Sony HCDRX-33 Service manual

HCD-RX33

MICROFILM

SERVICE MANUAL

HCD-RX33 is the tuner, deck, CD and

amplifier section in MHC-RX33.

Model Name Using Similar Mechanism HCD-G101

CD

SECTION

TAPE

DECK

SECTION

CD Mechanism Type CX3

Base Unit Type KSM-213BCM

Optical Pick-up Type KSS-213B/S-N

Model Name Using Similar Mechanism HCD-G101

Tape Transport

Mechanism Type

AEP Model

UK Model

DECK-A TK20FX-SW943-800

DECK-B TK20FX-SW943-800

The following measured at AC 230 V 50 Hz;

DIN power output (Rated) 25 W + 25 W (6 Ω at 1 kHz, DIN)

Continuous RMS power output (Reference)

35 W + 35W (6 Ω at 1 kHz, 10% THD)

Outputs

PHONES (stereo phone jack) :

accepts headphones of 8 Ω or more

SPEAKER : accepts impedance of 6 to 16 Ω

CD player section

System Compact disc and digital audio system

Laser Semiconductor laser (λ = 780 nm)

Emission duration: continuous

Laser output Max. 44.6 µW*

*This output is the value measured at a distance

of 200 mm from the objective lens surface on the

Optical Pick-up Block with 7 mm aperture.

Frequency response 20 Hz – 20 kHz (± 0.5 dB)

Wavelength 780 – 790 nm

SPECIFICATIONS

Tape deck section

Recording system 4 -track 2 -channel stereo

Frequency response 60 – 13,000 Hz (± 3dB), using Sony

TYPE Ι cassette

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

Antenna FM lead antenna

Antenna terminal 75 Ω unbalanced

Intermediate frequency 10.7MHz

AM tuner section

Tuning range 531 – 1,602 kHz

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

— Continued on next page —

MINI Hi-Fi COMPONENT SYSTEM

SERVICING NOTE

General

Power requirements 230V AC, 50/60Hz

Power consumption 80 W

Dimensions (w/h/d) incl. projecting parts and controls

Approx. 280 × 320 × 371 mm

(11 1/8 × 12 5/8 × 14 5/8 in)

Mass Approx. 7.2 kg (15 lb 14 oz.)

Supplied accessories: AM loop antenna (1)

Remote RM-SG5 (1)

FM lead antenna (1)

Design and specifications are subject to change without notice.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated b y the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

This caution

label is located

inside the unit.

— 2 —

TABLE OF CONTENTS

1. GENERAL ..........................................................................4

2. DISASSEMBLY

2-1. CD Door ............................................................................. 5

2-2. CD Mechanism Deck ......................................................... 5

2-3. Front Panel ......................................................................... 6

2-4. Main Board and H.P Board ................................................6

2-5. CD Tray .............................................................................. 7

2-6. CD Decoder Board ............................................................. 7

2-7. Base Unit ............................................................................8

2-8. Cassette Lid (L)/(R)............................................................ 8

3. MECHANICAL ADJUSTMENTS ............................... 9

4. ELECTRICAL ADJUSTMENTS .................................9

5. DIAGRAMS

5-1. Circuit Boards Location ................................................... 14

5-2. Block Diagrams

• Deck Section ................................................................... 15

• Tuner/CD Section............................................................ 17

5-3. IC Block Diagrams........................................................... 19

5-4. Schematic Diagram —Main Section —........................... 24

5-5. Printed Wiring Board — Main Section — ....................... 29

5-6. Printed Wiring Board —CD Section — ........................... 34

5-7. Schematic Diagram —CD Section —.............................. 39

5-8. Schematic Diagram — Panel Section — ......................... 43

5-9. Printed Wiring Board —Panel Section —........................47

5-10. IC Pin Function ................................................................52

6. EXPLODED VIEWS

6-1. Cabinet Section.................................................................54

6-2. Front Panel Section ..........................................................55

6-3. Cassette Button Section.................................................... 56

6-4. Cassette Mechanism Deck Section................................... 57

6-5. CD Mechanism Deck Section 1 ....................................... 58

6-6. CD Mechanism Deck Section 2 ....................................... 59

6-7. Base Unit Section (KSM-213BCM)................................. 60

7. ELECTRICAL PARTS LIST ........................................ 61

— 3 —

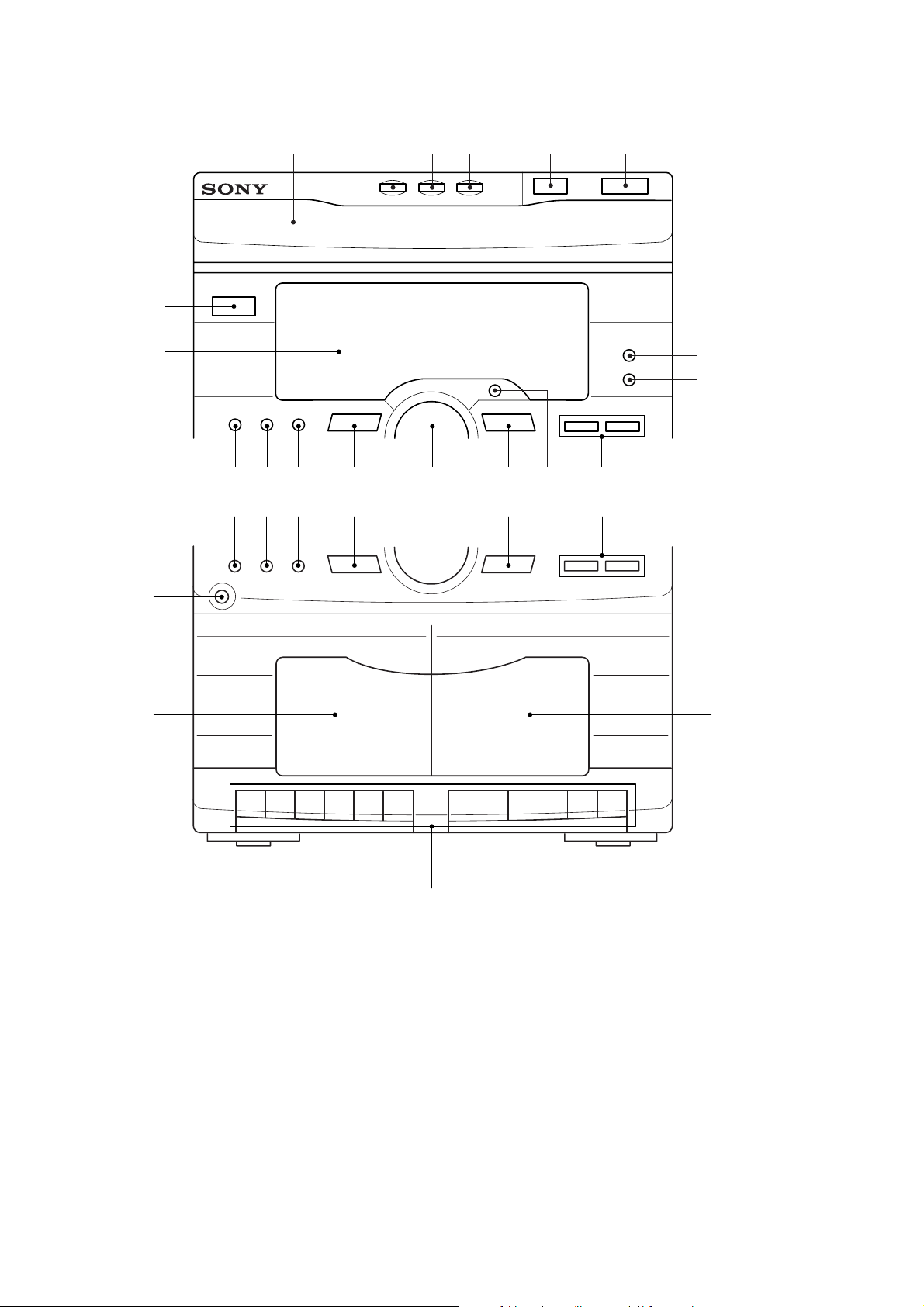

LOCATION OF PARTS AND CONTROLS

123456

!•

SECTION 1

GENERAL

@∞

@§

9

!¡

!º

!ª @º @¡ @™ @£ @¢

!¢8!£!™

!∞

!§

7

!¶

@¶

1 Disc tray

2 DISC 1 button

3 DISC 2 button

4 DISC 3 button

5 DISC SKIP button

6 § OPEN/CLOSE button

7 DBFB button

8 VOLUME knob

9 Display window

!º CLOCK TIMER SET button

!¡ TIMER ON/OFF button

!™ DISPLAY DEMO

!£ TUNER/BAND

!¢ · ∏ (play/pause) button

!∞ ENTER/NEXT button

!§ ≠ ± CD AMS/TUNER PRESET TIMER

SET buttons

@•

!¶ FILE SELECT

!• I/u (POWER) button

!ª TUNER MEMORY REPEAT button

@º EDIT button

@¡ STEREO/M NO, PLAY MODE button

@™ TAPE button

@£ π (STOP) button

@¢ 0 ) CD/TUNER button

@∞ PHONES jack

@§ Deck A, PLAY/REC

@¶ Deck B, PLAY

@• Tape operaying buttons

r (recording)

( (play)

0 (fast rewind)

) (fast forward)

p 6 (stop/eject)

P (pause)

— 4 —

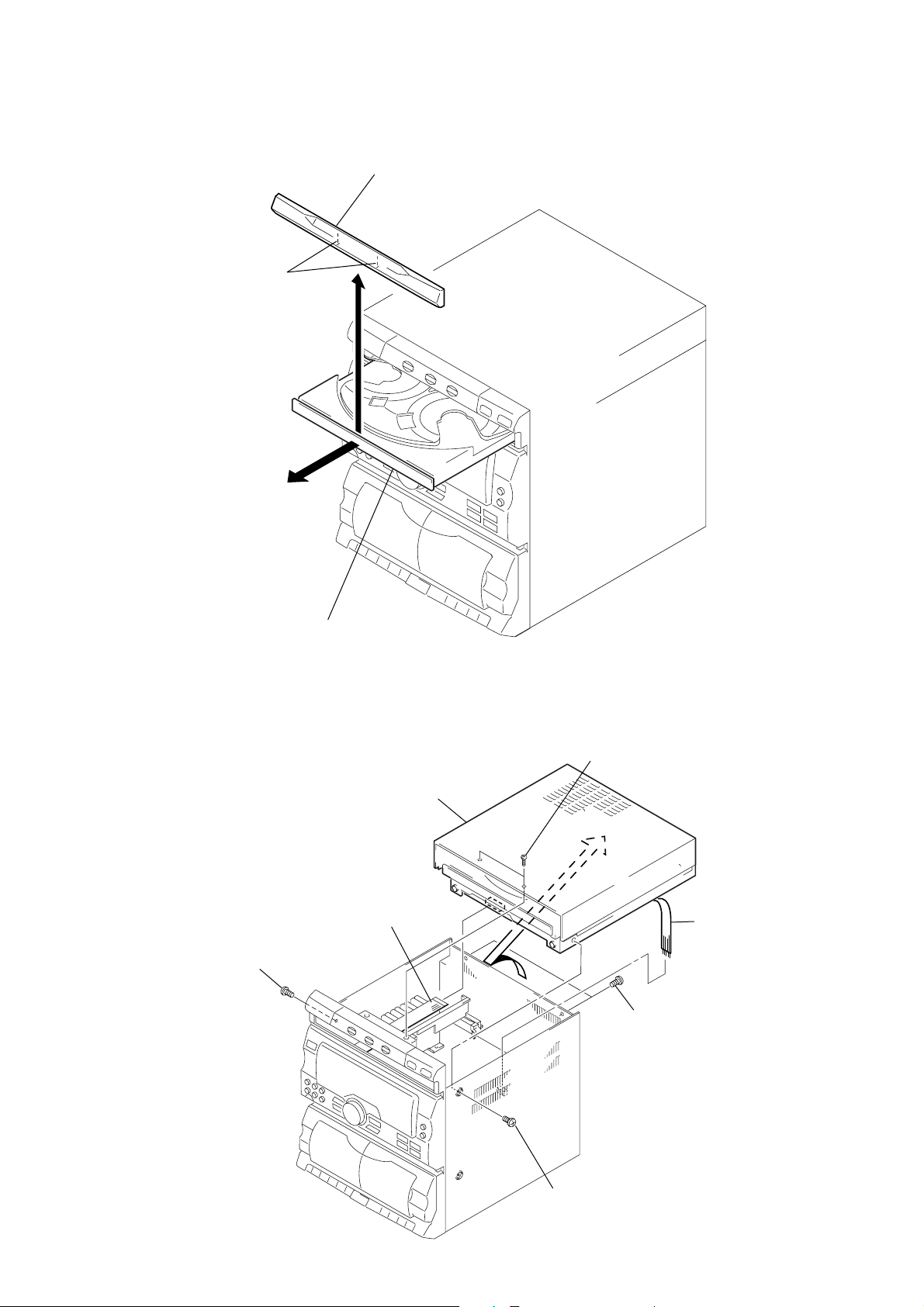

SECTION 2

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

2-1. CD DOOR

Two claws

2

CD door

1

Pull out the CD tray and remove the CD door

with releasing claws into the direction of arrow.

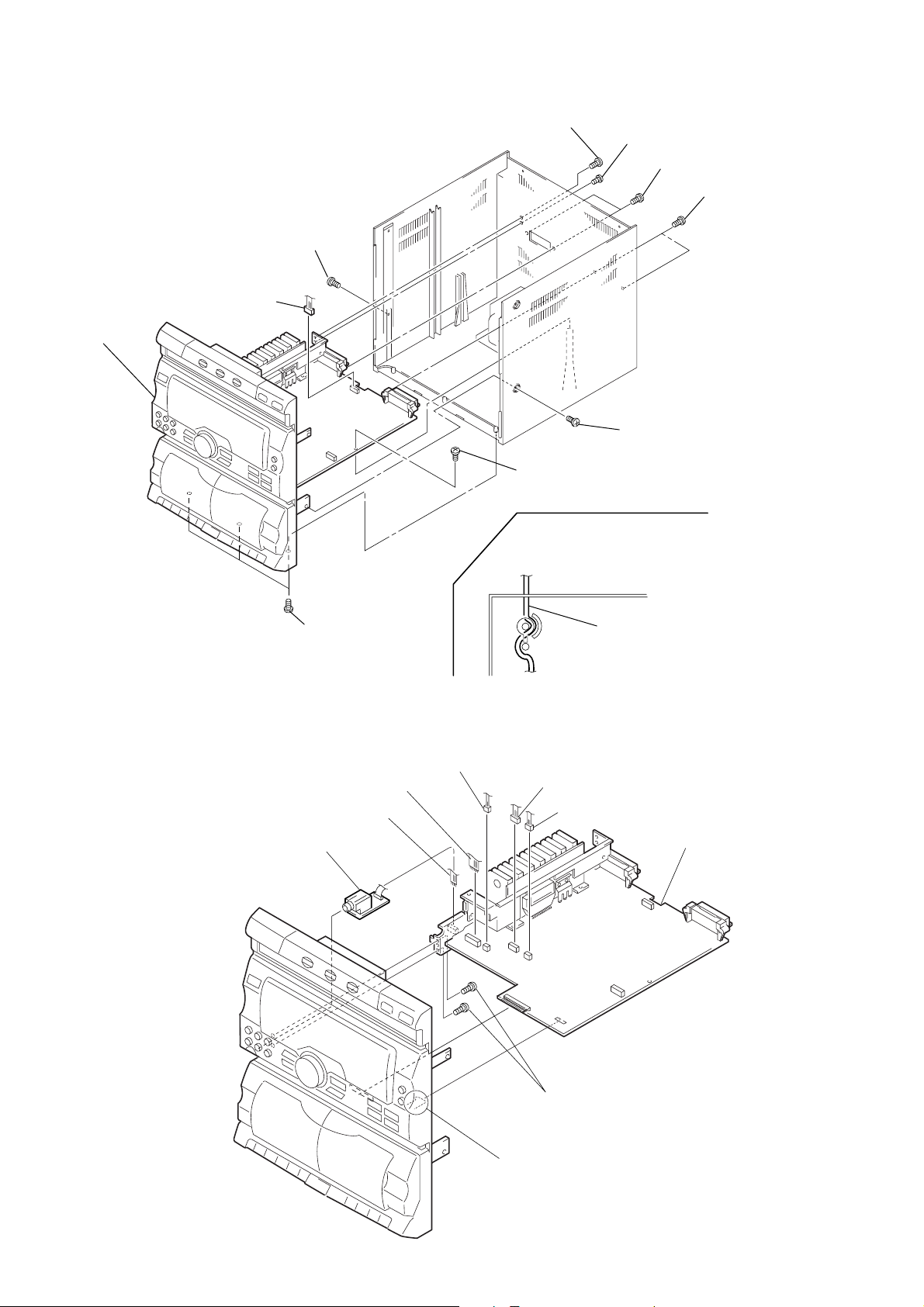

2-2. CD MECHANISM DECK

2

Screw (+PTPWH 3 × 10)

6

CD mechanism deck

4

Flat type wire (CN09)

1

Two screws (+B 3 × 8)

3

Two screws (+BVTP 3 × 10)

5

Harness (CN302)

— 5 —

2

Screw (+PTPWH 3 × 10)

2-3. FRONT PANEL

1

Connector (CN401)

9

Front panel

7

Screw

(+PTPWH 3 × 10)

3

Screw (+BVTP 3 × 10)

8

Screw (+BVTP 3 × 10)

HOW TO SET THE

POWER CORD

4

Screw (+BVTP 3 × 10)

5

Two screws (+BVTP 3 × 10)

6

Two screws

(+BVTP 3 × 10)

7

Screw (+PTPWH 3 × 10)

2-4. MAIN BOARD AND H.P BOARD

1

8

2

Three screws

(+BVTP 3 × 10)

2

Harness (CN204)

Harness (CN303)

H.P board

3

Connector

4

Connector (CN202)

5

Connector (CN201)

power cord

7

MAIN board

— 6 —

Craw

6

Two screws

(+KTP 3 × 8)

)

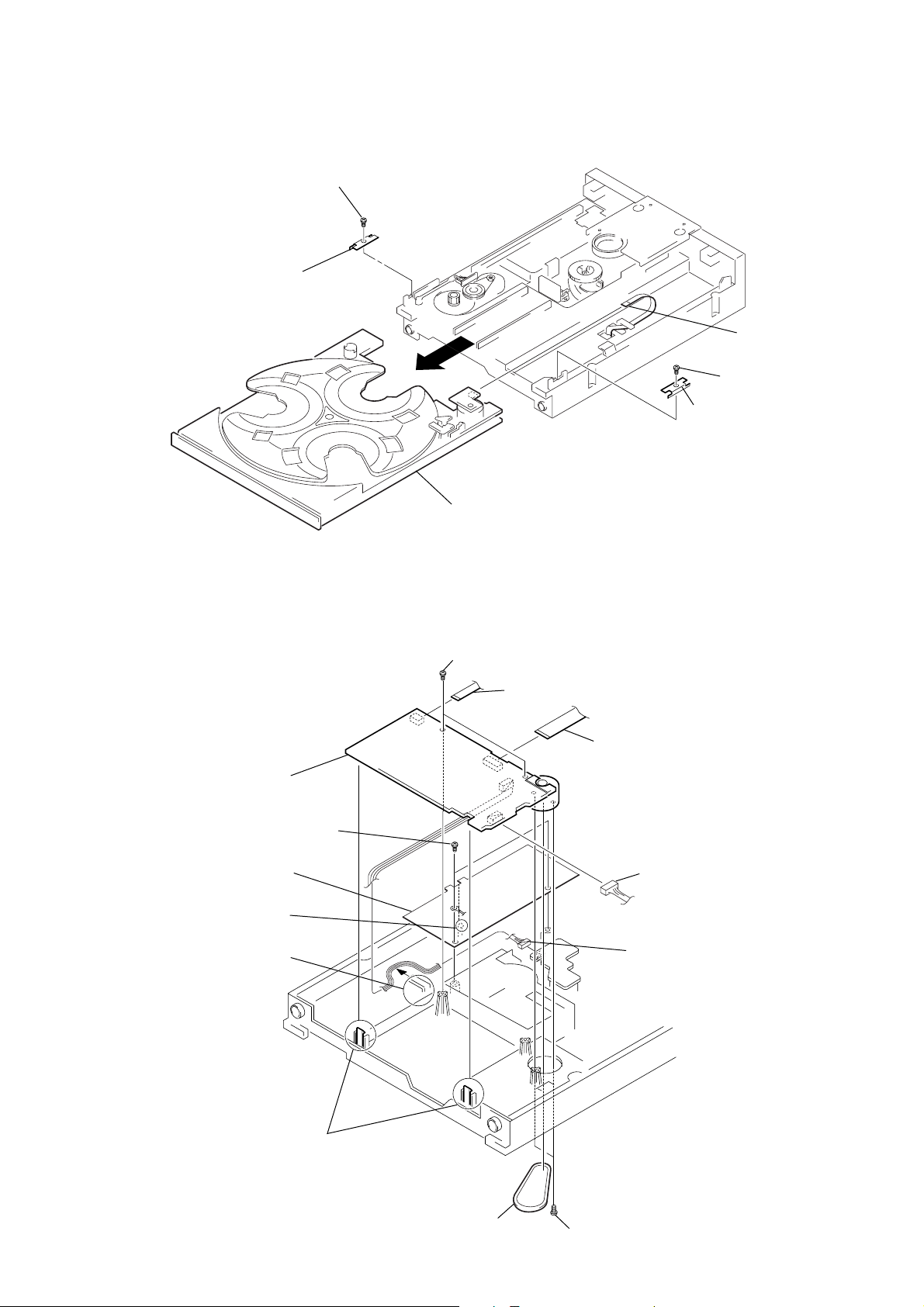

2-5. CD TRAY

2

Bracket

1

Screw (+P 2.6 × 4)

6

CD tray

4

Bracket

5

Flat type wire

(CN06)

3

Screw (+P 2.6 × 4

2-6. CD DECODER BOARD

7

CD DECODER board

8

Two screw

(+BVTP 3 × 10)

9

Sheet

Claw

Claw

1

Two screws (+BVTP 3 × 10)

6

Flat type wire (CN06)

5

Flat type wire (CN01)

4

Connector (CN05)

!º

Connector (CN03)

Two claws

3

Belt

— 7 —

2

Two screws (+BVTP 3 × 10)

)

2-7. BASE UNIT

5

UD-Cam

4

Screw (+PTPWH 2.6 × 8)

2

Screw (+PTPWH 2.6 × 8)

3

UD-gear

7

Spring

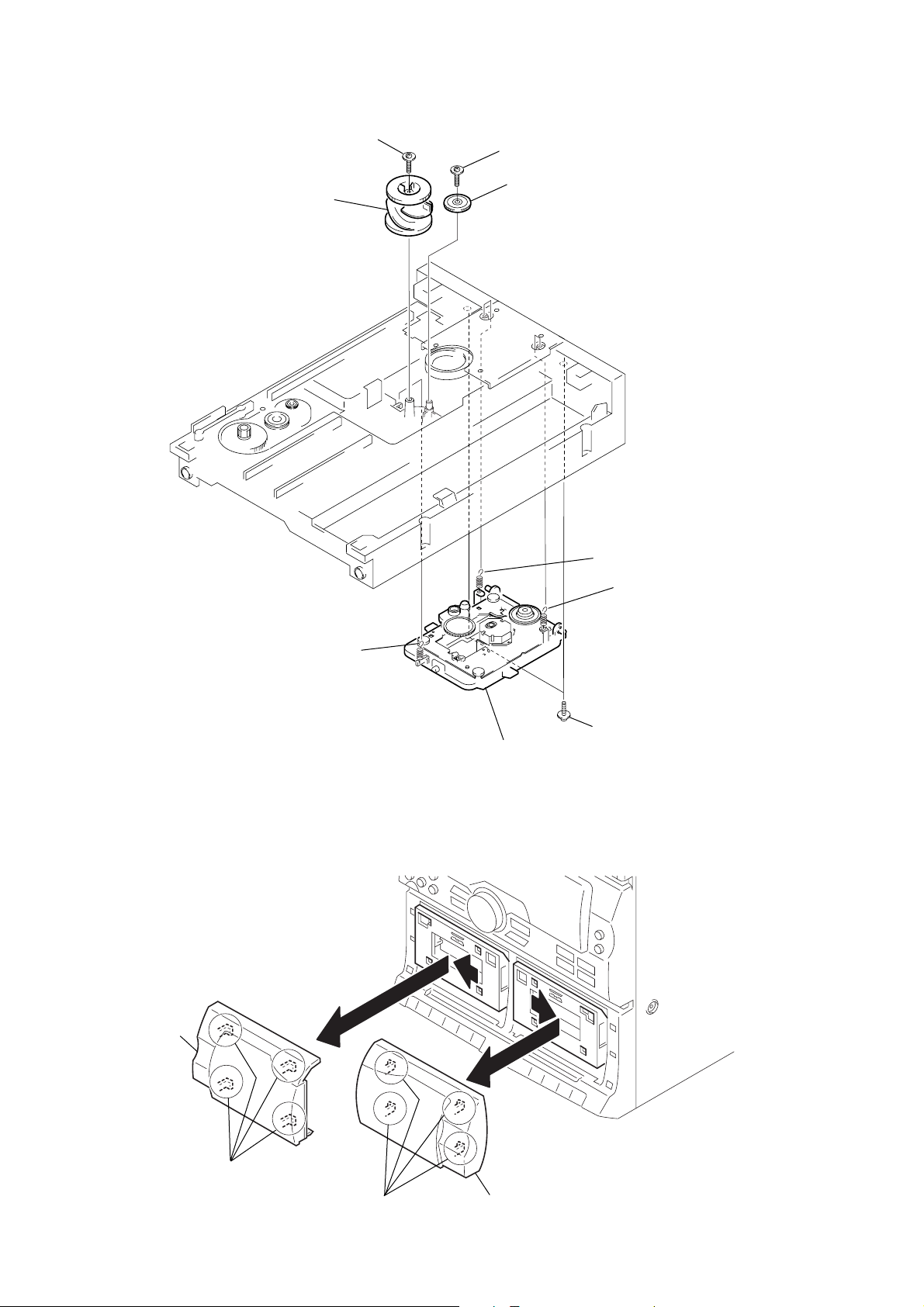

2-8. CASSETTE LID (L) / (R)

1

Cassette lid (L)

8

Spring

9

Base unit

6

Spring

1

Two screws (+KTP 3 × 8

Four claws

Four claws

— 8 —

2

Cassette lid (R)

SECTION 3

MECHANICAL ADJUSTMENTS

SECTION 4

ELECTRICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback head pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head

demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

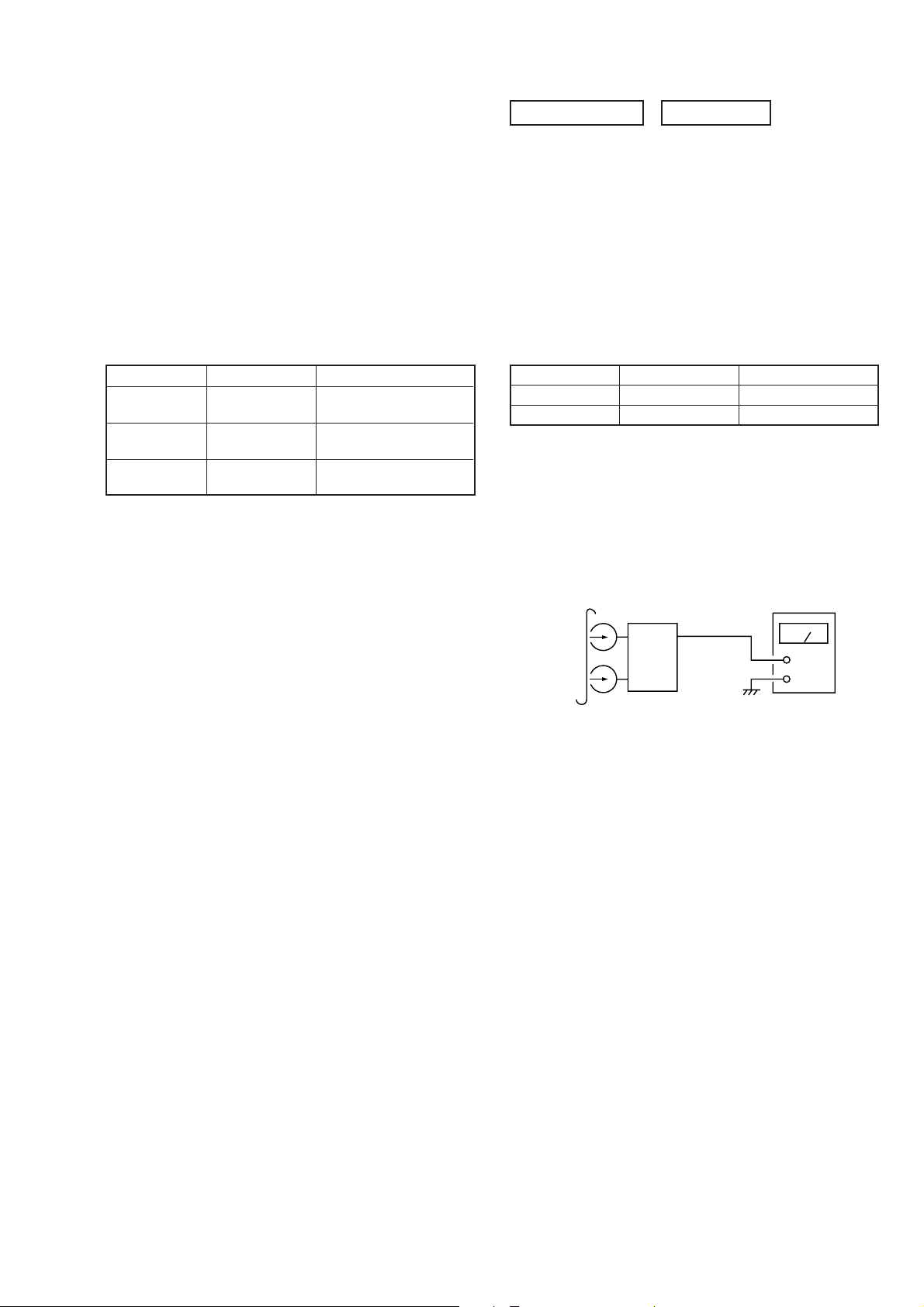

Torque Measurement

Torque

FWD

FWD

back tension

FF/REW

Torque meter

CQ-102C

CQ-102C

CQ-201B

Meter reading

40 to 70 g • cm

(0.56 - 0.97 oz • inch)

1 to 5 g • cm

(0.01 - 0.07 oz • inch)

55 to 140 g • cm

(0.76 - 1.94 oz • inch)

DECK SECTION 0 dB=0.775V

1. Demagnetize the record/playback head with a head

damagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjusted.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit

adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

Tape

P-4-A100

WS-48B

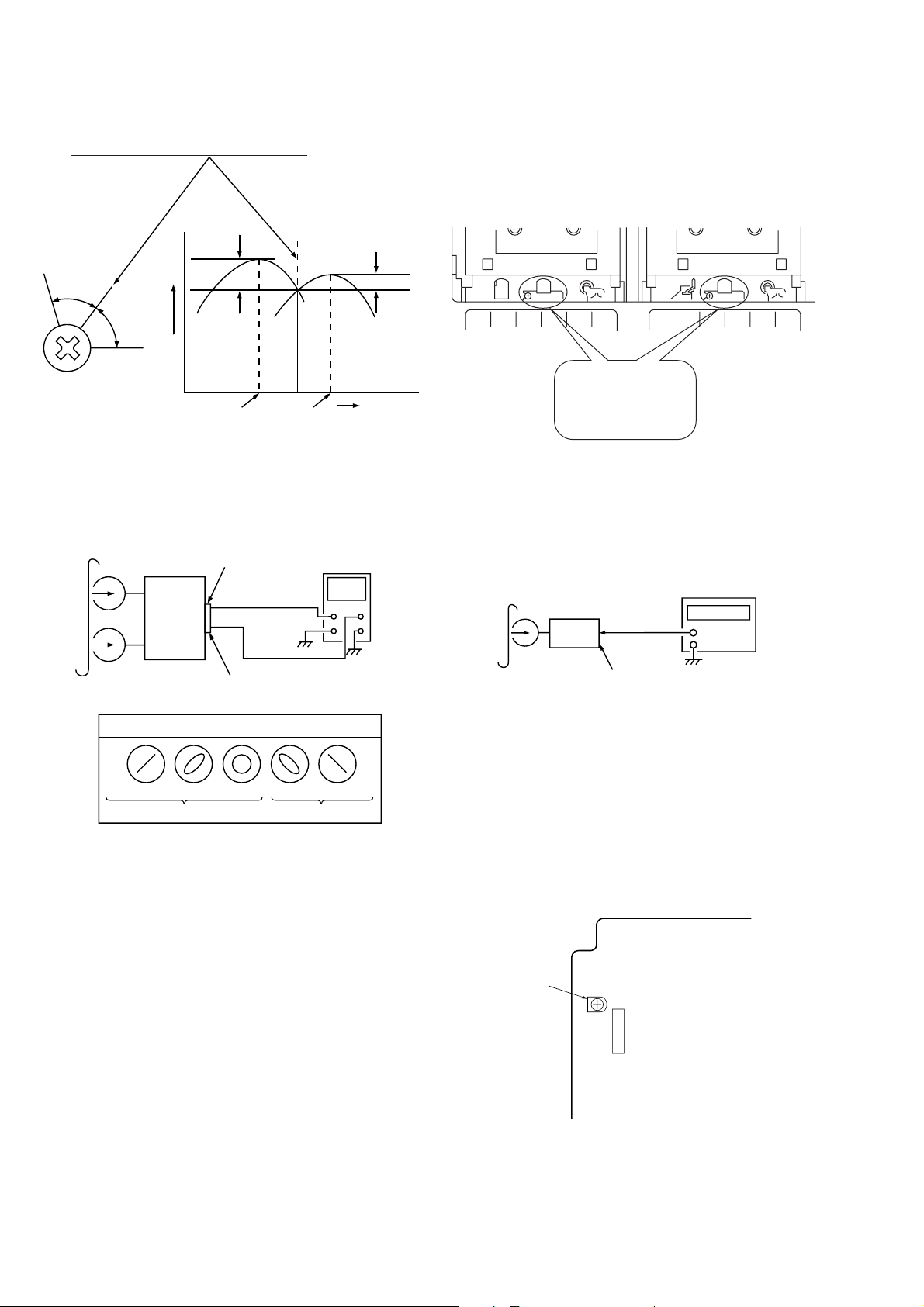

Record/Playback Head Azimuth Adjustment

(Deck A, Deck B)

Note: Perform this adjustments for both decks.

Procedure:

1. Mode : Playback

test tape

P-4-A100

(10kHz, –10dB)

Signal

10 kHz, –10 dB

3 kHz, 0 dB

SPEAKER

terminal (JK501)

Used for

Azimuth Adjustment

Tape Speed Adjustment

level meter

set

+

–

— 9 —

2. Turn the adjustment screw and c heck output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 2 dB of peak.

L-CH

peak

screw

position

R-CH

peak

output

level

within

2dB

L-CH

peak

R-CH

peak

within 2dB

screw

position

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

Adjustment Location:

Remove the cassette lid before adjustment (See page 8)

Adjustment screws

REC/PB head (deck A)

or PB head (deck B)

3. Mode: Playback

test tape

P-4-A100

(10kHz, –10dB)

in phase 45˚ 90˚ 135˚ 180˚

SPEAKER

terminal (JK501)

(L-CH)

L

set

R

SPEAKER

terminal (JK501)

(R-CH)

Waveform of oscilloscope

good

oscilloscope

wrong

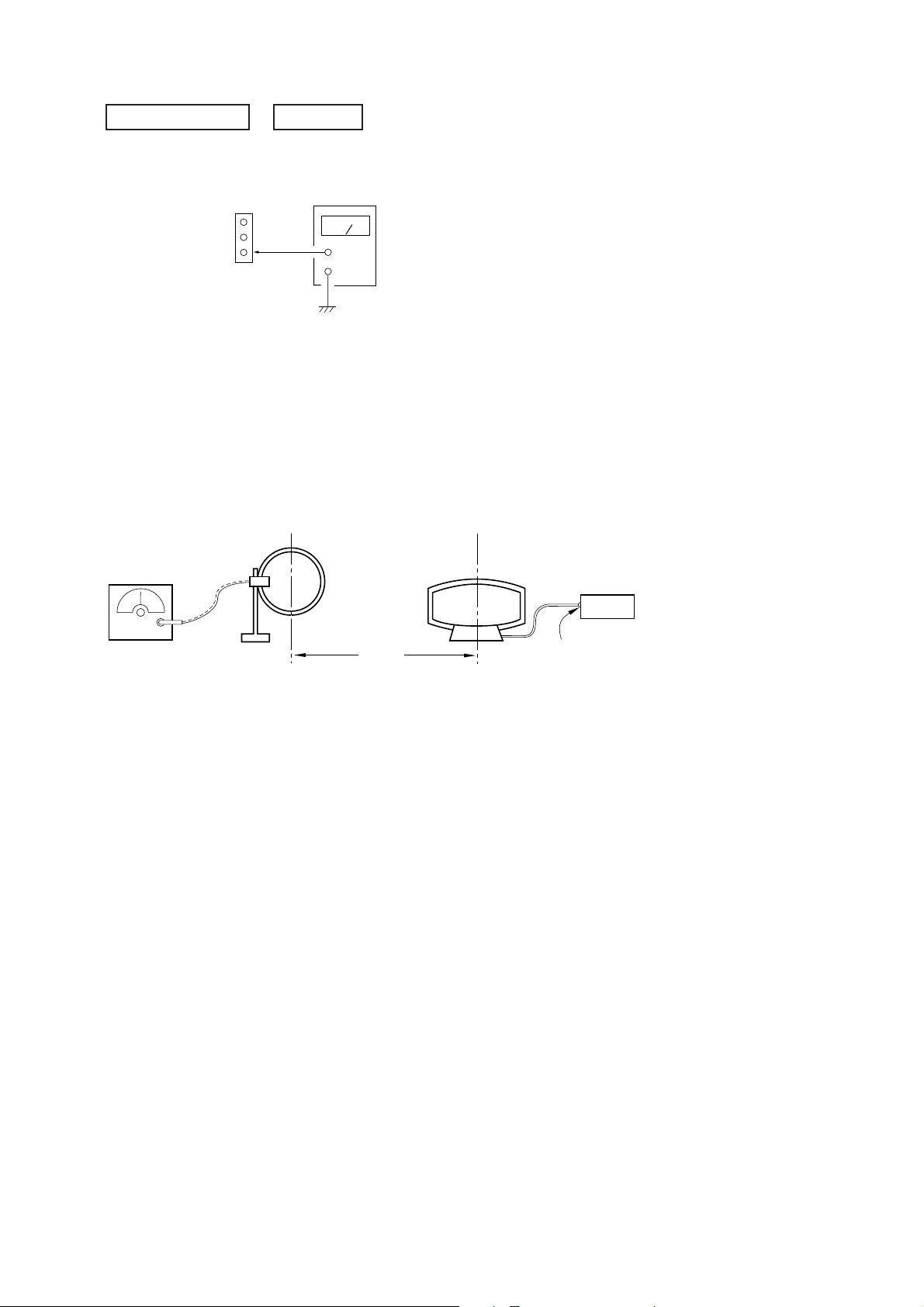

Tape Speed Adjustment (Deck A)

Procedure:

1. Mode: Playback

test tape

WS-48B

(3kHz, 0dB)

set

SPEAKER

terminal (JK501)

frequency counter

+

–

2. Adjust the SFR201 so that the frequency counter reads 3,000

Hz ± 90Hz.

Adjustment Location: MAIN board

Sample Value of Wow and flutter

W. RMS (JIS) within 0.3%

(test tape: WS-48B)

[MAIN BOARD] — Component side —

— 10 —

Tape Speed

SFR201

CN204

TUNER SECTION 0 dB=1µV

AM T uning Voltage Adjustment

Main board

TP1

F

G

VT

DC voltmeter

+

–

Procedure:

1. Set the reception frequency of the unit to 531 kHz.

2. Adjust L108 for 1.2 ± 0.05 V reading on the DC voltmeter.

3. Set the reception frequency of the unit to 1,602 kHz.

4. Confirm that the voltage reading on the DC voltmeter is within

8.0 ± 0.5 V.

Adjustment Location: MAIN board (See page 12)

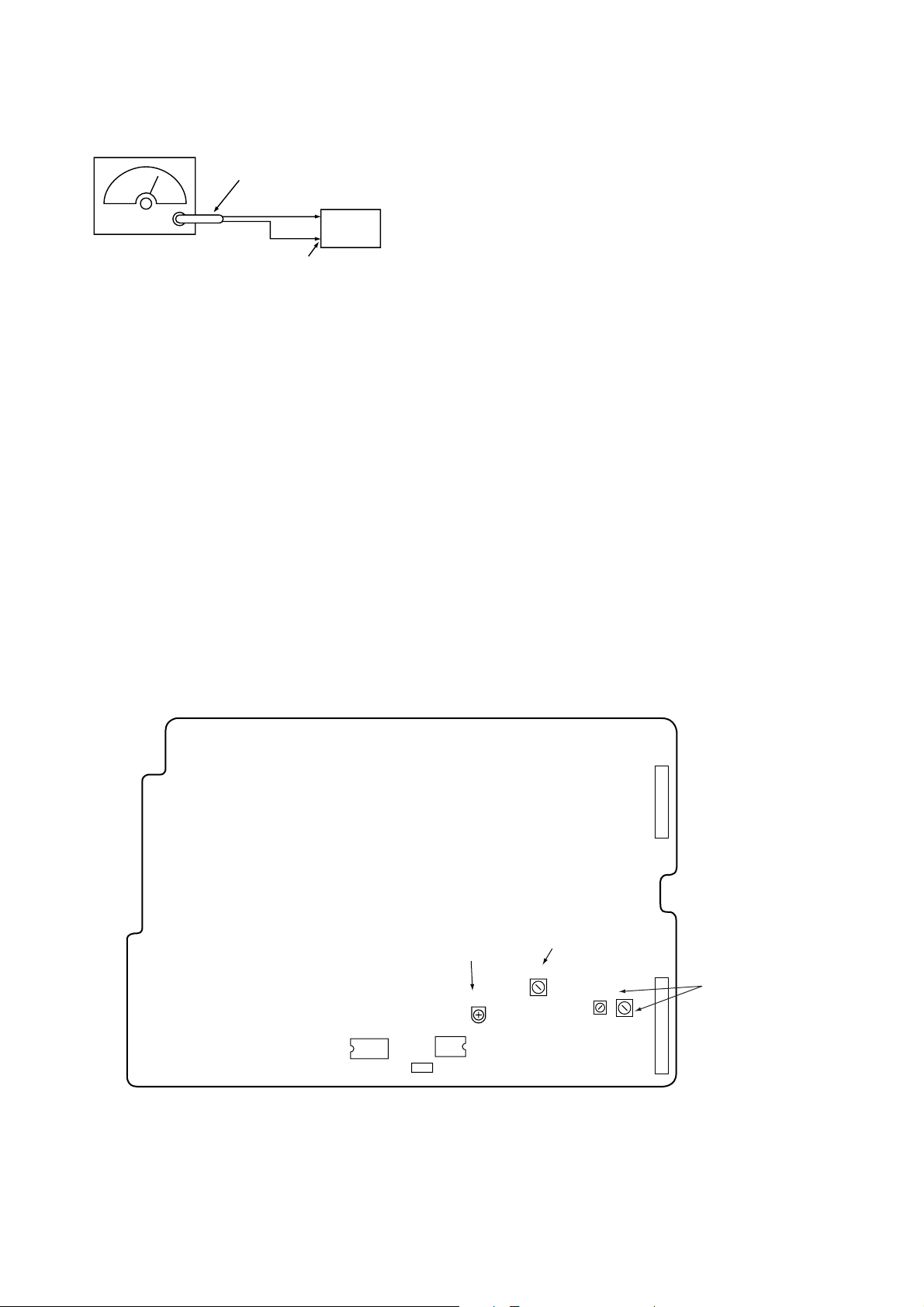

AM Trac king Adjustment

loop antenna

AM RF SSG

loop antenna

(Supplied accessories)

set

30% amplitude

modulation by

400 Hz signal

60 cm

Field strength dB (

µ

V/m) =SSG output level dB (µV/m) –26 dB.

Procedure:

1. Tune the set to 600 kHz.

2. Set the output of AM RF SSG so that the input level of the set

will become 60 dB (µV/m).

3. Adjust L107 so that when the waveform on the oscilloscope is

maximum, no noise appears.

4. Tune the set to 1,400 kHz.

AM ANTENNA

terminal (TM1)

5. Adjust TC101 so that when the waveform on the oscilloscope

is maximum, no noise appears.

• Repeat the procedures in each adjustment several times, and the

tracking adjustment should be finally done by the trimmer

capacitors.

Adjustment Location: MAIN board (See page 12)

— 11 —

FM Tuned Level Adjustment

g

FM RF SSG

75

Ω

coaxial

set

Carrier frequency : 98 MHz

Modulation : AUDIO 1 kHz, 75 kHz

deviation (100%)

Output level : 28 dB (at 75 Ω open)

FM ANTENNA terminal

(JK101)

Procedure:

1. Supply a 28 dB 98 MHz signal from the ANTENNA terminal.

2. Tune the set to 98 MHz.

3. Adjust SFR101 to the point (moment) when the TUNED

indicator will change from going off to going on.

Adjustment Location: MAIN board

Adjustment Location

[MAIN BOARD] — Component side —

IC103

FM Tuned Level

TP1

SFR101

IC102

AM Tuning

Voltage

L108

TC101

L107

JK501

JK101

AM

Trackin

— 12 —

CD SECTION

Note:

1. CD Block is basically constructed to operate without

adjustment. Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indica ted.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

5. Adjust the focus bias adjustment when optical block is replaced.

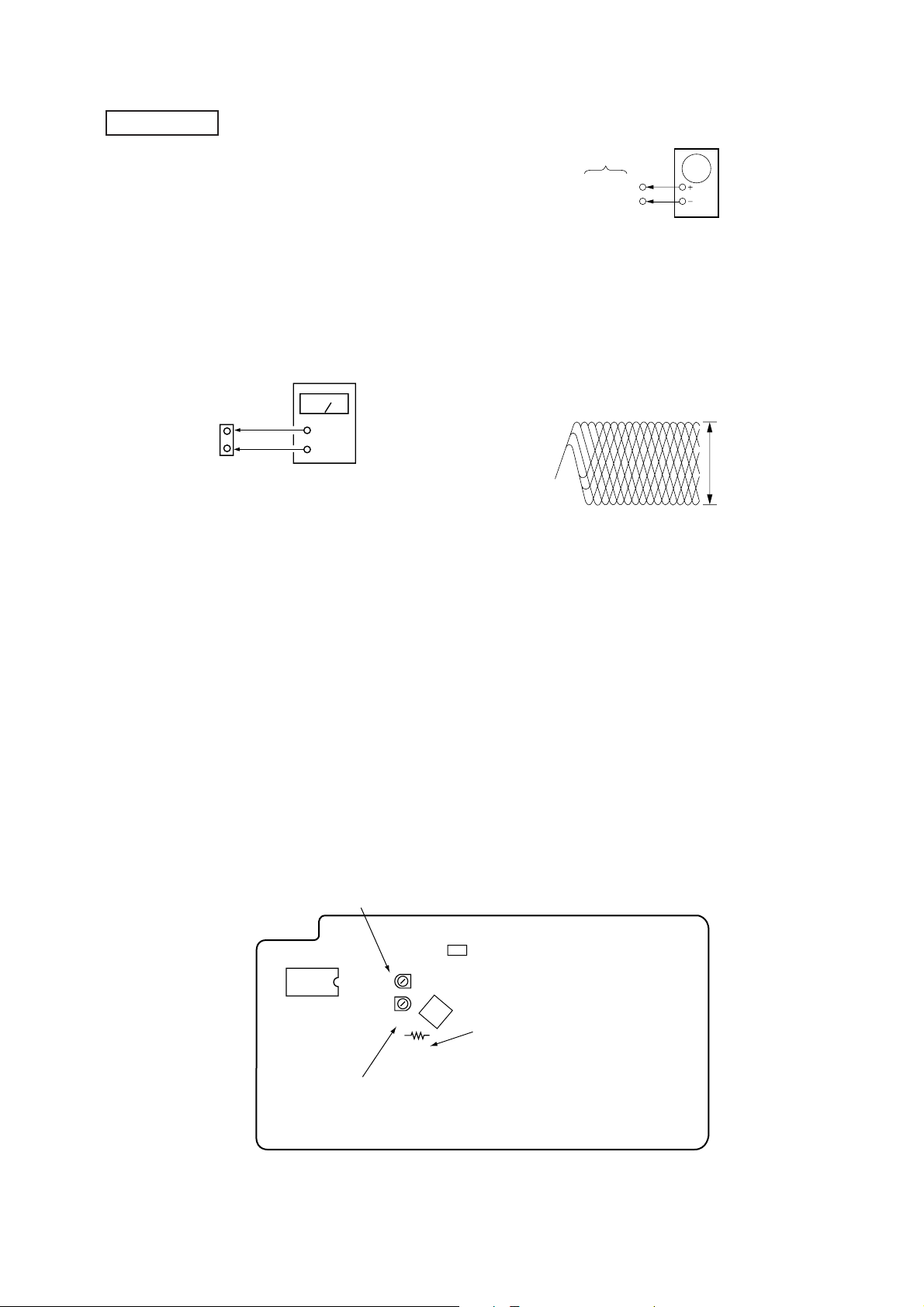

Focus Bias Adjustment

CD DECODER

board

CN12

FEO

VC

Procedure:

1. Connect DC voltmeter to test point CN12 (FEO), (VC) on CD

DECODER board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and stop.

4. Adjust VR01 so that the DC voitmeter reading is 0 ± 20 mV.

DC voltmeter

+

–

RF Level Check

CD DECODER

board

TP (RF)

CN12 (VC)

oscilloscope

Procedure :

1. Connect oscilloscope to test point TP (RF) on CD DECODER

board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

Note: Clear RF signal w aveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

VOLT/DIV: 200 mV

TIME/DIV: 500 nS

level: 1.0 Vp-p

+0.3

–0.2

Adjustment Location: CD DECODER board

Adjustment Location: CD DECODER board

Focus Gain Adjustment (VR02)

This gain has a margin, so even if it is slightly off.

There is no problem.

Therfore, do not perform this adjusment.

Please note that it should be fixed to mechanical center position

when you moved and do not know original position.

Adjustment Location

[CD DECODER BOARD] — Component side —

Focus Gain

CN12

VR02

IC03

VR01

IC01

R07

RF Level

Focus Bias

— 13 —

Loading...

Loading...