Sony ICFCD-823 Service manual

ICF-CD823

SERVICE MANUAL

Ver 1.0 2000. 05

SPECIFICATIONS

CD player section

System: Compact disc digital audio system

Laser diode properties: Material: GaAlAs

Wavelength: 780 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW

(This output is the value measured at a

distance of about 200 mm from the objective

lens surface on the optical pick-up block with

7 mm aperture.)

Frequency response: 20-20,000 Hz

Wow and flutter: Below measurable limit

Radio section

Frequency range:

Band Channel step

US, Canadian:

FM 87.5-108 MHz 0.1 MHz

AM 530-1,710 kHz 10 kHz

AEP:

FM 87.5-108 MHz 0.05 MHz/0.1 MHz

AM 531-1,602 kHz 9 kHz

530-1,610 kHz 10 kHz

Australian:

FM 87.5-108 MHz 0.05 MHz

AM 531-1,602 kHz 9 kHz

–1.5

+1

dB

US Model

Canadian Model

AEP Model

Australian Model

Model Name Using Similar Mechanism ICF-CD820

Optical Device Name KSM-213CDM

Optical Pick-UP Name KSS-213C

General

Time display:

North and South America and Australia:

12-hour system

Other countries: 24-hour system

Speaker:

77 mm (3 1⁄8 inches) dia., 4 Ω

Output:

i (headphones) jack (ø 3.5 mm stereo minijack)

(except North American model)

Power outputs:

1.2 W + 1.2 W

(at 10% harmonic distortion)

Power requirements:

North and South American model:

120 V AC, 60 Hz

Australian model:

240 V AC, 50 Hz

Other models:

220-230 V AC, 50 Hz

Dimensions:

Approx. 250 × 153 × 207 mm (w/h/d)

(Approx. 9 7⁄8 × 6 1⁄8 × 8 1⁄4 inches) incl.

projecting parts and controls

Mass:

Approx. 1,700 g (3 lb. 12 oz.)

Design and specifications are subject to change

without notice.

FM/AM CD CLOCK RADIO

TABLE OF CONTENTS

r

1. GENERAL ········································································ 4

2. DISASSEMBLY

2-1. CABINET, LOWER ······················································ 5

2-2. MAIN BOARD ····························································· 6

2-3. PANEL (FRONT) SUB ASSY ······································ 6

2-4. OPTICAL PICK-UP BOLCK (KSM-213CDM) ·········· 7

2-5. TRANSFORMER BOARD··········································· 7

3. TEST MODE ·······························································8

4. ELECTRICAL ADJUSTMENTS ························ 10

5. DIAGRAMS

5-1. BLOCK DIAGRAM ··················································· 11

5-2. CIRCUIT BOARDS LOCATION ······························· 13

5-3. SCHEMATIC DIAGRAM

– MAIN SECTION (1/2) – ·········································· 14

5-4. SCHEMATIC DIAGRAM

– MAIN SECTION (2/2) – ·········································· 17

5-5. PRINTED WIRING BOARD

– MAIN SECTION – ·················································· 20

5-6. PRINTED WIRING BOARD

– PANEL SECTION – ················································· 23

5-7. IC PIN FUNCTION DESCRIPTION ························· 25

5-8. IC BLOCK DIAGRAMS ············································ 26

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

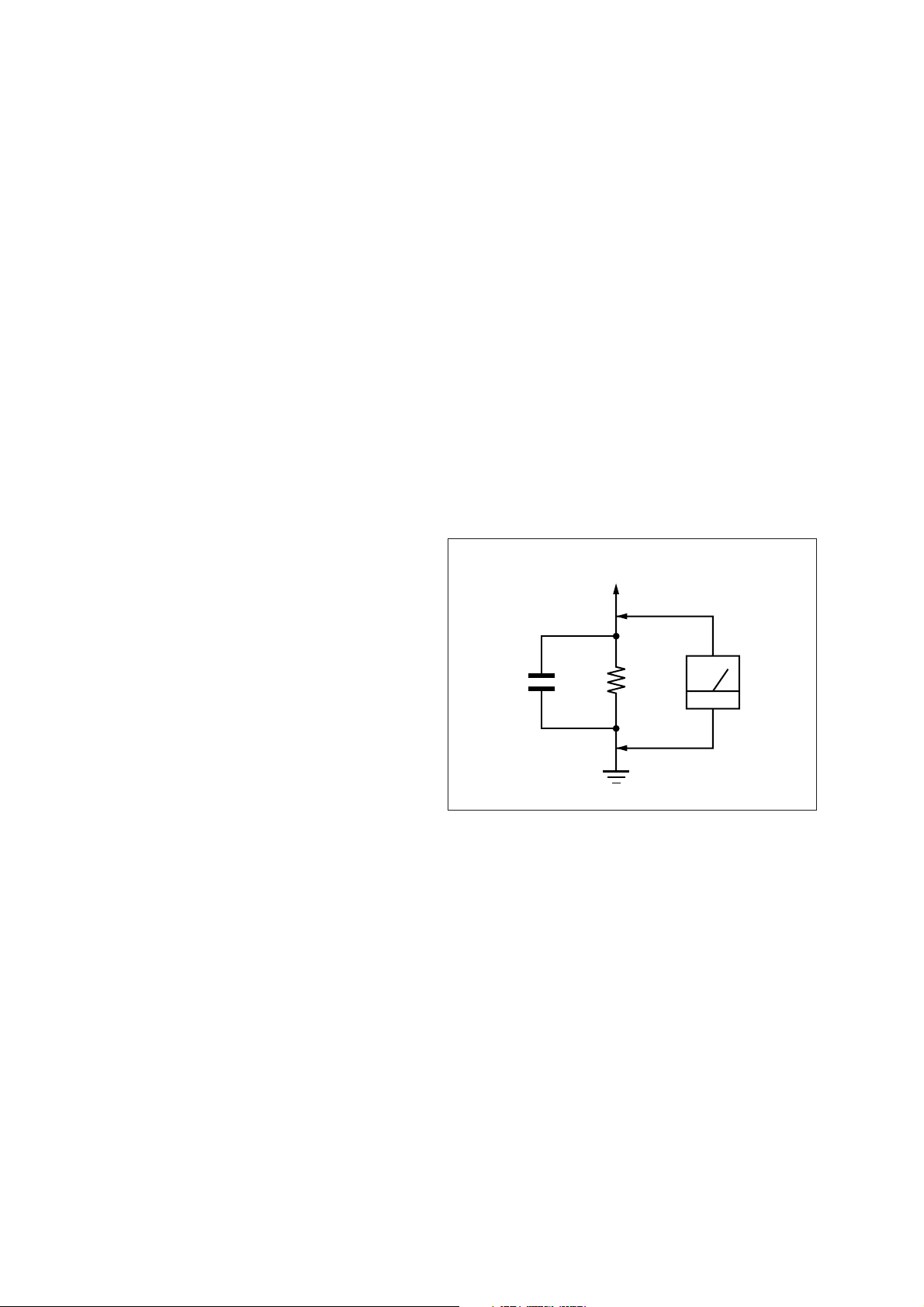

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a

passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2 V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

6. EXPLODED VIEWS

6-1. LOWER CABINET SECTION··································· 29

6-2. UPPER CABINET SECTION ···································· 30

6-3. OPTICAL PICK-UP SECTION

(KSM-213CDM) ························································· 31

7. ELECTRICAL PARTS LIST ································· 32

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

AC

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

Ω

Earth Ground

voltmete

(0.75 V)

Note on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU DANS

LES SUPPLÉMENTS PUBLIÉS PAR SONY.

À LA SÉCURITÉ!

— 2 —

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

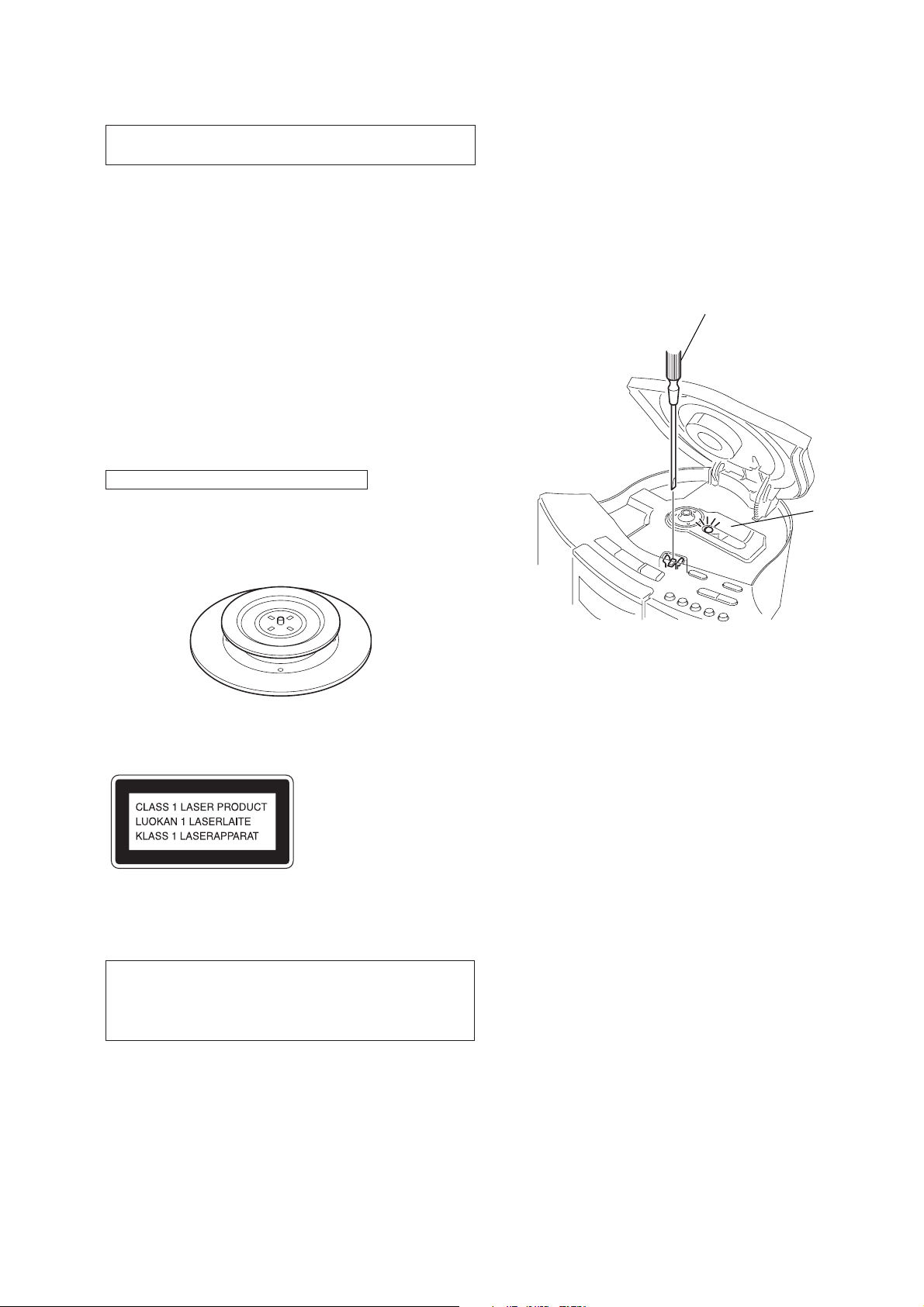

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the CD lid, use

Chuck Plate Jig.

• Code number of Chuck Plate Jig: X-4918-255-1

LASER DIODE AND FOCUS SEARCH

OPERATION CHECK

1. Open the CD lid.

2. Turn on S501 as following figure.

3. Confirm that the laser diode emission while observing the

objecting lens. When there is no emission, Auto Power Control

circuit or Optical Pick-up is broken.

Objective lens moves up and down once for the focus search.

Insert a precision

screwdriver and

push S501.

laser diode

emission

This Compact Disc player is classified as a CLASS 1

LASER product.

The CLASS 1 LASER PRODUCT label is located on the

bottom exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

— 3 —

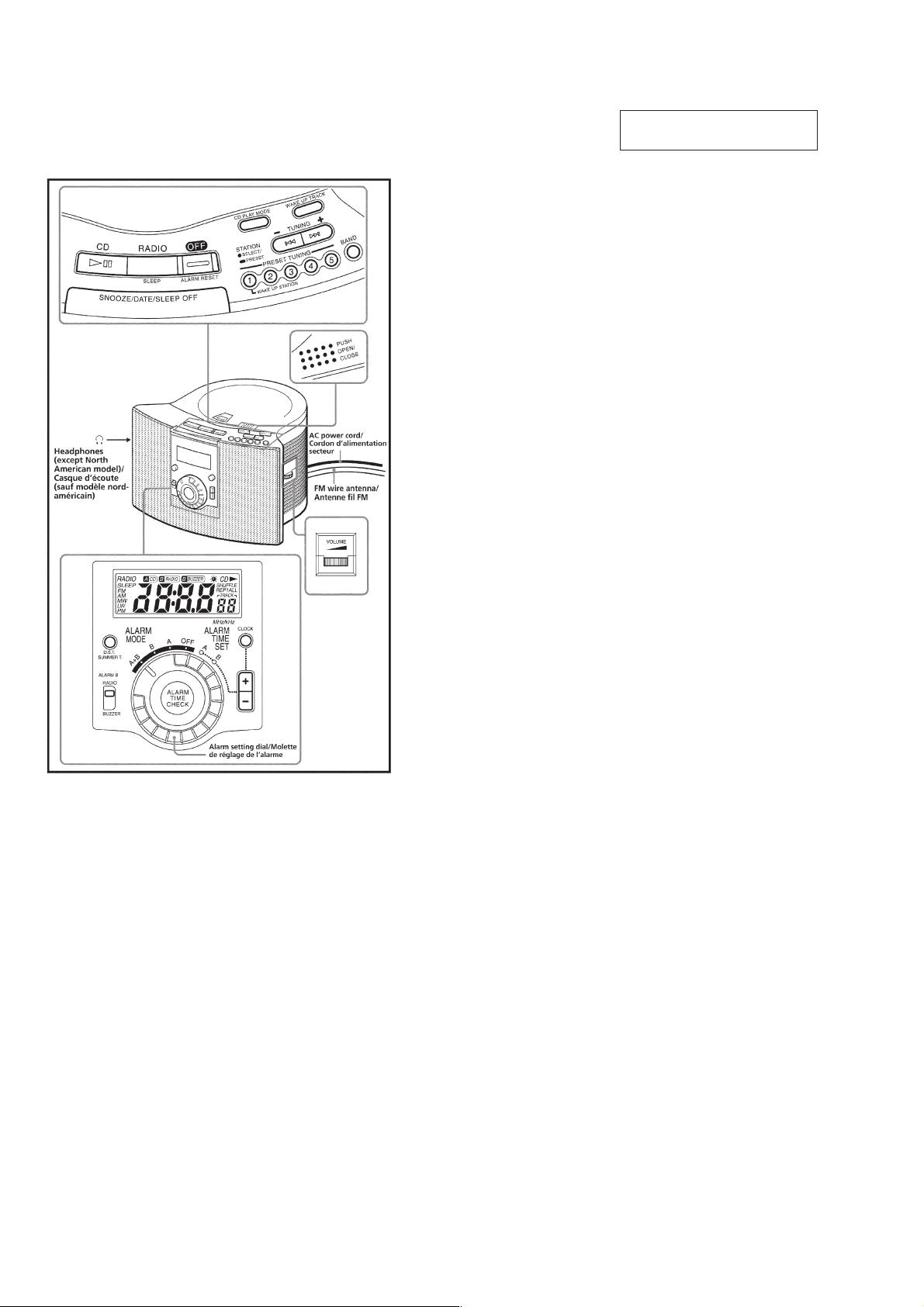

SECTION 1

GENERAL

Setting the Clock

and Date

1 Set the alarm setting dial to ALARM

MODE OFF.

2 Plug in the clock radio.

The display will flash “AM 12:00” or “0:00”.

3 Press CLOCK for a few seconds.

You will hear a beep and the year will start to

flash in the display.

4 Press CLOCK + or – until the correct

year appears in the display.

5 Press CLOCK once.

6 Repeat steps 4 and 5 to set the month,

day, hour, and minute.

After setting the minute, press CLOCK to start

the counting of the seconds, and you will

hear two short beeps.

This section is extracted from

instruction manual.

• To display the year and date, press SNOOZE/

DATE/SLEEP OFF once for the date, and within

2 seconds press it again for the year. The

display shows the date or year for a few

seconds and then changes back to the current

time.

• To set the current time rapidly, hold down

CLOCK + or –.

• The clock system varies depending on the

model you own.

12-hour system: “AM 12:00” = midnight

24-hour system: “0:00” = midnight

• In step 6, when you press CLOCK after the

minute setting to activate the clock, the seconds

start counting from zero.

• When the alarm setting dial is set to ALARM

TIME SET A or B, the clock cannot be set.

To change the display to the

daylight saving time (summer time)

indication

Press D.S.T./SUMMER T.

“s” is displayed and the time indication

changes to summer time.

To deactivate the summer time function, press

D.S.T./SUMMER T. again.

— 4 —

SECTION 2

r

DISASSEMBLY

• The equipment can be removed using the following procedure.

Cabinet, lower

Set

Note: Follow the disassembly procedure in the numerical order given.

Main board

Transformer board

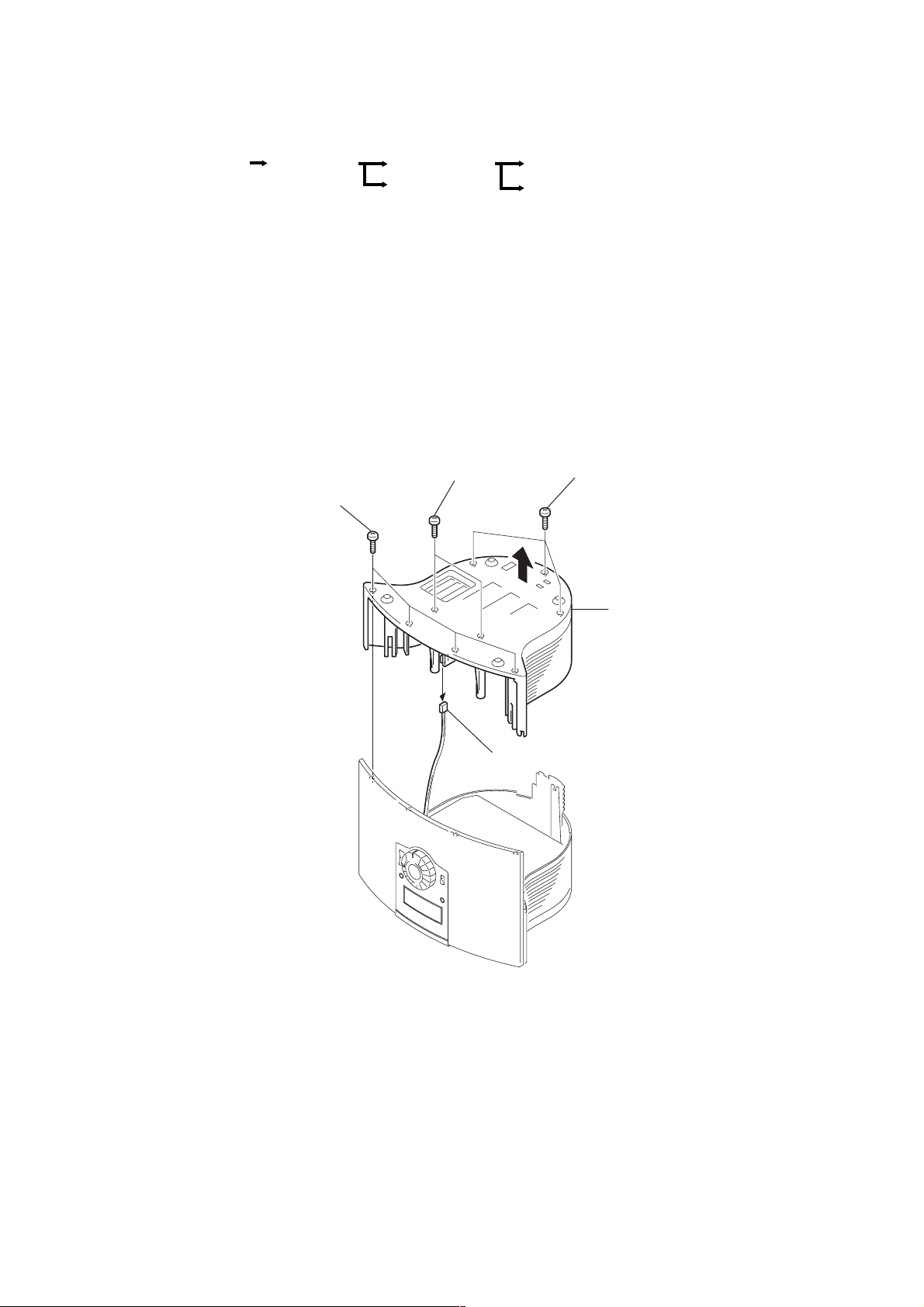

2-1. CABINET, LOWER

2

Two screws

1

Four screws

(+BVTP 3

×

(+P 3

10)

Panel (front) sub assy

Optical pick-up block (KSM-213CDM)

×

14)

3

Three screws

(+P 3

×

5

Cabinet, lowe

14)

4

Connector

— 5 —

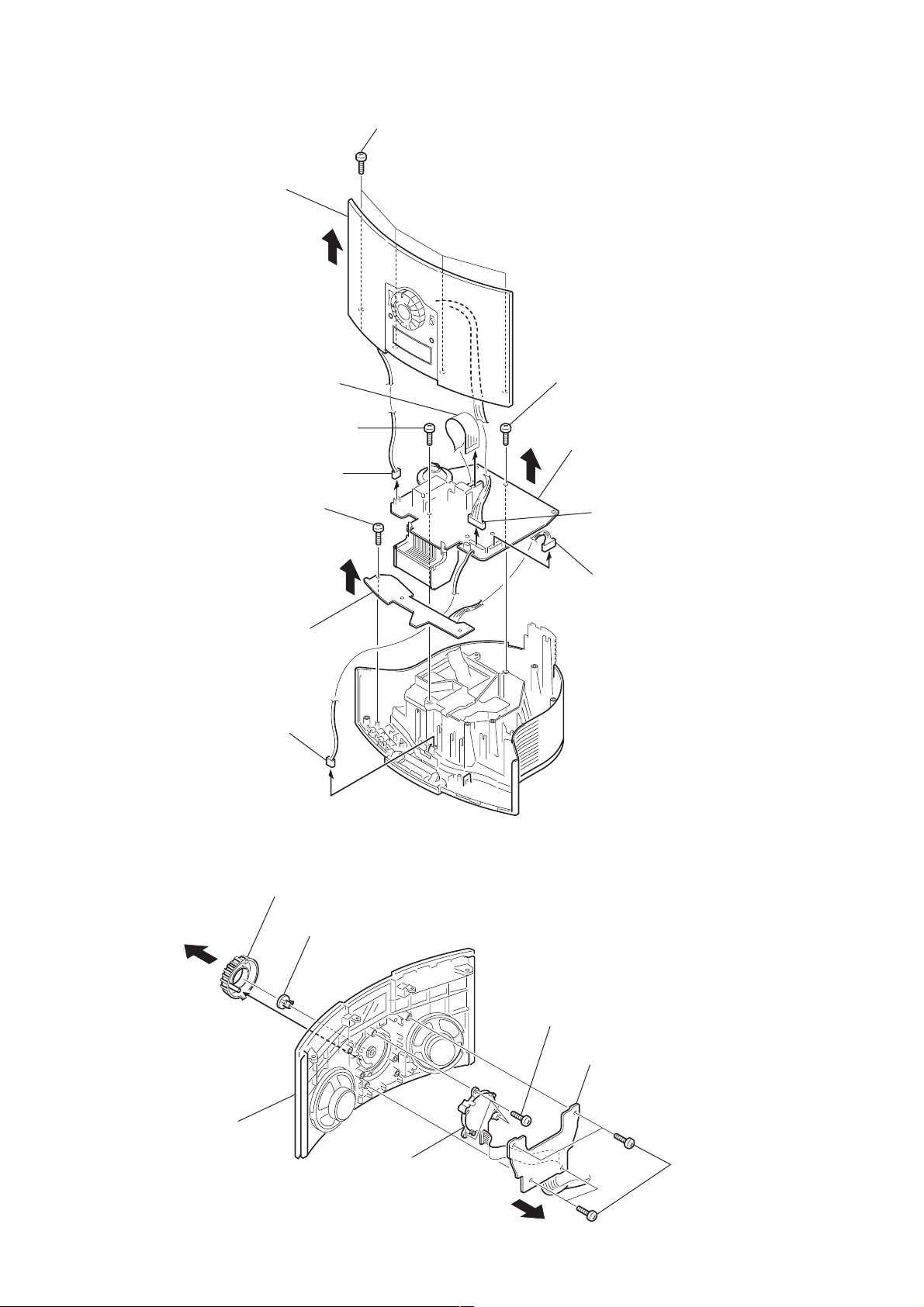

2-2. MAIN BOARD

r

r

)

4

Panel (front) assy

0

Flat cable

2

Connector

5

Screw

(+P 3

8

Screw

(+P 3

×

6)

×

6)

1

Four screws

(+P 3

×

6)

9

Screw

(+P 3

×

qs

Main board

3

Connecto

6)

7

Key (upper) board

qa

Connector

2-3. PANEL (FRONT) SUB ASSY

5

Knob (alarm) (A)

6

Button (alarm) (A)

6

Connecto

3

Three screws

(+BTP 2.6 × 6)

7

Panel (front)

sub assy

4

Dial (alarm) assy

— 6 —

2

Key (front) board

1

Four screws

(+BTP 2.6 × 6

s

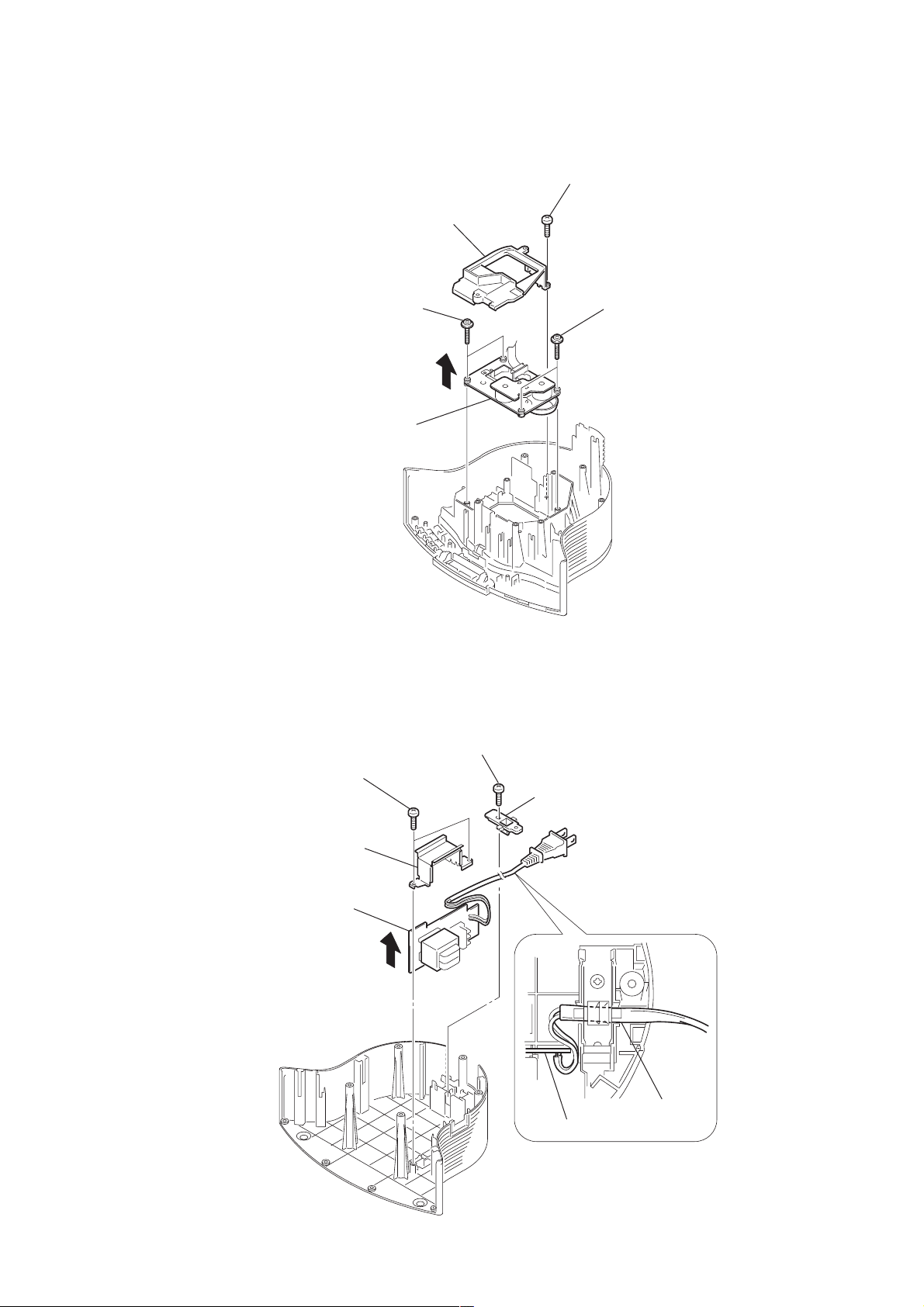

2-4. OPTICAL PICK-UP BLOCK (KSM-213CDM)

2

Cover (unit)

4

Two screws

(2.6

×

10)

5

Optical pick-up

block (KSM-213 CDM)

1

Screw

(+P 3

×

6)

3

Two screw

(2.6 × 10)

2-5. TRANSFORMER BOARD

4

5

3

Two screws

(+BTP 3 × 6)

Heat sink

Transformer board

1

Screw (+BTP 3 × 10)

2

Stopper, cord

Power board

power cord

— 7 —

SECTION 3

TEST MODE

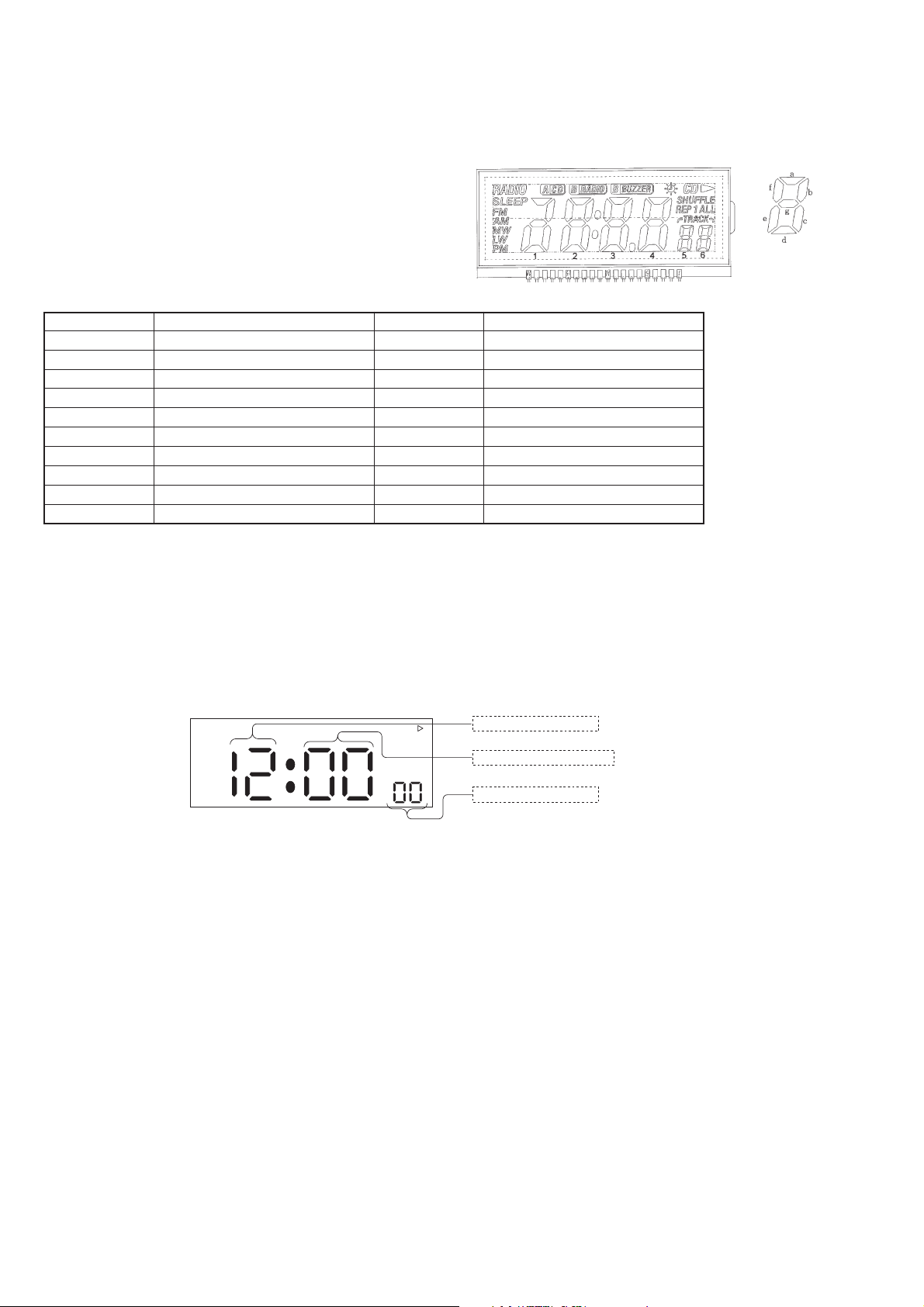

3-1 LCD Test Mode

• The LCD test mode is initiated by turning off the main power once then back on or by resetting the machine while TP415 (LCD TEST, pin60 terminal) is connected to GND.

• The LCD test mode operations are listed in the following table.

• When the machine enters the LCD test mode, all LCDs turn on.

• Pressing any key turns off the corresponding segment of the LCD.

Correspondence between the keys and segments of LCD are as follows.

(LCD segment)

KEY

1

2

3

4

5

BAND

SNOOZE

D.S.T

CLOCK +

CLOCK

1a, 1b, 1c, 1d, 1e, 1g

2a, 2b, 2c, 2d, 2e, 2f, 2g,

3a, 3b, 3c, 3d, 3e, 3f, 3g,

4a, 4b, 4c, 4d, 4e, 4f, 4g,

5a, 5b, 5c, 5d, 5e, 5f, 5g,

FM, MW, LW

SLEEP

s

6a, 6b, 6c, 6d, 6e, 6f, 6g,

:, .

SEGMENT

KEY

CLOCK

OFF

CD

RADIO

WAKE UP TRACK

CD PLAY MODE

TUEN +

TUEN –

SEGMENT

AM, PM,

A CD

CD H

RADIO

TRACK

REP, 1, ALL, SHUFFLE, CD

B RADIO

B BUZZER

• Pressing the [ALARM TIME CHECK] button at end of the LCD test mode shows the version number of the software on the LCD.

• The alarm-dial position detection can be checked and displayed if the alarm-dial is operated while the version number is being displayed

on LCD.

• State of the [ALARM-B: RADIO/BUZZER] slide switch position can be detected and displayed on the alarm picture.

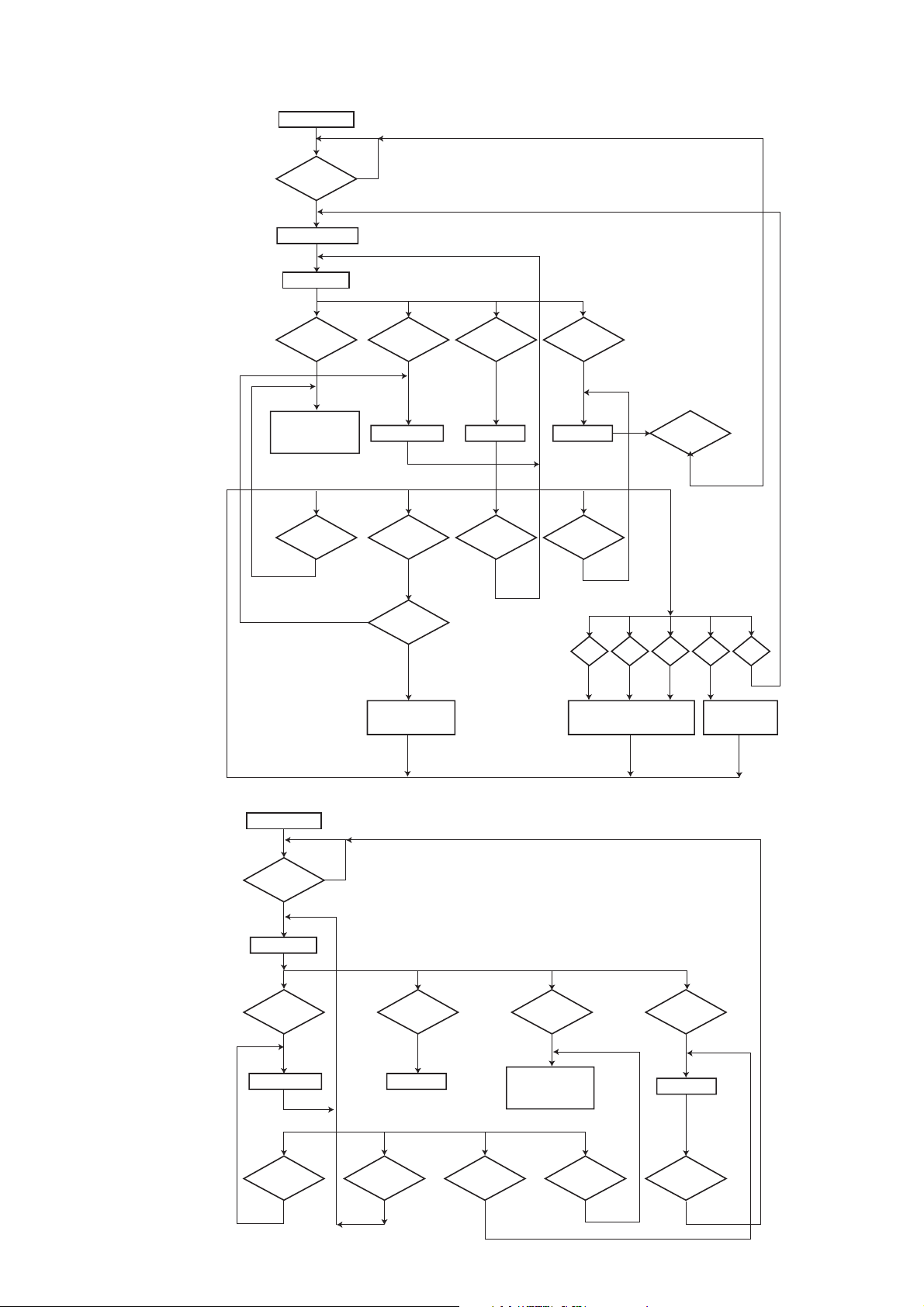

3-2 CD Test Mode

3-2-1 CD TEST-1 (AUTO)

• The CD TEST-1 (AUTO) mode is initiated by turning off the main power once then back on or by resetting the machine while TP414 (CD

TEST, pin-59 terminal) is connected to GND.

• When the machine enters CD TEST-1 (AUTO) mode, it repeats the focus search until the focus becomes OK.

• After the focus becomes OK and the focus is automatically adjusted, rough servo is locked in and the adjustment value is displayed.

F-E BALANCE ADJUSTMENT

TRACKING GAIN ADJUSTMENT

FOCUS BIAS ADJUSTMENT

AM

CD

SRUFFLE

TRACK

• The sled can be moved to the innermost track by pressing the minus (-) button. The sled can be moved to the outermost track by pressing

the plus (+) button.

• When the BAND button is pressed, the machine enters the CLVA (servo ON) and the mute is turned OFF if data is read successfully.

When the following button is pressed, the corresponding operations are performed.

a) 1 Setting the 1 track jump

b) 2 Setting the 10 track jump

c) 3 Setting the 100 track jump

Afterwards the desired track jump can be set by pressing the plus (+) or minus (-) button.

d) 4 TRACKING GAIN-UP

e) BAND’s rough servo

• P5 Restarts CD TEST-1 (AUTO) mode from the focus automatic adjustment

• When the CD button is pressed then, the track jumps to the second session and the machine exits the CD TEST-1 (AUTO) mode.

• When the OFF button is pressed, the CD playback is stopped. If the CD button is pressed again, the machine repeats operations from the

focus search.

3-2-2 CD TEST-2 (MANUAL)

• The CD TEST-2 (MANUAL) mode is initiated by turning off the main power once then back on or by resetting the machine while TP413

(A MUT, pin-58 terminal) is connected to GND.

• When the machine enters CD TEST-2 (MANUAL) mode, it repeats the focus search until the focus becomes OK.

• After the focus becomes OK, the machine enters the rough servo.

• The sled can be moved to the innermost track by pressing the minus (-) button. The sled can be moved to the outermost track by pressing

the plus (+) button.

• When the BAND button is pressed, the machine enters the CLVA (servo ON) and the mute is turned OFF if data is read successfully. When

the BAND button is pressed again, the machine enters the rough servo.

• When the CD button is pressed then, the track jumps to the second session and the machine exits the CD TEST-2 (MANUAL) mode.

• When the OFF button is pressed, the CD playback is stopped. If the CD button is pressed again, the machine repeats operations from the

focus search.

— 8 —

CD TEST-1

FOCUS

OK

Y

Auto adjustment

Rough servo

CD button

TEST MODE END

The second music

played back.

CD button

Y

N

Sled maement

N

+button

+button

jump has

been set?

Y

BAND

button

Servo ON

BAND

button

OFF

button

YYYY

CD STOP

OFF

button

YYY

123 45

Y

YYYY

CD

button

CD TEST-2

FOCUS

OK

Y

Rough servo

+button

Y

Sled maement

Execntes the

setting of jump.

N

BAND

button

Y

Servo ON

button

TEST MODE END

The second music

played back.

Sets the respective

setup valnes.

CD

YY

CD STOP

OFF

button

TRACKING

GAIN UP

+button

BAND

button

OFF

button

— 9 —

CD

button

CD

button

YYYYY

Loading...

Loading...