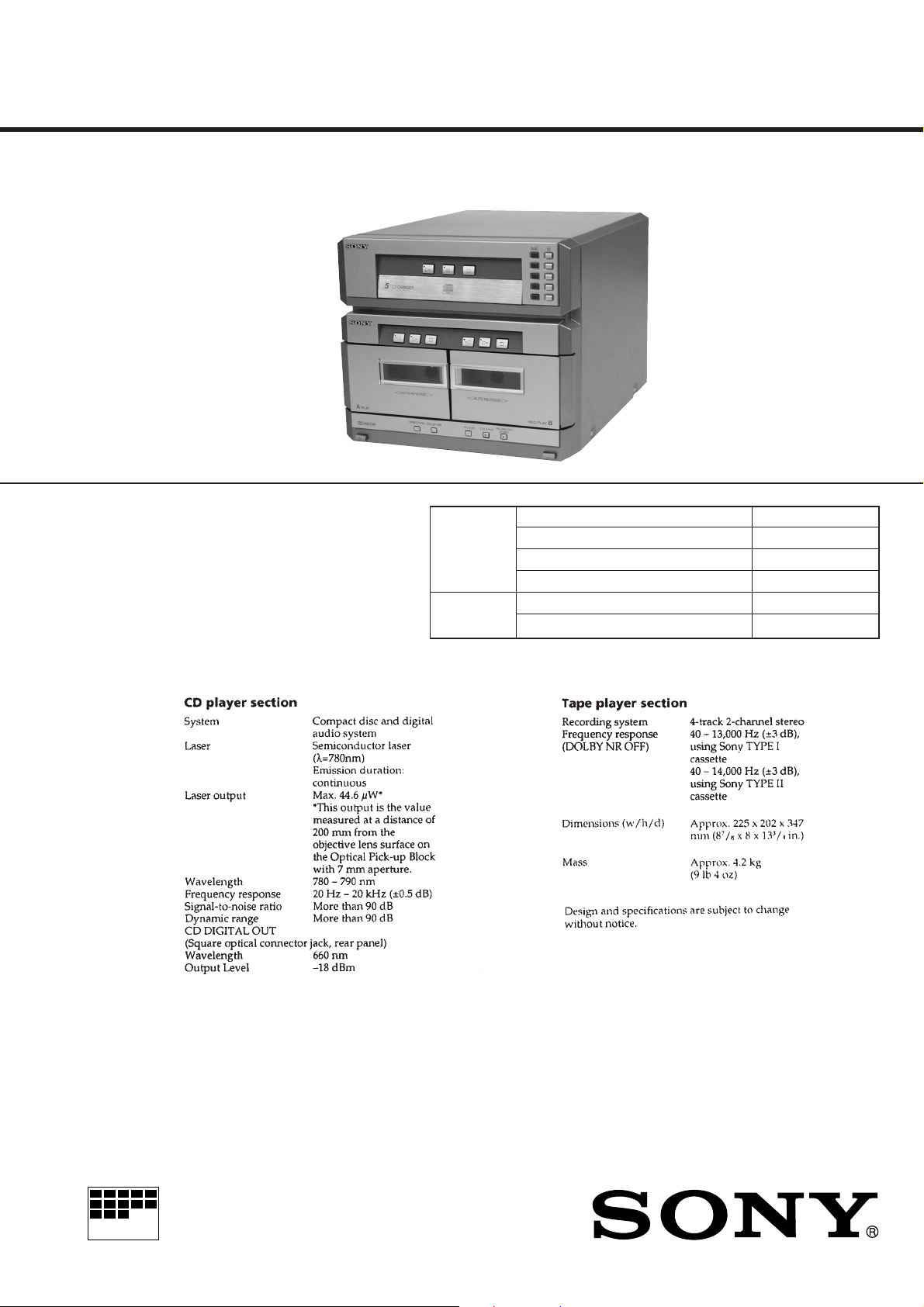

Sony HTCNX-1 Service manual

HTC-NX1

SERVICE MANUAL

HTC-NX1 is the CD player and Tape

Deck section in MHC-NX1/NX3AV.

Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks of Dolby Laboratories Licensing Corporation.

CD

Section

Tape Deck

Section

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Tourist Model

Model Name Using Similar Mechanism HCD-MD555

CD Mechanism Type CDM53D-K1BD33

Base Unit Name Type BU-K1BD33

Optical Pick-up Name KSM-213BFN-C2NP

Model Name Using Similar Mechanism HCD-GRX7

Tape Transport Mechanism Type TCM-230AWR2

SPECIFICATIONS

MICROFILM

MINI Hi-Fi COMPONENT SYSTEM

SECTION 1

SERVICING NOTES

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 2

2. GENERAL

Location of Controls ....................................................... 5

3. DISASSEMBLY ......................................................... 6

4. TEST MODE.............................................................. 13

5. MECHANICAL ADJUSTMENTS....................... 14

6. ELECTRICAL ADJUSTMENTS

TAPE DECK Section ...................................................... 14

CD Section ...................................................................... 17

7. DIAGRAMS

7-1. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 19

7-2. Printed Wiring Board – BD Board – ............................. 20

7-3. Schematic Diagram – BD Board – ................................ 21

7-4. Printed Wiring Boards

– CD MOTOR/SENSOR Section – ................................ 22

7-5. Schematic Diagram

– CD MOTOR/SENSOR Section – ................................ 23

7-6. Printed Wiring Board – AUDIO Board – ...................... 24

7-7. Schematic Diagram – AUDIO Board – ......................... 25

7-8. Printed Wiring Board – LEAF SW Board –.................. 26

7-9. Schematic Diagram – LEAF SW Board –..................... 26

7-10. Printed Wiring Board – MAIN Board – ........................ 27

7-11. Schematic Diagram – MAIN Board (1/2) – .................. 28

7-12. Schematic Diagram – MAIN Board (2/2) – .................. 29

7-13. Printed Wiring Boards – PANEL Section – .................. 30

7-14. Schematic Diagram – PANEL Section – ....................... 31

7-15. IC Pin Function Description ........................................... 34

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

CAUTION :

INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

ADVARSEL :

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION. UNDGÅ UDSAETTELSE

FOR STRÅLING.

VORSICHT :

ABDECKUNG GEÖFFNET UND SICHEREITSVERRIEGELUNG

ÜBERBRÜCKT. NICHT DEM STRAHL AUSSETZEN.

VARO!:

TIINA NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VARNING :

OCH SPÄRREN ÄR URKOPPLAD. BETRAKTA EJ STRÅLEN.

ADVERSEL :

SIKKERHEDSLÅS BRYTES. UNNGÅ EKSPONERING FOR STRÅLEN.

VIGYAZAT!:

GÁRVESZÉLY

INVISIBLE LASER RADIATION WHEN OPEN AND

USYNLIG LASERSTRÅLING VED ÅBNING NÅR

UNSICHTBARE LASERSTRAHLUNG, WENN

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALT -

OSYNLING LASERSTRÅLING NÄR DENNA DEL ÄR ÖPPNAD

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG

A BURKOLAT NYITÁSAKOR LÁTHATATLAN LÉZERSU-

!

KERÜLJE A BESUGÁRZÁST!

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

8. EXPLODED VIEWS ................................................ 37

9. ELECTRICAL PARTS LIST ............................... 44

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQ UE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objecti ve lens.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

2

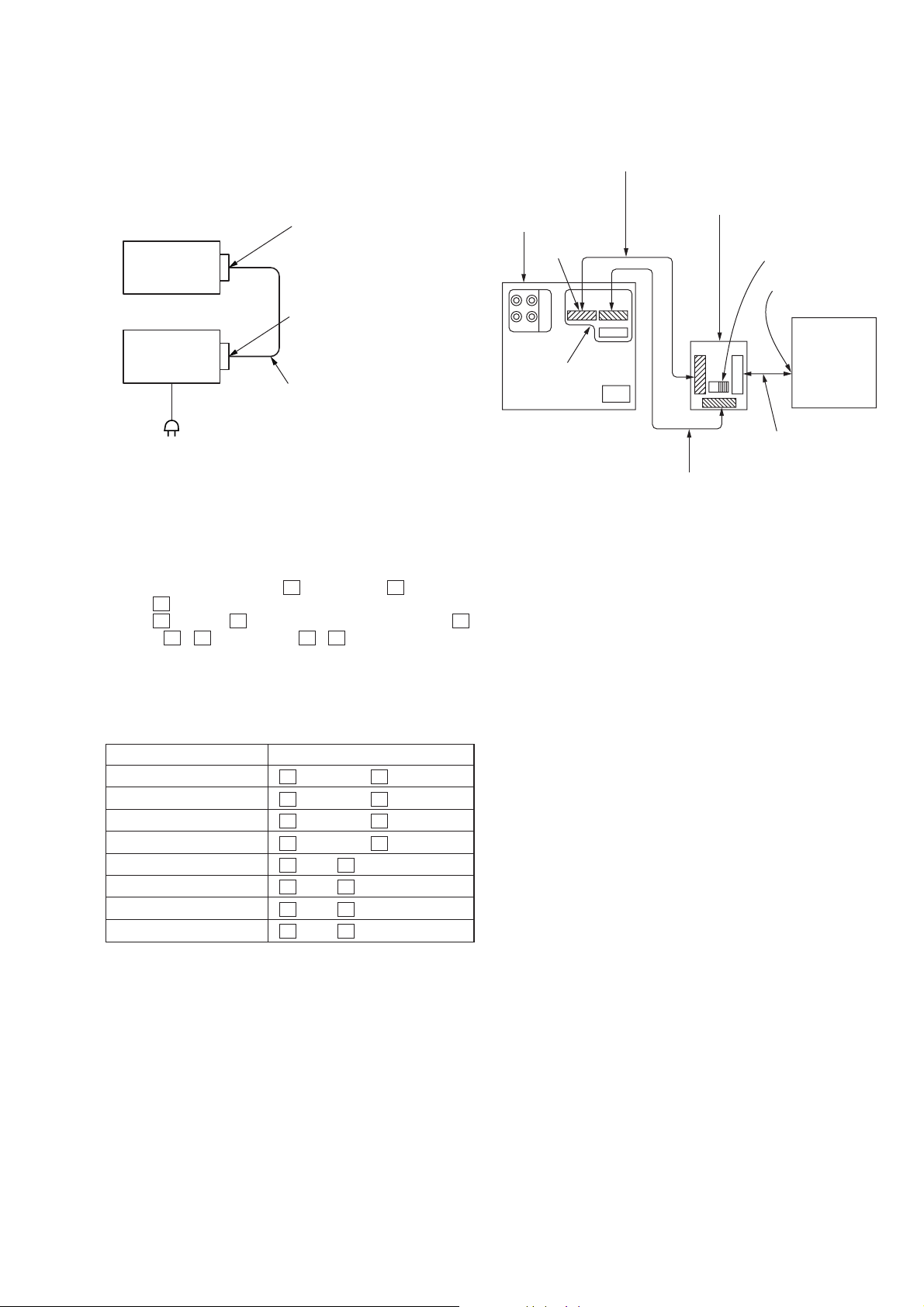

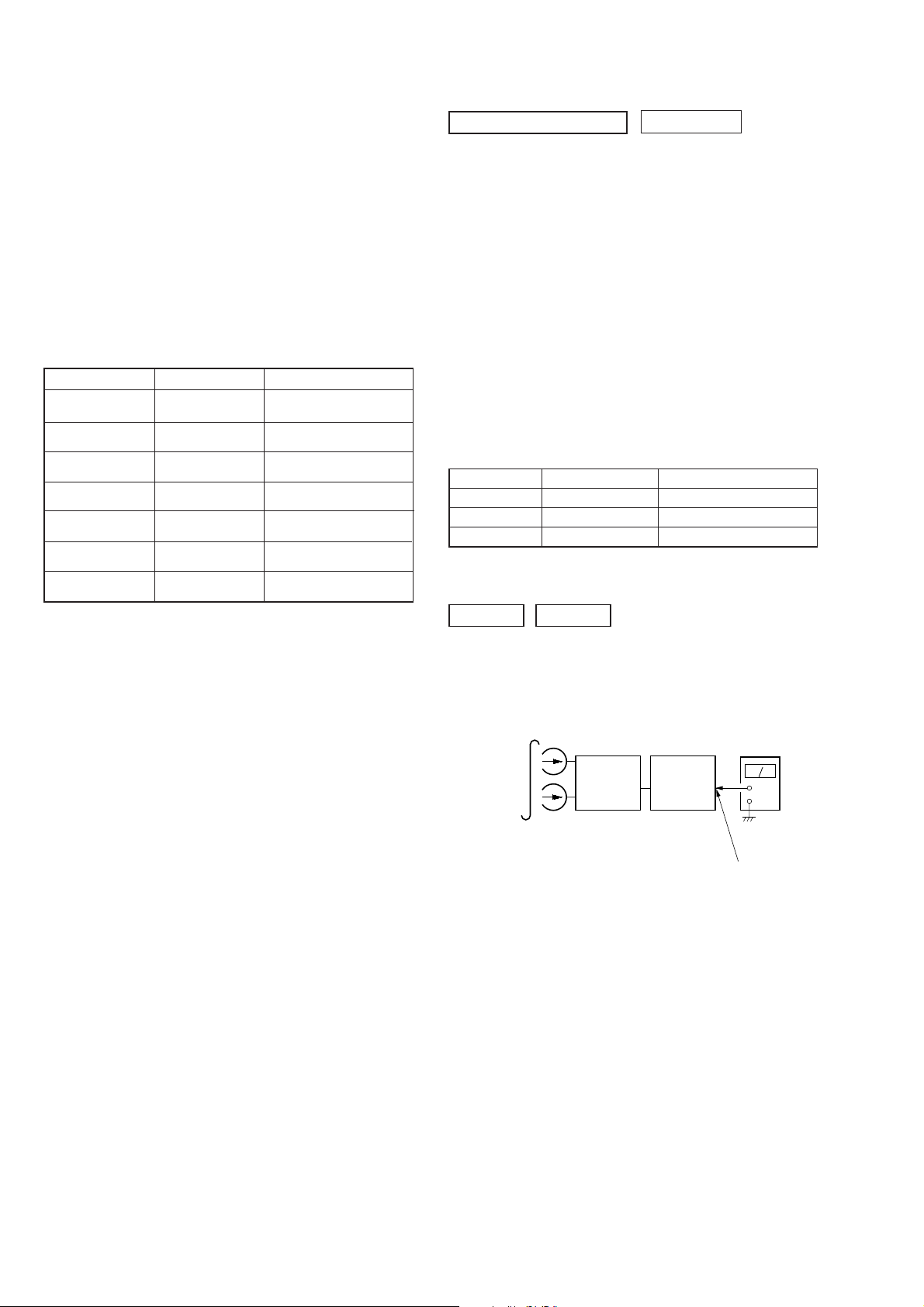

POWER SUPPLY DURING SERVICING

l

Connection:

• As this set has not own power supply, it does not operate independently. Therefore, during servicing, connect it to the PreMain amplifier and T uner Unit (STR-NX1/NX3) of MHC-NX1/

NX3AV.

SYSTEM CONTROL termina

Set

SYSTEM CONTROL terminal

Pre-Main AMP

and T uner Unit

Connector cable (19P)

AC IN

If STR-NX1/NX3 are not available, use the Po wer Feed Jig (PFJ-

1) and Relay Connector Jig.

In this case, after turn on the POWER switch on the Power Feed

Jig, supply power with the following methods.

Procedure:

1. Press three buttons of s (DECK B), A (DISC 1),

and s (CD) simultaneously.

2. The G (CD) and S (CD) LEDs blink, and then pressing G

(CD), G / g (DECK A), or G / g (DECK B) button can

make each play possible.

3. Also, the other functions are enabled by pressing two buttons

simultaneously.

A combination of respective functions and buttons is as follows.

Connector cable (17P) of

attachment to power feed jig

Power feed jig

(PFJ-1)

CDP/TC

P707, P909

Relay connector jig

(J-2501-174-A)

ST

Exclusive cable (15P)

CD/TC signal

change switch

CN101 (15P)

SYSTEM CONTROL

terminal

Set

system cable

function button

CD AMS – s (DECK A), S (CD)

AMS + s (DECK A), s (CD)

FR s (DECK B), S (CD)

FF s (DECK B), s (CD)

Deck-A REW/AMS – s (CD), g (DECK A)

FF/AMS + s (CD), G (DECK A)

Deck-B REW/AMS – s (CD), g (DECK B)

FF/AMS + s (CD), G (DECK B)

3

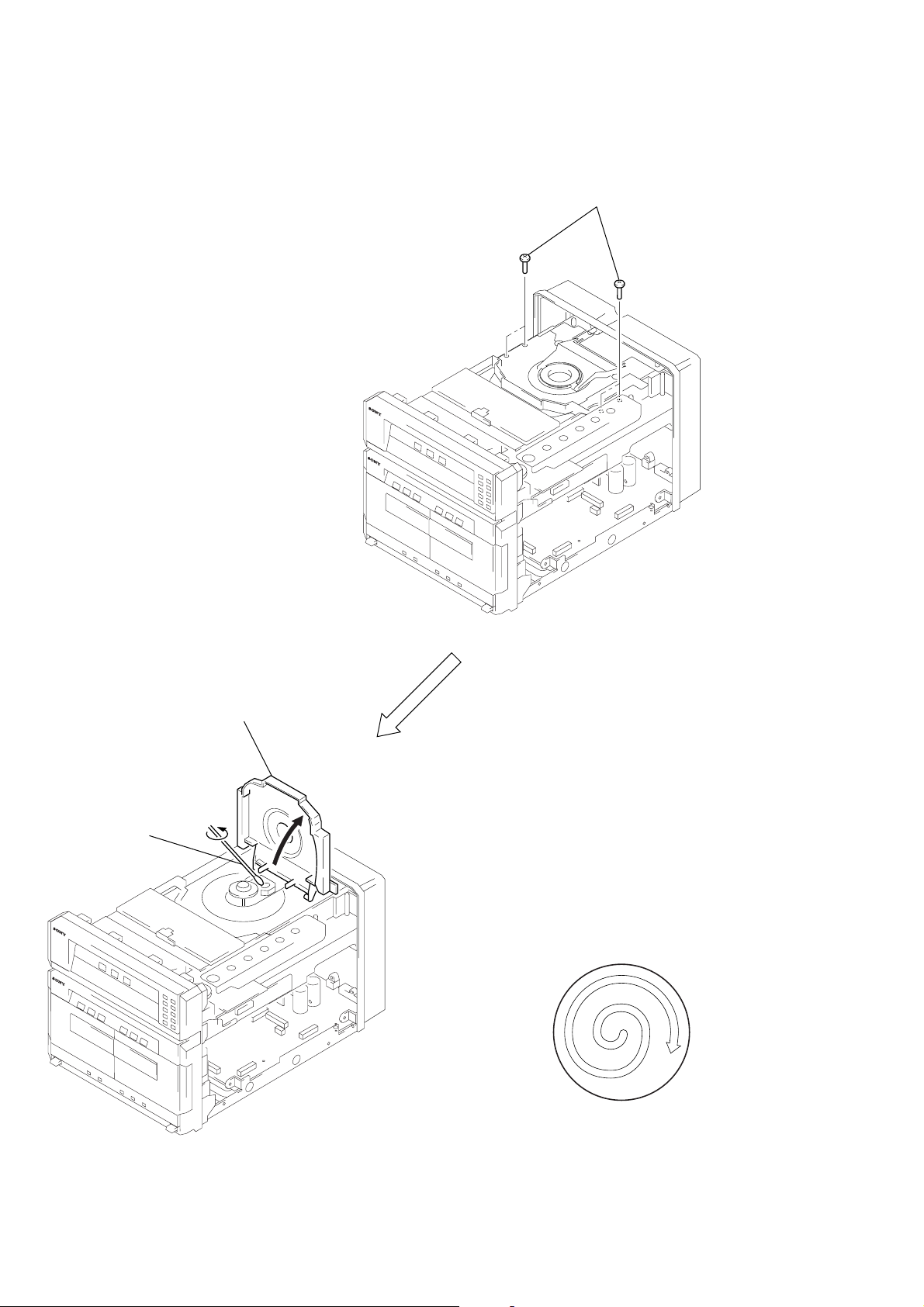

OPTICAL PICK-UP CLEANING

1

Remove the case. (Refer to disassembly page 8)

2

four screws

(BVTP M2.6)

4

Cleaning the

optical pick-up.

3

Open the magnet

ass’y.

Note 1: In cleaning the lens, do not apply an excessive force.

As the optical pick-up is vulnerable, application of

excessive force could damage the lens holder.

Note 2: In cleaning, do not use a cleaner other than exclusive clean-

ing liquid (KK-91 or isopropyl alcohol).

Note 3: Wipe the objective lens spirally from center toward outside.

(See Figure A)

(Figure A)

4

• LOCATION OF CONTROLS

– Front Panel –

SECTION 2

GENERAL

6

7

8

123 45

qs qd qf qg qh qj qk

9

q;

qa

1 G (CD) button and indicator

2 S (CD) button and indicator

3 s (CD) button

4 DISC1 to 5 buttons and indicators

5 A (DISC1 to 5) buttons and indicators

6 g (DECK A) button and indicator

7 G (DECK A) button and indicator

8 s (DECK A) button

9 s (DECK B) button

q; G (DECK B) button and indicator

qa g (DECK B) button and indicator

qs A (DECK A) button

qd DIRECTION button

qf DOLBY NR button

qg HI DUB button

qh CD SYNC button and indicator

qj REC PAUSE/START button and indicator

qk A (DECK B) button

5

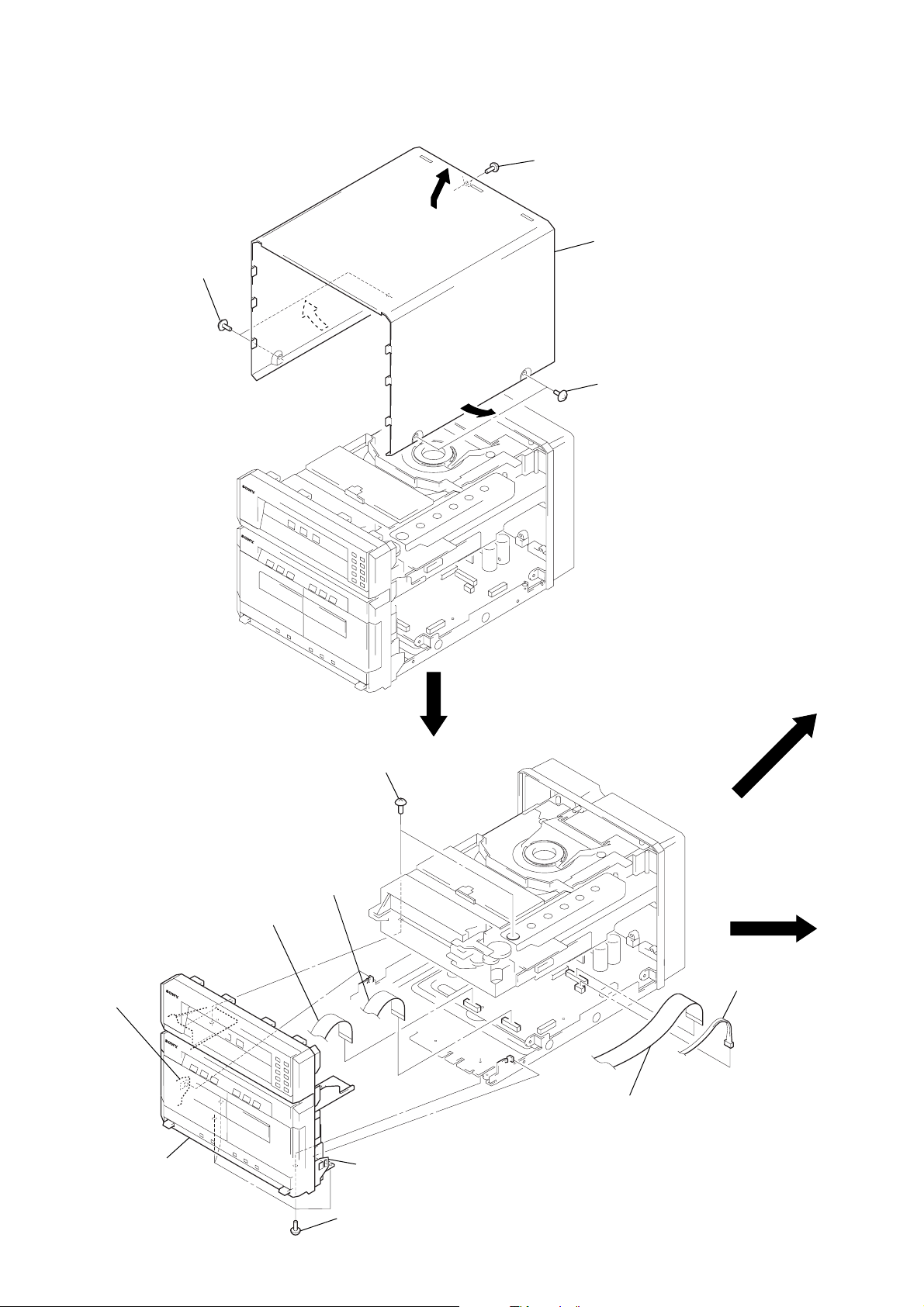

SECTION 3

r

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

CASE

2

two screws

(case 3 TP2)

A

1

screw

(BVTP3

×

10)

3

Remove the case

in the arrow

direction.

2

two screws

(case 3 TP2)

A

FRONT PANEL SECTION

1

flat cable (15 core)

(CNS101)

4

claw

5

front panel

section

3

1

flat cable (17 core)

(16 cm)(CNS104)

two screws

(BVTP3 × 10)

4

claw

1

flat cable (21 core)

(CN102)

2

connecto

(CN105)

3

four screws

(BVTP3 × 5)

6

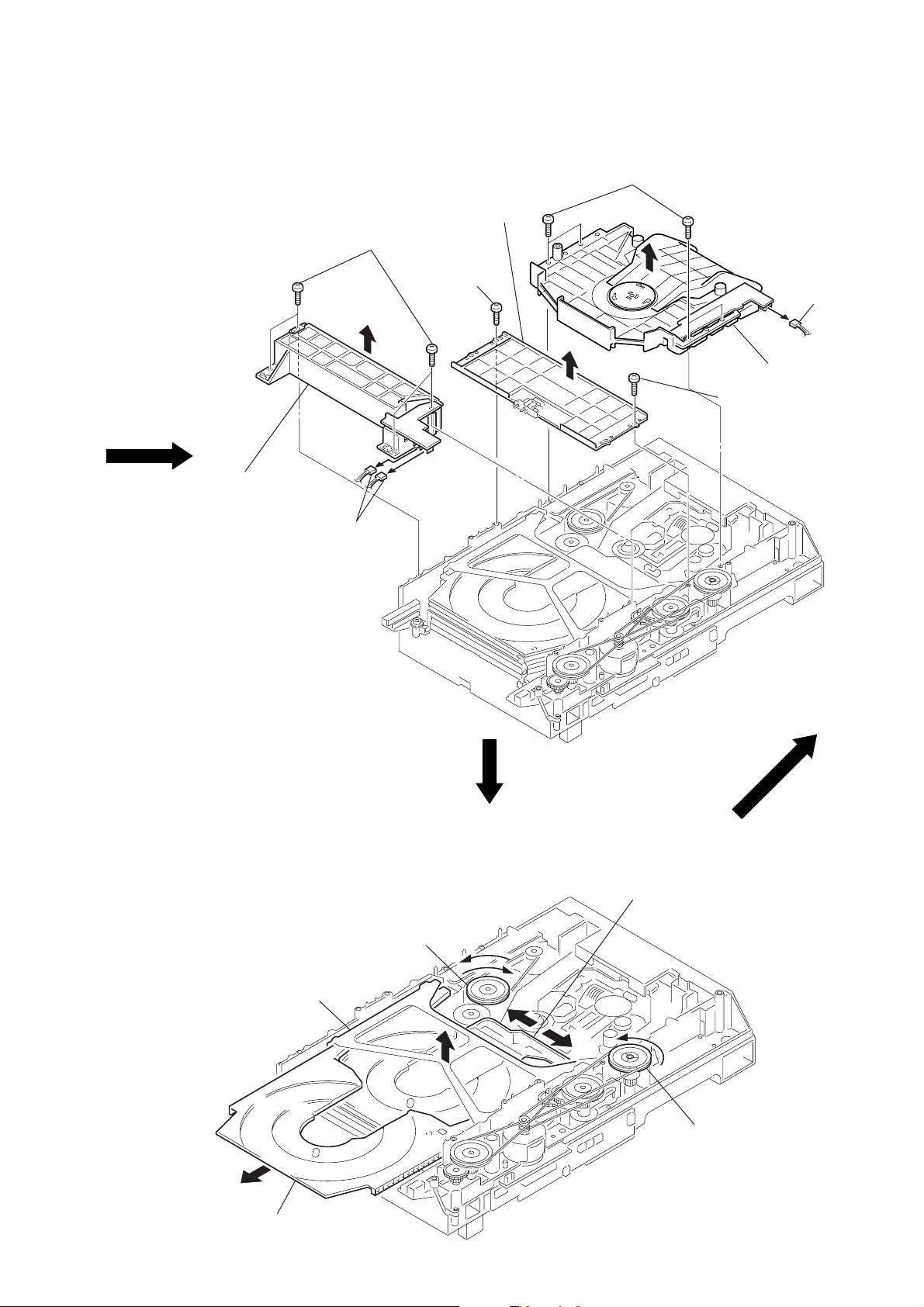

CD MECHANISM DECK SECTION

3

four screws

(BVTP3 × 10)

1

flat cable (17 core)

(12 cm) (CN112)

4

Remove the CD mechanism deck

section (CDM53D-K1BD33) in

the arrow A direction.

1

flat cable (19 core)

(CN111)

2

connector

(CN713)

A

to fitting base (guide)

ass’y, bracket (chassis)

and magnet ass’y

(page 9)

)

(CDM53D-K1BD33)

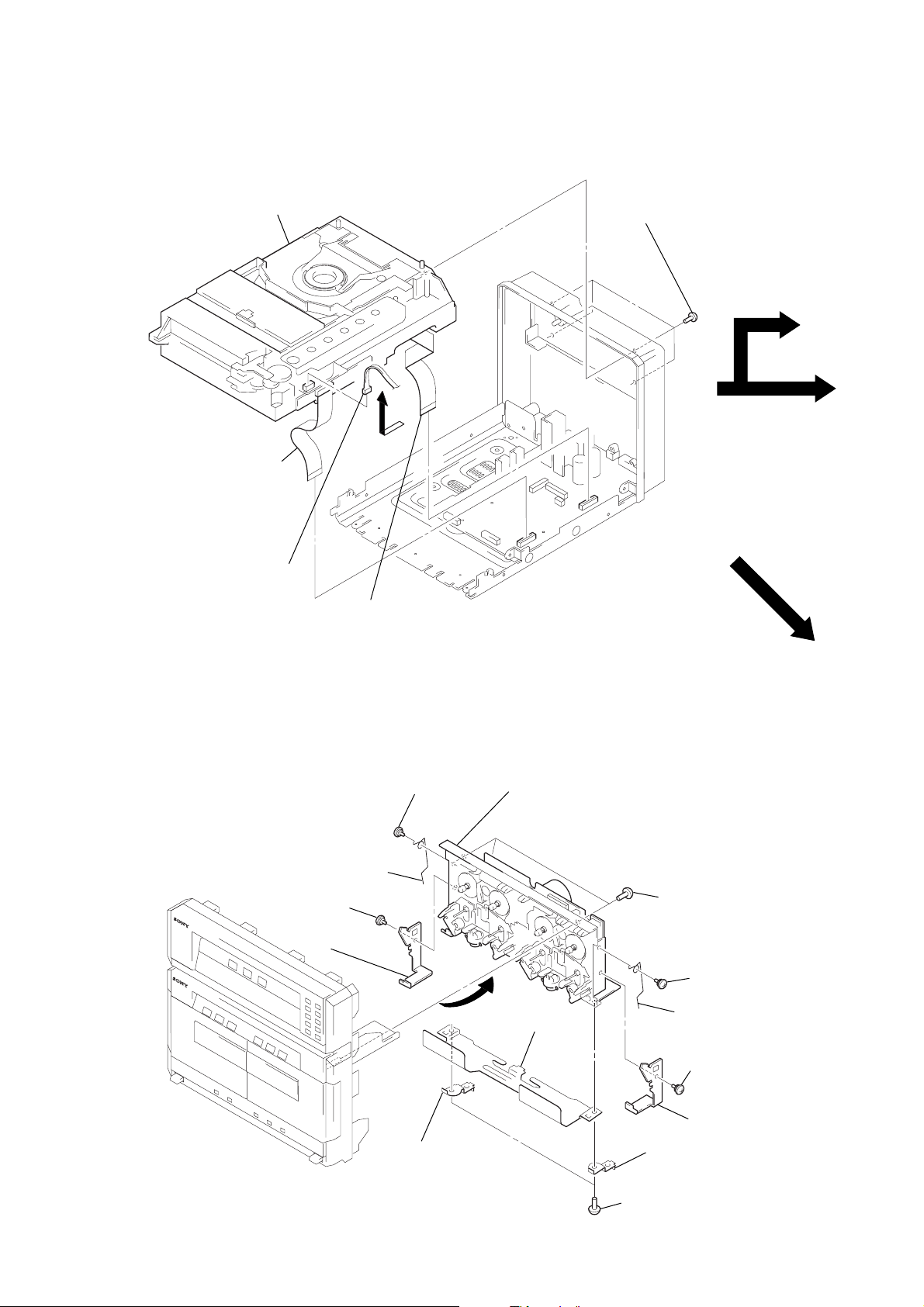

TAPE MECHANISM DECK SECTION

(TCM-230AWR2)

3

spring (eject A)

6

step screw

8

eject lever (A)

1

step screw

qa

bracket (MD A)

A

5

Remove the tape mechanism deck

section (TCM-230AWR2) in the

arrow A direction.

qs

shield plate

q;

4

two screws

(BVTP3 × 10)

1

step screw

2

spring (eject B)

6

step screw

7

eject lever (B

bracket (MD B)

9

two screws

(BVTT 2.6 × 6)

7

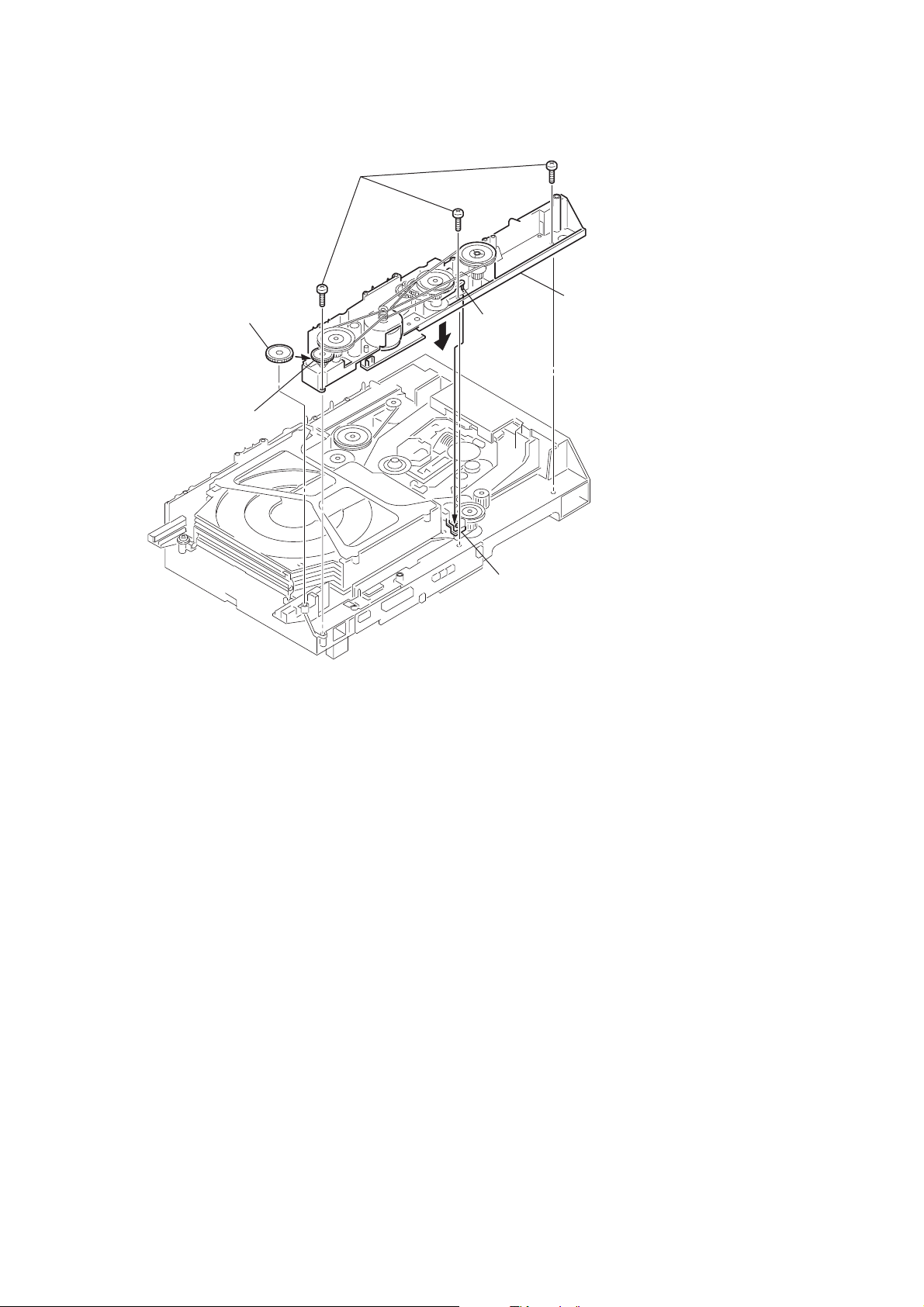

CD BASE UNIT (BU-K1BD33)

3

compression spring

(black)

1

two screws

(PTPWH M2.6)

4

CD base unit

(BU-K1BD33)

2

1

two screws

(PTPWH M2.6)

compression spring

(silver)

MAIN BOARD

2

4

two screws

(BVTP3 × 8)

A

Remove the MAIN board

in the arrow A direction.

3

three PC board

holders

2

1

connection cord

(CN101)

two screws

(BVTP3 × 10)

8

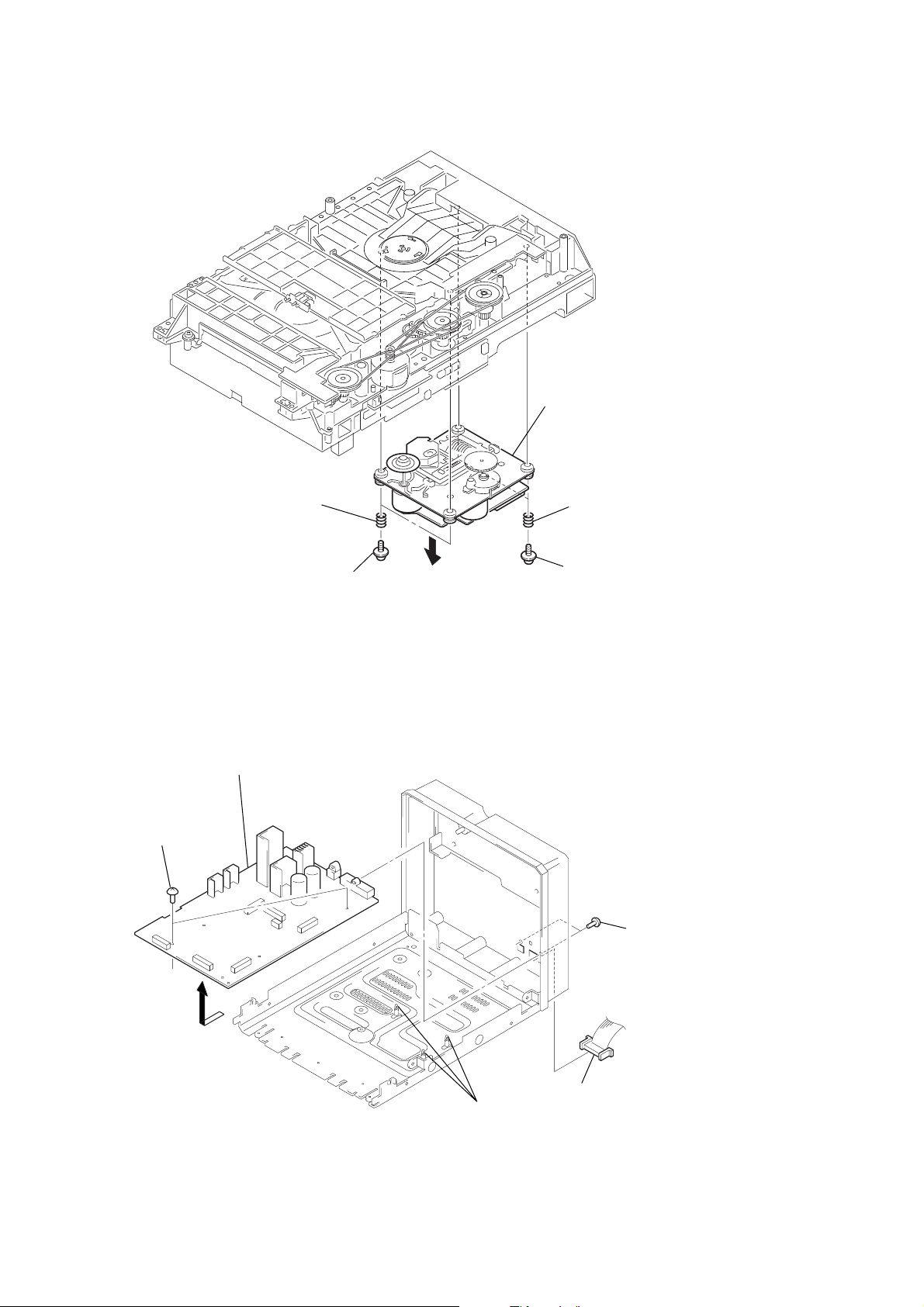

FITTING BASE (GUIDE) ASS’Y, BRACKET (CHASSIS) AND

MAGNET ASS’Y

5

bracket

(chassis)

screw

(BVTP M2.6)

from CD mechanism

deck section

(CDM53D-K1BD3)

(page 7)

3

fitting base

(guide) ass’y

2

four screws

(BVTP M2.6)

1

two connectors

(CN709, 715)

4

7

four screws

(BVTP M2.6)

4

screw

(BVTP M2.6)

6

connector

(CN710)

8

magnet ass’y

TRAY (SUB)

1

Rotating the pulley (LD), shift the slider (selection) in the arrow A direction.

2

Rotating the pulley (mode) in the arrow direction, adjust the tray (sub) to be removed.

3

Rotating the pulley (LD), shift the slider (selection) in the arrow B direction.

4

Rotating the pulley (mode) in the arrow direction, remove the tray (sub) to be removed.

pulley (LD)

stocker

section

tray (sub)

A

slider (selection)

B

pulley (mode)

9

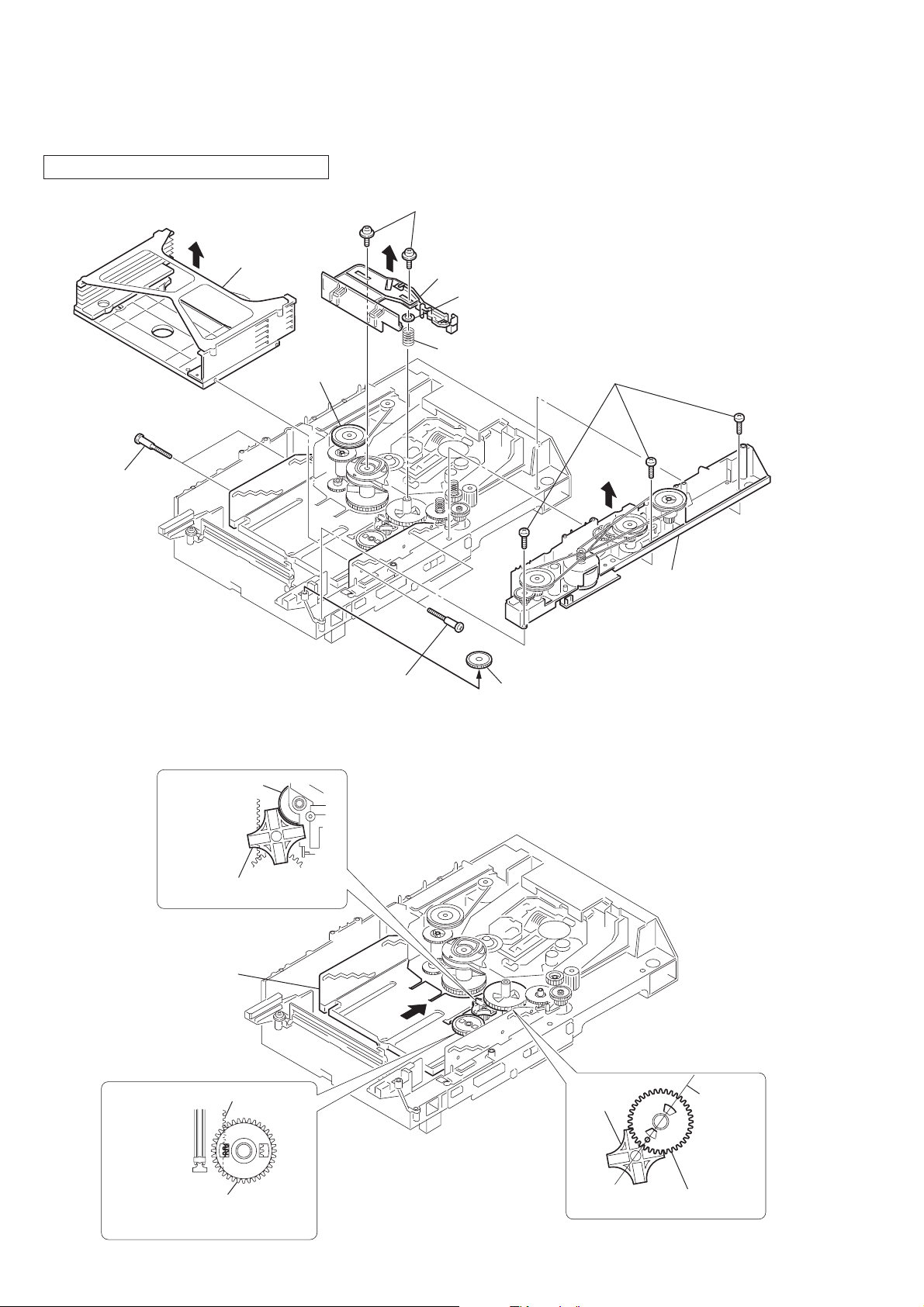

CHASSIS (MOLD B) SECTION, STOCKER SECTION AND

)

SLIDER (SELECTION)

Note: In mounting the parts, refer to page 11 and 12.

6

two screws

(PTPWH M2.6)

5

stocker

4

section

pulley (LD)

two step

screws

7

slider (selection)

8

9

compression

spring

washer

1

three screws

(BVTP M2.6)

GEARS INSTALLATION

3

gear (gear B)

Adjust the gear (gear B) with the

portion A as shown.

1

Slide the slider (U/D)

fully in the arrow

direction.

portion A

4

two step screws

3

gear (eject)

2

chassis (mold B) section

Note: Rotating the pulley (LD),

shift the slider (selection

to the left.

10

2

gear (U/D slider)

slider (U/D) gear

Adjust the gear so that it meshes with

the bottom tooth of slider (U/D)gear,

as shown.

4

gear (gear A)

gear

(gear B)

Adjust so as to be aligned with

gear (B) linearly,as shown.

linearly

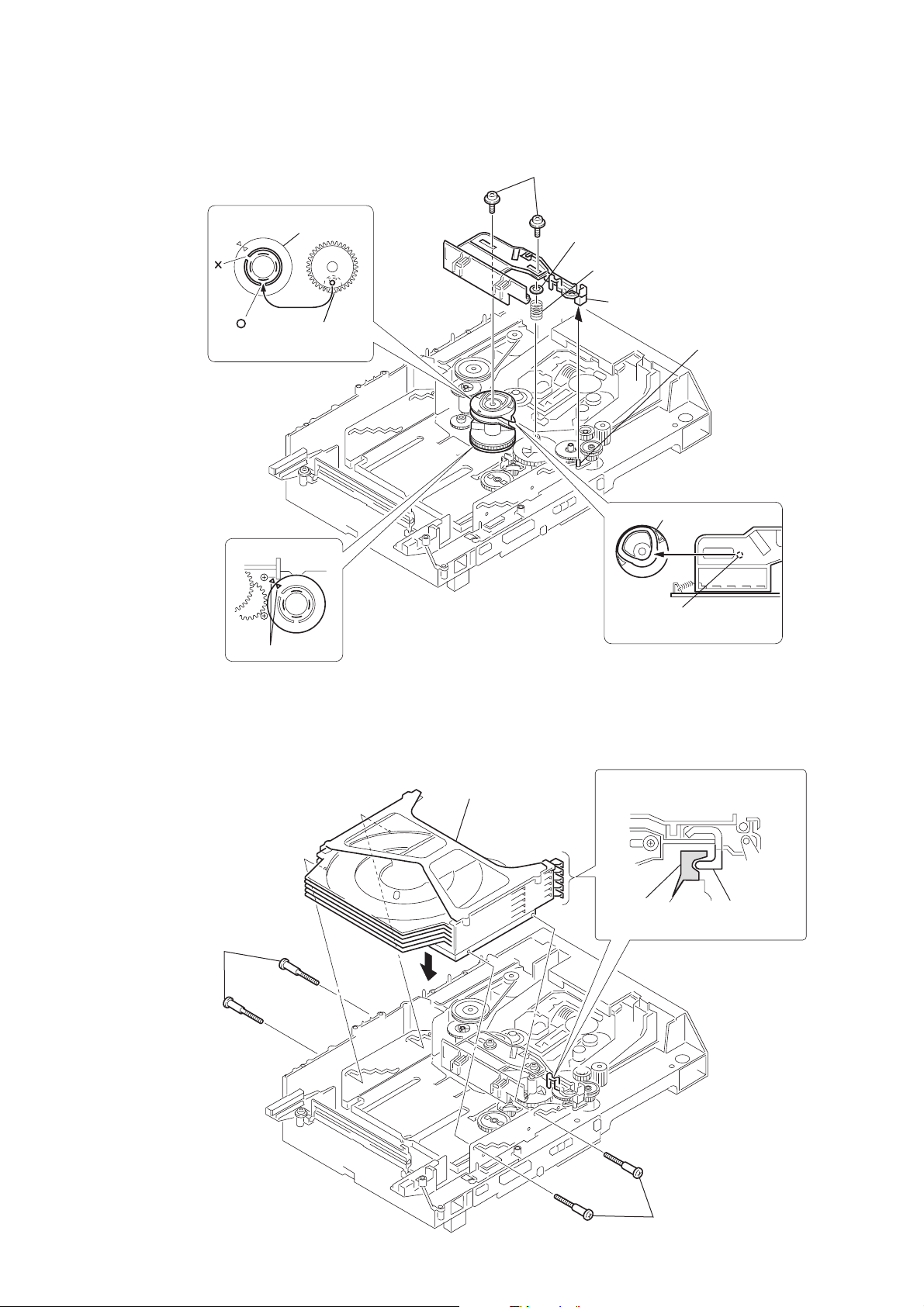

SLIDER (SELECTION) INSTALLATION

2

gear (chuking)

rotary encoder

Align with the slot of

rotary encoder.

1

rotary encoder

6

two screws

(PTPWH M2.6)

5

washer

4

compression spring

7

3

Insert the slider (selection)

into the portion A.

portion A

convex portion of

slider (selection)

gear (chuking)

align marking

STOCKER SECTION INSTALLATION

3

two step screws

1

stocker section

Insert a convex portion into

a groove of gear (chuking).

2

portion A of tray (sub)

Hook the portion A of tray (sub)

to the slider (selection).

potion A

of tray (sub)

sticking of

slider (selection)

3

two step screws

11

CHASSIS (MOLD B) SECTION INSTALLATION

n

3

three screws

(BVTP M2.6)

2

Insert the gear (eject)

under the gear (LD

deceleration).

gear (LD deceleration)

portion A

1

Insert the portion A of

chassis (mold B) sectio

into the portion B of

slider (selection).

portion B of

slider (selection)

12

SECTION 4

TEST MODE

[LED All Lit, Key Check Mode]

Procedure:

1. Press the ?/1 button to turn the power ON.

2. Press three buttons of s (DECK B), A (DISC 1), and

[DISC 5] simultaneously.

3. LEDs are all turned on.

Press the G (CD) button, and the key check mode is acti vated.

LEDs are all OFF.

4. When a button is pressed, the LED near the pressed button

blinks or lights up.

Also, if all buttons are pressed, all LEDs light up (not blink).

5. To release from this mode, press three buttons in the same

manner as step 2, or remove the power cord.

[CD Delivery Mode]

• This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the ?/1 button to turn the power ON.

2. Press the s (DECK B) and [DISC 1] buttons simultaneously.

3. A message “LOCK” is displayed on the liquid crystal display

of the STR-NX1/NX3, and the CD delivery mode is set.

[Tape Deck Test Mode]

(In case of connected to the STR-NX1/NX3)

• If connected to the STR-NX1/NX3, the mode also acts as the

STR-NX1/NX3 amplifer test mode.

Procedure:

1. Press the ?/1 button to turn the power ON.

2. Press three buttons of s (DECK B), A (DISC 1), and S (CD)

simultaneously.

3. On liquid crystal display of the STR-NX1/NX3, the disc cal-

endar blinks, and “ALC OFF” is displayed, then the function

which was set before the test mode became active is displayed.

4. The automatic level control of the tape deck is in OFF status,

but while the

pressed during recording, automatic level control goes in ON

status.

[Tape Deck Test Mode]

(In case of connected to the power feed jig)

Procedure:

1. Turn on the Power switch on the power feed jig.

2. Press three buttons of s (DECK B), A (DISC 1),

and s (CD) simultaneously.

3. The G (CD) and S (CD) LEDs blink, and then pressing G

(CD), G / g (DECK A), or G / g (DECK B) button can

make each play possible.

4. Also, the other functions are enabled by pressing two buttons

simultaneously.

A combination of respective functions and buttons is as follows.

s (CD) and [REC PAUSE/START] buttons are

function button

CD AMS – s (DECK A), S (CD)

AMS + s (DECK A), s (CD)

FR s (DECK B), S (CD)

FF s (DECK B), s (CD)

Deck-A REW/AMS – s (CD), g (DECK A)

FF/AMS + s (CD), G (DECK A)

Deck-B REW/AMS – s (CD), g (DECK B)

FF/AMS + s (CD), G (DECK B)

Note: Check that CD/TC signal change switch of relay connector jig is

set to the TC position.

13

SECTION 5

k

MECHANICAL ADJUSTMENTS

SECTION 6

ELECTRICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

Torque Measurement

Mode

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

Torque meter

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

Meter reading

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

2 to 6 g • cm

(0.03 – 0.08 oz • inch)

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

2 to 6 g • cm

(0.03 – 0.08 oz • inch)

71 to 143 g • cm

(0.99 – 1.99 oz • inch)

100 g or more

(3.53 oz or more)

100 g or more

(3.53 oz or more)

TAPE DECK SECTION

0 dB=0.775 V

1. Demagnetize the record/playback head with a head demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in

this service manual. (As a general rule, playback circuit adjustment should be completed before performing recording

circuit adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise specified.

8. Set to the DOLBY NR OFF.

9. Set to the test mode. (See page 13)

• Test Tape

Tape Signal Used for

P-4-A100 10 kHz, –10 dB Azimuth Adjustment

WS-48B 3 kHz, 0 dB Tape Speed Adjustment

P-4-L300 315 Hz, 0 dB Level Adjustment

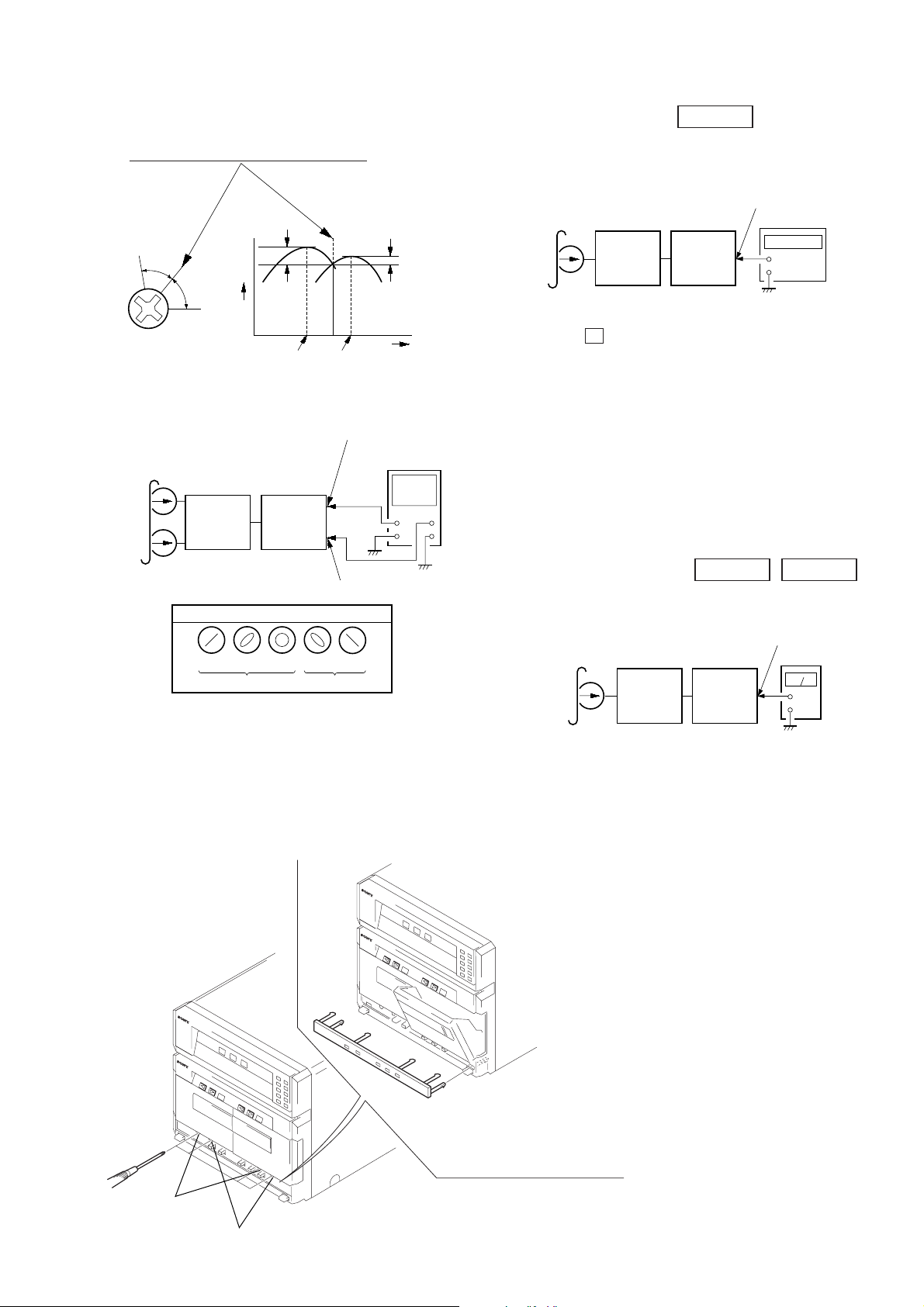

Record/Playback Head Azimuth Adjustment

DECK A DECK B

Note: Perform this adjustments for both decks

Procedure:

1. Mode: Playback

test tape

P-4-A100

(10 kHz, –10 dB)

set

PFJ-1

or

STR-NX1/

NX3

level meter

+

–

AUDIO OUT jac

14

2. T urn the adjustment screw and check output peaks. If the peaks

+

–

AUDIO OUT jack

test tape

WS-48B

(3 kHz, 0 dB)

frequency counter

set

STR-NX1/

NX3

+

–

test tape

P-4-L300

(315 Hz, 0 dB)

level meter

AUDIO OUT jack

PFJ-1

or

STR-NX1/

NX3

set

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

Tape Speed Adjustment DECK B

• Execute only if connected to the STR-NX1/NX3

Mode: Playback

L-CH

peak

R-CH

Screw

position

peak

3. Mode: Playback

test tape

P-4-A100

(10 kHz, –10 dB)

L-CH

R-CH

in phase 45°90°135°180

within

1dB

Output

level

L-CH

peak

set

waveform of oscilloscope

STR-NX1/

good

R-CH

peak

AUDIO OUT (L) jack

PFJ-1

or

NX3

AUDIO OUT (R) jack

wrong

L-CH

R-CH

°

within

1dB

Screw

position

oscilloscope

H

V

1. Insert the WS-48B into the deck B.

2. Press the G (DECK B) button.

3. Press the [HI-DUB] button in playback mode.

Then at HIGH speed mode.

4. Adjust RV1001 on the LEAF SW board do that frequency

counter reads 6,000 ± 180 Hz.

5. Press the [HI-DUB] button.

Then back to NORMAL speed mode.

6. Adjust RV1002 on the LEAF SW board so that frequency

counter reads 3,000 ± 90 Hz.

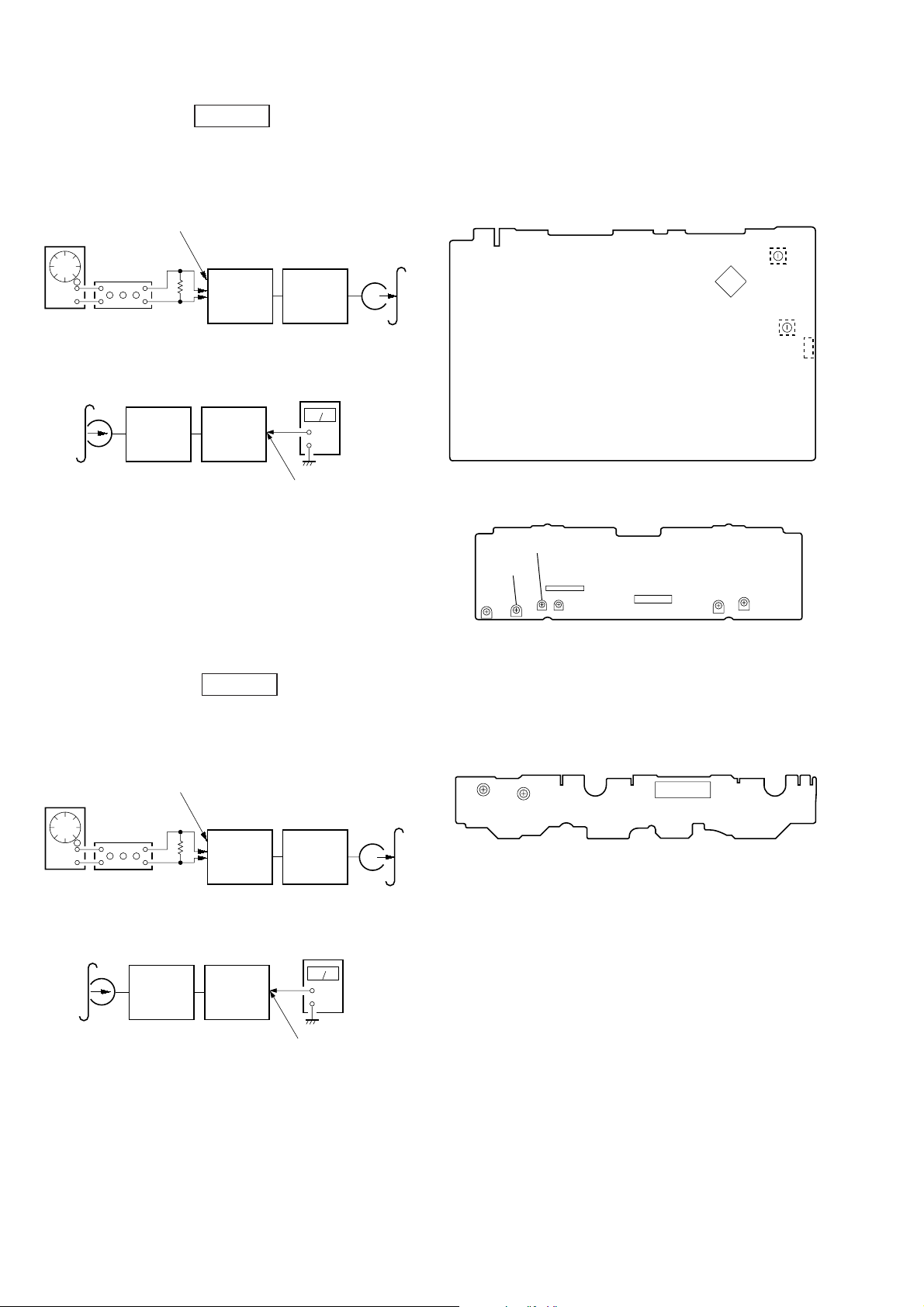

Adjustment Location: LEAF SW board

Sample value of Wow and Flutter: 0.3% or less W.RMS (JIS)

(WS-48B)

Playback level Adjustment

DECK A DECK B

Procedure:

Mode: Playback

4. Repeat step 1 to 3 in playback (REV) mode.

5. After the adjustments, apply suitable locking compound to the

pats adjusted.

Adjustment Location:Playback Head (Deck A).

Record/Playback/Earth Head (Deck B).

Open the cassette holder

and unhock six claws of

the sub panel (TC2)

with tweezers or something,

then remove the sub panel (TC2).

Deck A is RV311 (L-CH) and RV411 (R-CH), Deck B is RV301

(L-CH) and RV401 (R-CH) so that adjustment within specified

value as follows.

Specified Value:

AUDIO OUT jack PB level: 301.5 to 338.3 mV (–8.2 to –7.2

dB) level

difference between the channels: within ± 0.5 dB

Adjustment Location: AUDIO board

forward

reverse

15

REC Bias Adjustment DECK B

Procedure:

1. Mode: Record

Specified value:

AUDIO OUT jack PB level: 47.2 to 53.0 mV (–24.3 to –23.3 dB)

Adjustment Location: MAIN board

AUDIO IN jack

50 mV (–23.8 dB)

600

Ω

PFJ-1

or

STR-NX1/

NX3

blank tape

CN-123

set

AF OSC

1) 315 Hz

2) 10 kHz

attenuator

2. Mode: Playback

recorded

portion

set

PFJ-1

or

STR-NX1/

NX3

level meter

+

–

AUDIO OUT jack

3. Conf irm playback the signal recorded in step 1 become specified value as follows.

If these values are out of specified value, adjust the RV341 (LCH) and RV441 (R-CH) on the AUDIO board to repeat steps

1and 2.

Specified value: Playback output of 315 Hz to playback

output of 10 kHz: ± 0.5 dB

Adjustment Location: AUDIO board

REC Level Adjustment DECK B

Procedure:

1. Mode: Record

AUDIO IN jack

315 Hz, 50 mV (–23.8 dB)

AF OSC

attenuator

600

Ω

PFJ-1

or

STR-NX1/

NX3

set

blank tape

CN-123

– MAIN BOARD (Conductor Side) –

REC

LEVEL

– AUDIO BOARD (Component Side) –

RV441

RV401

RV301

LR

PB LEVEL

– DECK B –

– LEAF SW BOARD (Component Side) –

TAPE SPEED

(NORMAL) (HIGH)

RV1002

REC BIAS

RV1001

IC602

RL

CN601

RV341

CN1001

RV351

(R-CH)

RV311

LR

PB LEVEL

– DECK A –

IC301

RV301

(L-CH)

CN301

RV411

1

3

2. Mode: Playback

recorded

portion

set

PFJ-1

or

STR-NX1/

NX3

level meter

+

–

AUDIO OUT jack

3. Conf irm playback the signal recorded in step 1 become specified value as follows.

If these values are out of specified value, adjust the RV301 (LCH) and RV351 (R-CH) on the MAIN boar d to repeat ste ps 1

and 2.

16

Loading...

Loading...