Sony KV-25X3A, KV-25X3B, KV-25X3D, KV-25X3E SERVICE MANUAL 4

KV-25X3

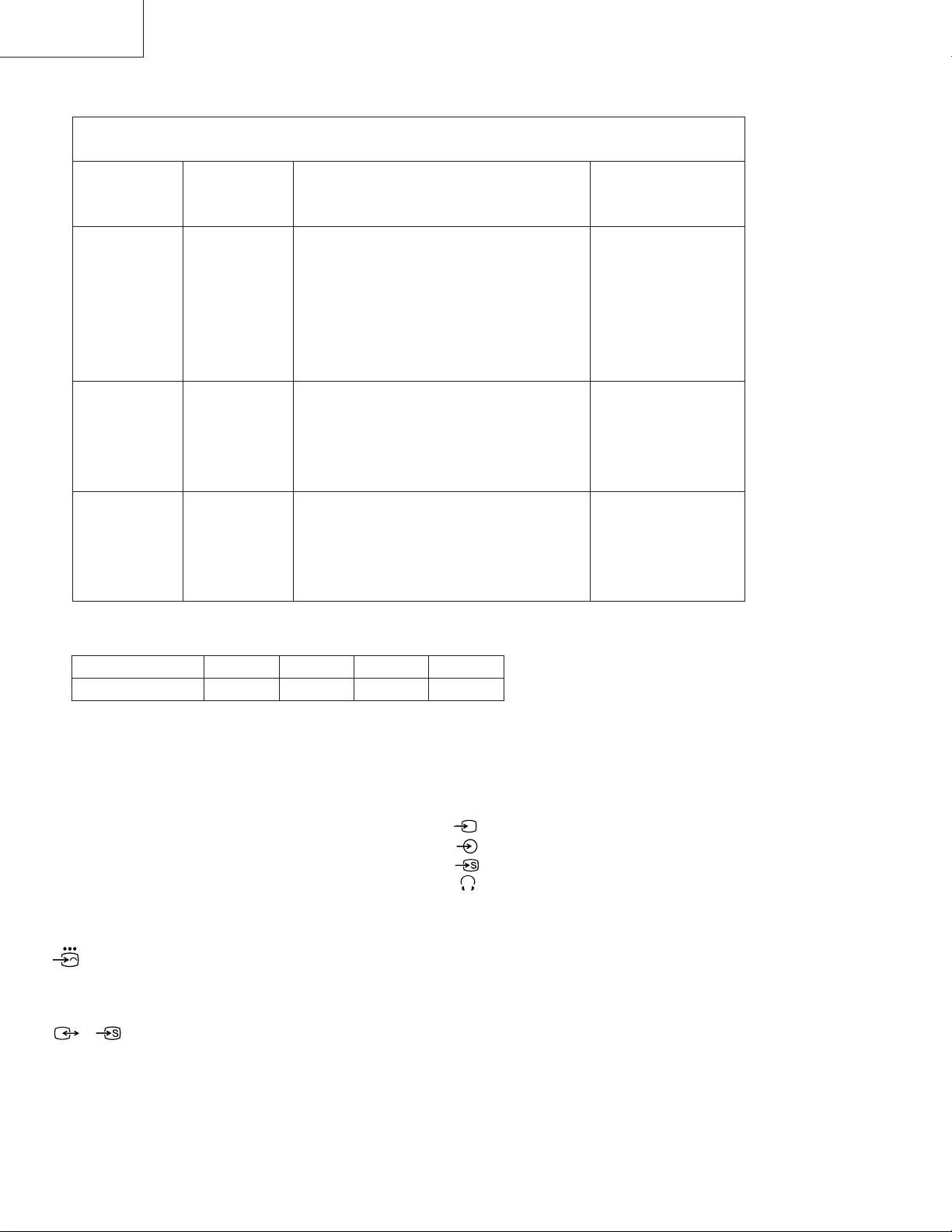

metsySruoloCegarevoClennahCmetsySnoisiveleTLEDOMMETI

nailatIH/G/B

hcnerFI,L,K/D,H/G/B

PEAK/D,H/G/B

hsinapSK/D,H/G/B

96E-12E:FHU

2H,1H,H-A,02S-1S,21E-2E:FHV

96F-12F:FHU01F-2F:FHVMACESL

44S-12S:FHUQ-B:FHV)1(VTELBACVT

96E-12E:FHU21E-2E:FHVH/G/BLAP

14S-1S:)1(VTELBAC

01U-1U,01M-1M,50S-10S:)2(VTELBAC

2H,1H,H-A:FHVAILATI

96B-12B:FHUILAP

96R-12R:FHU21R-10R:FHVK/D

50S-10S:FHU,14S-1S:FHVVTELBAC

02S-1S:FHU21E-2E:FHVH/G/B

14S-1S:)1(VTELBAC

01U-1U,01M-1M,50S-10S:)2(VTELBAC

2H,1H,H-A:FHVAILATI

96R-12R:FHU21R-10R:FHVK/D

50S-10S:FHU,14S-1S:FHVVTELBAC

96E-12E:FHU21E-2E:FHVH/G/BLAP

14S-1S:)1(VTELBAC

01U-1U,01M-1M,50S-10S:)2(VTELBAC

2H,1H,H-A:FHVAILATI

96R-12R:FHU21R-10R:FHVK/D

50S-10S:FHU,14S-1S:FHVVTELBAC

MACES,LAP

34.4/85.3CSTN

)ylnotupnioediv(

MACES,LAP

34.4/85.3CSTN

)ylnotupnioediv(

MACES,LAP

34.4/85.3CSTN

)ylnotupnioediv(

MACES,LAP

34.4/85.3CSTN

)ylnotupnioediv(

LEDOMA3X52B3X52D3X52E3X52

noitpmusnoCrewoPW011W721W721W721

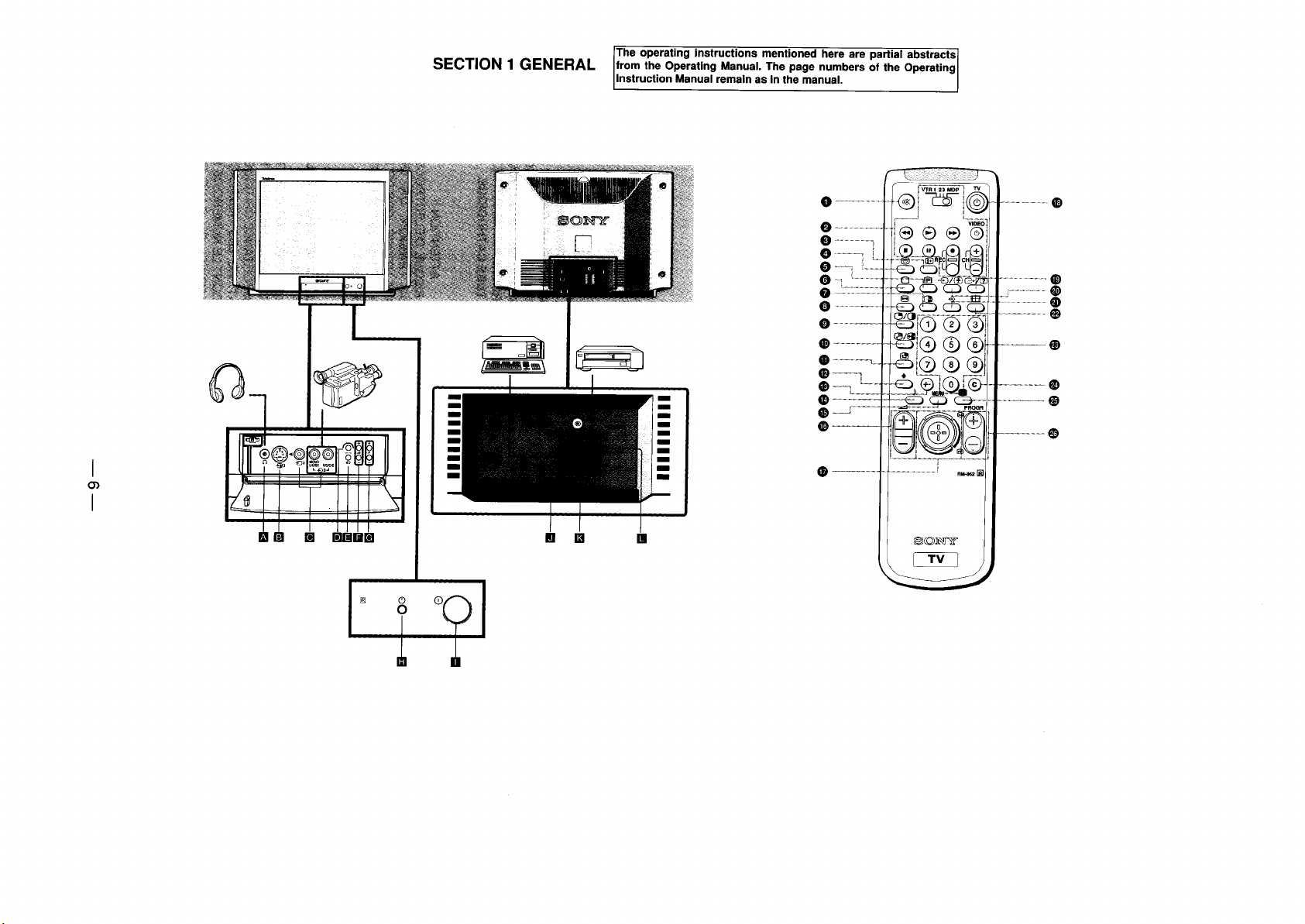

Picture Tube Super Trinitron

Approx. 63 cm (25inches)

(Approx. 59 cm picture measured

diagonally) 110˚ deflection

Rear/Front Terminals

[REAR]

21-pin Euro connector (CENELEC standard)

- Inputs for audio and video signals

- Inputs for RGB

- Outputs of TV video and audio signals

2/ 2 21-pin Euro connector

- Inputs for audio and video signals

- Inputs for S video

- Outputs for audio and video signals (selectable)

SPECIFICATIONS

[FRONT]

3 Video input - phono jack

3 Audio inputs - phono jacks

3 S video input - 4 pin DIN

Headphones jack: stereo minijack

Sound output 2x30W (music power), 2x15W (RMS)

Dimensions 593x502x508 mm approx.

Weight Approx. 33.1kg

Supplied accessories Remote Commander RM-862 (1)

Batteries R6 (2)

Aerial cable (1)

Other features

FASTEXT, 100Hz Digital Plus, PIP,

NICAM stereo (KV-25X3B/25X3E only)

— 2 —

[RM-862]

Remote control system Infrared control

Power requirements 3V dc (2 batteries) R6 (size AA)

Dimensions Approx. 210x56x24 mm (w/h/d)

Weight Approx. 110g

(Not including battery)

Design and specifications are subject to change without

notice.

KV-25X3

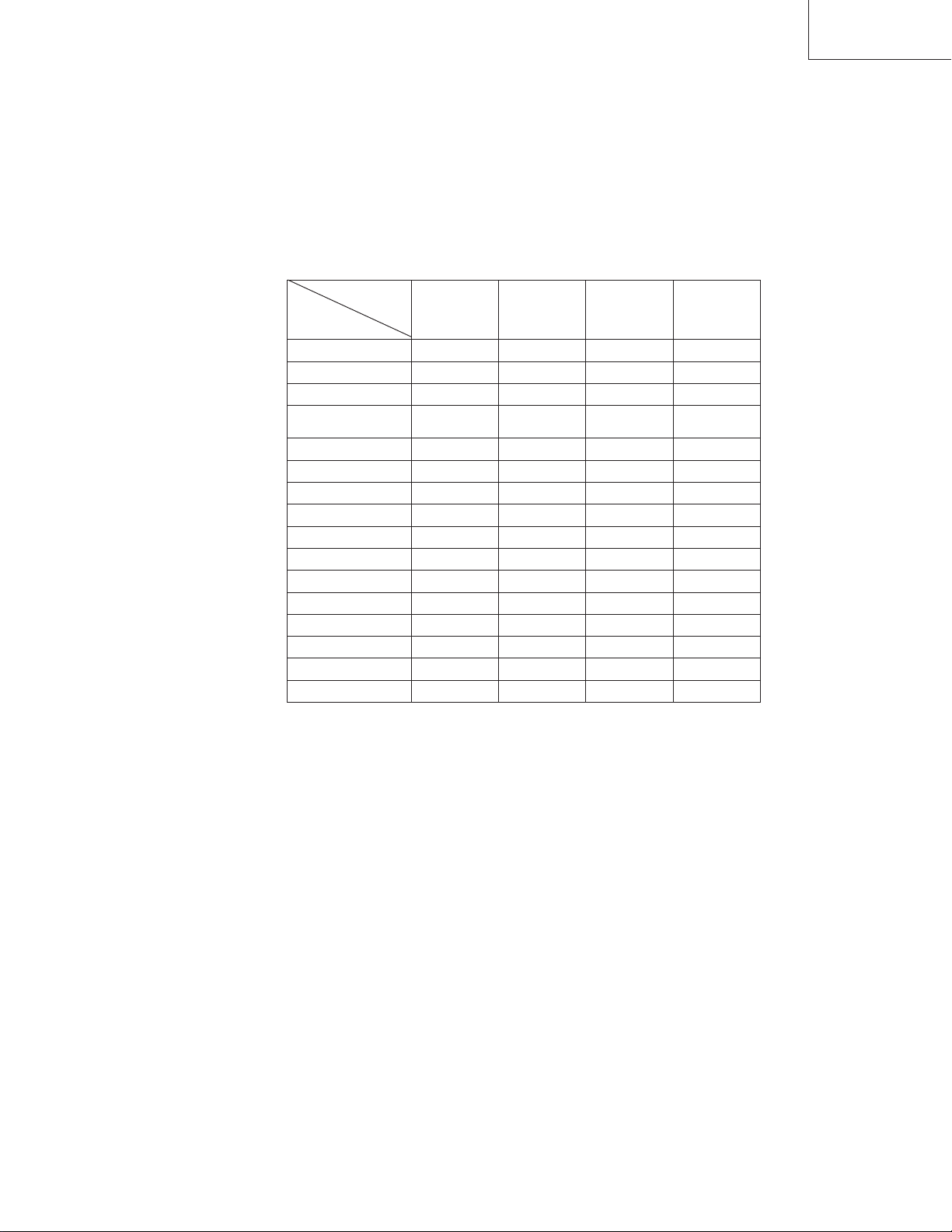

emanledoM

metI

PIPNONONONO

PIPMFFOFFOFFOFFO

lioCnoitatoRNONONONO

teSMV

)noitaludoMyticoleV(

1tracSNONONONO

2tracSNONONONO

)3(nitnorFNONONONO

edom9:61niBKANONONONO

TXTNONONONO

FOLFNONONONO

POTNONONONO

H/G/BmroNNONONONO

ImroNFFONOFFOFFO

K/DmroNFFONONONO

LmroNFFONOFFOFFO

teserPegaugnaLnailatIhcnerFnamreGhsinapS

A3X52-VKB3X52-VKD3X52-VKE3X52-VK

NONONONO

— 3 —

KV-25X3

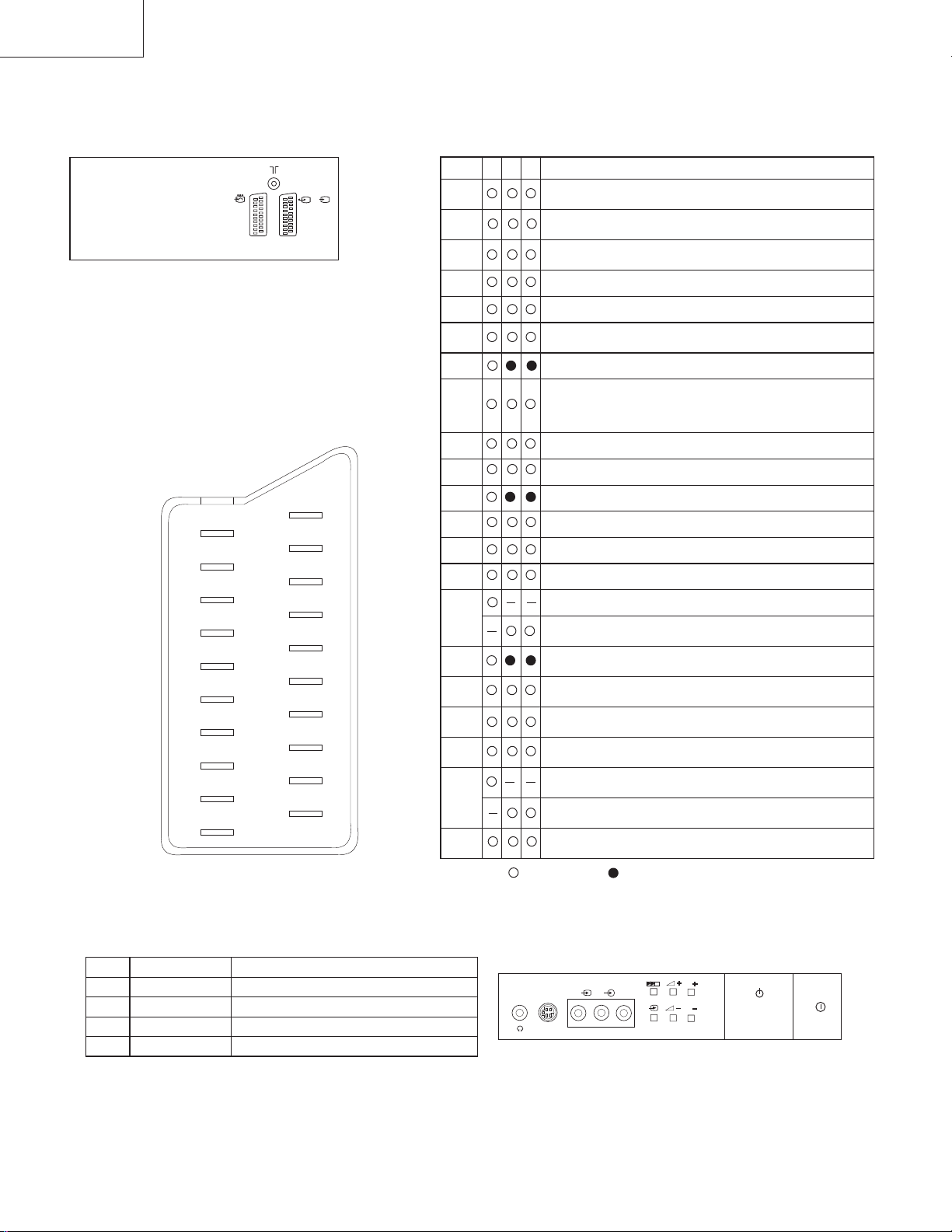

21 pin connector (G1, Y2/ j2)

1

21

19

17

15

13

11

9

7

5

3

1

20

18

16

14

12

10

8

6

4

2

.oNniP 124 langiSleveLlangiS

S

2 /

2

1

2

3

4

5

6

7

8

9

01

11

21

31

41

51

61

71

81

91

02

12

BtuptuooiduA

)thgiR(

BtupnioiduA

)thgiR(

AtuptuooiduA

)tfeL(

)oiduA(dnuorG

)eulB(dnuorG

AtupnioiduA

)tfeL(

tupnieulB7.0 ± evitisop,smho57,Bd3

tcelesnoitcnuF

)lortnocVA(

)neerG(dnuorG

nepO

neerG

nepO

)deR(dnuorG

)gniknalB(dnuorG

tupnideR7.0 ± evitisop,smho57,Bd3

)langisS(

tupniamorc

tupnigniknalB

)langissY(

dnuorG

)tuptuooediV(

dnuorG

)tupnioediV(

tuptuooediV

tupnioediV

tupnioediV

)langisS(Y

dnuorgnommoC

)dliehs,gulp(

7.0 ± evitisop,smho57,Bd3

V1 ± ,smho57,Bd3

V1 ± ,smho57,Bd3

V1 ± ,smho57,Bd3

smrV5.0:leveldradnatS

smrV5.0:leveldradnatS

smrV5.0:leveldradnatS

smrV5.0:leveldradnatS

edomVT:)V2-0(etatswoL

smho57:ecnadepmitupnI

*smhok1nahtsseL:ecnadepmituptuO

*smhok01nahteroM:ecnadepmituptuO

*mhok1nahtsseL:ecnadepmituptuO

*mhok01nahtsseL:ecnadepmituptuO

edomtraP:)V21-5.9(etatshgiH

smhok01eroM:ecnadepmitupnI

Fn2nahtsseL:ecnaticapactupnI

)V4.0-0(etatswoL)V3-1(etatshgiH

)Bd01+3-(V3.0:cnysevitisop

)Bd01+3-(V3.0:cnysevitisop

)Bd01+3-(V3.0:cnysevitisop

Connected Not Connected (Open) * at 20Hz - 20kHz

.oNniPlangiSleveLlangiS

1dnuorG

2dnuorG

3tupni)langisS(YV1 ± Bd01+3-V3.0.cnySevitisop,mho57Bd3

4tupni)langisS(CV3.0 ± .cnySevitisop,mho57Bd3

— 4 —

3 ,

3

P

P

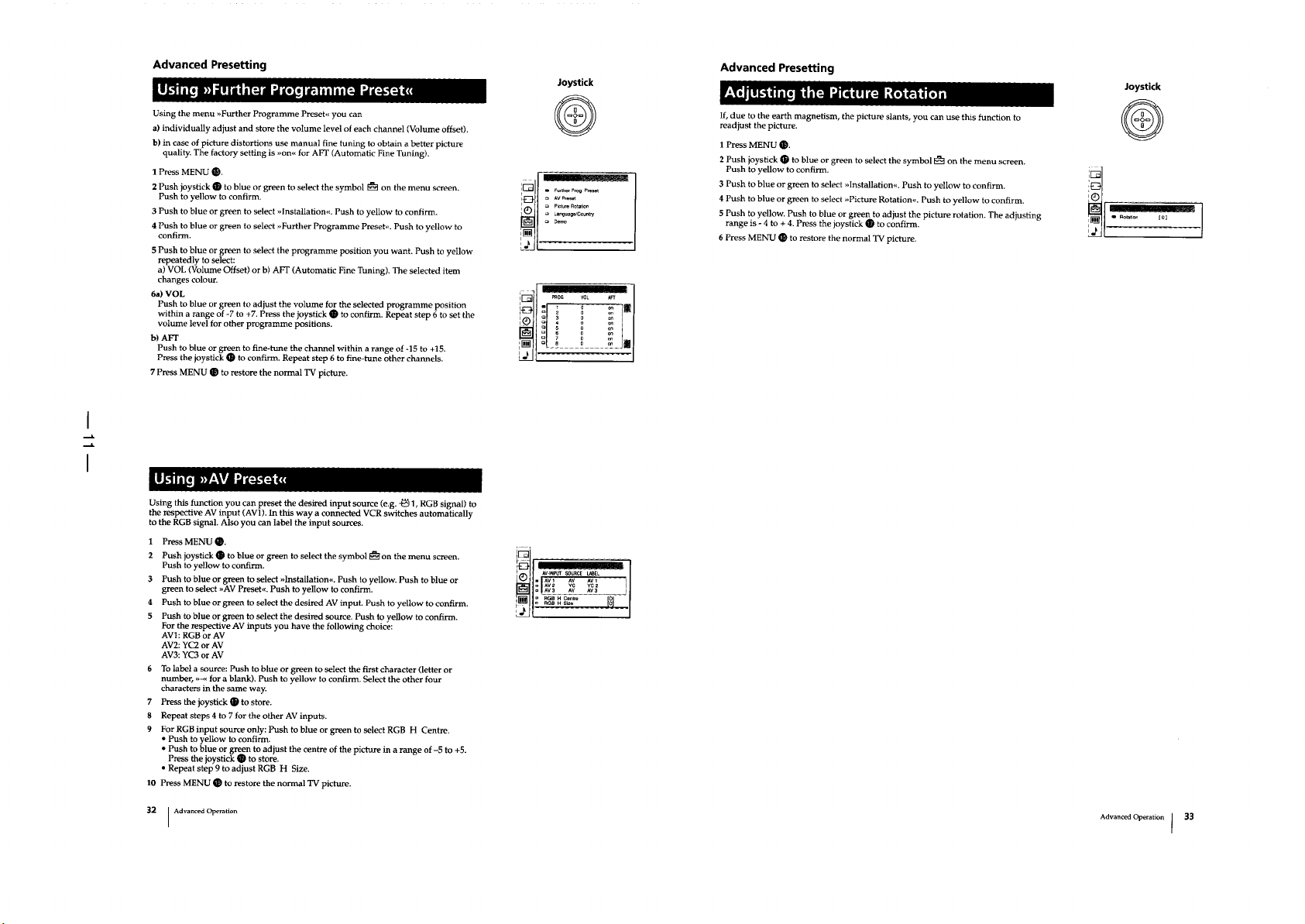

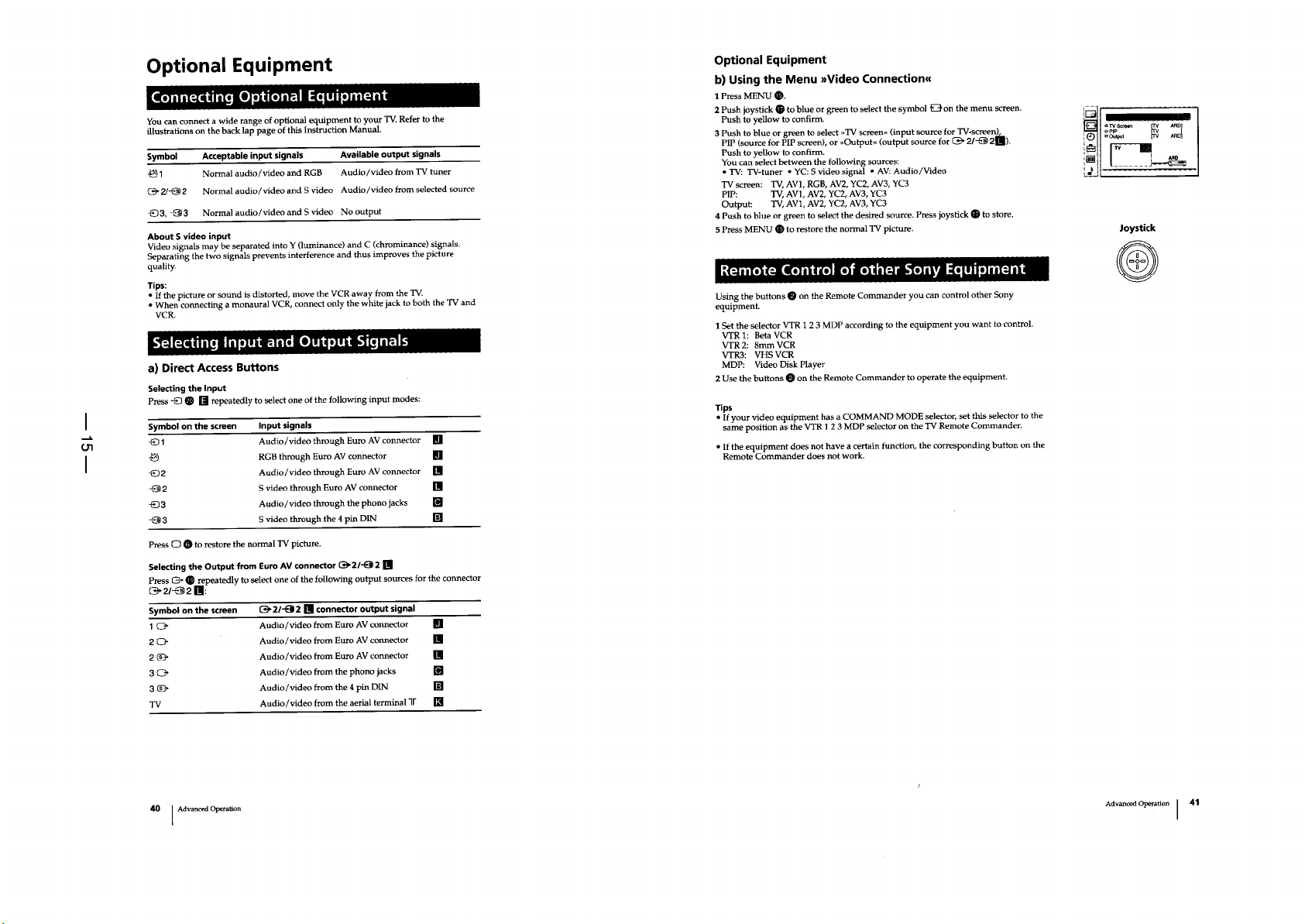

TABLE OF CONTENTS

Section Title PageSection Title Page

KV-25X3

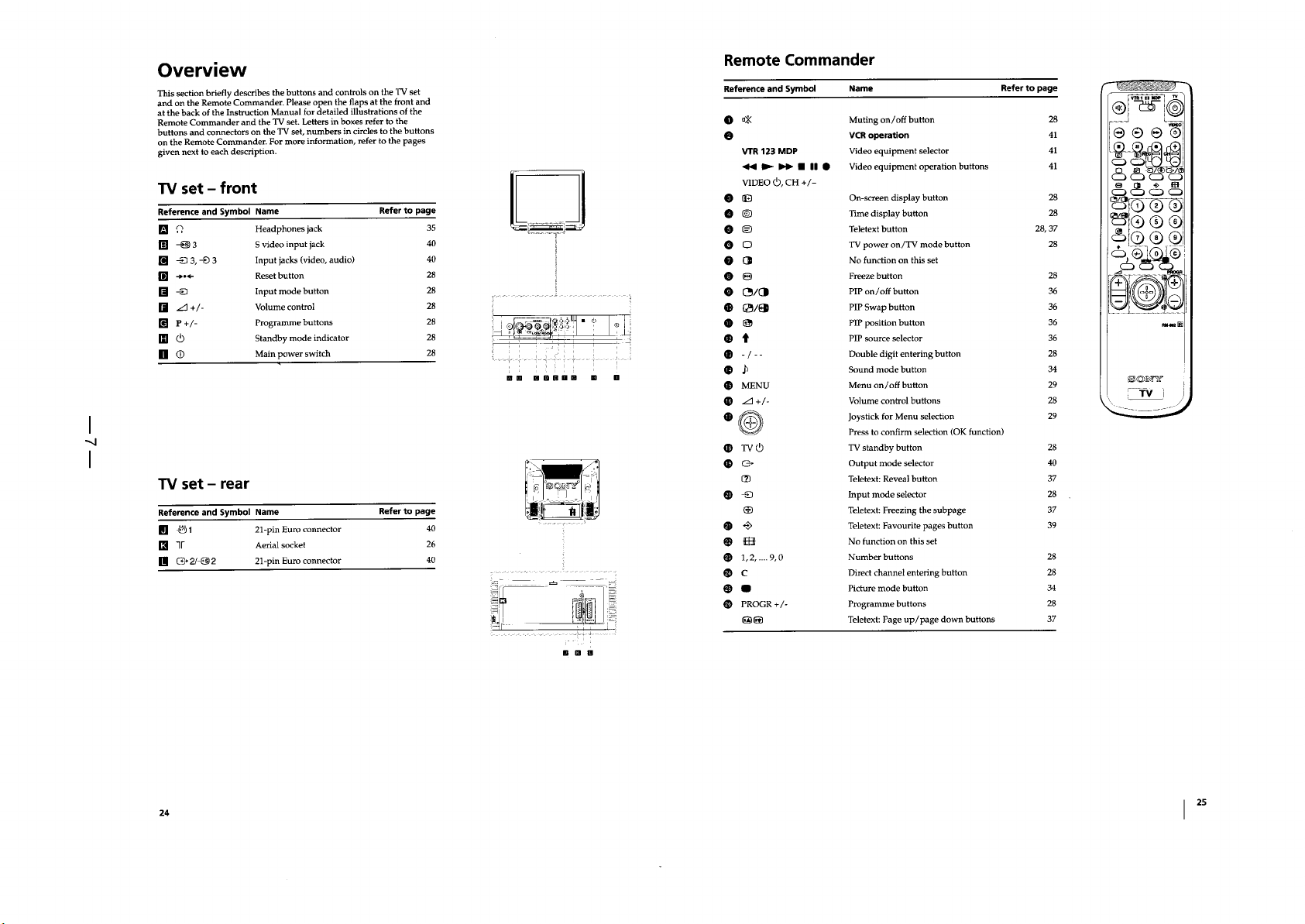

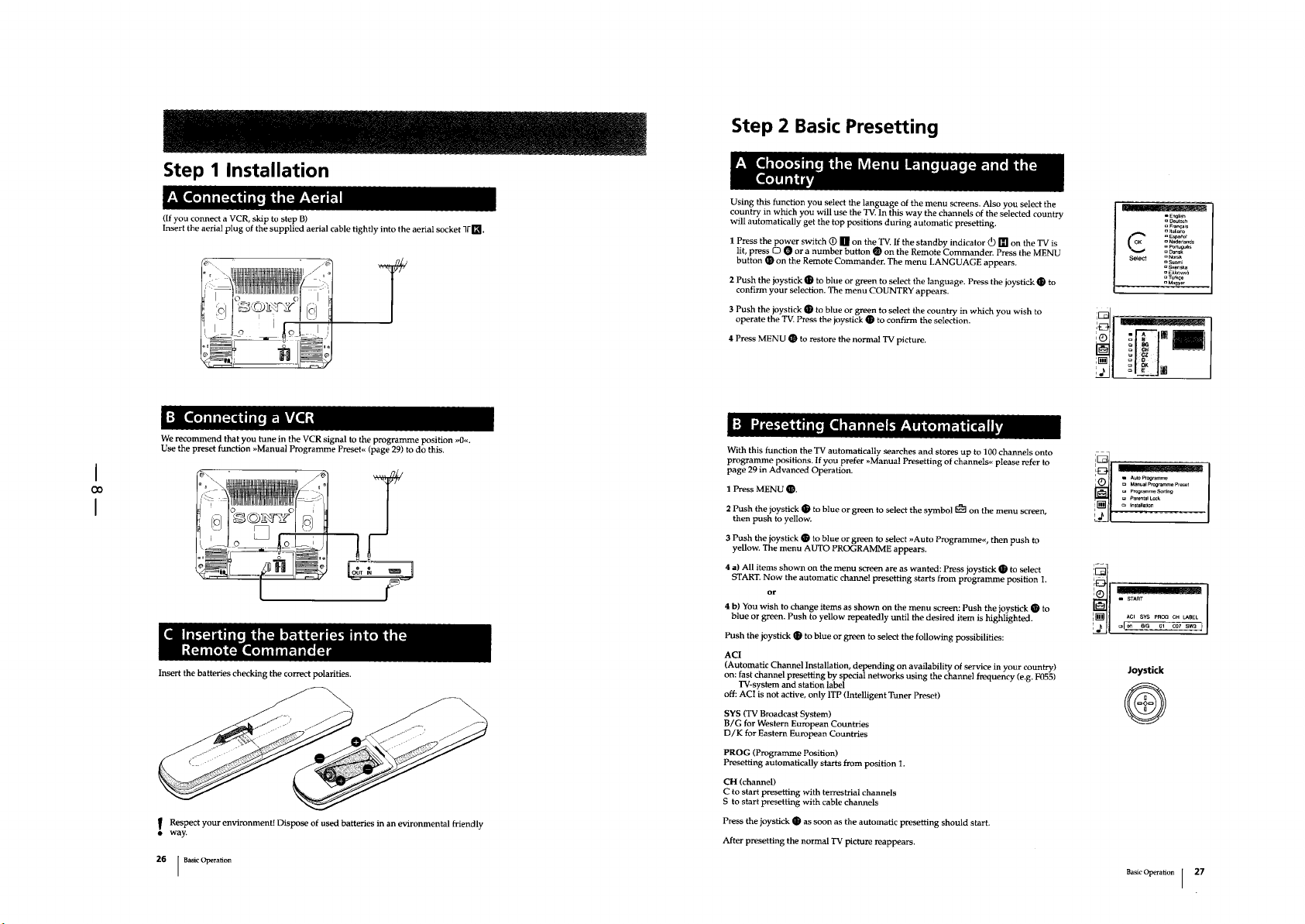

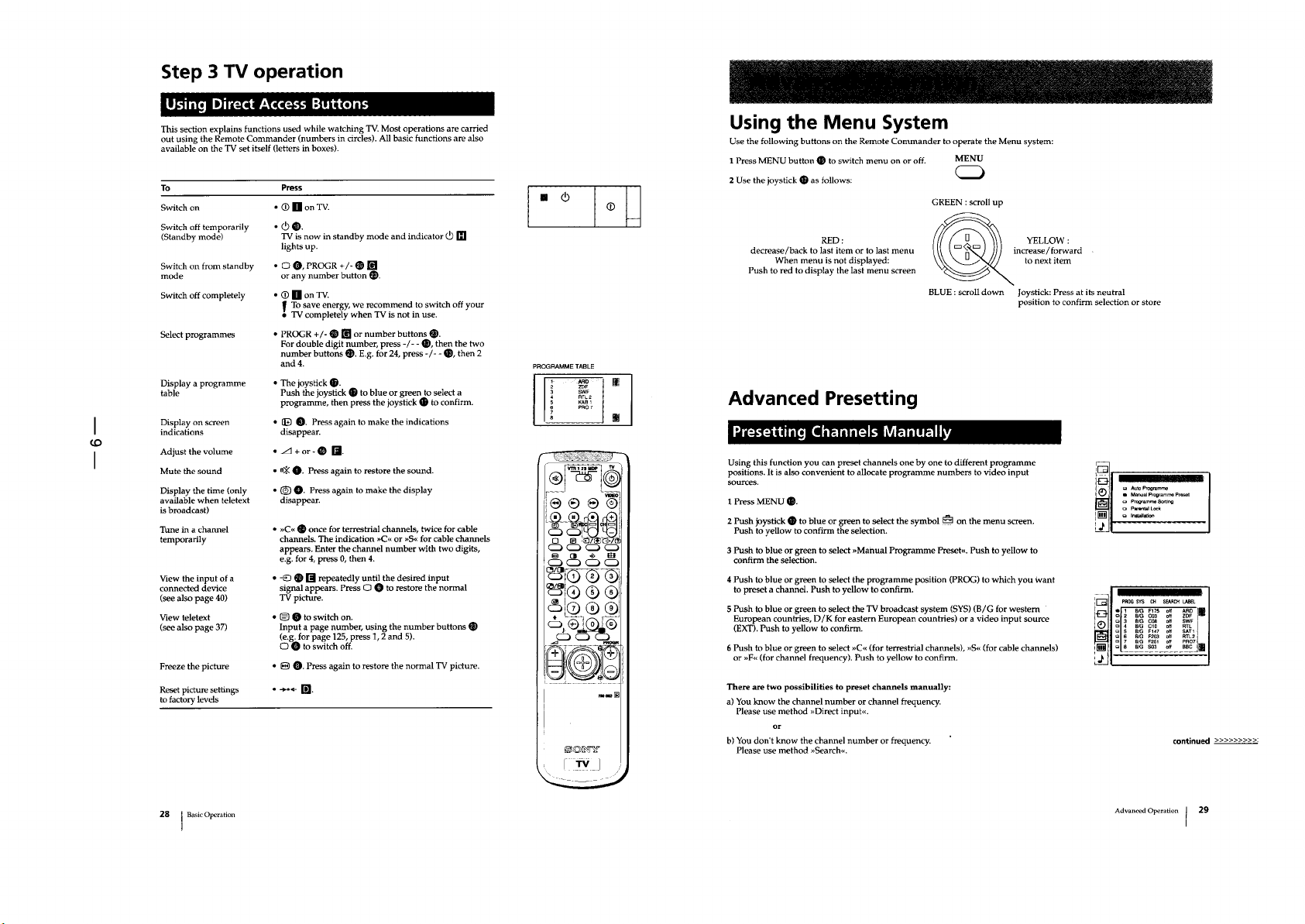

1. GENERAL

Overview ...........................................................................

Basic Operation .................................................................

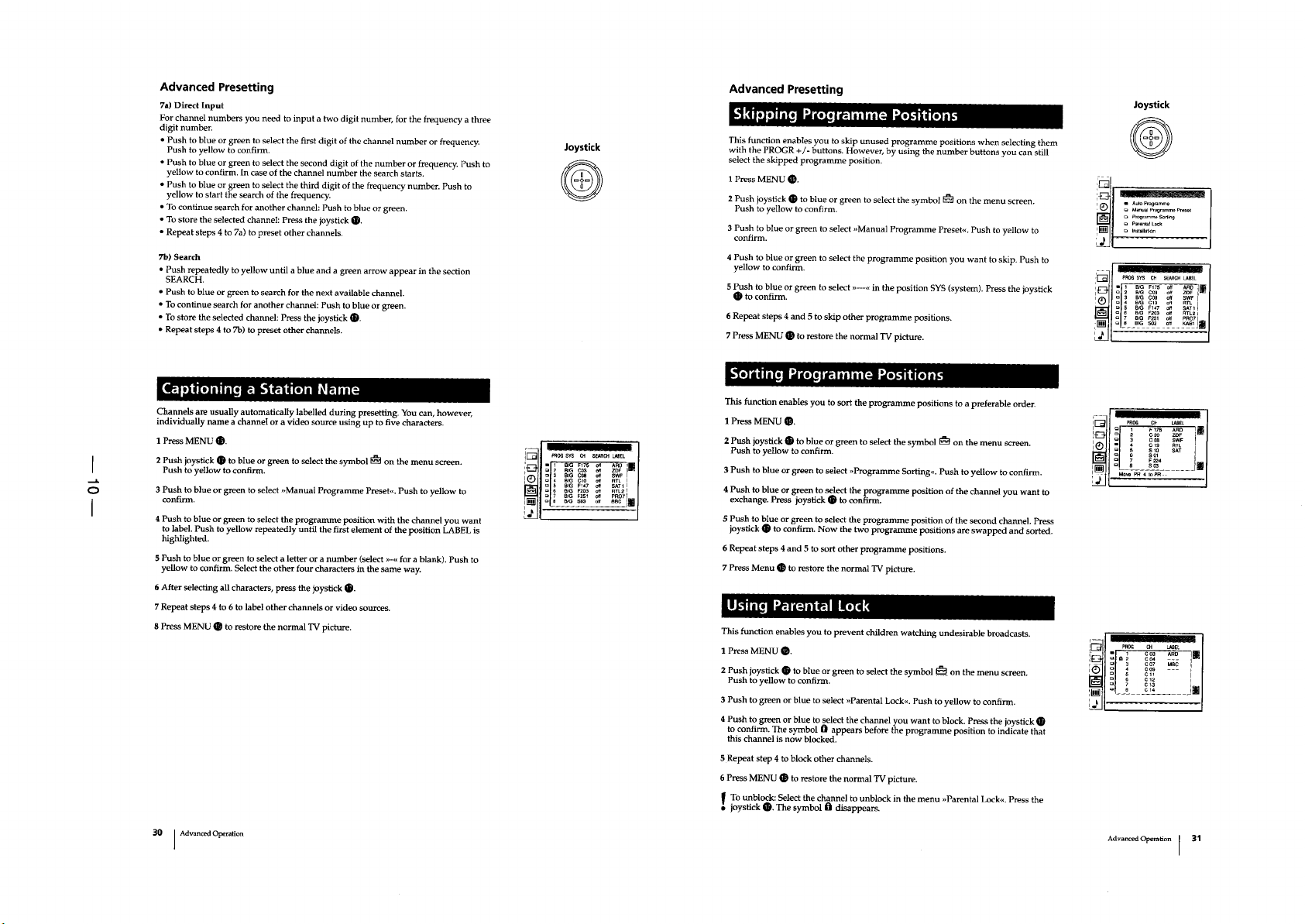

Advanced Operation..........................................................

Teletext ..............................................................................

Optional Equipment ..........................................................

Additional Information......................................................

2. DISASSEMBLY

2-1. Rear Cover Removal ..................................................

2-2. Chassis Assy Removal ...............................................

2-3. Service Position ..........................................................

2-4. G Board Removal .......................................................

2-5. A Board Removal .......................................................

2-6. Picture Tube Removal ................................................

Removal amd Replacement of

the Main - Bracket Bottom Plates ..............................

3. SET-UP ADJUSTMENTS

3-1. Beam Landing ............................................................

3-2. Convergence ...............................................................

3-3. Focus ..........................................................................

3-4. Screen (G2), White Balance,

(Adjustment in the service mode

with remote commander)............................................

4. CIRCUIT ADJUSTMENTS

4-1. Electrical Adjustments................................................

4-2. Volume Electrical Adjustments..................................

4-3. Test Mode 2:...............................................................

5. DIAGRAMS

7

8

9

13

15

16

17

17

17

17

18

18

19

5-1. Block Diagram (1) ......................................................

Block Diagram (2) ......................................................

Block Diagram (3) ......................................................

Block Diagram (4) ......................................................

Block Diagram (5) ......................................................

5-2. Circuit Boards Location .............................................

5-3. Schematic Diagrams and Printed Wiring Boards .......

*A Board ....................................................................

*C Board.....................................................................

*VM Board .................................................................

* B Board....................................................................

*G Board ....................................................................

*D Board ....................................................................

5-4. Semiconductors ..........................................................

5-5. IC Block Diagrams .....................................................

6. EXPLODED VIEWS

20

21

23

23

24

28

29

6-1. Chassis ........................................................................

6.2 Picture Tube ...............................................................

7. ELECTRICAL PARTS LIST ...............................

31

33

35

39

41

44

44

49

57

60

67

75

80

86

89

90

91

92

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR CARBON

PAINTED ON THE CRT, AFTER REMOVING THE ANODE.

AN ISOLATION TRANSFORMER SHOULD BE USED DURING ANY

SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF

LIVE CHASSIS.

THE CHASSIS OF THIS RECEIVER IS DIRECTLY CONNECTED TO

THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND, IN THE PARTS

LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

CAUTION

WARNING !!

!

APRES AVOIR DECONNECTE LE CAP DE L'ANODE, COURTCIRCUITER L'ANODE DU TUBE CATHODIQUE ET CELUI DE

L'ANODE DU CAP AU CHASSIS METALLIQUE DE L'APPAREIL,

OU AU COUCHE DE CARBONE PEINTE SUR LE TUBE CATHODIQUE

OU AU BLINDAGE DU TUBE CATHODIQUE.

AFIN D'EVITER TOUT RISQUE D'ELECTROCUTION PROVENANT

D'UN CHÁSSIS SOUS TENSION, UN TRANSFORMATEUR

D'ISOLEMENT DOIT ETRE UTILISÉ LORS DE TOUT DÉPANNAGE.

LE CHÁSSIS DE CE RÉCEPTEUR EST DIRECTEMENT RACCORDÉ

À L'ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS À LA

LES COMPOSANTS IDENTIFIÈS PAR UNE TRAME ET PAR UNE

MARQUE SUR LES VUES EXPLOSÉES ET LES LISTES DE

PIECES SONT D'UNE IMPORTANCE CRITIQUE PUR LA SÉCURITÉ

DU FONCTIONNEMENT. NE LES REMPLACER QUE PAR DES

COMPOSANTS SONY DONT LE NUMÉRO DE PIÉCE EST INDIQUÉ

DANS LE PRÉSENT MANUEL OU DANS DES SUPPLÉMENTS

PUBLIÉS PAR SONY.

!

ATTENTION

ATTENTION !!

SÉCURITÉ!!

— 5 —

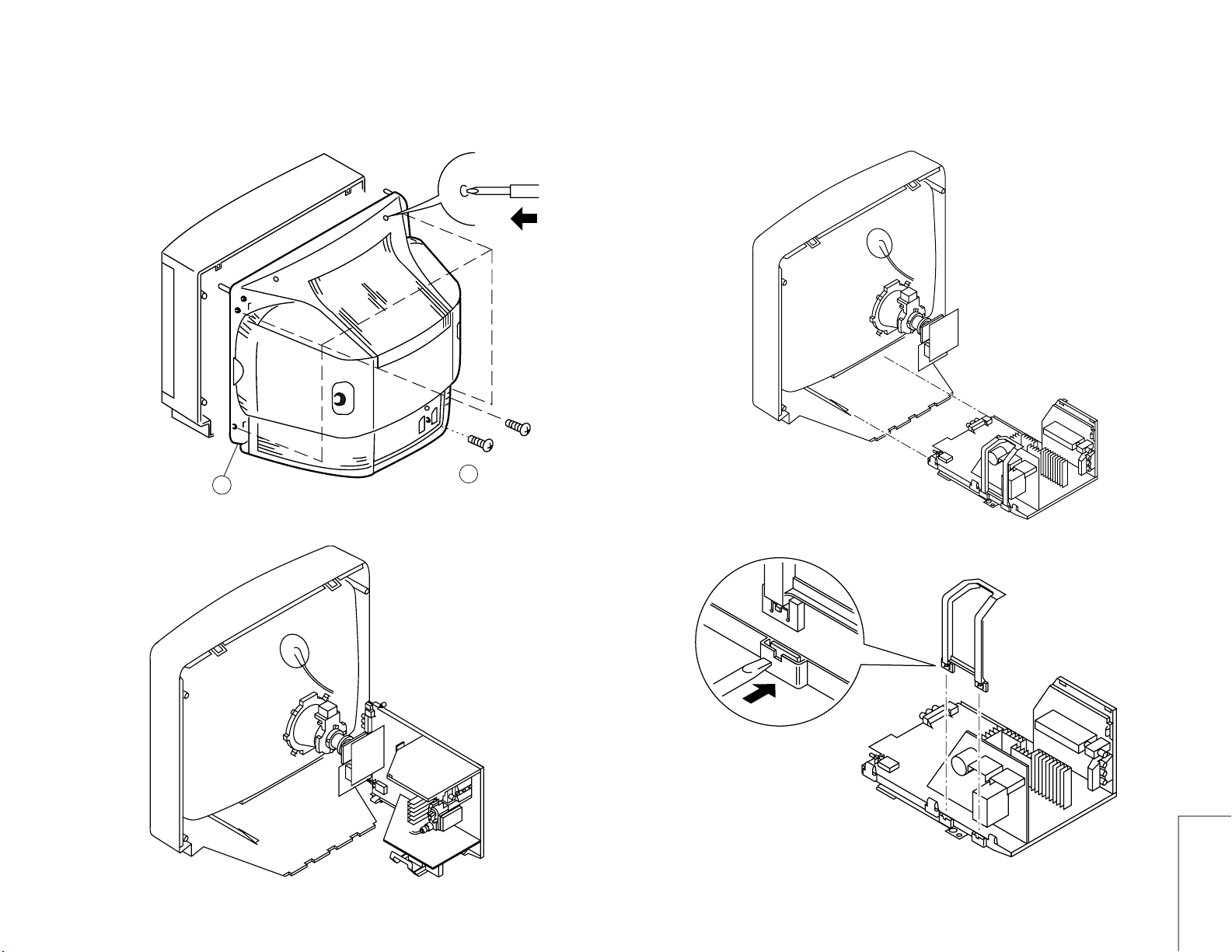

SECTION 2

DISASSEMBLY

— 17 —

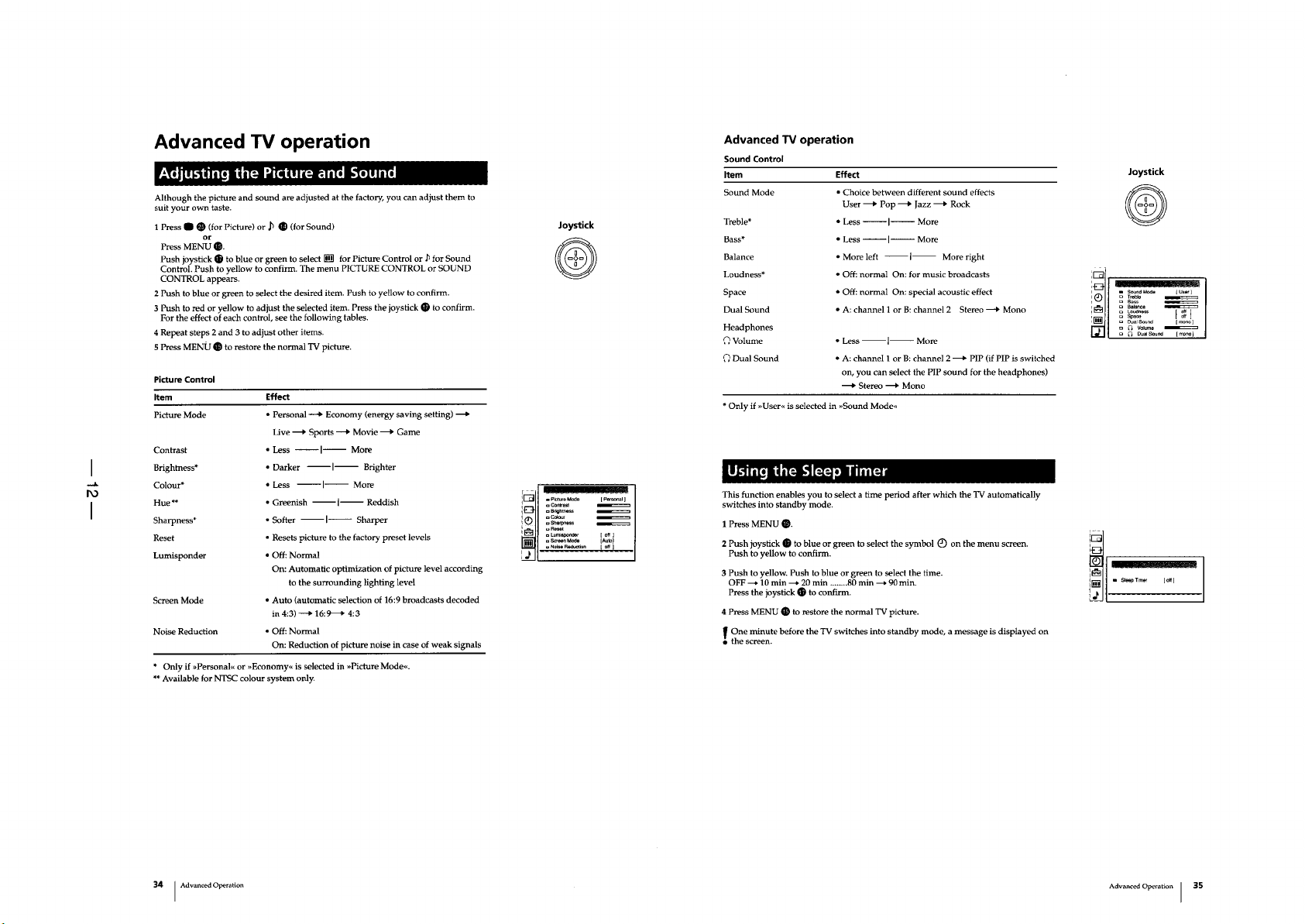

2-1. REAR COVER REMOVAL

Rear Cover

2

1

Five screws

(BVTP 4x16)

2-2. CHASSIS ASSY REMOVAL

2-3. SERVICE POSITION 2-4. G BOARD REMOVAL

Push the claw of the bracket

in the direction of the arrow

and remove.

KV-25X3

— 18 —

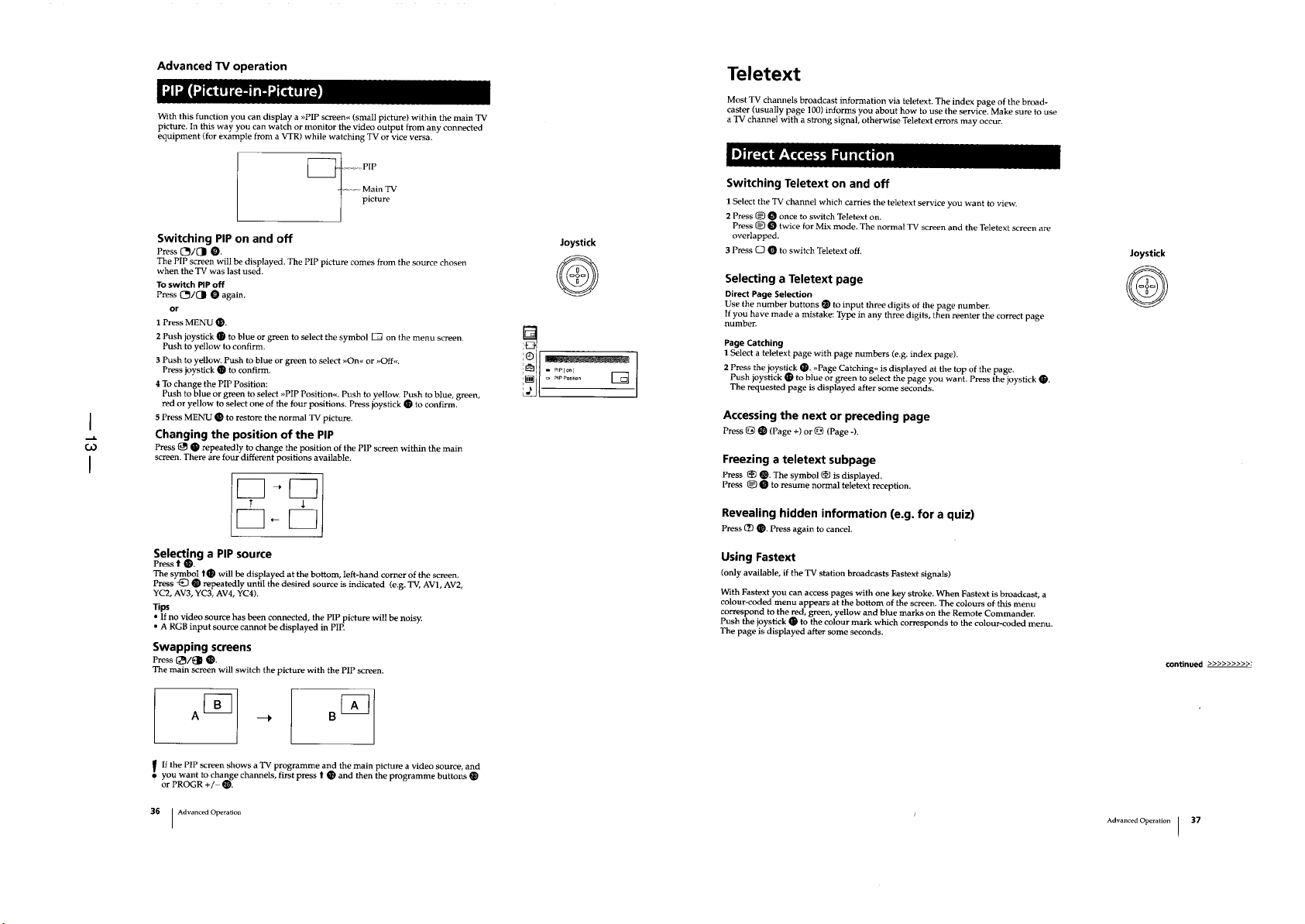

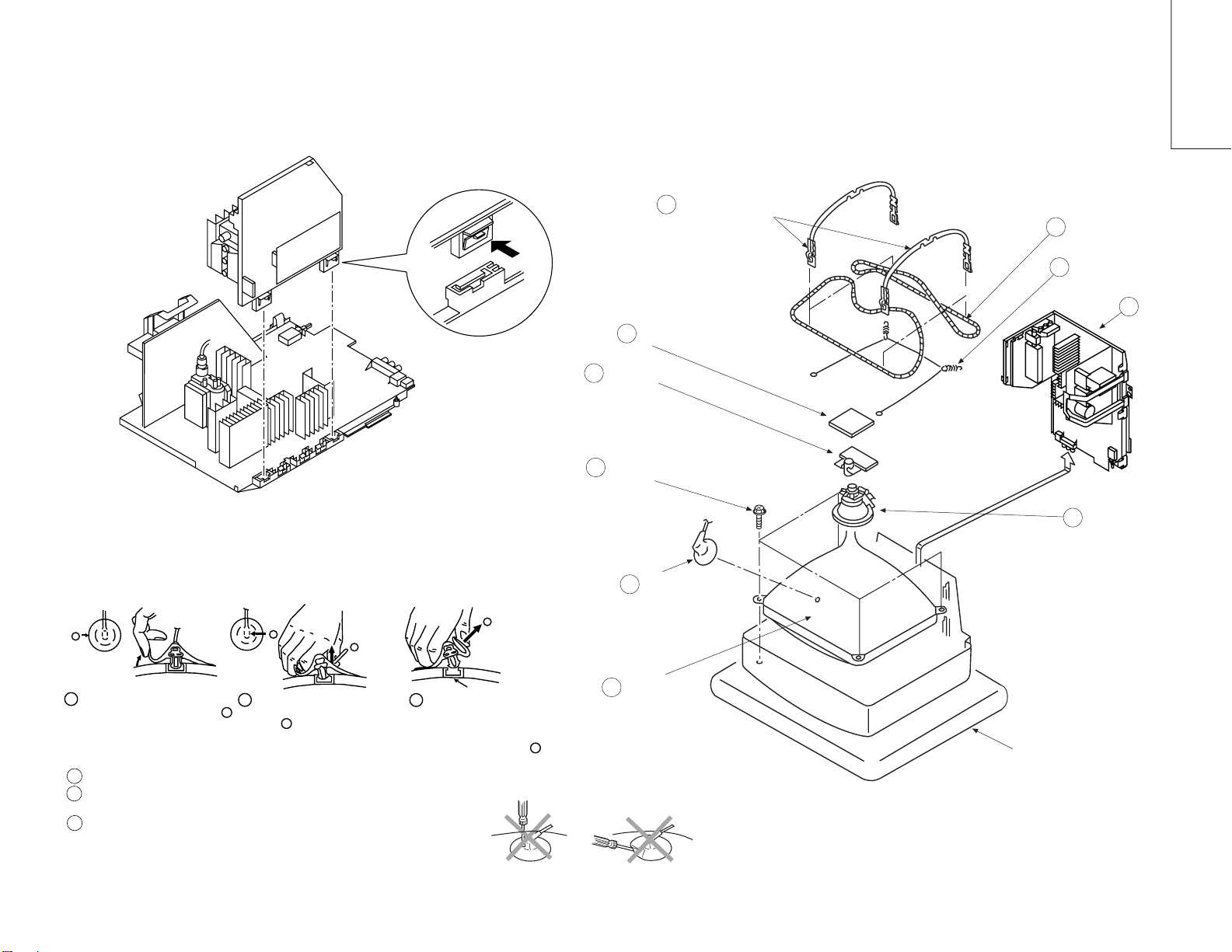

2-5. A BOARD REMOVAL 2-6. PICTURE TUBE REMOVAL

Push the claw of the bracket

in the direction of the arrow

and remove.

6

Two DGC Holders

3

C board

4

Neck Assembly

9

Four tapping screws (M)

7

Degaussing coil

8

Spring tension

2

Chassis

KV-25X3

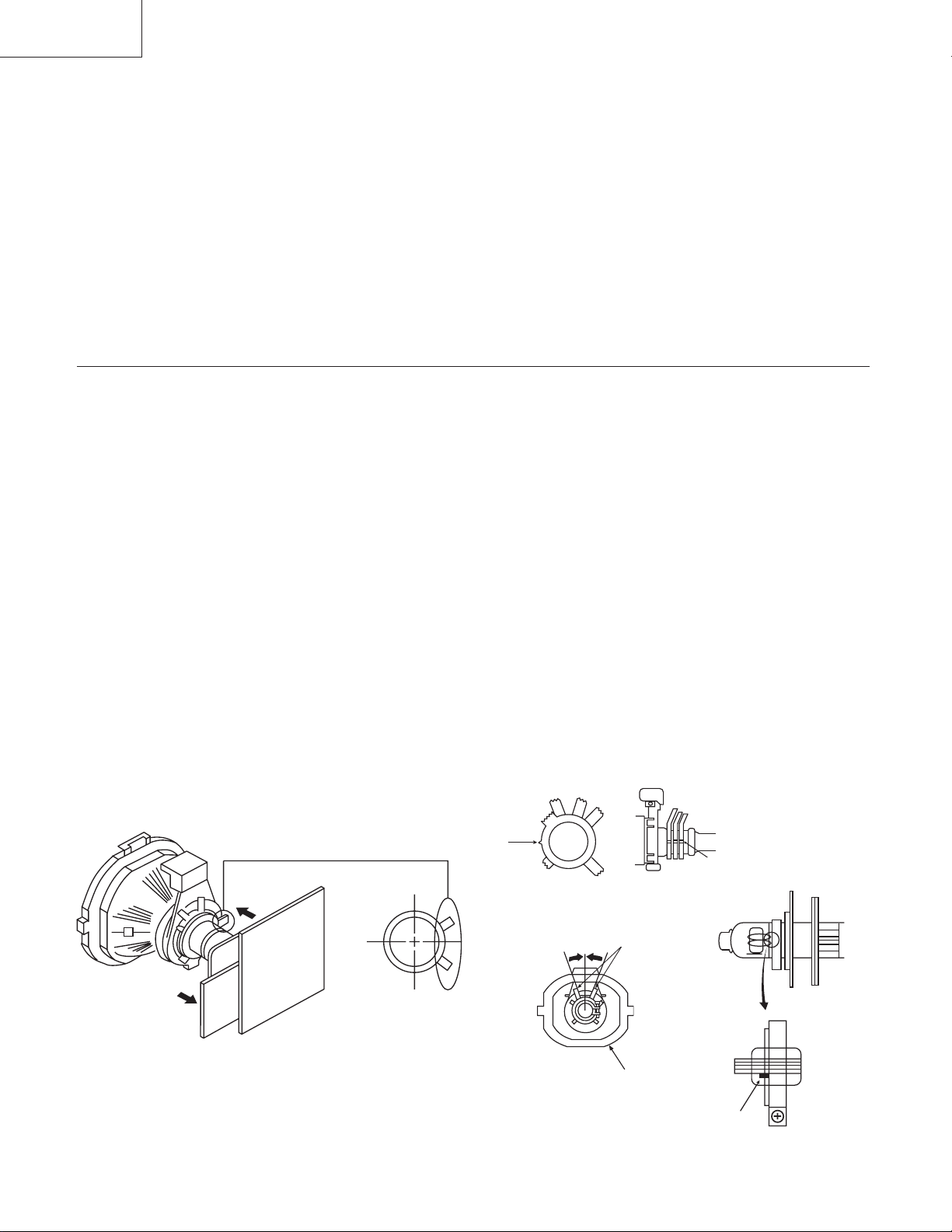

• REMOVAL OF ANODE-CAP

Note:

Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield or

carbon paint on the CRT, after removing the anode.

* REMOVING PROCEDURES.

a

1

Turn up one side of the rubber cap in

the direction indicated by the arrow a

b

2 Using a thumb pull up the rubber cap

firmly in the direction indicated by the

arrow b

b

3 When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling it up in

the direction of the arrow c

c

Anode button

• HOW TO HANDLE AN ANODE-CAP

1

Don't damage the surface of anode-cap with sharp shaped material !

Don't press the rubber hardly not to hurt inside of anode-caps !

2

A metal fitting called a shatter-hook terminal is built into the rubber.

3

Don’t turn the foot of rubber over hardly !

The shatter-hook terminal will stick out or damage the rubber

.

1

Anode cap

10

Picture tube

Cushion

5

Deflection Yoke

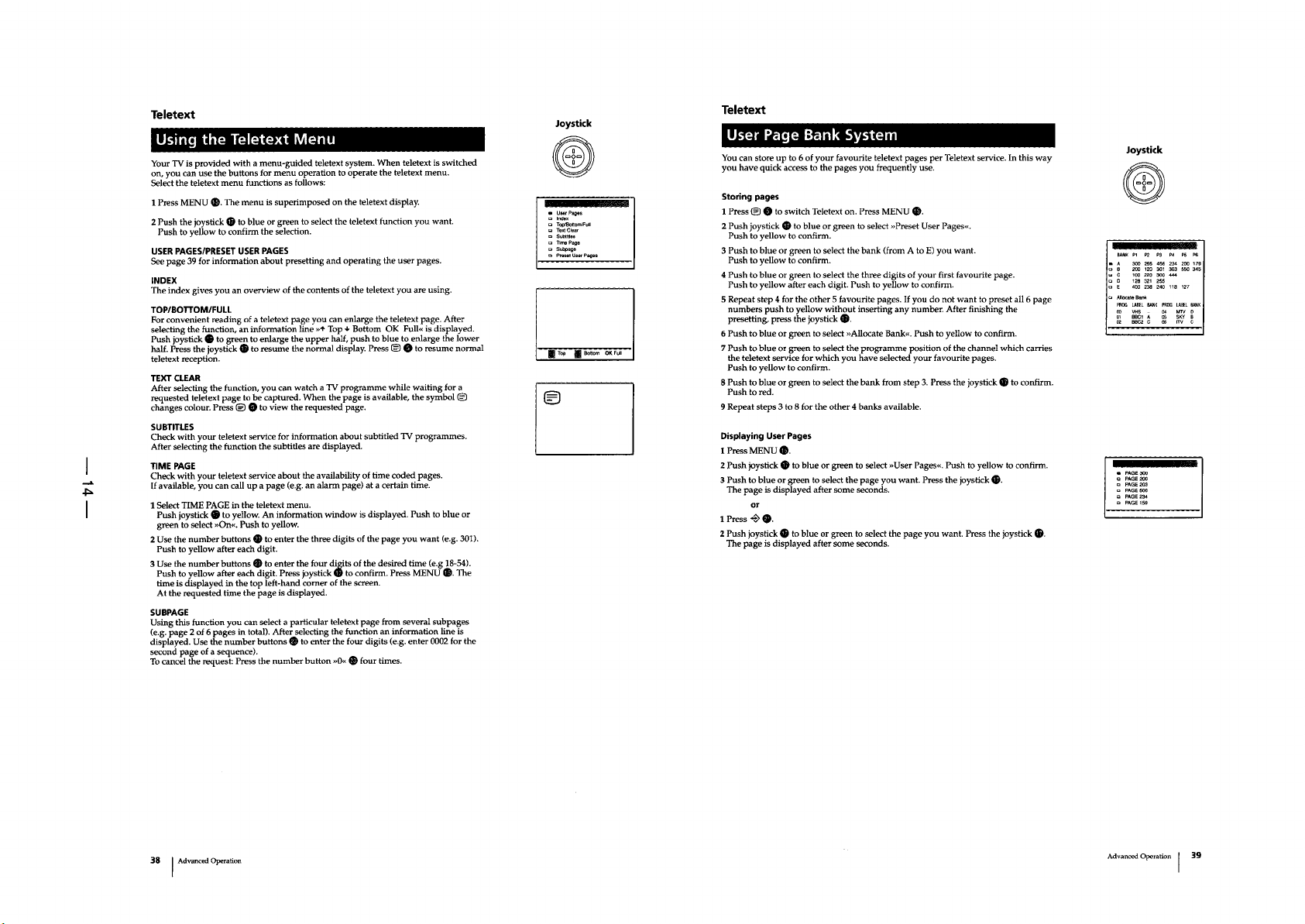

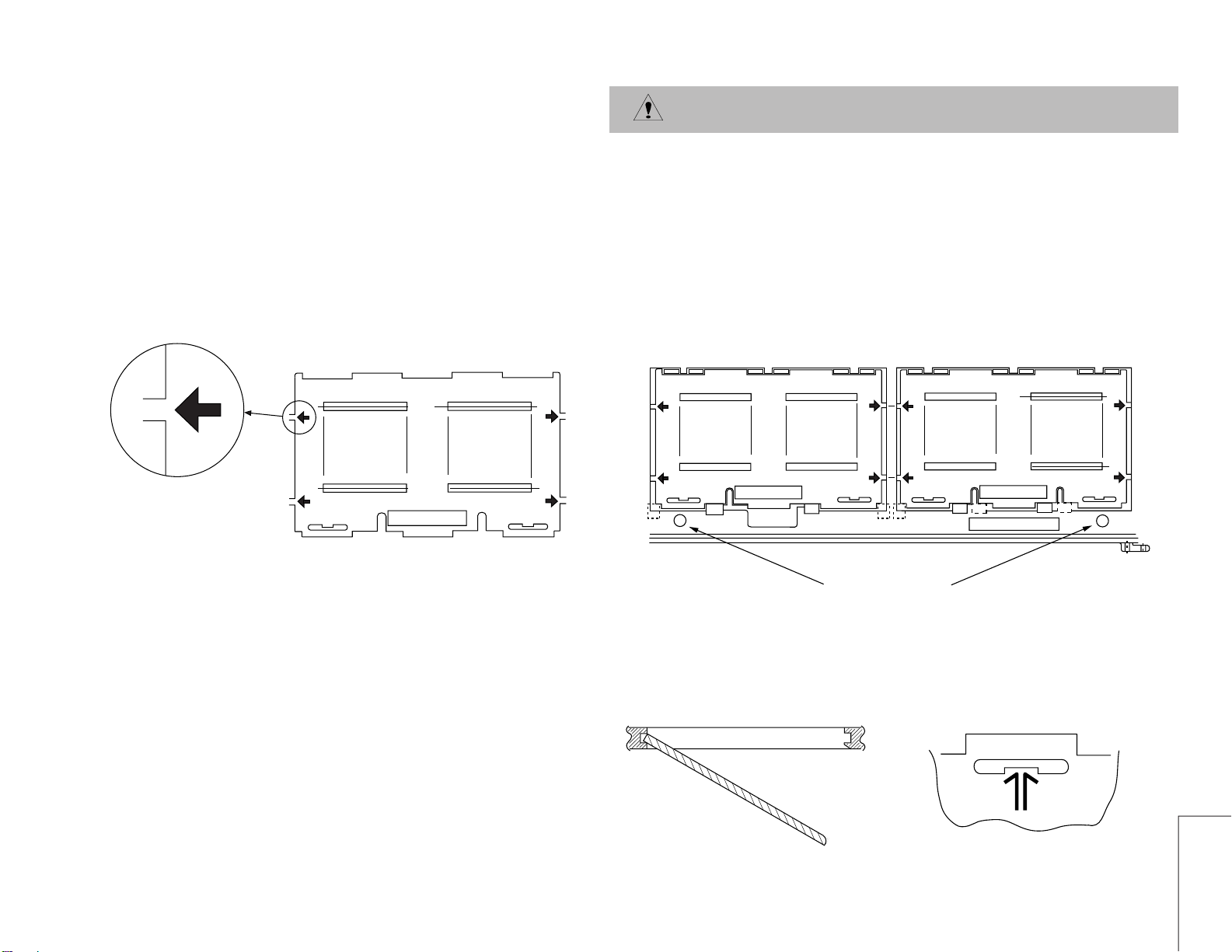

REMOVAL AND REPLACEMENT OF THE MAIN-BRACKET

BOTTOM PLATES.

For safety reasons, on no account should the plates be removed

and not refitted after servicing.

— 19 —

(1) REMOVING THE PLATES

In the event of servicing being required to the solder side of the D Board printed

circuit, the bottom plates fitted to the main chassis bracket require to be removed.

This is performed by cutting the gates with a sharp wire cutter at the locations

shown and indicated by arrows.

Note : There are 5 plates fitted to the main bracket and secured by 4 or 6 gates.

Only remove the necessary plate to gain access to the circuit board.

FOR SAFETY REASON THIS

PLATE MUST BE REMOUNTED

AFTER CUTTING AND

TAKING AWAY.

Fig 1

(2) REFITTING THE PLATES

Because the plates differ in size it is important that the correct plates are refitted in their

original location.

The plates are identified by markings A-B-C-D-E on their top side.

1. Identify the plate by locating its marking.

2. Turn the plate over noting where the marking is located.

3. Locate the corresponding marking indicated on the main chassis bracket. See Fig 2.

4. Refit the plate as indicated in Fig 3 with the markings located next to each other.

FOR SAFETY REASON THIS

PLATE MUST BE REMOUNTED

AFTER CUTTING AND

TAKING AWAY.

ATTENTION

D

E

Fig 2

FOR SAFETY REASON THIS

PLATE MUST BE REMOUNTED

AFTER CUTTING AND

TAKING AWAY.

ATTENTION

INDEX MARKING

AT BRACKET FRAME

INSERT FROM

THE BOTTOM

SIDE

Fig 3

MAIN BRACKET

In the event of the plates requiring to be

removed at a later stage, this can be achieved

by inserting a screwdriver in the snap-recess

indicated as in Fig 4 and lifting out.

KV-25X3

Fig 4

KV-25X3

SECTION 3

SET -UP ADJUSTMENTS

• When complete readjustment is necessary or a new picture

tube is installed, carry out the following adjustments.

• Unless there are specific instructions to the contrary, carry

out these adjustment with the rated power supply.

• Unless there are specific instructions to the contrary, set the

controls and switches as follows.

Contrast............ normal

Brightness ........ normal

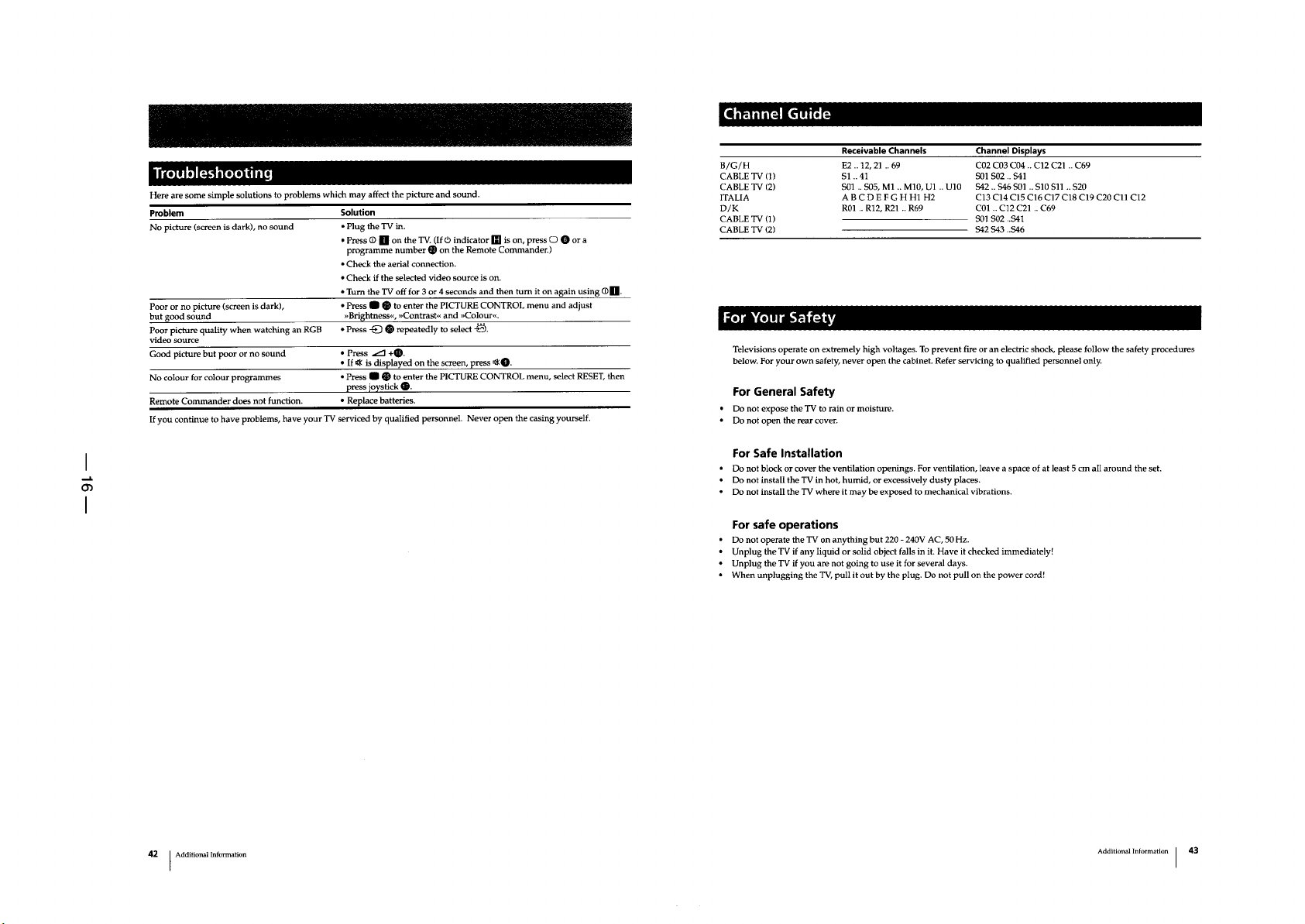

3-1. BEAM LANDING

Preparation:

1. In order to reduce the influence of geomagnetism on the set’s

picture tube face it in an easterly or westerly direction.

2. Switch on the set’s power and degauss with the degausser.

(1) Adjustment of Correction Magnet for Y-Splitting

Axis

1. Input a crosshatch signal from the pattern generator.

2. Picture control is minimum and brightness control is still

normal.

3. Position the neck assy as shown in Fig. 3-2.

4. Move the deflection yoke forward to touch the CRT and it

stands up rightly.

5. Adjust the upper pin and the lower pin symmetrically by

opening or closing the Y-splitting axis correction magnets

on the neck assy.

6. Return the deflection yoke to its original position.

• Carry out the following adjustments in this order:

3-1. Beam landing

3-2. Convergence

3-3. Focus

3-4. White balance

Note:Testing equipment required.

1. Color bar/pattern generator

2. Degausser

3. Vector scope

(2) Landing

Note: Before carrying out the following adjustments adjust the

magnets as indicated below (See Fig.3-3).

1. Input an all-white signal from the pattern generator.

Maximize the picture setting and adjust the brightness setting.

2. Rough-adjust the focus and horizontal convergence.

3. Loosen the deflection yoke screws, align the purity adjustment

knob to the central position. (See Fig. 3-1)

4. Switch from the all-white pattern to an all-green pattern.

5. Move the deflection yoke backwards and adjust with the

purity magnet so that the green is at the center and it aligns

symmetrically. (See Fig. 3-4)

6. Move the deflection yoke forward and adjust so that entire

screen becomes green.

7. Switch the raster signal to red, then to blue and verify the

landing condition.

8. When the position of the deflection yoke has been

determined, fasten the deflection yoke with the screw.

9. If the beam does not land correctly in all the corners, use

magnets to correct it. (See Fig. 3-5)

Y-splitting axis correction magnet

— 20 —

Purity Adjustment

Purity

Deflection yoke

Fig.3-1

Align the bottom edge of the neck

assy with the G3 hole center.

Fig.3-3

Align Pips

on each

magnet

Neck assy

Fig.3-2

Loading...

Loading...