Sony kdl52xbr6ex1 schematic

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KDL-40XBR6

KDL-40XBR6

KDL-46XBR6

KDL-46XBR6

KDL-52XBR6

KDL-52XBR6

RM-YD024 US/CND

RM-YD024 MX/LATIN AMERICA

RM-YD024 US/CND

RM-YD024 MX/LATIN AMERICA

RM-YD024 US/CND

RM-YD024 MX/LATIN AMERICA

EX1

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 8/2008

REVISION DATE SUBJECT

8/2008 No revisions or updates are applicable at this time.

9-883-802-01

LCD DIGITAL COLOR TELEVISION

Self Diagnosis

Supported model

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KDL-40XBR6

KDL-40XBR6

KDL-46XBR6

KDL-46XBR6

KDL-52XBR6

KDL-52XBR6

RM-YD024 US/CND

RM-YD024 MX/LATIN AMERICA

RM-YD024 US/CND

RM-YD024 MX/LATIN AMERICA

RM-YD024 US/CND

RM-YD024 MX/LATIN AMERICA

EX1

CHASSIS

9-883-802-01

KDL-46XBR6 RM-YD024

LCD DIGITAL COLOR TELEVISION

KDL-40XBR6/46XBR6/52XBR6

TABLE OF CONTENTS

SECTION TITLE PAGE SECTION TITLE PAGE

Specifi cations ................................................................................. 4

Warnings and Cautions - English ................................................... 6

Warnings and Cautions - French .................................................... 7

Safety-Related Component Warning .............................................. 8

Safety Check-Out ......................................................................... 10

Self-Diagnostic Function ................................................................11

SECTION 1: DISASSEMBLY ............................................................... 13

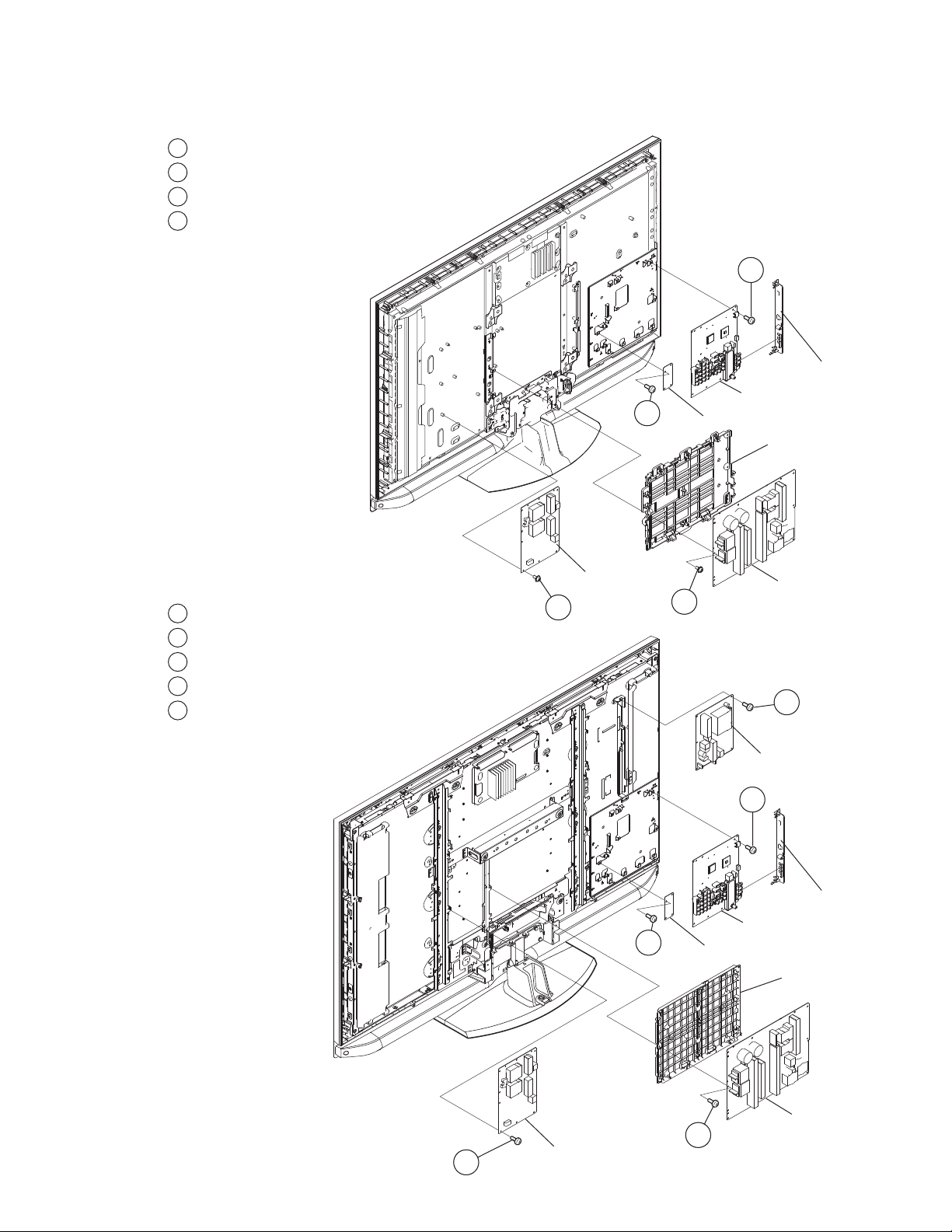

1-1. Rear Cover and Switch Unit (Contains H1 Board) Removal 13

1-1-1. KDL-40XBR6/46XBR6 Only .................................... 13

1-1-2. KDL-52XBR6 Only ................................................... 13

1-2. Woofer Box Removal ........................................................... 14

1-2-1. KDL-40XBR6/46XBR6 Only .................................... 14

1-2-2. KDL-52XBR Only ..................................................... 14

1-3. AWF Board, BU Board, G Board and D Board Removal ..... 15

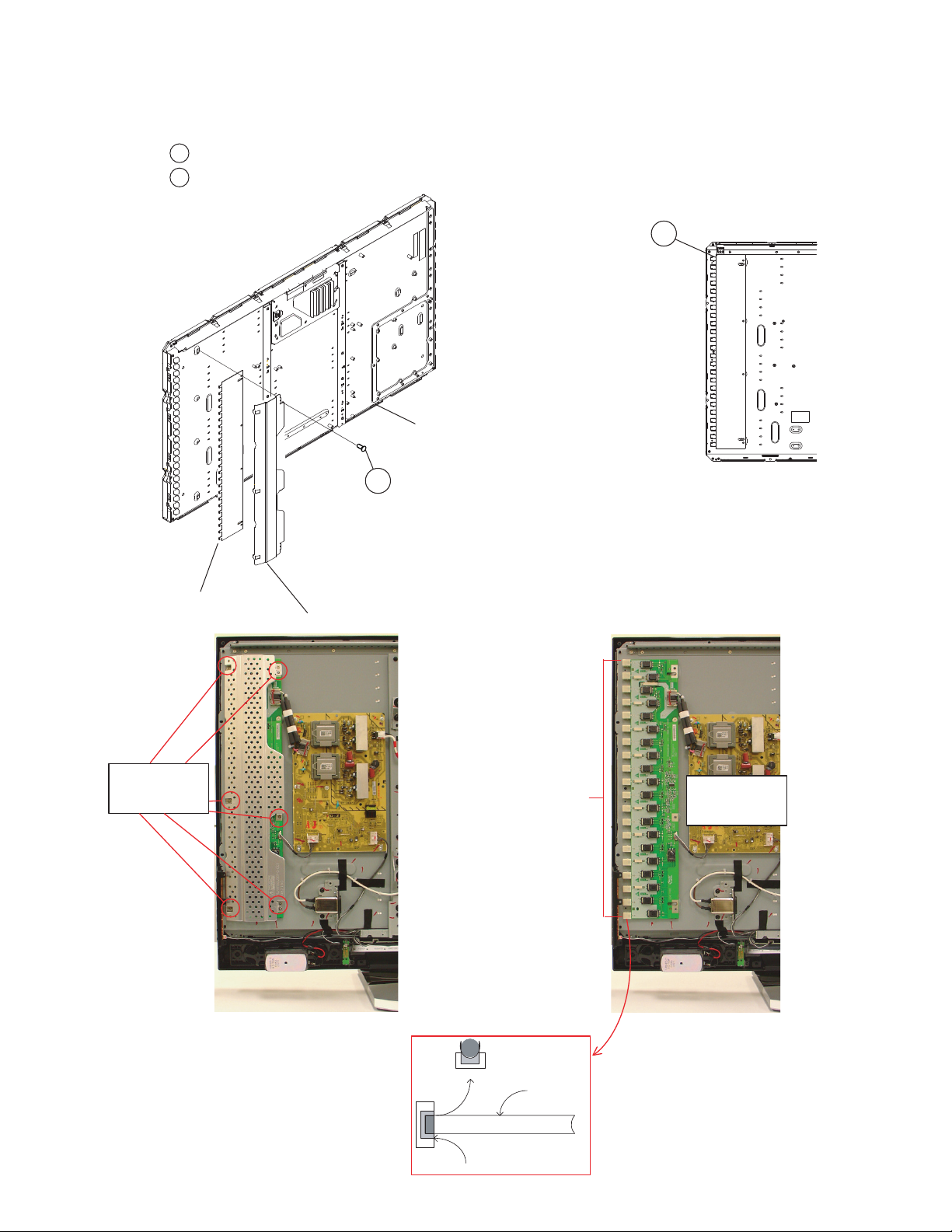

1-3-1. KDL-40XBR6/46XBR6 Only .................................... 15

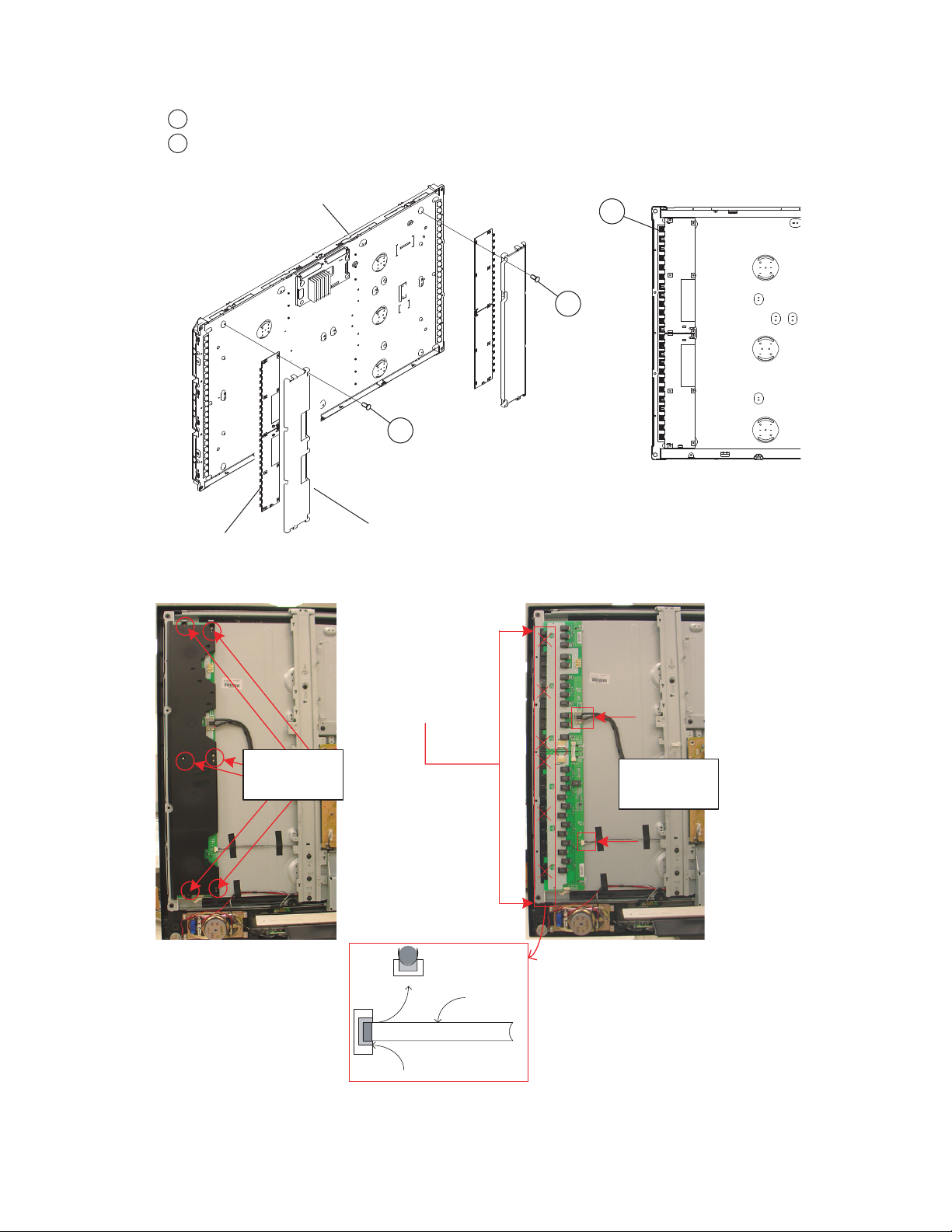

1-3-2. KDL-52XBR6 Only ................................................... 15

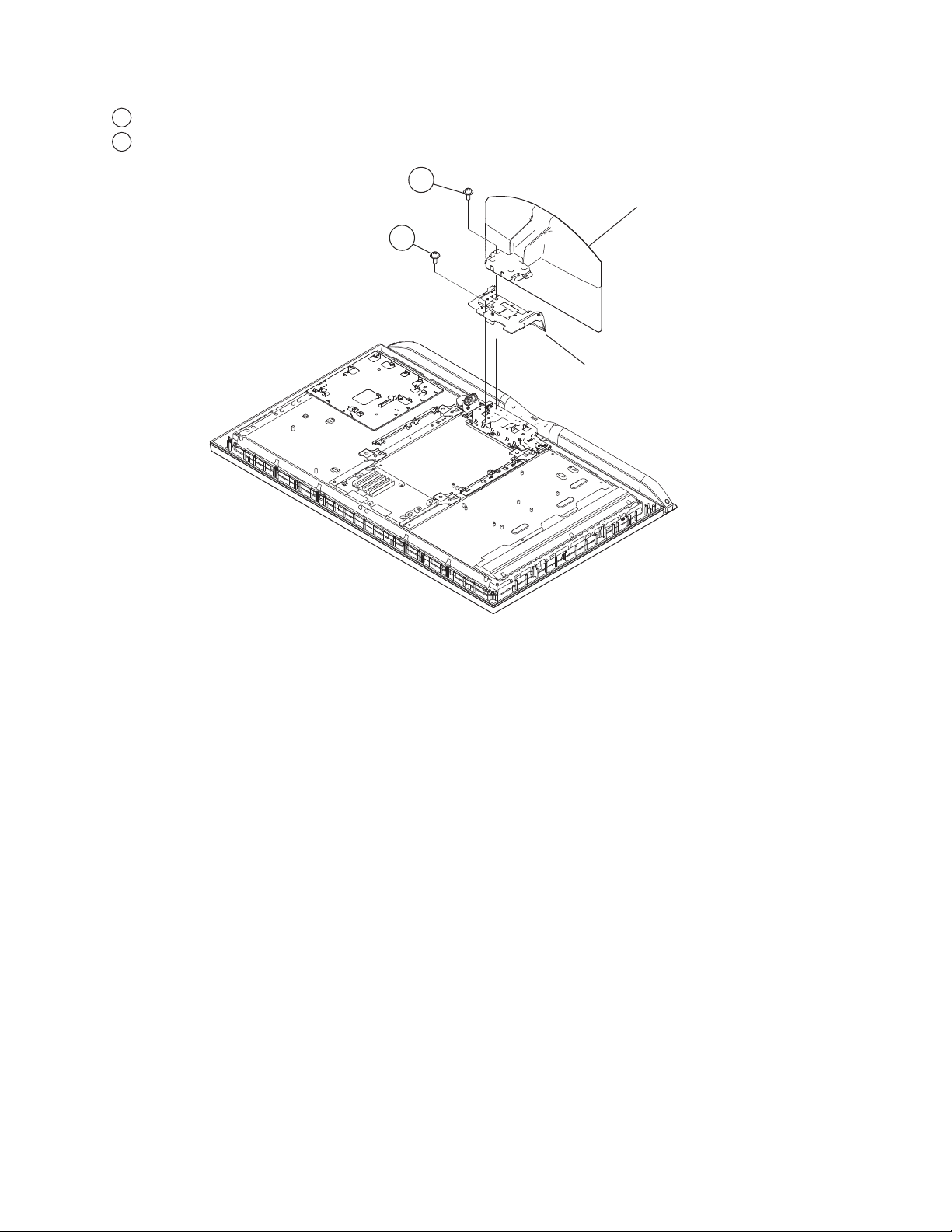

1-4. Table-Top Stand and Under Cover Removal ........................ 16

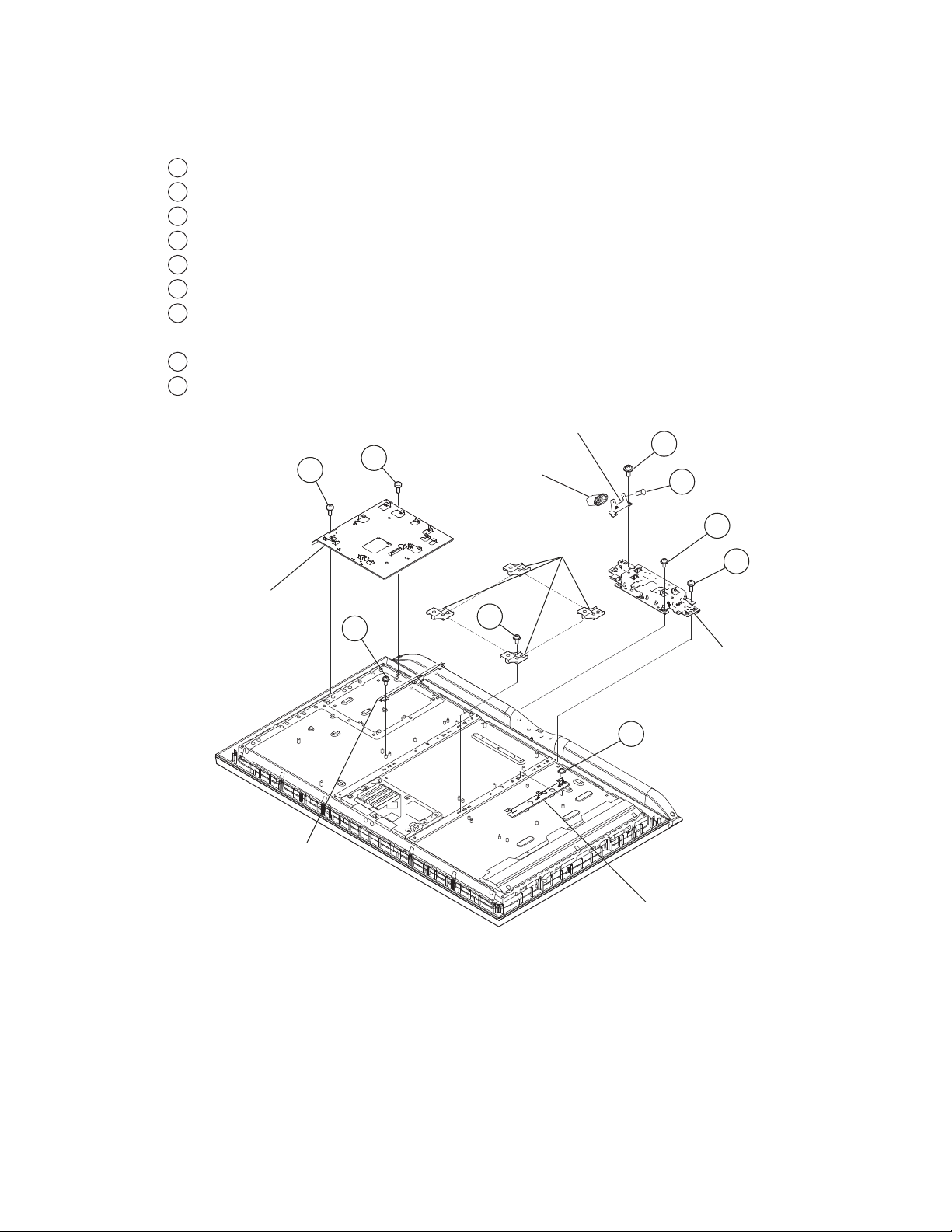

1-5. Structural Frames, Brackets and AC Inlet Removal ............. 17

1-5-1. KDL-40XBR6/46XBR6 Only .................................... 17

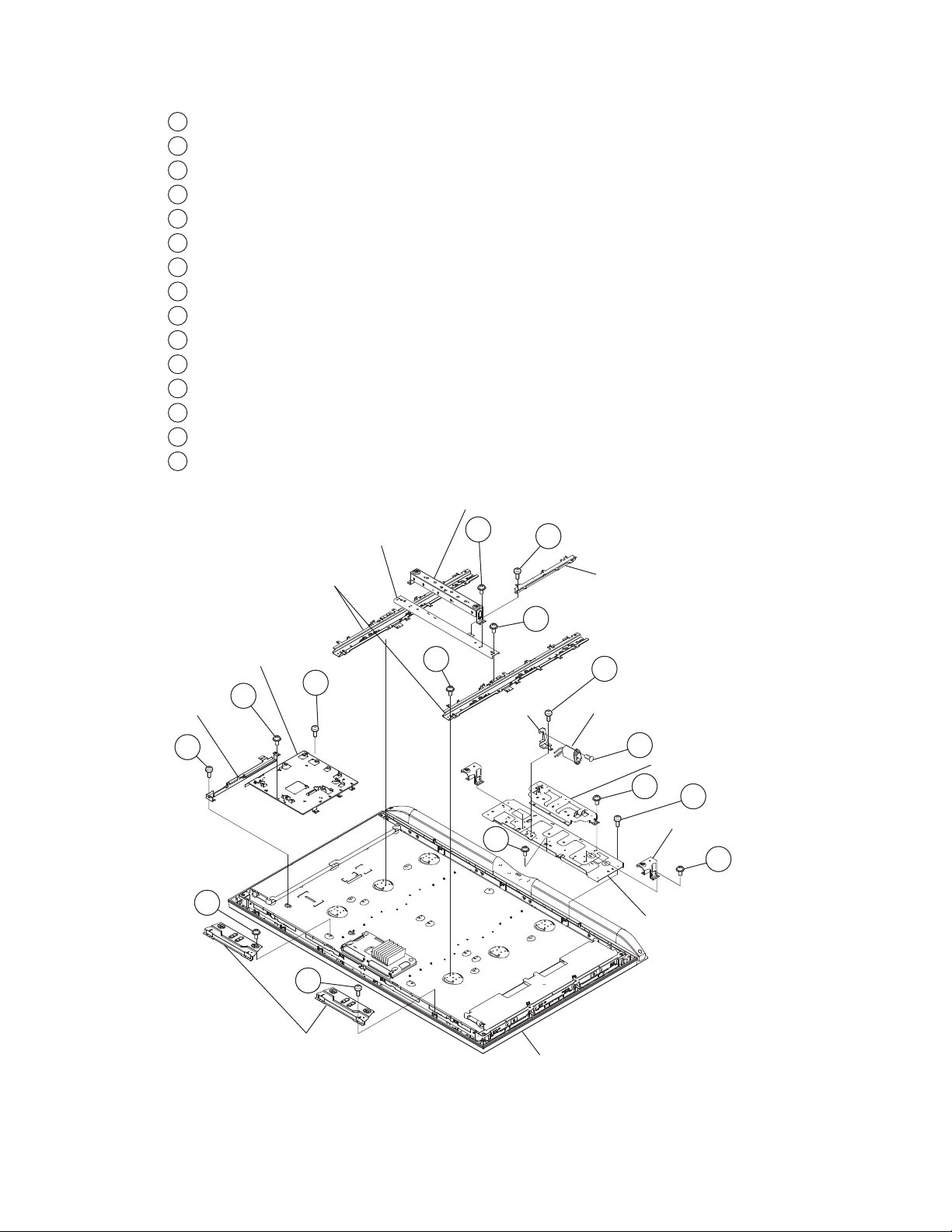

1-5-2. KDL-52XBR6 Only ................................................... 18

1-6. Speaker Cover and Speaker Box Removal ........................ 19

1-7. H3R Board and H4R Board Removal .................................. 20

1-8. LCD Panel, Illumination Module and Logo Holder Removal 20

1-8-1. Cleaning the LCD Panel .......................................... 20

1-9. Inverter Board Removal ....................................................... 21

1-9-1. KDL-40XBR6/46XBR6 Only .................................... 21

1-9-2. KDL-52XBR6 Only ................................................... 22

WIRE DRESSING ........................................................................ 23

SECTION 2: SERVICE ADJUSTMENTS ............................................. 24

2-1. Viewing Service Adjustment Data ........................................ 24

2-2. Accessing Service Adjustment Mode ................................... 24

2-3. Viewing the Service Menus .................................................. 24

2-4. Using the Remote Commander to View Service Data ......... 25

2-5. Resetting to Factory Defaults ............................................... 25

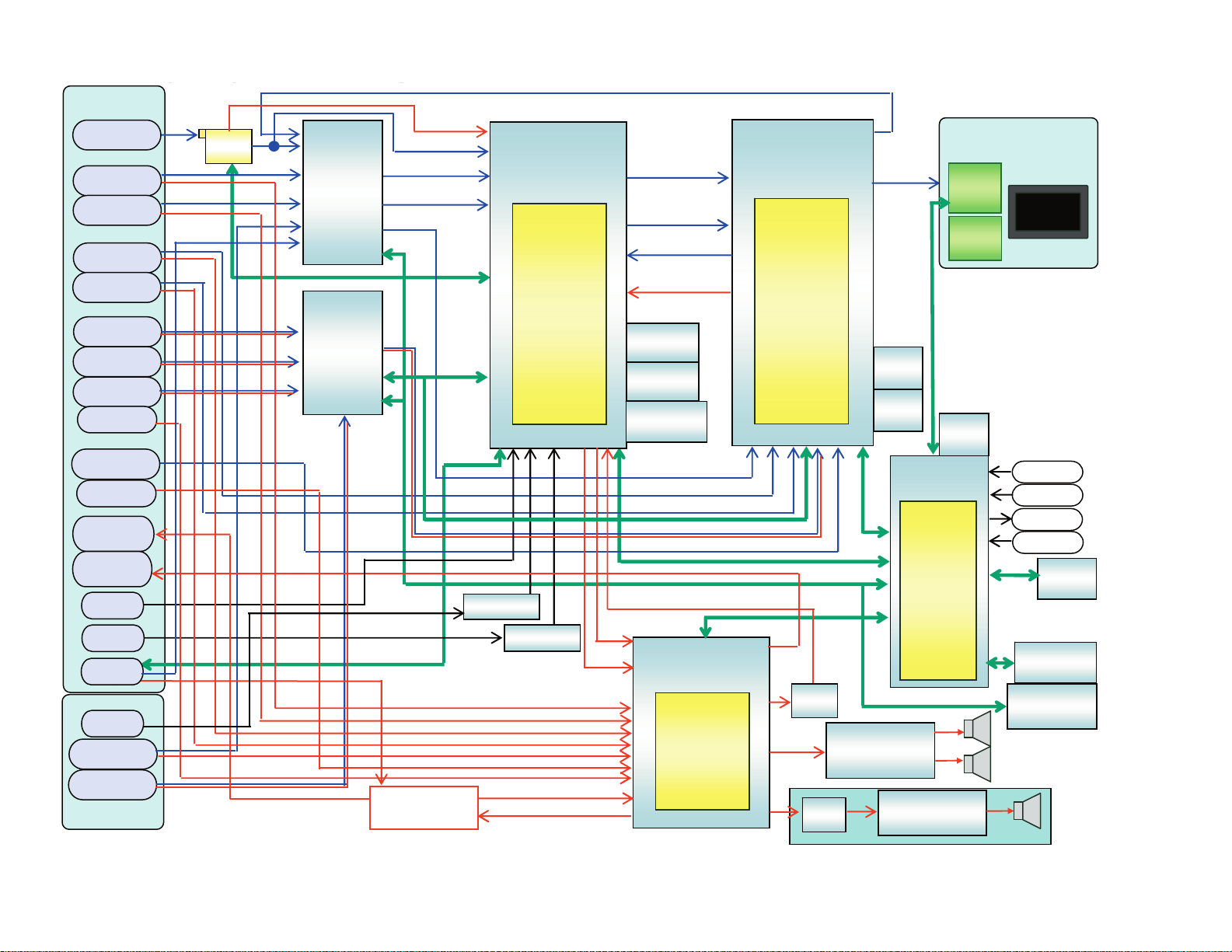

SECTION 3: DIAGRAMS ..................................................................... 26

3-1. Circuit Boards Location ........................................................ 26

3-2. Printed Wiring Boards and

Schematic Diagrams Information ......................................... 26

3-3. Block Diagram ...................................................................... 28

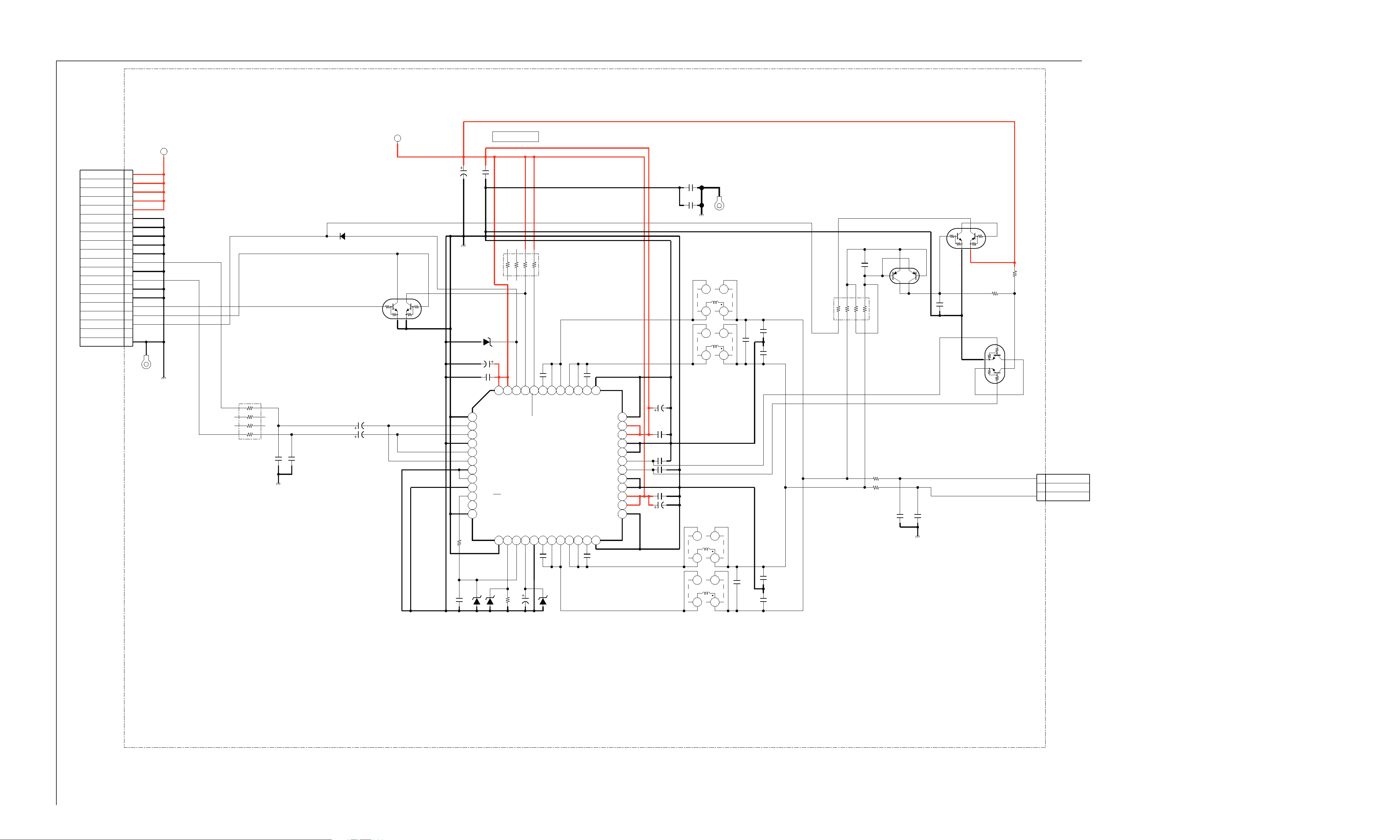

3-4. Schematics and Supporting Information .............................. 29

AWF Board Schematic Diagram .......................................... 29

BU Board Schematic Diagram (1 of 12) ............................... 32

BU Board Schematic Diagram (2 of 12) ............................... 33

BU Board Schematic Diagram (3 of 12) ............................... 34

BU Board Schematic Diagram (4 of 12) ............................... 35

BU Board Schematic Diagram (5 of 12) ............................... 36

BU Board Schematic Diagram (6 of 12) ............................... 37

BU Board Schematic Diagram (7 of 12) ............................... 38

BU Board Schematic Diagram (8 of 12) ............................... 39

BU Board Schematic Diagram (9 of 12) ............................... 40

BU Board Schematic Diagram (10 of 12) ............................. 41

BU Board Schematic Diagram (11 of 12) ............................. 42

BU Board Schematic Diagram (12 of 12) ............................. 43

D3 Board Schematic Diagram

(KDL-40XBR6/46XBR6 Only) .................................. 45

D4 Board Schematic Diagram (KDL-52XBR6 Only) ............ 47

D5 Board Schematic Diagram (KDL-52XBR6 Only) ............ 49

G5 Board Schematic Diagram (KDL-52XBR6 Only) ............ 51

G6 Board Schematic Diagram (1 of 2)

(KDL-40XBR6/46XBR6 Only) ................................. 54

G6 Board Schematic Diagram (2 of 2)

(KDL-40XBR6/46XBR6 Only) ................................. 55

H3R Board Schematic Diagram ........................................... 58

H4R Board Schematic Diagram ........................................... 60

3-5. Semiconductors ................................................................... 62

SECTION 4: EXPLODED VIEWS ........................................................ 63

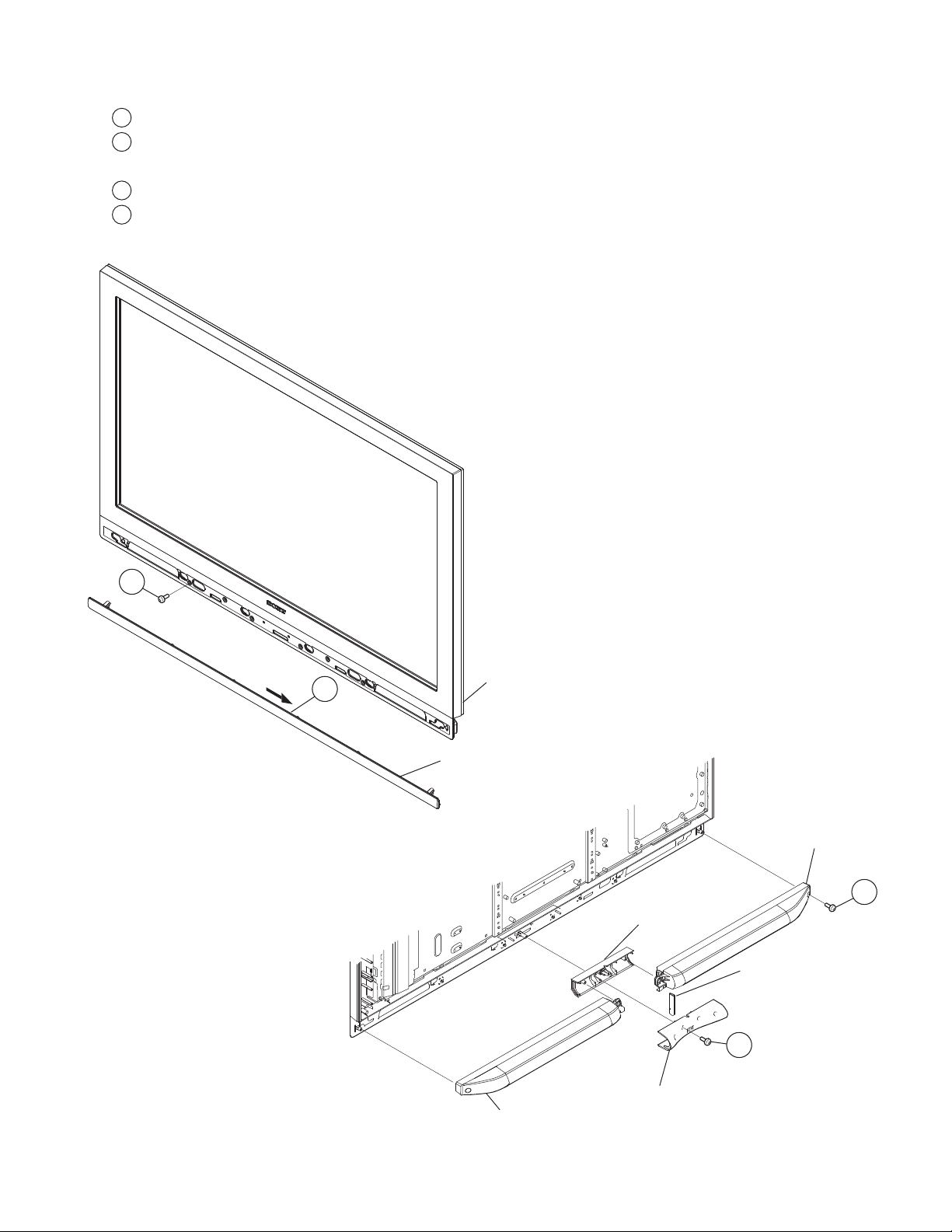

4-1. Rear Cover Assembly and Table-Top Assembly ................. 63

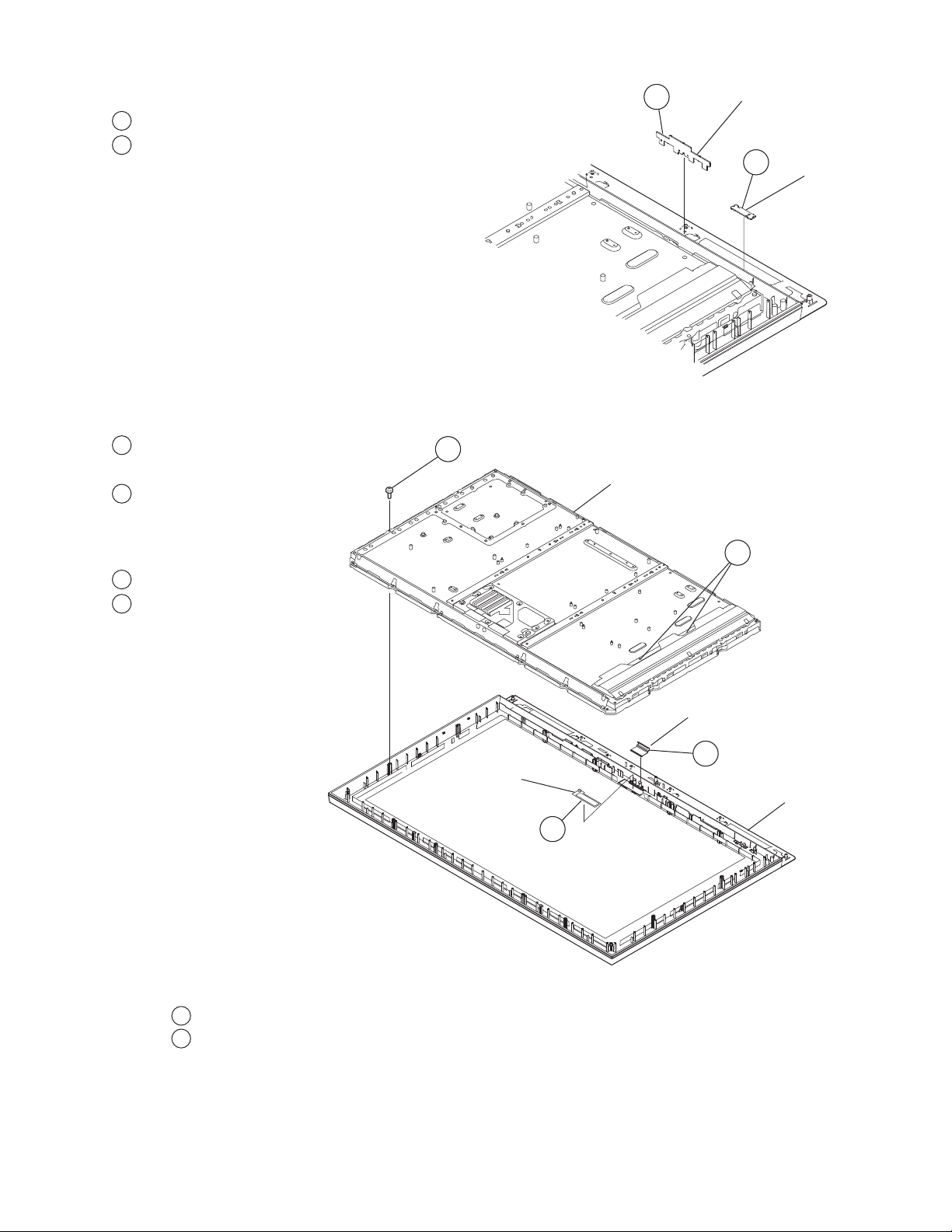

4-2. Chassis (KDL-40XBR6/46XBR6 Only) ................................. 64

4-3. Chassis (KDL-52XBR6 Only) ............................................... 65

4-4. Connectors (KDL-40XBR6/46XBR6 Only) ........................... 66

4-5. Connectors (KDL-52XBR6 Only) ......................................... 67

4-6. Bezel Assembly and LCD Panel

(KDL-40XBR6/46XBR6 Only) .............................................. 68

4-7. Bezel Assembly and LCD Panel (KDL-52XBR6 Only) ......... 69

4-5. Screw Legend ...................................................................... 70

KDL-40XBR6/46XBR6/52XBR6

SECTION 5: ELECTRICAL PARTS LIST ............................................ 71

APPENDIX A: ENCRYPTION KEY COMPONENTS ..........................A-1

3

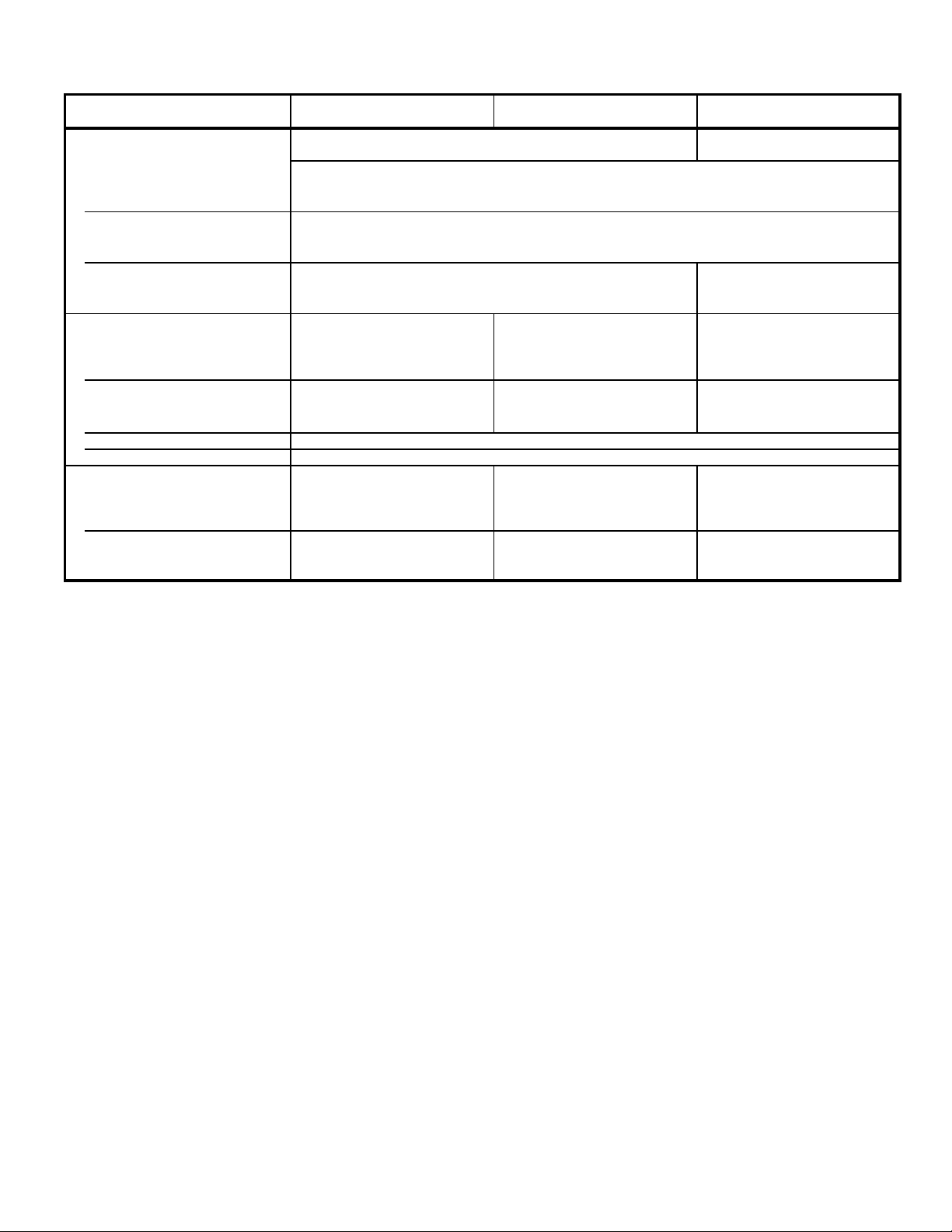

SPECIFICATIONS

KDL-40XBR6/46XBR6/52XBR6

Power Requirements

Power Consumption (W)

In Use (Max)

In Standby

120V AC, 60Hz

225W (KDL-40XBR6 Only)

285W (KDL-46XBR6 Only)

295W (KDL-52XBR6 Only)

Less than 0.2W

VIDEO (IN) 1/2/3:

S Video (4-Pin Mini DIN (VIDEO 1 Only)

Y: 1.0 Vp-p, 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

Video

1.0 Vp-p, 75 ohms unbalanced, sync negative

Audio

500 mVrms (Typical)

Impedance:47 kilohms

COMPONENT IN 1/2:

YP

(Component Video)

BPR

Y:1.0 Vp-p, 75 ohms unbalanced, sync negative

PB:0.7 Vp-p, 75 ohms

PR:0.7 Vp-p, 75 ohms

Signal format: 480i, 480p, 720p, 1080i, 1080p

AUDIO

500 mVrms (Typical)

Impedance: 47 kilohms

HDMI IN 1/2/3/4:

HDMI: Video: 480i, 480p, 720p, 1080i,1080p, 1080/24p

Audio: Two channel linear PCM 32, 44.1 and

48 kHz, 16, 20 and 24 bits, Dolby Digital

AUDIO (for HDMI IN 4):

500 mVrms (Typical) (Fixed)

Impedance: 47 kilohms

AUDIO OUT:

500 mVrms (Typical)

DIGITAL AUDIO OUT (OPTICAL):

PCM/Dolby Digital optical signal

PC IN:

D-sub 15-pin, analog RGB, 0.7 Vp-p, 75 ohms, positive

PC AUDIO INPUT:

Stereo mini jack, 500 mVrms (Typical)

Impedance: 47 kilohms

LAN (10/100):

10 BASE-T/100 BASE-TX Connector

DMPORT:

VIDEO: 1.0 Vp-p, 75 ohms unbalanced, sync negative

AUDIO: 500 mVrms (Typical)/Impedance: 47 kilohms

USB:

Hi-Speed USB

,ICENSING)NFORMATION

-ACINTOSHISATRADEMARKOF!PPLE)NC

REGISTEREDINTHE53ANDOTHERCOUNTRIES

($-)THE($-)LOGOAND(IGH$EFINITION

-ULTIMEDIA)NTERFACEARETRADEMARKSOR

REGISTEREDTRADEMARKSOF($-),ICENSING

,,#

&ERGASON0ATENT0ROPERTIES,,#

530ATENT.O

530ATENT.O

-ANUFACTUREDUNDERLICENSEFROM$OLBY

,ABORATORIES$OLBYANDTHEDOUBLE$SYMBOL

ARETRADEMARKSOF$OLBY,ABORATORIES

)NTHE5NITED3TATES46'UIDEANDOTHER

RELATEDMARKSAREREGISTEREDMARKSOF

'EMSTAR46'UIDE)NTERNATIONAL)NCANDOR

ONEOFITSAFFILIATES)N#ANADA46'UIDEISA

REGISTEREDMARKOF4RANSCONTINENTAL)NCANDIS

USEDUNDERLICENSEBY'EMSTAR46'UIDE

)NTERNATIONAL)NC

4HE46'UIDE/N3CREENSYSTEMIS

MANUFACTUREDUNDERLICENSEFROM'EMSTAR46

'UIDE)NTERNATIONAL)NCANDORONEOFITS

AFFILIATES

4HE46'UIDE/N3CREENSYSTEMISPROTECTED

BYONEORMOREOFTHEFOLLOWING5NITED3TATES

PATENTS

TO

'EMSTAR46'UIDE)NTERNATIONAL)NCANDOR

ITSSUBSIDIARIES

'EMSTAR46'UIDE)NTERNATIONAL)NCANDORITS

RELATEDAFFILIATESARENOTINANYWAYLIABLEFOR

THEACCURACYORAVAILABILITYOFTHEPROGRAM

SCHEDULEINFORMATIONOROTHERDATAINTHE46

'UIDE/N3CREENSYSTEMANDCANNOTGUARANTEE

SERVICEAVAILABILITYINYOURAREA)NNOEVENT

SHALL'EMSTAR46'UIDE)NTERNATIONAL)NC

ANDORITSRELATEDAFFILIATESBELIABLEFORANY

DAMAGESINCONNECTIONWITHTHEACCURACYOR

AVAILABILITYOFTHEPROGRAMSCHEDULE

INFORMATIONOROTHERDATAINTHE46'UIDE/N

3CREENSYSTEM

"LURAY$ISCISATRADEMARK

h"2!6)!vAND 3&ORCE

-OTIONFLOW"2!6)!3YNC $-E

-)#2/6!5,4ANDhXV#OLORvARE

TRADEMARKSORREGISTEREDMARKSOF3ONY

#ORPORATION

h8ROSS-EDIA"ARvISATRADEMARKOF3ONY

#ORPORATIONh8-"vISATRADEMARKOF3ONY

#ORPORATIONAND3ONY#OMPUTER

%NTERTAINMENT)NC

h0,!934!4)/.vISAREGISTEREDTRADEMARK

ANDh03vISATRADEMARKOF3ONY#OMPUTER

%NTERTAINMENT)NC

!DOBEISAREGISTEREDTRADEMARKORATRADEMARK

OF!DOBE3YSTEMS)NCORPORATEDIN5NITED

3TATESANDOROTHERCOUNTRIES

®

$,.!

THE$,.!,OGOAND$,.!

#%24)&)%$ARETRADEMARKSSERVICEMARKS

ORCERTIFICATIONMARKSOFTHE$IGITAL,IVING

.ETWORK!LLIANCE

X

KDL-40XBR6/46XBR6/52XBR6

Design and specifi cations are subject to change without notice.

4

r

5/8

7/8

1/8

1/8

1/2

1/2

5/8

Speaker Output

Speaker/Front (2)

Tweater (2)

Assist Woofe

Dimensions (W x H x D)

with stand

without stand

wall-mount hole pattern (mm)

wall-mount screw size (mm)

Mass

with stand

without stand

KDL-40XBR6/46XBR6/52XBR6

KDL-52XBR6KDL-46XBR6KDL-40XBR6

8W(L)+8W(R)+11W (Assist Woofer)

mm

in

mm

in

mm 55 x 120

in

50 x 100

2 x 4

34 x 104

3/8

1

x 4

30

1/8

1

x 1

1/8

mm 983 x 684 x 279 mm 1,089 x 765 x 307 mm 1,257 x 874 x 346 mm

37

in

mm 953 x 645 x 103 mm 1,089 x 723 x 104 mm 1,257 x 831 x 127 mm

in

x 27 x 11 in 42

5/8

1/2

37

x 25

1/8

x 4

in 42

7/8

x 30

x 28

x 12

in 49

1/2

1/8

x 4

in 49

300 x 300 mm

M6 X 8 -12

kg 23.5 kg 28 kg 42.5 kg

lbs 52 lbs 62 lbs 94 lbs

kg 20 kg 23.5 kg 35.5 kg

lbs 45 lbs 52 lbs 79 lbs

10W(L)+10W(R)+15W

(Assist Woofer)

1/8

3/4

2

x 4

x 34

x 13

in

1/2

3/4

x 32

x 5 in

All measurements are approximations.

Television system

NTSC American TV Standard

ATSC (8VSB terrestrial) ATSC compliant 8VSB

QAM on cable ANSI/SCTE 07 2000

Channel coverage

Analog

2-69 Terrestrial

1-135 Cable

Digital

2-69 Terrestrial

1-135 Cable

Antenna

75-ohm external terminal for RF inputs

Panel System

LCD (Liquid Crystal Display) Panel

Display Resolution (horizontal x vertical)

1,920 dots x 1,080 lines

Screen Size (measured diagonally)

approx. 40 inches (KDL-40XBR6 Only)

approx. 46 inches (KDL-46XBR6 Only)

approx. 52 inches (KDL-52XBR6 Only)

Supplied Accessories

Remote Commander RM-YD024

Two Size AA (R6) Batteries

AC Power Cord

Cable Holder (1 attached to the TV)

Operating Instructions

Quick Setup Guide

Warranty Card

Safety and Regulatory Booklet

Attaching the Table-Top Stand (KDL-40XBR6/46XBR6 Only)

Screws (4) (KDL-40XBR6/46XBR6 Only)

Optional Accessories

Connecting Cables

Suport Belt Kit

Colour Variation Unit

Wall-Mount Bracket

SU-WL500

TV-Stand

WS-S10LS

SU-FL71M (KDL-40XBR6/46XBR6 Only)

KDL-40XBR6/46XBR6/52XBR6

5

KDL-40XBR6/46XBR6/52XBR6

E

WARNINGS AND CAUTIONS - ENGLISH

CAUTION

These servicing instructions are for use by qualifi ed service personnel only. To reduce the risk of electric shock, do not perform any servicing other

than that contained in the operating instructions unless you are qualifi ed to do so.

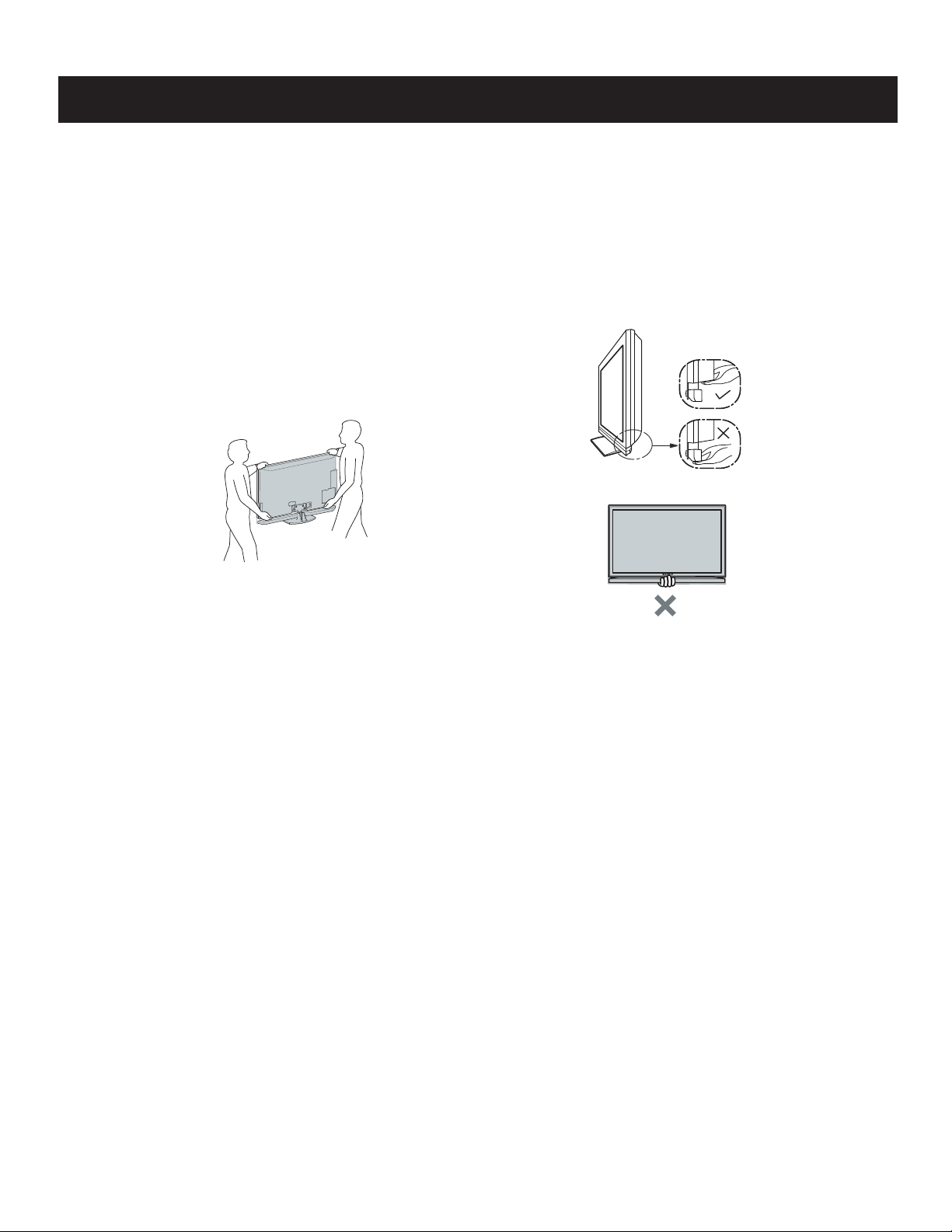

CARRYING THE TV

"ESURETOFOLLOWTHESEGUIDELINESTOPROTECTYOUR

PROPERTYANDAVOIDCAUSINGSERIOUSINJURY

s "EFORECARRYINGTHE46DISCONNECTALLCABLES

s #ARRYINGTHELARGESIZE46REQUIRESTWOORMORE

PEOPLE

s 7HENCARRYINGTHE46PLACEYOURHANDAS

ILLUSTRATEDANDHOLDITSECURELY$ONOTSUBJECTTHE

46TOSHOCKSVIBRATIONOREXCESSIVEFORCE

s ,IFTTHE46BYPLACINGYOURPALMDIRECTLY

UNDERNEATHTHEPANELBUTDONOTPUTSTRESSONTH

,#$PANEL

s $ONOTLIFTTHE46FROMTHEBOTTOMCENTER

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of this receiver is

directly connected to the ac power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe operation. Replace

these components with Sony parts whose part numbers appear as shown in this manual or in supplements published by Sony. Circuit adjustments that

are critical for safe operation are identifi ed in this manual. Follow these procedures whenever critical components are replaced or improper operation is

suspected.

KDL-40XBR6/46XBR6/52XBR6

6

KDL-40XBR6/46XBR6/52XBR6

A

WARNINGS AND CAUTIONS - FRENCH

ATTENTION!!

Ces instructions de service sont à l’usage du personnel de service qualifi é seulement. Pour prévenir le risque de choc électrique, ne pas faire

l’entretien autre que celui contenu dans le Mode d’emploi à moins que vous soyez qualifi é faire ainsi.

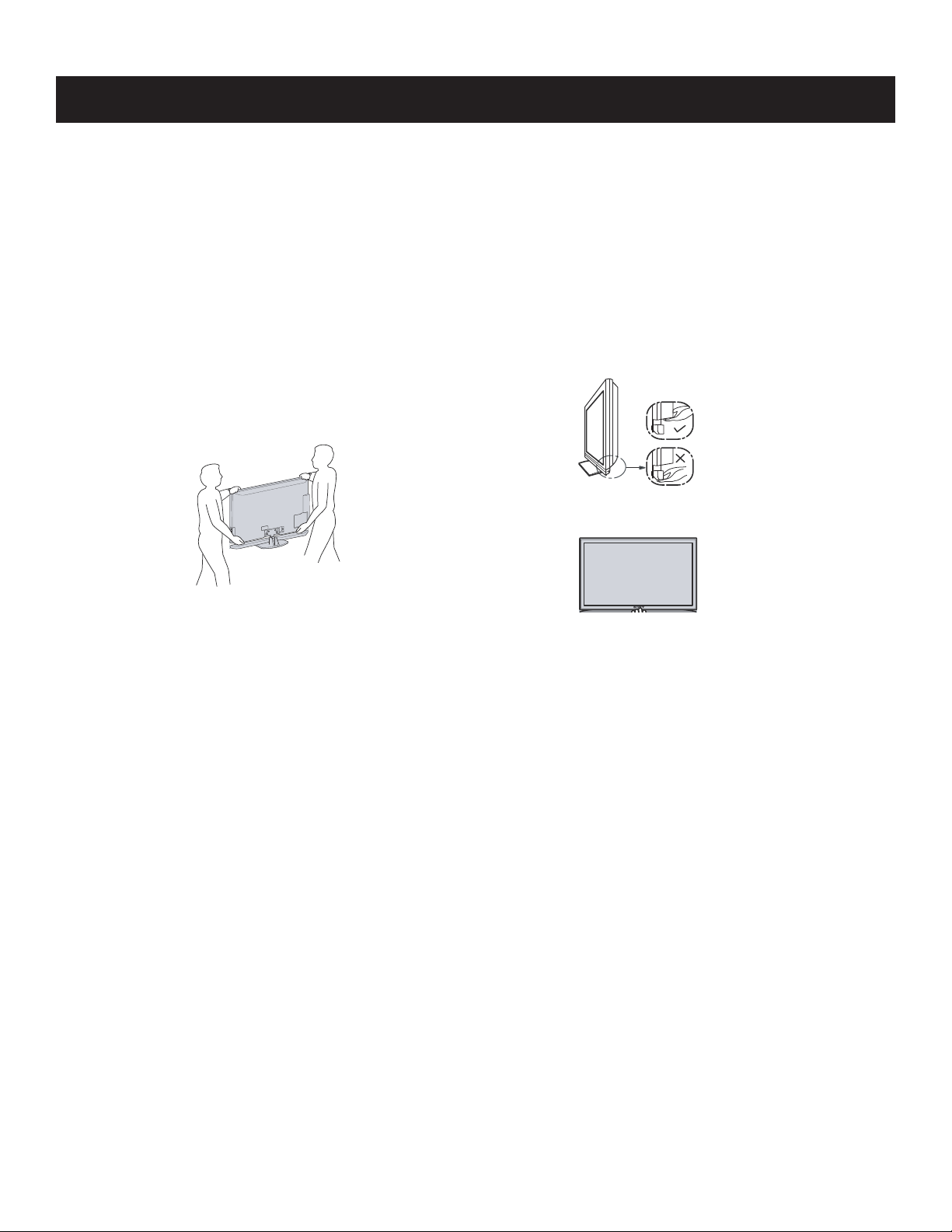

POUR TRANSPORTER LE TÉLÉVISEUR

ssurez-vous de suivre les consignes suivantes pour

protéger votre bien et éviter les blessures graves.

• Avant de transporter le téléviseur, débranchez

tous les câbles.

• Le transport d’un téléviseur de grande taille doit

être effectué par au moins deux personnes.

• Lorsque vous transportez le téléviseur, placez vos

mains tel qu’illustré et tenez solidement

l’appareil. Ne soumettez pas le téléviseur à des

chocs ou à des vibrations, ni à une force excessive.

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout dépannage. Le

chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

• Soulevez le téléviseur en plaçant la paume de votre

main directement en dessous du panneau, mais :

• n’appuyez pas sur la région de la grille de

haut-parleur

• ne placez pas vos doigts dans le sillon audessus de la région de la grille de haut-parleur

• n’imposez pas de charge sur le panneau ACL.

• ne soulevez pas le téléviseur en plaçant vos

mains en dessous au centre.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque ! sur les schemas de principe, les vues explosees et les listes de pieces sont d’une

importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants Sony dont le numero de piece est indique dans le

present manuel ou dans des supplements publies par Sony. Les reglages de circuit dont l’importance est critique pour la securite du fonctionnement

sont identifi es dans le present manuel. Suivre ces procedures lors de chaque remplacement de composants critiques, ou lorsqu’un mauvais

fonctionnement suspecte.

KDL-40XBR6/46XBR6/52XBR6

7

SAFETY-RELATED COMPONENT WARNING

KDL-40XBR6/46XBR6/52XBR6

There are critical components used in LCD color TVs that are important for safety. These components are identifi ed with shading and

mark on the schematic diagrams and the electrical parts list. It is essential that these critical parts be replaced only with the part number

specifi ed in the electrical parts list to prevent electric shock, fi re, or other hazard.

NOTE: Do not modify the original design without obtaining written permission from the manufacturer or you will void the original parts and

labor guarantee.

!

USE CAUTION WHEN HANDLING THE LCD PANEL

When repairing the LCD panel, be sure you are grounded by using a wrist band.

When installing the LCD panel on a wall, the LCD panel must be secured using the 4 mounting holes on the rear cover.

To avoid damaging the LCD panel:

do not press on the panel or frame edge to avoid the risk of electric shock.

do not scratch or press on the panel with any sharp objects.

do not leave the module in high temperatures or in areas of high humidity for an extended period of time.

do not expose the LCD panel to direct sunlight.

avoid contact with water. It may cause a short circuit within the module.

disconnect the AC adapter when replacing the backlight (CCFL) or inverter circuit.

(High voltage occurs at the inverter circuit at 650Vrms.)

always clean the LCD panel with a soft cloth material.

use care when handling the wires or connectors of the inverter circuit. Damaging the wires may cause a short.

protect the panel from ESD to avoid damaging the electronic circuit (C-MOS).

LEAKAGE CURRENT HOT CHECK CIRCUIT

KDL-40XBR6/46XBR6/52XBR6

8

The circuit boards used in these models have been processed using

Lead Free Solder. The boards are identified by the LF logo located

close to the board designation e.g. H1 etc [ see example ]. The

servicing of these boards requires special precautions to be taken as

outlined below.

KDL-40XBR6/46XBR6/52XBR6

example 1

It is strongly recommended to use Lead Free Solder material in order to guarantee optimal quality of new solder joints.

Lead Free Solder is available under the following part numbers :

rebmuntraP retemaiD skrameR

91-500-046-7mm3.0gK52.0

02-500-046-7mm4.0gK05.0

12-500-046-7mm5.0gK05.0

22-500-046-7mm6.0gK52.0

32-500-046-7mm8.0gK00.1

42-500-046-7mm0.1gK00.1

52-500-046-7mm2.1gK00.1

62-500-046-7mm6.1gK00.1

Due to the higher melting point of Lead Free Solder the soldering iron tip temperature needs to be set to 370 degrees centigrade.

This requires soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

For more information on the use of Lead Free Solder, please refer to

http://www.sony-training.com

KDL-40XBR6/46XBR6/52XBR6

9

SAFETY CHECK-OUT

KDL-40XBR6/46XBR6/52XBR6

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the antenna terminals, metal trim, “metallized” knobs, screws,

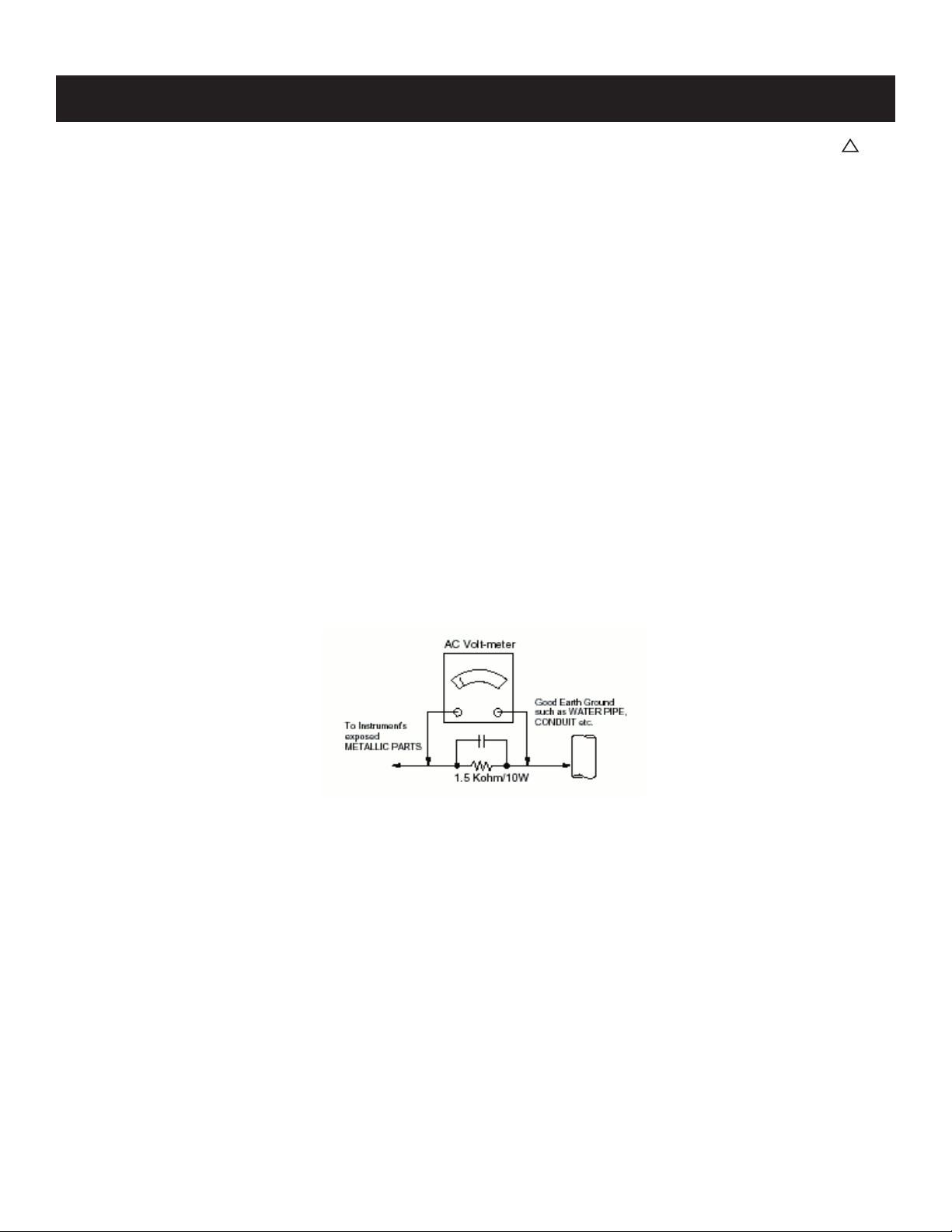

and all other exposed metal parts for AC leakage. Check leakage as

described below.

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of

passive VOMs that are suitable. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable (see Figure A).

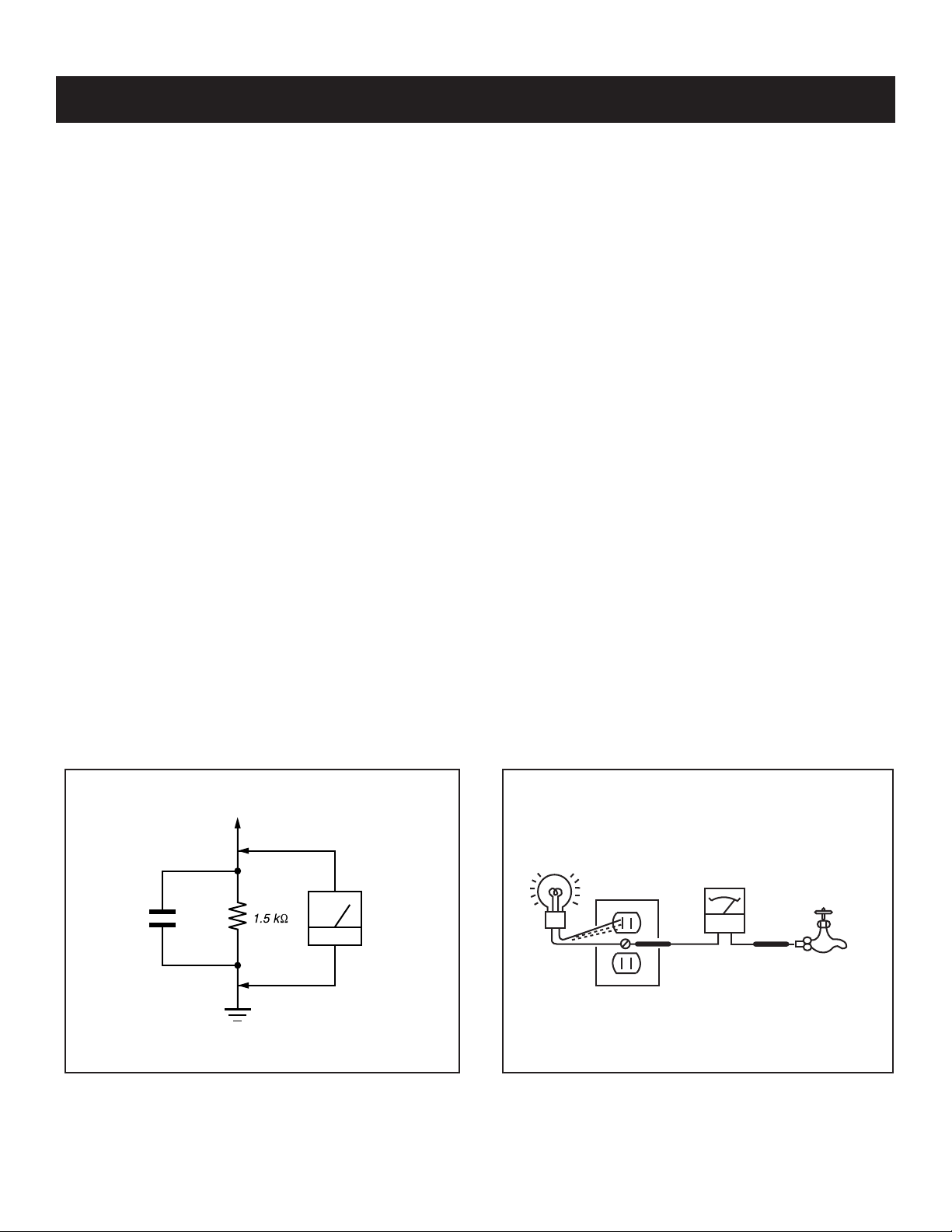

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground. If the

retaining screw is to be used as your earth ground, verify that it is at

ground by measuring the resistance between it and a cold-water pipe

with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt

trouble- light (not a neon lamp) between the hot side of the receptacle

and the retaining screw. Try both slots, if necessary, to locate the hot

side on the line; the lamp should light at normal brilliance if the screw

is at ground potential (see Figure B).

Leakage Test

0.15 F

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

To Exposed Metal

Parts on Set

Earth Ground

AC

Voltmeter

(0.75V)

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

KDL-40XBR6/46XBR6/52XBR6

10

KDL-40XBR6/46XBR6/52XBR6

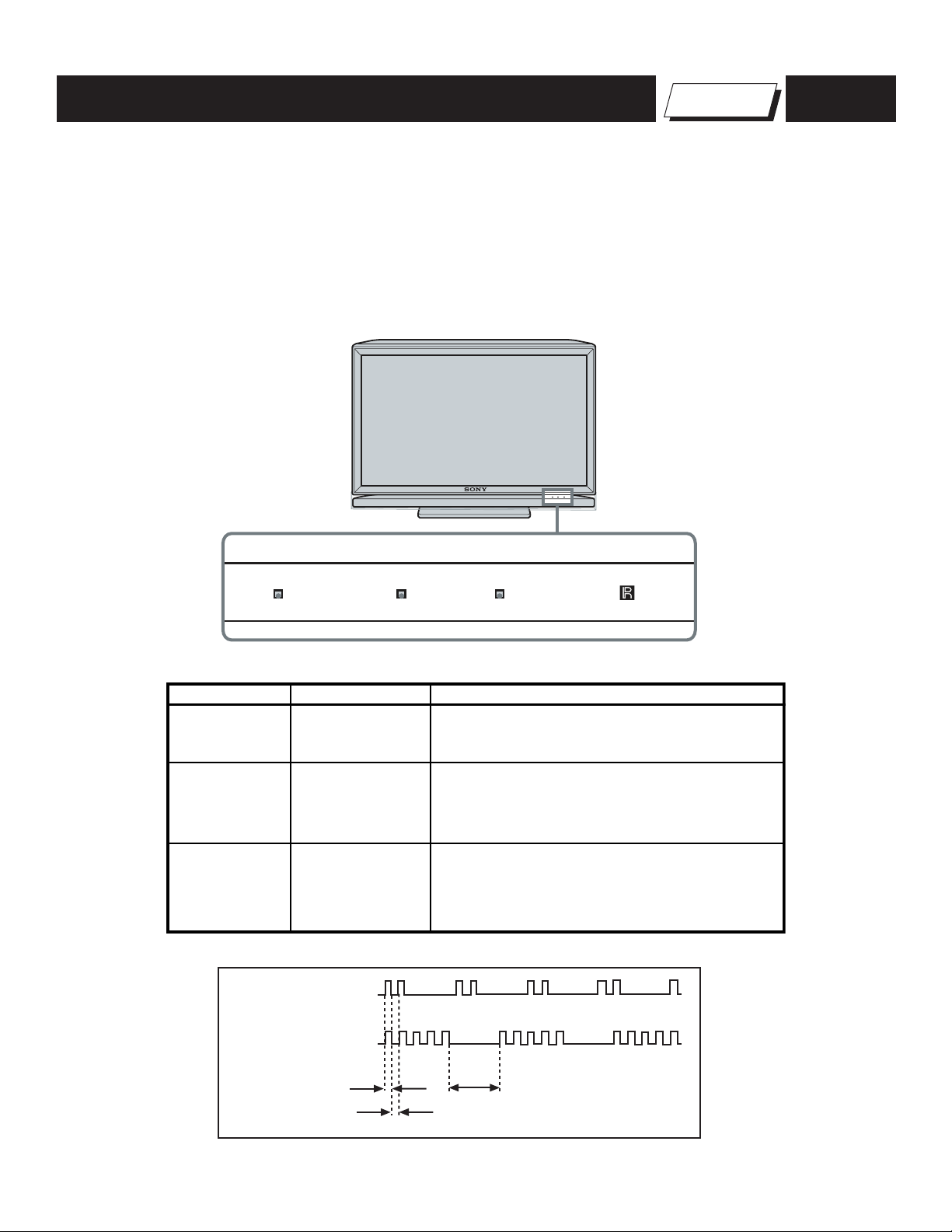

SELF-DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY LED indicator will automatically begin to fl ash. The number

of times the LED fl ashes translates to a probable source of the problem. A defi nition of the STANDBY LED fl ash indicators is listed in the instruction

manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote Commander can be used to review the failure

occurrence data stored in memory to reveal past problems and how often these problems occur.

1. Diagnostic Test Indicators

When an error occurs, the STANDBY LED indicator will fl ash a set number of times to indicate the possible cause of the problem. If there is more than

one error, the indicator will identify the fi rst of the problem areas.

Control Buttons

Self Diagnosis

Supported model

Description of LED Indictors

LED LED Type Description

POWER LED

STANDBY LED

PIC OFF/

TIMER

LED

0)#/&&4)-%2 34!.$"9

Green LED

Red LED

* Lights up in green when the TV set is turned on.

* Lights up in red when TV is in PC standby mode.

* If LED blinks continuously, this may indicate

that the TV needs servicing.

Green or Orange

LED

* Lights up in green when Picture Off is activated.

* Lights up in orange when the timer is set.

When timer is set, this LED remains lit even

when the TV is turned off.

2 times

5 times

0/7%2

LED ON 0.3 sec.

LED OFF 0.3 sec.

KDL-40XBR6/46XBR6/52XBR6

LED OFF

3 sec.

11

KDL-40XBR6/46XBR6/52XBR6

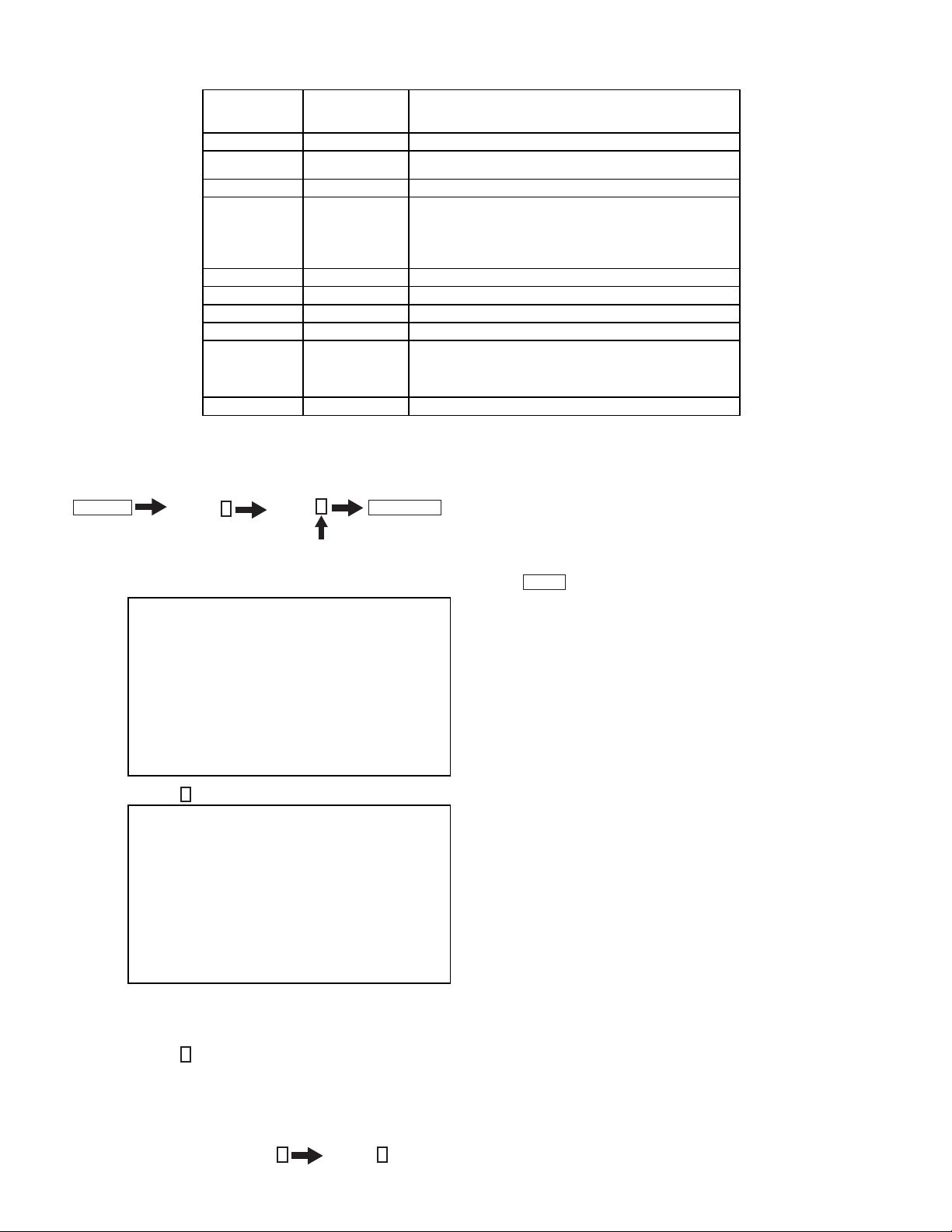

LED Indicators

Diagnostic Item

Description

Main Power 2 times Power Supply Board

DC Alert 3 times

Panel Alert 5 times LCD Panel

Backlight 6 times

Temp 7 times Main Board

SP Prot 8 times Main Board

Trident IC 11 times Main Board

TCON Error 12 times LCD Panel

Backlight Balance 13 times

HFR Error 14 times LCD Panel

Number of times

STANDBY lamp

flashes

Possible Location

Main Board

Power Supply Board

Main Board

Power Supply Board

Inverter Boards (D3, D4, or D5)

Balancer Boards (ETC-Inverter MT on LCD panel) 40" & 46" Only

LCD Panel

Inverter Boards (D4 & D5) 52" Only

Balancer Boards (ETC-Inverter MT on LCD panel) 40" & 46" Only

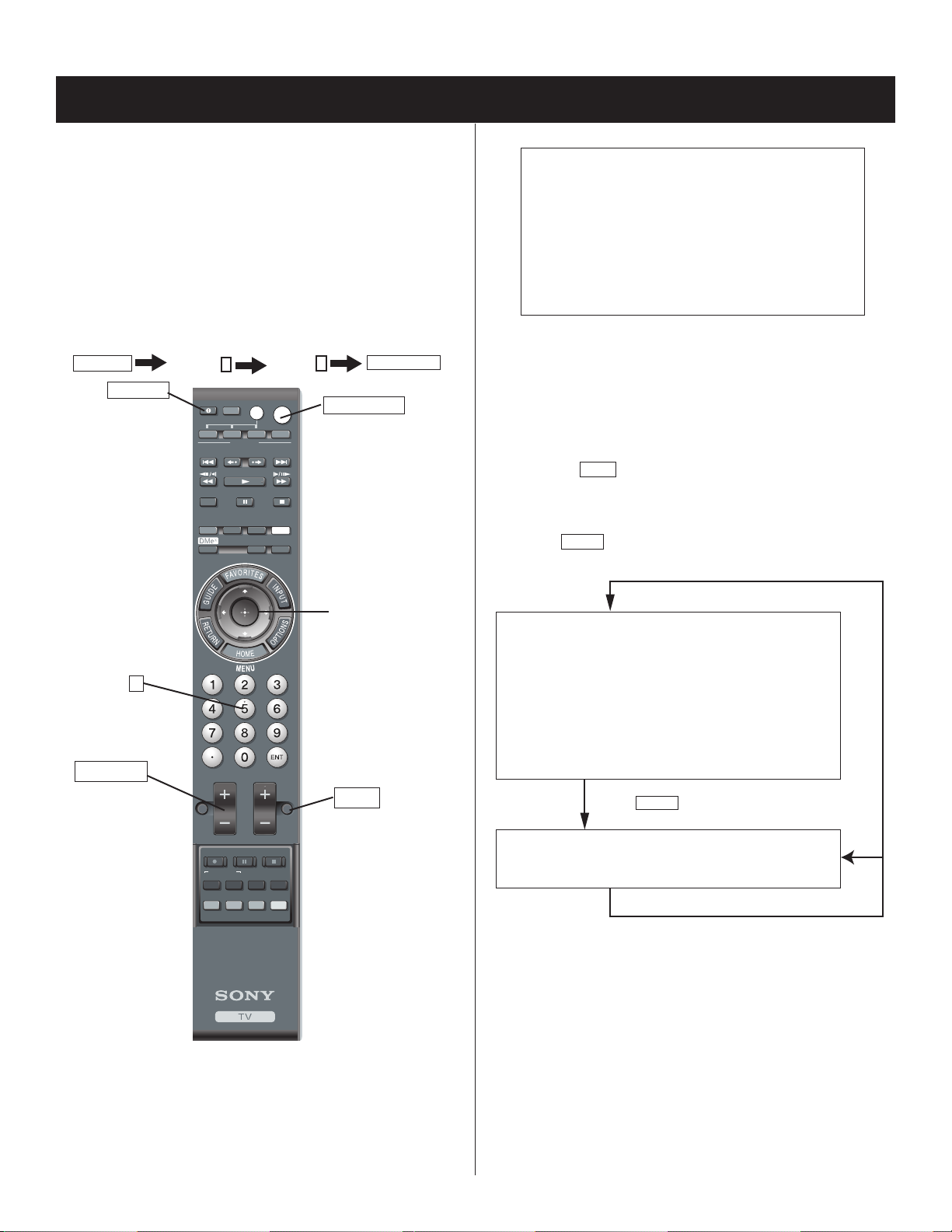

Viewing the Self Check Diagnostic List

1. TV must be in standby mode. (Power off).

2. Press the following buttons on the Remote Commander within a second of each other:

DISPLAY

Channel 5 Volume -

TV POWER

.

The Self Check list displays. This differs from accessing Service Adjustments.

Results for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

NOTE: If the Service Menu display text is not completely visible, press the Menu

button on the Remote Commander to refresh the display.

HOME

SELF CHECK PAGE 1

002 MAIN_POWER 01

003 DC_ALERT1 00

Í 1 indicates an error was detected

Í 0 indicates no error was detected

005 PANEL_ALERT 00

006 BACKLIGHT 00

013 BACKLIGHT_BALANCE 00

00001 00027 00009 00000

3. Press the Channel 1 button on the Remote Commander to go to Page 2 of the Self Check list.

SELF CHECK PAGE 2

007 TEMP 00

008 SP_PROT 00

011 TRIDENT_IC 00

012 HFR_ERROR 00

Í Displays as 12 Blinks, but is actually 14 Blinks

012 TCON_ERROR 00

00001 00027 00009 00000

ÏÏ Total Panel Hours

Ï

Ï Total Hours of Operation

Ï

Ï Boot Count

4. Press the Channel

5. To exit Self Check display, turn the power off.

4

button on the Remote Commander to go back to Page 1 of the Self Check list.

Clearing the Self Check Diagnostic List

1. In Service Mode, press the Channel 8 Channel 0.

KDL-40XBR6/46XBR6/52XBR6

12

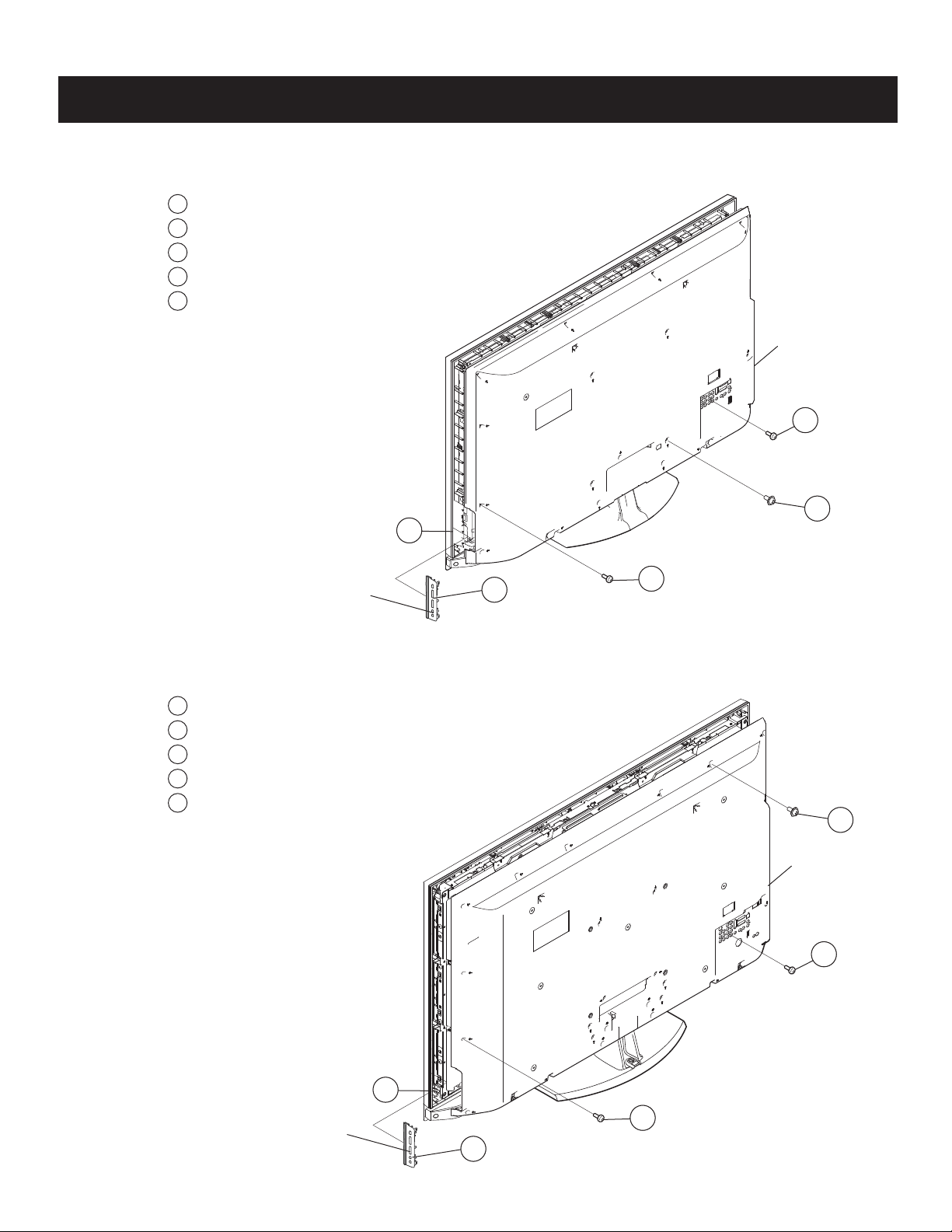

SECTION 1: DISASSEMBLY

1-1. REAR COVER AND SWITCH UNIT (CONTAINS H1 BOARD) REMOVAL

1-1-1. KDL-40XBR6/46XBR6 ONLY

1

Remove 1 Screw from Terminal Position

2

Remove 4 Screws from Vesa Positions

3

Remove 15 Screws

4

Slide out Switch Unit from Front Cabinet

5

Disconnect 1 Connector

KDL-40XBR6/46XBR6/52XBR6

Rear Cover

1

Switch Unit

(Contains H1 Board)

1-1-2. KDL-52XBR6 ONLY

1

Remove 1 Screw from Terminal Position

2

Remove 4 Screws from Vesa Positions and 4 Screws from Top Bracket Positions

3

Remove 15 Screws

4

Slide out Switch Unit from Front Cabinet

5

Disconnect 1 Connector

2

4

5

3

2

Rear Cover

1

Switch Unit

(Contains H1 Board)

KDL-40XBR6/46XBR6/52XBR6

4

3

5

13

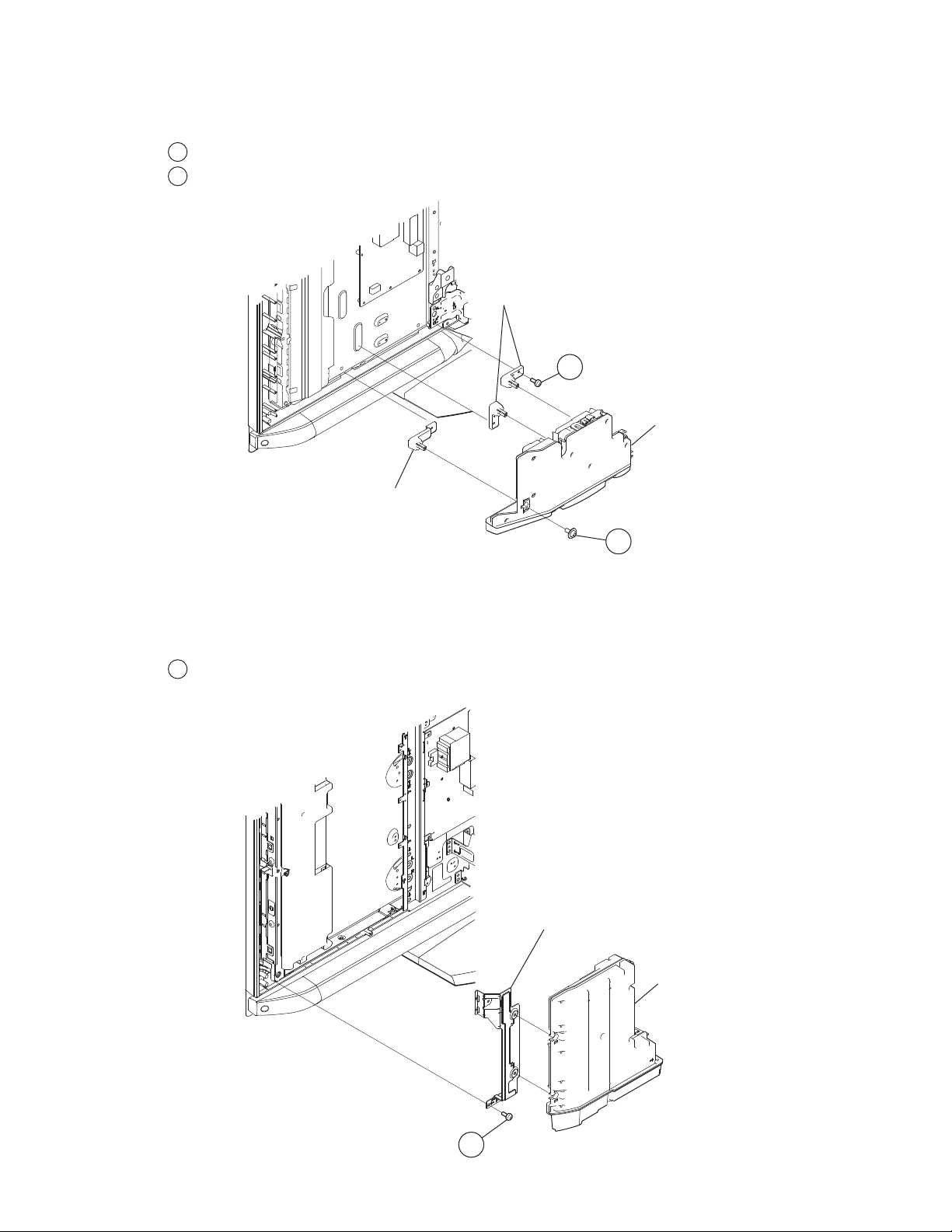

1-2. WOOFER BOX REMOVAL

1-2-1. KDL-40XBR6/46XBR6 ONLY

1

Remove 3 Screws from Woofer Box

2

Remove 3 Screws from Holders and Bracket

KDL-40XBR6/46XBR6/52XBR6

Woofer Holder

2

Woofer Box

1-2-2. KDL-52XBR ONLY

1

Remove 2 Screws from Woofer Box and 1 Screw from Bracket

Woofer Bracket

1

Woofer Bracket

KDL-40XBR6/46XBR6/52XBR6

Woofer Box

1

14

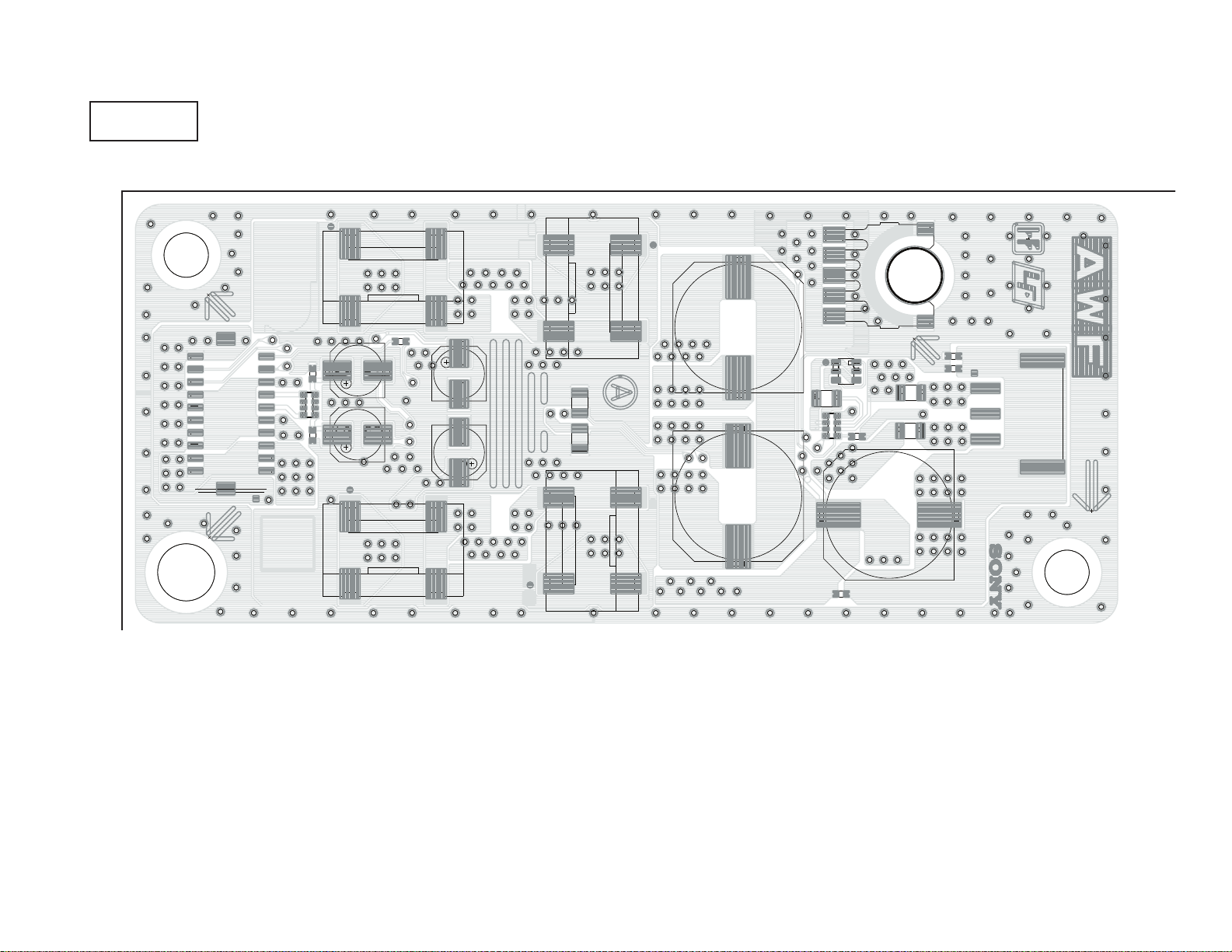

1-3. AWF BOARD, BU BOARD, G BOARD AND D BOARD REMOVAL

1-3-1. KDL-40XBR6/46XBR6 ONLY

1

Disconnect 6 Connectors and remove 9 Screws from BU Board

2

Disconnect 2 Connectors and remove 2 Screws from AWF Board

3

Disconnect 8 Connectors and remove 6 Screws from G6 Board

4

Disconnect 4 Connectors and remove 6 Screws from D3 Board

2

KDL-40XBR6/46XBR6/52XBR6

1

Side Jack Bracket

BU Board

AWF Board

G Bracket

1-3-2. KDL-52XBR6 ONLY

1

Disconnect 3 Connectors and remove 4 Screws from D5 Board

2

Disconnect 6 Connectors and remove 9 Screws from BU Board

3

Disconnect 2 Connectors and remove 2 Screws from AWF Board

4

Disconnect 5 Connectors and remove 6 Screws from G5 Board

5

Disconnect 4 Connectors and remove 4 Screws from D4 Board

D3 Board

4

3

3

AWF Board

G6 Board

1

D5 Board

2

Side Jack Bracket

BU Board

G Bracket

KDL-40XBR6/46XBR6/52XBR6

4

5

D4 Board

G5 Board

15

1-4. TABLE-TOP STAND AND UNDER COVER REMOVAL

1

Remove 4 Screws

2

Remove 1 Screw

1

2

KDL-40XBR6/46XBR6/52XBR6

Table-Top Stand Assembly

Under Cover

KDL-40XBR6/46XBR6/52XBR6

16

1-5. STRUCTURAL FRAMES, BRACKETS AND AC INLET REMOVAL

1-5-1. KDL-40XBR6/46XBR6 ONLY

1

Remove 1 Screw from side of Main Bracket

2

Remove 7 Screws from Main Bracket

3

Remove 3 Screws from GL frame

4

Remove 4 Screws from Vesa Brackets

5

Remove 1 Screw from AC Bracket

6

Remove 2 Screws from AC Inlet

7

Remove 7 Screws from Bottom Frame (KDL-40XBR6 ONLY)

Remove 8 Screws from Bottom Frame (KDL-46XBR6 ONLY)

8

Remove 2 Screws from Bottom Frame

9

Remove 3 Screws from G Frame

AC Bracket

1

2

AC Inlet

KDL-40XBR6/46XBR6/52XBR6

5

6

Main Bracket

GL Frame

7

VESA Frame

3

4

9

G Frame

8

Bottom Bracket

KDL-40XBR6/46XBR6/52XBR6

17

1-5-2. KDL-52XBR6 ONLY

1

Remove 1 Screw from D5 Frame

2

Remove 1 Screw from D5 Frame and Main Bracket

3

Remove 3 Screws from Main Bracket

4

Remove 2 Screws from Top Vesa Bracket

5

Remove 1 Screw from G5 Frame

6

Remove 2 Screws from Center Frame

7

Remove 12 Screws from Spine Frames

8

Remove 1 Screw from AC Bracket

9

Remove 2 Screws from AC Inlet

10

Remove 5 Screws from Stand Holder

11

Remove 4 Screws from Bottom Frame

12

Remove 4 Screws from Bottom Vesa Brackets

13

Remove 1 Screw from Bottom Frame

14

Remove 4 Screws from Top Frames

15

Remove 2 Screws from Top Frames

KDL-40XBR6/46XBR6/52XBR6

D5 Frame

1

15

Spine Frame

Main Bracket

2

Top Vesa Bracket

Center

Frame

3

4

7

Bracket

13

AC

5

G Board Support

6

8

AC Inlet

9

Stand Holder

10

11

Bottom Vesa Bracket

12

Bottom Frame

KDL-40XBR6/46XBR6/52XBR6

14

Top Frame

Front Assembly

18

1-6. SPEAKER COVER AND SPEAKER BOX REMOVAL

1

Slide Speaker Cover and remove from Front Assembly

2

Remove 4 Screws (KDL-40XBR6/46XBR6 ONLY)

Remove 6 Screws (KDL-52XBR6 ONLY)

3

Remove 2 Screws

4

Remove 2 Screws from Speaker Joint (KDL-40XBR6 ONLY)

Remove 4 Screws from Speaker Joint (KDL-46XBR6/52XBR6 ONLY)

KDL-40XBR6/46XBR6/52XBR6

2

1

Front Assembly

Speaker Cover Assembly

Speaker Box (L)

3

Speaker Joint (Front)

Speaker Cable Cover

KDL-40XBR6/46XBR6/52XBR6

4

Speaker Joint (Rear)

Speaker Box (R)

19

KDL-40XBR6/46XBR6/52XBR6

1-7. H3R BOARD AND H4R BOARD REMOVAL

1

Disconnect 1 Connector and release H3R Board from Center Cabinet

2

Disconnect 1 Connector and release H4R Board from Center Cabinet

1

1-8. LCD PANEL, ILLUMINATION MODULE AND LOGO HOLDER REMOVAL

1

Remove 2 Screws (KDL-40XBR6/52XBR6 ONLY)

Remove 4 Screws (KDL-46XBR6 ONLY)

2

Disconnect 2 Connectors from inverter board

(KDL-40XBR6/46XBR6 ONLY)

Disconnect 3 Connectors from inverter boards

(KDL-52XBR6 ONLY)

3

Release Logo Holder from Center Cabinet

4

Disconnect 1 Connector and

remove Illumination Module from Center Cabinet

1

LCD Panel

H3R Board

2

H4R Board

2

1-8-1. CLEANING THE LCD PANEL

CAUTION: When cleaning the TV, be sure to unplug the power cord to avoid any chance of electric shock.

1

Clean the cabinet of the TV with a dry soft cloth.

2

Wipe the LCD screen gently with a soft cloth.

Stubborn stains may be removed with a cloth slightly moistened with a solution of mild soap and warm water.

If using a chemically pretreated cloth, please follow the instruction provided on the package.

Never use strong solvents such as a thinner, alcohol or benzine for cleaning.

Periodic vacuuming of the ventilation openings is recommended to ensure to proper ventilation.

Illumination

Module

Logo Holder

3

Front Assembly

4

KDL-40XBR6/46XBR6/52XBR6

20

1-9. INVERTER BOARD REMOVAL

1-9-1. KDL-40XBR6/46XBR6 ONLY

1

Remove 6 Screws from Cover

2

Slide out Inverter Board from Light Sockets

KDL-40XBR6/46XBR6/52XBR6

2

LCD Panel

1

Balancer Board

REMOVE SCREWS

SECURING

SHIELD

Cover

SHIE LD REMOVAL

END VIEW

Light Sockets

REMOVE

CONNECTOR AND

PULL BOARD TO

THE RIGHT

BALANCER (ETC-INVERTER) BOARD REMOVAL

Only remove the screws securing the inverter

cover which may be metal or plastic.

The sockets for the fluorescent backlights should never be

loosened. The backlights will pop out of the

sockets and/or break the backlight requiring a

LCD panel replacement.

KDL-40XBR6/46XBR6/52XBR6

SOCKET

21

1-9-2. KDL-52XBR6 ONLY

1

Remove 7 Screws from both inverter Covers

2

Slide out Inverter Boards from Light Sockets

KDL-40XBR6/46XBR6/52XBR6

Balancer Board

LCD Panel

1

Cover

WARNING

NEVER REMOVE THE

SCREWS SECURING THE

PLASTIC STRIP HOLDING

THE LAMP SOCKETS

DAMAGE TO THE

BACKLIGHT TUBES WILL

OCC UR!

!

2

1

.

REMOVE SCREWS

SHIELD REMOVAL

KDL-40XBR6/46XBR6/52XBR6

SECURING

SHIELD

END VIEW

SOCKET

BACKLIGHT

REMOVE

CONNECTORS AND

PULL BOARDS TO

THE RIGHT

BALANCER (ETC-INVERTER) BOARD REMOVAL

Only remove the screws securing the inverter

cover which may be metal or plastic. The

remaining plastic strip contains sockets for the

fluorescent backlights and should never be

loosened. The backlights will pop out of the

sockets and/or break the backlight requiring a

LCD panel replacement.

22

WIRE DRESSING

DUE TO THE FILE SIZE OF THE WIRE

DRESSING DIAGRAMS, THEY WILL BE

PROVIDED IN A SEPERATE MANUAL

KDL-40XBR6/46XBR6/52XBR6

KDL-40XBR6/46XBR6/52XBR6

23

3

SECTION 2: SERVICE ADJUSTMENTS

2-1. VIEWING SERVICE ADJUSTMENT DATA

There are no adjustments necessary for these models. All data has

been set for optimal viewing for our customers. The following sections

are for informational purposes only.

2-2. ACCESSING SERVICE ADJUSTMENT

MODE

1. TV must be in standby mode. (Power off).

2. Press the following buttons on the Remote Commander within a

second of each other:

DISPLAY

Channel 5 Volume +

DISPLAY

$)30,!9

,)'(4 0/7%2

460/7%2

$6$ !-0 34" 46

&5.#4)/.

02%6 2%0,!9 !$6!.#% .%84

0,!9

9.#-%.5 0!53%

TV POWER

34/0

TV POWER

.

KDL-40XBR6/46XBR6/52XBR6

TVLF CHECK

001 COLOR ADJ

001 R_DRV

DIGITAL PROGRAM

DATA

BE PROGRAM

NVM

PACK

BOOT

Sample TV Service Menu

SERVICE

00100

: H801.03 0070

: S001000

: TM1.000

: TD1.000

: TP1.000

: TB1.000

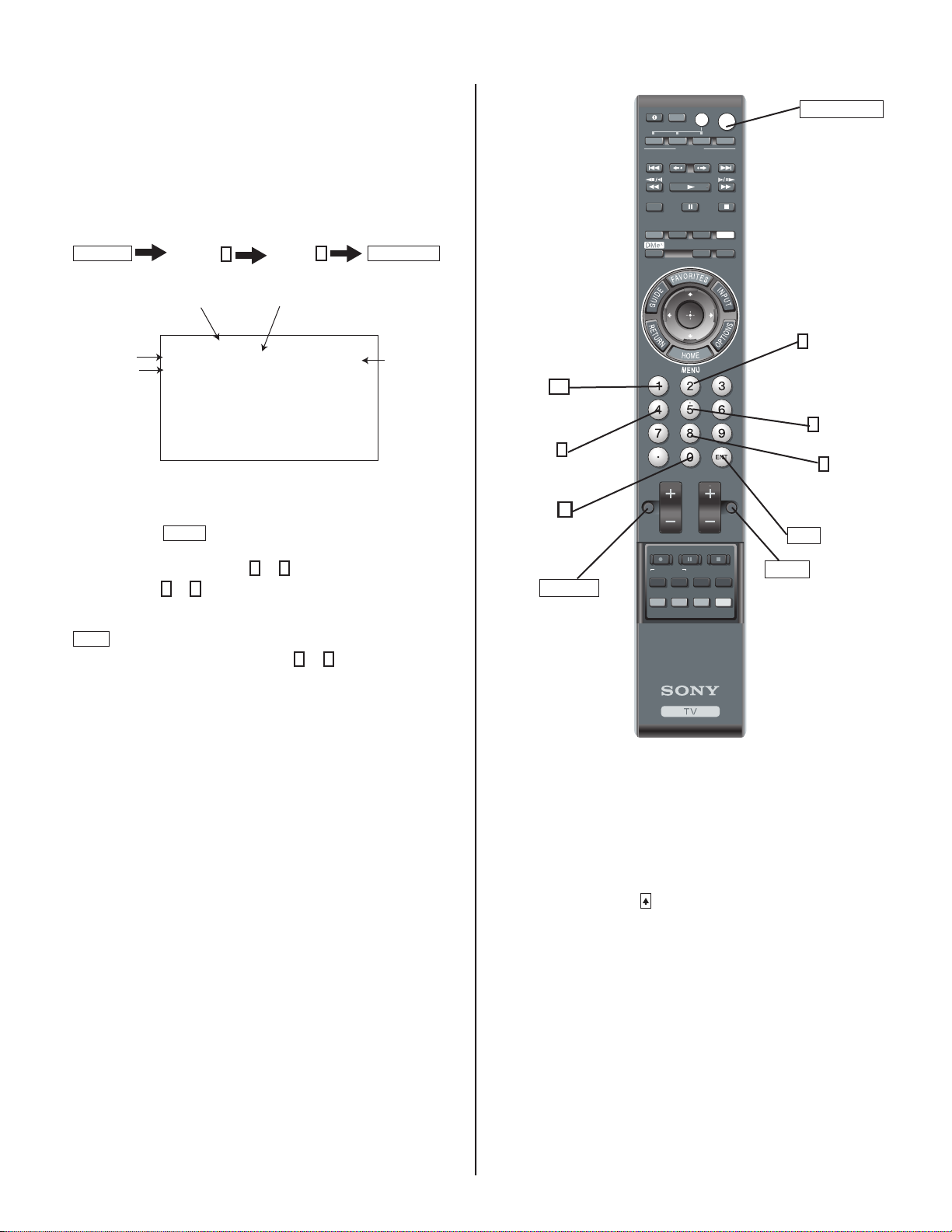

2-3. VIEWING THE SERVICE MENUS

Use the Remote Commander to view the BE and Digital service menus

options.

1. To display the Service Menu that contains the Category you want to

adjust, press

(For a complete list of the service Categories refer to Service Menus)

JUMP

on the Remote Commander.

4(%!4%23/5.$ 0)#452% 7)$%

## &2%%:%

NOTE: If the Service Menu display text is not completely visible, press

the Menu

button on the Remote Commander to refresh the

HOME

display.

Onscreen cursor

and select button

VOLUME+

5

6/, #(

-54).'

2%#

"$$6$

-%.54/0-%.5

2%#0!53% 2%#34/0

*5-0

&&

JUMP

TVLF CHECK

001 COLOR ADJ

00100

001 R_DRV

DIGITAL PROGRAM

DATA

BE PROGRAM

NVM

PACK

BOOT

Press JUMP

: H801.03 0070

: S001000

: TM1.000

: TD1.000

: TP1.000

: TB1.000

QM 0 0

INFO

DTV

Sample Service Menus

SERVICE

SERVICE

RM-YD024

The fi rst service menu (TV) displays.

KDL-40XBR6/46XBR6/52XBR6

24

KDL-40XBR6/46XBR6/52XBR6

2-4. USING THE REMOTE COMMANDER TO

VIEW SERVICE DATA

Use the buttons on the Remote Commander to access the service menu

items and adjust the data values.

1. Access Service Mode.

Press the following buttons on the Remote Commander within a

second of each other:

DISPLAY

Category

Number

Adjustment

Item Number

The screen displays the fi rst category in the selected service menu.

NOTE: If the Service Menu display text is not completely visible,

press the Menu

the display.

2. To change the category, press 2 or 5 on the Remote Commander.

Note: Pressing 2 or 5 only changes the categories within the service

menu displayed.

To change a category on one of the other service menus, press the

JUMP

3. To change the adjustment item, press 1 or 4 on the Remote

Commander.

4. To exit service mode, turn the power off.

Channel 5 Volume +

TV POWER

Adjustment

Category

TVLF CHECK

001 COLOR ADJ

001 R_DRV

DIGITAL PROGRAM

DATA

BE PROGRAM

NVM

PACK

BOOT

button on the Remote Commander to refresh

HOME

Item

SERVICE

00100

: H801.03 0070

: S001000

: TM1.000

: TD1.000

: TP1.000

: TB1.000

Data Value

button until the correct service menu is displayed.

.

Next item

Read data

from last

saved NVM

Previous

item

MUTING

Write into

memory

$)30,!9

,)'(4 0/7%2

460/7%2

$6$ !-0 34" 46

&5.#4)/.

02%6 2%0,!9!$6!.#% .%84

0,!9

39.#-%.5 0!53%

4(%!4%23/5.$ 0)#452% 7)$%

## &2%%:%

34/0

TV POWER

Next

2

Category

1

Previous

5

4

6/, #(

-54).'

Restore User Control

*5-0

and Channel Memory

Category

8

0

ENT

2%#

2%#0!53% 2%#34/0

"$$6$

&&

-%.54/0-%.5

JUMP

Displays

Service

Menus

KDL-40XBR6/46XBR6/52XBR6

RM-YD024

2-5. RESETTING TO FACTORY DEFAULTS

Use the following instructions to restore the User Controls and

Channel Memory settings to the preset factory conditions.

1. While holding down the

POWER button on the Front Panel of the set.

The set restarts and displays the initial setup screen. This may take

several minutes.

on the Remote Commander, press the

25

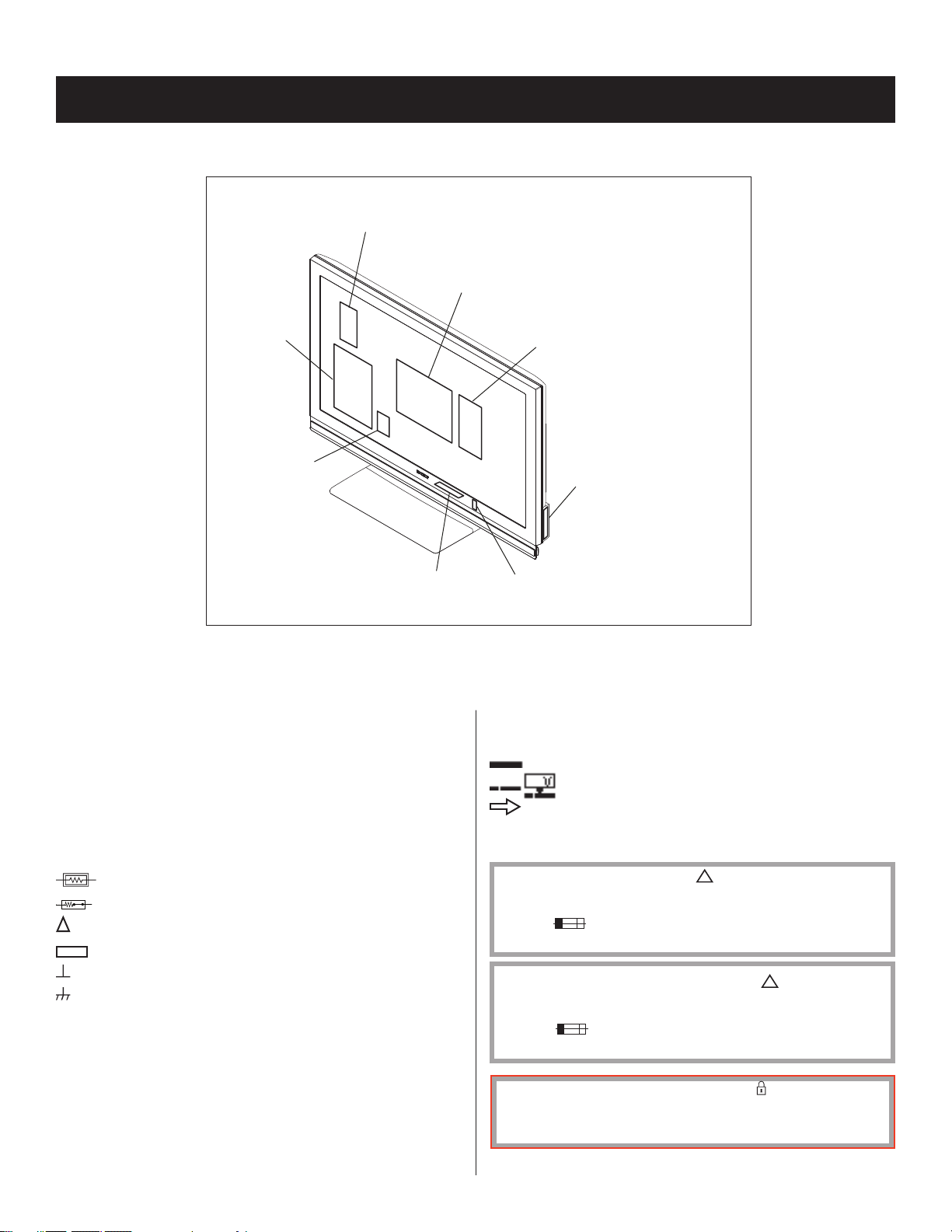

3-1. CIRCUIT BOARDS LOCATION

D5 (KDL-52XBR6 ONLY)

KDL-40XBR6/46XBR6/52XBR6

SECTION 3: DIAGRAMS

G6 (KDL-40/46XBR6 ONLY)

G5 (KDL-52XBR6 ONLY)

BU

D3 (KDL-40/46XBR6 ONLY)

D4 (KDL-52XBR6 ONLY)

AWF

SWITCH UNIT

(Contains H1 Board)

H3R

3-2.

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS INFORMATION

All capacitors are in μF unless otherwise noted. pF : μμF 50WV or

less are not indicated except for electrolytics and tantalums.

All electrolytics are in 50V unless otherwise specifi ed.

All resistors are in ohms. kΩ=1000Ω, MΩ=1000kΩ

Indication of resistance, which does not have one for rating

electrical power, is as follows: Pitch : 5mm

Rating electrical power :

1

/

W in resistance, 1/

4

W and 1/

10

W in chip resistance.

16

1

/

W

4

: nonfl ammable resistor

: fusible resistor

: internal component

: panel designation and adjustment for repair

: earth ground

: earth-chassis

All variable and adjustable resistors have characteristic curve B,

unless otherwise noted.

H4R

All voltages are in V.

S : Measurement impossibility.

: B+line.

: B-line. (Actual measured value may be different).

: signal path. (RF)

Circled numbers are waveform references.

The components identifi ed by shading and ! symbol are critical for safety. Replace

only with part number specifi ed.

The symbol indicates a fast operating fuse and is displayed on the component

side of the board. Replace only with fuse of the same rating as marked.

Les composants identifi es per un trame et une marque

securite. Ne les remplacer que par une piece portant le numero specifi e.

Le symbole indique une fusible a action rapide. Doit etre remplace par une

fusible de meme yaleur, comme maque.

Readings are taken with a color-bar signal input.

Readings are taken with a 10MΩ digital multimeter.

Voltages are DC with respect to ground unless otherwise noted.

Voltage variations may be noted due to normal production

tolerances.

NOTE: The components identifi ed by a red outline and a mark contain confi dential

information. Specifi c instructions must be adhered to whenever these components

are repaired and/or replaced.

See Appendix A: Encryption Key Components in the back of this manual.

!

sont critiques pour la

KDL-40XBR6/46XBR6/52XBR6

26

REFERENCE INFORMATION

RESISTOR

: RN METAL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RW NONFLAMMABLE WIREWOUND

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: ADJUSTMENT RESISTOR

COIL

: LF-8L MICRO INDUCTOR

CAPACITOR

: TA TANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

KDL-40XBR6/46XBR6/52XBR6

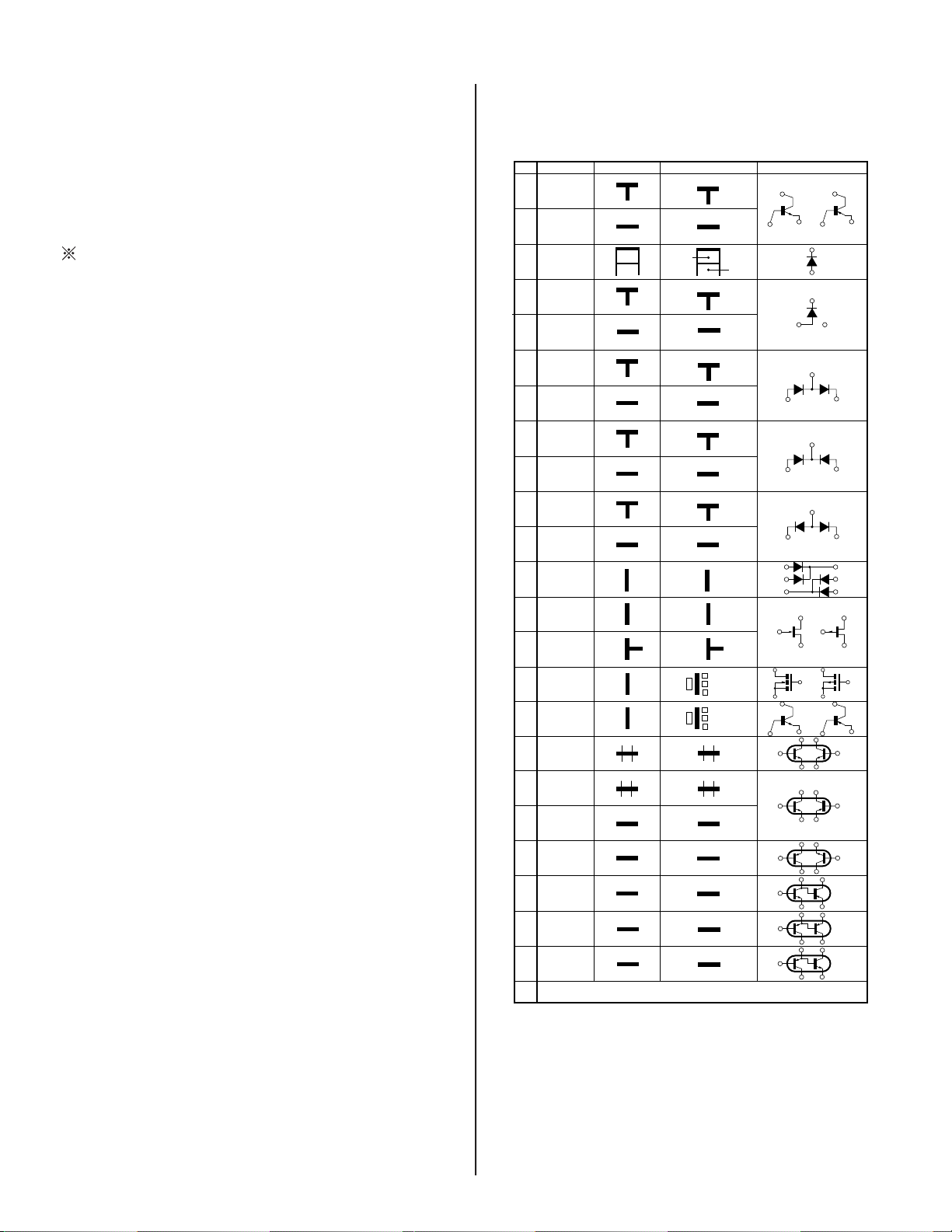

Terminal name of semiconductors in silk screen

printed circuit ( )

Device Printed symbol Terminal name

Transistor

1

Transistor

2

3

Diode

4

Diode

Diode

5

Diode

6

Diode

7

8

Diode

Diode

9

Diode

0

Diode

!¡

Diode

!™

Transistor

!£

(FET)

Transistor

!¢

(FET)

Transistor

!?

(FET)

Transistor

!§

Transistor

!¶

Transistor

!•

Transistor

!ª

Transistor

@º

Transistor

@¡

Transistor

@™

Transistor

@£

Discrete semiconductot

–

(Chip semiconductors that are not actually used are included.)

*

Collector

Base

Collector

Base

Cathode

Cathode

Anode

Cathode

Anode

Common

Anode

Common

Anode Cathode

Common

Anode

Common

Anode Anode

Common

Cathode

Common

Cathode

Anode

Anode

Cathode

Drain

Drain

B1 E1

C2

B2 C1E2

B2 E2

C1

B1 C2

E1

B2 E2

C1

B1 C2E1

B2 E2

C1

B1 C2E1

E2

B1 E1

C2

(B2)

E1

B1

C1

(B2)

E1

E2

C2

Emitter

Emitter

Anode

(NC)

(NC)

Cathode

Anode

Cathode

Cathode

Cathode

Anode

Anode

Source

Gate

Source

Gate

Source

Drain

Gate

Emitter

Collector

Base

C1(B2)

E2

C2

B1

C1

Circuit

D

G

D

S

B1

B1

B1

B1

B1

B1

D

G

S

S

D

G

C1

E1

C1

E1

E1

C1

E2

C1

C1

G

S

C2

B2

E2

C2

B2

E2

E2

B2

C2

C2C1(B2)

E2

E2E1(B2)

C2

C2E1(B2)

C2

Ver.1.6

KDL-40XBR6/46XBR6/52XBR6

27

3-3. BLOCK DIAGRAM

㱍

() g

KDL-40XBR6/46XBR6/52XBR6

Rear Inputs

RF

S + Video1

Video3

Component1

Component2

HDMI1

HDMI3

HDMI4

Audio

for DVI

PC (HD15)

Audio

for PC

Audio out

(Var./Fix)

Optical

Audio Out

USB1.1

Ether

DMP

Side Inputs

USB2.0

Video2

HDMI2

CDVA

Tu.

Tu.

Video SW

Video SW

CXA2241

CXA2241

( 90h )

( 90h )

HDMI

HDMI

EQ_SW

EQ_SW

AD8197

AD8197

to 1

44to 1

( 9Eh )

( 9Eh )

SIF

for ATSC

NTSC for PAP

for Slicer

IIC

UART

Audio

Compound IC

AMD x245

AMD x245

IIC

USB2.0PHY

USB2.0PHY

Ether PHY

Ether PHY

YOUT for Slicer

CPU

Demodu.

MPEG2 Dec.

3D GPX

CC/PL

Sub Chroma

EPG(Gemstar)

USB

Ether

SPDIF

Digital Video

ITU-R BT.656

ITU-R BT.1120

Digital GPX

RGB

HV Sync/CLK

NAND

NAND

64MB

DDR2

DDR2

64MB

EEPROM

EEPROM

8kB ( A0h )

8kB ( A0h )

NTSC

YUV

YUV

HDMI

RGB

IIC

IIS

64MB

64MB

H/V/CLK

for GPX

IIS(HDMI)

IIC

TAS3308

TAS3308

( 68h )

( 68h )

Audio SW

ADC

DSP

Surround

DAC

Trident WX2

Trident WX2

ADC

3D Comb.

Chroma Dec.

IPC

HDMI Rx

ME/MC

YC Process

Scalar

RGB Process

PIP Process

GPX Mix

LVDS Tx

8bit bus

UART

SPDIF

ADC

ADC

Audio Amp.

TPA3100D2

AWF

DAC

DAC

LVDS

IIC

DDR2

DDR2

32MB

32MB

DDR2

DDR2

32MB

32MB

Assist Woofer

Flash

Flash

2MB

2MB

BE Micro

MB91305

[Control]

Trident

ATI

Video SW

HDMI SW

Power

TAS

HFR

CEC

Audio Mute

AMP

HFR

FHD

( 18h )

T-Con

FHD

FHD Panel

with HFR

LCD

FHD

Buttons

SIRCS

LEDs

ECS

IIC

EEPROM

EEPROM

32kB ( A0h )

32kB ( A0h )

IIC

Temperature

Temperature

Sensor

Sensor

( 92h )

( 92h )

RTC

RTC

( 64h )

( 64h )

KDL-40XBR6/46XBR6/52XBR6

28

3-4. SCHEMATICS AND SUPPORTING INFORMATION

AWF BOARD SCHEMATIC DIAGRAM

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 |

A

—

KDL-40XBR6/46XBR6/52XBR6

B

—

C

—

D

—

E

—

F

—

G

—

H

—

I

—

J

—

TO BU

CN2000

AU_13V

AU_13V

AU_13V

AU_13V

AU_13V

AWF_L

AWF_R

SDO_MUTE

X_SP_MUTE

SW_FAULT

SW_SYNC

CN5701

20P

GND

GND

GND

GND

GND

GND

GND

GND

GND

AU_13V

AUDIO_13V

AU_13V

C5710

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

E

ET5702

GND_AU

AWF_L

7

5

3

1

RB5703

8

6

4

2

1k

1005

B

25V

0.01

C5736

GND_AU

1005

B

25V

0.01

C5735

SDO_MUTE

C5707

4.7

25V

C5708

4.7

25V

MA2J1110GLS0

D5704

RT3N11M-TP-1

Q5705

X_SP_MUTE

CHIP

0

R5725

C5712

470

25V

0.001

50V

X7R

1005

GND_AU

MAZ8056G0LS0

D5702

C5711

0.22

25V

X7R

1608

12345678

P1

P2

P3

P4

P5

P6

P7

P8

9101112

P9

P10

P11

P12

GND

RINN

RINP

AGND

LINP

LINN

GAIN0

GAIN0

GAIN1

MSTR/SLV

SYNC

GND

C5713

4.7

25V

48

13

P48

AVCC

GND

47

14

P47

AVCC

ROSC

46

FAULT

VREG

15

P46

45

MUTE

VBYP

16

RB5701

10k

C5715

0.22

25V

X7R

1608

P42

P43

P44

P45

TPA3100D2PHPR

43

44

BSRP

SHUTDOWN

IC5701

BSLP

AGND

17

18

42

ROUTP

LOUTP

19

41

ROUTP

LOUTP

20

P41

40

ROUTN

LOUTN

21

P40

C5717

39

ROUTN

LOUTN

22

0.22

25V

X7R

1608

P39

38

23

BSRN

BSLN

P37

P38

37

GND

PVCCR

PVCCR

PGNDR

PGNDR

VCLAMPR

VCLAMPL

PGNDL

PGNDL

PVCCL

PVCCL

GND

24

GND

GND

C5741

0.01

25V

X7R

1005

C5742

0.01

25V

X7R

1005

C5719

470

25V

P36

P35

P34

P33

P32

P31

P30

P29

P28

P27

P26

252627282930313233343536

P25

C5721

1

25V

2012

X7R

C5722

2012

C5720

25V1

X7R

C5724

0.22

25V

X7R

1608

470

25V

C5723

0.22

25V

X7R

1608

L5701

22uH

4

GND_D

ET5700

E

L5703

22uH

4

1

23

4

1

23

L5704

22uH

C5726

0.68

25V

B

3216

3216

B

25V

1

C5737

3216

B

25V

1

C5739

RB5702

47K

C5731

10

6.3V

X6S

2012

2143658

7

R5721

0

CHIP

R5722

0

CHIP

C5732

0.001

50V

X7R

1005

Q5702

RT3AMMM

C5733

0.001

X7R

1005

GND_D

2

50V

1

4

3

6

C5734

0.1

25V

X7R

1608

Q5701

RT3N33M-T111-1

5

RT3T11M-TP-1

Q5703

R5729

47k

1/16W

CHIP

5%

R5730

10k

1/16W

CHIP

5%

1

SW+

2

NC

3

SW-

CN5702

3P

K

—

L

—

M

—

N

—

C5709

0.01

25V

X7R

1005

D5700

MAZ8056G0LS0

P13

R5717

100k

D5701

MAZ8056G0LS0

P14

C5714

4.7

25V

P17

P15

P16

C5716

0.22

25V

X7R

1608

D5703

MAZ8056G0LS0

P18

P19

P20

P21

P22

C5718

0.22

25V

X7R

1608

P23

P24

1

23

4

1

23

L5702

22uH

C5725

0.68

25V

B

3216

3216

B

25V

1

C5740

3216

B

25V

1

C5738

AWF

SUB WOOFER

O

A-1494-142-A <EX1> AWF

—

P

KDL-40XBR6/46XBR6/52XBR6 29

KDL-40XBR6/46XBR6/52XBR6

AWF

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

A

—

B

—

C

—

D

[SUBWOOFER]

COMPONENT SIDE

1-875-866-11

(172941811)

9

CN5701

25

CN5701

8

C5735

RB5703

C5736

C5708

C5707

32

L5702

R5727

L5703

C5714

C5713

L5701

C5722

C5721

L5704

C5724

C5719

Q5702

C5731

RB5702

R5728

C5712

ET5700

R5721

R5722

C5710

C5741

C5742

CN5702

CN5702

A-1494-142-A

KDL-40XBR6/46XBR6/52XBR6

30

Loading...

Loading...