Sony KDL-43W750E Schematic

HISTORY INFORMATION FOR THE FOLLOW ING MANUAL:

SERVICE MANUAL (COMMON)

GN3UN CHASSIS

Segment: KM, KMW

Version Date Subject

1 02/2017 1st Issue.

2 02/2017 1. Add Segments KML, KMLW , KL , KLW .

2. Add Block and Connector D iagram for all segments

3. Add Note for Sect ion 5 Circuit B oard Location.

3 03/2017 1. Add Model Name on pg 3

KML, KMLW

KL, KLW.

LCD TV

9-888-723-03

For SM - Unique , please refer :

9-888-723-Ax ( America )

9-888-723-Cx ( China)

9-888-723-Ex ( Europe )

9-888-723-Px ( Pan As ia)

SERVICE MANUAL (COMMON)

GN3UN CHASSIS

Segment: KM, KMW

KML, KMLW

KL, KLW.

LCD TV

KDL

KDL

KDL

KDL

KDL

KDL

KLV

KLV

KLV

KDL

KDL

KLV

KLV

KDL

KDL

KDL

KDL

KLV

KLV

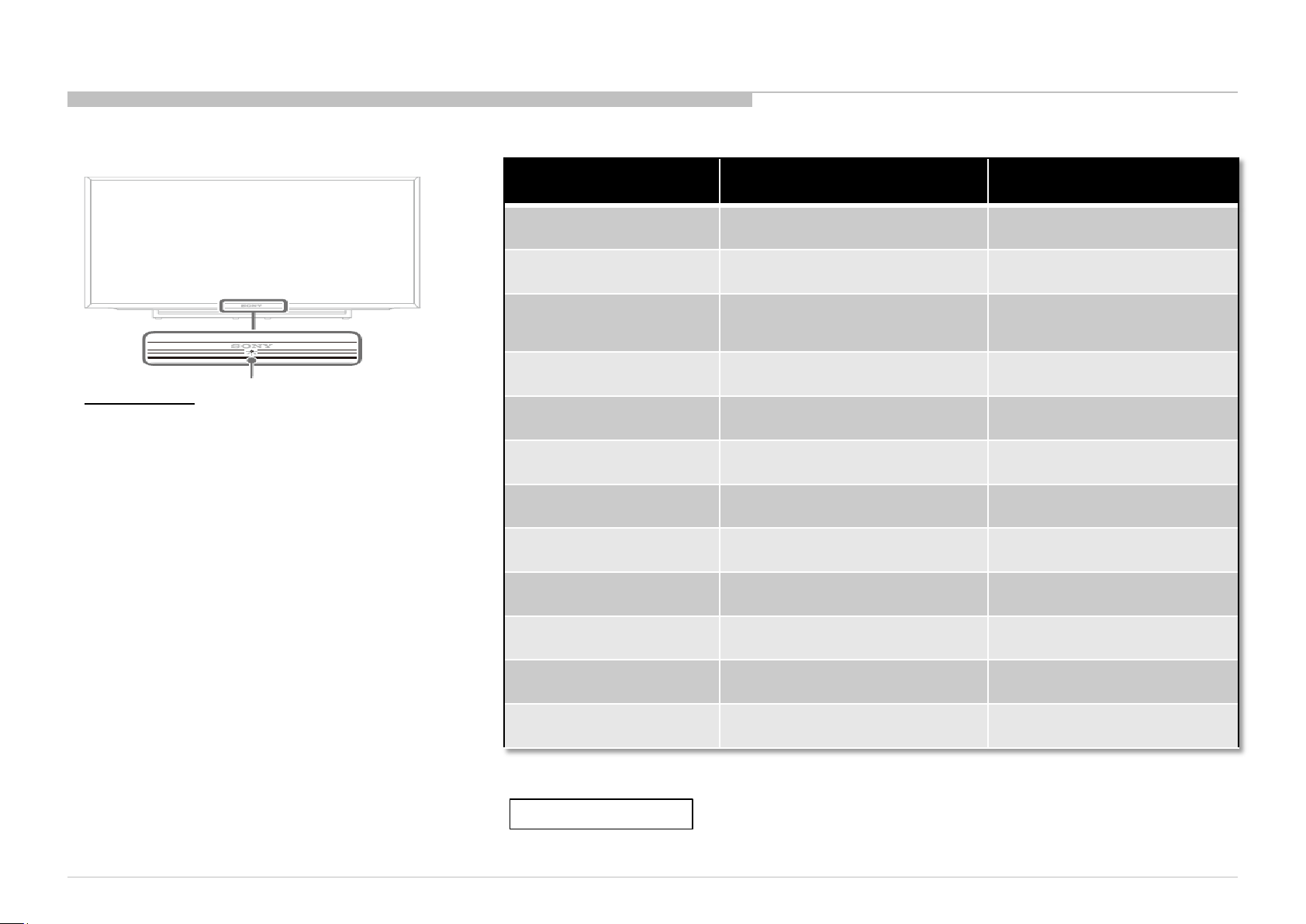

MODEL LIST

THIS SERVICE MANUAL CONTAINS COMMON INFORMA TION F OR BELOW REGIONS AND MODELS:

REGION

ASIA AMERICA EUROPE CHINA

SEGMENT MODEL

KM

KMW

KML

KMLW

KL

KLW

-32W6*E

-32WE6*

-32W6*E

-32RE4*

-32R4*E

-43W750E

-43WE753

-43W772E

-40W6*E

-40WE6*

-40W6*E

-40RE4*

-40R4*E

-43W750E

-43WE753

-49W772E

-49W6*E

-49WE6*

-49W6*E

4. SERVICE ADJUSTMENTS

5. DIAGRAMS

TABLE OF CONTEN TS

Section Title Page

1. SAFETY NOTES 5

2. SELF DIA GNOSTIC FUN CTION 14

3. TROUBL E SHOOTIN G 17

123

151

Please refer to GN3UN Service Procedure for Panel , Board and Software Change /

Upgrade Manual , part number 9-888-724-0x in TISS .

Please refer Service Manual – Unique for below information :

-Safety Warnings

-Wire Dressing

-Circuit Board Location

-Disassembly and Exploded View.

Note: Pictures provided in this Service Manual might have slight difference from the

actual sets.

4

SECTION 1

SAFETY NOTES

1-1. Warn ings and Caution

1) These servicing instructions are for use by qualified service personnel only.

2) To reduce the risk of electric shock, do not perform any servicing other than

that contained in the operating instructions unless you are qualified to do so.

3) An isolation transformer should be used during any service to avoid

Possible shock hazard, because of live chassis. The chassis of this receiver is

directly connected to the ac power line.

4) Be sure to follow these guidelines to protect your property and

avoid causing serious injury :

• Carry the TV with an adequate number of people; larger size TVs require

two or more people.

• Correct hand placement while carrying the TV is very important for

safety and to avoid damages.

5) Components identified by shading and mark on the exploded views,

and in the parts list are critical for safe operation. Replace these

components with Sony parts whose part numbers appear as shown in this

manual or in supplements published by Sony. Circuit adjustments that are

critical for safe operation are identified in this manual. Follow these

procedures whenever critical components are replaced or improper

operation is suspected.

!

1-2. Caution Handling o f LCD Panel

When repairing t he LCD Panel, make s ure you are grounded wi th a wrist band.

When repairing t he LCD Panel on the wall, the panel must be secur ed usi ng the

4 mounting hol es on the rear cover .

1) Do not press the panel or frame edge to av oid the risk of electric shock.

2) Do not scr atch or press on the panel with any sharp objec ts.

3) Do not leave the module in high temper ature or in areas of high humidi ty for

an extended per iod of time.

4) Do not expose the LCD panel to direct sunlight.

5) Avoid contact with water . I t may cause short c irc uit within the module.

6) Disc onnect the AC power when replaci ng the backl ight (C CFL) or

inverter cir cuit . (Hi gh voltage occur s at the inver ter ci rcui t at 650Vrms)

7) Always clean the LCD panel with a soft cloth mater ial .

8) Use care when handli ng the wir es or connectors of the inver ter ci rcui t.

Damaging the wires may cause a short circuit.

9) Protect the panel from ESD to avoid damaging the elec troni c circuit (C-MOS).

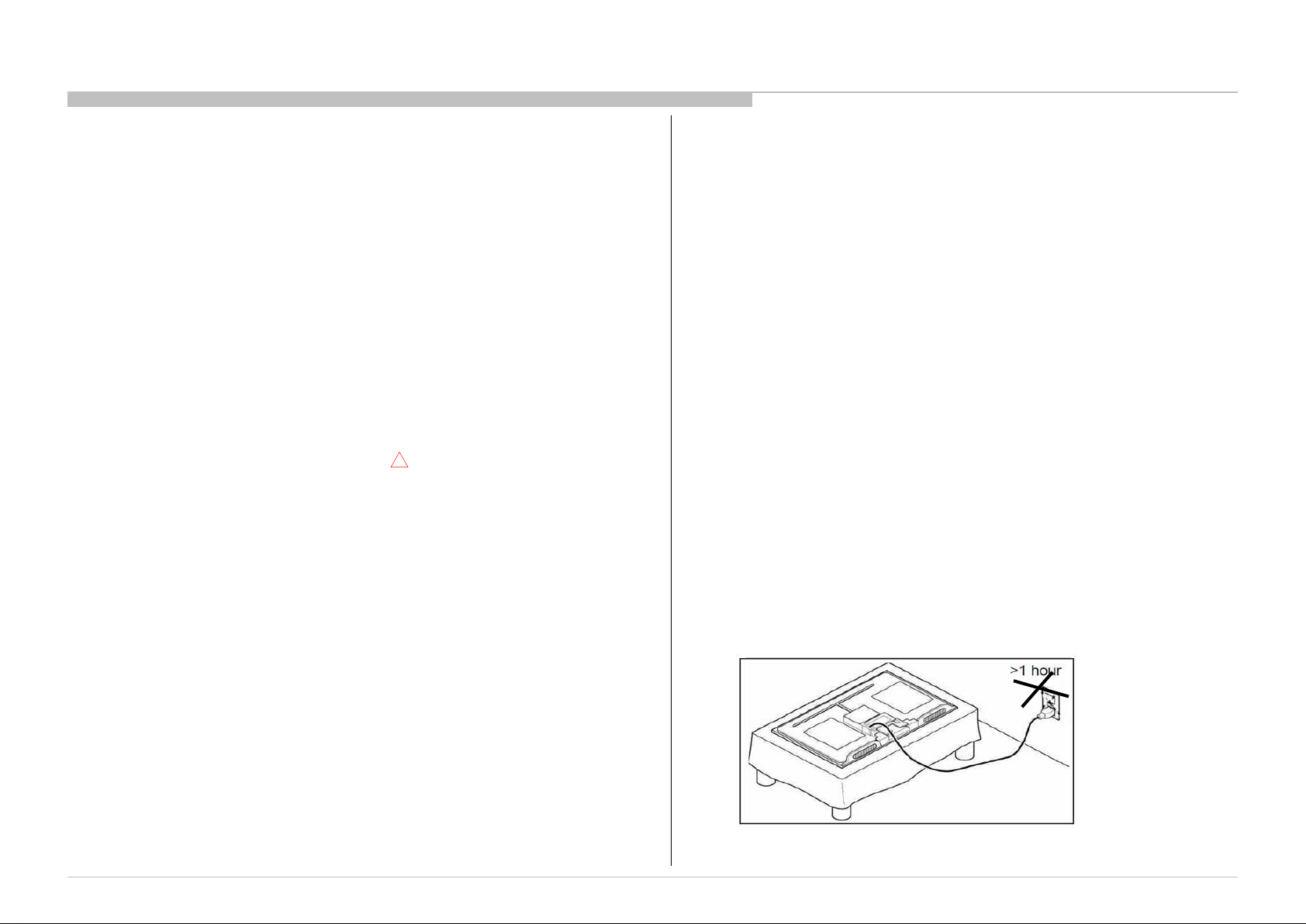

10) Dur i ng the r epai r , D O NO T l eav e the Pow er On or Burn-in period for more

than 1 hour w hil e the T V i s face dow n on a c l oth.

Figure 1. TV is faced down on a cloth during repair.

5

1-3. Caution About the Lithium Battery

1) Danger of explosion if battery is incorrectl y replaced. Replace only with

the same or equivalent type.

2) Outer case broken battery shoul d not contact to water.

1-4. Safety Check-Out

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:-

1) Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and bridges.

2) Check the inter board wiring to ensure that no wires are pinched or

contact high-wattage resistors.

3)Check all control knobs, shields, covers, ground straps and mounting

hardware have been replaced. Be absolutely certain you have replaced all

the insulators.

4) Look for unauthorized replacement parts, particularly transistors that

were installed during a previous repair. Point them out to the customer and

recommend their replacement.

5) Look for parts which, though functioning show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6) Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7) Check the antenna terminals, metal trim, metalized knobs, screws and all

other exposed metal parts for AC leakage. Check leakage test as described

next.

8. For safety reasons, repairing the Power board and/or Inverter board is

prohibited.

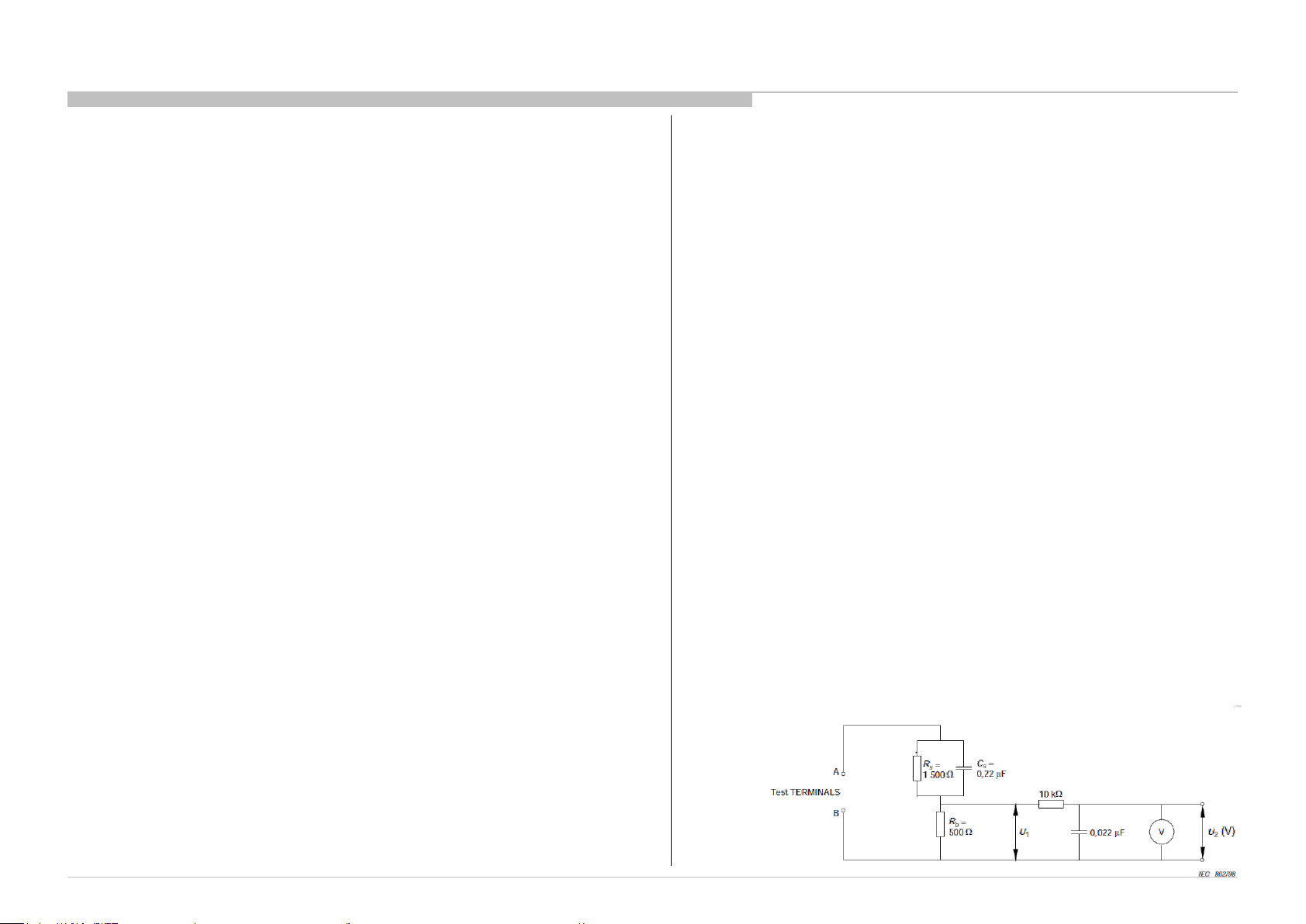

1-5.Leakage Test

(To protect elec tri c shock when custom er touch the ter minal .)

Leakage curr ent can be measured by V: Voltmeter or oscilloscope (r.m.s. or

peak reading)

Stabilized pow er supply instrument and isol ated voltage transform er:

Use too much curr ent c apacity and isol ated voltage tr ansformer does not

need to use stabili zed power supply equipm ent.

Specificati on of RM S volt meter: I nput res istanc e > 1 Mohm, Input

capacitance < 200 pF, Frequency range: 15 Hz – 1M Hz . Refer Figure 1.

Isolated ty pe volt -meter (FLUKE 8921A etc *1)

*1 Not use FLU KE 8920A that connect ed to protec tive earth by diode

# Leakage current of measurement instr ument is less than 10μArms when

under test equi pment AC plug is opened

# Set up the following conditi on and tur n on the set. Applied v oltage:

Nominal i nput volt age (Des cri ption on Nam eplate)

# Measur e the leakage cur rent bet ween one phas e conduc tor and neutral

for terminal 1 and terminal

2. Read rms value, and then calculate to peak value PEAK VALUE =√2

RMS VALUE

Comply w ith the following requir ement

Class II equipment (2-pin pl ug): for each ter mi nal, the w orst value of

measurement must not exceed AC 283uA peak).

Note: includi ng AC adaptor, AC adaptor/DC operated unit combi nation

Note: Pr oduct s which ar e al w ays used in touch w i th hum an body : 141uA

(peak)

Note: As for products destined for Southeast Asia (Rod Antenna is

accessory . Or it is packed with a pr oduc t.) , the worst value must not exceed

AC 141uA (peak).

Figure 1 – Measuring network

for Leakage Current

6

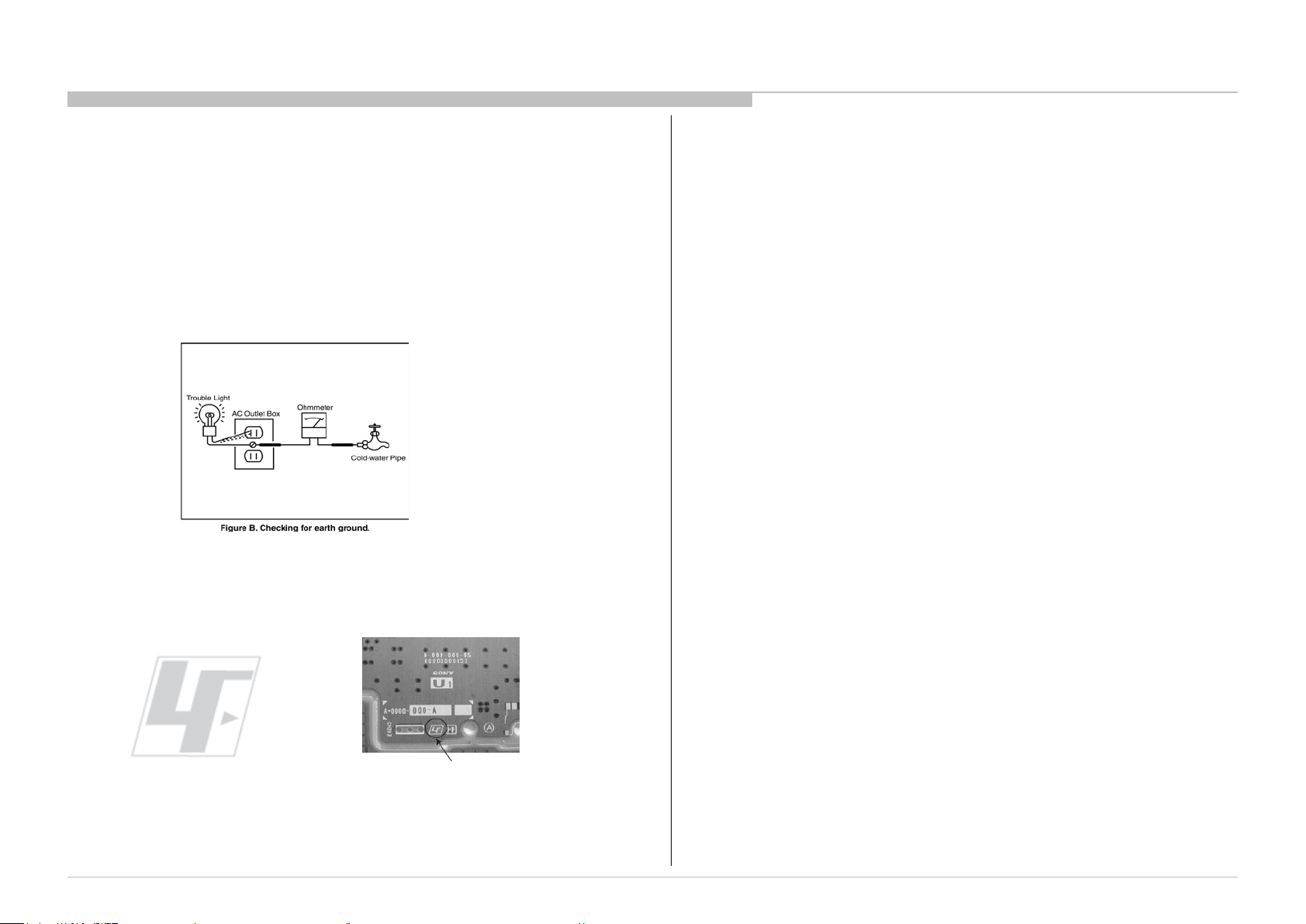

1-6. How to Find a Good Earth Ground

1) A cold-water pi pe is a guaranteed ear th ground; t he cover-pl ate retaini ng

screw on most AC outlet boxes i s also at earth ground.

2) If the retaining scr ew is to be used as your earth ground, veri fy that it is at

ground by measuri ng the resistanc e between i t and a c ol d-w ater pipe w ith an

ohmmeter. The readi ng should be zer o ohms.

3) I f a cold-w ater pi pe is not accessi ble, connect a 60- to 100-watt t roublelight (not a neon lamp) between the hot side of the recept acle and the

retaining scr ew. Tr y both slots, if necess ary, to locate the hot s ide on the line;

the l am p shoul d l i ght at normal br il l i ance i f the sc r ew i s at gr ound pot enti al

(see Figur e 3).

Figure 3. Checking for earth

ground.

1-7. Lead Free Information

The circui t boards used i n these model s have been pr ocessed using Lead

Free Solder. The boards ar e identified by the LF logo loc ated clos e to the

board designation.

The servic ing of these boar ds r equires special precautions. It is strongly

recommended to use Lead Free Solder m ateri al in order to guarantee optim al

Figure 4: LF Logo

Figure 5: LF logo on circuit board

quality of new solder joi nts.

7

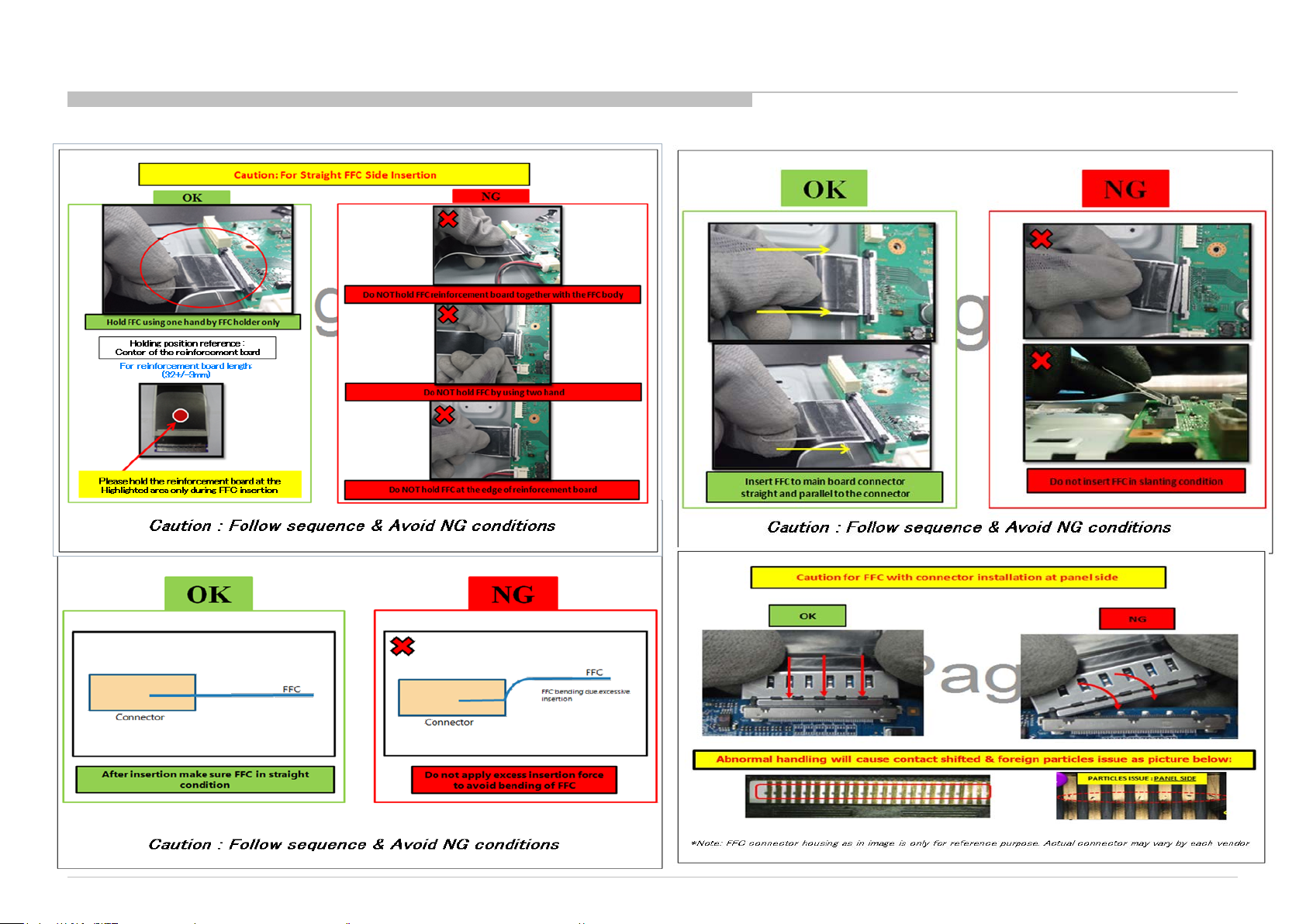

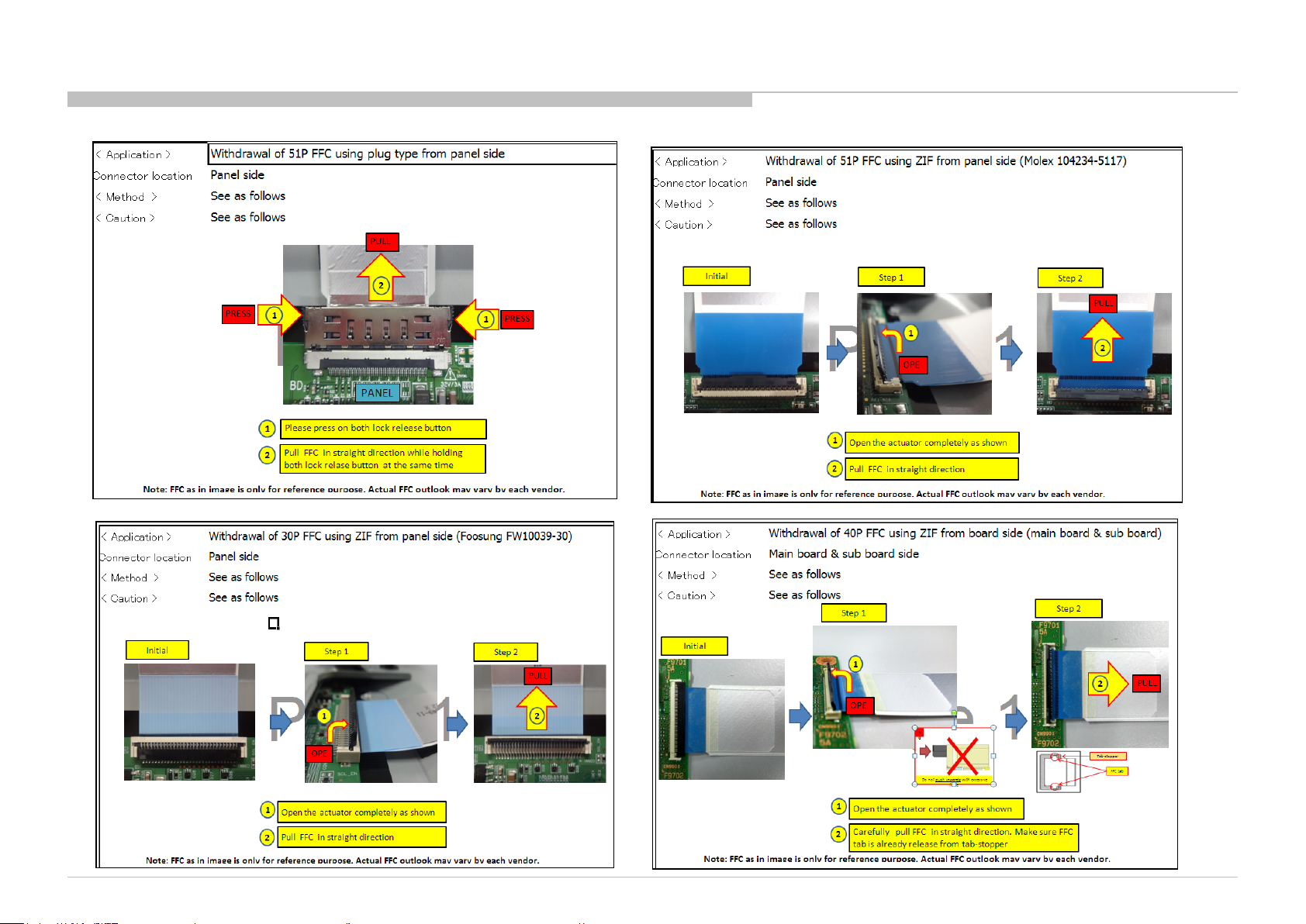

1-8. Handling the FLEXIBLE FLAT CABLE (FFC) ( continue )

8

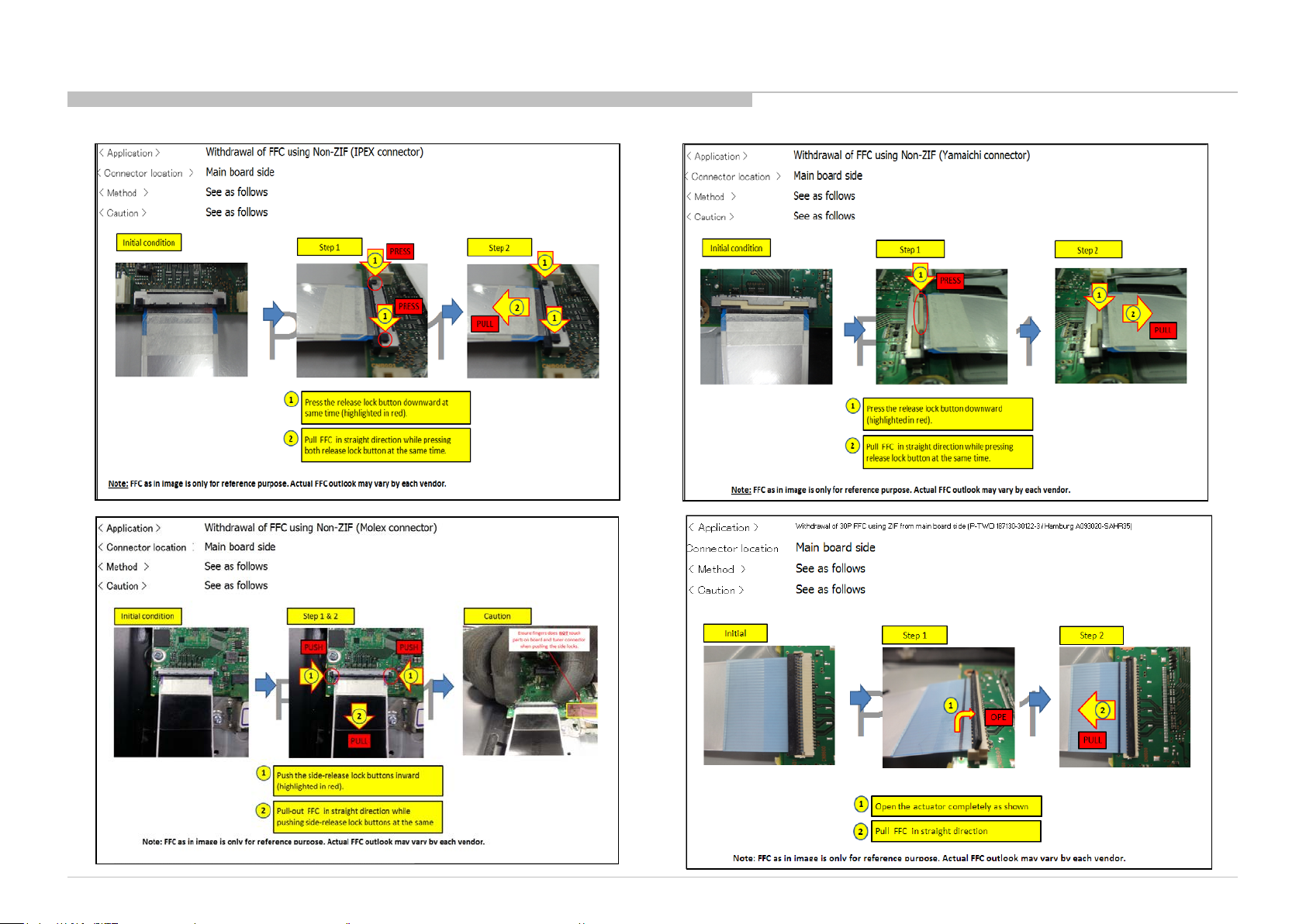

1-8. Handling the FLEXIBLE FLAT CABLE (FFC) ( continue )

9

1-8. Handling the FLEXIBLE FLAT CABLE (FFC) ( continue )

10

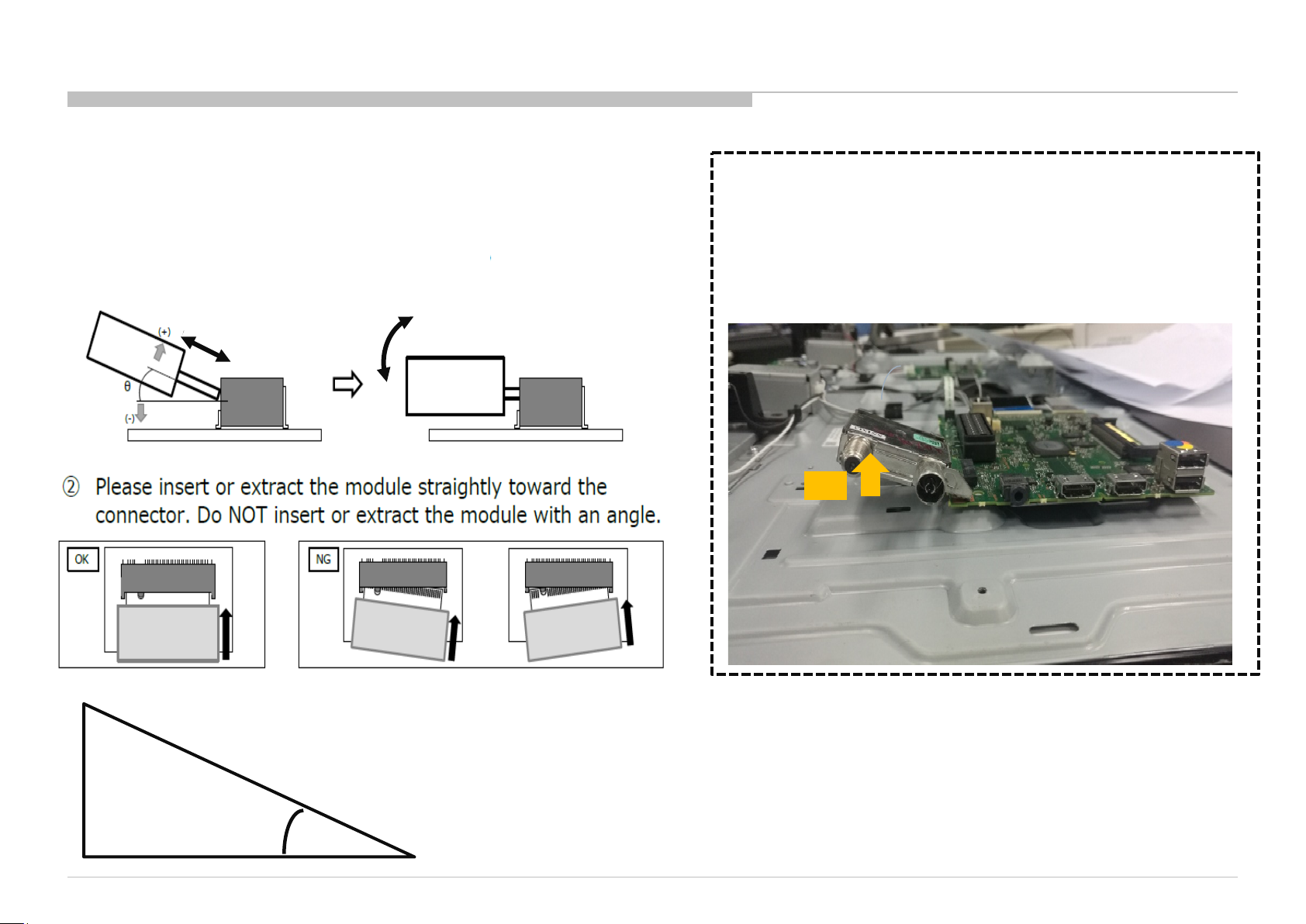

1-9. Solder-less tuner replacement procedure

Tuner Module treatment way

① The insertion & extraction angle of the module is permitted to

specified degree for connector

θ≒20°

Push down to screw.

For removing Tuner Module,

After un screwed, Automatically the Module

will float to correct degree.

So please extract it with keeping this degree.

20°

20°

Reference paper for 20 degree

(If need please use for fit by cutting t his paper)

11

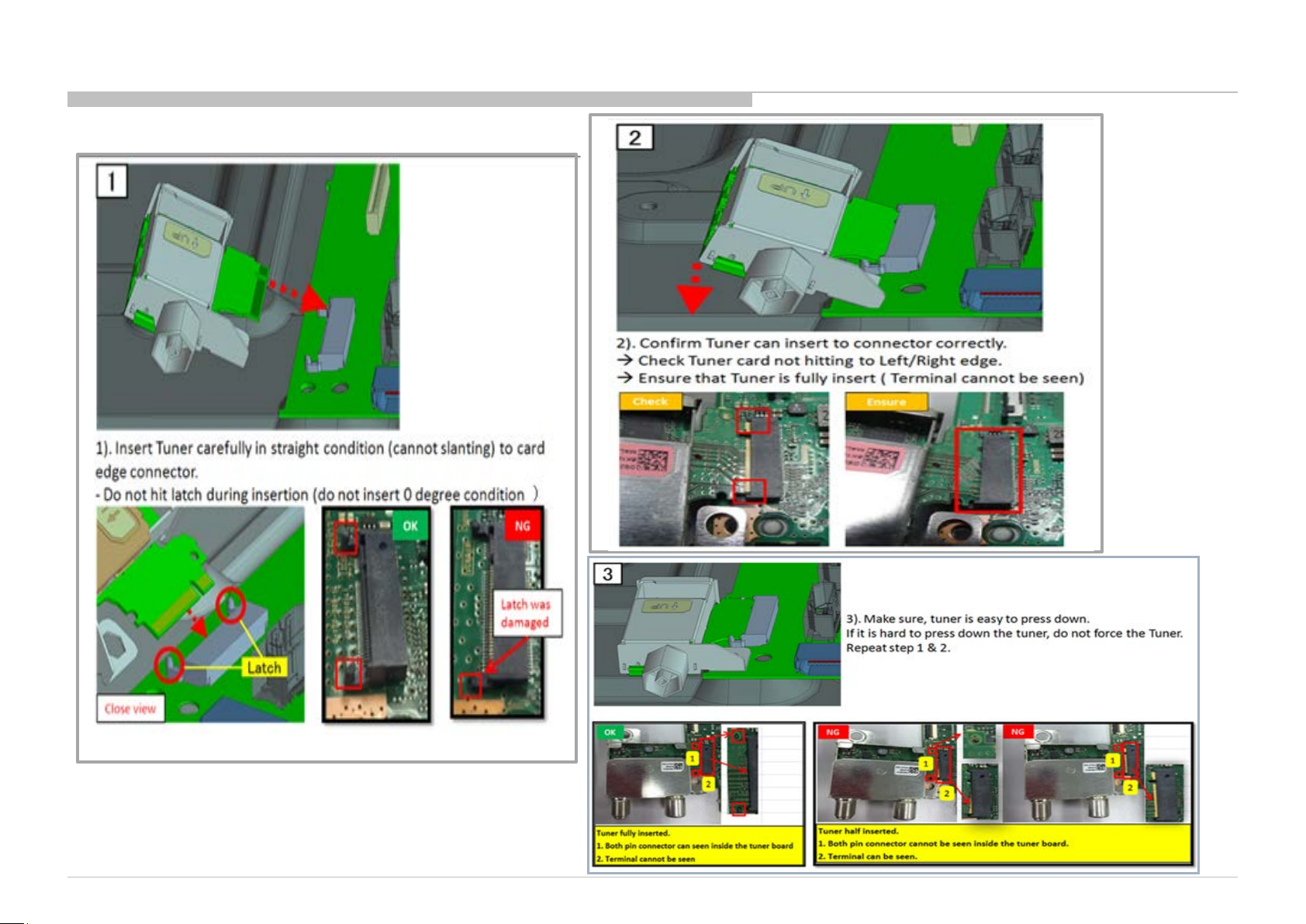

1-9. Solder-less tuner replacement procedure (Cont. )

12

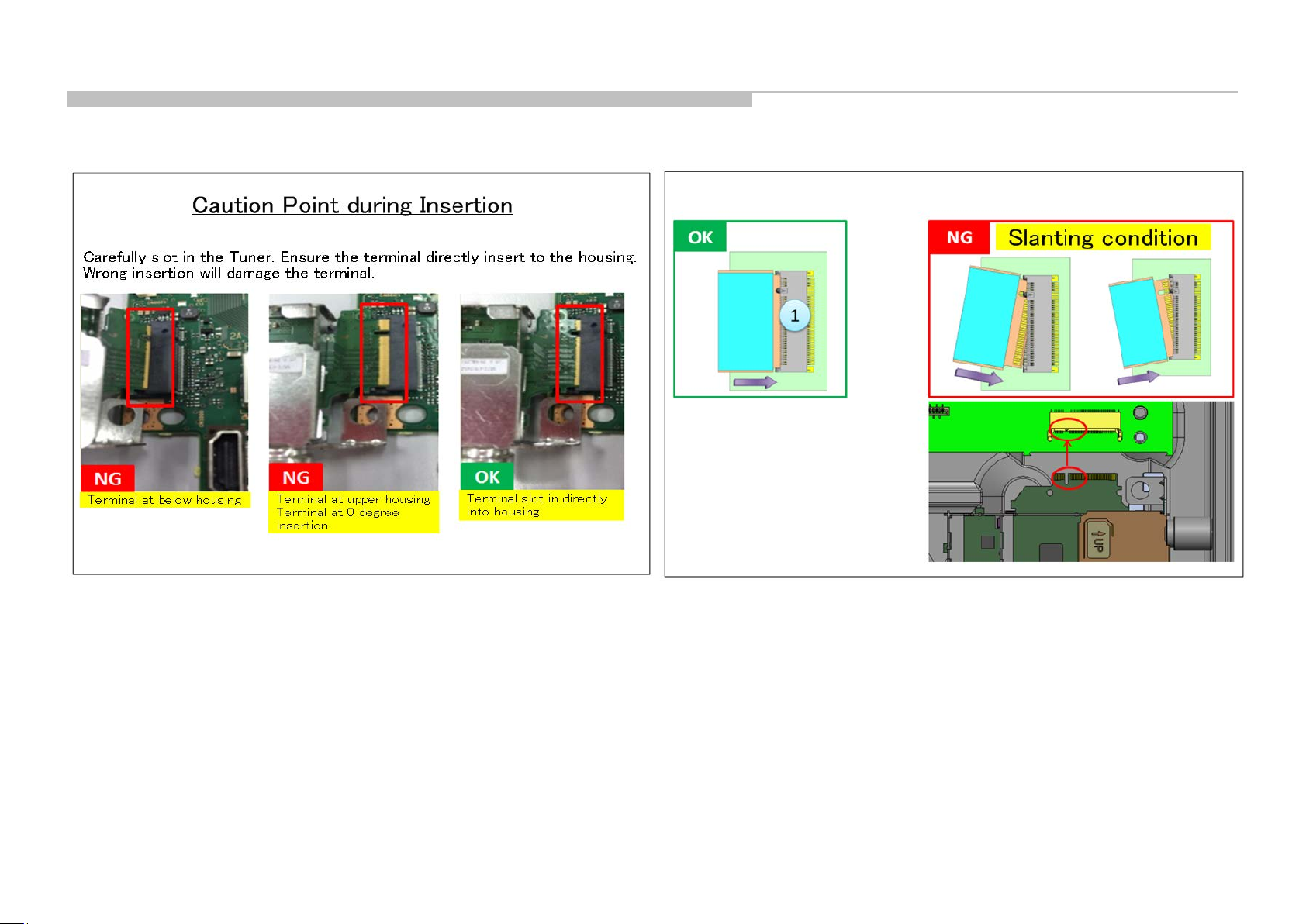

1-9. Solder-less tuner replacement procedure ( Cont. )

13

SECTION 2

SELF DIAGNOSTIC FUNCTION

LED Indicator

• Lights up in white when you select “ Pict ure Off”.

• Lights up in amber when you set the tim er or

“Photo Frame Mode”.

• Lights up in white when the TV is turned on.

• Flashes whil e the remote is being oper ated.

Status

Power Off

( AC Off and *1)

Power On

Standby

( by remote control of f

and Side Key off)

Picture Off

Set "Sleep Timer"

Set "On Timer"

( Power On )

Set "On Timer"

( Standby )

Picture Frame

Failure

Error of panel ID

LED Colour

OFF

White

OFF

White

Amber

Amber

Amber

Amber

Red Blinking

Amber / Green Blinking

Remarks

*1 power swit ch of f (by Side

Key)

The number of LED blinking

indicates cause of failure.

Blinki ng:0.5sec Amber/ 0 .5sec

Green

Software Updating

Softwa re U pdati ng

failure

Amber = Red + Green

Amber Blinking

Amber / Red Blinking

Blinking: 1sec On / 1sec Off

Blinking:1 sec Amber/ 1sec R ed

14

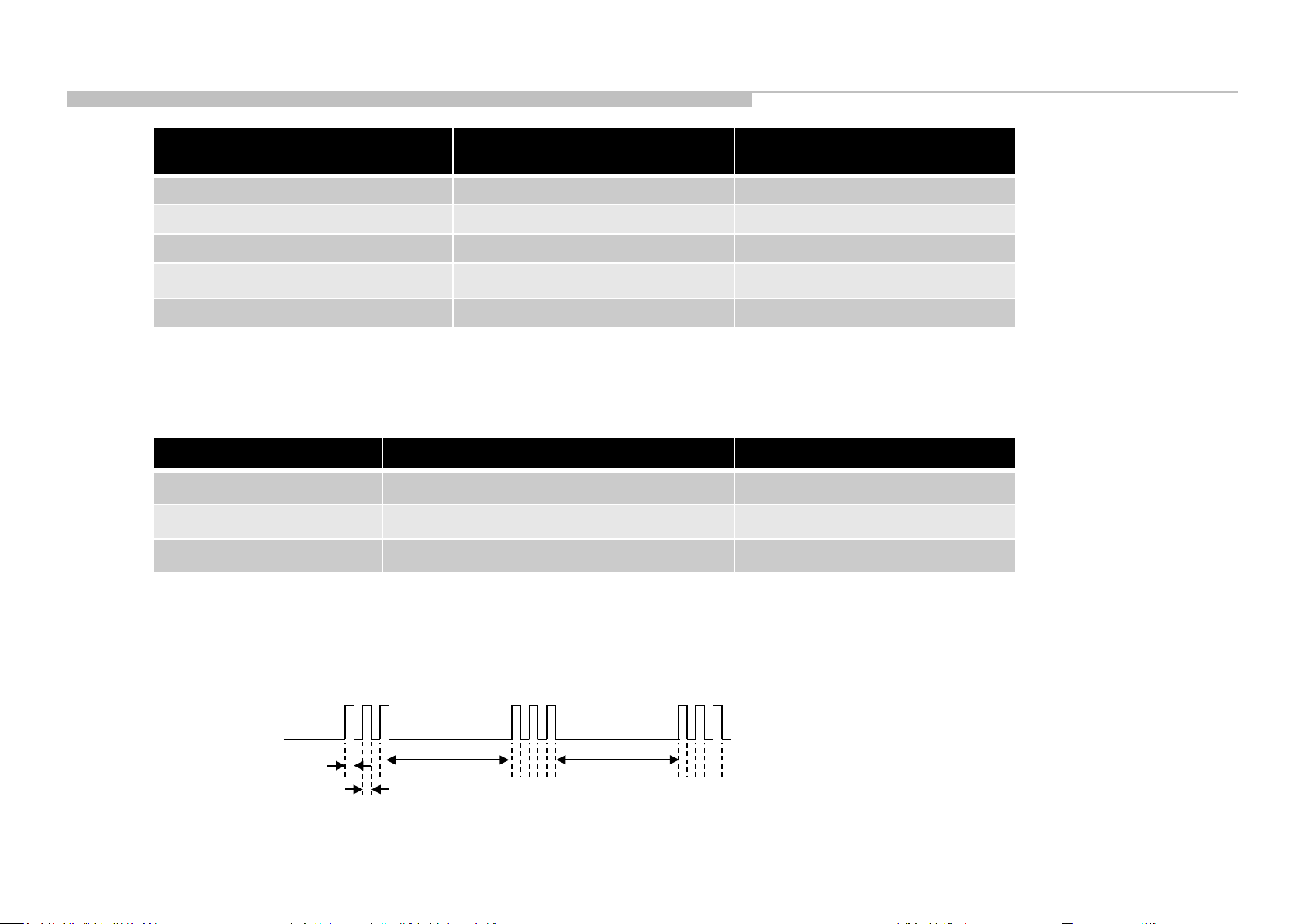

The Number of Standby LED

(RED blinking)

Error Detection Error Location

2 Main Powe r Error AC Adaptor

3 Audio Error Main Board or Sub Board (LK)

4 Panel Po wer E rror Main Board

5 Panel I2C Comm Error Main Bo ard or Source Board

6 Backli ght E rror Main Board or Sub Board (LK)

Tuner Demod Error, BE_I2C Error and PMIC_I2C do not go to Safety Shutdown and

do not have RED blinking.

Error Detection Symptoms Error Location

Tuner Demod Error Cannot tune Digital RF/ Analog RF Main Board/Tuner Module

BE I2C Error No picture display Main Board

PMIC I2C error No power Main Board

LED Pattern

When safety shutdown occurs, Standby LED display reports the cause by using the lightning patterns as indicated below.

0.5sec

Example: The figure above shows LED display when SHUTDOW N is caused by Audio Error.

It repeats f lashing f or a specified number of times in 0.5s ec/cycl e and has a 3 seconds interval of lighting off.

Please note t hat a 3 sec onds int erv al of light ing off is fixed regar dl ess of abnor m al s tate typ es.

0.5sec

3.0sec 3.0sec

15

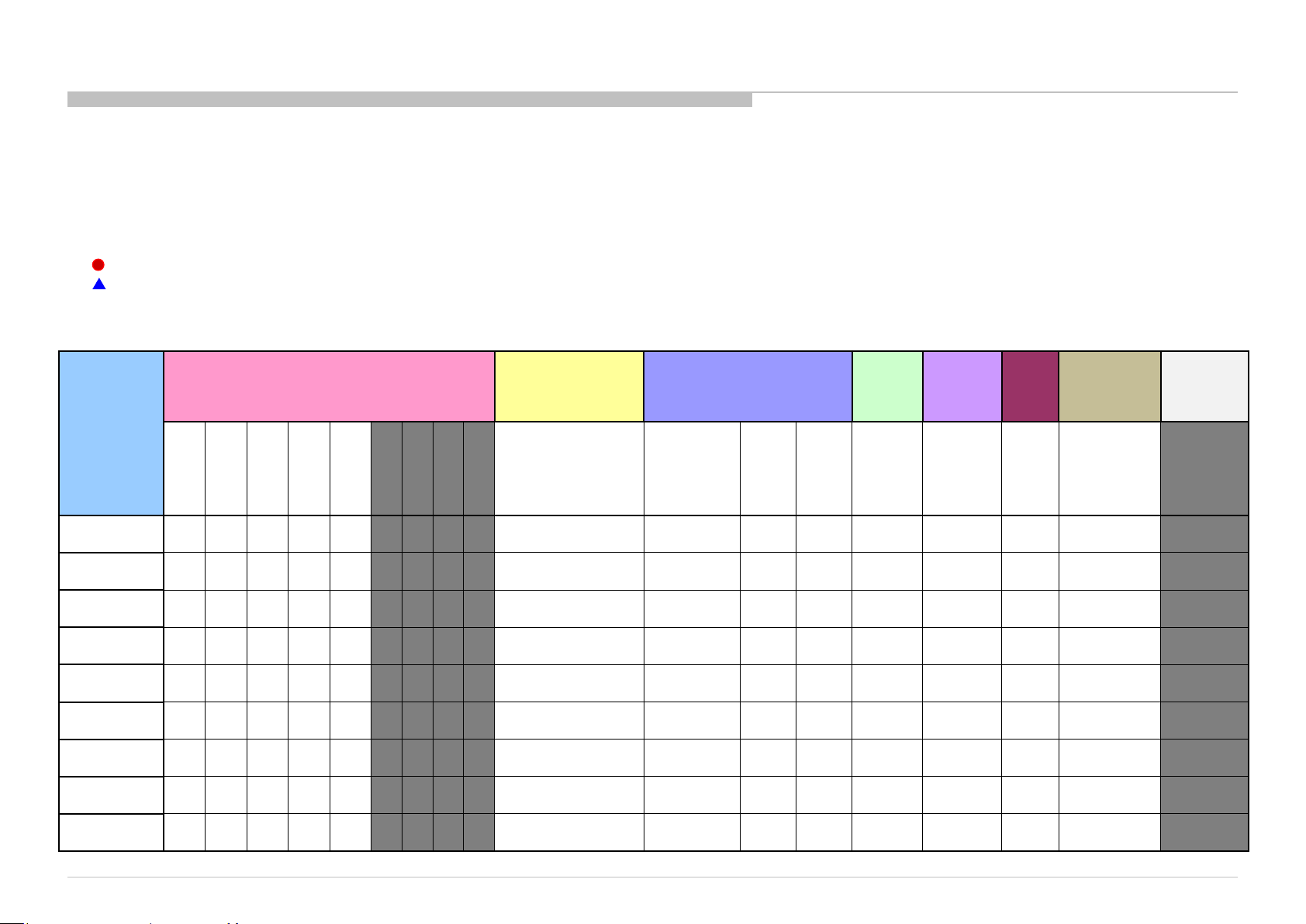

Triage C hart

Before you make t he service cal l…

1. Confirm the symptom from the customer.

2. Select that sympto m fro m the chart.

3. Bring a ll the b o a r d s and ca b les liste d for that symp to m.

4. Follow the troub lesho oting c harts in the technical guid es to isolate the boar d.

5. Chart

Remote

Smart Core

(KL) / LED

Bluetooth

reponse to remote

Stationary

dots

One of

no LED (Set

Bluetooth

/ One Step

(OSR)can't

Wifi Module

Color Code

RED DOT: Mo st likely defective pa r t

BLUE TRIANGLE: Secondary possible defective part

ABC BLACK TEXT: Board that may correct the symptom

GN3UN Chassis

Reference

Symptoms - Shutdown. Power LED

blinking red diagnostics sequences

2 3 4 5 6 7 8 9 10

No White Po wer

LED & does not

No

Power

(Dead Set)

B* Board

LK* Board

H* Board

K* Board

Speaker &

Subwoofer

Adaptor

LCD Panel

Tcon

Video

- mi ssing or distorted

colored

lines or

No

video

Inputs

No

video

all

Inputs

Network Audio

(KM)

No

Remote

Wireless

can't

connect

Audio

No

Smart Core

is still alive)

(BT)

Remote

connect

16

Problem/Issue

SECTION 3

Trouble Shooting Flow

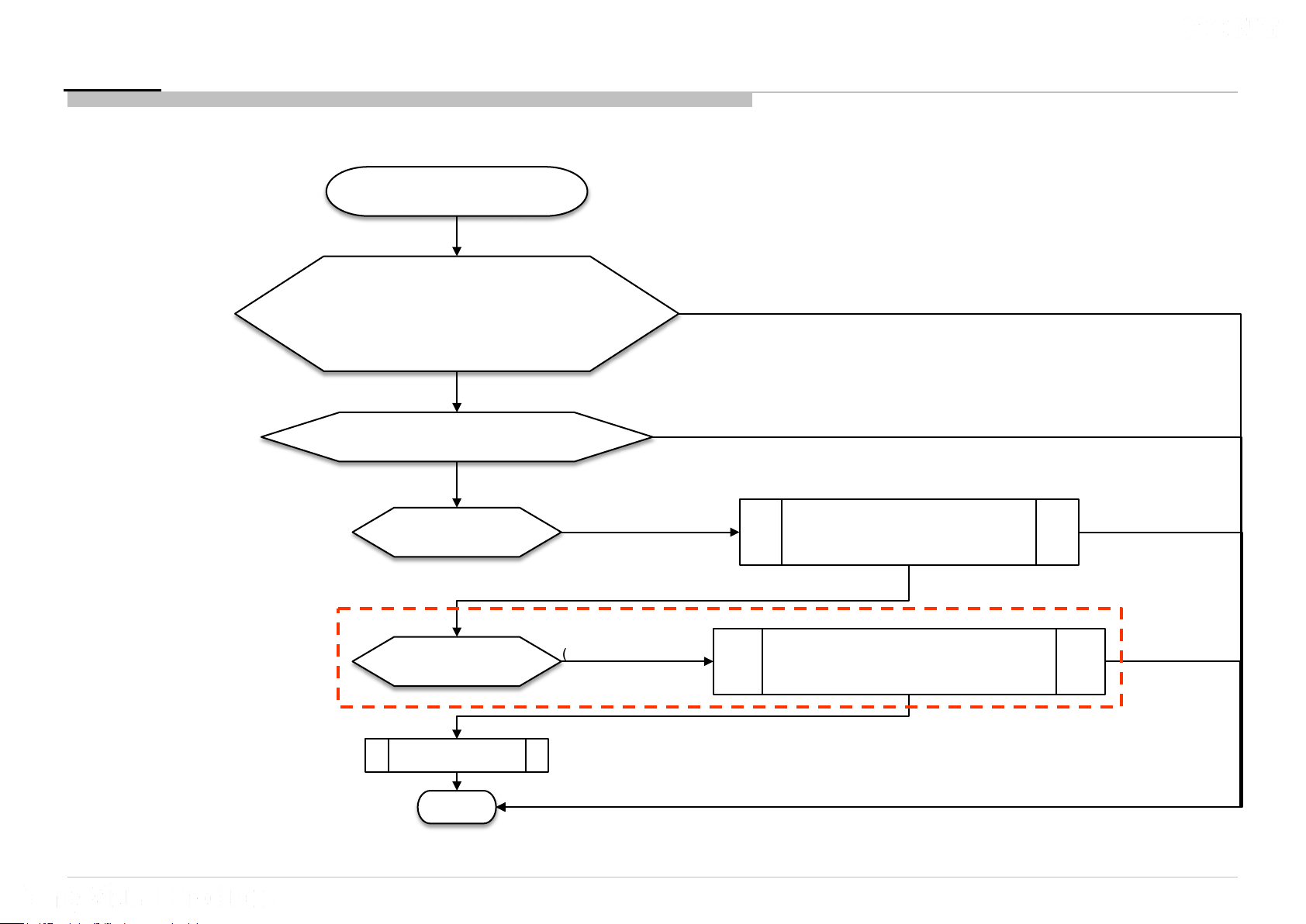

3a Trouble Shooting Flow 2x blinking – Main Power Error

Section

3

2x blinking –

Main Powe r Error

Title

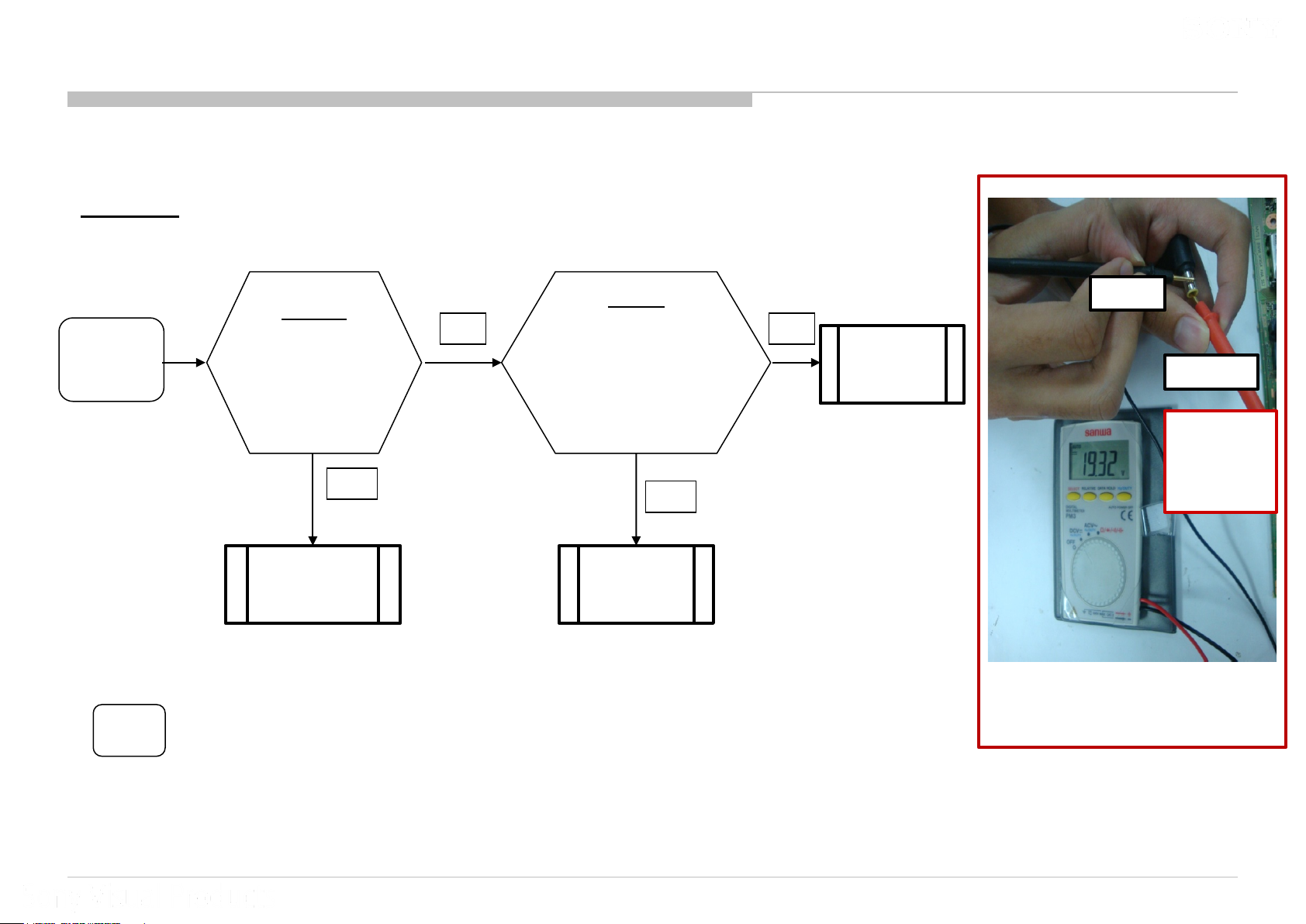

3a.1 2x blinking – Main Power Error

17

3a.1. 2x Blinking – Main Power Error

LK Board

2 times

Blinking

*For LK2

LK-Board

Check DC voltage at

Q6020/ *Q6022

18V – 22.5V?

*Typical: 19.5V

Yes

Change LK-

board

No

Adaptor

Take out adaptor

and check the output voltage.

18V – 22.5V?

(Refer Figure 1)

*Typical: 19.5V

Yes

Change LK-

Board

No

Change

Adaptor

-ve

+ve

Ensure that

+ve probe is

touching the

needle.

Figure 1: How to check adaptor’s output

voltage.

18

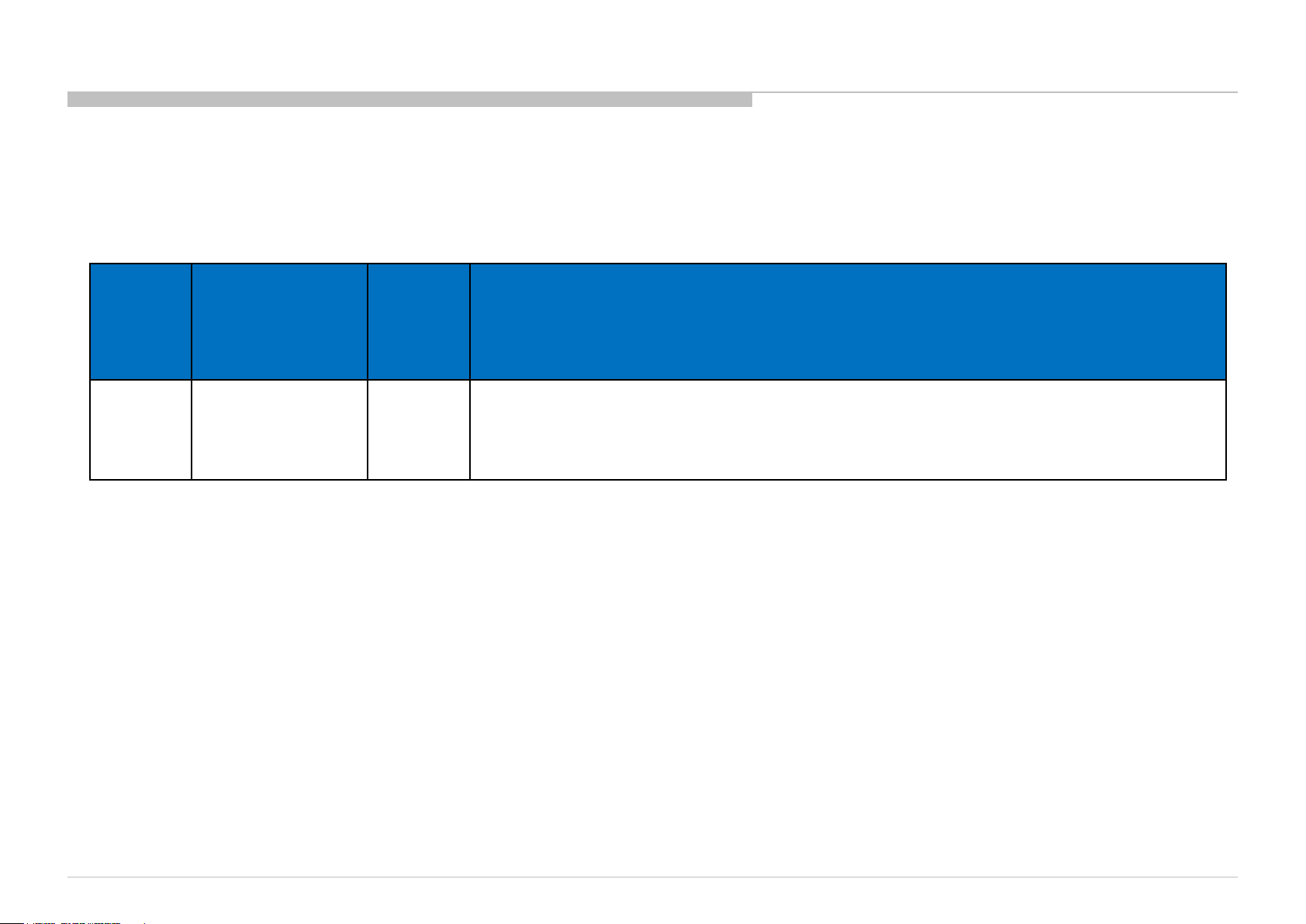

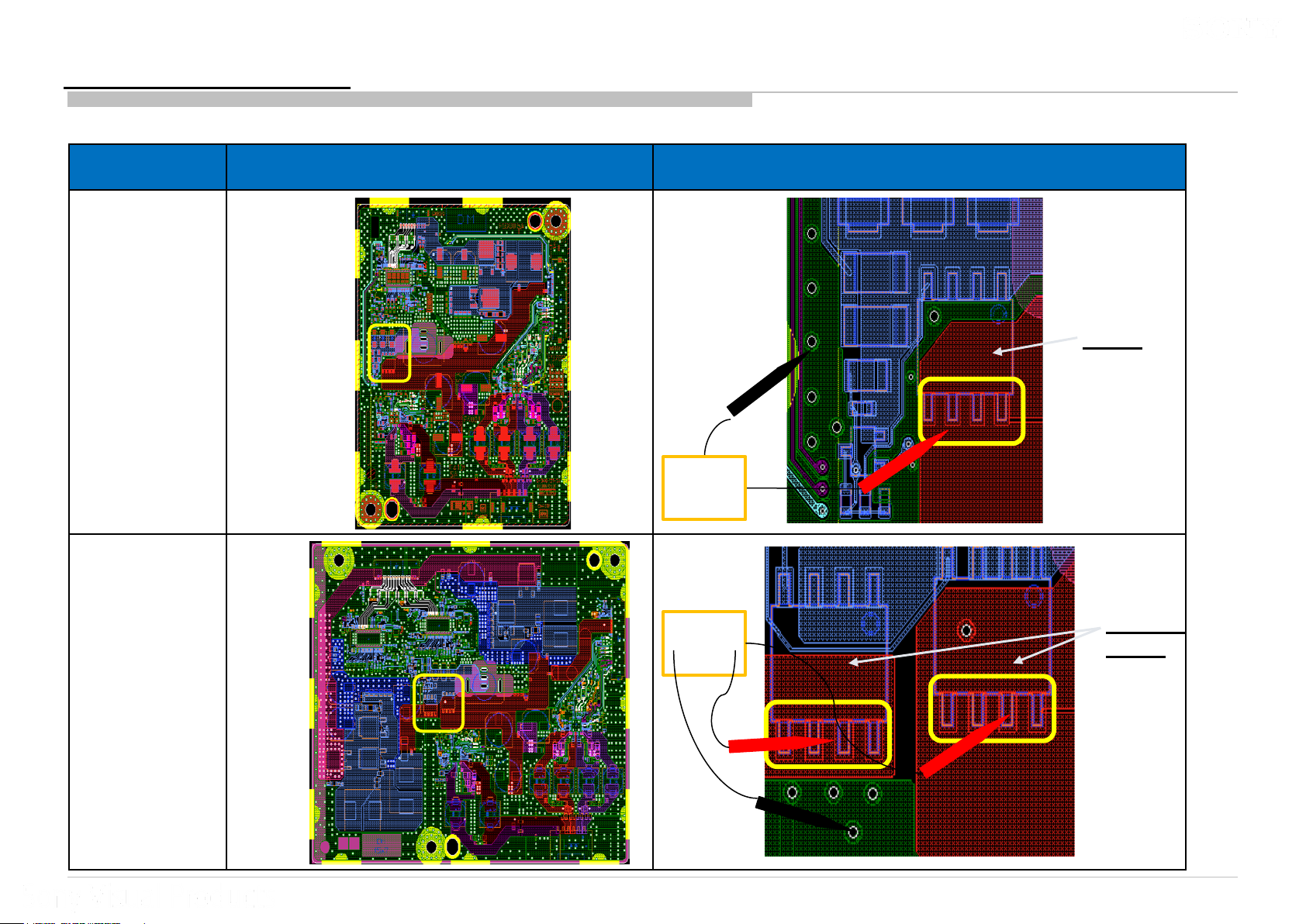

3a.1 : 2x Blinking – Main Power Error

LK Board (Checking point)

Board Name Board PWB (A side) Detail

LK1

(Q6020)

19.5

V

Q6020

LK2

(Q6020 &

Q6022)

19.5

V

Q6020 &

Q6022

19

Problem/Issue

3b Trouble Shooting Flow 3x blinking – Audio Error

Section

3

3x blinking –

Audio Error

Title

3b.1 3x blinking – Audio Error

20

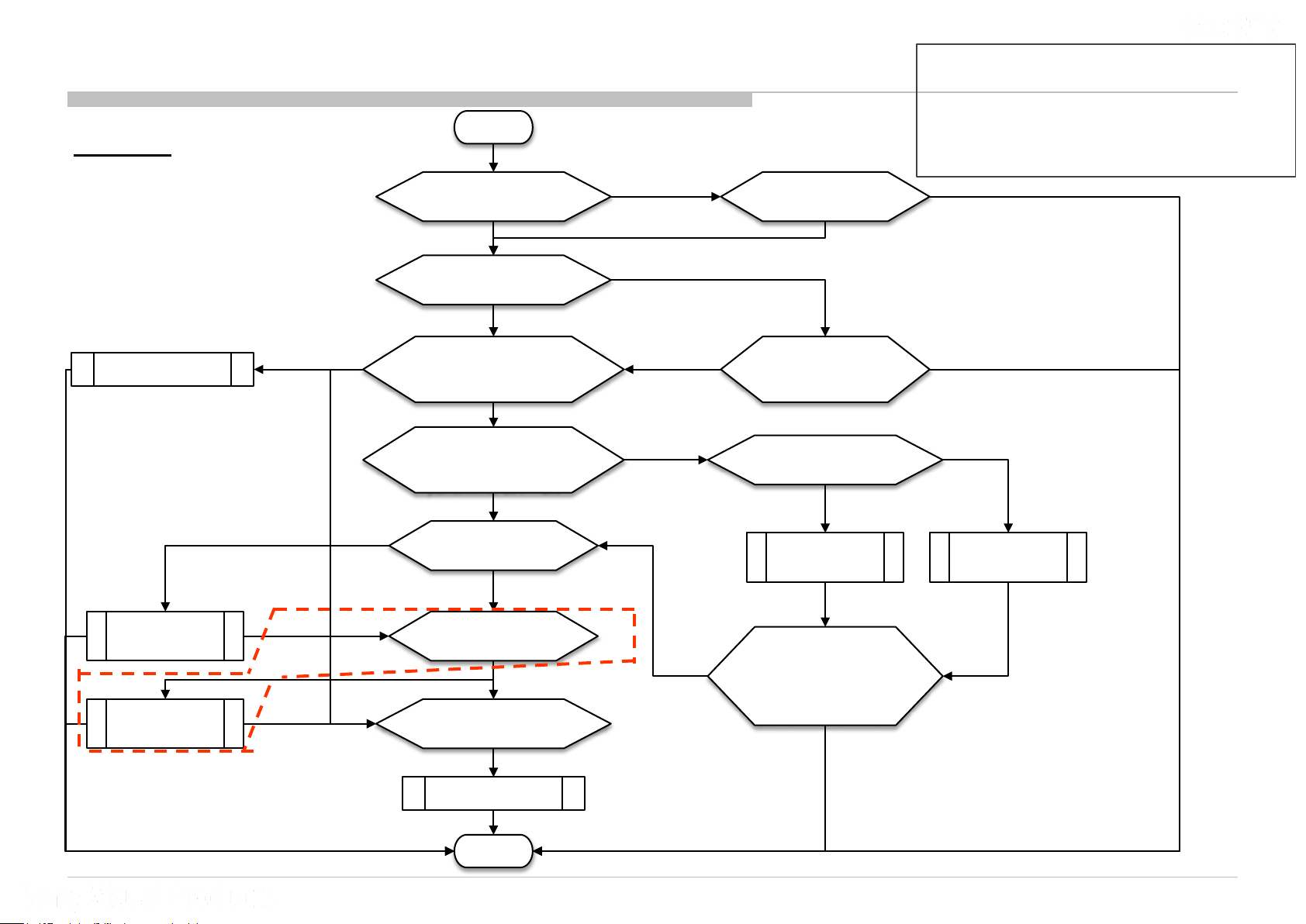

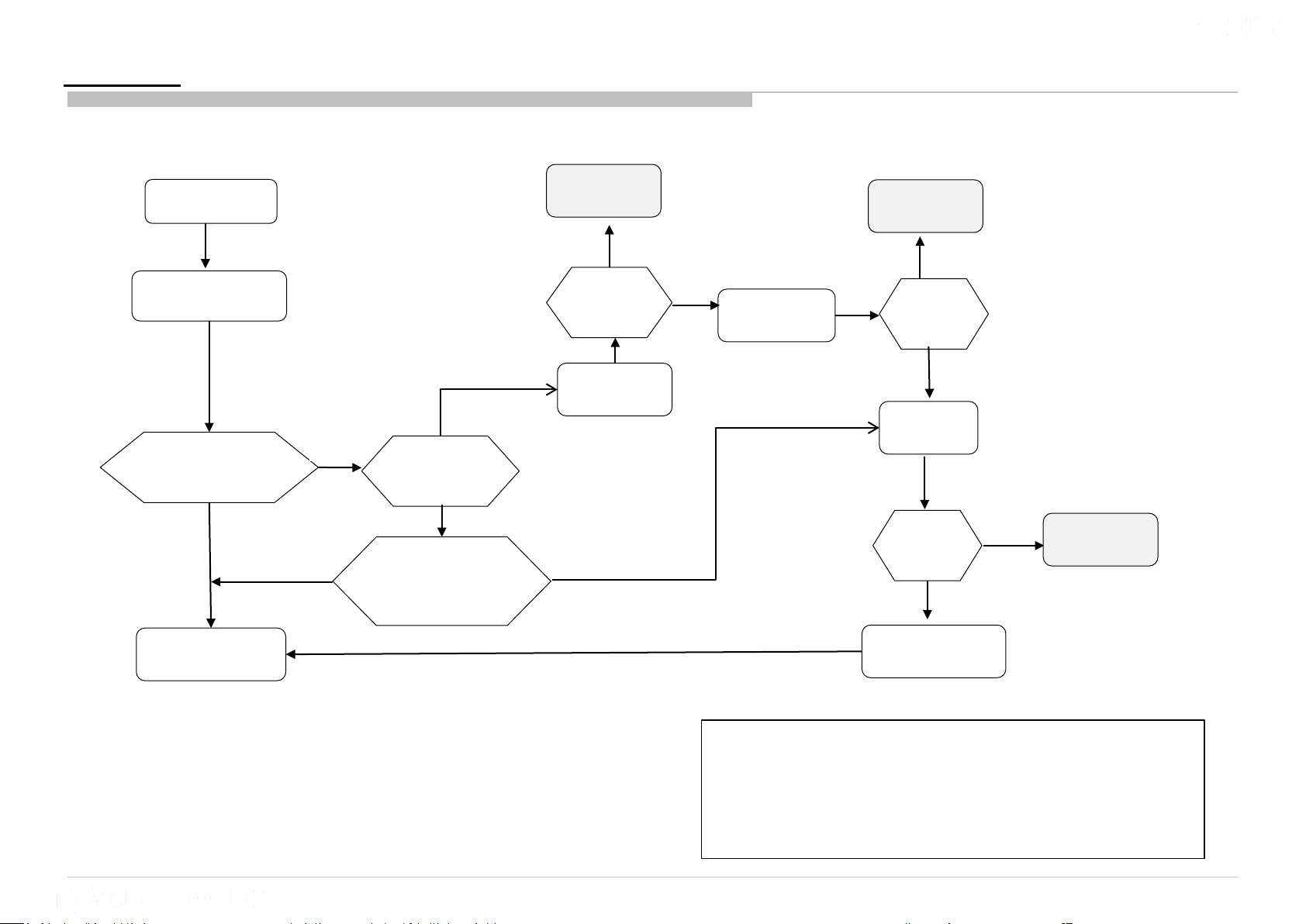

3b.1 : 3x Blinking – Audio Error

START

LK Board

Check FFC correct insert? Insert FFC correctly

3x blinking

Important No te :

TV must be power OFF condition before plug

or unplug any of the FFC/FPC /wire / cable

from the board. -> This is to preven t

possibility c ir cuit damag e h a ppen.

FFC not insert correctly

Change B-board

LK-board Audio Error p in

short to GND

No connectivity of F4001

F4001 broken,

Replace

F4001

F4101 broken,

Replace

F4101

Check correct Option bit is set?

B-board Audio Error pin

short to GND

3x blinking

No connectivity of F4101

3x blinking

Disconnect B-board to LK-board FFC

Remove Speaker Connector

#Audio IC (IC4001/IC4101) p roblem

3x blinking

Correct Option bit & 3x blinking

and check Audio E rror pin

Audio Error pin no short to GND

at CN4001/CN4002 an d

perform AC OFF - ON

3x blinking

Check connectivity

of F4001

3x blinking & F4001 OK

Check connectivity

of F4101

3x blinking & F4101 OK

3x blinking

Wrong Option bit

3x blinking

No 3x blinking

3x blinking

Set correct O ption bit an d

perform AC OFF - ON

Check Speaker harness and

Speaker impedance

Speaker harness

shorted

Change

Speaker

Harness

Connect back

Speaker Connector

to CN4001/CN4002 an d

perform AC OFF - ON

No 3x blinking

Main or Assist Speaker

Impedance ≠ 6~8 Ω

Change Main

or Assist

Speaker

For model with Assist Spe aker only

Change LK-board

No 3x blinking

DONE

Note : IC4101 and F4101 available to check for model with woofer (Assist Speake r) only.

No 3x blinking

21

3b.1 : 3x Blinking – Audio Error

LK Board

Important No te :

(#Audi o IC (IC4001/IC4101) problem)

#Audio IC (IC4001/IC4101) p roblem

3x blinking and F4001 & F4101 OK

Check Audio IC pins and surrounding part,

Replace the NG part if have any

(For example, fuse broken, e.capacitor blow,

c.capacitor short connection, zener diode open or short,

inductor open connection and etc.)

3x blinking

Check have any burn mark on Audio IC,

If have burn mark, replace the NG Audio IC

3x blinking

Disable Error Detection,

Remove F4101 if have

START

Main Speaker No Sound

(Ignore Assist Speaker if have)

3x blinking

TV must be power OFF condition bef o r e

plug or unplug any of the FFC/FPC/wire

/cable from the board. -> This is to prevent

possibility c ir cuit damag e h a ppen.

Remember enable back Error Detection if

previously h a v e disable it .

IC4001 problem, Change IC4001,

Mount back F4101 if have removed,

Enable back Error Detection

No 3x blinking

No 3x blinking

No 3x blinking

For model with

Assist Speaker only

Note : IC4101 and F4101 available to check for model with woofer (Assist Speake r) only.

Disable Error Detection,

Remove F4001

Change LK-board

DONE

Assist Speaker No Soun d

(Ignore Main Speaker)

3x blinking

IC4101 problem, Change IC4101,

Mount back F4001 & F4101 if have removed,

Enable back Error Detection

No 3x blinking

22

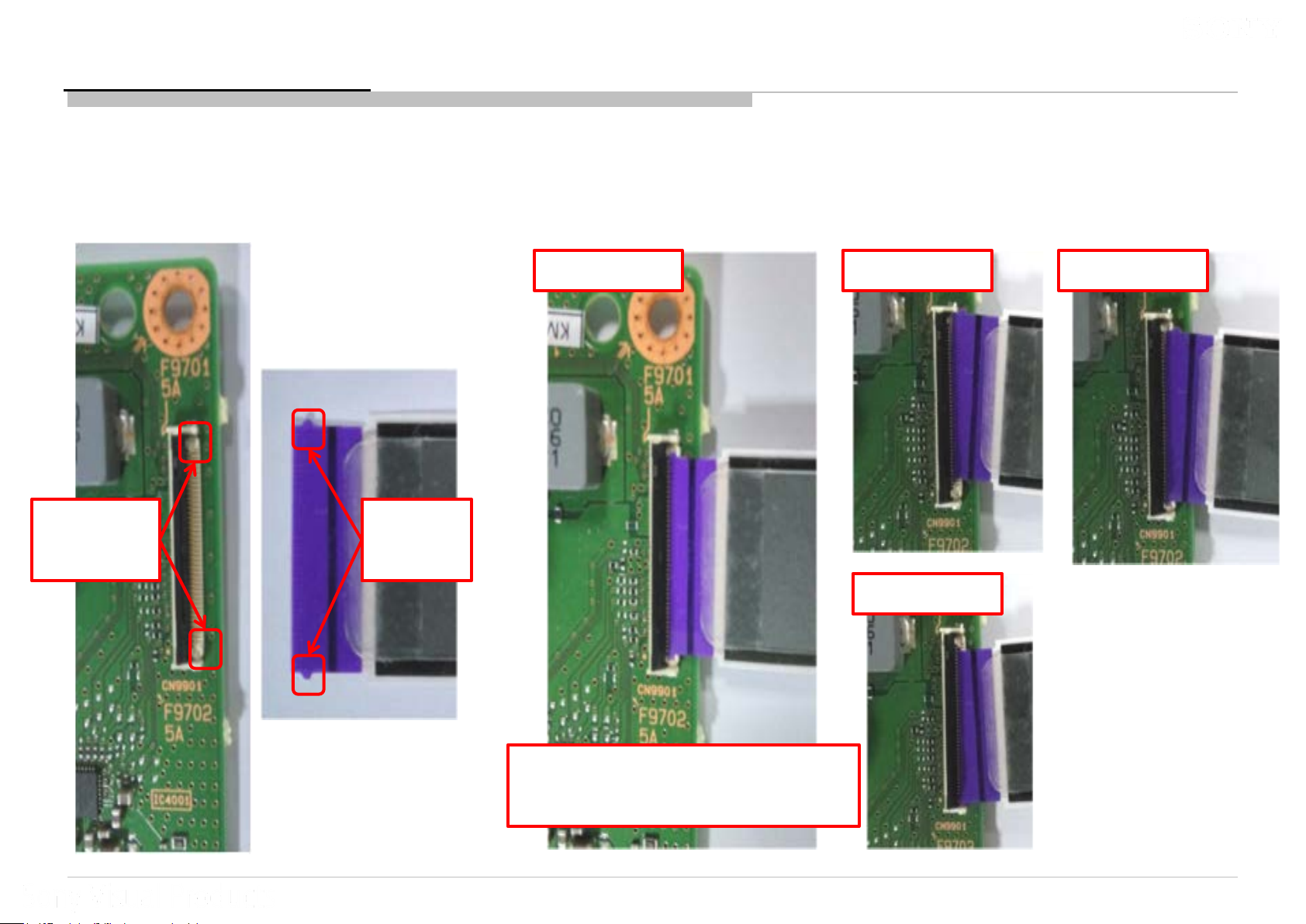

3b.1 : 3x Blinking – Audio Error

LK1/2 Board (FFC insertion)

Same apply to B-board FFC connector side

Important No te :

TV must be power OFF condition bef o r e

plug or unplug any of the FFC/FPC/wire

/cable from the board. -> This is to prevent

possibility c ir cuit damag e h a ppen.

OK example NG example NG example

Guide at

Connector

Guide at

FFC

NG example

FFC guide need insert fully over

the connector guide

23

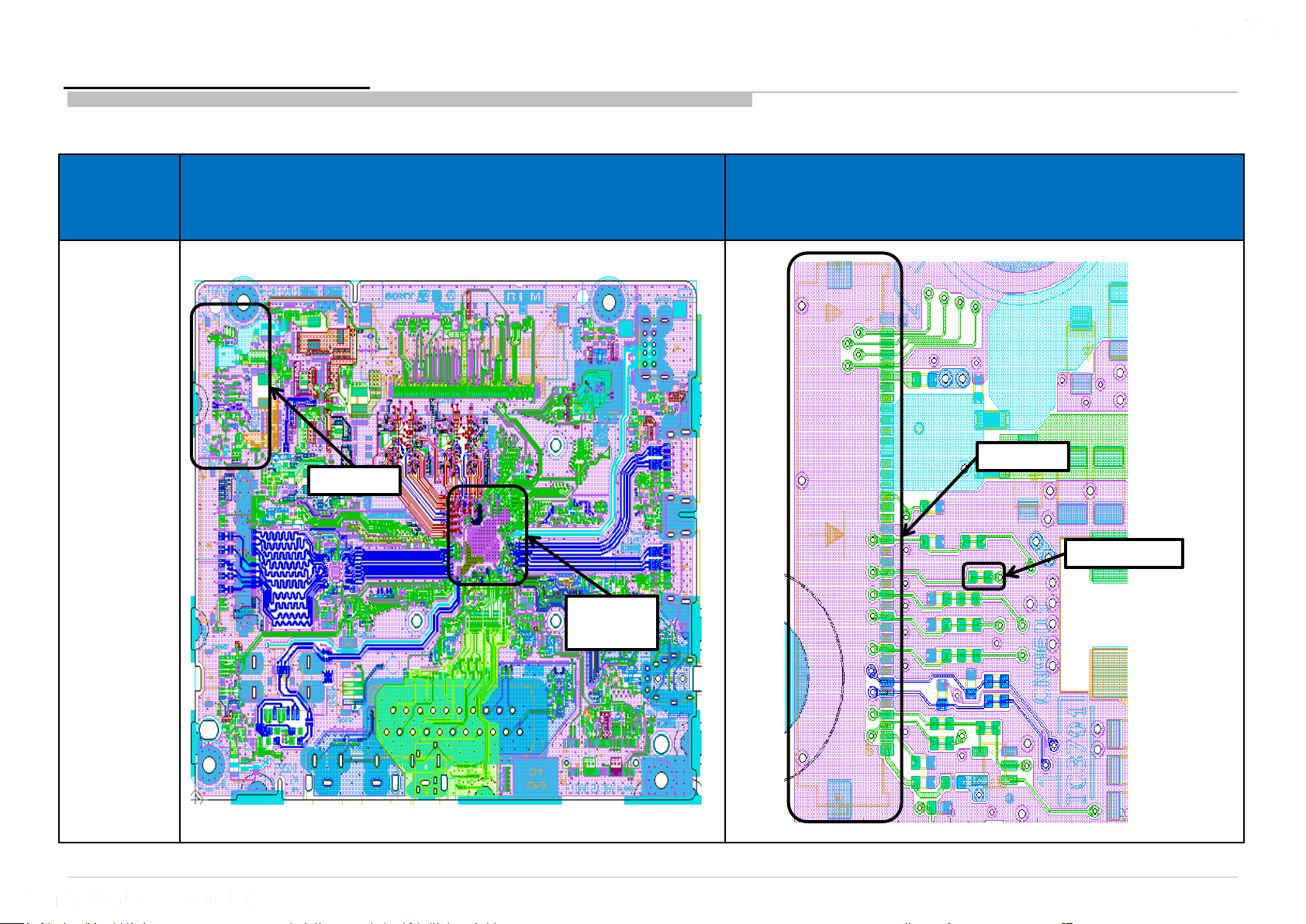

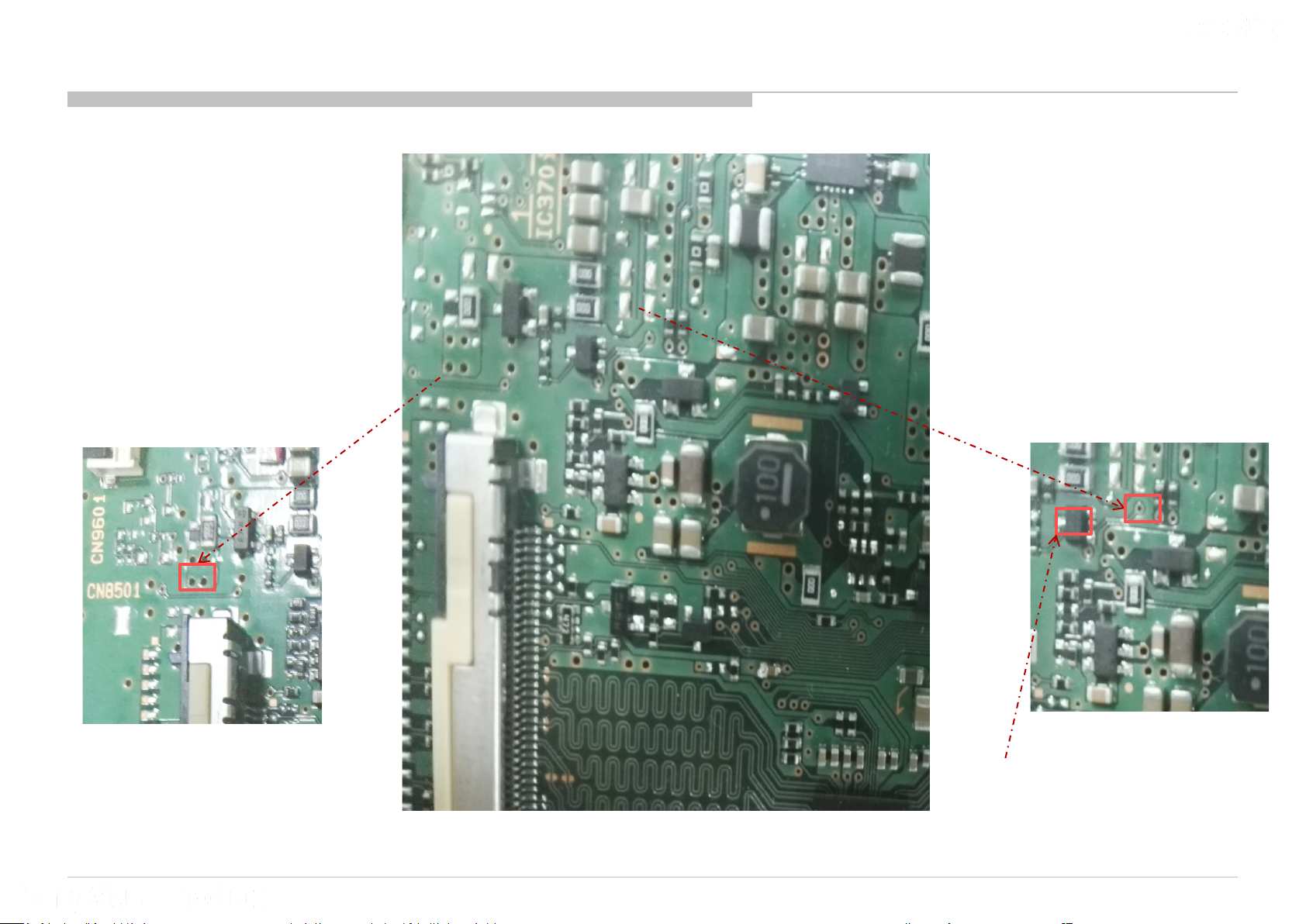

3b.1 : 3x Blinking – Audio Error

BLM Board (Checking Point)

Board

PWB

(A side)

Checking

Audio Error

pin not short

to GND

BLM (KM, KMW, KML, KMLW, KL, KLW) Details

Details

CN9601

Main IC

(IC5000)

Audio Error pin

24

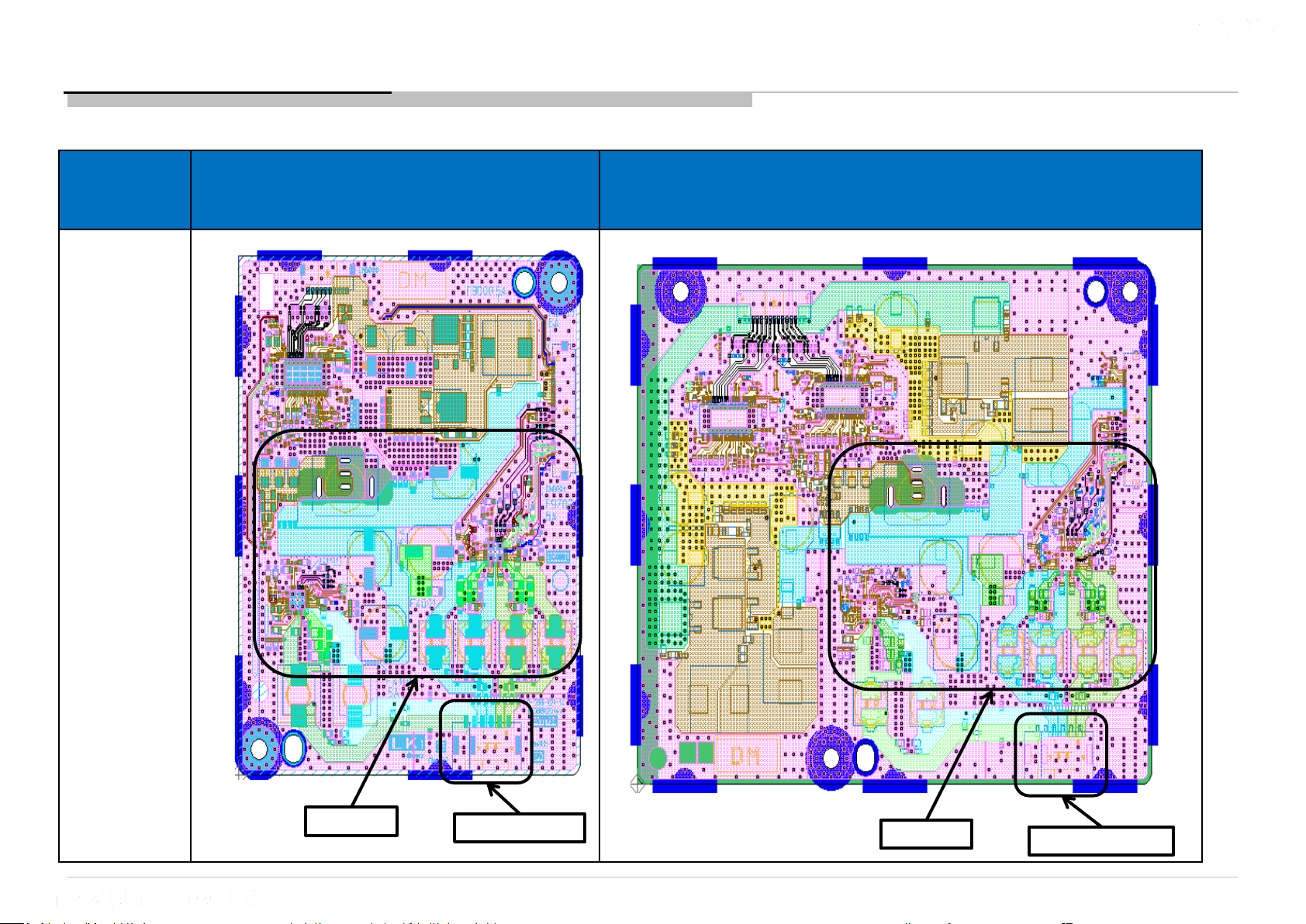

3b.1 : 3x Blinking – Audio Error

LK1/2 Board (Checking Point)

Board PWB

(A side)

Detail refer

next slide

LK1 (KM, KMW, KML, KMLW, KL, KLW) LK2 (KL, KLW)

Details

CN4001/CN4002

Details

CN4001/CN4002

25

3b.1 : 3x Blinking – Audio Error

LK1/2 Board (Checking Point)

Board PWB

(A side)

Purpose :

Checking Audio

Error pin not

short to GND

Checking fuse

condition

Change Audio IC

if need

Audio IC each pin

checking, please

refer to “Audio

No Sound”

Details

Audio Error pin

Zener Diode

IC4101

IC4001

F4101

F4001

26

Problem/Issue

3c Trouble Shooting Flow 4x blinking – Panel Power Error

Section

3

4x blinking –

Panel Po wer E rror

Title

3c.1 4x blinking – Panel Power E rror

27

3c.1 : 4x Blinking – Panel Power Error

BLM Board

Start

*Check LK board FFC

Or LVDS FFC

TV boot up normally?

Yes

End

Yes

No

No

Check PANEL_PWR

3.00V-3.33V?

Check voltage at

+12V_PANEL

11-V-12.82V?

Yes

TV was in

standby

Yes

TV turn on

Normally?

RC ON

No

No

Replace

Main IC / B-

Board

B-Board/Main

IC problem

Yes

TV turn on

Normally?

No

Replace

LK board

TV turn on

Normally?

No

Replace O-cell/

Panel module

Yes

LK board

problem

*Check LK board FFC Or LVDS FFC

Step 1: Rem ove and reinsert both FFC in correct position

Step 2: Replace w ith new FFC

28

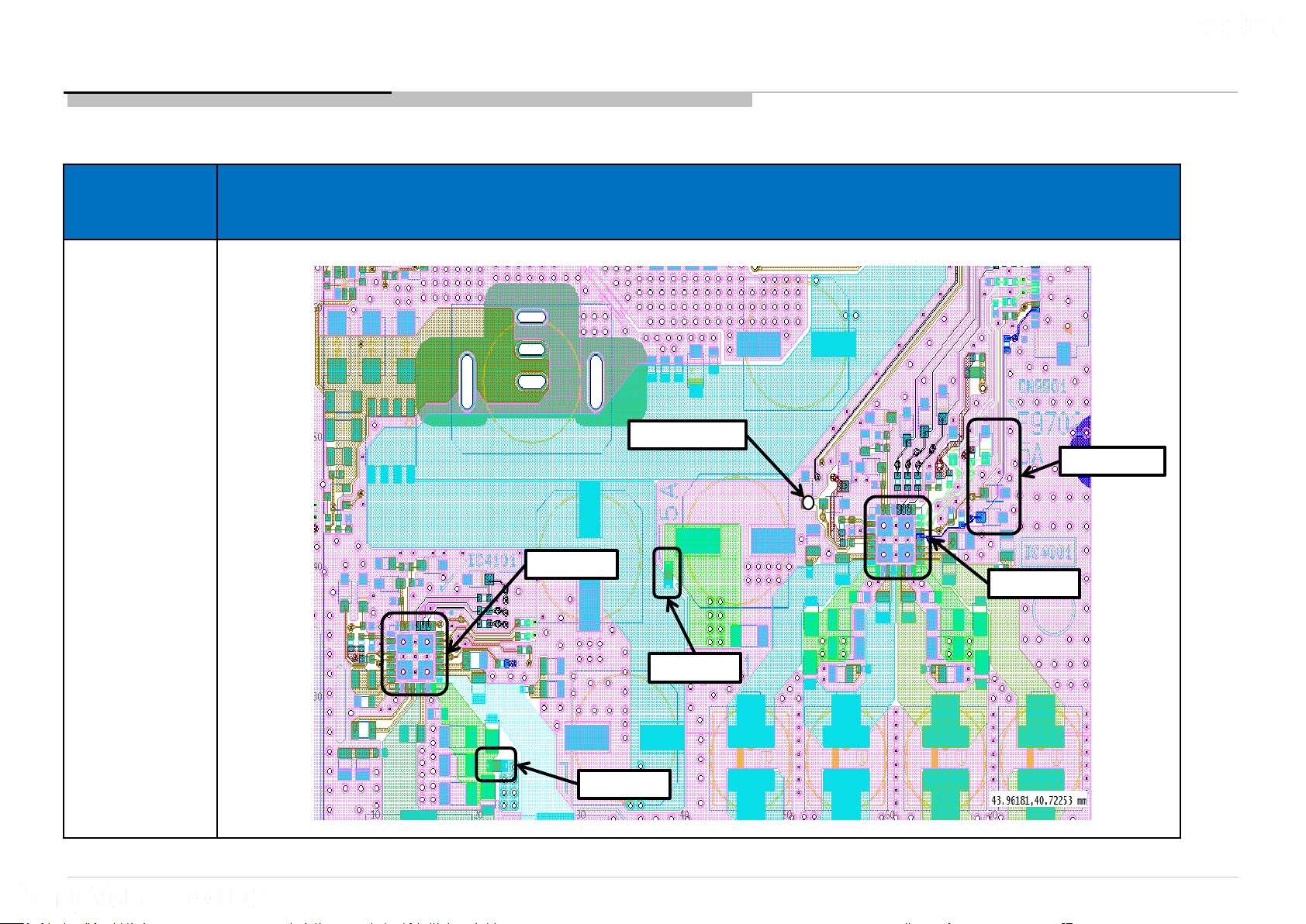

BLM layout

+12V_PANEL line

PANEL_PWR

Q6001

Only present in EU regions

29

Problem/Issue

3d Trouble Shooting Flow 5x blinking – Panel I2C Er ror

Section

3

5x blinking –

Panel I2C Error

Title

3d.1 5x blinking – Panel I2C Error

30

Loading...

Loading...