Sony KV-HW21P80A Schematic

REVISION HISTORY

BG2T

CHASSIS

MODEL

KV-HW21P80A

NO. SUFFIX DATE SUPP / CORR DESCRIPTION

1 -01 2003/10 _ _ 1st Issue

PA RT NO. : 9-872-406-01

SERVICE MANUAL

BG2T

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-HW21P80A RM-969 Pakistan

(Silver)

RM 969

(Light Blue)

MODEL COMMANDER DEST. CHASSIS NO.

3

1

2

6

4

5

9

7

8

JUMP

-

0

SOUND

PROGR

2

MODE

SPACE

SOUND

TV

TRINITRON

3

1

2

6

4

5

9

7

8

JUMP

-

0

SOUND

PROGR

2

MODE

SPACE

SOUND

TV

®

COLOR TV

KV-HW21P80A

RM-969

TABLE OF CONTENTS

Section Title Page

SELF DIAGNOSIS FUNCTION...................................... 3

1. DISASSEMBLY

1-1. Rear Cover Removal ................................................. 6

1-2. Speaker Removal ...................................................... 6

1-3. Chassis Assy Removal .............................................. 6

1-4. Service Position ........................................................ 6

1-5. Terminal Bracket Removal ....................................... 6

1-6. A Board Removal...................................................... 6

1-7. Picture Tube Removal ............................................... 7

2. SET-UP ADJUSTMENTS

2-1. Beam Landing ........................................................... 8

2-2. Convergence .............................................................. 9

2-3. Focus Adjustment.................................................... 11

2-4. G2 (SCREEN) and White Balance Adjustments ... 11

3. CIRCUIT ADJUSTMENTS

3-1. Adjustment With Commander ................................ 12

3-2. Adjustment Method ................................................ 12

3-3. Picture Quality Adjustment .................................... 18

3-4. Deflection Adjustment ............................................ 18

3-5. A Board Adjustment After IC003 (MEMORY)

Replacement ............................................................ 18

3-6. Picture Distortion Adjustment ................................ 19

Section Title Page

4. DIAGRAMS

4-1. Block Diagram ........................................................ 20

4-2. Circuit Boards Location .......................................... 22

4-3. Schematic Diagram ................................................. 22

(1) A Board Schematic Diagram ............................ 23

(2) C Board Schematic Diagrams ........................... 25

4-4. Voltage Measurement and Wareforme ................... 26

4-5. Printed Wiring Boards and Parts Location ............. 29

4-6. Semiconductors ....................................................... 32

5. EXPLODED VIEWS

5-1. Picture Tube and Chassis ........................................ 34

6. ELECTRICAL PARTS LIST .................................... 35

OPERATING INSTRUCTIONS

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND

THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD,

OR CARBON PAINTED ON THE CRT, AFTER REMOVING THE

ANODE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

KV-HW21P80A

SELF DIAGNOSIS FUNCTION

The units in this manual contain a self-diagnosis function. If an error occurs, the STANDBY (1) indicator will automatically begin to flash. A description of the self-diagnosis function is explained in the instruction manual.

The number of times the STANDBY (1) indicator flashes translates to a probable source of the problem. If an error

symptom cannot be reproduced, the remote commander can be used to review the failure occurrence data stored in

memory to reveal past problems and how often these problems occur.

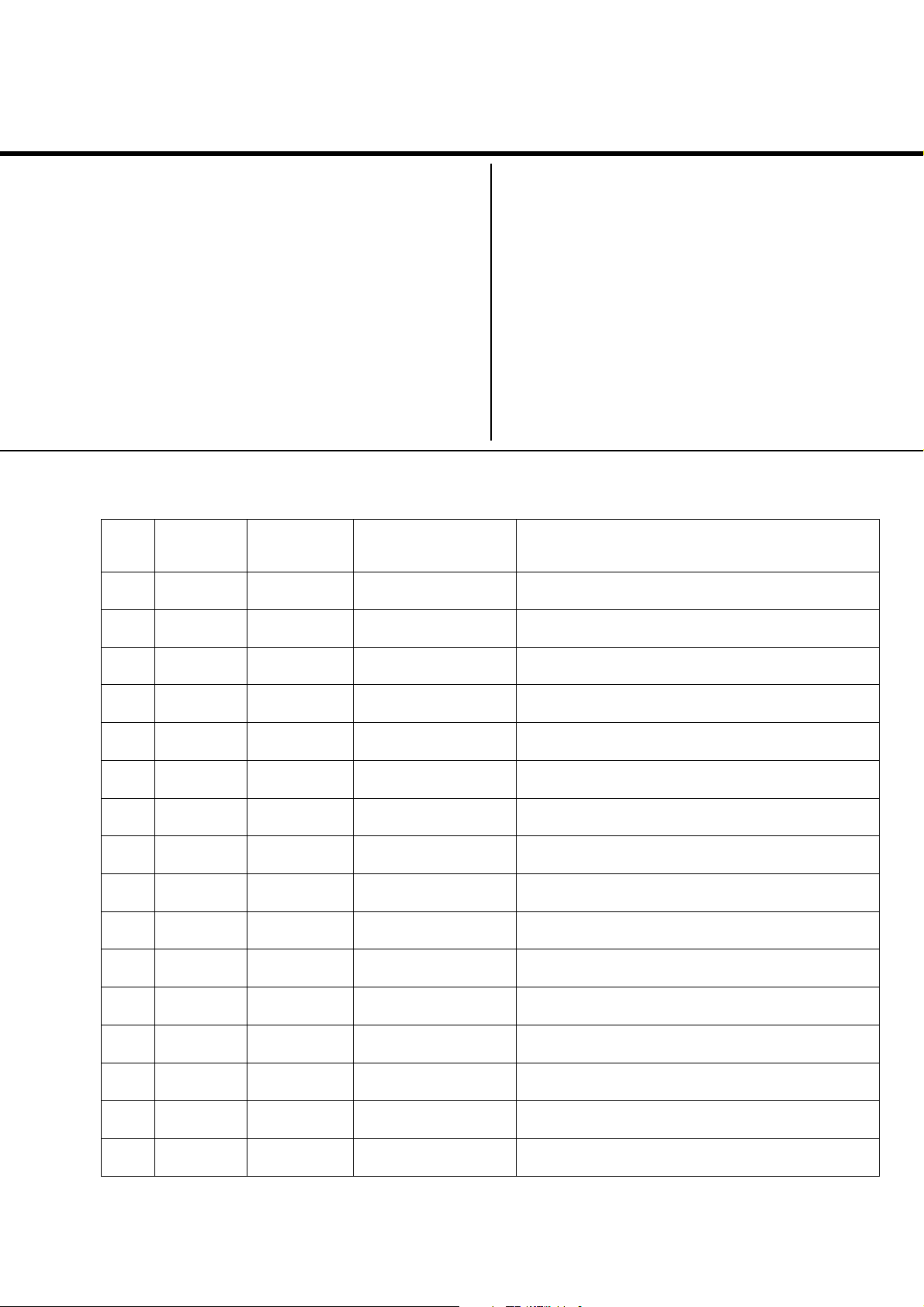

1. DIAGNOSIS TEST INDICATORS

When an errors occurs, the STANDBY (1) indicator will flash a set number of times to indicate the possible cause of the

problem. If there is more than one error, the indicator will identify the first of the problem areas.

Result for all of the following diagnosis items are displayed on screen. No error has occured if the screen displays a “0”.

RM-969

Diagnosis

Item

Description

• Power does not

turn on

• +B overcurrent

(OCP)

• Horizontal

deflection

overdrive

• White balance

failure (no

PICTURE)

• Vertical deflection

stopped

• Micro reset

No. of times

STANDBY (1)

indicator flashes

Does not light

2 times

4 times

—

Self-diagnostic

display/Diagnosis

result

—

002:000 or

002:001~255

004:000 or

004:001~225

101:00 or

101:001~225

Probable

Cause

Location

• Power cord is not

plugged in.

• Fuse is burned out

F600 (F)

• H.OUT Q801 is shorted.

(A board)

• -13V is not supplied.

(A board)

• IC 551 faulty (A board)

• Discharge CRT

(C Board)

• Static discharge

• External noise

Detected

Symptoms

• Power does not turn on.

• No power is supplied to

the TV.

• AC power supply is faulty.

• Power does not turn on.

• Load on power line is

shorted.

• Has entered standby state

after horizontal raster.

• Power line is shorted or

power supply is stopped.

• Vertical deflection pulse

is stopped

• Power is shut down

shortly, after this return

back to normal.

• Detect Micro latch up.

Note 1: If a + B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously.

The symptom that is diagnosed first by the microcontroller is displayed on the screen.

Note 2: Refer to screen (G2) Adjustment in section 3-4 of this manual.

– 3 –

KV-HW21P80A

RM-969

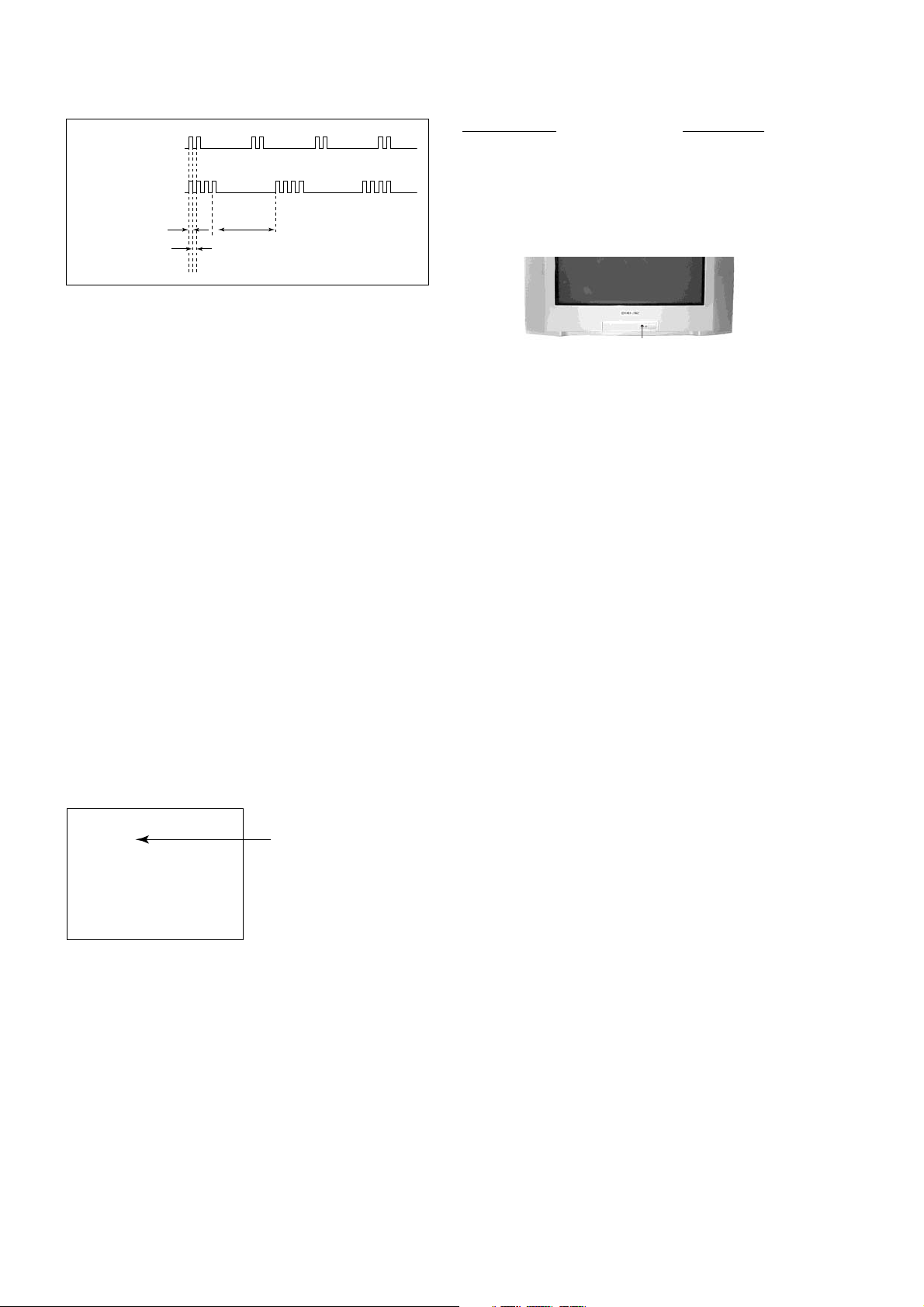

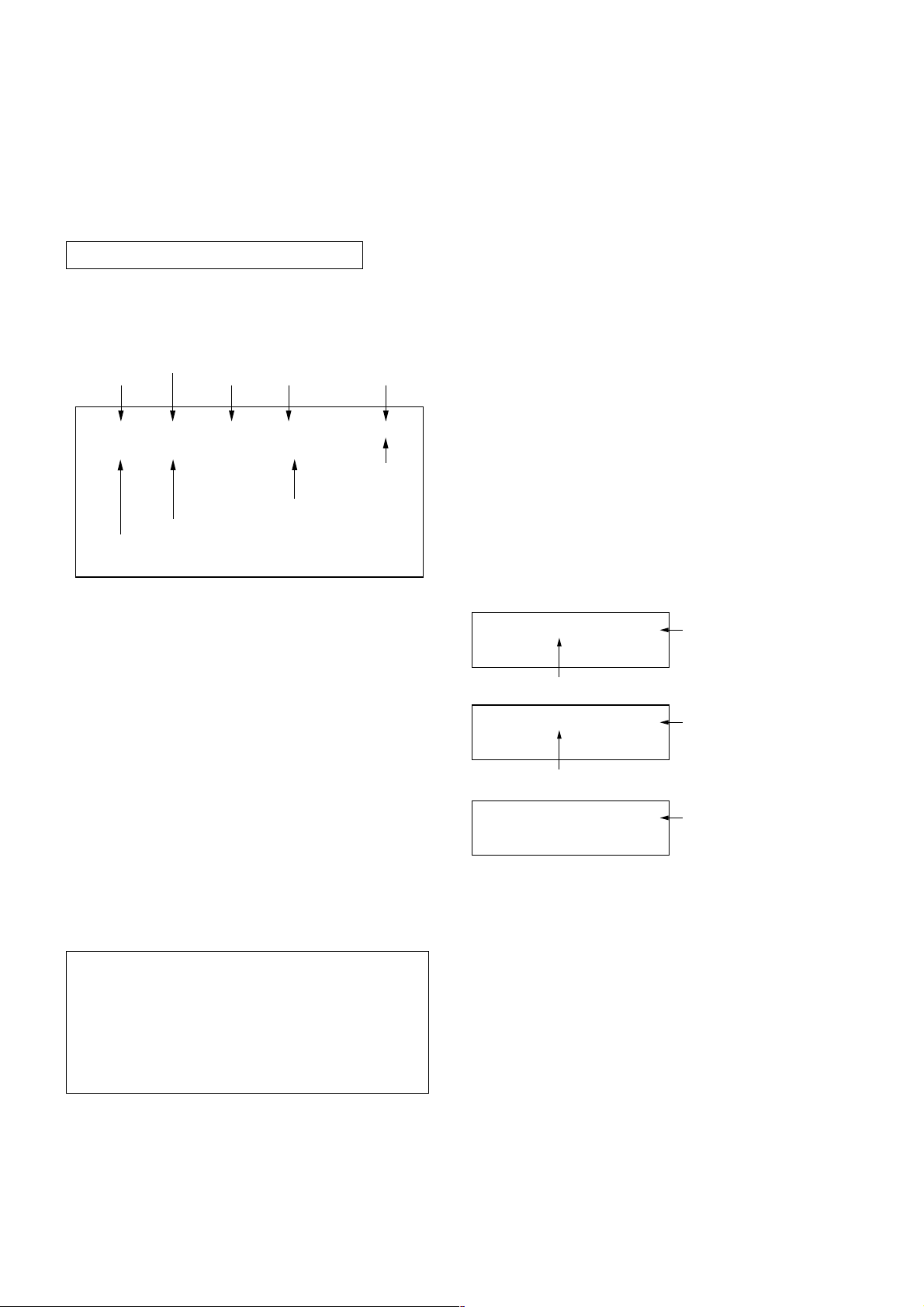

2. DISPLAY OF STANDBY (1) INDICATOR FLASH COUNT

2 times

Diagnosis Item Flash Count*

+B overcurrent/overvoltage 2 times

4 times

Lamp ON 0.3 sec.

Lamp OFF 0.3 sec.

Lamp OFF 3 sec.

Vertical deflection stopped 4 times

* One flash count is not used for self-diagnosis.

STANDBY (1) indicator

3. STOPPING THE STANDBY (1) INDICATOR FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY (1)

indicator from flashing.

4. SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it is possible to bring up past occurances of failure for confirmation on the screen:

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

[Screen display] / channel [5] / Sound volume [-] / Power ON

˘

Note that this differs from entering the service mode (volume [+]).

Self-Diagnostic screen display

SELF DIAGNOSTIC

002 : 000

004 : 000

101 : 000

Numeral "0" means that no fault has been detected.

– 4 –

KV-HW21P80A

5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

Since the diagnosis results displayed on the screen are not automatically cleared, always check the self-diagnostic

screen during repairs. When you have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnosis function will not be able to detect subsequent faults after

completion of the repairs.

[Clearing the result display]

To clear the result display to “0”, press buttons on the remote commander sequentially as shown below when the selfdiagnostic screen is being displayed.

Channel [8] / 0

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

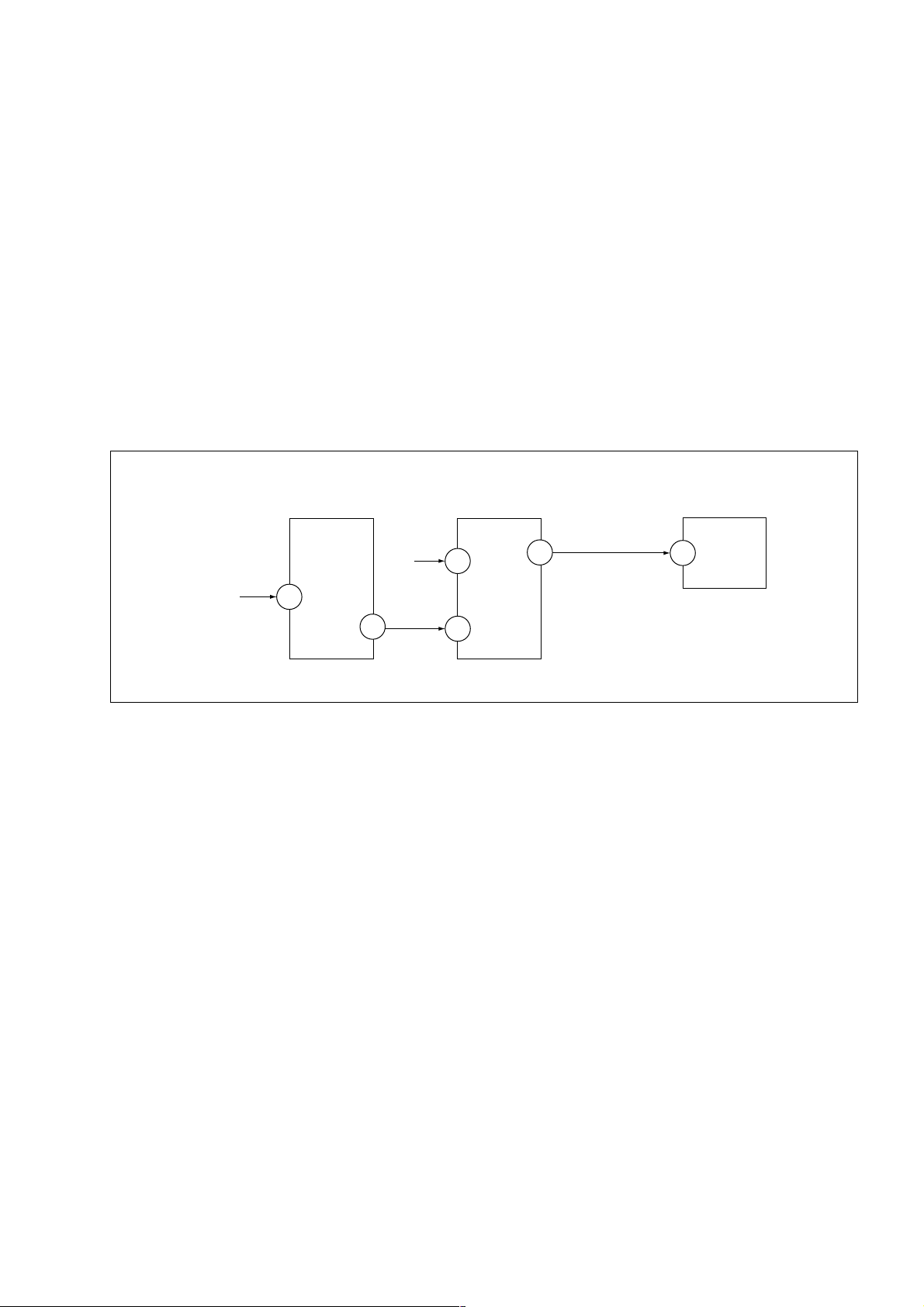

6. SELF-DIAGNOSIS CIRCUIT

RM-969

FROM

[+B] Q500

IC301

Y/CHROMA JUNGLE

MP/

50

PROTECT

8

SDA

[V]

D553

IC001

SYSTEM

11 DAT1 DAT

17

54

11 DAT0

53

IC003

MEMORY

5

[+B overcurrent $OCP%] Occurs when an overcurrent on the +B(135) line is detected by Q500. If Q500 go to

ON and the voltage to pin 50 of IC301 more than 3.5V when V.SYNC is more than

seven verticals in a period, the unit will automatically turn off.

[Vertical deflection stopped] Occurs when an absence of the vertical deflection pulse is detected by Pin 17 and

IC001 shut down the power supply.

[White balance failure] If the RGB levels* do not balance or become low level within 5 seconds, this error

will be detected by IC301. TV will stay on, but there will be no picture.

* (Refers to the RGB levels of the AKB detection Ref pulse that detects IK.)

– 5 –

KV-HW21P80A

RM-969

SECTION 1

DISASSEMBLY

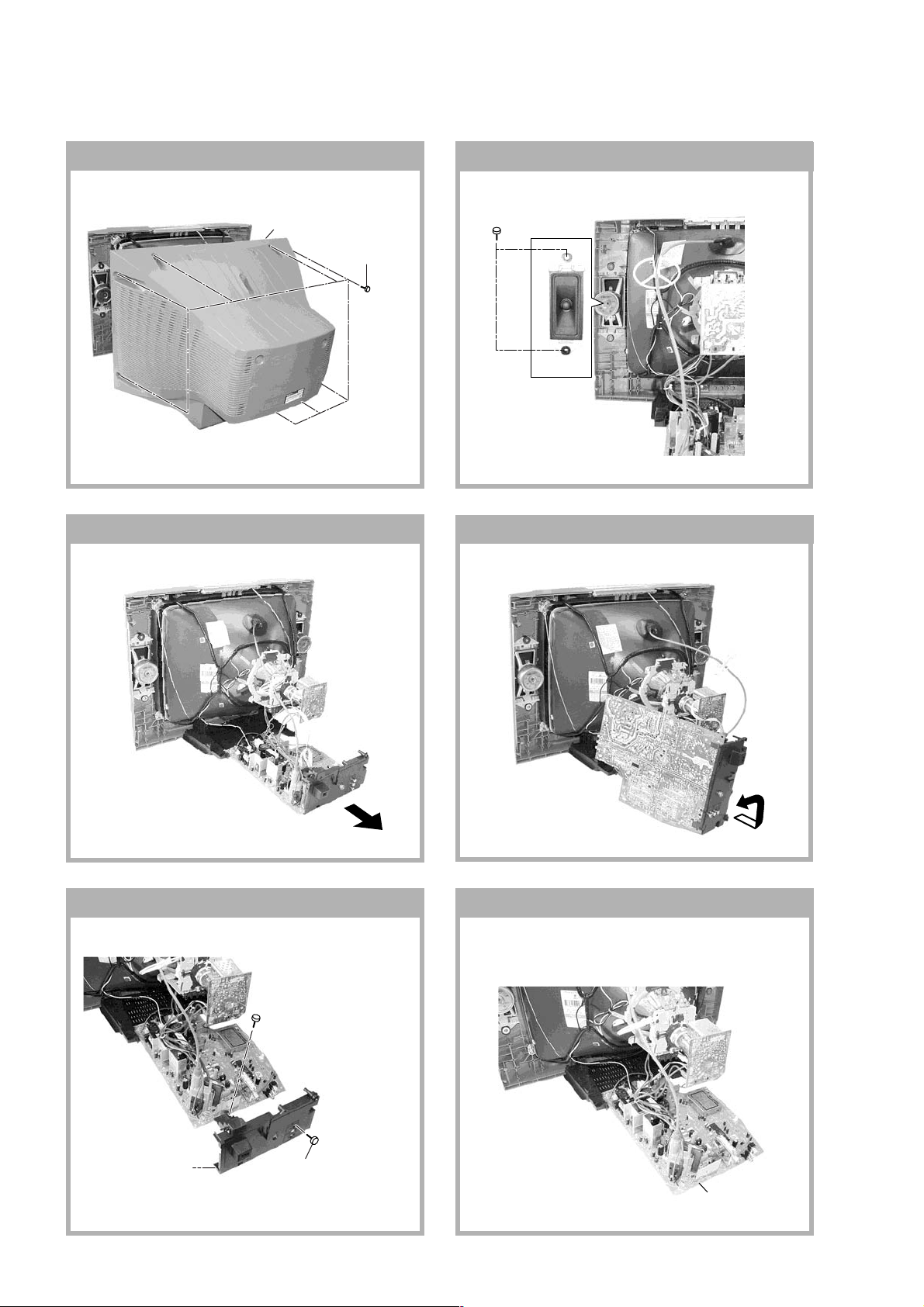

1-1. REAR COVER REMOVAL

2 Rear cover

1-3. CHASSIS ASSY REMOVAL

1Eight screws

(BVTP 4 × 16)

1-2. SPEAKER REMOVAL

1 Two screw

(+BVTP 4 × 16)

1-4. SERVICE POSITION

1-5. TERMINAL BRACKET REMOVAL 1-6. A BOARD REMOVAL

2 One screw

(+BVTP 3 × 16)

1 Terminal

bracket

3 Two screw

(+BVTP 4 × 16)

– 6 –

A board

KV-HW21P80A

c

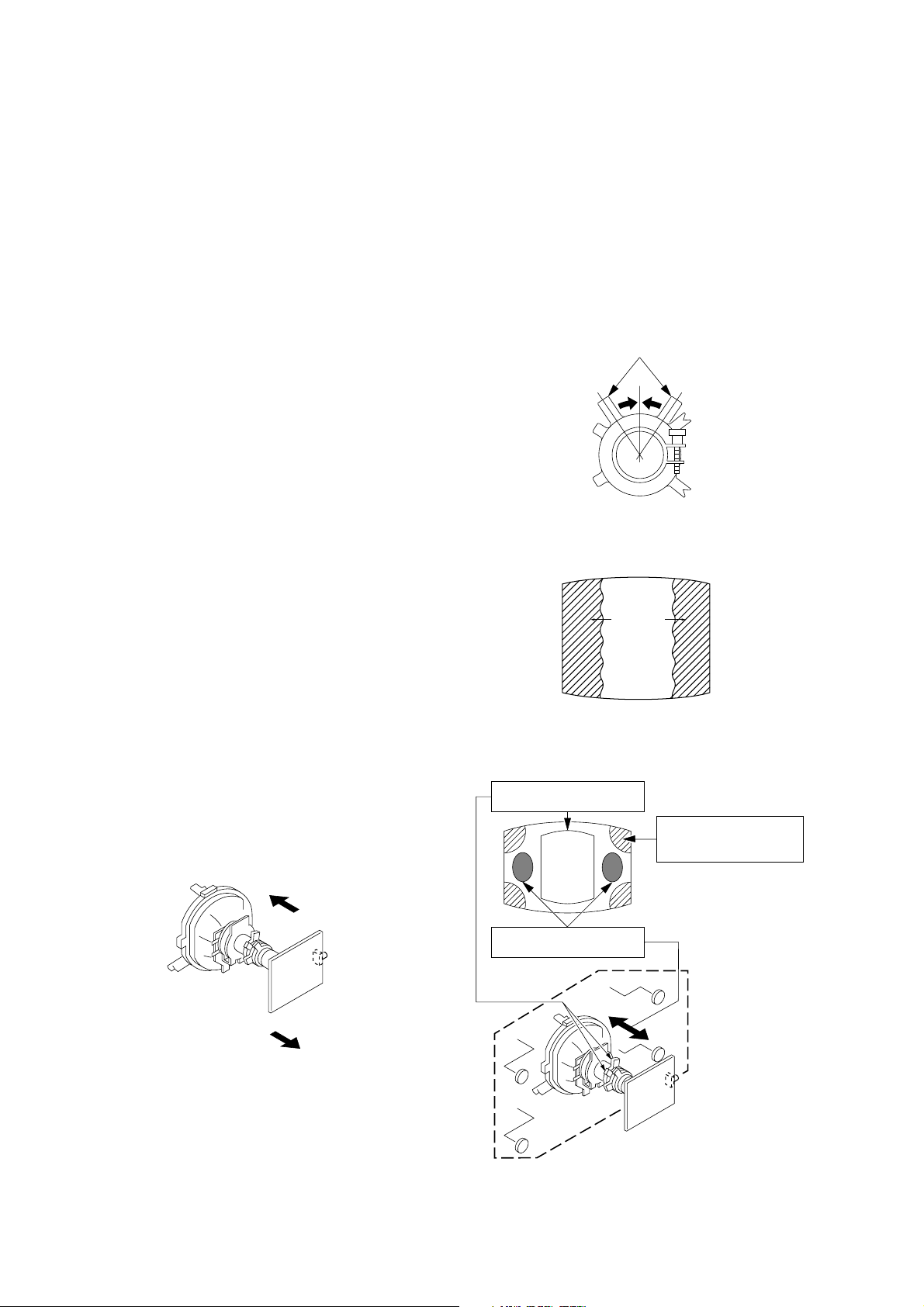

1-7. PICTURE TUBE REMOVAL

Note:

• The picture tube is upside-down and the position for the anode cap and tension springs are changed accordingly.

• Please make sure the TV set is not in standing position before removing necessary CRT support located on bottom

right and left.

1) Place the TV set with the CRT face down on a cushion jig.

2) Remove the rear cover.

3) Unplug all inder connecting leads from the Deflection Yoke, Degaussing Coil and CRT grounding strap.

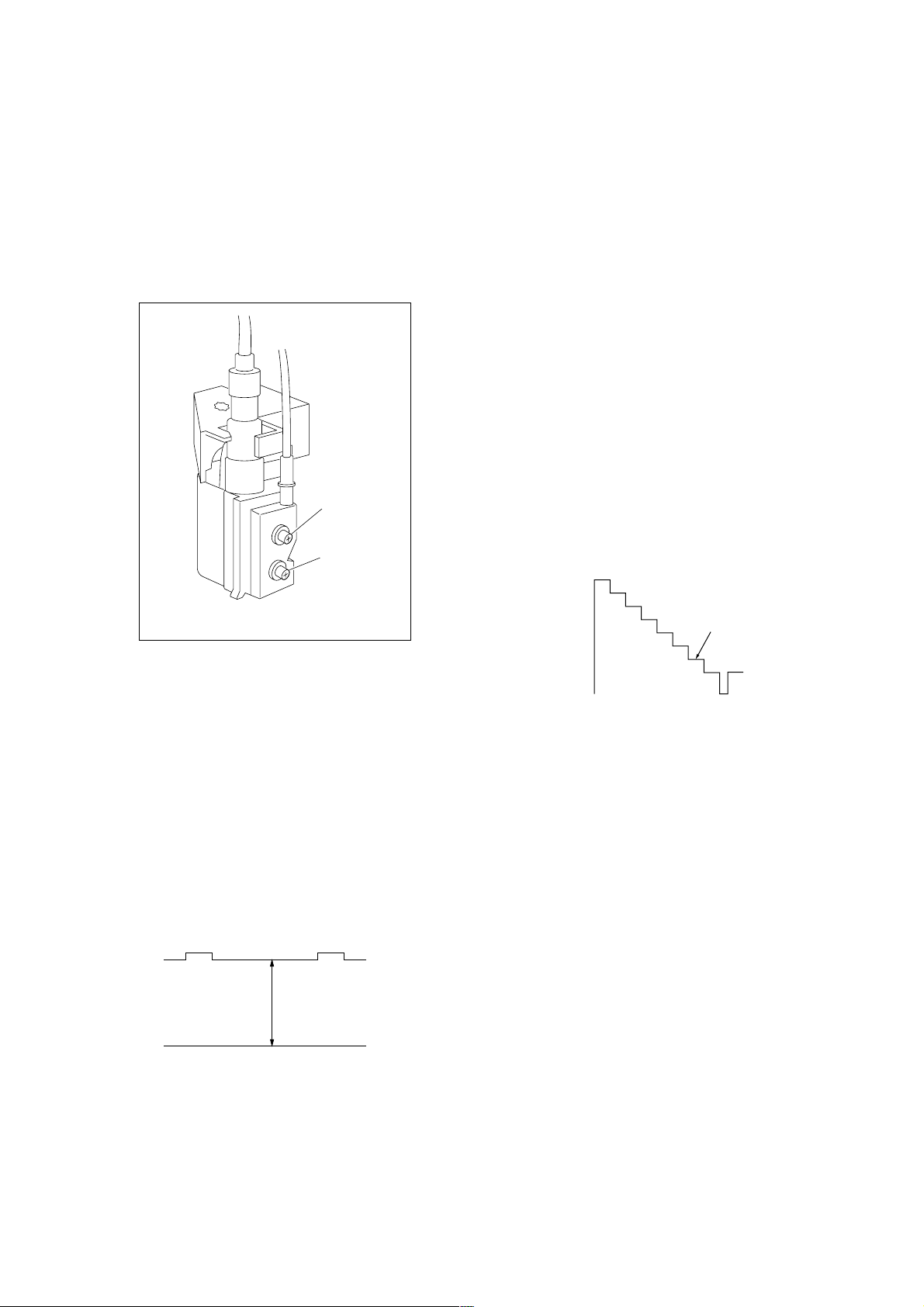

qd Top Switch Block

qs Nut, Special, CRT (4)

4 Anode Cap Removal

qa Degaussing Coil

0 Earth Coating Assy

5 C Board Removal

9 Spring Tension Removal

RM-969

8 Support, CRT(2) Removal

7 Loosen the Deflection Yoke

fixing screw and remove

6 Chassis Assy Removal

• REMOVAL OF ANODE-CAP

Note:

• After removing the anode, short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT

shield or carbon paint on the CRT.

• REMOVING PROCEDURES

a

a

1 Turn up one side of the rubber cap in the direction

indicated by the arrow A.

b

b

turning up the rubber cap and pulling it up in the

direction of the arrow C.

• HOW TO HANDLE AN ANODE-CAP

1 Do not damage the surface of anode-caps with

sharp shaped objects.

2 Do not press the rubber too hard so as not to

damage the inside of anode-cap.

A metal fitting called the shatter-hook terminal is

built into the rubber.

3 Do not turn the foot of rubber over too hard.

The shatter-hook terminal will stick out or damage

the rubber.

anode button

2 Using a thumb pull up the rubber cap firmly in the di-

rection indicated by the arrow B.

3 When one side of the rubber cap is separated from

the anode button, the anode-cap can be removed by

– 7 –

KV-HW21P80A

RM-969

SECTION 2

SET-UP ADJUSTMENTS

The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

These adjustments should be performed with rated power

supply voltage unless otherwise noted.

Controls and switches should be set as follows unless otherwise

noted:

PICTURE control ........................................................... normal

BRIGHTNESS control................................................... normal

................................................................................................................................................................................................................................

Preparation :

In order to reduce the influence of geomagnetism on the

set's picture tube, face it east or west.

Switch on the set's power and degauss with the degausser.

Perform the adjustments in the following order :

1. Beam Landing

2. Convergence

3. Focus

4. White Balance

Note : Test Equipment Required.

1. Pattern Generator

2. Degausser

3. Oscilloscope

Purity control

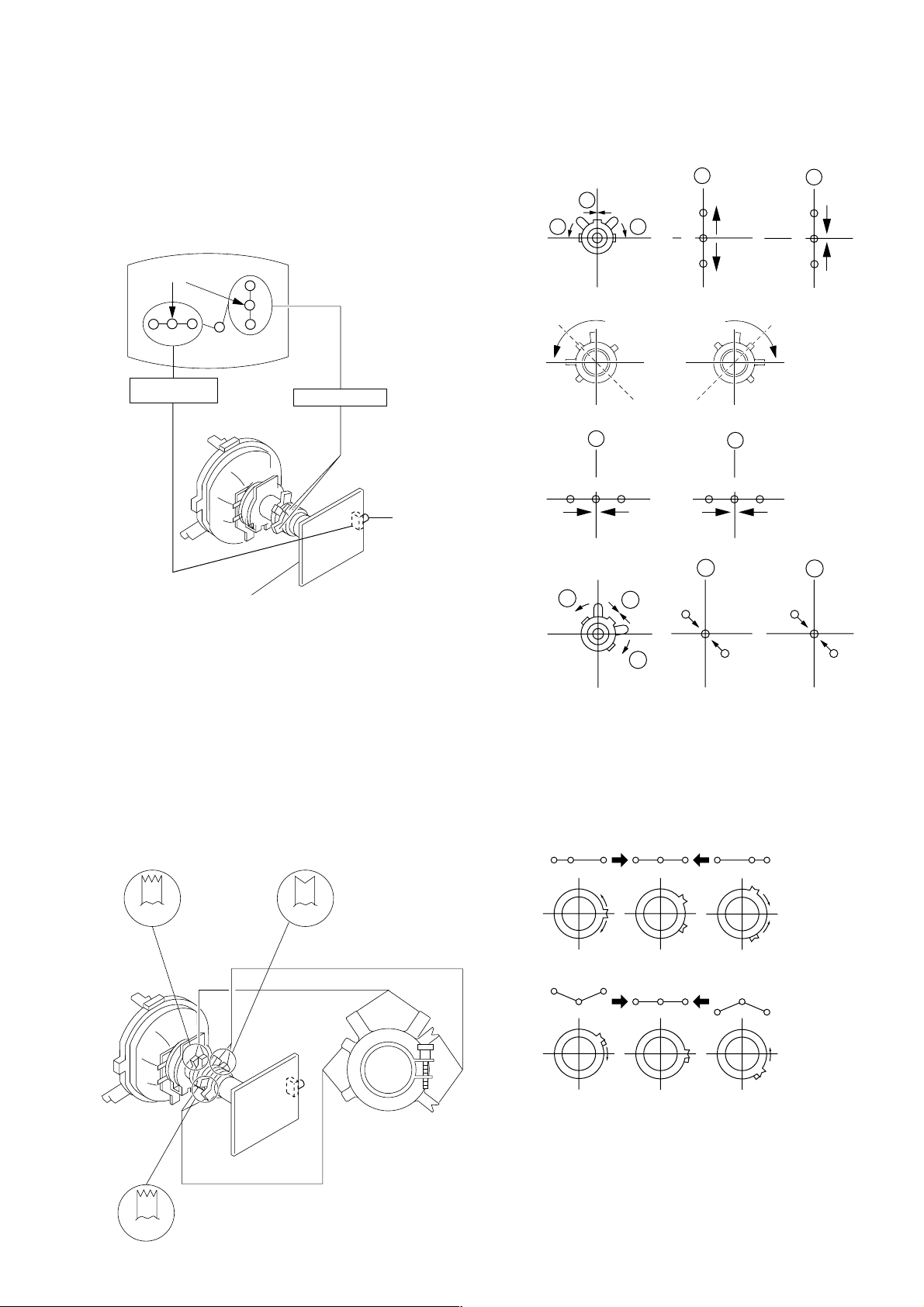

2-1. BEAM LANDING

1. Input a white signal with the pattern generator.

Contrast

Brightness

2. Set the pattern generator raster signal to a green raster.

3. Move the deflection yoke to the rear and adjust with the

purity control so that the green is at the center and the blue

and the red take up equally sized areas on each side.

(See Figures 2-1 through 2-4.)

4. Move the deflection yoke forward and adjust so that the

entire screen is green. (See Figure 2-1.)

5. Switch the raster signal to blue, then to red and verify the

condition.

6. When the position of the deflection yoke has been decided,

fasten the deflection yoke with the screws and DY spacers.

7. If the beam does not land correctly in all the corners, use a

magnet to adjust it.

(See Figure 2-4.)

}

normal

Fig. 2-2

Red

Green

Fig. 2-3

Purity control corrects

this area.

ba

Blue

Disk magnets or rotatable

disk magnets correct

these areas (a-d).

Fig. 2-1

– 8 –

c

Deflection yoke positioning

corrects these areas.

a

d

d

Fig. 2-4

b

c

KV-HW21P80A

R

R

G

G

B

B

a

a

b

b b

RM-969

2-2. CONVERGENCE

Preparation :

• Before starting this adjustment, adjust the focus, horizontal

size and vertical size.

• Receive dot/hatch signal.

• Pic mode: Soft.

(1) Horizontal and Vertical Static Convergence

Center dot

R G B

H. STAT VR

R

G

B

V.STAT Magnet

RV 702

• Operation of V. Stat magnet

If the V. Stat magnet is moved in the "a" and "b" arrows, the

red, green and blue dots move as shown below.

1

2

a

a

RGGBB

b

b

R

C board

1. (Moving vertically), adjust the V.STAT magnet so that the

red, green and blue dots are on top of each other at the

center of the screen.

2. (Moving horizontally), adjust the H.STAT VR control so

that the red, green and blue dots are on top of each other at

the center of the screen.

3. If the H.STAT variable resistor cannot bring the red, green

and blue dots together at the center of the screen, adjust the

horizontal convergence with the H.STAT variable resistor

and the V.STAT magnet in the manner given below.

(In this case, the H.STAT variable resistor and the V.STAT

magnet influence each other, so be sure to perform

adjustments while tracking.)

BMCPurity

BMC (Hexapole)

Purity

3

b

a

a

R

B

G

b

B

4 BMC (Hexapole) Magnet.

If the red, green and blue dots are not balanced or aligned,

then use the BMC magnet to adjust in the manner described

below.

RG B R G B R GB

RB

G

RG

GB

RB

b

G

R

V.STAT

V.STAT

– 9 –

KV-HW21P80A

RM-969

(2) Dynamic Convergence Adjustment

Preparation:

Before starting this adjustment, adjust the horizontal static

convergence and the vertical static convergence

RB

TLH Insert TLH Correction Plate to DY Pocket (Left or

Right)

YCH Rotate YCH VOL on DY

TLV Rotate TLV VOL ON DY

XCV Rotate XCV Adj core on DY

ON DY:

B

R

TLVYCH

YCH TLV

(3) Screen-corner Convergence

ba

a-d : screen-corner

misconvergence

cd

– 10 –

Fix a Permalloy assy

corresponding to the

misconverged areas

a

d

b

c

a to d : Permalloy assembly

KV-HW21P80A

RM-969

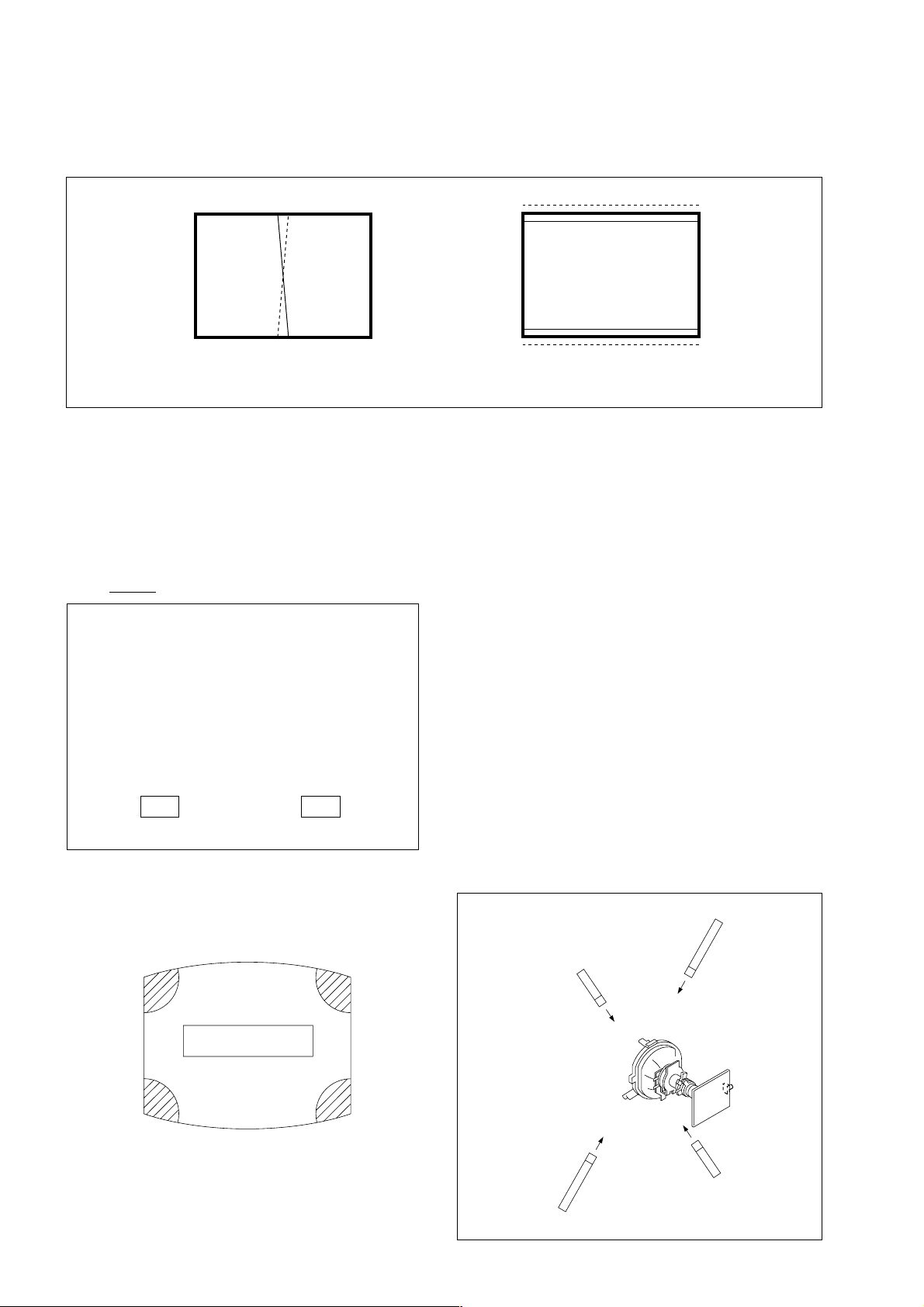

2-3. FOCUS ADJUSTMENT

FOCUS adjustment should be completed before W/B adjustment.

1. Receive digital monoscope pattern.

2. Set "Picture Mode" to "DYNAMIC".

3. Adjust focus VR so that the center of screen becomes

just focus.

4. Change the receiving signal to white pattern and blue back.

5. Confirm magenta ring is not noticeable. Incase magenta is

very obvious, adjust focus VR to take balance of magenta

ring and focus.

FOCUS

SCREEN

2.a) WHITE BALANCE ADJUSTMENT

1) Set to Service Mode (Refer Section 3-1: ADJUSTMENTS

WITH COMMANDER).

2) Input white raster signal.

3) Set 49 (ABL) and IF (VP2) service mode to 00.

4) Set Picture to DYNAMIC.

5) Select OB (RDR) with [1] and [4], and set the level to 25

with [3] and [6] for best white balance.

6) Select OC 'GDR' and OD 'BDR' with [1] and [4], and adjust

the level with [3] and [6] for the best white balance.

7) Write into the memory by pressing [MUTING] then [0].

8) Set back 49 'ABL' and IF 'VP2' service mode to original data.

2.b) SUB BRIGHT ADJUSTMENT

1) Set to service mode.

2) Set 49(ABL) and IF (VP2) service mode to 00

3) Input a staircase signal of black to white from the pattern

generator.

4) BRIGHTNESS ....50%.

PICTURE ............MINIMUM

5) Select OE 'SBR' with [1] and [4], and adjust OE 'SBR' level

with [3] and [6] so that the second stripe from the right is

dimly lit.

6) Write into the memory by pressing [MUTING] then [0].

7) Set back 49 (ABL) and IF (VP2) service mode to original data.

FLYBACK TRANSFORMER (T503)

2-4. G2 (SCREEN) AND WHITE BALANCE

ADJUSTMENTS

1. G2 (SCREEN) ADJUSTMENT

1) Set the PICTURE to normal.

2) Put to VIDEO input mode without signals.

3) Connect R, G and B of the C board cathode to the

oscilloscope.

4) Adjust BRIGHTNESS to obtain the cathode voltage to the

value below.

5) Adjust G2 (screen) on the FBT until picture shows the point

before cut off.

Cathode setting voltage:

175 V ± 2 (VDC)

White

second from the right

Black

0 V

– 11 –

KV-HW21P80A

RM-969

SECTION 3

CIRCUIT ADJUSTMENTS

3-1. ADJUSTMENT WITH COMMANDER

Service adjustments to this model can be performed using the

supplied Remote Commander RM-969.

a. ENTERING SERVICE MODE

With the unit on standby

n

[DISPLAY] n [5] n [VOL$+%] n [POWER]

This operation sequence puts the unit into service mode.

The screen display is :

Item

Adjustment

Mode

Item No

HPS 33 SERVICE

00

080S

Suffix No

(OEM Code)

b. METHOD OF CANCELLATION FROM SERVICE

MODE

Set the standby condition (Press [POWER] button on the commander), then press [POWER] button again, hereupon it becomes

TV mode.

1.6C

Software version

Data

00 000A

Total Power-On time (hours)

Depends on signal

50

PAL,SECAM:50

NTSC :60

e. OTHER FUNCTION VIA REMOTE COMMANDER

[7], [0] All the data becomes the values in memory.

[8], [0] All user control goes to the standard state.

[5], [0] Service data initialization (Be sure not to use

usually.)

[2], [0] Copy and write all data.

[MUTE], [0] Write 50Hz adjustment data to 60Hz or vice

versa.

3-2. ADJUSTMENT METHOD

Item Number 00 HPS

This explanation uses H Shift as an example.

1. Select “00 HPS” with the

2. Raise/lower the data with the [3] and [6] buttons.

3. Select the optimum state. (The standard is 1F for PAL

reception.)

4. Write with the

WRITE.)

5. Execute the writing with the

display will be changed to red color while excuting, and

back to SERVICE.)

Example on screen display :-

00

Adjusted with [3] and [6] buttons.

[MUTING] button. (The display changes to

33 SERVICE 50HPS

[1] and [4] buttons.

[0] button. (The WRITE

GREEN

c. METHOD OF WRITE INTO MEMORY

1) Set to Service Mode.

2) Press

4) Press [MUTING] button to indicate WRITE on the screen.

5) Press [0] button to write into memory.

d. MEMORY WRITE CONFIRMATION METHOD

1) After adjustment, pull out the plug from AC outlet, and then

2) Turn the power switch ON and set to Service Mode.

3) Call the adjusted items again to confirm adjustments were

[1] (UP) and [4] (DOWN), to select the adjustment.

plug into AC outlet again.

made.

[1], [4] Select the adjustment item.

↓

[3], [6] Raise/lower the data value.

↓

[MUTING] Writes.

↓

[0] Executes the writing.

00

00

Write executed with [0]

Use the same method for all Items. Use 1 and 4 to select the

adjustment item, use 3 and 6 to adjust, write with [MUTING],

then execute the write with -.

Note : 1. In [WRITE], the data for all items are written into

2. For adjustment items that have different standard

33 WRITE 50HPS

Write with [MUTING]

33 WRITE 50HPS

memory together.

data between 50Hz or 60Hz, be sure to use the

respective input signal after adjustment.

GREEN

The WRITE display

then returns to

SERVICE

– 12 –

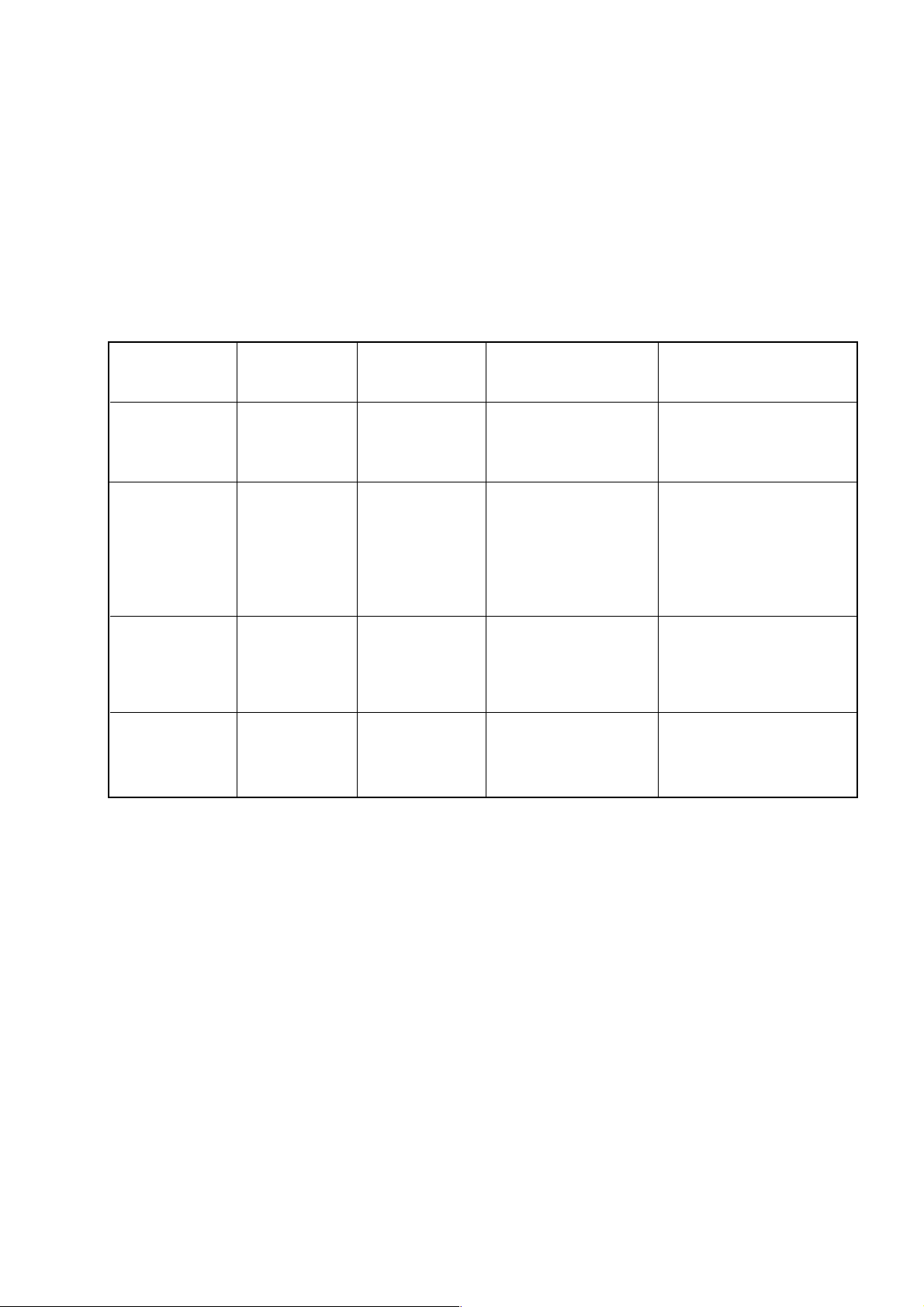

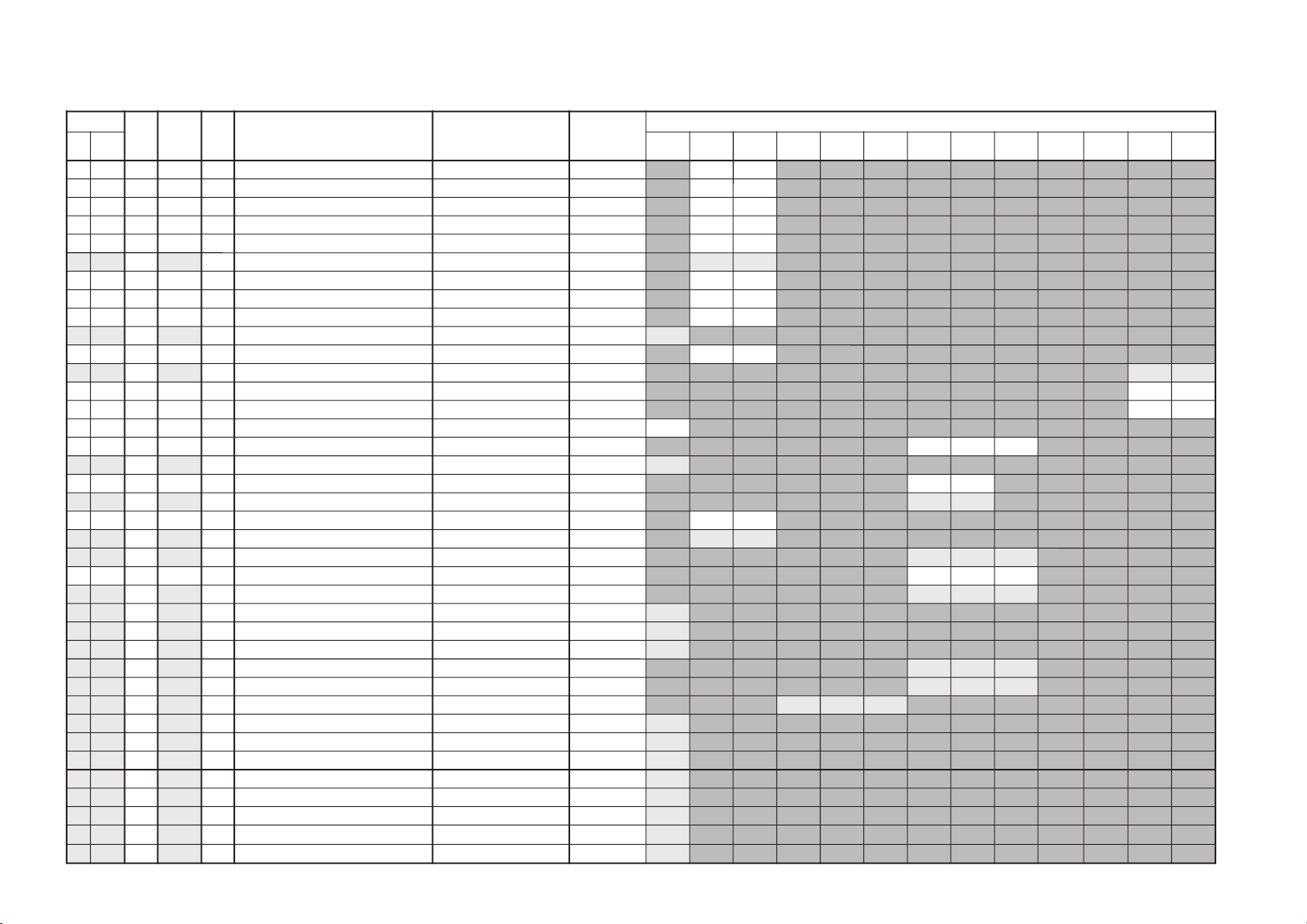

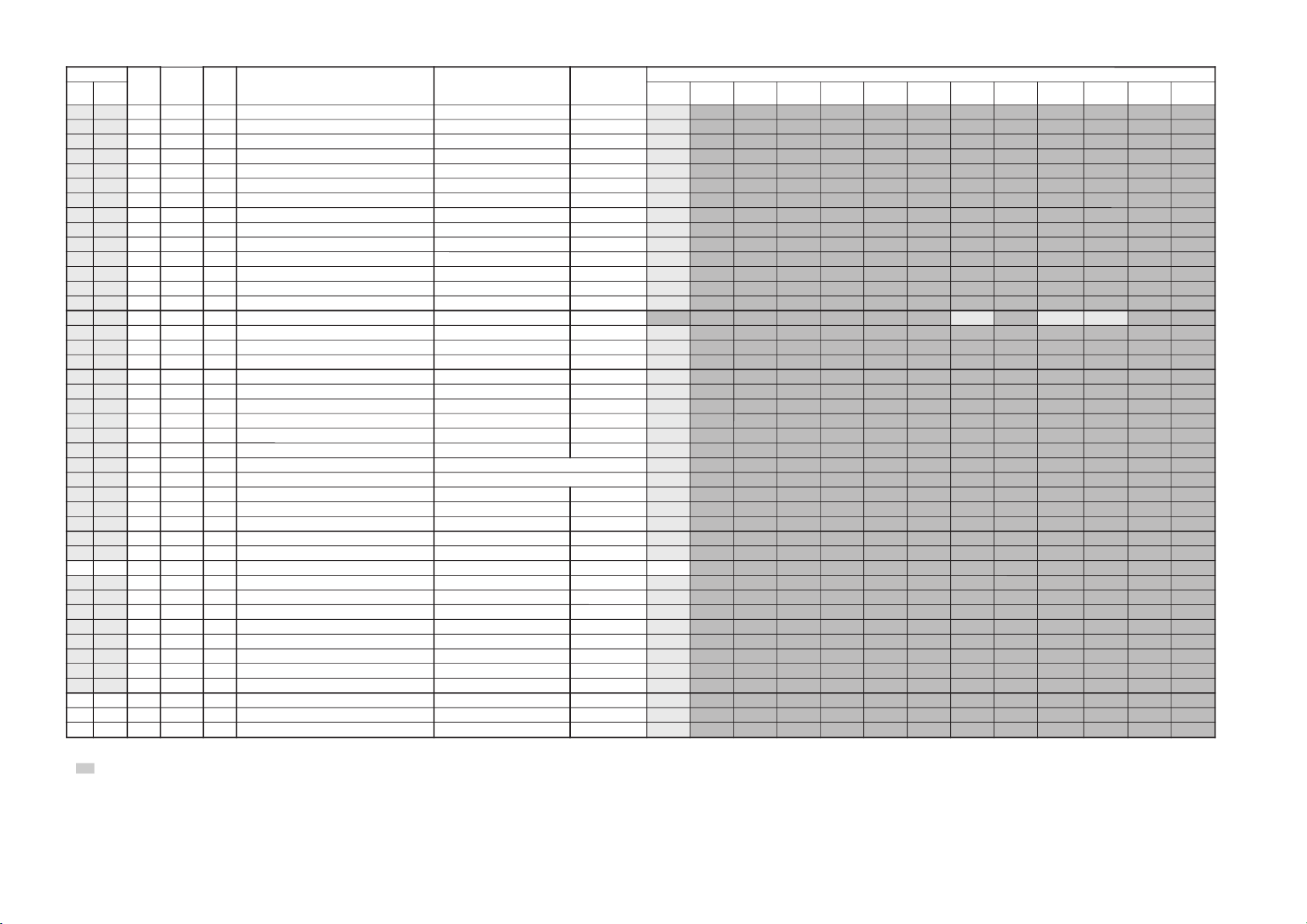

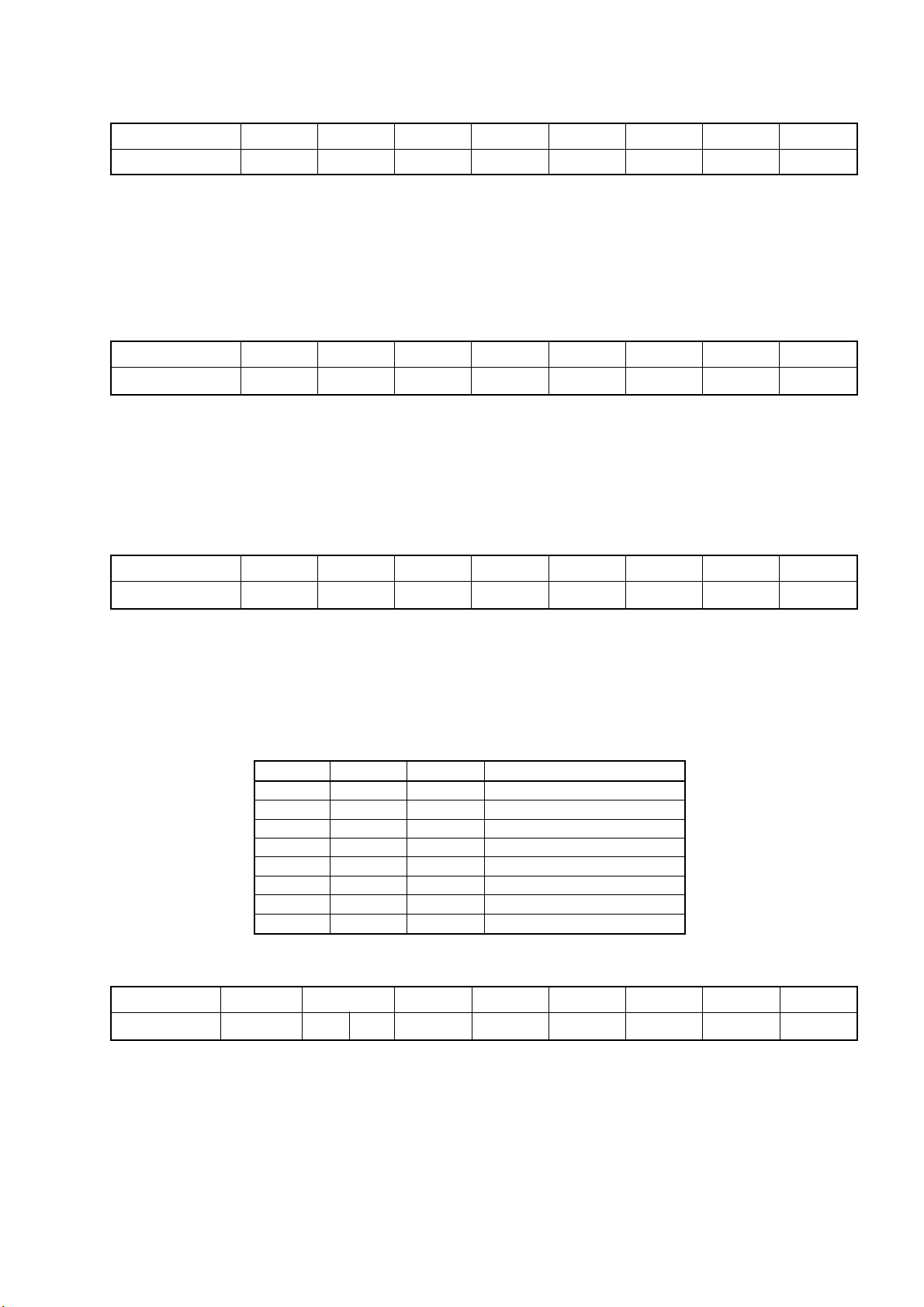

Adjustment Item Table

ytilanoitcnuF.tinIecivreS

atad

egnaRnoitcnuFetoN&elbaTemaNeciveD

)sserddAevalS(

.oNemaN nommoC0506MACESCSTNLAPVToediVtxeteleTmetsySMM-noN

metsyS

cimanyDsrehtO

00SPHA242F3noitisoPHzH06/05)A8(44/3488ADT

A2A2

10ZSHF132F3eziSHzH06/05

F1F1

20PAPF112F3edutilpmAniPzH06/05

F1F1

30NPCF192F3niPrenroCzH06/05

F1F1

40TLTF102F3tliTzH06/05

F1F1

50

LSV62

02F3epolSVzH06/05

02

02

60PAVF0D1F3edutilpmAVzH06/05

F0F0

70OCSF002F3noitcerroCSzH06/05

F0F0

80SPVF102F3tfihSVzH06/05

F1F1

90

MZV91

91F3mooZlacitreV

91

A0CSVF1F1F3llorcSlacitreVzH06/05

F1F1

B0

RDRF1

42/F1F3evirDR srehtO/cimanyD

#

#

C0RDG5252F3evirDG srehtO/cimanyD

5252

D0RDB5252F3evirDB srehtO/cimanyD

5202

E0RBS85B4F7ssenthgirBbuS 85

F0XMP0272F3ataDmumixaMerutciP txeteleT/oediV/VT

020202

01

IMP40

40F3ataDmuminiMerutciP

40

11UHS7050F0euHbuSoediV/VT

7090

21

HSS10

30/1030ssenprahSbuSoediV/VT

# #

311CS02F1F3rewoLroloCbuSzH06/05

02C1

41

2CS80

#F3rehgiHroloCbuSzH06/05

#

#

51

OF00

0030tnatsnoCemiT10 txeteleT/oediV/VT

00

00

00

61TGA000F3revOekaTCGA txeteleT/oediV/VT

000000

71

WSV00

0/1/010hctiwSetuMoediV txeteleT/oediV/VT

00 10

00

81

ROF30

3030ycneuqerFdleiFdecroF

30

91

LD00

010ecalretni-eD

00

A1

COP00

010edoM.orhcnyS10dexiF

00

B1

ROC10

0/0/110gniroCesioN txeteleT/oediV/VT

10

00

00

C1

LBR00

010gniknalBBGR txeteleT/oediV/VT

00

00 00

D1

LDYA0

A0/C0/60F0yaleD-Y MACES/CSTN/LAP

A0

C0

60

E1

1PV00

#FF)segapdeificepsees(stiBartxE

#

F1

2PV10

10FF)segapdeificepsees(stiBartxE

10

02

3PVF0

#FF)segapdeificepsees(stiBartxE

#

12

TSW51

51FFdlohserhToeretSG/W )08(G7143PSM

51

22

TBWCE

CBFFdlohserhTlaugniliBG/W

CE

32

LLW50

50FFdlohserhTlaruanoMG/W

50

42

CAW10

10F0tnuoCtnemeergAG/W

10

52

LDW03

03FFyaleDhcraeSG/W

03

– 13 –

KV-HW21P80A

RM-969

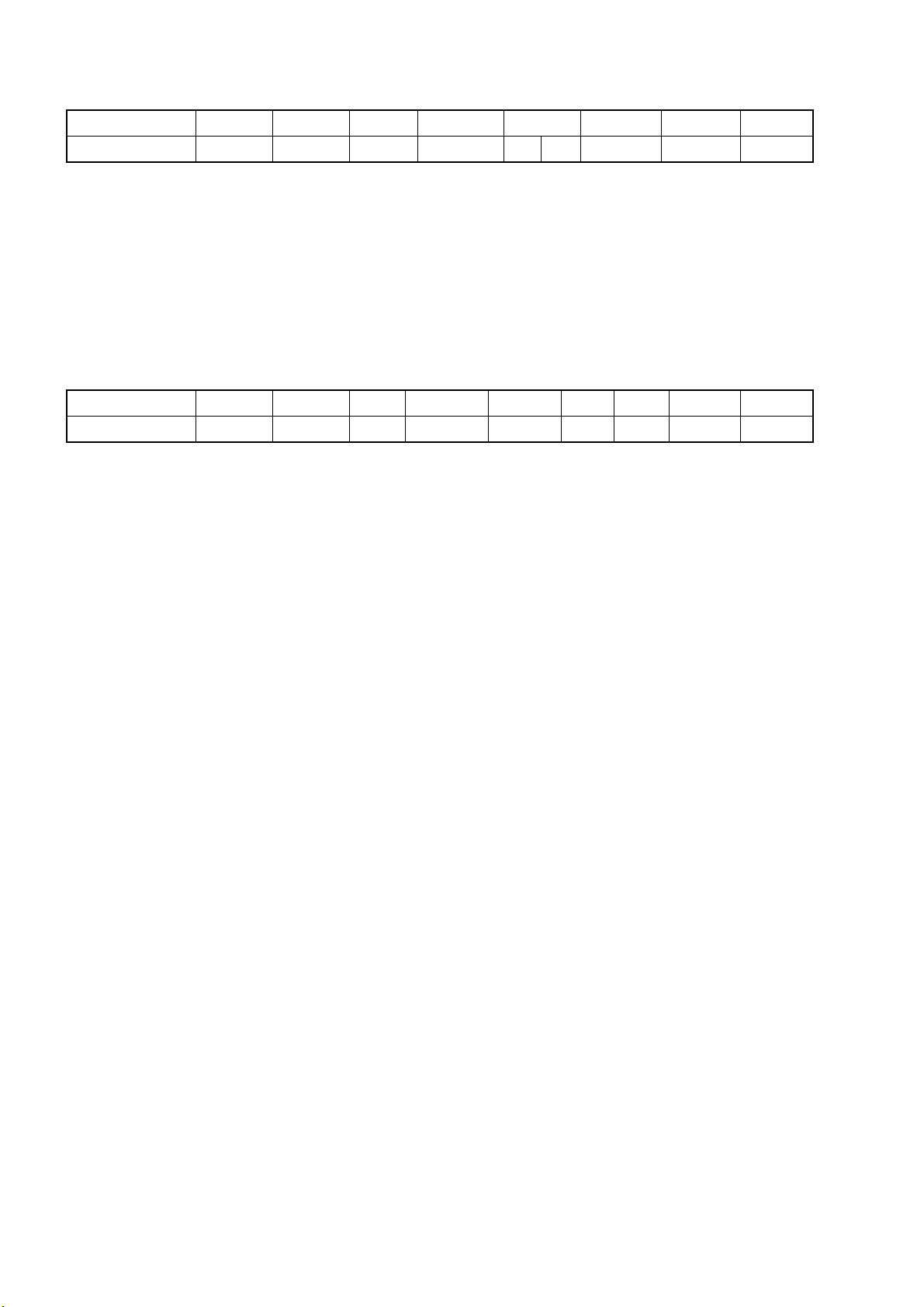

Adjustment Item Table

ytilanoitcnuF.tinIecivreS

atad

egnaRnoitcnuFetoN&elbaTemaNeciveD

)sserddAevalS(

atademaN nommoC0506MACESCSTNLAPVToediVtxeteleTmetsySMM-noN

metsyS

cimanyDsrehtO

62

LDN0202FFyaleDhcraeSMACIN

02

72

LDS0101FFyaleDdaeRsutatSoeretS

01

82

CGA101010tnatsnoc/otuahctiwSCGA

10

92

LER8282F3edoMtnatsnoCtaniaGCGA

82

A2

MRC00010ffo/nognituMreirraC

00

B2

OCA10110ffo/notuo-kcolCoiduA

10

C2

PFB1B1F7K/D,I,G/BrofelacserPMF

B1

D2

MPF2323F7MrofelacserPMF

23

E2

HF6363F7)M-non(VEDHrofelacserPMF

63

F2

MHF5656F7)M(VEDHrofelacserPMF

56

03

PGWC1C1F7elacserPG/W

C1

13

PINF7F7F7elacserPMACIN

F7

23

RRE0505FFdlohserhThctiwSMFotuA

05

33

LOVD6#F7mumixaMemuloVPFD

#

43

GNI00#F0niaGtupnI oediV/M-non/metsySM)88(8347ADT

#

#

#

53

MOV00#F3niaGtuptuOemuloV ylnometsySM

#

63

SCB10#30tfihSretneCssaB

#

73

SCT20#30tfihSretneCelberT

#

83

HXTA2A2FFnoitisoPyalpsiDlatnoziroH )85(4625AAS

A2

93

VXT7272F3)cnys-Vmorftesffoenil(noitisoPyalpsiDlacitreV

72

A3

DHT0000F7tfihSegdEevitcAcnys-H

00

B3

DVTF3F3F7tfihSegdEevitcAcnys-V

F3

C3

LPH101010noitarugifnoCytiraloPcnys-H evitageN:10,evitisoP:00

10

D3

LPV101010noitarugifnoCytiraloPcnys-V evitageN:10,evitisoP:00

10

E3

LPF101010noitarugifnoCytiraloPdleiF enilflahtsrifcnys-V:10,enilflahdnocescnys-V:00

10

F3

DMF000000edoMecroF edoMpoT:30,txetsaF:20,tluafeD:10,otuA:00

00

04

RBT8080F0ssenthgirBBGRtxeteleTteS

80

14

PON1010F0noitarugifnoCelbaTnoitpOlanoitaN

10

24

HCT101030noitarugifnoCteSretcarahCdetsiwT

10

34

PKB0000F3FFOgniknalBtaataDerutciP lortnoCrehtO

00

44

LDO01#FFyaleDNOrewoP

#

54HSOA0A0F3noitisoPHDSO A0

64

YST000030teserPotuAtametsySVT M:30,K/D:20,I:10,G/B:00

00

74

SKD101010elbasid/elbaneoeretSK/D

10

84

TUM000010cnySoNtaffo/nognituM

00

94

LBA101010hctiwSLBAthgirB

10

A4

MCS101010evitcani/evitcaparTMACES

10

B4

SLS101010cnySIFI.RO.LSetavitcA

10

C4

VSS202070pUpetSemuloVdnuoSecapS

20

D4

WPV5353F7tiawputratsrossecorPoediVforemiT

53

E41POF2#FF)segapdeificepsees(0sgalFlanoitpO

#

F42POF0#FF)segapdeificepsees(1sgalFlanoitpO

#

053PO00#FF)segapdeificepsees(2sgalFlanoitpO

#

KV-HW21P80A

RM-969

– 14 –

NOTE:

•

Bold item :- are fixed data

•

Standard data listed on the Adjustment Item Table are reference values, therefore it may be different for each model and for each mode.

•

Note for Different Data Those are the standard data values written on the microprocessor. Therefore, the data values of the modes and stored respectively in the memory.

In case of a device replacement, adjustment by rewriting the data value is necessary for some items.

ITEM INFORMATION

No. 1E VP1

Item

KV-HW21P80A

BCO Switch-on behaviour 1=Switch -on of picture via internal delay 0=Without delay 00(4)

OSO 1=Switch off in vertical overscan 0=Switch-off undefind 18(7)

SBL Service blanking 1= on 0= off 0B(7)

HBL RGB Blanking Mode 1 = wide blanking, 0 = normal blanking 02(7)

FCO Forced Color-on 1=no colour killer 0=normal colour killer function 1B(0)

FFI Fast filler IF-PLL 1=increased time constant 0=normal time constant 1A(1)

No. 1F VP2

KV-HW21P80A

RM-969

-

0

-

0

BCO

0

OSO

0

SBL

0

HBL

0

FCO

0

FFI

0

Item

KV-HW21P80A

MAT PAL-SECAM-/NTSC Matrix 1 =PAL matrix, 0=adapted to standard 0E(7)

DS Dynamic skin control on/off 1= on 0= off 1A(3)

DSA Dynamic skin control angle 1=correction angle 117 degrees 0=correction angle 123 degrees 1A(2)

EBS Extended Blue Stretch 1= on 0= off 1A(0)

BLS Blue stretch 1= on 0= off 18(4)

BKS Black stretch 1= on 0= off 18(3)

No. 20 VP3

Item

KV-HW21P80A

BB Blue back when no video signal is identified 1= on 0= off 18(0)

AKB Black current stabilisation 1=not active 0=active 02(6)

BPS Bypass of chroma base-band delay line 1=bypassed 0=active 19(6)

CB Chroma bandpass centre frequency 1= 1.1x Fsc 0=Fsc 18(5)

ACL Automatic colour limiting 1= active 0= not active 19(5)

-

0

BB

0

CL2 CL1 CL0 Cathode Drive amplitude

0 0 0 57V

0 0 1 63V

0 1 0 70V

0 1 1 77V

1 0 0 84V

1 0 1 91V

1 1 0 99V

1 1 1 107V

-

0

AKB

0

MAT

0

BPS

0

DS

0

CB

0

DSA

0

ACL

1

EBS

0

CL2

0

BLS

0

CL1

0

BKS

1

CL0

0

No. 4E OP1

Item

KV-HW21P80A

HA ME Vol Tone controller Volume curve setting. 1 = for HA(ME), 0 = for HA(GE)

AV Input 00 = no AV Input model 01 = 1 AV Input model

COMB (for NTSC model) 1 = Enable external comb filter, 0 =Disable external comb filter

Other optional function will be enabled if the corresponding bit is set to 1.

HA ME VOL0AV Input

01

COMB

0

10 = 2 AV Input model 11 = Not available

B/G

1

I

0

D/K

0

– 15 –

M

0

HEX

28

KV-HW21P80A

RM-969

No. 4F OP2

Item

KV-HW21P80A

No NICAM 1 = NICAM search is disable in any TV system, 0 = NICAM search operates

US ST (Reserved for NTSC model)

1 V-Curve 1 = using common volume curve for every mode and every TV system

(for monaural mode) 0 = another volume curve available for video mode and M system

XTAL SEL 00 = only 4.43 XTAL 01 = only 3.58 XTAL

Other optional function will be enabled if the corresponding bit is set to 1.

No. 50 OP3

Item

KV-HW21P80A

No Bal. 1 = no balance in analog select items, 0 = balance included

(for AV stereo model)

SPC SOUND 1 = Space Sound available, 0 = not available

Korean ST (Reserved for NTSC model)

No NICAM

1

Pict Rot.

0

US ST

0

Auto TV Sys.

0

HDEV

0

10 = not used 11 = both 4.43 and 3.58 XTAL

No Bal.

0

IV-Curve

0

SPACE SOUND

1

XTAL

11

KOREAN ST

0

VM

0

SECAM

0

H.K. BIL

2nd Lang.

Thai Bil.

0

HEX

1

0

8D

HEX

10

H.K. Bil. 1 = NICAM bilingual available (No NICAM stereo), 0 = not available

(for monaural model)

Other optional function will be enable if the corresponding bit is set to 1.

– 16 –

Loading...

Loading...