Sony KDL-43W807C Schematic

HISTORY INFORMATION FOR THE FOLLOW ING MANUAL:

SERVICE MANUAL (COMMON)

Version Date Subject

1 3/2015 1st Issue.

GN1G CHASSIS

Segment: XM-A

2 4/2015 Update Connecting Diagrams pg 89 - 91.

3 4/2015 Update 55” Circuit Board Location pg 82.

4 7/2015

2. T/shooting : Remov e Tuner related checking ( pg20 )

3. Triage Chart : Delete Local I2C from 3x blinking ( pg 10 )

4. Self Diagnosis :Remove TU_DEMOD error from 3x blinking & add remark (pg 9)

Updates for : 1. Adjustment Section ( pg 76 )

LCD TV

9-888-172-04

For SM - Uni q u e , pleas e ref er :

9-888-172-Ax( America )

9-888-172-Ex ( Europe )

9-888-172-Px ( Pan Asia )

SERVICE MANUAL (COMMON)

GN1G CHASSIS

Segment: XM-A

LCD TV

MODEL LIST

THIS SERVICE MANUAL CONTAINS COMMON INFORMA TION F OR BELOW REGIONS AND MODELS:

REGION

ASIA EUROPE AMERICA

MODEL

KDL-43W7*C KDL-50W7*C KDL-55W7*C

KDL-43W8*C KDL-50W8*C KDL-55W8*C

Sec tion T itle

1. SAFETY NOTES

1

1

1

1

1

1

1

1

2. SELF DIAGNOSTIC FUNCTION

2

Overvie w of C on trol B utton s .......... .. ... .. ... .. .... . .... . .... .. ... .. ... .. ... .. ... .. .... . ....

2

2

2

2

3. TROU BL E S HOOT ING

3

3

3

3

3

3

3

3

3

3

TABLE OF CONTEN TS

Accessing Service Mode

Accessing Software Version................................................................

Accessing Serial Number Edit………………………………… ..…….....

Accessing Model Number Setting

W/B Adjustment via Service Mode

WB/Mura/CUC data transfer via Se rvice

HDD Performance Check…………………….......................................

HDD Re

Accessing Self Diagnostic Menu……………………………… ………..

Summary of Service Control……………………… …… …………........

Circuit Board Location

Block Diagram

Connector Diagram

Page

-1. Warnings and Caution……………………………………… ……………… . 5

-2. Caution Handling of LCD Panel ......…………….................................... 5

-3. Caution About the Lithium Batter………………………………… ……….. 6

-4. Safety Ch e ck Out ........................……………......................................... 6

-5. Leakage Test .......................................................................................... 6

-6. How to Find a Good Earth Ground………………………………………… 6

-7. Lead Free Information….…………………………………………………… 7

-8. Handli ng the Flexible Flat Cable (FFC)……………………………………. 7

-1.

-2. LED Display Control ………..................................................................... 9

-3. LED Pattern………………........................................................................ 9

-4. Standby LED Error Display…………………………………………………. 9

-5. Triage Chart ............................................................................................ 10

-1. No Power…….……………………………………………………………….. 11

-2. LED Blinking……………….………………………………………............... 18

-3. No Sound……………………………......................................................... 30

-4. No Picture................................................................................................. 42

-5. Side Buttons Malfunction……………………………………………………. 66

-6. IR Remote Commander Malfunction……………………………………… 68

-7. Light Sensor Error……………………………… ……………… ………… . 70

-8. Network Malfunction: Ethernet (Wired)………………………… …………. 72

-9. Wireless Network Malfunction…………………………… ………………. 73

-10. Bluetooth Malfunction……………………………………………………….. 75

8

Sec tion T itle Page

4. SERVICE ADJUSTMENTS

4-1.

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

4-8.

4-9.

4-10.

5. DIAGRAMS

5-1.

5-2.

5-3.

-Register……………………………......................................... 80

………………………………………...................... 83

..................................................................... 76

76

77

…………………………………........ 78

.…………………………................ 79

Mode…………………........ 79

80

81

81

......................................................................... 82

………………………………………...................... 89

Please refer Service Manual – Unique for below information :

-Safety Warnings

-Wire Dressing

-Circuit Board Location

-Disassembly and Exploded View.

4

SECTION 1

SAFETY NOTES

1-1. Warn ings and Caution

1) These servicing instructions are for use by qualified service personnel only.

2) To reduce the risk of electric shock, do not perform any servicing other than

that contained in the operating instructions unless you are qualified to do so.

3) An isolation transformer should be used during any service to avoid

Possible shock hazard, because of live chassis. The chassis of this receiver is

directly connected to the ac power line.

4) Be sure to follow these guidelines to protect your property and

avoid causing serious injury :

• Carry the TV with an adequate number of people; larger size TVs require

two or more people.

• Correct hand placement while carrying the TV is very important for

safety and to avoid damages.

5) Components identified by shading and mark on the exploded views,

and in the parts list are critical for safe operation. Replace these

components with Sony parts whose part numbers appear as shown in this

manual or in supplements published by Sony. Circuit adjustments that are

critical for safe operation are identified in this manual. Follow these

procedures whenever critical components are replaced or improper

operation is suspected.

!

1-2. Caution Handling of LCD Panel

When repairing t he LCD Panel, make s ure you are grounded wi th a wrist band.

When repairing t he LCD Panel on the wall, the panel must be secur ed usi ng the

4 mounti ng hol es on the rear cover .

1) Do not press the panel or frame edge to av oid the risk of electric shock.

2) Do not scr atch or press on the panel with any sharp objec ts.

3) Do not leave the module in high temperat ure or in areas of high hum idity for

an extended per iod of time.

4) Do not expose the LCD panel to direc t sunlight.

5) Avoid contact w ith water . It may cause short ci rcui t within the module.

6) Disconnec t the AC power when r eplacing t he backli ght (C CFL) or

inverter cir cuit . (Hi gh voltage occur s at the inver ter ci rcui t at 650Vrms)

7) Always clean the LCD panel with a soft cloth mater ial.

8) Use care when handling the w ires or connectors of the invert er ci rcui t.

Damaging the wires may cause a short circuit .

9) Protect the panel from ES D to avoid damaging the elect ronic circuit (C-MOS).

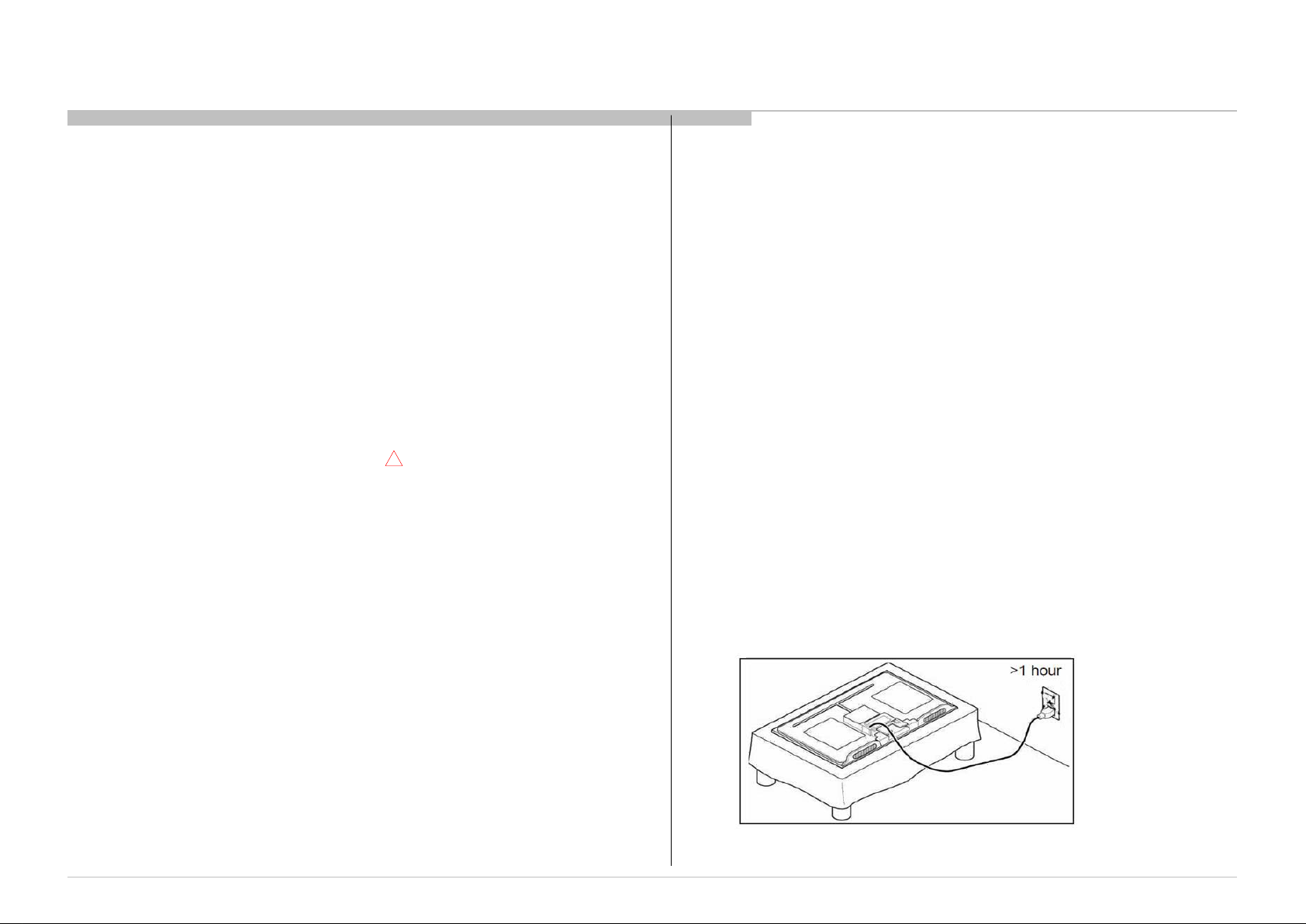

10) Dur i ng the r epai r , D O NO T l eav e the Pow er On or Burn-in period for more

than 1 hour while the T V i s face dow n on a c lot h.

Figure 1. TV is faced down on a cloth during repair.

5

Safety Notes

1-3. Caution About the Lithium Battery

1) Danger of explosion if battery is incorrectl y replaced. Replace only with

the same or equivalent type.

2) Outer case broken battery shoul d not contact to water.

1-4. Safety Check-Out

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:-

1) Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and bridges.

2) Check the inter board wiring to ensure that no wires are pinched or

contact high-wattage resistors.

3)Check all control knobs, shields, covers, ground straps and mounting

hardware have been replaced. Be absolutely certain you have replaced all

the insulators.

4) Look for unauthorized replacement parts, particularly transistors that

were installed during a previous repair. Point them out to the customer and

recommend their replacement.

5) Look for parts which, though functioning show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6) Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7) Check the antenna terminals, metal trim, metalized knobs, screws and all

other exposed metal parts for AC leakage. Check leakage test as described

next.

8. For safety reasons, repairing the Power board and/or Inverter board is

prohibited.

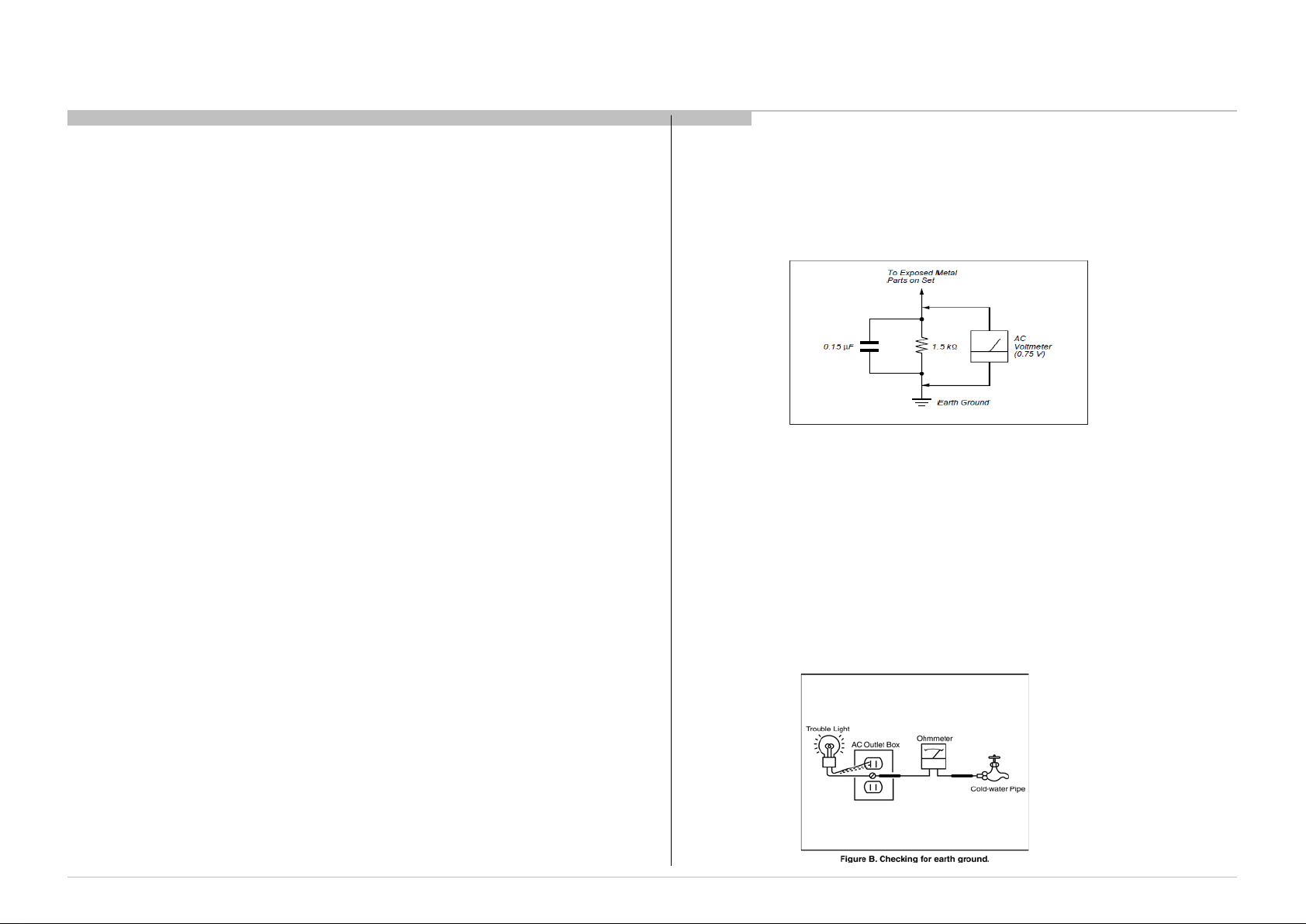

1-5.Leakage T est

The AC leakage from any exposed m etal par t to earth ground and from all

exposed metal par ts to any exposed metal part having a retur n to chass is must

not exceed 0.5mA (500 micr oamperes) .

Leakage c urrent can be measur ed by any one of the three methods:-

1) A commerc ial leakage t ester such as the SIM PSON 229 or RCA WT540A.

Follow the manufacturers instr uctions to use those instruc tions.

2) A battery-operate d AC milliampmeter The DATA PRECISI ON 245 digital

multimeter is suitable for this job.

3) Meas uring the volt age dr op across a resistor by means of a VOM or battery

operated AC voltmeter. The 'li mi t' indication is 0.75V so analog meters m ust

have an accurate low volt age scale. T he SIM PSON' S 250 and SANWA SH63TRD are exampl es of pass ive VOM s that are sui table. N early all battery

operated digi tal mult imeter that have a 2 VAC range are sui table.

(see Figur e 2.)

Figure 2. AC voltmeter to check AC leakage

1-6. How to Find a Good Earth Ground

1) A cold-water pi pe is a guaranteed ear th ground; t he cover-pl ate retaini ng

screw on most AC outlet boxes i s also at earth ground.

2) If the retaining scr ew is to be used as your earth ground, veri fy that it is at

ground by measuri ng the resistanc e between i t and a c ol d-w ater pipe w ith an

ohmmeter. The readi ng should be zer o ohms.

3) I f a cold-w ater pi pe is not accessi ble, connect a 60- to 100-watt t roublelight (not a neon lamp) between the hot side of the recept acle and the

retaining scr ew. Tr y both slots, if necess ary, to locate the hot s ide on the line;

the l am p shoul d l i ght at normal br il l i ance i f the sc r ew i s at gr ound potent i al

(see Figur e 3).

Figure 3. Checking for earth

ground.

6

Safety Notes

1-7. Lead Free Inform ation

The circui t boards used i n these model s have been pr ocessed using Lead

Free Solder. The boards ar e identified by the LF logo loc ated clos e to the

board designation.

Pleas e hol d rei nfor ce me nt b oard an d

plunge it to depths.

Main Board

Please pull out FFC while pushing the

but ton of both end s at the s ame tim e.

Main Board

The servic ing of these boar ds r equires special precautions. It is strongly

recommended to use Lead Free Solder m ateri al in order to guarantee optimal

Figure 4: LF Logo

Figure 5: LF logo on circuit board

quality of new solder joi nts.

1-8. Handling the FLEXIBLE FLAT CABLE (FFC)

When you insert / pull out FFC, please grasp a reinforcement board and main

body of FFC.

< Insertion>

Release Button

of Connector

FFC connector broken if pull out FFC

without press and hold both Release

Button of connector . Symptom 5X blinking

will be appear due to improperly seated.

<Pull out>

7

Self Diagnostic Function

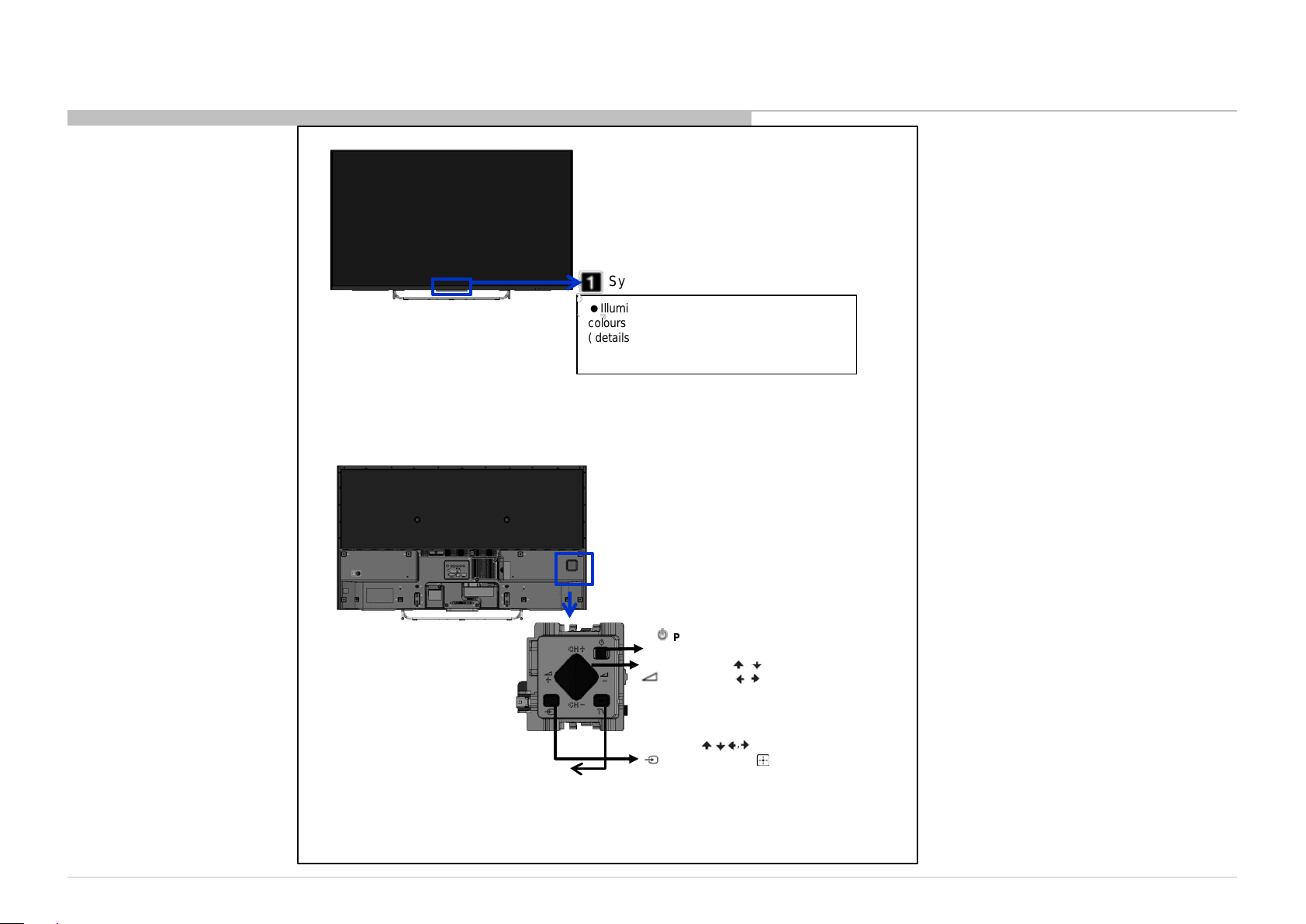

2-1. Overview of Control Buttons

2-1-1.

FRONT

REAR OF TV

SECTION 2

SELF DIAGNOSTIC FUNCTION

TV CONTROLS/ TERMINALS/ INDICATOR

Remote Control Sensor /

Light sensor / * Illumination LED/ 3D

Sync Transmitter

Illumination light s up or blinks in different

col ours ac cor di n g t o the s t atus of the T V

( details refer to 2-2. LED Dis play Control

TV

Press to

display

the TV Home

Menu.

Power

Turn the TV on or switch to standby mode

CH+/- (Channel) / / ,

+/- (Volume) / / .

Press to select the next or

previous channel.

Press to adjust the volume.

In TV Home Menu: buttons

will work as , , , .

INPUT SELECT /

SELECT/ CONFIRM

Press to select the next or

previous channel.

In TV Home Menu: buttons

will work as (select/confirm)

8

Side Amber

Timer/Reminder/REC T imer/Photo

W hite when

Self Diagnostic Function

2-2. LED Display Control

Status

Power Of f

( by power saving switch off and

*1)

Power On White Off Off

STBY/i.LINK ST BY/PC STBY

( by remot e contr ol off on ly )

Picture Off White looping

Devic e Con nec ti on White Cyan on e shot Off

Power ON A n imatio n White

Sleep Tim er/O n

Frame

( Power On )

On Timer/Reminder/REC Timer

( Deep Standby )

Self Diagn osis Off

Aging mode White

Sof tware U pdati ng white blinking white blinking off

Sof twar e Up dati ng f ini sh White Blue lit off

Test Reset White white blinking

Error of p anel I D White

REC (SCART REC & HDD

REC/LIVE PAUSE) [AEP/J only]

ePOP/

Shop Illumination

White Center

LED

Off Off Off

Off Off Off

White

Off Off Amber

White

White Cyan l oop Off

Side RGB LE D

White one shot Off

White one shot Off

Amber

One s h ot ->

Lit*2

Red

Blinking

Green Blinking Off

Gr een /Am ber

Blinking

Red(Pink)

One s h ot ->

Lit*2

LED

Off

Off

Amber

blinking

Off

Off

*1 power switc h off (by side

*2 One Shot is only user

Af ter 5 m i n u tes , sid e amber

The number of LED blinkin g

ind icat es c aus e of failu re

( refer to Led Error / Triage

Blinking:0.5s ec O n / 0.5s ec

Blinking:0.5s ec O n / 0.5s ec

*2 One Shot is only user

One s h ot Center

Remarks

key)

action.

LED On

chart)

Off

Off

action.

feat ur e chan ge

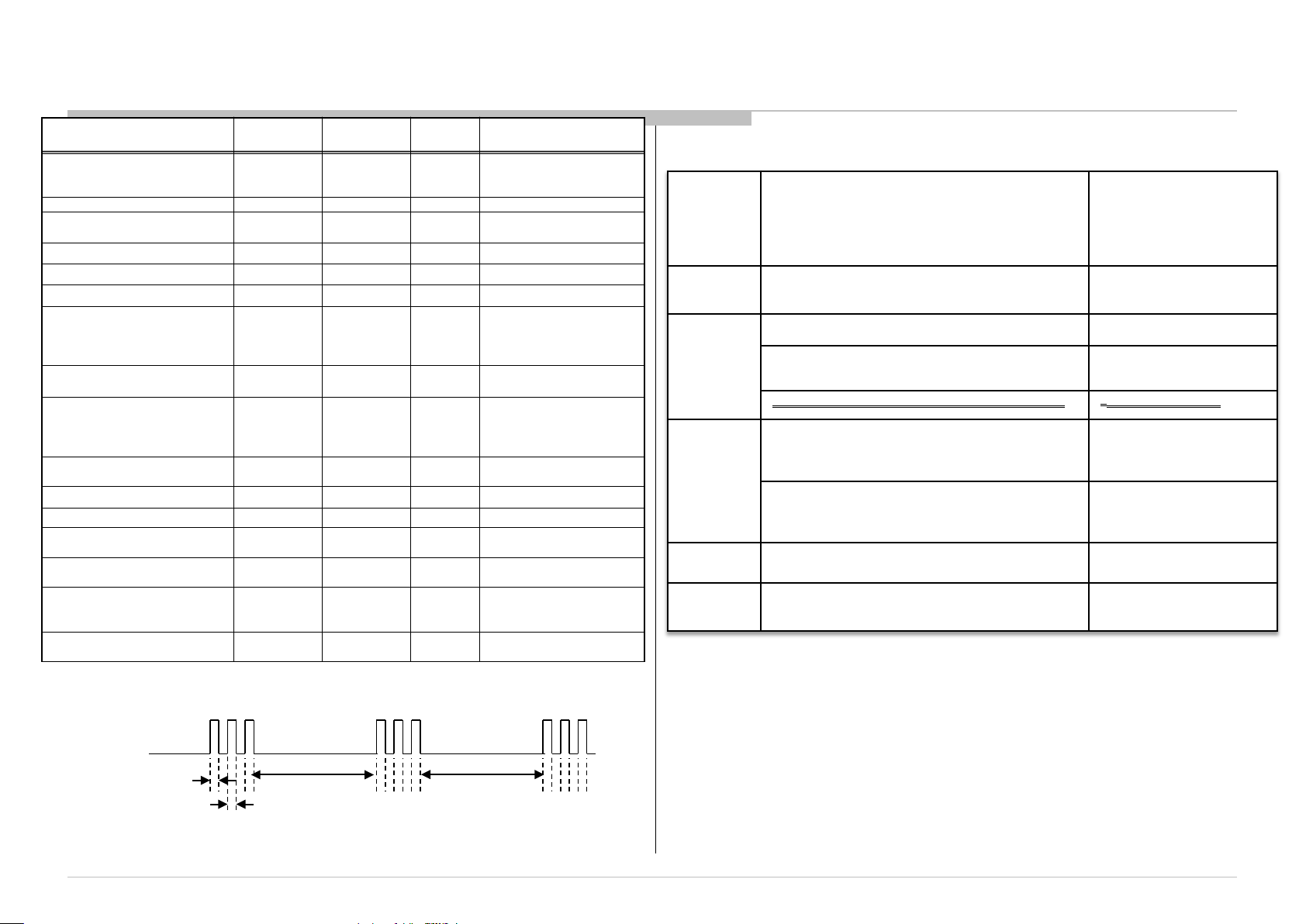

2-3. LED Pattern

When safety shutdown occurs, Standby LED display reports the cause by using the lightning

patterns as indicated below

.

2-4. Standby LED Error Display

Smart

Core RED

Detection Items

LED

blinking

count

2x

Main 19.5V overvoltage [MAIN_POWE]

* This failure is not saved

Main 5.0V failure [DC_ALERT]

3x

Audio amp. protection [AUD_ERR]

Tuner or demodulator I2C NACK [TU_DE MOD] BMX Board Error

Panel ID EEPROM I2C No AC K (Also panel

power failure is a suspect) [P_ID_ERR]

- dete ct at startup sequence only

5x

-FRC device I2C No ACK [FRCTC_I2C]

-FRC device Initialization failure [FRCTC_I2C]

-detect at startup sequence only

6x LED driver [BACKLIGHT]

7x

Over temperature protection [TEMP_ERR]

Temp. sensor I2C NACK [TEMP_ERR]

Remarks For 3x blinking :

Tuner error don’t have Red LED blinking indication.

Board Erro r Item

Power Adapter

BMX Board Error

BMX Board Error

BMX Board Error

Speaker

Panel modul e

Tcon board

BMX Board Error

Tcon board

LED driver (LD) board

BMX Board Error

Example: The figure above shows LED display when SHUTDO WN is caused by Audio

Error. It repeats f lashing f or a specified number of times in 0.5sec/cycle and has a 3 seconds

interval of lighting off. Please note that a 3 seconds interval of lighting off is fixed regardless of abnormal state types.

0.5sec

0.5sec

3.0sec 3.0sec

9

Self Diagnostic Function

No White

response

to remote

dots

Core no

Emitter

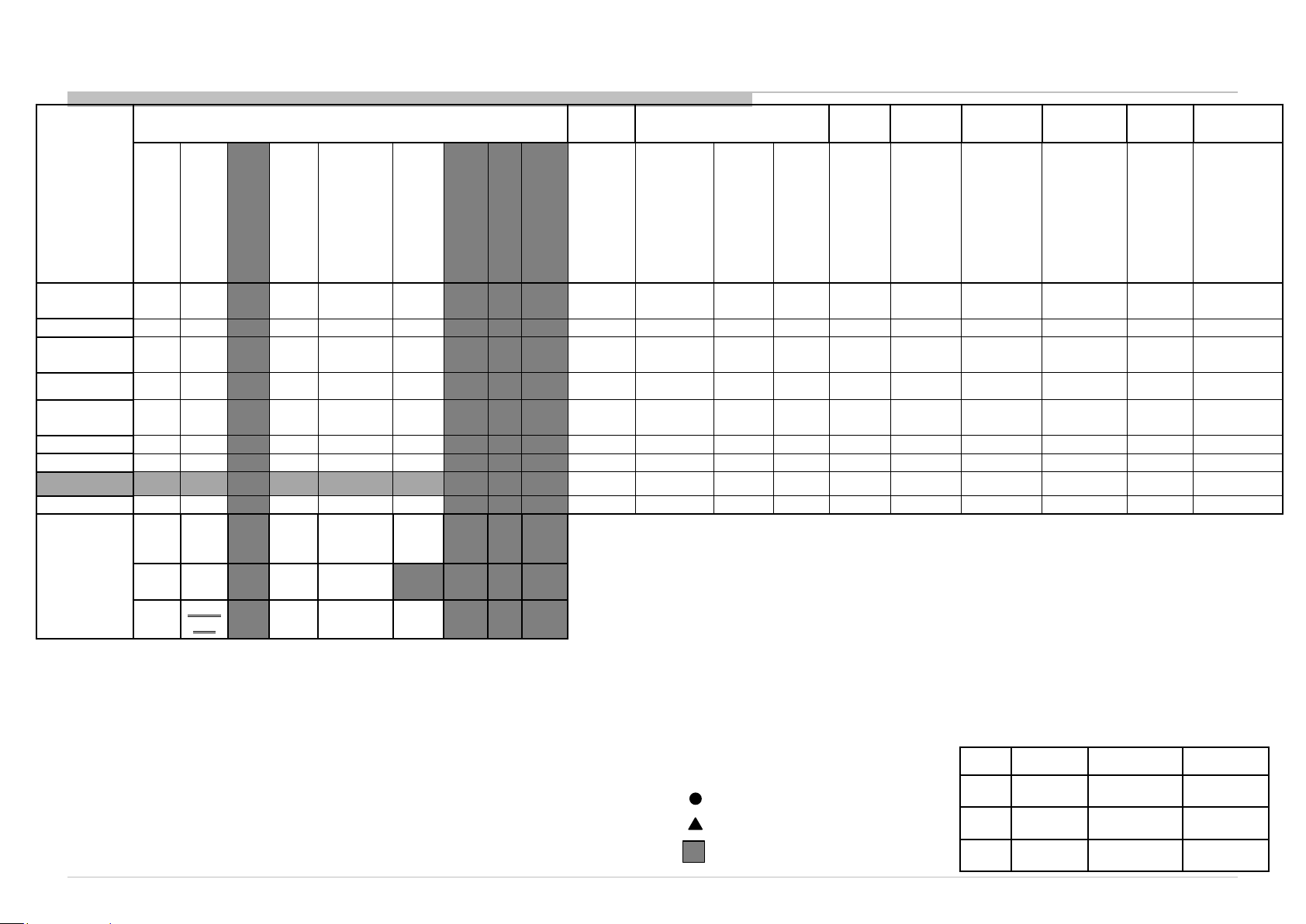

2-5. T riage Char t

Reference

2

B* Board

G* Board

H* Board

Speaker

Wifi & BT

Module

LD Board

LVDS FFC

Tcon

LCD Panel

Power Power LD

Problem

Audio

Local

I2C

Symptoms - Shutdown. Power LED

blinking red diagnostics sequences

3 4 5 6 7 8 9 10

Panel

(Tcon)

Panel

(Backlight)

Soft-

TEMP

ware

FAN

(N/A)

No

Power

Power

LED &

does not

(Dead

- missing or distorted

Stationary

coloured

lines or

Video

No

video

One of

Inputs

No

video

all

Inputs

Remote Network Audio Skype

No

Remote

Wireless

can't

connect

No Audio

Skype

Can't Work

Smart

Core

Smart

LED (Set

is still

alive)

Bluetooth /

(OSR) can 't

Set)

Bluetooth

(BT)

One Step

Remote

connect

Size B* Board G* Board H* Board

Most likely defective part

Secondary possible defective part

Not Applicable

43” BMX Not applicab le HSC3_S_M

50” BMX Not applicab le HSC3_S_M

55” BMX Not applicab le HSC3_S_M

10

Troubleshooting

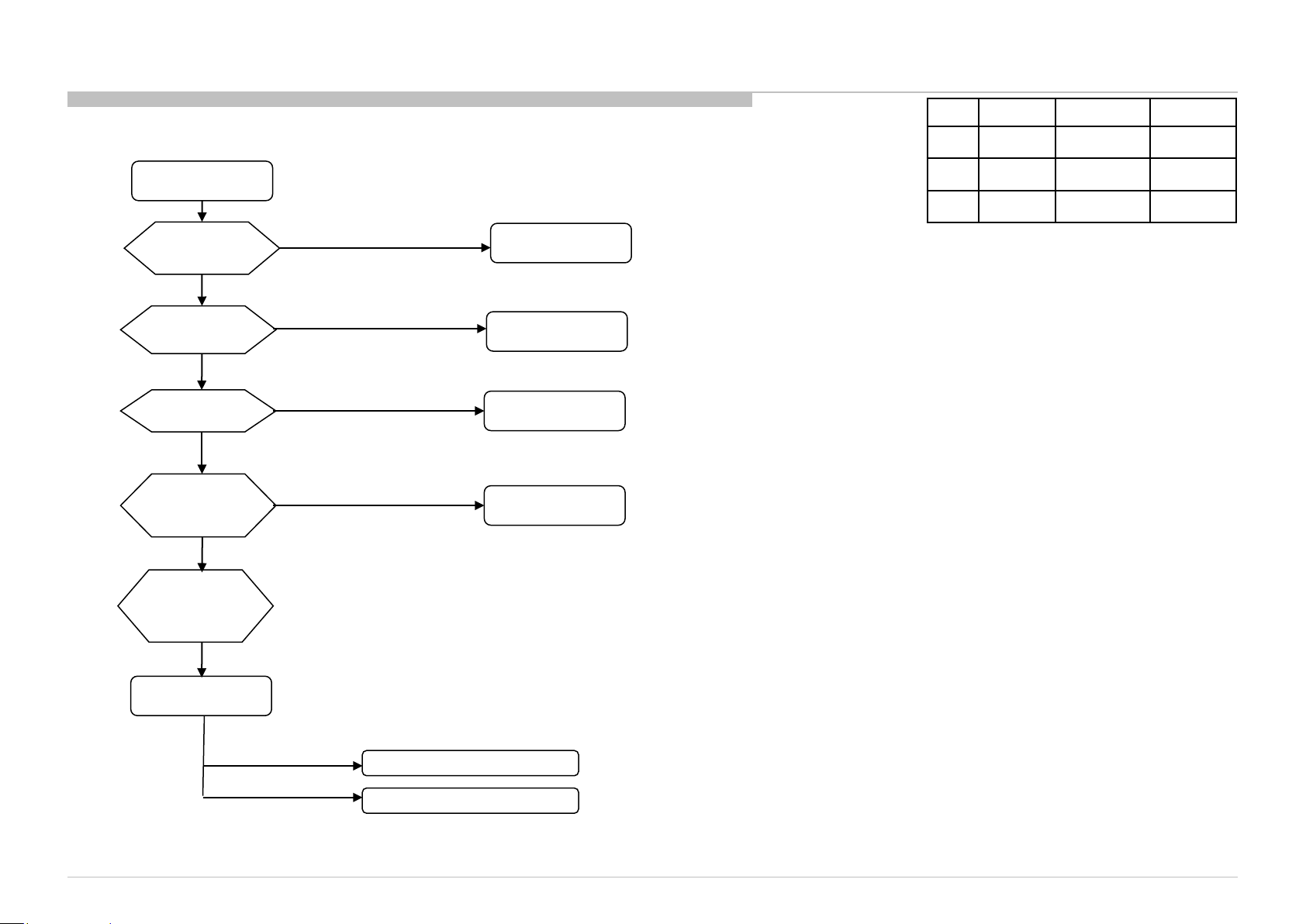

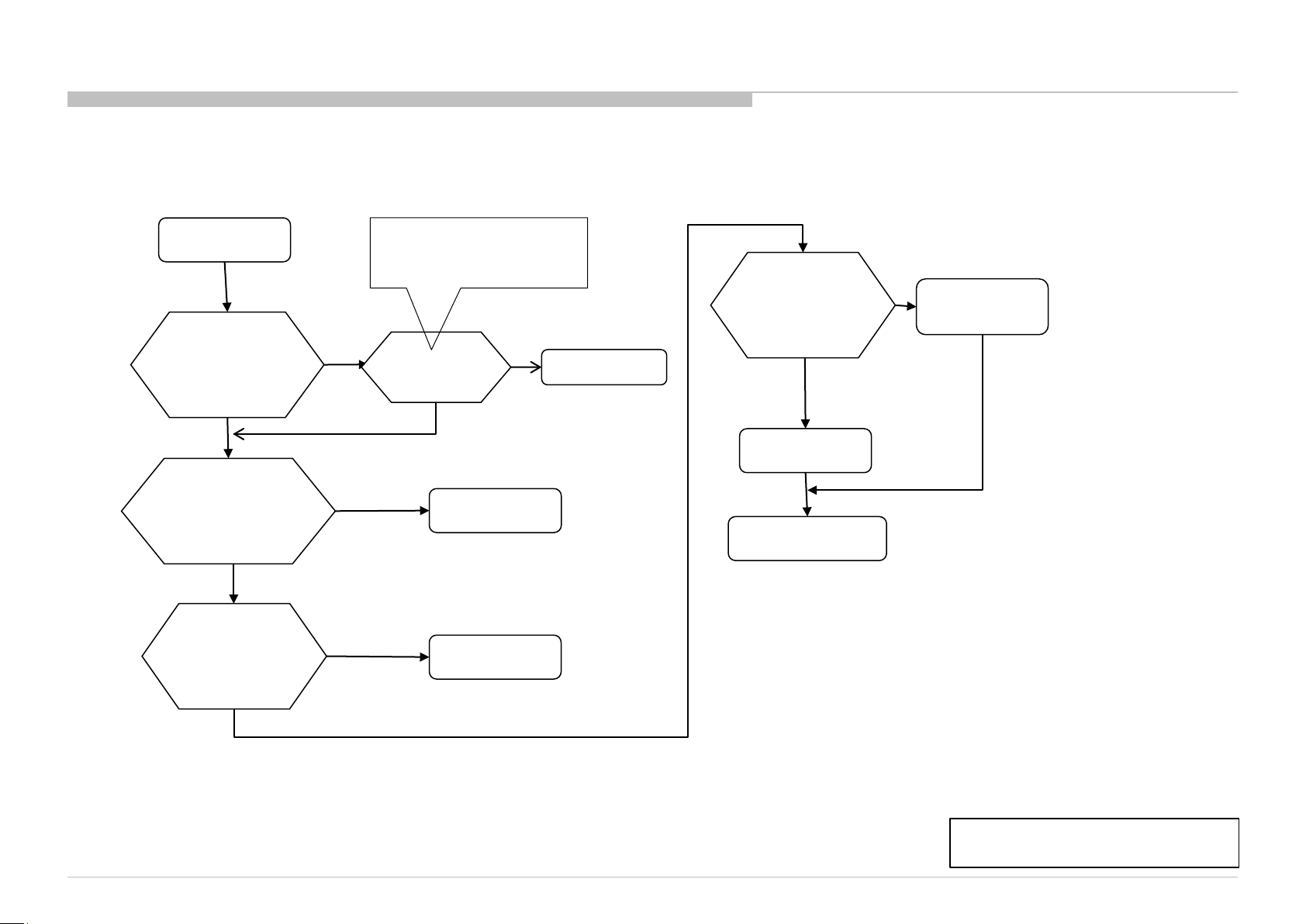

3-1. NO POWER

3-1-1 No Power – LD Board

SECTION 3

TROUBLESHOOTING

Size B* Board G* Board H* Board

43” BMX Not applicab le HSC3_S_M

No Power

Check Fuse F1000

OK

Check DIODE

D1001

OK

Check 19.5V_SS

JL1000

OK

Check Fuse

12V DDCON

F9104

OK

Check connection

harness

CN4001

OK

NG: DC Voltage is 0V

NG: Diode are shorted

NG: DC Voltage is 0V

NG: DC Voltage is 0V

50” BMX Not applicab le HSC3_S_M

55” BMX Not applicab le HSC3_S_M

FUSE F1000

broken

DIODE D1001

broken

MOSFET Q1003

broken

FUSE F9104

broken

B* Board

Symptoms

Symptoms

DC/DC converter check

NO POWER: MUFFIN

11

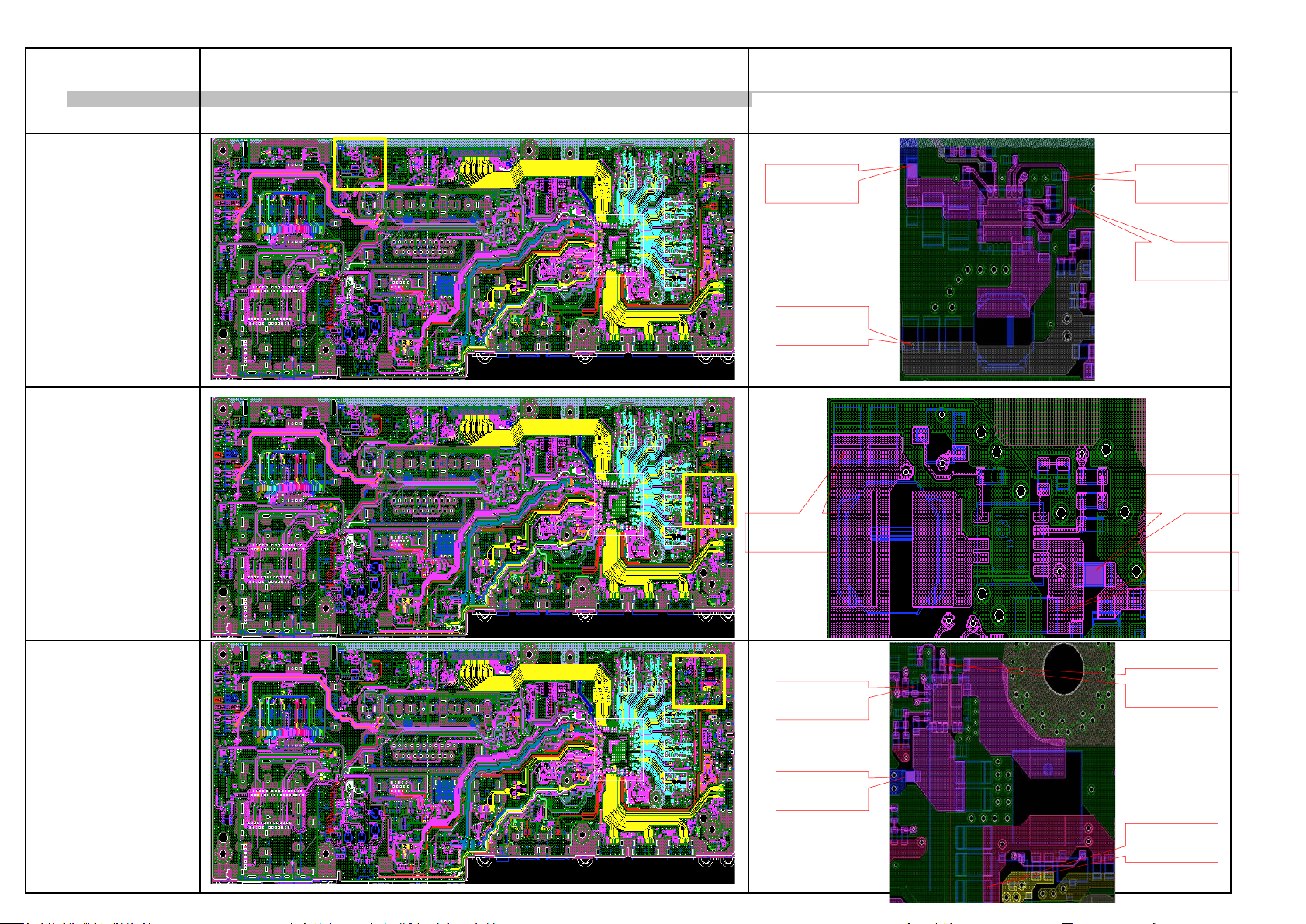

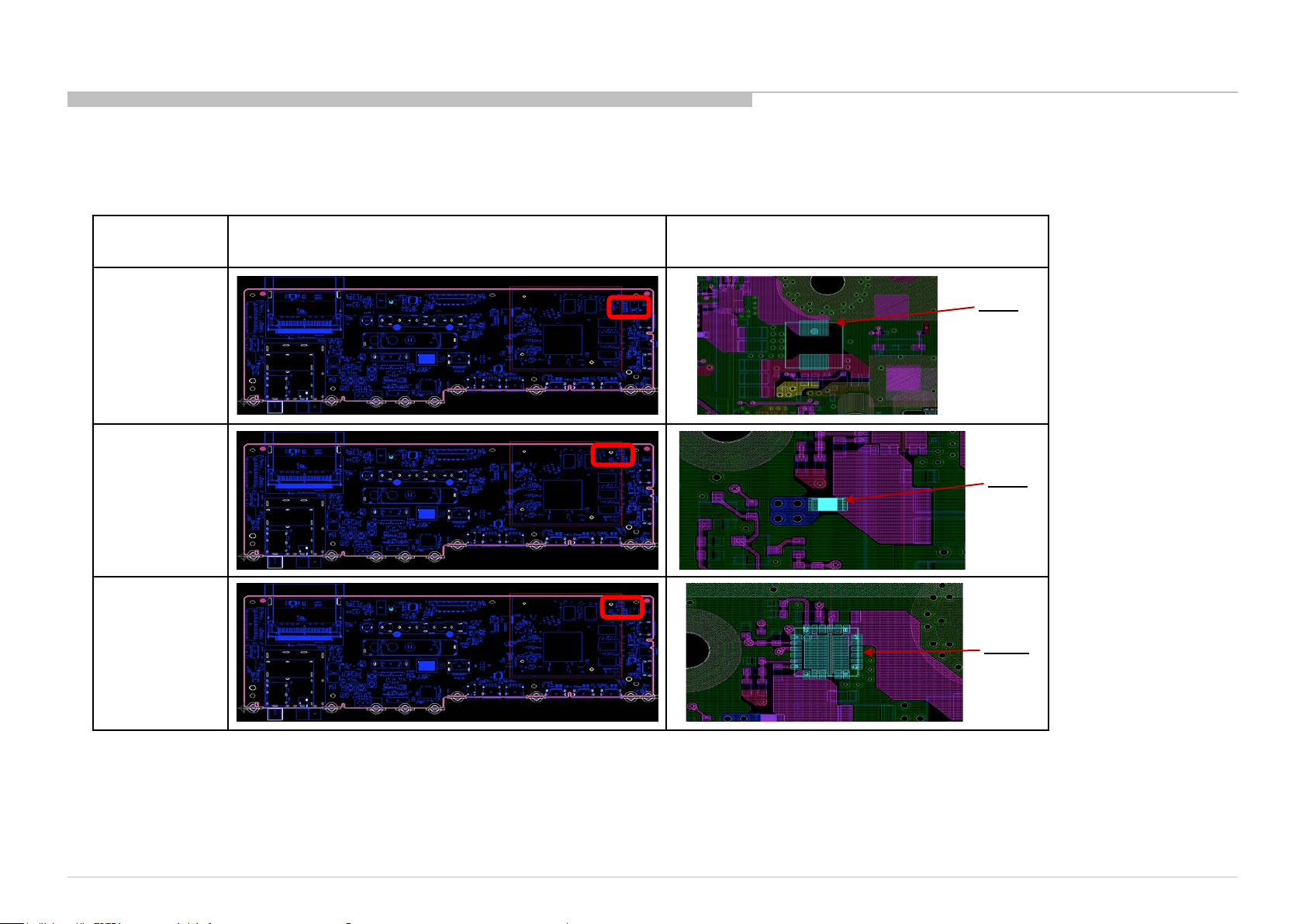

Troubleshooting

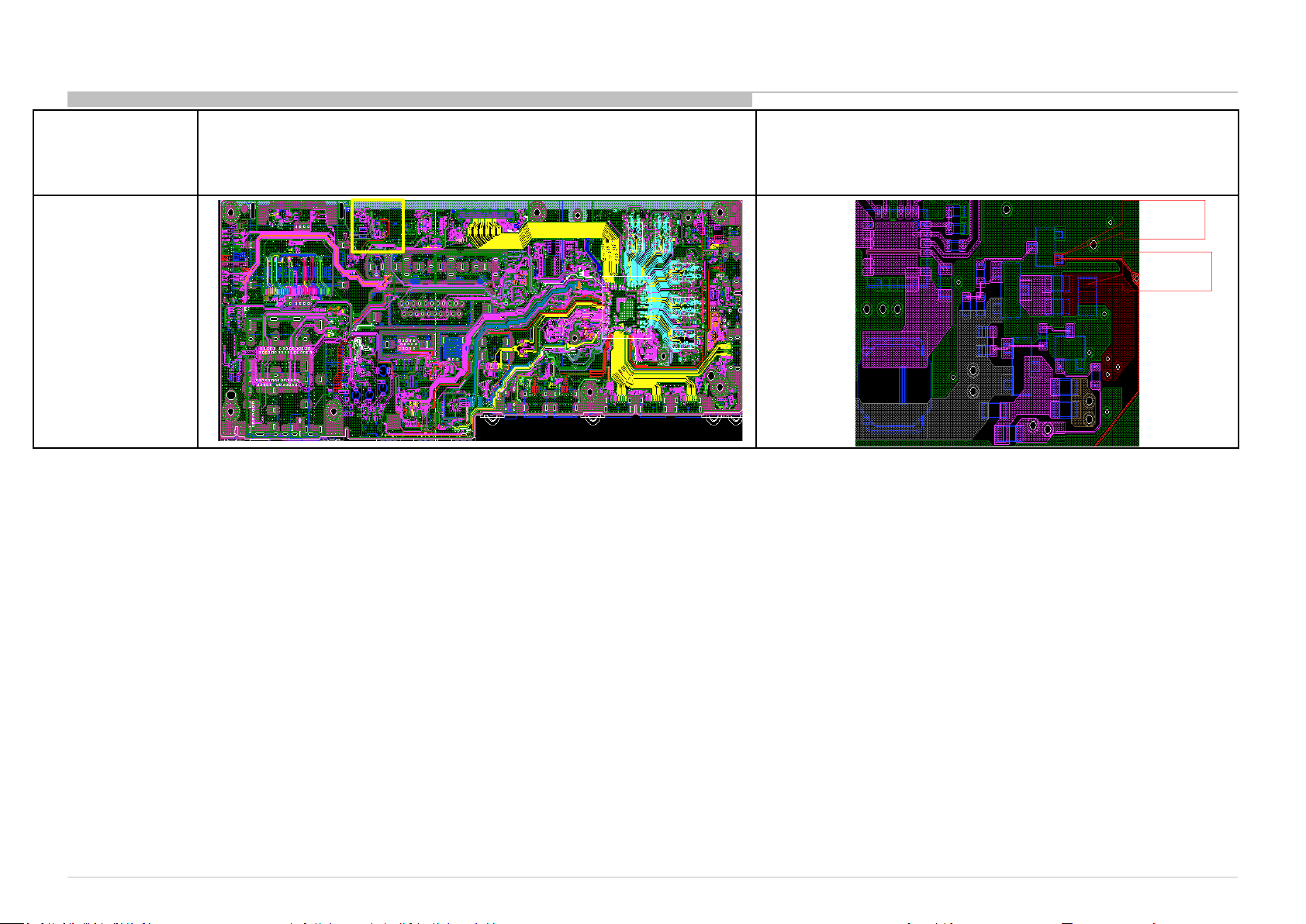

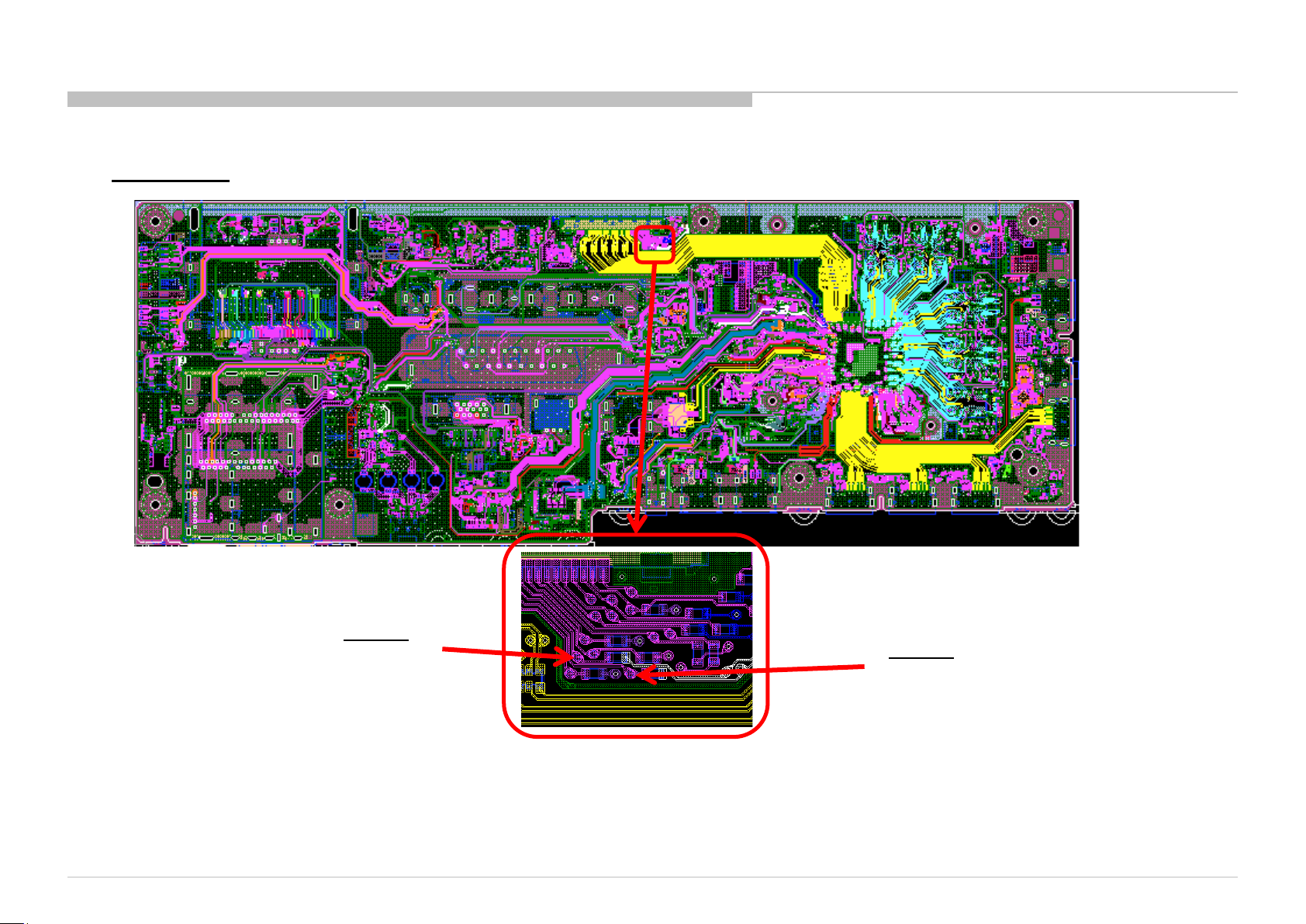

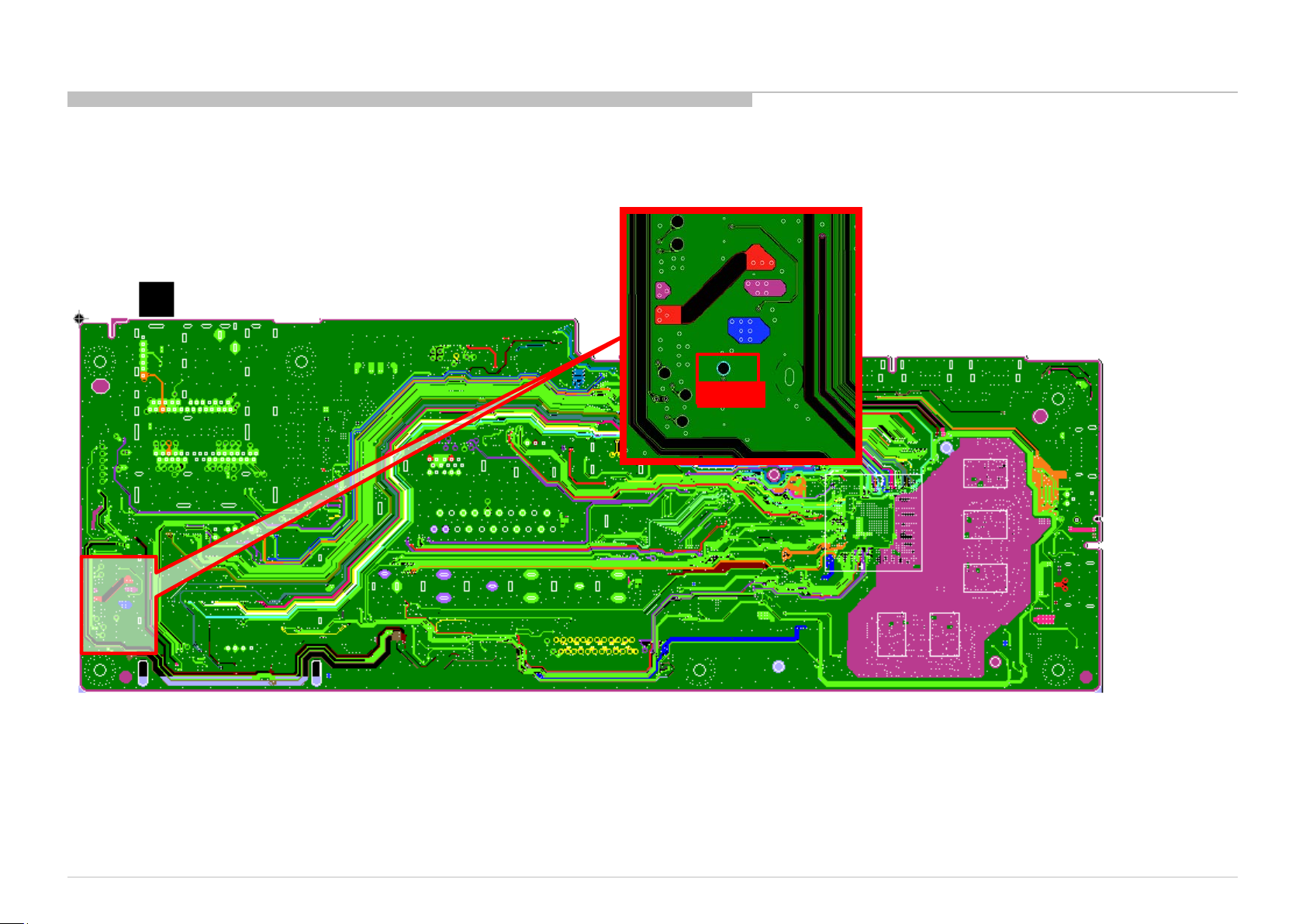

Board Name Board PWB (A side) Detail

LDB1

(XMDT 43,

XMAT 43)

F1000

D1001

JL1000

CN4001

F9104

LDB2

(XMDT 50,

XMAT 50)

F1000

D1001

JL1000

CN4001

F9104

Details

F9104

Details

F9104

JL1000

CN4001

F1000

D1001

D1001

CN4001

JL1000

F1000

12

Troubleshooting

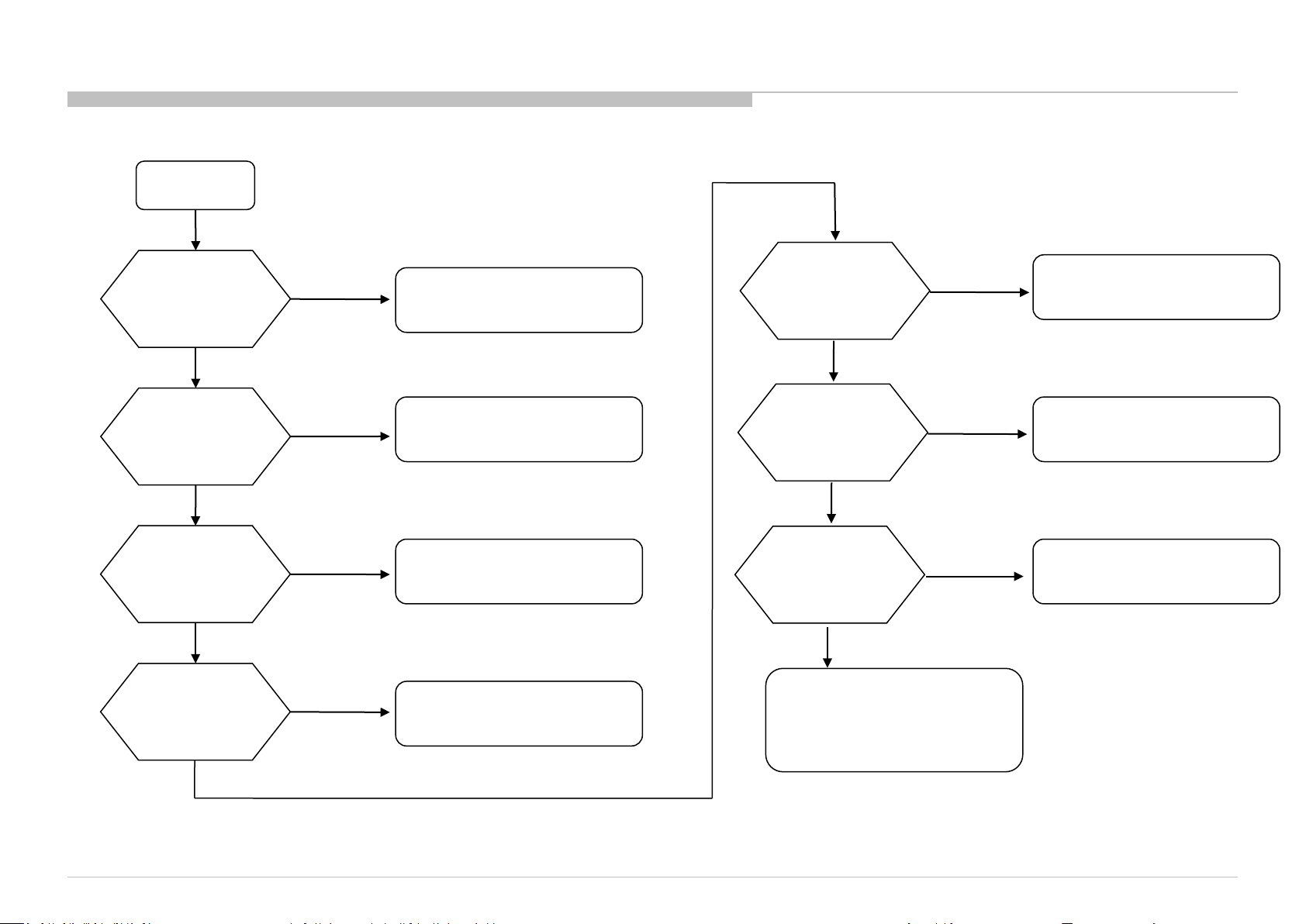

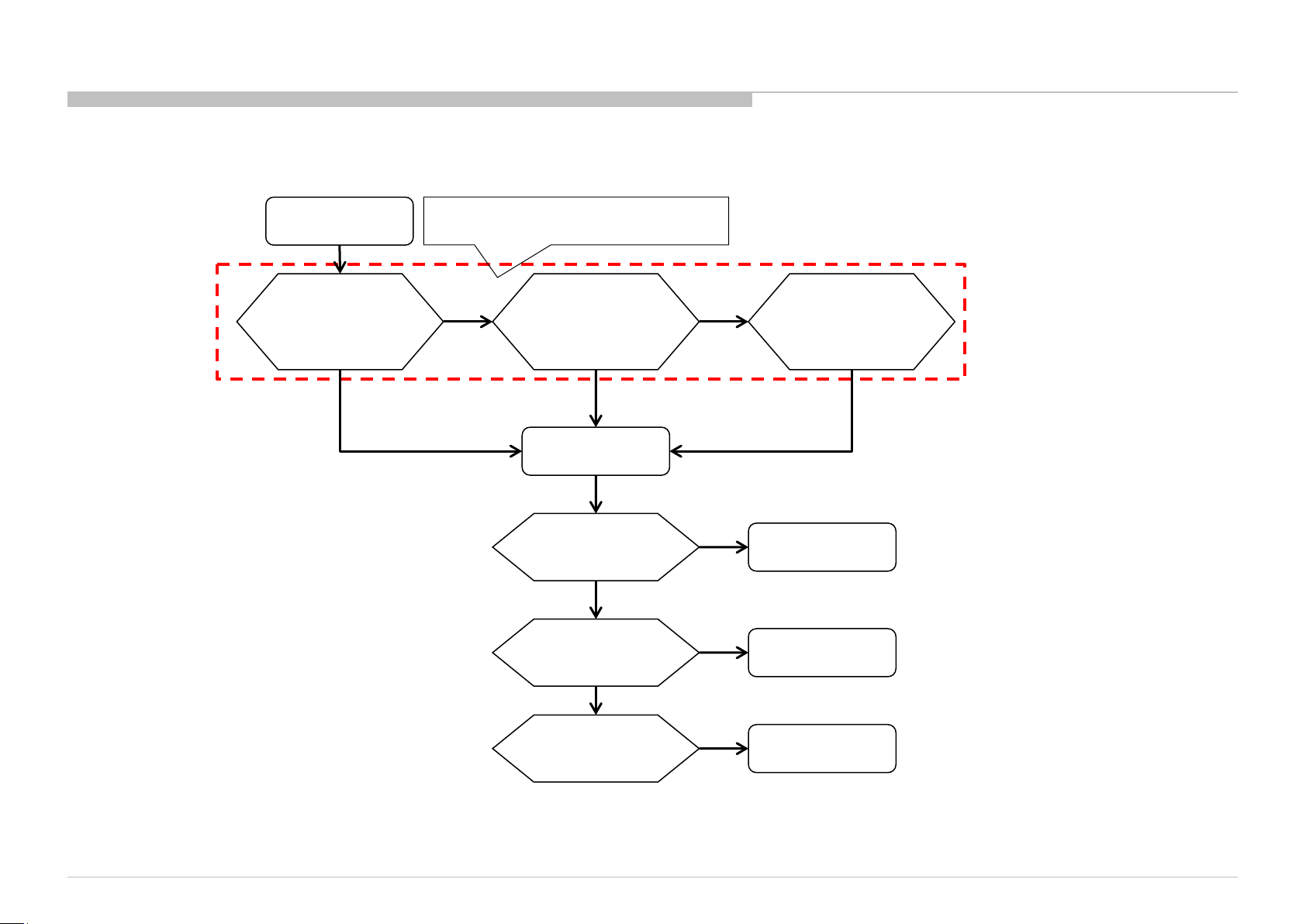

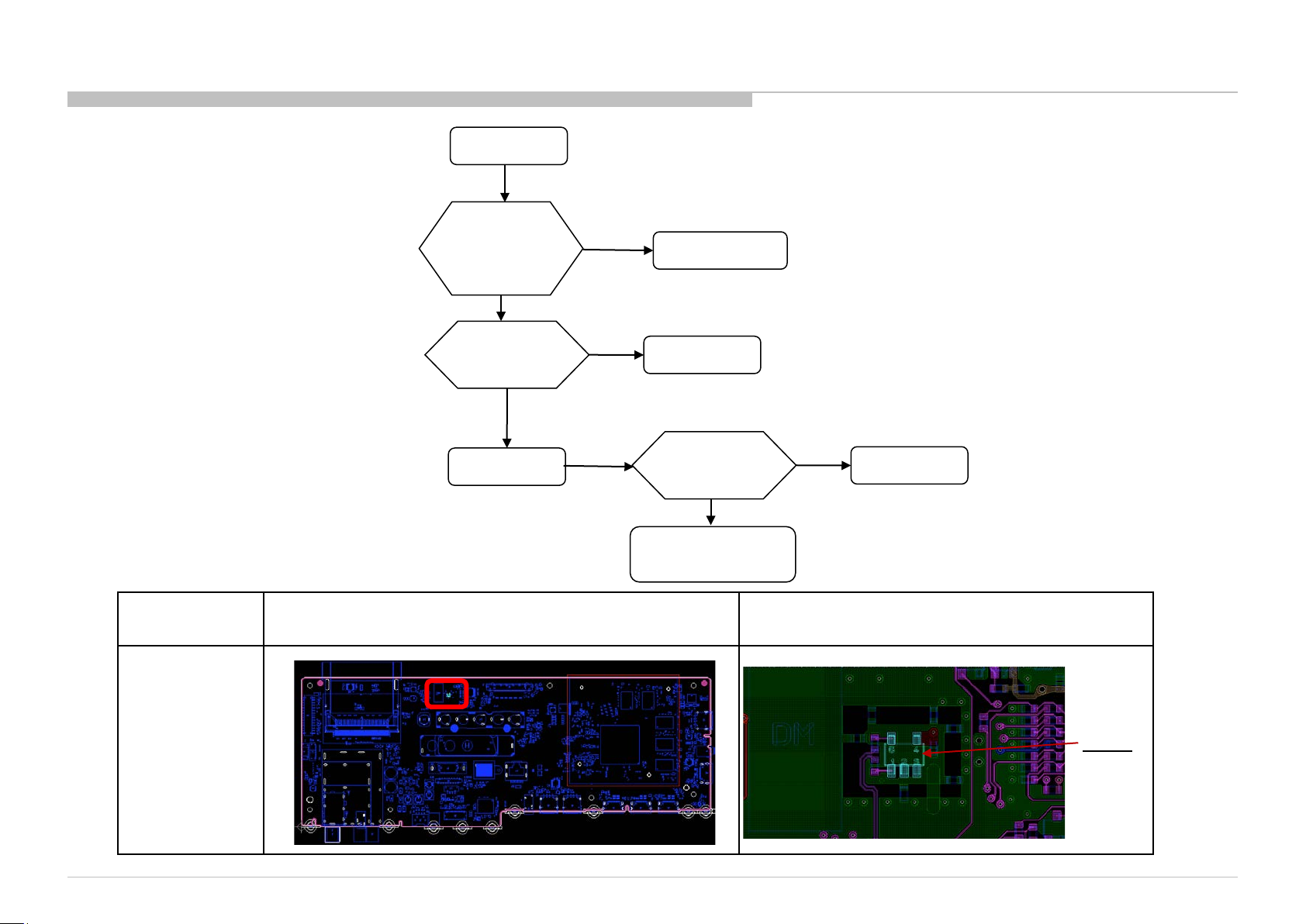

3-1-2 No POWER - DC/DC converter check

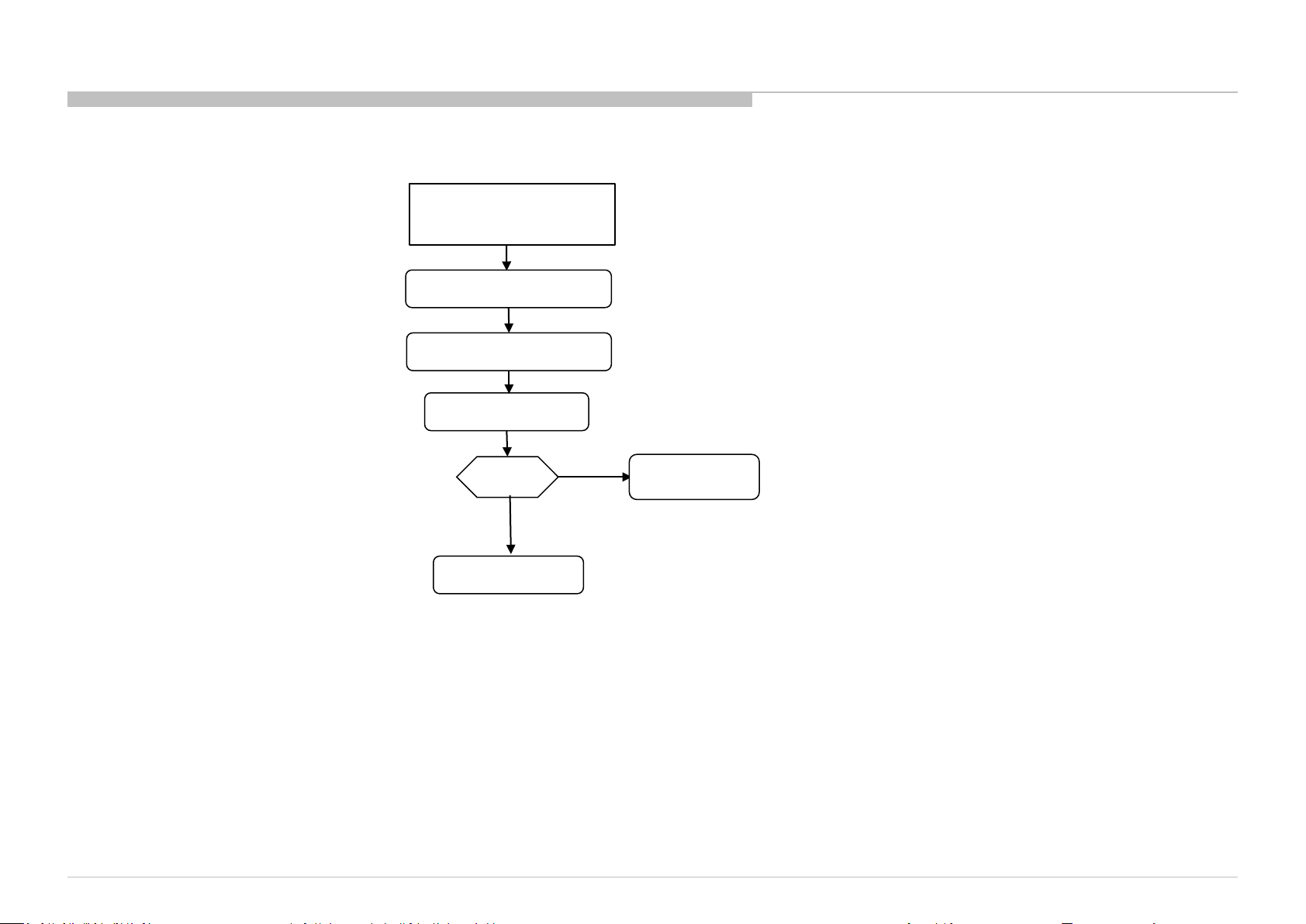

START

Check C9216 Voltage.

Is the voltage 3.3V?

yes

Check C9224 Voltage.

Is the voltage 1.5V?

yes

Check C9188 Voltage.

Is the voltage 5V?

yes

Check C9203 Voltage.

Is the voltage 1V?

no

no

no

no

3.3V DDCON check

(Change B* Board)

1.5V DDCON check

( Change B* Board)

5.0V DDCON check

(Change B* Board)

1.0V DDCON check

(Change B* Board)

Check C9207 is

it 1.05V?

yes

Check C9230 is

it 1.8V?

yes

Check 3.3V_MAIN

C9005 Voltage.

Is the voltage 3.3V?

yes

END

DDCON/LDO working normal

no

no

no

1.05V LDO check

(Change B* Board)

1.8V DDCON check

(Change B* Board)

3.3V_MAIN check

(Change B* Board)

yes

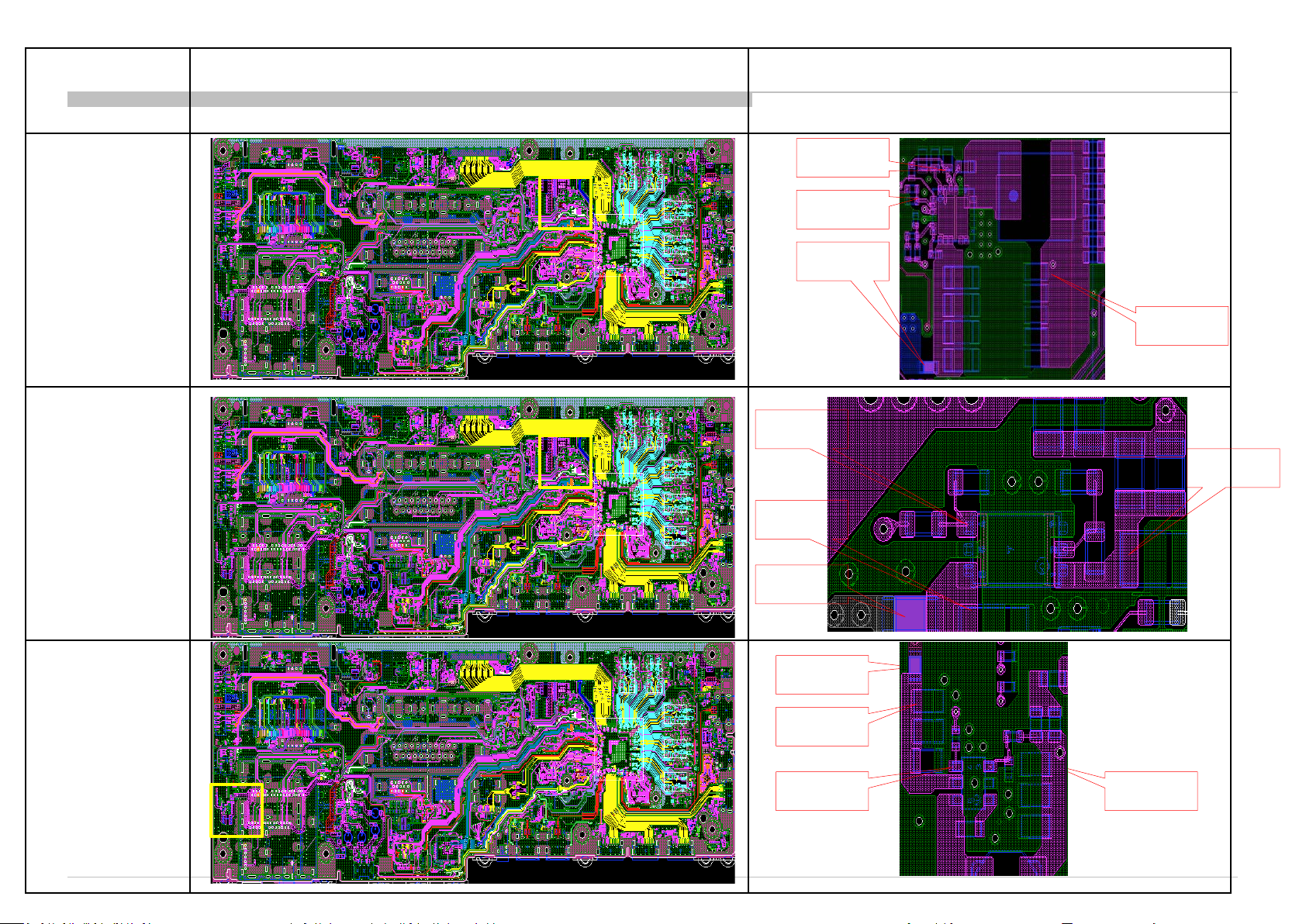

BMX Board PWB (A side) Detail

3.3V

1.5V

F9015

C9216

C9224

R9321

C9213

F9016

C9222

5.0V

R9277

C9185

F9013

C9188

BMX Board PW B (A side) Detail

1.0V

1.05V

C9169

C9263

F9012

C9203

#PIN4

C9207

C9206

F9014

1.8V

F9017

C9229

#PIN4

C9230

15

BMX Board PW B (A side) Detail

3.3V_MAIN

#PIN1

Q9002

C9005

16

Troubleshooting

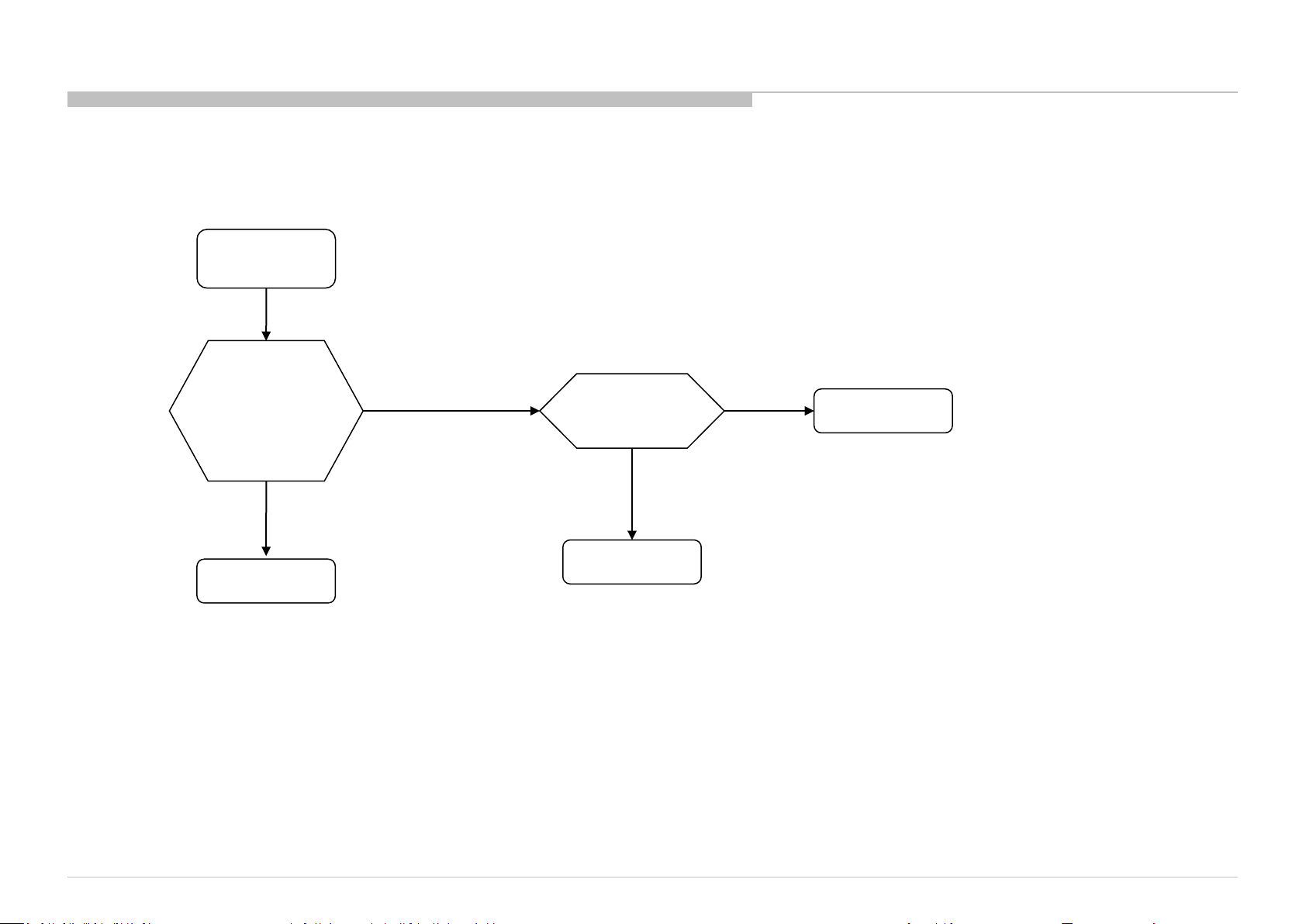

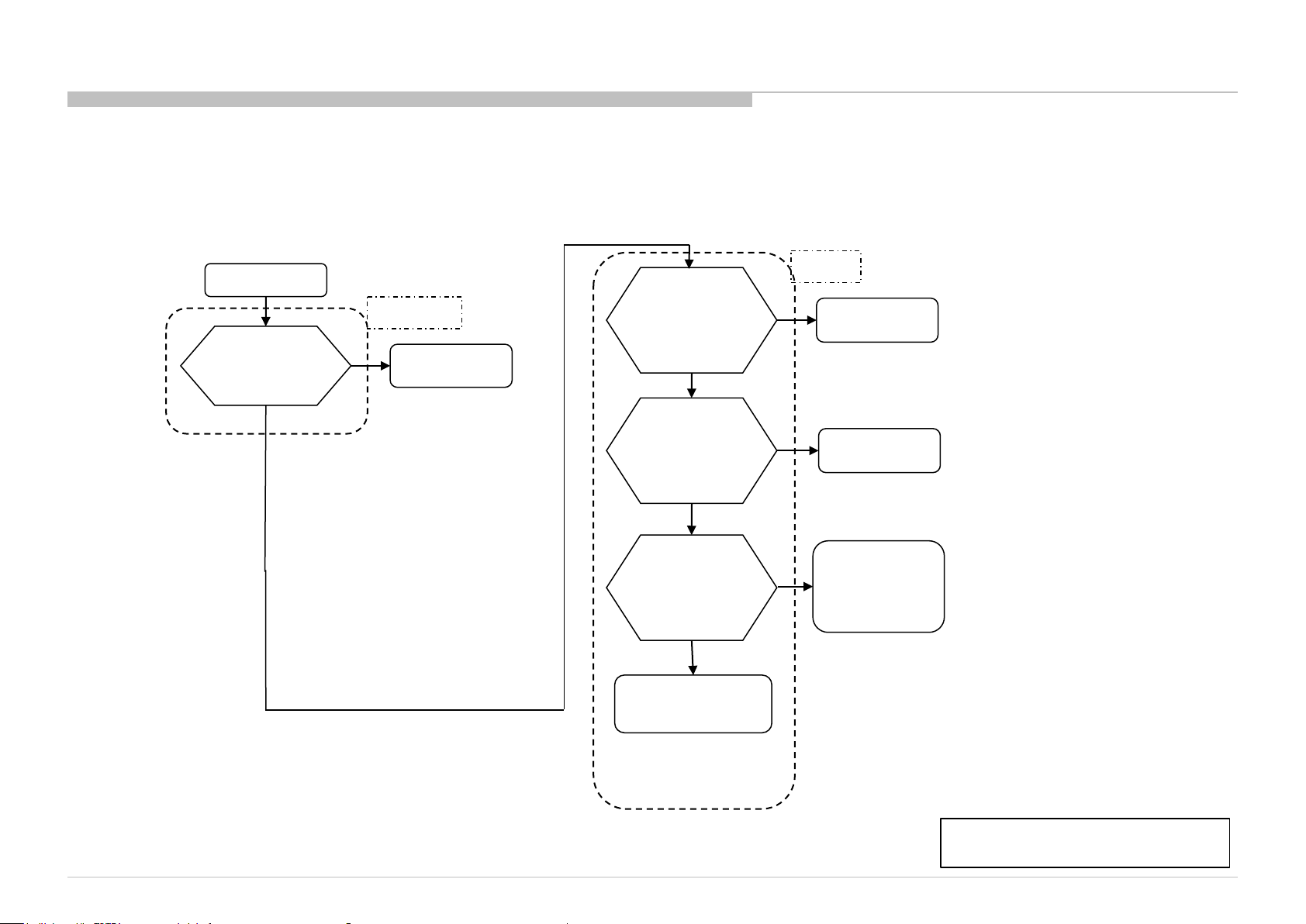

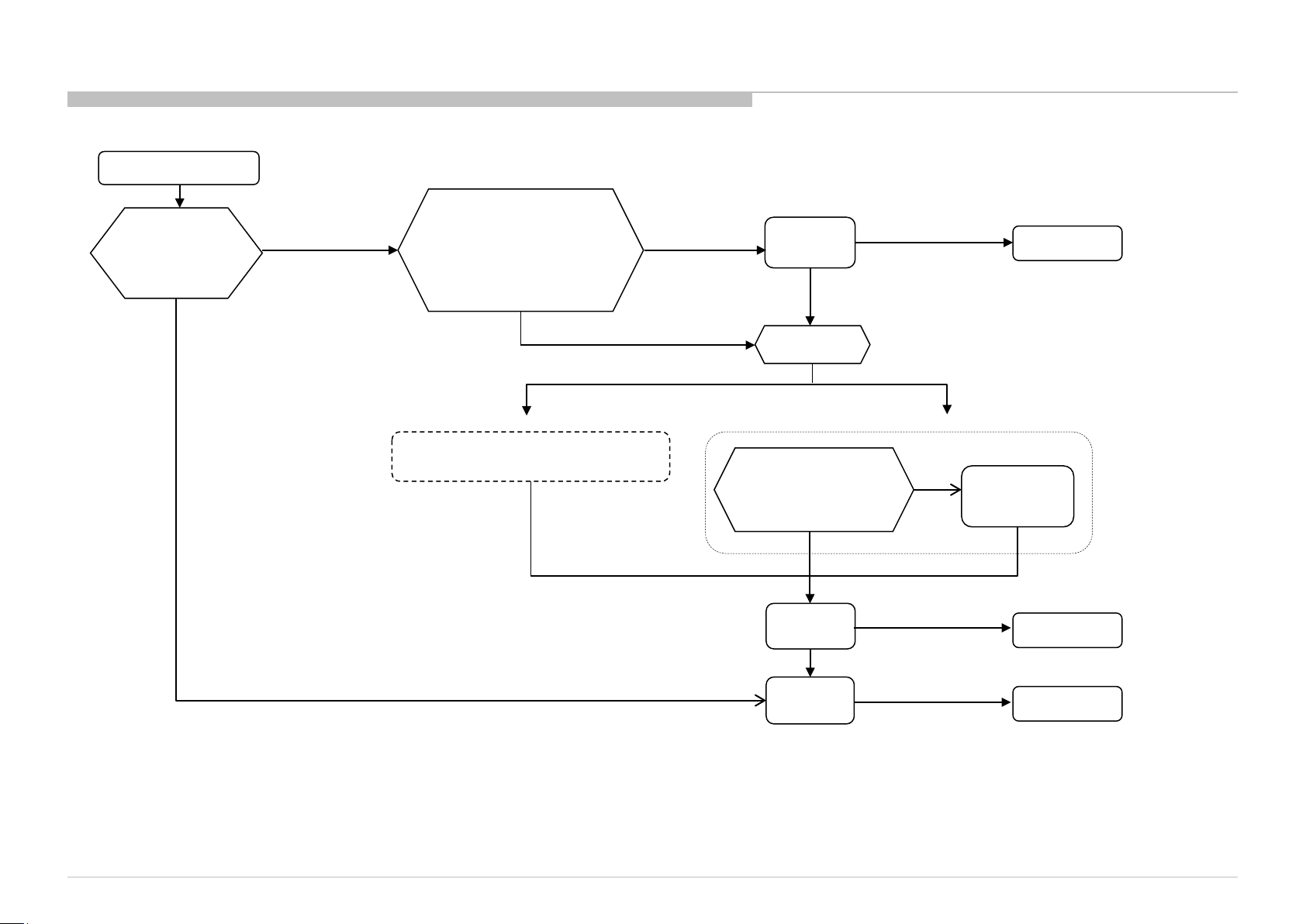

3.1-3 NO POWER – Muffin Replacement (Main Device)

Muffin

replacement flow

eMMC erase

Muffin replacement

Product SW write

Recover?

Yes

Muffin issue

Data on eMMC

need to be erase

first before

changing Muffin

No

Board Issue

17

Troubleshooting

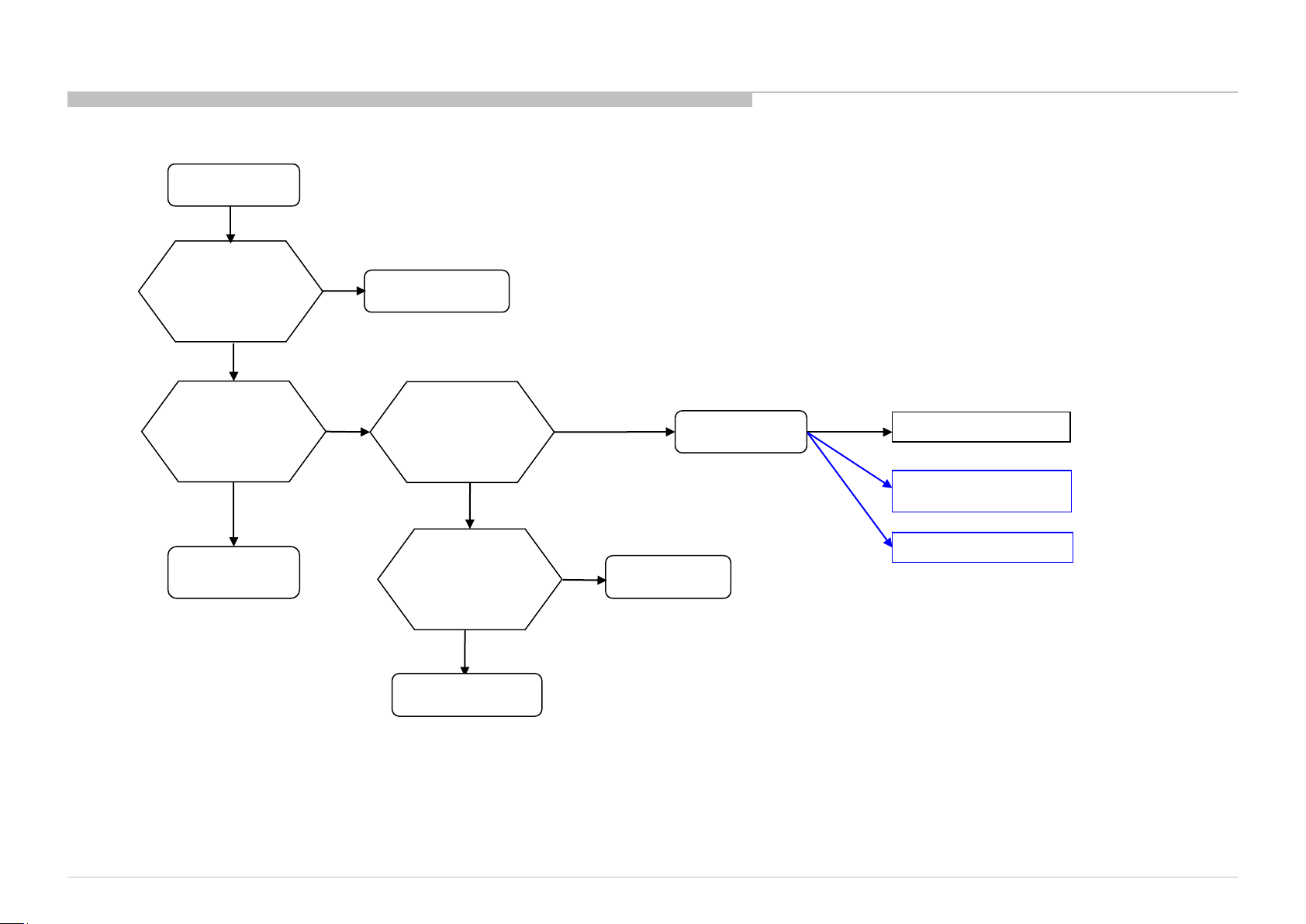

3-2. LED BLINKING

3-2-1. LED Blinking: 2x (Main power Error)

BMX board (XM-A, XM -AT and XM-DT) only AC Adapter

2-time blinking

Check +19.5V_SS

at pin 15/17 of CN9000,

or JL9011

on B* Board

Voltage > 23V

Replace

LD* Board

NG

AC Adapter

Voltage < 23V

OK

LD* Board

B* Board

18

Troubleshooting

3-2-1. LED Blinking: 2x (Main power Error)

Troubleshooting References

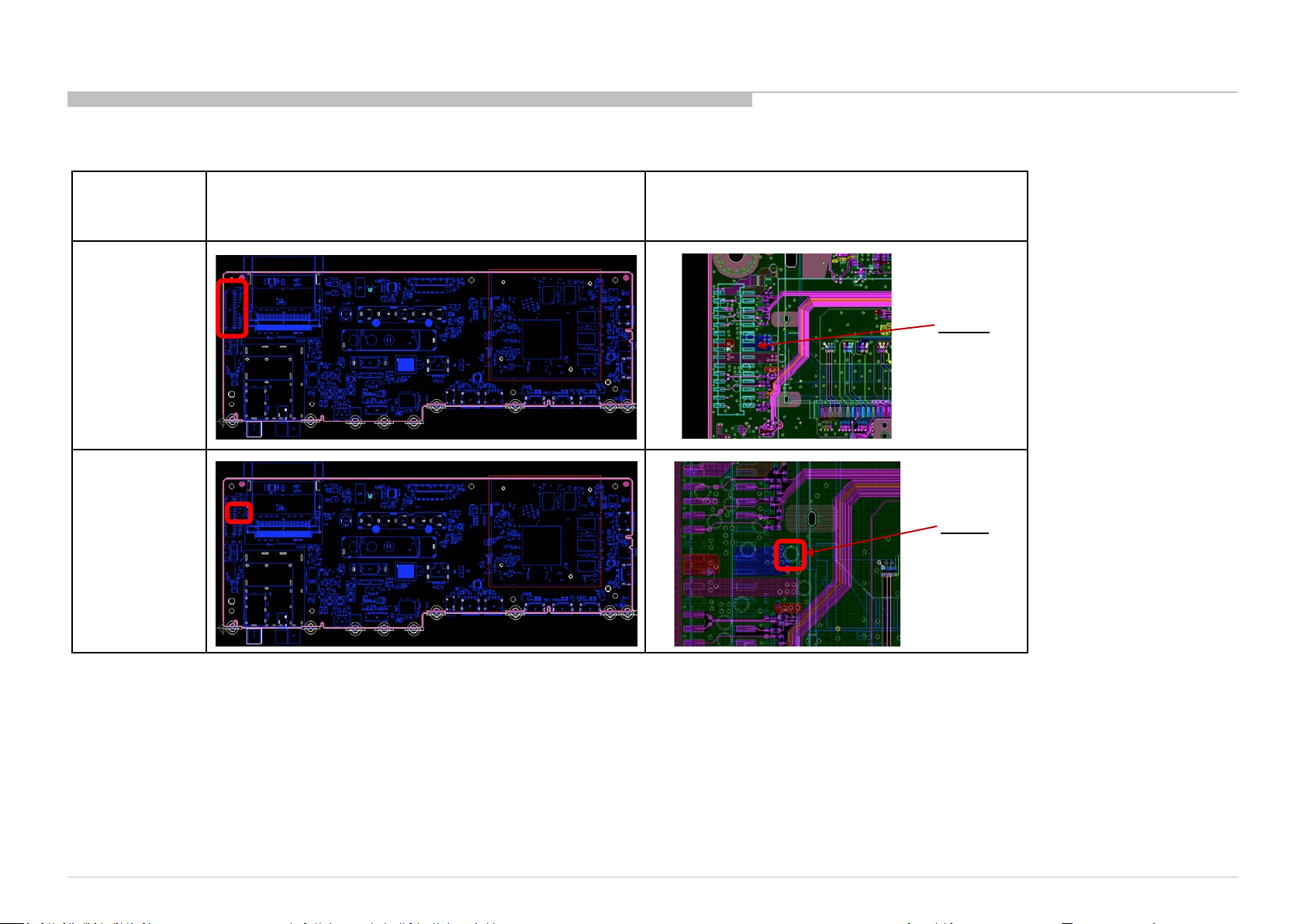

Board Name Board PWB (A side) Detail

BMX

(CN9000)

BMX

(JL9011)

CN9000

JL9011

19

Troubleshooting

3-2-2. LED Blinking : 3x (DC Alert & Communi cation Error)

3-time blinking

Check +5.0V_MAIN

at L9015, 4.959V

<Voltage<5.285V?

OK

DC_ALERT

NG

F9013, IC9021,

etc (B* Board)

Check

Speaker Impedance

at SP Connector,

8Ω±1.2Ω ?

OK

Check Audio

+19.5V

at pin 16/18 of CN9000

on the B* Board

OK

Check +19.5V

at Power Amp side

of F7751 on

the B* Board

OK

IC7751, etc

NG

NG

NG

AUDIO

Speaker

LD* Board

F7751, IC7751

, etc (B* Board)

(B* Board)

Note: Board Details refer Section 3

main page.

20

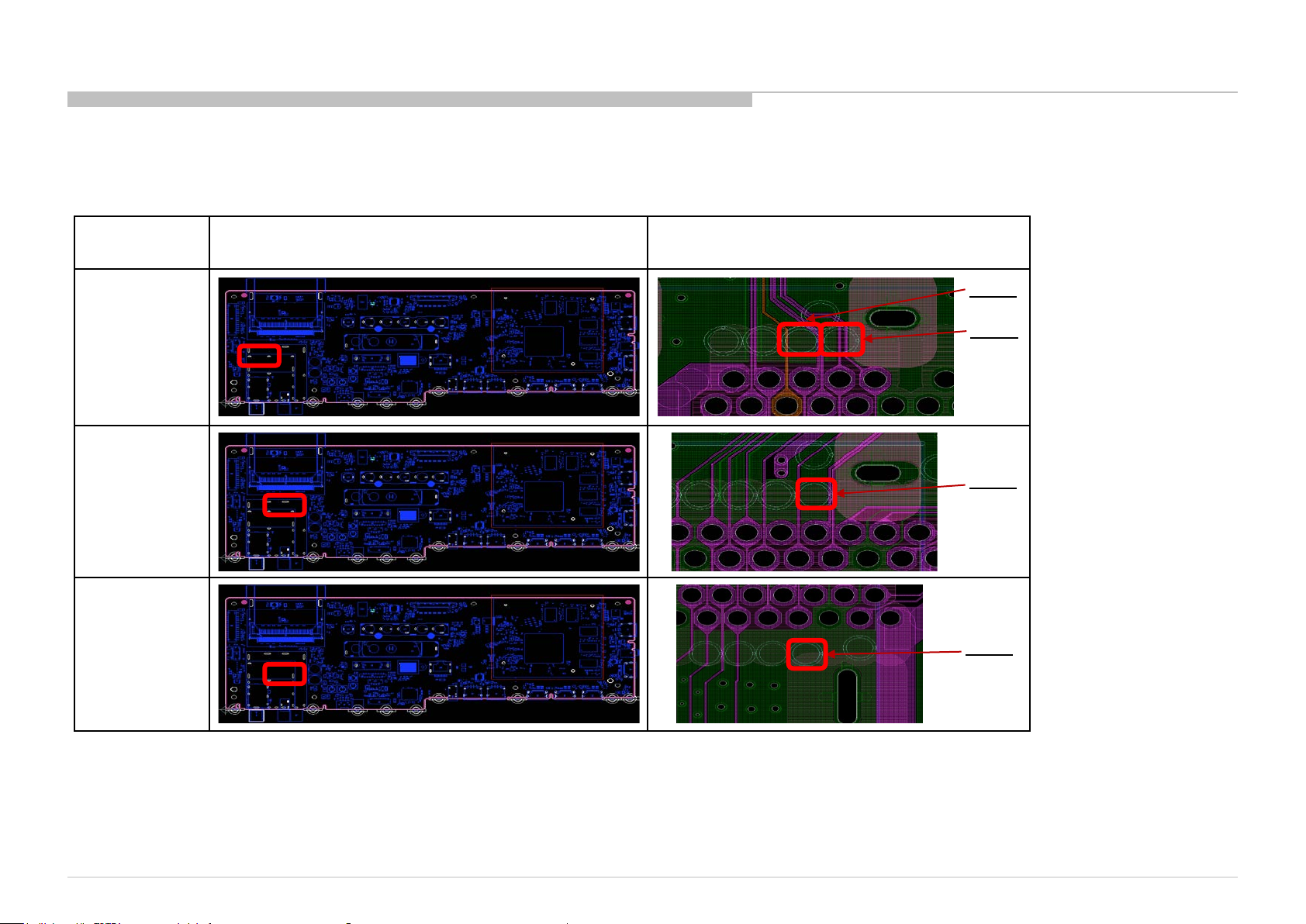

Troubleshooting

3-2-2. LED Blinking : 3x (DC Alert & Communi cation Error)

Troubleshooti ng References

Board Name Board PWB (A side) Detail

BMX

(L9015)

BMX

(F9103)

L9015

F9103

BMX

(IC9021)

IC9021

21

Troubleshooting

3-2-2. LED Blinking: 3x (DC Alert & Co mmunication Erro r)

Troubleshooti ng References

Board Name Board PWB (A side) Detail

BMX

(JL6010,

JL6011)

BMX

(JL6021)

BMX

(JL6022)

JL6010

JL6011

JL6021

JL6022

22

Troubleshooting

3-2-2. LED Blinking : 3x (DC Alert & Communi cation Error)

Troubleshooti ng References

Board Name Board PWB (A side) Detail

BMX

(CN9000)

BMX

(F7751)

CN9000

F7751

BMX

(IC7751)

IC7751

23

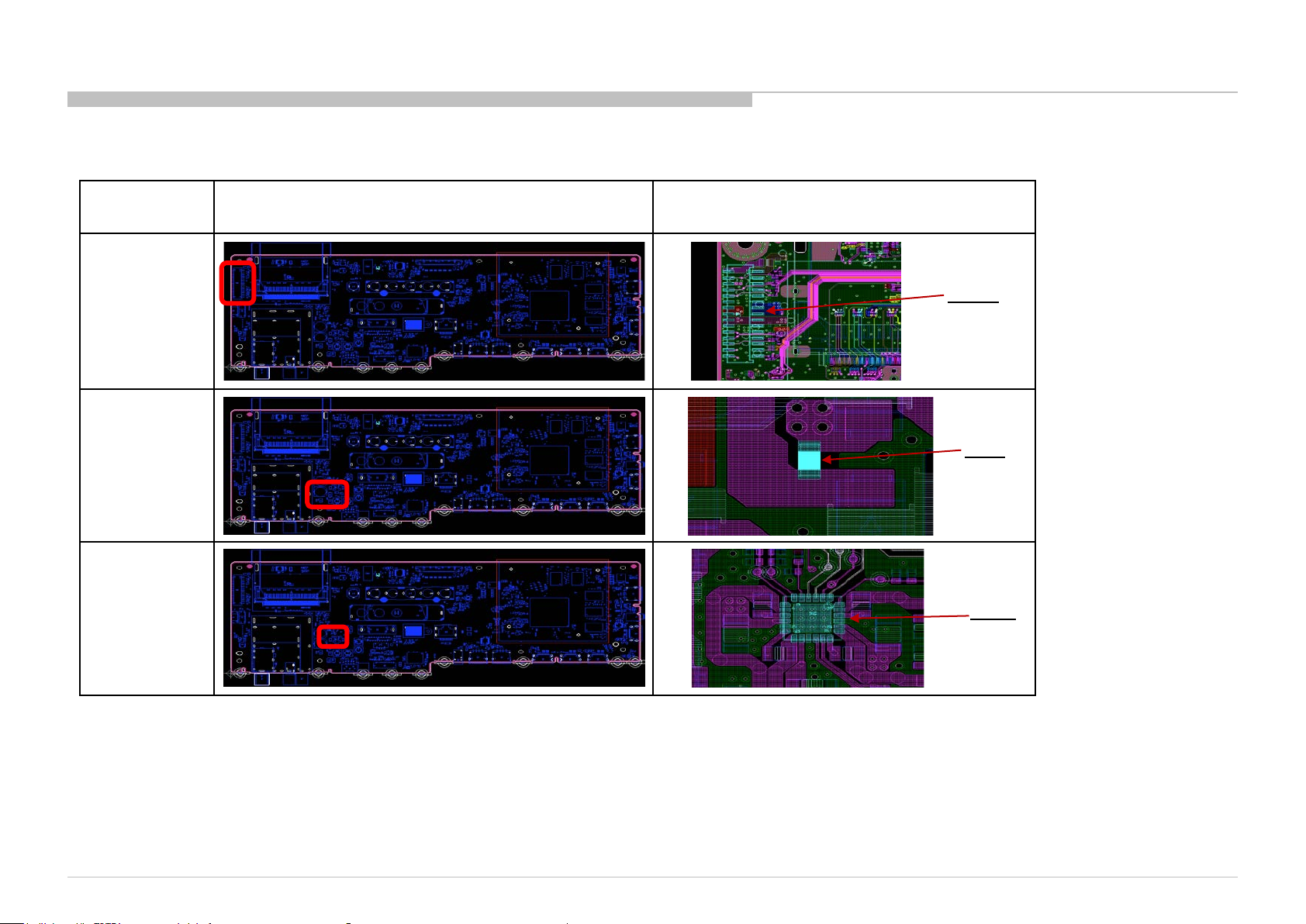

Troubleshooting

3-2-4. LED BLINKING 5x (Panel Communication Error) – a) 12.5V NG

5-times blinking

Check

PANEL_VCC 12.5V at

CN8400

on the B* Board

OK

Replace the Harness

Between G* /LD board

and B board

NG

Replace

the LVDS Harness

NG

Symptom

improve

Symptom

improve

XM-A/DT : *3-1-1 No Power

– LD Board

Check 12.5V

G*/LD Board

OK

LVDS Harness

NG

G* Board/LD

Harness

Change

B* Board

Symptom

improvement

B*Board

Refer I2C Error

Checking in next slide

NG

Change

Panel (T-con)

NG

Note: Board Details refer Section 3

main page.

24

Troubleshooting

3-2-4. LED BLINKING 5x (Panel Communication Error) – b) 12C Error

5-times blinking

PANEL ID Check

Check I2C (Data & CLK)

At CL

NG NG NG

XM-H/A/DT ( BM X) : CL8411 &

CL8412

OK OK

INIT_DONE

Check I2C (Data & CLK)

At CL

I2C Error

Change B-Board

NG

Change FFC

OK

OK

I2C Communication

Check I2C (Data & CLK)

At CL

B-Board NG

FFC NG

NG

Change FRC

OK

FRC NG

25

Troubleshooting

BMX (A-Side)

BMX Probing Points – I2C Line Check

CL8411

(I2C_S_DATA)

CL8412

(I2C_S_CLOCK)

26

Troubleshooting

3-2-5. LED BLINKING 6x (Backlight Error)

6-times blinking

Check

**JL9008

BL_ERR_DET

on B*Board

Voltage < 1.8 V

Voltage ≥ 1.9 V

Check

harness/connection

G*board to B*Board

or

LD board to B*Board

Harness /

Connection OK

G* Board

Refer to 1.5

Out1 & Out2 Check (LED_Output)

PSU OK

Harness /

Connection

broken

improvement

Improveme

Change

harness

No

G*Board

or LD?

Visual Check LS Bar

FFC Conductive Copper

Peel Off?

Yes

Change

Panel

No

Change

nt

B* board

Improvement

Symptom

LD

No

Symptom

Improvement

Symptom

Improvement

Harness

Suspect LS

Bar Broken

Panel

B* Board

**BMX: JL9008 BL_ERR_DET

27

Troubleshooting

3-2-5. LED BLINKING 6x (Backlight Error)

BMX: B Side

JL9008

28

Troubleshooting

3-2-6. LED BLINKING 7x (Temperature Error)

7-time blinking

Setting

circumstance is OK?

Temperature,

Ventilation, etc.

Yes

Change B* Board,

and Aging a few

hours

Symptom

improvement

B* Board

No

NG

Set to another

location, etc.

Panel

Check I2C_C bus

communication OK?

Yes

Temp sensor

IC1401

No

I2C_C bus dumping or

Troubleshooting Reference

Muffin check

Board Name Board PWB (A side) Detail

BMX

(IC1401)

IC1401

29

Troubleshooting

3-3. No Sound

No Sound

Check the UI

“Speakers” setting

In “AV Set-up”

“TV Speakers ”

Change the Speaker

Speaker Harness

Harness

Symptom

improvement

NG

“Audio System ”

Change to

“TV Speakers”

NG

the B* Board

Speaker impedanc e

~ 8ohm (+-1.2ohm ) ?

Replace speaker

Replace

NG

NG

Symptom

improvement

No problem

B* Board

No Sound: Audio

No Sound: Tuner

No Sound: HDMI

30

Loading...

Loading...