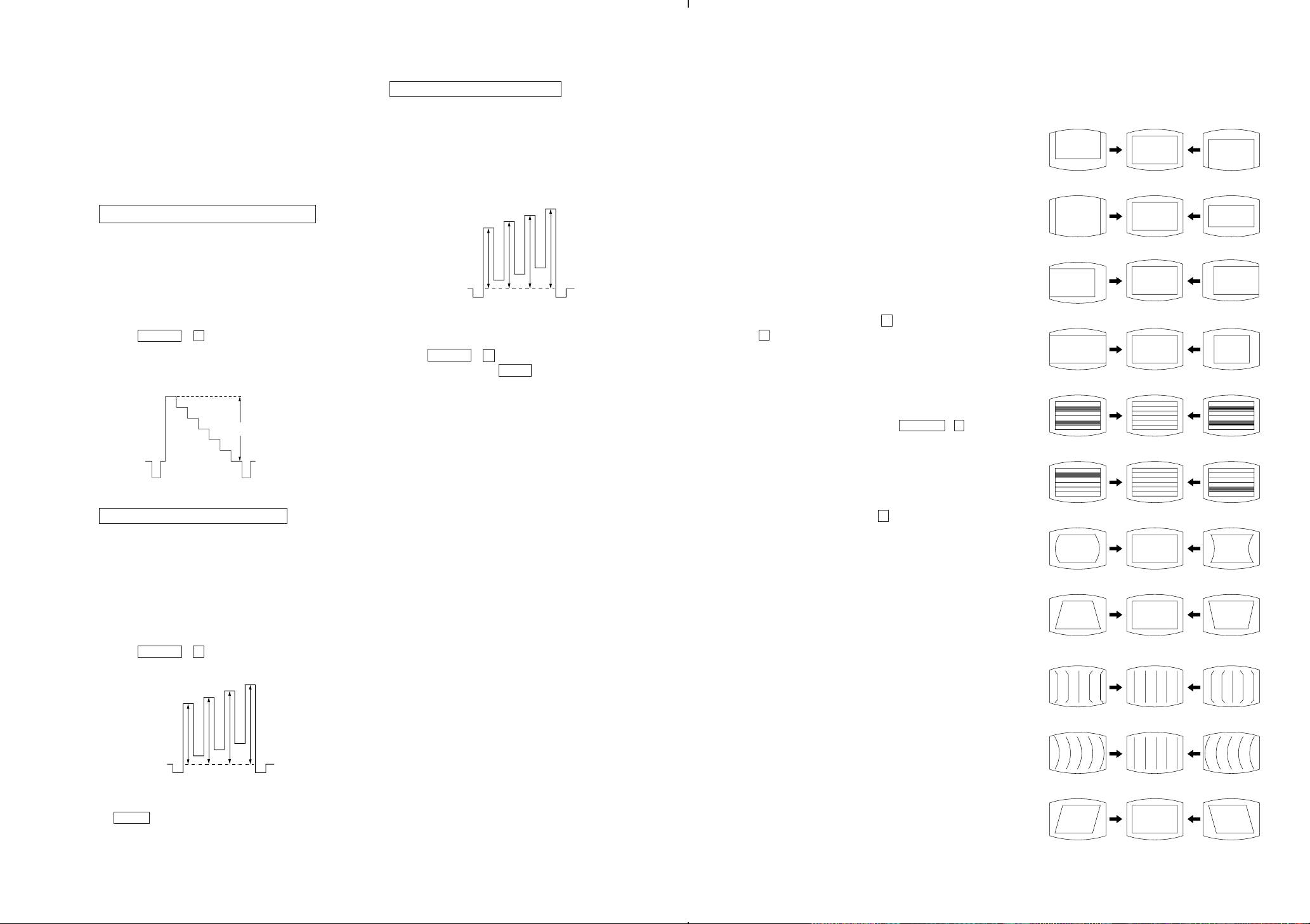

3-2. CONVERGENCE

Preparations :

• Before starting this adjustment, adjust the focus, horizontal size

and vertical size.

• Minimize the brightness setting.

• Provide dot pattern.

(1) Horizontal and Vertical Static Convergence

Center dot

R G B

H. STAT

R

G

B

V. STAT

Magnet

• Tilt the V.STAT magnet and adjust the static convergence by

opening or closing the V.STAT magnet.

If the V.STAT magnet is moved in the direction of the a and

b arrows, the red, green, and blue points move as shown

below.

1

2

a

bb

a

ab

B

GG

R

R G B

B

R

a

RV702

H. STAT

RV701

SCREEN (G2)

C Board

1. (Moving horizontally), adjust the H.STAT control so that the

red, green and blue points are on top of each other at the center

of the screen.

2. (Moving vertically), adjust the V.ST AT magnet so that the red,

green and blue points are on top of each other at the center of

the screen.

3. If the H.STAT variable resistor cannot bring the red, green and

blue points together at the center of the screen, adjust the horizontal convergence with the H.STAT variable resistor and the

V.STAT magnet in the manner given below.

(In this case, the H.STAT variable resistor and the V.STAT

magnet influence each other.)

b

3

b

a

b

a

R

G

B G R

B

b

b

B

G

R

– 16 –

• Operation of BMC (Hexapole) Magnet

If the red, green and blue dots are not balanced or aligned, then

use the BMC magnet to adjust in the manner described below .

RG B

RGB R GB

• Use the H.STAT VR to adjust the red, green, and blue dots so

that they coincide at the center of screen.

The respective dot position resulting from moving each

magnet interact, so be sure to perform adjustment while

tracking.

R

B

G

RGB

G

R

B

1 Y separation axis correction magnet adjustment receive the

cross-hatch signal and adjust [PICTURE] to [MIN] and

[BRIGHTNESS] to [STANDARD] .

2 Adjust the Y separation axis correction magnet on the neck

assembly so that the horizontal lines at the top and bottom of

the screen are straight.

BLUE Paint

VM Board

VM Board

RED Paint

RED Paint

BLUE Paint

Note 1) The Red and Blue magnets should be equally far from

the horizontal center line.

2) Do not seperate the Red and Blue magnets too far.

(Less than 8 mm)

– 17 –

(2) Dynamic Convergence Adjustment

Preparation:

• Before starting this adjustment, adjust the horizontal static

convergence and the vertical static convergence

1. Slightly loosen the deflection yoke screws.

2. Remove the deflection yoke spacer.

3. Move the deflection yoke as shown in the figure below and

optimize the convergence.

4. Tighten the deflection yoke screws.

5. Install the deflection yoke spacer.

R G B B G R

R

B G R

G

R G B

B

B

R G B

G

B G R

R

B

G

R

B G R R G B

R

G

B

(3) Screen-corner Convergence

b

a-b:scrren-corner

misconvergence

c

Affix a Permalloy assy corresponding to the misconverged

a

d

areas.

a

d

Permalloy assembly

b

c

– 18 –

3-3. FOCUS ADJUSTMENT

Adjust FOCUS control on the flyback transformer for the best

focus.

Focus

d. MEMORY WRITE CONFIRMATION METHOD

1) After adjustment, pull out the plug from AC outlet, and then

plug into AC outlet again.

2) Turn the power switch ON and set to Service Mode.

3) Call the adjusted items again to confirm adjustments were made.

DATA

SERVICE

07

LCP

09

Adjustment Item

Item number

FLYBACK TRANSFORMER (T801)

a. AN ITEM OF ADJUSTMENT

Adjustment

Item

number

37

item

SBR

Standard DA TA

1F

Note

SUBBRIGHTNESS

39

3A

3B

3C

GDR

BDR

GCF

BCF

2C

2C

07

07

G. Drive

B. Drive

G. CUT-OFF

B. CUT-OFF

b. METHOD OF CANCELLATION FROM SERVICE

MODE

Set the standby condition (Press POWER button on the

commander), then press POWER button again, hereupon it becomes TV mode.

c. METHOD OF WRITE FOR MEMORY

1) Set to Service Mode.

2) Press 1 (UP) and 4 (DOWN), select an item of adjustments.

3) Press MUTING button indicate WRITE (RED) on screen.

4) Press `º button to write into memory.

WRITE07LCP09

MUTING

0

Executes the writing

– 19 –

3-4. G2 (SCREEN) AND WHITE BALANCE

ADJUSTMENTS

1. G2 (SCREEN) ADJUSTMENT (RV701)

1) Set the PICTURE and BRIGHTNESS to normal.

2) Put to VIDEO input mode without signals.

3) Set to Service Mode.

4) Change BLU data of the item number 8C from 01 to 00 .

(To turn off Blue Back.)

5) Press MUTING , and `0 to write the data in the memory.

6) Connect R, G, and B of the C board cathode to the oscilloscope.

7) Adjust G2 (RV701) volume to the value below.

170V ±2(VDC)

170 V ±2(VDC)

3. SUB BRIGHT ADJUSTMENT

1) Set to service mode.

2) Input a staircase signal of black and white from the pattern

generator.

3) BRIGHTNESS .... RESET.

PICTURE ............ minimum

4) Select SBR(55) with 1 and 4 , and adjust SBR level with

3 and 6 so that the stripe second from the right is dimly lit.

White

second from the right

0V

8) Re-set BLU data of the item number 8C from 00 back to 01

9) Press MUTING , and 0 to write the data in the memory.

2. WHITE BALANCE ADJUSTMENTS

1) Set to service Mode.

2) Input white raster signal.

3) Set the PICTURE to minimum.

4) Select SBR(35) with 1 and 4 , and then set the level to

minimum with 3 and 6 .

5) Select GCF(39) and BCF(3A) with 1 and 4. And adjust

the level with 3 and 6 for the best white balance.

6) Set the PICTURE to maximum.

7) Select GDR(37) and BDR (38) with 1 and 4, and adjust the

level with 3 and 6 for the best white balance.

8) Write into the memory by pressing MUTING then 0 .

Black

.

– 20 –

SECTION 4

SELF DIA GNOSIS FUNCTION

If no acknowledgement is returned from a device which is turned "ON", the device has a problem.

In this case, one of the LED's responding to the problem device will flicker a defined number of times.

The flickering frequuncy responding to each failed device is shown below.

Board name A Board A Board A Board A Board

Ref. No IC003 IC1201 IC104 IC206

Device NONVOLA- AV SWITCH MAIN Y/C AUDIO

TILE (CXA1855S) (CXA2050S) PROCESSOR

MEMORY (TDA8424)

Flickering

Frequency

All the device are checked one after another from the left on the table.

If an error is found, the responding LED will start flickering.

So, if more than 2 device are failed, the one on the left side will start flickering first.

1236

– 21 –

SECTION 5

CIRCUIT ADJUSTMENTS

5-1. ADJUSTMENTS WITH COMMANDER

Service adjustments are made with the RM-871 that comes with

this unit.

Entering service mode

With the unit on standby

↓

DISPLAY

↓

5

↓

VOL (+)

↓

POWER

The operation sequence puts the unit into service mode.

1, 4 Select the adjustment item.

↓

3, 6 Raise/lower the data value.

↓

MUTING Writes.

↓

0 Executes the writing.

7, 0 All the data becomes the values in memory.

8, 0 All user control goes to the standard state.

5, 0 Service data initialization (Be sure not to use

usually.)

2, 0 Write 50Hz adjustment data to 60Hz, or vice

versa.

The screen display is :

DISPLAY

REVEAL

MUTING

TEXT

123

456

789

A/B

ENLARGE

WAKE UP

INDEX

SLEEP

TEXT CLR

R

RM-873

VIDEO

HOLD

0

POWER

MENU

MENU

PROGRVOL

RM-873

JUMP

Adjstment item

TV

Item number

DATA

00 VSH 1F SERVICE 50

XXX 00 00 00 20V2 1C

Mode

Depends on the signals

PAL, SECAM : 50

NTSC : 60

SOFTWAR VERSION

H SYNC COUNTEROEM CODE

– 22 –

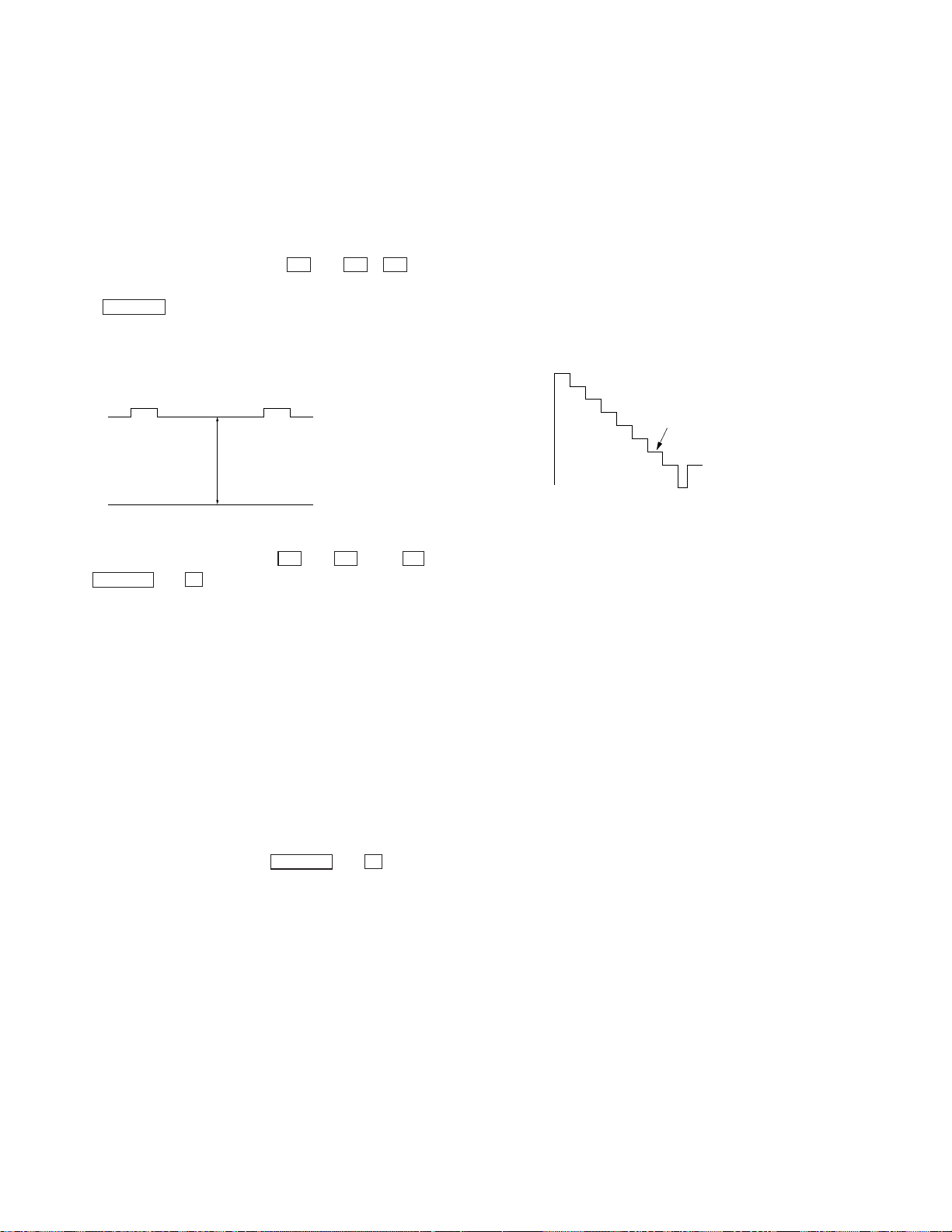

5-2. ADJUSTMENT METHOD

Item Number 00

This explanation uses V-Position as an example.

1. Select 00 VSH with the 1 and 4 buttons.

2. Raise/lower the data with the 3 and 6 buttons.

3. Select the optimum state. (The standard is IF for P AL reception.)

4. Write with the MUTING button. (The display changes to

WRITE.)

5. Execute the writing with the 0 button. (The WRITE

display will be changed back to SERVICE.)

Use the same method for Items Number 00-96. Use 1 and 4 to

select the adjustment item, use 3 and 6 to adjust, write with

MUTING , then execute the write with 0 .

Note : In WRITE , the data of all items are into memory.

• As for V-FREQ, by searching the bolded screen V range with

adjusting data.

Note : For adjustment Items that have differnt standard data

between 50Hz or 60Hz and novwel or wid, be sure to use

the respective input signal ather adjusting.

1FVSF00

SERVICE 50

WRITE 50

WRITE 50

00

Adjusted with [3] and [6] buttons

Written with [MUTING]

GREEN1FVSF

GREEN1FVSF00

GREEN

The WRITE display

then the display

returns to a green

SERVICE.

Write executed with [0]

– 23 –

Adjustment Item Table

Item Adjustment Data

number Item range

00 VSH 00-3F 1F V Position CXA2050S

01 VSZ 00-3F 1F V Size (Y/C/J)

02 HSH 00-0F 07 H Position Slv:88H

03 HSZ 00-3F 1F H Size

04 SRC 00-0F 07 S Correction

05 VLN 00-0F 07 V Linearity

06 PAP 00-3F 1F Pin Comp

07 PPH 00-0F 07 Pin Phase

08 UCP 00-0F 07 Up Corner Pin

09 LCP 00-0F 07 Low Corner Pin

0A BOW 00-0F 07 AFC-Bow

0B ANG 00-0F 07 AFC-Angle

0C VAP 00-3F 2F V Aspect

0D VSC 00-3F 1F V Scroll

0E ULN 00-0F 00 UP V Linearity

0F LLN 00-0F 00 LOW V Linearity

10 EHH 00-03 01 00 EHT- H

11 EHV 00-03 01 EHT - V

12 HBS 00-01 01 H Blk Wid. ON/OFF

13 LBK 00-0F 0F L Blk Width

14 RBK 00-0F 0F R Blk Width

15 JSW 00-01 00 Jump ON/OFF Sw

16 VBW 00-03 02 V Blk Wid. Con.

17 AFC 00-03 01 AFC-Mode

18 FHH 00-01 00 FH-HI

19 VFQ 00-03 00 V-Freq

1A VOF 00-01 00 V OFF

1B VMD 00-01 00 CD-Mode 2

1C CMD 00-01 00 CD-Mode

1D ITL 00-03 00 Inter Iace

1E ZSW 00-01 00 ZOOM SW

1F POV 00-03 03 Pre-Over

20 CT1 00-01 01 C-Trap(NTSC)

21 CT2 00-01 00 C-Trap(PAL)

22 CF0 00-0F 00 C-Trap f0 Adj

23 SF0 00-01 00 01 Sharpness f0 Adi

24 TOT 00-01 01 TOT Filter SW

25 CSW 00-03 00 Color SW

26 XTL 00-03 00 Xtal

27 CV1 00-01 01 CV/YC Select(NTSC)

28 CV2 00-01 00 CV/YC Select(PAL)

29 VM 00-01 01 VM ON/OFF

2A YVM 00-01 00 YSI/VM SW(0:YSI)

2B DPC 00-01 01 D-Pic ON/OFF

2C DCO 00-01 01 Dynamic Color

2D GMM 00-03 01 Gamma

2E DTR 00-01 01 DC-Tran

2F DL1 00-07 01 Delay Ctrl.(PAL)

30 DL2 00-07 03 Delay Ctrl.(NTSC)

31 DL3 00-07 03 Delay Ctrl.(SECAM)

32 SCN 00-0F 09 Sub-Contrast

33 SC1 00-0F 07 Sub-Color(PAL)

34 SC2 00-0F 06 Sub-Color(NTSC)

35 SH1 00-0F 07 Sub-Hue(TV)

36 SH2 00-0F 07 Sub-Hue(VIDEO)

37 SBR 00-3F 1F Sub-Bright

38 SSH 00-07 04 04 Sub-Sharpness

39 GDR 00-3F 2C G-Drive

Standard data

J29 J25

Note Device

Note: Bold items are fixed data.

: NTSC , NO MARK : PAL

*

– 24 –

Adjustment Item Table

Item Adjustment Data

number Item range

3A BDR 00-3F 2C B-Drive CXA2050S

3B GCF 00-0F 07 G-Cutoff (Y/C/J)

3C BCF 00-0F 07 B-Cutoff Slv:88H

3D RPO 00-03 01 Ref-Position

3E PON 00-01 01 Pic-ON

3F RON 00-01 01 R ON

40 GON 00-01 01 G ON

41 BON 00-01 01 B ON

42 AKF 00-01 00

43 ESY 00-01 00

44 AGG 00-01 00

45 ABL 00-01 00 Picture Booster

46 LIM 00-01 00 Black Offset

47 PB 00-01 00 Picture Booster TDA9170

48 BOF 00-00 00 Black Offset (Picture

49 UVG 00-3F 00 User Var Gamma Improve)

4A ADG 00-3F 00 Adaptive Gamma Slv:D0H

4B NLA 00-3F 00 Non-linear Amp

4C WDS 00-02 00 Window Select

4D LST 00-0F 00 Window Line Start

4E LSP 00-0F 00 Window Line Stop

4F FST 00-0F 00 Window Field Start

50 FSP 00-0F 00 Window Field Stop

51 VA 00-01 00 V Aperture on/off CXA1315

52 VAW 00-03 00 V Aperture white (V-AP)

53 VAB 00-03 00 V Aperture black Slv:48H

54 VAC 00-0F 00 V Aperture core

55 SHP 00-3F 00 Sharpness CXA1315

56 VML 00-3F 00 VM mitter (LTI)

57 COR 00-3F 00 Conng Slv:42H

58 DOF 00-3F 00 DSC Offset

59 DGA 00-3F 00 DSC Gain

5A DLT 00-01 00 Delay Time

5B SDL 00-0F 00 SEL Pin Delay SDA9189X

5C POH 00-FF 00 H Position(MSB 8bit) (PinP)

5D POV 00-FF 00 V Position Slv:D6H

5E PMD 00-1F 00 PinP Display Mode

5F WRP 00-0F 00 Write Position

60 HDL 00-1F 00 HS Delay

61 AMS 00-01 00 Decimation Filter

62 VDL 00-1F 00 VS Delay

63 VSP 00-1F 00 VSP Delay

64 CON 00-0F 00 Contrast

65 FRY 00-0F 00 Frame Y

66 FRV 00-0F 00 Frame V

67 FRU 00-0F 00 Frame U

68 INF 00-01 00 Inner Frame

69 FWV 00-03 00 Frame Width V

6A FWH 00-07 00 Frame Width H

6B PLL 00-03 00 PLL Loop Filter

6C PDV 00-0F 00 Pedestal V

6D PDU 00-0F 00 Pedestal U

6E DAT 00-01 00 DAC Stream Control

6F DAN 00-01 00 DAC Control

Standard data

J29 J25

Note Device

Note: Bold items are fixed data.

– 25 –

Adjustment Item Table

Item Adjustment Data

number Item range

70 WIP 00-01 00 Wipe on/off SDA9189X

71 WSP 00-03 00 Wipe Speed (PinP)

72 FAW 00-FF 08 NICAM FAW Thresh MSP3410

73 CTM 00-FF 08 NICAM Error Bit(MONO) (Stereo Decoder)

74 CTN 00-FF 50 NICAM Error Bit(NICAM) Slv:80H

75 WCD 00-FF 0A W.G.DA T A CHANGE

76 WST 00-FF 15 W.G.STEREO Threshold

77 WTM 00-FF 50 W.G.Timer

78 WBT 00-01 EA W .G.bilingual Threshold

79 ACG 00-01 01 AGC AUTO/CONST

7A CDB 00-3F 28 AGC GAIN CONST.

7B FGP 00-7F 24 FM(BG,I,DK)Prescale

7C FMP 00-7F 40 FM(M)Prescale

7D WGP 00-7F 3C W.G.Prescale

7E NIP 00-7F 7F NICAM Prescale

7F CRM 00-01 00 Carrier Mute

80 CML 00-03 00 Carrier Mute Level

81 ACO 00-01 01 Audio Clock Out

82 WAC 00-0F 01 W.G.Agreement count

83 DL Y 00-FF 30 Stereo Search Delay

84 DLG 00-FF 10 W.G.Search Delay

85 TXP 00-0F 0E Text Picture cont. SAA 5281

86 MXP 00-0F 0F Text Mix Mode Pic (Text decoder)

87 BB1 00-3F 00 BBE control High CXA1315

88 BB2 00-3F 1D BBE control Middle (BBE)

89 BB3 00-3F 28 BBE control Low Slv:40H

8A ATW 00-03 00 Auto Wide Ident speed CXP5068

8B BKP 00-FF 00 Blk off Picture CXP85340

8C OSH 00-3F 0E OSD Position H (MICRO8D ODL 00-FF 10 Power On Delay CONTROLLER)

8E BLU 00-01 01 Blue Back on/off

8F ROC 00-0F 08 N/S Center Vol.

90 ROS 00-07 07 User Step

91 DKS 00-01 00 D/K Stereo Serch

92 MUT 00-01 01 No.Sync.Mute

93 DID 00-01 00 Disable Degauss

94 DWZ 00-01 00 Disable Widezoom

95 BCS 00-01 00 BASS Center Shift

96 BVS 00-01 00 BASS Volume Shift

97 WBS 00-03 01 Woofer off Bass Shift

98 OPO 00-FF 01 Option 0

99 OP1 00-FF 32 02 Option 1

Standard data

J29 J25

Note Device

Slv:D6H

Slv:58H

(Auto wide)

Note: Bold items are fixed data.

ITEM INFORMATION

...

• 50

50Hz data, 60

• Standard data listed on the Adjustment Item Table are reference values, therefore if is different for every model.

...

60Hz data

– 26 –

5-3. PICTURE QUALITY ADJUSTMENTS

Item Number 33-36

33 SCO Sub-Color

34 SHU Sub-Hue

35 SBR Sub-Bright

5-4. A BOARD ADJUSTMENT

SUB CONTRAST ADJUSTMENT (SCN)

1. Receive a PAL color-bar.

2. Set service item 3E GON and 3F BON to data "00". Set the

PICTURE 100%, BRIGHT 50% and COLOR MIN.

3. Connect an oscilloscope to the pin 6 (R OUT) of CN117, A

board.

4. Set to Service Mode and select 32 (SCN) using 1 and 4 of

the commander to adjust to 2.10 ± 0.05V.

5. Press MUTING → 0 of the commander to write the data.

6. Receive a NTSC color-bar and adjust 32 (SCN) as step 2~5.

7. Set servce item 3E GON and 3F Bon to data "01".

white

2.45 ± 0.05 Vp-p

black

SUB COLOR ADJUSTMENT (SCO)

1. select Video1

2. Input a PAL color-bar, video into video1.

Set to the following condition:

PIC 100%, BRT 50%, COL 50%

3. Connect an oscilloscope to the pin 5 (B OUT) of CN117, A

board.

4. Set to Service Mode and select 33 (SCO) with 1 and 4 of

the commander to adjust to VB2=VB3=VB4 with 3 and 6.

5. Press MUTING → 0 of the commander to write the data.

6. Adjust 33 (SCO) as step 1~4.

SUB HUE ADJUSTMENT (SHU)

1. select Video1

2. Input a NTSC color-bar, video into video1.

3. Connect an oscilloscope to the pin 4 (B OUT) of CN117, A

board.

4. Select 34 (SHU) with 1 and 4 of the commandar by setting

to Service Mode and adjust to VB1=VB2=VB3=VB4 with 3

and 6.

VB1 VB2 VB3 VB4

VB2 = VB3 = VB4

5. Press MUTING → 0 of the commander to write the data.

6. Set to WIDE Mode by MENU button to write the same value

as in step 3.

PIP POSITION (POH, POV)

1. Receive a PAL color-bar.

2. Set the PIP picture by pressing PIP button of the commander.

3. Set to Service Mode.

4. Select 5A (POH) with the 1and 4of the commander to set

the data "14" with 3and 6.

5. Select 5B (POV) to set the data "27"

6. Press MUTING → 0 of the commander to write the data.

7. Check by changing using menu .

5-5. A BOARD ADJUSTMENT AFTER IC003

(MEMORY) REPLACEMENT

When replacing IC003(MEMORY) be sure to change IC001(µ-COM)

to the following new IC at the same time.

IC001 (µ-COM)

• GE, EM, E, HK model

CXP85340A-072S to CXP85340A-099S (8-752-880-11)

• ME (Arabic) model

CXP85340A-084S to CXP85340A-098S (8-752-879-23)

1. Enter to Service Mode.

2. Press commander buttons 5 and 0 (Data Initialize), and 2

and 0 (Data Copy) to initialize the data.

3. Call each item number, and check if the respective screen shows

the normal picture.

In cases where items are not well adjusted, rectify the items

with fine adjustment.

Write the data per each item number ( MUTING + 0 ).

4. Select item numbers “95” (OP0) and “96” (OP1) and

respectively set the bit per model with command buttons 3

and 6.

5. Press commander buttons 8 and 0 (Test Normal) to return to

the data that was set on the shipment from the factory.

(This will also cancel Service Mode.)

5-6. PICTURE DISTORTION ADJUSTMENT

Item Number 00 – 0B

00 VSH(V POSITION)

01 VSZ(V SIZE)

02 HSH(H POSITION)

03 HSZ (H SIZE)

04 SCR(VERTICAL Scorrection)

05 VLN(V LINEARITY)

06 PAP (PIN AMP)

07 PPH(PIN PHASE)

08 UCP(Upper Corner Pin)

09 LCP(Lower Corner Pin)

VB1 VB2 VB3 VB4

VB2 = VB3 = VB4

7. Receive the NTSC color-bar and adjust as step 6.

–27–

0A VBOW(AFC.BOW)

0B VAG(AFC.ANGLE)

– 28 –

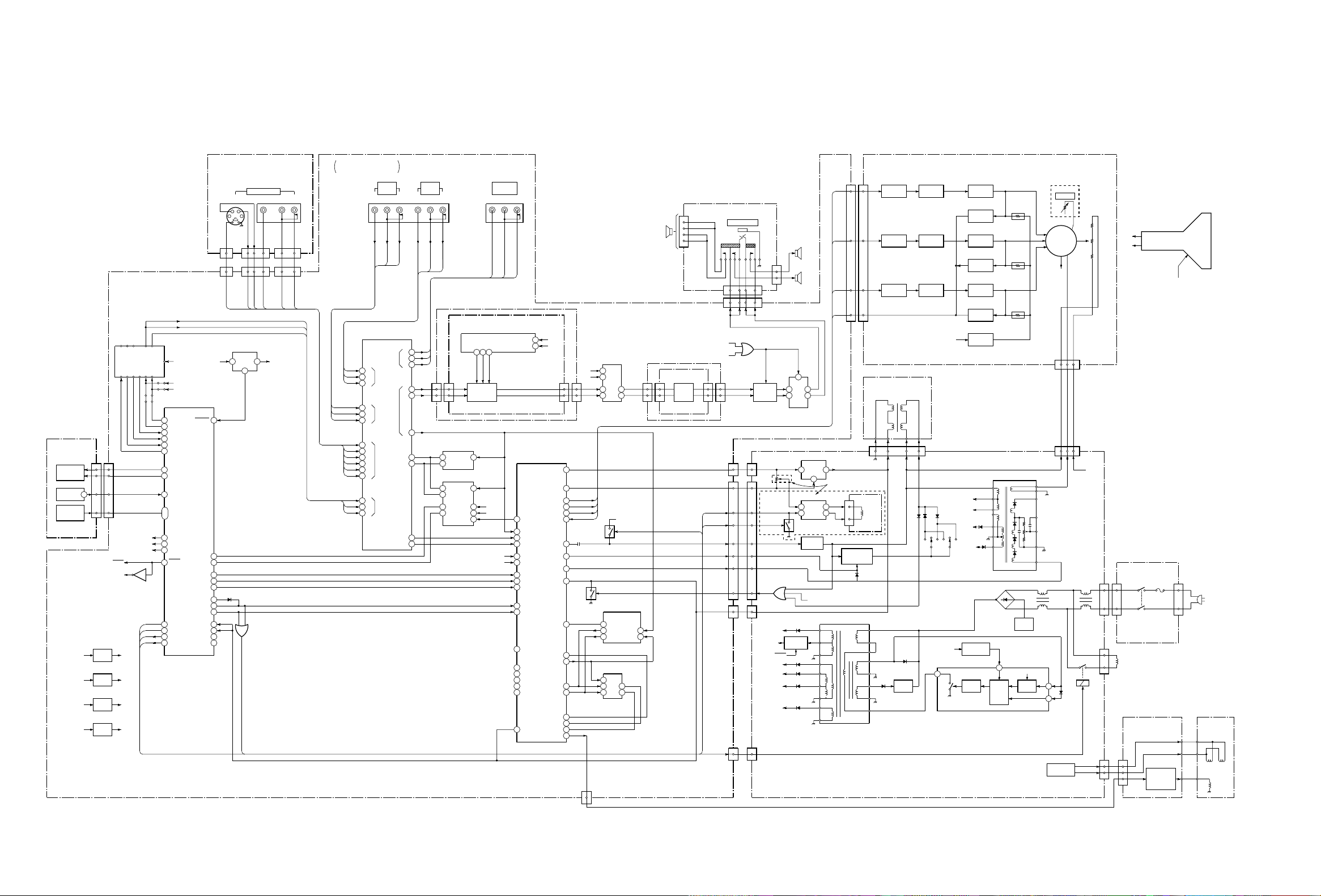

6-1. BLOCK DIAGRAM

IF

SFI

DET

MS IF

H3(1/3)

(CONTROL SW.)

RED/

GREEN LED

D904

SIRCS

IC900

KEY-IN

MATRIX

S901-910

+11V

TU001

TUNER

CN103CN905

6

10

4

12

2

14

1

1, 3

13

STBY

REG

IC080

REG

IC201

REG

IC205

REG

+7V

IC010

RED

GREEN

+12VAUDIO 30V

DE EM

NC

RF

AFT

SW2

SW1

SCL

SDA

MUTE

SCL

SDA

Q033

MUTE

+5V+9V

+9V

+5V

H3(2/3)

(AV INPUT)

VIDEO 3 INPUT

S

43

J902

21

CN905

15

CN103 CN102 CN103

MUTE STBY 5V

BACK UP

SCL

SDA

TUNING CONTROLLER

IC001

BAND0

RESET

58

57

7

8

40

9

6

5

26

41

•

42

11

56

54

30STBY

16

27

31

60

BAND1

TSW0

TSWI

AFTI

AGC

NICAM

TIMER

SIRCS

KEY1, 2

MUTE

11 CLK0

11 DAT0

STBY

DEGAUSS

HD SW

NS MUTE

NS ROT

PAL/NT

H SYNC

H SYNC

V SYNC

V PULSE

36

3

THR

4

R

47

G

48

B

49

BLK

12

YS

51

YS

52

1

25

2

17

141

S3

REG

15

IC002

4

Q304

D303

V MUTE

VM MUTE

(FRONT)

CN901 CN905

141154122

L3

V3C3Y3

SECTION 6

DIAGRAMS

MAIN TUNER,VIF,SIF

A

AV SW Y/C DECODE JUNGLE

RLV

J903

4122

R3

LT

RT

VT

L1

R1

S1

V2

L2

R2

C3

Y3

V3

L3

R3

S3

VT

LT

RT

VLR

V2

2

L

4

R

6

S1

7

V

8

L

10

R

17

C

15

Y

13

V

14

L

16

R

18

S3

V

47

L

48

R

49

VIDEO

IN2

L2

A/V SELECT

IC1201

MON2

S1

MON1

S2

S3

TV

R2

J1202 RLV

V

L

R

L

R

V

Y

C

Y

C

VIDEO

IN1

L1

V1

VM

29

LM

28

RM

26

CN121 CN2201

39

38

40

37

35

43

45

R1

S1(1/2)

123

LR787

8

EQ. CHANGE

IC2211, 2212

Y/C SEP

YCM301

26

Y

V

4

C

Y/C SEP

IC301

Y

V

46

C

2

PAL/NT

13

18

THR

12

17

CLK

15

MONITOR

OUT

VM

(AUDIO EFFECT)

D/A CONVERTOR

SW1

SW0

DAC4

SCL

SDA

SCL

SDA

LM

IC2201

RM

6

60

62

64

56

57

23

24

25

21

22

58

63

18

19

20

17

36

J1202VLR

Y/C JUNGLE

FSC

V

Y

C

SCL

SDA

R2

G2

B2

YS2

VIDEO

EXT SYNC

R1

G1

B1

YS1

VTIM

1514SCL

SDA

IC104

AFCP IN/

SECAM

CN2201

VD-

VD+

E-W

ABL

H OFF

REF

SCP

B-Y

R-Y

YRET

B-Y

R-Y

VM

R

G

B

IK

HD

Y

101110

37

36

28

30

32

33

43

39

34

44

7

11

12

10

9

13

15

14

55

SCL

SDA

11

CN121

Q105

12

11

13

1

3

IC206

AUDIO PROCESSOR

STBY 5V

Q030

SECAM PROCESSOR

IC354

S REF

1

B-Y

12

R-Y

11

1H DELAY

IC351

SYNC

14512

16

11

CN120

H3(3/3)

4

3

OUT

WOOFER

CN128 CN128

232

9

SIN

20

SYNC

19

2

1

CN908

S1(2/2)

L

AMP

3

IC2213,

R

2214

CN2208 CN2208

HD SW

IN

CN901

CN102

161

NS ROT

NS MUTE

DEGUSS

HEAD PHONE

15 13 8 10

1386

MUTE

STBY

6

CN108

CN109

CN107

CN106

J901

Q211,D218

PROTECTOR

Q205, 210

D

2

2

CN506

8

8

9

3

3

7

7

4

4

1

1

CN520

2

2

CN528

22

4

1

Q1803

Q803,1501

+33V

STBY

+7V

+14V

+11V

SP R

SP L

11

MUTE

4

2

IC203

RIPPLE FILTER

1 5

6

3 1

H DRIVE

REG

Q601-603

7

12

V OUT

IC1501

IC1800

DRIVE

T2502

135V

CN902

MUTE

(POWER SUPPLY DEFLECTION)

CN526

ROTATION

E/W

ABL

X-RAY

BACK UP

AUDIO 30V

7

14

13

12

16

18

17

15

CN117 CN703

R

G

B

IK

29 inch ONLY

CN1804

7

T601

SRT

6

5

4

1

N/S COIL

PIN DRIVE

IC2504

T2503,2504

C2

6

5

4

1

DY ASS'Y

VM

(2/2)

(RGB OUT)

Q712

R DRIVE

Q711

G DRIVE

Q710

B DRIVE

V DV H DV

56 13

6

7

2

4

3

CLAMP

Q600

4

9

Q706

R AMP

Q705

G AMP

Q704

B AMP

+9V

S2501 S2502

+33V

1

SWITCHING REG

IC601

+200V

+135V

+15V

-15V

LEVEL DED

IC602,603

Q703

R OUT

Q709

IK LIMIT

Q702

G OUT

Q708

IK LIMIT

Q701

B OUT

Q707

IK LIMIT

Q714

BIAS

10

D2600

29 inch ONLY

RV702

H. STAT

J701

13

10

983

5

1

H1

FV

H1

+200V

+1000V

CN701

142

142

CN0521

H1

+1000V

T801

FBT

1

4

2

9

8

7

H1

5

H2

HV

DF

FV

11

ABL

+200V

F1

CN2600

1

T2602

PC SW

Q2601

7

REF

COMPOSCDRIVE

6

8

QP DRIVE

Q1804,1805

RV2600

11

5

5

1

3

CN518

3

QP-

QP+

2

VM OUT

H

(AC IN)

DGC

VM(1/2)

6

5

2

CN961

PICTURE

TUBE

HV.FV

(VM OUT)

VELOCITY

MOD

Q961-963

Q965,967,968

FROM FBT

4

QP-

QP+

VM

NECK

ASS'Y

QP QP

VM

– 29 – – 30 –

DY

VM

S1

A

D

TUNER

C2

F1

H3

OPEN

6-2. FRAME SCHEMATIC DIAGRAM

PICTURE

TUBE

CN1690 CN2600

CN704

CN703

CN117

1

2

3

4

1

1

2

3

4

5

6

1

2

3

4

5

6

F1

(AC IN)

C2

(RGB OUT)

CN102

AC

NC

NC

AC

GND

1K

GND

9V

B

G

R

1K

GND

9V

B OUT

G OUT

R OUT

CN1691

AC OUT

1

2

3

4

5

1

2

3

4

123456789

SP L

SP L

PH L

CN701

SP GND

SP GND

SP R

NC

NC

NC

AC OUT

1000V

200V

E

H1

SP R

PH R

GND

CN118

123

1011121314

GND

SP GND

SP GND

OPEN

B INT

B CLK

B DAT

4

GND

FR Y OUT

FR C OUT

15

CN103

FR V OUT

123456789

S3

AC IN

NC

NC

NC

AC IN

1000V

200V

GND

H1

GND

FR L OUT

CN0521

GND

GND

FR R OUT

1

2

3

4

5

1

2

3

4

GND

STBY +5V

1011121314

7V

RED

GND

KEY 2

GREEN

SIRCS

15

KEY 1

1

CN2601

GND

2

GND

3

GND

1234567

CN528

DEG

ST-BY

AUDIO GND

AUDIO MUTE

DEG

ST-BY

AUDIO GND

AUDIO MUTE

CN106

1234567

CN525

DY1

1 A GND

(POWER SUPPLY,DEFLECTION)

1234567

8

CN520

30V/1A

AUDIO GND

AUDIO GND

30V/1A

AUDIO GND

AUDIO GND

30V/1A

30V/1A

8

AFC

H RELAY

AFC

H RELAY

CN107

1234567

H-

H-

H+

H+

12345

D

14V

33V

GND

BACKUP

14V

33V

GND

BACKUP

V-

GND

GND

V+

6

8

7V

7V

8

1234567

CN526

GND

CLH/D

V-OUT

H ZOOM SW

N.C

N.C

N.C

GND

CN108

1234567

11V

11V

11V

11V

GND

GND

DGC CHK

CN2602

1

8

CN506

GND

GND

CN109

8

DGCNCDGC

DGC CHK

CN2605

2

123

123456789

ABL9VE/W

GND

VTIM

X-RAY

H DRIVE

VTIM

X-RAY

H DRIVE

123456789

ABL9VE/W

GND

V+OUT

V+OUT

CN527

1

2

3

4

5

1

2

ONLY

3

4

KV-J29MF8J

1

10

N/S-MUTE

ROTATION

N/S-MUTE

ROTATION

10

SW Y/C DECODE JUNGLE

GND

CN518 5P

GND1

QP+

QPN.C

135V

CN1804

15V

N/S COIL -

GND

N/S COIL +

CN530

GND

MAIN TUNER,VIF,SIF

12345

CN128

VL IN

VL OUT

A

GND

VR OUT

6

VR IN

W-MUTE

CN127

1 GND

VM OUT

N/S COIL -

N/S COIL +

KV-J29MF8J

ONLY

9V

QP+

QP-

N.C

TB

15V

GND

CN961

CN962

1

2

3

4

5

6

7

8

1

2

3

4

VM

(VM OUT)

321

CN963

ONLY

KV-J29MF8J

N.C

N/S-

N/S+

123456789

CN121

9V

SCLK

SDAT

GND

12V

GND

L IN

GND

CN120

123

R IN

GND

9V

VM OUT

101112

L OUT

R OUT

W-MUTE

E

E

OPEN

SP L

SP L

PH L

SP R

SP GND

SP GND

CN901

15

CN907

CN902

1

2

3

1

2

3

4

GND

SP L

SP R

GND

GND

SP L

SP GND

SP GND

SPR

1011121314

SP R

PH R

GND

GND

SP GND

SP GND

FR Y OUT

FR C OUT

(CONTROL SW,INPUT TERMINAL)

FR V OUT

123456789

S3

CN905

FR L OUT

H3

GND

131415

FR R OUT

GND

GND

101112

GND

STBY +5V

7V

RED

GND

KEY 2

GREEN

SIRCS

KEY 1

123456789

W IN

CN908

123

W IN

W OUT

W OUT

4

VL OUT

VL IN

VR IN

GND

W-MUTE

VR OUT

CN2202

9V

GND

SCLK

SDAT

CN2201

123456789

1

2

3

4

5

6

(AUDIO EFFECT)

12V

S1

GND

L IN

R IN

GND

L OUT

R OUT

101112

W-MUTE

6-2. CIRCUIT BOARDS LOCATION

6-3. SCHEMATIC DIAGRAMS AND PRINTED WIRING BOARDS

Note:

• All capacitors are in µF unless otherwise noted.

• All electrolytic capacitors are rated at 50V unless otherwise noted.

• All resistors are in ohms.

kΩ = 100Ω, MΩ = 1000kΩ

• Indication of resistance, which does not have one for

rating electrical power, is as follows.

Pitch: 5 mm

Rating electrical power 1/4W (CHIP: 1/10W)

• : nonflammable resistor.

• ¢ : internal component.

• : panel designation, or adjustment for repair.

• All variable and adjustable resistors have characteristic curve

B, unless otherwise noted.

• Readings are taken with a color-bar signal input.

no mark : PAL

( ) : SECAM

[ ] : NTSC 3.58

Reference information

RESISTOR : RN METAL FILM

COIL : LF-8L MICRO INDUCTOR

CAPACIT OR : TA TANTALUM

« » : NTSC 4.43

• Readings are taken with a 10 MΩ digital multimeter.

• Voltage are dc with respect to ground unless otherwise noted.

• Voltage variations may be noted due to normal production toler-

ances.

• All voltages are in V.

• : Can not be measured.

*

• Circled numbers are waveform reference.

• : B + bus.

• : B – bus.

• : signal path.

Note:The component identified by shading and

: RC SOLID

: FPRD NONFRAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: RW NONFLAMMABLE WIREWOUND

: * ADJUSTMENT RESISTOR

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

!!

mark

! are critical for safety. Replace only

!!

with part number specified.

Terminal name of semiconductors in silk screen

printed circuit ( )

Device Printed symbol Terminal name

1

2

3

Transistor

Transistor

Diode

Base

Base

Cathode

Collector

Emitter

Collector

Emitter

Anode

Cathode

4

Diode

Diode

5

Diode

6

Diode

7

8

Diode

Diode

9

Diode

0

Diode

!¡

Transistor

!™

(FET)

Transistor

!£

(FET)

Transistor

!¢

(FET)

Transistor

!∞

Transistor

!§

Transistor

!¶

Transistor

!•

Transistor

!ª

Transistor

@º

Transistor

@¡

Discrete semiconductot

–

Cathode

Cathode

(NC)

Anode

Cathode

(NC)

Anode

Common

Anode

Cathode

Common

Anode Cathode

Common

Anode

Anode

Common

Anode Anode

Common

Cathode

Common

Cathode

Source

Drain

Gate

Source

Drain

Gate

Source

Drain

Gate

B1 E1C2

B2 C1E2

B2 E2C1

B1 C2E1

B2 E2C1

B1 C2E1

B2 E2C1

B1 C2E1

E2

B1 E1

C1(B2)C2

(B2)

E1

B1

E2

C2C1

(B2)

E1

E2

B1

C1C2

(Chip semiconductors that are not actually used are included.)

Circuit

D

G

D

S

B1

B1

B1

B1

B1

B1

D

G

S

S

D

G

C1

E1

C1

E1

E1

C1

E2

C1

C1

G

S

C2

B2

E2

C2

B2

E2

E2

B2

C2

C2C1(B2)

E2

E2E1(B2)

C2

C2E1(B2)

C2

Ver.1.3

– 31 –

– 32 –

– 33 –

– 34 –

(5) Schematic Diagram of VM Board

1

A

TO D BOARD

CN518

B

TO A BOARD

CN120

C

D

E

2

+B

NC

QPQP+

E

9V

VM OUT

E

CN961

8P

WHT

:S-MICRO

8

7

6

5

4

3

2

1

L961

JW(5.0)

VM

3456789

NECK ASSY

QP QP VM

D965

* LIMITTER

R983

*

C971

R984

*

Q962

2SC2785

AMP

2.1

R970

R973

68

R971

220

69.5

R972

18k

C978

0.001

:PT

C968

0.047

200V

:PT

R981

820

R978

R977

10k

120

R980

120

*

5.0

2.8

C980

100

16V

2.1

68

C970

0.1

200V

:PT

R975

1k

:FPRD

D967 D968

MTZJ39

DC.BIAS

C969

2.2

160V

:HT

MTZJ39

DC.BIAS

C979

0.001

:PT

5.9

5.0

C982

22p

R974

180

3W

:RS

VM.DRIVE.2

R976

18k

2SC2785

BUFFER

5.5

2SA1175

BUFFER

Q965

2SC4793

0.4

0.9

C973

0.047

:PT

Q967

Q968

R979

R982

1.5

:FPRD

C975

560

JW(5)

470

16V

R986

:FPRD

R985

47

R1837

*

C983

Q.P.Q.P.+

E

VM

R1838

*

D1833

*

DC SHIFT

Q1834

*

DRIVE

R1840

*

R1842

*

R1839

*

*

R1831R1841 R1835

***

R1832

Q1833

DRIVE

D1831

DC SHIFT

*

*

Q1831

*

*

DRIVE

R1834

*

R1833

*

R1836

*

C967

*

B-SS6667<ME.>-VM.

C965

*

C966

*

* DRIVE

Q1832

1

N/S-

2

NC

3

N/S+

TO N/S COIL

1

15V

2

N/S-

3

GND

4

N/S+

TO D BOARD

CN1804

CN963

*

CN962

*

C972

330

16V

:HT

0.0047

R962

47

1SS119

TEMP-CORR

C961

500V

E

R964

47

1/2W

:FPRD

0.047

D964

(VM OUT)

C962

:PT

R967

330

C964

470

10V

R965

560

:FPRD

R966

1k

R968

1k

2.8

R963

1k

Q961

2SC2785

AMP

C963

33

160V

R969

1.5

137.2

:FPRD

Q963

2SA1837

VM.DRIVE.1

136.8

9V

VM BOARD∗MARK LIST

C965 # 0.0022 50V

C966 # 0.0022 50V

C967 # 10 50V

C971 # 1 50V

C983 # 0.082 50V

CN962 #

CN963 # 3P BLK : S-MICRO

D965 # 1SS119-25TD

D1831 # 1SS119-25TD

D1833 # 1SS119-25TD

Q1831 # 2SD773-T-34

Q1832 # 2SB733-T-34

Q1833 # 2SD773-T-34

Q1834 # 2SB733-T-34

R983 # 56k 1/4W

R984 # 82k 1/4W

R1831 # 1k 1/4W

R1832 # 1k 1/4W

R1833 # 1k 1/4W

R1834 # 1k 1/4W

R1835 # 15 1/2W : FPRD

R1836 # 10 1/4W : FPRD

R1837 # 1k 1/4W

R1838 # 1k 1/4W

R1839 # 1k 1/4W

R1840 # 1k 1/4W

R1841 # 15 1/2W : FPRD

R1842 # 10 1/4W : FPRD

KV-J25MF8J KV-J29MF8J

4P WHT : S-MICRO

# Mark : not mounted

F

G

H

I

Schematic diagrams

? C2 boards

VM

VM OUT

-VM BOARD-

– 56 –– 55 –

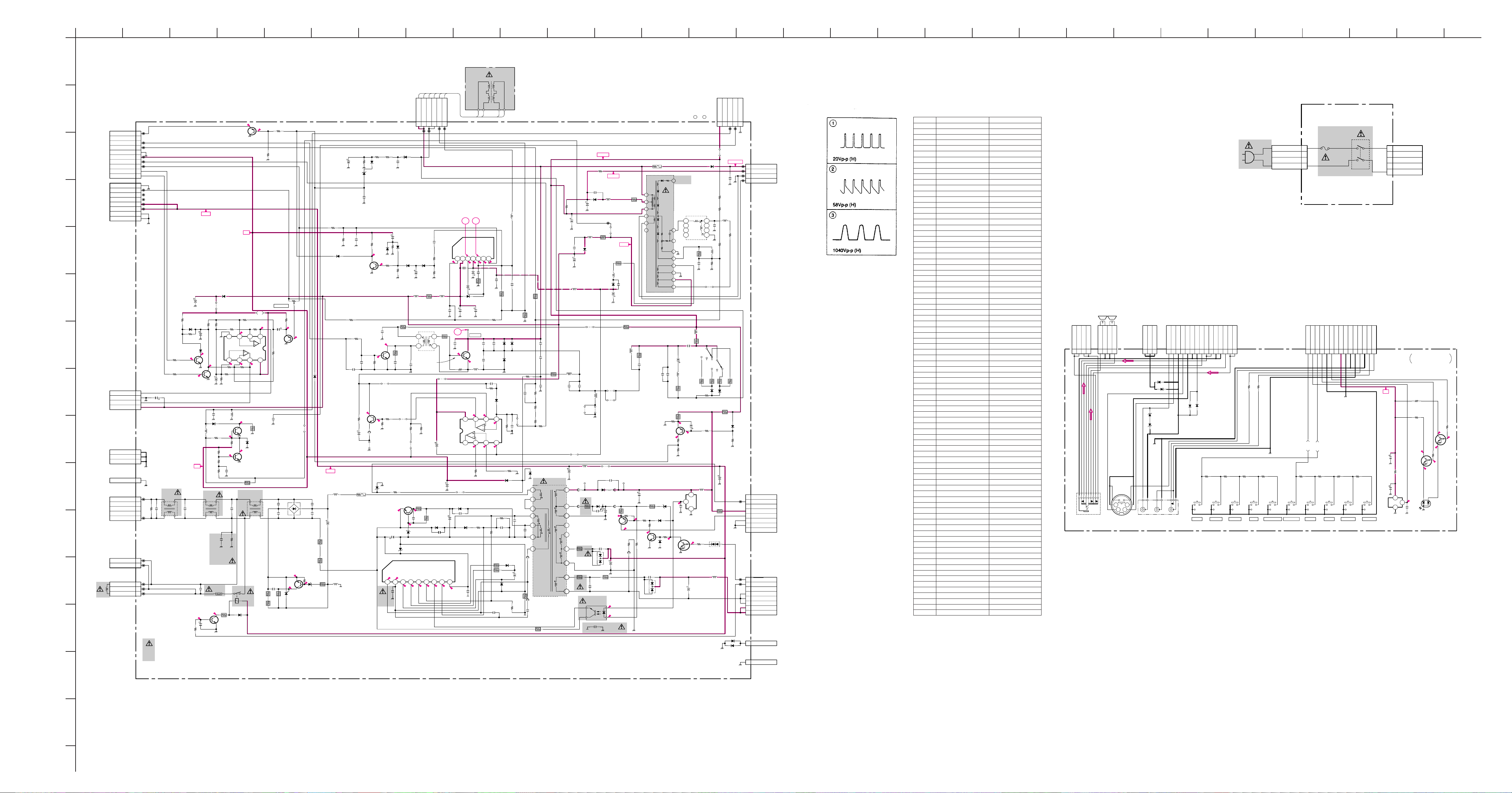

D

POWER SUPPLY, DEFLECTION

– D Board –

D BOARD

IC

IC601 C–5

IC602 E–3

IC603 E–5

IC1501 D–8

IC1800 G–7

IC2504 F–5

TRANSISTOR

Q600 D–5

Q601 E–3

Q602 E–2

Q603 G–1

Q803 F–3

Q1501 F–7

Q1502 H–4

Q1800 G–6

Q1802 H–5

Q1803 H–6

Q1804 G–2

Q1805 G–2

Q2502 F–10

Q2503 F–6

Q2591 D–10

Q2600 B–1

Q2601 B–6

DIODE

D601 D–5

D602 D–4

D603 D–5

D604 D–1

D605 G–10

D606 D–4

D608 D–2

D609 E–2

D611 E–1

D612 E–2

D614 E–3

D616 D–5

D617 C–5

D618 G–1

D619 G–10

D621 C–5

D633 E–2

D801 D–8

D803 F–4

D814 B–7

D815 C–8

D816 C–7

D824 G–8

D825 F–6

D1501 F–7

D1502 F–6

D1503 E–8

D1504 E–8

D1505 G–4

D1506 F–8

D1509 F–8

D1510 F–8

D1511 F–8

D1803 H–6

D1804 H–6

D1805 G–3

D1806 G–2

D1808 H–7

D2500 G–4

D2501 F–5

D2502 F–4

D2506 D–9

D2507 D–10

D2508 E–10

D2510 G–7

D2511 F–8

D2515 G–5

D2600 A–6

D2602 B-1

D2603 A–6

D2604 B–6

VARIABLE

RESISTOR

RV1801 G–5

F1

AC IN

– F1 Board –

– H3 Board –

H3

CONTROL SW, INPUT TERMINAL

– 35 –

– 36 –

– 37 –

– 38 –

0

0

5.2

5.2

0

0

5.1

5V

AUDIO(R)

AUDIO(L)

AUDIO(R)

AUDIO(L)

123

4

123

4

V

L

R

-2

-2

G

R

123

3

1

2

123456789

1011121314

15

123456789

1011121314

15

12

34

J901

D904

C901

R918

S902 S904

S906 S908

S910 S909 S907 S905 S903 S901

J903

J902

IC900

CN902

CN908

CN907

CN905CN901

D915

D914

Q900

Q901

D916

D917

D902

D905

R900 R901

R902 R904 R906 R908 R903 R905 R907 R909

C902

R912

C900

R917

R914

R915

SPB-26MVWF

2 COLOR LED

470p

100

SBX1981-11

4P

WHT

S-MICRO

4P

S-MICRO

3P

BLACK

:S-MICRO

15P

BRIDGE

15P

BRIDGE

1SS119

LIMITTER

1SS119

LIMITTER

DTC144ES

LED DRIVE

DTC144ES

LED DRIVE

1SS119

LIMITTER

1SS119

LIMITTER

JW(5MM)

75

4.7k 4.7k

470 1k 1.8k 3.3k 470 1k 1.8k 3.3k

47

16V

47

47

16V

100

330

330

KEY 1

KEY 2

SP L

SP L

SP R

SP R

PH R

SP R

SP L

PH L

W IN

W IN

W OUT

W OUT

FR L OUT

GND

FR R OUT

GND

GND

RED

GREEN

GND

FR Y OUT

FR C OUT

GND

FR V OUT

GND

SIRCS

STBY+5V

GND

S3

KEY 2

KEY 1

GND

SP GND

SP GND

SP GND

SP GND

SP GND

SP GND

7V

GND

GND

BRIDGEBRIDGE

SP(L)SP(R)

TO A BOARD CN103

H3

CONTROL SW,

INPUT TERMINAL

TV/VIDEO VOL - VOL + PROGR - PROGR +MENU +ENTER MENU - MENU AUTO PROG

TO A BOARD CN102

TO D BOARD 2601

SIRCS

RECEIVER

STANDBY/STEREO/

WAKEUP INDICATOR

B-SS6667<ME.>-H3.

1

2

3

4

1

2

3

4

5

S1690

F1690

CN1691CN1690

5P

:VH-L

4P

:VH-L

34

12

AC OUT

NC

NC

NC

AC OUT

NC

NC

AC

AC

F1

TO D BOARD

CN2600

(AC IN)

B-SS6534<EM.>-F1.

(1) Schematic Diagrams of D, F1 and H3 Boards

1 2 3 4 5 6 7 8 9 101112131415161718 2019 21 22 23 24 25 29282726 30

A

B

C

D

CN506

10P

BLK

:BRIDGE(R)

TO A BOARD

CN109

X-RAY

VTIM

H DRIVE

ABL

GND

9V

E/W

V+OUT

ROTETION

N/S-MUTE

GND

V-OUT

N.C

N.C

11V

11V

GND

GND

CN526

8P

BLK

:BRIDGE(R)

TO A BOARD

CN108

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

11V

E

F

G

H

I

J

K

L

M

N

O

P

CN1804

*

BLK

:S-MICRO

TO VM BOARD

CN962

N/S COIL+

GND

N/S COIL-

15V

CN2601

3P

WHT

TO H3 BOARD

CN907

GND

GND

GND

CN525

1P

A GND

AC IN

NC

NC

NC

AC IN

CN2600

5P WHT :VH

TO F1 BOARD

CN1691

CN2602

2P

WHT

:MINI

DGC CHK

DGC CHK

OPEN

DGC

NC

DGC

CN2605

3P

WHT

:MINI

TO DGC

R1806

*

R1805

*

R1807

*

4

3

2

1

1

2

3

1

R2612

1/2W

1

2

3

4

5

1

2

1

2

3

1M

TH

C2620

0.22

250V

C1812

*

T2603

8.2MH

21

34

D

(POWER SUPPLY,DEFLECTION)

C1809

*

D1803

*

STOPPER

C1804

*

R1808

*

D1804

*

0.4

Q1802

*

PVM-AMP

0.3

(0)<0>

Q1803

*

N/S-MUTE

D1805

*

L1805

*

9V

C2602

0.22

250V

C2618

0.01

630V

:PP

Q2600

2SC2785TP-HFE

0

C2605

R2602

1k

R1821

0.9

C1813

T2601

11.5

47

– 39 –

0.7

Q1502

2SA1175TP-HFE

9V

D1808

*

STOPPER

JW028

*

R1825

*

R1822 R1823

IC1800

* N/S-DRV

**

*

R1824

4.8

GND

5 6 7 8

(0.3)<5.0>

*

R1814

R1817

R1816

R1815 C1806

C622

470p

250V

4.8

4.8

R1811

R1812

*

*

R1810

*

R1809

*

C1805 L1806

**

Q1805

0.4

R1818

*

*

*

**

C2604

B

THP260

R2603

JW(5MM)

14.8

*

*

-0.8

0.22

250V

R2601

8.2M

D2602

1SS119-25TD

D1806

0.4

Q1804

*

21

34

1W

RY2600

T2602

8.2MH

R1523

0

100

R1524

22k

RV1801

H.POST

9V

R1800

4.8

*

C1800

*

1234

R1801

9V

4.5

C1807

R1820

*

*

R1819

*

C2607

0.0047

500V

E

C2606

0.0047

500V

D2603

5P4M

POWER-SW

C2613

0.68

B

R2604

3.3

10W

:RB

R2607

3.3

10W

:RB

R2605

820

:FPRD

*

*

3.8

3.2

Q1800

*

BUFFER

*

*

JW1802

D2600

D4SB60L

AC-RECT

E

-0.4

-0.1

2

3

2SC2785TP-HFE

1

1SS119-25TD

D1505

*

C2610

0.0047

500V

E

R2611

8.2k

3W

:RS

R2610

8.2k

3W

:RS

R2608

47k

-1.6

D2604

RD8.2ESB2

Q2601

PC-SW

1SS119-25TD

11V

C2609

0.0047

500V

E

R2606

820

:FPRD

C877

0.47

D1502

RD33ES-T1B

PROTECT

R1501

10k

R1502

6.8k

D1501

R1508

10k

C2553

R2529

JW(5MM)

C2552

22

L601

0.45µH

C2617

560

400V

L600

0.45µH

R895

R898 R894

18k

1SS119-25TD

C1518

0.1

:PT

C1501

330p

D1509

1SS119

R1504

4.7k

0.2

0.7

Q1501

2SC2785TP-HFE

V-PROTECT

R2521

C2522

330

*

74.7

Q2502

2SC2688-LK

H-DRIVE

C2547

-0.1

330p

R2520

B

*

Q2503

17.0

2SD2394

2

PIN-OUT

1

0.5

3

R2510

FB2502

JW(5MM)

JW2522

5MM

MTZJ-T-77-5.6B

R611

0.1

1/2W

:RF

C2603

DY1

6P

H+H+H-H-V-

WHT

:DY

12345

D824

560k470k

RGP02-17

R1506

R1503

15k

R2517

R2556

2.7k

33k

1.2k

3W

:RS

C1511

100

16V

R1525

100k

R2519

C2524

820p

500V

JW2505

C875

1000p

500V

E

D1510

1SS119

D1511

1SS119

*

B

5MM

C1510

0.1

:PT

D1506

1SS119-25TD

C1521

47

L1503

R1520 JW067

10µH

0.39

2W

:RS

1

T2502

HDT

3 4

Q2591

2SC4927-01

H-OUT

C2523

*

JW2510

7.5MM

R2505R2508

**

JW2512 C2543

5MM 220

IC1501

TDA8172

V.OUT

R1550

10k

R1551

2.2k

7.5MM

C1503

5

PIN-CONTROL

D825

(0)

3.3k

JW2517

5MM

2.2k

D2500

2W

R601

10k

3W

:RS

81.6

D601

1.5

C2504

100

25V

D602

D1NL20-TA

C624

680p

500V

0.20.1

R2582 JW2502

470 7.5MM

R616

Q600

100

2SD1640Q

:RS

CLAMP

8.6

C633

1000p

500V

8.5

470

16V

0.1273

RD7.5ES-T1B1

D621

RD13ES-T1B

IC601

STR-S6708N

0.9

-0.1

C618

1 2 3 4 5 6 7 8 9

470p

250V

B

V+

6

1.5

C1509

2.2

:BP

C1505

220

330p

IC2504

µPC4558C

35V

C602

10

100V

B

DY

H.DY H.DY V.DY V.DY

12

Vcc

F.B.-PLS

Vee

DRV-IN

1 2 3 4 5 6 7

3

0

R2516

47

D606

RGP10G

8.61.6

C626

1000p

OUT-PUT

-15.6

-14.2

C1579

470 25V

R1515

1.5

:FPRD

D1503

GP08DPKG23 V.BOOST

C1504

C1515

470

0.1

25V

:MPS

TP84

H.OUT

C2519

*

0

L2506

0.68µH

0.2 3.7

1 2 3 4

6.3 1.7 0

R2531

JW(5MM)

C620

680p

500V

B

D616

D1NL20-TA

R612

1.8k

B

Vcc(OUT)

REF-VOLT

1.5

14.5

C1506

0.33

0.3

:MPS

C1514

0.1

:MPS

R1509

6.8k

:RN

ERC06-15S

C2548C2520R2515

***

C2521

0.047

400V

:PP

R2580

*

5678

1.6

1SS119-25TD

R620

4.7k

R604

10

3W

:RS

R621

JW(5MM)

C629

680p 2kV B

R1511

220

3W

:RS

D2506

DAMPER

ERD29-08J

PIN-DANPER

C2510

*

D2515

JW(5MM)

CLAMP

R2564

*

R2526

JW(5MM)

D2501

R614

1.2k

C604

1000p

:B

D617

JW(10MM)

D603

D1NL20-TA

R619

100

L1502

10µH

:LHL08

C1507

0.1

100V

R876

:MPS

2.2k

:FPRD

R1512

1

2W

:RS

D2507

ERC06-15S

DAMPER

D2508

R2536

C2501

*

R2548

JW(5MM)

R2547

JW2515

5MM

C2540

0.022

:PT

C642

820p

500V

B

D2

C643

1000p

500V

B

FB601

1.1UH

C603

330

16V

R618

0.18

2W

:WW

C2518

*

C2515

0.0047

R2512

*

*

D2502

1SS119-25TD

6

P1

7

8

2

3

D1

4

P2

9

FB602

1.1UH

C605

1000p

3kV

R602

1k

:FPRD

680p

2kV

B

C2517

*

R2501

2.2

:FPRD

200V

:PT

R2543

*

T601

SRT

C684

2200

16V

S1

S5

S3

S4

S2

CN518

5P

TO VM BOARD

CN961 4 - 8 PIN

135V

NC

QP-

QP+

GND

12345

D BOARD WA VEFORMS

D BOARD MARK LIST

C818 # 0.047 630V : PP

C1800 # 10 50V

C1804 # 10 50V

C1805 # 0.047 200V : PP

C1806 # 0.015 50V : MPS

C1807 # 0.68 50V : MPS

C1809 # 1000 25V

C1812 # 22 50V

C1813 # 10 50V

C2501 0.22 50V : PT #

C2505 # 0.1 200V : PP

C2510 0.0027 50V : PT 0.0022 50V : PT

C2517 330p 2kV B 680p 2kV B

C2519 0.017 2kV : PP 16000p 2kV : PP

C2520 680p 2kV B 330p 2kV B

C2522 0.01 200V : PT 0.047 200V : PT

C2523 680p 50V B #

C2528 1.8 200V : PP 1.2 200V : PP

C2530 0.91 200V : PP 0.82 200V : PP

C2546 # 0.047 400V

C2548 560p 2kV B #

C2553 # 220p 50V B

CN1804 # 4P BLK : S-MICRO

D1803 # 1SS119-25TD

D1804 # 1SS119-25TD

D1805 # RGP10GPKG23

D1806 # 1SS119-25TD

D1808 # GP08DPKG23

IC1800 # M5216P

JW018 # 10.0MM

JW028 # 7.5MM

JW029 # 10.0MM

C846

33

160V

:HR

R836

68k

L1501

10µH

:LHL08

C839

47

250V

C836

470p

500V

B

C835

470

25V

L815

10µH

:LHL08

135V

R856

JW(5)

200V

C816

220p

500V

B

L812

D815

RGP10GPKG23

200V.RECT

R853

0.47

1/2W

JW018

:FPRD

D814

RGP10GPKG23

+15V.RECT

D816

RGP10GPKG23

-15V.RECT

*

15V

R854

0.47

1/2W

:FPRD

L816

10µH

:LHL08

C840

470

25V

:FPRD10µH

C841

470p

500V

B

R885

0.47

1/2W

+B

H2

H1

C

200V

R804

1

4

2

5

6

3

1k 1W :RF

NX-4002

HV

13

FV

12

11

ABL

7

-15V

8

E

9

15V

10

T801

FBT

8

7

6

5

R855

1k

1/2W

:RS

D801

RGP02-20EL

1000V.RECT

T804

*

4

3

2

1

L802

*

C842

0.068

200V

:PT

JW029

JW036

12.5MM

0.0047

R871

20k

:RN

R869

*

C818

*

L801

*

R810

*

R868

*

R858

4.7k

:RN

*

1000V

C808

2kV

E

CN0521

:MINI

TO C2 BOARD

1

1000V

2

200V

3

GND

4

H1

4P

CN701

JW064 # 7.5MM

JW083 # 10.0MM

JW1802 # 5.0MM

L801 # : CD1

L802 47k 1/4W 2.2mmH : EL0606

L1805 # 10mmH

L1806 # 3.3mmH

Q1800 # 2SA1175TP-HFE

Q1802 # 2SC2785TP-HFE

Q1803 # 2SC2785TP-HFE

Q1804 # 2SC2785TP-HFE

Q1805 # 2SC2958-TL

R810 # 33 1/4W

R868 18k 1/4W : RN 22k 1/4W : RN

R869 20k 1/4W : RN 22k 1/4W : RN

R1800 # 1k 1/4W

R1801 # 5.6k 1/4W

R1805 # 10k 1/4W

R1806 # 4.7k 1/4W

R1807 # 10k 1/4W

R1808 # 4.7k 1/4W

R1809 # 33k 1/4W

R1810 # 33k 1/4W

R1811 # 33k 1/4W

R1812 # 33k 1/4W

R1814 # 10k 1/2W

R1815 # 10k 1/2W

R1816 # 3.3k 1/4W

R1817 # 100k 1/4W

R1818 # 2.2k 1/4W

R1819 # 100 2W : FPRD

R1820 # 1.8k 1W : RS

R1821 # 33k 1/4W

R1822 # 33k 1/4W

R1823 # 5.6k 1/4W

R1824 # 33k 1/4W

R1825 # 3.3k 1/4W

R2503 JW (15.0MM) 68 3W : RS

R2505 560 1/4W 1.5k 1/4W

R2506 JW (20.0MM) 56 3W : RS

R2508 2.2k 1/4W 1.8k 1/4W

R2512 56k 1/4W 220k 1/4W

R2515 0.22 1W : RS 0.39 1W : RS

R2519 5.6k 1/4W : FPRD 4.7k 1/4W : FPRD

R2522 # 180 2W : RS

R2523 # 220 2W : RS

R2532 68 3W : RS JW (15.0MM)

R2536 3.9k 1/4W 2.7k 1/4W

R2543 3.9k 1/4W 4.7k 1/4W

R2547 180k 1/4W 0.047 50V : PT

R2564 2.7k 1/4W #

R2580 56k 1/4W 82k 1/4W

RV1801 # 47k

S2501 # 1-572-707-21

T804 # 1-413-059-11 (DFT)

L2510

3.3mmH

14

56V

13

12

16

18

17

15

30V

11

10

JW2514

7.5MM

FB604

1.1UH

+B

FB605

1.1UH

GND

7V

14V

11V

R625

GND

R624

JW877

15MM

C2530C2546

**

L2504

PmC

JW2518JW2506

7.5MM7.5MM

L607

150µH

:LHL13

RGP15G

R615

0.47

:FPRD

7A

D604

D5LC20U

ON3171-R

3

4

PHOTO COUPLER

JW624

7.5MM

C610

1000p 3kV

RU4AM-T3

C621

680p

D608

500V

B

2SA1315-Y

C612

680p

500V

B

C644 R629

820p

0.56

500V

5W

B

:RS

IC603

2

1

JW2507

5MM

JW2508

5MM

D609

FB603

1.1UH

C609

4.7

100V

Q601

C2601

470p

250V

FB600

1.1UH

69.2

70.2

B

L2509

HLC

R606

75.3

R628

4.7

1/2W

FB607

1.1UH

C614

2200

25V

R2518

1.5k

3W

:RS

TP602

18

1W

:RS

R690

820

10.5

R2528

680

1/2W

:FPRD

C2529

0.001

100V

:PT

2SA1091R-TPE2

C613

560

160V

RD7.5ESB1

R608

22k

1/2W

:FPRD

75.3

1SS119

R607

R634

3.3k

100

75.2

R609

5.6k

1/2W

Q602

2SC3209-L

C611

680p

500V

B

R887

1.8k

:FPRD

R884

200k

1/2W

:RN

Q803

D612

D614

R635

470

0

D633

1SS119

PROTECT

D611

D5LC20U

**

0

R861

56k

C632

0.047

100V

C2526

0.15

200V

:PT

C2527

10

160V

L2508C2528C2505

1.5mmH

NSL0808

R2527

47

1W

:RS

137.2

R860

56k

IC602

SE135N

:PT

2

69.1

Q603

DTD114ES

L2505

10mH

:DCC

R2533

4.7

:FPRD

S2501

*

R2503R2523

**

R2532

*

D2511

GP08DPKG23

H-POSI

C814

100

16V

R892

137.0

4.7k

L606

1

15µH

:LHL08

R603

33k

2W

3

:RS

3.5

R622

100

C615

2200

S2502

SW

R2522

*

R2506

*

D2510

GP08DPKG23

H-POSI

R886

1.2

2W

:RS

D803

R890

150k

1/2W

C683

2200

16V

D618

1K

L605

15µH

:LHL08

D605

1SS119

D619

1SS119

B-SS6667<ME.>-D..

1SS119-25TD

1

H RELAY

2

AFC

3

14V

4

33V

5

BACKUP

6

GND

7

GND

8

7V

CN520

8P

BLK

:BRIDGE(R)

TO A BOARD CN107

CN528

8P

BLK

:BRIDGE(R)

TO A BOARD CN106

1

STBY

2

DEGUSS

3

NC

4

AUDIO GND

5

AUDIO GND

6

AUDIO GND

7

AUDIO 30V

8

AUDIO 30V

CN530

1P

TO A BOARD CN127

1

GND

CN527

1P

1

GND

– 40 – – 41 –

*

KV-J25MF8J KV-J29MF8J

# Mark : not mounted

– 42–

(2) Schematic Diagrams of A Board

V SYNC

SEP

H SYNC

SEP

25

35 34

2423

31

33

32

30

28

37

38

41

40

36

12

43

42

50

48

45444746

5352515961

555657

5463

58

60

62

64

1

26

6

16

39

2927

222120191817151413111097634249

COL

COLOR

& AXIS

BRT

BRT

D.

COL

γ

D. COL γ

PIC

PIC

BLK

LIMIT

VLIN, SCORR

VPOSI, VOFF,

VBIZE

H POSI

AFC

GB CUT

CUT

OFF

GB

DRV

GB DRV

ABL

OSD

MIX

YM/YSZ

SW

YS1

SW

YS1 OFF

Y/C

MIX

VIDEO

SW

AKB

H.DRIVE

ABL

AKB

OFF

EHT

H, V

HV

COMR

PHASE

DET

32f

H

VCO

2f

H

CD MODE

INTERLACE

V FREQ

PHASE

SHIFT

Sand

Castle

KILLER

DET

DEM

AXIS

fsc B-Y

fsc R-Y

PRE/OVER

TOT

WIDE

Parabola

Gen.

1/32GATE

50/60 ID

PHASE

DET

INTER

-LACE

Count Down

525/625

D PIC

DC

TRAN

CLP

SHARP

NESS

SUB

CONT

SUB CONT

EXT

SYNC

TRAP OFF

CV/YC

DL

SHARP

VM

2Vp-p

SHP 10

AGING D PIC

1Vp-p

DC

TRAN

TOTACC

IREF VCO

APC

SUB COLOR

HUE

TRAP

1Vp-p

DL

GATE

WIDE

Saw tooth

Gen.

DEM

XTAI

COLOR SW

HUE

6dB

SYSTEM

INDENT

PAL

ID

ACC

DET

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 2019 21 22

A

B

C

D

E

55

F

G

H

I

J

K

L

M

N

O

? D F1 F3 boards

Schematic diagrams

TO D BOARD

CN530

FR Y OUT

FR C OUT

FR V OUT

BRIDGE

TO H3 BOARD

CN901

FR L OUT

FR R OUT

STBY+5V

CN103

15P

BRIDGE

TO H3 BOARD

CN905

GND

CN127

1P

SP L

SP L

PH L

GND

GND

SP R

SP R

PH R

GND

GND

GND

GND

CN102

15P

S3

GND

GND

GND

GND

7V

RED

GND

GREEN

KEY 2

SIRCS

KEY1

TU001

BTV-FG441

C078

100

16V

1

B:CHIP

L004

10µH :EL0606

AUDIO(L/R)

1

SPL

2

PHL

3

G

4

G

5

6

SPR

7

PHR

8

G

9

10

G

11

Y

12

13

14

15

10

11

12

13

14

15

SCL

G

C

SDA

V

S3

1

L

2

3

R

4

5

6

7

8

9

7V

C054

0.01

B:CHIP

RED

GRN

KEY2

KEY1

C080

0.01

L080

10µH

:EL0606

GRN

RED

R020

100

:CHIP

R073

10k

:CHIP

VCC5V

VCC30V

SCL

9V

(VC)

(U/V)

C079

C082

0.1 :MPS

220 :CHIP

R071

JR081 JR083

0

:CHIP0:CHIP

BAND 1

C107 R103

100p

:CHIP

1k :CHIP

R008

:CHIP

R031

1k :CHIP

(-0.4)

<-0.3>

SDA

AS

(L/H)

(NC)

C083

0.01

0.01 B:CHIP

B:CHIP

R070

220 :CHIP

D101

BAND 2

1SS119

STOPPER

D102

15K

470

:CHIP

R010

R013