Page 1

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KDL-26M3000

KDL-26M3000

KDL-26ML130

KDL-32M3000

KDL-32M3000

KDL-32ML130

RM-YD021 US/CANADA

RM-YD021 LATIN NORTH/LATIN SOUTH

RM-YD021 US/CANADA

RM-YD021 US/CANADA

RM-YD021 LATIN NORTH/LATIN SOUTH

RM-YD021 US/CANADA

MA1

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 7/2007

:UPDATED ITEM

☛

REVISION DATE SUBJECT

7/2007 No revisions or updates are applicable at this time.

9/2007 PC Audio Input specifi cation updated. Replaced Page 4.

Added Battery Cover PN for Remote Commander. Replaced Page 93.

12/2007 Corrected LED blink count for Audio error. Replaced Page 11.

3/2008 Corrected PN for screws to connect Stand. Replaced Page 12 & 67.

LCD DIGITAL COLOR TELEVISION

9-883-757-04

Page 2

Self Diagnosis

Supported model

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KDL-26M3000

KDL-26M3000

KDL-26ML130

KDL-32M3000

KDL-32M3000

KDL-32ML130

RM-YD021 US/CANADA

RM-YD021 LATIN NORTH/LATIN SOUTH

RM-YD021 US/CANADA

RM-YD021 US/CANADA

RM-YD021 LATIN NORTH/LATIN SOUTH

RM-YD021 US/CANADA

MA1

CHASSIS

9-883-757-04

KDL-32M3000 RM-YD021

LCD DIGITAL COLOR TELEVISION

Page 3

KDL-26M3000/26ML130/32M3000/32ML130

TABLE OF CONTENTS

SECTION TITLE PAGE SECTION TITLE PAGE

Specifi cations ................................................................................. 4

Warnings and Cautions .................................................................. 6

Safety-Related Component Warning .............................................. 7

Safety Check-Out ........................................................................... 9

Self-Diagnostic Function ............................................................... 10

SECTION 1: DISASSEMBLY ............................................................... 12

1-1. Rear Cover Removal ............................................................ 12

1-2. Arm, Under Cover and Stand Removal ................................ 12

1-3. HM1 Board Removal ............................................................ 13

1-4. UM Board and Jack Holder Removal ................................... 13

1-5. Speaker, Light Guide and HM3 Board Removal .................. 14

1-6. BM Board Removal .............................................................. 14

1-7. G1 Bracket and G1M Board Removal .................................. 15

1-8. VESA Bracket Removal ....................................................... 15

1-9 LCD Panel/Bracket and LED Light Guide Removal ............. 16

Wire Dressing ............................................................................... 17

KDL-26M3000/26ML130 Only .............................................. 17

KDL-32M3000/32ML130 Only .............................................. 27

SECTION 2: SERVICE ADJUSTMENTS ............................................. 38

2-1. Using the Remote Commander for Electrical Adjustments .. 38

2-2. Accessing Service Adjustment Mode ................................... 38

2-3. Viewing the Service Menus .................................................. 39

2-4. Resetting to Factory Defaults ............................................... 39

SECTION 3: DIAGRAMS ..................................................................... 40

3-1. Circuit Boards Location ........................................................ 40

3-2. Printed Wiring Boards and

Schematic Diagrams Information ......................................... 40

3-3. Block Diagram ...................................................................... 42

3-4. Connection Diagram ............................................................ 43

3-5. Schematics and Supporting Information .............................. 44

BM Board Schematic Diagram (1 of 12) .............................. 44

BM Board Schematic Diagram (2 of 12) .............................. 45

BM Board Schematic Diagram (3 of 12) .............................. 46

BM Board Schematic Diagram (4 of 12) .............................. 47

BM Board Schematic Diagram (5 of 12) .............................. 48

BM Board Schematic Diagram (6 of 12) .............................. 49

BM Board Schematic Diagram (7 of 12) .............................. 50

BM Board Schematic Diagram (8 of 12) .............................. 51

BM Board Schematic Diagram (9 of 12) .............................. 52

BM Board Schematic Diagram (10 of 12) ............................ 53

BM Board Schematic Diagram (11 of 12) ............................. 54

BM Board Schematic Diagram (12 of 12) ............................ 55

G1M Board Schematic Diagram .......................................... 57

HM1 Board Schematic Diagram ........................................... 60

HM3 Board Schematic Diagram ........................................... 62

UM Board Schematic Diagram ............................................. 64

3-6. Semiconductors ................................................................... 66

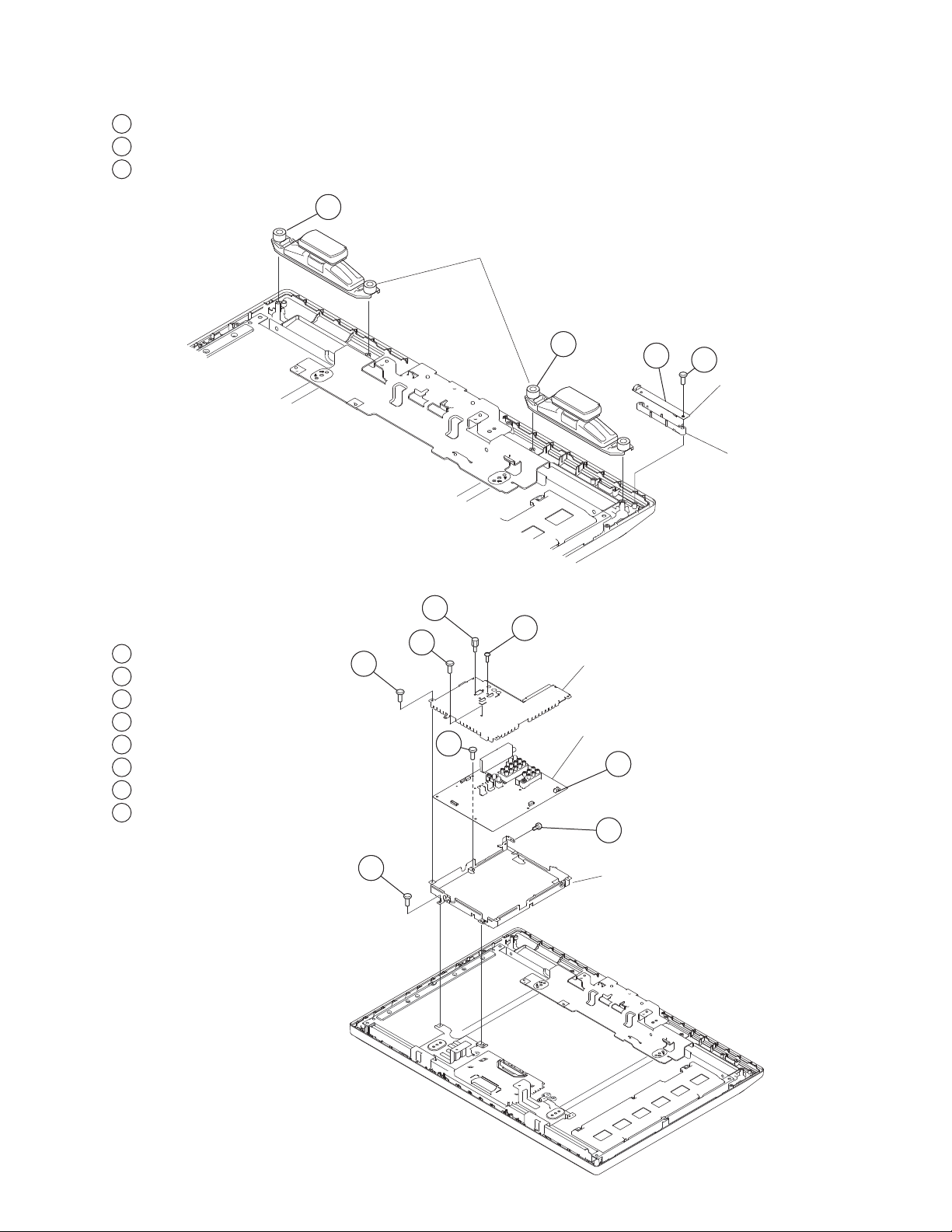

SECTION 4: EXPLODED VIEWS ........................................................ 67

4-1. Rear Cover Assembly and Stand Assembly ........................ 67

4-2. Chassis ................................................................................ 68

4-3. Connectors ........................................................................... 69

4-4. Bezel Assembly, LCD Panel and Speakers ......................... 70

SECTION 5: ELECTRICAL PARTS LIST ............................................ 71

APPENDIX A: ENCRYPTION KEY COMPONENTS ..........................A-1

KDL-26M3000/26ML130/32M3000/32ML130

3

Page 4

SPECIFICATIONS

KDL-26M3000/26ML130/32M3000/32ML130

Power Requirements

120V AC, 60Hz

220V, 50/60 Hz (Chile, Perú)

Video (IN) 1/2/3

S Video (4-Pin Mini DIN (VIDEO 1 Only)

Y: 1.0 Vp-p, 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

Video

1.0 Vp-p, 75ohms unbalanced, sync negative

Audio

500 mVrms (100% modulation)

Impedance:47 kilohms

COMPONENT IN 1/2

YP

Y:1.0 Vp-p, 75 ohms unbalanced, sync negative

P

PR:0.7 Vp-p, 75 ohms

Signal format: 480i, 480p, 720p, 1080i

AUDIO

500 mVrms (100% modulation)

Impedance: 47 kilohms

(Component Video)

BPR

:0.7 Vp-p, 75 ohms

B

HDMI IN 1/2:

HDMI: Video:480i, 480p, 720p, 1080i

Audio: Two channel linear PCM 32, 44.1 and

48 kHz, 16, 20 and 24 bits

AUDIO: (HDMI IN 2 only) 500 mVrms (100% modulation)

Impedance: 47 kilohms

AUDIO OUT:

500 mVrms (100% modulation)

More than 1 Vrms at the maximum volume setting (Variable)

More than 500 mVrms (Fixed)

PC IN:

D-sub 15-pin, analog RGB, 0.7 Vp-p, 75 ohms, positive

PC AUDIO INPUT:

☛

Stereo mini jack, 500 mVrms, 47 kilohm

HEADPHONES:

Stereo mini jack

Impedance: 16 ohms

Trademark Information

Manufactured under license from Dolby Laboratories. “Dolby” and

double-D symbol are trademarks of Dolby Laboratories.

This TV incorporates High-Definition Multimedia Interface (HDMI™)

technology. HDMI, the HDMI logo and High-Definition Multimedia

Interface are trademarks or registered trademarks of HDMI Licensing

LLC.

Blu-ray is a trademark. “BRAVIA” and , , and PS3 are

trademarks or registered marks of Sony Corporation.

KDL-26M3000/26ML130/32M3000/32ML130

Design and specifi cations are subject to change without notice.

4

Page 5

Power Consumption

in use

in standby

Speaker Output (W)

mm

Dimensions (W x H x D)

with stand

mm

Dimensions (W x H x D)

without stand

mm

Mass

with stand

without stand

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000 KDL-26ML130 KDL-32M3000 KDL-32ML130

170W

796 x 590 x 214 mm

3/8

x 23

1/4

x 8

31

796 x 544 x 100 mm

3/8

x 21

1/2

x 4 in

31

16 kg

36 lbs

14 kg

31 lbs

in

in

in

kg

lbs

kg

lbs

135W

662 x 515 x 214 mm

1/8

3/8

26

x 20

x 8

1/2

in

662 x 468 x 108 mm

1/8

1/2

26

x 18

x 4

3/8

in

13 kg

29 lbs

11 kg

25 lbs

Less than 1W

10W + 10W

146 x 35 mm

3/4

3/8

5

x 1

in

All measurements are approximations.

1/2

in

Television system

NTSC American TV Standard

ATSC (8VSB terrestrial) ATSC compliant 8VSB

QAM on cable: ANSI/SCTE 07 2000

Channel coverage

Analog Digital

Terrestrial 2-69 2-69

Cable 1-125 1-135

Antenna

75-ohm external terminal for VHF/UHF

Panel System

LCD (Liquid Crystal Display) Panel

Display Resolution (horizontal x vertical):

1,366 dots x 768 lines

Screen Size (measured diagonally)

approx. 26 inches (KDL-26M3000/26ML130 Only)

approx. 31.5 inches (KDL-32M3000/32ML130 Only)

Supplied Accessories

Remote Commander RM-YD021

Two Size AA (R6) Batteries

AC Power Cord

Suport Belt, Securing Screw, and Wood Screw

Cable Holder

Operating Instructions

Quick Setup Guide

Warranty Card

Online Registration Card

Wall-Mount Instructions

Optional Accessories

Headphones Plug Adapter

Connecting Cables

Wall-Mount Bracket

SU-WL100 (KDL-26M3000/26ML130 Only)

SU-WL500 (KDL-32M3000/32ML130 Only)

HD15-HD15 Cable

75-ohm Coaxial Cable

KDL-26M3000/26ML130/32M3000/32ML130

5

Page 6

KDL-26M3000/26ML130/32M3000/32ML130

WARNINGS AND CAUTIONS

CAUTION

These servicing instructions are for use by qualifi ed service personnel only. To reduce the risk of electric shock, do not perform any servicing other

than that contained in the operating instructions unless you are qualifi ed to do so.

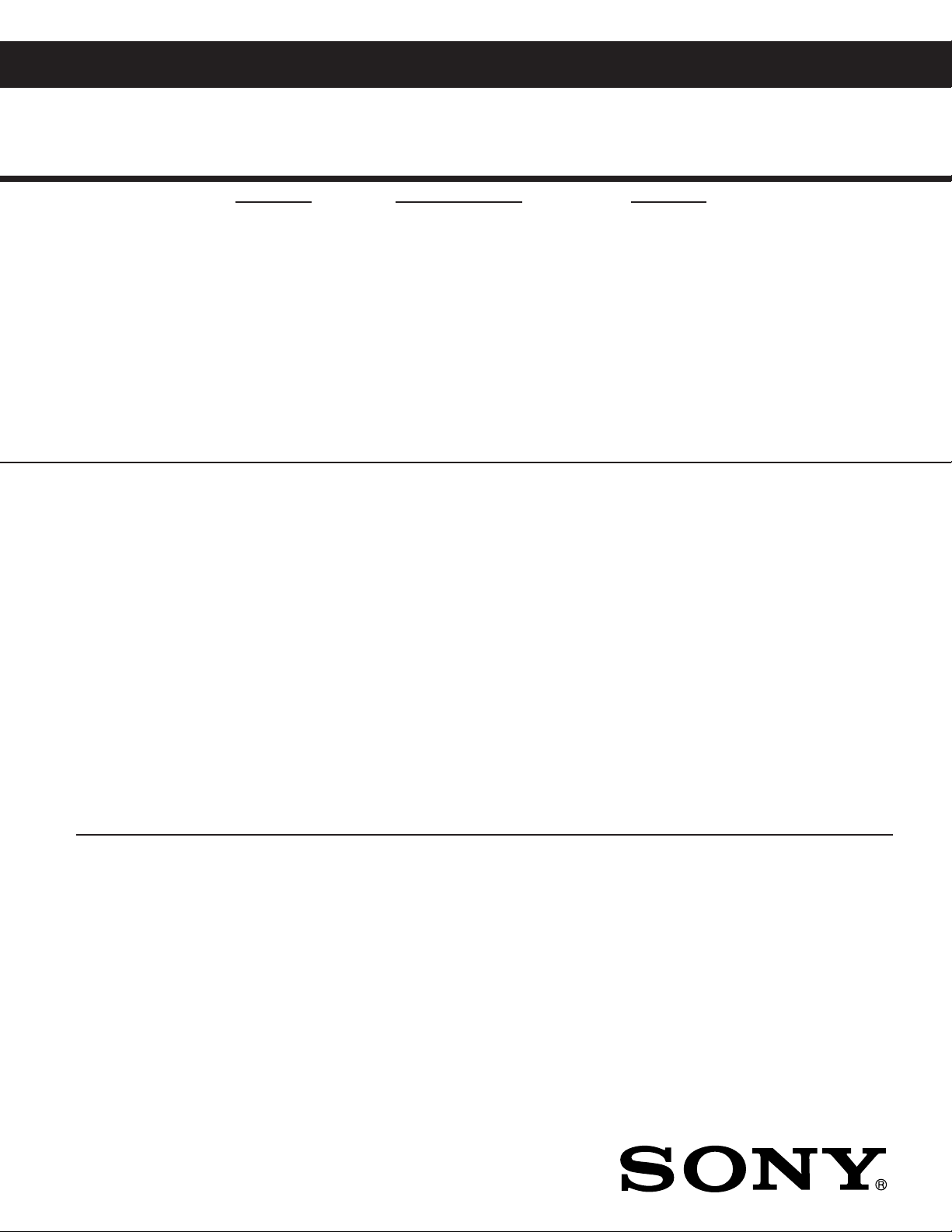

CARRYING THE TV

To avoid dropping the TV and causing serious injury, be sure to follow

these guidelines:

s Before carrying the TV, disconnect all cables.

s Carrying the large size TV requires two or more people.

s When you carry the TV, place your hand as illustrated and hold it

securely. Do not put stress on the LCD panel.

KDL-32M3000/32ML130KDL-26M300026ML130

s When lifting or moving the TV, hold it firmly from the bottom. Place

your palm directly under the panel.

s When carrying, do not subject the TV to shocks or vibration, or

excessive force.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of this receiver is

directly connected to the ac power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe operation. Replace

these components with Sony parts whose part numbers appear as shown in this manual or in supplements published by Sony. Circuit adjustments that

are critical for safe operation are identifi ed in this manual. Follow these procedures whenever critical components are replaced or improper operation is

suspected.

ATTENTION!!

Ces instructions de service sont à l’usage du personnel de service qualifi é seulement. Pour prévenir le risque de choc électrique, ne pas faire

l’entretien autre que celui contenu dans le Mode d’emploi à moins que vous soyez qualifi é faire ainsi.

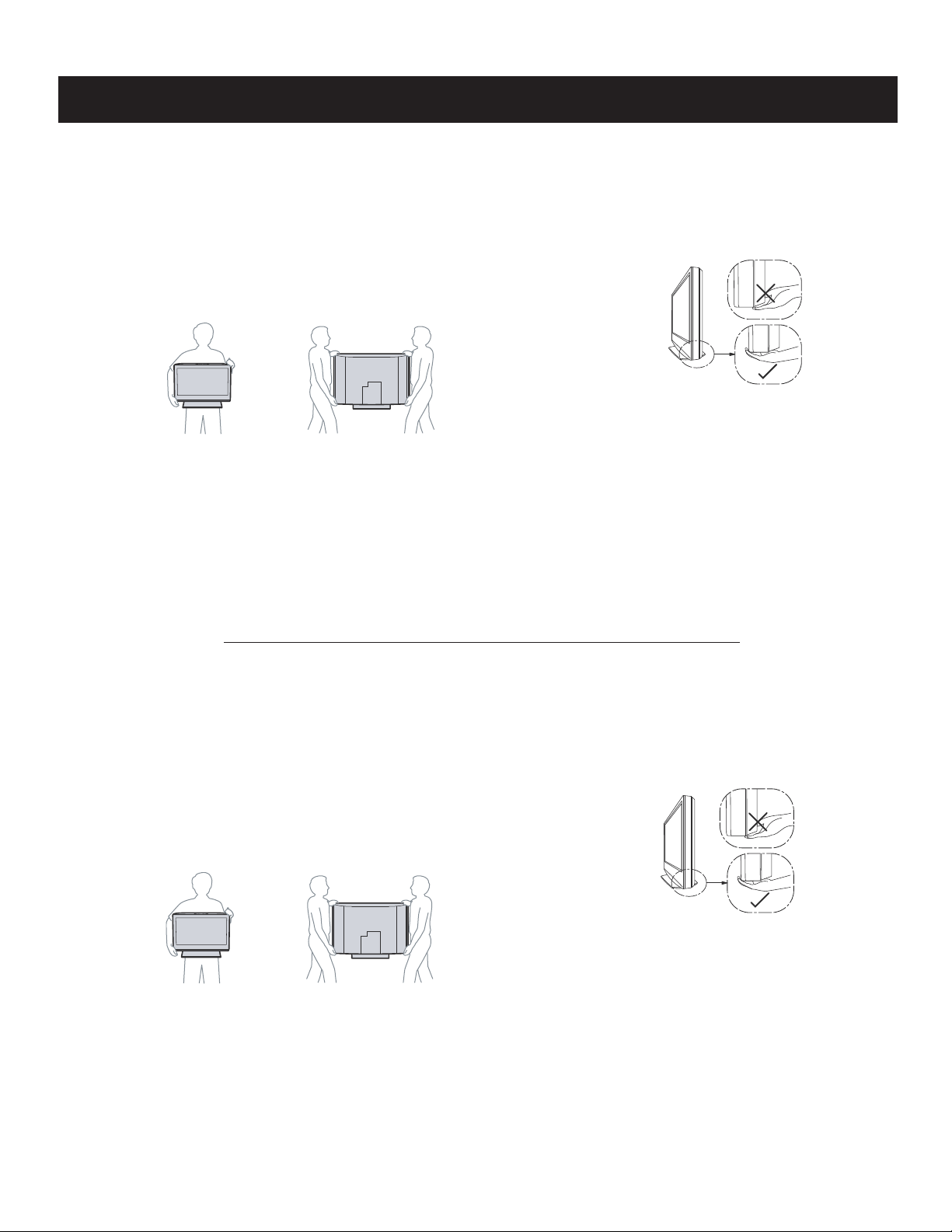

POUR TRANSPORTER LE TÉLÉVISEUR

Assurez-vous de suivre ces consignes pour éviter de laisser tomber le

téléviseur et de provoquer des blessures graves :

s Avant de transporter le téléviseur, débranchez tous les câbles.

s Le transport du téléviseur doit être effectué par au moins deux

personnes.

s Lorsque vous le transportez, placez vos mains tel que cela est illustré

et tenez solidement l’appareil. N’appliquez pas de pression sur

l’écran ACL.

KDL-26M300026ML130

KDL-32M3000/32ML130

s Lorsque vous levez ou déplacez le téléviseur, assurez-vous de tenir

solidement de la base. Placez la paume des mains directement sous

le panneau.

s Lorsque vous transportez le téléviseur, ne le soumettez pas à des

chocs ou vibrations, ni à une force excessive.

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout dépannage. Le

chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque ! sur les schemas de principe, les vues explosees et les listes de pieces sont d’une

importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants Sony dont le numero de piece est indique dans le

present manuel ou dans des supplements publies par Sony. Les reglages de circuit dont l’importance est critique pour la securite du fonctionnement

sont identifi es dans le present manuel. Suivre ces procedures lors de chaque remplacement de composants critiques, ou lorsqu’un mauvais

fonctionnement suspecte.

KDL-26M3000/26ML130/32M3000/32ML130

6

Page 7

SAFETY-RELATED COMPONENT WARNING

KDL-26M3000/26ML130/32M3000/32ML130

There are critical components used in LCD color TVs that are important for safety. These components are identifi ed with shading and

mark on the schematic diagrams and the electrical parts list. It is essential that these critical parts be replaced only with the part number

specifi ed in the electrical parts list to prevent electric shock, fi re, or other hazard.

NOTE: Do not modify the original design without obtaining written permission from the manufacturer or you will void the original parts and

labor guarantee.

!

USE CAUTION WHEN HANDLING THE LCD PANEL

When repairing the LCD panel, be sure you are grounded by using a wrist band.

When installing the LCD panel on a wall, the LCD panel must be secured using the 4 mounting holes on the rear cover.

To avoid damaging the LCD panel:

do not press on the panel or frame edge to avoid the risk of electric shock.

do not scratch or press on the panel with any sharp objects.

do not leave the module in high temperatures or in areas of high humidity for an extended period of time.

do not expose the LCD panel to direct sunlight.

avoid contact with water. It may cause a short circuit within the module.

disconnect the AC adapter when replacing the backlight (CCFL) or inverter circuit.

(High voltage occurs at the inverter circuit at 650Vrms.)

always clean the LCD panel with a soft cloth material.

use care when handling the wires or connectors of the inverter circuit. Damaging the wires may cause a short.

protect the panel from ESD to avoid damaging the electronic circuit (C-MOS).

LEAKAGE CURRENT HOT CHECK CIRCUIT

KDL-26M3000/26ML130/32M3000/32ML130

7

Page 8

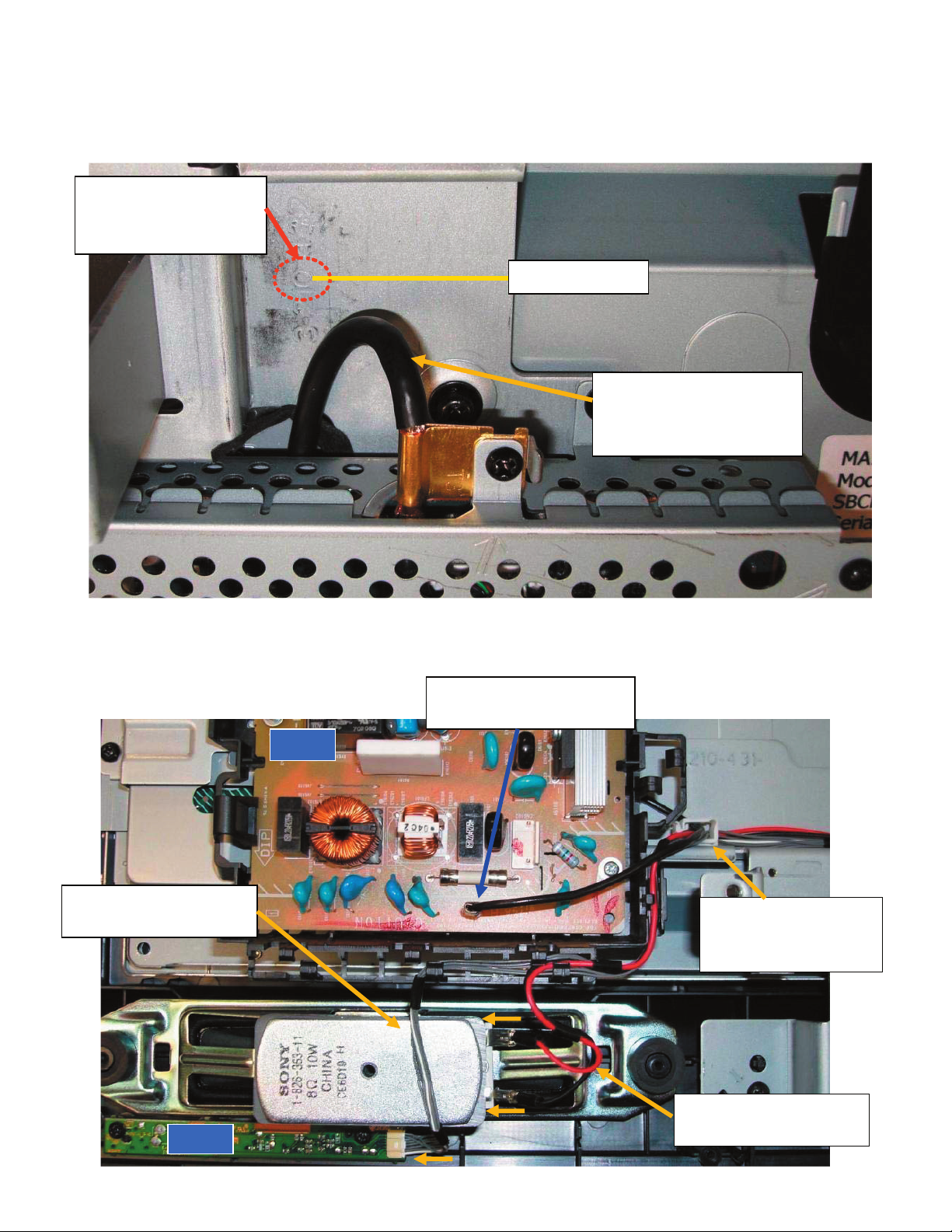

The circuit boards used in these models have been processed using

Lead Free Solder. The boards are identified by the LF logo located

close to the board designation e.g. H1 etc [ see example ]. The

servicing of these boards requires special precautions to be taken as

outlined below.

KDL-26M3000/26ML130/32M3000/32ML130

example 1

It is strongly recommended to use Lead Free Solder material in order to guarantee optimal quality of new solder joints.

Lead Free Solder is available under the following part numbers :

rebmuntraP retemaiD skrameR

91-500-046-7mm3.0gK52.0

02-500-046-7mm4.0gK05.0

12-500-046-7mm5.0gK05.0

22-500-046-7mm6.0gK52.0

32-500-046-7mm8.0gK00.1

42-500-046-7mm0.1gK00.1

52-500-046-7mm2.1gK00.1

62-500-046-7mm6.1gK00.1

Due to the higher melting point of Lead Free Solder the soldering iron tip temperature needs to be set to 370 degrees centigrade.

This requires soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

For more information on the use of Lead Free Solder, please refer to

http://www.sony-training.com

KDL-26M3000/26ML130/32M3000/32ML130

8

Page 9

SAFETY CHECK-OUT

KDL-26M3000/26ML130/32M3000/32ML130

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

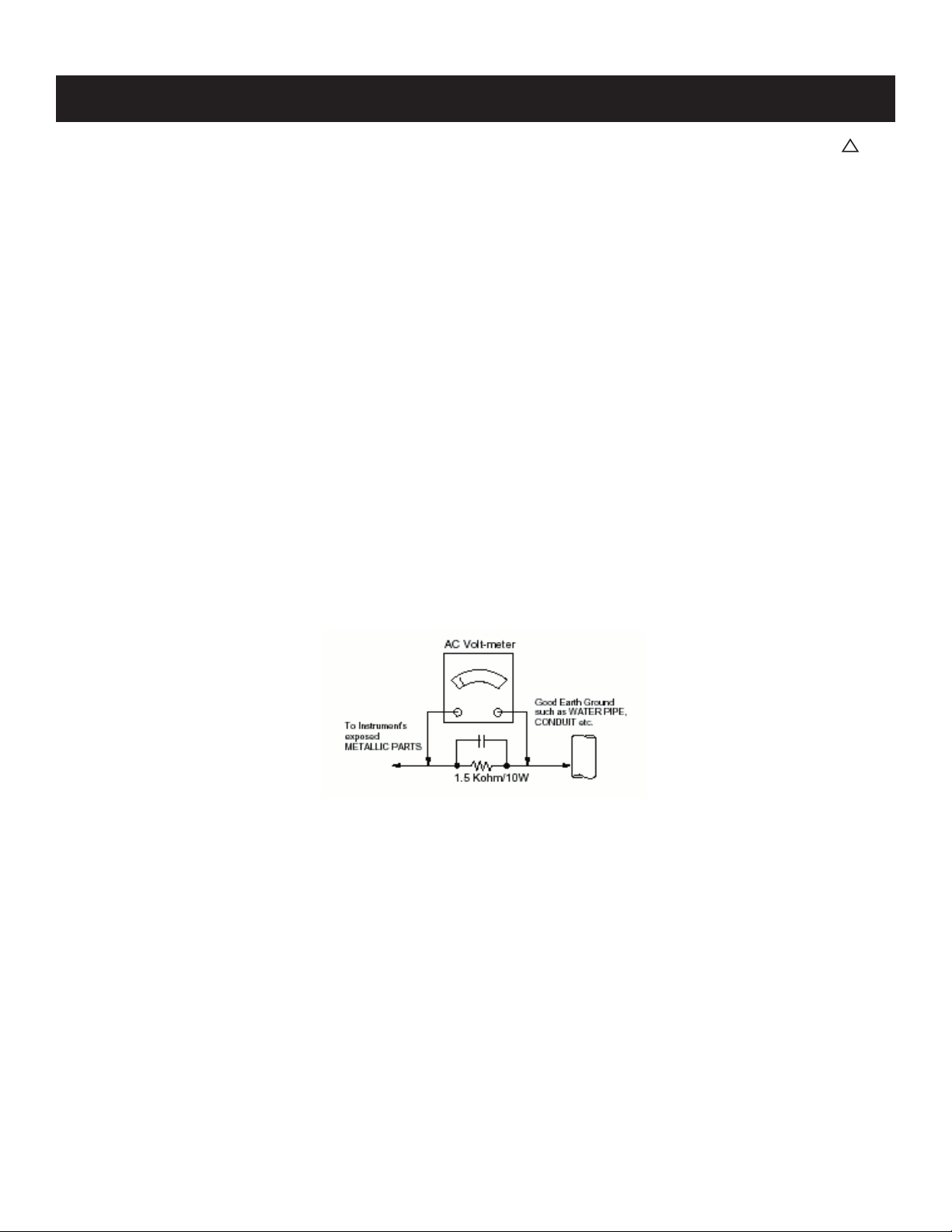

7. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of

passive VOMs that are suitable. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable (see Figure A).

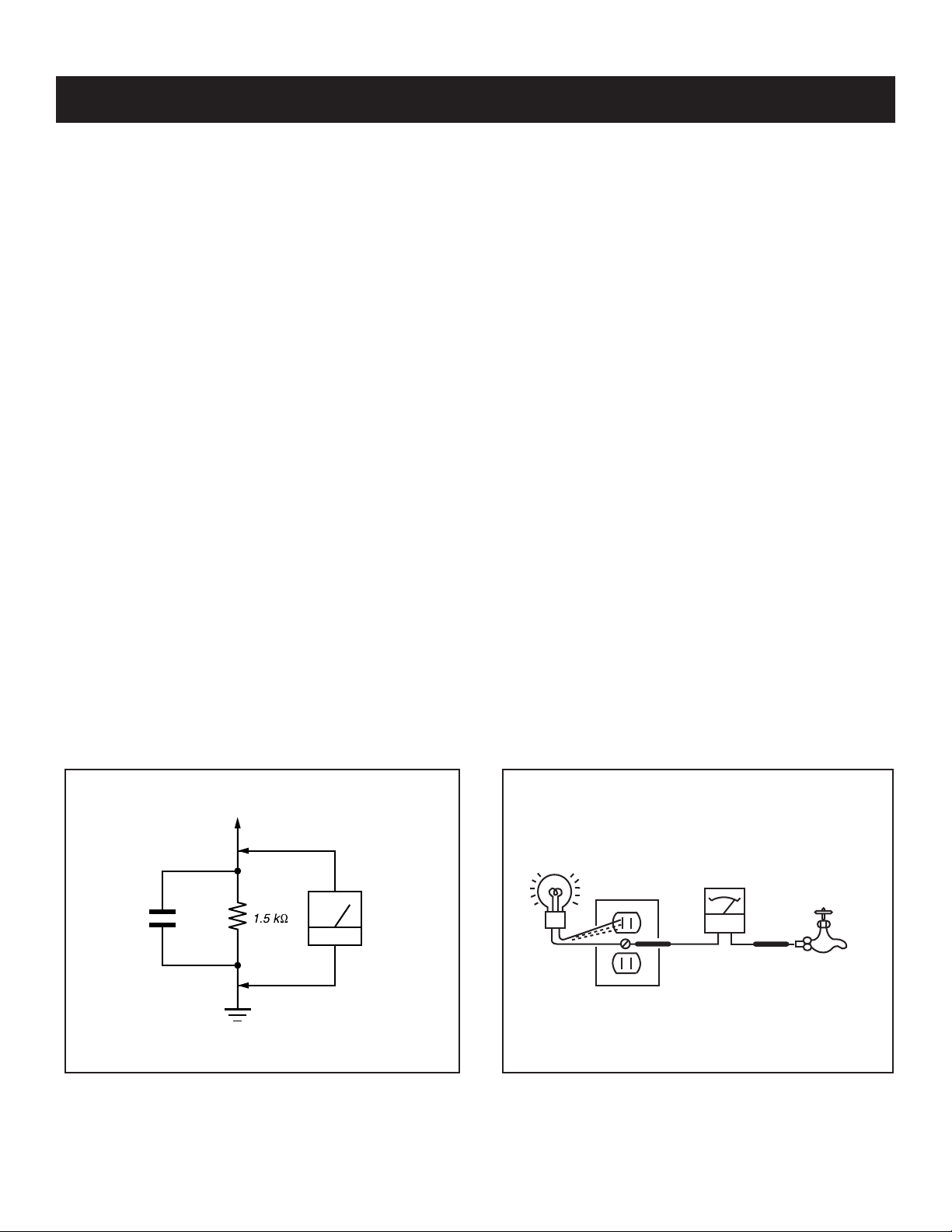

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground. If the

retaining screw is to be used as your earth ground, verify that it is at

ground by measuring the resistance between it and a cold-water pipe

with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt

trouble- light (not a neon lamp) between the hot side of the receptacle

and the retaining screw. Try both slots, if necessary, to locate the hot

side on the line; the lamp should light at normal brilliance if the screw

is at ground potential (see Figure B).

Leakage Test

0.15 μF

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

To Exposed Metal

Parts on Set

Earth Ground

AC

Voltmeter

(0.75V)

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

KDL-26M3000/26ML130/32M3000/32ML130

9

Page 10

KDL-26M3000/26ML130/32M3000/32ML130

g

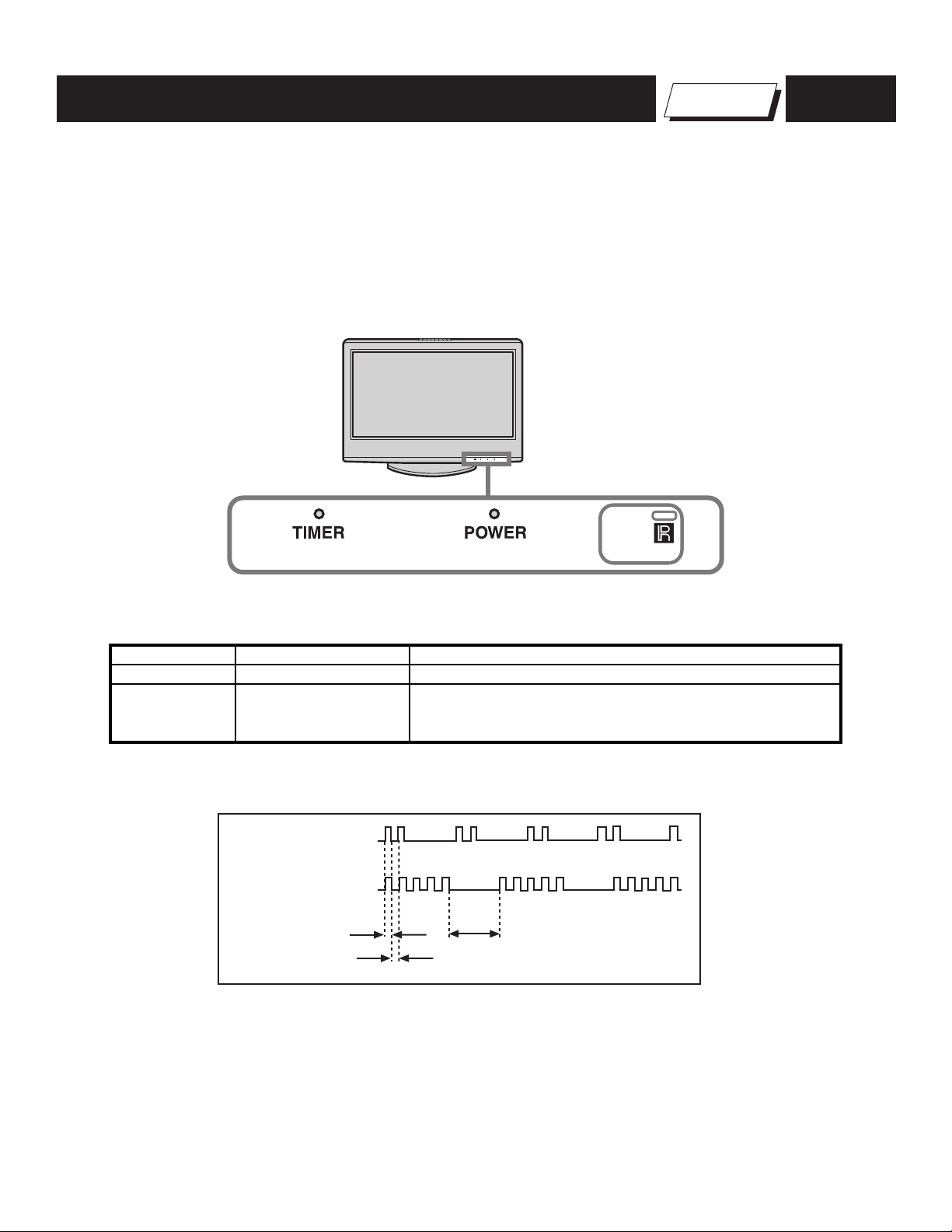

SELF-DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the TIMER LED indicator will automatically begin to fl ash. The number

of times the LED fl ashes translates to a probable source of the problem. A defi nition of the TIMER LED fl ash indicators is listed in the instruction

manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote Commander can be used to review the failure

occurrence data stored in memory to reveal past problems and how often these problems occur.

1. Diagnostic Test Indicators

When an error occurs, the TIMER LED indicator will fl ash a set number of times to indicate the possible cause of the problem. If there is more than

one error, the indicator will identify the fi rst of the problem areas.

Control Buttons

Self Diagnosis

Supported model

Description of LED Indictors

LED LED Type Description

POWER LED Green LED

TIMER

LED

Display of TIMER LED Flash Count

Amber/Green/Red LED

LED ON 0.3 sec.

LED OFF 0.3 sec.

2 times

5 times

* Light is green when the TV set is on

* Li

ht is green when the Picture Offfeature is activated.

* Light is amber when the timer is set.

* Blinks red when indicating the TV may need servicing

LED OFF

3 sec.

KDL-26M3000/26ML130/32M3000/32ML130

10

Page 11

KDL-26M3000/26ML130/32M3000/32ML130

Viewing the Self Check Diagnostic List

1. TV must be in standby mode. (Power off).

2. Press the following buttons on the Remote Commander within a second of each other:

DISPLAY

The Self Check list displays. This is the SAME as accessing Service Adjustments.

Results for all of the following diagnostic items are displayed at the bottom of the screen. No error has occurred if the screen displays a “0”.

Channel 5 Volume +

TV POWER

.

2: MAIN_POWER 0 6: BL (Back Light) 0

3: DC_ALERT1 0 7: TEMP 1

4: DC_ALERT2 0 8: Audio 0

5: DC_ALERT3 0

Clearing the Self Check Diagnostic List

1. In Service Mode, press the Channel

Channel 0.

8

NOTE: The On Screen Displays shows 7,

but it should be 8 for Audio.

Í 0 indicates no error was detected

Í 1 indicates an error was detected

☛

KDL-26M3000/26ML130/32M3000/32ML130

11

Page 12

1-1. REAR COVER REMOVAL

1

Remove 2 screws from Rear Cover arm positions, +PSW M5X16

2

Remove 2 screws from Terminals, +BVTP 3X12 TYPE2 TT(B)

3

Remove 14 screws from Rear Cover, +BVTP2 4X16

KDL-26M3000/26ML130/32M3000/32ML130

SECTION 1: DISASSEMBLY

2

1

Rear Cover

3

1-2. ARM, UNDER COVER AND STAND REMOVAL

1

Remove 2 screws from bottom of VESA Arms, +PSW M5X16

2

☛

Remove 3 screws from Under Cover and Stand, +PSW M5X16

3

Remove 2 screws from Under Cover and Bezel, +BVTP2 4X16

VESA Arms

Bezel

1

Stand Assembly

2

3

Under Cover

Bottom Bracket

Top Brackets

KDL-26M3000/26ML130/32M3000/32ML130

12

Page 13

1-3. HM1 BOARD REMOVAL

1

Remove from bezel

2

Disconnect one connector

3

Release hooks and remove HM1 Board

KDL-26M3000/26ML130/32M3000/32ML130

2

HM1 Board

3

Multi Button Assembly

1

Bezel

1-4. UM BOARD AND JACK HOLDER REMOVAL

1

Remove one screw, +BVTP 3X12 TYPE2 TT(B)

2

Disconnect 2 connectors

3

Remove 2 screws, +BVTP 3X12 TYPE2 TT(B)

2

UM Board

1

3

Side Jack Holder

Bezel

KDL-26M3000/26ML130/32M3000/32ML130

13

Page 14

1-5. SPEAKER, LIGHT GUIDE AND HM3 BOARD REMOVAL

1

Slide out Speakers from Bezel

2

Disconnect one connector

3

Remove 2 screws, +BVTP 3X12 TYPE2 TT(B)

1

Speakers

KDL-26M3000/26ML130/32M3000/32ML130

1-6. BM BOARD REMOVAL

1

Remove 4 screws, +BVST 3X8

2

Remove 2 screws, +BVST 3X8

3

Remove 2 screws, HEX

4

Remove 2 screws, +PSW M3X5

5

Remove 7 screws, +BVST 3X8

6

Disconnect 8 connectors

7

Remove one screw, +PSW M3X5

8

Remove 4 screws, +PSW M3X5

1

3

2

1

5

4

Top Shield

BM Board

7

2

6

3

HM3 Board

Light Guide

KDL-26M3000/26ML130/32M3000/32ML130

8

Bottom Shield

14

Page 15

1-7. G1 BRACKET AND G1M BOARD REMOVAL

1

Remove 3 screws (32”), 4 screws (26”), +PSW 3SG

2

Disconnect 3 connectors

1

KDL-26M3000/26ML130/32M3000/32ML130

2

G1M Board

G1 Bracket

1-8. VESA BRACKET REMOVAL

1

Remove 4 screws, +PSW M4X8

2

Remove 2 screws, +BVTP2 4X16

3

Remove 4 screws, +PSW M4X8

4

Remove 2 screws, +BVTP2 4X16

5

Remove 4 screws, +PSW M4X8

6

Remove 2 screws, +BVTP2 4X16

6

5

Top Bracket (L)

1

2

Bottom Bracket

3

4

Top Bracket (R)

KDL-26M3000/26ML130/32M3000/32ML130

15

Page 16

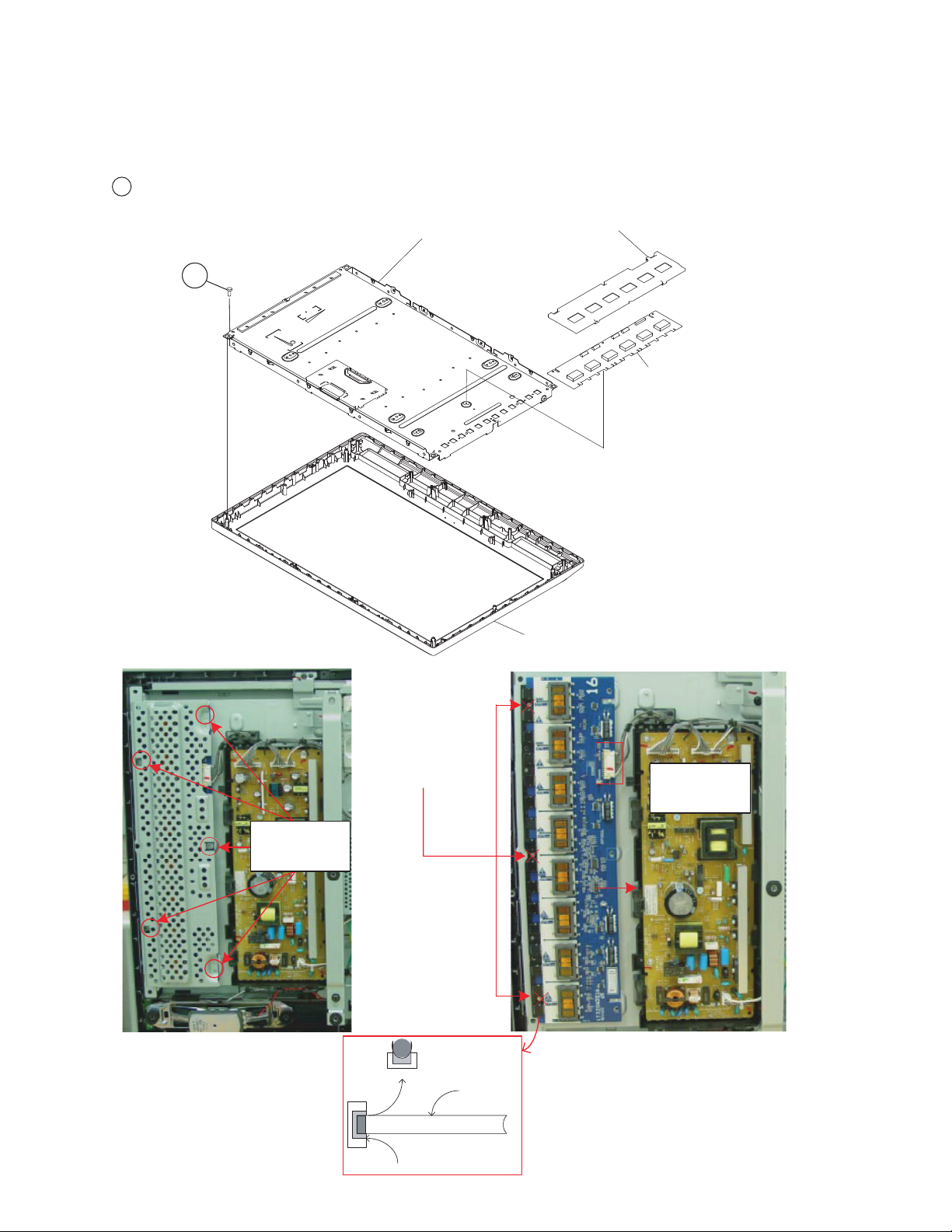

1-9 LCD PANEL/BRACKET AND LED LIGHT GUIDE REMOVAL

CAUTION:

Be sure to identify the inverter cover screws before proceeding. DO NOT remove the screws securing the plastic strip holding the lamp

sockets.

1

Remove 2 screws, +BVTP2 4X16

KDL-26M3000/26ML130/32M3000/32ML130

LCD Panel

Inverter Board Cover

1

Inverter Board

Bezel

REMOVE SCREWS

SECURING

SHIELD

SHIELD REMOVAL

KDL-26M3000/26ML130/32M3000/32ML130

WARNING

NEVER REMOVE THE

SCREWS SECURING THE

PLASTIC STRIP HOLDING

THE LAMP SOCKETS

DAMAGE TO TH E

BACKLIGHT TUBES WILL

OCCUR!

END VIEW

SOCKET

!

.

BACKLIGHT

REMOVE

CONNECTOR AND

PULL BOARD TO

THE RIGHT

INVERTER BOARD REMOVAL

Only remove the screws securing the inverter

cover which may be metal or plastic. The

remaining plastic strip contains sockets for the

fluorescent backlights and should never be

loosened. The backlights will pop out of the

sockets and/or break the backlight requiring a

LCD panel replacement. The example shown

is a 32” model but applies to all models.

16

Page 17

KDL-26M3000/26ML130 ONLY

KDL-26M3000/26ML130/32M3000/32ML130

WIRE DRESSING

OVERALL

VIEW

KDL-26M3000/26ML130/32M3000/32ML130

17

Page 18

KDL-26M3000/26ML130 ONLY

MA1 Wire Dressing [Rev: 0.6]

26 inch.

GND Cable,

1-910-036-30 (165mm)

MA1 Wire Dressing [Rev: 0.6]

26 inch.

GND Cable,

1-910-036-30 (165mm)

LVDS Cable,

1-834-383-11 (350mm)

TCON

Reference:

End of color wires

LVDS cable goes under the BM Bottom Shield.

Use middle of plastic clamp as Reference.

CAUTION POINT: Do not rou

te cable between

bottom sh

ield and TCON only between bottom

shield a

nd Panel.

Shield Tape,

2-688-010-01 (20x40)

Panel

GROUND CABLE

KDL-26M3000/26ML130/32M3000/32ML130

LVDS CONNECTOR

KDL-26M3000/26ML130/32M3000/32ML130

18

Page 19

KDL-26M3000/26ML130 ONLY

MA1 Wire Dressing [Rev: 0.6]

Draw a horizontal line

using the number “0”

as a reference

R

eference Line

Dress LVDS cable to

have this route. Do not

cross the Reference line

MA1 Wire Dressing [Rev: 0.6]

Draw a horizontal line

using the number “0”

as a reference

R

eference Line

Dress LVDS cable to

have this route. Do not

cross the Reference line

G1M

HM3/HM1 cable:

1-910-038-35 (550mm)

Speaker cable:

1-910-038-30 (350mm)

HM3, SpkrR and

GND cables trough

this clamp.

GND cable connected to

GND Tab on G1M Board.

HM3

LVDS CONNECTOR (CONTINUED)

KDL-26M3000/26ML130/32M3000/32ML130

HM3 BOARD AND SPEAKERS

KDL-26M3000/26ML130/32M3000/32ML130

19

Page 20

KDL-26M3000/26ML130 ONLY

26 inch.

HM3 cable and SpkrL

cable trough this clamp.

HM3 cable goes from

right to left side and

White Spkr cable goes

o

pp

osite direction.

Fix cable to metal part using:

Himelon Tape (LCD)

2-688-062-01 (8x30)

Cable and Himelon position

should be as shown in picture.

D

ifferen

t Angle

HM3 BOARD AND SPEAKERS (CONTINUED)

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

20

Page 21

KDL-26M3000/26ML130 ONLY

Inverter cable:

Inverter

Hold cables using 2 Pin

Wir

es on G1M

Inverter cable

1-910-038-36 (300mm)

Use clamps on bracket

to route cables

Area under

G1M Board

StandBy cable

1-910-038-29 (450mm)

G1M

Inverter cable

Goes under G1M

INVERTER BOARD CONNECTORS

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

21

Page 22

KDL-26M3000/26ML130 ONLY

MA1 Wire Dressing [Rev: 0.6]

HM3/HM1 cable:

1-910-038-35 (220mm)

HM1

EMI:

Himelon Tape

2-688-011-01 (15x60)

Inverter cable: 2 cables

coming from under G1M

Reference

CAUTION POINT:

On this CLAMP,

Inverter cable must be

i

nserted b

efore the rest

of cables.

HM1 cable must go

under t

hese wires.

EMI Gasket on BM Bottom Shield:

GASKET (30x12)

2-676-705-01

Reference

HDMI CONNECTORS

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

22

Page 23

KDL-26M3000/26ML130 ONLY

Video 2 cable with GND:

Video2 cable:

1-910-038-33 (210mm)

Ferrite Core (140005211)

ZCAT 2235-1030

Fix ferrite to panel using:

Himelon

Core Sheet (A)

2-688-014-01

Use clamp to route

GND cable and Wires

CAUTION POINT:

GND cable must go

under Video 2 Cable, as

shown on picture.

G

ND Cable FASTON

1-910-038-32 (100mm)

Reference

VIDEO CONNECTORS AND GROUND CABLE

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

23

Page 24

KDL-26M3000/26ML130 ONLY

MA1 Wire Dressing [Rev: 0.6]

Ferrite Core (150002111)

ZCAT 3035-1330

Completely cover Ferrite using:

Himelon Cushion LB x 2 (140x20)

2-686-782-11

120 mm

60 mm

G1M

Route the cable

using this Cut and

C

lamp on Bracket

Fix ferrite to panel using:

Himelon Cushion LB (140x20)

2-686-782-11

Reference

Reference

AC HOLDER

4-022-115-12

AC CORD CONNECTOR

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

24

Page 25

KDL-26M3000/26ML130 ONLY

DPU:

Shield Tape (20x40mm)

2-688-010-01

Top view and Bottom View

A side

B side

For Reference

SHIELD TAPE PLACEMENT

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

25

Page 26

KDL-26M3000/26ML130 ONLY

Tuner

STEP 1:

Add 1 Himelon Tape (LCD)

PN: 2-688-062-01 (8x30mm)

Note:

R7853 should be covered

with himel

on.

For Reference: Edge of Tuner

For Reference

For Reference

For Reference

Screw and himelon

is under the tape

STEP 2:

Add 1 Shield Tape

PN: 2-688-010-01 (20x40mm)

Apply

after putting the himelon

(step

1) and the screw.

SHIELD TAPE PLACEMENT (CONTINUED)

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

26

Page 27

KDL-32M3000/32ML130 ONLY

OVERALL VIEW

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

27

Page 28

KDL-32M3000/32ML130 ONLY

32 inch.

GND Cable:

GND Cable,

1-910-026-38 (65mm)

32 inch.

GND Cable:

GND Cable,

1-910-026-38 (65mm)

LVDS Cable:

Shield Tape,

2-688-010-01 (20x40)

LVDS cable pass trough

the middle of this gasket

EMI GASKET 30x12

2-676-705-01

Reference

LVDS Cable,

1-834-383-11 (350mm)

GROUND CABLE

KDL-26M3000/26ML130/32M3000/32ML130

LVDS CONNECTOR

KDL-26M3000/26ML130/32M3000/32ML130

28

Page 29

KDL-32M3000/32ML130 ONLY

MA1 Wire Dressing [Rev: 0.6]

Dress LVDS cable to

have this route.

GND cable connected to

GND Tab on G1M Brd.

Speaker cable:

1-910-038-07 (410mm)

HM3/HM1 cable:

1-910-038-28 (690mm)

G1M

HM3 and SpkrR cables

trough this clamp.

Himelon Tape x 2 (LCD)

2-688-062-01 (8x30)

Route cable by inserting it trough

these 4 Holder Ribs on Bezel

HM3

MA1 Wire Dressing [Rev: 0.6]

Dress LVDS cable to

have this route.

LVDS CONNECTOR (CONTINUED)

KDL-26M3000/26ML130/32M3000/32ML130

HM3 BOARD AND SPEAKERS

KDL-26M3000/26ML130/32M3000/32ML130

29

Page 30

KDL-32M3000/32ML130 ONLY

Different Angle

Ferrite Core (146908911)

ZCAT 1730-0730

Completely cover Ferrite and

grab the HM3 cable using:

Himelon Core Sheet (A)

2-688-014-01

HM3 cable and SpkrL

cable trough this clamp.

Reference

Himelon Tape (LCD)

2-688-062-01 (8x30)

HM3 BOARD AND SPEAKERS (CONTINUED)

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

30

Page 31

KDL-32M3000/32ML130 ONLY

32 inch.

Inverter cable:

Hold cables using 3 Pin

Wir

es on G1M

Use clamps on braket

to route cables

StandBy cable

1-910-038-29 (450mm)

Hold cable to G1M

Bracket using:

Himelon Tape

2-688-011-01

(

15x60

)

Inverter cable

1-910-038-31 (420mm)

G1M

G1M

INVERTER BOARD CONNECTORS

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

31

Page 32

KDL-32M3000/32ML130 ONLY

MA1 Wire Dressing [Rev: 0.6]

32 inch.

Himelon Tape

2-688-011-01 (15x60)

Reference

HM1 cable must go over

LVDS cable

HM1 cable must go

under t

hese wires.

EMI Gasket on BM Bottom Shield:

GASKET 30x12

2-676-705-01

Reference

Reference

Himelon Tape (LCD)

2-688-062-01 (8x30)

Himel

on Position:

Use UL Tape Position

o

n cable to set the

himelon, DO NOT

STRESS THE CABLE

HM1

HM3/HM1 cable:

1-910-038-28 (290mm)

HDMI CONNECTORS

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

32

Page 33

KDL-32M3000/32ML130 ONLY

32 inch.

Video 2 cable with GND:

Video2 cable:

1-910-038-33 (210mm)

GND Cable FASTON

1-910-038-32 (100mm)

Use clamps to route

GND cable and Wires

Reference

Ferrite Core (140005211)

ZCAT 2235-1030

Fix ferrite to panel using:

Himelon

Core Sheet (A)

2-688-014-01

VIDEO CONNECTORS AND GROUND CABLE

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

33

Page 34

KDL-32M3000/32ML130 ONLY

MA1 Wire Dressing [Rev: 0.6]

Ferrite Core (150002111)

ZCAT 3035-1330

Completely cover Ferrite using:

Himelon Cushion LB x 2 (140x20)

2-686-782-11

120 mm

80 mm

G1M

Route the cable

using this Cut and

C

lamp on Bracket

Reference

Fix ferrite to panel using:

Himelon Cushion LB (140x20)

2-686-782-11

AC HOLDER

4-022-115-12

AC CORD CONNECTOR

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

34

Page 35

KDL-32M3000/32ML130 ONLY

DPU:

Shield Tape (20x40mm)

2-688-010-01

Top view and Bottom View

A side

B side

For Reference

SHIELD TAPE PLACEMENT

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

35

Page 36

KDL-32M3000/32ML130 ONLY

Tuner

STEP 1:

Add 1 Himelon Tape (LCD)

PN: 2-688-062-01 (8x30mm)

Note: R7853 should be covered

with himel

on.

For Reference: Edge of Tuner

For Reference

For Reference

For Reference

Screw and himelon

is under the tape

STEP 2:

Add 1 Shield Tape

PN: 2-688-010-01 (20x40mm)

Apply

after putting the himelon

(step

1) and the screw.

SHIELD TAPE PLACEMENT (CONTINUED)

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

36

Page 37

KDL-32M3000/32ML130 ONLY

MA1 Wire Dressing [Rev: 0.6]

32 inch.

For Reference

Shield Tape (20x40mm)

2-688-010-01

SHIELD TAPE PLACEMENT (CONTINUED)

KDL-26M3000/26ML130/32M3000/32ML130

KDL-26M3000/26ML130/32M3000/32ML130

37

Page 38

KDL-26M3000/26ML130/32M3000/32ML130

SECTION 2: SERVICE ADJUSTMENTS

2-1. USING THE REMOTE COMMANDER FOR ELECTRICAL ADJUSTMENTS

To adjust various set features, use the Remote Commander to put the set into service mode to display the service menus and categories.

Equipment Needed:

Pattern Generator (with component outputs)

Oscilloscope

Digital multimeter

2-2. ACCESSING SERVICE ADJUSTMENT MODE

1. TV must be in standby mode. (Power off).

2. To display the service menu, press the following buttons on the Remote Commander within a second of each other:

DISPLAY

Channel 5 Volume +

POWER

.

POWER

5

VOLUME+

DISPLAY

Onscreen cursor

and select button

RM-YD021

KDL-26M3000/26ML130/32M3000/32ML130

38

Page 39

2-3. VIEWING THE SERVICE MENUS

Use the Remote Commander to view the BE and Digital service menus options.

KDL-26M3000/26ML130/32M3000/32ML130

Sample Service Menu

2-4. RESETTING TO FACTORY DEFAULTS

The following instructions restore the User Controls and Channel Memory settings to the preset factory conditions.

1. In Service Mode to select Factory Default press

, then to select Yes press .

KDL-26M3000/26ML130/32M3000/32ML130

39

Page 40

3-1. CIRCUIT BOARDS LOCATION

KDL-26M3000/26ML130/32M3000/32ML130

SECTION 3: DIAGRAMS

BM BOARD

UM BOARD

3-2. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS INFORMATION

All capacitors are in μF unless otherwise noted. pF : μμF 50WV or

less are not indicated except for electrolytics and tantalums.

All electrolytics are in 50V unless otherwise specifi ed.

All resistors are in ohms. kΩ=1000Ω, MΩ=1000kΩ

Indication of resistance, which does not have one for rating

electrical power, is as follows: Pitch : 5mm

Rating electrical power :

1

/

W in resistance, 1/

4

W and 1/

10

W in chip resistance.

16

: nonfl ammable resistor

: fusible resistor

: internal component

: panel designation and adjustment for repair

: earth ground

: earth-chassis

All variable and adjustable resistors have characteristic curve B,

unless otherwise noted.

Readings are taken with a color-bar signal input.

Readings are taken with a 10MΩ digital multimeter.

Voltages are DC with respect to ground unless otherwise noted.

Voltage variations may be noted due to normal production

tolerances.

1

/

W

4

HM1 BOARD

G1M BOARD

HM3 BOARD

All voltages are in V.

S : Measurement impossibility.

: B+line.

: B-line. (Actual measured value may be different).

: signal path. (RF)

Circled numbers are waveform references.

The components identifi ed by shading and ! symbol are critical for safety. Replace

only with part number specifi ed.

The symbol indicates a fast operating fuse and is displayed on the component

side of the board. Replace only with fuse of the same rating as marked.

!

Les composants identifi es per un trame et une marque

securite. Ne les remplacer que par une piece portant le numero specifi e.

Le symbole indique une fusible a action rapide. Doit etre remplace par une

fusible de meme yaleur, comme maque.

NOTE: The components identifi ed by a red outline and a mark contain confi dential

information. Specifi c instructions must be adhered to whenever these components

are repaired and/or replaced.

See Appendix A: Encryption Key Components in the back of this manual.

sont critiques pour la

KDL-26M3000/26ML130/32M3000/32ML130

40

Page 41

KDL-26M3000/26ML130/32M3000/32ML130

REFERENCE INFORMATION

RESISTOR

: RN METAL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RW NONFLAMMABLE WIREWOUND

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: ADJUSTMENT RESISTOR

COIL

: LF-8L MICRO INDUCTOR

CAPACITOR

: TA TANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

Terminal name of semiconductors in silk screen

printed circuit ( )

Device Printed symbol Terminal name

Transistor

1

Transistor

2

3

Diode

4

Diode

Diode

5

Diode

6

Diode

7

8

Diode

Diode

9

Diode

0

Diode

!¡

Diode

!™

Transistor

!£

(FET)

Transistor

!¢

(FET)

Transistor

!?

(FET)

Transistor

!§

Transistor

!¶

Transistor

!•

Transistor

!ª

Transistor

@º

Transistor

@¡

Transistor

@™

Transistor

@£

Discrete semiconductot

–

(Chip semiconductors that are not actually used are included.)

*

Collector

Base

Collector

Base

Cathode

Cathode

Anode

Cathode

Anode

Common

Anode

Common

Anode Cathode

Common

Anode

Common

Anode Anode

Common

Cathode

Common

Cathode

Anode

Anode

Cathode

Drain

Drain

B1 E1

C2

B2 C1E2

B2 E2

C1

B1 C2

E1

B2 E2

C1

B1 C2E1

B2 E2

C1

B1 C2E1

E2

B1 E1

C2

(B2)

E1

B1

C1

(B2)

E1

E2

C2

Emitter

Emitter

Anode

(NC)

(NC)

Cathode

Anode

Cathode

Cathode

Cathode

Anode

Anode

Source

Gate

Source

Gate

Source

Drain

Gate

Emitter

Collector

Base

C1(B2)

E2

C2

B1

C1

Circuit

D

G

D

S

B1

B1

B1

B1

B1

B1

D

G

S

S

D

G

C1

E1

C1

E1

E1

C1

E2

C1

C1

G

S

C2

B2

E2

C2

B2

E2

E2

B2

C2

C2C1(B2)

E2

E2E1(B2)

C2

C2E1(B2)

C2

Ver.1.6

KDL-26M3000/26ML130/32M3000/32ML130

41

Page 42

3-3. BLOCK DIAGRAM

KDL-26M3000/26ML130/32M3000/32ML130

V

i

d

1

V

i

d

3

C

o

m

p

1

C

o

m

p

2

HDMI 1

HDMI 2

VGA IN

NVM

NVM

1Kb

1Kb

Tuner

L/R

L/R

L/R

L/R

YPbPr

L/R

YPbPr

L/R

NVM

1Kb

L/R

Audio

SW

Y/C

CVBS

CVBS

HDMI

switch

L/R

Digital IF

Tuner CVBS

YUV

switch

IIC

Audio ADC

(AK5365)

RGB

HDMI/

VGA/

YUV

Receiver

(AD9380)

AVSW

I2S

Y/C

YCbCr

I2S

24

I2S In 2

I2S In 1

2

st

Audio Out

1

DAC

CS4335

CVBS

Xilleon

242

DVOP

SPDIF Out

nd

Audio Out

IIC

Serial Flash

NAND Flash

UART0

JIG

connector

for Service

RGB

24

DAC

CS4335

L/R

512 K

16 MB

DDR

64 MB

UART1

SIRCS

Temp.

Sensor

NVM

RTC

ECS

DCP

CXD9690

$88

24

AMP

RGB

SPDIF

IIC

TV Micro

LVDS Tx

USB

SIRCS/

LED/

L.Sensor

Backlight

L/R

Key/Power

Dimer

LVDS

L

R

BM

Video 2

Headphones

UM

LED, SIRCS,

Light sensor

HM3

Top Keys

Power button

HM1

USB for Service

LCD

PANEL

SBCT-PD

KDL-26M3000/26ML130/32M3000/32ML130

42

Page 43

3-4. CONNECTION DIAGRAM

KDL-26M3000/26ML130/32M3000/32ML130

INVERTER

32"

VDDB

VDDB

VDDB

VDDB

VDDB

GND

GND

GND

GND

GND

NC

VBLON

DIMMER

NC

INVERTER

26"

VDDB

VDDB

VDDB

VDDB

VDDB

GND

GND

GND

GND

GND

VDIM

VBLON

NC

DET

Speakers

Speakers

R

L

CN6202

REG24V

REG24V

REG24V

REG24V

GND

GND

GND

GND

REG 5V

REG 5V

REG12V

REG12V

GND

GND

CN6201

STBY3.3V

GND

POWER ON

AC OFF DET

UNREG13V

UNREG13V

AU_GND

AU_GND

NC

POWER 3

GND

GND

GND

-

+

-

+

GM1

SIGNAL

POWER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

1

2

3

1

2

GND

CN201

V2_IN_AU_L

D3.3V

AU_IN_GND

GND

V2_IN_AU_R

V2_IN_SSW

AU_IN_GND

V2_IN_C

HP_OUT_AU_L

V2_IN_S2SW

HP_IN_GIND

GND

HP_OUT_AU_R

V2_IN_Y

HP_DET

GND

GND

V2_IN_V

D5V

GND

CN301

GND

STBY3.3V

STBY_LED

ON_TIMER

PWR/RESERVE

BL_IN

VD3.3V

SIRCS

CN101

GND

POWERINT

KEY1

CN102

GND

GND

UM

HM3

HM1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

CN4003

1

DIMMER

2

BACKLIGHT

3

PANEL_DET

4

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

14

13

12

11

10

9

8

7

6

5

4

3

2

1

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

CN4002

PANEL5V

PANEL5V

REG12V

REG12V

GND

GND

CN4001

STBY3.3V

GND

POWER_ON

AC_OFF_DET

AU_13V

AU_13V

AU_GND

AU_GND

NC

POWER 3

GND

GND

CN2000

RR+

L+

L-

CN9102

TAGND

TA+

DCC

TBGND

TB+

GND

TCGND

TC+

GND

TCKLGND

TCKL+

VCC

TDVCC

TD+

GND

DCC

GND

NC

GND

NC

VCC

DCC LUT

VCC

VCC

DCC MODE

BM

CN1400

V2_IN_AU_L

D3.3V

AU_IN_GND

GND

V2_IN_AU_R

V2_IN_SSW

AU_IN_GND

V2_IN_C

HP_OUT_AU_L

V2_IN_S2SW

HP_IN_GIND

GND

HP_OUT_AU_R

V2_IN_Y

HP_DET

GND

GND

V2_IN_V

D5V

GND

CN3008

GND

STBY3.3V

STBY_LED

ON_TIMER_LED

POWER_LED

BL_IN

VD3.3V

SIRCS

GND

POWER_INT

KEY1

CN3004

GND

TXD

RXD

RES

VIN

MOD

UART1_RXD

PROG_CLK

SDA_DEVICE

SCL_DEVICE

PROG_GD

UART1_TXD

NC

VIN

B INT

RXD

TXD

GND

CN7303

DIAG_TXD

DIAB_RXD

GND

/RESET_OUT

SPI_CLK

SPI_IN

SPI_OUT

/SPI_DET

SPI_CS0

NC

CN7301

5V

PB

NB

GND

GND

/RST

GND

TDI

GND

TDO

GND

TMS

GND

TCK

GND

/RST

NC

DINT

VIO

NC

CN7600

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

KDL-26M3000/26ML130/32M3000/32ML130

43

Page 44

3-5. SCHEMATICS AND SUPPORTING INFORMATION

BM BOARD SCHEMATIC DIAGRAM (1 OF 12)

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20

KDL-26M3000/26ML130/32M3000/32ML130

A

—

B

—

C

—

D

—

E

—

F

—

G

—

H

—

I

—

J

—

K

—

L

VideoInput1

VideoInput3

ComponentInput1

ComponentInput2

J1000

NC

4

3

12

V1

L1

R1

V2

L2

R2

VD1004

GND_A

GRN

1

2

BLU

3

4

RED

5

6

WHT

7

8

RED

9

10

GRN

11

12

BLU

13

14

RED

15

16

WHT

17

18

RED

19

20

J1100

VD1109

GND_A

GND_T

R1401

GND_T

R1867

CHIP

1608

D3.3V

CHIP0

5V_TU

FB1700

MA8100-TX

0.5%

RN-CP

1/10W

R1871

220

R1022

R1024

CHIP

CHIP

R1142

220

1/10W

RN-CP

0.5%

1608

0

0

0.5%

RN-CP

1/10W

R1112

MA8100-TX

C1739

CHIP

220

C1736

CHIP

0

R1114

CHIP

1005

R1116

CHIP

1005

R1136

1/10W

RN-CP

0.5%

R1144

CHIP

1005

R1146

CHIP

1005

0

D1014

0

0

220

1608

0

0

D1013

GND_A

R1014

1/16W

CHIP

R1012

470k

1/16W

CHIP

470k

R1886

0.5%

RN-CP

1/10W

R1106

GND_A

GND_A

CHIP

1608

220

0

R1137

1/10W

RN-CP

0.5%

1608

R1866

0

CHIP

1608

R1876

0

CHIP

1608

R1877

0

CHIP

1608

0.5%

RN-CP

1/10W

R1887

R1133

1/10W

RN-CP

220

RN-CP

1/10W

R1102

220

0.5%

1608

0.5%

220

C1005

C1007

A_V3_IN_AU_L

A_V3_IN_AU_R

RN-CP

C1100

1

16V

B

2012

C1102

1

16V

B

2012

R1134

220

1/10W

RN-CP

0.5%

1608

C1130

1

16V

B

2012

C1132

1

16V

B

2012

A_V1_IN_AU_L

1

16V

B

2012

A_V1_IN_AU_R

1

16V

B

2012

0.5%

1/10W

220

0.5%

R1103

R1013

0

CHIP

R1015

0

CHIP

GND_T

GND_T

C1010

1

16V

B

2012

C1012

1

16V

B

2012

0.5%

0.5%

RN-CP

RN-CP

1/10W

1/10W

220

220

R1107

R1108

R1138

R1132

220

220

220

1/10W

1/10W

RN-CP

RN-CP

0.5%

0.5%

1608

1608

0.5%

R1016

CHIP

1005

GND_A

VD1001

0

VD1002

VD1106

GND_A

GND_A

VD1108

VD1107

R1115

1/16W

CHIP

1005

R1117

470k

1/16W

CHIP

1005

R1145

1/16W

CHIP

1005

R1147

470k

1/16W

CHIP

1005

470k

470k

0.5%

RN-CP

1/10W

R1869

R1110

1/10W

RN-CP

R1140

1/10W

RN-CP

220

0.5%

1608

0.5%

1608

RN-CP

1/10W

R1859

220

220

220

R1021

470k

1/16W

CHIP

R1023

470k

1/16W

CHIP

RN-CP

1/10W

R1870

0.5%

220

GND_TGND_T

GND_T

R1141

1/10W

RN-CP

0.5%

1608

RN-CP

1/10W

R1111

220

0.5%

220

0

R1868

0

CHIP

1608

GND_T

GND_A

GND_A

VD1003

GND_A

R1025

0

CHIP

1005

0

CHIP

6.3V

1000

C1755

GND_T

0.5%

RN-CP

1/10W

220

R1878

GND_T

A_V1_IN_AU_L,A_V1_IN_AU_R

MA8100-TX

D1016

C1745

0

CHIP

GND_A

GND_A

A_V3_IN_AU_L,A_V3_IN_AU_R

GND_A

VD1100

1/10W

220

R1104

A_D1_IN_AU_L,A_D1_IN_AU_R

RN-CP

A_D1_IN_AU_L

A_D1_IN_AU_R

GND_A

VD1130

A_D2_IN_AU_L,A_D2_IN_AU_R

A_D2_IN_AU_L

A_D2_IN_AU_R

GND_T

VD1101

VD1131

GND_A

GND_A

R1894

CHIP

1608

MA8100-TX

D1015

C1742

0

CHIP

0

GND_A

VD1102

GND_A

VD1132

GND_A

GND_A

R1885

CHIP

1608

R1113

1/16W

CHIP

1005

R1143

1/16W

CHIP

1005

0

R1109

22

1/16W

CHIP

5%

1005

R1139

1/16W

CHIP

1005

V4PB

V5Y

22

5%

V4Y

22

5%

22

5%

A_V1_IN_Y

A_V1_IN_C

A_V1_IN_V

A_V3_IN_V

R1105

22

1/16W

CHIP

5%

1005

R1135

22

1/16W

CHIP

5%

1005

V4PR

V5PR

VIDEO1-3

10V

C1726

R1943

0

CHIP

2012

R1944

0

CHIP

2012

R1945

0

CHIP

2012

R1946

0

CHIP

2012

GND_D GND_D

0

RB1003

GND_D

0

RB1011

R1833

0

CHIP

GND_DGND_A

0

RB1007

R1845

0

CHIP

GND_AGND_D

REG5V

GND_T

R1924

CHIP0

R1925

CHIP0

R1926

CHIP0

R1927

CHIP0

R1928

CHIP0

R1929

CHIP0

R1930

CHIP0

CHIP0

R1931

R1932

CHIP0

CHIP0

R1933

R1934

CHIP0

CHIP0

R1935

0

RB1008

R1848

0

CHIP

GND_D

GND_T

BM 1/12

I/O TERMINALS

RB1005

R1839

CHIP

0

0

1608

25V

C1730

0.1

GND_T

F

R1942

0

CHIP

2012

GND_A GND_A1

GND_A1 GND_D

GND_D

10V

100

C1733

6.3V

1000

C1731

R1850

100

1/10W

RN-CP

5%

GND_D

RB1002

R1822

CHIP

RB1001

R1832

CHIP

GND_A

0

0

0

0

R1936

CHIP0

R1937

CHIP0

R1938

CHIP0

R1939

CHIP0

0

RB1006

R1842

0

CHIP

L1001

10uH

AVSW_1

GND_A

R1940

0

CHIP

2012

R1941

0

CHIP

2012

GND_T

GND_A

C1727

100

10V

100

10V

C1728

R1726

100

CHIP

0

R1727

0

CHIP

R1728

CHIP

RB1004

0

0

R1836

CHIP

V45PR

0

87654321

V45PB

GND_D

M52055FP

IC1001

IN1B

SW1

OUT1

E

OUT2

OUT3

SW3

IN3A IN3B

V45Y

V45YPBPR

GND_T

RB1010

RB1009

IN1A

IN2B

IN2A

10V

100

C1732

0

GND_AGND_T

0

GND_AUGND_T

GND_A

C1729

100

10V

16 15 14 13 12 11 10 9

E

VCC

SW2

E

GND_T

GND_T

TO AUDIO

A_V2_IN_AU_L,A_V2_IN_AU_R

Coax/Audio Output

—

M

—

N

—

O

—

P

VideoInput2

V2_IN_AU_L

AU_IN_GND

V2_IN_AU_R

HP_OUT_AU_L

AU_IN_GND

USB_5V

USB_PA

USB_NA

USB_GND

HP_OUT_AU_R

HP_IN_GND

HP_DET

V2_IN_V

CN1400

20P

D3.3V

DVI_IN_L

R1402

CHIP0

1

2

3

GND

4

5

NC

6

7

GND_T

8

R1922

0

9

10

R1923

0

11

GND

12

13

14

15

GND

16

GND

17

18

D5V

19

GND

GND_HP

20

GND_A

R1408

C1403

0.001

50V

X7R

1005

REG5V

USB_PA

USB_NA

GND_D

CHIP0

R1405

GND_T

R1403

R1404

CHIP0

R1406

A_V2_IN_AU_L

A_V2_IN_AU_R

CHIP0

1005

50V

220p

C1752

USB_5V

5V_TU

VIDEO2

R1947

2.2UH

3225

1005

1005

GND_A

GND_A

5%

CHIP

1/16W

22k

R1917

CHIP

1/16W

R1918

R1919

1/16W

CHIP

5%

10k

100

5%

RN-CP

1/10W

R1920

0.5%

470

Q1007

2SD601A-QRS-TX

MA8100-TX

0.5%

RN-CP

1/10W

R1916

D1019

C1754

10

10V

X7R

220

3216

0.5%

L1007

2.2uH

1005

B

50V

220p

C1753

GND_T

GND_T

RN-CP

0.5%

1/10W

RN-CP

220

1/10W

R1915

220

R1914

B

GND_T

B

16V

22

C1756

A_V2_IN_V

GND_A

CHIP0

CHIP0

A_HP_OUT_AU_L

A_HP_OUT_AU_R

HP_DET

PC_LR IN

PC_IN_L

PC_IN_R

1

C1714

B

16V

2012

1k

R1712

1/16W

1005

J1710

CHIP

R1713

1

B

16V

C1715

1k

CHIP

1/16W

5%

470k

CHIP

R1710

1/16W

VD1711

VD1710

2012

R1711

470k

GND_T

GND_D

C1724

1

16V

R1722

B

2012

1k

1/16W

DVI_IN_R

A_AUOUT_AU_R

A_AUOUT_AU_L

5%

5%

220k

1/16W

1/16W

CHIP

CHIP

GND_A

CHIP

1005

1005

R1701

1/16W

5%

5%

2.2k

CHIP

R1703

1/16W

COAXS

COAXG

GND_A

VD1701

GND_T

GND_T

4

3

R

J1701

D1020

MA8100-TX

J1722

A-1278-778-A <MA1>BM-P1

220k

D1021

MA8100-TX

R1700

2.2k

R1702

VD1700

1

2

L

1

B

16V

2012

C1725

B

B

50V

50V

1000p

C1722

CHIP

470k

R1720

VD1720

L

1608

R

R1723

VD1721

C1723

1k

1000p

1/16W

CHIP

J1720

1608

1005

R1721

470k

1/16W

CHIP

GND_T

5%

GND_D

GND_T

AUDIO IN

KDL-26M3000/26ML130/32M3000/32ML130 44

Page 45

BM BOARD SCHEMATIC DIAGRAM (2 OF 12)

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23

A

TV_R

—

B

—

C

—

D

A_V3_IN_AU_L

A_V2_IN_AU_L

A_V1_IN_AU_L

TV_L

A_SW_AD_L

R2222

47k

1/16W

CHIP

5%

47K

RB 2003

C2176

A_V2_IN_AU_R

A_V1_IN_AU_R

A_V3_IN_AU_R

47K

RB 2002

40

414243

44

T7

12345678

V3L

T1

V2L

T2

V1L

T3

TVL

T4

91011

SWL

R2230

24k

1/16W

CHIP

5%

4.7

25V

LOPIN

LOUT

V2RT8V3R

AUDIOSWITCH/ ADC

AK 5366V Q-L

IC 2014

IPGAR

ROPIN

IPGAL

121314

AVDD

16171819202122

15

ROUT

A_SW_AD_R

5%

CHIP

1/16W

47k

R2227

39

M/S

SWRT5TVRT6V1R

AVSS

DVSS

SDTO

DVDD

VCOM

—

GND_T

E

25V

C2177

5%

CHIP

1/16W

24k

R2231

4.7

16V

C2181

10

C2178

1608

B

C2179

0.1

25V

1608

C2180

0.1

25V

B

0.1

25V

B

C2182

10

16V

—

REG5V

D3.3V

F

—

G

—

H

I2S_SD_OUTA

I2S_SCK _OUTA

I2S_WS_OUTA

1005

CHIP

R2283

GND_T

GND_T

22

RB 2005

R2253

0

CHIP

0

L2005

10uH

CS 4335-K SZR

SDATA

SCLK /DEM

LRCK

4321

MCLK AOUTR

FB 2000

0uH

IC 2015

C2000

AOUTL

AGND

R2252

4.7k

1/16W

CHIP

5%

3435363738

I2C

CSN

SCL

SDA

SEL2

SEL1

SEL0

SMUTE

TVDD

PDN

MCLK

LRCK

BICK

0uH

R2232

10

16V

C2183

1608

ATI_SDO

22

16V

8765

VA+

KDL-26M3000/26ML130/32M3000/32ML130

AUDIO_9V

MA 111-T X

D2002

IC 2005

BA09FP-E2

OUT

VCC

0.5%

RN-CP

1/16W

5.6k

R2143

5.6k

R2133

47k

5%

1/16W

CHIP

C2095

0.1

25V

B

1608

SP_MUTE

R2281

3.3k

1/16W

RN-CP

0.5%

R2210

C2094

330p

2.2k

50V

1/16W

CH

RN-CP

1608

0.5%

4321

V-

A- IN

A+IN

NJM 4558V -TE 2

IC 2006

B- IN

B+IN

BOUT

C2096

330p

50V

CH

1608

R2211

2.2k

1/16W

RN-CP

0.5%

0.5%

RN-CP

1/16W

100k

R2282

2012

B

10V

2.2

C2217

AOUT

V+

8765

C2086

0.001

50V

X7R

1005

GND_D

100

RB 2004

GND_DGND_D

2627282930313233

GND_D

C2195

0.1

25V

B

1608

232425

R2228

R2250

0

CHIP

R2249

100

1/16W

CHIP

5%

REG5VREG5V

0uH

FB 2013

1005

X7R

25V

0.01

C2198

0uH 0uH

2012

B

16V

1

C2200

R2229

0.5%

RN-CP

1/16W

270k

R2258

D2022

MA8056-TX

R2233

D2020

MA8056-TX

I2CA_SCL

I2CA_SDA

D2021

MA 8056-T X

GND_D

B

50V

1608

0.047

C2216

/R ES E T_ OUT

ATI_MCLK

ATI_WS

0uH

C2204

0.5%

RN-CP

1/16W

270k

R2257

C2205

4.7

25V

ATI_SCK

MAIN_R

MAIN_L

GND_T

R2265

CHIP

1/16W

10k

R2261

5%

CHIP

1/16W

10k

R2262

560

1/16W

CHIP

5%

5%

B

50V

1005

1005

1500p

C2208

R2266

560

1/16W

B

50V

1005

1500p

1005

C2210

CHIP

5%

4.7

25V

R2269

100

1/16W

CHIP

B

B

5%

R2270

100

1/16W

CHIP

5%

CHIP

5%

CHIP

5%

50V

1500p

C2209

50V

1500p

C2211

MAIN_L

47k

R2273

1/16W

MAIN_R

47k

R2274

1/16W

CHIP

R2114

CHIP

0

R2116

L2015

10uH

R2117

25V

1.5k

4.7

1/16W

C2074

RN-CP

R2118

25V

1.5k

4.7

C2075

0

1/16W

RN-CP

CHIP

1/16W

47k

R2121

CHIP

1/16W

R2122

C2169

2700p

50V

B

1608

2012

B

10V

47k

2.2

C2078

C2168

2700p

50V

1608

5%

B

R2129

1/16W

CHIP

16V

47

C2085

0.5%

RN-CP

1/16W

R2145

47k

GND

HP_DET

Q2006

2SC 4154TP- 1E F

C2097

25V

1608

C2098

C2100

0.1

100

16V

25V

B

1608

R2251

R2148

47k

1/16W

CHIP

R2147

0

CHIP

HN1B01FU-TE 85R

SP_SD

RT 1N141M -T P-1

Q2010

Q2009

C2102

0.001

50V

X7R

1005

R2149

22k

1/16W

CHIP

R2150

1/16W

CHIP

22k

1

4

5

2

6

3

R2151

47k

1/16W

CHIP

5%

25V

C2105

1005

R2163

47k

1/16W

CHIP

C2101

5%

0.001

50V

X7R

1005

1k

1/16W

CHIP

5%

0.1

AU _13V

A UD IO_13V

12

F2000

4A

24V

C2117

0.001

50V

AU_HP9V

P48

48

AVCC

AVCC

ROSC

GND

131415

P13

C2113

JL2002

P46

P47

FAULT

VREG

P14

P15

100k

R2162

0.01

25V

X7R

1005

25V

4.7

C2112

C2111

0.1

25V

B

1608

C2103

4.7

25V

25V

4.7

4.7

C2104

25V

4.7

C2106

CHIP

0

R2277

123456789101112

P1

GND

P2

RINN

P3

RINP

P4

AGND

P5

LINP

P6

LINN

P7

GAIN0

P8

GAIN0

P9

GAIN1

P10

MSTR/SLV

P11

SYNC

P12

GND

R2278

0

CHIP

X7R

1005

C2115

0.22

25V

B

2012

P42

P43

P44

P45

44

454647

BSRP

MUTE

ROUTP

SHUTDOWN

TP A3100D2P HPR

IC 2009

AUDIOAMP

BSLP

VBYP

LOUTP

AGND

17181920212223

16

P16

P17

P18

P19

C2116

0.22

25V

B

2012

25V

4.7

C2114

L2016

22uH

C2118

0.001

50V

X7R

1005

C2119

0.22

25V

B

2012

P37

P38

P39

P40

P41

37383940414243

GND

BSRN

ROUTN

ROUTN

ROUTP

PVC CR

PVC CR

PGNDR

PGNDR

VCLAMPR

VCLAMPL

PGNDL

PGNDL

PVC CL

PVC CL

BSLN

LOUTP

GND

LOUTN

LOUTN

24

P20

P21

P22

P23

P24

C2120

0.22

25V

B

2012

C2121

0.001

50V

X7R

1005

GND_AU

GND

GND

C2123

470

25V

TO DETECT

R2177

100k

1/16W

CHIP

R2178

100k

1/16W

CHIP

7

RB 2001

100k

1

23

22uH

L2018

4

NC

C2128

20V

22

NC

NC

NC

NC

NC

4

1

NC

4

1

NC

4

1

2012

B

22uH

L2019

25V

0.22

23

C2132

22uH

L2026

23

2012

22uH

B

L2027

25V

23

0.22

C2133

B

25V

0.22

2012

C2136

B

25V

0.22

2012

C2137

B

25V

0.22

2012

C2138

B

25V

0.22

2012

C2139

C2124

22

20V

C2125

P36

0.1

25V

B

P35

1608

P34

P33

C2126

1

P32

25V

2012

P31

P30

C2127

P29

1

25V

2012

P28

P27

P26

252627282930313233343536

C2129

P25

0.1

25V

B

1608

2143658

FB 2006

0uH

FB 2007

0uH

FB 2008

0uH

FB 2009

0uH

C2146

25V

2012

C2145

25V

2012

B

1

1

B

D2014

MM3Z9V 1ST1

R2198

1/16W

R2199

10k

1/16W

CHIP

FB2010

CHIP

6.8k

0uH

Q2012

RT3AMMM

Q2013

RT3AMMM

GND_D

2012

10V

C2218

B

2.2

R2202

10k

1/16W

CHIP

RT 1N141M -T P-1

Q2017

RT 1N141M -T P-1

1608

B

25V

0.1

C2157

R2201

0

CHIP

1005

Q2016

RT 1N141M -T P-1

Q2018

R2204

100k

1/16W

CHIP

R2205

1/16W

CHIP

C2159

0.001

50V

X7R

1005

SP1

1608

B

25V

47k

0.1

C2158

CN2000

4P

1

R-

2

R+

3

L+

4

L-

TOSPEAKERS

—

I

—

J

—

K

—

L

—

M

—

N

—

O

—

I2S_SD_OUTB

I2S_SCK_OUTB

I2S_WS_OUTB

I2S_SOSCK_OUTB

PIN A S SIGME NT B Y A TI

PIN A S SIGNM ENT BY AT I

002:6F

A_D1_IN_AU_R

AVSW_1

002:6H

A_D2_IN_AU_R

AVSW_2

002:15F

PC_IN_R

002:6F

A_D1_I N_AU _L

002:6H

A_D2_I N_AU _L

002:15F

PC_IN_L

COAXS

COAXG

RB 2006

5%

RN-CP

1/10W

220

R2235

UDZ ST E- 1710B

D2018

22

R2214

1/16W

CHIP

10k

5%

R2215

10k

1/16W

CHIP

5%

GND_T

GND_TGND_T

REG5V

R2254

0

CHIP

GND_T

2SD601A -QR S- TX

5%

RN-CP

1/10W

68

R2236

16V

47

C2185

Q2021

L2025

10uH

16V

C2172

10

16V

C2173

10

RN-CP

1/10W

R2238

RN-CP

5%

1k

1/10W

R2237

5%

1k

R2234

1/10W

RN-CP

1608

4321

87654321

10k

5%

CS 4335-K SZR

IC 2016

SDATA

AOUTL

SCLK /DEM

LRCK

AGND

MCLK AOUTR

NJM 2750M-T E 2

IC 2013

D1R

GND

SW1

OUTR

D2R

VCC

SW2

DVIR

PCR

VREF

D1L

OUTL

D2L

PCL DV IL

C2186

47

16V

8765

VA+

16 15 14 13 12 11 10 9

NC

NC

RN-CP

1/10W

R2239

5%

1k

C2174

100

16V

1005

X7R

C2199

25V

0.01

FB 2014

C2175

10

16V

0uH

R2216

100k

1/16W

CHIP

GND_T

C2201

5%

GND_T

GND_T

2012

B

16V

1

C2197

GND_T

GND_T

R2217

C2196

100k

1/16W

CHIP

GND_T

5%

C2206

4.7

25V

0.5%

RN-CP

1/16W

270k

R2259

C2207

4.7

25V

0.5%

RN-CP

1/16W

270k

R2260

GND_T

4.7

25V

4.7

25V

SPDIF

A_SW_AD_R

GND_T

DVI_IN_R

A_SW_AD_L

DVI_IN_L

CHIP

1/16W

R2263

CHIP

1/16W

R2264

R2267

560

1/16W

CHIP

5%

5%

10k

5%

10k

R2268

560

1/16W

CHIP

B

50V

1005

1005

1500p

C2212

B

5%

50V

1005

1005

1500p

C2214

R2271

100

5%

CHIP

1/16W

CHIP

B

B

5%

50V

1500p

C2213

R2272

100

1/16W

CHIP

5%

50V

1500p

C2215

5%

CHIP

D2019

UDZ ST E- 1710B

L2023

CHIP

0

GND_T

GND_T

LINE_L

47k

R2275

1/16W

LINE_R

47k

R2276

1/16W

L2022

LINE_L

LINE_R

10uH

L2011

C2069

10V