Page 1

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KV-21FA340

KV-21FA340

KV-21FA540

KV-21FA540

KV-29FA340

KV-29FA340

KV-29FA540

KV-29FA540

RM-Y194 LATIN NORTH SCC-S82C-A

RM-Y194 LATIN SOUTH SCC-S82D-A

RM-Y194 LATIN NORTH SCC-S82A-A

RM-Y194 LATIN SOUTH SCC-S82B-A

RM-Y194 LATIN NORTH SCC-S73V-A

RM-Y194 LATIN SOUTH SCC-S73W-A

RM-Y194 LATIN NORTH SCC-S73X-A

RM-Y194 LATIN SOUTH SCC-S73Y-A

BA-6

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 3/2006

REVISION DATE SUBJECT

3/2006 No revisions or updates are applicable at this time.

TRINITRON® COLOR TELEVISION

9-883-701-01

Page 2

Self Diagnosis

Supported model

SERVICE MANUAL

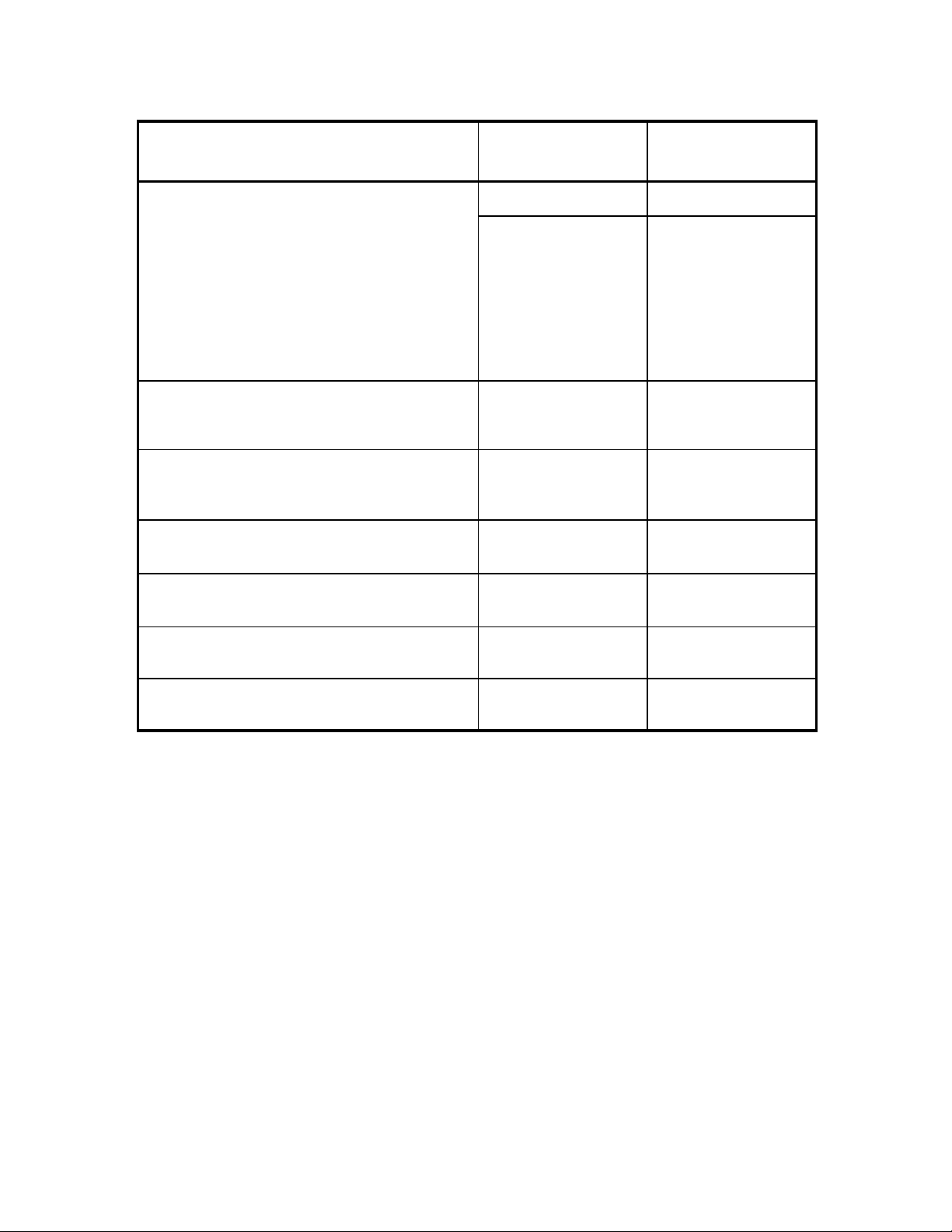

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KV-21FA340

KV-21FA340

KV-21FA540

KV-21FA540

KV-29FA340

KV-29FA340

KV-29FA540

KV-29FA540

RM-Y194 LATIN NORTH SCC-S82C-A

RM-Y194 LATIN SOUTH SCC-S82D-A

RM-Y194 LATIN NORTH SCC-S82A-A

RM-Y194 LATIN SOUTH SCC-S82B-A

RM-Y194 LATIN NORTH SCC-S73V-A

RM-Y194 LATIN SOUTH SCC-S73W-A

RM-Y194 LATIN NORTH SCC-S73X-A

RM-Y194 LATIN SOUTH SCC-S73Y-A

BA-6

CHASSIS

9-883-701-01

KV-21FA540 RM-Y194

TRINITRON® COLOR TELEVISION

Page 3

KV-21FA340/21FA540/29FA340/29FA540

TABLE OF CONTENTS

SECTION TITLE PAGE SECTION TITLE PAGE

Specifi cations ................................................................................. 4

Warnings and Cautions .................................................................. 6

Safety Check-Out ........................................................................... 7

Self-Diagnostic Function ................................................................. 8

SECTION 1: DISASSEMBLY ............................................................... 10

1-1. Rear Cover Removal ............................................................ 10

1-2. Chassis Assembly Removal ................................................. 10

1-3. Service Position .................................................................... 11

1-4. Picture Tube Removal .......................................................... 12

Anode Cap Removal Procedure .......................................... 12

Cable Wire Dressing ............................................................ 13

KV-21FA340/21FA540 Models Only ................................ 13

KV-29FA340/29FA540 Models Only ................................ 21

SECTION 2: SET-UP ADJUSTMENTS ................................................ 31

2-1. Beam Landing ...................................................................... 31

2-2. Convergence ........................................................................ 32

2-3. Focus ................................................................................... 33

2-4. Screen (G2) .......................................................................... 34

SECTION 3: SAFETY RELATED ADJUSTMENTS ............................. 35

3-1.

X

R530, R531 Confi rmation Method (HV Hold-Down

Confi rmation) and Readjustments ........................................ 35

3-2. B+ Voltage Confi rmation and Adjustment ............................ 35

SECTION 4: CIRCUIT ADJUSTMENTS .............................................. 36

4-1. Remote Adjustment Buttons and Indicators ......................... 36

4-2. Accessing the Service Adjustment Mode ............................. 36

4-3. Confi rming Service Adjustment Changes ............................. 37

4-4. Service Data Lists ................................................................ 38

4-5. ID Map Table ........................................................................ 45

4-6. White Balance Adjustments ................................................. 46

4-7. A Board Adjustments ............................................................ 46

SECTION 5: DIAGRAMS ..................................................................... 49

5-1. Circuit Boards Location ........................................................ 49

5-2. Printed Wiring Board and

Schematic Diagram Information ........................................... 49

5-3. Block Diagrams and Schematics ......................................... 50

Signal Flow Block Diagram .................................................. 50

Audio Block Diagram ............................................................ 51

A Board Schematic Diagram (1 of 2) .................................... 52

A Board Schematic Diagram (2 of 2) .................................... 53

CV Board Schematic Diagram ............................................. 55

HC Board Schematic Diagram ............................................. 56

K1 Board Schematic Diagram (1 of 2)

(KV-21FA540/29FA540 Only) .......................................... 58

K1 Board Schematic Diagram (2 of 2)

(KV-21FA540/29FA540 Only) .......................................... 59

K2 Board Schematic Diagram

(KV-21FA340/29FA340 Only) .......................................... 60

MT Board Schematic Diagram ............................................. 62

5-4. Semiconductors ................................................................... 64

SECTION 6: EXPLODED VIEWS ........................................................ 65

6-1. Chassis ................................................................................ 65

6-2. Picture Tube ......................................................................... 66

SECTION 7: ELECTRICAL PARTS LIST ........................................... 67

KV-21FA340/21FA540/29FA340/29FA540

3

Page 4

KV-21FA340/21FA540/29FA340/29FA540

/

r

p

)

r

r

p

SPECIFICATIONS

KV-21FA340 KV-21FA540

Power Requirements 120V, 60Hz 120V, 60Hz

(Chile, Perú, Bolivia)

Number of Inputs/Outputs

S Video

Y,P

External for Center/Subwoofe

Audio Panel 11

Front Panel Audio 11

Right & Left Satelite Speakers 1

eaker Output(W

S

Subwoofe

Satelite S

Power Consumption (W)

In Use (Max) 155W 180W

(Chile, Perú, Bolivia)

In Standby (Max)

Dimensions with Subwoofer (W x H x D)

Dimensions of Satelite Speakers (W x H x D)

Mass

Mass of Satelite Speakers

1)

Video

2)

3)

, P

B

R

4)

Audio

5)

RF

Cente

eakers

5)

mm 648 x 569 x 497 mm 648 x 568.5 x 496.4 mm

in

mm 112 x 478.4 x 87 mm

in

kg 28.2 kg 28.2 kg

lbs 62 lbs 1 oz 62 lbs 1 oz

kg .6 kg

lbs 1 lbs 5 oz

220V, 50/60Hz 220V, 50/60Hz

33

11

11

44

11

5W x 2 5W x 2

15W 15W

5W 5W

5W x 2

150W 175W

<1W <1W

25

1/2

x 22

1/2

1/2

x 19

in 25

1)

1 Vp-p 75 ohms unbalanced, sync negative

2)

Y: 1 Vp-p 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

3) Y: 1.0 Vp-p, 75 ohms, sync negative; PB: 0.7 Vp-p, 75 ohms;

PR Vp-p, 75 ohms.

4)

500 mVrms (100% modulation), Impedance: 47 kilohms

5)

This specifi cation is the maximum wattage.

1/2

x 22

3/8

x 18

4

1/2

3/4

x 19

x 3

1/2

1/2

in

in

KV-21FA340/29FA340 MODELS KV-21FA540/29FA540 MODELS

En calidad de compañía asociada a ENERGY

®

, Corporación Sony ha determinado que

STAR

este producto cumple con las directrices de uso

eficiente de energía de ENERGY STAR

ENERGY STAR

EEUU.

Fabricado bajo licencia de SRS Labs, Inc. WOW y los

símbolos SRS son marcas registradas de SRS Labs,

//

Inc.

Bajo licencia de BBE Sound, Inc. Licenciado de BBE

Sound, Inc. sobre el número USP4638258, 5510752 Y

5736897. BBE y el símbolo son marcas registradas de

BBE Sound, Inc.

Sony, FD Trinitron, WEGA, ClearEdge VM, Intelligent

Picture y Dynamic Bass Response System son marcas

comerciales de Sony.

®

es una marca registrada de

®

.

KV-21FA340/21FA540/29FA340/29FA540

En calidad de compañía asociada a ENERGY

®

, Corporación So ny ha determinado que

STAR

este producto cumple con las directrices de uso

eficiente de energía de ENERGY STAR

ENERGY STAR

EEUU.

Fabricado bajo licencia de SRS Labs, Inc. TruSurround

y los símbolos SRS son marcas registradas de SRS

Labs, Inc.

Fabricado bajo licencia de Dolby Laboratories.

“Dolby”, “Pro Logic” y el símbolo de la doble-D son

marcas comerciales de Dolby Laboratories.

Sony, FD Trinitron, WEGA, ClearEdge VM, Intelligent

Picture y Dynamic Bass Response System son marcas

comerciales de Sony.

®

es una marca registrada de

®

.

Design and specifi cations are subject to change without notice.

4

Page 5

KV-21FA340/21FA540/29FA340/29FA540

r

p

)

r

r

p

KV-29FA340 KV-29FA540

Power Requirements 120V, 60Hz 120V-220V, 50/60Hz

(Chile, Perú, Bolivia)

Number of Inputs/Outputs

S Video

Y,P

External for Center/Subwoofe

Audio Panel 11

Right & Left Satelite Speakers 1

eaker Output(W

S

Subwoofe

Satelite S

Power Consumption (W)

In Use (Max) 220W 240W

(Chile, Perú, Bolivia)

In Standby (Max)

Dimensions with Subwoofer (W x H x D)

Dimensions of Satelite Speakers (W x H x D)

Mass

Mass of Satelite Speakers

1)

Video

2)

3)

, P

B

R

4)

Audio

5)

RF

Cente

eakers

5)

mm 804 x 697 x 509 mm 804 x 697 x 509 mm

in

mm 112 x 605 x 87 mm

in

kg 49.8 kg 49.8 kg

lbs 109 lbs 10 oz 109 lbs 10 oz

kg .8 kg

lbs 1 lbs 12 oz

220V, 50/60Hz 220V, 50/60Hz

33

11

11

44

11

11

7W x 2 7W x 2

20W 20W

7W 7W

7W x 2

215W 235W

<1W <1W

5/8

31

x 27

1/2

x 20 in 31

1)

1 Vp-p 75 ohms unbalanced, sync negative

2)

Y: 1 Vp-p 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

3) Y: 1.0 Vp-p, 75 ohms, sync negative; PB: 0.7 Vp-p, 75 ohms;

PR Vp-p, 75 ohms.

4)

500 mVrms (100% modulation), Impedance: 47 kilohms

5)

This specifi cation is the maximum wattage.

5/8

x 27

3/8

4

x 23

3/4

1/2

x 20 in

x 3

1/2

in

Television system

American TV standard, NTSC

Actual screen size

21-inch measured diagonally (KV-21FA340/21FA540 Only)

29-inch measured diagonally (KV-29FA340/29FA540 Only)

Channel coverage

VHF: 2-13/ UHF: 14-69/ CATV: 1-125

Antenna

75-ohm external antenna terminal for VHF/UHF

Picture tube

FD Trinitron® tube

Visible screen size

20-inch picture measured diagonally (KV-21FA340/21FA540 Only)

27-inch picture measured diagonally (KV-29FA340/29FA540 Only)

KV-21FA340/21FA540/29FA340/29FA540

Supplied Accessories

Remote Commander RM-Y194

Two Size AA (R6) Batteries

Telescopic Antenna (KV-21FA340/21FA540 Only)

Optional Accessories

Connection Cables

VMC-810S/820S

VMC-720M

YC-YC-15V/30V

RK74FA

5

Page 6

KV-21FA340/21FA540/29FA340/29FA540

WARNINGS AND CAUTIONS

CAUTION

Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield, or carbon painted on the CRT, after

removing the anode.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of

this receiver is directly connected to the AC power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe

operation. Replace these components with Sony parts whose part numbers appear as shown in this manual or in supplements

published by Sony. Circuit adjustments that are critical for safe operation are identifi ed in this manual. Follow these procedures

whenever critical components are replaced or improper operation is suspected.

KV-21FA340/21FA540/29FA340/29FA540

6

Page 7

SAFETY CHECK-OUT

KV-21FA340/21FA540/29FA340/29FA540

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if sets

always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

Leakage Test

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of

passive VOMs that are suitable. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground. If the

retaining screw is to be used as your earth ground, verify that it is at

ground by measuring the resistance between it and a cold-water pipe

with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt

trouble- light (not a neon lamp) between the hot side of the receptacle

and the retaining screw. Try both slots, if necessary, to locate the hot

side on the line; the lamp should light at normal brilliance if the screw

is at ground potential (see Figure B).

To Exposed Metal

Parts on Set

0.15 F

1.5 K Ω

Earth Ground

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

KV-21FA340/21FA540/29FA340/29FA540

AC

Voltmeter

(0.75 V)

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

7

Page 8

KV-21FA340/21FA540/29FA340/29FA540

SELF-DIAGNOSTIC FUNCTION

Self Diagnosis

Supported model

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER LED will automatically begin to fl ash. The number

of times the LED fl ashes translates to a probable source of the problem. A defi nition of the STANDBY/TIMER LED fl ash indicators is listed in the

instruction manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote Commander can be used to review

the failure occurrence data stored in memory to reveal past problems and how often these problems occur.

Diagnostic Test Indicators

When an error occurs, the STANDBY/TIMER LED will fl ash a set number of times to indicate the possible cause of the problem. If there is more than

one error, the LED will identify the fi rst of the problem areas.

Results for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

Diagnostic Item Descrip-

tion

Power does not turn on

+B overcurrent (OCP)*

I-Prot

IK (AKB)

No. of times

STANDBY/ TIMER

lamp fl ashes

Does not light

2 times

4 times

5 times

Self-Diagnositc

Display/

Diagnostic Result

2:0 or 2:1

4:0 or 4:1

5:0 or 5:1

Probable Cause Location

• Power cord is not plugged in.

• Fuse is burned out (F601). (A Board)

• H.OUT (Q502) is shorted. (A Board)

• IC702 is shorted. (CV Board)

• +13V is not supplied. (A Board)

• IC561 is faulty. (A Board)

• IC001 is faulty. (MT Board)

• Screen (G2) is improperly adjusted.**

Detected Symptoms

• Power does not come on.

• No power is supplied to the TV.

• AC Power supply is faulty.

• Power does not come on.

• Load on power line is shorted.

• Has entered standby state after horizontal raster.

• Vertical defl ection pulse is stopped.

• Power line is shorted or power supply is stopped.

• No raster is generated.

• CRT Cathode current detection reference pulse

output is small.

*If a +B overcurrent is detected, stoppage of the vertical defl ection is detected simultaneously. The symptom that is diagnosed fi rst by the

mircrocontroller is displayed on the screen.

**Refer to Screen (G2) Adjustments in Section 2-4. of this manual.

Display of Standby/Timer LED Flash Count

2 times

4 times

5 times

LED ON 0.3 sec.

LED OFF 0.3 sec.

LED OFF

3 sec.

Standby/Timer LED

Diagnostic Item Flash Count*

+B Overcurrent 2 times

I-Prot 4 times

IK (AKB) 5 times

*One fl ash count is not used for self-diagnostic.

Stopping the Standby/Timer LED Flash

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER LAMP from fl ashing.

KV-21FA340/21FA540/29FA340/29FA540

8

Page 9

KV-21FA340/21FA540/29FA340/29FA540

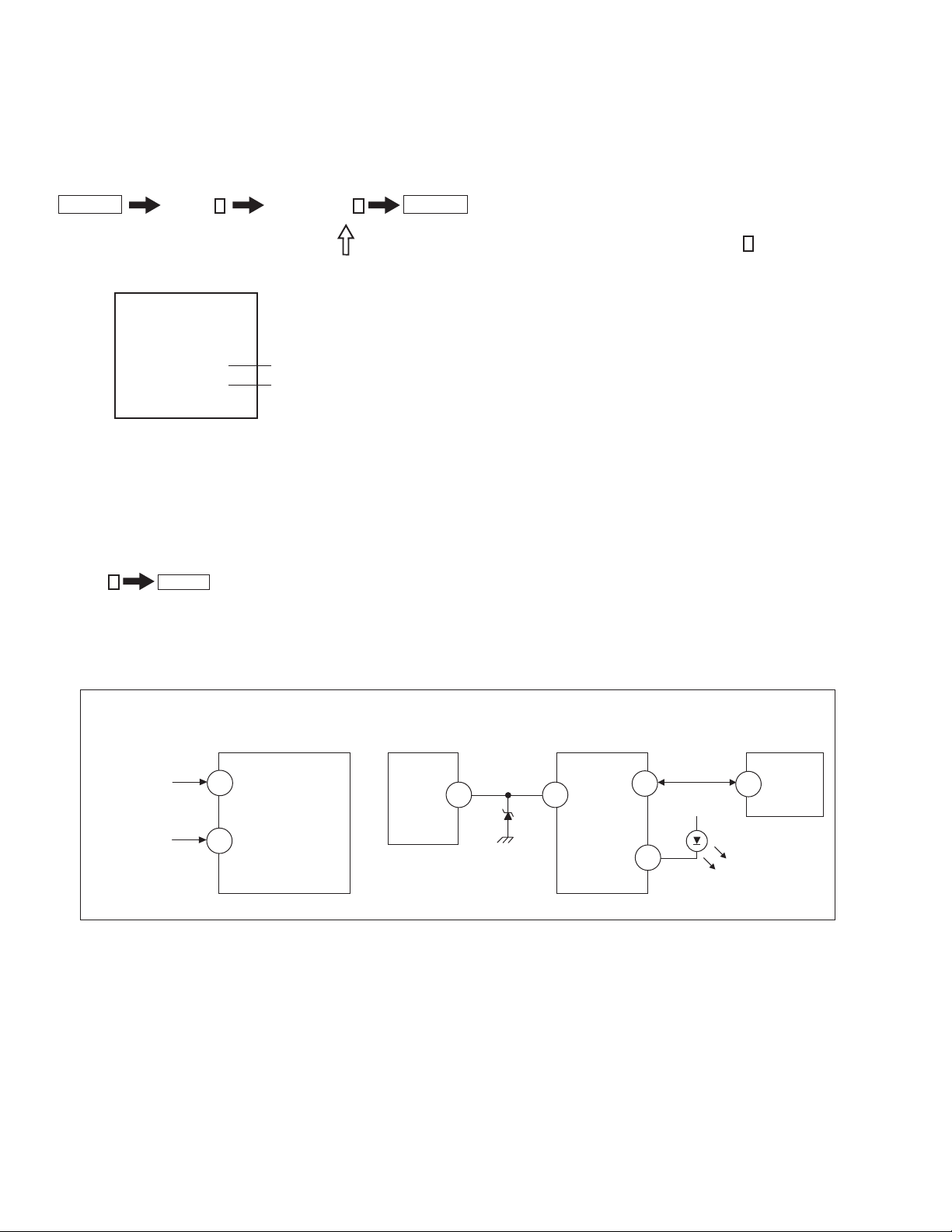

Self-Diagnostic Screen Display

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confi rmed, it is possible to bring up past

occurrences of failure on the screen for confi rmation.

To Bring Up Screen Test

In standby mode, press buttons on the Remote Commander sequentially, in rapid succession, as shown below:

DISPLAY

Self-Diagnostic Screen Display

Handling of Self-Diagnostic Screen Display

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen during repairs. When you

have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of the repairs.

Clearing the Result Display

To clear the result display to “0”, press buttons on the Remote Commander sequentially when the diagnostic screen is displayed, as shown below:

Channel 8

Quitting the Self-Diagnostic Screen

To quit the entire self-diagnostic screen, turn off the power switch on the Remote Commander or the main unit.

Channel

SELF DIAGNOSTIC

2: +B OCP 0

3: +B OVP N/A

4: VSTOP 0

5: AKB 1

101: WDT N/A

ENTER

5

Sound Volume -

Numeral “0” means that no fault was detected.

Numeral “1” means a fault was detected one time only.

POWER

Note that this differs from entering the Service Mode (Sound Volume

+

).

Self-Diagnostic Circuit

FROM

CV BOARD

IC702 PIN 5

MT BOARD

IC001

Y/CHROMA JUNGLE

51

IK-AKBIN

A BOARD

IC561

V. OUT

REF

3

MT BOARD

IC001

SYSTEM

IO-BDAT

78

I-Prot

53

MT BOARD

IC002

MEMORY

5

BDA

FROM

72

A BOARD

IC501

PIN 1

+B overcurrent (OCP)

Occurs when an overcurrent on the +B (135V) line is detected by pin 72 of IC001 (MT Board). If the voltage of pin 72 of IC001 (MT Board) is less than

1V when V.SYNC is more than seven verticals in a period, the unit will automatically turn off.

I-Prot

Occurs when an absence of the vertical defl ection pulse is detected by pin 78 of IC001 (MT Board). Power supply will shut down when waveform

interval exceeds 2 seconds.

IK (AKB)

If the RGB levels* do not balance within 2 seconds after the power is turned on, this error will be detected by IC001 (MT Board). TV will stay on, but

there will be no picture.

I-HLDWN

O-LED

79

DISPLAY

*(Refers to the RGB levels of the AKB detection Ref pulse that detects IK).

KV-21FA340/21FA540/29FA340/29FA540

9

Page 10

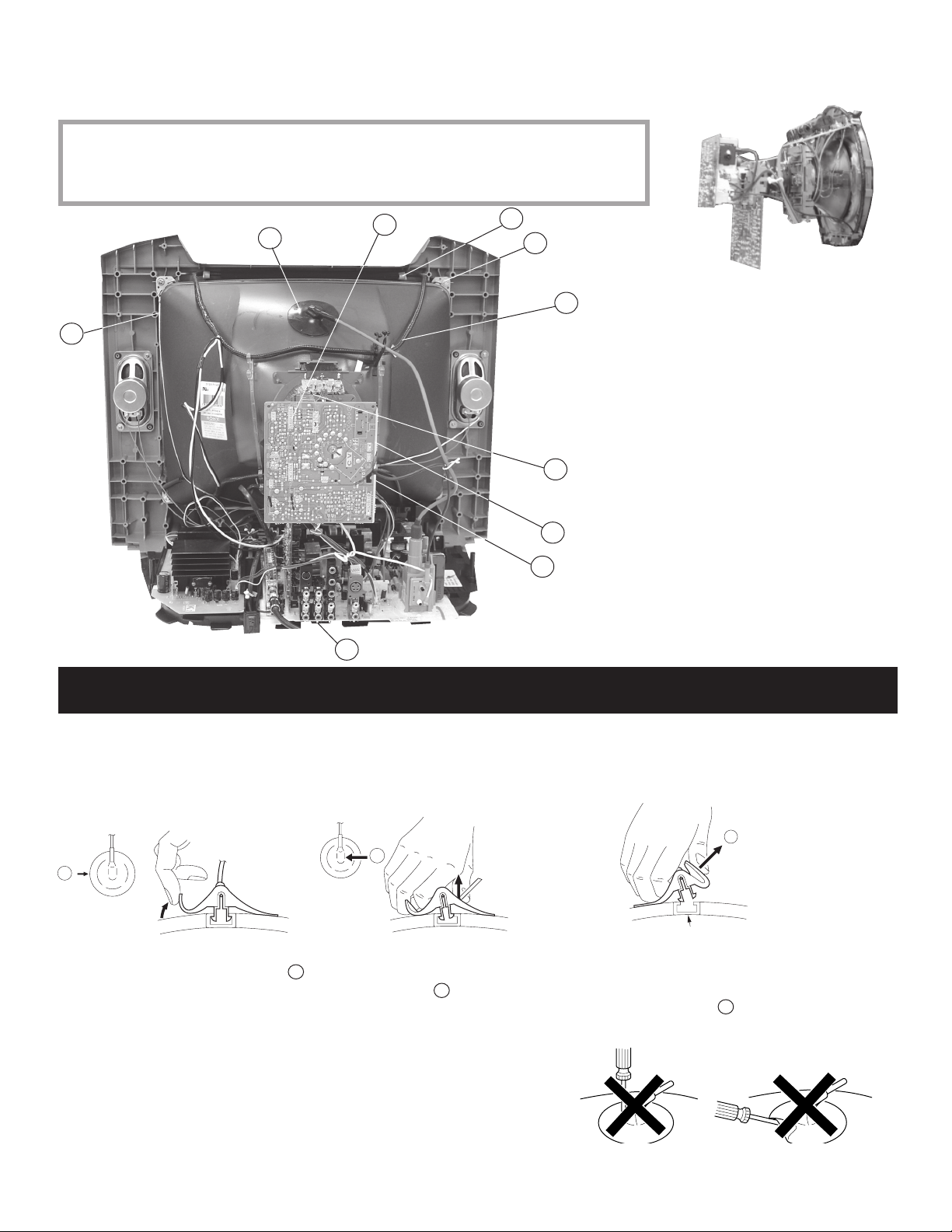

SECTION 1: DISASSEMBLY

KV-21FA340/21FA540/29FA340/29FA540

1-1. REAR COVER REMOVAL

(KV-29FA540 PICTURED)

1

Lift to remove Subwoofer

from top of Rear Cover.

2

Remove screws from back of cover.

5 Screws

1 Screw +BVTP 4X16 TYPE2 IT-3

3

Remove screws from sides of cover.

3

(

KV-29FA340/29FA540 Only)

2 SCREW +BVTP 4X16 TYPE2 IT-3

(KV-21FA340/21FA540 Only)

Remove screws from top of cover.

4

4

(

KV-29FA340/29FA540 Only)

2 SCREW +BVTP 4X16 TYPE2 IT-3

(KV-21FA340/21FA540 Only)

Remove rear cover

5

SCREW +BVTP 3X12 TYPE2 TT (B)

SCREW +BVTP 4X16 TYPE2 IT-3

SCREW +BVTP 4X16 TYPE2 IT-3

each side

each side

1

4

5

3

2

1-2. CHASSIS ASSEMBLY REMOVAL

(KV-21FA540 PICTURED)

CV Board

KV-21FA340/21FA540/29FA340/29FA540

Claw

Chassis Assembly

10

Page 11

1-3. SERVICE POSITION

(KV-21FA540 SHOWN)

1

Disconnect the CN501 cable from the A Board.

2

Press on catch tab to release A Board.

3

Gently pull the K1 or K2 Board and the A Board forward to access the HC Board.

Disconnect the speaker cable from the HC Board.

4

Gently continuing pulling the A Board and HC Board forward to place in

5

service position.

Reconnect CN501 and speaker cables

6

KV-21FA340/21FA540/29FA340/29FA540

HC Board

A Board

CV Board

K1 Board (KV-21FA540/29FA540 Only)

K2 Board (KV-21FA340/29FA340 Only)

KV-21FA340/21FA540/29FA340/29FA540

11

Page 12

1-4. PICTURE TUBE REMOVAL

WARNING: BEFORE REMOVING THE ANODE CAP

High voltage remains in the CRT even after the power is disconnected. To avoid electric shock,

discharge CRT before attempting to remove the anode cap. Short between anode and CRT

coated earth ground strap.

KV-21FA340/21FA540/29FA340/29FA540

1

3

9

4

7

10

1. Discharge the anode of the CRT and remove the

8

6

2

5

anode cap.

2. Unplug all interconnecting leads from the

defl ection yoke, neck assembly, degaussing coils

and CRT grounding strap.

3. Remove the CV Board from the CRT.

4. Remove the chassis assembly.

5. Loosen the neck assembly fi xing screw and

remove.

6. Loosen the defl ection yoke fi xing screw and

remove.

7. Place the set with the CRT face down on a

cushion and remove the degaussing coil holders.

8. Remove the degaussing coils.

9. Remove the CRT grounding strap and spring

tension devices.

10. Unscrew the four CRT fi xing screws [located on

each CRT corner] and remove the CRT [Take

care not to handle the CRT by the neck].

ANODE CAP REMOVAL PROCEDURE

WARNING: High voltage remains in the CRT even after the power is disconnected. To avoid electric shock, discharge CRT before attempting to

remove the anode cap. Short between anode and coated earth ground strap of CRT.

NOTE: After removing the anode cap, short circuit the anode of the picture tube and the anode cap to either the metal chassis, CRT shield, or carbon

painted on the CRT.

REMOVAL PROCEDURES

c

b

a

Anode Button

Turn up one side of the rubber cap in

the direction indicated by arrow a .

HOW TO HANDLE AN ANODE CAP

1. Do not use sharp objects which may cause damage to the surface of the anode

cap.

2. To avoid damaging the anode cap, do not squeeze the rubber covering too

hard. A material fi tting called a shatter-hook terminal is built into the rubber.

3. Do not force turn the foot of the rubber cover. This may cause the shatter-hook

terminal to protrude and damage the rubber.

Use your thumb to pull the rubber

cap fi rmly in the direction indicated

by arrow b .

When one side of the rubber cap separates from

the anode button, the anode cap can be removed

by turning the rubber cap and pulling it in the

direction of arrow c .

KV-21FA340/21FA540/29FA340/29FA540

12

Page 13

CABLE WIRE DRESSING

KV-21FA340/21FA540 MODELS ONLY

KV-21FA340/21FA540/29FA340/29FA540

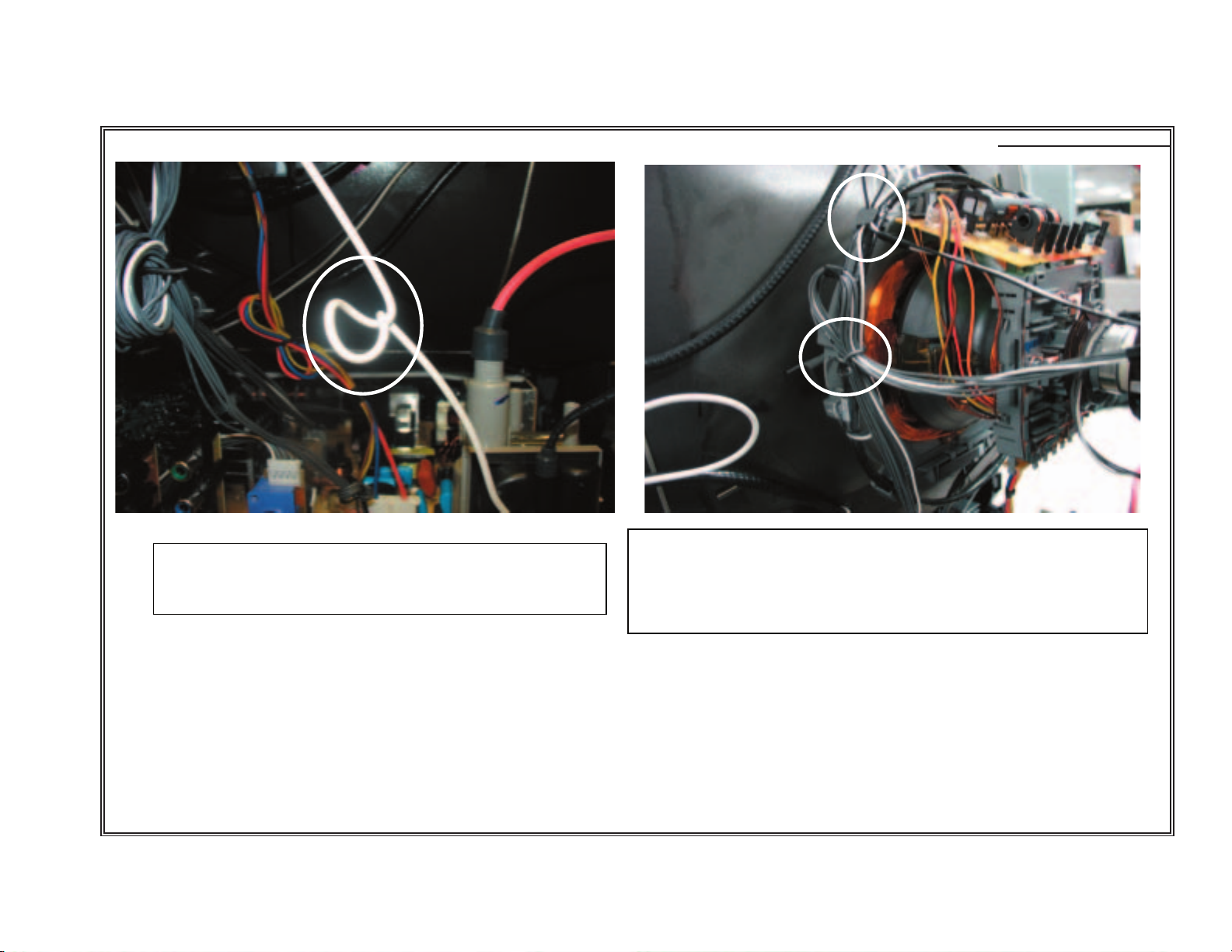

21FA540/540C/340/340C

- Dress left speaker wire using DY purse lock as

shown in picture. Keep away from DY cable.

- Dress DY's lead wire harness using a purse lock

(4-081-411-02)

Dress right speaker wire using a purse lock (4072-499-12) as picture shown.

Rev 1.1 2/9

KV-21FA340/21FA540/29FA340/29FA540

13

Page 14

KV-21FA340/21FA540 MODELS ONLY

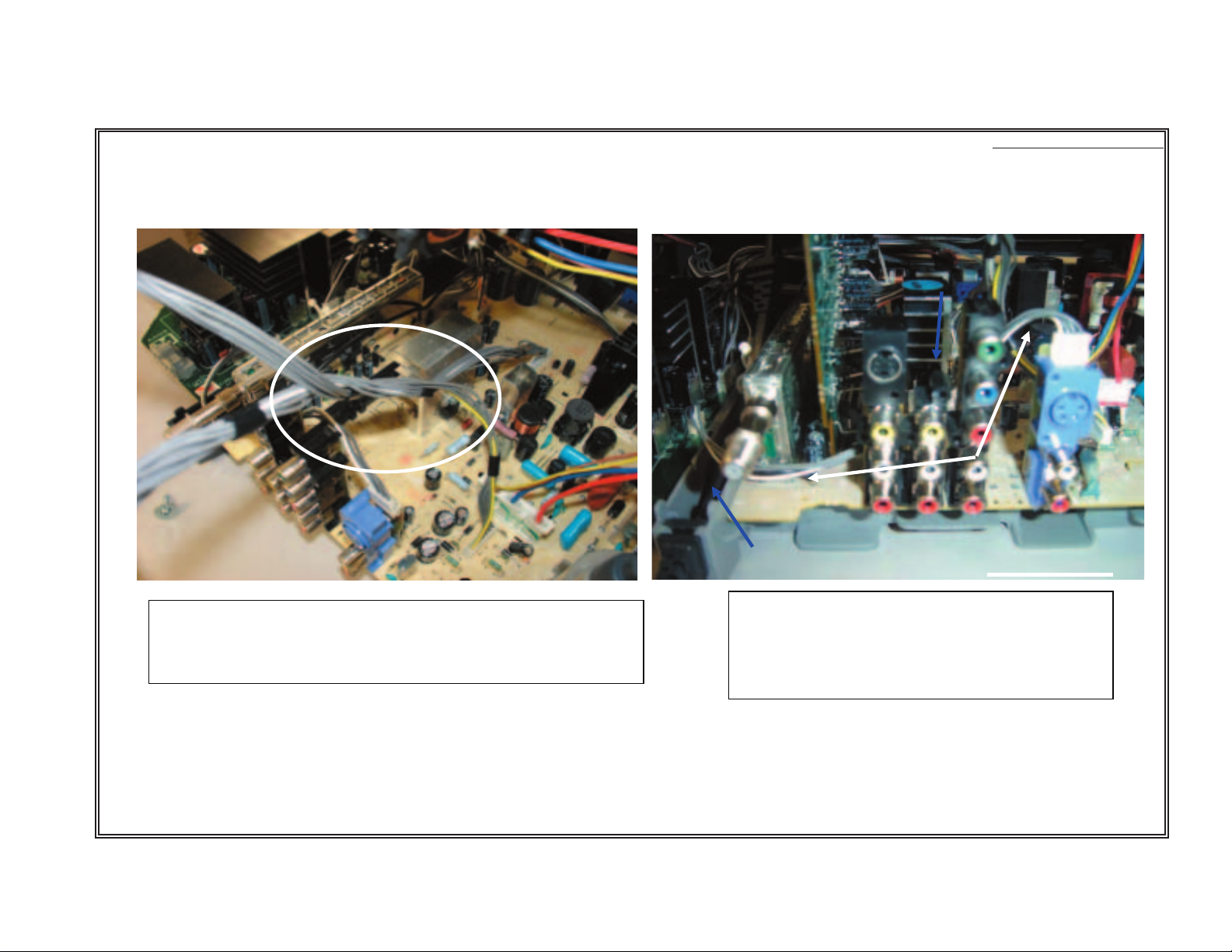

KV-21FA340/21FA540/29FA340/29FA540

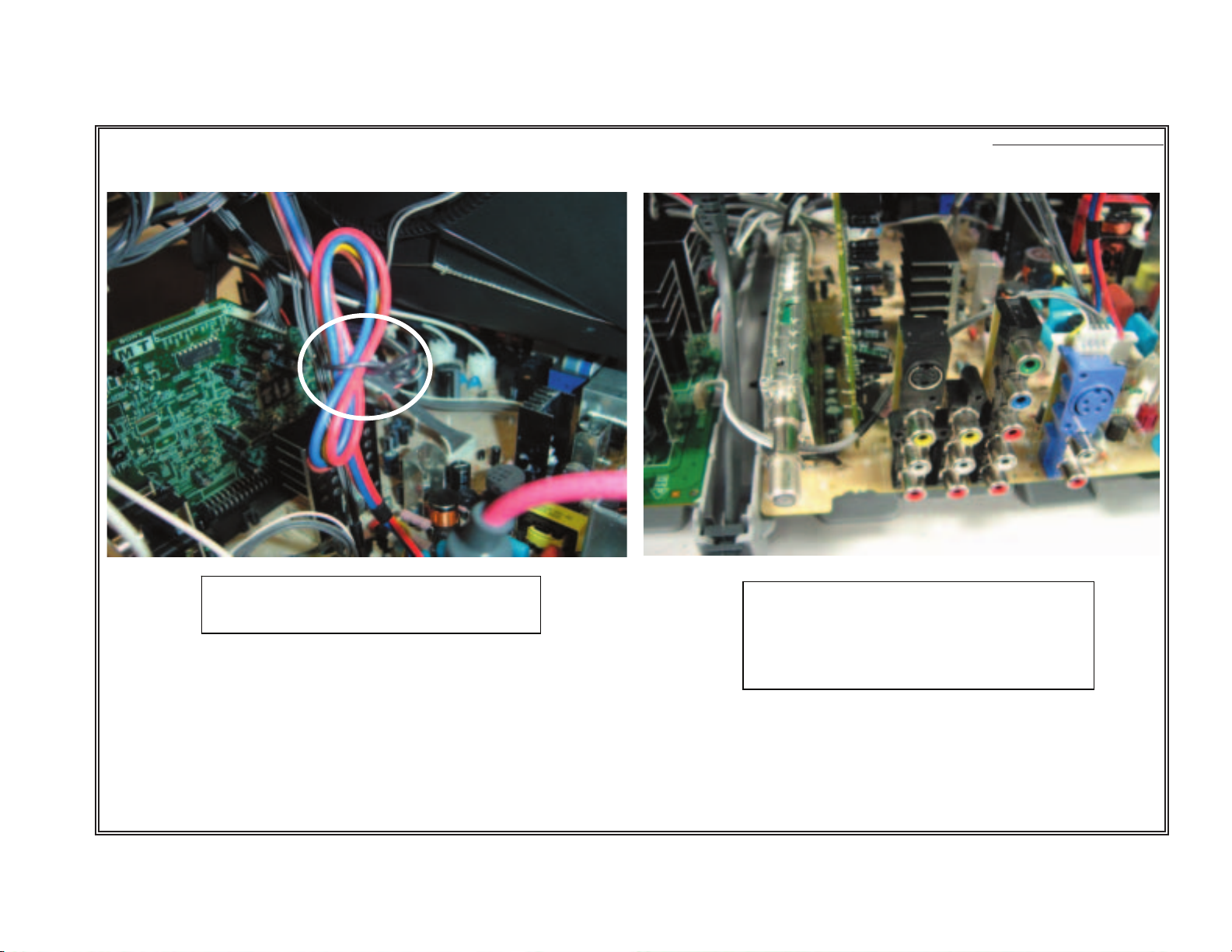

21FA540/540C/340/340C

Jacks

subwoofer

cable

AC cord

Interlace once VM (A/CN502~CV/CN901) and heater

(A/CN503~CV/CN706) harnesses together as shown in

picture.

Dress subwoofer harness (K1/CN2403 or

K2/CN3403~A/J207) pass under F-Pin,

behind video jacks & over AC cord as

picture shown.

Rev 1.1 3/9

KV-21FA340/21FA540/29FA340/29FA540

14

Page 15

KV-21FA340/21FA540 MODELS ONLY

KV-21FA340/21FA540/29FA340/29FA540

21FA540/540C/340/340C

100mm

Pass CRT ground wire over DY's cilp & behind DGC as shown

in picture.

- Dress focus lead and HV cable together using 5mm purse lock

(3-703-981-02), install purse lock 100mm from HV cable's cap. And

pass focus lead through CV board's hook

Rev 1.1 4/9

KV-21FA340/21FA540/29FA340/29FA540

15

Page 16

KV-21FA340/21FA540 MODELS ONLY

KV-21FA340/21FA540/29FA340/29FA540

21FA540/540C/340/340C

Twist G2 wire without stressing it

- Fix G2 wire through FBT G2 clip.

- Pass G2 wire between Focus wire & FBT

as shown in picture.

Rev 1.1 5/9

KV-21FA340/21FA540/29FA340/29FA540

16

Page 17

KV-21FA340/21FA540 MODELS ONLY

KV-21FA340/21FA540/29FA340/29FA540

21FA540/540C/340/340C

Dress 3P (HC/CN2403~K1/CN2405), 4P

(HC/CN2401~K1/CN2400), 12P harness

(HC/CN2005~MT/CN303) & Right speaker

using a purse lock (3-703-982-02) as shown

in picture.

Dress right

speaker only with

this purse lock

CAUTION POINT:

Avoid wires to

touch LFT or any

other primary

components

- Dress 3P (HC/CN2403~K1/CN2405), 4P

(HC/CN2401~K1/CN2400), 12P harness

(HC/CN2005~MT/CN303) & Right speaker using two

purse lock (4-072-499-12) to avoid primary circuit.

Rev 1.1 6/9

KV-21FA340/21FA540/29FA340/29FA540

17

Page 18

KV-21FA340/21FA540 MODELS ONLY

KV-21FA340/21FA540/29FA340/29FA540

21FA540/540C/340/340C

For FA540/340C

Dress 3P (K1/CN2402~A/CN412), 5P (A/CN201~K1/CN2600), 10P (A/CN411~K1/CN2401), 3P (HC/CN2403~K1/CN2405), 4P

(HC/CN2401~K1/CN2400), 12P harness (HC/CN2005~MT/CN303) using a 5mm purse lock (3-703-981-02)

For FA340/340C

Dress 3P (K2/CN3404~A/CN412), 10P (A/CN411~K2/CN3405), 3P (HC/CN2403~K2/CN3402), 4P (HC/CN2401~K2/CN3401),

12P harness (HC/CN2005~MT/CN303) using a 5mm purse lock (3-703-981-02)

Rev 1.1 7/9

KV-21FA340/21FA540/29FA340/29FA540

18

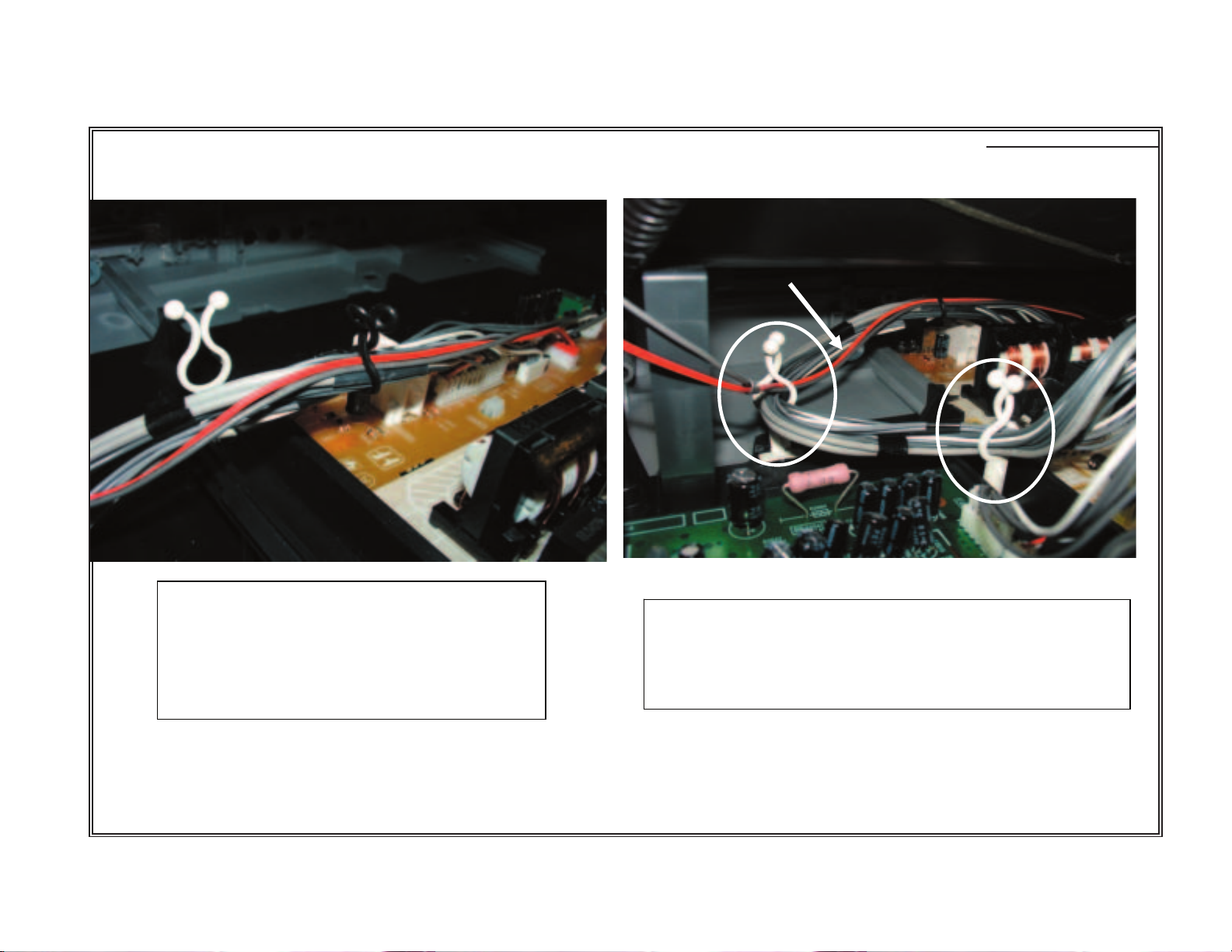

Page 19

KV-21FA340/21FA540 MODELS ONLY

KV-21FA340/21FA540/29FA340/29FA540

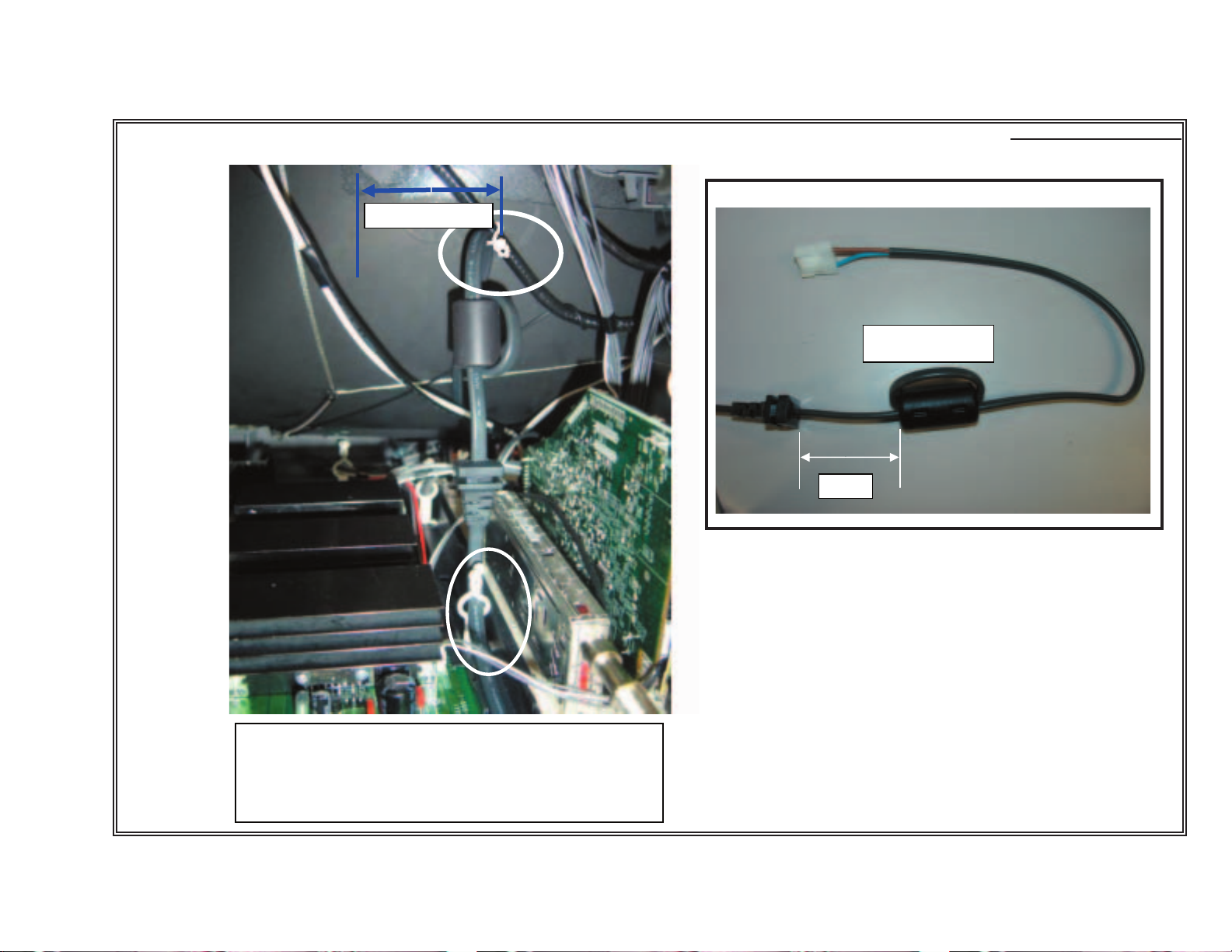

21FA540/540C/340/340C

ONLY FOR CHILE MODELS

Ferrite

P/N:1-500-586-11

50mm

Dress AC-Cord wire through DGC band lower hook

and using a purse lock (4-072-499-11) as shown in

picuture.

Rev 1.1 8/9

KV-21FA340/21FA540/29FA340/29FA540

19

Page 20

KV-21FA340/21FA540 MODELS ONLY

KV-21FA340/21FA540/29FA340/29FA540

21FA540/540C/340/340C

Rev 1.1 9/9

KV-21FA340/21FA540/29FA340/29FA540

20

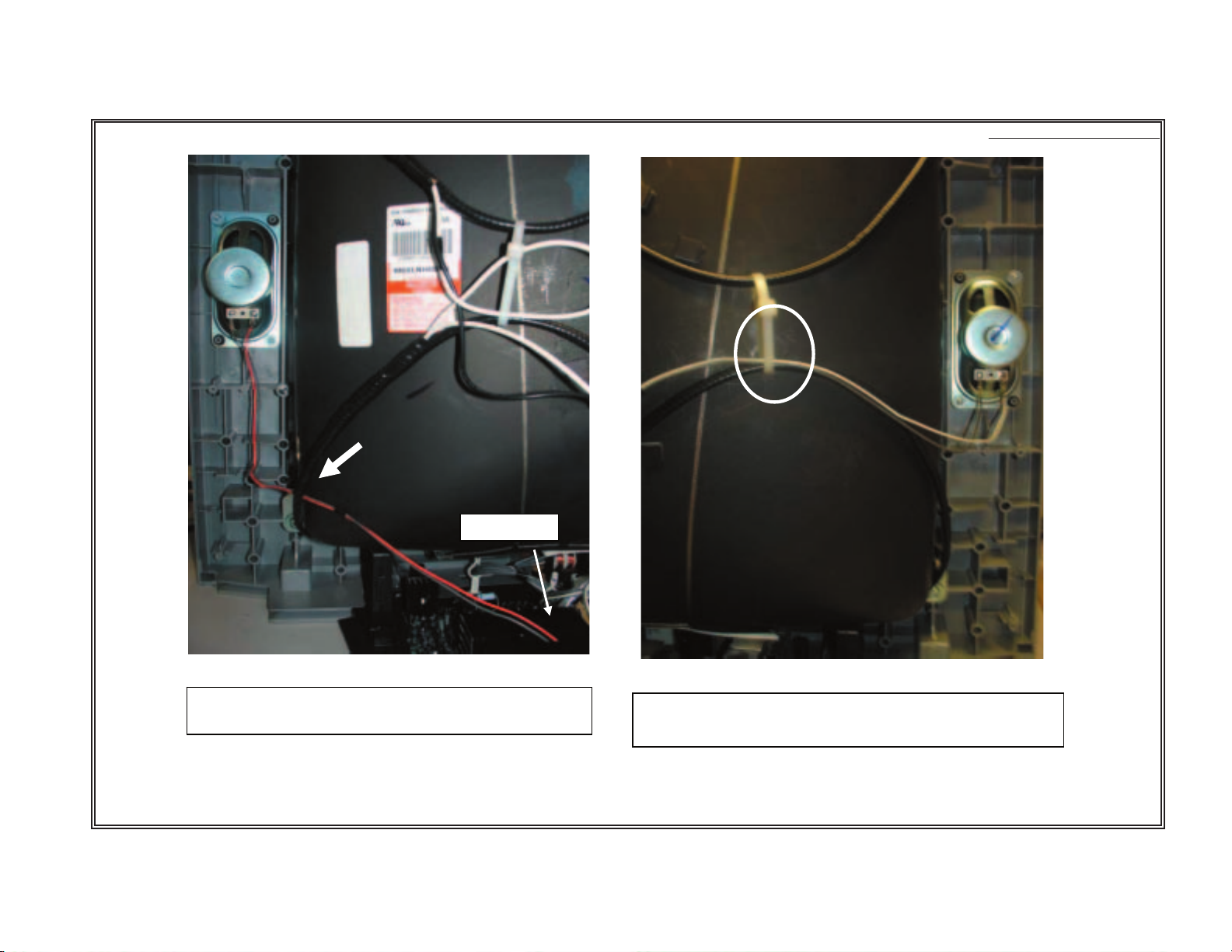

Page 21

KV-29FA340/29FA540 MODELS ONLY

KV-21FA340/21FA540/29FA340/29FA540

29FA540/540C/340/340C

Heatsink

Pass right speaker under DGC & over

Dress left speaker wire through DGC's tie wrap.

heatsink as shown in picture.

Rev 1.1 2/11

KV-21FA340/21FA540/29FA340/29FA540

21

Page 22

KV-29FA340/29FA540 MODELS ONLY

KV-21FA340/21FA540/29FA340/29FA540

29FA540/540C/340/340C

Part Number

Label

Part Number

Label

OK

NG

CAUTION POINT: Install Rotation coil in the correct position as

shown in picture.

NOTE: If Rotation coil is inverted, tilt correction (by menu) will

work in different direction.

Rev 1.1 3/11

KV-21FA340/21FA540/29FA340/29FA540

22

Page 23

KV-29FA340/29FA540 MODELS ONLY

KV-21FA340/21FA540/29FA340/29FA540

29FA540/540C/340/340C

Dress G2 wire twist once as picture shown, do not

over stress wire.

using a 9mm purse lock (3-703-982-02).

- Dress Rotation coil lead wire through DY clip as shown in

picture.

Rev 1.1 4/11

KV-21FA340/21FA540/29FA340/29FA540

- Fix RGB harness (MT/CN301~C/CN705) to rotation coil

23

Page 24

KV-29FA340/29FA540 MODELS ONLY

KV-21FA340/21FA540/29FA340/29FA540

29FA540/540C/340/340C

Dress DY's lead wire using a 9mm

purse lock (3-703-982-02)

Dress subwoofer harness (K1/CN2403

or K2/CN3403~A/J207) pass under FPin, behind video jacks & over AC cord

as picture shown.

Rev 1.1 5/11

KV-21FA340/21FA540/29FA340/29FA540

24

Page 25

KV-29FA340/29FA540 MODELS ONLY

A

RGB

harness

VM

harness

12P cable

KV-21FA340/21FA540/29FA340/29FA540

29FA540/540C/340/340C

Caution point:

void wires to touch LFT or

any other primary components

- Dress VM & Heater harnesses using a 9mm purse

lock (3-703-982-02) as picture shown.

- Dress 12P (HC/CN2005~MT/CN303) through purse lock (4072-499-12) as shown in picture.

Rev 1.1 6/11

KV-21FA340/21FA540/29FA340/29FA540

25

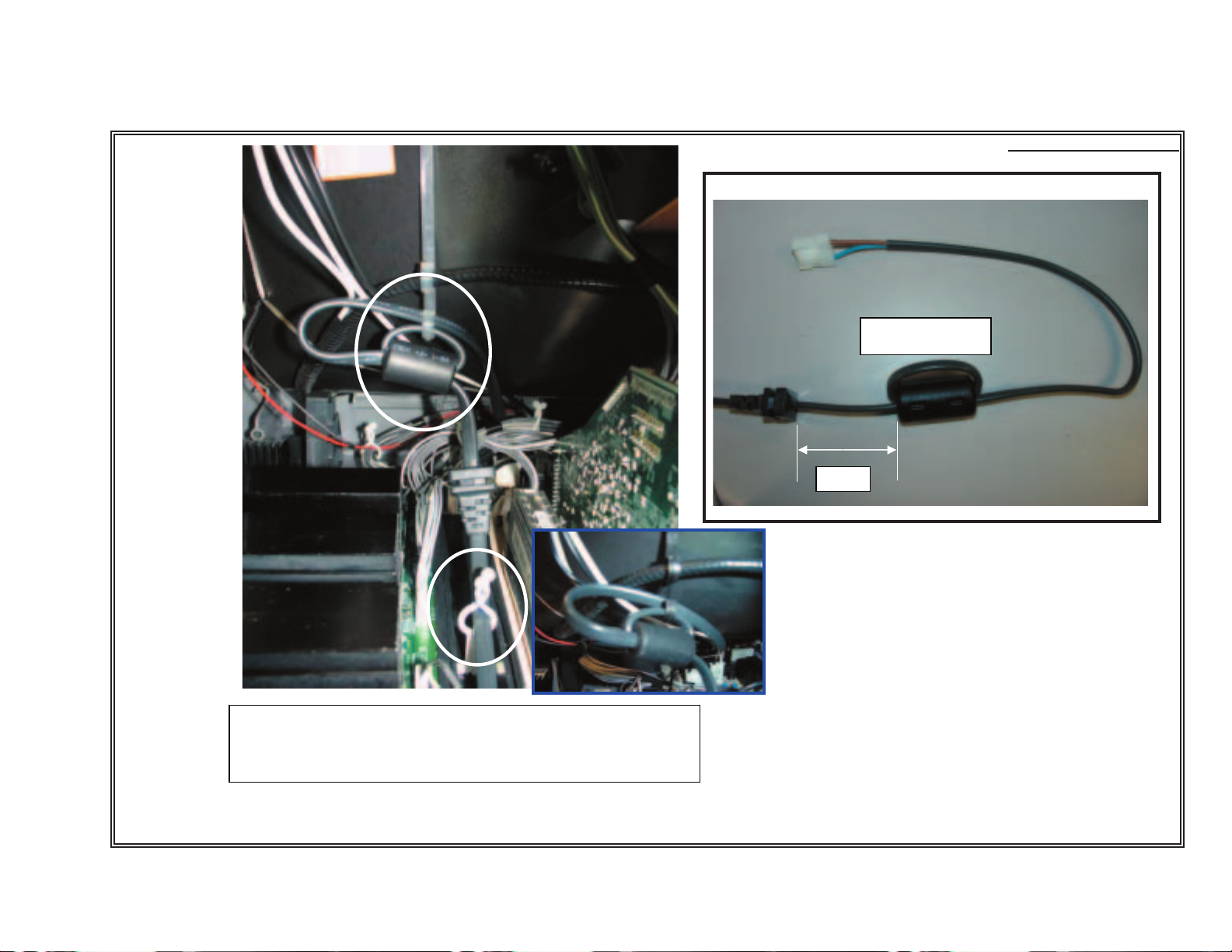

Page 26

KV-29FA340/29FA540 MODELS ONLY

Focus

cable

KV-21FA340/21FA540/29FA340/29FA540

29FA540/540C/340/340C

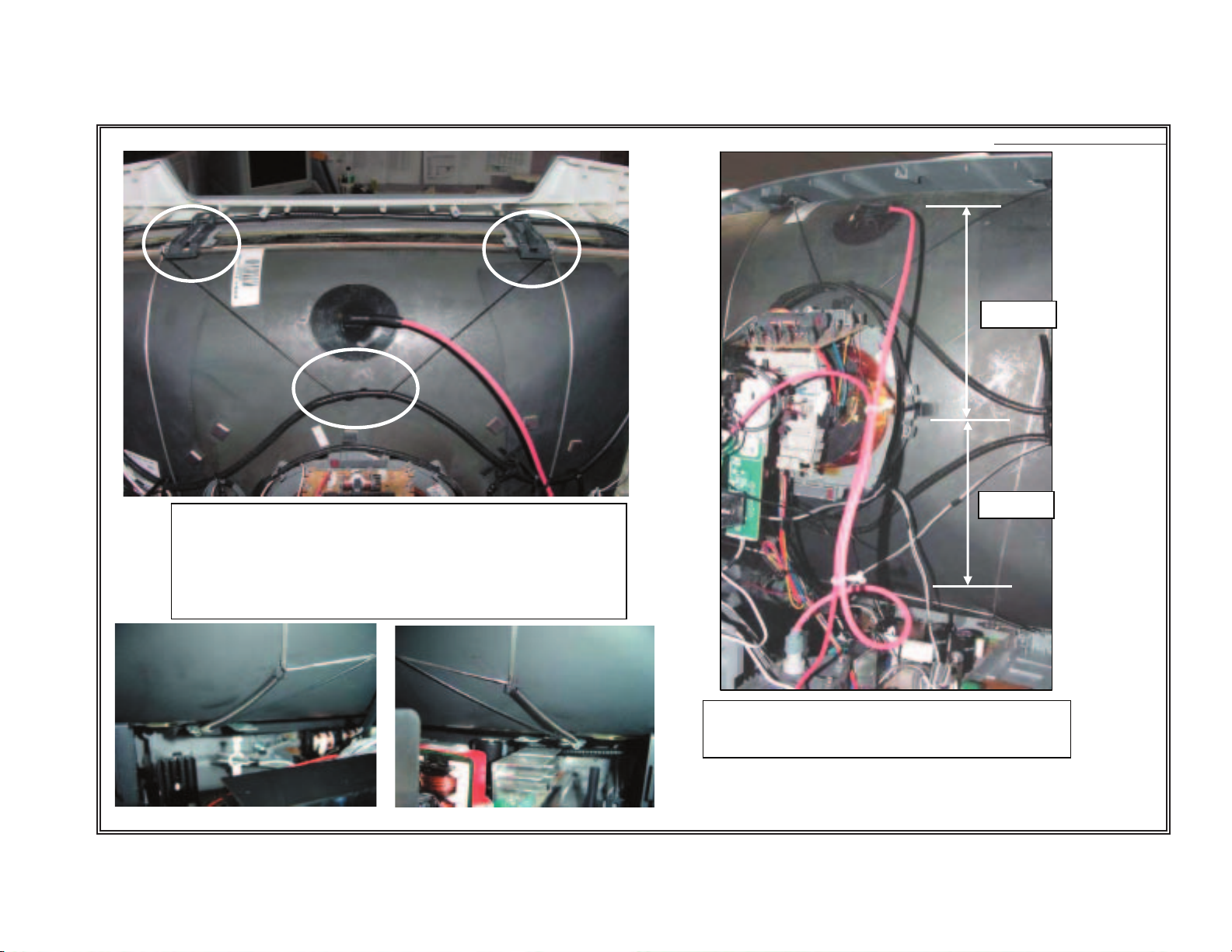

30 ±1 cm

Fix DGC coils using (2) strain cables add 2 turns,

17 ±1 cm

hook cables on outer CRT hooks,

Use 1 in uper coil and 1 in lower coil.

Hook CRT ground wire (top) and springs(bottom) on

outer hooks

Dress together focus lead and HV

cable using (2) 5mm (3-703-981-02)

Rev 1.1 7/11

KV-21FA340/21FA540/29FA340/29FA540

26

Page 27

KV-29FA340/29FA540 MODELS ONLY

ONLY FOR FA340 ONLY FOR FA540

12P cable

KV-21FA340/21FA540/29FA340/29FA540

29FA540/540C/340/340C

- Dress 10P(A/CN411~K2/CN3405),

3P (A/CN412~K2/CN3404) & Left

speaker harnesses using a 9mm

purse lock (3-703-982-02) as shown

in picture.

Rev 1.1 8/11

KV-21FA340/21FA540/29FA340/29FA540

- Dress 10P(A/CN411~K1/CN2401), 5P

(A/CN201~K1/CN2600), 3P (A/CN412~K1/CN2402) &

Left speaker harnesses using a 9mm purse lock (3703-982-02) as shown in picture.

27

Page 28

KV-29FA340/29FA540 MODELS ONLY

50mm +/- 30mm

KV-21FA340/21FA540/29FA340/29FA540

29FA540/540C/340/340C

ONLY FOR CHILE MODELS

Ferrite

P/N:1-500-586-11

50mm

Fix AC-Cord to DGC using a 11mm purse lock (3703-983-02) & through purse lock (4-072-499-12)

as shown in picture. Take as reference carbon

line of CRT.

Rev 1.1 9/11

KV-21FA340/21FA540/29FA340/29FA540

28

Page 29

KV-29FA340/29FA540 MODELS ONLY

KV-21FA340/21FA540/29FA340/29FA540

29FA540/540C/340/340C

Rev 1.1 10/11

KV-21FA340/21FA540/29FA340/29FA540

29

Page 30

KV-29FA340/29FA540 MODELS ONLY

RGB

harness

VM

harness

KV-21FA340/21FA540/29FA340/29FA540

29FA540/540C/340/340C

Dress CRT groun through rotation coil

and pass beside V board as shown in

picture.

Rev 1.1 11/11

KV-21FA340/21FA540/29FA340/29FA540

30

Page 31

SECTION 2: SET-UP ADJUSTMENTS

KV-21FA340/21FA540/29FA340/29FA540

The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

These adjustments should be performed with rated power supply

voltage unless otherwise noted.

Set the controls as follows unless otherwise noted:

VIDEO MODE: Pro

PICTURE CONTROL: Normal

BRIGHTNESS CONTROL: Normal

2-1. BEAM LANDING

Before beginning adjustment procedure:

1. Feed in the white pattern signal.

Adjustment Procedure

1. Input a raster signal with the pattern generator.

2. Loosen the defl ection yoke mounting screw, and set the purity

control to the center as shown below:

Purity Control

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

3. Focus

4. Screen (G2)

5. White Balance

Note Test Equipment Required:

1. Color Bar Pattern Generator

2. Degausser

3. DC Power Supply

4. Digital Multimeter

6. Switch over the raster signal to red and blue and confi rm the

condition.

7. When the position of the defl ection yoke is determined, tighten it with

the defl ection yoke mounting screw.

8. If landing at the corner is not right, adjust by using the disk magnets.

3. Turn the raster signal of the pattern generator to green.

4. Move the defl ection yoke backward, and adjust with the purity control

so that green is in the center and red and blue are even on both

sides.

Blue Red

Green

5. Move the defl ection yoke forward, and adjust so that the entire

screen becomes green.

KV-21FA340/21FA540/29FA340/29FA540

Purity control

corrects this area.

Disk magnets

or rotatable disk

magnets correct

these areas (a-d).

Deflection yoke positioning

b

d

b

a

cd

corrects these areas.

a

c

31

Page 32

KV-21FA340/21FA540/29FA340/29FA540

2-2. CONVERGENCE

Before starting convergence adjustments:

1 Perform FOCUS, VLIN and VSIZE adjustments.

2. Set BRIGHTNESS control to minimum.

3. Feed in dot pattern.

Vertical Static Convergence

1. Adjust V. STAT magnet to converge red, green and blue dots in the

center of the screen.

Center dot

RV701

R

B

G

H.STAT

R

G

B

Horizontal Static Convergence

If the blue dot does not converge with the red and green dots, perform

the following:

1. Move H STAT VR magnet (a) to correct insuffi cient H.Static

convergence.

V. STAT

BMC MAGNET

PURITY

V.STAT magnet

2. Tilt the V. STAT magnet and adjust static convergence to open or

close the V. STAT magnet.

When the V. STAT magnet is moved in the direction of arrow a and b,

red, green, and blue dots move as shown below:

1

a

b

2

a

a

b

B

G

R

b

b

B

G

R

a

RGB

b

BGR

3

a

b

R

b

KV-21FA340/21FA540/29FA340/29FA540

a

G

b

B

G

B

R

32

Page 33

Dynamic Convergence Adjustment

Before performing this adjustment, perform Horizontal and Vertical

Static Convergence Adjustment.

1. Slightly loosen defl ection yoke screw.

2. Remove defl ection yoke spacers.

3. Move the defl ection yoke for best convergence as

shown below:

G

B

R

R

G

B

BGR

B

G

R

R

B

G

R

B

G

KV-21FA340/21FA540/29FA340/29FA540

B R R B

(R)(B) (B)(R)

4. Adjust XCV core to balance X axis.

5. Adjust YCH VR to balance Y axis.

6. Adjust vertical red and blue convergence with V.TILT (TLV VR.)

Note: Perform adjustment 3-6 while tracking OSD items 1 and 2.

TLH+

TLH-

Screen-Corner Convergence

BGR

B

G

R

B

G

R

B

R

G

B

R

G

R

GB

4. Tighten the defl ection yoke screw.

5. Install the defl ection yoke spacers.

TLH Plate Adjustment

1. Input crosshatch pattern.

2. Adjust PICTURE QUALITY to standard, PICTURE and

BRIGHTNESS to 50%, and OTHER to standard.

3 Adjust the Horizontal Convergence of red and blue dots by tilting the

TLH plate on the defl ection yoke.

RV701

V.STAT

TLH Plate

1. Affi x a permalloy assembly corresponding to the misconverged areas:

b

a

ba

a-d: screen-corner

misconvergence

c

d

c

d

2-3. FOCUS

1. Adjust FOCUS control for best pictures.

Focus (FV)

Screen (G2)

CV

Board

KV-21FA340/21FA540/29FA340/29FA540

XCV

(TLV)

YCH

TLV

33

Page 34

2-4. SCREEN (G2)

1. Input a dot pattern.

2. Set the PICTURE and BRIGHTNESS controls at minimum and

COLOR control at normal.

3. Adjust SBRT, GCUT, BCUT in service mode with an oscilloscope as

shown below so that voltages on the red, green, and blue cathodes

are 172 ± 2VDC.

±

172 – 2VDC

Ground

4. Observe the screen and adjust SCREEN (G2) VR in FBT to obtain

the faintly visible background of dot signal.

Pedestal

KV-21FA340/21FA540/29FA340/29FA540

KV-21FA340/21FA540/29FA340/29FA540

34

Page 35

SECTION 3: SAFETY RELATED ADJUSTMENTS

KV-21FA340/21FA540/29FA340/29FA540

3-1. X R530, R531 CONFIRMATION METHOD

(HV HOLD-DOWN CONFIRMATION) AND

READJUSTMENTS

The following adjustments should always be performed when replacing

the following components which are marked with

Y

on the schematic

diagram:

Part Replaced (Y) Adjustment (X)

C531, C532, D519, D520,

D521, IC501, IC600, PH602,

HV HOLD-DOWN

R530, R531

R529, R530, R531, R532,

R533, R550, T503 (FBT),

T504 (DFT)

Preparation Before Confi rmation

1. Using a Variac, apply AC input voltage: 120 +/- 2.0 VAC.

2. Turn the POWER switch ON.

3. Input a white signal and set the PICTURE and BRIGHT controls to

maximum.

4. Confi rm that the voltage of more than 23.0 VDC appears between

TP85 and ground on the A Board.

Hold-Down Operation Confi rmation

1. Connect the current meter between Pin 11 of the FBT (T503) and the

PWB land where Pin 11 would normally attach. (See Figure 1).

2. Input a dot signal and set PICTURE and BRIGHTNESS to minimum:

IABL = 2175 + 100/ -325 µA.

3. Confi rm the voltage of A Board TP91 is 134.6 ± 1.0 VDC.

4. Connect the digital voltmeter and the DC power supply to TP85 and

ground. (See Figure 1).

5. Increase the DC power voltage gradually until the picture blanks out.

6. Turn DC power source off immediately.

7. Read the digital voltmeter indication: (standard = 27.24 + 0.0/ - 0.1

VDC).

8. Input a white signal and set PICTURE and BRIGHTNESS to

maximum: IABL = 2175 + 100/ -325 µA.

9. Repeat steps 4 to 7.

Hold-Down Readjustment

If the setting indicated in Step 2 of Hold-Down Operation Confi rmation

cannot be met, readjustment should be performed by altering the

resistance value of R530, R531 component marked with

digital multimeter

+

-

T503

FBT

FBT

R531

R530

TP85

TP85

ammeter

3mA DC range

A

+

-

DC Power Supply

+

-

X

.

Figure 1

3-2. B+ VOLTAGE CONFIRMATION AND

ADJUSTMENT

Always perform the following adjustments when replacing the following

components, which are marked with

A Board:

Adjustment (Y)

A BOARD

IC600, PH602

1. Using a Variac, apply AC input voltage: 130 + 2.0/-0.0 VAC

2. Input a monoscope signal.

3. Set the PICTURE control and the BRIGHT control to

minimum.

4. Confi rm the voltage on A Board between TP23 and ground is less

than 136.5 VDC.

5. If step 4 is not satisfi ed, replace R530 and R531 on A Board and

repeat the above steps.

Y

on the schematic diagram on the

KV-21FA340/21FA540/29FA340/29FA540

35

Page 36

KV-21FA340/21FA540/29FA340/29FA540

SECTION 4: CIRCUIT ADJUSTMENTS

Electrical Adjustments by Remote Commander

Use the Remote Commander (RM-Y194) to perform the circuit adjustments in this section.

Test Equipment Required: 1. Pattern generator 2. Frequency counter 3. Digital multimeter 4. Audio oscillator

4-1. REMOTE ADJUSTMENT BUTTONS AND

INDICATORS

DISPLAY

(Service Mode)

MUTING

(Enter into

memory)

1

(Display)

Item up

2

(Display)

Category up

4

(Display)

Item down

8

(Initialize)

VOLUME (+)

(Service Mode)

RM-Y194

POWER

(Service Mode)

3

(Adjust)

Data up

6

(Adjust)

Data down

5

(Display)

Category

down

ENT

(Enter into

memory)

0

(Remove

from

memory)

4-2. ACCESSING THE SERVICE

ADJUSTMENT MODE

1. Standby mode (Power off).

2. Press the following buttons on the remote commander within a

second of each other:

DISPLAY

Channel

5

Sound Volume +

The screen displays the fi rst service data device OSD item.

OSD

Item

Initial

Data

Value

Signal

Device

HSIZ 1:35 NVM:OK

M6J586MK-050FP F1.2

Type

NTSC VIDEO1DEF

Channel

Type

1. On the Remote Commander press 2 or 5 to select the device.

2. Press 1 or 4 to select the OSD.

3. Press 3 or 6 to change the data value.

4. Press

Device

OSD

Item

Initial

Data

Value

MUTING

HSIZ 1:35 NVM:OK

M6J586MK-050FP F1.2

then

ENTER

Signal

Type

NTSC WRITEDEF

to write into memory.

Channel

Type

POWER

Te xt

changes to

“WRITE” and

changes

colors from

green to red

KV-21FA340/21FA540/29FA340/29FA540

36

Page 37

KV-21FA340/21FA540/29FA340/29FA540

Service Adjustment Mode Memory

4-3. CONFIRMING SERVICE ADJUSTMENT

Use the following procedure when adjusting IDs 0-7 and when replacing

and adjusting IC002.

1. Access Service Adjustment Mode.

2. Press 8 then

Device

OSD

Item

Initial

Data

Value

ENTER

HSIZ 1:35 NVM:OK

M6J586MK-050FP F1.2

on the Remote Commander to initialize.

Signal

Type

NTSC RESETDEF

Channel

Type

Text

changes to

“RESET”

and changes

colors from

green to red

1. After completing adjustments, pull out the plug from the AC outlet,

2. Access Service Adjustment Mode.

3. Using the buttons on the Remote Commander, locate the adjusted

The TV powers off after completing the initialization process.

CHANGES

then replace the plug in the AC outlet again.

OSD items again to confi rm they were adjusted.

KV-21FA340/21FA540/29FA340/29FA540

37

Page 38

4-4. SERVICE DATA LISTS

KV-21FA340/21FA540/29FA340/29FA540

KV-21FA340/21FA540/29FA340/29FA540

38

Page 39

KV-21FA340/21FA540/29FA340/29FA540

KV-21FA340/21FA540/29FA340/29FA540

39

Page 40

KV-21FA340/21FA540/29FA340/29FA540

KV-21FA340/21FA540/29FA340/29FA540

40

Page 41

KV-21FA340/21FA540/29FA340/29FA540

KV-21FA340/21FA540/29FA340/29FA540

41

Page 42

KV-21FA340/21FA540/29FA340/29FA540

KV-21FA340/21FA540/29FA340/29FA540

42

Page 43

KV-21FA340/21FA540/29FA340/29FA540

KV-21FA340/21FA540/29FA340/29FA540

43

Page 44

KV-21FA340/21FA540/29FA340/29FA540

KV-21FA340/21FA540/29FA340/29FA540

44

Page 45

KV-21FA340/21FA540/29FA340/29FA540

4-5. ID MAP TABLE

Note: The Device name for ID Map group is “Feature”

KV-21FA340/21FA540/29FA340/29FA540

45

Page 46

KV-21FA340/21FA540/29FA340/29FA540

4-6. WHITE BALANCE ADJUSTMENTS

1. Input an entire white signal with burst.

2. Access Service Adjustment Mode.

3. Set the PICTURE and BRIGHTNESS to minimum.

4. Adjust with SBRT if necessary.

5. Press

6. Press 1 or 4 to display the GCUT OSD item.

7. Press 3 or 6 to adjust for the best white balance.

8. Press 1 or 4 to display the BCUT OSD item.

9. Press 3 or 6 to adjust for the best white balance.

10. Set the PICTURE and BRIGHTNESS to maximum.

11. Press 1 or 4 to display the GDRV OSD item.

12. Press 3 or 6 to adjust for the best white balance.

13. Press 1 or 4 to display the BDRV OSD item.

14. Press 3 or 6 to adjust for the best white balance.

15. Press

2

or 5 to select the VP1 device.

ENTER

MUTING

then

to save into the memory.

4-7. A BOARD ADJUSTMENTS

H. Frequency (Free Run) Check

1. Input a TV mode (RF) with no signal.

2. Connect a frequency counter to base of Q501

(TP-25 H. DRIVE) on the A Board.

3. Check H. Frequency for 15735 ± 200 Hz.

V. Frequency (Free Run) Check

1. Select video 1 with no signal input.

2. Set the conditions for a standard setting.

3. Connect the frequency counter to TP-27 (V OUT) or CN501 pin

(V DY+) and ground on the A Board .

4. Check that V. Frequency shows 60 ± 4 Hz.

6

Drive (SCON)

1. Input a color-bar signal and set the level to 75%.

2. Set in Pro mode + PICTURE MAX.

3. Access Service Adjustment Mode.

4. Press 2 or 5 to select the VP1 device.

5. Press 1 or 4 to display the GON OSD item.

6. Press 3 or 6 to adjust to 0.

7. Press 1 or 4 to display the BON OSD item.

8. Press 3 or 6 to adjust to 0.

Note: Leave RON set to “1”.

R ON: ON (1)

G ON: OFF (0)

B ON: OFF (0)

9. Connect an oscilloscope probe to C Board, CN705 pin3 (KR).

10. Press 1 or 4 to display the SCON OSD item.

11. Press 3 or 6 to adjust the value of SCON to 85 ± 2Vpp.

85 + 2Vpp

12. Repeat steps 5 thru 8 to reset GON and BON values to “1”.

R ON: ON (1)

G ON: ON (1)

B ON: ON (1)

13. Press

MUTING

then

ENTER

to write into memory.

Display Position Adjustment (DISP)

1. Input a color-bar signal.

2. Access Service Adjustment Mode.

3. Press 2 or 5 to select the Microprocessor device.

4. Press 1 or 4 to display the DISP OSD item.

5. Press 3 or 6 to adjust characters to the center.

6. Press

7. Check to see if the text is displayed on the screen.

MUTING

then

ENTER

to write into memory.

Sub Bright Adjustment (SBRT)

1. Input a monoscope signal.

2. Access Service Adjustment Mode.

3. Set the PICTURE and BRIGHTNESS to minimum.

4. Press 2 or 5 to select the VP1 device.

5. Press 1 or 4 to display the SBRT OSD item.

6. Press 3 or 6 to obtain a faintly visible 20 IRE mark, after that

increase +3 steps.

7. Press

MUTING

then

ENTER

to write into memory.

KV-21FA340/21FA540/29FA340/29FA540

46

Page 47

KV-21FA340/21FA540/29FA340/29FA540

Sub Hue, Sub Color Adjustment

(SHUE, SCOL)

1. Input color-bar signal at 75%.

2. Access Service Adjustment Mode.

3. Set (PIC) to Max and (COL) to 50%.

4. Connect an oscilloscope probe to C Board, CN705 pin 4 (Blue Out).

5. Press 2 or 5 to select the VP1 device.

6. Press 1 or 4 to display the SHUE or SCOL OSD item.

7. While showing the SHUE OSD item, adjust the waveform by pressing

3

or 6 until the second and third bars show the same level

(V2 = V3 < 0.15Vp-p). Set Sub Hue -2 Step.

8. While showing the SCOL OSD item, adjust the waveform by pressing

3

or 6 until the fi rst and fourth bars show the same level

(V1 = V4 < 0.15Vp-p). Set Sub Col + 2 Step.

V2 V3

V1

V4

H. Center Adjustment (HPOS)

Perform this adjustment after performing H. Frequency (Free Run)

Check.

1. Input a crosshatch signal.

2. Access Service Adjustment Mode.

3. Press 2 or 5 to select the DEF device.

4. Press 1 or 4 to display the HPOS OSD item.

5. Adjust the value of HPOS by pressing 3 or 6 for the best horizontal

6. Press

H. Size Adjustment (HSIZ)

1. Input a monoscope signal.

2. Access Service Adjustment Mode.

3. Press 2 or 5 to select the DEF device.

9. Press

MUTING

then

ENTER

to write into memory.

V. Size Adjustment (VSIZ)

1. Input a crosshatch signal.

2. Access Service Adjustment Mode.

3. Press 2 or 5 to select the DEF device.

4. Press 1 or 4 to display the VSIZ OSD item.

5. Adjust value of VSIZ by pressing 3 or 6 for the best vertical size.

6. Press

MUTING

then

ENTER

to write into memory.

4. Press 1 or 4 to display the HSIZ OSD item.

5. Adjust value of HSIZ by pressing 3 or 6 for the best horizontal size.

6. Press

center.

MUTING

MUTING

then

then

ENTER

ENTER

to write into memory.

to write into memory.

V. Center Adjustment (VPOS)

Perform this adjustment after performing H. Frequency

(Free Run) Check.

1. Input a crosshatch signal.

2. Access Service Adjustment Mode.

3. Press 2 or 5 to select the DEF device.

4. Press 1 or 4 to display the VPOS OSD item.

5. Adjust value of VPOS by pressing 3 or 6 for the best vertical center.

6. Press

MUTING

KV-21FA340/21FA540/29FA340/29FA540

then

ENTER

to write into memory.

47

Page 48

KV-21FA340/21FA540/29FA340/29FA540

V. Linearity (VLIN), V. Correction (SCOR),

PIN Amp (PAMP), and Trapezoid (TRAP)

Adjustments

1. Input a crosshatch signal.

2. Access Service Adjustment Mode.

3. Press 2 or 5 to select the DEF device.

4. Press 1 or 4 to display the VLIN OSD item.

5. Adjust the value of VLIN by pressing 3 or 6 for the best horizontal

size.

6. Repeat steps 4 and 5 for SCOR, PAMP, and TRAP.

7. Press

MUTING

then

ENTER

V LINEARITY (VLIN)

V CORRECTION (SCOR)

PIN AMP (PAMP)

to write into memory.

V. Angle (VANG), V. Bow (VBOW), Upper PIN

(UPIN) and Low PIN (LPIN) Adjustments

1. Input a crosshatch signal.

2. Access Service Adjustment Mode.

3. Press 2 or 5 to select the DEF device.

4. Press 1 or 4 to display the VANG OSD item.

5. Adjust the value of VANG by pressing 3 or 6 for the best picture.

6. Repeat steps 4 and 5 for VBOW, UPIN, and LPIN.

7. Press

MUTING

then

ENTER

V ANGLE (VANG)

V BOW (VBOW)

UPPER PIN (UPIN)

LOW PIN (LPIN)

to write into memory.

TRAPEZOID (TRAP)

Reading Adjustments to Memory

1. After completing all adjustments, 0 then

memory.

Signal

Type

NTSC READDEF

OSD

Item

Initial

Data

Value

Device

HSIZ 1:35 NVM:OK

M6J586MK-050FP F1.2

ENTER

Channel

Type

to read into

Text

changes to

“READ” and

changes

colors from

green to red

KV-21FA340/21FA540/29FA340/29FA540

48

Page 49

SECTION 5: DIAGRAMS

KV-21FA340/21FA540/29FA340/29FA540

5-1. CIRCUIT BOARDS LOCATION

K1 Board

(KV-21FA540/29FA540 ONLY)

K2 Board

(KV-21FA340/29FA340 ONLY)

MT Board

A Board

5-2. PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM INFORMATION

All capacitors are in µF unless otherwise noted. pF : µµF 50WV or less

are not indicated except for electrolytics and tantalums.

All electrolytics are in 50V unless otherwise specifi ed.

All resistors are in ohms. k=1000, M=1000k

Indication of resistance, which does not have one for rating electrical

power, is as follows: Pitch : 5mm Rating electrical power :

1

/

W in resistance, 1/

4

W and 1/

10

W in chip resistance.

8

: nonfl ammable resistor.

: fusible resistor.

: internal component.

: panel designation and adjustment for repair.

: earth ground

: earth-chassis

All variable and adjustable resistors have characteristic curve B, unless

otherwise noted.

Readings are taken with a color-bar signal input.

Readings are taken with a 10M digital multimeter.

Voltages are DC with respect to ground unless otherwise noted.

Voltage variations may be noted due to normal production tolerances.

(Refer to Section 3: Safety Related Adjustments on Page 35.)

When replacing the parts listed in the table below, it is important to

perform the related adjustments.

RESISTOR

: RN METAL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RW NONFLAMMABLE WIREWOUND

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: ADJUSTMENT RESISTOR

COIL

: LF-8L MICRO INDUCTOR

The components identifi ed by shading and !

symbol are critical for safety. Replace only with

part number specifi ed.

CV Board

The symbol

and is displayed on the component side of the

board. Replace only with fuse of the same rating

as marked.

All voltages are in V.

indicates a fast operating fuse

S : Measurement impossibillity.

: B+line.

: B-line.

(Actual measured value may be different).

: signal path. (RF)

Circled numbers are waveform references.

The components identifi ed by

basic schematic diagram have been carefully

factory-selected for each set in order to satisfy

regulations regarding X-ray radiation. Should

HC Board

replacement be necessary, replace only with

the value originally used.

When replacing components identifi ed by

make the necessary adjustments as indicated.

If the results do not meet the specifi ed value,

change the component identifi ed by

repeat the adjustment until the specifi ed value

is achieved.

Part Replaced (Y) Adjustment (X)

C531, C532, D519, D520,

D521, IC501, IC600, PH602,

HV HOLD-DOWN

R530, R531

R529, R530, R531, R532,

R533, R550, T503 (FBT),

T504 (DFT)

REFERENCE INFORMATION

CAPACITOR

: TA TANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

X

in this

X

Y

and

,

KV-21FA340/21FA540/29FA340/29FA540

49

Page 50

5-3. BLOCK DIAGRAMS AND SCHEMATICS

KV-21FA340/21FA540/29FA340/29FA540

SIGNAL FLOW BLOCK DIAGRAM

L/R

MAIN VID

CVBS

IIC

Y/C

16 MAIN_TV_IN

18 Y_IN (YC)

19 C_IN

21 VIDO_1_IN

23 VIDO_2_IN

25 Y_IN (YUV)

26 U_IN

27 V_IN

54 SDAT (IIC)

56 SCLK (IIC)

R_OUT 31

G_OUT 33

B_OUT 35

H_OUT 50

VD-_VRAMP 44

VD+_VRAMP 45

EW_OUT 47

FBP_IN 49

4O#6"OARD

R

G

B

HOUT

V-RAMP

V+RAMP

EW

MAIN-VID

L/R

YUV

CVBS

65 O-Tri

79 O-LED

67 O-SEL1

68 O-SEL0

I-HP

KV-21FA340/21FA540/29FA340/29FA540

50

Page 51

AUDIO BLOCK DIAGRAM

6

Stereo

Inputs

Monitor Out

L

R

L

R

L

R

L

R

L

R

L

R

Dolby Pro Logic II

NJW1134

Audio

Switch

DSP

TC94A48FG

KV-21FA340/21FA540/29FA340/29FA540

A

MCU

Power

Supply

MT

K1

Subwoofer 15W

Amplifier

TDA8947J

SW

C

L

R

Ls

Rs

NJM2180

TruSurround

NJW1151

Volume

Control

Amplifier

TDA8947J

Center Speaker 5W

Front Left Speaker 5W

Front Right Speaker 5W

HC

KV-21FA340/21FA540/29FA340/29FA540

DSP Reset

Head Phones

DSP Error

Virtualizer

M62320P

Port Expander

Rear Switch

Mute SW and Center

Mute Front

Mute Rear

Amplifier

TDA8947J

Rear Left Speaker 5W

Rear Right Speaker 5W

51

Page 52

A BOARD SCHEMATIC DIAGRAM (1 OF 2)

KV-21FA340/21FA540/29FA340/29FA540

A BOARD WAVEFORMS

A

—

B

—

C

—

D

—

E

—

F

—

G

—

H

—

I

—

J

—

K

—

L

—

M

—

N

—

O

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23

2SC3052EF-T1-1EF

TO K1 BOARD

CN2401

OR

TO K2 BOARD

CN3405

0.1 16V

STEREO

V

V

V

0

9

5

3

R108

100

4

C059

0

0

0.1

L

C050

470

TP602-9V

32V

J207

2P

Q402

MUTE

0.0

R405 R408

2.2k

2.2k

0.0

0.0

2SC3052EF-T1-1EF

R416

4.7k

R477

680

D414

1/10W

MTZJ-T

77-7.5B

C470

470

16V

J206

5P

VIDEO3

1/10W

J203

R478

10k

3P

0.7

V3

J201

34

12

V1

L1

R1

V2

L2

R2

A

L

C

D

S

S

6.3V

R107

100

:CHIP

R236 R237

100 100

Q403

MUTE

0.0

2SC3052EF-T1-1EF

UDZSTE-179.1B

UDZSTE-179.1B

TUNER

TU001

4700p

:CHIP

C362

TP102

R367

0

C052

R089

4.7k

1/16W

2SC3052EF-T1-1EF

JR332

0

Q005

AGC

R369

:CHIP

UDZS-TE-10B

2

T

T

D

U

U

O

N

D

O

O

N

T

I

N

O

E

I

T

D

T

M

P

E

O

E

A

T

D

D

1/10W

:CHIP

R102

R086

33k

:CHIP

4.9

0.1

0

D308

F

M

S

S

R099

100

D405

MA111-TX

R087

22k

0

C056

DET OUT

T

E

U

U

T

O

O

C

U

C

N

M

R

L

N

C200

0.1

16V

R202

220

C201

1/10W

0.1

16V

C080

0.33

10V

B

R206

220

:CHIP

R422

C081

6.8k

0.33

:CHIP

10V

B

TV-R

S

A

TP100

MTZJ-30D

0.0

R479

1k

1/10W

D418

Q412

MUTE

C374

0.1

D325

F

I

V

F

N

R

V

9

A

G

C051

RF-AGC

C049

100

L003

10

C053

0.1

16V

:CHIP

D009

0

4.5

D311

R396

220

R085

15k

4.4

RD9.1EW

C055

100

L009

C054

47

R303

560

1

R302

5V

R301

470

5V

100

5.2

:CHIP

TP603

6

.

4

Q300

2SA1235TP-1EF

BUFFER

R235

C212

220

4.7

:CHIP

R232

470k

:CHIP

R233

470k

1/16W

5

6

7

8

D310

R390

R394

220

C434

470p

D219

ZENER 9.1

R234

220

C213

:CHIP

4.7

D218

ZENER 9.1

C476

TV-VID

0.4

4

S1

V3

VCC

OUT

GND

NJM2534M

VIDEO SW

220

TUNER

IC302

UDZSTE-179.1B

UDZSTE-179.1B

JR335

D306

UDZSTE-9.1B

R397

220

4.5

3

V1

0.3

2

S0

4.5

1

D324

D309

JR334

0

0

C366

:CHIP

C368

R395

220

R398

220

C431

470pF

FSS BTF-WA421

T

C

U

G

O

A

F

T

D

C206

R217

0.1

100k

:CHIP

:CHIP

C207

0.1

R218

:CHIP

100k

:CHIP

TV-L

5

.

4

C400

0.33

:CHIP

5

.

4

C208

0.1

:CHIP

R222

100k

:CHIP

C209

0.1

:CHIP

R225

100k

UDZSTE-9.1B

:CHIP

C365

C309

R393

75

:CHIP

MTZJ-T-77-9.1B

5

.

4

B

1

N

I

A

1

N

I

123456 789

5

.

4

D212

UDZSTE-9.1B

D211

*

D210

5

.

4

B

2

N

I

A

2

N

I

R224

220

MTZJ-T-77-9.1B

5

.

4

B

3

N

I

A

3

N

I

5

5

.

.

4

4

R223

220

:CHIP

R219

220

1/16W

:CHIP

D209

R220

220

:CHIP

C402

R400

8200p

4.7k

:CHIP

:CHIP

6

5

5

.

.

.

4

4

4

B

B

B

B

N

5

4

6

O

N

N

N

M

I

I

I

A

A

A

A

N

6

5

4

O

N

N

N

M

I

I

I

5

5

5

.

.

.

4

4

4

C401

22000p

:CHIP

D305

PDZ9.1B-115

1

C

V

6

1

p

3

F

0

3

p

0

0

0

3

.

8

3

0

6

4

6

8

0

0

0

4

4

4

C

C

C

6

6

6

.

.

.

4

4

4

B

B

B

2

1

H

2

L

E

-

E

I

B

B

E

F

B

N

B

S

O

R

T

S

A

H

S

A

-

A

S

1

E

2

/

E

N

E

S

B

O

B

R

B

T

B

S

10 11 12 13 14 15 16 17 18 19 20

5

5

5

.

.

.

4

4

4

V

6

1

p

0

0

3

3

3

3

0

.

0

3

0

4

C

5

0

4

C

:CHIP

C367

0.1

16V

D307

PDZ9.1B-115

7

4

2

.

.

0

2

0

2

1

1

4

4

C

C

6

6

6

6

.

.

.

.

4

0

4

4

B

S

L

B

B

-

R

-

E

E

C

T

N

N

U

I

O

T

O

L

A

A

A

L

-

E

-

C

T

N

E

G

N

U

I

A

O

O

L

T

5

6

5

5

.

.

.

.

4

0

4

4

7

F

4

p

3

.

0

3

0

8

.

6

0

9

0

7

1

4

0

1

C

4

4

C

C

+5V

R391

75

0

0

7

.

.

.

1

1

4

0

.

1

4

6

8

1

1

1

4

4

4

C

0

C

C

2

4

R411

C

1/4W

4

8

8

0

.

.

.

.

4

3

3

4

7

.

1

A

V

C

C612

H

T

C

0

.

1

3

1

4

C

DIN54-TA2

100

2122232425262728293031323334353637383940

+

F

L

S

V

E

T

B

R

C

C

V

D

L

A

B

N

C

D

V

G

S

S

C

7

7

7

.

.

.

4

1

4

R403

100

P

I

:CHIP

H

C

:

0

0

.

0

1

1

5

1

1

0

4

4

C

R

D213

Q611

KSC2383-0

5V REG

R661

5.6

D651

MTZJ-T-77

-6.2B

R209

C203

100k

0.1

:CHIP

:CHIP

D201

MTZJ-T-77-9.1B

C202

R207

0.1

100k

16V

:CHIP

10

C422

47

16V

C417

1000p

:CHIP

NJW1134AGK1-TE2

AUDIO PROCESSOR

R84

0.47

1/4W

IC400

MTZJ-T-77-9.1B

D200

+9V

680

C661

47

FB613

1.1U

CN411

8P

R208

220

1/4W

:CHIP

R210

220

:CHIP

D509

MA111-TX

2SA1235TP-1EF

C523

16V

9.0

R514

10k

:CHIP

C

C

C

C

V

V

O

O

I

I

D

D

U

U

A

A

7

8

Q583

H-OUT

8.7

R513

47k

:CHIP

0.0

V

D

D

D

L

5

A

N

N

N

C

.

D

G

G

G

S

7

S

P

P

4

2

6

5

3

1

-2

JR444

-2 -2-2

JR445

C502

0.47

R521

330

0.0

C503

470p

:CHIP

R502

4.7k

Q511

2SC3052EF-T1-1EF

PIN-DRIVE

R516

5MM

TP89

:CHIP

E/W DRIVE

B

+

R359

10k

R533

:CHIP

47k

R1511

10k

:CHIP

D526

MA111-TX

D525

MA111-TX

CN412

D

H

H

N

C

C

G

R

L

S

2

3

1

RT

LT

HDRIVE

78.0

Q501

2SC3209LK

H-DRIVE

3

2

R545

3.3

:FPRD

R517

680

R518

10k

:CHIP

C534

47

0.0

+

C

C

V

0

.

0

1234

8.2 7.2

R1510

10k

D522

:CHIP

MA111-TX

D520

MA111-TX

9V

3P

C506

0.047

5.0

C528

0.0022

:CHIP

3.1

TO K1 BOARD

TO K2 BOARD

CN3404

R503

4.7k

C504

470p

R519

330

0.2

C532

*

D521

CN2402

R504

*

R552

+12V

C522

1.0

C530

*

*

5678

R531

OR

1

3

MA111-TX

*

C

C

V

*

C505

470p

D535

H-PULSE

T501

:HDT

C520

R506

Q512

2SC4159-E

PIN-OUT

C548

*

NJM2903M-TE2

PIN-CONTROL

R530

R532

*

:CHIP

GND

50

C-YC

49

GND

48

Y-YC

47

GND

46

O-SEL0

45

GND

44

TV-VID

SDAT

SCL

AUD_VCC18V

R425

1.5k

9V

:CHIP

R424

1k

:CHIP

R429

47k

9V

0.7

UDZSTE-177.5B

0.0

D425

2SC3052EF-T1-1EF

Q405

MUTE

R450

22k

-2

+9V

+9V

DGC

Z-DET

V

9

C512

470p

:CHIP

R541

47k

:CHIP

R542

10k

D508

MA111-TX

:CHIP

L510

*

R508

10k

1/10W

JW519

:CHIP

D551

UDZS-5.6B

4

C507

680p

5

4

2kV

6

*

47

C519

0.2

220p

0.8

C549

*

IC501

R529

*

*

O-RELAY

B

R507

0.0

*

Q502

FB501

*

0UH

H-OUT

L511

FB503

8mH

0UH

D515

PR1004GT

PIN-OUT

C525

220p

C526

22

250V

FB502

0UH

R523

*

D516

R528

MA111-TX

*

H.PRT

TP85

C531

*

PIN

:CHIP

131.8

FB505

0UH

R525

8.2k

C529

22 25V

MA111-TX

2SC3052EF-T1-1EF

P

C

F

A

1/10W

D589

R524

10k

MA111-TX

Q564

OCP

*

C509

680p

2kV

B

C527

680p

2kV

B

C510

0.01

100V

:PT

D518

EL1Z-V1

0.0

C563

220

25V

135V

R584

10k

2SC3052EF-T1-1EF

OCP-LATCH

JW520

*

5

D500

BY228

C511

*

C554

*

C513

0.047

R561

10k

R566

6.8k

:CHIP

R574

*

R563

*

D519

R586

68k

R583

:CHIP

4.7k

:CHIP

0.0

D590

MA111-TX

B+

R599

4.4

2.2k

:CHIP

4.4

Q530

C535

:CHIP

R544

1k

:CHIP

7.7

0.0

T505

*

T502

FR305G-EB

R565

330

R559

47

:CHIP

TH501

R589

4.7k

:CHIP

4.4

2SC3052EF-T1-1EF

NECK-PROT

R593

R597

0

*

D503

D504

Q561

2SA1235TP-1EF

0.0

:CHIP

Q582

2SC3052EF-T1-1EF

I-HP

4

2

3

5

1

3

47

*

C514

*

6

E

V

+

I

C

R

C

D

V

1234567

0

5

.

.

2

1

1

-

2SA1235TP-1EF

I-PROT

R570

10k

:CHIP

0.0

R571

10k

:CHIP

1k

C590

R595

10

330k

25V

Q531

133.8

OCP-LATCH

R500

220

:CHIP

R598

R596

6.8k

100k

:CHIP

1

10

9

8

R509

*

F

E

R

C565

220

JL501

Q562

R572

10k

:CHIP

R592

0.33

133.6

KTA1279

OCP LATCH

C518

GP08D

PKG23

JW570

2.2mH

:LHL08

C515

0.001

C553

IC561

*

VOUT

C

C

V

3

.

0

C561

47

:CHIP

R573

12k

:CHIP

0.0

C588

1W

D580

1SS133T

-77

R594

10k

R564

470k

Q532

*

D505

*

L502

7

OUT

C568

0.22

:MPS

R567

2.2

:FPRD

R590

10k

MA111-TX

STAND-BY

-15V

L503

10mH

:HCC

L501

10mH

:HCC

R576

*

S501

D506

GP08D

PKG23

S502

*

R520

R512

C516

*

2

.

4

1

*

C517

*

1N4003GA

V-BOOST

*

*

R510

*

L505

*

8

+

E

V

I

R

D

R569

10k

;CHIP

4

.

1

R568

6.8k

:CHIP

V DRIVE

D561

-15V

+12V

TP99

-15V

D530

PG154R

C537

470

25V

E

V

I

R

D

.

V

+12V

C539

470mF

R546

25V

22k

R547

*

R548

22k

TP52

R536

0.47

1/2W

D531

PG154R

C541

22

R538

100V

220k

D534

PG154R

H.DY(+)

200V

TP94

TP94

200V

R549

2.2k

1/4W

R553

0.47

R551

R543

0.47

L517

*

C545

TP96

C

1

200V

4

B+

2

6

H

5

R537

0.47

1/2W

C540

100

160V

*

R591

*

HV

T503

*

FV

13

SV

12

11

10

+15V

9

8