Sony HCD-CP1 Service manual

HCD-CP1

SERVICE MANUAL

Ver 1.1 2001.02

With SUPPLEMENT-1

(9-928-809-81)

Note

CD block, tape dec k block and

tuner pack are supplied with

the assembled block.

HCD-CP1 is the Amplifier, CD pla yer,

Tape Deck and Tuner section in

CMT-CP1.

Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks of Dolby Laboratories Licensing Corporation.

CD

Section

Tape deck

Section

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type KSL-2130CCP/K1N

Optical Pick-up Name KSS-213C/K1N

Model Name Using Similar Mechanism HCD-ED1

Tape Transport Mechanism Type CMAL1Z023A

SPECIFICATIONS

– Continued on next page –

9-928-809-12 Sony Corporation

2001B0500-1 Audio Entertainment Group

C 2001.2 General Engineering Dept.

MICRO HiFi COMPONENT SYSTEM

– 2 –

TABLE OF CONTENTS

SECTION 1

SERVICING NOTES

1. SERVICING NOTES............................................... 3

2. GENERAL

Location of Controls ....................................................... 5

Setting the Time .............................................................. 6

3. DISASSEMBLY ......................................................... 7

4. SERVICE MODE...................................................... 11

5. ELECTRICAL CONFIRMATIONS AND

ADJUSTMENTS

DECK Section ................................................................. 12

6. DIAGRAMS

6-1. Block Diagram – TAPE Section – .................................. 15

6-2. Block Diagram – MAIN Section –................................. 17

6-3. Block Diagram

– DISPLAY/POWER SUPPLY Section – ...................... 19

6-4. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 21

6-5. Printed Wiring Board – MAIN Section –....................... 23

6-6. Schematic Diagram – MAIN Section (1/4) –................. 25

6-7. Schematic Diagram – MAIN Section (2/4) –................. 27

6-8. Schematic Diagram – MAIN Section (3/4) –................. 29

6-9. Schematic Diagram – MAIN Section (4/4) –................. 31

6-10. Printed Wiring Boards

– PANEL/CD LOADING Section – ............................... 33

6-11. Printed Wiring Boards – CONTROL Section – ............. 37

6-12. Schematic Diagram – CONTROL Section –.................. 39

6-13. Printed Wiring Board – POWER Section –.................... 41

6-14. Schematic Diagram – POWER Section – ...................... 42

6-15. IC Pin Function Description ........................................... 43

7. EXPLODED VIEWS................................................ 45

8. ELECTRICAL PARTS LIST ............................... 49

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

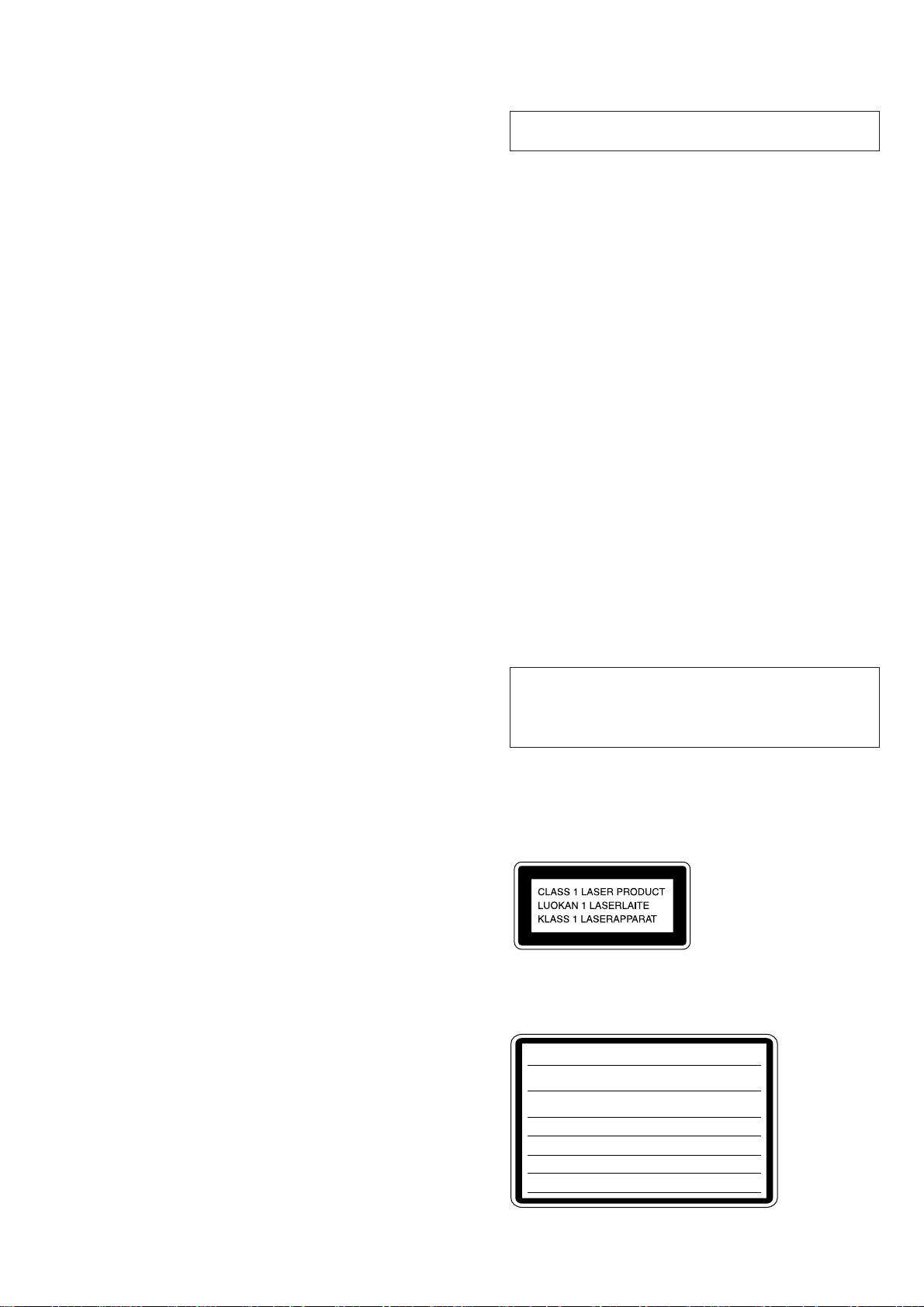

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

CAUTION : INVISIBLE LASER RADIATION WHEN OPEN AND

INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

ADVARSEL : USYNLIG LASERSTRÅLING VED ÅBNING NÅR

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION. UNDGÅ UDSAETTELSE

FOR STRÅLING.

VORSICHT : UNSICHTBARE LASERSTRAHLUNG, WENN

ABDECKUNG GEÖFFNET UND SICHEREITSVERRIEGELUNG

ÜBERBRÜCKT. NICHT DEM STRAHL AUSSETZEN.

VARO

!

TIINA NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VARNING : OSYNLING LASERSTRÅLING NÄR DENNA DEL ÄR ÖPPNAD

OCH SPÄRREN ÄR URKOPPLAD. BETRAKTA EJ STRÅLEN.

ADVERSEL : USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG

SIKKERHEDSLÅS BRYTES. UNNGÅ EKSPONERING FOR STRÅLEN.

VIGYAZAT!: A BURKOLAT NYITÁSAKOR LÁTHATATLAN LÉZERSU-

GÁRVESZÉLY

: AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALT-

!

KERÜLJE A BESUGÁRZÁST!

– 3 –

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

MODEL IDENTIFICATION

– Back Panel –

Power Voltage Indication

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

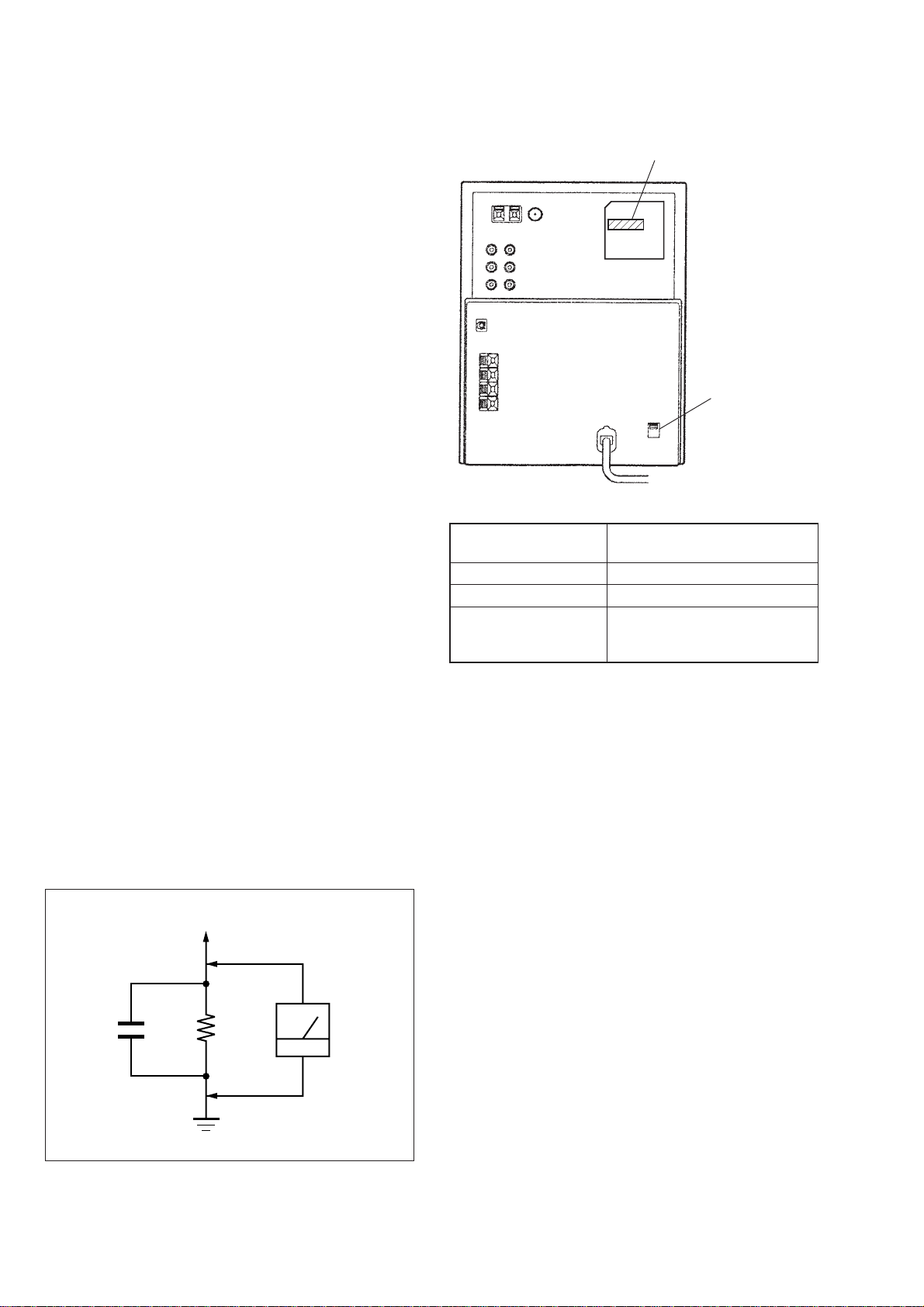

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

VOLTAGE SELECTOR

Switch

Model

Pow er V oltage

Incdication

US, Canadian models AC: 120 V 60 Hz 55 W

AEP, UK models AC: 230 V ⁄50 Hz 55 W

Malaysia, Singapore,

Hong Kong and

Thai models

AC: 110 – 120/

220 – 240 V ⁄50/60 Hz 55 W

To Exposed Metal

Parts on Set

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

Ω

Earth Ground

AC

voltmeter

(0.75 V)

– 4 –

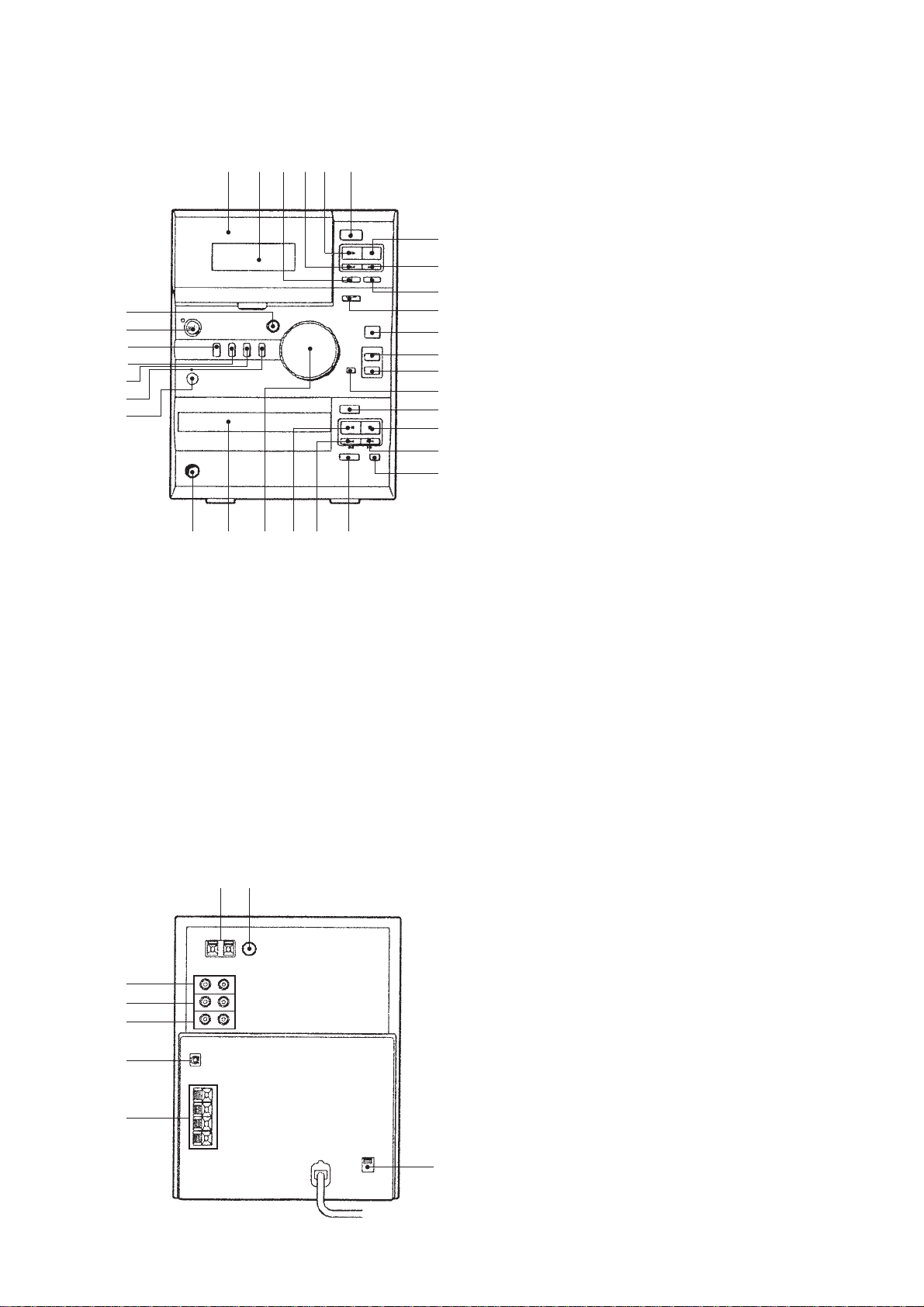

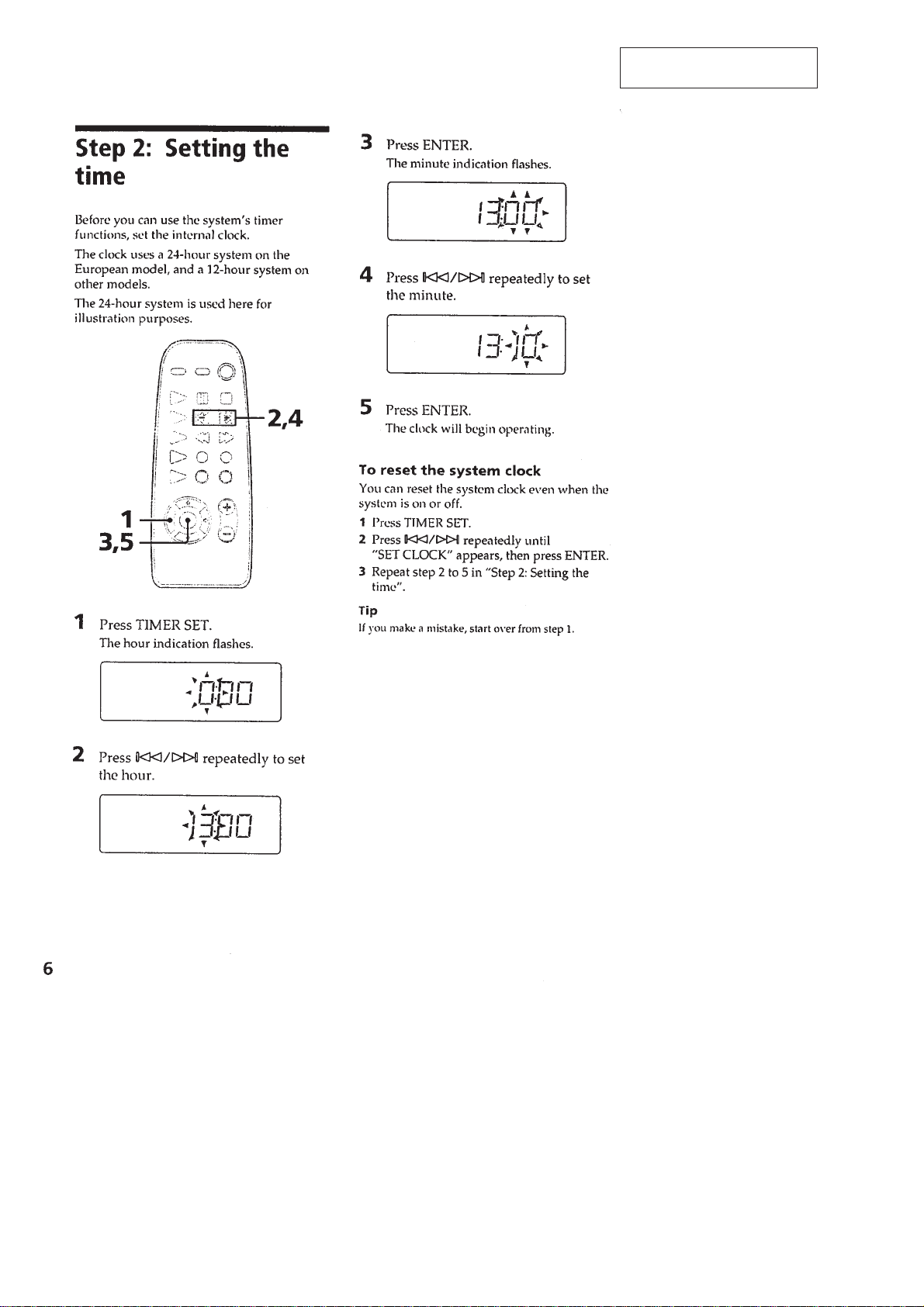

LOCATION OF CONTROLS

• Front View

1 2 3 4 5 6

!ª

@º

@¡

@™

@£

@¢

@∞

@§ @¶ @• @ª #¡

#º

SECTION 2

GENERAL

1 TAPE deck

2 Liquid crystal display

3 TAPE P button

7

8

9

!º

!¡

!™

!£

!¢

!∞

!§

!¶

!•

4 TAPE 0 button

5 TAPE œ button

6 TAPE 6 button

7 TAPE p button

8 TAPE ) button

9 TAPE REC r button

0 CD SYNC button and indicator

!¡ BAND button

!™ TUNING + button

!£ TUNING – button

!¢ TUNING MODE button

!∞ CD EJECT 6 button

!§ CD p button

!¶ CD + ) button

!• CD REPEAT button

!ª DSG button and indicator

@º STANDBY 1/u button and indicator

@¡ MD/VIDEO button and indicator

@™ TAPE button and indicator

@£ CD button and indicator

@¢ TUNER button and indicator

@∞ Remote sensor

@§ PHONES jack

@¶ CD disc tray

@• VOLUME knob

@ª CD ^ button

#º CD = 0 button

#¡ CD PLAY MODE button

• Rear View

4

5

6

7

8

21

3

1 AM ANTENNA terminals

2 FM ANTENNA jack or terminals

3 VOLTAGE SELECTOR switch

(Malaysia, singapore and Hong Kong)

4 LINE OUT jacks

5 MD IN jacks

6 VIDEO IN jacks

7 CD DIGITAL OUT OPTICAL connector

8 SPEAKER terminals

– 5 –

This section is extracted from

instruction manual.

– 6 –

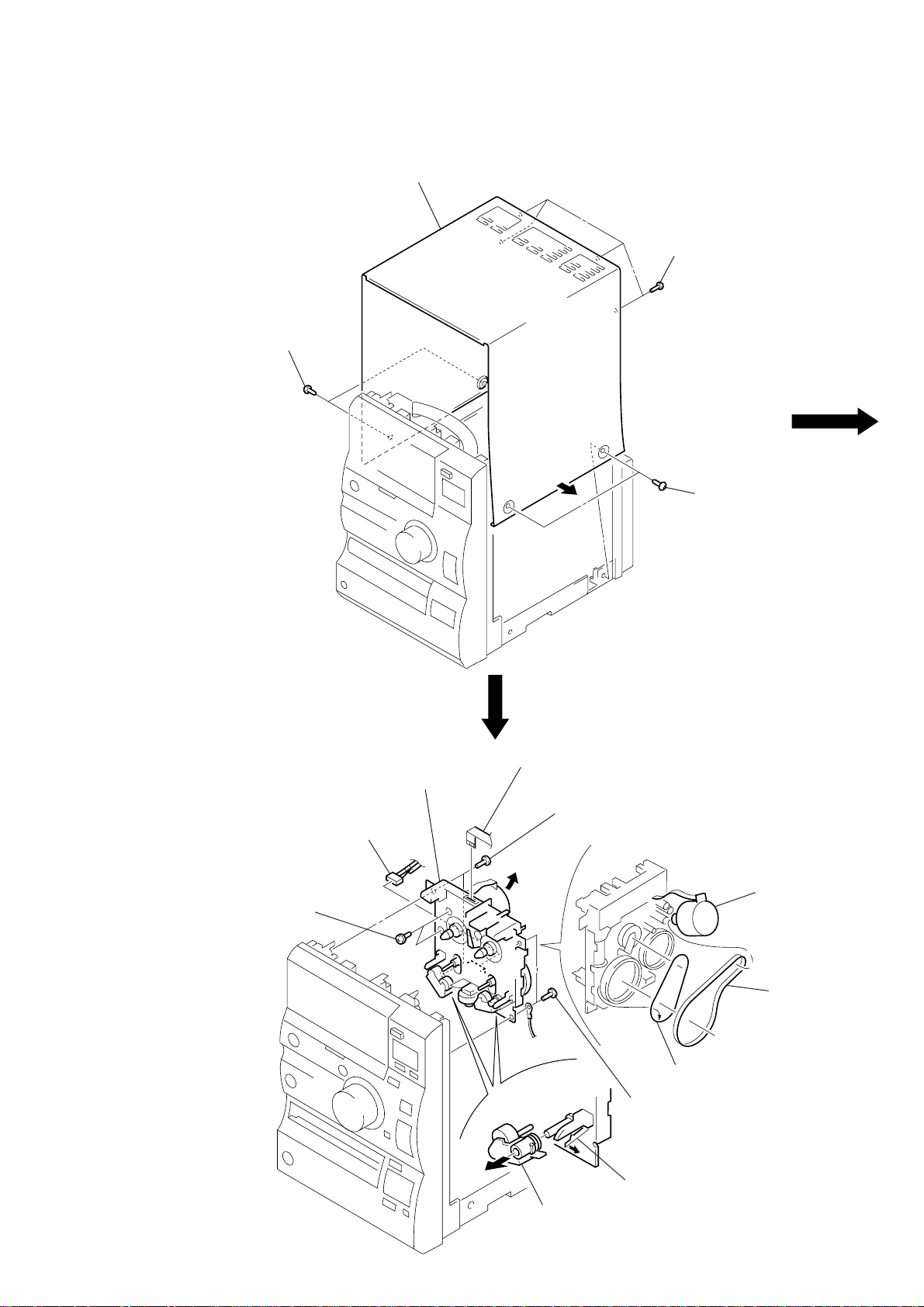

SECTION 3

)

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

COVER (UPPER)

3

cover (upper)

1

two screws

(case3 TP2)

2

four screws

(BTP3

1

×

8)

two screws

(case3 TP2

TAPE MECHANISM DECK

5

two screws

2

connector

4

tape

mechanism deck

1

flat wire (12 core)

3

two screws

(BTP3 × 8)

3

two screws

(BTP3 × 8)

9

claw

8

F/R belt

6

motor

7

main belt

– 7 –

0

pinch roller

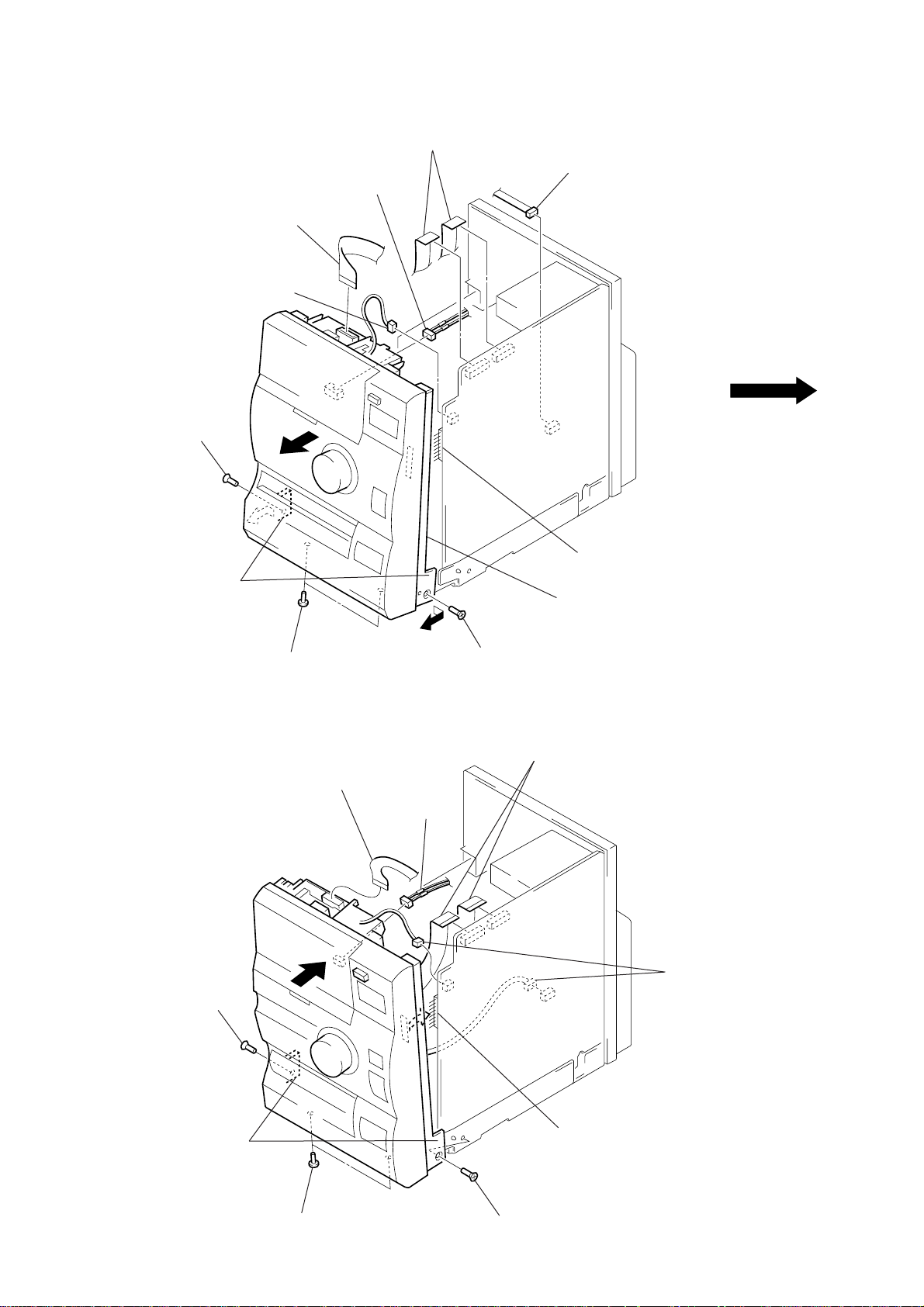

FRONT PANEL SECTION

)

3 screw

(KTP3 × 6)

5 two claws

2 flat wire

(12 core)

1 connector

(CN809)

1 connector

2 two flat wires

(CN802, 804)

1 connector

(CN303)

6 connector (CN603

7 front panel section

4 two screws

(BTP3 × 8)

• FRONT PANEL SECTION INSTALLATION

Note: Follow the assembly procedure in the numerical order given.

5 flat wire (12 core)

3 screw

(KTP3 × 6)

3 screw

(KTP3 × 6)

5 two flat wires

(CN802, 804)

6 connector

6 two connectors

(CN303, 809)

1 two claws

4 two screws

(BTP3 × 8)

– 8 –

3 screw

(KTP3 × 6)

2 connector

(CNP806)

Note: As CNP806 pin is bent easily,

treat is carefully.

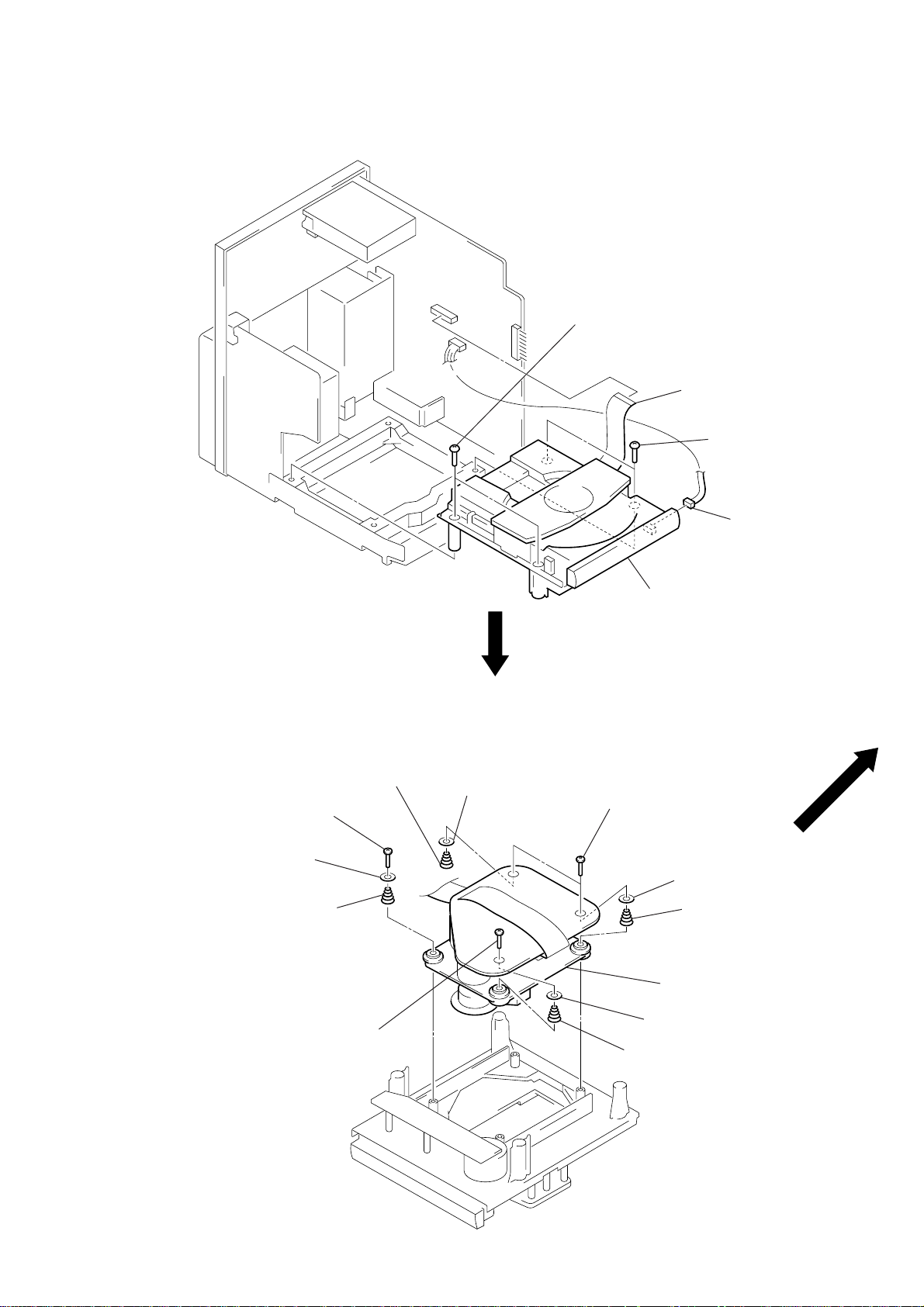

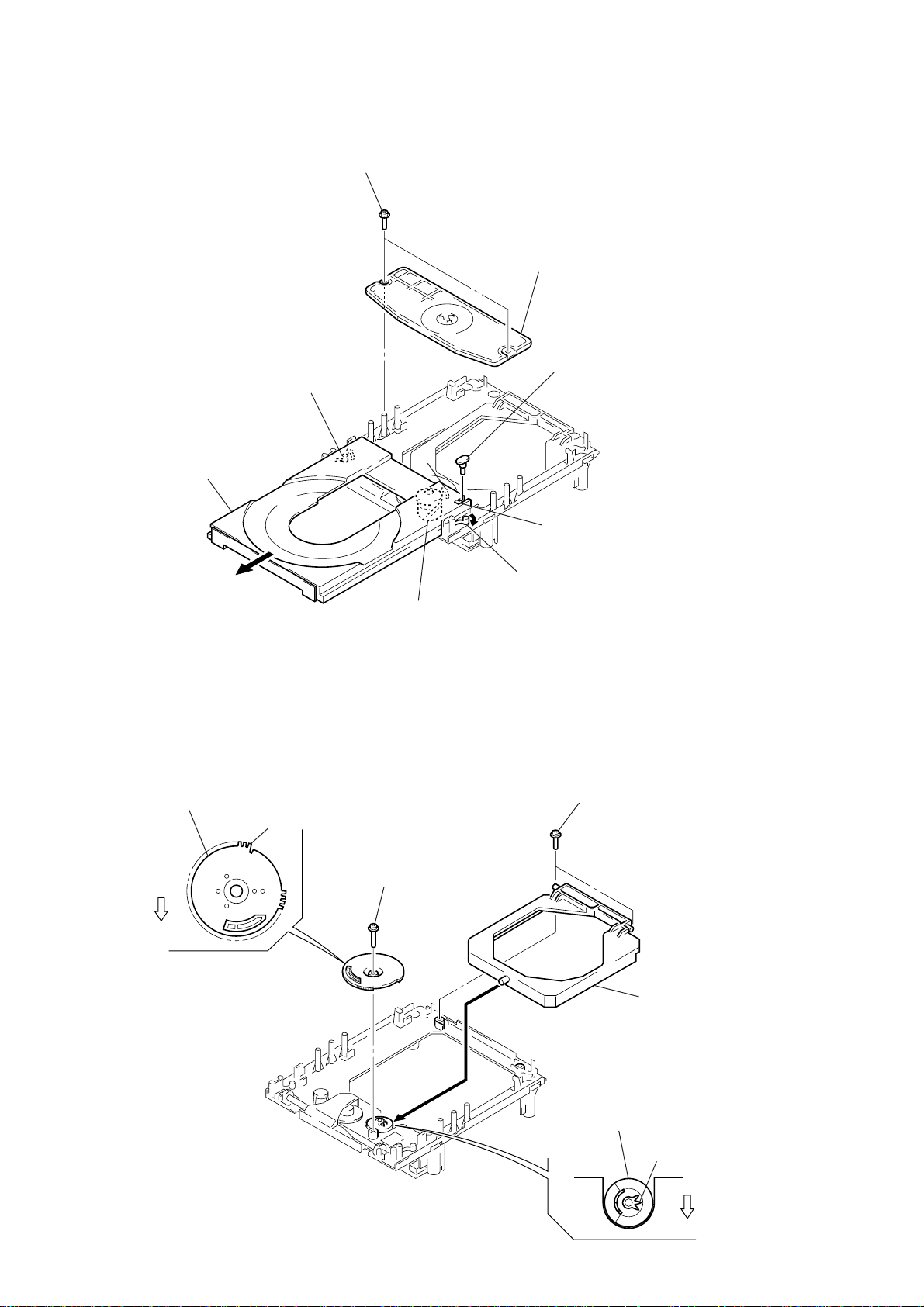

CD MECHANISM DECK

3

two screws

(BTP3

×

8)

2

flat wire (19 core)

(CN805)

3

two screws

×

8)

(BTP3

1

connector

BU ASS’Y

Note: As 3 coil springs are missed easily, treat them carefully.

3

coil spring

(rear)

1

screw

(P2.6

×

10)

2

washer

3

coil spring

(front)

1

screw

×

10)

(P2.6

2

washer

1

two screws

(P2.6

3

4

CD mechanism deck

×

10)

2

washer

3

coil spring

(rear)

4

BU ass’y

2

washer

coil spring

(front)

– 9 –

TRAY

4

Pull the tray.

8

Remove the tray.

7

lock lever

1

two screws

(PTPWH2.6

×

7)

2

chucking yoke (K)

6

damper (S)

A

5

claw

• SUB CHASSIS INSTALLATION

Note: Follow the assembly procedure in the numerical order given.

2

Install the drive gear with gear

position as shown in figure.

gear

3

screw

(PTPWH2.6 × 16)

front side

3

Rotate the control cam

in the direction of arrow

7

lock lever

A

.

5

two screws

(PTPWH2.6 × 7)

4

sub chassis

– 10 –

1

Install the control cam

with gear position as shown

in figure.

gear

front side

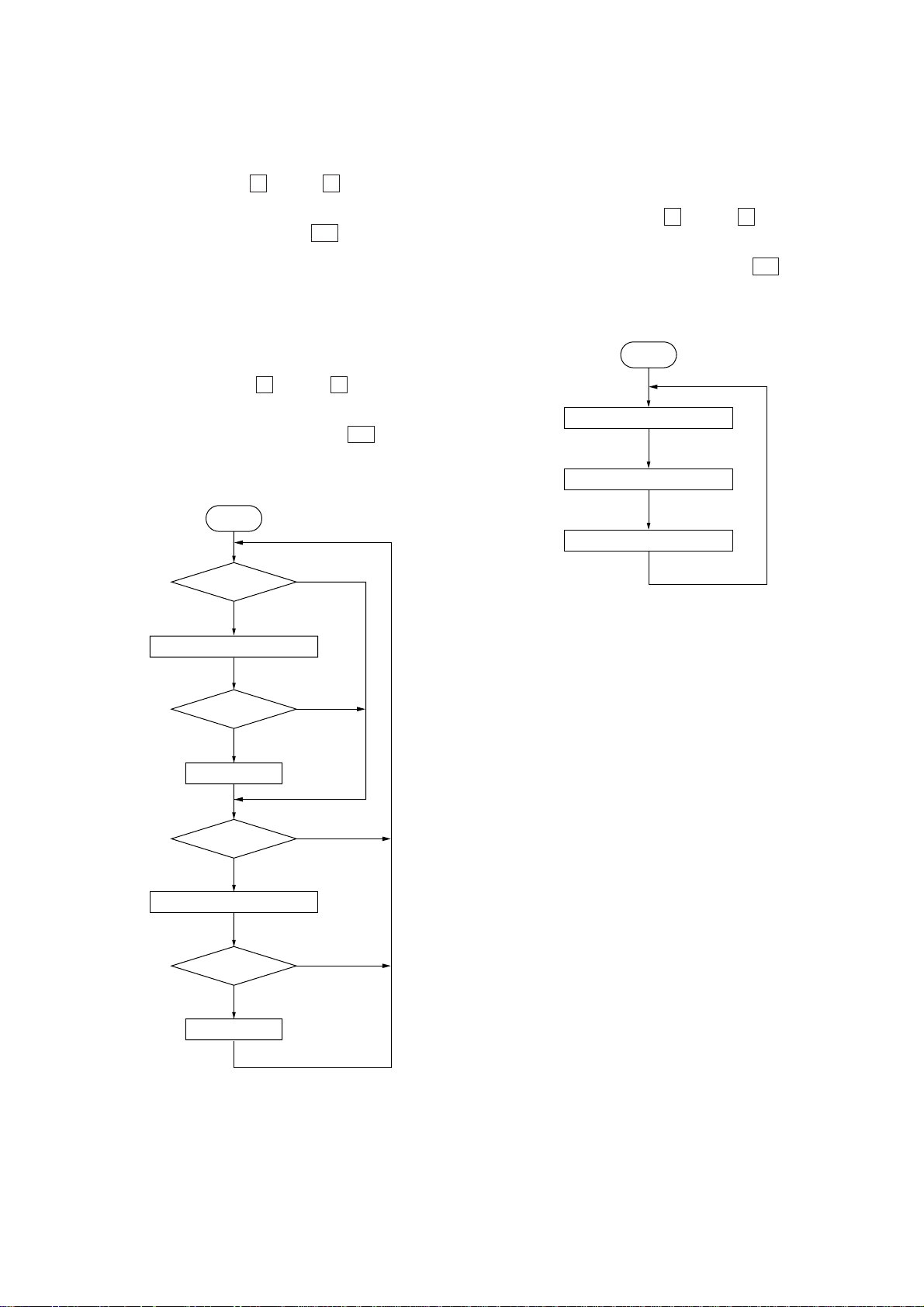

SECTION 4

SERVICE MODE

[Liquid Crystal Display All Lit Check Mode]

Procedure:

1. Set to standby state.

2. Press three buttons of p (TAPE), p (CD), and [MD/VIDEO]

simultaneously.

3. Liquid crystal display are all turned on.

4. To e xit from this mode, press the 1/u button to turn the power

OFF .

[Tape Deck Aging Mode]

This mode can be used for operation check of tape deck section.

Procedure:

1. Set a tape in the tape deck.

2. Set to standby state.

3. Press three buttons of p (TAPE), p (CD), and [TAPE] simultaneously.

4. The aging is executed in bellow sequence.

5. T o exit from the aging mode, press the 1/u button to turn the

power OFF.

Aging mode sequence:

Start

[CD Aging Mode]

This mode can be used for operation check of CD section.

Procedure:

1. Load a CD disc.

2. Set to standby state.

3. Press three buttons of p (TAPE), p (CD), and [TUNER]

simultaneously.

4. The aging is executed in bellow sequence.

5. To e xit from the aging mode, press the 1/u button to turn the

power OFF.

Aging mode sequence:

Start

Open the disc tray

Close the disc tray

Play the last track

FWD Play

1 minute

REC pause for 3 seconds

FWD REC

3 minutes

Fast forward

REV Play

1 minute

REC pause for 3 seconds

REV REC

3 minutes

Shut off

Shut off

Shut off

Shut off

Rewind

– 11 –

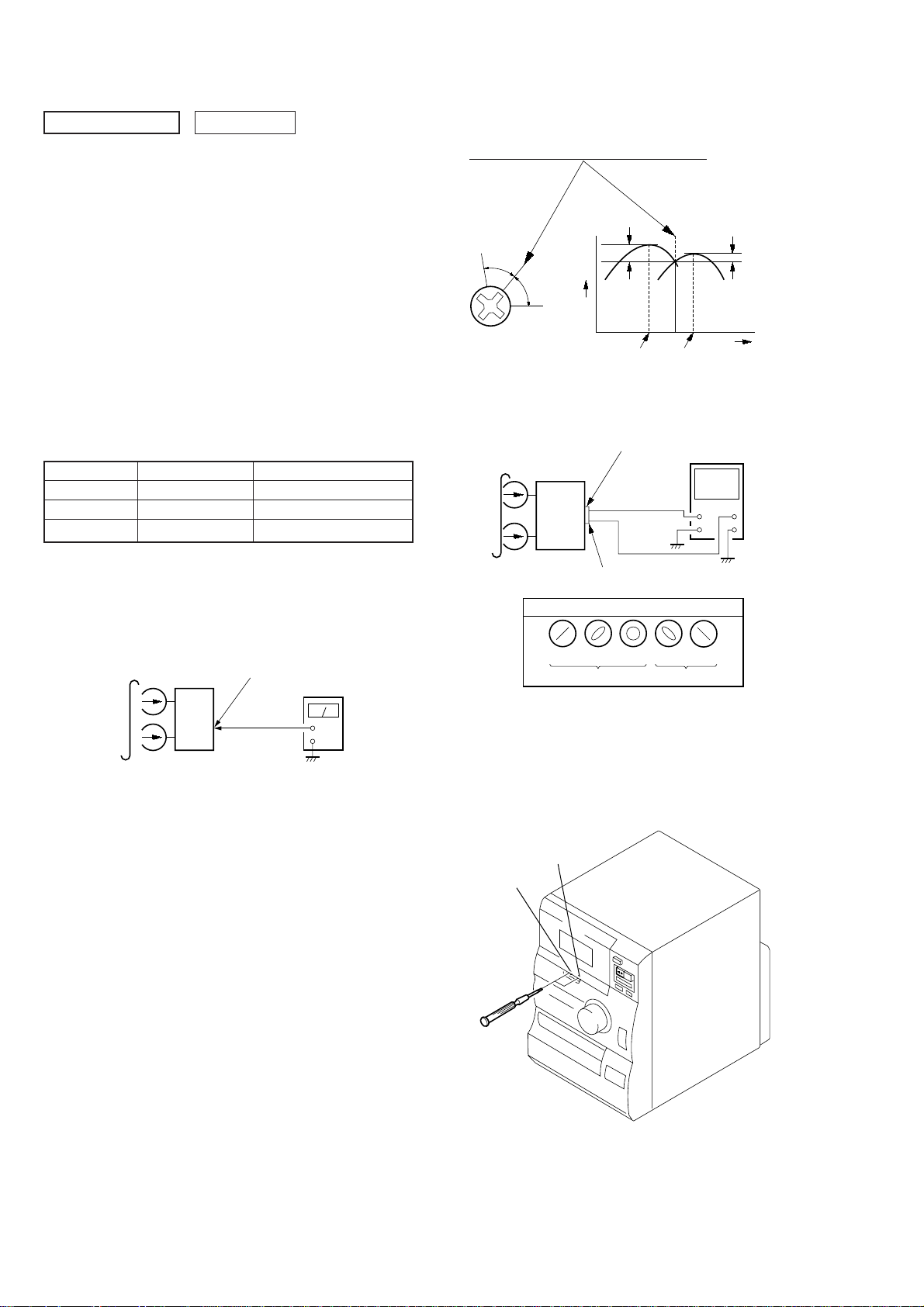

SECTION 5

r

ELECTRICAL CONFIRMATIONS AND ADJUSTMENTS

DECK SECTION

Note: Confirm each contents of this section first of all. If the results are

not satisfied, do the adjustment.

0 dB=0.775 V

1. Demagnetize the record/playback head with a head demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in

this service manual. (As a general rule, playback circuit adjustment should be completed before performing recording

circuit adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise specified.

• Test Tape

Tape Signal Used for

P-4-A100 10 kHz, –10 dB Azimuth Adjustment

WS-48B 3 kHz, 0 dB Tape Speed Adjustment

P-4-L300 315 Hz, 0 dB Level Adjustment

Record/Playback Head Azimuth Adjustment

Procedure:

1. Mode: Playback

test tape

P-4-A100

(10 kHz, –10 dB)

MAIN board

LINE OUT jack (PJ301)

L-CH, R-CH

level mete

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

Output

level

within

1dB

L-CH

peak

R-CH

peak

within

1dB

Screw

position

L-CH

peak

Screw

position

R-CH

peak

3. Mode: Playback

MAIN board

test tape

P-4-A100

(10 kHz, –10 dB)

L-CH

MAIN

board

CN301

set

R-CH

in phase 45°90°135°180

LINE OUT jack (PJ301)

L-CH

R-CH

waveform of oscilloscope

good

oscilloscope

wrong

H

V

°

set

+

–

4. Repeat step 1 to 3 in playback (REV) mode.

5. After the adjustments, apply suitable locking compound to the

pats adjusted.

Adjustment Location:

reverse

forward

– 12 –

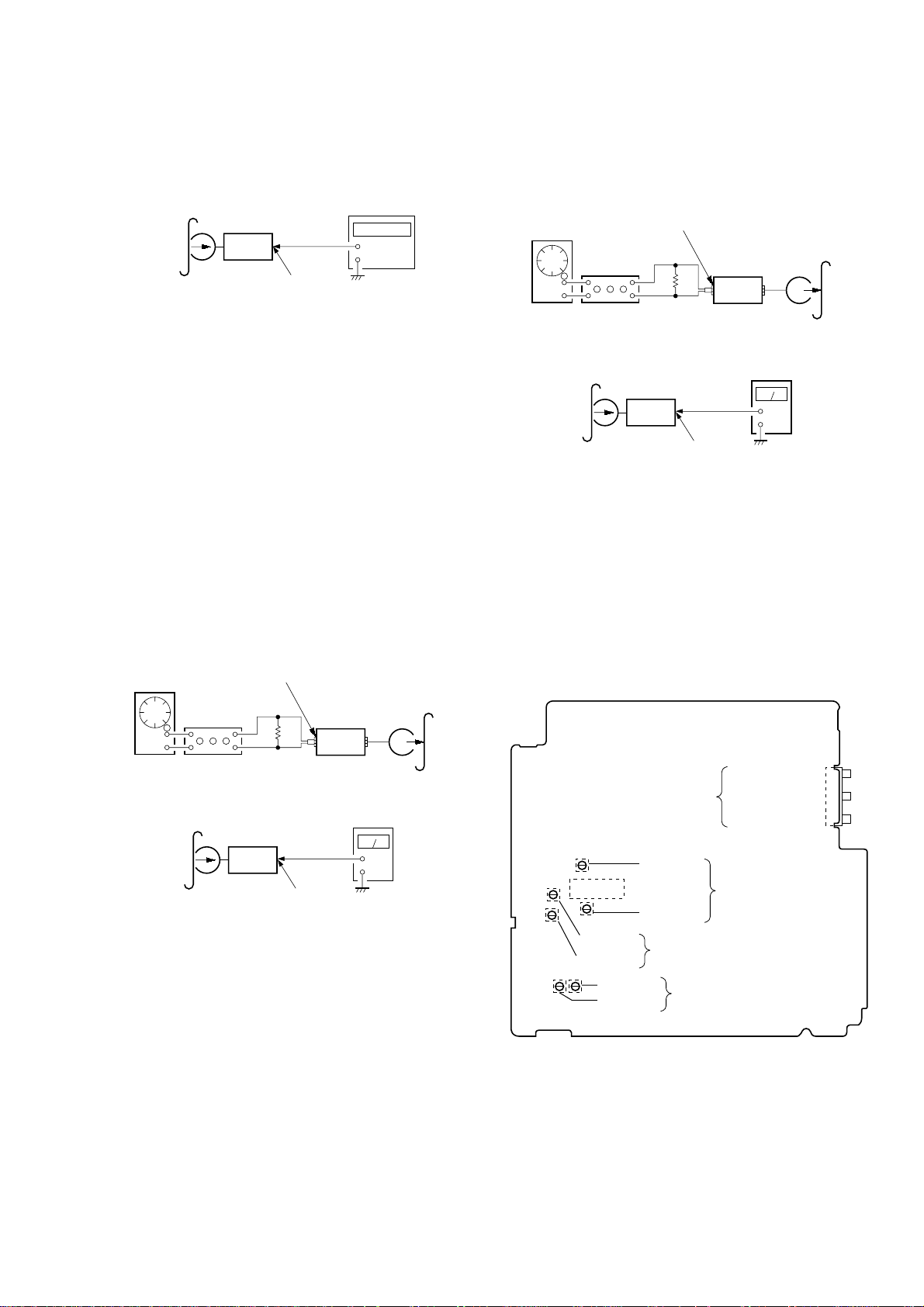

Playback level Confirmation and Adjustment

set

MAIN board

MD IN jack (PJ301)

L-CH, R-CH

315 Hz, 50 mV (–23.8 dB)

blank tape

CS-123

600

Ω

attenuator

AF OSC

+

–

set

recorded

portion

MAIN board

LINE OUT jack (PJ301)

L-CH, R-CH

level meter

PJ301

Playback Level

REC Bias

REC Level

RV252 (R)

IC352

LINE OUT (L/R)

MD IN (L/R)

VIDEO IN (L/R)

RV152 (L)

RV251 (R)

RV151 (L)

RV253 (R)

RV153 (L)

Procedure:

Mode: Playback

test tape

WS-48B

(3 kHz, 0 dB)

frequency counter

REC Level Confirmation and Adjustment

Procedure:

1. Mode: Record

set

MAIN board

LINE OUT jack (PJ301)

L-CH, R-CH

+

–

Confirm playback level is within specification values as follows.

If these levels are out of specification values, adjust the RV151

(L-CH) and RV251 (R-CH) on the MAIN board so that the level

meter reading become within specification values.

Specification values:

PJ301 PB level: 301.5 to 338.3 mV (–8.2 to –7.2 dB) lev el diff erence between the channels: within ±0.5 dB

Adjustment Location: MAIN board

REC Bias Confirmation and Adjustment

Procedure:

1. Mode: Record

MAIN board

MD IN jack (PJ301)

L-CH, R-CH

50 mV (–23.8 dB)

600

Ω

set

blank tape

CN-123

AF OSC

1) 315 Hz

2) 10 kHz

attenuator

2. Mode: Playback

3. Confirm playback the signal recorded in step 1 become specification values as follows.

If these values are out of specification v alues, adjust the R V252

(R-CH) and R V152 (L-CH) on the MAIN board to repeat steps

1 and 2.

Specification values:

PJ301 PB level: 47.2 to 53.0 mV (– 24.3 to – 23.3 dB)

Adjustment Location: MAIN board

– MAIN BOARD (Conductor Side) –

2. Mode: Playback

3. Confirm playback the signal recorded in step 1 become specification values as follows.

If these values are out of specification v alues, adjust the R V153

(L-CH) and R V253 (R-CH) on the MAIN board to repeat steps

1and 2.

Specification values: Playback output of 315 Hz to playback out-

Adjustment Location: MAIN board

recorded

portion

level meter

set

MAIN board

LINE OUT jack (PJ301)

L-CH, R-CH

put of 10 kHz: ± 0.5 dB

+

–

– 13 –

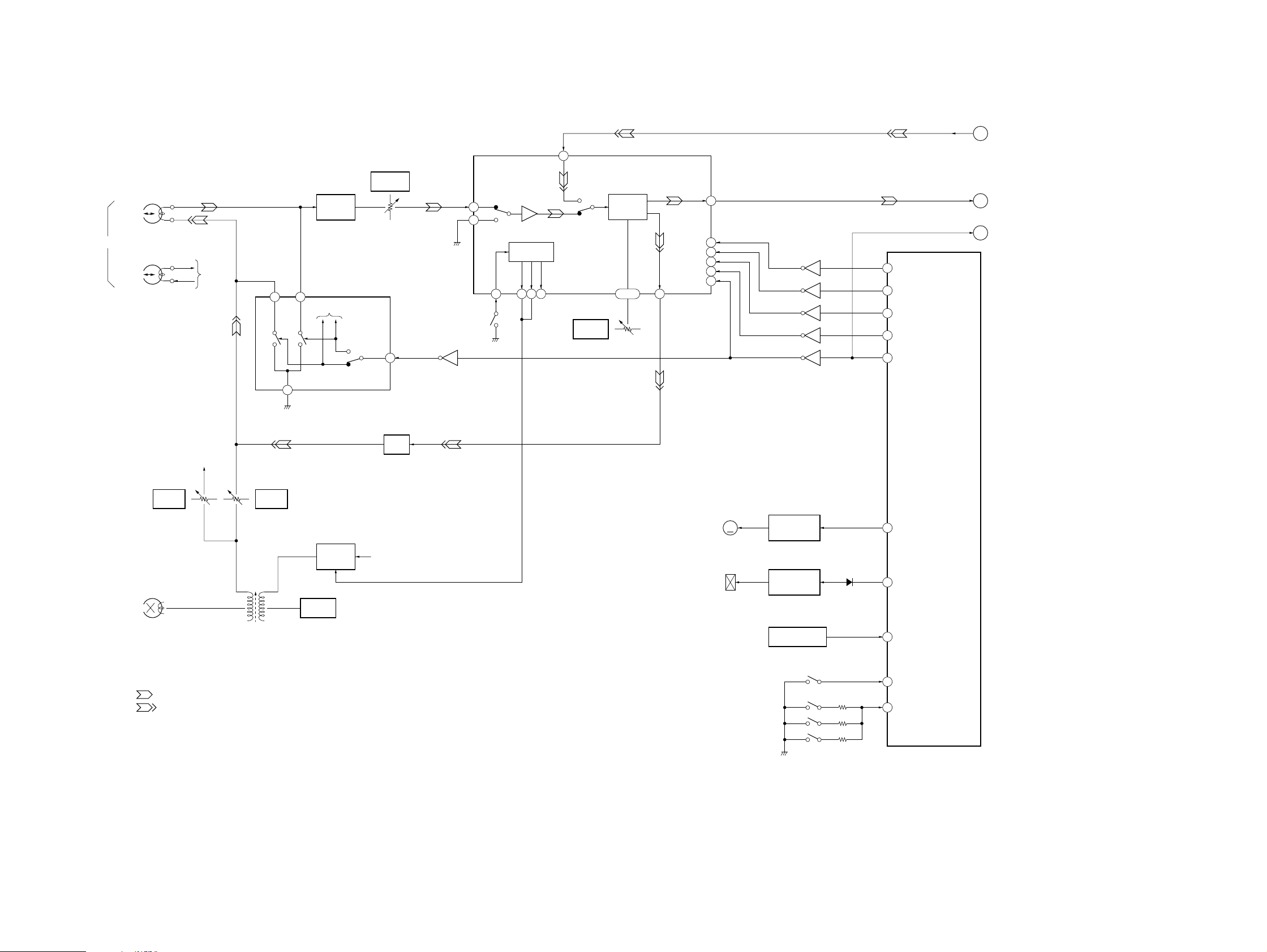

6-1. BLOCK DIAGRAM – TAPE Section –

HCD-CP1

SECTION 6

DIAGRAMS

L-CH

(RECORD/PLAYBACK)

R-CH

(ERASE)

RV253

RECORD

BIAS (R)

R-CH

R-CH

RECORD

BIAS (L)

BIAS OSC

T351

RV153

7 9

8

PLAYBACK

R-CH

REC BIAS

Q359, 360

BIAS OSC

Q357, 358

EQ AMP

IC351

REC/PB SWITCHING

IC350

SWITCH

RV151

PLAYBACK

LEVEL (L)

4

T150

BIAS

TRAP

+8V

Q351

(CrO

41

39

2 DET)

DECK A/B

SELECT

N/C/M

15

BIAS SWITCH

CIRCUIT

N

C

M

25 24 23

37

REC/PB

RV152

RECORD

LEVEL (L)

DOLBY NR

AMP

CIRCUIT

33, 34

DECK PROCESS,

DOLBY NR AMP

IC352

R/MUTE

NR-ON

32

(CAPSTAN/REEL)

(TRIGGER PLUNGER)

BIAS

L/M

R/P

REC-L

35

16

17

18

20

19

M

Q352

Q353

Q354

Q356

Q355

CAPSTAN/REEL

MOTOR DRIVE

Q657, 659

TRIGGER

PLUNGER DRIVE

Q656, 658

D817

REC-BIAS

86

REC-MUTE

87

DOLBY

88

L-MUTE

96

REC/PB

95

SYSTEM CONTROLLER

MOT-CON

4

SOL-CON

5

PB-L

REC/PB

IC801 (1/3)

A

B

C

(Page 18)

(Page 17)

(Page 19)

05

• SIGNAL PATH

: TAPE PLAY

: TAPE RECORD

(HEAD POSITION DET)

(HALF DET (SIDE-A))

(HALF DET (SIDE-B))

(CASSETTE IN DET)

TAPE END DETECT

SENSOR

1

6

32

TAPE-END

T-MODE

TC-SW

– 15 – – 16 –

HCD-CP1

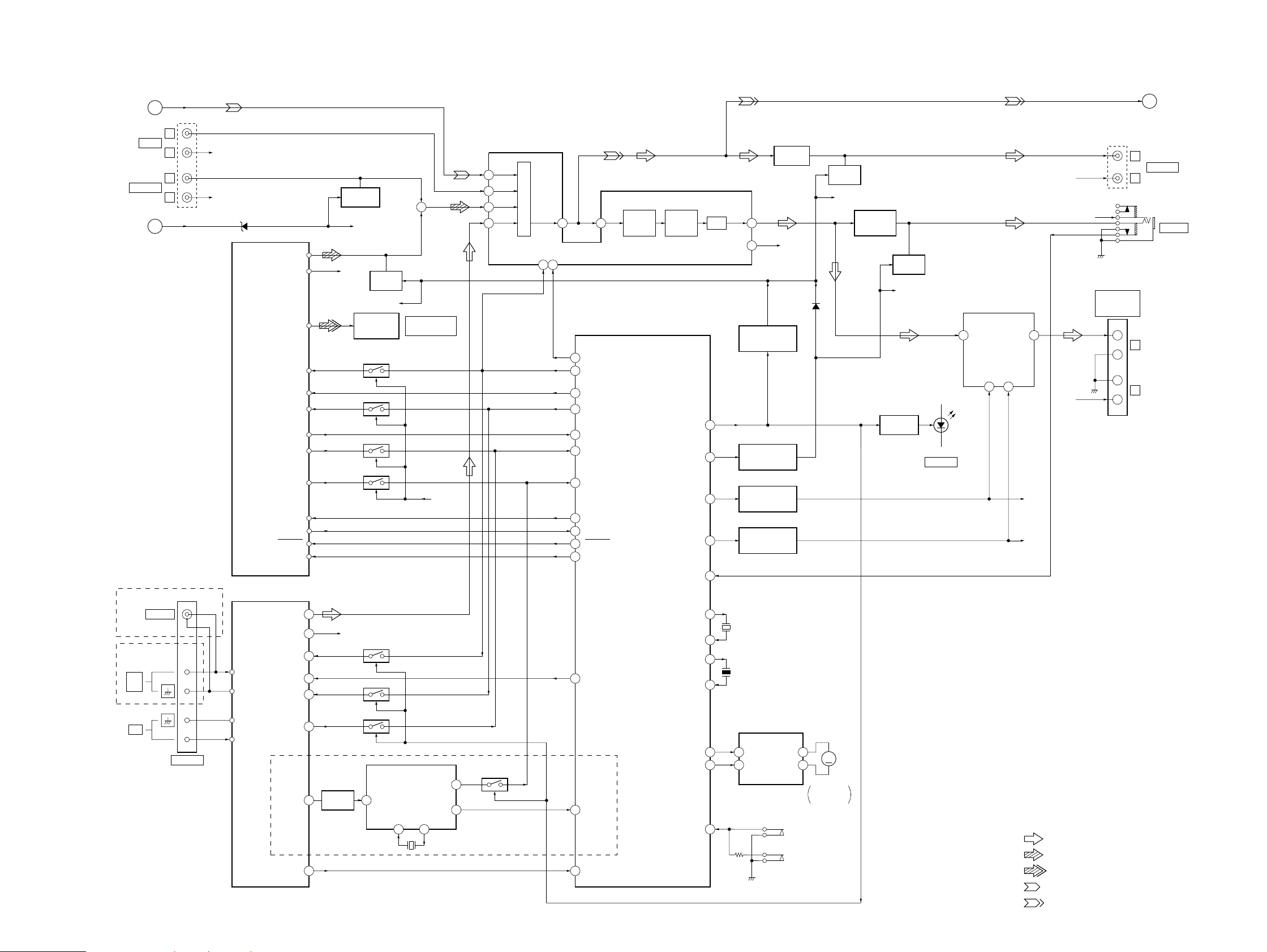

6-2. BLOCK DIAGRAM – MAIN Section –

(Page 16)

MD IN

VIDEO IN

(Page 20)

(AEP, UK, E)

FM 75Ω

(US, Canadian)

FM

75Ω

AM

B

D

PJ301 (1/2)

L

R

L

R

ANTENNA

PB-L

CD ON

R-CH

R-CH

05

D302

TUNER PACK

FM ANT

ANT GND

ANT GND

AM ANT

CD BLOCK

CD-L-OUT

CD-R-OUT

D-OUT

CD-DATA

CD-CLK

CD-LATCH

CD-SENSE1

CD-SENSE2

CD-SQSO

CD-SQCK

CD-SCOR

CD-XRST CD-XRST

CD-MUTE

L-CH

2

R-CH

3

DI

10

CK

9

11

CE

DO

8

FM-DET

TUNED

DET AMP

4

Q810

5

MUTING

Q102, 103

R-CH

R-CH

TRANSCEIVER

Q803

Q805

Q813

Q809

R-CH

Q808

Q806

Q812

MUTING

Q106

OPTICAL

IC308

MUX

4

R-CH

CD DIGITAL OUT

RDS DECODER

IC804

XI XO

13 14

+

OPTICAL

Q803, 805, 809, 813

CD ON SWITCH

CD +5V

Q806, 808, 812

TUNER ON SWITCH

RDATA

2

16

RCLK

X803

4.332MHz

INPUT SELECT SWITCH,

TONE CONTROL,

ELECTRICAL VOLUME

LIN2

12

LIN1

11

LIN4

14

LIN3

13

RDS ON SWITCH

Q816

IC301

MOL

15

INPUT SELECT SWITCH

SDA

SCL

1 30

INL

16

SCK

28

CD-DATA/TU-DATA/

10

SDA

CD-CLK

8

CD-LATCH/TU-CE

19

CD-SENSE1

16

18

CD-SENSE2/TU-COUNT

CD-SQSO/RDS-DATA

12

CD-SQCK

11

CD-SCOR

100

17

CD-MUTE

14

SYSTEM CONTROLLER

29

TU-CLK

(AEP, UK)

RDS-CLK

2

9

TUNED

VOLUME

CONTROL

CIRCUIT

IC801 (2/3)

TONE

CONTROL

CIRCUIT

VIDEO-ON

LINE OUT-MUTE

AMP-STBY

AMP-MUTE

HP-CHK

TEX

XTAL1

EXTAL1

TRAY-SW

LOUT

ATT

24

97

23

22

31

92

TX

93

40

39

13

15 6 10

33

6

5

ROUT

MUTING

CONTROL SWITCH

Q317, 318

MUTING

CONTROL SWITCH

Q303, 304

STANDBY ON/OFF

CONTROL SWITCH

Q305, 306

MUTING

CONTROL SWITCH

Q308, 320

X802

32.768kHz

X801

4.19MHz

DISC TRAY OPEN/CLOSE

MOTOR DRIVE

IC309

IN1TRAY-OPEN

5 2

IN2TRAY-CLOSE

LINE AMP

IC307

R-CH

D304

OUT1

OUT2

(DISC TRAY CLOSE DET)

(DISC TRAY OPEN DET)

M

M901

DISC TRAY

OPEN/CLOSE

S901

S902

MUTING

Q101

R-CH

HEADPHONE

AMP

IC303

MUTING

Q132

R-CH

LED DRIVE

Q853

D853

MD/VIDEO

3

POWER AMP

IC101

IN+

STBY

9 10

OUT

14

MUTE

R-CH

R-CH

• SIGNAL PATH

REC-L

L

R-CH

R-CH

USE 4⁄16Ω

SJ301

SPEAKER

IMPEDANCE

R

+

L

–

–

R-CH

: TUNER

: CD PLAY (ANALOG OUT)

: CD PLAY (OPTICAL OUT)

: TAPE PLAY

: TAPE RECORD

R

+

A

(Page 16)

PJ301 (2/2)

LINE OUT

J301

PHONES

– 17 –

– 18 –

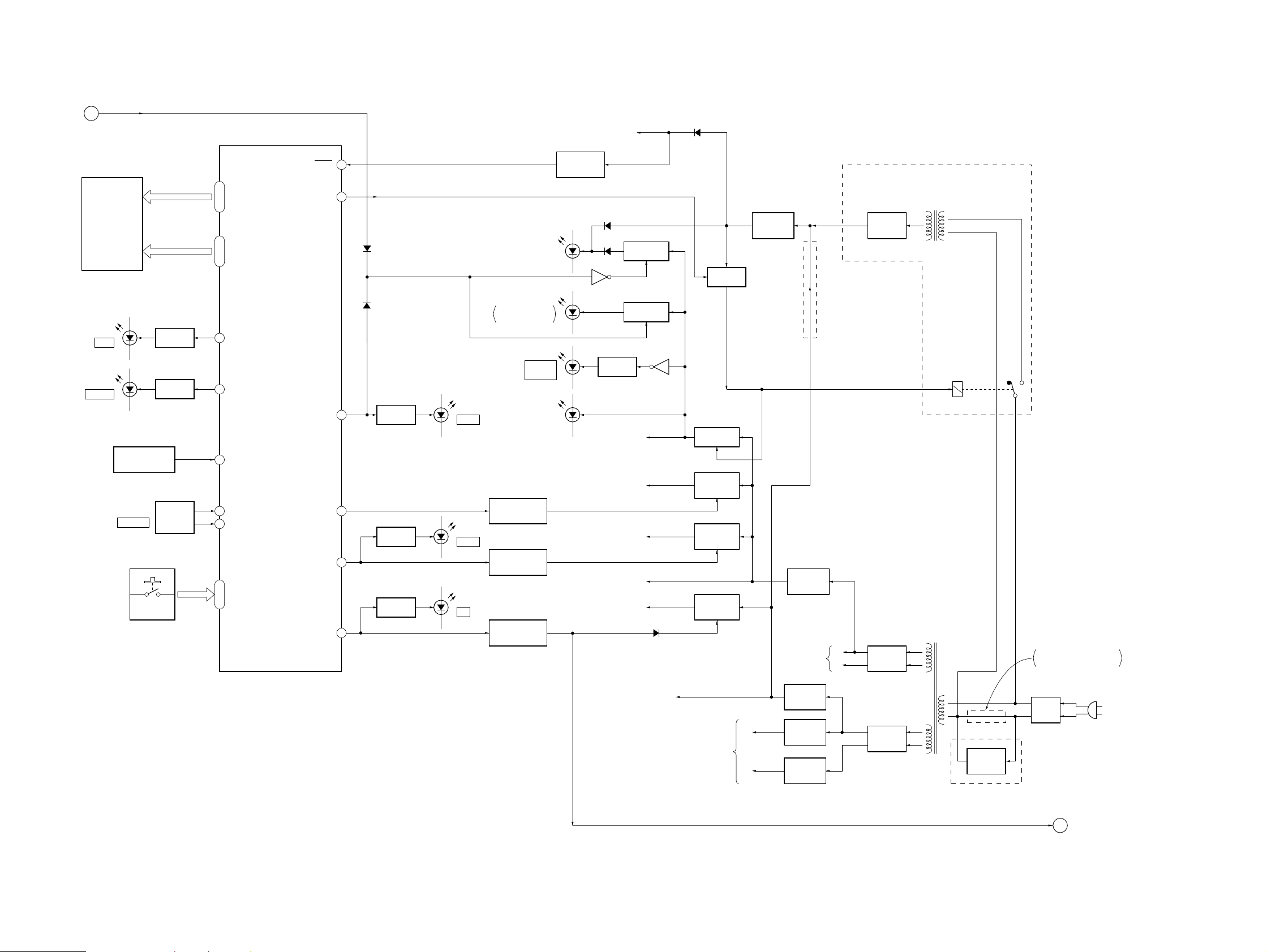

6-3. BLOCK DIAGRAM – DISPLAY/POWER SUPPLY Section –

REC/PB

C

(Page 16)

LIQUID CRYSTAL

DISPLAY

LCD801

D856

DSG

D857

CD SYNC

LED DRIVE

LED DRIVE

REMOTE CONTROL

RECEIVER

IC802

RV801

VOLUME

S801 – 822, 824, 825

ENCODER

Q856

Q857

ROTARY

RV801

05

54 – 85

50 – 53

26

27

3

21

20

36 – 34

REMOCON

SEG0 – SEG31

COM0 – COM3

D.S.G.

CD-SYNC

JOG-A

JOG-B

KEY1 – KEY3

SYSTEM CONTROLLER,

LCD DRIVER

IC801 (3/3)

RESET

REG-CON

TC-ON

RDS-ON

TU-ON

CD-ON

38

7

D812

D813

98

30

25

94

LED DRIVE

Q854

LED DRIVE

Q855

LED DRIVE

Q852

D854

TAPE

D855

TUNER

D852

CD

D657 – 660

(LCD BACK LIGHT)

CASSETTE HOLDER

BACK LIGHT

D851

STANDBY

(DISC TRAY ILLUMINATION)

REGULATOR

CONTROL SWITCH

Q315, 316

REGULATOR

CONTROL SWITCH

Q321, 322

REGULATOR

CONTROL SWITCH

Q311, 312

BACK UP +5V

SYSTEM CONTROLLER (IC801) B+

RESET SIGNAL

GENERATOR

IC803

D815

D814

Q655

LED DRIVE

I/u

D858

Q858

FM 7.5V

FM CIRCUIT B+

+10V

TUNER PACK B+

+12V

TDA7439 (IC301) B+

CD BLOCK B+

B+ SWITCH

Q653, 654

B+ SWITCH

Q651, 652

LED B+

+5V

Q859

D315

D801, 802

B+ SWITCH

REGULATOR

REGULATOR

REGULATOR

SWITCHING

Q323, 324

Q661, 662

+7.5V

Q314

+10V

Q313

+5V

Q310

+5.6V

REGULATOR

IC310

(EXCEPT Hong Kong, Malaysia, Singapore, Thai)

(Hong Kong, Malaysia, Singapore, Thai)

+12V

REGULATOR

IC306

POWER AMP

(IC101, 201)

B+

B–

RECT

D903 – 906

RECT

D907 – 910

POWER TRANSFORMER

(SUB)

T902

RY901

POWER TRANSFORMER

(MAIN)

T901

EXCEPT Hong Kong, Malaysia,

Singapore, Thai

HCD-CP1

– 19 –

CD BLOCK, DISC TRAY OPEN/

CLOSE MOTOR DRIVER (IC309) B+

+8V

AUDIO

CIRCUIT

+8V

–8V

+8V

REGULATOR

IC311

+8V

REGULATOR

IC304

–8V

REGULATOR

IC305

RECT

D911 – 914

LINE

FILTER

LF901

VOLTAGE

SELECTOR

S901

(Hong Kong, Malaysia, Singapore, Thai)

CD ON

– 20 –

D

AC IN

(Page 17)

Loading...

Loading...