Sony KDL-22P5500, KDL-32P5500 Schematic

SERVICE MANUAL

SERVICE MANUAL

Ver 2.0

NEX09 CHASSIS

MODEL

MODEL

DEST

DEST

KDL-22P5500

WE / OIRT

MODEL

MODEL

DEST

DEST

KDL-32P5500

WE / OIRT

- 1 -

RM-ED017

RM-ED017

FLAT PANEL COLOR TV

FLAT PANEL COLOR TV

TABLE OF CONTENTS

Section Title Page Section Title Page

1. GENERAL ................................................................... 3

Caution................................................................ 3

Specifications ..................................................... 4

Connectors .......................................................... 5

Self Diagnosis ..................................................... 6

2. DISASSEMBLY

2-1. Rear Cover & Stand Removal (22 inches) ........ 7

2-2. Rear Cover & Stand Removal (32 inches) ........ 7

2-3. Button Bracket Removal .................................... 7

2-4. H1 Board Removal ............................................. 7

2-5. Cover, Under Removal (32 inches) ................... 8

2-6. Speaker Removal (22 inches) ............................ 8

2-7. Speaker Removal (32 inches) ............................ 8

2-8. H2 Board Removal ............................................. 8

2-9. Side Jack bracket Removal ................................ 8

2-10. A Board Removal ............................................... 9

2-11. G Board Removal (22 inches) ............................ 9

2-12. G2BE Board Removal (32 inches) .................... 9

3. ADJUSTMENTS

3-1. How to enter the Service Mode ........................ 10

3-2. Service Menu Structure ..................................... 10

3-2-1. Service General Menu ................................. 10

3-2-2. Service Alignments Menu ........................... 10

3-2-3. OSD Service Menu ...................................... 11

3-2-4. Country Selection Menu .............................. 11

3-2-5. Reset ............................................................. 11

3-3. White Balance Adjustment ............................... 12

3-3-1. Preparation ................................................... 12

3-3-2. “COOL” White Balance Adjustment .......... 12

3-3-3. “NEUTRAL” White Balance Adjustment .. 12

3-3-4. “WARM” White Balance Adjustment ........ 12

4. DIAGRAMS

4-1. Block Diagram 1 (22 inches) ............................. 13

Block Diagram 2 (32 inches) ............................. 14

4-2. Circuit Board Location ....................................... 15

4-3. Schematic Diagrams and Printed Wiring

Boards ................................................................. 15

A Board Schematic Diagram ............................. 16

G Board Schematic Diagram (22 inches) .......... 28

G2BE Board Schematic Diagram (32 inches) ... 30

H1 Board Schematic Diagram ........................... 31

H2 Board Schematic Diagram ........................... 31

A Printed Wiring Board ..................................... 32

G Printed Wiring Board (22 inches) .................. 34

G2BE Printed Wiring Board (32 inches) ........... 36

H1 Printed Wiring Board ................................... 38

H2 Printed Wiring Board ................................... 38

5. EXPLODED VIEWS

5-1a. Chassis (22 inches) ............................................. 39

5-1b. Chassis (32 inches) ............................................. 40

5-2. Bezel & Stand Assy ............................................ 41

5-3a. Rear Cover & Power Supply Cords (22 inches) 42

5-3b. Rear Cover & Power Supply Cords (32 inches) 43

Accessories & Connectors ................................. 47

Remote Commander ........................................... 47

WARNING !!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING ANY

SERVICE WORK TO AVOID POSSIBLE SHOCK HAZARD DUE TO

LIVE CHASSIS, THE CHASSIS OF THIS RECEIVER IS DIRECTLY

CONNECTED TO THE POWER LINE.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY SHADING AND MARKED

THE EXPLODED VIEWS AND IN THE PARTS LIST ARE CRITICAL

FOR SAFE OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN

THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

- 2 -

ON

SECTION 1 GENERAL

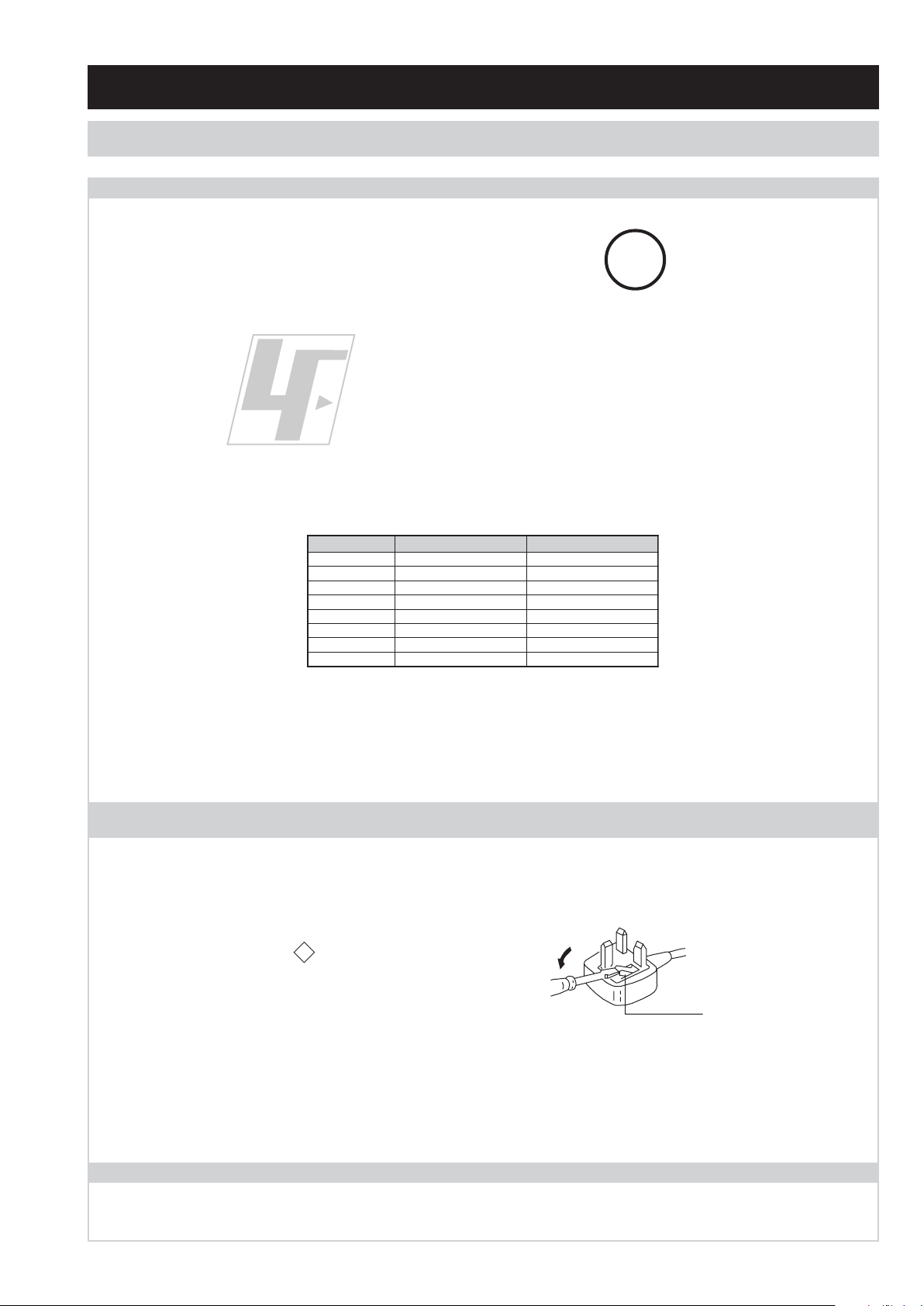

How to replace the fuse.

Open the fuse compartment with

a screwdriver blade and replace

the fuse.

FUSE

SECTION 1 GENERAL

CAUTION

Lead Free Soldered Boards

example

The circuit boards used in these models have been processed using

Lead Free Solder. The boards are identified by the LF logo located

close to the board designation e.g. H1 etc [ see example ]. The

servicing of these boards requires special precautions to be taken as

outlined below.

Lead Free Solder material must be used to comply with environmental requirements of new solder joints. Lead Free Solder is available under

the following part numbers :

rebmuntraP retemaiD skrameR

91-500-046-7mm3.0gK52.0

02-500-046-7mm4.0gK05.0

12-500-046-7mm5.0gK05.0

22-500-046-7mm6.0gK52.0

32-500-046-7mm8.0gK00.1

42-500-046-7mm0.1gK00.1

52-500-046-7mm2.1gK00.1

62-500-046-7mm6.1gK00.1

Due to the higher melting point of Lead Free Solder the soldering iron tip temperature needs to be set to 370 degrees centigrade. This requires

soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

For more information on the use of Lead Free Solder, please refer to http://www.sony-training.com

UK PLUG WARNING

WARNING (UK Models only)

The flexible mains lead is supplied connected to a B.S. 1363 fused

plug having a fuse of the correct rating for the set. Should the fuse

need to be replaced, use a fuse of the same rating approved by ASTA

to BS 1362, ie one that carries the

IF THE PLUG SUPPLIED WITH THIS APPLIANCE IS NOT SUITABLE

FOR THE OUTLET SOCKETS IN YOUR HOME, IT SHOULD BE CUT

OFF AND AN APPROPRIATE PLUG FITTED. THE PLUG SEVERED

FROM THE MAINS LEAD MUST BE DESTROYED AS A PLUG WITH

BARED WIRES IS DANGEROUS IF ENGAGED IN A LIVE SOCKET.

ASA

T

mark.

When an alternative type of plug is used, it should be fitted with the

correct rating fuse, otherwise the circuit should be protected by the

same rating fuse at the distribution board.

LCD PANEL CAUTION

Whilst working on this product, it is not recommended to lay the TV set face down when powered up, as this can result in panel problems. If

it is necessary to power up the TV set when face down, the time should be minimised as much as possible.

- 3 -

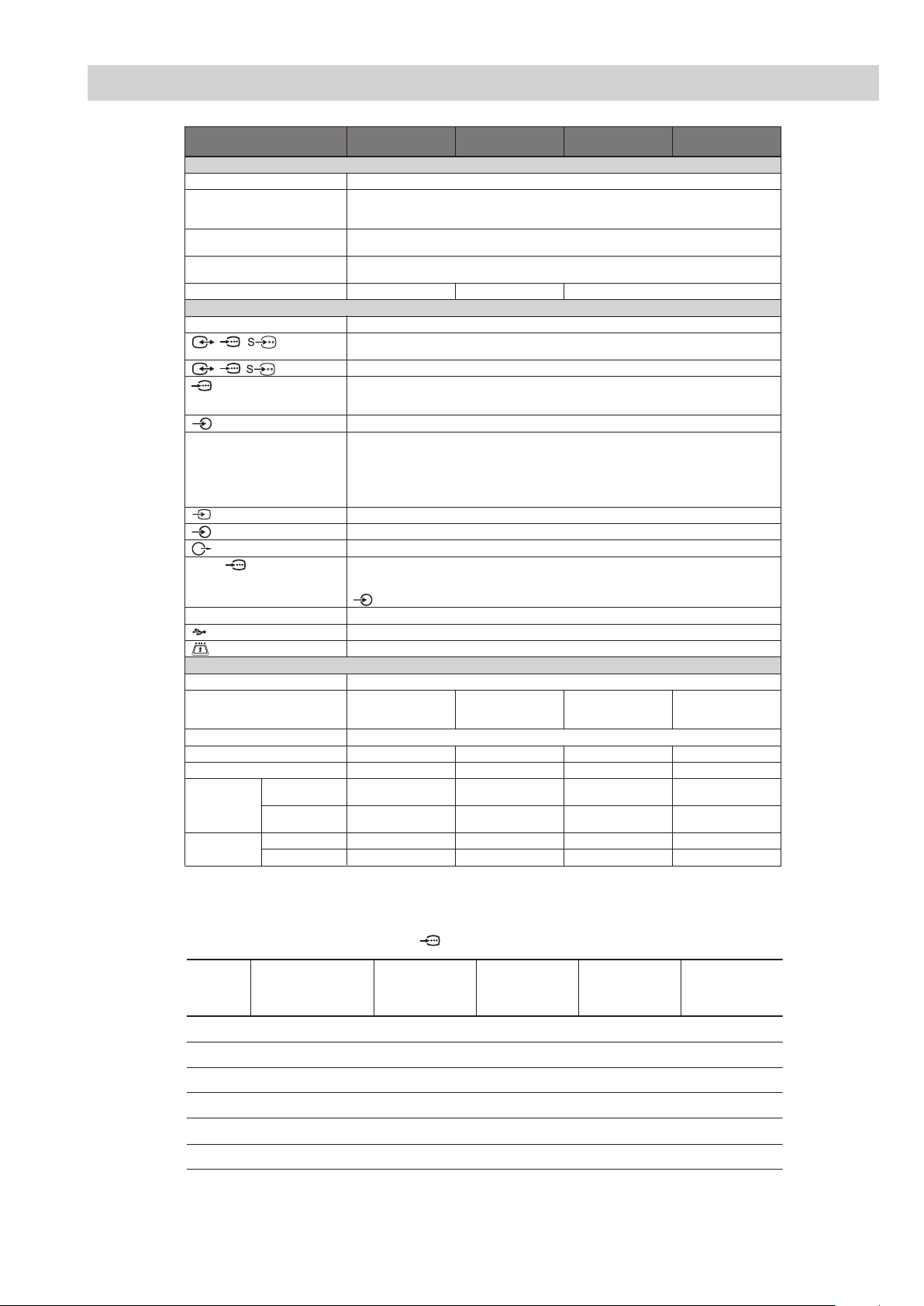

SPECIFICATIONS

Model name KDL-32S55xx/

KDL-32P55xx

KDL-26S55xx/

KDL-26P55xx

KDL-22S55xx/

KDL-22P55xx

System

Panel System

TV System

Colour/Video System

Channel Coverage

Sound Output

LCD (Liquid Crystal Display) Panel

Depending on your country/region selection

Analogue: B/G/H, D/K, L, I

Digital: DVB-T

Analogue: PAL, SECAM, NTSC 3.58, 4.43 (only Video In)

Digital: MPEG-2 MP@ML

Analogue:48.25 - 855.25 MHz

Digital: VHF Band III (177.5 - 226.5 MHz)/UHF E21 - E69 (474 - 858 MHz)

10 W + 10 W (RMS) 8 W + 8 W (RMS) 5 W + 5 W (RMS)

Input/Output jacks

Aerial

/ / AV1*

/ / AV2*

COMPONENT IN

COMPONENT IN

HDMI IN 1, 2, 3*

AV3

AV3

PC IN

i

4

75 ohm external terminal for VHF/UHF

1

21-pin scart connector including audio/video input, RGB input, S-Video input, and Analogue TV

audio/video output.

2

21-pin scart connector including audio/video input, RGB input, S-Video input, and audio/video output.

Supported formats: 1080i, 720p, 576p, 576i, 480p, 480i

Y: 1 Vp-p, 75 ohms, 0.3V negative sync/P

P

R/CR: 0.7 Vp-p, 75 ohms

Audio input (phono jacks)

Video: 1080i, 720p, 576p, 576i, 480p, 480i

Audio: Two channel linear PCM

32, 44.1 and 48 kHz, 16, 20 and 24 bits

PC (See below)

Analogue audio (minijack) (HDMI2 only) (KDL-32S55xx, KDL-32P55xx, KDL-26S55xx, KDL-26P55xx)

Analogue audio (minijack) (HDMI1 only) (KDL-22S55xx, KDL-22P55xx, KDL-19S55xx, KDL-19P55xx)

Video input (phono jack)

Audio input (phono jacks)

Audio output (Left/Right) (phono jacks)

PC Input (15 Dsub) (see page 35)

G: 0.7 Vp-p, 75 ohms, non Sync on Green/B: 0.7 Vp-p, 75 ohms/

R: 0.7 Vp-p, 75 ohms, H/V Sync: TTL level

PC audio input (minijack)

Headphones jack

USB port

CAM (Conditional Access Module) slot

B/CB: 0.7 Vp-p, 75 ohms/

Power and others

Power Requirements

Screen Size

Display Resolution

Power Consumption

Standby Power Consumption*

Dimensions

(with stand)

(w × h × d)

(without stand)

Mass (with stand)

(without stand)

*1AV1 outputs available only for analogue TV.

2

*

AV2 outputs watching screen (except PC, HDMI, Component 1080i).

3

*

Specified standby power is reached after the TV finishes necessary internal processes.

4

*

HDMI3 is available only for KDL-32S55xx, KDL-32P55xx, KDL-26S55xx and KDL-26P55xx.

220–240 V AC, 50 Hz

32 inches

(Approx. 80.0 cm

measured diagonally)

1,366 dots (horizontal) × 768 lines (vertical)

135 W 110 W 60 W 55 W

3

0.5 W or less 0.5 W or less 1 W or less 1 W or less

Approx. 80.7 × 55.7 ×

22.2 cm

Approx. 80.7 × 50.8 ×

9.4 cm

Approx. 12.7 kg Approx. 10.0 kg Approx. 6.9 kg Approx. 5.8 kg

Approx. 11.4 kg Approx. 8.7 kg Approx. 6.1 kg Approx. 5.0 kg

26 inches

(Approx. 66.1 cm

measured diagonally)

Approx. 67.9 × 48.5 ×

22.2 cm

Approx. 67.9 × 43.5 ×

9.3 cm

22 inches

(Approx. 54.8 cm

measured diagonally)

Approx. 55.8 × 41.7 ×

21.5 cm

Approx. 55.8 × 37 ×

7.9 cm

PC Input Signal Reference Chart for PC IN , HDMI IN 1, 2 and 3 *

KDL-19S55xx/

KDL-19P55xx

19 inches

(Approx. 47.0 cm

measured diagonally)

Approx. 48.7 × 37.5 ×

21.5 cm

Approx. 48.7 × 32.8 ×

7.9 cm

Signals Horizontal (Pixel) Vertical (Line)

Horizontal

frequency

(kHz)

Ver tical

frequency (Hz)

Standard

VGA 640 480 31.5 60 VGA

SVGA 800 600 37.9 60 VESA Guidelines

XGA 1024 768 48.4 60 VESA Guidelines

WXGA 1280 768 47.4 60 VESA

WXGA 1280 768 47.8 60 VESA

WXGA 1360 768 47.7 60 VESA

• This TV’s PC input does not support Sync on Green or Composite Sync.

• This TV’s PC input does not support interlaced signals.

• This TV’s PC input supports signals in the above chart with a 60 Hz vertical frequency.

* HDMI3 is available only for KDL-32S55xx, KDL-32P55xx, KDL-26S55xx and KDL-26P55xx.

- 4 -

21 Pin Connector (SCART)

1

21

19

17

15

13

11

9

7

5

3

1

20

18

16

14

12

10

CONNECTORS

Pin No 1 Signal Signal level

1 Audio output B

(right)

Audio input B

2

(right)

Audio output A

3

(left)

4 Ground (audio)

5 Ground (blue)

6 Audio input A

(left)

7 Blue input 0.7 +/- 3dB, 75 ohms positive

8 Function select

(AV control)

9 Ground (green)

10 AVlink

11 Gre en Green signal : 0.7 +/- 3d B, 75 ohms,

12 Ope n

8

6

4

2

13 Ground (red)

14 Gro und (blanking)

_ _ Red input 0.7 +/- 3dB, 75 ohms, positive

15

_ (S signal Chroma

-

input)

16 B lanking input

(Ys signal)

17 Ground (video

output)

18 Ground (video

input)

19 V ideo output 1V +/- 3dB, 75ohms, positive sync 0.3V

Video input 1V +/- 3dB, 75ohms, po sitive sync 0.3V

20

Video input

-

Y (S signal)

21 C ommon ground

(plug, shield)

Connected Not Connected (open) * at 20Hz - 20 kHz

Standard level : 0.5V rms

Output impedence : Less tha n 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

Standard level : 0.5V rms

Output impedence : Less tha n 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

High state (9.5-12V) : Par t mode

Low state (0-2V) : TV mode

Input impedence : More than 10K ohms

Input capacitance : Less than 2n F

positive

0.3 +/- 3dB, 75 ohms, positive

High state (1-3V) Low stat e (0-0.4V)

Input impedence : 75 ohms

(-3+10dB)

(-3+10dB)

1V +/- 3dB, 75ohms, positive sync 0.3V

(-3+10dB)

HDMI Connector

15 Pin D Sub Connector (PC)

Pin No Signal Assignment Pin No Signal Assignment

1 TMDS Da ta2+ 11 TMDS Cl ock Shiel d

2 TMDS Data2 Shield 12 TMDS Clock-

3TMDS Data2- 13CEC

4 TMDS Data1+ 14 Reserved (N.C. on device)

5 TMDS Data1 Shield 15 SCL

6TMDS Data1- 16SDA

7 TMDS Data0+ 17 DDC/CEC Ground

8 TMDS Data0 Shield 18 +5V Power

9 TMDS Data0- 19 Hot Plug Detect

10 TMDS Clock+

Pin No Signal Assignment Pin No Signal Assignment

1Red Out 9 +5V DC

2 Green Out 10 Sync Return (Ground)

3 Blue Out 11 Monitor ID0 in Display

4 Unused 12 DCC Serial Data

5 Ground 13 Horizontal Sync

6 Red Re turn 14 Vertical Sync

7 Green Return (Ground) 15 DCC Serial Clock

8 Blue Return (Ground)

- 5 -

NEX SELF DIAGNOSTIC SOFTWARE

IMPORTANT:

The TV sets in this manual DO NOT contain a self-diagnostic function. If an error occurs, the TV will not stay on.

Control LED’s

LED Error Codes and Descriptions

The TV sets in this manual DO NOT contain a self-diagnostic function.

- 6 -

SECTION 2 DISASSEMBLY

2-2. Rear Cover & Stand Removal (32 inches)2-1. Rear Cover & Stand Removal (22 inches)

See Appendix-A.See Appendix-A.

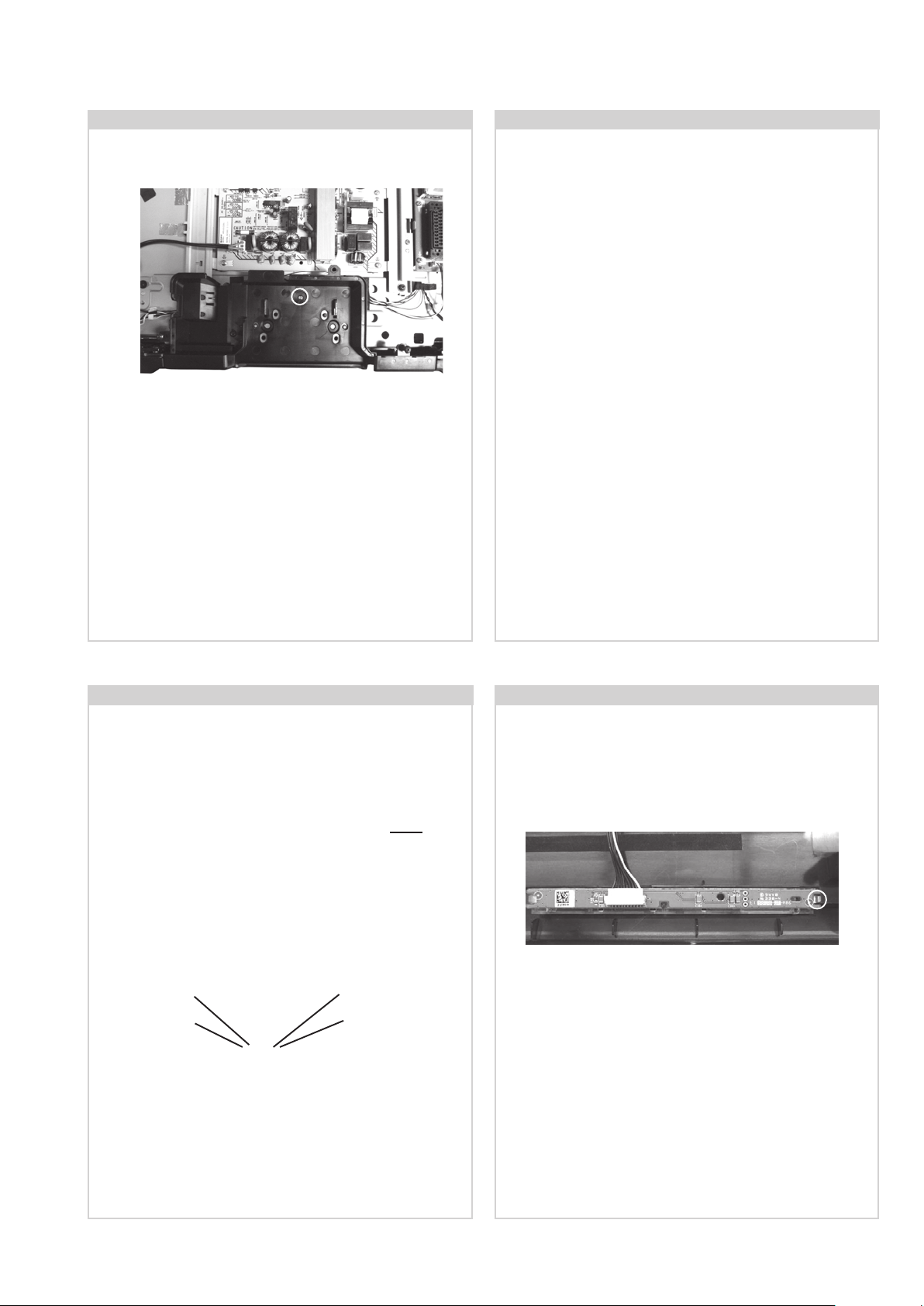

2-3. Button Bracket Removal

To remove the Button Bracket, lift the bottom of the bracket

towards the TV set. Push the top of the bracket in the

shaded area in the photograph. The bracket will then release from its boss and can be removed from the TV set.

2-4. H1 Board Removal

To remove the H1 board from the bracket, disconnect the

wire harness, remove the 2 screws circled and lift the board

out of the bracket.

Screw Part number(s) and Description(s)

7-685-504-19 SCREW, +BTP 2 X 6 2 Screws

- 7 -

2-5. Cover, Under Removal (32 inches)

To remove the Cover, Under, remove the screw circled

and ease the cover away from the TV set.

Screw Part number(s) and Description(s)

7-682-961-09 SCREW, +PSW M4X8 1 Screw

2-6. Speaker Removal (22 inches)

To remove the speakers disconnect the speaker wire harnesses from each speaker , remove the 4 screws circled from

the bracket and ease the complete assy away from the TV set.

Screw Part number(s) and Description(s)

7-685-661-79 SCREW, +BVTP2 4 X 12 4 Screws

To remove the speakers from the speaker bracket, remove

the 4 screws circled on each speaker and separate the

speakers from the bracket.

Screw Part number(s) and Description(s)

7-685-661-79 SCREW, +BVTP2 4 X 12 8 Screws

2-7. Speaker Removal (32 inches)

To remove the speakers disconnect the speaker wire

harness , remove the 1 screw circled from the bracket

and ease the complete assy away from the TV set.

Screw Part number(s) and Description(s)

2-580-640-01 SCREW, +BVTP2 4 X 16 1 Screw

Screw

To remove the speakers from the speaker bracket,

remove the 4 screws circled and separate the speaker

from the bracket.

2-8. H2 Board Removal

Remove the Speakers (See Sec 2-4 2-5).

Screw

Disconnect the wire harness, release the clip circled and

ease the H2 board away from the TV set.

Screw Part number(s) and Description(s)

2-580-640-01 SCREW, +BVTP2 4 X 16 4 Screws

The procedure is identical for both speakers.

- 8 -

2-9. Side Jack Bracket Removal

2-10. A Board Removal

Clip

Clip

Release the 2 clips indicated and gently pull the bracket

away from the A board in the direction of the arrow.

2-11. G Board Removal (22 inches)

Disconnect the 6 harnesses from the board. Remove the 9

screws circled. The board can then be carefully lifted from the

TV.

Screw Part number(s) and Description(s)

4-382-854-01 SCREW, +PSW M3 X 8 9 Screws

2-12. G2BE Board Removal (32 inches)

Disconnect the 3 harnesses from the board. Remove the 6

screws circled and ease the board gently away from the back

of the TV set.

Screw Part number(s) and Description(s)

4-382-854-01 SCREW, +PSW M3 X 8 6 Screws

Disconnect the 3 harnesses from the board. Remove the 6

screws circled and ease the board gently away from the back

of the TV set.

Screw Part number(s) and Description(s)

4-382-854-01 SCREW, +PSW M3 X 8 6 Screws

- 9 -

SECTION 3 ADJUSTMENTS

3-1. How to enter the Service Mode

Service adjustments to this model can be performed using the

supplied Remote Commander RM-ED017.

1. Turn on the power to the TV set.

2. Press the following sequence of buttons on the Remote

Commander.

i+

(ON SCREEN

DISPLAY)

3. The following menu appears on the screen (See Pic.1).

Pic.1

5

(DIGIT 5) (VOLUME +)

+

I/

3-2. Service Menu Structure

The following description shows the items that can be

viewed and/or adjusted using the Service Menu.

3-2-1. Service General Menu

The following menu appears on the screen when you enter

the ‘Service General Menu’ (See Pic.2). This menu allows

you to view the product information, set the TV into Aging

Mode and perform Software Upgrade to the TV set.

Pic.2

4. Move to the corresponding adjustment item using the

‘ ’ or ‘ ’ arrow buttons on the Remote Commander.

5. Press the ‘ ’ arrow button to enter into the required menu

item.

6. Adjust the data value using the ‘ ’ or ‘ ’ arrow buttons on

on the Remote Commander.

7. To go back at any time press the ‘ ’ button on the Remote

Commander.

8. Ensure you return to the top level menu, shown above in

Pic 1, and press the Green button on the Remote

Commander to Store all the adjustments.

9. Press the Red button or ‘Menu’ button on the Remote

Commander to quit the Service Mode when all adjustments

have been completed.

• After carrying out the service adjustments, to prevent the

customer accessing the ‘Service Menu’ switch the TV set

OFF and then ON again.

3-2-2. Service Alignments Menu

The following menu appears on the screen when you enter

the ‘Service Alignments Menu’ (See Pic.3). This menu

allows adjustment of the TV picture levels. These adjustments

are set during manufacture and should not normally require

further adjustment.

Pic.3

- 10 -

3-2-3. OSD Service Menu

3-2-4. Country Selection Menu

The following menu appears on the screen when you enter

the ‘OSD Service Menu’ (See Pic.4). This menu

allows viewing and adjustment of the AGC and viewing of the

Sound Status.

Pic.4

The following menu appears on the screen when you enter

the ‘Country Selection Menu’ (See Pic.5). Using this menu

the destination country of the TV can be set.

Pic.5

3-2-5. Reset

Selection of ‘Reset’ (See Pic.6) allows the TV to be reset to

factory shipping condition. This will restore all settings to those

which were contained in the TV on first shipment.

Pic.6

- 11 -

3-3. White Balance adjustment

3-3-4. “WARM ” White Balance Adjustment

3-3-1. Preparation

1. Allow approximately 30 minutes for the set to warm up

before proceeding with the white balance adjustment.

2. Connect the signal source to the 3 terminals of the

Component In input (Y/Pb/Pr).

3. Set the Picture Mode to “VIVID” in the user menu.

4. Select the Component In input.

5. Open the Factory Service Menu (see section 3-1.) and select

“Service Alignments Menu”.

6. Set “White Point Red”, “White Point Green”, “White Point

Blue” and “Black Level Offset Red”, “Black Level Offset

Green”, “Black Level Offset Blue” to average values as

shown in Table 1 (22 inches) and Table 2 (32 inches).

Table 1

22 inches

Red Green Blue Red Green Blue

Gain Gain Gain Offset Offset Offset

Cool 121.8 115.05 125 7.55 7 2.5

Neutral 120.65 114 110.25 7.55 7 2.2

Warm 123.25 104.1 81.0 9.3 7 3.45

1. Select “WARM” from Color Tone in Service Alignments

Menu.

2. Input 70IRE full white pattern signal into Component In.

3. Adjust “White Point Red”, “White Point Green”, “White Point

Blue” in Service Alignments Menu if needed.

4. Input 25IRE full white pattern signal into Component In.

5. Adjust “Black Level Offset Red”, “Black Level Offset Green”,

“Black Level Offset Blue” in Service Alignments Menu if

needed.

6. Repeat steps 2 to 5 to achieve desired White Balance.

7. Save the settings.

Table 2

32 inches

Red Green Blue Red Green Blue

Gain Gain Gain Offset Offset Offset

Cool 127 107.6 115.15 7.9 7 10.9

Neutral 127 102.75 111.75 7 7 8.3

Warm 126.85 90.8 59.7 5.55 5 10.15

3-3-2. “Cool ” White Balance Adjustment

1. Select “COOL” from Color Tone in Service Alignments

Menu.

2. Input 70IRE full white pattern signal into Component In.

3. Adjust “White Point Red”, “White Point Green”, “White Point

Blue” in Service Alignments Menu if needed.

4. Input 25IRE full white pattern signal into Component In.

5. Adjust “Black Level Offset Red”, “Black Level Offset Green”,

“Black Level Offset Blue” in Service Alignments Menu if

needed.

6. Repeat steps 2 to 5 to achieve desired White Balance.

3-3-3. “NEUTRAL ” White Balance Adjustment

1. Select “NEUTRAL” from Color Tone in Service Alignments

Menu.

2. Input 70IRE full white pattern signal into Component In.

3. Adjust “White Point Red”, “White Point Green”, “White Point

Blue” in Service Alignments Menu if needed.

4. Input 25IRE full white pattern signal into Component In.

5. Adjust “Black Level Offset Red”, “Black Level Offset Green”,

“Black Level Offset Blue” in Service Alignments Menu if

needed.

6. Repeat steps 2 to 5 to achieve desired White Balance.

- 12 -

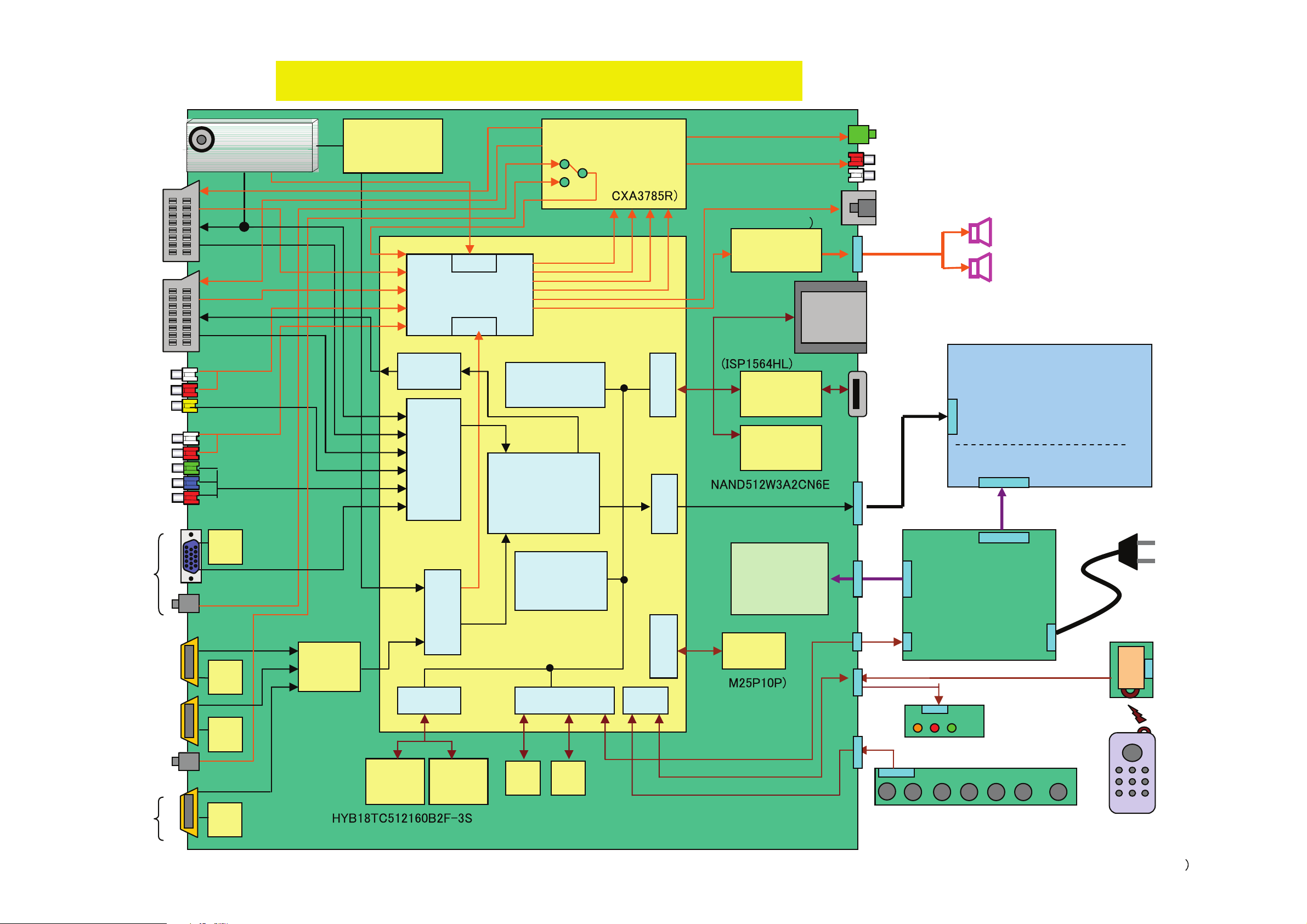

4-1. BLOCK DIAGRAM 1

RF in

TV Tuner

NAND Flash

4MB

DDR2

32MB

Main board

Micro

processor

DC-DC/

Reg. ICs

18.5“/21.6”WXGA DVB-T TV System Architecture

Line Out

LCD Panel

Power

&Inverter

Speaker

5W+5W

Remote

Controller

Analog Front End

I/O

Panasonic

ENG37E10KF

Audio

Processor

AC in

YPbPr

HDMI 1

PC

Video 1

I2S

Keyboard

VOL + CH +Enter/

Input

VOL - CH-

Power

Menu

EEP

ROM

USB 2.0

TS

HDMI

LVDS

EEP

ROM

(PNX8541)

( x2)

()

(cxb1444R)

8bit

Video 2

SIF

SPDIF

Digital

Front End

HDMI

Switch

I2S

Ir

Rx

LED

Ir

EEP

ROM

(

PCMCIA

Flash

HP Out

(TDA10048HN)

(

EEP

ROM

(M24C64)

(M24C04)

(

HDMI 2

(side)

EEP

ROM

Video 3

(side)

PCI

controller

CVBS

Power AMP

(TFA9810T

AMPs &

Selector

DDR2

32MB

PCI

SPI

MCU

Memory

Controller

I/O

Digital Video

Processor

Demodulator

18.5“ : CMO M185 B1- L01

21.6“: CMO V216B1- L01

CVBS/YC/

RGB

CVBS/YC/

RGB

Back Light

RRS1002-8902E

- 13 -

4-1. BLOCK DIAGRAM 2

RF in

TV Tuner

NAND Flash

4MB

DDR2

32MB

Main board

Micro

processor

DC-DC/

Reg. ICs

26“/32” WXGA DVB-T TV System Architecture

Line Out

LCD Panel

Power supply

unit (PSU)

(G2)

Inverter

Speaker

10W+10W (32”)

8W+8W (26”)

Remote

Controller

Analog Front End

I/O

Panasonic

ENG37E10KF

Audio

Processor

AC in

YPrPb

HDMI 1

PC

Video 1

I2S

HDMI 3

Keyboard

VOL + CH +Enter/

Input

VOL - CH-

Power

Menu

EEP

ROM

USB 2.0

TS

HDMI

LVDS

EEP

ROM

EEP

ROM

(PNX8541)

( x2)

()

(cxb1444R)

8bit

Video 2

SIF

SPDIF

Digital

Front End

HDMI

Switch

I2S

Ir

Rx

LED

Ir

EEP

ROM

(

PCMCIA

Flash

HP Out

(TDA10048HN)

(

EEP

ROM

(M24C64)

(M24C04)

(

HDMI 2

(side)

EEP

ROM

Video 3

(side)

PCI

controller

CVBS

Power AMP

(TFA9810T

AMPs &

Selector

DDR2

32MB

PCI

SPI

MCU

Memory

Controller

I/O

Digital Video

Processor

Demodulator

32“: SL C D

26“: CMO V260B1-L11

CVBS/YC/

RGB

CVBS/YC/

RGB

RRS1002-8902E

LTZ320AA03

- 14 -

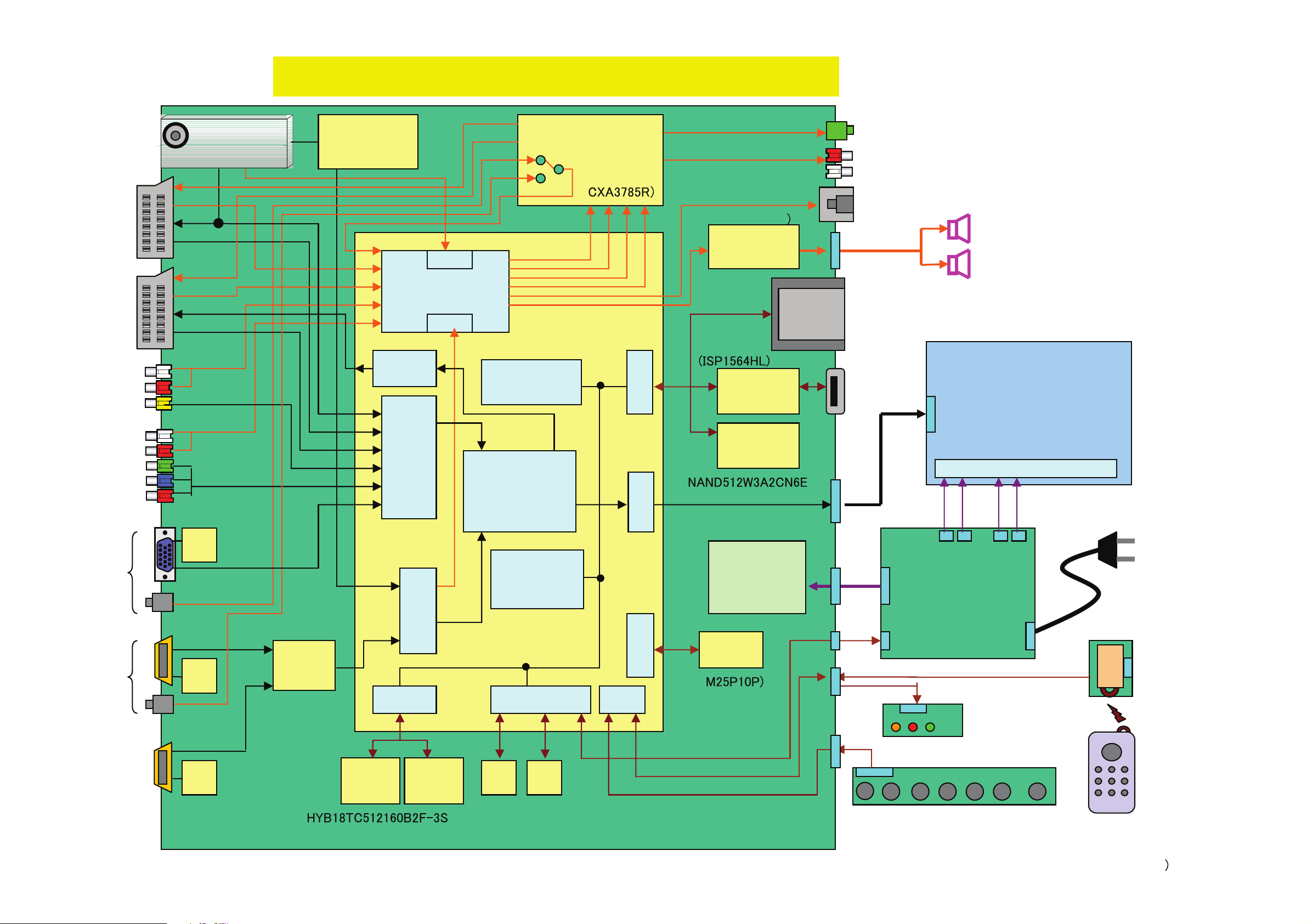

4-2. CIRCUIT BOARD LOCATION

5-2. CIRCUIT BOARD LOCATION

A (MAIN)

G (POWER) 22 inches

G2BE (POWER) 32 inches

C

C

N

VM

CVM Board

H

D1

4-3. SCHEMATIC DIAGRAMS AND

5-3. SCHEMATIC DIAGRAMS AND

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

Note :

• All capacitors are in µF unless otherwise noted.

• pF : µµF 50WV or less are not indicated except for

electrolytic types.

• Indication of resistance, which does not have one for

rating electrical power, is as follows.

Pitch : 5mm

Electrical power rating : 1/4W

• Chip resistors are 1/10W

• All resistors are in ohms.

k = 1000 ohms, M = 1000,000 ohms

• : nonflammable resistor.

• : fusible resistor.

• : internal component.

• : panel designation or adjustment for repair.

• All variable and adjustable resistors have

characteristic curve B, unless otherwise noted.

• All voltages are in Volts.

• Readings are taken with a 10Mohm digital mutimeter.

• Readings are taken with a color bar input signal.

• Voltage variations may be noted due to normal production

tolerences.

•: B + bus.

A

H2 (IR & LED)

A Board

D2

D

H1 (KEY)

S1 Board

A

J

A1

A2

Reference Information

RESISTOR RN

RC

FPRD

FUSE

RS

RB

RW

COIL LF-8L

CAPACITOR TA

PS

PP

PT

MPS

MPP

ALB

ALT

ALR

Note :

The components identified by shading

and marked are critical for safety.

Replace only with the part numbers

specified in the parts list.

Note :

Les composants identifiés par une trame et

par une marque sont d'une importance

critique pour la sécurité. Ne les remplacer

que par des pièces de numéro spécifié.

specified.

Note :

The components identified by mark

confidential information.

Strictly follow the instructions whenever the

components are repaired and/or replaced.

: METAL FILM

: SOLID

: NON FLAMMABLE CARBON

: NON FLAMMABLE FUSIBLE

: NON FLAMMABLE METAL OXIDE

: NON FLAMMABLE CEMENT

: NON FLAMMABLE WIREWOUND

: ADJUSTMENT RESISTOR

: MICRO INDUCTOR

: TANTALUM

: STYROL

: POLYPROPYLENE

: MYLAR

: METALIZED POLYESTER

: METALIZED POLYPROPYLENE

: BIPOLAR

: HIGH TEMPERATURE

: HIGH RIPPLE

contain

• : B - bus.

• : RF signal path.

• : earth - ground.

• : earth - chassis.

- 15 -

Loading...

Loading...