Page 1

HISTORY

When clicking an item, it’s detail is displayed.

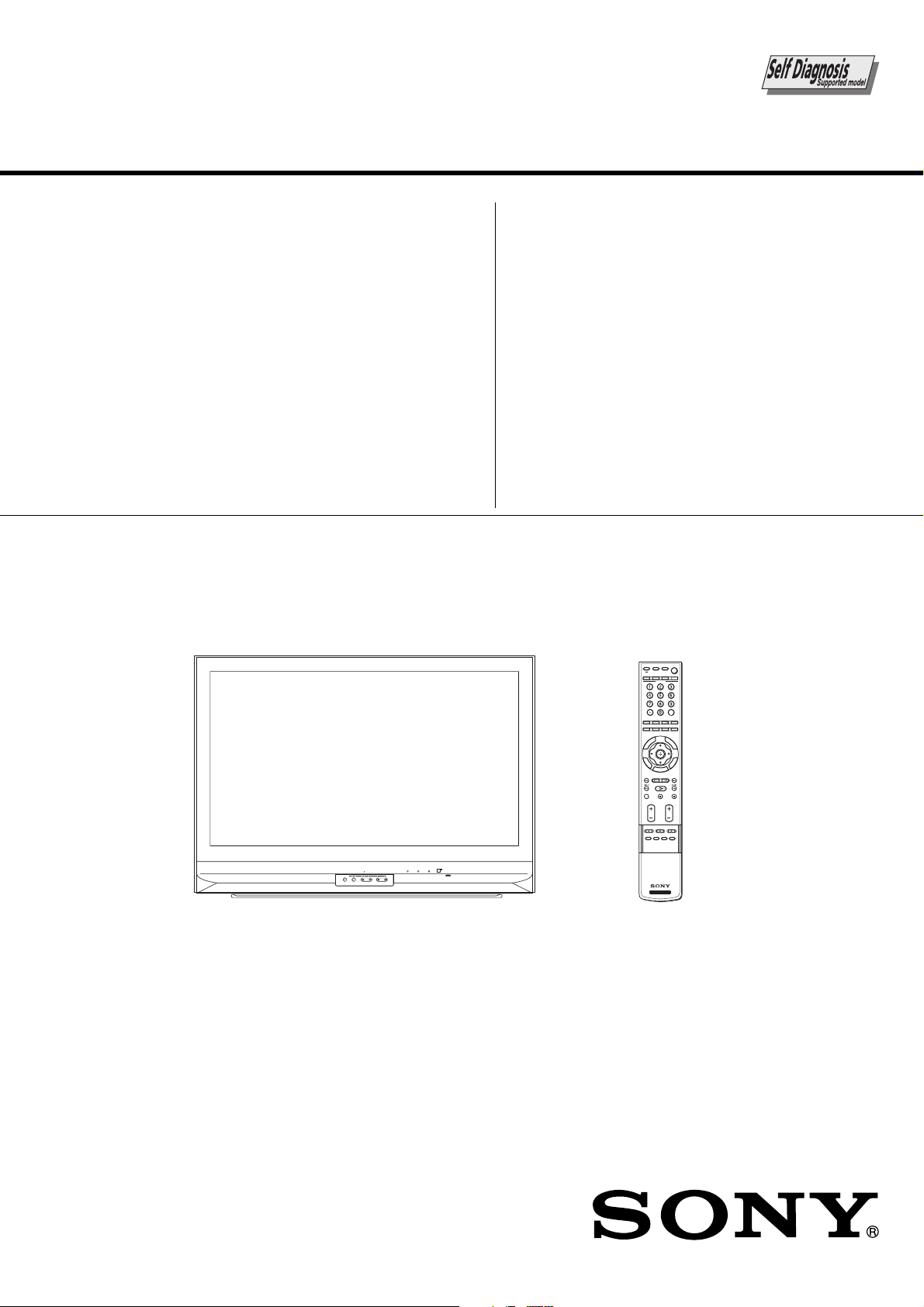

Model Name: KDF-E42A10/E50A10

SERVICE MANUAL

Part No. : 9-872-749-02

Date SUPP./CORR. Description of SUP/COR

2005.6 – NEW –

2005.8 CORR.-1 Addition of LAMP XL-2400 (Page 72) Yes

Change of

main text

Page 2

SERVICE MANUAL

MIX5

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

KDF-E42A10

KDF-E42A10

KDF-E42A10

KDF-E50A10

KDF-E50A10

KDF-E50A10

RM-YD003

RM-YD003

RM-YD003

RM-YD003

RM-YD003

RM-YD003

USA

CANADA

MEXICO

USA

CANADA

MEXICO

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

TIMER LAMP

PUSH OPEN

WEGA GATE

TV/VIDEO

CANNELVOLUME

KDF-E42A10/E50A10

POWER/STANDBY

TV/VIDEO

POWER TV POWER

MUTING

DVD/

SAT/

VCR

CABLE

DVR

TV

FUNCTION

ENT

JUMP ANT MTS/SAP FREEZE

SOUND PICTURE

TV/SAT

WIDE

SUR

DISP

LAY

GUIDE

RETURN

OOLS

T

WEGA

TE

GA

REPLAY ADVANCE NEXTPREV

PLAY

VISUAL SEARCH

PAUSE

STOP

CH

VOL

REC REC PAUSE REC STOP

TOP MENU MENU F1 F2

POWER

RM-YD003

LCD PROJECTION TV

Page 3

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

Specifications

Projection System 3 LCD Panels, 1 lens projection system

LCD Panel 0.73 inch TFT LCD panel (1,280

Projection Lens High Performance, large diameter hybrid lens F2.4

Antenna 75-ohm external terminal for VHF/UHF

Lamp 100W, XL-2400

Telev is io n System NTSC American TV Standard

ATSC ( 8VSB terrestrial) ATSC compliant 8VSB

QAM on cable ANSI/SCTE 07 2000

Visible Screen Size (Picture measured

diagonally)

Channel Coverage Terrestrial (analog) 2-69

Number of Inputs/Outputs

HDMI IN Video 1080i, 720p, 480p, 480i

Vid eo (I N) 3 total (1 on side panel) 1 Vp-p, 75 ohms unbalanced, sync negative

S Video (IN) 1 Y: 1 Vp-p, 75 ohms unbalanced, sync

Audio (IN) 5 total (1 on side panel) 500 mVrms (100% modulation)

Component Video Input 2 (Y P

AUDIO (VAR/FIX) OUT 1 500 mVrms at the maximum volume setting

RF Inputs 2

PC Input 1

Digital Audio Optical Output

(PCM/Dolby Digital)

CableCARD Slot PCMCIA Type I/II

Speaker output 12 W + 12 W

Power requirement120 V, 60 Hz

Power consumption In use: 210 W

KDF-E42A10: 42 inches

KDF-E50A10: 50 inches

Cable TV (analog) 1-125

Terrestrial (digital) 2-69

Cable TV (digital) 1-135

Audio Two channel linear PCM 32, 44.1 and 48 kHz,

B/CB PR/CR

1Optical Rectangular (1)

In standby: Less than 17 W

) Y: 1 Vp-p, 75 ohms unbalanced, sync

⋅

720 pixels)

16, 20 and 24 bit

negative

C: 0.286 Vp-p (Burst signal), 75 ohms

Impedance: 47 kilohms

negative

B/CB

: 0.7 Vp-p, 75 ohms

P

P

R/CR

: 0.7 Vp-p, 75 ohms

(Variable)

500 mVrms (Fixed)

Impedance (output): 2 kilohms

AUDIO OUT jacks are operable o nly w hen the

TV ’s S pe aker is set to O ff.

– 2 –

Page 4

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

Dimensions (W/H/D)

Mass KDF-E42A10: 28 kg (61 lb. 12 oz.)

Supplied Accessories

Remote Control RM-YD003

AA (R6) Batteries 2 supplied for remote control

Operati ng Instructions 1

Quick Setup Guide 1

Warranty Card 1

Product Registration Card 1

Optional accessories:

KDF-E42A10: 999 ⋅ 722 ⋅ 35 7 mm (39 3/8⋅ 28 1/2⋅ 14 1/8 inches)

KDF-E50A10: 118 4 ⋅ 827 ⋅ 408 mm (46

KDF-E50A10: 33 kg (72 lb. 13 oz.)

HDMI cable

HDMI-to-DVI cable

Component video cable

S VIDEO cable

A/V cable

Audio cable

Optical cable

TV Stand : (SU-RG11S for KDF-E42A10, SU-RG11M for KDF-E50A10)

Theatre Stand System: RHT-G2000

Lamp : XL-2400

5

/8⋅ 32 5/8⋅ 16 1/8 inches)

The availability of optional accessories

depends on stock.

Design and specifications are subject to change without notice.

Non-metric weights and measures are approximate.

– 3 –

Page 5

Indicators

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

Screen

POWER/ST

TIMER LAMP

ANDBY

PUSH OPEN

Indicators

The indicators show the current status of your TV. If there is a change in the

condition or a problem with the TV, the indicators will flash or light up in

the manner described below to let you know that it requires your attention.

Indicator Flashing because...

POWER/

STANDBY flashing

LAMP indicator

flashes

TIMER indicator is

lit

green : The lamp for the light source is preparing to turn

on. When it is ready, it turns on.

red : The lamp door or the lamp is not securely attached.

The red indicator will continue to flash in intervals of three

blinks at a time until the lamp door or the lamp is placed

correctly. When the lamp door or the lamp is securely

attached, the TV will turn on with green indicator.

The projection lamp has burned out. Replace it with new

one (see page 86).

When one of the timers is set, the indicator will remain lit

(will not flash) even when the TV is turned off.

POWER

Projection Lamp

Your T V u ses a projection lamp as its light source. As with any lamp, it has

lifespan and needs to be replaced when the Lamp indicator flashes or the

screen becomes darker. Note the following:

After turning on your TV, it may take a while (1 minute or less) before

the picture appears.

When the projection lamp wears out, the screen goes dark. Replace the

lamp with a new Sony XL-2400 replacement lamp (not supplied).

The light emitted from the lamp is quite bright when your TV i s in

use. To avoid eye discomfort or injury, do not look into the light

housing when the power is on.

– 4 –

Page 6

Replacing the Lamp

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

The projection lamp, which illuminates the picture, has a limited life.

If the screen becomes dark, the color looks unusual, or the LAMP indicator

on the front of the TV flashes, it is time to replace the lamp with a new one

(not supplied).

WARNING

Electric appliances can cause fire or high temperature, resulting in

injury or death. Be sure to follow the instructions below.

Use a Sony XL-2400 replacement lamp (not supplied) for replacement.

Use of any other lamp may damage the TV.

Do not remove the lamp for any purpose other than replacement. Doing

so may cause injury or fire.

Do not put flammable materials and metal objects inside the lamp

receptacle of the TV after removing the lamp. Doing so may cause fire

or electrical shock. Do not touch the lamp receptable once the lamp has

been removed.

When the lamp eventually burns out, you may hear a noticeable pop

sound. This is normal and it is inherent to this type of lamp.

In rare instances, the bulb may pop inside the lamp unit, but the lamp

unit is designed to contain all of the broken glass pieces inside the lamp

unit.

The lamps contain mercury. For proper disposal of the used lamps,

follow and observe the local ordinances. See page 89.

How to Replace the

Lamp

1

Turn off the power on the main unit. Wait several minutes, then unplug

the power cord.

(The cooling fan will continue to operate for about two minutes after

turning the power off.)

2

Wait at least 30 minutes after unplugging the power cord to allow the

lamp to cool down before replacing it. To avoid being burned, do not

touch the lamp receptable once the lamp has been removed.

3

Take th e new lamp out of the box.

Do not touch the glass portion of the new lamp.

Do not shake the lamp. Vi bration can damage the lamp or

shorten its life.

Avoid touching the front glass of a new lamp or the glass of

the lamp receptacle. Th is may reduce picture quality or lamp

life.

– 5 –

Page 7

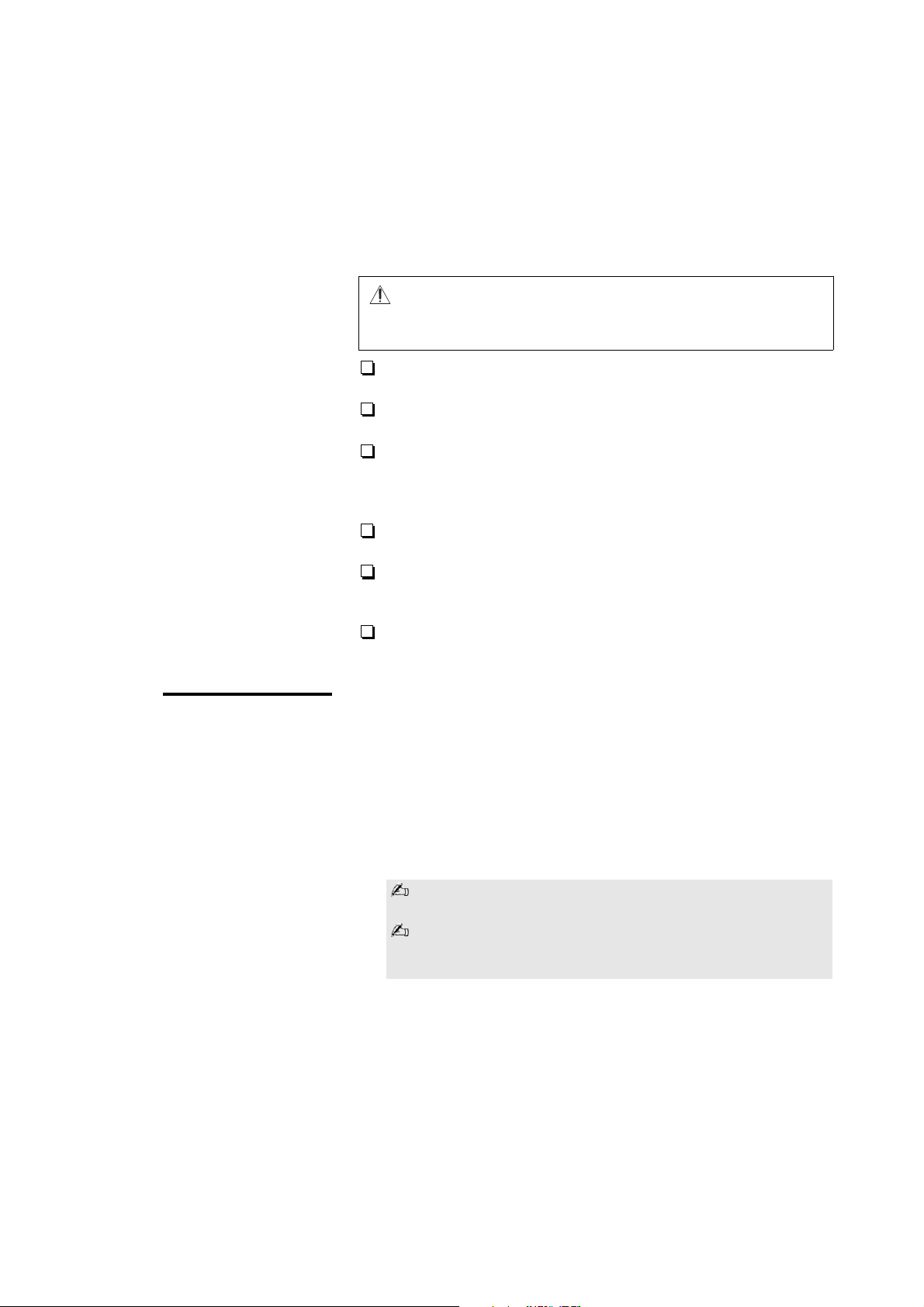

4 Remove the outside lamp cover.

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

7

Put the new lamp into its place.

Mount the new lamp securely. Failure to do so may cause

a fire or the

screen to go dark.

5 Remove the lamp door.

Turn the knob counterclockwise to OPEN and pull out

the cover.

Lamp door

6 Pull out the lamp.

Hook a finger through the loop of the lamp handle and

pull the handle

upwards. Then pull the lamp straight out.

If the lamp is not securely reattached, the self-

di a gnostic

POWER/STANDBY indicator

times (see page 12).

8

Reattach the lamp door.

Turn the knob back to CLOSE and secure the cover.

9

Put the outside lamp cover back in its place.

function may be triggered and the

flashes three

The lamp is very hot immediately after use.

Never touch the

the surrounding parts.

After the used lamp has cooled, place it into

the empty box of

Never put the used lamp into a plastic

The used lamp

This product contains mercury. Disposal of this product may be

regulated if

information,

Industries Alliance

Do not leave the used lamp near flammable materials or

within the

Do not pour water onto the used lamp or put any object

inside the lamp.

sold in the United States. For disposal or recycling

please

reach of children.

glass portion of the lamp or

the replacement lamp.

bag.

contact your local authorities or

(http://www.eiae.org).

Doing so may cause the lamp to burst.

the Electronics

– 6 –

Consult your Sony dealer for a Sony XL-2400

replacement

Take gr eat care when replacing the lamp or plugging

in/unplugging the connecting cords. Rough handling

may

cause the TV to fall, damaging the TV, the TV

st

and and the

For replacement lamp information visit:

U. S. residents: http://www.sonystyle.com/tv/

Canadian residents: http://www.sonystyle.ca/tv/

lamp.

floor.

Page 8

K RM-YD003 RM-YD003

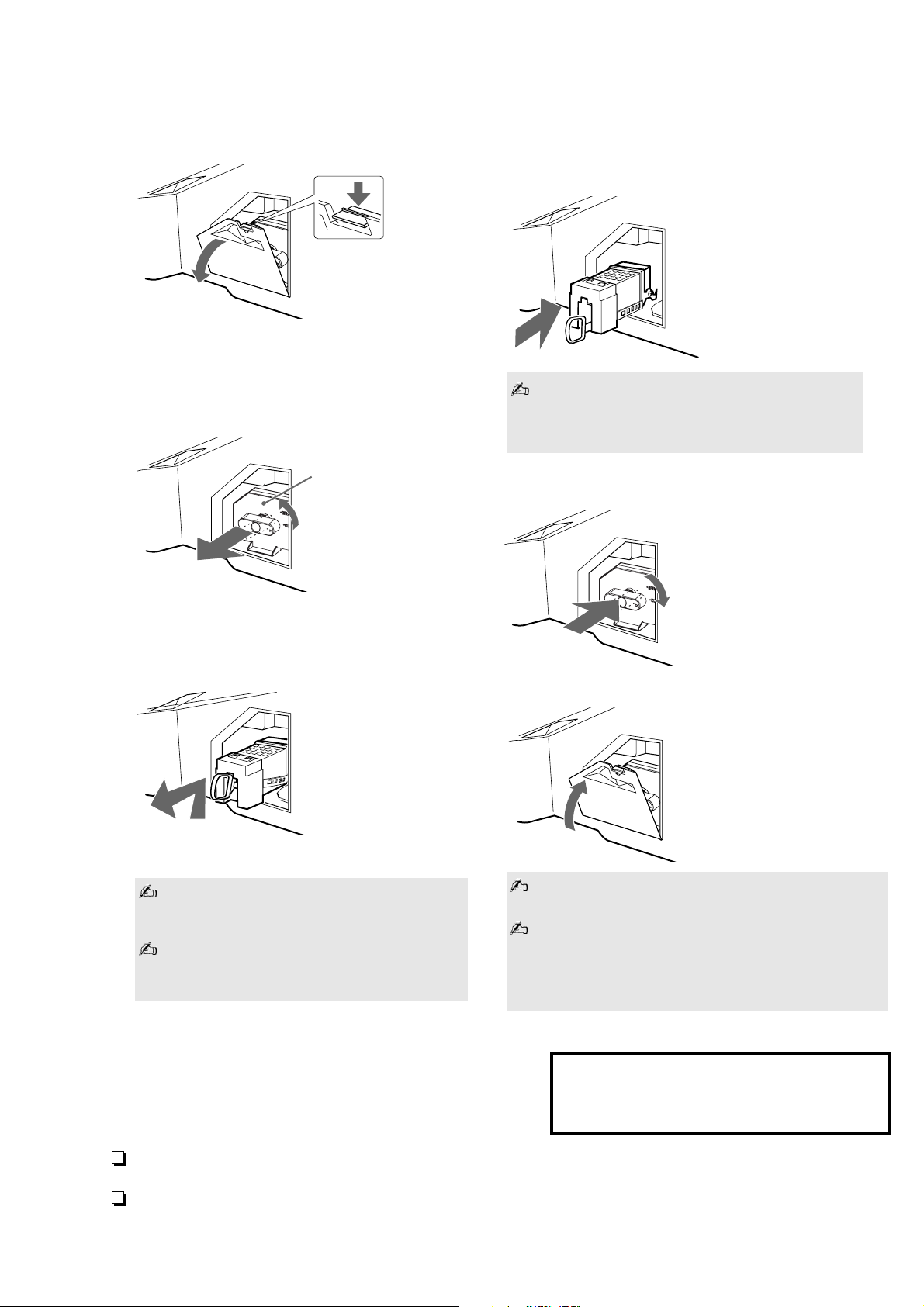

Fig. B. Checking for earth ground.

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

SAFETY CHECK-OUT

( US model only )

KDF-E42A10/E50A10

After correcting the original service problem, perfom the follow-

ing safety checks before releasing the set to the customer:

l. Check the area of your repair for unsoldered or poorly-sol-

dered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps,

and mounting hardware have been replaced. Be absolutely

certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

5. Look for parts which, through functioning, show obvious

signs of deterioration. Point them out to the customer and

recom mend their replacement.

6. Check the line cords for cracks and abrasion. Recommend

the replacement of any such line cord to the customer.

7. Check the condition of the monopole antenna (if any). Make

sure the end is not broken off, and has the plastic cap on it.

Point out the danger of impalement on a broken antenna to

the customer, and recommend the antenna’s replacement.

8. Check the B+ and HV to see they are at the values specified.

Make sure your instruments are accurate;be suspicious of

your HV meter if sets always have low HV.

9. Check the antenna temminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5mA (500 microampers) . Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to

usc these instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are

examples of a passive VOM that is suitable. NearIy all battery operated digital multimeters that have a 2V AC range

are suitable. (See Fig. A)

HOW TO FIND A GOOD EARTH GROUND

A cold-water pipe is guaranteed earth ground;the cover-plate retaining screw on most AC outlet boxes is also at earth ground. If

the retaining screw is to be used as your earth-ground, verify that it

is at ground by measuring the resistance between it and a coldwater pipe with an ohmmeter. The reading should be zero ohms. If

a cold-water pipe is not accessible, connect a 60-l00 watts trouble

light (not a neon lamp) between the hot side of the receptacle and

the retaining screw. Try both slots, if necessary, to locate the hot

side of the line, the lamp should light at normal brilliance if the

screw is at ground potential. (See Fig. B)

Fig. A. Using an AC voltmeter to check AC leakage.

1.5 µ F

To Exposed Metal

Parts on Set

1.5k Ω

Earth Ground

AC

voltmeter

(0.75V)

– 7 –

Page 9

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

CAUTION

These servicing instructions are for use by qualified service personnel only.

To reduce the risk of electric shock, do not perform any servicing

other than that contained in the operating instructions unless you

are qualified to do so.

WARNING!!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECElVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL TO SAFE OPERATION ARE IDENTIFIED IN THIS

MANUAL. FOLLOW THESE PROCEDURES WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

ATTENTION!!

AFIN D’EVITER TOUT RISQUE DELECTROCUTION PROVENANT D’UN CHÁSSIS SOUS TENSION, UN TRANSFORMATEUR

D’ISOLEMENT DOIT ETRE UTILISÉ LORS DE TOUT DEPANNAGE.

LE CHÁSSIS DE CE RECEPTEUR EST DIRECTEMENT RACCORDÉ Á L’ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS ÁLA

SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE FRAME ET PAR UNE

MAPQUE ! SUR LES SCHÉMAS DE PRINCIPE, LES VUES EXPLOSÉES ET LES LISTES DE PIECES SONT D’UNE IMPORTANCE

CRITIQUE POUR LA SÉCURITÉ DU FONCTIONNEMENT. NE LES

REMPLACER QUE PAR DES COMPOSANTS SONY DONT LE

NUMÉRO DE PIÉCE EST INDIQUÉ DANS LE PRÉSENT MANUEL OU DANS DES SUPPLÉMENTS PUBLIÉS PAR SONY. LES

RÉGLAGES DE CIRCUIT DONT L’IMPORTANCE EST CRITIQUE

POUR LA SÉCURITÉ DU FONCTIONNEMENT SONT IDENTIFIES

DANS LE PRÉSENT MANUEL. SUIVRE CES PROCÉDURES

LORS DE CHAQUE REMPLACEMENT DE COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS FONCTIONNEMENT SUSPECTÉ.

– 8 –

Page 10

K RM-YD003 RM-YD003

TABLE OF CONTENTS

KDF-E42A10/E50A10

Section Title Page

–––––– –––– ––––

1. SELF DIAGNOSIS FUNCTION ..................... 11

2. DISASSEMBLY

2-1. Rear Cover .......................................................... 16

2-2. Service Position .................................................. 17

2-3. Antenna Switch, QU Block Assembly .............. 18

2-4. K Board............................................................... 19

2-5. Terminal Bracket ................................................ 19

2-6. HPC Board .......................................................... 19

2-7. B Block ............................................................... 20

2-8. OU Bracket ......................................................... 20

2-9. B Board ............................................................... 20

2-10. B, QM and QT Boards ....................................... 21

2-11. QT Board ............................................................ 21

2-12. QM Board ........................................................... 21

2-13. P Board ............................................................... 21

2-14. AGU Board ......................................................... 22

2-15. DC Fan ................................................................ 22

2-16. Main Duct (R) .................................................... 23

2-17. Duch Block Assembly

(Without Main Duct (R)) ................................... 23

2-18. D.C. Fan (Sirocco) ............................................. 23

2-19. Speaker Grill Block Assembly ........................... 23

2-20. HA and HB Boards ............................................ 24

2-21. Screen Frame Block Assembly .......................... 24

2-22. Speakers .............................................................. 24

2-23. Rear Cover (With Mirror) .................................. 24

2-24. How to Replace Optics Unit .............................. 25

2-24-1. Remove Lamp Bloxk (1) ............................ 25

2-24-2. Remove Lamp Bloxk (2) ............................ 25

2-24-3. Remove Lamp Bloxk (3) ............................ 25

2-24-4. Remove Cover, Rear (1) ............................. 25

2-24-5. Remove Cover, Rear (1-2) .......................... 25

2-24-6. Remove Cover, Rear (2) ............................. 25

2-24-7. Remove Stay (L), Side ................................ 26

2-24-8. Pull Out Some Blocks (1) ........................... 26

2-24-9. Pull Out Some Blocks (2) ........................... 26

2-24-10. Pull Out Some Blocks (3) ........................... 26

2-24-11. Pull Out Some Blocks (4) ........................... 26

2-24-12. Pull Out Some Blocks (5) ........................... 27

2-24-13. Pull Out Some Blocks (6) ........................... 27

Section Title Page

–––––– –––– ––––

2-24-14. Pull Out Some Blocks (7) ........................... 27

2-24-15. Pull Out Some Blocks (8) ........................... 28

2-24-16. Pull Out Some Blocks (9) ........................... 28

2-24-17. Pull Out Some Blocks (10) ......................... 28

2-24-18. Remove Optics Unit .................................... 28

3. ELECTRICAL ADJUSTMENTS

3-1. Electrical Adjustment by Remote Commander .... 29

3-1-1. Method of Setting the Service Adjustment

Mode ............................................................... 29

3-1-2. Service Mode Adjustment ............................ 29

3-1-3. Memory Write Confirmation Method .......... 29

3-1-4. Adjusting Buttons and Indicator ................... 29

3-2. To read Lamp and Panel time ............................ 30

3-3. Test Reset ........................................................... 30

4. DIAGRAMS

4-1. Block Diagram (1) .............................................. 31

Block Diagram (2) .............................................. 32

Block Diagram (3) .............................................. 33

Block Diagram (4) .............................................. 34

Block Diagram (5) .............................................. 35

Block Diagram (6) .............................................. 36

Block Diagram (7) .............................................. 37

4-2. Frame Schematic Diagram ................................. 38

4-3. Circuit Boards Location ..................................... 39

4-4. Schematic Diagrams ........................................... 39

(1) Schematic Diagram of GT Board ...................... 40

(2) Schematic Diagram of HA Board ..................... 41

(3) Schematic Diagram of HB Board ..................... 42

(4) Schematic Diagram of HC Board ..................... 43

(5) Schematic Diagram of K Board ......................... 44

(6) Schematic Diagram of QT (1/3) Board ............ 45

(7) Schematic Diagram of QT (2/3) Board ............ 46

(8) Schematic Diagram of QT (3/3) Board ............ 47

(9) Schematic Diagram of QU Board ..................... 48

(10) Schematic Diagram of S2 Board ........................ 49

(11) Schematic Diagram of T1 Board ....................... 50

(12) Schematic Diagram of T2 Board ....................... 51

– 9 –

Page 11

Section Title Page

–––––– –––– ––––

4-5. Printed Wiring Boards........................................ 52

(1) GT Board ............................................................ 52

(2) HA, HB Boards .................................................. 53

(3) HC, K Boards ..................................................... 54

(4) QT Board ............................................................ 55

(5) QU Board............................................................ 56

(6) S2 Board ............................................................. 57

(7) T1, T2 Boards ..................................................... 58

4-6. Semiconductors .................................................. 59

5. EXPLODED VIEWS

5-1. Screen Mirror Block, Cover ............................... 60

5-2. B Block, Chassis Assembly ............................... 61

5-3. Lamp Duct Assembly, Optics Unit Block ......... 62

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

6. ELECTRICAL PARTS LIST

• GT Board .................................................................. 63

• HA Board .................................................................. 65

• HB Board .................................................................. 65

• HC Board .................................................................. 66

• HPC Board ................................................................ 66

• K Board ..................................................................... 67

• QT Board .................................................................. 69

• QU Board .................................................................. 71

• S2 Board .................................................................... 71

• T1 Board ................................................................... 71

• T2 Board ................................................................... 71

– 10 –

Page 12

SECTION 1

r

K RM-YD003 RM-YD003

SELF DIAGNOSIS FUNCTION

1. Summary of Self-Diagnosis Function

-This device includes a self-diagnosis function.

-Incaseofabnormalities, the POWER/STANDBY indicator automatically blinks. It is

possible to predict the abnormality location by the number of blinks. The Instruction

Manual describes blinking of the POWER/STANDBY indicator.

-Ifthe symptom is not reproduced sometimes in case of a malfunction, there is recording of

whether a malfunction was generated or not. Operate the remote command to confirm the

matter on the screen and to predict the location of the abnormality.

2. Diagnosis Items and Prediction of Malfunction Location

-When a malfunction occurs the POWER/STANDBY indicator only blinks for one of the

following diagnosis items. In case of two or more malfunctions, the item which first

occurred blinks. If the malfunctions occurred simultaneously, the item with the lowe

blink count blinks first.

-The screen display displays the results regarding all the diagnosis items listed below.

Thedisplay "0" means that no malfunctions occurred.

KDF-E42A10/E50A10

Number of times

Diagnosis Item

POWER/STANDBY

indicator blinks

Temp error

La

mp cover error 3 times

2 times

Fanstopped 4 times

Lamp driver error 5 times

Low B error 6 times

Probable Cause

Location

Defected symptoms

- Set temperture is high.

- Temp sensor connector

is not attached securely.

-Nopicture/No sound

(CN7020 on HB board,

CN7180 on S2 board)

-L

amp cover is not

attached securely.

-Nopicture/No sound

-Lamp is not set securely.

-Fan 1-4

power is not

supplied. (AGU board)

an connector is not

-F

-Nopicture/No sound

attached securely.

-Fan caught wires or

harnesses.

-Lampdriver is faulty. - No picture/No sound

- B_12V is not

(GT board)

supplie

d.

-Nopicture/No sound

- Short-circuit of Audio power

supply line.

Audio error 7 times

D-

OVP error 8

ATSC OVP

times

10 times

Lamp error LAMP-LED flashes - No picture/No sound

-Blow out of fuse.

(PS3001 on K board)

-IC failure.

(IC3005 on K board)

-B -12V is over voltage.

(B board)

-Q_10.5V is over voltage.

(GT board)

-Lampfor the light

source burns out.

-Nopicture/No sound

-Nopicture/No sound

-Nopicture/No sound

– 11 –

Page 13

K RM-YD003 RM-YD003

m

r

m

m

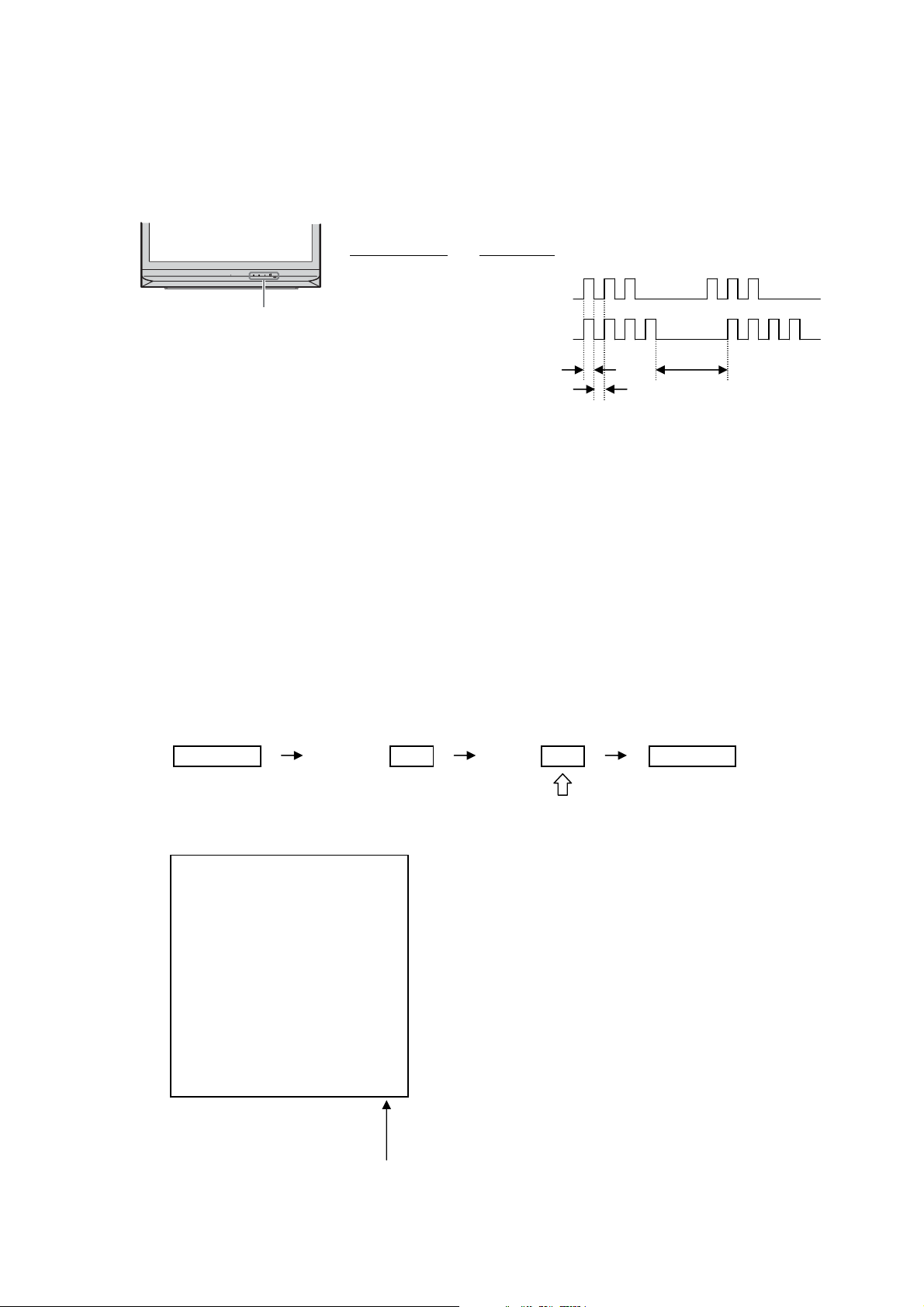

3. Blinking count display ofPOWER/STANDBY indicator

-One blink is not used for self-diagnosis.

-Example

Diagnosis ite

POWER/STANDBY

TIMER LAMP

POWER

PUSH OPEN

Lamp cove

Indicators

Fan 4 times

-Release of POWER/STANDBY indicator blinking

The POWER/STANDBY indicatorblinking display is released by removing the plug fro

the power or leaving for 2 minutes.

LEDblinks

3 times

LEDON:0.3sec

LEDOFF : 0.3sec

KDF-E42A10/E50A10

LED OFF

3.0sec

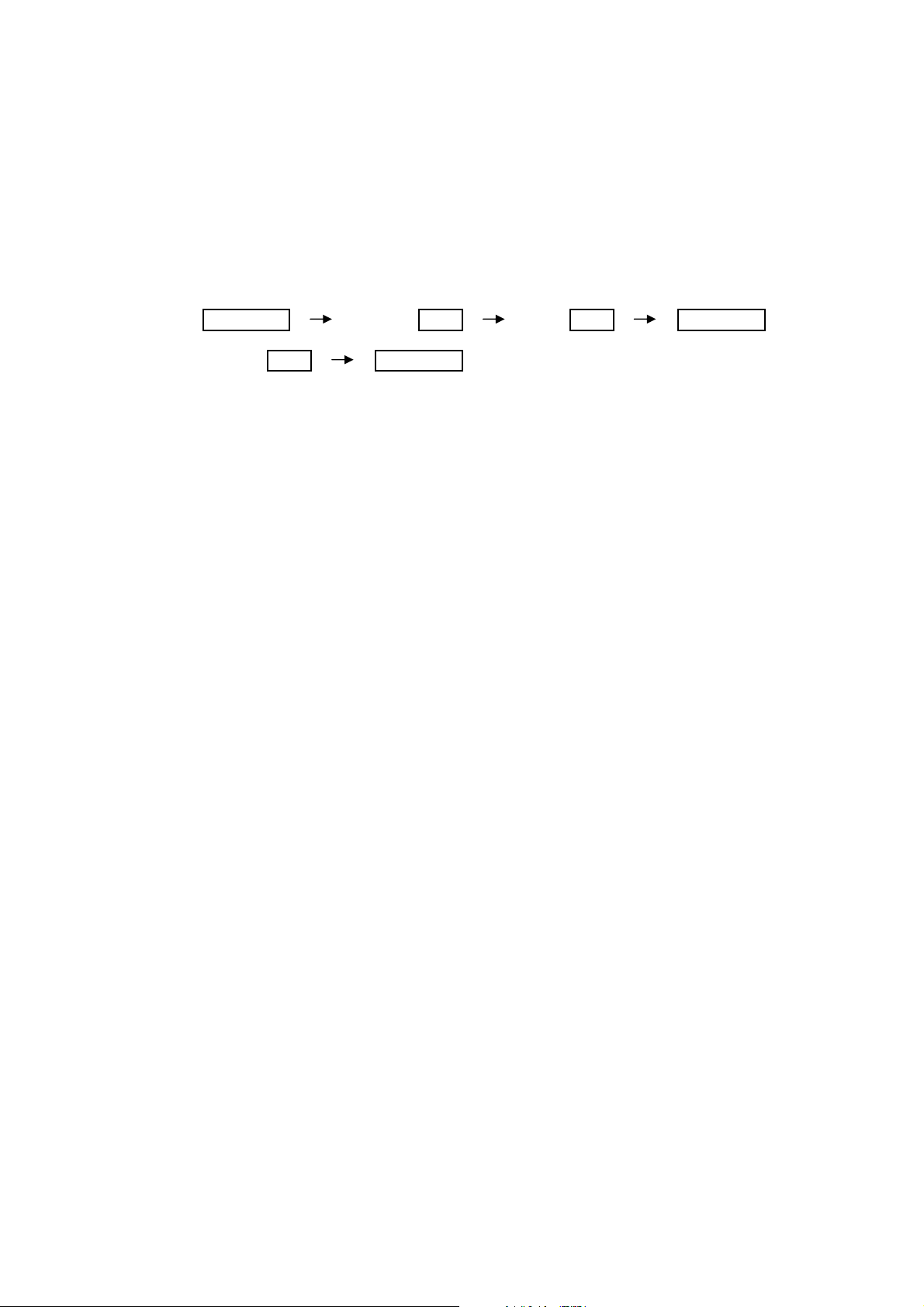

4. Self-diagnosis screen displays

-Incases of malfunctions where it is not possible to determine the symptom such as when

the power goes off occasionally or when the screen disappears occasionally, there is a

screen display on whether the malfunction occurred or not in the past (and whether the

detection circuit operated or not) in order to allow confirmation.

<Screen Display Method>

-Quickly press the remote command button in the following order from the standby state.

DISPLAY 5 - POWER

ChannelVol

Be aware that thisdiffers fro

the method of entering the

service mode (Vol +).

SELF CHECK

1:LAMP_ERROR 0

2 : TEMP_ERROR 0

2 : LAMP_TEMP 0

3:LAMP_COVER 0

4:FAN_ERROR 0

5:LAMP_DRIVER 1

6:LOWB_ERROR 0

7:AUDIO_PROT 0

8:D_OVP 0

10 : ATSC_OVP 0

-Numeral "1" means a fault was detected one time

-Numeral "0" means that no fault was detected

– 12 –

Page 14

KDF-E42A10/E50A10

k

K RM-YD003 RM-YD003

-The results display is not automatically cleared. In case of repairs and after repairs, chec

the self-diagnosis screen and be sure to return the results display to "0".

-Ifthe results display is not returned to "0" it will not be possible to judge a new malfunction

after completing repairs.

<Method of Cle aring Results Display>

1. Power off (Set to the standby mode)

2. Channel Vol

DISPLAY 5 - POWER

3. Channel

<Method of Ending Self-Diagnosis Screen>

-When ending the self-diagnosis screen completely, turn the power switch OFF on the

remote commander or the main unit.

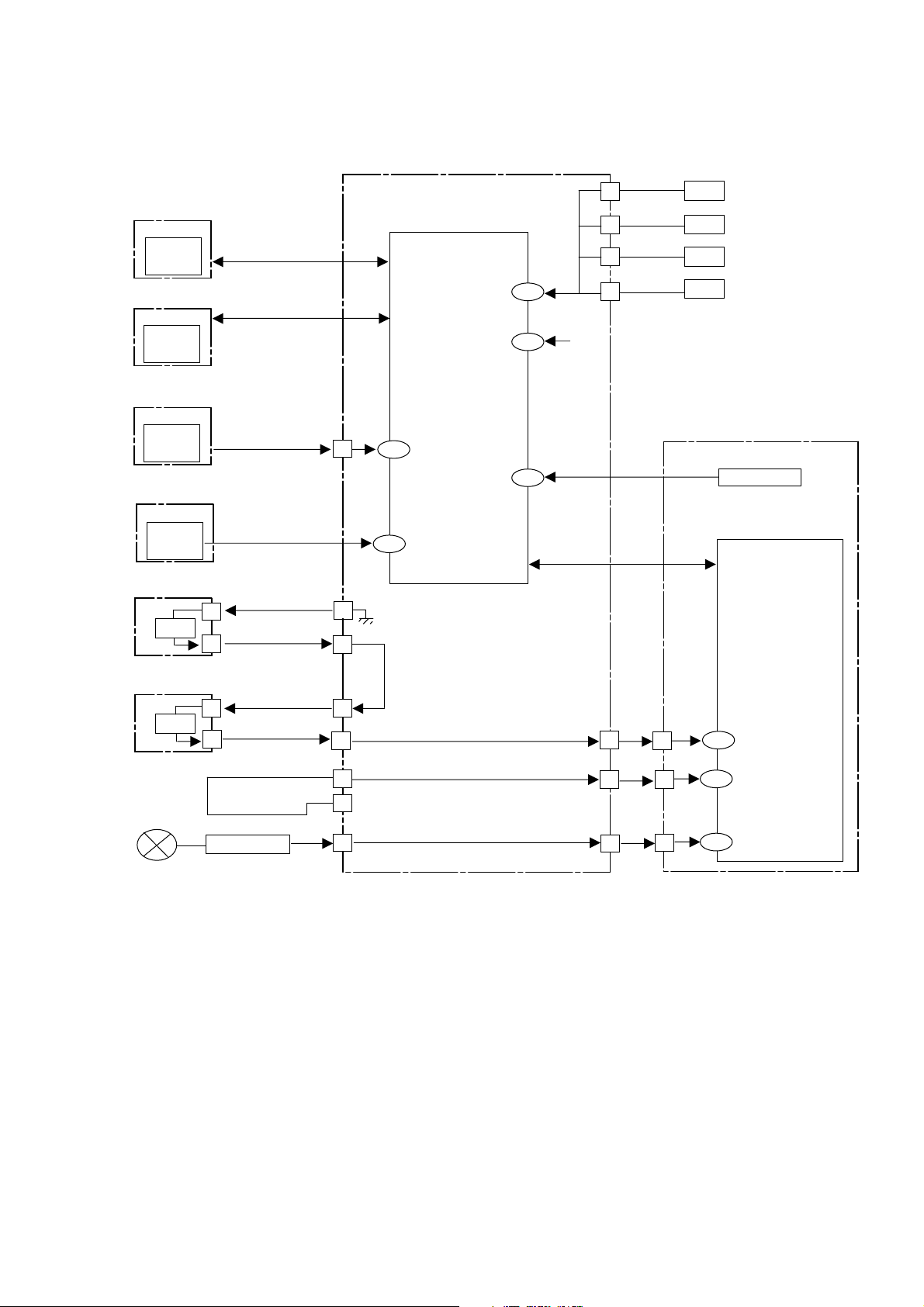

5. Self-Diagnosis function operation

2:Temp When the temperature sensor on the S2 board detects high temperature, or IIC

3:Lamp cover The rib at the back of the lamp cover closes the SW on the T1 board. The lamp

4:Fan Fan rotation is detected by ‘‘FAN-PROT” and the TV-micro (pin 38 of IC8002)

8ENTER

line connector (CN8410:AGU board, CN7180:S2 board) is not seated securely,

the TV-micro tums off the lamp.

When the temperature sensor on the HB board detects high temperature, or IIC

line connector (CN8004:AGU board, CN7020:HB board) is not seated securely,

the TV-micro tums off the lamp.

closes the SW on the T2 board.

It is monitored by the BE micro (pin133 of IC4100) and tums off the lamp when

it is opened.

tums off the lamp when it is ‘‘high”.

5:Lamp Driver When the ‘‘LAMP-PROT” (pin132 of IC4100) is high, the lamp is not tumed

on. If the ‘‘LAMP-HV-DET” (pin134 of IC4100) is low at the same time, it

is classified as no high voltage of the lamp driver.

6:Low B error When no ‘‘B_12V” is detected, pin 128 of TV-micro is low and it tums off the

main power.

7:Audio When DC voltage is detected at the speaker output, pin 149 of TV-micro is low

and it tums off the main power.

8:D-OVP When overvoltage of ‘‘B_12V” is detected, pin 127 of TV-micro is low and it

tums off the main power.

10 : ATSC-OVP When overvoltage of ‘‘Q_10.5 V” is detected, pin 126 of TV-micro is low

and it tums off the main power.

LAMP : Lamp When the ‘‘LAMP-PROT” (pin132 of IC4100) is high, the lamp is not tumed

on. If the ‘‘LAMP-HV-DET” (pin134 of IC4100) is high at the same time, it

is classified as no lamp or a dead lamp.

– 13 –

Page 15

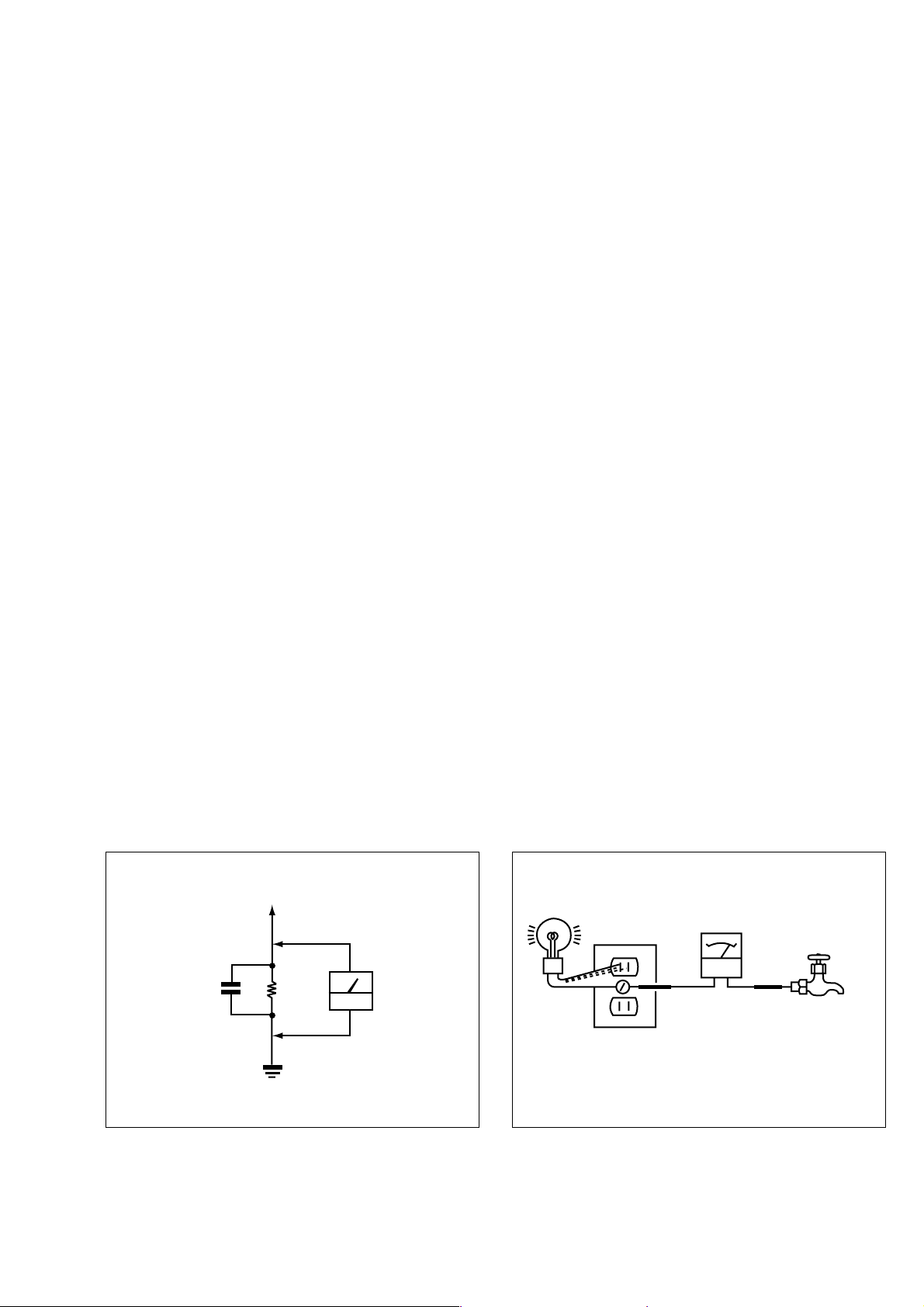

BLOCK DIAGRAM

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

AGU board

S2 board

IC7180

Temp.

Sensor

HB board

IC7021

Temp.

Sensor

K board

Audio

Amp.

QM board

ATSC

10.5V

T2 board

SW

IC8002

TV Micro-computer

IIC-TV

FAN-ERR

IIC-TV

LB-ERR

13

CN8403

3

1

149

SP_PROT

BE-OVP

ATSC-OVP

126

2

1

38

128

127

IIC

4

7

10

13

CN8002

+12V

Fan1

Fan2

Fan3

Fan4

B board

B_12V

IC4100

BE Micro-computer

IIC

T1 board

SW

Lamp

1

3

HV-DET

Lamp Driver

CN8410

CN8410

CN8410

14

15

13

12

CN8003

8

5

CN8003

CN8003

7

7

8

5

7

133

LAMP COVER

134

LAMP-HV-DET

132

LAMP-PROT

– 14 –

Page 16

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

Reading Lamp and Panel time

Use the following to determine the lamp and panel time of a set.

Screen Display Method

In standby mode, press the buttons on the Remote Commander sequentially, in rapid succession, as shown below:

1. Press Display , Channel 5 , Sound Volume + , Power ON

2. To enter BE-micro service menu, press JUMP 2 times.

3. To display the lamp time, press Channel-4.

The screen displays:

“ Total lamp time is 14 hours”

4. To display the panel time, press Channel-4.

The screen displays:

“ Total panel time is 14 hours”

5. To display the lamp time clear, press Channel-5

7 times and Channel-1.

To reset the lamp time press Channel-3 > MUTING > ENT.

WRITE (Character color is red) is momentarily displayed and the lamp time is reset to “0”.

Exiting Service Mode

After completing the changes exit service mode by turning off the set using the Remote Commander or the

power switch.

CONFIGRATION 00 SERVICE

CP18_COLOR_SYS 00 00A0 BE Micro

Press Channel-4

m

GW_SPECIAL 34 SERVICE

LAMP_TIME 02 00000014 BE Micro

Press Channel-4

m

GW_SPECIAL 34 SERVICE

PANEL_TIME 01 00000014 BE Micro

Press Channel-5 7 times,

m

Channel-1

OPTION_E 20 SERVICE

LAMP 01 0000 BE Micro

– 15 –

Page 17

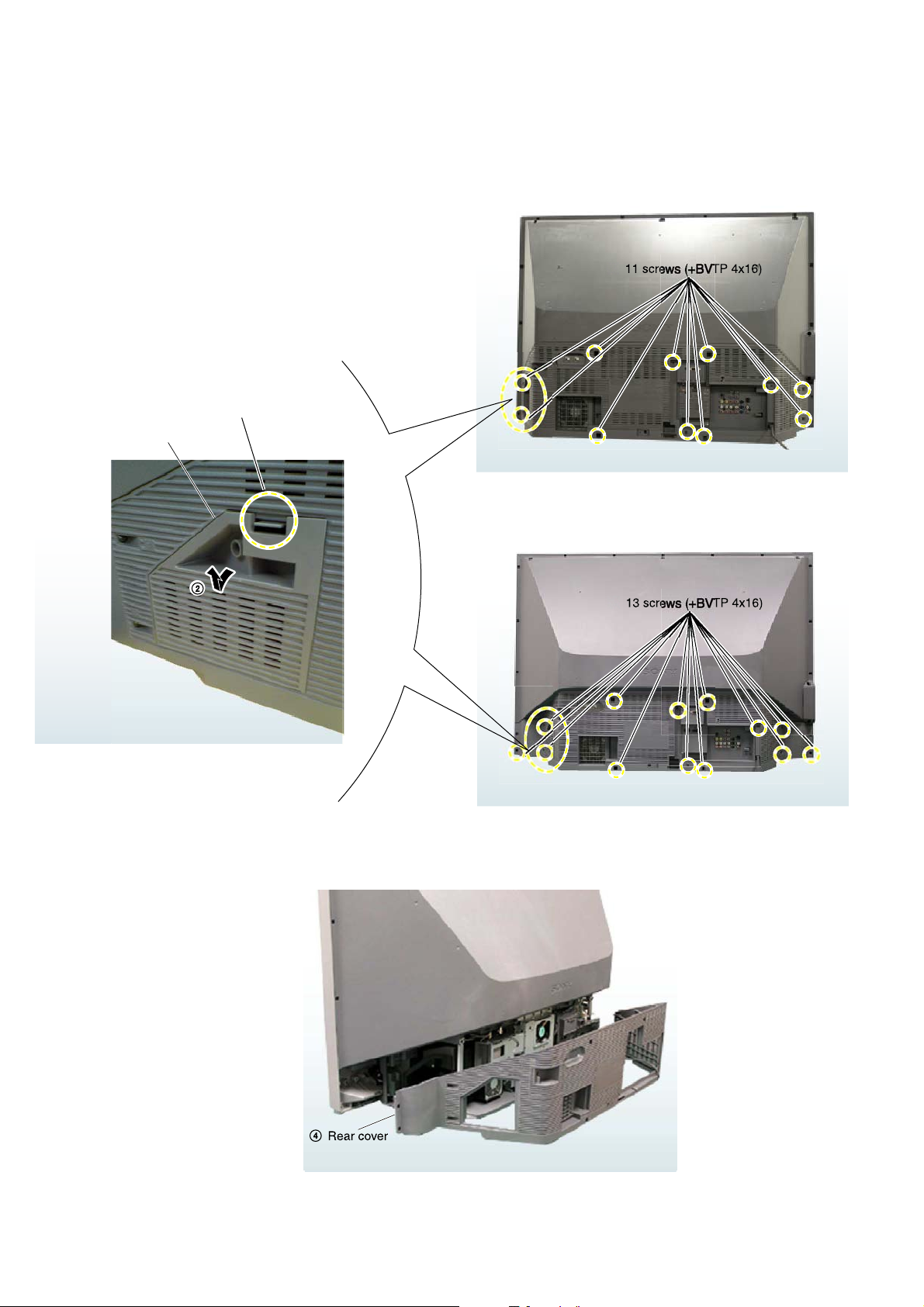

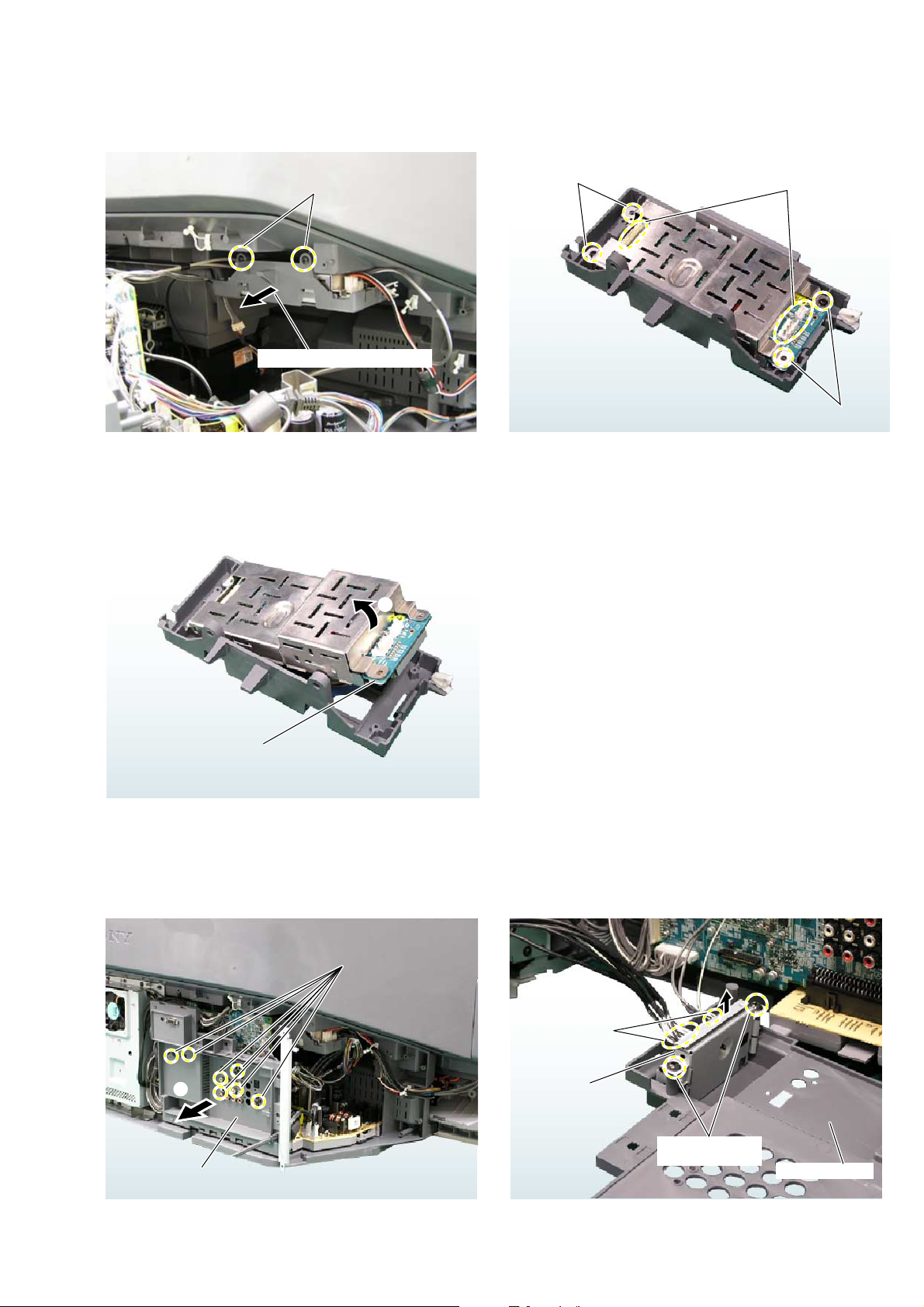

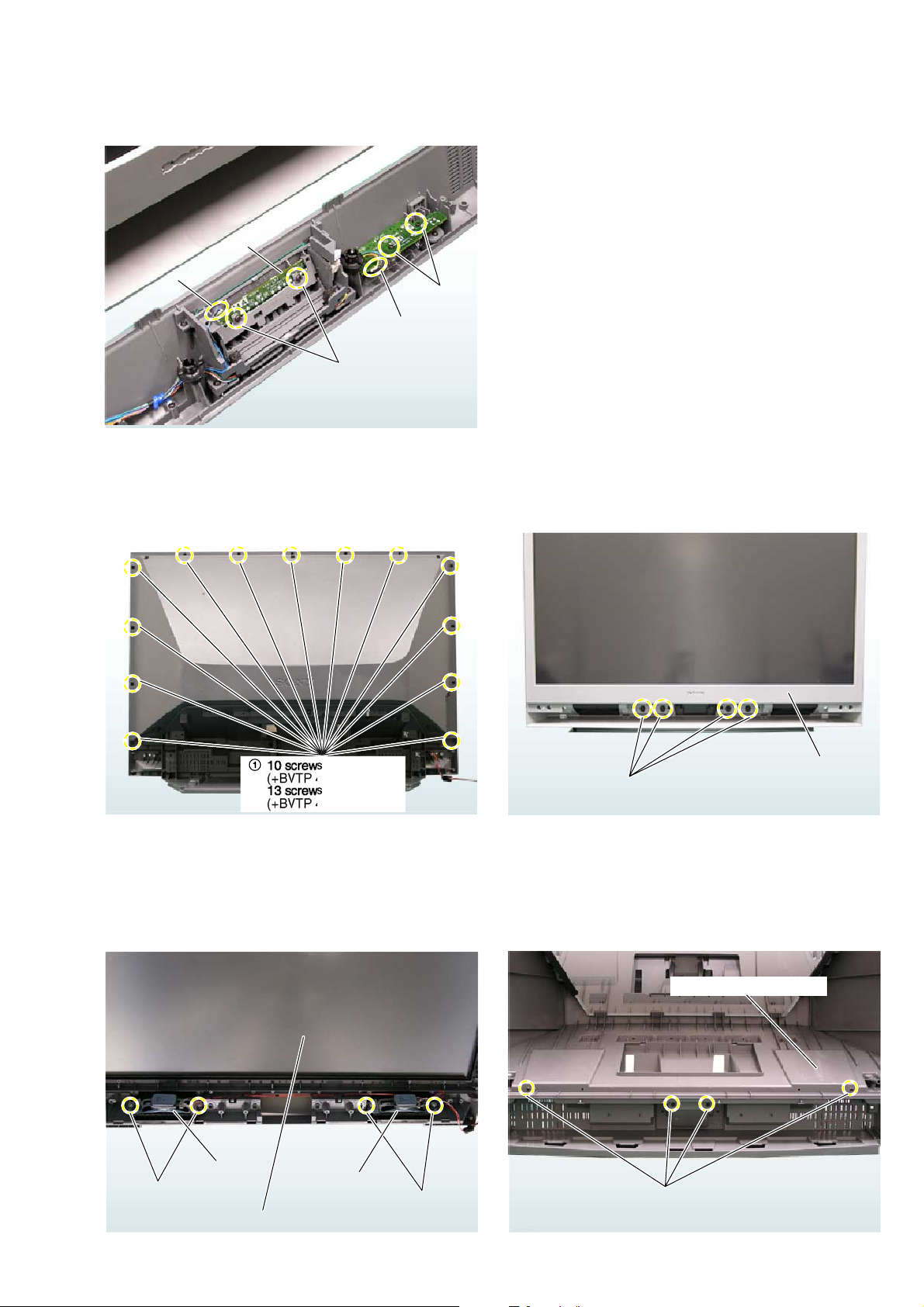

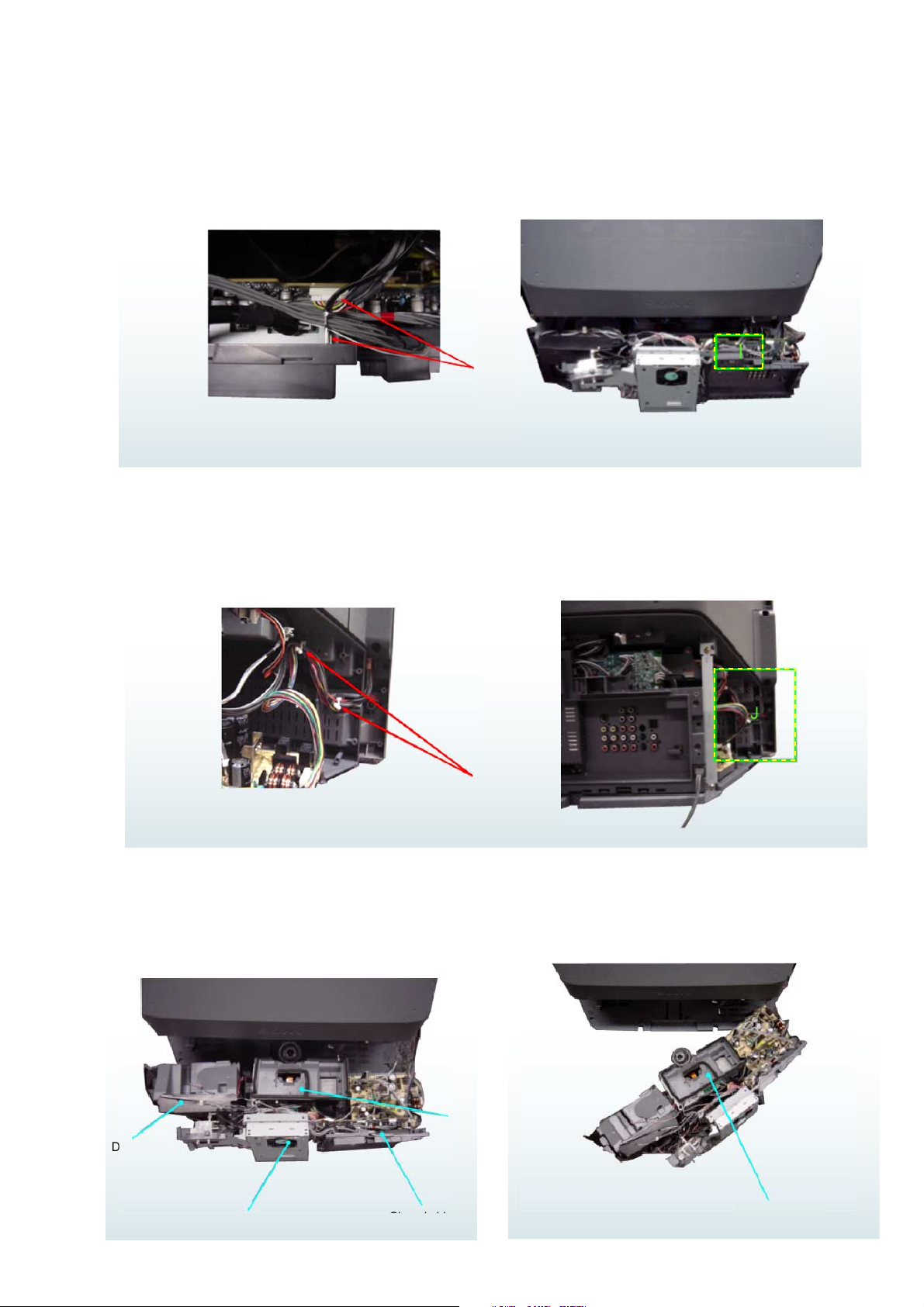

2-1. REAR COVER

3

3

1 Pull down the claw

Lamp door

SECTION 2

DISASSEMBLY

E42A10

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

E50A10

– 16 –

Page 18

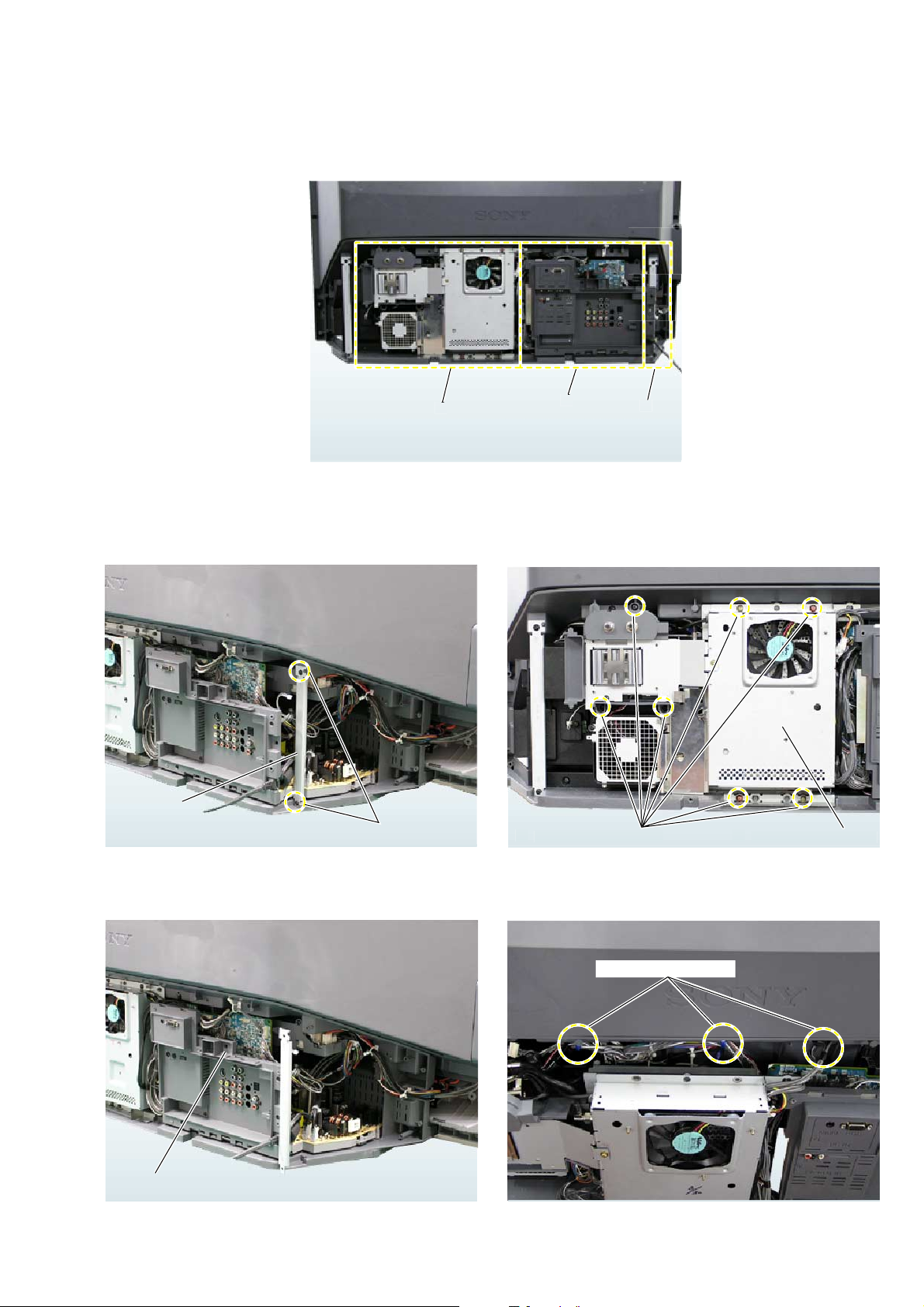

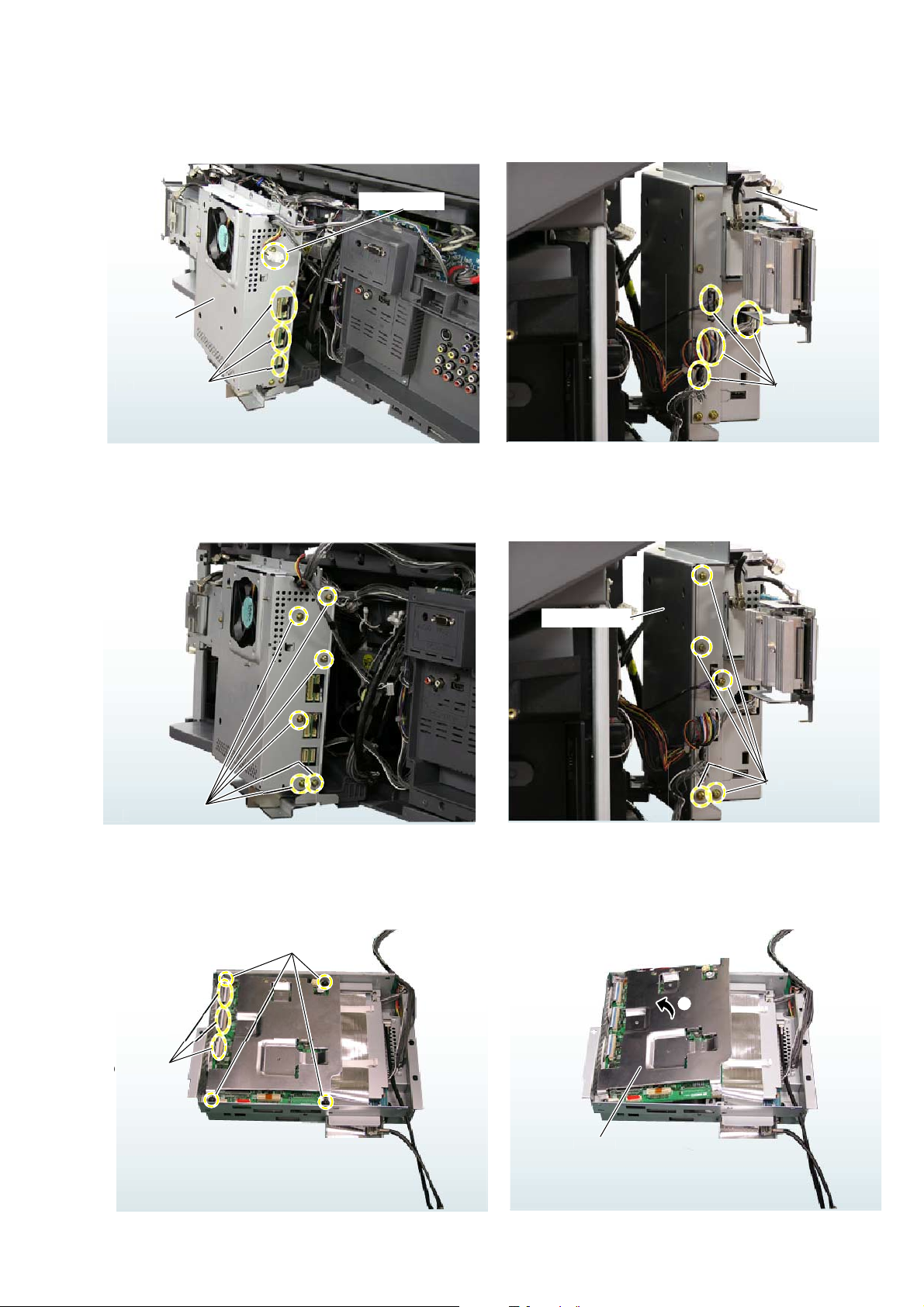

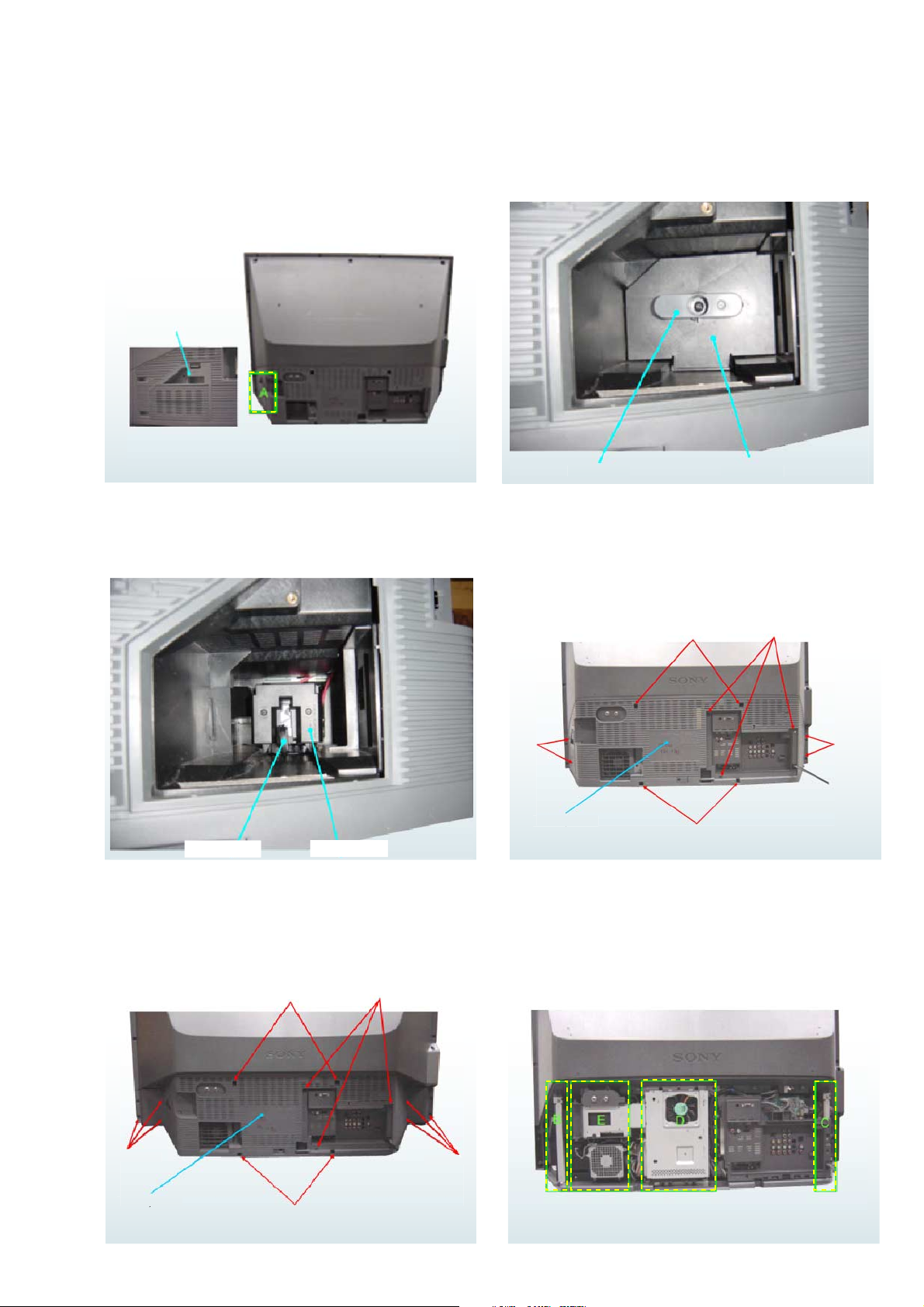

2-2. SERVICE POSITION

A

C

B

4

)

5

lightl

holders

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

A

3 Side stay (L)

C

1 2 screws (+BVTP 4x16)

B

7 screws (+BVTP 4x16

n wire

ull out B block s

y

6 Pull out chassis block slightly

– 17 –

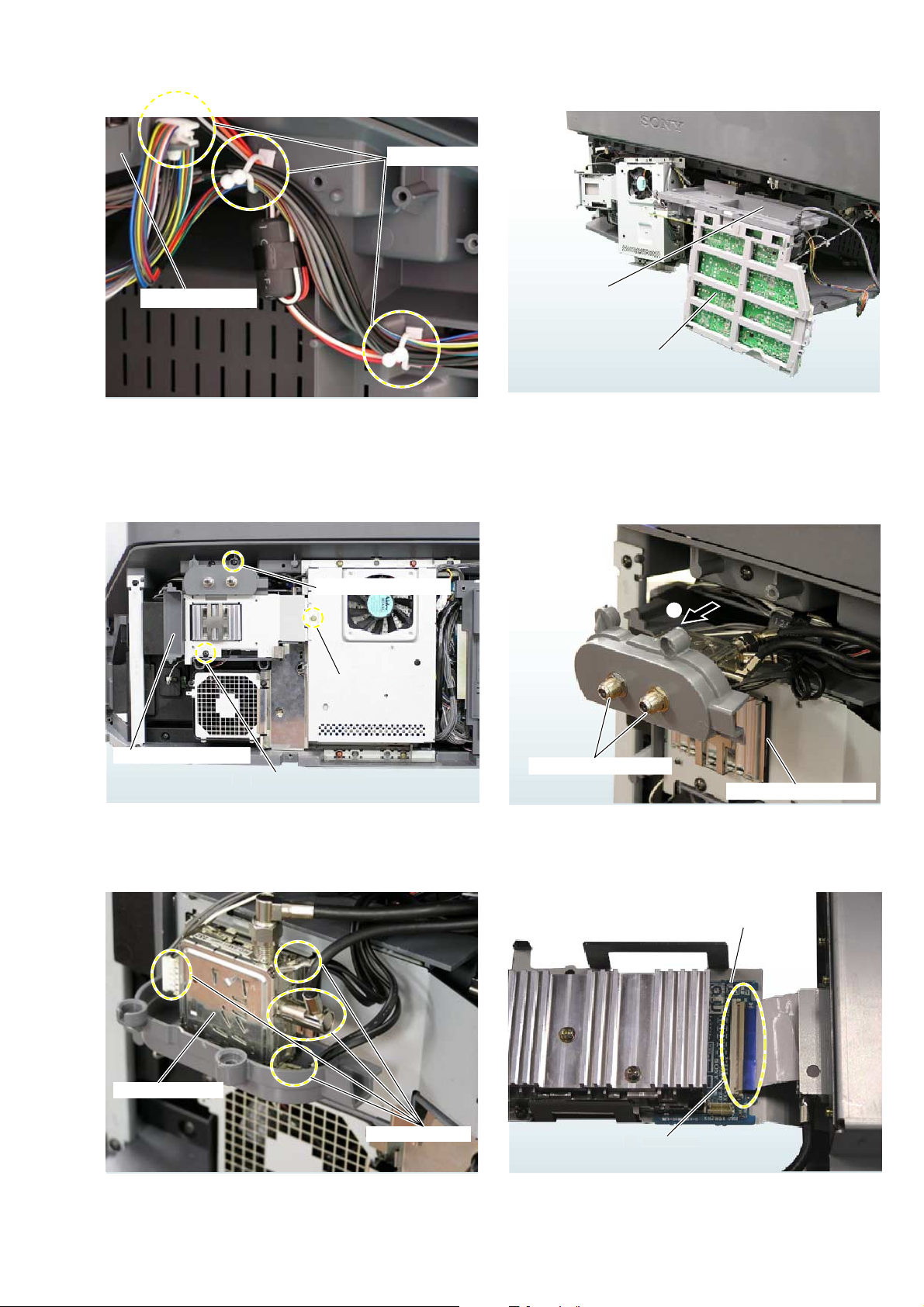

Page 19

8 Loosen wire holders

)

backward

)

)

itch bracket

y

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

K board assembly

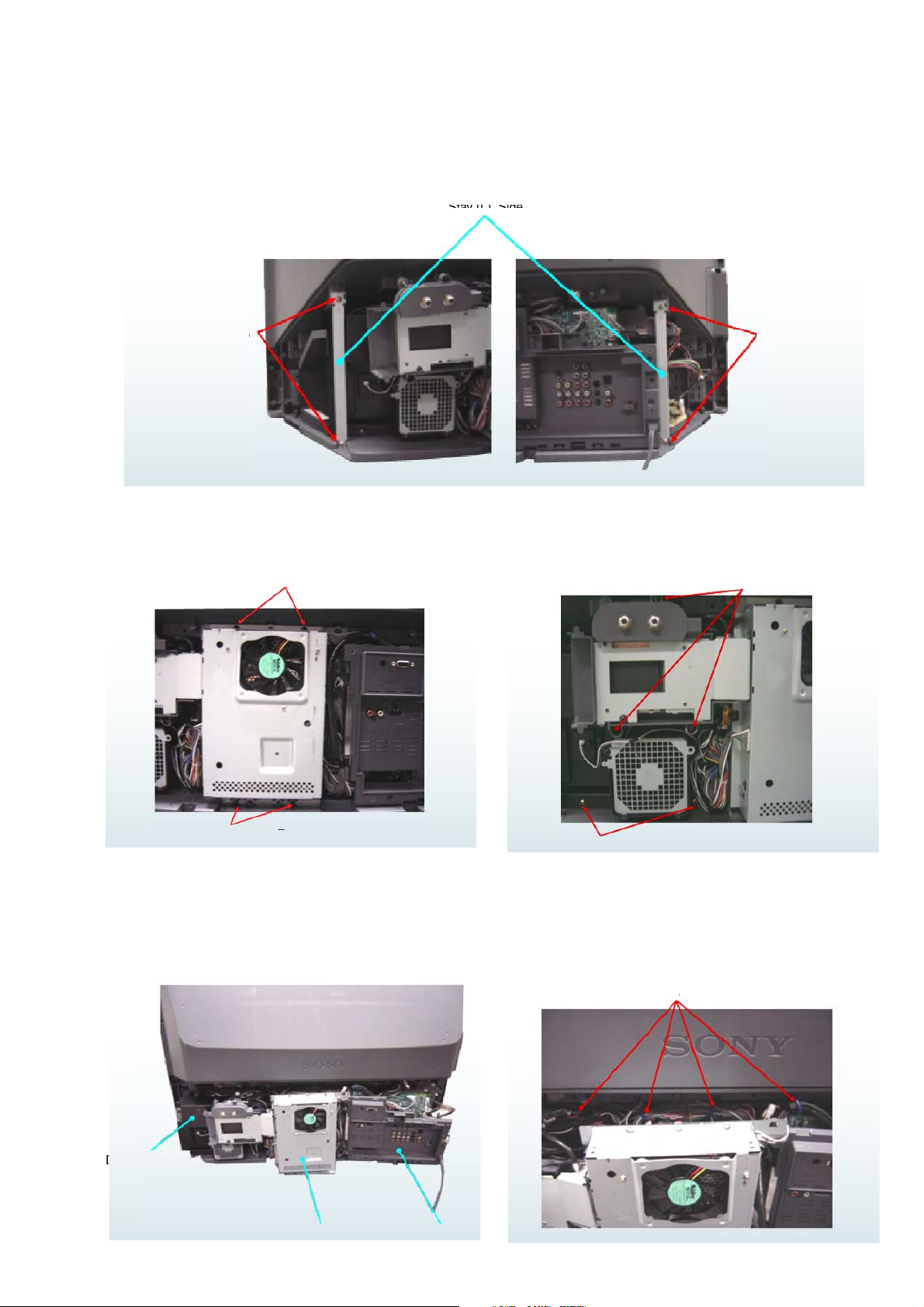

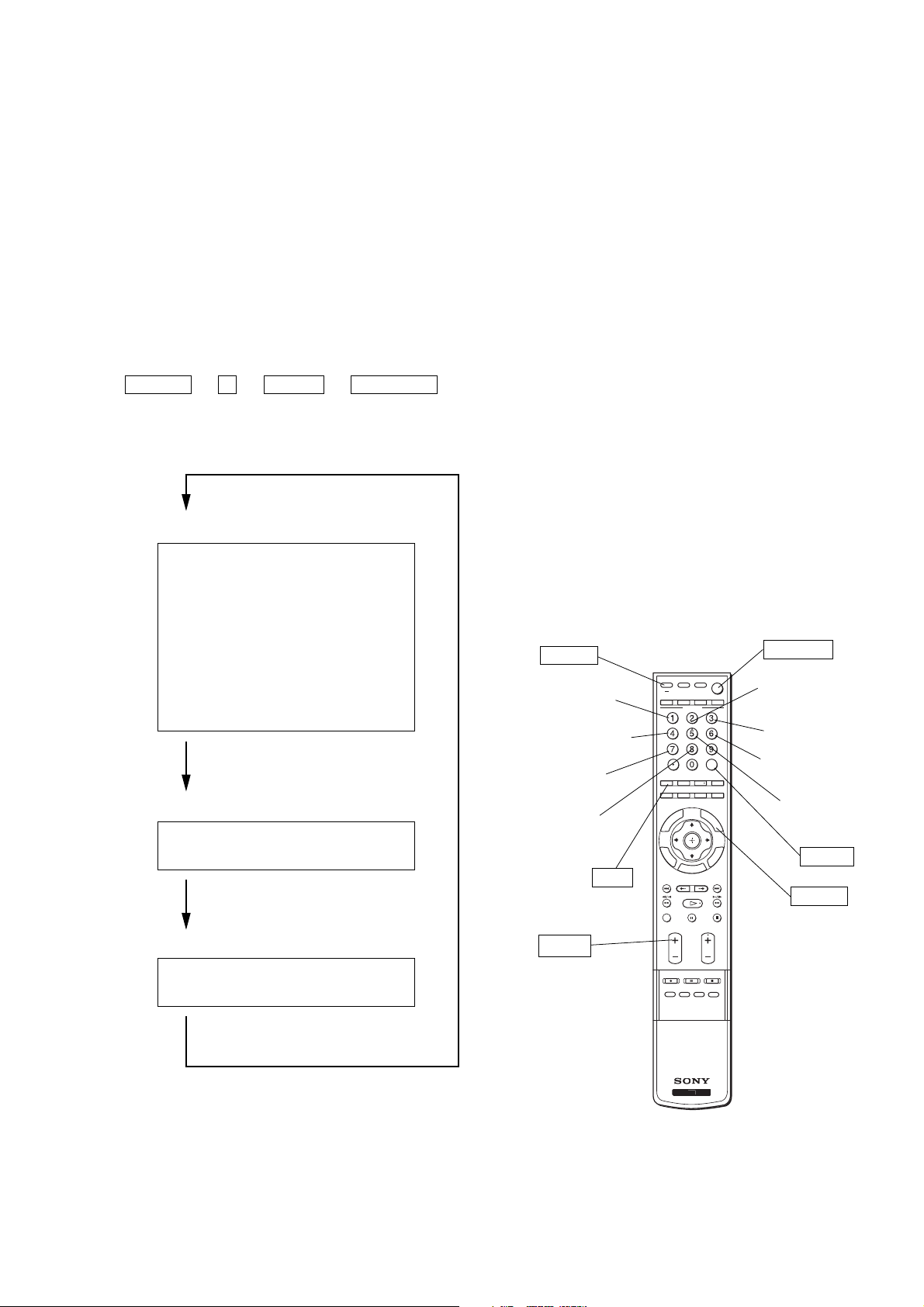

2-3. ANTENNA SWITCH, QU BLOCK ASSEMBLY

crew (+BVTP 4x16

crew (+BVTP 4x16

9 Tu rn chassis dssembly

GT board B side

cover

6 Antenna switch

crew (+BVTP 4x16

5 5 connectors

2 hexdgonal washers

a

s

U block assembl

ntenna sw

– 18 –

Page 20

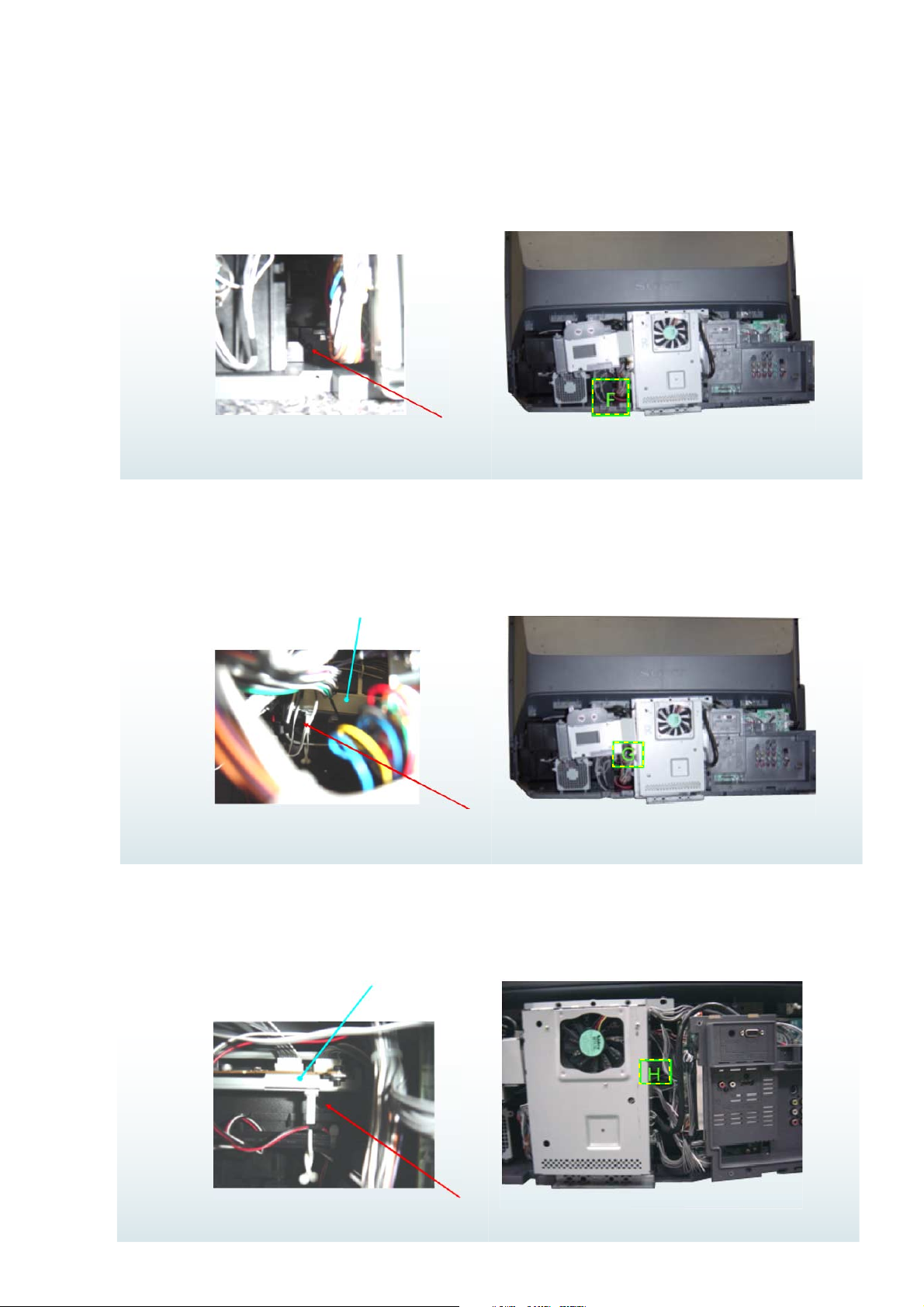

2-4. K BOARD

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

1 2 screws (+BVTP 4x16)

2 Pull out K board assembly

6

5 2 screws (+BVTP 3x12)

3 3 connectors

4 2 screws (+BVTP 3x12)

K board

2-5. TERMINAL BRACKET

1 7 screws (+BVTP 3x12)

2

Te r mi nal brdcket

2-6. HPC BOARD

3

1 2 connectors

HPC baord

2 2 screws

(+PVTP 4x16)

Te r minal bracket

– 19 –

Page 21

ectors

block

ecto

block

ectors

()

)

et

s

)

)

ecto

board

2-7. B BLOCK

nn

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

r

conn

2-8. OU BRACKET

6 screws (+PSW M 3x8

conn

brack

screw

(+PSW M3x8

2-9. B BOARD

conn

4 screws (+PSW M3x8

r

– 20 –

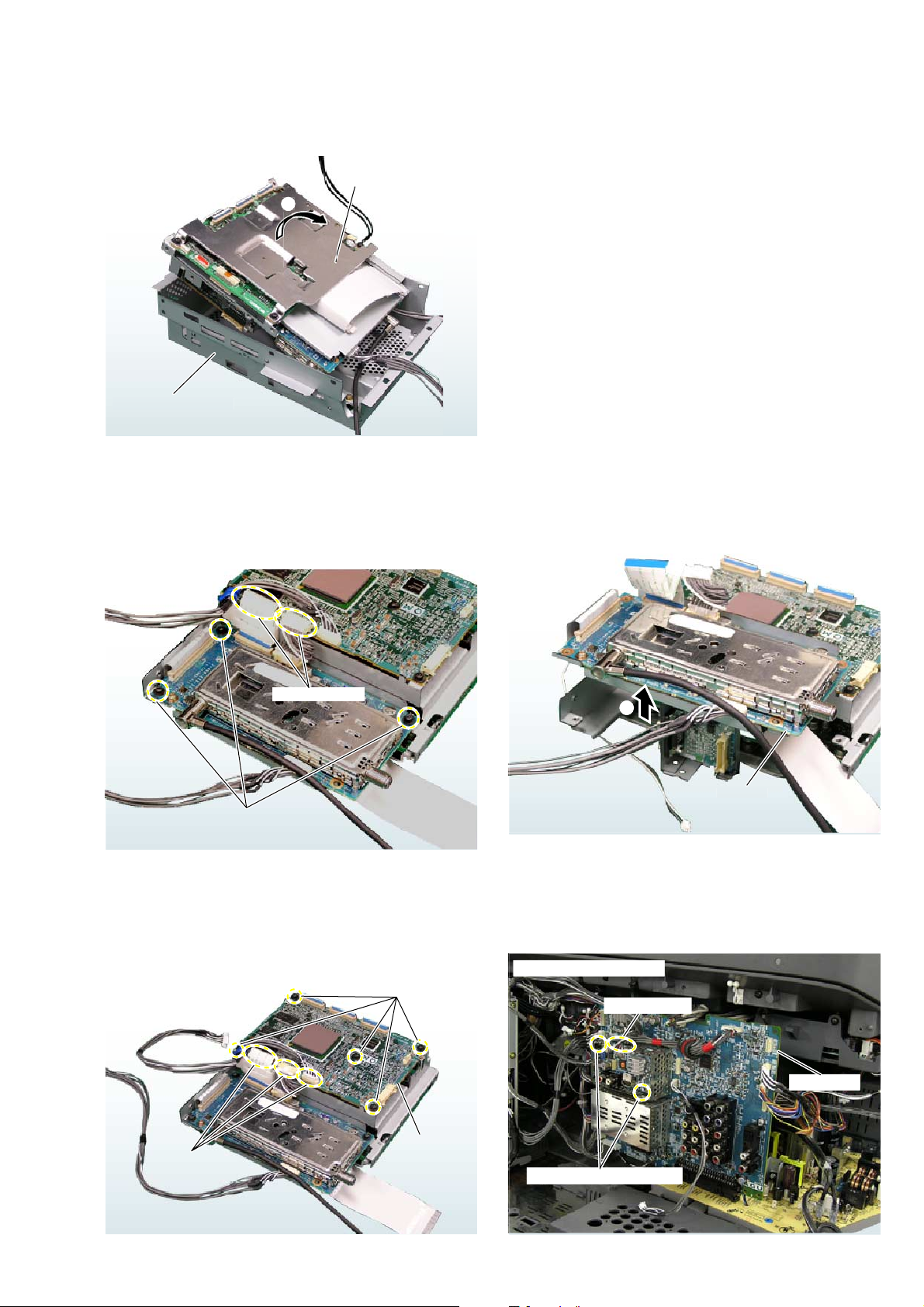

Page 22

)

a

2-10. B, QM AND QT BOARDS

board

ecto

lid of shield

)

hield case (DIGITAL

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

rdsB, QM and QT bo

2-11. QT BOARD

1 Place the pod bracket assembly

upside down.

2 3 connector

3 3 screws

(+PSW M3x8)

2-12. QM BOARD 2-13. P BOARD

T board

2 5 screws

er

(+PSW M3x8)

3 QM board

1 3 connectors

2 screws (+PSW M3x8

case

nn

r

AGU

– 21 –

Page 23

2-14. AGU BOARD

)

2 AUG board

2-15. DC FAN

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

1 Connector

+BVTP 4x16

2

80 fan plate

DC fan

– 22 –

Page 24

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

2-16. MAIN DUCT (R)

2 Pull out main duct (R)

2-18. D.C. FAN (SIROCCO)

1 2 screws (+BVTP 4x16)

2-17. DUCT BLOCK ASSEMBLY

(WITHOUT MAIN DUCT (R))

2 Pull out duct block assembly

1 Screw (+BVTP 4x16)

Lamp duct cover

1 2 claws

4 Remove SIROCCO

fan cover upward

3 Screw (+BVTP 4x16)

2-19. SPEAKER GRILL BLOCK ASSEMBLY

Remove D.C. fan

sirrocco) upward

2

1 2 screws

(+BVTP 4x16)

Speaker grill block assembly

– 23 –

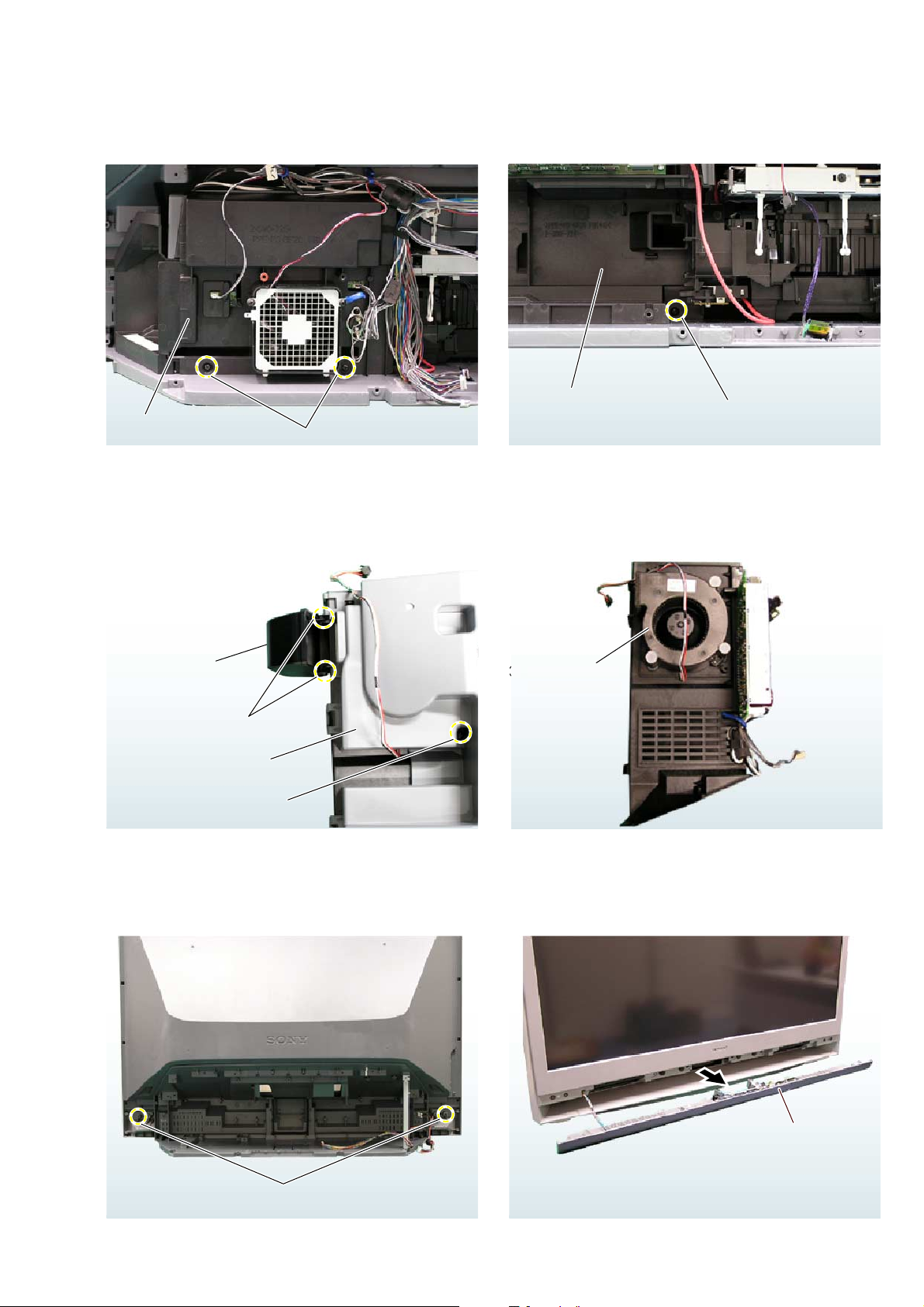

Page 25

2-20. HA AND HB BOARDS

)

)

3 HA board

1 Connector

5 2 Screws

4 Connector

2 2 screws

(+BVTP 4x12)

2-21. SCREEN FRAME BLOCK ASSEMBLY

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

3 Screen frame

x13) (E42A10

x13) (E50A10

2 4 screws

(+BVTP 4x16)

block assembly

2-22. SPEAKERS 2-23. REAR COVER (WITH MIRROR)

2 Rear cover (with mirror)

2 Speaker

1 2 screws

(+PWTP2 4x16)

Screen frame block assembly

4 Speaker

3 2 screws

(+PWTP2 4x16)

1 4 screws

(+BVTP 4x16)

– 24 –

Page 26

2-24. HOW TO REPLACE OPTICS UNIT

k

p

k

p

s

s

s

screws

ew

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

2-24-1. Remove Lamp Block (1)

Remove '' Door, Lamp ".

Door, Lamp

A

< A > < REAR VIEW >

2-24-3. Remove Lamp Block (3)

Pull the "Lever, Lock" below to remove "Lamp block".

2-24-2. Remove Lamp Block (2)

Turn left "Lever, Lock" below, and then remove "Door, Lamp".

ever, Loc

oor, Lam

2-24-4. Remove Cover, Rear (1)

Take off 11 screws (42"), and then pull out "Cover, Rear".

2 screws

over, Rear

ever, Loc

2-24-5. Remove Cover, Rear (1-2)

oor, Lam

2-24-6. Remove Cover, Rear (2)

Take off 13 screws (50"). It is removed "Cover, Rear".

3 screws

screw

2 screws

screw

2 screws

B

screw

over, Rear

E

scr

2 screws

D

C

– 25 –

Page 27

2-24-7. Remove Stay (L), Side

screws

s

Side (L)

s

screws

s

block

block

,

Take off 4 screws, and then remove 2 "Stay (L), Side".

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

,

screw

2-24-8. Pull Out Some Blocks (1)

Take off 4 screws.

2 screws

< B >

< C >

2-24-9. Pull Out Some Blocks (2)

Take off 5 screws.

screw

screw

2-24-10. Pull Out Some Blocks (3)

Pull out "B block", "Chassis block", and "Duct (R), Main"

a little bit.

uct (R), Main

2-24-11. Pull Out Some Blocks (4)

Unlock "Holder, Wire" as shown below.

older, Wire

– 26 –

Page 28

2-24-12. Pull Out Some Blocks (5)

Take off 1 screw.

< F >

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

3 screws

F

1 screw

2-24-13. Pull Out Some Blocks (6)

Loose 1 special screw. (This screw can not be taken off.)

Optics unit block

< G >

2-24-14. Pull Out Some Blocks (7)

Take off 1 screw.

G

1 special screw

Optics unit block

< H >

H

1 special screw

– 27 –

Page 29

unit block

2-24-15. Pull Out Some Blocks (8)

k

u

block

Remove 2 connecters to pull out some blocks as shown below.

< I >

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

I

Connector

2-24-16. Pull Out Some Blocks (9)

Unlock "Purse Lock" to pull out some blocks as shown below.

< J >

2-24-17. Pull Out Some Blocks (10)

Pull out "B block", "Chassis block", "Duct block", and "Optics

Unit block".

J

Purse lock

2-24-18. Remove Optics Unit

Remove all connecters to remove "Optics Unit block" and then it.

nit bloc

ics

B block

– 28 –

Page 30

SECTION 3

ELECTRICAL ADJUSTMENTS

3-1. ELECTRICAL ADJUSTMENT BY REMOTE

COMMANDER

By using remote commander (RM-YD003), all circuit adjust-

ments can be made.

NOTE : Test Equipment Required.

1. Pattern Generator (with component outputs)

2. Oscilloscope

3. Digital multimeter

3-1-1. Method of Setting the Service Adjustment

Mode

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

3-1-2. Service Mode Adjustment

1. The SCREEN displays the item being adjusted.

2. Press “1” or “4” on the remote commander to select the

adjustment item.

3. Press “3” or “6” on the remote commander to change the data.

4. Press “2” or “5” on the remote commander to select the category.

Every time you press “2” (Category up).

5. If you want to recover the latest values press “-” then

“[ENTER]” to read the memory.

6. Press “[MUTING]” then “[ENTER]” to write into memory.

7. Turn power off.

1. Standby mode. (Power off)

2. DISPLAY t 5 t VOL (+) t TV POWER

on the remote commander.

(Press each button within a second.)

The following service screen will appear.

<TV micro>

STATUS 0 SERVICE

SHUTDOWN_LOG1 0 TV MICRO

ATI : H05-01.xx

SAIPH PROGRAM : 1.xxx

BOOT : x.xxx

CHIMERA PROGRAM : 1.xxx

PACK : 1.xxx

OSD : x.xxx

NVM A0 : x.xxx

NVM AC : x.xxx

NVM AE : ----

HDMI : 1.xxx

Press “JUMP” key.

<Digiotal Module micro>

QM 0 0 SERVICE

INFO DTV

Press “JUMP” key.

<BE micro>

<Method of setting the shipping condition>

1. Service Adjustment mode.

2. Press “8” then “[ENTER]”

3. Wait until appearing “ Initial Setup” display.

4. Disconnect AC plug and connect again to change factory re-

set condition completely.

3-1-3. Memory Write Confirmation Method

1. After adjustment, turn power off with the remote commander.

2. Turn power on and set to service mode.

3. Call the adjusted items again and confirm they were adjusted.

3-1-4. Adjusting Buttons and Indicator

MUTING

Adjustment item

up

Adjustment item

down

Initialize data

(Not stored)

User control goes

to the standerd state

(Shipping Conditions)

JUMP

VOL +

TV/VIDEO

POWER TV POWER

MUTING

DVD/

SAT/

VCR

CABLE

DVR

FUNCTION

JUMP ANT MTS/SAP FREEZE

SOUND PICTURE

TV/SAT

SUR

UIDE

G

RETURN

WEGA

TE

GA

REPLAY ADVANCE NEXTPREV

PLAY

VISUAL SEARCH

PAUS E

VOL

TV

ENT

WIDE

DISPLAY

TOOLS

STOP

CH

TV POWER

Adjustment category

up

Data up

Data down

Adjustment category

down

ENTER

DISPLAY

CONFIGRATION 00 0 SERVICE

CP18_COLOR_SYS

00 00A0 BE Micro

Press “JUMP” key.

REC REC PAUSE REC STOP

TOP MENU MENU F1 F2

RM-YD003

– 29 –

Page 31

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

FUNCTION OF KEYS ON COMMANDER

• 1 : Changes adjustment item. (item No. moves up)

• 4 : Changes adjustment item. (item No. moves down)

• 2 : Changes adjustment category.

(category moves up)

• 5 : Changes adjustment category.

(category moves down)

• 3 : Changes data value. (up)

• 6 : Changes data value. (down)

Commander Function

Button Mode Description

[MUTING] + [ENTER] WRITE Writes data to NVM.

- + [ENTER] READ Reads data from NVM.

8 + [ENTER] RESET Set the shipping condition.

3-2. H/V Center Confirmation and Adjustment

Please check the picture horizontal/vertical center after the replace-

ment of the following parts .

• Optical block

• Top assembly

1, Check H/V center with 480i monoscope signal in “Full “ mode .

2, If the center is shifted , adjust it with the following service items .

3-3. IRIS Adjustment

Please check it after the replacement of the following parts.

• IRIS unit+Optics unit block+C board

• B board

Check values of the service data in NVM on C board

#0 BL_U_TOP

#1 BL_U_BOTTOM

DBL_CTRL_AC

and write the same values on C board to the service data in NVM

on B board.

DBL_CTRL

#2 BL_MAX

#3 BL_MIN

#4 IRIS_GAIN

#5 HALL_GAIN

#0 BL_U_TOP

#1 BL_U_BOTTOM

#2 BL_MAX

#3 BL_MIN

#4 IRIS_GAIN

#5 HALL_GAIN

ODHS (for H center)

ODVS (for V center)

ODHS

ODVS

– 30 –

Page 32

4-1. BLOCK DIAGRAM (1)

SECTION 4

DIAGRAMS

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

Rear

Note:

AGU, B, HPC, P and QM boards are supplied as the block for service.

C board is included in the Optics Unit Block.

(The parts on each boards are not supplied individually.)

CXD9855GP

Rear

AGU

AK5357

CXA2188Q

CS4335

Rear

– 31 –

Left Side

Page 33

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

BLOCK DIAGRAM (2)

TU7800

TUNER

DET_OUT

VHF/UHF

CABLE

TO

QM BOARD

CN7307

R_OUT

L_OUT

AFT_OUT

AGC_IN

TU_SDA

TU_SDA

TU_CLK

TU_CLK

12C_SW

FAT_LOCK

FDC_LOCK

DATA0/SDATA

MPEG_CLK

MPEG_ENA

CRX

DRX

RESET

DEM_SDA

DEM_CLK

MPEG_ERR

CN7800

10.5V

6.0V

3.4V

1.5V

VIDEO VIDEO

AUDIO R

AUDIO L

RESTE_FE

FE_SDA

FE_SCL

2

4

6

8

Q7802

BUFFER

Q7803

AGC AMP

D7802

(FAT LOCK)

D7801

(FDC LOCK)

XPOD_STBY

Q7804,7805

LED DRIVER

Q7806,7807

B+ SWITCH

+10.5V

+6.0V

+3.4V

+1.5V

TO

QU BOARD

CN7951

CN7801

AUDIO R

AUDIO L

IC7806

NTSC/ATSC TUNING SELECT

Y

15

Y0 Y1

2

14

X

12

X0

11

10

9

32V DC/DC CONVERTER

VIN

1 4

OSC

2

VIN

1 5

ON/OFF

3

VIN

2 4

CTRL

1

VIN

2 4

CTRL

1

VIN

1 5

CE

3

VIN

4 5

VBIAS

2

A

B

C

D7803

(ERROR)

IC7804

IC7803

9V REG.

IC7802

5V REG.

IC7808

5V REG.

IC7801

1.8V REG.

IC7800

1.1V REG.

ENA/ADJ

X1

VOUT

VOUT

VADJ

VOUT

VOUT

VOUT

VOUT

1

13

DK

3

4

1

A

POD_VCC

POD_VCC

1

PODVCC

POD_VPP

TU_R_OUT

42597

AUDIO R

AUDIO L

PODVPP

TO

AGU BOARD

CN8006

AFT_OUT

TU_L_OUT

TU_V_OUT

101413

VIDEO

+32V

+9V

+5V

POD_5V

+1 .8V

+1.1V

TU_SCL

TU_SDA

12

AGC_MUTE

CN7802

SCLK

246

NCNCNC

TO

QM BOARD

CN7306

HD0

HD1

HD2

HD3

HD6

HD4

HD5

HD6

HD4

HD5

IC7807

DATA SWITCH

3

1Y

6

2Y

3Y

8

4Y

11

1OEN

1

4

2OEN

10

3OEN

13

4OEN

HD7

HD7

HACK

SDATA

FE_SCL

FE_SDA

RESTE_FE

AGC_MUTE/LRCLK

RESET_POD

8

1011121314161820222426283032343637383940424446

FE_SDA

HRESET#

FE_SCL

RESTE_FE

33M_CLK

HACKPOL

XPOD_STBY

XPOD_STBY

HACKPOL

33M_CLK

HIRQ#

HIRQ#

HACK#

TU_TSDATA

TU_TSCLK

TU_TSENA

TU_SSYNC

HD0

HD1

HD2

HD3

QT

CS#

HA0

HA1

HA1

1A

2A

3A

4A

HCS

12

HRW

HA0

HRW#

2

5

9

FF_SCLK

FE_SYNC

TU_TSDATA

TU_SSYNC

TU_TSCLK

FE_VAL

FE_SDATA

48

TU_TSENA

IC7906

HRW#

33M_CLK

HRESET#

HACKPOL

HIRQ#

HACK#

HD0

HD1

HD2

HD3

HD4

HD5

HD6

HD7

HA0

HA1

HCS

MPEG_SDATA

MPEG_CLK

MPEG_ENA

POD_5V

+3.4V

3

5

93

92

91

90

89

88

87

86

85

84

83

79

81

80

82

98

99

96

100

73

72

71

76

78

CLK

HRESET#

HACKPOL

HIRQ

HACK

HD0_SDA

HD1_SCL

HD2

HD3

HD4

HD5

HD6

HD7

HA0

HA1

HCS

HRW

TDO

TOCLK

TOVAL

TOSTRT

TID

TICLK

TIVAL

CRX

DRX

11

IC7900

POD INTERFACE

CONTROLLER

VPPSEL

IC7906

POWR SWITCH

2 7

IN1

4

EN1

IN2

3

5

EN2#

IC7906

POWR SWITCH

2,3

IN

4

EN#

CD2#

MDO2

MDO1

MDO0

MOSTRT

MOVAL

WAIT#

A4_CTX

RST

MDI7

MDI6

MDI5

MCLKI

MDI4

MIVAL

MDI3

IREQ#

MDI2

WE#

MDI1

MCK0

MDI0

MISTRT

A8_CRX

IOWR#

A9_DRX

IORD#

OE#

CE2#

MDO7

CE1#

MDO6

MDO5

MDO4

MDO3

CD1#

OUT

D2

D1

D0

A0

A1

A2

A3

A5

A6

A7

A11

A10

D7

D6

D5

D4

D3

OUT1

OUT2

70

69

58

68

57

67

56

66

54

65

55

52

53

64

51

63

48

46

62

47

61

60

45

59

44

28

43

26

42

25

41

23

21

40

20

39

19

37

35

18

34

17

33

16

32

15

31

14

29

13

30

12

27

6

5-8

PODVCC

PODVPP

PODVCC

(TUNER, POD INTERFACE CONTROLLER, POWER SUPLLY)

CN7903

3

CD2#

5

MDO2

D2

6

MDO1

7

D1

8

MDO0

9

D0

10

11

MOSTRT

13

A0

MOVAL

14

15

A1

A2

17

INPACK#

18

19

A3

21

WAIT#

A4_CTX

22

23

RESET

A5_ITX

24

26

A6_ETX

27

MDI7

A7_QTX

29

MDI6

30

A12

31

32

MDI5

33

MCLKI

34

MDI4

35

MIVAL

36

VPP-1, 2

40

41

VCC

45

MDI3

46

47

IREQ#

48

MDI2

49

WE#

MDI1

50

MCK0

51

MDI0

52

54

A13

MISTRT

55

56

A8_CRX

57

IOWR#

A9_DRX

58

59

IORD#

60

NC

A11

VS1#

62

63

OE#

64

CE2#

A10

65

MDO7

66

CE1#

67

MDO6

68

70

D7

71

MDO5

72

D6

73

MDO4

D5

74

75

MDO3

76

D4

77

CD1#

78

D3

B

TO

QU BOARD

CN7953

– 32 –

Page 34

BLOCK DIAGRAM (3)

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

TO

AGU BOARD

CN8001

CN3002

SCSHIFT

SCDT

DF_FLAG

KCLATCH

LR_DATA

BCLK

LRCK

MCLK

AMP_RST

SP-PROT

3.3V_SW

IC3002 (1/2)

BUFFER

14A_MUTE

6M_RST

11

9

8

7

5

3

4

1

12

13

15

D+3.3V

5

4

IC3004

BUS BUFFER

2

4

3

6

8

7

9

11

IC3002 (2/2)

GATE

6

18

16

17

14

12

13

11

12

13

IC3006

PCM/PWM PROCESSOR

SOFTMUTE

19

INIT

27

22

SCSHIFT

SCDT

21

23

SCLATCH

31

DATA

30

BCK

29

LRCK

36

XFSDN

25

DVF FLAGL

24

DVF FLAGR

+12V

+3.3V

+1.8V

48

XFSDIN

OUTL1

OUTL2

OUTR1

OUTR2

IC3008

4 5 3

+1.8V REG.

AUDIO L

AUDIO R

X3001

49.1MHz

IC3007

CLOCK GENERATOR

4

2

IC3005

DIGITAL POWER AMP

411

PWM_A

PWM_B

69

146

PWM_C

PWM_D

16

5

/RST_AB

/RST_CD

15

3

/SD

IC3003

+3.3V REG.

VOUT VIN

ON OFF CONT

2

OUT_A

OUT_B

OUT_C

OUT_D

1

AUDIO L

32

30

AUDIO R

25

224

3 1

LPF

IC3001

+12V REG.

VOUT VIN

ON OFF CONT

2

Q3002,3003

Q3005,3006

ZERO VOLTAGE

DETECT

Q3004

PROTECT

PS3001

AUDIO L

AUDIO R

CN3003

1L+

L-

2

3R+

R-

4

CN3001

4

PVDD

PVDD

3

GND

2

1 GND

C

SPEAKER

(L-CH)

SPEAKER

(R-CH)

TO

GT BOARD

CN6002

(AUDIO AMP)

K

– 33 –

Page 35

BLOCK DIAGRAM (4)

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

Cable

Card

CN7952 CN7953

MDO2

MDO1

MDO0

MOSTRT

MOVAL

INPACK#

WAIT#

A4_CTX

RESET

A5_ITX

A6_ETX

A7_QTX

MCLKI

MIVAL

VPP-2

VPP-1

IREQ#

MISTRT

A8_CRX

IOWR#

A9_DRX

IORD#

MDO7

MDO6

MDO5

MDO4

MDO3

CD2#

D2

D1

D0

A0

A1

A2

A3

MDI7

MDI6

A12

MDI5

MDI4

VCC

VCC

MDI3

MDI2

WE#

MDI1

MCK0

MDI0

A13

A11

VS1#

OE#

CE2#

A10

CE1#

D7

D6

D5

D4

CD1#

D3

B33

B32

A32

B31

A31

B30

A30

B29

A29

B28

A28

A27

B26

A26

B25

A25

B24

A24

A23

B22

A22

B21

A21

B20

A20

B19

A19

B18

A18

B17

A17

B16

A16

B15

A15

B14

A14

B13

A13

B12

A12

B11

A11

B10

A10

3

CD2#

5

MDO2

D2

6

MDO1

7

D1

8

MDO0

9

D0

10

11

MOSTRT

13

A0

MOVAL

14

15

A1

A2

17

INPACK#

18

19

A3

21

WAIT#

22

A4_CTX

23

RESET

A5_ITX

24

26

A6_ETX

27

MDI7

A7_QTX

29

MDI6

30

A12

31

32

MDI5

33

MCLKI

34

MDI4

35

MIVAL

36

VPP-1, 2

40

41

VCC

45

MDI3

46

47

IREQ#

48

MDI2

49

WE#

MDI1

50

MCK0

51

MDI0

52

54

A13

MISTRT

55

56

A8_CRX

57

IOWR#

A9_DRX

58

59

IORD#

60

B9

A9

B8

A8

B7

A7

B6

A6

B5

A5

B4

A4

B3

A3

B2

A2

A11

VS1#

62

63

OE#

64

CE2#

A10

65

MDO7

66

67

CE1#

MDO6

68

70

D7

71

MDO5

72

D6

73

MDO4

D5

74

75

MDO3

76

D4

77

CD1#

78

D3

CN7951

VCC

1

VCC

2

5

VPP

B

A

TO

QT BOARD

CN7903

TO

QT BOARD

CN7904

(CABLE CARD

QU

CONNECTOR)

– 34 –

Page 36

BLOCK DIAGRAM (5)

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

IC7180

TEMPERATURE

SENSOR

(LAMP TEMPERATURE )

S2

S7150

LAMP DOOR

DETECTION

(LAMP DOOR DETECTION )

T1

2

1

8

4

3

1

1

2

3

CN7180

SCL_TV

SDA_TV

SET_5V

CN7150

LAMP_COV

NC

GND

TO

AGU BOARD

CN8410

TO

AGU BOARD

CN8410

S7155

LAMP CONNECTOR

DETECTION

(LAMP CONNECTOR DETECTION )

T2

– 35 –

1

2

3

CN7155

LAMP_COV

NC

GND

TO

AGU BOARD

CN8403

Page 37

BLOCK DIAGRAM (6)

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

CN7000

KEY

2

NC

3

1

GND

TO

AGU BOARD

CN8004

TIMER

LAMP

POWER/

STANDBY

TEMPERATURE

SENSOR

D7024

D7023

D7022

IC7020

G

R

G

R

IC7021

OUT

2

1

8

HA

Q7023

LED DRIVER

Q7021

LED DRIVER

S7001S7002S7003S7004S7005

CH-VOL+VOL-TV/VIDEOVEGA GATE

S7000

CH+

(PANEL SWITCH )

Q7024

LED DRIVER

Q7022

LED DRIVER

Q7022

LED DRIVER

S7020

POWER

STBY

+3.3V

CN7020

STBY+3.3V15

TIMER_LED13

P_MUTE_LED

12

LAMP_LED

11

POW_LED

8

STBY_LED

9

7

SIRCS

5

P.ON

SCL

4

SDA

3

5V

1

TO

AGU BOARD

CN8004

VIDEO/HD/DVD IN2

(1080i/720p/480p/480i)

AUDIO

PR/CR

PB/CB

Y

VIDEO

L

(MONO)

R

J7100

J7101

(SIRCS, LED)

HB

(VIDEO 2 INPUT)

HC

CN7102

COMP2_CR

5

3

COMP2_CB

1

COMP2_Y

CN7101

1

2

4

5

COMP DET

V2-V

V2-L

V2-R

TO

AGU BOARD

CN8814

TO

AGU BOARD

CN8400

– 36 –

Page 38

BLOCK DIAGRAM (7)

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

AC IN

CN6010

AC (L)

AC (N)21

F6001 L6012 L6011

D6000

RECT

RELAY_VCC

RY6001

D6289

RECT

R6006

D6300

Q6007

RELAY DRIVER

PH6001

R6045

REGULATOR

1

2

VG(H)

VSENSE

1

VS

VG(L)

DCP

VC1

DCP

IC6000

SWITCHING

REGULATOR

IC6008

SWITCHING

16

15

14

9

8

9

RY6002

7

9

4

3

Q6303,6304

DELAY GATE

D6298

D6284

Q6001

DRIVE

Q6008

DRIVE

D6015

SET 5V

6

4

2

1

T6004

PH6002

PH6004

11,12

T6000

11

10

181

17

2

16

15

4

14

13

5

12

9

8

PH6003

D6301

7,8

D6043

RECT.

D6018

D6020

D6019

D6029

RECT.

Q6000,6009

B+ SWITCH

1

VCC

VCC

23

R6100

IC6003

+9V REG

IC6002

+5V REG

IC6007

+3.3V REG.

1

IC6009

1

DC/DC

CONVERTER

IC6001

SHUNT

REGULATOR

1

IC6005

+5V

REG.

OUT

OUT

2

4

2

SET 9V

REG_12V

UNREG_6V

SET5V

5

L6002

Q10.5V

Q5V

SUB-ON

SET 5V

RELAY_VCC

VCC

IC6012

+10V REG

OUT

CN6018

1 LAMP DC

3 LAMP GND

CN6009

2 17V

46V

56V

893.3V

3.3V

CN6019

9 FAN_VCC

10 FAN_VCC

16 SET 9V

19 SET 5V

20 SET 5V

23 SET 3.3V

24 SET 3.3V

28 STBY 5V

31 B-12V

32 B-12V

35 AUDIO 5V

38 UNREG_6V

40 UNREG_6V

45 Q_10.5V

46 Q_10.5V

49 Q_5V

11 RELAY_VCC

12 AC_RLY

13 SUB_ON

CN6002

4 AU_VCC

3 AU_VCC

2 AU_GND

1 AU_GND

TO

LAMP DRIVER

TO

C BOARD

CN604

TO

AGU BOARD

CN8401

K BOARD

C

CN3001

TO

IC6004

STBY 5V

1

32

IC6010

SHUNT

REGULATOR

+5V

VCC OUT

REG.

Q6010,6011

– 37 –

GT

(POWER SUPPLY)

Page 39

4-2. FRAME SCHEMATIC DIAGRAM

KDF-E42A10/E50A10

K RM-YD003 RM-YD003

G

H

123456

A

B

C

T2

D

T1

E

S2

BiMetal

FAN1

F

FAN2

FAN3

FAN4

CN to AGU

HOLE10 1 3 HOUT(-) 6 FAN 2_POW 5 BREAK 4 SCLK 69

HOLE8 2 4HIN(-) 7 FAN 2_PROT 6 ICD3 5 SDAT 70

HOLE11 3 5 HOUT(+) 8 GND 7 ICD2 CN8400 to HC 6 A GND 71

HOLE9 4 6HIN(+) 9 FAN 3_POW 8 ICD1 1 COMP_DET 7 R 72

BRAKE6 5 7 FB(+) 10 FAN 3_PROT CN8814 9 ICD0 2 V2_Y 8 L 73

BRAKE7 6 8 DRIVE(+) 11 GND 1 COMP2_Y 10 ICS2 3 GND 9 GND 74

BRAKE4 7

BRAKE5 8 13 FAN 4_PROT 3 COMP2_CB 12 ICS0 5V2_R 11 GND 76

C

Note:

The parts on this board are

not supplied individually

for service.

LVDS

CN to BE 5 P_ON 6 GND 5 GND 20 FR_RST_INT 21 GND 21 GND 21 GND 20 TD+ 21 GND

1TA- 6GND 5 PC-B 6MAIN RED/V 21 ACOFFDET 22 DT_DC5 22 DTOSD_R3IN 22 DTOSD_A0IN 21 TD2TA+ 7SIRCS 4 GND 7 GND 22 IRIS_CTL 23 GND 23 GND 23 GND 22 GND(LVDS-CLK) CN5400 to C

3 DRAIN(GND) 8 POW_LED 3 PC-H 8MAIN CV/Y 23 GND 24 DT_DC4 24 DTOSD_R4IN 24 DTOSD_A1IN 23 TCLK+ 1 GND

4TB- 9 STBY_LED 2 GND 9 GND CN5001 24 GND 25 GND 25 GND 25 GND 24 TCLK- 2 MUTE

5TB+ 10GND 1 PC-V 10 MAIN C 1 GND 25 CMCPU SDA 26 DT_DC3 26 DTOSD_R5IN 26 DTOSD_A2IN 25 GND(LVDS-TC) 3 LVDS PD

6 DRAIN(GND) 11 LAMP_LED 11 GND 2 GND 26 CMCPU SCL 27 GND 27 GND 27 GND 26 TC+ 4 GND

7TC- 12P_MUTE_LED 12 SUB GRN/Y 3 GND 27 CMCPU TXD 28 DT_DC2 28 DTOSD_R6IN 28 DTOSD_A3IN 27 TC- 5 SDA

8TC+ 13 TIMER_LED CN7202 (PA) 13 GND 4 GND 28 CMCPU RXD 29 GND 29 GND 29 GND 28 GND(LVDS-TB) 6 SCL

9 DRAIN(GND) 14 GND 1 L 14 SUB BLUE/U 5 PANEL VCC 29 GND 30 DT_DC1 30 DTOSD_R7IN 30 DTOSD_A4IN 29 TB+ 7 WP-C

CN604 to G 11 TCLK+ 3R 16 SUB RED/V 7 PANEL VCC 31 HALL_OUT 32 DT_DC0 32 DTOSD_G0IN 32 DTOSD_A5IN 31 GND(LVDS-TA) 9 PAWN_RST

1 GND CN602 to BE 12 DRAIN(GND) 4GND 17 GND 8 MAIN 11V 32 FR_FLASH 33 GND 33 GND 33 GND 32 TA+

2 +17V 1 GND 13 TD- 5 SW_5V 18 SUB HS 9 MAIN 11V 33 LUMIDET 34 DT_DY7 34 DTOSD_G1IN 34 DTOSD_A6IN 33 TA3 GND 2 MUTE 14 TD+

4+ 6.5V 3 LVDS PD 15 DRAIN(GND) 20 SUB VS 11 GND 35 JIG FRRST 36 DT_DY6 36 DTOSD_G2IN 36 DTOSD_A7IN 35 GND CN4003 for JIG

5 +6.5V 4 GND 16 TE- 36 JIG BINT 37 GND 37 GND 37 GND 36 GND 1 UVCC

6 GND 5 SDA 17 TE+ 37 JIG API TXD 38 DT_DY5 38 DTOSD_G3IN 38 CLKGO 37 VCC 2 XTRST

7 GND 6 SCL 18 GND 38 JIG API RXD 39 GND 39 GND 39 GND 38 VCC 3 XRSTIN

8+ 3.3V 7 WP-C 19 GND CN 4601 CN 4600 39 GND 40 DT_DY4 40 DTOSD_G4IN 40 VSGO 39 VCC 4 XINIT

9+ 3.3V 8 WP-LUT 20 GND 1 GND 1 GND 40 GND 41 GND 41 GND 41 GND 40 VCC 5 BREAK

10 GND 9 yobi 21 GND 2PC-R 2 PC-R 42 DT_DY3 42 DTOSD_G5IN 42 HSGO 41 VCC 6 ICD3

GH GH

CN6009 to C CN8815 CN8004 to HA, HB CN8405 to B CN8003 to B CN8404 to B 8 PC-H 8 PC-H 48 DT_DY0 48 DTGRACKIN 48 3 SDA_A 12 ICS0 CN3002 CN3001

1 GND 1 PC_L 1 5V GND 1 MAIN_YS 1 MAIN GRN/Y 9 GND 9 GND 49 GND 49 GND 49 GND 4 SCL_A 13 GND 1 MCLK GND 1

2 +17V 2 GND 2 GND 21GND 2 GND 2 GND 10 PC-V 10 PC-V (straight) (straight)

CN7155 4 + 6.5V CN6019 to A 4 GND 4 SCL 4 GND 4 FV_SUB 4 GND 4LRCK PVDD 4

1LAMP_POS 5 +6.5V 1 GND 5 SW_5V 5 P_ON 5 PANEL_VCC 5 LAMP_HVDET 5 MAIN RED/V 5LR_DATA

2NC 6 GND 2 GND

3 GND 7 GND 3 GND 7 SIRCS 7 PANEL_VCC 7 LAMP_PROT 7 MAIN CV/Y 7 SCLATCH1

GH

CN7150 8 GND 2 GND 12 NC PA 12 BE_WDT 12 GND 2 GND 2 GND 12 AMP_RST

1 LAMP_COV 9 UNREG_11V 3 GND 13 LAMP_LED 13 VSW_VS 13 SUB BLUE/U 3 GND 3 CD2# 13 SP_PROT

2NC 10 UNREG_11V 4 GND 14 GND 14 VSW_HS 14 GND 4 GND 4 IOIS16# 14 A_MUTE CN3003

3 GND 11 RELAY_VCC 5 GND 15 P_MUTE_LED 15 FH_MAIN 15 SUB RED/V 5MDO2 15 3.3V_SW L + 1

GH

CN7180 23 SET 3.3V 17 GND 27 CMCPU_TXD 4 LRCK 4 6.0V 4 SDATA 17 A2

1 SET_5V CN6014 24 SET 3.3V 18 GND 28 CMCPU_RXD 5 LR_DATA 5 GND 5 GND 18 INPACK#

2 GND 1 GND 25 GND 19 SET 5V CN8008(for JIG) 29 GND 6 M_RST 6 3.4V 6 AG_MUTE/LRCLK 19 A3

3 SDA_TV 26 GND 20 SET 5V 1 GND 30 GND 7 SCLATCH1 7 GND 7 GND 20 GND

4 SCL_TV CN6015 27 GND 21 GND 2 GND 31 IRIS_HALL 8 OF_FLAG 8 1.5V 8 FE_SCL 21 WAIT# CN7317 CN7316 CN7315 CN7313

5 GND 1 GND 28 STBY 5V 22 GND 3 E_MD 32 FR_FLASH 9 SCDT 9 GND 22 A4_CTX 1 GND_1 1 GND_1 1 GND_1 1 QT-DET CN7903 1

GH

Fasten 187 32 B_10.5V 26 GND 7 NC(IIC1) 36 JIG_BINT 13 SP_PROT 3 GND 13 XPOD_STBY 26 A6_ETX 5 GND_1 5 GND_1 5 NC 5 GND 4 IOIS16# 5

1 Thermo 33 GND 27 GND 8NC(IIC1) 37 JIG_API_TXD 14 A_MUTE 4 5.0V 14 HACKPOL 27 MDI7 6 DT_DY2 6 DYOSD_G6IN 6 NC 6 AG_MUTE/LRCLK 5 MDO2

Fasten 187 34 GND 28 STBY 5V 9 NC(IIC2) 38 JIG_API_RXD 15 3.3V_SW 5 TU_R_OUT 15 GND 28 GND 7 GND_1 7 GND_1 7 GND_1 7 GND 6D2 CN7952

1 Thermo 35 AUDIO 5V 29 GND 10 NC(IIC2) 39 GND

R

R

R

P

3 GND (B to B) 3 PC_R 3 SDA_ 3 GND 3 FH_SUB 3 MAIN BLUE/U

P

8+ 3.3V 4 GND 8 GND 8 +12V 8 LAMP_COVER 8 GND 8OF_FLAG

9+ 3.3V 5 GND (B to B) 9 POW_LED 9 +12V 9 PANEL_SCL 9 MAINC 9 SCDT

10 GND 6 GND CN8401 to G 10 NC 10 PC_3.3V 10 SDA_PANEL 10 GND CN7903(2/2) CN7903(1/2) 10 GND

XA

CN6013 21 GND 15 GND 25 CMCPU_SDA 2 GND 2 10.5V 2 SCL 15 A1

1 GND 22 GND 16 SET 9V 26 CMCPU_SCL 3 BCLK 3 GND 3 SDA 16 REG#

(VH, PC Board) CN6012 6 NC 32 NC(USB3) 14 Q_10.5V 1 SUB_V 38 CS# 51

CN6018 to LAMP Driver 1 GND CN8403 to QM 7 LAMP_PROT 33 NC(USB3) PA 2 GND 39 HA0 52

1LAMP DC 1 LAMP_POS 8 GND 34 NC 3 TU_R 40 HRW 53

NC 2 GND 9 LAMP_5V 35 TV_RST 4 GND 41 GND 54

2LAMP GND 3 GND/UNREG_11V 10 LAMP_CTRL 36 E_RST 5 TU_L 42 FE_SYNC 55

VH

(POWER) 2 AU_GND 6 SDAT 13 HV_DET 39 TU_V_OOUT 8 TU_V 45 GND 58

CN6010 AC 3 AU_VCC 7 GND 14 LAMP_COVER(+) 40 GND 9 GND 46 FE_SDATA 59

1 AC (N) 4 AU_VCC 8 LRCK 15 LAMP_COVER(-) 41 GND 10 TU_SCL 47 GND 60

2 AC (L)

VT

10 TCLK- 15 STBY 3.3V 2 GND 15 GND 6 PANEL VCC 30 GND 31 GND 31 GND 31 GND 30 TB- 8 WP-LUT

actual connection:17pins(LVDS)

GH

7 GND 1 GND 11 STBY_LED 11 GND 11 GND 11 SUB GRN/Y 1 GND 1 GND 11 SCSHIFT

12 AC_RLY 6 GND 16 GND 16 FV_MAIN 16 GND 6D2

13 SUB_ON 7 GND 17 TIMER_LED 17 FR_RST 17 SUB HS 7MDO1 R + 3

14 LOW_B_DET 8 GND 18 GND 18 CMCPU_BUSY 18 GND 8D1 R - 4

15 AC_OFF_DET 9 +12V 19 STBY 3.3V 19 LAMP_CTRL 19 SUB VS 9MDO0

16 SET 9V 10 +12V 20KEY 20 FR_RST_INT 20 GND 10 Do

17 GND 11 RELAY_VCC 21 ACOFF_DET SHLD 11 MOSTRT

18 GND 12 AC_RLY To HB --- 1,2,3,4,5,6,7,8,9,11,13,14,15,17,19 22 DIMMER 12 GND

19 SET 5V 13 SUB_ON To HA --- 16,18,20 23 GND CN8001 CN7800 CN7802 13 A0

20 SET 5V 14 GND 24 GND 1 MCLK 1 GND 1 GND 14 MOVAL

29 GND 23 SET 3.3V 4 E_BINT 33 LUMI_DET 10 GND CN7801 10 FE_SDA 23 RESET 2 DT_DY0 2 DTSD_GRACKIN 2 NC 2 I2S_SCLK 1 GND 2

30 GND 24 SET 3.3V 5 SCL_TV 34 BE_BINT 11 SCSHIFT 1 3.3V 11 RESET_FE 24 A5_ITX 3 GND_1 3 GND_1 3 NC 3 GND 2 GND 3

31 B_10.5V 25 GND 6 SDA_TV 35 JIG_FRRST 12 AMP_RST 2 3.3V 12 RESET_POD 25 VS2# 4 DT_DY1 4 DYOSD_7IN 4 NC 4 I2S_SDATA 3CD2# 4

36 AUDIO_GND 30 GND 11 SCL_E 40 GND 7 TU_L_OUT 17 GND 30 MDI6 9 GND_1 9 GND_1 9 GND_1 9 GND 8D1 D3

37 SP_MUTE 31 +12V 12 SDA_E

38 AUDIO_MUTE 32 +12V 13 3.3V 9AFT_OUT 19 GND 32 MD15 11 GND_1 11 GND_1 11 GND_1 11 RESET_FE# 10 Do 4 D5

39 AUDIO_GND 33 GND 14 NC 10 TU_V_OUT 20 HACK 33 MCLKI 12 DT_DY5 12 DYOSD_G3IN 12 CLKGO 12 RESET_POD# 11 MOSTRT 5 D6

40 AUDIO_R 34 GND 15 TV_TXD 11 GND 21 GND 34 MDI4 13 GND_1 13 GND_1 13 GND_1 13 POD_STBY 12 GND 6 D7

41 AUDIO_GND 35 AUDIO 5V 16 TV_RXD 12 TU_SCL 22 HD0 35 MIVAL 14 DT_DY6 14 DYOSD_G2IN 14 DYOSD_A7IN 14 HACKPOL 13 A0 7 CE1#

42 AUDIO_L 36 AUDIO_GND 17 E_TXD 13 TU_SDA 23 GND 36 VPP-2 15 GND_1 15 GND_1 15 GND_1 15 GND 14 MOVAL 8 A10

43 Q_GND 37 AUDIO_GND 18 E_RXD CN8005 to QM 14 AGC_MUTE 24 HD1 37 VPP-2 16 DT_DY7 16 DTOSD_G1IN 16 DTOSD_A6IN 16 33M_CLK 15 A1 9 OE#

44 Q_GND 38 UNREG_6V 19 NC(UART3) 1 10.5V/+12V 25 GND 38 VPP-2 17 GND_1 17 GND_1 17 GND_1 17 GND 16 REG# 10 A11

45 Q_10.5V 39 GND 20 NC(UART3) 2 10.5V/+12V 26 HD2 39 VPP-1 18 DT_DC0 18 DTOSD_G0IN 18 DTOSD_A5IN 18 HIRO# 17 A2 11 A9_DRX

46 Q_10.5V 40 UNREG_6V 21 5V 3 GND 27 GND 40 VPP-1 19 GND_1 19 GND_1 19 GND_1 19 GND 18 INPACK# 12 A8_CRX

47 GND 41 GND 22 5V 4 GND 28 HD3 41 VCC 20 DT_DC1 20 DTOSD_R7IN 20 DTOSD_A4IN 20 HACK 19 A3 13 A13

48 GND 42 GND 23 NC(USB1) 5 JIG_TXD 29 GND 42 VCC 21 GND_1 21 GND_1 21 GND_1 21 GND 20 GND 14 MCLKO

GT

49 Q_5V 43 Q_GND 24 NC(USB1) 6 JIG_RXD 30 HD4 43 VCC 22 DT_DC2 22 DTOSD_R6IN 22 DTOSD_A3IN 22 HD0 21 WAIT# 15 WE#

50 GND 44 Q_GND 25 NC(USB1) 7 GND 31 GND 44 VCC 23 GND_1 23 GND_1 23 GND_1 23 GND 22 A4_CTX 16 IREQ#

CN6011 48 GND 3 SDA_5V 29 NC(USB2) 11 ANT_SW1 35 GND 48 MDI2 27 GND_1 27 GND_1 27 GND_1 27 GND 26 A6_ETX 20 MCLKI

1 GND 49 Q_5V 4 SCL_5V 30 3.3V 12 GND 36 HD7 49 WE# 28 DT_DC5 28 DTOSD_R3IN 28 DTOSD_A0IN 28 HD3 27 MDI7 21 A12

CN6002 4 SPDIF 11 100W/120W 37 MD0 6 GND 43 GND 56

1 AU_GND 5 GND 12 GND 38 DTT_LOG 7 AFT 44 FE_SCLK 57

PA

45 Q_10.5V CN8410 26 NC 8 ATSC_RST 32 HD5 45 VCC 24 DT_DC3 24 DTOSD_R5IN 24 DTOSD_A2IN 24 HD1 23 RESET 17 VCC

46 Q_10.5V 1 5V 27 NC(USB2) 9 ATSC_TXD 33 GND 46 MDI3 25 GND_1 25 GND_1 25 GND_1 25 GND 24 A5_ITX 18 VPP-1

47 GND 2 GND 28 NC(USB2) 10 ATSC_RXD 34 HD6 47 IREQ# 26 DT_DC4 26 DTOSD_R4IN 26 DTOSD_A1IN 26 HD2 25 VS2# 19 MIVAL

50 GND 5 GND 31 NC(USB3) 13 Q_5V CN8006 37 HA1 50

9 GND

10 SCLK 12 AGC 49 GND 62

11 GND CN8002

12 MCLK 1 STBY 5V CN8007(for JIG) (L-TYPE, PC Board) 64

GH

CN8406 3 FAN 1_POW 2 XTRST 1 11V 66

1 FB(-) 4 FAN 1_PROT 3 XRSTIN 2 RESET 67

2 DRIVE(-) 5 GND 4 XINIT 3 CEC 68

GH

IRIS

HV-

DET

ZM9P 3

CN to G CN to AGU

1LAMP DC LAMP_PROT 1

2NC GND 2

3LAMP GND LAMP_5V 3 8NC 10 PR

I

VH

LAMP_CTRL 4 9NC 11 GND

100W/120W 5 10 NC 12 PB 14 NC 5 GND 3 GND 2 D- 75

SH

LAMP

ZH9P Q_5V 4

Lamp

Connector

HA

CN7000 to AGU 6PANEL_VCC 7 ACN MAIN CV/Y 5 LAMP_HVDET 6 (GND) 6 PC_EXIST_V(NC) 6 DTOSD_B0IN 5 GND 6 DRAIN(GND)

1 GND 7PANEL_VCC 8 GND 6 PC_WAKEUP 7 (GND) 7 PC_WAKEUP(NC) 7 GND 6 LCD_DCCSEL0 7 TC2 KEY 8 MAIN11V 9 ACN MAINC 7 LAMP_PROT 8 (GND) 8 A_CMRST(NC) 8 DTOSD_B1IN 7 LCD_DCCSEL1 8 TC+

3 GND 9 MAIN11V 10 GND 8 LAMP_COVER 9 DTT_MUTE 9 A_CMBUSY(NC) 9 GND 8 PAWN RST 9 DRAIN(GND)

GH

HB

CN7020 to AGU CN7201 (PA) CN5000 17 ACN SUB HS 15 FH MAIN 16 M_D2H 16 DTOSD_R0IN 16 DTOSD_B5IN 15 LCD_BBCSEL 16 TE-

15V 10 GND 1 GND 18 GND 16 FV MAIN 17 GND 17 GND 17 GND 16 GND(LVDS-TE) 17 TE+

2 GND 9 PC-R 2MAIN GRN/Y 19 ACN SUB VS 17 FR_RST 18 DT_DC7 18 DTOSD_R1IN 18 DTOSD_B6IN 17 TE+ 18 GND

3 SDA 8 GND 3 GND 20 GND 18 CM_BUSY 19 GND 19 GND 19 GND 18 TE- 19 GND

4 SCL 7 PC-G 4MAIN BLUE/U 19 BACKLIGHT 20 DT_DC6 20 DTOSD_R2IN 20 DTOSD_B7IN 19 GND(LVDS-TD) 20 GND

SHLD

(L-TYPE, Header)

6 GND 6 PANEL_VCC 6 PC_WAKEUP_INT 6 GND 6M_RST

AGU

Note:

The parts on this board are

not supplied individually

for service .

GH

2 RELAY_VCC 1 UVCC CN8402 to P 65

12 FAN 4_POW 2 GND 11 ICS1 4 V2_L 10 PR 75

14 GND 4 GND 13 GND 6 GND 12 PB 77

GH

ANT_SW1 1 111V

GND 2 CN7102 CN7101 to AGU 2 RESET

Q_10.5V 5

S Micro

ANT Sw

5 COMP2_CR 14 ICLK

6 GND FFC/FPC 14 Y 79

PA

Note:

The parts on this board are

not supplied individually

for service.

HPC

GH

(Straight, Header) (Straight, Header) 7 GND 7 GND 47 GND 47 GND 47 2 B_INT 11 ICS1

SHLD

42 GND 11 TU_SDA 48 FE_VAL 61

GH

COMP2_Y 1 COMP_DET 3 CEC

1

GND 2 V2_V 4 SCLK

2

COMP2_CB 3 GND 5 SDAT

3

GND 4 V2_L 6A GND

4

COMP2_CR 5 V2_R 7R

5

GND 6 GND 8L

6

PA

7NC 9 GND

11 NC 13 GND 15 DDC CLK 6 LRCK 4 6.0V 3 D+ 76

12 NC 14 Y 16 DDC DAT 78GND 5 GND 4 GND 77

GH

GH

GH

13 GND 78

15 GND 80

GH

HC

7

CN5004 to AGU 1 ACN MAIN GRN/Y CN4801 to QG CN4802 to QG CN4803 to QG CN5401 to C

1 GND 2 GND CN5005 to AGU 1 GND 1 GND 1 GND CN5403 1 TA2 GND 3 ACN MAIN BLUE/U 1 MAINYS 2 (GND or DTT_DE) 2 SCL(NC) 2 DT_GRAVSIN 1 GND 2 TA+

3 GND 4 GND 2 GND 3 GND 3 SDA(NC) 3 GND 2 PANEL_SDA 3 DRAIN(GND)

4 GND 5 ACN MAIN RED/V 3 FH SUB 4 (GND) 4 GND 4 DT_GRAHSIN 3 PANEL_SCL 4 TB5PANEL_VCC 6 GND 4 FV SUB 5 GND 5 PC_EXIST_H(NC) 5 GND 4 BINT_WPC 5 TB+

10 PC3.3V 11 ACN SUB GRN/Y 9 PANEL_SCL 10 GND 10 C_BOOT(NC) 10 DTOSD_B2IN 9 LVDS_PD 10 TCLK11 GND 12 GND 10 PANEL_SDA 11 GND 11 NC 11 GND 10 IRQRET 11 TCLK+

PA

19 GND 10 PC3.3V 34 CM_BINT 35 GND 35 GND 35 GND 34 GND

3 GND 3 GND 43 GND 43 GND 43 GND 7 ICD2

4PC-G 4 PC-G 44 DT_DY2 44 DTOSD_G6IN 44 ACOFFDET 8 ICD1

5 GND 5 GND 45 GND 45 GND 45 CN4150 XX 9 ICD0

6PC-B 6 PC-B 46 DT_DY1 46 DTOSD_G7IN 46 1 GND 10 ICS2

PA FFC/FPC(SB-L5905)

6 GND 16 33M_CLK 29 A7_QTX 8 DT_DY3 8 DYOSD_G5IN 8 HSGO 8 FE_SCL 7 MDO1 12GND

8 GND 18 HIRO# 31 A12 10 DT_DY4 10 DYOSD_G4IN 10 VSGO 10 FE_SDA 9 MDO0 3 D4

CN5003 to AGU (L type)

13 ACN SUB BLUE/U 11 GND 12 M_D2CLK 12 GND 12 DTOSD_B3IN 11 LUT0/PLERST 12 DRAIN(GND)

14 GND 12 BE-WDG 13 GND 13 Tx(NC) 13 GND 12 LUT1/CPUGO 13 TD15 ACN SUB RED/V 13 VSW_VS 14 M_D2V 14 Rx(NC) 14 DTOSD_B4IN 13 LCD_LUT2 14 TD+

16 GND 14 VSW_HS 15 GND 15 GND 15 GND 14 ACC/PDPGO 15 DRAIN(GND)

QT

CN 9504 2 E 6 JG_RXD 63

15 GND 17 E SCLK 6 3.4V 5 SHIELD 78

GH

891011 12 13

LVDS

actual connection:

17pins(LVDS)

GH

B

Note:

The parts on this

board are not

supplied individually

for service.

MDI1

MCLKO

MDI0

GND

A13

MISTRT

A8_CRX

IOWR#

A9_DRX

IORD#

A11

GND

VS1#

63

OE#

CE2#

A10

MDO7

CE1#

MDO6

GND

D7

MDO5

D6

NDO4

D5

MDO3

D4

CD1#

D3

GND

GND

CN9505

1 DEBUG1

2 BEBUG2

3P87

4P86

5P85

6 Nmi

7 VCC 3.3V

8 RESET

9 GND

SH

HDMI

Connector

P

29 GND_1 29 GND_1 29 GND_1 29 GND 28 GND 22 A7_QTX

30 DT_DC6 30 DTOSD_R2IN 30 DTOSD_B7IN 30 HD4 29 A7_QTX 23 A6_ETX

31 GND_1 31 GND_1 31 GND_1 31 GND 30 MDI6 24 A5_ITX

32 DT_DC7 32 DTOSD_R1IN 32 DTOSD_B6IN 32 HD5 31 A12 25 A4_CTX

33 GND_1 33 GND_1 33 GND_1 33 GND 32 MD15 26 A3

34 M_D2H 34 DTOSD_R0IN 34 DTOSD_B5IN 34 HD6 33 MCLKI 27 A2

35 GND_1 35 GND_1 35 GND_1 35 GND 34 MDI4 28 A1

36 M_D2V 36 NC 36 DTOSD_B4IN 36 HD7 35 MIVAL 29 A0

37 GND_1 37 NC 37 GND_1 37 HA1 36 VPP-2 30 D0

38 M_D2CLK 38 GND_1 38 DTOSD_B3IN 38 CS# 37 VPP-2 31 D1

39 GND_1 39 NC 39 GND_1 39 HA0 38 VPP-2 32 D2

40 GND_1 40 NC 40 DTOSD_B2IN 40 HRW 39 VPP-1 33 IOIS16#

41 DTT_MUTE 41 NC 41 GND_1 41 GND 40 VPP-1 34 GND

42 TEMPT(GND) 42 NC 42 DTOSD_B1IN 42 FE_SYNC 41 VCC 35 GND

43 TEMP(GND) 43 NC 43 GND_1 43 GND 42 VCC 36 CD1#

44 TEMP(GND) 44 NC 44 DTOSD_B0IN 44 FE_SCLK 43 VCC 37 MDO3

45 GND_1 45 NC 45 GND_1 45 GND 44 VCC 38 MDO4

46 TEMP(GND) 46 GND_1 46 DT_GRAHSIN 46 FE_SDATA 45 VCC 39 MDO5

47 GND_1 47 NC 47 GND_1 47 GND 46 MDI3 40 MDO6

48 TEMP(GND) 48 NC 48 DT_GRAVSIN 48 FE_VAL 47 IREQ# 41 MDO7

49 GND_1 49 GND_1 49 GND_1 49 GND 48 MDI2 42 CE2#

CN7300 57

1

TV_RXD

2

TV_TXD

CN9500 4 GND 61

1 D2 + 5 JG_TXD 62