Sony HTC-NX300 Service manual

HTC-NX300

SERVICE MANUAL

HTC-NX300 is the CD player and Tape

Deck section in MHC-NX300AV.

Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol ; are trademarks of Dolby Laboratories Licensing Corporation.

CD

Section

Tape Deck

Section

E Model

Chinese Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM53E-K3BD37

Base Unit Name Type BU-K3BD37

Optical Pick-up Name KSM-213BFNV/Z-NP

Model Name Using Similar Mechanism HCD-GRX7

Tape Transport Mechanism Type TCM-230AWR2

SPECIFICATIONS

CD player section

System Compact disc and digital

Laser Semiconductor laser

Laser output Max. 44.6

Wavelength 780 – 790 nm

Frequency response 20 Hz – 20 kHz (±0.5 dB)

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

Video color system format

CD DIGITAL OUT

(Square optical connector jack, rear panel)

Wavelength 660 nm

Output Level –18 dBm

audio system

(λ=780nm)

Emission duration:

continuous

*This output is the value

measured at a distance of

200 mm from the

objective lens surface on

the Optical Pick-up Block

with 7 mm aperture.

NTSC, PAL

µ

W*

Tape player section

Recording system 4-track

Frequency response 40 – 13,000 Hz (±3 dB),

(DOLBY NR OFF) using Sony TYPE I

General

Dimensions (w/h/d) Applox. 225 x 202 x 347

Mass Applox. 4.6 kg

Design and specifications are subject to change

without notice.

2-channel stereo

cassette

40 – 14,000 Hz (±3 dB),

using Sony TYPE II

cassette

mm

MICROFILM

MINI Hi-Fi COMPONENT SYSTEM

TABLE OF CONTENTS

1. SERVICING NOTES............................................... 3

2. GENERAL

Location of Controls ....................................................... 6

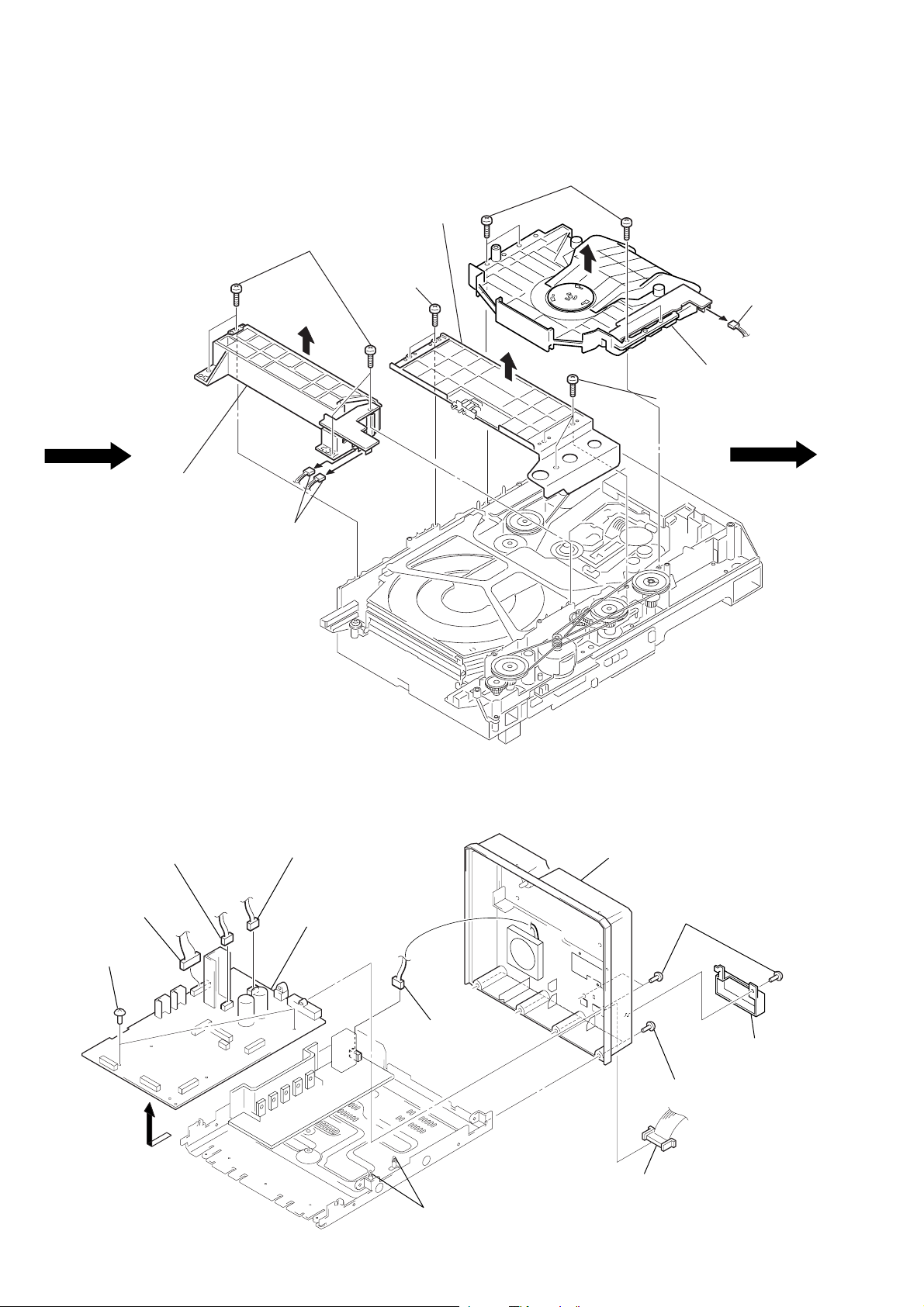

3. DISASSEMBLY ......................................................... 7

4. TEST MODE.............................................................. 14

5. MECHANICAL ADJUSTMENTS....................... 15

6. ELECTRICAL ADJUSTMENTS

TAPE DECK Section ...................................................... 15

CD Section ...................................................................... 18

VIDEO Section ............................................................... 19

7. DIAGRAMS

7-1. Block Diagram – SERVO Section – .............................. 21

7-2. Block Diagram – AUDIO/VIDEO CD Section –.......... 22

7-3. Block Diagram – TAPE DECK Section – ..................... 23

7-4. Block Diagram – POWER SUPPLY Section – ............. 24

7-5. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 25

7-6. Printed Wiring Board – BD Board – ............................. 26

7-7. Schematic Diagram – BD Board – ................................ 27

7-8. Schematic Diagram – VIDEO Board (1/2) – ................ 28

7-9. Schematic Diagram – VIDEO Board (2/2) – ................ 29

7-10. Printed Wiring Board – VIDEO Board –....................... 30

7-11. Printed Wiring Boards

– CD MOTOR/SENSOR Section – ................................ 32

7-12. Schematic Diagram

– CD MOTOR/SENSOR Section – ................................ 33

7-13. Printed Wiring Board – AUDIO Board – ...................... 34

7-14. Schematic Diagram – AUDIO Board – ......................... 35

7-15. Printed Wiring Board – LEAF SW Board –.................. 36

7-16. Schematic Diagram – LEAF SW Board –..................... 36

7-17. Printed Wiring Board – MAIN Board – ........................ 37

7-18. Schematic Diagram – MAIN Board (1/2) – .................. 38

7-19. Schematic Diagram – MAIN Board (2/2) – .................. 39

7-20. Printed Wiring Board – POWER Board – ..................... 40

7-21. Schematic Diagram – POWER Board –........................ 41

7-22. Printed Wiring Boards – PANEL Section – .................. 42

7-23. Schematic Diagram – PANEL Section –....................... 43

7-24. IC Pin Function Description ........................................... 48

8. EXPLODED VIEWS ................................................ 57

9. ELECTRICAL PARTS LIST ............................... 64

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

SECTION 1

3

SERVICING NOTES

SELF-DIAGNOSIS

This unit is equipped with a self-diagnosis function.

The function is used for diagnosing the conditions of the circuits

of the VIDEO board.

The circuits can be determined if normal or abnormal by the lighting of D502 of the VIDEO board.

Lighting of D502

When lit : Operates normally

Blinks repeatedly: The circuit may be faulty.

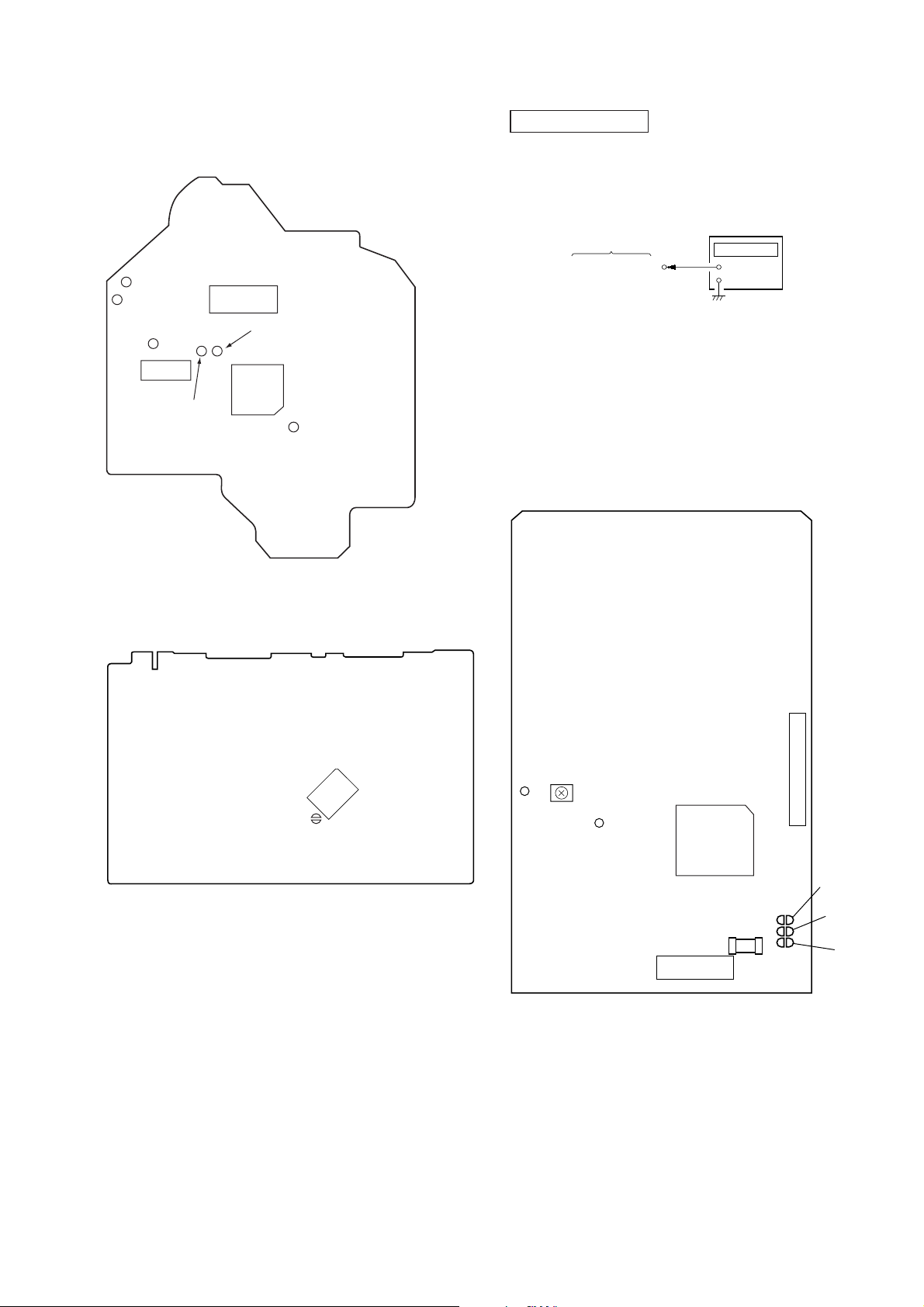

[VIDEO Board] (Side B)

CN501

IC505

SL501

SL502

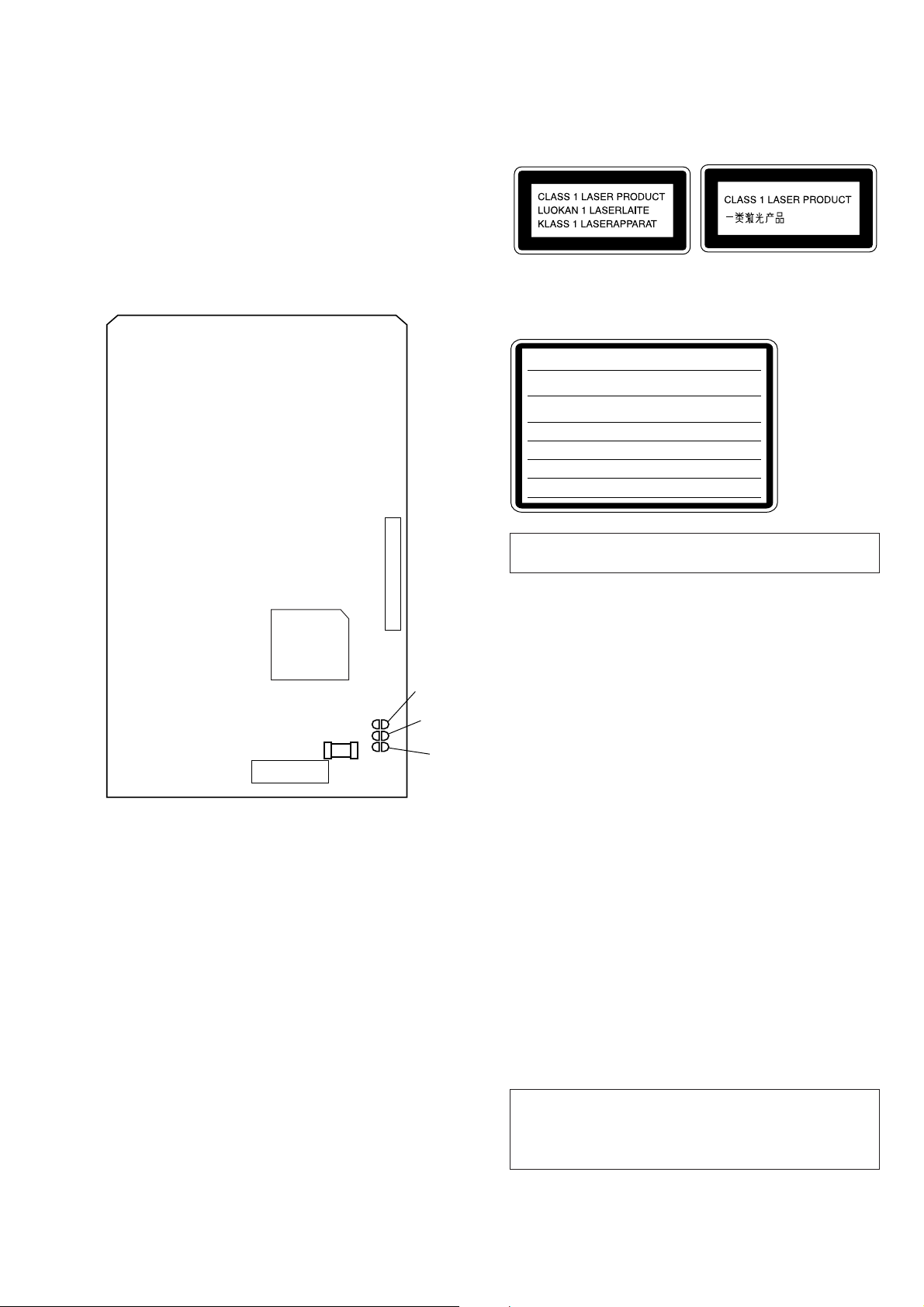

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

CAUTION : INVISIBLE LASER RADIATION WHEN OPEN AND

INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

ADVARSEL : USYNLIG LASERSTRÅLING VED ÅBNING NÅR

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION. UNDGÅ UDSAETTELSE

FOR STRÅLING.

VORSICHT : UNSICHTBARE LASERSTRAHLUNG, WENN

ABDECKUNG GEÖFFNET UND SICHEREITSVERRIEGELUNG

ÜBERBRÜCKT. NICHT DEM STRAHL AUSSETZEN.

VARO!: AVATT AESSA JA SUOJ ALUKITUS OHITETTAESSA OLET ALT-

TIINA NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VARNING : OSYNLING LASERSTRÅLING NÄR DENNA DEL ÄR ÖPPNAD

OCH SPÄRREN ÄR URKOPPLAD. BETRAKTA EJ STRÅLEN.

ADVERSEL : USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG

SIKKERHEDSLÅS BRYTES. UNNGÅ EKSPONERING FOR STRÅLEN.

VIGYAZAT!: A BURKOLAT NYITÁSAKOR LÁTHATATLAN LÉZERSU-

!

KERÜLJE A BESUGÁRZÁST!

GÁRVESZÉLY

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

CN502

D502

SL50

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

3

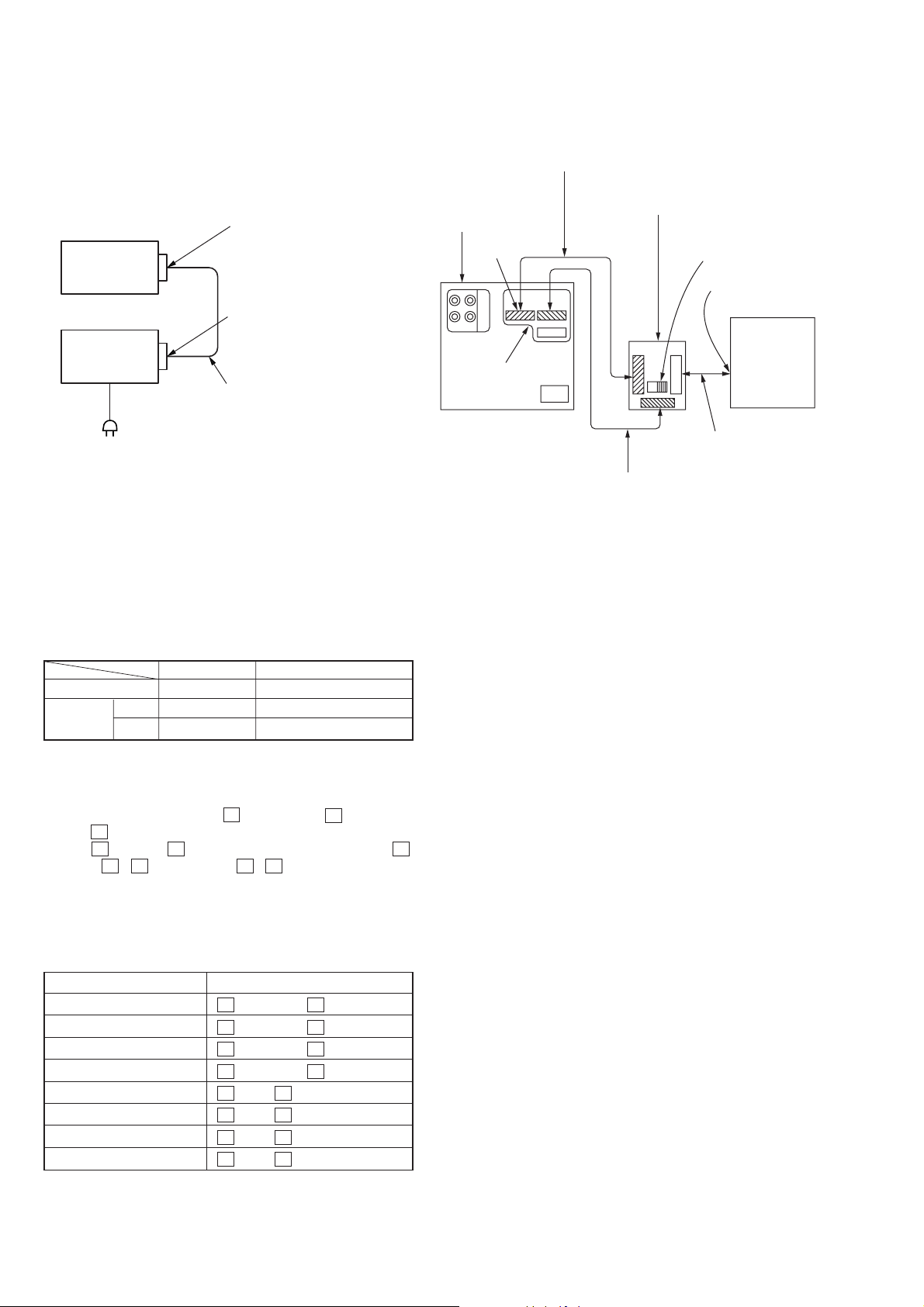

POWER SUPPLY DURING SERVICING

l

Connection:

• As this set has not own power supply, it does not operate independently. Therefore, during servicing, connect it to the PreMain amplifier and Tuner Unit (STR-NX300) of MHCNX300AV.

SYSTEM CONTROL termina

Set

SYSTEM CONTROL terminal

Pre-Main AMP

and T uner Unit

Connector cable (19P)

AC IN

If STR-NX300 are not available, use the Power Feed Jig (PFJ-

1) and Relay Connector Jig.

In this case, after turn on the POWER switch on the Power Feed

Jig, supply power with the following methods.

[Note]

The Power Feed Jig (PFJ-1) is deficient in power to drive this

set.

The details are listed below. For the items with × marking, use

the STR-NX300.

Connector cable (17P) of

attachment to power feed jig

Power feed jig

(PFJ-1)

CDP/TC

P707, P909

Relay connector jig

(J-2501-174-A)

ST

Exclusive cable (15P)

CD/TC signal

change switch

CN101 (19P)

SYSTEM CONTROL

terminal

Set

system cable

Operation check Characteristic measurement

Tape Deck af*1

CD section

CD a ×

SVCD ××

*1: Possible when a flat cable between CN111 (MAIN board) and

CN502 (VIDEO board) is disconnected.

Procedure:

1. Press three buttons of s (DECK B), A (DISC 1),

and s (CD) simultaneously.

2. The G (CD) and S (CD) LEDs blink, and then pressing G

(CD), G / g (DECK A), or G / g (DECK B) button can

make each play possible.

3. Also, the other functions are enabled by pressing two buttons

simultaneously.

A combination of respective functions and buttons is as follows.

function button

CD AMS – s (DECK A), S (CD)

AMS + s (DECK A), s (CD)

FR s (DECK B), S (CD)

FF s (DECK B), s (CD)

Deck-A REW/AMS – s (CD), g (DECK A)

FF/AMS + s (CD), G (DECK A)

Deck-B REW/AMS – s (CD), g (DECK B)

FF/AMS +

s (CD), G (DECK B)

4

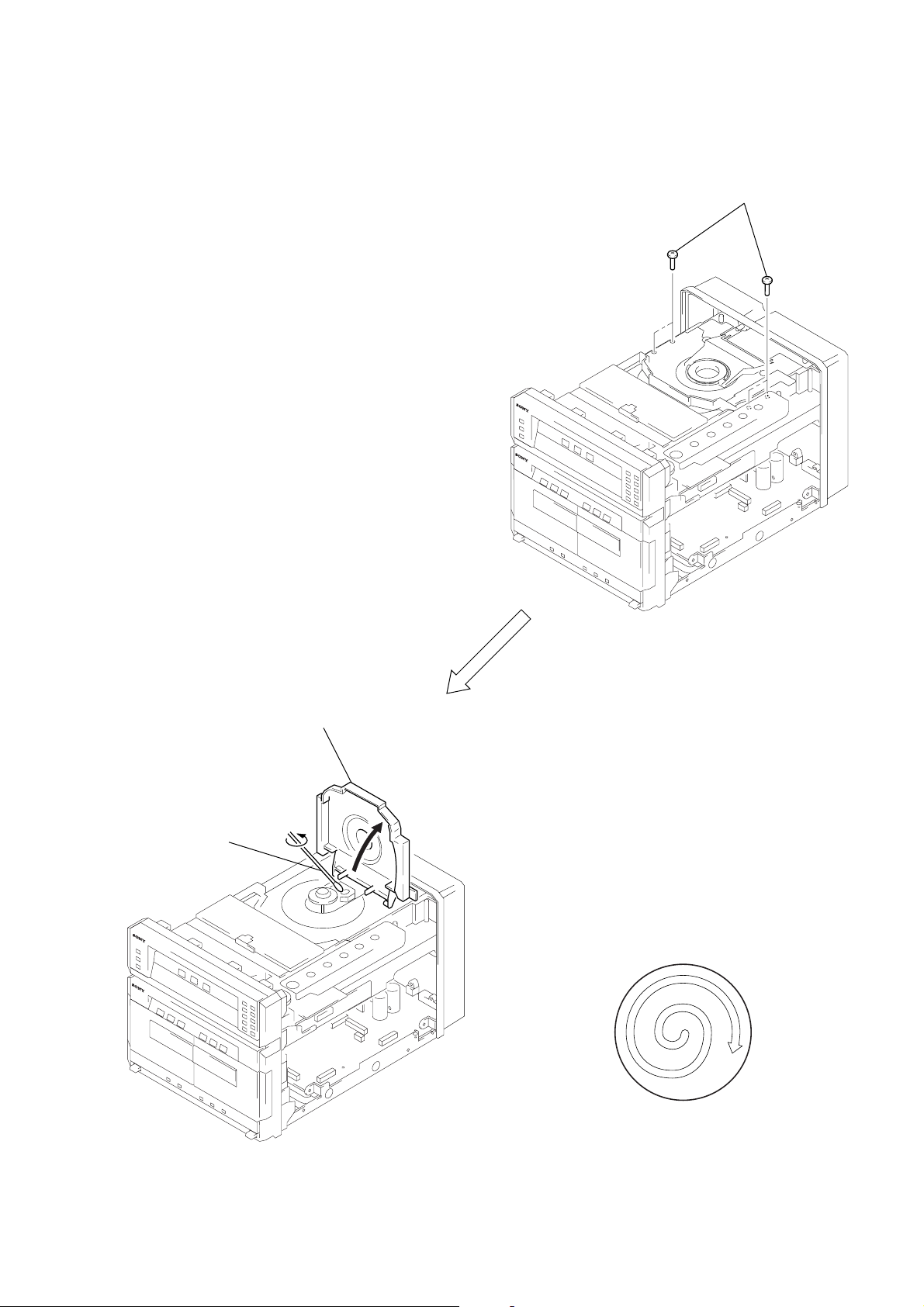

OPTICAL PICK-UP CLEANING

(Figure A)

2

four screws

(BVTP M2.6)

1

Remove the case. (Refer to disassembly page 7)

4

Cleaning the

optical pick-up.

3

Open the magnet

ass’y.

Note 1: In cleaning the lens, do not apply an excessive force.

As the optical pick-up is vulnerable, application of

excessive force could damage the lens holder.

Note 2: In cleaning, do not use a cleaner other than exclusive clean-

ing liquid (KK-91 or isopropyl alcohol).

Note 3: Wipe the objective lens spirally from center toward outside .

(See Figure A)

5

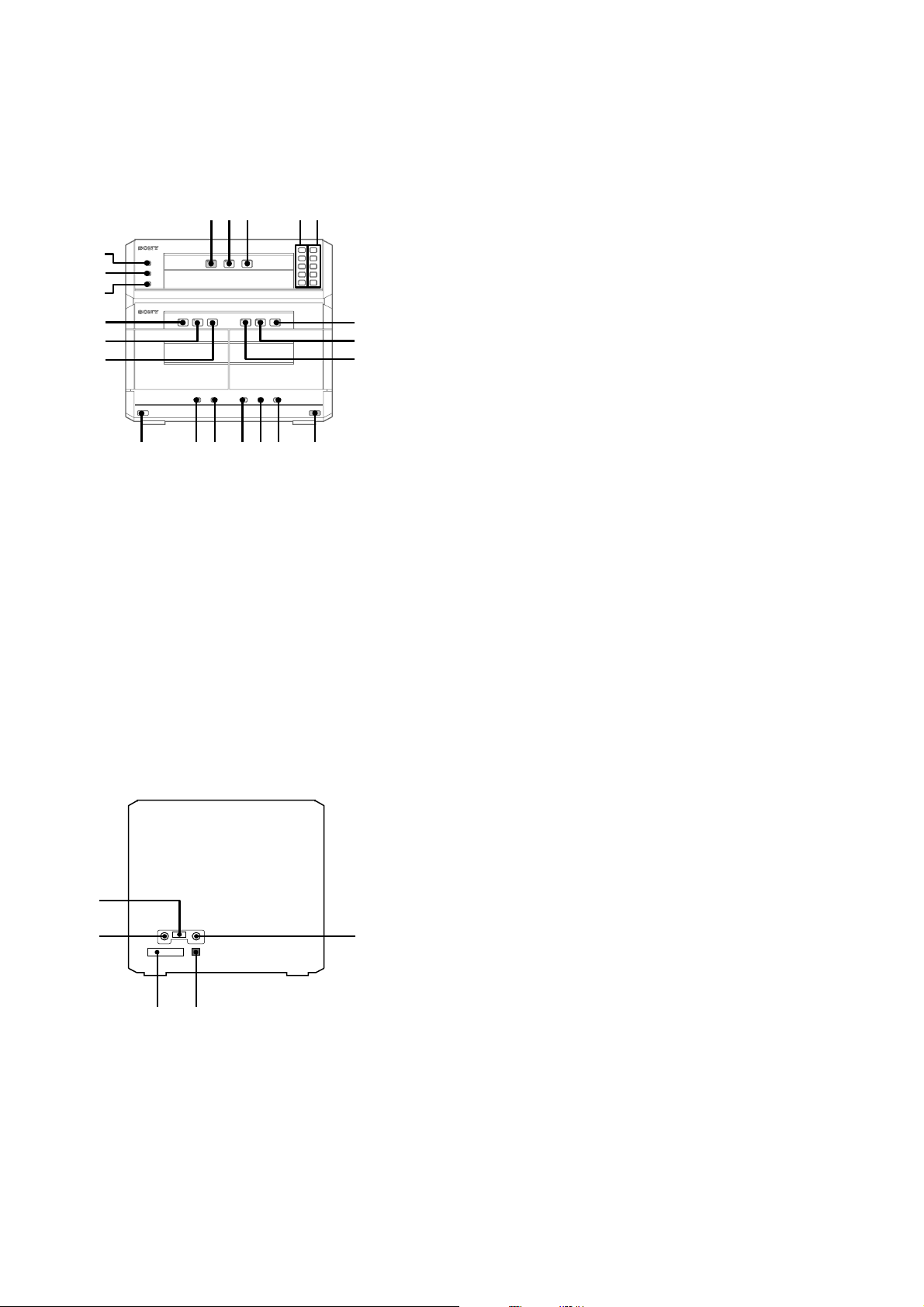

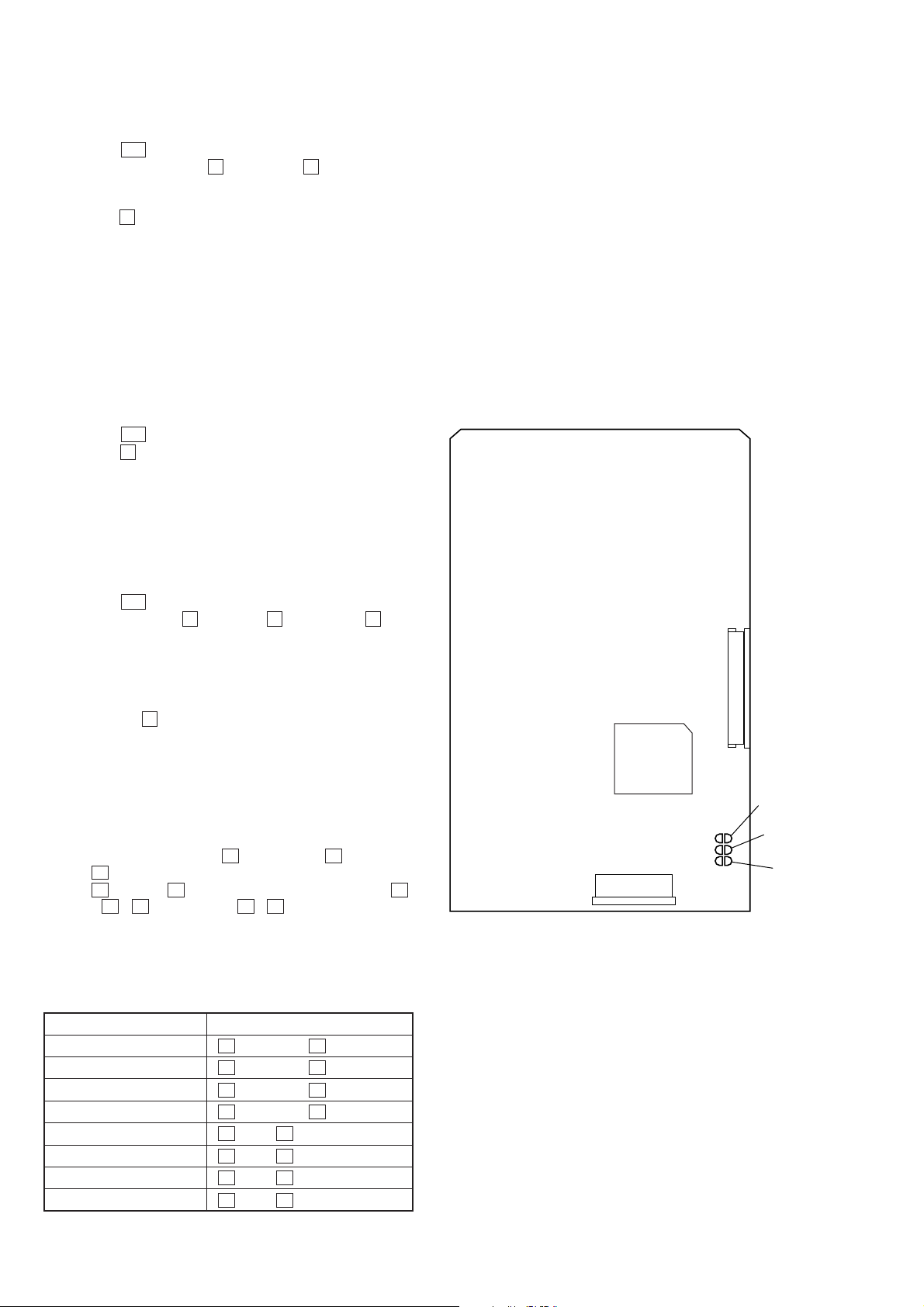

• LOCATION OF CONTROLS

– Front Panel –

123 45

6

H

S

7

8

9

hH s

0

qa

s

hH s

qhqgqfqdqs

SECTION 2

GENERAL

1 G (CD) button and indicator

2 S (CD) button and indicator

3 s (CD) button

A

1

2

3

4

5

ql

w;

wa

AA

qkqj

4 DISC1 to 5 buttons and indicators

5 A (DISC1 to 5) buttons and indicators

6 RETURN button

7 NEXT button

8 PREV button

9 g (DECK A) button and indicator

0 G (DECK A) button and indicator

qa s (DECK A) button

qs A (DECK A) button

qd DIRECTION button

qf DOLBY NR button

qg HI DUB button

qh CD SYNC button and indicator

qj REC PAUSE/START button and indicator

qk A (DECK B) button

ql s (DECK B) button

w; G (DECK B) button and indicator

wa g (DECK B) button and indicator

– Rear Panel –

1

1 SYSTEM SELECT switch

2 S VIDEO OUT jack

3 SYSTEM CONTROL connector

4 CD DIGTAL OUT OPTICAL terminal

5 VIDEO OUT jack

5

324

6

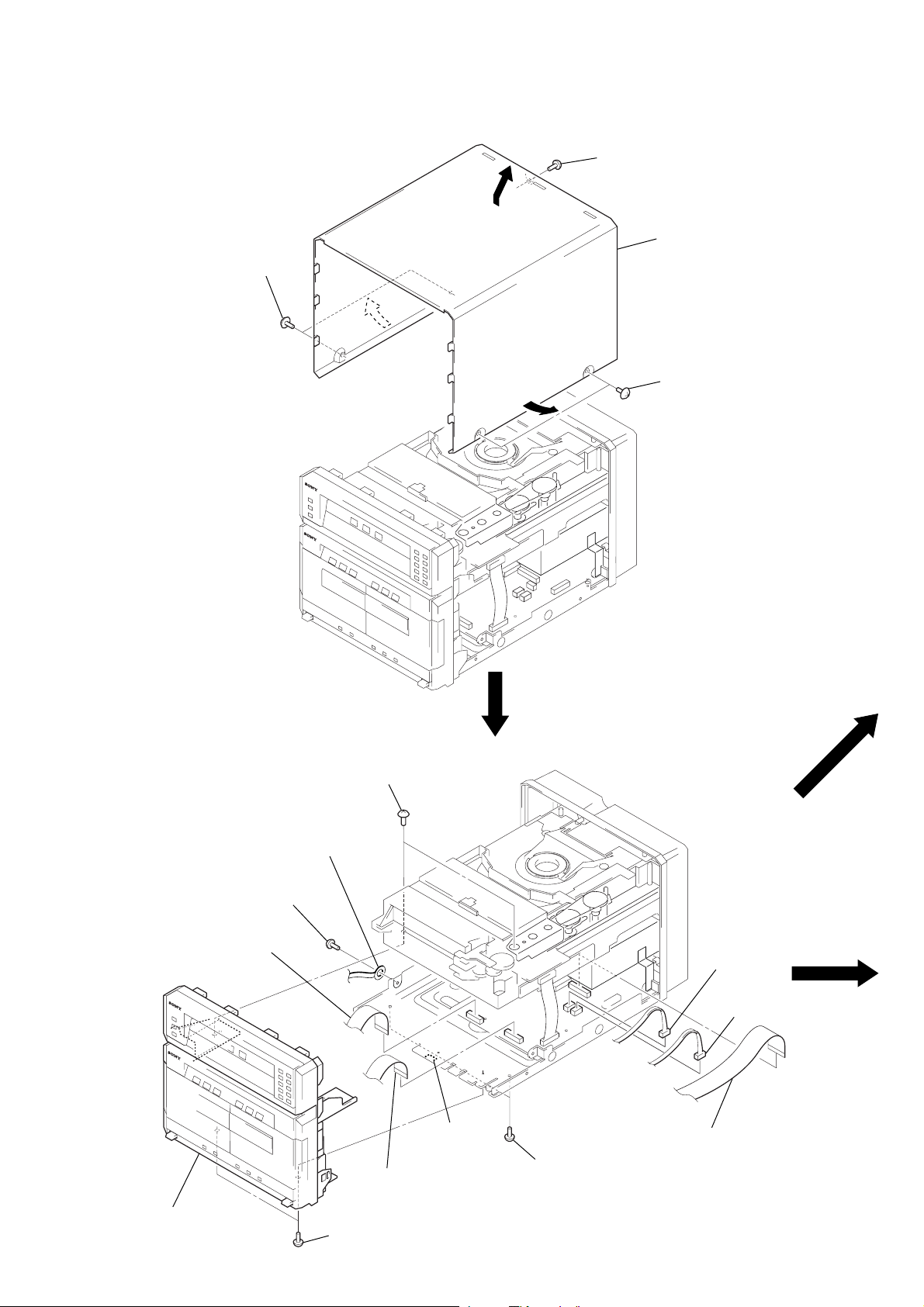

SECTION 3

r

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

CASE

2

two screws

(case 3 TP2)

A

1

screw

(BVTP3

×

10)

3

Remove the case

in the arrow

direction.

2

two screws

(case 3 TP2)

A

FRONT PANEL SECTION

4

3

screw (BVTP3 × 5)

1

flat cable (15 core)

(CNS101)

8

front panel

section

harness

6

two screws

(BVTP3

1

flat cable (17 core)

(16 cm) (CNS104)

5

two screws

(BVTP3

×

10)

2

connector

(CN106)

2

connecto

(CN105)

7

claw

5

two screws

(BVTP3

×

5)

×

5)

1

flat cable (21 core)

(CN102)

7

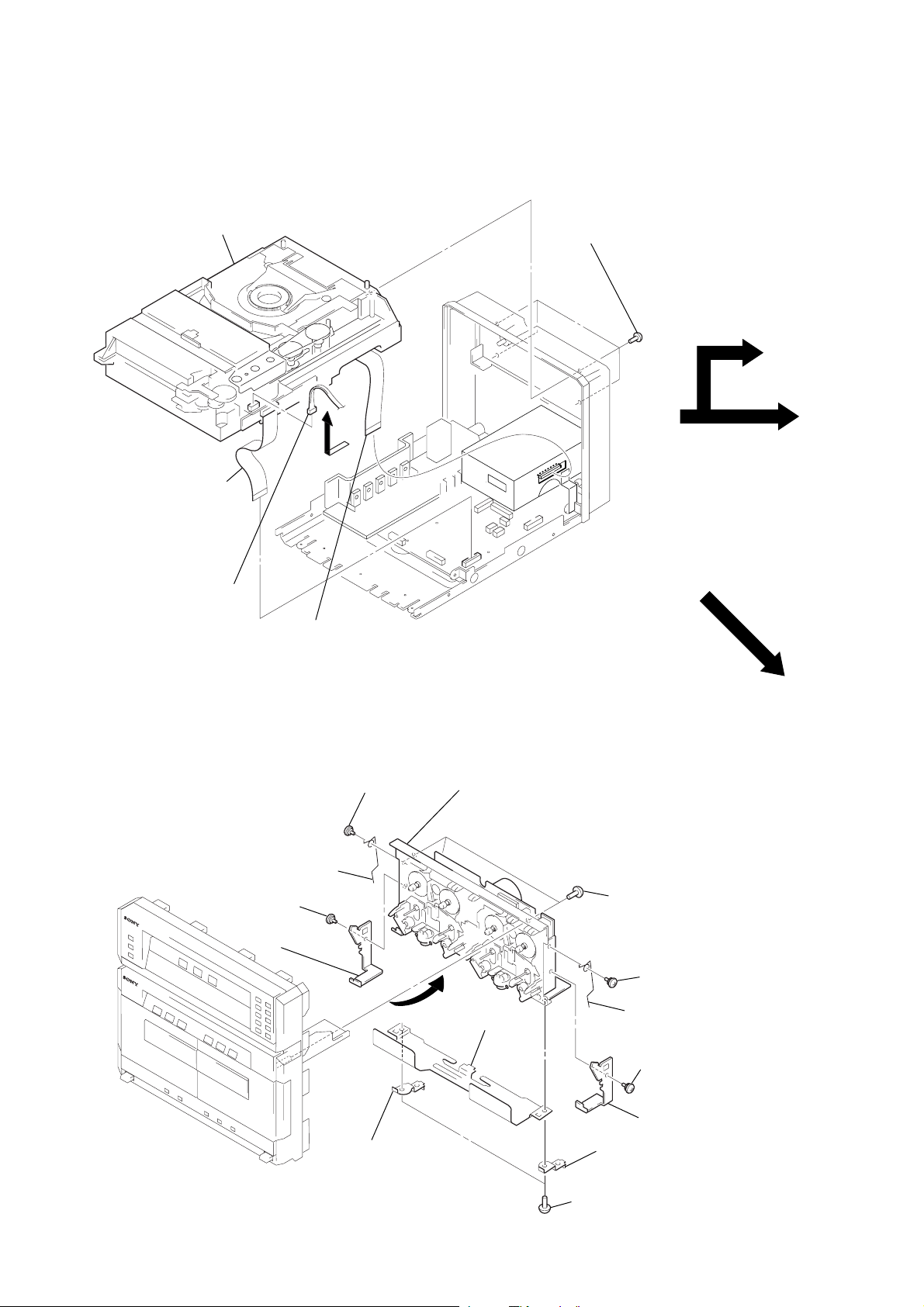

CD MECHANISM DECK SECTION

)

(CDM53E-K3BD37)

4

Remove the CD mechanism deck

section (CDM53E-K3BD37) in

the arrow A direction.

1

flat cable (17 core)

(12 cm) (CN112)

A

3

four screws

(BVTP3 × 10)

to fitting base (guide)

ass’y, bracket (chassis)

and magnet ass’y

(page 10)

2

connector

(CN713)

1

flat cable (19 core)

(CN501)

TAPE MECHANISM DECK SECTION

(TCM-230AWR2)

3

spring (eject A)

6

step screw

8

eject lever (A)

1

step screw

A

5

Remove the tape mechanism deck

section (TCM-230AWR2) in the

arrow A direction.

qs

shield plate

4

two screws

(BVTP3 × 10)

1

2

spring (eject B)

step screw

6

step screw

7

eject lever (B

q;

qa

bracket (MD A)

9

bracket (MD B)

two screws

(BVTT 2.6 × 6)

8

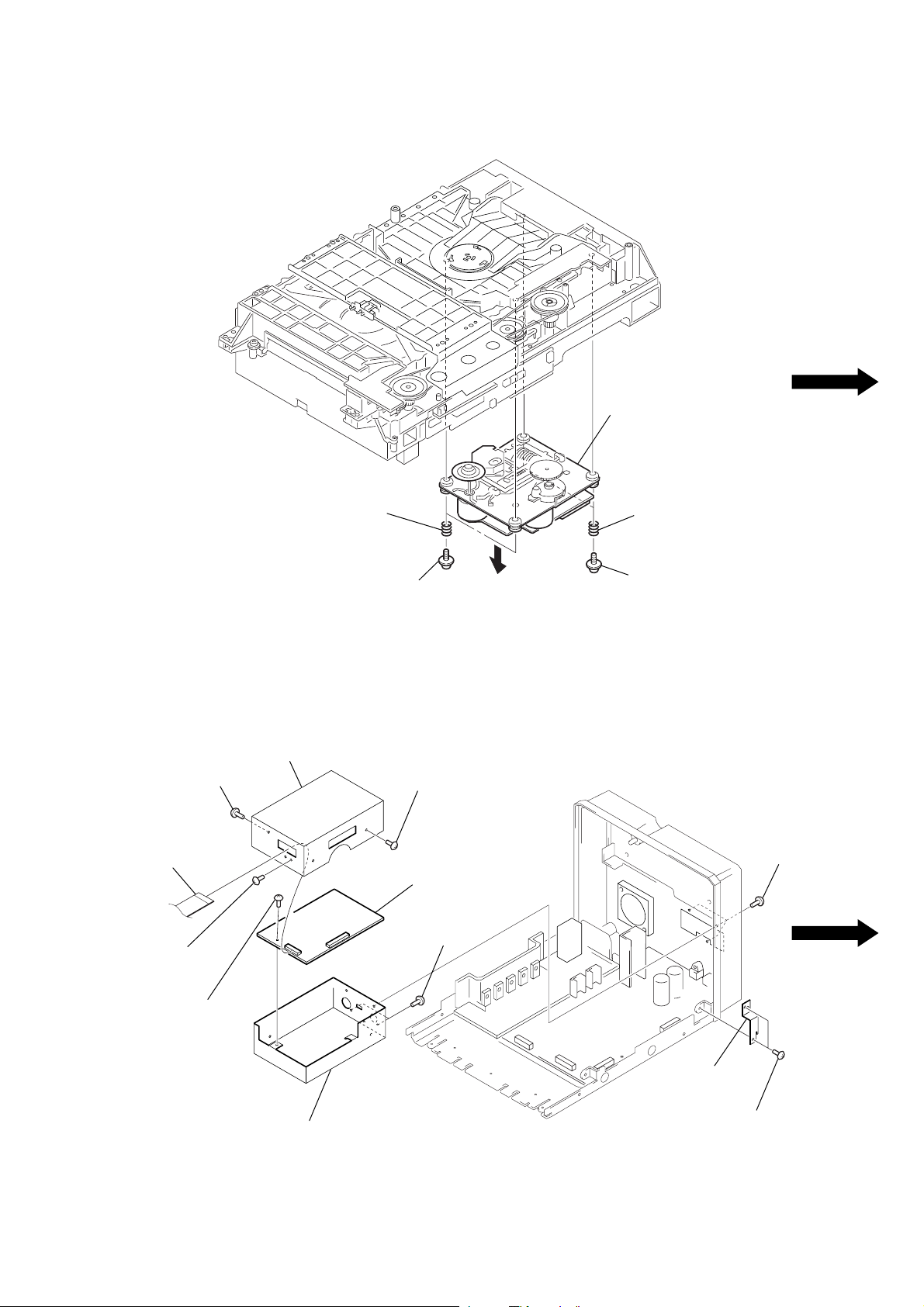

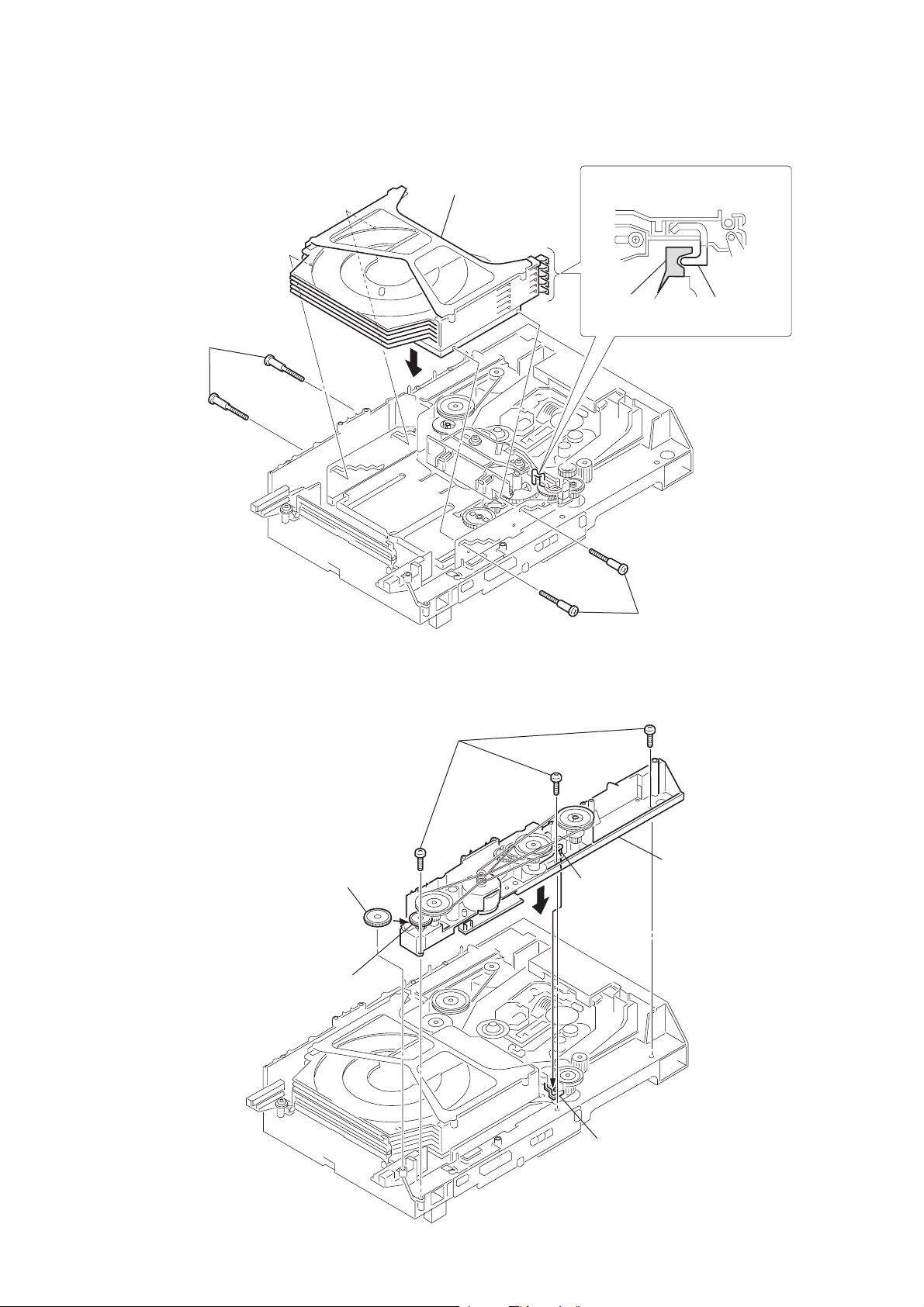

CD BASE UNIT (BU-K3BD37)

3

compression spring

(black)

4

CD base unit

(BU-K3BD37)

2

compression spring

(silver)

VIDEO BOARD

6

screw

(BVTT3 × 5)

3

flat cable (15core)

(CN713)

6

screw

(BVTT3 × 5)

8

screw

(BVTT3 × 5)

7

SVCD shield (U)

1

two screws

(PTPWH M2.6)

6

0

9

two screws

(BVTP3 × 8)

screw

(BVTT3 × 5)

VIDEO board

1

two screws

(PTPWH M2.6)

4

three screw

(BVTT3 × 8)

5

SVCD shield (B)

2

ground plate

1

two screws

(BVTT3 × 5 (S))

9

FITTING BASE (GUIDE) ASS’Y, BRACKET (CHASSIS) AND

MAGNET ASS’Y

5

bracket

(chassis)

two screws

(BVTP M2.6)

from CD mechanism

deck section

(CDM53E-K3BD37)

(page 8)

3

fitting base

(guide) ass’y

2

four screws

(BVTP M2.6)

1

two connectors

(CN709, 715)

4

7

four screws

(BVTP M2.6)

4

three screws

(BVTP M2.6)

6

connector

(CN710)

8

magnet ass’y

MAIN BOARD

6

connector

(CN109)

6

connector

(CN107)

7

two screws

(BVTP3

A

6

connector

(CN108)

9

Remove the MAIN board

in the arrow

×

8)

A

direction.

8

1

connector

(CN505)

two PC board

holders

5

back panel

2

three screws

(BVTP3

2

4

connection cord

(CN101)

×

10)

3

cover

(connector)

four screws

(BVTP3

×

10)

10

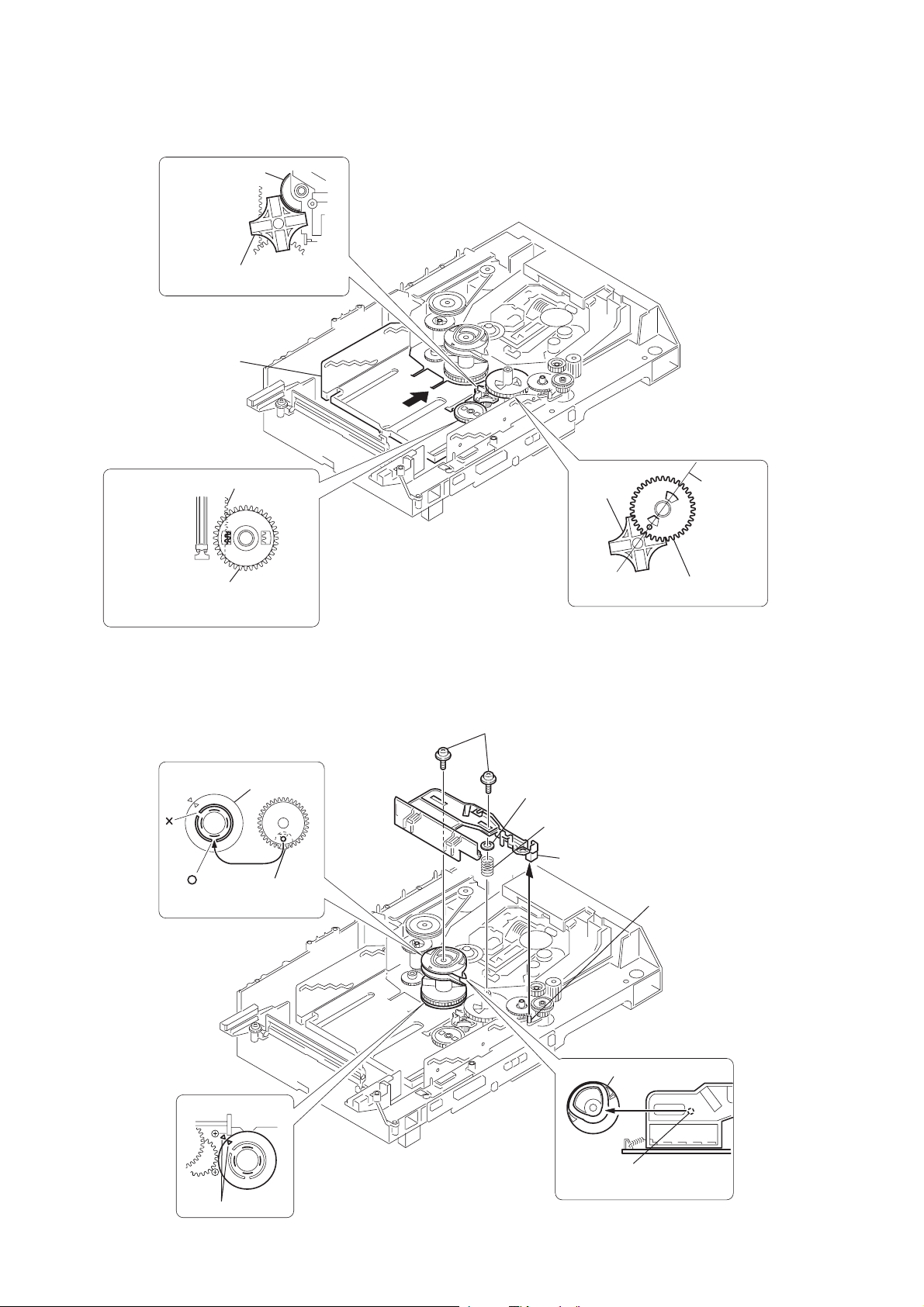

TRAY (SUB)

)

1

2

3

4

Rotating the pulley (LD), shift the slider (selection) in the arrow A direction.

Rotating the pulley (mode) in the arrow direction, adjust the tray (sub) to be removed.

Rotating the pulley (LD), shift the slider (selection) in the arrow B direction.

Rotating the pulley (mode) in the arrow direction, remove the tray (sub) to be removed.

pulley (LD)

stocker

section

tray (sub)

A

B

slider (selection)

pulley (mode)

CHASSIS (MOLD B) SECTION, STOCKER SECTION AND

SLIDER (SELECTION)

Note: In mounting the parts, refer to page 12 and 13.

5

stocker

section

pulley (LD)

4

two step

screws

6

two screws

(PTPWH M2.6)

7

slider (selection)

9

compression

spring

8

washer

1

three screws

(BVTP M2.6)

2

chassis (mold B) section

Note: Rotating the pulley (LD),

shift the slider (selection

to the left.

4

two step screws

3

gear (eject)

11

GEARS INSTALLATION

3

gear (gear B)

Adjust the gear (gear B) with the

portion A as shown.

1

Slide the slider (U/D)

fully in the arrow

direction.

2

gear (U/D slider)

slider (U/D) gear

portion A

4

gear (gear A)

gear

(gear B)

linearly

Adjust the gear so that it meshes with

the bottom tooth of slider (U/D) gear,

as shown.

SLIDER (SELECTION) INSTALLATION

2

gear (chucking)

rotary encoder

Align with the slot of

rotary encoder.

6

two screws

(PTPWH M2.6)

5

washer

4

compression spring

7

Adjust so as to be aligned with

gear (B) linearly, as shown.

Insert the slider (selection)

into the portion A.

portion A

12

1

rotary encoder

align marking

3

convex portion of

slider (selection)

gear (chucking)

Insert a convex portion into

a groove of gear (chucking).

STOCKER SECTION INSTALLATION

n

1

stocker section

2

portion A of tray (sub)

Hook the portion A of tray (sub)

to the slider (selection).

3

two step screws

CHASSIS (MOLD B) SECTION INSTALLATION

3

three screws

(BVTP M2.6)

potion A

of tray (sub)

3

sticking of

slider (selection)

two step screws

2

Insert the gear (eject)

under the gear (LD

deceleration).

gear (LD deceleration)

portion A

portion B of

slider (selection)

1

Insert the portion A of

chassis (mold B) sectio

into the portion B of

slider (selection).

13

SECTION 4

3

TEST MODE

[LED All Lit, Key Check Mode]

Procedure:

1. Press the ?/1 button to turn the power ON.

2. Press three buttons of s (DECK B), A (DISC 1), and

[DISC 5] simultaneously.

3. LEDs are all turned on.

Press the G (CD) button, and the key check mode is activated.

LEDs are all OFF.

4. When a button is pressed, the LED near the pressed button

blinks or lights up.

Also, if all buttons are pressed, all LEDs light up (not blink).

5. To release from this mode, press three buttons in the same

manner as step 2, or remove the power cord.

[CD Delivery Mode]

• This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the ?/1 button to turn the power ON.

2. Press the s (DECK B) and [DISC 1] buttons simultaneously.

3. A message “LOCK” is displayed on the liquid crystal display

of the STR-NX300, and the CD delivery mode is set.

[Tape Deck Test Mode]

(In case of connected to the STR-NX300)

• If connected to the STR-NX300, the mode also acts as the STRNX300 amplifier test mode.

Procedure:

1. Press the ?/1 button to turn the power ON.

2. Press three buttons of s (DECK B), A (DISC 1), and S (CD)

simultaneously.

3. On liquid crystal display of the STR-NX300, the disc calen-

dar blinks, and “ALC OFF” is displayed, then the function

which was set before the test mode became active is displayed.

4. The automatic level control of the tape deck is in OFF status,

but while the

pressed during recording, automatic level control goes in ON

status.

[Tape Deck Test Mode]

(In case of connected to the power feed jig)

Procedure:

1. Turn on the Power switch on the power feed jig.

2. Press three buttons of s (DECK B), A (DISC 1),

and s (CD) simultaneously.

3. The G (CD) and S (CD) LEDs blink, and then pressing G

(CD), G / g (DECK A), or G / g (DECK B) button can

make each play possible.

4. Also, the other functions are enabled by pressing two buttons

simultaneously.

A combination of respective functions and buttons is as follows.

s (CD) and [REC PAUSE/START] buttons are

[VIDEO CD Color-bars Mode]

On this mode, the data of the color-bars signal as a picture signal

and the 1 kHz sine wave signal as a sound signal are output by the

mechanism controller (IC505) for the video CD signal check.

When measurement of the voltage and waveform on the VIDEO

board, perform it in this mode.

For reference, the color-bars signal can be observed at J502

(VIDEO OUT) and the sound signal can be observed at J101

(VIDEO/MD (AUDIO) OUT) (STR-NX300) using an oscilloscope.

Procedure:

1. Short the both ends of the land of SL503 of the VIDEO board.

2. Turn the power on. Press the [FUNCTION] button to select

CD.

3. The color-bars appears when the CD is in stop status, and it

disappears when the CD goes in play status.

4. After measuring, remove the lead wire connected.

– VIDEO board (Side B) –

CN501

IC505

SL501

SL502

SL50

CN502

function button

CD AMS – s (DECK A), S (CD)

AMS + s (DECK A), s (CD)

FR s (DECK B), S (CD)

FF s (DECK B), s (CD)

Deck-A REW/AMS – s (CD), g (DECK A)

FF/AMS + s (CD), G (DECK A)

Deck-B REW/AMS – s (CD), g (DECK B)

FF/AMS + s (CD), G (DECK B)

Note: Check that CD/TC signal change switch of relay connector jig is

set to the TC position.

14

SECTION 5

k

MECHANICAL ADJUSTMENTS

SECTION 6

ELECTRICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

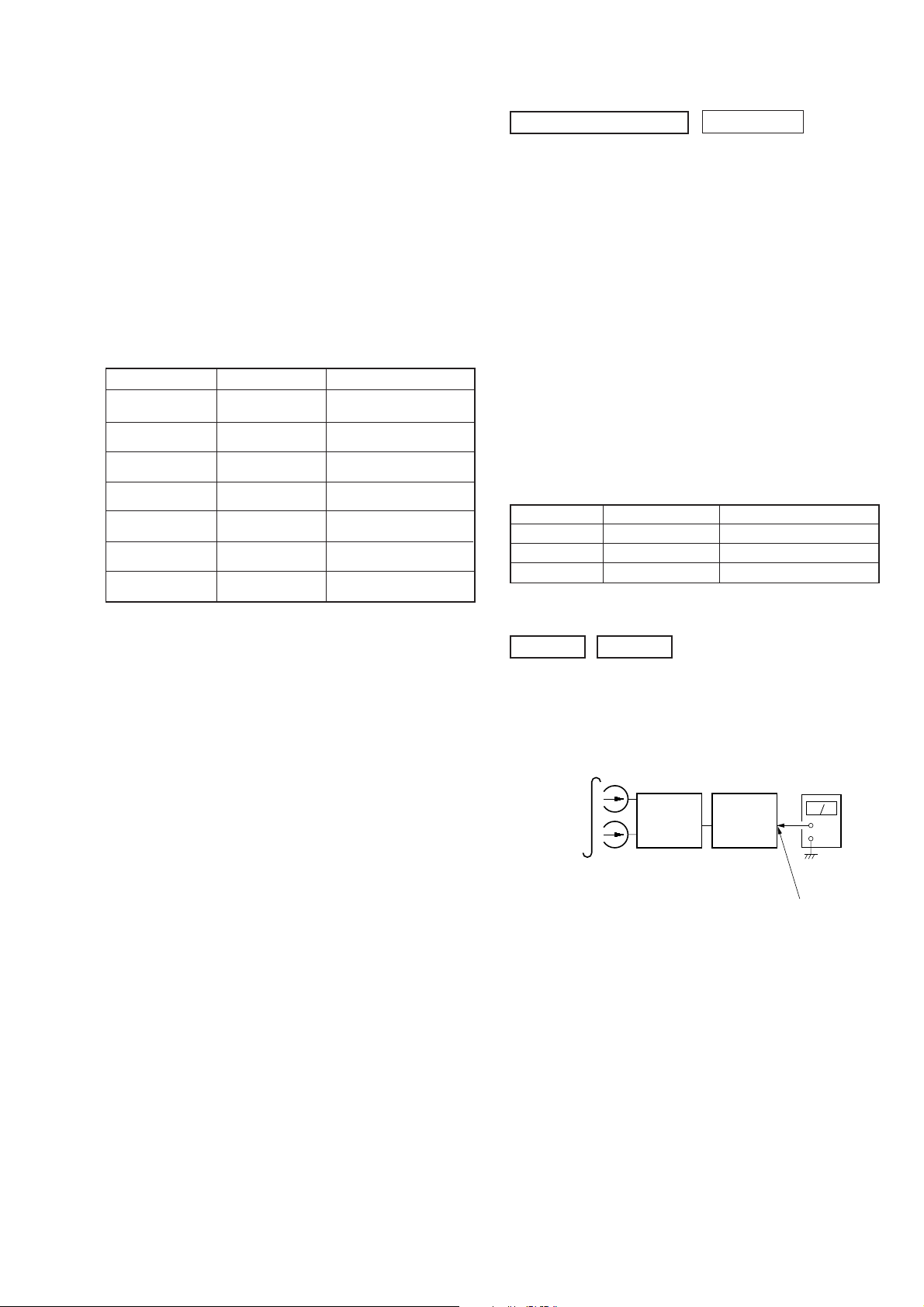

Torque Measurement

Mode

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

Torque meter

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

Meter reading

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

2 to 6 g • cm

(0.03 – 0.08 oz • inch)

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

2 to 6 g • cm

(0.03 – 0.08 oz • inch)

71 to 143 g • cm

(0.99 – 1.99 oz • inch)

100 g or more

(3.53 oz or more)

100 g or more

(3.53 oz or more)

TAPE DECK SECTION

0 dB=0.775 V

1. Demagnetize the record/playback head with a head demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in

this service manual. (As a general rule, playback circuit adjustment should be completed before performing recording

circuit adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise specified.

8. Set to the DOLBY NR OFF.

9. Set to the test mode. (See page 14)

10. When using the PFJ-1, disconnect a flat cable between CN111

(MAIN board) and CN502 (VIDEO board).

• Test Tape

Tape Signal Used for

P-4-A100 10 kHz, –10 dB Azimuth Adjustment

WS-48B 3 kHz, 0 dB Tape Speed Adjustment

P-4-L300 315 Hz, 0 dB Level Adjustment

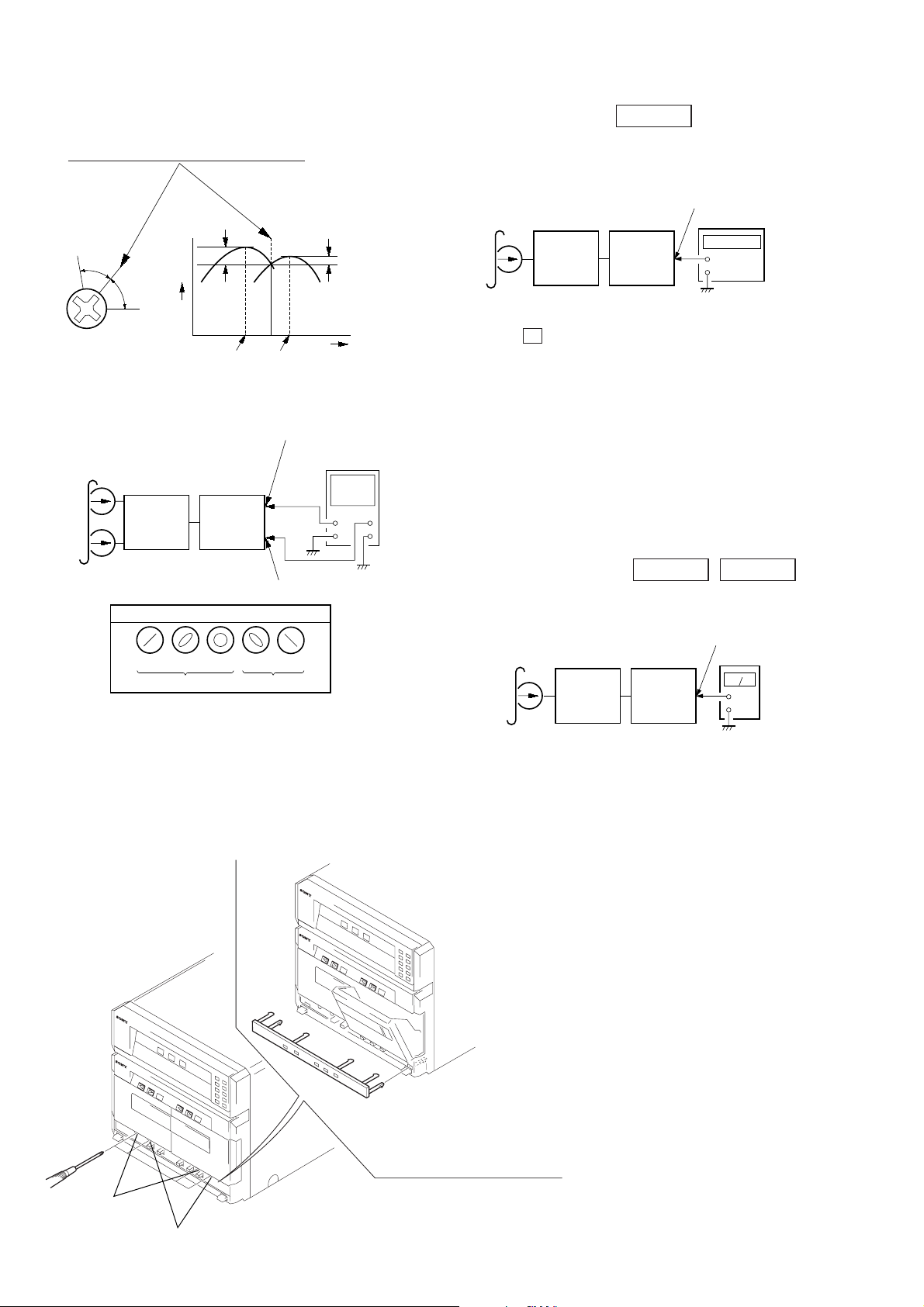

Record/Playback Head Azimuth Adjustment

DECK A DECK B

Note: Perform this adjustments for both decks

Procedure:

1. Mode: Playback

test tape

P-4-A100

(10 kHz, –10 dB)

PFJ-1

set

or

STR-

NX300

AUDIO OUT jac

level meter

+

–

15

2. T urn the adjustment screw and check output peaks. If the peaks

k

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

Output

level

within

1dB

within

1dB

L-CH

peak

Tape Speed Adjustment DECK B

• Execute only if connected to the STR-NX300

Mode: Playback

test tape

WS-48B

(3 kHz, 0 dB)

set

STR-

NX300

AUDIO OUT jack

frequency counter

+

–

R-CH

Screw

position

peak

L-CH

peak

R-CH

peak

Screw

position

3. Mode: Playback

test tape

P-4-A100

(10 kHz, –10 dB)

L-CH

set

NX300

R-CH

waveform of oscilloscope

in phase 45°90°135°180

good

AUDIO OUT (L) jack

PFJ-1

or

STR-

AUDIO OUT (R) jack

wrong

L-CH

R-CH

°

oscilloscope

H

V

4. Repeat step 1 to 3 in playback (REV) mode.

5. After the adjustments, apply suitable locking compound to the

pats adjusted.

Adjustment Location:Playback Head (Deck A).

Record/Playback/Earth Head (Deck B).

1. Insert the WS-48B into the deck B.

2. Press the G (DECK B) button.

3. Press the [HI-DUB] button in playback mode.

Then at HIGH speed mode.

4. Adjust RV1001 on the LEAF SW board do that frequency

counter reads 6,000 ± 180 Hz.

5. Press the [HI-DUB] button.

Then back to NORMAL speed mode.

6. Adjust RV1002 on the LEAF SW board so that frequency

counter reads 3,000 ± 90 Hz.

Adjustment Location: LEAF SW board

Sample value of Wow and Flutter: 0.3% or less W.RMS (JIS)

(WS-48B)

Playback level Adjustment

DECK A DECK B

Procedure:

Mode: Playback

test tape

P-4-L300

(315 Hz, 0 dB)

set

PFJ-1

STR-

NX300

or

AUDIO OUT jac

level meter

+

–

Deck A is RV311 (L-CH) and RV411 (R-CH), Deck B is RV301

(L-CH) and RV401 (R-CH) so that adjustment within specified

value as follows.

Specified Value:

AUDIO OUT jack PB level: 301.5 to 338.3 mV (–8.2 to –7.2

dB) level

difference between the channels: within ± 0.5 dB

16

Adjustment Location: AUDIO board

Open the cassette holder

and unhock six claws of

the sub panel (TC2)

with tweezers or something,

then remove the sub panel (TC2).

forward

reverse

REC Bias Adjustment DECK B

RV401

RV301

RV341

RV311

RV411

IC602

CN601

LR

RL

RV441

PB LEVEL

– DECK B –

REC BIAS

LR

PB LEVEL

– DECK A –

RV351

(R-CH)

RV301

(L-CH)

IC301

REC

LEVEL

CN301

1

3

Procedure:

1. Mode: Record

Specified value:

AUDIO OUT jack PB level: 47.2 to 53.0 mV (–24.3 to –23.3 dB)

Adjustment Location: MAIN board

AUDIO IN jack

50 mV (–23.8 dB)

600

Ω

PFJ-1

or

STR-

NX300

blank tape

CN-123

set

AF OSC

1) 315 Hz

2) 10 kHz

attenuator

2. Mode: Playback

recorded

portion

set

PFJ-1

or

STR-

NX300

level meter

+

–

AUDIO OUT jack

3. Confirm playback the signal recorded in step 1 become specified value as follows.

If these values are out of specified value, adjust the RV341

(L-CH) and RV441 (R-CH) on the AUDIO board to repeat

steps 1 and 2.

Specified value: Playback output of 315 Hz to playback

output of 10 kHz: ± 0.5 dB

Adjustment Location: AUDIO board

– MAIN BOARD (Conductor Side) –

– AUDIO BOARD (Component Side) –

REC Level Adjustment DECK B

Procedure:

1. Mode: Record

AUDIO IN jack

315 Hz, 50 mV (–23.8 dB)

AF OSC

attenuator

600

Ω

PFJ-1

or

STR-

NX300

set

blank tape

CN-123

2. Mode: Playback

recorded

portion

set

PFJ-1

or

STR-

NX300

level meter

+

–

AUDIO OUT jack

3. Confirm playback the signal recorded in step 1 become specified value as follows.

If these values are out of specified value, adjust the RV301

(L-CH) and R V351 (R-CH) on the MAIN board to repeat steps

1 and 2.

– LEAF SW BOARD (Component Side) –

TAPE SPEED

(NORMAL) (HIGH)

RV1002

RV1001

CN1001

17

CD SECTION

+

–

BD board

TP (RF)

TP (VC)

oscilloscope

V

Note:

1. CD Block is basically designed to operate without adjustment. Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10 MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specified value with the following checks.

5. Use the following extension cables and relay connector.

• Extension cable (19P) (Part No. J-2501-011-B)

Relay connector (Part No. J-2501-167-A)

(BD board CN101 to VIDEO board CN501)

• Extension cable (17P) (with connector) (Part No. J-2501-167-A)

(CONNECTOR board CN701 to MAIN board CN112)

6. Perform measurement by connecting to the STR-NX300.

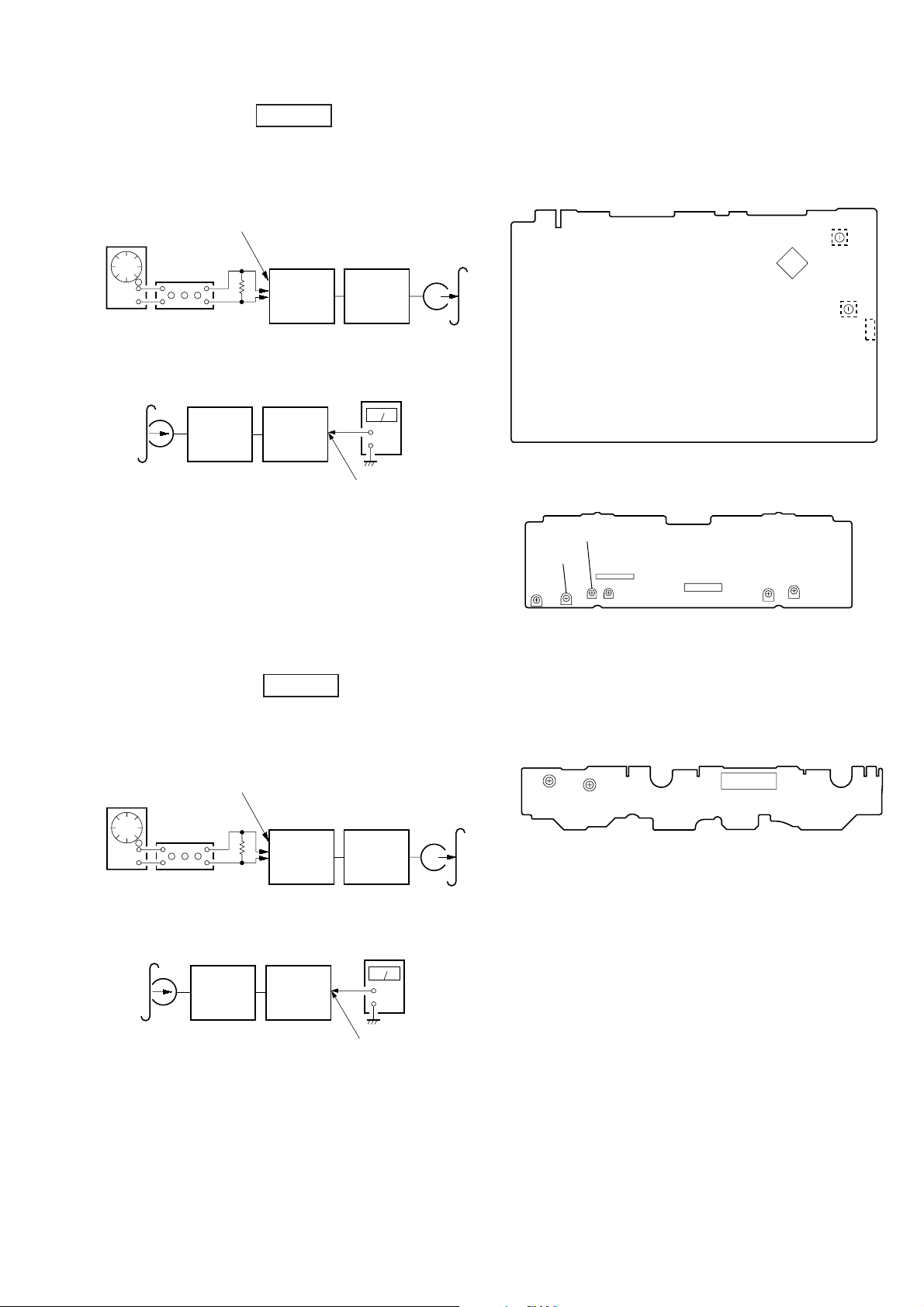

1. S-CURVE CHECK

oscilloscope

BD board

TP (FEO)

TP (VC)

+

–

2. RF LEVEL CHECK

Procedure:

1. Connect oscilloscope to TP (RF).

As TP (RF) and TP (VC) are located at the edge of board, clip

them together with the board using alligator clips.

2. Turn the power ON.

3. Load a disc (YEDS-18) and playback.

4. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

Note: Clear RF signal waveform means that the shape “ ” can be clearly

distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV: 200 m

TIME/DIV: 500 ns

Procedure:

1. Connect oscilloscope to TP (FEO).

2. Connect between TP (FEO) and TP (VC) by lead wire.

3. Connect between TP (A GCCON) and TP (GND) by lead wire.

4. Turn the power ON.

5. Load a disc (YEDS-18) and turn the power ON again and actuate the focus search. (Actuate the focus search when disc

tray is moving in and out)

6. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B. And confirm peak to peak level within 2.4

± 0.7 Vp-p.

S-curve waveform

symmetry

A

within 2.4

B

±

0.7 Vp-p

7. After check, remove the lead wire connected in step 2.

Note: • Try to measure several times to make sure than the ratio of A : B

or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the brightness

to obtain best waveform.

level:

1.2

±

0.2 Vp-p

18

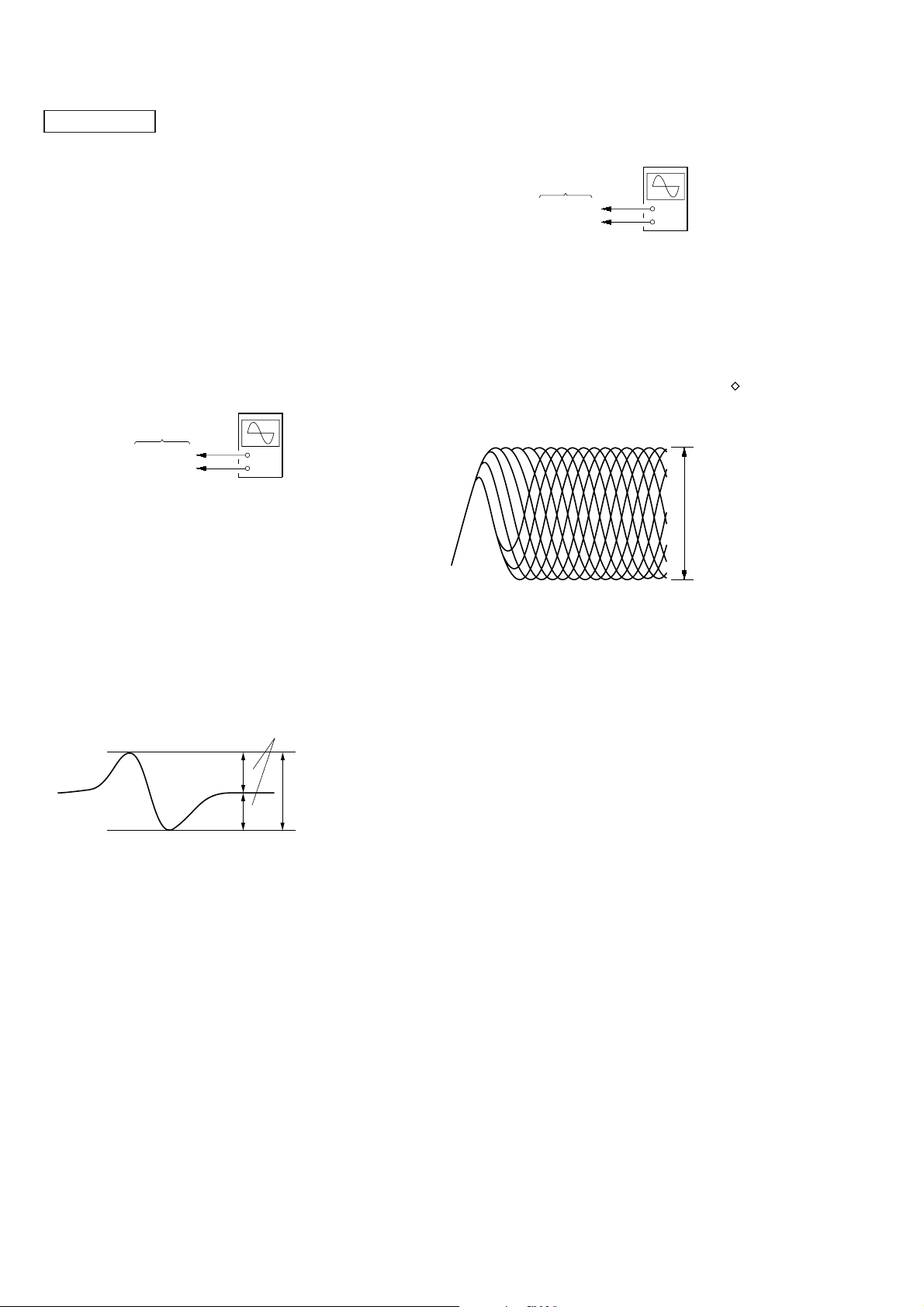

Connecting points:

+

–

TP (27 MHz)

VIDEO board

frequency counter

TP

(GND)

CT503

VIDEO

Frequency

Adjustment

TP

(27 MHz)

CN501

SL501

SL502

SL503

CN502

IC505

D502

– BD BOARD (Side B) –

TP

TP

(VC)

(RF)

TP

(AGCCON)

IC103

(FEO)

TP (FEI)

IC102

IC101

TP

TP

(TEO)

(GND)

TP

VIDEO SECTION

Note:

1. Perform measurement by connecting to the STR-NX300.

Frequency Adjustment

Connection:

Procedure:

1. Connect the frequency counter to TP (27 MHz) on VIDEO

board.

2. Turned power switch on.

3. Press the [FUNCTION] button to select the CD.

4. Adjust CT503 on the VIDEO board so that the frequency

counter reading 27.0 MHz ± 80 Hz at stop status.

Adjustment Location:

– VIDEO Board (Side B) –

– MAIN BOARD (Conductor Side) –

IC101

SL101

(ADJ)

19

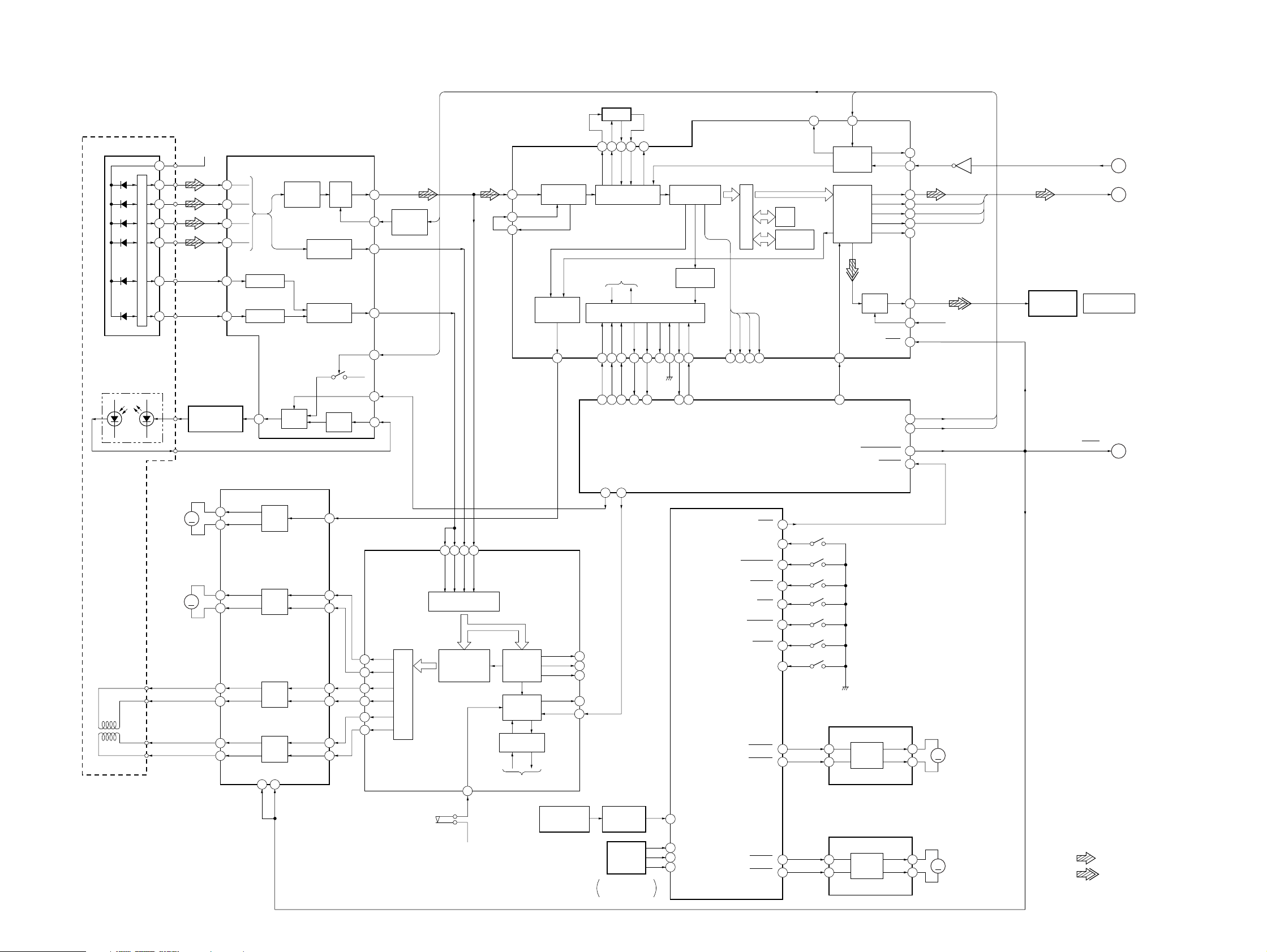

7-1. BLOCK DIAGRAM – SERVO Section –

RF AMP,

DETECTOR

A

B

C

D

I-V AMP

F

E

OPTICAL PICK-UP BLOCK

(KSS-213B/Z-N)

CD A+5V

7

4

2

1

5

10

6

10

11

FOCUS/TRACKING ERROR AMP

A

5

B

6

C

7

D

8

F

F I-V AMP

E

E I-V AMP

IC103

RF

SUMMING

AMP

SECTION 7

DIAGRAMS

RFO

RF EQ

AMP

FOCUS

ERROR AMP

TRACKING

ERROR AMP

RFE

HOLD SW

16

15

FE

14

TE

13

21

CTL2

RF EQ

SWITCH

Q102

CTL1

DIGITAL SIGNAL PROCESSOR

IC101 (1/2)

RFAC

50

49

48

ASYMMETRY

CORRECTOR

ASYI

ASYO

DIGITAL

CLV

PROCESSOR

MDP

25 76 77

FILTER

53 55

FILI

PCO

FILO

CLTV

DIGITAL PLL

TO SERVO AUTO

SEQUENCER

CPU INTERFACE

SENSE

DATA

CLOK

XLAT

125254

XPCK

EFM

DEMODULATOR

32K

RAM

INTERNAL BUS

SUBCODE

PROCESSOR

EXCK

SCOR

SBSO

SQCK

SQSO

79 801574 6 5 10 111368 3

WFCK

XUGF

GFS

EMPH

ERROR

CORRECTOR

16 69

C4M

CLOCK

GENERATOR

DIGITAL

INTERFACE

MUTE

D/A

CTL1

XTSL

DIGITAL

OUT

XTAO

XTAI

PCMD

BCK

LRCK

C2PO

WDCK

DOUT

MD2

XRST

HTC-NX300

72

71

66

67

65

14

17

64

63

2

IC104

DATA

BCK

LRCK

C2PO

CD A+5V

OPTICAL

TRANSCEIVER

IC207

MCLK

33.8MHz

DATA, BCK,

LRCK, C2PO

CD DIGITAL OUT

OPTICAL

A

B

(Page 22)

(Page 22)

LASER DIODE

2-AXIS

DEVICE

(TRACKING)

(FOCUS)

LDON

22

AUTOMATIC

POWER CONTROL

LD

PD

M101

(SPINDLE)

M102

(SLED)

Q101

FOCUS/TRACKING COIL DRIVE,

VO3 (+)

15

M

M

VO3 (–)

16

VO4 (+)

17

VO4 (–)

18

VO2 (+)

12

VO2 (–)

11

VO1 (+)

14

VO1 (–)

13

LD

APC LD

3

AMP

SPINDLE/SLED MOTOR DRIVE

IC102

OPIN3 (–)

MOTOR

DRIVE

OPIN4 (+)

MOTOR

OPIN4 (–)

DRIVE

OPIN2 (+)

COIL

OPIN2 (–)

DRIVE

OPIN1 (+)

COIL

OPIN1 (–)

DRIVE

STBY2STBY1

209

APC PD

AMP

23

27

26

5

6

2

3

PD

4

DIGITAL SERVO

SFDR

29

SRDR

30

TFDR

31

TRDR

32

FFDR

33

FRDR

34

PROCESSOR

IC101 (2/2)

PWM GENERATOR

FOCUS/TRACKING/SLED

40 41 39 43

FE

TE

SE

RFDC

A/D

CONVERTER

FOCUS/

TRACKING/SLED

SERVO DSP

SSTP

26

MIRR,

DFCT, FOK

DETECTOR

SERVO

INTERFACE

SERVO AUTO

SEQUENCER

TO CPU INTERFACE

FOK

MIRR

DFCT

COUT

SCLK

3 5 4 1 18 36 37 10

SCOR

SENSE

DSP CLK

DSP DATA

DSP LATCH

SENSE CLK

LDON

6 2

22

20

21

19

8

SUBQ CLK

SUBQ DATA

CD MECHANISM CONTROLLER

IC505 (1/2)

SYSTEM CONTROLLER

IC101 (1/3)

XRST

PRTC SW

MIDOUT SW

OUT SW

IN SW

MIDIN SW

INIT SW

CNT SW

LOD NEG

LOD POS

4

56

60

58

59

61

57

93

63

65

CTRL1

11

19

DSP MUTE

S702

S701

S708

S704

S703

S705

S706

LOADING MOTOR DRIVE

IN1

3

IN2

6

CTRL2

XRESET

OUT1

OUT2

77

12

7

M

2

(LOADING)

DEVICE RESET

S702 (LID)

(ON: When CD lid is close.)

S701 (MID OUT)

(ON: When tray is going to open/close.)

S708 (OUT)

(ON: When tray is open.)

S704 (IN)

(ON: When sub tray set to play position.)

S703 (MID IN)

(ON: When sub tray move between tray and stocker.)

S705 (INIT)

(ON: When elevator down to bottom.)

S706 (COUNT)

(ON: When elevator up/down each sub tray stock position.)

IC702

MOTOR

DRIVE

M702

CTL1

CTL2

RESET

C

(Page 22)

S101

05

(LIMIT)

CD A+5V

DISC IN DETECT

SENSOR

D704,Q703

LEVEL SHIFT

Q701

ROTARY

ENCODER

S707

DISC TRAY

ADDRESS DETECT

92

70

69

68

DISC SENS

ENCODE0

ENCODE1

ENCODE2

CLP POS

CLP NEG

ELEVATOR

UP/DOWN MOTOR DRIVE

IC701

• SIGNAL PATH

IN1

67

66

3

IN2

6

MOTOR

DRIVE

OUT1

OUT2

7

M

2

M701

(ELEVATOR UP/DOWN)

: CD PLAY

: DIGITAL OUT

2121

HTC-NX300

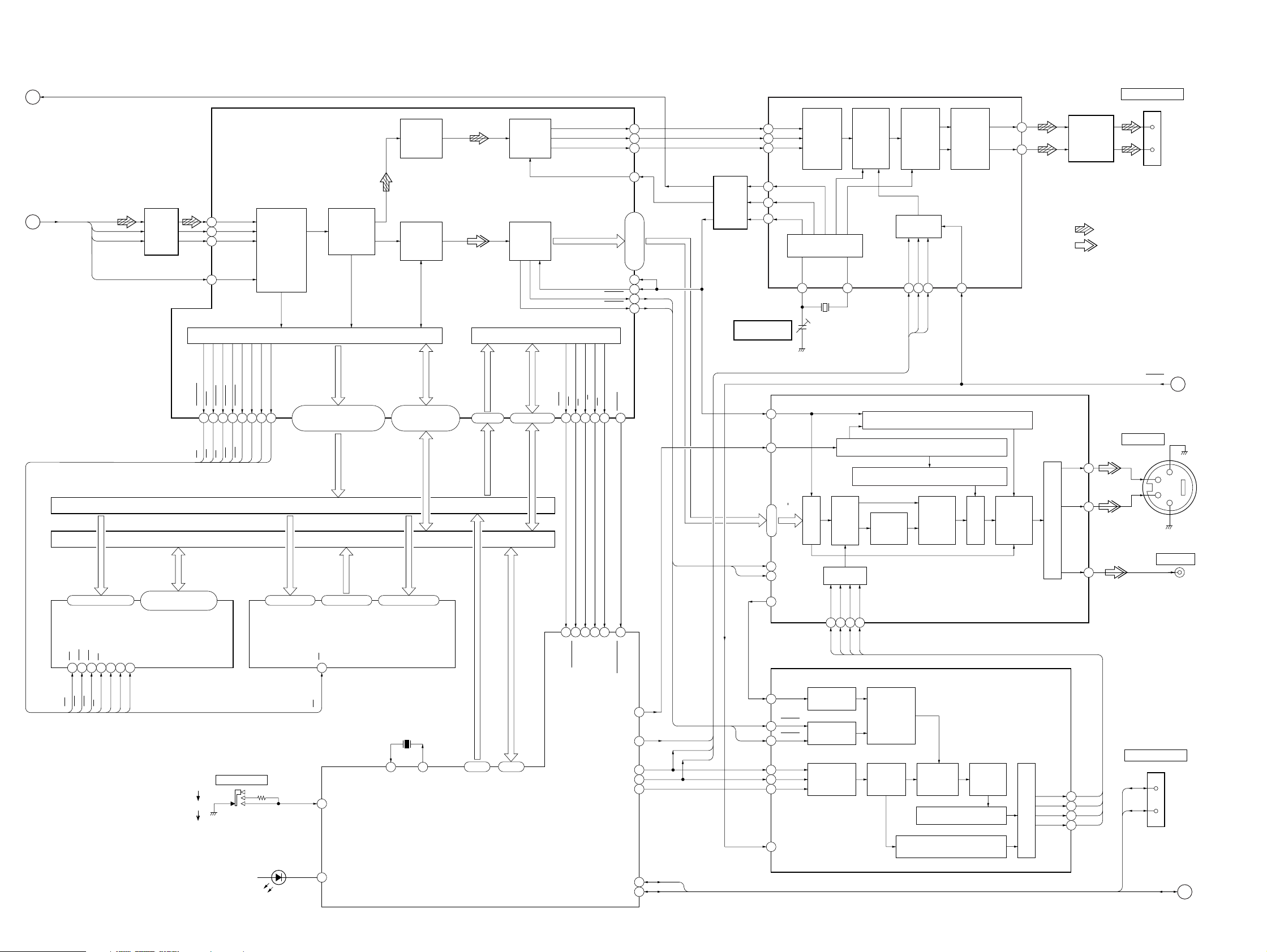

7-2. BLOCK DIAGRAM – AUDIO/VIDEO CD Section –

MCLK 33.8MHz

A

(Page 21)

B

(Page 21)

DATA, BCK,

LRCK, C2PO

05

DATA

BCK

LRCK

C2PO

A0-A11

A0-A10, BA

LDQM

CS

RAS

CAS

WE

15 16 17 18 14 80 84 22

UDQM

LDQM

CS

RAS

CAS

WE

LEVEL

SHIFT

IC501

2, 3, 5, 6, 8, 9, 11, 12, 39

40, 42, 43, 45, 46, 48, 49

SD-CLK

UDQM

CLK

D0-D15

DQ0-DQ15

MPEG VIDEO/AUDIO DECODER,

VIDEO SIGNAL PROCESSOR

IC505

CD-DATA

4

CD-BCK

3

CD-LRCK

5

CD-C2PO

6

SD-RAS

SD-CS0

MWE

ROM-CS

128

82 90 86 85 35 36 79 15 16 13

RAS

CS

WE

CE

D-RAM

IC507

S501

SYSTEM SELECT

NTSC

AUTO

PAL

CD-ROM

INTERFACE

CIRCUIT

SD-CLK

UDQM

LDQM

SD-CAS

UDQM

CLK

CAS

LDQM

12 – 5, 27, 26, 23 13 – 15, 17 – 21 25, 4, 28, 29, 3, 2, 3021 – 24, 27 – 32, 20, 19

D502

(SELF DIAGNOSIS)

D-RAM/ROM INTERFACE

104, 106, 110, 112, 111, 108,

105, 102, 99, 96, 100, 98, 114,

116, 118, 120, 121, 122, 124

ADDRESS BUS

DATA BUS

A0-A10

A0-A10 O0-O7 A11-A17

CE

93

73

MA0-MA7

A0-A17

CE

NT/PAL

TEST LED

MPEG

SYSTEM

DECODER

D0-D7

MPEG

AUDIO

DECODER

MPEG

VIDEO

DECODER

MD0-MD5

54, 58, 60, 64, 68,

72, 74, 78, 76, 73, 70,

66, 62, 59, 56, 53,

D0-D15

A11-A17

PROGRAM ROM

IC508

X501

10MHz

15

13

AUDIO

INTERFACE

CIRCUIT

VIDEO

PROCESS

CIRCUIT

CPU INTERFACE

HA0-HA2

202 – 204

A0-A2

A0-A2

71 – 73 81 – 88

A2-A0XOUTXIN

CD MECHANISM CONTROLLER

HD0-HD7

2 – 4, 6, 8 – 11

D0-D7

D0-D7

D0-D7

IC505 (1/2)

VDATA0-VDATA7

WAIT

INTCSR/W

206 207 208

39 20

47 46 44 24

8830-CS

8830 HINT

BUS-XRDY

DA-DATA

DA-BCK

DA-LRCK

DA-XCLK

SYSCLK

VCK-IN

HSYNC

VSYNC

RD

BUS-XRD

BUS-XWR

NT/PAL OUT

DF LATCH

CLK1

DATA1O

OSD CS

I2C/RX

I2C/TX

161

167

166

169

150, 152, 154, 155

142, 143, 145, 148,

178

177

HSYNC

157

VSYNC

158

RESET

8830 RESET

21

22

33

31

28

DATA

29

CLK

30

LATCH

OSC

BUFFER

IC504

VIDEO FREQUENCY

HSYNC

VSYNC

HSYNC

VSYNC

CT503

(27MHz)

18

17

19

21

20

4

51

22

28

27

29

8

20

19

1

3

2

4

DATA

BCK

LRCK

768FSO

384FSO

MCKO

2 – 8, 10

INTERFACE

TIMING CONTROL/

CLOCK GENERATOR

XT2

24 1

VCLK

NTB

YUV0

YUV7

HSY

VSY

PIXCLK

OSC IN

HSYNC

VSYNC

CLK

DATA

CS

RESET

INPUT

CIRCUIT

X503

27MHz

LATCH

OSD-SW

15

BLKRG

CLOCK

CONTROL

PROTECTIVE

CIRCUIT

INTERFACE

CIRCUIT

XT1

RGB

OSD

ROSD

GOSD

57 64 1

DIGITAL FILTER,

D/A CONVERTER

IC509

DIGITAL

FILTER,

NOISE

SHAPER

CIRCUIT

MODE/FIELD/FLAME CONTROL

SUB CARRIER BURST GENERATOR

FILTER

BOSD

B

HORIZONTAL/

VIRTICAL

CONTROL

ADDRESS

REGISTER

U/V

CONVERTER

MODE

CONTROL

MDMCML

DATA

D/A

8 7 109

CLK

VIDEO TIMING CONTROL

DISPLAY/BACKGROUND

LATCH

Y-LEVEL

ADJ.

CHROMA

GEN.

DATA

SELECTOR

CHARACTOR ROM

CONTROL

LOW-PASS

FILER

RSTB

VOUTL

14

VOUTR

11

MIX

SIGNAL

SYNC

BURST

Y/C FILTER

DIGITAL RGB ENCODER

ON SCREEN

DISPLAY CONTROLLER

VIDEO

RAM

D/A CONVERTER

IC514

B-BLK

V-R

V-G

V-B

OUTPUT CONTROL

LOW-PASS

FILER

IC101

• SIGNAL PATH

: CD PLAY (AUDIO)

: CD PLAY (VIDEO)

COUT

37

YOUT

45

VOUT

39

BLK

15

R

16

G

17

B

18

CN101 (1/4)

SYSTEM CONTROL

(TO STR-NX300AV)

3

CD. L

2

CD. R

RESET

(Page 21)

J301

S VIDEO OUT

C

3

4

Y

VIDEO OUT

CN101 (2/4)

SYSTEM CONTROL

(TO STR-NX300AV)

14

DATA

17

CLK

DATA,

CLK

C

1

2

J302

IIC DATA

IIC CLK

D

(Page 24)

2222

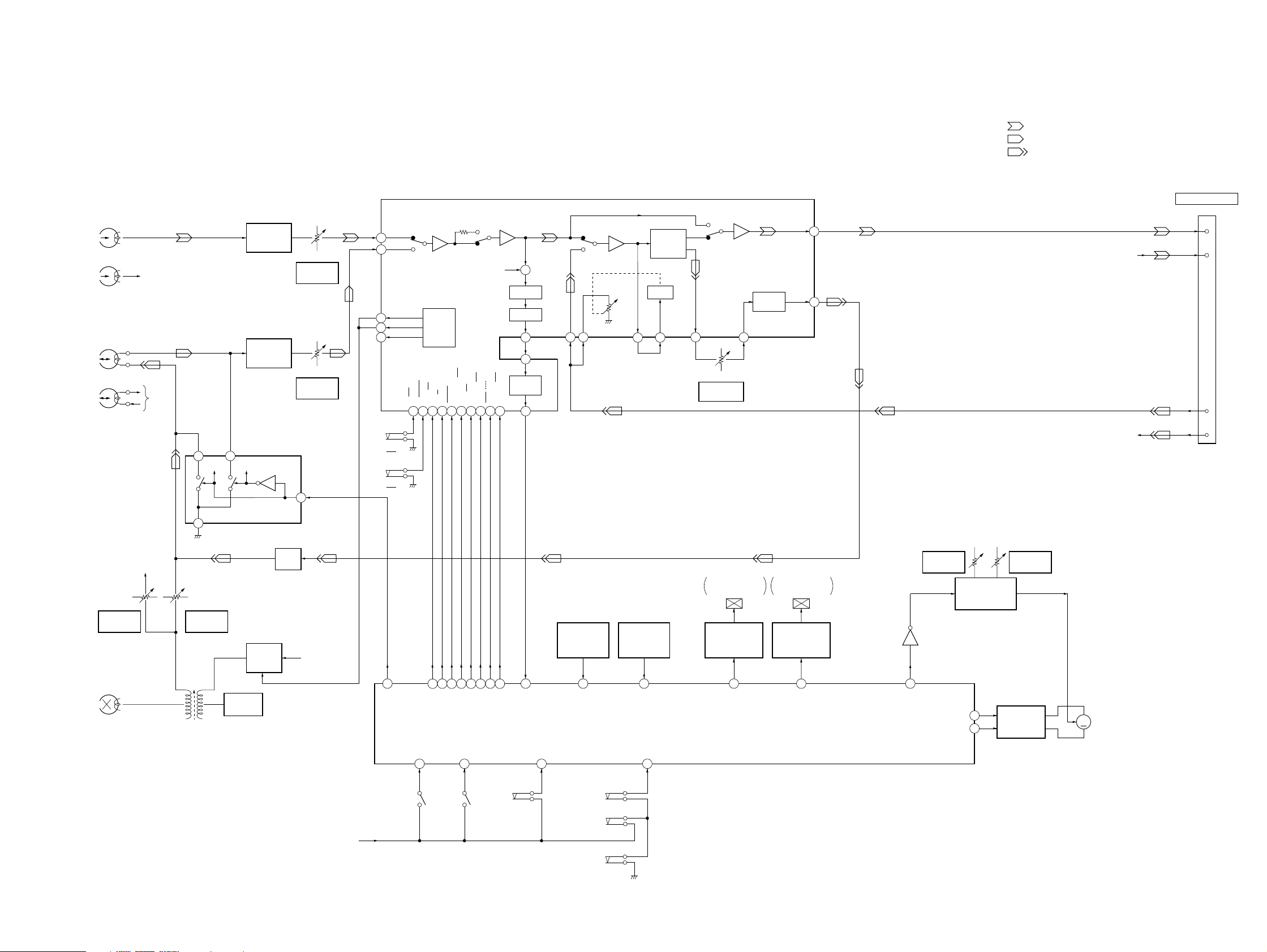

7-3. BLOCK DIAGRAM – TAPE DECK Section –

HP101

(PLAYBACK)

L-CH

R-CH R-CH

HRPE101 (1/2)

(RECORD/PLAYBACK)

L-CH

R-CH R-CH

3

R-CH

PB EQ AMP

(DECK A)

IC611

PB EQ AMP

(DECK B)

IC601

REC/PB SWITCHING

IC602

1

R-CH

RV311

PB LEVEL (L)

(DECK A)

RV301

PB LEVEL (L)

(DECK B)

4

DECK PROCESS

DECK A/B SELECT, PB/REC EQ AMP,

DOLBY NR AMP, ALC, AMS

AIN (L)

48

BIN (L)

46

BIAS (N)

33

BIAS (C)

32

BIAS (M)

31

A 120/70

19

S1004

(DECK A 120/70)

S1008

(DECK B 120/70)

IC301

BIAS

CONTROL

CIRCUIT

B NORM/CROM

ALC ON/OFF

NORM/HIGH

PB A/B

1516182022 23242517

70

120

R-CH

NR ON/OFF

BIAS ON/OFF

RM ON/OFF

L.P.F.

BUFFER

28

27

AMS

CIRCUIT

REC/PB/PASS

LM ON/OFF

26

+

MAOUT

MSIN

MSOUT

RIN (L)

43

ALC (L)

44

DOLBY PASS

ALC

ROUT (L)

35 34

DOLBY NR

AMP

CIRCUIT

ALC

IN (L)

REC OUT (L)

39

RV301

REC LEVEL (L)

(DECK B)

EQ IN (L)

38

REC

EQ AMP

PB OUT (L)

EQ OUT

HTC-NX300

• SIGNAL PATH

: PLAYBACK (DECK A)

: PLAYBACK (DECK B)

: RECORD

CN101 (3/4)

SYSTEM CONTROL

(TO STR-NX300AV)

40

R-CH

(L)

36

7

PB-L

9

PB-R

6

REC-L

4

REC-RR-CH

RV441

REC BIAS (R)

(DECK B)

HRPE101 (2/2)

(ERASE)

R-CH

05

2

RV341

REC BIAS (L)

(DECK B)

BIAS OSC

T621

BIAS OSC

Q621, 622

REC BIAS

SWITCH

Q623

C331, L331

BIAS

TRAP

B+

(A+7V)

D+5V

100

TC-RELAY

(DECK A PLAY)

8584838281 807978

PB-A/B

EQ-H/N

ALC-ON/OFF

A-PLAY-SW

87

S1001

S1002

(DECK B PLAY)

BIAS

REC-MUTE

B-PLAY-SW

86

TC-MUTE

R/P-PASS

NR-ON/OFF

(DECK A HALF)

S1003

77

AMS-IN

A-HALF

88

ROTATION

DETECT SENSOR

(DECK A)

IC1001

91

A-SHUT

S1006

(DECK B HALF)

S1005

(DECK A REC)

S1009

(DECK B REC)

ROTATION

DETECT SENSOR

(DECK B)

IC1002

90

B-SHUT

SYSTEM CONTROLLER

B-HALF

89

IC101 (2/3)

TRIGGER PLUNGER

DECK A

TRIGGER

PLUNGER DRIVE

(DECK A)

Q333, 334

73

A-TRG

TRIGGER PLUNGER

DECK B

TRIGGER

PLUNGER DRIVE

(DECK B)

Q331, 332

72

B-TRG

Q335

76

CAP-M-H/L

RV1001

TAPE SPEED

(HIGH)

CAPM-CNT1

CAPM-CNT2

CAPSTAN MOTOR

CONTROL SWITCH

Q1001

75

MOTOR DRIVE

74

RV1002

TAPE SPEED

(NORMAL)

CAPSTAN

Q336 – 343

M

M1

(CAPSTAN)

2323

Loading...

Loading...