SONY KV-29FS140 Diagram

SERVICE MANUAL BX1

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-21CL5K

RM-W100 OIRT SCC-U92G-A

MODEL COMMANDER DEST. CHASSIS NO.

TRINITR ON

®

COLOR TV

KV-21CL5K

RM-W100

TABLE OF CONTENTS

Section Title Page

CAUTION & WARNING.......................................................3

WARNING (UK only)..........................................................3

SELF DIAGNOSTIC FUNCTION ........................................4

1. DISASSEMBLY

1-1. Rear Cover Removal................................................... 7

1-2. Speaker Block Assy Removal..................................... 7

1-3. Chassis Assy Removal ................................................ 7

1-4. Service Position .......................................................... 7

1-5. T erminal Brack et Remov al ......................................... 7

1-6. A Board Removal ....................................................... 7

1-7. Picture Tube Removal................................................. 8

2. SET-UP ADJUSTMENTS

2-1. Beam Landing ............................................................. 9

2-2. Convergence.............................................................. 10

2-3. Focus Adjustment ..................................................... 12

2-4. G2 (SCREEN) Adjustment....................................... 12

2-5. White Balance Adjustment....................................... 12

Section Title Page

4. DIAGRAMS

4-1. Block Diagram .......................................................... 27

4-2. Circuit Boards Location ........................................... 28

4-3. Schematic Diagram................................................... 28

4-3-1. A Board – Processor (Block A) ..................... 29

4-3-2. A Board – Audio (Block B) ........................... 31

4-3-3. A Board – Power Supply (Block C) .............. 33

4-3-4. A Board – Deflection (Block D).................... 35

4-3-5. A Board – T uner (Block E)............................ 37

4-3-6. A Board – Jack, Scart T erminal (Block F) .... 39

4-3-7. C Board .......................................................... 41

4-4. Voltage Measurement And Waveform...................... 42

4-5. Printed Wiring Boards And Parts Location.............. 45

4-6. Semiconductors......................................................... 48

5. EXPLODED VIEWS

5-1. Chassis ...................................................................... 50

6. ELECTRICAL PARTS LIST......................................... 51

3. CIRCUIT ADJUSTMENTS

3-1. Adjustment With Commander .................................. 13

3-2. Adjustment Item T able ............................................. 14

3-3. T -Mode ...................................................................... 24

3-4. TT-Mode ................................................................... 24

3-5. T -Cyan Mode ............................................................ 24

3-6. Sub Brightness Adjustment ...................................... 25

3-7. Sub Contrast Adjustment.......................................... 25

3-8. Sub Colour Adjustment ............................................ 25

3-9. Tuner A GC Adjustment ............................................ 25

3-10. Deflection Adjustment.............................................. 26

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR THE

CARBON PAINTED ON THE CRT, AFTER REMOVAL OF THE

ANODE CAP.

WARNING !!

INSTRUCTION MANUAL

ATTENTION

APRES AVOIR DECONNECTE LE CAP DE’LANODE,

COURT-CIRCUITER L’ANODE DU TUBE CATHODIQUE ET

CELUI DE L’ANODE DU CAP AU CHASSIS METALLIQUE DE

L’APPAREIL, OU AU COUCHE DE CARBONE PEINTE SUR LE

TUBE CATHODIQUE OU AU BLINDAGE DU TUBE

CATHODIQUE.

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE WORK TO AVOID POSSIBLE SHOCK HAZARD

DUE TO LIVE CHASSIS, THE CHASSIS OF THIS RECEIVER IS

DIRECTLY CONNECTED TO THE POWER LINE.

SAFETY -RELA TED COMPONENT WARNING !!

!

COMPONENTS IDENTIFIED BY SHADING AND MARKED

ON

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION !!

AFIN D’EVITER TOUT RISQUE D’ELECTROCUTION

PROVENANT D’UN CHÁSSIS SOUS TENTION, UN

TRANSFORMATEUR D’ISOLEMENT DOIT ETRE UTILISÈ LORS

DE TOUT DÈPANNAGE LE CHÁSSIS DE CE RÈCEPTEUR EST

DIRECTMENT RACCORDÈ Á L’ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS Á

LA SECURITÈ!!

LES COMPOSANTS IDENTIFIÈS PAR UNE TRAME ET PAR UNE

MARQUE

!

SUR LES SCHÈMAS DE PRINCIPE, LES VUES

EXPLOSÈES ET LES LISTES DE PIECES SONT D’UNE

IMPOR-TANCE CRITIQUE POUR LA SÈCURITÈ DU

FONCTIONNEMENT,

NE LES REMPLACER QUE PAR DES COMPSANTS SONY DONT

LE NUMÈRO DE PIÈCE EST INDIQUÈ DANS LE PRÈSENT

MANUEL OU DANS DES SUPPLÈMENTS PUBLIÈS P AR SONY .

– 2 –

CAUTION

Lead Free Soldered Boards

The circuit boards listed below (Table 1) may have been processed using Lead Free Solder. The boards are

identified by the LF logo . e.g A,C board (see example).

Board Function

A ONE CHIP PROCESSOR, DEFLECTION,

POWER SUPPL Y , AUDIO, TUNER, IF ,

JACK,SCART TERMINAL

C RGB AMP

(Table 1)

KV-21CL5K

RM-W100

example 1 (A Board) example 2 (C Board)

The servicing of these boards requires special precautions to be taken as outlined below:

1. It is strongly recommended to use Sony Approved Lead Free Solder material in order to guarantee optimal

quality of new solder joints.

2. Due to higher melting point of Lead Free Solder, the soldering iron tip temperature needs to be set to chip

(350 degree centigrade) and lead component (380 degree centigrade) for not more than 4 seconds. This requires

soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

WARNING

(FOR EUROPE MODEL WITH “U” (UK) ONLY)

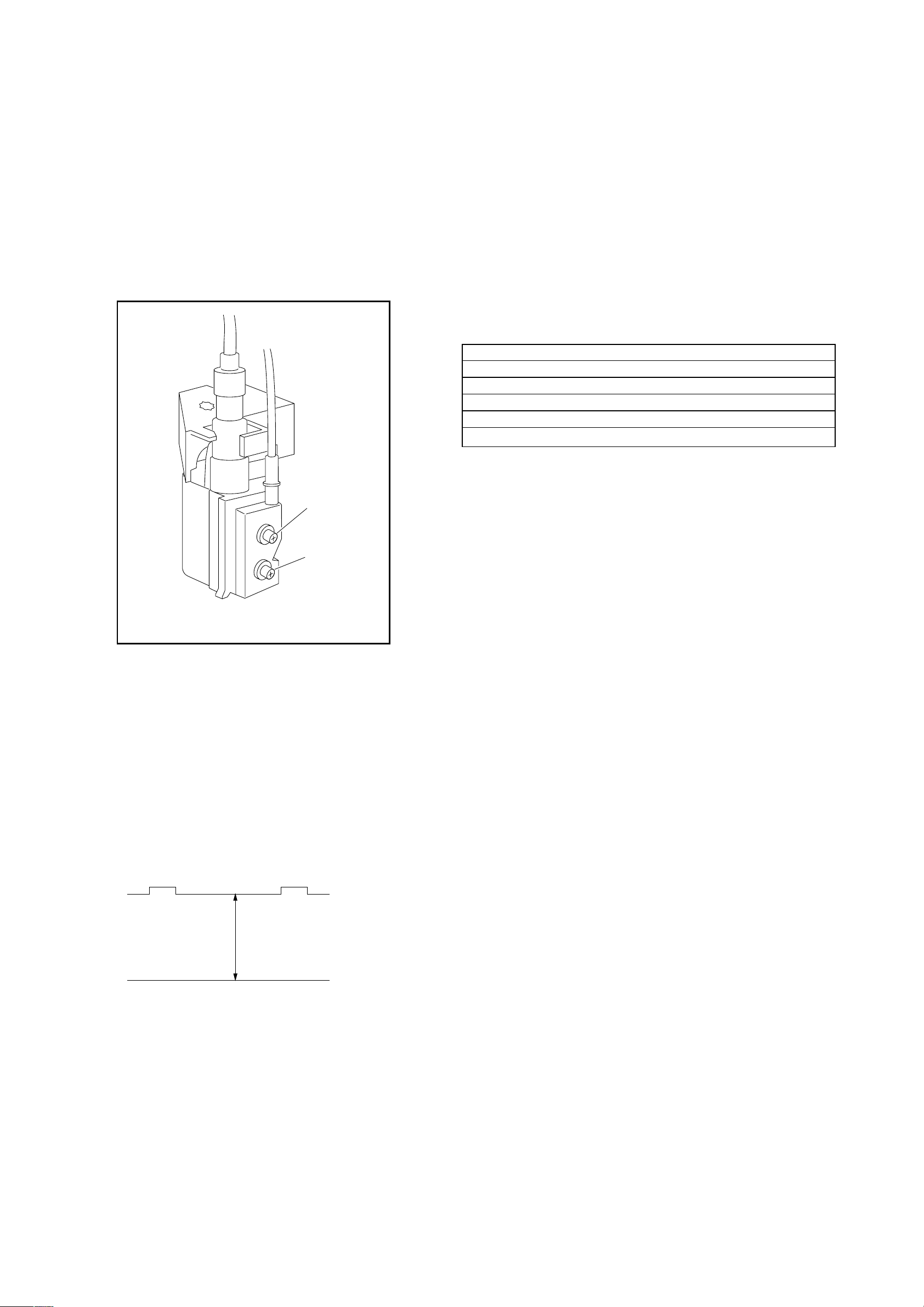

The flexible mains lead is supplied to connected a B.S. 1363 fused plug having a fuse of 5 AMP rating. Should the

fuse need to be replaced, use a 5 AMP FUSE approved by ASTA to BS 1362, i.e one that carries the

ASA

T

mark.

IF THE PLUG SUPPLIED WITH THIS APPLIANCE IS NO T SUITABLE FOR THE OUTLET SOCKETS IN Y OUR

HOME, IT SHOULD BE CUT OFF AND APPROPRIATE PLUG FITTED. THE PLUG SEVERED FROM THE MAINS

LEAD MUST BE DESTROYED AS A PLUG WITH BARED WIRES IS DANGEROUS IF ENGAGED IN A LIVE

SOCKET.

When an alternative type of plug is used, it should be fitted with a 5 AMP FUSE, otherwise the circuit should be

protected by a 5 AMP FUSE at the distribution board.

How to replace the fuse?

Open the fuse compartment with

a screw driver blade and replace

the fuse.

– 3 –

KV-21CL5K

RM-W100

The units in this manual contain a self diagnostic function. If an error occurs, the STANDBY (1) indicator will automatically

begin to flash. A description of the self-diagnosis function is explained in the instr uction manual. The number of times the

STANDBY (1) indicator flashes translates to a probable source of the problem. If an error symptom cannot be reproduced,

the remote commander can be used to review the failure occurrence data stored in memory to reveal past problems and

how often these problems occur.

1. DIAGNOSTIC TEST INDICATORS

When an errors occurs, the STANDBY (1) indicator will flash a set number of times to indicate the possible cause of the

problem. If there is more than one error, the indicator will identify the first of the problem areas.

SELF DIAGNOSTIC FUNCTION

Result for all of the following diagnosis items are displayed on screen. No error has occured if the screen displays a “0”.

Diagnosis

Item

Description

Power does

not turn on

+B overcurrent

(OCP)*

V-Protect

No. of timer

STANDBY (1)

indicator flashes

Does not light

2 times

4 times

Self-Diagnostic

display/

Diagnosis result

–

2:0

or

2:1 ~ 255

4:0

or

4:1 ~ 255

Probable Cause

Location

• Power cord is not plugged

in.

• Fuse is burned out (F600)

A board.

• H OUT (Q805) is shorted.

(A board)

• IC751 is shorted. (C board)

• +13V is not supplied.

(A board)

• IC804 is faulty. (A board)

Detected

Symptoms

• Power does not come on.

• No power is supplied on

TV.

• AC Power supply is faulty.

• Power does not come on.

• Load on power line is

shorted.

• Has entered standby state

after horizontal raster.

• Ver tical deflection pulse is

stopped.

• Power line is shorted or

power supply is shorted.

IK (AKB)

HV Protect

* If a +B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously. The symptom that is

diagnosed first by the mirco controller is displayed on the screen.

** Refer to Screen (G2) Adjustment in this manual.

5 times

8 times

5:0

or

5:1 ~ 255

8:0

or

8:1 ~ 255

• Video OUT (IC1545) is

faulty. (A board)

• IC001 is faulty. (A board)

• Screen (G2) is improperly

adjusted.**

• IC604 faulty.

• IC602 faulty.

• No raster is generated.

• CRT Cathode current

detection reference pulse

output is small.

• No power supply to CRT

ANODE.

• No RASTER is generated.

– 4 –

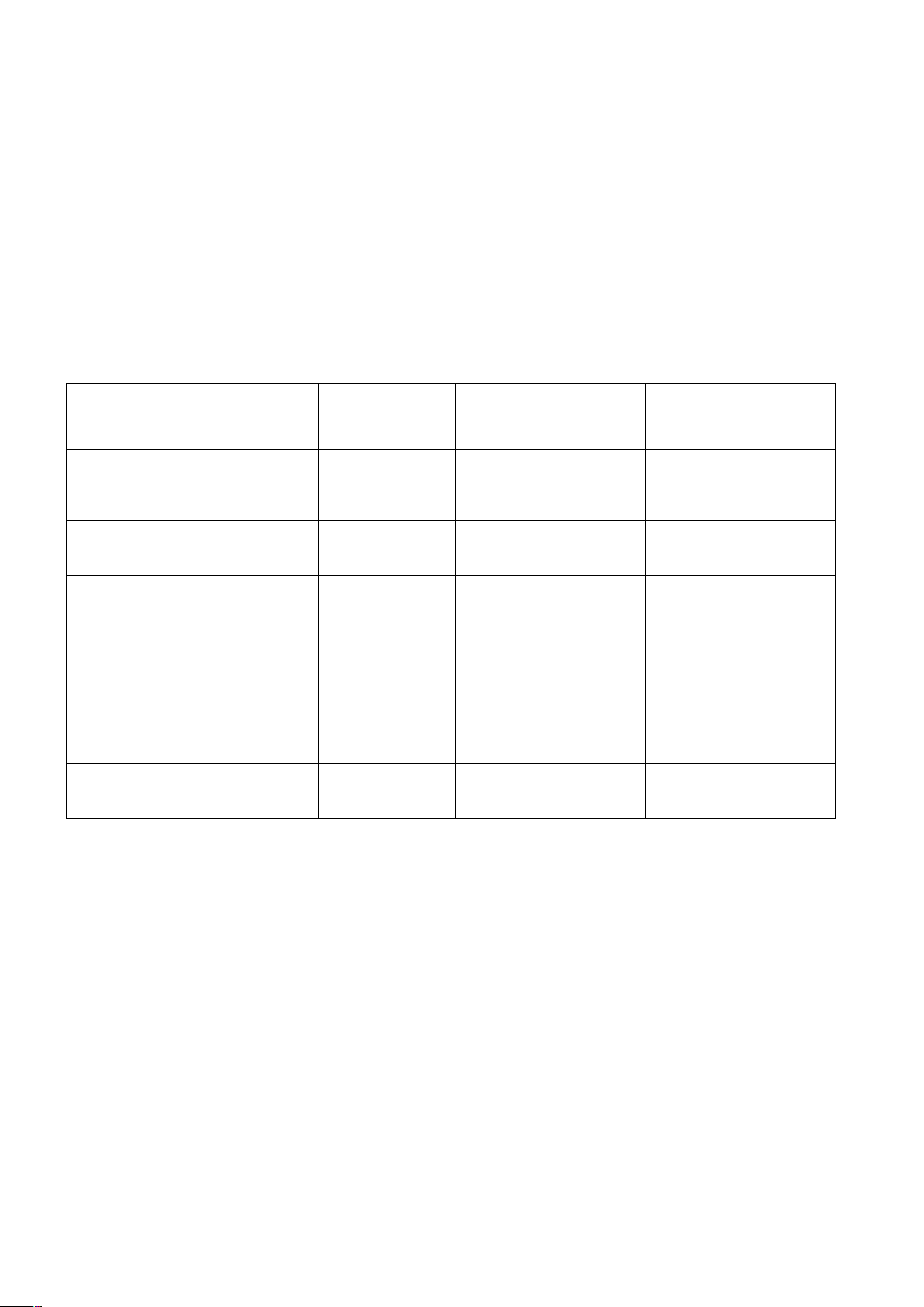

2. DISPLAY OF STANDBY (1) INDICATOR

KV-21CL5K

RM-W100

FLASH COUNT

Lamp ON 300ms

Lamp OFF 300ms

Diagnostic Item Flash Count*

+B overcurrent 2 times

V-Protect 4 times

IK (AKB) 5 times

HV Protect 8 times

* One flash count is not used for self-diagnosis.

Lamp OFF 3 sec

STANDBY u indicator

3. STOPPING THE

STANDBY (1) INDICATOR FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY (1)

indicator from flashing.

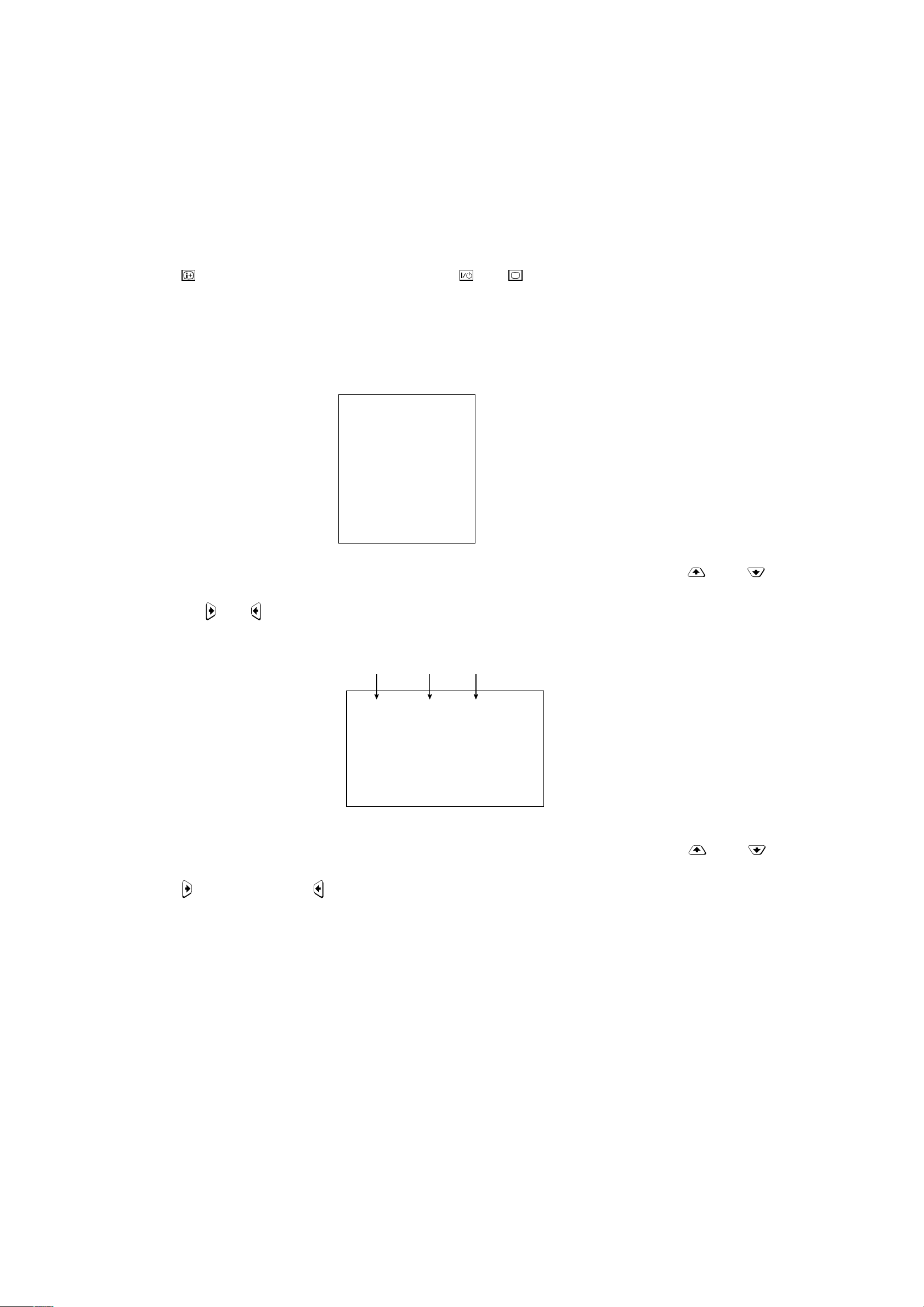

4. SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as "power sometimes shuts off" or "screen sometimes goes off" that cannot be confirmed,

it is possible to bring up past occurrences of failure on the screen for confirmation.

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

Display

/ Channel 5 / Volume / Power / TV

˘

Note that this differs from entering the service mode (volume [+]).

The following screen will be displayed indicating the error count.

ERROR MENU

2 : 0

3 : N/A

4 : 0

5 : 1

8 : 0

101 : N/A

Numeral "0" means that no fault was detected.

Numeral "1" means the number of a fault occurrence (1 ~ 255).

– 5 –

KV-21CL5K

RM-W100

5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen

during repairs. When you have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnosis function will not be able to detect subsequent faults after

completion of the repairs.

[Clearing the result display]

To clear the result display to “0”, press buttons on the remote commander subsequent as shown below when the

self-diagnostic screen is being displayed.

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

8 / -

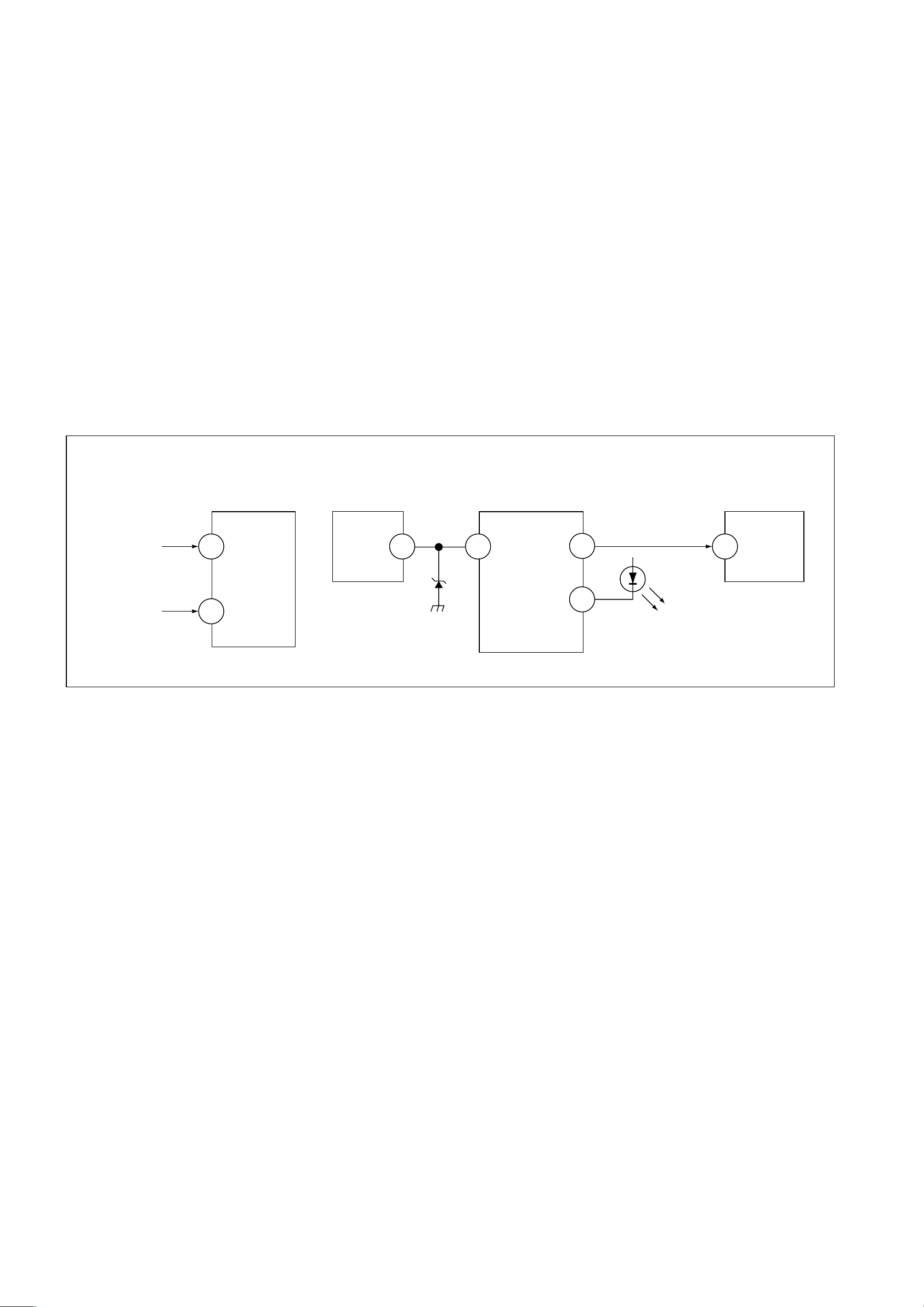

6. SELF-DIANOSTIC CIRCUIT

FROM

C BOARD

IC751 PIN 5

A BOARD

FROM

Q804

COLLECTOR

A BOARD

IC001

Y/CHROMA JUNGLE

IK

32

EHTO

A BOARD

IC804

V.OUT

F.B-PLS

A BOARD

IC001

SYSTEM

SDA1

3 1384

V.GUARD

RED LED

99

122

DISPLAY

A BOARD

IC003

MEMORY

5

SDA

[+B overcurrent $OCP%] Occurs when an overcurrent on the +B(135V) line is detected by pin 32 of IC001 (A board).

If the voltage of pin 32 of IC001 (A board) is more than 4V, the unit will automatically go to

standby.

[V-PROTECT] Occurs when an absence of the vertical deflection pulse is detected by pin 13 of IC001

(A board).

[IK $AKB%] If the RGB levels* do not balance within 15 sec after the power is tur ned on, this error will be

detected by IC001 (A board). TV will stay on, but there will be 5 times LED blinking.

[HV PROTECT] Occurs when IC001 internal HV protect detects an abnormal H-Pulse (frequency) due to

improper power supply to IC001. TV cuts off high voltage power of anode CRT. No picture will

be detected. eg: IC602, IC604 go faulty.

* (Refers to the RGB levels of the AKB detection Ref pulse that detects IK.)

– 6 –

SECTION 1

DISASSEMBLY

KV-21CL5K

RM-W100

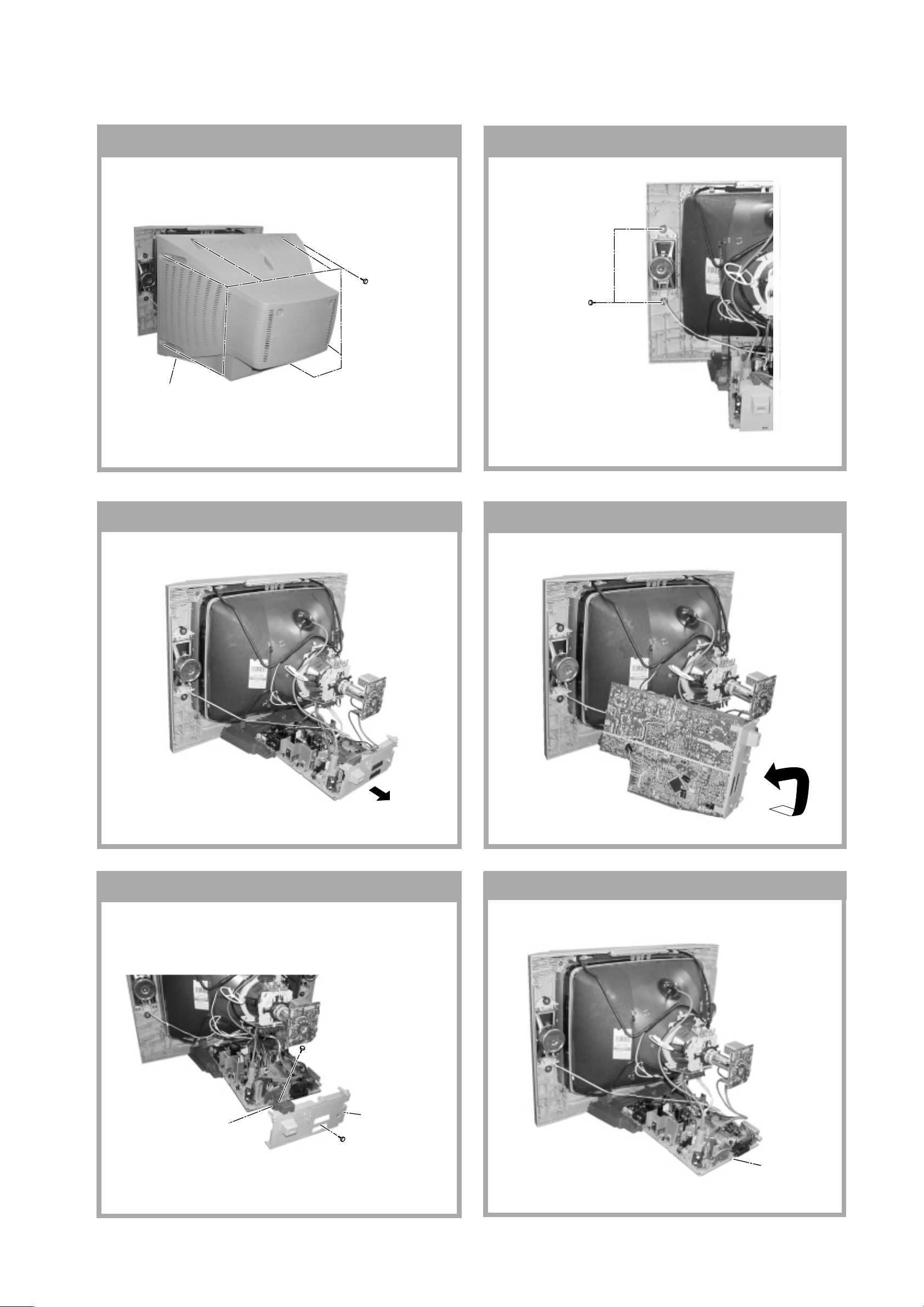

1-1. REAR COVER REMOVAL

2 Rear cover

1 Eight Screws

(PT screws)

1-2. SPEAKER BLOCK ASSY REMOVAL

Two Screws

(4 x 16)W(+)

P TAPPING

1-3. CHASSIS ASSY REMOVAL

1-4. SERVICE POSITION

1-5. TERMINAL BRACKET REMOVAL

1 One screw

(+BVTP 3x16)

3 Terminal

Bracket FBT

2 One screw

(PT screws)

bracket

1-6. A BOARD REMOVAL

A Board

– 7 –

KV-21CL5K

c

RM-W100

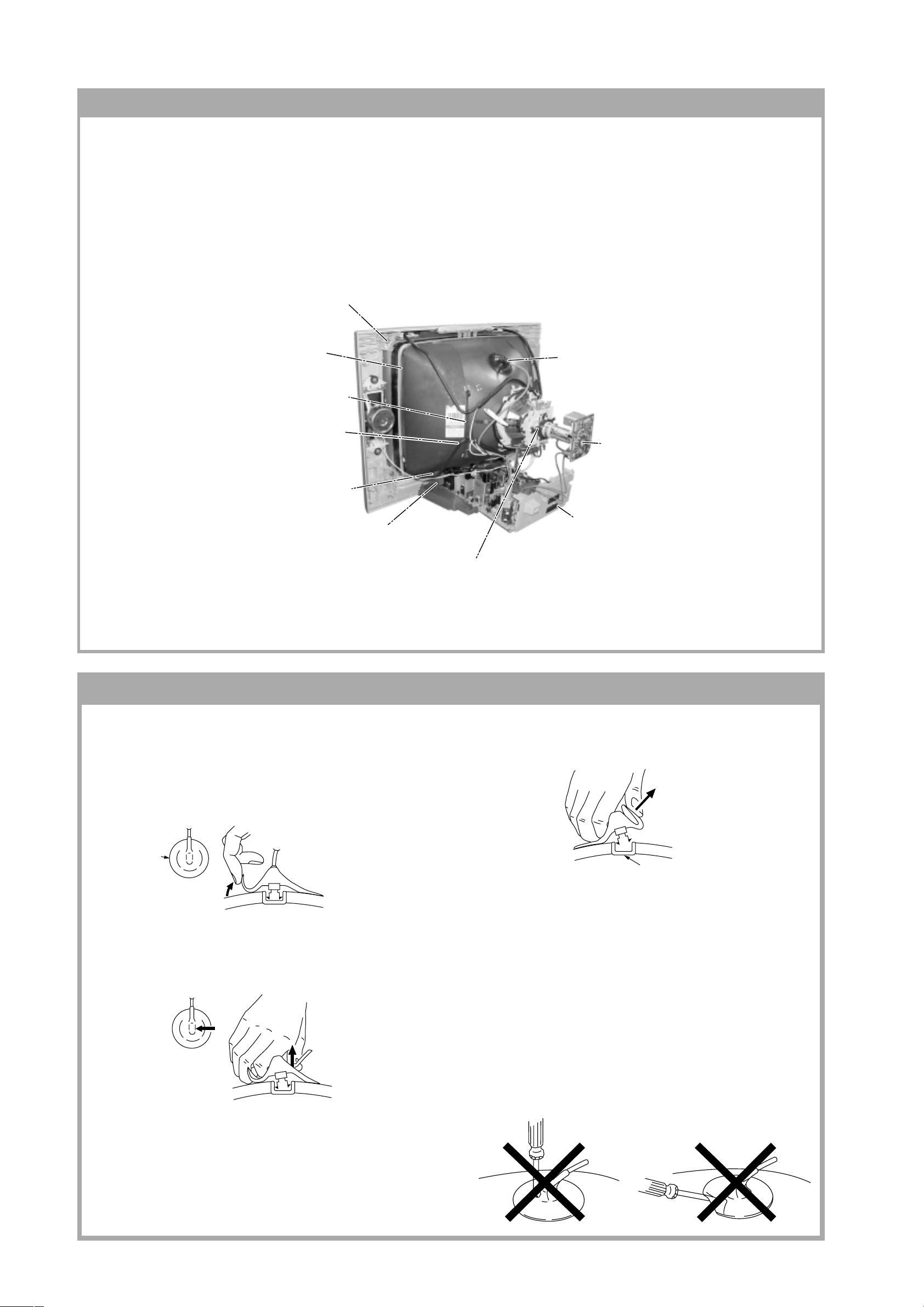

1-7. PICTURE TUBE REMOVAL

Note:

• Please make sure the TV set is not in standing position before removing necessary CRT support located on bottom

right and left.

1)Place the TV set with the CRT face down on a cushion jig.

2)Removal the rear cover.

3)Unplug all interconnecting leads from the Deflection Y oke, Degaussing Coils and CRT grounding strap.

qd unscrew — PT Screw (x4)

qs Earth Coating Assy Removal

9 Holder, DGC Removal (x2)

0 Degaussing Coil

Removal (x2)

qa Spring Tension

Removal (x1)

8 Support, CRT(21)

Removal (x2)

4 Anode Cap Removal

5 C Board Removal

7 Chassis Assy Removal

6 Loosen the Deflection Yoke

fixing screw and remove

• REMOVAL OF ANODE-CAP

Note:

• After removing the anode, short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT

shield or carbon paint on the CRT.

• REMOVING PROCEDURES

a

a

1 Turn up one side of the rubber cap in the direction

indicated by the arrow a.

b

b

the anode button, the anode-cap can be removed by

turning up the rubber cap and pulling it up in the

direction of the arrow c.

• HOW TO HANDLE AN ANODE-CAP

1 Do not damage the surface of anode-caps with

sharp shaped objects.

2 Do not press the rubber too hard so as not to

damage the inside of anode-cap.

A metal fitting called the shatter-hook terminal is

built into the rubber.

3 Do not turn the foot of rubber over too hard.

The shatter-hook terminal will stick out or damage

the rubber.

anode button

2 Using a thumb pull up the rubber cap firmly in the di-

rection indicated by the arr ow b.

3 When one side of the rubber cap is separated from

– 8 –

SECTION 2

SET-UP ADJUSTMENTS

KV-21CL5K

RM-W100

• The following adjustments should be made when a

complete realignment is required or a new picture tube is

installed.

Perform the adjustments in the following order :

1. Beam Landing

2. Convergence

3. Focus

Set the controls as follows unless otherwise noted:

VIDEO MODE.................................................. STANDARD

PICTURE CONTROL .......................................... NORMAL

BRIGHTNESS CONTROL.................................... NORMAL

4. Screen (G2)

5. White Balance

Note : Test Equipment Required.

1. Pattern Generator

2. Degausser

3. DC Power Supply

4. Digital Multimeter

5. Oscilloscope

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

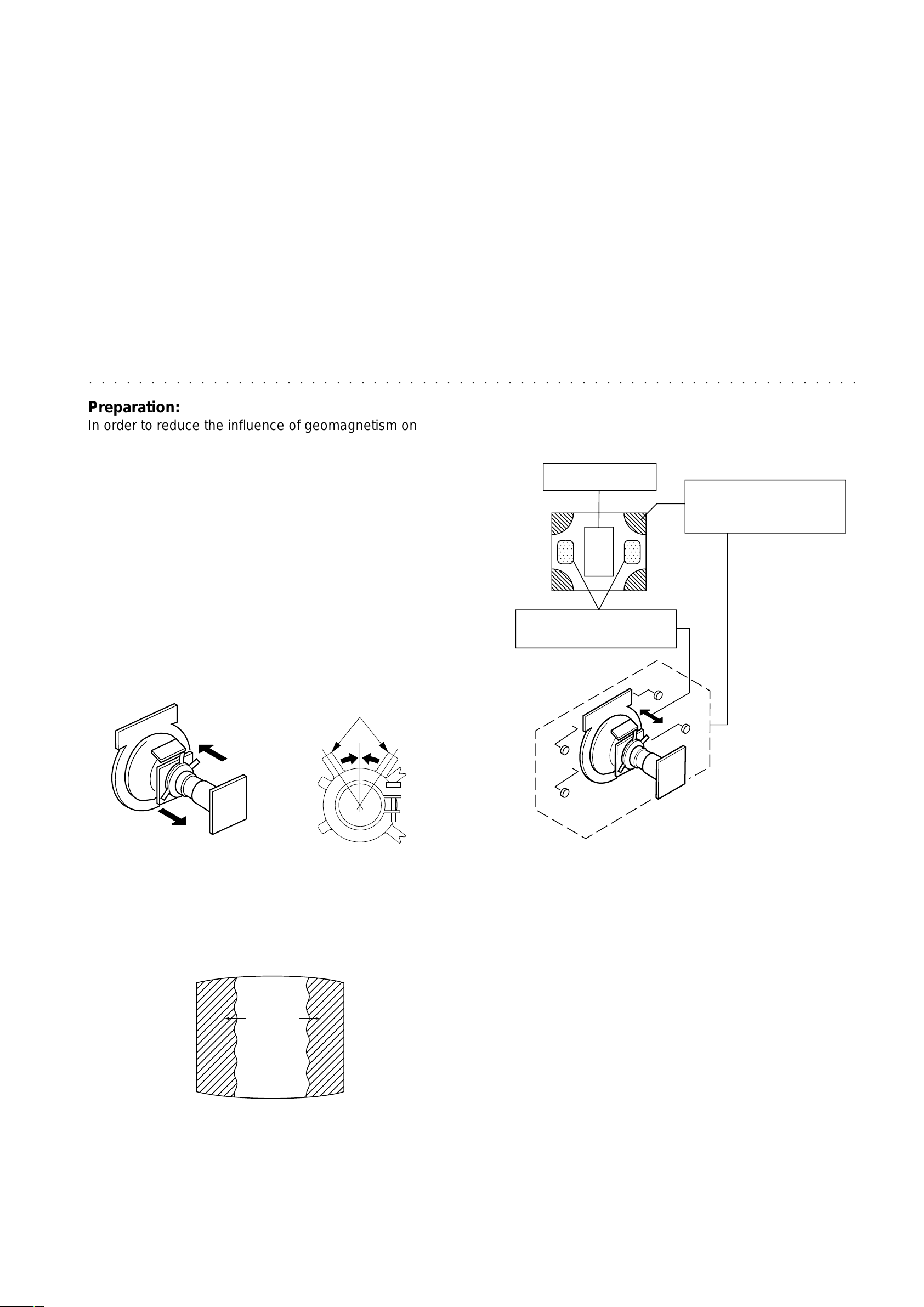

Preparation:

In order to reduce the influence of geomagnetism on the

7. If the beam does not land correctly in all the corners,

use a magnet to correct if. (see figure 2-1-3)

set's picture tube, face it east or west. Switch on the set's

power and degauss with the degausser.

Purity control

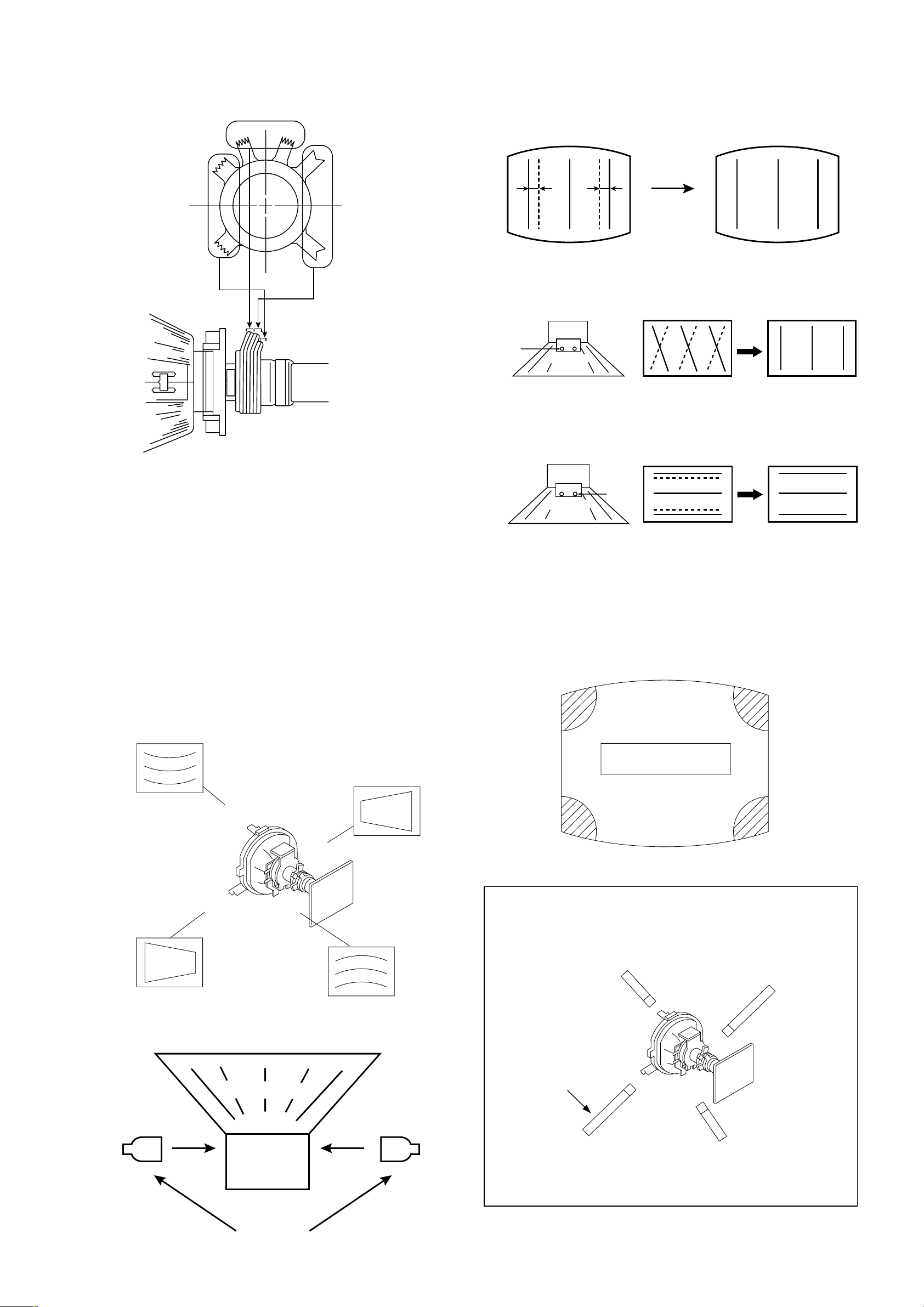

2-1. BEAM LANDING

Picture Mode : LIVE

corrects this area.

b

a

Disk magnets or rotatable

disk magnets correct these

areas (a-d).

1. Input a white signal with the pattern generator.

Set the contrast and brightness to normal.

2. Set the pattern generator raster signal to a green raster.

c

d

3. Move the deflection yoke to the rear and adjust with the

purity control so that the green is at the centre and the

blue and red take up equally sized areas on each side

Deflection yoke positioning

corrects these areas.

of the screen. (see figure 2-1 and figure 2-1-1)

Purity control

Figure 2-1 Figure 2-1-1

4. Move the deflection yoke forward and adjust so that the

entire screen is green. (see figure 2-1-2)

b

c

a

d

Figure 2-1-3

Caution:

High voltages are present on the Deflection yoke

terminals. Take care when handling the deflection yoke

whilst carrying out adjustments.

Blue

Red

Green

Figure 2-1-2

5. Switch the raster signal to blue, then red and verify the

condition.

6. When the position of deflection yoke have been

decided, fasten the deflection yoke with the screws and

DY spacers.

– 9 –

KV-21CL5K

BGR

A

RGB

B

RM-W100

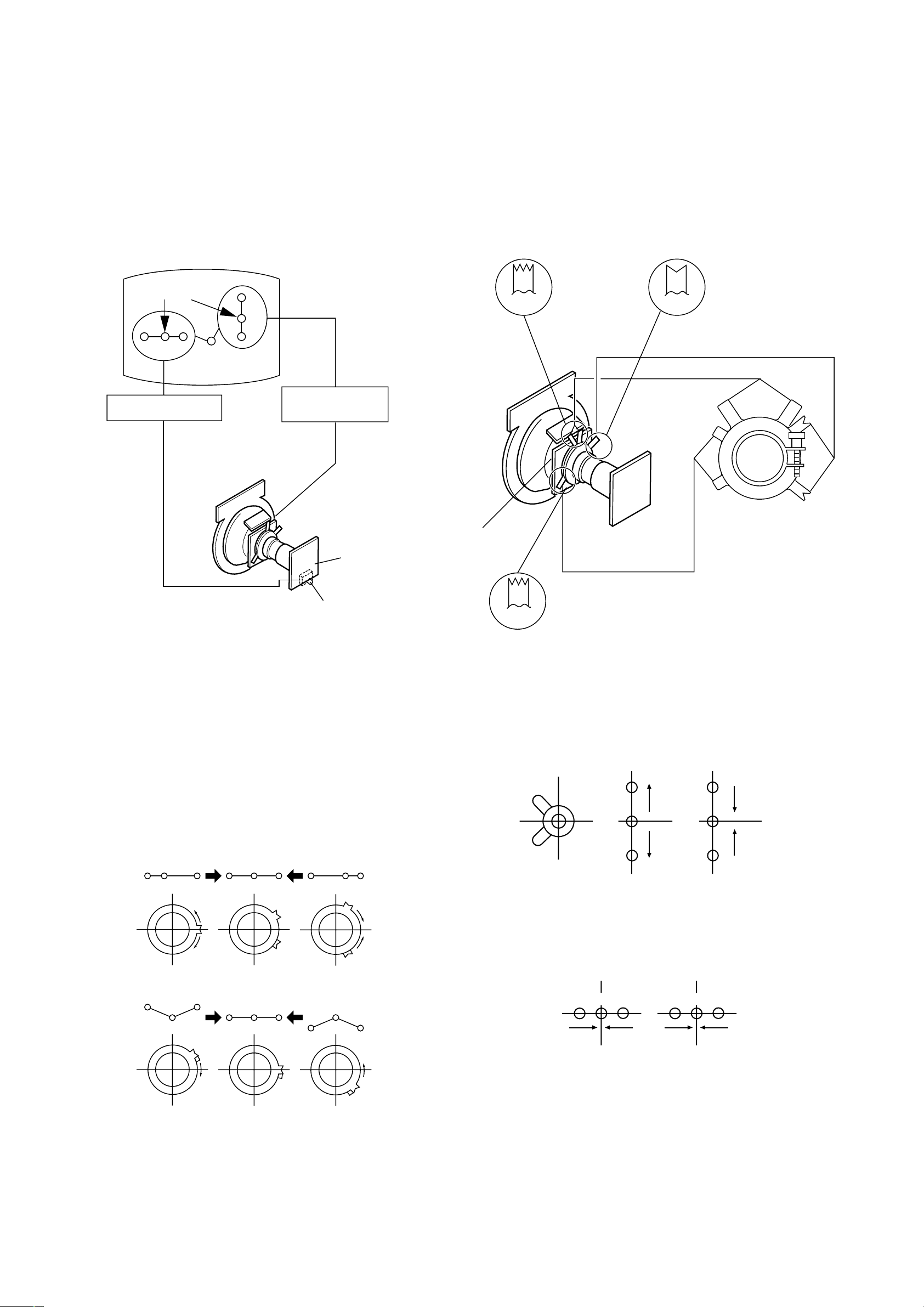

2-2. CONVERGENCE

Preparation:

• Before starting this adjustment, adjust the focus,

horizontal size and vertical size.

• Receive dot/hatch signal.

• Picture Mode : MOVIE

(A) Horizontal and Vertical Static Convergence

Centre dot

R G B

H. STAT VR

R

G

B

V. STAT

Magnet

4. If the H.STAT variable resistor cannot bring the red,

green and blue dots together at the centre of the

screen, adjust the horizontal convergence with the H.

STAT var iable resistor and the V.STAT magnet in the

manner given below.

(In this case, the H.STAT variable resistor and the

V.STAT magnet influence each other, so be sure to

perform adjustments while tracking.)

BMCPurity

BMC (Hexapole)

Purity

C Board

RV750

1. (Moving vertically), adjust the V.STAT magnet so that

the red, green and blue dots are on top of each other at

ther centre of the screen.

2. (Moving horizontally), adjust the H.STAT VR control so

that the red, green and blue dots are on top of each

other at the centre of the screen.

3. BMC (Hexapole)Magnet

If the red, green and blue dots are not balanced or

aligned then use the BMC magnet to adjust in the

manner described below.

DY pocket

V.STAT

V.STAT

Operation of V.STAT magnet.

If the V.STAT is moved in the "A" and "B" arrows, the red,

green and blue dots moves as shown below.

AB

B

G

B

G

BG R R G B R GB

RB

G

RG

GB

RB

R

R

Moved RV750 H.STAT the red, green and blue dots move

as shown below.

– 10 –

KV-21CL5K

RM-W100

5. Layout of each control.

V.STAT

Purity

BMC (Hexapole)

H-TILT correction can be performed by adding a TLH

correction assembly to the Deflection Y oke.

8. YCH Adjustment

YCH VR

Deflection Yoke

6. Geometr y Adjustment.

Preparation:

Before starting this adjustment, adjust the horizontal and

vertical static convergence.

a) Remove the deflection yoke spacer.

b) Tilt the deflection yoke as indicated in the figure below

and optimise the geometry.

Tilting the DY up and down will balance the upper and

lower pin adjustment.

Tilting the DY left and right will balance the H-Trap

adjustment.

c) Re-install the deflection yoke spacer.

9. TLV Adjustment

TLV VR

Deflection Yoke

10.Screen Corner Convergence.

If you are unable to adjust the corner convergence

properly, this can be corrected with the use of Piece

A(90) Conv. Correct.

ba

7. H-TILT Adjustment

,

,

,

,

Tilt Direction

Deflection Yoke

a-d : screen-corner

misconvergence

cd

,

Install the Piece A(90) Conv. Correct

assembly for the area that needs correcting.

a

b

Piece A(90) Conv. Correct

4-094-690-01

TLH pieces

– 11 –

d

Convergence adjustment with

Piece A(90) Conv. Correct

c

KV-21CL5K

RM-W100

2-3. FOCUS ADJUSTMENT

1. Receive digital monoscope pattern.

2. Set Picture Mode to PERSONAL.

3. Adjust focus VR to obtain the best focus at the centre of

the screen.

4. Change the receiving signal to white pattern and blue

back.

5. Confirm magenta ring is not noticeable. In case

magenta is very obvious, adjust the focus VR to take

balance of magenta ring and focus.

2-5. WHITE BALANCE ADJUSTMENT

1. Enter into Service Menu.

2. Input white pattern signal.

3. Set picture to PERSONAL mode.

4. Select WHBL "RDRV" and fix the value to 25 hex.

5. Adjust WHBL "GDRV" and "BDRV" and adjust the data

for best white balance in highlight condition.

6. Adjust WHBL "BKOR" and "BKOG" and adjust the data

for best white balance cut-off condition.

7. Set the offset settings for LIVE and GAME mode as

stated in the table 1 below:-

OFFSET TABLE (Table 1)

Live T Personal T Game

Adjusted value +2 BKOR (adjusted) Adjusted value

Adjusted value -3 BKOG (adjusted) Adjusted value

25hex RDRV (25hex) 25hex

Adjusted value +2 GDRV (adjusted) Adjusted value -2

Adjusted value +4 BDRV (adjusted) Adjusted value -6

FOCUS

SCREEN

FLYBACK TRANSFORMER (T801)

2-4. G2(SCREEN) ADJUSTMENT

1. Input a dot signal from the pattern generator.

2. Set the Picture, Brightness and Colour to minimum.

3. Apply 167V DC from an external power supply to the

R,G and B cathodes of the CRT.

4. Adjust brightness to obtain cathode value to value

below.

5. Whilst watching the picture, adjust the G2 control

[SCREEN] located on the Flyback Transformer to the

point just before the flyback return lines disappear.

Cathode setting voltage:

167 V ± 2 (VDC) — 21"

– 12 –

SECTION 3

CIRCUIT ADJUSTMENTS

3-1. ADJUSTMENT WITH COMMANDER

Service adjustment to this model can be performed using the supplied remote commander RM-W100.

a. ENTERING SERVICE MODE

With the unit on standby, press the following sequence of buttons on the remote commander.

/ Display / Channel 5 / Volume [+] / Power / TV

'TT – –'will appear in the upper right cor ner of the screen.

KV-21CL5K

RM-W100

Other status information will also be displayed.

b. Press 'MENU' on the remote commander to obtain service menu on the screen.

GEOM

WHBL

SADJ

YC

SYNC

PICT

SW

VIF

c. The screen only displays 8 items at one time. To move to the corresponding item use the up

the remote commander.

d. Press the right

/ left button or ENTER button on the remote commander to enter into the required item.

Item

Name

Range Data

down buttons on

HPOS

HPAR

e. The screen only display 12 items at one time. To move to the corresponding item use the up

the remote commander.

f. Press right

g. Press the 'MENU' button on the remote commander to quit from Service Menu. Screen will still display 'TT – –'. To exit

from 'TT – –' menu, press 0 twice, 'TEST', 'TV' or switch the TV into standby mode.

Note:

• After carrying out the ser vice adjustments, to prevent the customer accessing the 'Service Menu' switch the TV set

OFF and then ON.

to increase or left to decrease the data.

52(0,63)

40(0,63)

down buttons on

– 13 –

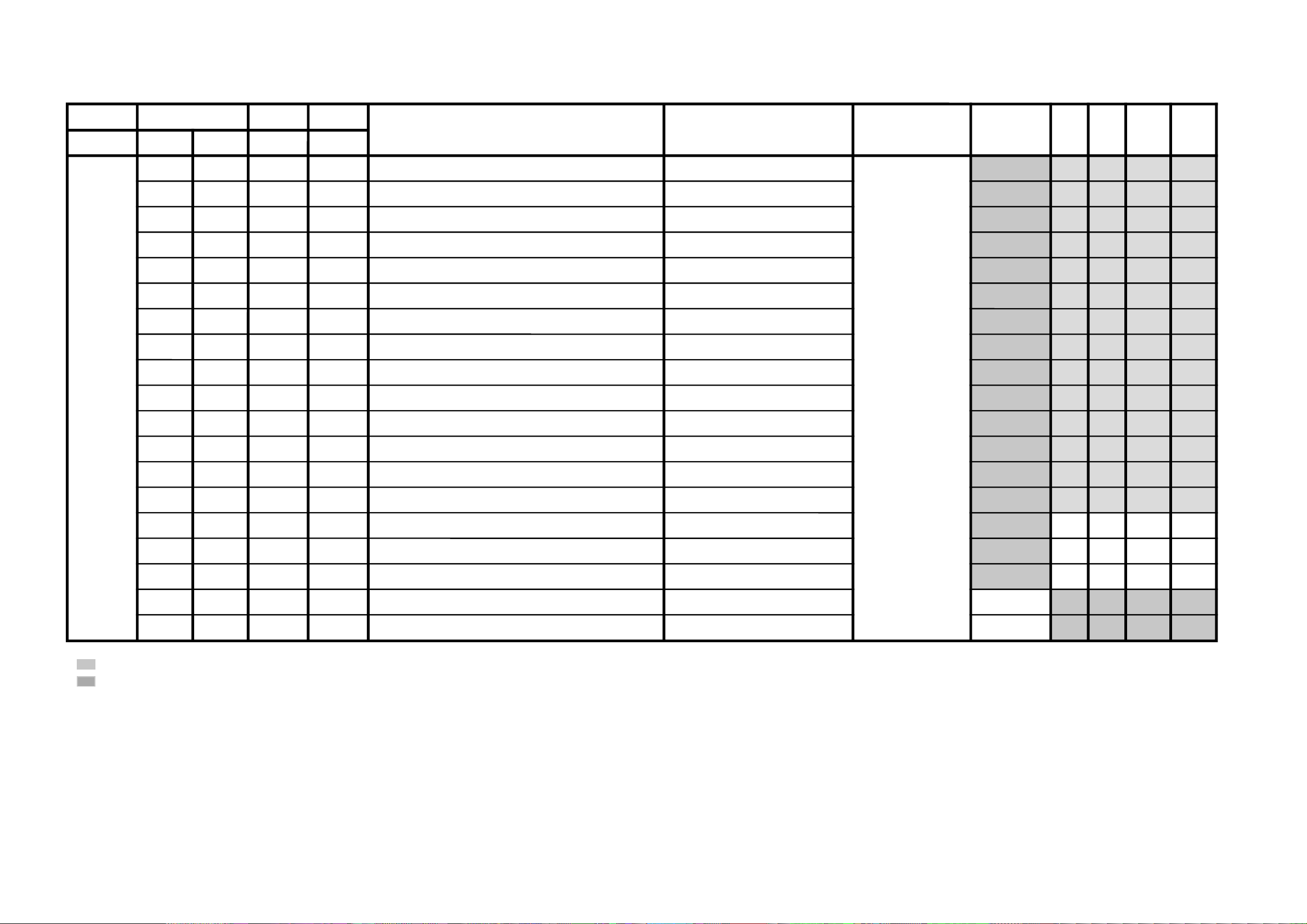

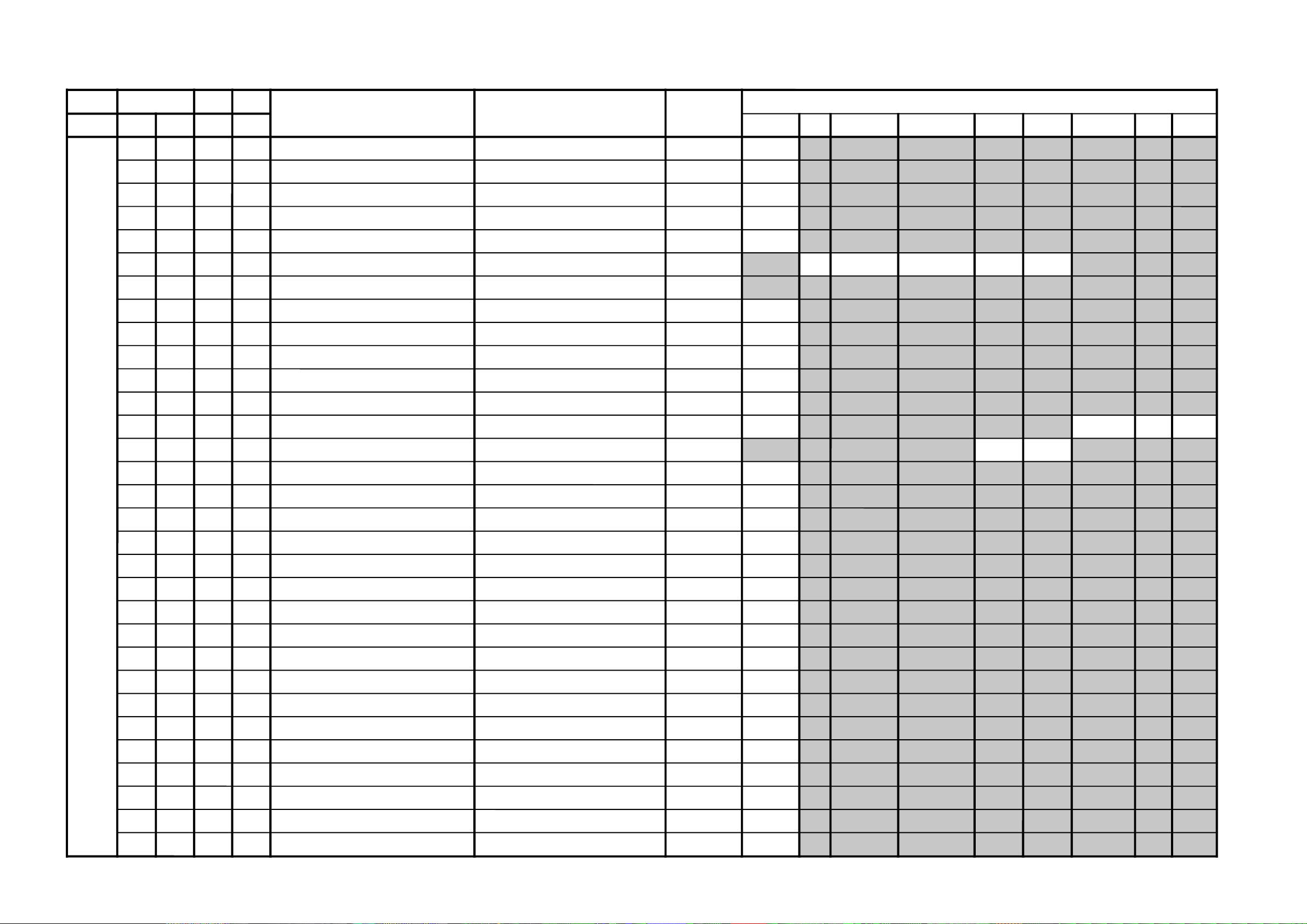

JVTytilanoitcnuFlaitinIegnaR

noitcnuFetoN&elbaTemaNeciveDnommoC050605w06w

yrogetaCoNemaNceDceD

MOEG

000SOPH130360)SH(tfihSlatnoziroH )BGRNPJ+(06w/05w/06/05

rossecorP-VT

13

13

13

13

100RAPH130360margolellaraPlatnoziroH06w/05w/06/05

13

13

13

13

200WOBH130360woBlatnoziroH06w/05w/06/05

13

13

13

13

300NILV130360ytiraeniLlacitreV06w/05w/06/05

13

13

13

13

400RCSV130360llorcSlacitreV06w/05w/06/05

13

13

13

13

500ZISH130360)WE(htdiWWE )BGRNPJ+(06w/05w/06/05

13

13

13

13

600WPWE130360)WP(htdiW/alobaraPWE06w/05w/06/05

13

13

13

13

700POCU710360alobaraPrenroCreppUWE06w/05w/06/05

71

71

71

71

800POCL710360alobaraPrenroCrewoLWE06w/05w/06/05

71

71

71

71

900ZTWE130360muizeparTWE06w/05w/06/05

13

13

13

13

010PLSV130360)SV(epolSlacitreV06w/05w/06/05

13

13

13

13

110ZISV510360edutilpmAlacitreV06w/05w/06/05

51

51

51

51

210ROCS410360)CS(noitcerroC-S06w/05w/06/05

41

41

41

41

310SOPV130360)HSV(tfihSlacitreV06w/05w/06/05

13

13

13

13

410LBH000100edoMgniknalBBGR06w/05w/06/05

10101010

510FBW700510)FBW(gniknalBediWfognimiT06w/05w/06/05

90909090

610RBW700510)RBW(gniknalBediWfognimiT06w/05w/06/05

01010101

710LBS000100gniknalBecivreSenon00

810YPOC000100aeraMVNzH06/05llaotatadOEGehtypoCenon00

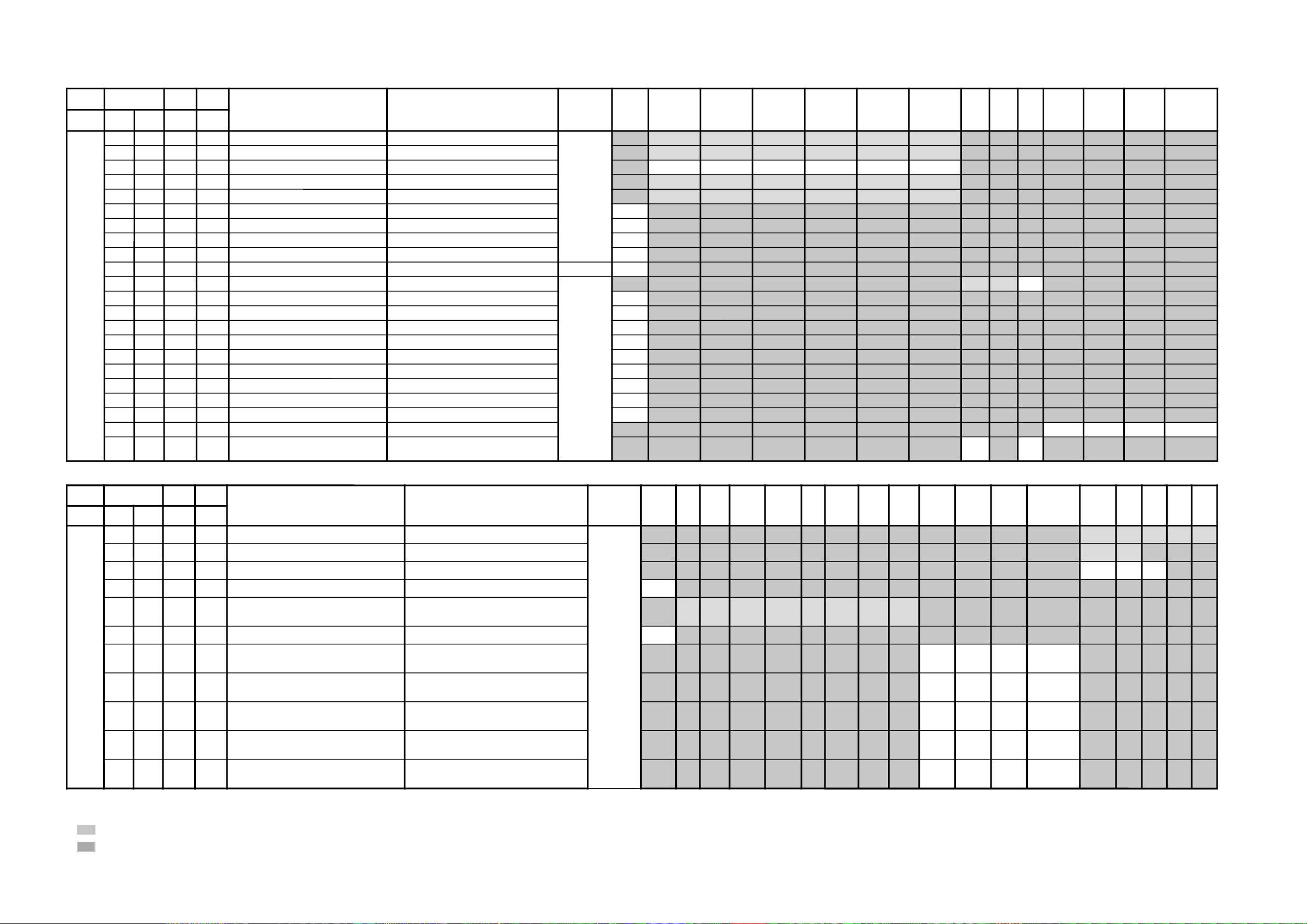

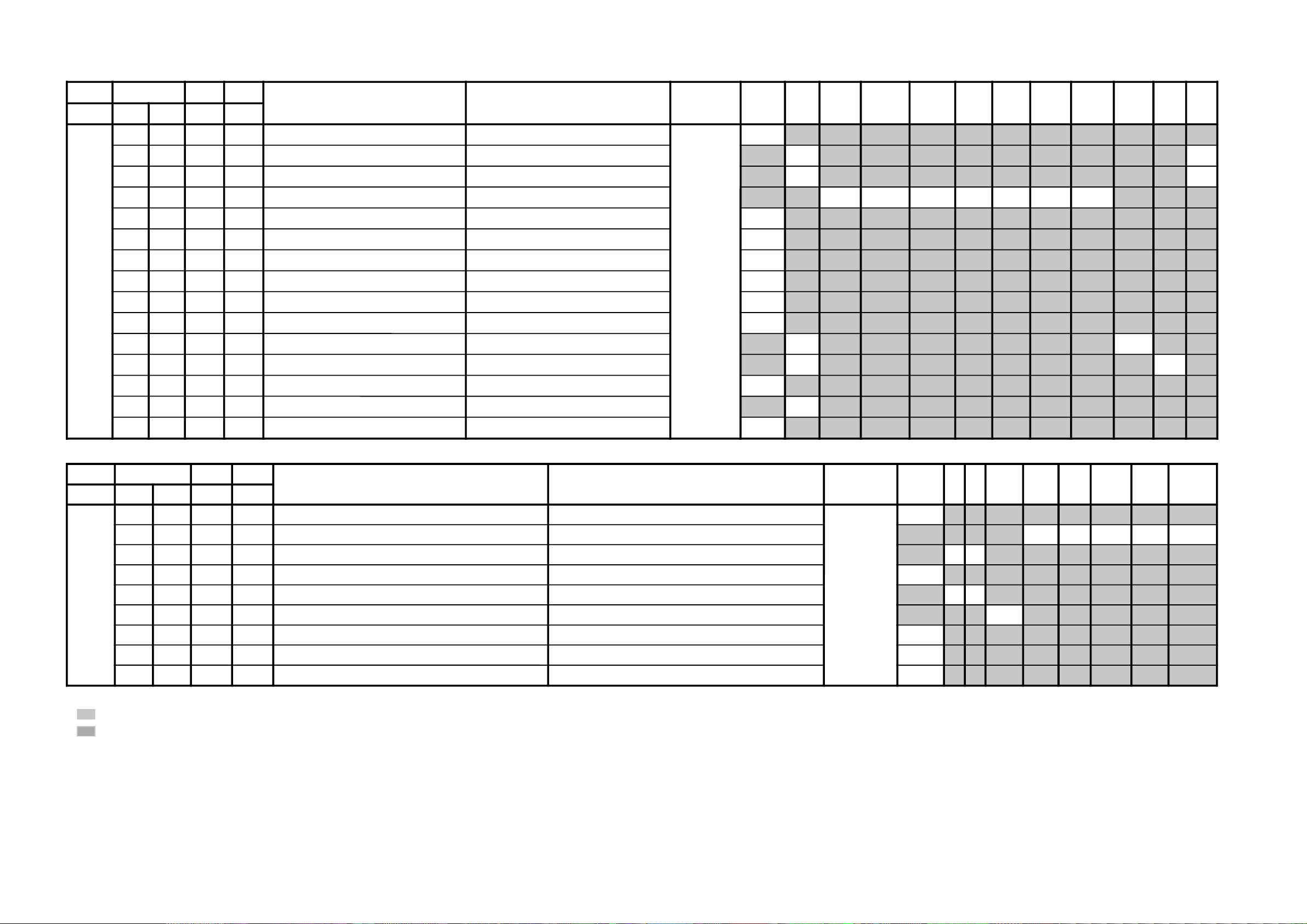

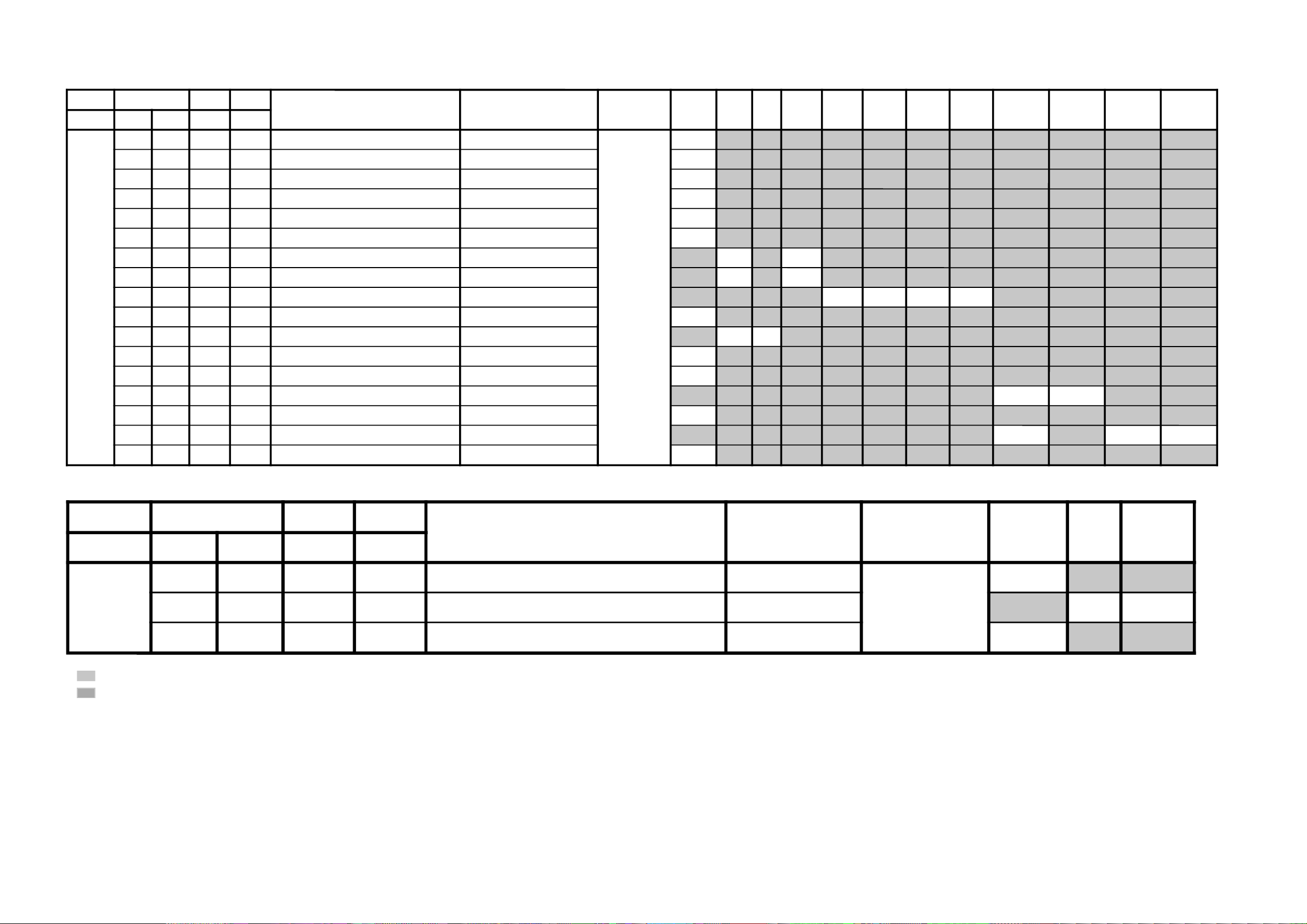

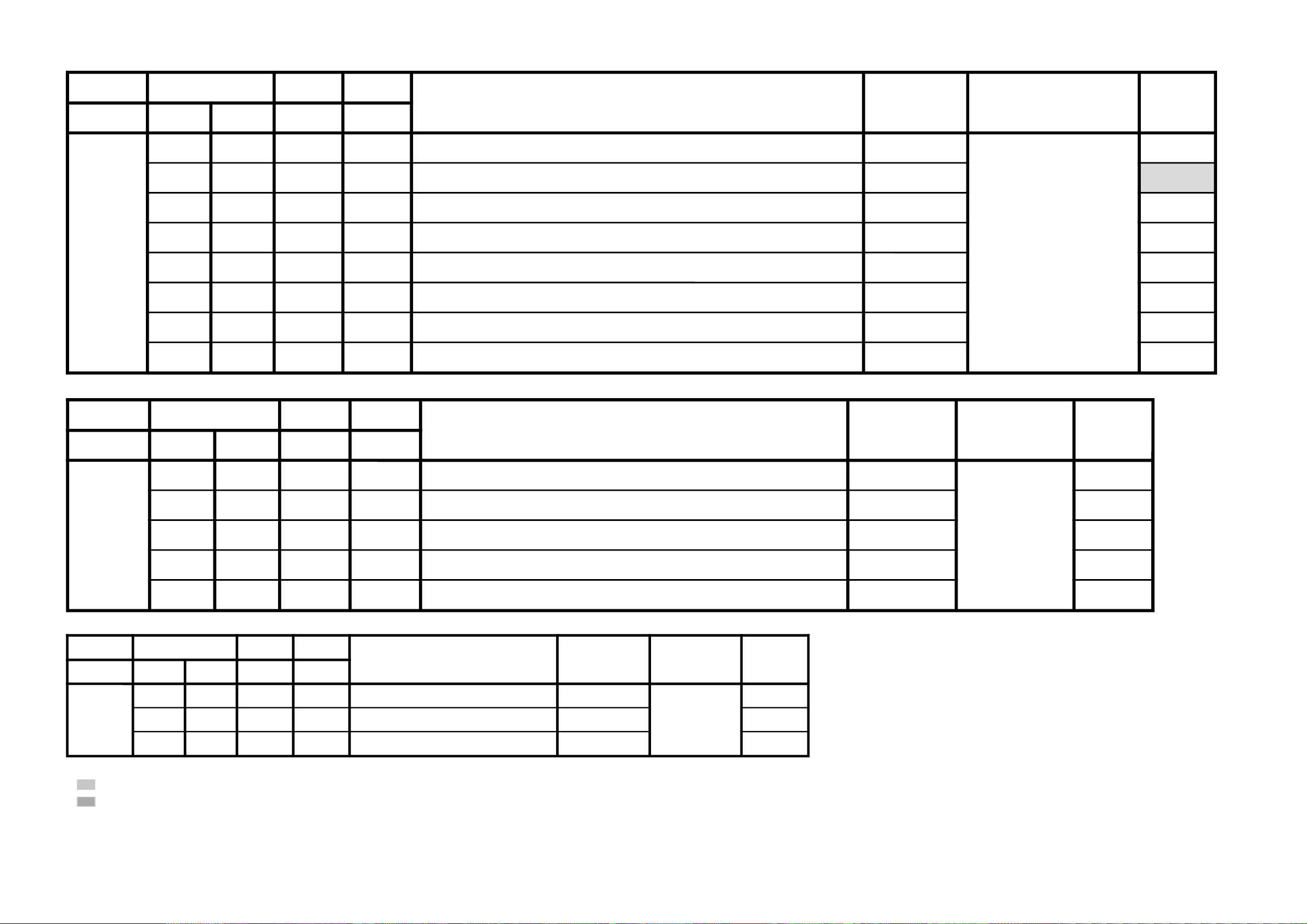

3-2. ADJUSTMENT ITEM TABLE

KV-21CL5K

RM-W100

– 14 –

•

•

shaded items are adjustable data.

no data.

– 15 –

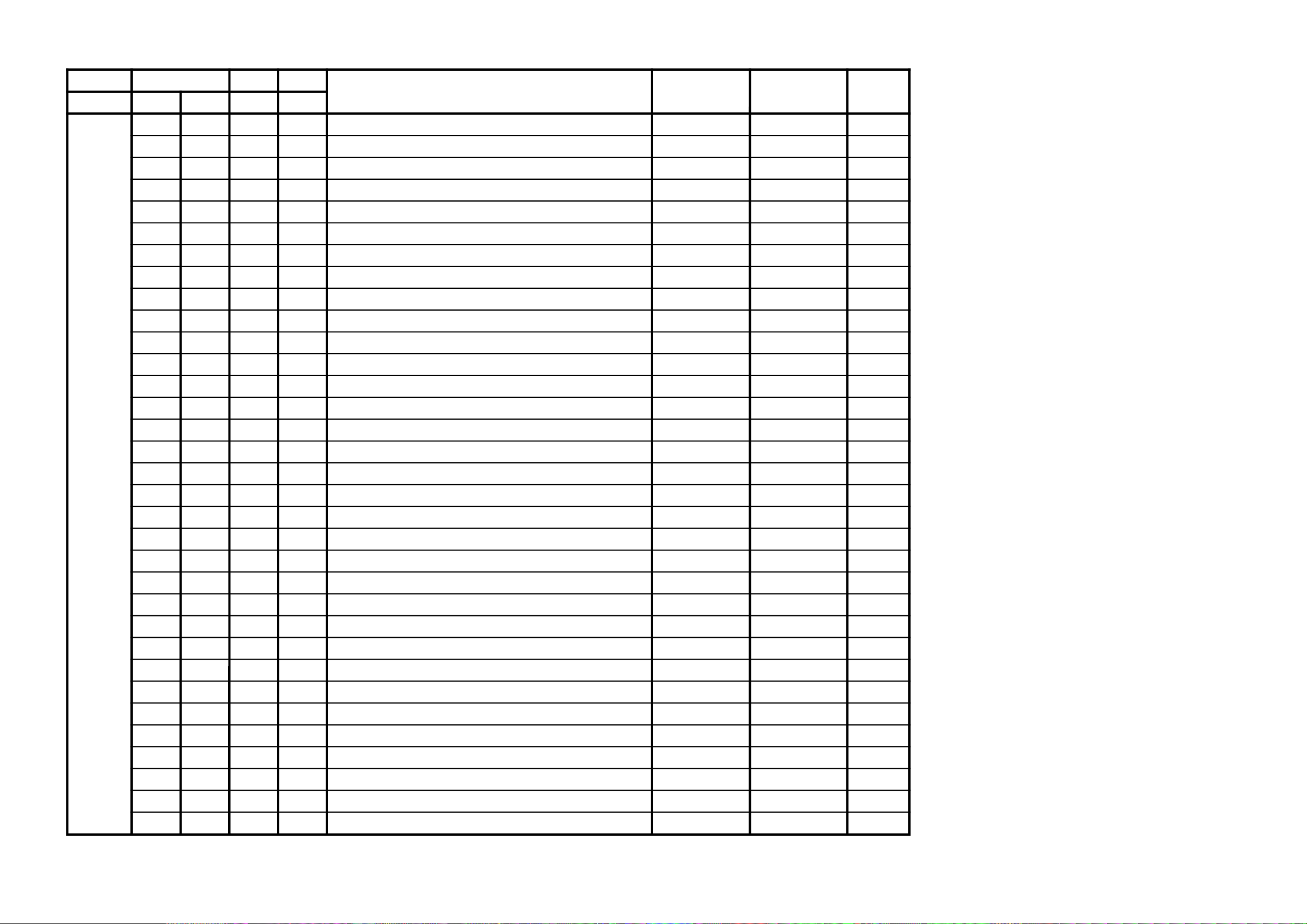

JVTytilanoitcnuFlaitinIegnaR

noitcnuFetoN&elbaTemaNeciveDnommoCeviL

)rehtoLOOC(

EMAG

)rehtoMRAW(

/EIVOM

LANOSREP

LARTUEN(

)rehto

EVIL

)BGRLOOC(

EMAG

)BGRMRAW(

/EIVOM

LANOSREP

LARTUEN(

)BGR

rehtOBGRVUYedomciP

0

)EVIL(

edomciP

1

)EIVOM(

edomciP

2

)EMAG(

edomciP

3

)LANOSREP(

yrogetaCoNemaNceDceD

LBHW000ROKB130360RtesffOleveLkcalB )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetlocrossecorP-VT

13

13

13

13

13

13

100GOKB130360GtesffOleveLkcalB )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

13

13

13

13

13

13

200VRDR730360RtnioPetihW )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

737373737373

300VRDG730360GtnioPetihW )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

73

73

73

73

73

73

400VRDB730360BtnioPetihW )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

73

73

73

73

73

73

500GPL000100teserPniaGBGR enon00

600RGP130721)RGP(RniaGteserP enon54

700GGP130721)GGP(GniaGteserP enon54

800BGP130721)BGP(BniaGteserP enon54

900FONG000510tesffOniaGteserP enonpoolCCC80

010TRBS130360ssenthgirB-buS VUY/BGR/srehtO

83

4300

110ORBS000300)ciPtnegilletnI(tesffOssenthgirB-buS enon00

210LGE000100metsySCCCpooLniaGelbanE enon00

310LGS000300metsySCCCnitnerruChgiHfonoitceleS enon00

410BKA000100noitazilibatStnerruCkcalB enon00

510SBC000100gnitimiLtnerruCmaeBfoecneuqeSlortnoC enon00

610BBGR000300gniknalBBGR enon00

710GBLB000100tuptuOneerG&eulBfogniknalB enon00

810BFO000100eulBtesffOleveLkcalB enon00

910RBSN000510tesffOssenthgirBdradnatS-noN enon00

020PBW000300)woL:3,2,lamroN:1,hgiH:0(gnittespmeTroloC edoMerutciP

00102010

120VUO000300slangistupnIVUnolortnoCtesffO

)napaJdnaSUrofylno(

VUY/srehtO

00

00

JVTytilanoitcnuFlaitinIegnaR

noitcnuFetoN&elbaTemaNeciveDnommoClap05

)VT(

lap05

)oediV(

maces05

)VT(

maces05

)oediv(

VT06oediV06BGR05BGR06edomciP

0

)EVIL(

edomciP

1

)EIVOM(

edomciP

2

)EMAG(

edomciP

3

)LANOSREP(

PI-VT

NO

oediVBGRVT

ediW

oediV

ediW

yrogetaCoNemaNceDceD

JDAS000XAMP360360mumixaMerutciP )BGRNPJ+(>ediW/lamroN</)ediW/lamroN(*)oediV/VT(rossecorP-VT

43

43

62

62

100EUHS700510euH-buS oediV/VT

70

80

200PHSS510360ssenprahS-buS )BGRNPJ+(VUY/oediV/VT

428351

300OHSS000300)ciPtnegilletnI(tesffOssenprahS-buS enon

30

400LOCS130360roloC-buS /)oediv(maces05/)vt(maces05/)oediv(lap05/)vt(lap05

BGR06/BGR05/VUY06/VUY05/oediv06/VT06

52

82

52

82

32

62

82

62

500OOCS000300)ciPtnegilletnI(tesffOroloC-buS enon

20

600CIP130721,)dilavni(001>;)dilav(001~0:AG[lortnoCerutciP

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ataDteseRresU=lanosreP:AG(edoMerutciP

36538355

700LOC130721,)dilavni(001>;)dilav(001~0:AG[lortnoCroloC

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ataDteseRresU=lanosreP:AG(edoMerutciP

83131313

800TRB130721,)dilavni(001>;)dilav(001~0:AG[lortnoCssenthgirB

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ataDteseRresU=lanosreP:AG(edoMerutciP

13531313

900EUH130721,)dilavni(001>;)dilav(001~0:AG[lortnoCeuH

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ataDteseRresU=lanosreP:AG(edoMerutciP

13131313

010PHS130721,)dilavni(001>;)dilav(001~0:AG[lortnoCssenprahS

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ataDteseRresU=lanosreP:AG(edoMerutciP

24821313

•

shaded items are adjustable data.

•

no data.

KV-21CL5K

RM-W100

KV-21CL5K

JVTytilanoitcnuFlaitinIegnaR

noitcnuF etoN&elbaTemaNeciveDnommoC0506srehtOPI-VT

NO

oediVtxeteleTPI-VT

FFO

langiSoN

yrogetaCoNemaNceDceD

CNYS000SYS000100tupnICNYSYnonoitazinorhcnyS rossecorP-VT

00

100OF000300tnatsnoCemiT1esahP

)FR(langisoNrogninuTotuA/txeteleT/oediV/FFOPIVT/NOPIVT

0030103000

200DIV000100edoMtnedIoediV

06/05

0000

300LSF000100cnySlacitreVrofleveLgnicilSdecroF

00

400LSS000100rotarapeScnySleveLgnicilS

06/05

0000

500DIVS100700noitacifitnedIoediVrofnoitceleSecruoS

srehtO/VUY

00

600FROF000300ycneuqerFdleiFdecroF

30

700KVM000100gniyeKnoisiVorcaM

10

800TCFA000300)821niP:NPJ,oruE,611niP:SU,AG(lortnoChctiwSgnimiTCFA 30

JVTytilanoitcnuFlaitinIegnaR

noitcnuFetoN&elbaTemaNeciveDnommoCsrehtO)VT(LAP)VT(CSTNMACES

)VT(

LAP

)oediV(

CSTN

)oediV(

MACES

)oediV(

TUPNI-SMACESCSTNVT

yrogetaCoNemaNceDceD

CY000QRFP000300yaleDdnaycneuqerFretneCgnikaeP rossecorP-VT

00

100APR100300toohSrevO&erPoitaR rehto/VT

20

10

200OPR200300skaePevitageN&evitisoPfooitaR rehto/VT

10

10

300YLDY210510yaleD-Y TUPNI-S/VUY+)OEDIV/VT(*)MACES/CSTN/LAP(

60606050505001

400TAMC000300xirtaM)ASU/napaJ(CSTNroMACES-LAP )BGRNPJ(

00

500LCA100100gnitimiLroloCcitamotuA

10

600BC000100ycneuqerFretneCssapdnaBamorhC )xif0:oediV*(VThtiwylnodilav

00

700OBS100300tesffOkcalBMACES

10

800ESHC100300ytivitisneStnedICSTN/LAP

20

900OLC000100retliF)lleB(ehcolCfoycneuqerFretneC

00

010PRTC000100edoMparTamorhC srehto/MACES

00

10

110SPB000100eniLyaleDdnab-esaBamorhCfossapyB srehto/CSTN

00

00

210OCF000100nOroloCdecroF

00

310TNIT130360lortnoCtniTdnaB-esaB srehtO/VUY

13

410VUT000100slangiSVUnolortnoCtniT

00

RM-W100

– 16 –

•

shaded items are adjustable data.

•

no data.

– 17 –

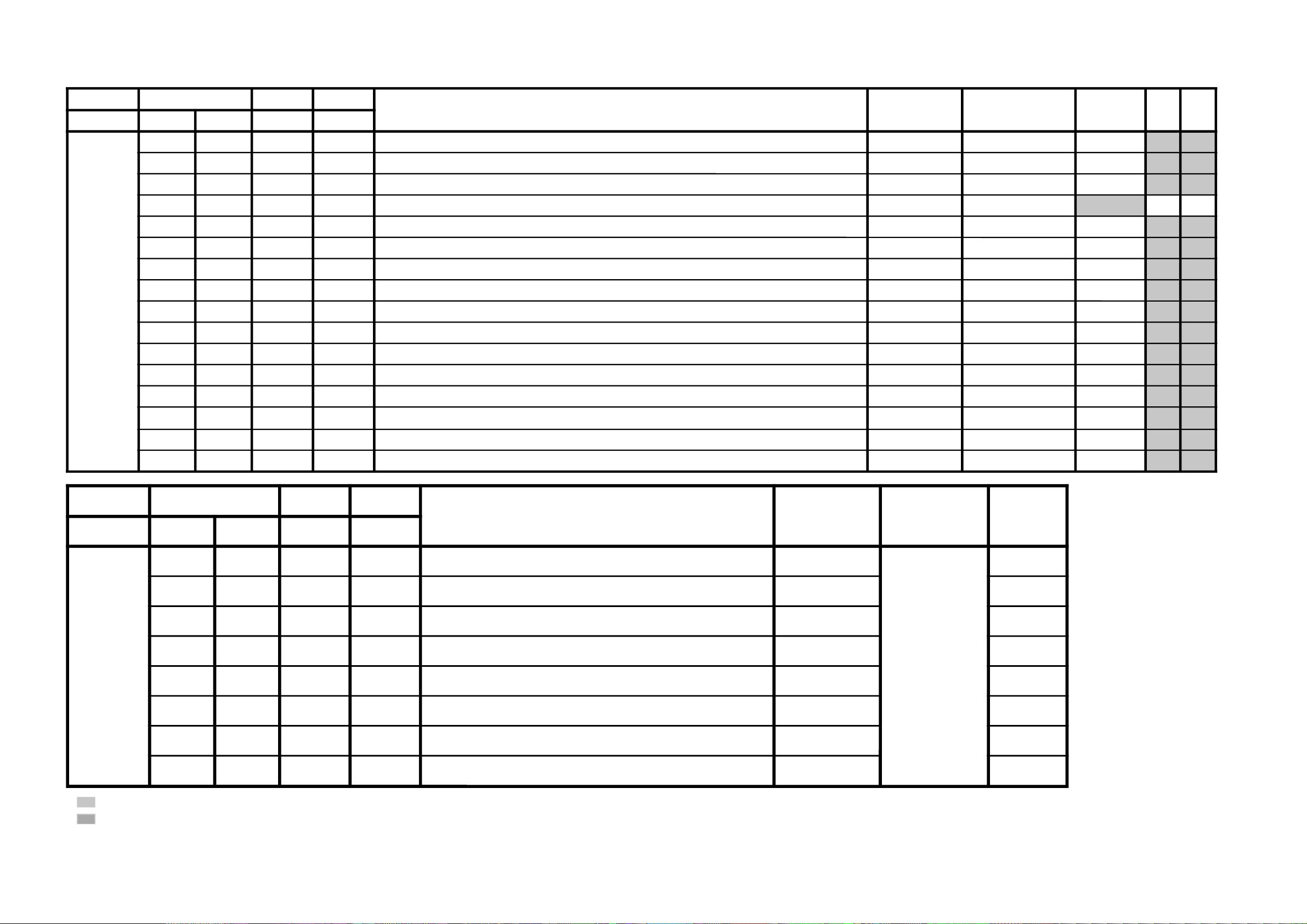

JVTytilanoitcnuFlaitinIegnaR

noitcnuFetoN&elbaTemaNeciveDnommoCsrehtOBGR:erutciP

eviL

VT

)eviL(

VT

)srehtO(

oediV

)eviL(

oediV

)srehtO(

pmeTroloC

)LOOC(

pmeTroloC

)srehtO(

pmeTroloC

)mraW(

pmeTroloC

)lartueN(

yrogetaCoNemaNceDceD

TCIP

000LDAC700510leveLevirDedohtaC

rossecorP-VT

20

100AFC000300edoMretliFbmoC 10

200COS200300leveLgnippilCtfoS 00

300LWP100100hctiwSgnitimiLetihWkaeP 10

400LTHW600510gnitimiLetihWkaeP 50

500MAG100100ammaG 10

600STW100300hctertSetihWdnalortnoCammaGsrehtO/eviL

00

10

700RFT000100langiSecnanimuLfooitaRrefsnarTCD )BGRNPJ+(srehtO/eviL

00

10

800ROC300300gniroC )srehto/anyD(*)oediV/VT(

20200010

900OROC000100)ciPtnegilletnI(tesffOgniroC 10

010SKB300300hctertSkcalBsrehto/BGR

2020

110SAA100100hctertSkcalBehtffohctiwSotaerAkcalB 10

210KSD000100lortnoCnikScimanyD 00

310SLB000100hctertSeulB )SREHTO/HGIH(pmetloc

1000

410SLBN000100tiucriChctertSeulBnoitarepO 00

510RRN000100noitcudeRdeRnoN )LAMRON/WOL/HGIH(pmetloc

10

0000

6102AFC000100)NPJ&SUrofylnO(noretliFbmoCdecroFenon00

JVTytilanoitcnuFlaitinIegnaR

noitcnuFetoN&elbaTemaNeciveDnommoCVToediV

yrogetaCoNemaNceDceD

WS

0002VC000100noitceleSlangiStupnI2SBVC

rossecorP-VT

00

100OVS10030084@niPISBVC/OVS/OVFIfonoitcnuFVUY/oediV/VT

1010

200LFD000100noitcetorPhsalF 00

•

shaded items are adjustable data.

•

no data.

KV-21CL5K

RM-W100

KV-21CL5K

JVTytilanoitcnuFlaitinIegnaR

noitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaCoNemaNceDceD

MEDS

000SWMF000300rotaludomeDMFrofnoitceleSwodniW

rossecorP-VT

20

100SSQ100100)ledoMAGtpecxe(edoMrefilpmA)SSQ(dnuoStilpSisauQ 10

200BPB000100retliFssapdnaBdnuoSfossapyB 00

300OLMA000100dnuoSMAroflangiStuptuOoiduA 00

400CVPH000100lortnoCemuloVenohPdaeH 00

JVTytilanoitcnuFlaitinIegnaR

noitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaCoNemaNceDceD

FIV

000DFIO630360rotaludomeDFItesffO

rossecorP-VT

63

100TCGA130360revo-ekaTCGA

63

200MTS000100edoMgninuThcraeS 10

300DG000100langiS1SBVCnoyaleDpuorG 00

400SCGA100300deepSCGAFI 00

500IFF000100LLPFIretliFtsaF 00

600PMAO300300)metsyS'L&Lylno(edutilpmAlangiStuptuOoediV 30

700IAV000100)metsyS'L&Lylno(noitcerroCedutilpmAlangiStuptuOImetsyS 10

JVTytilanoitcnuFlaitinIegnaR

noitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaCoNemaNceDceD

TXT

000VXT930360spilihProfnoitisoPlacitreVtxeteleT

redoceDtxeT

73

100DHT500721tfihSegdEevitcAcnys-HtxeteleT 50

200RBT400510ssenthgirBBGRtxeteleT 01

RM-W100

– 18 –

•

•

shaded items are adjustable data.

no data.

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)sserddAevalS(

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD nommoCffOWOW/SRSdnuorrusurToeretsIonomI)oruE(L-VTVToediV

PSDS000MVA200700edoMLVA DSS20

100VVA500510leveLecnerefeRLVA )h08(90

200LBB000510ruotnoCEBB 00

300HBB000510ssecorPEBB 00

400WLBB000510tesffOruotnoCEBB 60

500FOVS000510tesffOemuloVedoMtceffE/dnuorruS onomI/oeretsI/dnuorrusurT/)WOW/SRS(ffO

0070002000

600FOVI000700tesffOevitisoPemuloVretsaM

700FOVE000700tesffOevitageNemuloVretsaM 60

800DAL000130tsujdAleveLredoceD 60

900MAL000130tsujdAleveLonoM 50

010NAL000130tsujdAleveLmaciN 50

110SAL000130tsujdAleveLPAS 71

210AAL000130tsujdAleveLCDA oediV/Lnon-VT/L-VTI)oruEnoN(oediV/vT80

000000

310FES300700tceffEoeretS/onoMelbidercnI onomI/oeretsI

5030

410L1A000552tfeLemuloV1XUA 00

510R1A000552thgiRemuloV1XUA 00

610SAB800510tesffOssaBniaM 41

710ERT800510tesffOelberTniaM 11

8101QE800510tesffO)zH001(dnaBlennahCniaMrezilauqE 01

9102QE800510tesffO)zH003(dnaBlennahCniaMrezilauqE 10

0203QE800510tesffO)zH0001(dnaBlennahCniaMrezilauqE 00

1204QE800510tesffO)zH0003(dnaBlennahCniaMrezilauqE 01

2205QE800510tesffO)zH0008(dnaBlennahCniaMrezilauqE 00

320TCFB500700lortnoCEBBdnaBUD,EBD 00

420NECS100510lortnoCretneCD3SRS 40

520APSS000510lortnoCecapSD3SRS 10

620WHBB000510edomWOWnitesffossecorpEBB 00

720ERTS200700edomdnuorrusroftesffOelberT 10

820THBB000510edomVTnitesffOEBB 00

920AWD000000???AWD 00

030ERTT200700edoMVTnitesffOelberT 30

– 19 –

KV-21CL5K

RM-W100

KV-21CL5K

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)sserddAevalS(

nommoC

yrogetaC.oNemaNceDceD

CEDS000UTPM300510)CSTB(noitcetedtolipXPMrofdlohserhTreppU DSS20

100LTPM900510)CSTB(noitcetedtolipXPMrofdlohserhTrewoL 50

200UTPS300510noitcetedreirracPASrofdlohserhTreppU 80

300LTPS600510noitcetedreirracPASrofdlohserhTrewoL 51

400HT1C0001301CSfonoitcetedrofdlohserhTlamroN 00

500PA1C0001301CSfonoitcetedrofdlohserhTmargorPotuA 00

600HTPS000130PASfoetumotuarofdlohserhTesioN 00

700YHPS400510PASfoetumotuarofezissiseretsyH 30

800HTMF000130dradnats2AMFni2CSfoetumotuarofdlohserhTesioN 81

900YHMF400510dradnats2AMFni2CSfoetumotuarofezissiseretsyH 70

010HTTB000130reirracoeretsCSTBfoetumotuarofdlohserhTesioN 00

110YHTB400510oeretsCSTBfoetumotuarofezissiseretsyH 30

210HTJE000130reirracbusMFJAIEfoetumotuarofdlohserhTesioN 00

310YHJE400510reirracbusMFJAIEfoetumotuarofezissiseretsyH 40

410YLNO000100tuptuoCEDnoMACINdetalerylnoecudorpeR 00

510MAXE000100)PEDD(LdradnatsnietumotuafoesacniecruoskcabllaF 00

610TMIN000100)PEDD(etarrorretibnodnepednoitcnufetumotuaMACIN 00

710ELIN001552)PEDD(timilrorrerewolMACIN 05

810EUIN002552)PEDD(timilrorrereppuMACIN 002

910DMPE100300)PEDD(gnimmargorPysaECEDMED 10

020SDTS910130sedomSSSdnaDSArofdexelpitlumstiB 91

120AMVO100100noitpadanoitaludomrevoMF 00

220WBLF000300htdiwdnabretlifrotaludomedMA/MF 30

320DMDI000300edomSSSnideepstnediMF 00

420LAPF000100gnidocedCSTBrofycneuqefeniL 00

520TMVO100200lanimonotevitalerdlohserhtlevelnoitaludomrevO 30

620IXCD000100retrevnIlortnoCgnilacSOXCDMACIN 00

720GXCD000700niaGlortnoCgnilacSOXCDMACIN 00

820LLCD110510)L(timiLlortnoCgnilacSOXCDMACIN 00

920HLCD000130)H(timiLlortnoCgnilacSOXCDMACIN 00

030UEDI100300DTS2AnaeporuErofgnittesDOMDI 00

130RKDI100300DTSMnaeroKrofgnittesDOMDI 00

230PJDI100300DTSJAIErofgnittesDOMDI 00

RM-W100

– 20 –

– 21 –

JVTytilanoitcnuFlaitinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC0506

yrogetaCoNemaNceDceD

MTPO000THSA600700)nim5*atad(remitffotuhsotua 60

100BDSO000510ssenthgirBDSO h06orciM/RMM30

200HDSO500510noitisoPlatnoziroHDSO h06orciM/RMM60

300VDSO730360noitisoPlacitreVDSO 06/05h06orciM/RMM

1633

400ETUM000100)delbane=1(hctiwSetuMlangiSoN 10

500LUFR510510)hf0nehwelbasiD(dekcolnUretfaretnuoCegnahClangiSFR 40

600KLFR510510)hf0nehwelbasiD(dekcoLretfaretnuoCegnahClangiSFR 00

700LUVA510510)hF0nehwelbasiD(dekcolnUretfaretnuoCegnahClangiSVA 51

800KLVA510510)hF0nehwelbasiD(dekcoLretfaretnuoCegnahClangiSVA 51

900GNAL000300noitidnocgnippihsegaugnalDSO 00

010TXTH000100wsrotarapescnys rossecorP-VT00

110SSMC000100wscnyS rossecorP-VT10

210OXCD721552eulaVhsalFmorftesffoOXCD h06orciM/RFS07

310LBXE000510esioNetihWetanimilEotremiTgniknalBdednetxE 70

410SYST000300)ledoMAG(teseRtseTtaMVNnimetsySVTeziromeM 00

510UOVT100100 )ledomORUE(langistuohtiwetuM:1,ffoetuMsyawlA:0noitidnoCetuMtuOVT 10

JVTytilanoitcnuFlaitinIegnaR

noitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaCoNemaNceDceD

BTPO

000LLAI000100)MVNnideziromemton(hctiwSetirWdradnatS 00

1001BPO000552)detalermetsyS(1noitpO

*

2002BPO000552)detalerlangiSoediV(2noitpO

*

3003BPO000552)detalergnidoceDoeretS(3noitpO

*

4004BPO000552)suoenallecsiM(4noitpO

*

5005BPO000552)suoenallecsiM(5noitpO

*

6006BPO000552)detaleregaugnaLDSO(6noitpO

*

700TWSB000510)MVNnideziromemton(emiTtiaWhctiwSdnaB 00

•

•

• * Please refer page 22 and 23.

shaded items are adjustable data.

no data.

KV-21CL5K

RM-W100

Loading...

Loading...