HCD-JZ8888K

SERVICE MANUAL

Ver. 1.0 2009.06

• HCD-JZ8888K is the amplifi er, DVD/CD

and tuner section in DAV-JZ8888K.

This system incorporates with Dolby* Digital and Dolby Pro

Logic (II) adaptive matrix surround decoder and the DTS** Digital

Surround System.

* Manufactured under license from Dolby Laboratories.

Dolby, Pro Logic, and the double-D symbol are trademarks of

Dolby Laboratories.

** Manufactured under license under U.S. Patent #’s:

5,451,942; 5,956,674; 5,974,380; 5,978,762; 6,487,535 & other

U.S. and worldwide patents issued & pending. DTS and DTS

Digital Surround are registered trademarks and the DTS logos

and Symbol are trademarks of DTS, Inc. © 1996-2008 DTS, Inc.

All Rights Reserved.

Model Name Using Similar Mechanism

Mechanism Type CDM85-DVBU102

Optical Pick-up Name KHM-313CAA

E Model

HCD-DZ290K/DZ295K/DZ390K/

DZ590K/DZ690K/DZ790K

Amplifi er Section

Stereo mode (rated) 108 W + 108 W (at 3 ohms,

1 kHz, 1% THD)

Surround mode (reference) RMS output power

FL/FR/C/SL/SR*: 144

watts (per channel at 3

ohms, 1 kHz, 10% THD)

Subwoofer L/Subwoofer

R*: 140 watts (at 3 ohms,

80 Hz, 10% THD)

* Depending on the decoding mode settings and the

source, there may be no sound output.

Inputs (Analog)

TV (AUDIO IN) Sensitivity: 450/250 mV

SAT/CABLE (AUDIO IN) Sensitivity: 450/250 mV

AUDIO IN/MIC Sensitivity: AUDIO IN

250/125 mV/MIC 1 mV

Inputs (Digital)

TV (COAXIAL IN/OPTICAL IN)

Impedance: 75 ohms/ Input Stream: Dolby

Digital 5.1ch/DTS 5.1ch/

Linear PCM 2ch

(Sampling Frequency: less

than 48 kHz)

Outputs (Analog)

Phones Accepts low- and high impedance headphones.

SPECIFICATIONS

Super Audio CD/DVD System

Laser Diode Properties Emission Duration:

Continuous

Laser Output: Less than

44.6μW

* This output is the value measurement at a distance

of 200mm from the objective lens surface on the

Optical Pick-up Block with 7mm aperture.

Signal format system

Mexican and Latin American models:

NTSC

Other models: NTSC/PAL

USB Section

(USB) port:

Maximum current: 500 mA

Tuner Section

System PLL quartz-locked digital

synthesizer

FM Tuner section

Tuning range

North American models: 87.5 MHz - 108.0 MHz

(100 kHz step)

Other models: 87.5 MHz - 108.0 MHz

(50 kHz step)

Antenna (aerial) FM wire antenna (aerial)

Antenna (aerial) terminals 75 ohms, unbalanced

Intermediate frequency 10.7 MHz

Video Section

Outputs VIDEO: 1 Vp-p 75 ohms

COMPONENT:

Y: 1 Vp-p 75 ohms

P

75 ohms

HDMI OUT: Type A (19 pin)

General

Power requirements

Mexican models: 120 V AC, 60 Hz

Latin American models: 110 V - 240 V AC,

50/60 Hz

Other models: 220 V - 240 V AC,

50/60 Hz

Power consumption On: 185 W

Standby: 0.3 W (at the

Power Saving mode)

Output voltage (DIGITAL MEDIA PORT)

DC 5 V

Output current (DIGITAL MEDIA PORT)

700 mA

Dimensions (approx.) 430 mm × 66 mm × 390 mm

(w/h/d) incl. projecting parts

Mass (approx.) 4.3 kg

B/CB, PR/CR: 0.7 Vp-p

– Continued on next page –

DVD RECEIVER

9-889-548-01

2009F04-1

2009.06

©

Sony Corporation

Audio&Video Business Group

Published by Sony Techno Create Corporation

HCD-JZ8888K

Supported fi le format

MP3 (MPEG 1 Audio Layer-3)

File Extension: mp3

Bitrate: 32 kbps - 320 kbps

Sampling frequencies: 32/44.1/48 kHz

WMA (USB device only)

File Extension: wma

Bitrate: 48 kbps - 192 kbps

Sampling frequencies: 44.1 kHz

AAC (USB device only)

File Extension: m4a

Bitrate: 48 kbps - 320 kbps

Sampling frequencies: 44.1 kHz

DivX

File Extension: avi/divx

Video codec: DivX video

Bitrate: 8 Mbps (MAX)

Frame rate: 30 fps

Resolution: 720 × 576

Audio codec: MP3

MPEG4

File format: MP4 File Format

File Extension: mp4/m4v

Video codec: MPEG4 Simple Profi le

(AVC is not compatible.)

Bitrate: 4 Mbps

Frame rate: 30 fps

Resolution: 720 × 576

Audio codec: AAC-LC (HE-AAC is not

compatible.)

DRM: Not compatible

Design and specifi cations are subject to change

without notice.

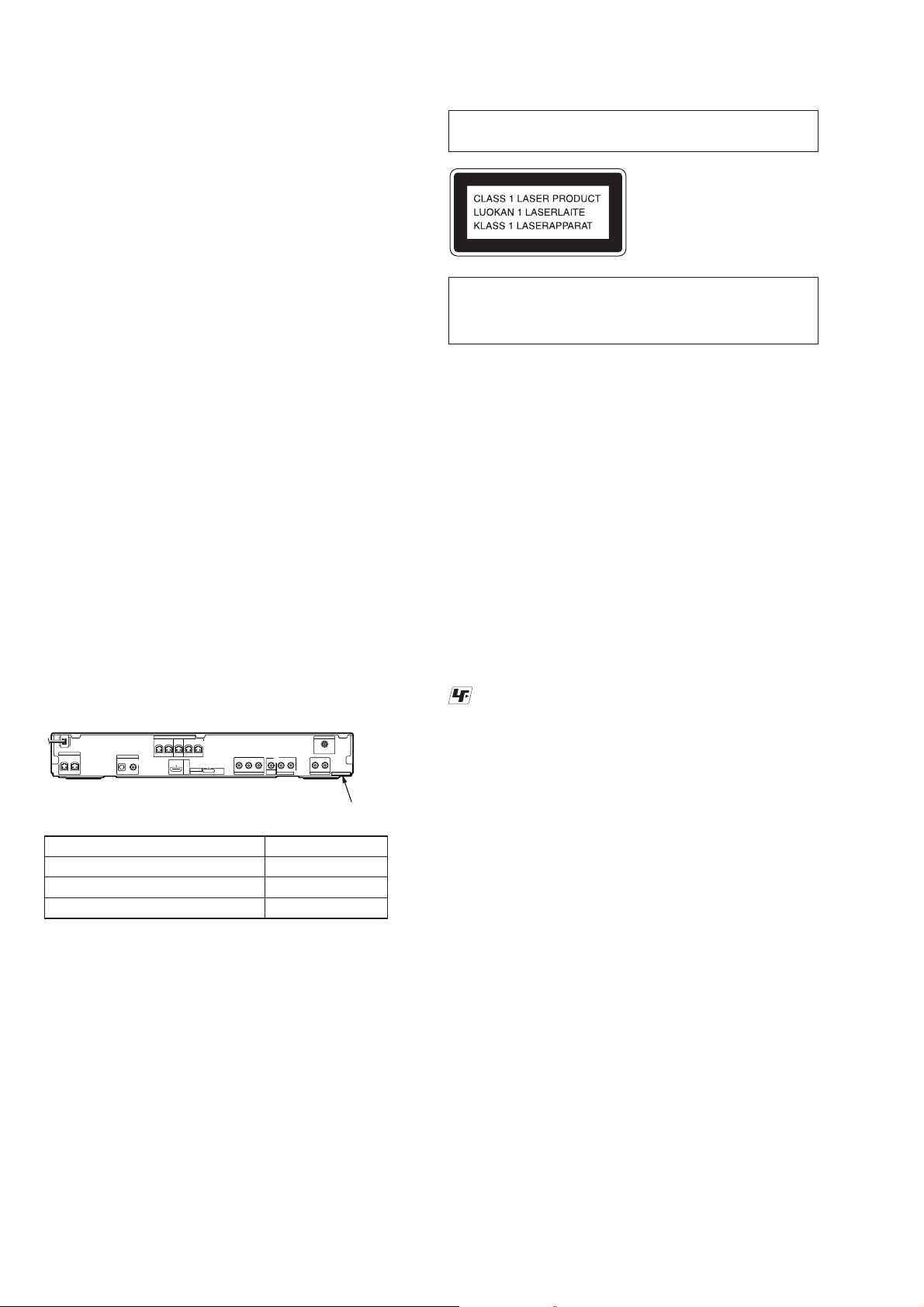

MODEL IDENTIFICATION

– Back Panel –

Model Part No.

E32 model

MX model

SP model

• Abbreviation

E32 : 110 – 240V AC area in E model

MX : Mexican model

SP : Singapore model

Parts No.

4-122-169-0[]

4-122-169-1[]

4-122-169-3[]

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classifi ed as

a CLASS 1 LASER product.

This marking is located on the

rear or bottom exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specifi ed herein may result in hazardous radia-

tion exposure.

NOTES ON CHIP COMPONENT REPLACEMENT

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

FLEXIBLE CIRCUIT BOARD REPAIRING

• Keep the temperature of soldering iron around 270 °C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

SAFETY-RELATED COMPONENT WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

SPECIAL COMPONENT NOTICE

The components identifi ed by mark 9 contain confi dential infor-

mation.

Strictly follow the instructions whenever the components are repaired and/or replaced.

TABLE OF CONTENTS

HCD-JZ8888K

1. SERVICING NOTES

............................................. 4

2. DISASSEMBLY

2-1. Case ................................................................................ 7

2-2. Front Panel Section ......................................................... 7

2-3. Back Panel Section ......................................................... 8

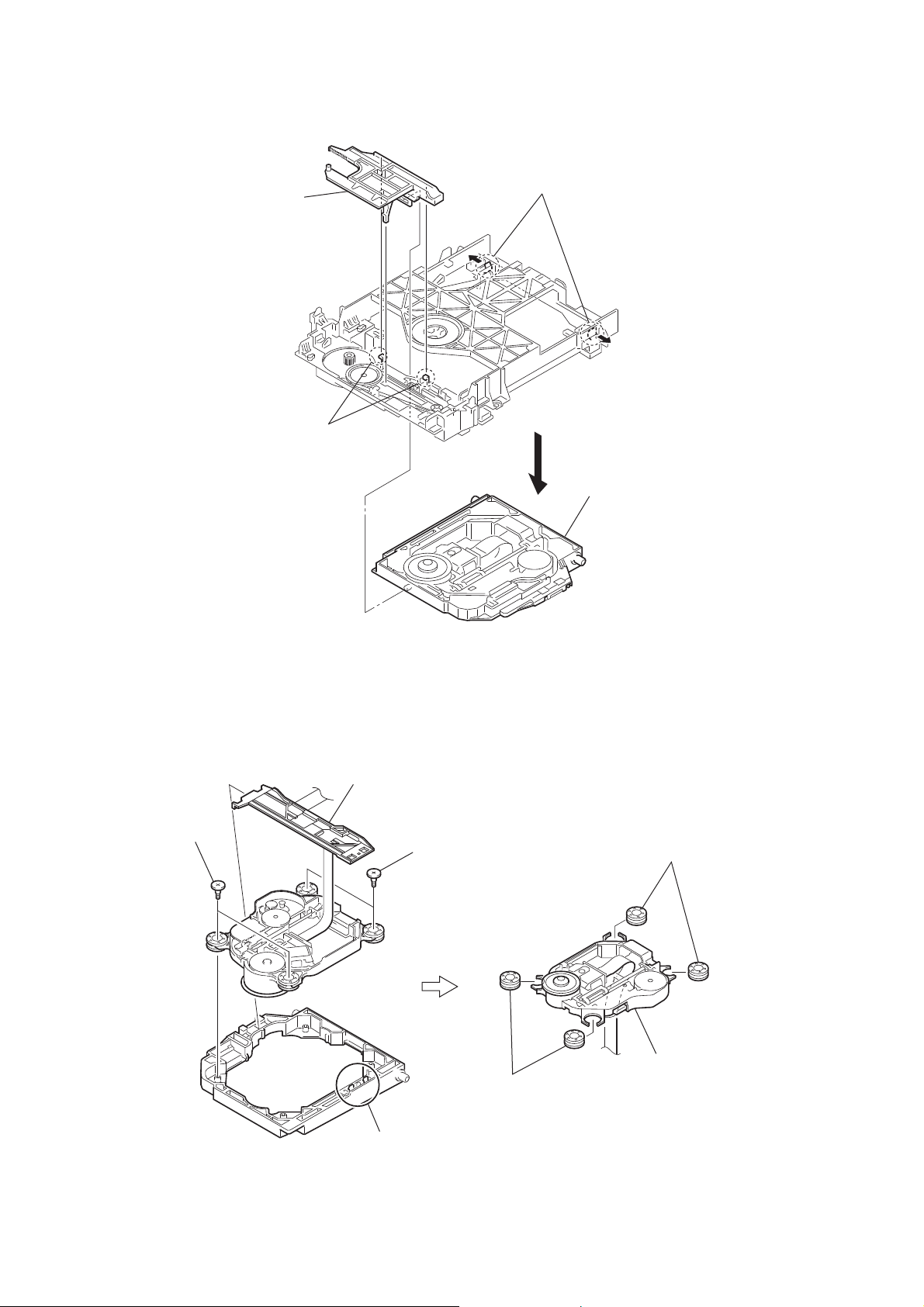

2-4. DVD Mechanism Deck ................................................... 8

2-5. POWER Board, USB Board ........................................... 9

2-6. MAIN Board, SP Board, DSP Board .............................. 9

2-7. IO-COMPONENT Board ............................................... 10

2-8. Tray ................................................................................. 10

2-9. Belt .................................................................................. 11

2-10. MS-203 Board ................................................................. 11

2-11. Base Unit ......................................................................... 12

2-12. Optical Pick-up ............................................................... 12

3. TEST MODE ............................................................ 13

4. ELECTRICAL ADJUSTMENTS ........................ 19

5. DIAGRAMS

5-1. Block Diagram –RF Section– ......................................... 21

5-2. Block Diagram –VIDEO Section– ................................. 22

5-3. Block Diagram –AUDIO Section– ................................. 23

5-4. Block Diagram –DSP Section– ....................................... 24

5-5. Block Diagram –AMP Section– ..................................... 25

5-6. Block Diagram –POWER Section– ................................ 26

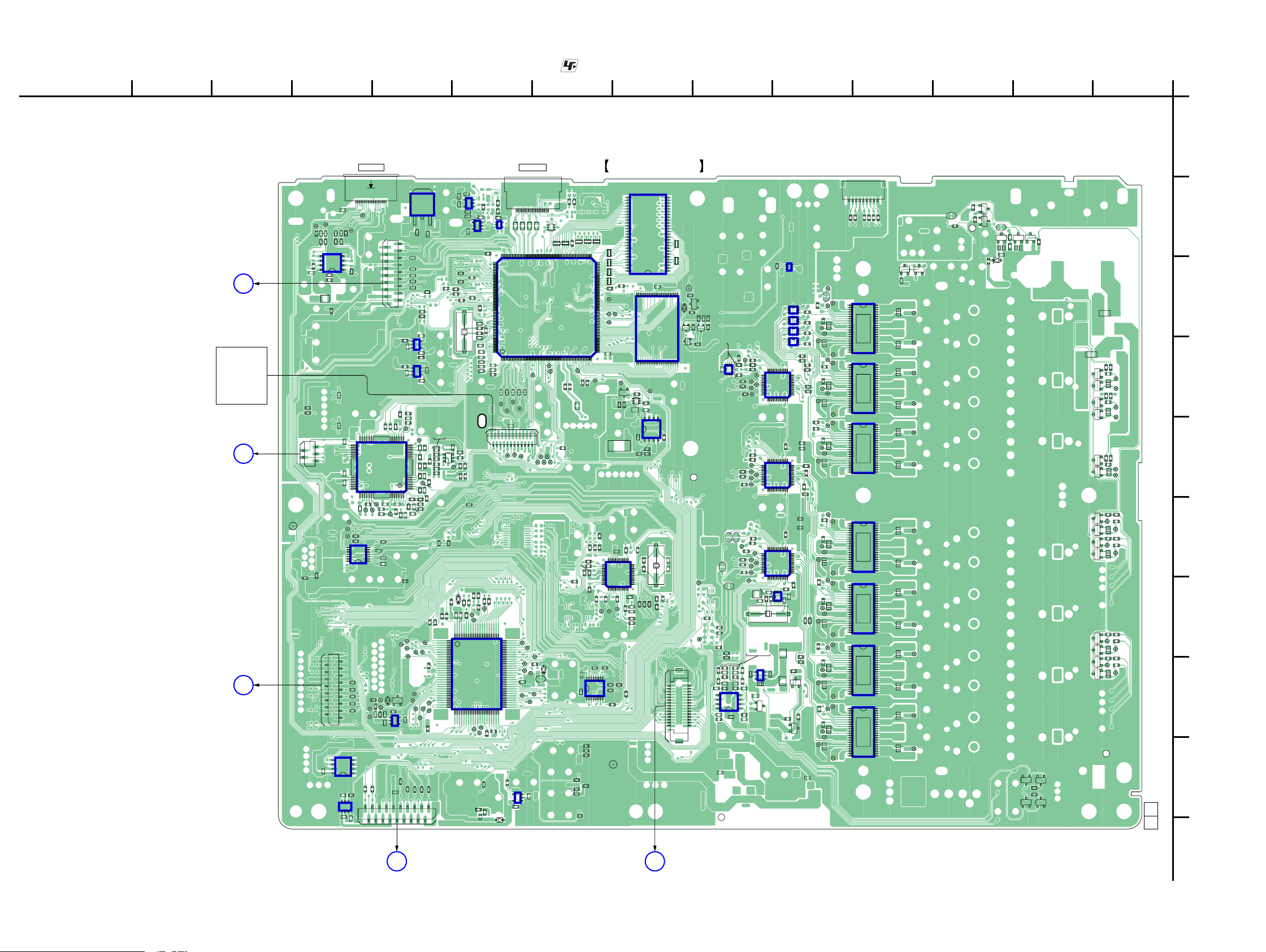

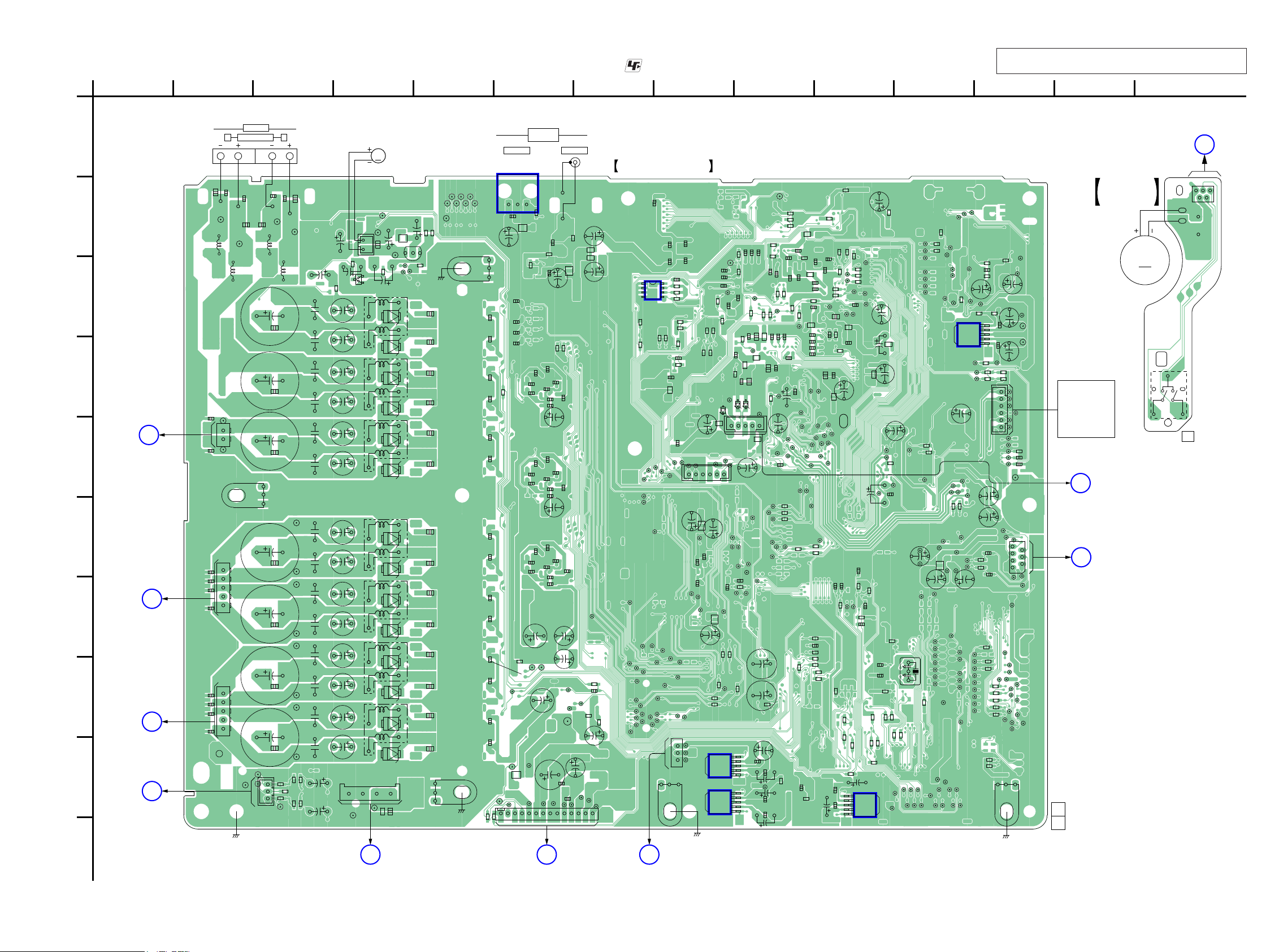

5-7. Printed Wiring Board –MAIN Section (1/2)– ................. 28

5-8. Printed Wiring Boards –MAIN Section (2/2)– ............... 29

5-9. Schematic Diagram –MAIN Section (1/10)– ................. 30

5-10. Schematic Diagram –MAIN Section (2/10)– ................. 31

5-11. Schematic Diagram –MAIN Section (3/10)– ................. 32

5-12. Schematic Diagram –MAIN Section (4/10)– ................. 33

5-13. Schematic Diagram –MAIN Section (5/10)– ................. 34

5-14. Schematic Diagram –MAIN Section (6/10)– ................. 35

5-15. Schematic Diagram –MAIN Section (7/10)– ................. 36

5-16. Schematic Diagram –MAIN Section (8/10)– ................. 37

5-17. Schematic Diagram –MAIN Section (9/10)– ................. 38

5-18. Schematic Diagram –MAIN Section (10/10)– ............... 39

5-19. Printed Wiring Board –IO-COMPONENT Section– ...... 40

5-20. Schematic Diagram –IO-COMPONENT Section– ........ 41

5-21. Printed Wiring Board –DSP Section (1/2)– .................... 42

5-22. Printed Wiring Board –DSP Section (2/2)– .................... 43

5-23. Schematic Diagram –DSP Section– ................................ 44

5-24. Printed Wiring Board –SCORE Section– ....................... 45

5-25. Schematic Diagram –SCORE Section– .......................... 46

5-26. Printed Wiring Boards –FL-JACK, KEY-SW Section– .. 47

5-27. Schematic Diagram –FL-JACK Section– ....................... 48

5-28. Printed Wiring Boards –LED Section– ........................... 49

5-29. Schematic Diagram –LED Section– ............................... 50

5-30. Printed Wiring Boards –SP, USB Section– ..................... 51

5-31. Schematic Diagram –SP, USB Section– ......................... 52

5-32. Printed Wiring Board –POWER Section– ...................... 53

5-33. Schematic Diagram –POWER Section– ......................... 54

6. EXPLODED VIEWS

6-1. Overall Section ............................................................... 73

6-2. Front Panel Section ......................................................... 74

6-3. Chassis Section ............................................................... 75

6-4. DVD Mechanism Deck Section (CDM85-DVBU102) .. 76

7. ELECTRICAL PARTS LIST .............................. 77

3

HCD-JZ8888K

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The fl exible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc refl ective surface by the objective lens in the optical

pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH

1. Open the case and turn POWER on with no disc inserted.

2. Confi rm that the following operation is performed while

observing the objecting lens from the clearance of DVD

mechanism deck.

1) Confi rm that laser beam is spread.

2) Up and down motion of the objective lens. (2 times)

DISC TRAY LOCK

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Setting Procedure :

1. Press the [

2. Press the [FUNCTION] button to set DVD function.

3. Insert a disc.

4. Press the [x] button and the [Z] button simultaneously for fi ve

seconds.

5. The message “LOCKED” is displayed and the tray is locked.

Releasing Procedure :

1. Press the [x] button and the [Z] button simultaneously for fi ve

seconds again.

2. The message “UNLOCKED” is displayed and the tray is

unlocked.

Note: When “LOCKED” is displayed, the tray lock is not released by

turning power on/off with the [

On cleaning discs, disc/lens cleaners

• Do not use cleaning discs or disc/lens cleaners (including wet

or spray types). These may cause the apparatus to malfunction.

IMPORTANT NOTICE

Caution: This system is capable of holding a still video image or

on-screen display image on your television screen indefi nitely.

If you leave the still video image or on-screen display image

displayed on your TV for an extended period of time you risk

permanent damage to your television screen.

Projection televisions are especially susceptible to this.

] button to turn the set on.

?/1

?/1

] button.

How to open the disc table when power switch turns off

Insert a tapering driver into the aperture of the unit bottom, and

slide it in the direction of the arrow.

Peel off the lavel and so the lever is moved

in the direction of the arrow with the thin rod.

lavel

tray

Precaution when installing a new OP unit/

Precaution before unsoldering the static electricity

prevention solder bridge

When installing a new OP unit, be sure to connect the fl exible

printed circuit board fi rst of all before removing the static electricity

prevention solder bridge by unsoldering.

Remove the static electricity prevention solder bridge by

unsoldering after the fl exible printed circuit board has already been

connected.

(Do not remove nor unsolder the solder bridge as long as the OP

unit is kept standalone.)

Attention when transported

Use this mode when returning the set to the customer after repair.

Procedure:

1. Press the [

2. Press the [FUNCTION] button to set the function “DVD”.

3. Remove all discs, and then press two buttons [

simultaneously.

4. After a message “MECHA LOCK” is displayed on the

fl uorescent indicator tube, pull out the AC plug.

5. To exit from this mode, press the [

on.

] button to turn the set on.

?/1

] and [

N

] button to turn the set

?/1

?/1

]

4

Discharge the charged electricity in capacitors to prevent electric shock as follows

When disassembling the machine, be sure to discharge the charged electricity in the following capacitors.

Use a resistor of 800 ohms, 2 Watts for discharging the following capacitors.

POWER board

C903: 390V

C932, C933, C934, CN904: 30V

Point of capacitor discharge for C932, C933, C934:

Connect to the red and black wire of CN904.

HCD-JZ8888K

Point of capacitor discharge for C903:

Connect to the foot of C903.

800:/2W

5

HCD-JZ8888K

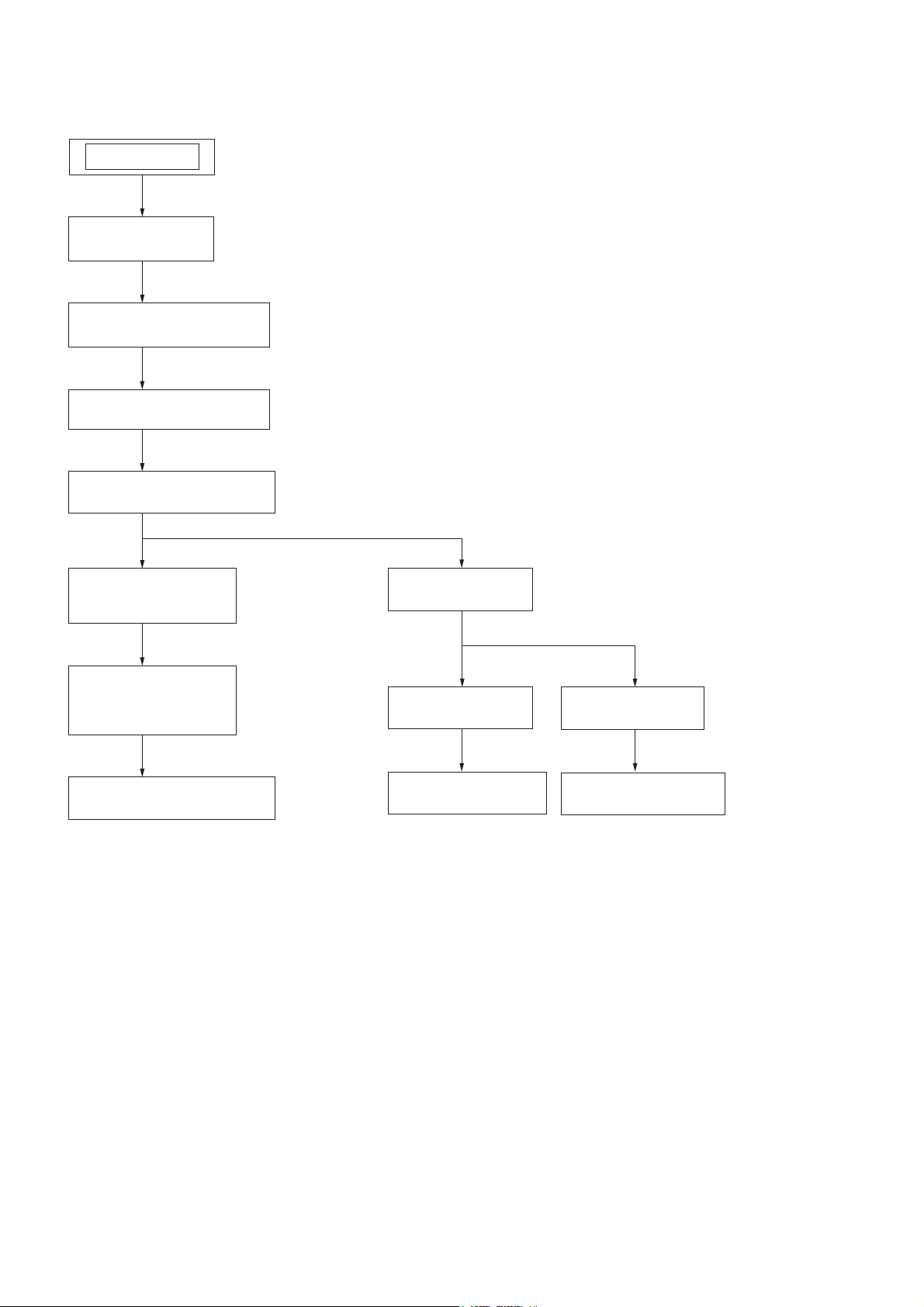

DISASSEMBLY

• This set can be disassembled in the order shown below.

SET

2-1. CASE

(Page 7)

2-2. FRONT PANEL SECTION

(Page 7)

2-3. BACK PANEL SECTION

(Page 8)

2-4. DVD MECHANISM DECK

(Page 8)

SECTION 2

2-5. POWER BOARD,

USB BOARD

(Page 9)

2-6. MAIN BOARD,

SP BOARD,

DSP BOARD

(Page 9)

2-7. IO-COMPONENT BOARD

(Page 10)

2-8. TRAY

(Page 10)

2-9. BELT

(Page 11)

2-10. MS-203 BOARD

(Page 11)

2-11. BASE UNIT

(Page 12)

2-12. OPTICAL PICK-UP

(Page 12)

6

Note: Follow the disassembly procedure in the numerical order given.

HCD-JZ8888K

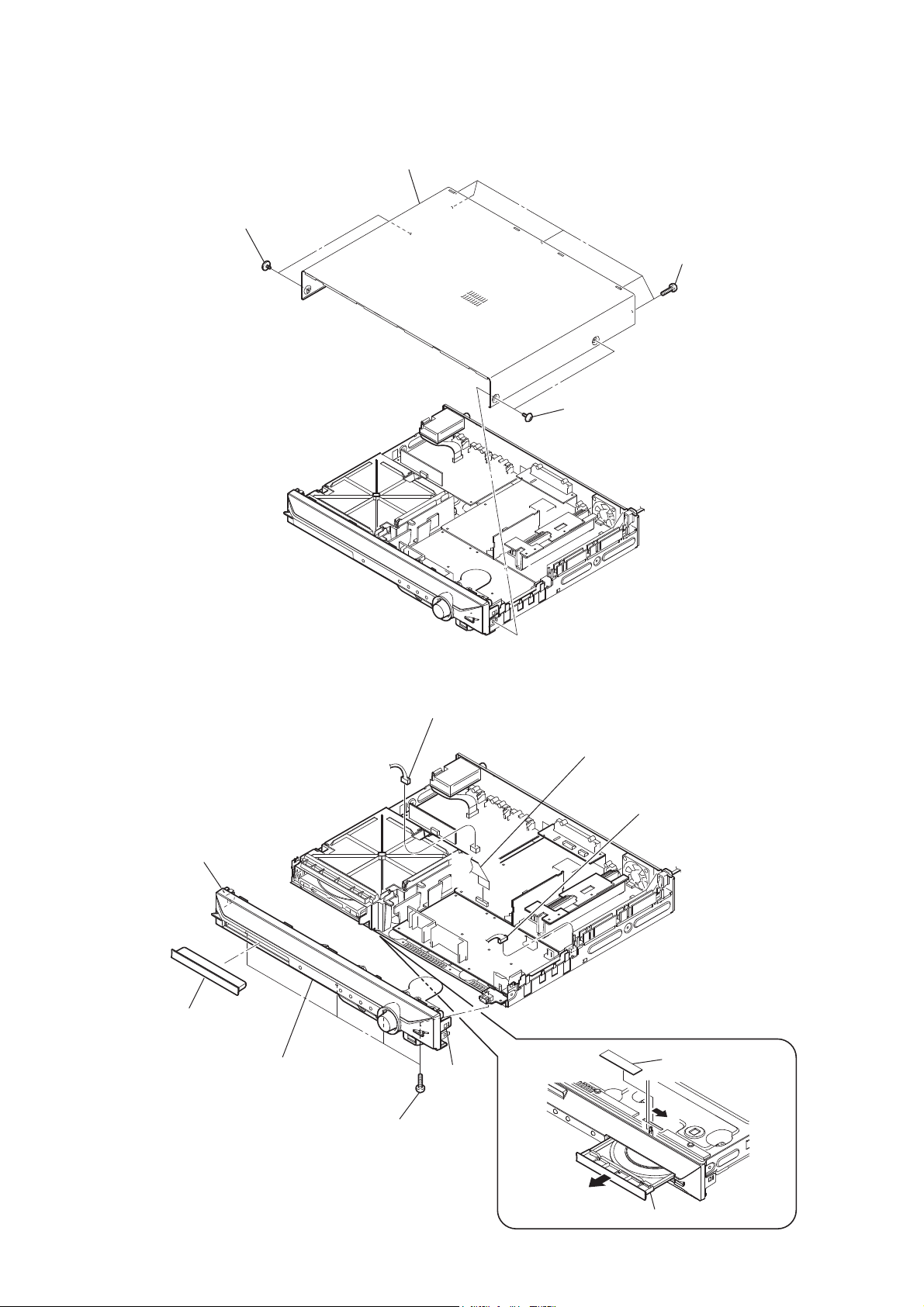

2-1. CASE

4 case

2 two screws

(case 3 TP2)

3 five screws

(BV/ring)

1 two screws

(case 3 TP2)

2-2. FRONT PANEL SECTION

9 claw

4 loading panel

0 front panel section

5 CN4014 (4P)

9 claw

8 four screws

(+BV3 (3-CR))

6 wire (flat type)(19 core)

(CN507)

7 CN3001 (3P)

1 label

2

3

tray

7

HCD-JZ8888K

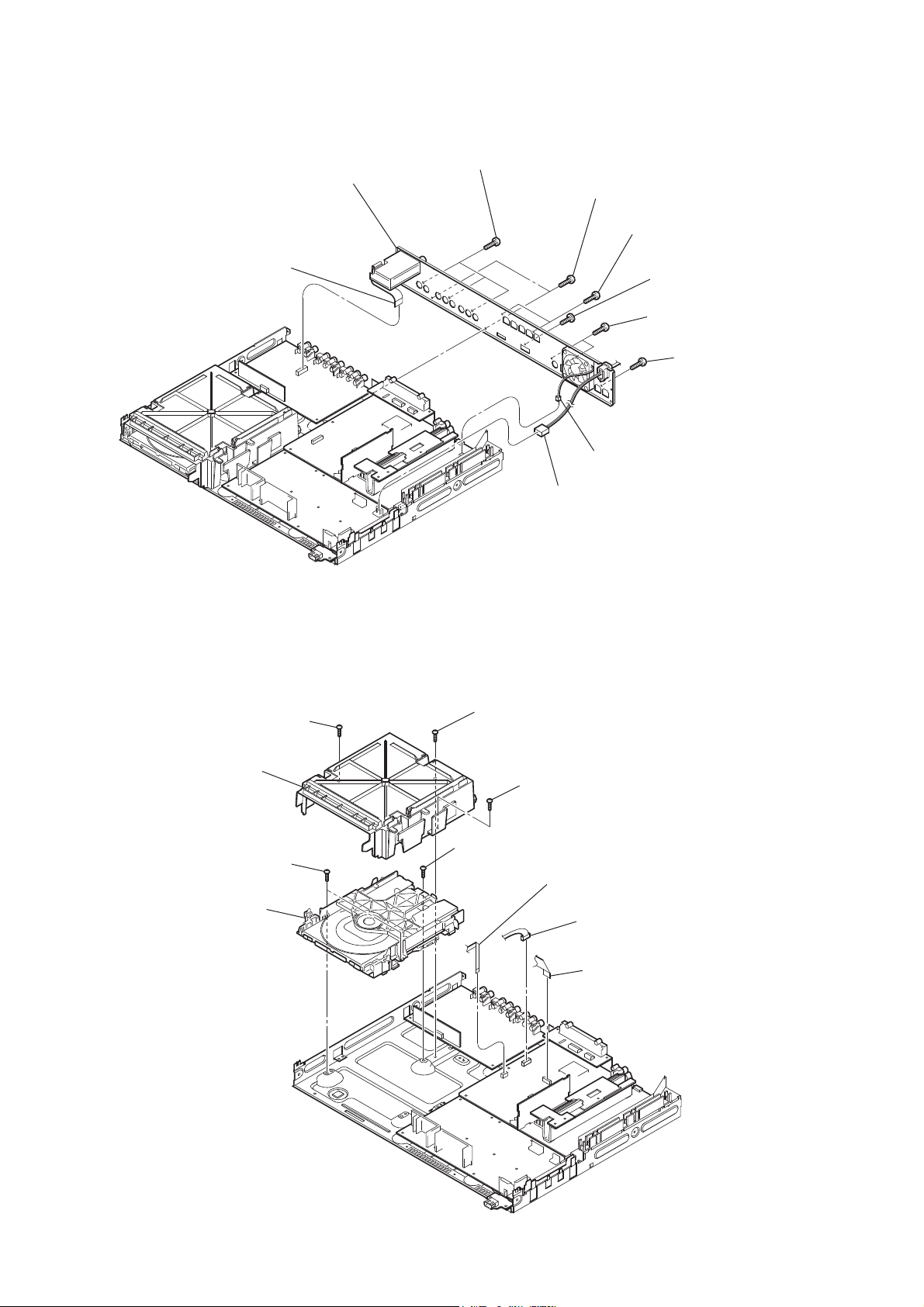

2-3. BACK PANEL SECTION

3 wire (flat type) (9 core)

(CN4016)

0 back panel section

4 three screws

(+BVTP 3 u8)

5 two screws

(+BVTP 3 u8)

6 two screws

(+BVTP 3 u8)

7 screw

(+B 3 u6)

8 two screws

(+BVTP 3 u8)

9 screw

(+BVTP 3 u8)

2 CN3000 (2P)

1 CN901 (2P)

2-4. DVD MECHANISM DECK

4 screw

(+BV3 (3-CR))

7 cover (CDM-DSY)

8 two screws

(+BV3 (3-CR))

0 DVD mechanism deck

5 screw

(+BV3 (3-CR))

6 screw

(+BV3 (3-CR))

9 screw

(+BV3 (3-CR))

3 wire (flat type)(5 core)

(CN1202)

2 CN1201 (6P)

1 wire (flat type)(24 core)

(CN1101)

8

2-5. POWER BOARD, USB BOARD

HCD-JZ8888K

qd three screws

(+PWH 3 u8)

qh POWER board

1 two screws

(+BV3 (3-CR))

7 CN906 (13P)

qf three screws

(+PWH 3 u8)

8 CN904 (4P)

qa screw

(+BV3 (3-CR))

qs cover (rear)

9 screw

(+BV3 (3-CR))

0 cover (front)

4 two screws

(+BVTP 3 u8)

5 plate (POW) insulated

6 bracket (POW-DSY)

(SP model)

2 CN5201 (5P)

3 USB board

2-6. MAIN BOARD, SP BOARD, DSP BOARD

qs three screws

5 wire (flat type) (17 core) (CN472)

6 wire (flat type) (7 core) (CN302)

7 wire (flat type) (17 core) (CN503)

qg six screws

9 screw

(+BV3 (3-CR))

0 screw

(+BV3 (3-CR))

8 CN700 (3P)

qa DSP board

(+BV3 (3-CR))

lug

(+BV3 (3-CR))

qg two holder PC boards

qd heat sink section

4 SP board

3 two screws

(+BV3 (3-CR))

qf three radiation sheet

qf four radiation sheet

1 CN303 (4P)

2 CN304 (6P)

qh MAIN board

9

HCD-JZ8888K

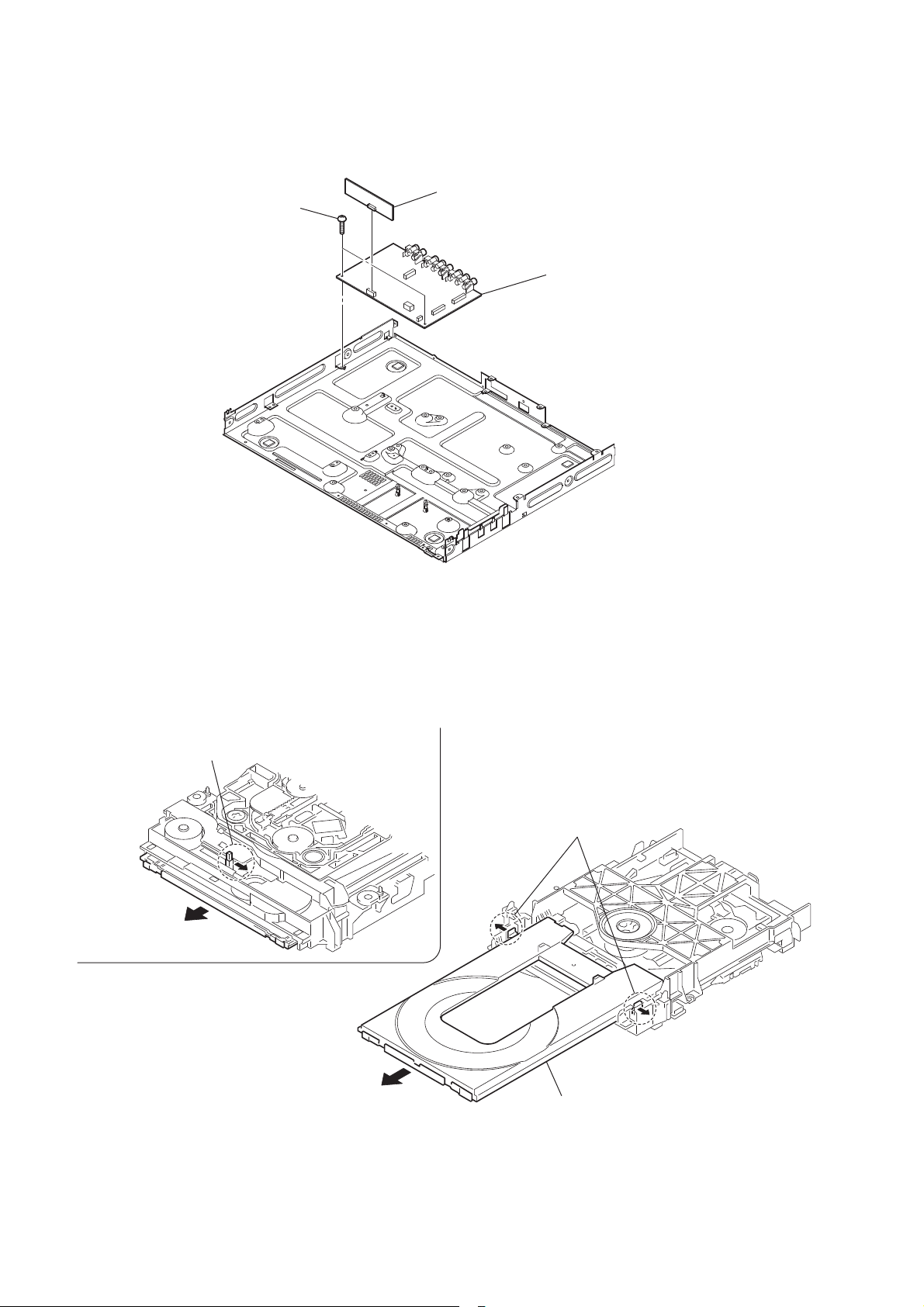

2-7. IO-COMPONENT BOARD

1 two screws

(+BV3 (3-CR))

3 SCORE board

2 IO-COMPONENT board

2-8. TRAY

Move the chuck cam

in the direction of the arrow.

bottom side

two claws

tray

10

2-9. BELT

chuck cam

HCD-JZ8888K

belt

2-10. MS-203 BOARD

two claws

MS-203 board

DC motor

three claws

screw

(M 1.7 × 2.5)

11

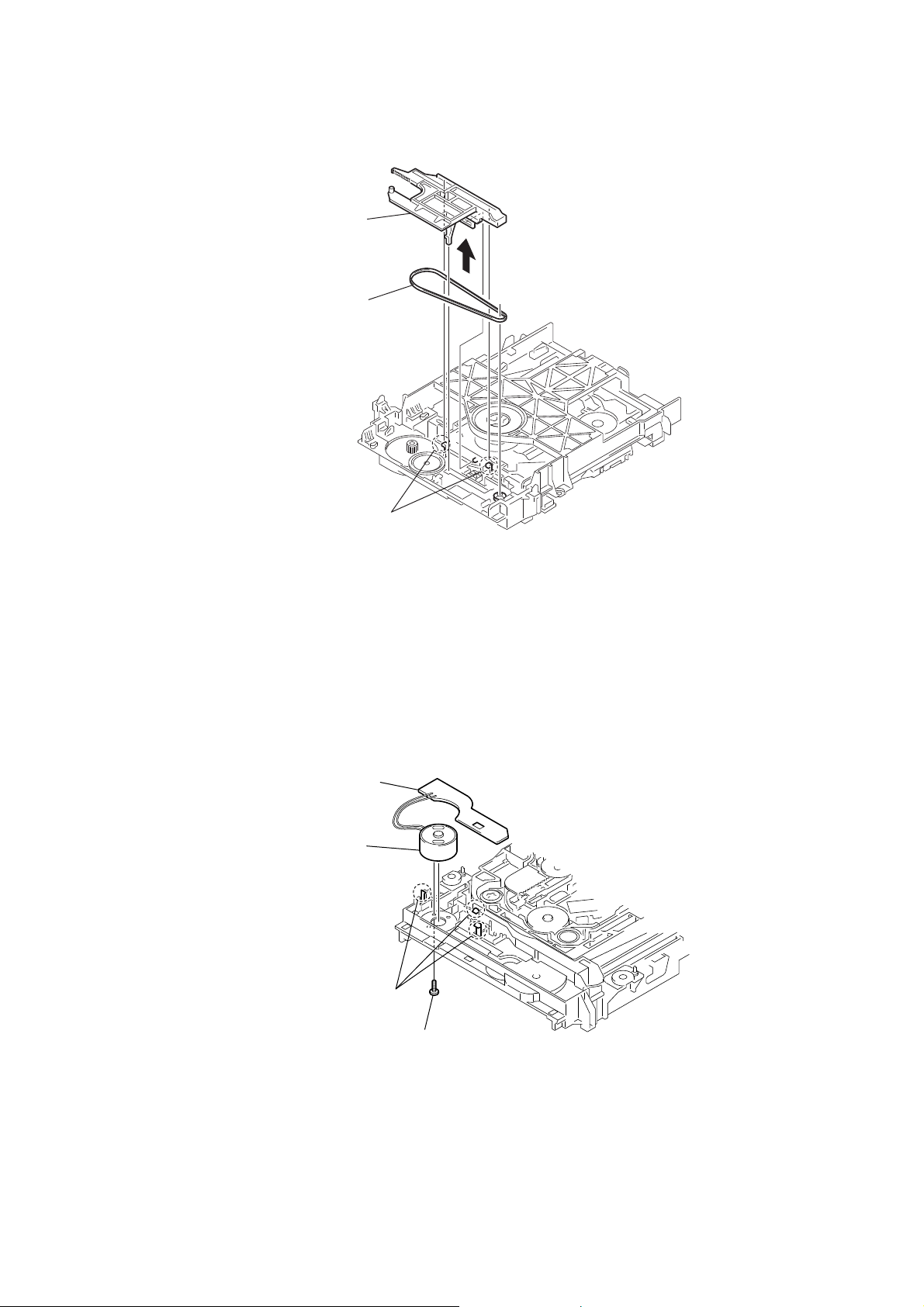

HCD-JZ8888K

2-11. BASE UNIT

chuck cam

two claws

two claws

base unit

2-12. OPTICAL PICK-UP

two insulator screws

FFC holder

two insulator screws

two claws

two insulators

two insulators

optical pick-up

(KHM-313CAA)

12

SECTION 3

TEST MODE

HCD-JZ8888K

Note: Incorrect operations may be performed if the test mode is not

entered properly.

In this case, press the [?/1] button to turn the power off, and

retry to enter the test mode.

1. Cold Reset

• The cold reset clears all data including preset data stored

in the RAM to initial conditions. Execute this mode when

returning the set to the customers.

Procedure:

1. Press the [

2. Press three buttons [

] button to turn the power on.

?/1

], [N] and [

x

] simultaneously.

?/1

3. When this button is operated, display as “COLD RESET” for

a while and all of the settings are reset.

2. Panel Test Mode

• This mode is used to check the software version, FL and

KEY.

2-1. Display Test Mode

Procedure:

1. Press the [

2. Press three buttons [

] button to turn the power on.

?/1

], [.] and [FUNCTION] simultane-

x

ously.

3. When the display test mode is activated, all segments are turned

on. When the mode in, lamps of “MOVIE”, “MUSIC” and

“i-ENHANCER” are turn off.

4. To exit from this mode, press three buttons [x], [.] and

[FUNCTION] simultaneously.

2-2. Version Test Mode

Procedure:

1. When the display test mode is activated, press the [.] button and the message “TIGRE100K” (JZ8888K) is displayed,

the version test mode is activated.

2. Whenever the [.] button is pressed, the display changes in

the following order.

“TIGRE100K” (Model name) t “AS1A2*1” (Destination) t

t MC Version t SYS Version t UI Version t

t DVD Version t ST Version t TA Version t

t DSP Version t TM Version t MM Version t

t CLA Version t CEC Version t SAIR Version

*1: AS1A2 changes depending on destination.

3. Press the [>] button and the date of the software production

is displayed.

4. Press the [>] button again and the version is displayed.

5. To exit from this mode, press three buttons [x], [.] and

[FUNCTION] simultaneously.

2-4. Key Test Mode

Procedure:

1. When the display test mode is activated, press the [N] button,

to select the key test mode.

2. To enter the KEY test mode, the fl uorescent indicator displays

“K0 V0”. Each time an another button is pressed, “KEY” value

increases. However, once a button is pressed, it is no longer

taken into account. When all keys are pressed correctly, “K9

V0” is displayed.

3. When the [VOLUME] control is turned in the direction of (+),

“V0” is changed to “V1”, then ... “V9”.

When the [VOLUME] control is turned in the direction of (–),

“V0” is changed to “V9”, then ... “V1”.

4. To exit from this mode, press three buttons [

], [.] and

x

[FUNCTION] simultaneously.

3. Disc Tray Lock

• The disc tray lock function for the antitheft of an demonstra-

tion disc in the store is equipped.

Setting Procedure :

1. Press the [

] button to turn the set on.

?/1

2. Press the [FUNCTION] button to set DVD function.

3. Insert a disc.

4. Press the [x] button and the [Z] button simultaneously for fi ve

seconds.

5. The message “LOCKED” is displayed and the tray is locked.

Releasing Procedure :

1. Press the [x] button and the [Z] button simultaneously for fi ve

seconds again.

2. The message “UNLOCKED” is displayed and the tray is unlocked.

Note: When “LOCKED” is displayed, the tray lock is not released by

turning power on/off with the [?/1] button.

4. DVD Ship Mode

• Use this mode when returning the set to the customer after

repair.

Procedure:

1. Press the [

] button to turn the set on.

?/1

2. Press the [FUNCTION] button to set the function “DVD”.

3. Remove all discs, and then press two buttons [N] and [

?/1

simultaneously.

4. After a message “MECHA LOCK” h “UNPLUG” is displayed on the fl uorescent indicator tube, pull out the AC plug.

5. To exit from this mode, press the [

] button to turn the set

?/1

on.

]

2-3. FL Pattern Test Mode

Procedure:

1. When the display test mode is activated, press the [x] button,

to select the FL pattern test mode. When the FL pattern test

mode, half segments of FL display and lamps of “MOVIE”,

“REC TO USB” are turn on.

2. Press the [x] button, half segments of FL display and lamp of

“MUSIC” and “

, VOLUME Illumination” are turn on.

"/1

3. Next press the [x] button, all segments of FL display is turn

on.

4. To exit from this mode, press three buttons [x], [.] and

[FUNCTION] simultaneously.

13

HCD-JZ8888K

5. Product Out

• This mode moves the optical pick-up to the position durable

to vibration and clears all data including preset data stored in

the RAM to initial conditions. Use this mode when returning

the set to the customer after repair.

Procedure:

1. Press the [

] button to turn the power on.

?/1

2. Press the [FUNCTION] button to set the function “DVD”.

3. Remove all discs, and then press three buttons [x], [Z] and

[VOLUME+] simultaneously.

4. Displayed to message “SERVICE IN” on the fl uorescent indi-

cator tube when pressing in turn the [4] t [DVD MENU] t

[CLEAR] buttons on the remote commander.

5. After the “STANDBY” blinking display fi nishes, the message

“MECHA LOCK” h “UNPLUG” is displayed on the fl uo-

rescent indicator tube disconnect the AC power plug, then the

product out mode is set.

6. Color System Change (Except E32 model)

• Color system change to video signal format (NTSC/PAL).

Procedure:

1. Press the [

] button to turn the set on.

?/1

2. Press the [FUNCTION] button to set the function “DVD”.

3. Press the [

4. Press two buttons [.] and [

] button to turn the set OFF.

?/1

?/1

] simultaneously, and the

display of fl uorescent indicator tube changes to “COLOR

PAL” or “COLOR NTSC”.

DVD SECTION

7-1. GENERAL DESCRIPTION

• The IOP measurement allows you to make diagnosis and adjustment simply by using the remote commander and monitor TV. The instructions, diagnosis results, etc. are given on

the on-screen display (OSD).

Be sure to execute the IOP measurement when a BU (Base

Unit) is replaced.

7-2. HOW TO ENTER TEST MODE

While pressing the [

[VOLUME] control in the direction of (+) with the DVD player

in power on.

The Test Mode starts, displayed “SERVICE IN” on this model

display then the menu shown below will be displayed on the TV

screen.

* The display of the “Model Name” of the “Remocon Diagnosis

Menu” change with the model and the destination. Refer to

below on the model name.

JZ8888K : TIGRE100K

Remocon Diagnosis Menu

0. External Chip Check

1. Servo Parameter Check

2. Drive Manual Operation

3. Emergency History

4. Version Information

] and [Z] buttons simultaneously, turn

x

1

Model Name

IF-con : Ver. XX.XX (XXXX)

Syscon : Ver. X.XXX

*1: Changes depending on destination

: TIGRE100K_XX

*

The menu above is the Remocon Diagnosis Menu screen which

consists of fi ve main functions. At the bottom of the menu screen,

the model name and IF-con version. To exit from the Test Mode,

press the [

] button on the remote commander.

?/1

7-3. EXECUTING IOP MEASUREMENT

In order to execute IOP measurement, the following standard procedures must be followed.

(1) In power on, while pressing the [

] and [Z] buttons simultane-

x

ously, turn the [VOLUME] control in the direction of (+).

Remocon Diagnosis Menu

0. External Chip Check

1. Servo Parameter Check

2. Drive Manual Operation

3. Emergency History

4. Version Information

1

Model Name

IF-con : Ver. XX.XX (XXXX)

Syscon : Ver. X.XXX

*1: Changes depending on destination

: TIGRE100K_XX

*

14

HCD-JZ8888K

(2) Select “2. Drive Manual Operation” by pressing the [2] button

on the remote commander. The screen will appear as shown.

Drive Manual Operation

1. Servo Control

2. Track/Layer Jump

3. Manual Adjustment

4. Tray Aging Mode

5. MIRR time adjust

0. Return to Top Menu

(3) Select “3. Manual Adjustment” by pressing the [3] button on

the remote commander. The screen will appear as shown.

Manual Adjust

1. Track Balance Adjust:

2. Track Gain Adjust:

3. Focus Balance Adjust:

4. Focus Gain Adjust:

5. Eq Boost Adjust:

6. Iop:

7. TRV. Level:

8. S curve(FE) Level:

9. RFL(PI) Level:

0. MIRR Time:

Oo Change Value

[RETURN] Return to previous menu

(4) Select “6. IOP” by pressing the [6] button on the remote

commander.

7-4. EMERGENCY HISTORY

To check the emergency history, please follow the following procedure.

(1) From the Top Menu of Remocon Diagnosis Menu, select “3.

Emergency History Check” by pressing the [3] button on the

remote commander. The following screen appears on the onscreen display.

Emg. History Check

Laser Hours CD

01. 01 05 04 04

00 00 00 00 00 00 23 45

02. 02 02 01 01 00 A9 4B 00

00 00 00 00 00 00 23 45

[Next] Next Page [Prev] Prev Page

[O] Return to Top Menu

999h 59min

DVD 999h 59min

00 92 46 00

(2) You can check the total time when the laser is turned on during

playback of DVD and CD from the above menu. The maximum time, which can be displayed are 999h 59min.

(3) You can check the error code of latest 10 emergency history

from the above menu. To view the previous or next page of

emergency history, press [

] or [>] button on the remote

.

commander. The error code consists of the following three

blocks. The fi rst block indicates the error code. The second

block indicates the parameter and the third block indicates the

time of error code as shown below.

• Error Code

(5) Wait until a hexadecimal number appear.

Manual Adjust

1. Track Balance Adjust:

2. Track Gain Adjust:

3. Focus Balance Adjust:

4. Focus Gain Adjust:

5. Eq Boost Adjust:

6. Iop. 4E:

7. TRV. Level:

8. S curve(FE) Level:

9. RFL(PI) Level:

0. MIRR Time:

Oo Change Value

[RETURN] Return to previous menu

(6) Convert each data from hexadecimal to decimal using

conversion table.

(7) Please fi nd the label on the rear of the BU (Base Unit).

The default IOP value is written in the label.

(8) Subtract between these two values.

(9) If the remainder is smaller than 93 (decimal), then it is

OK. However if the value is higher than 93, then the BU is

defective and need to be change.

(10) Press the [RETURN] button on the remote commander to

return back to previous menu.

(11) Press the [0] button on the remote commander to return to Top

Menu.

Emg. History Check

Laser Hours CD 999h 59min

*1 *2

01. 01 05 04 04

00 00 00 00 00 00 23 45

02. 02 02 01 01 00 A9 4B 00

00 00 00 00 00 00 23 45

[Next] Next Page [Prev] Prev Page

[O] Return to Top Menu

DVD 999h 59min

00 92 46 00

*3

*1 : Error Code

*2 : Parameter of error code

*3 : Time of error code

The meaning of error code is as below:

01: Communication error (No reply from syscon)

02: Syscon hung up

03: Power OFF request when syscon hung up

19: Thermal shutdown

24: MoveSledHome error

25: Mechanical move error (5 Changer)

26: Mechanical move stack error

30: DC motor adjustment error

31: DPD offset adjustment error

32: TE balance adjustment error

33: TE sensor adjustment error

34: TE loop gain adjustment error

35: FE loop gain adjustment error

36: Bad jitter after adjustment

40: Focus NG

42: Focus layer jump NG

51: Spindle stop error

52: Open kick spindle error

15

HCD-JZ8888K

60: Focus on error

61: Seek fail error

62: Read Q data/ID error

70: Lead in data read fail

71: TOC read time out (CD)

80: Can’t buffering

81: Unknown media type

7-4-1. Clear the Laser Hour

Press [

DISPLAY] button and then press [CLEAR] button on the

remote commander. The data for both CD and DVD data are reset.

Emg. History Check

Laser Hours CD 0h 0min

01. 01 05 04 04

00 00 00 00 00 00 23 45

02. 02 02 01 01 00 A9 4B 00

00 00 00 00 00 00 23 45

[Next] Next Page [Prev] Prev Page

[O] Return to Top Menu

DVD 0h 0min

00 92 46 00

7-4-2. Clear the Emergency History

Press [DVD TOP MENU] button and then press [CLEAR] button

on the remote commander. The error code for all emergency history would be reset.

Emg. History Check

7-4-4. Return to the Top Menu of Remocon Diagnosis

Menu

Press [0] button on the remote commander.

7-5. CHECK VERSION INFORMATION

To check the version information, please follow the following procedure.

(1) From the Top Menu of Remocon Diagnosis Menu, select “4.

Version Information” by pressing the [4] button on the remote

commander. The following screen appears on the on-screen

display.

Version information

Firm (Main) : Ver. xxxxx

Firm (Sub) : xxxxx

RISC : xxxxx

8032 : xxxxx

Audio DSP : xxxxx

Servo DSP : xxxxx

Phy,Adr, : F.F.F.F

[O] Return to Top Menu

To return to the Top Menu of Remocon Diagnosis Menu, press

[0] button on the remote commander.

8. D.C.A.C. (AUTOMATIC ACOUSTIC FIELD CALIBRATION) TEST MODE

Laser Hours CD 999h 59min

01. 00 00 00 00

00 00 00 00 00 00 00 00

02. 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00

[Next] Next Page [Prev] Prev Page

[O] Return to Top Menu

DVD 999h 59min

00 00 00 00

7-4-3. Clear the Initialize Setup Data

Press [DVD MENU] button and then press [CLEAR] button on the

remote commander.

Emg. History Check

Laser Hours CD

initialize setup data...

[Next] Next Page [Prev] Prev Page

[O] Return to Top Menu

999h 59min

DVD 999h 59min

Procedure:

1. Press the [

] button to turn the power on.

?/1

2. Press the [FUNCTION] button to set the function “ DVD”.

3. Insert Calibration mic (ECM-AC2) supplied as an accessory

into the AUDIO IN/A.CAL MIC jack.

4. While pressing the [x] and [Z] buttons simultaneously, turn

the [VOLUME] control in the direction of (–).

5. Confi rm that the following are shown on the display panel.

The JACK inserted/non-inserted detection display and the

STEREO/MONO detection display.

JACK :* * * *

1

1 “NON” : Not detected

“ST” : STEREO

“NOMO” : MONO

6. To exit from this mode, press the [x] and [Z] buttons simultaneously, turn the [VOLUME] control in the direction of (–).

16

HCD-JZ8888K

9. AMP TEST MODE

• This mode is used to measurement and test of the AMP connection.

Procedure:

1. Press the [

] button to turn the power on.

?/1

2. Press three buttons [x], [N] and [Z] simultaneously. When

the this mode, blink to segments (“SA-CD” and “CAT”) on FL

display.

3. Press [DISPLAY] button of the remote commander. When the

this mode is displayed as “MEASURE” on FL display.

Whenever the [DISPLAY] button is pressed, the AMP test

mode changes in the following order.

MEASURE t SAFETY

MEASURE: AMP measurement mode

SAFETY: AMP regulations, temperature, character mode

4. Press [MUTING] button on the remote commander. When the

this mode is displayed as “VOL N” on FL display.

Whenever the [MUTING] button is pressed, the VOL test

mode changes in the following order.

VOL N t VOL M/M

VOL N: Turn the [VOLUME] control, the display is

change in succession (MIN y MAX)

VOL M/M: Turn the [VOLUME] control in the direction of

(+) is change to “MIN”, turn the direction of (–)

is change to “MAX”.

5. To exit from this mode, press the [

] button to “COLD RE-

?/1

SET” and turn the power off.

10. DEMO PLAY MODE OUT

It is a mode to release the demonstration reproduct by the dedicated demonstration disc.

1. During playback the DEMO Disc, press the [

] and [N] but-

x

tons for fi ve seconds simultaneously.

2. The message “DEMO OFF” is displayed, a mode to reproduct

the demonstration is released.

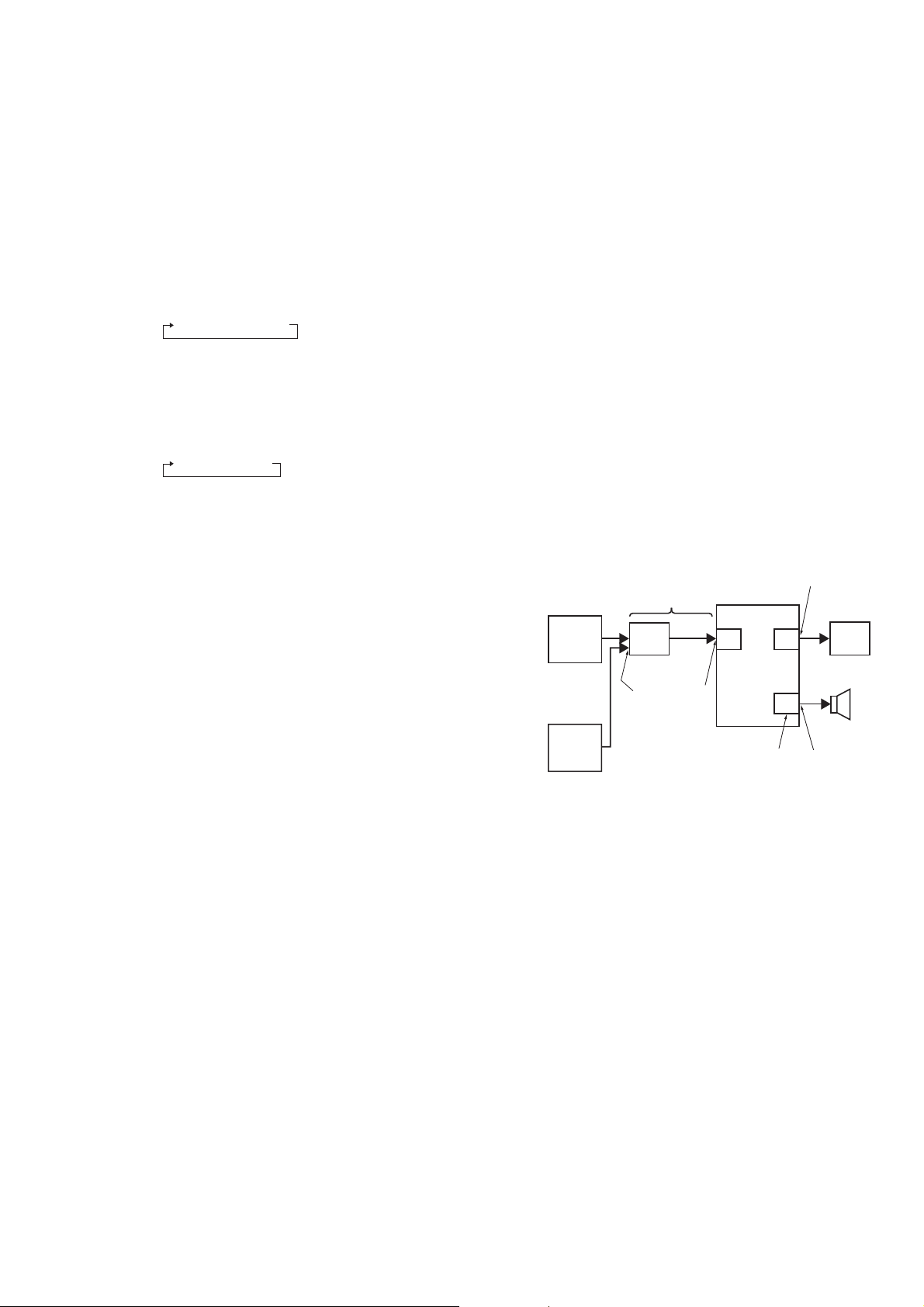

11. DMPORT (DIGITAL MEDIA PORT) TEST

1. Connect the DMPORT CHECK JIG (P/N: J-2501-309-A) with

the terminal DMPORT.

2. Press the [

] button to turn the power on.

?/1

3. Confi rm that both LEDs of the DMPORT confi rmation JIG

lights. (Confi rmation the power supply line.)

4. Set the [FUNCTION] button with “DMPORT” on this model.

5. Press three buttons [x], [N] and [FUNCTION] simultaneously, the DMPORT test mode is activated.

6. It is confi rmed that “DMPORT OK” is displayed on this set

display. (Confi rmation of communication line)

7. To a pin jack of the DMPORT confi rmation JIG input informa-

tion relevant to audio signal (sine-wave 1.0Vrms) and composite video signal (white 100% 1.0Vp-p, color bar, etc.)

8. Confi rm the output of speakers and monitor TV. (Confi rmation

of analog signal)

9. To exit from this mode, press three buttons [x], [N] and

[FUNCTION] simultaneously.

VIDEO

AUDIO

color pattern

generator

AF oscillator

DMPORT

CHECK JIG

(P/N: J-2501-309-A)

J001 V

CN451

SET

MAIN

board

IO-COMPONENT

SP board

J4001

TV

board

FL speaker,

FR speaker

TB301

17

HCD-JZ8888K

12. PROTECTION FACTOR (SD DETECTION/

DC DETECTION) IDENTIFICATION TEST MODE

When an error is detected, the FL tube alternately displays

“PROTECTOR h PUSH POWER”.

r Press the [

* Buttons other than the [

“STANDBY” blinks three times on the FL tube.

r

The protection release state (POWER OFF) is established.

(No FL tube display)

r Press the [

The power to the system turns on, and the normal operation is

established. (Restore)

During the protection state:

1. If the AC plug is connected or disconnected during the

protection state, the protection state is released, and the

normal operation is established. (The protection state is not

maintained.)

2. The protection factor is displayed by pressing the [RETURN]

t [3] t [2] t [0] t [0] t [ANGLE] buttons of the

remote commander.

(during the “PROTECTOR h PUSH POWER” display).

k When SD is detected: Repeats

“SD DETECT h PROTECTOR”.

k When DC is detected: Repeats

“DC DETECT h PROTECTOR”.

] button.

?/1

] button two times.

?/1

] button are invalid.

?/1

PL: SD detection

When the “L” output from the SD (shutdown) port on the

S-MASTER POWER Driver Shutdown and voltage descent

(15V or less) of 30V power supply (PVDD) are detected.

DC detection

When the “L” output from the power/speaker error detection

circuit (DC detection port) is detected for two seconds

continually, the power system other than that of the FL tube

is turned off, and the protection state is established.

18

SECTION 4

ELECTRICAL ADJUSTMENTS

DVD SECTION

When the optical pick-up assy is replaced, perform the

“EXECUTING IOP MEASUREMENT”.

EXECUTING IOP MEASUREMENT (See page 14)

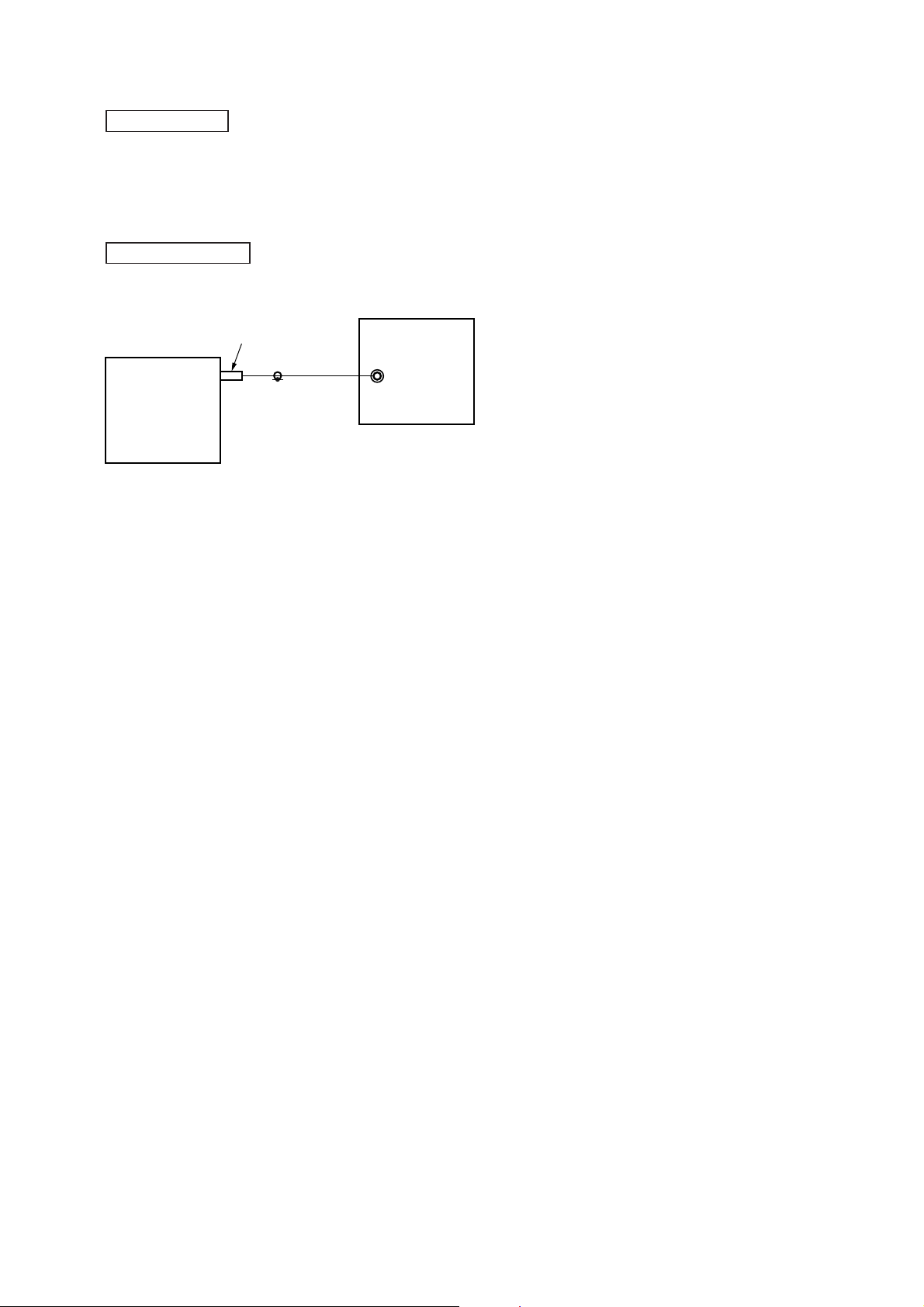

TUNER SECTION

[FM Tune Level Check]

generator

HCD-JZ8888K

SET

Procedure:

1. Turn the power on.

2. Input the following signal from Signal Generator to FM antenna input directly.

* Carrier Freq : A = 87.5 MHz, B = 98 MHz, C = 108 MHz

Deviation : 75 kHz

Modulation : 1 kHz

ANT input : 35 dBu (EMF)

Note: Please use 75 ohm “coaxial cable” to connect SG and the set. You

cannot use video cable for checking.

Please use SG whose output impedance is 75 ohm.

3. Set to FM tuner function and tune A, B and C signals.

4. Confi rm “TUNED” is lit on the display for A, B and C signals.

The mark of “TUNED” means “The selected station signal is received in good condition.”

FM ANTENNA

OUT (75 :)

19

HCD-JZ8888K

SECTION 5

DIAGRAMS

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For Printed Wiring Boards.

Note:

• X : Parts extracted from the component side.

• a : Through hole.

• : Pattern from the side which enables seeing.

(The other layers’ patterns are not indicated.)

Caution:

Pattern face side:

(SIDE B)

Parts face side:

(SIDE A)

• Indication of transistor.

C

Q

B

E

CEB

• Abbreviation

E32 : 110 – 240V AC area in E model

MX : Mexican model

SP : Singapore model

These are omitted.

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

These are omitted.

For Schematic Diagrams.

Note:

• All capacitors are in μF unless otherwise noted. (p: pF) 50

WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and 1/4 W or less unless otherwise

specifi ed.

• f : Internal component.

• C : Panel designation.

Note: The components identifi ed by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specifi ed.

• A : B+ Line.

• B : B– Line.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

• Voltages and waveforms are dc with respect to ground in

service mode.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

no mark : TUNER (FM)

< > : DVD PLAY

* : Impossible to measure

• Voltages are taken with VOM (Input impedance 10 MΩ).

• Circled numbers refer to waveforms.

• Signal path.

F : TUNER

J : DVD PLAY

L : VIDEO

E : Y

a : CHROMA

r : COMPONENT VIDEO

N : MIC

• Abbreviation

E32 : 110 – 240V AC area in E model

MX : Mexican model

SP : Singapore model

• Circuit Boards Location

P-LED board

MS-203 board

IO-COMPONENT board

SCORE board

FL-JACK board

KEY-SW board

J-LED board

SP board

DSP board

MAIN board

POWER board

U-LED board

USB board

20

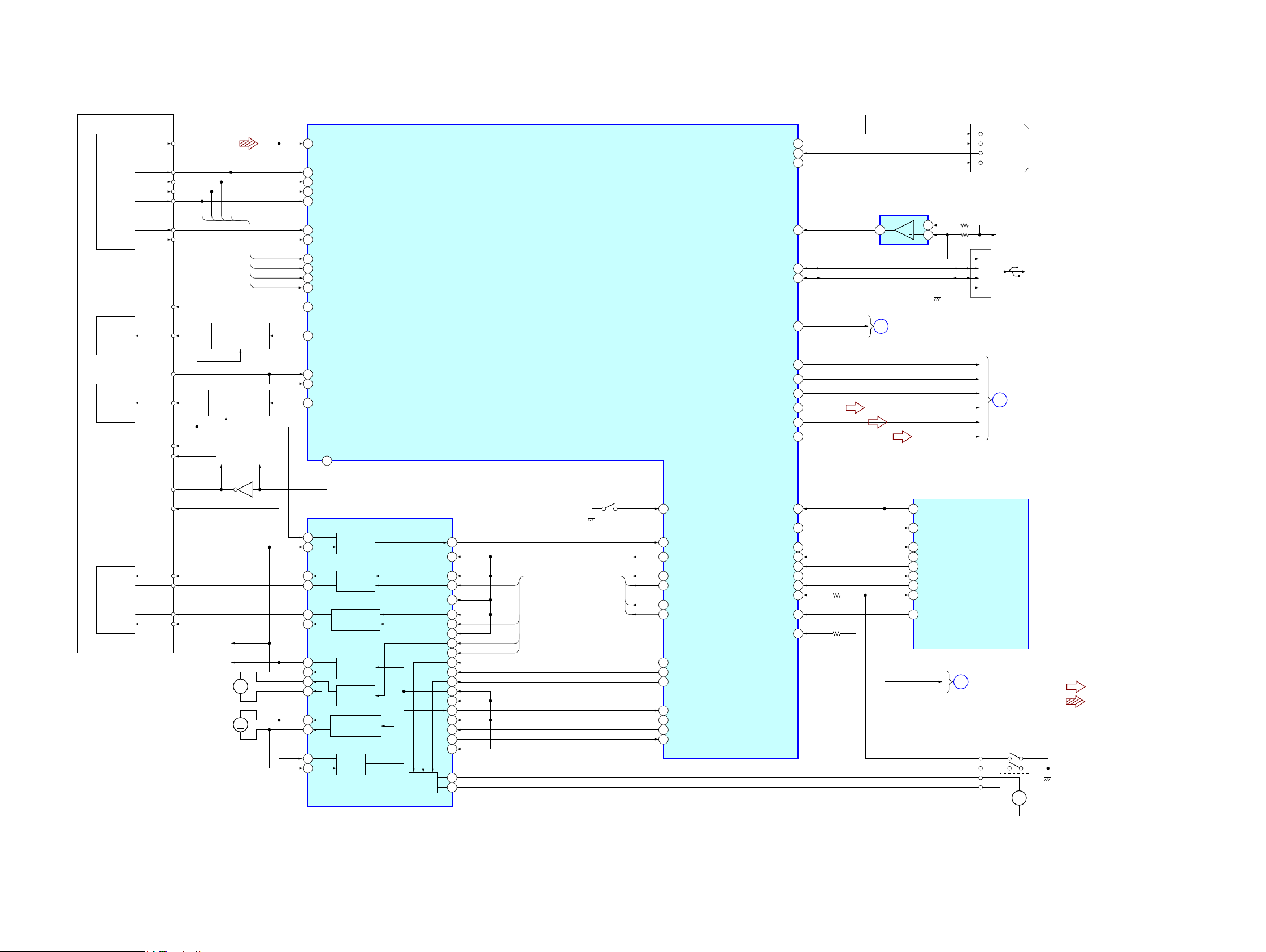

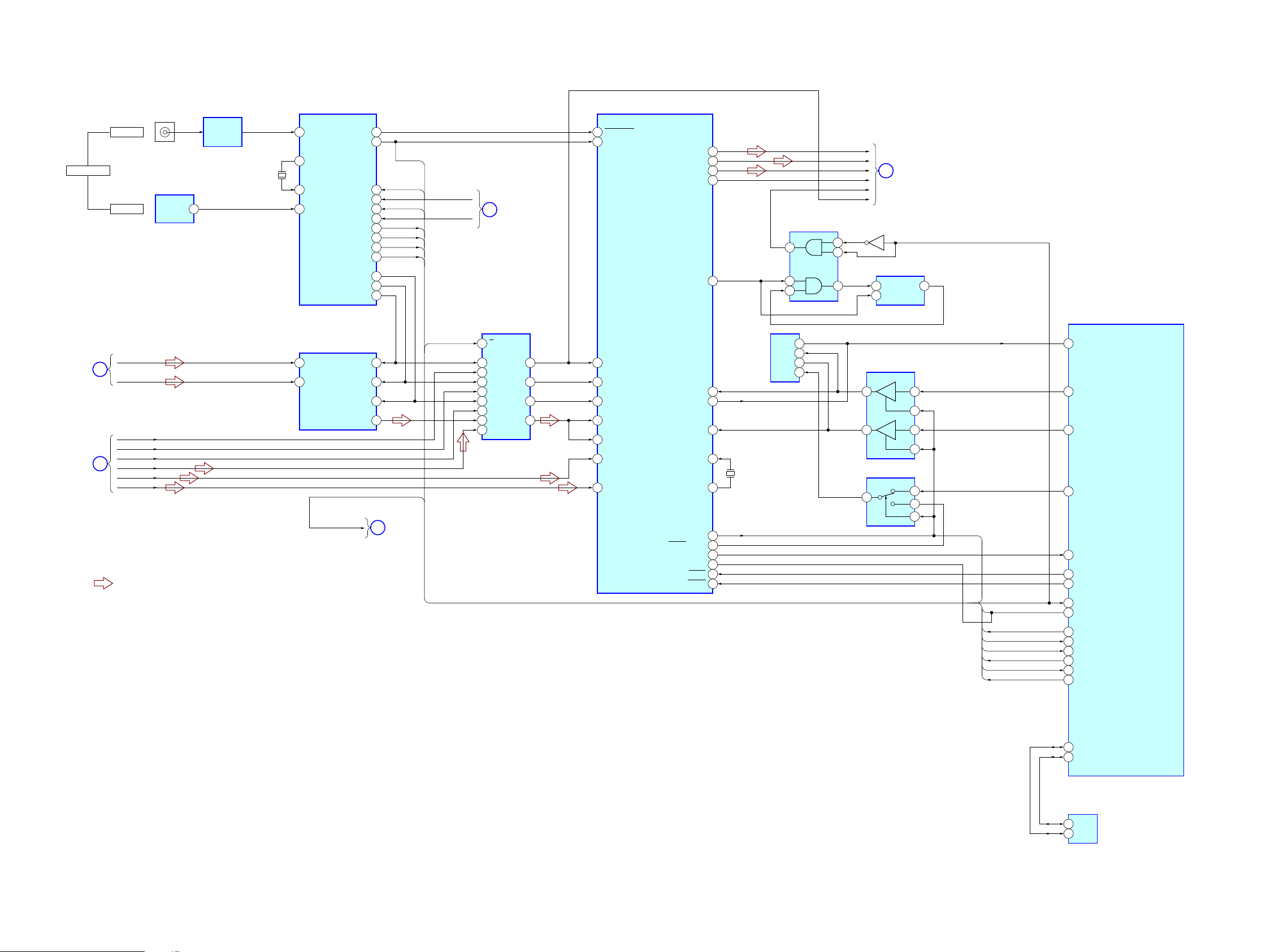

5-1. BLOCK DIAGRAM – RF Section –

RF

VOA/A

DETECTOR

OPTICAL PICK-UP

BLOCK

(KHM-313CAA)

LASER

DIODE

(FOR CD)

LASER

DIODE

(FOR DVD)

VOB/B

VOC/C

VOD/D

VOE/E+G

VOF/F+H

LD (780)

LD (650)

VR (650)

VR (780)

A

B

C

D

A

B

C

D

VC

Q1102 (1/2)

LD DRIVE

CONTROL (FOR CD)

PD

Q1102 (2/2)

LD DRIVE

CONTROL (FOR DVD)

Q1101

PD VOLUME

CONTROL

10

6

7

8

9

17

18

11

12

13

14

28

22

19

20

21

DVDRFIP

DVDA

DVDB

DVDC

DVDD

TNI

TPI

MA

MB

MC

MD

V20 (2.0V)

LD01

MDI1

MDI2

LD02

MSW

54

IC1101 (1/2)

CD/DVD RF AMP,

FOCUS/TRACKING ERROR AMP,

DVD SYSTEM CONTROL, DSP

V2REFO (2.8V)

RXD

TXD

VBUS_OC

USB_DM

USB_DP

VBUS_OE

ACLK

ALRCK

ABCK

ASDATA2

ASDATA1

ASDATA0

27

105

106

VBUS OVER CURRENT DETECT

197 1

45

44

196

203

205

204

223

225

226

VBUS_SW

IC2101

POWER

L

SECTION

(Page 26)

HCD-JZ8888K

CN1105

6

RFMON

5

V2REFO

RXD

TXD

USB 5V

CN5200

SECTION

(Page 24)

(SERVICE JIG)

DSP

2

1

2

3

VBUS

1

D-

2

D+

3

GND

4

ACLK

ALRCK

ABCK

AMP_D02

AMP_D01

AMP_D00

A

2AXIS

DEVICE

FOCUS/

TRACKING

COIL

MSW

VCC

FCS+

FCS-

TRK+

TRK-

REG02

REG01

(SLED MOTOR)

(SPINDLE MOTOR)

Q1103

MM

MM

SP+

SP-

SLSL+

I0P

IC1201

FOCUS/TRACKING DRIVER,

LOADING/SPINDLE/SLED MOTOR DRIVER

42

41

36

37

35

34

32

31

30

29

27

28

46

47

BUFFER

FOCUS COIL

DRIVE

TRACKING COIL

DRIVE

BUFFER

SLED MOTOR

DRIVE

SPINDLE MOTOR

DRIVE

BUFFER

MCS

40

43

48

1

12

3

4

9

10

13

16

17

15

6

7

45

19

20

22

21

25

24

VREFO

FOO

TRO

FMO

DMO

SPFG

(LIMITSW)

FMO

FOO

DMO

TRO

LIMITSW

53

39

IOPMON

VREFO [1.4V]

29

FMO

37

FOO

41

DMO

36

TRO

40

FWD

94

REV

95

38

TROPENPWM

OP_INP

35

MUTE123

157

MUTE

158

TSD_M

130

XSYSRST

IFCK

IFSDO

IFSDI

XIFCS

KMOD

MIC

OCSW

XIFBSY

CKSW

108

98

97

100

99

213

208

104

110

103

XSYSRST

IFSCK

IFSDO

IFSDI

XIFCS

KMOD

MIC

DVD RST

45

DVD_SCO

49

DVD_SDO

48

DVD_SDI

47

DVD XIFCS

51

KMODE

53

TV_SEL/MIC_DET_OUT/LED_LAT

52

CDM_OPEN_SW

44

DVD_XIFBUSY

50

XSYSRST

IC503 (1/6)

SYSTEM CONTROL

VIDEO

C

SECTION

(Page 22)

OCSW1/REVOCSW

CKSW/FWDCKSW

(CHUCK/TRAY DETECT)

LDM+

LDM-

S001

M

SIGNAL PATH

M001

(LOADING MOTOR)

: TUNER

: DVD PLAY

HCD-JZ8888K

2121

HCD-JZ8888K

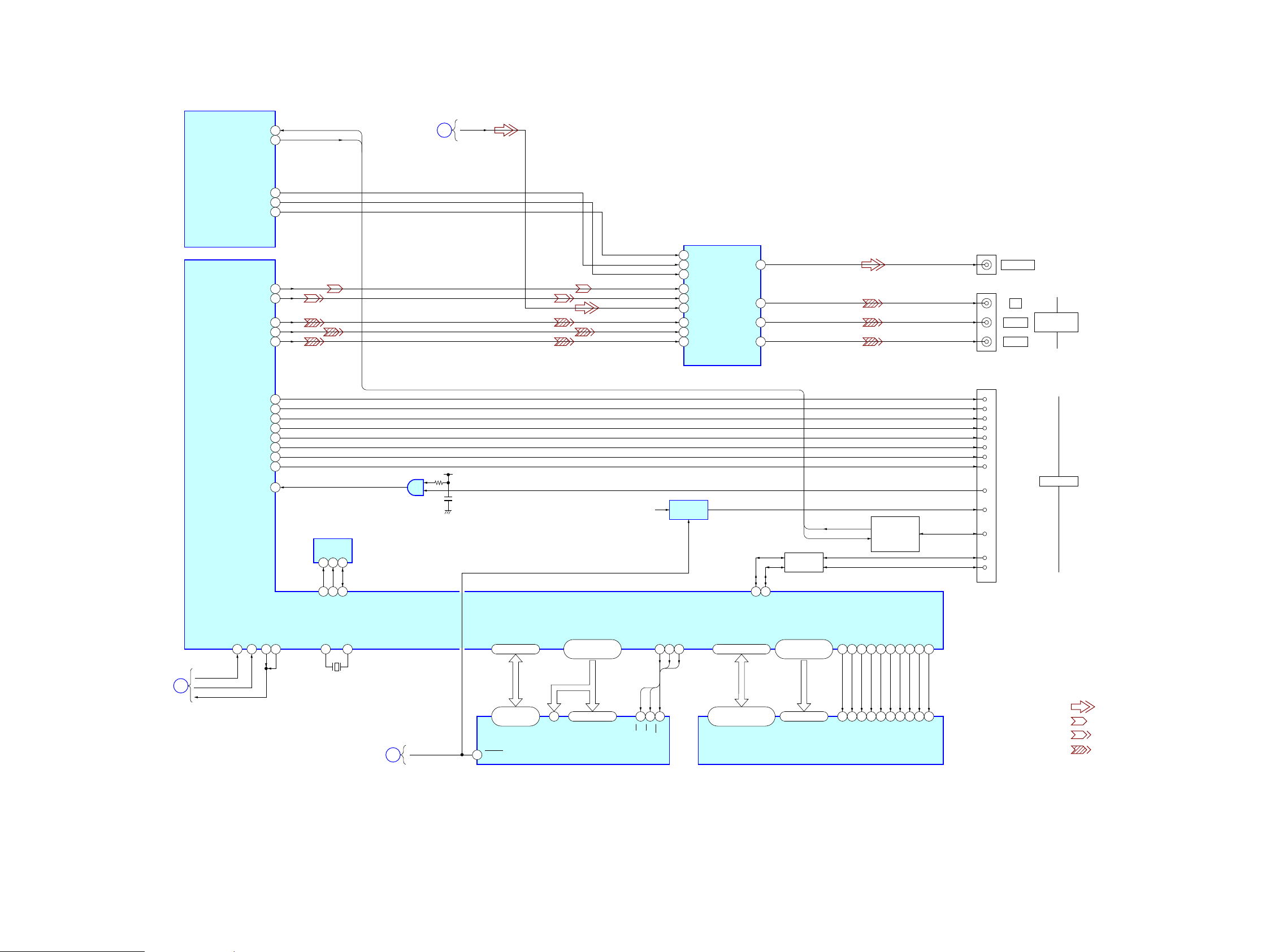

5-2. BLOCK DIAGRAM – VIDEO Section –

IC503 (2/6)

SYSTEM CONTROL

CEC_RX_IN

CEC_TX_OUT

6

26

82V_SEL1

81V_SEL0

83V_SEL2

191Y

189C

185Y/G

183B/Cb/Pb

182R/Cr/Pr

180TX2P

179TX2N

177TX1P

176TX1N

174TX0P

173TX0N

171TCKP

170TCKN

162HTPLG

CEC_RX_IN

CEC_TX_OUT

IC1103

EEPROM

WFEEWP

SCL6SDA

7

AUDIO

SECTION

VIDEO

B

(Page 23)

V_SEL1

V_SEL0

V_SEL2

IC4002

VIDEO DRIVER

5YC MIX

13 MUTE2

3MUTE1

6YIN

2CIN

4 CVBSIN

10 CYIN

12 CBIN

14 CRIN

+3.3V

2

4

IC1705

BUFFER

5

1

+6V

IC1707

+5V REG.

23CVBSOUT

20CYOUT

18CbOUT

16CrOUT

Q1701

LEVEL SHIFT

VOUT

CYOUT

CBOUT

CROUT

CEC_RX_IN

CEC_TX_OUT

Q9724,9726,

Q9728,9729

CEC RX/TX

INTERFACE

J4001 (1/2)

J4000

CN1701

1

3

4

6

7

9

10

12

19

18

13

15

16

VIDEO OUT

Y

PB/CB

PR/CR

TMDS DATA2 +

TMDS DATA2 –

TMDS DATA1 +

TMDS DATA1 –

TMDS DATA0 +

TMDS DATA0 –

TMDS CLOCK +

TMDS CLOCK –

HPD

+5V POWER

CEC

SCL

SDA

COMPONENT

VIDEO OUT

HDMI OUT

HCD-JZ8888K

AUDIO

SECTION

(Page 23)

112 101 102

SCL

SDA

SCORE/DIR_XSTATE

XVOICE/DIR_CSFLAG

Rt/DIR_DI

198

SCORE

XVOICE

D

MUSIC

Lt/DIR_DO

214

230

231 239 238

XTALI

X1101

27MHz

XTALO

RF

SECTION

IC1101 (2/2)

DVD SYSTEM CONTROL, DSP

XSYSRST

C

12

HD0–HD7

79,80,82–86,89

HD0–HD7

HD0–HD7

29,31,33,35,

38,40,42,44

DQ0–DQ7

RESET

HA0–HA21

56–64,67–75,77,

A0–A21

A0

25–16,10–1,48

A0–A19,NCDQ15/A-1

IC1102

FLASH ROM

87,91,92

A1–A21

XRD

XROMCS

76

XWR

11OE28CE2645

XWR66XRD78XROMCS

2,4,5,7,8,10,11,13,42,

WE

44,45,47,48,50,51,53

161

RD0–RD15

117–113,119–129

RD0–RD15

159

DDC_DA

DDC_CLK

RA0–RA11

139–141,143,144

149–155

22–26,29–35

A0–A11

IC1104

SDRAM

BA0

138

137

135

133

136

146

147

132

111

134

CKE

DQM1

DQM0

_CAS

_RAS

_RWE

_RCS

DRCLK

BA1

v SIGNAL PATH

: VIDEO

20

/CS

/WE

BA121BA0

CLK

/CAS17/RAS

CLKE

LDQM

UDQM

: Y

: CHROMA

37

39

15

18

16

19

38

: COMPONENT VIDEO

(Page 21)

2222

5-3. BLOCK DIAGRAM – AUDIO Section –

Q5007,5009,5012

MIC DC SWITCH

PLUG_DET

MO/ST_DET

Q5004,5005,5011

MIC DC SWITCH

D5008

(Page 25)

J5000

AUDIO IN/MIC/

A.CAL MIC

AMP

SECTION

F

PLUG_DET

SW3.3V

3 1

5

6

IC5003

MIC AMP

Q5010

7

F-AUDIO (R)

F-AUDIO (L)/MIC1

R-CH

DC_CONT

GAIN_CONT

IC4008

ELECTRONIC VOLUME

1

VIN1

4

DATA

5

CLK

INPUT SELECT

5 3

2

4

1

OUT1

IC4007

Y1 Y

Y2

Y3

Y0

HCD-JZ8888K

IC4202

ALC

SCORE DETECT

2

3

6

5

Q4201,4202

SCORE

DETECT

8

4

D4008

1

SCORE

7

VIDEO

XVOICE

D

SECTION

(Page 22)

MUSIC

IC4201

AF AMP

A+9V

D4203,4204

2

6

IC4010

ALC EQ AMP

5

MIC1+2

2

L-IN

R-IN

R-CH

Q4012

10

A

Q4011

9

B

ASEL0

ASEL1

E

SECTION

(Page 24)

3

MUSIC

DSP

7

D4201

D4202

1

TV

SAT/

CABLE

AUDIO

IN

AUDIO

IN

CN451

DMPORT

DIGITAL

MEDIA PORT

ANTENNA

75Ω FM

COAXIAL

J4001(2/2)

L

R

L

R

J4002

17

13

14

5

6

7

2

4

TU4001

FM

TUNER

PAC K

VIDEO

LCH

RCH

RXD

TXD

DET

VBUS (5V)

VIDEO 5V

R-CH

R-CH

L-CH

R-CH

TUNED

DI

DO

CK

CE

VIDEO

R-CH

VIDEO 5V

(DMPOART)

R-CH

B

(Page 22)

VIDEO

SECTION

DMP_TXD

DMP_RXD

DMP_DET

IC451

DMPOART

AUDIO AMP

3 1

Q5006,5008

MIC GAIN CONTROL

IC4005

INPUT SELECT

5 3

Y1 Y

2

Y2

4

Y3

10

A

1

Y0

9

B

R-CH

Q4013Q4014

Q4010

Q4009

DMP_DET

ASEL2

ASEL3

ASEL0

ASEL1

ASEL2

ASEL3

PLUG_DET

MO/ST_DET

GAIN_CONT

DC_CONT

DMP_TXD

DMP_RXD

TUNED

DI

DO

CK

CE

DSP_MASTER

IO_CE/ASEL0

84

IO_RESET/ASEL1

85

IO_DI/ASEL2

86

IO_DO/ASEL3

87

JACK1/JACK2/S-ART DET

65

MONO/ST_DET

90

MIC_GAIN

43

A.CAL MIC LEVEL/DSP_MASTER

91

DC_CONT

42

DMP_TX_OUT

35

DMP_RX_IN

36

TUNED

80

ST_DI/MIC_DATA

77

ST_DO

78

ST_CLK/MIC_CLK

79

ST_CE

76

DSP

G

SECTION

(Page 24)

IC503 (3/6)

SYSTEM CONTROL

R-ch is omitted due to same as L-ch.

SIGNAL PATH

: TUNER

DI

CK

: VIDEO

: MIC

HCD-JZ8888K

2323

HCD-JZ8888K

5-4. BLOCK DIAGRAM – DSP Section –

TV DIGITAL IN

AUDIO

SECTION

(Page 23)

RF

SECTION

(Page 21)

COAXIAL

OPTICAL

L-IN

E

R-IN

ACLK

ALRCK

ABCK

AMP_D00

A

AMP_D01

AMP_D02

v SIGNAL PATH

: TUNER

J501

IC502

OPTICAL

RECEIVER

OUT

IC501

WAVE

SHAPE

X301

24.576MHz

IC304

DIR

DIN2 (I)

5

(COAX)

XOUT (O)

21

XIN (I)

22

DIN (I)

42

(OPT)

13 VINL 14 4A

14 VINR

AUDIO (O)

DATA (O)

XMODE (I)

DO (O)

ERROR (O)

CSFLAG (O)

XSTATE (O)

BCK (O)

LRCK (O)

CKOUT (O)

IC303

A/D CONVERTER

DSP_MASTER

CL (I)

CE (I)

DI (I)

SCKI

LRCK

BCK

DOUT

24

16

DIR_ZERO

DIR_RST

48

DIR_CLK

38

DIR_CE

37

DIR_DIN

36

DIR_DO

35

DIR_ERR

34

CSFLAG

25

DIR_XSTATE

17

14

15

13

6

7

8

9

DSP_MASTER

AUDIO

G

SECTION

SI_A

DIR_CLK

DIR_DIN

SACD_SEL

H

SACD SELECT

1A/B

13 4B

11 3 A

10 3B

52A

62B

21A

31B

(Page 23)

AMP

SECTION

(Page 25)

IC306

4Y

3Y

2Y

1Y

SI_C

SI_D

IC700

DSP

NONAUDIO FLAG2

97

DSPIA DAI_P11

78

SI_B

DPFSCK DAI_P20

94

DPLRCK DAI_P18

88

DPBCK DAI_P19

89

LPCM FL/FR

79

DPSIB DAI_P12

LPCM SBL/SBR

82

DPSIE DAI_P15

LPCM SL/SR

80

DPSIC DAI_P13

LPCM C/SW

81

DPSID DAI_P14

12

LRCK

9

BCK

7

4

FL/FR DPSOA DAI_P6

SL/SR DPSOB DAI_P7

C/SW DPSOC DAI_P8

DPDVBCK DAI_P17

DPDVRCK DAI_P16

MOSI

MISO

SPICLK

CLKIN

XTAL

SPI_MAS DAI_P5

SF_CE FLAG3

FLAG0 INT_REQ

FLAG1 DIR_ERR

SPIDS

RESET

64

65

70

87

AND GATE

7

86

IC706

EEPROM

127

126

125

142

X700

25MHz

143

63

98

15

16

122

121

SCK

2

1

2

SO

5

SI

6

1

CE

IC705

AMP_D1

AMP_D2

AMP_D3

BCKO

LRCKO

MCKO

5

6

3

AMP

J

SECTION

(Page 25)

Q700

DELAY

IC703

DATA LATCH

1

D

CLK

2

IC702

BUS BUFFER

3 5

6

IC701

DATA SELECT

5

SF_MASTER

SF_CE

DIR_XSTATE

4

Q

IC503 (4/6)

SYSTEM CONTROL

DSP_MISO

DSP_MOSI

7

2

1

1

2

6

DSP_SPICLK

DSP_SF_CE

DSP_MASTER

DIR_XSTATE

DIR_ERR

DIR_CE

DIR_DO

CSFLAG

DIR_RST

DIR_ZERO

SACD_SEL

DSP_MISO

22

DSP_MOSI

24

DSP_SPICLK

23

DSP_SF_CE

21

68

A.CAL_OUT/DSP_INTR

DSP_SPIDS

25

DSP_RESET

27

17

DIR_XSTATE

10

DIR_ERR

70

DIR_HCE/eHDMI_SEL

100

DIR_HDOUT

19

DIR_CSFLAG

11

DIR_RST

18

DIR_ZERO

69

SACD_SEL

HCD-JZ8888K

29

E2P_CLK/S-AIR_CLK

30

E2P_SDA/S-AIR_SDA

IC505

EEPROM

5

SDA

6

SCL

2424

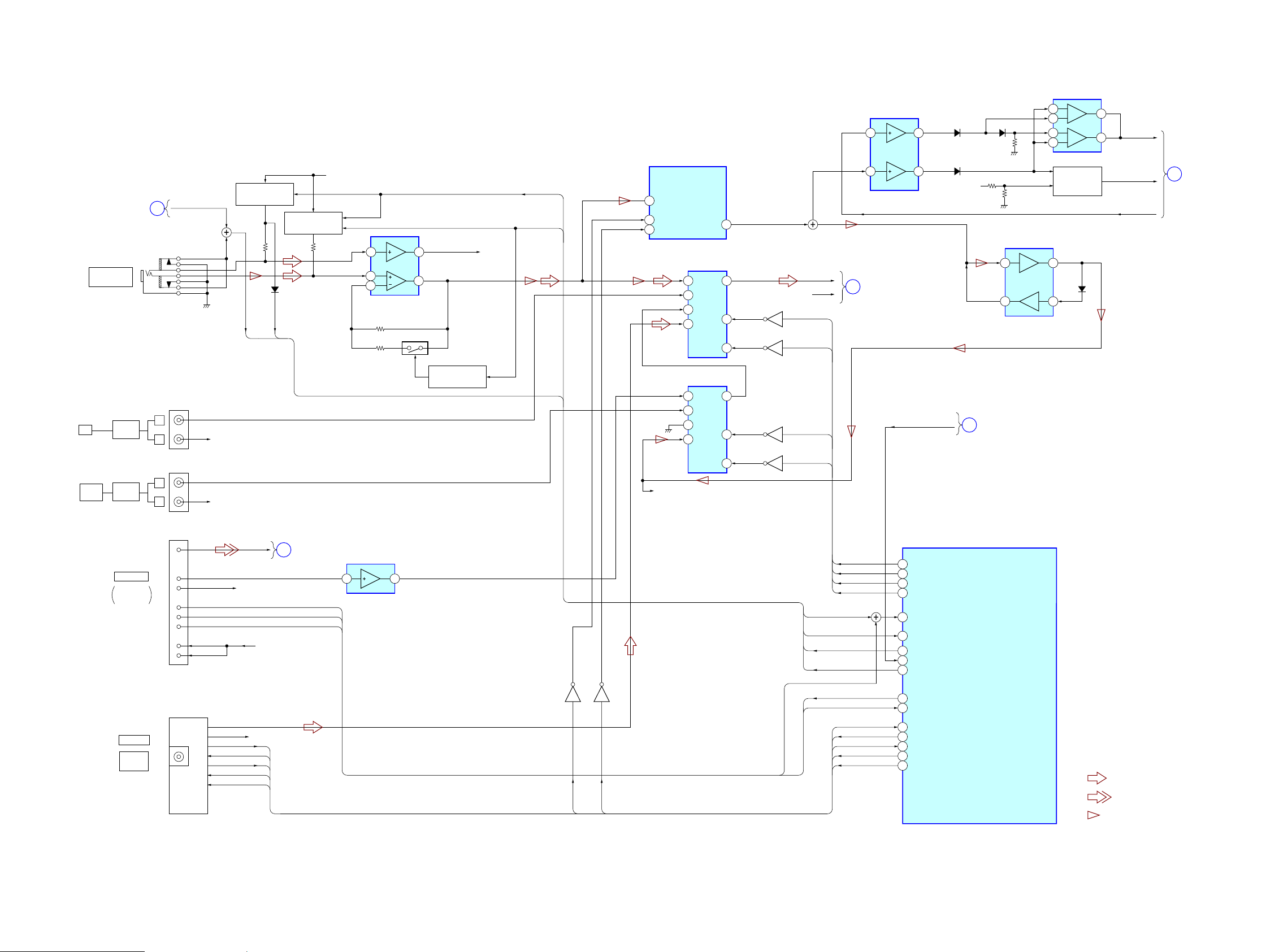

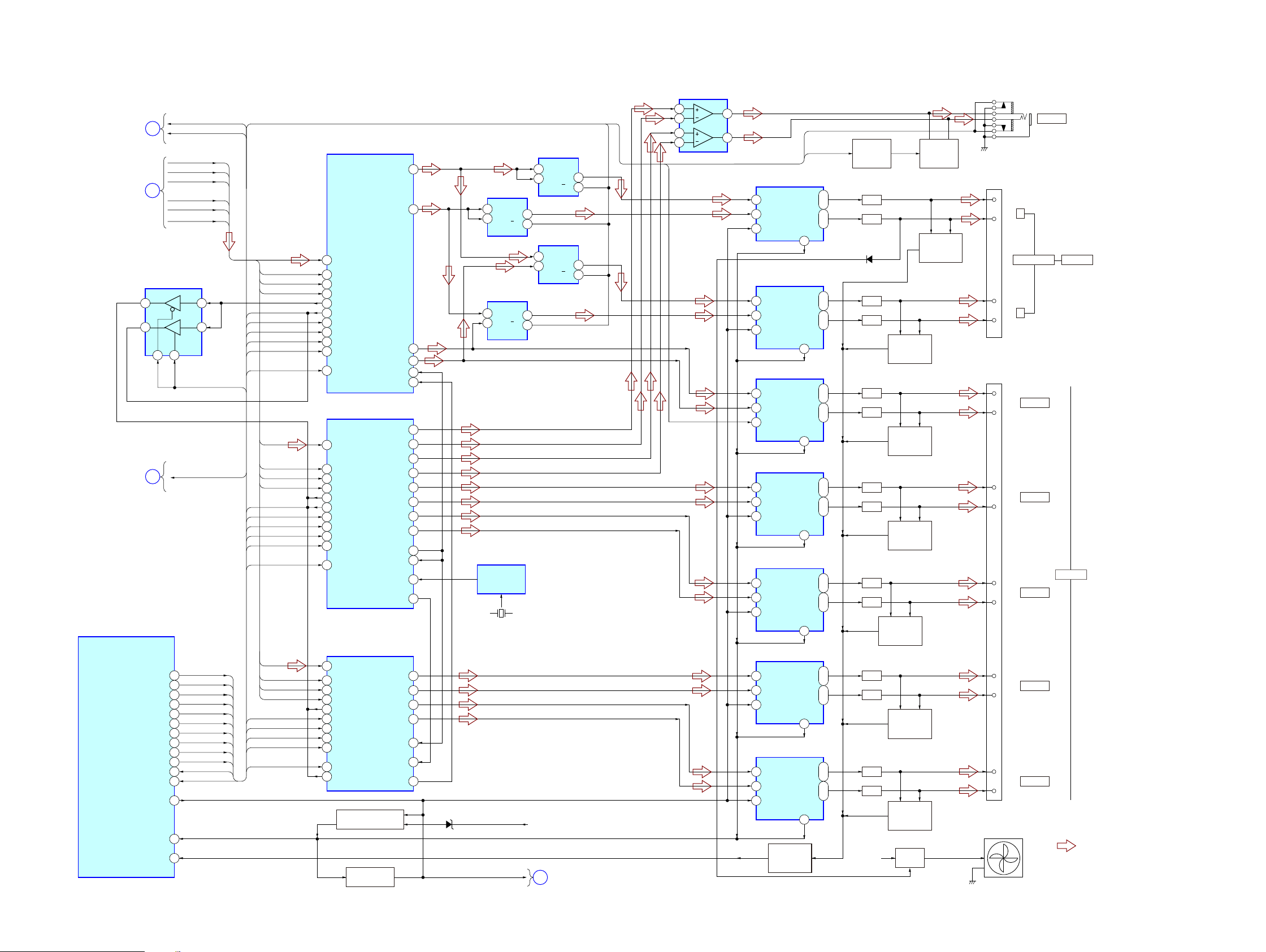

5-5. BLOCK DIAGRAM – AMP Section –

DSP

SECTION

(Page 24)

DSP

SECTION

(Page 24)

AUDIO

SECTION

(Page 23)

IC503 (5/6)

SYSTEM CONTROL

S_AIR_RST/C_SWR_SEL

S_AIR_ADC_SEL/DRIVER_C_EN

HP_MUTE/S_AIR_Rcv_SEL

DIR_CLK SHIFT

DIR_DIN SCDT

H

AMP_D1

AMP_D2

AMP_D3

J

BCKO

LRCKO

MCKO

IC3905

C/SWR SELECT

6

3

1 7

PLUG_DET

F

37

38

71

1DAMP_SCDT/DIR_DIN

2DAMP_SHIFT/DIR_CLK

59DAMP LAT1

60DAMP LAT2

61DAMP LAT3

57DAMP INIT

58SOFT MUTE

55OVERFLOW1

56OVERFLOW2

54DRIVE RST(EN)

67SD(DIAG)/PVDD_DET

66DC_DET

2

5

C_SWR_SEL

C_SWR_SEL

EN_C

HPMUTE

SCDT

SHIFT

LAT1

LAT2

LAT3

NS_INIT

SOFTMUTE

OVF1

OVF2

SD_PVDD_DET

DC-DET

AMP_D3

MCK0

BCK0

LRCK0

OVF2

SCDT

SHIFT

LAT3

NS_INIT

SOFTMUTE

AMP_D1

MCK0

BCK0

LRCK0

OVF1

SCDT

SHIFT

LAT1

NS_INIT

SOFTMUTE

AMP_D2

MCK0

BCK0

LRCK0

SCDT

SHIFT

LAT2

NS_INIT

SOFTMUTE

EN

IC3030

S-MASTER PROCESSOR

31

DATA

36 XFSIIN

30 BCK

29 LRCK

25 OVF FLAGL

24 OVF FLAGR

21 SCDT

22 SCSHIFT

23 SCLATCH

27 INIT

19 SOFTMUTE

IC3010

S-MASTER PROCESSOR

31

DATA

36 XFSIIN

30 BCK

29 LRCK

25 OVF FLAGL

24 OVF FLAGR

21 SCDT

22 SCSHIFT

23 SCLATCH

27 INIT

19 SOFTMUTE

IC3020

S-MASTER PROCESSOR

DATA

31

36 XFSIIN

30 BCK

29 LRCK

25 OVF FLAGL

21 SCDT

22 SCSHIFT

23 SCLATCH

27 INIT

19 SOFTMUTE

24 OVF FLAGR

Q3552 – 3555

B+ DOWN PROTECT

Q502,503

BUFFER

OUTR1(+)

OUTR1(+)

HCD-JZ8888K

IC3001

HEADPHONE AMP

3

2

5

IC3904

Y

A/B

Y

A/B

C/SWR SELECT

1

A

2

B

5

6

C/SWR SELECT

1

A

2

B

5

6

+31V

K

A/B

IC3902

A/B

POWER

SECTION

5

6

5

6

C_SWR_SELECT

Y

Y

SW

6OUTR1(+)

IC3903

SW

6OUTR2(–)

9OUTL1(–)

11OUTL2(+)

38FS0I

48XFS0IN

43HPOUTL2

45HPOUTL1

39HPOUTR2

41HPOUTR1

6

4OUTR2(–)

11OUTL1(+)

9OUTL2(–)

37FS0CKOUT

38FS0I

48XFS0IN

14XFS0OUT

6

4OUTR2(–)

11OUTL1(+)

9OUTL2(–)

38FS0I

48XFS0IN

14XFS0OUT

C

C

D3552

EN

C/SWR SELECT

1

A

2

B

IC3901

C/SWR SELECT

1

A

2

B

HP

HP

HP

HP

FR

FR

FL

FL

IC3051

CLOCK

OSCILLATOR

X3051

49.1MHZ

SR

SR

SL

SL

6

EN_C

1

7

(Page 26)

L

R

IC3500

DIGITAL POWER AMP

16 PWM_B

8 PWM_A

76/RESET

IC3400

DIGITAL POWER AMP

16 PWM_B

8 PWM_A

7

/RESET

IC3300

DIGITAL POWER AMP

16 PWM_B

8 PWM_A

76/RESET

IC3100

DIGITAL POWER AMP

16 PWM_B

8 PWM_A

7

/RESET

IC3150

DIGITAL POWER AMP

8 PWM_A

16 PWM_B

76/RESET

IC3200

DIGITAL POWER AMP

16 PWM_B

8 PWM_A

7

/RESET

IC3250

DIGITAL POWER AMP

8 PWM_A

16 PWM_B

7

/RESET

Q3551

DC BALANCE

PROTECT

OUT_B

OUT_A

SD

OUT_B

OUT_A

SD

6

OUT_B

OUT_A

SD

OUT_B

OUT_A

SD

6

OUT_A

OUT_B

SD

OUT_B

OUT_A

SD

6

OUT_A

OUT_B

SD

6

PLUG DET

HPMUTE

31

33

34

36

31

33

34

36

31

33

34

36

31

33

34

36

34

36

31

33

31

33

34

36

34

36

31

33

Q3081

H/P MUTE

DRIVE

LPF

LPF

D3551

LPF

LPF

LPF

LPF

LPF

LPF

LPF

LPF

LPF

LPF

LPF

LPF

M+14V

Q3251,3252

DC BALANCE

DETECT

Q3301,3302

DC BALANCE

DETECT

Q3101,3102

DC BALANCE

DETECT

Q3151,3152

DC BALANCE

DETECT

Q3401,3402

DC BALANCE

DETECT

Q3202,3201

DC BALANCE

DETECT

Q3000 – 3002

FAN

DRIVE

Q3116—3119

MUTE

Q3451,3452

DC BALANCE

DETECT

TB3901

TB301

FAN3001

DC FAN

(+)

L

(–)

SUBWOOFER

(+)

L

(–)

(–)

(+)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

J5001

PHONES

SPEAKER

CENTER

FRONT R

SPEAKER

FRONT L

SUR R

SUR L

v SIGNAL PATH

: TUNER

HCD-JZ8888K

2525

HCD-JZ8888K

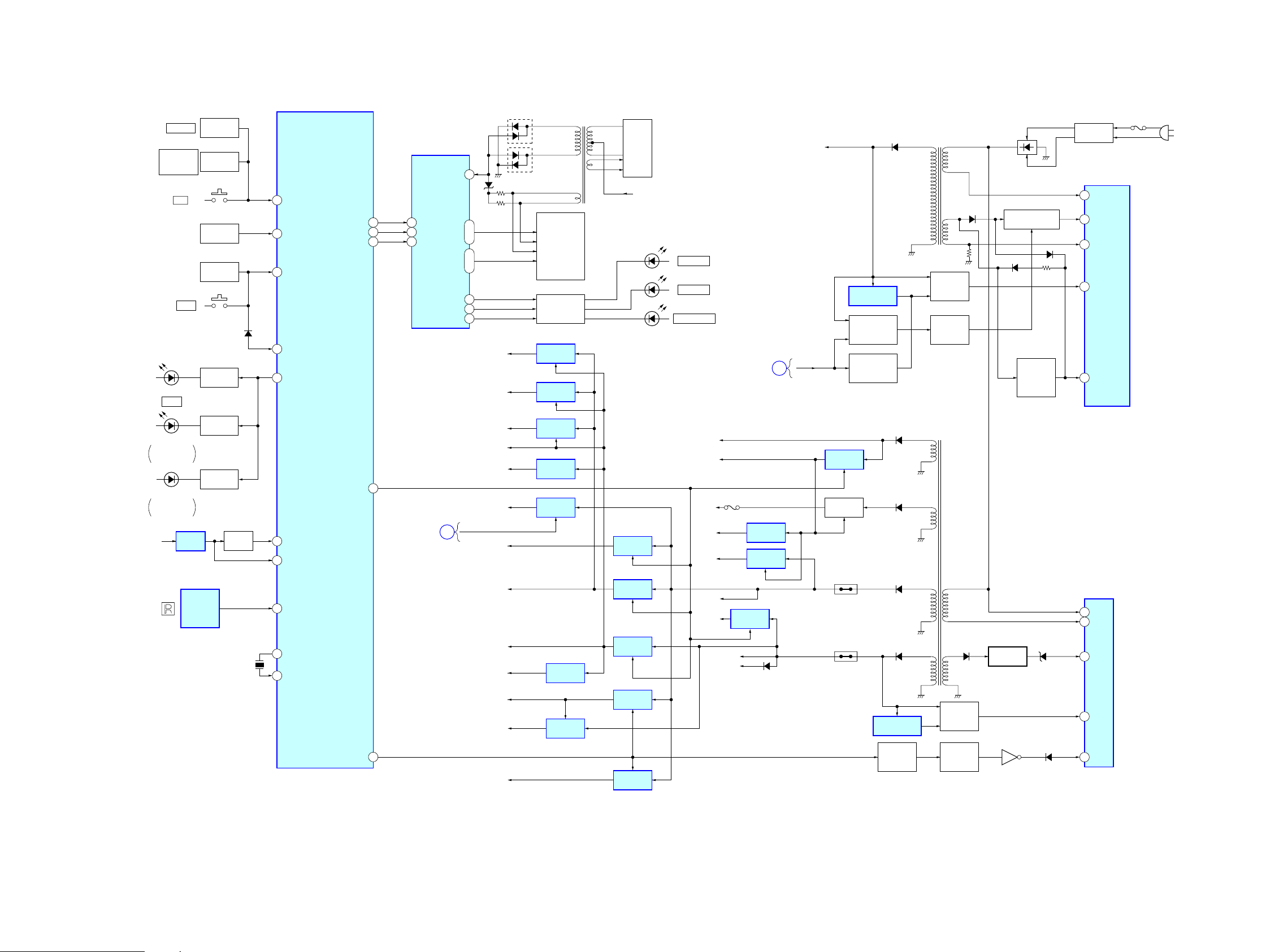

5-6. BLOCK DIAGRAM – POWER Section –

OPERATION

. >

D5400

@/1

D5601

KEY

ILLUMINATION

D5500—5502

KEY

ILLUMINATION

E+4V

S5501

VOLUME

S5500

DIAL

S5109

N

S5400

@/1

IC506

RESET

S5103,5600

FUNCTION

S5100—5102

FUNCTION

LED DRIVER

LED DRIVER

LED DRIVER

IC5002

REMOTE

CONTROL

RECEIVER

ROTARY

SWITCH

ROTARY

SWITCH

KEY

KEY

Q5400

Q5600

Q5500

D501

Q501

RESET

SYSTEM CONTROL

94 KEY2

95 KEY1

97 KEY0

73 KEY_INT

28 LED_PWM

12 RESET

20 AC CUT

4 SIRCS_IN

IC503 (6/6)

FL_CS

T5000

DC/DC

D5000

IC5001

FL DISPLAY

DRIVER

30VEE

7FL_CLK/LED_CLK

5FL_DATA/LED_DATA

3

39P.CONT1

8CLK

7DIN

9STB

P.CONT1

RF

SECTION

(Page 21)

S2 – 16

G1 – 12

L

15

–

29

42

–

31

1LED1

2LED2

3LED3

VBUS_SW

VIDEO+5V

(DMPORT)

D5002

+3.3V-3

(IC1101)

RF+3.3V

(IC1101)

+3.3V-2

(IC1101)

+3.3V-1

(IC1101)

+1.8V

(IC1101)

USB 5V

+5V

D5001

F1

F2

CONVERTER

TRANSFORMER

ND5000

FLUORESCENT

INDICATOR

TUBE

Q5001,5002,5601

LED DRIVER

IC1105

+3.3V REG.

IC1107

+3.3V REG.

IC1708

+3.3V REG.

IC 1110

+1.8V REG.

IC509

+5V REG.

Q5000

5V (FL)

IC452

+5V REG.

IC507

+5V REG.

DC/DC

CONVERTER

D5003

MOVIE

D5004

MUSIC

D5600

REC TO USB

M+14V

M+9V

(VIDEO)

(DSP)

A12V

+9V

+5V

+6V

+1.2V

F945

+1.2V REG.

AMP

SECTION

(Page 25)

P.CONT1

M+9V

IC4009

+9V REG.

IC4003

+5V REG.

IC707

K

M+14V

12V

+31V

(DIGITAL AMP)

EN

6V

IC941

+12V REG.

Q945

B+ SWITCH

PS956

IC932

SHUNT REG.

Q943,947

POWER DOWN

DETECT

Q949,950

POWER

PROTECT

D931

D912

D916

D911

T901

MAIN

TRANSFORMER

PC901

FEED BACK

PC903

STANDBY

CONTROL

T903

SUB

TRANSFORMER

D905

D901

Q901

POWER CONTROL

D914

Q951

OVER

CURRENT

PROTECT

D906

LF901,902

FILTER

IC901

SWITCHING

REGULATOR

3D

4VCC

2GND

5FB/OLP

1 OCP/SYNC

IC921

SWITCHING

REGULATOR

7VIN

9D

F901

(AC IN)

HCD-JZ8888K

X501

5MHz

Xout

13

15

Xin

41WRITE EMP P_CONT3

P.CONT3

D3.3V

+1.8V

(D-AMP)

5V

(FL)

+3.3V

(IC5001)

LED+5V

IC3050

+1.8V REG.

IC5000

+3.3V REG.

IC510

+3.3V REG.

IC504

+5V REG.

IC508

+5V REG.

E4V

E3.3V

D503

E+4V

PS954

P.CONT3

D947

IC923

SHUNT REG.

Q930

POWER

CONTROL

D902

PC902

FEED BACK

PC904

STANDBY

CONTROL

Q922

+21V REG.

Q921

DZ904

D923

4VCC

2FB

1ZC

2626

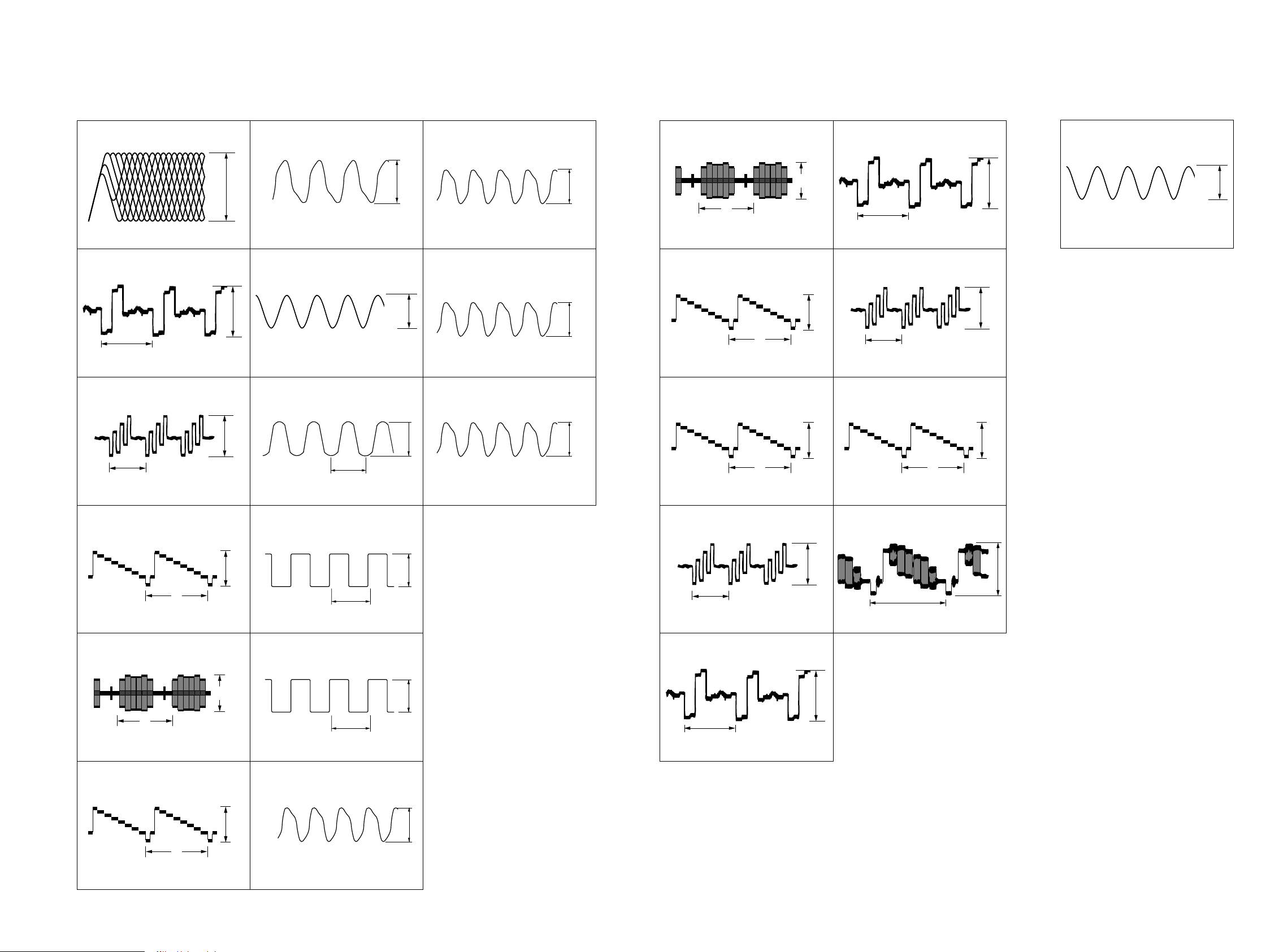

• Waveforms

HCD-JZ8888K

– MAIN Board –

1 IC1101 0 (DVDRFIP)

200 mV/DIV, 100 ns/DIV

2 IC1101 <z,x (R/Cr/Pr)

H

200 mV/DIV, 20 Ps/DIV

3 IC1101 <z,c (B/Cb/Pb)

650mVp-p

0.72Vp-p

7 IC1101 <xc, (XTALO)

27MHz

500 mV/DIV, 20 ns/DIV

8 IC503 qd (Xout)

5MHz

1 V/DIV, 100 ns/DIV

9 IC304 qd (CKOUT(O))

qd IC3051 2 (3Y)

1.6Vp-p 5Vp-p

1 V/DIV, 10 ns/DIV

49.1MHz

qf IC3010 rk (XFSOIN)

3.4Vp-p

49.1MHz

1 V/DIV, 10 ns/DIV

4.3Vp-p

qg IC3010 qf (XFSOOUT)

3.5Vp-p

– IO-COMPONENT Board –

1 IC4002 2 (Cin)

H

500 mV/DIV, 20 Ps/DIV

2 IC4002 6 (Yin)

H

500 mV/DIV, 20 Ps/DIV

3 IC4002 0 (CYin)

1Vp-p

1Vp-p

1Vp-p

6 IC4002 qh (Cr OUT)

H

500 mV/DIV, 20 Ps/DIV

7 IC4002 qk (Cb OUT)

H

500 mV/DIV, 20 Ps/DIV

8 IC4002 w; (CY OUT)

2Vp-p

1Vp-p

2Vp-p

– DSP Board –

1 IC700 <zvc (XTAL)

1.8Vp-p

25MHz

0.5 V/DIV, 20 ns/DIV

H

200 mV/DIV, 20 Ps/DIV

4 IC1101 <z,b (Y/G)

500 mV/DIV, 20 Ps/DIV

5 IC1101 <z,. (C)

H

500 mV/DIV, 20 Ps/DIV

6 IC1101 <z.z (Y)

H

0.72Vp-p

1Vp-p

1Vp-p

40.7nsec

1 V/DIV, 20 ns/DIV

0 IC304 qf (BCK(O))

163nsec

1 V/DIV, 50 ns/DIV

qa IC304 qg (LRCK(O))

10.4Psec

1 V/DIV, 5 Ps/DIV

qs IC304 wa (XOUT(O))

3.5Vp-p

3.5Vp-p

49.1MHz

1 V/DIV, 10 ns/DIV

4Vp-p

H

500 mV//DIV, 20 Ps/DIV

4 IC4002 qs (Cb in)

H

200 mV/DIV, 20 Ps/DIV

5 IC4002 qf (Cr in)

H

200 mV/DIV, 20 Ps/DIV

H

1 V/DIV, 20 Ps/DIV

9 IC4002 wd (CVBS OUT)

2.6Vp-p

0.72Vp-p

H

1 V/DIV, 20 Ps/DIV

0.72Vp-p

500 mV/DIV, 20 Ps/DIV

HCD-JZ8888K

1Vp-p

H

1 V/DIV, 20 ns/DIV

24.576MHz

4Vp-p

2727

HCD-JZ8888K

5-7. PRINTED WIRING BOARD – MAIN Section (1/2) –

CL327

R453

C457

R1246

R1247

2

4

CN1202

R328

IO-COMPONENT

BOARD

CN4003

(Page 40)

(KHM-313CAA)

IO-COMPONENT

K

DVD DRIVE

(1/2)

OPTICAL

( )

PICK-UP

D

MS-203

BOARD

CN001

(Page 29)

J

BOARD

CN4006

(Page 40)

(17P)

CN472

(17P)

CN503

• See page 20 for Circuit Boards Location.

CN451 CN1701

DMPORT HDMI OUT

IC1707

C1727

C1729

3

C1730

54

1

C1734

R1757

C1733

C1732

45

C1731

IC1708

R1159

R1160

R1161

R2187

R1146

R1183

R1184

R1185

C1153

X1101

C1152

C1148

C1147

C1139

C1138

C1137

C1135

R1114

C1113

R1123

R1107

R1124

Q1102

CL2103

R1109

R1110

R346

R344

R347

R531

R535

D501

R537

R540

R543

R532

R538

R539

CL529

CL528

R544

C514

C515

100 81

180

13

13

R1219

C1210

R1224

I

R2135

R1212

FB2124

FB2125

FB2122

FB2121

FB2120

C1186

C1195

C1208

R1210

C1203

R1215

R1214

JL510

C1198

C1211

JL506

O

C1183

R2116

IC1105

45

C1182

R1151

C1193

45

R1121

R1120

R1118

R1115

R1113

R1112

R1216

R1204

R1207

C1206

R1209

CL1201

C1205

R1208

R1225

R1220

R546

R547

R564

IC503

JL518

JL526

JL527

30 51

JL528

JL520

JL525

R592

R558

R570

R571

1

2

JL524

JL522

JL523

R621

R626

R620

JL453

R465

R451

L451

1

5

IC504

JL451

C452

C453

R452

IC451

85

R327

16

2

IC505

C526

C451

C462

C461

R456

14

C456

R454

R462

C1222

C1221

C1223

CL304

CL348

CL349

17

CN503

1

58

C520 R569

46

C516

18

JL452

R466

JL454

R457

R460

C1219

C1224

C1215

R343

R345

14 8

IC303

R514

R516

R518

R520

R523

JL532

JL531

14

13

C521

CN451

24

2536

IC1201

37

R1233

CL1208

17

R596

R598

R552

19

18

CL1207

R553

C1214

CL1206

R1230

C523

R1228

R1231

R348

C310

C309

C308

JL530

JL529

R597

C525

IC506

17

16

CN472

2

1

R1186

R1192

C1192

IC1107

R1222

R1227

C1213

13

48

C1212

R1223

CL1213

R1221

R333

JL507

JL508

JL509

JL517

Q501

D502

EB

R599

C524

R554

C522

CN507

(19P)

CN507

I

(Page 47)

IC1110

R2111

R2112

C1184

CL1205

CL1204

12

1

R1206

R1226

C1233

C1209

JL511

JL519

C527

R555

FL-JACK

BOARD

CN5001

• : Uses unleaded solder.

MAIN BOARD (SIDE A)

CN1701

R2115

CL2101

CL1121

C1136

R394

R407R408

RB1110

RB1112

R337

CL343

R405 R406

R384

RB1109

RB1113

R1156

JL1160

CL2102

Q1103

IC2101

R2191

C330

IC304

1

CL345

CL344

R356

JL471

CL2109

EB

R1116

R338

R1108

R395

C321

R340

R1117

FB2102

2536

12

C318

R574

2854

IC1104

IC1102

1

Q1101

85

C2103

14

R2192

R372

R370

24

R371

13

R342

R366

C319

R330

R341

3

1

R2101

193

R1752

R1742

C1725

13

45

IC1705

19

R1747

Q1701

64

RB1114

R1748

31

RB1103

RB1111

RB1104

R2114

RB1115

129192

128

1

L1701

L1702

L1703

L1704

IC1101

R2168

R1142

R2167

256

164

CL1116

1

2

R533

R534

JL501

R627

IC508

R622

D505

C1133

C1132

R1136

R577

CL1115

5031

C1120

C1101

CN1101

R618

C1121

CL1112

JL505

JL512

C533

C1122

CL1118

CL1114

JL502

C517

JL516

45

C1123

JL513

CL1117

CL1113

CL1101

C1124

23

JL503

R556

JL521

13

CL1105

CL1108

24

R2110

CL1302

CL1303

CL1301

CL1304

CL1305

JL504

D503

SL501

JL515

C542

65

CL1110

CL2107

R2127

R2128

R2121

R2123

L2101

R398

R397

R396

R364

37

R361

R362

R391

R390

R358

C332

16

18

C328

48

R336

9

IC306

R619

R617

R616

R625

R613

R610

R611

R615

R1111

C2101

R2193

R2194

R367

N

C1110

CL2108

X301

R368

R374

27

RB1106

RB1105

1

2548

D9712

R9935

Q9728

EB

Q9724

24

R2195

C327

C326

TP3006

R369

JL3062

29

CN305

1

DSP

BOARD

CN701

(Page 42)

CL1702

R9945

EB

EB

R9941

EB

LP301

30

IC3001

2

Q9729

C9972

R9929

R9934

R9928

Q9726

R9924

IC3905

R411

R3067

R3068

C3092

C3083

R3916

R3915

R3092

R3088

C544

LP501

C3919

SL3005

SL3006

R3076

R3074

R3075

R3922

85

1

4

TP3229

R3034

R3035

TP3231

R3037

TP3022

TP3129

R3023

R3024

TP3131

R3026

SL3003

SL3004

TP3024

R3012

TP3029

R3014

R3015

TP3002

R3017

14

85

C3008

TP3005

TP3032

TP3136

R3013

R3011

TP3036

TP3015

R3053

L3054

C3060

R3091 R3093

C3085 C3086

R3087 R3089

C3087 C3088

R3098 R3099

IC3050

R3094

R3090

C3055

C3093

R3086

C3084R3085

IC3903

IC3904

IC3901

IC3902

R3033

R3031

R3032

TP3230

TP3236

R3021

R3022

TP3130

IC3010

TP3026

TP3030

IC3051

C3059

R3052

X3051

45

C3052

R3047

EB

R505

IC501

24

2536

37

IC3030

R3057

24

2536

37

IC3020

24

2536

37

58

14

C3053

13

Q3081

L3053

L3051