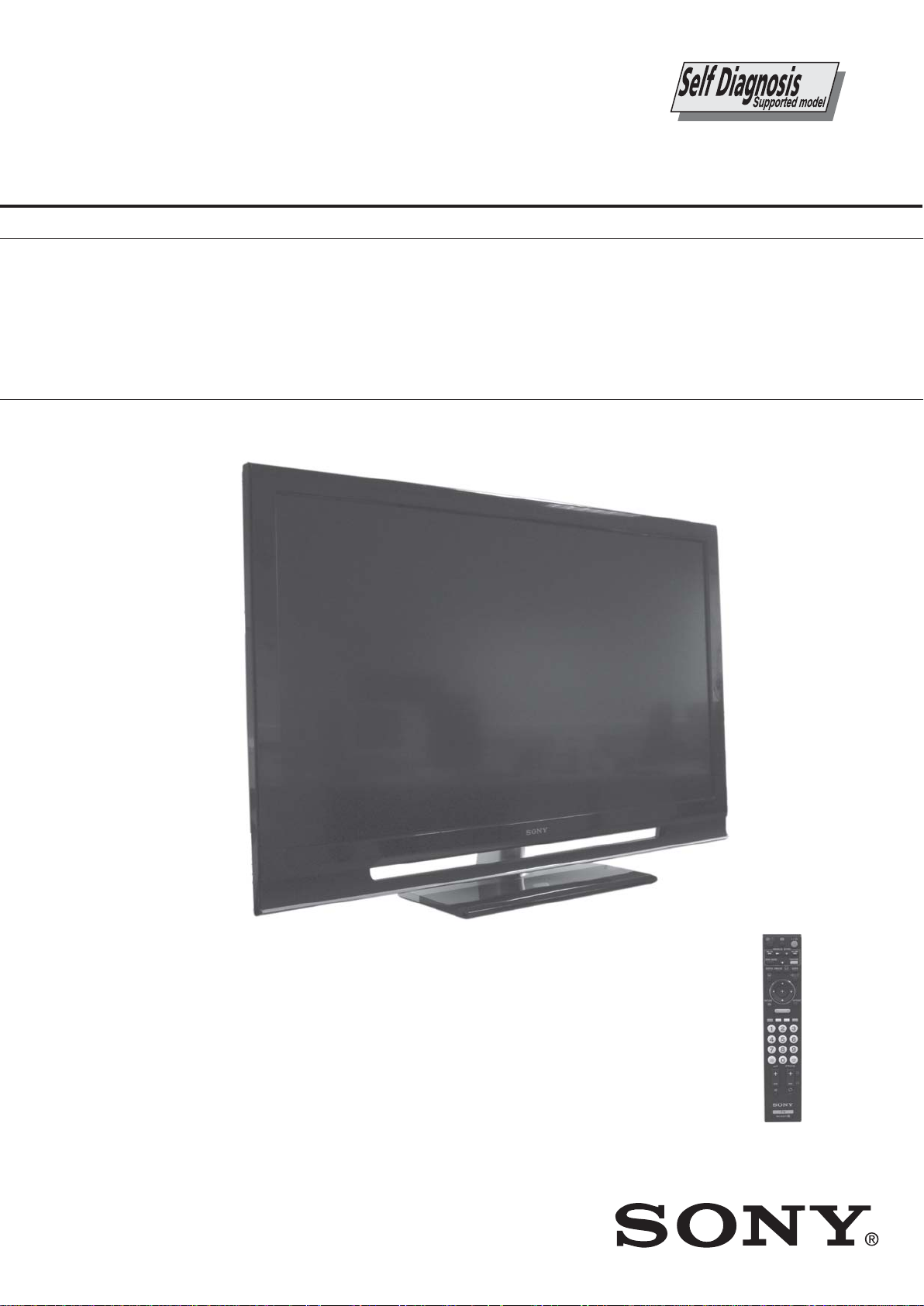

Sony KDL-40W4500, KDL-46W4500, KDL-52W4500 Service Manual

HISTORY

Model Name :

SERVICE MANUAL

Click on Page Number to display detail of changes.

Date Part Number Description of Revisions

Original Manual.

KDL-40/46/52W4500

Version

1.09-927-586-01 2008.08

SERVICE MANUAL

EG1L

CHASSIS

MODEL

DEST

KDL-40W4500

KDL-46W4500

KDL-52W4500

AEP/UK

AEP/UK

AEP/UK

- 1 -

RM-ED011

FLAT PANEL COLOR TV

TABLE OF CONTENTS

Section Title Page Section Title Page

1. GENERAL ................................................................... 3

Caution................................................................ 3

Specifications ..................................................... 5

Connectors .......................................................... 6

Self Diagnosis..................................................... 7

2. DISASSEMBLY

2-1. Rear Cover Removal .......................................... 8

2-2. Stand Removal ................................................... 8

2-3. Loudspeaker Removal........................................ 8

2-4. Side Jack Bracket Assy Removal ...................... 8

2-5. BGE Board Removal.......................................... 9

2-6. D4 Board Removal (52 inches).......................... 9

2-7. D5 Board Removal (52 inches).......................... 9

2-8. G5 Board Board Removal (52 inches)............... 9

2-9. H3E Board Removal .......................................... 10

2-10. H4 Board Removal ............................................. 10

2-11. IP5 Board Removal (40/46 inches).................... 10

3. SERVICE MENUS

3-1. How to enter the Service Mode ........................ 11

3-2. Product Version ................................................. 11

3-3. Service Config ................................................... 11

3-3-1. Set-Up.............................................................. 12

3-3-2. Sound ............................................................... 12

3-3-3. IF Adjust .......................................................... 12

3-3-4. White Balance ................................................. 12

3-4. Error Menu ........................................................ 13

3-5. TT Mode ............................................................ 13

4. DIAGRAMS

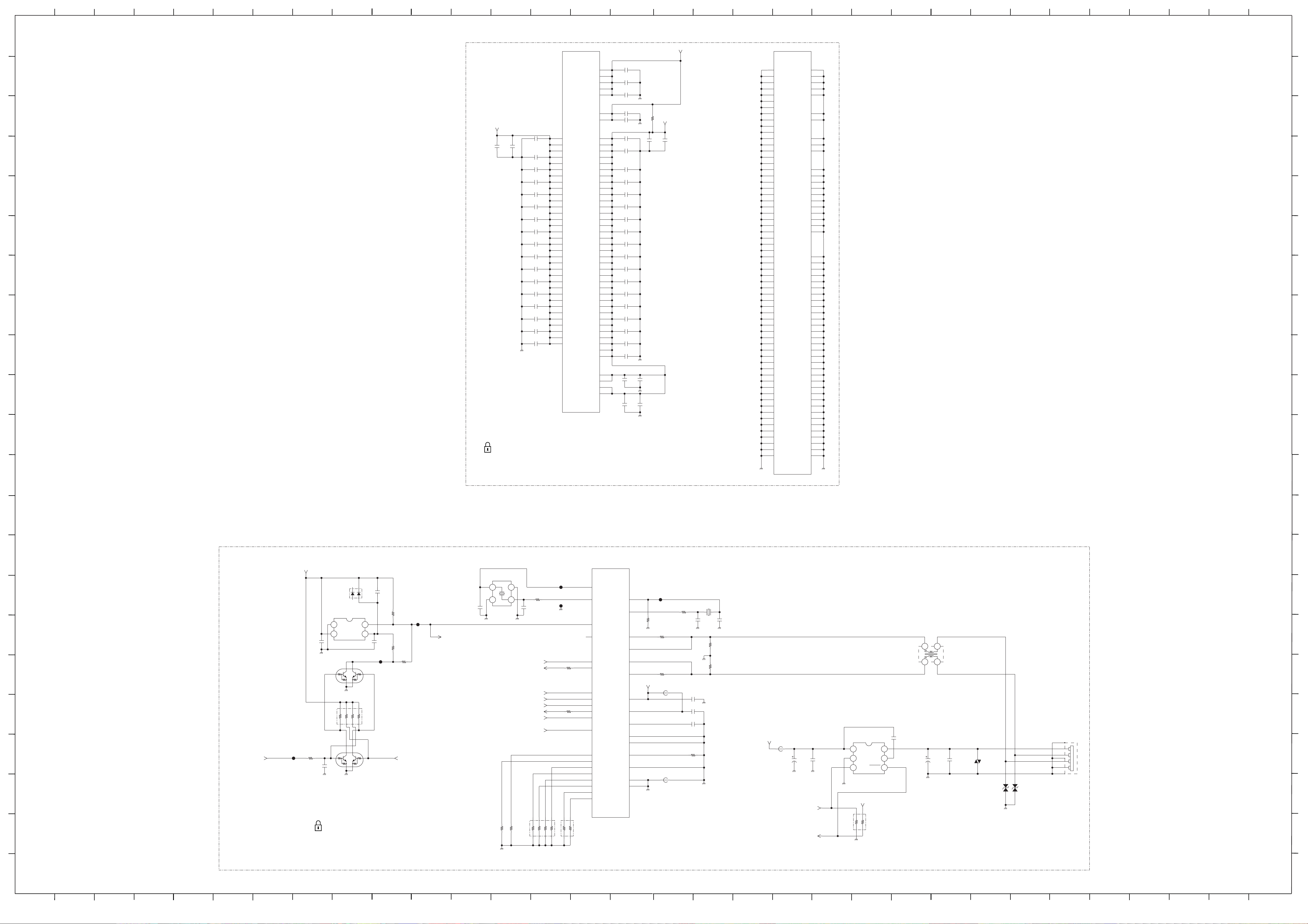

4-1. Block Diagram ................................................... 14

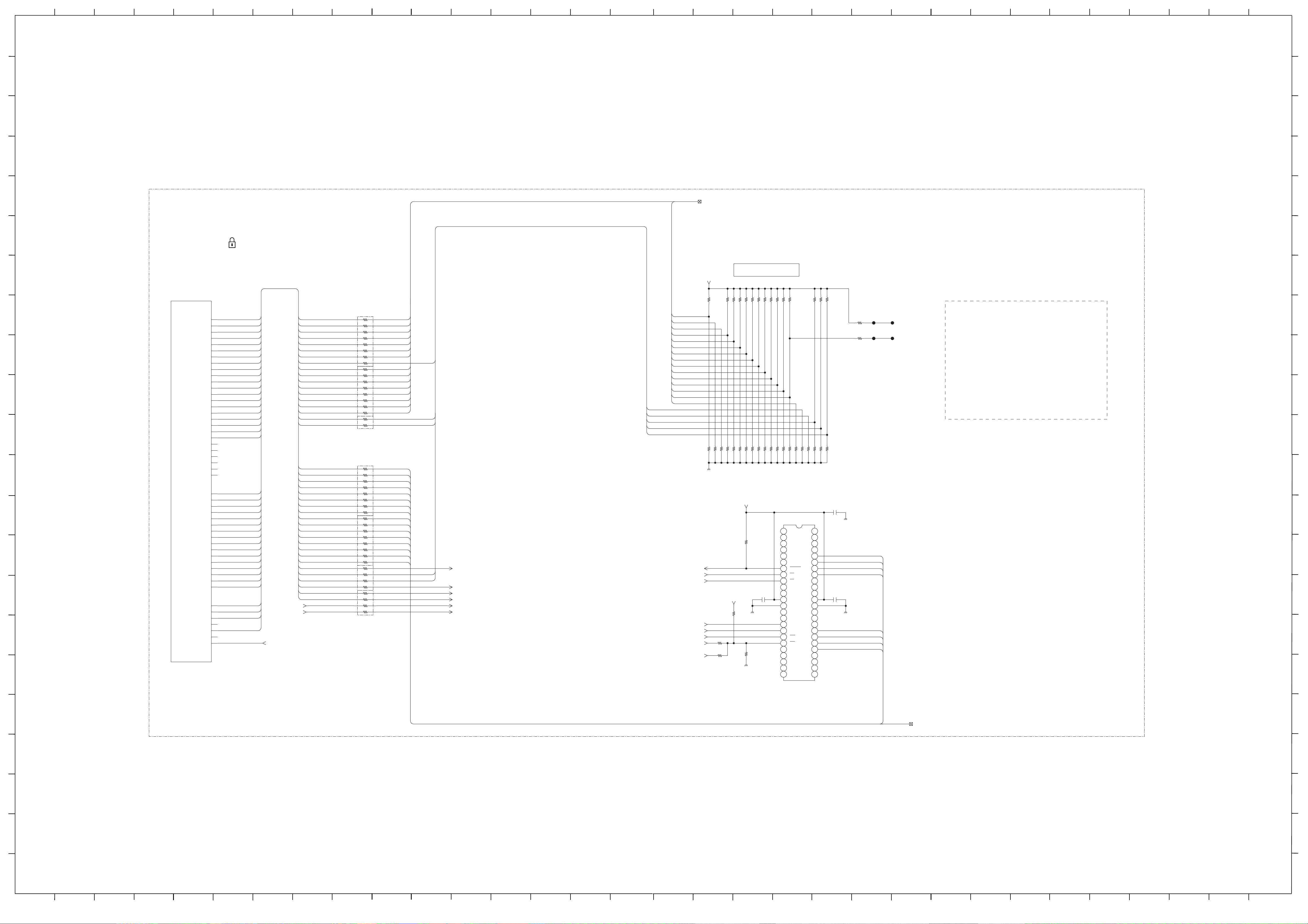

4-2. Circuit Board Location....................................... 15

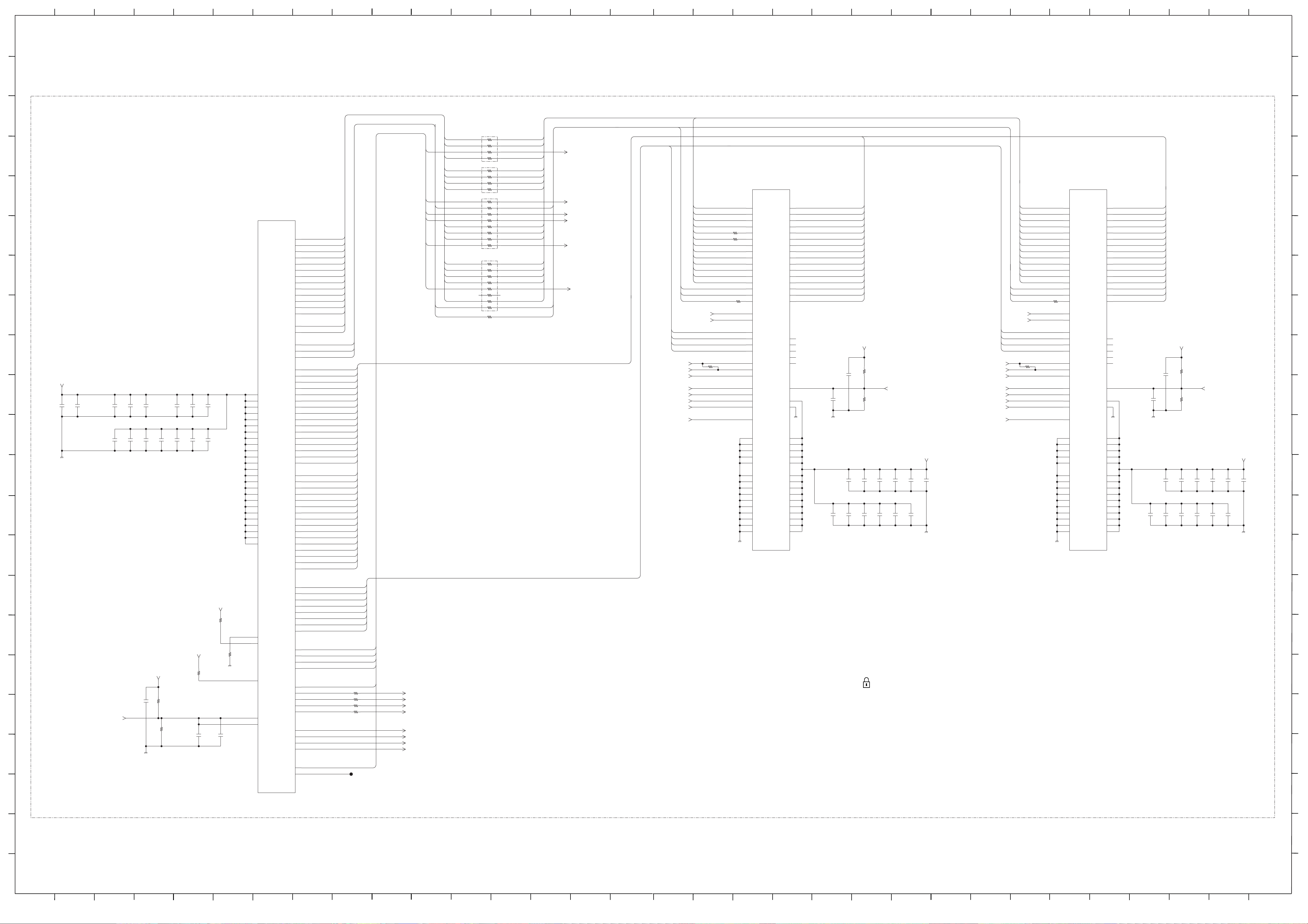

4-3. Schematic Diagrams and Printed Wiring

Boards ................................................................. 15

BGE Board Schematic Diagram ........................ 16

D4 Board Schematic Diagram (52 inches) ........ 36

D5 Board Schematic Diagram (52 inches) ........ 37

G5 Board Schematic Diagram (52 inches) ........ 38

H3E Board Schematic Diagram ......................... 37

H4 Board Schematic Diagram ........................... 37

IP5 Board Schematic Diagram (40/46 inches) .. 39

BGE Printed Wiring Board ................................ 41

D4 Printed Wiring Board (52 inches) ................

43

D5 Printed Wiring Board (52 inches) ................ 44

G5 Printed Wiring Board (52 inches) ................ 45

H3E Printed Wiring Board................................. 44

H4 Printed Wiring Board ................................... 44

IP5 Printed Wiring Board (40/46 inches) .......... 47

5. EXPLODED VIEWS

5-1. Chassis ................................................................ 49

5-2. Bezel ................................................................... 51

5-3. Rear Cover & Power Supply Cords ................... 52

6. ELECTRICAL PARTS LIST .................................. 53

WARNING !!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING ANY

SERVICE W ORK TO AVOID POSSIBLE SHOCK HAZARD DUE TO

LIVE CHASSIS, THE CHASSIS OF THIS RECEIVER IS DIRECTLY

CONNECTED TO THE POWER LINE.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY SHADING AND MARKED

THE EXPLODED VIEWS AND IN THE PARTS LIST ARE CRITICAL

FOR SAFE OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN

THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ON

- 2 -

SECTION 1 GENERAL

How to replace the fuse.

Open the fuse compartment with

a screwdriver blade and replace

the fuse.

FUSE

SECTION 1 GENERAL

CAUTION

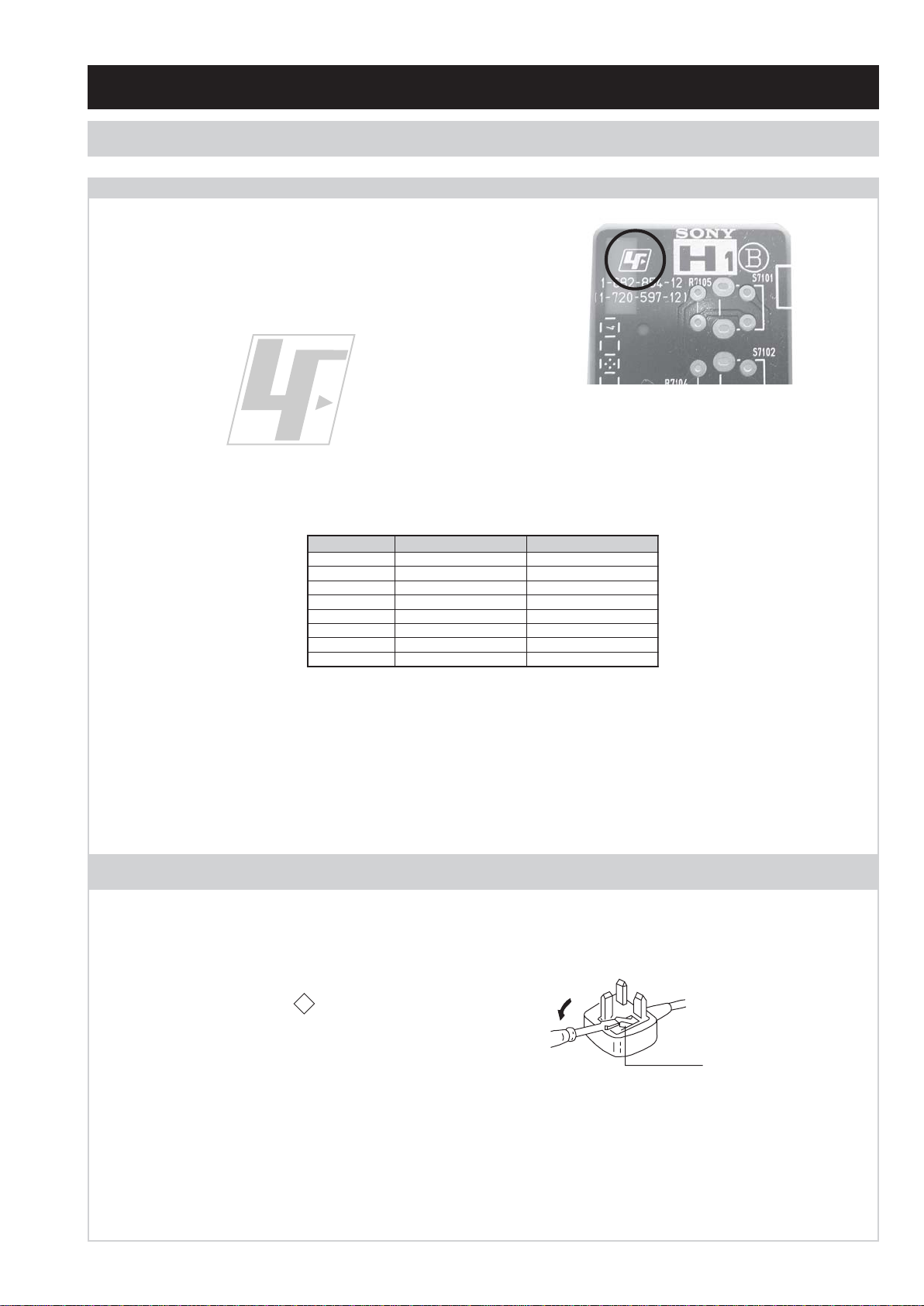

Lead Free Soldered Boards

example

The circuit boards used in these models have been processed using

Lead Free Solder. The boards are identif ied by the LF logo located

close to the board designation e.g. H1 etc [ see example ]. The

servicing of these boards requires special precautions to be taken as

outlined below.

Lead Free Solder material must be used to comply with environmental requirements of new solder joints. Lead Free Solder is available under

the following part numbers :

rebmuntraP retemaiD skrameR

91-500-046-7mm3.0gK52.0

02-500-046-7mm4.0gK05.0

12-500-046-7mm5.0gK05.0

22-500-046-7mm6.0gK52.0

32-500-046-7mm8.0gK00.1

42-500-046-7mm0.1gK00.1

52-500-046-7mm2.1gK00.1

62-500-046-7mm6.1gK00.1

Due to the higher melting point of Lead Free Solder the soldering iron tip temperature needs to be set to 370 degrees centigrade. This requires

soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

For more information on the use of Lead Free Solder, please refer to http://www.sony-training.com

UK PLUG W ARNING

WARNING (UK Models only)

The flexible mains lead is supplied connected to a B.S. 1363 fused

plug having a fuse of the correct rating for the set. Should the fuse

need to be replaced, use a fuse of the same rating approved by ASTA

to BS 1362, ie one that carries the

ASA

T

mark.

IF THE PLUG SUPPLIED WITH THIS APPLIANCE IS NOT SUITABLE

FOR THE OUTLET SOCKETS IN YOUR HOME, IT SHOULD BE CUT

OFF AND AN APPROPRIA TE PLUG FITTED. THE PLUG SEVERED

FROM THE MAINS LEAD MUST BE DESTROYED AS A PLUG WITH

BARED WIRES IS DANGEROUS IF ENGAGED IN A LIVE SOCKET .

When an alternative type of plug is used, it should be fitted with the

correct rating fuse, otherwise the circuit should be protected by the

same rating fuse at the distribution board.

- 3 -

Attachment of HIROSE MDF 61 connector

locked state

1. Insertion

(1) Hold the center

of a connector

CAUTION

(2) Press the center of

the connector to insert

it

(3) Slide the

slider to lock the

connector

Detachment of HIROSE MDF61 connector

2. Detachment

(1) Slide the slider to

release the slider lock

Lock

(2) Press the center

lock tab to release

the lock and pull the

connector up

Unlock

- 4 -

- 4 -

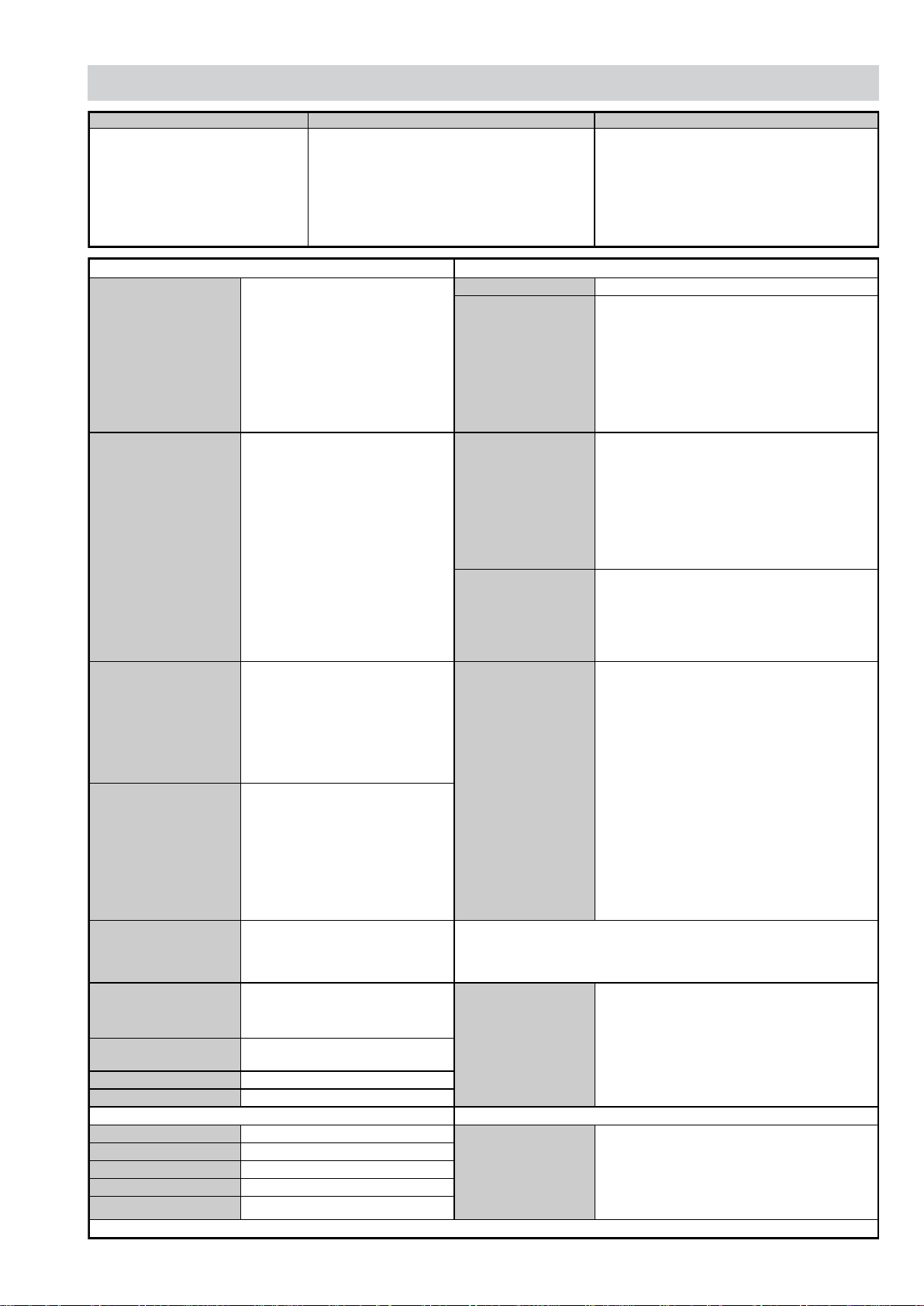

SPECIFICATIONS

Analogue:

Depending on your country/region

B/G/H, D/K, L, I

Digital:

Depending on model

DVB-T/DVB-C

Input/Output Terminals [REAR] General Specifications

1: 21-pin Euro connector

(CENELEC standard)

2: 21-pin Euro connector

(CENELEC standard)

Television System Channel Coverage Colour/Video System

Inputs for Audio and Video signals.

Inputs for RGB.

Outputs of TV Video and Audio

signals.

Inputs for Audio and Video signals.

Inputs for RGB and S Video.

Outputs of Video and Audio signals

(Selectable). SmartLink interface.

Analogue: VHF : E2-E12

UHF : E21-E69

CATV : S1-S20

HYPER : S21-S41

D/K: R1-R12, R21-R69

L: F2-F10, B-Q, F21-F69

I: UHF B21-B69

Digital: VHF/UHF

Power Requirements 220 - 240V

Power Consumption/

Standby

Dimensions

Weight

Analogue:

PAL, SECAM

NTSC 3.58/4.43

(VIDEO IN)

Digita l:

MPEG-2 MP@ML/HL, H.264/MPEG-4 AVC

HP@L4.0, MP@L3.0

(40 inches):

Approx 205W/0.2W (Home/Standard mode)

Approx 234W/0.2W (Shop/Vivid mode)

(46 inches):

Approx 256W/0.2W (Home/Standard mode)

Approx 282W/0.2W (Shop/Vivid mode)

(52 inches):

Approx 257W/0.2W (Home/Standard mode)

Approx 293W/0.2W (Shop/Vivid mode)

(40 inches):

Approx 986x684x279mm (With stand)

Approx 986x646x110mm (Without stand)

(46 inches):

Approx 1120x782x307mm (With stand)

Approx 1120x742x115mm (Without stand)

(52 inches):

Approx 1262x871x347mm (With stand)

Approx 1262x829x119mm (Without stand)

Approx 23.0kg (40 inches with stand)

Approx 19.5kg (40 inches without stand)

Approx 31.0kg (46 inches with stand)

Approx 26.5kg (46 inches without stand)

Approx 39.5kg (52 inches with stand)

Approx 33.0kg (52 inches without stand)

Supported formats: 1080p, 1080i,

720p, 576p, 576i, 480p, 480i

Component In

HDMI Inputs

PC Input

DMPORT Digital Media Port

Digita l Ou t

LAN 10BASE-T/100BASE-TX connector

CAM Conditional Access Module Slot

Input/Output Terminals [SIDE] Remote control system : Infrared control

Headphone jack Stereo mini jack

Audio input Phono jacks

Video input Phono jack

USB input USB port

HDMI input HDMI Connector

Y: 1 Vp-p, 75 ohms, 0.3 negative

sync

PB/CB: 0.7 Vp-p, 75 ohms

PR/CR: 0.7 Vp-p, 75 ohms

Video: 1080/24p, 1080p, 1080i,

720p, 576p, 576i, 480p, 480i

Audio: Two channel linear PCM

32, 44.1 and 48kHz,

16, 20 and 24 bits

Analogue audio: 500mVrms,

(HDMI IN 2 only)

Video:15 Pin D Sub Connector

Audio: Minijack

Digital Optical Jack

Audio Output: Phono jack

Design and specifications are subject to change without notice.

High Picture & Sound Quality, Bravia Sync,

Full HD Resolution 1920x1080, XMB,

Live Colour Creation / WCG-CCFL Backlight,

Other Features

Sound Output

Right and Left speaker 2 x 10W (RMS)

Power requirements

High Dynamic Contrast Ratio, USB Input,

3 HDMI inputs, PC input, New S-Force, PAP,

MPEG Noise Reduction, Digital Media Port,

Radio Screen Saver, Picture Frame Mode,

24P True Cinema, PAP, PIP Freeze, Photo Map.

3V dc

2 batteries IEC designation

R06 (size AA)

- 5 -

21 Pin Connector (SCART)

1

21

19

17

15

13

11

9

7

5

3

1

20

18

16

14

12

10

CONNECTORS

Pin No 1 2 Signal Signal level

1 Audio output B

2

3

4 Ground (audio)

5 Ground (blu e)

6 Audio input A

7 Blue input 0.7 +/- 3dB, 75 ohms positive

8 Function select

9 Ground (green)

10 AVlink

11 Green Green signal : 0.7 +/- 3dB, 75 ohms,

12 Open

8

13 Ground (red)

14 Ground (blanking)

6

4

2

15

16 Blanking input

17 Ground (video

18 Ground (video

19 Video output 1V +/- 3dB, 75ohms, positive sync 0.3V

20

21 Common ground

(right)

Audio input B

(right)

Audio output A

(left)

(left)

(AV control)

_ _ Red input 0.7 +/- 3dB, 75 ohms, positive

_ (S signal Chroma

-

-

input)

(Ys signal)

output)

input)

Video input 1V +/- 3dB, 75ohms, positive sync 0.3V

Video input

--

Y (S signal)

(plug, shield)

Connected Not Connected (open) * at 20Hz - 20kHz

Standard level : 0.5V rms

Output impedence : Less than 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

Standard level : 0.5V rms

Output impedence : Less than 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

High state (9.5-12V) : Part mode

Low state (0-2V) : TV mode

Input impedence : More than 10K ohms

Input capacitance : Less than 2nF

positive

0.3 +/- 3dB, 75 ohms, positive

High state (1-3V) Low state (0-0.4V)

Input impedence : 75 ohms

(-3+10dB)

(-3+10dB)

1V +/- 3dB, 75ohms, positive sync 0.3V

(-3+10dB)

HDMI Connector

15 Pin D Sub Connector (PC)

Pin No Signal Assignment Pin No Signal Assignment

1 TMDS Da t a 2+ 11 TMDS Cl o ck S hield

2 TMDS Data2 Shield 12 TMDS Clock-

3TMDS Data2- 13CEC

4 TMDS Data1+ 14 Reserved (N.C. on device)

5 TMDS Data1 Shield 15 SCL

6 TMDS Data1- 16 SDA

7 TMDS Data0+ 17 DDC/CEC Ground

8 TMDS Data0 Shield 18 +5V Power

9 TMDS Data0- 19 Hot Plug Detect

10 TMDS Clock+

Pin No Signal Assignment Pin No Signal Assignment

1Red Out 9+5V DC

2 Green Out 10 S ync Return (Ground)

3 Blue Out 11 Monitor ID0 in Display

4 Unused 12 DCC Serial Da ta

5 Ground 13 Horizontal Sync

6 Red Re t urn 14 Vertical Sy n c

7 Green Return (Ground) 15 DCC Serial Clock

8 Blue Return (Ground)

- 6 -

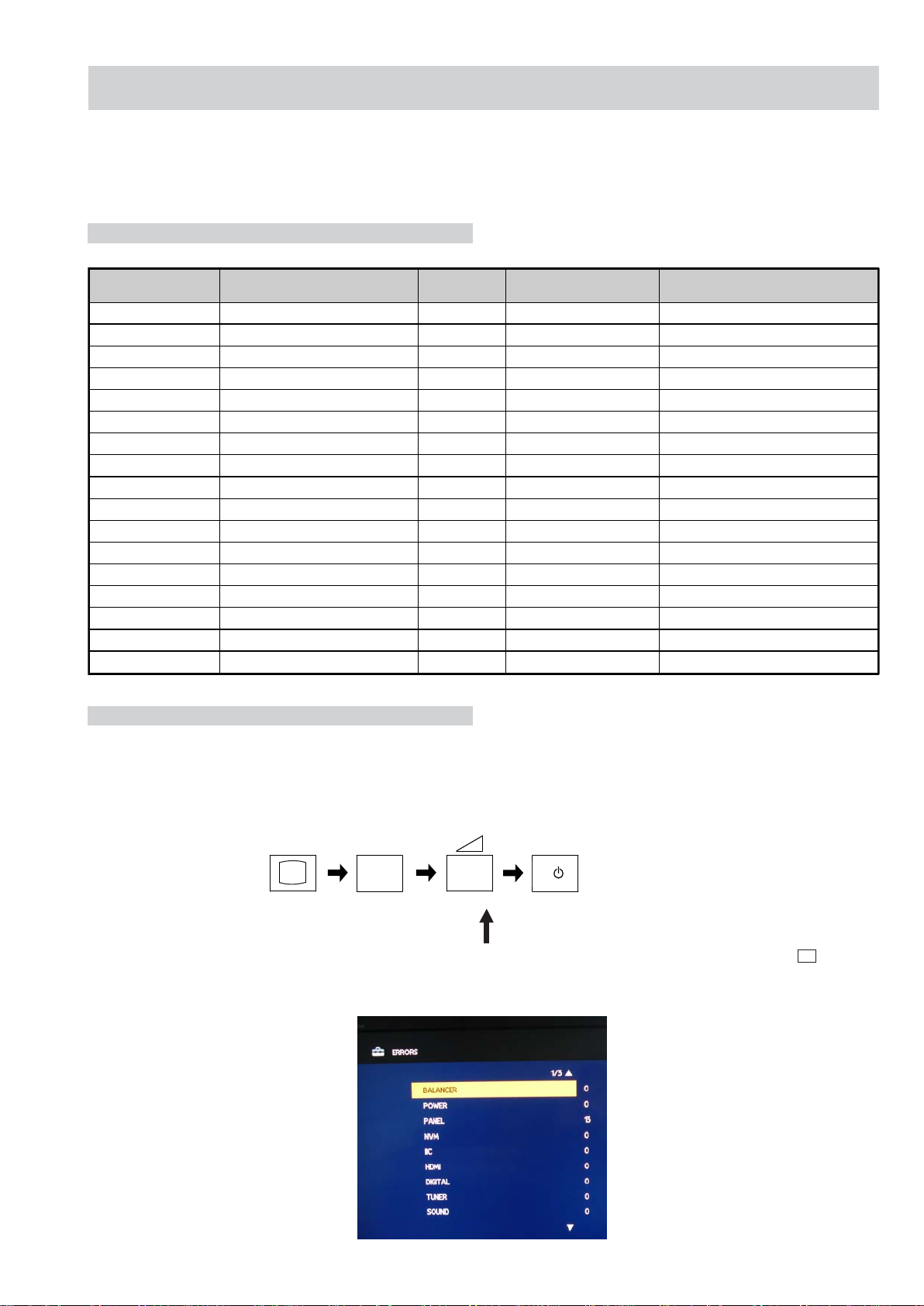

EG1L SELF DIAGNOSTIC SOFTWARE

The identification of errors within the EG1L chassis is triggered in one of two ways :- 1: Busy or 2: Device failure to respond to IIC. In the

event of one of these situations arising the software will f irst try to release the bus if busy (Failure to do so will report with a continuous

flashing LED) and then communicate with each device in turn to establish if a device is faulty. If a device is found to be faulty the relevant

device number will be displayed through the LED (Series of flashes which must be counted).

LED Error Codes and Descriptions

Number of LED

Flashes

02 DC_DET (12V main voltage). VERD In normal mode. Goes into standby and LED flashes.

06 Panel Det error. VERD In normal mode. Goes into standby and LED flashes.

07 Internal temperature error. VERD In normal mode. Goes into standby and LED flashes.

08 Audio error (SP protection). VERD In normal mode. Goes into standby and LED flashes.

10 Digital error. VCT In normal mode. Adds error to error menu.

11 NVM error. VCT In initialisation state. Adds error to error menu.

12 I2C error VCT. VCT In normal mode. Adds error to error menu.

13 Balancer error. VERD In normal mode. Goes into standby and LED flashes.

14 HDMI error. VCT In initialisation state. Adds error to error menu.

15 Tuner Error VCT In initialisation state. Adds error to error menu.

16 I2C CH1 (VERD TAS). VERD Factory mode. LED error.

17 I2C CH0 (VERD NVM/RTC). VERD Factory mode. LED error.

18 Digital demod. EMMA In normal mode. Adds error to error menu.

19 USB error EMMA In normal mode. Adds error to error menu.

20 CI error EMMA In nor mal mode. Adds error to error menu.

21 VCT error VERD In normal mode. LED error.

22 MSP error. VCT In initialisation state. Adds error to error menu.

Error Description Micro Checked Action

Self Diagnostic Screen Display

To bring up the self diagnostic screen display

In standby mode, press the following sequence of buttons in quick succession on the remote commander as shown below:

TV

i+

(ON SCREEN (DIGIT 5) (VOLUME +) (TV)

DISPLAY)

DISPLAY)

5

(DIGIT 5) (VOLUME -)

+

I/

(TV POWER) (ON SCREEN

Note that this differs from entering the service mode (volume + )

The following menu appears as shown below:

- 7 -

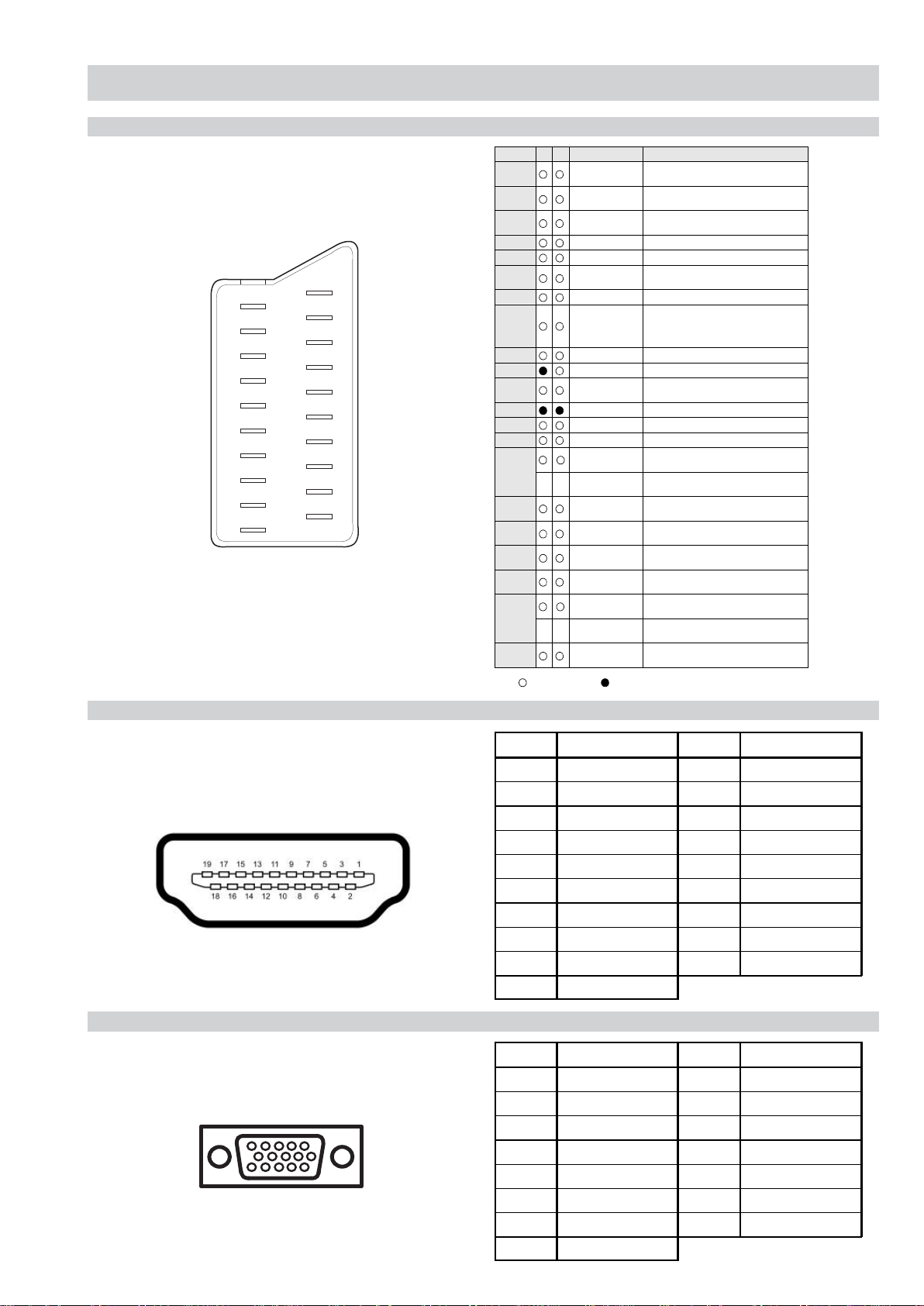

SECTION 2 DISASSEMBLY

2-1. Rear Cover Removal

=>

3

=>

=>

1

=>

2

3

=>

=>

=>

2

=>

2

=>

1

=>

1

11

=>

=>

=>

33

1

=>

1

=>

=>

3

1

1

1

1

1

=>

=>

=>

=>

=>

1

=>

=>

1

3

=>

1

Remove the rear cover fixing screws indicated and pull the rear cover

gently backwards away from the back of the TV set.

Screw Part number(s) and Description(s)

1) 2-580-640-01 SCREW, +BVTP2 4X16 (21 Screws)

2) 7-685-648-79 SCREW, +BVTP 3X12 TYPE2 IT-3 (3 Screws)

3) 2-580-608-01 SCREW, +PSW M5X16 (6 Screws)

2-2. Stand Removal

=>

1

=>

1

=>

=>

1

=>

1

=>

1

=>

1

Remove the 4 stand fixing screws as indicated.

Screw Part number(s) and Description(s)

2-580-608-01 SCREW, +PSW M5X16 (4 Screws)

=>

=>

=>

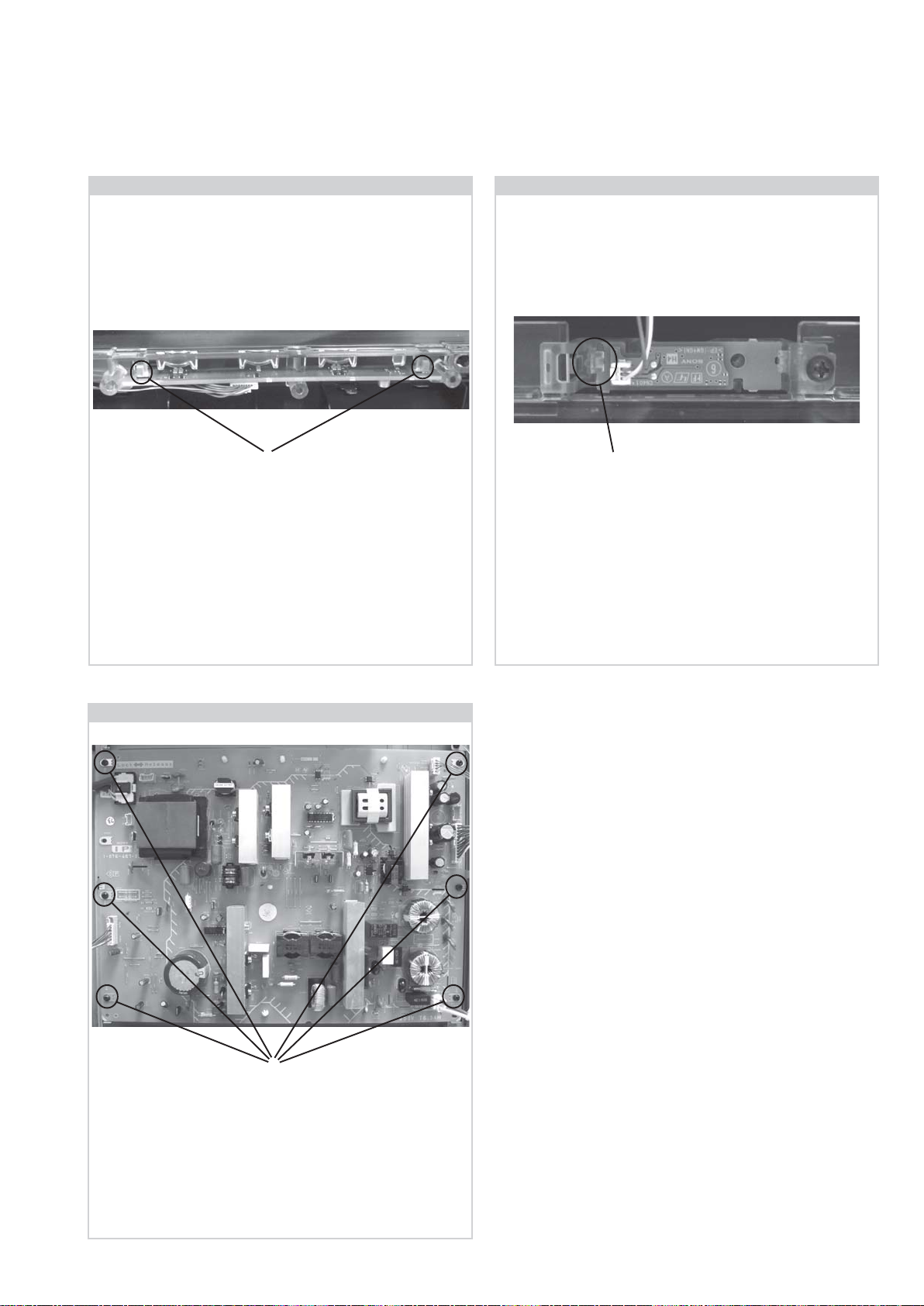

2-3. Loudspeaker Removal

T o remove the loudspeaker disconnect the speak er cables and then

pull the loudspeaker gently backwards away from the back of the TV

set.

2-4. Side Jack Bracket Assy Removal

Clips

T o remove the side jack bracket assy release the 2 clips circled.

- 8 -

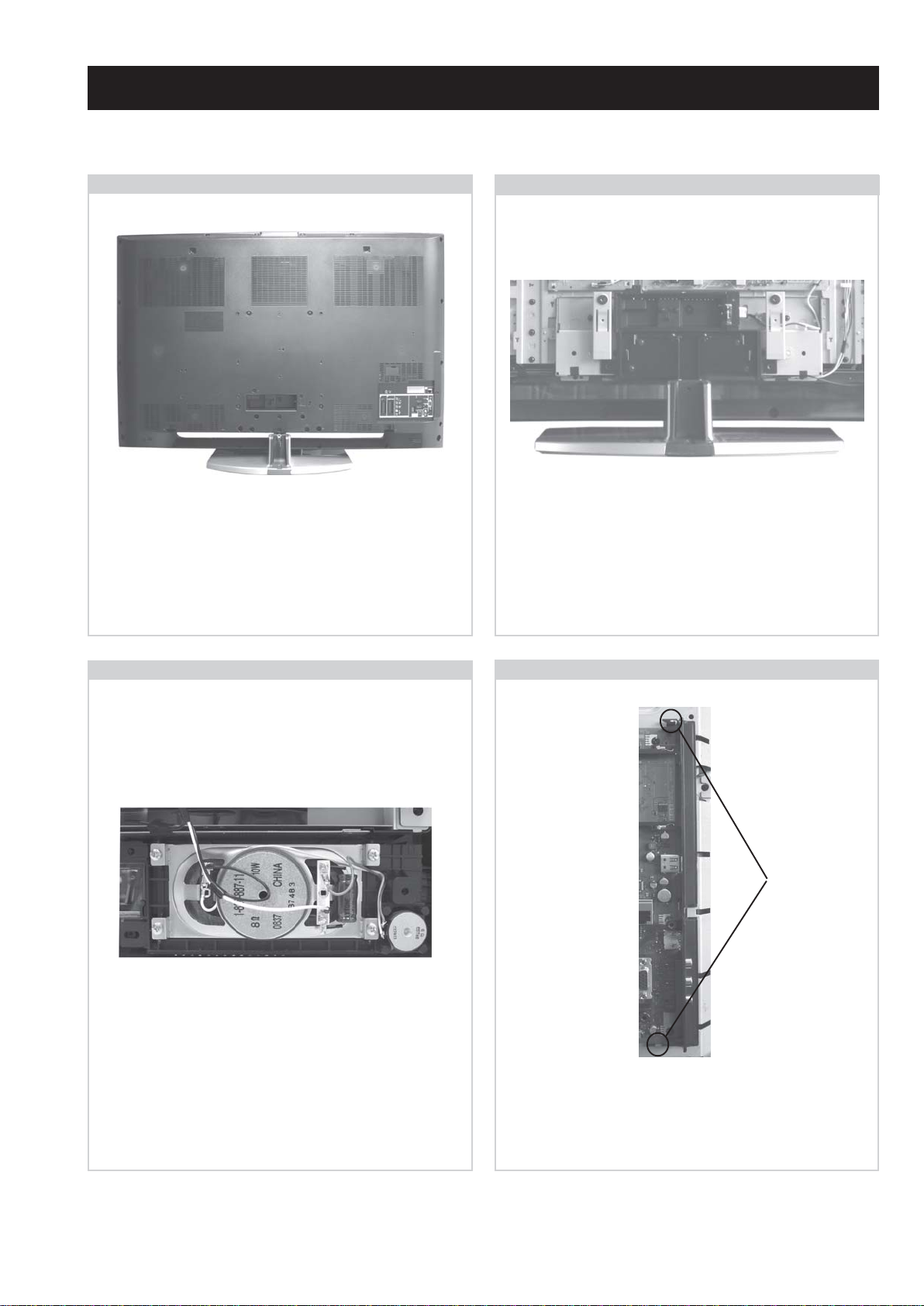

2-5. BGE Board Removal

2-6. D4 Board Removal (52 inches)

ScrewsScrews

T o remove the BGE board disconnect all connectors and then remo ve

the 9 screws circled and ease the board gently away from the back of the

TV set.

Screw Part number(s) and Description(s)

2-580-629-01 SCREW, +BVST 3X8 (9 Screws)

T o remove the D4 board disconnect all connectors and then remove the

6 screws circled and ease the board gently away from the back of the

TV set.

Note: Refer to page 4 - Hirose MDF61 connector.

Screws

Screw Part number(s) and Description(s)

2-580-629-01 SCREW, +BVST 3X8 (6 Screws)

2-7. D5 Board Removal (52 inches) 2-8. G5 Board Removal (52 inches)

Screws

T o remove the D5 board disconnect all connectors and then remove the

4 screws circled and ease the board gently away from the back of the

TV set.

Note: Refer to page 4 - Hirose MDF61 connector.

Screw Part number(s) and Description(s)

2-580-629-01 SCREW, +BVST 3X8 (4 Screws)

Screws

T o remove the G5 board disconnect all connectors and then remov e the

6 screws circled and ease the board gently away from the back of the

TV set.

Screw Part number(s) and Description(s)

2-580-629-01 SCREW, +BVST 3X8 (6 Screws)

- 9 -

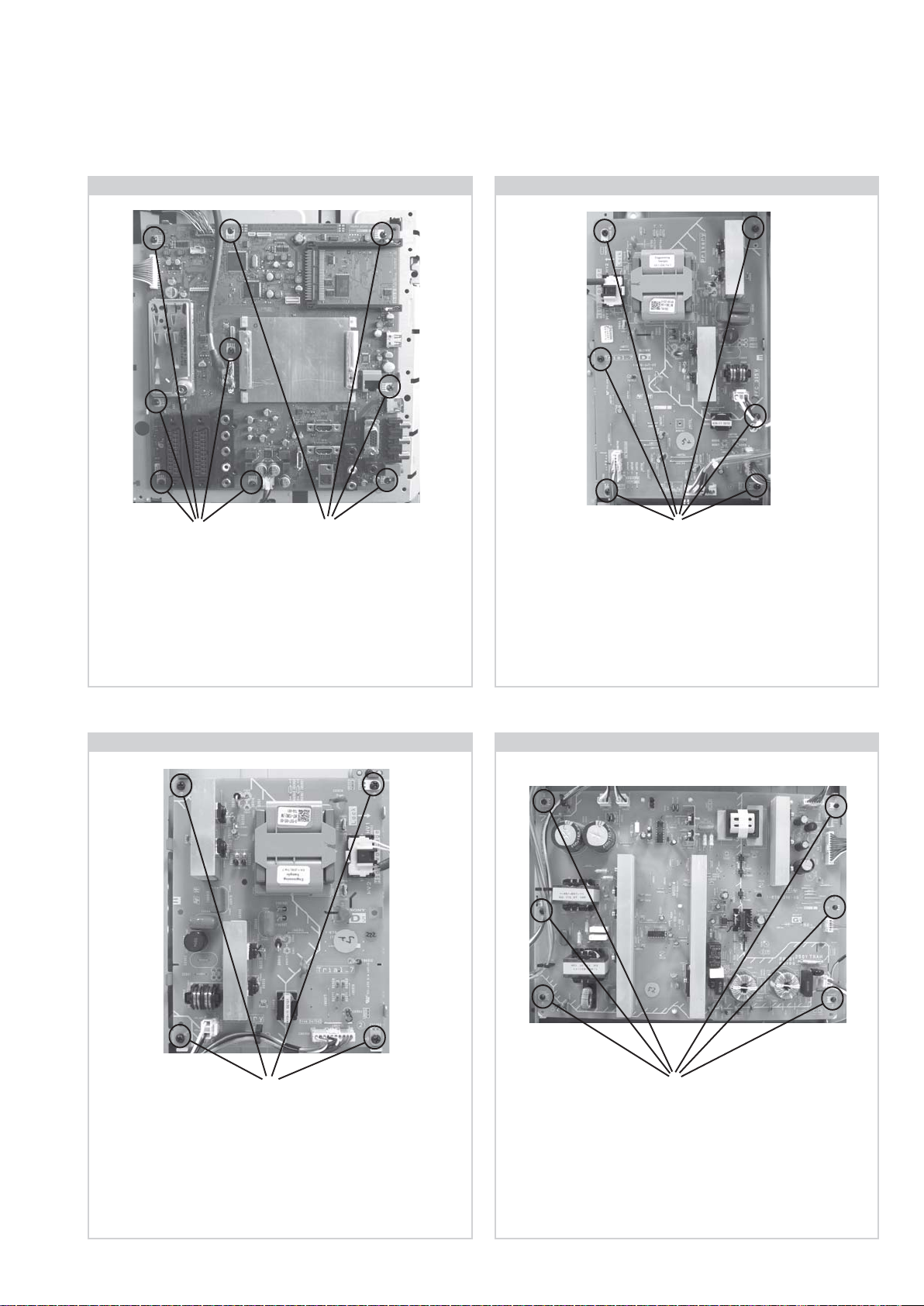

2-9. H3E Board Removal 2-10. H4 Board Removal

Clips

T o remove the H3E board disconnect the connector and then release the

clips circled and gently ease the board towards you and away from the

back of the TV set.

2-11. IP5 Board Removal (40/46 inches)

Clip

T o remove the H4 board disconnect the connector and then release the

clip circled and ease the board gently towards you and away from the

back of the TV set.

Screws

T o remove the IP5 board disconnect all connectors and then remove the

6 screws circled and ease the board gently away from the back of the

TV set.

Note: Refer to page 4 - Hirose MDF61 connector.

Screw Part number(s) and Description(s)

2-580-629-01 SCREW, +BVST 3X8 (6 Screws)

- 10 -

SECTION 3 SERVICE MENUS

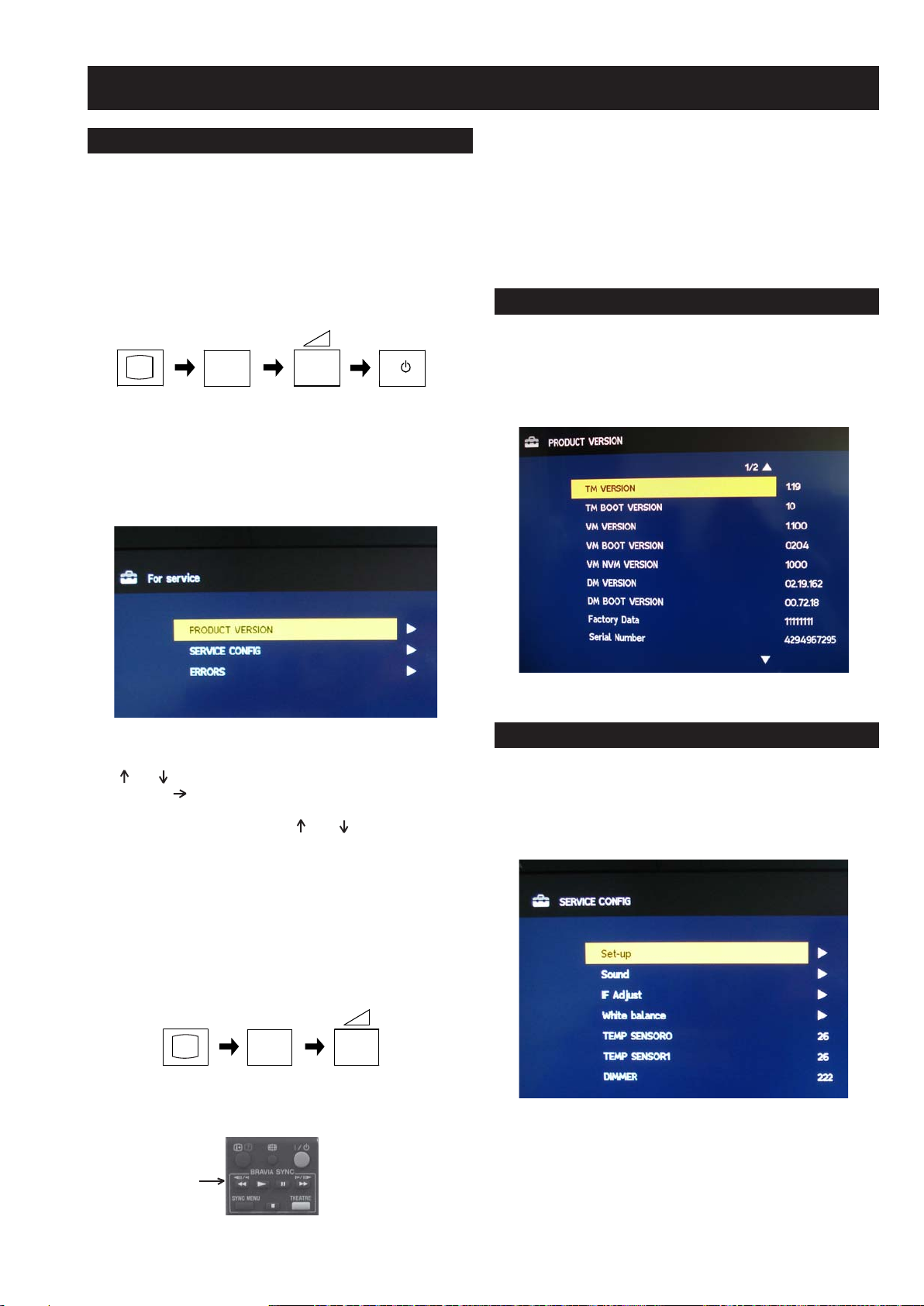

3-1. How to enter the Service Mode

Service adjustments to this model can be performed using the

supplied Remote Commander RM-ED011.

1. Turn on the power to the TV set and enter into the stand-by

mode.

2. Press the following sequence of buttons on the Remote

Commander.

i+

(ON SCREEN (DIGIT 5) (VOLUME +) (TV)

DISPLAY)

DISPLAY)

3. The following menu appears on the screen (See Pic.1).

Pic.1

5

(DI GIT 5)

+

+

(VOLUME +)

TV

I/

(TV POWER) (ON SCREEN

• T o take the Remote Commander out of ‘Service Mode’ press the

same buttons above together again for two seconds or remove

thebatteries from the Remote Commander.

• After carrying out the service adjustments, to prevent the

customer accessing the ‘Service Menu’ switch the TV set

OFF and then ON again.

3-2. Product V ersion

1. The following menu appears on the screen when you enter the

‘Product Version’ menu (See Pic.2). Be sure to check all pages.

Pic.2

4. Move to the corresponding adjustment item using the

‘ ’ or ‘ ’ arrow buttons on the Remote Commander.

5. Press the ‘ ’ arrow button to enter into the required menu

item.

6. Adjust the data value using the ‘ ’ or ‘ ’ arrow buttons on

on the Remote Commander.

7. To go back at any time press the ‘Return’ b utton on the Remote

Commander.

8. Press the ‘Menu’ button on the Remote Commander to quit

the Service Mode when all adjustments have been completed.

Note :

• T o place the Remote Commander in ‘Service Mode’ press the

following buttons together for two seconds.

i+

(ON SCREEN (DIGIT 5) (VOLUME +) (TV)

DISPLAY)

• T o use the Remote Commander in ‘Service Mode’ press the

rewind button on the Remote Commander twice.

Rewind

Button

5

+

3-3. Service Config

1. The following menu appears on the screen when you enter the

‘Service Config’ menu (See Pic.3).

Pic.3

TT will then appear in the bottom right hand corner of the TV.

- 11 -

3-3-1. Set-Up

3-3-3. IF Adjust

1. The following menu appears on the screen when you enter the

‘Set-up’ menu (See Pic.4). Be sure to check all pages.

Pic.4

3-3-2. Sound

1. The following menu appears on the screen when you enter the

‘Sound’ menu (See Pic.5).

1. The following menu appears on the screen when you enter the

‘IF Adjust’ menu (See Pic.6).

Pic.6

3-3-4. White Balance

1. The following menu appears on the screen when you enter the

‘White balance’ menu (See Pic.7).

Pic.5

Pic.7

- 12 -

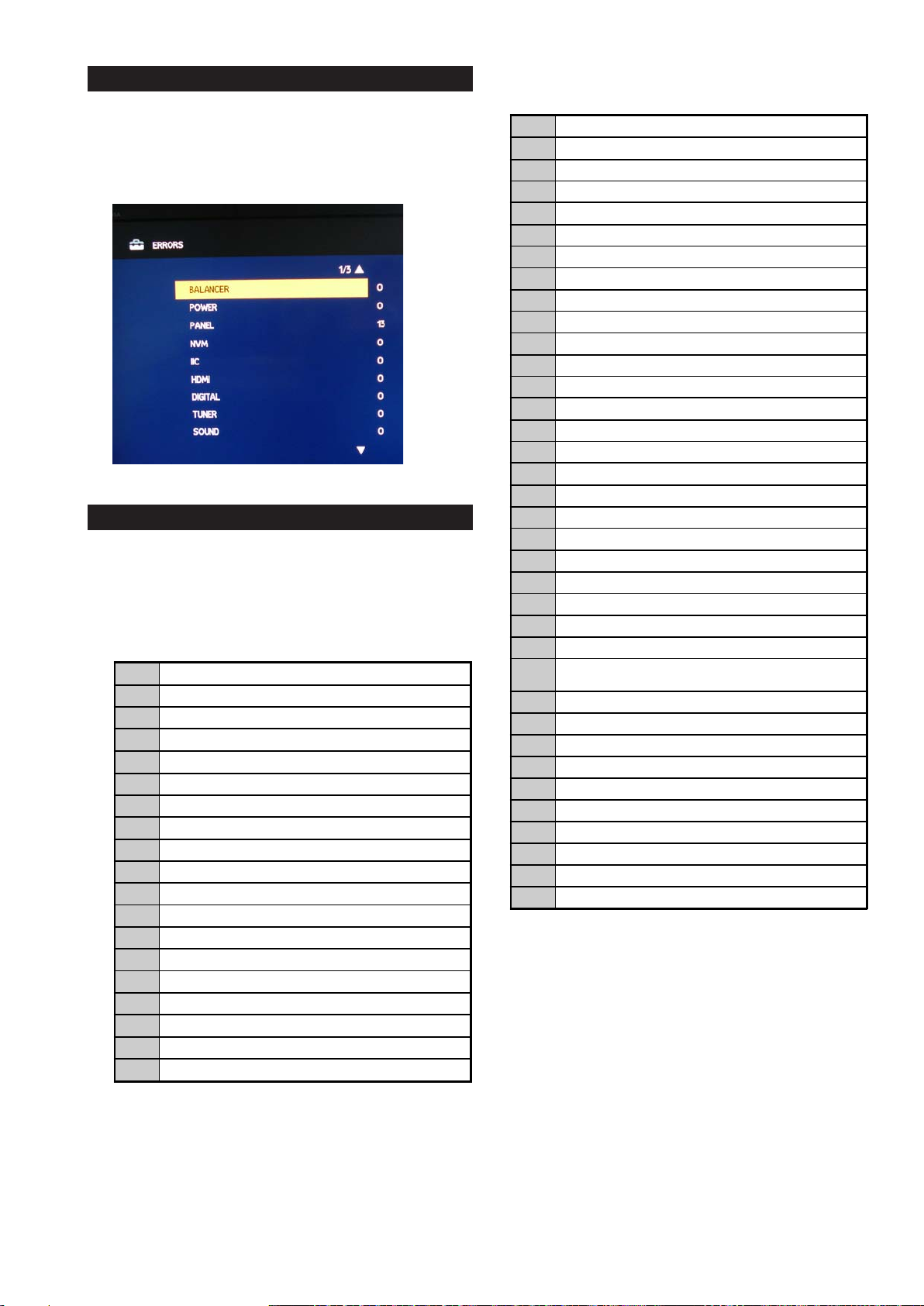

3-4. Error Menu

1. The following menu appears on the screen when you enter the

‘Error Menu’ menu (See Pic.8). Be sure to check all pages.

Pic.8

3-5. TT MODE

TT mode is available by setting the TV and Remote Commander for

operation in Service Mode [ As sho wn on P age 11 ]. The functions

described below are then available by selecting the tw o numbers. T o

release the ‘TT mode’ press 00. T o release the TT menu press the

menu key .

'TT' mode off

00

Set volume to 35%

03

Set volume to 50%

04

Set volume to 65%

05

Set volume to 80%

06

Ageing mode on

07

Shipping Condition

08

WB adj initial condition

09

Factory mode toggle (on/off)

19

40" FHD//EM model

25

26 46" FHD//EM model

CBA mode toggle (ON/OFF)

27

31 ECS mode toggle (ON/OFF)

Set BCN channels preset

32

34 HDMI log enable/disable

Hotel mode toggle

35

OTRUM mode toggle

38

Enable digital test

39

Re-initialise NVM

41

Select Dual Sound A

43

Select Dual Sound B

44

Select Dual Sound Mono

45

Select Dual Sound Stereo

46

Set NVM as non-virgin

48

Set NVM as virgin

49

Watchdog toggle

54

Gemstar Service Mode (EG1L)

57

Reset package version

58

Visual I2C toggle (VCT micro slave mode)

59

Set 52" FHD//EM model

61

WXGA/FHD panel selection

69

Auto AGC

71

72 VES A/JEIDA panel selection

HDMI number of inputs (0 to 2)

73

DDC enable

74

75 Set centred balance

Set volume to max

76

Set volume to min

77

78 Set balance full left

Set balance full right

79

Digital BER display

81

Digital Service menu

82

Digital colour bar output from DENC

83

TS CI path through

84

Digital tuner power down (Only one power cycle,

85

default is no power down)

Switch between two digital SW banks

86

Local keys test

87

Digital shipping conditions (Clear tune database)

88

LED test

89

OAD enable/disable toggle

91

TS CI path through with Reed Solomon off

92

Ether Check Ping (EG1H)

95

Digital debug output enable/disable

96

Digital 656 output enable/disable

97

Digital Auto Reset function enable/disable

98

- 13 -

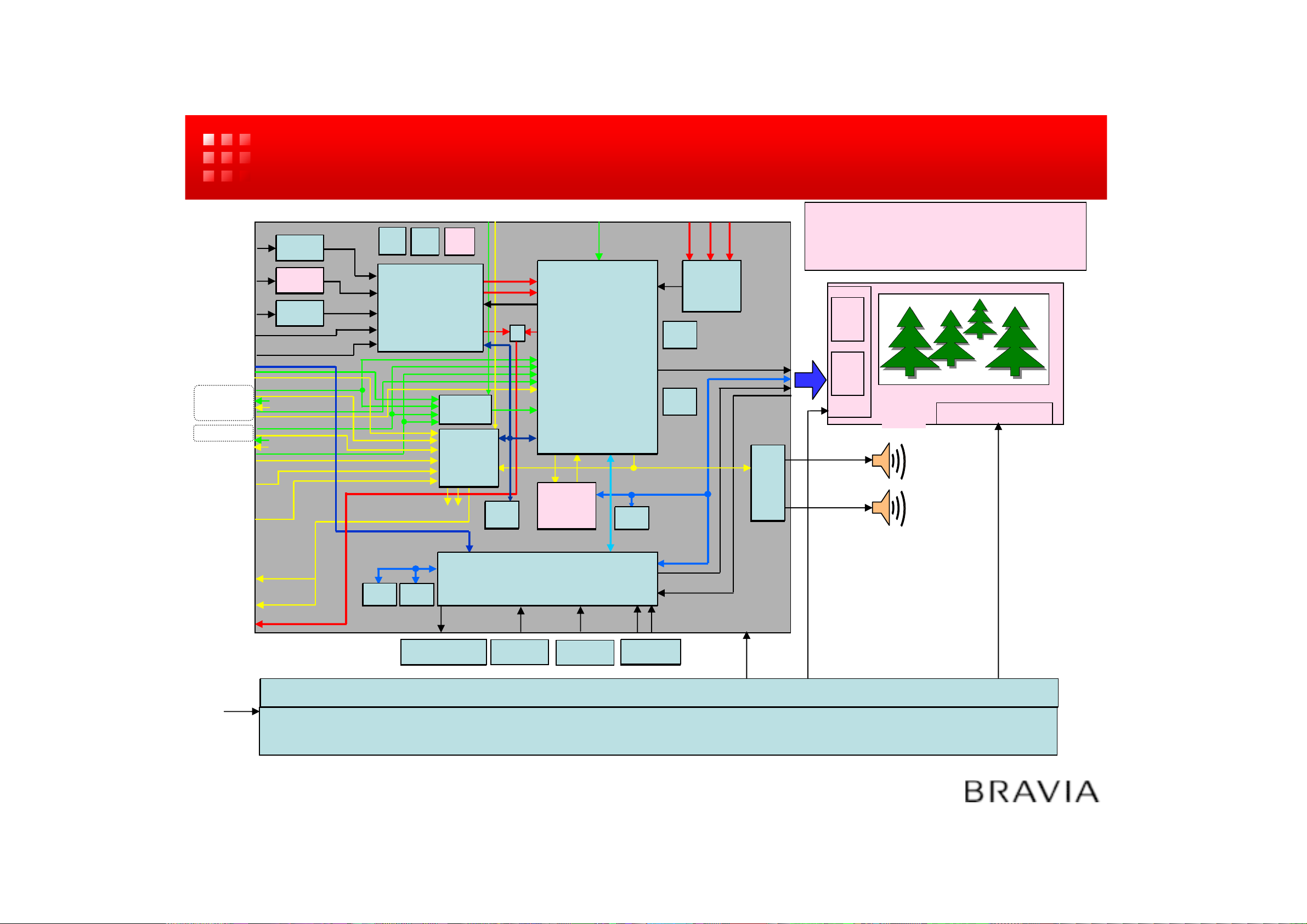

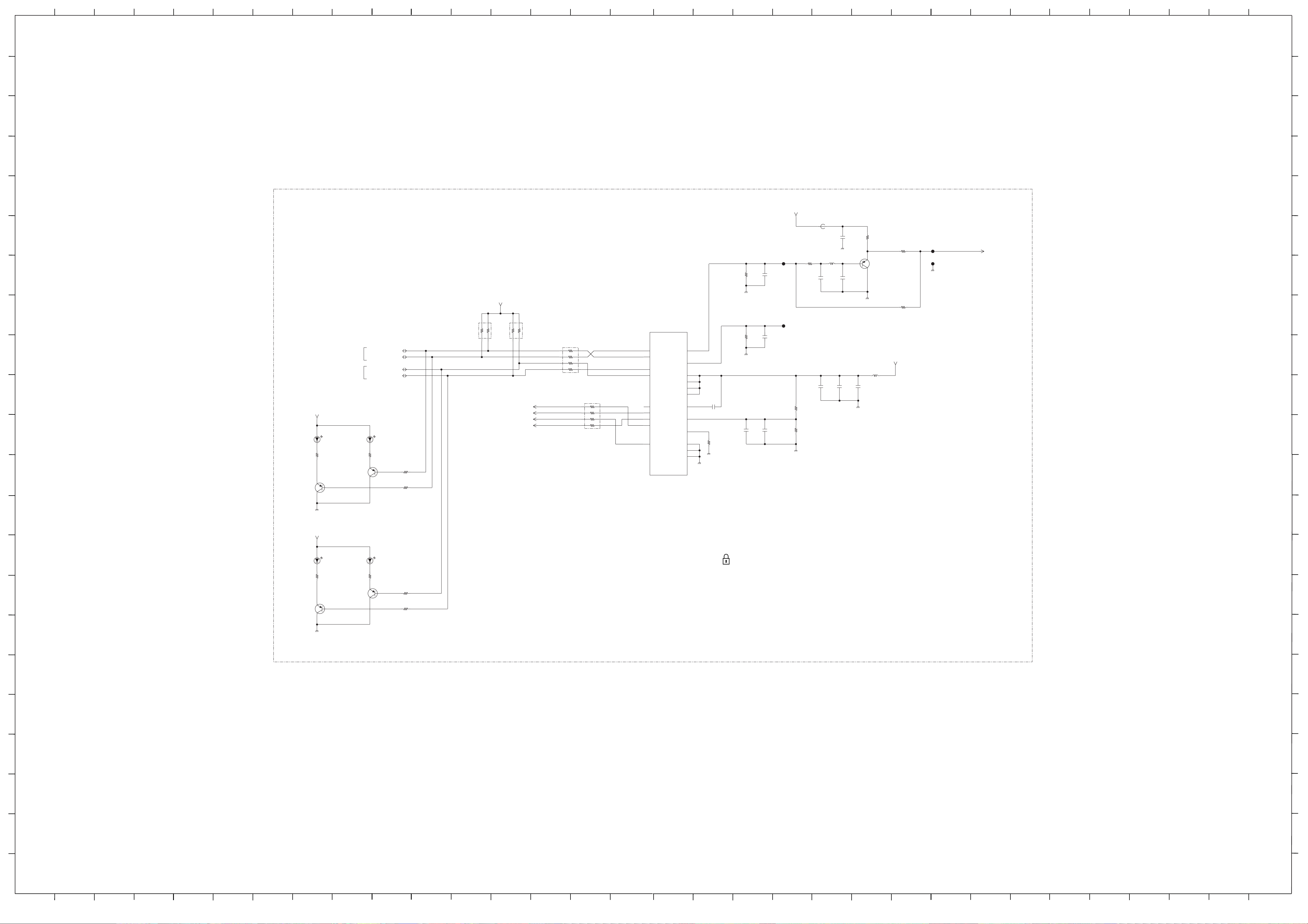

4-1. BLOCK DIA GRAM

Block Diagram (W4500 AEP/UK)

RF

Ether

PCM-CIA

MS

USB

DMP

SCART

RGB1

Video IN

RGB2

SCART

Comp1

HDMI-A

IN

PC-A

IN

UFE4

UFE4

PHY

PHY

CI-Buff

CI-Buff

Sel out

Sel out

NAND

DDR

DDR

Audio OUT

NAND

FLASH

FLASH

V-SW

V-SW

BASI

BASI

BASI

(Audio)

(Audio)

DDR

DDR

EMMA3SL

EMMA3SL

(MPEG/AVC Dec)

(MPEG/AVC Dec)

Video IN

(Side)

TEMP

TEMP

Sens

Sens

LAN

Premium

Premium

(A/V SW,C-Dec

(A/V SW,C-Dec

3D-Comb,ADC

3D-Comb,ADC

NR,Histogram

NR,Histogram

HDMI Dec

HDMI Dec

IIC

TAS

TAS

IIC_EXTRA

PC IN

VCT-

VCT-

Scaler)

Scaler)

NVM

NVM

IIC_TAS

HDMI2

HDMI1

HDMI

HDMI

DDR

DDR

DDR

EQ

EQ

HDMI3

BGE

MAIN

MAIN

AMP

AMP

Change point from

W4000(AEP) Spring Model

T-

CON

Caye

LVDS

nne-S

Panel

L-SP

R-SP

Balancer

A-Out

HP-Out

Opt-Out

AC

IN

IIC_RTC

RTC

RTC

NVM

NVM

Logo-LED

Logo-LED

VERD

VERD

Top Key

H3E

H4

H4

IP5 (40”)

IP5 (40”)

IP5 ( 46”)

G5 +D4+D5 (52”)

- 14 -

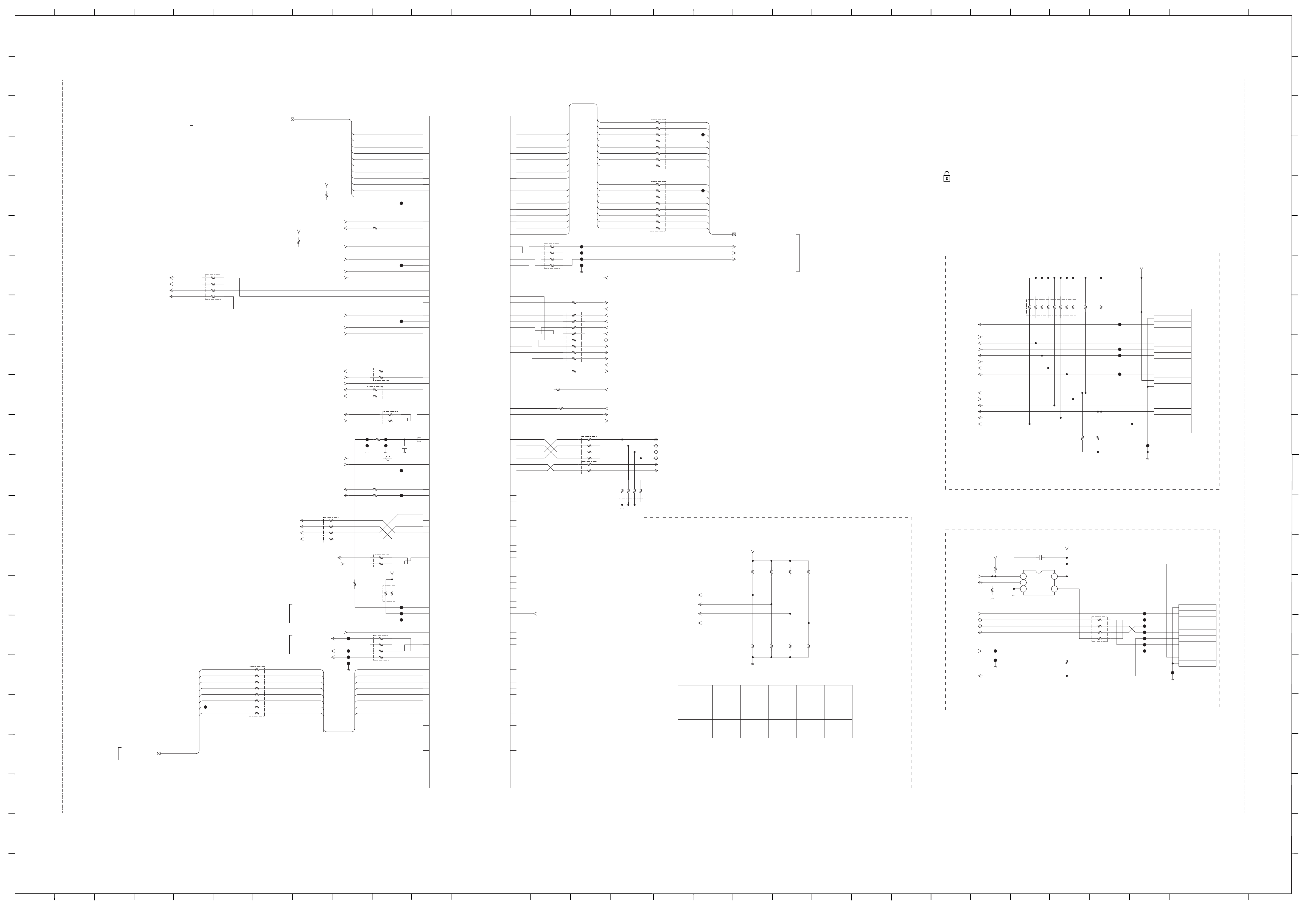

4-2. CIRCUIT BO ARD LOCA TION

5-2. CIRCUIT BOARD LOCATION

Reference Information

C

C

N

VM

D4

CVM Board

H

D1

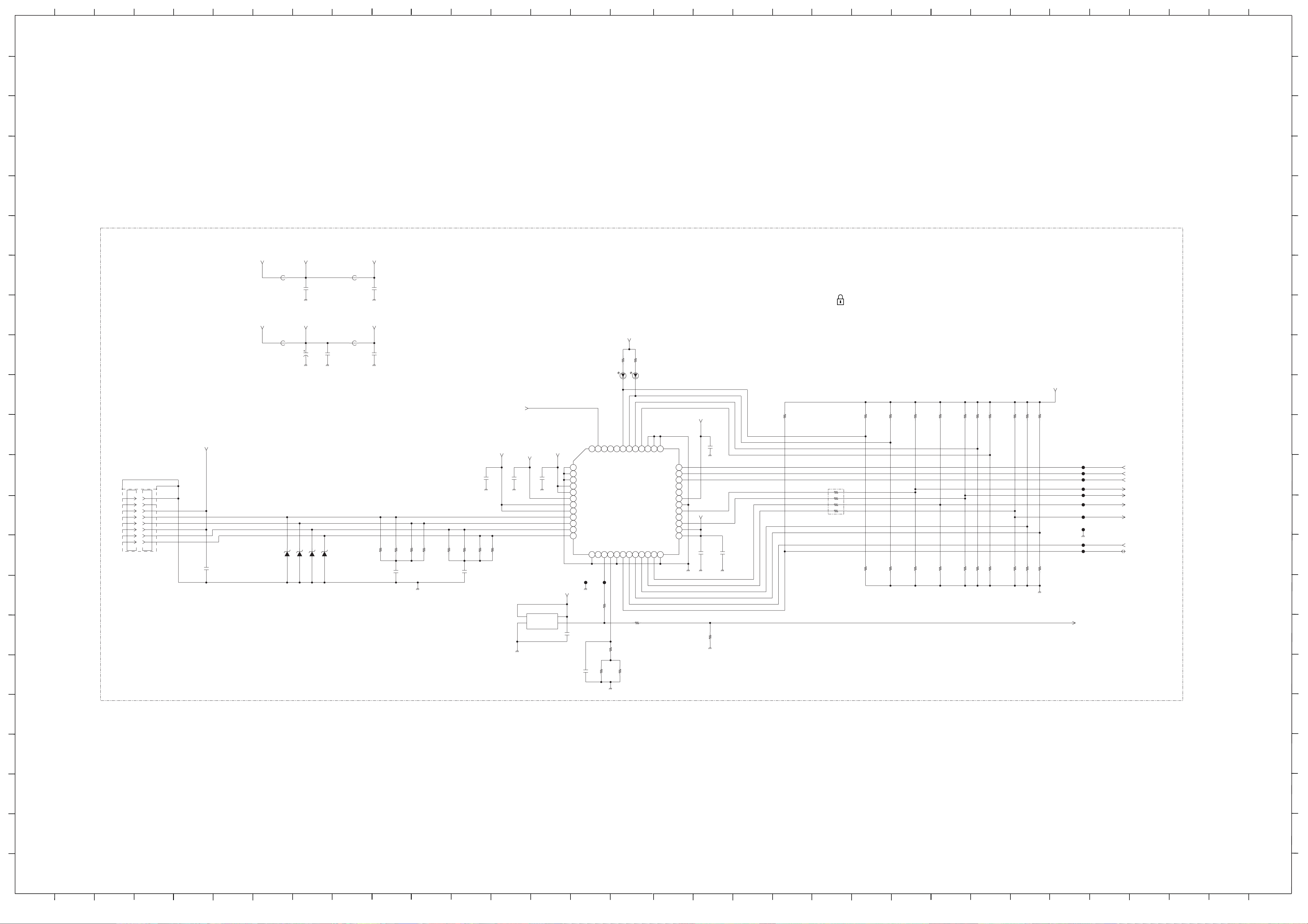

4-3. SCHEMA TIC DIA GRAMS AND

5-3. SCHEMATIC DIAGRAMS AND

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

Note :

• All capacitors are in µF unless otherwise noted.

• pF : µµF 50WV or less are not indicated except for

electrolytic types.

• Indication of resistance, which does not have one for

rating electrical power, is as follows.

Pitch : 5mm

Electrical power rating : 1/4W

• Chip resistors are 1/10W

• All resistors are in ohms.

k = 1000 ohms, M = 1000,000 ohms

• : nonflammable resistor.

• : fusible resistor.

• : internal component.

• : panel designation or adjustment for repair.

• All variable and adjustable resistors have

characteristic curve B, unless otherwise noted.

• All voltages are in Volts.

• Readings are taken with a 10Mohm digital mutimeter.

• Readings are taken with a color bar input signal.

• Voltage variations may be noted due to normal production

tolerences.

•: B + bus.

H4

A

A Board

H3E

D

S1 Board

G5/IP5

D2

A

D5

BGE

J

A1

A2

RESISTOR RN

RC

FPRD

FUSE

RS

RB

RW

COIL LF-8L

CAPACITOR TA

PS

PP

PT

MPS

MPP

ALB

ALT

ALR

Note :

The components identified by shading

and marked are critical for safety.

Replace only with the part numbers

specified in the parts list.

Note :

Les composants identifiés par une trame et

par une marque sont d'une importance

critique pour la sécurité. Ne les remplacer

que par des pièces de numéro spécifié.

specified.

Note :

The components identified by mark

confidential information.

Strictly follow the instructions whenever the

components are repaired and/or replaced.

: METAL FILM

: SOLID

: NON FLAMMABLE CARBON

: NON FLAMMABLE FUSIBLE

: NON FLAMMABLE METAL OXIDE

: NON FLAMMABLE CEMENT

: NON FLAMMABLE WIREWOUND

: ADJUSTMENT RESISTOR

: MICRO INDUCTOR

: TANTALUM

: STYROL

: POLYPROPYLENE

: MYLAR

: METALIZED POLYESTER

: METALIZED POLYPROPYLENE

: BIPOLAR

: HIGH TEMPERATURE

: HIGH RIPPLE

contain

• : B - bus.

• : RF signal path.

• : earth - ground.

• : earth - chassis.

Note: Schematic dia grams are for reference onl y . Please refer to the electrical parts list for

the correct value and part number of components.

- 15 -

ABC D EFG H JIKLMN

O

P

QRST UVWXY AA

Z

DDCCBB

EE

FF

10

11

1

BGE - EG1L

1

FE_PLL_1.05V

013:4K

0.01

25V

X7R

C7026

0.01

25V

X7R

C7031

XX

C7034

0.01

25V

X7R

C7036

0.01

25V

X7R

C7038

0.01

25V

X7R

C7042

XX

C7019

0.01

25V

C7020

0.01

25V

C7021

0.01

25V

X7R

C7022

0.01

25V

X7R

C7028

0.01

25V

X7R

C7029

0.01

25V

X7R

C7030

0.01

25V

X7R

C7032

XX

C7033

XX

C7035

0.01

25V

X7R

C7037

0.01

25V

X7R

C7039

0.01

25V

X7R

C7040

0.01

25V

X7R

C7041

0.01

25V

X7R

C7043

0.01

25V

X7R

C7044

10

6.3V

2012

C7045

10

6.3V

2012

XX

R7000

C7046

XX

FE_1.05V

C7047

XX

SPLL VDD

2

SPLL VDD

SPLL VDD

SPLL VDD

SPLL VDD

Y10

Y11

Y12

Y13

Y14

C7023

0.01

25V

X7R

C7024

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

CVDD

VDD10

VDD10

VDD10

VDD10

H19

J20

D1

D2

D23

D24

E3

E22

F4

F21

G5

G20

H6

L11

L13

L15

M10

M12

M14

N11

N13

N15

P10

P12

P14

R11

R13

R15

T10

T12

T14

U11

U13

U15

V10

V12

V14

W15

K10

K11

K14

K15

C7025

XX

C7027

0.01

25V

X7R

3

C7002

FE_3.3V

4

C7000

C7001

4.7

4.7

10V

10V

2012

2012

C7005

0.01

25V

X7R

5

C7007

0.01

25V

X7R

C7008

0.01

25V

X7R

C7009

0.01

6

7

8

25V

X7R

C7010

0.01

25V

X7R

C7011

0.01

25V

X7R

C7013

0.01

25V

X7R

C7014

0.01

25V

X7R

C7015

0.01

25V

X7R

C7017

0.01

25V

X7R

9

BGE

0.01

25V

X7R

G21

H1

C7003

0.01

25V

X7R

C7004

0.01

25V

X7R

J2

J6

J21

K3

K20

L4

L6

C7006

0.01

25V

X7R

L19

L21

M20

N6

N23

R6

R23

U6

U21

W6

W21

AA6

AA21

C7012

XX

AC6

AC21

AD11

AD18

AE11

AG7

AG10

C7016

XX

AG12

AG19

AH7

AH10

AH12

C7018

0.01

25V

X7R

UPD61300F1-230-LU2-A

1/22 MAIN MICROCONTROLLER, HDMI/AV SIDE/PC INPUT, AUDIO PROCESSOR, SCARTS

DPLL VDD

DPLL VDD

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

VDD3

IC7000

C1

C2

C23

C24

D3

D22

E4

E21

F6

F19

F20

G6

G7

G19

G23

H21

J23

K6

K19

K21

L10

L12

L14

L20

L23

M6

M11

M13

M15

M19

M21

N1

N10

N12

N14

N22

N24

P6

P11

P13

P15

R3

R10

R12

R14

R22

R24

T6

T11

T13

T15

U2

U10

U12

U14

V1

V6

V11

V13

V15

V21

V23

Y5

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

SPLLGND

SPLLGND

SPLLGND

SPLLGND

SPLLGND

DPLLGND

DPLLGND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

W10

W11

W12

W13

W14

H20

J19

A6

A19

B6

B19

C17

D16

E10

E15

F11

F14

K12

K13

AJ12

AJ10

AJ7

AJ4

AH23

AH21

AH19

AG11

AG9

AG8

AG3

AF23

AF17

AF15

AF14

AF11

AF6

AE1

AE14

AE17

AD23

AD19

AD3

AC5

AB23

AB21

AB6

AB1

AA3

Y23

Y21

Y15

2

3

4

C8

D9

5

6

7

8

9

10

11

Y6

12

13

14

15

16

17

18

19

20

21

BGE - EG1L

FE_MASTER_RSTB

014:7E;020:3H;017:9D

CL7100

FE_3.3V

C7101

R7100

100

16V

0.1

C7100

50V

0.001

BGE

IC7100

PST3629UL

12

GND

Vcc CD

RT3N11M-TP-1

2143658

10k

RB7100

RT3N11M-TP-1

OUT

Q7100

Q7101

D7100

MA4J1130GLS0

43

7

2/22

C7103

0.1

16V

R7103

C7102

0.47

16V

1608

CL7101

1k

R7104

100

R7121

XX

FE_DBG_RSTB

CL7103

005:10H;008:8D

FE_RSTB

007:14E

COMPONENTS MARKED AS XX REFER TO PARTS LIST, WILL ONLY BE LISTED IF FITTED

~ BGE Board Schematic Diagram [ Main Microcontr oller , HDMI/A V Side/PC Input, Audio Pr ocessor , Scarts ] Page 1/22 ~

X7100

18.432MHz

C7104

9p

50V

1

2

014:16D;007:14E

014:16C;007:14E

007:14F

007:14F

007:14F

007:14F

007:14F

007:14F

0

47

R7122

R7123

C7105

9p

50V

FE_RXD1B

FE_TXD1B

FE_JTCK

FE_JTMS

FE_JTDI

FE_JTDO

FE_JTRST

FE_NMI

2143658

47

RB7105

470R7107

CL7104

CL7106

AH8

SYS_XT1

AJ8

SYS_XT2

AH9

RSTSWB

AJ9

R4

47R7108

T5

RSTOUT

RXD1B

TXD1B

USB_RSDP1

USB_RSDM1

USB_XT1

USB_XT2

USB_DP1

USB_DM1

AJ11

AH11

AD16

AE16

AE15

AD15

CL7108

R7120

XX

FE_3.3V

V20

JTCK

V19

U20

47R7109

U19

T20

T19

W20

AA19

AB19

AE19

AE18

AF18

V5

U5

3

47

RB7104

7

214

USB_VDD331

JTMS

JTDI

USB_AVDD

JTDO

JTRST

USB_PVDDFIL

NMI

USB_AVSS

TEST

TESTP1

TESTP2

TESTP3

TESTP4

TESTP5

TESTP6

TESTP7

UPD61300F1-230-LU2-A

USB_RREF

USB_GND1

USB_GND2

IC7000

USB_PVSS

USB_COM

AF16

AF13

AE13

AD12

AF12

AD13

AE12

AD17

AD14

FB7100

FB7101

R7110

R7111

IC7000

UPD61300F1-230-LU2-A

12

13

14

15

470R7112

C7106

18p

50V

X7101

30MHz

C7110

15p

50V

16

0.5%39

0.5%39

16080uH

16080uH

USB_GND

R7114

15k

R7115

15k

C7107

0.01

25V

C7108

0.01

25V

C7109

0.001

50V

R7113

1.6k

0.5%

5V_MAIN

FB7102

0uH

1608

C7111

820

6.3V

FE_USB_PPON

FE_USB_OCIB

C7112

0.1

16V

007:5F

007:5F

IC7101

MIC2005-0.5YM6TR

123

VIN

GND

EN

VOUT

CSLEW

FAULT

FE_3.3V

10k

RB7103

4

L7100

1

23

17

18

CN7100

4P

C7115

0.001

50V

C7113

220

456

16V

C7114

0.1

16V

VD7100

D7101

PGB0010603NR

D7102

PGB0010603NR

BLK

1234

19

20

21

22

COMPONENTS MARKED AS XX REFER TO PARTS LIST, WILL ONLY BE LISTED IF FITTED

ABCDEF GH JIKLMN

O

22

~ BGE Board Schematic Diagram [ Main Microcontr oller , HDMI/A V Side/PC Input, Audio Pr ocessor , Scarts ] Page 2/22 ~

P

Q

R

S

T

U

V

W

X

Y

Z

- 16 -

AA

BB

CC

DD

EE

FF

ABC D EFG H JIKLMN

O

P

QRST UVWXY AA

Z

DDCCBB

EE

FF

1

1

2

2

3

3

4

4

BGE - EG1L

5

5

FE_RADD[0-14]

10

11

12

13

14

15

16

17

6

6

BGE

3/22

PWB LA Y OUT NO TE:

Place fitted strap resistors in groups

7

FE_3.3V

STRAP SETTINGS

of 4 or 8 to allow replacement by

resistor arrays during later trial

7

PWB LA Y OUT NO TE:

Pin-swap allowed on

these resistor arrays

for optimal PWB layout

8

9

HSDCLK/RADD15

HSDE/RADD16

PKTSTRT/RADD17

HSD0/RADD18

HSD1/RADD19

HSD2/RADD20

HSD3/RADD21

HSD4/RADD22

HSD5/RADD23

HSD6/RADD24

HSD7/RADD25

RDATA0

RDATA1

RDATA2

RDATA3

RDATA4

RDATA5

RDATA6

RDATA7

STP0DA TA0/RDA T A8

STP0DA TA1/RDA T A9

STP 0DATA2 /RDATA 10

STP 0DATA3 /RDATA 11

STP 0DATA4 /RDATA 12

STP 0DATA5 /RDATA 13

STP 0DATA6 /RDATA 14

STP 0DATA7 /RDATA 15

IC7000

UPD61300F1-230-LU2-A

RADD0

RADD1

RADD2

RADD3

RADD4

RADD5

RADD6

RADD7

RADD8

RADD9

RADD10

RADD11

RADD12

RADD13

RADD14

FOEB

FWEB

FCSB0

FCSB1

GCSB0

GCSB1

GRDY

AE5

AF4

AG4

AH4

AJ3

AH3

AJ2

AH2

AJ1

AH1

AG2

AG1

AF3

AF2

AF1

AE4

AE3

AE2

AD5

AD4

AD2

AD1

AC4

AC3

AC2

AC1

AB4

AB3

AB2

AA5

AA4

AA2

AA1

Y4

Y3

Y2

Y1

W5

W4

W3

W2

W1

AF5

AH6

AJ5

AJ6

AH5

AG5

AG6

FE__RADD[0]

FE__RADD[1]

FE__RADD[2]

FE__RADD[3]

FE__RADD[4]

FE__RADD[5]

FE__RADD[6]

FE__RADD[7]

FE__RADD[8]

FE__RADD[9]

FE__RADD[10]

FE__RADD[11]

FE__RADD[12]

FE__RADD[13]

FE__RADD[14]

FE__RADD[15]

FE__RADD[16]

FE__RADD[17]

FE__RADD[18]

FE__RADD[19]

FE__RDAT[0]

FE__RDAT[1]

FE__RDAT[2]

FE__RDAT[3]

FE__RDAT[4]

FE__RDAT[5]

FE__RDAT[6]

FE__RDAT[7]

FE__RDAT[8]

FE__RDAT[9]

FE__RDAT[10]

FE__RDAT[11]

FE__RDAT[12]

FE__RDAT[13]

FE__RDAT[14]

FE__RDAT[15]

FE__FOEB

FE__FWEB

FE__FCS0B

FE__GCS0B

FE_CI_WAITB

FE__RADD[3]

FE__RADD[4]

FE__RADD[5]

FE__RADD[6]

FE__RADD[0]

FE__RADD[2]

FE__RADD[1]

FE__RADD[15]

FE__RADD[7]

FE__RADD[8]

FE__RADD[12]

FE__RADD[9]

FE__RADD[10]

FE__RADD[11]

FE__RADD[13]

FE__RADD[14]

FE__RADD[16]

FE__RADD[17]

FE__RDAT[12]

FE__RDAT[11]

FE__RDAT[7]

FE__RDAT[3]

FE__RDAT[4] FE_RDAT[4]

FE__RDAT[1]

FE__RDAT[2]

FE__RDAT[5]

FE__RDAT[6]

FE__RDAT[8]

FE__RDAT[9]

FE__RDAT[10]

FE__RDAT[13]

FE__RDAT[14] FE_CI_TSD[6]

FE__RDAT[15]

FE__FOEB

FE__RADD[18]

FE__RADD[19]

FE__FWEB

FE__GCS0B

FE__FCS0B

FE__NALE007:9F

FE__NCLE007:9F

009:D3

RB7300

47

RB7301

47

RB7302

47

RB7303

47

RB7304

47

RB7305

47

1

3

5

7

9

11

13

15

1

3

5

7

9

11

13

15

1

1

3

5

7

9

11

13

15

1

3

5

7

9

11

13

15

1

RB7306

2

4

6

8

10

12

14

16

2

4

FE_RADD[12]

6

8

10

12

FE_RADD[13]

14

FE_RADD[14]

16

2

4

6

8

10

12

14

16

2

4

6

8

10

12

14

16

47

FE_RADD[3]

FE_RADD[4]

FE_RADD[5]

FE_RADD[6]

FE_RADD[0]

FE_RADD[2]

FE_RADD[1]

FE_RADD[15]

FE_RADD[7]

FE_RADD[8]

FE_RADD[9]

FE_RADD[10]

FE_RADD[11]

FE_RADD[16]

FE_RADD[17]

FE_CI_TSD[4]

FE_CI_TSD[3]

FE_RDAT[7]

FE_RDAT[3]

FE_RDAT[0]FE__RDAT[0]

FE_RDAT[1]

FE_RDAT[2]

FE_RDAT[5]

FE_RDAT[6]

FE_CI_TSD[0]

FE_CI_TSD[1]

FE_CI_TSD[2]

FE_CI_TSD[5]

FE_CI_TSD[7]

FE_RADD[18]

FE_RADD[19]

005:10H

005:10H

FE_FOEB

FE_FWEB

FE_CI_CE1B

FE_FCS0B

FE_NALE

FE_NCLE

005:10G;009:D1

005:10H;009:B10;009:D1

009:B10;009:D1

005:10G

FE_RADD[15]

FE_RADD[16]

FE_RADD[17]

FE_RADD[18]

FE_RADD[19]

005:7G;009:B10;009:D1

FE_RADD[0]

FE_RADD[1]

FE_RADD[2]

FE_RADD[3]

FE_RADD[4]

FE_RADD[5]

FE_RADD[6]

FE_RADD[7]

FE_RADD[8]

FE_RADD[9]

FE_RADD[10]

FE_RADD[11]

FE_RADD[12]

FE_RADD[13]

FE_RADD[14]

007:9F

005:7G;009:D1

005:7G

005:7G

005:7G

007:5G

003:7D;008:8D

FE_NRBB

FE_FOEB

FE_FCS0B

FE_NCLE

FE_NALE

FE_FWEB

FE_NWPB

FE_RSTB

10kR7300

XXR7301

10kR7302

H;007:14H;007:15H;007:16D;008:4D;009:B7

R7303

R7304

10kR7305

XX

XX

XXR7309

10kR7306

XXR7307

10kR7310

FE_3.3V

XXR7311

R7312 10k

FE_3.3V

R7308

10k

R7314

XX

10kR7315

XXR7316

R7313

470

10kR7317

10kR7319

XXR7318

XXR7320

R7321 10k

R7322 XX

X7R

C7300

XXR7323

10kR7324

25V0.01

XXR7327

XXR7332

*R7325 10k

10kR7328

10kR7329

10kR7330

10kR7331

*R7326 XX

K9F1208U0C-PCB0T

1234567

N.C

N.C

N.C

N.C

N.C

N.C

RY_BY

RE

CE

N.C

N.C

VCC

GND

N.C

N.C

1615141312111098

CLE

17 18 19 20 21 22 23

ALE

WE

WP

N.C

N.C

N.C

N.C

24

N.C N.C

R7333 10k

*IC7300

N.C

N.C

N.C

N.C

IO8

IO7

IO6

IO5

N.C

N.C

N.C

VCC

GND

N.C

N.C

N.C

IO4

IO3

IO2

IO1

N.C

N.C

N.C

XXR7336

R7334 10k

XXR7335

R7337 10k

42434445464748 41

40 39 38 37 36 35 34 33

32 31 30 29 28 27 26

25

10kR7339

XXR7340

C7301

1608

C7302

10V

X7R

R7341

470

R7338

470

CL7302

2.5mm

CL7303

2.5mm

To force Boot from MS:

connect (short) together

CL7302 & CL.7303

Place CLs together and

in accessible location

1

FE_RDAT[7]

FE_RDAT[6]

FE_RDAT[5]

FE_RDAT[4]

25V0.01

FE_RDAT[3]

FE_RDAT[2]

FE_RDAT[1]

FE_RDAT[0]

JL7300

STRAP SETTINGS

RADD[ 0] = CPU_ENDIAN = 1 = Big

JL7301

RADD[ 1] = test = 0

RADD[ 2] = test = 0

RADD[ 4: 3] = CPUCLK_SEL[1:0] = 01 = 262.144MHz

RADD[ 5] = MCLK_SEL = 0 = 327.680MHz

RADD[ 6] = ROM_ENDIAN = 1 = Big

RADD[ 7] = ROM_BWSEL = 1 = 8-bit

RADD[10: 8] = BOOT_MODE[2:0] = 011 = NAND, then MS

RADD[12:11] = BOOT_NAND_SEL[1:0] = 01 = =>512Mb 00 = <=256MB

RADD[13] = NAND_CS = 0 = CS0

RADD[14] = test = 0

RADD[15] = test = 0

RADD[16] = test = 0

RADD[17] = EJTAG_MODE = 1 = EJTAG

RADD[18] = DINT_EN = 0 = Disable

RADD[19] = DSYSELB = 1 = Only Main CPU

PWB LA Y OUT NO TE:

Place NAND-FLASH with consideration

for changing from TSOP to FBGA package

8

9

10

11

12

13

14

15

16

17

18

19

20

21

COMPONENTS MARKED AS XX REFER TO PARTS LIST, WILL ONLY BE LISTED IF FITTED

FE_CI_TSD[0-7],FE_RDAT[0-7]

FE_CI_TSD[0-7],FE_RDAT[0-7]

~ BGE Board Schematic Diagram [ Main Micr ocontroller , HDMI/A V Side/PC Input, Audio Pr ocessor , Scarts ] Page 3/22 ~

18

19

20

21

22

ABCDEF GH JIKLMN

O

22

P

Q

R

S

T

U

V

W

X

Y

Z

AA

BB

CC

DD

EE

FF

- 17 -

ABC D EFG H JIKLMN

O

P

QRST UVWXY AA

Z

DDCCBB

EE

FF

10

11

12

13

14

1

1

2

2

BGE - EG1L

3

3

22

FE_DADD[0]

FE_DADD[2]

FE_DODT0

4

FE_DADD[11]

FE_DADD[4]

FE_DADD[14]

FE_DADD[5]

FE_DADD[15]

5

FE_DRASB

FE_BA[0]

FE_DCASB

FE_DCKE

FE_DADD[6]

FE_DADD[7]

6

7

8

9

FE_1.8V

A4

C7200

10

6.3V

X6S

2012

C7201

10

6.3V

X6S

2012

C7202

0.01

25V

X7R

C7203

0.01

25V

X7R

C7204

0.01

25V

X7R

C7205

0.01

25V

X7R

C7206

0.01

25V

X7R

C7207

0.01

25V

X7R

C7210

0.01

25V

X7R

C7211

0.01

25V

X7R

C7212

0.01

25V

X7R

C7213

0.01

25V

X7R

C7214

0.01

25V

X7R

C7216

0.01

25V

X7R

C7217

0.01

25V

X7R

A15

A21

B4

B9

A10

B15

B21

C5

C9

C11

C14

C20

D6

D7

D12

D13

E14

D19

E7

E18

F13

F17

F18

F5

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

VDD18

DADD0

DADD1

DADD2

DADD3

DADD4

DADD5

DADD6

DADD7

DADD8

DADD9

DADD10

DADD11

DADD12

DADD14

DADD15

DBA0

DBA1

DCSB1

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

DQ16

DQ17

DQ18

DQ19

DQ20

DQ21

DQ22

DQ23

DQ24

DQ25

DQ26

DQ27

DQ28

DQ29

DQ30

DQ31

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

A9

B14

C10

A14

B11

A12

C12

D11

D10

A13

A16

A11

C13

B12

B13

D14

C16

B16

D18

E17

E19

A18

B18

D17

C19

E16

E20

B24

D21

A23

C22

D20

A24

C21

C6

E9

E6

C7

D8

B7

E8

F8

B1

D4

A1

A2

D5

C3

E5

C4

FE_DADD[0]

FE_DADD[1]

FE_DADD[2]

FE_DADD[3]

FE_DADD[4]

FE_DADD[5]

FE_DADD[6]

FE_DADD[7]

FE_DADD[8]

FE_DADD[9]

FE_DADD[10]

FE_DADD[11]

FE_DADD[12]

FE_DADD[14]

FE_DADD[15]

FE_BA[0]

FE_BA[1]

FE_BA[2]

FE_DDR_DQ[0]

FE_DDR_DQ[1]

FE_DDR_DQ[2]

FE_DDR_DQ[3]

FE_DDR_DQ[4]

FE_DDR_DQ[5]

FE_DDR_DQ[6]

FE_DDR_DQ[7]

FE_DDR_DQ[8]

FE_DDR_DQ[9]

FE_DDR_DQ[10]

FE_DDR_DQ[11]

FE_DDR_DQ[12]

FE_DDR_DQ[13]

FE_DDR_DQ[14]

FE_DDR_DQ[15]

FE_DDR_DQ[16]

FE_DDR_DQ[17]

FE_DDR_DQ[18]

FE_DDR_DQ[19]

FE_DDR_DQ[20]

FE_DDR_DQ[21]

FE_DDR_DQ[22]

FE_DDR_DQ[23]

FE_DDR_DQ[24]

FE_DDR_DQ[25]

FE_DDR_DQ[26]

FE_DDR_DQ[27]

FE_DDR_DQ[28]

FE_DDR_DQ[29]

FE_DDR_DQ[30]

FE_DDR_DQ[31]

FE_DADD[8]

FE_DCSB

FE_DADD[9] FE_DDR_DADD[9]

FE_DADD[12] FE_DDR_DADD[12]

FE_DADD[3] FE_DDR_DADD[3]

FE_DADD[1] FE_DDR_DADD[1]

FE_DWEB

FE_BA[2] FE_DDR_BA[2]

RB7200

68

RB7201

22

RB7203

22RB7202

22R7209

FE_DDR_DADD[0]

FE_DDR_DADD[2]

FE_DDR_DODT0

FE_DDR_DADD[11]

FE_DDR_DADD[4]

FE_DDR_DADD[14]

FE_DDR_DADD[5]

FE_DDR_DADD[15]

FE_DDR_DRASB

FE_DDR_BA[0]

FE_DDR_DCASB

FE_DDR_DCKE

FE_DDR_DADD[6]

FE_DDR_DADD[7]

FE_DDR_DADD[8]

FE_DDR_DCSB

FE_DDR_DADD[10]FE_DADD[10]

FE_DDR_DQS0,FE_DDR_DQS0B,FE_DDR_DQS1,FE_DDR_DQS1B,FE_DDR_DQS2,FE_DDR_DQS2B,FE_DDR_DQS3,FE_DDR_DQS3B

FE_DDR_DODT0

004:10F;004:14F

*IC7200

EDE5116AJBG-6E-E

FE_DDR_DRASB

FE_DDR_DCASB

FE_DDR_DCKE

FE_DDR_DCSB

FE_DDR_DWEB

FE_DDR_BA[1]FE_BA[1]

FE_DDR_DADD[0]

FE_DDR_DADD[1]

FE_DDR_DADD[2]

FE_DDR_DADD[3]

FE_DDR_DADD[4]

FE_DDR_DADD[5]

FE_DDR_DADD[6]

FE_DDR_DADD[7]

FE_DDR_DADD[8]

FE_DDR_DADD[9]

FE_DDR_DADD[10]

FE_DDR_DADD[11]

FE_DDR_DADD[12]

FE_DDR_BA[0]

FE_DDR_BA[1]

FE_DDR_BA[2]

FE_DDR_DM1

FE_DDR_DM0

004:6J

M8

A0

M3

A1

M7

A2

N2

10R7219

10R7220

*R7212 XX *R7216 XX

A3

N8

A4

N3

A5

N7

A6

P2

A7

P8

A8

P3

A9

M2

A10

P7

A11

R2

A12

L2

BA0

L3

BA1

L1

BA2

B3

UDM

F3

LDM

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

G8

G2

H7

H3

H1

H9

F1

F9

C8

C2

D7

D3

D1

D9

B1

B9

004:6J

FE_DDR_DQS1

FE_DDR_DQS1B FE_DDR_DQS3B

FE_DDR_DQS0

FE_DDR_DQS0B

FE_DDR_DCK0B

FE_DDR_DCKE

150R7211 150R7215

004:6I

004:6I

B7

UDQS

A8

UDQS#

F7

LDQS

E8

LDQS#

J8

CK

K8

CK#

K2

CKE

NC

NC

NC

NC

NC

A2

E2

R3

R7

R8

004:8C;004:14E

FE_DDR_DCSB

FE_DDR_DRASB

FE_DDR_DCASB

FE_DDR_DWEB

FE_DDR_DODT0

004:8D;004:14E

004:8C;004:14F

004:8C;004:14F

004:8D;004:14F

004:8B;004:14F

L8

CS#

K7

RAS#

L7

CAS#

K3

WE#

K9

ODT

A3

VSS

E3

VSS

J3

VSS

N1

VSS

P9

VSS

A7

VSSQ

B2

VSSQ

B8

VSSQ

D2

VSSQ

D8

VSSQ

E7

VSSQ

F2

VSSQ

F8

VSSQ

H2

VSSQ

H8

VSSQ

VDDL

VSSDL

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VREF

VDD

VDD

VDD

VDD

VDD

J2

J1

J7

A1

E1

J9

M9

R1

A9

C1

C3

C7

C9

E9

G1

G3

G7

G9

FE_DDR_DQ[0-31]

FE_DDR_DQ[0]

FE_DDR_DQ[1]

FE_DDR_DQ[2]

FE_DDR_DQ[3]

FE_DDR_DQ[4]

FE_DDR_DQ[5]

FE_DDR_DQ[6]

FE_DDR_DQ[7]

FE_DDR_DQ[8]

FE_DDR_DQ[9]

FE_DDR_DQ[10]

FE_DDR_DQ[11]

FE_DDR_DQ[12]

FE_DDR_DQ[13]

FE_DDR_DQ[14]

FE_DDR_DQ[15]

C7221

0.1

16V

C7220

0.1

16V

C7222

0.1

16V

C7219

C7223

0.1

0.1

16V

16V

FE_1.8V

R7213

XX

R7214

XX

C7224

0.1

16V

C7225

0.1

16V

C7226

0.1

16V

C7227

0.1

16V

FE_DDR2_VREF_0.9V

C7230

C7228

16V

C7229

16V

0.1

0.1

0.1

16V

C7231

0.1

16V

*IC7201

EDE5116AJBG-6E-E

FE_DDR_DQ[16]

FE_DDR_DQ[17]

FE_DDR_DQ[18]

FE_DDR_DQ[19]

FE_DDR_DQ[20]

FE_DDR_DQ[21]

FE_DDR_DQ[22]

FE_DDR_DQ[23]

FE_DDR_DQ[24]

FE_DDR_DQ[25]

FE_DDR_DQ[26]

FE_DDR_DQ[27]

FE_DDR_DQ[28]

FE_DDR_DQ[29]

FE_DDR_DQ[30]

FE_DDR_DQ[31]

FE_DDR_BA[0]

FE_DDR_BA[1]

FE_DDR_BA[2]

FE_DDR_DM3

FE_DDR_DM2

FE_DDR_DADD[0]

FE_DDR_DADD[1]

FE_DDR_DADD[2]

FE_DDR_DADD[3]

FE_DDR_DADD[14]

FE_DDR_DADD[15]

FE_DDR_DADD[6]

FE_DDR_DADD[7]

FE_DDR_DADD[8]

FE_DDR_DADD[9]

FE_DDR_DADD[10]

FE_DDR_DADD[11]

FE_DDR_DADD[12]

004:6J

M8

A0

M3

A1

M7

A2

N2

A3

N8

A4

N3

A5

N7

A6

P2

A7

P8

A8

P3

A9

M2

A10

P7

A11

R2

A12

L2

BA0

L3

BA1

L1

BA2

B3

UDM

F3

LDM

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

G8

G2

H7

H3

H1

H9

F1

F9

C8

C2

D7

D3

D1

D9

B1

B9

004:6J

FE_DDR_DQS3

FE_DDR_DQS2

FE_DDR_DQS2B

FE_DDR_DCK1FE_DDR_DCK0

FE_DDR_DCK1B

FE_DDR_DCKE

FE_DDR_DCSB

FE_DDR_DRASB

FE_DDR_DCASB

FE_DDR_DWEB

FE_DDR_DODT0

FE_1.8V FE_1.8V

C7232

10

6.3V

X6S

2012

B7

UDQS

A8

UDQS#

F7

LDQS

E8

LDQS#

J8

CK

K8

CK#

K2

CKE

L8

CS#

K7

RAS#

L7

CAS#

K3

WE#

K9

ODT

A3

VSS

E3

VSS

J3

VSS

N1

VSS

P9

VSS

A7

VSSQ

B2

VSSQ

B8

VSSQ

D2

VSSQ

D8

VSSQ

E7

VSSQ

F2

VSSQ

F8

VSSQ

H2

VSSQ

H8

VSSQ

VSSDL

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VDDQ

VREF

VDDL

VDD

VDD

VDD

VDD

VDD

NC

NC

NC

NC

NC

A2

E2

R3

R7

R8

C7235

0.1

FE_1.8V

R7217

XX

16V

J2

J1

J7

A1

E1

J9

M9

R1

A9

C1

C3

C7

C9

E9

G1

G3

G7

G9

C7234

0.1

16V

C7233

0.1

16V

C7236

0.1

16V

C7237

0.1

16V

R7218

XX

C7238

0.1

16V

C7239

0.1

16V

C7240

0.1

16V

C7241

0.1

16V

FE_DDR2_VREF_0.9V

C7244

C7242

16V

C7243

16V

0.1

0.1

0.1

16V

C7245

0.1

16V

C7246

6.3V

X6S

2012

10

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

FE_DDR2_VREF_0.9V

C7208

0.1

16V

FE_1.8V

XXR7200

XXR7201

FE_1.8V

R7202

150

C7215

0.1

16V

FE_1.8V

C7218

0.1

16V

R7204

150

0.5%

FE_RQ0

FE_RQ1

R7203

150

0.5%

FE_CKERSTE

E13

D15

E12

F15

F10

DRQ0

DRQ1

DCKERSTB

DVREF0

DVREF1

DQS0

DQSB0

DQS1

DQSB1

DQS2

DQSB2

DQS3

DQSB3

DCSB0

DRASB

DCASB

DW

DCKE

DCLKB0

DCLK0

DCLKB1

DCLK1

DQM0

DQM1

DQM2

DQM3

FE_DDR_DQS0

A17

FE_DDR_DQS0B

B17

FE_DDR_DQS1

A22

FE_DDR_DQS1B

B22

FE_DDR_DQS2

A8

FE_DDR_DQS2B

B8

FE_DDR_DQS3

A3

FE_DDR_DQS3B

B3

15

16

FE_DCSB

F7

FE_DRASB

F16

FE_DCASB

F12

FE_DWEB

C15

EB

17

FE_DCKE

F9

B20

A20

B5

A5

C18

B23

A7

B2

FE_DCK0B

FE_DCK0

FE_DCK1B

FE_DCK1

FE_DDR_DM0

FE_DDR_DM1

FE_DDR_DM2

FE_DDR_DM3

22R7205

22R7206

22R7207

22R7208

FE_DDR_DCK0B

FE_DDR_DCK0

FE_DDR_DCK1B

004:14E

FE_DDR_DCK1

BGE

FE_DDR_DM0

004:10E

FE_DDR_DM1

004:10D

FE_DDR_DM2

004:14E

FE_DDR_DM3

004:14D

4/22

18

19

20

21

22

DODT0

DODT1

IC7000

UPD61300F1-230-LU2-A

ABCDEF GH JIKLMN

E11

FE_DODT1

JL7200

O

FE_DODT0

B10

20

COMPONENTS MARKED AS XX REFER TO PARTS LIST, WILL ONLY BE LISTED IF FITTED

~ BGE Board Schematic Diagram [ Main Microcontr oller , HDMI/A V Side/PC Input, Audio Pr ocessor , Scarts ] Page 4/22 ~

21

22

P

Q

R

S

T

U

V

W

X

Y

Z

- 18 -

AA

BB

CC

DD

EE

FF

ABC D EFG H JIKLMN

O

P

QRST UVWXY AA

Z

DDCCBB

EE

FF

1

1

2

2

3

3

4

4

BGE - EG1L

5

5

10

11

5V_MAIN

FB7400

C7410

XX

XX

C7409

XX

C7406

0.1

16V

C7407

10

6.3V

X6S

2012

R7415

XX

Q7404

XX

L7400

10uH

R7416

R7414

1005

FE_3.3V

XX

6

CL7402

CL7403

FE_CVBS_RF_DIGIT AL

020:5C

7

0

8

9

10

11

R7413

XX

XX

L7401

C7408

XX

6

CL7400

R7409

7

FE_3.3V

200

0.5%

C7403

10p

50V

CH

8

C7404

10p

50V

CH

C7402

10

6.3V

X6S

2012

CL7401

R7411

200

0.5%

R7412

130

0.5%

C7405

0.1

16V

4.7kRB7400

9

TO DEMODs (TUNER)

TO TV MICRO (DPI)

FE_3.3V

D7400

SML-310MTT86

R7400

390

SML-310MTT86

FE_SDA_DIGITAL

FE_SCL_DIGIT AL

D7402

FE_SDA_EMMA

FE_SCL_EMMA

R7402

390

XXRB7401

FE_AO0_BD0

FE_AO0_LRCK

FE_SPDIF

FE_AO0_BCK

020:7I

020:7I

016:15F

020:7I

100

RB7402

FE_EMMA_SCL0

FE_EMMA_SDA0

FE_EMMA_SDA1

FE_EMMA_SCL1

1

47RB7404

AJ16

AH15

AH16

AJ15

AG15

E1

E2

F1

F2

IIC_SCL0

IIC_SDA0

IIC_SCL1

IIC_SDA1

AO0_MCK

AO0_LRCK

AO0_BCK

AO0_BD0

ATX

VAY

VAC

SVA VDD1

SVA VDD2

SVA VDD3

SVDVDD

DAC_COM0

DAC_REF0

DAC_RSET0

SVA-GND1

SVA-GND2

SVA-GND3

P24

P23

N21

N20

N19

R19

P21

P20

P19

P22

R21

R20

C7400

0.1

16V

R7408

620

0.5%

R7410

200

0.5%

C7401

0.1

16V

12

13

14

15

Q7400

2SA2029T2LQ/R

FE_3.3V

D7401

SML-310MTT86

Q7401

2SA2029T2LQ/R

R7401

390

Q7402

2SA2029T2LQ/R

D7403

SML-310MTT86

Q7403

2SA2029T2LQ/R

R7403

390

R7404

R7405

R7406

R7407

100

100

100

100

IC7000

UPD61300F1-230-LU2-A

BGE

12

13

14

5/22

15

16

17

18

19

20

COMPONENTS MARKED AS XX REFER TO PARTS LIST, WILL ONLY BE LISTED IF FITTED

~ BGE Board Schematic Diagram [ Main Microcontr oller , HDMI/A V Side/PC Input, Audio Pr ocessor , Scarts ] Page 5/22 ~

16

17

18

19

20

21

22

ABCDEF GH JIKLMN

O

21

22

P

Q

R

S

T

U

V

W

X

Y

Z

AA

BB

CC

DD

EE

FF

- 19 -

ABC D EFG H JIKLMN

O

P

QRST UVWXY AA

Z

DDCCBB

EE

FF

1

1

2

2

3

3

4

4

5

5

BGE - EG1L

6

6

FE_ETH_1.8V

7

FE_ETH_1.8V_OUT

*C7602

22

FE_ETH_1.8V_A

*FB7601 0uH*FB7600 0uH

*C7604

XX

BGE

6/22

7

8

8

FE_ETH_3.3V

FE_3.3V

*FB7602 0uH

*FB7603

0uH

9

*C7601

47

*C7603

0.1

FE_ETH_3.3V_A

*C7605

22

FE_ETH_3.3V

*R7609

330

*R7611

330

*D7604 *D7605

SPEED LINKA CT

9

FE_ETH_3.3V

10

11

12

13

14

15

16

910

8

7

6

5

4

3

2

1

*CN7600

TDK RJ-45 TLA-6T724

FE_ETH_3.3V_A

*C7600

10

6.3V

X6S

2012

*D7600XX*D7601 XX

10

FE_RSTB

FE_ETH_1.8V

008:4C

4.7k

*R7612

4.7k

*R7613

4.7k

*R7615

XX

R7617

4.7k

*R7619

SPEED

AUTONEGO

CONFIG[1]

CONFIG[0]

ISOLA TE

CONFIG[2]

DUPLEX

PHY ADD[2]

PHY ADD[1]

PHY ADD[0]

100

*RB7600

XX

*R7614

XX

*R7616

1k

*R7618

XX

*R7620

*C7613

22

*C7612

0.1

*C7614

0.1

FE_ETH_3.3V_A

*C7608

0.1

*R7635

XX

*D7603

*D7602 XX

*R7600

100

100

*C7606

0.1

*R7601

100

*R7636

100

*R7602

100

*R7637

100

*C7607

0.1

1005

16V

*R7603

100

*R7638

FE_ETH_1.8V_OUT

100

*C7609

0.1

FE_ETH_1.8V_A

*C7610

0.1

123 45678

9 101112

48

GND

GND

GND

VDDA_1.8

VDDA_1.8

V1.8_OUT

VDDA_3.3

VDDA_3.3

RXRX+

TXTX+

131415

NC

GND

RST#

XO

NC

NC

NC

LED1

*IC7600

XI

REXT

MDIO

GND

17181920212223

16

LED0

MDC

COL / CFG0

CRS / CFG1

RXD3 / PHYADD0

RXD2 / PHYADD1

TXD3

RXD1 / PHYADD2

GND

TXD2

VDD_1.8

RXDV/CFG2

VDDIO_3.3

VDDIO_3.3

RXD0

GND

24

TXD1

TXD0

TXEN

TXC

INTRP

GND

RXER

RXC

2930313233343536

FE_ETH_3.3V

25262728

37

38

39

40

41

42

43

44

45

46

47

CL7600 CL7601

FE_ETH_3.3V

*R7606

*X7600

1

E/D VDD

23

GND

4

OUT

0

22*R7610

*C7611

0.1

XX

*R7607

47

*R7634

XX

*R7621XX*R7623

1k

1k

5%

1005

CHIP

1/16W

*R7624

*R7622

4.7k

*R7625

XX

*R7626

XX

*R7627

1k

*R7628

XX

*R7629

1k

*R7630

4.7k

*R7631

XX

*R7632

CL7602

CL7603

CL7604

CL7605

CL7606

CL7607

CL7608

CL7609

CL7610

CL7611

FE_ETH_RMII_REF_CLK

FE_ETH_RMII_TXD1

FE_ETH_RMII_TXD0

FE_ETH_RMII_TXEN

FE_ETH_RMII_RXER

FE_ETH_RMII_CRSDV

FE_ETH_RMII_RXD0

FE_ETH_RMII_RXD1

FE_ETH_MDC

FE_ETH_MDIO

11

12

13

14

15

16

17

18

19

20

*C7615

100p

*R7605

6.8k

*R7608

120k

= 6.49k

17

COMPONENTS MARKED AS XX REFER TO PARTS LIST, WILL ONLY BE LISTED IF FITTED

~ BGE Board Schematic Diagram [ Main Microcontr oller , HDMI/A V Side/PC Input, Audio Pr ocessor , Scarts ] Page 6/22 ~

18

19

20

21

22

ABCDEF GH JIKLMN

O

21

22

P

Q

R

S

T

U

V

W

X

Y

Z

AA

BB

CC

DD

EE

FF

- 20 -

ABC D EFG H JIKLMN

O

P

QRST UVWXY AA

Z

DDCCBB

EE

FF

10

11

12

13

14

15

16

17

18

19

1

1

2

BGE - EG1L

2

PIN-SWAP ALLO WED ON

IC7000

3

FROM

TUNER OUTPUTS

FE_M_CKOUT,FE_M_DA TA[0-7],FE_M_SYNC,FE_M_VAL

UPD61300F1-230-LU2-A

FE_EMMA_VDO_C[3]

FE_EMMA_VDO_C[1]

FE_M_CKOUT

FE_M_DATA[0]

FE_M_DATA[1]

FE_M_DATA[2]

4

FE_M_DATA[3]

FE_M_DATA[4]

FE_M_DATA[5]

FE_M_DATA[6]

FE_3.3V

5

FE_3.3V

5%

CHIP

007:14F

007:14E

10k

R7530

1/16W

FE_RXD2B

FE_TXD2B

FE_M_DATA[7]

FE_M_VAL

FE_M_SYNC

JL7515

47R7500

6

5%

10k

CHIP

R7531

1/16W

47RB7500

7

009:B10;009:D1

009:D1

009:D1

009:D2

FE_CI_RSTB

FE_CI_IORDB

FE_CI_IOWRB

FE_CI_REGB

1

FE_EMMA_CI_IORDB

FE_EMMA_CI_IOWRB

FE_EMMA_CI_RESET

009:M4

009:M4

009:B9

FE_CI_IREQB

FE_CI_CD1B

FE_CI_VS1B

FE_CI_TSCLK

009:D3

SIGN7647

JL7516

FE_EMMA_CI_REGB

8

009:M4

009:B9

009:B9

FE_CI_CD2B

FE_CI_TSVAL

FE_CI_TSSYNC

JL7517

9

47

009:N10

FE_CI_PWR_EN

009:P10

FE_CI_OVRB

007:10I

017:9E

017:2J

003:12G

003:12G

FE_CONF0

FE_DEMOD_RSTB

FE_LNA_SWB

FE_USB_PPON

FE_USB_OCIB

FE_TUNER_SW

005:10H

009:B8

FE_CI_TS_ENB

022:10G

FE_BE_BUF_FLIP

JL7500

CL7506

FE_NWPB

RB7520

1

47RB7503

47

RB7521

R7532

100

1/16W

CHIP

5%

CL7505

JL7501

C7501

XX

FB7500

0uH

JL7519

47R7503

JL7518

R7523

47

1/16W

CHIP

5%

47RB7504

1

FE_MSMODE

FE_JIG_MODE

007:10I

022:6F

022:6F

FE_CONF1

R7520

100

CL7503

CL7504

CL7502

CL7501

47

RB7522

FE_3.3V

214

10k

RB7523

3

47RB7505

1

FE_EMMA_VDOE_A[0]

FE_EMMA_VDOE_A[1]

FE_EMMA_VDOE_A[2]

FE_EMMA_VDOE_A[3]

FE_EMMA_VDOE_A[4]

FE_EMMA_VDOE_A[5]

FE_EMMA_VDOE_A[6]

FE_EMMA_VDOE_A[7]

CL7515

CL7516

CL7517

CL7500

FE_VDOE_A[6]

FE_VDOE_A[5]

FE_VDOE_A[4]

FE_VDOE_A[3]

FE_VDOE_A[2]

FE_VDOE_A[0]

FE_VDOE_A[1]

022:9H

022:9G

009:B11

009:B8;009:D1

FROM BE OSD

SYNC OUTPUTS

TO BE OSD

SYNC INPUTS

1

3

5

7

9

11

13

15

FE_VIDEO_MUTE

FE_OSD_ACTIVE

FE_CI_ROM_DIR1

FE_CI_ENB

47RB7501

FE_EMMA_VDOE_A[6]

2

FE_EMMA_VDOE_A[5]

4

FE_EMMA_VDOE_A[4]

6

FE_EMMA_VDOE_A[7]FE_VDOE_A[7]

8

FE_EMMA_VDOE_A[3]

10

FE_EMMA_VDOE_A[2]

12

FE_EMMA_VDOE_A[0]

14

FE_EMMA_VDOE_A[1]

16

007:14H

014:16C;007:14F

FE_VDOE_VVSB_OUT

022:6F;022:10G

FE_VDOE_CLK_OUT

FE_VDOE_VHSB_OUT

PIN-SWAP ALLO WED ON

THESE RESISTORS

TO BE OSD

DATA INPUTS

FE_VDOE_A[0-7]

FB7501

0uH

K1

PPT0/STP0CLK/STS0CLK

L1

PPT1/STP0DAT0/STS0DAT

L2

PPT2/STP0DAT1

L3

PPT3/STP0DAT2

M1

PPT4/STP0DAT3

M2

PPT5/STP0DAT4

M3

PPT6/STP0DAT5

N2

PPT7/STP0DAT6

N3

PPT8/STP0DAT7

K2

PPT9/STP0EN/STS0EN

J1

PPT10/STP0STRT/STS0STRT

M4

PPT11/STP0ERRB/STS0ERRB

U4

PPT12/RXD2B

T4

PPT13/TXD2B

AF9

PPT14(READY/IREQB)

AD10

PPT15/IOIS16B

AE9

PPT16(CD1B)

AF7

PPT17/PCE0B

AD9

PPT18(VS1B)

V2

PPT19/STP0CLK

AF8

PPT20/IORDB

AE8

PPT21/IOWRB

AF10

PPT22(RESET)

AD8

PPT23

AB5

PPT24/REGB

AE10

PPT25(CD2B)

AD7

PPT26/PCE1B

V4

PPT27/STP0EN

V3

PPT28/STP0STRT

P5

PPT29/SMRST0

N5

PPT30/SMVCC0

M5

PPT31/SMOFF0

L5

PPT32/SMCLKD

K5

PPT33/SMDAT0

AG14

PPT34/USB_OCI1

AG13

PPT35/USB_PPON1

K4

PPT36/CLK27OUT

N4

PPT37/IR_IN1

P4

PPT38/IR_OUT

R5

PPT41/IR_IN0

T24

PPT46

T23

PPT47

AB20

PPT42/ROM_DIR1

AC20

PPT43/ROM_DIR2

Y20

PPT48/ROM_CI

AC19

PPT49/ROM_CI_PC

AA20

PPT50/ROM_PC

T22

PPT54

T21

PPT55

AD24

PPT56/VDOE_CLK_IN

U23

PPT57/VDOE_VVSB_IN

U24

PPT58/VDOE_VHSB_IN

AG20

PPT59/VDOE_FLD

AJ20

PPT60/VDOE_CLK_OUT

AJ19

PPT61/VDOE_VVSB_OUT

AH20

PPT62/VDOE_VHSB_OUT

U22

PPT63/VDOE_A0

V24

PPT64/VDOE_A1

V22

PPT65/VDOE_A2

W24

PPT66/VDOE_A3

W23

PPT67/VDOE_A4

W22

PPT68/VDOE_A5

Y24

PPT69/VDOE_A6

Y22

PPT70/VDOE_A7

AA24

PPT71/VDOE_R0

AA23

PPT72/VDOE_R1

AA22

PPT73/VDOE_R2

AB24

PPT74/VDOE_R3

AB22

PPT75/VDOE_R4

AC24

PPT76/VDOE_R5

AC23

PPT77/VDOE_R6

AC22

PPT78/VDOE_R7

PPT156/VDO_C7

PPT155/VDO_C6

PPT154/VDO_C5

PPT153/VDO_C4

PPT152/VDO_C3

PPT151/VDO_C2/PKTSTRT

PPT150/VDO_C1/HSDE

PPT149/VDO_C0/HSDCLK

PPT148/VDO_D7/VDO_Y7

PPT147/VDO_D6/VDO_Y6

PPT146/VDO_D5/VDO_Y5

PPT145/VDO_D4/VDO_Y4

PPT144/VDO_D3/VDO_Y3

PPT143/VDO_D2/VDO_Y2

PPT142/VDO_D1/VDO_Y1

PPT141/VDO_D0/VDO_Y0

PPT140/VDO_VCK

PPT139/VDO_VHSB/VDO0_FBLK

PPT138/VDO_VVSB

PPT137/VDO_FLD

PPT136/RMII_MDIO

PPT135/RMII_MDC

PPT134/RMII_REF_CLK

PPT133/RMII_RX_ER

PPT132/RTS0B/RMII_CRS_DV

PPT131/CTS0B/RMII_RXD1

PPT130/DSR0B/RMII_RXD0

PPT129/DTR0B/RMII_TX_EN

PPT128/DCD0B/RMII_TXD1

PPT127/RI0B/RMII_TXD0

PPT126/RXD0B

PPT53/TXD0B

PPT124

PPT125/NRBB

PPT123/NALE

PPT122/NCLE

PPT121/MSDATA3

PPT120/MSDATA2

PPT119/MSDATA1

PPT118/MSDATA0

PPT117/MSBS

PPT116/MSCLK

PPT115/MSDIR

PPT45/AO1_BD2

PPT44/AO1_BD1