SONY KV-27HS420, KV-29DRC420, KV-30HS420, KV-32HS420, KV-34HS420 Service Manual

...

Self Diagnosis

Supported model

SERVICE MANUAL

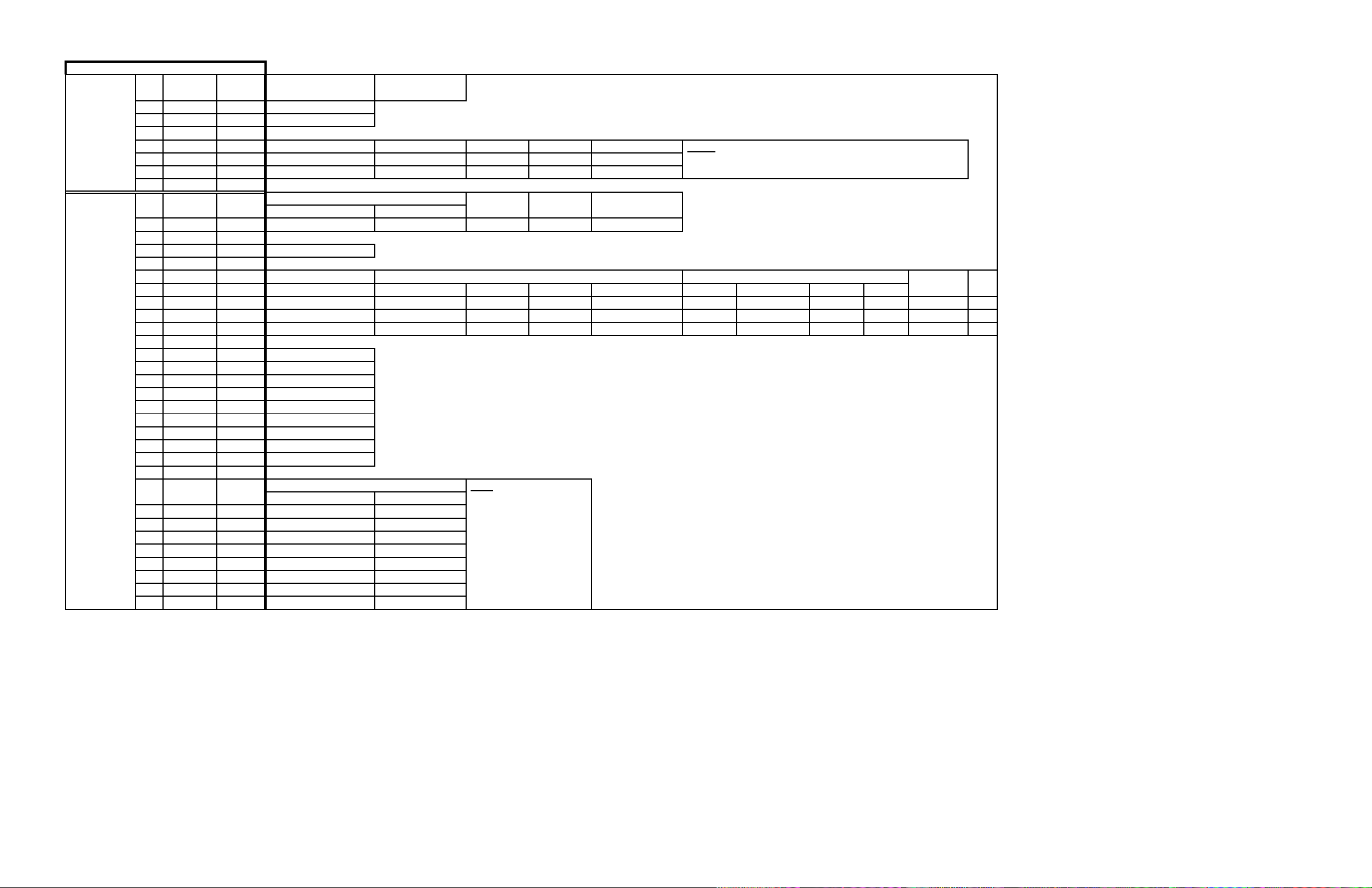

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KV-27HS420

KV-27HS420

KV-29DRC420

KV-29DRC420

KV-30HS420

KV-30HS420

KV-30HS420

KV-32HS420

KV-32HS420

KV-34HS420

RM-Y197 US SCC-S66P-A

RM-Y197 CANADA SCC-S70N-A

RM-Y197 LATIN NORTH SCC-S71L-A

RM-Y197 LATIN SOUTH SCC-S71M-A

RM-Y197 US SCC-S66Q-A

RM-Y197 CANADA SCC-S70P-A

RM-Y197 HAWAII SCC-S69H-A

RM-Y197 US SCC-S66R-A

RM-Y197 CANADA SCC-S70Q-A

RM-Y197 US SCC-S66S-A

DA-4

CHASSIS

KV-34HS420

KV-36HS420

KV-36HS420

KV-36HS420

RM-Y197 CANADA SCC-S70R-A

RM-Y197 US SCC-S66T-A

RM-Y197 CANADA SCC-S70S-A

RM-Y197 HAWAII SCC-S69J-A

RM-Y197

KV-30HS420

9-965-963-01

TRINITRON® COLOR TELEVISION

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

TABLE OF CONTENTS

SECTION TITLE PAGE SECTION TITLE PAGE

Specifi cations ................................................................................. 4

Warnings and Cautions .................................................................. 6

Safety Check-Out ........................................................................... 7

Self-Diagnostic Function................................................................. 8

SECTION 1: DISASSEMBLY................................................................11

1-1. Rear Cover Removal.............................................................11

1-2. Chassis Assembly Removal ..................................................11

1-3. Service Position ....................................................................11

1-4. Picture Tube Removal .......................................................... 12

Anode Cap Removal Procedure........................................... 12

SECTION 2: SET-UP ADJUSTMENTS................................................ 13

2-1. Beam Landing ...................................................................... 13

2-2. V-PIN and V-CEN Adjustment.............................................. 14

2-3. Convergence........................................................................ 14

2-3.1. Vertical and Horizontal Static Convergence ............ 14

2-3.2. Operation of BMC (Hexapole) Magnet .................... 14

2-3.3. TLH Plate Adjustment.............................................. 14

2-3.4. Screen-Corner Convergence................................... 15

2-3.5. Dynamic Convergence Adjustments........................ 15

2-4. Focus Adjustment................................................................. 16

2-4.1. Dynamic Focus/Dynamic Quadra-Pole Data........... 16

2-5. Screen (G2).......................................................................... 17

2-6. Picture Quality Adjustments ................................................. 17

2-6.1. Video Input - Sub Contrast Adjustment.................... 17

2-6.2. Video Input - Sub Hue/Sub Color Adjustment.......... 18

2-6.3. RF Input - Sub Contrast Adjustment........................ 18

2-6.4. RF Input - Sub Hue/Sub Color Adjustment.............. 19

2-7. White Balance (CRT) and Sub Bright Adjustment................ 19

2-7.1. Color Offset Adjustment Procedure......................... 19

2-8. H Raster Center Adjustment ................................................ 20

2-9. Picture Distortion Adjustments ............................................. 20

2-9.1. NTSC (DRC) Full Mode Adjustment ........................ 20

2-9.2. 1080i HD Mode Adjustment..................................... 21

2-9.3. Vertical Compressed Mode Check and Confi rmation

(For 4x3 CRT Only) ................................................. 21

SECTION 3: SAFETY RELATED ADJUSTMENTS............................. 22

3-1. Preparation Before Confi rmation.......................................... 22

3-1.1 Hold-Down Operation Confi rmation......................... 22

3-2. B+ Max Confi rmation ........................................................... 22

3-3. B+ Voltage Check ................................................................ 22

3-4. High Voltage (HV) Check ..................................................... 22

3-5. Preparation for HV and Ik Protector Check .......................... 22

3-6. HV Protector Check ............................................................. 22

3-6-1. Cut Off Condition..................................................... 22

3-6-2. High Light Condition ................................................ 23

3-7. IK Protector Check ............................................................... 23

3-8. Hold Down Check ................................................................ 23

3-9. Restoration........................................................................... 23

3-10. HV Service Flowchart........................................................... 24

3-10.1. HV Service Flowchart Table..................................... 25

SECTION 4: CIRCUIT ADJUSTMENTS.............................................. 26

4-1. Setting Service Adjustment Mode ........................................ 26

4-1.1. Service Adjustment Mode In.................................... 26

4-1.2. Service Adjustment Mode Memory.......................... 26

4-1.3. Reading the Memory ............................................... 26

4-1.4. Adjusting the Picture................................................ 26

4-1.5. Resetting the Data................................................... 26

4-1.6. Resetting the MID NVM Data .................................. 26

4-1.7. Resetting the System NVM Data............................. 26

4-1.8. Copy Function.......................................................... 26

4-2. Memory Write Confi rmation Method .................................... 27

4-3. Remote Adjustment Buttons and Indicators ......................... 27

4-4. Service Data......................................................................... 28

4-5. ID Map Table ........................................................................ 51

SECTION 5: DIAGRAMS..................................................................... 52

5-1. Circuit Boards Location ........................................................ 52

5-2. Printed Wiring Boards and

Schematic Diagrams Information ......................................... 52

5-3. Block Diagrams .................................................................... 53

5-4. Schematics and Supporting Information .............................. 56

DZ Board Schematic Diagram (1 of 2) ................................. 56

DZ Board Schematic Diagram (2 of 2) ................................. 57

UY Board Schematic Diagram ............................................. 60

HBY Board Schematic Diagram........................................... 61

AY Board Schematic Diagram (1 of 2) ................................. 64

AY Board Schematic Diagram (2 of 2) ................................. 65

HCX Board Schematic Diagram........................................... 68

CH Board Schematic Diagram ............................................. 70

HAX Board Schematic Diagram .......................................... 72

WY Board Schematic Diagram ............................................ 73

BY Board Schematic Diagram (1 of 4) ................................. 75

BY Board Schematic Diagram (2 of 4) ................................. 76

BY Board Schematic Diagram (3 of 4) ................................. 77

BY Board Schematic Diagram (4 of 4) ................................. 78

MY Board Schematic Diagram (1 of 4) ................................ 79

MY Board Schematic Diagram (2 of 4) ................................ 80

MY Board Schematic Diagram (3 of 4) ................................ 81

MY Board Schematic Diagram (4 of 4) ................................ 82

P Board Schematic Diagram ............................................... 85

5-5. Semiconductors (1 of 2) ....................................................... 86

Semiconductors (2 of 2) ....................................................... 87

SECTION 6: EXPLODED VIEWS........................................................ 88

6-1. Chassis (KV-27HS420/29DRC420) ..................................... 88

6-2. Picture Tube (KV-27HS420/29DRC420) .............................. 89

6-3. Chassis (KV-30HS420/34HS420) ........................................ 90

6-4. Picture Tube (KV-30HS420/34HS420)................................. 91

6-5. Chassis (KV-32HS420/36HS420) ........................................ 92

6-6. Picture Tube (KV-32HS420/36HS420)................................. 93

SECTION 7: ELECTRICAL PARTS LIST........................................... 94

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

3

SPECIFICATIONS

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

KV-29DRC420

Power Requirements 220V, 50-60Hz

Number of Inputs/Outputs

Audio Out

Video

S Video

Y,PB, PR

Audio

1)

2)

3)

4)

5)

4

3

2

7

1

Monitor Out 1

Control-S (In/Out) YES

Memory Stick NO

Speaker Output (W)

10w x 2

15W Subwoofer

Power Consumption (W)

In Use (Max) 240W

In Standby 1W

Dimensions (W x H x D)

mm 784 x 601.5 x 520 mm 784 x 601.5 x 520 mm 898 x 604 x 564.5 mm 898 x 698 x 598 mm

7/8

x 23

5/8

x 20

30

in

Mass

kg 50.2 kg 50.2 kg 68 kg 74.8 kg

lbs 111 lbs 111 lbs 150 lbs 165 lbs

KV-27HS420 KV-30HS420 KV-32HS420

1/2

in 30

10W x 2

15W Subwoofer

7/8

5/8

x 23

x 20

1/2

in 35

10W x 2

15W Subwoofer

3/8

3/4

x 23

x 22

1/4

in 35

120V, 60Hz

4

3

2

7

1

1

YES

NO

10W x 2

15W Subwoofer

240W

1W

3/8

1/2

x 27

x 23

994 x 654 x 604 mm

1/2

in

39

KV-34HS420 KV-36HS420

10W x 2

15W Subwoofer

1/8

3/4

x 25

x 23

88 kg

194 lbs

1) 1 Vp-p 75 ohms unbalanced, sync negative

2) Y: 1 Vp-p 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

3) Y: 1.0 Vp-p, 75 ohms unbalanced, sync negative;

PB: 0.7 Vp-p, 75 ohms

PR: 0.7 Vp-p, 75 ohms

4) 500 mVrms (100% modulation), Impedance: 47 kilohms

5) More than 408 mVrms at the maximum volume setting (variable)

More than 408 mVrms (fi x); Impedance (output): 2 kilohms

6) 3.3V T.M.D.S., 50 ohms

The DVI-HDTV input terminal is complieant with the EIA-861

standard and is not intended for use with personal computers.

994 x 776.5 x 634 mm

3/4

1/8

in

39

5/8

x 30

104.3 kg

230.0 lbs

x 25 in

TruSurround

by SRS

™

®

TruSurround is a trademark of SRS Labs, Inc. SRS and the SRS

symbol are registered trademarks of SRS Labs, Inc. in the United

States and in select foreign countries. SRS and TruSurround are

incorporated under license from SRS Labs, Inc. and are protected

under United States Patent Nos. 4,748,669 and 4,841,572 with

numerous additional issued and pending foreign patents. Purchase of this product does not convey the right to sell recordings

made with the TruSurround technology.

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

SRS (SOUND RETRIEVAL SYSTEM)

The SRS (SOUND RETRIEVAL SYSTEM) is manµFactured

by Sony Corporation under license from SRS Labs, Inc. It is

covered by U.S. Patent No. 4,748,669. Other U.S. and foreign

patents pending.

The word ‘SRS’ and the SRS symbol are registered trademarks of SRS Labs, Inc. BBE and BBE symbol are trademarks of

BBE Sound, Inc. and are licensed by BBE Sound, Inc. under U.S.

Patent No. 4,638,258 and 4,482,866.

Design and specifi cations are subject to change without notice.

4

Television system

American TV standard, NTSC

Channel coverage

VHF: 2-13/ UHF: 14-69/ CATV: 1-125

Picture tube

FD Trinitron® tube

Visible screen size

27-inch picture measured diagonally (KV-27HS420/29DRC420 Only)

30-inch picture measured diagonally (KV-30HS420 Only)

32-inch picture measured diagonally (KV-32HS420 Only)

34-inch picture measured diagonally (KV-34HS420 Only)

36-inch picture measured diagonally (KV-36HS420 Only)

Actual screen size

29-inch measured diagonally (KV-27HS420/29DRC420 Only)

32-inch measured diagonally (KV-30HS420 Only)

34-inch measured diagonally (KV-32HS420 Only)

36-inch measured diagonally (KV-34 HS420 Only)

38-inch measured diagonally (KV-36HS420 Only)

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

Antenna

75 ohm external terminal for VHF/UHF

Supplied Accessories

Remote Commander RM-Y197

Two Size AA (R6) Batteries

Optional Accessories

AV Cable: VMC-810/820/830 HG

Audio Cable: RKC-515HG

Component Video Cable: VMC-10/30 HG

TV Stand: SU-27HX1 (KV-27HS420/29DRC420 Only)

TV Stand: SU-30HX1 (KV-30HS420 Only)

TV Stand: SU-32HX1 (KV-32HS420 Only)

TV Stand: SU-34HX1 (KV-34HS420 Only)

TV Stand: SU-36HX1 (KV-36HS420 Only)

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

5

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

WARNINGS AND CAUTIONS

CAUTION

Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield, or carbon painted on the CRT, after

removing the anode.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of

this receiver is directly connected to the ac power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe

operation. Replace these components with Sony parts whose part numbers appear as shown in this manual or in supplements

published by Sony. Circuit adjustments that are critical for safe operation are identifi ed in this manual. Follow these procedures

whenever critical components are replaced or improper operation is suspected.

ATTENTION!!

Apres avoir deconnecte le cap de l’anode, court-circuiter l’anode du tube cathodique et celui de l’anode du cap au chassis metallique

de l’appareil, ou la couche de carbone peinte sur le tube cathodique ou au blindage du tube cathodique.

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout

dépannage. Le chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque ! sur les schemas de principe, les vues explosees et les listes de pieces

sont d’une importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants Sony dont le numero

de piece est indique dans le present manuel ou dans des supplements publies par Sony. Les reglages de circuit dont l’importance

est critique pour la securite du fonctionnement sont identifi es dans le present manuel. Suivre ces procedures lors de chaque

remplacement de composants critiques, ou lorsqu’un mauvais fonctionnement suspecte.

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

6

SAFETY CHECK-OUT

g

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if

sets always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

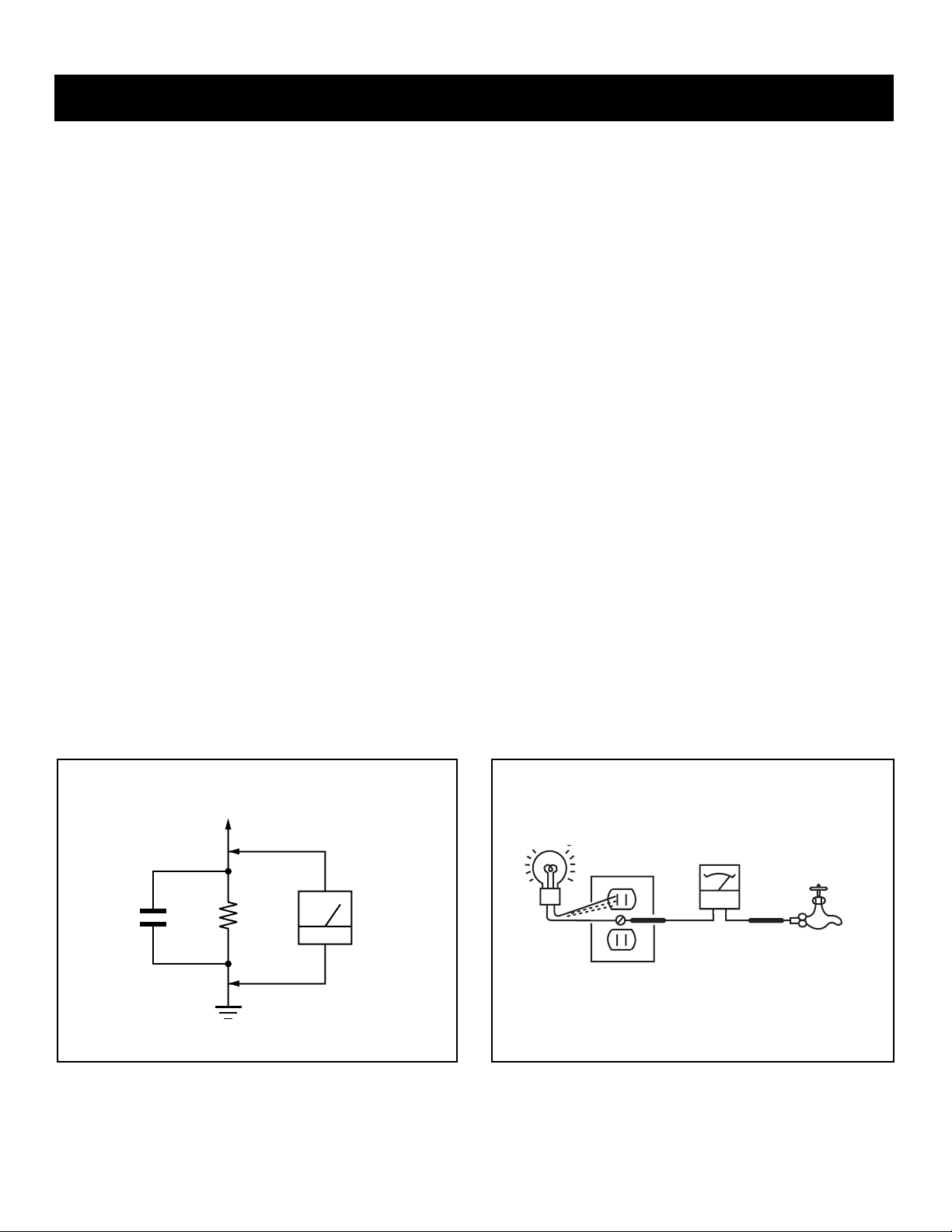

Leakage Test

The AC leakage from any exposed metal part to earth ground and from

all exposed metal parts to any exposed metal part having a return to

chassis, must not exceed 0.5 mA (500 microamperes). Leakage current

can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manµFacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245 digital

multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75 V,

so analog meters must have an accurate low voltage scale. The

Simpson’s 250 and Sanwa SH-63TRD are examples of passive

VOMs that are suitable. Nearly all battery-operated digital multimeters

that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate retaining

screw on most AC outlet boxes is also at earth ground. If the retaining

screw is to be used as your earth ground, verify that it is at ground by

measuring the resistance between it and a cold-water pipe with an

ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt troublelight (not a neon lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary, to locate the hot side on the

line; the lamp should light at normal brilliance if the screw is at ground

potential (see Figure B).

To Exposed Metal

Parts on Set

0.15 µF

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

kΩ

1.5

Earth Ground

AC V oltmeter

(0.75 V)

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

AC Outlet Box

Ohmmeter

Cold-water Pipe

7

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

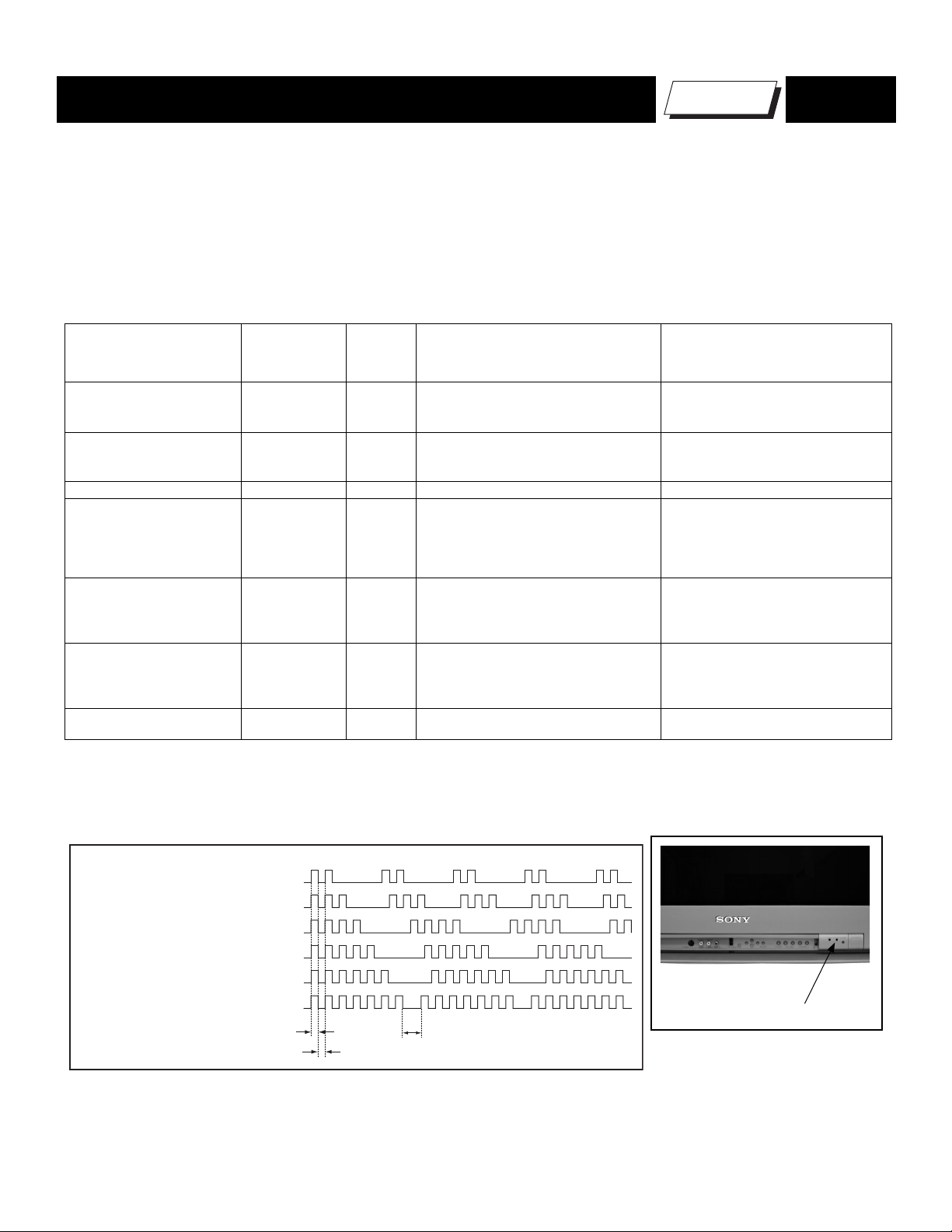

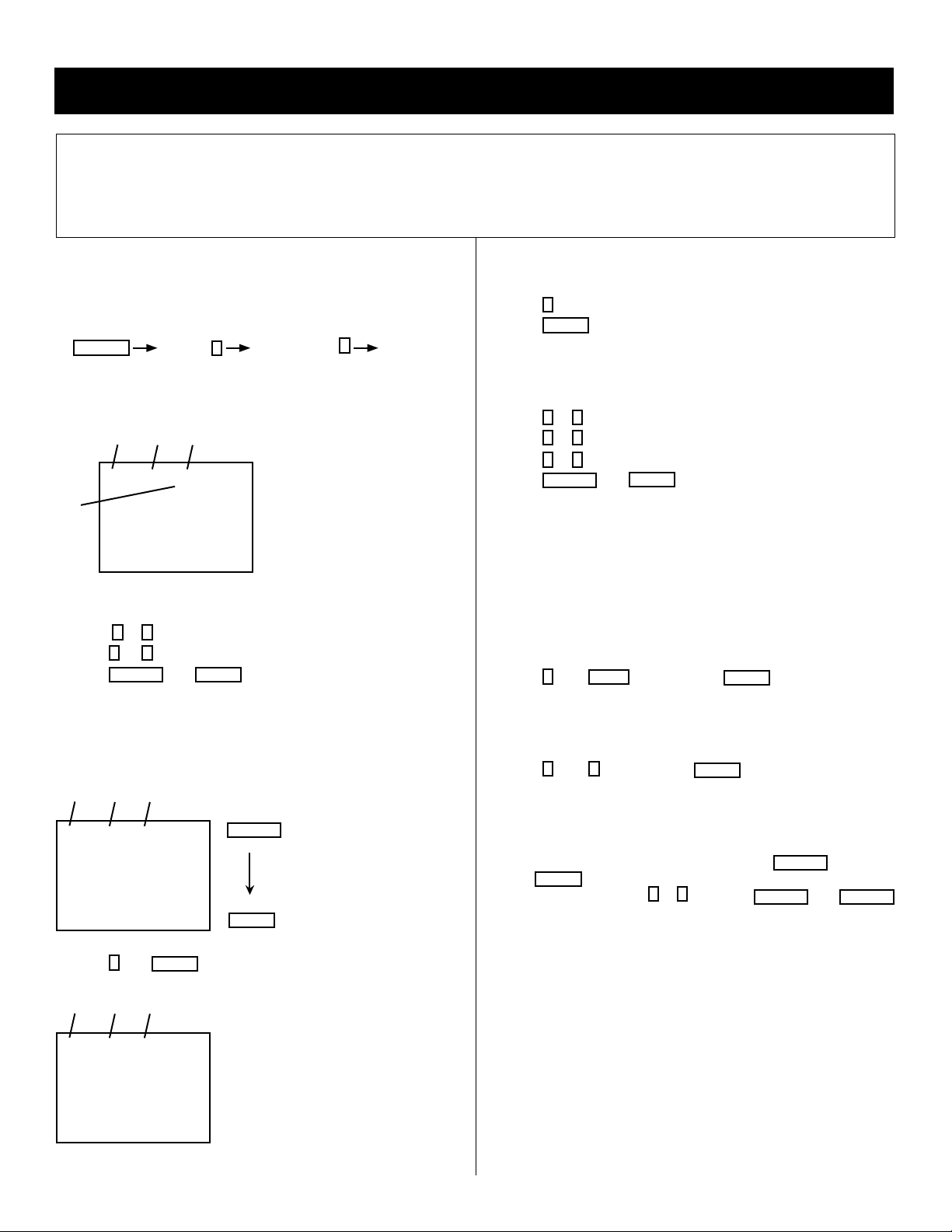

SELF-DIAGNOSTIC FUNCTION

Self Diagnosis

Supported model

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER LED will automatically begin to fl ash. The number

of times the LED fl ashes translates to a probable source of the problem. A defi nition of the STANDBY/TIMER LED fl ash indicators is listed in the

instruction manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote Commander can be used to review

the failure occurrence data stored in memory to reveal past problems and how often these problems occur.

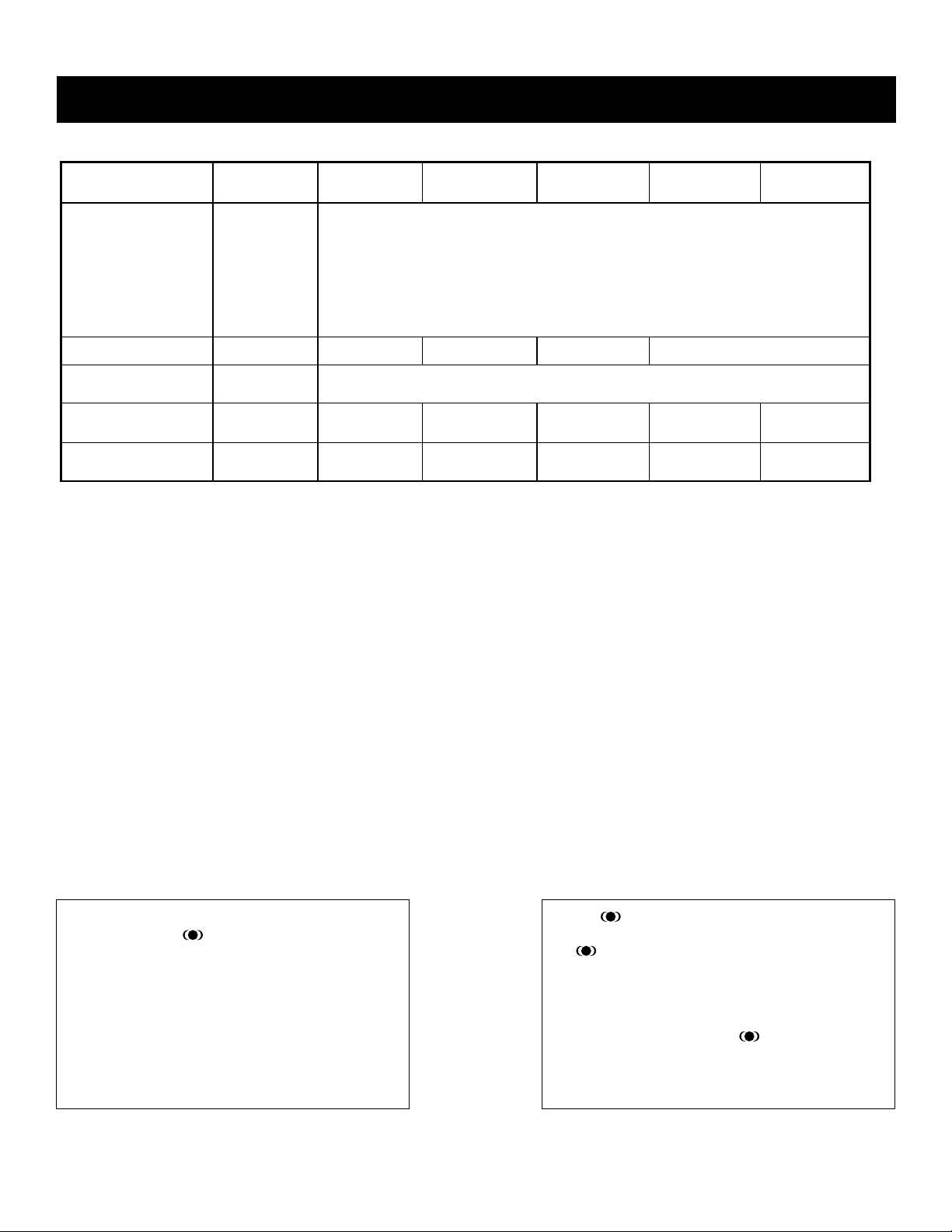

Diagnostic Test Indicators

When an error occurs, the STANDBY/TIMER LED will fl ash a set number of times to indicate the possible cause of the problem. If there is more than

one error, the LED will identify the fi rst of the problem areas.

Results for all of the following diagnostic items are displayed on screen. If the screen displays a “0”, an error has occurred.

No. of times

Diagnostic Item

Power does not turn on Does not light _______

+B Overcurrent (OCP)* 2 times 2:0 or 2:1

Low +B Overvoltage (OVP) 3 times 3:0 or 3:1

Vertical Deflection Stopped 4 times 4:0 or 4:1

White Balance Failure

(not balanced)

LOW +B OCP/OVP

(overcurrent/overvoltage)***

Horizontal Deflection

Stopped

STANDBY /

TIMER lamp

flashes

5 times 5:0 or 5:1

6 times 6:0 or 6:1

7 times 7:0 or 7:1

Display

Result

Probable Cause Location Detected Symptoms

• Power cord is not plugged in.

• Fuse is burned out (F501). (AY Board)

• H.OUT (Q5030) is shorted. (DZ Board)

• +B PWM (Q5003) is shorted.

(DZ Board)

• IC6505 is faulty. (DZ Board) • Has entered standby mode.

• 15V is not supplied. (DZ Board)

• IC5004 is faulty. (DZ Board)

• Video OUT (IC9001-IC9003) is faulty.

(CH, Board)

• CRT drive (IC2801) is faulty. (BY Brd.)

• G2 is improperly adjusted.**

• +5 line is overloaded. (AY, BY, MY

Boards)

• +5 line is shorted. (AY, BY, MY Brds.)

• IC504 is faulty. (AY Board)

• Power does not come on.

• No power is supplied to the TV.

• AC Power supply is faulty.

• Power does not come on.

• Load on power line shorted.

• Has entered standby mode after

Horizontal raster.

• Vertical deflection pulse is stopped.

• Power line is shorted or power

supply is stopped.

• No raster is generated.

• CRT cathode current detection

reference pulse output is small.

• No picture

• No picture

* If a +B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously. The symptom that is diagnosed first by the

microcontroller is displayed on the screen.

** Refer to Screen (G2) in Section 2-5 of this manual.

*** If STANDBY/STEREO LED flashes six (6) times, unplug the unit and wait 10 seconds before performing the adjustment.

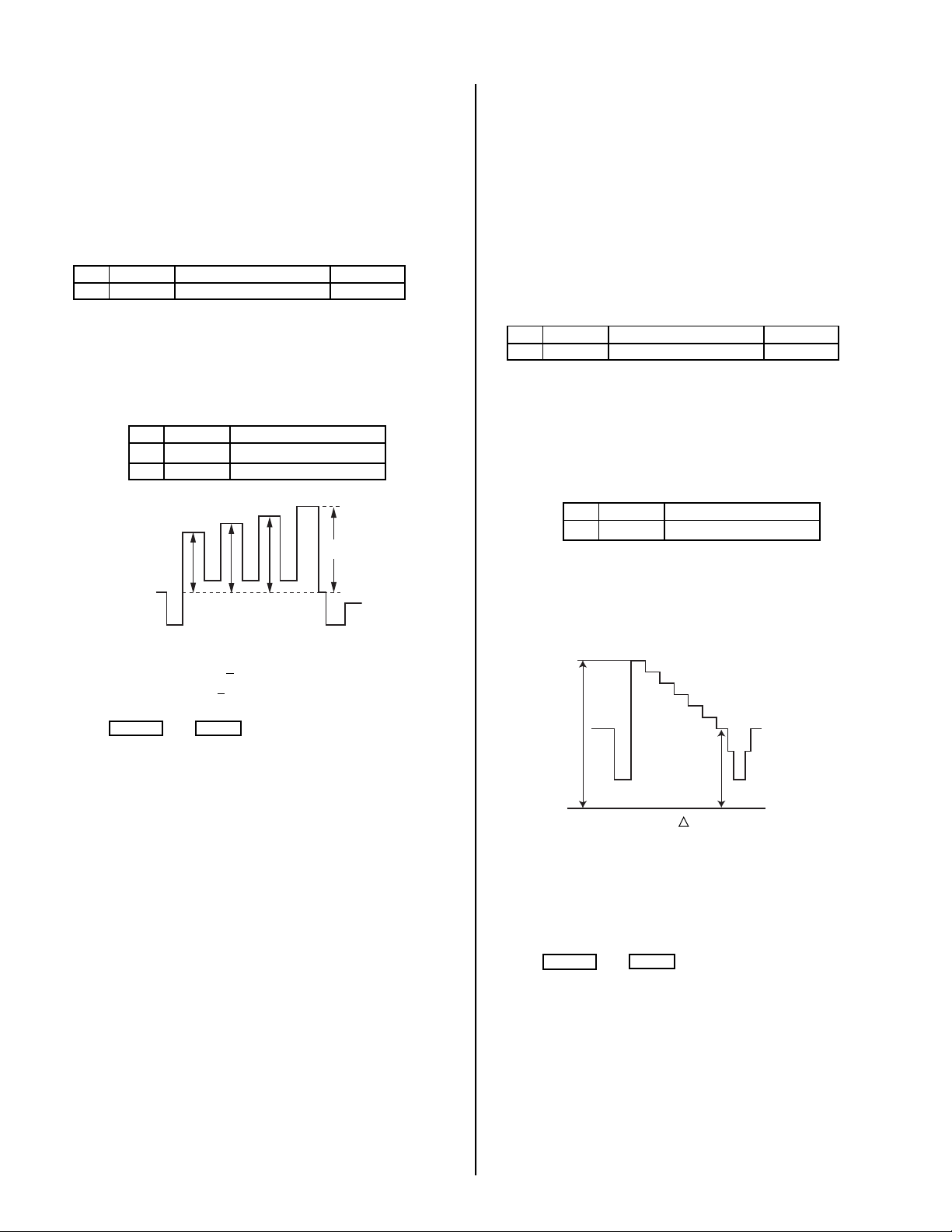

Display of Standby/Timer LED Flash Count

Diagnostic items Flash count

+BfiOvercurrentfi 2fitimes

Lowfi+BfiOvervoltagefi 3fitimes

Vert.fiDeflectionfiStoppedfi 4fitimes

WhitefiBalancefiFailurefi 5fitimes

Lowfi+BfiOCP/OVPfi 6fitimes

Horiz.fiDeflectionfiStoppedfi 7fitimes

Lamp ON 0.3 sec.

Lamp OFF 0.3 sec.

Lamp OFF 3 sec.

* One fl ash count is not used for

self-diagnostic.

Standby/Timer LED

Stopping the Standby/Timer LED Flash

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER LAMP from fl ashing.

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

8

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

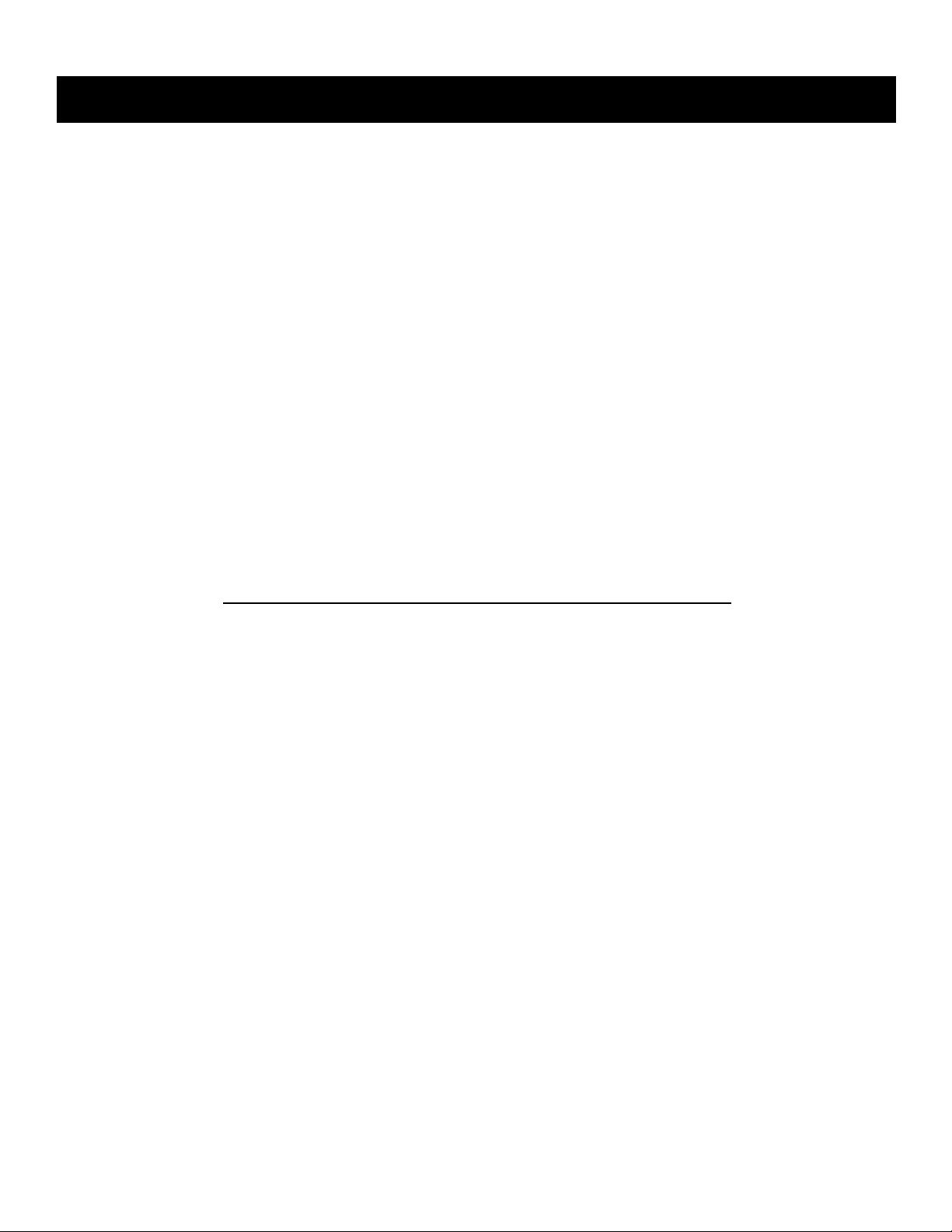

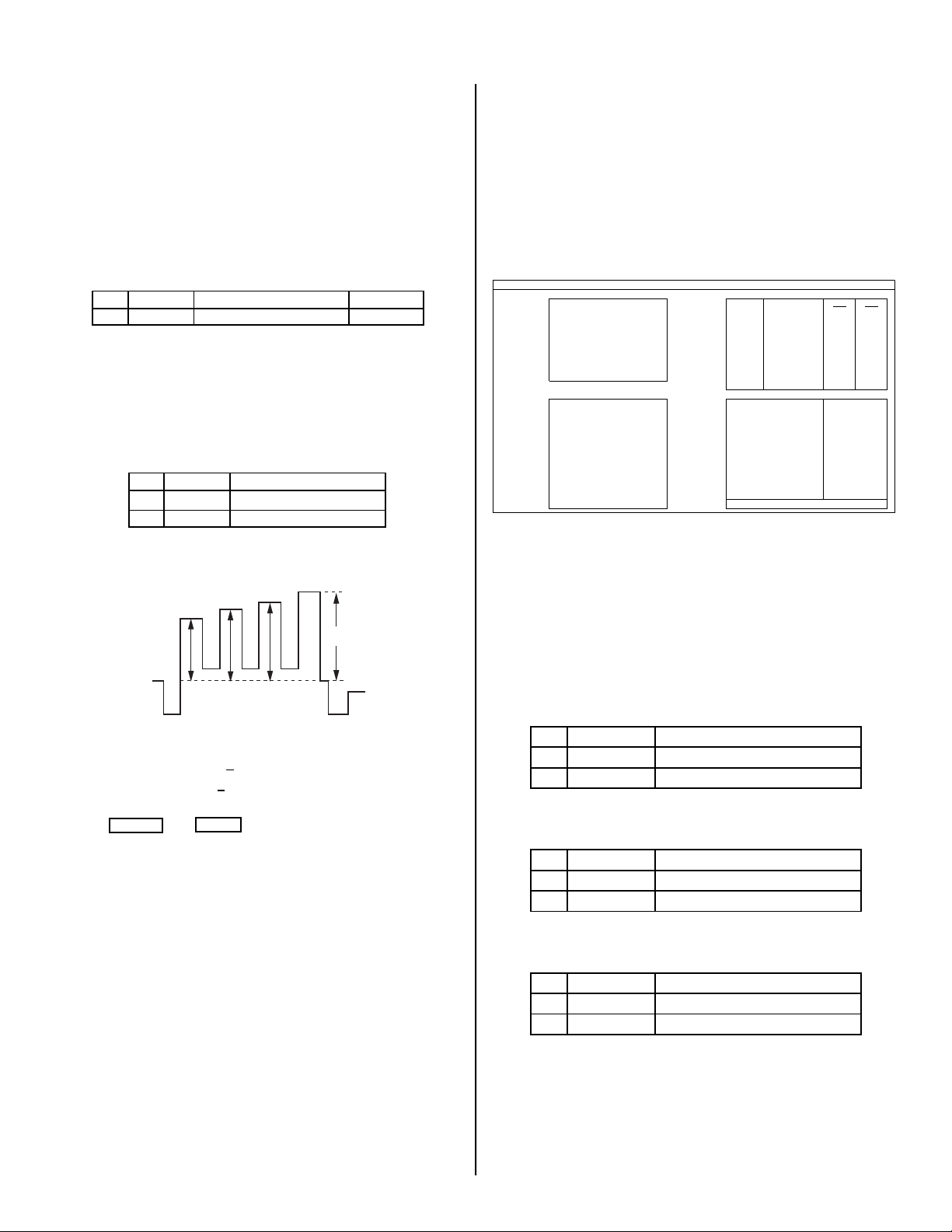

Self-Diagnostic Screen Display

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confi rmed, it is possible to bring up past

occurrences of failure on the screen for confi rmation.

To Bring Up Screen Test

In standby mode, press buttons on the Remote Commander sequentially, in rapid succession, as shown below:

DISPLAY

Channel 5 Sound volume - Power ON.

SELF DIAGNOSIS

2: +B OCP 0

3: +B OVP 0

4: VSTOP 0

5: AKB 1

6: LOWB 0

7: H-STOP 0

Numeral “0”

means that no fault was detected.

Numeral “1”

means a fault was detected one

time only.

101: WDT 24

Handling of Self-Diagnostic Screen Display

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen during repairs. When you

have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of the repairs.

Clearing the Result Display

To clear the result display to “0”, press buttons on the Remote Commander sequentially when the diagnostic screen is displayed, as shown below:

NOTE: This will also reset all user functions (including auto programming and picture settings)

8

ENTERChannel

Quitting the Self-Diagnostic Screen

To quit the entire self-diagnostic screen, turn off the power switch on the Remote Commander or the main unit.

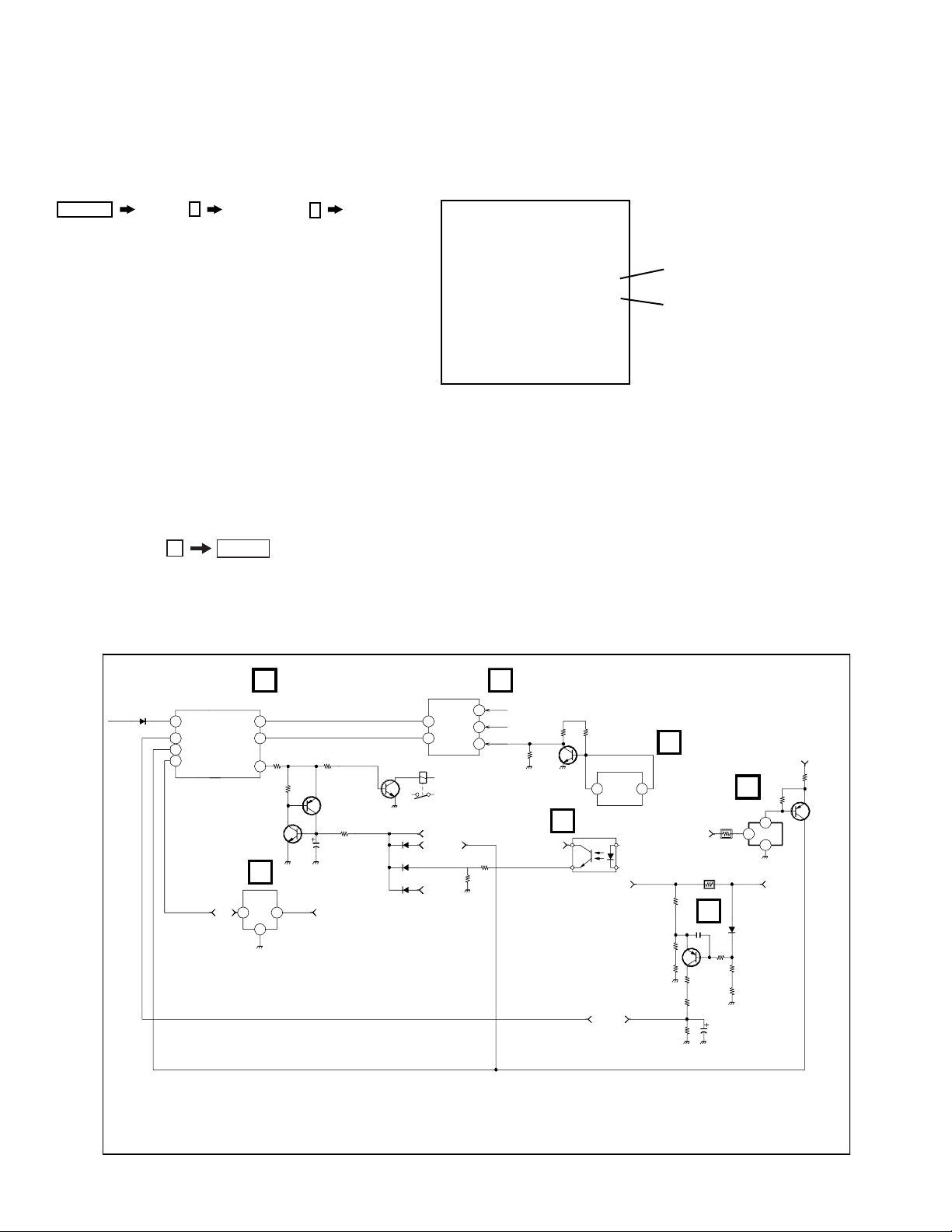

Self-Diagnostic Circuit

STBY-LED

IC2300

MAIN MICRO

STR

48

STBY-LED

44

OCP

45

OVP

43

LOW B ERR

AC RLY

5V UNREG 7V

MY

CLKO

29

DATO

30

69

Q6527

Q6530

Q6532

AY

IC504

IO

O

IC2801

Y/C JUNGLE

SCL

26

25

SDA

RY6501

P_SW(-)

21

34

1K-PROT2

+B OVP

D6537

D6505

HV PROT

D5007

MY

AKB

58

CRT

35

VPROT

HPROT

VDY-

34

R5104 R5105

R5125

UNREG 11V

DZ

Q5018

BY

IC5007

2

14

PH6501

1

4

2

3

+B +B

5V

DZ

IC6505

+B

R5013

2

1

3

Q6522

DZ

Q5004

+B OCP

D5005

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

9

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

+B overcurrent (OCP)

Occurs when excessive current fl ows through R5013. The increase in voltage across R5013 causes the output of Q5004 to go high, and this high

signal goes to the micro.

+B overvoltage (OVP)

IC6505 detects +B OVP condition and turns on Q6522. This sends a high signal to the micro and also shuts down the AC relay.

V-STOP

Occurs when an absence of the vertical defl ection pulse is detected by pin 24 of IC2801 (BY Board). Power supply will shut down when waveform

interval exceeds 2 seconds.

White Balance Failure

If the RGB levels* do not balance within 2 seconds after the power is turned on, this error will be detected by IC2801. TV will stay on, but there will be

no picture.

*(Refers to the RGB levels of the AKB detection Ref pulse that detects 1K).

Low B OCP/OVP

Occurs when set 5V is out.

Horizontal Defl ection Stopped

Occurs when either:

1) a +B overcurrent is detected (IC5007), or

2) overheating is detected (Thermistor TH5002).

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

10

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

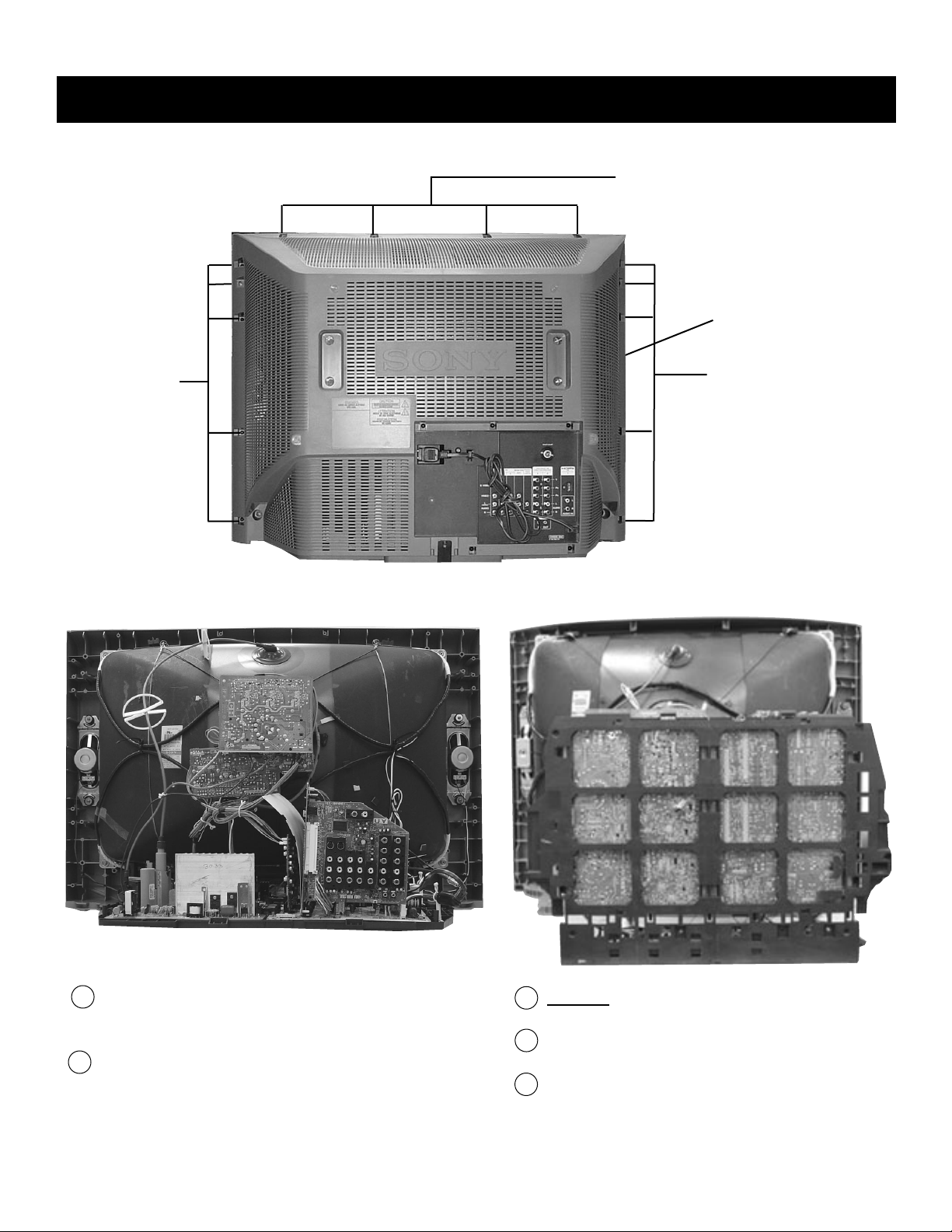

SECTION 1: DISASSEMBLY

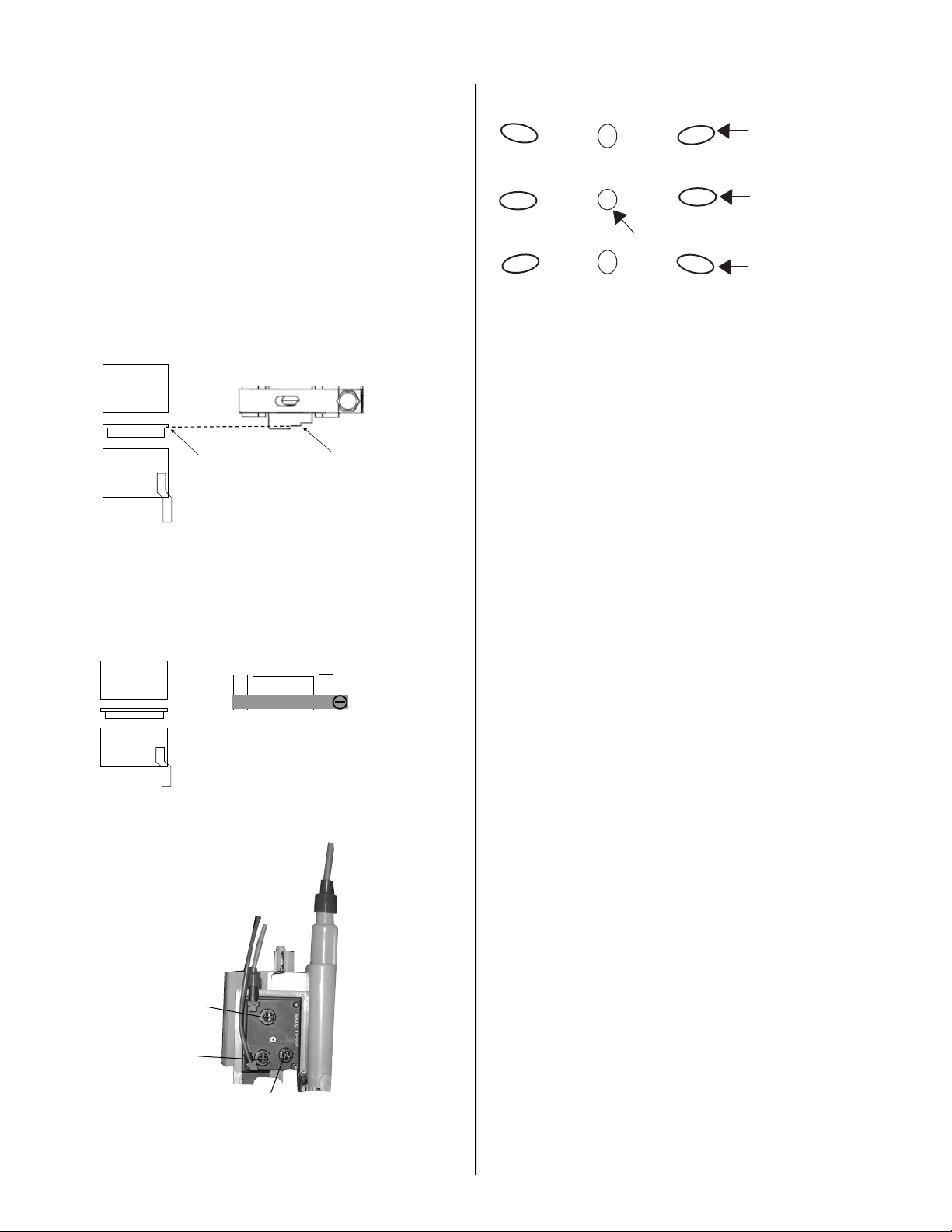

1-1. REAR COVER REMOVAL

5 Screws

+BVTP 4 x 16

TYPE2 TT (B)

1-2. CHASSIS ASSEMBLY REMOVAL

4 Screws

+BVTP 4 x 16

TYPE2 TT (B)

Rear Cover

5 Screws

+BVTP 4 x 16

TYPE2 TT (B)

1-3. SERVICE POSITION

1

Lift lever up on the right and left sides of the chassis

bracket and gently pull the chassis assembly away from

the bezel.

Pull up and rotate both the AY and DZ Boards in order to

2

service the unit.

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

1

CAUTION! - Heat sink on IC5004 is -15V. Care must be

taken not to allow heat sink to touch any other components.

2

Lift lever up on the right and left sides of the chassis bracket

and gently pull the chassis assembly away from the bezel.

Pull up and rotate both the AY and DZ Boards in order to

3

service the unit.

11

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

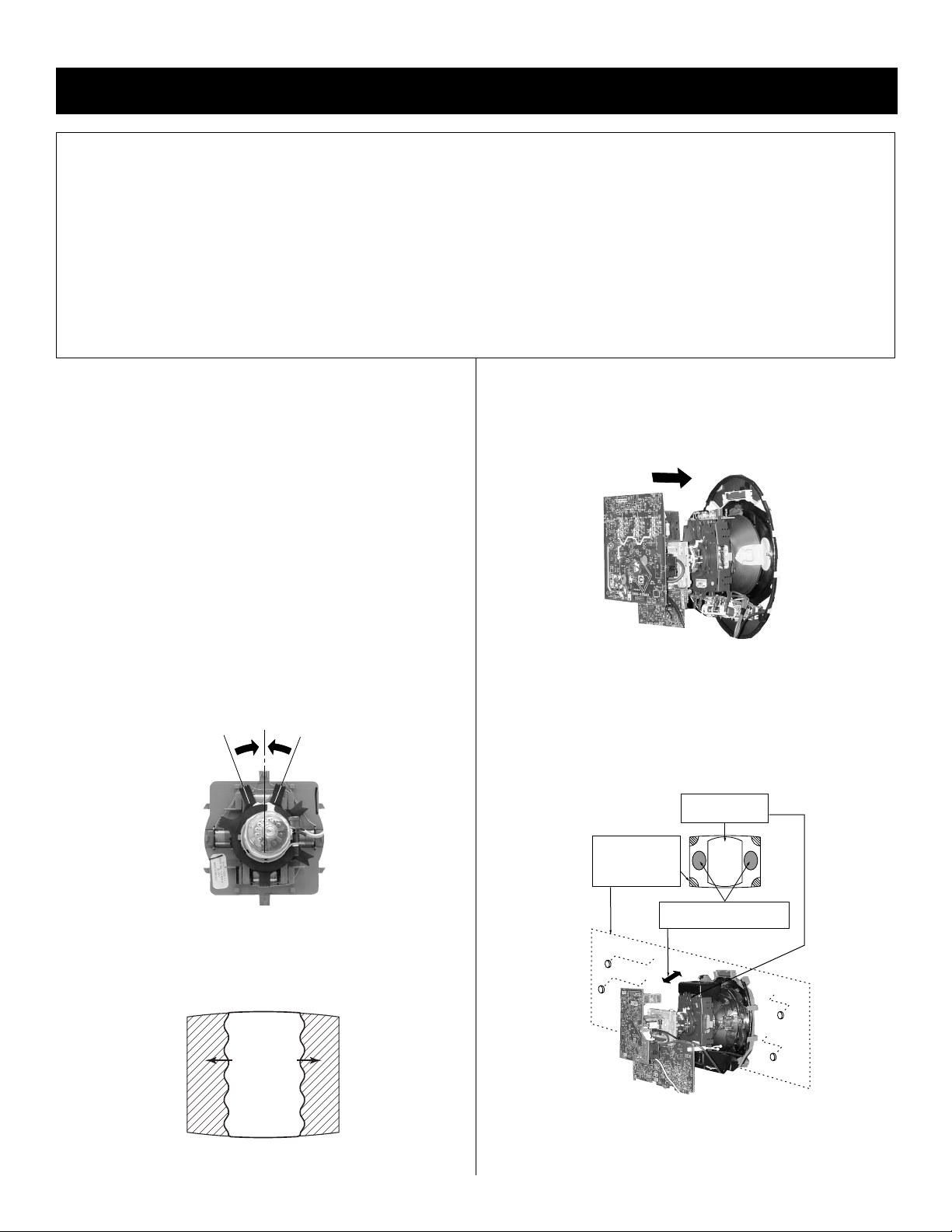

1-4. PICTURE TUBE REMOVAL

WARNING: BEFORE REMOVING THE ANODE CAP

High voltage remains in the CRT even after the power is disconnected. To avoid electric shock,

discharge CRT before attempting to remove the anode cap. Short between anode and CRT

coated earth ground strap.

1

6

5

2

9

4

7

10

1. Discharge the anode of the CRT and remove the

anode cap.

8

2. Unplug all interconnecting leads from the defl ection

yoke, neck assembly, degaussing coils and CRT

3

4

grounding strap.

3. Remove the CH Board from the CRT.

3

4. Remove the chassis assembly.

5. Loosen the neck assembly fi xing screw and remove.

6. Loosen the defl ection yoke fi xing screw and remove.

7. Place the set with the CRT face down on a cushion

and remove the degaussing coil holders.

8. Remove the degaussing coils.

9. Remove the CRT grounding strap and spring

tension devices.

10. Unscrew the four CRT fi xing screws [located on

each CRT corner] and remove the CRT

[Take care not to handle the CRT by the neck].

Coated

Earth

Ground

Strap

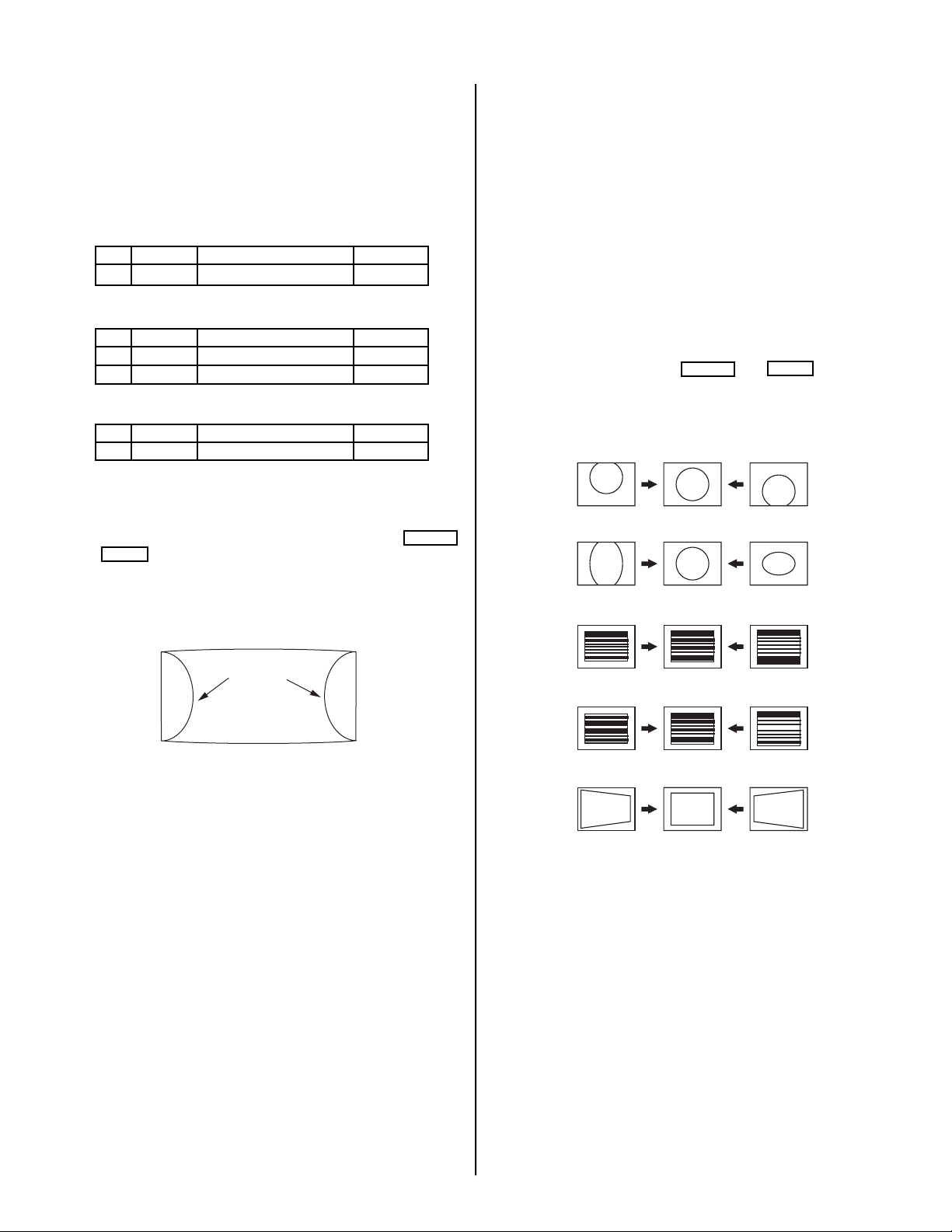

ANODE CAP REMOVAL PROCEDURE

WARNING: High voltage remains in the CRT even after the power is disconnected. To avoid electric shock, discharge CRT before attempting to

remove the anode cap. After removing the anode cap, short circuit to either the metal chassis, CRT shield, or carbon painted on the CRT.

NOTE: After removing the anode cap, short circuit the anode of the picture tube and the anode cap to either the metal chassis, CRT shield or carbon

painted on the CRT.

REMOVAL PROCEDURES

a

Turn up one side of the rubber cap in

the direction indicated by arrow a .

b

Use your thumb to pull the rubber

cap fi rmly in the direction indicated

by arrow b .

HOW TO HANDLE AN ANODE CAP

1. Do not use sharp objects which may cause damage to the surface of the anode

cap.

2. To avoid damaging the anode cap, do not squeeze the rubber covering too

hard. A material fi tting called a shatter-hook terminal is built into the rubber.

3. Do not force turn the foot of the rubber cover. This may cause the shatter-hook

terminal to protrude and damage the rubber.

Anode Button

When one side of the rubber cap separates from

the anode button, the anode cap can be removed

by turning the rubber cap and pulling it in the

direction of arrow c .

c

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

12

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

SECTION 2: SET-UP ADJUSTMENTS

The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

These adjustments should be performed with rated power supply

voltage unless otherwise noted.

The controls and switch should be set as follows unless otherwise

noted:

VIDEO MODE: STANDARD (RESET)

2-1. BEAM LANDING

Preparation:

• Use cross hatch signal to rough adjust focus, G2 and then input a

white pattern signal.

• Face the picture tube in an East or West direction to reduce the

infl uence of geomagnetism.

• Confi rm data in service mode to match with CRT screen size.

• CXA2170D-4

• CXA8070 (Should be set to default) - or unplug CRT from DY.

• VCEN, VPIN, HTPZ, PPHA, VANG, LANG, VBOW, LBOW

(Should be set to default value).

NOTE: Do not use the hand degausser; it magnetizes the CRT .

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

3. Focus

4. Screen (G2)

5. White Balance

Test Equipment Required:

1. Color Bar Pattern Generator

2. Degausser

3. DC Power Supply

4. Digital Multimeter

5. Move the defl ection yoke forward, and adjust so that the entire screen

becomes green.

1. Input white pattern from pattern generator. Set the PICTURE control

to maximum, and the BRIGHTNESS control to standard.

2. Loosen the defl ection yoke mounting screw, and set the purity

control to the center as shown below:

Purity Control

3. Input a green pattern from the pattern generator.

4. Move the defl ection yoke backwards, (See Figure 1) and adjust with

the purity control so that green is in the center and red and blue are

even on both sides.

Blue Red

Figure 1

6. Switch over the raster signal to red and blue and confi rm the

condition.

7. When the position of the defl ection yoke is determined, tighten it with

the defl ection yoke mounting screw.

8. If landing at the corner is not right, adjust it by using the disk

magnets.

Purity control

corrects this area

Disk magnets

or rotatable disk

magnets correct

these areas (a-d)

b

d

cd

Deflection yoke positioning

corrects these areas

ba

a

c

Green

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

13

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

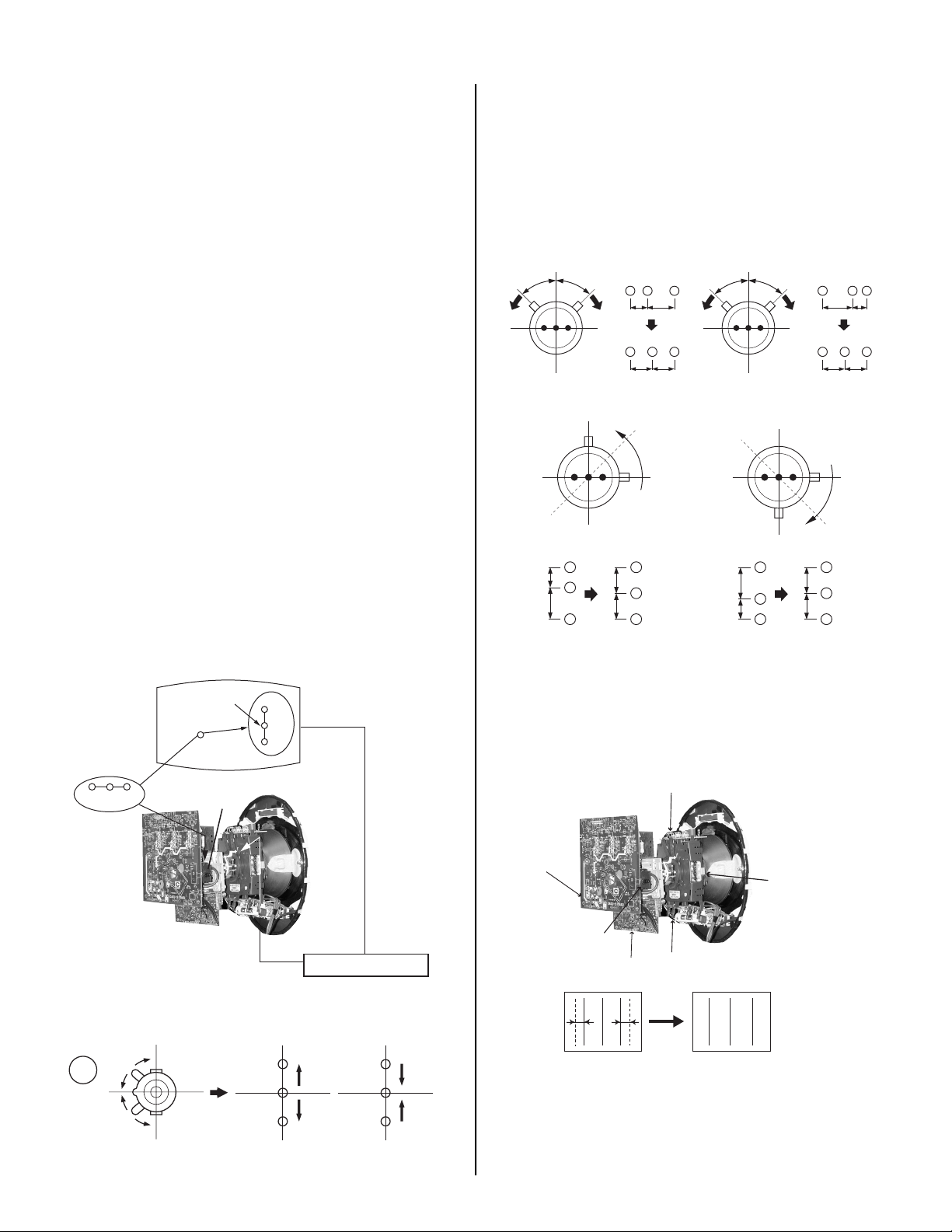

2-2. V-PIN AND V-CEN ADJUSTMENT

2-3.2. OPERATION OF BMC (HEXAPOLE)

Preparation:

• Input a cross hatch pattern signal.

• Set Video Mode to: Standard (Reset)

The respective dot positions result from moving each magnet interact.

Perform the following adjustments while tracking.

• For all 4X3 CRT, VPIN data has separate register for full and Vcompress. Adjust both modes if needed.

1. Use the BMC tabs to adjust the red, green and blue dots so that

1. Adjust service mode CXA2170D-1 05 V-CEN so that the top pin and

bottom pin are symmetrical from top to bottom.

2. Adjust service mode CXA2170D-1 06 V-PIN so that the top pin and

bottom pin are symmetrical from top to bottom.

3. Horizontal lines should be straight from left to right. Check landing for

side effect.

2-3. CONVERGENCE

Preparation:

• Set the CONTRAST and BRIGHTNESS control to standard (reset).

• Input a cross hatch pattern signal.

2-3.1. VERTICAL AND HORIZONTAL STATIC

CONVERGENCE

1. Disconnect the dynamic convergence before adjusting static

convergence (CN903), except for minor touch-up.

2. Adjust H.STAT convergence, RV9001, to converge red, green, and

blue dots in the center of the screen.

3. Connect dynamic convergence back.

4. Adjust V. STAT magnet to converge red, green and blue dots in the

center of the screen.

2-3.3. TLH PLATE ADJUSTMENT

MAGNET

they line up at the center of the screen (move the dots in a horizontal

direction).

HMC Correction HMC Correction

A>B

A=B

R

B

GB

R

AB

RGB

AB

C=D

R

G

B

A=B

VMC Correction

C<D

R

C

G

D

B

A<B

R

AB

RGB

AB

C=D

GB

R

G

B

VMC Correction

C<D

C

G

D

Center dot

R

G

B

RV9001

R G B

H-STAT

V.STAT magnet

5. Tilt the V.STAT magnet and adjust static convergence to open or

close the V.STAT magnet.

1

B

G

R

B

G

R

Preparation:

• Input a cross hatch pattern signal.

• Adjust unbalanced horizontal convergence of red and blue dots by

adjusting the TLH Plate on the defl ection yoke.

TLV

CH Board

RV9001

B R

(R)(B)

WY Board

R B

(B)(R)

XCV

TLH+

TLH-

TLH Plate

1. Adjust XCV core to balance X axis.

2. Adjust the vertical red and blue convergence with V.TILT (TLV VR).

Note: Perform adjustments while tracking Item 1.

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

14

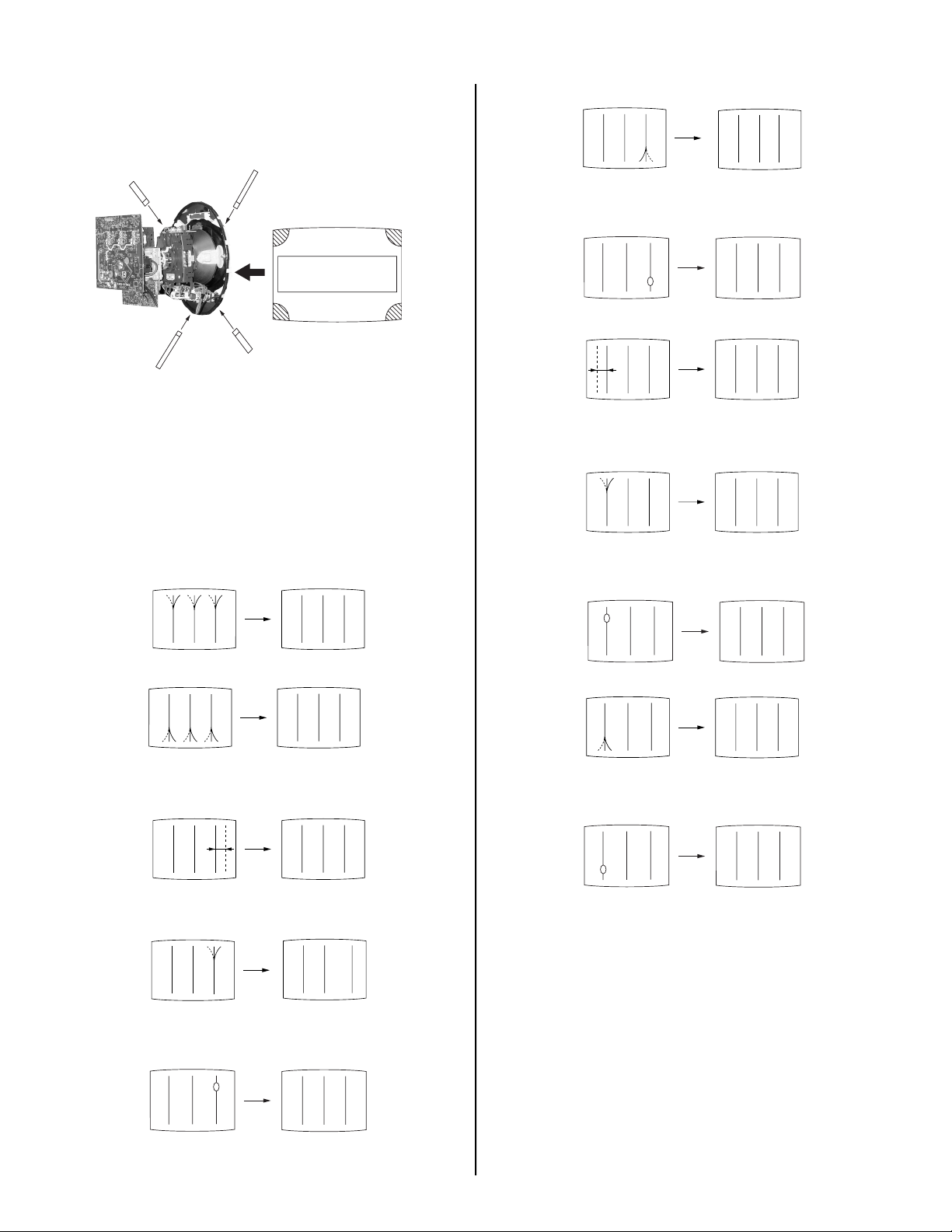

2-3.4. SCREEN-CORNER CONVERGENCE

Preparation:

• Input a cross hatch pattern signal.

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

5. RLBW (Right Lower BOW)

1. Affi x a permalloy assembly corresponding to the misconverged areas.

b

a

6. RLMB (Right Lower Middle BOW)

ab

a-d: screen-corner

misconvergence

cd

7. LSAP (Left H AMP)

d

c

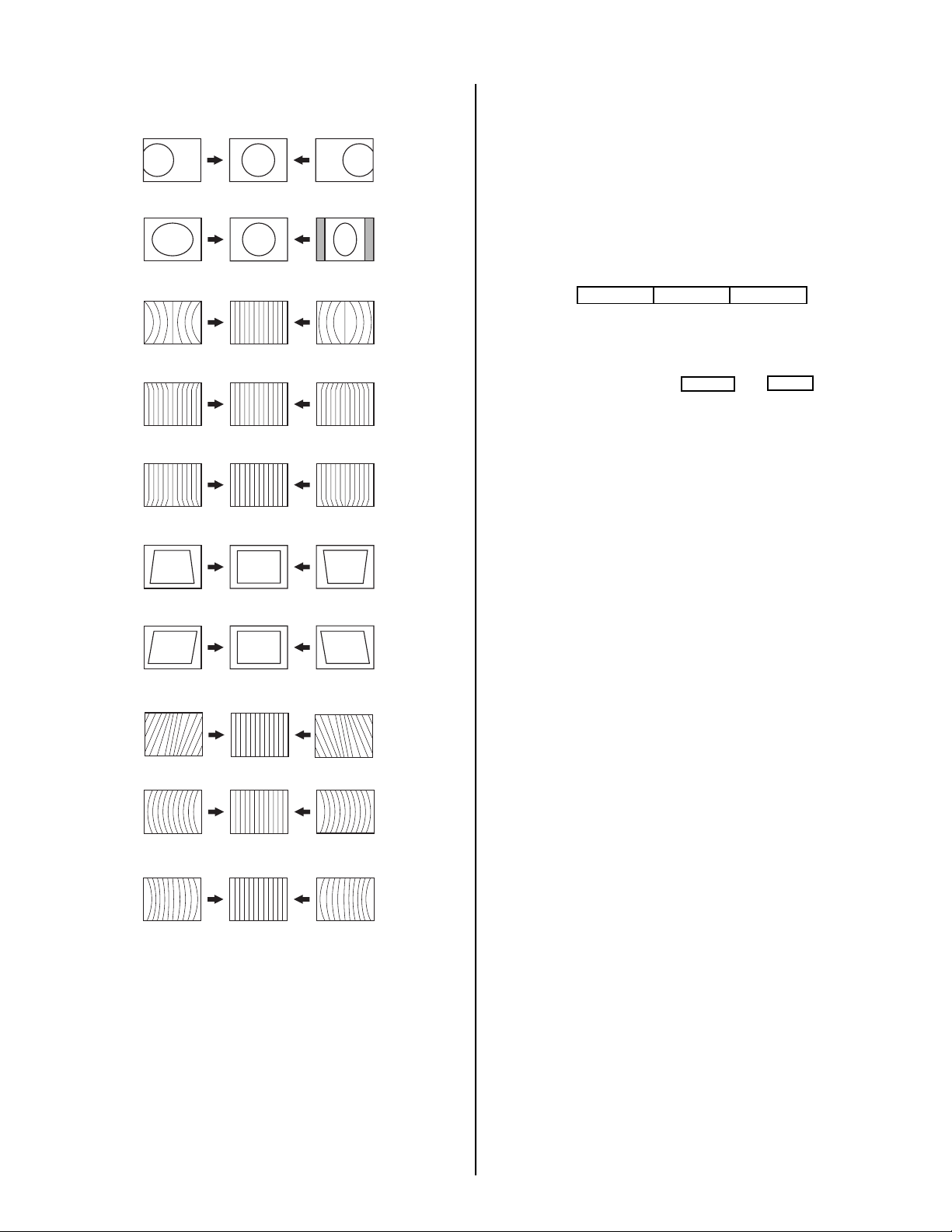

2-3.5. DYNAMIC CONVERGENCE

ADJUSTMENTS

• Set dynamic convergence using the following service mode

adjustment data.

• Only H-component can be corrected, for vertical component use

permalloy to compensate.

0. YBWU (Upper Y-BOW)

BR BR

8. LUBW (Left Upper BOW)

9. LUMB (Left Upper Middle BOW)

RB

BR

BR

BR

BR

1. YBWL (Lower Y BOW)

BR BR

2. RSAP (Right H AMP)

RB

3. RUBW (Right Upper BOW)

BR

4. RUMB (Right Upper Middle BOW)

BR

10. LLBW (Left Lower BOW)

BR

11. LLMB (Left Lower Middle BOW)

BR

12. CADJ Fix 29

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

15

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

y

p

p

r

2-4. FOCUS ADJUSTMENT

Confi rm neck assembly Z axis position. (See Figure 1)

1. Input a dot signal.

2. Set Video Mode to STANDARD.

3. Adjust focus VR clockwise (DE-Focus) to confi rm the dot’s shape.

Center should be oval with left and right sides balanced.

4. Input a HD monoscope signal.

5. Confi rm center focus with focus VR.

KV-27/29/30 HS420

CRT: 29RSN/32RVE (NON-Super-Fine Pitch)

Neck Assy:NA2920 (VA-Type, Square pin assignment, VPIN harness)

Neck-Assy: NA2920

G3

G2

Edge of G2 part Center Step

G1

Position tolerance: Just position +/- 0.5mm

KV-32/34/36 HS420

CRT: 34RSN/36RV2/38RSN (NON-super-fi ne pitch and round

fannel)

Neck Assy:NA328 (VA-type, square pin assignment, VPIN harness)

DQP Dot Pattern

Upper Corner

Center Horizontal Line

Center Dot Slightly Oval

Lower Corner

NOTE: Changing neck assembly position will affect corner convergence.

2-4.1. DYNAMIC FOCUS/DYNAMIC QUADRA-

POLE DATA

Normally, no adjustments are necessary for these systems. If for some

reason the data is lost, use the data from Table 1 on Page 24:

Write the data from any non-vertically compressed mode, then use

the CPY1 function (CXA2170D-4 Item 6) to copy the data to the

vertical compressed modes. V-compressed data is identical to non-vcompressed data. Service personnel with a trained eye can adjust the

DF or DQP registers to adjust DF phase (Item 7) or DQP phase (Item 8),

respectively, to balance left and right focus. Refrain from adjusting more

than 5 steps from table data below. Further adjustment indicates a circuit

problem -- troubleshoot to cause. Be sure that Neck Assembly is in the

proper location. Always mark position before moving or replacing neck

assembly.

G3

G2 Neck-Ass

G1

Position tolerance: Just

Holde

G1 Cu

Figure 1

Focus

Screen (G2)

MVD

: NA328

osition +/- 0.5mm

(See Section 2-4 Figure 1 - before changing DF/DQP data or

troubleshooting circuit when DF/DQP is suspect.)

Procedure to adjust or check:

1. Input a cross hatch signal.

2. Short Q8018 B-E to disable DF – Markings are on the circuit board.

Circuit connection changes should always be done with the power off.

Caution: Q8018 heatsink is live and peak voltage is 250V.

3. Defocus or overfocus to adjust DQP phase. Adjust the data

(CXA2170-D4 item 8) to balance left and right vertical line width.

4. Once DQP is balance, remove the short from DF circuit and refocus

the set.

5. Adjust DF (CXA2170-D4 item 7) to balance left and right vertical line

width.

6. Reconfi rm focus performance.

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

16

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

NO. Name Control Function

02 SCON SUB-CONT

2103-1

2-5. SCREEN (G2)

1. Input composite white fi eld into Video 1.

2. Set to service mode and adjust as follows:

(Fig. 1) Opeartion Procedure Standards Notes

1) In Full mode, apply changes in Fig. 1

CXA2170P-2 PICO 1-> 0

2) Mount G2 adjustment jig. Adjust Cathode

voltage if the standard is not met. Standard 34RSN, 36RV2, 38RSN

varies by CRT size.

3) Adjust G2 by Flyback transformer (T8001).

4) Return data changes in 1) to original condition.

170 +/- 5 (V

175 +/- 5 (V

)

29RSN, 32RVEN

DC

)

DC

2-6. PICTURE QUALITY ADJUSTMENTS

Preparation:

• Set PRO MODE (Reset).

1. Input signal (480i Composite):

• Color Bar Video 75 IRE (White) 75% modulation 7.5% Set-up.

• Color Bar RF 75 IRE (White) 75% modulation 7.5% Set-up.

2-6.1. VIDEO INPUT - SUB CONTRAST

ADJUSTMENT

Preparation:

• Input a Color Bar signal to VIDEO 1 (75 IRE 75%).

• Set picture mode: Single (Full) (PRO MODE Reset).

• Picture: Max

1. Set to Service Mode and adjust as follows:

2170P-2

NO. Name Control Function Avg. Data

01 RGBS R ON 4

2. Connect oscilloscope to Pin 1 of CN9001 (R.DRV) on the CH Board.

3. Adjust contrast according to the service mode item: SPIO.

white

VR1

black

VR2

GND

4. Press

MUTING

VR

(27HS/29HS) = 1.84 ± 0.05 Vpp

(30HS) = 1.92 ± 0.05 Vpp

(32HS) = 1.92 ± 0.05 Vpp

(34HS) = 1.92 ± 0.05 Vpp

(36HS) = 2.00 ± 0.05 Vpp

ENTER

then

to write into memory.

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

17

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

NO. Name Control Function Avg. Data

01 RGBS R ON 4

2170P-2

NO. Name Control Function

02 SCON SUB-CONT

2103-1

2-6.2. VIDEO INPUT - SUB HUE/SUB COLOR

ADJUSTMENT

Preparation:

• Input a Color Bar signal to VIDEO 1 (75 IRE 75%).

• Set picture mode: Single (Full) (PRO MODE Reset).

• Picture: Max

1. Set to Service Mode and adjust as follows:

2170P-2

NO. Name Control Function Avg. Data

01 RGBS R ON 4

2. Connect an oscilloscope to Pin 5 of CN9001 (B. DRV) on the CH

Board.

3. Adjust color according to Service Mode for SCLO.

4. Adjust color according to Service Mode for SHUO.

2103-1

NO. Name Control Function

03 SCOL SUB-COL

04 SHUE SUB-HUE

7

2-6.3. RF INPUT - SUB CONTRAST

ADJUSTMENT

Preparation:

• Input a Color Bar signal to RF (75 IRE 75%).

• Set picture mode: Single (Full) (PRO MODE).

• Picture: Max

• Color: Min

1. Set to Service Mode and adjust as follows:

2. Connect an oscilloscope to Pin 1 of CN9001 (R. DRV) on the CH

Board.

3. Adjust contrast according to service mode for SCON.

5. Press

VB3VB2VB1

COLOR: VB1 < VB4 (=20mV ± 200 mV)

MUTING

HUE: VB2 <

then

VB3 (=20mV ± 200 mV)

ENTER

to write into memory.

VB4

4. Press

VR1

MUTING

white

black

VR2

VR

(27HS/29HS) = 1.84 ± 0.05 Vpp

(30HS) = 1.92 ± 0.05 Vpp

(32HS) = 1.92 ± 0.05 Vpp

(34HS) = 1.92 ± 0.05 Vpp

(36HS) = 2.00 ± 0.05 Vpp

ENTER

then

to write into memory.

GND

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

18

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

VIDEO 1

CXA2170P1

NO. Name Control Function

3 CBOF CB OFFSET

4 CROF CR OFFSET

VIDEO 5

CXA2170P1

NO. Name Control Function

3 CBOF CB OFFSET

4 CROF CR OFFSET

VIDEO 7 -

CXA2170P1

NO. Name Control Function

3 CBOF CB0F (FROM VIDEO 5) +3

4 CROF CR0F (FROM VIDEO 5) - 4

2-6.4. RF INPUT - SUB HUE/SUB COLOR

ADJUSTMENT

Preparation:

• Input a Color Bar signal to RF (75 IRE 75%).

• Set picture mode: single (FULL) (PRO MODE Reset).

• Picture: Max

1. Set to Service Mode and adjust as follows:

2170P-4

NO. Name Control Function Avg. Data

01 RGBS R ON 7

2. Connect an oscilloscope to pin 5 of CN9001 (B. DRV) on the CY

Board.

3. Adjust color according to Service Mode for SCOL.

4. Adjust color according to Service Mode for SHUE.

2103-1

NO. Name Control Function

03 SCOL SUB COLOR

04 SHUE SUB HUE

2-7. WHITE BALANCE (CRT) AND SUB

BRIGHT ADJUSTMENT

Preparation

• Input an all white 480I (15.734 KHz) signal into the VIDEO 1 input

terminal to perform the White Balance (highlight, cut-off) adjustments.

The parameters to adjust are in the CXA2170P1 in Service Mode.

• Set Picture Mode: Single (FULL) ( POR MODE Reset)

• Picture: Max

• Color: Min

WHITE BALANCE ADJUSTMENT PROCEDURE (Compos ite White Field Signal into Video 1)

Old Calibration R/G

Highlight/Cutoff 29RSN/29RSEN .790 .903

9300K + 8MPCD

Specification W B701

Condition Registers BDRV 2170P-1-08

(R/G 1.000, B/G 1.000) 32RVE/32RV .775 .915

New Calibration Preset 34RSN .689 .883

Highlight/Cutoff

10,900K + 2MPCD 36RV2 .745 .905

(R/G 1.007, B/G 1.139)

Picture Mode: Single (Full) RDRV (fixed)** 2170P-1-06

Picture Setting:Pro

Color Temp: Neutral Adjustm ent

Picture: 63 write to 86h:01h:FFh (Service Mode)

Color: 0 write to 86h:03h:00h RCUT fixed)** 2170P-1-09

38RSN .679 .872

GDRV 2170P-1-0

GCUT 2170P-1-10

BCUT 2170P-1-11

** Data will differ by model

B/G

2-7.1. COLOR OFFSET ADJUSTMENT

PROCEDURE

COLOR: VB1 < VB4 (=20mV ± 200 mV)

5. Press

MUTING

HUE: VB2 <

then

VB3 (=20mV ± 200 mV)

ENTER

to write into memory.

Preparation:

• Input an all white (30 IRE) signal to the specifi ed input.

VB4

• Adjust the white balance using the specifi ed registers.

• Set picture mode: Single (FULL) (PRO MODE Reset)

• Color: Max

VB3VB2VB1

HDMI 480i Signal

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

19

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

2-8. H RASTER CENTER ADJUSTMENT

Preparation:

• Input a monoscope signal.

• Set to NTSC (DRC) mode.

1. Set to Service Mode and adjust as follows:

CXA2170P-2

NO. Name Control Function Data

05 AGNG AGING 1, AGING 2 2

CXA2170D-2

NO. Name Control Function Avg. Data

01 HPOS Horiz Position 34

02 HSIZ Horiz Size 34

CXA2170D-3

NO. Name Control Function Avg. Data

00 HBLK Blanking Enable 0

2. Reduce HSIZ to see sides of raster. (See Figure A below)

3. Adjust H-Center with CXA2170D-2.

4. Adjust to the best screen position with H-CENT, then press

ENTER

then

5. Restore aging, HSIZ and HBLK to original condition.

to write into memory.

MUTING

2-9. PICTURE DISTORTION ADJUSTMENTS

2-9.1. NTSC (DRC) FULL MODE

ADJUSTMENT

1. Face the picture tube in an east-west direction. (For best condition.)

2. Complete V-PIN and V-CEN adjustments fi rst (A2170-D1 06 V-PIN,

A2170-D1 05 V-CEN).

3. Input a monoscope and crosshatch signal. Adjust the picture

distortion with the following service parameters to balance the best

condition for these two signals.

NOTE: Make sure that the picture size is within specs. Vertical size

is 11.8 ± 0.1 sq. and horizontal size is 15.8 ± 0.1 sq.

4. Before changing modes, press

memory.

MUTING

then

ENTER

to write into

CXA2170D-1

Item 0. VPOS (V-POSITION)

Item 1. VSIZ (V-SIZE)

Raster Edge Equal:

RASTER

EDGES

RASTER

Figure A

Item 3. VLIN (V-LINE)

Item 4. VSCO (VS-COR)

Item 9. HTPZ (H-TRAPEZOID)

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

20

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

A

2150-D2 01 HPOS

CXA2170D-2

Item 1. HPOS (H-POSITION)

Item 2. HSIZ (H-SIZE)

Item 5. PIN (PIN AMP)

Item 7. UCP (UP COR PIN COR)

Item 8. LCP (LOW CO PIN COR)

Item 14. PPHA (PIN PHASE)

2-9.2. 1080I HD MODE ADJUSTMENT

1. Input a 1080i cross-hatch signal and an HD monoscope signal that

contains overscan markers. (From service mode, verify 1080I mode).

2. Adjust the raster position per Section 2-8., only if this procedure was

not performed for full mode.

3. Adjust the geometry similar to Full DRC mode. Vertical size is 11.7

± 0.1 sq. and horizontal size is 15.6 ± 0.1 sq., if monoscope signal is

available. Otherwise, set the Vertical size to 91.0 ± 0.6% scan and

Horizontal size as 91.0 ± 0.6% scan.

4. Use the following register to adjust the horizontal parameter:

NOTE: If necessary, touch up the geometry using the data register

listed above for Full mode. Check NTSC full mode for side

effect and balance.

5. Before changing modes, press

memory.

MUTING

then

ENTER

to write into

2-9.3. VERTICAL COMPRESSED MODE

CHECK AND CONFIRMATION

(FOR 4X3 CRT ONLY)

1. Input a monoscope and crosshatch signal.

2. Check vertical compressed mode.

3. Adjust VPIN if needed.

Item 15. VANG (AFC-ANGLE)

Item 16. LANG (L-ANGLE)

Item 17. VBOW (AFC-BOW)

Item 18. LBOW (L-BOW)

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

21

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

SECTION 3: SAFETY RELATED ADJUSTMENTS

3-1. PREPARATION BEFORE

3-5. PREPARATION FOR HV AND IK

CONFIRMATION

Standard.............................................................................135.3 ± 1 VAC

Check Condition:

AC input voltage: 120 (± 2) VAC

Note: If using a stabilized power supply, make sure that the distortion

factor is 3% or less.

Setting Mode: ............................................................................ Full mode

Signal Input: ............................................................Cross-hatch of NTSC

Initial Setting:.....................................................Standard Reset condition

Confi rm Point:..........................Across CN5509 PIN 9 for B+ of DZ Board

3-1.1 HOLD-DOWN OPERATION

1. Remove DZ board screws and carefully lift board as necessary to

2. Unsolder CN5001 pin 1 to open ABL connection to AY or AZ board.

(Alternately, open AY or AZ - DZ connector (CN509-CN5001) and

3. Install jumper wire from MY or MZ board connection CN2304 pin 1

4. Unsolder CN5009 pin 8 (H-prot).

5. Open ABL pin 1 of T8001 (RHT) on DZ board and connect analog

CONFIRMATION

1. Using an external DC power supply, apply 5.3 ± 0.5 Vdc between

Pin 2 of CN507 (jig connector) and ground (Pin 8); confi rm set goes

to hold-down (main power relay click).

2. Remove the external DC power supply.

3-2. B+ MAX CONFIRMATION

Standard 135.3 ± 1 VAC

Check Condition:

AC input voltage: 120 (± 2) VAC

Note: If using a stabilized power supply, make sure that the distortion

factor is 3% or less.

Setting Mode: ............................................................................ Full mode

Signal Input: ............................................................Cross-hatch of NTSC

Initial Setting:.....................................................Standard Reset condition

Confi rm Point:..........................Across CN5509 PIN 9 for B+ of DZ Board

3-3. B+ VOLTAGE CHECK

Standard:..........................................................................135.3 ± 1 VDC

Measurement point:

CN5509 pin (9) for B+ of [DZ] board

Input Video Signal:............................................................All Black Signal

Picture level:..................................................Picture/Brightness Minimum

3-4. HIGH VOLTAGE (HV) CHECK

Standard:............................................................................30.5 ± 0.5 kV

(KV-27HS420/29DRC420/30HS420 only)

Standard:............................................................................31.5 ± 0.5 kV

(KV-32HS420/34HS420/36HS420 only)

Measurement point:............................................................Anode of CRT

Input Video Signal:............................................................All Black Signal

Picture level:..................................................Picture/Brightness Minimum

3-6. HV PROTECTOR CHECK

3-6-1. CUT OFF CONDITION

Input Video Signal:............................................................All Black Signal

Picture level:..................................................Picture/Brightness Minimum

1. Confi rm ABL current which should be approximately 0.160mA.

2. Short across C8002, C8021, and C8052.

3. Turn off the set and install precision VR1 jig (initially set to 100K) to

4. Restore power and adjust HV to obtain

34.4 ± 0.15kV (KV-27HS420/29DRC420/30HS420 only)

or

35.2 ± 0.15kV (KV-32HS420/34HS420/36HS420 only)

by precision VR1 jig.

Note: If the picture turns bright red or other color and the set shuts

5. Remove short from C8002 and confi rm that hold down activates.

6. Short C8002 again and confi rm that HV recovers.

7. Re-adjust HV to obtain

31.5 ± 0.2 kV (KV-27HS420/29DRC420/30HS420 only)

or

32.5 ± 0.2 kV (KV-32HS420/34HS420/36HS420 only)

by precision VR1 jig.

8. Remove short from C8002 and C8021 and C8052.

9. Confi rm that hold down does not activate.

Note: Remove the 10 M resistor , if installed in step D above

PROTECTOR CHECK

gain access to the bottom of the board.

carefully push pin 1 metal tab (ABL) up from the bottom and pull up

from the top using long nose pliers and release it from the connector,

then close the connector with pin 1 connection now open.)

to CN509 pin 1 to inject 5V to ABL line. (Alternately, use STBY 5V,

IC501 Pin O on AY or AZ board)

current meter.

IC8005 pin 1 (It’s the unmarked IC8005 pin on PWB A side, neither K

nor A.) and GND (C8076 -).

down, place a 10 M resistor on the CX board between G2 and E2

pins on the socket. Confi rm G2 adjustment before returning set to

production.

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

22

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

3-6-2. HIGH LIGHT CONDITION

Input Video Signal:............................................................All White Signal

Picture level:..............................................Picture/Brightness Adjustment

1. Short across C8002, C8021, C8052, C8012, and C8015.

2. Set ABL current to 2.76mA by adjusting picture and brightness

towards max condition.

3. Adjust HV to obtain

33.6 ± 0.15kV (KV-27HS420/29DRC420/

30HS420 only)

or

34.5 ± 0.15kV (KV-32HS420/34HS420/36HS420 only)

by precision RV1 jig.

4 Remove short from C8002 and confi rm that hold down activates.

5. Short C8002 again and confi rm that HV recovers.

6. Re-adjust HV to obtain

31.2 ± 0.2 kV (KV-27HS420/29DRC420/30HS420 only)

or

32.2 ± 0.2 kV (KV-32HS420/34HS420/36HS420 only)

by precision VR1 jig.

7. Remove shorts from C8002, C8021, and C8052.

8. Confi rm that hold down does not

9. Remove short from C8012 and C8015.

10. Remove VR1 jig from DZ board

activate.

3-8. HOLD DOWN CHECK

1. Using an external DC power supply, apply 5.3 + 0.5 Vdc

between Pin 2 of CN507 (jig connector) and ground (Pin 8) on AY

or AZ board.

2. Confi rm that hold down activates.

3. Remove the external DC power supply.

3-9. RESTORATION

1. Re-solder CN5001 pin 1 and CN5009 pin 8 to restore AY or AZ -DZ

connections. (Or as applicable, restore AY or AZ –DZ connector

by carefully pressing the tab back into the slot and snapping the

connector shut. Be sure the tab is fl ush and level with the other tabs

on the connector.)

2. Remove jumper wire from MY or MZ board connection CN2304 pin 1

to CN509 pin 1.

3. Remove current meter from ABL pin and restore ABL pin connection.

4. Replace all DZ board screws and restore user menu settings to reset

condition.

3-7. IK PROTECTOR CHECK

Input Video Signal:............................................................All White Signal

Picture level:...............................................Picture/Brightness Adjustment

1. Short across C8015.

2. Set ABL current to 2.76mA by adjusting picture and brightness

towards max condition.

3. Confi rm that AC Relay shuts off.

4. Remove short from C8015 and Short across C8012.

5. Turn the set off and on to reset AC relay latch.

6. Confi rm the voltage at CN5009 pin 8 (H_prot) = 3.6 ± 0.5V.

7. Remove short from C8012.

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

23

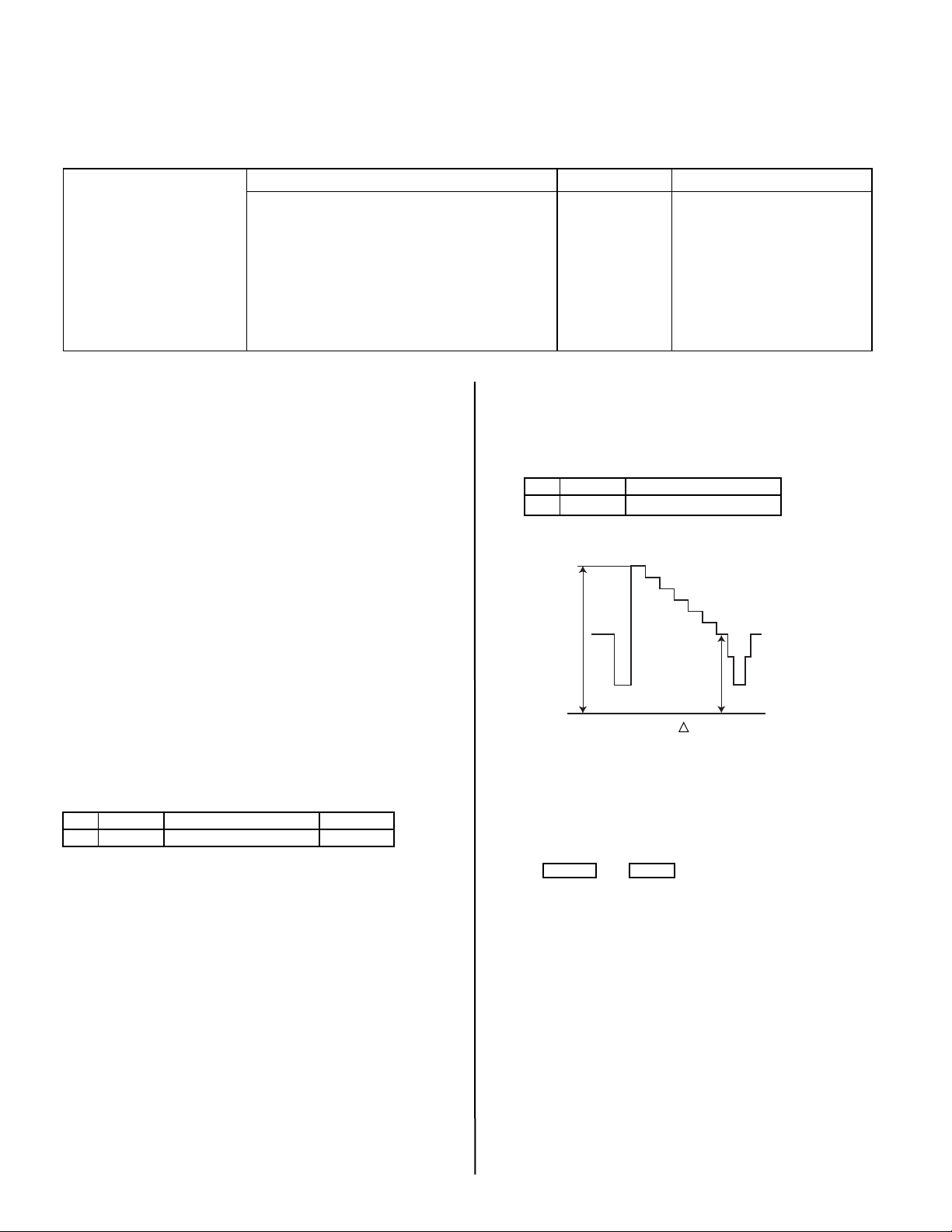

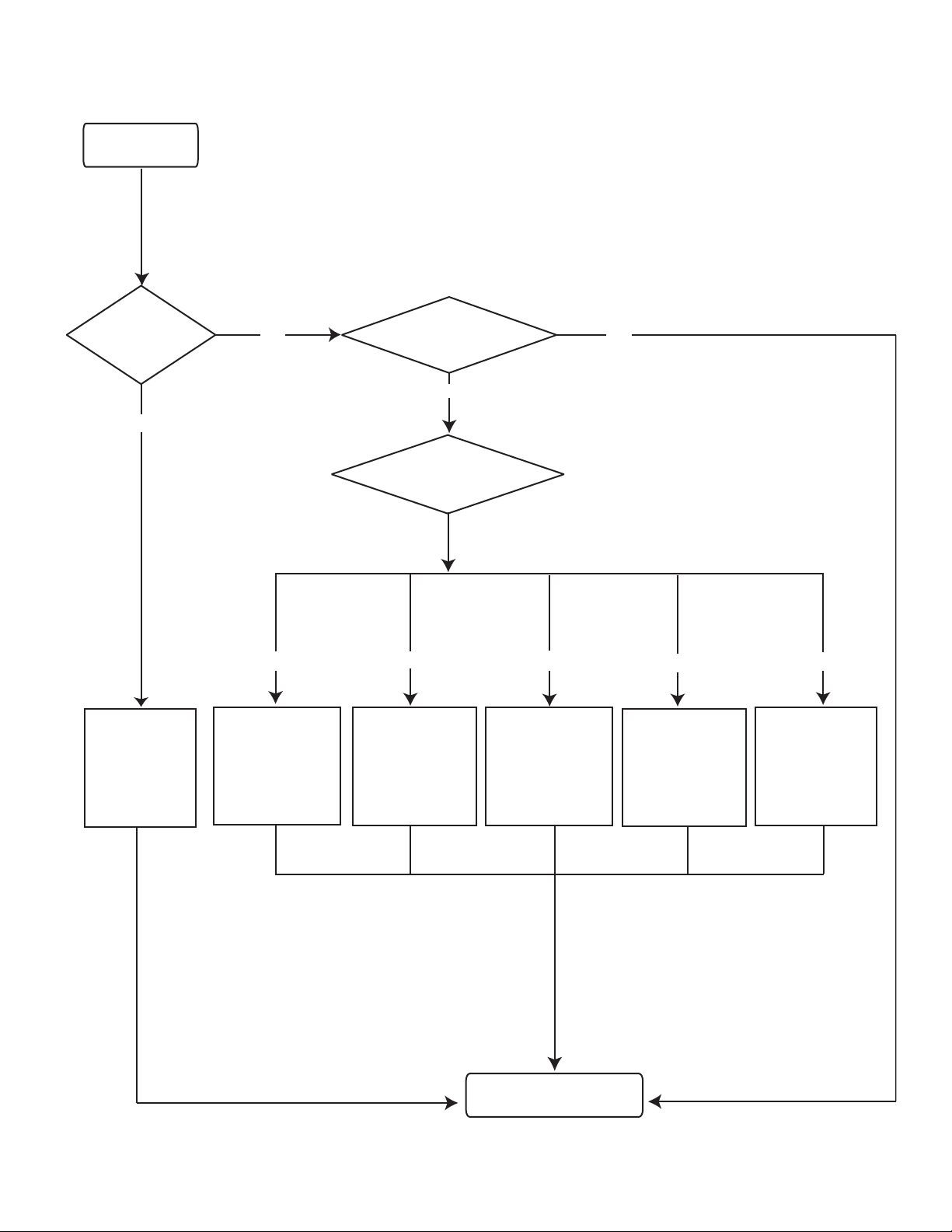

3-10. HV SERVICE FLOWCHART

Start

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

Is DZ Board

changed?

YES

Confirm:

- B+

- Hold Down

NO

Category A

Confirm:

- HV

- HV Protector

- Ik Protector

Is the spare part on

P. 25 changed?

YES

Which category part

on P. 25 changed?

Category B

Confirm:

- B+

Category C

Confirm:

- HV

NO

Category D

Confirm:

- HV Protector

Category E

Confirm:

- Ik Protector

Refer to P. 22

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

Refer to P. 22/23

Refer to P. 22

Finished with HV service

Refer to P. 22/23

Refer to P. 22/23

Refer to P. 23

24

y

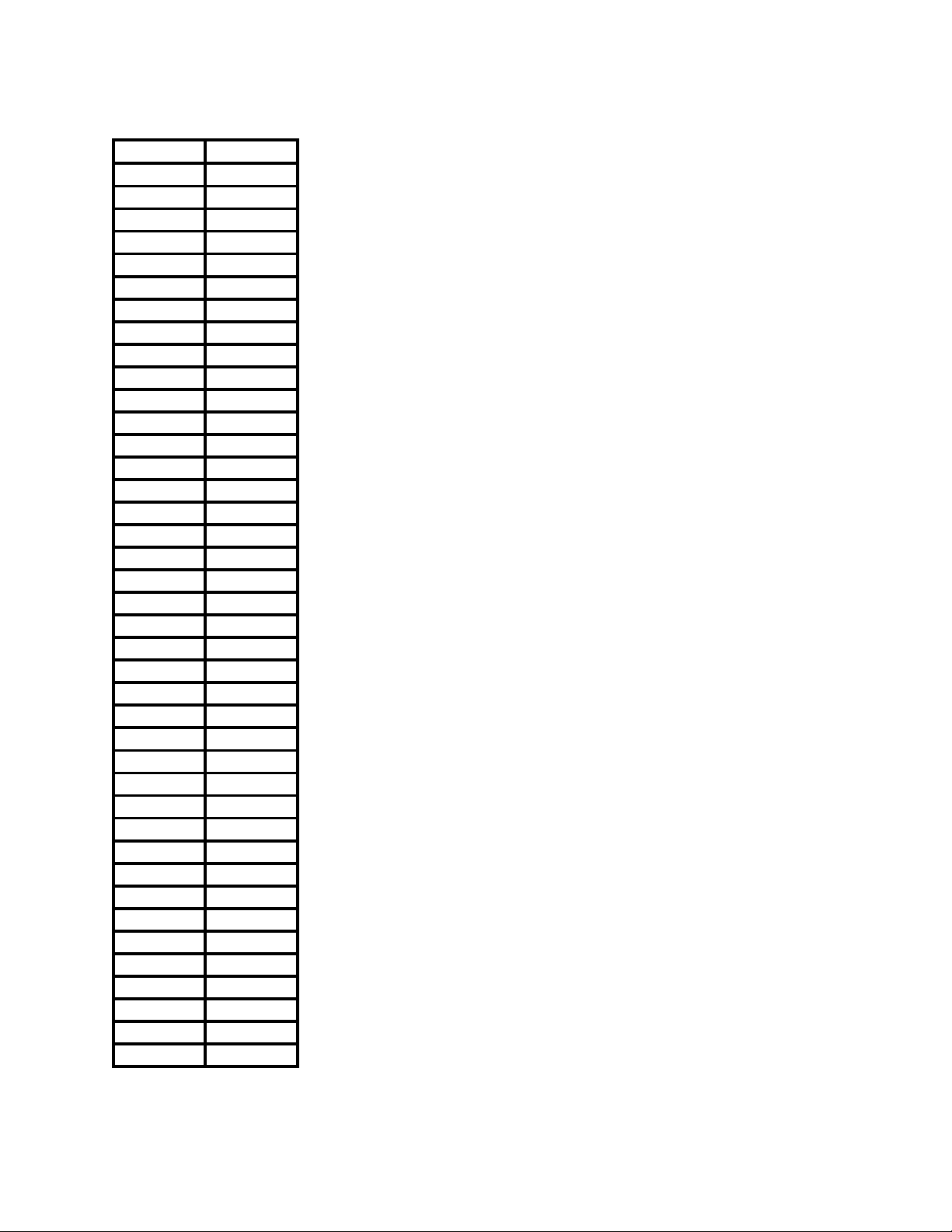

3-10.1. HV SERVICE FLOWCHART TABLE

Ref. # Categor

T8001 A

R8015 C

R8017 C

R8019 D

R8035 E

R8036 E

R8037 E

R8038 E

R8039 E

R8040 E

R8043 E

R8078 D

R8165 D

IC8005 C

IC8104 D

R8012 C

R8014 C

R8016 D

R8021 C

R8027 E

R8029 E

R8030 E

R8031 E

R8046 D

R8052 D

R8059 C

R8060 C

R8066 C

R8072 D

R8079 D

R8082 E

R6590 B

D8022 D

PH8003 C

Q8007 E

Q8008 E

IC8001 D

IC8002 C

IC8004 C

IC6503 B

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

25

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

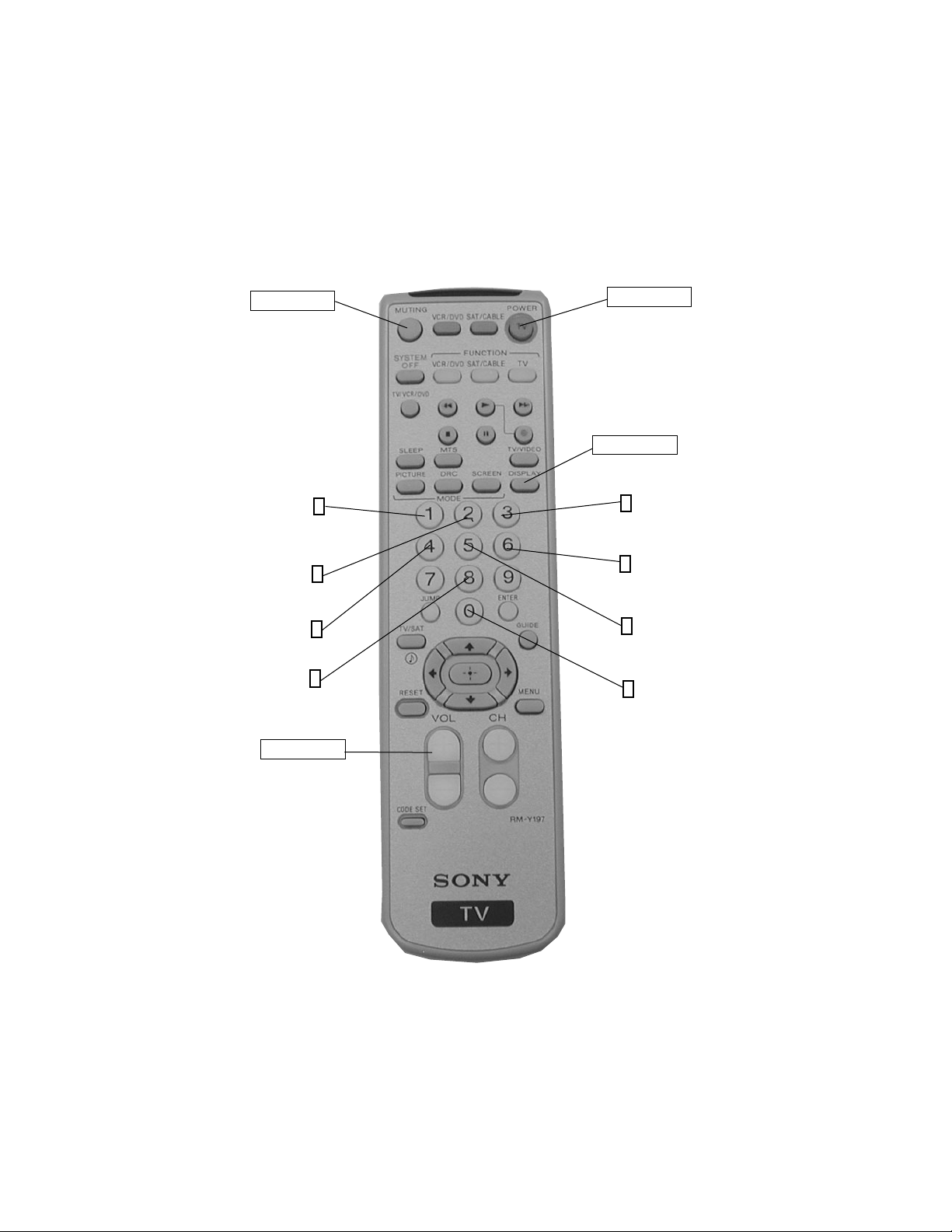

SECTION 4: CIRCUIT ADJUSTMENTS

ELECTRICAL ADJUSTMENTS BY REMOTE COMMANDER

Use the Remote Commander (RM-Y197) to perform the circuit adjustments in this section.

Test Equipment Required: 1. Pattern generator 2. Frequency counter 3. Digital multimeter 4. Audio oscillator

4-1. SETTING SERVICE ADJUSTMENT MODE

1. Standby mode (Power off).

2. Press the following buttons on the remote commander within a second

of each other:

DISPLAY

Channel 5 Sound Volume

+

Power

4-1.3. READING THE MEMORY

1. Enter into Service Mode.

2. Press 0 on the Remote Commander.

3. Press

4-1.4. ADJUSTING THE PICTURE

4-1.1. SERVICE ADJUSTMENT MODE IN

Item

order

0

TV

Item

data

7

SERVICE

Mode

Disp.

(Item)

VP

HSIZ

1. Enter into Service Mode

2. Press 2 or 5 on the remote to select the device item.

3. Press

4. Press

5. Press

4-1.5. RESETTING THE DATA

Note: Be careful when using the remote! It will clear and re-initialize

3. The CRT displays the item being adjusted.

4. Press

5. Press

6. Press

1

or 2 on the Remote Commander to select the item.

3

or 6 on the Remote Commander to change the data.

ENTER

MUTING

then

to write into memory.

4-1.6. RESETTING THE MID NVM DATA

1. Enter into Service Mode.

2. Press

ENTER

to read memory.

1

or 4 on the remote to select an item.

or 6 on the remote to change the data.

3

ENTER

MUTING

then

to write into memory.

ALL NVM data including defl ection adjustment data if not reset

properly as follows:

7

, then

JUMP

, and then press

ENTER

on the remote.

4-1.2. SERVICE ADJUSTMENT

MODE MEMORY

Item

order

0

8

Item

order

0

7

TV

then

7

TV

Item

data

SERVICE

ENTER

Item

data

MUTING

ENTER

Green

Red

on the Remote Commander to initialize.

WRITE

Disp.

(Item)

VP

HSIZ

1. Press

Disp.

(Item)

VP

HSIZ

2. DO NOT turn off set until SERVICE appears.

4-1.7. RESETTING THE SYSTEM NVM DATA

1. Enter into Service Mode.

2. Press

7

, then 9, and then press

ENTER

on the remote.

4-1.8. COPY FUNCTION

How to use copy function for DA4 Chassis:

• After writing your adjusted data into NVM press

ENTER

then

changing copy data from

to write the data into memory. You can data by

0

to 1 then press

MUTING

MUTING

again.

WARNING: DO NOT copy data before writing your corrected data in

NVM. If data is copied before writing corrected data, old

data will be copied.

• CPY1: DF/DQP DATA (CXA2170D-4 Item 6)

• CPY2: CONVERGENCE DATA (D-CONV Item 13)

then

ENTER

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

26

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

4-2. MEMORY WRITE CONFIRMATION METHOD

1. After adjustment, pull out the plug from the AC outlet, then replace the plug in the AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confi rm they were adjusted.

4-3. REMOTE ADJUSTMENT BUTTONS AND INDICATORS

MUTING

(Enter into

memory)

1

Disp. (Item Up)

2

Device (Item up)

4

Disp.(Item Down)

8

(Initialize)

POWER

(Service Mode)

DISPLAY

(Service Mode)

3

Item

(Data Up)

6

Item

(Data Down)

5

(Device Item

Down)

0

(Remove from

Memory)

VOLUME (+)

(Service Mode)

RM-Y197

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

27

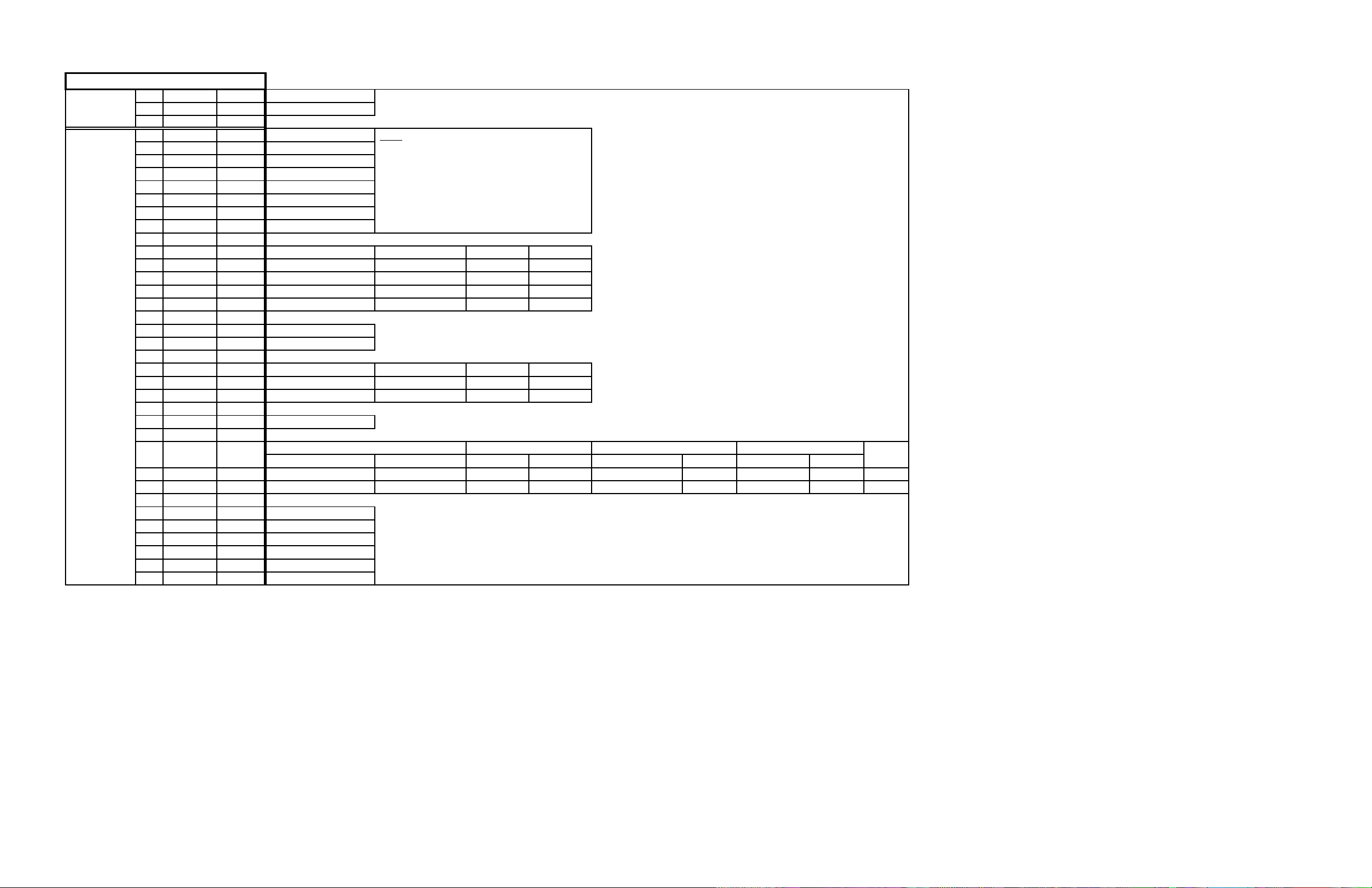

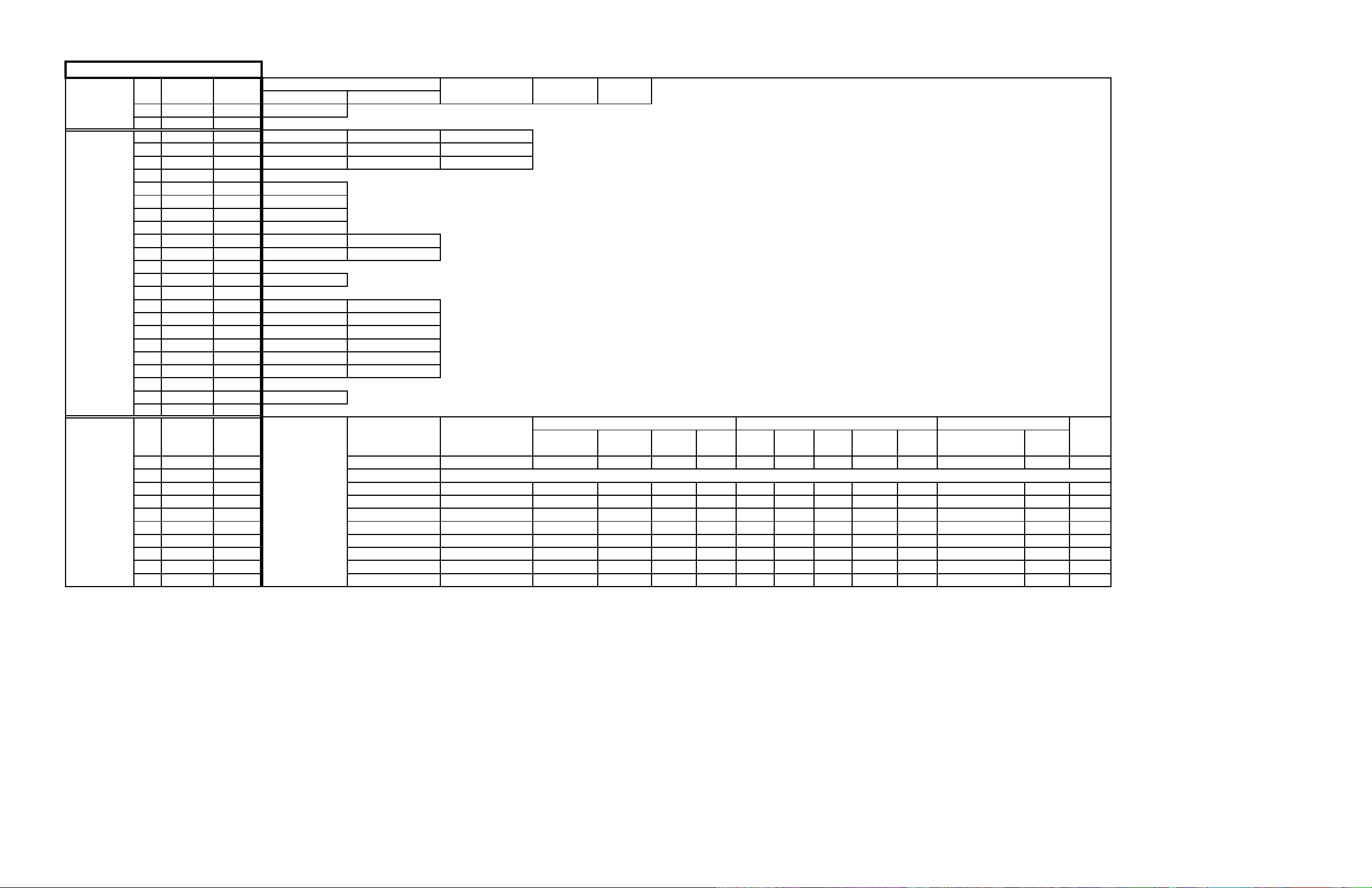

4-4. SERVICE DATA

Category No Item Range *NOT be memorized

VERSION 0 VER* 0,1 0 *

1DMY1*0-255 0

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

3D-COMB 0 NRMD* 0-3 0 *

1CLKS 0-3 1

2 NSDS* 0-3 0 *

3 MSS* 0-3 0 *

4KILS* 0-3 1 *

5FRZE* 0,1 0 *

6 EXCS 0-3 1

7 CDL 0-7 4

NRMD=0 NRMD=1 NRMD=2 NRMD=3

8DYCO 0-15 2 2 2 2

9DYGA 0-15 10 10 10 10

10 DCCO 0-15 5 5 5 5

11 DCGA 0-15 5 5 5 5

12 WSC 0-2 1

13 WSS 0,1 0

Vivid Standard Movie Pro

14 VAPG 0-7 4 2 2 0

15 VAPI 0-31 4 4 4 0

16 TEST* 0,1 0 *

RF CV/YC RF CV/YC RF CV/YC RF CV/YC

17 YPFT 0-33 33333333

18 YPFG 0-15 9 5 7 5 5 6 5 5 6

Note

:

Item * uses the fixed setting in

normal TV operations.

{Its setting can be changed for

testing in Servcie mode only.

But the change will not be

memorized after leaving

Service mode.}

StandardVivid

Movie Pro

Twin

19 SEDC 0,1 0

20 SEDY 0,1 1

21 YHCO 0-3 1

22 YHCG 0,1 0

23 SYSP 0-3 0

24 TES2* 0-7 0 *

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

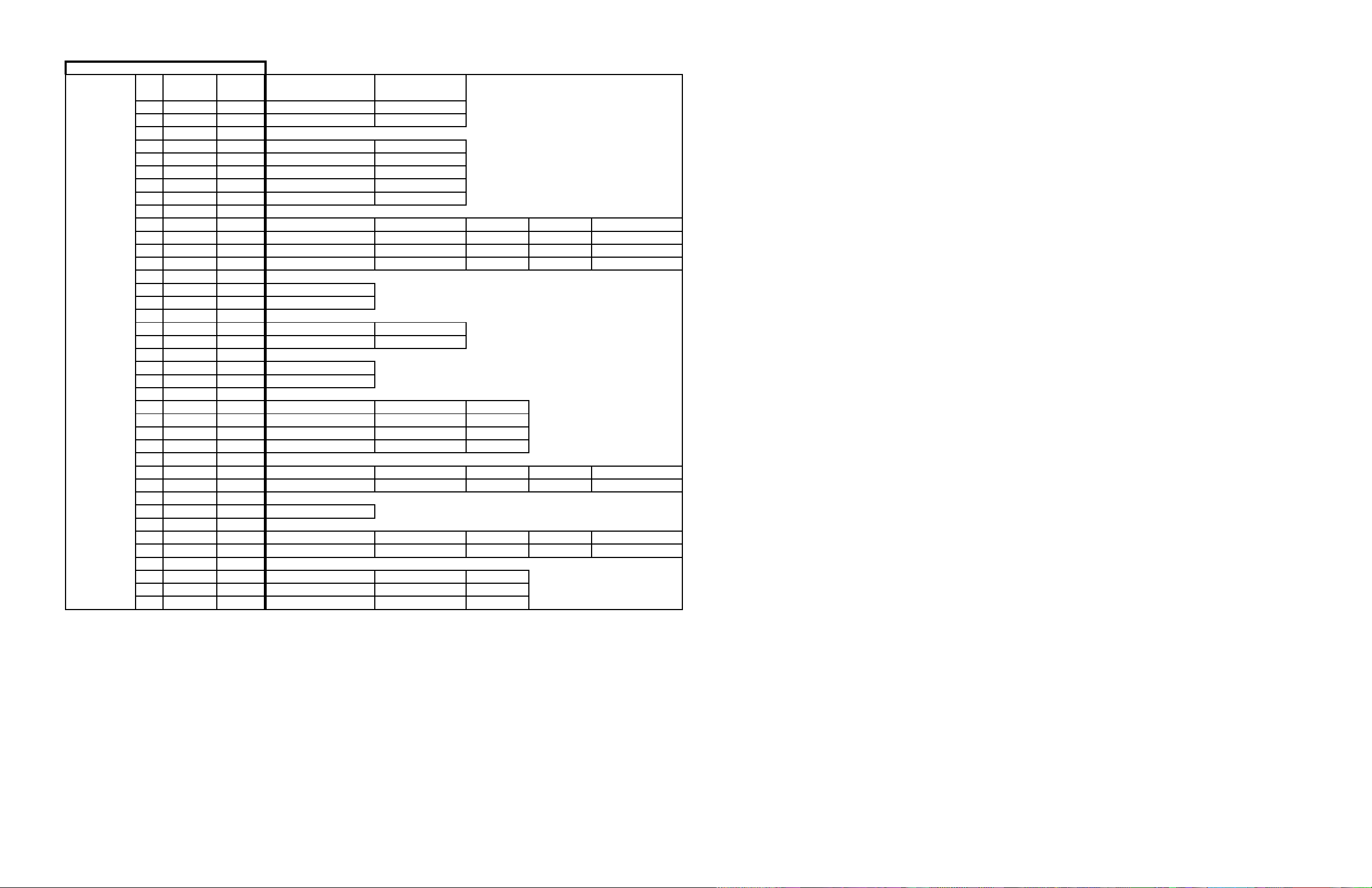

28

Category No Item Range *NOT be memorized

2103-1

0YLEV 0-62 34 20

1CLEV 0-63 40 17

2SCON 0-15 9 9

3SCOL 0-15 2 2

4 SHUE 0-15 11 5

5YDLY 0-3 0 0

6SHAP 0-15 6 8 4 8 8

7SHF0 0-30 0300

8PRE0 0-33 3333

9BPF0 0-3 3

10 BPFQ 0-3 2

11 BPSW 0,1 1 0

V5/V6

HDMI

RF CV/YC

RF CV/YC V5/V6 HDMI MemoryStick

RF CV/YC

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

Others

12 TRAP 0,1 0

13 LPF 0,1 1

RF CV/YC Others

14 AFCG 0,1 1 0 0

15 CDMD 0-3 3 3 3

16 SSMD 0-3 0 0 0

RF CV/YC V5/V6 HDMI MemoryStick

17 HMSK 0,10 1100

18 HALI 0,1 0

RF CV/YC V5/V6 HDMI MemoryStick

19 PPHA 0-15 7 7 7 7 7

V5/V6 MemoryStick Others

20 CBO1 0-63 36 32 34

21 CRO1 0-63 38 32 32

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

29

Category No Item Range *NOT be memorized

2103-1

22 CBO2 0-63 32

23 CRO2 0-63 32

V5/V6

HDMI

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

Others

2170P-1

Single BLK=0 BLK=1 BLK=2 BLK=3

24 ATPD 0-30 1121

25 DCTR 0-30 2132

V5/V6

Memory

Stick

PT

DRC Comp /

CV/YC 480i

0YOSW 0,11 0100

1TCOF* 0,1 0 *

DRC

RF/CV/YC 480i 480p 720p 1080i 480i 480p/VGA 720p 1080i

2YOF 0-15 0 7 7 7 7 7 0 7 7 7 7

3 CBOF 0-63 31 31 46 51 49 31 40 31 31 38 38

4 CROF 0-63 31 31 45 51 48 31 40 31 31 34 34

ColorTemp

Neutral

5 SBRT 0-63 31

6 RDRV 0-63 45

7 GDRV 0-63 35

8 BDRV 0-63 34

9 RCUT 0-63 41

10 GCUT 0-63 32

11 BCUT 0-63 35

HDMI

Notes

:

Settings applied to CXA2103 (M&S), if applied.

Settings also based on 2170P-4/BLK data

HDMI

Memory

Stick

PT

Color Temp

Cool Warm

12 WBSW 0,1 0 Service Data *

13 SBOF 0-15 7 7

14 RDOF 0-63 31 31

15 GDOF 0-63 31 34

16 BDOF 0-63 34 45

17 RCOF 0-63 31 31

18 GCOF 0-63 31 37

19 BCOF 0-63 34 63

:

Note

The WBSW setting

in Warm can be

memorized in NVM.

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

30

Category No Item Range *NOT be memorized

2170P-1

CV/YC 480i

DRC

HDMI

20 DCOL 0-3 3

2170P-2 Blanking On Blanking Off Power Off

0PICO* 0,1 1 * 1 * 0 *

1RGBS* 0-7 0 * 7 * 0 *

2BLKB 0-3 3

3RGBL 0-3 2

4YLMT 0-3 3

Aging On Aging Off

5 AGNG* 0-3 2 * 0 *

6 AKBO* 0,1 0 *

Other PT

7CLPP 0-3 3 3

8CLPG 0,1 0 0

9CLPS 0,1 0 0

10 PPAD 0-7 3 3

11 SYNP 0,1 0 0

Memory

Stick

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

Comp /

PT

2170P-3

12 HVBT 0,1 0

HDMI Memory Stick

RF CV/YC

V5/V6

480i 480p 1080i 720p 480i 480p VGA 1080i 720p

0 SYSM 0-3 1 1 1 1 3 3111 3 3

1VMLV* 0-15 7 *

2VMCR 0-3 1 0 0 0 0 0000 0 0

3VMLM 0-3 3 3 3 3 3 3333 3 3

Vivid

4VMF0 0-3 1 1 1 1 0 0111 0 0

5VMDL 0-15 5 5 5 5 13 13 5 5 5 13 13

6SHOF 0-3 2 2 2 1 1 1210 1 1

7SHF0 0,1 1 1 1 1 1 1111 1 1

8PROV 0-3 0 3 2 0 3 3200 3 3

9F1LV 0-3 1 0 1 0 0 1101 0 1

Slide Show /

Still Picture

1

0

3

1

1

2

1

3

0

Menu

Twin

Index

12

03

33

10

110

22

11

33

00

KV-27HS420/29DRC420/30HS420/32HS420/34HS420/36HS420

31

Loading...

Loading...