Sony KP-FX532M90, KP-FX432M90 Service Manual

SERVICE MANUAL

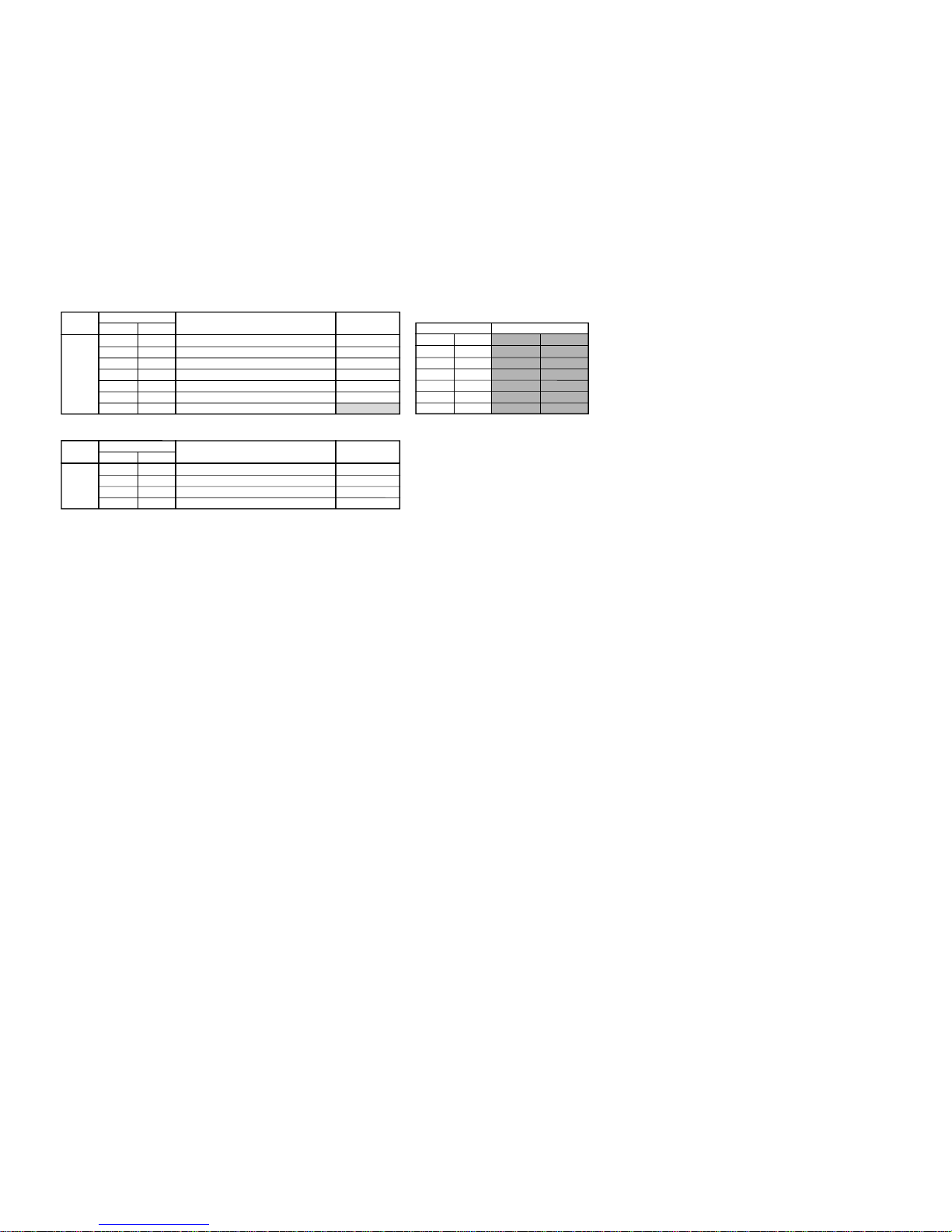

MODEL COMMANDER DEST. CHASSIS NO.

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

AX-1

PROJECTION TV

KP-FX432M90 RM-1014 CH SCC-M14H-A

KP-FX532M90 RM-1014 CH SCC-M14G-A

RM-1014 KP-FX432M90

KP-FX532M90

1 2 3

4 5 6

7 8 9

0

JUMP

PROGR

MENU

PIC

MODE

DRC-MF

SOUND

MODE

WIDE

MODE

SURROUND

RESET

TV

HD/DVD

– 2 –

KP-FX432M90/FX532M90

RM-1014

CAUTION

SHORT CIRCUIT THE ANODE OF HTE PICTURE TUBE

AND THE ANODE CAP TO THE METAL CHASSIS, CRT

SHIELD, OR CARBON PAINTED ON THE CRT, AFTER

REMOVING THE ANODE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK

! ON THE SCHEMATIC DIAGRAMS, EXPLODED

VIEWS AND IN THE PARTS LIST ARE CRITICAL TO

SAFE OPERATION. REPLACE THESE COMPONENTS

WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

SPECIFICATIONS

Projection system

Picture tube

Projection lenses

Screen size

Television system

Color system

Stereo/Bilingual

system

Channel coverage

B/G

I

D/K

M

8(Antenna)

Audio output (Speaker)

Number of terminal

(Video)

(Audio)

(S Video)

(Component

Video)

(G/B/R/HD/

VD Video)

i (Headphones)

Power requirements

Power consumption (W)

Dimensions (w/h/d, mm)

Mass (kg)

KP-FX532M90

3 picture tubes, 3 lenses, horizontal inline system

7 inch high-brightnes monochorome tubes (6.3 raster size), with optical coupling

and liquid cooling system

High performance, large-diameter highbrid lens F1.0

53 inches (134cm)

B/G, I, D/K, M

PAL, PAL 60, SECAM, NTSC4.43, NTSC3.58

NICAM Stereo/Bilingual D/K

VHF : E2 to E12 / UHF : E21 to E69 / CATV : S01 to S03, S1 to S41

UHF : B21 to B68 / CATV : S01 to S03, S1 to S41

VHF : C1 to C12, R1 to R12 / UHF : C13 to C57, R21 to R60 / CATV : S01 to S03,

S1 to S41, Z1 to Z39

VHF : A2 to A13 / UHF : A14 to A79/CATV : A-8 to A-2, A to W+4,

W+6 to W+84

75-ohm external terminal

12W + 12W (7% distortion)

Input: 4 Output: 1 Phono jacks; 1 Vp-p, 75 ohms

Input: 6 Output: 1 Phono jacks; 500 mVrms

Input: 2 Y: 1 Vp-p, 75 ohms,

unbalanced, sync negative

C: 0.286 Vp-p, 75 ohms

Input: 2 Phono jacks

Y: 1 Vp-p, 75 ohms, sync negative

P

B/CB: 0.7 Vp-p, 75 ohms

P

R/CR: 0.7 Vp-p, 75 ohms

Audio: 500 mVrms

Input: 1 Phono jacks

G: 0.7 Vp-p, 75 ohms

B: 0.7 Vp-p, 75 ohms

R: 0.7 Vp-p, 75 ohms

HD: 0.7 Vp-p, 75 ohms

VD: 0.7 Vp-p, 75 ohms

Output: 1 Stereo minijack

220 V AC, 50/60Hz

250 W

1136 × 1438× 666

78

Design and specifications are subject to change without notice.

KP-FX432M90

926 × 1255 × 634

60

43 inches (108cm)

– 3 –

KP-FX432M90/FX532M90

RM-1014

1. SELF DIAGNOSIS FUNCTION

1-1. Diagnostic Test Indicators ................................. 5

1-2. Display of STANDBY/TIMER

Light Flash Count............................................... 6

1-3. Stopping the STANDBY/TIMER Flash ............ 6

1-4. Self-Diagnostic Screen Display ......................... 7

1-5. Handling of Self-Diagnostic

Screen Display.................................................... 7

1-6. Self-Diagnostic Circuit ...................................... 8

2. DISASSEMBLY

2-1. REAR BOARD REMOVAL ............................. 9

2-2. MAIN BRACKET REMOVAL......................... 9

2-3. SERVICE POSITION ........................................ 9

2-4. FRONT PANEL REMOBAL ............................ 10

2-5. HC, HA AND HB1 REMOVAL ....................... 11

2-6. MIRROR COVER AND BEZNET

BLOCK REMOVAL.......................................... 11

2-7. BEZNET ASSY REMOVAL ............................ 12

2-8. TERMINAL BRACKET REMOVAL............... 13

2-9. UG BOARD REMOVAL .................................. 14

2-10. AD, BM, DS AND MG BOARDS REMOVAL 14

2-11. A AND D BOARDS REMOVAL ..................... 15

2-12. CRT AND PWB BLOCK REMOVAL ............. 15

2-13 HIGH-VOLTAGE CABLE

INSTALLATION AND REMOVAL ................ 16

2-14. MECHANICAL ASSY REMOVAL ................. 16

3. SET-UP ADJUSTMENTS

3-1. SCREEN VOLTAGE ADJUSTMENT

(ROUGH ALIGNMENT) ................................ 17

3-2. SCREEN (G2) ADJUSTMENT

(FINE ADJUSTMENT) ..................................... 17

3-3. FOCUS ROUGH ADJUSTMENT .................... 17

3-4. DEFLECTION YOKE TILT ADJUSTMENT.. 17

3-5. 2-POLE and 4-POLE MAGNET

ADJUSTMENT .................................................. 18

3-5-1. Adjustment of 2-pole magnets....................... 18

3-5-2. Green, Red, Blue adjustment of

4-pole magnets ............................................... 18

3-5-3. Blue left side dot adjustment of

2-pole Magnets............................................... 18

3-6. BLUE DEFOCUS ADJUSTMENT ................... 18

3-7. GREEN, RED AND BLUE FOCUS

ADJUSTMENT .................................................. 18

3-7-1. Green, Red and Blue lens focus adjustment .... 18

3-7-2. Green and Red electrical focus adjustment ..... 18

3-8. ADJUSTMENTS WITH COMMANDER ........ 19

3-8-1. How to Select Each Mode ............................. 19

3-8-2. How to Enter Service Mode .......................... 19

TABLE OF CONTENTS

3-8-3. Method of Cancellation from Service Mode. 20

3-8-4. How to Adjustments ...................................... 20

3-8-5. How to Write the Data ................................... 20

3-8-6. Memory Write Confirmation Method ........... 20

3-9. SERVICE LIST .................................................. 21

3-10. Registration Adjustment .................................... 67

3-10-1. Adjustment Flow ............................................ 67

3-10-2. Setup for Adjustment ..................................... 67

3-10-3.Method of Main Deflection Adjustment ....... 67

3-10-4.Operation Method for Projector

Engine(PJE) Mode ......................................... 68

3-10-5.Method of Projector Engine Adjustment....... 69

3-11. Auto Convergence Setting ................................. 72

3-12. Blue Offset Adjustment...................................... 72

3-13. White Balance Adjustment ................................ 72

3-14. Auto Convergence Error Code List ................... 73

4. ADJUSTMENT

4-1. HV Regulation Adjustment ............................... 74

4-2. +B Max Voltage Confirmation ......................... 74

4-3. +B OVP Voltage Confirmation ........................ 74

5. ELECTRICAL ADJUSTMENTS

5-1. Picture Quality Adjustment................................ 75

5-1-1. Preparation ..................................................... 75

5-1-2. NTSC Video Input (Main Picture) ................ 76

5-1-3. NTSC RF Input (Main Picture) ..................... 76

5-1-4. PAL Video Input (MainPicture) .................... 77

5-1-5. PAL RF Input (MainPicture) ......................... 77

6. DIAGRAMS

6-1. BLOCK DIAGRAMS ........................................ 79

6-2. FRAME SCHEMATIC DIAGRAM.................. 97

6-3. CIRCUIT BOARDS LOCATION ..................... 99

6-4. SCHEMATIC DIAGRAMS AND

PRINTED WIRING BOARDS........................ 100

(1) Schematic Diagram of A Board......................... 101

(2) Schematic Diagram of AD Board...................... 109

(3) Schematic Diagram of BM Board...................... 113

(4) Schematic Diagram of CR Board ...................... 123

(5) Schematic Diagram of CB Board ...................... 125

(6) Schematic Diagram of CG Board ...................... 127

(7) Schematic Diagram of D Board......................... 129

(8) Schematic Diagram of DS Board....................... 137

(9) Schematic Diagram of HA and HB1 Boards..... 141

(10) Schematic Diagram of HC Board ...................... 143

(11) Schematic Diagram of MG Board ..................... 145

(12) Schematic Diagram of SR Board ....................... 153

(13) Schematic Diagram of VM Board ..................... 154

(14) Schematic Diagram of UG Board ...................... 155

6-5. SEMICONDUCTORS ....................................... 161

Section Title PageSection Title Page

– 4 –

KP-FX432M90/FX532M90

RM-1014

7. EXPLODED VIEWS

7-1. FRONT PANEL BLOCK .................................. 167

7-2. CABINET BLOCK (KP-FX532)....................... 168

7-3. CABINET BLOCK (KP-FX432)....................... 169

7-4. BEZENET AND MIRROR COVER BLOCK

(KP-FX532) ........................................................ 170

7-5. BEZENET AND MIRROR COVER BLOCK

(KP-FX432) ........................................................ 171

7-6. MAIN BRACKET AND PICTURE TUBE

BLOCK............................................................... 172

8. ELECTRICAL PARTS LIST ....................... 173

KP-FX432M90/FX532M90

RM-1014

– 5 –

•Power does not

turn on

•+B overcurrent

(OCP)

•+B overvoltage

(OVP)

•Vertical deflection

stopped

•White balance

failure

(not balanced)

•

LOW B down***

•Horizontal

deflection stopped

•Audio Protection

•Zero crossing

detector

•HV protection

•Power does not come on.

•No power is supplied to the PJ.

•AC power supply is faulty.

•Power does not come on.

•Load on power line is shorted.

•Has entered standby mode.

•Has entered standby mode after

horizontal raster.

•Vertical deflection pulse is

stopped.

• Power line is shorted or power.

• No raster is generated.

•CRT cathode current detection

reference pulse output is small.

•No picture.

•No picture.

•No picture.

•No picture.

•No picture.

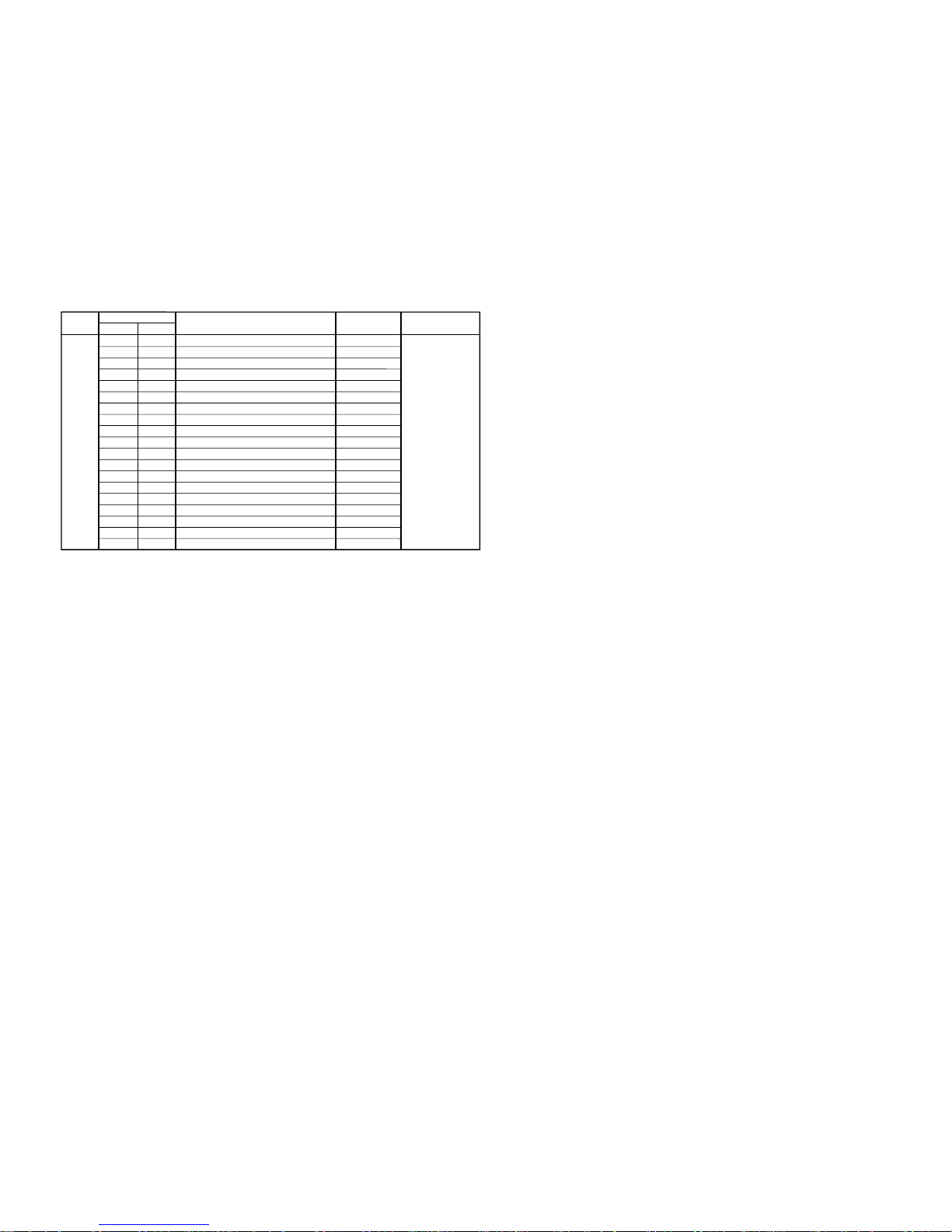

SECTION 1

SELF DIAGNOSIS FUNCTION

The unit in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER LED will automatically

begin to flash.

The number of times the LED flashes translates to a probable source of the problem. A definition of the STANDBY/TIMER LED

flash indicators is listed in the instruction manual for the user's knowledge and reference. If an error symptom cannot be reproduced, the remote commander can be used to review the failure occurrence data stored in memory to reveal past problems and

how often these problems occur.

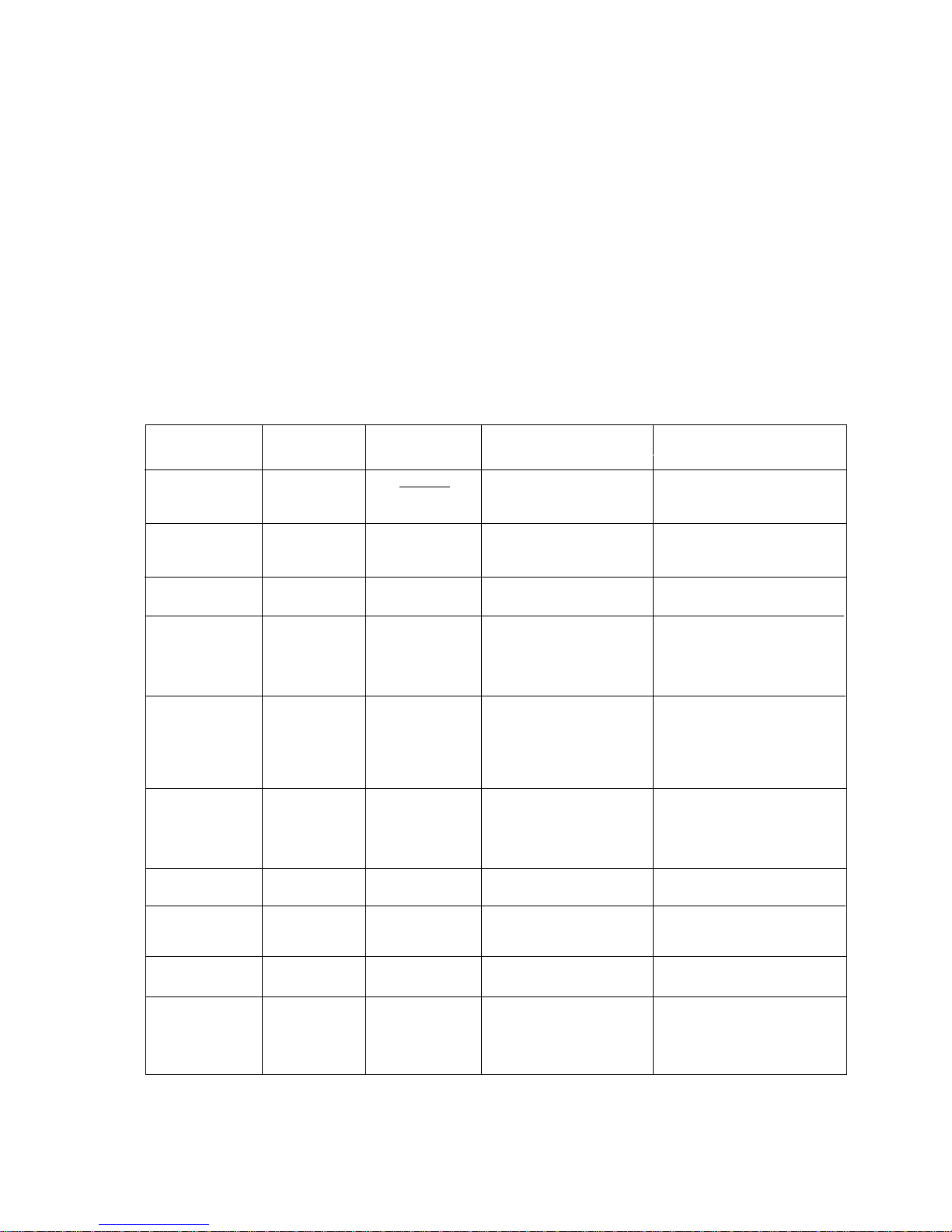

1-1. DIAGNOSTIC TEST INDICATORS

When an error occurs, the STANDBY/TIMER LED will flash a set number of times to indicate the possible cause of the problem.

If there is more than one error, the LED will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen. If the screen displays a “0”, no error has occurred.

Item 2:1

or more than 1

Item 3:1

or more than 1

Item 4:1

or more than 1

Item 5:1

or more than 1

Item 6:1

or more than 1

Item 7:1

or more than 1

Item 8:1

or more than 1

Item 9:1

or more than 1

Item 10:1

or more than 1

No. of times

STANDBY/TIMER

LED flashes

Symptoms

Diagnostic

Item

Description

Self-diagnostic

display/

Diagnostic result

Probable Cause Location

Does not light

2 times

3 times

4 times

5 times

6 times

7 times

8 times

9 times

10 times

•Power cord is not plugged in.

•Fuse (F6000) is burned out.

(A board)

•H. OUT(Q5001) is shorted.

•+B PWM(Q5201) is shorted.

(D board)

•IC6503 is faulty. (D board)

•15V is not supplied. (D board)

•IC5101 is faulty. (D baord)

•Video

OUT(IC9101,IC9201,IC9301)

is faulty. (CR,CG,CB board)

•CRT drive (IC0401) is faulty.

(MG board)

•G2 is impropenrly adjustd.**

• +5V line is overloaded.

(A, BM, MG boards)

• +5V line is shorted.

(A, BM, MG boards)

•IC6201is faulty. (A board)

•Q5006 is broken. (D board)

•IC0401 is faulty. (MG board).

•+ or - 22V audio supply is not

present - Check PS2001 &

PS2000

•D6166 or D6114 is open.

(A board)

• Q8014 or Q6013 have

shorted replace along with

R8051 on D board.

•IC8005 is damaged.

(D board)

* If a +B overcurrent is detected, stoppage of the vertical detection is detected simultaneously. The

symptom that is diagnosed first by the microcontroller is displayed on the screen.

** Refer to screen (G2) adjustment (fine adjustment) in section 2 of this manual.

*** Is STNDBY/TIMER LED flashes six (6) times, unplug the unit and wait 10 seconds before

performing the adjustment.

KP-FX432M90/FX532M90

RM-1014

– 6 –

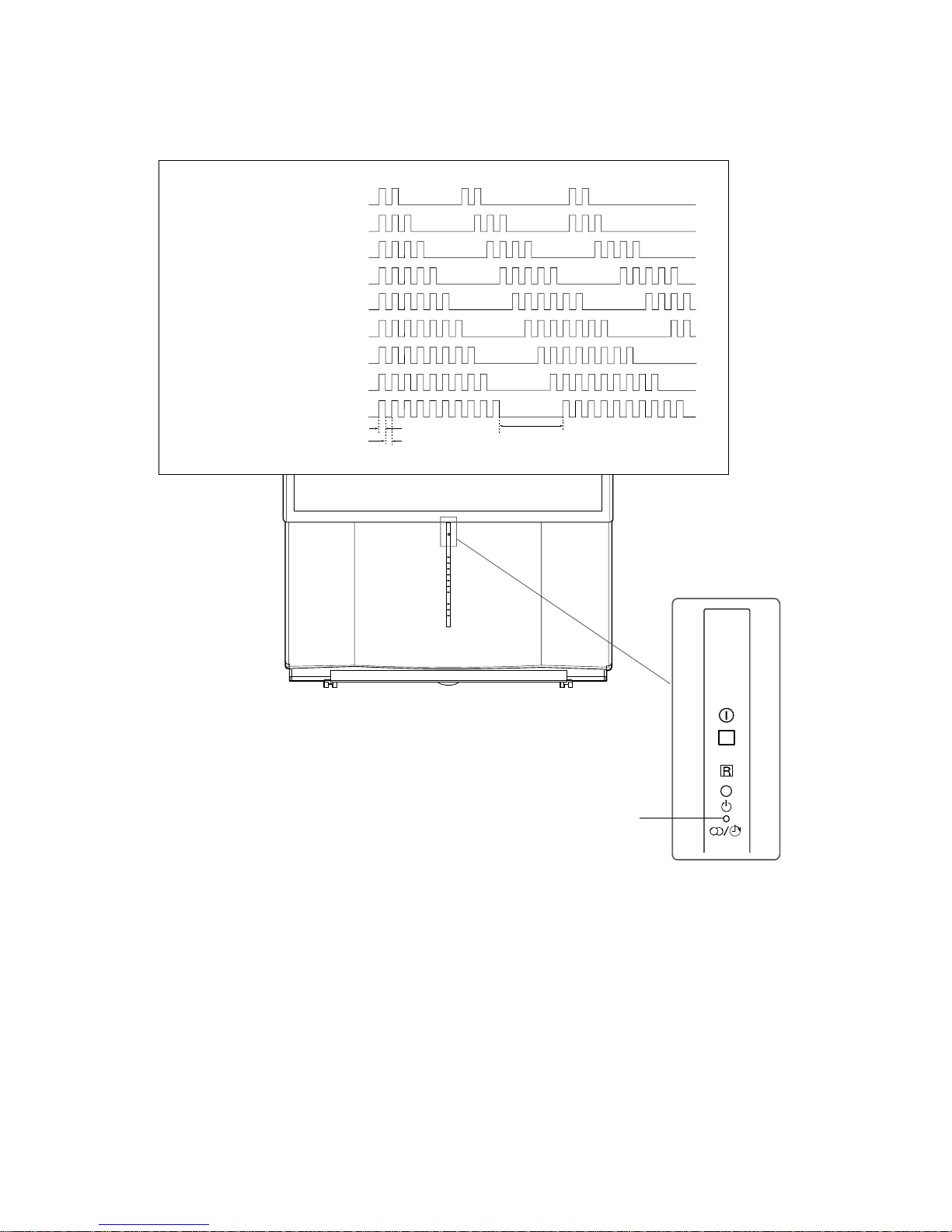

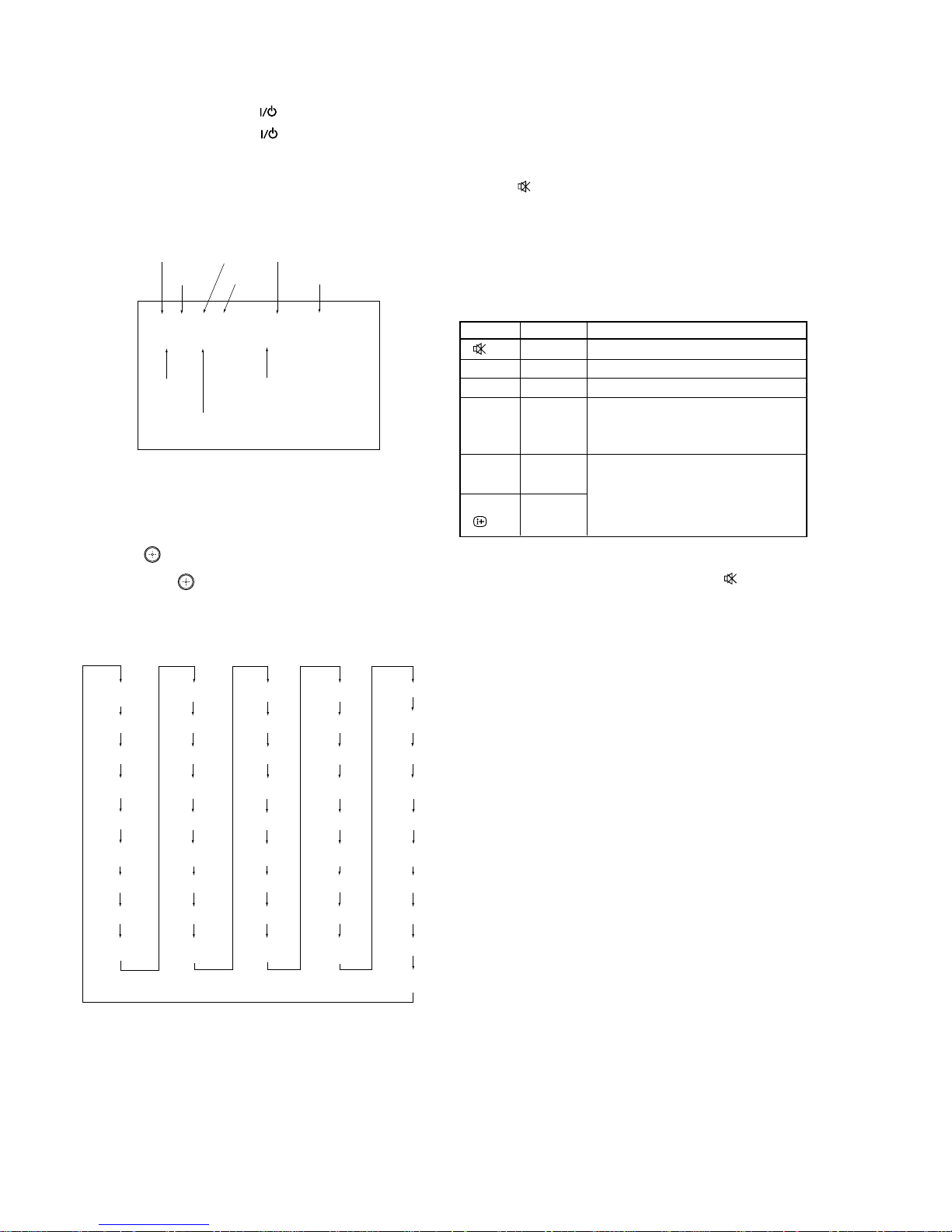

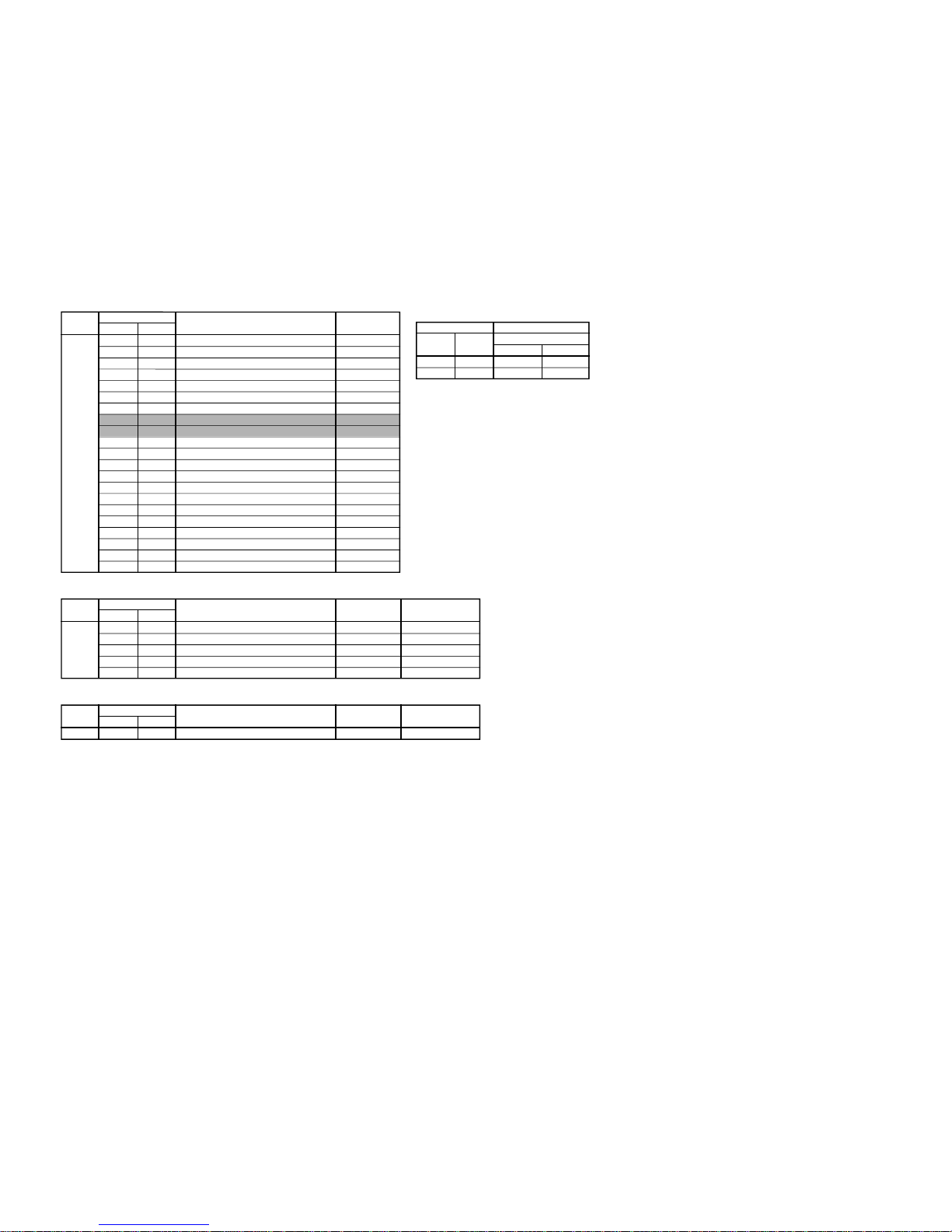

1-2. DISPLAY OF STANDBY/TIMER LIGHT FLASH COUNT

1-3. STOPPING THE STANDBY/TIMER FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER lamp from

flashing.

LED OFF 3 sec

LED ON 0.3 sec.

LED OFF 0.3 sec.

4 tims

5 tims

6 tims

7 tims

8 tims

9 tims

10 tims

HV protection

2 tims

3 tims

Audio protection

Zero crossing detector

Low +B OVP/OCP

Horiz. deflection stopped

Vert. deflection stopped

White balance failure

+B Overcurrent

Low +B Overvoltage

Flash count

Diagnostic items

* One flash counts is not used for silf-diagnostic.

STANDBY/TIMER

lamp

KP-FX432M90/FX532M90

RM-1014

– 7 –

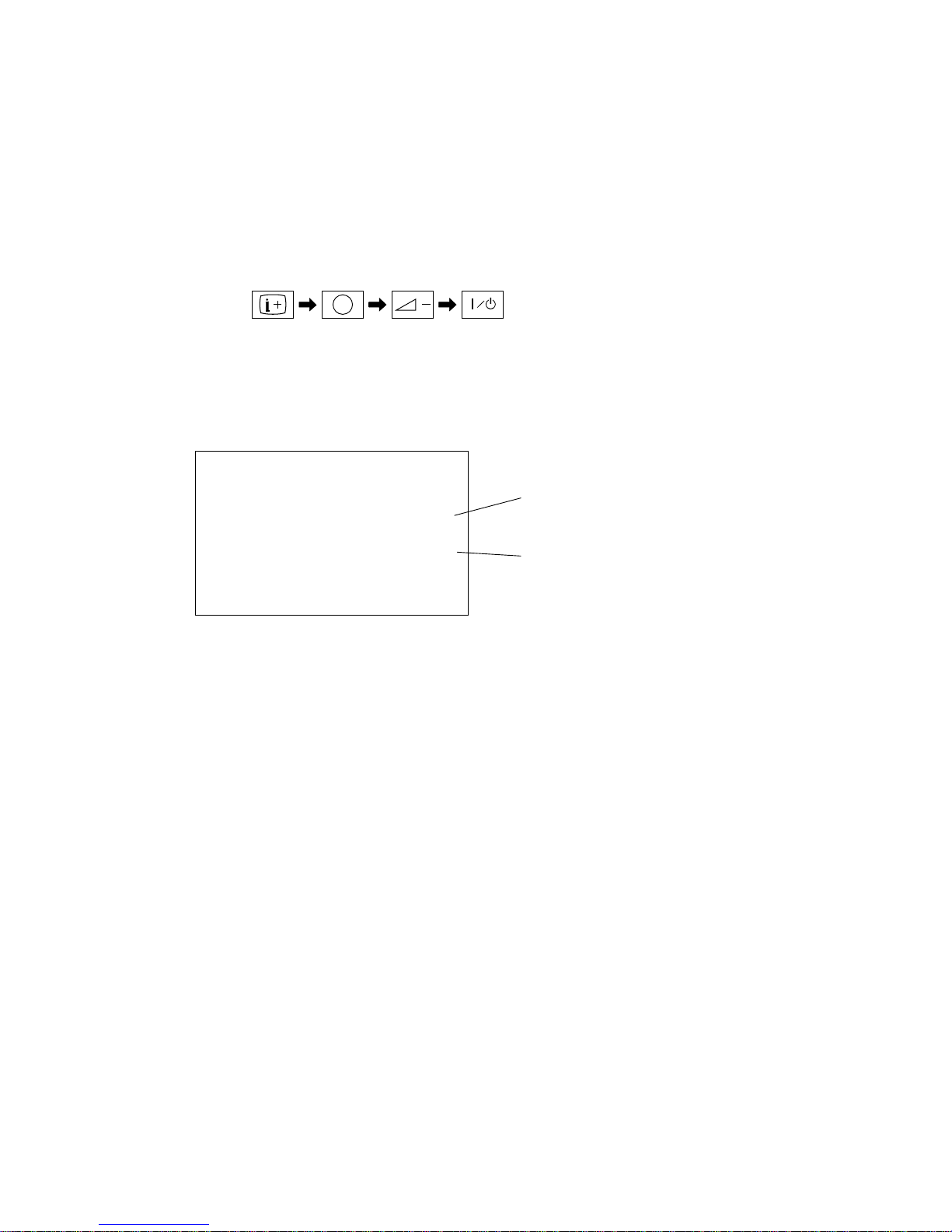

1-4. SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it is

possible to bring up past occurrences of failure for confirmation on the screen:

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

Self-Diagnosis screen display

1-5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

5

(DIGIT 5) (VOLUME –) (POWER)ON SCREEN

DISPLAY

(

)

*

* : Note that this differs from entering the service mode (volume +)

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen.

After you have completed the repairs, clear the result display to “0”.

[Clearing the result display]

To clear the result display to “0”, press button on the remote commander sequentially as shown below when the diagnostic

screen is being displayed.

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

Press “8” button

(It will indicate “CLEAR” on the screen.)

Press “-” button

(The “CLEAR” display change to red color.)

,

SELF DIAGNOSTIC

2 OCP : 0

3 OVP : 0

4 V STOP: 0

5 AKB : 0

6 LOW-B : 0

7 H STOP : 0

8 A PRT : 1

9 Z DET : 0

10 HV PRT : 0

101 WDT : 0

102 WDT PF : 24

Number "1 "

means a fault was detected one

time only.

Number "0 "

means that no fault detected.

KP-FX432M90/FX532M90

RM-1014

– 8 –

+B overcurrent (OCP) Occurs when excessive current flows through R6812.

The increase in voltage across Q6803 causes it to turn on which sends

a high signal to the micro.

+B overvoltage (OVP) IC6801 detects +B OVP condition and Q6802.

This sends a high signal to the micro and also shuts down the AC

relay.

V-STOP Occurs when an absence of the vertical deflection pulse is detected by

pin 56 of IC0404 (MG board).

Power supply will shut down when waveform interval exceeds 2 seconds.

White balance failure If the RGB levels* do not balance within 2 seconds after the power is

turned on, this error will be detected by IC0401.

TV will stay on, but there will be no picture.

Low +B OCP/OVP Occurs when set 5V is out.

Horizontal deflection stopped Occurs when either :

1)a +B overcurrent is detected (Q6803), or

2)IC0401 (MG board) is damaged.

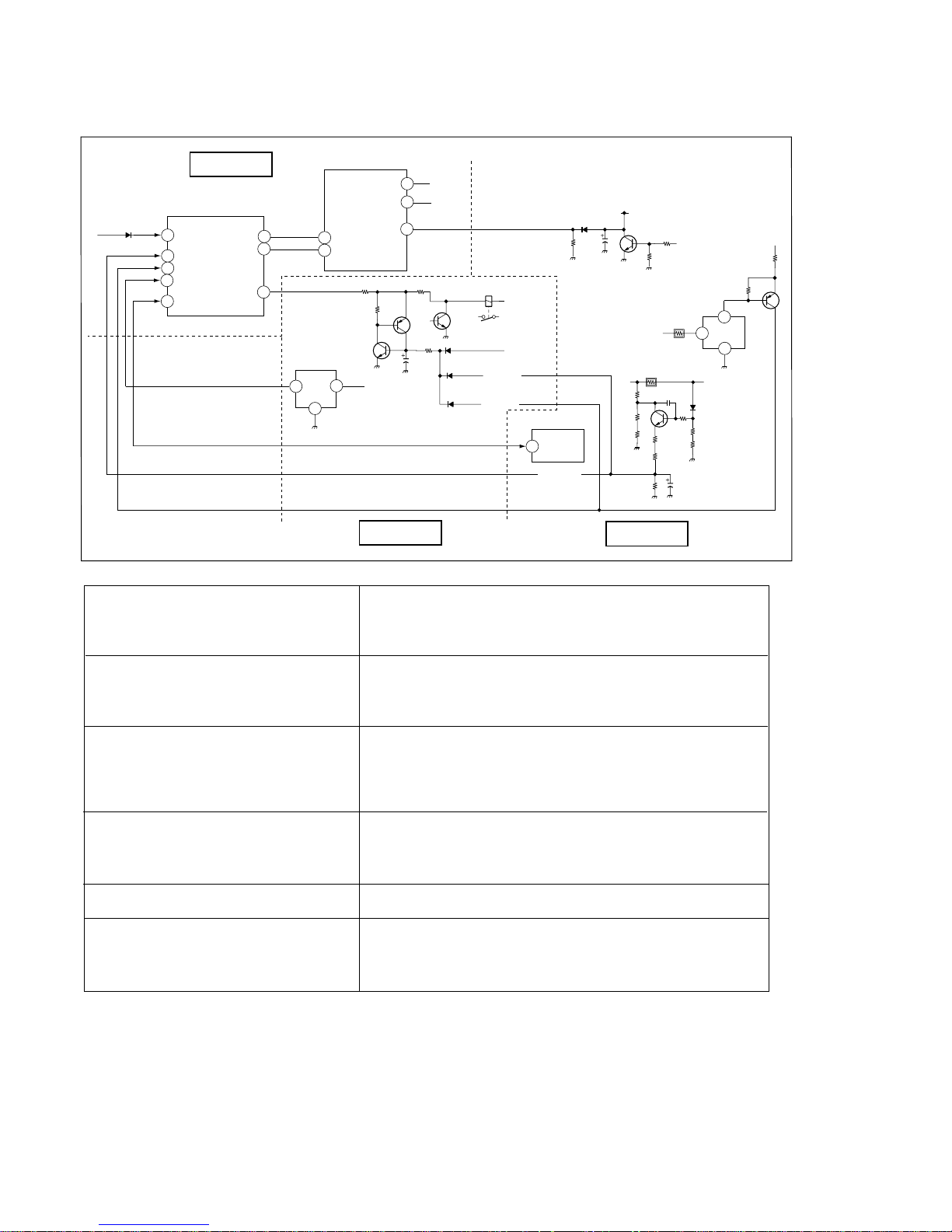

1-6. SELF-DIAGNOSTIC CIRCUIT

IC0001

MAIN MICRO

22

STBY-LED

5

OCP

6

OVP

53

SCL

52

SDA

AKB

24

CLKO

14

V PROT

56

87

LOW B ERR

33 HV PROT

AC RLY 36

DATO

13

HG PROT

57

2

1

3

1

< +15V

<

+B OCP

>

<

IK PROT2

>

<

+B OCP

>

<

+B OVP

>

2

3

1

< H PLS

Q6108

Q6102

Q6803

CRT

VDY-

+12V

Q5202

RY6000

<

P_SW(-)

IC6201

+B

>

IC8001

IC6801

+15V

<

Q6802

+B >

D6805

< +B

STBY-LED

Q6105

D6803

D6122

D6121

MG BOARD

A BOARD

D BOARD

– 9 –

KP-FX432M90/FX532M90

RM-1014

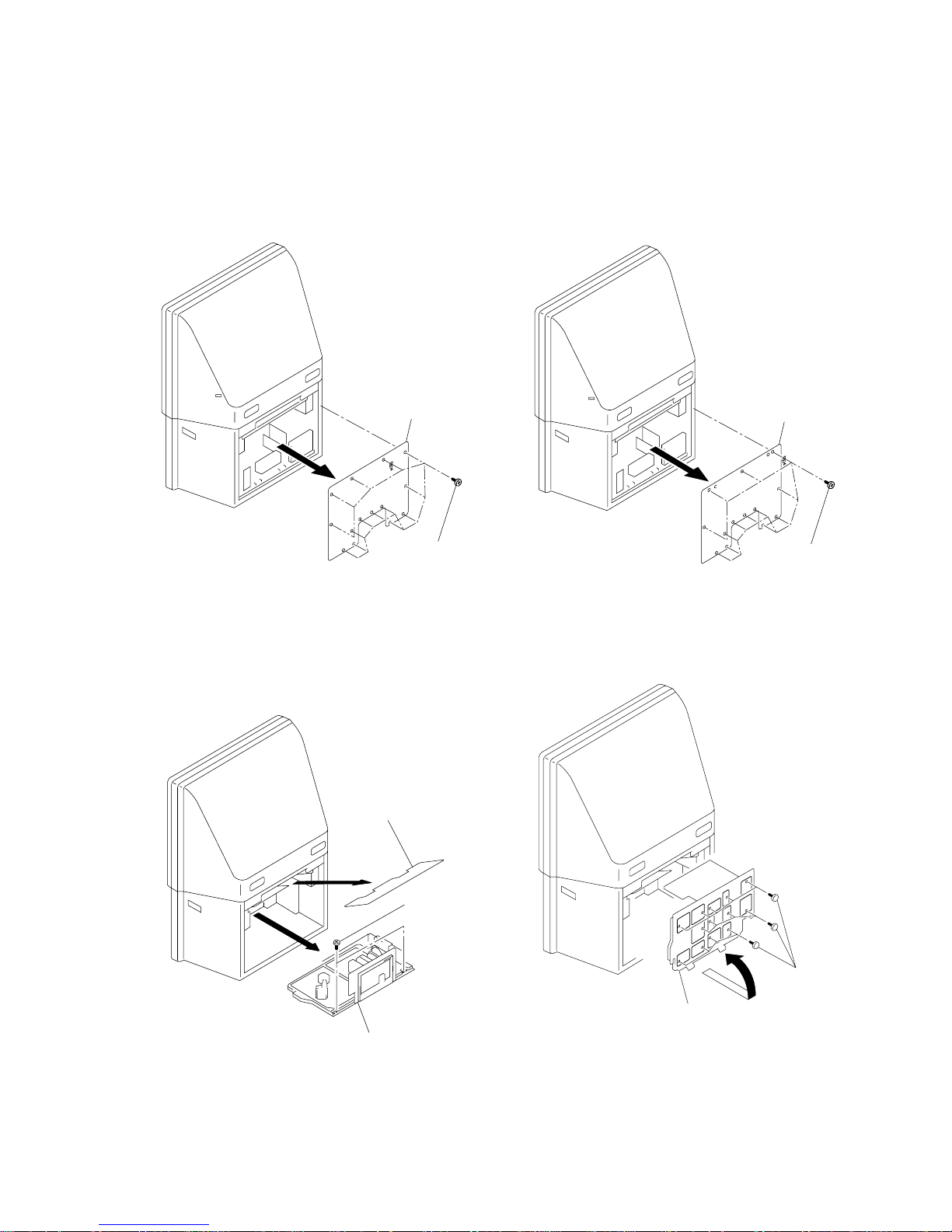

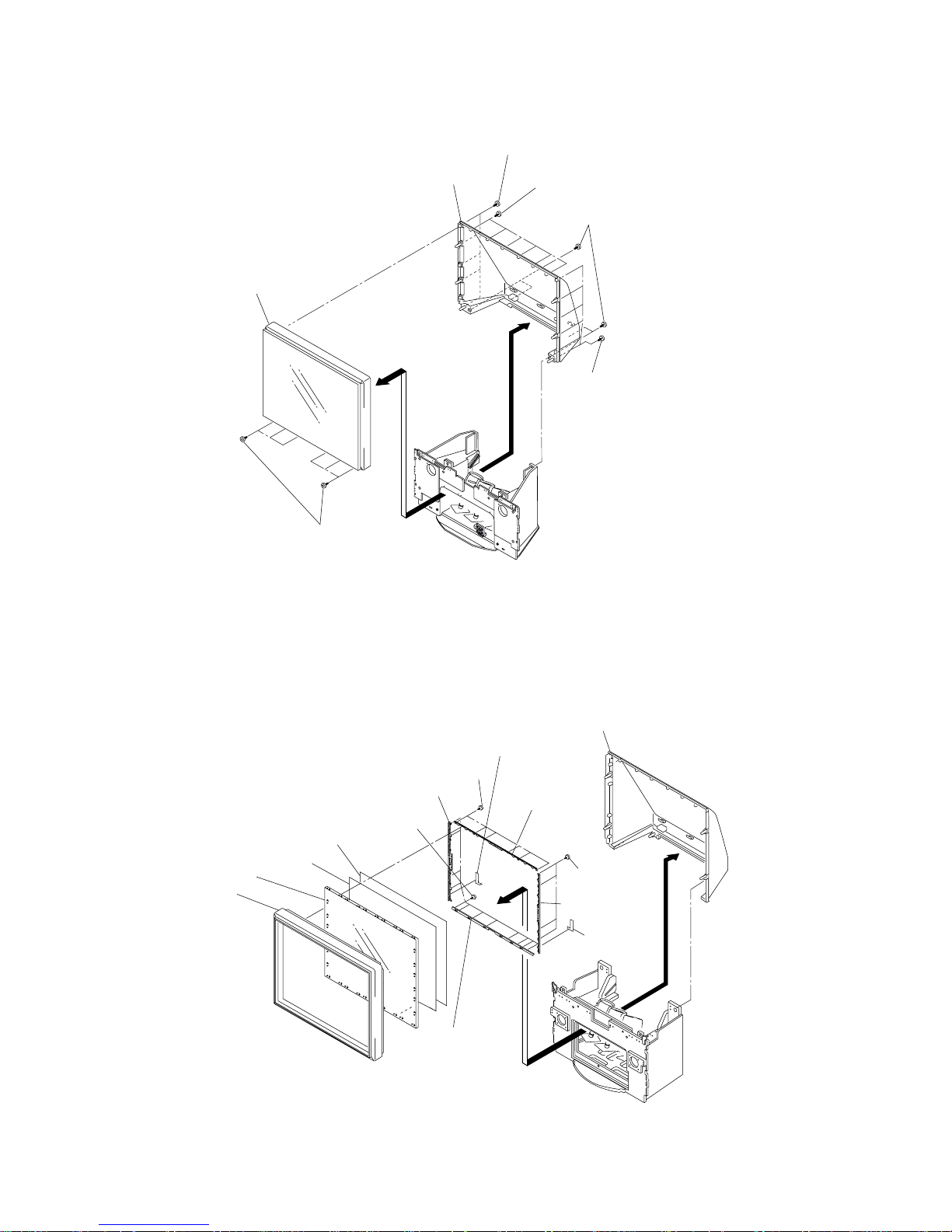

2-1. REAR BOARD REMOVAL

2-2. MAIN BRACKET REMOVAL 2-3. SERVICE POSITION

2 COVERS

Cut them off with a plier or the like from

chassis assembly in case of checking

printed circuit boards.

After checking, turn over the covers and

secure them with screws.

(screws 7-685-648-79 -BVTP 3X12)

SECTION 2

DISASSEMBLY

1 Fourteen screws

(Hexagon head)

2 Rear board

2 T wo screws

(Tapping screw

hexagon head)

3 PWB block assy

1 Optical shield

2 Thirteen screws

(BVTP 3X12)

1 Main bracket section

(1) KP-FX432

(2) KP-FX532

1 Thirteen screws

(Hexagon head)

2 Rear board

– 10 –

KP-FX432M90/FX532M90

RM-1014

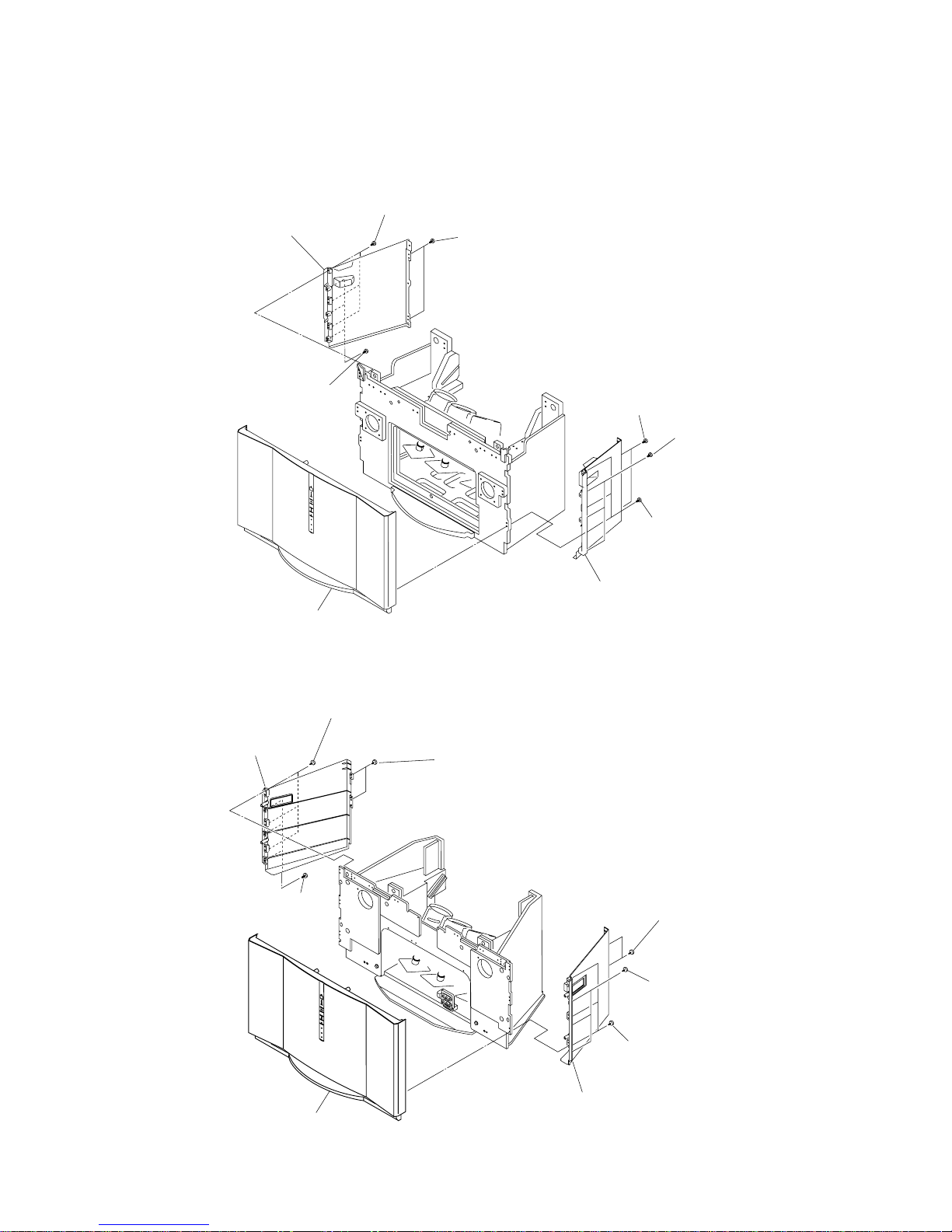

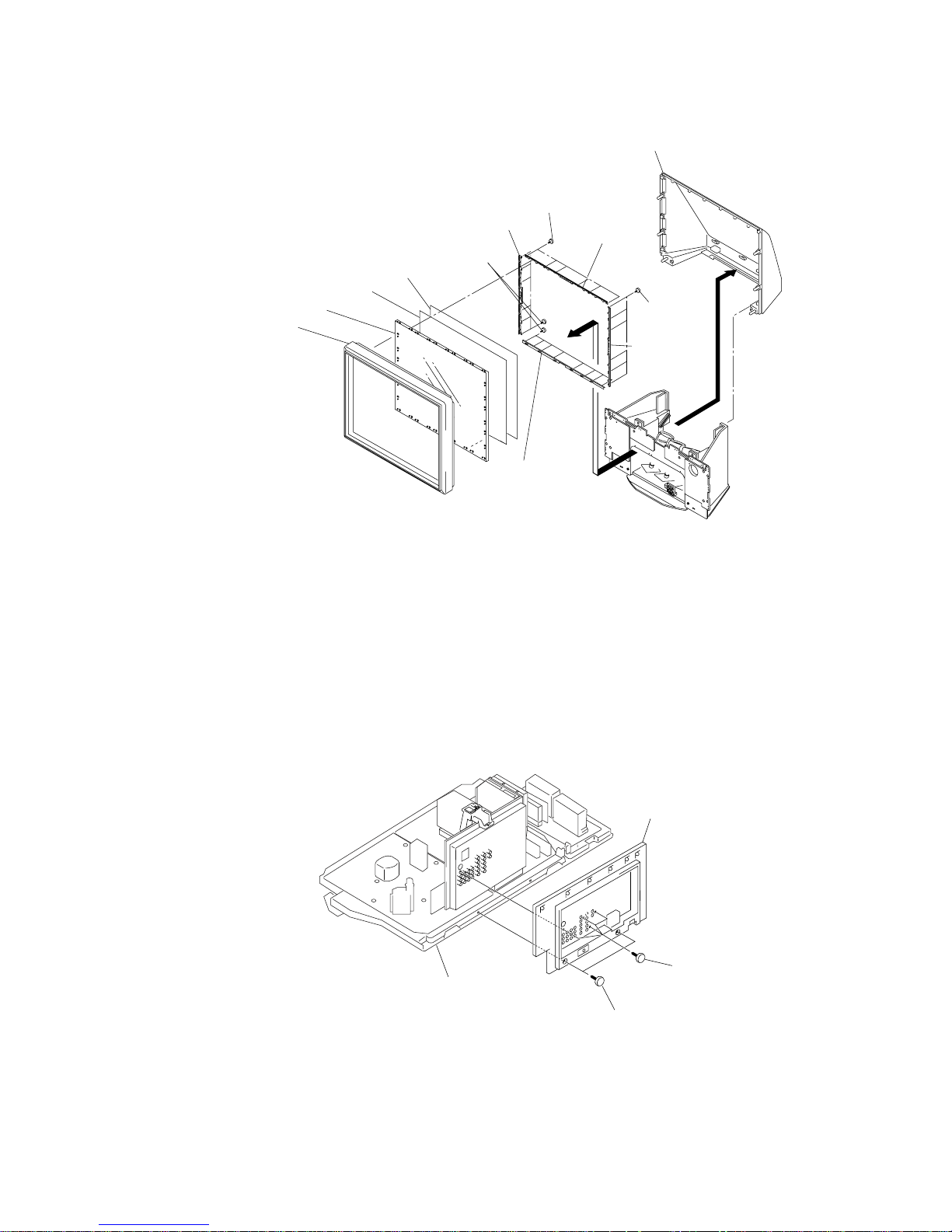

2-4. FRONT PANEL ASSY REMOVAL

(1) KP-FX432

2 T wo screws

(tapping screw

hexagon head)

2 Three screws

(tapping screw

hexagon head)

1 Three screws

(BVTP 4x16)

4 three screws

(BVTP 4x16)

5 T wo screws

(tapping screw

hexagon head)

5 Three screws

(tapping screw

hexagon head)

6 Side pane (53R) assy

7 Front panel (53) assy

3 Side pane (53L) assy

(2) KP-FX532

2 T wo screws

(tapping screw

hexagon head)

1 Three screws

(BVTP 4x16)

7 Front panel (43) assy

4 Three screws

(BVTP 4X16)

5 T wo screws

(tapping screw

hexagon head)

5 Three screws

(tapping screw

hexagon head)

6 Side panel (43R) assy

2 Three screws

(tapping screw

hexagon head)

3 Side panel (43L) assy

– 11 –

KP-FX432M90/FX532M90

RM-1014

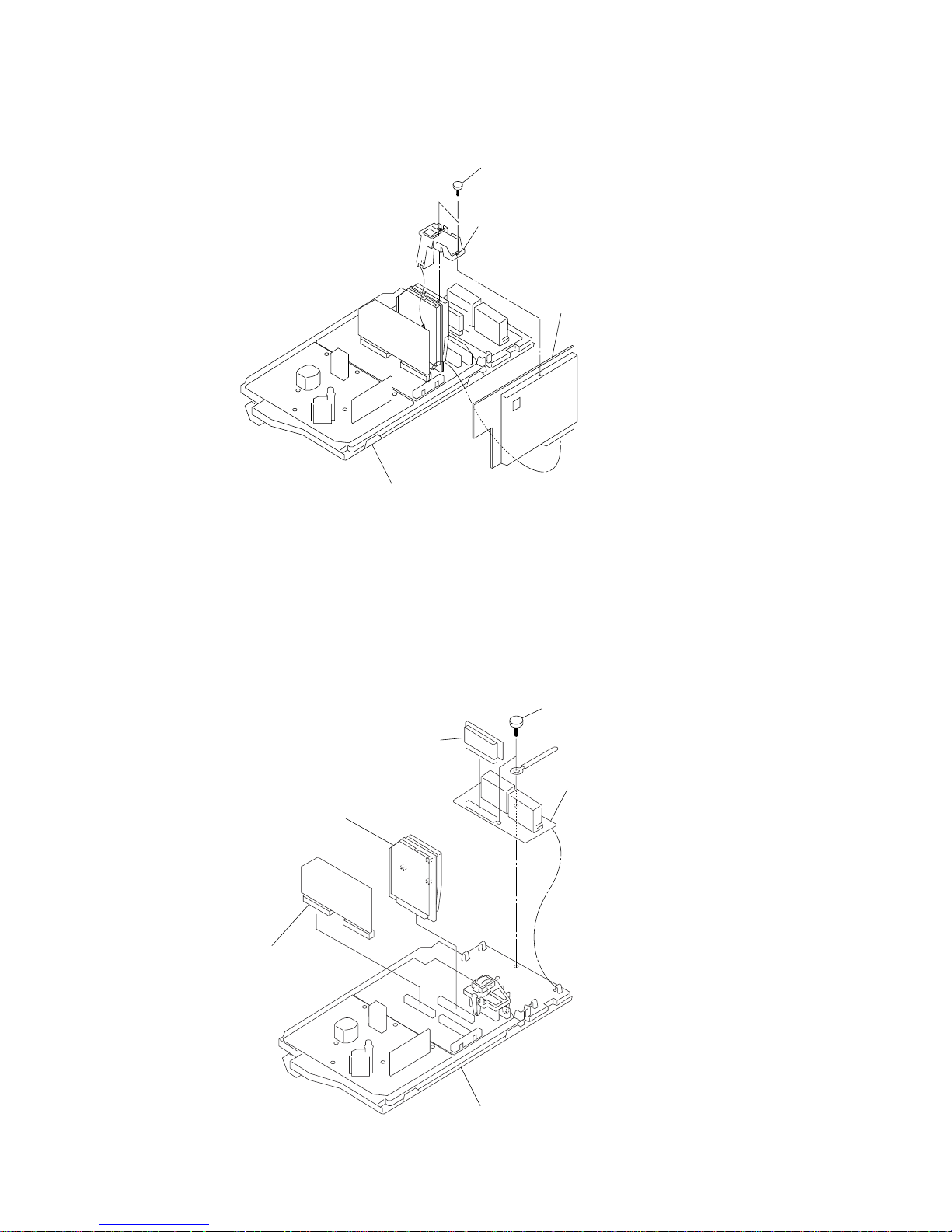

6 T wo screws

(BVTP 3x12)

1 T wo screws

(BVTP 3x12)

6 T wo screws

(BVTP 3x12)

4 Three screws

(BVTP 3x12)

5 HA board

7 Control button

2 HC bracket

3 HC board

Front panel assy

9 HB1 board

8 T wo screws

(BVTP 3x12)

2-5. HC, HA AND HB1 BOARDS REMOVAL

5 Beznet block

4 Four screws

(BVTP 4X12)

2 Four screws

(BVTP 4X16)

2 Six screws

(BVTP 4X16)

1 Four screws

(Hexagon head)

2 Four screws

(BVTP 4X16)

3 Mirror cover

2-6. MIRROR COVER AND BEZNET BLOCK REMOVAL

(1) KP-FX432

– 12 –

KP-FX432M90/FX532M90

RM-1014

2-7. BEZNET ASSY REMOVAL

(1) KP-FX432

(2) KP-FX532

5 Beznet block

4 Six screws

(Hexagon head)

3 Mirror cover

1 Six screws

(BVTP 4X16)

2 Four screws

(Hexagon head)

1 Six screws

(BVTP 4X16)

1 Six screws

(BVTP 4X16 )

Mirror cover

6 Screen

holder (SIDE)

5 Screen holder (SIDE)

4 Screen

holder (TOP)

7 Screen

holder (LOW)

3 Six screws (BVTP 4X16)

3 Four screws

(BVTP 4X16)

3 Twelve screws (BVTP 4X16)

1 Holder

Bracket(43R)

8 Diffusion plate (F)

9 Diffusion plate (L)

0 Contrast screen

2 Holder Bracket(43L)

!¡ Beznet assy

– 13 –

KP-FX432M90/FX532M90

RM-1014

2-8. TERMINAL BRACKET REMOVAL

(2) KP-FX532

PWB block assy

4 T erminal bracket

3 T ow screws

(Hexagon head)

2 Four screws

(BVTP 3X12)

Mirror cover

4 Screen

holder (SIDE)

3 Screen holder (SIDE)

2 Screen

holder (TOP)

5 Screen

holder (LOW)

1 Six screws (BVTP 4X16)

1 Six screws

(BVTP 4X16)

1 Fourteens screws (BVTP 4X16)

6 Diffusion plate (F)

7 Diffusion plate (L)

8 Contrast screen

9 Beznet assy

– 14 –

KP-FX432M90/FX532M90

RM-1014

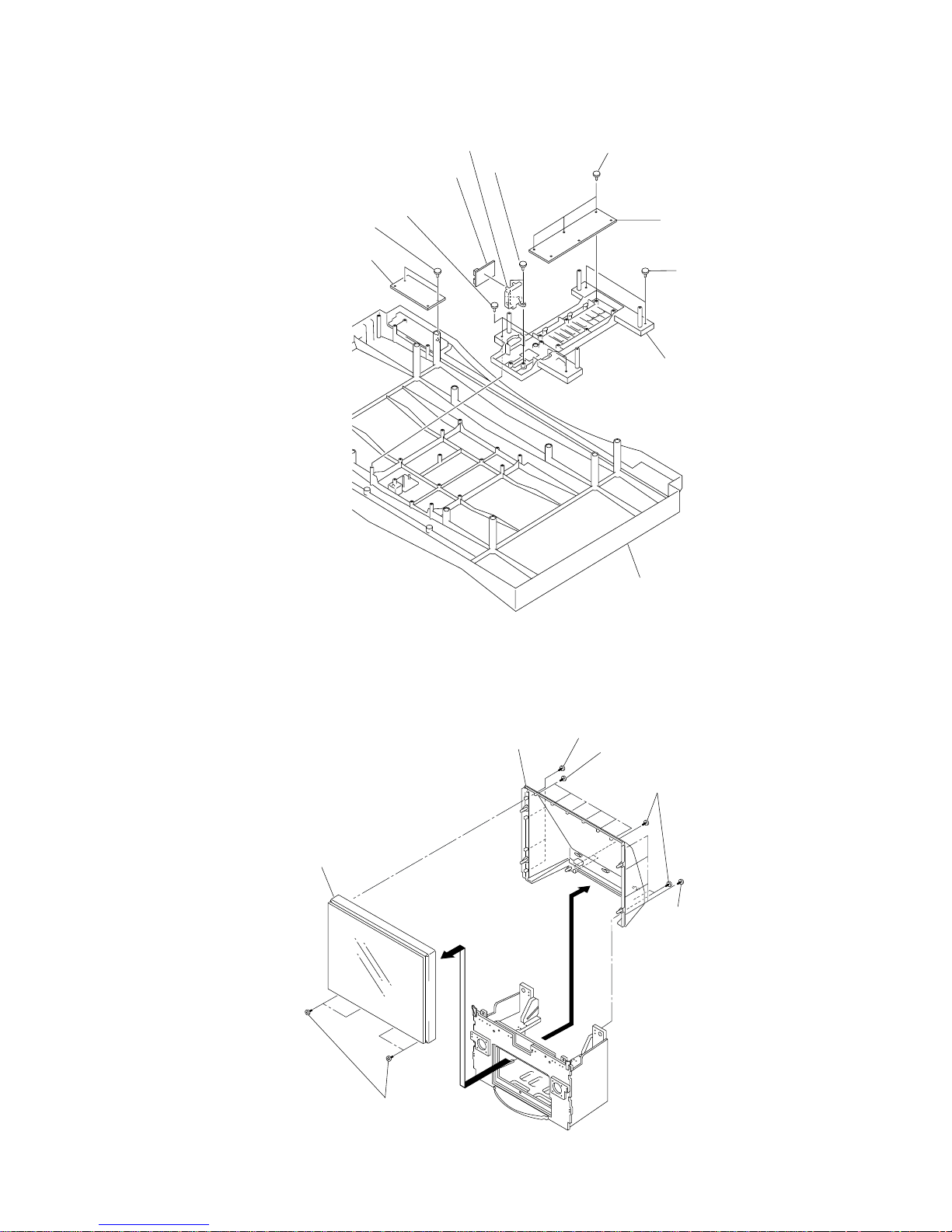

2-10. AD, BM, DS AND MG BOARDS REMOVAL

Main bracket section

2 BM board

1 MG Board

4 DS board

3 T wo screws

(BVTP 3x12)

4 AD Board

2-9. UG BOARD REMOVAL

3 UG board

2 B bracket

Main bracket section

1 T wo screws

(PSW 3x8)

– 15 –

KP-FX432M90/FX532M90

RM-1014

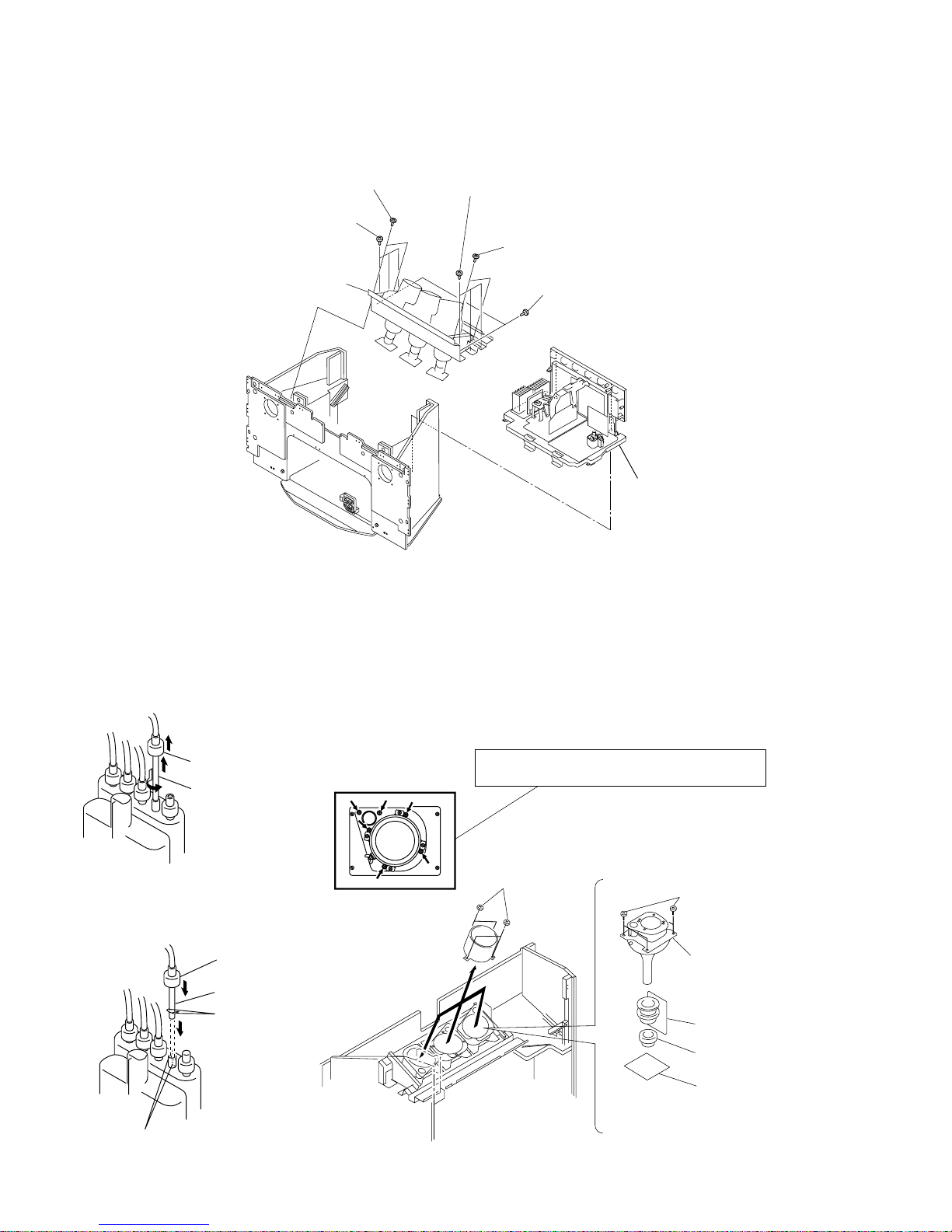

6 D board

4 A board

Main bracket section

3 Five screws

(BVTP 3x12)

5 Six screws

(BVTP 3x12)

2 G1 bracket

1 Three screws

(BVTP 3x12)

2-11. A AND D BOARDS REMOVAL

2-12. CRT AND PWB BLOCK REMOVAL

(1) KP-FX432

PWB block assy

3 Picture tube block assy

2 Three screws

(Hexagon head)

(4X20)

2 T wo screws

(Hexagon head)

(4X20)

2 Three screws

(Hexagon head)

(4X20)

1 T wo screws

(BVTP 4X16)

1 T wo screws

(BVTP 4X16)

– 16 –

KP-FX432M90/FX532M90

RM-1014

1 Four screws

(BVTP 4X16)

5 Four screws

(BVTP 4X16)

Removing the arrow-marked screw is strictly inhibited.

If removed, it may cause liquid spill.

2 CR board

3 Neck assy

4 Deflection yoke

6 Mechaseal assy (R)

2-14. MECHANICAL ASSY REMOVAL2-13 HIGH-VOLTAGE CABLE

INSTALLATION AND REMOVAL

(2) Installation

(1) Remover

2 Rubber cap

1 HV cable

Hook

Gutter

1 Rubber cap

2 HV cable turn 90

°

(2) KP-FX532

PWB block assy

3 Picture tube block assy

2 Three screws

(Hexagon head)

(4X20)

2 T wo screws

(Hexagon head)

(4X20)

2 Three screws

(Hexagon head)

(4X20)

1 T wo screws

(BVTP 4X16)

1 T wo screws

(BVTP 4X16)

– 17 –

KP-FX432M90/FX532M90

RM-1014

SECTION 3

SET-UP ADJUSTMENTS

3-1. SCREEN VOLTAGE ADJUSTMENT

(ROUGH ALIGNMENT)

1. Receive the Monoscope signal.

2. Set 50% BRIGHTNESS and minimum PICTURE.

3. Turn the red VR on the focus pack all the way to the left and

then gradually turn it to the right until the point where you

can see the retrace line.

4. Next gradually turn it to the left to the position where the

retrace line disappears.

Fig. 3-1

3-2. SCREEN (G2) ADJUSTMENT

(FINE ADJUSTMENT)

1. Turn on the power of the set.

2. Select VIDEO1 and make no signal input.

3. Supply DC (177.5 ± 0.5V) from external power supply to

KR. (Fig.3-2)

3. Turn red of G2 VR clockwise, then retrace line appear.

4. Turn G2 VR counterclockwise and set retrace line just

disappear.(Fig.3-3)

5. Add DC voltage DC (174 ± 0.5V) to KR.

6. Confirm if retrace can be seen.

7. Adjust green and blue at the same method.

3-4. DEFLECTION YOKE TILT ADJUSTMENT

1. Receive the Monoscope signal.

2. Place the caps on the red and blue lens so that only the green

color.

3. Loosen the deflection yoke setscrew and align the tilt of the

Deflection yoke so that the bars at the center of the

monoscope pattern are horizontal.

4. After aligning the deflection yoke, fasten it securely to the

funnel-shaped portion of the CRT.

5. The tilt of the deflection yoke for red and blue is aligned the

same as was done for green.

Fig. 3-6

VMcoil Assy

Make sure deflection yoke is

touching CRT closely.

2-pole magnet

4-pole magnet

Deflection yoke

Anode cap

Centering magnet

Fig. 3-5

Lens

Fig. 3-4

Minimize both A and B.

A

B

Scanning line visible.

3-3. FOCUS ROUGH ADJUSTMENT

1. Connect VIDEO-1 terminal.

2. Receive video dot hatch pattern.

3. Use lens-cover to red and blue.

Fig. 3-3

+

–

Power

Supply

Dummy Resister

3k ohm 20W

Fig. 3-2

Test signal

SCREEN

B

RG

FOCUS

Focus Pack

BRG

4. Adjust electric focus. (roughly)

5. Rotate the green lens and adjust to obtain the best lens focus.

6. Rotate the green focus volume on the focus pack and adjust to

obtain best electrical focus.

7. If focus is not good, repeat 4 process.

8. Repeat above process for red and blue lenses and electric focus.

9. Fix lens screw.

– 18 –

KP-FX432M90/FX532M90

RM-1014

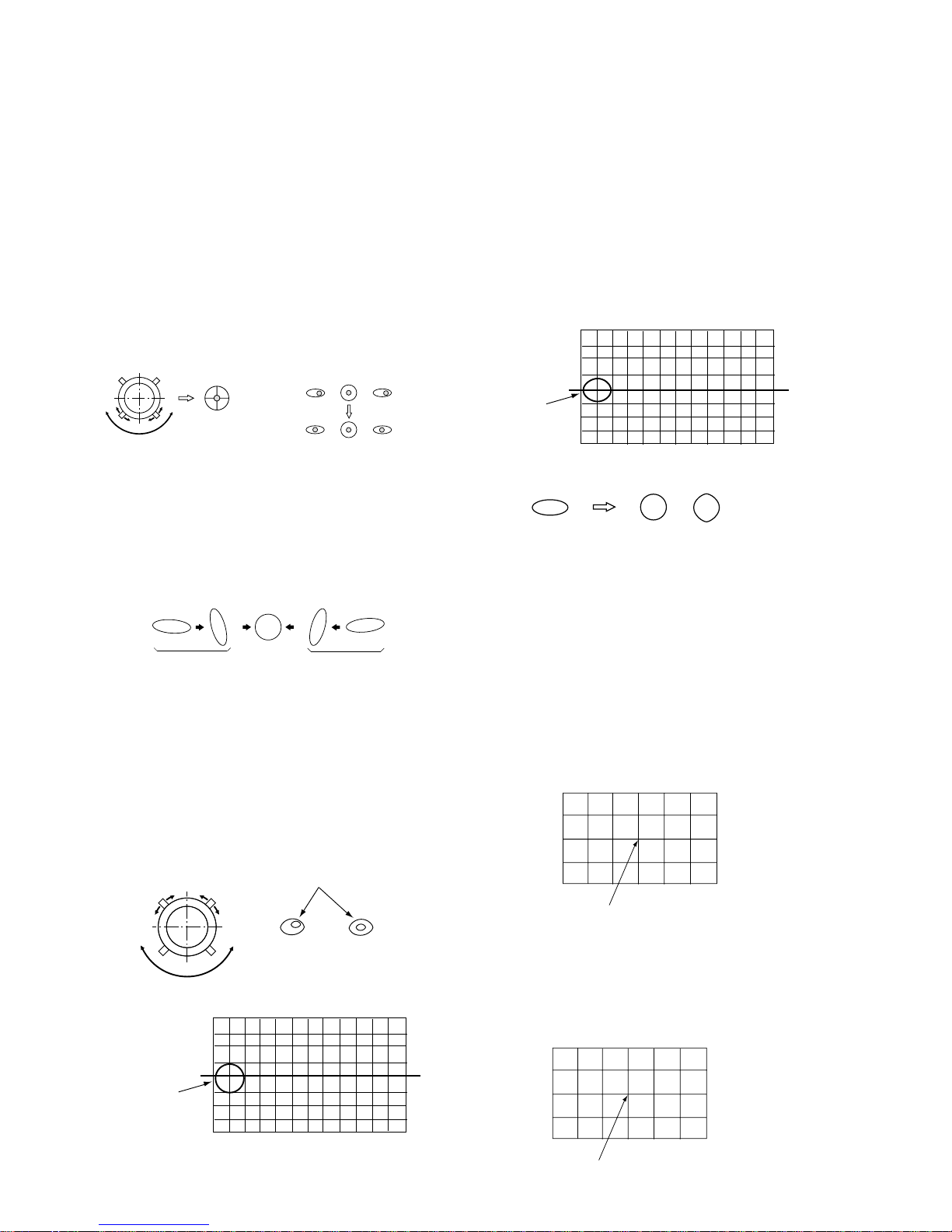

3-5-2. Green, Red, Blue adjustment of 4-pole

magnets

1. Turn Grenn focus volume of focus pack clockwise.

2. By using 4 pole magnets make the spot size round.

3. Repeat for red and blue.

4. Turn focus pack counter-clockwise and "Just Focus" red,

green and blue.

3-5-3. Blue left side dot adjustment of 2-pole Magnets

1. Turn blue focus volume of focus pack counter-clockwise, so

that diameter of the dot becomes large, and can see bright

core position.

2. Pay attentio to left side dot of the screen. (Fig.3-10)

3. Adjustment 2 pole magnet, so that bright core position of dot

become center position of dot. (Fig.3-11)

3-5. 2-POLE and 4-POLE MAGNET ADJUST-

MENT

3-5-1.Adjustment of 2-pole magnets

1. Receive the Dot signal( 1080i/50Hz) from HD/DVD 1 terminal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Turn the green focus volume of focus pack counter-clockwise, so that diameter of the dot become large.

4. Adjust the 2-pole magnet, counter-clockwise and clockwise

center of the dot doesn't move. (Use focus volume)

5. Center position is changed by 2-pole magnet adjustment.

So, center magnet adjustment and 2-pole magnet adjustment

are needed tracking adjustment.

6. Repeat same adjustment method for red and blue.

Fig. 3-7

3-7. GREEN, RED AND BLUE FOCUS

ADJUSTMENT

3-7-1. Green, Red and Blue lens focus adjustment

1. Input a cross hatch signal into VIDEO 1 (composite video

input)

2. Place a lens cover over red and blue lenses and project only

green.

3. Rotate the green lens and adjust to obtain the best lens focus

at the center area.

4. Fix lens screw.

5. Repeat above process for red and blue.

3-7-2. Green and Red electrical focus adjustment

1. Input a cross-hatch signal into VIDEO 1.

2. Project only Green.

3. Rotate the green focus volume on the focus pack and adjust

to obtain the best focus at the center screen.

4. Repeat above process for red.

Adjust Point center

Use the center dot

Fig. 3-14

3-6. BLUE DEFOCUS ADJUSTMENT

1. Receive 1080i/50Hz dot signal from HD/DVD 1 terminal.

2. Set "Hi Fine" and PICTURE 100%, other 50% and white

balance "COOL"(VM OFF).

3. Blue 4 pole : make round in the center of screen.

4. Confirm that center dot focus is adjusted in focus.

(Fig.3-12a)

5. Adjust blue electrical focus to make the left side spot nearly

round by minimizing width and height. (Slight overfocus is

OK) (Fig.3-12b)

6. Confirm that the green to blue spot size is within spec.

Blue center dot height shall be ≤1.2 times the green dot

heght.

7. Return making condition data to orignal data.

Fig. 3-12a

Fig. 3-8

NG

OK

Left-end dot

(BLUE)

Right-end dot

(BLUE)

OKNG

NG

Use the center dot

Bright Core

Fig. 3-10

Fig. 3-9

Blue 2 Pole magnet

Adjustment Position

Fig. 3-11

Blue 2 Defocus

Adjustment Position

OK

Fig. 3-12b

Adjust Point

Fig. 3-13

– 19 –

KP-FX432M90/FX532M90

RM-1014

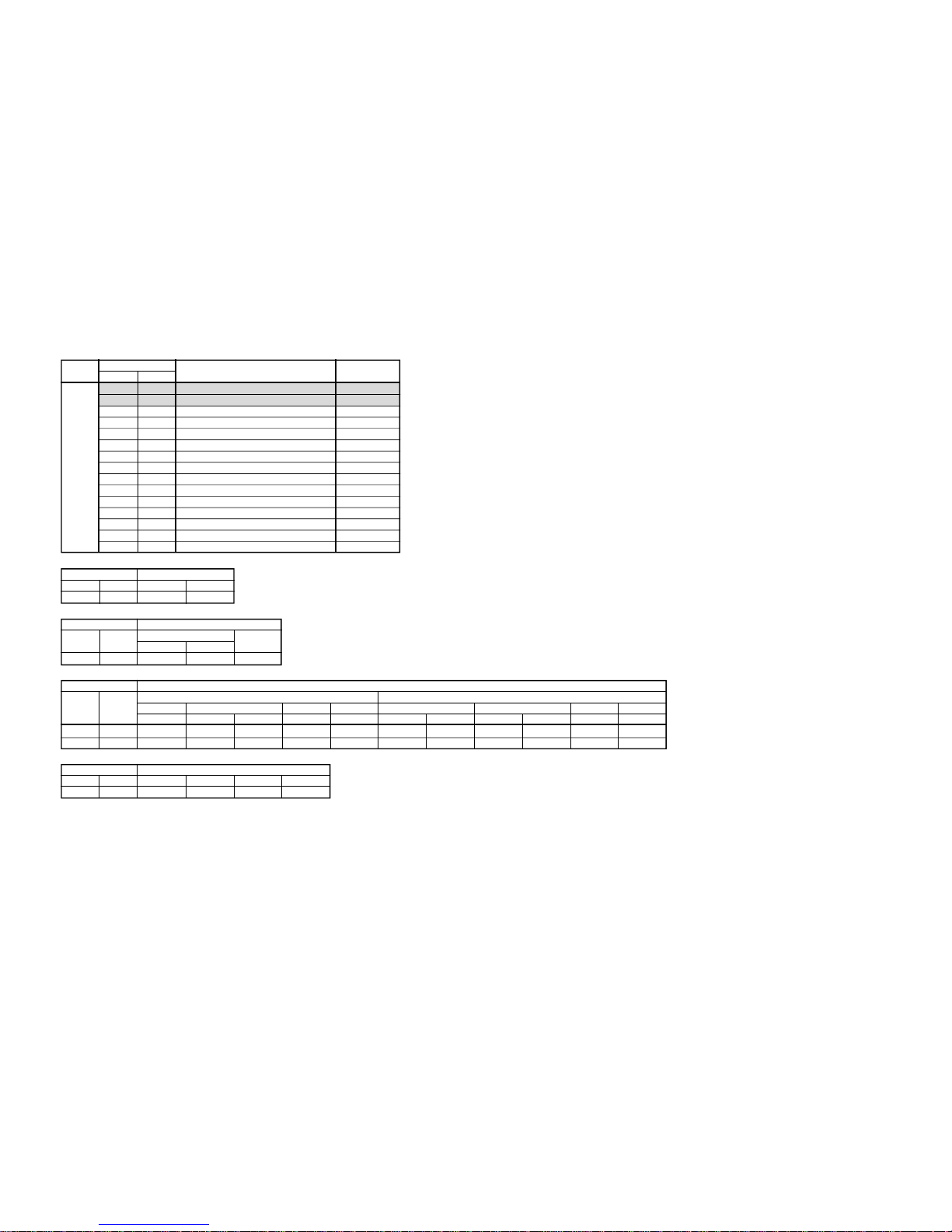

3-8-1. How to Select Each Mode

50 Hz 60 Hz WIDE 60 Hz WIDE 50 Hz

(PAL) (NTSC) (NTSC) (PAL)

DRC1250 aa a a

DRC100 aa a a

1. Selection of Mode Between 50 Hz and 60 Hz

50 Hz : Enter the PAL signal.

60 Hz : Enter the NTSC signal.

WIDE 60 Hz : Enter the NTSC signal MENU WIDE ON.

WIDE 50 Hz : Enter the PAL signal MENU WIDE ON.

2. Selection of DRC Mode

1) Press “DRC-MF (blue)” button on the commander, repeatedly until displays the mode that you want to select on the

screen.

→ DRC1250 → DRC100 → PROGRESSIV

Note : The DRC-MF mode is not selectable when using the

“PROGRAM INDEX” or “TWIN” mode is turned “ON”.

3. Selection of WIDE mode

1) Press “MENU” button on the commander and move “

” up

or down to enter the “FEATURE” b “WIDE MODE”.

2) Move “ ” up or down to select “ON” or “OFF”, and push

“

(ENTER)” button.

3) Press “MENU” button to return to normal screen.

3-8-2. How to Enter Service Mode

1. Turn on the main power switch to place this set in standby

mode. (LED will light in red.)

2. Press the buttons on the commander as follows, and enter service mode.

3. After entering service mode, reset current aadjustment data.

Then turn off the power switch.

4. Turn on the main power switch and enter mode again as step 2

above.

3-8. ADJUSTMENTS WITH COMMANDER

Service adjustment to this model can performed with the supplied

remote commander RM-1014.

1 2 3

4 5 6

7 8 9

0

JUMP

PROGR

MENU

PIC

MODE

DRC-MF

SOUND

MODE

WIDE

MODE

SURROUND

RESET

TV

HD/DVD

Copy PAL data

to NTSC

Adjustment item

up

Adjustment item

down

User control goes

to the standard state

Write data to NVM

Read data from

NVM

Initialize data

(Not stored)

Data down

Data up

Copy data to all

mode

Up : Category up

Down : Category down

Push : Enter

Change

the PICTUER MODE

blue

RM-1014

Enter the

“Service mode”

5

(DIGIT 5) (VOLUME +)ON SCREEN

DISPLAY

(

)

TV

STANDBY

(

)

Enter the

“Reset”

8

(DIGIT 8)

(ENTER)

– 20 –

KP-FX432M90/FX532M90

RM-1014

PIC

SOU

DRCV

LUMA

YCTM

YCTS

YCTC

MCP

MID1

VSW

MID3

MID2

PFOP

* : When it moves from PJE to other categrys,

repeat 1 or 4 button and press it.

PFID

AP

GRN

PJE*

DDEV

COLR

CLTY

DEF1

DEF2

CRNR

RNR

MSMO

3CM

POWR

GUID

MIDE

CCPM

COMB

DEF3

DEF4

DEF5

BNR

SNNR

AWID

OSDP

ASEL

VSEL

OPM

OPB

SRV

OSD

MSP

TEXT

OSD 0 OSV 32 SERVICE 60 480IL

000Q 3.1M 0010 0000 20 00 00 0000

Category Name

Item Name

Mode

Item No.

Suffix No.

Total Power On time

(Hours)

Software

Version

Data

50 : PAL, SECAM

60 : NTSC

3-8-3. Method of Cancellation from Service Mode

1. Set the standby mode (Press “ (TV STANDBY)” button on

the commander), then press “

(TV

STANDBY)” button again, hereupon it becomes TV mode.

3-8-4. How to Adjustments

1. Set in the service mode, the following screen will appear.

2. Press “1” or “4” button on the commander to select the adjustment item.

3. Press “3” or “6” button on the commander to change the

adjustment data.

4. Move “

” up or down to select the adjustment category.

When move “

” up (category up), service mode changes in

the order as shown below.

3-8-5. How to Write the Data

1. Set in the service mode.

2. Press “1” or “4” button on the commander, select the adjustment item, and press “3” or “6” button to change the

data.

3. Press “

(MUTE)” button on the commander and it will indi-

cate “WRITE” on the screen.

4. Press “-” button on the commander to write into memory.

(The “WRITE” display will be changed to red color while

executing, and back to “SERVICE”.)

Commander Function (Except PJE mode)

Button Mode Description

+ - WRITE Writes data to NVM.

7 + - READ Reads data from NVM.

8 + - NORMAL All user control goes to the standard.

5 + - INITIAL Service data initialization. Not

stored.

(Be sure not to use usually)

2 + - COPY Do not operate with a remote

commander.

(The data vary with among mode.)

+ - WRT5060

Note : Before changing to other modes, press “ (MUTE)” +

“-” buttons on the commander to write the data.

(Omission of this operation causes the data to be returned

to the data before adjustment.)

: Confirm the adjustment mode before writing data for data

values because to vary in each adjustment mode.

: The adjustment item that there are no relations in the ad-

justment is not to change data values because all items are

written in each adjustment mode.

3-8-6. Memory Write Confirmation Method

1. After adjustment, turn off the AC main power switch off.

2. Turn the power switch ON and set in service mode.

3. Call the adjustment items again to confirm adjustments were

made.

– 21 –

KP-FX432M90/FX532M90

RM-1014

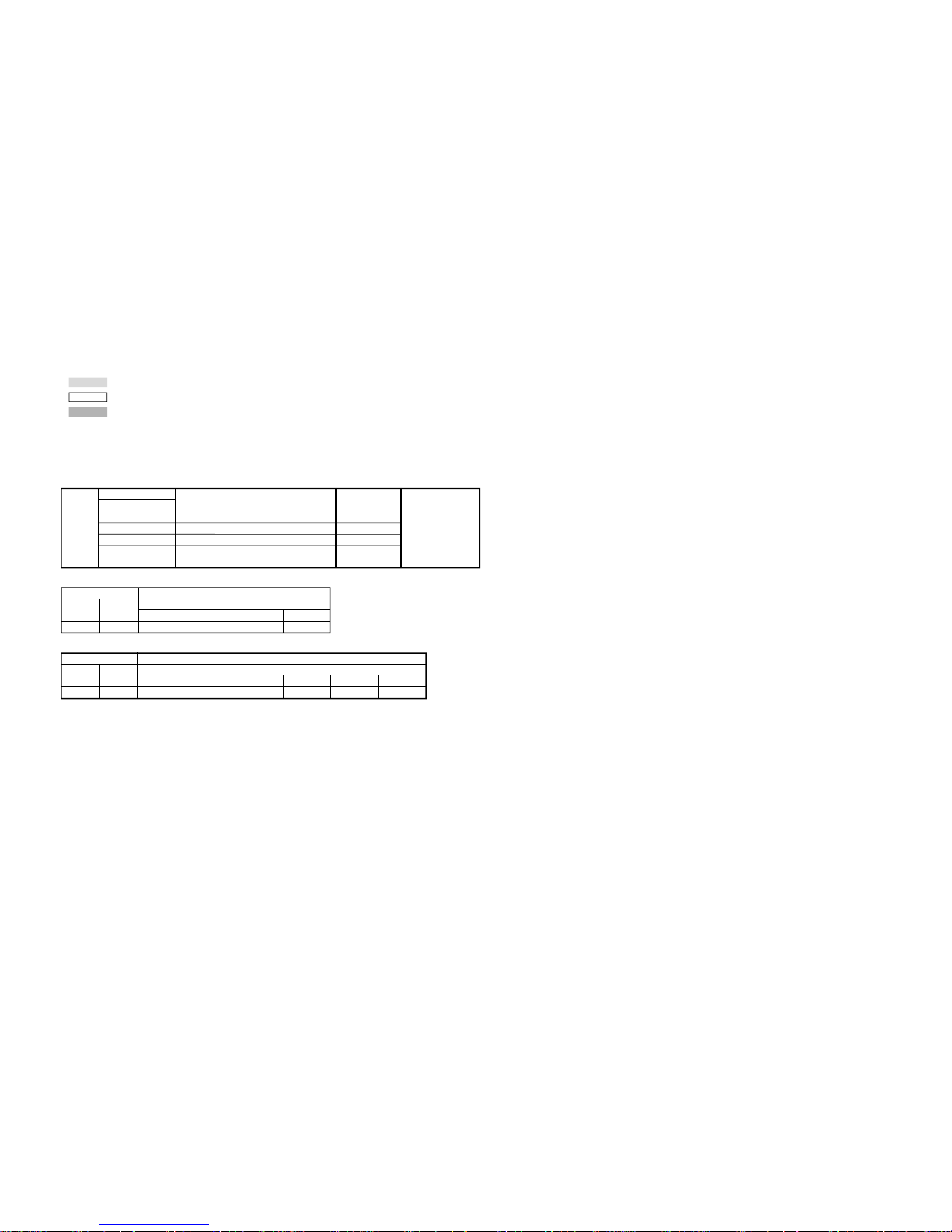

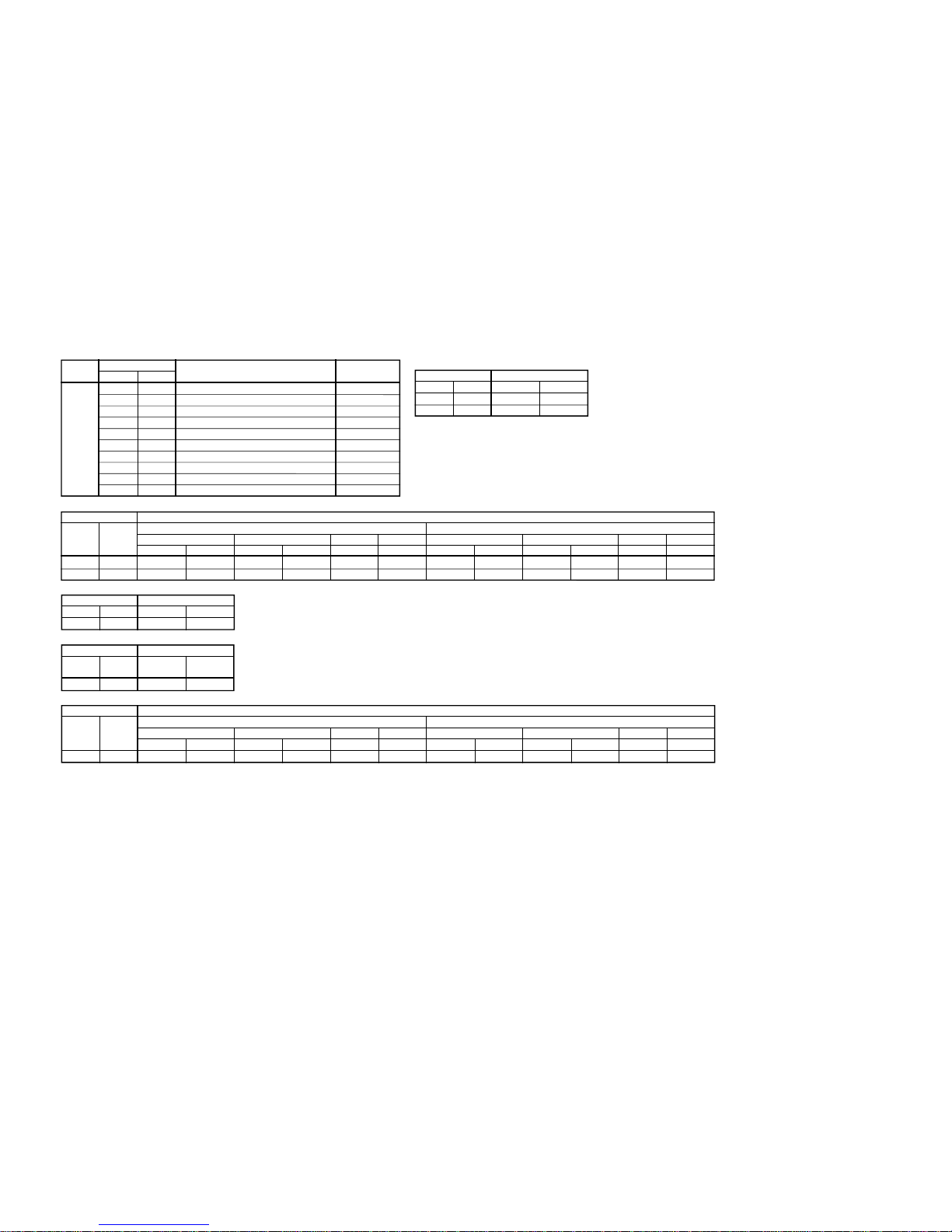

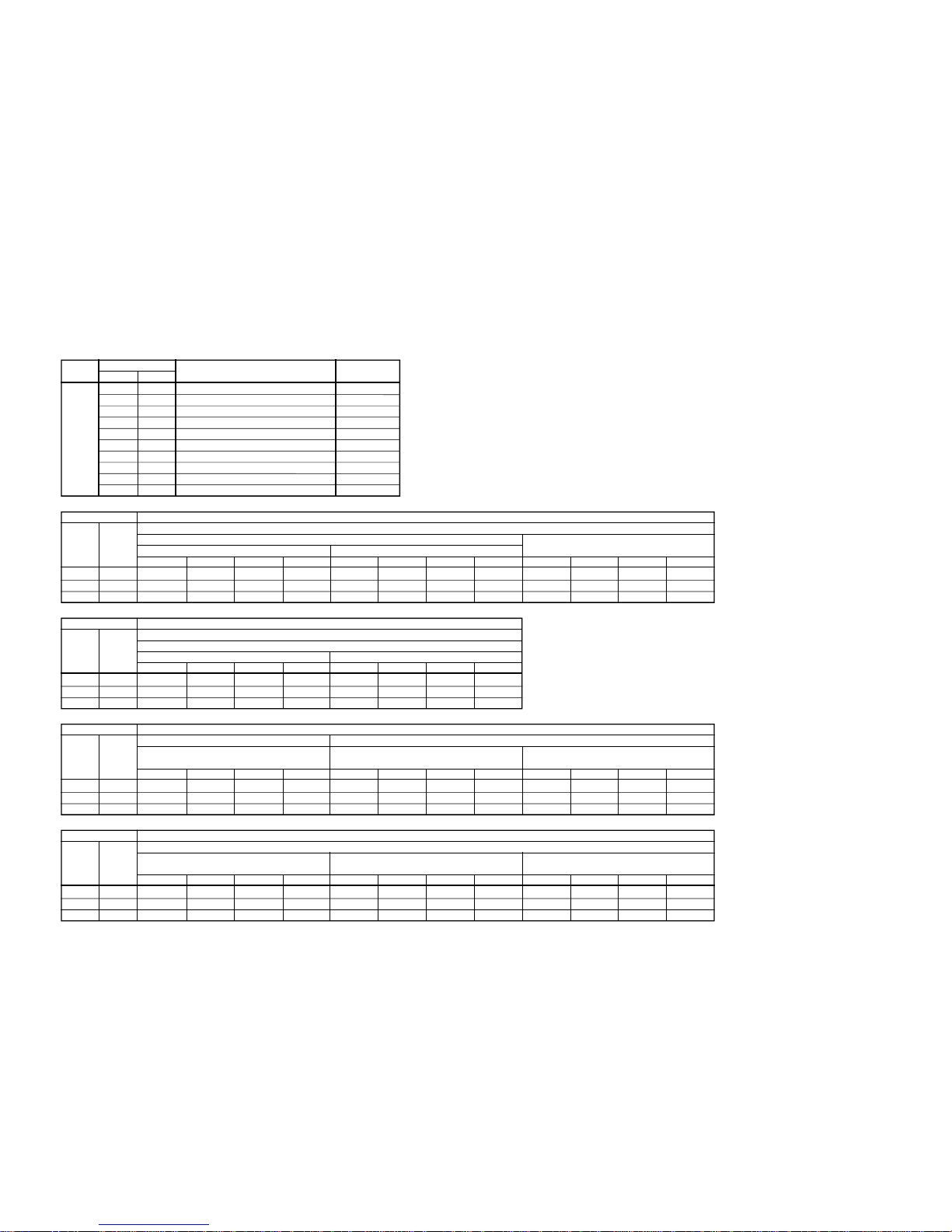

3-9. SERVICE LIST

Category

Item

Function Standard Data

Device Name

No. Name (Slave Address)

OSD 0 OSV OSD V Position 32 CXP961F064(60H)

1 OSH OSD H Position 13

2 FW1 OSD ODD/EVEN Field Window Setup #1 7

3 FW2 OSD ODD/EVEN Field Window Setup #2 20

4 VOF OSD V Position (Offset) *1

OSD: Standard Data *1

Item Standard Data

No. Name

OSD V OFFSET

HD50 HD60 VCOMP VCOMP60 VCOMP100 VCOMP120

4 VOF 32 32 32 32 32 32

OSD: Standard Data *1

Item Standard Data

No. Name

OSD V OFFSET

FULL50 FULL60 FULL100 FULL120

4 VOF 32 32 16 16

Note

•

: The data value of each mode. Other are set up by each mode.

• : Shaded items are fixed data.

•

: Though data value is indicated on the screen, it is not used.

• Standard data listed on the Adjustment Item Table are reference valies, therefore it may be different for each model and each m

ode.

• Note for Different Data :

Those are the standard data values written on the microprocessor. Therefore , the data values of the modes and stored respectiv

ely in the memory.

In case of a device replacement, adjustment by rewriting the data value is necessary for some items.

– 22 –

KP-FX432M90/FX532M90

RM-1014

Category

Item

Function Standard Data

Device Name

No. Name (Slave Address)

MSP 0 WST W/G Stereo Threshold 21 MSP3415D(84H)

1 WBT W/G Bilingual Threshold 236

2 WLL W/G Monaural Threshold 5

3 WAC W/G Agreement Count 1

4 WDL W/G Search Delay48

5 NDL NICAM Search Delay32

6 SDL Stereo status Read Delay16

7 AGC AGC Switch Auto/Constant 1

8 REL AGC Gain at Constant Mode 40

9 CRM Carrier muting on/off 0

10 ACO Audio Clock out on/off 1

11 FP FM Prescale for non-M system 27

12 FPM FM Prescale for M system 50

13 FH FM Prescale for HDEV 54

14 FHM FM Prescale for HDEV and M 101

15 WGP W/G Prescale 28

16 NIP NICAM Prescale 127

17 ERR Auto FM switch Threshold 80

18 VOL Loud Speaker gain 0700h to 07FFh 48

– 23 –

KP-FX432M90/FX532M90

RM-1014

Category

Item

Function Standard Data

Device Name

No. Name (Slave Address)

PIC 0 PIC User Picture *1 PFED-PICTURE

1 COL User Color *1

2 BRI User Bright *1

3 HUE User Hue *1

4 SHP User Sharp *1

5 PIOF Picture Offset (Picture * (20-data)/20 * Eco(75%) *1

PIC: Standard Data *1

Item Standard Data

No. Name

Picture/

Picture Offset

Sound Mode Table

Dynamic

Standard/

Hi-Fine/Soft Personal Normal(4:3) HD Other

Drama

0 PIC 100 70 60 50

1 COL 60 55 50 50

2 BRI 45 50 50 50

3 HUE 50 50 50 50

4 SHP 45 50 50 50

5 PIOF 220

Category

Item

Function

Standard Data

No. Name

Picture/

Device Name

Sound Mode Table

Dynamic

Standard/

Hi-Fine/Soft Personal

(Slave Address)

Drama

SOU 0 BAS User Bass 74 50 50 50 PFED-SOUND

1 TRE User Treble 50 50 42 50

Category

Item

Function Standard Data

Device Name

No. Name (Slave Address)

PFED 0 PFED PF-Engine Service * Pf-Engine

Category

Item

Function Standard Data

Device Name

No. Name (Slave Address)

GUID 0 GUID

Guide Select country ID (0:English,1:Tiwan,2:Korea,3:English)

0

Category

Item

Function Standard Data

Device Name

No. Name (Slave Address)

POWR 0 DLY1 Power On Delay1 4

1 DLY2 Power On Delay2 0

2 DLY3 Power On Delay3 4

3 ZDET Zero Detect Delay 31

4 ZTMO Zero Detect Timeout (*10ms min 300ms) 30

– 24 –

KP-FX432M90/FX532M90

RM-1014

Category

Item

Function Standard Data

No. Name

OPM 0 APC APC Switch 1

1 TSY

TV System Selection under searching with Auto TV System

2

2 AFM Auto FM switch 1

3 DBL Disable Blueback function 1

4 SSO Speed CH Search Selection 1

5 SCH CH Selection for Shipping Condition 1

6 SCA Cable/Air Selection for Shipping Condition 1

7 DMG Disable Menu-operation Guide 0

8 VSN Enable Noise Reduction in Video Mode 0

9 LBB Lower Blue Back Intensity 1

10 23P 2/3 Pull Down Mode 0: Force OFF, 1: Auto 1

11 DF DF_PHA 31

12 DQP DQP_PHA 31

13 VLIM Wide V-Center Limit 15

14 TUT1

Tune Wait Time Mode1 (Max) 30[ms] + 10[ms] * service_data

8

15 TUT2

Tune Wait Time Mode2 (Max) 30[ms] + 10[ms] * service_data

5

16 TUT3

Tune Wait Time Mode3 (Max) 30[ms] + 10[ms] * service_data

2

17 TUTW Tune Wait Time 6 point sense 5

18 3NR 3D-NR INIT (User Reset or Test Reset) 1

19 SIG No-Signal Detect number of lock detect count. *1

20 NSIG No-Signal Detect number of unlock detect counter.*1

Category

Item

Function Standard Data

Device Name

No. Name (Slave Address)

OPB 0 OP0 Optional Bits 0 60 Option-Bits

1 OP1 Optional Bits 1 75

2 OP2 Optional Bits 2 3

3 OP3 Optional Bits 3 8

4 OP4 Optional Bits 4 13

Category

Item

Function Standard Data

Device Name

No. Name (Slave Address)

SRV 0 COM Service Command *

OPM: Standard Data *1

Item Standard Data

No. Name

Signa-Detect

RF Video

19 SIG 0 0

20 NSIG 0 0

– 25 –

KP-FX432M90/FX532M90

RM-1014

Category

Item

Function Standard Data

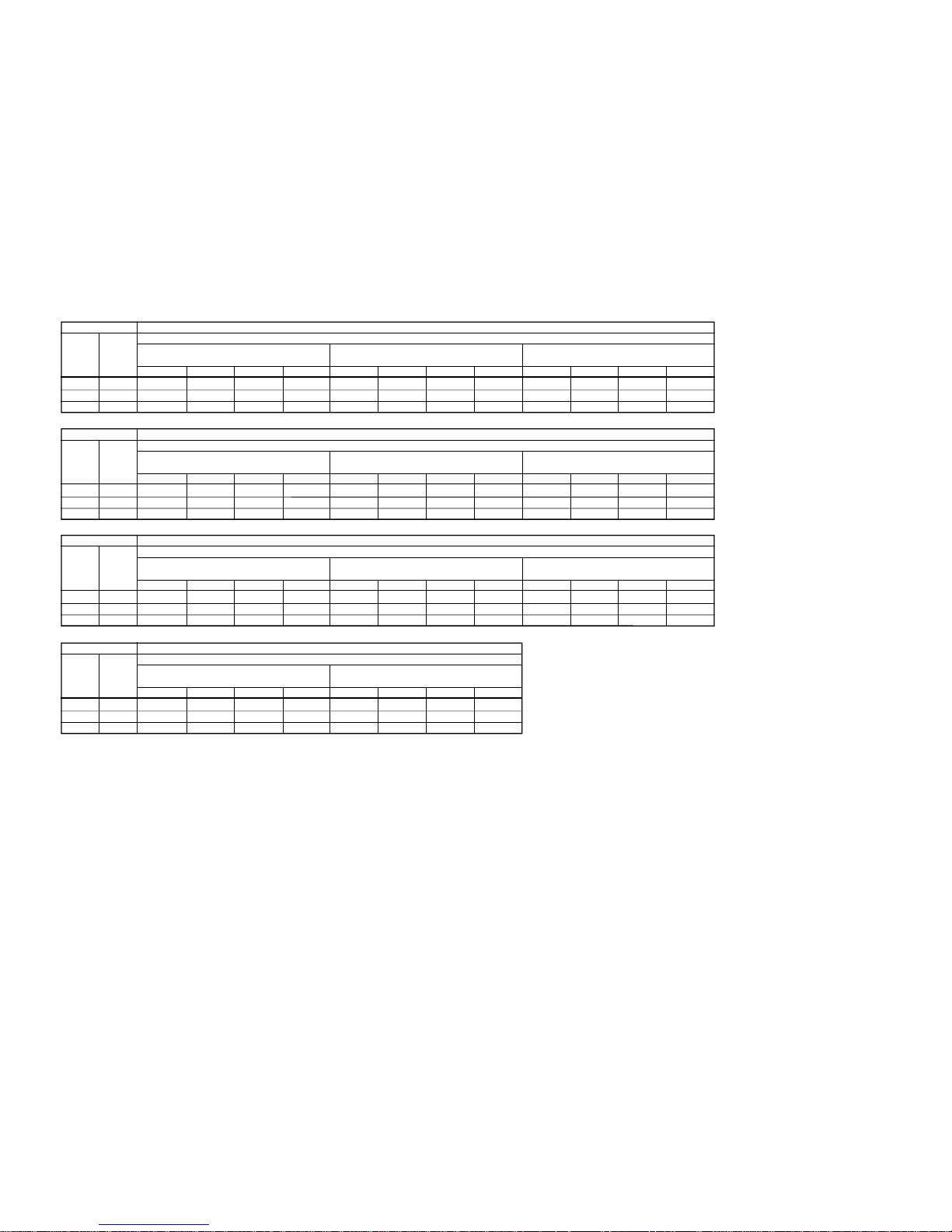

No. Name

DEF1 0 VPOS 18

1 VSIZ 27

2 VLIN 5

3 VSCO 8

4 VCEN 31

5 VPIN *1

6 NSCO 31

7 HTPZ 15

8 ZOOM 0

9 APSW *2

10 ASPT *3

11 SCRL *3

12 UVLN 0

13 LVLN 0

14 VPSO *4

DEF1: Standard Data *1

Item Standard Data

No. Name Vcomp Othe

5 VPIN 15 15

DEF1: Standard Data *2

Item Standard Data

No. Name

HD

SD

50Hz 60Hz

9 APSW 1 0 1

DEF1: Standard Data *3

Item Standard Data

No. Name

Full VComp/Normal

50Hz 60Hz 100Hz 120Hz 50Hz 60Hz 100Hz 120Hz

SD SD HD SD SD SD HD SD HD SD SD

10 ASPT 50 50 44 48 48 48 63 48 48 45 45

11 SCRL 29 29 29 29 29 29 29 29 29 29 29

DEF1: Standard Data *4

Item Standard Data

No. Name 50Hz 60Hz 100Hz 120Hz

14 VPSO 8 7 4 2

– 26 –

KP-FX432M90/FX532M90

RM-1014

Category

Item

Function Standard Data

No. Name

DEF2 0 HCNT 31

1 HPOS *1

2 HSIZ 16

3 SLIN 7

4 MPIN 0

5 PIN 3

6 UCP 31

7 LCP 31

8 PPHA 31

9 VANG 31

10 LANG 31

11 VBOW 31

12 LBOW 31

13 UXCG 0

14 LXCG 0

15 UXCP 2

16 LXCP 2

17 XCPP 0

18 PPHO *2

19 PINO 0

20 UCPO 0

21 LCPO 0

22 VAOC 0

23 HIHS 1

24 HISL 1

25 HIMP 1

26 HIPN 1

DEF2: Standard Data *1

Item Standard Data

No. Name HD SD

1 HPOS 24 24

DEF2: Standard Data *2

Item Standard Data

No. Name 50Hz 60Hz 100Hz 120Hz

18 PPHO 7 7 7 7

– 27 –

KP-FX432M90/FX532M90

RM-1014

Category

Item

Function Standard Data

No. Name

DEF3 0 HBLK 1

1 LBLK *1

2 RBLK *1

3 VBLK 1

4 TBLK *2

5 BBLK *2

6 AFCM 3

7 JUMP *3

8 VDJP *4

9 AKBT *5

DEF3: Standard Data *1

Item Standard Data

No. Name HD SD

1 LBLK 63 63

2 RBLK 23 23

DEF3: Standard Data *2

Item Standard Data

No. Name

Full VComp/Normal

50Hz 60Hz 100Hz 120Hz 50Hz 60Hz 100Hz 120Hz

SD HD SD HD SD SD SD HD SD HD SD SD

4 TBLK 0 15 0 4 12 8 15 15 9 12 14 14

5 BBLK 0 15 0 6 15 8 15 15 15 14 15 15

DEF3: Standard Data *3

Item Standard Data

No. Name Vcomp Other

7 JUMP 1 0

DEF3: Standard Data *4

Item Standard Data

No. Name

HD Other

8VDJP 1 1

DEF3: Standard Data *5

Item Standard Data

No. Name

Full VComp/Normal

50Hz 60Hz 100Hz 120Hz 50Hz 60Hz 100Hz 120Hz

SD HD SD HD SD SD SD HD SD HD SD SD

9 AKBT 22 9 16 16 9 9 20 9 18 9 16 9

– 28 –

KP-FX432M90/FX532M90

RM-1014

Category

Item

Function Standard Data

No. Name

DEF4 0 QPDC *1

1 QPDV *1

2 QPDP *1

3QPAM *1

4QPAV *1

5QPAP *1

6 COPY 0

DEF4: Standard Data *1

Item Standard Data

No. Name Vcomp Other

0 QPDC 42 42

1 QPDV 63 63

2 QPDP 6 6

3QPAM 38 38

4QPAV 47 47

5QPAP 6 6

Category

Item

Function Standard Data

No. Name

DEF5 0 VON 1

1 EWDC 0

2 AGCS 0

3 ACMP 0

– 29 –

KP-FX432M90/FX532M90

RM-1014

0BROF230323030202

1 GAMM 3 16131614161

6BLK420242023202

LUMA: Standard Data *1

Item Standard Data

No. Name

Comp

480_60P 576_50P 720_60P

Dynamic Standard Hi-fine Personal Dynamic Standard Hi-fine Personal Dynamic Standard Hi-fine Personal

0BROF230323032303

1 GAMM 3 16131613161

6BLK420242024202

LUMA: Standard Data *1

Item Standard Data

No. Name

CV/YC Comp

576_50I 480_60I 576_50I

Dynamic Standard Hi-fine Personal Dynamic Standard Hi-fine Personal Dynamic Standard Hi-fine Personal

0BROF23032313

1 GAMM 3 1 6 13161

6BLK42024202

LUMA: Standard Data *1

Item Standard Data

No. Name

CV/YC

480_60I

NTSC PAL

Dynamic Standard Hi-fine Personal Dynamic Standard Hi-fine Personal

0BROF573757375737

1 GAMM 5 16151615161

6BLK420242024202

LUMA: Standard Data *1

Item Standard Data

No. Name

RF

480_60I

576_50I

NTSC PAL

Dynamic Standard Hi-fine Personal Dynamic Standard Hi-fine Personal Dynamic Standard Hi-fine Personal

Category

Item

Function Standard Data

No. Name

LUMA 0 BROF *1

1 GAMM *1

2 GAMS *2

3 RGAM *2

4 GGAM *2

5 BGAM *2

6 BLK *1

7 APED *3

8 DCTR *3

9 ABLM *3

– 30 –

KP-FX432M90/FX532M90

RM-1014

0BROF020202020202

1 GAMM 4 16141614161

6BLK320232023202

LUMA: Standard Data *1

Item Standard Data

No. Name

Comp

720_50P 1080_60I 1080_50I

Dynamic Standard Hi-fine Personal Dynamic Standard Hi-fine Personal Dynamic Standard Hi-fine Personal

0BROF230323032303

1 GAMM 3 16131613161

6BLK420242024202

LUMA: Standard Data *1

Item Standard Data

No. Name

RGB

480_60I 576_50I 480_60P

Dynamic Standard Hi-fine Personal Dynamic Standard Hi-fine Personal Dynamic Standard Hi-fine Personal

0BROF02020202

1 GAMM 4 1 6 14161

6BLK32023202

LUMA: Standard Data *1

Item Standard Data

No. Name

RGB

1080_60I 1080_50I

Dynamic Standard Hi-fine Personal Dynamic Standard Hi-fine Personal

0BROF230302020202

1 GAMM 3 16141614161

6BLK420232023202

LUMA: Standard Data *1

Item Standard Data

No. Name

RGB

576_50P 720_60P 720_50P

Dynamic Standard Hi-fine Personal Dynamic Standard Hi-fine Personal Dynamic Standard Hi-fine Personal

Loading...

Loading...