SONY KV-32HS500, KV-32HV600, KV-34XBR800, KV-36HS500, KV-36XBR800 Training Manual

...

KV-36HV500

Training Manual

KV-57WV700

Direct View/Projection

Television Troubleshooting

DA-4 & DA-4X Chassis

Models: DA-4 DA-4X

KV-32HS500 KP-57WV600

KV-32HV600 KP-57WV700

KV-34XBR800 KP-65WV600

KV-36HS500 KP-65WV700

KV-36XBR800

KV-40XBR800

Theory of Operation & Practical Troubleshooting Tips

Course: C31P15

Table of Contents

1. DA-4 & DA-4X Introduction and

PCB Interconnection ............................1

Introduction............................................................ 1

DA-4 & DA-4X PCD Interconnection................. 1

2. New Features (DA-4 Chassis).........6

Scrolling Index ....................................................... 6

Digital Visual Interface (DVI) ............................... 6

Memory Stick® Interface...................................... 8

3. Power Supply

(DA-4 & DA-4X Chassis).....................12

DA-4 Chassis Power Supply.............................. 12

DA-4X Chassis Power Supply ........................... 20

DA-4 & DA-4X Regulators.................................. 26

4. DA-4 & DA-4X

Protection Circuits ...............................27

5. DA-4 & DA-4X Video Procesing ....45

DA-4 & DA-4X Acceptable Inputs .................... 45

Overall Block Diagram ........................................ 45

6. DA-4 & DA-4X Chassis

Deflection Circuit .................................51

Horizontal Drive Circuit ....................................... 51

DA-4 Vertical Deflection Circuit ......................... 53

DA-4X Horizontal Deflection Circuit .................. 54

DA-4X Vertical Deflectin Circuit......................... 55

7. DA-4 & DA-4X Chassis

Communication Bus Networks ..........56

DA-4 & DA-4X Data Communication

Diagram................................................................ 56

8. DA-4 & DA-4X Audio Circuits ........58

DA-4 & DA-4X Audio Block Diagram.............. 58

DA-4 Protection Circuits ..................................... 27

DA-4X Protection Circuits................................... 37

1. Introduction and DA-4 & DA-4X PCB Interconnection

Chapter 1 - Introduction and

DA-4 & DA-4X PCB Interconnection

Introduction

Overview

The C31P15 course covers the DA-4 (Direct View) and the DA-4X (Projection) chassis. The content includes

new features such as Memory Stick and DVI. Also included is theory of operation and troubleshooting tips for all

major circuits (Power Supplies, Protection, Deflection, Communications and Audio) in the DA-4 and DA-X chassis.

This training manual is based on the KV-32HV600 model.

Objectives

• New Features

• Circuit Theory of Operation

• Component and Board level troubleshooting

DA-4 & DA-4X PCB Interconnection

Overview

The DA-4 (Direct View) and DA-4X (Projection) chassis share many of the same PCBs. The only differences are

found in the RGB Drive, Power Supply and Flash Focus circuits. Table 1-1 indicates the circuits found on each

PCB and if the PCB is board or component level repairable for both the DA-4 and DA-4X chassis.

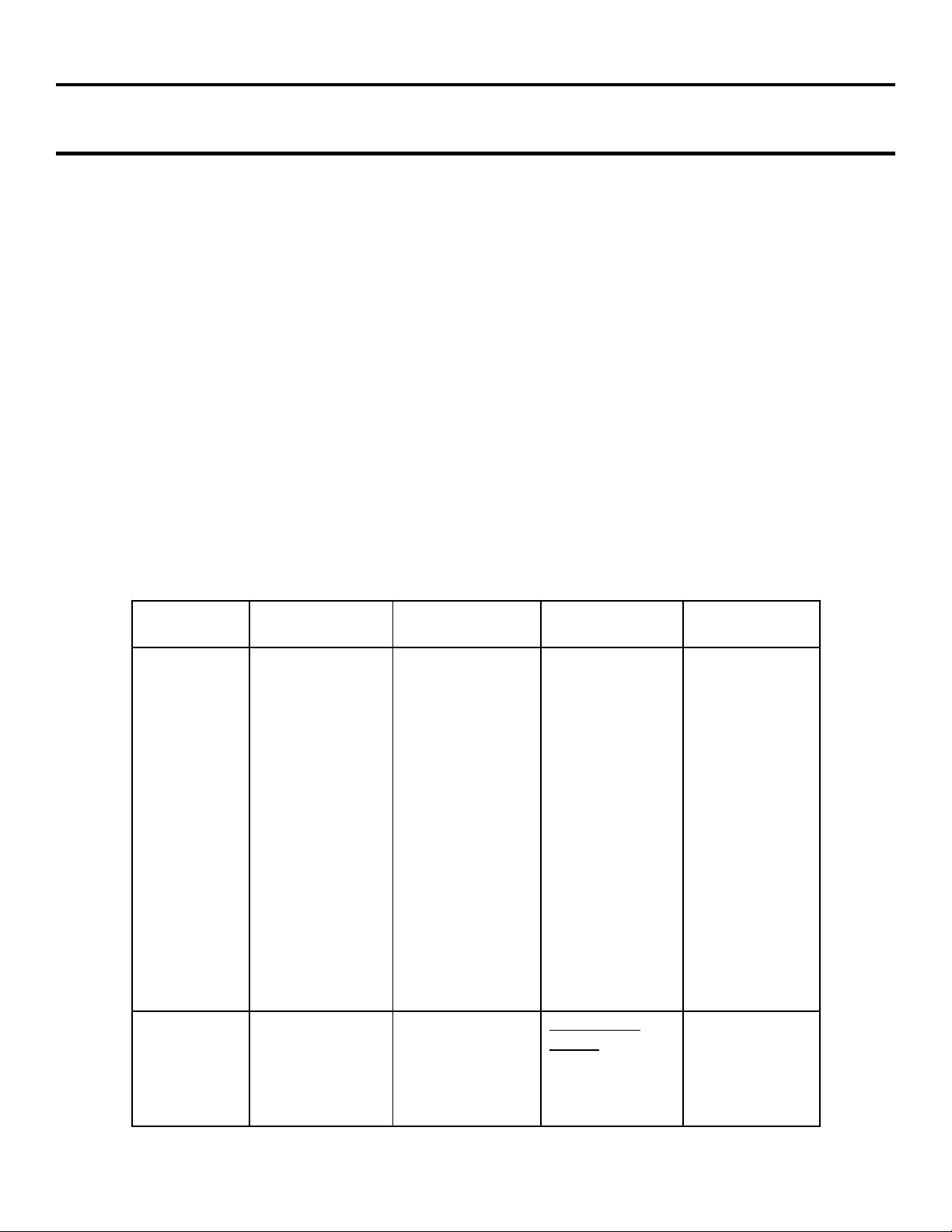

Table 1-1 DA-4 & DA-4X PCB Circuits and Repair Information

Board Circuits (DA-4) Circuits (DA-4X) Field

Reparability

A

AD

•

A/C

Input

•

STBY 5V

PS

• +9V

Reg.

• +3.3V

Reg.

•

+5V

Reg.

• Main &

Sub.

Tuners

•

Audio

Output

IC’s

•

DYConv.

•

N/A

•

A/C Input

•

STBY 5V

PS

• +9V Reg.

• +3.3V

Reg.

•

+5V Reg.

•

Main &

Sub.

Tuners

• Audio

Output

IC’s

•

Flash

Focus

•

Picture

Centering

•

5V Reg.

Possible

Component

Level Repair

Board Level

Repair

Comments

No DY-Conv.

Circuit for DA4X Chassis

DA-4X chassis

ONLY

1

1. Introduction and DA-4 & DA-4X PCB Interconnection

B

C

D

• H-Protect

•

V-Protect

•

AD-DRC

•

MID-XA

• HD-ADC

• CRT Drive

• A/D DNR

•

Differential

Input

(Memory

Stick®)

• +1.8V Reg.

• +2.5V

Regs.

•

+3V Reg.

•

+3.3V Reg.

•

+5V Reg.

CH (HS) or

CX (HV/XBR)

• RGB Drive

• H & V

Drive

•

H & V DY

•

Main

Power

Supply

+/-15V

+7V

+5V

+11V

+12V

+200V

+33V

Heater

• HV Power

Supply

•

Protection

Circuits

HV Protect

+135

OVP/OCP

HD Protect

IK Protect

• H-Protect

•

V-Protect

•

AD-DRC

•

MID-XA

• HD-ADC

• CRT Drive

• A/D DNR &

SRAM

•

Differential

Input

(Memory

Stick®)

• +1.8V Reg.

• +2.5V Regs.

•

+3V Reg.

•

+3.3V Reg.

•

+5V Reg.

CR, CG, CB

•

RGB Drive

• H & V Drive

•

H & V D

•

HV Drive

•

Convergence

Amps

• +12V Reg.

• +5V Reg.

• +210V

•

+135V

•

Heater

•

Protection

Circuits

HV Protect

HD Drive

+135 OVP/OCP

Board Level

Repair

Possible

Component

Level Repair

Possible

Component

Level Repair

Additional

Circuits on DA4X chassis:

• Extra

VM

circuits

• D-Brd

RGB

connecti

ons

•

SRAM

(IC3001)

Separate RGB

drive boards in

DA-4X chassis

Main Power

Supply located

on D-Brd in DA4 chassis.

Main Power

Supply located

on G-Board in

DA-4X Chassis

2

1. Introduction and DA-4 & DA-4X PCB Interconnection

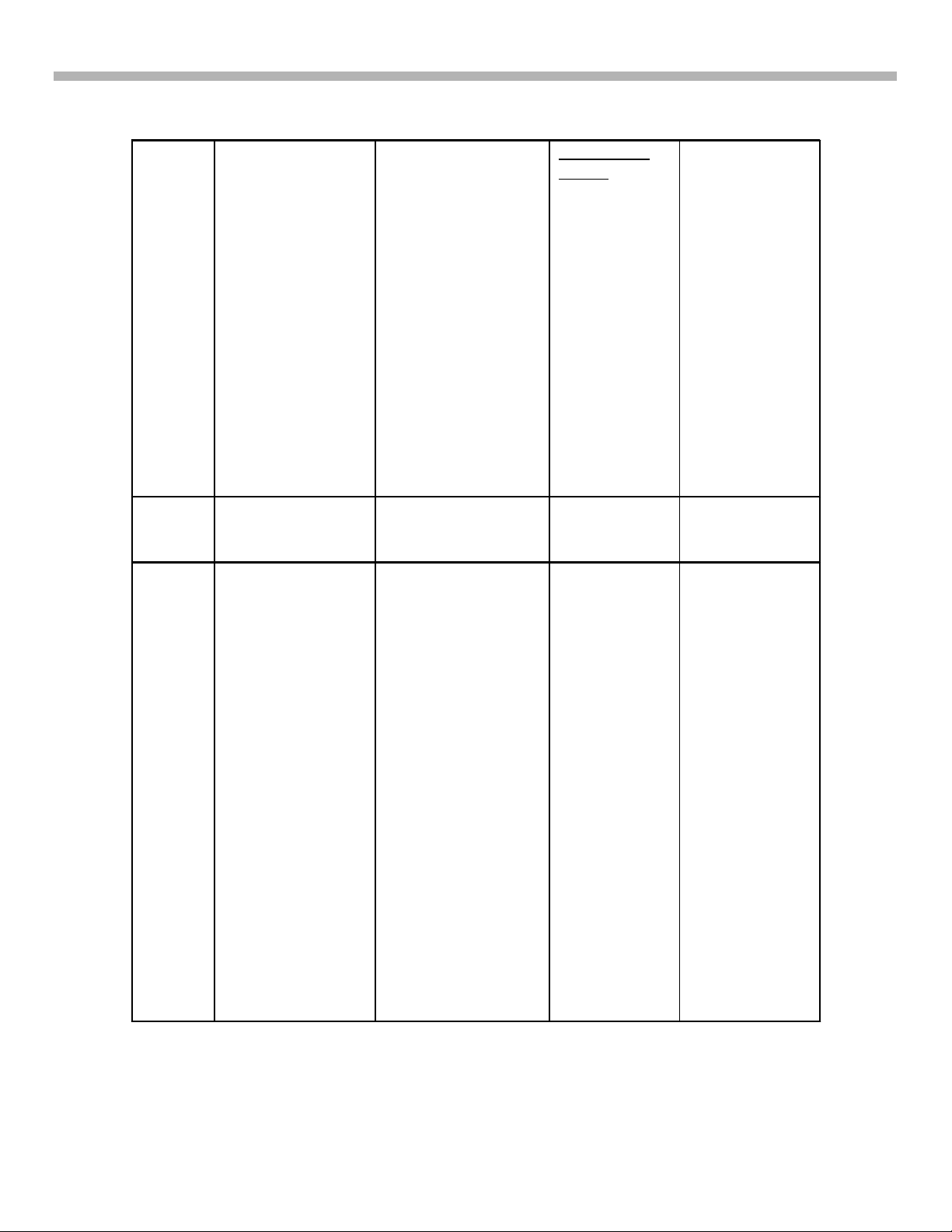

DH

G

HA

HC

• N/S

Correction

•

E/W

Correction

• N/A

• Key Input

• LED

• Remote

Control

•

Key Input

• LED

• Remote

Control

• N/A

Power Supply

• Unreg. 7V

• Unreg. 5V

•

+/- 15V

•

+/- 19V

•

+135V

•

+33V

• +12V

• +36.5V

• RY6701

•

RY6702

• Key Input

• LED

• Remote

Control

•

N/A

Possible

Component

Level Repair

Possible

Component

Level Repair

Possible

Component

Level Repair

Possible

Component

Level Repair

KV-40XBR800

ONLY

DA-4X chassis

ONLY

All models and

both Da-4 and

DA-4X chassis

Different Part#

for DA-4 & DA 4X

XBR models

ONLY

HB

HM

M

• Front

Video

Input

• Memory

Stick®

• Terminal

Board

• Main

System

Control

•

A/V

Processin

g

• 3D Comb

Filter

• 5V Reg.

• Front

Video

Input

• Memory

Stick®

Terminal

Board

• Main

System

Control

•

A/V

Processin

g

• 3D Comb

Filter

• 5V Reg.

Possible

Component

Level Repair

Board Level

Repair

Board Level

Repair

All models and

both DA-4 and

DA-4X chassis

Different Part#

for DA-4 & DA 4X

All models and

both DA-4 and

DA-4X

chassis’s

Same Part# for

both DA-4 &

DA-4X

All models and

both DA-4 and

DA-4X chassis

Different Part#

for DA-4 & DA 4X

3

1. Introduction and DA-4 & DA-4X PCB Interconnection

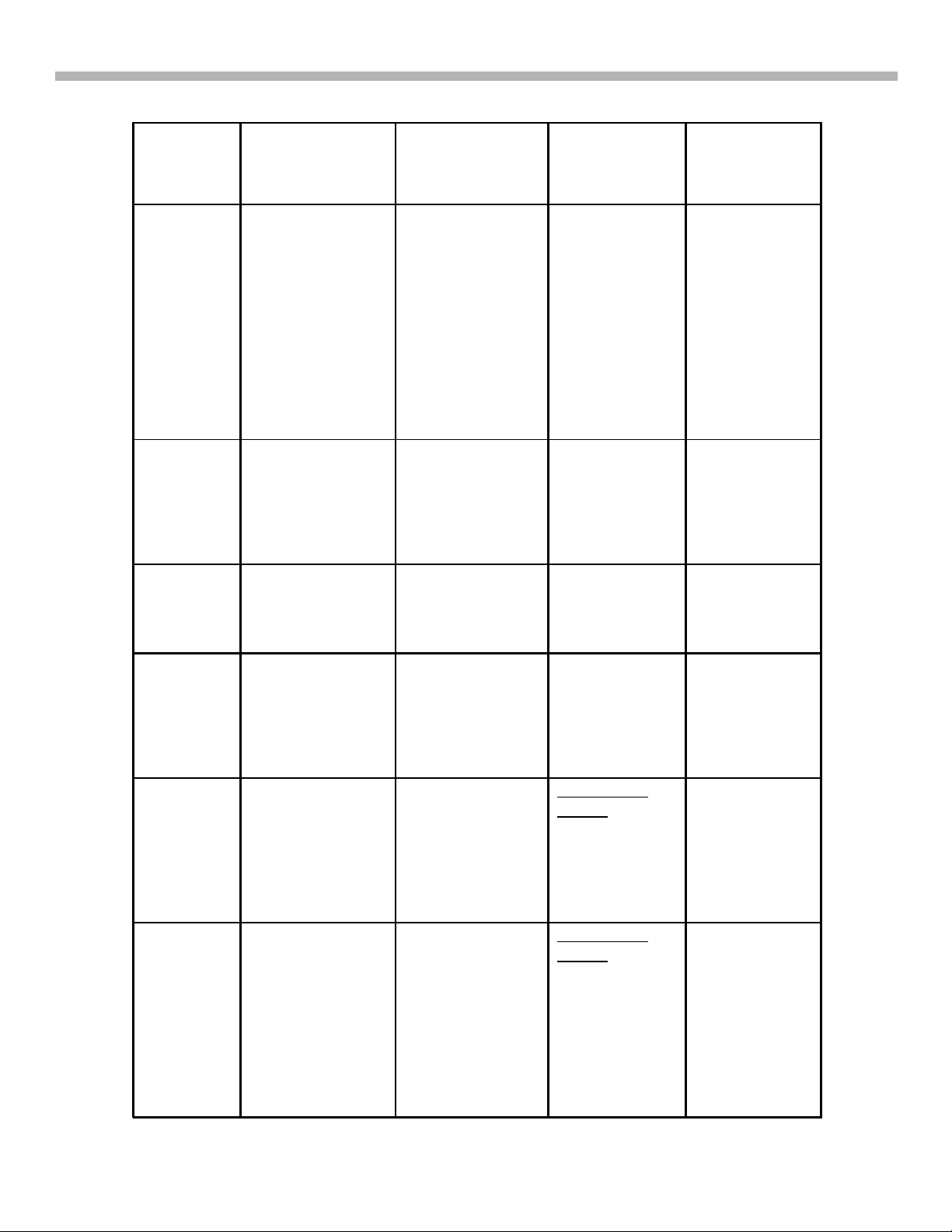

MS1

SR

U

UD

VM

W

• Memory

Stick®

Processor

• N/A • Flash

•

A/V

Switch

Terminal

board

•

DVI

Decoder

•

N/A

•

Velocity

Modulatio

n

• Vertical

Pincushio

n

•

N/S

Correction

• Memory

Stick®

Processor

Focus

Sensor

•

A/V

Switch

Terminal

board

•

DVI

Decoder

•

Velocity

Modulatio

n

•

N/A

Board Level

Repair

Board Level

Repair

All models and

Board Level

Repair

Possible

Component

Level Repair

Possible

Component

Level Repair

All models and

both DA -4 and

DA-4X

chassis’s

Different Part#

for DA-4 &

DA-4X

DA-4X chassis

ONLY

both DA -4 and

DA-4X chassis

Same Part#

for both DA -4

& DA -4X

All models and

both DA -4 and

DA-4X chassis

Same Part#

for both DA -4

& DA -4X

DA-4X chassis

ONLY

DA-4 chassis

ONLY

4

1. Introduction and DA-4 & DA-4X PCB Interconnection

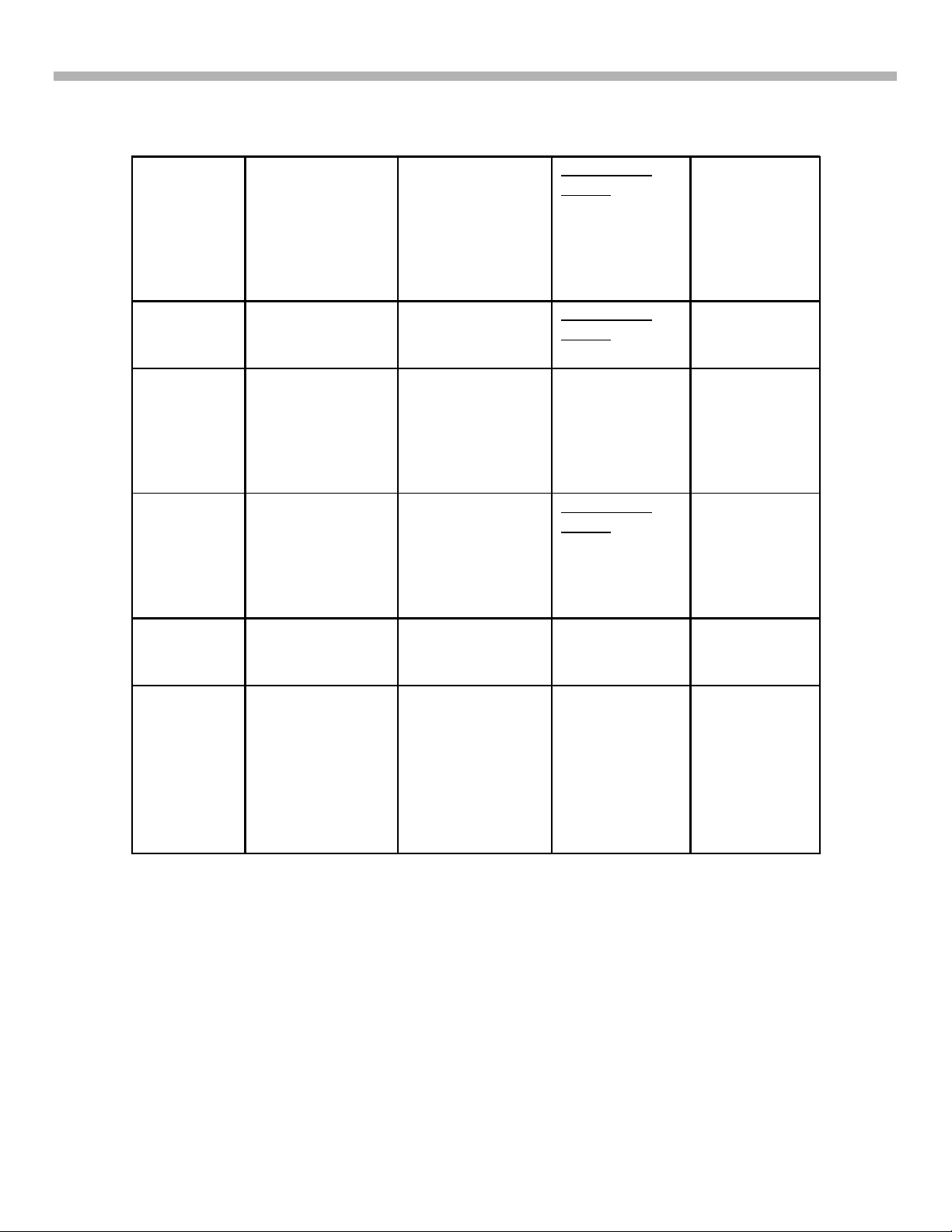

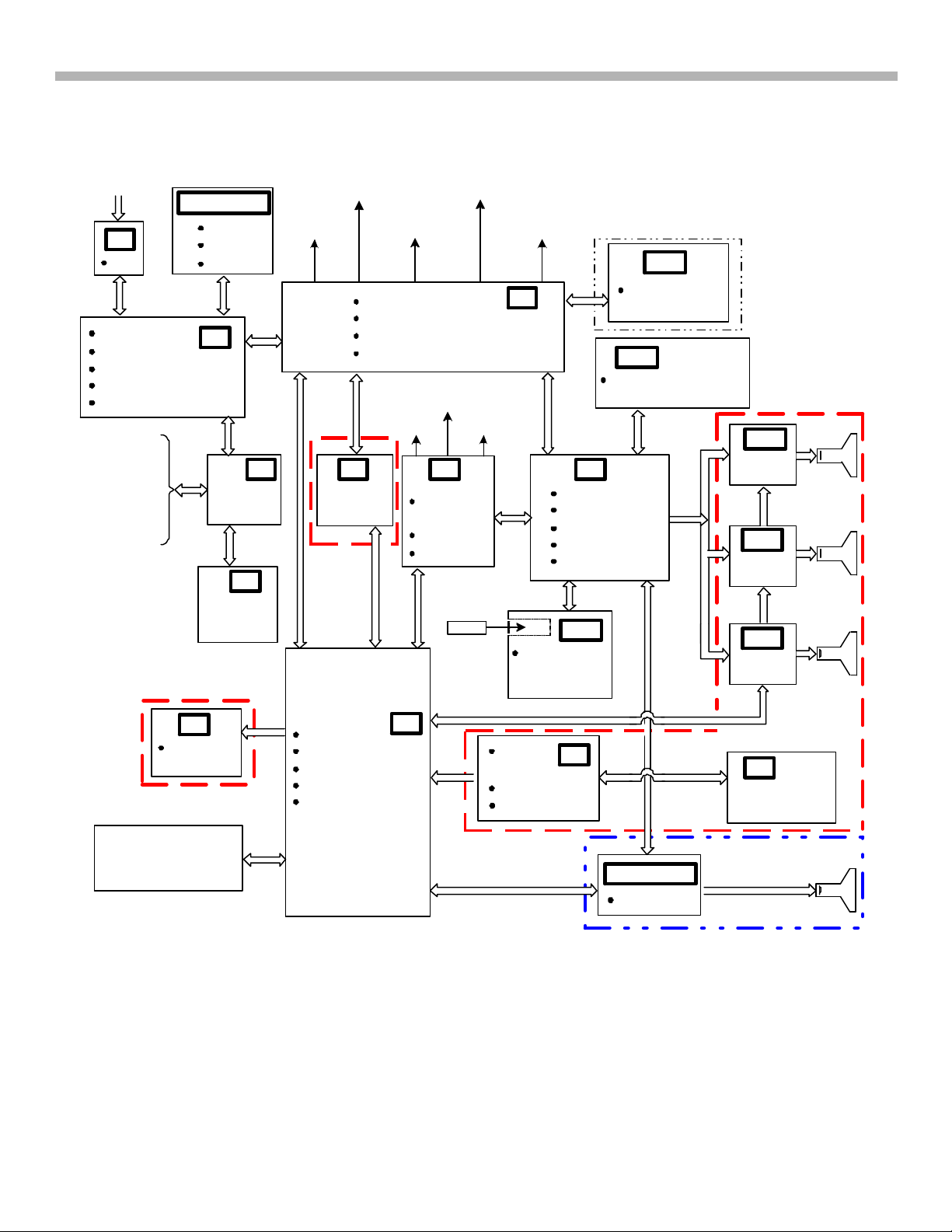

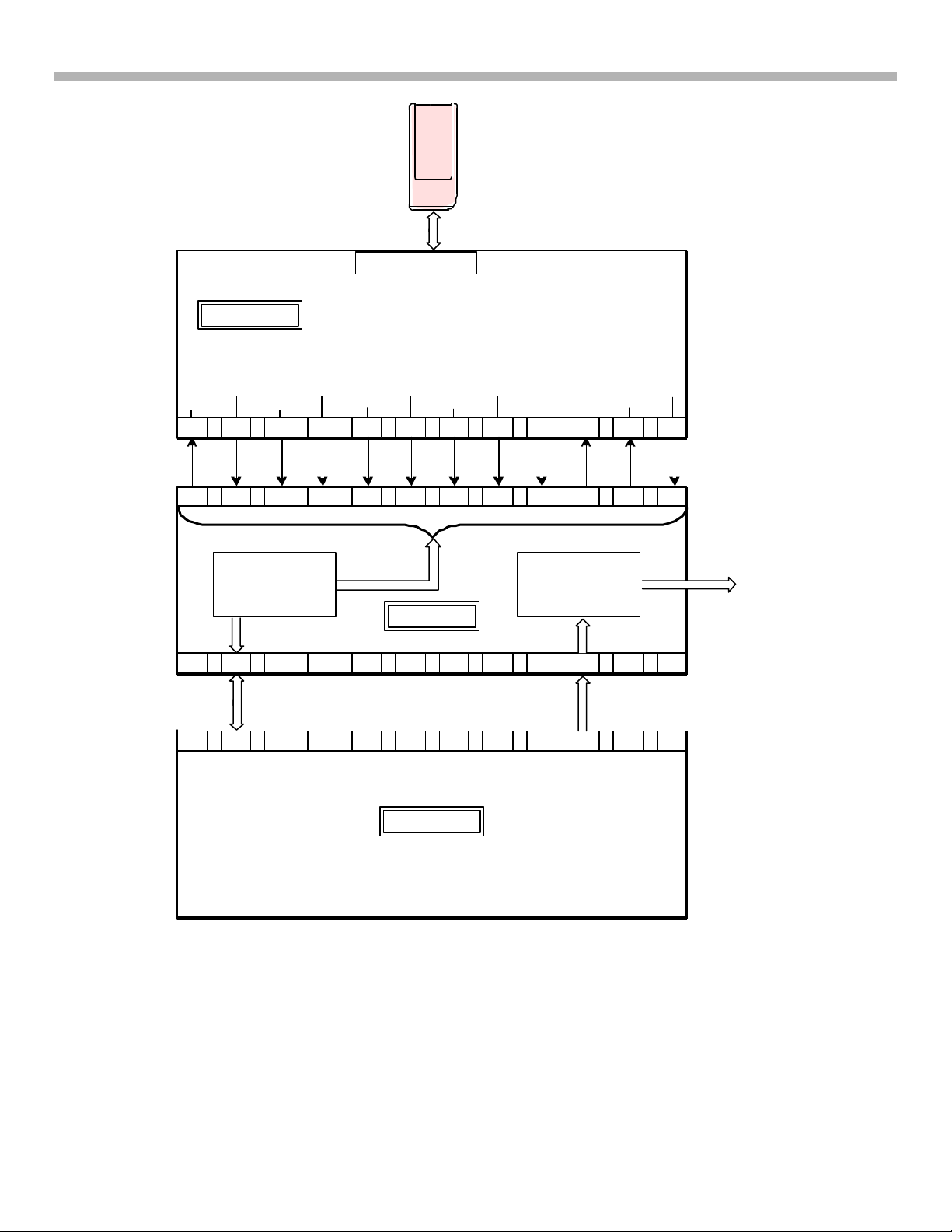

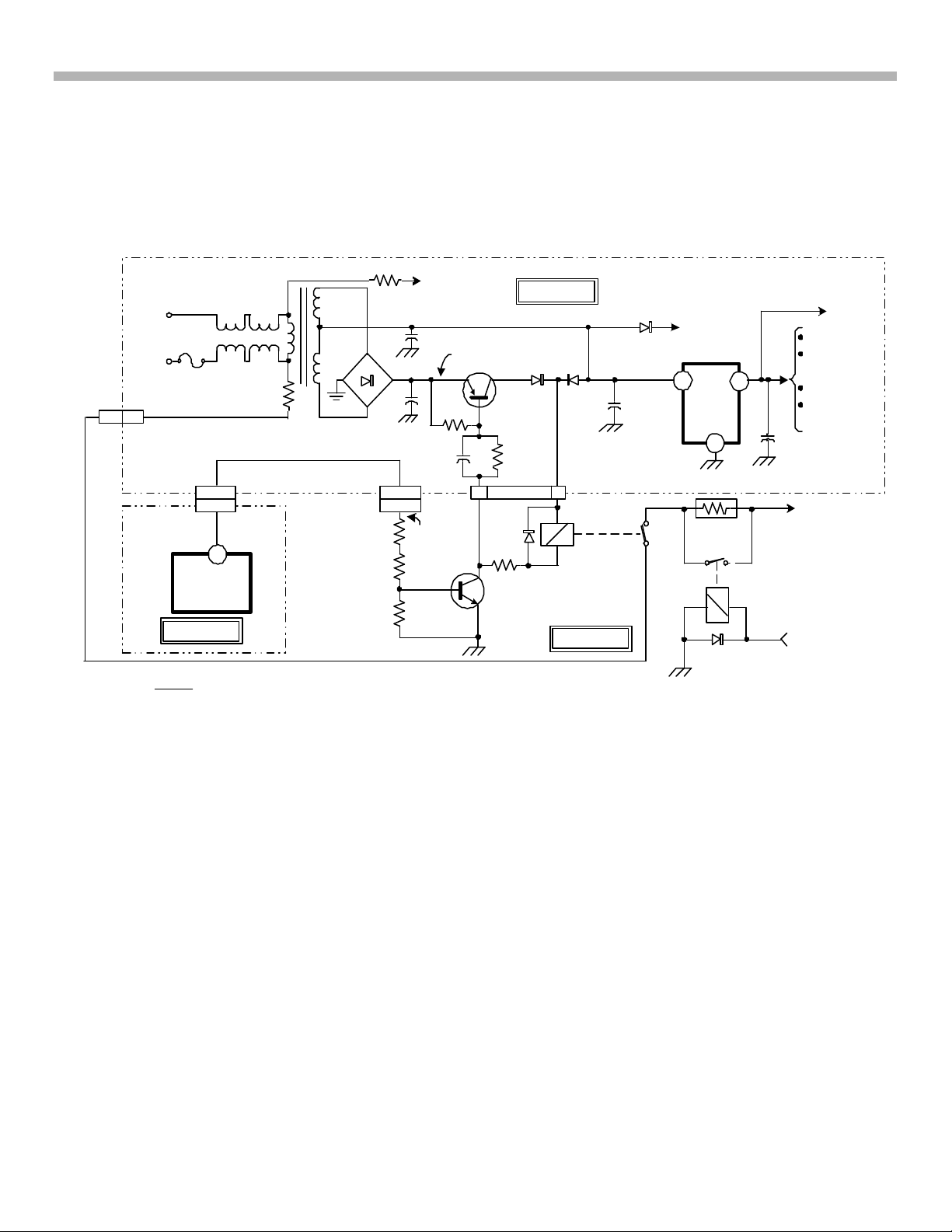

Figure 1-1 illustrates the PCB interconnections for both the DA-4 and DA-4X chassis.

DVI MOLEX

CONNECTOR

UD

DVI

MAIN MICRO

MAIN MICRO

3D COMB

3D COMB

VIDEO PROCESSOR

VIDEO PROCESSOR

AUDIO PROCESSOR

AUDIO PROCESSOR

CCD,V-CHIP,ID1

CCD,V-CHIP,ID1

A/V INPUTS

(1-7)

AUDIO OUT

MONITOR

OUT

S-CONTROL

CHASSIS

HA/HC (XBR)

KEYS

SIRCS

LED

M

A/V

SWITCH

HB

FRONT

A/V INPUT

DA-4X

SPEAKERS

DGC

U

SUPPLY

DA-4X

CHASSIS

CONVERTER

AC/DC POWER

AUDIO POWER

TUNER

DY CONV.,(DA-4)

N/S COIL

G

POWER

ANTENNA

SWITCH

DY

V-PIN COIL

W

VELOCITY

MOD.

V - PIN

N/S DRIVE

MEMORY

STICK

QP COIL

AC

INPUT

A

AD DRC

MID - XA

HD - ADC

CRT DRIVE

AD DNR

HM

MEMORY

STICK

INTERFACE

KV40XBR 800 ONLY

DH

LANDING

CORRECTION

MS 1

MEMORY

STICK PROCESSOR

B

CR

VIDEO

OUT

CG

VIDEO

OUT

CB

VIDEO

OUT

DA-4X

CHASSIS

CRT

CRT

CRT

VM

VELOCITY

MOD

HORIZONTAL &

VERTICAL

DEFLECTION YOKE

FIGURE 1-1 - DA-4 & DA-4X PCB BLOCK INTERCONNECTION DIAGRAM

H/V DRIVE

H/V DY

POWER SUPPLY

AC RECT.

DEFLECTION

D

DIGITAL

REG

PJED CPU

PJE DRIVE

DA-4X

CHASSIS

5

DA-4

CHASSIS

AD

CH/CX(XBR)

VIDEO OUT

SR

FLASH FOCUS

SENSORS

CRT

1C31P15 1478 11/7/02

Chapter 2 - New Features (DA-4 & DA-4X Chassis)

Three new features will be discussed in this section:

• Scrolling Index

• DVI Interface

• Memory Stick® Interface

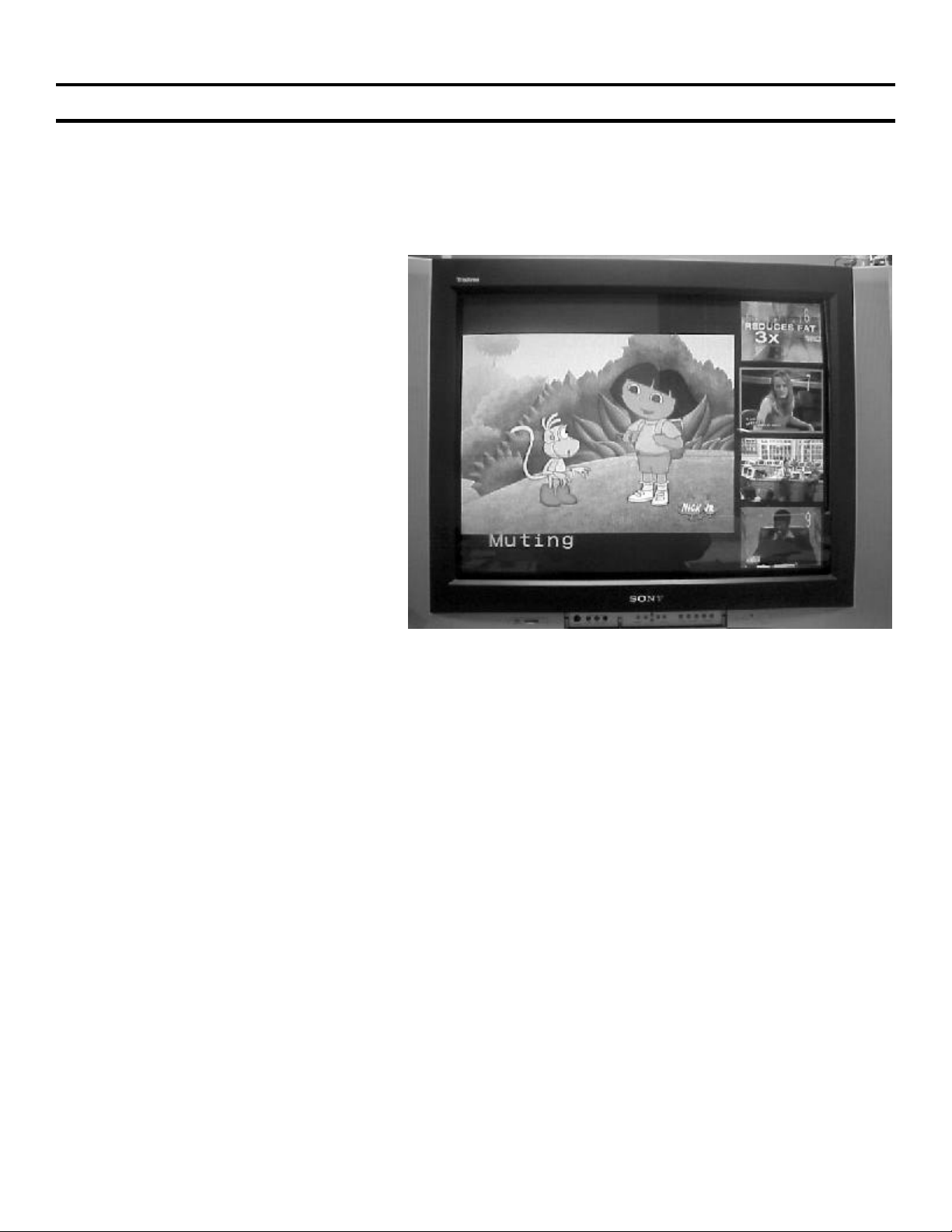

Scrolling Index

The Scrolling Index allows you to select your

main video from a scrolling index of video

pictures.

The Scrolling Index appears with the currently

selected program in the main (left) window

and four scrolling video pictures in windows

down the right side of the picture tube.

As each picture on the right scrolls to the live

preview window, it changes briefly from a

frozen video to live video. The right side

continues to scroll through the entire channel

list.

2. New Features (DA-4 Chassis)

Factors Affecting the Scrolling Index:

Ø Scrolling Index does not function

if you use a cable box to view all

channels.

Ø Sources connected to the AUX,

Video 5, Video 6 and Video 7 inputs

are visible in the left window, but not in the scrolling right windows.

Ø Scrolling Index does not function if the parental controls are set.

Figure 2-1

Scrolling Index

Digital Visual Interface (DVI)

Introduction

As the digital display technology (e.g. Plasma and LCD) grows so does the need to replace the present analog

HD component connection between external digital device (e.g. Digital TV/Satellite Receiver) and the HDTV

set. The issue is the inherent picture quality problems caused by Digital-to Analog (D/A) and Analog-to-Digital

(A/D) conversion processes.

For example, if you have a digital Plasma display HDTVTM and a Digital TV/Satellite Receiver, the digital video

signal in the Digital TV/Satellite Receiver must be converted to a analog component video signal and then sent

to the HDTVTM where it must be converted back to a digital signal video to drive the Plasma display. Because of

the two video signals conversion steps and the possible analog signal loss across the connection between the

HDTVTM and the Digital TV/Satellite Receiver, the picture quality will suffer. Even with an analog CRT the Digital

TV/Satellite Receiver video signal must go through D/A conversion, which can adversely affect picture quality.

TM

The resolution to this dilemma is the creation of a complete end-to-end standard digital video interface, such as

DVI. The DVI interface is a high-speed digital video interface allowing uncompressed high-definition content to

be passed to another DVI equipped device such as an HDTVTM set. DVI is the only digital interface capable of

6

2. New Features (DA-4 Chassis)

accommodating uncompressed digital data such as HD video. DVI also has the bandwidth to support higher

audio fidelity.

DVI has a bandwidth of up to 5 Gigabits/sec, which is more then enough to accommodate an uncompressed HD

video transmission that typically requires 2.2 Gigabits/sec bandwidth.

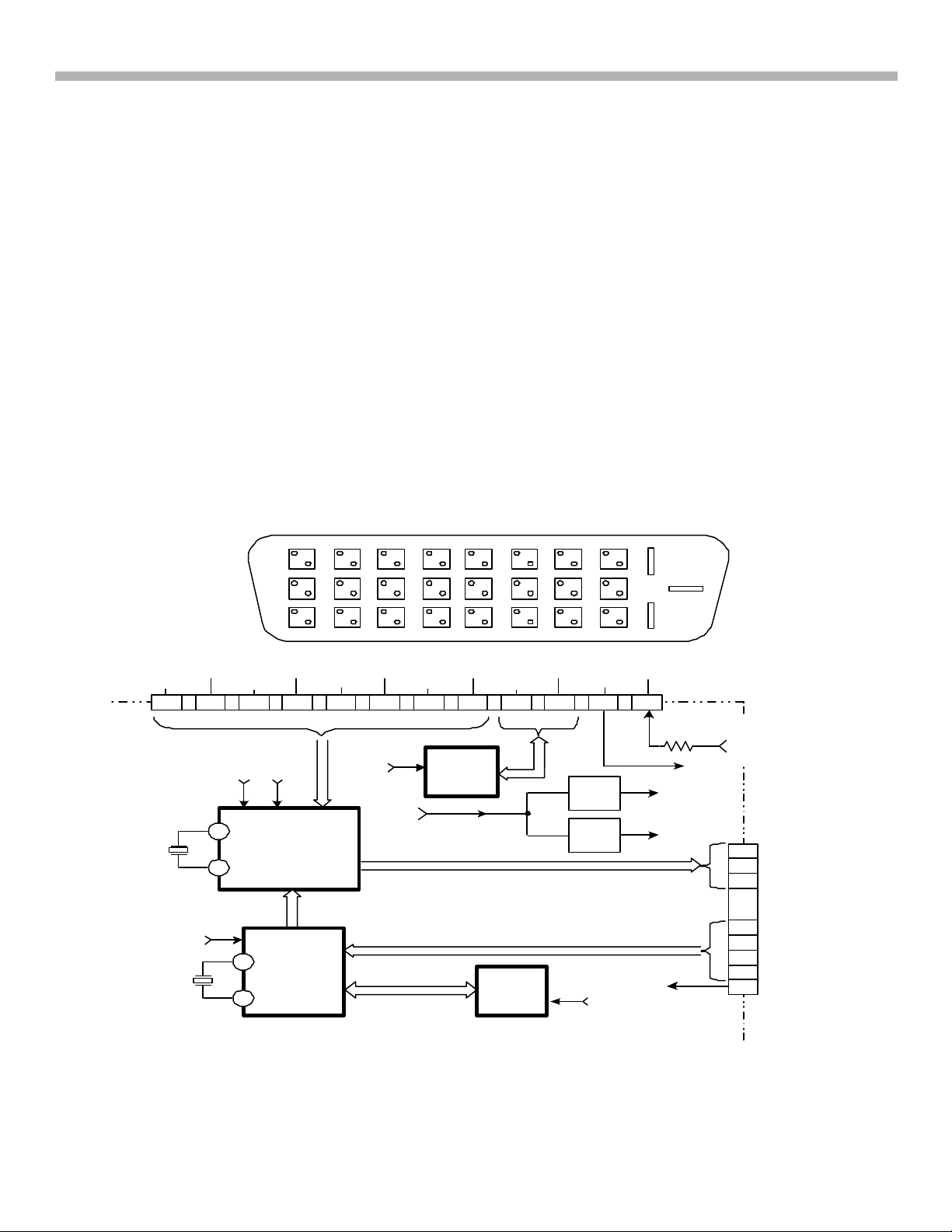

DVI Connector and Decoding Block

The DVI Molex connector and Decoding circuitry for both the DA-4 and DA-4X chassis are located on the UDBoard (NOTE: This board is NOT field repairable). Figure 2-2 shows a block diagram for the UD-Board. The

DVI signal (from a Digital TV/Satellite Receiver) is received at the 24-pin Molex connector CN7001. There are

three serial data differential channels RX0+/RX0-, RX1+/RX1-, RX2+/RX2- and one reference clock differential

channel RXC+/RXC-.

IC7001 NVM is also connected to the external device through the SDA and SCL (I2C) bus. IC7001 stores the

EDID data (Extended Display Identification Data) and HDCP (High Definition Digital Content Protection).

EDID is sent to inform the external digital device of the TV’s identity and capabilities.

HDCP is an Authentication protocol between the external digital device (transmitter) and the TV (receiver) that

affirms to the transmitter that the receiver is authorized to receive the protected information.

CN 7001/pin 14 (5V) is supplied from the external digital device to power IC7001 (NVM) so EDID can be sent

when the TV set is OFF. If the TV set is ON, IC7001 will receiver 5V from CN7002 through D7001.

CN7001/pin 16 is the Hot Plug Detect pin (HPD). The TV set supplies 5V to the external digital device to verify

proper connection between the two devices.

CONNECTOR

R x 2+

R x 2-

1 2 9

X7001

14.31818MHz

5V

X7002

12MHz

R x 1+

R x 1-

3.3V

2.5V

94

95

IC7004

DVI-DECODER

2

IC7005

MCU

3

R x 0-

10 17

SDA,

SCL

R x C+

IC7001

R x C-

NVM

SCL

IC7006

NVM

R x 0+

18 23 24 6 7

5V

5V

SDA, SCL

SDA

5V

14

3.3V

REG

2.5V

REG

5V

HPD

16

5V

CN7001

24P MOLEX

CONNECTOR

R7021

10kHz

3.3V

2.5V

5V TO

D7001

CN2304/

PIN 1

5V

10

8

6

13

4

3

2

1

CN7002

Y

PB

PR

SET-UP

MUTE

VGA

RESET

5V

FIGURE 2-2 - UD - BOARD BLOCK (DVI DECODER)

C31P15-2-2 1501 10/31/02

The DVI Decoder, IC7004 receives the three channels of digital video data and outputs analog component video

(Y, PB, PR) to CN7002/pins 10, 8 and 6 respectively.

7

2. New Features (DA-4 Chassis)

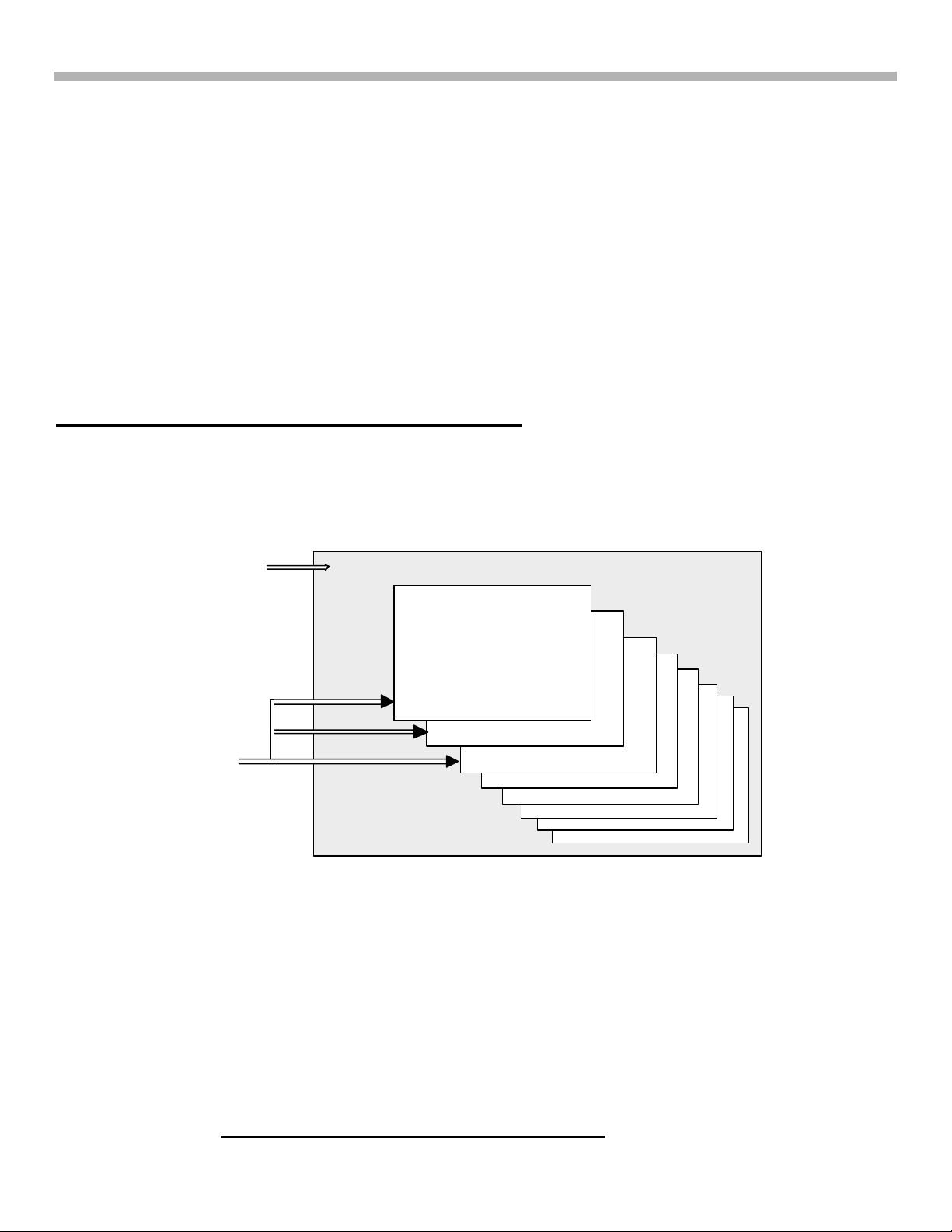

Memory Stick® Interface

Introduction

Memory Stick® is a new compact, portable and versatile Integrated Circuit Recording Medium with a data

capacity that exceeds that of a floppy disk. The internal memory circuit structure is a type of Flash Memory

similar to that found in a personal computer. It is a solid-state design, which basically means there are no moving

parts. Inside the Memory Stick® is a grid of columns and rows with a two-transistor cell at each intersection point

on the gird, which is used to store a 1 or 0. The Memory Stick® is specially designed for the exchange and

sharing of digital data among Memory Stick® compatible products such as Digital Still Cameras and Digital Video

Cameras. Because it is removable, Memory Stick® can also be used for external data storage.

Memory Stick® technology allows you to view on the TV digital (JPEG) still images that are stored on Memory

Stick® medium. You can choose from an index of the images stored on the Memory Stick® or you can run a

slideshow of those images.

The DA-4 and DA-4X chassis Memory Stick® viewer can display ONLY Still Images that have been recorded on

Memory Stick® media by Sony brand digital still and video cameras.

Recorded images must meet the following specifications:

Ø Compression format: JPEG

Ø File format: DCF compliant

NOTE: Most Sony brand digital still and video cameras automatically record still images using DCF

(Design rule for Camera File system) compliant directory and file names as shown in Figure 2-3:

IMAGE

DIRECTORY

NAME

IMAGE FILE

NAMES

NOTE:

DO NOT RENAME DIRECTORIES.

IF THE NAMES ARE CHANGED,

THE STILL IMAGES CANNOT BE

DISPLAYED ON YOUR TV.

100MSDCF

DSC0001

DSC0002

DSC0003

FIGURE 2-3 - DCF DIRECTORY

C31P15-2-3 1504 9/26/02

The main advantage of the Memory Stick® is its size, which measures approximately 2’’x3/4"x1/8", making it

extremely portable (reference Figure 2-3). However, do not let the size fool you; the Memory Stick® comes in

five data capacity ratings: 8MB, 16MB, 32MB, 64MB, 128MB and 256MB.

Note: The DA-4 and DA-4X chassis Memory Stick® viewer is compatible with Memory Sticks® up to and

including 128MB. **The 256MB Memory Stick® is not compatible.**

8

2. New Features (DA-4 Chassis)

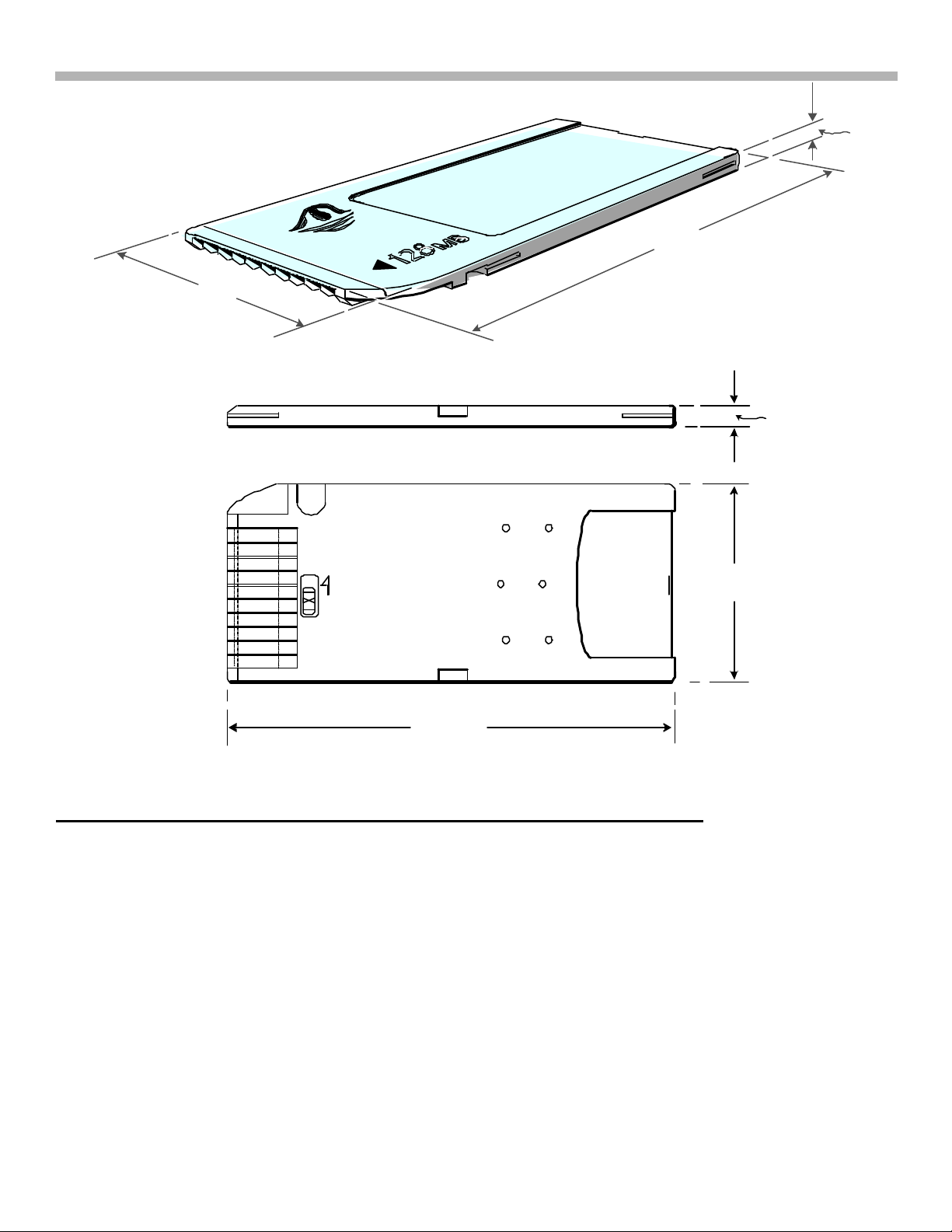

TOP VIEW

VIEW OF

LOWER

SIDE

MEMORY STICK

7/8"

1/8"

2"

1/8"

7/8"

LOCK

2"

FIGURE 2-4 - MEMORY STICK DIMENSIONS

C31P15-2-4 1505 9/16/02

The DA-4 and DA-4X Memory Stick® viewer cannot display any of the following:

Ø Images recorded on digital still cameras and digital video cameras that are not Sony brand.

Ø Images recorded using products that are not DCF complaint, including the following Sony products:

• Digital still cameras DSC-D700

DSC-D770

• Digital video cameras DCR-TRV900

DSR-PD100A

Ø Images stored on a Memory Stick® that has a capacity that exceeds 128MB.

Ø Images stored in TIFF or any other non-JPEG compression format.

Ø Images in directories that were modified or renamed on a computer.

Ø Images with less than 16 horizontal and/or vertical dots per line.

Ø Images with more than 4096 horizontal and/or vertical dots per line.

9

Memory Stick Interface and Processing Block

MEMORY

STICK

CN7201

HM BOARD

2. New Features (DA-4 Chassis)

MS-BS+

3.3V

3

5 6 7 8 9 10

B3 A4 BY A5

MS-DIR+

MS-BS-

DIFF. - AMPS

& BUFFER

MS-SCLK-MS-DIR-

A6 B6 A7 B7

B5

B BOARD

MS1 BOARD

MS-SDO+MS-SCLK+

11

MS-SDI+ MS-INS

MS-SDO-

12 13

A8

MID

MS-SDI

14

B8 B9

15

CN7202

CN3603

TO CRT

DRIVE

CN3601

CN104

MS DECODER BOARD

FIGURE 2-5 - MEMORY STICK INTERFACE & PROCESSING BLOCK

C31P15-2-5 1502 11/7/02

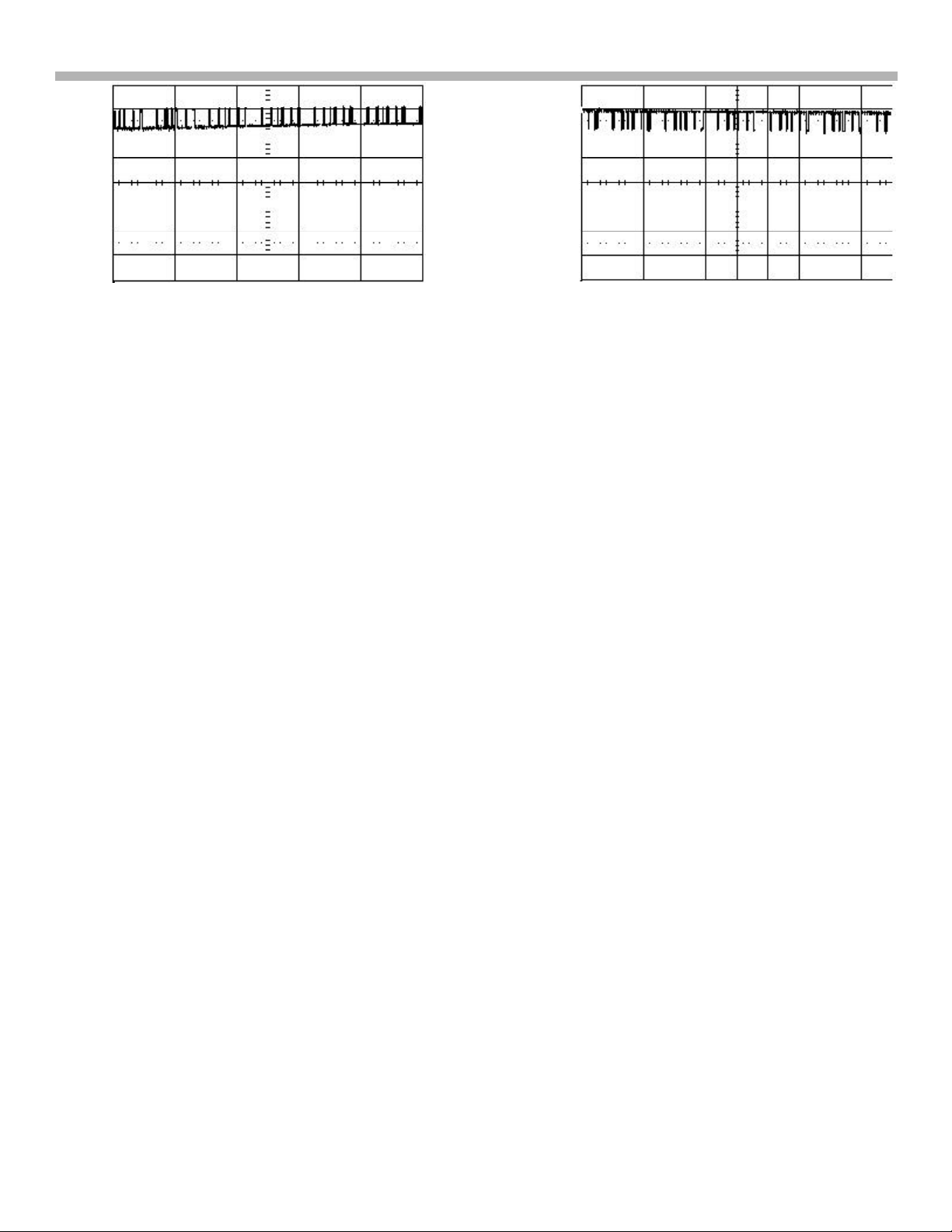

The Memory Stick® (MS) is inserted into CN7201 on the HM-Board. Once the MS is completely seated

in the slot, the Memory Stick® applies a ground to CN7202/pin 15 (MS-INS), which goes Low (from

3.3V to 0V). This notifies the MS1-Board that a MS has been inserted. Initial data will be transferred at

this time between the HM-Board and MS1-Board and can be viewed at CN7202/pins 5 through 14

(reference Waveforms 2-1 and 2-2). The data signals are all in differential format with a positive and

negative signal. The differential format is incorporated to eliminate noise on the data lines. Data can be

viewed on these pins when the MS is initially inserted and when an image is selected for display on the

CRT.

10

2. New Features (DA-4 Chassis)

CH2

.5v

100us

Waveform 2-1

MS - SDI (+)

CH2

.5v

100us

Waveform 2-2

MS - SDI (-)

The MS-INS is applied to the B Board/pin B3 and forwarded on to the MS1- Board. The MS-Data

signals are amplified on the HM-Board and then applied to the B Board/pins A4/B4 through A8/B8

where they are converted from differential format to single data lines, and further amplified and applied

to the MS1-Board.

The MS1 Board performs the following functions:

• Memory Stick® System Control

• JPEG Processing

• Memory Stick Decoding

The Memory Stick® JPEG data is then converted into digital Y, CB, CR data on the MS1 Board. The

digital Y, CB, CR data is then sent back to the B Board and is D/A converted to analog component video

signals (Y, CB and CR), which drive the CRT.

Troubleshooting Tips

1) All three boards (HM, Band MS1) are Not Field Repairable .

2) Confirm CN7202/pin 15 (MS-INS) goes low when Memory Stick® is inserted.

3) Confirm CN7202/pin 3 (3.3V supply).

4) Confirm CN7202/pins 5 through 14 have data activity during the following two events:

a. When the Memory Stick® is initially inserted; and

b. When an image is selected for display on the CRT.

5) Confirm the voltages and signals in steps 2, 3 and 4 are applied to CN3603/pins B3, A4/B4

through A8/B8 and B9.

6) If all voltages and signals are applied to the B Board, further troubleshooting will be board swap

due to inaccessibility to connectors on the B Board and MS1 Board.

There is not much signal processing performed on the B Board, so the most likely defect at this point

would be the MS1 Board.

11

3. Power Supply (DA-4 & DA-4X Chassis)

Chapter 3 - Power Supply (DA-4 & DA-4X Chassis)

This chapter will cover the power supply section for both the DA-4 and DA-4X chassis. The degauss circuit for

the DA-4 chassis will also be discussed.

The power supplies for the DA-4 and DA-4X chassis are almost identical except in the following two main areas:

1) High Voltage (HV) development: The HV on the DA-4 chassis is Switch-mode power supply derived, whereas

the HV on the DA-4X chassis is scan derived.

2) Circuit Location: On the DA-4 chassis, the power supply circuitry is located on the A and D-boards, whereas

on the DA-4X chassis, the circuitry is on the A, D and G boards.

Except for the development of the HV, the circuit operation for the Standby 5V and Main Converter Power

Supplies is identical. Notes and references are placed on each diagram where the circuit operation is

identical between the two chassis. The circuit itself may be located on a different board and component

reference numbers may be different, but the components are the same. As you read this section, note the

similarities and differences between the DA-4 and DA-4X chassis.

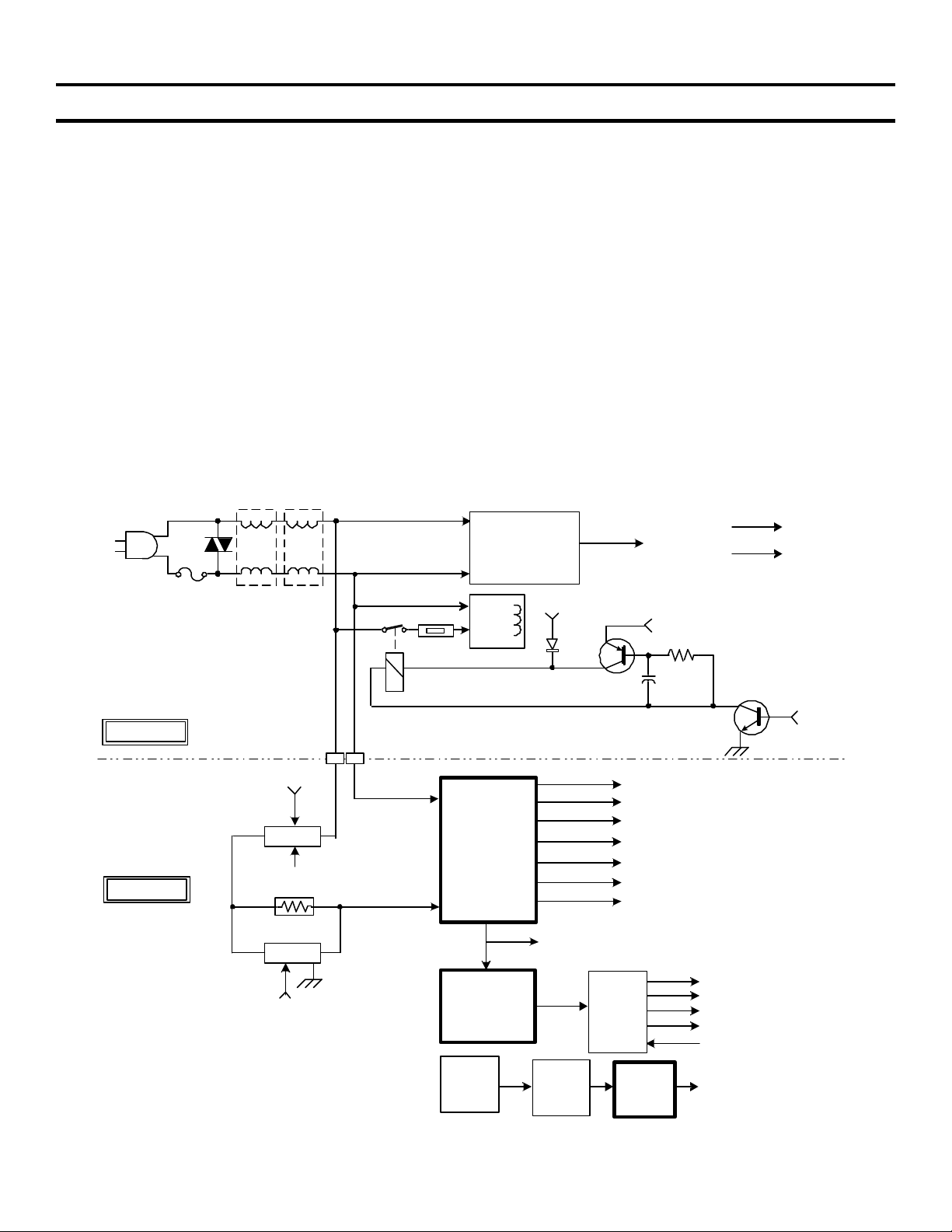

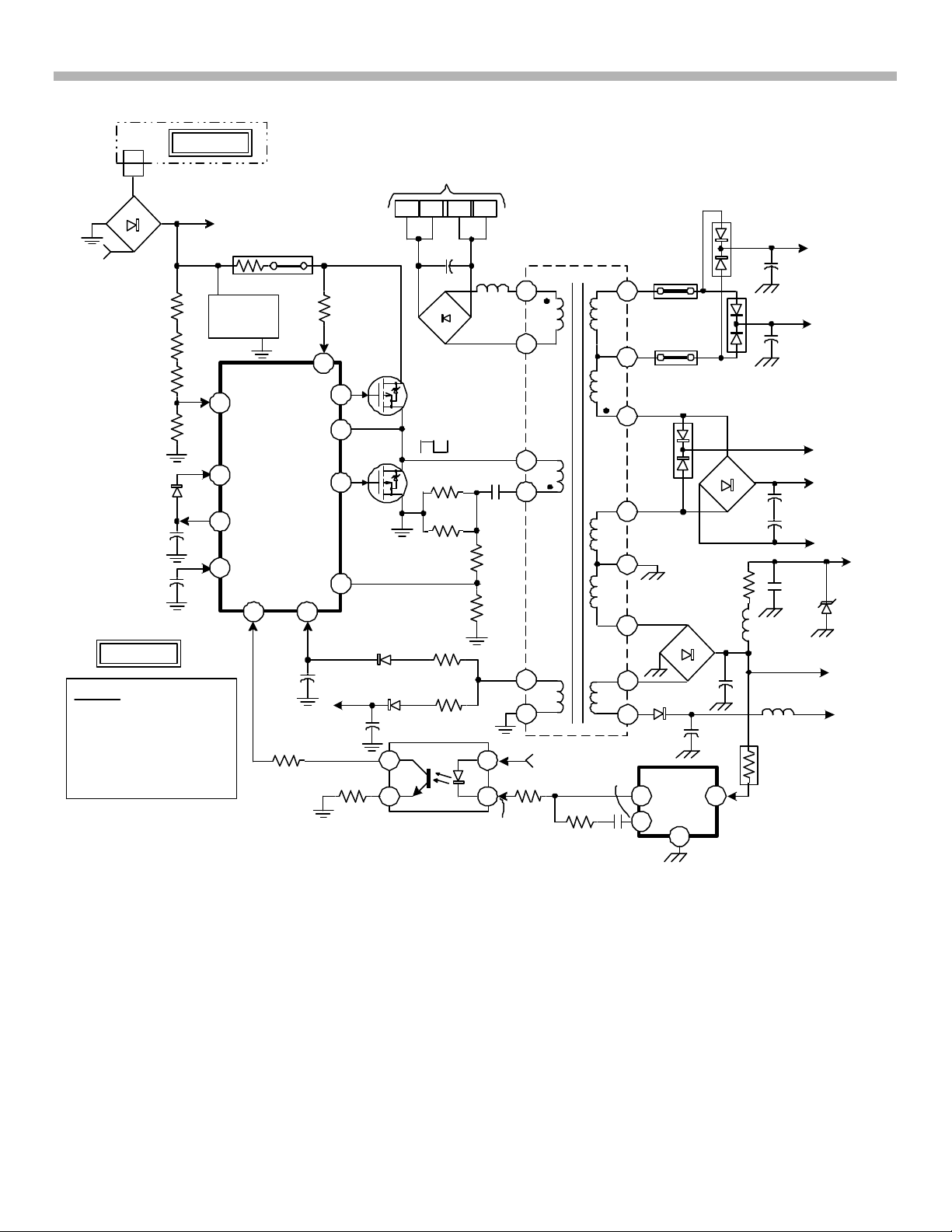

DA-4 Chassis Power Supply

DA-4 Overall Power Supply Block

VD501

AC

T510 T511

STANDBY 5V

POWER

SUPPLY

STANDBY

5V CIRCUIT

HA/HE BD.

M BD.

A BOARD

D BOARD

FH501

GND.FROM

Q6527

(AC

RELAY)

FROM D508,D509

(INRUSH

RELAY)

UNREG

RY6501

R6516

RY6502

FROM

11V

1 2

CN514

CN6502

TH501

RY501

DGC

IC6501

MAIN

POWER

SUPPLY

AC-RECT

IC8002

HV POWER

SUPPLY

13V FROM 5V STBY

D501

Q502

FROM AC RECT.

BLOCK D6530

T8001

FBT

D503/C506

+

C507

36.5V

+/- 15V

UNREG 7V

UNREG 5V

UNREG 11V

+135V

+200V

R506

HV

G2

FV

ABL

DF

Q501

DGC-ON

FROM

IC2300

/PIN 68

( M-BD.)

H-OUT

Q5030

FIGURE 3-1 - DA-4 POWER SUPPLY OVERALL BLOCK

HOT

T5001

IC5006

12

H1( HEATER)

C31P15-3-1 1509 10/28/02

3. Power Supply (DA-4 & DA-4X Chassis)

DA-4 Overall Power Supply Block Description

Once 120V AC power is applied to the TV set (set plugged into the AC outlet), the Standby 5V power supply

(located on the A-board) is active and outputs regulated 5V (reference Figure 3-1). The STBY 5V is sent to the

M-board to partially power-up system control IC2300 and is also sent to the HA/HC board to power the Remote

Control Sensor (SIRCS).

The Main Converter power supply (DA-4) located on the D-board is fed AC (from A-Board) through the AC-

Relay (RY6501) and through Inrush-Current resistor (R6516). This limits the initial high current produced when

the TV set is first turned ON. The Inrush-Current resistor (R6516) is removed from the AC input path using

RY6501. Once the Main Converter power is up and running, the unreg11V output is fed back to RY6501, the

relay switch is closed and R6516 is bypassed in normal operation. The Main Converter power supply outputs the

following voltages:

• +/- 15V

• Unreg7V

• Unreg5V

• Unreg11V

• 36.5V

• +135

• +200

The High Voltage (HV) on the DA-4 chassis is developed using a switch-mode power supply identical to the one

found in the Main Converter power supply except for the use of the Flyback (FB) T8001 as the output transformer

(reference Figure 3-1). The HV power supply is located on the D-board. The HV power supply is activated

simultaneously with the Main Converter power supply. AC power is fed to the HV power supply from the ACRECT block (D6530), which also feeds the Main Converter power supply. The HV Converter output then drives

the FB transformer, which outputs the following voltages:

• High Voltage (HV)

• Focus Voltage (FV)

• G2

• ABL

The Heater Voltage is scan derived using H-Out (Q5030), T5001 and IC5006 also located on the D-board.

The Degauss Circuit (reference Figure 3-1) will be activated after IC2300 (M-board) receives an ON command

from either the ON/OFF button or the remote control, and after one of the following events have occurred:

• The AC power was disconnected (indicating that the TV was possibly relocated).

• The TV has been turned OFF for more then 15 minutes.

The base of Q501 receives a high from IC2300/pin 68 (turning Q501 ON). The ground path for the degauss relay

RY501 and the base circuit of Q502 are completed through the collector/emitter circuit of Q501. Q502 supplies

the initial kick voltage and current to RY501. Once C504 in the base circuit charges completely, Q502 will turn off

and a hold voltage is supplied through D501 (13V) from the STBY Power Supply circuit.

RY501 switch closes and sends AC through the degauss coil, eliminating any magnetic fields present in the

metallic parts in the picture tube, which could cause color purity problems. The degauss relay remains closed for

approximately six seconds and then opens.

13

3. Power Supply (DA-4 & DA-4X Chassis)

Three relay clicks will be heard when the set is first turned on in the following order:

1) Degauss Relay (RY501)

2) AC Relay (RY6501)

3) Inrush Current Relay (RY6502)

DA-4 STBY 5V Power Supply and Power-On Switching Circuit

CN6502

T502

L511

L510

AC

INPUT

FH501

CN514

22

CN523

CN2002

IC2300

M BOARD

NOTE

CIRCUIT OPERATION IS THE SAME FOR BOTH DA-4 & DA-4X CHASSIS

R509

19

19

69

D503

R510

C507

C506

CN900

CN5011

R6528

R6509

R6530

TO D-BOARD

AC TO D6530

+

+

R513

C513

7

7

ON 0.6V

STBY-0V

CN6701

ON 20V

STBY 23V

+

8

A BOARD

D508

Q503

R516

D6534

R6519

Q6527

D509

ON-8.5V

STBY-22V

CN521

5

CN6506

AC RELAY

RY6501

D BOARD

D501

ON 9V

STBY 11V

+

C514

(AC)

TO RY501

DEGAUSS

RELAY

SOLENOID

I

IC501

STBY

5V

G

R6516

D6533

BD.

O

5V

+

RY6502

(INRUSH)

RELAY

HA/HC

BD.

Q2312

M

IC2300

SYSCON

IC2302 NVM

IC2305 3.3V

REG

C515

TO D6530

MAIN POWER

SUPPLY

UNREG 11V

OUTPUT FROM

MAIN POWER

SUPPLY

FIGURE 3-2 - DA-4 STANDBY 5V POWER SUPPLY & POWER ON SWITCHING CIRCUIT

C31P15-3-2 1508 11/12/02

Standby 5V Power Supply

Reference Figure 3-2 during the following circuit description:

The Standby Power Supply (located on the A-board) is operational as long as the set is plugged into an AC outlet.

AC power is applied to T502 through fuse FH501 and chokes L510 and L511. T502 couples the AC across to

D503 rectifier block and filter capacitor C507 (AC is also coupled to Q503; this is part of the power-on switching

circuit which will be discussed next).

The Standby 5V power supply is a simple conventional full-wave (only two diodes in D503 are used) rectifier

circuit. The resulting DC voltage (11V) is applied to the input pin of IC501 (5V regulator), which then supplies

regulated 5V to the following components:

• IC2300 System Control (M-board)

• IC2302 NVM (M-board)

• IC2305 3.3V Regulator (M-board)

• Q2312 Remote Input Buffer

• HA/HC boards (Key Input, LED and Remote Sensor)

14

3. Power Supply (DA-4 & DA-4X Chassis)

Power-ON Switching Circuit

Reference Figure 3-2 during the following circuit description:

In the Standby mode, System Control (IC2300) is partially powered (using STBY 5V) and waiting for an ON

command from either the Front Panel Controls (IC2300/pins 93 and 94) or the Remote Control (IC2300/pin 7).

Once the ON command is received, IC2300/pin 69 (AC_RLY) outputs a high, which is applied to the base of

Q6527 (turning Q6527 ON). This completes the ground path for the AC Relay (RY6501) and for the base circuit

of Q503.

Q503 turns on and supplies the initial kick voltage and current through D508 to RY6501, closing the relay switch

and supplying AC power to the Main Power Supply through Inrush resistor R6516 and D6530. Once C513 in the

base circuit charges completely Q503 turns off; D508 reverse biases and D509 forward biases, supplying a hold

voltage (9V) to keep the relay switch closed in the ON mode.

At this point the Main Power supply is turning ON (operation will be discussed next). The initial AC power to the

Main Power Supply is through Inrush resistor R6516, which limits the high surge current that occurs momentarily

at turn ON. Once the secondary voltage UNREG 11V is developed on T6502 in the Main Power Supply, it is fed

back to the Inrush Relay (RY6502). RY6502 turns on and bypasses R6516 in the ON mode. R6516 is only in

the circuit during initial power-up of the set.

Troubleshooting Tip:

Obviously, if a failure occurs in the 5V Standby Power Supply the unit will not even attempt to turn ON. If this

condition occurs, check the following components:

1) FH501

2) 13V at IC501 Input Pin (I). If missing, suspect T502, D503 and/or C507.

3) 5V at IC501 Output Pin (O). If missing, suspect a defective IC501.

4) NOTE: Q503 is used as a current source for the AC relay (RY6501). If the collector/emitter junction of

Q503 becomes an Open circuit, the set will still turn ON (using voltage through D509) and function

properly with sufficient AC power input. If the AC power input is weak (Low Voltage ~90VAC, the unit will

have difficulty turning ON without Q503 functioning properly.

15

DA-4 Main Switching Power Supply Circuit

3. Power Supply (DA-4 & DA-4X Chassis)

CN6701

CN514

1

1

D6530

AC RECT.

FROM

RY6501

R6646

R6514

R6513

R6517

D6502

+

C6508

+

C6519

D-BOARD

NOTE:

CIRCUIT OPERATION

IS THE SAME FOR

BOTH DA4 & DA4X

CHASSIS'

A-BOARD

TO IC8002/PIN 1

HV POWER SUPPLY

R6526

FILTER

CIRCUIT

V-SENSE

2.7V

1

IC6501

MCZ

3001D

14

VB

10.6V

10

VC2

6

TIMER

F/B

2 8

1.9V

TO IC8002/

R6525

VG

(H)

VS

VG

(L)

OCP

VCI

+

PIN 8

R6536

279V

18

141V

16

15

12

4.8V

9

18V

C6558

R6524

5

136V

Q6506

0V

D6519

D6520

+

C6549

4 1

3 2

TO A BD.

AUDIO VCC

(36.5V)

2

4

C6546

+

D6514

Q6507

275Vp-p

78kHz

C6352R6557

R6556

R6501

R6505

R6508

R6510

PH6502

1

CN6503

L6516

R6544

11V

1

2

6

7

8

9

+15V

R6503

T6502

18

17

16

15

14

13

2.4V

C6551

D6513

PS6506

PS6505

D6504

D6524

11

C6556

10

D6518

IC6503

4 1

DM-58

CONT.

3

+

5

R6539

+

C6557

133V

+

D6516

+

D6523

+

+

L6505

L6501

R6590

UNREG

7V

UNREG

5V

UNREG

11V

+15V

C6597

C6559

-15V

+33V

C6502

D6508

33V

+135V

+200V

FIGURE 3-3- DA-4 MAIN POWER SUPPLY CIRCUIT

C31P15-3-3 1506 11/8/02

The Main Switching Power supply is basically IC6501 (Switch Regulator Controller). IC6501 contains all the

major circuitry necessary to function as a switching power supply, except for the Power Switching MOSFETS

(Q6507 and Q6506).

IC6501 contains:

• Control circuit

• Oscillator/Oscillator control

• Output Driver transistors

• 10V regulator

• Shut-Off Timer

• Over Current Protection

16

3. Power Supply (DA-4 & DA-4X Chassis)

Main Switching Power Supply Operation

Reference Figure 3-3 for the following circuit description:

AC signal is applied to the rectifier block D6530. The AC component is filtered-out by the filter circuit (shown in

block form). A DC voltage of 293V is produced at the output of the filter circuit.

IC6501 Startup Sequence

1) Turn ON voltage: The 293Vdc from the filter circuit is voltage divided by R6646, R6514, R6513 and

R6517 down to 2.7Vdc. This voltage is applied to IC6501/pin 1 (Vsense) and IC6501 turns ON. IC6501/

pin1 (Vsense) is also used for OVP protection (IC6501/pin 1 > 8V will trigger OVP).

2) Internal circuit Start Voltage: The 293Vdc also passes through voltage dropping resistors R6526 and

R6536, and 279Vdc is applied to IC6501/pin 18. This voltage is used to initially power the internal circuits

and begin oscillations. Note that the 293Vdc from R6526 is connected directly to the Drain of Q6507 and

serves as the High-side FET power source.

Internal circuits initially powered by IC6501/pin 18

• Internal drive transistors for High-side output FET Q6507.

• Oscillator

• Control circuit

• 10V regulator (IC6501/pin 10)

Note: The 10V output at IC6501/pin 10 passes through D6502 and supplies power to the internal

driver transistor for the Low-side output FET Q6506

3) Output Oscillations: At this point, initial square-wave oscillations of approximately 125KHz are output at

IC6501/ pins 16 and 12. Normal operation frequency is approximately 85KHz.

4) Regulator Feedback: The feedback line is connected to the +135V secondary output. Once IC6501 is

turned ON and oscillations begin, the secondary winding at T6502/pin 13 and associated circuitry produces

+135V. The +135V is applied to IC6503/pin 1 (DM-58 Control).

IC6503 controls the voltage at the PH6502/pin 2, which controls the current output of the optic-coupler

PH6502. The amount of current supplied to IC6501/pin 2 depends on how hard PH6502 is turned ON. In

normal operation, a voltage of 1.9Vdc (which is proportional to the amount of current) is present at

IC6501/pin 2. The feedback loop is now complete.

5) IC6501 normal operating power supply (VC1): Produced simultaneously with the oscillator feedback is

the operating power source VC1.

IC6501/pin 8 (VC1) is produced using a winding on T6502/pin 8. The AC is rectified and filtered, and a

DC voltage of 18V is applied to IC6501/pin 8. Once the 24V is stable, IC6501’s internal control circuit

disconnects (internally) the power source at IC6501/pin 18. All IC6501 internal circuits are now powered

from IC6501/pin 8.

Over Current Protection (OCP): ref. Figure 3-3

The current flowing through the switching FETS (Q6507 & Q6506) also passes through T6502/pins 6 and 7,

C6532 and resistor bank R6557 and R6556. The voltage drop across resistor bank R6557 and R6556 is

directly proportional to the current through the switching FETS. The voltage across R6557 and R6556 is

further voltage divided by R6501 and R6505 and applied to IC6501/pin 9. The OCP is activated when the

voltage at IC6501/pin 9 exceeds 0.2V. The self-diagnostic indicator will flash four times, pause and then

repeat.

17

Loading...

Loading...