Page 1

HCD-CP11

SERVICE MANUAL

Ver 1.1 2002. 07

HCD-CP11 is the Amplifier, CD

player, Tape Deck and Tuner section

in CMT-CP11/CP11K.

Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks of Dolby Laboratories Licensing Corporation.

CD

Section

Tape deck

Section

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM55D-K5BD41

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type CMAL1Z212

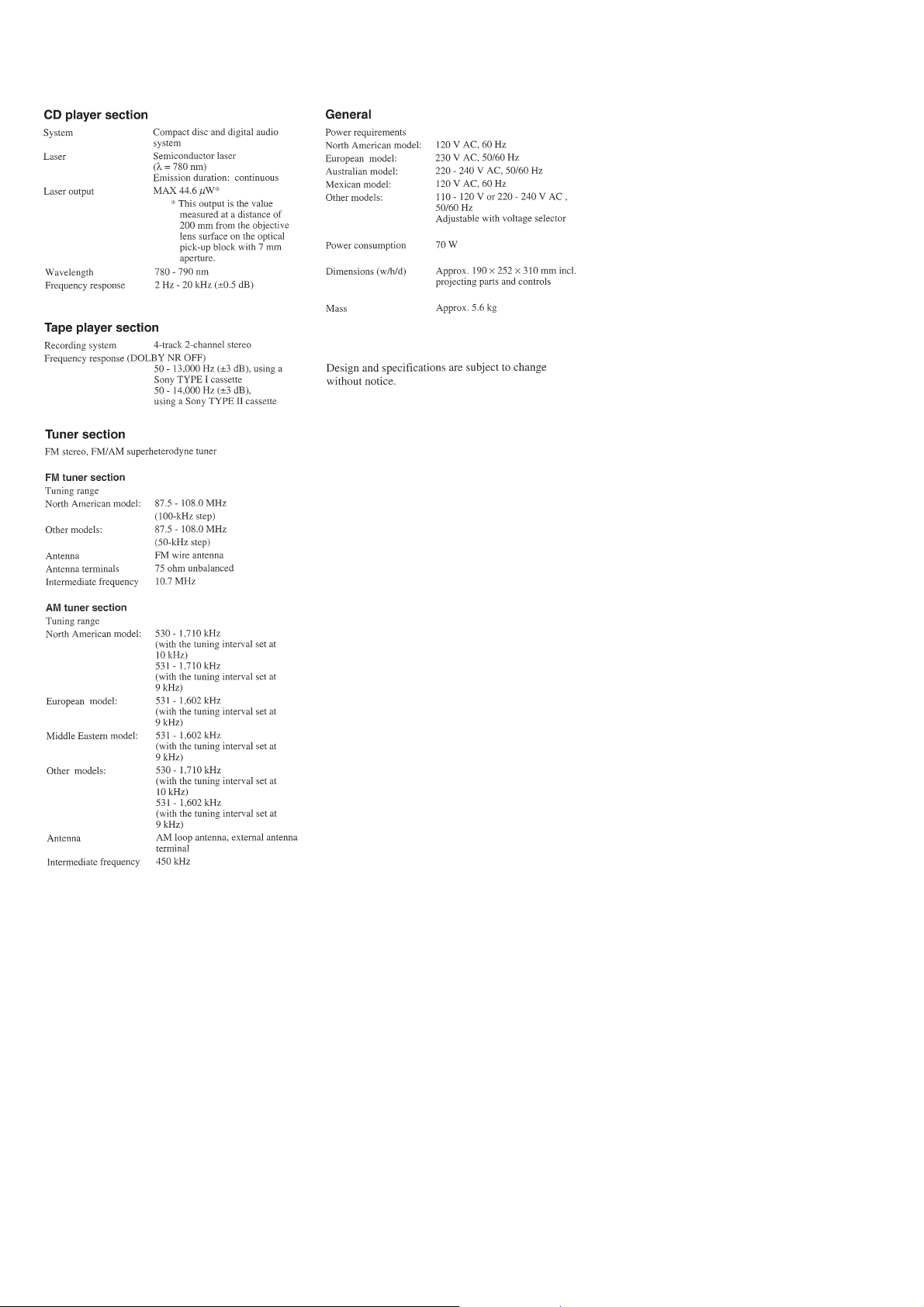

SPECIFICATIONS

— Continued on next page —

9-929-095-12

2002G1600-1

© 2002.07

MICRO Hi-Fi COMPONENT SYSTEM

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

Page 2

2

Page 3

TABLE OF CONTENTS

SECTION 1

SERVICING NOTES

1. SERVICING NOTES ······················································ 3

2. GENERAL ·········································································· 5

3. DISASSEMBLY ································································ 7

4. SERVICE MODE··························································· 11

5. ELECTRICAL CONFIRMATIONS AND

ADJUSTMENTS ···························································· 12

6. DIAGRAMS

6-1. Circuit Boards Locations ··················································· 14

6-2. Block Diagram – TAPE Section – ····································· 15

6-3. Block Diagram – MAIN Section – ···································· 16

6-4. Block Diagram

– DISPLAY/POWER SUPPLY Section – ························· 17

6-5. Printed Wiring Board – MAIN Section – ·························· 18

6-6. Schematic Diagram – MAIN Section (1/2) – ···················· 19

6-7. Schematic Diagram – MAIN Section (2/2) – ···················· 20

6-8. Printed Wiring Boards

– LCD/HEADPHONE/LOADING/SPEAKER Section –· 21

6-9. Schematic Diagrams

– HEADPHONE/SPEAKER Section – ····························· 21

6-10.Printed Wiring Boards – CONTROL Section – ················· 22

6-11.Schematic Diagram – CONTROL Section –····················· 23

6-12.Printed Wiring Board – POWER Section – ······················· 24

6-13.Schematic Diagram – POWER Section –·························· 25

6-14.IC Block Diagrams ···························································· 26

6-15.IC Pin Function Description ·············································· 28

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

7. EXPLODED VIEWS ····················································· 30

8. ELECTRICAL PARTS LIST····································· 34

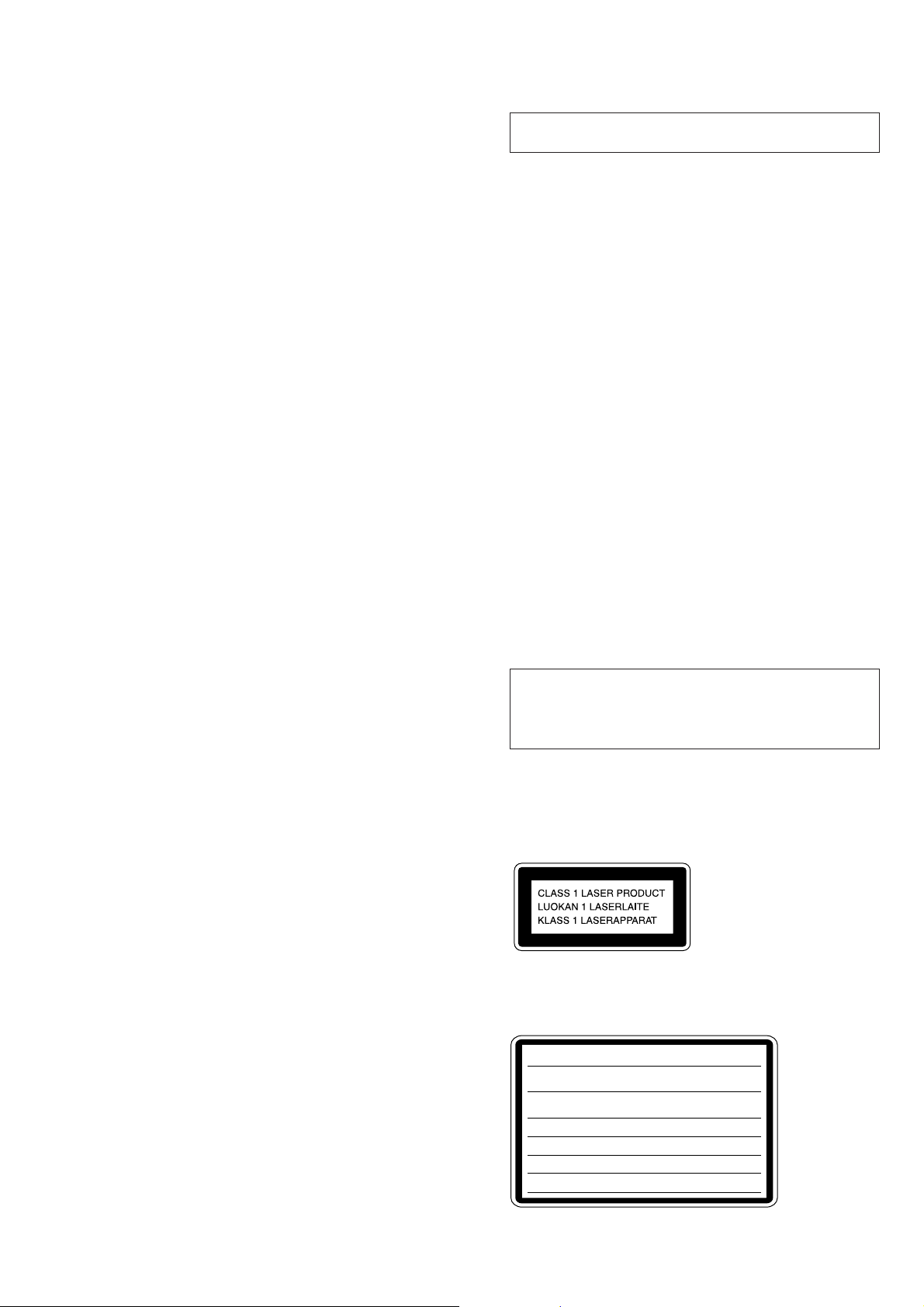

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

CAUTION :

INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

ADVARSEL :

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION. UNDGÅ UDSAETTELSE

FOR STRÅLING.

VORSICHT :

ABDECKUNG GEÖFFNET UND SICHERUEITSVERRIEGELUNG

ÜBERBRÜCKT. NICHT DEM STRAHL AUSSETZEN.

VARO!:

TIINA NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VARNING :

OCH SPÄRREN ÄR URKOPPLAD. BETRAKTA EJ STRÅLEN.

ADVERSEL :

SIKKERHEDSLÅS BRYTES. UNNGÅ EKSPONERING FOR STRÅLEN.

VIGYAZAT!:

GÁRVESZÉLY

INVISIBLE LASER RADIATION WHEN OPEN AND

USYNLIG LASERSTRÅLING VED ÅBNING NÅR

UNSICHTBARE LASERSTRAHLUNG, WENN

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET AL T-

OSYNLING LASERSTRÅLING NÄR DENNA DEL ÄR ÖPPNAD

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG

A BURKOLAT NYITÁSAKOR LÁTHATATLAN LÉZERSU-

!

KERÜLJE A BESUGÁRZÁST!

3

Page 4

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

MODEL IDENTIFICATION

– Back Panel –

Power Voltage

Indication

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the

following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakag e. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part having

a return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

Model

US, CND, MX, KR models

AEP, UK, AED, CIS, models

E, EA, AR, HK, MY, SP,

TW , A US models

• Abbreviation

EA : Saudi Arabia model.

AUS : Australian model.

SP : Singapore model.

MY : Malaysia model.

TW : Taiwan model.

HK : Hong Kong model.

AR : Argentine model.

CND : Canadian model.

AED : North European model.

MX : Mexican model.

KR : Korean model.

VOLTAGE SELECTOR

Switch

Power Voltage

Incdication

AC: 120 V 60 Hz 55 W

AC: 230 V ⁄50 Hz 55 W

AC: 110 – 120/

220 – 240 V / 50/60 Hz 55 W

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated A C voltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate lo w-v oltage

scale. The Simpson 250 and Sanwa SH-63Trd are e xamples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

T o Exposed Metal

Parts on Set

AC

0.15

µ

F

Fig. A. Using an AC voltmeter to check AC leakage.

1.5 k

Ω

Earth Ground

Voltmeter

(0.75 V)

4

Page 5

SECTION 2

GENERAL

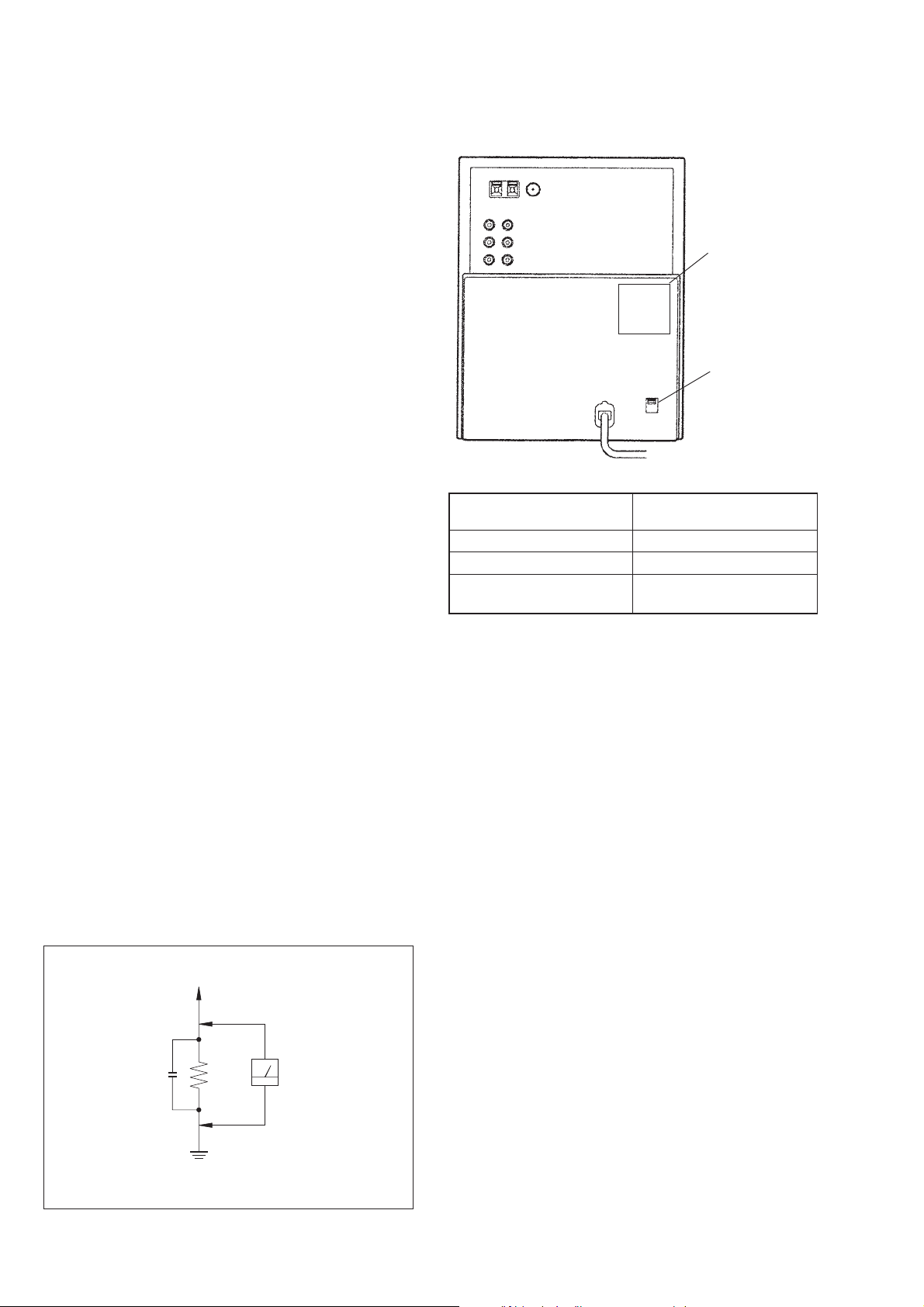

LOCATION OF CONTROLS

• Front View

2

1

ql

w;

wa

ws

wd

wf

wg

wh

1 TAPE deck

2 Liquid crystal display

6543

7

8

9

0

qa

qs

qd

qf

qg

qh

qj

qk

wl

eseae;wkwj

3 TAPE P button

4 TAPE 0 button

5 TAPE œ button

6 TAPE 6 button

7 TAPE p button

8 TAPE ) button

9 TAPE REC r button

0 CD SYNC button and indicator

!¡ BAND button

!™ TUNING + button

!£ TUNING – button

!¢ TUNING MODE button

!∞ CD EJECT 6 button

!§ CD p button

!¶ CD + ) button

!• CD REPEAT button

!ª DSG button and indicator

@º STANDBY 1/u button and indicator

@¡ MD/VIDEO button and indicator

@™ TAPE button and indicator

@£ CD button and indicator

@¢ TUNER button and indicator

@∞ Remote sensor

@§ jack

@¶ PHONES jack

@• CD disc tray

@ª VOLUME knob

#º CD ^ button

#¡ CD = 0 button

#™ CD PLAY MODE button

• Rear View

4

5

6

7

1

2

1 AM ANTENN A terminals

2 FM ANTENNA jack or terminals

3

3 SPEAKER terminals

4 LINE OUT jacks

5 MD IN jacks

6 VIDEO IN jacks

7 CD DIGITAL OUT OPTICAL connector

5

Page 6

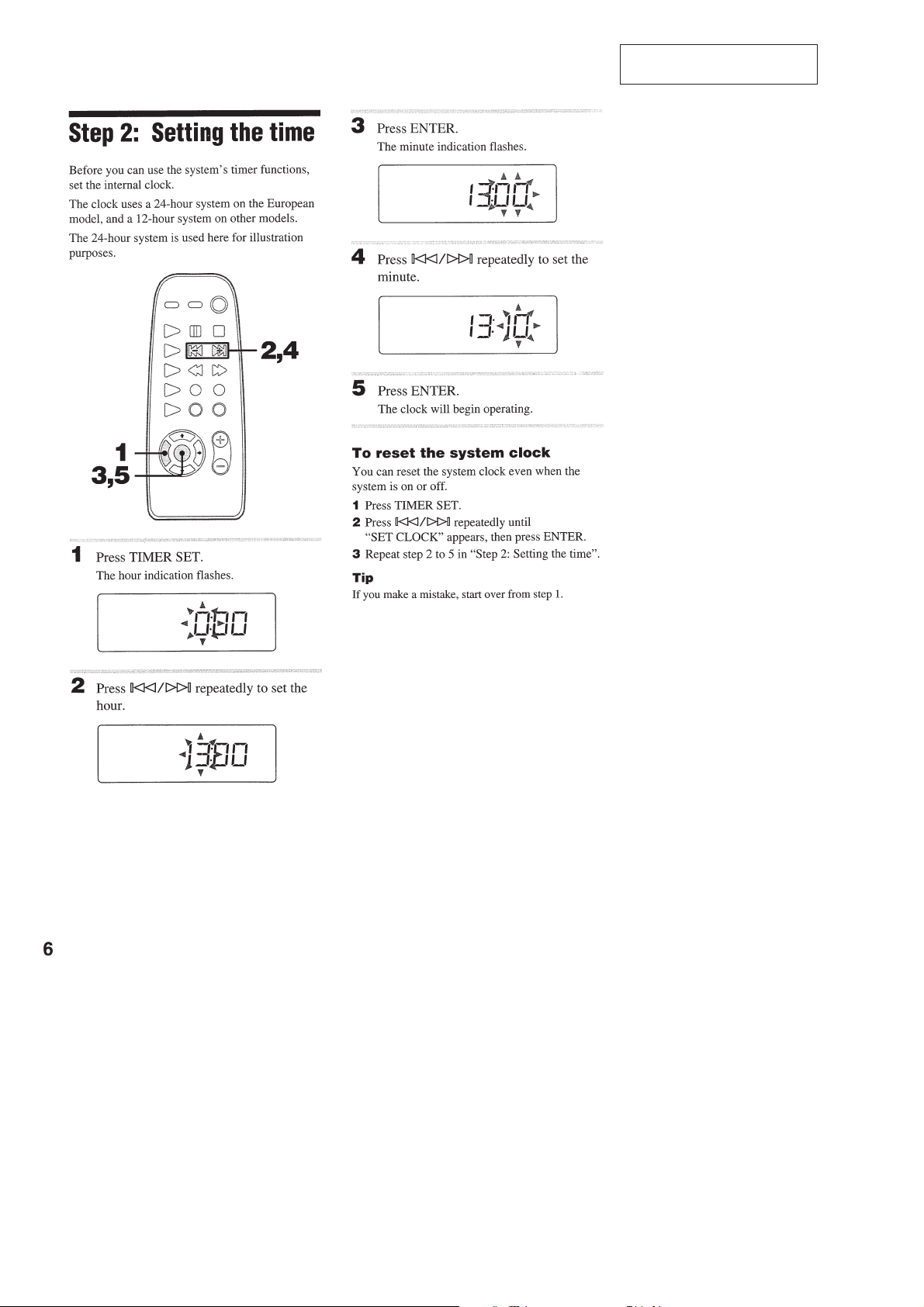

This section is extracted from

instruction manual.

6

Page 7

SECTION 3

)

s

DISASSEMBLY

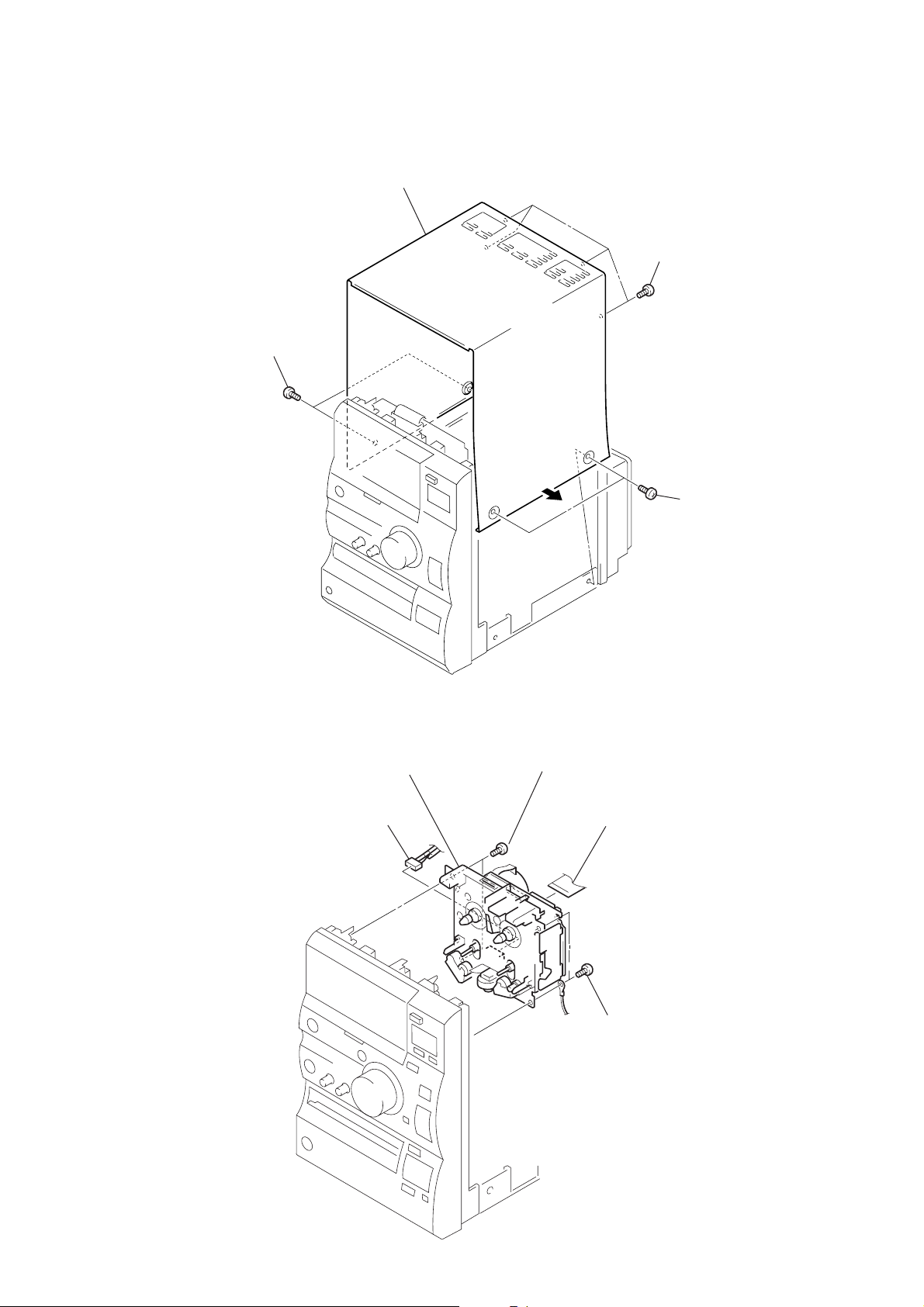

Note: Follow the disassembly procedure in the numerical order given.

3-1. COVER (UPPER)

4

Cover (upper)

1

Two screws

(case3 TP2)

2

Four screws

(BTP3

3

×

8)

Two screws

(case3 TP2

3-2. TAPE MECHANISM DECK

5

T ape

mechanism deck

2

Connector

3

Two screws

(BTP3

×

8)

1

Flat wire (12 core)

4

Two screw

(BTP3 × 8)

7

Page 8

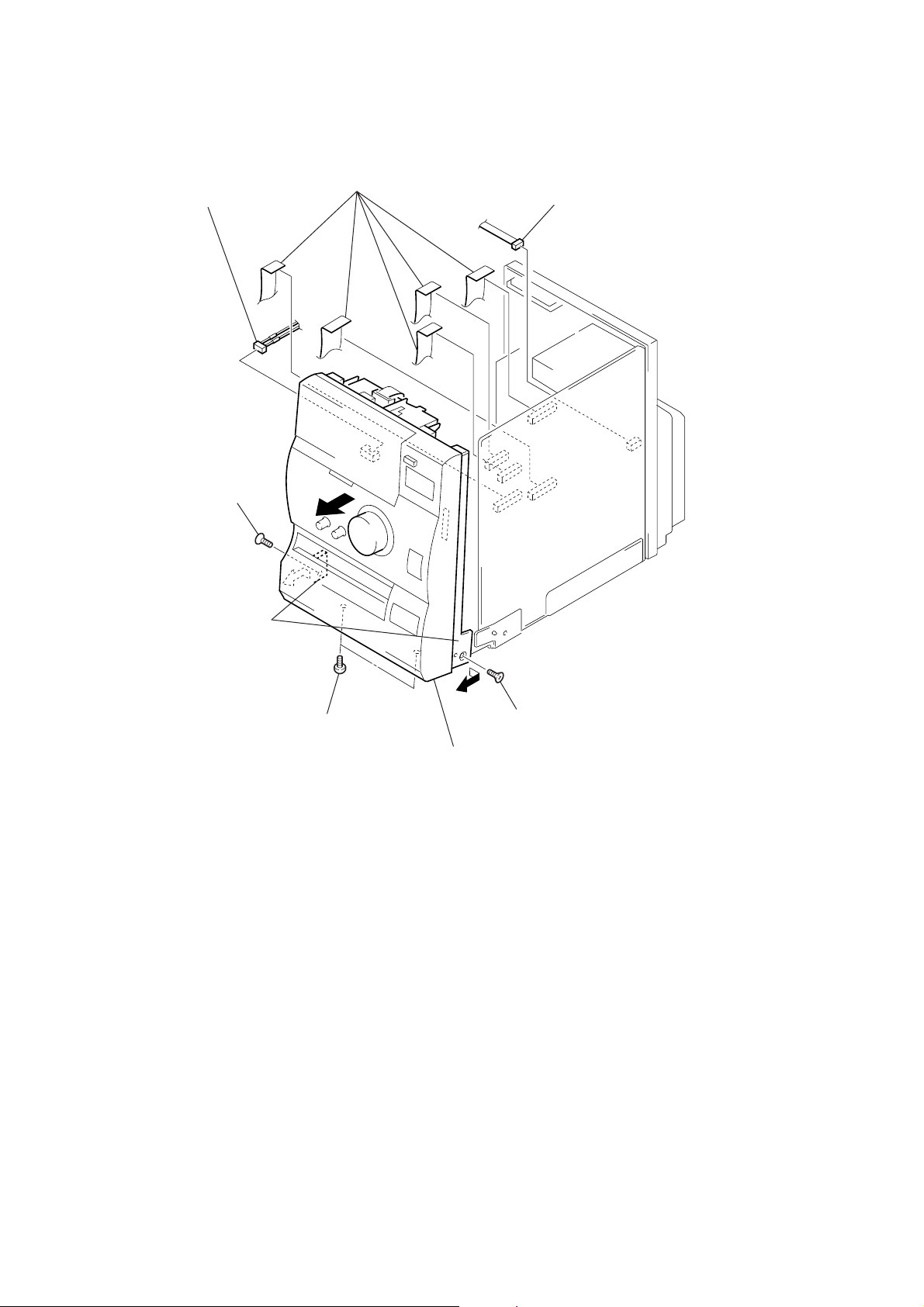

3-3. FRONT PAENL SECTION

3

Connector

4

Screw

(TP3

×

6)

2

Flat wire

1

Connector

(CN303)

Two claws

5

Two screws

(BTP3

×

8)

7

(There is a claw.)

6

Screw

(KTP3

Front panel section

×

6)

8

Page 9

3-4. CD MECHANISM DECK

r

w

3

Screw

(BTP3

×

8)

2

flat wire (19 core)

(CN805)

1

connecto

3-5. UPPER CHASSIS

2

Upper chassis

4

CD mechanism deck

1

Scre

9

Page 10

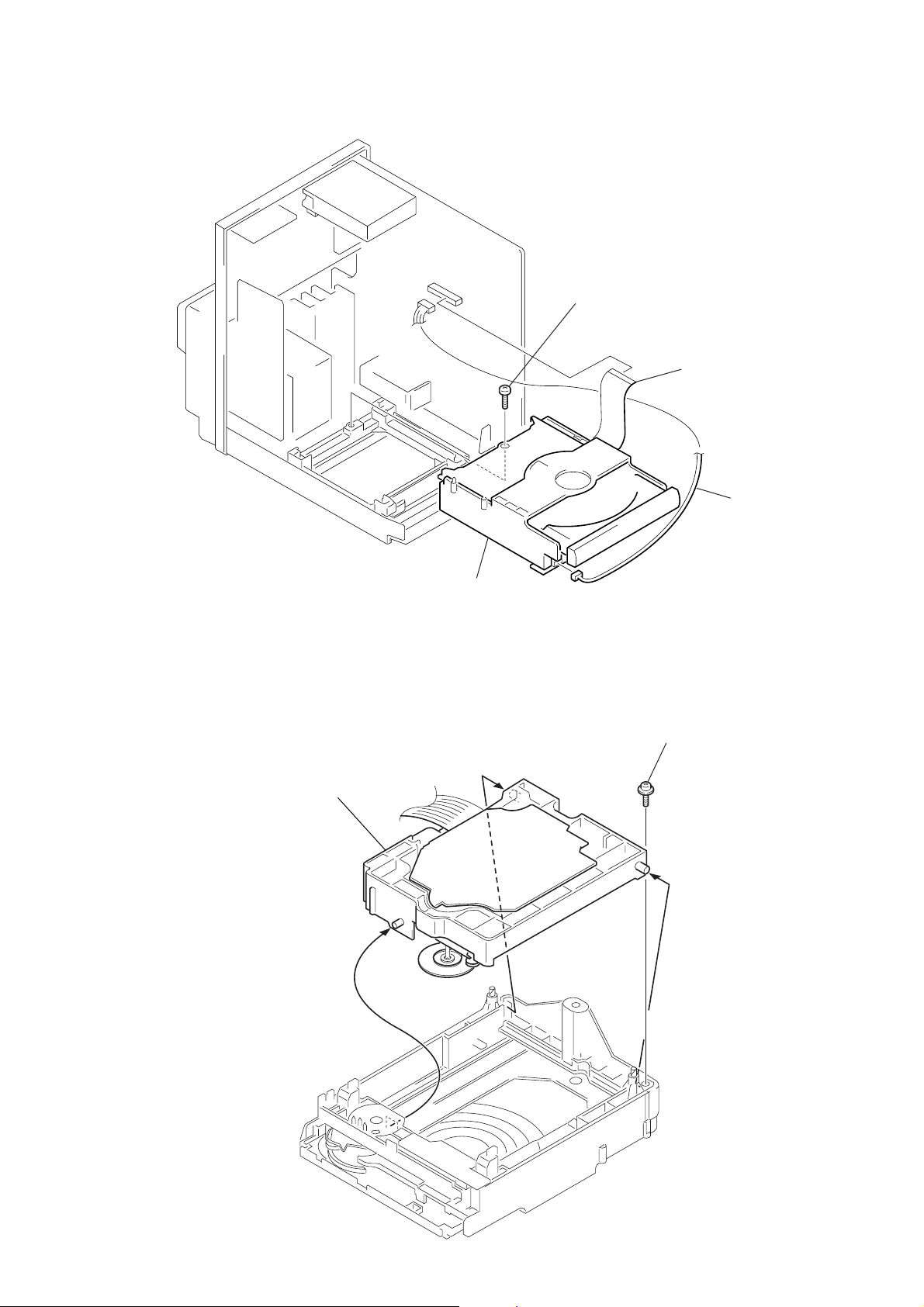

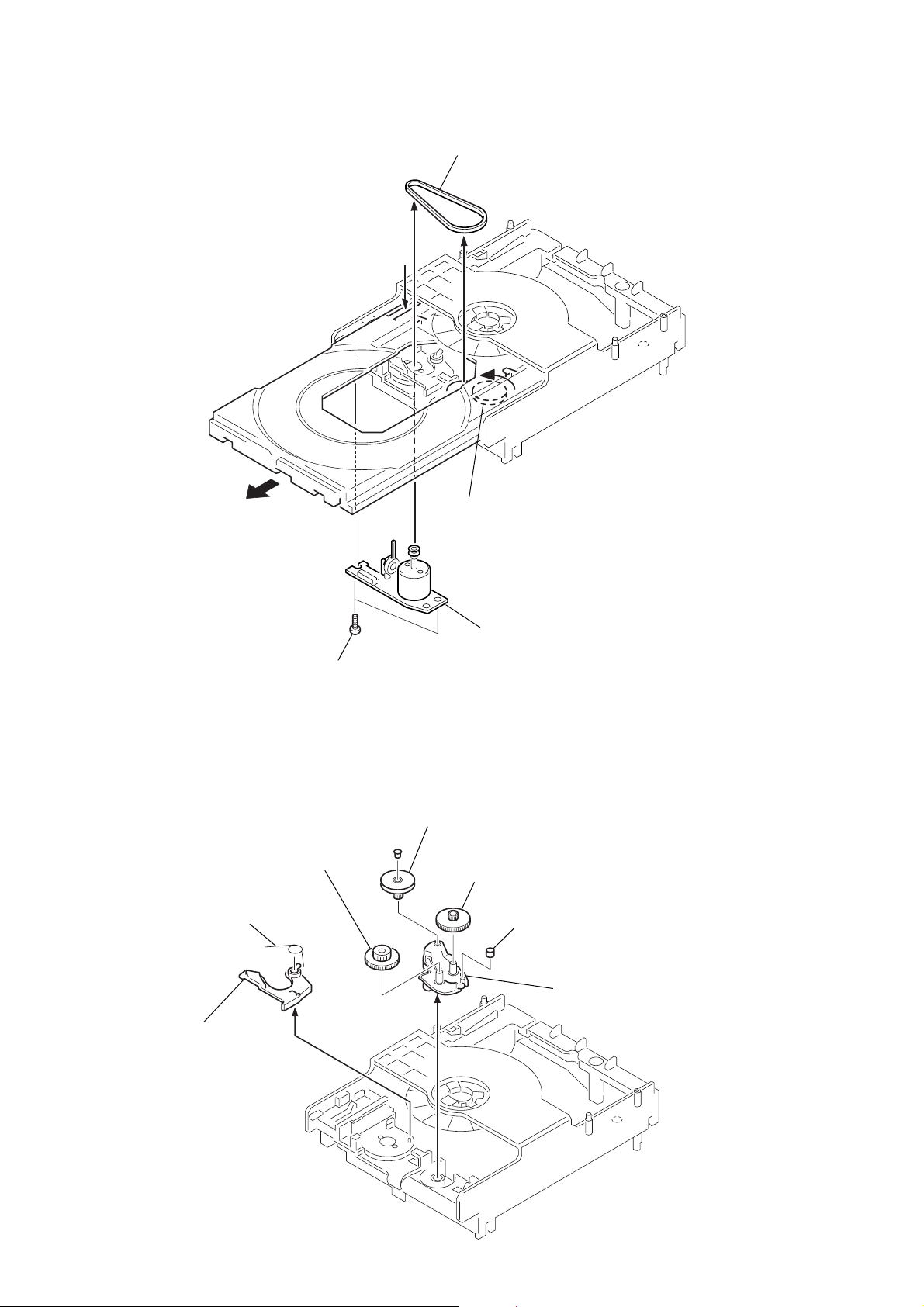

3-6. TRA Y

5

Pull the tray

2

Belt

A

1

Rotate the control cam in

the direction of arrow

A

3-7. CAM

2

SW lever

1

Torsion spring

3

5

Two screws

Gear

3

Pulley

4

4

Gear

Motor board

6

Roller

7

Cam

10

Page 11

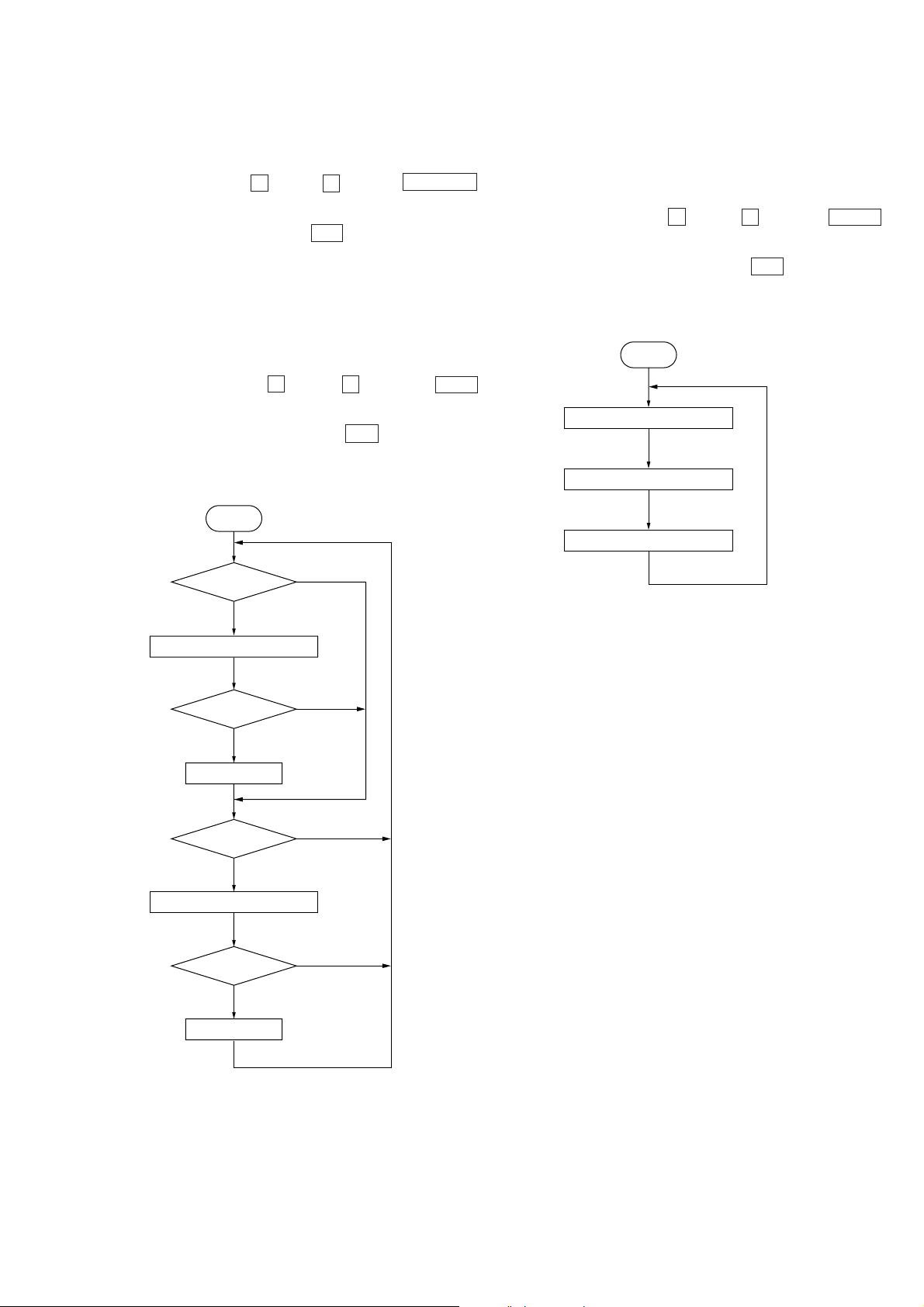

SECTION 4

SERVICE MODE

[Liquid Crystal Display All Lit Check Mode]

Procedure:

1. Set to standby state.

2. Press three buttons of x (T APE), x (CD), and MD/VIDEO

simultaneously.

3. Liquid crystal display are all turned on.

4. To e xit from this mode, press the ?/1 button to turn the power

OFF .

[Tape Deck Aging Mode]

This mode can be used for operation check of tape deck section.

Procedure:

1. Set a tape in the tape deck.

2. Set to standby state.

3. Press three buttons of x (TAPE), x (CD), and TAPE

simultaneously.

4. The aging is executed in bellow sequence.

5. To e xit from the aging mode, press the ?/1 button to turn the

power OFF.

Aging mode sequence:

Start

[CD Aging Mode]

This mode can be used for operation check of CD section.

Procedure:

1. Load a CD disc.

2. Set to standby state.

3. Press three buttons of x (TAPE), x (CD), and TUNER

simultaneously.

4. The aging is executed in bellow sequence.

5. To e xit from the aging mode, press the ?/1 button to turn the

power OFF.

Aging mode sequence:

Start

Open the disc tray

Close the disc tray

Play the last track

FWD Play

1 minute

REC pause for 3 seconds

FWD REC

3 minutes

Fast forward

REV Play

1 minute

REC pause for 3 seconds

REV REC

3 minutes

Shut off

Shut off

Shut off

Shut off

Rewind

11

Page 12

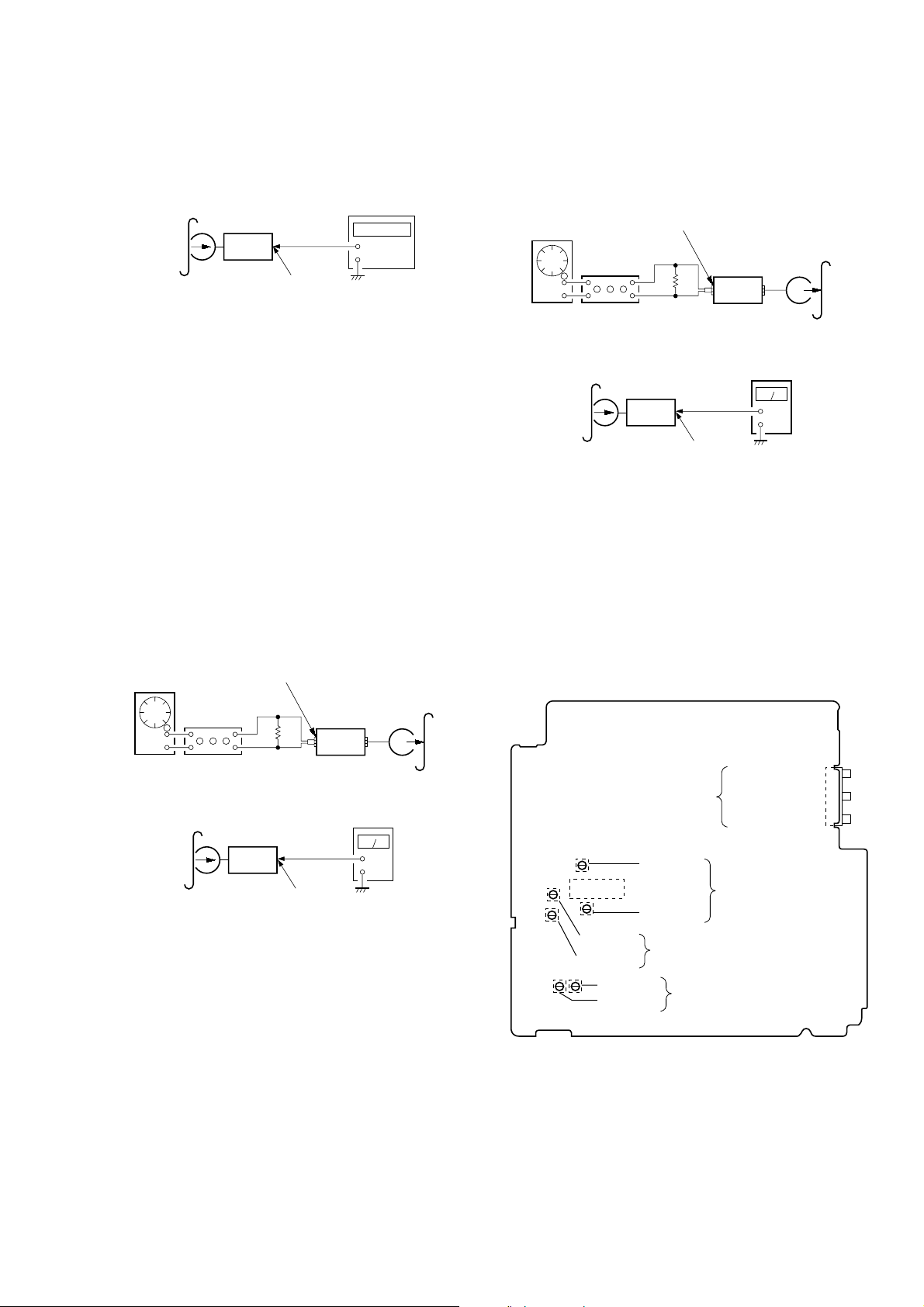

SECTION 5

r

ELECTRICAL CONFIRMATIONS AND ADJUSTMENTS

DECK SECTION

Note: Confirm each contents of this section first of all. If the results are

not satisfied, do the adjustment.

0 dB=0.775 V

1. Demagnetize the record/playback head with a head

demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit

adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise

specified.

• Test Tape

Tape Signal Used for

P-4-A100 10 kHz, –10 dB Azimuth Adjustment

WS-48B 3 kHz, 0 dB Tape Speed Adjustment

P-4-L300 315 Hz, 0 dB Level Adjustment

Record/Playback Head Azimuth Adjustment

Procedure:

1. Mode: Playback

test tape

P-4-A100

(10 kHz, –10 dB)

MAIN board

LINE OUT jack (PJ301)

L-CH, R-CH

level mete

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

Output

level

within

1dB

L-CH

peak

R-CH

peak

within

1dB

Screw

position

L-CH

peak

Screw

position

R-CH

peak

3. Mode: Playback

MAIN board

test tape

P-4-A100

(10 kHz, –10 dB)

L-CH

MAIN

board

CN301

set

R-CH

in phase 45°90°135°180

LINE OUT jack (PJ301)

L-CH

R-CH

waveform of oscilloscope

good

oscilloscope

wrong

H

V

°

set

+

–

4. Repeat step 1 to 3 in playback (REV) mode.

5. After the adjustments, apply suitable locking compound to the

pats adjusted.

Adjustment Location:

reverse

forward

12

Page 13

Playback level Confirmation and Adjustment

r

set

MAIN board

MD IN jack (PJ301)

L-CH, R-CH

315 Hz, 50 mV (–23.8 dB)

blank tape

CS-123

600

Ω

attenuator

AF OSC

+

–

set

recorded

portion

MAIN board

LINE OUT jack (PJ301)

L-CH, R-CH

level meter

PJ301

Playback Level

REC Bias

REC Level

RV252 (R)

IC352

LINE OUT (L/R)

MD IN (L/R)

VIDEO IN (L/R)

RV152 (L)

RV251 (R)

RV151 (L)

RV253 (R)

RV153 (L)

Procedure:

Mode: Playback

test tape

WS-48B

(3 kHz, 0 dB)

frequency counter

REC Level Confirmation and Adjustment

Procedure:

1. Mode: Record

set

MAIN board

LINE OUT jack (PJ301)

L-CH, R-CH

+

–

Confirm playback level is within specification values as follows.

If these levels are out of specification v alues, adjust the RV151 (LCH) and RV251 (R-CH) on the MAIN boar d so that the lev el meter

reading become within specification values.

Specification values:

PJ301 PB level: 301.5 to 338.3 mV (–8.2 to –7.2 dB) lev el difference

between the channels: within ±0.5 dB

Adjustment Location: MAIN board

REC Bias Confirmation and Adjustment

Procedure:

1. Mode: Record

MAIN board

MD IN jack (PJ301)

L-CH, R-CH

50 mV (–23.8 dB)

600

Ω

set

blank tape

CN-123

AF OSC

1) 315 Hz

2) 10 kHz

attenuator

2. Mode: Playback

3. Confirm playback the signal recorded in step 1 become

specification values as follows.

If these values are out of specification v alues, adjust the R V252

(R-CH) and RV152 (L-CH) on the MAIN boar d to repeat steps

1 and 2.

Specification values:

PJ301 PB level: 47.2 to 53.0 mV (– 24.3 to – 23.3 dB)

Adjustment Location: MAIN board

– MAIN BOARD (Conductor Side) –

2. Mode: Playback

3. Confirm playback the signal recorded in step 1 become

specification values as follows.

If these values are out of specification v alues, adjust the R V153

(L-CH) and R V253 (R-CH) on the MAIN board to repeat steps

1and 2.

Specification values: Playback output of 315 Hz to playback

Adjustment Location: MAIN board

recorded

portion

level mete

set

MAIN board

LINE OUT jack (PJ301)

L-CH, R-CH

+

–

output of 10 kHz: ± 0.5 dB

13

Page 14

SECTION 6

d

DIAGRAMS

NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGARAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• b : Pattern from the side which enables seeing.

• Waveforms

– MAIN Board –

1

IC801 el

4.6Vp-p

5.0Vp-p

4.3Vp-p

2

3

238ns

IC801 os

30.5µs

IC804 qf

230ns

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

• C : panel designation.

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

• U : B+ Line.

• V : B– Line.

• H : adjustment for repair.

• Voltages are taken with a VOM (Input impedance 10 M Ω).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

• Abbreviation

: internal component.

Voltage var iations may be noted due to normal production tolerances.

Voltage var iations may be noted due to normal production tolerances.

F : TUNER

E : TAPE PLAY

a : TAPE RECORD

J : CD PLAY (ANALOG OUT)

c : CD PLAY (OPTICAL OUT)

EA : Saudi Arabia model.

AUS : Australian model.

SP : Singapore model.

MY : Malaysia model.

TW : Taiwan model.

HK : Hong Kong model.

AR : Argentine model.

CND : Canadian model.

AED : North European model.

MX : Mexican model.

KR : Korean model.

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

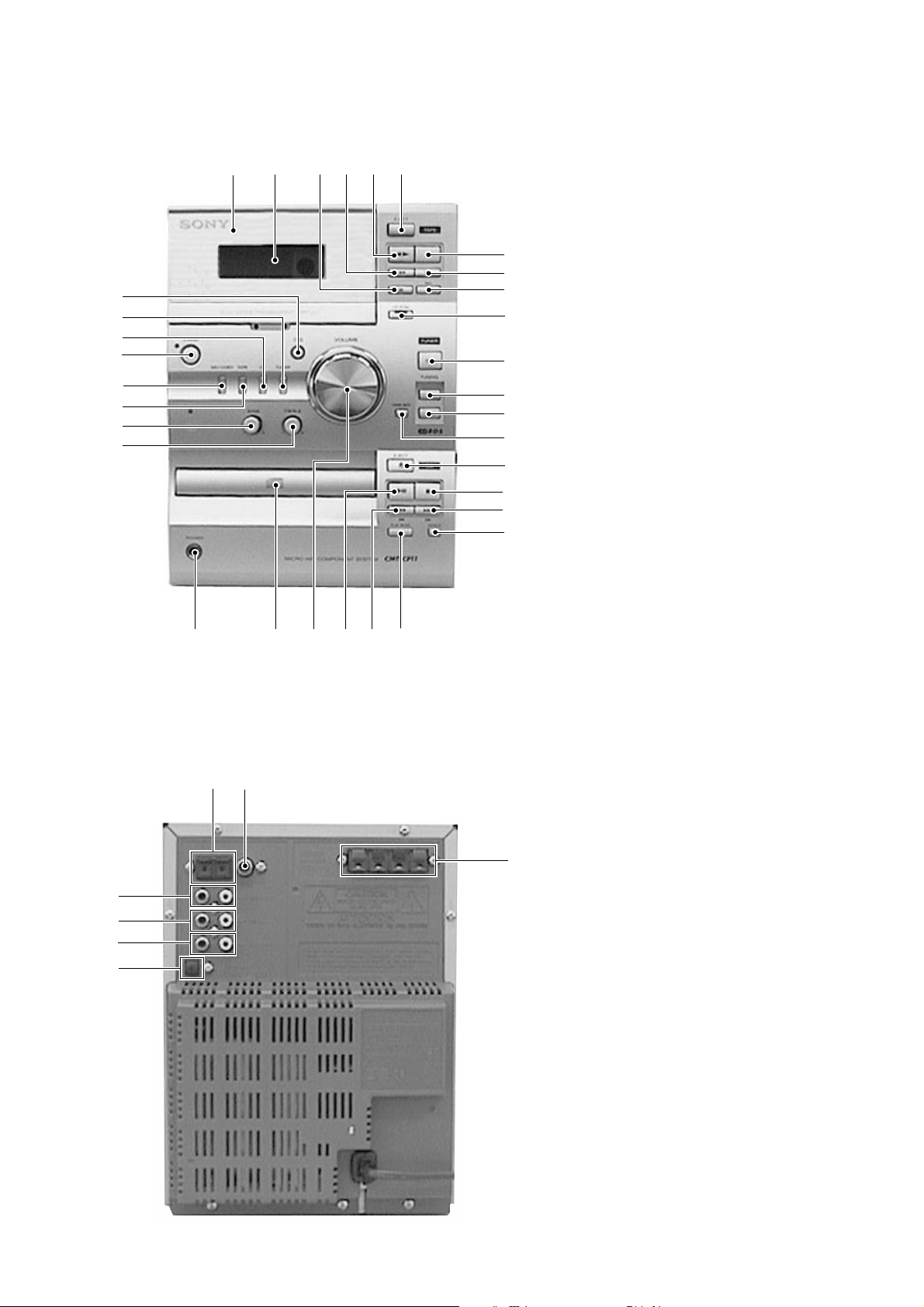

6-1. CIRCUIT BOARDS LOCATION

LCD board

HEADPHONE board

LOADING board

14

SPEAKER board

POWER board

MAIN boar

CONTROL board

Page 15

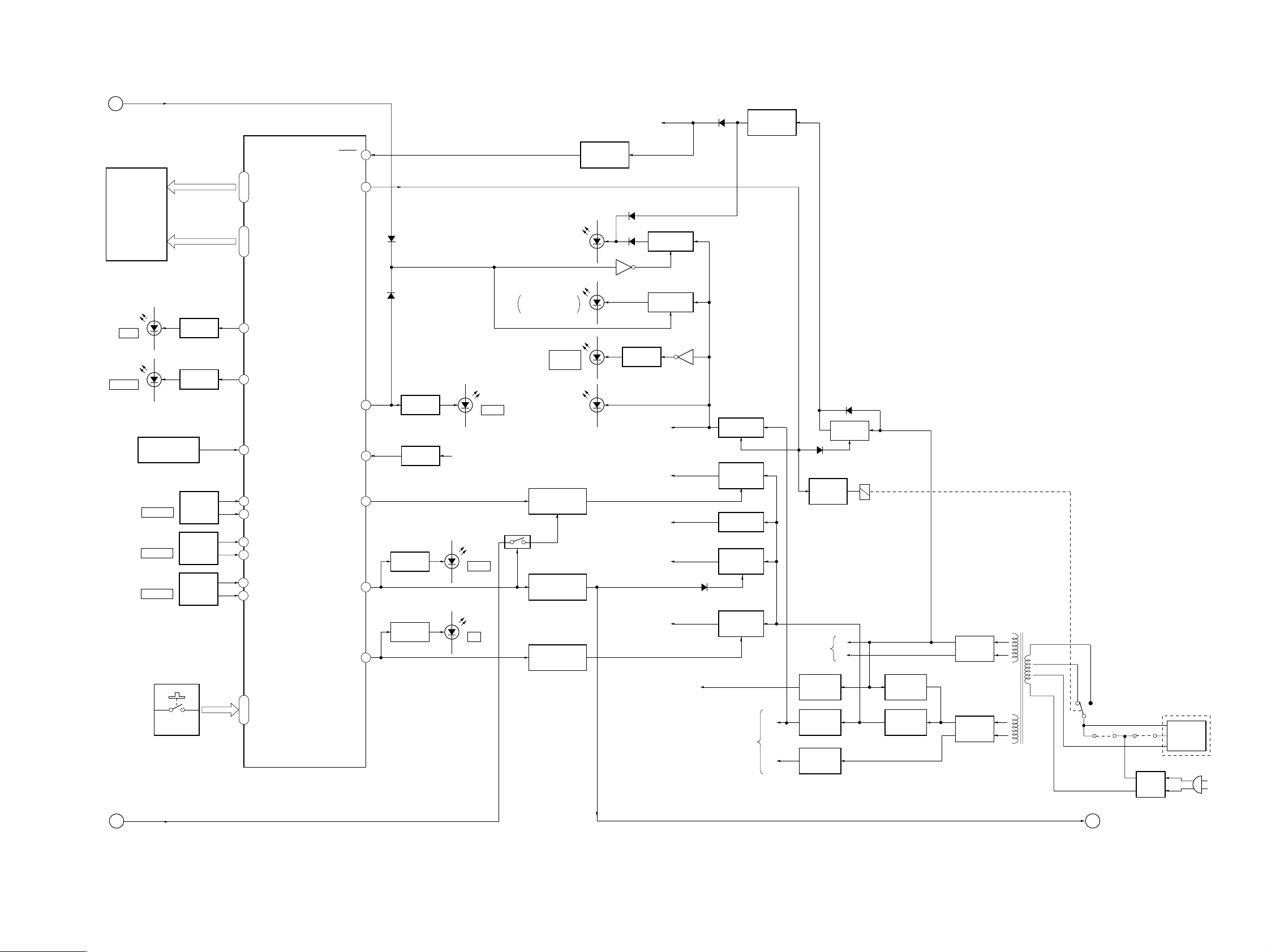

6-2. BLOCK DIAGRAM – TAPE Section –

HCD-CP11

L-CH

(RECORD/PLAYBACK)

R-CH

(ERASE)

RV253

RECORD

BIAS (R)

R-CH

R-CH

BIAS OSC

T351

7 9

RV153

RECORD

BIAS (L)

REC-L

RV151

PLAYBACK

LEVEL (L)

PLAYBACK

EQ AMP

IC351

R-CH

Q351

4

REC/PB SWITCHING

REC BIAS

SWITCH

Q359, 360

IC350

+8V

T150

BIAS

TRAP

8

BIAS OSC

Q357, 358

(CrO

41

39

2 DET)

DECK A/B

SELECT

N/C/M

15

BIAS SWITCH

CIRCUIT

N

25 24 23

37

DOLBY NR

REC/PB

C

M

RV152

RECORD

LEVEL (L)

AMP

CIRCUIT

33, 34

DECK PROCESS,

DOLBY NR AMP

IC352

R/MUTE

NR-ON

32

(CAPSTAN/REEL)

(TRIGGER PLUNGER)

BIAS

L/M

R/P

35

16

17

18

20

19

M

Q352

Q353

Q354

Q356

Q355

CAPSTAN/REEL

MOTOR DRIVE

Q657, 659

TRIGGER

PLUNGER DRIVE

Q656, 658

REC-BIAS

86

REC-MUTE

87

DOLBY

88

L-MUTE

96

REC/PB

95

SYSTEM CONTROLLER

MOT-CON

4

SOL-CON

10

PB-L

REC/PB

IC801 (1/3)

A

B

C

(Page 16)

(Page 16)

(Page 17)

16

• SIGNAL PATH

: TAPE PLAY

: TAPE RECORD

(HEAD POSITION DET)

(HALF DET (SIDE-A))

(HALF DET (SIDE-B))

(CASSETTE IN DET)

TAPE END DETECT

SENSOR

1

6

32

TAPE-END

T-MODE

TC-SW

1515

Page 16

HCD-CP11

6-3. BLOCK DIAGRAM – MAIN Section –

(Page 15)

VIDEO IN

(Page 17)

MD IN

B

D

PJ301 (1/2)

L

R

L

R

PB-L

CD ON

R-CH

R-CH

CD BLOCK

CD-L-OUT

CD-R-OUT

CD-LATCH

CD-SENSE1

CD-SENSE2

CD-SQSO

CD-SQCK

D-OUT

CD-DATA

CD-CLK

MUTING

Q102, 103

R-CH

R-CH

TRANSCEIVER

Q803

Q823

Q805

Q813

Q809

Q825

OPTICAL

IC308

+

CD DIGITAL OUT

OPTICAL

Q803, 805, 809, 813

Q823,825,827

CD ON SWITCH

INPUT SELECT SWITCH,

TONE CONTROL,

ELECTRICAL VOLUME

IC301

LIN2

12

LIN1

11

LIN3

13

LIN4

14

INPUT SELECT SWITCH

MOL

SCL

30 1

15

SDA

28

5

8

19

16

18

12

11

VOLUME

INL

CONTROL

16

CIRCUIT

SDA

CD-DATA/TU-DATA/

SCK

CD-CLK/TU-CLK

CD-LATCH/TU-CE

CD-SENSE1

CD-SENSE2/TU-COUNT

CD-SQSO/RDS-DATA

CD-SQCK/TUNED

TONE

CONTROL

CIRCUIT

MD/VIDEO-ON

VIDEO/MD-MUTE

AMP-STBY

REC-L

LINE AMP

IC307

LOUT

ATT

24

97

23

6

5

ROUT

MUTING

CONTROL SWITCH

Q317, 318

MUTING

CONTROL SWITCH

Q303, 304

R-CH

D313

MUTING

Q101

R-CH

12V

MUTING

CONTROL SWITCH

Q325,326

LED DRIVE

Q853

MUTING

Q111

R-CH

D853

MD/VIDEO

HEADPHONE

AMP

IC303

POWER AMP

IN+

3

9 10

IC101

STBY

MUTING

Q132

R-CH

OUT

MUTE

14

R-CH

R-CH

R-CH

R-CH

SJ301

SPEAKER

IMPEDANCE

USE 6Ω

A

(Page 15)

L

PJ301 (2/2)

LINE OUT

R

J301

PHONES

+

–

L

+

–

–

+

R

–

+

(Page 17)

(AEP, UK, E)

FM 75Ω

(US, Canadian)

FM

75Ω

AM

CD-SCOR

DET AMP

Q810

Q827

R-CH

Q808

Q824

Q806

Q812

Q826

4

RDS DECODER

MUX

CD +5V

MUTING

Q106

R-CH

Q806, 808, 812,824,826

TUNER ON SWITCH

IC804

RDATA

XI XO

13 14

4.332MHz

RCLK

X803

RDS ON SWITCH

2

16

Q816

TU 9V

CD-XRST

HOLD

E

RDS ON

ANTENNA

TUNER PACK

L-CH

2

R-CH

3

DI

10

CK

TUNED

FM-DET

9

11

CE

DO

8

5

4

FM ANT

ANT GND

ANT GND

AM ANT

16

CD-SCOR

100

CD-XRST/RDS ON

17

HOLD

14

AEP MODEL

RDS-CLK

2

SYSTEM CONTROLLER

IC801 (2/3)

AMP-MUTE

HP-CHK

TEX

XTAL1

EXTAL1

TRAY-SW

22

31

92

TX

93

40

39

13

15 5 2

33

X802

32.768kHz

X801

4.19MHz

DISC TRAY OPEN/CLOSE

MOTOR DRIVE

IC309

IN2TRAY-OPEN

6 10

IN1TRAY-CLOSE

OUT2

OUT1

(DISC TRAY CLOSE DET)

(DISC TRAY OPEN DET)

M

M901

DISC TRAY

OPEN/CLOSE

S901

S902

R-CH

• SIGNAL PATH

: TUNER

: CD PLAY (ANALOG OUT)

: CD PLAY (OPTICAL OUT)

: TAPE PLAY

: TAPE RECORD

1616

Page 17

6-4. BLOCK DIAGRAM – DISPLAY/POWER SUPPLY Section –

REC/PB

C

(Page 15)

LIQUID CRYSTAL

DISPLAY

LCD801

D856

DSG

D857

CD SYNC

E

(Page 16)

REMOTE CONTROL

RECEIVER

IC802

RV801

VOLUME

RV802

TREBLE

RV803

BASE

S801 – 824

RDS ON

LED DRIVE

Q856

LED DRIVE

Q857

ROTARY

ENCODER

RV801

ROTARY

ENCODER

RV802

ROTARY

ENCODER

RV803

16

26

27

3

21

20

29

30

9

16

54 – 85

50 – 53

D.S.G.

CD-SYNC

REMOCON

JOG-A

JOG-B

JOG-E

JOG-F

JOG-C

JOG-D

36 – 34

SEG0 – SEG31

COM0 – COM3

KEY1 – KEY3

SYSTEM CONTROLLER,

LCD DRIVER

IC801 (3/3)

RESET

REG-CON

TC-ON

TC-ON

WP

RDS-ON

TU-ON

CD-ON

38

7

D812

D813

98

98

99

30

LED DRIVE

Q855

25

LED DRIVE

Q852

94

LED DRIVE

LED DRIVE

Q854

Q854

SWITCH

Q829,830

+5V

D855

TUNER

D852

CD

D854

TAPE

(LCD BACK LIGHT)

CASSETTE HOLDER

BACK LIGHT

REGULATOR

CONTROL SWITCH

Q828

REGULATOR

CONTROL SWITCH

REGULATOR

CONTROL SWITCH

BACK UP +5V

SYSTEM CONTROLLER (IC801) B+

RESET SIGNAL

GENERATOR

IC803

D657 – 660

D851

STANDBY

I/u

D858

(DISC TRAY ILLUMINATION)

Q315, 316

Q321, 322

Q311, 312

CLOSE MOTOR DRIVER (IC309) B+

D815

D814

B+ SWITCH

Q653, 654

Q655

B+ SWITCH

Q651, 652

LED DRIVE

Q858

FM 7.5V

FM CIRCUIT B+

+12V

TDA7439 (IC301) B+

+9V

TUNER PACK B+

CD BLOCK B+

CD BLOCK, DISC TRAY OPEN/

Q859

LED B+

+5V

+8V

D801, 802

D307

B+ SWITCH

Q661, 662

+7.5V

REGULATOR

Q314

B+ SWITCH

Q325,326

+9V

REGULATOR

Q313

+5V

REGULATOR

Q310

AUDIO

CIRCUIT

+5.6V

GENERATOR

IC310

+8V

–8V

D392

RELAY

DRIVE

Q323,324

POWER AMP

(IC101, 201)

+8V

REGULATOR

IC311

+8V

REGULATOR

IC304

–8V

REGULATOR

IC305

D390

SWITCHING

Q390-392

RY901

B+

B–

+12V

REGULATOR

Q301-303

+12V

REGULATOR

Q350-351

RECT

D907 – 910

RECT

D911 – 914

POWER TRANSFORMER

T901

SUB 230V

230V

115V

COM

CD ON

D

(Page 16)

LINE

FILTER

LF901

HCD-CP11

E MODEL

VOLTAGE

SELECTOR

S901

AC IN

1717

Page 18

HCD-CP11

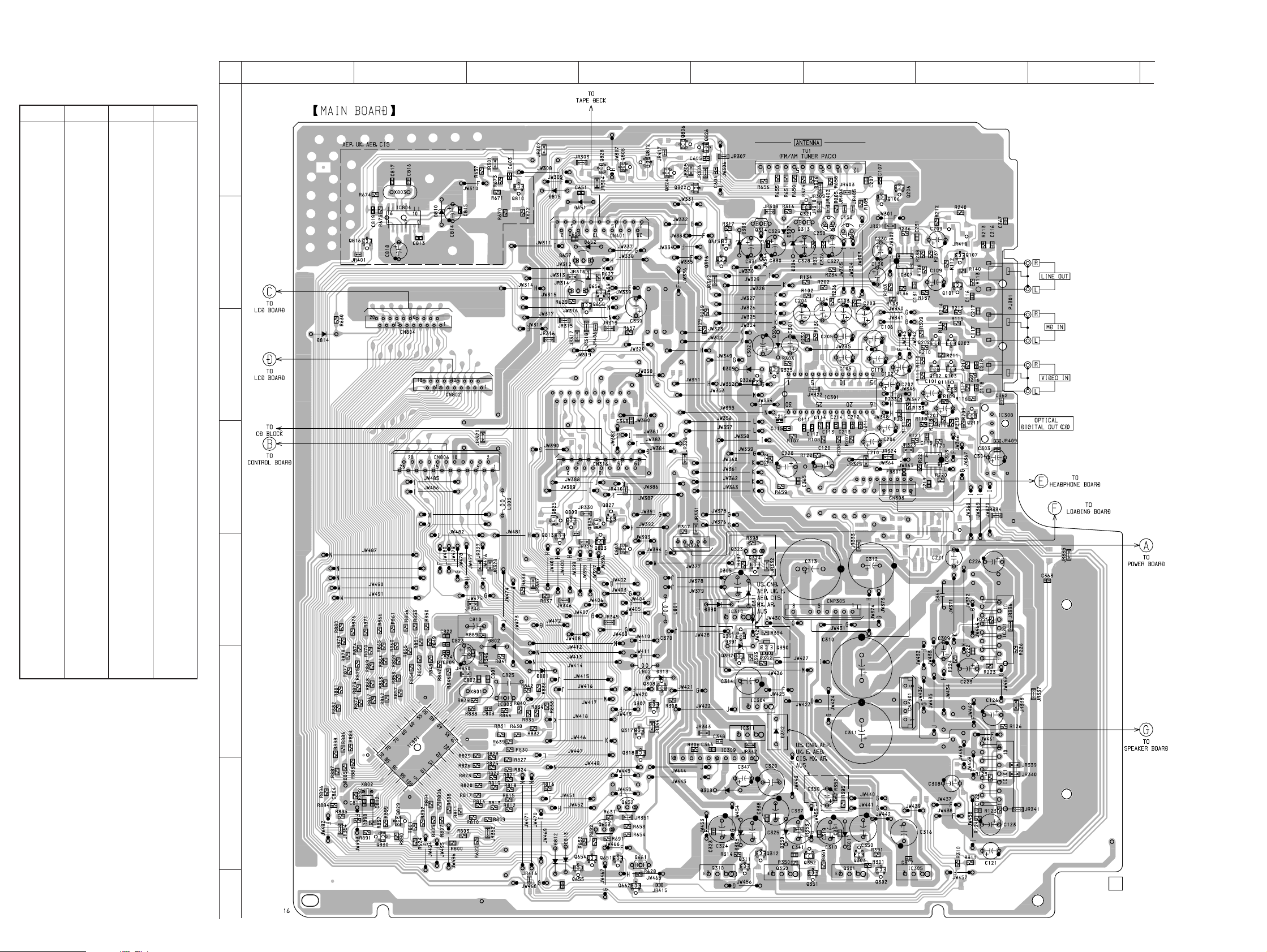

6-5. PRINTED WIRING BOARD – MAIN Section – • See page 14 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

D301 G-6

D303 B-5

D304 B-5

D305 G-5

D306 C-5

D307 B-5

D308 G-5

D309 C-5

D311 E-5

D313 F-4

D350 G-5

D390 E-5

D391 E-5

D392 F-5

D651 A-3

D652 B-4

D801 E-3

D802 E-3

D812 G-3

D813 G-4

D814 C-1

D815 A-3

IC101 G-7

IC201 E-7

IC301 C-6

IC303 D-7

IC304 F-5

IC305 G-6

IC307 B-6

IC308 D-7

IC309 F-5

IC310 E-5

IC311 F-5

IC801 F-2

IC803 F-3

IC804 B-2

Q101 B-7

Q102 C-7

Q103 C-7

Q106 A-6

Q111 C-7

Q202 C-7

Q203 C-7

Q206 A-6

Q211 C-7

Q301 G-6

Q302 G-6

Q303 G-6

Q307 F-4

Ref. No. Location

Q308 F-4

Q310 G-5

Q311 G-5

Q312 G-5

Q313 A-6

Q314 B-5

Q315 B-5

Q316 B-5

Q317 F-4

Q318 F-4

Q321 B-6

Q322 A-4

Q323 D-5

Q324 D-5

Q325 C-5

Q326 C-5

Q350 G-5

Q351 G-6

Q352 G-6

Q390 E-5

Q391 E-5

Q392 E-5

Q651 G-4

Q652 G-4

Q653 G-4

Q654 G-4

Q655 G-4

Q656 B-4

Q657 B-3

Q658 B-4

Q659 B-4

Q661 G-4

Q662 G-4

Q803 D-4

Q805 D-4

Q806 A-4

Q808 A-4

Q809 D-3

Q810 A-3

Q812 A-4

Q813 D-3

Q816 B-2

Q823 D-4

Q824 A-4

Q825 D-3

Q826 A-5

Q827 D-4

Q828 A-4

Q829 G-2

Q830 G-2

12

A

B

(Page 21)

C

(Page 21)

(Page 22)

D

E

345678

(Page 21)

(Page 21)

(Page 24)

, KR

F

G

H

, KR

1-677-142-

(Page 21)

11

1818

Page 19

6-6. SCHEMATIC DIAGRAM – MAIN Section (1/2) – • See page 35 for IC Block Diagram.

HCD-CP11

1919

Page 20

HCD-CP11

6-7. SCHEMATIC DIAGRAM – MAIN Section (2/2) –• See page 35 for IC Block Diagrams. • See page 14 for Waveforms.

1.6M : KR

PIN FUNCTION

2020

Page 21

HCD-CP11

6-8. PRINTED WIRING BOARDS – LCD/HEADPHONE/LOADING/SPEAKER Section –

• See page 14 for Circuit Boards Location.

• See page 20 for LCD BOARD Schematic Diagram.

• See page 19 for LOADING BOARD Schematic Diagram.

12

345

A

B

(Page 18)

(Page 18)

6-9. SCHEMATIC DIAGRAMS – HEADPHONE/SPEAKER Section –

C

D

(Page 18)

E

F

(Page 18)

(Page 18)

2121

Page 22

HCD-CP11

6-10. PRINTED WIRING BOARDS – CONTROL Section – • See page 14 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

D851 C-7

D852 D-5

D853 D-6

D854 D-5

D855 D-4

D856 C-4

D857 B-2

D858 E-4

IC802 E-6

Q852 D-5

Q853 D-6

Q854 D-5

Q855 D-4

Q856 C-4

Q857 B-2

Q858 C-6

Q859 C-6

12

A

B

C

34567

D

E

F

(Page 18)

G

H

2222

Page 23

6-11. SCHEMATIC DIAGRAM – PANEL Section –

HCD-CP11

(Page 20)

2323

Page 24

HCD-CP11

6-12. PRINTED WIRING BOARD – POWER Section – • See page 14 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

D901 C-4

D907 D-5

D908 D-5

D909 D-4

D910 D-4

D911 C-6

D912 D-6

D913 D-6

D914 D-6

12

A

B

C

345678

, KR

, KR

D

E

(Page 18)

2424

Page 25

6-13. SCHEMATIC DIAGRAM – POWER Section –

HCD-CP11

25

Page 26

6-14. IC BLOCK DIAGRAMS

8

7

6

5

1

2

3

4

2CH

1CH

VCC

OUT2

–IN2

+IN2

OUT1

–IN1

+IN1

VEE

– MAIN Board –

IC101, 201 TDA7296

IC303 NJM3414AM-TE2

BIPOLAR

TRANSCONDACTANCE

INPUT STAGE

–

+

IN–

IN+

STBY-GND

IN+ MUTE

IC301 TDA7439

SCL

DIG GND

TREBLE (R)

TREBLE (L)

MIN (L)

NC

MOUT (L)

BOUT (L)

LEVEL SHIFTING

BIN (L)

BOUT (R)

MOS GAIN &

STAGE

BOOST-

STRAP

BOOSTSTRAP

BIN (R)

MOUT (R)

MIN (R)

+VS

VOLUME

STANDBY/

MUTE

–VS

STBY

INR

18

THERMAL

SHUTDOWN

MOS

OUTPUT

STAGE

MUTE

SHORT

CIRCUIT

PROTECTION

NC

NC

MUX OUT (R)

14 1512 1310 118 96 753 41 2

OUT

+PWVS

–PWVS

INL

161727282930 22 21 20 1926 25 24 23

VOLUME

IC309 KA3082

DRIVER OUT

IIC BUS

DECODER &

LATCH

VREF

SUPPLY

1 2 3 4 5 6

CREF

VS

AGND

SDA

ATTENUATOR

LOUT

ROUT

TREBLE

MIDDLE

BASS

SPEAKER

GAIN AMP

MULTIPLEXER

7 8

9 10

R-IN4

R-IN3

R-IN2

R-IN1

TREBLE

MIDDLE

BASS

SPEAKER

ATTENUATOR

GAIN AMP

MULTIPLEXER

11 12

13 14

L-IN1

L-IN2

L-IN3

L-IN4

15

MUX OUT (L)

BIAS

GND

OUT1

VZ1

PRE DRIVER

LOGIC

SWITCH

5 6 7 8 9 101 2 3 4

IN1

VCTL

IN2

VCC1

TSD

VCC2

VZ2

OUT2

26

Page 27

IC804 BU1924F-E2

RCLK

VDD2

NC

XO

141516 13 121110 9

VSS2

XI

T2

T1

PLL

1187.5Hz

BIPHASE

DECODER

DEFFERENTIAL

DECODER

1 43 65 872

QUAL

CLOCK

PLL 57kHz

RDS/ARI

COMPARATOR

8th SWITCHED

CAPACITOR

FILTER

ANTI-ALIASING

FILTER

RDAT

VREF

MUX

ANALOG

VDD1

VSS1

VSS3

CMP

TEST

DIGITAL

27

Page 28

6-15. IC PIN FUNCTION DESCRIPTION

e

• MAIN BOARD IC801 CXP83124A-040Q (SYSTEM CONTROLLER, LCD DRIVER)

Pin No. Pin Name I/O Description

1 TAPE-END I

2

RDS-CLK

3 REMOCON I

4 MOT-CON O

5 SOL-CON O

6 T-MODE I

7 REG-CON O

8

9

CD-CLK

TUNED

CD-DATA/

10

TU-DATA/

SDA

11

12

13

14

15

16

17

18

19

CD-SQCK

CD-SQSO/

RDS-DATA

TRAY-OPEN

CD-MUTE

TRAY-CLOSE

CD-SENSE1

CD-XRST

CD-SENSE2/

TU-COUNT

CD-LATCH/

TU-CE

20 JOG-B I

21 JOG-A I

22

23

24

AMP-MUTE

AMP-STBY

VIDEO-ON

25 TU-ON O

26 D.S.G. O

27 CD-SYNC O

28

29

SCK

TU-CLK

Tape end detect sensor input terminal “H” input when the tape end detected

Serial data reading clock signal input from the RDS decoder (IC804)

I

(Used for the AEP and UK models only)

Sircs remote control signal input from the remote control receiver (IC802)

Capstan/reel motor on/off control signal output terminal “H”: motor on

Trigger plunger on/off control signal output terminal “H”: plunger on

Head position detect switch input terminal “L”: forward direction, “H”: reverse direction

Main system power supply on/off control signal output terminal “H”: power on

O

Serial data transfer clock signal output to DSP/SSP on the CD block (at CD function)

I

Tuning detection signal input from the tuner pack “L”: tuned

Serial data output to DSP/SSP on the CD block (at CD function)

PLL serial data output to PLL IC on the tuner pack (at tuner function)

O

2

C data output to the TDA7439 (IC301) (all functions)

I

O

Subcode Q data reading clock signal output to DSP on the CD block (at CD function)

Subcode Q data input from DSP on the CD block (at CD function)

I

RDS serial data input from the RDS decoder (IC804) (at tuner function)

(RDS decoder: used for the AEP and UK models only)

O

Motor drive signal output to the disc tray open/close motor driver (IC309) “H” active *1

O

Muting on/off control signal output to the CD block “H”: muting on

O

Motor drive signal output to the disc tray open/close motor driver (IC309) “H” active *1

Internal status detection monitor input from CD block

I

(for FZC, DFCT1, TZC, etc.) (at CD function)

O

Reset signal output to the CD block “L”: reset

Internal status detection monitor input from the CD block

I

(for MIRR, DFCT2, etc.) (at CD function)

PLL count data input from PLL IC on the tuner pack (at tuner function)

Serial data latch pulse output to DSP on the CD block (at CD function)

O

PLL serial chip enable signal output to PLL IC on the tuner pack (at tuner function)

Jog dial pulse input from the rotary encoder (RV801 VOLUME) (B phase input)

Jog dial pulse input from the rotary encoder (RV801 VOLUME) (A phase input)

Muting on/off control signal output to the power amplifier (IC101, 201)

O

“H”: muting on

Standby on/off control signal output to the power amplifier (IC101, 201)

O

“L”: standby mode

VIDEO/MD function control signal output terminal

O

“H”: VIDEO/MD (“L” output when other functions)

Power supply on/off control signal output of the tuner pack (+10V)

LED drive signal output of the TUNER indicator (D855) “H”: tuner power on (LED on)

LED drive signal output of the DSG (Dynamic Sound Generator) indicator (D856)

“H”: LED on

LED drive signal output of the CD SYNC indicator (D857) “H”: LED on

O

Serial data transfer clock signal output to the TDA7439 (IC301)

O

PLL serial data transfer clock signal output to PLL IC on the tuner pack (at tuner function)

*1 Disc tray open/close motor control

Mod

Terminal

TRAY-OPEN (pin )

TRAY-CLOSE (pin )

qd

qg

28

Stop Table In Table Out Brake

“L” “L” “H” “H”

“L” “H” “L” “H”

Page 29

Pin No. Pin Name I/O Description

Power supply on/off control signal output of the tuner pack (+7.5V) and RDS decoder (IC804)

30 RDS-ON O

31

32 TC-SW I

33

34 KEY3 I

35 KEY2 I

36 KEY1 I

37 SIMUKE I

38 RESET I

39

40

41 VSS —

42 XTAL2 O

43

44 AVREF I

45 AVSS —

46

47 to 49

50 to 53 COM0 to COM3 O

54 to 85 SEG0 to SEG31 O

86 REC-BIAS O

87 REC-MUTE O

88 DOLBY O

89 VDD —

90 NC —

91 VSS —

92

93

94 CD-ON O

95 REC/PB O

96 L-MUTE O

97

98 TC-ON O

99 WP I

100

HP-CHK

TRAY-SW

EXTAL1

XTAL1

EXTAL2

VL

VLC3 to VLC1

TX

TEX

LINE OUT-MUTE O

CD-SCOR

(RDS decoder: used for the AEP and UK models only)

LED drive signal output of the TUNER indicator (D855) “H”: tuner power on (LED on)

I

Headphone check detection signal input terminal

Half detect (side A and B) switch and cassette in detect switch input terminal (A/D input)

Disc tray position detect switch (S901, 902) input terminal (A/D input)

I

“L”: close position, “M”: open position, “H”: moving

Key input terminal (A/D input) S817 to S822, S824 and S825 (STANDBY I/u, CD, TUNER,

TAPE, MD/VIDEO, DSG, TUNER BAND, CD SYNC keys input)

Key input terminal (A/D input) S801 to S808 (TUNING MODE, CD ^/p/+/=, PLAY

MODE, REPEAT, CD EJECT 6 keys input)

Key input terminal (A/D input)

S809 to S816 (TAPE 9 (/p/)/0/P, REC r, TUNING +/– keys input)

Destination setting terminal (A/D input)

System reset signal input from the reset signal generator (IC803) “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

I

Main system clock input terminal (4.19 MHz)

O

Main system clock output terminal (4.19 MHz)

Ground terminal

Sub system clock output terminal (500 kHz) Not used (open)

I

Sub system clock input terminal (500 kHz) Not used (fixed at “L”)

Reference voltage (+5V) input terminal (for A/D conversion)

Ground terminal (for A/D conversion)

O

Liquid crystal display bias on/off control signal output terminal

—

Power supply terminal for the liquid crystal display bias

Common drive signal output to the liquid crystal display (LCD801)

Segment drive signal output to the liquid crystal display (LCD801)

Recording bias on/off selection signal output to the HA12203NT (IC352)

“L”: bias on, “H”: bias off

Recording muting on/off selection signal output to the HA12203NT (IC352)

“L”: muting on, “H”: muting off

Dolby NR on/off selection signal output to the HA12203NT (IC352)

“L”: dolby on, “H”: dolby off

Power supply terminal (+5V)

Connected to power supply (+5V)

Ground terminal

O

Sub system clock output terminal (32.768 kHz)

I

Sub system clock input terminal (32.768 kHz)

Power supply on/off control signal output of the CD block (+5V)

LED drive signal output of the CD indicator (D852) “H”: CD power on (LED on)

Recording/playback selection signal output to the BA3126N (IC350) and HA12203NT (IC352)

“L”: playback mode, “H”: recording mode

Line muting on/off selection signal output to the HA12203NT (IC352)

“L”: muting on, “H”: muting off

Muting on/off control signal output terminal “H”: muting on

Power supply on/off control signal output of the cassette holder back light

LED drive signal output of the TAPE indicator (D854) “H”: back light on (LED on)

Wakeup control signal input terminal

I

Subcode sync (S0+S1) detection signal input from DSP on the CD block (at CD function)

29

Page 30

SECTION 7

EXPLODED VIEWS

NOTE:

• -XX, -X mean standardized parts, so they may

have some differences from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

• The mechanical parts with no reference number

in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of this

parts list.

7-1. COVER, TAPE MECHANISM DECK SACTION

• Abbreviation

EA : Saudi Arabia model.

AUS : Australian model.

SP : Singapore model.

MY : Malaysia model.

TW : Taiwan model.

HK : Hong Kong model.

AR : Argentine model.

CND : Canadian model.

AED : North European model.

MX : Mexican model.

KR : Korean model.

3

The components identified by mark 0 or

dotted line with mark 0 are critical for safety .

Replace only with part number specified.

Les composants identifiés par une marque

0 sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

#1

#2

#1

#1

2

3

#1

1

not

supplied

Chassis section

Front panel

secrtion

Ref. No. Part No. Description Remarks

1 1-772-001-11 DECK,MECHANICAL (TAPE DECK BLOCK)

2 4-217-341-21 COVER(UPPER)

3 4-221-580-01 SCREW, CASE

#1

#2

30

Page 31

7-2. FRONT PANEL SACTION

not

supplied

53

55

57

69

56

52

60

61

58

59

#3

63

62

64

not

supplied

66

#1

#1

not

supplied

#1

64

64

65

supplied

with RV801

51

68

67

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

51 X-4952-336-1 KNOB ASSY

52 X-4952-728-1 PANEL SUB ASSY, FRONT (AEP,AED,CIS,UK)

52 X-4952-896-1 PANEL SUB ASSY, FRONT

(US,CND,MX,E,EA,AR,HK,MY,SP,TW,AUS)

52 X-4953-006-1 PANEL SUB ASSY, FRONT (KR)

53 4-227-956-01 WINDOW (CASSETTE)

55 4-217-316-01 LID,CASSETTE

56 1-678-282-11 LCD BOARD

57 4-217-319-01 PLATE, LCD LIGHT

58 4-217-317-01 HOLDER (CASSETTE)

59 4-217-345-01 SPRING, CASSETTE

(US,CND,MX,E,EA,AR,HK,MY,SP,KR,TW,AUS)

59 4-229-069-01 SPRING, CASSETTE (AEP,AED,CIS,UK)

60 1-792-413-11 WIRE(FLAT TYPE) 18CORE

61 1-792-413-11 WIRE(FLAT TYPE) 20CORE

62 4-217-320-01 PLATE, BACK LIGHT

63 X-4951-107-1 LOCK(EJECT) ASSY

64 4-931-757-31 SCREW(DIA.2.6X8)(IT3B),TAPPING

65 A-4428-915-A CONTROL BOARD, COMPLETE

66 3-351-377-11 GEAR, DAMPER

67 4-218-204-01 FOOT(FRONT)

68 1-677-147-11 HEADPHONE BOARD

69 4-227-282-01 KNOB(BASS)

31

Page 32

7-3. CHASSIS SECTION

US,CND,MX,

E,AR,AUS

AEP,UK,AED,CIS,EA,

HK,MY,SP,KR,TW

UK,HK

101

#5

119

not

supplied

#5

#1

#5

115

not

supplied

105

T901

#1

#4

not

supplied

109

112

#1

110

not

supplied

116

117

118

111

112

107

115

#1

113

EA,MY,

SP,TW

114

113

#1

#1

#1

not

supplied

#1

106

not

supplied

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

101 4-227-281-01 LID(CD)

102 4-217-355-01 FOOT

* 103 4-217-354-01 BUSHING, INSULATING

104 A-4428-920-A MAIN BOARD, COMPLETE (AEP,AED,CIS,UK)

104 A-4473-503-A MAIN BOARD, COMPLETE (MX)

104 A-4473-505-A MAIN BOARD, COMPLETE (US,CND)

104 A-4473-507-A MAIN BOARD, COMPLETE (EA,HK,MY,SP,TW)

104 A-4473-512-A MAIN BOARD, COMPLETE (AUS)

104 A-4473-513-A MAIN BOARD, COMPLETE (E,AR)

104 A-4473-652-A MAIN BOARD, COMPLETE (KR)

105 1-677-145-11 POWER BOARD (AEP,AED,CIS,UK,AUS)

105 1-677-145-21 POWER BOARD (E,EA,AR,HK,MY,SP,TW)

105 1-677-145-31 POWER BOARD (US,CND,MX)

105 1-677-145-41 POWER BOARD (KR)

106 4-931-757-31 SCREW(DIA.2.6X8)(IT3B),TAPPING

107 4-227-293-01 PANEL, BACK (AEP,AED,CIS,UK)

107 4-227-293-11 PANEL, BACK (US,CND,MX,KR)

107 4-227-293-21 PANEL, BACK (E,EA,AR,HK,MY,SP,TW)

107 4-227-293-41 PANEL, BACK (AUS)

109 4-217-350-01 STOPPER, CORD

(US,CND,MX,E,EA,AR,MY,SP,KR,AUS)

109 4-217-350-11 STOPPER, CORD (AEP,AED,CIS,UK,HK,TW)

110 A-4303-600-A TUNER BLOCK (AED,CIS,AUS)

110 A-4303-604-A TUNER BLOCK

(MX,E,EA,AR,HK,MY,SP,KR,TW)

32

102

110 A-4303-605-A TUNER BLOCK(US,CND)

110 A-4303-600-A TUNER BLOCK(AEP,UK)

111 1-677-146-11 SPEAKER BOARD

0 112 1-696-169-11 CORD, POWER

0 112 1-696-848-41 CORD, POWER (AUS)

0 112 1-769-079-21 CORD, POWER (KR)

0 112 1-775-789-91 CORD, POWER (MX,E)

0 112 1-783-820-11 CORD, POWER (US,CND)

0 112 1-783-941-21 CORD, POWER (AR)

0 113 1-770-019-11 ADAPTOR, CONVERSION PLUG 3P (UK,HK)

0 113 1-569-008-21 ADAPTOR, CONVERSION PLUG 2P

114 1-792-409-11 WIRE (FLAT TYPE) 21CORE

115 1-792-411-11 WIRE (FLAT TYPE) 19CORE

116 1-792-412-11 WIRE (FLATTYPE) 20CORE

117 1-172-413-11 WIRE (FLATTYPE) 18CORE

118 1-792-410-11 WIRE (FLAT TYPE) 23CORE

119 A-4677-289-A CD BLOCK

0 T901 1-435-101-11 TRANSFORMER, POWER

0 T901 1-435-385-11 TRANSFORMER, POWER (US,CND,MX)

0 T901 1-435-386-11 TRANSFORMER, POWER

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

103

(AEP,AED,CIS,UK,EA,HK,MY,SP,TW)

104

#1

(EA,MY,SP,TW)

(E,EA,AR,HK,MY,SP,TW)

(AEP,AED,CIS,UK,AUS,KR)

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

Page 33

7-4. CD MECHANISM DECK SECTION

154

155

152

153

157

156

160

158

not

supplied

151

M901

159

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

151 4-224-894-01 TRAY

152 4-220-229-01 LEVER (SW)

153 4-220-239-01 SPRING, TORSION

154 4-221-816-01 BELT (CDM55)

155 4-220-234-01 PULLEY (LDG)

156 4-220-237-01 GEAR (A)

157 4-220-238-01 GEAR (B)

158 4-220-233-01 CAM(CDM55)

159 1-676-599-11 LOADING BOARD

160 4-221-815-01 ROLLER

M901 1-763-418-11 MOTOR, DC

33

Page 34

CONTROL

SECTION 8

ELECTRICAL PARTS LIST

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when

ordering these items.

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

MET AL OXIDE: Metal Oxide-f ilm resistor

F: nonflammable

• CAPACITORS:

uF: µF

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

A-4428-915-A CONTROL BOARD, COMPLETE

************************

< CAPACITOR >

C601 1-124-259-11 ELECT 4.7uF 20.00% 16V

C602 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

< CONNECTOR >

CN805 1-569-939-31 SOCKET, CONNECTOR 23P

• COILS

uH: µH

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , uPC... , µPC... ,

uPD..., µPD...

When indicating parts by reference number,

please include the board name.

The components identified by mark 0 or

dotted line with mark 0 are critical for safety .

Replace only with part number specified.

Les composants identifiés par une marque

0 sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

R602 1-216-045-00 METAL CHIP 680 5% 1/10W

R603 1-216-047-91 RES-CHIP 820 5% 1/10W

R604 1-216-051-00 METAL CHIP 1.2K 5% 1/10W

R605 1-216-055-00 METAL CHIP 1.8K 5% 1/10W

R606 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R607 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R608 1-216-079-00 METAL CHIP 18K 5% 1/10W

R609 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R610 1-216-045-00 METAL CHIP 680 5% 1/10W

R611 1-216-047-91 RES-CHIP 820 5% 1/10W

• Abbreviation

EA : Saudi Arabia model.

AUS : Australian model.

SP : Singapore model.

MY : Malaysia model.

TW : Taiwan model.

HK : Hong Kong model.

AR : Argentine model.

CND : Canadian model.

AED : North European model.

MX : Mexican model.

KR : Korean model.

< DIODE >

D851 8-719-074-42 DIODE SLR325VR-T31 (STANDBY)

D852 8-719-074-40 DIODE SLR325DU-T31 (CD)

D853 8-719-074-40 DIODE SLR325DU-T31 (MD/VIDEO)

D854 8-719-074-40 DIODE SLR325DU-T31 (TAPE)

D855 8-719-074-40 DIODE SLR325DU-T31 (TUNER)

D856 8-719-074-42 DIODE SLR325VR-T31 (DSG)

D857 8-719-074-42 DIODE SLR325VR-T31 (CD SYNC)

D858 8-719-075-50 DIODE SELS6B14C-TP5 (CD DISC)

< IC >

IC802 8-742-208-20 IC SBX3076-01 (REMOTE CONTROL RECEIVER)

< TRANSISTOR >

Q852 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q853 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q854 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q855 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q856 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q857 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q858 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q859 8-729-900-53 TRANSISTOR DTC114EKA-T146

< RESISTOR >

R590 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R591 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R592 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R593 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R601 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R612 1-216-051-00 METAL CHIP 1.2K 5% 1/10W

R613 1-216-055-00 METAL CHIP 1.8K 5% 1/10W

R614 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R615 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R616 1-216-079-00 METAL CHIP 18K 5% 1/10W

R617 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R618 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R660 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R661 1-216-033-00 METAL CHIP 220 5% 1/10W

R662 1-216-043-91 RES-CHIP 560 5% 1/10W

R666 1-216-051-00 METAL CHIP 1.2K 5% 1/10W

R667 1-216-051-00 METAL CHIP 1.2K 5% 1/10W

R668 1-216-041-00 METAL CHIP 470 5% 1/10W

R669 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R680 1-216-045-00 METAL CHIP 680 5% 1/10W

R681 1-216-047-91 RES-CHIP 820 5% 1/10W

R683 1-216-051-00 METAL CHIP 1.2K 5% 1/10W

R684 1-216-055-00 METAL CHIP 1.8K 5% 1/10W

R685 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R686 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R687 1-216-079-00 METAL CHIP 18K 5% 1/10W

R688 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

< VARIABLE RESISTOR >

RV801 1-473-392-11 ENCODER, ROTARY (VOLUME)

RV802 1-418-859-11 ENCODER, ROTARY (TREBLE)

RV803 1-418-859-11 ENCODER, ROTARY (BASS)

< SWITCH >

S801 1-571-760-11 SWITCH, KEY BOARD (TUNING MODE)

S802 1-571-760-11 SWITCH, KEY BOARD (CD PLAY)

S803 1-571-760-11 SWITCH, KEY BOARD (CD STOP)

S804 1-571-760-11 SWITCH, KEY BOARD (CD FWD)

S805 1-571-760-11 SWITCH, KEY BOARD (CD REV)

34

Page 35

HEADPHONE LCDCONTROL LOADING MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

S806 1-571-760-11 SWITCH, KEY BOARD (CD PLAY MODE)

S807 1-571-760-11 SWITCH, KEY BOARD (CD REPEAT)

S808 1-571-760-11 SWITCH, KEY BOARD (CD EJECT)

S809 1-571-760-11 SWITCH, KEY BOARD (TAPE PLAY)

S810 1-571-760-11 SWITCH, KEY BOARD (TAPE STOP)

LCD801 1-803-542-11 DISPLAY PANEL, LIQUID CRYSTAL

< LIQUID CRYSTAL DISPLAY >

< RESISTOR >

S811 1-571-760-11 SWITCH, KEY BOARD (TAPE FF)

S812 1-571-760-11 SWITCH, KEY BOARD (TAPE REW)

S813 1-571-760-11 SWITCH, KEY BOARD (TAPE PAUSE)

S814 1-571-760-11 SWITCH, KEY BOARD (TAPE REC)

S815 1-571-760-11 SWITCH, KEY BOARD (TUNING +)

S816 1-571-760-11 SWITCH, KEY BOARD (TUNING -)

S817 1-571-760-11 SWITCH, KEY BOARD (STANDBY)

S818 1-571-760-11 SWITCH, KEY BOARD (CD)

S819 1-571-760-11 SWITCH, KEY BOARD (TUNER)

S820 1-571-760-11 SWITCH, KEY BOARD (TAPE)

S821 1-571-760-11 SWITCH, KEY BOARD (MD/VIDEO)

S822 1-571-760-11 SWITCH, KEY BOARD (DSG)

S823 1-571-760-11 SWITCH, KEY BOARD (TUNER BAND)

S824 1-571-760-11 SWITCH, KEY BOARD (CD SYNC)

************************************************************

1-677-147-11 HEADPHONE BOARD

****************

< CAPACITOR >

C132 1-124-584-00 CAP, ELECT 100MF

C134 1-163-037-11 CAP, CERAMIC 22000PF B (2012)

C232 1-124-584-00 CAP, ELECT 100MF

C234 1-163-037-11 CAP, CERAMIC 22000PF B (2012)

< TRANSISTOR >

Q132 8-729-920-31 TRANSISTOR DTC343TK-T-146

Q232 8-729-920-31 TRANSISTOR DTC343TK-T-146

< JACK >

R647 1-249-408-11 CARBON 180 5% 1/4W F

R649 1-249-408-11 CARBON 180 5% 1/4W F

************************************************************

1-676-599-11 LOADING BOARD

*************

< CONNECTOR >

* CN1 1-568-943-11 PIN, CONNECTOR 5P

< SWITCH >

S1 1-771-799-11 SWITCH, LEVER (SLIDE)

************************************************************

A-4428-920-A MAIN BOARD, COMPLETE (AEP,AED,CIS,UK)

********************

A-4473-503-A MAIN BOARD, COMPLETE (MX)

********************

A-4473-505-A MAIN BOARD, COMPLETE (US,CND)

********************

A-4473-513-A MAIN BOARD, COMPLETE (E,AR)

********************

A-4473-507-A MAIN BOARD, COMPLETE (EA,HK,MY,SP,TW)

********************

A-4473-512-A MAIN BOARD, COMPLETE (AUS)

********************

A-4473-652-A MAIN BOARD, COMPLETE (KR)

********************

* 4-217-354-01 BUSHING, INSULATING

4-931-757-31 SCREW(DIA.2.6X8)(IT3B),TAPPING

7-685-546-14 SCREW+BTP 3X8 TYPE2 N-S

J301 1-785-925-11 JACK (PHONES)

< COIL >

L102 1-416-993-41 INDUCTOR 1uH

L202 1-416-993-41 INDUCTOR 1uH

L302 1-416-993-41 INDUCTOR 1uH

< RESISTOR >

R128 1-216-019-00 RES, CHIP 56 (2012)

R228 1-216-019-00 RES, CHIP 56 (2012)

************************************************************

1-678-282-11 LCD BOARD

*********

< CONNECTOR >

CN801 1-785-950-11 CONNECTOR, FFC/FPC 18P

CN803 1-785-949-11 CONNECTOR, FFC/FPC 20P

< DIODE >

D657 8-719-075-51 DIODE SELS6B14C-LF62 (LCD BACK LIGHT)

D658 8-719-075-51 DIODE SELS6B14C-LF62 (LCD BACK LIGHT)

D659 8-719-075-51 DIODE SELS6B14C-LF62 (LCD BACK LIGHT)

D660 8-719-075-51 DIODE SELS6B14C-LF62 (LCD BACK LIGHT)

< CAPACITOR >

C101 1-126-964-11 ELECT 10uF 20.00% 50V

C102 1-126-963-11 ELECT 4.7uF 20.00% 50V

C103 1-126-963-11 ELECT 4.7uF 20.00% 50V

C104 1-126-963-11 ELECT 4.7uF 20.00% 50V

C105 1-126-963-11 ELECT 4.7uF 20.00% 50V

C106 1-126-963-11 ELECT 4.7uF 20.00% 50V

C107 1-163-020-00 CERAMIC CHIP 0.0082uF 10% 50V

(EA,HK,MY,SP,TW)

C107 1-163-022-00 CERAMIC CHIP 0.012uF 10% 50V

(US,CND,E,MX,AR,AUS,KR)

C107 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

(AEP,UK,AED,CIS)

C109 1-126-963-11 ELECT 4.7uF 20.00% 50V

C110 1-126-963-11 ELECT 4.7uF 20.00% 50V

C111 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C112 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C113 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C114 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C115 1-163-014-00 CERAMIC CHIP 0.0027uF 10.00% 50V

C116 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C117 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C118 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C119 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

35

Page 36

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

C120 1-104-665-11 ELECT 100uF 20.00% 16V

C121 1-126-963-11 ELECT 4.7uF 20.00% 50V

C122 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C123 1-126-965-11 ELECT 22uF 20.00% 50V

C126 1-126-965-11 ELECT 22uF 20.00% 50V

C324 1-104-666-11 ELECT 220uF 20.00% 10V

C325 1-126-964-11 ELECT 10uF 20.00% 50V

C326 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C327 1-104-665-11 ELECT 100uF 20.00% 16V

C328 1-104-665-11 ELECT 100uF 20.00% 16V

C130 1-104-664-11 ELECT 47uF 20.00% 16V

C131 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

C150 1-126-572-11 ELECT 4.7uF 20.00% 35V

C201 1-126-964-11 ELECT 10uF 20.00% 50V

C202 1-126-963-11 ELECT 4.7uF 20.00% 50V

C203 1-126-963-11 ELECT 4.7uF 20.00% 50V

C204 1-126-963-11 ELECT 4.7uF 20.00% 50V

C205 1-126-963-11 ELECT 4.7uF 20.00% 50V

C206 1-126-963-11 ELECT 4.7uF 20.00% 50V

C207 1-163-020-00 CERAMIC CHIP 0.0082uF 10% 50V

(EA,HK,MY,SP,TW)

C207 1-163-022-00 CERAMIC CHIP 0.012uF 10% 50V

(US,CND,E,MX,AR,AUS,KR)

C207 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

(AEP,UK,AED,CIS)

C209 1-126-963-11 ELECT 4.7uF 20.00% 50V

C210 1-126-963-11 ELECT 4.7uF 20.00% 50V

C211 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C212 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C213 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C214 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C215 1-163-014-00 CERAMIC CHIP 0.0027uF 10.00% 50V

C216 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C217 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C218 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C219 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

C220 1-104-665-11 ELECT 100uF 20.00% 16V

C221 1-126-963-11 ELECT 4.7uF 20.00% 50V

C222 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C223 1-126-965-11 ELECT 22uF 20.00% 50V

C226 1-126-965-11 ELECT 22uF 20.00% 50V

C230 1-104-664-11 ELECT 47uF 20.00% 16V

C231 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

C250 1-126-572-11 ELECT 4.7uF 20.00% 35V

C301 1-126-964-11 ELECT 10uF 20.00% 50V

C302 1-124-119-00 ELECT 330uF 20% 16V

C303 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C304 1-126-964-11 ELECT 10uF 20.00% 50V

C305 1-104-666-11 ELECT 220uF 20.00% 16V

C308 1-126-963-11 ELECT 4.7uF 20.00% 50V

C309 1-126-964-11 ELECT 10uF 20.00% 50V

C310 1-126-955-11 ELECT 4700uF 20.00% 35V

C311 1-126-955-11 ELECT 4700uF 20.00% 35V

C312 1-126-942-61 ELECT 1000uF 20.00% 25V

C313 1-126-944-11 ELECT 3300uF 20.00% 25V

C314 1-104-666-11 ELECT 220uF 20.00% 16V

C315 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C316 1-104-666-11 ELECT 220uF 20.00% 16V

C329 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C330 1-104-665-11 ELECT 100uF 20.00% 16V

C331 1-104-665-11 ELECT 100uF 20.00% 16V

C337 1-104-666-11 ELECT 220uF 20.00% 16V

C338 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C341 1-104-665-11 ELECT 100uF 20.00% 16V

C346 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C347 1-104-664-11 ELECT 47uF 20.00% 16V

C348 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C350 1-104-665-11 ELECT 100uF 20.00% 16V

C351 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C359 1-126-963-11 ELECT 4.7uF 20.00% 50V

C362 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C363 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C364 1-164-159-21 CERAMIC 0.1uF 50V

C365 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C367 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C368 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C390 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

C603 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

(AEP,AED,CIS,UK)

C604 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C605 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C651 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C652 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C801 1-163-102-00 CERAMIC CHIP 24PF 5.00% 50V

C802 1-163-102-00 CERAMIC CHIP 24PF 5.00% 50V

C803 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C804 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C808 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C809 1-126-964-11 ELECT 10uF 20.00% 50V

C810 1-128-647-11 CAP, DOUBLE LAYER 0.1F

C811 1-163-235-11 CERAMIC CHIP 22PF 5.00% 50V

C812 1-163-237-11 CERAMIC CHIP 27PF 5.00% 50V

C813 1-163-135-00 CERAMIC CHIP 560PF 5% 50V

(AEP,AED,CIS,UK)

C814 1-104-664-11 ELECT 47uF 20.00% 16V

(AEP,AED,CIS,UK)

C815 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

(AEP,AED,CIS,UK)

C816 1-163-096-00 CERAMIC CHIP 13PF 5% 50V

(AEP,AED,CIS,UK)

C817 1-163-096-00 CERAMIC CHIP 13PF 5% 50V

(AEP,AED,CIS,UK)

C818 1-126-963-11 ELECT 4.7uF 20.00% 50V

(AEP,AED,CIS,UK)

C819 1-163-003-11 CERAMIC CHIP 330PF 10% 50V

(AEP,AED,CIS,UK)

C317 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C318 1-104-666-11 ELECT 220uF 20.00% 16V

C319 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C320 1-126-935-11 ELECT 470uF 20.00% 16V

C323 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

36

C820 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

C821 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

C822 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C823 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C824 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

Page 37

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

C825 1-164-159-21 CERAMIC 0.1uF 50V

C827 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

< CONNECTOR >

L801 1-414-138-11 INDUCTOR 0.33uH

L802 1-414-138-11 INDUCTOR 0.33uH

< COIL >

* CN303 1-568-954-11 PIN, CONNECTOR 5P

* CN306 1-568-954-11 PIN, CONNECTOR 5P

* CN316 1-569-935-11 SOCKET, CONNECTOR 19P

CN401 1-569-937-11 SOCKET, CONNECTOR 21P

CN802 1-785-951-11 CONNECTOR, FFC/FPC (ZIF) 18P

CN804 1-785-952-11 CONNECTOR, FFC/FPC (ZIF) 20P

CN806 1-569-939-31 SOCKET, CONNECTOR 23P

* CN807 1-569-935-11 SOCKET, CONNECTOR 19P

* CN808 1-569-935-11 SOCKET, CONNECTOR 19P

< DIODE >

D301 8-719-110-31 DIODE MTZJ-T-77-12B

D303 8-719-921-63 DIODE MTZJ-T-77-7.5B

D304 8-719-921-75 DIODE MTZN-T-77-10B

D305 8-719-109-89 DIODE MTZJ-T-77-5.6B

D306 8-719-110-03 DIODE MTZJ-T-77-7.5C

D307 8-719-991-33 DIODE 1SS133T-77

D308 8-719-982-11 DIODE MTZJ-T-77-4.3B

(US,CND,MX,E,EA,AR,HK,MY,SP,KR,TW,AUS)

D308 8-719-109-85 DIODE MTZJ-T-77-5.1B (AEP,AED,CIS,UK)

D309 8-719-110-08 DIODE MTZJ-T-77-8.2B

D311 8-719-991-33 DIODE 1SS133T-77

D313 8-719-991-33 DIODE 1SS133T-77

D350 8-719-110-31 DIODE MTZJ-T-77-12B

D390 8-719-200-82 DIODE 11ES2-TA1B

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

D391 8-719-921-75 DIODE MTZN-T-77-10B

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

D392 8-719-991-33 DIODE 1SS133T-77

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

D651 8-719-200-82 DIODE 11ES2-TA1B

D652 8-719-200-82 DIODE 11ES2-TA1B

D801 8-719-991-33 DIODE 1SS133T-77

D802 8-719-991-33 DIODE 1SS133T-77

D810 8-719-982-11 DIODE MTZJ-T-77-4.3B (AEP,AED,CIS,UK)

D812 8-719-991-33 DIODE 1SS133T-77

D813 8-719-991-33 DIODE 1SS133T-77

D814 8-719-991-33 DIODE 1SS133T-77

D815 8-719-991-33 DIODE 1SS133T-77

< IC >

IC101 8-759-584-38 IC TDA7296

IC201 8-759-584-38 IC TDA7296

IC301 8-759-585-01 IC TDA7439

IC303 8-759-545-66 IC NJM3414AM-TE2

IC304 8-759-584-41 IC K1A7808PI

IC305 8-759-584-40 IC KA7908

IC307 8-759-909-71 IC BA4558F-E2

IC308 8-749-921-12 IC GP1F32T (CD DIGITAL OUT OPTICAL)

IC309 8-759-584-65 IC KA3082

IC310 8-759-324-40 IC KIA7805PI

IC311 8-759-584-41 IC K1A7808PI

IC801 8-752-898-87 IC CXP83124A-040Q

IC803 8-759-584-64 IC BMR0301H

IC804 8-759-557-36 IC BU1924F-E2(AEP,AED,CIS,UK)

< JACK >

PJ301 1-785-926-11 JACK, PIN 6P (LINE OUT/MD IN/VIDEO IN)

< TRANSISTOR >

Q101 8-729-920-31 TRANSISTOR DTC343TK-T-146

Q102 8-729-920-31 TRANSISTOR DTC343TK-T-146

Q103 8-729-920-31 TRANSISTOR DTC343TK-T-146

Q106 8-729-920-31 TRANSISTOR DTC343TK-T-146

Q111 8-729-920-31 TRANSISTOR DTC343TK-T-146

Q201 8-729-920-31 TRANSISTOR DTC343TK-T-146

Q202 8-729-920-31 TRANSISTOR DTC343TK-T-146

Q203 8-729-920-31 TRANSISTOR DTC343TK-T-146

Q206 8-729-920-31 TRANSISTOR DTC343TK-T-146

Q211 8-729-920-31 TRANSISTOR DTC343TK-T-146

Q301 8-729-019-00 TRANSISTOR 2SD2394-G

Q302 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q303 8-729-901-00 TRANSISTOR DTC124EKA-T146

Q307 8-729-027-31 TRANSISTOR DTA124EKA-T146

Q308 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q310 8-729-019-00 TRANSISTOR 2SD2394-G

Q311 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q312 8-729-901-00 TRANSISTOR DTC124EKA-T146

Q313 8-729-028-54 TRANSISTOR KTC3205-Y-AT

Q314 8-729-028-54 TRANSISTOR KTC3205-Y-AT

Q315 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q316 8-729-901-00 TRANSISTOR DTC124EKA-T146

Q317 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q318 8-729-901-00 TRANSISTOR DTC124EKA-T146

Q321 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q322 8-729-901-00 TRANSISTOR DTC124EKA-T146

Q323 8-729-801-84 TRANSISTOR 2SB1013-TP-34

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

Q324 8-729-901-00 TRANSISTOR DTC124EKA-T146

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

Q325 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q326 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q350 8-729-019-00 TRANSISTOR 2SD2394-G

Q351 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q352 8-729-901-00 TRANSISTOR DTC124EKA-T146

Q390 8-729-019-72 TRANSISTOR 2SB1260T100

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

Q391 8-729-920-31 TRANSISTOR DTC343TK-T-146

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

Q392 8-729-920-31 TRANSISTOR DTC343TK-T-146

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

Q651 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q652 8-729-801-84 TRANSISTOR 2SB1013-TP-34

Q653 8-729-801-84 TRANSISTOR 2SB1013-TP-34

Q654 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q655 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q656 8-729-202-56 TRANSISTOR 2SA950-Y-TPE2

Q657 8-729-202-56 TRANSISTOR 2SA950-Y-TPE2

Q658 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q659 8-729-900-53 TRANSISTOR DTC114EKA-T146

37

Page 38

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

Q661 8-729-040-76 TRANSISTOR KTA1273-Y-AT

Q662 8-729-900-53 TRANSISTOR DTC114EKA-T146

Q803 8-729-027-44 TRANSISTOR DTC114TKA-T146

Q805 8-729-027-44 TRANSISTOR DTC114TKA-T146

Q806 8-729-027-44 TRANSISTOR DTC114TKA-T146

R131 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R133 1-216-049-91 RES-CHIP 1K 5% 1/10W

R134 1-216-025-91 RES-CHIP 100 5% 1/10W

R136 1-216-049-91 RES-CHIP 1K 5% 1/10W

R137 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

Q808 8-729-027-44 TRANSISTOR DTC114TKA-T146

Q809 8-729-027-44 TRANSISTOR DTC114TKA-T146

Q810 8-729-120-28 TRANSISTOR 2SC2412K-T-146-R

(AEP,AED,CIS,UK)

Q812 8-729-027-44 TRANSISTOR DTC114TKA-T146

Q813 8-729-027-44 TRANSISTOR DTC114TKA-T146

Q816 8-729-027-44 TRANSISTOR DTC114TKA-T146

(AEP,AED,CIS,UK)

Q823 8-729-027-44 TRANSISTOR DTC114TKA-T146

Q824 8-729-027-44 TRANSISTOR DTC114TKA-T146

Q825 8-729-027-44 TRANSISTOR DTC114TKA-T146

Q826 8-729-027-44 TRANSISTOR DTC114TKA-T146

Q827 8-729-027-44 TRANSISTOR DTC114TKA-T146

Q828 8-729-027-44 TRANSISTOR DTC114TKA-T146

Q829 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q830 8-729-920-31 TRANSISTOR DTC343TK-T-146

< RESISTOR >

R102 1-216-079-00 METAL CHIP 18K 5% 1/10W

R103 1-216-049-91 RES-CHIP 1K 5% 1/10W

R105 1-216-071-00 METAL CHIP 8.2K 5% 1/10W

(US,CND,MX,E,EA,AR,HK,MY,SP,KR,TW,AUS)

R105 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

(AEP,AED,CIS,UK)

R106 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R107 1-216-071-00 METAL CHIP 8.2K 5% 1/10W

R108 1-216-072-00 METAL CHIP 9.1K 5% 1/10W

R109 1-216-049-91 RES-CHIP 1K 5% 1/10W

(US,CND,MX,E,EA,AR,HK,MY,SP,KR,TW,AUS)

R109 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

(AEP,AED,CIS,UK)

R110 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R111 1-216-049-91 RES-CHIP 1K 5% 1/10W

R112 1-216-049-91 RES-CHIP 1K 5% 1/10W

(US,CND,MX,E,EA,AR,HK,MY,SP,KR,TW,AUS)

R112 1-216-043-91 RES-CHIP 560 5% 1/10W

(AEP,AED,CIS,UK)

R113 1-216-089-91 RES-CHIP 47K 5% 1/10W

R114 1-216-055-00 METAL CHIP 1.8K 5% 1/10W

R115 1-216-067-00 METAL CHIP 5.6K 5% 1/10W

R116 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R117 1-216-089-91 RES-CHIP 47K 5% 1/10W

R118 1-216-089-91 RES-CHIP 47K 5% 1/10W

R119 1-216-051-00 METAL CHIP 1.2K 5% 1/10W

(US,CND,MX,E,EA,AR,HK,MY,SP,KR,TW,AUS)

R119 1-216-043-91 RES-CHIP 560 5% 1/10W

(AEP,AED,CIS,UK)

R120 1-216-073-00 METAL CHIP 10K 5% 1/10W

R121 1-216-049-91 RES-CHIP 1K 5% 1/10W

R122 1-216-025-91 RES-CHIP 100 5% 1/10W

R123 1-216-045-00 METAL CHIP 680 5% 1/10W

R124 1-216-081-00 METAL CHIP 22K 5% 1/10W

R125 1-216-091-00 METAL CHIP 56K 5% 1/10W

R126 1-216-097-91 RES-CHIP 100K 5% 1/10W

R129 1-216-073-00 METAL CHIP 10K 5% 1/10W

R130 1-216-073-00 METAL CHIP 10K 5% 1/10W

R138 1-216-073-00 METAL CHIP 10K 5% 1/10W

R139 1-216-296-91 SHORT 0

R202 1-216-079-00 METAL CHIP 18K 5% 1/10W

R203 1-216-049-91 RES-CHIP 1K 5% 1/10W

R205 1-216-071-00 METAL CHIP 8.2K 5% 1/10W

(US,CND,MX,E,EA,AR,HK,MY,SP,TW,AUS,KR)

R205 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

(AEP,AED,CIS,UK)

R206 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R207 1-216-071-00 METAL CHIP 8.2K 5% 1/10W

R208 1-216-072-00 METAL CHIP 9.1K 5% 1/10W

R209 1-216-049-91 RES-CHIP 1K 5% 1/10W

(US,CND,MX,E,EA,AR,HK,MY,SP,KR,TW,AUS)

R209 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

(AEP,AED,CIS,UK)

R210 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R211 1-216-049-91 RES-CHIP 1K 5% 1/10W

R212 1-216-049-91 RES-CHIP 1K 5% 1/10W

(US,CND,MX,E,EA,AR,HK,MY,SP,KR,TW,AUS)

R212 1-216-043-91 RES-CHIP 560 5% 1/10W

(AEP,AED,CIS,UK)

R213 1-216-089-91 RES-CHIP 47K 5% 1/10W

R214 1-216-055-00 METAL CHIP 1.8K 5% 1/10W

R215 1-216-067-00 METAL CHIP 5.6K 5% 1/10W

R216 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R217 1-216-089-91 RES-CHIP 47K 5% 1/10W

R218 1-216-089-91 RES-CHIP 47K 5% 1/10W

R219 1-216-051-00 METAL CHIP 1.2K 5% 1/10W

(US,CND,MX,E,EA,AR,HK,MY,SP,KR,TW,AUS)

R219 1-216-043-91 RES-CHIP 560 5% 1/10W

(AEP,AED,CIS,UK)

R220 1-216-073-00 METAL CHIP 10K 5% 1/10W

R221 1-216-049-91 RES-CHIP 1K 5% 1/10W

R222 1-216-025-91 RES-CHIP 100 5% 1/10W

R223 1-216-045-00 METAL CHIP 680 5% 1/10W

R224 1-216-081-00 METAL CHIP 22K 5% 1/10W

R225 1-216-091-00 METAL CHIP 56K 5% 1/10W

R226 1-216-097-91 RES-CHIP 100K 5% 1/10W

R229 1-216-073-00 METAL CHIP 10K 5% 1/10W

R230 1-216-073-00 METAL CHIP 10K 5% 1/10W

R231 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R233 1-216-049-91 RES-CHIP 1K 5% 1/10W

R234 1-216-025-91 RES-CHIP 100 5% 1/10W

R236 1-216-049-91 RES-CHIP 1K 5% 1/10W

R237 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R238 1-216-073-00 METAL CHIP 10K 5% 1/10W

R239 1-216-296-91 SHORT 0

R301 1-216-043-91 RES-CHIP 560 5% 1/10W

(EA,HK,MY,SP,TW)

R301 1-216-047-91 RES-CHIP 820 5% 1/10W

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

R303 1-216-035-00 METAL CHIP 270 5% 1/10W

R306 1-216-001-00 METAL CHIP 10 5% 1/10W

R307 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R308 1-216-041-00 METAL CHIP 470 5% 1/10W

38

Page 39

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

R309 1-216-081-00 METAL CHIP 22K 5% 1/10W

R310 1-216-073-00 METAL CHIP 10K 5% 1/10W

R311 1-216-073-00 METAL CHIP 10K 5% 1/10W

R314 1-216-047-91 RES-CHIP 820 5% 1/10W

R316 1-216-033-00 METAL CHIP 220 5% 1/10W

R317 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R321 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R325 1-216-089-91 RES-CHIP 47K 5% 1/10W

R325 1-216-089-91 RES-CHIP 47K 5% 1/10W

R326 1-216-089-91 RES-CHIP 47K 5% 1/10W

R350 1-216-043-91 RES-CHIP 560 5% 1/10W

(EA,HK,MY,SP,TW)

R350 1-216-047-91 RES-CHIP 820 5% 1/10W

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

R351 1-216-089-91 RES-CHIP 47K 5% 1/10W

R352 1-216-073-00 METAL CHIP 10K 5% 1/10W

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

R391 1-216-089-91 RES-CHIP 47K 5% 1/10W

R392 1-216-089-91 RES-CHIP 47K 5% 1/10W

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

R393 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

R394 1-216-089-91 RES-CHIP 47K 5% 1/10W

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

R395 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

R397 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

R398 1-216-105-91 RES-CHIP 220K 5% 1/10W

(US,CND,AEP,UK,E,AED,CIS,MX,AR,AUS,KR)

R622 1-216-097-91 RES-CHIP 100K 5% 1/10W