Sony KP-XR432K90, KP-XR432N90 Service manual

SERVICE MANUAL

RA-3A

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

KP-XR432K90 RM-Y906KKorean SCC-P50D-A

KP-XR432N90 RM-Y906 Taiwan SCC-P50C-A

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

DVD/

POWER

MUTING

SAT/

VTR

CABLE

TV

FUNCTION

SYSTEM

OFF

DVD/VTR SAT/CABLE

TV

TV/VTR

FREEZE

SWAP PIP

m

N

M

AUDIO

POSITION ACTIVE

X

xz

ANT

TV/VIDEO

SLEEP

PICTURE

CC

MODE

DISPLAYMTS/SAP

2

1

3

5

6

4

8

7

9

JUMP

ENTER

0

INDEX

GUIDE

RESET

MENU

VOL CH

CODE SET

TV

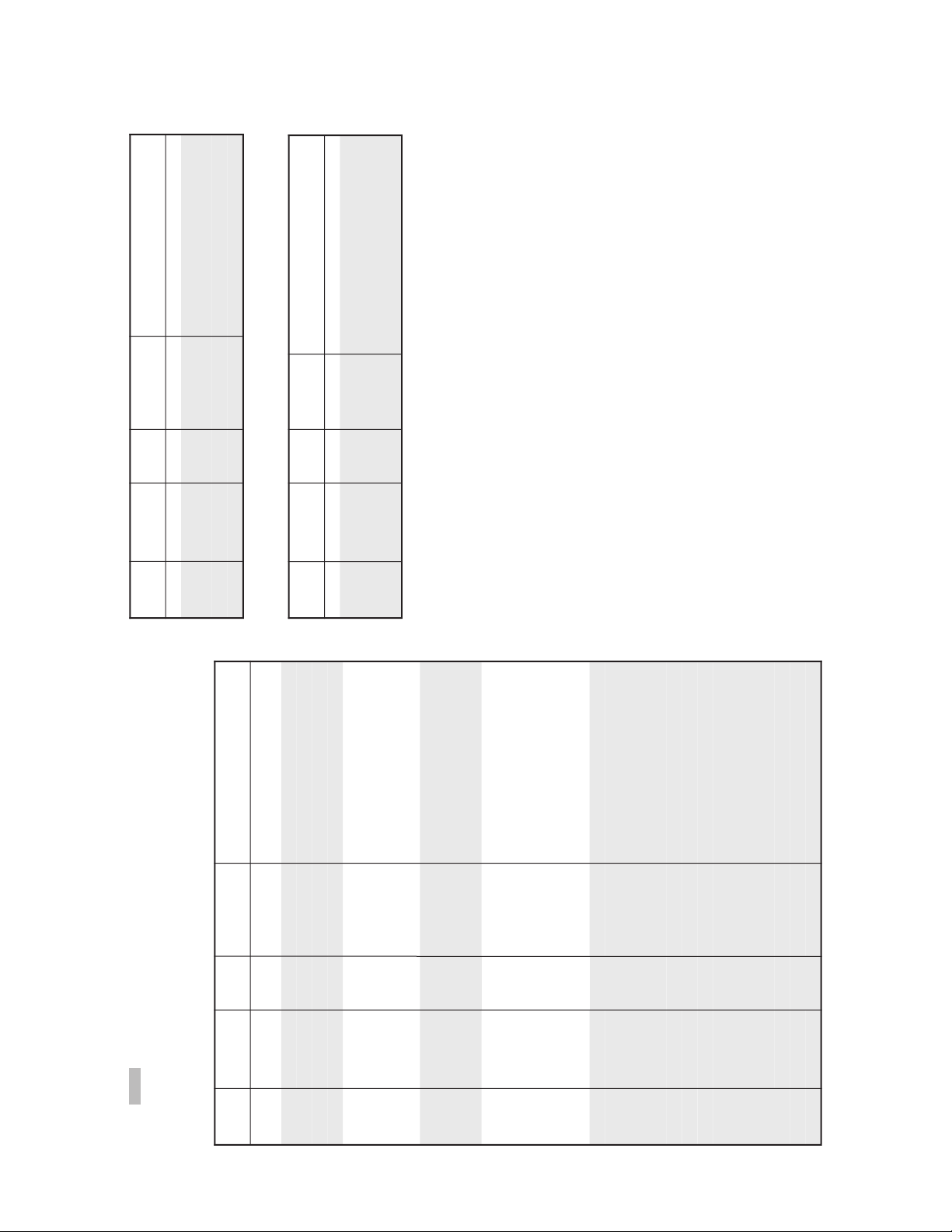

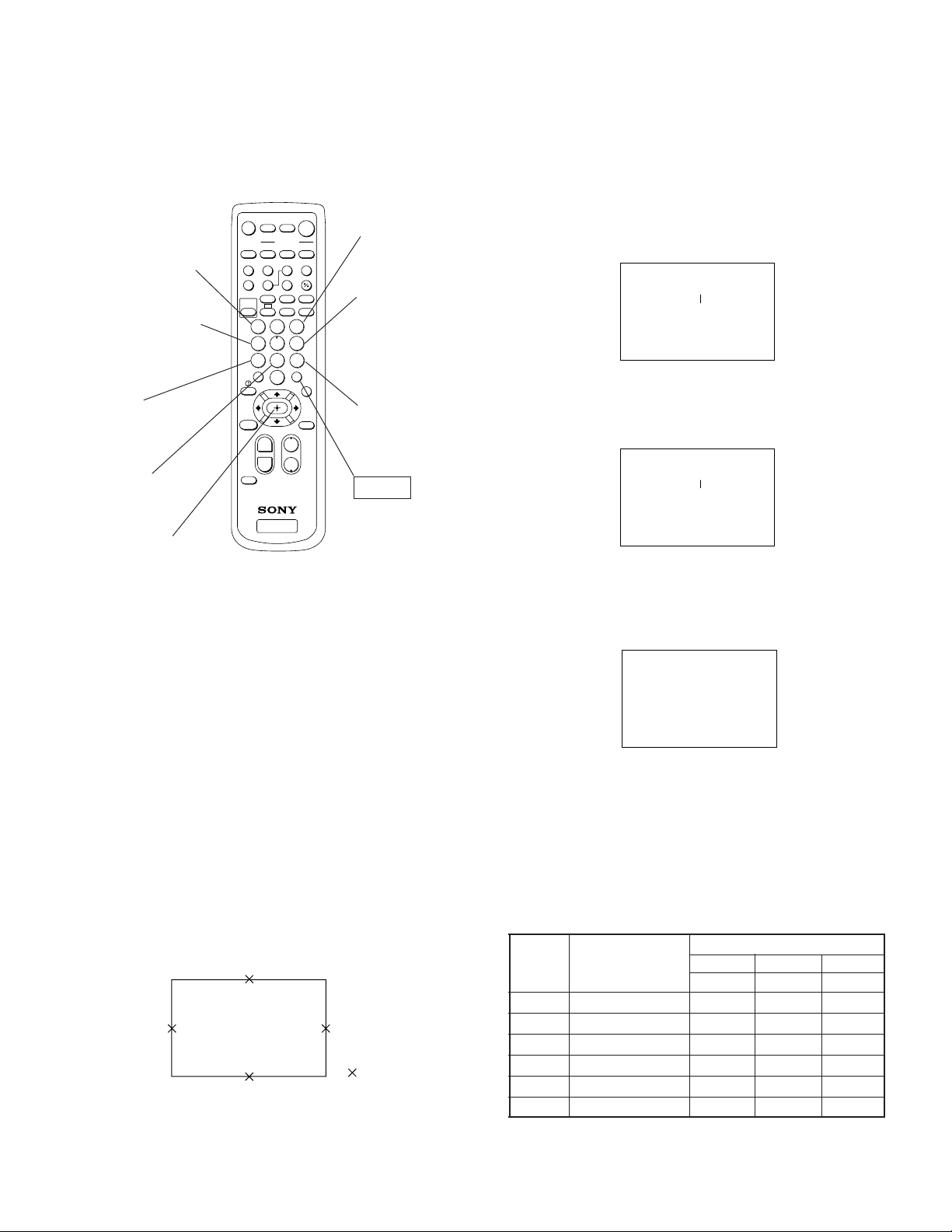

RM-Y906/Y906K

KP-XR432K90/432N90

PROJECTION TV

SPECIFICATIONS

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

Projection system

3 picture tubes, 3 lenses, horizontal in-line

system

Picture tube

7-inch high-brightness monochrome tubes (6.3 raster size),

with optical coupling and liquid cooling system

Projection lenses

High performance, large diameter hybrid lens F1.05

Television system

American TV standard

Channel coverage

VHF: 2–13/UHF: 14 –69/CATV: 1 – 125

Antenna

75 ohm external terminal for VHF/UHF

Screen size (measured diagonally)

43 inches

Inputs/outputs

VIDEO 1 IN

VIDEO 2 INPUT

S VIDEO IN (4-pin mini DIN):

Y: 1 Vp-p, 75-ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

VIDEO (phono jack): 1 Vp-p, 75-ohms unbalanced, sync

negative

AUDIO (phono jacks): 500 mVrms (100% modulation),

Impedance: 47 kilohms

VIDEO 3 IN

S VIDEO IN (4-pin mini DIN):

Y: 1 Vp-p, 75-ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

VIDEO (phono jack): 1 Vp-p, 75-ohms unbalanced, sync

negative

Y: 1 Vp-p, 75 ohms, sync negative

PB : 0.7 Vp-p, 75 ohms

PR : 0.7 Vp-p, 75 ohms

AUDIO (phono jacks): 500 mVrms (100% modulation),

Impedance: 47 kilohms

MONITOR OUT

VIDEO (phono jack): 1 Vp-p, 75-ohms unbalanced, sync

negative

AUDIO (phono jacks): 500 mVrms (100% modulation),

Impedance: 470 ohms

AUDIO (VAR/FIX) OUT (phono jacks): 500 mVrms (100%

modulation), Impedance: 470 ohms

CONTROL S OUT: minijack

Speaker

100 mm (4”) x 2

Speaker output

15W x 2

Power requirement

110 V AC, 60 Hz (KP-XR432N90)

220 V AC, 60 Hz (KP-XR432K90)

Power consumption

In use (Max.):210W (KP-XR432N90)

200W (KP-XR432K90)

In standby: 1 W

Dimensions (W/H/D)

966 x 1,063 x 508 mm (38 1 /8 x 41 7 /8 x 20 inches)

Mass

61.5 kg (135 lbs 9 oz)

Supplied accessories

Remote control RM-Y906K (1) (KP-XR432K90), RM-Y906

(KP-XR432N90)

Batteries (2) size AA (R6)

Design and specifications are subject to change without

notice.

– 2 –

TABLE OF CONTENTS

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

Section Title Page

–––––– –––– ––––

SELF DIAGNOSIS FUNCTION............................................ 3

1. SELF DIAGNOSIS FUNCTION

2. DISASSEMBLY

2-1. Rear Board Removal ................................................... 7

2-2. Chassis Assy Removal ................................................ 7

2-3. Service Position........................................................... 7

2-4. HA and HB Board Removal....................................... 7

2-5. Mirror Cover Removal ................................................ 8

2-6. Beznet Assy Removal.................................................. 8

2-7. HC Board Removal ..................................................... 8

2-8. A, G and FA Boards Removal..................................... 8

2-9. Picture Tube Removal ................................................. 9

2-10. High-Voltage Cable Installation and Removal ............ 9

3. SET-UP ADJUSTMENTS

3-1. Screen Voltage Adjustment (Coarse Adjustment) ..... 10

3-2. Screen (G2) Adjustment (Fine Adjustment) .............. 10

3-3. Deflection Y ork Tilt Adjustment ............................... 10

3-4. Focus Lens Adjustment ............................................. 10

3-5. Focus VR Adjustment ............................................... 11

3-6. 2-Pole Magnet Adjustment (Green, Red).................. 11

3-7. 4-Pole Magnet Adjustment........................................ 11

3-8. Defocus Adjustment (Blue) ....................................... 11

3-9. Electrical Adjustment by Remote Commander......... 12

3-10. Registration Adjustment(PJE) ................................... 17

3-11. Auto Registration Error Code List ............................ 20

4. CIRCUIT ADJUSTMENTS

4-1. TV Input Sub Contrast Adjustment

(VPNT-SCON) .......................................................... 21

4-2. VIDEO Input Sub-HUE and Sub-Color Adjustment

(VPNT-SHUE, SCOL) .............................................. 21

4-3. Component Input Sub-HUE and Sub-Color

Adjustment (DAC-UVSH, UVSC) ........................... 21

4-4. P&P Sub Contrast Adjustment (SC-SYDR) ............. 21

4-5. Sub-HUE, Sub-Color and Main Contrast

Adjustment (MC-MYDR, MSHU, MSCL,

SC-SSHU,SSCL) ...................................................... 22

4-6. Bar Display Position Adjustment

(OP-DISP) ................................................................ 22

4-7. PIP Position Adjustment (PI-PIPH, PIPV)................ 22

Section Title Page

–––––– –––– ––––

5-1. HV Regulation Circuit Check and Adjustment ......... 23

5-2. HV Hold Down Circuit Operation Check and

Adjustment ................................................................ 23

5-3. +B Max Voltage Confirmation .................................. 24

5-4. +B OVP Confirmation............................................... 24

6. DIAGRAMS

6-1. Block Diagram (1) ..................................................... 25

Block Diagram (2)..................................................... 26

Block Diagram (3)..................................................... 27

Block Diagram (4)..................................................... 28

Block Diagram (5)..................................................... 29

Block Diagram (6)..................................................... 30

Block Diagram (7)..................................................... 31

Block Diagram (8)..................................................... 32

6-2. Circuit Boards Location ............................................ 33

6-3. Schematic Diagrams .................................................. 33

6-4. Printed Wiring Boards............................................... 50

6-5. Waveforns.................................................................. 56

6-6. IC Block Diagram ..................................................... 58

6-5. Semiconductors ......................................................... 62

7. EXPLODED VIEWS

7-1. Cover ......................................................................... 63

7-2. Chassis ....................................................................... 64

7-3. Picture Tube .............................................................. 65

8. ELECTRICAL PARTS LIST ................................... 66

5. SAFETY RELATED ADJUSTMENTS

(CAUTION)

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR CARBON PAINTED ON THE CRT, AFTER REMOVING THE ANODE.

WARNING!!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECElVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESECOMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL TO SAFEOPERATION ARE IDENTIFIED IN THIS

MANUAL. FOLLOW THESE PROCEDURES WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

– 3 –

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

SECTION 1

SELF DIAGNOSIS FUNCTION

1. Summary of Self-Diagnosis Function

• This device includes a self-diagnosis function.

• In case of abnormalities, the TIMER/STANDBY indicator automatically blinks. It is possible to predict the abnormality location

by the number of blinks. The Instruction Manual describes blinking of the TIMER/STANDBY indicator.

• If the symptom is not reproduced sometimes in case of a malfunction, there is recording of whether a malfunction was generated

or not. Operate the remote command to confirm the matter on the screen and to predict the location of the abnormality.

2. Diagnosis Items and Prediction of Malfunction Location

• When a malfunction occurs the TIMER/STANDBY indicator only blinks for one of the following diagnosis items. In case of two

or more malfunctions, the item which first occurred blinks. If the malfunctions occurred simultaneously, the item with the lower

blink count blinks first.

• The screen display displays the results regarding all the diagnosis items listed below. The display “ 0 ” means that no malfunctions occurred.

metisisongaiD

NOtonrewoP•0

noitcetedPCOB+semit2.tiucrichcaenimetsysylppusrewopfotiucrictrohS

noitcetedPVOB+semit3.nepo276R

potsnoitcelfedlacitreVsemit4

noitcetedytilamronbatuooediVsemit5

potsnoitcelfedlatnoziroHsemit6

noitcetedytilamronbaoiduAsemit8

* : 000 the range of values for number of operations is 000-255. For 256 or higher there is

no count up and the number remains at 255.

3. Blinking count display of TIMER/STANDBY indicator

YBDNATS/REMIT

retacidnI

sknilbforebmuN

noitcnuflamdesoppuSnoitidnoC

)draobBF(.nepo1006F

.nepo5656R

tiucrictrohs6056Q

]metsySylppuSrewoPniaM[

.nekorbera4156Rdna1056CI

)draobBF(tiucric-trohs1006DV

.nekorbsi)tuoV(9051CI

.tiucricsdraobBCdna

)draobA(022,912,812Q

.nepo615,515C

.nekorbsi)elgnuJCY(602CI

.nekorbsi).pmaoiduA(604CI

.nepo204,104SP

]metsySylppuSrewoPybdnatS[

.rewopehtnonruttonnaC

.knilbt'nseodDEL

edomybdnatsehtotseoG

enilB+fotiucrictrohS

edomybdnatsehtotseoG

tiucricylppusrewopfonoitcnuflaM

.nekorbsi)reffuBesluPV(5051Q

GC,RCnisrehtodna167,237,507Q,tuooediV

.detumsilangis

.sisongaidflesehtrofsknilbnehtdna

.raeppat'nseodretsaR000potSH:6

.tuotonsidnuosehT

edomybdnatsehtotseoG

oedivnehtdnaA,yllatnozirohenilenootseogretsaR

,sdnoces03.xorppasknilbDELYBDNATS/REMIT

sisongaid-fleS

,yalpsidneercs

stluseR:metisisongaiD

000PCOB+:2

000PVOB+:3

000potSV:4

000BKA:5

000oiduA:8

* One blink is not used for self-diagnosis.

< FRONT PANEL >

VOLUME

–+

TV/VIDEO

FLASH FOCUS

CHANNEL

–+

ON/OFF

•EXAMPLE

TIMER/STAND BY

<Diagnosis Items> <Number of Blinks>

• +B overcurrent 2 times

• +B overvoltage 3 times

TIMER/STANDBY indicator

• Vertical deflection stop 4 times

Lamp ON : 0.3 seconds

Lamp OFF : 0.3 seconds

Lamp OFF :

3.0 seconds

Release of TIMER/STANDBY indicator blinking.

• The TIMER/STANDBY indicator blinking display is released by turning OFF the power switch

on the TV main unit or removing the plug from the power.

– 4 –

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

4. Self-diagnosis screen displays

• In cases of malfunctions where it is not possible to determine the symptom such as when the power goes off occasionally or when

the screen disappears occasionally, there is a screen display on whether the malfunction occurred or not in the past (and whether

the detection circuit operated or not) in order to allow confirmation.

<Screen Display Method>

• Quickly press the remote command button in the following order from the standby state.

DISPLAY b Channel 5 b VOL – b POWER

˘

Be aware that this differs from the method of

entering the service mode (volume + ).

Self-diagnosis screen display

Self Check

2 : +B OCP 000

3 : +B OVP 000

4 : V Stop 000

5 : AKB 000

6 : H Stop 000

7 : HV 000

8 : Audio 000

101 : WDT 000

÷

2 : +B OCP 000

Diagnosis

Results

000 the range of values for number of

operations is 000-255.

For 256 or higher there is no count up

and the number remains at 255.

5. Self-Diagnosis Screen Display

• The results display is not automatically cleared. In case of repairs and after repairs, check the self-diagnosis screen and be sure

to return the results display to “ 0 ”.

• If the results display is not returned to “ 0 ” it will not be possible to judge a new malfunction after completing repairs.

<Method of Clearing Results Display>

1. Power off (Set to the standby mode)

2. DISPLAY b Channel 5 b VOL + b POWER (Service Mode)

3. Channel 8 b ENTER (Test reset = Factory preset condition)

<Method of Ending Self Diagnosis Screen>

• When ending the self-diagnosis screen completely, turn the power switch OFF on the remote commander or the main unit.

– 5 –

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

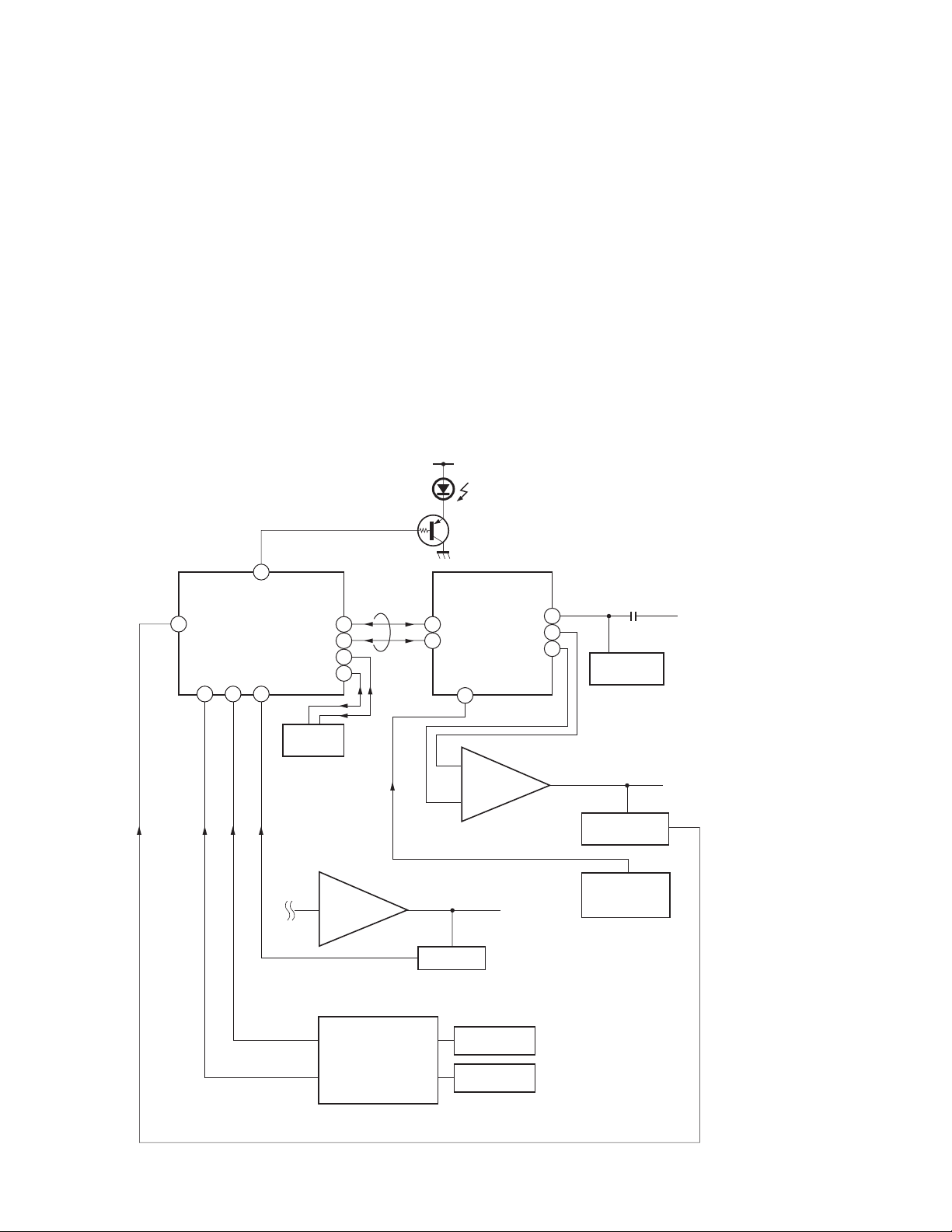

6. Self-diagnosis function operation

OCP Low B and +B line detect DET SHORT, and shut-down POWER ON RELAY.

Reset by turning power on/off.

In case of +B is loaded approx. 1.3A or more, microcomputer detects it via IC651.

OVP In case of +B becomes approx. 150V or more, POWER ON RELAY shuts down and microcomputer detects it via IC651.

Reset by turning power on/off just the same as OCP.

V Stop In case of microcomputer detects 2 seconds or more interval of V Pulse, Reference Pulse turns off by turning off the picture

signal in YC Jungle IC (IC206).

After the picture signal turns off, V Pulse is regenerated 2 seconds or more, the picture signal turns on.

AKB IK detection. Makes LED blinking in case of microcomputer doesn’t detect IK returns of IC206 CXA2147Q 30 seconds or more.

H Stop In case of HV becomes 33kV or more, IC502 detects it and shut-down H Drive Pulse.

Microcomputer receives H Stop data from IC206 and makes LED blinking.

Audio In case of DC component overlaps the output of Audio Amp., microcomputer detects it and makes LED blinking.

Microcomputer forces to shut down the power.

Self-diagnosis block diagram

D1201

TIMER/STANDBY

8

20 21 22

55

IC002

µProcessor

Audio

IC004

EEPROM

Audio AMP

5. AKB

6. H STOP

49

47

50

48

IC406

BUS

5. AKB

Q006

3

4

27

DC Detect

IC206

CXA2147

YCJ

IC1509

V Drive

43

35

34

6. HV STOP

IC502

HV Detector

Q1505

V Pulse Buffer

C Board

4. V.STOP (V Pulse)

3. OVP

2. OCP

IC651

OVP Buffer

OCP Buffer

OVP DETECT

OCP DETECT

– 6 –

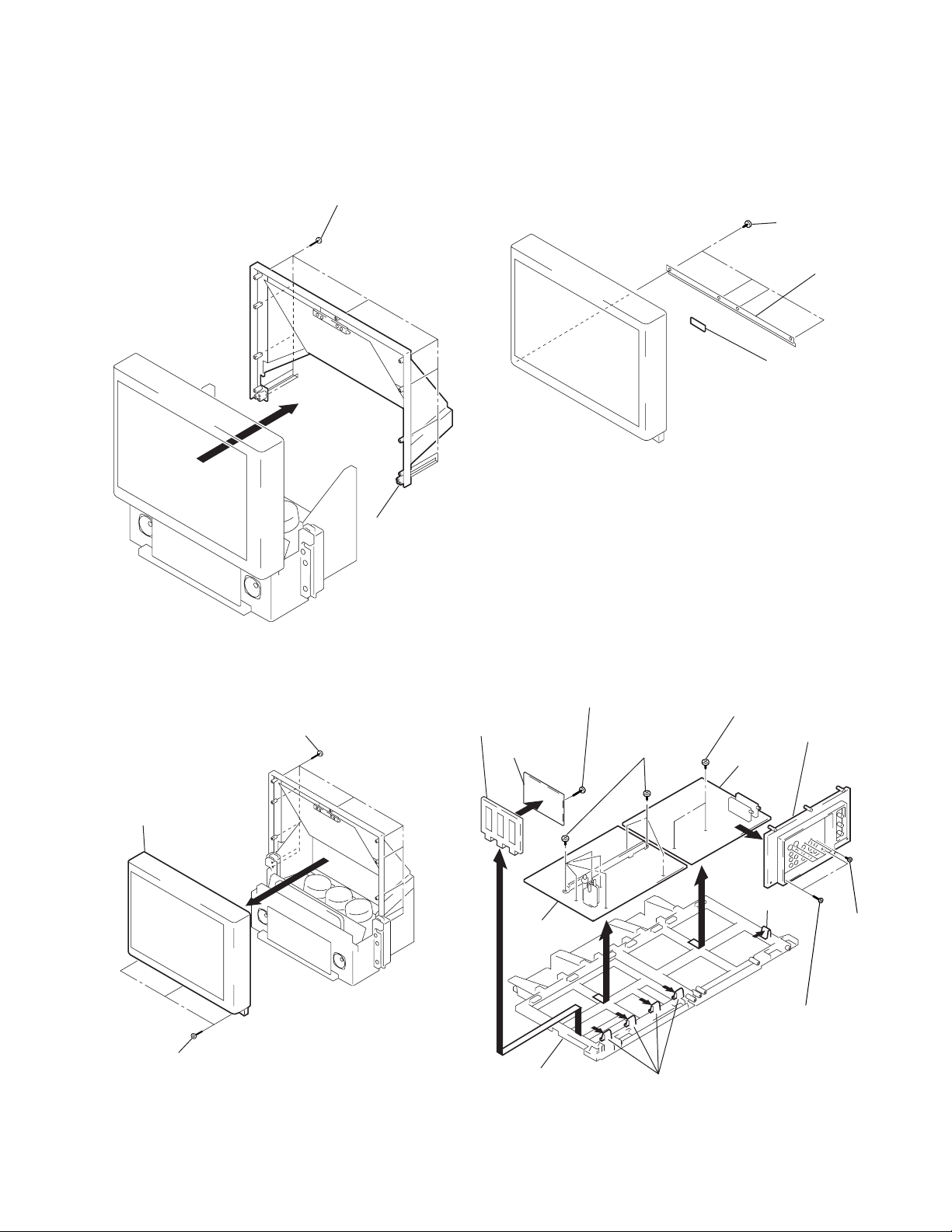

SECTION 2

DISASSEMBLY

2-1. REAR BOARD REMOVAL 2-3. SERVICE POSITION

1 Disconnect CN203

on A board.

From CG board CN1304.

(The extension cable is not

supplied because of the

countermeasure for radiation.)

2 Covers

Cut them off with a plier or the like

from chassis assembly in case of

checking printed circuit boards.

After checking, turn over the covers

and secure them with screws.

2 Rear board

A board

CN203

G board

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

1 Nine screws

(Screw, tapping haxagon head)

2-2. CHASSIS ASSY REMOVAL

1 Three screws

(Screw, tapping haxagon head)

Chassis assembly

Screws

(+BVTP3x12)

2-4. HA AND HB BOARD REMOVAL

8 HB board

7 Three screws

(+BVTP 3x12)

4 HA bracket

Panel ASSY, Control

1 Four screws

(Screw, tapping haxagon head)

2

3 Four screws

(+BVTP 3x12)

6 HA board

2 Chassis assy

5 Three screws

(+BVTP 3x12)

– 7 –

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

2-5. MIRROR COVER REMOVAL

1 Sixteen screws

(Screw, tapping haxagon head)

2-7. HC BOARD REMOVAL

1 T w o screws

(+BVTP 4x12)

2 L screen holder

3 HC board

2 Mirror cover

2-6. BEZNET ASSY REMOVAL

2 T w elve screws

(Screw, tapping haxagon head)

3 Beznet assy

1 Three screws

(Screw, tapping haxagon head)

2-8. A, G AND FA BOARDS REMOVAL

!¡ FA board bracket

!™ FA board

6 G board

Main bracket

0 Screw

(+BVTP 3x12)

4 Eight screws

(+BVTP 3x12)

5 Claws

7 T w o screws

(+BVTP 3x12)

3 T erminal board

9 A board

8 Claw

2 Seven screws

(+BVTP 3x12)

1 T w o screws

(Screw, tapping haxagon head)

– 8 –

2-9. PICTURE TUBE REMOVAL

CAUTION: Removing the arrow-marked

screws is strictly prohibited.

If removed, it may cause liquid spill.

Lens

Picture tube

2 Four screws

(Screw, tapping

haxagon head)

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

4 Four screws

(Screw, tapping haxagon head)

5 Lens

9 Four screws

(+BVTP 4x12)

0 Picture tube

8 Diflection yoke

7 Neck assy

6 CR board

3

2-10. HIGH-VOLTAGE CABLE INSTALLATION

AND REMOVAL

(1) Removal

1 Rubber cap

2 HV cable

turn 90°

(2) Installation

1 Four screws

(Screw, tapping haxagon head)

Gutter

1 HV cable

Hook

– 9 –

SECTION 3

SET-UP ADJUSTMENTS

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

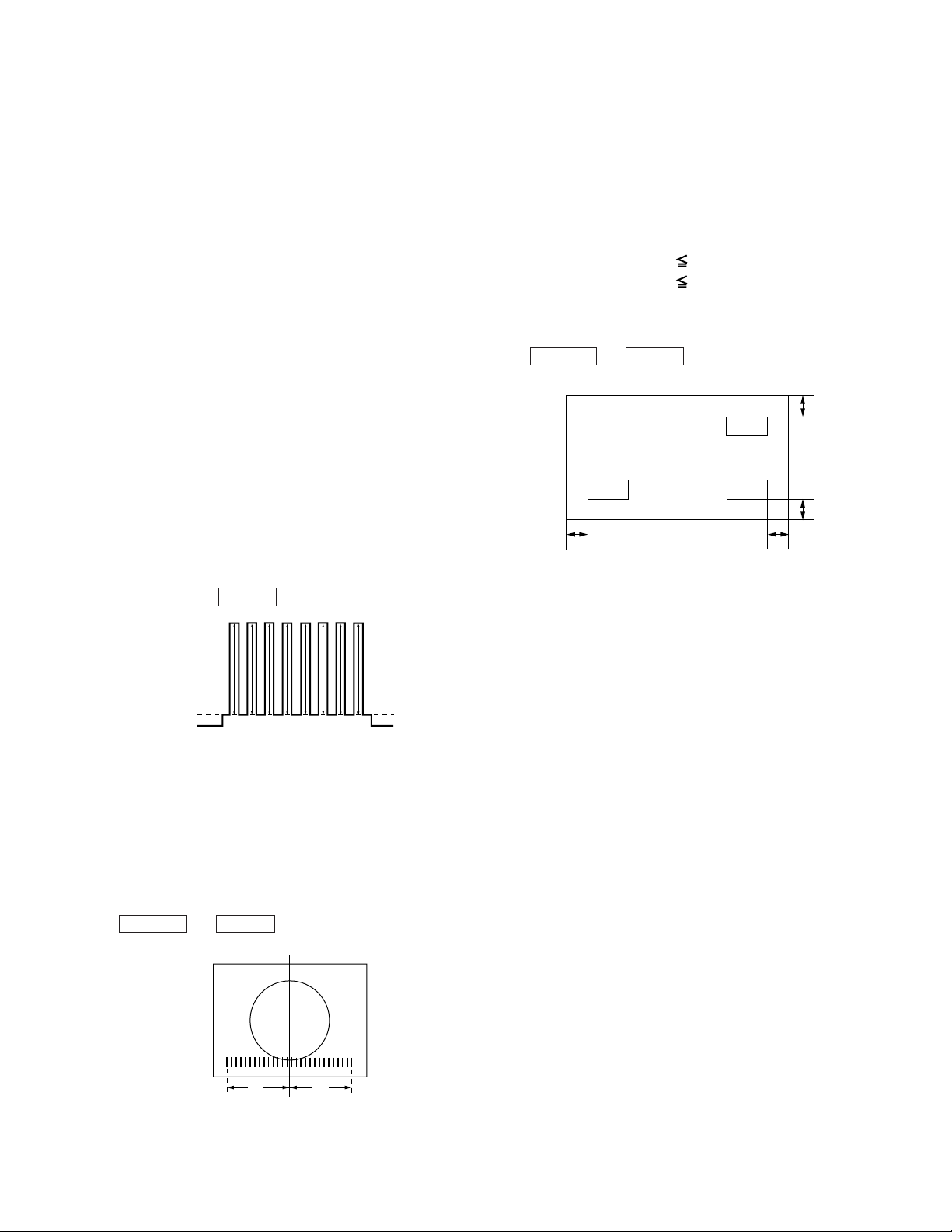

3-1. SCREEN VOL T AGE ADJUSTMENT

(COARSE ADJUSTMENT)

1. Receive the Monoscope signal.

2. Set 50% BRIGHTNESS and minimum PICTURE.

3. Turn the red VR on the FOCUS block all the way to the left

and then gradually turn it to the right until the point where you

can see the retrace line.

4. Next gradually turn it to the left to the position where the

retrace line disappears.

R G B

SCREEN

R G B

FOCUS

FOCUS block

Fig. 3-1

3-2. SCREEN (G2) ADJUSTMENT

(FINE ADJUSTMENT)

Fine Mode is recommended to set screen controls to their optimal

condition. It is necessary to build the simple jig, illustrated below,

using 3-watt resistors. Please note, that if the proper voltage is not

obtained with their listed values, resistors, then please increase or

decrease one of the values in the resistor network to obtain the

correct voltage.

1. Select VIDEO1 mode without signals.

2. Connect G2 JIG.

3. SW on JIG.

4. Connect an oscilloscope to the TP701(KR), TP732(KG) and

TP761(KB) of CR board, CG board and CB board.

5. Adjust R, G and B screen voltage to 168-172V with screen

VR on the Focus block.

K

G2 JIG

3.3k 5.6k 5.6k 5.6k

200V GND

SW

the mode Cover the both green and red picture lenses with the

lens caps is aligned the same as was done for green.

Note: Instead of items 3 and 6, you can cut off the unnecessary

color beams by controlling the service mode VPNT 28 RON,

29 GON, and 30 BON.

4-pole magnet

2-pole magnet

Fig. 3-3

Deflection yoke

Anode cap

3-4. FOCUS LENS ADJUSTMENT

In this adjustment, use the remote commander in the

service mode.

For details of the usage of the service mode and the remote

commander, please refer the item 3-9. ELECTRICAL

ADJUSTMENT BY REMOTE COMMANDER.

1. Loosen the lens screw.

2. Set to the service mode.

3. Receive the all-white signal.

4. Cover the both red and blue picture lenses with the lens caps

to show only the green color.

5. Set to PJE, and press 6 to display the test signal (crosshatch)“

on the screen.

6. Turn the green lens to adjust to the optimum focus point with

the test signal.

7. Tighten the lens screw.

8. Cover the both green and blue picture lenses with the lens caps

to show only the red color.

9. Set to PJE, and press 6 to display the test signal (crosshatch)“

on the screen.

10. Adjust red CRT lens just the same as green.

11. Cover the both green and red picture lenses with the lens caps

to show only the blue color.

175 ± 2V

GND

pedestal level

Fig. 3-2

3-3. DEFLECTION YOKE TIL T ADJUSTMENT

1. Receive the Monoscope signal.

2. Set in service mode.

3. Cover the both red and blue picture lenses with the lens caps

to show only the green color.

4. Loosen the deflection yoke set screw and align the tilt of the

Deflection Yoke so that the bars at the center of the

monoscope pattern are horizontal.

5. After aligning the deflection yoke, fasten it securely to the

funnel-shaped portion (neck) of the CRT.

6. The tilt of the deflection yoke for red is aligned in the mode

Cover the both green and blue picture lenses with the lens caps

and the tilt of the deflection yoke for blue is aligned with in

Test signal

Fig. 3-4

12. Set to PJE, and press 6 to display the test signal (crosshatch)“

on the screen.

13. Adjust blue CRT lens just the same as green.

14. After adjusting the items 3-5. Focus VR Adjustment, 3-6. 2Pole Magnet Adjustment and 3-7. 4-Pole Magnet Adjustment,

adjust again to the optimum focus point.

*:Every time you press 6, the test signal changes to

“crosshatch+video signal” - “dots+video signal” -

“crosshach(black)” - “dots(black)” - off.

Note: Instead of items 4, 8 and 11, you can cut off the unnecessary

color beams by controlling the service mode VPNT 28 RON,

29 GON, and 30 BON.

– 10 –

KP-XR432K90/XR432N90

/

x

y

x : y = 1:1.5 (BIue)

x : y = 1:1 (Green, Red)

Use the center dot

RM-Y906K RM-Y906

3-5. FOCUS VR ADJUSTMENT

1. Set to the service mode.

2. Receive the all-white signal.

3. Cover the both red and blue picture lenses with the lens caps

to show only the green color.

4. Set to PJE, and press 6 to display the test signal (crosshatch)

on the screen.

5. Turn the green focus VR on the focus block to adjust to the

optimum focus point with the test signal.

6. Cover the both green and blue picture lenses with the lens caps

to show only the red color.

7. Set to PJE, and press 6 to display the test signal (crosshatch)

on the screen.

8. Turn the red focus VR on the focus block to adjust to the

optimum focus point with the test signal.

9. Cover the both green and red picture lenses with the lens caps

to show only the blue color.

10. Set to PJE, and press 6 to display the test signal (crosshatch)

on the screen.

11. Turn the blue focus VR on the focus block to adjust to the

optimum focus point with the test signal.

12. After adjusting the items 3-4. Focus Lens Adjustment, 3-6. 2Pole Magnet Adjustment and 3-7. 4-Pole Magnet Adjustment,

adjust again to the optimum focus point.

Note: Instead of items 3, 6 and 9, you can cut off the unnecessary

color beams by controlling the service mode VPNT 28 RON,

29 GON, and 30 BON.

Use the center dot

Fig. 3-7

3-7. 4-POLE MAGNET ADJUSTMENT

1. Receive the Dot signal.

2. Set in service mode.

3. Cover the both red and blue picture lenses with the lens caps

to show only the green color.

4. Turn the green focus VR on the focus block to the left and set

to underfocus to enlarge the spot.

5. Now align the 4-Pole Magnet so that the enlarged spot

becomes a perfect circle for green and red.

6. Perform the same alignment for blue.

Scanning line visible.

A

Minimize both A and B.

Lens

Fig. 3-5

B

Center of crosshatch

Fig. 3-6

3-6. 2-POLE MAGNET ADJUSTMENT

(GREEN,RED)

1. Receive the Dot signal.

2. Set in service mode.

3. Cover the both red and blue picture lenses with the lens caps

to show only the green color.

4. Turn the green focus VR on the focus block to the right and

set to overfocus to enlarge the spot.

5. Now align the 2-Pole Magnet so that the enlarged spot is in

the center of the Just Focus spot.

6. Align the green focus VR and set for just (precise) focus.

7. Perform the same alignment for red.

Fig. 3-8

3-8. DEFOCUS ADJUSTMENT (BLUE)

Note: Please adjust the blue dot to be slightly larger than red and

green dots. This adjustment provides a more pleasing picture

to the customer.

1. Select the video menu and set the mode to “VIVID” mode.

2. Set to the service mode.

3. Change TV mode to the video input mode.

4. Set to PJE, and press 6 to display the test signal (dots) on the

screen.

5. Turn the blue focus VR on the focus block to adjust to the

diameter of the dots as shown in the figure below.

[Focus adjustment point]

Lmm Max

Inch

L

43"

6

Fig. 3-9

– 11 –

KP-XR432K90/XR432N90

2

5

8

0

1

4

7

3

6

9

ENTER

JUMP

GUIDE

INDEX

RESET

MENU

POWER

MUTING

FREEZE

AUDIO

ANT

TV/VIDEO

DISPLAYMTS/SAP

CC

PICTURE

MODE

POSITION ACTIVE

SWAP PIP

TV/VTR

SYSTEM

OFF

DVD/VTR SAT/CABLE

TV

DVD/

VTR

SAT/

CABLE

FUNCTION

SLEEP

m

N

M

xz

X

TV

RM-Y906K RM-Y906

3-9. ELECTRICAL ADJUSTMENT BY REMOTE

COMMANDER

By using Remote Commander (RM-Y906/Y906K),all circuit

adjustments can be made.

NOTE : Test Equipment Required.

1. Pattern Generator (with component outputs)

2. Frequency counter

3. Digital multimeter

4. Audio oscillator

1. METHOD OF SETTING THE SER VICE ADJUSTMENT MODE

SERVICE MODE PROCEDURE

1. Standby mode. (Power off)

2. DISPLAY n 5 n VOL (+) n TV POWER

on the Remote Commander.

(Press each button within a second.)

SERVICE MODE ADJUSTMENT

Category Adjustment item

DATA

SERVICE VPNT VPOS 031

000000 00

7. If you want to recover the latest v alues press - then [ENTER] to

read the memory.

8. Press [MUTING] then [ENTER] to write into memory.

9. Turn power off.

Note: Press 8 then [ENTER] on the Remote Commander to initialize

or turn set off and on to exit.

2. MEMORY WRITE CONFIRMATION METHOD

1. After adjustment, remove the plug from AC outlet, and then

replace the plug in AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again and confirm they were adjusted.

3. ADJUSTING BUTTONS AND INDICATOR

TV POWER ON

MUTING

(SCREEN DISPLAY)

3. The SCREEN displays the item being adjusted.

4. Press 1 or 4 on the Remote Commander to select the

adjustment item.

5. Press 3 or 6 on the Remote Commander to change the data.

6. Press 2 or 5 on the Remote Commander to select the

category.

Every time you press 2(Category up), Service mode changes

in the order as shown below.

VPNT

VPNV

VPNS

PJE

3DCM

TONE

DSP

MC

SC

IC

PP

DAC

PI

ID

CCD

OP

Category up

Adjustment item up

Adjustment item down

VOL (+)

RM-Y906/Y906K

Note : When the PJE mode is activated, which displays an

internally generated signal, several buttons on the remote

commander will have different functions than listed

above. Therefore, when in the PJE mode, refer to page 17

for button functions.

DISPLAY

Data up

Data down

Category down

ENTER

– 12 –

KP-XR432K90/XR432N90

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0SOPV36-013NOITISOPV

1ZISV36-013EZISV

2 MOCV

3-0

0

PMOCV

3

NILV

51-0

7

YTIRAENILV

4

OCSV

51-0

7

NOITCERROCEVRUCSV

5

SOPH

51-0

7

NOITISOPH

6ZISH36-013EZISH

7PMAP36-013PMANIP

8NIPU51-07 NOITROTSIDNIPRENROCREPPU

9NIPL51-07 NOITROTSIDNIPRENROCREWOL

01AHPP51-05 ESAHPNIP

11

CFA 3-0

2

NIAGPOOLCFA

21

WOBV

51-0

7 WOBV

31

GNAV

51-0

7

ELGNAV

41

FER

3-0

3

NOITISOPESLUPECNEREFER

51VRDR36-013NIAGEVIRDDER

61VRDB36-013NIAGEVIRDEULB

71TUCR51-07 FFOTUCDER

81TUCB51-07 FFOTUCEULB

91NOCS51-07 TSARTNOCBUS

02EUHS51-07 EUHBUS

12LOCS51-07 ROLOCBUS

22 2MDC

1,0

0

2EDOMNWODTNUOC

32

XIPD

1,0

1

ERUTCIPCIMANYD

42

CTON

1,0

0

PARTAMORHCY

52

MORC

51-0

7

0FPARTAMORHC

62

TOT

1,0

0

RETLIFTOTAMORHC

72

FPHS

3-0

3

0FSSENPRAHS

82

NOR

1,0

1

NODER

92

NOG

1,0

1

NONEERG

03

NOB

1,0

1

NOEULB

13

LOCD

1,0

1

ROLOCCIMANYD

23 DMDC

1,0

0

NWODTNUOCV

33

KLBL

51-0

31

HTDIWKNALBEDIS-TFEL

43

KLBR

51-0

31

HTDIWKNALBEDIS-THGIR

53

CERP

3-0

1

NIV.PMOCROFLEVELREVOERP

63

YERP

3-0

1

NIYROFLEVELREVOERP

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0VRBS36-072DIVIVROFSSENTHGIRBBUS

1

VMMG

3-0

2

DIVIVROFLEVELAMMAG

2

VCDY

1,0

1

DIVIVROFOITARREFSNARTCD-Y

3 VLBA

1,0

1

DIVIVROFEDOMLBA

4 VIXA

1,0

0

DIVIVROFY-G,Y-RSIXA

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0SRBS36-072DRADNATSROFSSENTHGIRBBUS

1

SMMG

3-0

2

DRADNATSROFLEVELAMMAG

2

SCDY

1,0

0

DRADNATSROFOITARREFSNARTCD-Y

3

SLBA

1,0

1

DRADNATSROFEDOMLBA

4 SIXA

1,0

0

DRADNATSROFY-G,Y-RSIXA

RM-Y906K RM-Y906

VPNV (Video Processor NTSC Vivid)

VPNS (Video Processor NTSC Standard)

in the sets individually. Basically, there is no need to change data, too.

of replacing printed circuit boards or devices.

• Usually, there is no need to adjust except for VPNT and PJE. Use data as a reference in case

4. SERVICE MODE LIST

Note: • shaded items are fixed. There is no need to change data. Others are different a little

VPNT (Video Processor NTSC)

– 13 –

KP-XR432K90/XR432N90

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0

SIDF

1,0

0

JDAENIFFOYALPSIDATADIGERTCELES

1

HDSO

552-1

13

NOITISOPHUNEMECIVRESDEJP

2

VDSO

552-1

52

NOITISOPVUNEMECIVRESDEJP

3

TSVF

552-0

52

TRATSTSUJDAENIFFOREBMUNENIL

4

TS1V

552-0

0

ATADTRATS1V

5

UC1V

552-0

26

ATADPUTNUOC1V

6 PHOC

552-0

0 JDAHGUORFOESAHP-H

7

PHIF

552-0

491

JDAENIFFOESAHP-H

8

PHPT

552-0

26

NRETTAPTSETFOESAHP-H

9

PHFD

552-0

522

SUCOFCIMANYDFOESAHP-H

01

GHFD

721-821-

08-

SUCOFCIMANYDFONIAG2-H

11

GVFD

721-821-

51-

SUCOFCIMANYDFONIAG2-V

21

lMWP

552-0

0

lMWP

31

2MWP

552-0

23

NRETTAPTSET.IGEROTUAFOESAHP-H

41

DLBH

552-0

442

ENILVEULBDENRUTERFOESAHP-H

51

WLBH

36-0

32

ENILVEULBDENRUTERFOHTDIWESLUP

61

PKLB

552-0

72

ESLUPKNALBTRATS

71

VGOC

721-821-

)1*(X

IGEROTUAFOATADTESFFOTNECVNEERG

81

VROC

721-821-

)1*(X

IGEROTUAFOATADTESFFOTNECVDER

91

VBOC

721-821-

)1*(X

IGEROTUAFOATADTESFFOTNECVEULB

02

HGOC

721-821-

)1*(X

IGEROTUAFOATADTESFFOTNECHNEERG

12

HROC

721-821-

)1*(X

IGEROTUAFOATADTESFFOTNECHDER

22

HBOC

721-821-

)1*(X

IGEROTUAFOATADTESFFOTNECHEULB

32

VGOS

721-821-

)1*(X

IGEROTUAFOATADTESFFOWEKSVNEERG

42

VROS

721-821-

)1*(X

IGEROTUAFOATADTESFFOWEKSVDER

52

VBOS

721-821-

)1*(X

IGEROTUAFOATADTESFFOWEKSVEULB

62

HGOS

721-821-

)1*(X

IGEROTUAFOATADTESFFOWEKSHNEERG

72

HROS

721-821-

)1*(X

IGEROTUAFOATADTESFFOWEKSHDER

82

HBOS

721-821-

)1*(X

IGEROTUAFOATADTESFFOWEKSHEULB

92

RRE

DEXIF

0 EDOCRORREIGEROTUA

03

MTDA

552-0

441

IGEROTUAFOATADD/ATEGOTGNIMIT

13

PUV

552-1

1

NOITISOPVREPPUNRETTAPIGEROTUA

23

DIMV

552-1

201

NOITISOPVELDDIMNRETTAPIGEROTUA

33

WOLV

552-1

212

NOITISOPVREWOLNRETTAPIGEROTUA

43

RPH

015-1

1

NOITISOPHNRETTAPIGEROTUA

NRG

TNEC115-215-000/000TNECV/HNEERG

WEKS115-215-000/000WEKSV/HNEERG

EZIS

115-215-

091-/07-

EZISV/HNEERG

NIL115-215-xxxx/xxxxNILV/HNEERG

YEK115-215-xxxx/xxxxYEKV/HNEERG

NIP115-215-172/xxxxNIPV/HNEERG

ULB

TNEC115-215-000/000TNECV/HEULB

WEKS115-215-031-/080WEKSV/HEULB

EZIS115-215-622-/02-EZISV/HEULB

NIL115-215-xxxx/781NILV/HEULB

YEK115-215-511-/xxxxYEKV/HEULB

NIP115-215-891/xxxxNIPV/HEULB

DER

TNEC115-215-000/000TNECV/HDER

WEKS115-215-031-/080WEKSV/HDER

EZIS115-215-602-/16-EZISV/HDER

NIL115-215-xxxx/591NILV/HDER

YEK115-215-421/xxxxYEKV/HDER

NIP115-215-052/xxxxNIPV/HDER

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0

DMRN

3-0

0

EDOMRECUDERESION

1

OCYD

51-0

2

∆ GNITTESLEVELGNIROCY

2

AGYD

51-0

01

∆ GNITTESNIAGY

3

OCCD

51-0

5

∆ GNITTESLEVELGNIROCC

4

AGCD

51-0

5

∆ GNITTESNIAGC

5 DLES

1,0

1

TCELES ∆ RETLIFLANGISY

6 AG2D

7-0

4

∆ GNITTESNIAGdn2C/Y

7 HRTV

3-0

1

GNITTESSISERETSYHCNYSHRTV

8

RRTV

3-0

1

GNITTESECNEREFERCNYSHRTV

9

RSDL

3-0

2

ECNEREFERLANGISDL

01

GPAV

7-0

5

NIAGERUTREPAV

11 IPAV

13-0

11

TNIOPTREVNIERUTREPAV

21

TFPY

3-0

0

PATRETLIFGNIKAEPY

31

GFPY

51-0

9

NIAGRETLIFGNIKAEPY

41

SP1V

3-0

2

ROTCELESENIL-1LACITREV

51 SGEV

3-0

1

ROTCELESEGDELACITREV

61

N3CC

1,0

0

RETLIFMOCENIL-3LANGISC

71

PDH

7-0

4

ESAHPLATNOZIROHDH

81

LDC

7-0

4

YALEDC

91

LSSH

51-0

21

LEVELECILSCNYSH

02

LSSV

51-0

8

LEVELECILSCNYSV

12

FLPH

1,0

1

RETLIFLLPH

22

FLPB

1,0

0

RETLIFLLPTSRUB

32

FCSF

1,0

1

NIAGRETLIFCSF

42

GFLP

1,0

1

NIAGRETLIFLLP

52

DAXE

1,0

1

NIDALANRETXE

62

SSM

1,0

0

LANGISNOITOMDECROF

72 TUOC

3-0

2

TUPTUOLANGISC

82

SPAY

3-0

1

ERUTREPAY

92

SDSN

3-0

0

.TCETEDLANGISDTSNON

03

PPC

3-0

0

EGNARDA&ESLUPPMALC

13

OCHY

3-0

1

GNIROCLANGIS.QERFHGIHY

23

OCPY

1,0

0

FFOGNIROCRETLIFKAEPY

33

RLIK

51-0

3

ECNEREFERRELLIK

43

SPGB

51-0

4

NOITISOPTRATSPGB

53

WPGB 51-0

01

HTDIWPGB

63

LCDA

3-0

2

YALEDKCOLCDA

73 FRWP

1,0

0

ECNEREFERHTDIWESLUP

83

GCHY

1,0

0

NIAG2/1GNIROCLANGIS.QERFHGIHY

93 2GKC

1,0

1

TIBTSETROTARENEGKCOLC

04 EGKC

1,0

0

TIBTSETROTARENEGKCOLC

RM-Y906K RM-Y906

3DCM (3D Comb Filter)

PJE (Projection TV Engine)

– 14 –

∗ 1 : Set correctly by the automatic resistration adjustment.

xxxx : Cannot change.

KP-XR432K90/XR432N90

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0

SABR

36-0

93

ATADSSABRESUFOEULAVTESER

1

ERTR

36-0

53

ATADELBERTRESUFOEULAVTESER

2 HEBB

51-0

-

YCNEUQERFHGIHEBB

3

LEBB

11-0

-

YCNEUQERFWOLEBB

4 EFUS

7 -

TCEFFEDNUORRUS

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0

H0BT

552-0

84

ESRAOC)R+L(TCEFFEDNUORRUSURT

1 L0BT

552-0

0

ENIF)R+L(TCEFFEDNUORRUSURT

2 H1BT

552-0

46

ESRAOC)R-L(TCEFFEDNUORRUSURT

3 L1BT

552-0

0

ENIF)R-L(TCEFFEDNUORRUSURT

4 H2BT

552-0

46

ESRAOC)C(TCEFFEDNUORRUSURT

5 L2BT

552-0

0

ENIF)C(TCEFFEDNUORRUSURT

6 HFBT

552-0

561

ESRAOC)S(TCEFFEDNUORRUSURT

7

LFBT

552-0

621

ENIF)S(TCEFFEDNUORRUSURT

8 H0CT

552-0

09

ESRAOC)S(TCEFFEDNUORRUSURT

9

L0CT

552-0

031

ENIF)S(TCEFFEDNUORRUSURT

01

H1CT

552-0

11

ESRAOC)R,L(TCEFFEDNUORRUSURT

11

L1CT

552-0

001

ENIF)R,L(TCEFFEDNUORRUSURT

21

HDAS

552-0

46

ESRAOCLEVELECAPSSRS

31

LDAS 552-0

0

ENIFLEVELECAPSSRS

41

H0BS

552-0

29

ESRAOCLEVELRETNECSRS

51

L0BS

552-0

0

ENIFLEVELRETNECSRS

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0RDYM13-022EVIRDYNIAM

1UHSM36-013EUHBUSNIAM

2LCSM36-013ROLOCBUSNIAM

3

DPUM

51-0

7

TESFFOLATSEDEPUNIAM

4

DPVM

51-0

7

TESFFOLATSEDEPVNIAM

5YLDM3-00 YALEDYNIAM

6P2UM51-07 TESFFOLATSEDEP2UNIAM

7P2VM51-07 TESFFOLATSEDEP2VNIAM

8

D2YM

13-0

91

EVIRD2YNIAM

9

D2UM

13-0

11

EVIRD2UNIAM

01

D2VM

13-0

11

EVIRD2VNIAM

11

ERPM

3-0

3

REVO-ERPNIAM

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0RDYS13-082EVIRDYBUS

1UHSS36-013EUHBUSBUS

2LCSS36-013ROLOCBUSBUS

3DPUS51-07 TESFFOLATSEDEPUBUS

4DPVS51-07 TESFFOLATSEDEPVBUS

5 YLDS

3-0

0

YALEDYBUS

6 P2US

51-0

7

TESFFOLATSEDEP2UBUS

7

P2VS

51-0

7

TESFFOLATSEDEP2VBUS

8 D2YS

3-0

02

EVIRD2YBUS

9 D2US

51-0

11

EVIRD2UBUS

01

D2VS 51-0

11

EVIRD2VBUS

11

ERPS

3-0

3

REVO-ERPBUS

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0 RDCP

51-0

7

ROLOCPIP

1

RDHP

51-0

7

EUHPIP

2 CFAP

3-0

2

NIAGPOOLCFAPIP

3

DATP

51-0

7

TNEMTSUJDA0FPARTPIP

4 TOTP

1,0

0

RETLIFTOTAMORHCPIP

5

NCSP 51-0

7

TSARTNOCBUSPIP

6

CDYP

7-0

0

NARTCDYPIP

7

PHSP

1,0

1

0FSSENPRAHSPIP

8

KSMP

1,0

0

KSAMNOISIVORCAMPIP

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0PHGB51-001NOITISOPHPIP

1NHGB51-07 LANGISONROFNOITISOPHPIP

2PVGB51-07 NOITISOPVPIP

3

TIB6

1,0

1

XIRTAM)6PIKS/6TRAMS(TIB6

4PHAM51-07 NOITISIUQCAHNIAM

5

PVAM

552-0

32

NOITISIUQCAVNIAM

6PHAS51-07 NOITISIUOCAHBUS

7

PVAS 552-0

32

NOITISIUQCAVBUS

8

SCED

13-0

81

SRETSIGERREDOCEDBUS

9 MCED 13-0

81

SRETSIGERREDOCEDNIAM

01

SID

721-0

66

GNITTESYALPSID

11

ZISB

51-0

2

EZISREDROB

21

DEPV

51-0

31

TESFFOLATSEDEPV

31

DEPU

51-0

31

TESFFOLATSEDEPU

RM-Y906K RM-Y906

SC (Sub Chroma Decoder)

IC (Inset Chroma Decoder)

PP (Picture In Picture Vseries Only)

TONE (Tone Control)

DSP (Digital Signal Processor)

– 15 –

MC (Main Chroma Decoder)

KP-XR432K90/XR432N90

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0HSVU36-013EUHBUSVUY

1CSVU36-013ROLOCBUSVUY

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0 AERA

3-0

0 DIAERA

1

SRES

3-0

0

DISEIRES

2

PHCV

3-0

0

DIPIHCV

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0

PHCC

36-0

93

SDX/CC&XEDNIROFISOPHDSO

1

NHCC

36-0

92

NOITCNUFON

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0 PSID 36-0

9

NOITISOPHDSO

1 lWF

7-0

2

WODNIW1DLEIF

2 2WF

7-0

3

WODNIW2DLEIF

METI

REBMUN

TNEMTSUJDA

METI

ATAD

EGNAR

DRADNATS

ATAD

ETON

0HPIP-NOITISOPHPIP

1VPIP-NOITISOPVPIP

2DSYP-YALEDTCELESPIP

3LDYP-YALEDYPIP

4LDHP-YALEDESLUP-H

5DVMP- YALEDESLUP-VNIAM

6DVIP- YALEDESLUP-VTESNI

7NOCP-TSARTNOCTESNI

8YMRF-YEMARF

9REPI-Y-RJIATSEDEPPIP

01BEPI-Y-BLATSEDEPPIP

11SPCP-PLCPIP

21FPCP-SELCYCPLCPIP

31LLPP- TNATSNOCEMITLLPPIP

41RNVP- NOITCUDERESIONESLUPPSVPIP

RM-Y906K RM-Y906

DAC (D/A Converter)

PI (Picture In Picture S Series only)

ID (Identification)

– 16 –

CCD (Closed Caption Decoder)

OP (Option)

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

3-10. REGISTRATION ADJUSTMENT (PJE)

• FUNCTION OF BUTTONS OF REMOTE

COMMANDER FOR PJE MODE.

DVD/

SAT/

VTR

CABLE

FUNCTION

DVD/VTR SAT/CABLE

FREEZE

SWAP PIP

m

N

AUDIO

POSITION ACTIVE

xz

ANT

SLEEP

CC

2

1

5

4

8

7

JUMP

0

VOL CH

TV

ENTER

3

6

9

POWER

TV

TV

M

TV/VIDEO

DISPLAYMTS/SAP

GUIDE

MENU

Color select

n

BLUnRED

GRN

Test signal select

crosshach+video signal

dots+video signal

crosshach+black

dots+black

off

Mode select

Coarse adjustment

(

Fine adjustment

ENTER

Adjustment item

up

Adjustment item

down

INIT*

READ*

MUTING

SYSTEM

OFF

TV/VTR

X

PICTURE

MODE

INDEX

RESET

CODE SET

data up/down

INIT*: Press 7, "INIT" green letters appear on the screen.

Then press ENTER, all the PJE data are reset.

READ*: Press 8, "READ" green letters appear on the screen.

Then press ENTER, all the PJE default data are

restored.

Note: Internal patterns are used for geometry and convergence

adjustments. However, sizing and centering must be done with

the use of an external generator. The recommended pattern

would be a monoscope, or equivalent pattern, which would

provide the means to adjust both the linearity and sizing of the

picture.

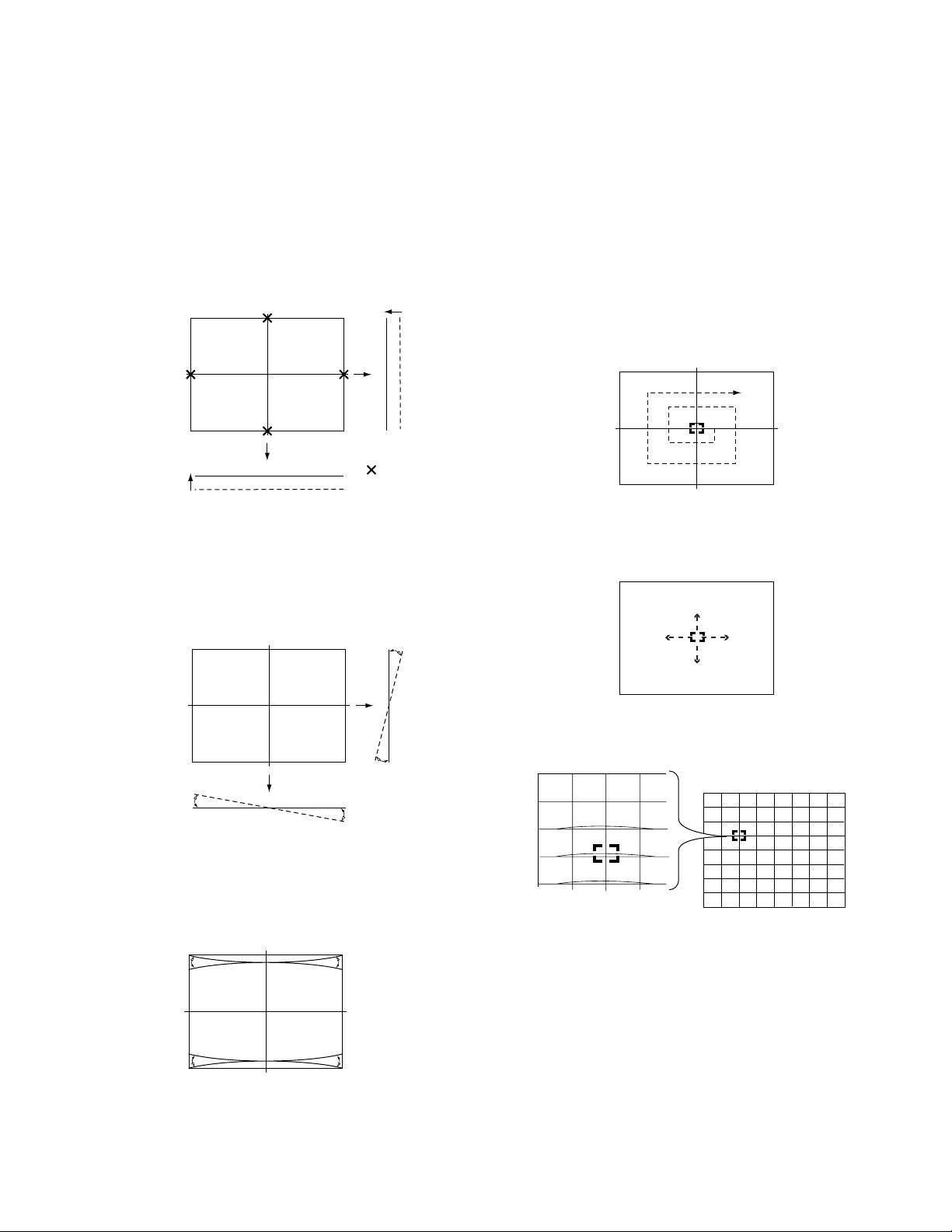

[SETUP FOR ADJUSTMENT]

• Current flow in circuit should be stable before attempting

adjustment. So wait 5 minutes after turning on the TV power.

• At the 4 insides of the screen, locate the middle. Use a tape

measure to identify the middle.

: middle

1. Set to the service mode by pressing quickly keys on the remote

commander in the standby mode in the following order:

[DISPLAY] n 5 n [VOL+] n [TVPOWER]

2. Change TV mode to the video input mode.

3. Change the VPNT mode to the PJE 00 FDIS.

PJE 00 00

FDIS

4. Set FDIS data to “01” to display the registration data of each

spot in the fine adjustment.

)

PJE 00 01

FDIS

5. Press 6 to display the test signal (crosshatch) on the screen.

6. Select GRN CENT(*) with the 1 and 4 keys on the remote

commander and check that the adjustment data is now “000”

both vertically and horizontally.

(H) (V)

GRN 000 000

CENT

*: In the factory preset, “GRN CENT” appears on the screen first.

In case of other colors “RED” or “BLU”, change color by

every pressing 3 key.

7. Cover the both red and blue picture lenses with the lens caps to

show only the green color.

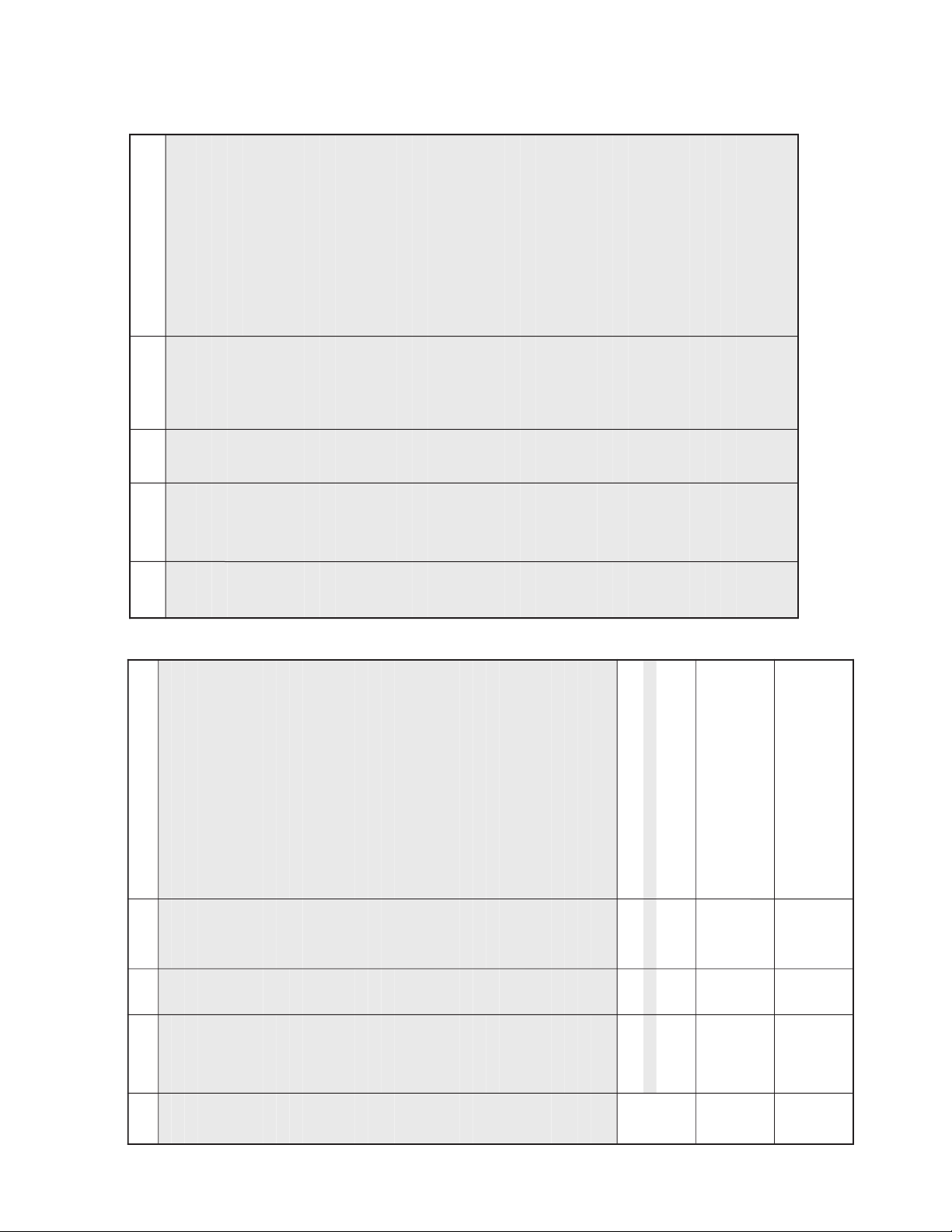

SUB DEFLECTION ADJUSTMENT ITEM

Adjustment O : Yes – : No

Adjustment type

Display Adjustment item G R B

H/V H/V H/V

CENT CENT O/O O/O O/O

SKEW SKEW O/O O/O O/O

SIZE SIZE –/– O/O O/O

LIN LIN –/– O/– O/–

KEY KEY –/––/O –/O

PIN PIN –/O –/O –/O

– 17 –

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

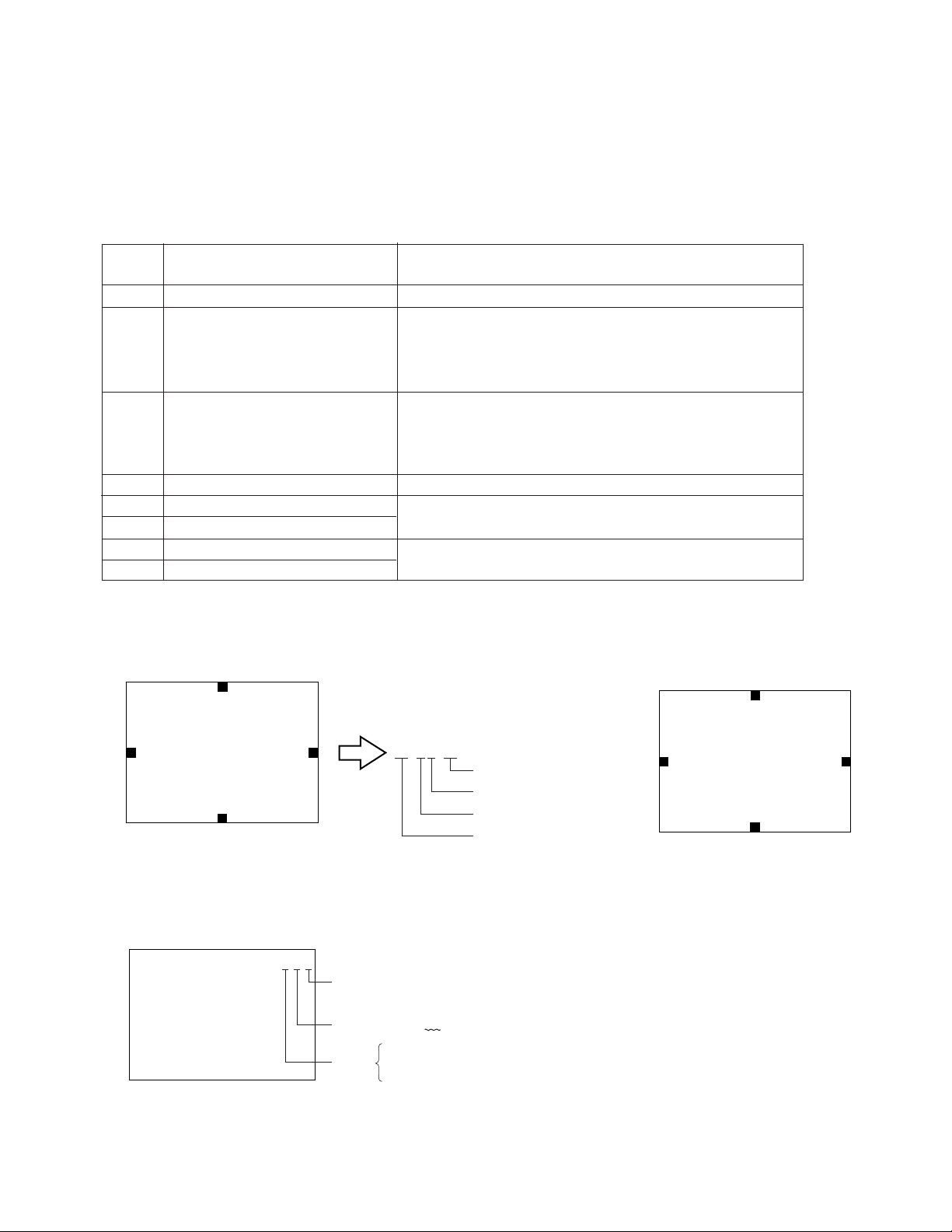

[GREEN REGISTRATION ADJUSTMENT]

<GREEN CENTER>

1. Select GRN CENT 1and 4 keys on the remote commander.

2. Adjust the center of crosshatch line goes the middle vertically

and horizontally (GRN CENT) with the joystick on the remote

commander.

GRN

CENT

<GREEN SKEW>

1. Select GRN SKEW with the 1and 4 keys on the remote

commander.

2. Adjust the crosshatch line goes straight vertically and horizontally with the joystick on the remote commander.

000

000

: Middle

<FINE ADJUSTMENT>

1. Press 9 key on the remote commander to shift to the fine

adjustment mode.

The green cursor (in the GRN mode) appears on the center of

the screen.

2. Use the 1and 4 keys or the joystick on the remote commander, move the cursor (see below) everywhere you want to

adjust and adjust with the joystic keys on the remote commander.

Marker movement by the 1 and 4 keys:

Press once the joystick the cursor turns green to white.

Then you can move the cursor up and down left and right every

where you want.

GRN

SKEW

000 000

<GREEN PINCUSHION>

1. Select GRN PIN with the 1and 4 keys on the remote

commander.

2. Adjust the crosshatch line goes straight horizontally with the

joystick on the remote commander.

GRN

XXXX 000

PIN

Note : These are required when either severe miss-adjustment or

data loss occurred.

Press once the joystick the cursor stops and returns green, you

can adjust around the cursor.

3. Press 9 key on the remote commander to shift to the coarse

adjustment mode.

– 18 –

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

[RED REGISTRATION ADJUSTMENT]

<RED CENTER, SKEW>

1. Cover the blue picture lens with the lens cap to show the green

and red colors.

2. Press 3 key on the remote commander to shift the GRN mode

to the RED mode.

3. Select RED CENT or RED SKEW with the 1 and 4 keys

on the remote commander and adjust while tracking each other

alternately.

4. Adjust the red crosshatch lines go straight vertically and

horizontally and overlaps the green lines with the joystick on

the remote commander.

<RED SIZE, LINEARITY>

1. Select RED SIZE (vertically and horizontally) or RED LIN

(vertically) with the 1 and 4 keys on the remote commander and adjust while tracking each other alternately.

2. Adjust the red crosshatch lines go straight vertically and

horizontally and overlaps the green lines with the joystick on

the remote commander.

<RED KEY, PINCUSHION>

1. Select RED KEY or PINCUSHION with the 1 and 4 keys

on the remote commander and adjust while tracking each other

alternately.

2. Adjust the red crosshatch lines go straight horizontally and

overlaps the green lines

with the joystick on the remote commander.

Note : These are required when either severe miss-adjustment or

data loss occurred.

[BLUE REGISTRATION ADJUSTMENT]

1. Remove the lens cap from the blue picture lens to show full

color.

2. Press 3 key on the remote commander to shift the RED mode

to the BLU mode.

3. Adjust BLU CENT, BLU SKEW, BLU SIZE, BLU LIN, BLU

KEY and BLU PIN in the same procedure of the red registration adjustment.

[FINAL CHECK]

1. Store the new adjustment (offset) value on the remote control

by pressing [MUTING] and [ENTER].

2. Press the FLASH FOCUS button on the front panel.

(The Offset value is now automatically stored.)

3. Check that no error message appears.

If an error message appears, recheck.

Note: In case of replacing CRTs, adjust the set-up adjustments

(items 3-1 to 3-8) and the registration adjustment (item 3-10).

In case of replacing two or three CRTs at the same time,

replace and adjust one by one.

<FINE ADJUSTMENT>

1. Press 9 key on the remote commander to shift to the fine

adjustment mode.

The red cursor (in the RED mode) appears on the center of the

screen.

2. Use the 1 and 4 keys or the joystick on the remote commander, move the cursor everywhere you want to adjust and

adjust with the joystick on the remote commander.

– 19 –

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

3-11. AUTO REGISTRATION ERROR CODE LIST

If an error code is displayed after the set has been fully adjusted, correctly, please check the following items: position, tilt and sizing. If

either of these adjustments are off, even slightly, the auto-registration pattern will not hit the four sensors properly. This occurs when the

internal generator patterns is being flashed on the screen for the sensors to read. Therefore, auto registration (called auto-focus) cannot

operate properly causing an error code to be displayed. In order for this function to operate properly, correct position, tilt and size must be

adjusted properly.

[ERROR CODE LIST]

ERROR

CODE

00 No Error

10 Sensor Output Level Low * Check wiring, beam position, sensor. 0 : Upper Center

20 Sensor Output Level High * Check OP-amp circuit. 0 : Upper Center

30 Adjustment Loop Counter Overflow * Check the registring information on the convergence board.

40 Regi Data Overflow

50 Regi Data Overflow

60 Offset Overflow

70 Offset Overflow

DISCRIPTION NOTE

1 : Middle Left

2 : Middle Right

3 : Lower Center

1 : Middle Left

2 : Middle Right

3 : Lower Center

* Check the convergence yoke driver ICs.

* Convergence patterns displayed are out of normal range.

* In case of multiple error, last error is displayed.

• ERROR CODE SCREEN DISPLAY

E 11 B

E 11 B

* Error code will be displayed on center of screen for 3 seconds.

• ERROR CODE DISPLAY IN REGI SERVICE MODE

PJE 2 9 1 4 0

ERR

ITEM NUMBER-29

SENSOR NUMBER

(ONLY "10"or "20")

ERROR CODE 40

G-0 (Blank)

R.G.B

R-1

B-2

R. G. B

SENSOR NUMBER

ERROR CODE 10

ERROR

[SENSOR POSITION]

0

12

SCREEN

3

0 : UPPER SENSOR

1 : LEFT SENSOR

2 : RIGHT SENSOR

3 : LOWER SENSOR

– 20 –

SECTION 4

CIRCUIT ADJUSTMENTS

4-1. TV INPUT SUB CONTRAST ADJUSTMENT

(VPNT-SCON)

1. Receive the color-bar signal.

2. Mode : Personal 1 or 2.

PICTURE : maximum

COLOR : maximum

BRIGHTNESS : center

TRINITONE : medium

SERVICE DATA VPNT SCON : 7

3. Set to service mode.

4. Connect an oscilloscope between pin 7 of CN204 (A board)

and ground.

5. Select “ VPNT-SCON ”, and adjust so that the wave from

level is 1.80 ± 0.05Vp-p.

6. Write the data into memory .

MUTING n ENTER

White

±

0.05Vp-p

1.80

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

4-3.

COMPONENT INPUT SUB-HUE AND SUB-COLOR

ADJUSTMENT

1. Select VIDEO 4 and supply the color-bar signal.

VIDEO input

2. Mode : Personal 1 or 2.

PICTURE : maximum

COLOR : center

BRIGHTNESS : center

TRINITONE : medium

SERVICE DATA DAC UVSH : 31

SERVICE DATA DAC UVSC : 31

3. Set to service mode.

4. Connect an oscilloscope between pin 5 of CN204 (A board)

connecter and ground.

5. Select “ DA C-UVSH, UVSC ”, and adjust them to have VB1

= VB4 and VB2 = VB3 in the waveform levels.

6. Write the data into memory .

MUTING n ENTER

(DAC-UVSH, UVSC)

Black

Fig. 4-1

4-2. VIDEO INPUT SUB-HUE AND SUB-COLOR

ADJUSTMENT (VPNT-SHUE, SCOL)

1. Select VIDEO1 input and supply the color-bar signal.

2. Mode : Personal 1 or 2.

PICTURE : maximum

COLOR : center

BRIGHTNESS : center

TRINITONE : medium

SERVICE DATA VPNT-SHUE : 7

SERVICE DATA VPNT-SCOL : 7

3. Set to service mode.

4. Connect an oscilloscope between pin 5 of CN204 (A board)

connecter and ground.

5. Select “ VPNT-SHUE, SCOL ”, and adjust them to have VB1

= VB4 and VB2 = VB3 in the waveform levels.

6. Increase SCOL by 2 steps.

7. Write the data into memory .

MUTING n ENTER

VB1 VB2 VB3 VB4

Fig. 4-3

4-4. P & P SUB CONTRAST ADJUSTMENT

(SC-SYDR)

1. Receive the signal.

TV terminal (sub) : color-bar signal

VIDEO terminal (main) : no signal

2. Set to service mode and set to P & P mode.

3. Connect an oscilloscope between pin 7 of CN204 (A board)

and ground.

4. Select “ SC-SYDR ”, and adjust so that the wave from level

is 1.65 ± 0.05Vp-p.

5. Write the data into memory .

MUTING n ENTER

White

±

0.05Vp-p

1.65

Black

VB1 VB2 VB3 VB4

Fig. 4-2

Fig. 4-4

– 21 –

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

4-5. SUB-HUE , SUB-COLOR AND MAIN

CONTRAST ADJUSTMENT (MC-MYDR,

MSHU, MSCL, SC-SSHU, SSCL)

1. Receive the color-bar signal.

2. Mode : Personal 1 or 2.

PICTURE : maximum

COLOR : center

BRIGHTNESS : center

TRINITONE : medium

SERVICE DATA MC-MYDR : 22

SERVICE DATA MC-MSHU : 31

SERVICE DATA MC-MSCL : 31

SERVICE DATA SC-SSHU : 31

SERVICE DATA SC-SSCL : 31

3. Set to service mode and set to P & P model .

4. Connect an oscilloscope between pin 5 of CN204 (A board)

connecter and ground.

5. Select “ MC-MYDR”, and adjust them to have VB1 = VB5

in the waveform levels.

6. Select “ MC-MSCL, SC-SSCL” and adjust so that the wave

form shows VB1=VB4 and VB5=VB8.

7. Select “ MC-MSHU, SC-SSHU” and adjust so that the wave

form shows VB2=VB3 and VB6=VB7.

8. Write the data into memory .

MUTING n ENTER

4-7. PIP POSITION ADJUSTMENT

(PI-PIPH, PIPV)

1. Set the PIP mode.

2. Receive the monoscope signal on the main/sub picture.

3. Check the sub picture position.

X1-X2

X1-X2

0.25sq

0.25sq

4. If necessary set to service mode and adjust "PIPH", "PIPV".

5. Write the data into memory .

MUTING n ENTER

Y1

Y2

X2X1

Fig. 4-7

VB1 VB2 VB3 VB4 VB5 VB6 VB7 VB8

Fig. 4-5

4-6. BAR DISPLAY POSITION ADJUSTMENT

(OP-DISP)

1. Receive the monoscope signal.

2. Set to service mode.

3. Push “ PICTURE +” . (Bar is displayed)

4. Select “ OP-DISP ” , and adjust so that the bar is as shown in

the figure.

5. Write the data into memory .

MUTING n ENTER

X1

Fig. 4-6

X2

X1 = X2

– 22 –

[ G BOARD]

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

SECTION 5

SAFETY RELATED ADJUSTMENTS

5-1. HV REGULATION CIRCUIT CHECK AND

ADJUSTMENT

When replacing the following components marked with

on the schematic diagram always check HV regulation, and

if necessary re-adjust.

: C517

: C517, C521, C522

IC654, L504

T502, T504 (FBT)

D.Y, A board, G board

OPERATION CHECK

1. Connect a HV static voltmeter to the unconnected plug of

the high-voltage block. (Fig.5-1)

2. Power on the set.

3. Receive the dot signal. (PICTURE and BRIGHTNESS to

minimum)

4. Check that the HV static voltmeter is

reading 31.00

+0.95

-1.45

kVdc.

HV Regulation adjustment

1. Connect a HV static voltmeter to the unconnected plug of

the hight-voltage block.

2. Power on the set.

3. Receive the dot signal. (PICTURE and BRIGHTNESS to

minimum)

4. If anode voltage is 31.95kV or higher, replace C517 of 470PF/

2kV with that of 680PF/2kV , and check if the v oltage is within

the standard range.

5. If anode voltage is 29.66kV or lower , replace C517 of 470PF/

2kV with that of 100PF/2kV , and check if the v oltage is within

the standard range.

Remove the cap off from

the unused terminal and

cpmmect a static voltmeter

there.

5-2. HV HOLD DOWN CIRCUIT OPERATION

CHECK AND ADJUSTMENT

When replacing the following components marked with

on the schematic diagram always check hold-down voltage

and if necessary re-adjust.

: R536, R545

: C516, C536

D506, D507, D522

IC206, IC502, IC654

L504, R511, R522, R536, R538, R545,

R548, R584

T502, T504 (FBT)

D.Y, A board, G board

OPERATION CHECK

1. Remove CN652 connecter.

2. Short-circuit across TP-PROT and ground.

3. Connect a HV static voltmeter to the unconnected plug of

the high-voltage block.

4. Connect a 220 Ω/200W variable resistor, across pin 2 and

pin 1 of CN652 and connect an external dc power supply

unit (200V, class 2A) to pin 3 of CN652.

5. First turn on the external power supply (+B=135V), then turn

on the power of the set.

6. Receive the dot signal. (PICTURE and BRIGHTNESS to

minimum)

7. Gradually increase the value of the external dc po wer supply

and check that the hold-down circuit operates at a static voltmeter reading of 33.5±0.95kVdc when the raster disappears.

HV HOLD-DOWN ADJUSTMENT

1. Repeat steps 1 ~ 7 as above.

2. If hold down voltage is 34.45kV or higher, remove R536,

mount a resistor (150kΩ, 1/4W : RN) onto R545 instead, and

check again if the hold-down voltage is within the standard

range.

3. If hold down voltage is 32.55kV or lower, mount a resistor

(220kΩ, 1/4W : RN) onto R536 and check again if the holddown voltage is within the standard range.

Fig. 5-1

NOTE : Please finish the adjustment as soon as possible

– 23 –

5-3. +B MAX VOLTAGE CONFIRMATION

The following adjustments should always be performed when

replacing IC654.

1. Supply 130VAC to with variable autotransformer.

2. Input a dot signal.

3. Set the PICTURE control and the BRIGHTNESS controls to

minimum.

4. Confirm the voltage of G BOARD TP135V is less than

137.0Vdc.

5. If step 4 is not satisfied, replace IC654 and repeat above steps.

5-4. +B OVP CONFIRMATION

1. Connect an external dc power supply to TP OVP.

2. Supply 120VAC to variable autotransformer.

3. Set PICTURE and the BRIGHTNESS controls to minimum.

4. Gradually turn the external dc power supply, and check if

OVP works properly when the voltage of the external dc

power supply is between 139.0 ~ 155.0V.

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

– 24 –

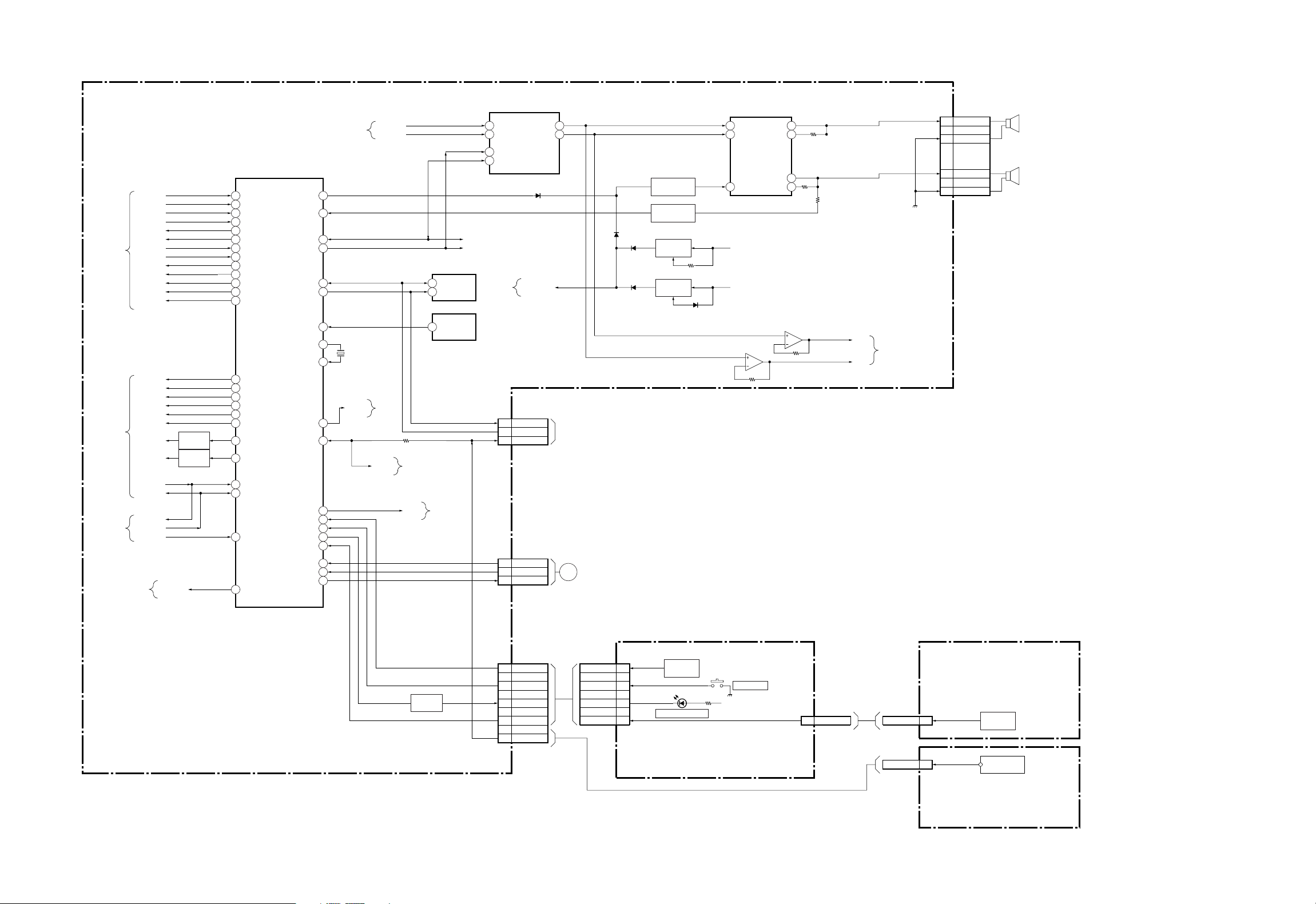

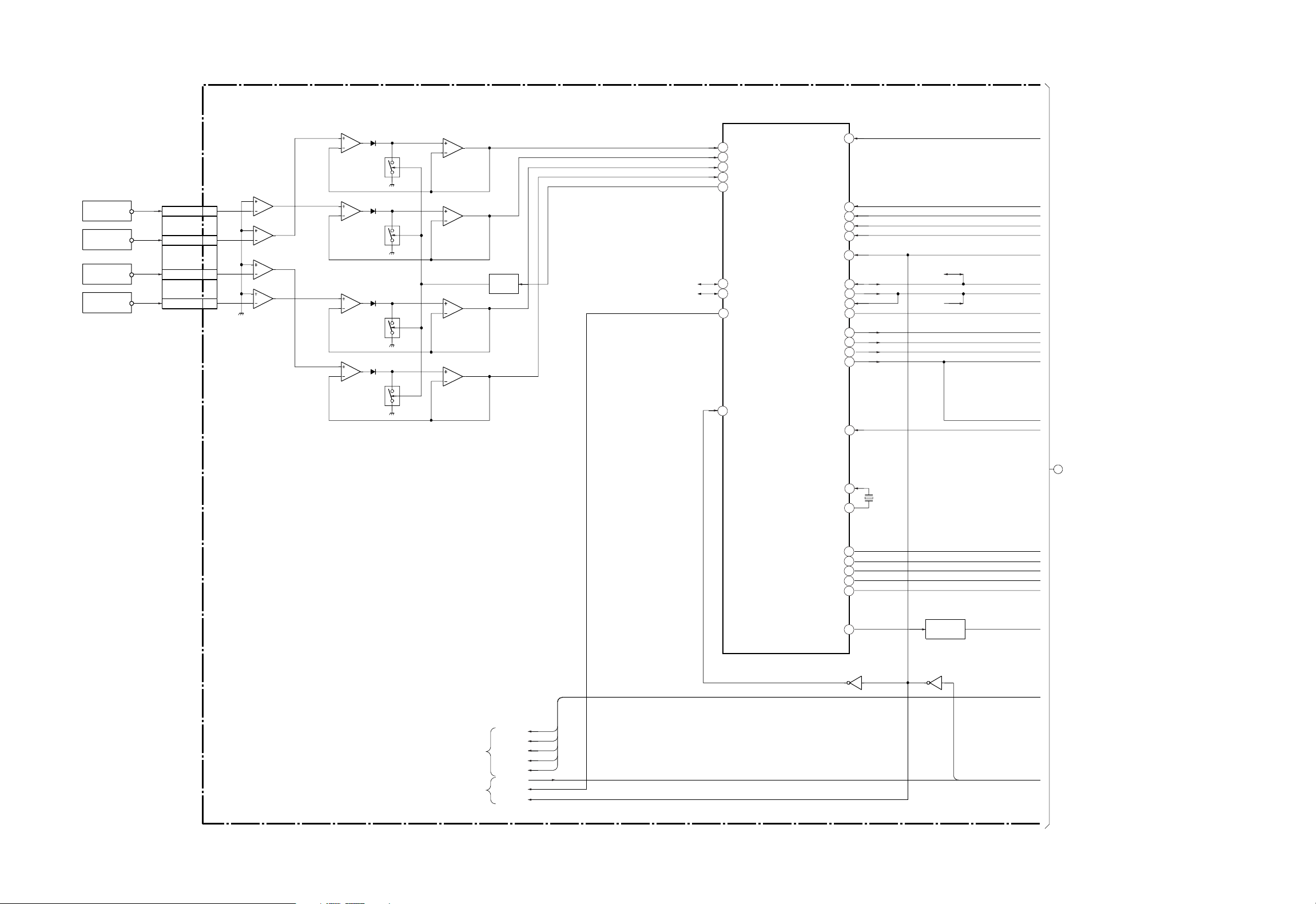

6-1. BLOCK DIAGRAM (1)

SECTION 6

DIAGRAMS

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

TO

A

BOARD

TUNER

BLOCK

TO

A

BOARD

VIDEO

BLOCK

TO A

BOARD

PJED

BLOCK

STU AUMT

MTU AUMT

TO A

BOARD

TUNER

BLOCK

STUH

MTUH

STU AFT

MTU AFT

MONO

SAP

SAP IND

ST IND

AGC ATT

ANT SW1

ANT SW2

MICRO R

MICRO G

MICRO B

MICRO I

OSD YS

DISP YM

SBLK

MBLK

VP-BUFF

VP-BUFF

B INT

HP

HP

YUV MT

SWITCH

Q024

SWITCH

Q007

IC002

SYSTEM CONTROL

I-2HSYNC

1

I-HSYNC

2

SUBTU AFT

15

MAINTU AFT

16

O-MONO

17

O-SAP

18

I-SAPN

43

I-STEREN

60

O-2MUTE

61

O-MUTE

62

O-AGC ATT

51

ANT SW1

52

ANT SW2

53

32

O-R

33

O-G

34

O-B

35

O-I

36

O-OSDYS

37

O-DISPYM

O-SBLK

45

O-MBLK

46

7

I-HP

8

I-VP

I-BINTN

6

O-YUVMT

57

O-SPK MT

I-APROT

IO-SDAT

O-SCLK

IO-B DAT

O-B CLK

I-RESET

O-OSC

I-OSC

O-SIRCS

I-RMCN

O-GRAY

KEY

I-POWERN

O-TMRLED

MENU

I-OVP

I-OCP

O-RELAY

IC403

SDA

SCL

28

5

17

18

BOARD

TUNER

BLOCK

D/A CONVERTER

TO A

IN1

IN2

SCL

SDA

11

10

3

8

7

4

CN003

BCLK

B DAT

SIRCS

CN681

OVP

OCP

RELAY

OUT1

OUT2

P-MUTE

21

12

FOR

CHECK

G

TO G

BOARD

CN605

L/R MUTE

Q403, 404

PROTECT

Q408-411

OFF MUTE

Q402

ON MUTE

Q401

TO A

BOARD

TUNER

BLOCK

58

22

47

49

48

50

9

11

12

X001

16MHz

63

64

23

14

44

55

13

21

20

56

S OUT

ML OUT1

HR OUT1

TO A

BOARD

TUNER

BLOCK

RM IN

TO A

BOARD

TUNER

BLOCK

GRAY

IC004

EEPROM

5

B DAT

6

B CLK

4

RESET

IC001

RESET

TO A

BOARD

VIDEO

BLOCK

7

11

5

IN+(L)

IN+(R)

MUTE

+11V

STBY

+5V

3

2

IC404

IC406

L/R AMP

OUT(L)

IN-(L)

OUT(R)

IN-(R)

1

IC404

5

6

CN403

1

4

8

2

10

7

R OUT

L OUT

TO A

BOARD

TUNER

BLOCK

L

2

E

3

R

4

E

A

(AUDIO, SYSTEM CONTROL)

(1/6)

LED BUFF

Q006

CN002 CN1203

KEY

6

POWER

7

TIMER LED

8

MENU

9

SIRCS

2

KEY

POWER

TIMER LED

MENU

S1201-1206

3

4

5

6

CONTROL

SWITCHES

D1201

TIMER/STANDBY

POWER

STBY +5V

S1207

HA

(CONTROL SWITCHES)

– 25 –

CN1202

1 MENU KEY

CN1252

MENU KEY

CN1291

HB

(2/2)

(MENU SWITCHES)

S1251-1255

MENU

SWITCHES

OUT

D1291

REMOTE SENSOR

SIRCS

1

2

HC

(REMOTE SENSOR)

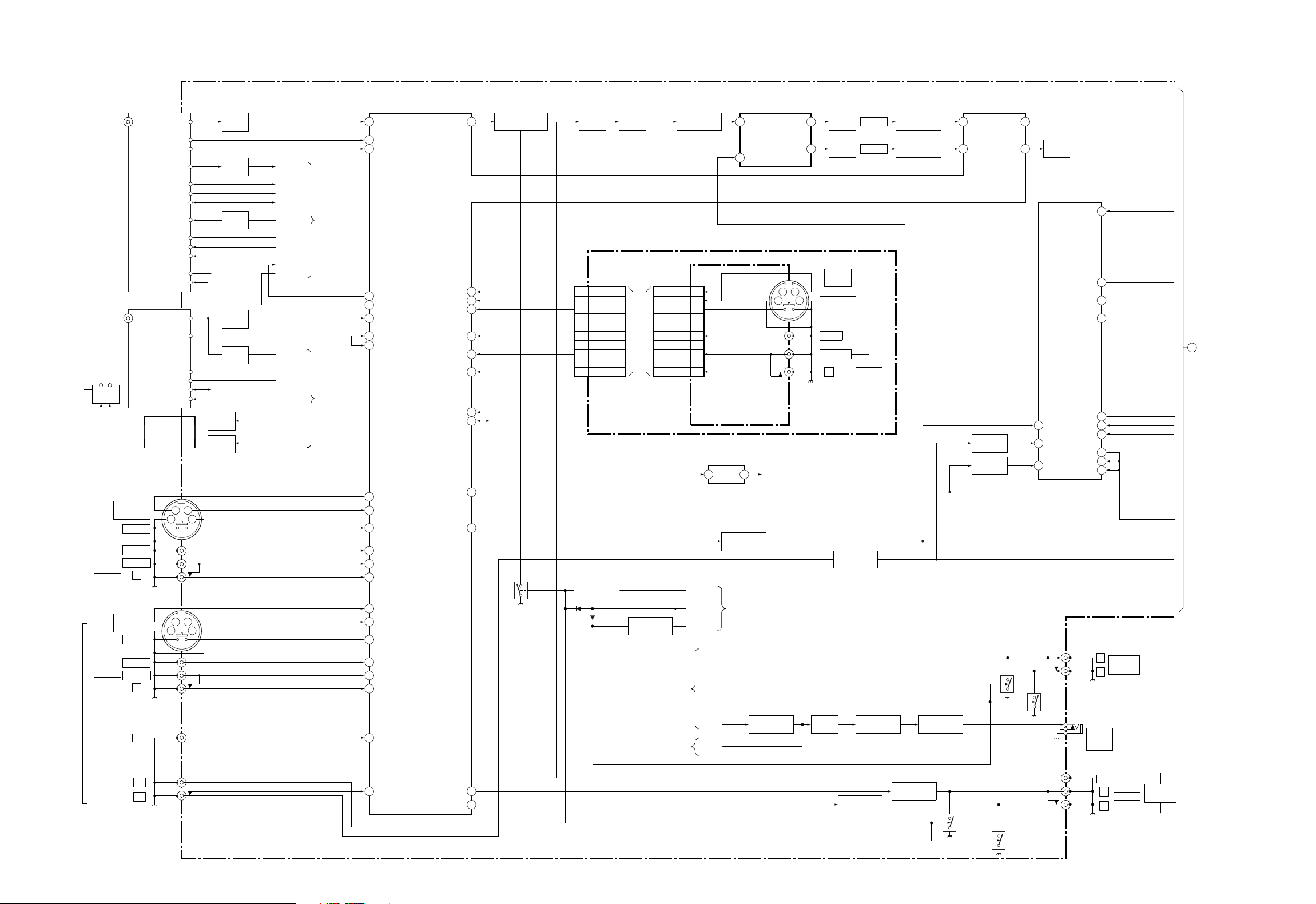

BLOCK DIAGRAM (2)

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

ANT

SW

AUDIO

AUDIO

J1102

VIDEO 1

IN

S VIDEO

VIDEO

L(M

J1101

VIDEO 3

IN

S VIDEO

VIDEO

L(M

MAIN TUNER

SUB TUNER

ONO)

R

ONO)

R

TU151

DET OUT 2

DET OUT

AFT OUT

TU152

DET OUT

DE-EM

AFT OUT

CN004

ANT SW

ANT SW

L OUT

R OUT

ST IND

SAP IND

RF AGC

ODE

M

ONO

F M

UTE

M

SDA

SCL

OUT

UTE

M

SDA

SCL

1

2

3

1 2

3

1 2

IC1101

BUFFER

Q152

H.SEP

Q004

ITCH

SW

Q151

SDA

SCL

BUFFER

Q153

H.SEP

Q001

SDA

SCL

ITCH

SW

3

Q005

ITCH

SW

1

Q003

4

4

DET OUT

AFT OUT

ST IND

SAP IND

RF AGC

MODE

F MONO

TU AUM

M

L OUT1

M

HR OUT1

STUH

STUAFT

STUAUM

ANT SW

ANT SW

SYSTEM

T

T

SYSTEM CONTROL

1

2

TO A BOARD

CONTROL

BLOCK

TO A BOARD

BLOCK

63

62

64

52

54

60

59

61

12

10

14

11

19

17

21

15

16

18

8

9

MTV V

MTV L

TV R

M

ML OUT1

HR OUT1

STV V6

STV L6

STV R6

C1

Y1

-1

SSW

V1

L1

R1

C3

Y3

-3

SSW

V3

L3

R3

A/V SWITCH

M

AIN V OUT

SSW

SCL

SDA

SY OUT1

SC OUT1

C2

Y2

-2

V2

L2

R2

VIDEO BUFFER

41 41 23

5

3

7

1

2

4

33

34

56

58

SCL

SDA

Q1103,1104

Q1110

BUFFER

Q1701

10

7

9

5

3

1

UTE BUFFER

M

Q1122

CN1702

FR C IN

FR Y IN

FRONT SW

FR V IN

FR L IN

FR R IN

FL1701

UTE BUFFER

M

Q1117

FROM

SYSTEM

BLOCK

A BOARD

CONTROL

CN1253

FR C OUT

FR Y OUT

FRONT SW

FR V OUT

FR L OUT

FR R OUT

+11V

BUFFER

Q1702,1703

10

7

9

5

3

1

HB

(LINE IN 1)

IC1701

5V REG

I O

Q1119,1124

T

YUV M

UTE

P M

T

TU AUM

M

L OUT

R OUT

COMB FILTER

ADIN

CKIN

11

(1/2)

BUFFER

A BOARD

FROM

SYSTEM

BLOCK

IC1702

REG 5V

CONTROL

COUT

YOUT

3

1 2

BUFFER

FL1702

Q1704

BUFFER

Q1705

J1251

IN

ONO)

Q1118,1125

FL1703

AUDIO

BUFFER

25

VIDEO2

4

S VIDEO

VIDEO

L(M

R

BUFFER

Q1707,1708

BUFFER

Q1706,1709

43

C IN2

Y IN2

45

V BUFFER

Q1920

Y BUFFER

Q1914

Q1109

C OUT2

Y OUT2

37

39

BUFFER

Q1102

YUV SWITCH

DU IN

13

DV IN

3

1

DY IN

Q1108

IC1903

DVD SW

DVD SW

DVD SW

Y OUT

U OUT

V OUT

J1104

INH

V IN

U IN

Y IN

6

15

14

4

5

12

2

9

10

11

L

R

AUDIO OUT

(VAR/FIX)

TO BLOCK

1

DIAGRM(3)

J1106

Y

PB

PR

(2/6)

A

Y4

24

28

-4

SSW

L OUT

R OUT

38

40

TO A BOARD

SYSTEM

CONTROL

BLOCK

S OUT

RM

IN

SAVA CONT

Q1121

BUFFER

Q1114

AUDIO BUFFER

Q1112,1113

(TUNER, VIDEO, AUDIO IN/OUT)

SIRCS M

Q1111

IX

AUDIO BUFFER

Q1115,1116

BUFFER

Q1106,1107

Q1101

Q1105

J1105

J1103

CONTROL

S

OUT

VIDEO

L

R

AUDIO

ONIT OR

M

OUT

– 26 –

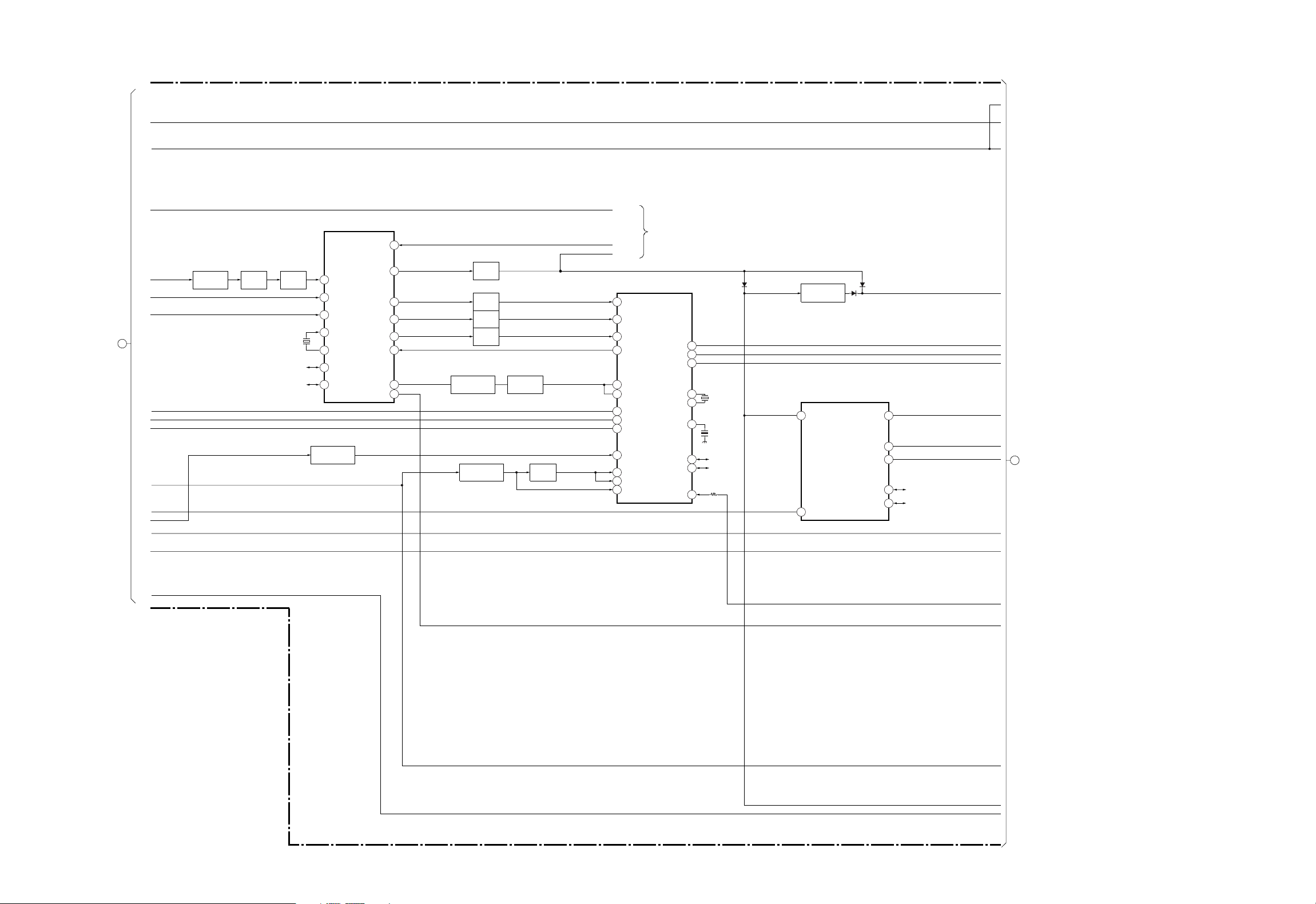

BLOCK DIAGRAM (3)

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

TO BLOCK

DIAGRM(2)

IC1905

PIP PROCESSOR

M.VSYNC

17

SEL

Y OUT

U OUT

V OUT

S.VSYNC

S.HSYNC

M.HSYNC

12

8

9

7

19

20

18

Y BUFFER

Q1916

1

Y AMP

Q1917

BUFFER

Q1918

X1903

20.48MHz

SDA

SCL

YIN

28

UIN

30

VIN

32

XIN

3

XQ

4

SDA

21

SCL

22

SUB C BUFFER

Q1906

BUFFER

Q1915

BUFFER

Q1905

BUFFER

Q1907

BUFFER

Q1903

INV

Q1910,1911

SUB Y BUFFER

Q1904

BUFFER

1909

BUFFER

Q1908

SBLK

VP-BUFF

MBLK

SUB DECODER

11

RY IN

12

RU IN

13

RV IN

VTIM

14

SCP

16

HTIM

15

V OUT

20

U OUT

19

Y OUT

18

CIN

32

VSYNC

38

HSYNC

39

34

CVBS/Y IN

FROM A BOARD

SYSTEM CONTROL

BLOCK

IC1902

RY OUT

RU OUT

RV OUT

XNTSC

APC

CERA

SDA

SCL

CP IN

SYNC BUFFER

Q1913

8

7

6

X1902

26

3.58MHz

29

X1901

503.5KHz

1

37

SDA

36

SCL

10

IC1904

D/A CONVERTER

1

FULL

DVD

3

DVD SW2

MAIN YSM

HUE

COL

SDA

SCL

7

6

5

14

SDA

15

SCL

TO BLOCK

2

DIAGRM(4)

(3/6) (YUV CONTROLLER)

A

– 27 –

BLOCK DIAGRAM (4)

YVU CONTROLLER

TVIN

19 12

DVD Y

23

6

YUVSW

1

P Y

3

P B-Y

2

P R-Y

IC1901

TVOUT

YOUT

RYOUT

BYOUT

CLAMP

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

Q232

Q304

Q229

CN204

9

R

7

G

5

B

1

1K

CN003

G

6

B

7

RGB MUTE

Q303

Q302

HP

Q301

+11V

10

4

5

6

8

2

CN801

ABL

HV PROT

PIN

HP

HD

V.BLK

H

FOR

CHECK

I

TO CG

BOARD

CN731

TO G

BOARD

CN1502

IC206

YCJ

CIN

IC301

INV

Q1912

8

9

10

5

PEEKING

Q262,227

BUFFER

Q305,306

BUFFER

Q228

LEVEL SHIFT

Q1901,1902

YUV SWITCH

1

3

2

7

GRAY

TO A BOARD

SYSTEM CONTROL

BLOCK

64

20

ROUT

63

YIN

EYIN

7

ERYIN

8

EBYIN

10

ABLIN/VCCOMP

AFCPIN/HOFF

BGP

55

GOUT

BOUT

IKIN

L2FIN

AFCFIL

E/WDRIVE

HDOUT

VTIM

24

26

27

COG AMP

44

45

28

43

37

41

31

Q225

AFC AMP

Q217

COG BUFFER

+9V

BUFFER

Q220

BUFFER

Q219

BUFFER

Q218

BUFFER

Q231

BUFFER

Q230

Q223

COG UNIT

Q205,224

FROM A BOARD

SYSTEM CONTROL BLOCK

TO BLOCK

DIAGRM(3)

Q011

Q018

SYNC BUFFER

Q221

BUFFER

Q002

BUFFER

Q008

BUFFER

Q009

BUFFER

Q010

BUFFER

Q014

BUFFER

Q015

BUFFER

Q016

BUFFER

0017

SCL

SDA

13

DLYSW

18

YSW

HUE

17

16

21

22

COLOR

DVD B-Y

DVD R-Y

IC1603

RESET

RST

BUFFER

Q1602

FROM A BOARD

SYSTEM CONTROL

BLOCK

IC1601

MAIN V CHIP/CC

7

VIDEO

5

HIN

45

SEN

SCL

SDA

14 15

14 15

5

HIN

SCL

SDA

SEN

4

7

VIDEO

IC1602

SUB V CHIP

R

G

B

BOX

2

MICRO R

MICRO G

MICRO B

MICRO I

DSD YS

DISP YM

18

2

3

Q021

Q022

Q023

17

SDA

SCL

BUFFER

Q1603

BUFFER

Q1601

FROM A BOARD

PJED

BLOCK

Q013

Q020

Q012

Q019

RE YM

RE YS

RE R

RE G

RE B

VSIN

51

HSIN

52

14

RIN

15

GIN

16

BIN

SCL

3

SDA

4

12

YM

13

YS

YUVSW

5

FSCOUT

57

VDRIVE-/VPROT

VDRIVE+

CERA

XTAL

34

35

X203

503.5KHz

46

X202

3.58MHz

59

54

VM

IC681

9V REG

+11V

I O

IC682

9V REG

I O

I

+11V

(4/6) (YC JUNGLE)

A

VM BUFFER

Q222

+9V

O

PIP 9V

5

6

6

CN202

V.DRIVE(-)

V.DRIVE(+)

CN203

VM

J

K

TO G

BOARD

CN501

TO CG

BOARD

CN1304

– 28 –

BLOCK DIAGRAM (5)

KP-XR432K90/XR432N90

RM-Y906K RM-Y906

LEFT

SENSOR

UPPER

SENSOR

LOWER

SENSOR

RIGHT

SENSOR

CN802

UPPER

LOWER

RIGHT