Sony KP-XR43KR1, KP-XR43TW1, KP-XR48KR1, KP-XR53KR1, KP-XR53TW1 Service Manual

SERVICE MANUAL

RA-3A

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

KP-XR43KR1 RM-Y906K Korean SCC-P50A-A

KP-XR43TW1 RM-Y906 Taiwan SCC-P51A-A

KP-XR48KR1 RM-Y906K Korean SCC-P50C-A

KP-XR53KR1 RM-Y906K Korean SCC-P50B-A

KP-XR53TW1 RM-Y906 Taiwan SCC-P51B-A

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

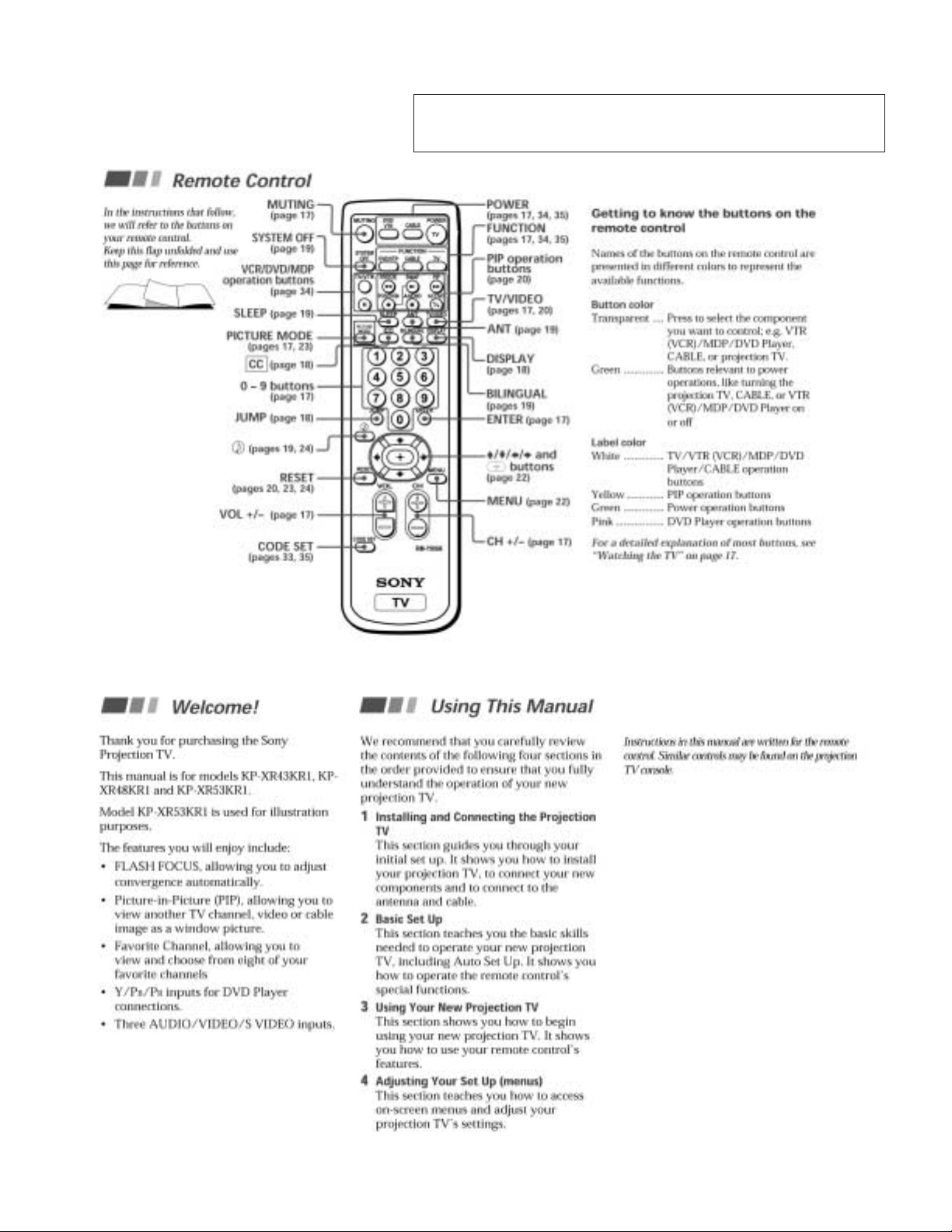

DVD/

POWER

MUTING

SAT/

VTR

CABLE

TV

FUNCTION

SYSTEM

OFF

TV

DVD/VTR SAT/CABLE

TV/VTR

FREEZE

SWAP PIP

m

N

M

AUDIO

POSITION ACTIVE

X

xz

ANT

TV/VIDEO

SLEEP

PICTURE

CC

MODE

DISPLAYMTS/SAP

2

1

3

5

6

4

7

9

8

JUMP

ENTER

0

INDEX

GUIDE

RESET

MENU

VOL CH

CODE SET

TV

RM-Y906/Y906K

KP-XR43KR1/XR43TW1 KP-XR48KR1/XR53KR1/XR53TW1

∗ Please file according to model size. .......

43

48 53

PROJECTION TV

KP-XR43KR1/XR43TW1/XR48KR1/XR53KR1/XR53TW1

RM-Y906K RM-Y906 RM-Y906K RM-Y906K RM-Y906

SPECIFICATIONS

Projection system

3 picture tubes, 3 lenses, horizontal in-line

system

Picture tube

7-inch high-brightness monochrome tubes (6.3 raster size),

with optical coupling and liquid cooling system

Projection lenses

High performance, large diameter hybrid lens F1.05

Television system

American TV standard

Channel coverage

VHF: 2–13/UHF: 14 –69/CATV: 1 – 125

Antenna

75 ohm external terminal for VHF/UHF

Screen size (measured diagonally)

43 inches (KP-XR43KR1/XR43TW1)

48 inches (KP-XR48KR1)

53 inches (KP-XR53KR1/XR53TW1)

Inputs/outputs

VIDEO 1 IN

VIDEO 2 INPUT

S VIDEO IN (4-pin mini DIN):

Y: 1 Vp-p, 75-ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

VIDEO (phono jack): 1 Vp-p, 75-ohms unbalanced, sync

negative

AUDIO (phono jacks): 500 mVrms (100% modulation),

Impedance: 47 kilohms

VIDEO 3 IN

S VIDEO IN (4-pin mini DIN):

Y: 1 Vp-p, 75-ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

VIDEO (phono jack): 1 Vp-p, 75-ohms unbalanced, sync

negative

Y: 1 Vp-p, 75 ohms, sync negative

PB : 0.7 Vp-p, 75 ohms

PR : 0.7 Vp-p, 75 ohms

AUDIO (phono jacks): 500 mVrms (100% modulation),

Impedance: 47 kilohms

MONITOR OUT

VIDEO (phono jack): 1 Vp-p, 75-ohms unbalanced, sync

negative

AUDIO (phono jacks): 500 mVrms (100% modulation),

Impedance: 470 ohms

AUDIO (VAR/FIX) OUT (phono jacks): 500 mVrms (100%

modulation), Impedance: 470 ohms

CONTROL S OUT: minijack

Speaker

Tweeter: 66 mm (2 5 /8 ”) x 2 (KP-XR48KR1/XR53KR1/

XR53TW1)

Woofer: 130 mm ( 17 /32 ”)x 2 (KP-XR48KR1/XR53KR1/

XR53TW1)

100 mm (4”) x 2 (KP-XR43KR1/XR43TW1)

Speaker output

15W x 2

Power requirement

110 V AC, 60 Hz (KP-XR43TW1/XR48TW1/XR53TW1)

220 V AC, 60 Hz (KP-XR43KR1/XR53KR1)

Power consumption

In use (Max.): 160 W

In standby: 1 W

Dimensions (W/H/D)

966 x 1,063 x 508 mm (38 1 /8 x 41 7 /8 x 20 inches)

(KP-XR43KR1/XR43TW1)

1,091 x 1,337 x 588 mm (43 x 52 3 /4 x 23 1 /4 inches)

(KP-XR48KR1)

1,218 x 1,423 x 618 mm (48 x 56 1 /8 x 24 3 /8 inches)

(KP-XR53KR1/XR53TW1)

Mass

61.5 kg (135 lbs 9 oz) (KP-XR43KR1/XR43TW1)

65 kg (143 lbs 5 oz) (KP-XR48KR1)

69.5 kg (153 lbs 4 oz) (KP-XR53KR1/XR53TW1)

Supplied accessories

Remote control RM-Y906K (1) (KP-XR43KR1/XR48KR1/

XR53KR1), RM-Y906 (KP-XR43TW1/XR53TW1)

Batteries (2) size AA (R6)

Design and specifications are subject to change without

notice.

– 2 –

KP-XR43KR1/XR43TW1/XR48KR1/XR53KR1/XR53TW1

RM-Y906K RM-Y906 RM-Y906K RM-Y906K RM-Y906

SELF DIAGNOSIS FUNCTION

1. Summary of Self-Diagnosis Function

• This device includes a self-diagnosis function.

• In case of abnormalities, the TIMER/STANDBY indicator automatically blinks. It is possible to predict the abnormality location

by the number of blinks. The Instruction Manual describes blinking of the TIMER/STANDBY indicator.

• If the symptom is not reproduced sometimes in case of a malfunction, there is recording of whether a malfunction was generated

or not. Operate the remote command to confirm the matter on the screen and to predict the location of the abnormality.

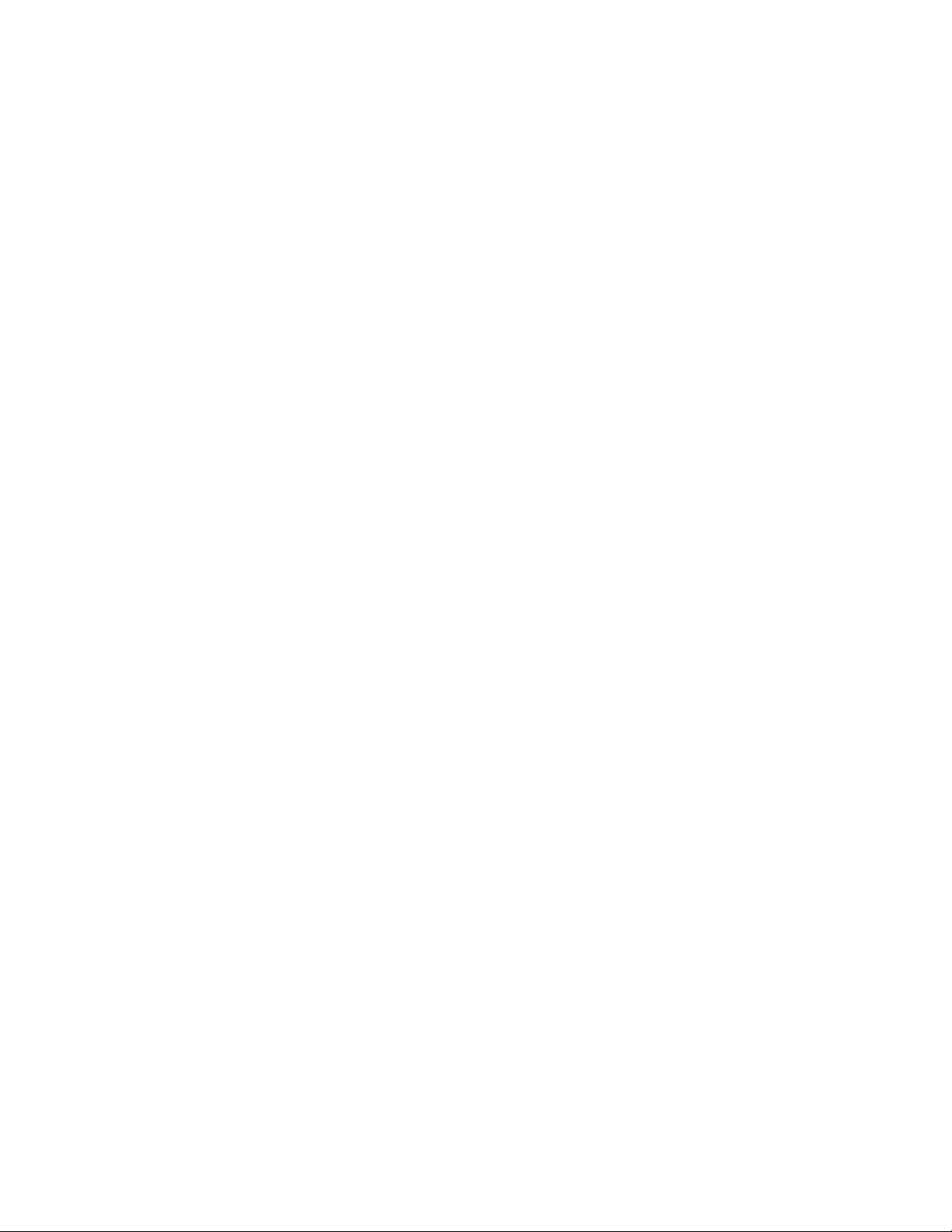

2. Diagnosis Items and Prediction of Malfunction Location

• When a malfunction occurs the TIMER/STANDBY indicator only blinks for one of the following diagnosis items. In case of two

or more malfunctions, the item which first occurred blinks. If the malfunctions occurred simultaneously, the item with the lower

blink count blinks first.

• The screen display displays the results regarding all the diagnosis items listed below. The display “ 0 ” means that no malfunc-

tions occurred.

metisisongaiD

NOtonrewoP•0

noitcetedPCOB+semit2.tiucrichcaenimetsysylppusrewopfotiucrictrohS

noitcetedPVOB+semit3.nepo276R

potsnoitcelfedlacitreVsemit4

noitcetedytilamronbatuooediVsemit5

potsnoitcelfedlatnoziroHsemit6

noitcetedytilamronbaoiduAsemit8

* : 000 the range of values for number of operations is 000-255. For 256 or higher there is

no count up and the number remains at 255.

3. Blinking count display of TIMER/STANDBY indicator

YBDNATS/REMIT

retacidnI

sknilbforebmuN

noitcnuflamdesoppuSnoitidnoC

)draobBF(.nepo1006F

.nepo5656R

tiucrictrohs6056Q

]metsySylppuSrewoPniaM[

.nekorbera4156Rdna1056CI

)draobBF(tiucric-trohs1006DV

.nekorbsi)tuoV(9051CI

.tiucricsdraobBCdna

)draobA(022,912,812Q

.nepo615,515C

.nekorbsi)elgnuJCY(602CI

.nekorbsi).pmaoiduA(604CI

.nepo204,104SP

]metsySylppuSrewoPybdnatS[

.rewopehtnonruttonnaC

.knilbt'nseodDEL

edomybdnatsehtotseoG

enilB+fotiucrictrohS

edomybdnatsehtotseoG

tiucricylppusrewopfonoitcnuflaM

.nekorbsi)reffuBesluPV(5051Q

GC,RCnisrehtodna167,237,507Q,tuooediV

.detumsilangis

.sisongaidflesehtrofsknilbnehtdna

.raeppat'nseodretsaR000potSH:6

.tuotonsidnuosehT

edomybdnatsehtotseoG

oedivnehtdnaA,yllatnozirohenilenootseogretsaR

,sdnoces03.xorppasknilbDELYBDNATS/REMIT

sisongaid-fleS

,yalpsidneercs

stluseR:metisisongaiD

000PCOB+:2

000PVOB+:3

000potSV:4

000BKA:5

000oiduA:8

* One blink is not used for self-diagnosis.

< FRONT PANEL >

VOLUME

–+CHANNEL–+

TV/VIDEO

FLASH FOCUS

POWER

•EXAMPLE

TIMER/STAND BY

<Diagnosis Items> <Number of Blinks>

• +B overcurrent 2 times

• +B overvoltage 3 times

TIMER/STANDBY indicator

• Vertical deflection stop 4 times

Lamp ON : 0.3 seconds

Lamp OFF : 0.3 seconds

Lamp OFF :

3.0 seconds

Release of TIMER/STANDBY indicator blinking.

• The TIMER/STANDBY indicator blinking display is released by turning OFF the power switch

on the TV main unit or removing the plug from the power.

– 3 –

KP-XR43KR1/XR43TW1/XR48KR1/XR53KR1/XR53TW1

RM-Y906K RM-Y906 RM-Y906K RM-Y906K RM-Y906

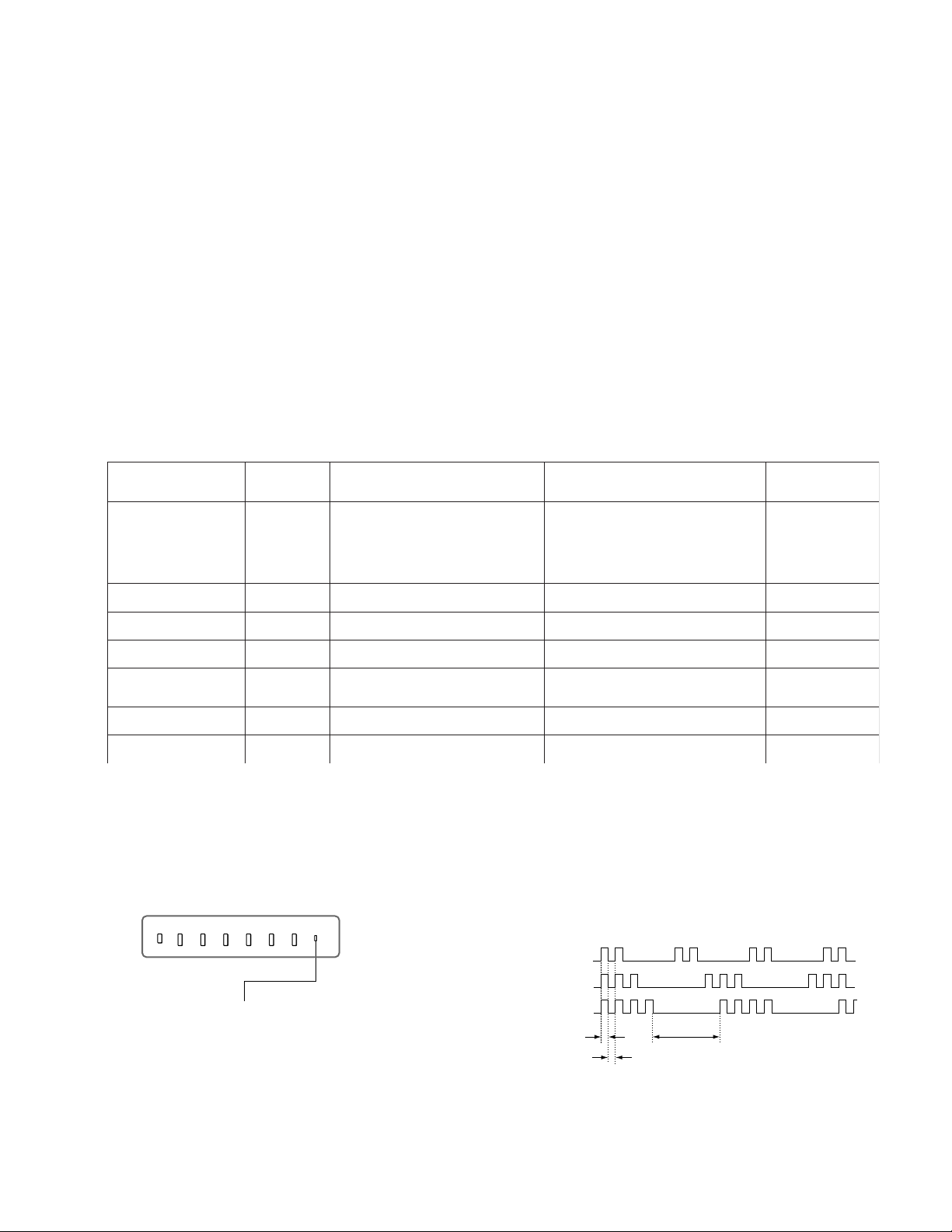

4. Self-diagnosis screen displays

• In cases of malfunctions where it is not possible to determine the symptom such as when the power goes off occasionally or when

the screen disappears occasionally, there is a screen display on whether the malfunction occurred or not in the past (and whether

the detection circuit operated or not) in order to allow confirmation.

<Screen Display Method>

• Quickly press the remote command button in the following order from the standby state.

DISPLAY b Channel 5 b VOL – b POWER

˘

Be aware that this differs from the method of

entering the service mode (volume + ).

Self-diagnosis screen display

Self Check

2 : +B OCP 000

3 : +B OVP 000

4 : V Stop 000

5 : AKB 000

6 : H Stop 000

7 : HV 000

8 : Audio 000

101 : WDT 000

÷

2 : +B OCP 000

Diagnosis

Results

000 the range of values for number of

operations is 000-255.

For 256 or higher there is no count up

and the number remains at 255.

5. Self-Diagnosis Screen Display

• The results display is not automatically cleared. In case of repairs and after repairs, check the self-diagnosis screen and be sure

to return the results display to “ 0 ”.

• If the results display is not returned to “ 0 ” it will not be possible to judge a new malfunction after completing repairs.

<Method of Clearing Results Display>

1. Power off (Set to the standby mode)

2. DISPLAY b Channel 5 b VOL + b POWER (Service Mode)

3. Channel 8 b ENTER (Test reset = Factory preset condition)

<Method of Ending Self Diagnosis Screen>

• When ending the self-diagnosis screen completely, turn the power switch OFF on the remote commander or the main unit.

– 4 –

KP-XR43KR1/XR43TW1/XR48KR1/XR53KR1/XR53TW1

RM-Y906K RM-Y906 RM-Y906K RM-Y906K RM-Y906

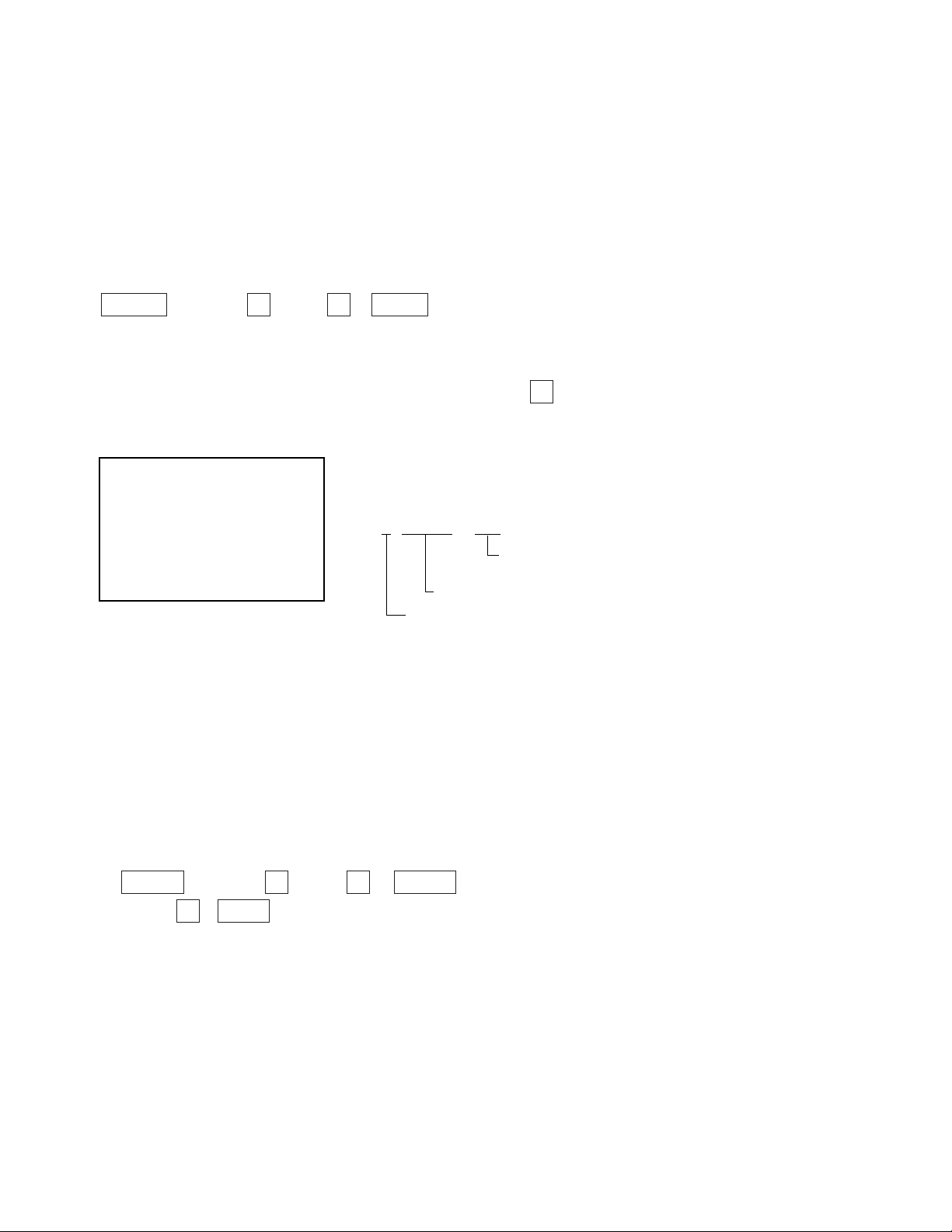

6. Self-diagnosis function operation

OCP Low B and +B line detect DET SHORT, and shut-down POWER ON RELAY.

Reset by turning power on/off.

In case of +B is loaded approx. 1.3A or more, microcomputer detects it via IC651.

OVP In case of +B becomes approx. 150V or more, POWER ON RELAY shuts down and microcomputer detects it via IC651.

Reset by turning power on/off just the same as OCP.

V Stop In case of microcomputer detects 2 seconds or more interval of V Pulse, Reference Pulse turns off by turning off the picture

signal in YC Jungle IC (IC206).

After the picture signal turns off, V Pulse is regenerated 2 seconds or more, the picture signal turns on.

AKB IK detection. Makes LED blinking in case of microcomputer doesn’t detect IK returns of IC206 CXA2147Q 30 seconds or more.

H Stop In case of HV becomes 33kV or more, IC502 detects it and shut-down H Drive Pulse.

Microcomputer receives H Stop data from IC206 and makes LED blinking.

Audio In case of DC component overlaps the output of Audio Amp., microcomputer detects it and makes LED blinking.

Microcomputer forces to shut down the power.

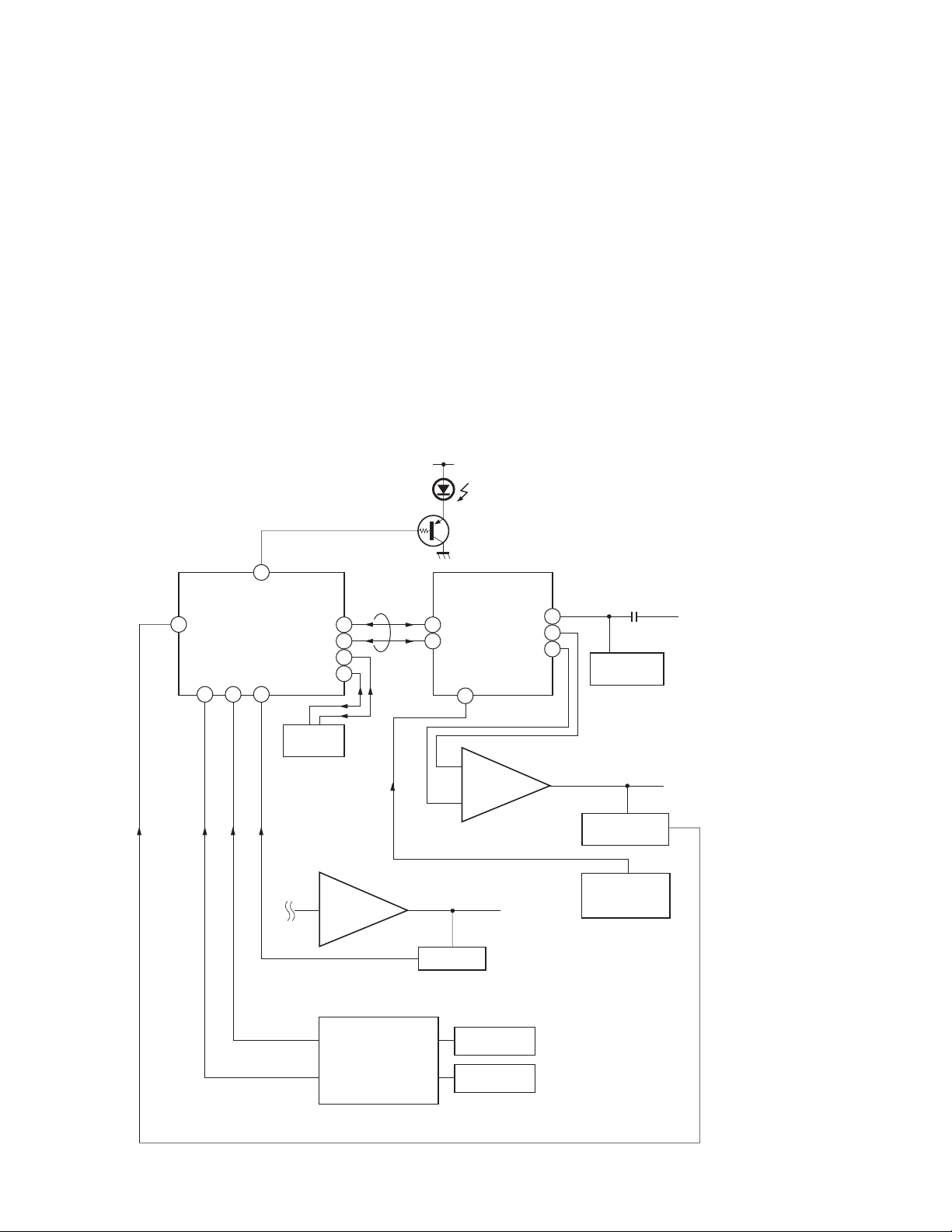

Self-diagnosis block diagram

D1201

TIMER/STANDBY

8

20 21 22

55

IC002

µProcessor

Audio

IC004

EEPROM

Audio AMP

5. AKB

6. H STOP

49

47

50

48

IC406

BUS

5. AKB

Q006

3

4

27

DC Detect

IC206

CXA2147

YCJ

IC1509

V Drive

43

35

34

6. HV STOP

IC502

HV Detector

Q1505

V Pulse Buffer

C Board

4. V.STOP (V Pulse)

3. OVP

2. OCP

IC651

OVP Buffer

OCP Buffer

OVP DETECT

OCP DETECT

– 5 –

KP-XR43KR1/XR43TW1/XR48KR1/XR53KR1/XR53TW1

RM-Y906K RM-Y906 RM-Y906K RM-Y906K RM-Y906

TABLE OF CONTENTS

Section Title Page

–––––– –––– ––––

SELF DIAGNOSIS FUNCTION ............................................ 3

1. GENERAL

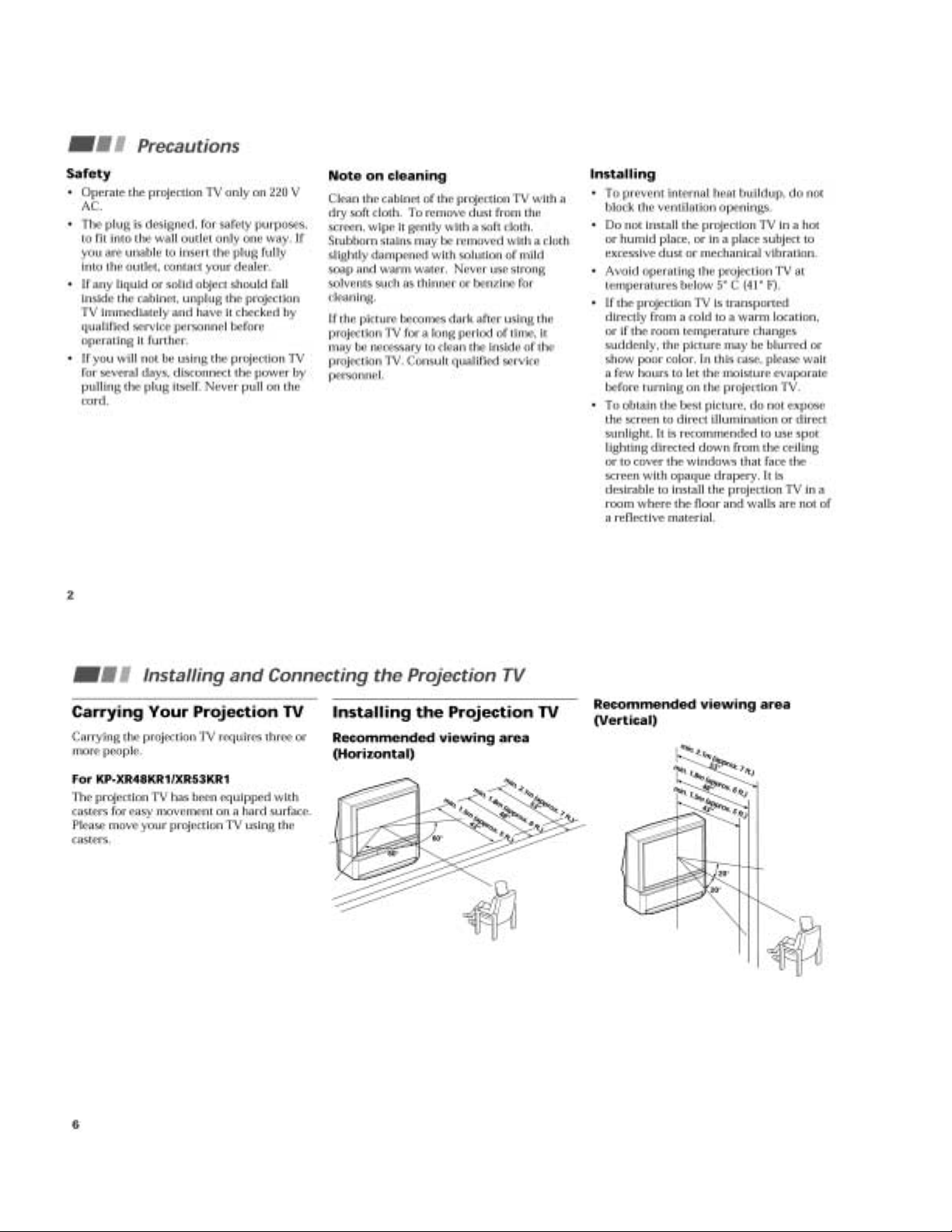

Remote Control ....................................................................... 7

Precautions .............................................................................. 8

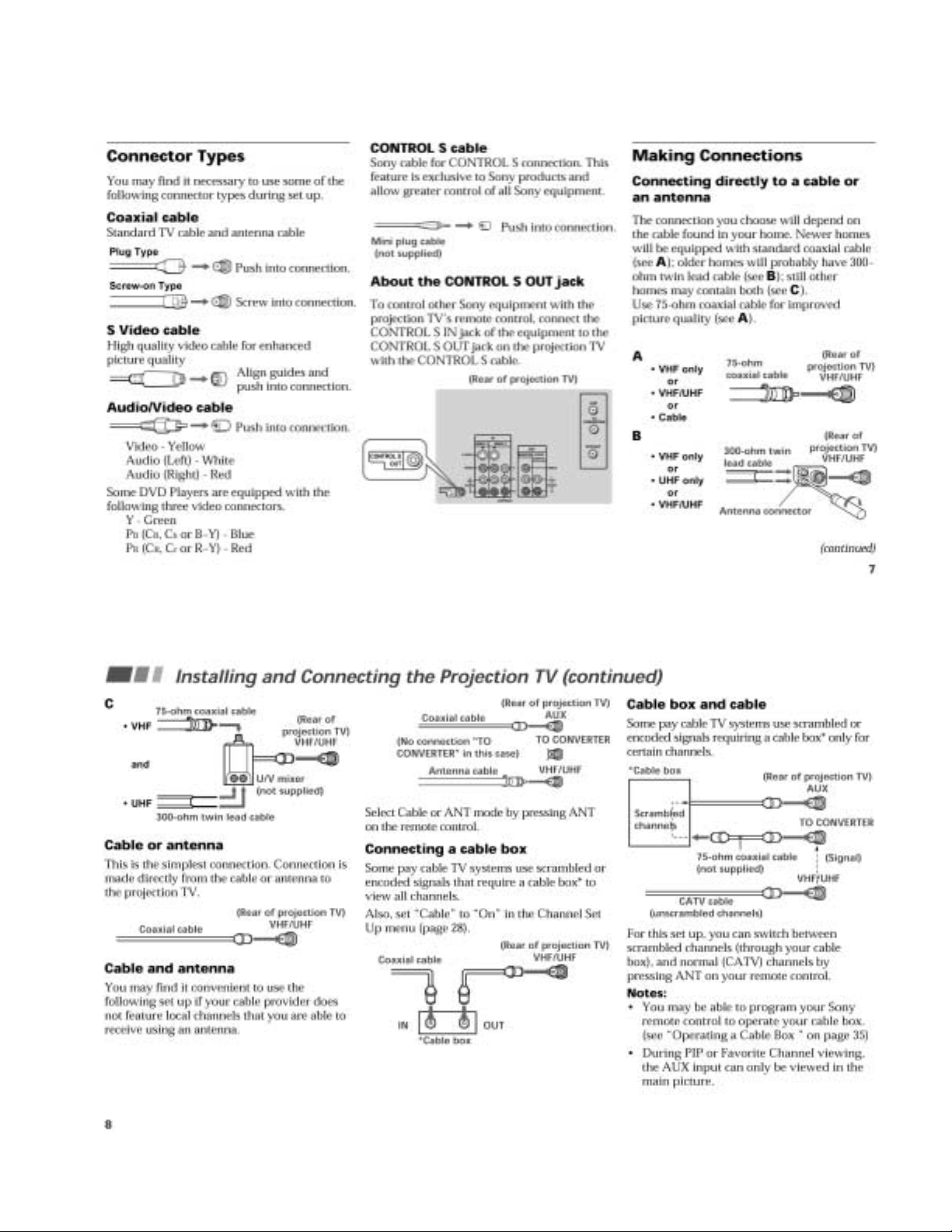

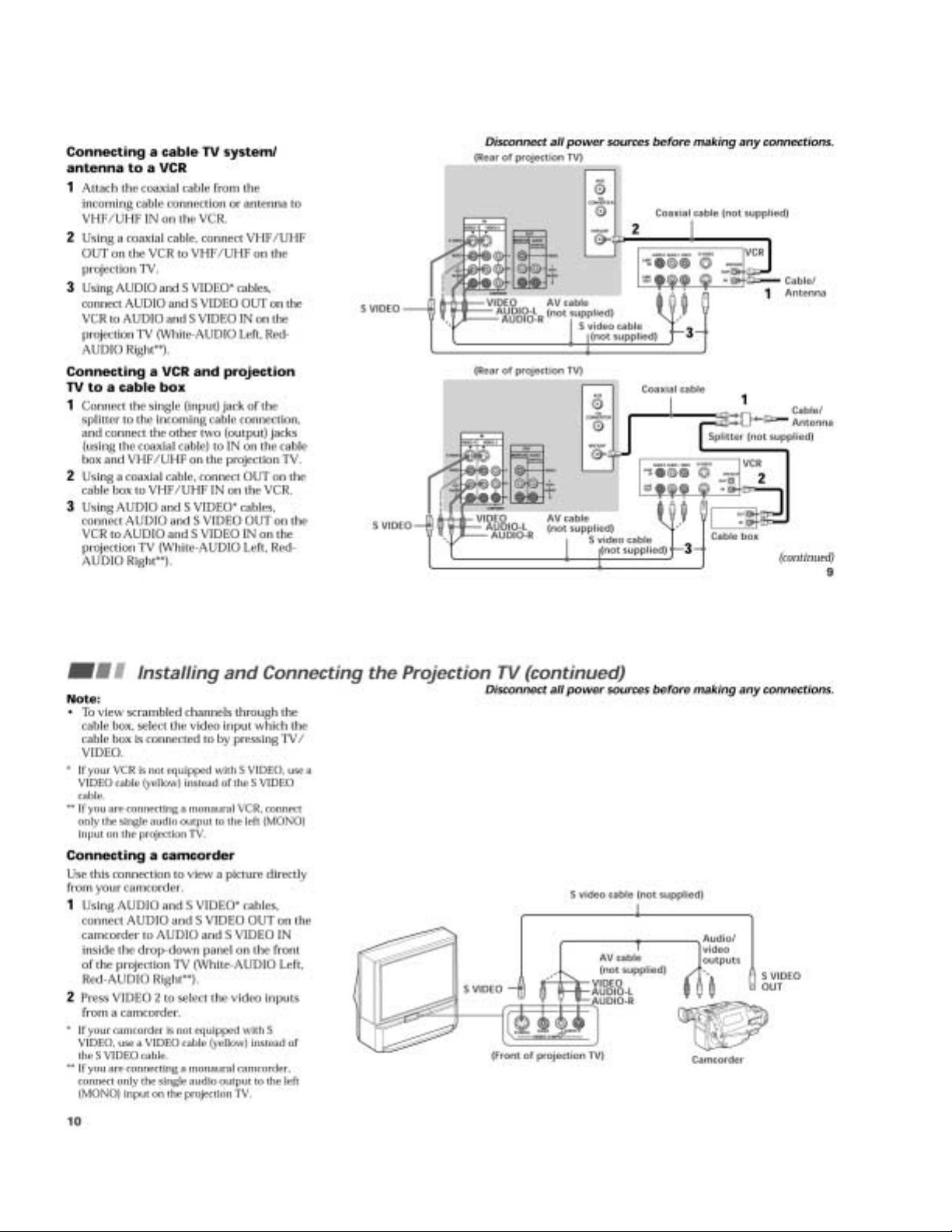

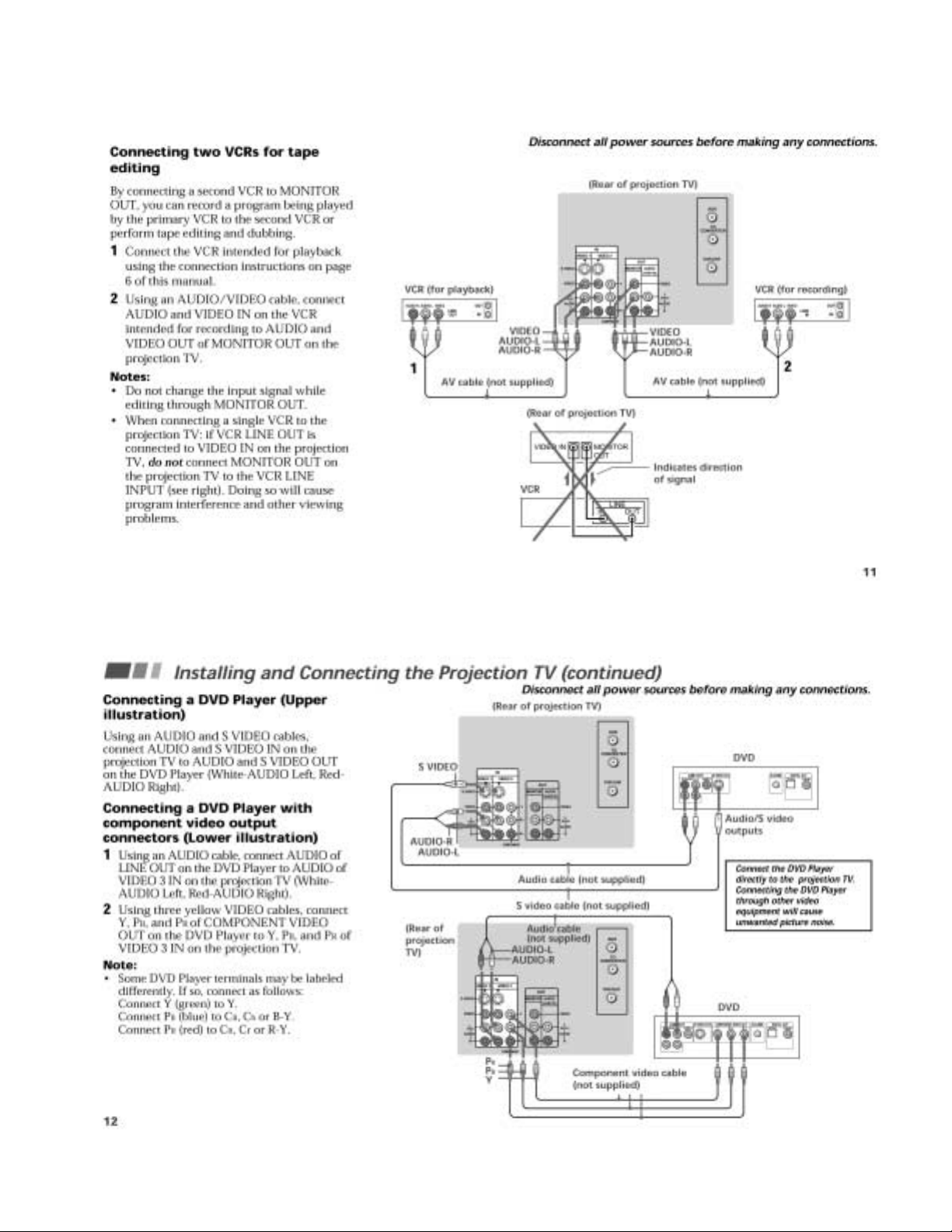

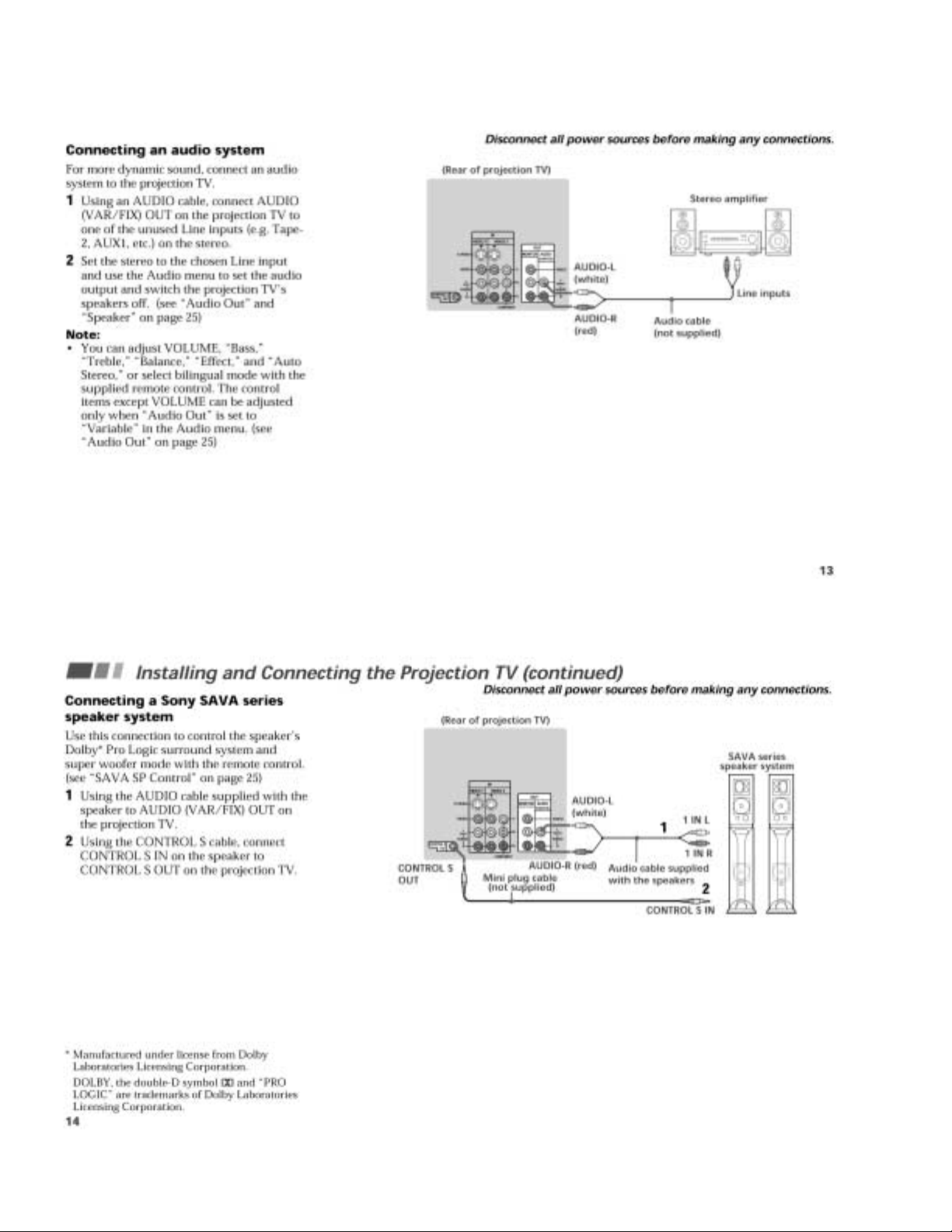

Installing and Connecting the Projection TV .......................... 8

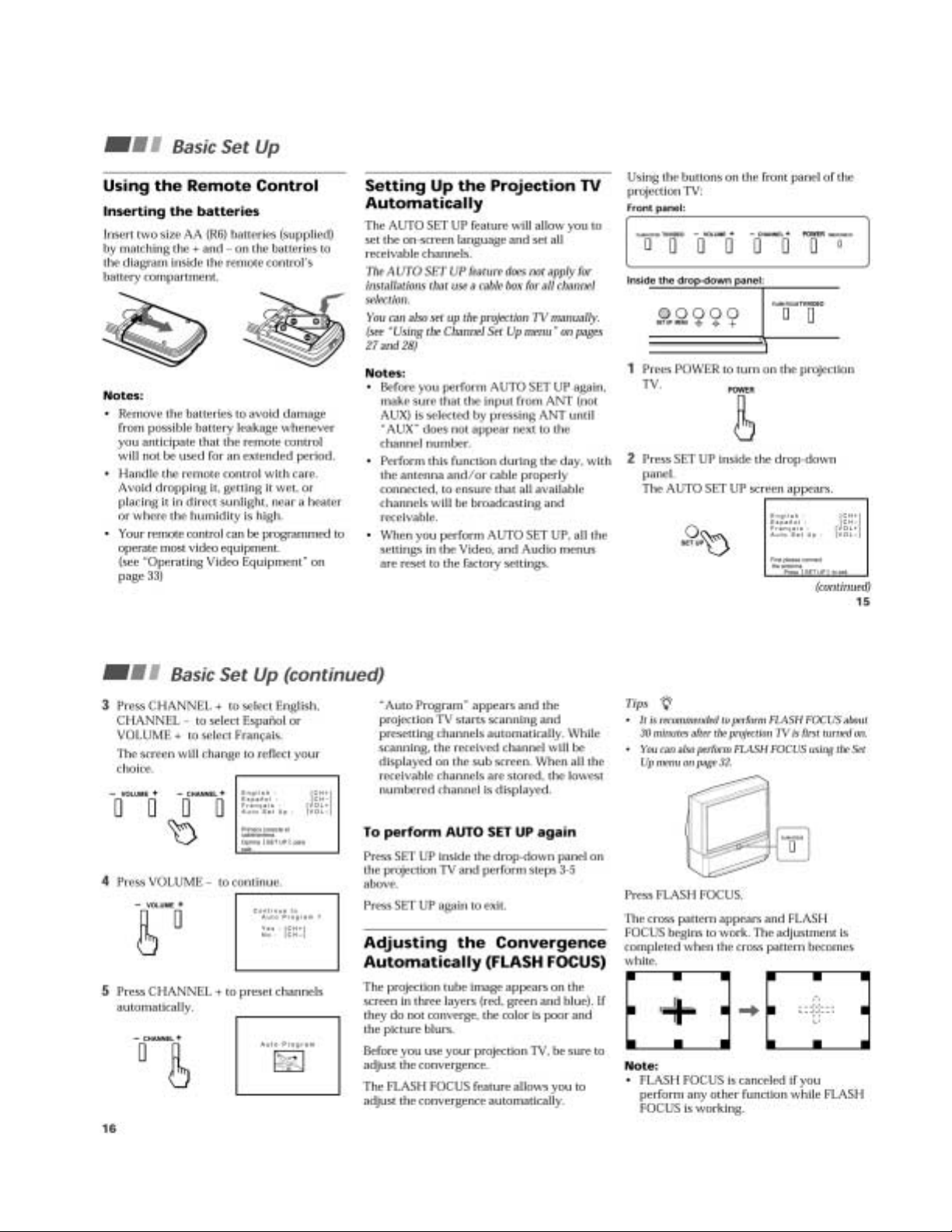

Basic Set Up .......................................................................... 13

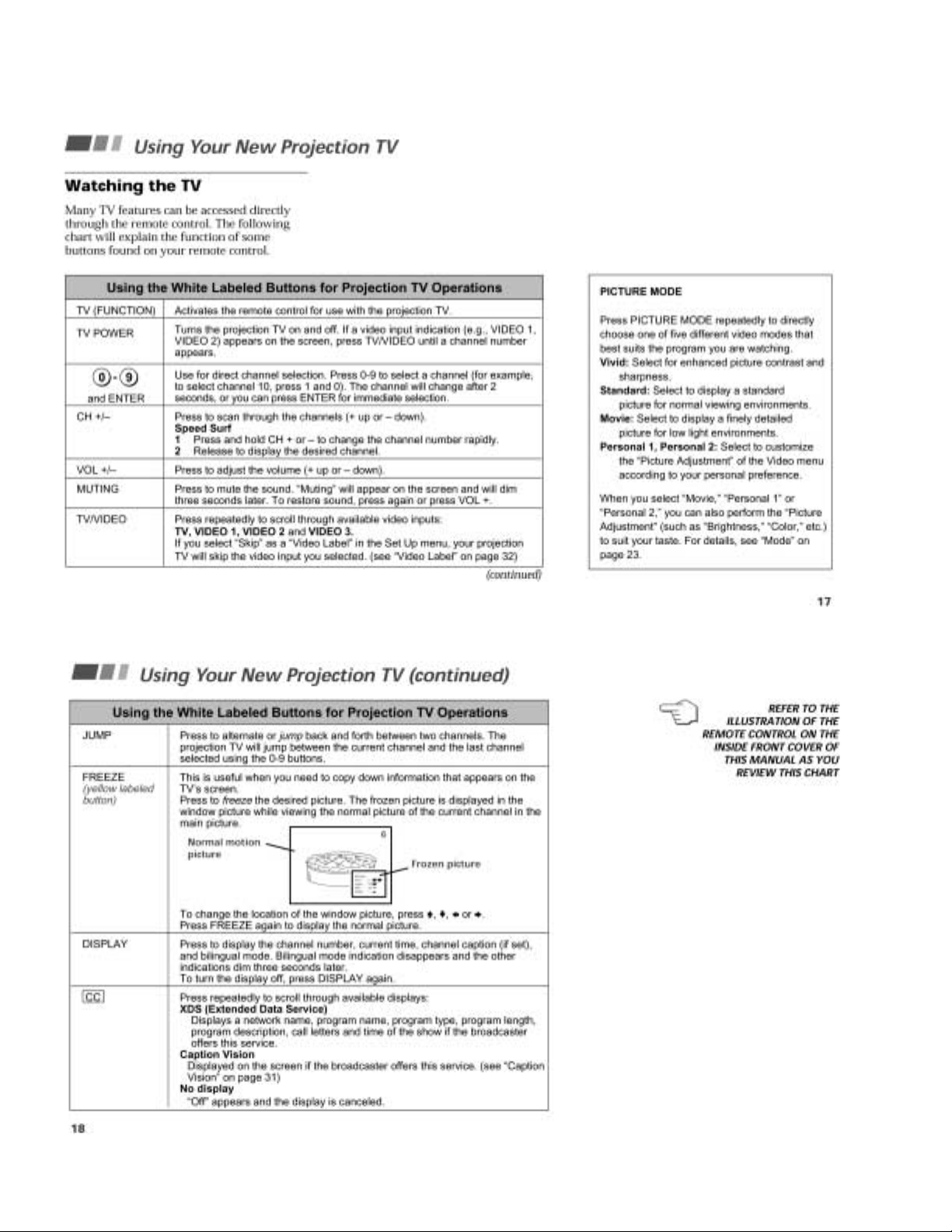

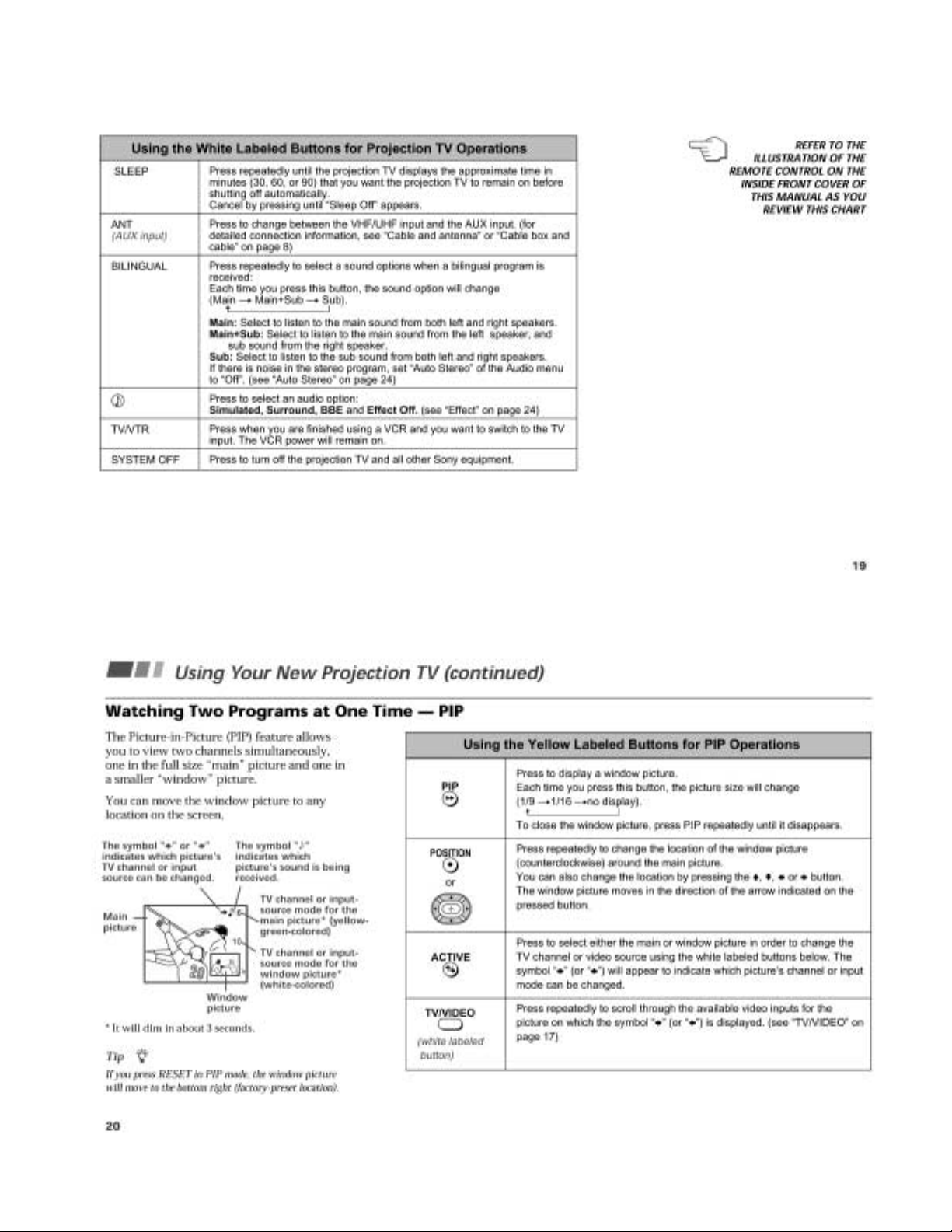

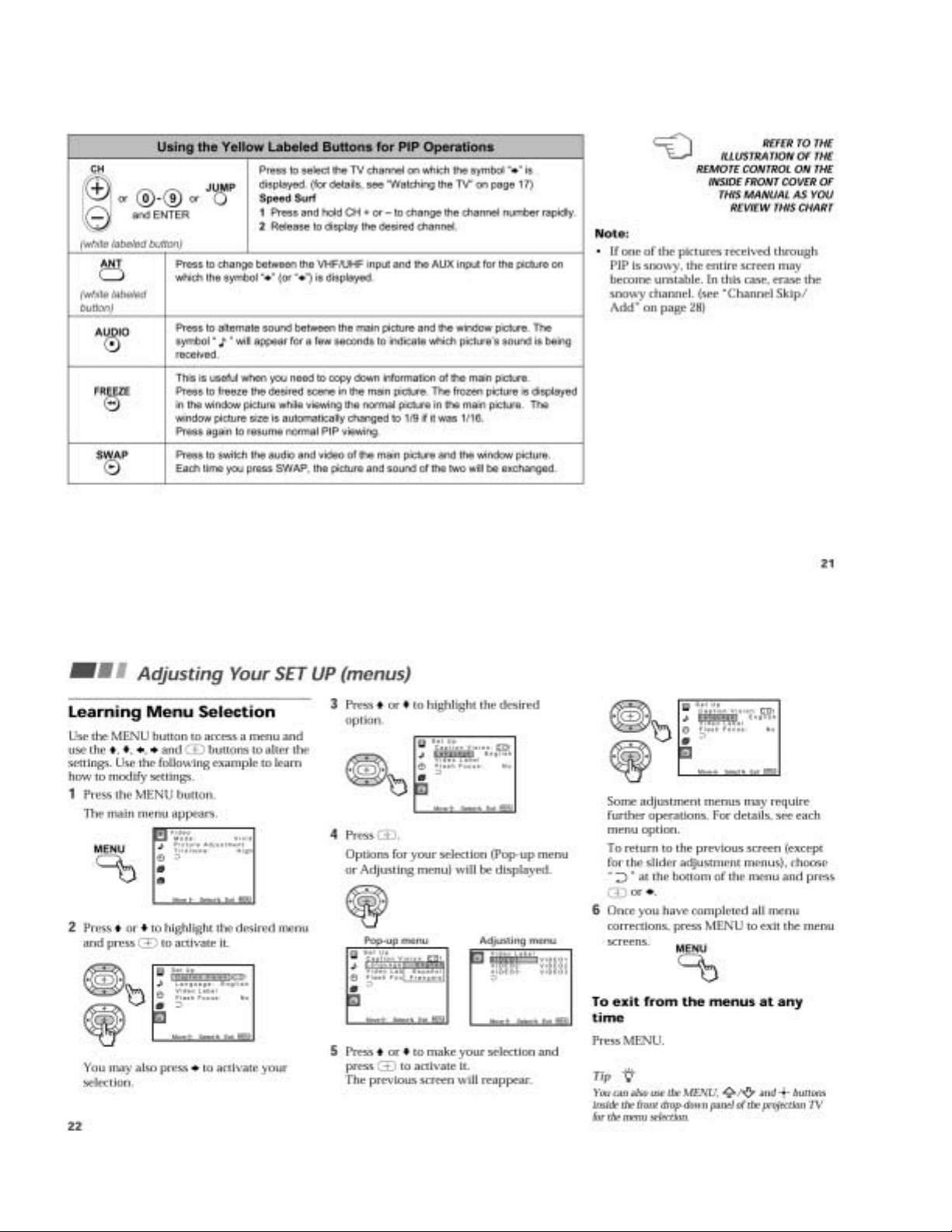

Using Your New Projection TV ............................................ 14

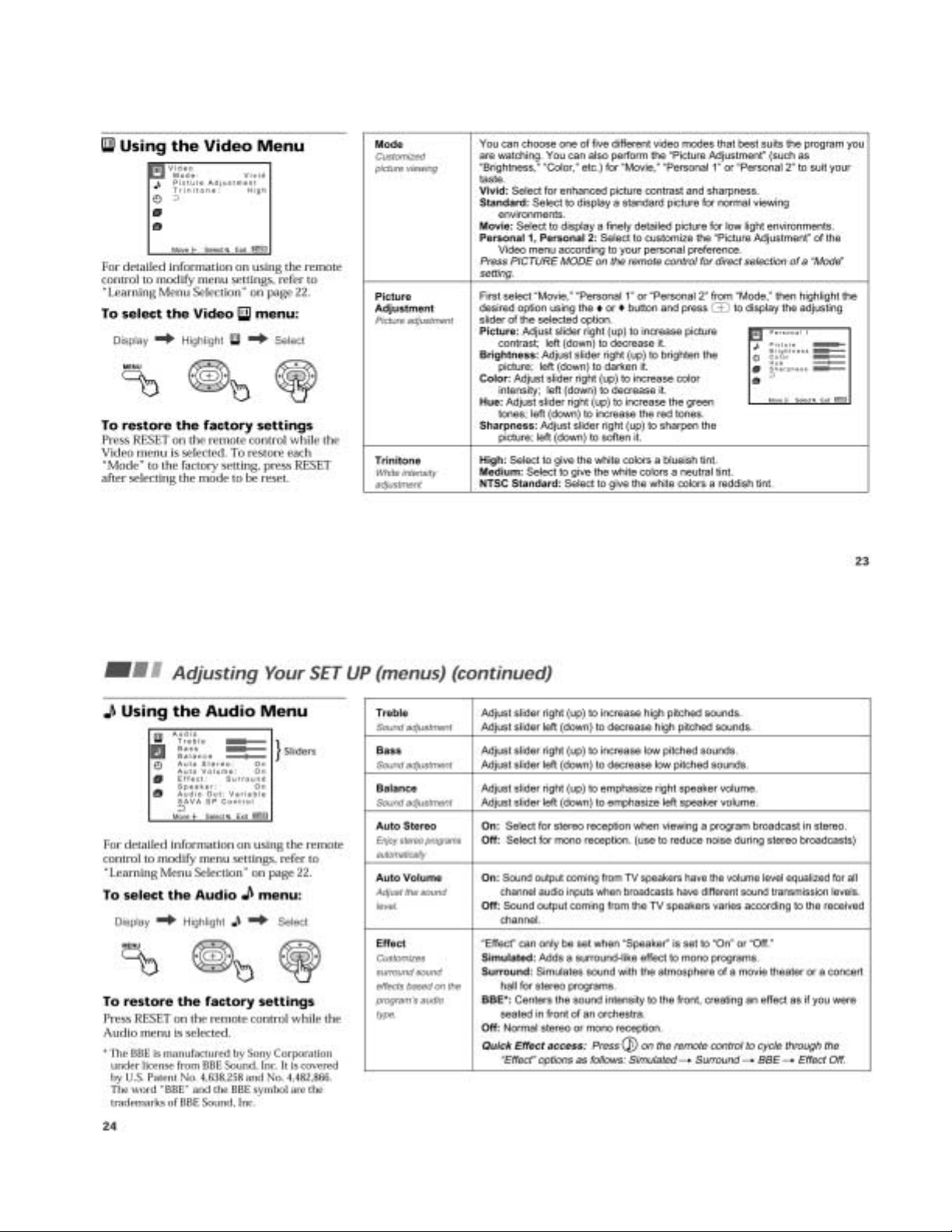

Adjusting Your SET UP (menus) .......................................... 16

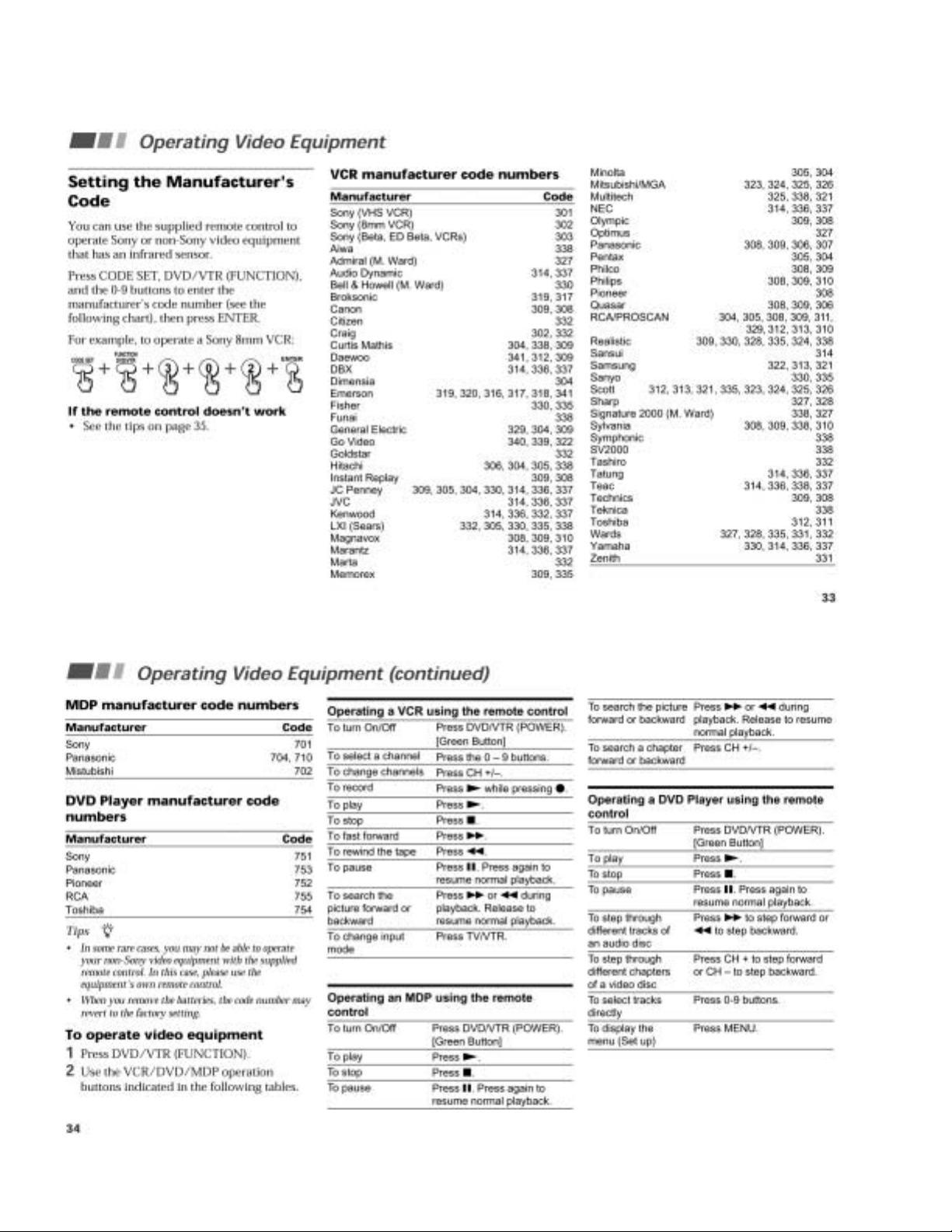

Operating Video Equipment .................................................. 22

Operating a Cable Box .......................................................... 23

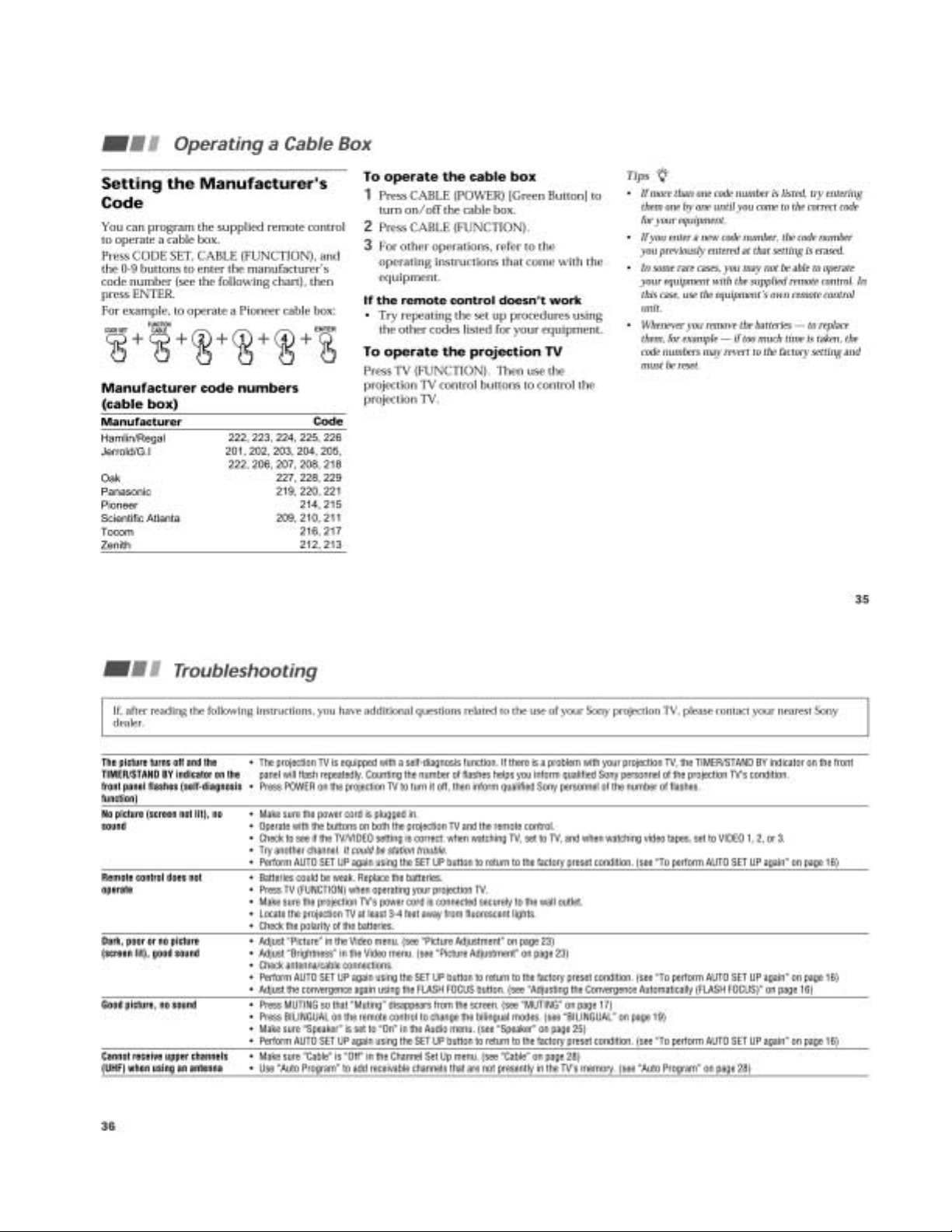

Troubleshooting .................................................................... 23

2. DISASSEMBLY

2-1. Rear Board Removal ................................................. 25

2-2. Chassis Assy Removal .............................................. 25

2-3. Service Position ......................................................... 25

2-4. HA Board and HB Board Removal

(Except KP-XR43KR1/XR43TW1) .......................... 25

2-5. HA and HB Board Removal

(KP-XR43KR1/XR43TW1) ...................................... 26

2-6. Mirror Cover Removal .............................................. 26

2-7. Beznet Assy Removal................................................ 26

2-8. HC Board Removal ................................................... 26

2-9. A, G and FA Boards Removal ................................... 27

2-10. Picture Tube Removal ............................................... 27

2-11. High-Voltage Cable Installation and Removal .......... 27

3. SET-UP ADJUSTMENTS

3-1. Screen Voltage Adjustment (Coarse Adjustment) ..... 28

3-2. Screen (G2) Adjustment (Fine Adjustment) .............. 28

3-3. Deflection York Tilt Adjustment ............................... 28

3-4. Focus Lens Adjustment ............................................. 28

3-5. Focus VR Adjustment ............................................... 29

3-6. 2-Pole Magnet Adjustment (Green, Red) .................. 29

3-7. 4-Pole Magnet Adjustment........................................ 29

3-8. Defocus Adjustment (Blue) ....................................... 29

3-9. Electrical Adjustment by Remote Commander......... 30

3-10. Registration Adjustment(PJE) ................................... 35

3-11. Auto Registration Error Code List ............................ 38

4. SAFETY RELATED ADJUSTMENTS

4-1. HV Regulation Circuit Check and Adjustment ......... 39

4-2. HV Hold Down Circuit Operation Check and

Adjustment ................................................................ 39

4-3. +B Max Voltage Confirmation .................................. 40

4-4. +B OVP Confirmation............................................... 40

Section Title Page

–––––– –––– ––––

5. CIRCUIT ADJUSTMENTS

5-1. TV Input Sub Contrast Adjustment

(VPNT-SCON) .......................................................... 41

5-2. VIDEO Input Sub-HUE and Sub-Color Adjustment

(VPNT-SHUE, SCOL) .............................................. 41

5-3. Component Input Sub-HUE and Sub-Color

Adjustment (DAC-UVSH, UVSC) ........................... 41

5-4. P&P Sub Contrast Adjustment (SC-SYDR) ............. 41

5-5. Sub-HUE, Sub-Color and Main Contrast

Adjustment (MC-MYDR, MSHU, MSCL,

SC-SSHU,SSCL) ...................................................... 42

5-6. Bar Display Position Adjustment

(OP-DISP) ................................................................ 42

5-7. PIP Position Adjustment (PI-PIPH, PIPV)................ 42

6. DIAGRAMS

6-1. Block Diagram (1) ..................................................... 43

Block Diagram (2) ..................................................... 45

Block Diagram (3) ..................................................... 51

Block Diagram (4) ..................................................... 55

Block Diagram (5) ..................................................... 58

6-2. Frame Schematic Diagram ........................................ 61

6-3. Circuit Boards Location ............................................ 64

6-4. Printed Wiring Boards and Schematic Diagrams ...... 64

• A (1/3)Board ........................................................... 65

• A (2/3)Board ........................................................... 69

• A (3/3)Board ........................................................... 73

• G Board ................................................................... 81

• CG Board ................................................................ 88

• CR Board ................................................................ 89

• CB Board ................................................................ 89

• HA Board ................................................................ 91

• HC Board ................................................................ 91

• HB Board ................................................................ 92

• FA Board ................................................................. 93

6-5. Semiconductors ......................................................... 94

7. EXPLODED VIEWS

7-1. Cover (KP-XR43KR1/XR43TW1) ........................... 96

7-2. Cover (Except KP-XR43KR1/XR43TW1) ............... 97

7-3. Chassis (KP-XR43KR1/XR43TW1) ........................ 98

7-4. Chassis (Except KP-XR43KR1/XR43TW1) ............ 99

7-5. Picture Tube ............................................................ 100

8. ELECTRICAL PARTS LIST ................................. 101

(CAUTION)

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR CARBON PAINTED ON THE CRT, AFTER REMOVING THE ANODE.

WARNING!!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECElVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESECOMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL TO SAFEOPERATION ARE IDENTIFIED IN THIS

MANUAL. FOLLOW THESE PROCEDURES WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

– 6 –

SECTION 1

GENERAL

The operating instructions mentioned here are partial abstracts from the

Operating Instructions Manual. The page numbers of the Operating

Instruction Manual remain as in the manual. (Part no :4-078-175-11)

– 7 –

– 8 –

– 9 –

– 10 –

– 11 –

– 12 –

– 13 –

– 14 –

– 15 –

– 16 –

– 17 –

– 18 –

– 19 –

– 20 –

– 21 –

– 22 –

– 23 –

– 24 –

KP-XR43KR1/XR43TW1/XR48KR1/XR53KR1/XR53TW1

RM-Y906K RM-Y906 RM-Y906K RM-Y906K RM-Y906

SECTION 2

DISASSEMBLY

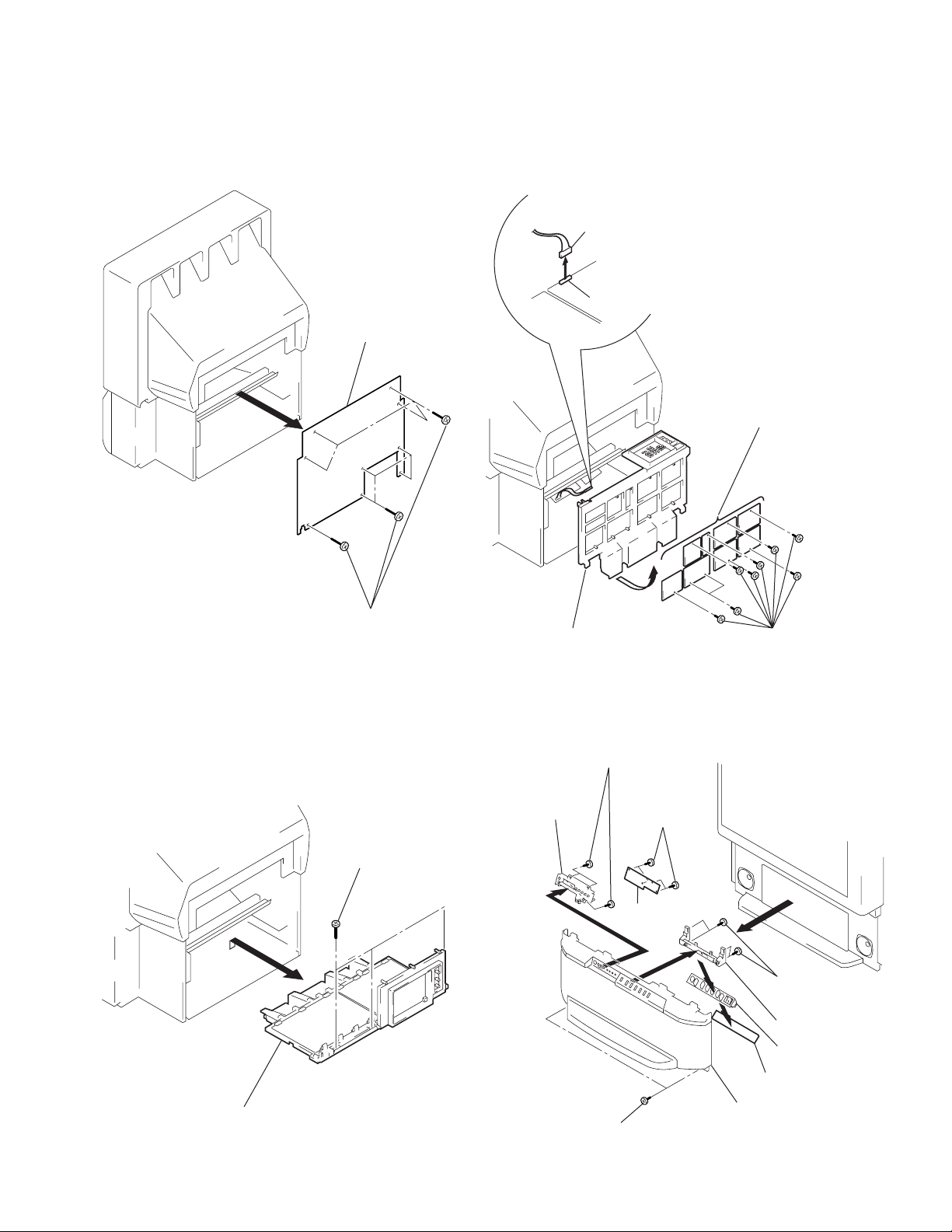

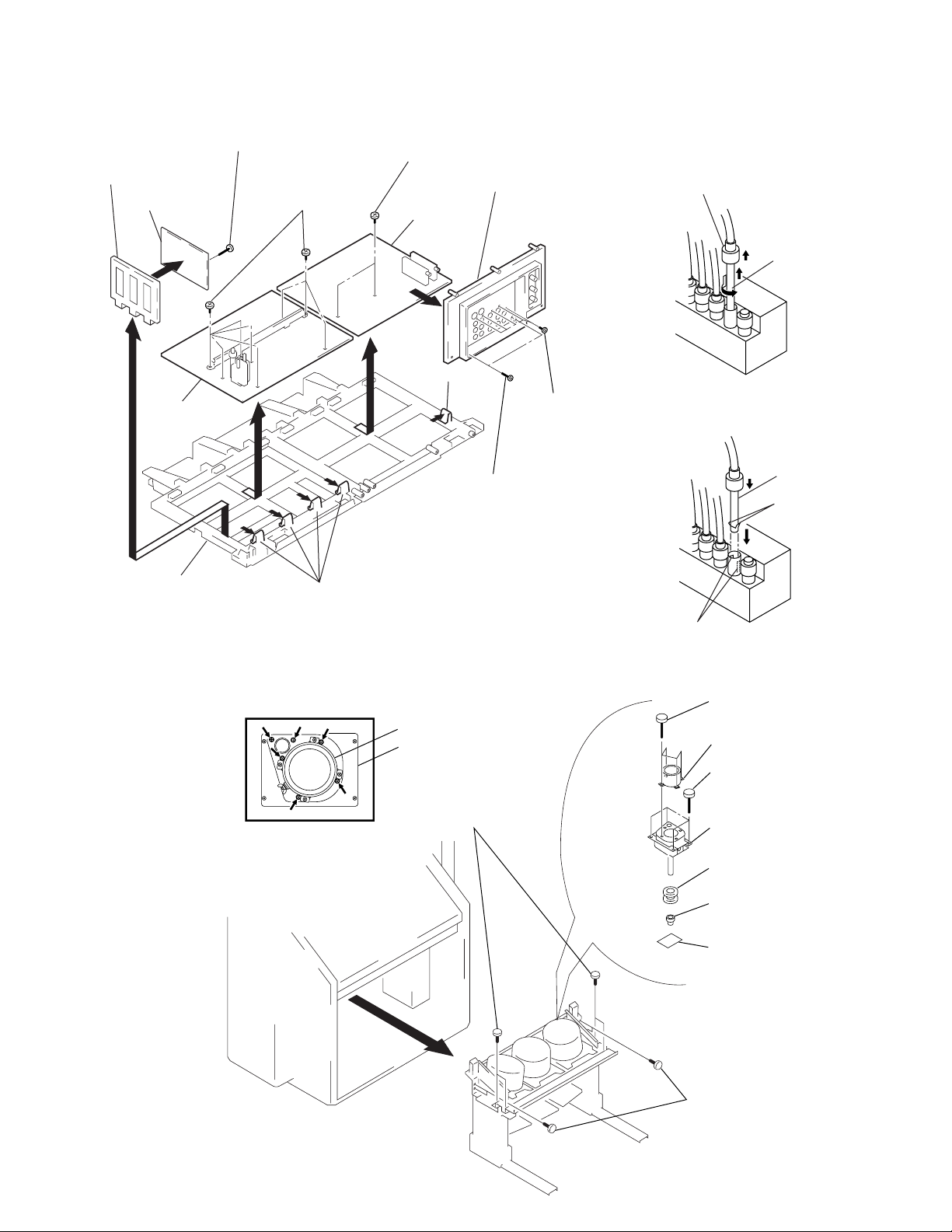

2-1. REAR BOARD REMOVAL 2-3. SERVICE POSITION

1 Disconnect CN203

on A board.

From CG board CN1304.

(The extension cable is not

supplied because of the

countermeasure for radiation.)

2 Covers

Cut them off with a plier or the like

from chassis assembly in case of

checking printed circuit boards.

After checking, turn over the covers

and secure them with screws.

2 Rear board

A board

CN203

G board

1 Nine screws

(Except KP-XR43KR1/XR43TW1)

Eight screws

(KP-XR43KR1/XR43TW1)

(Screw(4x20), tapping)

2-2. CHASSIS ASSY REMOVAL

1 Three screws

(Screw(4x20),tapping)

Chassis assembly

Screws

(+BVTP3x12)

2-4. HA BOARD AND HB BOARD REMOVAL

(EXCEPT KP-XR43KR1/XR43TW1)

6 Four screws

(+BVTP 4x16)

7 HB bracket

8 Three screws

(+BVTP 3x12)

9 HB board

2 Four screws

(+BVTP 4x16)

3 HA bracket

4 Multi button

2 Chassis assy

5 HA board

Speaker grille assy

1 Two screws

(Screws (4x20), tapping)

– 25 –

KP-XR43KR1/XR43TW1/XR48KR1/XR53KR1/XR53TW1

RM-Y906K RM-Y906 RM-Y906K RM-Y906K RM-Y906

2-5. HA AND HB BOARD REMOVAL

(KP-XR43KR1/XR43TW1)

8 HB board

7 Three screws

(+BVTP 3x12)

4 HA bracket

2

Panel ASSY, Control

1 Four screws

(Screws (4x20), tapping)

3 Four screws

(+BVTP 3x12)

6 HA board

5 Three screws

(+BVTP 3x12)

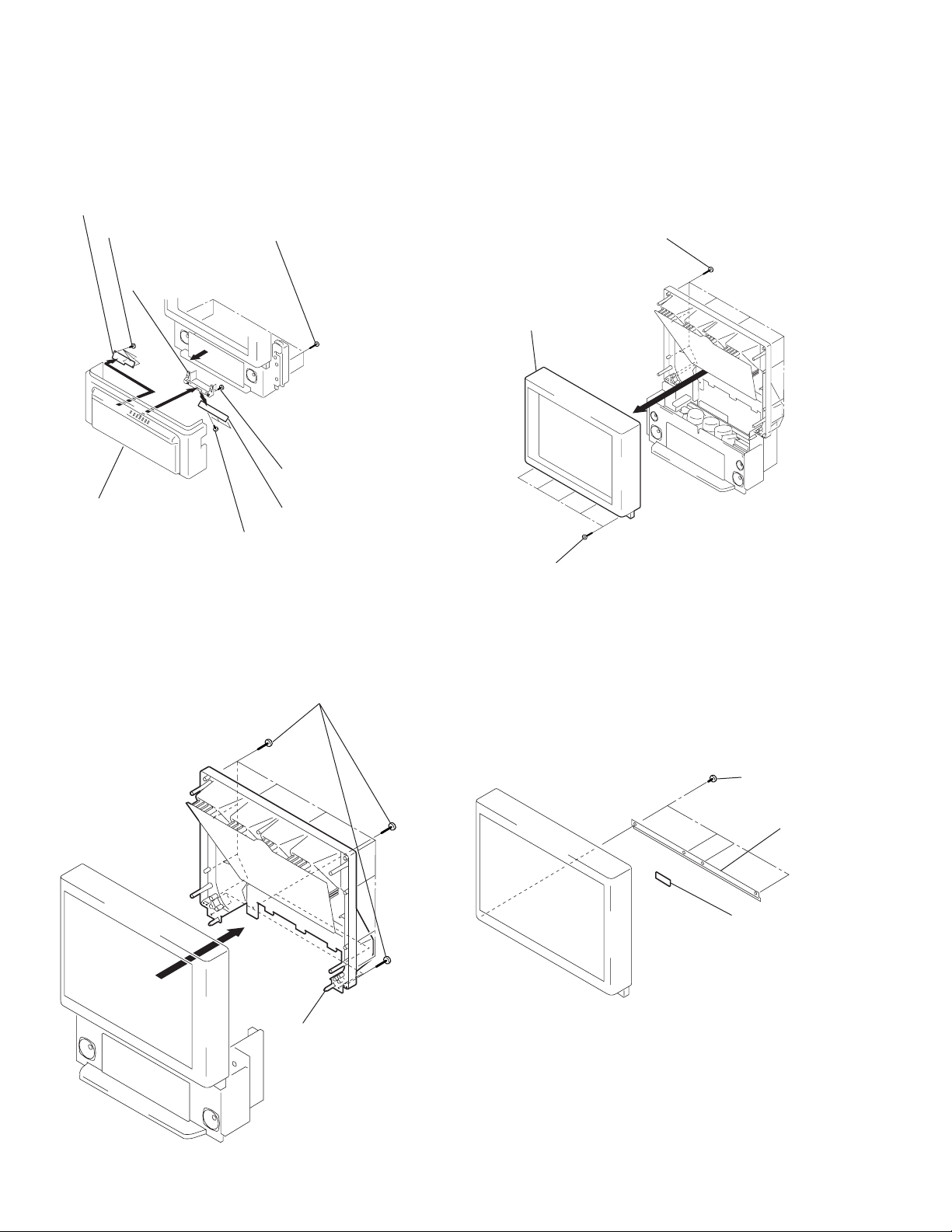

2-6. MIRROR COVER REMOVAL

1 Seventeen screws (KP-XR43KR1/XR43TW1)

Twenty four screws (KP-XR48KR1)

Nineteen screws (KP-XR53KR1/XR53TW1)

(Screw(4x20), tapping)

2-7. BEZNET ASSY REMOVAL

2 Eleven screws (KP-XR43KR1/XR43TW1)

Twelve screws (KP-XR48KR1)

Fifteen screws (KP-XR53KR1/XR53TW1)

(Screws (4x20), tapping)

3 Beznet assy

1 Three screws

(KP-XR43KR1/XR43TW1/XR48KR1)

Five screws (KP-XR53KR1/XR53TW1)

(Screws (4x20), tapping)

2-8. HC BOARD REMOVAL

2 Mirror cover

1 Two screws

(+BVTP 4x12)

2 L screen holder

3 HC board

– 26 –

KP-XR43KR1/XR43TW1/XR48KR1/XR53KR1/XR53TW1

RM-Y906K RM-Y906 RM-Y906K RM-Y906K RM-Y906

2-9. A, G AND FA BOARDS REMOVAL 2-11. HIGH-VOLTAGE CABLE INSTALLATION

!¡ FA board bracket

!™ FA board

0 Screw

(+BVTP 3x12)

4 Eight screws

(+BVTP 3x12)

7 Two screws

(+BVTP 3x12)

3 Terminal board

9 A board

8 Claw

AND REMOVAL

(1) Removal

1 Rubber cap

2 HV cable

turn 90°

6 G board

Main bracket

5 Claws

2-10. PICTURE TUBE REMOVAL

CAUTION: Removing the arrow-marked

screws is strictly prohibited.

If removed, it may cause liquid spill.

2 Seven screws

(+BVTP 3x12)

1 Two screws

(Screws (4x20), tapping)

Lens

Picture tube

2 Four screws

(Screw(4x20), tapping)

(2) Installation

1 HV cable

Hook

Gutter

4 Four screws

(Screw(4x20), tapping)

5 Lens

9 Four screws

(+BVTP 4x12)

0 Picture tube

3

8 Diflection yoke

7 Neck assy

6 CR board

1 Four screws

(Screw(4x20), tapping)

– 27 –

KP-XR43KR1/XR43TW1/XR48KR1/XR53KR1/XR53TW1

RM-Y906K RM-Y906 RM-Y906K RM-Y906K RM-Y906

SECTION 3

SET-UP ADJUSTMENTS

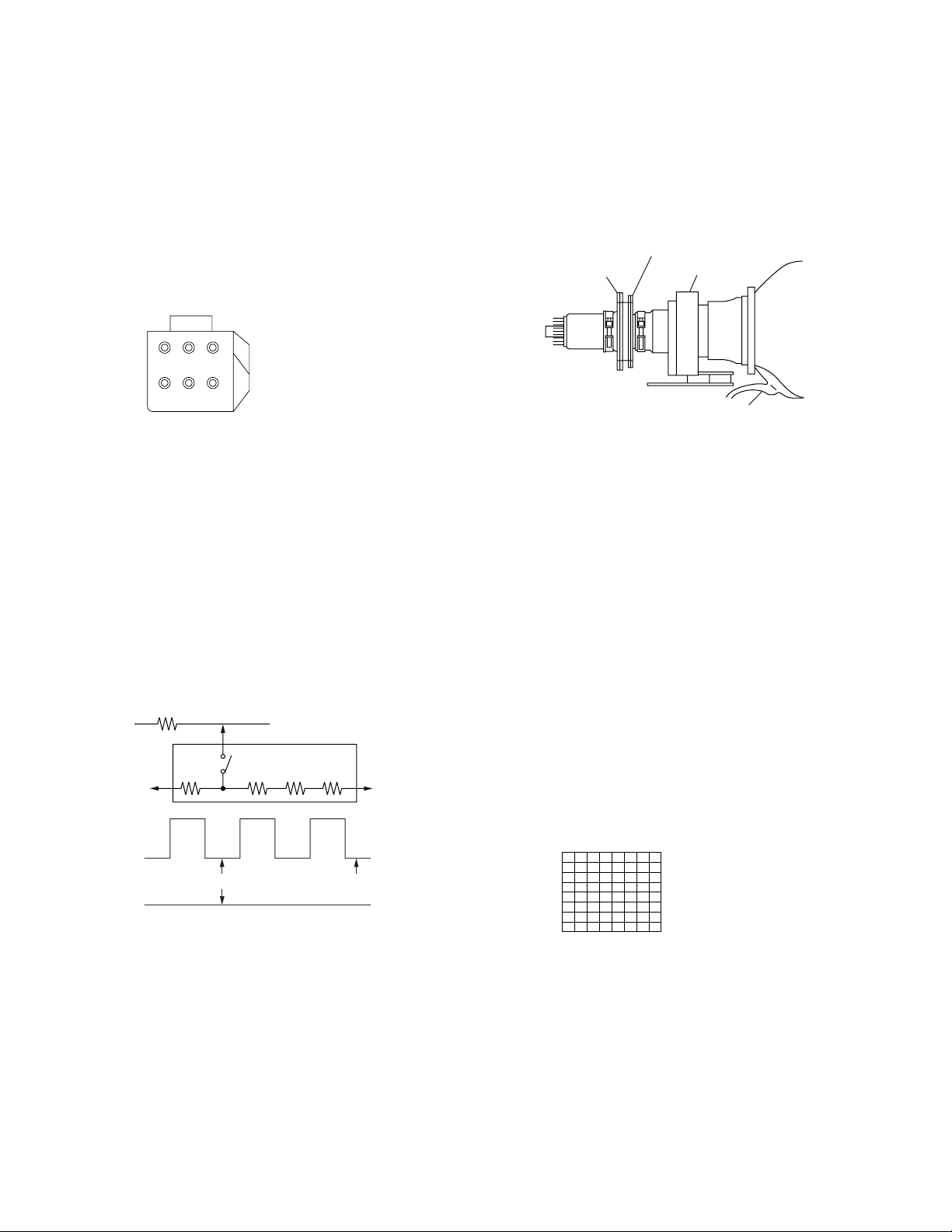

3-1. SCREEN VOLTAGE ADJUSTMENT

(COARSE ADJUSTMENT)

1. Receive the Monoscope signal.

2. Set 50% BRIGHTNESS and minimum PICTURE.

3. Turn the red VR on the FOCUS block all the way to the left

and then gradually turn it to the right until the point where you

can see the retrace line.

4. Next gradually turn it to the left to the position where the

retrace line disappears.

R G B

SCREEN

R G B

FOCUS

FOCUS block

Fig. 3-1

3-2. SCREEN (G2) ADJUSTMENT

(FINE ADJUSTMENT)

Fine Mode is recommended to set screen controls to their optimal

condition. It is necessary to build the simple jig, illustrated below,

using 3-watt resistors. Please note, that if the proper voltage is not

obtained with their listed values, resistors, then please increase or

decrease one of the values in the resistor network to obtain the

correct voltage.

1. Select VIDEO1 mode without signals.

2. Connect G2 JIG.

3. SW on JIG.

4. Connect an oscilloscope to the TP701(KR), TP732(KG) and

TP761(KB) of CR board, CG board and CB board.

5. Adjust R, G and B screen voltage to 168-172V with screen

VR on the Focus block.

K

G2 JIG

3.3k 5.6k 5.6k 5.6k

200V GND

SW

the mode Cover the both green and red picture lenses with the

lens caps is aligned the same as was done for green.

Note: Instead of items 3 and 6, you can cut off the unnecessary

color beams by controlling the service mode VPNT 28 RON,

29 GON, and 30 BON.

4-pole magnet

2-pole magnet

Fig. 3-3

Deflection yoke

Anode cap

3-4. FOCUS LENS ADJUSTMENT

In this adjustment, use the remote commander in the

service mode.

For details of the usage of the service mode and the remote

commander, please refer the item 3-9. ELECTRICAL

ADJUSTMENT BY REMOTE COMMANDER.

1. Loosen the lens screw.

2. Set to the service mode.

3. Receive the all-white signal.

4. Cover the both red and blue picture lenses with the lens caps

to show only the green color.

5. Set to PJE, and press 6 to display the test signal (crosshatch)“

on the screen.

6. Turn the green lens to adjust to the optimum focus point with

the test signal.

7. Tighten the lens screw.

8. Cover the both green and blue picture lenses with the lens caps

to show only the red color.

9. Set to PJE, and press 6 to display the test signal (crosshatch)“

on the screen.

10. Adjust red CRT lens just the same as green.

11. Cover the both green and red picture lenses with the lens caps

to show only the blue color.

175 ± 2V

GND

pedestal level

Fig. 3-2

3-3. DEFLECTION YOKE TILT ADJUSTMENT

1. Receive the Monoscope signal.

2. Set in service mode.

3. Cover the both red and blue picture lenses with the lens caps

to show only the green color.

4. Loosen the deflection yoke set screw and align the tilt of the

Deflection Yoke so that the bars at the center of the

monoscope pattern are horizontal.

5. After aligning the deflection yoke, fasten it securely to the

funnel-shaped portion (neck) of the CRT.

6. The tilt of the deflection yoke for red is aligned in the mode

Cover the both green and blue picture lenses with the lens caps

and the tilt of the deflection yoke for blue is aligned with in

– 28 –

Test signal

Fig. 3-4

12. Set to PJE, and press 6 to display the test signal (crosshatch)“

on the screen.

13. Adjust blue CRT lens just the same as green.

14. After adjusting the items 3-5. Focus VR Adjustment, 3-6. 2Pole Magnet Adjustment and 3-7. 4-Pole Magnet Adjustment,

adjust again to the optimum focus point.

*: Every time you press 6, the test signal changes to

“crosshatch+video signal” - “dots+video signal” -

“crosshach(black)” - “dots(black)” - off.

Note: Instead of items 4, 8 and 11, you can cut off the unnecessary

color beams by controlling the service mode VPNT 28 RON,

29 GON, and 30 BON.

Loading...

Loading...