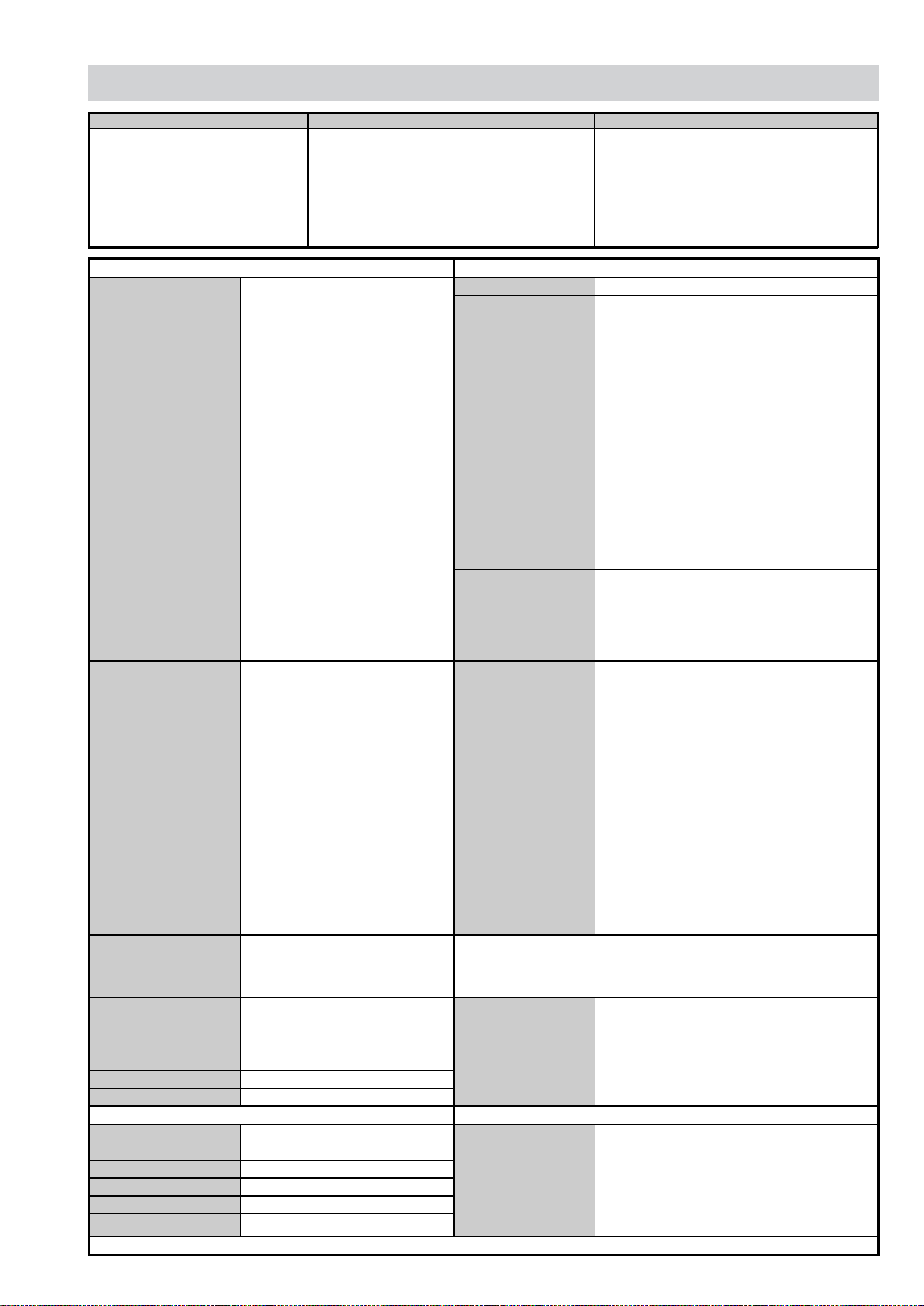

Sony KDL-40X4500, 46X4500, 55X4500 Schematic

HISTORY

Model Name :

SERVICE MANUAL

Click on Page Number to display detail of changes.

Date Part Number Description of Revisions

Original Manual.

Add inverter board part number for 40 inches. (P.79)

KDL-40/46/55X4500

Version

1.09-883-412-01 2008.09

2.09-883-412-02 2008.09

SERVICE MANUAL

EG1H

CHASSIS

MODEL

DEST

KDL-40X4500

KDL-46X4500

KDL-55X4500

AEP/UK

AEP/UK

AEP/UK

- 1 -

RM-ED012

FLAT PANEL COLOR TV

TABLE OF CONTENTS

Section Title Page Section Title Page

1. GENERAL ................................................................... 3

Caution................................................................ 3

Specifications ..................................................... 5

Connectors .......................................................... 6

Self Diagnosis..................................................... 7

2. DISASSEMBLY

2-1. Rear Cover Removal .......................................... 9

2-2. Stand Removal ................................................... 9

2-3. Speaker Box Removal ........................................ 9

2-4. Woofer Box Removal......................................... 9

2-5. CB1 Board Removal(46/55 inches) ................... 10

2-6. D4 Board Removal (40 inches).......................... 10

2-7. FBA Board Removal .......................................... 10

2-8. G6 Board Board Removal .................................. 10

2-9. G7 Board Removal(55 inches)........................... 11

2-10. GL Board Removal(46/55 inches) ..................... 11

2-11. H1VM Board Removal ...................................... 11

2-12. H3VM Board Removal ...................................... 11

2-13. H4 Board Removal ............................................. 12

2-14. K2 Board Removal ............................................. 12

2-15. AE Board Removal ............................................ 12

2-16. Sensor Module Removal .................................... 12

3. SERVICE MENUS

3-1. How to enter the Service Mode ........................ 13

3-2. Changing TVM Data Settings ........................... 13

3-3. Writing TVM Data ............................................ 13

3-4. Entering BEM Service Menu ............................ 13

3-5. Changing BEM Data Settings ........................... 13

3-6. Writing BEM Data ............................................ 13

3-7. Trouble Shooting ............................................... 14

3-7-1. No Power ......................................................... 14

3-7-2. Set Reboots...................................................... 14

3-7-3. Power Error ..................................................... 14

3-7-4. T-Con Error ..................................................... 14

3-7-5. Back Light Error ............................................. 14

3-7-6. Temperature Error ........................................... 14

3-7-7. Audio Error ..................................................... 14

3-7-8. Fan Error..........................................................

14

3-7-9. Balancer Error ................................................. 14

3-8. CB1 Board Replacement (46/55 inches) .......... 14

3-8-1. Copying data from Panel to CB1 Board ......... 14

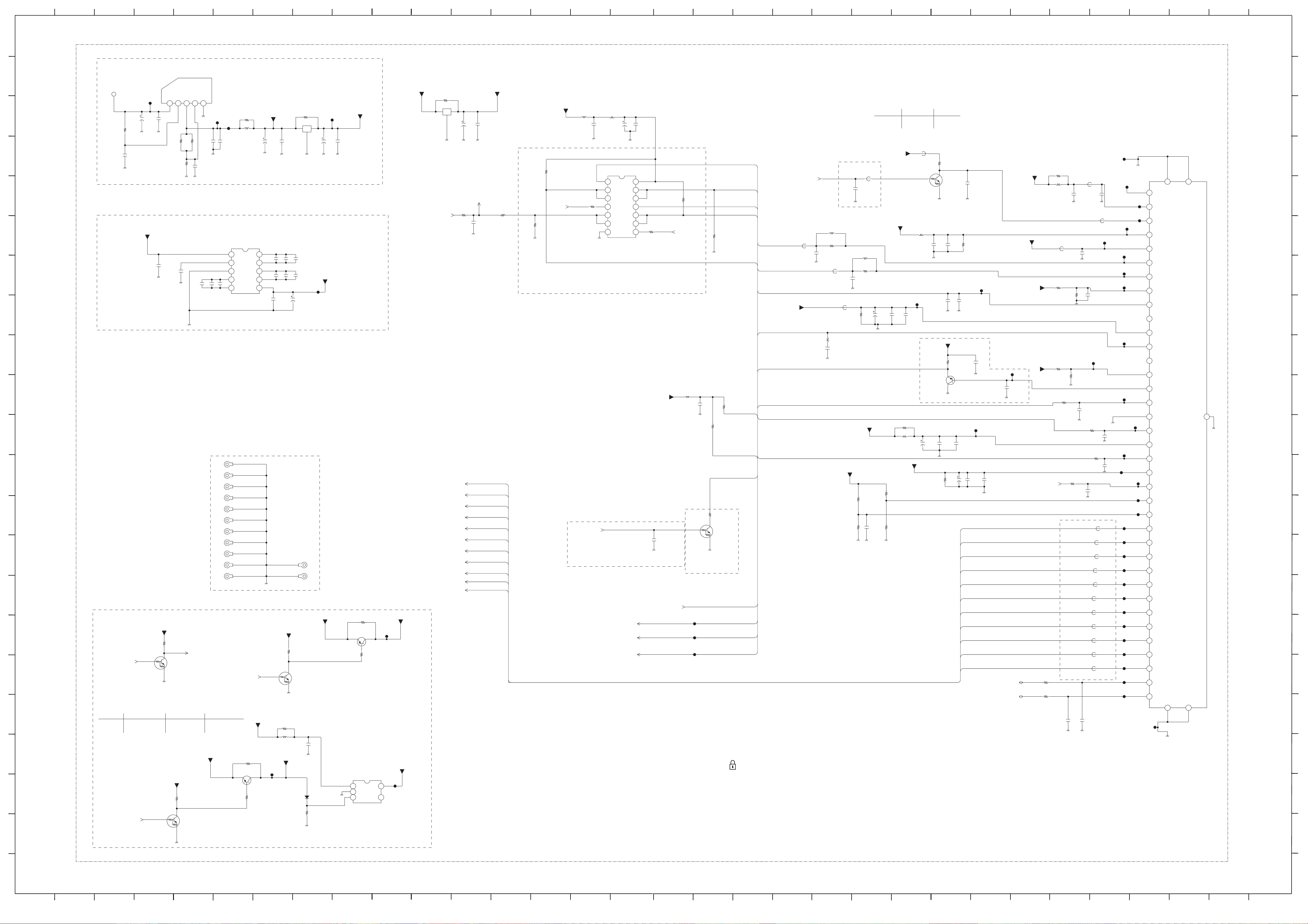

4. DIAGRAMS

4-1. Block Diagram ................................................... 20

4-2. Circuit Board Location....................................... 21

4-3. Schematic Diagrams and Printed Wiring

Boards ................................................................. 21

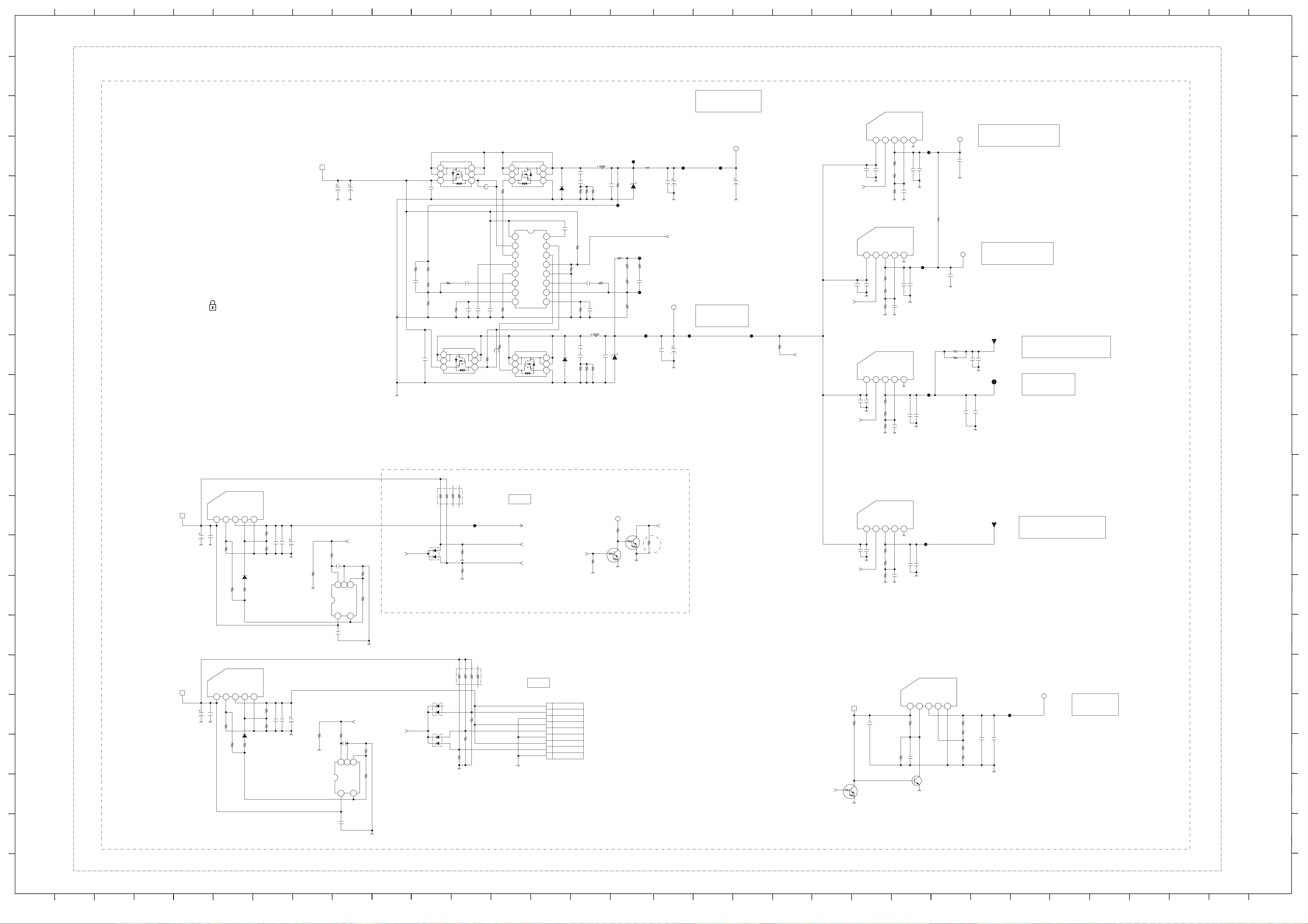

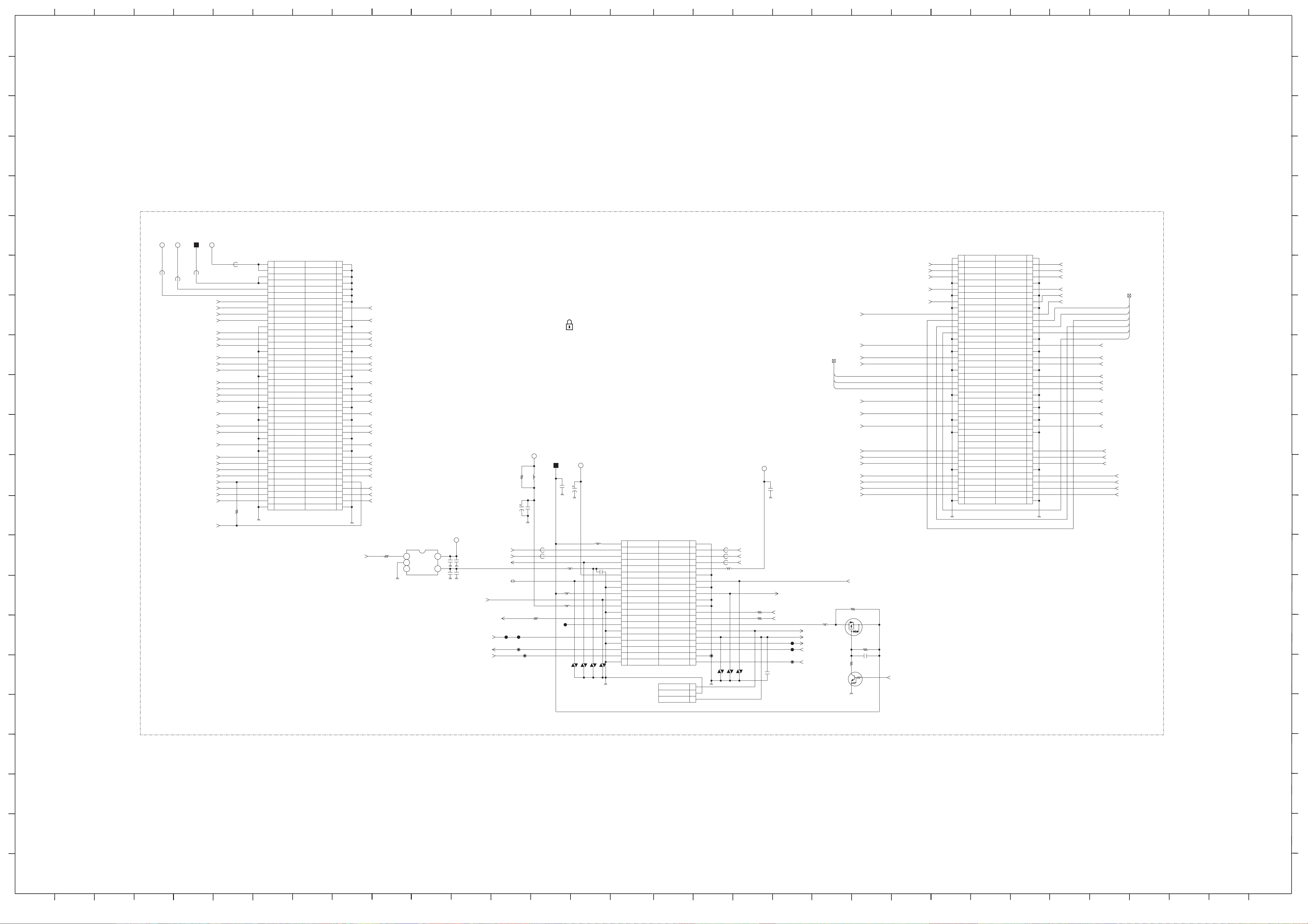

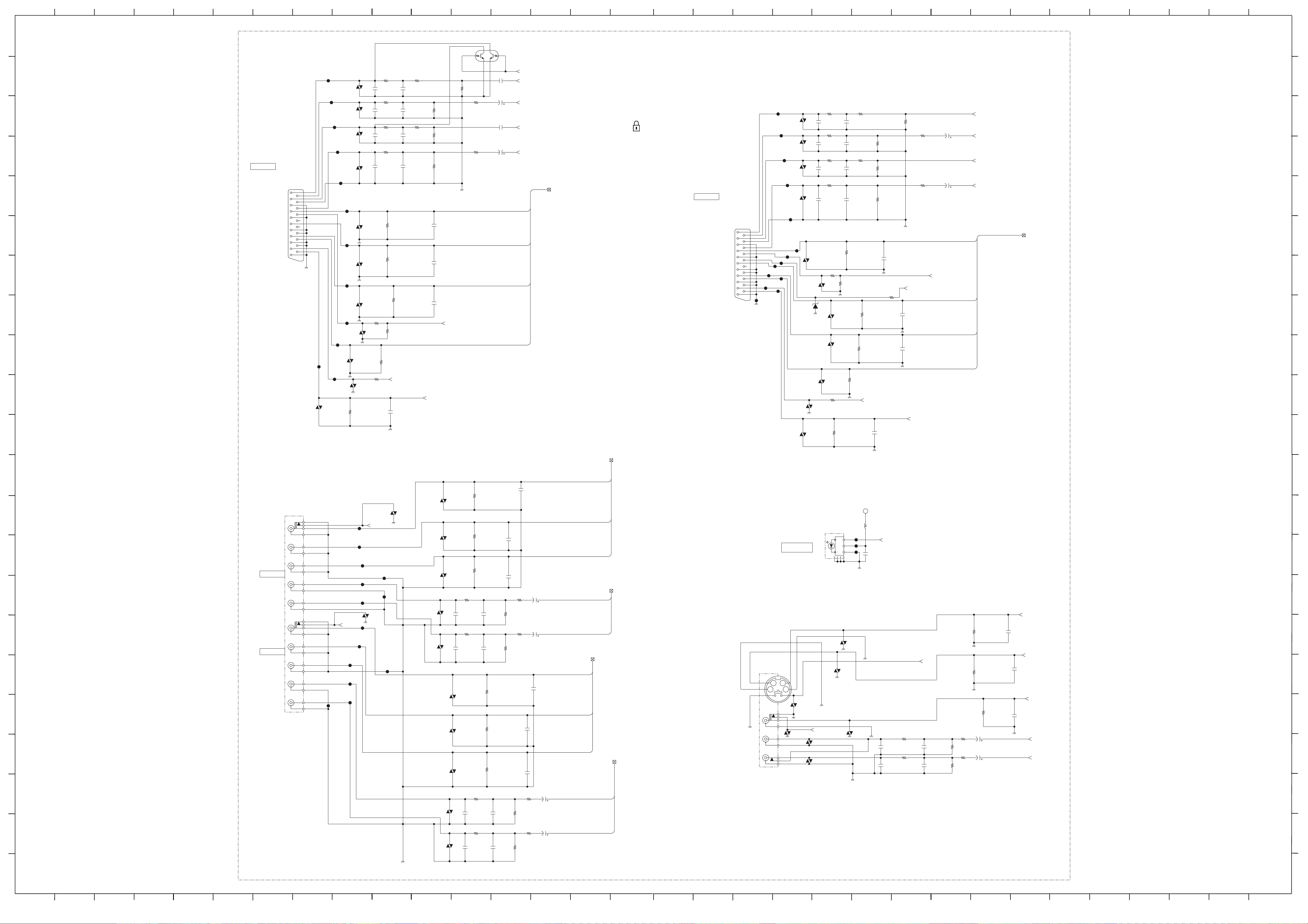

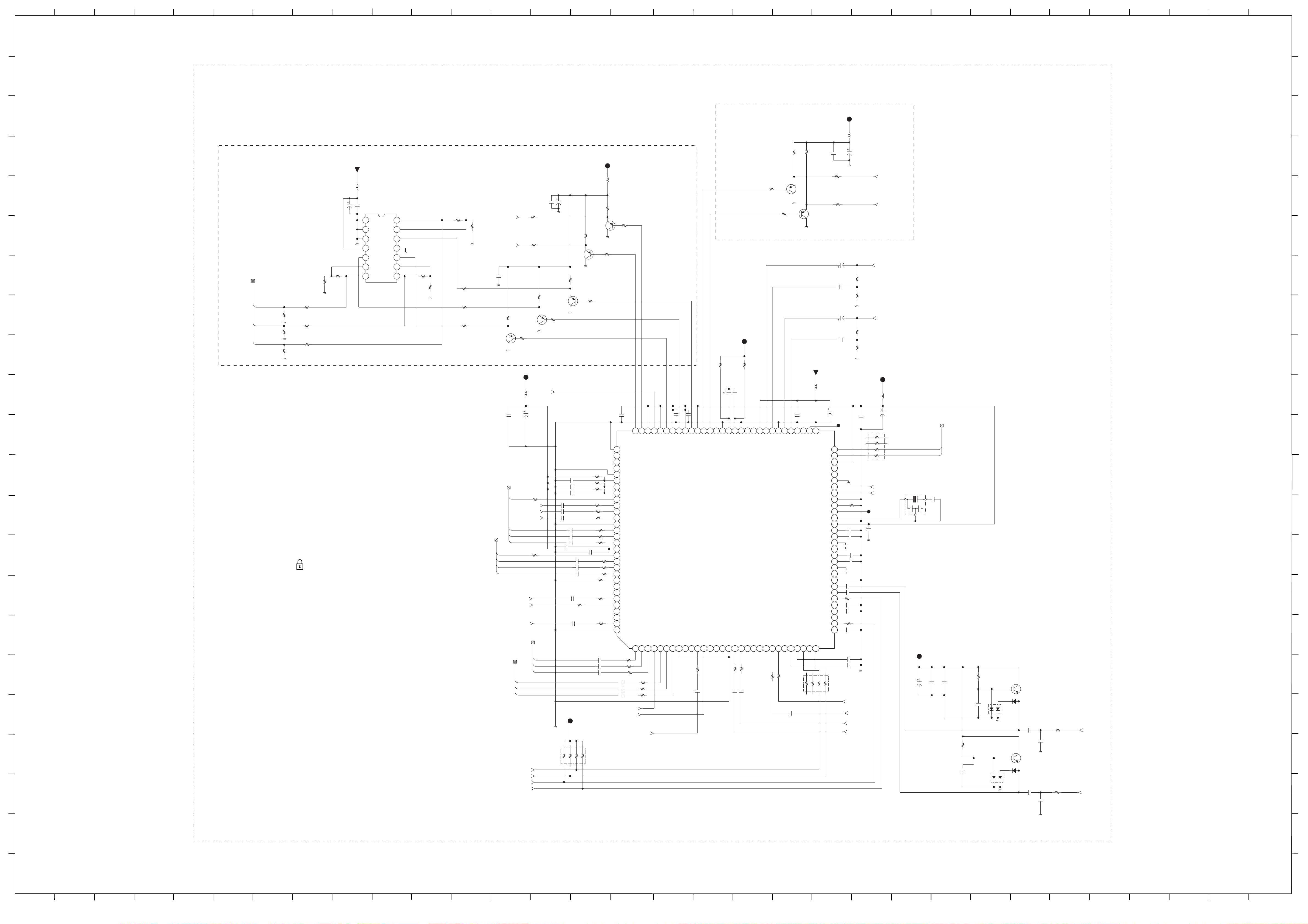

AE Board Schematic Diagram ........................... 22

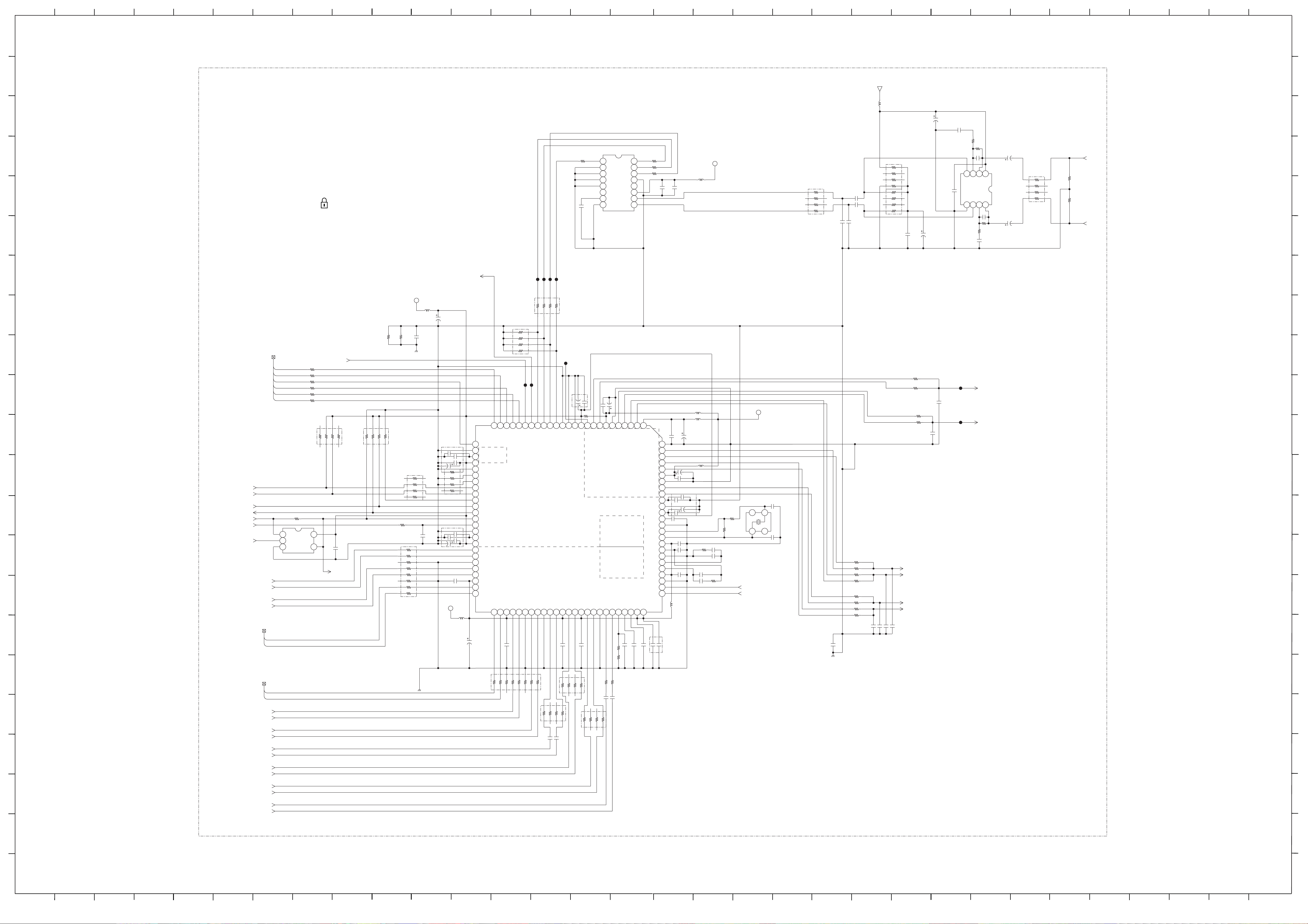

CB1 Board Schematic Diagram(46/55 inches) . 31

D4 Board Schematic Diagram(40 inches) ......... 38

FBA Board Schematic Diagram ........................ 39

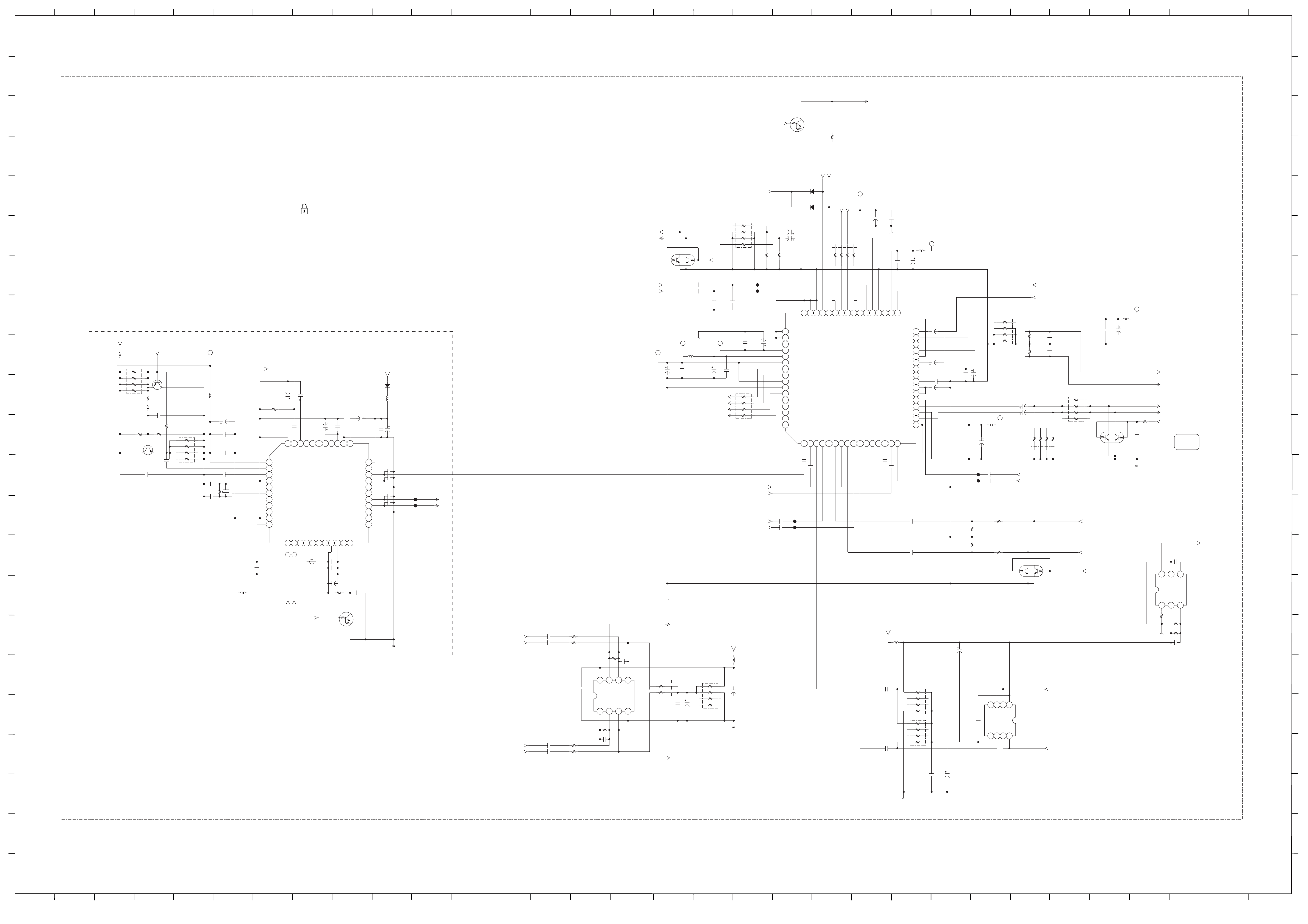

G6 Board Schematic Diagram ........................... 60

G7 Board Schematic Diagram (55 inches) ........ 62

GL Board Schematic Diagram(46/55 inches) ... 63

H1VM Board Schematic Diagram ..................... 65

H3VM Board Schematic Diagram ..................... 65

H4 Board Schematic Diagram ........................... 65

K2 Board Schematic Diagram ........................... 66

AE Printed Wiring Board................................... 67

CB1 Printed Wiring Board(46/55 inches) ......... 69

D4 Printed Wiring Board (40 inches) ................ 70

FBA Printed Wiring Board ................................ 71

G6 Printed Wiring Board ................................... 73

G7 Printed Wiring Board(55 inches) ................. 75

GL Printed Wiring Board(46/55 inches) ........... 76

H1VM Printed Wiring Board............................. 78

H3VM Printed Wiring Board............................. 78

H4 Printed Wiring Board ................................... 78

K2 Printed Wiring Board ................................... 78

5. EXPLODED VIEWS

5-1. Chassis ................................................................ 79

5-2. Stand Assy & Speakers ...................................... 80

5-3. Bezel ................................................................... 81

5-4. Rear Cover & Power Supply Cords ................... 82

6. ELECTRICAL PARTS LIST .................................. 83

WARNING !!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING ANY

SERVICE W ORK TO AVOID POSSIBLE SHOCK HAZARD DUE TO

LIVE CHASSIS, THE CHASSIS OF THIS RECEIVER IS DIRECTLY

CONNECTED TO THE POWER LINE.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY SHADING AND MARKED

THE EXPLODED VIEWS AND IN THE PARTS LIST ARE CRITICAL

FOR SAFE OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN

THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

- 2 -

ON

SECTION 1 GENERAL

How to replace the fuse.

Open the fuse compartment with

a screwdriver blade and replace

the fuse.

FUSE

SECTION 1 GENERAL

CAUTION

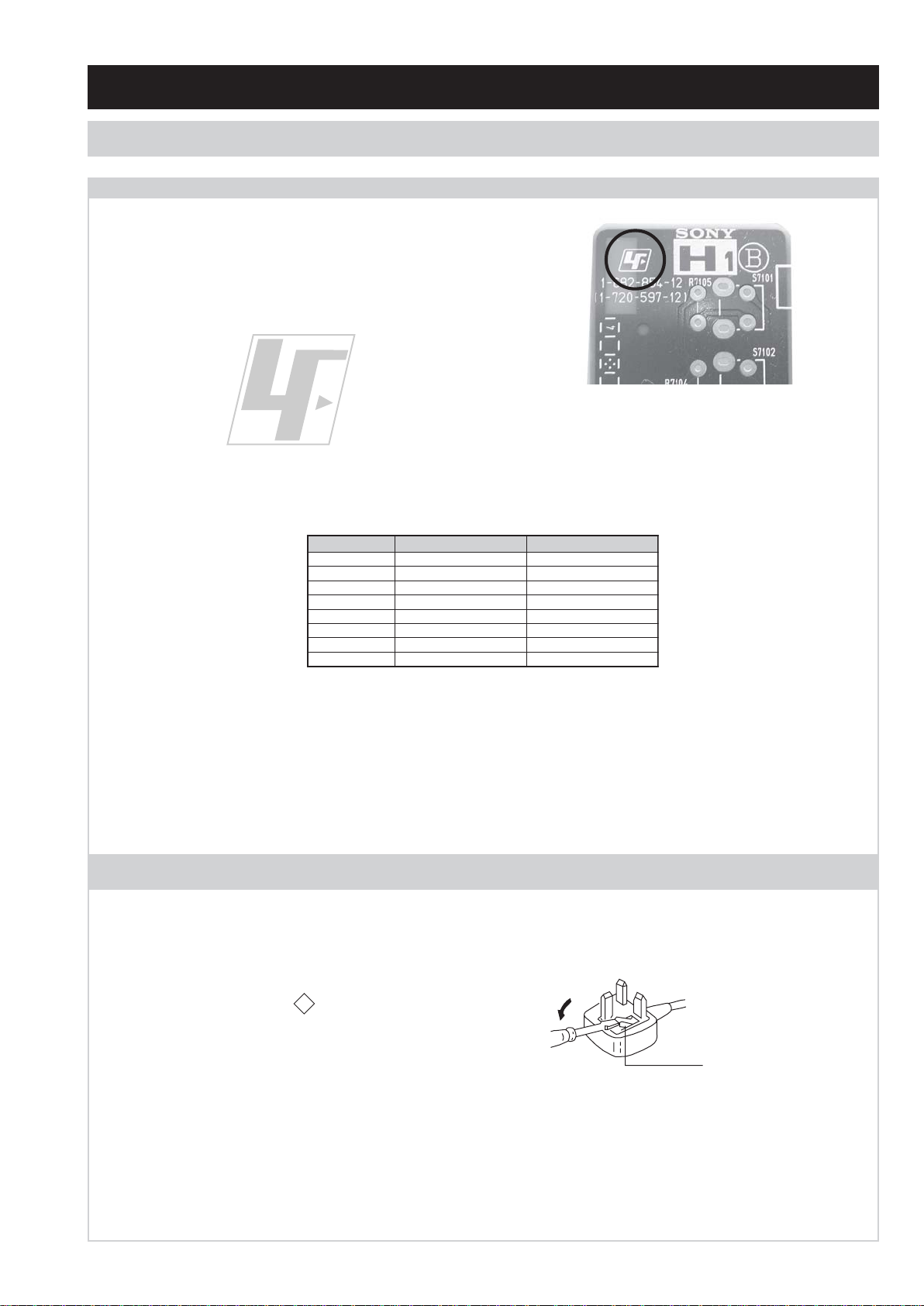

Lead Free Soldered Boards

example

The circuit boards used in these models have been processed using

Lead Free Solder. The boards are identif ied by the LF logo located

close to the board designation e.g. H1 etc [ see example ]. The

servicing of these boards requires special precautions to be taken as

outlined below.

Lead Free Solder material must be used to comply with environmental requirements of new solder joints. Lead Free Solder is available under

the following part numbers :

rebmuntraP retemaiD skrameR

91-500-046-7mm3.0gK52.0

02-500-046-7mm4.0gK05.0

12-500-046-7mm5.0gK05.0

22-500-046-7mm6.0gK52.0

32-500-046-7mm8.0gK00.1

42-500-046-7mm0.1gK00.1

52-500-046-7mm2.1gK00.1

62-500-046-7mm6.1gK00.1

Due to the higher melting point of Lead Free Solder the soldering iron tip temperature needs to be set to 370 degrees centigrade. This requires

soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

For more information on the use of Lead Free Solder, please refer to http://www.sony-training.com

UK PLUG W ARNING

WARNING (UK Models only)

The flexible mains lead is supplied connected to a B.S. 1363 fused

plug having a fuse of the correct rating for the set. Should the fuse

need to be replaced, use a fuse of the same rating approved by ASTA

to BS 1362, ie one that carries the

ASA

T

mark.

IF THE PLUG SUPPLIED WITH THIS APPLIANCE IS NOT SUITABLE

FOR THE OUTLET SOCKETS IN YOUR HOME, IT SHOULD BE CUT

OFF AND AN APPROPRIA TE PLUG FITTED. THE PLUG SEVERED

FROM THE MAINS LEAD MUST BE DESTROYED AS A PLUG WITH

BARED WIRES IS DANGEROUS IF ENGAGED IN A LIVE SOCKET .

When an alternative type of plug is used, it should be fitted with the

correct rating fuse, otherwise the circuit should be protected by the

same rating fuse at the distribution board.

- 3 -

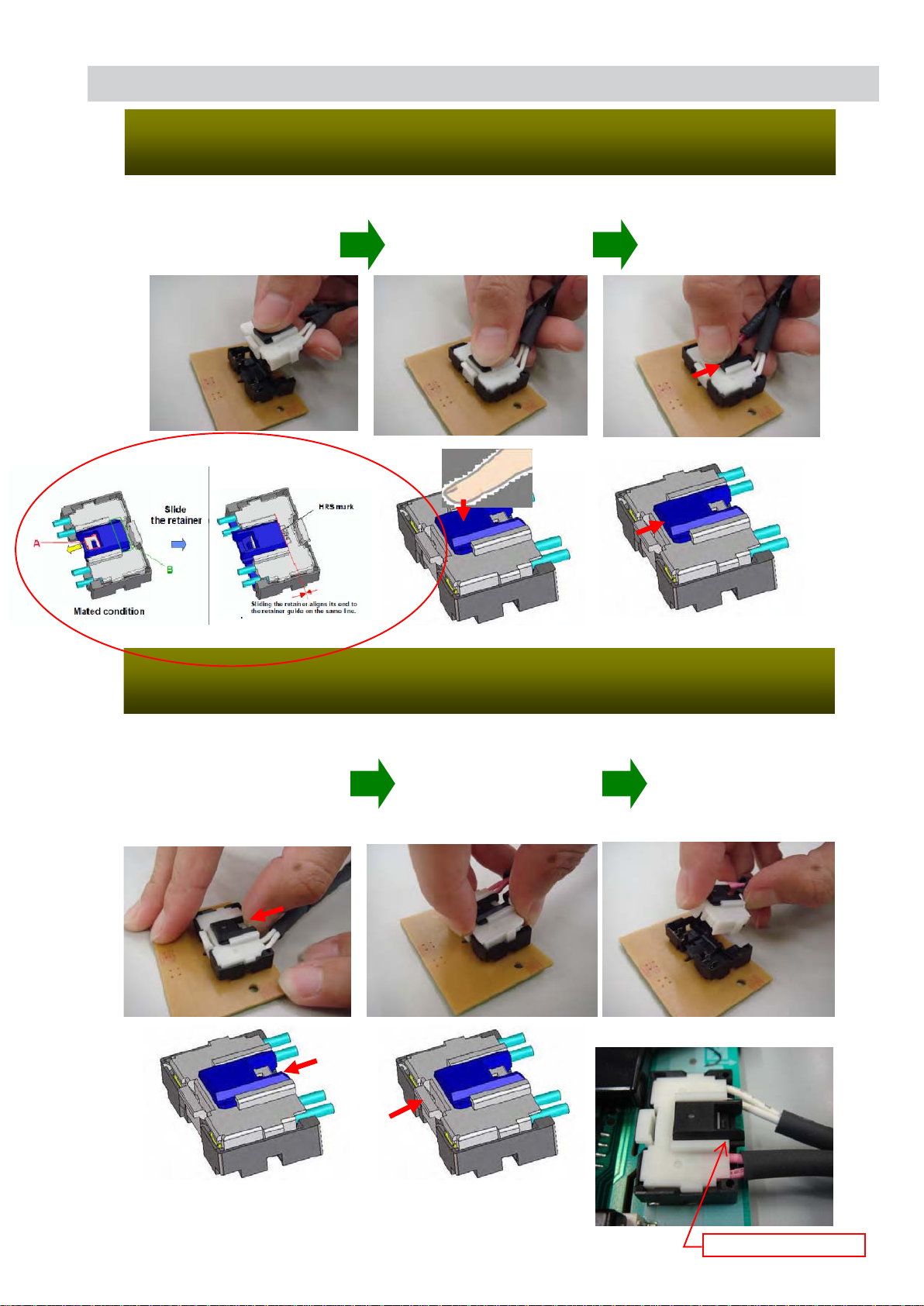

Attachment of HIROSE MDF 61 connector

locked state

1. Insertion

(1) Hold the center

of a connector

CAUTION

(2) Press the center of

the connector to insert

it

(3) Slide the

slider to lock the

connector

Detachment of HIROSE MDF61 connector

2. Detachment

(1) Slide the slider to

release the slider lock

Lock

(2) Press the center

lock tab to release

the lock and pull the

connector up

Unlock

- 4 -

- 4 -

SPECIFICATIONS

Analogue:

Depending on your country/region

B/G/H, D/K, L, I

Digital:

Depending on model

DVB-T/DVB-C

Input/Output Terminals [REAR] General Specifications

1: 21-pin Euro connector

(CENELEC standard)

2: 21-pin Euro connector

(CENELEC standard)

Television System Channel Coverage Colour/Video System

Inputs for Audio and Video signals.

Inputs for RGB.

Outputs of TV Video and Audio

signals.

Inputs for Audio and Video signals.

Inputs for RGB.

Outputs of Video and Audio signals

(Selectable). SmartLink interface.

Analogue: VHF : E2-E12

UHF : E21-E69

CATV : S1-S20

HYPER : S21-S41

D/K: R1-R12, R21-R69

L: F2-F10, B-Q, F21-F69

I: UHF B21-B69

Digital: VHF/UHF

Power Requirements 220 - 240V

Power Consumption/

Standby

Dimensions

Weight

Analogue:

PAL, PA L 60(VIDEO IN), SECAM

NTSC 3.58, NTSC4.43(VIDEO IN)

Digita l:

MPEG-2 MP@ML/HL, H.264/MPEG-4 AVC

MP/HP@L4.0

(40 inches):

Approx 210W/0.2W (Home/Standard mode)

Approx 230W/0.2W (Shop/Vivid mode)

(46 inches):

Approx 270W/0.5W (Home/Standard mode)

Approx 350W/0.5W (Shop/Vivid mode)

(55 inches):

Approx 370W/0.6W (Home/Standard mode)

Approx 480W/0.6W (Shop/Vivid mode)

(40 inches):

Approx 1128x655x279mm (With stand)

Approx 1128x603x125mm (Without stand)

(46 inches):

Approx 1259x737x315mm (With stand)

Approx 1259x685x144mm (Without stand)

(55 inches):

Approx 1486x855x356mm (With stand)

Approx 1486x803x147mm (Without stand)

Approx 27.0kg (40 inches with stand)

Approx 23.5kg (40 inches without stand)

Approx 38.0kg (46 inches with stand)

Approx 33.0kg (46 inches without stand)

Approx 54.0kg (55 inches with stand)

Approx 47.5kg (55 inches without stand)

Supported formats: 1080p, 1080i,

720p, 576p, 576i, 480p, 480i

Y: 1 Vp-p, 75 ohms, 0.3 negative

Component In

HDMI Inputs

PC Input

DMPORT Digital Media Port

Digital Audio Out Digital Optical Jack

LAN 10BASE-T/100BASE-TX connector

CAM Conditional Access Module Slot

Input/Output Terminals [SIDE] Remote control system : Infrared control

Headphone jack Stereo mini jack

Audio input Phono jacks

Video input Phono jack

S Video input 4-pin mini DIN

USB input USB port

HDMI input HDMI Connector

sync

PB/CB: 0.7 Vp-p, 75 ohms

PR/CR: 0.7 Vp-p, 75 ohms

Audio input: Phono jacks

Video: 1080/24p, 1080p, 1080i,

720p, 576p, 576i, 480p, 480i

Audio: Two channel linear PCM

32, 44.1 and 48kHz,

16, 20 and 24 bits

Analogue audio: Minijack

(HDMI IN 1 only)

Video:15 Pin D Sub Connector

Audio: Minijack

Design and specifications are subject to change without notice.

High Picture & Sound Quality, Bravia Sync,

Full HD with 10bit panel, XMB,

Live Colour Creation, 2CH speaker system,

Other Features

Sound Output

Right and Left speaker 2 x 10W, 2 x 12W(Woofer)

Power requirements

Illuminated logo, USB Input, 4 HDMI inputs,

PC input, S-Force, Digital Media Port,

Picture Frame Mode, 24P True Cinema,

PAP, PIP Freeze, Photo Map, Swivel.

3V dc

2 batteries IEC designation

R06 (size AA)

- 5 -

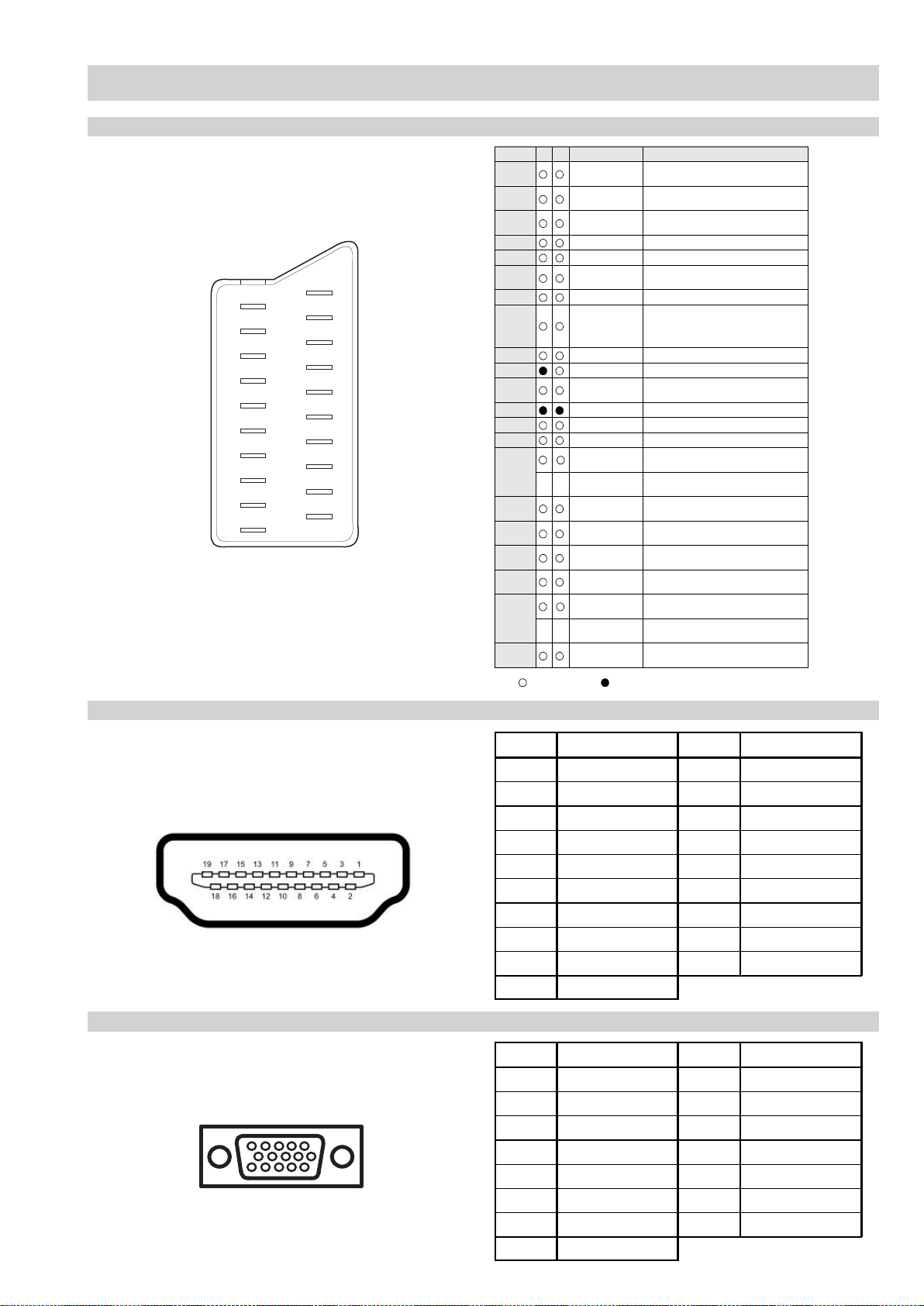

21 Pin Connector (SCART)

1

21

19

17

15

13

11

9

7

5

3

1

20

18

16

14

12

10

CONNECTORS

Pin No 1 2 Signal Signal level

1 Audio output B

2

3

4 Ground (audio)

5 Ground (blu e)

6 Audio input A

7 Blue input 0.7 +/- 3dB, 75 ohms positive

8 Function select

9 Ground (green)

10 AVlink

11 Green Green signal : 0.7 +/- 3dB, 75 ohms,

12 Open

8

13 Ground (red)

14 Ground (blanking)

6

4

2

15

16 Blanking input

17 Ground (video

18 Ground (video

19 Video output 1V +/- 3dB, 75ohms, positive sync 0.3V

20

21 Common ground

(right)

Audio input B

(right)

Audio output A

(left)

(left)

(AV control)

_ _ Red input 0.7 +/- 3dB, 75 ohms, positive

_ (S signal Chroma

-

-

input)

(Ys signal)

output)

input)

Video input 1V +/- 3dB, 75ohms, positive sync 0.3V

Video input

--

Y (S signal)

(plug, shield)

Connected Not Connected (open) * at 20Hz - 20kHz

Standard level : 0.5V rms

Output impedence : Less than 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

Standard level : 0.5V rms

Output impedence : Less than 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

High state (9.5-12V) : Part mode

Low state (0-2V) : TV mode

Input impedence : More than 10K ohms

Input capacitance : Less than 2nF

positive

0.3 +/- 3dB, 75 ohms, positive

High state (1-3V) Low state (0-0.4V)

Input impedence : 75 ohms

(-3+10dB)

(-3+10dB)

1V +/- 3dB, 75ohms, positive sync 0.3V

(-3+10dB)

HDMI Connector

15 Pin D Sub Connector (PC)

Pin No Signal Assignment Pin No Signal Assignment

1 TMDS Da t a 2+ 11 TMDS Cl o ck S hield

2 TMDS Data2 Shield 12 TMDS Clock-

3TMDS Data2- 13CEC

4 TMDS Data1+ 14 Reserved (N.C. on device)

5 TMDS Data1 Shield 15 SCL

6 TMDS Data1- 16 SDA

7 TMDS Data0+ 17 DDC/CEC Ground

8 TMDS Data0 Shield 18 +5V Power

9 TMDS Data0- 19 Hot Plug Detect

10 TMDS Clock+

Pin No Signal Assignment Pin No Signal Assignment

1Red Out 9+5V DC

2 Green Out 10 S ync Return (Ground)

3 Blue Out 11 Monitor ID0 in Display

4 Unused 12 DCC Serial Da ta

5 Ground 13 Horizontal Sync

6 Red Re t urn 14 Vertical Sy n c

7 Green Return (Ground) 15 DCC Serial Clock

8 Blue Return (Ground)

- 6 -

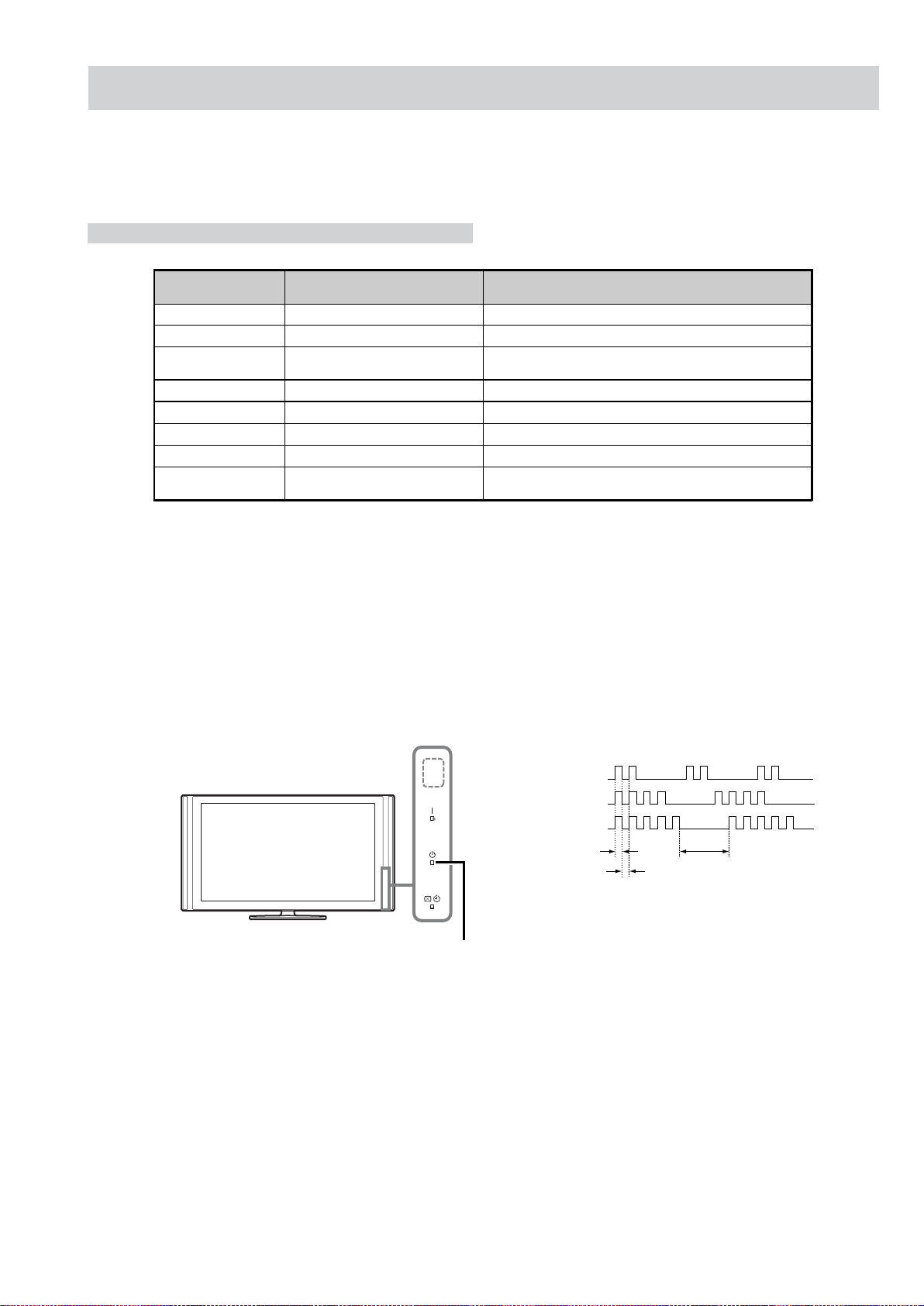

EG1H SELF DIAGNOSTIC SOFTWARE

The identification of errors within the EG1H chassis is triggered in one of two ways :- 1: Busy or 2: Device failure to respond to IIC. In the

event of one of these situations arising the software will f irst try to release the bus if busy (Failure to do so will report with a continuous

flashing LED) and then communicate with each device in turn to establish if a device is faulty. If a device is found to be faulty the relevant

device number will be displayed through the LED (Series of flashes which must be counted).

LED Error Codes and Descriptions

Number of LED

Flashes

02 POW ERR1 Power error (Watching 12v rail).

05 T_CON T-CON error.

06 BACKLITE

07 PANEL TEMP Panel temperature abnormal detection.

08 AUD_PROT Audio abnormal detection.

09 FAN_ERR Fan error

10 DTT ERR EMMA WDT - Not detected (Reboot operation).

13 BALANCER

Display Error Description

DISPLAY OF STANDBY LIGHT FLASH COUNT

[CCFL] Panel inverter error.

[LED] GL board error.

[CCFL] Panel balancer error.

[LED-BL] SPI error(Babylon communication error).

[ FLASH COUNT ]

2 times

4 times

5 times

LED ON 0.3 sec.

LED OFF 0.3 sec.

Note: One flash count is not self-diagnostic.

LED OFF

2 sec.

STANDBY LED

STOPPING THE STANDBY FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY LED for flashing.

- 7 -

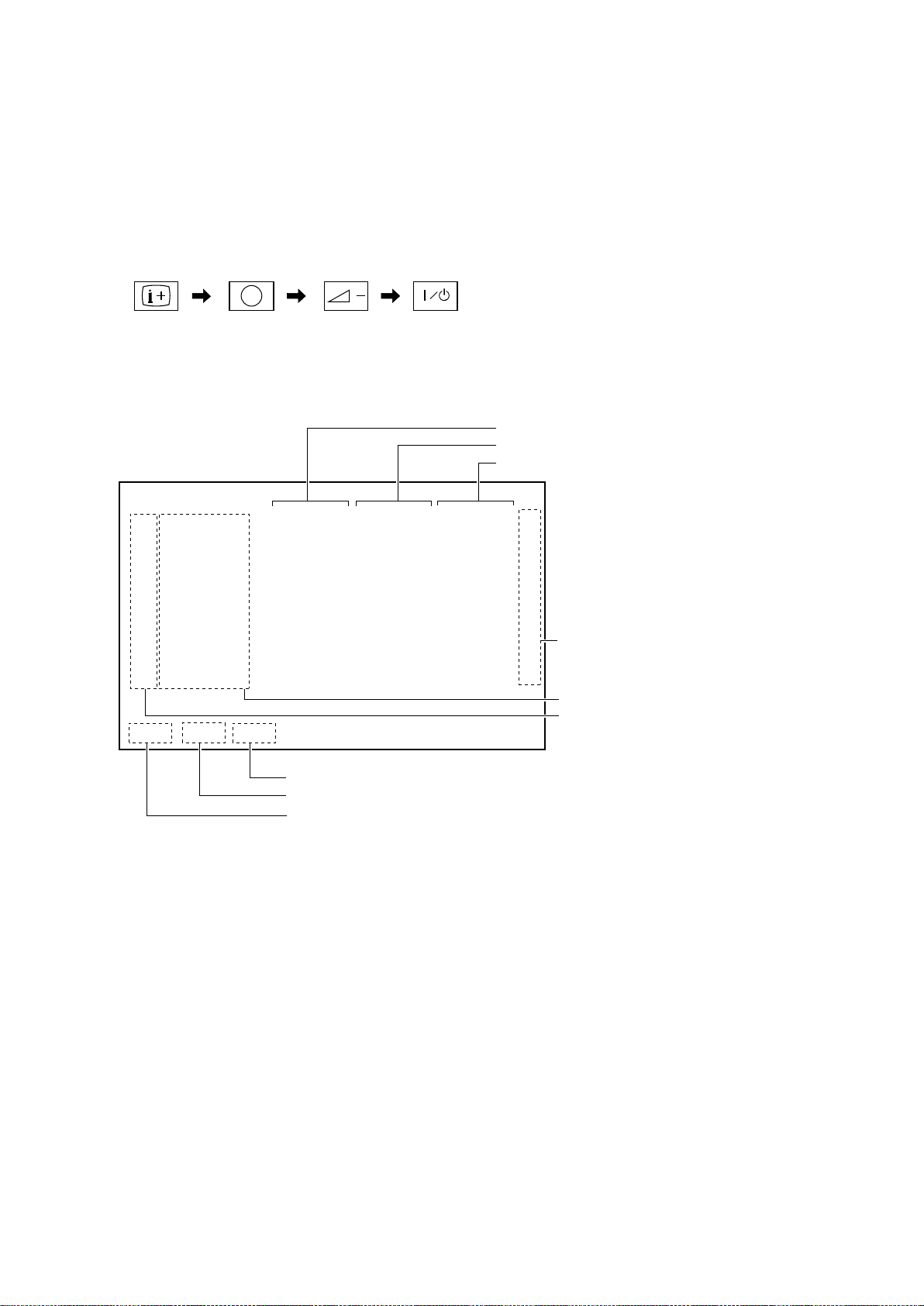

SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it is possible to

bring up past occurrences of failure for confirmation on the screen:

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

5

( Info/Text reveal )

( Number button )

* ( Volume ) ( TV standby )

* : Note that this differs from entering the service mode (volume +)

[ SELF-DIAGNOSTIC SCREEN DISPLAY ]

SELF CHECK

002 POW_ERR1

005 T_CON

006 BACKLITE

007 PANL TEMP

008 AUD_PROT

009 FAN_ERR

010 DTT_ERR

013 BALANCER

12345 - 00333 - 06789

0501210811 0412311234 0311111825 00

0000000000 0000000000 0000000000 00

0000000000 0000000000 0000000000 00

0000000000 0000000000 0000000000 00

0000000000 0000000000 0000000000 00

0000000000 0000000000 0000000000 00

0000000000 0000000000 0000000000 00

0000000000 0000000000 0000000000 00

Panel operation time by hour (max 99999)

Boot count (max 99999)

Total operation time by hour (max 99999)

The last failure time

Falure time before last

Last failure time beforehand

Error count (00-99)

Item name

Frequency of LED blinking.

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen

After you have completed the repairs, clear the result display to “0”.

Clearing the result display

To clear the result display to “0”, press button on the remote commander sequentially as shown below when the diagnostic screen is being

displayed.

<Delection of Error Count and Error History>

Press “8” button

<Delection of Panel Operation Time>

Press “7” button

Press “-” button

,

Press “-” button

,

Quitting Self-diagnostic screen

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

- 8 -

SECTION 2 DISASSEMBLY

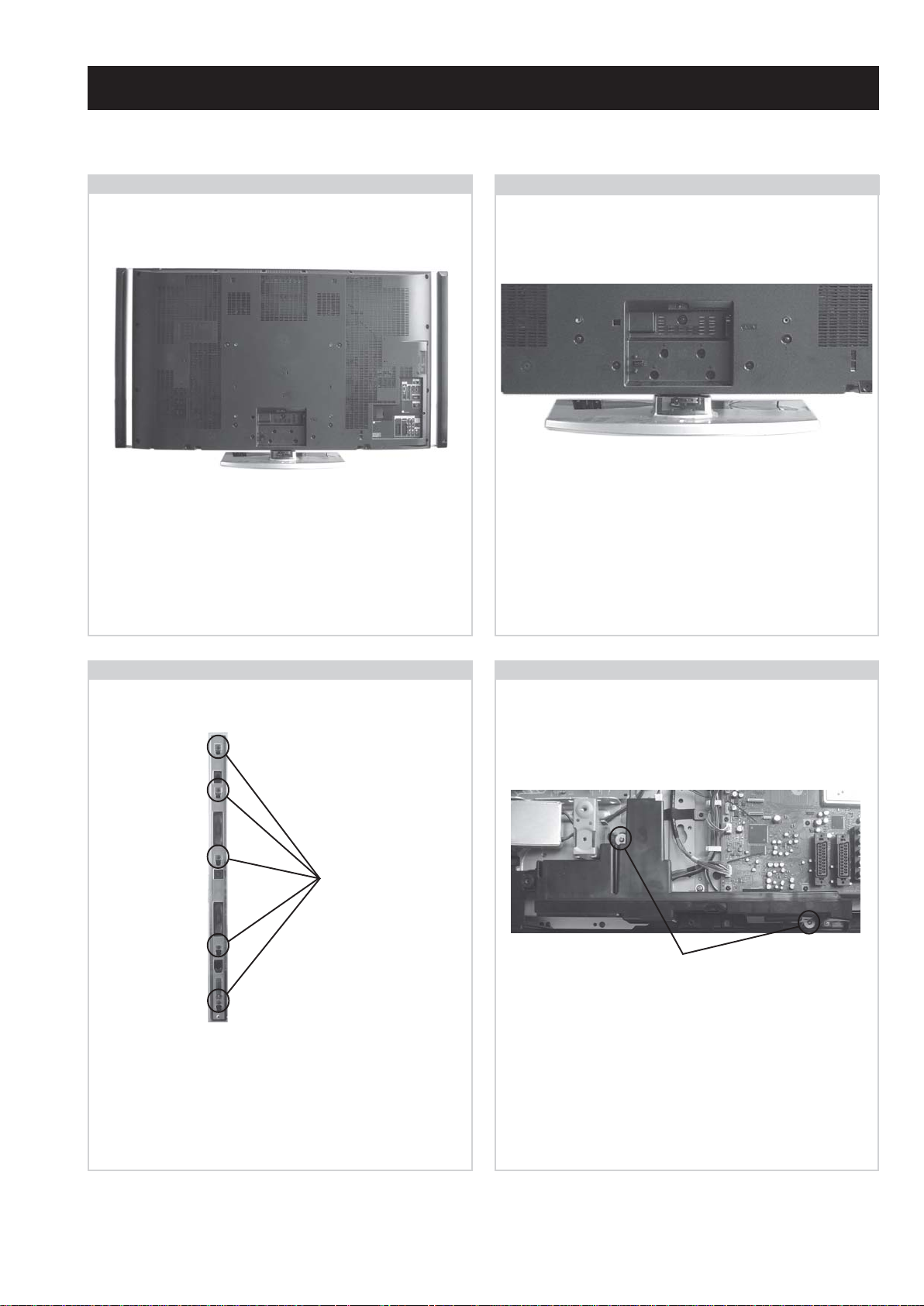

2-1. Rear Cover Removal

1

=>

=>

1

=>

1

=>

1

=>

1

=>

3

1

=>

3

=>

1

=>

1

Remove the rear cover fixing screws indicated and pull the rear cover

gently backwards away from the back of the TV set.

Screw Part number(s) and Description(s)

1) 2-580-640-01 SCREW, +BVTP2 4X16 (18 Screws)

2) 7-685-648-79 SCREW, +BVTP 3X12 TYPE2 IT-3 (2 Screws)

3) 2-580-608-01 SCREW, +PSW M5X16 (4 Screws)

1

=>

=>

1

=>

1

=>

1

=>

3

=>

1

=>

3

=>

=>

1

=>

1

=>

2

=>

2

=>

1

=>

1

=>

1

2-2. Stand Removal

=>

=>

Remove the 4 stand fixing screws as indicated.

Screw Part number(s) and Description(s)

2-580-608-01 SCREW, +PSW M5X16 (4 Screws)

=>

=>

2-3. Speaker Box Removal

Screws

T o remove the speaker box f irstly remove the speaker grille by

pushing the grille upwards, disconnect the speaker cable and then

remove the 5 screws circled.

Screw Part number(s) and Description(s)

2-580-640-01 SCREW, +BVTP2 4X16 (5 Screws)

2-4. W oof er Box Remova l

Screws

T o remove the w oofer box disconnect all connectors and then remove

the 2 screws circled and ease the box gently away from the back of the

TV set.

Screw Part number(s) and Description(s)

2-580-654-01 SCREW, +PWTP2 4X16 (2 Screws)

- 9 -

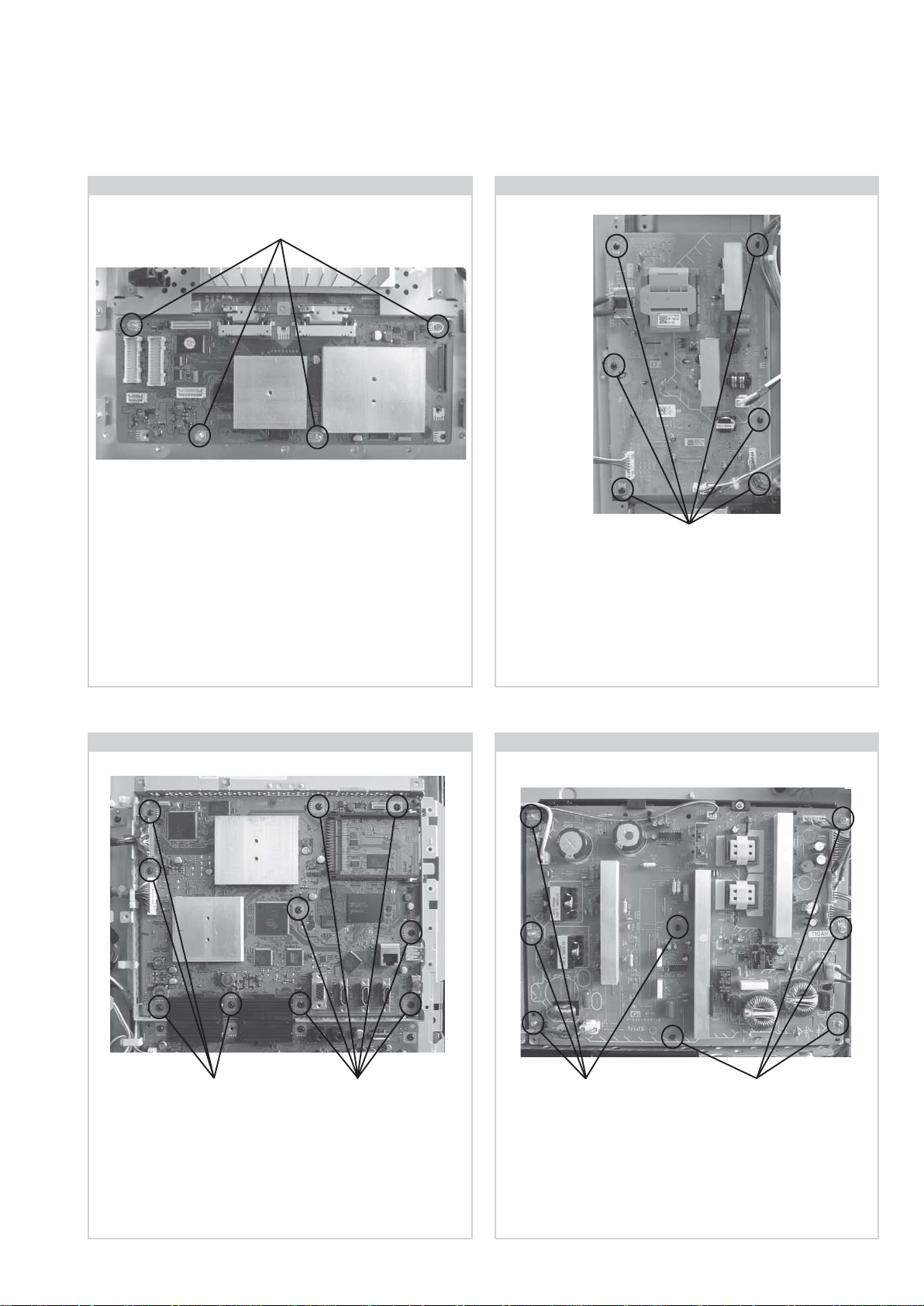

2-5. CB1 Board Removal

Screws

2-6. D4 Board Removal (40 inches)

Screws

T o remov e the CB1 board disconnect all connectors and then remo ve

the shield. Then remove the 4 screws circled and ease the board gently

away from the back of the TV set.

Screw Part number(s) and Description(s)

7-682-948-01 SCREW, +PSW 3X8 (4 Screws)

T o remove the D4 board disconnect all connectors and then remove the

6 screws circled and ease the board gently away from the back of the

TV set.

Note: Refer to page 4 - Hirose MDF61 connector.

Screw Part number(s) and Description(s)

2-674-965-51 SCREW, +PSW 3SG (6 Screws)

2-7. FBA Board Removal 2-8. G6 Board Removal

T o remove the FBA board disconnect all connectors and then remove

the 10 screws circled and ease the board gently away from the back of

the TV set.

Screw Part number(s) and Description(s)

2-580-629-01 SCREW, +BVST 3X8 (10 Screws)

Screws

ScrewsScrews Screws

T o remove the G6 board disconnect all connectors and then remov e the

8 screws circled and ease the board gently away from the back of the

TV set.

Screw Part number(s) and Description(s)

7-682-948-01 SCREW, +PSW 3X8 (8 Screws)

- 10 -

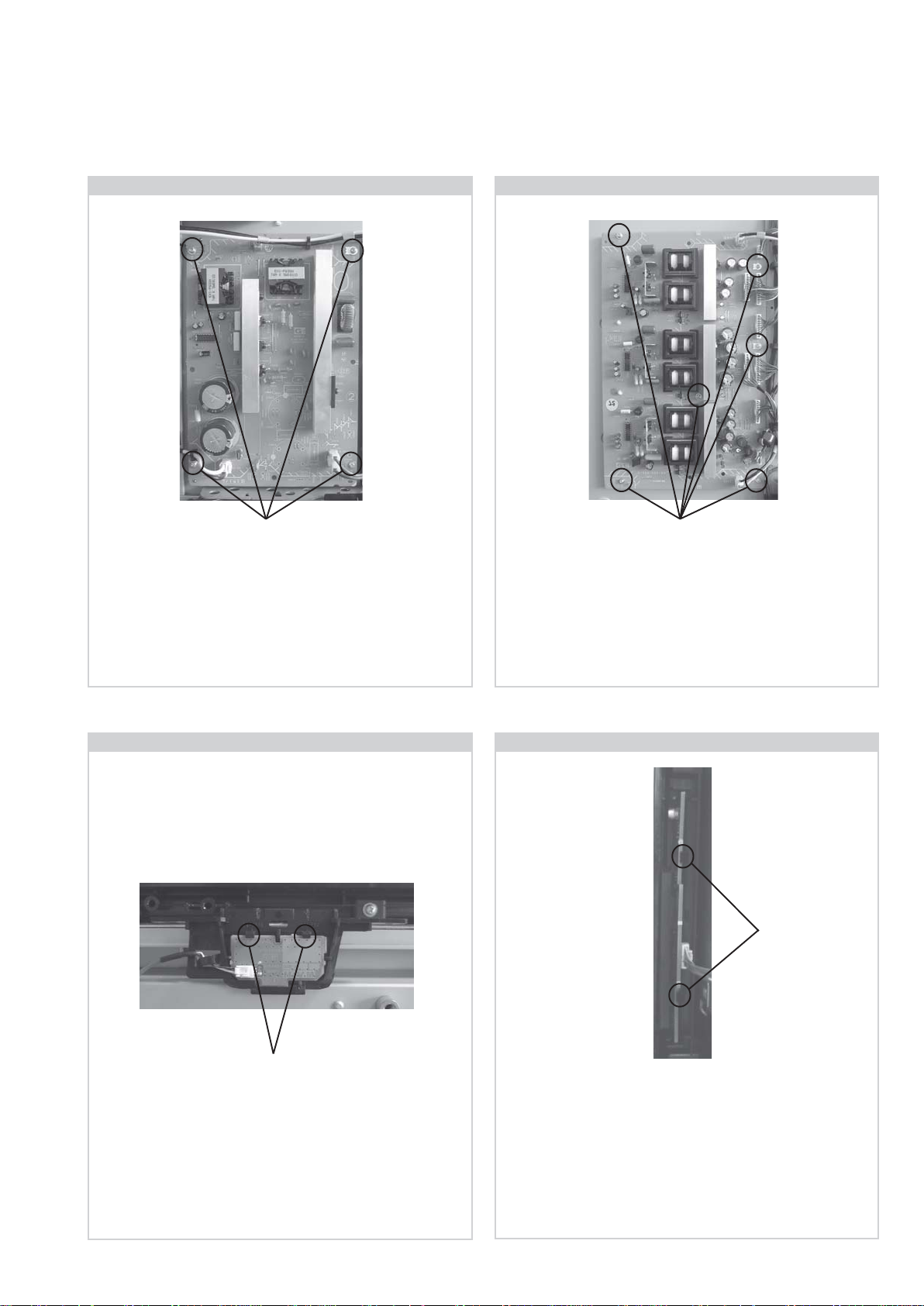

2-9. G7 Board Removal (55 inches)

2-10. GL Board Removal (46 & 55 inches)

Screws

To remo ve the G7 board disconnect all connectors and then remove the

4 screws circled and ease the board gently away from the back of the

TV set.

Screw Part number(s) and Description(s)

7-682-948-01 SCREW, +PSW 3X8 (4 Screws)

T o remove the GL board disconnect all connectors and then remove the

6 screws circled and ease the board gently away from the back of the

TV set.

Note: Refer to page 4 - Hirose MDF61 connector.

Screw Part number(s) and Description(s)

7-682-948-01 SCREW, +PSW 3X8 (6 Screws)

2-11. H1VM Board Removal 2-12. H3VM Board Removal

Screws

Clips

Clips

To remove the H1VM board firstly remove the power button assy

away from the bezel assy , disconnect the connector and then release the

2 clips circled and ease the board gently of its housing.

T o remove the H3VM board disconnect the connector and then release

the 2 clips circled and ease the board gently away from the back of the

TV set.

- 11 -

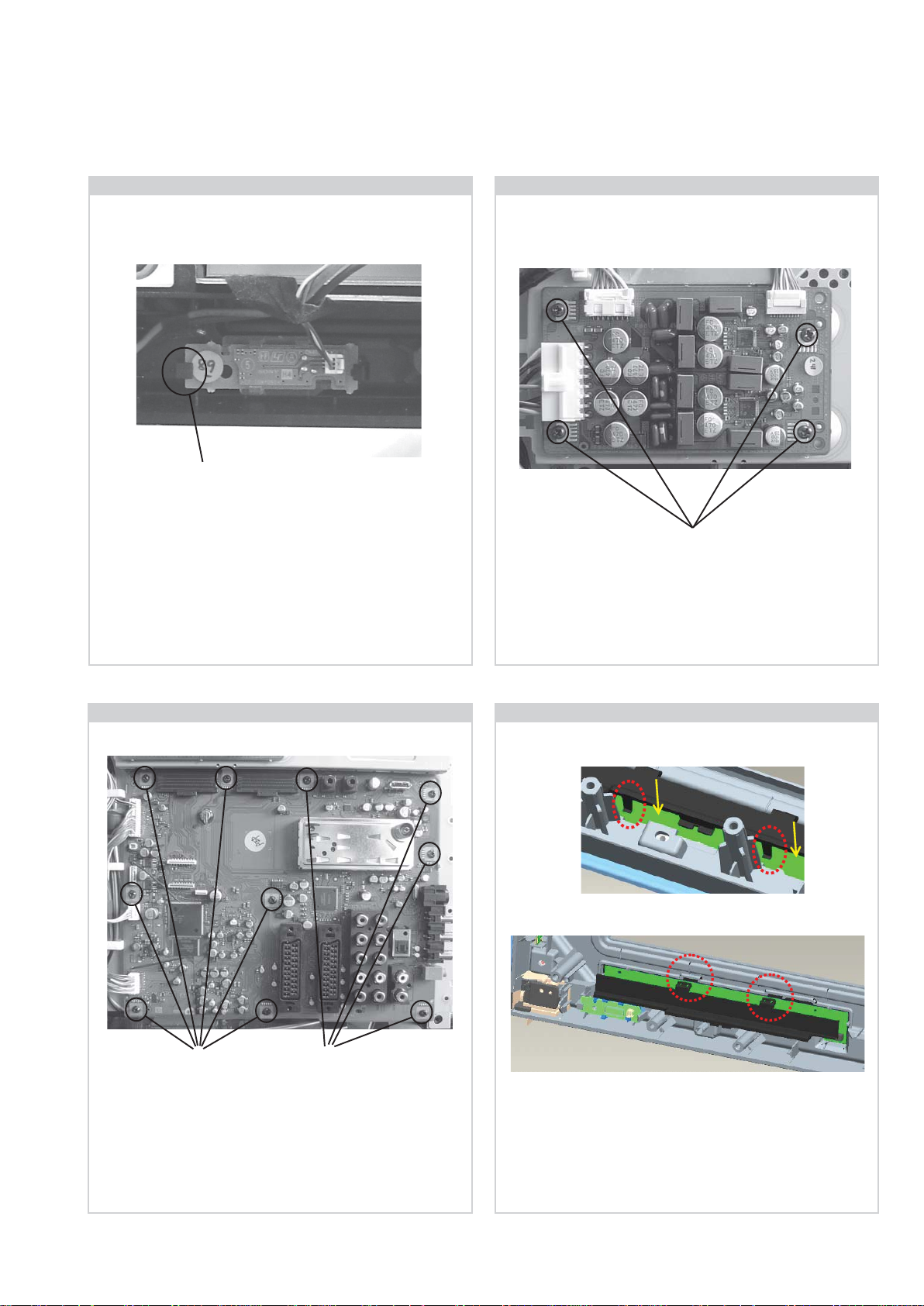

2-13. H4 Board Removal 2-14. K2 Board Removal

Clip

T o remove the H4 board disconnect the connector and then release the

clip circled and gently ease the board towards you and away from the

back of the TV set.

T o remove the K2 board disconnect all connectors and then remove the

4 screws circled and ease the board gently away from the back of the

TV set.

Screw Part number(s) and Description(s)

2-580-629-01 SCREW, +BVST 3X8 (4 Screws)

Screws

2-15. AE Board Removal

ScrewsScrews

To remo ve the AE board disconnect all connectors and then remove the

10 screws circled and ease the board gently away from the back of the

TV set.

Screw Part number(s) and Description(s)

2-580-629-01 SCREW, +BVST 3X8 (9 Screws)

2-16. Sensor Module Removal

Pic.1

Pic.2

T o remove the sensor module remov e the connector . Then remov e the

‘holder, touch’ by releasing the 2 clips circled in Pic.1and then releasing

the 2 clips circled in Pic.2, you can then remove the the sensor module.

- 12 -

SECTION 3 SERVICE MENUS

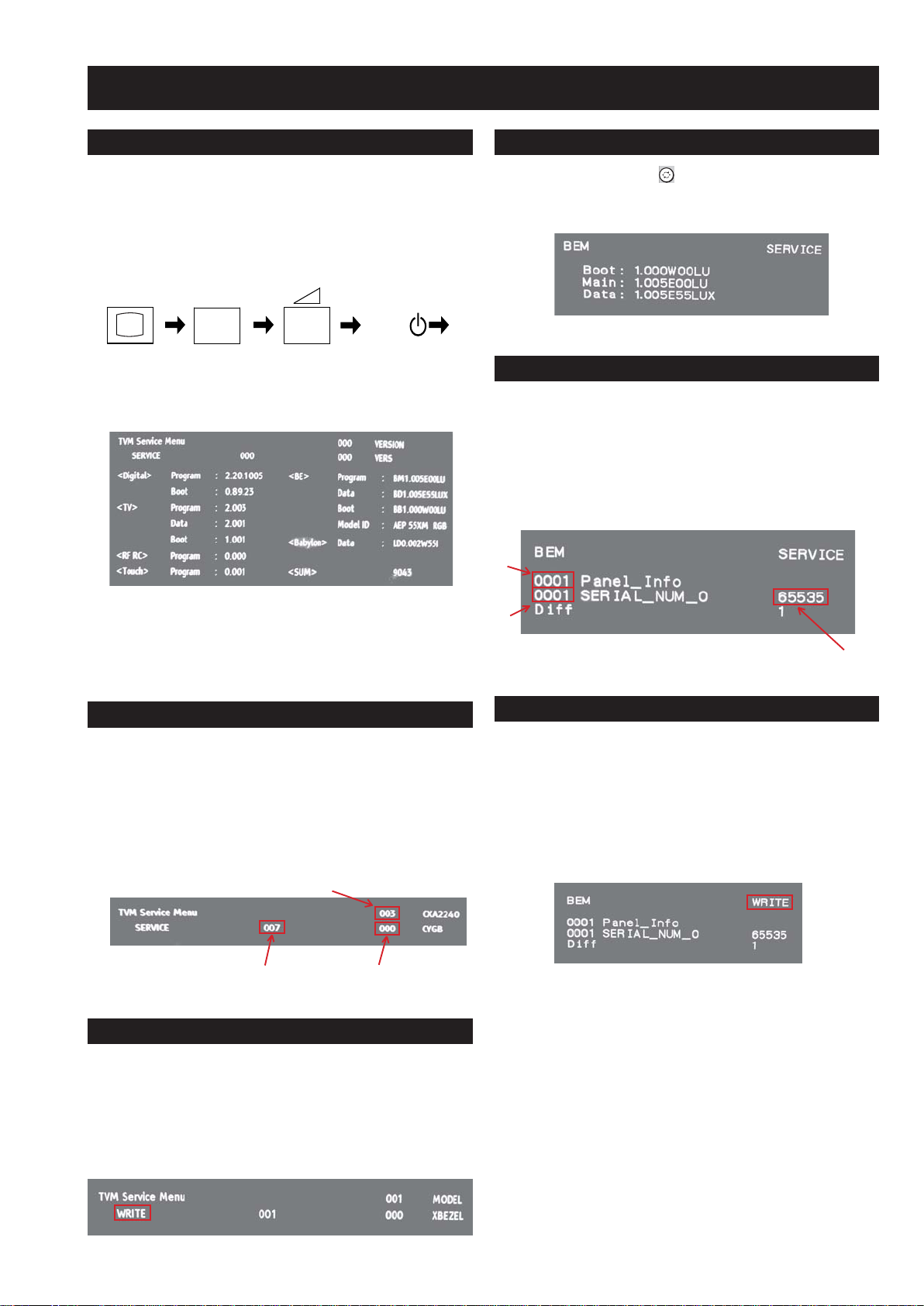

3-1. How to enter Service Mode

Service adjustments to this model can be performed using the

supplied remote Commander RM-ED012.

1. Turn on the power to the TV set and enter into the stand-by

mode.

2. Press the following sequence of buttons on the Remote

Commander.

i+

(ON SCREEN (DIGIT 5) (VOLUME +) (TV)

DISPLAY)

3. The TVM Service Menu appears on the screen (See Pic.1).

Pic.1

5

+

TV

I/

3-4. Entering BEM Service Menu

1. Press “Previous channel ” on the remote commander and the

BEM menu appears (See Pic.4)

Pic.4

3-5. Changing BEM Data Settings

1. Press “2 / 5” on the remote commander to select (up / down)

category (See Pic.5).

2. Press “1 / 4” on the remote commander to select (up / down)

item (See Pic.5).

3. Press “3 / 6” on the remote commander to select (up / down)

data (See Pic.5).

Pic.5

Category

Note :

• After carrying out the service adjustments, to prevent the

customer accessing the ‘Service Menu’ switch the TV set OFF

and then ON.

3-2. Changing TVM Data Settings

1. Press “2 / 5” on the remote commander to select (up / down)

category (See Pic.2).

2. Press “1 / 4” on the remote commander to select (up / down)

item (See Pic.2).

3. Press “3 / 6” on the remote commander to select (up / down)

data (See Pic.2).

Pic.2

Data

Category

Item

3-3. Writing TVM Data

Item

Data

3-6. Writing BEM Data

1. Press “Mute” on the remote commander. The word “SER VICE”

in green changes to “WRITE” (See Pic.6).

2. Press “0” on the remote commander. The word “WRITE” in

green changes to red. This indicates writing is in progress

(See Pic.6).

3. When “WRITE” changes to green “SERVICE”. This indicates

writing is complete.

Pic.6

1. Press “Mute” on the remote commander. The word “SER VICE”

changes to “WRITE” (See Pic.3).

2. Press “0” on the remote commander.

3. After approximately 1 minute, “WRITE” changes to

“SER VICE”. This indicates writing is complete.

Pic.3

- 13 -

3-7. T rouble Shooting

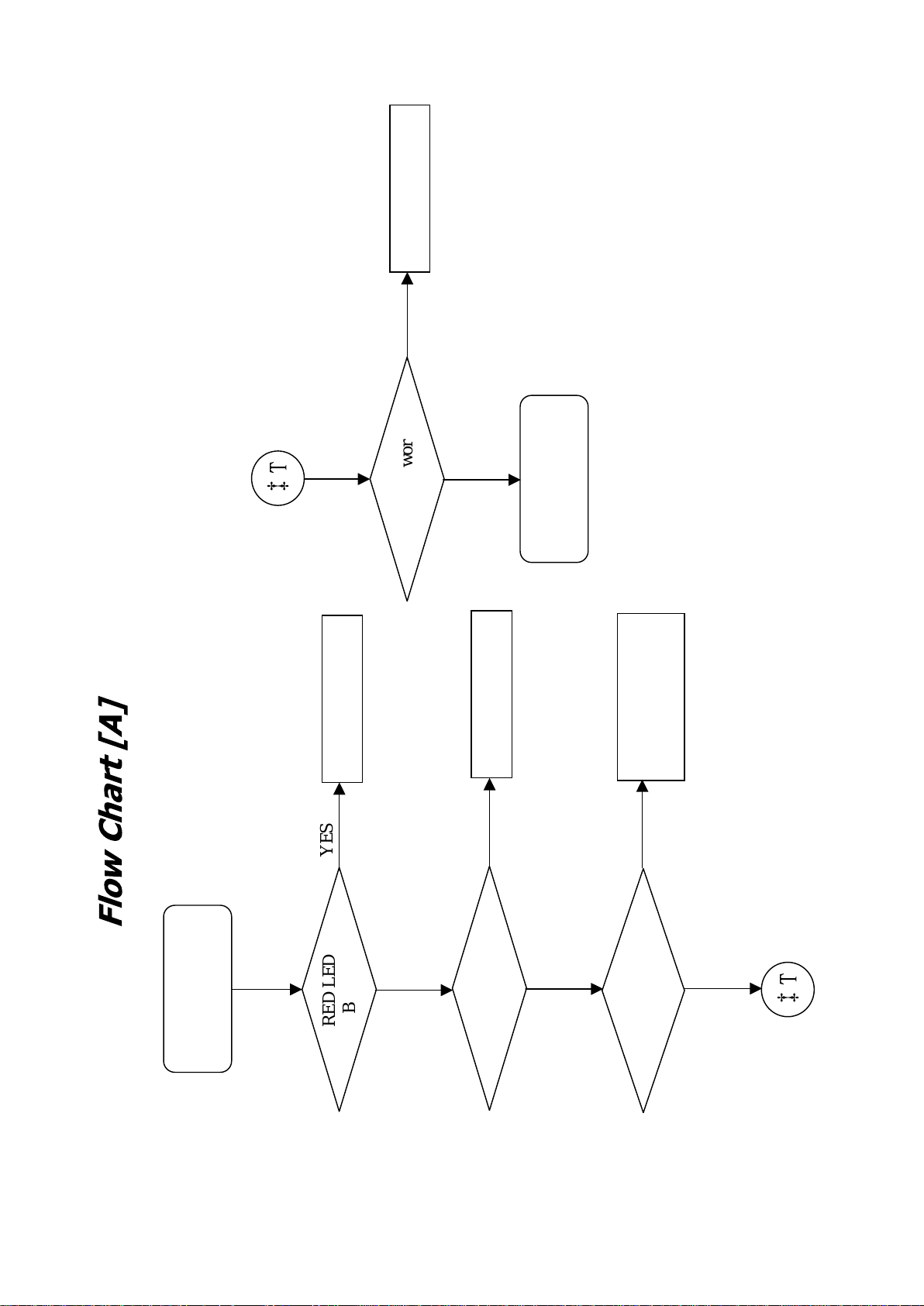

3-7-1. No Power

When the TV Set has no power please see flowchart [A].

3-7-2. Set Reboots

When the TV Set tries to restart please check the following:-

1. FBA board.

- CN2800 12v power and harness to G6.

- F4100, F4101, F4102, F5400, F7800, F7801

for conduction .

2. If no problems are found with the power rail replace the

FBA board.

3-7-3. Power Error

When the TV Set indicates a power error please check the following:-

1. Check the TV micro pin 79 and 138 on the AE boar d.

2. Check 12V at CN1000 and F1001 on the AE board .

3. Check the G6 board.

3-7-4. T-Con Error

When the TV Set has a T-Con error please check the following:-

1. Check the BE micro pin 128 on the FBA board.

2. Replace the panel module.

3-7-9. Balancer Error

When the TV Set has a Balancer board error please check the

following:-

1. Check the BE micro pin 163 on the FBA board.

2. Check harness connection CN6700 on the D4 board and

CN104 on tne balancer board of panel module (40 inches).

3. Check harness connection CN9700, CN9701 on the CB1

board and panel module (46/55 inches).

4. Replace the panel module.

5. Replace CB1 board (46/55 inches).

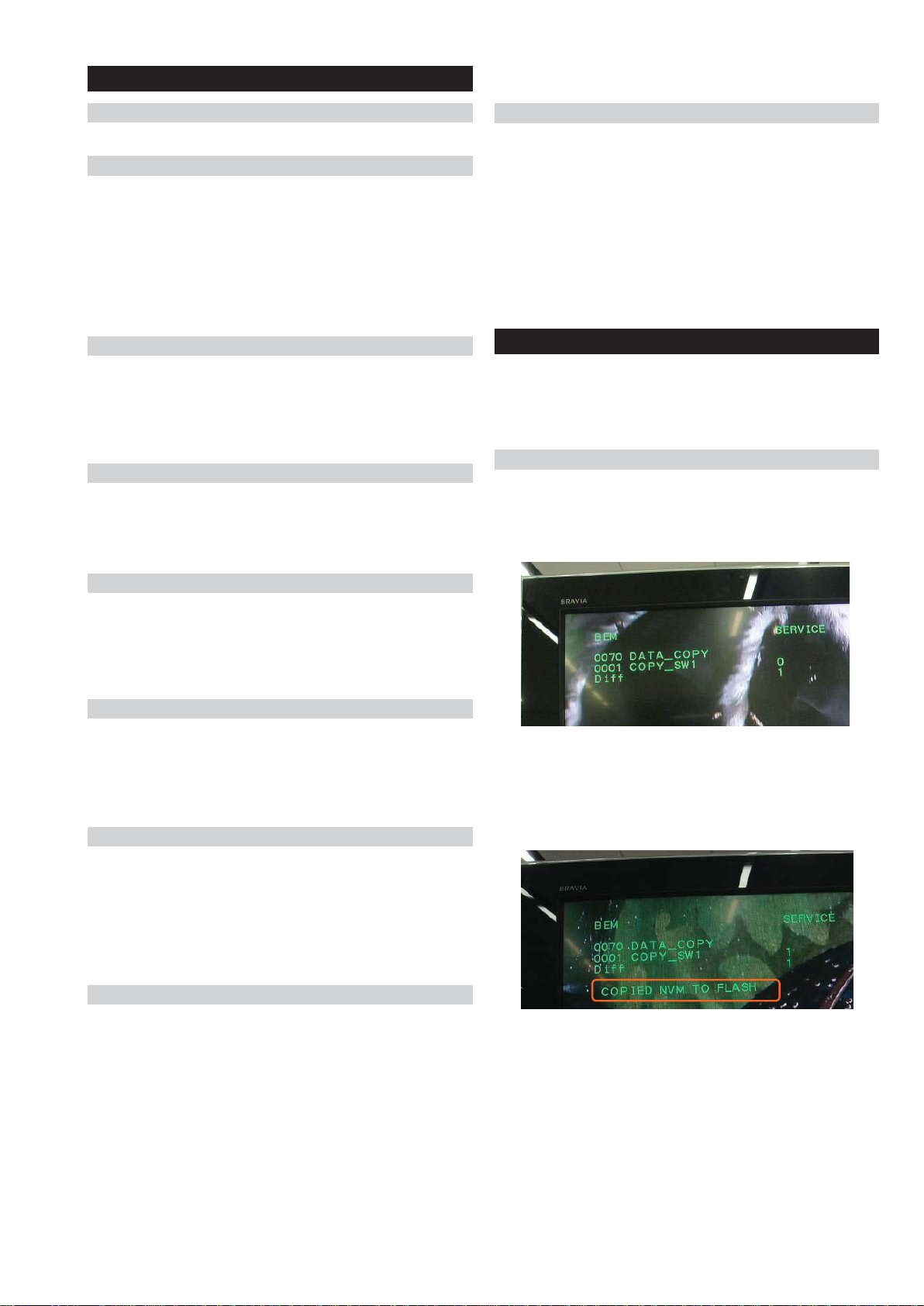

3-8. CB1 Board Replacement (46/55 inches)

When replacing the CB1 board adjustment data held in the backlight

NVM of the panel can be copied to the CB1 board. Data held on the

CB1 board can also be copied to the panel in the case of panel

replacement.

3-8-1. Copying data from Panel to CB1 Board

1. Enter Service Mode (See 3-1).

2. Go in to BEM Service Mode (See 3-4) and go to

‘DATA_COPY’ (See Pic.7).

Pic.7

3-7-5. Back Light Error

When the TV Set has a Back Light error please check the following:-

1. Check the BE micro pin 78 on the FBA board.

2. Replace the D4 board in CCFL model and GL board in LED

models.

3-7-6. Temperature Error

When the TV Set temperature is high please check the following:-

1. Check IC1000 on the AE board and replace the AE board

if the temperature monitoring circuit has a problem.

2. Check the panel.

3-7-7. Audio Error

When the TV Set has an audio error please check the following:-

1. Check IC1800 on AE board. The audio amp detects ov er

current, thermal shutdown and/or low voltage.

2. Check voltage at CN1002 pin 20 on the AE board.

3. Replace the AE board.

3-7-8. Fan Error

When the TV Set has a fan error please check the following:-

1. Check the BE micro pin 154 on the FBA board.

2. Check fan harness connection.

3. Check the voltage on CN1301 the AE board.

4. Replace the fan.

3. Change ‘COPY_SW1’ to 1 and wait until the message

“ COPIED NVM TO FLASH” appears (See Pic.8).

At this point make sure the TV set is not powered off until

this message appears.

Pic.8

4. Software has now been copied. Switch AC of f and back on

again to confirm.

- 14 -

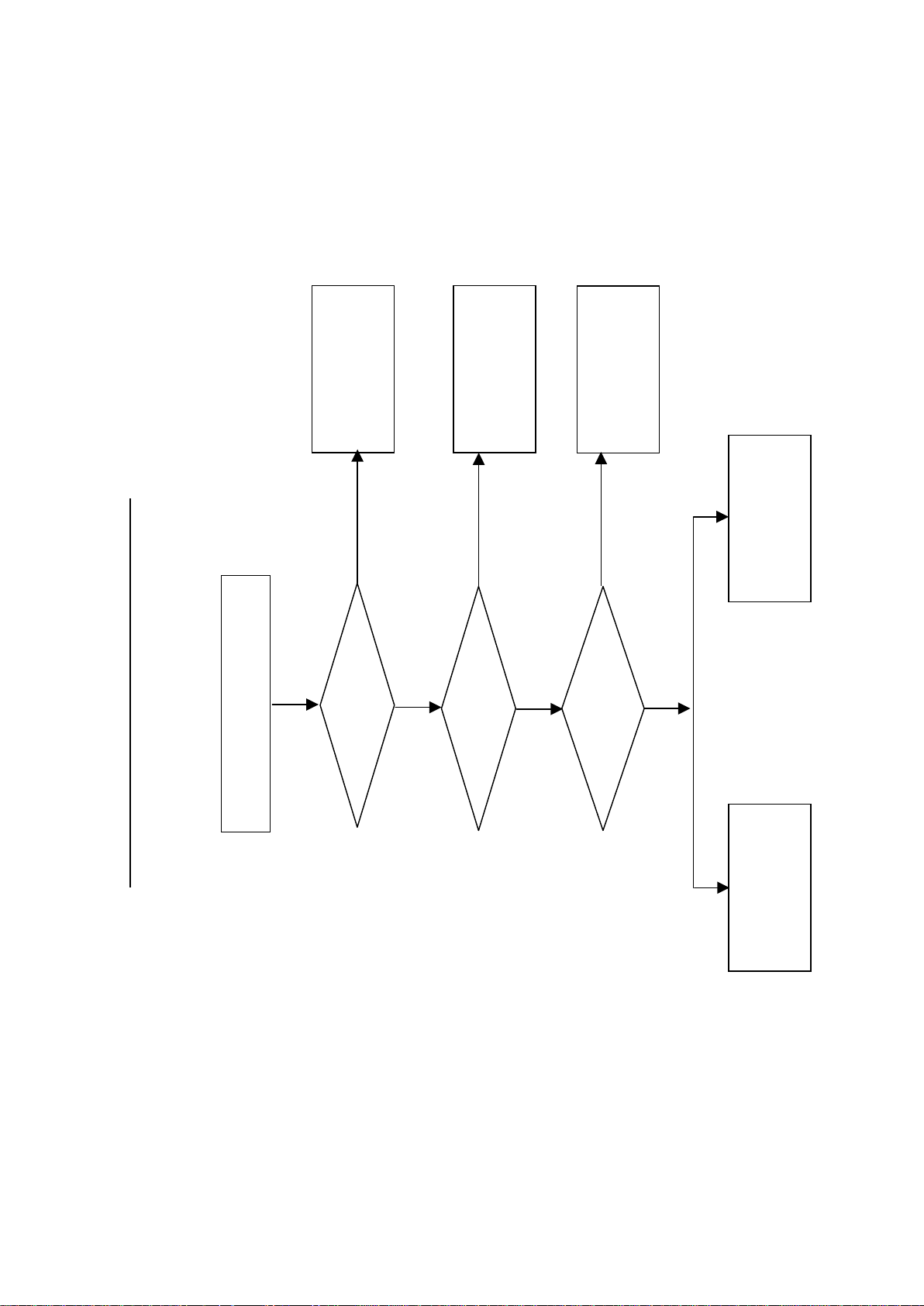

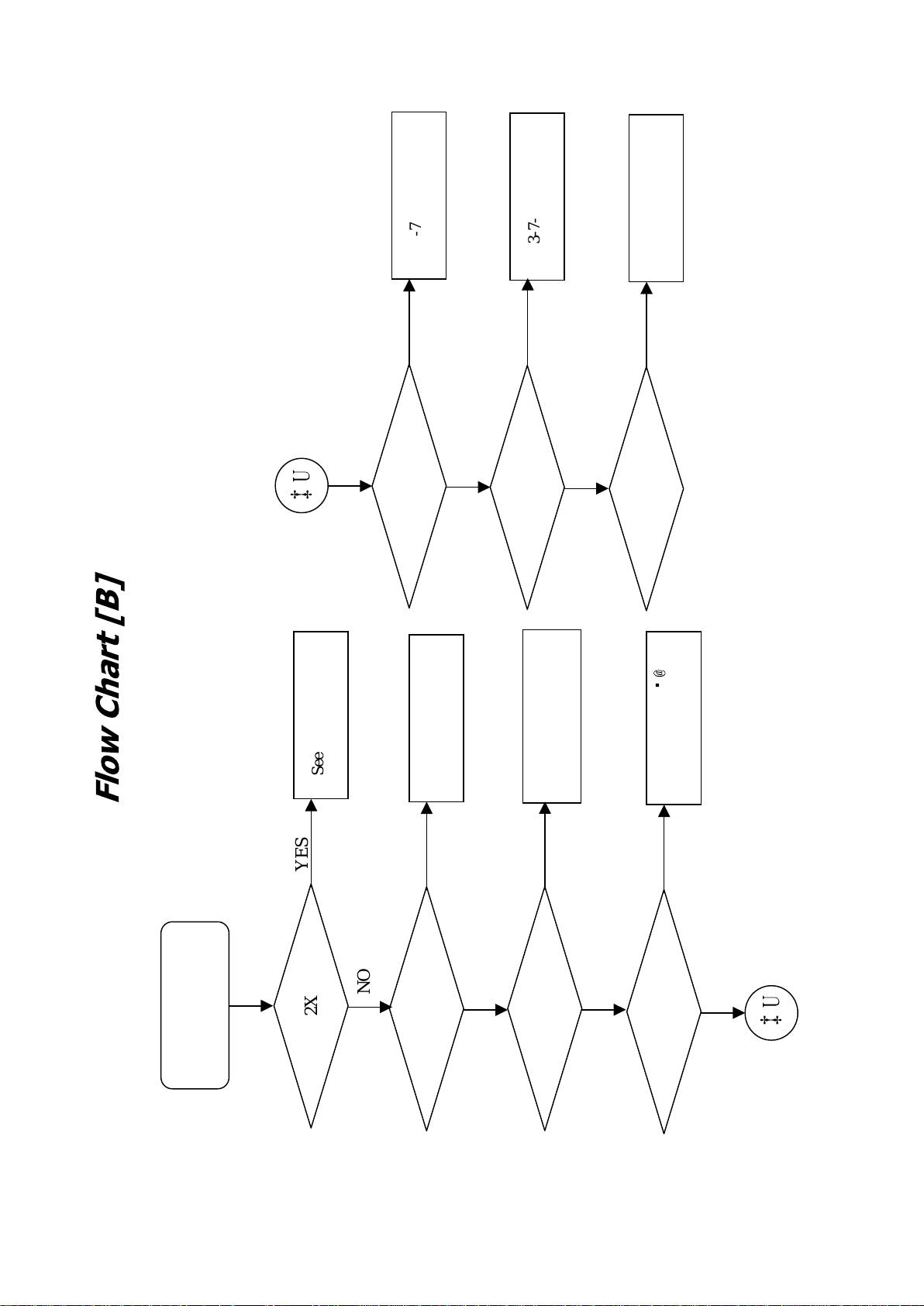

See Flow Chart [A]

See (3-7-2)

See Flow Chart [B]

NO

Trouble

Set Power

EG1H Trouble Shooting

YES

YES

NO

Set Re-boots

YES

Self diagnosis

Video

See Flow Chart [C]

NO

Audio

See Flow Chart [D]

- 15 -

H1VM board

NO

W6

See Flow Chart [B]

YES

works

key

Power

YES

NO

AC cable or AC inlet

AE board

G6 board

(No STBY5V)

NO

No Power

(No relay clicks)

NO

Blinks

RED LED

110-240Vac

- 16 -

YES

CN6000 on G6

5Vdc

CN2800 #7

YES

on FBA

W6

See 3-7-7 AUDIO ERR

See 3-7-8 FAN ERR

See 3-7-9 Balancer ERR

W7

See 3-7-3 POW ERR

YES

8X

YES

NO

9X

See 3-7-4 T-CON ERR

NO

See 3-7-5 BACK LIGHT

YES

13X

ERR

Q(

See 3-7-6 TEMP

YES

2X

RED LED Blinks

NO

YES

5X

- 17 -

NO

YES

6X

NO

YES

7X

NO

W7

VCBS

Problem?

NO

Problem?

Component

NO

YES

YES

Check

AE board

Check

FBA board

AE board

Joint connector

Video

problem

Digital

/Analog

Channel

NO

HDMI

Problem?

NO

have

All inputs

Problem?

problem?

YES YES

YES

Check

FBA board

AE board

Check

FBA board

AE board

Joint connector

YES

OSD

appear?

Joint connector

YES

turn on?

Back Light

NO

NO

Check

FBA board

Check

LVDS harness

FBA board

CB1 board

Here is trouble shooting flow related Video

- 18 -

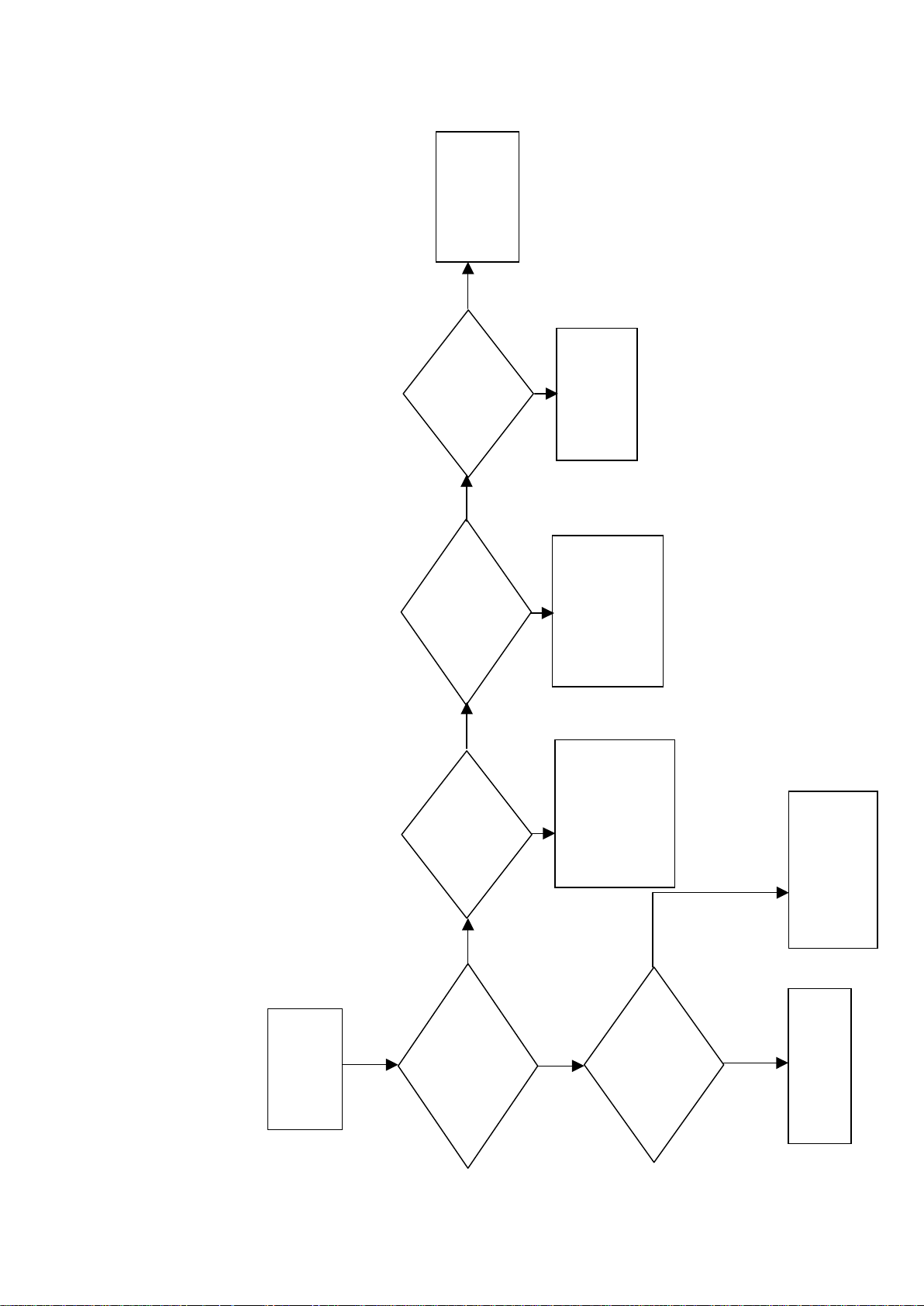

Check

LVDS harness

G6/7/GL boards

FBA board

Panel Module

CB1 board

D4 board

Check

AE Board

NO

Analog

Channel

NO

Digital

Channel

K2 Board

YES

Problem?

YES

Problem?

Check

AE Board

Check

FBA Board

AE Board

Joint connector

Flow Chart [D]

Audio

problem

Here is trouble shooting flow related audio

NO

HDMI

Problem?

NO

Only

Speaker

out?

YES

YES

Check

FBA board

AE Board

UI setting

K2 Board

Joint connector

YES

off/On

correct?

HP Link

Volume, SP

NO

Check Speaker

AE Board

K2 Board

Set correctly or

reset by menu.

- 19 -

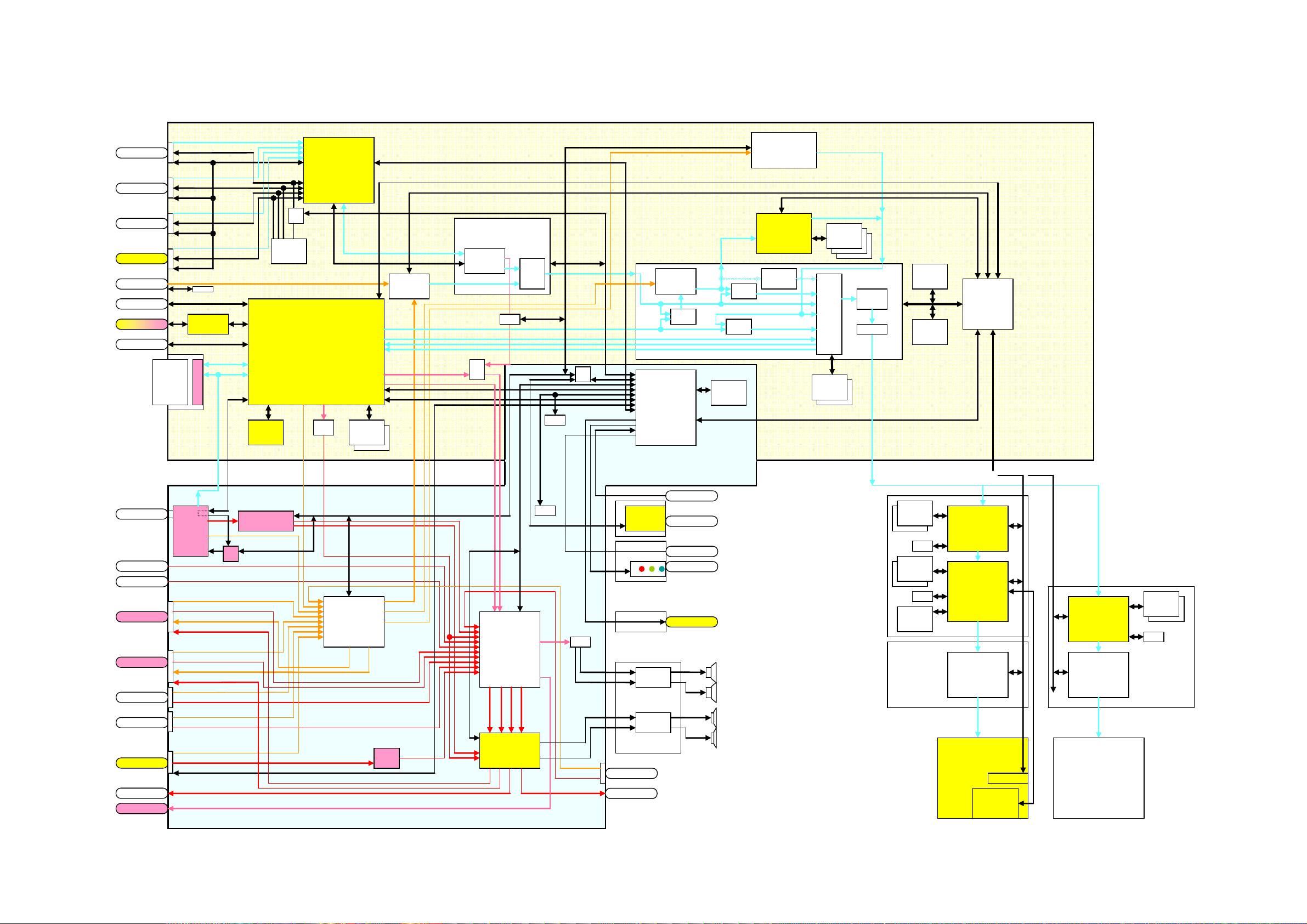

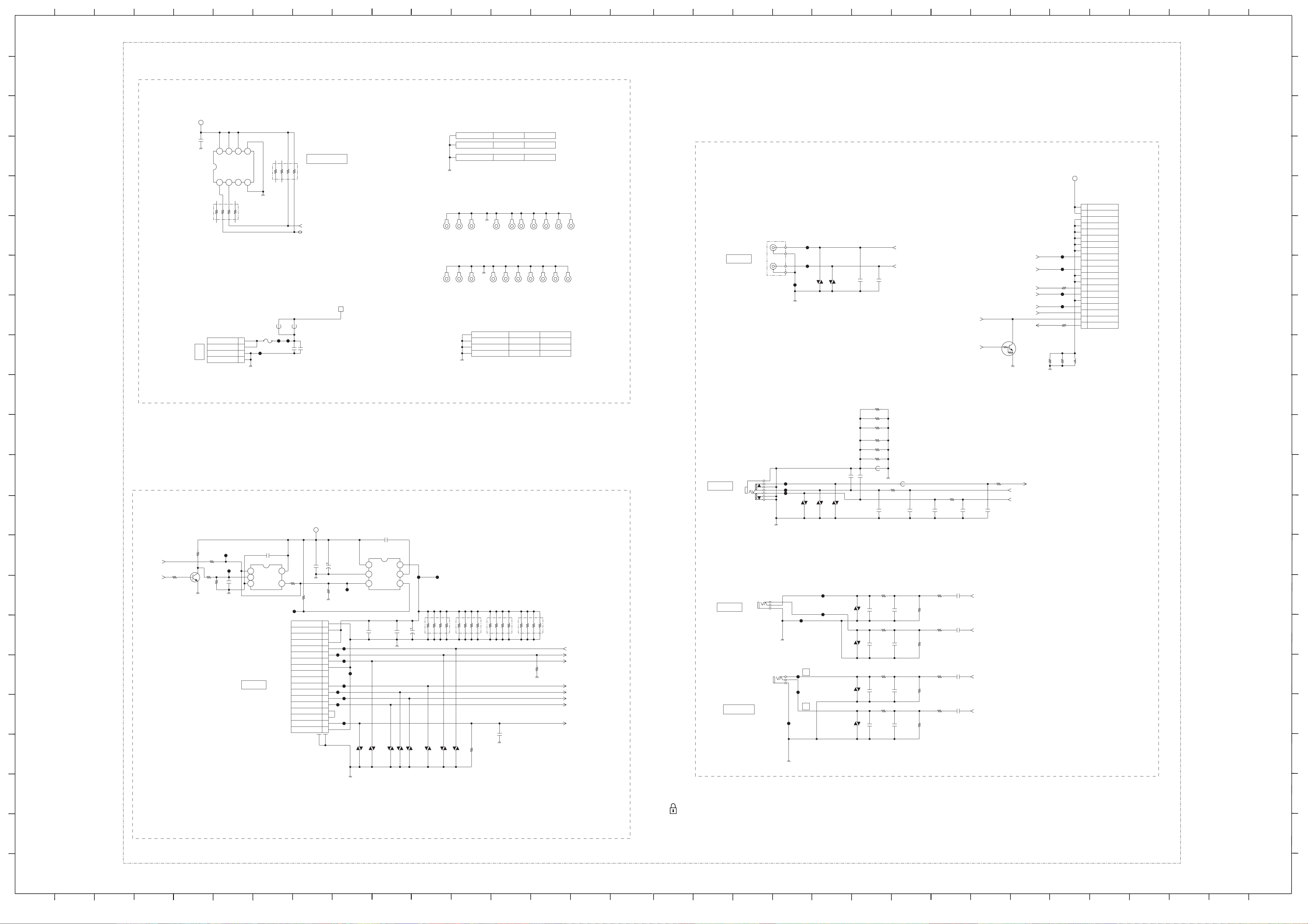

4-1. BLOCK DIA GRAM

EG-1H Block Diagram

HDMI1

HDMI2

HDMI3

HDMI4

PC In

MS (JIG)

Ether

USB

TMDS

DDC

CEC

TMDS

DDC

CEC

TMDS

DDC

CEC

TMDS

DDC

CEC

PCMCIA

NVM

PHY

TS

TS

IIC

NAND

512Mb

HDMI EQ/SW

SW

FRAM

2Kb

EMMA3SL

YC

CXB1446

DAC

L/R

DDR2

512Mbx2

TMDS

DDC

CEC

ADC

TH7984

IIC

IIC

㧴㧰㧹㧵 㧾㨤

YCbCr16bit H/V/CK

GPX ARGB888 H/V/CK

H/V/CK (for GPX)

REC656 (for teletext)

I2S 2ch/5.1ch

SW

SPDIF

UART

UART

SPI

Companion

Sil19151

v1.3

DLY

I2S 2ch

IIC

IIC

BUS

SW

IIC

IIC

NVM

Sub Chrom

FBA

SAA7115A

IIC

IIC

IIC

DDR2

128Mbx3

IFP

core

RCP

LVDS

Flash

32Mb

BEM

SDR

64Mb

BUS

BUS

SW

DRC V3

DRC v1

SW

IIC

CCP-XA

core

BUS

SW

EPP

SW

IIC

DDR2

Flash

256Mbx2

Kaiser

MB91305

SIRCS

UART

IIC

Aerial/Cable

Audio-In DVI

S-Mini

PC Audio-In

S-Mini

SCART1

SCART2

Comp1

Comp2

DMPORT

Audio Out

Opt. Out

UFE4

Tuner

L/R

L/R

CVBS/RGB

L/R

CVBS (TVOUT)

L/R (TVOU T )

CVBS/RGB

L/R

CVBS (SELOUT)

L/R (SELOUT)

YCbCr

L/R

YCbCr

L/R

CVBS

L/R(diff)

UART

L/R

SPDIF

AE

QSS / FM

SW

MSP3417

L/R(M)

L/R(TVOUT)

Video SW

CXA2240

diff->

unbal

YCbCr/RGB

CVBS/YC(M)

CVBS/YC(S)

Audio

DSP

TAS3308

HP

SELOUT

LO

SP

BASI

CXA3767

RTC

Power SW

Touch

Panel

Key

IR

LED

DDR2

128Mbx2

NVM

DDR

128Mbx2

NVM

Cayenne-S

Babylon

DDR2

128Mb

SONY Logo

I2S

DAC

WL

WR

Amp

Flash

CB1

T-CON

Cayenne-S

NVM

T-CON

(CT)

L

R

CVBS / YC

L/R

Amp

K2

Side Video

HP Out

FHD HFR LED

55”,46”

BL_NVM

MEGA

SPI

FHD HFR CCFL

40”

MAC

- 20 -

4-2. CIRCUIT BO ARD LOCA TION

5-2. CIRCUIT BOARD LOCATION

Reference Information

CB1

H1VM

VM

D4/GL

CVM Board

H

A

H3VM

D1

A Board

H4

4-3. SCHEMA TIC DIA GRAMS AND

5-3. SCHEMATIC DIAGRAMS AND

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

C

C

N

S1 Board

G6

D2

A

D

G7

Note :

• All capacitors are in µF unless otherwise noted.

• pF : µµF 50WV or less are not indicated except for

electrolytic types.

• Indication of resistance, which does not have one for

rating electrical power, is as follows.

Pitch : 5mm

Electrical power rating : 1/4W

• Chip resistors are 1/10W

• All resistors are in ohms.

k = 1000 ohms, M = 1000,000 ohms

• : nonflammable resistor.

• : fusible resistor.

• : internal component.

• : panel designation or adjustment for repair.

• All variable and adjustable resistors have

characteristic curve B, unless otherwise noted.

• All voltages are in Volts.

• Readings are taken with a 10Mohm digital mutimeter.

• Readings are taken with a color bar input signal.

• Voltage variations may be noted due to normal production

tolerences.

•: B + bus.

FBA

K2

AE

J

A1

A2

RESISTOR RN

RC

FPRD

FUSE

RS

RB

RW

COIL LF-8L

CAPACITOR TA

PS

PP

PT

MPS

MPP

ALB

ALT

ALR

Note :

The components identified by shading

and marked are critical for safety.

Replace only with the part numbers

specified in the parts list.

Note :

Les composants identifiés par une trame et

par une marque sont d'une importance

critique pour la sécurité. Ne les remplacer

que par des pièces de numéro spécifié.

specified.

Note :

The components identified by mark

confidential information.

Strictly follow the instructions whenever the

components are repaired and/or replaced.

: METAL FILM

: SOLID

: NON FLAMMABLE CARBON

: NON FLAMMABLE FUSIBLE

: NON FLAMMABLE METAL OXIDE

: NON FLAMMABLE CEMENT

: NON FLAMMABLE WIREWOUND

: ADJUSTMENT RESISTOR

: MICRO INDUCTOR

: TANTALUM

: STYROL

: POLYPROPYLENE

: MYLAR

: METALIZED POLYESTER

: METALIZED POLYPROPYLENE

: BIPOLAR

: HIGH TEMPERATURE

: HIGH RIPPLE

contain

• : B - bus.

• : RF signal path.

• : earth - ground.

• : earth - chassis.

Note: Schematic dia grams are for reference onl y . Please refer to the electrical parts list for

the correct value and part number of components.

- 21 -

ABC D EFG H JIKLMN

O

P

QRST UVWXY AA

Z

DDCCBB

EE

FF

1

1

AE - EG1H

TEMP SENSOR/MECHA/PO WER CONNECTOR

2

3

D3.3V

2

3

AUDIO PIN JACK/K CONNECTOR

C1000

0.1

16V

1005

4

5

8765

IC1000

MM3286EFBE

4321

GND_1

2143658

XX

RB1004

•xZ T[

7

1

Mount Mecha

Mount Mecha

Mount Mecha

A1000

A1001

A1005

410268311

410268311

410268311

XX

XX

AUDIO_VCC

4

5

A Side

22

RB1003

E

ET1002

XX

E

ET1004

XX

BEM_SCL1

6

BEM_SDA1

E

ET1000

XX

E

ET1007

XX

E

ET1009

XX

E

ET1011

XX

E

ET1013

XX

E

ET1015

XX

B Side

E

E

7

12V

E

ET1001

ET1003

E

ET1005

E

ET1006

E

ET1008

8

FB1001XXFB1002

0uH

CL1002

12V

GND

GND

12V

1

2

JL1001

3

4

To G

9

CN1000

4P

F1001

5A

24V

JL1000

C1001

0.001

50V

X7R

1005

XX

C1032

Mount Mecha

A1004

T00016025

E

ET1010

E

ET1012

XX

ET1014

ET1016

E

ET1017

XX

E

ET1019

XX

E

ET1018

E

JL1014

Audio Out

L

L

JL1015

R

R

J1000

JL1013

GND_1

VD1008

VD1010

X7R

1005

50V

0.001

C1033

X7R

1005

50V

0.001

C1034

008:5E

008:5E

LINE_OUT_L

LINE_OUT_R

SP_MUTE

SP_MUTE3

008:5H

003:5H

003:11E

Q1000

UNR52A1G0LS0

GND_1

SP_MUTE_2

SDO_MUTE

MAIN_SW_FAULT

008:7C

SP_L008:12F

SP_R008:12F

AWF_R003:13D

AWF_L003:13C

R1044

GND_1

CL1004

CL1003

R1039

100

1/16W

CHIP

5%

1005

CL1005

CL1006

R1042

100

R1043

L1000

XX

XX

0uH

AUDIO_VCC

1

AUDIO_VCC

2

AUDIO_GND

3

AUDIO_GND

4

SP_MUTE3 (GND)

5

GND

6

SP_L-

7

GND(shield-L)

8

SP_L+

9

PFC_DET_AU

10

SP_R+

11

GND(shield-R)

12

SP_R-

13

X_SP_MUTE2

14

AWF_R

15

GND(shield-AWF)

16

AWF_L

17

SDO_MUTE (GND)

18

SP_MUTE

19

MAIN_SW_FAULT

20

CN1002

20P

WHT

6

7

8

9

10

11

12

13

14

15

16

17

18

19

SET_ON

DMP_DET

DIGITAL MEDIA PORT

R1018

XX

Q1001

XX

R1007

XX

GND_1

R1004

R1008

XX

DMP5V

XX

JL1025

C1005

XX

1k

JL1026

C1004

R1036

XX

XX

GND_1

IN B

IN A

321

GND OUT Y

IC1002

VCC

54

DMP

R1038

XX

JL1002

C1002

0.1

16V

R1003

10k

1/16W

CHIP

5%

CN1001

20P

BLK

GND_1

R1040

100k

1/16W

CHIP

5%

C1003

100

16V

CL1007

GND_1

1PGND

2VBUS(5V)

3NC

4VIDEO5V

JL1006

5RXD

JL1003

6TXD

JL1007

7DET

8DGND

9WM DET

10WM A/D

JL1008

11(Lch)AGND

JL1004

12(Rch)AGND

JL1009

13Lch

JL1005

14Rch

15WM RX

16WM TX

JL1010

17VIDEO

18VGND

JL1011

C1006

0.01

25V

X7R

1005

VD1000

XX

C1007

0.001

50V

X7R

1005

MIC2005-0.8YM6TR

IC1001

123

Vin

Vout

GND

C slew

ENABLE FAUL T/

C1008

0.1

16V

1005

GND_1

VD1001

XX

456

C1010

VD1002

XX

1000

6.3V

VD1003

XX

XX

VD1004

CL1008

1k

RB1005

JL1012

XX

VD1005

1k

XX

VD1006

RB1006

XX

VD1007

75

R1045

1/16W

RN-CP

1k

RB1007

0.5%

XX

C1011

1k

RB1008

GND_1

R1048

47k

DMP_TXD 010:8B

DMP_RXD 010:8B

DMP_DET 007:10I

A_DMP_L- 008:5H

A_DMP_R- 008:5H

A_DMP_L+ 008:5H

A_DMP_R+ 008:5H

CVBS_DMP 007:9I

HP OUT

DVI A UDIO

PC Audio

J1001

3

4

5

1

2

7

6

R

J1002

L

JL1016

JL1017

JL1018

GND_1

J1003

JL1019

GND_1

GND_1

JL1020

JL1021

L

R

VD1009

JL1022

R

L

VD1011

1

2

JL1023

JL1024

VD1014

1

2

C1015

XX

VD1015

C1019

VD1016

C1020

VD1012

C1013

VD1013

C1014

XX

XX

XX

XX

R

C1016

XX

L

R1054

XX

R1053

XX

R1052

XX

R1051

XX

R1050

XX

R1049

XX

FB1006

0uH

R1025

1/16W

CHIP

R1026

1/16W

CHIP

R1021

1/16W

CHIP

R1022

1/16W

CHIP

1k

5%

1k

5%

1k

5%

1k

5%

C1021

0.022

25V

X7R

1005

FB1007

GND_HP

R1027

RN-CP

100

1/10W 5%

C1022

0.001

50V

X7R

1005

C1023

0.001

50V

X7R

1005

C1018

0.001

X7R

1005

0uH

C1017

0.001

50V

X7R

1005

50V

R1033

1M

1/16W

CHIP

5%

R1029

1M

1/16W

CHIP

5%

C1024

470p

50V

X7R

1005

R1032

1/16W

1M

CHIP

5%

R1028

1M

1/16W

CHIP

5%

C1025

0.022

25V

X7R

1005

R1030

2.2k

1/16W

RN-CP

0.5%

R1031

2.2k

1/16W

RN-CP

0.5%

R1023

2.2k

1/16W

RN-CP

0.5%

R1024

2.2k

1/16W

RN-CP

0.5%

R1034

100

1/10W

RN-CP

5%

C1028

2.2

10V

X7R

2012

C1029

2.2

10V

X7R

2012

C1026

2.2

10V

X7R

2012

C1027

2.2

10V

X7R

2012

C1030

470p

50V

X7R

1005

C1031

1005

003:5J

003:5J

100p

CH

DVI_AU_L

DVI_AU_R

PC_AU_R

PC_AU_L

R1035

1k

003:5J

003:5J

HP_DET

HP_L 008:12G

HP_R 008:12G

10

11

12

010:8I

13

14

15

16

17

18

19

20

21

22

GND_1

ABCDEF GH JIKLMN

O

20

AE

1/9 TUNER, ANALOGUE SWITCH, AUDIO, I/O TERMINAL

21

COMPONENTS MARKED AS XX REFER TO PARTS LIST, WILL ONLY BE LISTED IF FITTED

22

P

Q

R

S

T

U

V

W

X

Y

Z

AA

BB

CC

DD

EE

FF

~ AE Board Schematic Diagram [ Tuner, Analogue Switch, Audio, I/O Terminal ] P age 1/9 ~

- 22 -

ABC D EFG H JIKLMN

O

P

QRST UVWXY AA

Z

DDCCBB

EE

FF

1

1

AE - EG1H

2

DD-CON/REGULATOR/FAN

DMP5V

PQ070XNA1ZPH

IC1108

2

3

3

DMP5V

DDG

321

Q1102

XX

654

SDD

C1123

C1124

D1106

M1FM3

JL1101

CL1104

C1134

XX

GND_1

R1145

XX

R1148

XX

L1109

4.7uH

C1130

10V

X7R

R1153

10

CL1101

A

˚zu

A

˚zu

0

XX

XX

R1141

XX

L1110

0uH

C1133

XX

D1109

DIODE PTZ-TE25-5.6B

CL1106

C1114

1000

6.3V

GND_1

REG_PWR_ON2

002:11E;002:11D;002:11F;002:11H

4

12V

C1117

C1172

C1171

XX

470

5

16V

GND_1

GND_1

4.7

25V

X7R

3216

Q1100

RSQ035P03TR

654

SDD

DDG

321

FB1100

XX

R1134

XX

12345

X7R

R1177

C1144

680

25V1

1/16W

2012

RN-CP

GND_1

0.5%

R1178

1k

1/16W

RN-CP

0.5%

R1179

1k

1/16W

RN-CP

0.5%

XX

C1139

GND_1

C1154

10

6.3V

X6S

2012

C1148

GND_1

GND_1

CL1110

C1157

XX

GND_1

XX

A_TAS3.3V

25V

X7R

1005

0.01

C1160

GND_1

A_TAS3.3V

4

5

10

11

XX

CL1112

XX

L1114

1005

X7R

25V

0.01

C1158

GND_1

L1113

XX

R1185

6

D3.3V

D3.3V

7

8

+5V

TUNER_5V

C1165

10

0.01

6.3V

XX

C1162

X6S

2012

GND_1

V5V

9

V5V

10

C1167

XX

XX

C1161

GND_1

11

2012

D1107

M1FM3

X7R

25V

1

C1122

C1125

3300p

C1126

3300p

R1139

10k

R1142

XX

R1143

15

R1140

XX

C1128

0.001

50V

X7R

1005

R1146

15

C1127

0.015

25V

X7R

1005

L1108

4.7uH

R1149

15

R1150

6.8k

1/16W

RN-CP

0.5%

A

˚zu

C1129

10

10V

X7R

3216

R1152

0

CL1102

R1154

47k

1/16W

RN-CP

0.5%

R1155

100k

1/16W

RN-CP

0.5%

CL1103

R1156

22k

1/16W

RN-CP

0.5%

D1108

PTZ-TE25-6.8B

R1157

18k

1/16W

RN-CP

0.5%

C1131

47p

50V

CH

1005

A

JL1102

A

˚zu

˚zu

C1132

XX

SUB_ON

6.1V

GND_1

C1135

XX

CL1105

6.1V

CL1107

R1161

10k

1/16W

CHIP

002:11D;002:11F;002:11H;002:11C

REG_PWR_ON2

XX

C1136

REG_PWR_ON2

002:11E;002:11F;002:11H;002:11C

X7R

REG_PWR_ON2

002:11E;002:11D;002:11H;002:11C

IC1104

IC BD9853AFV-E2

6

RN-CP

22k

0.5%

RN-CP

1/16W

33k

R1121

1/16W

R1119

0.5%

150k

R1120

R1122

6.8k

C1119

XX

R1123

RSQ035P03TR

Q1101

654

SDD

0.015

25V

X7R

1005

C1118

0.001

C1120

1

25V

2012

DDG

321

C1121

2012

XX

R1128

15

1

25V

X7R

FB1104

R1133

XX

RN-CP

1/16W

R1135

18k

R1118

7

47p

C1115

AE

2/9

8

9

GND_1

C1116

4.7

25V

X7R

3216

0.5%

8.2k

Vcc

OUT1_1

OUT1_2

VB

RT

654321

FB1

-INE1

87

CSCP1 CSCP2

DDG

321

XX

Q1103

OUT2_1

OUT1_2

CTL

GND

FB2

-INE2

VH

16 15 14 13 12 11

10 9

654

SDD

PQ070XNA1ZPH

IC1105

12345

C1149

10

6.3V

X6S

2012

C1145

GND_1

Vadj

C1146

GND_1

XX

C1151

10

10V

X7R

3216

XX

GND_1

GND

GND_1

X7R

R1167

C1140

680

25V1

1/16W

2012

RN-CP

0.5%

R1168

1k

1/16W

RN-CP

GND_1

0.5%

R1169

1k

1/16W

RN-CP

0.5%

GND_1

PQ070XNA1ZPH

IC1106

Vin

Vc

Vo

12345

C1141

25V

XX

C1137

2012

GND_1

R1170

1

2.7k

1/16W

RN-CP

0.5%

R1171

390

1/16W

RN-CP

0.5%

0.5%

GND_1

R1172

1k

1/16W

RN-CP

C1150

XX

GND_1

CL1111

C1155

GND_1

12

13

14

15

12V

C1100

XX

IC1100

PQ200WNA1ZPH

Vin

OnOffControl

Vout

12345

C1102

1

R1100

25V

10k

X7R

2012

R1104

R1102

2.2k

4.7k

1/16W

1/16W

RN-CP

RN-CP

0.5%

0.5%

1005

1005

Vadj

GND

D1100

MA2J1110GLS0

R1107

1.8k

1/16W

RN-CP

0.5%

R1106

5.6k

1/16W

RN-CP

0.5%

1005

C1104

10

16V

X6S

3216

C1106

XX

C1108

220

16V

R1196

1M

1/16W

CHIP

5%

GND_1

R1110

10k

1/16W

C1110

0.47

16V

X7R

1608

+INPUT

IC1102

V+

NJM2125F(TE2)

54

BE_FAN_DRIVE2

321

GND

-INPUTOUTPUT

R1112

10k

1/16W

RN-CP

0.5%

1005

R1113

10k

1/16W

RN-CP

0.5%

1005

BE_FAN_ERR_I

002:6J;002:8G

Put the circuit near CN1000

2143658

MA4J1130GLS0

D1113

10k

XX

XX

RB1100

JL1100

R1200

GND_1

R1201

GND_1

7

To FAN

FAN_DRV_M

FAN_ERR1

FAN_ERR2

BE_FAN_ERR_I

002:6G;002:6J

R1144

XX

R1151

1/16W

RN-CP

0.5%

1005

Q1104

UNR52A1G0LS0

GND_1

D3.3V

10k

UNR52A1G0LS0

GND_1

Q1105

BE_FAN_ERR

XX

R1158

GND_1

Invalid Fan Error

Vin

12345

C1142

1

25V

XX

X7R

C1138

2012

GND_1

REG_PWR_ON2

002:11E;002:11D;002:11F;002:11C

PQ070XNA1ZPH

IC1107

Vc

Vo

R1173

2.7k

1/16W

RN-CP

0.5%

R1174

390

1/16W

RN-CP

0.5%

0.5%

GND_1

R1175

1k

1/16W

RN-CP

Vadj

C1147

GND_1

C1152

10

10V

X7R

3216

XX

GND

GND_1

CL1114

C1156

GND_1

12

13

+5V

TUNER_5V

14

XX

15

16

17

18

19

20

12V

C1101

XX

IC1101

XX

Vin

OnOffControl

Vout

12345

R1101

XX

C1103

XX

R1103

R1105

XX

XX

C1111

0.01

25V

X7R

1005

Vadj

GND

R1108

XX

C1109

XX

R1111

D1101

C1107

XX

GND_1

R1109

XX

C1105

XX

R1197

XX

XX

GND_1

XX

C1112

XX

XX

IC1103

GND

+INPUT

V+

54

321

BE_FAN_DRIVE2

-INPUTOUTPUT

GND_1

R1114

R1115

BE_FAN_ERR_I

002:6G;002:8G

XX

XX

XX

D1110

XX

D1111

XX

RB1101

XX

214

R1205

GND_1

XX

3

XX

R1204

R1203

GND_1

To FAN

1

2

3

4

5

6

7

8

9

FAN_DRV4

FAN_ERR4

GND

FAN_DRV5

FAN_ERR5

GND

FAN_DRV6

FAN_ERR6

GND

CN1100

XX

SUB_ON

Q1106

UNR52A1G0LS0

12V

R1166

10k

1/16W

CHIP

GND_1

C1143

1

25V

X7R

2012

R1180

XX

IC1109

PQ200WNA1ZPH

Vin

Vc

Vo

12345

R1181

10k

1/16W

CHIP

C1153

XX

Q1107

2SC5950G0LS0

GND_1

A9V

Vadj

GND

A9V

R1189

100

1/16W

RN-CP

0.5%

R1191

1k

1/16W

RN-CP

0.5%

R1188

4.7k

1/16W

RN-CP

0.5%

R1190

1k

1/16W

RN-CP

0.5%

C1169

XX

C1170

10

16V

X6S

3216

GND_1

CL1113

16

17

18

19

20

21

22

C1113

XX

GND_1

ABCDEF GH JIKLMN

O

21

COMPONENTS MARKED AS XX REFER TO PARTS LIST, WILL ONLY BE LISTED IF FITTED

22

P

Q

R

S

T

U

V

W

X

Y

Z

AA

BB

CC

DD

EE

FF

~ AE Board Schematic Diagram [ Tuner, Analogue Switch, Audio, I/O Terminal ] P age 2/9 ~

- 23 -

ABC D EFG H JIKLMN

O

P

QRST UVWXY AA

Z

DDCCBB

EE

FF

1

1

AE - EG1H

2

2

A9V

L1707

10uH

3

PCM1754DBQR

4

5%47R1715 5%47R1723

5

C1720

10

AE

3/9

6.3V

X6S

2012

IC1701

16 15 14 13

SCK

SDA T A

FMT

MUTE

DEMP

12 11 10 9

TEST

ZEROA

VOUTL

VCOM

VOUTRAGND

_sOŁ ¢ª

A[Ȣ

BCK

LRCK

4321

DGND

NC

VCC

8765

R1725

V5V

5%47R1724

5%47

C1730

0.1

16V

1005

C1740

10

6.3V

X6S

2012

L1706

10uH

470

RB1722

C1748

0.1

16V

C1750

2.2

10V

X7R

2012

C1751

2.2

10V

X7R

2012

C1749

0.1

16V

6

ASSIST WOOFER

C1757

0.1

16V

1005

C1758

XX

R1743

XX

B-IN

BOUTPUT

A-IN

A+IN

GND B+IN

4321

R1746

XX

R1744

C1759

8765

VCC

AOUTPUT

C1761

XX

CHIP

XX

0

C1760

XX

R1745

CHIP

1005

2

4

6

8

10k

RB1723

RB1724

47K

C1756

10

16V

1

3

5

7

C1755

10V

2.2

2012

X7R

C1772

47

16V

IC1703

NJM4558V-TE2

0

C1765

22

16V

C1766

22

16V

100

RB1725

R1752

XX

R1753

XX

001:13D

AWF_L

001:13D

AWF_R

3

4

5

6

10

11

12

13

14

15

16

17

18

19

7

D3.3V

L1700

100

RB1717

C1702

0.1

16V

1cm

C1710

0uH

C1701

0.01

25V

X7R

1005

GND_1

¨zu

–

C1707

0.1

16V

47

6.3V

10k

RB1718

IC

s'

4.7˘0.1˝1_¯GND

GND_1

C1703

100

16V

C1704

4.7

10V

X7R

2012

C1705

0.1

16V

1005

C1711

47

6.3V

A_TAS3.3V

1cm

C1712

10V

2012

8

R1708

R1710

XX

XX

9

005:15C,005:13C,005:15C,005:13C,005:15C,005:13C

I2C_TAS_SDA

I2C_TAS_SCL

AUDIO_DSP_INT

SDO_MUTE001:13E

DSP_MUTE

DSP_RST

DSP_MUTE2

SC1/V1_AU_L

006:5D

SC1/V1_AU_R

006:5D

SC2/V3_AU_L

006:5F

006:5F

SC2/V3_AU_R

COMP1_LR_IN

COMP2_LR_IN

001:13I

PC_AU_L

001:13I

PC_AU_R

001:13H

DVI_AU_L

001:13H

DVI_AU_R

006:16I

SIDE/V2_AU_L

SIDE/V2_AU_R006:16I

FE_I2S

COMP1_LR_IN_L

COMP1_LR_IN_R

TV_L

004:11F

TV_R

004:11F

FE_BCK

FE_LRCK

FE_MCK

FE_DA T0

FE_DA T1

FE_DA T2

INB

INA

321

GND OUTY

TC7SET32FU(T5RSOJF)

R1701

R1702

5%

R1703

R1704

R1705

R1706

_sOŁ ¢ª

A[Ȣ

R1700

XX

VCC

IC1702

FE_SPDIF

47

47

47

47

47

47

7

54

SP_MUTE_2

001:13D

2143658

C1700

0.1

16V

1005

2.2k

RB1716

2143658

SC1/V1_AU_L

SC1/V1_AU_R

SC2/V3_AU_L

SC2/V3_AU_R

COMP1_LR_IN_L

COMP1_LR_IN_R

RB1701

7

10k

IC

s'

4.7˘0.1˝1_¯GND

R1709

1k

1/16W

CHIP

5%

RB1703

47k

SPDIF_OUT

C1706

0.1

16V

¨zu

–

4.7

C1708

0.1

16V

C1709

0.1

16V

L1701

10uH

COMP2_LR_IN_L

006:9I

MCLKIN

26

DVSS_DPLL

27

VR_DIG2

28

DVDD3

29

DVSS3

30

I2C_SDA2

31

I2C_SCL2

32

I2C_SDA1

33

I2C_SCL1

34

CS

35

GPIO1

36

GPIO2

37

/MUTE

38

/RESET

39

DVSS4

40

VR_DIG3

41

DVDD4

42

LINEIN1L

43

LINEIN1R

44

AVSS_LI1

45

LINEIN2L

46

LINEIN2R

47

AVDD_LI1

48

LINEIN3L

49

LINEIN3R

50

C1713

C1714

470

16V

16V

1005

RB1705

COMP2_LR_IN_R

PC_AU_L

SCLKIN

LRCLKIN

DPLL

Analog Block

LINEIN4L

LINEIN4R

515253

0.1

47k

PC_AU_R

CL1703

SDOUT1

CL1704

SCLKOUT

CL1705

2143658

LRCLKOUT

RB1708

CL1706

IC

s'

MCLKOUT

47

STEST

/VREG_EN

C1721

C1718

16V

47

6.3V

1cm

¨zu

DVSS2

XX

RB1706

2

4

6

8

CL1700 CL1701

23 24 25

SDIN3

SDIN2

SDIN1

CL1702

7

1

3

5

7

SPDIF_IN

SDOUT2/SPDIF_OUT

Digital Block

CXD9926A TQ

IC1700

LINEIN5L

AVDD_LI2

5455565758596061626364656667

LINEIN5R

DVI_AU_L

DVI_AU_R

AVSS_LI2

LINEIN6L

LINEIN6R

47K

TV_L

AVSS_ADC/REF

RB1719

C1715

10

10V

X7R

3216

TV_R

LINEIN7L

LINEIN7R

C1717

0.1

16V

1005

47K

RB1720

C1716

10

10V

X7R

3216

SIDE/V2_AU_L

SIDE/V2_AU_R

LINEIN8L

AVDD_ADC

LINEIN8R

C1719

0.1

16V

1005

100

RB1721

0.1

R1716

XX

DVDD2

AVDD_LI3

C1722

0.1

16V

6.3V

1005

47

C1723

12

910111213 14 15 16 17 18 19 20 21 22

PWM3_RD

PWM3_RI

VALID/SYNC

DVSS_PWM3

DVDD_PWM3

PWM Block

Xtal

APLL

LINEIN9L

LINEIN10L

LINEIN9R

RN-CP

C1770

10V

X7R

3216

LINEIN10R

AVSS_LI3

6869707172737475

R1718

R1717

1/16W

0.5%

10

47k

47k

1/16W

RN-CP

0.5%

C1771

10V

X7R

3216

10

PWM3_LD

PWM3_LI

BIAS_REF

BG_REF

2.2k

R1719

C1724

10V

X7R

1608

R1720

22k

1/16W

RN-CP

12345678

PWM2_RD

PWM2_RI

DVDD_PWM2

DVSS_PWM2

PWM2_LI

PWM2_LD

PWM1_RI

PWM1_RD

DVDD_PWM1

DVSS_PWM1

PWM1_LI

PWM1_LD

VR_DIG1

DVSS1

DVDD1

VR_ANA

AVSS_OSC

XTAL_OUT

XTAL_IN

AVDD_OSC

VR_ANA2

AVSS_PLL

PLL_FLTM

PLL_FLTP

AVDD_PLL

AVSS_LO

LINEOUT1R

LINEOUT1L

V1P5_REF

AVDD_REF

AVDD_LO

C1726

C1725

1

4.7

10V

X7R

2012

4.7

10V

X7R

2012

L1703

10uH

L1704

10uH

C1732

C1743

0.1

47

16V

6.3V

1005

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

C1727

0.1

16V

X7R

C1733

0.1

16V

1005

C1731

4.7

C1737

0.1

C1735

47

6.3V

4.7

C1738

C1739

0.1

L1702

0uH

C1741

10V

2012

C1734

16V

1005

C1736

0.1

16V

1005

4.7

0.1

IC

C1742

6.3V

C1745

0.1

L1705

10uH

s'

47

R1726

220

1cm

TAS DSP

4.7˘0.1˝1_¯GND

¨zu

R1731

0

CHIP

1005

R1730

1M

1/16W

C1746

0.1

C1747

0.01

25V

X7R

1005

C1744

0.01

25V

X7R

1005

R1727

220

AUDIO_REG33

–

X1700

24.576MHz

1

2

A_REC_R 008:12I

A_REC_L 008:12I

C1753

10p

50V

CH

1005

C1754

10p

50V

CH

1005

C1752

0.01

25V

X7R

1005

GND_1

R1734

R1735

R1736

R1737

R1738

R1739

R1740

R1741

1/16W

0.5%10k

1/16W

0.5%10k

1/16W

0.5%10k

1/16W

0.5%10k

1/16W

0.5%10k

1/16W

0.5%10k

1/16W

0.5%10k

1/16W

0.5%10k

C1762

680p

50V

CH

1005

C1764

680p

50V

CH

1005

C1763

680p

50V

CH

1005

C1767

680p

50V

CH

1005

1/16W

R1748

0.5%4.7k

1/16W

R1749

0.5%4.7k

1/16W

R1750

0.5%4.7k

1/16W

R1751

0.5%4.7k

C1768

470p

50V

X7R

1005

A_HP_OUT_L 008:12H

A_HP_OUT_R 00 8:1 2H

A_LINE_OUT_L

008:5E

A_LINE_OUT_R

008:5E

C1769

470p

50V

X7R

1005

CL1707

CL1708

SP_TAS_OUT_R

008:11E

SP_TAS_OUT_L

008:11E

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

008:5I

DMPORT_AU_L

008:5I

DMPORT_AU_R

ASUB_L

ASUB_R

ABCDEF GH JIKLMN

DMPORT_AU_L

DMPORT_AU_R

O

20

COMPONENTS MARKED AS XX REFER TO PARTS LIST, WILL ONLY BE LISTED IF FITTED

21

22

P

Q

R

S

T

U

V

W

X

Y

Z

AA

BB

CC

DD

EE

FF

~ AE Board Schematic Diagram [ Tuner, Analogue Switch, Audio, I/O Terminal ] P age 3/9 ~

- 24 -

ABC D EFG H JIKLMN

O

P

QRST UVWXY AA

Z

DDCCBB

EE

FF

1

1

2

2

3

3

4

4

5

5

10

11

12

13

AE - EG1H

6

6

V5V

A9V

STBY3.3V

V5V

XX

7

FB1301

0uH

0uH

FB1302

8

9

6.1V

FB1303

12V_SW

AC_DET_IN

BE_FAN_DRIVE2

BE_FAN_ERR

BEM_SCL1

BEM_SCL2

BEM_SCL3

BEM_LOG_TX

BEM_CODE_TX

TVM_BEM_TX

MODE_BEM

BE_RST

BE_BUSY

SET_ON

SCL_DEVICE

SUB_ON

I2S_SW_SEL

HDMI_SCL

HDMI_LATCH

HDMI_PC_WP

HDMI_OS_AB

HDMI_SEL1

PANELLESS1

HDMI_HPLG_CTRL

HDMI_INT

CEC_IN

FB1304

0uH

XX R1363

8

10

12

FAN_DRIVE2

20

22

BEM_LOG_TX

BEM_CODE_TX

TV_BEM_TX

MODE_BEM

42

44

46

48

50

SCL_DEVICE

52

I2S_SW_SEL

62

64

HDMI_LATCH

HDMI_PC_WP

68

HDMI_OS_AB

70

HDMI_SEL1

72

E_HDMI_CE

74

HDMI_HP_CTRL

76

78

CN1300

REC_6.1V

REC_6.1V

STBY3.3V

STBY3.3V

12V_SW

AC_DET_IN

FAN_ERR

GND

BEM_SCL2

BEM_SCL3

GND

GND

BE_RST

BE_BUSY

SET_ON

GND

GND

SUB_ON

GND

HDMI_SCL

HDMI_INT

CEC_IN

GND

A9V

WHT

CN1302

WHT

80P

GND

GND

GND

GND

GND

NC

GND

GND

GND

AC_RL Y

FAN_DRIVE1

BL_IN

GND

BEM_SDA1BEM_SCL1

BEM_SDA2

BEM_SDA3

GND

BEM_LOG_RX

BEM_CODE_RX

TV_BEM_RX

GND

JIG_BEM_RST

GND

BE_WDT

SET_ON2

GND

SDA_DEVICE

GND

SUBCHRO_RST

PC_DET

GND

HDMI_SDA

GND

HDMI_CE

HDMI_RST

HDMI_OS_CD

HDMI_SEL2

E_HDMI_RJ

HDMI_EDID_SW

CEC_ON

CEC_OUT

GND

12

3 4

56

7

9

11

13 14

15 16

17 18

19

21

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

39 40

41

43

45

47

49

51

53 54

55 56

57 58

59 60

61

63

65 66

67

69

71

73

75

77

79 80

AC_RL Y

BL_IN

BEM_SDA1

BEM_SDA2

BEM_SDA3

BEM_LOG_RX

BEM_CODE_RX

TVM_BEM_RX

JIG_BEM_RST

BE_WDT

SET_ON2

SDA_DEVICE

SUBCHRO_RST

PC_DET

HDMI_SDA

HDMI_CE

HDMI_RST

HDMI_OS_CD

HDMI_SEL2

HDMI_EDID_SW

CEC_ON

CEC_OUT

6.3V

220

C1311

XX

R1353

V5V

10uH

L1307

C1300

XX

STBY3.3V

XXC1301

AE

DMP5V

1000

C1304

4/9

D3.3V

C1302

XX

MAIN_COMP_OUT

TUNER_SCL_DIGITAL

FE_SPDIF

ASUB_L

PC_H_OUT

PC_H_IN

CCP_CB

CCP_CR

CCP_Y

S_CV/Y

REC_Y

TUNER_LNA_SW

TUNER_FE_CKOUT

TUNER_FE_SYNC

TUNER_DA T A_0

TUNER_DA T A_2

TUNER_DA T A_4

TUNER_DA T A_6

FE_TXD0B

FE_TXD1B

FE_TXD2B

FE_MASTER_RSTB

FE_SCL_EMMA

GND

FE_TXD0B

FE_TXD1B

FE_TXD2B

8

GND

10

FE_MASTER_RSTB

12

GND

FE_SCL_EMMA

GND

20

FE_SPDIF

22

FE_MCLK

FE_DA T A0

FE_DA T A2

GND

ASUB_L

GND

PC_H_OUT

PC_H_IN

GND

M_CB/B

M_CR/R

42

M_Y/G

44

46

GND

S_CV/Y

48

50

NC(S_CR)

52

REC_Y

GND

TUNER_SCL_DIGITAL

GND

NC

62

NC

64

TUNER_LNA_SW

TUNER_FE_CKOUT

68

TUNER_FE_SYNC

70

GND

72

TUNER_DA T A0

74

TUNER_DA T A2

TUNER_DA T A4

76

TUNER_DA T A6

78

GND

80P

GND

FE_RXD0B

FE_RXD1B

FE_RXD2B

GND

DTT_PON_DELAY

GND

FE_SDA_EMMA

GND

DSP_MUTE2

FE_BCLK

FE_LRCLK

FE_DA T A1

GND

ASUB_R

GND

PC_V_OUT

PC_V_IN

GND

M_CV/Y

M_C

M_YS

GND

S_C

GND

REC_C

GND

TUNER_SDA_DIGIT AL

GND

DEM_SEL

NC

TUNER_RST

TUNER_SW

TUNER_FE_VAL

GND

TUNER_DA T A1

TUNER_DA T A3

TUNER_DA T A5

TUNER_DA T A7

GND

12

34

5 6

7

9

11

13 14

15 16

17 18

19

21

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

39 40

41

43

45

47

49

51

53 54

55 56

57 58

59 60

61

63

65 66

67

69

71

73

75

77

79 80

FE_RXD0B

FE_RXD1B

FE_RXD2B

DTT_PON_DELAY

FE_SDA_EMMA

DSP_MUTE2

FE_I2S

005:2B

FE_BCK

FE_LRCK

FE_MCK

FE_DA T0

FE_DA T1

FE_DA T2

ASUB_R

005:2H;005:12I

PC_V_OUT

PC_V_IN

M_CV/Y

M_C

M_YS

S_C

REC_C

TUNER_SDA_DIGIT AL

TUNER_RST

TUNER_SW

TUNER_FE_VAL

TUNER_DA T A_1

TUNER_DA T A_3

TUNER_DA T A_5

TUNER_DA T A_7

7

8

9

10

11

12

13

14

15

16

17

PANELLESS2

TP_RST

R1346

1k

1/16W

NJM2878F3-05(TE2)

IC1300

CTRL

Vin

GND

321

NC Vout

6.1V

54

X7R

16V

0.47

C1307

X7R

10V

C1306

C1309

1

XX

XX

C1303

SONY_LOGO

FAN_DRV_M

002:6G;001:3B;001:3B

FAN_ERR2

PANELLESS2

STBY_LED

POWER_LED

I2C_SDA_TP

UART_RX_RF A

BL_IN

CL1301

JL1300

JL1301

JL1302

R1311

XX

FB1305

0uH

FB1306

0uH

L1306 0uH

L1300

0uH

L1301

0uH

CL1300

XX

VD1300XXVD1301

XX

VD1307

L1302

0uH

XX

VD1302

0.1

C1310

STBY3.3V

LED_1(STBY)

4

LED_5(POWER)

6

BL_IN

8

TOUCH_KEY_VDD

10

TOUCH_KEY_VCC

12

TOUCH_KEY_SDA

14

GND

16

STBY_3.3V

18

LOGO

20

REG5V

22

GND

24

RF_RXD/CAT

26

RF_BINT

28

GND

30

FAN_DRV1

32

GND

34

FAN_ERR2

36

FAN_DRV3

38

GND

40

CN1301

40P

WHT

LED_4(REC)

LED_3(TSUSHIN)

LED_2(PMUTE)

REC_3.3V

TOUCH_KEY_SCL

TOUCH_KEY_DET

SIRCS

POWER_SENSE

RF_TXD/SIRCS

STBY_3.3V

POWER_SW

FAN_ERR1

FAN_DRV2

FAN_ERR3

GND

GND

GND

GND

KEY

GND

12

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

FB1307

JL1303

0uH

FB1308

0uH

FB1309

0uH

XX

VD1303

L1303

0uH

XX

VD1304XXVD1305

REC_R_LED

ON_TIMER_LED

PIC_MUTE_LED

R1325

XX

XXR1326

I_SIRCS

RFC_RST 001:3C

UART_TX_RF A

0.1

C1317

POWER_SW

FAN_ERR1 002:6H

JL1304

FAN_DRV_M

JL1306

PANELLESS1

JL1305

KEY

L1304

XX

I2C_SCL_TP

R1341

XX

XX

R1342

S

XX

R1345

C1305

XX

XX

Q1301

RFC_RST

14

15

16

17

18

19

20

21

KEY

GND

POWER_SW

CN1303

XX

1

2

3

Q1302

XX

18

COMPONENTS MARKED AS XX REFER TO PARTS LIST, WILL ONLY BE LISTED IF FITTED

19

20

21

22

ABCDEF GH JIKLMN

O

22

P

Q

R

S

T

U

V

W

X

Y

Z

AA

BB

CC

DD

EE

FF

~ AE Board Schematic Diagram [ Tuner, Analogue Switch, Audio, I/O Terminal ] P age 4/9 ~

- 25 -

10

ABC D EFG H JIKLMN

O

P

QRST UVWXY AA

Z

DDCCBB

EE

FF

AE - EG1H

1

1

Q001

RT3XBBM-T111-1

2

JL1401

JL1403

3

JL1404

JL1406

4

SCART 1

21P

CN1400

R-OUT

5

6

R-IN

L-OUT

AUDIO-GND

GND

L-IN

BLUE

MODE

GND

GREEN

GND

GND

RED

BLK

GND

GND

TV-OUT

VIDEO-IN

SHILD-GND

NC

NC

GND_1

JL1408

JL1409

JL1410

VD1403

VD1404

VD1405

VD1406

VD1407

GND_1

VD1408

C1400

470p

C1401

XX

C1402

470p

C1403

XX

0.5%

RN-CP

0.5%

RN-CP

R1406

330

1/16W

CHIP

5%

R1407

1k

1/16W

CHIP

5%

R1408

330

1/16W

CHIP

5%

R1409

1k

1/16W

CHIP

5%

75

1/16W

75

1/16W

R1492

R1493

C1405

0.022

C1407

0.022

1/16W

C1406

0.001

50V

X7R

1005

1/16W

C1408

0.001

50V

X7R

1005

R1413

220

CHIP

5%

R1415

220

CHIP

5%

R1426

1M

1/16W

CHIP

5%

R1425

1M

1/16W

CHIP

5%

R1419

470k

C1409

XX

C1410

XX

GND_1

R1428

470k

R1414