SONY KF-42WE620 Service Manual

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KF-42WE620

KF-50WE620

RM-Y916 US/CND/MEXICO

RM-Y916 US/CND/MEXICO

LA-2

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 7/2004

REVISION DATE REVISION TYPE SUBJECT

7/2004 No revisions or updates are applicable at this time.

LCD PROJECTION TELEVISION

9-965-969-01

Self Diagnosis

Supported model

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KF-42WE620

KF-50WE620

RM-Y916 US/CND/MEXICO

RM-Y916 US/CND/MEXICO

LA-2

CHASSIS

9-965-969-01

KF-50WE620 RM-Y916

LCD PROJECTION TELEVISION

KF-42WE620/50WE620

TABLE OF CONTENTS

SECTION TITLE PAGE SECTION TITLE PAGE

Specifi cations ................................................................................. 4

Warnings and Cautions .................................................................. 5

Safety Check-Out ........................................................................... 6

Self-Diagnostic Function................................................................. 7

SECTION 1: DISASSEMBLY............................................................... 10

1-1. Rear Cover Removal............................................................ 10

1-2. Center Pillar Removal .......................................................... 10

1-3. Service Position ...................................................................11

1-4. Chassis Assembly and D.C. Fan Removal ...........................11

1-5. Power Supply Block Removal (Lamp Drive Unit) ................. 12

1-6. UD Board and RF Antenna Switch Removal........................ 12

1-7. U Board Removal ................................................................. 13

1-8. F and G1 Board Removal .................................................... 13

1-9. DIC Block, AU Board and C2 Board Removal ..................... 14

1-10. A Board Removal ................................................................. 14

1-11. T Board Removal ................................................................. 15

1-12. Front Cover Assembly Removal........................................... 15

1-12-1. Replacing the Lamp................................................. 15

1-13. H3 Board Removal (KF-42WE620 Only) ............................. 16

1-14. H4 Board Removal (KF-42WE610 Only) ............................. 16

1-15. H3 and H4 Board Removal (KF-50WE620 Only)................. 17

1-16. H2 Board Removal............................................................... 17

1-17. H1 Board Removal............................................................... 18

1-18. Screen Mirror Block Assembly Removal.............................. 18

SECTION 2: CIRCUIT ADJUSTMENTS.............................................. 19

2-1. Setting the Service Adjustment Mode .................................. 19

2-2. Service Adjustment Mode Memory ...................................... 19

2-3. Memory Write Confi rmation Method .................................... 20

2-4. Remote Adjustment Buttons and Indicators ......................... 20

2-5. Service Data......................................................................... 21

2-6. ID Map Table........................................................................ 93

3-4. Schematics and Supporting Information ............................ 102

A Board Schematic Diagram (1 of 4).................................. 102

A Board Schematic Diagram (2 of 4).................................. 103

A Board Schematic Diagram (3 of 4).................................. 104

A Board Schematic Diagram (4 of 4).................................. 105

AU Board Schematic Diagram (1 of 2)............................... 108

AU Board Schematic Diagram (2 of 2)............................... 109

G1 Board Schematic Diagram ............................................111

F Board Schematic Diagram ...............................................112

U Board Schematic Diagram (1 of 3) ..................................115

U Board Schematic Diagram (2 of 3) ..................................116

U Board Schematic Diagram (3 of 3) ..................................117

UD Board Schematic Diagram (1 of 2)................................119

UD Board Schematic Diagram (2 of 2)............................... 120

H1 Board Schematic Diagram............................................ 122

H2 Board Schematic Diagram............................................ 124

H3 Board Schematic Diagram............................................ 126

H4 Board Schematic Diagram............................................ 128

T Board Schematic Diagram .............................................. 129

3-5. Semiconductors ................................................................. 130

SECTION 4: EXPLODED VIEWS...................................................... 131

4-1. Cover, Screen Mirror Block ................................................ 131

4-2. Bottom Block ...................................................................... 132

4-3. Chassis - 1 ......................................................................... 133

4-4. Chassis - 2 ......................................................................... 134

4-5. Optical Unit Block ............................................................... 135

SECTION 5: ELECTRICAL PARTS LIST.......................................... 136

SECTION 3: DIAGRAMS..................................................................... 94

3-1. Circuit Boards Location ........................................................ 94

3-2. Printed Wiring Boards and

Schematic Diagrams Information ......................................... 94

3-3. Block Diagrams .................................................................... 96

A Block Diagram (1 of 2) ................................................. 96

A Block Diagram (2 of 2) ................................................. 97

AU Block Diagram ........................................................... 98

G1 Block Diagram ........................................................... 99

H3, H1, H2, and T Block Diagrams ............................... 100

U Block Diagram ........................................................... 101

KF-42WE620/50WE620

3

SPECIFICATIONS

p

)

r

KF-42WE620/50WE620

Power Requirements

Power Consumption (W)

In Use (Max)

In Standby

Inputs/Outputs

120V AC, 60Hz

210W

Under 1 W

DVI-HDTV

1 terminal, 3.3V T.M.D.S., 50 ohms

The DVI-HDTV input terminal is compliant with the EIA-861

standard and is not intended for use with personal computers.

Video (IN)

4 total

1Vp-p, 75ohms unbalanced, sync negative

S Video (IN)

4 total

Y: 1Vp-p, 75ohms unbalanced, sync negative

C: 0.286Vp-p (Burst signal), 75ohms

Audio (IN)

6 total

500 mVrms (100% modulation)

Impedance:47 kilo ohms

Audio (VAR/FIX)

1 total

500 mVrms at the maximum volume setting (Variable)

500 mVrms (Fixed)

Impedance (Output):2 kilo ohm

Control S (IN/OUT)

1 total

Minijacks

Component Video Input

2 (Y, PB, PR)

Y: 1.0 Vp-p, 75 ohms unbalanced, sync negative

PB: 0.7 Vp-p, 75 ohms;

PR: 0.7 Vp-p, 75 ohms

RF Inputs

2 total

Converter

1 total

KF-42WE620 KF-50WE620

S

eaker Output(W

Woofe

Dimensions (W x H x D)

mm 1,201 x 819 x 371 mm 1,377 x 928 x 452 mm

1/4

47

in

x 32

Mass

kg 32 kg 39.5 kg

lbs 70 lbs 12 oz 87 lbs 1 oz

Television system

American TV standard, NTSC

Channel coverage

VHF: 2-13/ UHF: 14-69/ CATV: 1-125

Antenna

75-ohm external antenna terminal for VHF/UHF

Projection System

3 LCD Panels, 1 lens projection system

LCD Panel

0.87 inch TFT LCD panel Approx. 3.28 million dots (1,092,168

pixels)

Projection Lens

High Performance, large diameter hybrid lens F2.4

1/4

x 14

5W x 2

20W

1/2

in 54

Supplied Accessories

Optional Accessories

1/4

x 36

Remote Commander RM-Y916

Two Size AA (R6) Batteries

Cleaning Cloth

TV Stand

SU-GW2 (KF-42WE620 Only)

SU-GW1 (KF-50WE620 Only)

Lamp

XL-2100U

Control S Cable

RK-G69

Component Video Cable

VMC-10/30

AV Receiver

STR series or equivalent

1/2

x 17

3/4

in

KF-42WE620/50WE620

Lamp

UHP lamp, 100W

XL-2100U

Design and specifi cations are subject to change without notice.

4

KF-42WE620/50WE620

WARNINGS AND CAUTIONS

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of

this receiver is directly connected to the AC power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe

operation. Replace these components with Sony parts whose part numbers appear as shown in this manual or in supplements

published by Sony. Circuit adjustments that are critical for safe operation are identifi ed in this manual. Follow these procedures

whenever critical components are replaced or improper operation is suspected.

ATTENTION!!

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout

dépannage. Le chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque ! sur les schemas de principe, les vues explosees et les listes de pieces

sont d’une importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants Sony dont le numero

de piece est indique dans le present manuel ou dans des supplements publies par Sony. Les reglages de circuit dont l’importance

est critique pour la securite du fonctionnement sont identifi es dans le present manuel. Suivre ces procedures lors de chaque

remplacement de composants critiques, ou lorsqu’un mauvais fonctionnement suspecte.

KF-42WE620/50WE620

5

SAFETY CHECK-OUT

KF-42WE620/50WE620

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if sets

always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

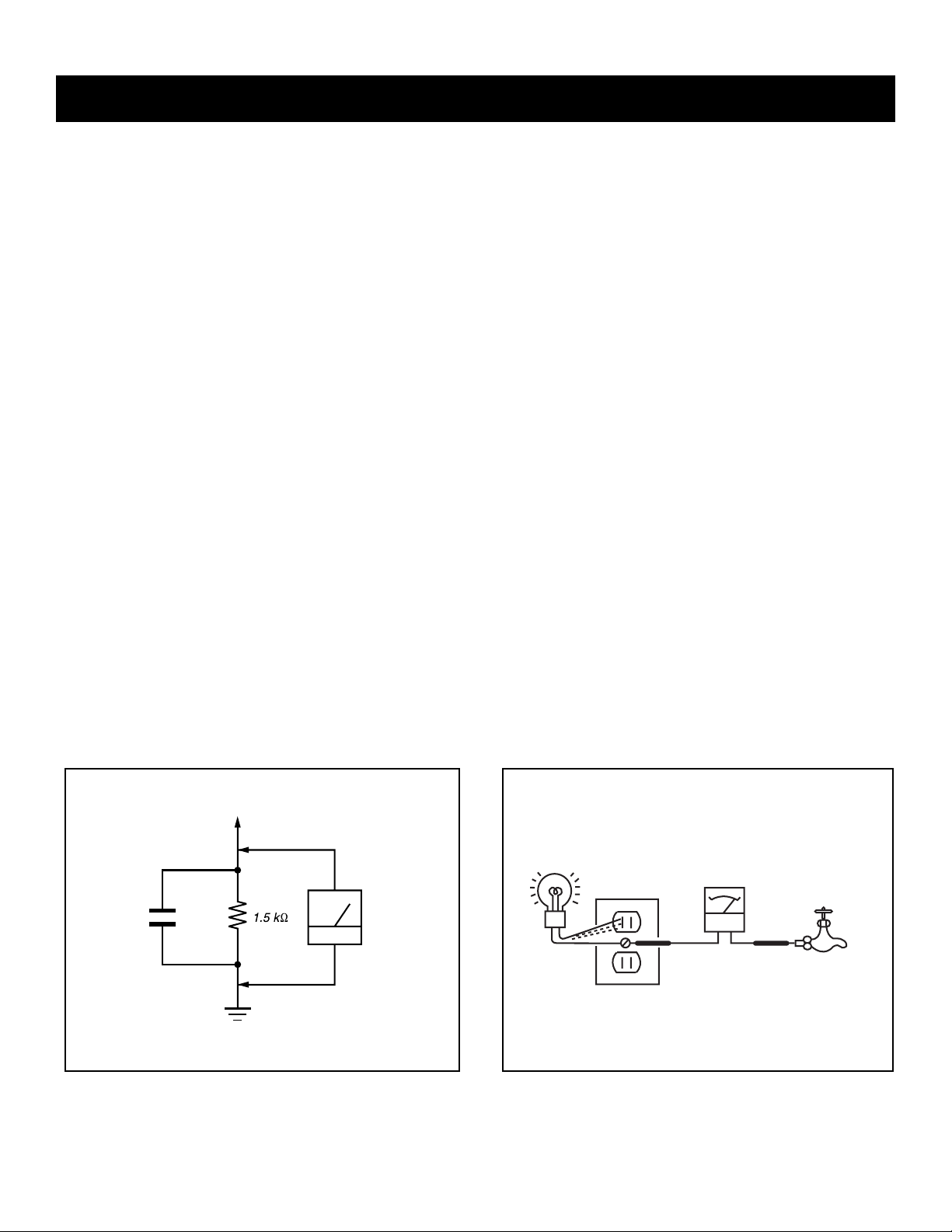

Leakage Test

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of

passive VOMs that are suitable. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground. If the

retaining screw is to be used as your earth ground, verify that it is at

ground by measuring the resistance between it and a cold-water pipe

with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt

trouble- light (not a neon lamp) between the hot side of the receptacle

and the retaining screw. Try both slots, if necessary, to locate the hot

side on the line; the lamp should light at normal brilliance if the screw

is at ground potential (see Figure B).

To Exposed Metal

Parts on Set

0.15 F

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

KF-42WE620/50WE620

Earth Ground

AC

Voltmeter

(0.75V)

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

6

KF-42WE620/50WE620

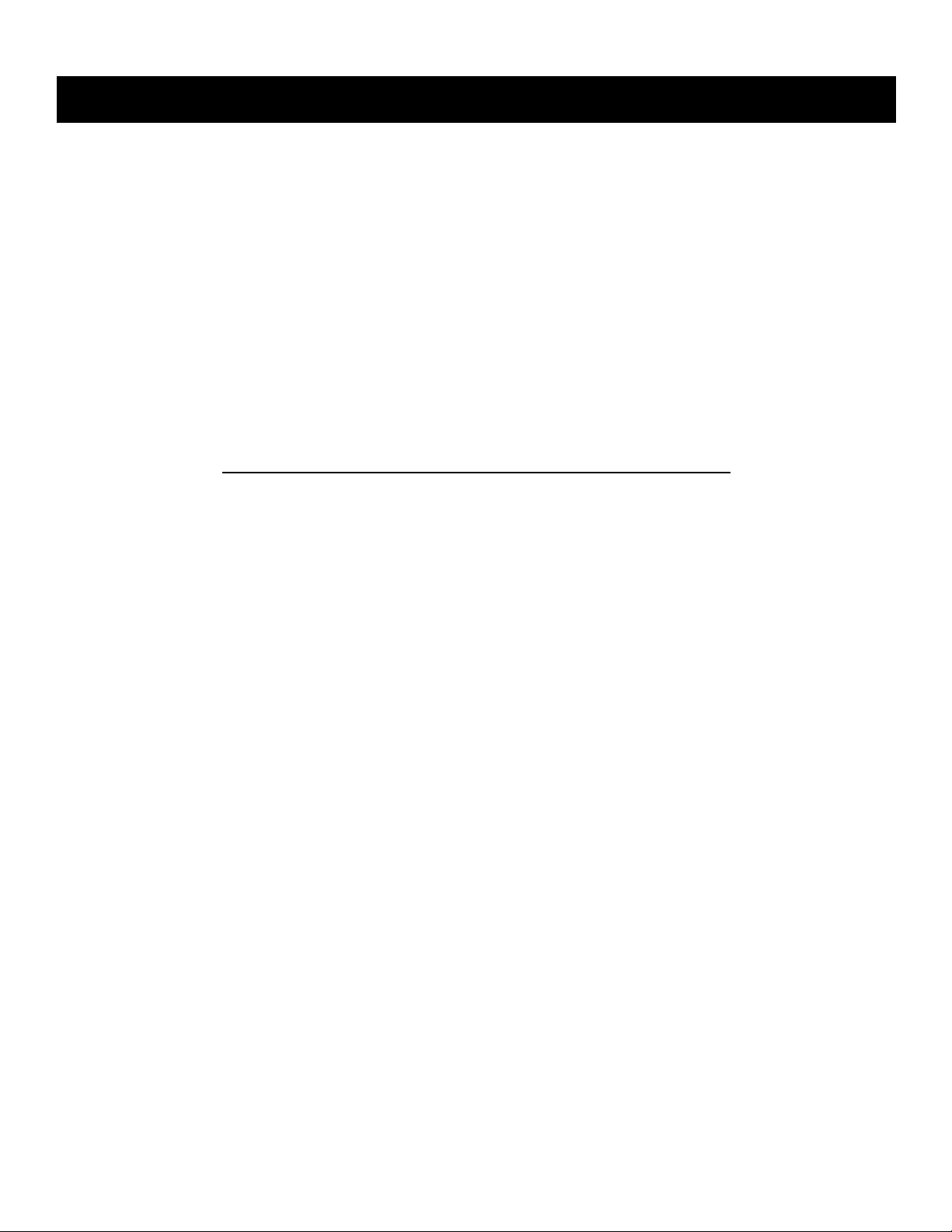

SELF-DIAGNOSTIC FUNCTION

Self Diagnosis

Supported model

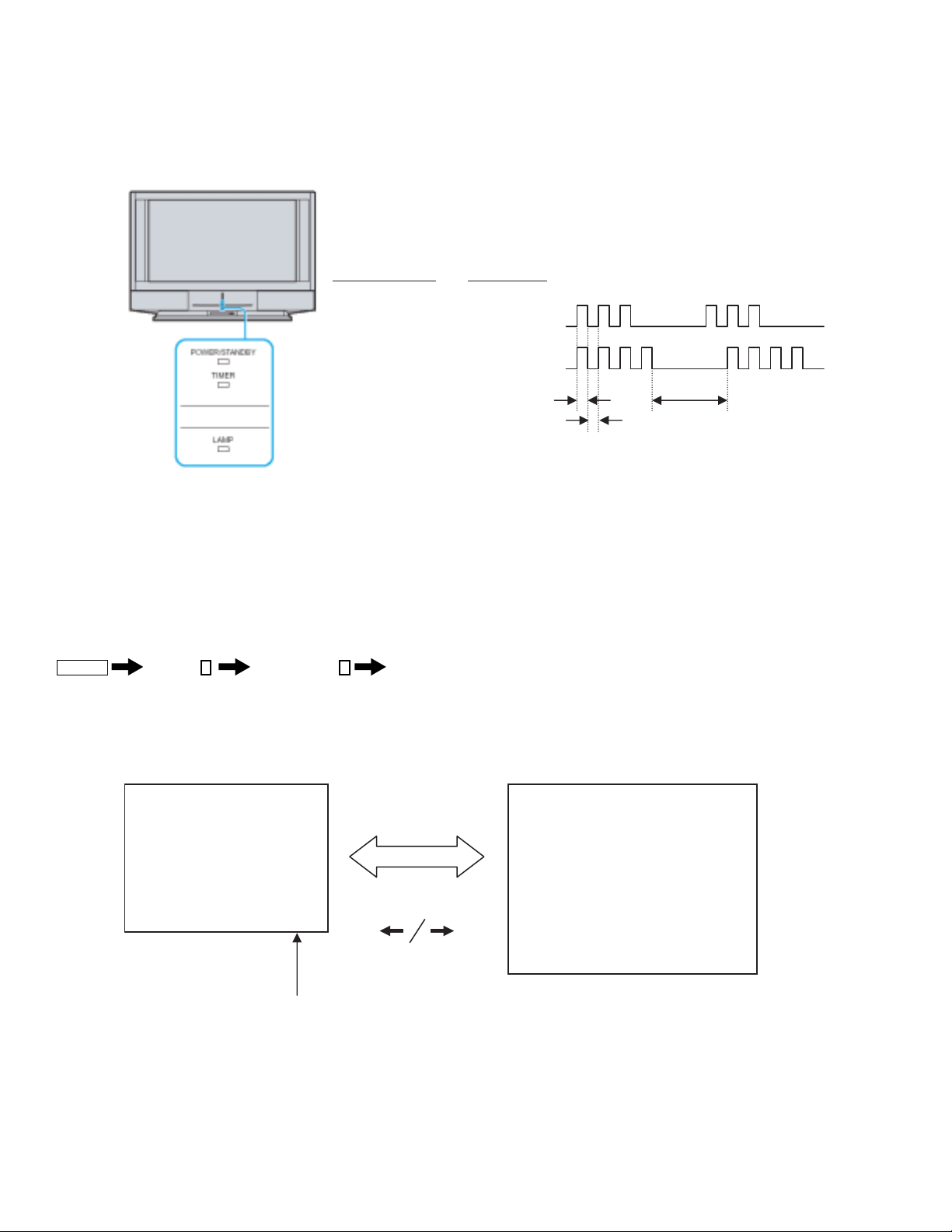

The units in this manual contain a self-diagnostic function. If an error occurs, the POWER/STANDBY will automatically begin to fl ash. The number of

times the LED fl ashes translates to a probable source of the problem. A defi nition of the POWER/STANDBY fl ash indicators is listed in the instruction

manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote Commander can be used to review the failure

occurrence data stored in memory to reveal past problems and how often these problems occur.

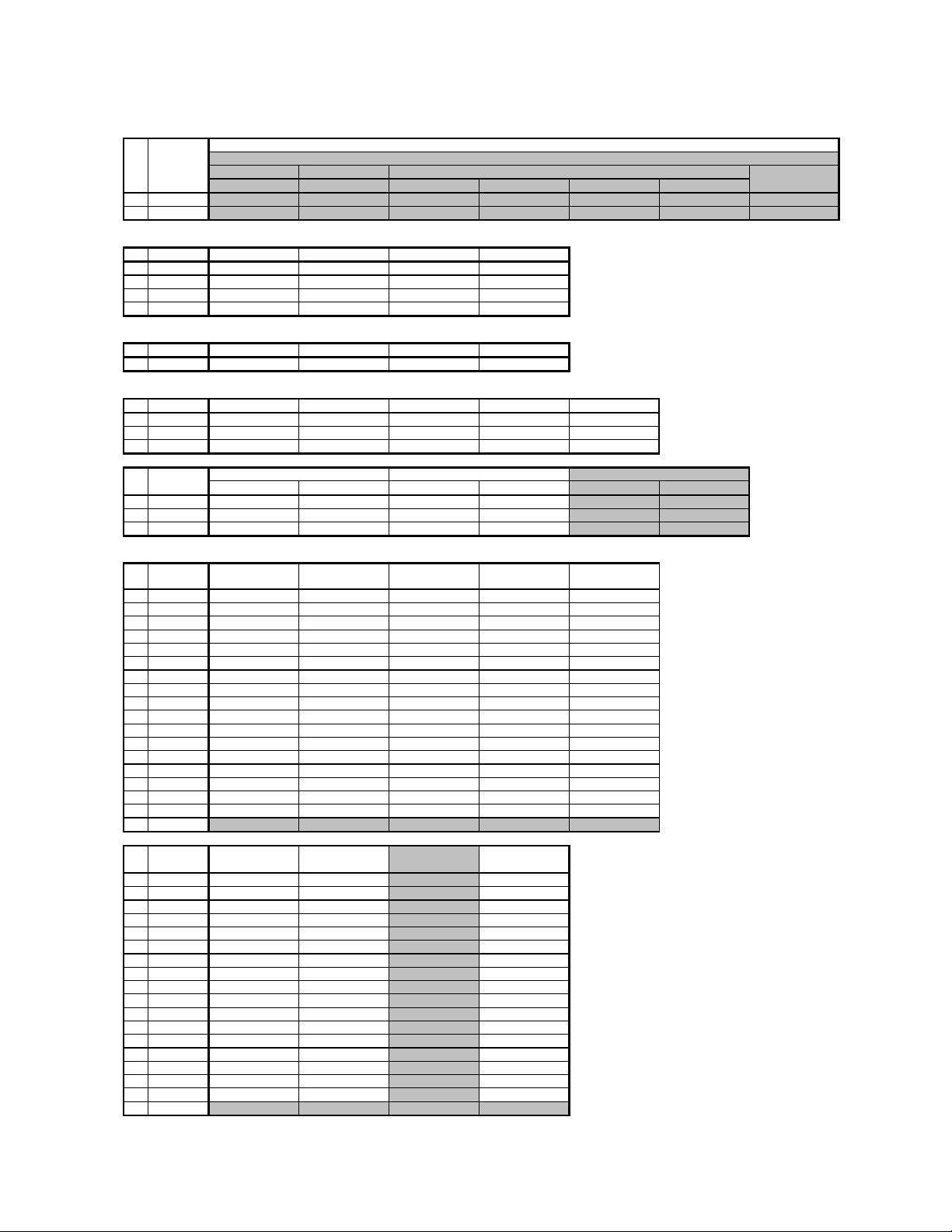

Diagnostic Test Indicators

When an error occurs, the POWER/STANDBY will fl ash a set number of times to indicate the possible cause of the problem. If there is more than one

error, the LED will identify the fi rst of the problem areas.

Results for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

Diagnostic Item

Description

Power does not turn on 0

Lamp cover error 3 times

Fan stopped 4 times

Temp error 4 times

Lamp driver error 5 times

+B OVP error 6 times

Audio error 7 times

D-OVP error 8 times

Lamp error LAMP-LED flashes

No. of times

POWER/STANDBY

lamp flashes

Probable Cause Location Detected Symptoms

• Power cord is not plugged in.

• Fuse is burned out.

(F1901 on F Board)

• Lamp cover is not attached

securely.

• Fan1, Fan2, or Fan 3 power

is not supplied. .

(A Board)

• Fan connector is not attached

securely

• Temperature is high.

• IIC-E line connector

(CN8023 on A Board,

CN44 on H Board) is not

attached securely.

• Lamp driver is faulty. • No picture/No sound

• +17V is not supplied.

(G1 Board)

• Audio line is shorted.

(A, G1 Board)

• IC8504 (A Board) or IC4704

(AU Board) is faulty.

• PS1601 or 1602 is opened.

(G1 Board)

• +3.3V or +2.5V or 1.8V is

over voltage.

(G3 Board)

• Lamp for the light source has

burnt out.

• Power does not come

on.

• No power is supplied

to the unit.

• AC power supply is

faulty.

• No picture/No sound

• No picture/No sound

• No picture/No sound

• No picture/No sound

• No picture/No sound

• No picture/No sound

• No picture/No sound

KF-42WE620/50WE620

7

KF-42WE620/50WE620

m

k

N

*If a +B overcurrent is detected, stoppage of the vertical defl ection is detected simultaneously. The symptom that is diagnosed fi rst by the

mircrocontroller is displayed on the screen.

Display of POWER/STANDBY Flash Count

- One blink is not used for self-diagnosis.

-Example

Diagnosis ite

LED blinks

Lamp cover 3 times

Fan 4 times

LED ON : 0.3sec

LED OFF : 0.3sec

LED OFF

3.0sec

Stopping the POWER/STANDBY LED Flash

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the POWER/STANDBY lamp from fl ashing.

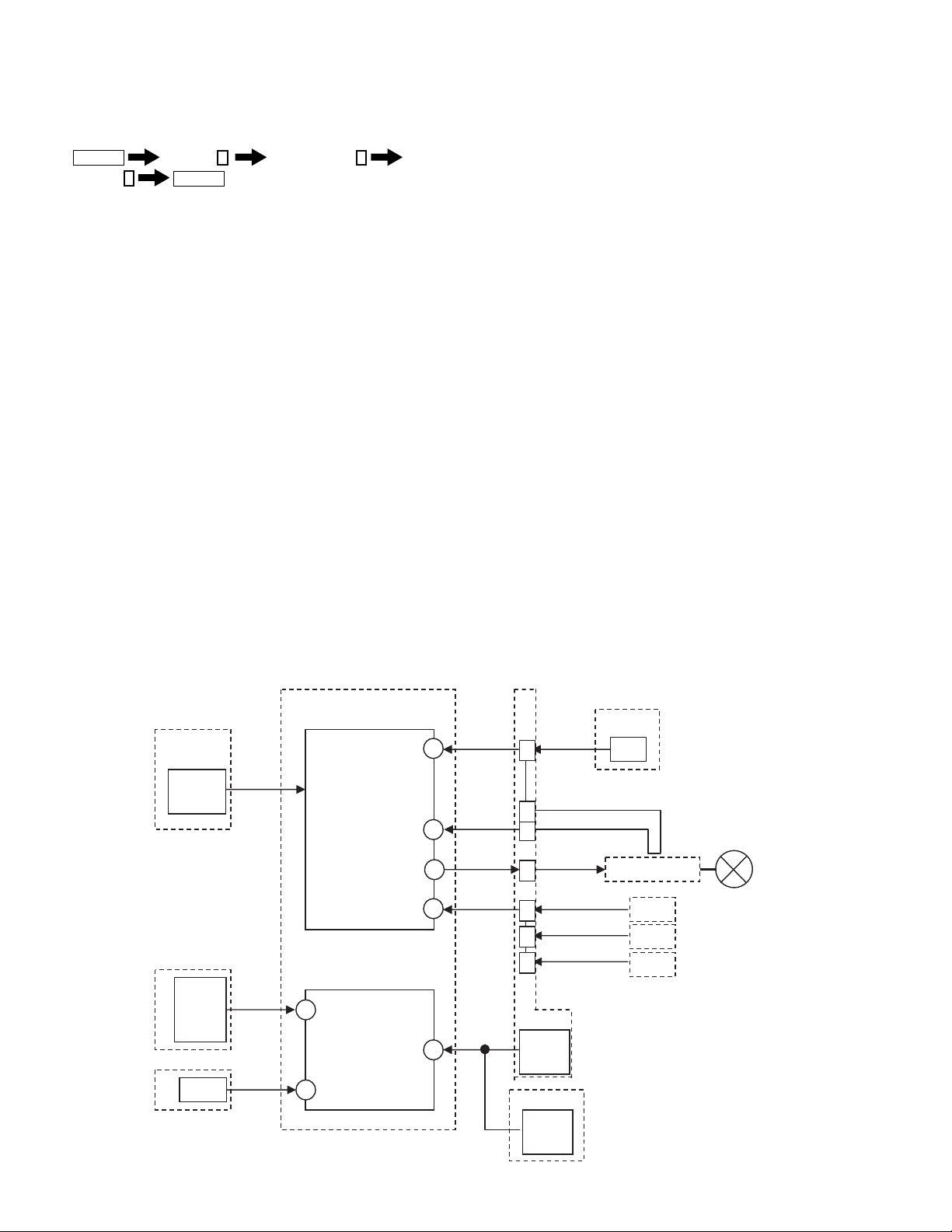

Self-Diagnostic Screen Display

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confi rmed, it is possible to bring up past

occurrences of failure on the screen for confi rmation.

To Bring Up Screen Test

In standby mode, press the buttons on the Remote Commander sequentially, in rapid succession, as shown below:

Display

Self-Diagnostic Screen Display

Channel

5

MAI

Sound Volume

-

Power ON

LCD ENGINE

Self Diagnosis SELF DIAGNOSIS

6 : +B OVP 0 1 : LAMP 0

7 : AUDIO 0 3 : LAMP COVER 0

8 : D-OVP 1 4 : FAN 1

101 : WDT 0 Move the joystic

4 : TEMP 0

5 : LAMP DRIVER 0

201 : WDT-ENGINE 0

- Numeral "1" means a fault was detected one time or more.

- Numeral "0" means that no fault was detected.

Handling of Self-Diagnostic Screen Display

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen during repairs. When you

have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of the repairs.

KF-42WE620/50WE620

8

KF-42WE620/50WE620

Clearing the Result Display

To clear the result display to “0”, press the buttons on the Remote Commander sequentially when the diagnostic screen is displayed, as shown below:

1. Power off (Set to Standby model)

Display

2.

3. Channel

8

Channel

ENTER

5

Sound Volume

Power ON

4. Wait until the initial setup display appears.

5. Disconnect the AC plug and then reconnect it.

Quitting the Self-Diagnostic Screen

To quit the entire self-diagnostic screen, turn off the power switch on the Remote Commander or the main unit.

Self-Diagnostic Circuit

Self-Diagnosis Function Operation

- 3 : Lamp cover If the lamp cover SW is opened then pin 1 of CN8034 on the A board is high. The LCD Engine u-com (pin 27 of

IC3208 on the C2 board) detects it and turns the lamp off.

- 4 : Fan If Fan1, Fan2, Fan3, or Fan4 stops then pin 2, 5, 8 or 11 of CN8035 on the A board is high. The LCD Engine

u-com (pin 24 of IC3208 on the C2 board) detects it and turns the lamp off.

- 4 : Temp If a temperature sensor on the H4 board detects a high temperature,

or the IIC-E line connector (CN8041:A board,CN3951 H4 board) is not attached securely, the LCD Engine ucom IIC-E Line detects it and turns the lamp off.

- 5 : Lamp drive If a lamp is not turned on, then pin 29 of LCD Engine u-com (IC3208 on the C2 board) is high and checks pin

28 of LCD Engine u-com. If pin 28 is low, it is judged no high voltage.

- 6 : +BOVP If +17V line drops then pin 53 of MAIN u-com (IC3405 on the C2 board) is low and automatically turns off the

main power.

- 7 : Audio If DC appears by the audio amp failure at the speaker line then it is detected by MAIN u-com (pin 59 of IC3405

on the C2 board) and automatically turns off the main power.

- 8 : D-OVP If +3.3V, +2.5V, or +1.8V line over, then pin 49 of MAIN u-com (IC3405 on the C2 board) is low and

automatically turns off the main power.

- LAMP : Lamp If a lamp is not turned on, then pin 29 of LCD Engine u-com (IC3208 on the C2 board) is high and checks pin

28 of LCD Engine u-com. If pin 28 is high the lamp is burned out.

H3/A board

IC41

Temp

sensor

G3/A board

+3.3V

+2.5V

+1.8V

+17V

G1/A board

4:Temp

8:D-OVP

6:+B OVP

17V-DET

C2 board

IC3208

LCD Engine u-com

LAMP COV

IIC-E

LAMP DRV

LAMP PROT

FAN PROT

IC3405

MAIN u-com

D-OVP

49

SP-DC-PROT

53

LOW-B-ERR

27

28

29

24

59

3:Lamp

cover

5:Lamp

driver

Lamp

4:Fan

CN8022

7:Audio

A board

CN8014

3

2

1

CN8003

1

2

5

8

IC8504

Audio

amp

IC4704

Audio

HV-DET

LAMP-PRT

FAN1-PRT

FAN2-PRT

FAN3-PRT

T/A board

S3999

SW

Lamp driver

Fan1

Fan2

Fan3

Lamp

amp

KF-42WE620/50WE620

AU board

9

1-1. REAR COVER REMOVAL

2

KF-42WE620/50WE620

SECTION 1: DISASSEMBLY

Rear cover

1-2. CENTER PILLAR REMOVAL

Disconnect

three ground wires

Two small screws

(+PSW 3x8)

1

Eleven screws

(+BVTP 4x16)

Gently lift the Center Pillar up then out

5

from the bottom bracket.

Three screws from the top of the center pillar

1

(+BVTP 4x16)

4

2

Center Pillar

KF-42WE620/50WE620

Two screws

(+BVTP 4x16)

3

10

1-3. SERVICE POSITION

r

Chassis assembly

Pull back on claw, then gently pull out chassis assembly

1

KF-42WE620/50WE620

1-4. CHASSIS ASSEMBLY AND D.C. FAN REMOVAL

Four screws

3

(+PWH 4x35)

Chassis assembly

Pull back on claw,

then gently pull out chassis assembly

4

Fan bracket with D. C. fan

2

Disconnect one connecto

D. C. FAN

1

Four screws

(+PWH 4x16)

KF-42WE620/50WE620

11

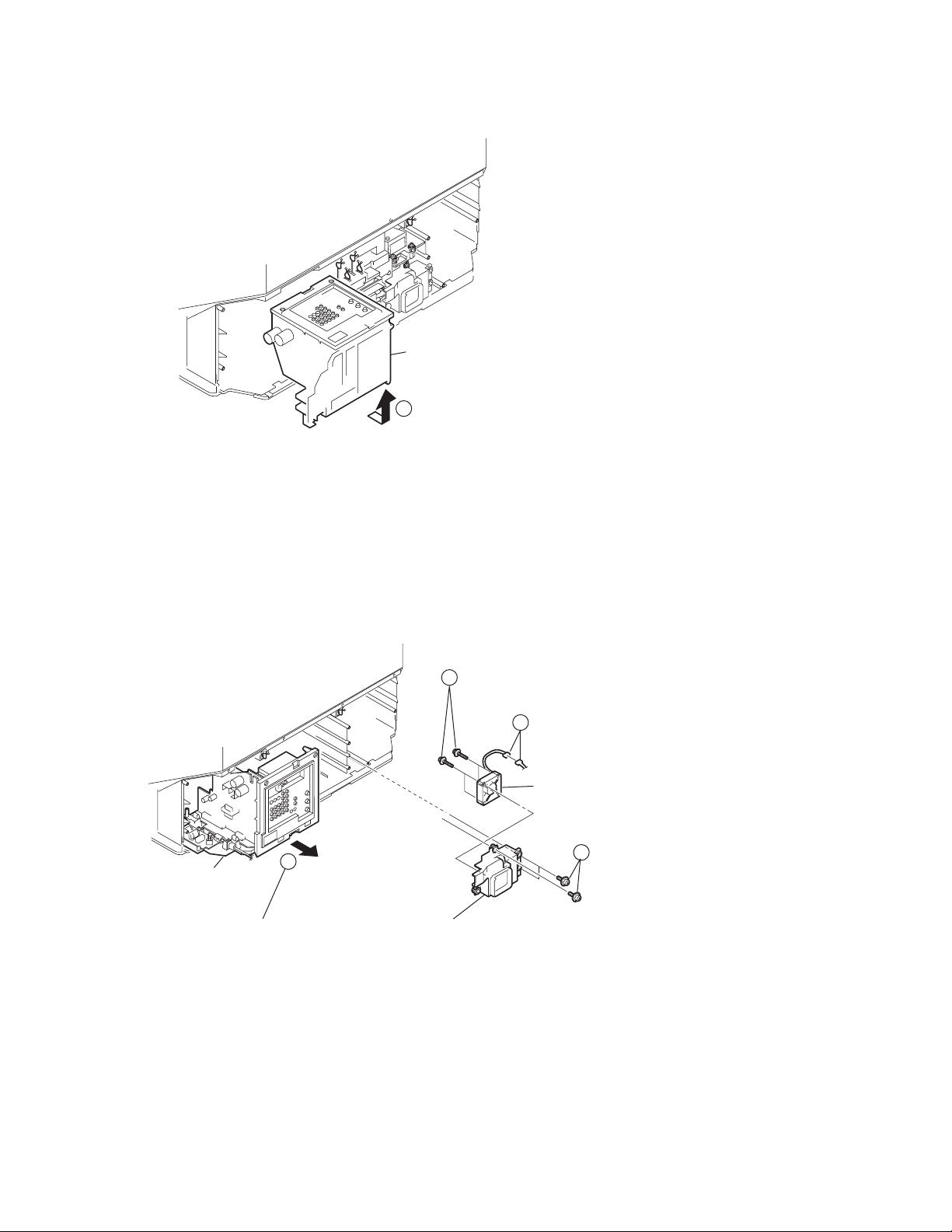

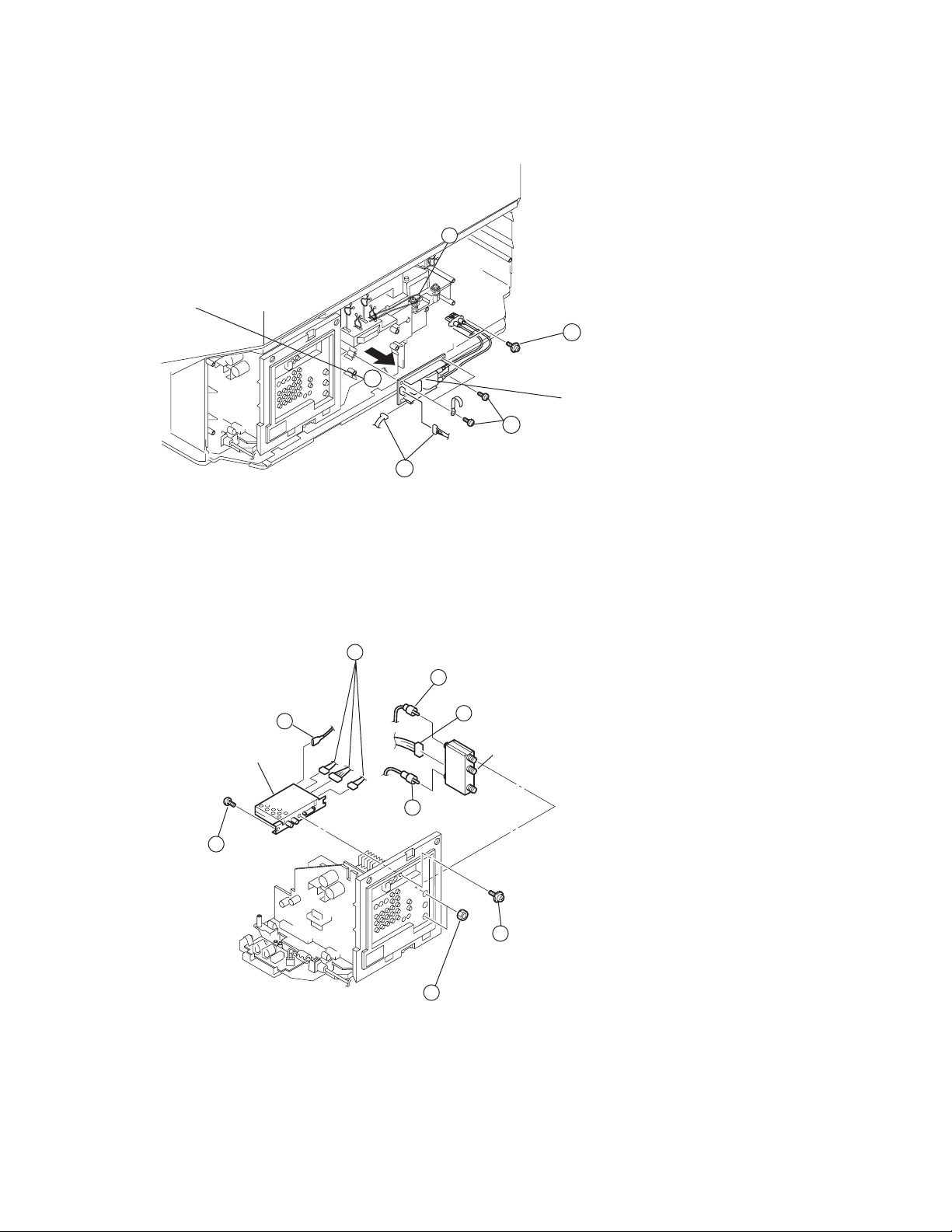

1-5. POWER SUPPLY BLOCK REMOVAL (LAMP DRIVE UNIT)

CAUTION: When removing the Power Supply Block be careful not to move the Optical Unit Block

KF-42WE620/50WE620

Unhook the antenna cable

3

Pull forward to remove

5

4

Four screws (+BVTP 3x12)

1

Disconnect two connectors

1-6. UD BOARD AND RF ANTENNA SWITCH REMOVAL

Disconnect three connectors

and the ground wire

1

1

4

Disconnect two Pin plugs

and one connector

4

2

Two screws (+PWH 4x16)

(to detach the cables from the

Optics Unit Block Assembly)

Power supply block

One screw

(+BVTP 3x8)

KF-42WE620/50WE620

UD board

3

4

5

Two screws (HEX)

RF antenna switch

2

One screw

(+PSW 3x8)

12

1-7. U BOARD REMOVAL

U board

Disconnect three connectors

2

Disconnect four ground wires

1

Six Screws (+BVTP 3x12)

3

U bracket

4

Gently pull back on the two clips

on the pin connection slot

while slowly lifting the U Board

KF-42WE620/50WE620

1-8. F AND G1 BOARD REMOVAL

Note:

Place the F Board on its side

to disconnect three ground wires.

Ttwo screws (+BVTP 3x12)

F board

Disconnect the Power cord

from CN1907 connector.

4

2

Claw

1

Disconnect two connectors (CN1602 & CN1605)

and one ground wire (CN1611)

6

G1 board

Disconnect one connector

(CN1609)

8

7

9

3

Remove wires from purse locks

5

Gently pull back on the two clips

on the pin connection slot

while slowly lifting the G1 Board.

Disconnect one ground wire

KF-42WE620/50WE620

13

1-9. DIC BLOCK, AU BOARD AND C2 BOARD REMOVAL

Note:

The C2 Board is part of the C2 Block Assembly and cannot be ordered separately.

Remove the AU Board after removing the C2 Block Assembly

Note:

2

The 14P Connector Assembly (LVDs cables) have colored tape (white tape)

to indicate which connection they plug into. Please note before removing the cables.

4

Note:

The 14P Connector Assembly (LVDs cables) have colored tape (red tape-right, black tape-left)

to indicate which connection they plug into. Please note before removing the cables.

1

Disconnect one ground wire from front screen

Remove cables

from purse locks

Two screws

2

(+BVWHTP 3x12)

6

5

KF-42WE620/50WE620

Gently squeeze the gray tabs on the sides of the

14P Connector Assembly (LVDs cables) to

disconnect the two cables.

Disconnect one connector

7

Gently squeeze the gray tabs

on the sides of the

14P Connector Assembly

(LVDs cables) to disconnect

the two cables.

Three screws

(+BVWHTP 3x12)

1-10.A BOARD REMOVAL

Disconnect one connector (CN8501)

3

DIC block

AU board

8

Gently pull the AU Board

C2 board

4

Disconnect remaining nine connectors

3

Disconnect three ground wires

1

2

from the two PCB supporters

Pull back on two claws,

then gently lift out

A Board.

KF-42WE620/50WE620

4

4

A board

14

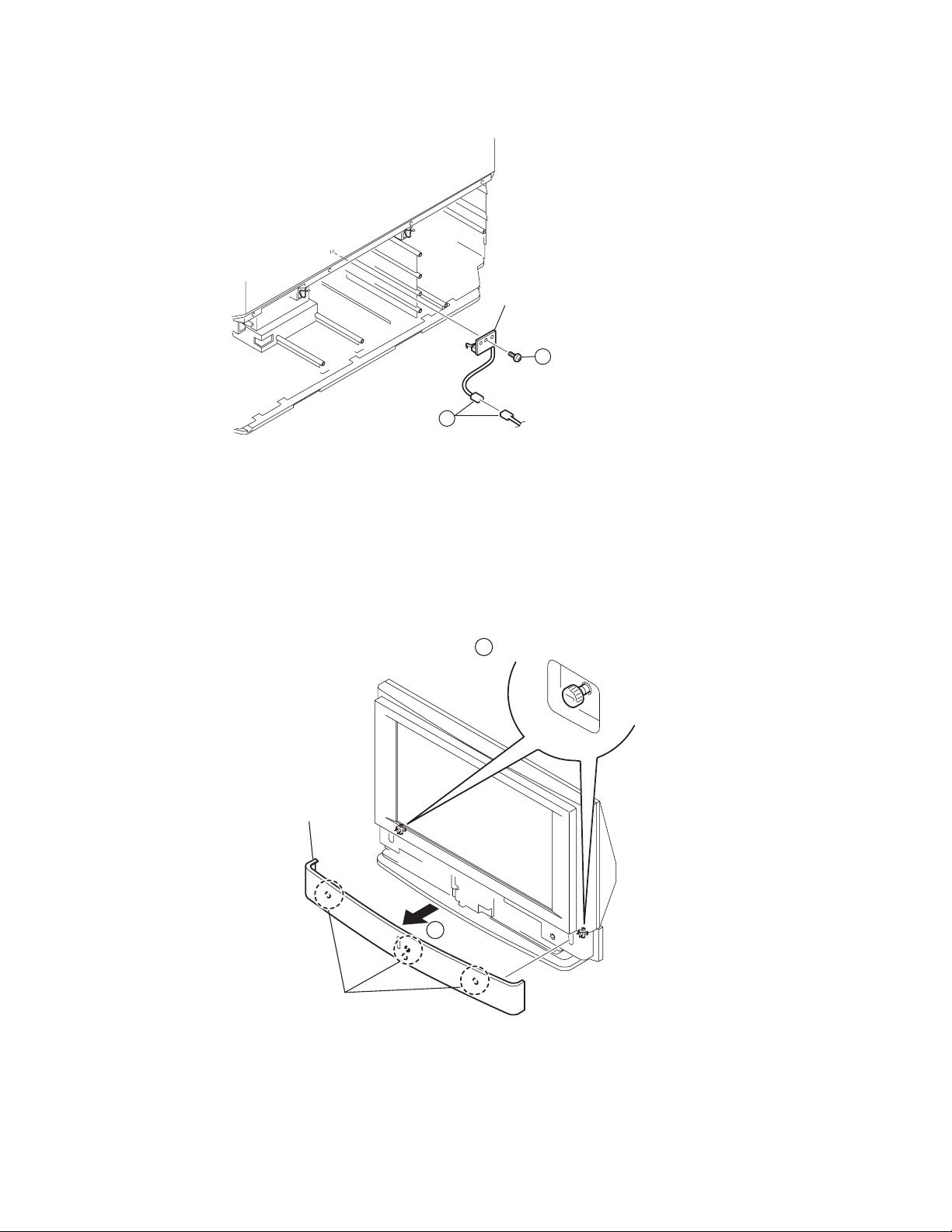

1-11. T BOARD REMOVAL

T board

2

One screw (+BVTP 3x12)

KF-42WE620/50WE620

Disconnect

one connector

1-12.FRONT COVER ASSEMBLY REMOVAL

Front cover

assembly

1

1 Two ornamental screws

Four latches

1-12-1.REPLACING THE LAMP

For detailed instructions on replacing the lamp, see

Page 15 of the Operating Instructions manual.

PN 2-108-981-11

KF-42WE620/50WE620

2

15

1-13.H3 BOARD REMOVAL (KF-42WE620 ONLY)

H3 board

1

3

H3 bracket

KF-42WE620/50WE620

Disconnect two connectors

and one ground wire

1

Spring

plate

Two screws

(+BVTP 3x12)

2

1-14.H4 BOARD REMOVAL (KF-42WE620 ONLY)

H2 block assembly

Two screws

(+BVTP 4x16)

1

Disconnect two connectors

MS panel

KF-42WE620/50WE620

4

2

3

Two screws

(+BVTP 4x16)

4

H4 board

16

1-15.H3 AND H4 BOARD REMOVAL (KF-50WE620 ONLY)

r

Note:

To remove the H4 Board you need to remove the screws inside the Bottom Cabinet Assembly

H3 board

KF-42WE620/50WE620

Spring

plate

H3 bracket

Two screws

(+BVTP 3x12)

One screw

4

MS bracket

3

1-16.H2 BOARD REMOVAL

2

1

Disconnect two connectors

and one ground wire.

Disconnect two connectors

3

H4 board

Bottom cover assembly

KF-42WE620/50WE620

Two screws

(+BVTP 3x12)

H2 board

H2 bracket

1

Four screws

(+BVTP 4x16)

3

2

Disconnect one connecto

Light guide (LED)

17

1-17.H1 BOARD REMOVAL

Disconnect one connector

Screen mirror block assembly

4

3

H1 board

One screw (3x12)

H1 button

H1 bracket

Two screws

2

(+BVTP 4x16)

1 H1 bracket cap

Using tweezers gently detach two

H1 Bracket Caps

KF-42WE620/50WE620

1-18.SCREEN MIRROR BLOCK ASSEMBLY REMOVAL

Note: For the model 50WE620, remove the screws that secure

the reinfocement plates (R)/(L).

Screen mirror block assembly

Seven screws

3

(+BVTP 4x16)

1

Disconnect three connectors

KF-42WE620/50WE620

2

Four screws

(+BVTP 4x16)

18

SECTION 2: CIRCUIT ADJUSTMENTS

KF-42WE620/50WE620

2-1. SETTING THE SERVICE ADJUSTMENT

MODE

1. Standby mode (Power off).

2. Press the following buttons on the remote commander within a

second of each other:

Display

The following screen appears:

Channel

Category Name

3D-COMB 0 0 SERVICE

NRMD TV

WSL: xxx

Item Name Input Signal

F/A FLAG: xxxxxxxx

CBA FLAG: xxxxxxxx

Category Name

L001OUT 0 0 G

OCKPN

Item Name

TEMP 42DEG

LCD PJ ENGINE VER.0.026

9/11

EE2F

5

Item No.

Sound Volumne

Data

Item No.

<LCD PROJECTOR ENGINE>

Mode

Data

Power

+

2-2. SERVICE ADJUSTMENT MODE MEMORY

1. The SCREEN displays the item being adjusted.

2. Press 1 or 4 on the Remote Commander to select the item.

3. Press

4. Press

Note: Every time you press

3

or 6 on the Remote Commander to change the data.

2

or 5 on the Remote Commander to change the category.

2

(Category Up), Service Mode changes

in the order as shown below:

VERSION0

CCPM-1

CCPM-2

CCPM-3

CCPM-4

CCPM-5

CCPM-6

CCPM-7

CCPM-8

CCPM-9

CCPM-10

CH-SET

CCPS-1

CCPS-2

CCPS-3

CCPS-5

CCPS-6

CCPS-7

CCPS-8

CCPS-10

DCP-INT

DCP-OSD

DCP-BLK

DCP-ADJ1

DCP-ADJ2

DCP-USER

DCP-AVP

USR-NR

CXA2171

AP

DLBY

MID1

MID2

MID3

MID4

MID5

MID6

MID7

MID8

MID9

SNNR

SNSS

DRCVR

CCD

D9671-1

D9671TPN

D9671CUR

D9671TG1

D9671TG2

D9671CSC

A7001R

A7001G

A7001B

SH SET

H POS SHI

TEMP

OSD-E

OPTION-E

FAN-CTL

GB RGB

KF-42WE620/50WE620

CCPS-4

AK4524

5. To go back to the most recently saved value

D9671PIC

0

then

OPTION-E

ENTER

ID

to read

the memory.

6. Press

MUTING

then

ENTER

to write into memory.

7. When you want to exit Service Mode, turn the power off.

Note: Press “8” then “[ENTER]” on the remote commander to set

the shipping conditions or turn set off and on to exit.

19

2-3. MEMORY WRITE CONFIRMATION METHOD

1. After adjustment, pull out the plug from the AC outlet, then replace the plug in the AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confi rm they were adjusted.

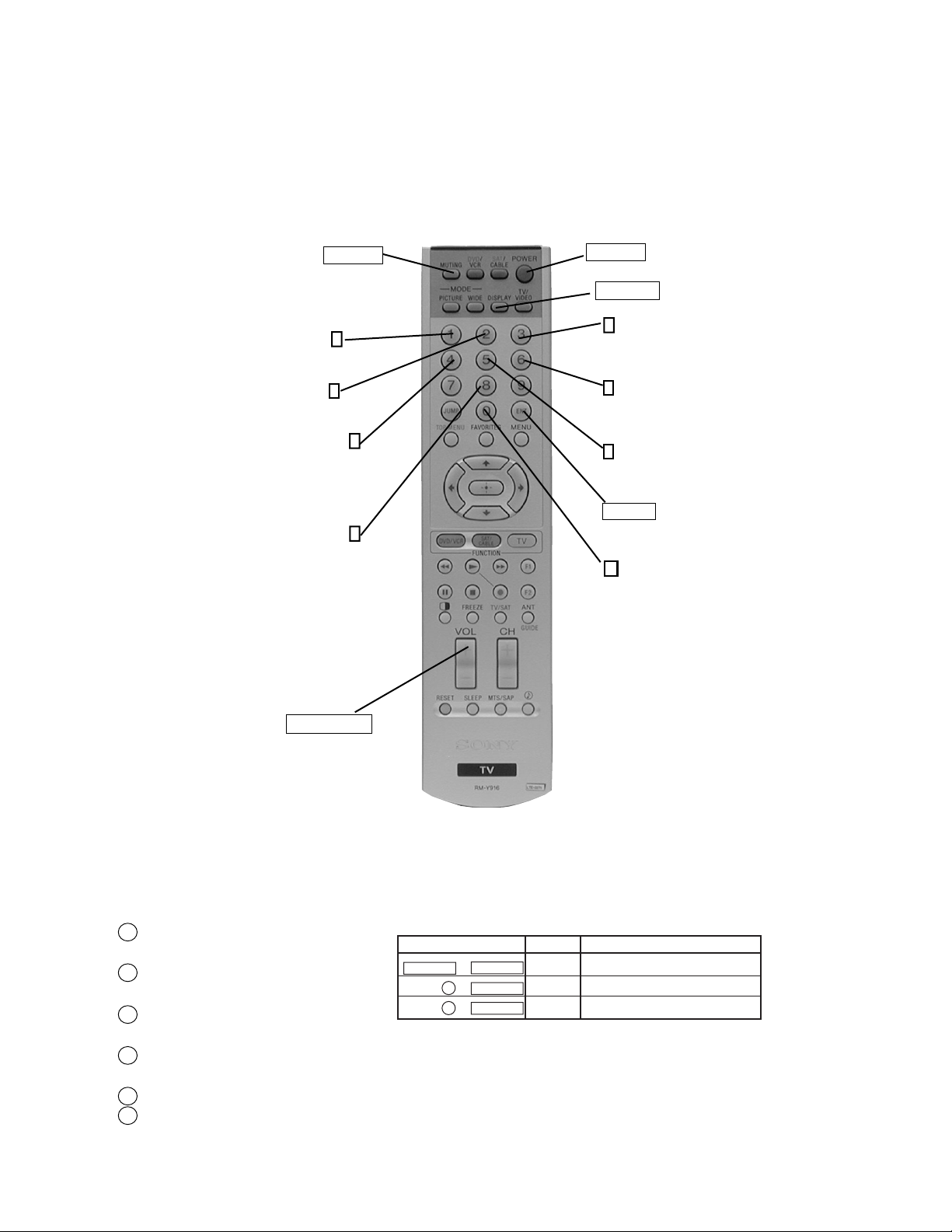

2-4. REMOTE ADJUSTMENT BUTTONS AND INDICATORS

KF-42WE620/50WE620

MUTING

(Enter into

memory)

Adjustment

Item up

Adjustment

Category up

Adjustment

Item down

User control goes to the

standard state (Shipping

Conditions)

1

2

4

8

POWER

(Service Mode)

DISPLAY

(Service Mode)

3

Data up

6

Data down

5

Adjustment

category down

ENTER

(Enter into

memory)

0

Read data

from NVM

VOLUME (+)

(Service Mode)

FUNCTION OF KEYS ON COMMANDER

• 1 : Changes adjustment item.

(item No. moves up)

• 4 : Changes adjustment item.

(item No. moves down)

• 2 : Changes adjustment category.

(category moves up)

• 5 : Changes adjustment category.

(category moves down)

• 3 : Changes data value. (up)

• 6 : Changes data value. (down)

RM-Y916

Commander Function

Button Mode Description

MUTING + ENTER WRITE Writes data to NVM.

0 + ENTER READ Reads data from NVM.

8 + ENTER RESET Set the shipping condition.

(Use only to reset to

shipping standards)

KF-42WE620/50WE620

20

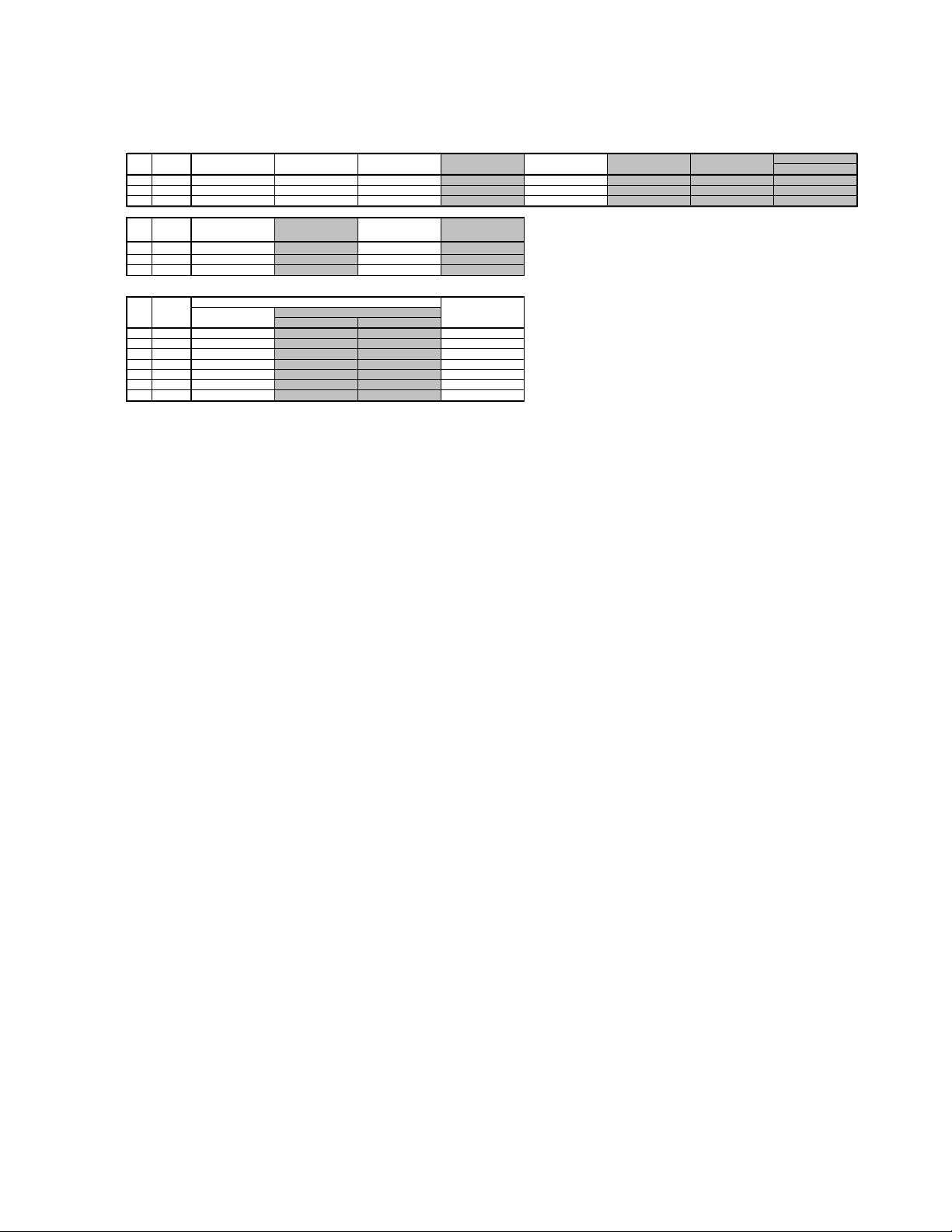

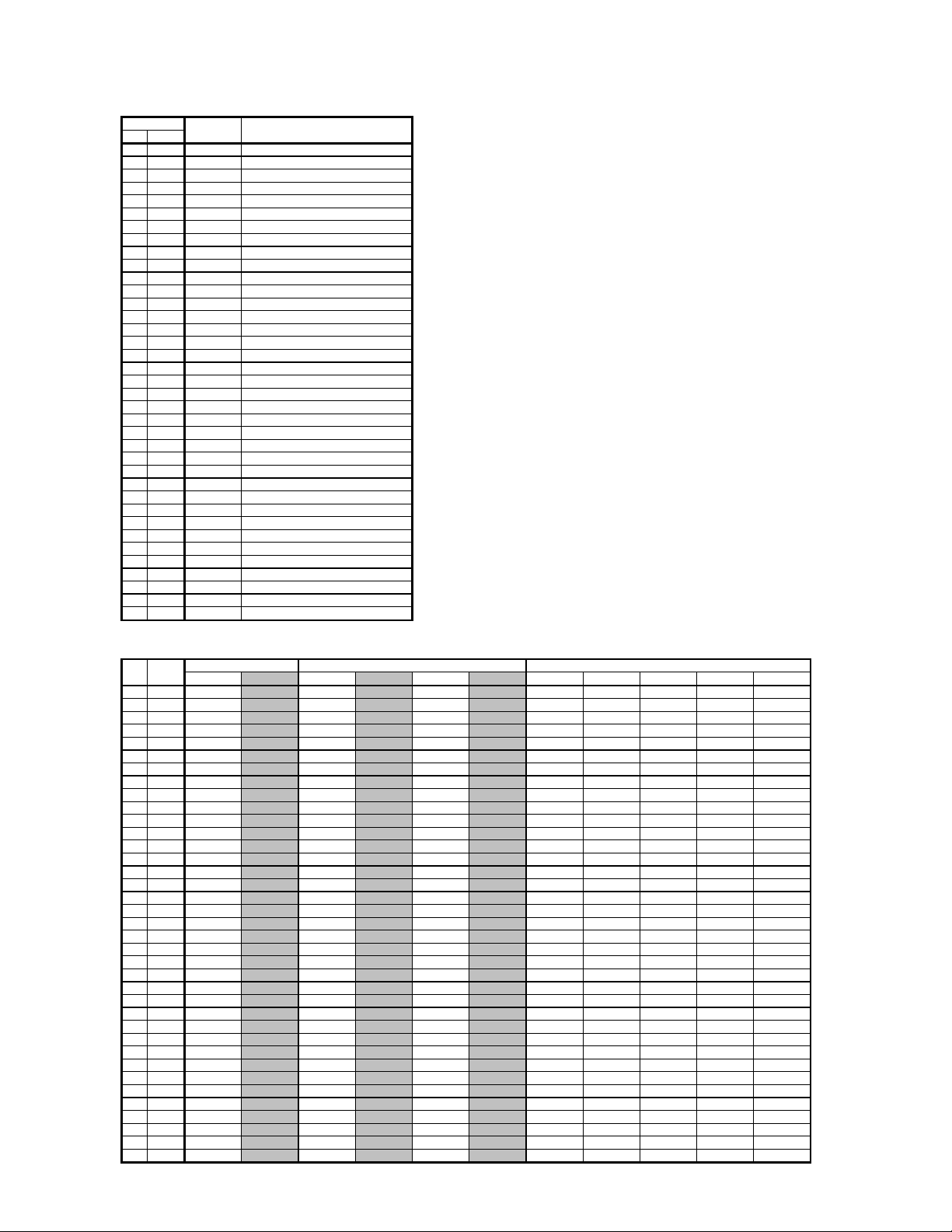

2-5. SERVICE DATA

CCPM-1

No. Nam

e

0SHPC *1

1FUP2 *1

2YNR *1

3CNR *1

4SSHP *1

5YEQ *1

6SHF0 *1

7SECA *2

8YCDL *3

9YLEV *3

10 CLEV *3

11 SHU

E

*4

12 CEQ *4

13 CBP

F

*4

14 CBPA *4

15 KILV *4

16 APGA *4

17 NCOM *4

Standards *1

Vivid Standar

dPro

Reserve

d

Vivid Standar

dPro

Reserve

d

0SHPC11101110

1FUP200000000

2YNR00000000

3CNR00000000

4SSHP21175557

5YEQ31131113

6SHF011111111

Vivid Standar

dPro

Reserve

d

Vivid Standar

dPro

Reserve

d

0SHPC00000000

1FUP200000000

2YNR00000000

3CNR00000000

4SSHP77777777

5YEQ33333333

6SHF011111111

Vivid Standar

dPro

Reserve

d

Vivid Standar

dPro

Reserve

d

0SHPC00000000

1FUP200000000

2YNR00000000

3CNR00000000

4SSHP77777777

5YEQ33333333

6SHF011111111

Vivid Standar

dPro

Reserve

d

Vivid Standar

dPro

Reserve

d

0SHPC00000000

1FUP200000000

2YNR00000000

3CNR00000000

4SSHP77777777

5YEQ33333333

6SHF011111111

Vivid Standar

dPro

Reserve

d

Vivid Standar

dPro

Reserve

d

0SHPC00000000

1FUP200000000

2YNR00000000

3CNR00000000

4SSHP77777777

5YEQ33333333

6SHF011111111

Vivid Standar

dPro

Reserve

d

0SHPC0000

1FUP20000

2YNR0000

3CNR0000

4SSHP7777

5YEQ3333

6SHF01111

Vivid Standar

dPro

Reserve

d

Vivid Standar

dPro

Reserve

d

0SHPC00000000

1FUP200000000

2YNR00000000

3CNR00000000

4SSHP77777777

5YEQ33333333

6SHF011111111

i.LINK(ex DV)for XBR(BS/CS/i.LINK(ex DV))

480i(ex DV Format)(480i) 480pNo. Name

DVI(AVM(RG B)/DVI)

VGA(VGA/O THER)

480

i

Component(AVM(YC bCr))

1080

i

720p

480p

DVI(AVM(RG B)/DVI)

1080

i

720p

DVI(AVM(RG B)/DVI)

Component(AVM(YC bCr))

480

i

480p

UV Video

Functionalit

y

Data Remarks

No. Name

No. Name

No. Name

No. Name

No. Name

No. Name

KF-42WE620/50WE620

KF-42WE620/50WE620

21

KF-42WE620/50WE620

dPro

d

dPro

d

dPro

dPro

d

dPro

d

dPro

d

dPro

d

dPro

d

dPro

dPro

d

dPro

d

dPro

d

dPro

e

o

i

i

i

i

i

r

i

i

r

i

i

i

r

i

i

r

No. Name

0SHPC00000000

1FUP200000000

2YNR00000000

3CNR00000000

4SSHP77777777

5YEQ33333333

6SHF011111111

No. Name

0SHPC00000000

1FUP200000000

2YNR00000000

3CNR00000000

4SSHP77777777

5YEQ33333333

6SHF011111111

No. Name

0SHPC00000000

1FUP200000000

2YNR00000000

3CNR00000000

4SSHP77777777

5YEQ33333333

6SHF011111111

Name

No.

0SHPC00000000

1FUP200000000

2YNR00000000

3CNR00000000

4SSHP77777777

5YEQ33333333

6SHF011111111

No. Name

0SHPC0000

1FUP20000

2YNR0000

3CNR0000

4SSHP7777

5YEQ3333

6SHF01111

No. Name

0SHPC00000000

1FUP200000000

2YNR00000000

3CNR00000000

4SSHP77777777

5YEQ33333333

6SHF011111111

No. Name

0SHPC00000000

1FUP200000000

2YNR00000000

3CNR00000000

4SSHP77777777

5YEQ33333333

6SHF011111111

Standards *2

No. Nam

7SECA 10 10

No. Name

7SECA000000000

No. Name

7SECA000000

No. Name

7SECA00000

No. Name

7SECA0000

Vivid Stand ar

i.LINK for XBR (BS/CS/i. LINK(ex D V))

Vivid Stand ar

Vivid Stand ar

Vivid Stand ar

Vivid Stand ar

Vivid Stand ar

Vivid Stand ar

UV Vide

480

480i(ex DV) 480p 1080

480

DATA(ADD) DATA(INDEPEND ENT)

480

1080

480i(DV Format)Lowe

480

1080

ATSC(DTT/ATSC)

Lowe

STILL(1080i)(480i)

MOVIE(LOW) (480i) MOVIE(HIGH) OTHER

Component(AVM(YCbCr)) DVI(AVM(RGB)/DVI)

480p 1080

i.LINK(ex DV) for XBR(BS/CS/i.LINK(ex DV))

480p 1080

OTHER 480

ATSC(DTT/AT SC)

i.LINK(ex DV)for XBR(BS/CS/i.LINK(ex DV))

Reserve

Mild Vivid Sta ndar

ATSC for XB R(DTT/ATSC)

Reserve

ATSC for XB R(DTT/ATSC)

Reserve

Mild

MS for XB R(DATA(ADD))

Reserve

MS for XB R(DATA(INDEPENDENT))

Reserve

720p 480

720p Lowe

720p Lowe

OTHER

Vivid Standar

Vivid Standar

Vivid Standar

Vivid Standar

Vivid Standar

MOVIE(CONT -PANEL) (OTHER)

i.LINK (DV)

720p

i.LINK (DV)

480p

720p

480p 1080

Reserve

Reserve

Reserve

Reserve

Reserve

Mild

720p V GA(VGA/OTHER)

KF-42WE620/50WE620

22

KF-42WE620/50WE620

E

F

t

Standards *3

No. Name

8YCDL88777777

9 YLEV 175 175 175 175 175 175 175 175

10 CLEV 97 97 185 185 185 185 185 185

No. Name

8YCDL7777

9 YLEV 175 175 175 175

10 CLEV 185 185 185 185

Standards *4

No. Name

11 SHU

12CEQ3110

13 CBP

14CBPA0110

15KILV2222

16APGA0000

17NCOM0000

UV Video Component (not 480i)

Component (480i)

UV(GR O FF)

ATSC for XBR (480i)

(AVM(Y/Cb/Cr))

UV

7777

3220

GCR ON GCR OFF

DVI (480i)

(AVM(RGB)/DVI)

GR ON Vide o

ATSC for XBR (no

480i)(AVM(Y/Cb/Cr))

i.LINK (not 480i and

ex DV) for XBR

DVI (not 480i)

(AVM(RGB)/DVI)

i.LINK (480i and ex

DV) for XBR

i.LINK (DV)

MS for XBR

(DTT/ATSC)

KF-42WE620/50WE620

23

CCPM-2

A

I

T

A

I

T

KF-42WE620/50WE620

Functionality

No. Name

0PACK *1

1CLPP *2

2 SSEP *2

3CLPG *2

4CLP

5AFCV *2

6 HSSL *2

7 VSSL *2

8STIP *2

9SYLP *2

10 SYF

11 AFCG *2

12 LOWG *2

13 AFCM *2

14 LOCO *2

15 HICO *2

16 CDM1 *2

17 CDM2 *2

18 CDM3 *2

19 BGPS *2

20 VINT *2

21 HSPO *2

22 MVSW *2

23 MVC

24 MVHC *2

25 CLAL *2

26 ADPS *2

27 CLGA *2

28 YTRP *2

29 CT RP *2

30 CROF *2

31 SDLP *2

32 ROM2 *2

Standards *1

No. Name UV Video1 Video2 Video3 Video4

0PACK04444

Data Remarks

*2

*2

*2

No. Name

0PACK56785678

No. Name

0PACK5678567813

Standards *2

No. Name PACK=0 PACK=1 PACK=2 PACK=3 PACK=4 PACK=5 PACK=6 PACK=7 PACK=8

1CLPP282828282828282828

2SSEP000000000

3CLPG000000000

4CLP

5AFCV111111111

6HSSL222200033

7VSSL222222233

8STIP2 22222222

9SYLP000000000

10 SYF

11AFCG112201111

12 LOWG 0 0 0 0 0 0 0 0 0

13AFCM000000000

14LOCO000000000

15HICO000000000

16CDM1222222222

17CDM2000000000

18CDM3000000000

19 BGPS 10 10 10 10 10 10 10 10 10

20 VINT 7 7 7 7 7 7 7 3 7

21HSPO777777777

22MVSW222222222

23 MVC

24MVHC444444444

25CLAL000000000

26ADPS0 00000000

27CLGA222222222

28YTRP1 11110000

29CTRP111110000

30CROF111111111

31SDLP111110000

32ROM2000000000

KF-42WE620/50WE620

480i 480p 1080i 720p 480i 480p 1080i 720p

480i 480p 1080i 720p 480i 480p 1080i 720p VGA/OTHER

000000000

101011000

777777777

Video5(COMPONENT1)

i.LINK/ATSC/MS for XBR(AVM(YCbCr))

Video6(COMPONENT2)

DVI(AVM(RGB)/DVI)

24

No. Name PACK = 9 PACK = 10 PACK = 11 PACK = 12 PACK = 13 PACK = 14 PACK = 15

A

I

T

K

F

R

H

L

L

F

L

P

1CLPP28282828282828

2SSEP0000000

3CLPG0000000

4CLP

5AFCV111 1111

6HSSL1111022

7VSSL2222222

8STIP2222222

9SYLP0000000

10 SYF

11AFCG1122123

12 LOWG 0 0 0 0 0 1 3

13AFCM0000000

14LOCO0000000

15HICO0000000

16CDM12222222

17CDM20000000

18CDM30000000

19 BGPS 10 10 10 10 10 10 10

20 VINT 7 7 7 7 7 7 7

21HSPO7777777

22MVSW2222222

23 MVC

24 MVHC 4 4 4 4 4 4 4

25CLAL0000000

26ADPS0 000000

27CLGA2222222

28 YTRP 1 1 1 1 0 1 1

29CTRP1111011

30 CROF 1 1 1 1 1 1 1

31SDLP1111011

32ROM20000000

0000000

1010011

7777777

KF-42WE620/50WE620

CCPM-3

Functionality

No. Name

0AD1E 0

1APED *1

2 AAT

3 AHLD *2

4 AARE *2

5 AHIS *2

6 DCTR *1

7 DCTC *3

8ID1W *4

9WSSO *4

10 SLIC *4

11 AWO

12 UPA

13 UPT

14 X149 *5

15 DMST *5

16 INST *5

17 UPR

18 OFS

19 SLO

20 FR43 *5

21 FRWI *5

22 FRTI *5

23 LPF

24 4CNT *5

25 REF

26 REFM *5

27 AWSN *5

28 AWRE *5

Data Remarks

*2

*5

*5

*5

*5

*5

*5

*5

*5

KF-42WE620/50WE620

25

KF-42WE620/50WE620

Standards *1

AD1E = 1 Or MULTI(TWIN,FAVORITES)

No. Name

1APED2101231

6DCTR2101231

Vivid Standard

BLK Correction Off BLK CorrectionLBLK CorrectionMBLK Correction H

480i(RF/Video/Component480i)

Pro

Reserved

AD1E = 1 Or MULTI(TWIN,FAVORITES)

No. Name

Vivid Standard

1APED2101231

6DCTR2101231

BLK Correction Off BLK CorrectionLBLK CorrectionMBLK Correction H

480p

Pro

Reserved

AD1E = 1 Or MULTI(TWIN,FAVORITES)

No. Name

Vivid Standard

BLK Correction Off BLK Correction L BLK Correction M B LK Correction H

1080i/60

Pro

Reserved

1APED2101231

6DCTR2101231

AD1E = 1 Or MULTI(TWIN,FAVORITES)

No. Name

Vivid Standard

BLK Correction Off BLK Correction L BLK Correction M B LK Correction H

720p/60

Pro

Reserved

1APED2101231

6DCTR2101231

AD1E = 1 Or MULTI(TWIN,FAVORITES)

No. Name

Vivid Standard

BLK Correction Off BLK Correction L BLK Correction M B LK Correction H

576i

Pro

Reserved

1APED3201231

6DCTR3201231

AD1E = 1 Or MULTI(TWIN,FAVORITES)

No. Name

Vivid Standard

BLK Correction Off BLK Correction L BLK Correction M B LK Correction H

576p

Pro

Reserved

1APED3201231

6DCTR3201231

AD1E = 1 Or MULTI(TWIN,FAVORITES)

No. Name

Vivid Standard

BLK Correction Off BLK Correction L BLK Correction M B LK Correction H

1080i/50

Pro

Reserved

1APED3201231

6DCTR3201231

KF-42WE620/50WE620

26

KF-42WE620/50WE620

K

F

R

H

L

L

F

L

P

F

R

H

L

L

F

L

P

AD1E = 1 Or MULTI(TWIN,FAVORITES)

No. Name

Vivid Standard

BLK Correction Off BLK Correction L BLK Correction M B LK Correction H

720p/50

Pro

Reserved

1APED3201231

6DCTR3201231

Standards *2

No. Name

2 AAT

APED = 0 APED = 1 APED = 2 APED = 3

2222

3 AHLD 2 2 2 2

4 AARE 2 2 2 2

5 AHIS 0 0 0 0

Standards *3

No. Name

DCTR = 0 DCTR = 1 DCTR = 2 DCTR = 3

7 DCTC 2 2 2 2

Standards *4

No. Name UV Video1 Video2 Video3 Video4

8ID1W11111

9WSSO00000

10 SLIC 5 5 5 5 5

No. Name

Video5(COMPONENT1) Video6(COMPONENT2)

480i 480p 480i 480p 480i 480p

i.LINK/ATSC for XBR(AVM(YCbCr))

8ID1W111111

9WSSO000000

10SLIC555555

Standards *5

No. Name UV Video1 Video2 Video3 Video4

11 AWO

12 UPA

13 UPT

00000

00000

00000

14 X149 0 0 0 0 0

15DMST11111

16 INST 0 0 0 0 0

17 UPR

18 OFS

19 SLO

11111

00000

00000

20 FR43 2 2 2 2 2

21FRWI22 222

22FRTI22222

23 LPF

11111

24 4CNT 1 1 1 1 1

25 REF

11111

26 REFM 5 5 5 5 5

27AWSN00000

28 AWRE 0 0 0 0 0

No. Name

11 AWO

12 UPA

13 UPT

14 X149 0 0 0 0

15DMST1111

16 INST 0 0 0 0

17 UPR

18 OFS

19 SLO

20 FR43 2 2 2 2

21FRWI22 22

22FRTI2222

23 LPF

24 4CNT 1 1 1 1

25 REF

26 REFM 5 5 5 5

27AWSN0000

28 AWRE 0 0 0 0

KF-42WE620/50WE620

Video5

480i(COMPONENT1 480i)

Video6

480i(COMPONENT2 480i)

i.LINK/ATSC for XBR 480i

(AVM(YCbCr) 480i)

DVI 480i(AVM(RGB)

480i)

0000

0000

0000

1111

0000

0000

1111

1111

27

CCPM-4

W

L

W

L

KF-42WE620/50WE620

Functionality

No. Name

0CLKS *1

1REFC *1

2SYMD *1

3SIFM *1

4DTO1 *1

5DTO2 *1

6DTO3 *1

7PIX1 *1

8PIX2 *1

9VLN1 *1

10 VLN2 *1

11 SYSC *1

12 DSPC *1

13 PLLD *1

14 PLLR *1

15 DCLP *1

16 DCON *1

17 CO2P *1

18 CONV *1

19 HO2O *1

20 BLKM *1

21 OSDL *1

22 OSDR *1

23 CO2O *1

24 COLS *1

25 VFRQ *1

26 PLLS *1

27 PIF

28 PIBW *1

29 PLL4 *1

30 CDAD *1

31 CDAS *1

32 PLD1 *1

33 PLTS *1

34 PLO

35 YRND *1

36 CRND *1

Data Remarks

*1

*1

Standards *1

No. Name

0CLKS000 00000000

1REFC1111111 1111

2SYMD0000558 8888

3SIFM00000 002342

4DTO16363636363636363636363

5 DTO2 254 254 254 254 254 254 254 254 254 254 254

6DTO38686868686868686868686

7PIX10000000 0000

8PIX20000000 0000

9VLN1000 00000000

10 VLN2 0 0 0 0 0 0 0 0 0 0 0

11SYSC11111110000

12DSPC33333331111

13PLLD00000000000

14PLLR11111111111

15DCLP22222222222

16 DCON 0 0 0 0 0 0 0 0 0 0 0

17CO2P00000000000

18CONV00000000000

19 HO2O 1 1 1 1 1 1 1 0 0 0 0

20BLKM11111111111

21 OSDL 3 3 3 3 3 3 3 3 3 3 3

22 OSDR 1 1 1 1 1 1 1 1 1 1 1

23CO2O11111110000

24COLS00000000000

25VFRQ33333333333

26PLLS00000000000

27 PIF

28 PIBW 0 0 0 0 0 0 0 0 0 0 0

29PLL400000000000

30CDAD00000000000

31CDAS00000000000

32PLD100000000000

33PLTS00000000000

34 PLO

35 YRND 1 1 1 1 1 1 1 1 1 1 1

36CRND11111111111

UV

3-D 2-D 3-D 2-D YC YC 480i 480p 1080i 720p VGA(DVI)

00000000000

00000000000

Video Component, ATSC, DVI

KF-42WE620/50WE620

28

KF-42WE620/50WE620

W

L

No. Name

0CLKS055 5504

1REFC1 111111

2 SYMD 5 14 14 14 14 8 12

3SIFM00234 315

4DTO163636363636363

5 DTO2 254 254 254 254 254 254 254

6DTO386868686868686

7PIX1000000255

8PIX200000015

9VLN1000 0000

10 VLN2 0 0 0 0 0 0 64

11SYSC1100000

12DSPC3200010

13PLLD0000000

14PLLR1211111

15 DCLP 2 2 2 2 2 2 2

16 DCON 0 0 0 0 0 0 0

17CO2P0000000

18 CONV 0 0 0 0 0 0 0

19 HO2O 0 0 0 0 0 0 0

20BLKM1111111

21 OSDL 3 3 3 3 3 3 3

22 OSDR 1 1 1 1 1 1 1

23CO2O0000000

24COLS0000000

25VFRQ3333333

26PLLS0000000

27 PIF

28PIBW0000000

29PLL40000000

30CDAD0000000

31 CDAS 0 0 0 0 0 0 0

32PLD10000000

33PLTS0000000

34 PLO

35 YRND 1 1 1 1 1 1 1

36CRND1111111

BS/DTT

YC

0000000

0000000

480i 480p 1080i 720p

BS/DTT

MS/CNM for

XBR

MS/CNM for

WE to CCPS

CCPM-5

No. Name

0NSS 8 8

1 TESS 0 0

2 NSC 15 15

3NSV 1 1

4STDH 2 2

5SHH 1 1

UV Video

DataFunctionality

Remarks

KF-42WE620/50WE620

29

CCPM-6

T

F

L

T

L

L

W

KF-42WE620/50WE620

Functionality Data

No. Name

0MC1 4 4

1MC2 3 3

2CR1 1 1

3CR2 1 1

4CR3 0 0

5CR4 1 1

6CCR 2 2

7CHED 2 2

8CVED 3 3

9CR5 4 4

10 YFL

11 C3LE 1 1

12 YMFH 3 3

13 YMFV 1 1

14 F2SW 0 0

15 MO1 15 15

16 MO2 3 3

17 MNNR 1 1

18 DTH 2 2

19 DTV 2 2

20 DT2D 2 2

21 DTHP 3 3

22 DTCR 4 4

23 D2FC 3 3

24 D2

25 D2F2 1 1

26 D2F

27 DC 0 0

28 CVF

29 HC2F 1 1

30 MNSW 0 0

31 MDYB 0 0

32 LCBP 2 2

33 BPSE 1 1

34 CR2H 0 0

35 IMPR 3 3

36 IMPS 1 1

37 IMPL 0 0

38 PLP

39 MDYE 3 3

40 PLCL 1 1

41 BPL2 1 1

42 HP

43 CVFP 0 0

44 BPL3 7 7

45 D2F3 2 2

46 LPS

47 LCR 1 1

48 F2CR 1 1

49 YIR 1 1

50 MOMO 0 0

UV Video

44

99

00

33

11

11

11

Remarks

KF-42WE620/50WE620

30

Loading...

Loading...