HCD-L7HD

Amplifier section

For the U.S. model

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION:

With 4-ohm loads, both channels driven, from

120 - 10,000 Hz; rated 25 watts per channel

minimum RMS power, with no more than 10%

total harmonic distortion from 250 milliwatts to

rated output.

North American model:

Continuous RMS power output (reference):

25 + 25 W

(4 ohms at 1 kHz, 10%

THD)

European model:

DIN power output (rated): 20 + 20 W

(4 ohms at 1 kHz, DIN)

Continuous RMS power output (reference):

25 + 25 W

(4 ohms at 1 kHz, 10%

THD)

Music power output (reference):

25 + 25 W

Other models:

The following measured at 220 V AC, 60 Hz

DIN power output (rated): 20 + 20 W

(4 ohms at 1 kHz, DIN,

110 V - 240 V AC)

Continuous RMS power output (reference):

25 + 25 W

(4 ohms at 1 kHz, 10%

THD, 110 V - 240 V AC)

Inputs

MD/TAPE IN (stereo minijack):

Sensitivity 450 mV (MD)/

250 mV (Tape),

impedance 47 kilohms

DIGITAL OPTICAL IN (Supported sampling

frequencies: 32 kHz, 44.1 kHz and 48 kHz)

Outputs

MD/TAPE OUT (stereo minijack):

Sensitivity 250 mV,

impedance 1 kilohmes

PHONES (stereo minijack):

Accepts headphones with

an impedance of 8 ohms

or more

DIGITAL CD OPTICAL OUT (Supported sampling

frequency: 44.1 kHz)

CD player section

System Compact disc and digital

audio system

Laser Semiconductor laser

(λ = 795 nm)

Emission

duration: continuous

Frequency response 2 Hz – 20 kHz

HD recorder section

Capacity 20 GB

Recording system ATRAC 3

Transfer rate 132 kbps

Maximum recording time About 300 h

Maximum number of albums

Library area: 250

Flexible area: 250

Maximum number of tracks

20,000

Maximum number of tracks per album

400

Maximum CD-HD ripping speed

Max. ×2

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range

North American model: 87.5 - 108.0 MHz

(100-kHz step)

Other models: 87.5 - 108.0 MHz

(50-kHz step)

Antenna FM wire antenna

Antenna terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

North American model: 530 - 1,710 kHz

(with the tuning interval

set at 10 kHz)

531 - 1,710 kHz

(with the tuning interval

set at 9 kHz)

European model: 531 - 1,602 kHz

(with the tuning interval

set at 9 kHz)

Other models: 530 - 1,710 kHz

(with the tuning interval

set at 10 kHz)

531 - 1,602 kHz

(with the tuning interval

set at 9 kHz)

Antenna AM loop antenna, external

antenna terminal

Intermediate frequency 450 kHz

SERVICE MANUAL

Ver 1.2 2003. 12

This set is the tuner, CD, HD and amplifier

section in CMT-L7HD.

CD

SECTION

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM71B

Base Unit Type BU-31BD63

9-874-073-03

2003L16-1

© 2003.12

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

MICRO Hi-Fi COMPONENT SYSTEM

— Continued on next page —

HCD-L7HD

General

Power requirements

North American model: 120 V AC, 60 Hz

European model: 230 V AC, 50/60 Hz

Other models: 110 - 240 V AC ,

Power consumption

European model: See the nameplate

Other models: See the nameplate

Dimensions (w/h/d) Approx. 293 × 246 ×

Mass Approx. 4.3 kg

Design and specifications are subject to change

without notice.

50/60 Hz

0.2 W (at the Power

Saving Mode)

131 mm incl. projecting

parts and controls

Self-diagnosis display

Messages

One of the following messages may appear or

flash in the display during operations.

CD

Complete!

CD editing (Disc Memo) finished normally.

File Full

There are already 100 disc titles stored in the

system.

Initialize

The system is being initialized. You cannot load a

CD during this time. Wait until “Initialize”

disappears from the display.

No Disc

There is no disc in the CD player.

—OVER—

You have reached the end of the CD while

pressing and holding down M during playing

pause.

Push STOP!

You pressed PLAY MODE on the remote during

playback.

You pressed STORAGE MODE during playback.

You pressed STORAGE MODE during manual

recording of a CD.

Step Full!

You tried to program 26 tracks (steps) or more.

HD

Already Done

You tried to perform High-Speed Synchro Storage

for a CD that has already been completely

recorded.

Auto Cut

The system is pausing the recording because

silence continued for 30 seconds or more during

digital recording.

Blank Disc

There is no track on the HD.

2

HCD-L7HD

Cannot Copy

You tried to play a CD with a format that the

system does not support, such as a CD-ROM. The

sound source is a copy of commercially available

music software.

Cannot Edit

You tried to edit in Shuffle Play, or you tried to

register a track to a playlist that already contains

400 tracks.

Cannot Play

The system cannot play the track because of

damage to the audio data.

Cannot Rec

You tried to record to the HD with HD selected as

the sound source.

You tried to perform manual recording from the

CD with “AUTO” selected as the storage mode.

You pressed REC with “AUTO” selected as the

storage mode.

You tried to record a CD to the HD without

loading the CD.

Cannot STORAGE

You tried to record to the HD with less than 131

recordable tracks remaining on the HD.

You tried to record to the HD with less than 240

minutes of recordable time remaining on the HD.

You tried to perform High-Speed Synchro Storage

with no blank album in the Library area.

Check OPT-IN

A moment’s lighting is due to the signals of the

digital program being recorded. This does not

affect the recorded material.

While recording from a digital component

connected through the DIGITAL OPTICAL IN

jack, the digital connecting cable was unplugged or

the digital component turned off.

Complete!

The editing operation of the HD is completed.

The system is copying a title or artist name.

Copying

The system is copying the text data.

Drive Error

Consult your Sony dealer or local authorized Sony

service facility.

Drive Full!

Recording tracks is not possible because there is

not enough recordable space on the HD or the

maximum number of recordable tracks has been

reached.

Erasing

The system is erasing data from the HD. Do not

disconnect the power cord.

Format Error

Consult your Sony dealer or local authorized Sony

service facility.

Impossible

You tried to make an impossible editing or

recording operation.

Library Making

The system is recording data to the HD.

Name Full!

The naming capacity of the HD has reached its

limit (about 127 characters).

No Name

The album or track has not been labelled.

No Signal

The system has detected a silent portion during

recording.

Not Found

No matches were found for Keyword Search.

Please Wait

You tried to perform High-Speed Synchro Storage

while the system was collating data between the

CD and the HD.

You tried to perform High-Speed Synchro Storage

while the system was preparing for Auto Storage

and High-Speed Synchro Storage.

Push STOP!

You pressed PLAY MODE on the remote during

playback.

You pressed SEARCH on the remote during

playback.

Rec Error

Proper recording is not possible.

– Rehearsal –

The HD is playing the specified dividing point for

confirmation during the Divide function.

The HD is playing the specified Highlight position

for confirmation during the Highlight Play

function.

REMOTE

The system is being connected to your computer.*

Retry

The system is retrying reading data from the CD

during High-Speed Synchro Storage.

Smart Space

The signal was input again after silence continued

for 3 or more but less than 30 seconds during

digital recording.

STORAGE NOW

You tried to turn off the system while the system

was storing data to the HD.

TOC Reading

The system is reading data from the HD.

Track End

You have reached the end of the track while

adjusting the dividing point during the Divide

function.

Track Full!

Recording tracks is not possible because there are

400 tracks in the album. Select another album for

recording.

Timer

OFF TIME NG!

The stopping time is the same as the starting time

in the Daily Timer operation.

OVERLAP!

The Daily Timer or timer-recording setting that

you attempted to make partially or wholly

coincides with another setting.

* If “REMOTE” appears under other circumstances,

turn off the system, then turn on it again.

3

HCD-L7HD

TABLE OF CONTENTS

1. SERVICING NOTES

2. GENERAL ·········································································· 8

3. DISASSEMBLY ······························································ 10

3-1. Bottom Plate,Case ·······················································11

3-2. Front Panel Section ····················································· 11

3-3. POWER Board, AM/FM Tuner ··································· 12

3-4. HDD Board, HDD SUB Board ··································· 12

3-5. MAIN Board ······························································· 13

3-6. Cover (HDD-Top), Cover (HDD-Bottom) ·················· 13

3-7. AMP Board, REG Board ············································· 14

3-8. Switching Regulator ···················································· 14

3-9. Indicator (BS), LED Board (R) ···································15

3-10.LED Board (L) ···························································· 15

3-11.FL Board ·····································································16

3-12.TOUCH SW Board, SWITCH Board ························· 16

3-13.CD Board·····································································17

3-14.BD Board·····································································17

3-15.Base Unit (BU-31BD63) ············································· 18

3-16.BU-31 Assy, Sled Motor Assy (M102) ······················· 18

3-17.CD Mechanism (CDM71B) ········································ 19

3-18.L.MOTOR Board ························································· 19

3-19.C.MOTOR Board, L.SENSOR Board ························· 20

3-20.ENCODER Board, D.SENSOR Board ······················· 21

3-21.Pulley (RTR) Assy, Pulley (RTL) Assy,

Belt (CDM71), Belt (Roller) (L) ································· 22

3-22.Pulley (SPT) Assy, Gear (RT) Assy, Gear(KT),

Belt (CDM71) ····························································· 24

4. TEST MODE ···································································· 26

······················································· 5

6. DIAGRAMS······································································31

6-1. Block Diagrams ··························································· 31

6-2. Circuit Boards Location ·············································· 34

6-3. Printed Wiring Board – BD Section (Side A) – ··········· 35

6-4. Printed Wiring Board – BD Section (Side B) –···········36

6-5. Schematic Diagram – BD Section – ···························· 37

6-6. Printed Wiring Board – MOTOR Section – ················38

6-7. Schematic Diagram – MOTOR Section – ··················· 39

6-8. Printed Wiring Board – HDD1 Section (Side A) – ····· 40

6-9. Printed Wiring Board – HDD1 Section (Side B) – ·····41

6-10.Schematic Diagram – HDD1 Section (1/2) –·············· 42

6-11.Schematic Diagram – HDD1 Section (2/2) –·············· 43

6-12.Printed Wiring Board – HDD2 Section –···················· 44

6-13.Schematic Diagram – HDD2 Section (1/2) –·············· 45

6-14.Schematic Diagram – HDD2 Section (2/2) –·············· 46

6-15.Printed Wiring Board – MAIN Section (Side A) – ····· 47

6-16.Printed Wiring Board – MAIN Section (Side B) – ·····48

6-17.Schematic Diagram – MAIN Section (1/2) –·············· 49

6-18.Schematic Diagram – MAIN Section (2/2) –·············· 50

6-19.Printed Wiring Board – CD Section – ························· 51

6-20.Schematic Diagram – CD Section –····························52

6-21.Printed Wiring Board – AMP Section (Side A) –········ 53

6-22.Printed Wiring Board – AMP Section (Side B) – ········ 54

6-23.Schematic Diagram – AMP Section – ························· 55

6-24.Printed Wiring Board – DISPLAY Section – ·············· 56

6-25.Schematic Diagram – DISPLAY Section – ················· 57

6-26.Printed Wiring Board – CONTROL Section – ············ 58

6-27.Schematic Diagram – CONTROL Section –···············59

6-28.Printed Wiring Board – POWER Section –·················60

6-29.Schematic Diagram – POWER Section – ··················· 61

6-30.IC Pin Function Descriptions ······································ 63

5. ELECTRICAL ADJUSTMENTS ·······························30

7. EXPLODED VIEWS ······················································ 72

7-1. Case Section ································································72

7-2. Chassis Section ···························································· 73

7-3. Frot Panel Section ······················································· 74

7-4. Mechanism Section(CDM71B)-1································ 75

7-5. Mechanism Section(CDM71B)-2································ 76

7-6. Base Unit (BU-31BD63) ············································· 77

8. ELECTRICAL PARTS LIST ······································· 78

4

SECTION 1

SERVICING NOTES

HCD-L7HD

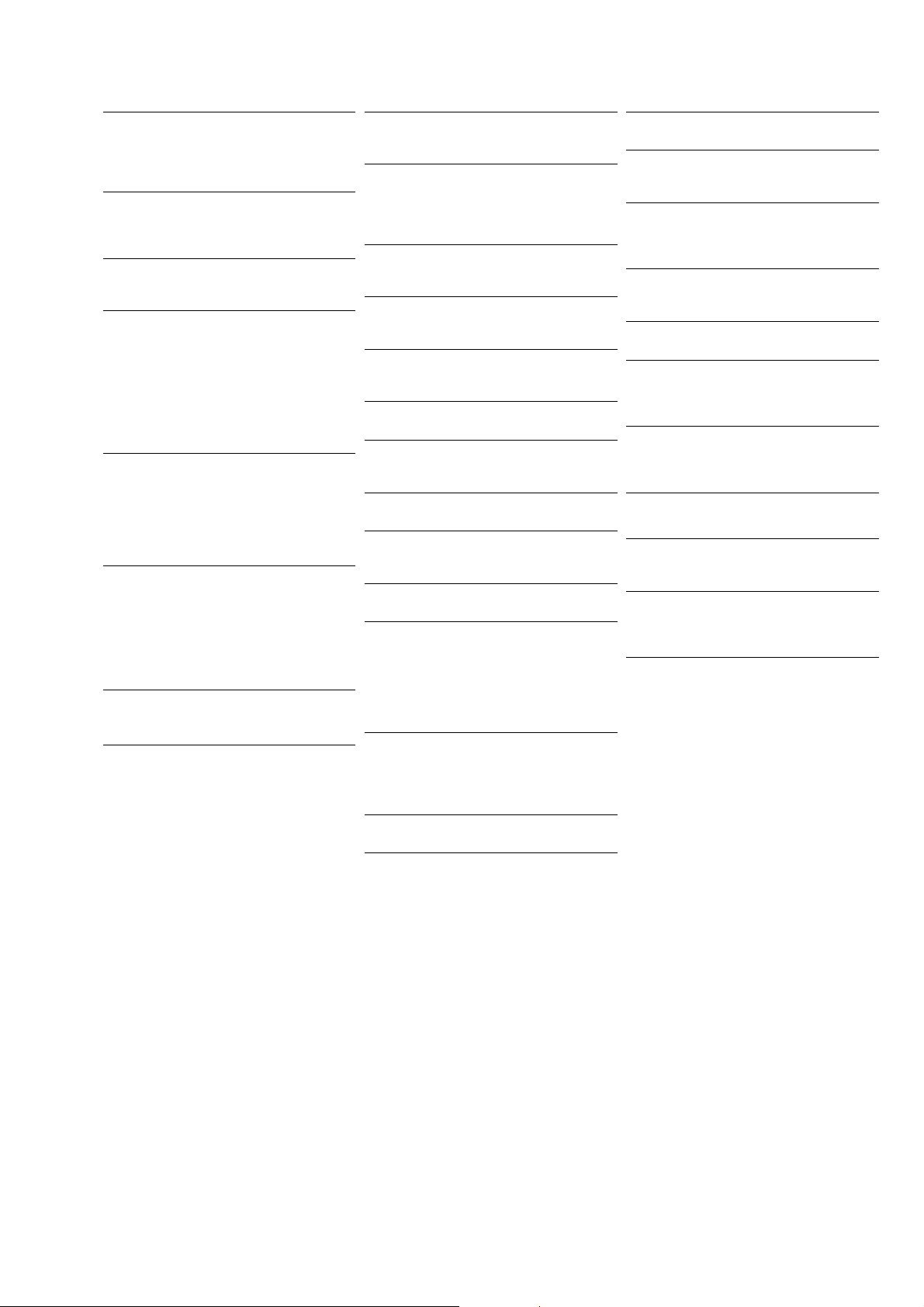

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

SAFETY CHECK-OUT

After correcting the original service problem, perform the

following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

LEAKAGE

The A C leakage from any exposed metal par t to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate lo w-v oltage

scale. The Simpson 250 and Sanwa SH-63Trd are e xamples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

This caution

label is

located inside

the unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

AC

0.15 µF

Fig. A. Using an A C v oltmeter to check A C leakage.

1.5 kΩ

Earth Ground

Voltmeter

(0.75 V)

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

À LA SÉCURITÉ!

5

HCD-L7HD

NOTES ON HARD DISC

The hard disc has a high storage density and reads or writes data in

a short time with compared to the floppy disk. On the other hand, it

may be easily damaged by mechanical vibration, shock or dust.

Keep the hard disc away from magnets.

Although the hard disc has safety devices to prevent losing data due

to mechanical vibration, shock or dust, you should be careful when

handling the recorder. Avoid damaging your data:

• Do not cause a shock or strong vibration to the recorder.

• Do not place the recorder in a location subject to mechanical

vibration or in unstable location.

• Do not move the recorder while the power is on.

• Do not turn off the recorder while the HDD indicator lights up

blue.

• Do not use the recorder in a place subject to extreme changes in

temperature (temperature gradient less than 18 °F (10 °C)/ hour).

•Keep any magnetic objects, including a TV set, speaker , magnet,

and magnetic bracelet, away from the recorder.

If the hard disc is damaged, data cannot be restored or recovered.

NOTES ON DIGITAL AMPLIFIER

Cause of the Digital Amplif ier, do not connect the speaker ter minals

to the chasis, or connect the terminals of the right speakers with

those of the left speaker. (None of the speaker terminals is the

negative(–) terminal of the speak er. So,do not connect the earth lead

of this unit to the speaker terminals.)

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky , less prone to flo w) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

6

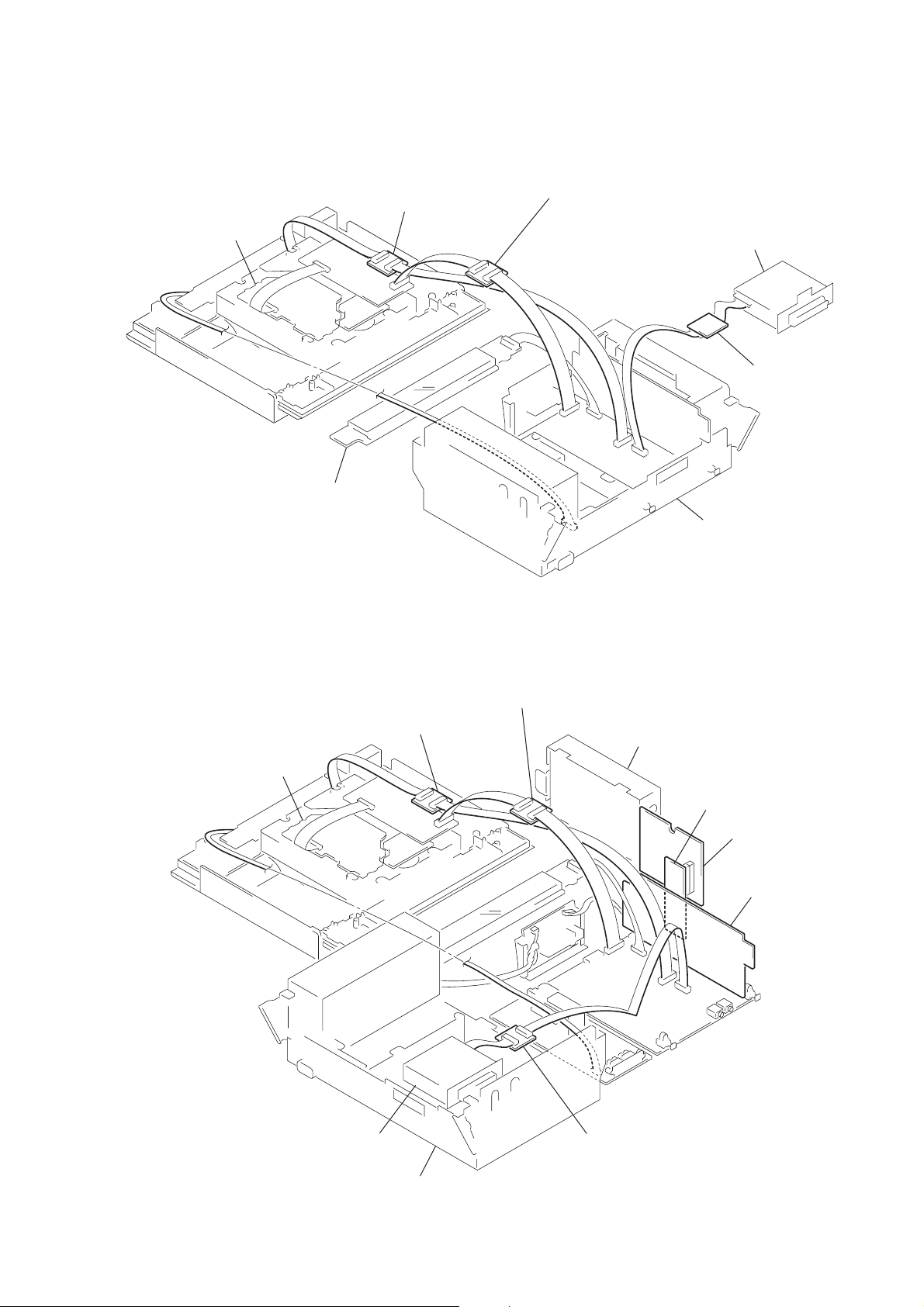

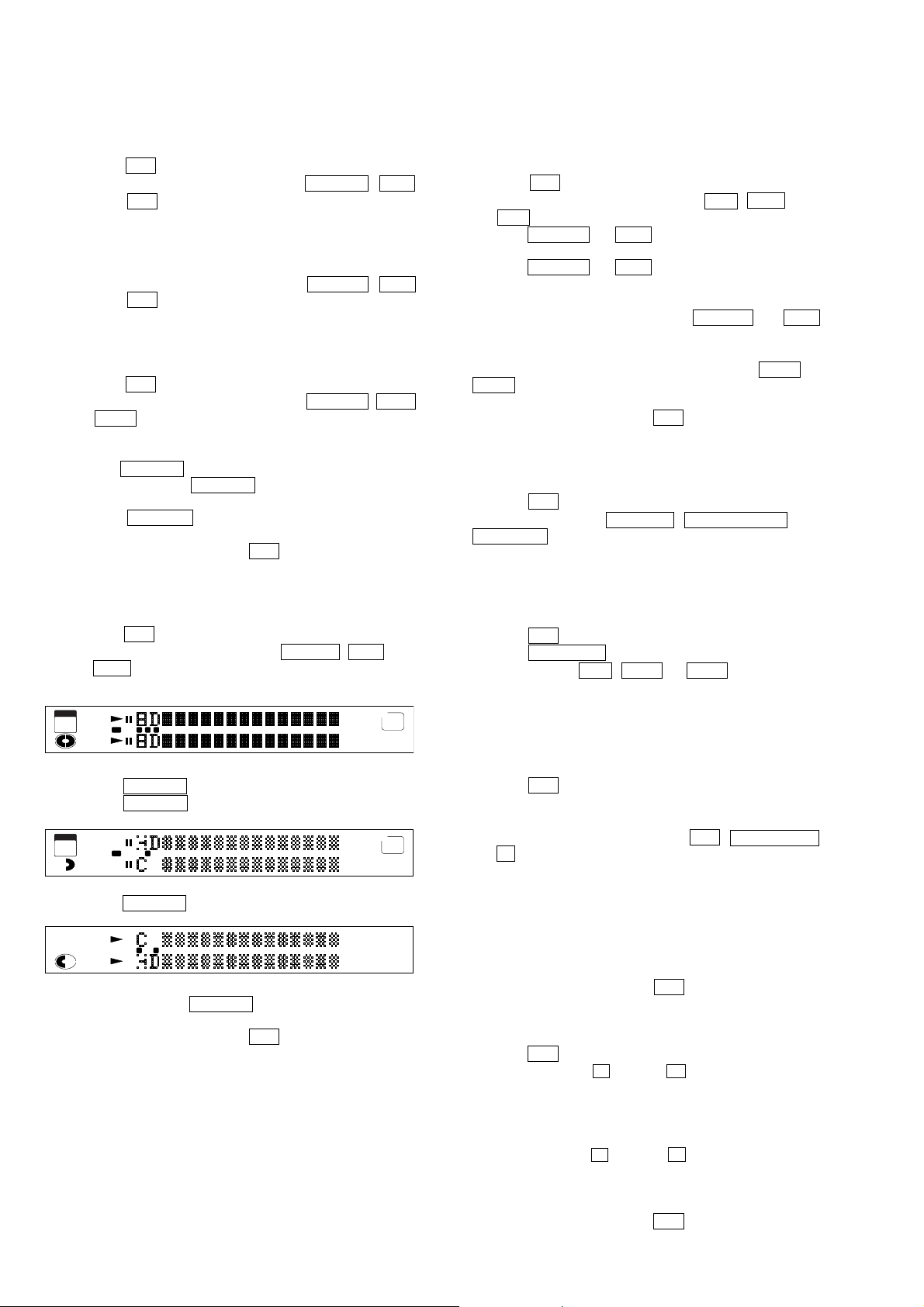

• Service Position -1

)

d

HCD-L7HD

BD board

FL board

JIG

(J-2501-077-A)(13P)

JIG

(J-2501-167-A)(17P)

FM/AM tuner

JIG

(J-2501-076-A)(11P

chassis

• Service Position -2

(Checking For Hard Disc Section)

BD board

JIG

(J-2501-077-A)(13P)

JIG

(J-2501-167-A)(17P)

hard disk

JIG

(J-2501-202-A)(11P)

HDD SUB boar

HDD IF board

FM/AM tuner

JIG

(J-2501-076-A)(11P)

chassis

7

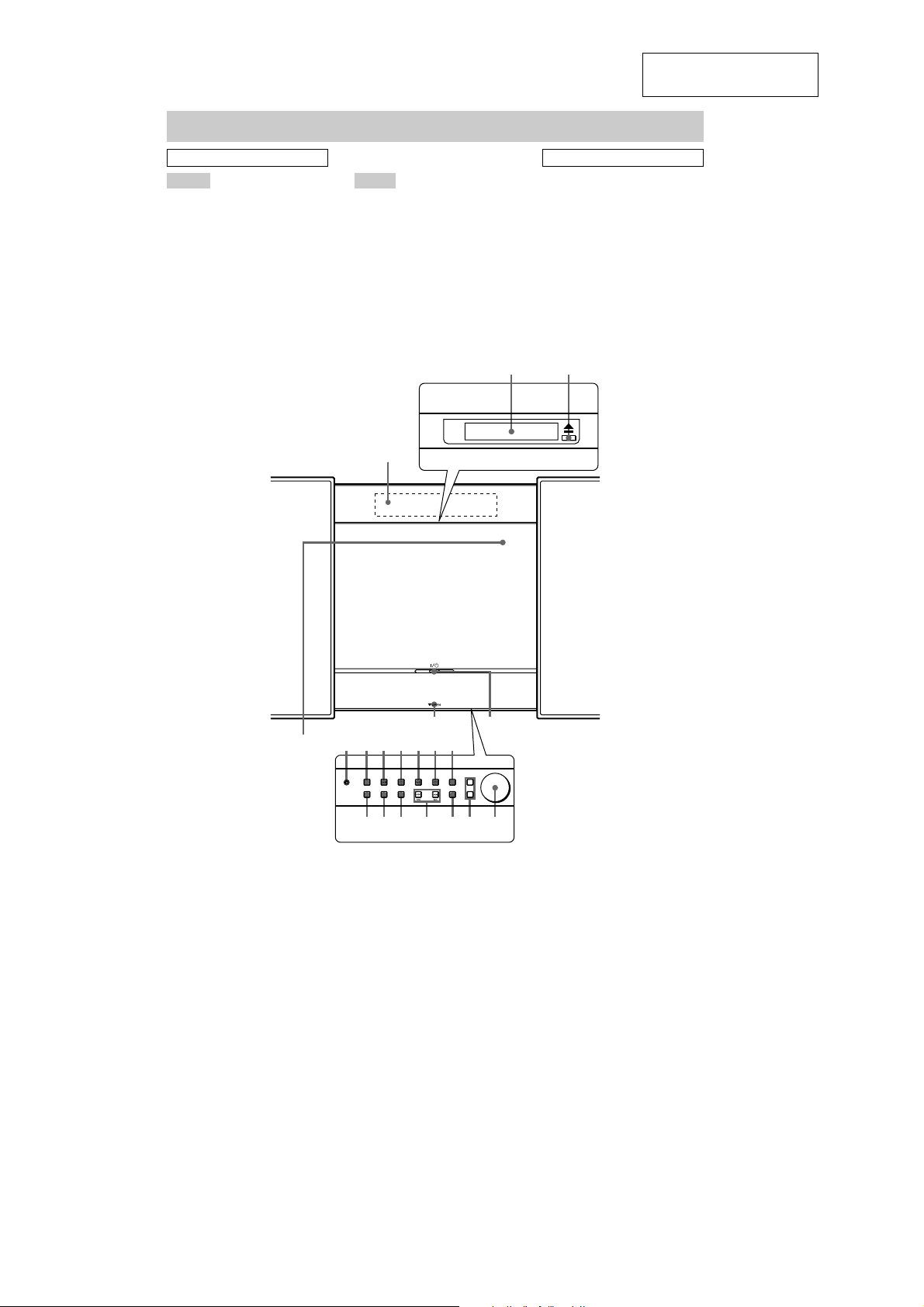

HCD-L7HD

Main unit

SECTION 2

GENERAL

This section is extracted

from instruction manual.

ALPHABETICAL ORDER

A – H

ALBUM dial qf (18, 19, 21, 26)

CD cover 2 (14, 15)

CD u qa (14 - 16, 25)

CD x qs (15, 16, 24, 25)

DISPLAY 8 (39, 44, 45)

Display window 1 (44, 45)

FUNCTION qh (14 - 22, 25 - 28,

30, 32 - 35, 57)

HD u 9 (18, 20 - 22, 25, 26)

HD x q; (18, 25, 26, 30)

HIGH SPEED SYNC ql (25)

P – Z

PHONES jack 7

REC w; (26, 28)

Remote sensor 6

STORAGE MODE qk (14, 25,

26)

TUNER/BAND qd (37, 38)

TUNING +/– qj (37, 38)

VOL +/– qg (41)

1

BUTTON DESCRIPTIONS

@/1 (power) 4 (11, 41, 42)

./> qj (15, 16, 18)

m/M qj (15, 18)

Z 3 (14, 15)

V OPEN 5

To open the front cover, push

down on V OPEN.

2

3

6

789q;

qlqk

54

qaqsqd

qgqhqjw;

qf

8

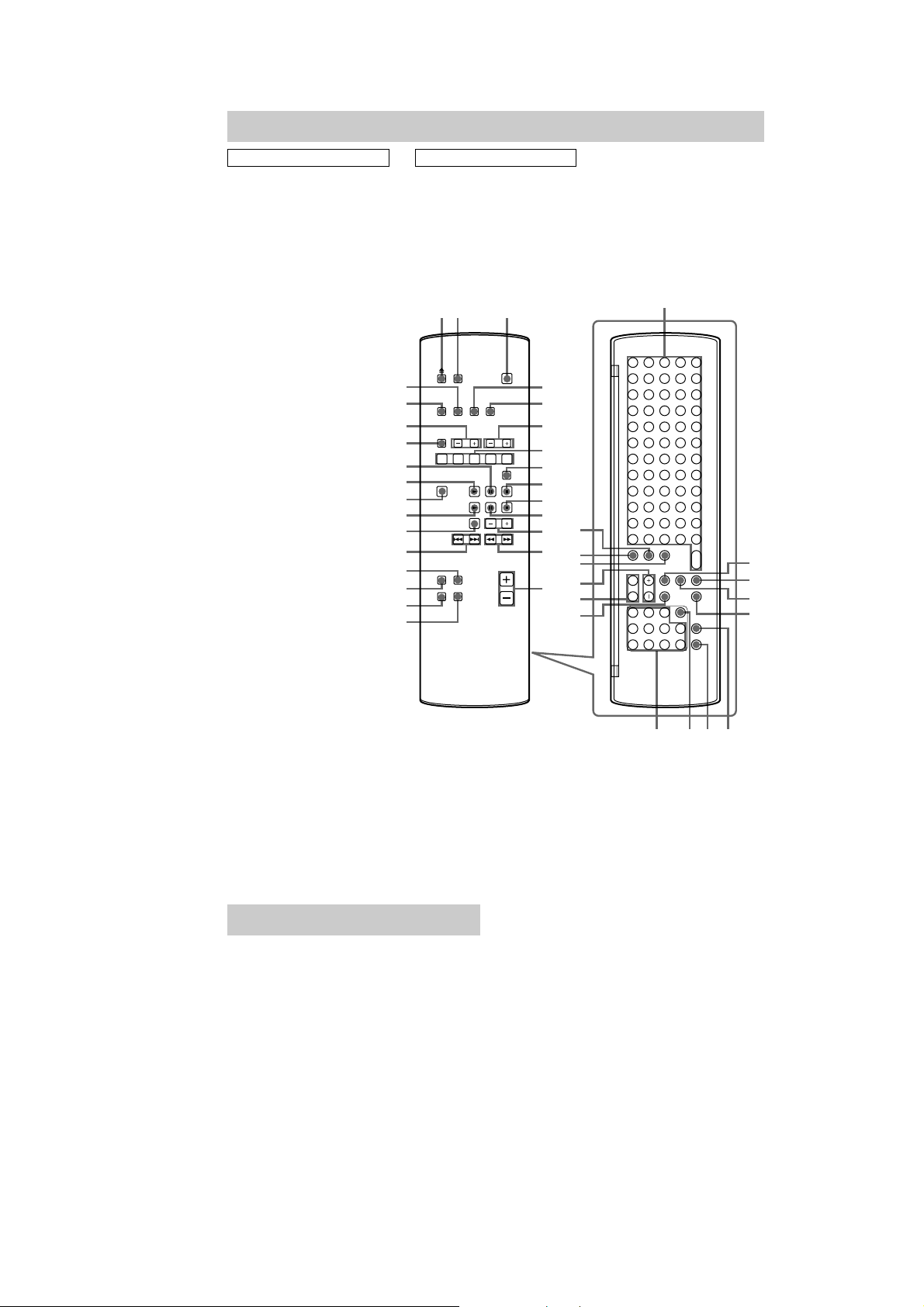

Remote control

HCD-L7HD

ALPHABETICAL ORDER

ALBUM eh (19)

ALBUM FAVORITES 7 (22)

ALBUM MEMORY 8 (22)

ALBUM +/– 6 (18, 19, 21, 26)

CAPS rd (16, 31)

CD N wa (14 - 16, 25)

CD X qa (15)

CD x q; (15, 16, 24, 25)

CLEAR es (15 - 17, 29, 31, 39)

CLOCK/TIMER SELECT eg

(41 - 43)

CLOCK/TIMER SET ef (13, 41,

42)

CURSOR T/t el (13, 17, 20,

21, 31, 35, 42)

DIMMER 5 (44)

DISPLAY wk (39, 44, 45)

DSG qk (40)

ENTER/YES e; (13, 15 - 17,

19 - 21, 27 - 37, 39, 41 - 43, 57)

FM MODE qg (38)

FUNCTION ws (14 - 22, 25 - 28,

30, 32 - 35, 57)

HD N wd (18, 20 - 22, 25, 26)

HD X wf (18, 25, 26)

HD x 9 (18, 25, 26, 30)

HIGHLIGHT wg (21)

HISTORY +/– wh (22)

MENU/NO ek (17, 20, 27 - 39,

57)

MENU +/– r; (13, 17, 20, 21,

27 - 36, 41 - 43)

NAME rs (16, 39)

Numeric buttons for selecting an

album or track ej (15, 19, 38)

PLAYLIST ed (19, 20)

PLAY MODE qh (14 - 18, 21)

PRESET EQ qj (40)

REPEAT qg (15, 18)

SCROLL 4 (17, 45)

SEARCH ea (20)

SLEEP 2 (40)

SML ra (16, 31)

Text input buttons wl (16, 31)

TIME wj (16, 44, 45)

TUNER BAND w; (37, 38)

TUNING MODE qh (37, 38)

TUNING +/– qs (37, 38)

VOL +/– qf (41)

BUTTON DESCRIPTIONS

@/1 (power) 3 (11, 41, 42)

./> ql (15, 16, 18)

m/M qd (15, 18)

Z 1 (14, 15)

12 3

wk

wj

wh

wg

wf

wd

ws

wa

w;

ql

qk

qj

qh

qg

4

5

6

7

8

9

q;

qa

qs

qd

qf

rd

rs

ra

r;

el

ek

wl

e;

ea

es

ed

ej ehegef

Setting the clock

1 Turn on the system.

2 Press CLOCK/TIMER SET on the

remote.

3 Press MENU + or – on the remote

repeatedly to set the day, and then

press ENTER/YES or CURSORt on

the remote.

The hour indication flashes.

4 Press MENU + or – on the remote

repeatedly to set the hour, and then

press ENTER/YES or CURSORt on

the remote.

The minute indication flashes.

5 Press MENU + or – on the remote

repeatedly to set the minute, and then

press ENTER/YES on the remote.

If you make a mistake

Press TCURSOR or CURSORt on the

remote repeatedly until the indication you want

to change (day, hour, minute) flashes, and then

change the setting.

To adjust the clock

1

Press CLOCK/TIMER SET on the remote.

2

Press MENU + or – on the remote repeatedly

until “CLOCK SET?” appears in the display,

and then press ENTER/YES on the remote.

3

Do the same procedures as steps 3 to 5

above.

9

HCD-L7HD

SECTION 3

DISASSEMBLY

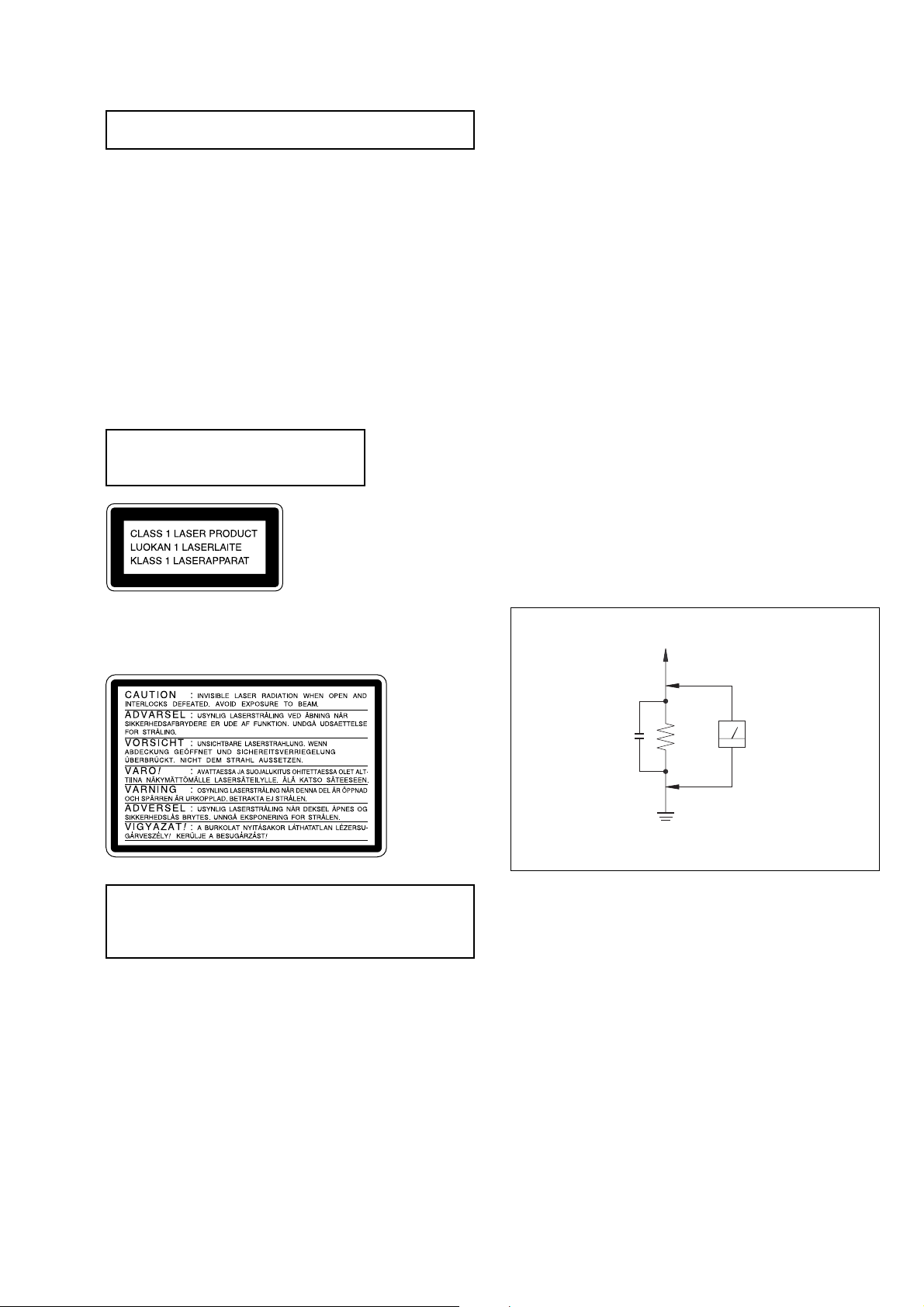

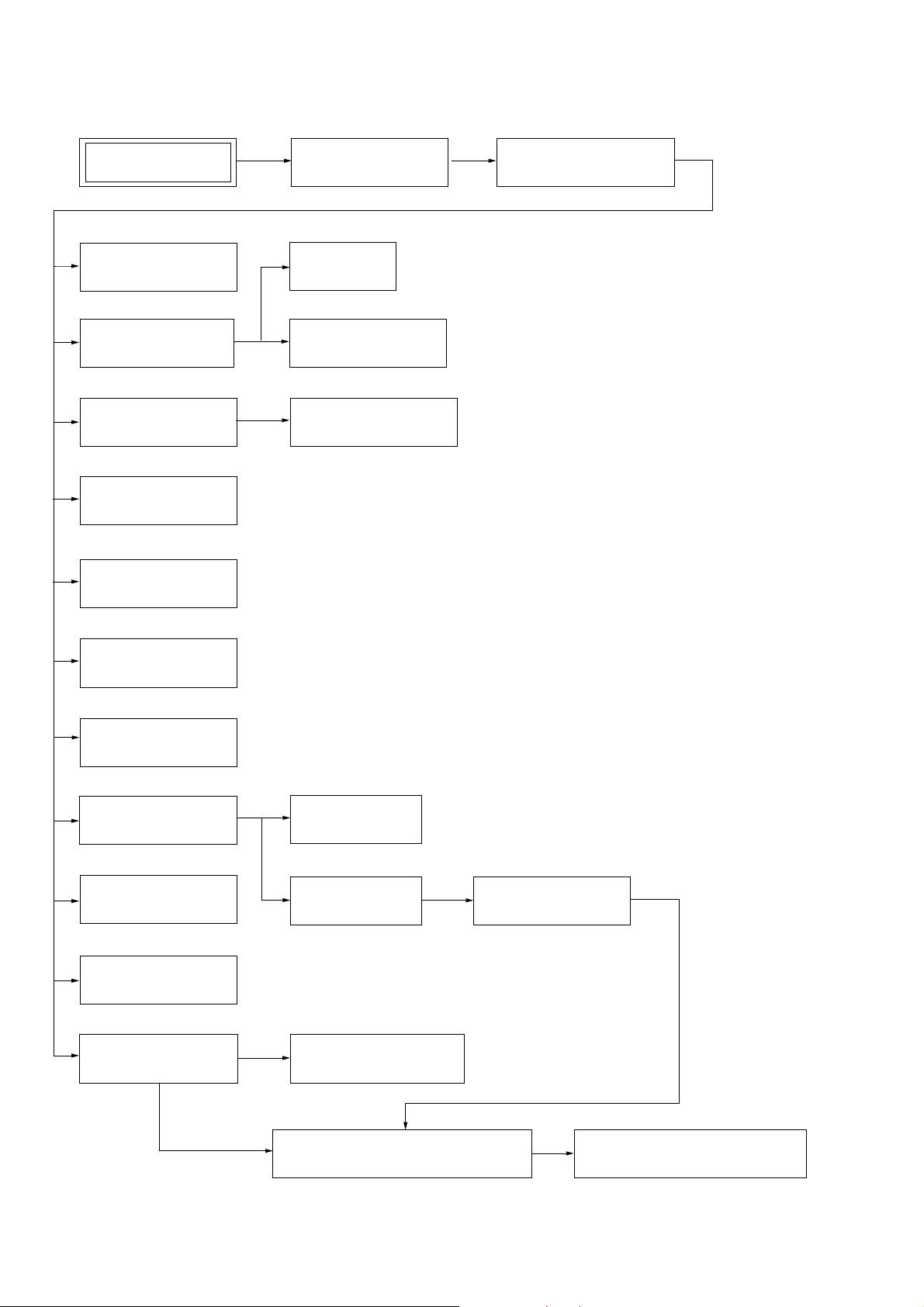

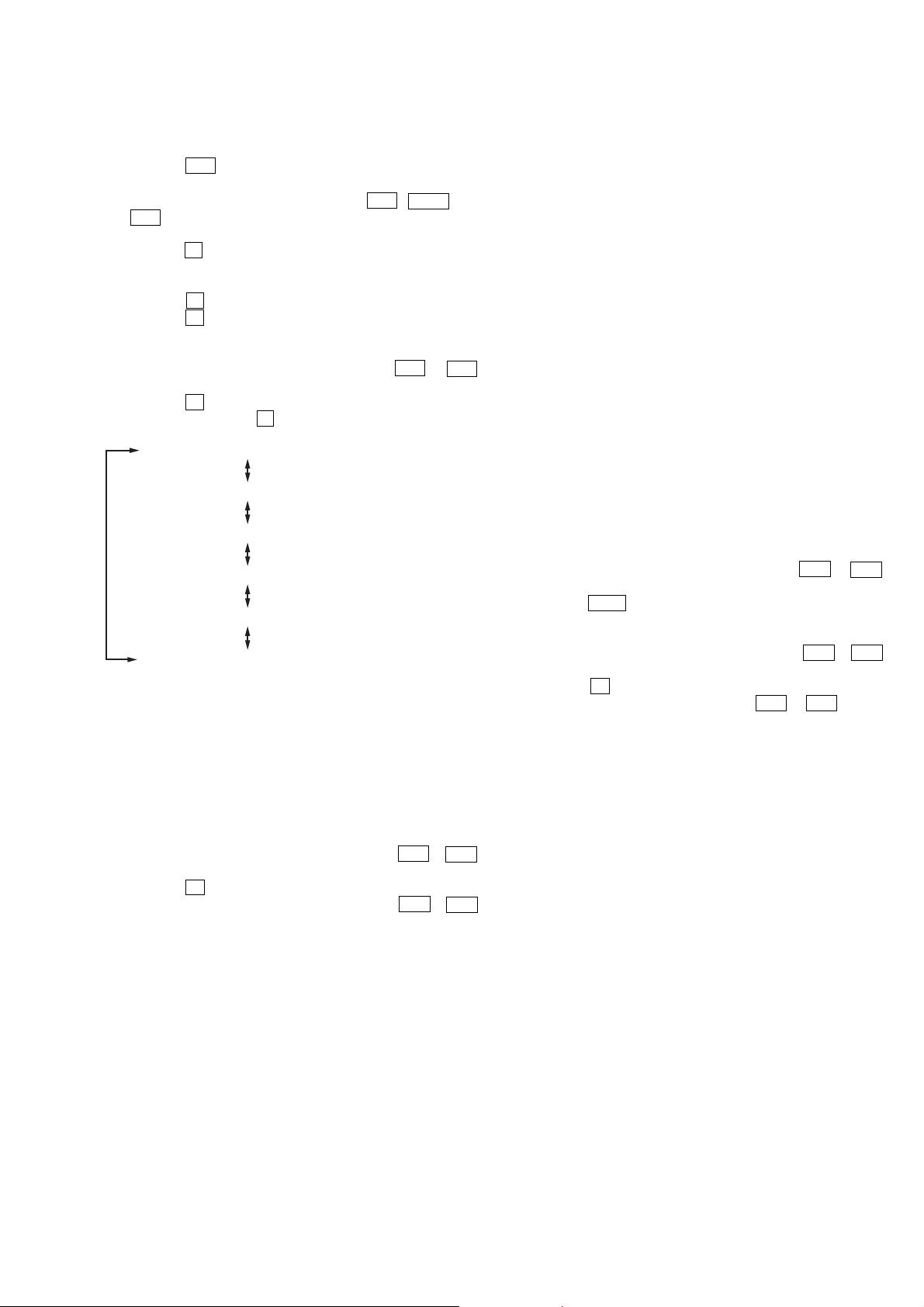

Note : This set can be disassembled in the order shown below.

SET (HCD-L7HD)

POWER BOARD,

AM/FM TUNER

HDD BOARD,

HDD SUB BOARD

AMP BOARD,

REG BOARD

INDICATOR (BS),

LED BOARD (R)

LED BOARD (L)

BOTTOM PLATE,CASE

MAIN BOARD

COVER (HDD-TOP),

COVER (HDD-BOTTOM)

SWITCHING REGULATOR

FRONT PANEL SECTION

FL

BOARD

TOUCH SW BOARD,

SWITCH BOARD

CD MECHANISM

(CDM71B)

CD

BOARD

BD

BOARD

BASE UNIT

(BU-31BD63)

C.MOTOR BOARD,

L.SENSOR BOARD

L.MOTOR BOARD

HOLDER ASSY ,

SLED MOTOR ASSY (M102)

ENCODER BOARD,

D.SENSOR BOARD

10

PULLEY (RTR) ASSY,PULLEY (RTL) ASSY,

BELT (CDM71), BELT (ROLLER) (L)

PULLEY (SPT) ASSY,GEAR (RT)ASSY,

GEAR (KT), BELT (CDM71)

Note : Follow the disassembly procedure in the numerical order given.

e

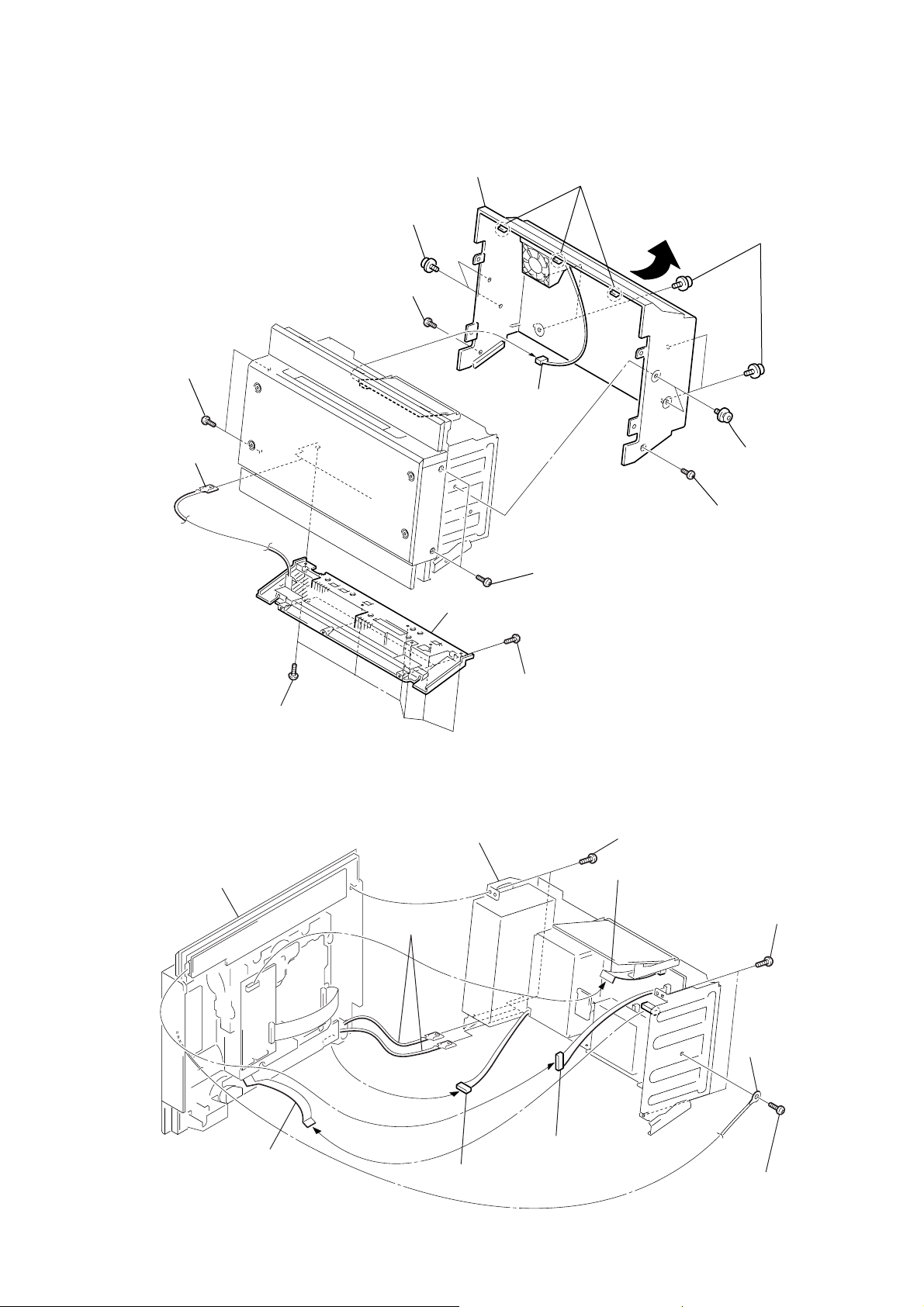

3-1. Bottom Plate,Case

qg

case

6

t

wo screws (SS)

7

s

qa

t

wo screws

(+PTT 3

3

earth plate

× 6

crew (+PTT 3

)

× 6

)

qd

qf

c

onnector

(CN801)

three

claws

qs

5

f

our screws (SS)

8

t

HCD-L7HD

wo screws (SS)

1

six screws (+BVTP 3

3-2. Front Panel Section

qa

front panel section

× 8

9

s

crew (+PTT 3

q;

t

wo screws (+PTT 3

4

b

ottom plate

2

three screws (+BVTP 2.6

)

q;

c

hassis section

7

1

two

earth plates

× 6

)

×

8)

6

two screws (+BVTP 2.6

flat type wire (17 core)

5

two

screws (+BVTP 2.6

×

× 6

)

8)

×

8)

9

f

lat type wire (13 core)

8

c

onnector

(CN1321)

4

c

onnector (CN1201)

2

3

ground wir

screw (+BVTP 3

×

6)

11

HCD-L7HD

)

)

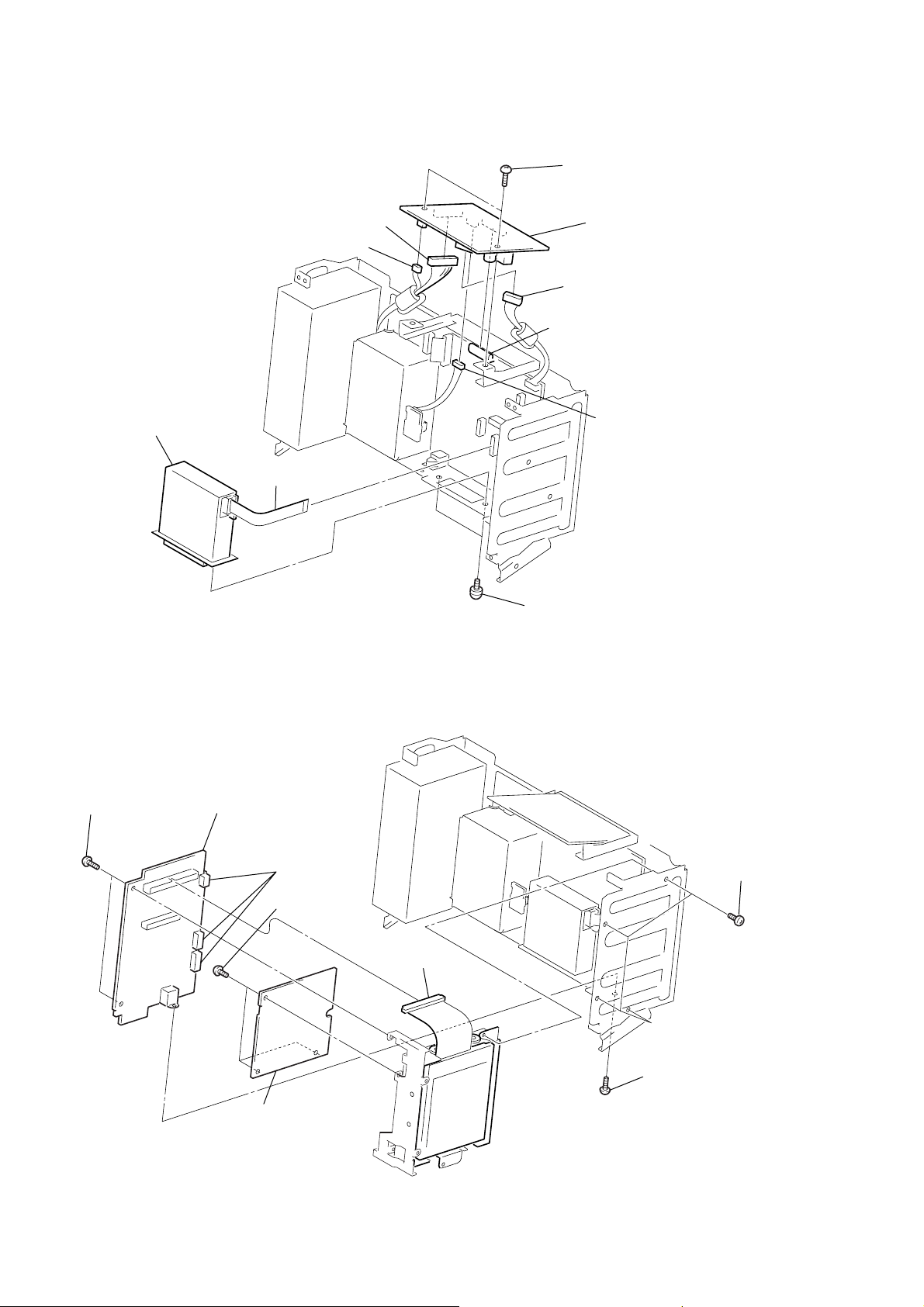

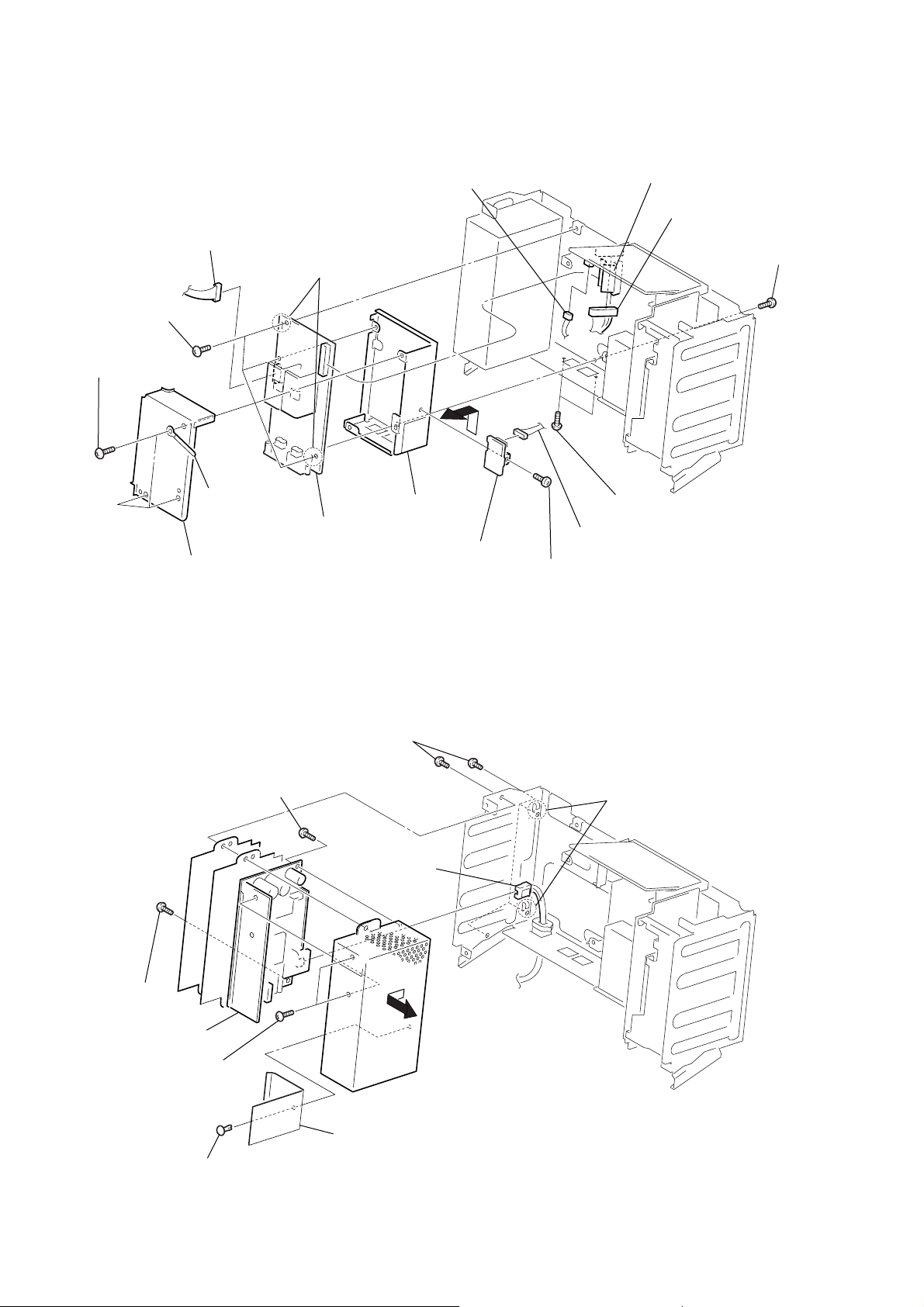

3-3. POWER Board, AM/FM Tuner

3

4

connector (CN851)

q;

AM/FM t

uner

9

flat type wire

(11core or 15core)

connector (CN800)

1

two

screws

(+BVTP 3

7

POWER board

5

connector (CN852)

2

connector (CN500)

6

connector (CN803

×

8)

3-4. HDD Board, HDD SUB Board

6

4

two

screws

(+BVTP 3

×

8)

HDD IF board

3

connector

(CN507,508,503)

7

(+BVTT 3

three

screws

×

6)

5

(CN1002)

harness

8

two

screws

(+BVTP 3

×

8)

2

four

screws

(+BVTP 3

×

8

12

8

HDD SUB board

1

screw

(+BVTP 3

×

8)

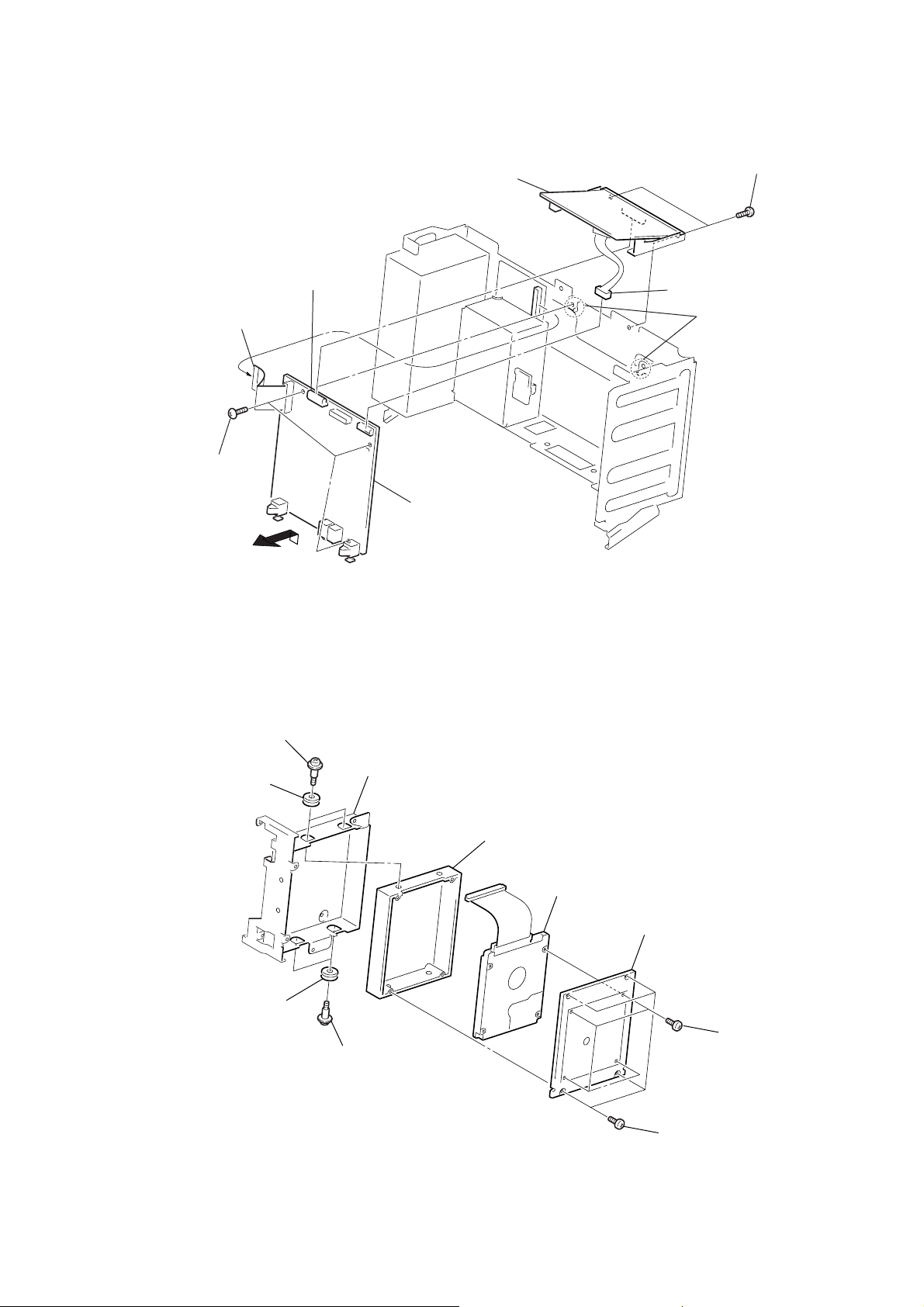

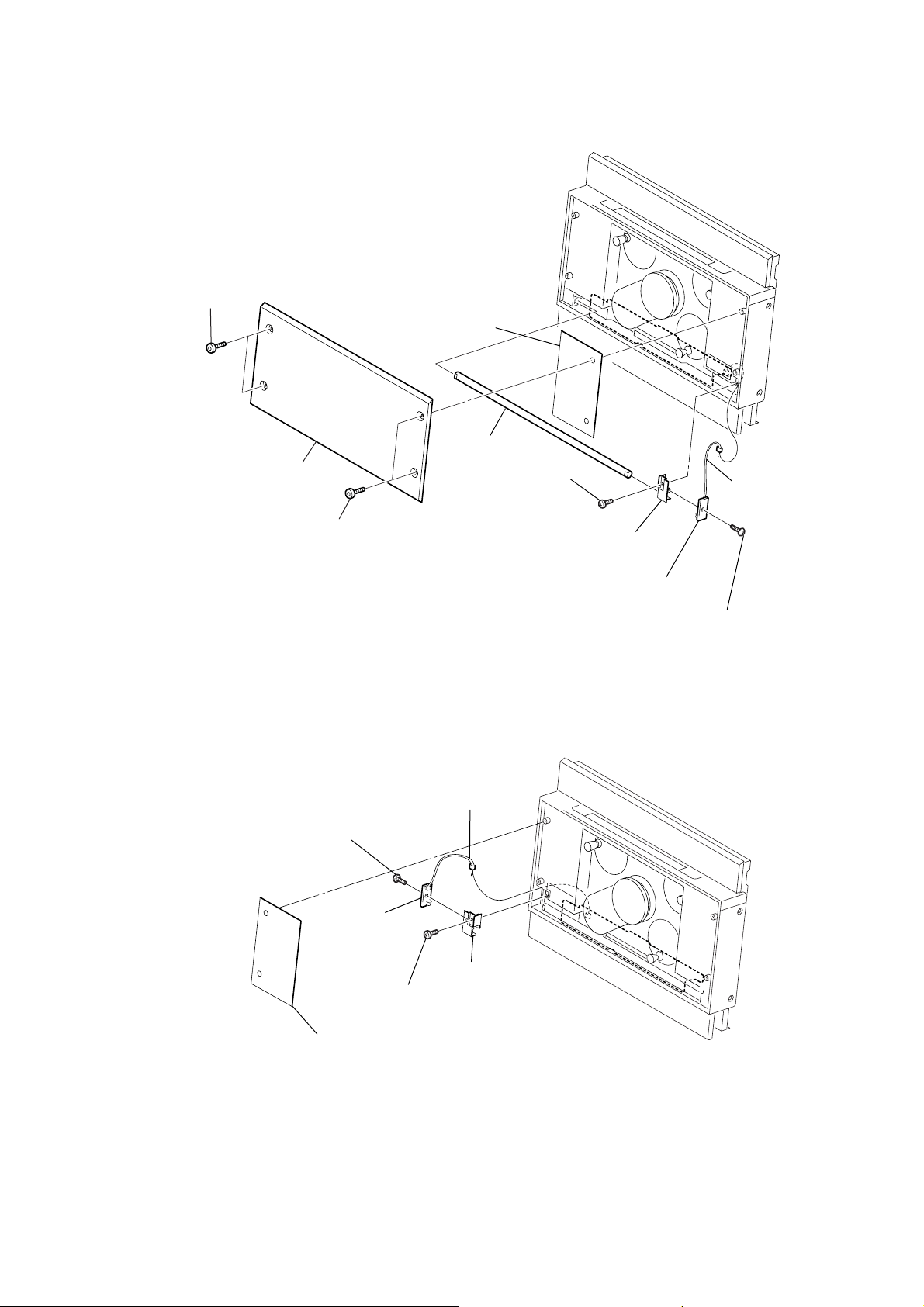

3-5. MAIN Board

)

)

5

flat type wire (23core)

three

6

(+BVTP 3

screws

3

connector (CN500)

×

8)

4

POWER

board

2

two

screws (+BVTP 3

1

connector (CN504)

8

two

HCD-L7HD

×

claws

8

9

7

3-6. Cover (HDD-Top), Cover (HDD-Bottom)

1

two

screws

(+BVTPWH M3)

5

shield case (HDD)

2

two insulators

MAIN board

7

cover (HDD-top)

9

HDD

q;

cover (HDD-bottom)

4

two insulators

3

two

screws

(+BVTPWH M3)

6

four

(+BVTP 3

8

four

(+BVTT 3

screws

×

8)

screws

×

6

13

HCD-L7HD

)

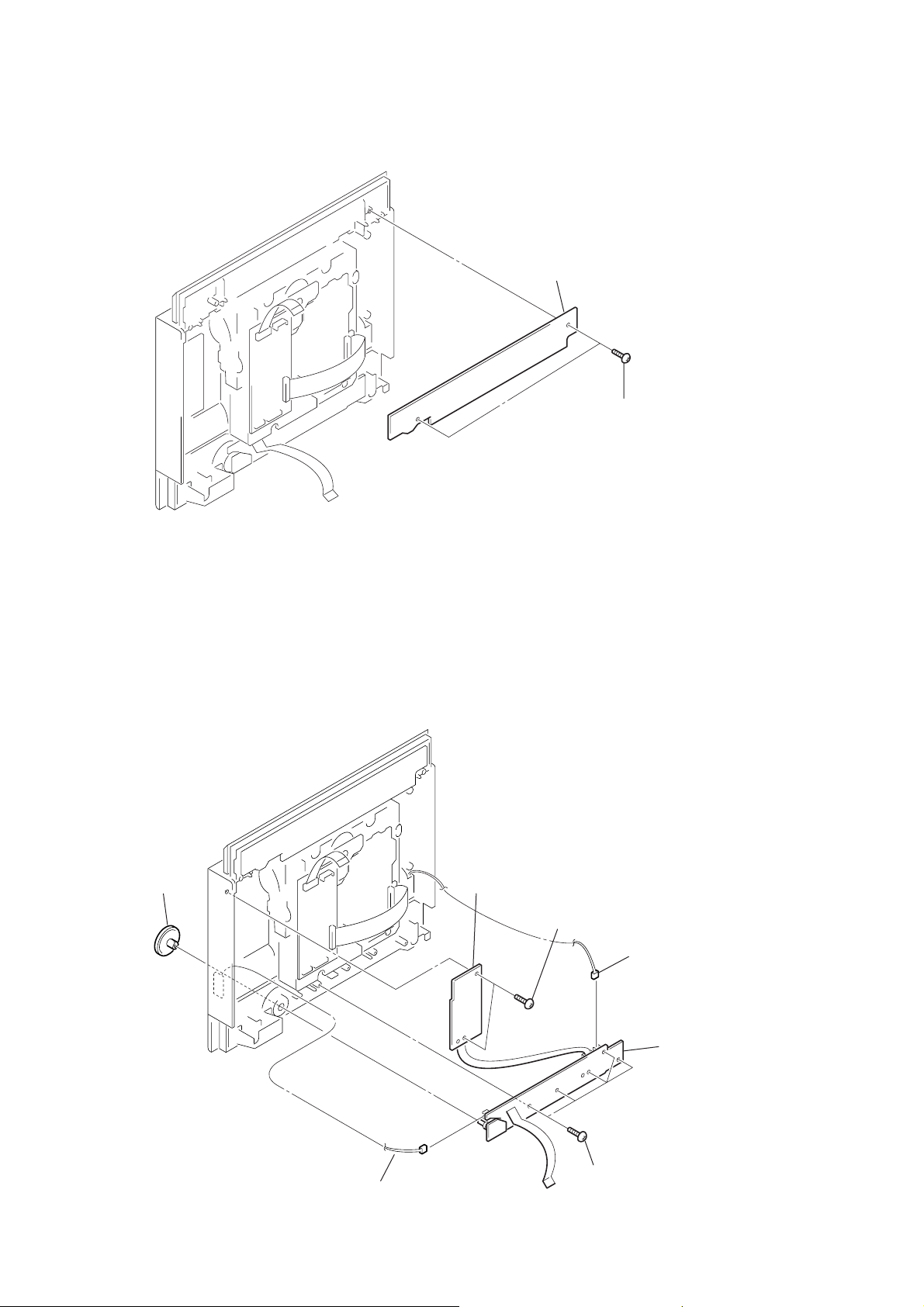

3-7. AMP Board, REG Board

9

connector (CN300)

q;

three

screws

× 6

screws

×

)

8)

(+BVTP 3

6

three

(+BVTP 3

qa

two

1

connector (CN851)

hooks

qs

3

flat type wire (23core)

2

connector (CN800)

5

screw

(+BVTP 3

×

8

7

8

shield case (SM-top)

3-8. Switching Regulator

6

(+BVTP 3

ground wire

qg

screw

AMP board

1

(+BVTP 3

×

8)

qf

(SM-bottom)

four

screws

4

shield case

×

6)

connector

qj

REG

board

qd

connector (CN804)

qh

screw

(+BVTP 3

3

4

two

screws

(+BVTP 3

×

8)

two

hooks

×

8)

14

5

screw

(+BVTP 3

q;

switching

7

(+BVTP 3

×

8)

regurator

two

screws

8

×

8)

nylon rivet

2

9

sheet (power box)

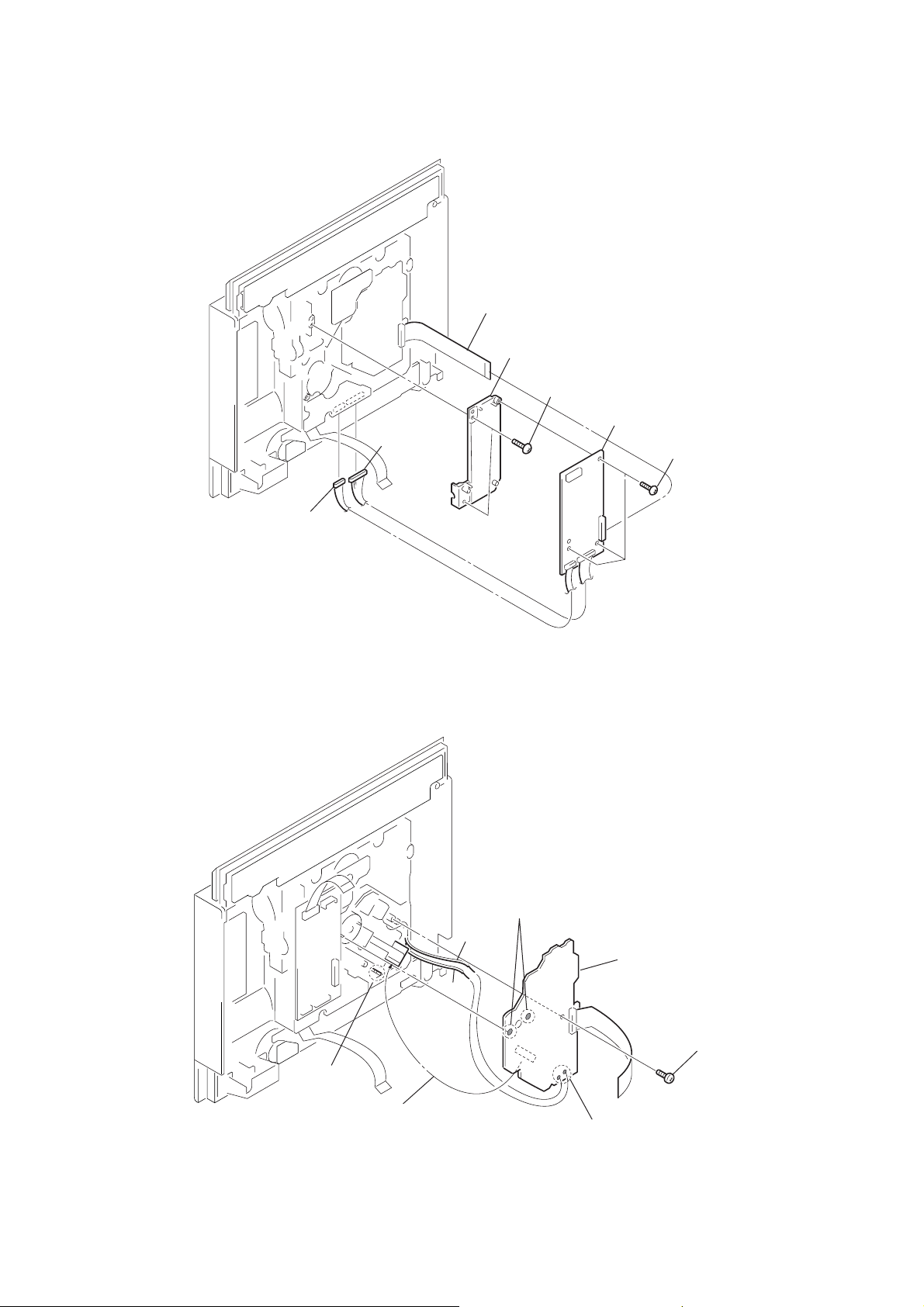

3-9. Indicator (BS), LED Board (R)

r

2

two screws

(panel)

3

ornamental plate (CD)

1

two screws

(panel)

4

sheet (CD2)

8

indicator (BS)

6

s

crew (+BTP 2.6

×

6)

7

holder (LED-R)

HCD-L7HD

5

connecto

(CN1303)

3-10. LED Board (L)

5

screw (+BVTP 2.6

×

8)

6

LED board (L)

1

connector (CN1302)

4

3

screw (+BTP 2.6

holder (LED-L)

×

6)

q;

LED board (R)

9

screw (+BVTP 2.6

×

8)

2

sheet (CD2)

15

HCD-L7HD

)

d

3-11. FL Board

2

FL board

1

two

screws (+BVTP 2.6

×

8

3-12. TOUCH SW Board, SWITCH Board

5

knob jog assy

2

TOUCH SW board

1

two

(+BVTP 2.6

screws

×

8)

3

c

onnector (CN1302)

7

SWITCH boar

16

4

c

onnector (CN1303)

6

f

ive screws

(+BVTP 2.6

×

8)

3-13. CD Board

)

)

4

c

onnector

(CN751)

1

f

lat type wire (19 core)

7

bracket (CD-MT)

6

two screws (+BVTP 3

5

CD board

×

8)

2

three screws

(+BVTP 2.6

HCD-L7HD

×

8

3-14. BD Board

3

c

onnector

(CN752)

1

Remove solder (two portions ).

(BLK)

6

BD board

5

h

ook

4

flxible

(RED)

board

2

Remove solder (two portions ).

3

screw

(+BTP 2.6

×

8

17

HCD-L7HD

)

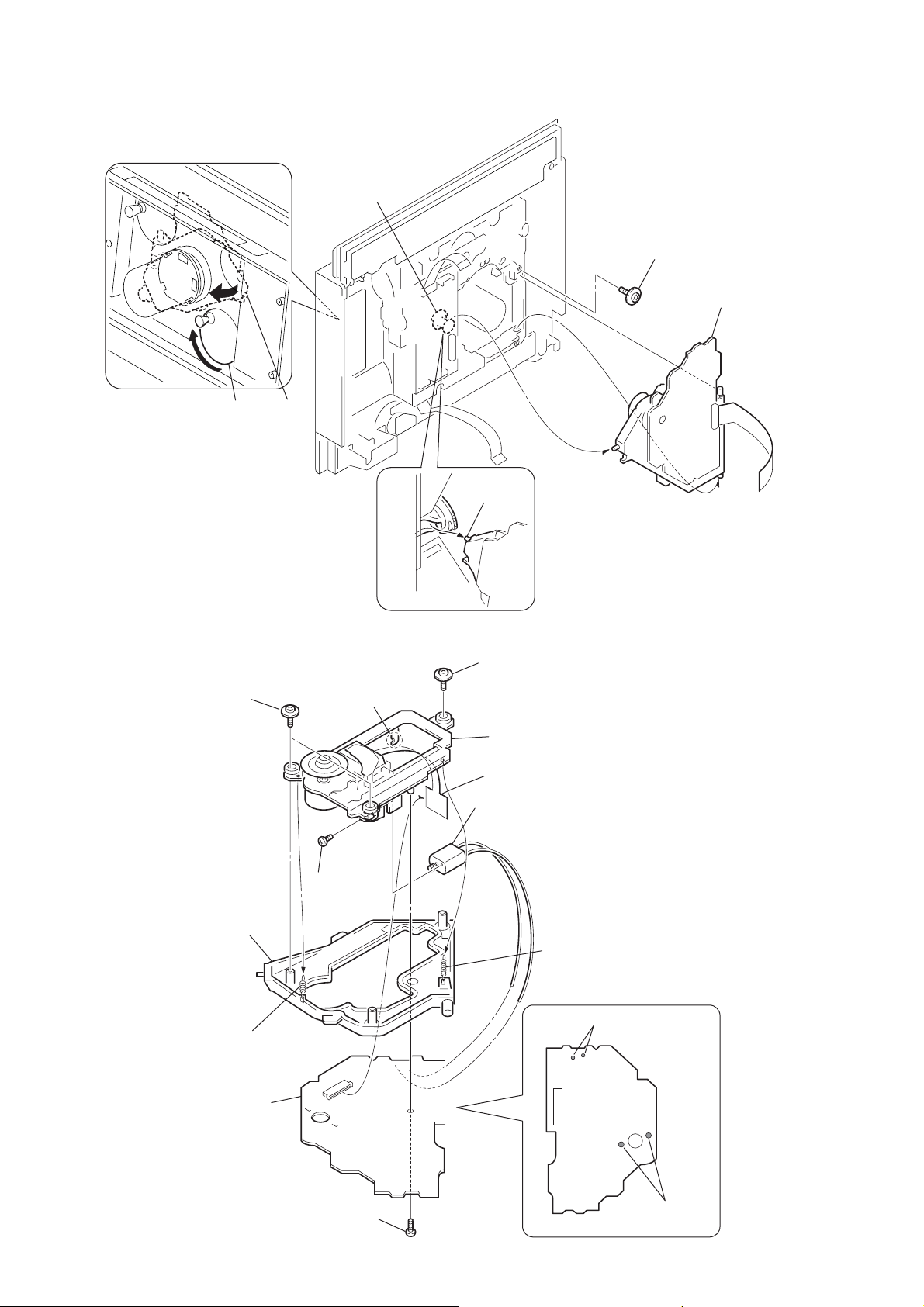

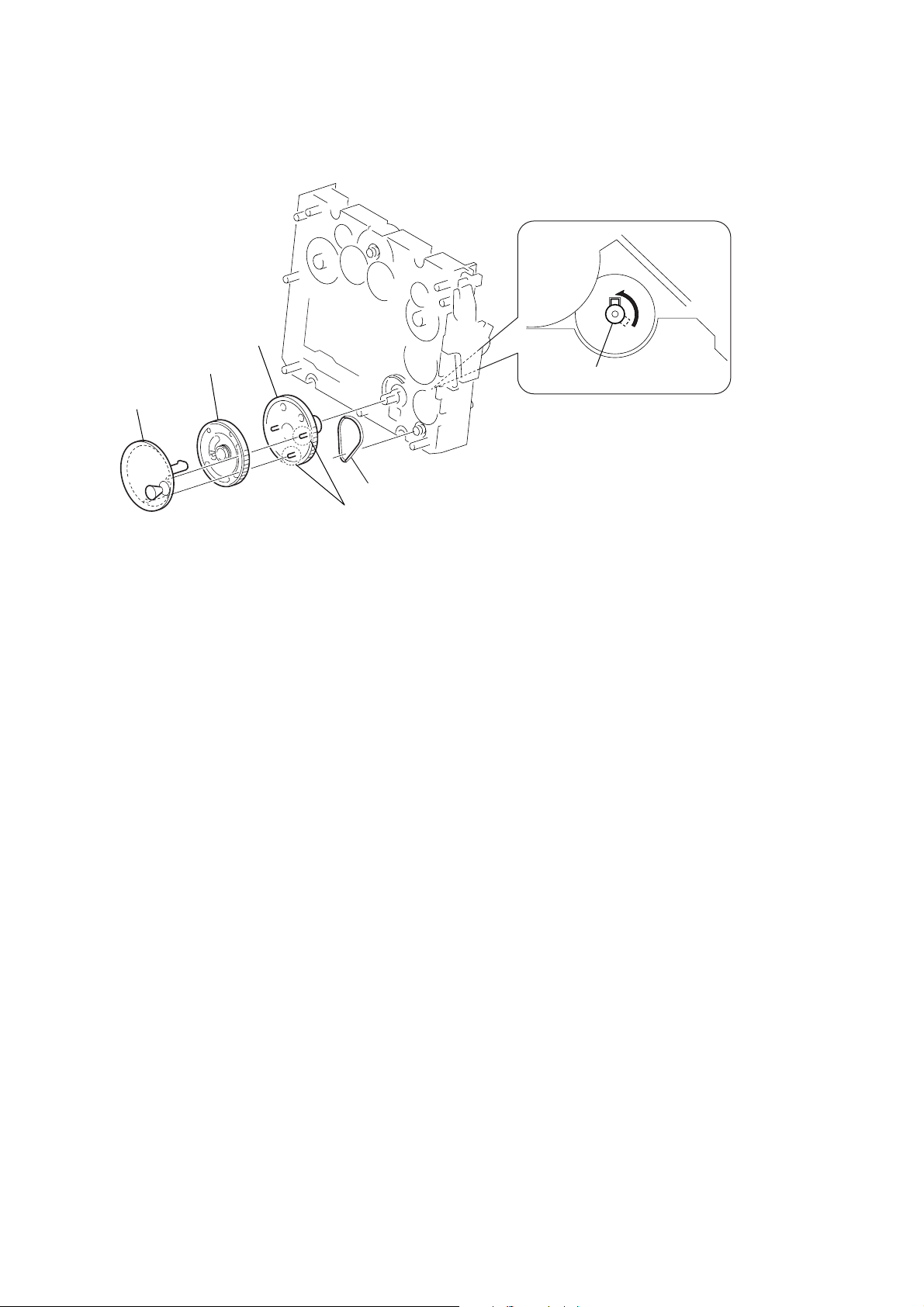

3-15. Base Unit (BU-31BD63)

Rotate the SPT pulley assy in the direction of to move the base unit shaft

forward.

1

SPT pulley assy

1

cam (A)

shaft

shaft

4

2

screw

(+PTPWH M2.6)

5

base unit

(BU-31BD63

3

3-16. BU-31 Assy, Sled Motor Assy (M102)

9

two screws

(+PTPWH M2.6)

holder assy

7

coil spring (C) (holder)

5

BD board

q;

qs

screw

(+P 2

h

×

ook

8

screw

(+PTPWH M2.6)

qa

BU-31 assy

4

flxible

board

qd

sled motor assy (M102)

3)

6

coil spring (B) (holder)

1

(two portions ).

(RED)

(BLK)

Remove solder

18

3

screw

(+BTP 2.6

×

2

8)

Remove solder

(two portions ).

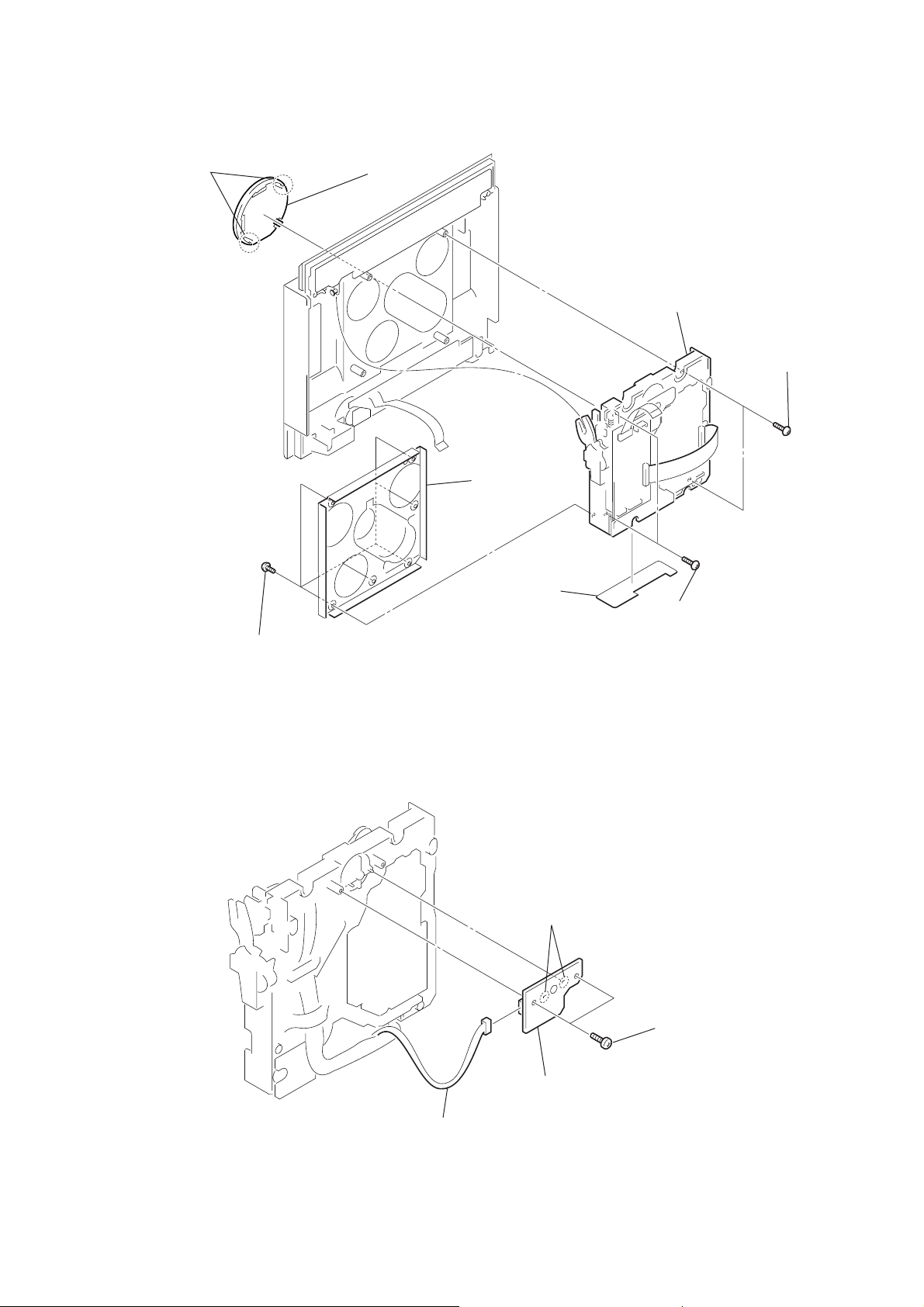

3-17. CD Mechanism (CDM71B)

1

two

claws

2

cap (chuck) assy

7

blacket

8

CD mechanism (CDM71B)

HCD-L7HD

4

two

screws

(+BVTP 2.6

×

8)

3-18. L.MOTOR Board

6

six

screws (+BTP 2.6

×

3

sheet

5

two

screws

×

× 6

8)

)

(+BVTP 2.6

6)

1

Remove solder (two portions ).

2

two

screws

(+BTP 2.6

3

connector

(CN711)

4

L.MOTOR board

19

HCD-L7HD

)

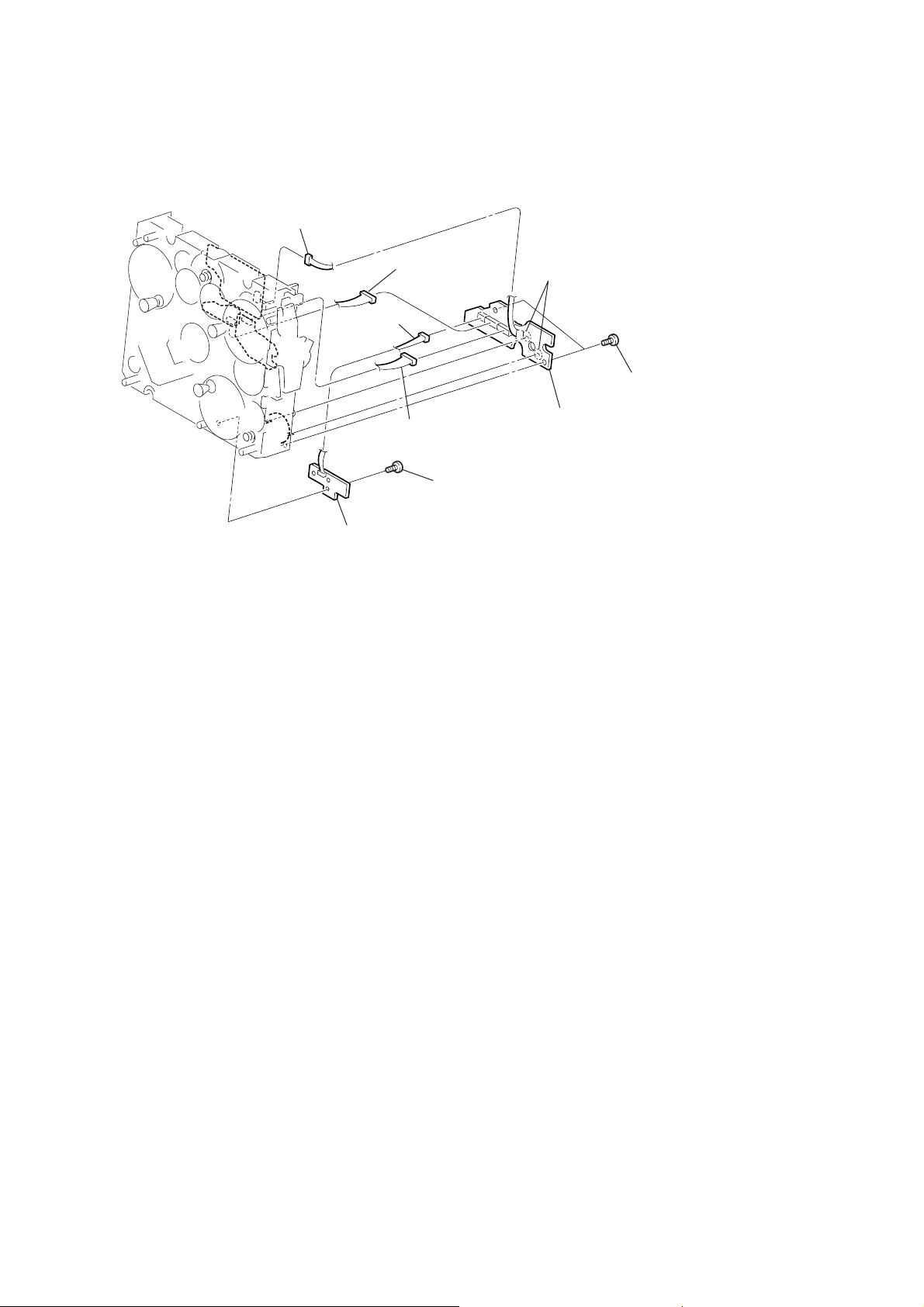

3-19. C.MOTOR Board, L.SENSOR Board

3

connector

(CN711)

5

(CN753)

c

onnector

6

(CN755)

4

c

onnector

(CN754)

c

onnector

8

(+BTP M 2.6

screw

1

Remove solder

(two portions ).

7

C.MOTOR board

×

6)

2

two screws

(+BTP M 2.6

×

6

9

L.SENSOR board (R)

20

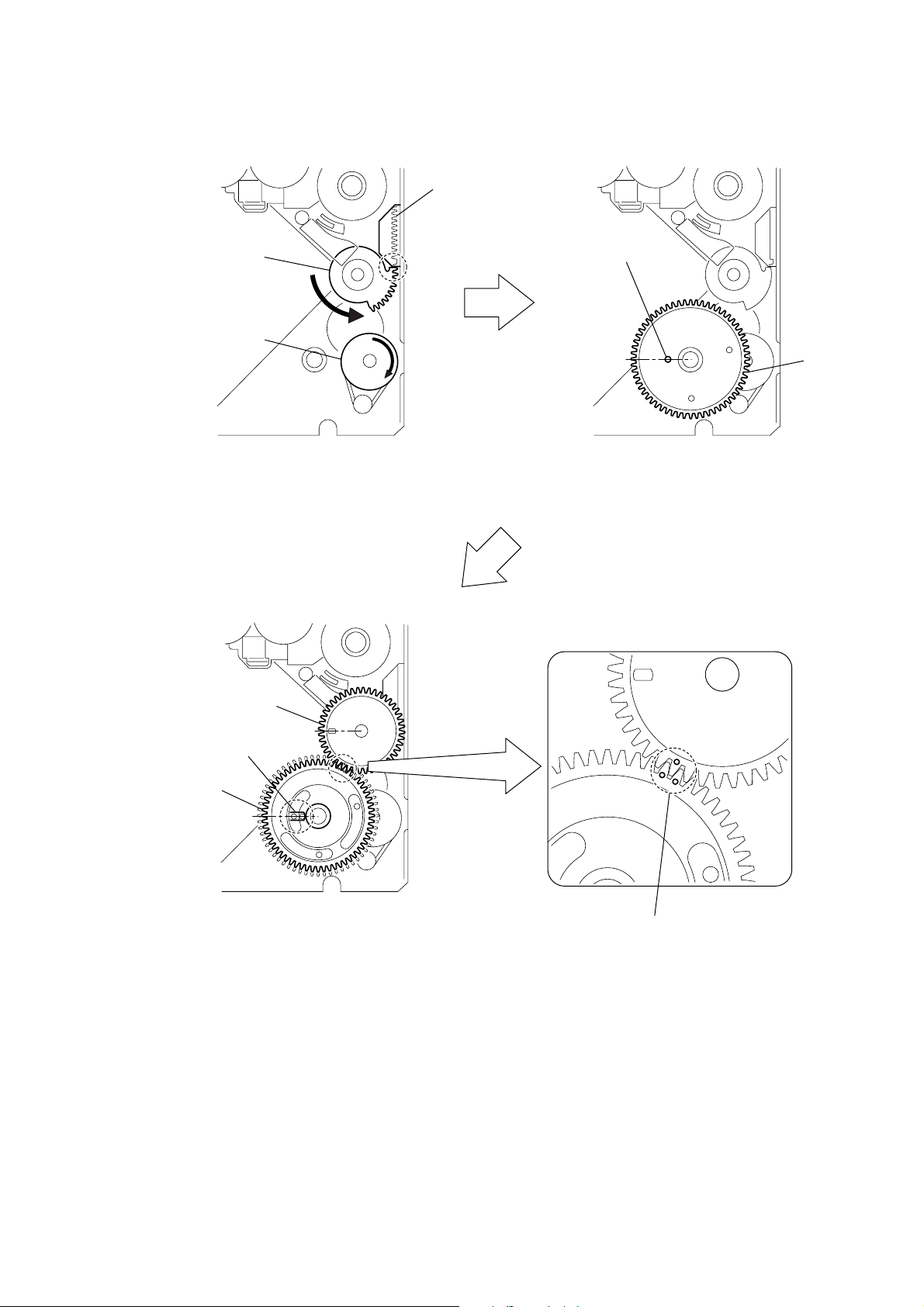

3-20. ENCODER Board, D.SENSOR Board

7

D.SENSOR board

4

6

(+BTP 2.6

screw (+PWH 2

5

ENCODER

screw

×

HCD-L7HD

Ver 1.2 2003.12

×

6)

2

screw (+BTP 2.6

6)

1

3

cover (encoder)

board

(+BTP 2.6

screw

× 8

×

)

6)

PRECAUTION DURING ENCODER board INSTALLATION

Rotate the pulley (LDG2) until the mark of the cam (A) becomes visible.

Install the ENCODER board in the way that it is sandwiched by

the cut-outs of the ENCODER board.

pulley (LDG2)

ENCODER board

cam (A)

21

HCD-L7HD

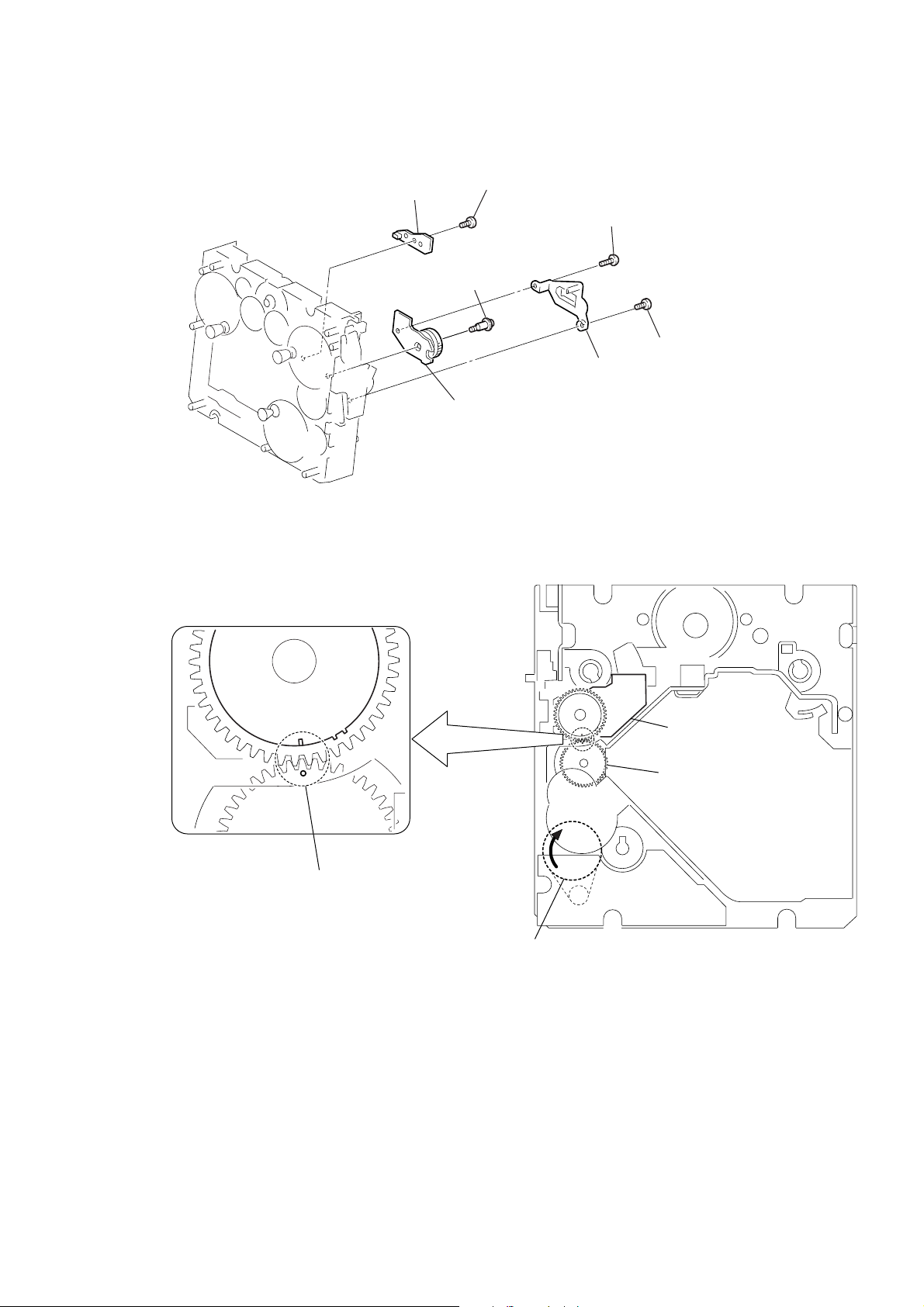

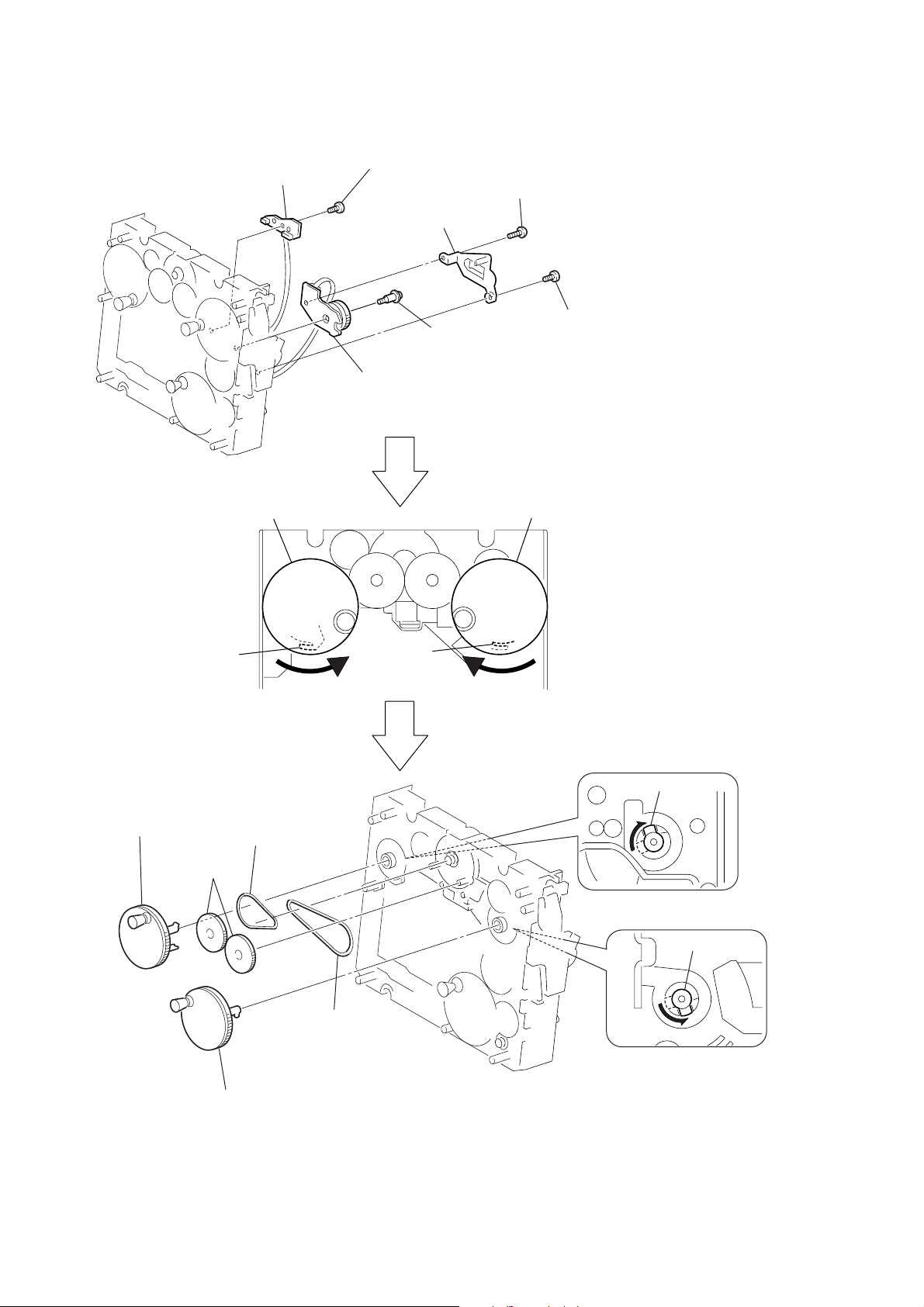

3-21. Pulley (RTR) Assy, Pulley (RTL) Assy, Belt (CDM71), Belt (Roller) (L)

6

screw

7

D.SENSOR board

(+BTP 2.6

5

ENCODER

(When installing it, see the ENCODER board item.)

×

6)

3

cover (encoder)

4

screw (+PWH 2

board

2

screw (+BTP 2.6

×

6)

× 8

1

screw

(+BTP 2.6

×

)

6)

qf

RTL pulley assy

9

qg

gear (S1)

c

law

qh

belt (CDM71)

q;

8

pulley (RTR) assypulley (RTL) assy

c

law

q;

RTL pulley assy

qd

RTR pulley assy

22

qs

RTR pulley assy

qj

belt (ROLLER) (L)

qa

PRECAUTION DURING PULLEY (RTR) ASSY, PULLEY (RTL) ASSY INSTALLATION

pulley (RTR) assy

pulley (RTR) assy

HCD-L7HD

gear (S2)

(9 o'clock position)

pulley (RTL) assy

claw

marks of the gear (S2)

Place the holes of the gear (S2) at the 9 o'clock position and install

the pulley (RTR) assy.

Install it in the way that the gear of the cut-out portion as shown is located in

between the marks of the gear (S2).

pulley (RTR) assy

claw

Then install the pulley (RTL) assy in the way that it can perform

the symmetrical movement with the pulley (RTR) assy.

Then lock both claws.

pulley (RTR) assy

pulley (RTL) assy

Confirm that the pulley (RTR) contacts the claws.

Opposite to it, the pulley (RTL) assy must

have clearance of 1 to 2 mm with the claw.

It should contact with claw.

If clearance is too large or it contacts with claw,

adjustment is necessary.

claw

1 to 2 mm

Method of adjustment is as follows.

Raise the right gear (S1) a little and perform adjustment

by moving the left gear (S1).

gear (S1)

23

HCD-L7HD

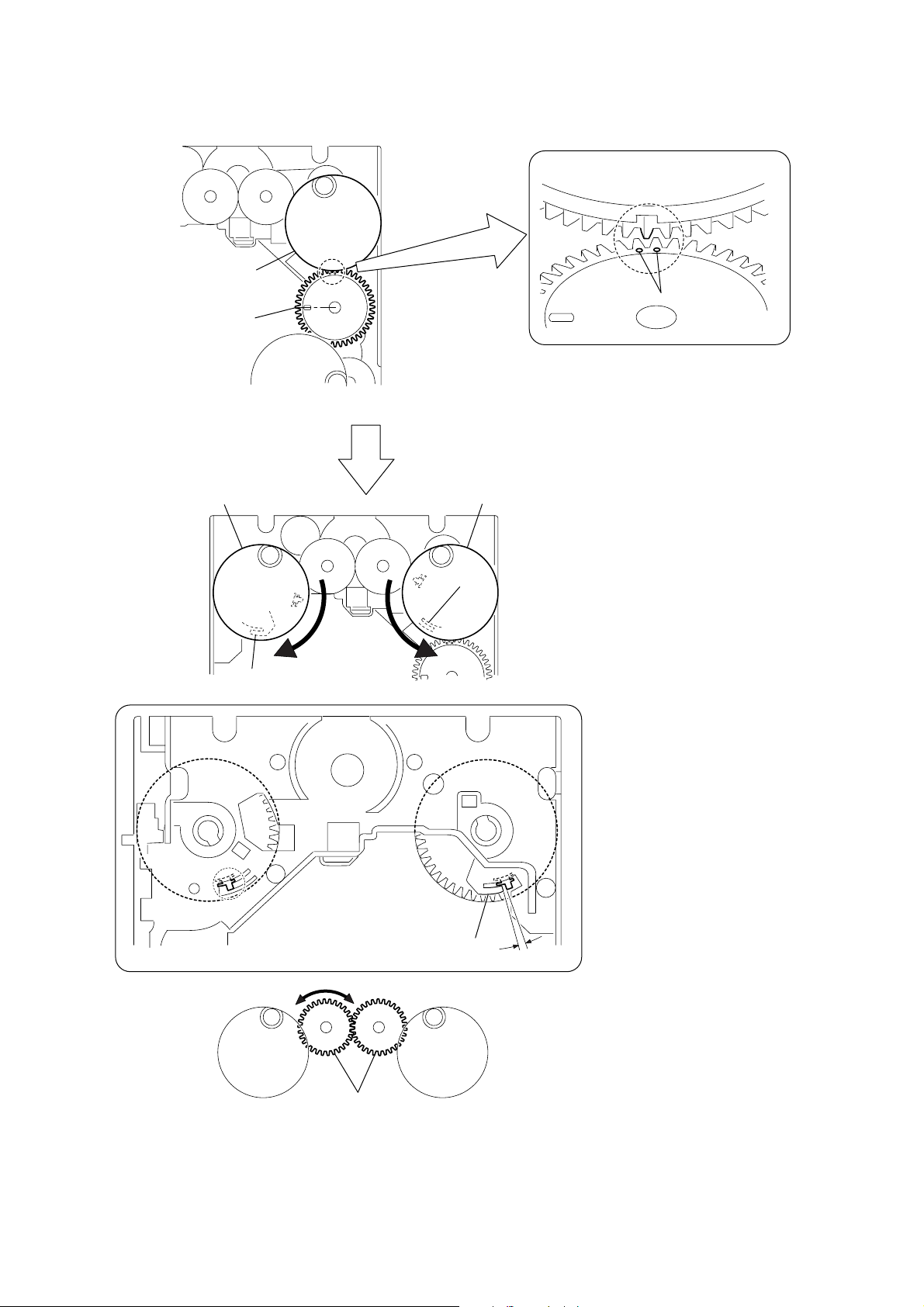

3-22. Pulley (SPT) Assy, Gear (RT) Assy, Gear(KT), Belt (CDM71)

3

2

SPT pulley assy

4

gear (KT)

gear (RT) assy

Rotate the SPT pulley assy in the direction of , and remove your hands

at the position where the shaft agrees with the hole shape on the chassis.

SPT pulley assy

5

belt (CDM71 )

When installing, align the protruded portion of the KT gear with groove of the SPT

pulley assy.

1

1

24

PRECAUTION DURING GEAR (RT) ASSY, GEAR (KT), GEAR (S2) INSTALLATION

gear (KT)

gear (RT) assy

gear (RT) assy

torsion spring (M)

gear (S2)

gear (S2)

pulley (LDG2)

lever (ST)

cam (A)

Confirm that the gear (S2) mark is located

in between the gear (RT) assy marks.

Rotate the pulley (LDG2) until it reaches the position

where the cam (A) contacts with the lever (ST).

Install the gear (KT) and position it so that the boss

that is closest to the inside is located at the 9 o'clock position.

The boss that is closest to the inside

Install the gear (RT) assy so that the two bosses are aligned

in between the torsion spring (M).

Install the gear (S2) so that its hole is located at the 9 o'clock position.

HCD-L7HD

25

HCD-L7HD

SECTION 4

TEST MODE

[Key Check Mode]

* Keyboard check.

Procedure:

1. Press the ?/1 button to turn the set ON.

2. To enter the test mode, press three buttons DISPLA Y , NX

(CD) and > simultaneously.

3. In the key check mode, the fluorescent indicator displays

“KEY00”. Each time a button is pressed, “KEY00” value

increases. However, once a button is pressed, it is no longer

taken into account.

4. T o exit from this mode, press three b uttons DISPLA Y , NX

(CD) and > simultaneously.

[Version Display Mode]

* The version or destination is displayed.

Procedure:

1. Press the ?/1 button to turn the set ON.

2. To enter the test mode, press three buttons DISPLA Y , V OL+

and VOL– simultaneously.

3. The model name and destination are displayed on the upper

line. The STR version is displayed on the lower line.

4. Press the DISPLA Y b utton again. The CD version is displayed.

5. Every pressing of the DISPLAY button displays the versin of

MMI, SH or USB.

6. Press the DISPLAY button. The STR version is displayed

again.

7. To exit from this mode, press the ?/1 button to turn off the set.

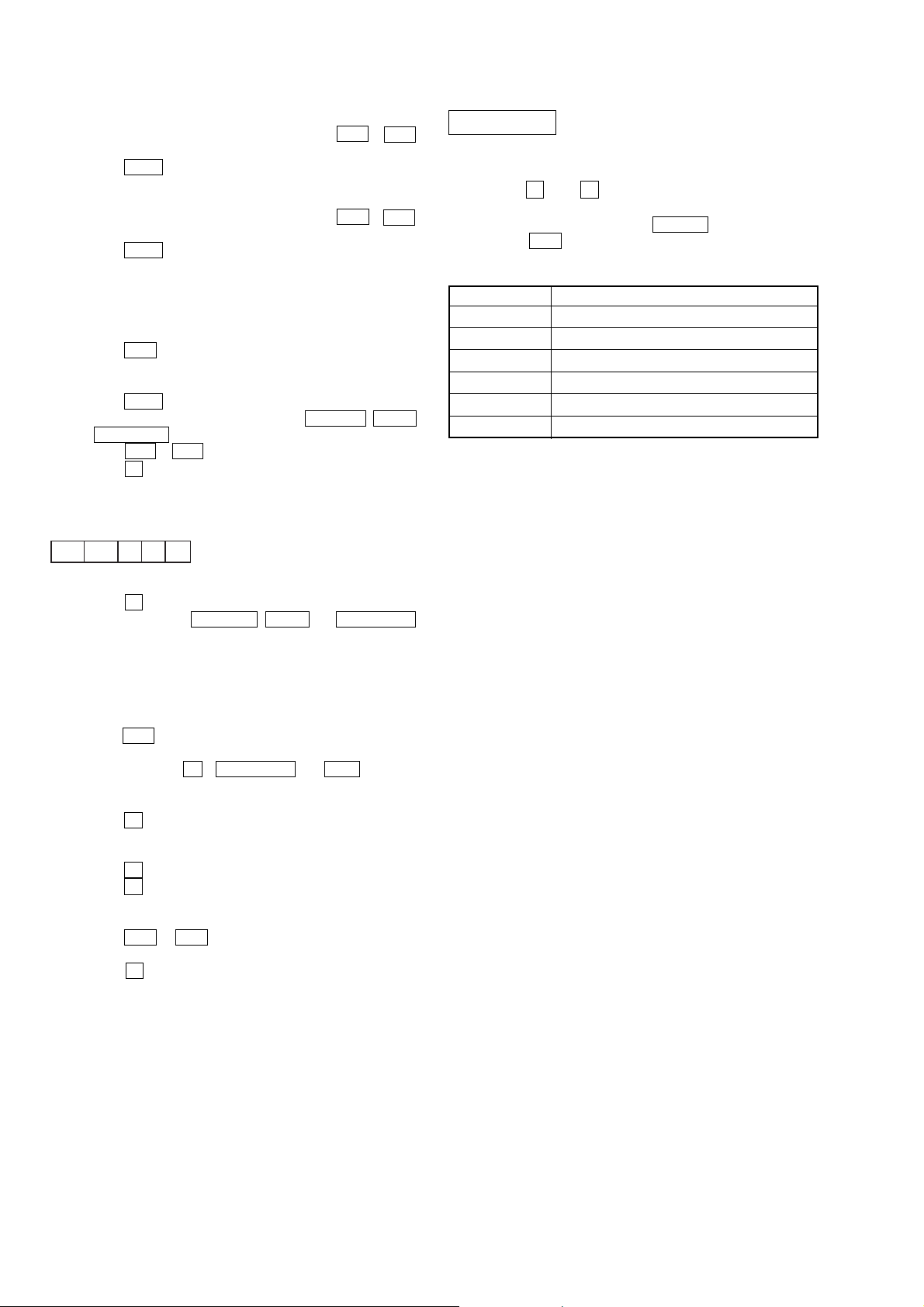

[FL T ube Test Mode]

* All fluorescent segments are tested.

Procedure:

1. Press the ?/1 button to turn the set ON.

2. To enter the test mode, press three buttons DISPLA Y , NX (CD)

and V OL– simultaneously.

3. All segments are turned on.

LIBRARY

AUTO

HIGH

STORAGE

1 ALBUM

ALL

PROGRAM

SHUFFLE

REP

1 L-SYNC

HIGHLIGHT

SEARCH

HISTORY

REC L F P

DISC DSG

ALBUM

TRACK

CD TEXT

L

OVER

R

MANUAL

PRESET

c

REC1 2 3

DAILY

STEREOAUTO

SLEEP

TUNED

MONO

4. Press the DISPLAY button. All segments are turned off.

5. Press the DISPLAY button. Confirm the pattern of segments.

LIBRARY

HIGH

STORAGE

1

PROGRAM

1

HIGHLIGHT

HISTORY

REC F

DISC

ALBUM

TRACK

L

R

c

13

TUNED

AUTO

MONO

6. Press the DISPLAY button. Confirm the pattern of segments.

CD TEXT

OVER

DSG

MANUAL

PRESET

REC 2

DAILY

SLEEP

STEREO

ALL

ALBUM

AUTO

SHUFFLE

REP

SEARCH

L-SYNC

L P

7. Every pressing of the DISPLAY button turns on each segment

one after another in the same order.

8. T o e xit from this mode, press the ?/1 button to turn off the set.

[Amp Test Mode]

* Combinatin of preset equalizer and volume is changed for the

amplifier test.

Procedure:

1. Press the ?/1 button to turn the set ON.

2. T o enter the test mode, press three buttons . , NX (CD)

and > simultaneously.

3. Press the DISPLAY and NX (CD) buttons simultaneouslly.

4. The message “7[TESTMIN]” appears.

5. Press the DISPLAY and NX (CD) buttons simultaneously.

6. The message “8[TESTMID]” appears.

7. The messages “9[TESTMAX]”, “10[TESTSUR]”, “7[TESTMIN]”,

, , are changed by every pressing of the DISPLAY and NX

(CD) buttons simultaneously.

8. Volume level is changeable at three steps as “V OLUME MIN”,

“VOLUME 21”, “VOLUME MAX” by pressing VOL+ or

VOL– button.

9. In this test mode, the tuning mode is set to the preset mode.

10. To exit from this mode, press the ?/1 button to turn off the set.

[Forced Reset]

* All micro-processors are forced to reset at the same time.

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Press three buttons DISPLAY , TUNER/BAND and

FUNCTION simultaneously.

3. The fluorescent indicator tube displays the message “COLD

RESET” and the set is reset. Then the set is turned off.

[CD Ship Position]

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Press the FUNCTION button for the setting CD.

3. Press three buttons . , VOL+ and V OL– simultaneously .

4. The fluorescent indicator tube displays the message “COLD

RESET” and CD is set to the shipment position. Then the set is

turned off.

[Aging Mode]

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Insert the disc.

3. Select the FUNCTION to CD.

4. To enter the test mode, press three buttons . , TUNER/BAND

and Z simultaneously.

5. Aging operation starts automatically.

6. The CD cover opens ,closes and the f irst tr ack is played. Then

the last track is played.

7. The CD cover opens a gain, and the message “ AGIN00000001”

is displayed. This value is cycle times of aging operation and

displays hexadecimal data.

8. The cover closes and aging operation is continued.

9. To exit from this mode, press the ?/1 button to turn off the set.

[Loading Mechanism Lock]

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Press two buttons of x (CD)and Z simultaneously for fiv e

seconds.

3. The message “LOCKED” is displayed and the loading

mechanism is locked. (Even if exiting from this mode, the

loading mechanism is still locked.)

4. Press two b uttons of x (CD) and Z simultaneously for five

seconds again.

5. The message “UNLOCKED” is displayed and the loading

mechanism is unlocked.

6. To exit from this mode, press the ?/1 button to turn the set off.

26

HCD-L7HD

[Error History Display Mode]

Procedure:

Setting Method of Test Mode

1. Press the ?/1 button to turn the set ON.

2. Select the FUNCTION to CD.

3. To enter the test mode, press three buttons . , VOL+ and

> simultaneously.

4. Confirm to display “dvt ERR CODE”.

5. Press the Z button.

Releasing Method of Test Mode

1. Press the x (CD) button to display “dvt ERR CODE”.

2. Press the x (CD) button.

Menu Selection of Error History Display Mode

1. Select the operation in the menu by pressing the . or >

button.

2. Press the Z button. The menu is selected. If returning to the

menu again, press the x (CD) button.

DISPLAY OF TIMES OF ERROR

DISPLAY OF MECHANISM ERROR HISTORY

RESET OF MECHANISM ERROR HISTORY

RESET OF ERROR HISTORY

RESET OF NO DISC ERROR HISTORY

DISPLAY OF NO DISC ERROR HISTORY

" Emc=**Edc=## "

" dvt ECODE MEC "

" dvt ECNT0 MEC "

" dvt ECNT0 ALL "

" dvt ECNT0 BU "

" dvt ECODE BU "

Display of Times of Error

* Number of times of mechanism error and no disc error is displayed

in hexadecimal.

DISPLAY : “ Emc=**Edc=## “

** : number of times of mechanism error (hexadecimal)

## : number of times of no disc error (hexadecimal)

Display of Mechanism Error History

1. Select the operation in the menu by pressing the . or >

button to display “dvt ECODE MEC”.

2. Press the Z button.

3. Select the mechanism error code by pressing the . or >

button.

DISPLAY : “ E**M##%%000000 “

** : order of mechanism error happens (hexadecimal)

00 : the newest error

09 : the error ten times before

## : completion of an initialization (hexadecimal)

ff : completion

others : not completed

%% : condition of CDM operation when the trouble happened

(hexadecimal)

00 : during an initialization

1x : during opening (x : not fixed)

16 to 19 : during a kick by falure of opening

2x : completion of opening

28 : completion of opening under the condition of no disc

3x : during close request

4x : during open request

5x : during closing

6x : during chucking

80 : during releasing

9x : during operation of BU down

ax : during operation of shutter opening or closing

b0 : during BU up request

c0 : during BU down request

dx : during operation of BU up

000000

: fixed

Reset of Mechanism Error History

1. Select the operation in the menu by pressing the . or >

button to display “dvt ECONT0 MEC”.

2. Press the NX (CD) button. Mechanism error history is reset.

Display of No Disc Error History

1. Select the operation in the menu by pressing the . or >

button to display “dvt ECODE BU”.

2. Press the Z button.

3. Select the no disc code by pressing the . or > button.

DISPLAY : “ E**D##%%@@&& “

** : order of no disc happens (hexadecimal)

00 : the newest

09 : ten times before

## : description of the trouble (hexadecimal)

01 : focus NG

02 : GFS NG

03 : time-over of starting

04 : continuous unlock of focus

05 : no input of Q-codes in fixed time

%% : condition when the trouble happened (hexadecimal)

01 : during shipment position processing

02 : during power off processing

03 : during processing of initialization

04 : during stop condition

05 : during stop processing

06 : during process of starting

07 : during process of TOC reading

08 : during search operation

09 : during playback

0a : during pause

0b : during playback manual searching

0c : during pause manual searching

@@ : do not care

&& : rotating speed of a disc when the trouble happened

(hexadecimal)

01 : x1

02 : x2 (double speed)

03 : x4

27

HCD-L7HD

Reset of No Disc Error History

1. Select the operation in the menu by pressing the . or >

button to display “dvt ECONT0 BU”.

2. Press the NX (CD) button. No disc error history is reset.

Reset of Error History

1. Select the operation in the menu by pressing the . or >

button to display “dvt ECONT0 ALL”.

2. Press the NX (CD) button. Error history is reset.

[Servo T est Mode]

*Error Rate Display

Procedure:

Setting Method of Test Mode

1. Press the ?/1 button to turn the set ON.

2. Insert the disc.

3. Select the FUNCTION to CD.

4. Press the NX (CD) button to play the CD.

5. To enter the test mode, press three buttons DISPLAY , VOL+

and FUNCTION simultaneously.

6. Press the . or > button to display “dvt ERR RATE”.

7. Press the Z button.

Description of Error Rate

" ****####%%@@&& "

C1 C2 TNO MIN SEC

HD SECTION

[HD Test Mode]

Procedure:

1. Press the x (CD), x (HD) and FUNCTION simultaneously .

2. The message “Format?” is displayed.

3. Select the menu by rotating the ALBUM dial.

4. Press the > button to execute the HD test.

HD Test Menu

Display Function

Format?Formatting the HD

Flash Init? Initialization of Flash

Read Test? Sector read test of the HD

Write Test? Sector write test of the HD

R/W Test? Sector write/read and verify test of the HD

Smart? Display of S.M.A.R.T. status

Releasing Method of Test Mode

1. Press the x (CD) button to display “dvt ERR RATE”.

2. Press three buttons DISPLAY , VOL+ and FUNCTION

simultaneously.

[CD Repeat 5 Times Limit Release Mode]

Procedure:

Setting Method of Test Mode

1. Press the ?/1 button to turn the set ON.

2. Select the FUNCTION to CD.

3. Press three buttons Z , VOLUME + and . simulta-

neously.

4. The message “dvt REP LMT” is displayed.

5. Press the Z button.

Releasing Method of Test Mode

1. Press the x (CD) button to display “dvt REP LMT”

2. Press the x (CD) button.

Selection of Repeat 5 Times Limit ON/OFF

1. Press the . or > button to display “REP LMT ON” or

“REP LMT OFF”.

2. Press the x (CD)button to select ON or OFF and “dvt REP

LMT” is displayed.

28

HCD-L7HD

Note :

If any of the following test modes is ex ecuted, data is written in the

HD.

Never execute an y of these test modes on the customer's HD, because

customer's data is erased during test mode.

1. FORMAT

4. WRITE TEST

5. R/W TEST

HD Aging Test

Note (When HD is replaced) :

When HD is replaced, perform the following steps.

(a) When HD is replaced, leave the set with the power on for

approximately thirty minutes . (Warming up the HD)

(b) Enter the HD test mode and format the HD.

(c) Turn off the power once and back on again.

(d) Record the music in the HD using CD-HDD Synchro-

Recording function for testing the HD. (about thirty minutes)

(e) Confirm that music is correctly recorded. After it is confirmed,

erase all recordings on the HD.

1. FORMAT

* This mode performs logical formatting HD. (about three minutes)

If formatting is performed, all data on the HD is erased.

*When HD is replaced, be sure to format the new HD. If the new

HD is not formatted, the error message "Format Error " will be

displayed.

*The 500 albums and 10 play lists are created at the same time of

logical formatting FAT32 on the HD.

Procedure:

(1) Enter the HD test mode, then rotate the ALBUM dial to display

“Format?”, and press the > button to display “F ormat OK?”.

(2) When the > button is pressed, The message “Format Now”

is displayed and it takes about three minutes.

(3) When format is complete, “Format End” is displayed.

(4) To exit from this mode, press the x (HD) button.

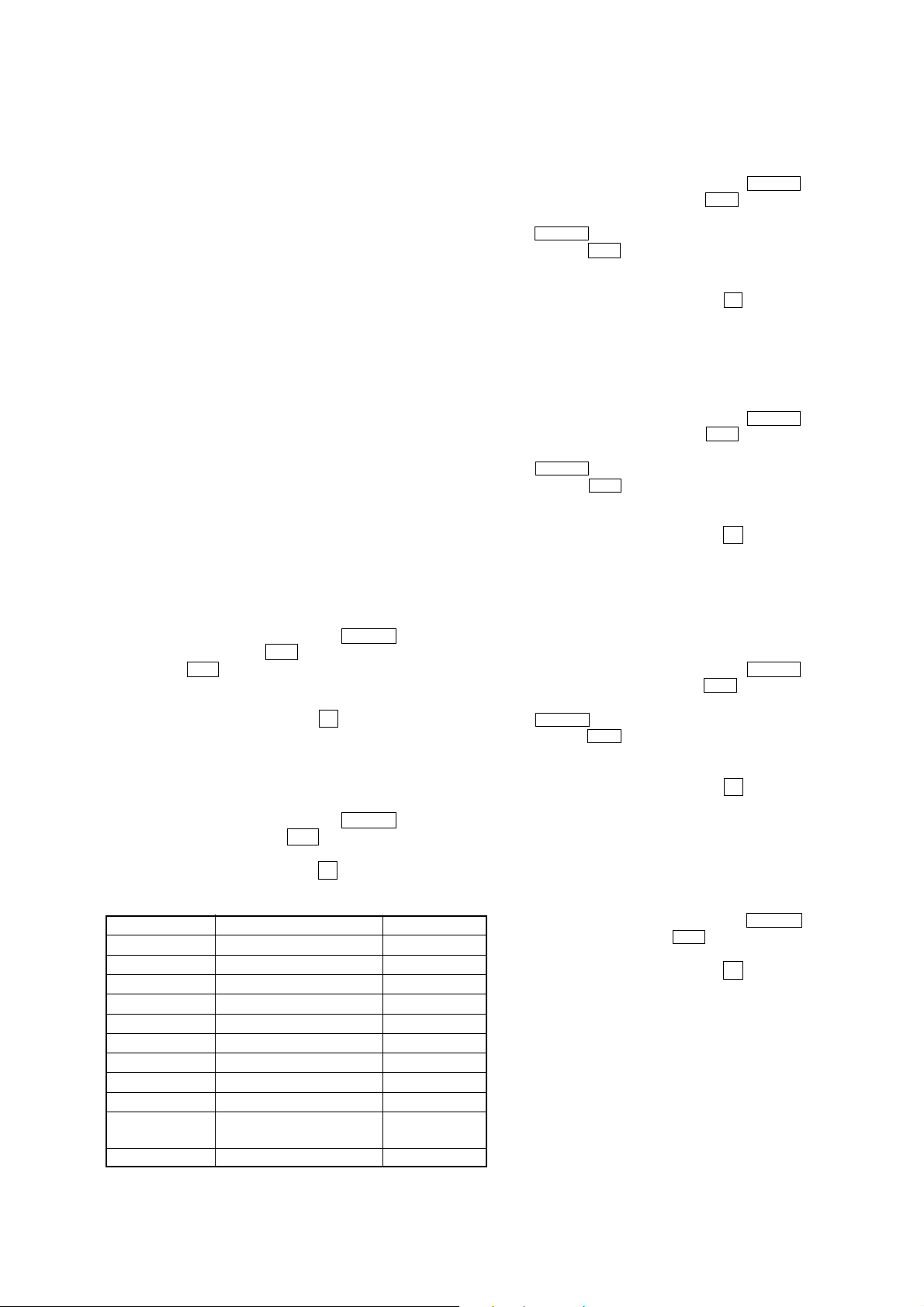

2. FLASH INITIALIZATION

*The last memory (which is stored before power-off) is initialized

to the default value of the factory setting.

Procedure:

(1) Enter the HD test mode, then rotate the ALBUM

“Flash Init?”, and press the > button.

(2) Initialization is performed and “OK” is displayed.

(3) To exit from this mode, press the x (HD) button.

Contents of the Last memory

Item Contents Default value

L.Sync Setup Level Syncro ON/OFF ON

L.Sync Th IDX Level-Sync THRESH value 50dB

S.Space Setup Smart Space ON/OFF ON

Text Save Setup TEXT SAVE ON/OFF ON

1/ALL Play mode of ALBUM ALL

PLAY MODE Play mode CONTINUE

REP MODE Repeat mode OFF

Display Mode Time Display mode Total playing time

Current Album No. The present Album Number 1

Album Favorite

History Playback history of Album None

ALBUM No. of Album Favorites

A to E

dial to display

No Assign

3. READ TEST

* This mode needs not be performed in normal operation.

*Perform this mode only for the newly formatted HD.

Procedure:

(1) Enter the HD test mode, then rotate the ALBUM dial to display

“Read Test?”, and press the > button to display “IN”.

“MID”, “OUT” or “THRU” is also selectable by rotating the

ALBUM dial.

(2) Press the > button and “T esting xx %” is displayed during

the read test.

(3) When the read test is good, “OK” will be displayed.

(4) To exit from this mode, press the x (HD) button.

* “THRU” test takes very long time.

4. WRITE TEST

* This mode needs not be performed in normal operation.

*Perform this mode only for the newly formatted HD.

Procedure:

(1) Enter the HD test mode, then rotate the ALBUM dial to display

“Write Test?”, and press the > button to display “IN”.

“MID”, “OUT” or “THRU” is also selectable by rotating the

ALBUM dial.

(2) Press the > button and “T esting xx %” is displayed during

the write test.

(3) When the write test is good, “OK” will be displayed.

(4) To exit from this mode, press the x (HD) button.

* “THRU” test takes very long time.

5. R/W TEST

*Perform the R/W TEST when checking the formatted HD.

* Confirmation is normally satisfied by each performing IN, MID

and OUT sector test.

Procedure:

(1) Enter the HD test mode, then rotate the ALBUM

“R/W Test?”, and press the > button to display “IN”.

“MID”, “OUT” or “THRU” is also selectable by rotating the

ALBUM dial.

(2) Press the > button and “T esting xx %” is displayed during

the R/W test.

(3) When the R/W test is good, “OK” will be displayed.

(4) To exit from this mode, press the x (HD) button.

* “THRU” test takes very long time.

6. SMART TEST

*This mode displayed status of S.M.A.R.T. functions of the HD.

* If "NG" appears in this mode, the HD may be damaged in the

near future. Replacement of the HD is recommended.

Procedure:

(1) Enter the HD test mode, then rotate the ALBUM dial to display

“Smart?”, and press the > button.

(2) When the test is complete, “OK” or “NG” is displayed.

(3) To exit from this mode, press the x (HD) button.

dial to display

29