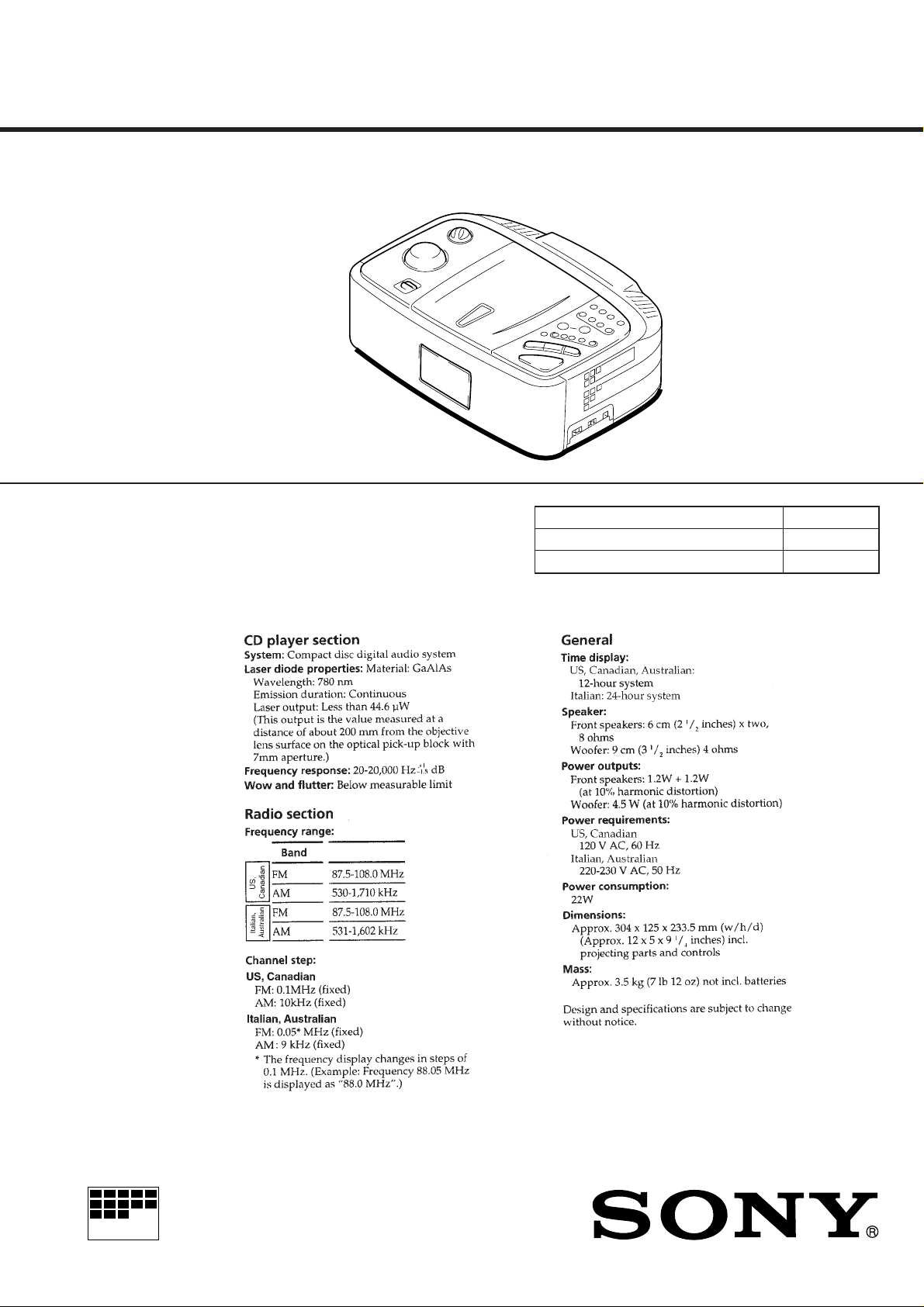

Sony ICFCD-873 Service manual

ICF-CD873

SERVICE MANUAL

Ver 1.1 1999. 06

With SUPPLEMENT 1

(9-927-109-81)

SPECIFICATIONS

US Model

Canadian Model

AEP Model

Australian Model

Model Name Using Similar Mechanism CFD-550

Optical Device Name KSM-213BAN

Optical Pick-UP Name KSS-213B

MICROFILM

FM/AM CD CLOCK RADIO

SECTION 1

SERVICING NOTES

TABLE OF CONTENTS

1. SERVICING NOTE.................................................. 2

2. GENERAL ................................................................... 4

3. DISASSEMBLY ......................................................... 6

4. POWER CORD SETTING................................... 8

5. ELECTRICAL ADJUSTMENTS......................... 9

Tuner Section .................................................................. 9

CD Section ...................................................................... 10

Main Clock Section......................................................... 12

6. DIAGRAMS

6-1. Block Diagram – CD Section – ..................................... 15

6-2. Block Diagram – TUNER Section – ............................. 17

6-3. Block Diagram – MAIN Section – ................................ 19

6-4. Printed Wiring Board – MAIN Section –...................... 23

6-5. Schematic Diagram – MAIN Section –......................... 27

6-6. Schematic Diagram – POWER SUPPLY Section –...... 32

6-7. Printed Wiring Board – POWER SUPPLY Section – ... 35

6-8. IC Pin Function Description ........................................... 41

7. EXPLODED VIEWS ................................................ 43

8. ELECTRICAL PARTS LIST ............................... 47

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

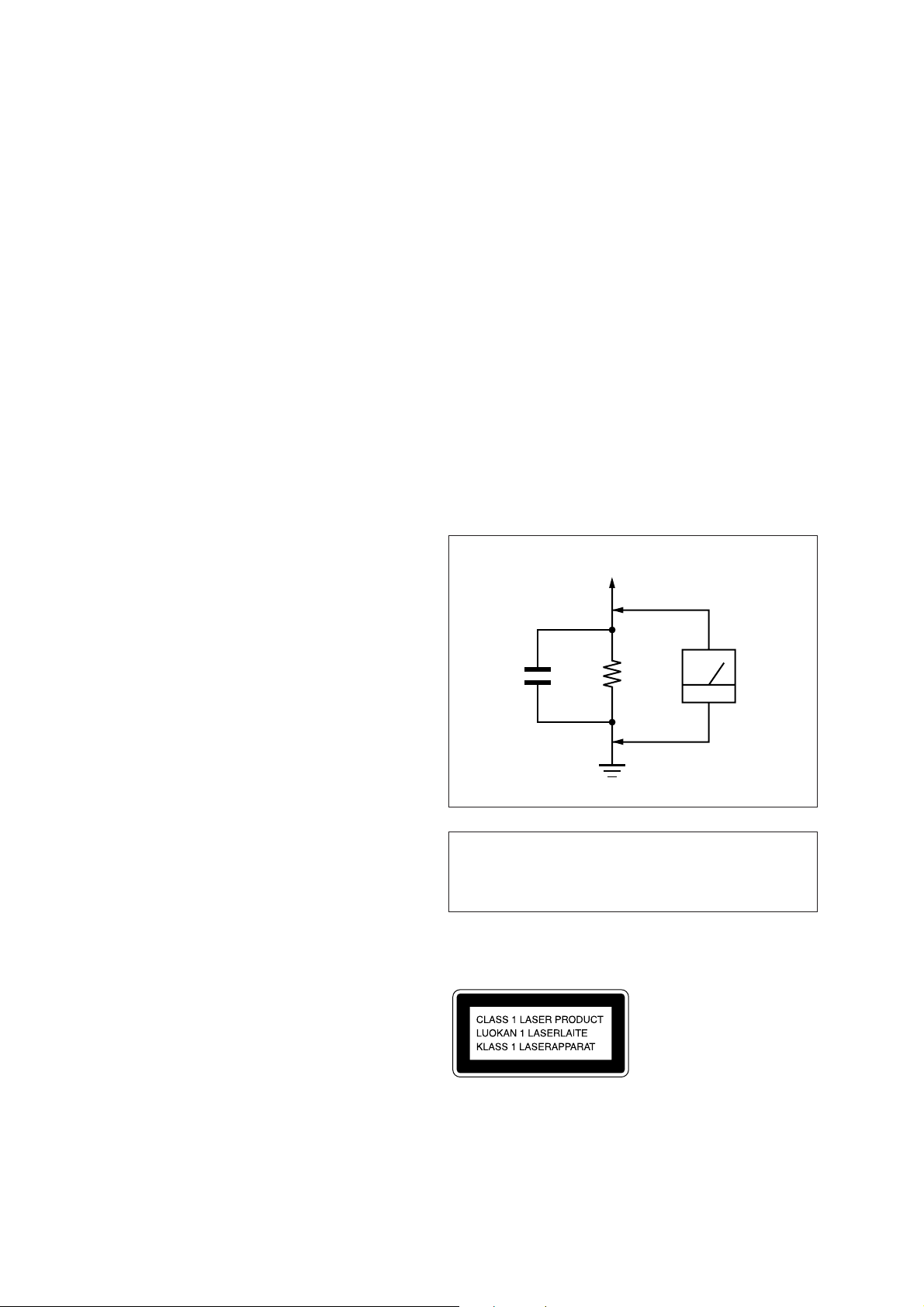

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

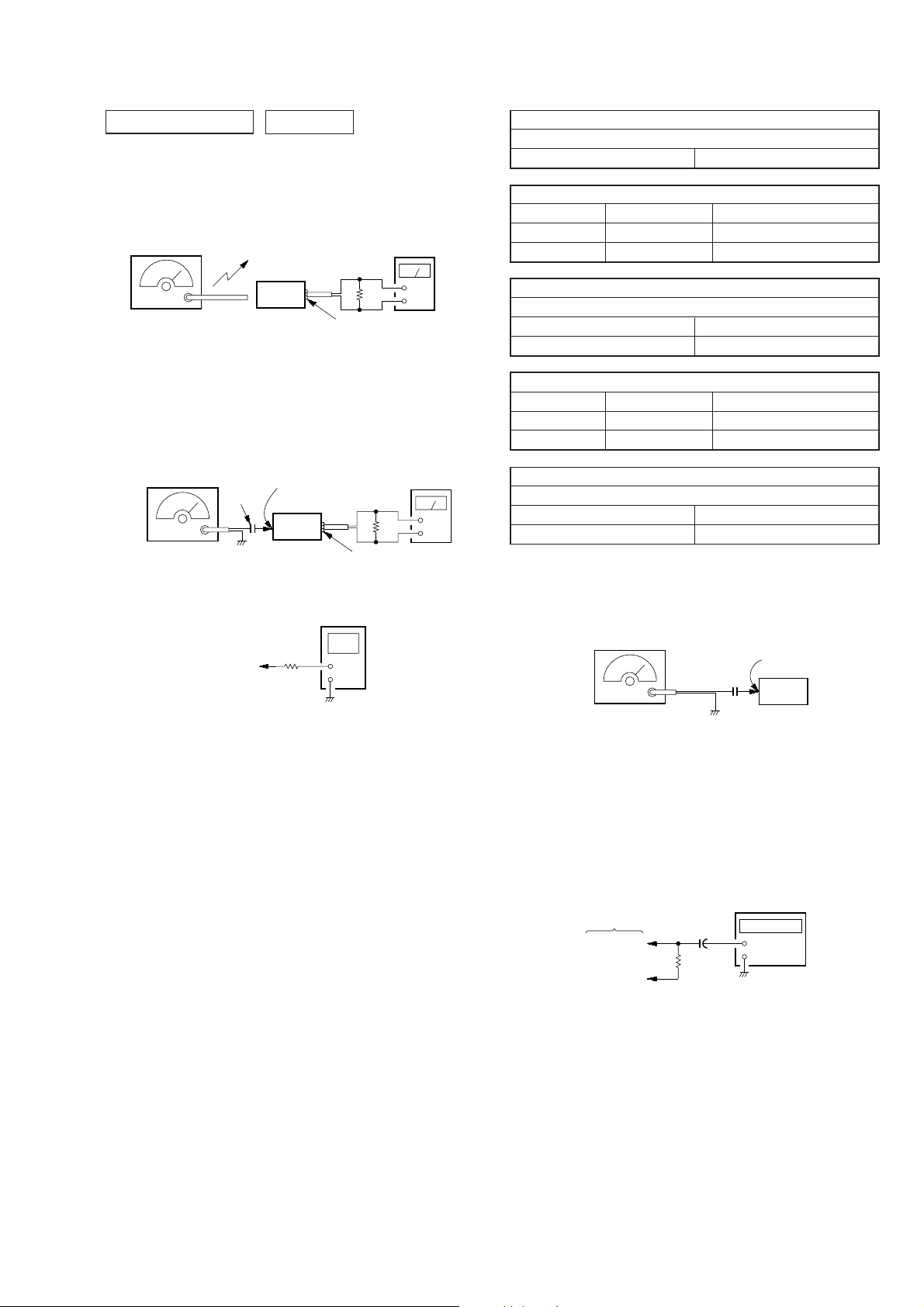

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

AC

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

Ω

Earth Ground

voltmeter

(0.75 V)

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

– 2 –

2

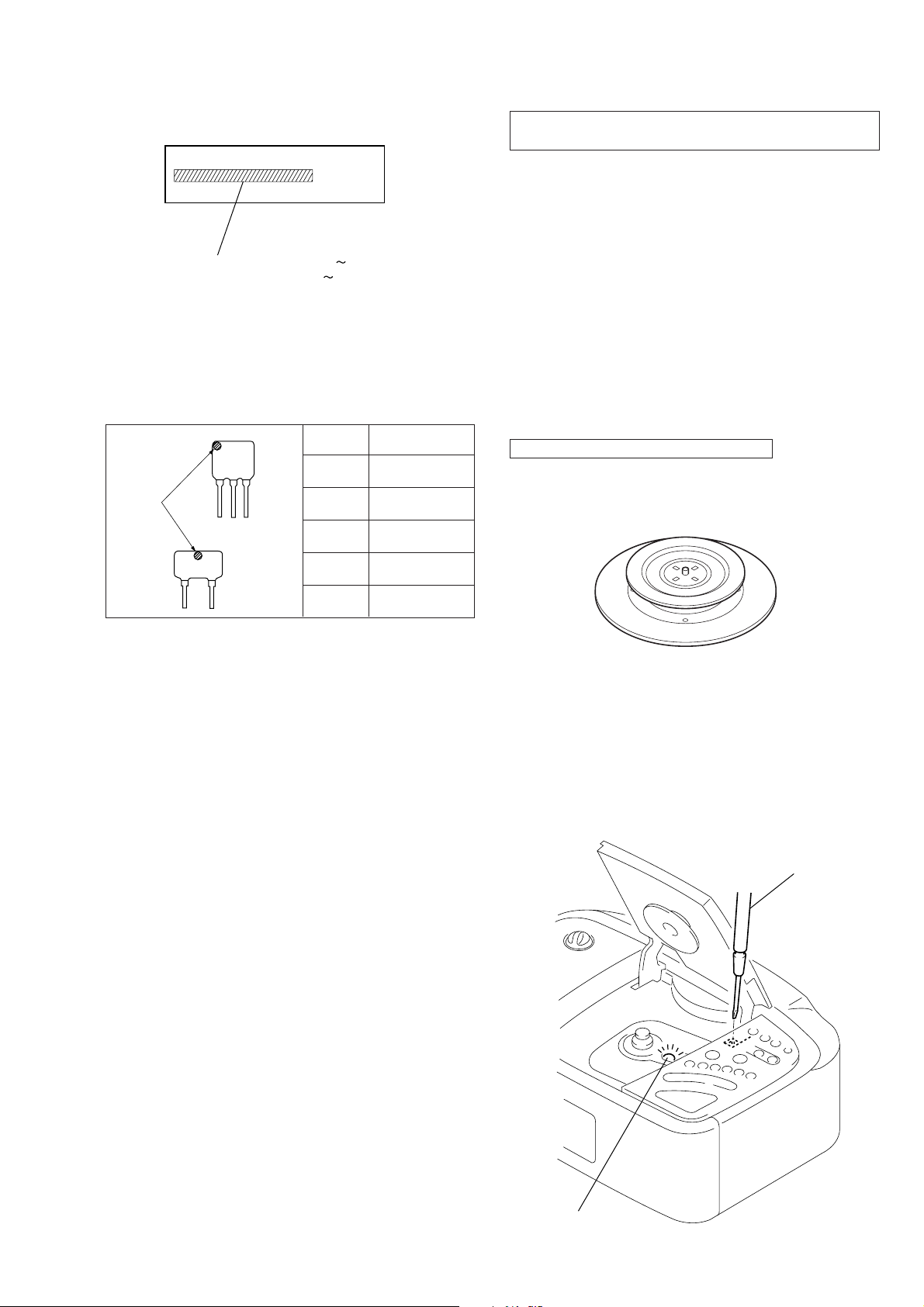

MODEL IDENTIFICATION – Rear View –

W

S

US, Canadian models: AC: 120 V 60 Hz 20

Other models: AC: 220 – 230 V 50 Hz 20 W

HOW TO CHANGED THE CERAMIC FILTERS

This model is used two ceramic filters of CF2 and CF3.

You must used same type of color marked ceramic filters in order

to meet same specifications.

Therefore, the ceramic filter must changed two pieces together

since it’s supply two pieces in one package as a spare parts.

mark

MODEL NO. ICF-CD873

MADE IN MALAYSIA

Mark Center frequency

CF

red 10.70 MHz

blue 10.67 MHz

orange 10.73 MHz

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

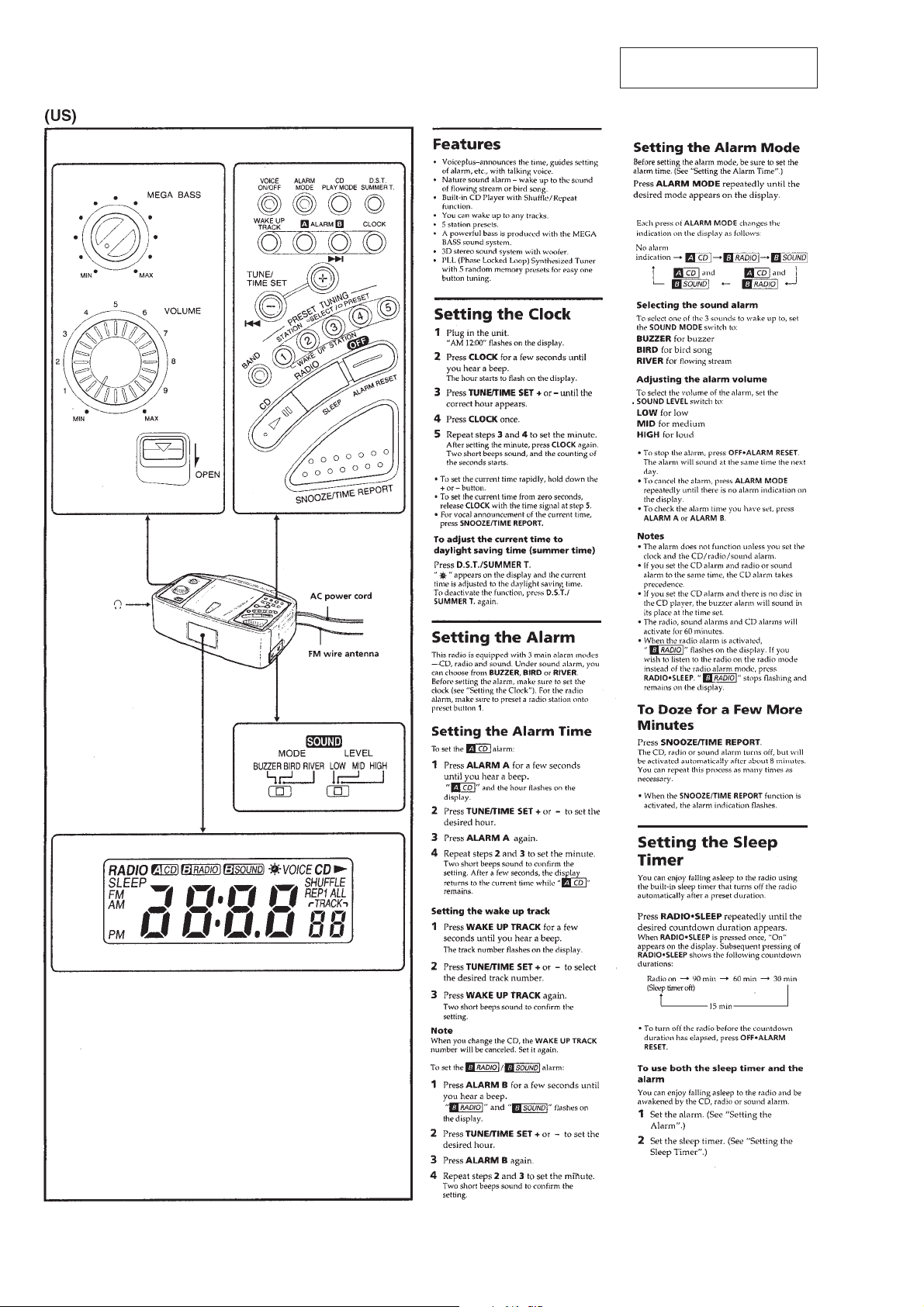

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the CD lid, use

Chuck Plate Jig.

• Code number of Chuck Plate Jig: X-4918-255-1

CF3

black 10.64 MHz

white 10.76 MHz

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

1. Open the CD lid.

2. Turn on S424 as following figure.

3. Conf irm that the laser diode emission while observing the objecting lens. When there is no emission, Auto Power Control

circuit or Optical Pick-up is broken.

Objective lens moves up and down once for the focus search.

Insert a precision

screwdriver and

push S424.

laser diode

emission

– 3 –

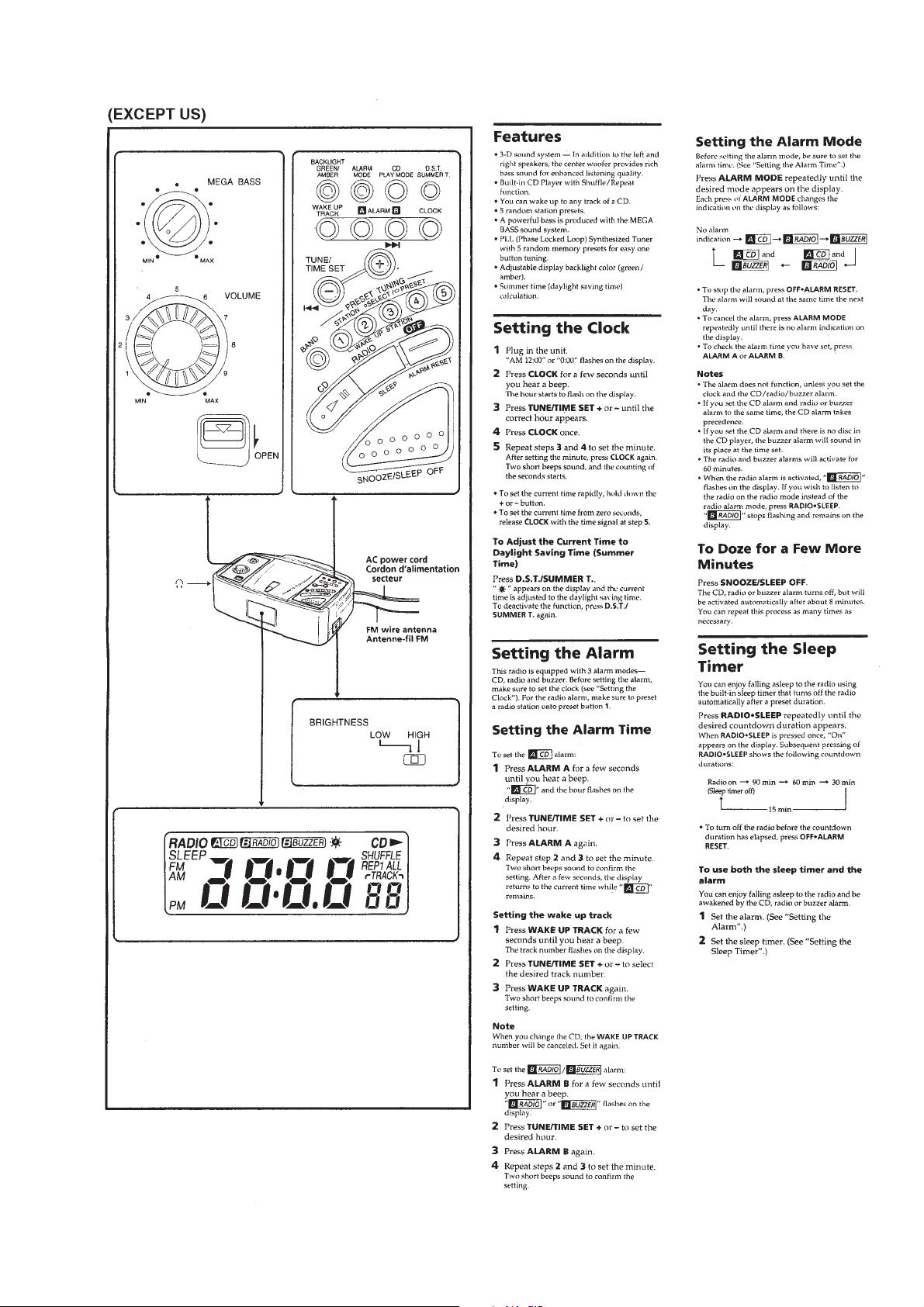

SECTION 2

GENERAL

This section is extracted from

instruction manual.

– 4 –

– 5 –

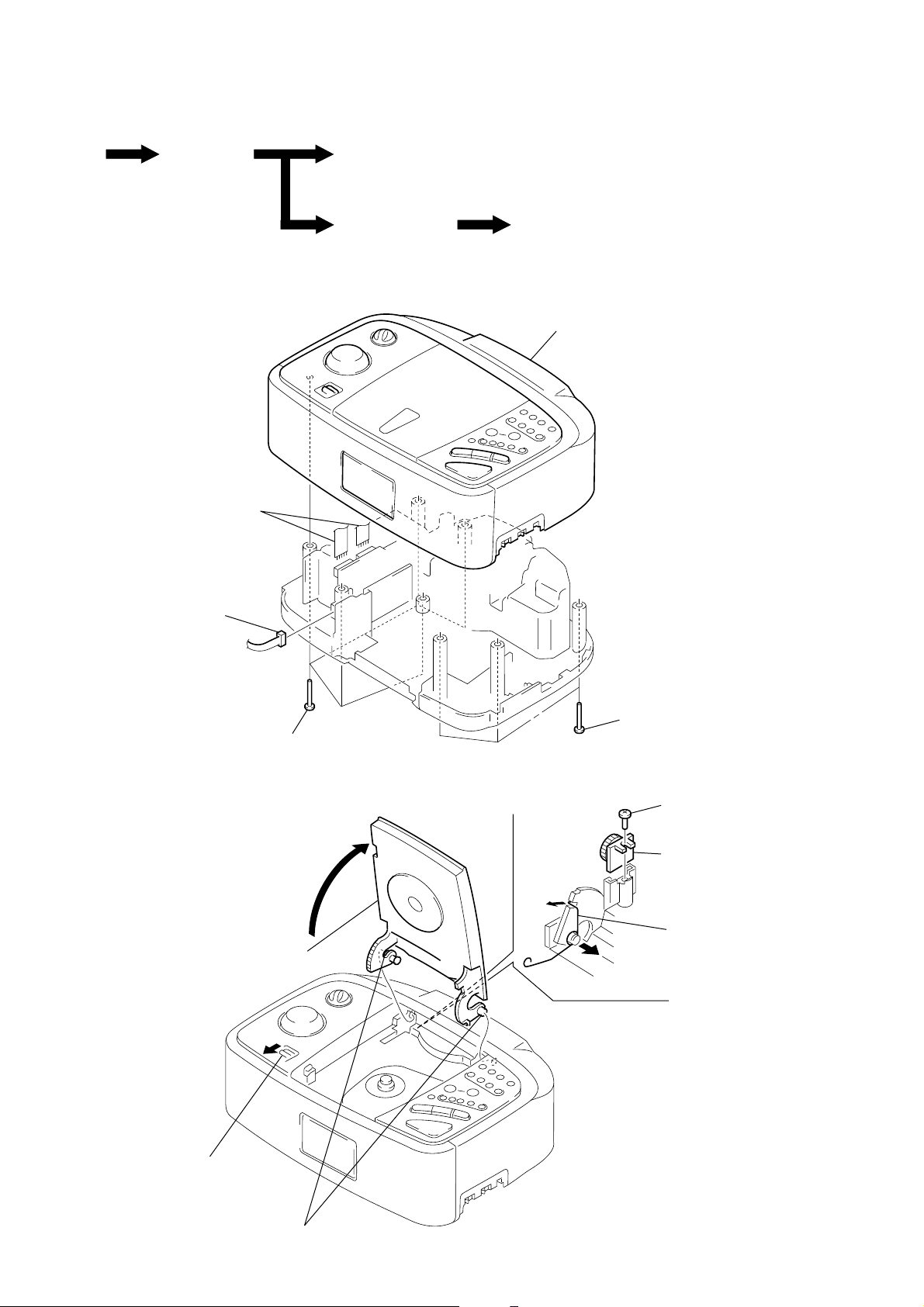

• This set can be disassembled in the order shown below.

SECTION 3

DISASSEMBLY

Set

Note: Follow the disassembly procedure in the numerical order given.

Upper cabinet

section

CD lid assy

Main board section Optical pick-up section

UPPER CABINET SECTION

3

two flat wires

(CN201, 202)

2

upper cabinet section

CD LID ASSY

4

connector

(CN204)

1

five screws

(P3

2

Open the CD lid assy.

7

Remove the CD lid

assy.

×

14)

1

three screws

(P3

×

14)

3

screw

(B3 × 10)

4

damper

5

spring

(CD open)

1

Pull the button (open).

6

two bosses

– 6 –

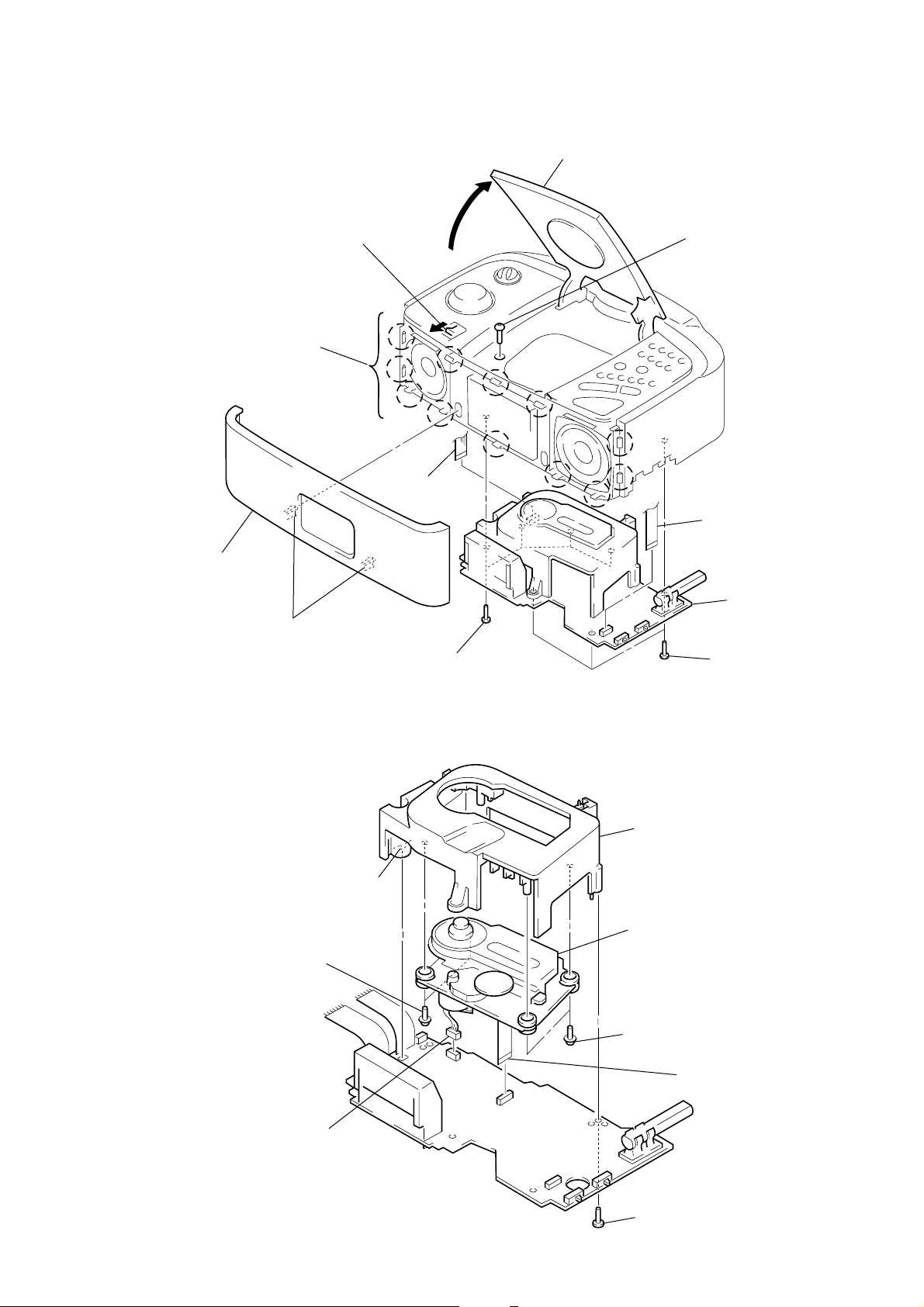

MAIN BOARD SECTION

1

2

net assy

3

Pull the button (open).

twelve

claws

8

flat wire

(CN101)

4

Open the CD lid.

5

screw

(B3 × 10)

8

flat wire

(CN402)

1

two claws

OPTICAL PICK-UP SECTION

6

two screws

(PWH2.6 × 10)

2

claw

6

four screws

(P3 × 14)

3

CD chassis

7

optical pick-up

section

6

two screws

(PWH2.6 × 10)

7

main board

section

6

three screws

(P3 × 14)

5

connector

(CN502)

– 7 –

1

screw

(BTP3 × 8)

4

flat wire

(CN501)

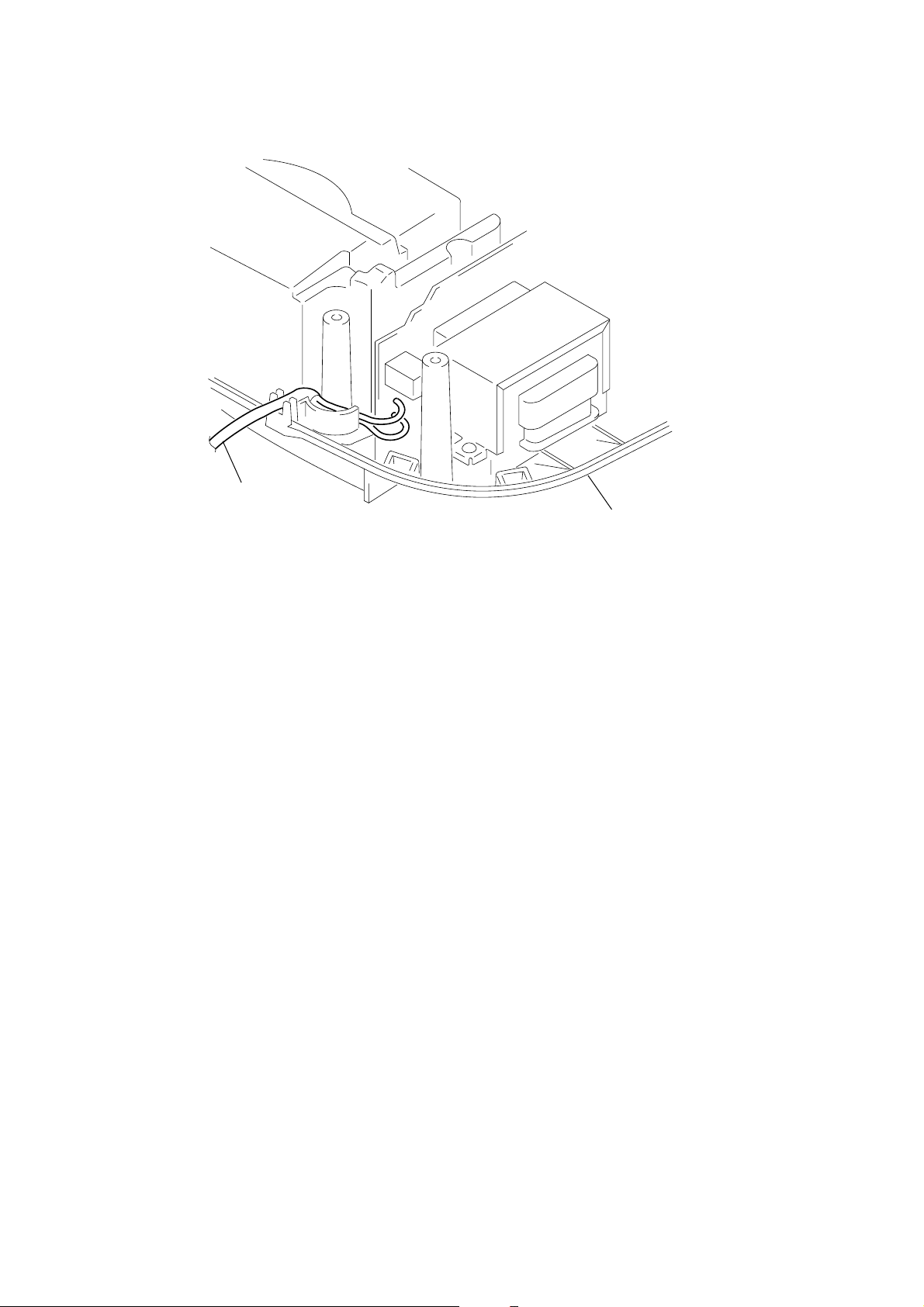

SECTION 4

POWER CORD SETTING

Set the power cord as illustrated below, then install the lower cabinet section.

Power Cord

lower cabinet section

– 8 –

SECTION 5

r

r

FM RF SSG

Carrier frequency: 98 MHz

Modulation: 400 Hz, 30% FM modulation

Output level: 0.1 V (100 dB)

MAIN board

TP12 (FM IN)

0.01 µF

set

1 µF

TP8 (VCO)

+

–

frequency counter

33 k

Ω

TP7 (+B)

+

MAIN board

ELECTRICAL ADJUSTMENTS

TUNER SECTION 0 dB=1 µV

[AM]

Setting:

Function : RADIO

Band switch: AM

AM RF signal

generator

30% amplitude

modulation by

400 Hz signal

Output level: as low as possible

[FM]

Setting:

Function : RADIO

Band switch: FM

FM RF signal

generator

22.5 kHz frequency

deviation by 400 Hz

signal

Output level: as low as possible

Put the lead-wire

antenna close to

the set.

set

MAIN board

TP12 (FM IN)

0.01 µF

set

digital voltmeter

32

Ω

2

jack (J301)

32

Ω

2

jack (J301)

level mete

+

–

level mete

+

–

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter

T1 450 kHz

AM FREQUENCY COVERAGE ADJUSTMENT

Adjustment Part Frequency Display Reading on Digital Voltmeter

L4 530 kHz 2.8 V

Confirmation 1,710 kHz 9.5V

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L3 580 kHz

CT2 1,490 kHz

FM FREQUENCY COVERAGE ADJUSTMENT

Adjustment Part Frequency Display Reading on Digital Voltmeter

L2 87.5 MHz 2.1 V

Confirmation 108 MHz 8.5 V

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L1 87.5 MHz

CT1 108 MHz

Adjustment Location: MAIN board (See page 11)

FM VCO Adjustment

Setting:

100 k

MAIN board

TP53 (VT)

Ω

• Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

• Remove FM antenna in FM adjustments.

Procedure:

1. Connect the frequency counter to TP7, 8 as shown the figure

below.

2. Tune the set to 98 MHz.

3. Adjust RV1 for 76 kHz reading on the frequency counter.

Specified Value: 75.95 to 76.05 kHz

Adjustment Location: MAIN board (See page 13)

– 9 –

CD SECTION

Note:

Tracking Balance Adjustment and Tracking Gain Adjustment are

done automatically in this set.

TEST MODE

1. Press the CD LID OPEN/CLOSE DET switch (S424) on the

PUSH SWITCH board.

2. Under standby condition (when the clock appear in the display), short the BP (CD TEST AUTO).

Note: If the power is supplied to the microprocessor once, it is backed up

for 3 minutes, therefore the TEST mode will not be activ ated within

3 minutes even if the power is turned on again. In this case, short

instantaneously the BP (CD TEST MANUAL).

3. Press the ^ key, and the focus search is repeated.

At this time, check that the optical pick-up objective lens mov es

smoothly without a sticking or noise.

4. Load the test disc (YEDS-18: Part No. 3-702-101-01), and perform automatic adjustment after the focus search succeded.

5. After automatic adjustment is finished, move the sled motor

to the center. At this time, keep pressing the + and =

keys to confirm that optical pick-up moves smoothly via most

inside track → most outside track → most inside track without a sticking or noise.

6. Confirm the traverse waveform.

7. Press the [WAKEUPTRACK] key.

8. The tracking servo and the sled servo are turned on, the mute

is cancelled.

9. Playback the 2nd track.

10. Adjust the RF and jitter waveforms.

Connecting points: MAIN Board (See page 13)

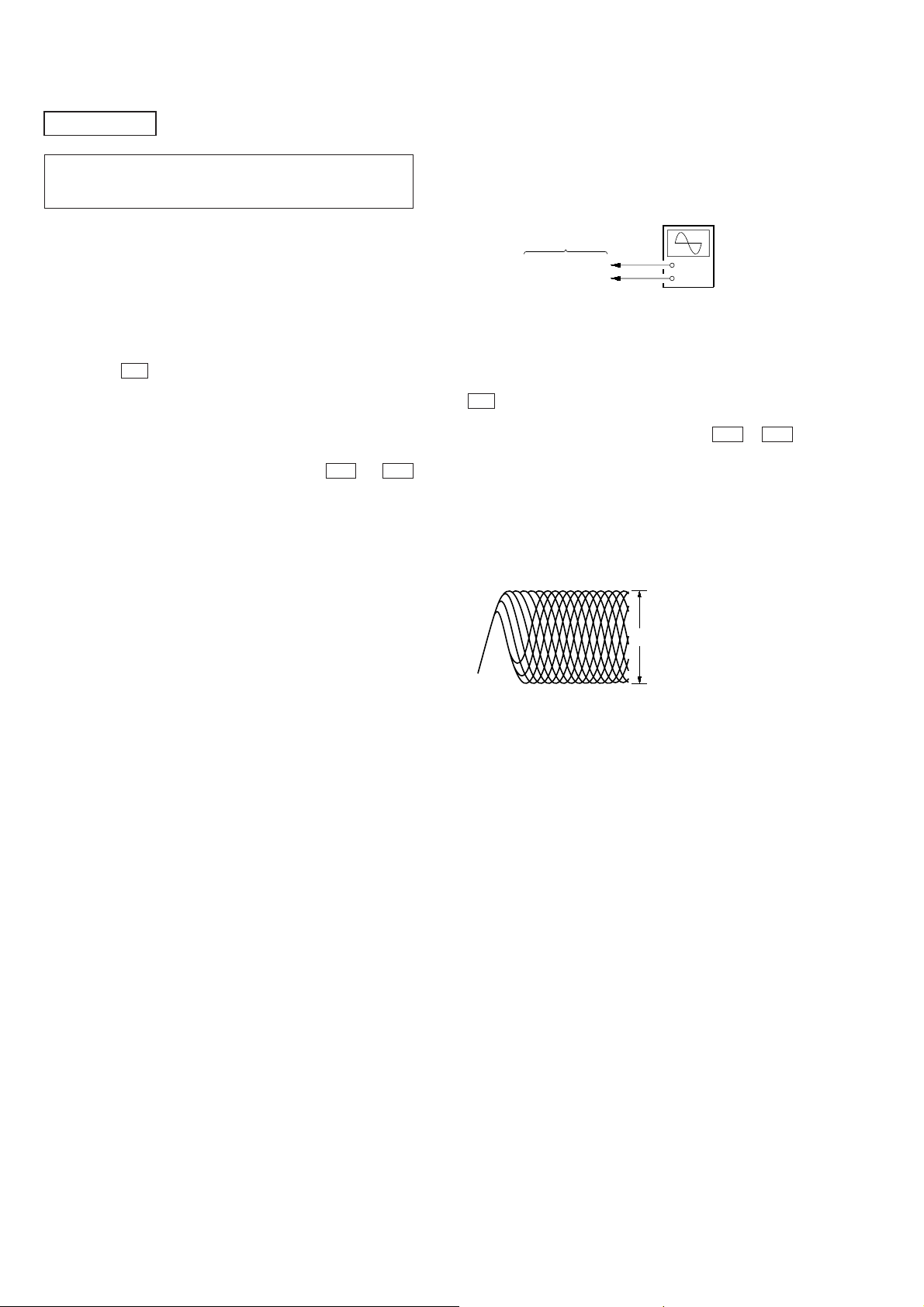

Focus Bias Adjustment

This adjustment is to be done when the optical block is replaced.

Connection:

oscilloscope

(AC range)

MAIN board

TP503 (RF)

TP504 (VREF)

+

–

Adjustment Procedure:

1. Connect the oscilloscope to TP504 (VREF) and TP503 (RF)

on the MAIN board.

2. Insert the test disc (YEDS-18: Part No.3-702-101-01) and press

^ key to play.

3. Move the optical pick-up to the music area on the disc to enable easy visibility of the eye pattern by + or = key

pressing.

4. Adjust RV501 so that the oscilloscope waveform is as shown

in the figure below (eye pattern).

A good eye pattern means that the diamond shape (≈) in the

center of the waveform can be clearly distinguished.

• RF signal reference waveform (eye pattern)

VOLT/DIV: 0.2 V

TIME/DIV: 500 ns

1.3

±

0.5 Vp-p

When observing the eye pattern, set the oscilloscope

for AC range and raise vertical sensitivity.

Adjustment Location: MAIN Board (See page 13)

– 10 –

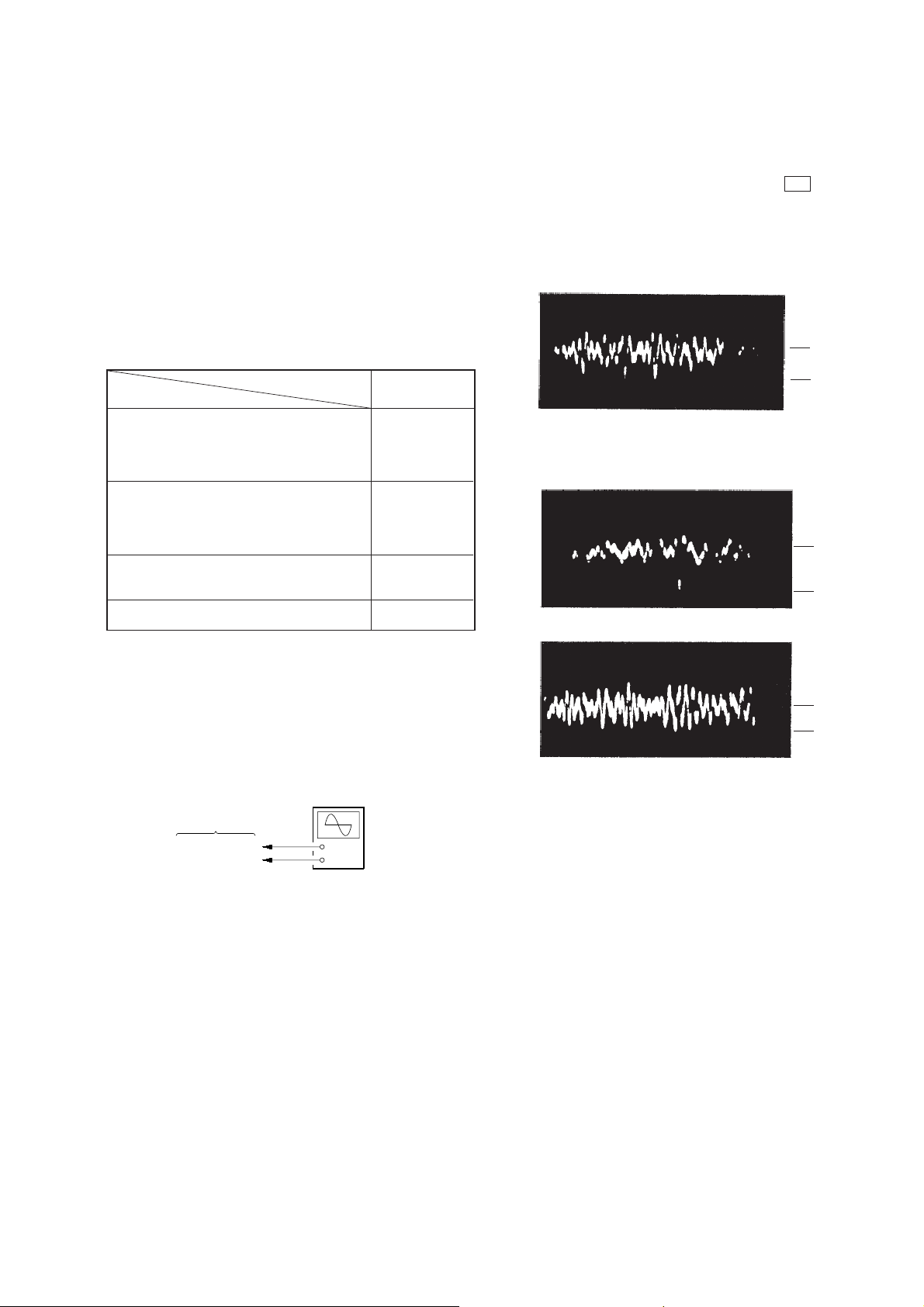

Focus Gain Adjustment

A frequency response analyzer is necessary in order to perform

this adjustment exactly.

However, this gain has a margin, so even if it is slightly off, there

is no problem. Therefore, do not perform this adjustment.

Focus gain determines the optical pick-up follow-up (vertical and

horizontal) relative to mechanical noise and mechanical shock

when the 2-axis device operate.

However , as these reciprocate, the adjustment is at the point where

both are satisfied.

• When gain is raised, the noise when the 2-axis device operates

increases.

• When gain is lowered, mechanical shock and skipping occurs

more easily.

• When gain adjustment is off, the symptoms below appear.

Procedure:

1. Keep the set horizontal.

If the set is not horizontal, this adjustment cannot be per-

(

formed due to the gravity against the 2-axis device

2. Insert the test disc (YEDS-18) and press the ^ button.

3. Connect the oscilloscope BT (FEO) and TP504 (VREF) on

the MAIN board.

4. Adjustment RV502 on the MAIN board so that the waveform

is as shown in the figure below.

VOLT/DIV: 100 mV

TIME/DIV: 2 mS

100 mV

)

Symptoms

• The time until music starts becomes longer for

STOP → PLAY or automatic selection.

(=, + buttons pressed)

(Normally takes about 2 seconds)

• Music does not start and disc continues to

rotate for STOP → PLAY or automatic

selection.

(=, + buttons pressed)

• Sound is interrupted during PLAY.

Or time counter display stops progressing.

• More noise during 2-axis device operation

Gain Focus

low

–

–

high

The following is a simple adjustment method.

– Primary Adjustment –

Note: Since exact adjustment cannot be performed, remember the posi-

tions of the controls before performing the adjustment. If the positions after the primary adjustment are only a little different, return

the controls to the original position.

Connection:

oscilloscope

MAIN board

BP (FEO)

TP504 (VREF)

+

–

0 V

• Incorrect Examples (DC level changes more than on adjusted

waveform)

low focus gain

high focus gain

VOLT/DIV: 100 mV

TIME/DIV: 2 mS

200 mV

0 V

VOLT/DIV: 100 mV

TIME/DIV: 2 mS

75 mV

0 V

Adjustment Location: MAIN Board (See page 13)

– 11 –

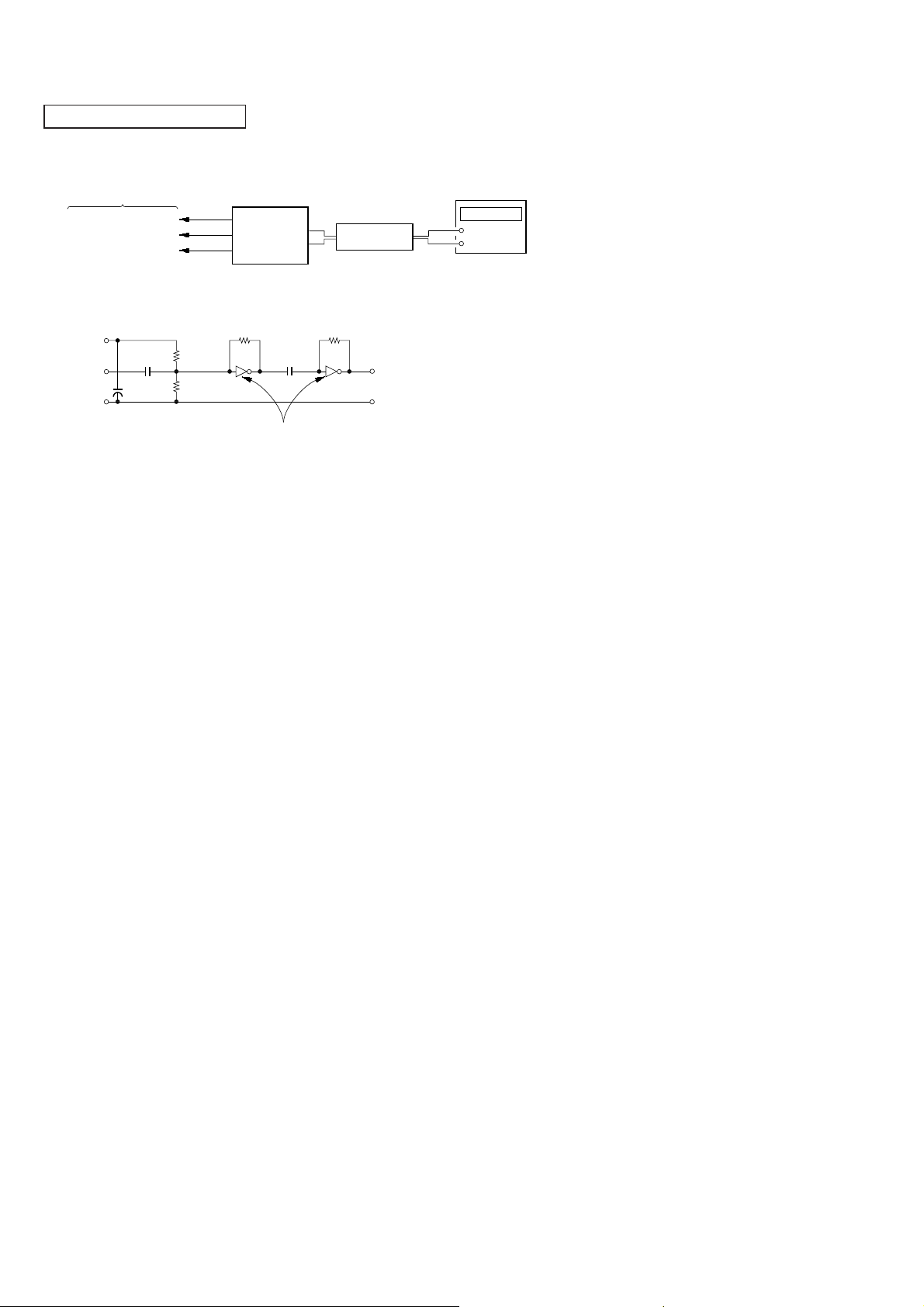

MAIN CLOCK SECTION

Main Clock Adjustment

Connection:

Ω

Ω

adjustment

+5

IN

GND

100 k

INVERTER

(TC7W04F)

jig

OUT

GND

Ω

1000 pF

100 k

10 : 1 probe

Ω

OUT

GND

MAIN board

TP (+5 V)

TP401 (4.194 MHz)

TP GND (SHIELD)

Adjustment jig:

+5 V

IN

GND

+

0.5 pF

47 uF

1 M

1 M

Procedure:

1. Connect the frequency counter as the above figures.

2. Adjust CT401 for 4.2495 MHz reading on the frequency

counter.

Specified Value: 4.2490 to 4.2500 MHz

frequency counter

+

–

– 12 –

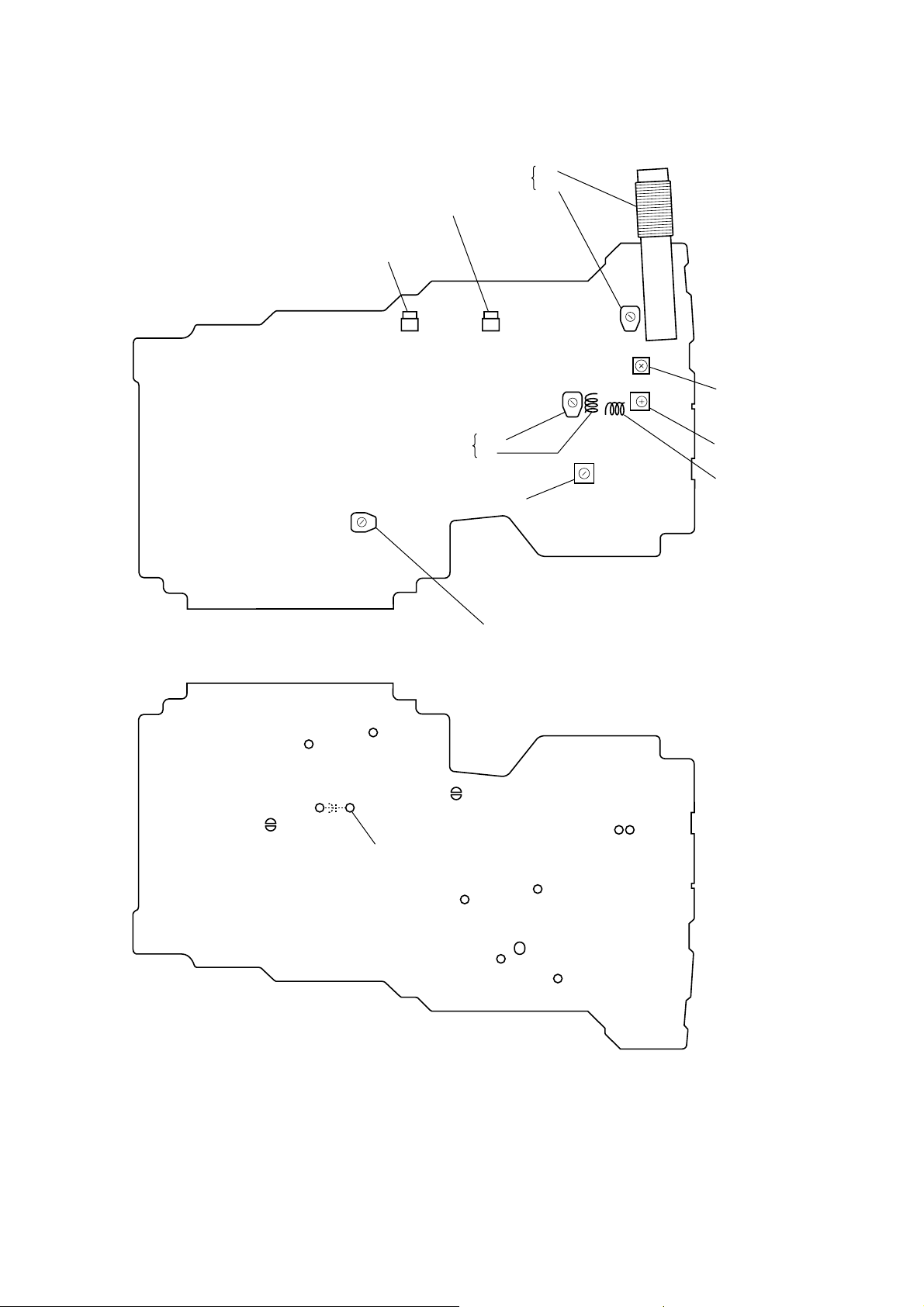

Adjustment Location and Connecting Points:

T1 AM IF Adjustment

CT401 Main Clock Adjustment

RV501 Focus Bias Adjustment

RV502 Focus Gain Adjustment

RV1 FM VCO Adjustment

AM Frequency Coverage

Adjustment

L4

L2 FM Frequency Coverage

Adjustment

L3

CT2

AM T rac king Adjustment

CT1

L1

FM T rac king Adjustment

– MAIN BOARD (Component Side) –

– MAIN BOARD (Conductor Side) –

BP (CD TEST AUTO)

BP (FEO)

BP (CD TEST MANUAL)

TP8

(VCO)

TP7

(+B)

TP12 (FM IN)

TP504 (VREF)

TP53 (VT )

TP503 (RF)

TP (+5 V)

C429

TP GND

(SHIELD)

TP401

(4.194 MHz)

+

– 13 –

Loading...

Loading...