Page 1

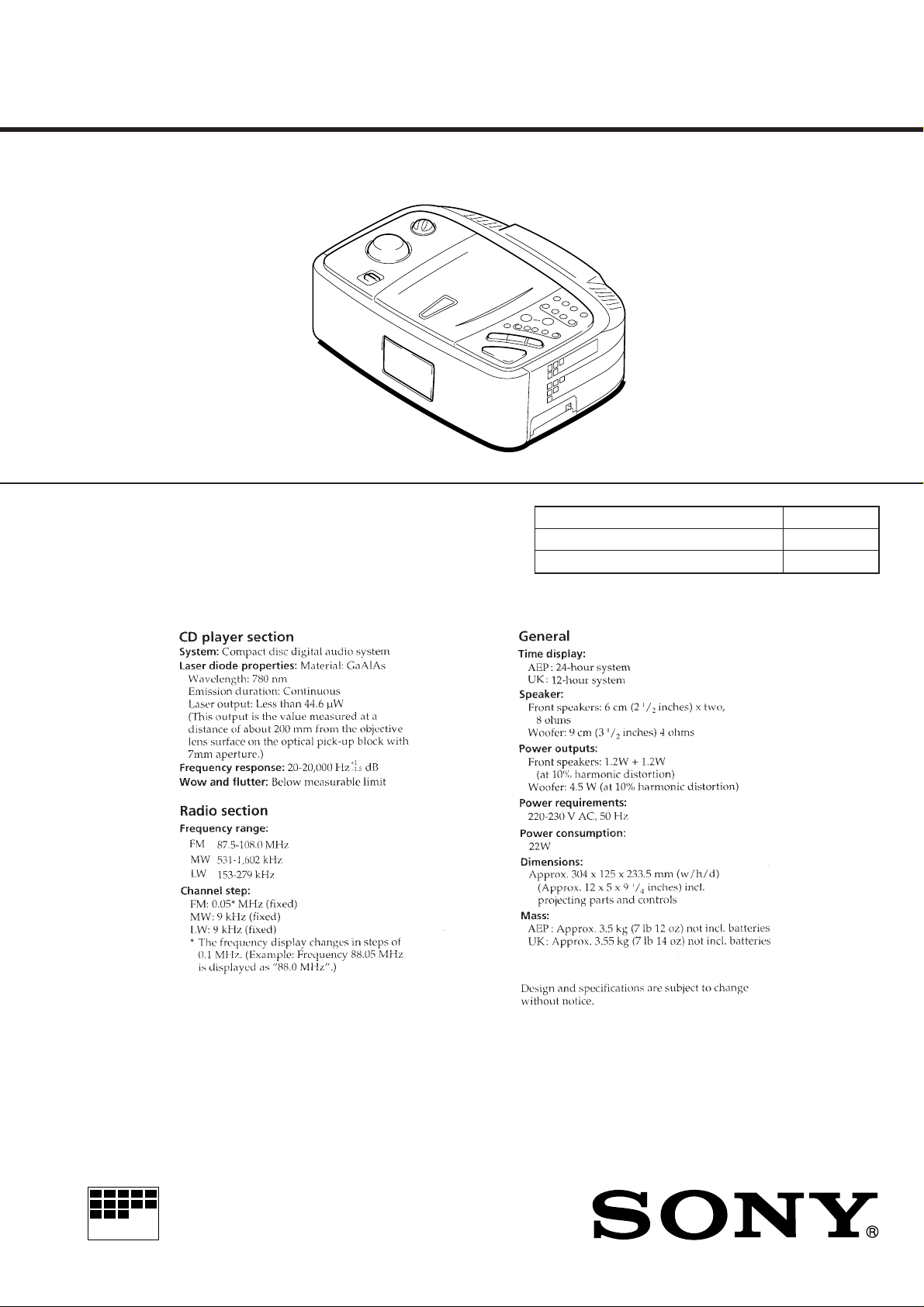

ICF-CD873L

SERVICE MANUAL

Ver 1.0 1999. 05

SPECIFICATIONS

AEP Model

UK Model

Model Name Using Similar Mechanism CFD-550

Optical Device Name KSM-213BAN

Optical Pick-UP Name KSS-213B

MICROFILM

Supplied accessories:

Instruction manual (1)

FM/MW/LW CD CLOCK RADIO

Page 2

TABLE OF CONTENTS

1. SERVICING NOTES............................................... 3

2. GENERAL ................................................................... 4

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

3. DISASSEMBLY ......................................................... 5

4. POWER CORD SETTING................................... 7

5. ELECTRICAL ADJUSTMENTS

Tuner Section .................................................................. 8

CD Section ...................................................................... 9

Main Clock Section......................................................... 11

6. DIAGRAMS

6-1. Block Diagram – CD Section – ..................................... 13

6-2. Block Diagram – TUNER Section – ............................. 15

6-3. Block Diagram – MAIN Section – ................................ 17

6-4. Printed Wiring Boards – MAIN Section – .................... 22

6-5. Schematic Diagram – MAIN Section –......................... 25

6-6. Schematic Diagram – POWER SUPPLY Section –...... 30

6-7. Printed Wiring Boards

– POWER SUPPLY Section – ...................................... 33

6-8. IC Pin Function Description ........................................... 39

7. EXPLODED VIEWS ................................................ 41

8. ELECTRICAL PARTS LIST ............................... 45

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

Page 3

SECTION 1

CF2

CF3

mark

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objecti ve lens.

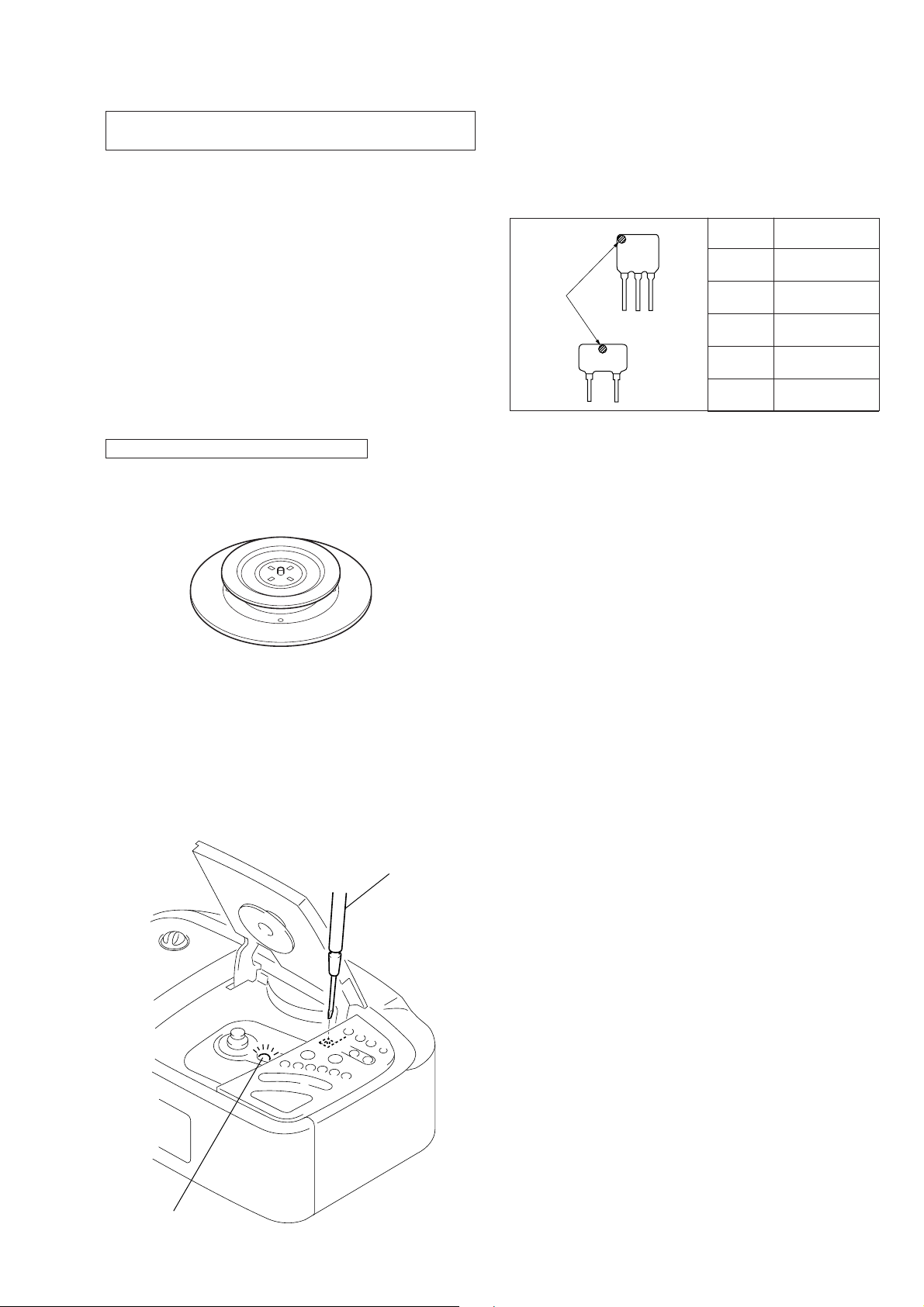

CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the CD lid, use

Chuck Plate Jig.

• Code number of Chuck Plate Jig: X-4918-255-1

HOW TO CHANGED THE CERAMIC FILTERS

This model is used two ceramic filters of CF2 and CF3.

You must used same type of color marked ceramic filters in order

to meet same specifications.

Therefore, the ceramic filter must changed two pieces together

since it’s supply two pieces in one package as a spare parts.

Mark Center frequency

red 10.70 MHz

blue 10.67 MHz

orange 10.73 MHz

black 10.64 MHz

white 10.76 MHz

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

1. Open the CD lid.

2. Turn on S424 as following figure.

3. Conf irm that the laser diode emission while observing the objecting lens. When there is no emission, Auto Power Control

circuit or Optical Pick-up is broken.

Objective lens moves up and down once for the focus search.

Insert a precision

screwdriver and

push S424.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

laser diode

emission

– 3 –

Page 4

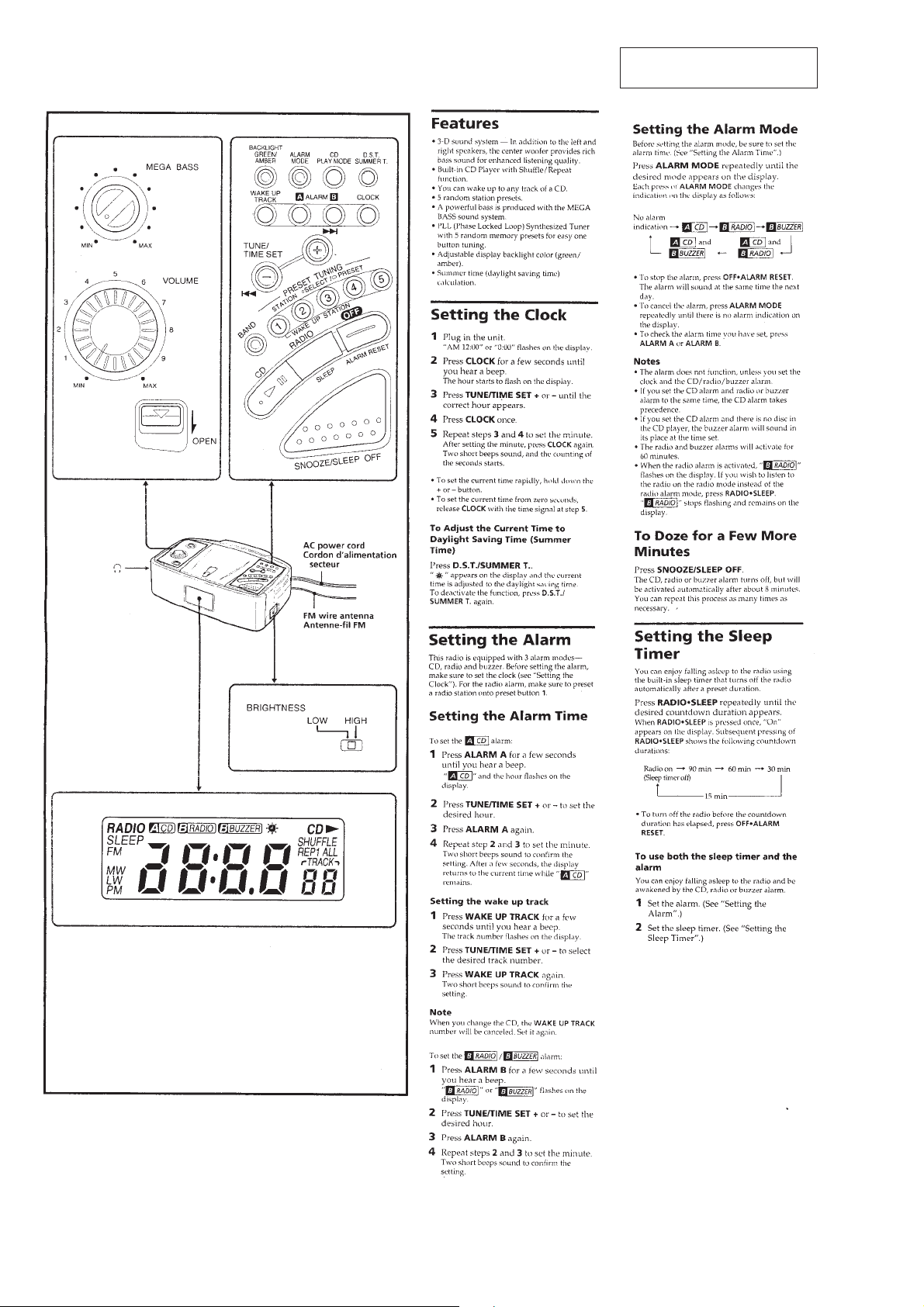

SECTION 2

GENERAL

This section is extracted from

instruction manual.

– 4 –

Page 5

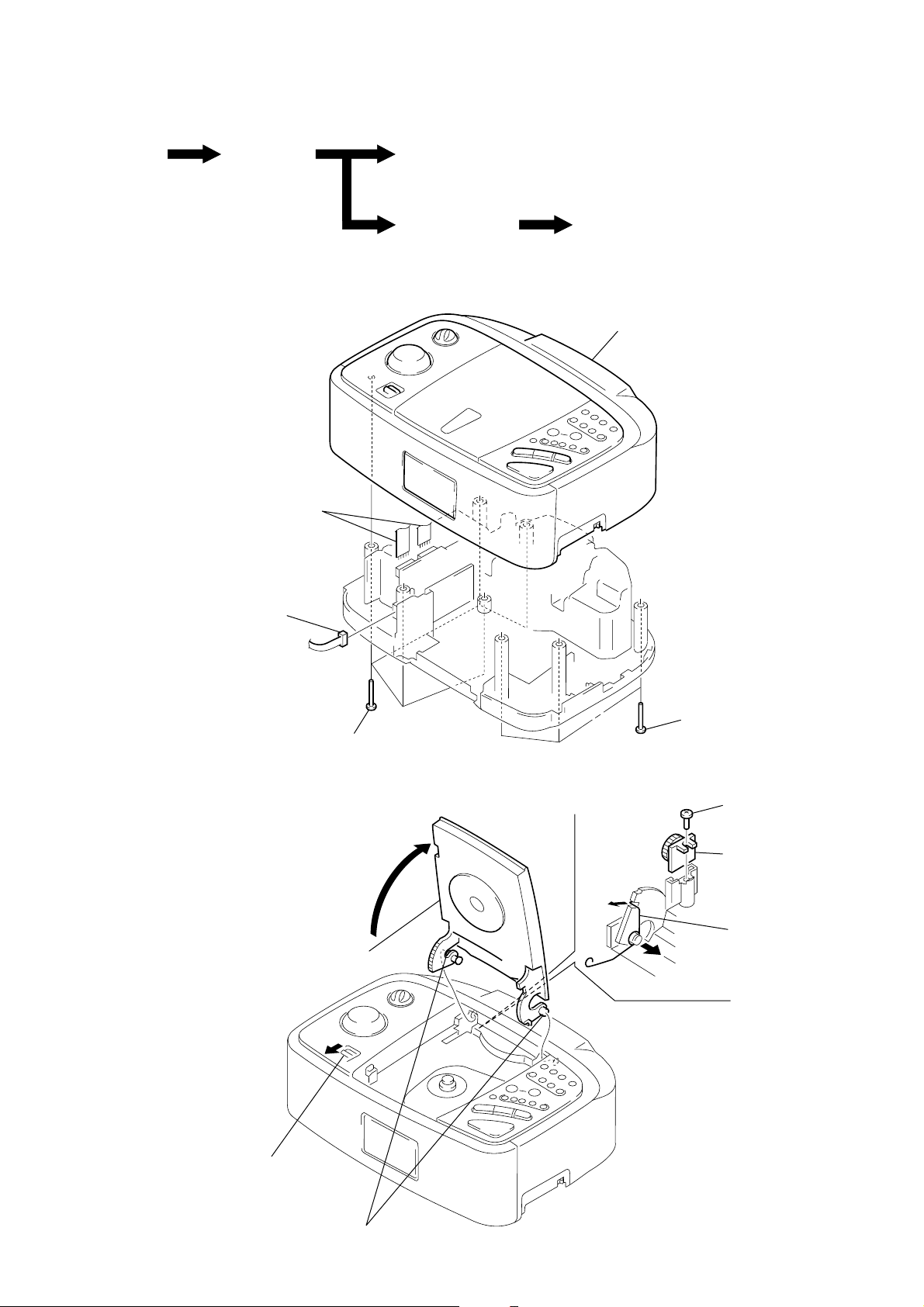

• This set can be disassembled in the order shown below.

SECTION 3

DISASSEMBLY

Set

Note: Follow the disassembly procedure in the numerical order given.

Upper cabinet

section

CD lid assy

Main board section Optical pick-up section

UPPER CABINET SECTION

3

two flat wires

(CN303, 304)

2

upper cabinet section

CD LID ASSY

4

connector

(CN306)

1

five screws

(P3

2

Open the CD lid assy.

7

Remove the CD lid

assy.

×

14)

1

three screws

(P3

×

3

4

14)

5

screw

(B3

damper

×

10)

spring

(CD open)

1

Pull the button (open).

6

two bosses

– 5 –

Page 6

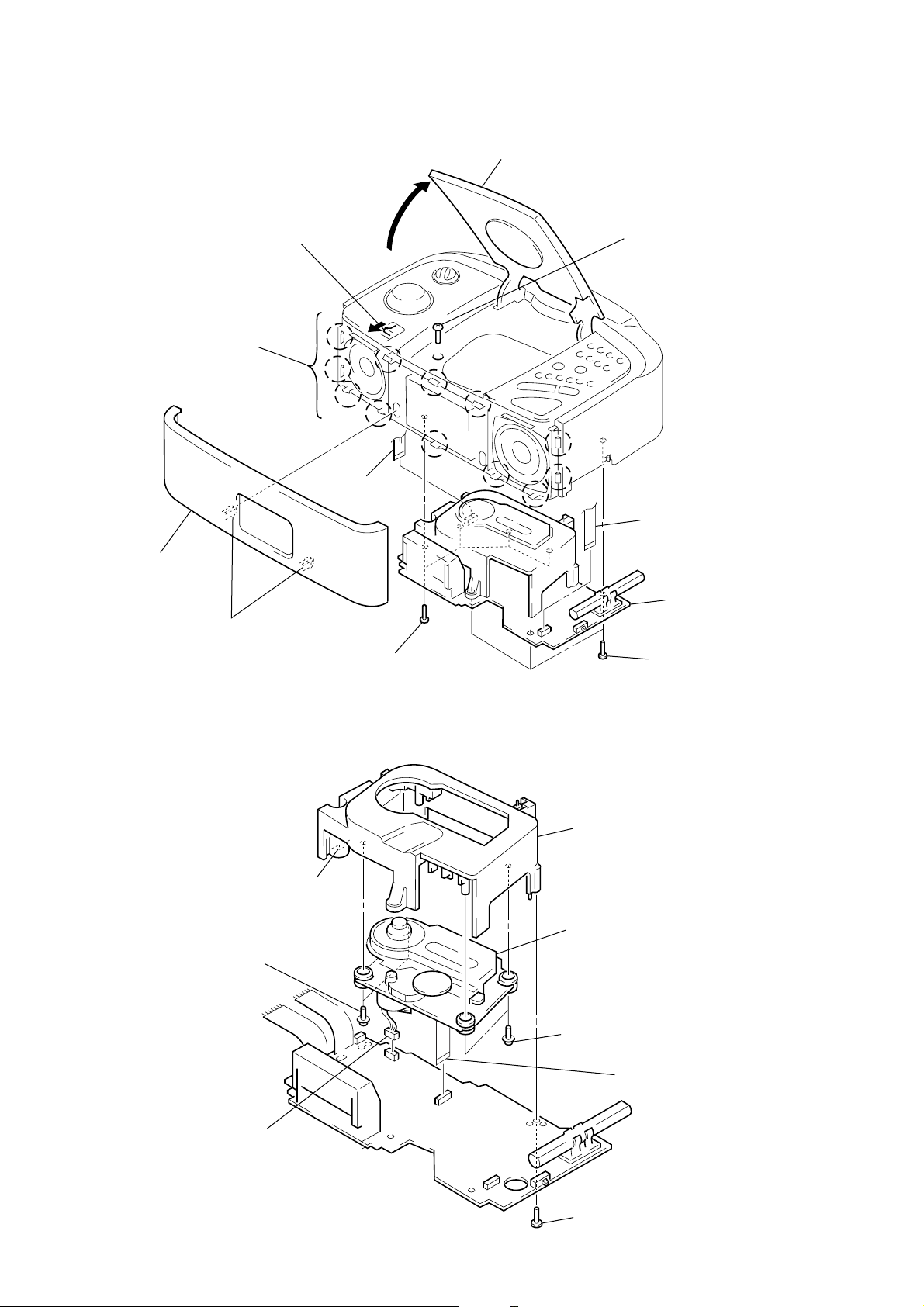

MAIN BOARD SECTION

1

2

net assy

3

Pull the button (open).

twelve

claws

7

flat wire

(CN301)

4

Open the CD lid.

5

screw

(B3

7

×

10)

flat wire

(CN402)

1

two claws

OPTICAL PICK-UP SECTION

6

two screws

(PWH2.6

×

2

10)

claw

6

four screws

(P3

×

14)

3

CD chassis

7

optical pick-up

section

6

two screws

(PWH2.6

×

6

10)

8

main board

section

three screws

(P3

×

14)

5

connector

(CN502)

– 6 –

1

4

screw

(BTP3

flat wire

(CN501)

×

8)

Page 7

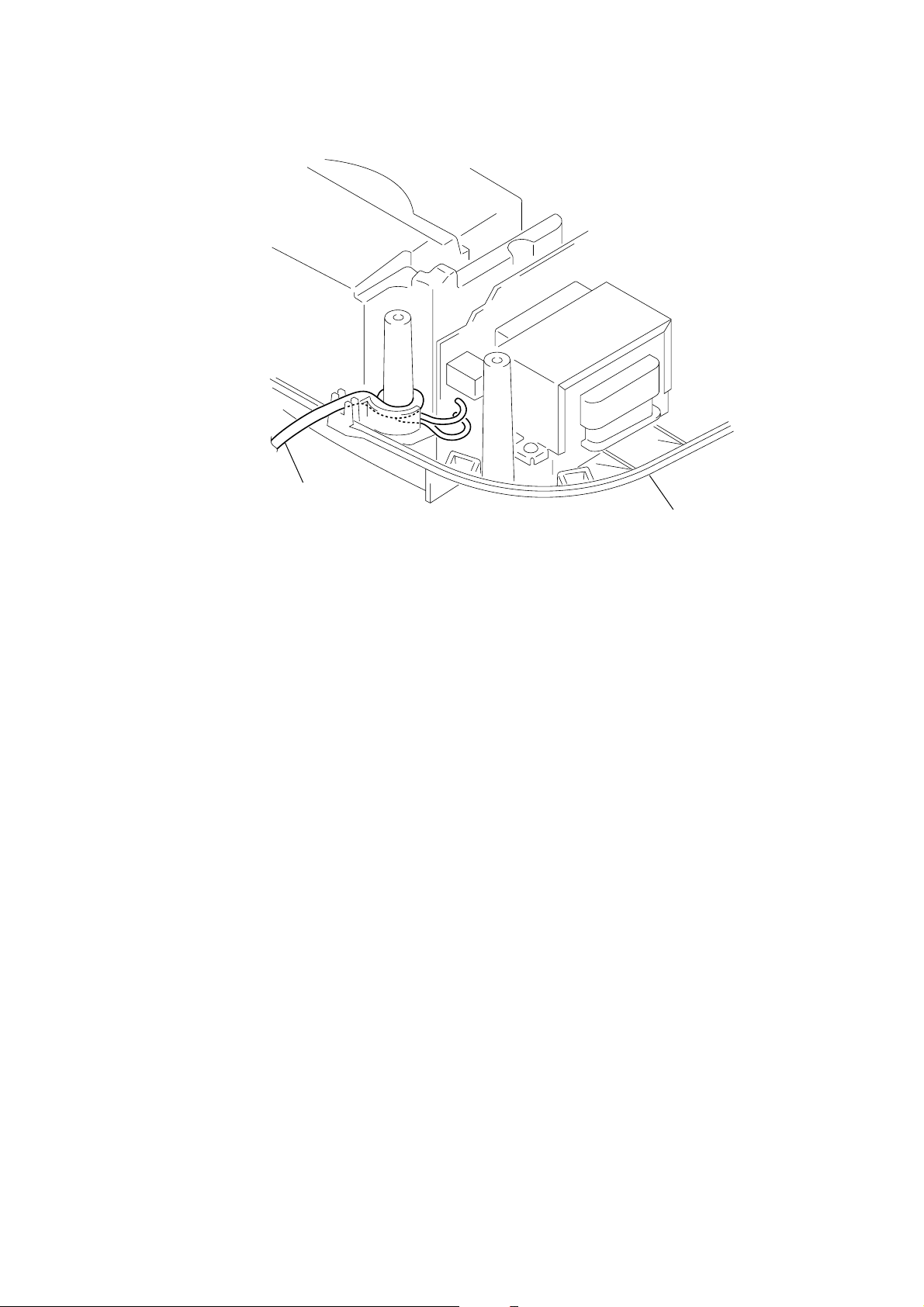

SECTION 4

POWER CORD SETTING

Set the power cord as illustrated below, then install the lower cabinet section.

Power Cord

lower cabinet section

– 7 –

Page 8

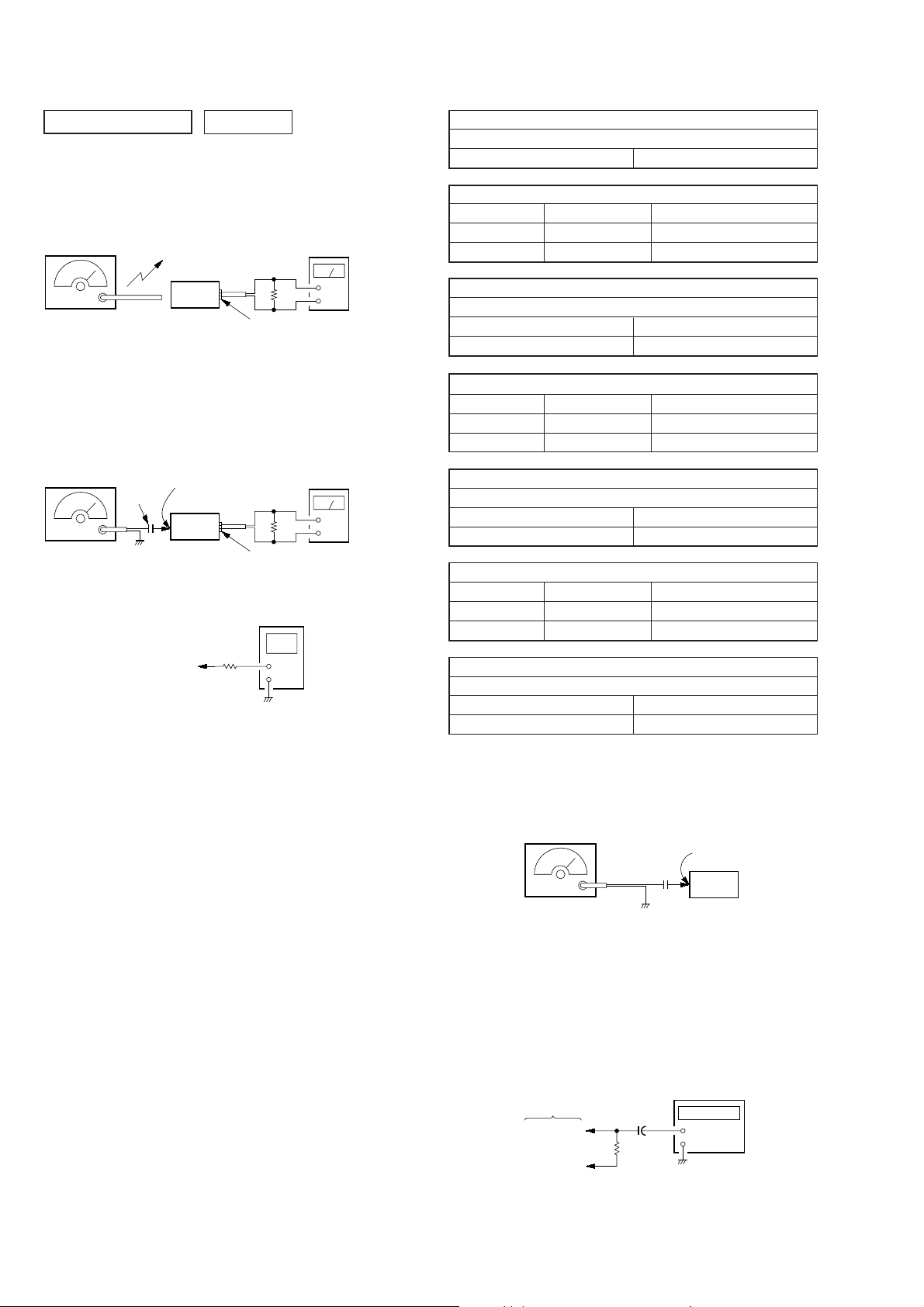

SECTION 5

)

)

1 µF

TP8 (VCO)

+

–

frequency counter

33 k

Ω

TP7 (+B)

+

MAIN board

ELECTRICAL ADJUSTMENTS

TUNER SECTION 0 dB=1 µV

[MW/LW]

Setting:

Function : RADIO

Band switch: MW or LW

AM RF signal

generator

30% amplitude

modulation by

400 Hz signal

Output level: as low as possible

[FM]

Setting:

Function : RADIO

Band switch: FM

FM RF signal

generator

22.5 kHz frequency

deviation by 400 Hz

signal

Output level: as low as possible

• Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

• Remove FM antenna in FM adjustments.

Put the lead-wire

antenna close to

the set.

set

MAIN board

TP12 (FM IN)

0.01 µF

set

MAIN board

TP53 (VT)

2

2

digital voltmeter

100 k

Ω

level meter

32

Ω

+

–

(headphone) jack (J301

level meter

32

Ω

+

–

(headphone) jack (J301

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter

T1 450 kHz

MW FREQUENCY COVERAGE ADJUSTMENT

Adjustment Part Frequency Display Reading on Digital Voltmeter

L4 531 kHz 2.8 V

Confirmation 1,602 kHz less than 10.5 V

MW TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L3-1 621 kHz

CT2 1,404 kHz

LW FREQUENCY COVERAGE ADJUSTMENT

Adjustment Part Frequency Display Reading on Digital Voltmeter

CT4 153 kHz 2.2 V

Confirmation 279 kHz less than 9.5 V

LW TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L3-2 162 kHz

CT3 243 kHz

FM FREQUENCY COVERAGE ADJUSTMENT

Adjustment Part Frequency Display Reading on Digital Voltmeter

L2 87.5 MHz 2.1 V

Confirmation 108 MHz 9.7 V

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L1 87.5 MHz

CT1 108 MHz

Adjustment Location: MAIN board (See page 12)

FM VCO Adjustment

Setting:

FM RF SSG

0.01 µF

Carrier frequency: 98 MHz

Modulation: 400 Hz, 30% FM modulation

Output level: 0.1 V (100 dB)

MAIN board

TP12 (FM IN)

set

Procedure:

1. Connect the frequency counter to TP7, 8 as shown the figure

below.

2. Tune the set to 98 MHz.

3. Adjust RV1 for 76 kHz reading on the frequency counter.

Specified Value: 75.95 to 76.05 kHz

Adjustment Location: MAIN board (See page 12)

– 8 –

Page 9

CD SECTION

Note:

Tracking Balance Adjustment and Tracking Gain Adjustment are

done automatically in this set.

TEST MODE

1. Press the CD LID OPEN/CLOSE DET switch (S424) on the

PUSH SWITCH board.

2. Under standby condition (when the clock appears in the display), short the BP (CD TEST AUTO).

Note: If the power is supplied to the microprocessor once, it is backed up

for 3 minutes, therefore the TEST mode will not be activ ated within

3 minutes even if the power is turned on again. In this case, short

instantaneously the BP (CD TEST MANUAL).

3. Press the fl key, and the focus search is repeated.

At this time, check that the optical pick-up objective lens moves

smoothly without a sticking or noise.

4. Load the test disc (YEDS-18: Part No. 3-702-101-01), and perform automatic adjustment after the focus search succeeded.

5. After automatic adjustment is finished, move the sled motor

to the center. At this time, keep pressing the + and =

keys to confirm that optical pick-up mov es smoothly via most

inside track → most outside track → most inside track without a sticking or noise.

6. Confirm the traverse waveform.

7. Press the [WAKEUPTRACK] key.

8. The tracking servo and the sled servo are turned on, the mute

is cancelled.

9. Playback the 2nd track.

10. Adjust the RF and jitter waveforms.

Connecting points: MAIN Board (See page 12)

Focus Bias Adjustment

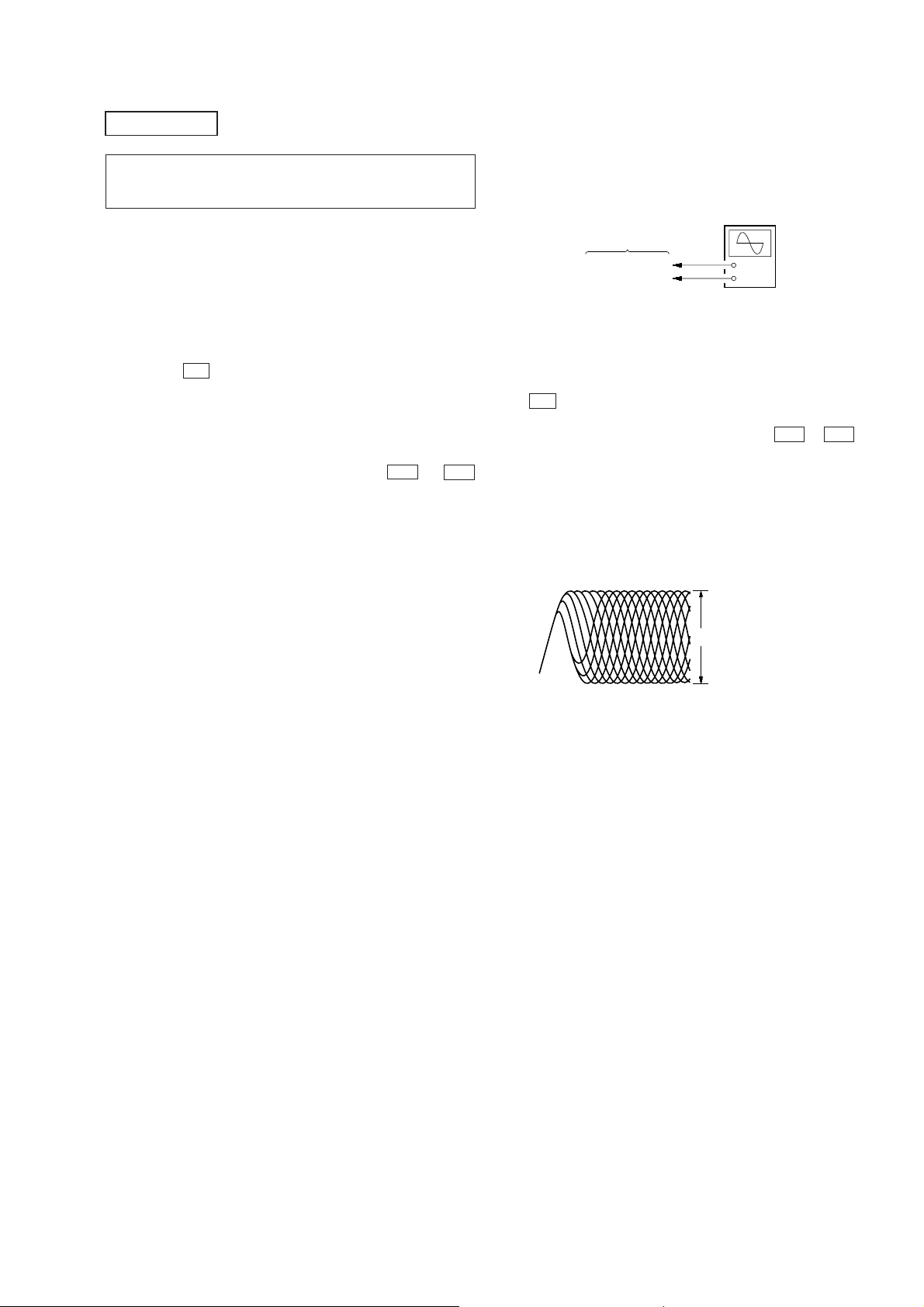

This adjustment is to be done when the optical block is replaced.

Connection:

oscilloscope

(AC range)

MAIN board

TP503 (RF)

TP504 (VREF)

+

–

Adjustment Procedure:

1. Connect the oscilloscope to TP504 (VREF) and TP503 (RF)

on the MAIN board.

2. Insert the test disc (YEDS-18: Part No.3-702-101-01) and press

fl key to play.

3. Move the optical pick-up to the music area on the disc to enable easy visibility of the eye pattern by + or = key

pressing.

4. Adjust RV501 so that the oscilloscope waveform is as shown

in the figure below (eye pattern).

A good eye pattern means that the diamond shape (≈) in the

center of the waveform can be clearly distinguished.

• RF signal reference waveform (eye pattern)

VOLT/DIV: 0.2 V

TIME/DIV: 500 ns

±

0.5 Vp-p

1.3

When observing the eye pattern, set the oscilloscope

for AC range and raise vertical sensitivity.

Adjustment Location: MAIN Board (See page 12)

– 9 –

Page 10

Focus Gain Adjustment

A frequency response analyzer is necessary in order to perform

this adjustment exactly.

However, this gain has a margin, so even if it is slightly off, there

is no problem. Therefore, do not perform this adjustment.

Focus gain determines the optical pick-up follow-up (v ertical and

horizontal) relative to mechanical noise and mechanical shock

when the 2-axis device operate.

However , as these reciprocate, the adjustment is at the point where

both are satisfied.

• When gain is raised, the noise when the 2-axis device operates

increases.

• When gain is lowered, mechanical shock and skipping occurs

more easily.

• When gain adjustment is off, the symptoms below appear.

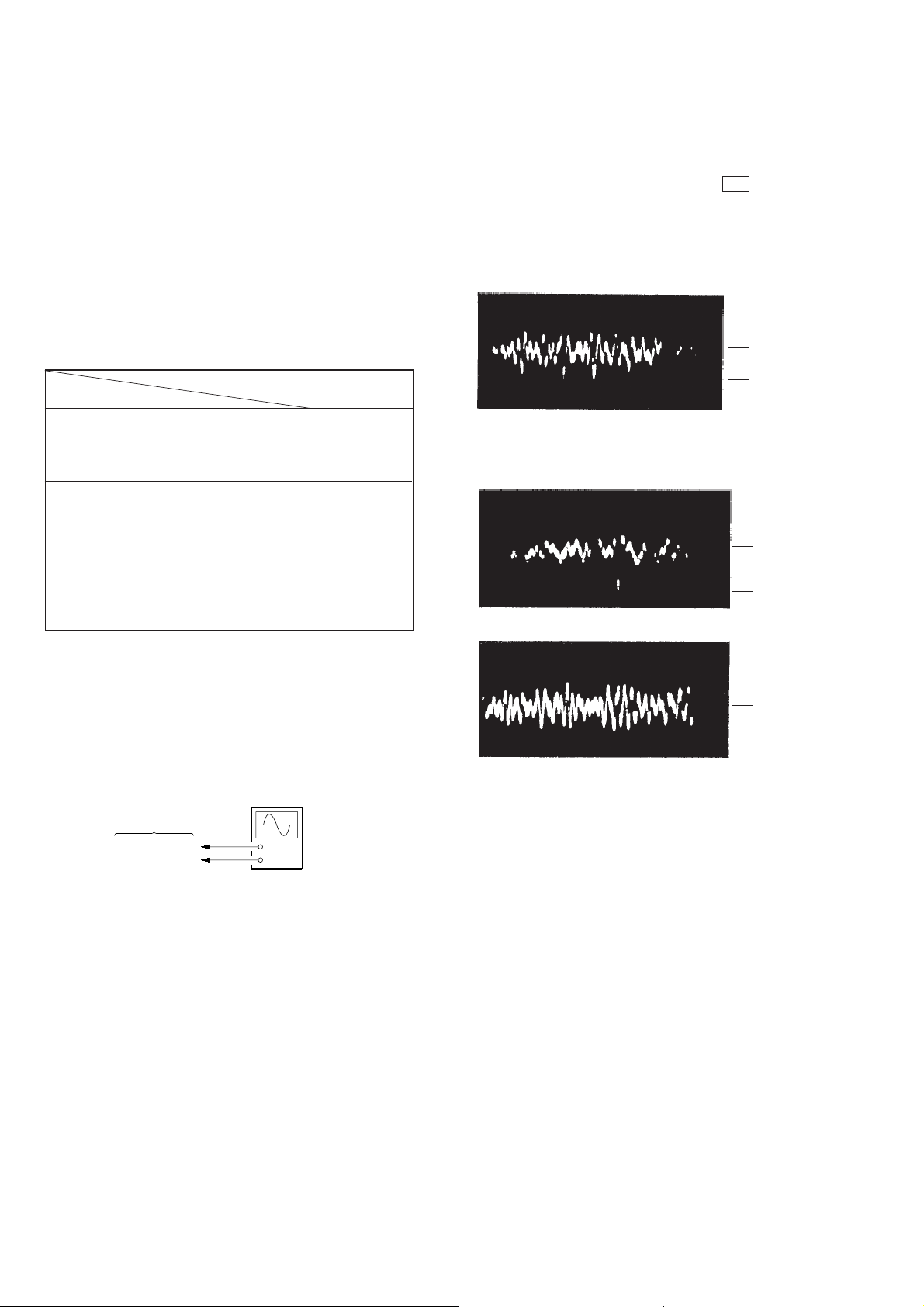

Procedure:

1. Keep the set horizontal.

If the set is not horizontal, this adjustment cannot be per-

(

formed due to the gravity against the 2-axis device

2. Insert the test disc (YEDS-18) and press the fl button.

3. Connect the oscilloscope BT (FEO) and TP504 (VREF) on

the MAIN board.

4. Adjustment RV502 on the MAIN board so that the w a veform

is as shown in the figure below.

VOLT/DIV: 100 mV

TIME/DIV: 2 mS

100 mV

)

Symptoms

• The time until music starts becomes longer for

STOP → PLAY or automatic selection.

(=, + buttons pressed)

(Normally takes about 2 seconds)

• Music does not start and disc continues to

rotate for STOP → PLAY or automatic

selection.

(=, + buttons pressed)

• Sound is interrupted during PLAY.

Or time counter display stops progressing.

• More noise during 2-axis device operation

Gain Focus

low

–

–

high

The following is a simple adjustment method.

– Primary Adjustment –

Note: Since exact adjustment cannot be performed, remember the posi-

tions of the controls before performing the adjustment. If the positions after the primary adjustment are only a little different, return

the controls to the original position.

Connection:

oscilloscope

MAIN board

BP (FEO)

TP504 (VREF)

+

–

0 V

• Incorrect Examples (DC level changes more than on adjusted

waveform)

low focus gain

high focus gain

VOLT/DIV: 100 mV

TIME/DIV: 2 mS

200 mV

0 V

VOLT/DIV: 100 mV

TIME/DIV: 2 mS

75 mV

0 V

Adjustment Location: MAIN Board (See page 12)

– 10 –

Page 11

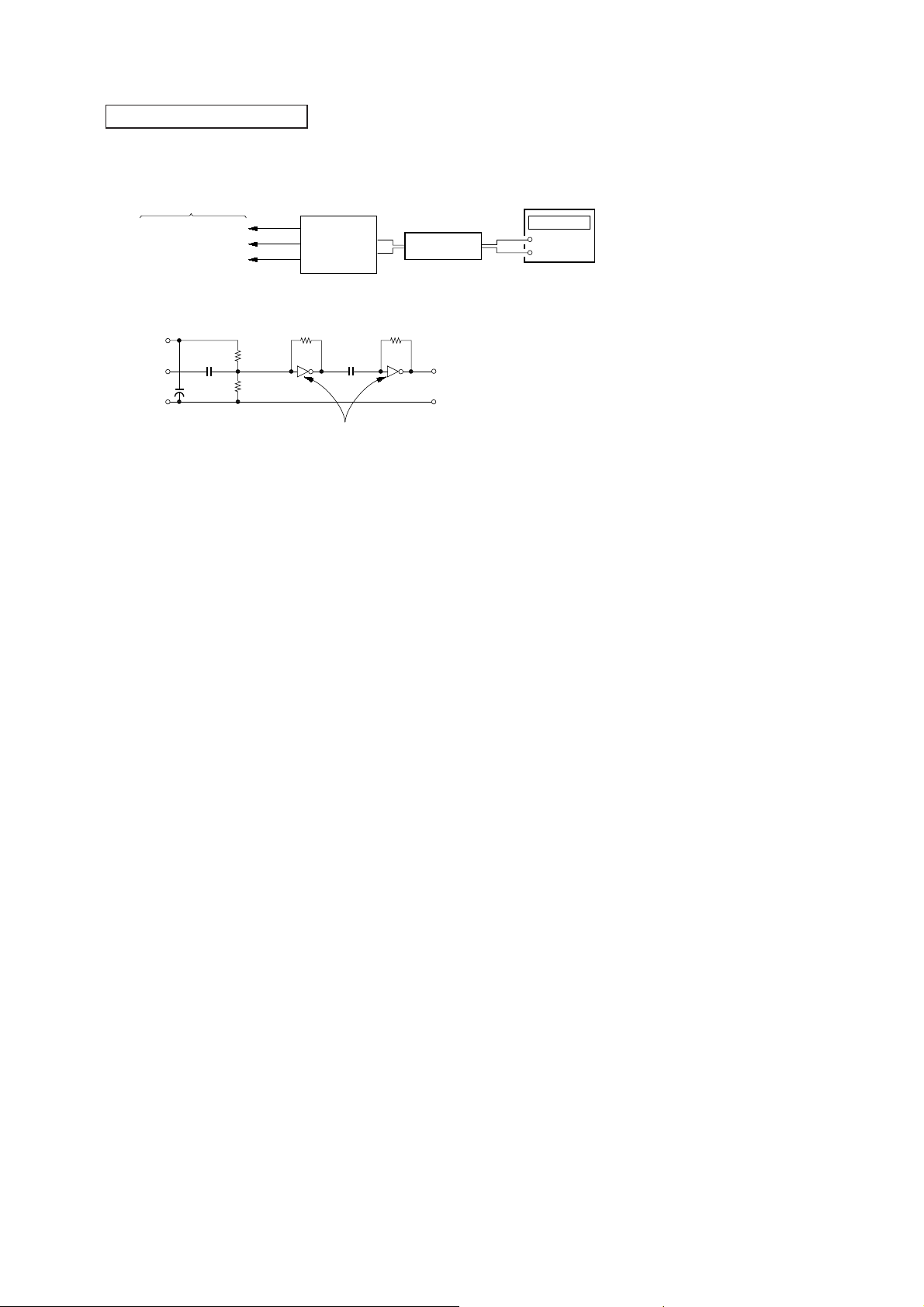

MAIN CLOCK SECTION

Main Clock Adjustment

Connection:

MAIN board

TP (+5 V)

TP401 (X2)

TP GND (SHIELD)

adjustment

jig

+5

OUT

IN

GND

GND

10 : 1 probe

Adjustment jig:

+5 V

IN

GND

+

0.5 pF

47 uF

1 M

1 M

Ω

Ω

Ω

1000 pF

INVERTER

(TC7W04F)

100 k

Ω

OUT

GND

100 k

Procedure:

1. Connect the frequency counter as the above figures.

2. Adjust CT401 for 4.2495 MHz reading on the frequency

counter.

Specified V alue: 4.2490 to 4.2500 MHz

frequency counter

+

–

– 11 –

Page 12

Adjustment Location and Connecting Points:

t

RV502 Focus Gain Adjustment

RV501 Focus Bias Adjustment

– MAIN BOARD (Component Side) –

L4 MW Frequency Coverage Adjustment

CT4 LW Frequency Coverage Adjustment

FM T rac king Adjustment

LW Tracking Adjustment

CT1

L1

T1 AM IF Adjustment

L3-2

CT3

CT2

MW T rac king Adjustmen

L3-1

RV1 FM VCO Adjustment

L2

FM Frequency Coverage

Adjustment

– MAIN BOARD (Conductor Side) –

TP401

(X2)

TP GND

(SHIELD)

C429

+

BP (CD TEST AUTO)

CT401 Main Clock Adjustment

BP (CD TEST MANUAL)

TP (+5 V)

TP503 (RF)

TP504 (VREF)

TP7

(+B)

TP13 (FM IN GND)

TP12 (FM IN)

TP50 (VT GND)

BP (FEO)

TP53 (VT )

TP8

(VCO)

– 12 –

Page 13

6-1. BLOCK DIAGRAM – CD Section –

ICF-CD873L

SECTION 6

DIAGRAMS

DETECTOR

D

A

C

B

F

E

OPTICAL PICK-UP

(KSS-213B)

LASER DIODE

PD

MAIN BOARD (1/3)

CN501

12

5

13 4

10 7

11 6

98

14 3

107

POWER CONTROL

LD

125

PHD1

35

PHD2

36

AUTOMATIC

Q502

PD1 I-V AMP

PD2 I-V AMP

+

F

38

E

39

LD

33

RF

SUMMING

AMP

RF AMP,

FOCUS/TRACKING

SERVO

IC501 (1/2)

F I-V

AMP

E I-V

AMP

LD

AMPPDAMP

FOCUS

ERROR

AMP

TRACKING

ERROR

AMP

FE BIAS

PHD

34

RFO

31

RFI

30

FOCUS OK

COMPARATOR

MIRR

DEFECT

FEO

1

37

TEO

42

EI

40

AMP

AMP

RV502

FOCUS

GAIN

RV501

FOCUS

BIAS

FOCUS OK

AMP

TTL

IIL

FEI FEO

2

TEI

44

TTL

IIL

IIL

IIL DATA REGISTER

TTL

FOCUS PHASE

COMPENSATION

TRACKING PHASE

COMPENSATION

FOK

DATA

CLK

XLT

XRST

SENS

C.OUT

TAO

25

21

19

20

22

24

23

6

13

DIGITAL SIGNAL PROCESSOR,

CLV SERVO, D/A CONVERTER

IC502

RF

ASYMMETRY

36

CORRECTION

ASYI

38

ASYO

39

XPCK

50

FOK

23

DATO

15

CLKO

17

XLTO

16

8

XRST

SERVO AUTO SEQUENCER

SEIN

13

CNIN

14

DIGITAL

CLV

MDP

MDS26MON24LOCK

25

FILTER

3031

3429

FILI

PCO

FILO

CLTV

DIGITAL PLL

27

D414

DEMODULATOR

SQSO

SQCK

SENS

4 5 7 9 11 1012 3

42CK39

41

SQSI

SENS

ERROR

CORRECTOR

EFM

SUB-CODE

PROCESSOR

CPU INTERFACE

DATA

CLOK

XLAT

30

31

32

DATA

CLOCK

MUTE

45

47

43

6

PCMDI

BCKI

LRCKI

63

CLOCK

GENERATOR

EMPHI

C4M

60

LPWM

70

NLPWM

69

RPWM

78

NRPWM

XTAI

XTAO

XTSL

77

73

74

21

DIGITAL FILTER &

1 BIT D/A CONVERTER

LOW-PASS

FILTER

IC301

X501

16.933MHz

DATA, CLOCK, LATCH

CD L-CH

CD R-CH

A

(Page 17)

B

(Page 16)

16K

RAM

PCMD

44

D/A INTERFACE

OUT

20

CLOCK

BCK

LRCK

C2PO

DOUT

XUGF

WFCK

EMPH

GFS

46

42

54

61

49

64

62

51

INTERNAL BUS

DIGITAL

XLON

EXCK

B+

22 18

SPOA

SPOB19SPOC

SCOR

SBSO

(CD 5V)

44

XLT

SCOR

M570

(SLED)

M571

(SPINDLE)

S570

(LIMIT)

2-AXIS

DEVICE

(FOCUS)

M

M

(TRACKING)

1

3

5

4

6

7

CIN

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

IC503

143

152

134

161

T-OUT+

27

T-OUT–

26

F-OUT+

18

F-OUT–

17

TRACKING

COIL DRIVE

FOCUS

COIL DRIVE

T-IN

F-IN

25

19

E-F BALANCE

CONTROL

Q501

BP

(CD TEST MANUAL)

43

CD ADJ

29

SYSTEM CONTROLLER

X-RESET

34

IC401 (1/2)

DATA

R-LAT

DOOR-IN

40

37

62

DATA

LATCH

S424

(CD LID OPEN/CLOSE DET)

PUSH SWITCH BOARD

SLED SERVO

CN502BH570

1

2

4

3

5

6

2

1

12

11

SL-OUT+

SL-OUT–

SP-OUT+

SP-OUT–

SLED

MOTOR DRIVE

SPINDLE

MOTOR DRIVE

SL-IN

3

SP-IN

10 1514

IC501 (2/2)

SLO

16 14

SLED

AMP

SLP

SP-OUT

SP-IN

MUTE

7

MOTOR BOARD

05

• SIGNAL PATH

: CD PLAY

– 13 – – 14 –

Page 14

ICF-CD873L

6-2. BLOCK DIAGRAM – TUNER Section –

ANT1

FM WIRE

ANTENNA

MAIN BOARD (2/3)

CT1, L1

FM TRACKING

CT2, L3-1

MW TRACKING

L3

MW/LW FERRITE-ROD

ANTENNA

L3-1

(MW)

L3-2

(LW)

CT3

CT3, L3-2

LW TRACKING

D4

(2/3)

B.P.F.

BPF1

L1

FM RF

Q1

VREF

Q1

MW/LW

SWITCHING

CT1

CT2

(1/3)

CT4

LW FREQUENCY

COVERAGE

CF3

10.7MHz

FM IF AMP/

AM IF AMP/

PD1

PD2

PILOT DET

LPF1

3

26

FM

DISCRI

DISCRI

DET

PILOT DET

LPF2

2

1/2

CONTER

PLL LPF1

1

TUNING

INDICATOR

L.P.F.

VCO

PLL LPF227VCO

29

DECODER

AMP

SWITCH

RV1

FM VCO

L-CH OUT

R-CH OUT

TUN IND

ST IND

6

5

12

4

TUNER L-CH

TUNER R-CH

C

(Page 17)

FM/AM FRONT-END,

FM/AM DET, MPX

IC1

FM RF

IN

18

FM RF

20

D2

AM RF

IN

19

D4

L4

MW/LW

OSC

Q2

MW/LW

SWITCHING

CT4

L4

MW FREQUENCY

COVERAGE

FM

FRONT-END

AM

FRONT-END

AM OSC

24

D4

(3/3)

FM OSC

22

FM/AM

FE OUT

16 13

L2

FM FREQUENCY

COVERAGE

FM OSC

D3

T1

AM IF

L2

REG

21

VREF B+

(FM/AM RF/OSC CIRCUIT)B+(5V)

CF2

10.7MHz

CF1

450kHz

STEREO/MONO

SELECT

FM/AM

SELECT

REGULATOR

FM

IF IN

AM

IF IN

14

VCC15BAND SELECT

7

05

• SIGNAL PATH

: FM

: MW/LW

LOW-PASS

FILTER

Q50, 51

15

VREF

FM/AM PLL

IC50

PD1

XIN

2

X50

75kHz

PHASE

DETECT

XOUT

11 12

AM IN

MAIN CONTROL

PRESCALLER

I/O CONTROL

REGISTER

DATA

CLK

CE

5 4 31

DATA

CLOCK

LATCH

FM IN

OUTPUT

CONTROL

IF

COUNTER

IF IN

P2

10

P1

8

P0

7

9

TUNER ON

DATA, CLOCK, LATCH

D

(Page 17)

B

(Page 14)

– 15 –

– 16 –

Page 15

6-3. BLOCK DIAGRAM – MAIN Section –

ICF-CD873L

MAIN BOARD (3/3)

CD

L-CH/R-CH

A

(Page 14)

TUNER

L-CH/R-CH

C

(Page 16)

TUNER ON

D

(Page 16)

BASS ON

POWER ON

BUZZER

COLOR

61

B+ (µ 5V)

05

A MUTE

V MUTE

CD L-CH

TUNER

L-CH

CD R-CH

(CD 5V)

TUNER R-CH

53

20

35

49

52

LED BOARD

D422 – 424

(LCD BACK LIGHT)

Q403 – 405

LED DRIVE

HIGH

LOW

S423

BRIGHTNESS

VOLUME BOARD POWER BOARD

CD/TUNER SELECT SWITCH

IC320

11

12

8

6

1

B+

D416

Q405

Q404

13

4

5

MUTING CONTROL

SWITCH

MUTING CONTROL

SWITCH

(LCD BACK LIGHT)

Q403

Q320

Q407

D419 – 421

10

9

2

3

B+ (µ 5V)

MUTING

Q120

MUTING

Q220

LIQUID CRYSTAL DISPLAY

LCD401

70 – 80, 1 – 10

SEG1 – SEG21

CT401

MAIN

CLOCK

Q401

D321

CN301

(1/2)

21 – 23

COM0 – COM2

X1

Q401, 402

SHIFT CLOCK

1

2

D320

D417

X2

X402

4.194MHz

Q402

CN302

(1/2)

7

–1

RV301

VOLUME

6

–2

RV302

MEGA BASS

MEGA BASS ON

DRIVE

Q406

SYSTEM CONTROLLER

SHIFT CK

XT1

6058 59 68

55 56

X401

32.768kHz

IC401 (2/2)

XT2

D404

CN401

CN402

KEY MATRIX

S401 – 420

CN302

(2/2)

5

2

3

1

KS0 – KS3

13 – 16

D403

3579

KS0

KS1

8642

D402

KS2

3

6

5

7

MEGA BASS

D401

KS3

CN301

(2/2)

MUTE

Q321

KEYRET0 – KEYRET4

63 – 67 17, 18

10 8 6 4

KR0

KR2

KR1

1357

10

KR3

6

8

9

2

1

4

2

CN304

(1/2)

CN303

(1/2)

2

KR4

9

L-CH

R-CH

VOL IN

VOL OUT

BASS ON

POWER ON

BUZZER

Q350, 351

V MUTE

•

VERSION1

+

VOICE

MUTE

VERSION2

D412, 413

+

38

POWER AMP

(FOR FRONT SPEAKER/HEADPHONE)

AC IN

36

IC350

IN1

IN2

POWER AMP

IC351

IN+

SW

Q904

RESET

BP

OUT1

OUT2

OUT

8

RESET SIGNAL

GENERATOR

IC402

1

3

10

8

(FOR MEGA BASS SPEAKER)

12 3

POWER ON

MUTE DRIVE

CD ON

(CD TEST AUTO)

(SYSTEM CONTROLLER (IC401) B+)

+

10

D351

D350

Q353

SPEAKER SWITCH

MUTE

MOTOR/COIL

DRIVER (IC503) B+

µ 5V

TUNER SECTION B+

IN–

OUT

CD 6V

CD 5V

(CD SECTION B+)

5

HEADPHONE

MUTE DRIVE

Q352

5V

VT B+

SPEAKER

SWITCH DRIVE

Q354, 355

D415

Q151, 251

SPEAKER ON

SWITCH

HEADPHONE

MUTE

Q150, 250

9

6

7

3

5

CN304

5

4

CN303

(2/2)

(2/2)

CD B+

SWITCH

Q903

CN306

Q151

Q251

CN307

CN305

REGULATOR

REGULATOR

D911

4

3

1

2

1

2

1

2

3

4

6

+6V

Q902

+5V

Q901

POWER AMP

(IC350, 351) B+

: CD PLAY

: TUNER (FM/MW/LW)

SP101

L-CH FRONT

SPEAKER

SP201

R-CH FRONT

SPEAKER

SP301

MEGA BASS

SPEAKER

HEADPHONE

BOARD

RECT

D905 – 908

RECT

D903, 904

RECT

D901, 902

T901

POWER

TRANSFORMER

J301

2

(HEADPHONE)

LINE

FILTER

LF901

AC IN

KEY BOARD

• SIGNAL PATH

– 17 –

– 18 –

– 19 –

Page 16

Page 17

6-5. SCHEMATIC DIAGRAM – MAIN Section – • See page 29 for Waveforms. • See page 35 for IC Block Diagrams.

ICF-CD873L

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

• C : panel designation.

Note: The components identified by mark ! or dotted line

• U : B+ Line.

• H : adjustment for repair.

• Voltages and waveforms are dc with respect to ground

• Voltages are taken with a VOM (Input impedance 10 M Ω).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.

with mark ! are critical for safety.

Replace only with part number specified.

under no-signal (detuned) conditions.

no mark : FM

( ) : MW

〈〈 〉〉 : LW

[ ] : CD PLAY

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

F : FM

f : MW/LW

J : CD PLAY

4

W or less unless otherwise

– 25 –

– 26 –

– 27 –

– 28 –

Page 18

ICF-CD873L

• Waveforms

– MAIN Board –

1 IC401 %• (X1) (RADIO ON mode)

1 V/DIV, 100 ns/DIV

3.7 Vp-p

238 ns

2 IC601 %∞ (XT1) (RADIO ON mode)

1 V/DIV, 10 µs/DIV

3.2 Vp-p

6 IC501 #¡ (RF O), IC502 #§ (RF)

(CD PLAY mode)

200 mV/DIV, 500 ns/DIV

7 IC501 $™ (TEO) (CD PLAY mode)

100 mV/DIV, 500 ns/DIV

Approx.

144 mVp-p

1.3 ± 0.5 Vp-p

6-6. SCHEMATIC DIAGRAM – POWER SUPPLY Section – • See page 38 for IC Block Diagrams.

!¡ IC50 1 (XOUT) (RADIO ON mode)

500 mV/DIV, 10 µs/DIV

1.3 Vp-p

13.3 µs

30.5 µs

3 IC501 1 (FEO) (CD PLAY mode)

100 mV/DIV, 50 ns/DIV

Approx.

136 mVp-p

4 IC501 !ª (CLK), IC502 !¶ (CLK0)

(CD PLAY mode)

5 V/DIV, 10 µs/DIV

µ

s

14.3

5 IC501 @º (XLT), IC502 !§ (XLT0)

(CD PLAY mode)

5 V/DIV, 200 ns/DIV

102 ns

5.4 Vp-p

5.2 Vp-p

8 IC502 $™ LRCK (CD PLAY mode)

2 V/DIV, 10 µs/DIV

µ

s

22.8

9 IC502 $§ (BCK) (CD PLAY mode)

2 V/DIV, 200 ns/DIV

472 ns

0 IC502 &£ (XTAI) (CD PLAY mode)

500 mV/DIV, 50 ns/DIV

59 ns

– 29 –

5.3 Vp-p

5.3 Vp-p

1.4 Vp-p

– 30 –

– 31 –

– 32 –

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• 5 : fusible resistor.

• C : panel designation.

Note: The components identified by mark ! or dotted line

with mark ! are critical for safety.

Replace only with part number specified.

• U : B+ Line.

• Voltages are dc with respect to ground under no-signal

(detuned) conditions.

no mark : FM

[ ] : CD PLAY

• Voltages are taken with a VOM (Input impedance 10 MΩ ).

Voltage variations may be noted due to normal production tolerances.

4

W or less unless otherwise

Page 19

Page 20

• IC Block Diagrams

36 35 34

33

32

31

30 29 28 27 26 25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

987

6

5

43

2

1

37

38

39

40

41

42

43

44

45

46

47

48

PHD 2

PHD 1

PHD

LD

RF O

RF I

CP

CB

CC1

CC2

FOK

SENS

C.OUT

XRST

DATA

XLT

CLK

VCC

ISET

SL O

SL M

SL P

TA O

TA M

FSET

TG2

TGU

SRCH

FE O

FLB

FGD

FDFCT

FE M

FEI

FEO

FE BIAS

F

E

EI

VEE

TED

LPFI

TEI

ATSC

TZC

TDFCT

VC

APC

LEVEL S

FOK

MIRR

RF IV AMP1

RF IV AMP2

FE AMP

TTL

IIL

FZC COMP

DFCT

IIL

TTL

IIL DATA REGISTER

INPUT SHIFT REGISTER

ADDRESS DECODER

OUTPUT DECODER

TTL

IIL

TOG1-3

BAL1-3

FS1-4 TG1-2 TM1-7 PS1-4

F IV AMP

E IV AMP

BAL1

BAL2

BAL 3

TE AMP

TZC COMP

DFCT

TM1

DFCT

FS4

ATSC

WINDOW COMP

TOG1

TOG2

TOG3

FCS PHASE

COMPENSATION

FS1

F SET

TG2

TM7

TM3

TM4

TM5

TM6

ISET

TRACKING

PHASE

COMPENSATION

HPF COMP

LPF COMP

TG1

FS2

TM2

RF M

– MAIN Board –

IC1 CXA1238M-T6

GND

PLL LPF2

MPX REG

28

2930 242526 212223 181920 1617

27

VCO

MUTE

FM DISCRI

AM OSC

AFC

REGULATOR

REG

FM OSC

AM RF IN

FM RF

FM FRONT-END

AM FRONT-END

FM RF IN

FM GND

FM/AM FE OUT

IC501 CXA1782CQ

1

2 3 4 5 6 7 8 9

PLL LPF1

PILOT DET LPF2

IC50 BU2614FS

PD1

VSS

16 12131415

PHASE

DETECT

XOUT

VCO

MONO/STEREO

PILOT DET LPF2

ST IND/VCO CHECK

VDD1

MAIN CONTROL

PRESCALLER

I/O CONTROL

XIN

SELECT

VDD2

REGISTER

4

CE

CK

5

DA

FM IN

61 2 3 7

CD

MPX

REGULATOR

1/2

COUNTER

1/2

COUNTER

MUTING

DECORD

AMP

R-CH OUT

AM IN

11

10

OUTPUT

CONTROL

P0

P2

8

P1

L-CH OUT

IF-IN

9

IF

COUNTER

PD1

PD2

AUTO

BLEND

RIPPLE

FILTER

VCC

AGC AFC1

RIPPLE FILTER

INDICATOR

BAND-PASS

MUTE

10

11

AGC AFC2

FM IF/

DISCRI

AM IF/

DET

TUNING

13

14

12

GND

TUNE IND

15

FM IF IN

AM IF IN

BAND SELECT

– 35 –

– 36 –

Page 21

IC502 CXD2508AQ

SCOR

1

SBSO

2

EXCK

3

SQSO

4

SQCK

5

MUTE

SENS

XRST

DATA

XLAT

CLOK

VSS

SEIN

CNIN

DATO

XLTO

CLKO

SPOA

SPOB

SPOC

XTSL

XLON

FOK

MON

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

CPU

INTERFACE

SERVO

AUTO

SEQUENCER

DTS3

DTS2

RPWM

NRPWM

AVSS2

AVSS3

XTAO

XTAI

AVDD3

AVDD2

LPWM

NLPWM

VDD

DIGITAL FILTER &

1 BIT D/A CONVERTER

SUB CODE

PROCESSOR

ERROR

16K

CORRECTOR

RAM

INTERNAL BUS

EFM

DEMODULATOR

LOCK

TEST

DIGITAL

PLL

FILI

FILO

PCO

VDD

DIGITAL

CLV

25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

MDP

MDS

AVSS1

CLTV

AVDD1

ASYMMETRY

CORRECTOR

RF

DTS1

D/A

BIAS

ZEROL

ZEROR

65666768697071727374757677787980

CLOCK

GENERATOR

INTERFACE

ASYI

ASYE

AYSO

DIGITAL

OUT

WFCK

64

EMPHI

63

EMPH

62

61

DOUT

C4M

60

FSTT

59

MNT0

58

MNT1

57

MNT3

56

XROF

55

C2PO

54

VSS

53

RFCK

52

GFS

51

XPCK

50

XUGF

49

48

GTOP

47

BCKI

46

BCK

45

PCMDI

44

PCMD

43

LRCKI

42

LRCK

41

WDCK

IC503 BA5930FP

GND

T-OUT+

T-OUT–

2728 26 18202122

LEVEL

SHIFT

LEVEL

SHIFT

SL-OUT–

SL-OUT+

SL-IN

T-IN

+

–

4 5 6 731 2 11 12 13 141098

T-NF

2425 19 17 16 15

23

–

+

+

–

+

–

REG.

SL-NF

REG IN

REG OUT

VCC

VCC

VREF

F-NF

–

+

MUTE

CONTROL

MUTE

GND

F-IN

SP-NF

LEVEL

SHIFT

+

–

F-OUT+

LEVEL

SHIFT

SP-IN

– 37 –

F-OUT–

SP-OUT–

SP-OUT+

SP-IN+

+

GND

SP-IN–

–

SP-OUT

Page 22

– POWER Board –

IC350 LA4601N

OUT1

GND

TSD

PROTECTOR

OUTPUT

AMP

OUTPUT

AMP

OUT2

DRIVE AMP

DRIVE AMP

RIPPLE

FILTER

VCC

PRE

PRE

FILTER

POP NOISE

PREVENTION

CIRCUIT

P.P.

INPUT

AMP

INPUT

AMP

STANDBY

SWITCH

STANDBY

REFERENCE

AMP

IC351 BA5417

T.S.D.

+

–

STANDBY

STBY

POWER GND

FILTER

FILTER

103 4 5 6

NF1

BS

2NC1 8 97 11 12 131415

BS2

OUT2

VCC

OUT1

BS

BS1

IN2

IN1

GND

10987654321

IN2

IN1

NF2

+

–

PRE GND2

PRE GND1

– 38 –

Page 23

6-8. IC PIN FUNCTION DESCRIPTION

• MAIN BOARD IC401 µPD753012AGC-F17-3B9 (SYSTEM CONTROLLER)

Pin No. Pin Name I/O Description

1 to 10 SEG12 to SEG21 O Segment drive signal output to the liquid crystal display (LCD401)

11, 12 SEG22, SEG23 O Segment drive signal output terminal Not used (open)

13 to 16 KS0 to KS3 O Key strobe signal output to the key matrix

17 VERSION1 O Initialize destination output terminal

18 VERSION2 O Initialize destination output terminal

19 ALARM O Alarm data output terminal Not used (open)

20 BASS ON O

21 to 23 COM0 to COM2 O Common drive signal output to the liquid crystal display (LCD401)

24 COM3 O Common drive signal output terminal Not used (open)

25 BIAS O Bias output for the liquid crystal display drive

26 to 28 VLC0 to VLC2 — Terminal for doubler circuit capacitor connection to develop liquid crystal display drive voltage

29 CD ADJ I/O

30 CLOCK O Serial data transfer clock signal output to the CXD2508AQ (IC502)

31 XLT O Serial data latch pulse signal output to the CXD2508AQ (IC502)

32 DATA O Serial data output to the CXD2508AQ (IC502)

33 VSS — Ground terminal

34 X-RESET O

35 POWER ON O Front side speaker on/off selection signal output terminal “L”: speaker on

36 CD ON I/O

37 R-LAT O PLL serial data latch pulse signal output to the FM/AM PLL (IC50)

38 AC IN I Power failure detection input terminal “L”: power failure, “H”: power on

39 CK O

40 DATA O PLL serial data output to the FM/AM PLL (IC50)

41 SQSI I Subcode Q data (80 bit serial) input from the CXD2508AQ (IC502)

42 SENS I Internal status signal (sense signal) input from the CXD2508AQ (IC502)

43 CIN I Track jump count detect signal input from the CXA1782BQ (IC501)

44 SCOR I Subcode sync (S0+S1) detection signal input from the CXD2508AQ (IC502)

45 AUTO/MANU I

46 DATA O Serial data output terminal Not used (open)

47 CLK O Serial data transfer clock signal output terminal Not used (open)

48 LAT O Serial data latch pulse signal output terminal Not used (open)

49 BUZZER O Buzzer sound drive signal output terminal

50 V-RESET O Reset signal output terminal “L”: reset Not used (open)

51 NAR I Not used (open)

52 V MUTE O Voice muting on/off selection signal output terminal “H”: muting on

53 A MUTE O Audio line muting on/off selection signal output terminal “L”: muting on

54

55 XT1 I Sub system clock input terminal (32.768 kHz)

56 XT2 O Sub system clock output terminal (32.768 kHz)

VDD — Power supply terminal (+5V)

Mega bass on/off selection signal output to the mega bass power amplifier (IC351)

“L”: mega bass on

At initial mode: Setting terminal for the test mode (manual mode) “L”: manual mode

At normal mode: E-F balance control signal output to the CXA1782BQ (IC501) “H” active

System reset signal output to the CXA1782BQ (IC501), CXD2508AQ (IC502) and BA6196FP

(IC503) “L”: reset

At initial mode: Setting terminal for the test mode (auto mode) “L”: auto mode

At normal mode: Power on/off control signal output for the CD +5V power supply

“L”: CD power on

At CD mode: Subcode Q data reading clock signal output to the CXD2508AQ (IC502)

At tuner mode: PLL serial data transfer clock signal output to the FM/AM PLL (IC50)

Setting terminal for the CD adjustment mode (auto mode/manual mode)

“L”: auto mode, “H”: manual mode (fixed at “L”)

– 39 –

Page 24

Pin No. Pin Name I/O Description

57 IC — Internal connection terminal (connected to power supply)

58 X1 I Main system clock input terminal (4.194 MHz)

59 X2 O Main system clock output terminal (4.194 MHz)

60 SHIFT CK O Shift clock output of the main system clock (4.194 MHz) “H” active

61 COLOR O LCD back light color selection signal output terminal “L”: amber, “H”: green

62 DOOR-IN I

63 to 67

KEYRET0 to

KEYRET4

CD lid open/close detection switch (S424) input terminal “L”: CD lid is closed

I Key return signal input from the key matrix

68 RESET I

69 SEG0 O Segment drive signal output terminal Not used (open)

70 to 80 SEG1 to SEG11 O Segment drive signal output to the liquid crystal display (LCD401)

System reset signal input from the reset signal generator (IC402) “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

– 40 –

Page 25

SECTION 7

EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

(1) UPPER CABINET SECTION

5

3

4

#3

2

#1

#2

SP101

17

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• The mechanical parts with no reference number in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of the

electrical parts list.

8

19

6

18

7

12

A

#6

20

#4

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

9

10

A

#1

11

13

14

21

15

#3

#1

SP201

1

#3

Ref. No. Part No. Description Remark

1 X-3377-171-1 NET ASSY (DARK BLUE)

1 X-3377-172-1 NET ASSY (RED)

2 3-034-584-11 BUTTON (OPEN)

* 3 1-673-800-11 VOLUME BOARD

4 1-790-755-11 WIRE (FLAT TYPE) (7 CORE)

5 3-034-585-11 KNOB (VOL)

6 3-034-586-11 KNOB (MEGABASS)

7 X-3377-457-1 CABINET (UPPER) ASSY

8 3-034-589-01 WINDOW (CD)

9 3-034-579-11 LID, CD

#3

16

#6

#3

#3

#3

Ref. No. Part No. Description Remark

12 3-910-112-01 PLATE, CHUCKING

13 1-790-756-11 WIRE (FLAT TYPE) (10 CORE)

* 14 A-3663-291-A KEY BOARD, COMPLETE

15 3-034-581-01 CHASSIS (BUTTON)

16 3-351-377-01 DAMPER

17 3-034-588-21 WINDOW (CLOCK)

18 3-037-757-01 CUSHON (LID)

19 3-039-135-01 SHEET (CD WINDOW, ADHESIVE)

20 3-037-756-01 CUSHION (CHUCK)

21 3-038-420-01 SHIELD (KEY)

10 3-034-592-01 SPRING (CD OPEN)

11 1-452-732-11 MAGNET

SP101 1-529-354-11 SPEAKER (6.6cm) (L ch)

SP201 1-529-354-11 SPEAKER (6.6cm) (R ch)

– 41 –

Page 26

(2) MAIN BOARD SECTION

56

57

not

supplied

58

LCD401

55

53

52

51

KSM-213BAN

54

52

60

59

61

ANT1

#3

Ref. No. Part No. Description Remark

* 51 1-673-804-11 MOTOR BOARD

52 3-921-725-01 SCREW (2.6X10), +PWH

53 3-910-095-31 RUBBER, VIBRATION PROOF (GREEN)

54 3-931-379-01 RUBBER, VIBRATION PROOF (RED)

55 3-910-116-01 COVER, CD

56 3-034-580-01 CHASSIS (CD)

* 57 1-673-802-11 PUSH SWITCH BOARD

Ref. No. Part No. Description Remark

* 58 1-673-803-11 LED BOARD

59 3-034-587-01 HOLDER (LCD)

* 60 A-3683-099-A MAIN BOARD, COMPLETE (AEP)

* 60 A-3683-100-A MAIN BOARD, COMPLETE (UK)

61 1-769-824-11 WIRE (FLAT TYPE) (16 CORE)

ANT1 1-501-907-21 ANTENNA, FM WIRE

LCD401 1-803-604-11 DISPLAY PANEL, LIQUID CRYSTAL

– 42 –

Page 27

(3) LOWER CABINET SECTION

#3

#3

not

supplied

101

T901

AEP

UK

102

102

108

#3

103

#3

104

#2

SP301

105

106

#1

Ref. No. Part No. Description Remark

* 101 A-3683-094-A POWER BOARD, COMPLETE (AEP)

* 101 A-3683-101-A POWER BOARD, COMPLETE (UK)

! 102 1-555-795-00 CORD, POWER (AEP)

! 102 1-696-572-21 CORD, POWER (UK)

* 103 1-673-801-11 HEADPHONE BOARD

107

not

supplied

#1

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

Ref. No. Part No. Description Remark

105 3-035-978-01 RUBBER (B)

106 3-034-577-01 CABINET (LOWER)

107 3-035-977-01 RUBBER (A)

108 3-368-852-01 FOOT

SP301 1-529-355-11 SPEAKER (9.2cm)

104 3-034-582-01 COVER (SP)

! T901 1-449-200-11 TRANSFORMER, POWER

– 43 –

Page 28

(4) OPTICAL PICK-UP SECTION

(KSM-213BAN)

151

152

not supplied

153

#5

M571

Ref. No. Part No. Description Remark

! 151 8-848-379-31 OPTICAL PICK-UP KSS-213B

152 2-626-907-01 GEAR (A)

153 2-627-003-02 GEAR (B) (RP)

154

M570

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

Ref. No. Part No. Description Remark

154 2-626-908-01 SHAFT, SLED

M570 X-2625-769-1 GEAR ASSY (MB), MOTOR (SLED)

M571 X-2625-770-1 CHASSIS ASSY (MB), (RP) (SPINDLE)

– 44 –

Page 29

SECTION 8

ELECTRICAL PARTS LIST

HEADPHONE

KEY LED

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 1-673-801-11 HEADPHONE BOARD

*****************

< CAPACITOR >

C380 1-128-551-11 ELECT 22uF 20% 25V

< JACK >

J301 1-568-267-11 JACK ( 2 (HEADPHONE))

< COIL >

L180 1-410-526-11 INDUCTOR 10uH

L280 1-410-526-11 INDUCTOR 10uH

L380 1-412-496-51 INDUCTOR 4.7uH

< RESISTOR >

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

S402 1-554-937-11 SWITCH, KEY BOARD (ALARM MODE)

S403 1-554-937-11 SWITCH, KEY BOARD (CD PLAY MODE)

S404 1-554-937-11 SWITCH, KEY BOARD (D.S.T. SUMMER T.)

S405 1-554-937-11 SWITCH, KEY BOARD (WAKE UP TRACK)

S406 1-554-937-11 SWITCH, KEY BOARD (ALARM A)

S407 1-554-937-11 SWITCH, KEY BOARD (ALARM B)

S408 1-554-937-11 SWITCH, KEY BOARD (CLOCK)

S409 1-554-937-11 SWITCH, KEY BOARD

S410 1-554-937-11 SWITCH, KEY BOARD (2)

S411 1-554-937-11 SWITCH, KEY BOARD (BAND)

S412 1-554-937-11 SWITCH, KEY BOARD (1)

S413 1-554-937-11 SWITCH, KEY BOARD

S414 1-554-937-11 SWITCH, KEY BOARD (3)

S415 1-554-937-11 SWITCH, KEY BOARD (4)

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

When indicating parts by reference

number, please include the board.

(TUNE/TIME SET – =)

(TUNE/TIME SET + +)

R380 1-216-041-00 METAL CHIP 470 5% 1/10W

R381 1-216-017-91 RES, CHIP 47 5% 1/10W

**************************************************************

* A-3663-291-A KEY BOARD, COMPLETE

********************

< CAPACITOR >

C446 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C455 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C456 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C457 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C458 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C459 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

< CONNECTOR >

CN402 1-793-080-11 CONNECTOR, FFC/FPC 10P

< RESISTOR >

R491 1-216-073-00 METAL CHIP 10K 5% 1/10W

R492 1-216-073-00 METAL CHIP 10K 5% 1/10W

R493 1-216-073-00 METAL CHIP 10K 5% 1/10W

R494 1-216-073-00 METAL CHIP 10K 5% 1/10W

R495 1-216-073-00 METAL CHIP 10K 5% 1/10W

< SWITCH >

S401 1-554-937-11 SWITCH, KEY BOARD

(BACK LIGHT GREEN/AMBER)

S416 1-554-937-11 SWITCH, KEY BOARD (5)

S417 1-554-937-11 SWITCH, KEY BOARD (fl CD)

S418 1-554-937-11 SWITCH, KEY BOARD (RADIO, SLEEP)

S419 1-554-937-11 SWITCH, KEY BOARD (OFF, ALARM RESET)

S420 1-554-937-11 SWITCH, KEY BOARD (SNOOZE/SLEEP OFF)

**************************************************************

* 1-673-803-11 LED BOARD

**********

(Included in MAIN BOARD, COMPLETE)

< DIODE >

D419 8-719-075-78 LED TLYE262A (K51.SOY.P)

(LCD BACK LIGHT)

D420 8-719-075-78 LED TLYE262A (K51.SOY.P)

(LCD BACK LIGHT)

D421 8-719-075-78 LED TLYE262A (K51.SOY.P)

(LCD BACK LIGHT)

D422 8-719-056-07 LED SLR-342MC3F (LCD BACK LIGHT)

D423 8-719-056-07 LED SLR-342MC3F (LCD BACK LIGHT)

D424 8-719-056-07 LED SLR-342MC3F (LCD BACK LIGHT)

< RESISTOR >

R483 1-216-041-00 METAL CHIP 470 5% 1/10W

R484 1-216-041-00 METAL CHIP 470 5% 1/10W

R485 1-216-041-00 METAL CHIP 470 5% 1/10W

R486 1-216-025-00 RES, CHIP 100 5% 1/10W

R487 1-216-025-00 RES, CHIP 100 5% 1/10W

R488 1-216-025-00 RES, CHIP 100 5% 1/10W

**************************************************************

– 45 –

Page 30

MAIN

Ref. No. Part No. Description Remark

* A-3683-099-A MAIN BOARD, COMPLETE (AEP)

* A-3683-100-A MAIN BOARD, COMPLETE (UK)

*********************

(Including LED/PUSH SWITCH BOARD)

3-034-587-01 HOLDER (LCD)

3-037-758-01 SHEET (LCD)

< BAND PASS FILTER >

BPF1 1-235-171-00 FILTER, BAND PASS

< CAPACITOR >

C1 1-163-141-00 CERAMIC CHIP 0.001uF 5% 50V

C2 1-163-141-00 CERAMIC CHIP 0.001uF 5% 50V

C3 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C4 1-163-220-11 CERAMIC CHIP 3PF 0.25PF 50V

C5 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C6 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C7 1-163-253-11 CERAMIC CHIP 120PF 5% 50V

C9 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C10 1-163-131-00 CERAMIC CHIP 390PF 5% 50V

C12 1-163-231-11 CERAMIC CHIP 15PF 5% 50V

C13 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C14 1-163-127-00 CERAMIC CHIP 270PF 5% 50V

C15 1-163-241-11 CERAMIC CHIP 39PF 5% 50V

C16 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C17 1-104-664-11 ELECT 47uF 20% 16V

C18 1-124-257-00 ELECT 2.2uF 20% 50V

C19 1-124-584-00 ELECT 100uF 20% 10V

C20 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C21 1-126-163-11 ELECT 4.7uF 20% 50V

C22 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C23 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C24 1-126-963-11 ELECT 4.7uF 20% 50V

C25 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C26 1-104-664-11 ELECT 47uF 20% 16V

C27 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C28 1-104-664-11 ELECT 47uF 20% 16V

C29 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C30 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C31 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C32 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C36 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C50 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C51 1-126-964-11 ELECT 10uF 20% 50V

C52 1-126-963-11 ELECT 4.7uF 20% 50V

C53 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C54 1-163-239-11 CERAMIC CHIP 33PF 5% 50V

C55 1-163-233-11 CERAMIC CHIP 18PF 5% 50V

C56 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C57 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C58 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C59 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C60 1-136-171-00 FILM 0.33uF 5% 50V

C61 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C62 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C63 1-126-947-11 ELECT 47uF 20% 35V

C64 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

Ref. No. Part No. Description Remark

C65 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C66 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C67 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C101 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C102 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C103 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C104 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C105 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C120 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C121 1-126-963-11 ELECT 4.7uF 20% 50V

C201 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C202 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C203 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C204 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C205 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C220 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C221 1-126-963-11 ELECT 4.7uF 20% 50V

C301 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C302 1-126-934-11 ELECT 220uF 20% 10V

C303 1-126-382-11 ELECT 100uF 20% 16V

C320 1-126-964-11 ELECT 10uF 20% 50V

C321 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C322 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C323 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C324 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C401 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C402 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C403 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C407 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C408 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C409 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C410 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C411 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C412 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C413 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C420 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C421 1-163-237-11 CERAMIC CHIP 27PF 5% 50V

C423 1-163-233-11 CERAMIC CHIP 18PF 5% 50V

C424 1-163-233-11 CERAMIC CHIP 18PF 5% 50V

C425 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C426 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C427 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C428 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C429 1-126-924-11 ELECT 330uF 20% 6.3V

C432 1-126-935-11 ELECT 470uF 20% 6.3V

C433 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C434 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C435 1-124-584-00 ELECT 100uF 20% 10V

C436 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C437 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C438 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C439 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C444 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C445 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C464 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C465 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C467 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C468 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

– 46 –

Page 31

MAIN

Ref. No. Part No. Description Remark

C470 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C471 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C472 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C473 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C501 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C502 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C503 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C504 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C505 1-126-963-11 ELECT 4.7uF 20% 50V

C506 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C507 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C508 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C509 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C510 1-126-963-11 ELECT 4.7uF 20% 50V

C511 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C512 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C513 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C514 1-104-665-11 ELECT 100uF 20% 10V

C515 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C516 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C517 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C518 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C519 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C520 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C521 1-163-085-00 CERAMIC CHIP 2PF 50V

C522 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

Ref. No. Part No. Description Remark

C554 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C555 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C556 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C557 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C558 1-104-665-11 ELECT 100uF 20% 10V

C559 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C560 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C561 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C562 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C563 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C564 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C565 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C566 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C567 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C568 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

< FILTER >

CF1 1-578-677-21 FILTER, CRYSTAL

CF2 1-760-238-11 FILTER, CERAMIC

CF3 1-760-238-11 FILTER, CERAMIC

< CONNECTOR >

CN301 1-695-330-31 PIN, CONNECTOR (PC BOARD) 7P

* CN401 1-770-641-11 CONNECTOR, FFC/FPC 10P

CN501 1-774-465-11 CONNECTOR, FFC/FPC 16P

* CN502 1-564-708-11 PIN, CONNECTOR (SMALL TYPE) 6P

C523 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C524 1-104-664-11 ELECT 47uF 20% 16V

C525 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C526 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C527 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C528 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C529 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C530 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C531 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C532 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C533 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C534 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C535 1-104-665-11 ELECT 100uF 20% 10V

C536 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C537 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C538 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C539 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C540 1-104-665-11 ELECT 100uF 20% 10V

C541 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C542 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C543 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C544 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C545 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C546 1-126-382-11 ELECT 100uF 20% 16V

C547 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C548 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C549 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C550 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C551 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C552 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

< TRIMMER >

CT1 1-141-601-21 CAP, ADJ

CT2 1-141-601-21 CAP, ADJ

CT3 1-141-604-11 CAP, ADJ

CT4 1-141-604-11 CAP, ADJ

CT401 1-141-601-21 CAP, ADJ

< DIODE >

D1 8-719-800-76 DIODE 1SS226

D2 8-713-100-11 DIODE 1T362

D3 8-713-100-11 DIODE 1T362

D4 8-719-023-99 DIODE KV1563M-3

D320 8-719-988-61 DIODE 1SS355TE-17

D321 8-719-914-44 DIODE DAP202K

D401 8-719-074-44 DIODE 1SS120RX

D402 8-719-074-44 DIODE 1SS120RX

D403 8-719-074-44 DIODE 1SS120RX

D404 8-719-074-44 DIODE 1SS120RX

D412 8-719-988-61 DIODE 1SS355TE-17 (UK)

D413 8-719-988-61 DIODE 1SS355TE-17 (AEP)

D414 8-719-988-61 DIODE 1SS355TE-17

D415 8-719-074-44 DIODE 1SS120RX

D416 8-719-988-61 DIODE 1SS355TE-17

D417 8-719-988-61 DIODE 1SS355TE-17

D501 8-719-074-44 DIODE 1SS120RX

< FERRITE BEAD >

FB501 1-410-397-21 FERRITE BEAD INDUCTOR

C553 1-163-038-00 CERAMIC CHIP 0.1uF 25V

– 47 –

Page 32

MAIN

Ref. No. Part No. Description Remark

< IC >

IC1 8-752-062-48 IC CXA1238M-T6

IC50 8-759-188-85 IC BU2614FS

IC301 8-759-909-71 IC BA4558F

IC320 8-759-008-67 IC MC14066BF

IC401 8-759-587-54 IC uPD753012AGC-F17-3B9

IC402 8-759-165-89 IC PST600L-T

IC501 8-752-074-34 IC CXA1782CQ

IC502 8-752-373-06 IC CXD2508AQ

IC503 8-759-336-75 IC BA5930FP

< COIL/SHORT >

L1 1-406-545-11 COIL, AIR-CORE

L2 1-406-546-11 COIL, AIR-CORE

L3 1-754-063-11 ANTENNA, FERRITE-ROD (MW/LW)

L4 1-406-269-11 COIL (OSC)

L5 1-412-959-11 INDUCTOR 47uH

L50 1-412-959-11 INDUCTOR 47uH

L51 1-412-951-11 INDUCTOR 10uH

L301 1-412-496-51 INDUCTOR 4.7uH

L302 1-216-295-00 SHORT 0

L401 1-410-526-11 INDUCTOR 10uH

L403 1-412-006-31 INDUCTOR CHIP 10uH

L501 1-412-496-51 INDUCTOR 4.7uH

L502 1-410-526-11 INDUCTOR 10uH

L503 1-410-526-11 INDUCTOR 10uH

L504 1-410-526-11 INDUCTOR 10uH

L505 1-410-526-11 INDUCTOR 10uH

< LIQUID CRYSTAL DISPLAY >

Ref. No. Part No. Description Remark

R6 1-216-121-00 RES, CHIP 1M 5% 1/10W

R7 1-216-065-00 RES, CHIP 4.7K 5% 1/10W

R8 1-216-121-00 RES, CHIP 1M 5% 1/10W

R9 1-216-097-00 RES, CHIP 100K 5% 1/10W

R10 1-216-061-00 RES, CHIP 3.3K 5% 1/10W

R11 1-216-049-11 RES, CHIP 1K 5% 1/10W

R12 1-216-025-00 RES, CHIP 100 5% 1/10W

R13 1-216-073-00 METAL CHIP 10K 5% 1/10W

R14 1-216-105-00 RES, CHIP 220K 5% 1/10W

R15 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R16 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R17 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R18 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R19 1-216-105-00 RES, CHIP 220K 5% 1/10W

R20 1-216-041-00 METAL CHIP 470 5% 1/10W

R50 1-216-065-00 RES, CHIP 4.7K 5% 1/10W

R51 1-216-041-00 METAL CHIP 470 5% 1/10W

R52 1-216-049-11 RES, CHIP 1K 5% 1/10W

R53 1-216-049-11 RES, CHIP 1K 5% 1/10W

R54 1-216-049-11 RES, CHIP 1K 5% 1/10W

R55 1-216-049-11 RES, CHIP 1K 5% 1/10W

R56 1-216-073-00 METAL CHIP 10K 5% 1/10W

R57 1-216-073-00 METAL CHIP 10K 5% 1/10W

R58 1-216-073-00 METAL CHIP 10K 5% 1/10W

R59 1-216-097-00 RES, CHIP 100K 5% 1/10W

R60 1-216-073-00 METAL CHIP 10K 5% 1/10W

R101 1-216-081-00 METAL CHIP 22K 5% 1/10W

R102 1-216-081-00 METAL CHIP 22K 5% 1/10W

R103 1-216-081-00 METAL CHIP 22K 5% 1/10W

R104 1-216-081-00 METAL CHIP 22K 5% 1/10W

LCD401 1-803-604-11 DISPLAY PANEL, LIQUID CRYSTAL

< TRANSISTOR >

Q1 8-729-200-86 TRANSISTOR 2SC2714-O

Q2 8-729-200-86 TRANSISTOR 2SC2714-O

Q50 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q51 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q120 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q220 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q320 8-729-027-31 TRANSISTOR DTA124EKA-T146

Q321 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q401 8-729-141-75 TRANSISTOR 2SD596DV345

Q402 8-729-141-75 TRANSISTOR 2SD596DV345

Q403 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q404 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q405 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q406 8-729-027-31 TRANSISTOR DTA124EKA-T146

Q407 8-729-027-31 TRANSISTOR DTA124EKA-T146

Q501 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q502 8-729-801-84 TRANSISTOR 2SB1013-4

< RESISTOR >

R1 1-216-097-00 RES, CHIP 100K 5% 1/10W

R2 1-216-097-00 RES, CHIP 100K 5% 1/10W

R3 1-216-065-00 RES, CHIP 4.7K 5% 1/10W

R4 1-216-073-00 METAL CHIP 10K 5% 1/10W

R5 1-216-121-00 RES, CHIP 1M 5% 1/10W

R105 1-216-089-00 RES, CHIP 47K 5% 1/10W

R106 1-216-089-00 RES, CHIP 47K 5% 1/10W

R107 1-216-073-00 METAL CHIP 10K 5% 1/10W

R108 1-216-073-00 METAL CHIP 10K 5% 1/10W

R109 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R110 1-216-295-00 SHORT 0

R120 1-216-049-11 RES, CHIP 1K 5% 1/10W

R121 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R122 1-216-049-11 RES, CHIP 1K 5% 1/10W

R201 1-216-081-00 METAL CHIP 22K 5% 1/10W

R202 1-216-081-00 METAL CHIP 22K 5% 1/10W

R203 1-216-081-00 METAL CHIP 22K 5% 1/10W

R204 1-216-081-00 METAL CHIP 22K 5% 1/10W

R205 1-216-089-00 RES, CHIP 47K 5% 1/10W

R206 1-216-089-00 RES, CHIP 47K 5% 1/10W

R207 1-216-073-00 METAL CHIP 10K 5% 1/10W

R208 1-216-073-00 METAL CHIP 10K 5% 1/10W

R209 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R210 1-216-295-00 SHORT 0

R220 1-216-049-11 RES, CHIP 1K 5% 1/10W

R221 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R222 1-216-049-11 RES, CHIP 1K 5% 1/10W

R302 1-216-065-00 RES, CHIP 4.7K 5% 1/10W

R303 1-216-065-00 RES, CHIP 4.7K 5% 1/10W

R320 1-216-065-00 RES, CHIP 4.7K 5% 1/10W

R321 1-216-073-00 METAL CHIP 10K 5% 1/10W

R322 1-216-049-11 RES, CHIP 1K 5% 1/10W

– 48 –

Page 33

MAIN

Ref. No. Part No. Description Remark

R323 1-216-049-11 RES, CHIP 1K 5% 1/10W

R324 1-216-073-00 METAL CHIP 10K 5% 1/10W

R325 1-216-049-11 RES, CHIP 1K 5% 1/10W

R401 1-216-049-11 RES, CHIP 1K 5% 1/10W

R402 1-216-049-11 RES, CHIP 1K 5% 1/10W

R403 1-216-049-11 RES, CHIP 1K 5% 1/10W

R404 1-216-049-11 RES, CHIP 1K 5% 1/10W

R405 1-216-049-11 RES, CHIP 1K 5% 1/10W

R406 1-216-049-11 RES, CHIP 1K 5% 1/10W

R407 1-216-049-11 RES, CHIP 1K 5% 1/10W

R408 1-216-049-11 RES, CHIP 1K 5% 1/10W

R409 1-216-049-11 RES, CHIP 1K 5% 1/10W

R410 1-216-049-11 RES, CHIP 1K 5% 1/10W

R411 1-216-073-00 METAL CHIP 10K 5% 1/10W

R412 1-216-073-00 METAL CHIP 10K 5% 1/10W

R413 1-216-073-00 METAL CHIP 10K 5% 1/10W

R414 1-216-073-00 METAL CHIP 10K 5% 1/10W

R416 1-216-049-11 RES, CHIP 1K 5% 1/10W

R417 1-216-049-11 RES, CHIP 1K 5% 1/10W

R418 1-216-049-11 RES, CHIP 1K 5% 1/10W

R419 1-216-077-00 METAL CHIP 15K 5% 1/10W

R420 1-216-077-00 METAL CHIP 15K 5% 1/10W

R421 1-216-077-00 METAL CHIP 15K 5% 1/10W

R423 1-216-049-11 RES, CHIP 1K 5% 1/10W

R424 1-216-049-11 RES, CHIP 1K 5% 1/10W

R425 1-216-049-11 RES, CHIP 1K 5% 1/10W

R426 1-216-041-00 METAL CHIP 470 5% 1/10W

R427 1-216-049-11 RES, CHIP 1K 5% 1/10W

R428 1-216-049-11 RES, CHIP 1K 5% 1/10W

R429 1-216-025-00 RES, CHIP 100 5% 1/10W

R430 1-216-049-11 RES, CHIP 1K 5% 1/10W

R431 1-216-049-11 RES, CHIP 1K 5% 1/10W

R432 1-216-049-11 RES, CHIP 1K 5% 1/10W

R433 1-216-049-11 RES, CHIP 1K 5% 1/10W

R434 1-216-049-11 RES, CHIP 1K 5% 1/10W

R435 1-216-049-11 RES, CHIP 1K 5% 1/10W

R436 1-216-049-11 RES, CHIP 1K 5% 1/10W

R438 1-216-089-00 RES, CHIP 47K 5% 1/10W

R439 1-216-089-00 RES, CHIP 47K 5% 1/10W

R440 1-216-081-00 METAL CHIP 22K 5% 1/10W

R441 1-216-097-00 RES, CHIP 100K 5% 1/10W

R442 1-216-073-00 METAL CHIP 10K 5% 1/10W

R443 1-216-049-11 RES, CHIP 1K 5% 1/10W

R444 1-216-049-11 RES, CHIP 1K 5% 1/10W

R445 1-216-073-00 METAL CHIP 10K 5% 1/10W

R446 1-216-073-00 METAL CHIP 10K 5% 1/10W

R447 1-216-113-00 METAL CHIP 470K 5% 1/10W

R448 1-216-113-00 METAL CHIP 470K 5% 1/10W

R449 1-216-113-00 METAL CHIP 470K 5% 1/10W

R450 1-216-113-00 METAL CHIP 470K 5% 1/10W

R451 1-216-113-00 METAL CHIP 470K 5% 1/10W

R452 1-216-049-11 RES, CHIP 1K 5% 1/10W

R453 1-216-049-11 RES, CHIP 1K 5% 1/10W

R454 1-216-049-11 RES, CHIP 1K 5% 1/10W

R455 1-216-049-11 RES, CHIP 1K 5% 1/10W

R456 1-216-049-11 RES, CHIP 1K 5% 1/10W

R457 1-216-049-11 RES, CHIP 1K 5% 1/10W

R458 1-216-049-11 RES, CHIP 1K 5% 1/10W

Ref. No. Part No. Description Remark

R459 1-216-049-11 RES, CHIP 1K 5% 1/10W

R460 1-216-049-11 RES, CHIP 1K 5% 1/10W

R461 1-216-049-11 RES, CHIP 1K 5% 1/10W

R462 1-216-049-11 RES, CHIP 1K 5% 1/10W

R463 1-216-049-11 RES, CHIP 1K 5% 1/10W

R464 1-216-049-11 RES, CHIP 1K 5% 1/10W

R465 1-216-049-11 RES, CHIP 1K 5% 1/10W

R466 1-216-049-11 RES, CHIP 1K 5% 1/10W

R467 1-216-049-11 RES, CHIP 1K 5% 1/10W

R468 1-216-049-11 RES, CHIP 1K 5% 1/10W

R469 1-216-113-00 METAL CHIP 470K 5% 1/10W

R470 1-216-049-11 RES, CHIP 1K 5% 1/10W

R471 1-216-049-11 RES, CHIP 1K 5% 1/10W

R472 1-216-049-11 RES, CHIP 1K 5% 1/10W

R473 1-216-025-00 RES, CHIP 100 5% 1/10W

R474 1-216-073-00 METAL CHIP 10K 5% 1/10W

R475 1-216-073-00 METAL CHIP 10K 5% 1/10W

R476 1-216-073-00 METAL CHIP 10K 5% 1/10W

R477 1-216-073-00 METAL CHIP 10K 5% 1/10W

R478 1-216-073-00 METAL CHIP 10K 5% 1/10W

R479 1-216-073-00 METAL CHIP 10K 5% 1/10W

R480 1-216-073-00 METAL CHIP 10K 5% 1/10W

R481 1-216-049-11 RES, CHIP 1K 5% 1/10W

R482 1-216-105-00 RES, CHIP 220K 5% 1/10W

R489 1-216-049-11 RES, CHIP 1K 5% 1/10W

R490 1-216-049-11 RES, CHIP 1K 5% 1/10W

R498 1-216-073-00 METAL CHIP 10K 5% 1/10W

R501 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R502 1-216-065-00 RES, CHIP 4.7K 5% 1/10W

R503 1-216-073-00 METAL CHIP 10K 5% 1/10W

R504 1-216-073-00 METAL CHIP 10K 5% 1/10W

R505 1-216-113-00 METAL CHIP 470K 5% 1/10W

R506 1-216-097-00 RES, CHIP 100K 5% 1/10W

R507 1-216-113-00 METAL CHIP 470K 5% 1/10W

R508 1-216-095-00 METAL CHIP 82K 5% 1/10W

R510 1-216-097-00 RES, CHIP 100K 5% 1/10W

R511 1-216-089-00 RES, CHIP 47K 5% 1/10W

R512 1-216-097-00 RES, CHIP 100K 5% 1/10W

R513 1-216-081-00 METAL CHIP 22K 5% 1/10W

R514 1-216-101-00 METAL CHIP 150K 5% 1/10W

R516 1-216-077-00 METAL CHIP 15K 5% 1/10W

R517 1-216-073-00 METAL CHIP 10K 5% 1/10W

R518 1-216-065-00 RES, CHIP 4.7K 5% 1/10W

R519 1-216-081-00 METAL CHIP 22K 5% 1/10W

R520 1-216-081-00 METAL CHIP 22K 5% 1/10W

R521 1-216-081-00 METAL CHIP 22K 5% 1/10W

R523 1-216-009-91 RES, CHIP 22 5% 1/10W

R524 1-216-089-00 RES, CHIP 47K 5% 1/10W

R525 1-216-119-00 METAL CHIP 820K 5% 1/10W

R529 1-216-101-00 METAL CHIP 150K 5% 1/10W

R530 1-216-105-00 RES, CHIP 220K 5% 1/10W

R531 1-216-113-00 METAL CHIP 470K 5% 1/10W

R532 1-216-097-00 RES, CHIP 100K 5% 1/10W

R533 1-216-109-00 METAL CHIP 330K 5% 1/10W

R534 1-216-095-00 METAL CHIP 82K 5% 1/10W

R535 1-216-089-00 RES, CHIP 47K 5% 1/10W

R536 1-216-089-00 RES, CHIP 47K 5% 1/10W

– 49 –

Page 34

MAIN MOTOR POWER

Ref. No. Part No. Description Remark

R537 1-216-089-00 RES, CHIP 47K 5% 1/10W

R538 1-216-089-00 RES, CHIP 47K 5% 1/10W

R539 1-216-097-00 RES, CHIP 100K 5% 1/10W

R540 1-216-073-00 METAL CHIP 10K 5% 1/10W

R541 1-216-073-00 METAL CHIP 10K 5% 1/10W

R542 1-216-049-11 RES, CHIP 1K 5% 1/10W

R543 1-216-061-00 RES, CHIP 3.3K 5% 1/10W

R544 1-216-073-00 METAL CHIP 10K 5% 1/10W

R545 1-216-121-00 RES, CHIP 1M 5% 1/10W

R546 1-216-073-00 METAL CHIP 10K 5% 1/10W

R547 1-216-105-00 RES, CHIP 220K 5% 1/10W

R548 1-216-097-00 RES, CHIP 100K 5% 1/10W

R549 1-216-097-00 RES, CHIP 100K 5% 1/10W

R550 1-216-073-00 METAL CHIP 10K 5% 1/10W

R551 1-216-049-11 RES, CHIP 1K 5% 1/10W

R552 1-216-073-00 METAL CHIP 10K 5% 1/10W

R553 1-216-097-00 RES, CHIP 100K 5% 1/10W

R554 1-216-073-00 METAL CHIP 10K 5% 1/10W

R555 1-216-073-00 METAL CHIP 10K 5% 1/10W

R556 1-216-081-00 METAL CHIP 22K 5% 1/10W

R557 1-216-081-00 METAL CHIP 22K 5% 1/10W

R558 1-216-089-00 RES, CHIP 47K 5% 1/10W

R559 1-216-089-00 RES, CHIP 47K 5% 1/10W

< VARIABLE RESISTOR >

RV1 1-238-601-11 RES, ADJ, CARBON 22K

RV501 1-230-497-11 RES, ADJ, CARBON 22K

RV502 1-230-497-11 RES, ADJ, CARBON 22K

< SWITCH >

S423 1-571-478-11 SWITCH, SLIDE (BRIGHTNESS)

Ref. No. Part No. Description Remark

< CAPACITOR >

C150 1-163-019-00 CERAMIC CHIP 0.0068uF 10% 50V

C151 1-126-963-11 ELECT 4.7uF 20% 50V

C152 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C153 1-110-501-11 CERAMIC CHIP 0.33uF 10% 16V

C154 1-110-501-11 CERAMIC CHIP 0.33uF 10% 16V

C155 1-126-926-11 ELECT 1000uF 20% 10V

C250 1-163-019-00 CERAMIC CHIP 0.0068uF 10% 50V

C251 1-126-963-11 ELECT 4.7uF 20% 50V

C252 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C253 1-110-501-11 CERAMIC CHIP 0.33uF 10% 16V

C254 1-110-501-11 CERAMIC CHIP 0.33uF 10% 16V

C255 1-126-926-11 ELECT 1000uF 20% 10V

C351 1-107-686-11 TANTALUM CHIP 4.7uF 10% 16V

C352 1-126-963-11 ELECT 4.7uF 20% 50V

C353 1-126-933-11 ELECT 100uF 20% 16V

C354 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C355 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C356 1-126-963-11 ELECT 4.7uF 20% 50V

C357 1-104-665-11 ELECT 100uF 20% 10V

C358 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C359 1-104-665-11 ELECT 100uF 20% 10V

C360 1-126-176-11 ELECT 220uF 20% 10V

C361 1-104-665-11 ELECT 100uF 20% 10V

C362 1-104-665-11 ELECT 100uF 20% 10V

C363 1-110-501-11 CERAMIC CHIP 0.33uF 10% 16V

C364 1-110-501-11 CERAMIC CHIP 0.33uF 10% 16V

C365 1-110-501-11 CERAMIC CHIP 0.33uF 10% 16V

C366 1-110-501-11 CERAMIC CHIP 0.33uF 10% 16V

C367 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C368 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

< TRANSFORMER >

T1 1-404-902-11 TRANSFORMER, IF

< VIBRATOR >

X50 1-760-130-11 VIBRATOR, CRYSTAL (75kHz)

X401 1-767-697-11 VIBRATOR, CRYSTAL (32.768kHz)

X402 1-781-357-21 VIBRATOR, CERAMIC (4.194MHz)

X501 1-760-793-11 VIBRATOR, CERAMIC (16.933MHz)

**************************************************************

* 1-673-804-11 MOTOR BOARD

*************

< SWITCH >

S570 1-571-936-11 SWITCH, LEAF (LIMIT)

**************************************************************

* A-3683-094-A POWER BOARD, COMPLETE (AEP)

* A-3683-101-A POWER BOARD, COMPLETE (UK)

***********************

1-533-217-31 HOLDER, FUSE

* 1-535-771-11 TERMINAL

! 1-555-795-00 CORD, POWER (AEP)

! 1-696-572-21 CORD, POWER (UK)

7-685-546-19 SCREW +BTP 3X8 TYPE2 N-S

C369 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C370 1-126-960-11 ELECT 1uF 20% 50V

C374 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C901 1-107-906-11 ELECT 10uF 20% 50V

C902 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C903 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C904 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C905 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C906 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C907 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C908 1-107-901-11 ELECT 0.47uF 20% 50V

C909 1-107-909-11 ELECT 47uF 20% 35V

C910 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C911 1-128-547-11 ELECT 6800uF 20% 16V

C912 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C913 1-107-889-11 ELECT 220uF 20% 10V

C914 1-107-869-61 ELECT 470uF 20% 6.3V

C915 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C916 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C917 1-107-889-11 ELECT 220uF 20% 10V

C918 1-107-869-61 ELECT 470uF 20% 6.3V

C919 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V