Page 1

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

ORIGINAL MANUAL ISSUE DATE: 7/2015

Version Date Subject

1.0 7/2015 Original manual issue.

GN1T CHASSIS

Segment: XFLL

LCD TV

9-888-579-01

Page 2

SERVICE MANUAL

GN1T CHASSIS

Segment: XFLL

LCD TV

9-888-579-01

Page 3

MODEL LIST

MODEL COLOR COMMANDER DEST.

KD-65X8000C Black RMT-TX100C CHINA

MODEL COLOR COMMANDER DEST.

KD-65X8000C(CH)

3

Page 4

WARNINGS AND CAUTIONS - ENGLISH

CAUTION

These servicing instructions are for use by qualified service personnel only.

To reduce the risk of electric shock, do not perform any servicing other than that contained in the operating instructions unless you are qualified to do so.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis.

The chassis of this receiver is directly connected to the ac power line.

CARRYING THE TV

Be sure to follow these guidelines to protect your property and avoid causing serious injury.

• Carry the TV with an adequate number of people; larger size TVs require two or more people.

• Correct hand placement while carrying the TV is very important for safety and to avoid damages.

SAFETY-RELATED COMPONENT WARNING!!

Components identified by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe operation. Replace these components with Sony

parts whose part numbers appear as shown in this manual or in supplements published by Sony. Circuit adjustments that are critical for safe operation are identified in this manual.

Follow these procedures whenever critical components are replaced or improper operation is suspected.

CAUTION ABOUT THE LITHIUM BATTERY

• Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type.

• Outer case broken battery should not contact to water.

KD-65X8000C(CH)

4

Page 5

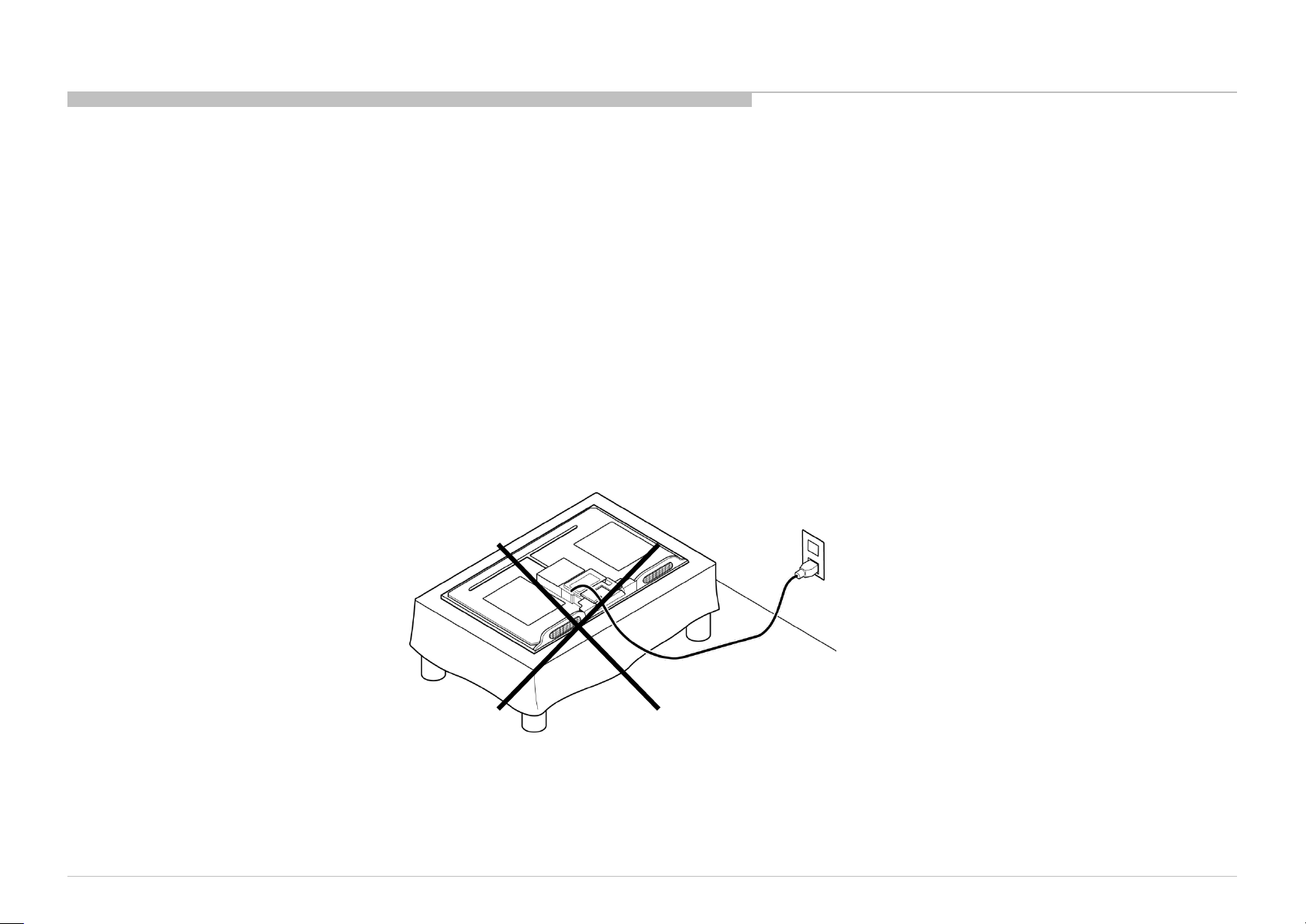

USE CAUTION WHEN HANDLING THE LCD PANEL

When repairing the LCD panel, be sure you are grounded by using a wrist band.

When repairing the LCD panel on the wall, the LCD panel must be secured using the 4 mounting holes on the rear cover.

1) Do not press on the panel or frame edge to avoid the risk of electric shock.

2) Do not scratch or press on the panel with any sharp objects.

3) Do not leave the module in high temperatures or in areas of high humidity for an extended period of time.

4) Do not expose the LCD panel to direct sunlight.

5) Avoid contact with water. It may cause a short circuit within the module.

6) Disconnect the AC power when replacing the backlight (CCFL) or inverter circuit. (High voltage occurs at the inverter circuit at 650Vrms.)

7) Always clean the LCD panel with a soft cloth material.

8) Use care when handling the wires or connectors of the inverter circuit. Damaging the wires may cause a short.

9) Protect the panel from ESD to avoid damaging the electronic circuit (C-MOS).

10) It is recommended not to exceed 1 hour of Power-On nor Burn-in period with LCD panel face down condition, in repair activity.

WARNINGS AND CAUTIONS

KD-65X8000C(CH)

5

Page 6

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered connections. Check the entire board surface for solder splashes and bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and mounting hardware have been replaced. Be absolutely certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them out to the customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of deterioration. Point them out to the customer and recommend their replacement.

6. Check the line cords for cracks and abrasion. Recommend the replacement of any such line cord to the customer.

7. Check the antenna terminals, metal trim, “metallized” knobs, screws, and all other exposed metal parts for AC leakage. Check leakage as described below.

8. For safety reasons, repairing the Power board and/or Inverter board is prohibited.

KD-65X8000C(CH)

6

Page 7

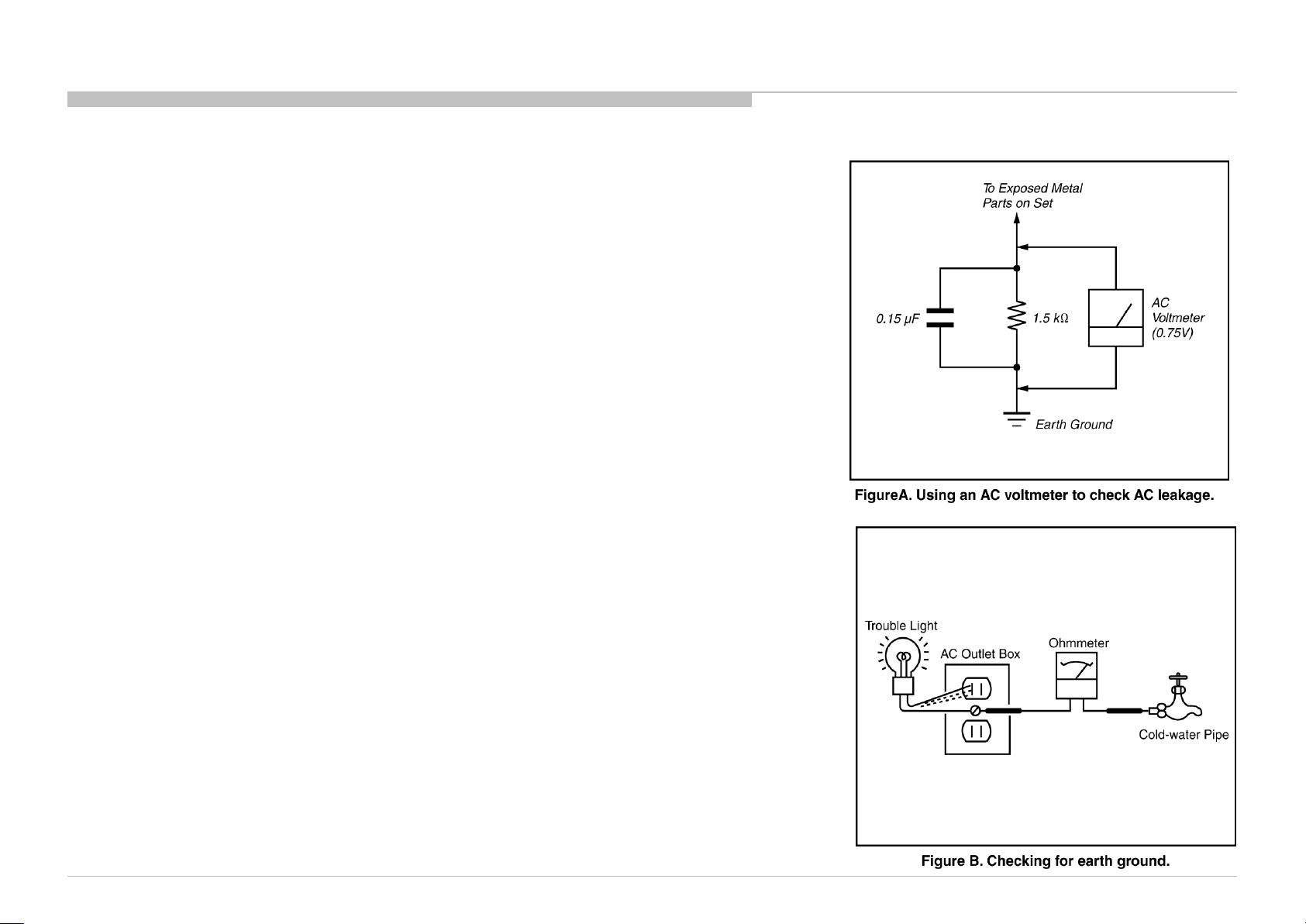

Leakage Test

The AC leakage from any exposed metal part to earth ground and from all exposed metal parts to any exposed

metal part having a return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA WT-540A. Follow the manufacturers’

instructions to use these instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245 digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM or battery-operated AC voltmeter. The

“limit” indication is 0.75 V, so analog meters must have an accurate low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of passive VOMs that are suitable. Nearly all

battery-operated digital multimeters that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate retaining screw on most AC outlet boxes is also

at earth ground.

If the retaining screw is to be used as your earth ground, verify that it is at ground by measuring the resistance

between it and a cold-water pipe with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt trouble- light (not a neon lamp) between the hot

side of the receptacle and the retaining screw. Try both slots, if necessary, to locate the hot side on the line; the

lamp should light at normal brilliance if the screw is at ground potential (see Figure B).

SAFETY CHECK-OUT

KD-65X8000C(CH)

7

Page 8

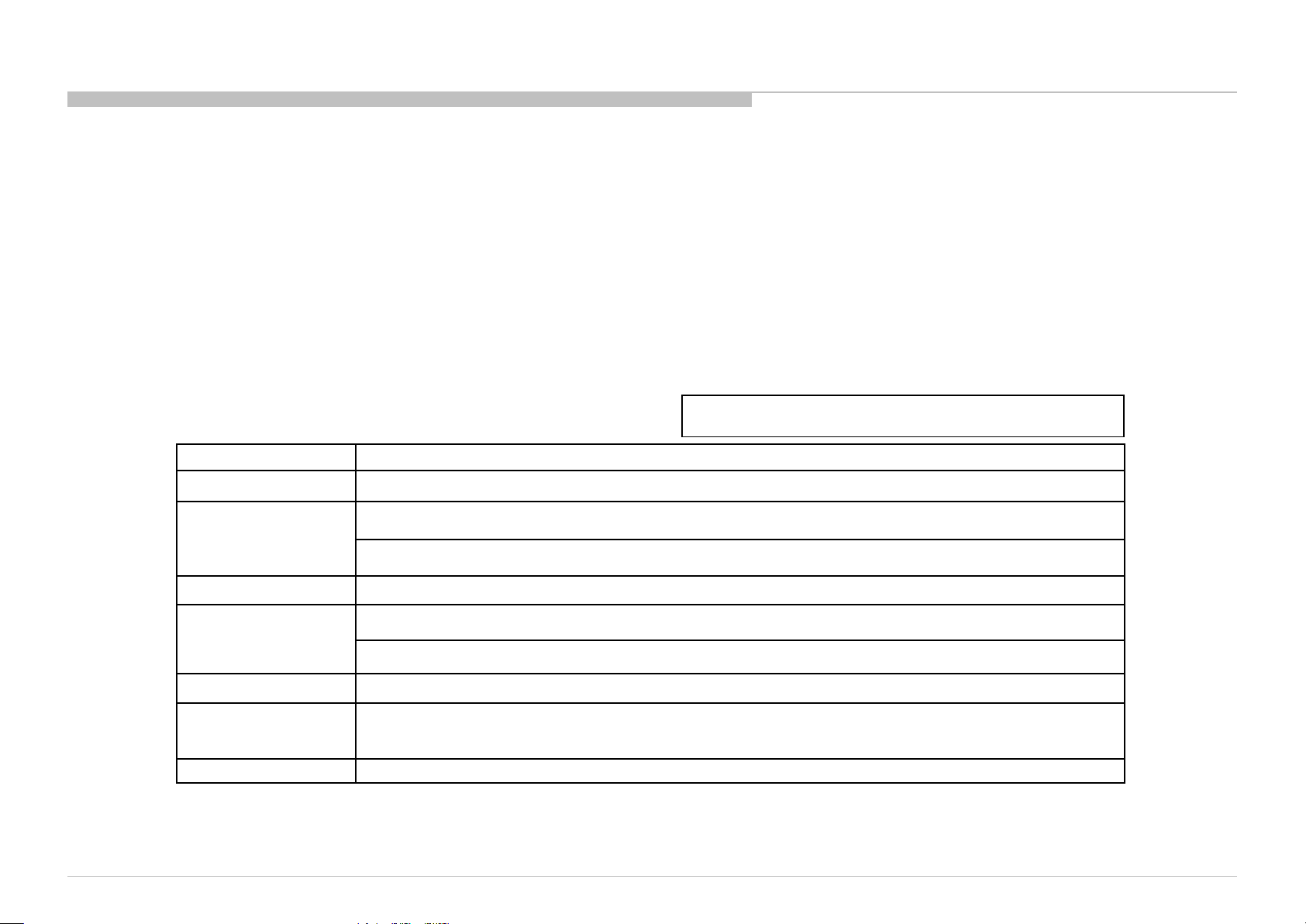

SELF DIAGNOSIS FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the Smart Core Red LED will automatically begin to flash.

The number of times the LED flashes translates to a probable source of the problem.

A definition of the Smart Core Red LED flash indicators is listed in the instruction manual for the user’s knowledge and reference.

If an error symptom cannot be reproduced, the remote commander can be used to review the failure occurrence data stored in memory to reveal past problems and how often these

problems occur.

DIAGNOSTIC TEST INDICATORS

When an error occurs, the Smart Core Red LED will flash a set number of times to indicate the possible cause of the problem.

If there is more than one error, the LED will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen.

If the screen displays a “0”, no error has occurred .

<G>: Power supply board, <B>: Main board, <T>: Tcon board,

<P>: Panel module , <S>: Speaker

RED LED blinking count Detection Items

2x

3x

<G/B> Main 12V over voltage [MAIN_POWER]

<B> Main 5.0V failure [DC_ALERT]

<B/S> Audio amp. protection [AUD_ERR]

KD-65X8000C(CH)

4x None

<P/T/G/B> Panel ID EEPROM I2C No ACK (Also panel power failure is a suspect) [P_ID_ERR]

5x

<T> TCon IC I2C communication error [TCON_ERR]

6x <G/P/B> Backlight failure [BACKLIGHT]

Over temperature protection [TEMP_ERR]

7x

8x <B> Software error [SW_ERR]

Red italic: detect at startup sequence only.

<B> Temp. sensor I2C No ACK [TEMP_ERR]

<B> V By One lock error between Main device and 4KBE device [4KBE_ERR]

8

Page 9

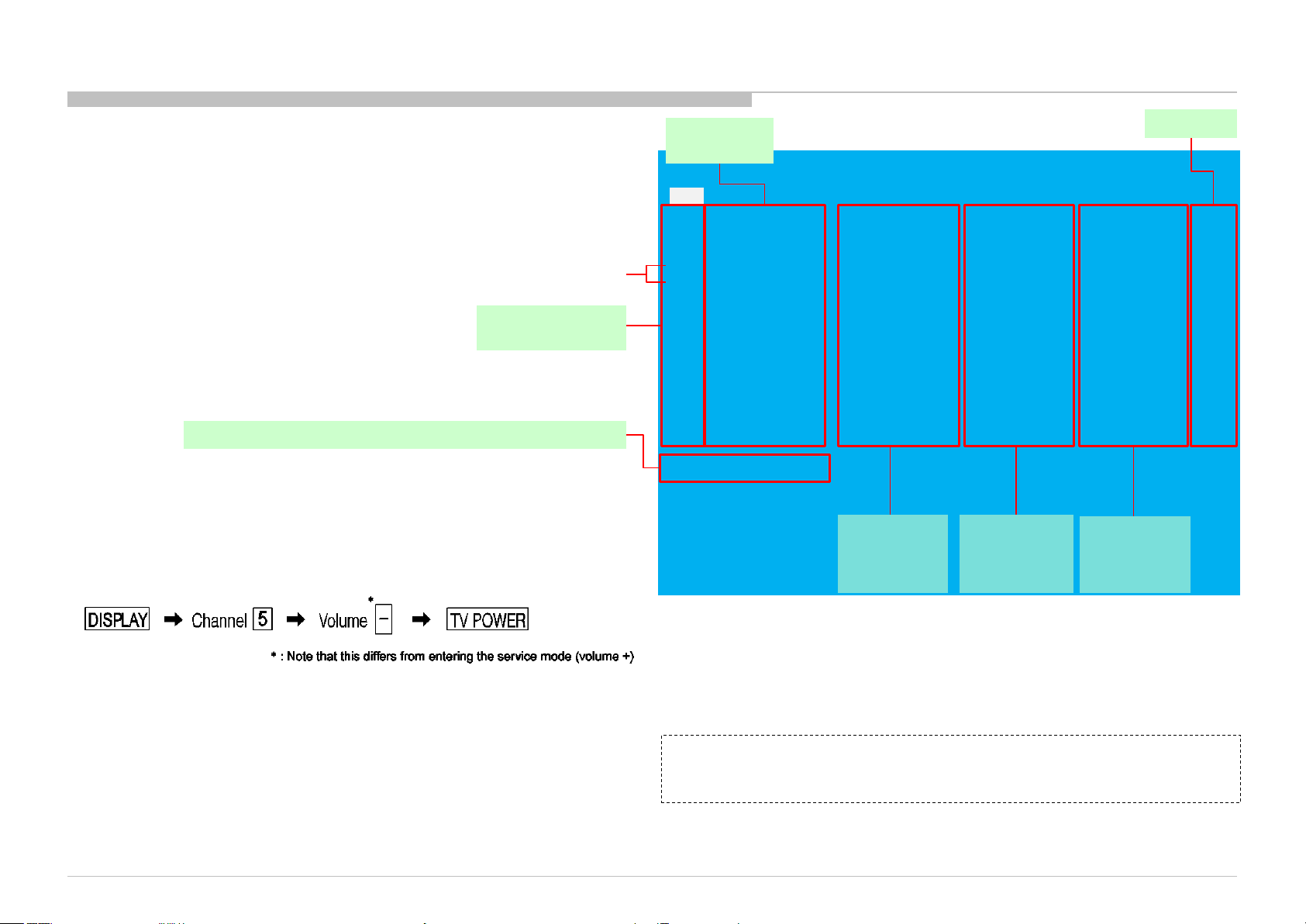

SELF DIAGNOSIS FUNCTION

[SELF DIAGNOSTIC SCREEN DISPLAY] [SELF DIAGNOSTIC SCREEN DISPLAY]

Format of error timestamps

YYMMDDhhmmss (in UTC)

Example:

120823132523 -> Aug 23 2012 13:25:23 UTC

* Only when time is set, an error timestamp

is saved.

• Panel Operation Time is recorded every

30 min, but Total Operation Time is recorded every 1 hr.

Therefore, the panel op. time might become larger than

the total op. time.

Total Operation Time [hr] – Boot Count – Panel Operation Time [hr]

" These error item

does not work."

Smart Core Red

LED blinking count

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes

out” that cannot be confirmed, it is possible to bring up past occurrences of failure for

confirmation on the screen.

In standby mode, press buttons on the remote commander sequentially in rapid succession

as shown below:

Error item

Naming

SELF CHECK

Back

<<

002 MAIN_POWER 000000000000 000000000000 000000000000 000

003 DC_ALERT 000000000000 000000000000 000000000000 000

003 AUD_ERR 150101000018 150101000018 150101000018 003

003 HDMI_EQ 150101000123 150101000045 150101000045 003

003 TU_DEMOD 150101000218 150101000223 150101000105 003

004 LD_ERR 000000000000 000000000000 000000000000 000

004 BCM_ERR 000000000000 000000000000 000000000000 000

005 TCON_ERR 150101000504 000000000000 000000000000 001

005 P_ID_ERR 000000000000 000000000000 000000000000 000

006 BACKLIGHT ERR 000000000000 000000000000 000000000000 000

007 TEMP_ERR 150101000200 150101000002 000000000000 002

007 4KBE_ERR 000000000000 000000000000 000000000000 000

008 SW_ERR 000000000000 000000000000 000000000000 000

00005 00414 00002

[Home]Exit

Error

timestamp for

last recorded

error

Error

timestamp for

second last

recorded error

Error

timestamp for

3rd last

recorded error

Error count

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen.

After you have completed the repairs, clear the result display to “0”.

Clearing the Self Check Diagnostic List

Panel operation time : Press the Channel 7 => Channel 0 .

To exit the Self Diagnostic screen...

NOTE:

This model does not have the function to clear the error history of self-diagnostic screen

by remote such as press the Channel 8 => Channel 0.

If you want to finish service mode app, do AC OFF/ON

→*Service mode app is disable perfectly if you want to move home menu, push <HOME>button

→*Service mode app do background(not disable perfectly)

KD-65X8000C(CH)

9

Page 10

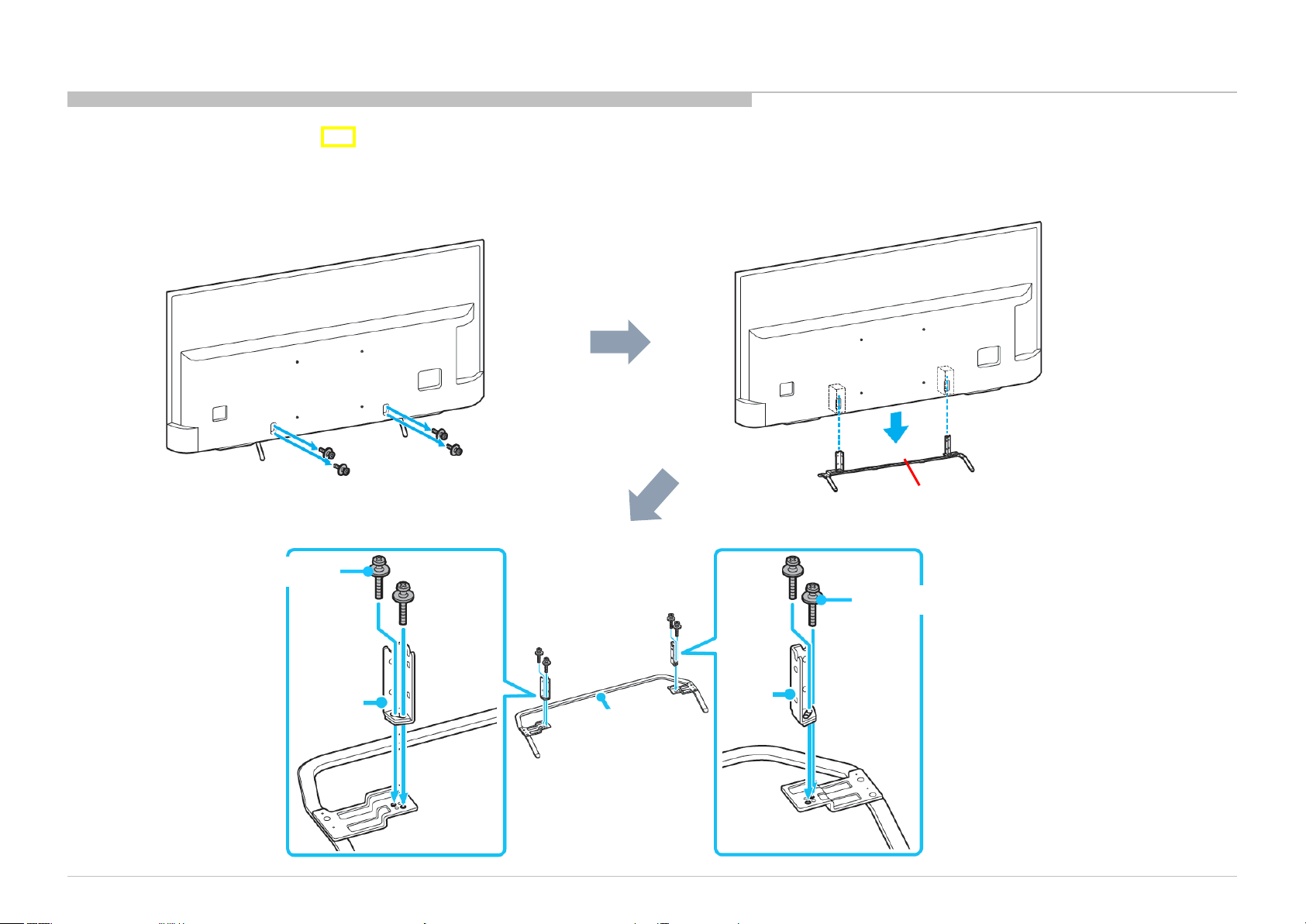

SEC 1. DISASSEMBLY

• There are clutch in the yellow frame[ ]. Therefore please be careful in the case of the disassembly or assembly of parts.

1-1. KD-65X8000C

1-1-1. STAND AND NECK

4 screws (SCREW, +PSW M5X12) P/N: 2-580-607-01

2 screws ( SCREW, +PSW M5X20)

KD-65X8000C(CH)

NECK

STAND

2 screws ( SCREW, +PSW M5X20)

NECK

STAND,

SHAFT (2L SWN) A

These screws are included in BAG,

SCREW (2L SWN). P/N: 4-570-853-01

10

Page 11

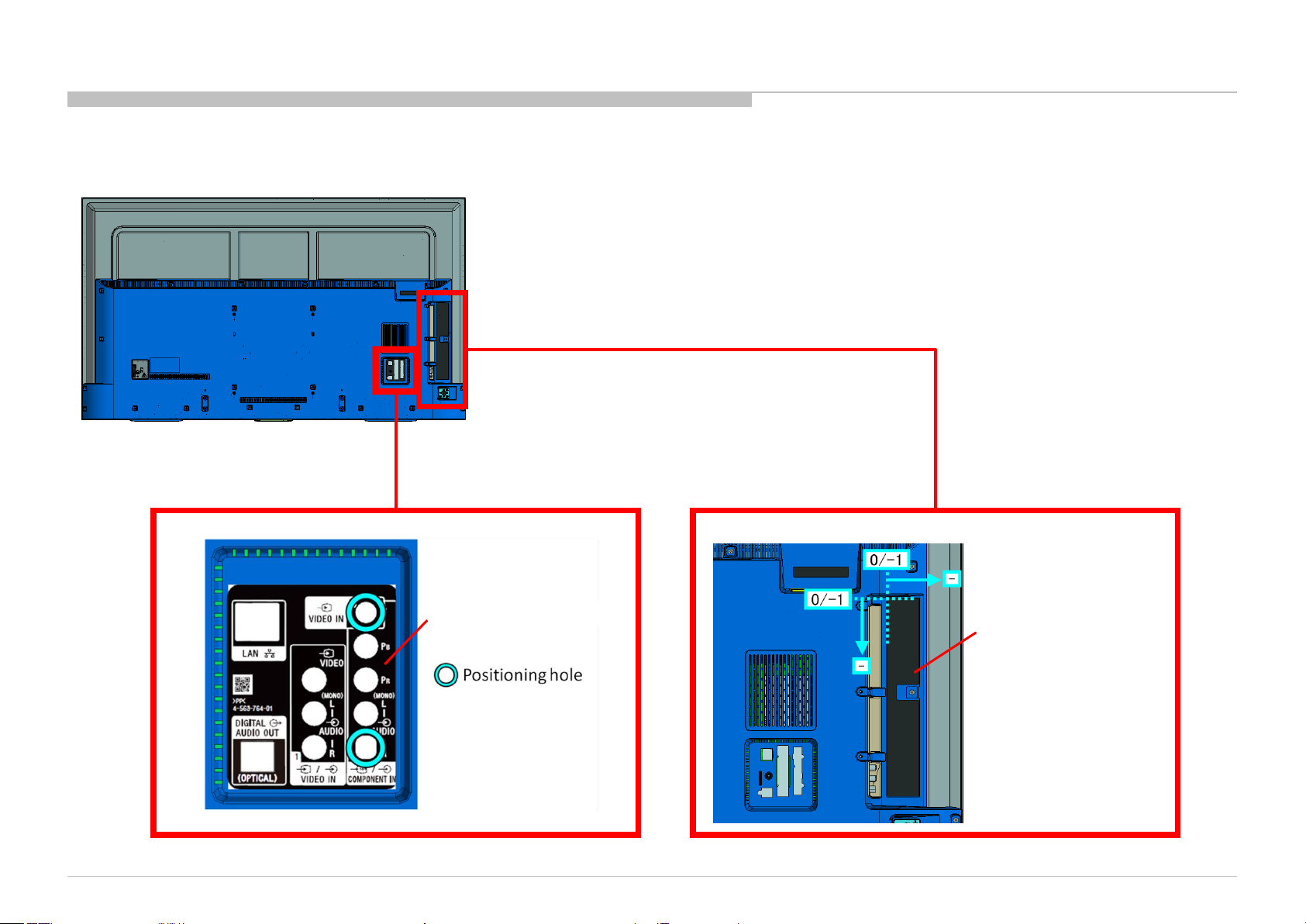

1-1. KD-65X8000C

1-1-2. LABEL, REAR TERMINAL AND LABEL, SIDE TERMINAL (W)

DISASSEMBLY

KD-65X8000C(CH)

LABEL, REAR TERMINAL

LABEL, SIDE TERMINAL (W)

11

Page 12

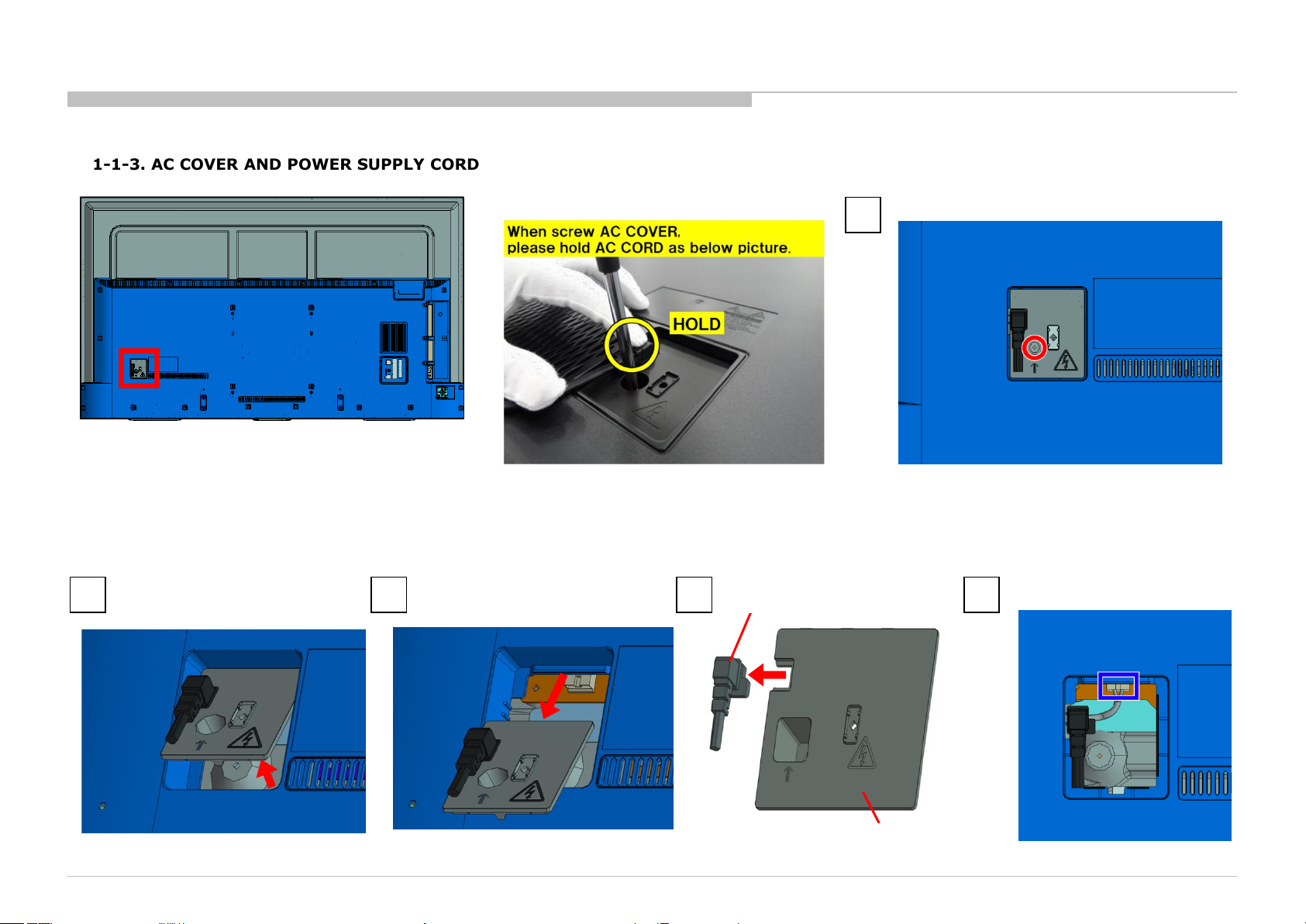

1-1. KD-65X8000C

1-1-3. AC COVER AND POWER SUPPLY CORD

DISASSEMBLY

1

Screw (SCREW, +PSW M4X10) P/N: 4-159-298-01

2 3 4

KD-65X8000C(CH)

POWER SUPPLY CORD

AC COVER

5

12

Page 13

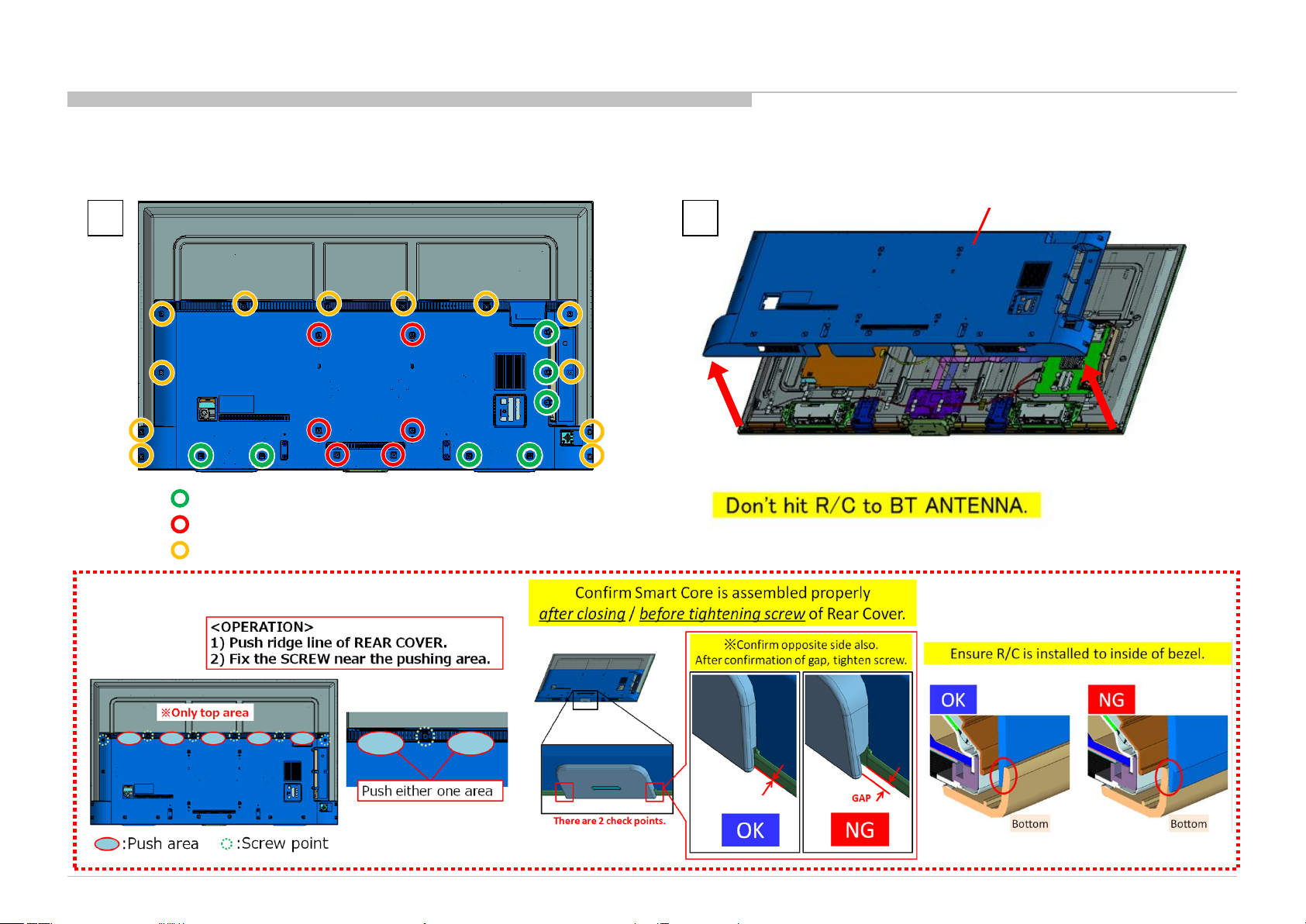

1-1. KD-65X8000C

1-1-4. COVER, REAR (2L SWN) A

1

7 screws (SCREW, +BVTP 4X12 TYPE2 IT-3) P/N: 2-580-639-01

6 screws (SCREW, +PSW M4X10) P/N: 4-159-298-01

12 screws (SCREW, +PWH M3X6) P/N: 4-452-935-11

DISASSEMBLY

COVER, REAR (2L SWN) A

2

NOTE:

KD-65X8000C(CH)

13

Page 14

1-1. KD-65X8000C

1-1-5. TAPE

DISASSEMBLY

TAPE

KD-65X8000C(CH)

TAPE

14

Page 15

1-1. KD-65X8000C

1-1-6. TAPE AND WIRE DRESSING

DISASSEMBLY

KD-65X8000C(CH)

TAPE

TAPE

TAPE

15

Page 16

1-1. KD-65X8000C

1-1-7. TAPE

DISASSEMBLY

TAPE

KD-65X8000C(CH)

TAPE

TAPE

TAPE (DK020FR-19) 19X50 SHEET

16

Page 17

1-1. KD-65X8000C

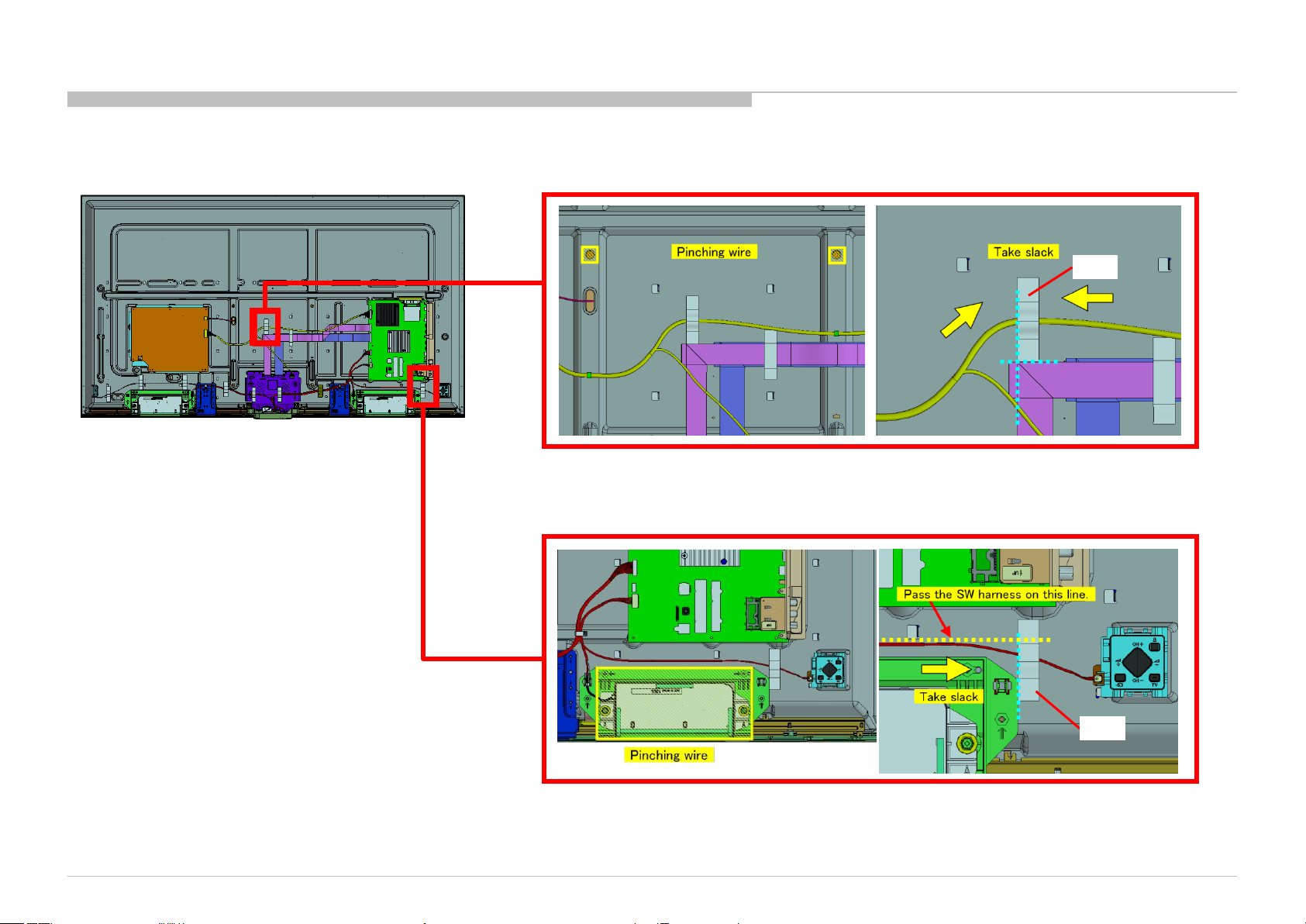

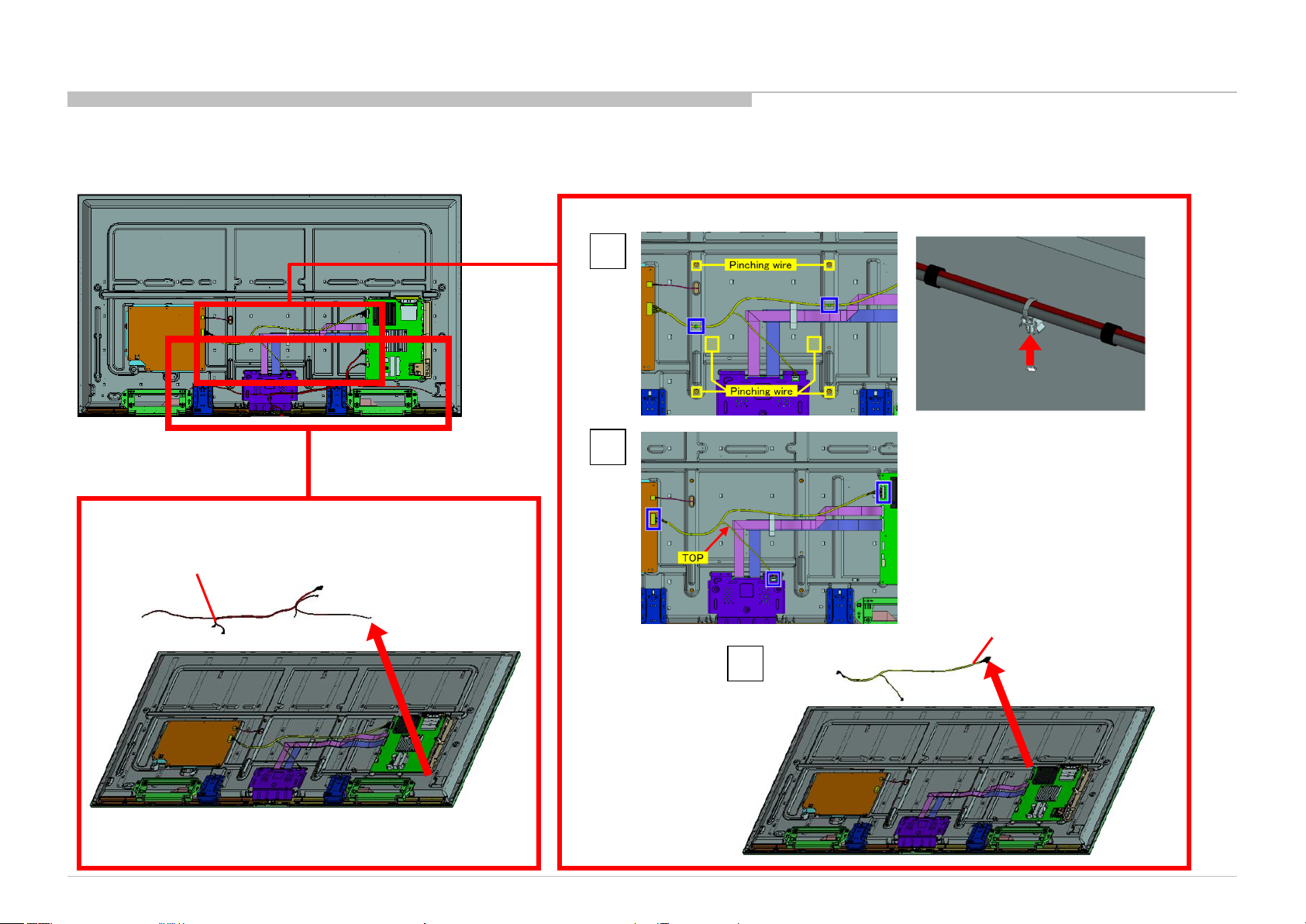

1-1-8. WIRE DRESSING

DISASSEMBLY

KD-65X8000C(CH)

17

Page 18

1-1. KD-65X8000C

1-1-9. SPEAKER BOX ASSY (L)

2 3

DISASSEMBLY

1

KD-65X8000C(CH)

SPEAKER BOX ASSY (L)

18

Page 19

1-1. KD-65X8000C

1-1-10. SPEAKER BOX ASSY (R)

2 3

DISASSEMBLY

1

KD-65X8000C(CH)

SPEAKER BOX ASSY (R)

19

Page 20

1-1. KD-65X8000C

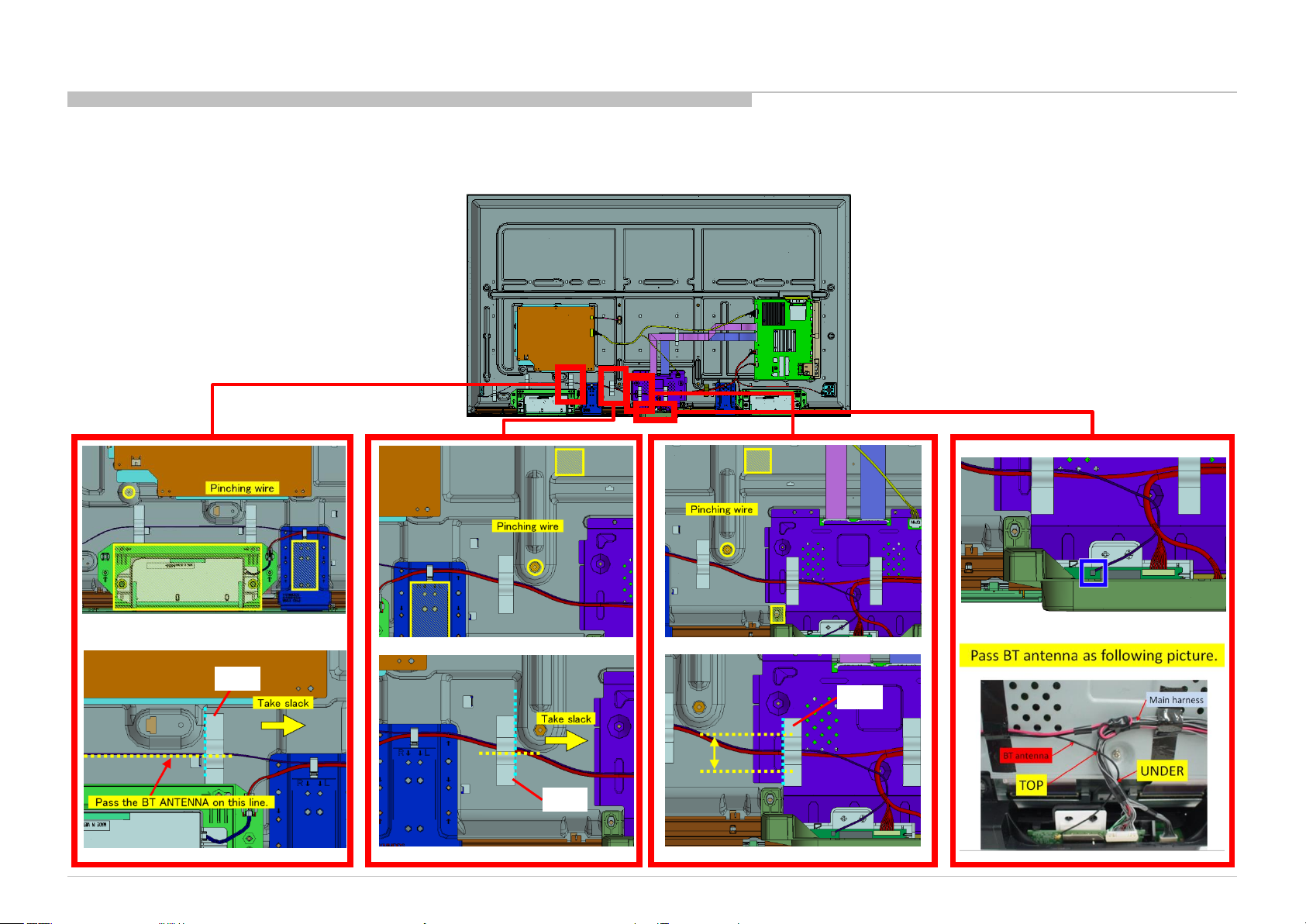

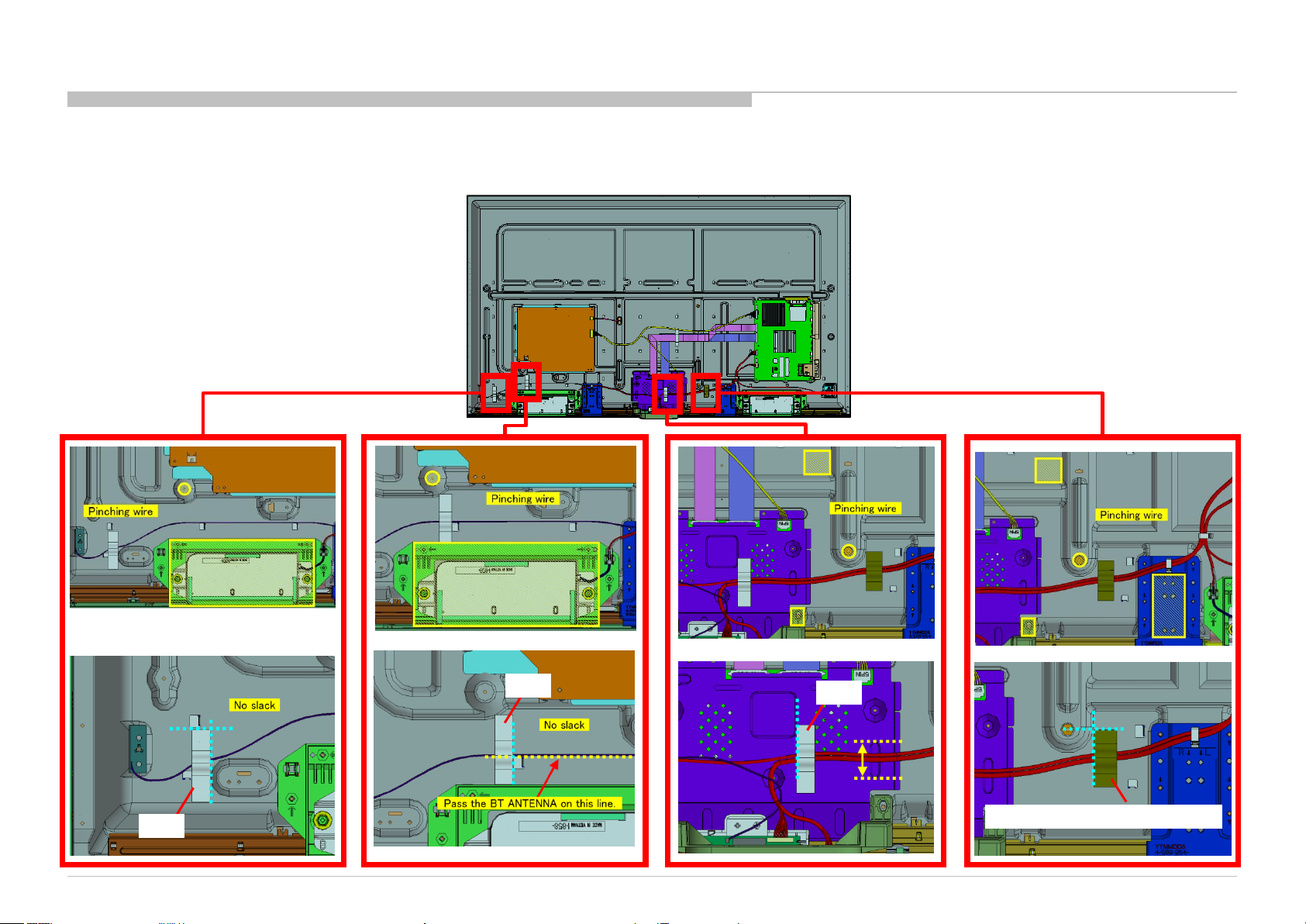

1-1-11. BT ANTENNA

2 3

DISASSEMBLY

1

Screw (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

KD-65X8000C(CH)

BT ANTENNA

20

Page 21

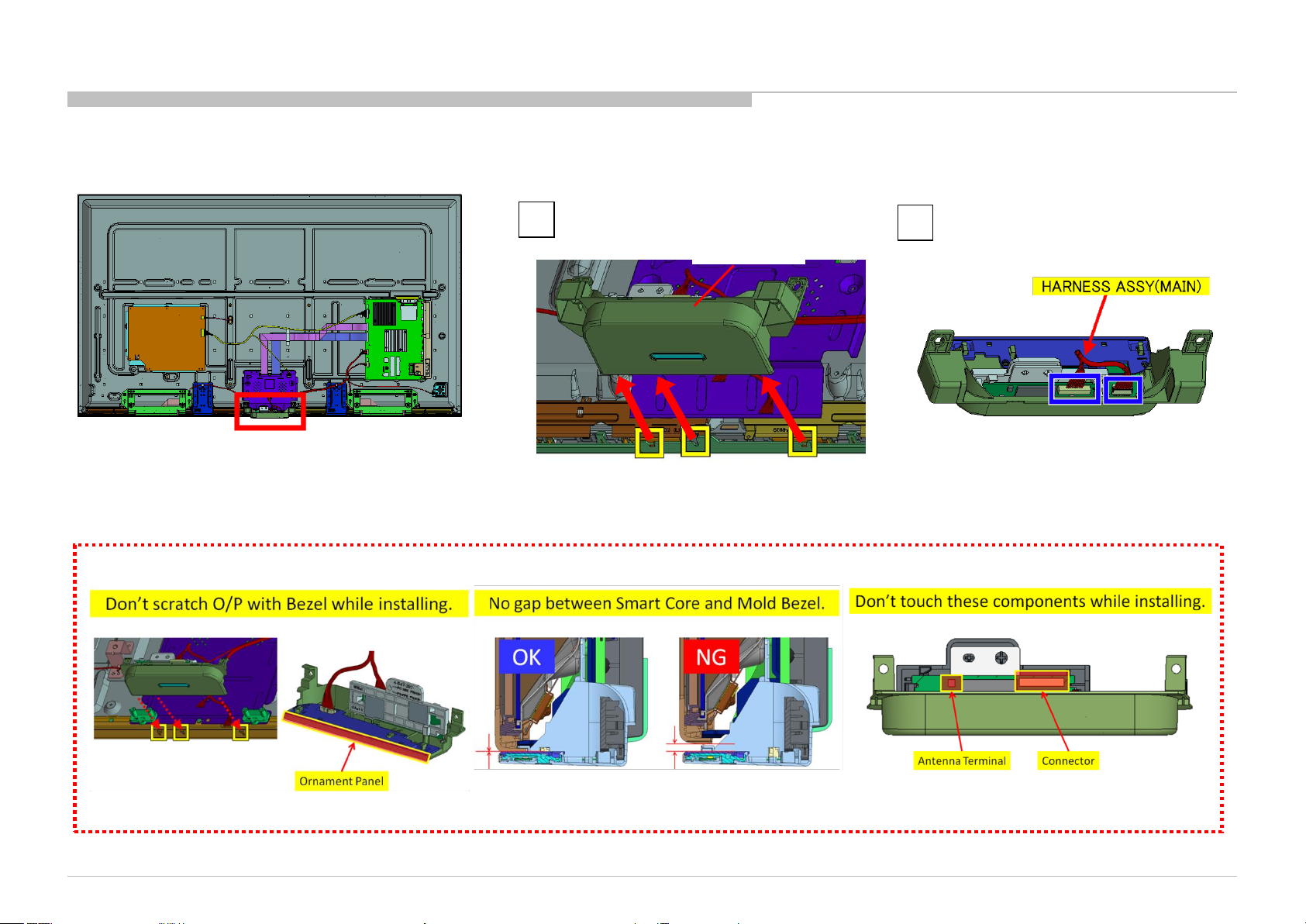

1-1. KD-65X8000C

1-1-12. SMART CORE

DISASSEMBLY

NOTE:

1

2

SMART CORE

KD-65X8000C(CH)

21

Page 22

1-1. KD-65X8000C

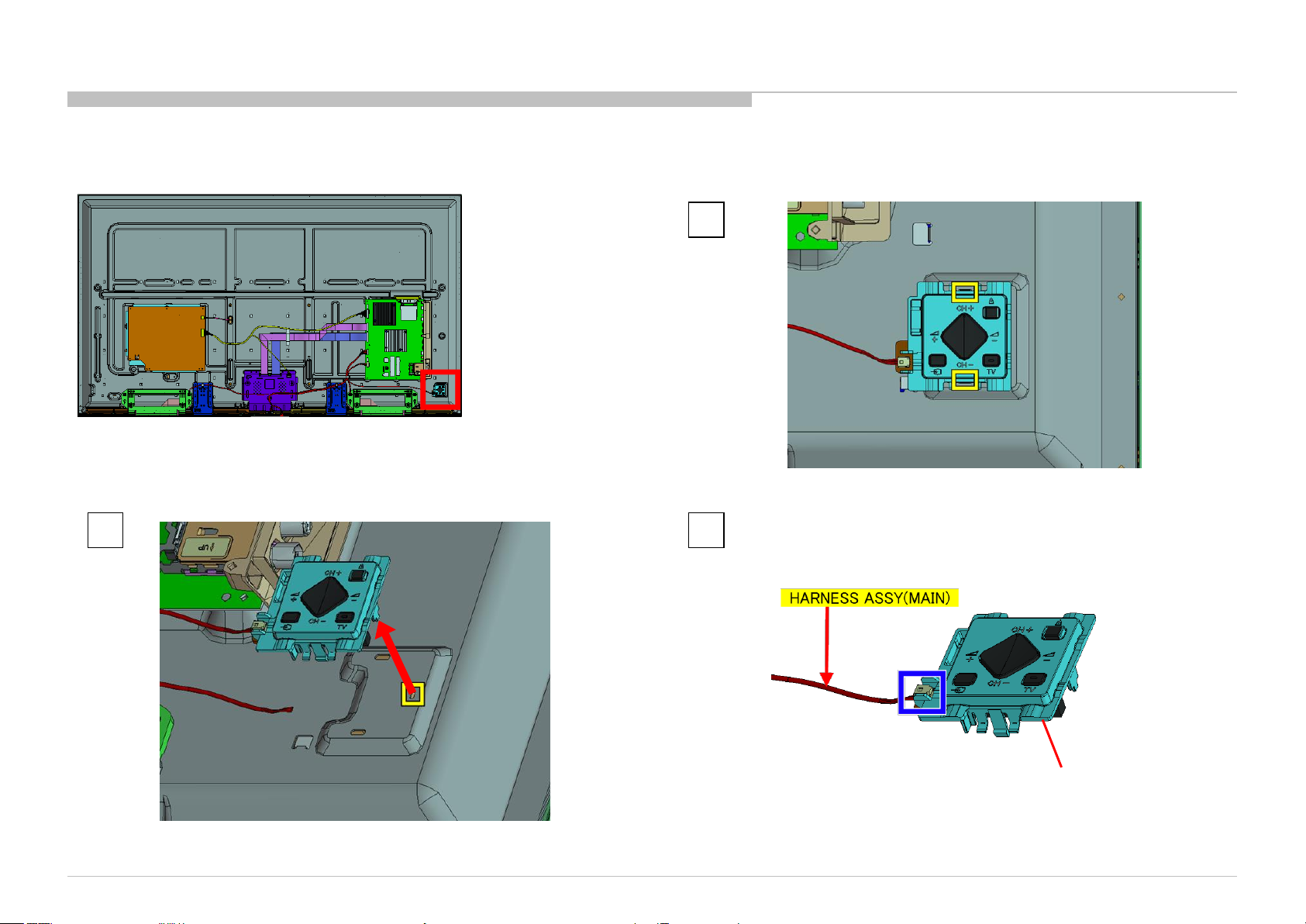

1-1-13. SWITCH UNIT

2 3

DISASSEMBLY

1

KD-65X8000C(CH)

SWITCH UNIT

22

Page 23

1-1. KD-65X8000C

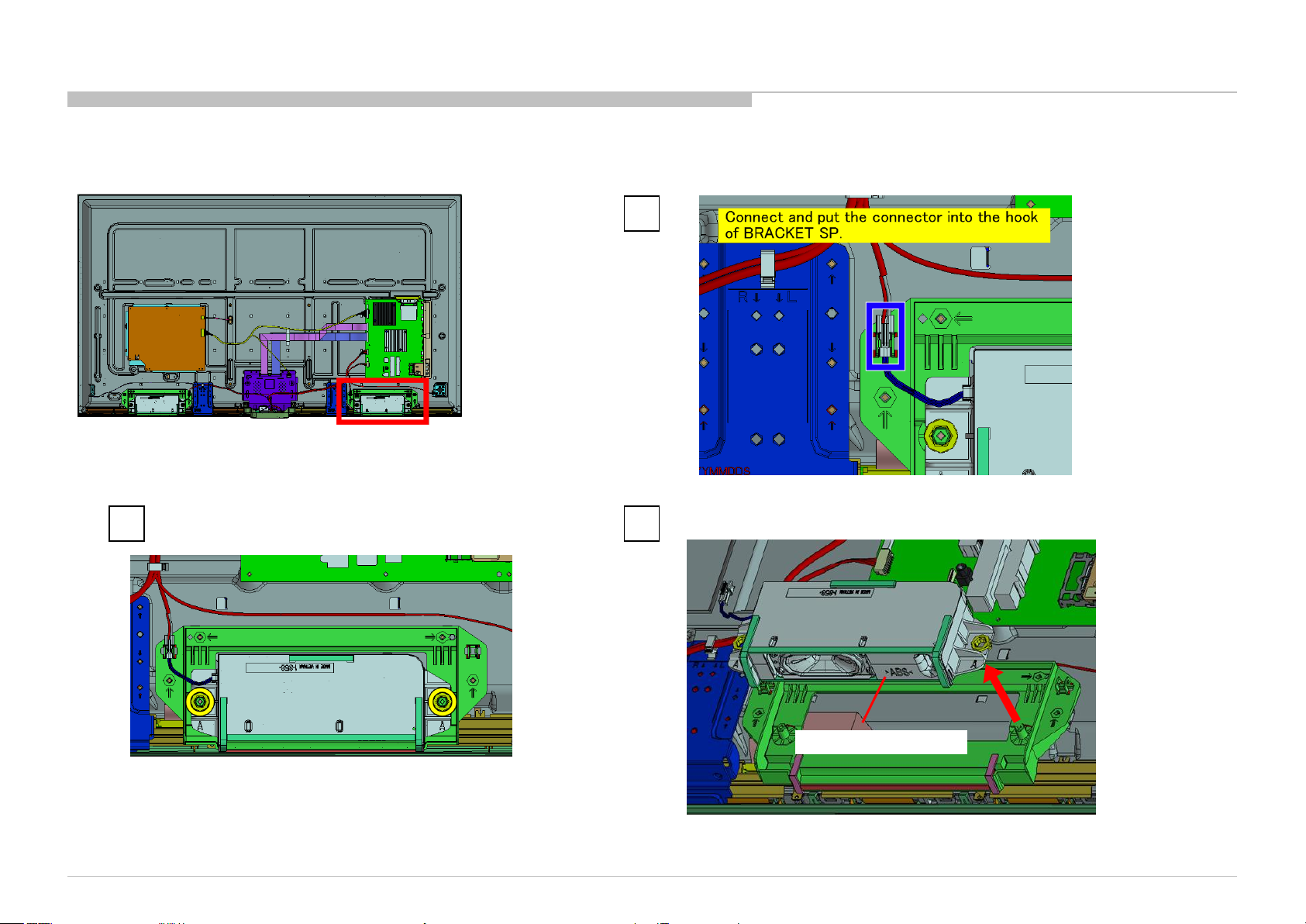

1-1-14. HARNESS ASSY (MAIN) AND CONNECTOR ASSY 28P

DISASSEMBLY

1

2

HARNESS ASSY(MAIN)

P/N: 1-910-110-66

KD-65X8000C(CH)

CONNECTOR ASSY 28P

P/N: 1-910-110-65

3

23

Page 24

1-1. KD-65X8000C

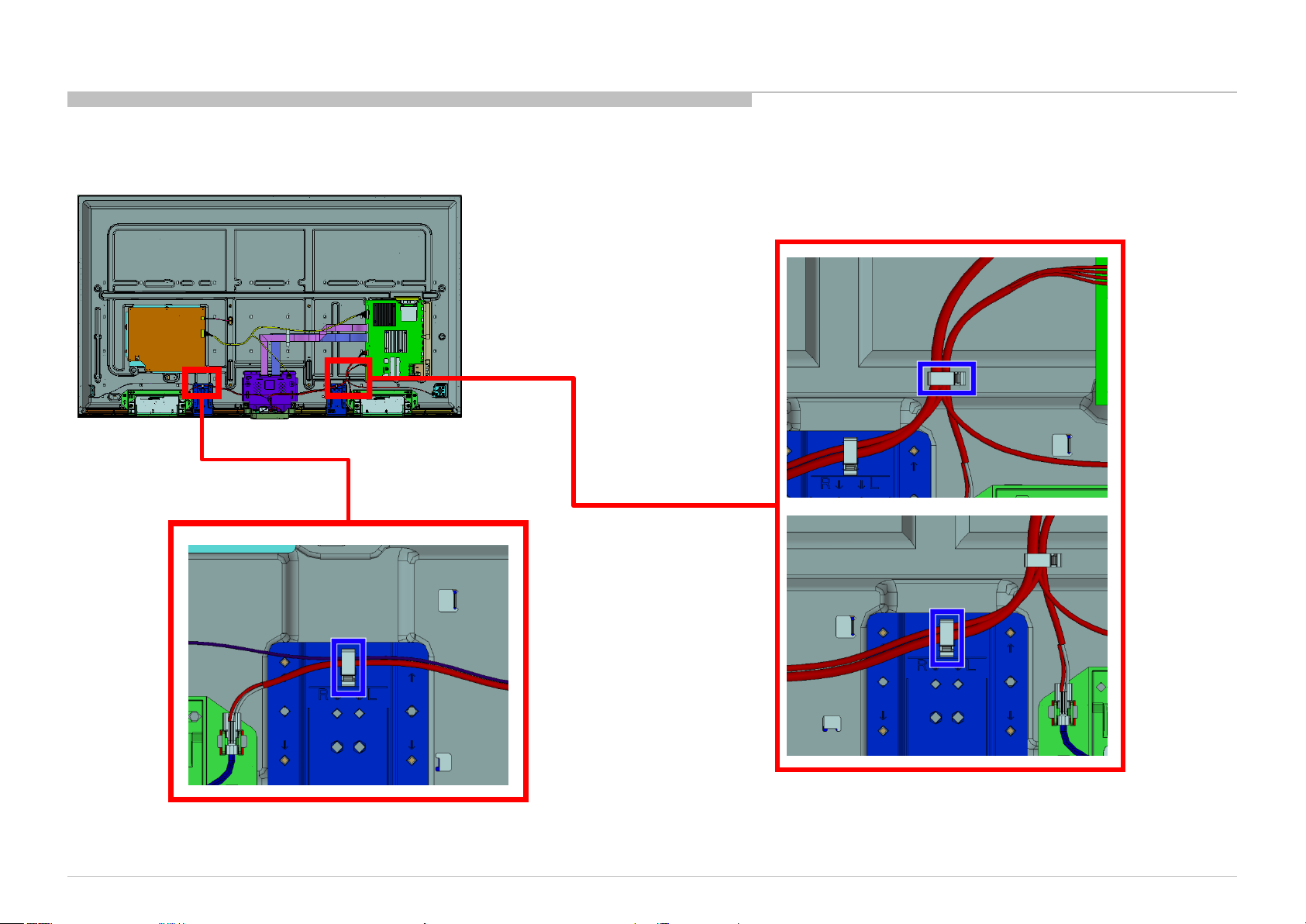

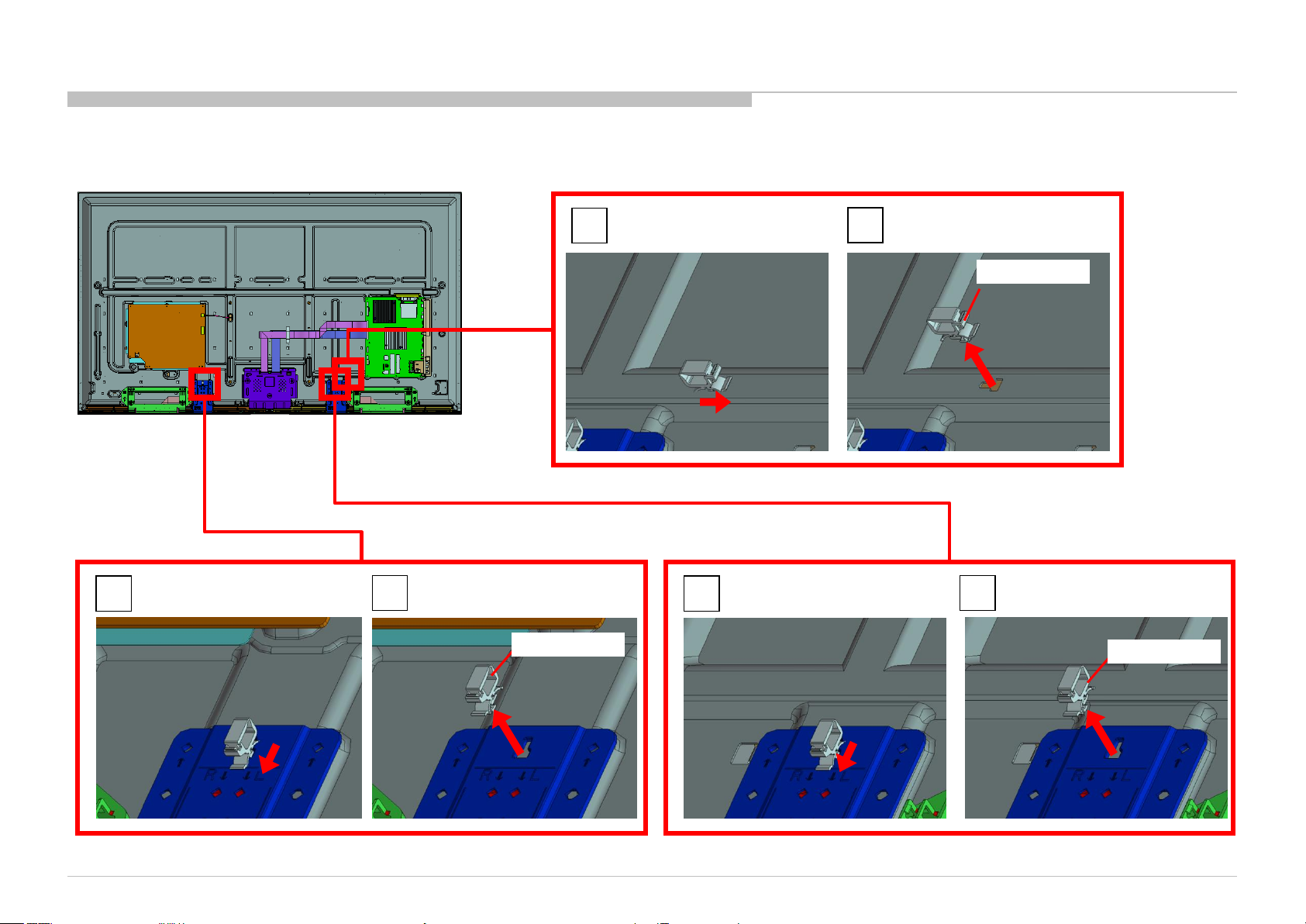

1-1-15. SLIDE, CLAMP

DISASSEMBLY

1

2

1

SLIDE, CLAMP

SLIDE, CLAMP

1

2

SLIDE, CLAMP

2

SLIDE, CLAMP

KD-65X8000C(CH)

24

Page 25

1-1. KD-65X8000C

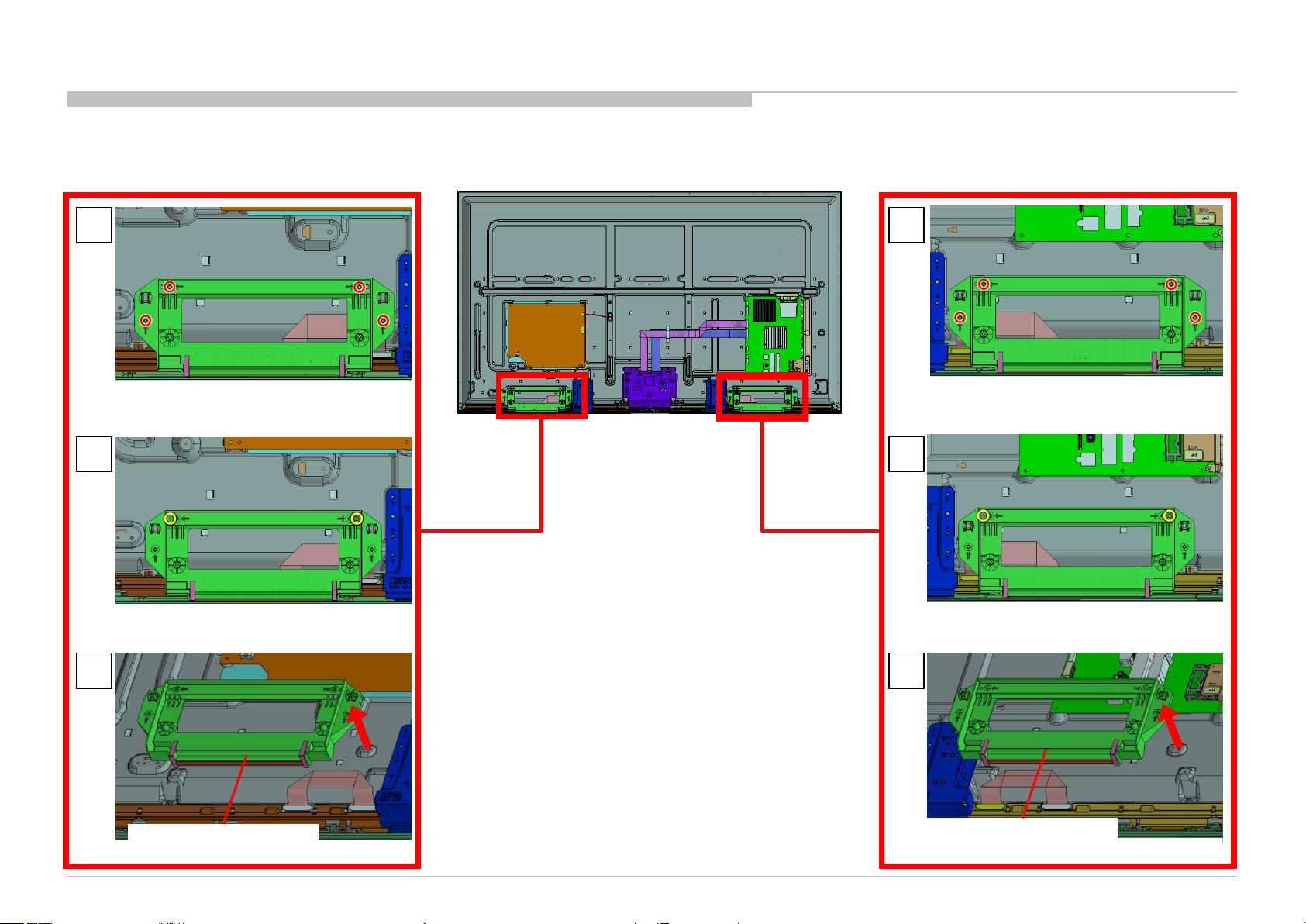

1-1-16. BRACKET, SP (2L SWN) A

DISASSEMBLY

1

4 screws (SCREW, +PSW M3X8) P/N: 2-580-593-01

2

3

1

4 screws (SCREW, +PSW M3X8) P/N: 2-580-593-01

2

3

BRACKET, SP (2L SWN) A

KD-65X8000C(CH)

BRACKET, SP (2L SWN) A

25

Page 26

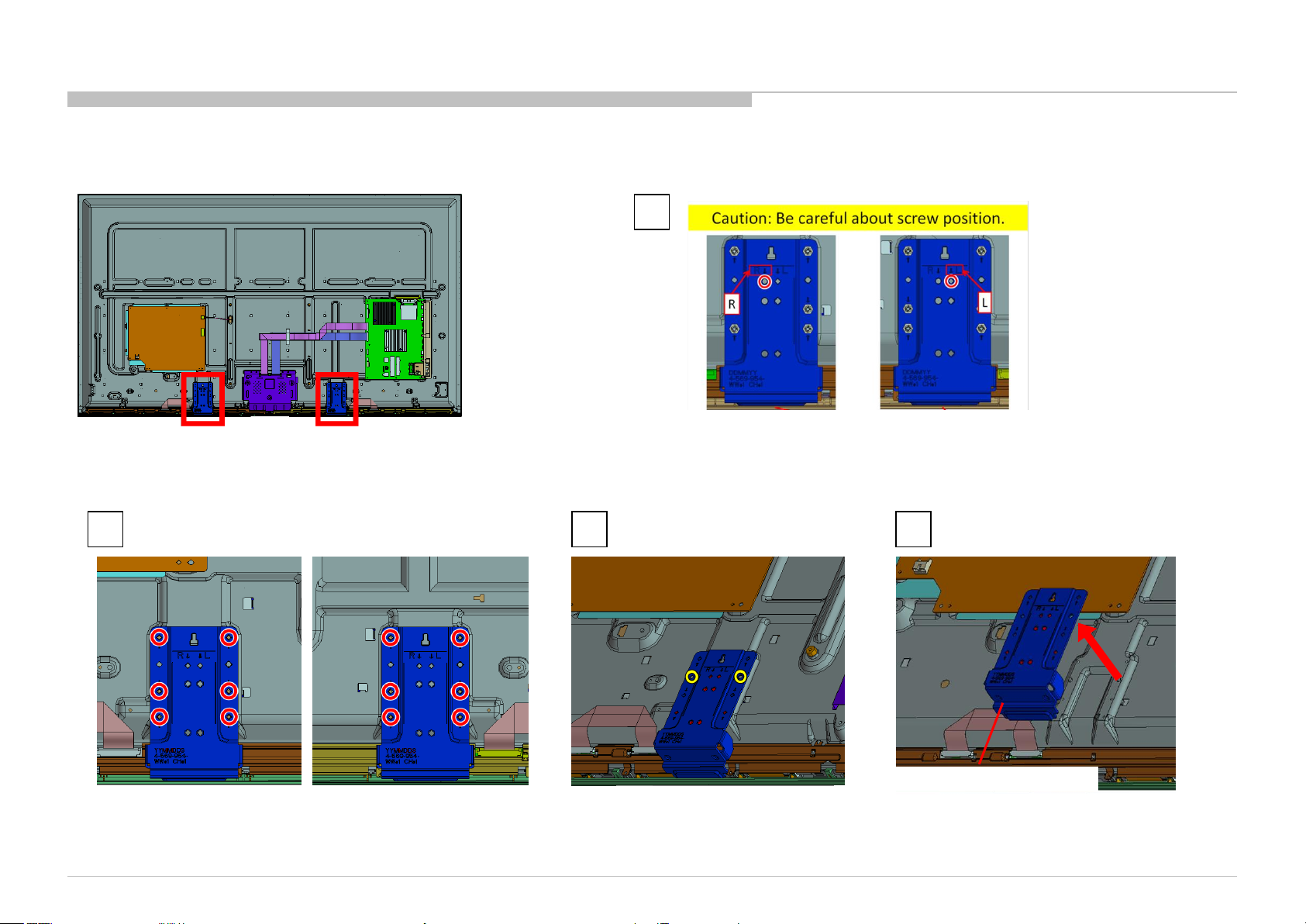

1-1. KD-65X8000C

1-1-17. BRACKET, STAND (2L SWN)

1

2 screws (PULLEY, STAND (HWI)) P/N: 4-534-964-01

2 3 4

DISASSEMBLY

12 screws (SCREW, +PSW M3X8) P/N: 2-580-593-01

KD-65X8000C(CH)

BRACKET, STAND (2L SWN)

26

Page 27

1-1. KD-65X8000C

1-1-18. GL6

DISASSEMBLY

1

6 screws (SCREW, +PSW M3X6 W12) P/N: 4-256-393-12

KD-65X8000C(CH)

3 2

4

GL6

27

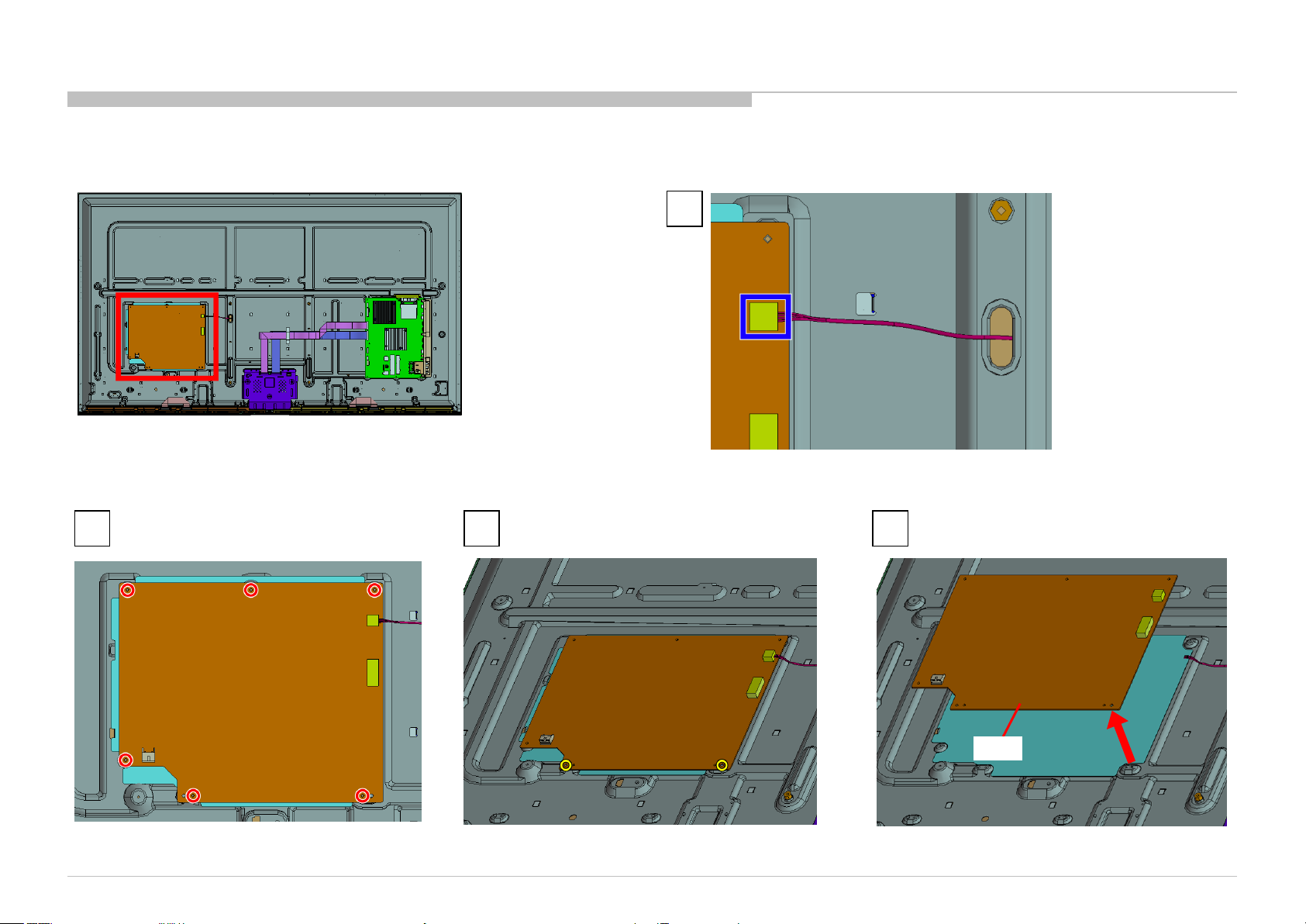

Page 28

1-1. KD-65X8000C

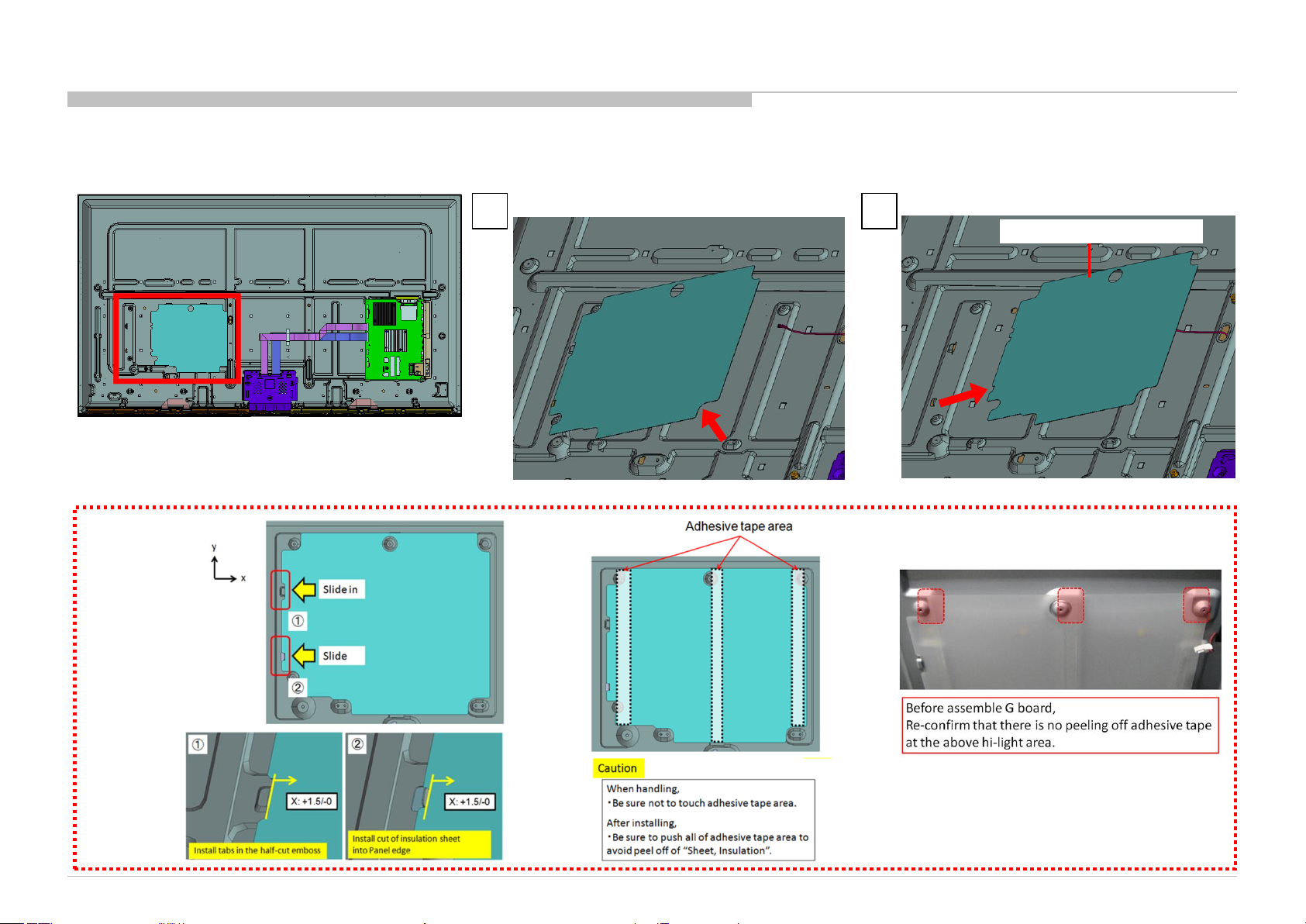

1-1-19. SHEET, INSULATION(HRN L)

NOTE:

DISASSEMBLY

1 2

SHEET, INSULATION (HRN L)

KD-65X8000C(CH)

28

Page 29

1-1. KD-65X8000C

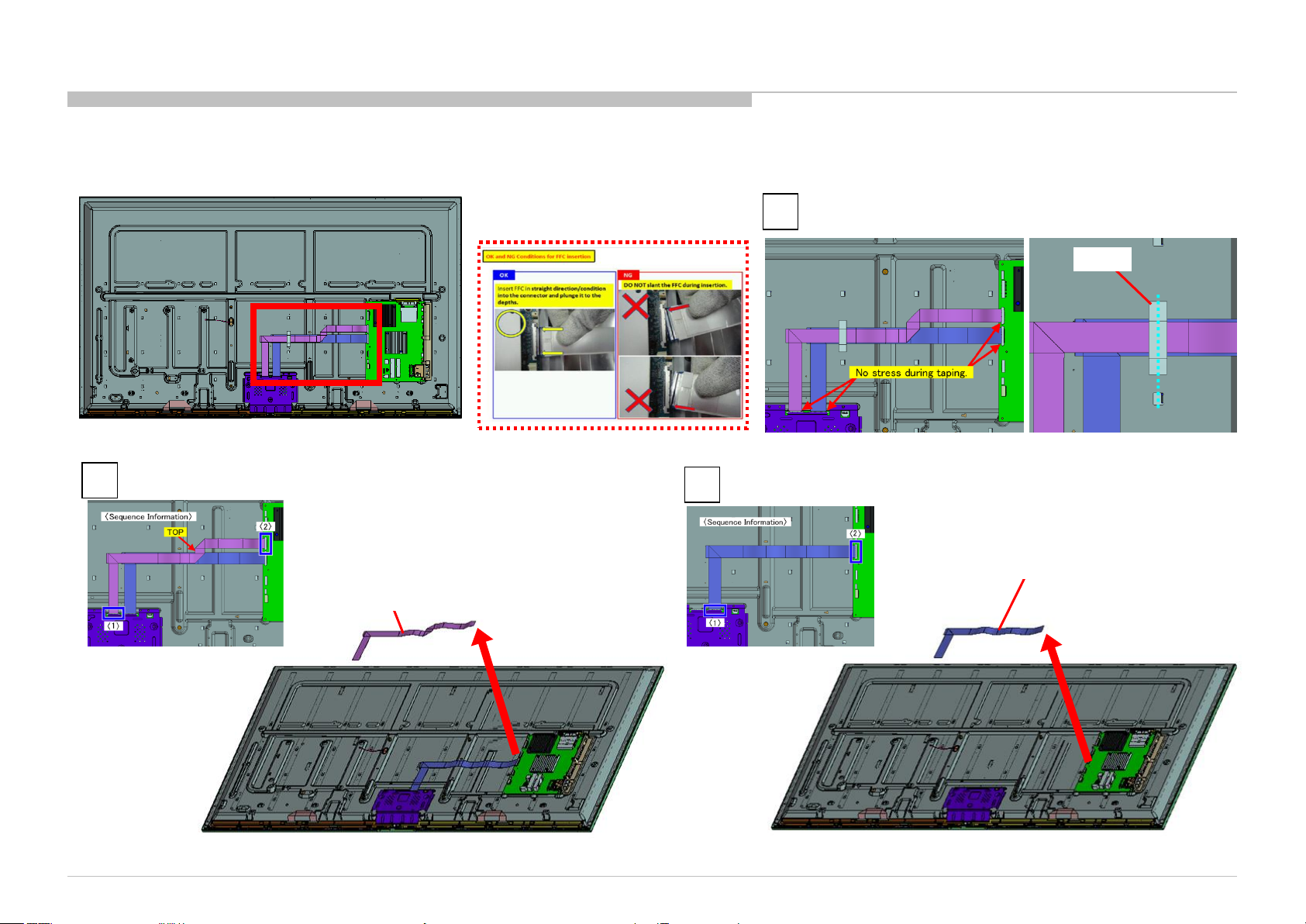

1-1-20. TAPE AND FLEXIBLE FLAT CABLE 41P (XFF) AND FLEXIBLE FLAT CABLE 51P (XFF)

1

DISASSEMBLY

TAPE

2

KD-65X8000C(CH)

3

FLEXIBLE FLAT CABLE 51P (XFF)

P/N: 1-849-079-11

FLEXIBLE FLAT CABLE 41P (XFF)

P/N: 1-849-078-11

29

Page 30

1-1. KD-65X8000C

1-1-21. BRACKET, SIDE F (MOLD)

2 3

DISASSEMBLY

1

KD-65X8000C(CH)

BRACKET, SIDE F (MOLD)

30

Page 31

1-1. KD-65X8000C

1-1-22. BMFW

2 3

DISASSEMBLY

1

8 screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

KD-65X8000C(CH)

BMFW

31

Page 32

1-1. KD-65X8000C

DISASSEMBLY

1-1-23. GASKET (BMF)

Five attachment positions of Gasket BMFW B-Side view

PWB P/N indication location

KD-65X8000C(CH)

NOTE:

When you replace a BMFW board, it is necessary to stick five new GASKET on a new BMFW board.

GASKET (BMF): 4-566-117-01

However, please confirm PWB P/N before that.

If the PWB P/N is old type(1-894-595-11/21), need gaskets.

If the PWB P/N is new type(suffix -12/22 or later), no need gaskets.

*There is no problem even if you were mounting a gasket on new type(suffix -12/22 or later).

32

Page 33

1-1. KD-65X8000C

1-1-24. SHEET, THERMAL(BM) AND PLATE, MAIN S (HRN)

1

DISASSEMBLY

NOTE:

SHEET, THERMAL (BM)

2 3 4

2 screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

KD-65X8000C(CH)

PLATE, MAIN S (HRN)

33

Page 34

1-1. KD-65X8000C

1-1-25. LCD PANEL

DISASSEMBLY

LCD PANEL

NOTE:

KD-65X8000C(CH)

34

Page 35

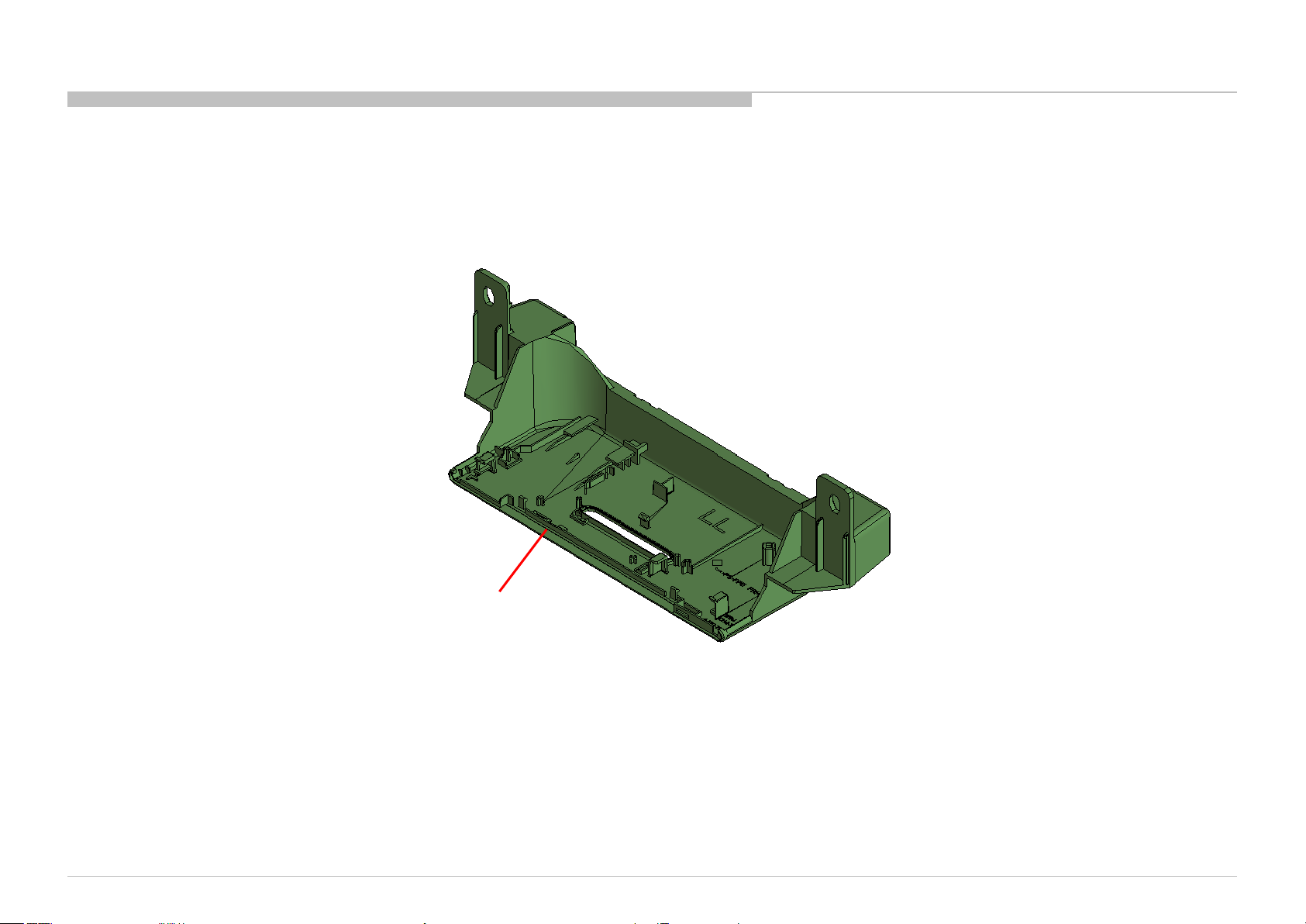

1-2. SMART CORE

1-2-1. BRACKET, WIFI ASSY

DISASSEMBLY

1

2

KD-65X8000C(CH)

3

BRACKET, WIFI ASSY

35

Page 36

1-2. SMART CORE

1-2-2. WLAN / BT MODULE(11AC) ASSY

DISASSEMBLY

3

2

1

2

NOTE:

KD-65X8000C(CH)

1

WLAN / BT MODULE(11AC) ASSY

36

Page 37

1-2. SMART CORE

1-2-3. SHEET, THERMAL (SC) AND WLAN / BT MODULE(11AC)

SHEET, THERMAL (SC)

Opposite side of WLAN / BT MODULE (11AC) ASSY

DISASSEMBLY

WLAN / BT MODULE(11AC)

1-2-4. HEAT SINK (SC) AND BRACKET, WIFI

KD-65X8000C(CH)

HEAT SINK (SC)

1 2

BRACKET, WIFI

37

Page 38

1-2. SMART CORE

1-2-5. COVER, TOP

DISASSEMBLY

NOTE:

1

KD-65X8000C(CH)

2

COVER, TOP

38

Page 39

1-2. SMART CORE

1-2-6. PANEL, ORNAMENT

DISASSEMBLY

1

2 3

KD-65X8000C(CH)

1

PANEL, ORNAMENT

2

39

Page 40

1-2. SMART CORE

1-2-7. LIGHT, GUIDE

DISASSEMBLY

1

KD-65X8000C(CH)

2 3

LIGHT, GUIDE

LOCK PORTION

40

Page 41

1-2. SMART CORE

1-2-8. HSC3_L MOUNT

DISASSEMBLY

3

1

2

NOTE:

HSC3_L MOUNT

KD-65X8000C(CH)

41

Page 42

1-2. SMART CORE

1-2-9. CASE, BOTTOM (LL)

DISASSEMBLY

KD-65X8000C(CH)

CASE, BOTTOM (LL)

42

Page 43

SEC 2. ADJUSTMENT

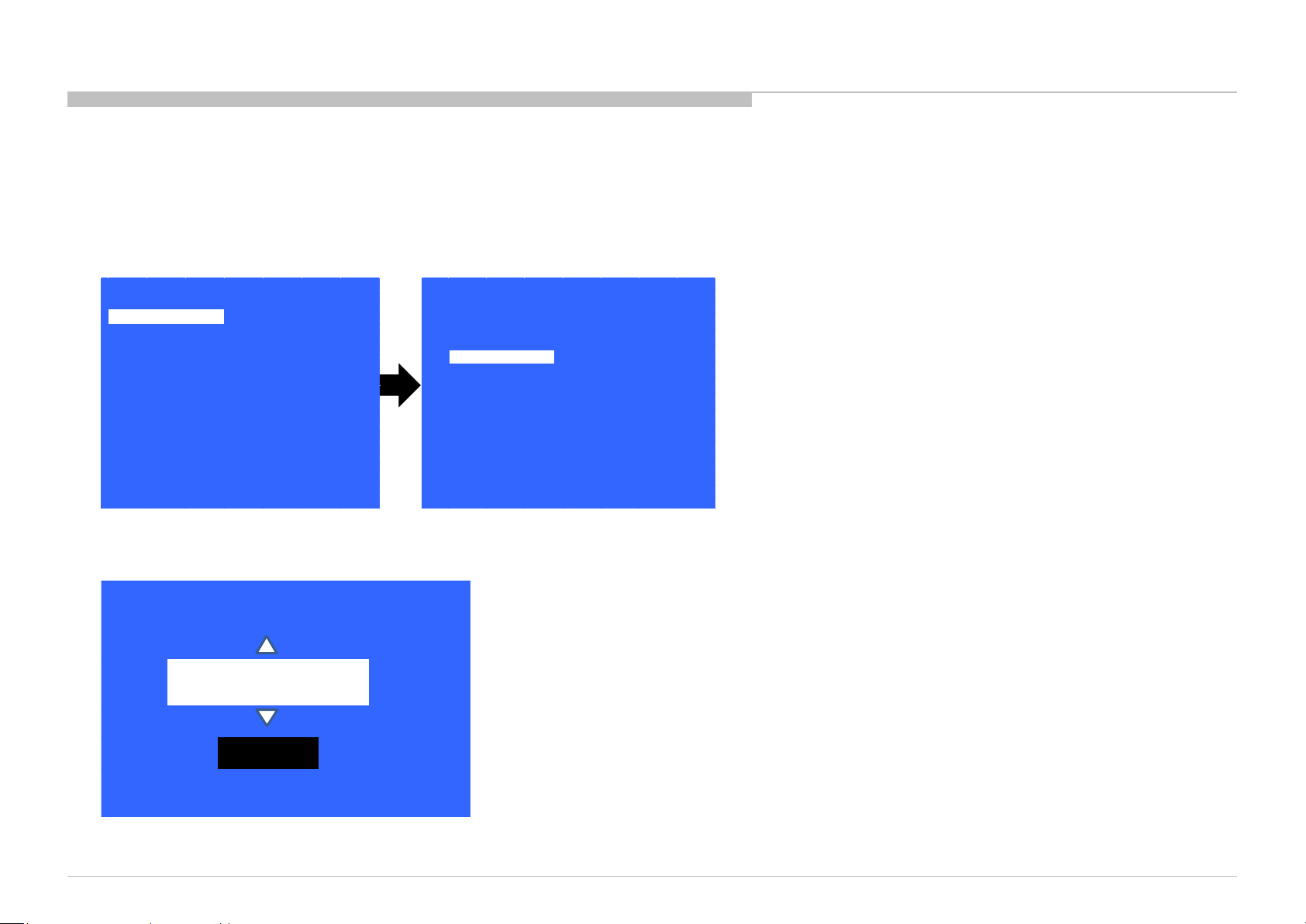

HOW TO ENTERING SERVICE MODE

1) Turn on the main power switch to place the set in standby mode.

2) Press the buttons on the remote commander as follows, and entering service mode.

3) Service mode display.

Service Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wifi

>>

>>

>>

>>

>>

>>

>>

[</>] Set [Home]Exit

4) How to use the remote commander.

Function The flow of control

Service mode on <Display><5><Vol Up><Power>

Service mode off <MENU>/<HOME>

Item up / down

Item select left/right <←>/<→>

Execute <OK>

5) When finished the operation of service mode , please AC Plug OFF/ON the TV set.

(*If you don’t do AC plug OFF/ON, remain the Service Mode App and User can see the Service Mode after RC ON.)

KD-65X8000C(CH)

<↑>/ <↓>

43

Page 44

SOFTWARE VERSION

>>

Model Information

>>

Model Number Setting

>>

SERIAL NUMBER EDIT

[</>] Set [Home]Exit

Model

Status Inf ormation

1) In Service Mode, select “Model Information”, press “Enter” or “→” button to enter Status Information.

ADJUSTMENT

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wifi

Service Mode

>>

>>

>>

>>

>>

>>

>>

[</>] Set [Home]Exit

2) Press “Enter” or “Return” button to return to Service Mode.

Service Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wifi

>>

>>

>>

>>

>>

>>

>>

>>

Main Micro

SW Version:

NVM Version:

Boot Version:

PQ Version:

AQ Version:

<Ext>

exFRC:

CameraVID:

CameraPIC:

CameraFW:

4k BE

MLFW:

MAFW:

ADSP

NDAT

PDAT

BDAT

BCM

FDAT

UDAT

BDIX

PKG2.011.0010NAB

0001 UC2

V1.000

102100006

AQ1.100

00.00.00.00

0

0

0

SF1.002

SF0.360

SF0.501

SD0.370

SD0.370

SD1.011

SD------SD0.002

SD0.000

SD0.370

KD-65X8000C(CH)

[</>] Set [Home]Exit

44

Page 45

SERIAL NUMBER EDIT (1)

ADJUSTMENT

1) In “Service Mode”, select “Model Information” by pressing “↑” or “↓” then pressing “Enter” or

“→” button to enter inside.

2) Select “Serial Number Edit” by pressing “↑” or “↓” button then pressing “Enter” or “→” button

3) Press “↑” or “↓” to input numbers.

4) After user input data , press <Enter> .

• Pop-up dialog appear to confirm input data correct

• Serial Number can be set ONLY ONCE

5) Press “→” or “←” button to select YES or NO.

Select YES if input data is correct.

Select NO if input data is incorrect.

Press <Enter> to save answer.

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wifi

Status Information

Model Information

Model Number Setting

Serial Number Edit

Status Information

Model Information

Model Number Setting

Serial Number Edit

Service Mode

>>

>>

>>

>>

>>

>>

>>

[</>] Set [Home]Exit

Mode

Service Mode

>>

>>

>>

_ _ _ _ _ _ _

>>

>>

>>

9 9 9 9 9 9 9

KD-65X8000C(CH)

Input Data correct?

Yes No

45

Page 46

SERIAL NUMBER EDIT (2)

Yes No

Input Data correct?

ADJUSTMENT

If YES is selected, the input data is saved into EEPROM.

SERIAL NUMBER EDIT is greyed out and the serial number that has been input is displayed.

User will not able to edit anymore.

If NO is selected, the input data is not saved into EEPROM.

The serial number that has been input is displayed.

User can still edit the Serial Number.

Status Information

Model Information

Model Number Setting

Serial Number Edit

Status Information

Model Information

Model Number Setting

Serial Number Edit

Service Mode

<[ ]>

Service Mode

<[ ]>

>>

>>

KDL-40X500B

9 9 9 9 9 9 9

>>

>>

KDL-40X500B

9 9 9 9 9 9 9

KD-65X8000C(CH)

46

Page 47

MODEL NUMBER SETTING

_ _ _ _ _ _ _ _ _ _ _ _

OK

[MODEL_NUMBER_SETTING]

1) In “Service Mode”, select “Model Information” by pressing “↑” or “↓” then pressing “Enter” or “→” button to enter inside.

2) Select “Model Number Setting” by pressing “↑” or “↓” button then pressing “Enter” or “→” button.

3) Press “↑” or “↓” arrow key to scroll Product Name Candidate.

(e.g. KDL-40X500B CO1,KDL-40X500C BR6)

ADJUSTMENT

Service Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wifi

>>

>>

>>

>>

>>

>>

>>

Status Information

Model Information

Model Number Setting

Serial Number Edit

Service Mode

>>

>>

>>

>>

[</>] Set [Home]Exit

4) Select one Product Name from the list, press <Enter> will pop dialog to inform user to confirm data. Model dependent settings will be overwritten into EEPROM.

KD-65X8000C(CH)

47

Page 48

ADJUSTMENT

Back

R WB Gain

<[ 0 ]>

G WB Gai n

<[ 0 ]>

B WB Gain

<[ 0 ]>

R WB Offs et

<[ 0 ]>

G WB Offs et

<[ 0 ]>

B WB Offs et

<[ 0 ]>

<<

[</>] Set [Home]Exit

>>

>>

>>

>>

>>

>>

>>

Service Mode

Tuner

Wifi / BT

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

WB ADJUSTMENT

(Please apply Main board or panel is replaced.)

In “Panel/PQ” service mode.

a. Go to “WB Adjustment” category by “↑” or “↓”.

b. To select “WB Adjustment”, press “→” button.

c. To change data , press “←” or “→” on remote commander.

KD-65X8000C(CH)

48

Page 49

ADJUSTMENT

>>

>>

>>

>>

>>

>>

>>

Service Mode

Tuner

Wifi / BT

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Back

<<

<[ 0. SoC to T-con ]>

Mura data transfer

<[ 0. SoC to T-con ]>

CUC data trans fer

<[ 0. SoC to T-con ]>

[Start]

[</>] Set [Home]Exit

WB/Gamma data trans fer

WB/MURA/CUC DATA TRANSFER

(Please apply Main board or panel is replaced.)

1. In “Panel/PQ” service mode.

a. Go to “WB/Mura/CUC data transfer” category by “↑” or “↓”.

b. To select “WB/Mura/CUC data transfer”, press “→” button.

c. To change data , press “←” or “→” on remote commander.

2. In “WB/Mura/CUC data transfer”.

a. Select “WB/Gamma data transfer” by pressing “↑” or “↓” on remote commander.

b. To change the items, press “←” or “→” on remote commander and press “Enter”

button.

Selectable items are:

0. SoC to T-con

1. T-con to SoC

2. Not atction

c. Select “[start]” and press “Enter” button to start transfer.

KD-65X8000C(CH)

49

Page 50

SEC 3. TROUBLE SHOOTING

Bluetooth

Power LED

not

response to

Stationary

colored

lines or

dots

No video One

No video all

Smart Core no

Bluetooth /

) can't

Wifi & BT Module

(Communi

TEMP

Software

Emitter

Local

UART

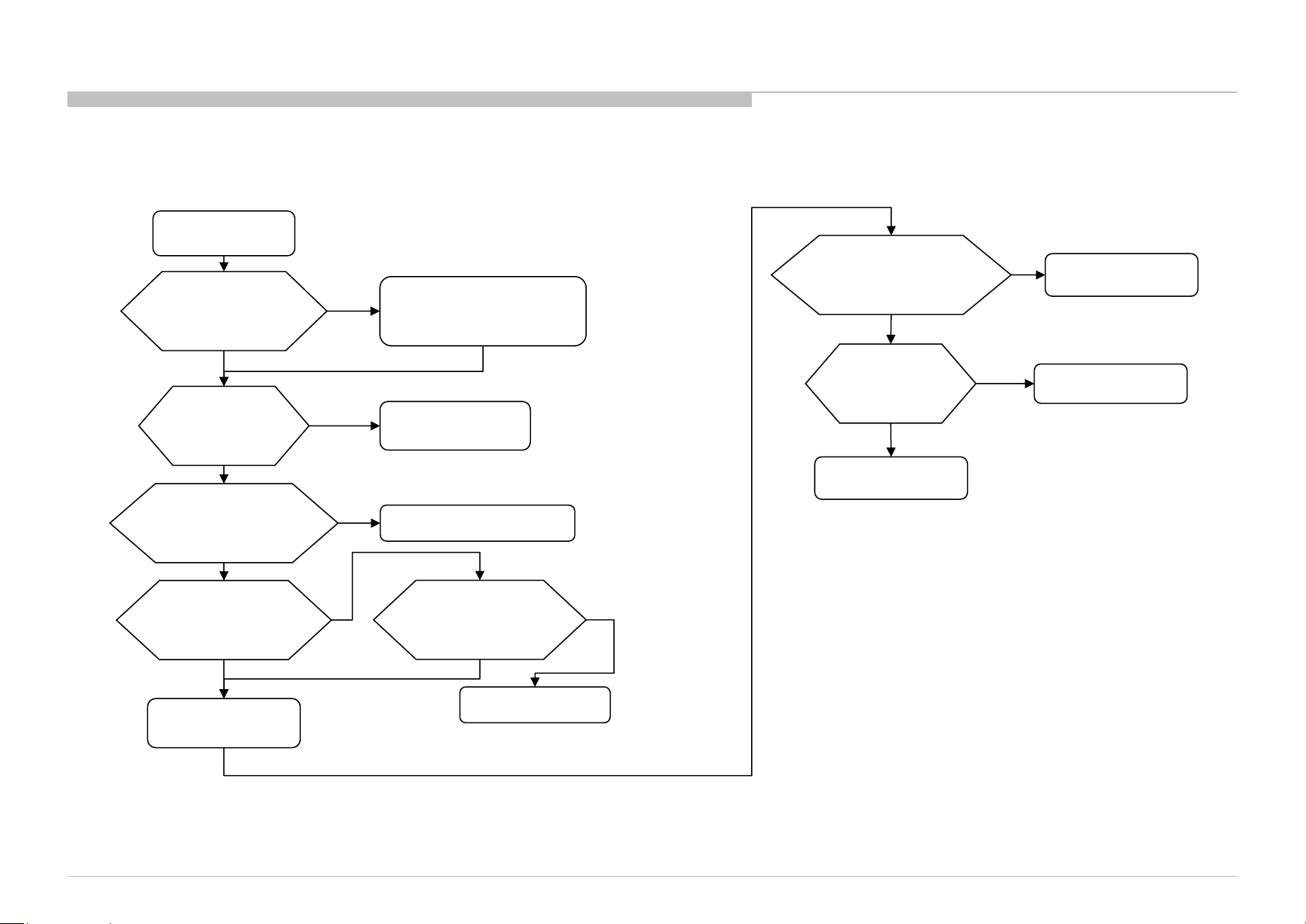

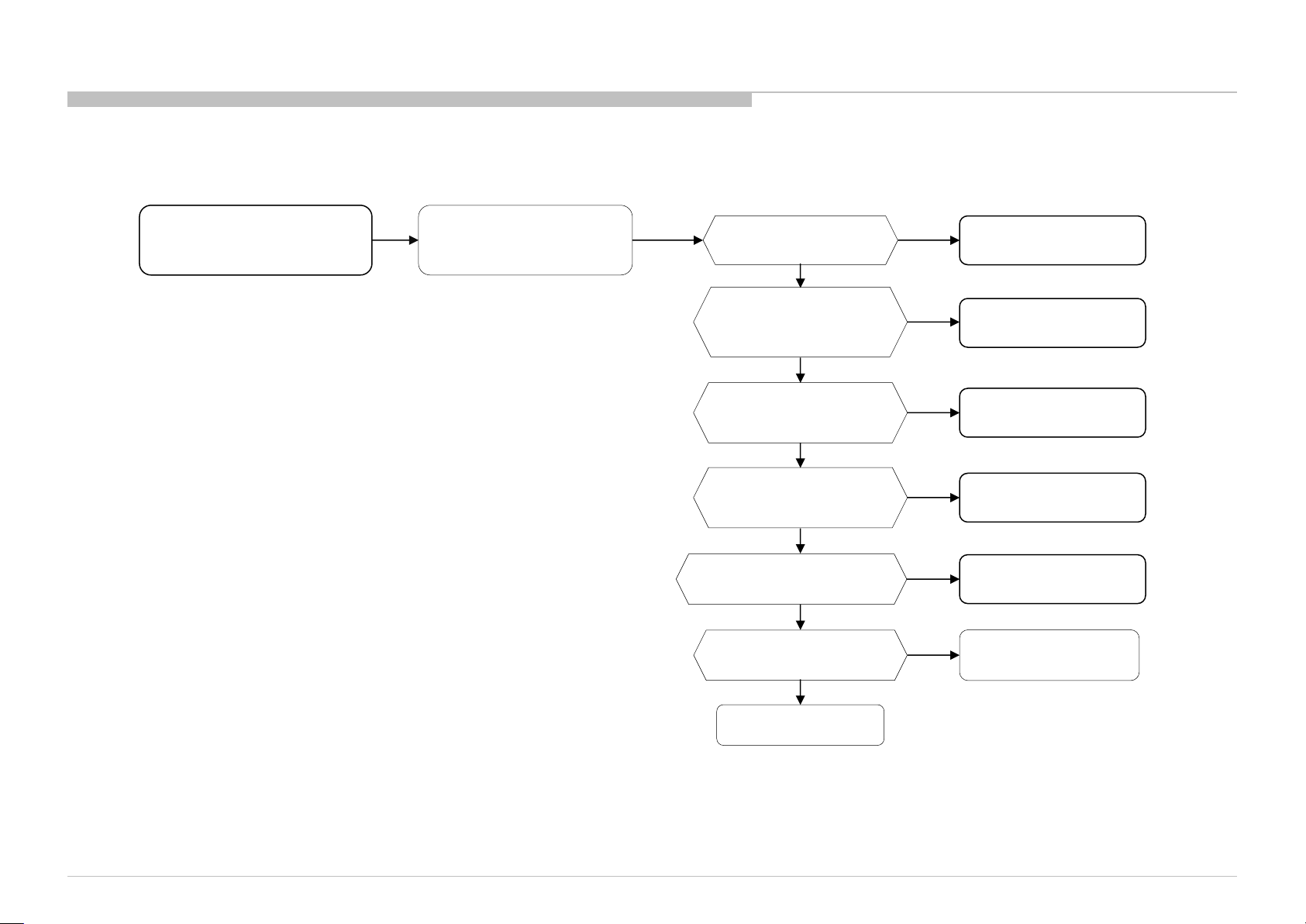

3-1. TRIAGE

1. Confirm the claimed symptom.

2. Select that symptom from the chart.

3. Bring all the boards and cables listed for that symptom.

4. Follow the troubleshooting charts in the technical guides to isolate the board.

5. Chart Color Code.

RED DOT: Most likely defective part

BLUE TRIANGLE: Secondary possible defective part

BLACK TEXT: Board that may correct the symptom

Reference

B* Board

G* Board

H* Board

K* Board

Speaker

LD* Board

V By One FFC

Tcon

LCD Panel

Problem

Symptoms - Shutdown. Power LED

blinking red diagnostics sequences

2 3 4 5 6 7 8 9 10

p l p

l p p

p

p

Power Power LD

Audio

Local

I2C

p p l l

p l

l

p

p

l

l l p

Panel

cation)

Panel

(Backlight)

l

p

No

Power

No White

& does

remote

(Dead Set)

p p l l p p l p p p

l

p

p

p

l

Video

- missing or distorted

of Inputs

Inputs

p

p

p

p

Remote Network Audio Skype Smart Core

No Remote

l

Wireless

can't connect

l

No Audio

p

l

l

Skype

Can't Work

p

LED (Set is still

alive)

l

(BT)

One Step

Remote

(OSR

connect

l

KD-65X8000C(CH)

50

Page 51

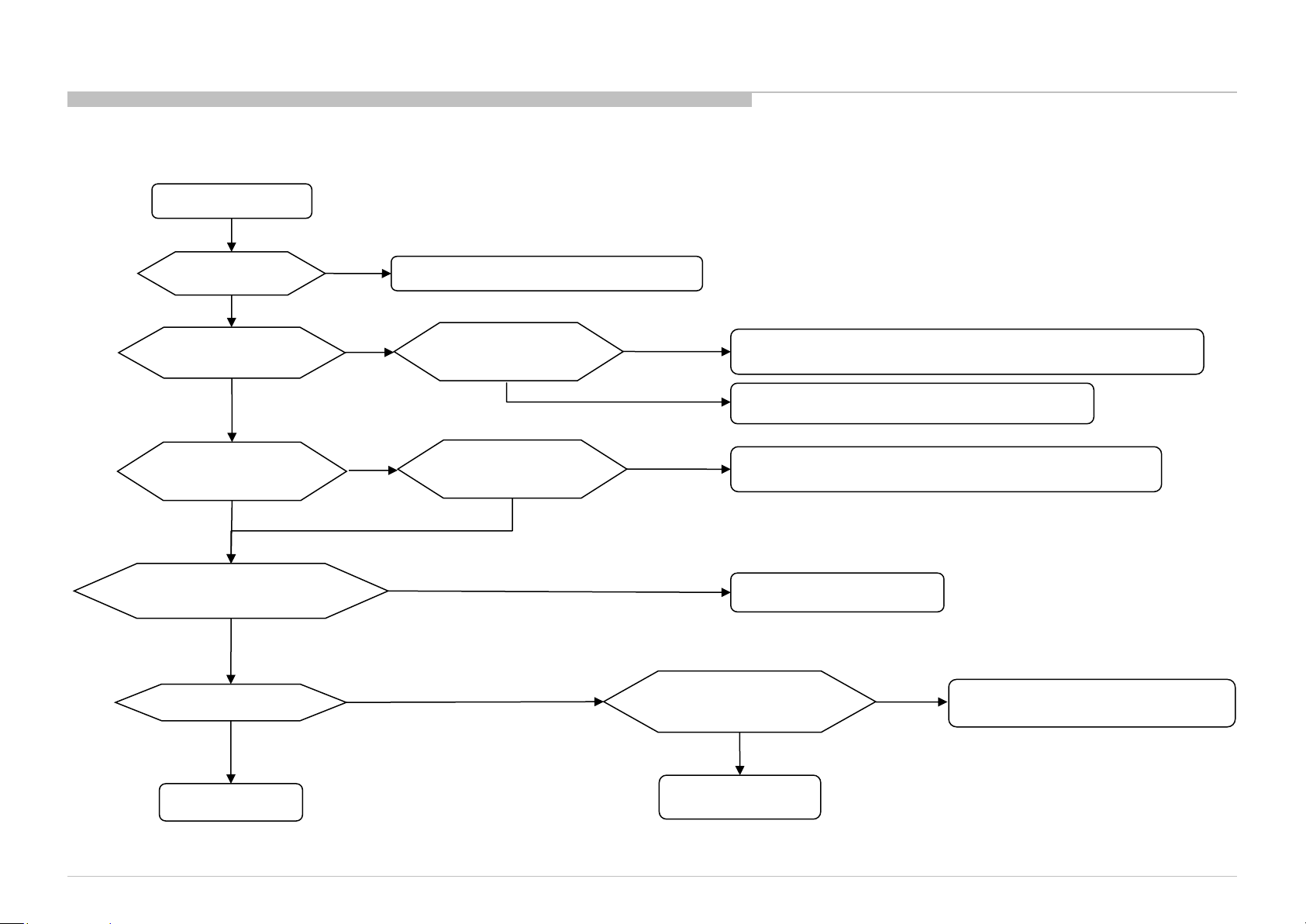

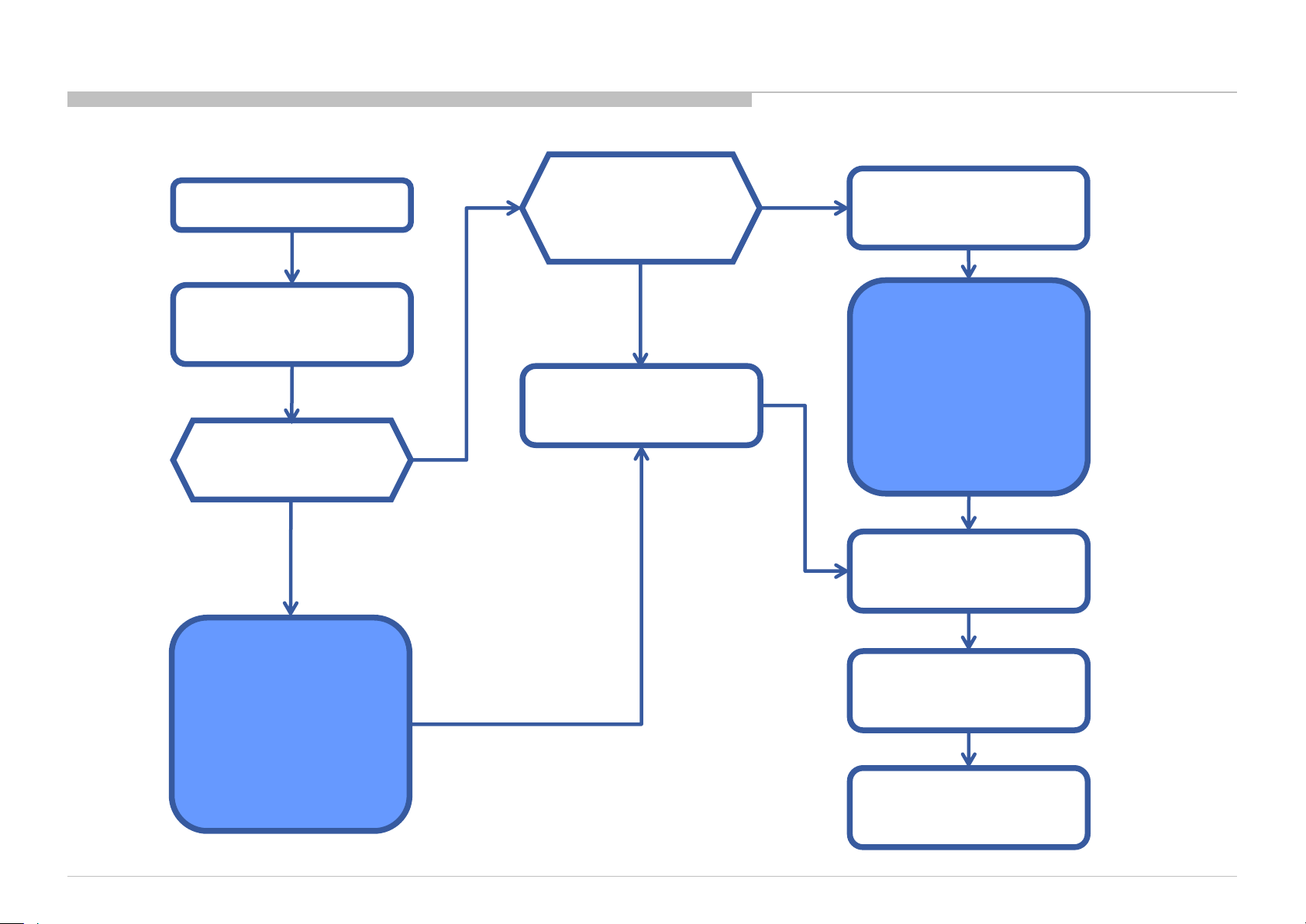

3-2. NO POWER

3-2-1. NO POWER-PCU

No Power

TROUBLE SHOOTING

Check STBY 3.3V

C9030

On B* board

OK

B* Board

NG

Replace

Between G* Board to

B* Board Harness

OK

Harness

u-Com Failure

DDCON/LDO

Main Device Failure

NG

G* Board

KD-65X8000C(CH)

51

Page 52

3-2-2. NO POWER-U-Com Failure (1/2)

START

TROUBLE SHOOTING

Check C9117 Voltage.

Is the voltage >3.0V?

Yes

Check R9186 Voltage.

Is the voltage >3.0V?

Yes

Check OPWRSB

R9179 Voltage.

Is the voltage 0V?

Yes

Check POWER_ON

P-on ucom #pin19

Is the voltage >3.0V?

yes

No

No

No

No

Check +3.3V_STBY

R9144, CN9000 #26pin

Check DC_OFF_DET

IC9018

Check STBY_MHL

R9176 Voltage.

Is the voltage >3.0V?

Yes

No problem

TV set stays in

STBY MHL charge mode.

Try AC Off and On after few minutes.

If #pin19 keep Low, change IC9017.

If #pin19 goes High few seconds and downs to Low,

Check G board and harness.

No

SOC

Muffin

problem

Check MAIN_VCC

R9175 Voltage.

Is the voltage >1.6V?

Yes

Check P_ON_VBUS

P-on ucom #pin11

is >3.0V?

Yes

Check P_ON_#1

P-on ucom #pin13

is >3.0V?

Yes

Check PGOOD_1

R9173 Voltage.

Is the voltage >3.0V?

A

No

No

No

No

G-Board

Change IC9017

Change IC9017

No POWER - DDCON/LDO

Check 1.0V DDCON (IC9008)

Check P_ON_LNB

P-on ucom #pin15

Is the voltage >3.0V?

KD-65X8000C(CH)

No

Change IC9017

Yes

52

Page 53

3-2-2. NO POWER-U-Com Failure (2/2)

A

Yes

TROUBLE SHOOTING

Check P_ON_#2

P-on ucom #pin14

Is the voltage >3.0V?

Yes

Check ORESETB

P-on ucom #pin12

Is the voltage >3.0V?

Yes

Check X_SYSTEM_RST

P-on ucom #pin16

Is the voltage >3.0V?

Yes

If PANEL_PWER_ON (R9172) is 0V

Check XRST

P-on ucom #pin17

Is the voltage >3.0V?

Yes

If BL_MUTE (R9174) is 0V

Check BL_ON

P-on ucom #pin18

Is the voltage >3.0V?

Yes

No

No

No

No

No

Change IC9017

Change IC9017

Change IC9017

Change IC9017

Change IC9017

Ucom IC9017 is working OK

KD-65X8000C(CH)

END

53

Page 54

TROUBLE SHOOTING

3-2-3. NO POWER: DC_OFF_DET check

START

Check Vdd

C9118

Is voltage >5V?

Yes

END

No

Change IC9018

3-2-4. NO POWER: DDCONs check

START

Check fuse

F9xxx

Is fuse OK?

Yes

Check Vcc voltage

C9xxx

Is voltage >12.0V?

Yes

Check Enable pin

voltage

Is voltage >2.5V?

Yes

Change DDCON IC

No

No

No

Check POWER_ON P-on ucom #pin19

(Refer to No Power U-Com Failure)

No Power U-Com Failure

Change Fuse

KD-65X8000C(CH)

54

Page 55

3-2-5. NO POWER: DDCON check

START

TROUBLE SHOOTING

Check IC9403 Vcc voltage

C9428

Is voltage >12V?

Yes

Check Vcc voltage

C9061

Is voltage >4V?

Yes

Check Enable

IC9010 #pin1

Is voltage >2.5V?

Yes

Change DDCON

IC9009

No

No

No

Check Vcc voltage

C9061

Is voltage >3V?

Yes

Check

D9001

Is diode ?

Yes

Change IC9010

No

No

Check

D9000

Is diode ?

No

Yes

Change D9001

Check +5V_MAIN DDCON (IC9001)

Change D9000

Check G board and harness

KD-65X8000C(CH)

55

Page 56

3-2-6. NO POWER: LDOs check check

START

Yes

TROUBLE SHOOTING

Check Vcc voltage

C9xxx

Is voltage >3V?

Yes

Check Enable pin

voltage

Is voltage >3V?

Yes

Change LDO IC

No

No

Check +3.3V_MAIN DDCON (IC9003)

1.2 No Power U-Com Failure

KD-65X8000C(CH)

56

Page 57

3-3. STANDBY LED BLINKING

3-3-1. 2 Times Blinking (Main power Error)

TROUBLE SHOOTING

3-3-2. 3 Times Blinking (DC Alert)

2-time blinking

Check +12V_REG

at pin 13/15/17 of CN9000

on B* Board,

Voltage > 13.2V ?

No

B* Board

Yes

G* Board

BMFL/BMFW board

3-time blinking

Check +5.0V_MAIN

at pin1 in IC8001, 4.959V

<Voltage<5.285V?

OK

AUDIO

Go to Audio check point

NG

DC_ALERT

IC9014,etc

(B* Board)

KD-65X8000C(CH)

57

Page 58

3-3-3. 3 Times Blinking (Audio Error)

TROUBLE SHOOTING

LED 3x blinking

Audio Error ?

Yes

Go to page

Power Off Checking*1

Go to page

Power off Checking*2

No

See other flow

Segment “XS”?

No

Yes

Replace B-K Harness

OK ?

No

Replace K-PWB

OK ?

No

Replace B-PWB

OK ?

Yes

Yes

Yes

B-K harness NG

K-PWB NG

B-PWB NG

KD-65X8000C(CH)

58

Page 59

1) Power Off Checking*1

Power Off Check*1

Segment “XS”?

Yes

No

(1) B-PWB

PVDD-GND short ?

(See Note 1)

Yes

(1) PVDD-GND short check

Measure impedance between PVDD and GND at C7706,

C7707.

If impedance is <100Ω → NG

(2) LDO out short check

Measure impedance between +3.3V and GND at C9130.

If impedance is <100Ω → NG

(3) Fuse open check

Measure impedance of fuse F7700, F7702 5A (12.5V)

If fuse open → NG

(1) K-PWB

PVDD-GND short ?

(See Note 2)

Yes

TROUBLE SHOOTING

Note 2: Note 1:

(1) PVDD-GND short check

Measure impedance between PVDD and GND at C7722, C7762, C7782,

C7834.

If impedance is <100Ω → NG

(2) LDO out short check

Measure impedance between +3.3V and GND at

C7909.

If impedance is <100Ω → NG

(3) Fuse open check

Measure impedance of fuse

F7702, F7704, F7705, F7701 5A (12.5V)

F7700 3.15A (DDC5V)

If fuse open → NG

Power Off Check*3

(2) B-PWB

LDO out short ?

(See Note 1)

(3) B-PWB

Fuse broken ?

(See Note 1)

KD-65X8000C(CH)

No

No

No

Yes

Yes

Replace B-PWB

No

(2) K-PWB

LDO out short ?

(See Note 2)

No

(3) K-PWB

Fuse broken ?

(See Note 2)

No

Yes

Yes

Replace K-PWB

Measure the Speaker

impedance by multi-meter

Less than 3Ω ?

No

Confirm the speaker

harness

Cut or shorted

to the chassis ?

No

Return to LED 3x blinking

or Power Off Checking*3

Yes

Replace Speaker

Replace Speaker Harness

Yes

59

Page 60

2) Power Off Checking*2

Power Off Check*2

Segment “XS”?

No

(4) 12.5V check

12.5V is supplied to

B-PWB for a moment

before LED 3x blinking ?

No

Yes

Yes

(5) 12.5V check

12.5V is supplied to

K-PWB for a moment

before LED 3x blinking ?

No

Yes

TROUBLE SHOOTING

(4) 12.5V check BMFL / BMFW

Measure voltage between PVDD and GND at

capacitor C7706 or C7707.(See 3.3)

Voltage rise more than 0V for a moment at

power on

→ Yes

(5) 12.5V check KS-PWB (XS)

Measure voltage between PVDD and GND at

capacitor C7722, C7762, C7782 or C7834. (See

3.3)

Voltage rise more than 0V for a moment at

power on

→ Yes

Replace B-K Harness

KD-65X8000C(CH)

OK ?

No

Replace G-PWB

OK ?

No

Return to

LED 3x blinking

Yes

Yes

Finish

Replace G-K Harness

OK ?

No

Replace G-PWB

OK ?

No

Return to

LED 3x blinking

Yes

Yes

Finish

60

Page 61

3) Power Off Checking*3

No Sound

Without LED 3x

AV receiver is connected

to HDMI in ?

Yes

Select [External Inputs]→

[BRAVIA Sync Settings]→

[BRAVIA Sync Control]→[off]

No sound only

Analog RF and Digital RF ?

No

TROUBLE SHOOTING

Yes

Go to

No Sound Tuner

No

[Speakers] setting is

[Audio System] ?

No

Headphone is connected to

HP/Audio Out terminal ?

No

[Sound]→

[Headphone Speaker Link]

setting is [On] ?

No

Go to

Power Off Checking*1

Yes

Yes

Yes

Change the setting to

[TV Speakers]

Disconnect the Headphone

Change [Sound]→

[Headphone Speaker Link]

Yes

to [Off], OK ?

No

Replace B-PWB

HP/Audio out terminal or Headphone detect

GPIO may be broken

No sound only HDMI ?

No

Go to

No Sound Audio

Yes

Go to

No Sound HDMI

KD-65X8000C(CH)

61

Page 62

3-3-4. 5 Times Blinking (Panel Communication Error)

5-times blinking

TROUBLE SHOOTING

Check

“+12.5V_TCON” at

CN9000

on the B-Board

OK

Replace the Harness

Between G-Board

and B-Board

NG

Replace

the V-By-One FFC

NG

NG

Replace G-Board

Symptom

improve

Symptom

improve

OK

NG

Harness is

suspicious

V-By-One FFC

is suspicious

G-Board is

suspicious

Change

B-Board

Symptom

improvement

B-Board is

suspicious

NG

Panel (T-con)

Panel (T-Con) is

suspicious

Change

Symptom

improvement

KD-65X8000C(CH)

62

Page 63

3-3-5. 6 Times Blinking (Backlight Error)

6-times blinking

TROUBLE SHOOTING

Check a voltage of

BL_ERR_DET.

Check point is

JL9007

or

23pin of CN9000

on B*Board

Voltage < 1.8 V

Voltage ≥ 1.9 V

Check

harness/connection

G*board to B*Board

or

LD board to B*Board

Harness /

Connection OK

Harness /

Connection

broken

Change LD board or G* board.

No improvement

No Improvement

Change

harness

No improvement

LED driver or G* board

Change

Panel

Change

B* board

Symptom

Improvement

Symptom

Improvement

Symptom

Improvement

Symptom

Improvement

Harness

LD board/G board

Panel

B* Board

KD-65X8000C(CH)

63

Page 64

3-3-6. 7 Times Blinking (Temperature Error)

7-time blinking

Setting

circumstance is OK?

Temperature,

No

Set to another

location, etc.

Ventilation, etc.

Yes

TROUBLE SHOOTING

Change B* Board,

and Aging a few

hours

Symptom

improvement

B* Board NG

NG

Panel

Check I2C_C bus

communication OK?

(check the next page)

No

I2C_C bus dumping or

Muffin check

Yes

Temp sensor

IC1400

KD-65X8000C(CH)

64

Page 65

3-4. NO SOUND

3-4-1. No Sound Audio

TROUBLE SHOOTING

3-4-2. No Sound : TUNER

No Sound

Audio

Segment “XS”?

No

Yes

Replace B-K Harness

OK ?

No

Replace K-PWB

OK ?

No

Yes

Yes

No Sound with normal picture

Only RF tuner input?

YES

Check IC1000 (SOC)

NO

Please refer Audio

troubleshooting

KD-65X8000C(CH)

Replace B-PWB

OK ?

Finish

Yes

65

Page 66

3-4-3. No Sound : MHL

No Sound

Check the picture

OK

TROUBLE SHOOTING

NG

Refer to MHL NO PICTURE

Check Sound by other TV set

which is same model

NG

Check Source equipment

by Reference TV set

(For example, Samsung TV(UN46ES7000),

Toshiba TV(42WL863), RB1 or RB2)

NG

Check the settings of

Source equipment

OK

Refer to No Sound Audio

OK

Change B-Board.

KD-65X8000C(CH)

66

Page 67

3-4-4. No Sound : HDMI1/2/3/4

No Sound

TROUBLE SHOOTING

Check the picture

OK

Check the mode

of Source equipment

HDMI

Does this model have

Analog Audio In

(Stereo minijack)?

NO

Check Sound by other TV set

which is same model

NG

Is Distributor used ?

YES

NG

DVI

YES

Refer to HDMI (1/2/3/4) NO PICTURE

Does this model have

“HDMI/DVI Audio Source”

Auto or HDMI Audio

OK

NO

Analog Audio In

(Stereo minijack)?

setting is?

YES

No

Analog Audio In

Check Source equipment

by Reference TV set

(For example, RB2, RB1)

Connect Stereo minijack cable between Source and the TV, and

Change “HDMI/DVI Audio Source” to Auto or Analog Audio In.

Change the mode of Source equipment to HDMI

Change “HDMI/DVI Audio Source” to Auto or HDMI Audio In

Refer to No Sound Audio

OK

Change B-Board.

NG

KD-65X8000C(CH)

Connect Source

equipment directly

Check the settings of

Source equipment

67

Page 68

3-5. NO PICUTURE

TROUBLE SHOOTING

No Picture

Got Any Normal

Display?

Yes

Check Other

Portion:

Ext. Video Input -

HDMI - No Picture

Tuner - No Picture

Check Smart Core

No

No Picture

Behavior

(5x Blinking)

Yes

5x Blinking

BL_ON (L or H): IC9017 #18pin (for 4K BMFW/BMFL board)

BL_ON:H

No

Check

BL_ON

on the main board

BL_ON:L

Backlight

Replace

the V by One FFC

Harness

Symptom

improvement

V by One FFC

Harness

NG

Replace

the main Board

Symptom

improvement

Main board NG

NG

LCD Panel

(T-CON)

KD-65X8000C(CH)

68

Page 69

3-5-1. No Picture CH/MX/PA/COL/LA (BMFL/BMFW)

No Picture Video

TROUBLE SHOOTING

Video 1

No Picture

Check if input OSD

is GREY OUT

OK if it is highlighted

OK

Check wave between

C7511 and IC1000

OK (Vpp: 1 V)

Muffin [IC1000]

Problem

NG

* Check J7505

Connection,

VIDEO2_DET

At R7562

** Detailed check all

parts at VIDEO2_DET

Signal Path [R7561]

NG (Vpp: 0 V)

J7505 Connector

Problem

NG (Vpp: 0 V)

OK (Vpp: 3.3 V)

NG (Vpp: 0 V)

OK (Vpp: 3.3 V)

** Detailed check all parts

at CVBS2P signal path

[D7514/R721/C7521/

J7505 Connectivity

Problem

R7519/C7534]

OK

NG

Parts Broken

Video 2

No Picture

Check if input OSD

is GREY OUT

OK if it is highlighted

OK

Check wave between

C7512 and IC1000

OK (Vpp: 1 V)

Muffin [IC1000]

Problem

NG

* Check J7504

** Detailed check all

parts at VIDEO_DET

Signal Path [R7535]

NG (Vpp: 0 V)

J7504 Connector

Connection,

VIDEO_DET

At R7539

OK (Vpp: 3.3 V)

OK (Vpp: 3.3 V)

Problem

NG (Vpp: 0 V)

NG (Vpp: 0 V)

J7504 Connectivity

** Detailed check all parts

at CVBS3P signal path

[D7530/R7524/R7525]

Problem

NG

OK

Parts Broken

[All voltage measurement using Oscilloscope]

KD-65X8000C(CH)

* OK Condition : No solder splash can be seen

NG Condition : Solder splash can be seen

** OK Condition : No part short-circuited

NG Condition : Part short-circuited

69

Page 70

3-5-2. No Picture : @ Tuner

RF input no picture / noisy picture

Check RF source cable

and antenna, OK?

Check Tuner power line:

3.3V at JL6005 = 3.3V?

1.8V at JL6006 = 1.8V?

DEM_3.3V at JL6019 = 3.3V?

A_RESET value at JL6012 = 3.3V?

For JP_SK only – TU1.1 V (Refer notes)

All broadcasting channel

cannot be received?

OK

OK

NO

NG

YES

Change RF cable and antenna

NG

Please refer DDCON

troubleshooting

Check part mounting condition

for “I2C_A_SDA, I2C_A_SCL

or

I2C_D_SDA, I2C_D_SCL”

Refer Note I2C

OK

NG

TROUBLE SHOOTING

Notes:

I2C line for all tuners except Japan_SKP

- Parts for I2C_A_SDA line: R6001, C6004.

- Parts for I2C_A_SCL line: R6002, C6005.

I2C line for Japan_SKP

- Parts for I2C_D_SDA line: R6003,C6006

- Parts for I2C_D_SCL line: R6004,C6007

TU_1.1V line only in Japan_SKP Tuner

- Parts for TU_1.1V: FB6800

Change NG parts

connected to I2C bus

KD-65X8000C(CH)

Analog

Refer Analog Tuning

Digital

Terrestrial/Cable

For TW & NA-ATSC

(MX/UC) only

Refer Digital Tuning 1

Satellite

Check Tuner power line

12V at JL6027 = 12V?

OK

All tuners except

TW & NA-ATSC(MX/UC)

Refer Digital Tuning 2

NG

12V LNB Voltage

Checking

70

Page 71

3-5-3. No Picture : HDMI1

No Picture

TROUBLE SHOOTING

Check other

HDMI input

All Inputs are NG

Check Picture by other TV set

which is same model

Target board & other TV set

both NG

Is Distributor used ?

No

Check Source equipment

by Reference TV set

(For example, RB1)

Reference TV set

NG

Check the settings of

Source equipment

Other Input is OK

Other TV set

OK

Yes

Reference TV Set OK

Change B-Board.

Change B-Board.

Connect Source

equipment directly

Change B-Board.

If you can do

component repair

If you can do

component repair

Check the below point at

Only +5V line

is NG

Spec:4.7~5.3V

Replace

R5515

JC5227, JC5228, JC5235, JC5236

JC5241, JC5242, JC5243, JC5244

Connector side

・Check +5V line

・Check HPD line

・Check DDC lines

・Check TMDS lines

+5V line is OK

and HPD line

is NG

Spec:2.4~5.3

V

Replace IC5212

(HDMI EQ).

Replace

IC1000

All lines

are NG

Only DDC

lines

are NG

Replace IC5212

(HDMI EQ).

Replace

CN5202

Only TMDS

lines

are NG

Replace

JC5216, JC5217

RB5209, RB5210

NG

NG

KD-65X8000C(CH)

71

Page 72

3-5-4. No Picture : HDMI2

No Picture

TROUBLE SHOOTING

Check other

HDMI input

All Inputs are

NG

Check Picture by other TV set

which is same model

Target board & other TV set

both NG

Is Distributor used ?

No

Check Source equipment

by Reference TV set

(For example, RB1)

Reference TV set

NG

Check the settings of

Source equipment

Other Input is OK

Other TV set

OK

Yes

Reference TV Set OK

Change B-Board.

Change B-Board.

Connect Source

equipment directly

Change B-Board.

If you can do

component repair

If you can do

component repair

Check the below point at

Connector side

・Check +5V line

・Check HPD line

・Check DDC lines

・Check TMDS lines

Only +5V line

is NG

Spec:4.7~5.3V

Replace

R5517, R5518

Replace IC5212

JC5227, JC5228, JC5235, JC5236

JC5241, JC5242, JC5243, JC5244

+5V line is OK

and HPD line

is NG

Spec:2.4~5.3

V

(HDMI EQ).

Replace

IC1000

All lines

are NG

Only DDC

lines

are NG

Replace IC5212

(HDMI EQ).

Replace

CN5202

Only TMDS lines

are NG

Replace

JC5208, JC5209

RB5211, RB5212

NG

NG

KD-65X8000C(CH)

72

Page 73

3-5-5. No Picture : HDMI3

No Picture

TROUBLE SHOOTING

Check other

HDMI input

All Inputs are

NG

Check Picture by other TV set

which is same model

Target board & other TV set

both NG

Is Distributor used ?

No

Check Source equipment

by Reference TV set

(For example, RB1)

Reference TV

set

NG

Check the settings of

Source equipment

Other Input is OK

Other TV

set OK

Yes

Reference TV Set OK

Change B-Board.

Change B-Board.

Connect Source

equipment directly

Change B-Board.

If you can do

component repair

If you can do

component repair

Check the below point at

Connector side

・Check +5V line

・Check HPD line

・Check DDC lines

・Check TMDS lines

Only +5V line

is NG

Spec:4.7~5.3V

Replace

R5428

Replace IC5212

JC5227, JC5228, JC5235, JC5236

JC5241, JC5242, JC5243, JC5244

+5V line is OK

and HPD line

is NG

Spec:2.4~5.3

V

(HDMI EQ).

Replace

IC1000

Only DDC lines

are NG

Replace IC5212

(HDMI EQ).

All lines

are NG

Replace

CN5203

Only TMDS lines

are NG

Replace

JC5237, JC5238

RB5213, RB5214

NG

NG

KD-65X8000C(CH)

73

Page 74

3-5-6. No Picture : HDMI4

No Picture

TROUBLE SHOOTING

Check other

HDMI input

All Inputs are NG

Check Picture by other TV set

which is same model

Target board & other TV set

both NG

Is Distributor used ?

No

Check Source equipment

by Reference TV set

(For example, RB1)

Reference TV

set

NG

Check the settings of

Source equipment

Other Input is OK

Other TV

set OK

Yes

Reference TV Set OK

Change B-Board.

Change B-Board.

Connect Source

equipment directly

Change B-Board.

If you can do

component repair

If you can do

component repair

Check the below point at

Only +5V line

is NG

Spec:4.7~5.3V

Replace

R5467

JC5227, JC5228, JC5235, JC5236

JC5241, JC5242, JC5243, JC5244

Connector side

・Check +5V line

・Check HPD line

・Check DDC lines

・Check TMDS lines

+5V line is OK

and HPD line

is NG

Spec:2.4~5.3

V

Replace IC5212

(HDMI EQ).

Replace

IC1000

Only DDC lines

are NG

Replace IC5212

(HDMI EQ).

All lines

are NG

Replace

CN5208

Only TMDS lines

are NG

Replace

JC5239, JC5240

RB5215, RB5216

NG

NG

KD-65X8000C(CH)

74

Page 75

3-5-7. FOR ANALOG TUNING: @ All destination except JP

Analog Tuning

For Other destination

For LA-ISDB(BR/AR), LA-T2(COL) and TW only

Confirm ANT or Cable connection A

OK

NG

TROUBLE SHOOTING

Notes:

- Parts for IFOUT_N line: R6007, FB6002, C6008, R6327,

C6301, R6301.

- Parts for IFOUT_P line: R6008, FB6003, C6009, R6326,

C6300, R6300.

- Parts for IFAGC line: R6072, R6009, R6010, R6069, C6302,

R6303.

A

: Insert correct signal in correct terminal.

KD-65X8000C(CH)

Check part mounting condition for

analog control line

“IFOUT_N, IFOUT_P, IFAGC”

OK

Check IC1000(SOC)

NG

Change NG parts

75

Page 76

3-5-8. FOR DIGITAL TUNING 2: @ AEP_W, JP_SKP, PA_T2, CH/HK, LA-ISDB(BR/AR) and LA-T2(COL)

TROUBLE SHOOTING

For LA-ISDB(BR) and

LA-T2(COL) only

NG

Confirm ANT or Cable connection Confirm ANT or Satellite connection

OK

Digital cable/ Terrestrial

Cable

Refer to Digital Tuning 1

“TU1_TS_DATA0, TU1_TS_CLK, TU1_TS_VALID, TU1_TS_SYNC”

Terrestrial

Check part mounting condition for digital data line

Digital Tuning 2

For PA_T2 and

A A A

Sound is normal?

No sound

Change NG parts

CH/HK only

On Service

mode display

TS_LOCK ?

UEC ?

CASE A

NG

OK

CASE B

For AEP-W

OK

OK

All except SKP_Opticast

Check IC1000 (SoC)

Change Tuner module

(Refer to Note tuner )

Check IC1000 (SoC)

NG

For JP_SKP

Confirm ANT or Satellite connection

OK

BS/CS or SKP_Opticast/

SKP_Premium or terrestrial

SKP_Opticast

Refer to Digital Tuning 1

Notes:

- Parts for TU1_TS_DATA0 line: R6015,

R6321.

- Parts for TU1_TS_CLK line: R6016, R6322.

- Parts for TU1_TS_VALID line: R6017, R6323.

- Parts for TU1_TS_SYNC line: R6018, R6324.

- CASE A : TS _LOCK = LOCK and UEC

constant

- CASE B : TS _LOCK = UNLOCK or UEC is

increasing

Note Tuner –

(IC reference -- destination)

TU6001 - PA-T2

TU6001 - LA-T2/LA-ISDB

TU6001 - CH, HK

TU6003 - AEP_W

TU6802 - JP_SKP

: Insert correct signal in correct terminal.

A

NG

KD-65X8000C(CH)

76

Page 77

3-6. SIDE BUTTONS MALFUNCTION

TROUBLE SHOOTING

Side Key button

malfunction

Change Switch Unit

OK

NG

Harness on Switch Unit

and B* Board properly connected

NG

Change

Switch unit-B* board Harness

NG

Power Key (B*Board)

Check parts value :

0 ohm < R1089 < 2 ohm

4.4k ohm < R1432 < 5k ohm

OK

Power Key Muffin Pin (B*Board)

Check voltage(Power ON condition) :

3.13V < Voltage < 3.47V

OK

OK

NG

OK

Switch unit issue

Harness

connection

issue

Harness issue

Parts Broken issue

Muffin IC1000

problem

NG

OK

NG

Key AD(B*Board)

Check parts value :

0 ohm < R1091 < 2 ohm

0 ohm < R1042 < 2 ohm

OK

Key AD muffin pin (B*Board)

Check voltage (Power ON condition):

1.62V < voltage < 1.84V

KD-65X8000C(CH)

NG

NG

Change B*Board

77

Page 78

3-7. IR REMOTE COMMANDER MALFUNCTION

TROUBLE SHOOTING

IR do not response to

Remote Commander

Center white LED

lit up when remote

control is pressed

NG

Harness on H-board

and B* Board

properly connected

NG

Change

H-B* board Harness

NG

Change Smart Core

NG

B*Board

Check parts value :

R1080 = zero ohm

OK

OK OK

OK

Check whether center

white LED blink ,when using

commander near the sensor

windows

Harness

connection

issue

OK

H-B* board harness

issue

OK

Smart core issue

NG

Parts Broken issue

Remote control battery

could be weak.

Change battery.

KD-65X8000C(CH)

SIRCS (IC1000 Pin Y35 , B*Board)

Check voltage (Power ON condition):

3.287V < Voltage < 3.55V?

NG

Change B*Board

OK

Muffin IC1000

problem

78

Page 79

3-8. LIGHT SENSOR ERROR

TROUBLE SHOOTING

Backlight doesn’t change

when ambient lighting

level changed

Check UI setting for light

Sensor. Make sure it is “on”

Change the UI setting

to “ON”

NG

Harness on H-board and

B* Board properly connected

NG

Change

H-B* board Harness

NG

Change Smart Core

NG

B*Board

Check LIGTH_SENSOR signal path :

R1079 = zero ohm

OK

LIGTH_SENSOR (Muffin Pin L35)

Check voltage variation from

room light to dark condition

NG

OK

OK

OK

OK

NG

OK

User did not activate light

sensor function

Harness connection

issue

H-B* board harness

issue

Smart Core issue

Part broken issue

Muffin IC1000 problem

KD-65X8000C(CH)

Change B*Board

79

Page 80

3-9. NETWORK MALFUNCTION

1) Ethernet (Wired)

[Network Set-up]

>[Wired Set-up]

on the TV

TROUBLE SHOOTING

OK

Connection Results

Cable Connection

Failed

OK

Check cable B board

NG

Ethernet Cable

Connection Results

Local Access

Failed

Wired Set-up

IP address setting

Manual

Check IP address

&

Local router setting

OK

Auto

Check

Local router

DHCP server

Connection Results

Internet Access

Failed

Proxy setting

OK

B board

KD-65X8000C(CH)

80

Page 81

2) Internal Wireless Network malfunction

Wireless Network

on the TV

TROUBLE SHOOTING

Error Message appear

when the Wireless

Network is selected?

Yes

From previous page

Check harness

connection is OK

between WiFi and Bxx

OK

Change

Wi-Fi module

OK If Wi-Fi malfunction happens,

Wi-Fi module

NG

No

NG

NG

Is the radio field

Strength too weak

or even No signal?

Yes

Change WiFi module

OK

WiFi module

Connect properly

OK

Change harness

between Bxx board

and WiFi

OK

Main Harness

No

NG

Loose harness

NG

Change Bxx board

Bxx Board

Access Point

• Wi-Fi module

• Harness between WiFi

and Bxx

• Bxx board

are suspected.

KD-65X8000C(CH)

81

Page 82

3) Bluetooth malfunction

Touch pad Remote doesn’t work

3D-glasses (Active) doesn’t work

Bluetooth Speaker/Headphone/Headset doesn’t work

Home > Settings >

Bluetooth Settings

NG

else

Or

Or

OK

Can read

Near discoverable

Bluetooth Device

Check BT antenna

Connection is OK

OK

NG

TROUBLE SHOOTING

Please refer

Touch pad Remote manual

3D-glasses (Active) manual

Or

Bluetooth Speaker/Headphone/Headset operation manual

Check harness

connection is OK

between BT and Bxx

KD-65X8000C(CH)

OK

Change BT module

OK

BT module

NG

NG

NG

NG

Connect properly

Change harness

Between Bxx board

and BT

Main Harness

Connect properly

OK

OK

NG

OK

Loose harness

Change Bxx board

Loose BT antenna

connection

82

Page 83

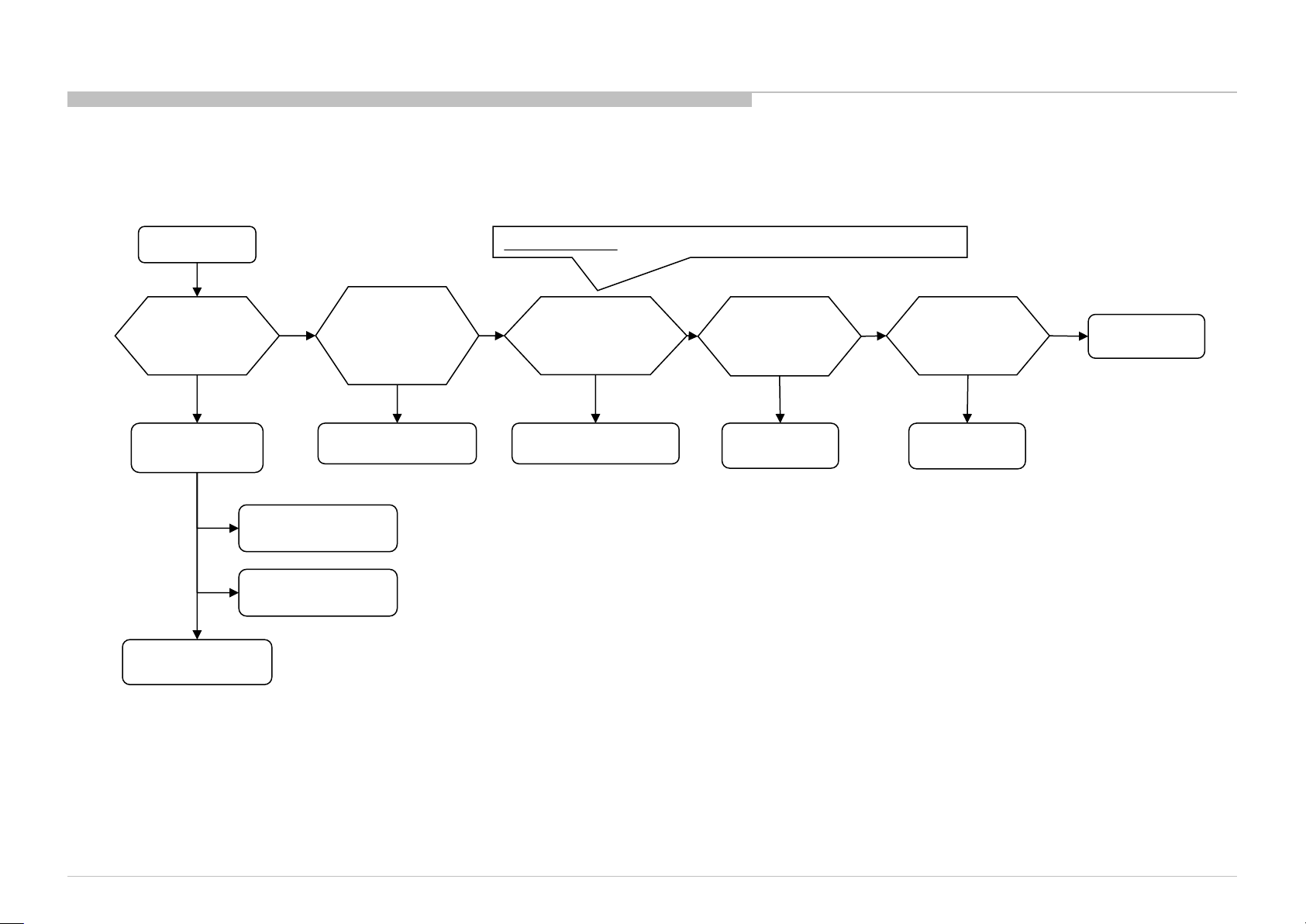

SEC 4. DIAGRAMS

4-1. BLOCK DIAGRAM

Tu Pack

Ether

HDMI1

HDMI2

/MHL

HDMI3

HDMI4

Tuner

CVBS Jack

I2C

(Audio)

TEMP

Sensor

HDMI EQ

Composite2/Component

DVI/HDMI3

Audio in

USB3.0 USB2.0

USB2.0

SmarCore

WIFI/BT

Main SoC

LOG

eMMC

DDR3

2Gb

I2C(Backlight,Panel)

UART(4KBE

Communication)

AudioAMP

HP/Line out

LOG

ECS

Vx1 x8

Vx1 x4

Key-pad

Sub SoC

Opt.Out

I2C(panel)

Vx1 x16

LD

I2C(Backlight)

I2C

(Audio)

AudioAMP

AudioAMP

AudioAMP

AudioAMP

AudioAMP

AudioAMP

LD

SoC

KD-65X8000C(CH)

83

Page 84

DIAGRAMS

(Only Interface between board and board)

CN360 1 To BMFW

CN203 GND 1 51 GND

1-798-511-11(ALPS)/ HUS_GND 1 19 VBTX7P 2 50 RxP7

1-798-510-12(NOBLE) HUS_KEY_AD 2 18 VBTX7N 3 49 RxN7

HUS_POWER_KEY 3 20 GN D 4 48 GND

1-821-143-11 1-821-117-11

VBTX6P 5 47 RxP6

JAM SYT10-3WL SYT10-03HG VBTX6N 6 46 RxN6

GND 7 45 GND

VBTX5P 8 44 RxP5

VBTX5N 9 43 RxN5

GND 10 42 GND

VBTX4P 11 41 RxP4

CN100 0 VBTX4N 12 40 RxN4

1 1 WIFI_GND GND 13 39 GND

2 2 X_WIFI_BT_RST VBTX3P 14 38 RxP3

3 3 X_WIFI_WAKEUP VBTX3N 15 37 RxN3

4 4 X_BT_WAKEUP GND 16 36 GND

5 5 WIFI_GND VBTX2P 17 35 RxP2

6 6 WIFI_STBY_3.3V VBTX2N 18 34 RxN2

USB 7 7 WIFI_STBY_3.3V GND 19 33 GND

USB 8 8 WIFI_STBY_3.3V VBTX1P 20 32 RxP1

9 9 WIFI_GND VBTX1N 21 31 RxN1

10 10 WIFI_GND GND 22 30 GND

USB 12 11

WIFI_GND

VBTX0P 23 29 RxP0

11 12 BT_3D_LR VBTX0N 24 28 RxN0

13 13 WIFI_GND GND 25 27 GND

USB 14 14 WIFI_USB_M VBTXLOCKN0 26 26 LOCKN

NC 15 NC VBTXHTPDN0 27 25 HTPDN

USB 15 16 WIFI_USB_P GND 28 24 GND

NC 17 NC GND 29 23 AGP/NSB (High/Open:AGP, Low: N SB)

2 18 HUS_KEY_AD NC 30 22 NC

1 19 CAM_GND BITSEL 31 21 NC (BITSEL(High/Open :10Bit; L:8Bit))

CN001 3 20 HUS_POWER_KEY /WP/(BINT) 32 20 nWP (High:Write; L/Open: Protect)

STBY3.3V 1 25 11 21 SC_OPT_SENSE SCL 33 19 SCL

5V_MAIN 2 22 2 22 5V_MAIN SDA 34 18 SDA

GND 3 27 12 23 SC_SIRCS 3D_EN/ (MUTE) 35 17 PCID _EN (High: Enable, Low/Open: Disable)

LED_AMBER 4 24 4 24 SC_ LED_AMBER 3D_SYNC_IN 36 16 NC

LED_PWM_W 5 26 1 25 SC_STBY_3.3V 3D_SYNC_OUT 37 15 NC

LEY_PWM_R 6 32 5 26 SC_LED_PWM_W GND 38 14 GND

LED_PWM_B 7 30 3 27 SC_GND PANEL_DET 39 13 GND

LED_PWM_G 8 28 8 28 SC_LED_PWM_G GND 40 12 GND

GND 9 29 9 29 SC_GND NC/GND 41 11 GND

MAIN_3.3V 10 31 7 30 SC_LED_PWM_B NC 42 10 GND

OPT_SENSE 11 21 10 31 SC_MAIN_3.3V NC 43 9 NC

SIRCS 12 23 6 32 SC_LED_PWM_R NC(PANEL_RESETX)/12V 44 8 NC

1-821-139-11 1-821-126-11 NC 33

SC_GND

NC(PANEL_READY)/12V 45 7 NC

JAM SY T10- 12W S SYT10-12HG NC 34

NC

NC/12V 46 6 NC

NC 35

MIC_GND

NC(PANEL_PWR)/12V 47 5 NC

NC 36

MIC_RESET

NC(PANEL_ON)/12V 48 4 NC

NC 37

I2S_BCK(SIELDED)

NC(ABL_HOT2)/12V 49 3 NC

NC 38

I2S_LRCLK(SIELDED)

NC(ABL_HOT1)/12V 50 2 NC

NC 39

HUS_GND

NC(ABL_HOT0)/12V 51 1 NC

USB Cable(UL2725) NC 40

CAM_POP

1-819-812-11

GND 1 1 1-819-538-11 1-818-692-23 FFC Dire ct Conn ect or :I PEX JAE/FI -RE5 1S-H F

RST_L 2 2 SHLD P-40V-S-1 (B) JST SM4 0B-S HLDS -GAN F-1- TF(L F)(S N)

WOW_L 3 3

WOBT_L 4 4 CN36 00 To BMFL

GND 5 5 NC/HTPDN1/ELTIMO3/POWER_ON 1 41 NC

VCC 6 6 CN800 4 NC/LOCKN1/ABL_PHT/READY 2 40 NC

VCC 7 7 3 BLK#2 8 1

CAMERA_5V

NC/SDA/PANEL_ERROR/PANEL ON 3 39 NC

VCC 8 8 3 RED#28 2

CAMERA_USB_M

NC/SCL/PANEL ERROR 4 38 NC

GND 9 9 3

CAMERA_USB_P

SPI_CS 5 37 NC

GND 10 10 4

ID (GND/CLK/CAM_POP) : Conne ct GND via R=0 Ohm

SPI_CK 6 36 NC

VSYNC 11 12 5

GND_S

NC/RESETX 7 35 NC

GND 12 11 3 Shield 1-822-265-21 NC 8 34 NC

GND 13 13 ACON Mini -USB NC 9 33 NC

DM 14 14 3 WHT#2 8 NC 10 32 NC

DP 15 16 3 GRN#28 NC 11 31 NC

1-819-332-11 1-819-502-11 VCA/(SPI_SEL0) 12 30 NC

JST SM 15B -GHS -TB (LF)( SN)

GHR-15V-S CN900 0 BUS_SW 13 29 NC

NC 30

DIGITAL_STBY

SPI_DI/(WDT) 14 28 NC

2 29

DC_DIMMER

SPI_DO 15 27 HTPDN (LGD Use Only)

3 28

BL_ON/ICS PCLK

SPI_ENB 16 26 LOCKN (LGD Use Only)

4 27

PWM_DIMMER

GND 17 25 GND

5 26

STBY_3.3V

VBTX15P 18 24 RxP15

6 25

BLINKING

VBTX15N 19 23 RxN15

NC 24

AC_OFF_DET

GND 20 22 GND

8 23 BL_ERR VBTX1 4P 21 21 RxP14

9 22

POWER_ON/ICSP DAT VBTX14N 22 20 RxN14

10 21 GND GND 23 19 GND

11 20 GND VBTX13P 24 18 RxP13 J110

12 19

GND

VBTX13N 25 17 RxN13

GND Ground

1

21 AWG#22

13 18

REG12V_Audio

GND 26 16 GND

GND Ground

2

23 AWG#22

14 17

REG12V

VBTX12P 27 15 RxP12

PWR Power V12 IN

3

NC

15 16

REG12V_Audio

VBTX12N 28 14 RxN12

PWR Power V12 IN

4

25 AWG#22

16 15

REG12V

GND 29 13 GND

PWR Power V12 IN

5

27 AWG#22

NC 14 REG12V_Audio VBTX11P 30 12 RxP11 1-822-322-11 1-820-264-11

18 13 REG12V VBTX11N 31 11 RxN11 JST SM05B-PASS-TBT(LF)(SN) PAP-05V-S

NC 12 GND GND 32 10 GND

20 11 GND VBTX10P 33 9 RxP10

NC 10

TCON_GND/VPP_ PIC VBTX10N 34 8 RxN10

22 9 GND GND 35 7 GND

NC 8 TCON_GND VBTX9P 36 6 RxP9

24 7 TCON_ON VBTX9N 37 5 RxN9

NC 6 TCON_VCC12V GND 38 4 GND

26 5 TCON_VCC12V VBTX8P 39 3 RxP8

NC 4 TCON_VCC12V VBTX8N 40 2 RxN8

NC 3 TCON_VCC12V GND 41 1 GND

NC 2 GND 1-819-564-11

NC 1 GND FFC D irec t Co nne ctor :IP EX JAE/FI- RE41 S-HF

1-843-925-11 1-843-917-11

PBDP-30V-S JST S M30B -PB DSS- TF

CN830 1

TM_SCL 1

TM_SDA 2

GND 3

TM_SPI1_SCK 4

TM_SPI1_MOSI 5

TM_SPI1_nSS 6

GND 7

TM_EMIT 8

BL_TYPE 9

TM_SPI0_SCK 10

TM_SPI0_MOSI 11

TM_SPI0_nSS 12

GND 13

TM_SPI_SYNC 14

TM_MODE0 15

TM_MODE1 16

TM_RDY 17

TM_LOG_RX 18

TM_LOG_TX 19

SA_MODE 20

VLEDPWM1 21

VLEDPWM0 22

CN770 6 Reserve 23

1 GND_D BL_ON 24

2 +5.0V_AUDIO 0-336-971-01

3 GND_D FFC 2 4pin IRI SO

4 X_SYSTEM_RST

5 X_DAMP_MUTE

6 X_AMP_ERR_DET

7 X_DAMP_RESET

8 I2C_C_SCL

9 I2C_C_SDA

10 DC_ OFF_DET

SPEAKE R

L+ 1 4 11 D AUOA_DAT3

Front

L- 2 3 12 D AUOA_DAT2

Lch

JST SMP-02VF-N 13 DAUOA_DAT1

1-784-991-21 14

DAUOA_DAT015DAUOA_LRCK16GND_D

SPEAKE R

R+ 1 1 17

DAUOA_BCK

Front

R- 2 2 18

GND_D

Rch

JST SMP-02VF-N 19

DAUOA_MCK

1-784-991-21 20

GND_D

1-819-407-71

IMSA-9 637 S-4 0-Y8 01

CN6401

1-842-551-11

SJM20 -28WL B/JAM

DIGITAL_STBY

1

NC

DC_DIMMER

2

29

BL_ON

3

28

PWM_DIMMER

4

27

STBY_3.3V

5

26 #22

BLINKING

6

25

AC_OFF_DET

7

NC CN770 0

BL_ERR

8

23 #24 1 1 SP_MAIN_RP

POWER_ON

9

22 #24 2 2 SP_MAIN_RN

GND

10

21 #22 #24 2 3 SP_MAIN_LN

GND

11

20 #22 #24 1 4 SP_MAIN_LP

GND

12

19 #22 1-842-593-11 1-842-566-12

REG12V

13

18 #22 PBVP0 4V-S SM 04B -PBV SS-T B(LF) (SN )(PS )

REG12V

14

17 #22

REG12V

15

16 #22

REG12V

16

15 #22

REG12V

17 NC

REG12V

18

13 #22

GND

19

NC

GND

20

11 #22

TCON_GND

21

1 #22

GND

22

9 #22

TCON_GND

23

2 #22

TCON_ON

24

7

TCON_VCC12V

25

4 #22

TCON_VCC12V

26

5

TCON_VCC12V

27

5 #22

TCON_VCC12V

28

NC

SJM20-28HG

1-842-598-11

CN6101

SFP79 -02WL B JAM

1-822-908-11

AC-N 1

AC-L 2

1-839-678-21

CN6801

1-822-360-11

53426-0510 Molex

NC1+OUT1

2

To LS

NC(No land)3NC(No land)4-OUT1

5

1-822-327-11

51103-0500

or Hi rose FH5 2-2 4S- 0.5S H

or Hi rose FH5 2-2 0S- 0.5S H

PANEL FFC

1-842-546-21

or Ya maich i 1 -84 3-1 07-X X

1-843-699-11

or Ya maich i 1 -84 3-7 08-X X

Main Harness

BAX_F Board

G-B Harness

GB Harness

GN1 Smart Core

Wifi/BT

BMFW Board

HSC3-L

SM (FY14)

GL6 Board

BT

Antena

51pin FFC

VbyOne-FFC

41pin FFC

VbyOne-FFC

AC pigtail

T-con Boar d

(LGD)

4-2. CONNECTOR DIAGRAM

KD-65X8000C(CH)

84

Page 85

4-3. PC BOARD DIAGRAM

BMFW (A SIDE)

DIAGRAMS

cam9

C7747

C7748

C7746

L7704

cam012

IRM001

KA001

C7715

C7716

C7714

C7873

C7874

C7731

TP3106

IC7700

R7758

C7711

cam058

C7708

C7863

C7704

R7748

R7749

R7760

R7761

cam103

cam095

KA003

cam100

cam101

C1441

cam102

IC1400

cam178

cam085

cam083

R1136

R1137

R1138

R1139

R1140

CN7703

R1141

cam017

cam3

TP3101

DM001

cam005

cam15

FB6001

C6002

C6001

R6063

R6062

R6061

C6024

C9077

L9005

C9071

C6013

C9066

C9063

C9111

C6014

C9079

C6015

C9083

FB6004

IC9005

cam12

R9052

R9049

C9057

C9054

R9057

R9047

C6003

C9052

R9056

cam086

cam4

cam010

cam001 cam002

KJ001 KJ002

C7749

CN7704

CN7700

L7705

L7706

C7717

L7700

R7766

R7750

R7751

R7752

R7967

F7700

C7706

R7728

cam003

CN1403

R1446

R1447

cam218

R1510

R1449

R1448

R1517

Q1402

C7764

C1463

cam043

Q1401

IC1408

R1518

Q1400

cam033

C7862

C7860

VR7701

R7964

R7966

C7858

R7961

C7861

C7859

VR7700

R7963

R7965

C7857

R7959

cam203

VD7532

VD7531

VD7530

C7542

C7541

C7540

D7535

VD7535

D7533

VD7534

D7534

C7544

C7548

C7549

R7577

R7574

R7576

CL7502

R7528

C7551

R7579

R7572

R7578

CL7505

C7547

C7550

CL7503

C7546

C6011

C6023

FB6003

C6009

R6008

FB6002

C6008

R6007

C6010

C6022

cam181

C1443

C1444

C1445

C1446

R1475

VD1402

TU6001

TU6000

cam004

CN7705

L7707

C7780

C7779

C7781

C7782

C7752

C7753

C7742

C7743

C7744

L7701

L7702

C7728

C7729

C7727

C7730

C7875

C7876

R7767

C7741

cam059

C2016

R2005

CN1400

VD7533

C7543

A6000

TU6802

TU6003

R1472

R1473

VD1401

C7707

IC7701

R7757

R7759

C7713

R7729

R7756

R7755

C7712

C7705

R7763

C7864

R7753

R7754

R7764

R7968

R2016

R2012

R2015

R2004

C2018

IC2002

R2003

C2015

C2021

R2013

C2019

cam046

IC2001

R2017

C2022

R2001

R2009

cam020

C2002

C1461

cam38

J7701

T8001

T8000

cam202

R8039

C8015

C8016

L8000

J7501

CN7501

J7504

VD7503

R7502

R7538

VD7502

VD7506

VD7501

CL7501

R7536

R7520

C7501

D7502

R7534

VD7505

D7505

D7536

D7501

D7508

R7509

R7503

D7511

R7505

C7508

R7517

C7510

C7545

C7506

R7506

C7503

L7500

R7510

D7510

R7518

C7509

R7533

CL7504

C1454

C1453

IC1402

R1481

J1401

cam006

CN7706

cam097

C7878

C7765

C7766

R7980

R7921

R7930

R7927

R7920

R7931

R7978

cam032

C7865

C7877

R7926

C7718

C7719

C7720

C7709

R7922

R1450

R7923

C7751

C7750

C7745

C7701

C7703

L7703

F7702

C7700

C7710

cam098

C2017

C2020

R2002

T8002

C8017

VD7504

VD7509

R7513

D7504

R7512

R7514

C7702

C2001

RB2003

RB2001

RB2002

RB2004

cam212

cam211

R1513

IC1407

IC1406

R1512

C2009

R2010

C2010

C2011

C2012

C2013

C2014

C1462

R1516

R1515

R1514

CN8003

RB8004

cam021

cam171

VD7507

R7524

D7500

D7532

D7506

C7514

R7531

C7519

D7530

R7523

R7529

C7517

D7531

R7532

R7552

VD7508

CM6004

C6016

R6015

R6070

CM6005

C6017

R6016

C6012

R6071

IC6000

CM6006

R6017

CM6012

R6072

R6018

CM6007

R6009

cam066

C6070

R6010

CM6008

R6020

C6025

R6069

CM6009

R6021

C6026

CM6010

R6022

R6033

CM6011

R6800

R6801

R6802

R6803

R6003

R6004

Q9018

C6007

C6006

F9009

C6004

C6005

R6001

R6005

R6006

R6002

R9190

R9189

C6021

C6020

FB6006

C9120

C6019

R9193

R9192

C6018

FB6005

F6000

Q9019

R6011

C6030

R6068

CM6003

TP3104

C6029

R6065

CM6002

R6014

C6028

R6064

CM6001

R6013

R6066

CM6000

R6012

C6027

R6067

R6019

C9053

R9058

R6036

R9050

R9048

Q6001

R9059

C9055

C9058

R9053

cam080

TP3103

C6800

FB6800

IC9006

C9084

R9079

C9078

C9072

F9010

C9067

C9080

R9078

C9112

R9080

C9064

L9006

C7521

D7512

R7558

R7521

R7592

VD7520

FB7502

D7514

D7513

COM751

R7562

cam8

R7561

cam007

J7505

cam002

cam005

CN1000

CL1008

CL1007

C1068

cam034

CL1006

C1067

CL1003

RB1000

VD1000

C1062

C1079

R1091

C1078

C1071

R1080

C1072

C1075

C1064

C1073

TP3111

R1109

R7932

R7933

R7934

R7935

R7936

R1000

R1004

VD7500

R7501

C7500

R7500

R7557

R7537

R7556

R7535

R7539

R1171

R7599

R7522

R1489

R1486

R1485

cam090

D1400

R1480

R1470

R1471

VD1400

C7560

R7593

C7562

C7559

C7561

VD7538

VD7539

D7537

D7538

cam288

C1061

R1062

R1088

R1075

R1079

VD1001

CL1004

C1070

R1085

R1082

R1107

C1065

CL1005

D1003

C1057

R1128

R1090

C1056

R1077

R1076

R1089

R1127

R1078

C1077

C1066

C1074

C1076

R1105

R1084

VD1002

R1106

C1083

R1081

R1087

R1086

R1083

C1055

R1108

R1126

R1129

D1002

D1001

R9154

R9156

C9117

cam217

R9155

R9179

R9157

R9210

R9177

R9158

R9176

R9161

R9159

R9173

R9175

R9162

R9172

CL5302

R9174

R9090

R1173

C8360

R8399

C1428

C1425

C8359

C8358

C1415

C1411

R1429

R1433

R1503